Method for synthesizing NaA zeolite membrane

A molecular sieve and seed crystal technology, which is applied in the field of molecular sieve membrane synthesis, can solve the problems such as the inability to eliminate large pore defects on the surface of the support body and the complicated operation, and achieves the advantages of large-scale preparation, high permeation flux, and synthesis. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

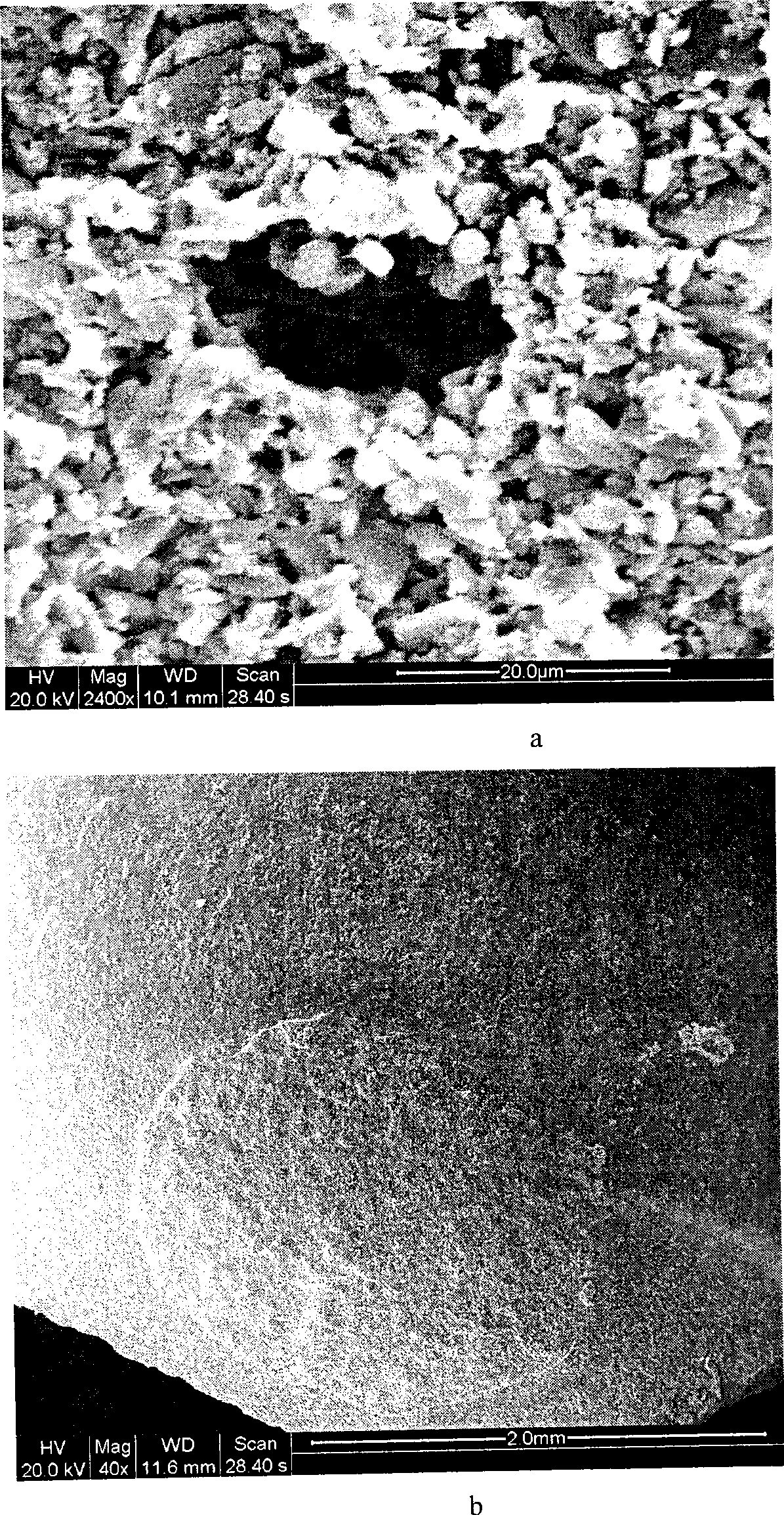

[0028] Step 1 Repair of support defects

[0029] Firstly, the support body is pretreated, and the tubular mullite support body is smoothed with sandpaper, and the residual powder in the support body is cleaned by ultrasonic cleaning, and then dried. Take 40g of NaA molecular sieve powder with a size of about 500nm, add 40ml of distilled water to make a paste, use the seed crystal paste to wipe the support body, and put it in an oven at 50°C to dry for later use.

[0030] Step 2 Preparation of seed crystal support body

[0031] Weigh 0.5g of NaA seed crystals, add 50ml of distilled water, stir evenly and then fully oscillate in ultrasonic to make it dispersed into a uniform molecular sieve suspension solution. The repaired support body is pre-coated with seed crystals by dipping, and the residence time of the support body in the solution is 5 seconds. After coating the seed crystals, place them in an oven at 50°C to dry for later use.

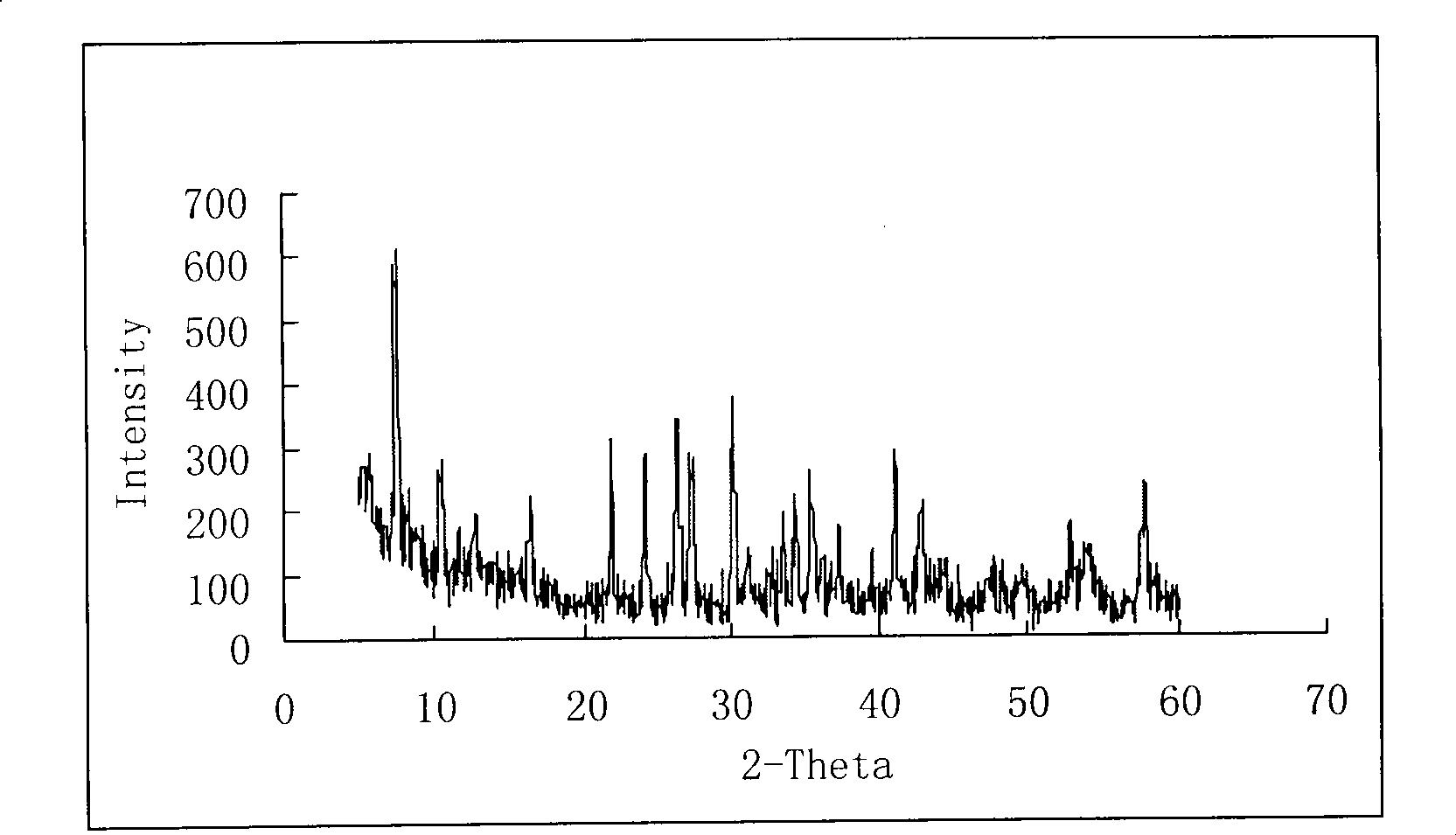

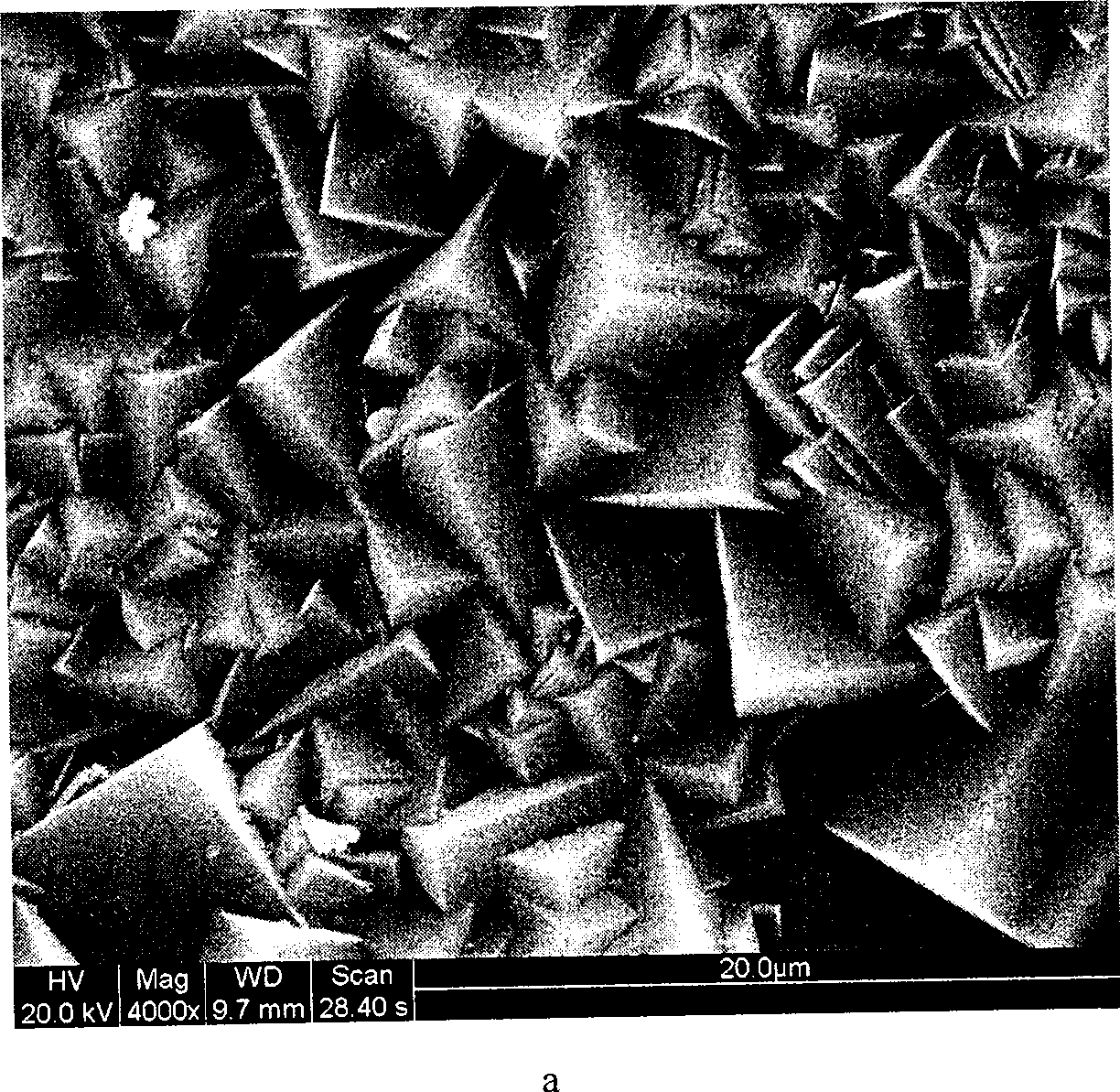

[0032] Step 3 Synthesis of NaA type mo...

Embodiment 2

[0035] The support is pretreated first. Take 80g of NaA molecular sieve powder with a size of about 300nm, add 40gml of distilled water to make a paste, use the seed crystal paste to wipe the support body, and put it in an oven at 50°C to dry for later use.

[0036]Step 2 Preparation of seed crystal support body

[0037] Weigh 1g of NaA seed crystal, add 50ml of distilled water, stir evenly, and then oscillate fully in ultrasonic to make it dispersed into a uniform molecular sieve suspension solution. The repaired support is pre-coated with seed crystals by dipping, and the residence time of the support in the solution is 3 seconds. After coating the seed crystals, place them in an oven at 50°C to dry for later use. The synthesis of step 3NaA type molecular sieve membrane, with embodiment 1 step 3

Embodiment 3

[0039] Step 1 Repair of support defects

[0040] Same as in Example 1, the support body is pretreated first. Take 40g of NaA molecular sieve powder with a size of about 600nm, add 40ml of distilled water to make a paste, use the seed crystal paste to wipe the support body, and put it in an oven at 50°C to dry for later use.

[0041] Step 2 Preparation of seed crystal support body

[0042] Weigh 1g of NaA seed crystal, add 50ml of distilled water, stir evenly, and then oscillate fully in ultrasonic to make it dispersed into a uniform molecular sieve suspension solution. The repaired support is pre-coated with seed crystals by dipping, and the residence time of the support in the solution is 9 seconds. After coating the seed crystals, place them in an oven at 50°C to dry for later use.

[0043] The synthesis of step 3 NaA type molecular sieve membrane, with embodiment 1 step 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com