Patents

Literature

494results about "Aluminosilicate zeolite type-A" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for improving viscosity of attapulgite clay

InactiveCN1699259AImprove processing technologyPhysical/chemical process catalystsAluminosilicate zeolite type-APolymer scienceViscosity

The invention discloses a jprocess for improving viscosity of attapulgite clay which comprises the steps of modification treatment, batching, agitating, milling and detect. The process can be applied into the real processing procedure of Attapulgite clay, and can increase the viscosity of the end product by over 35%.

Owner:许庆华

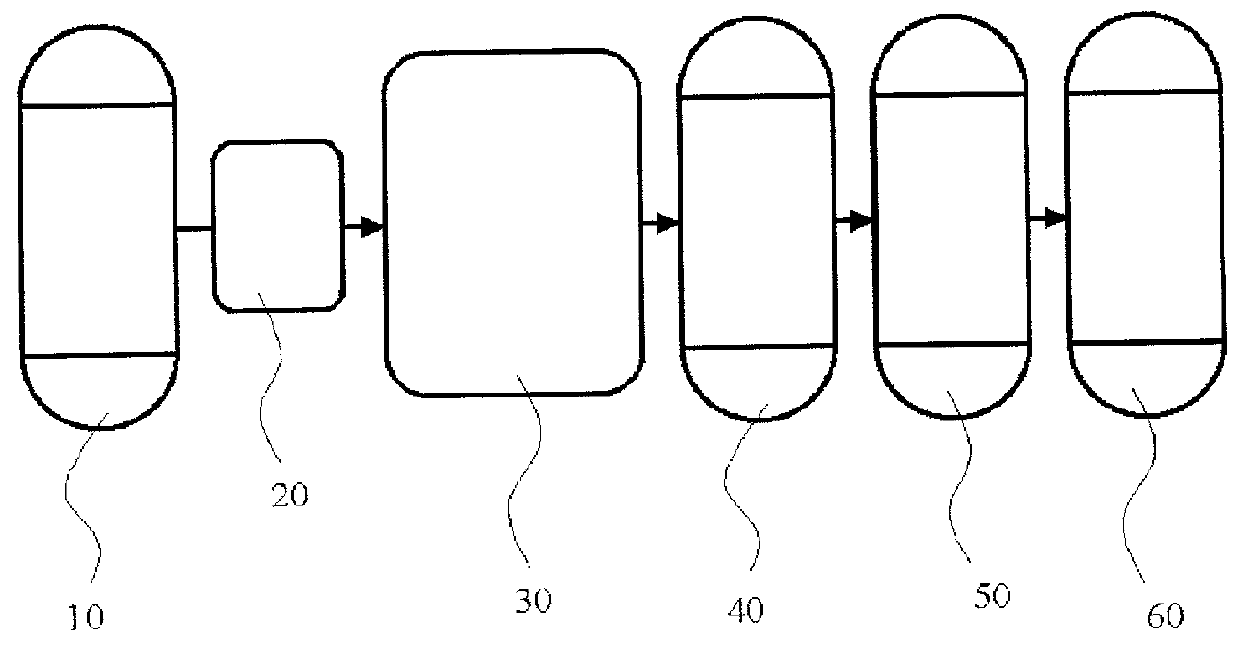

Continuous process and apparatus for preparing inorganic materials employing microwave

This invention relates to a continuous microwave synthesis process of inorganic materials and its apparatus and more particularly, to the process of synthesizing inorganic materials prepared in a manner such that after preparing a mixed solution of precursor materials for various inorganic materials such as porous molecular sieve, layered compounds and ceramics, this mixed solution is continuously added to a tube-type microwave reactor using a slurry pump for the synthesis and crystallization of inorganic materials. Thus the manufacturing process of this invention has the following advantages: (1) the reaction time is further shortened by several to tens of minutes for crystallization, compared to the conventional hydrothermal reaction requiring a prolonged time, (2) the continuous manufacturing and collection processes of this invention can give access to mass-scale production of inorganic materials with relatively small facility, compared to the conventional batch hydrothermal or microwave synthesis, and (3) less amount of organic templating agent can be required during the manufacture of porous molecular sieve.

Owner:KOREA RES INST OF CHEM TECH

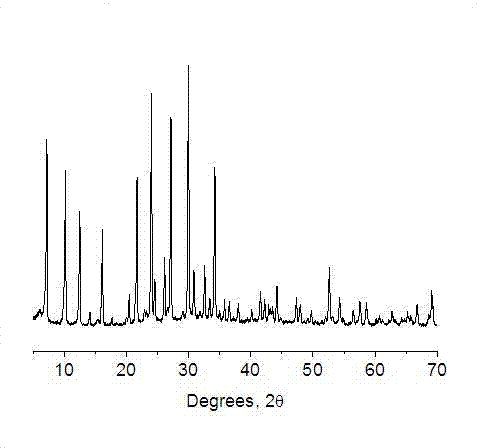

Method for synthesizing zeolite molecular sieve via solid phase method without organic template

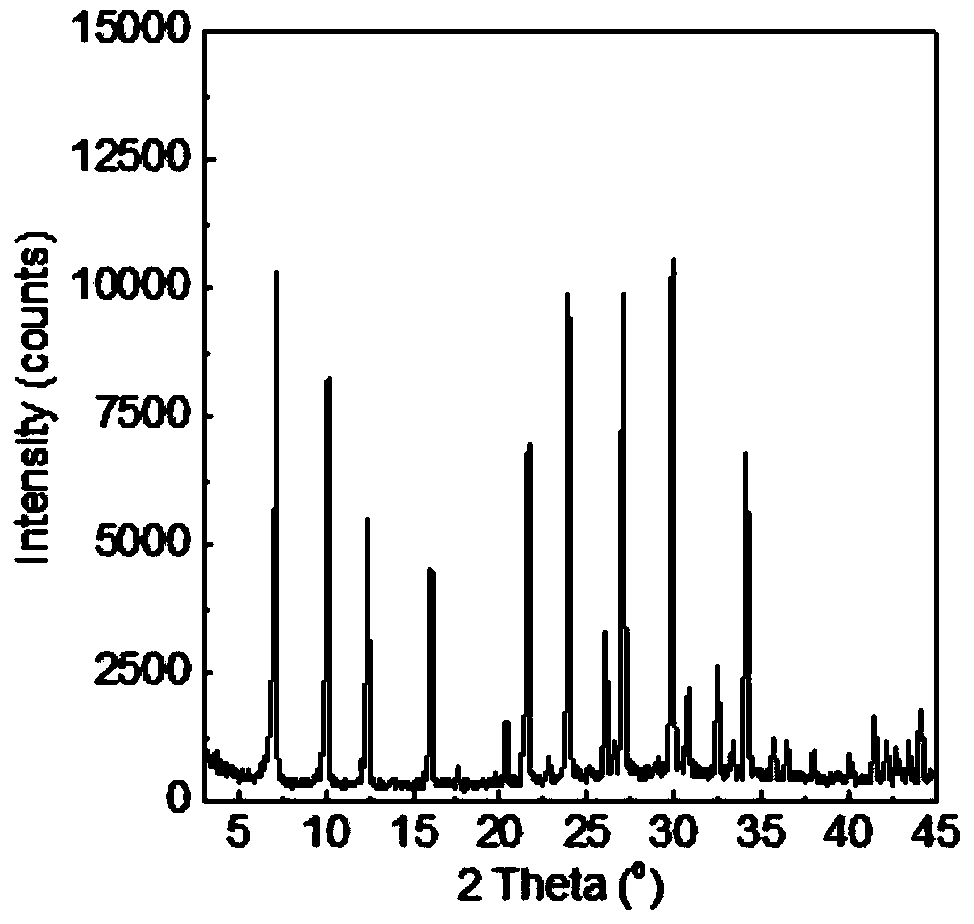

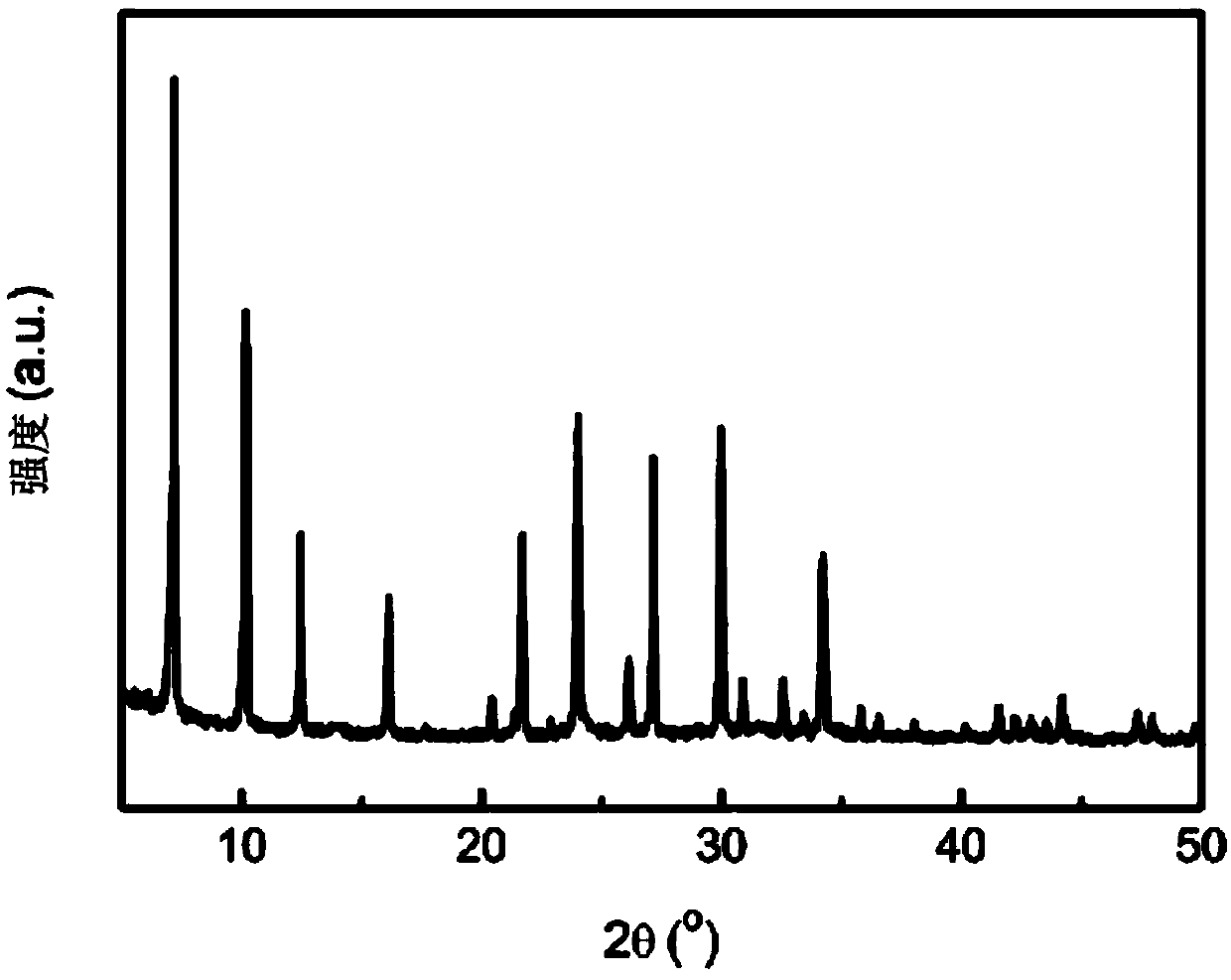

InactiveCN102992343AHigh crystallinityHigh purityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCrystallinity

The invention relates to a preparation method for a molecular sieve, and aims to provide a method for synthesizing a zeolite molecular sieve via a solid phase method without an organic template. The method comprises the steps of grinding and mixing weighed solid raw materials of silicon source, aluminium source and alkali source; putting the above mixture in a reaction kettle; performing a crystallization reaction for 5 h-20 d at a temperature of 50-200 DEG C; suction-filtering a product, and drying the product to obtain various molecular sieve raw powder. A ZSM-5 zeolite molecular sieve, a Beta zeolite molecular sieve, an FAU zeolite molecular sieve, an MOR zeolite molecular sieve, an LTA zeolite molecular sieve an a GIS zeolite molecular sieve which have relatively good crystallinity and controllable silica-alumina ratio in a certain range can be obtained through the method. The product has good crystallinity and purity; no organic template and solvent is used in the whole production process; so that unnecessary loss in the production process can be prevented greatly. Besides, a conventional method is simplified greatly; and single-kettle yield is increased greatly.

Owner:BASF AG

Nanometer A type molecular sieve preparation method

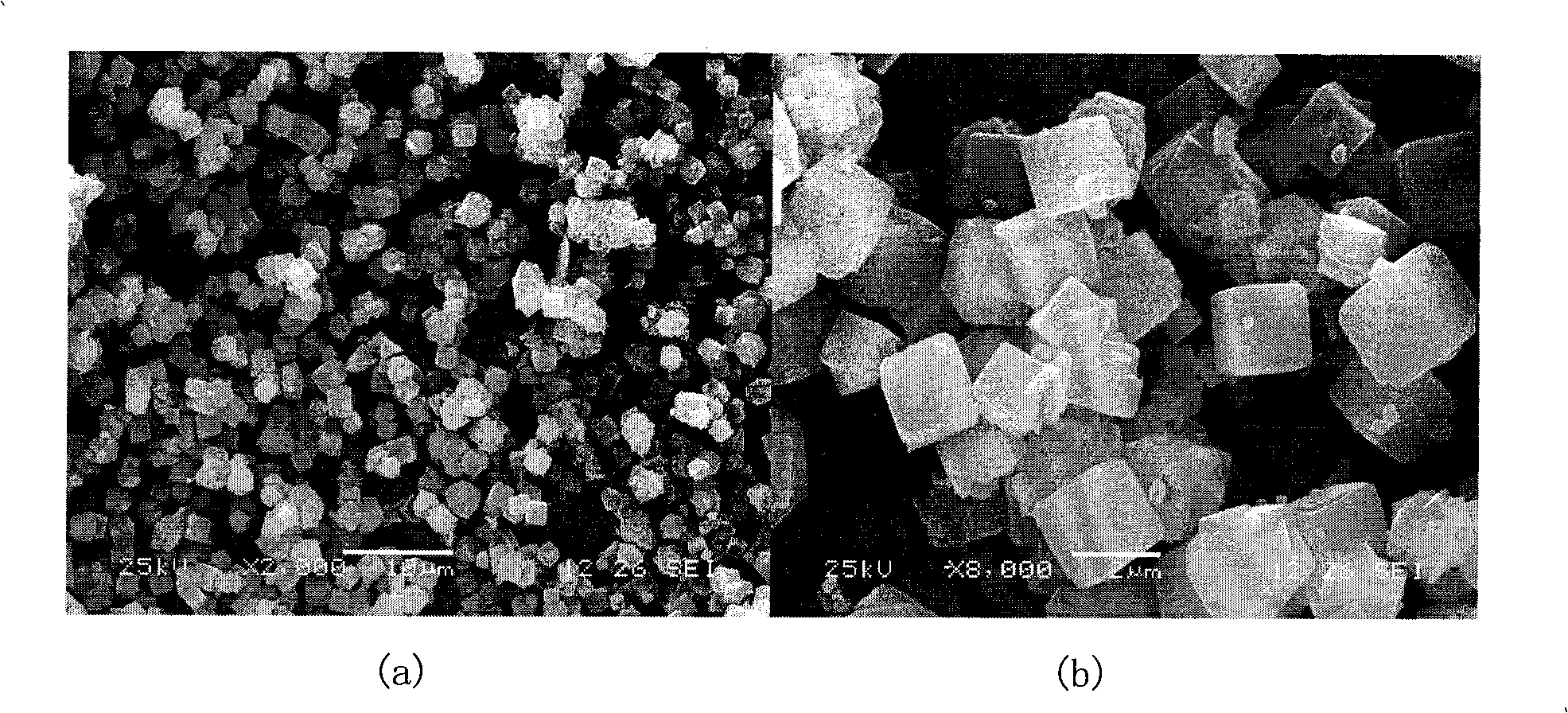

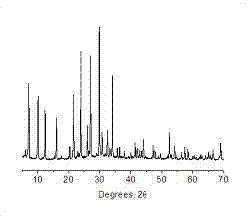

InactiveCN1544327AReduce energy consumptionHigh speedAluminosilicate zeolite type-AMolecular sieveMicrowave

The invention relates to a process for preparing nano A type molecular sieve, including 3A, 4A and 5A molecular sieves, wherein silicon source and aluminum source are selected according the mol ratio of silicon : aluminum = 2:1, and 3-7 mol / L NaOH solution is added by the proportion of total solid weight of silicon and aluminum source : NaOH = 1:5-12, the process comprises the steps of, adding NaOH solution into silicon and aluminum sources, carrying out ultrasonic and microwave combination treatment for 10-150 minutes, controlling the temperature between 90-100 deg. C, filtering, scouring till pH=7-10, post-treating to obtain the nano A type amolecular sieve.

Owner:JIANGXI NORMAL UNIV

Method for preparing 3A type zeolite molecular sieve

InactiveCN102351213ACalcination temperature is lowReduce pollutionAluminosilicate zeolite type-AMolecular sieveIon exchange

Belonging to the field of molecular sieve synthesis, the invention relates to a method for preparing a 3A type zeolite molecular sieve. The preparation method of a 3A type zeolite molecular sieve is characterized by comprising the steps of: 1) calcination of kaolin, thus obtaining metakaolin; 2) preparation of a 4A molecular sieve: mixing metakaolin and a NaOH aqueous solution uniformly, thus obtaining a mixture; filtering the mixture, washing the filter cake with distilled water, and conducting filtration again, drying the filter cake from second filtration at a temperature of 90-100DEG C for 2-4h, thus obtaining the 4A molecular sieve; 3) preparation of a 3A type zeolite molecular sieve: reacting the 4A molecular sieve with a KCl solution in a reaction vessel for 3-5h at a temperature of 70-90DEG C, then conducting cooling, washing, and filtering, drying the obtained filter cake at a temperature of 90-100DEG C for 2-4h, thus obtaining the 3A type zeolite molecular sieve. The method of the invention has simple process and low calcination temperature, and the prepared 3A type zeolite molecular sieve has great calcium ion exchange capacity and good performances.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

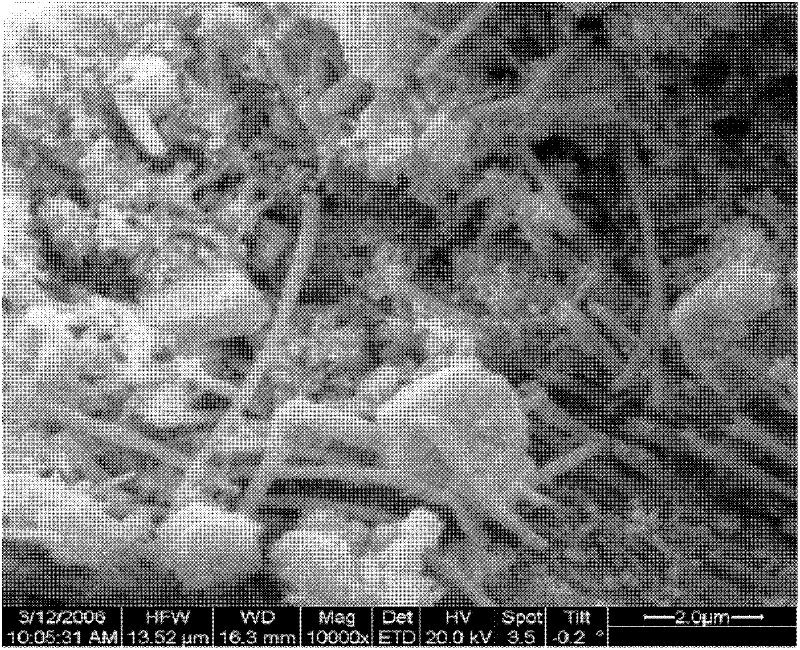

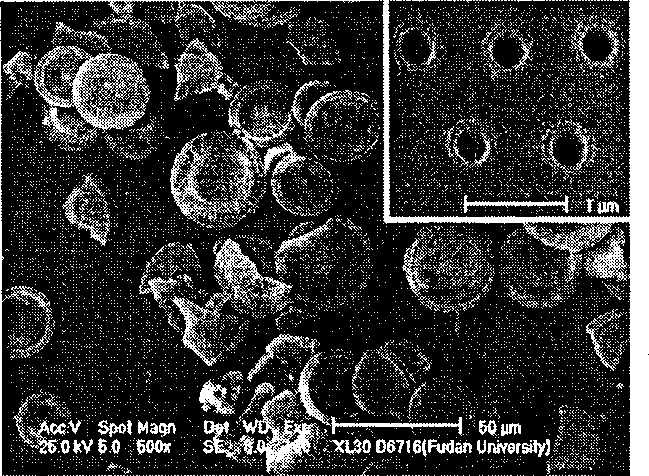

Process for preparing zeolite material with multi-class pore canal by zeolitizing diatomite

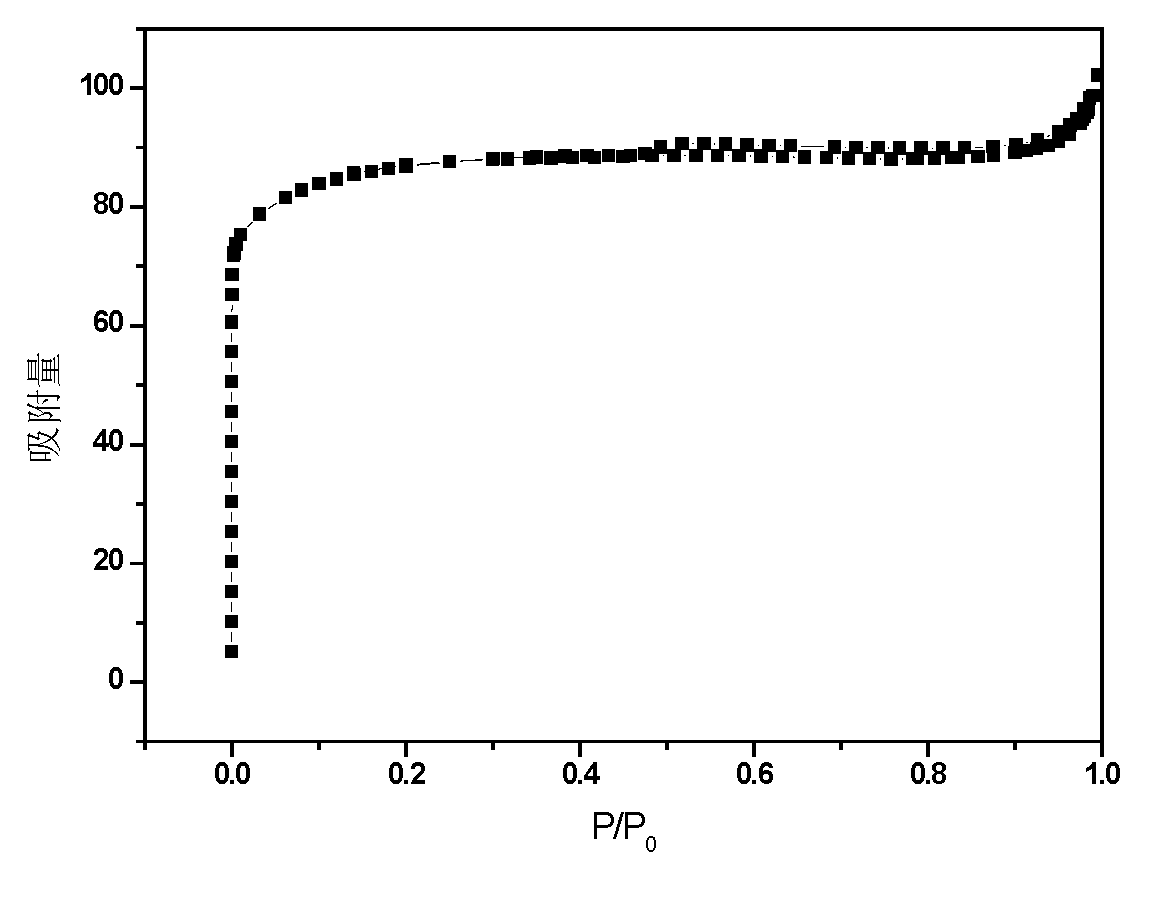

InactiveCN1346795AHigh zeolite contentUniformly enriched macroporous structureMolecular sieve catalystsAluminosilicate zeolite type-AMechanical stabilityColloid

A process for preparing zeolite with multi-class pore canal structure by zeolitizing diatomite features use of laminating technique and gas-solid crystal conversion technique. For the laminating technique, an electrostatic attraction is used to assemble the nano zeolite onto diatomite. For the gas-solid crystal conversion technique, the amorphous SiO2 is converted to zeolite without damage to the form and structure of diatomite. Its advantages are simple operation, high speed, rich macropores, environmentally friendly process and wide application range.

Owner:FUDAN UNIV

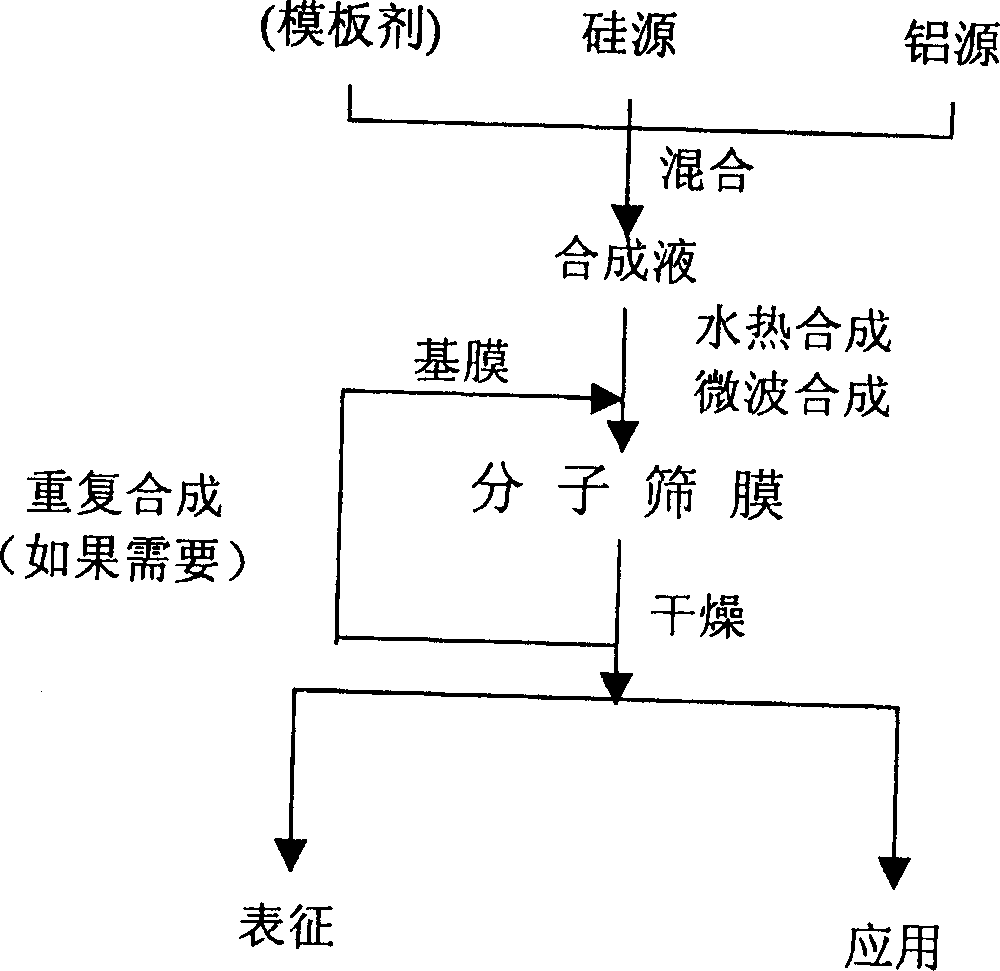

Method for synthesizing NaA zeolite membrane

ActiveCN101381087AHigh selectivityImprove permeabilitySemi-permeable membranesAluminosilicate zeolite type-AMolecular sieveHydrothermal synthesis

The invention relates to a method for synthesizing a NaA molecular sieve membrane. A seed crystal coating mode of combining the coating and the dipping of seed crystal is used for the synthesis of the molecular sieve membrane. Firstly, a supporting body is polished by sand paper and is dried; a seed crystal paste is coated on the surface of the supporting body to remove the possible defects on the surface of the supporting body; secondly, the seed crystal is precoated by a lifting and dipping method; and finally the NaA molecular sieve membrane is synthesized by a hydrothermal synthesis method. The NaA molecular sieve membrane synthesized by the method has continuous and compact surface, excellent separation performance and good repeatability and is suitable for scale preparation.

Owner:JIANGSU NINE HEAVEN HIGH TECH

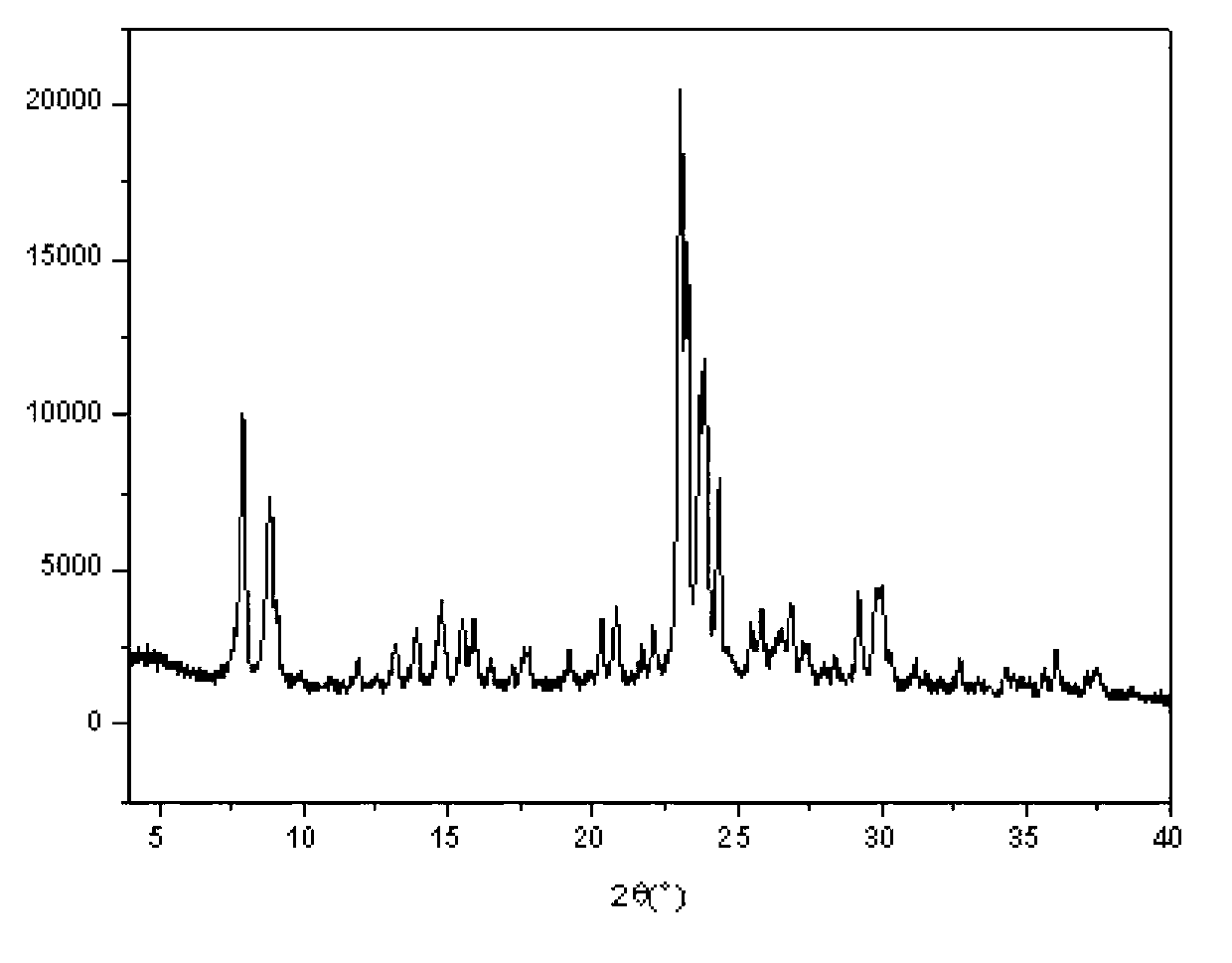

Method for synthesizing pure 4A zeolite, P-shaped zeolite and sodalite with concavo-convex attapulgite clay

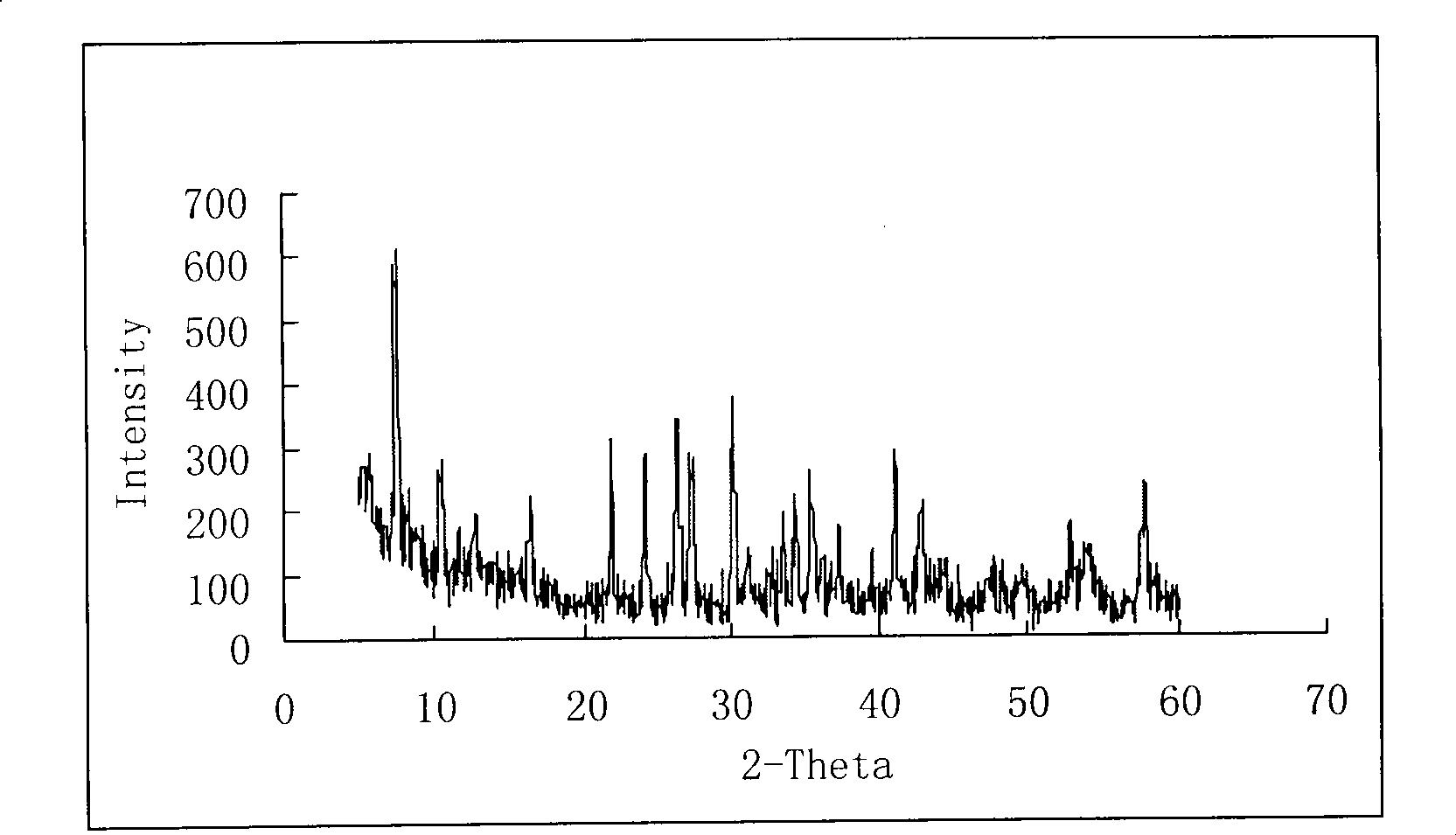

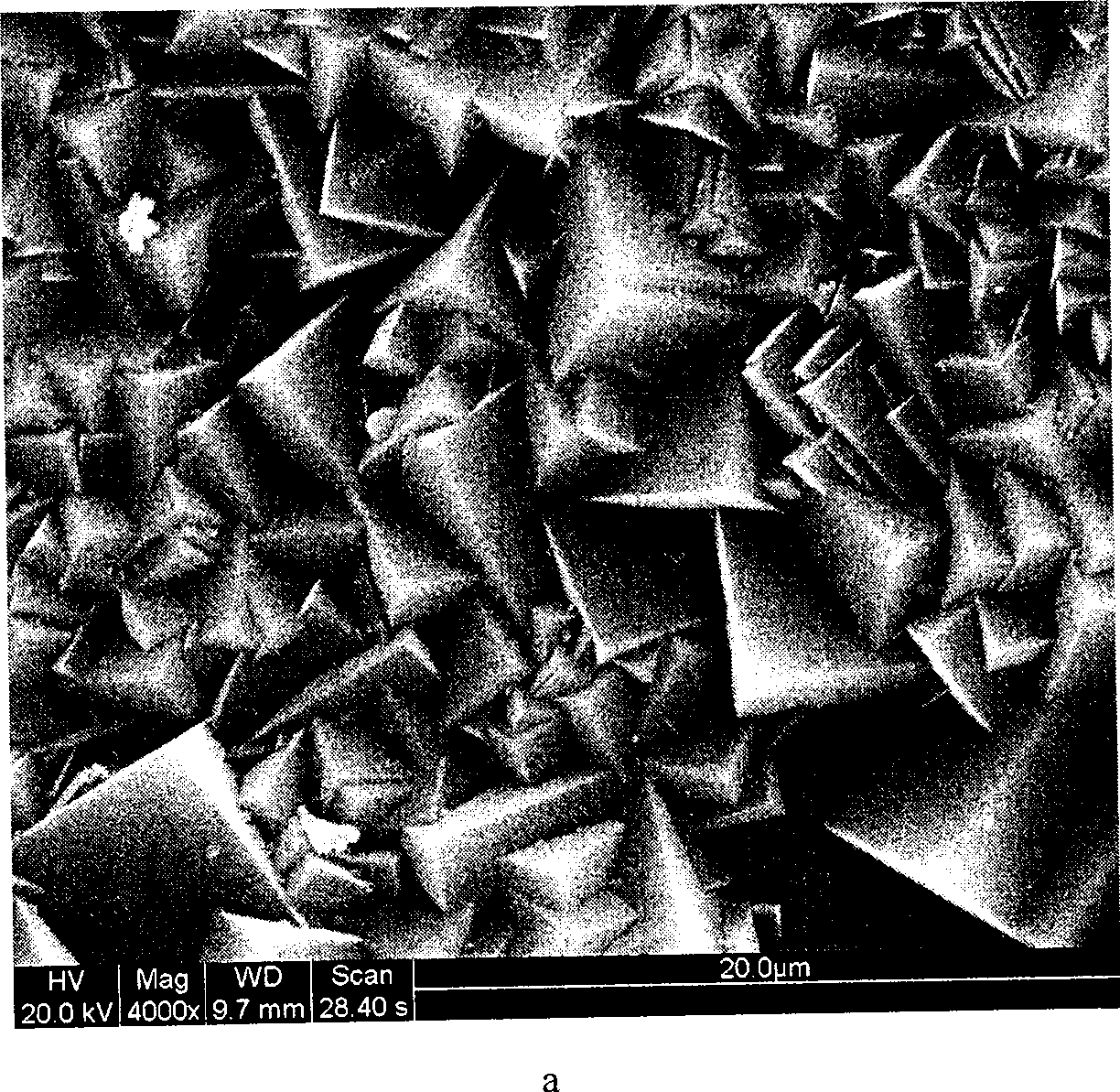

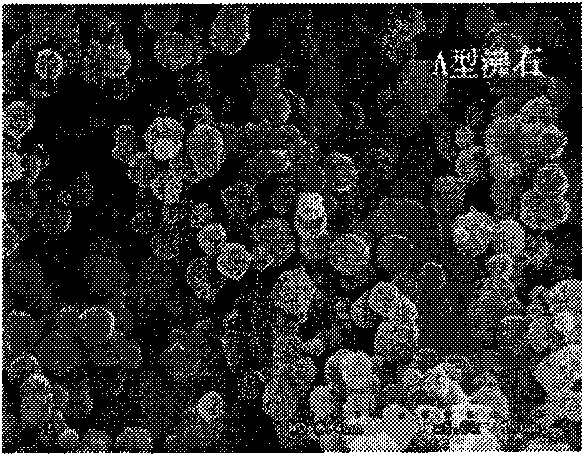

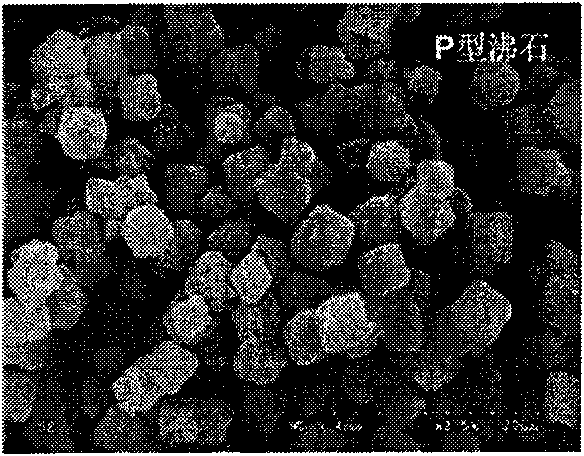

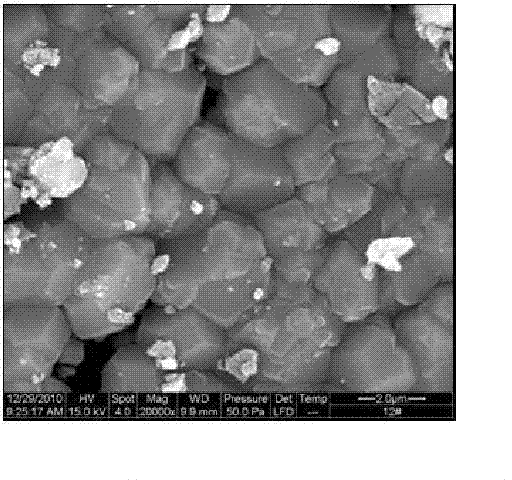

InactiveCN101618880AThe synthesis method is simpleRaw materials are easy to getAluminosilicate zeolite type-AFiltrationSynthesis methods

The invention discloses a method for synthesizing pure 4A zeolite, P-shaped zeolite and sodalite with concavo-convex attapulgite clay. The method is characterized by comprising the following steps: firstly, the concavo-convex attapulgite clay is calcined in high temperature; then, the calcined concavo-convex attapulgite clay is soaked by soda liquor to obtain leach liquor containing Na2SiO3; finally, an aluminum source is added into the soda leach liquor to carry out hydrothermal crystallization synthesis, and then, the pure 4A zeolite, the P-shaped zeolite and the sodalite are respectively obtained by filtration, rinsing and drying. In the method, the concavo-convex attapulgite clay is used as raw material, and the genuine 4A zeolite, the P-shaped zeolite and the sodalite are respectively obtained by calcination and soda-leach pretreatment through adjusting synthesis conditions, therefore the invention has the advantages of simple synthesis method, easily obtained raw material and low production cost.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

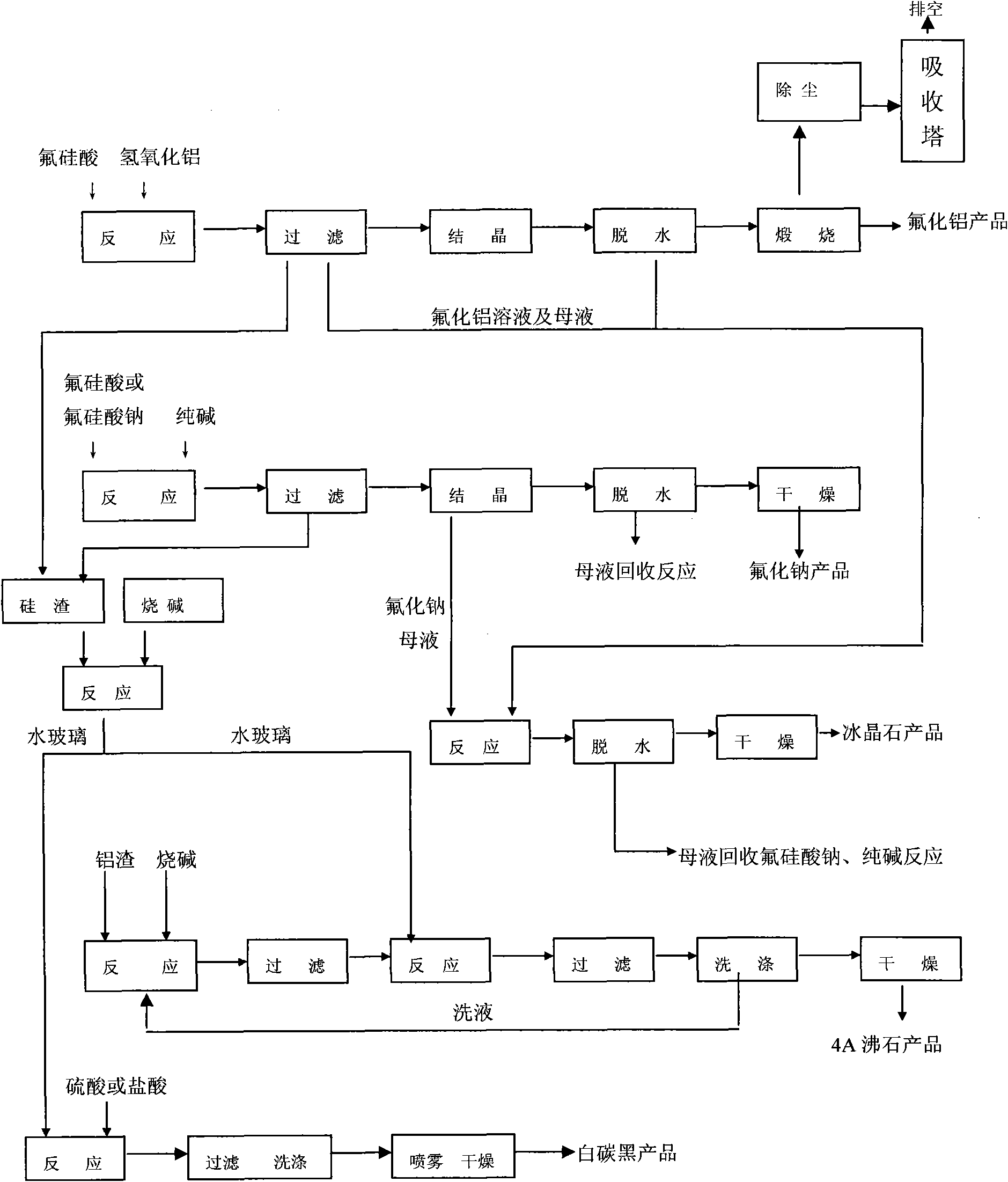

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

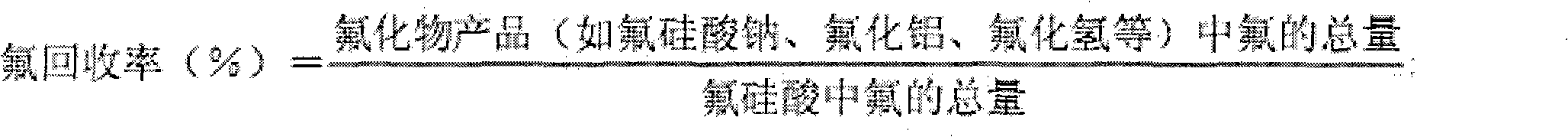

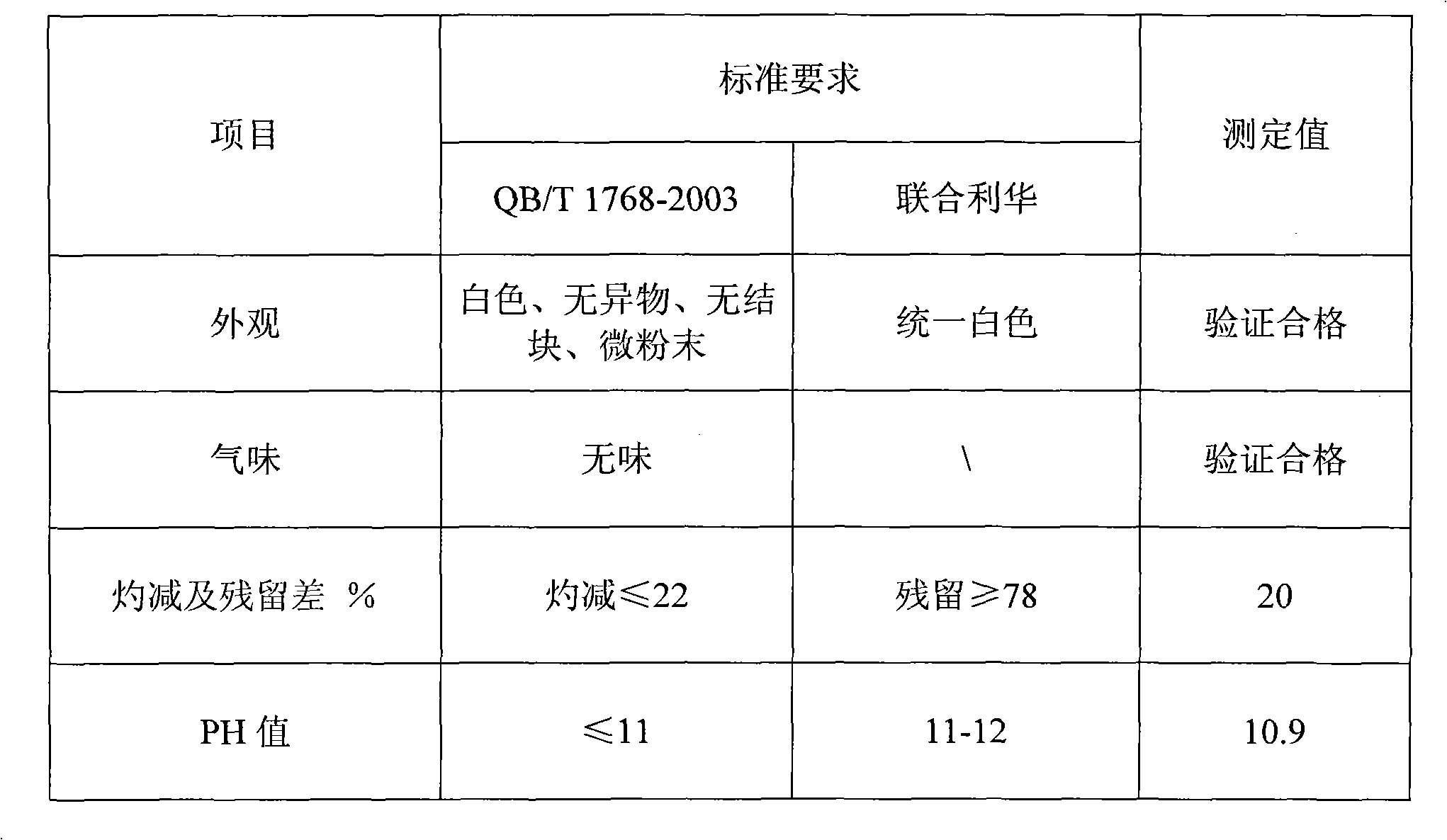

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

Method for synthesizing monolithic 4A molecular sieve by dry glue process

InactiveCN104163436ASimple methodEasy to operateAluminosilicate zeolite type-AMolecular sieveSorbent

The invention discloses a method for synthesizing a monolithic 4A molecular sieve by a dry glue process, relating to the technical field of molecular sieve synthesis. The method comprises the following steps: evenly mixing an alkali source, an aluminum source, a silicon source and water in a mole ratio of (0.3-5) Na2O:Al2O3:(1.7-2.5) SiO2:(3-12) H2O to prepare preformed dry glue; aging the preformed dry glue at room temperature for 0.5-30 hours, putting in a reaction kettle with a water jacket barrier, and crystallizing at 75-110 DEG C for 0.5-30 hours, wherein the mass ratio of the water to the preformed dry glue in the reaction kettle in the crystallization process is 0.05:(1-1.1); and washing the crystallization product, and drying to obtain the monolithic 4A molecular sieve. The monolithic 4A molecular sieve has favorable strength, does not need reforming, and can be directly used as an adsorbent or catalyst support. The method is capable of simplifying the traditional technical process, enhancing the synthesis efficiency and raw material utilization ratio and lowering the synthesis cost, and has the advantages of no mother solution discharge and environment friendliness.

Owner:CHINA NAT OFFSHORE OIL CORP +2

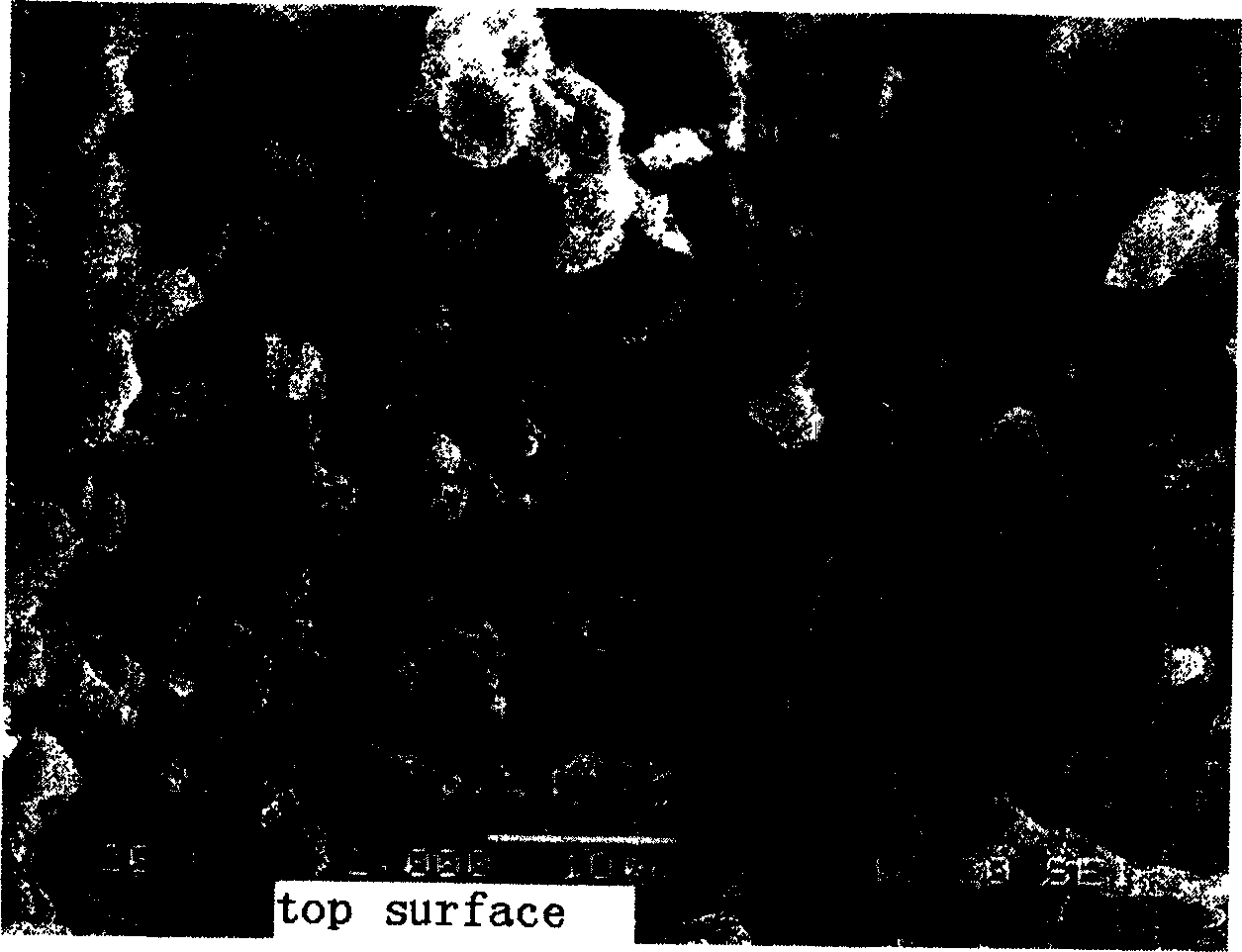

Preparation method of high performance permeation evaporation permeable membrane

InactiveCN1597072ALow purity requirementEasy to separateAluminosilicate zeolite type-ADistillationMolecular sieveEvaporation

A high-performance water-permeable osmosis-evaporation membrane is prepared through preparing a NaA-type molecular sieve membrane on the porous tubular ceramic substrate by hydrothermal synthetic reaction. Its raw materials are Na2O, Al2O3, SiO2 and H2O. Said Na-A-type molecular sieve membrane has excellent separation performance.

Owner:NANJING UNIV OF TECH

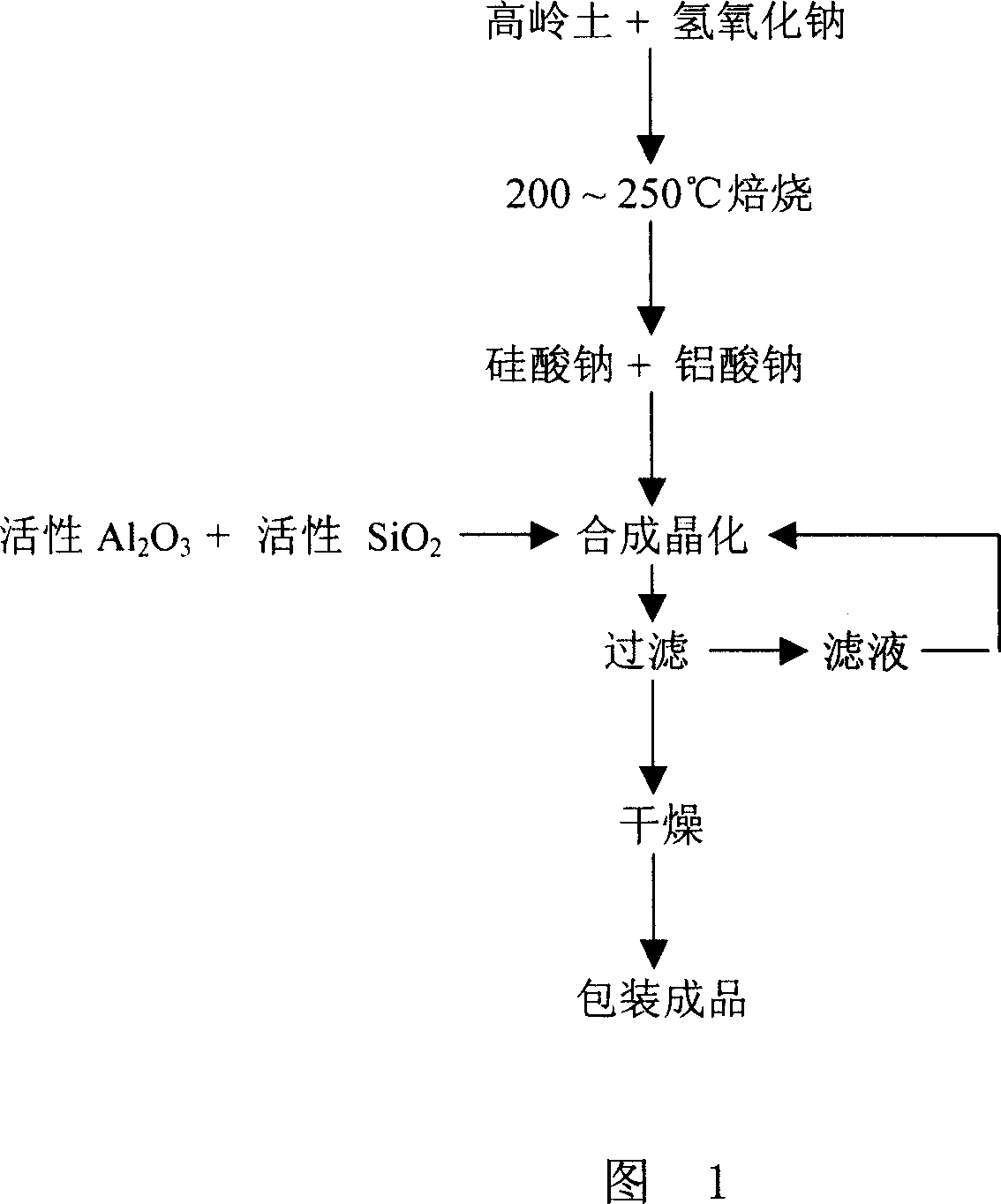

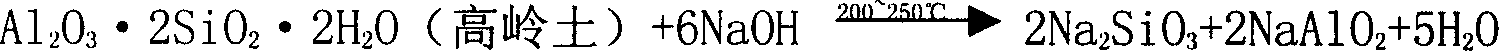

4A zeolite synthesized from kaolin by low-temperature alkali fusion method

InactiveCN101033070ALow reaction temperatureReduce energy consumptionAluminosilicate zeolite type-AChemical synthesisSilicon dioxide

This invention relates to a method for preparing 4A zeolite with kaoline as the raw material aiming at providing a preparation method for composite 4A zeolite with kaoline as the raw material against the shortcomings of the present chemosynthesis method, acidified bentonite method and a kaoline high temperature calcining method including the following steps: mixing uniformly kaolin and NaOH in a certain proportion and heating them for 1-3h, adding a certain volume of active Al2O3, active SiO2 and water in the activated product to be thermal-crystalized for 0.5-4h under 80-95deg.C then to filter the product and dry it to get the 4A zeolite product.

Owner:ZHEJIANG NORMAL UNIVERSITY

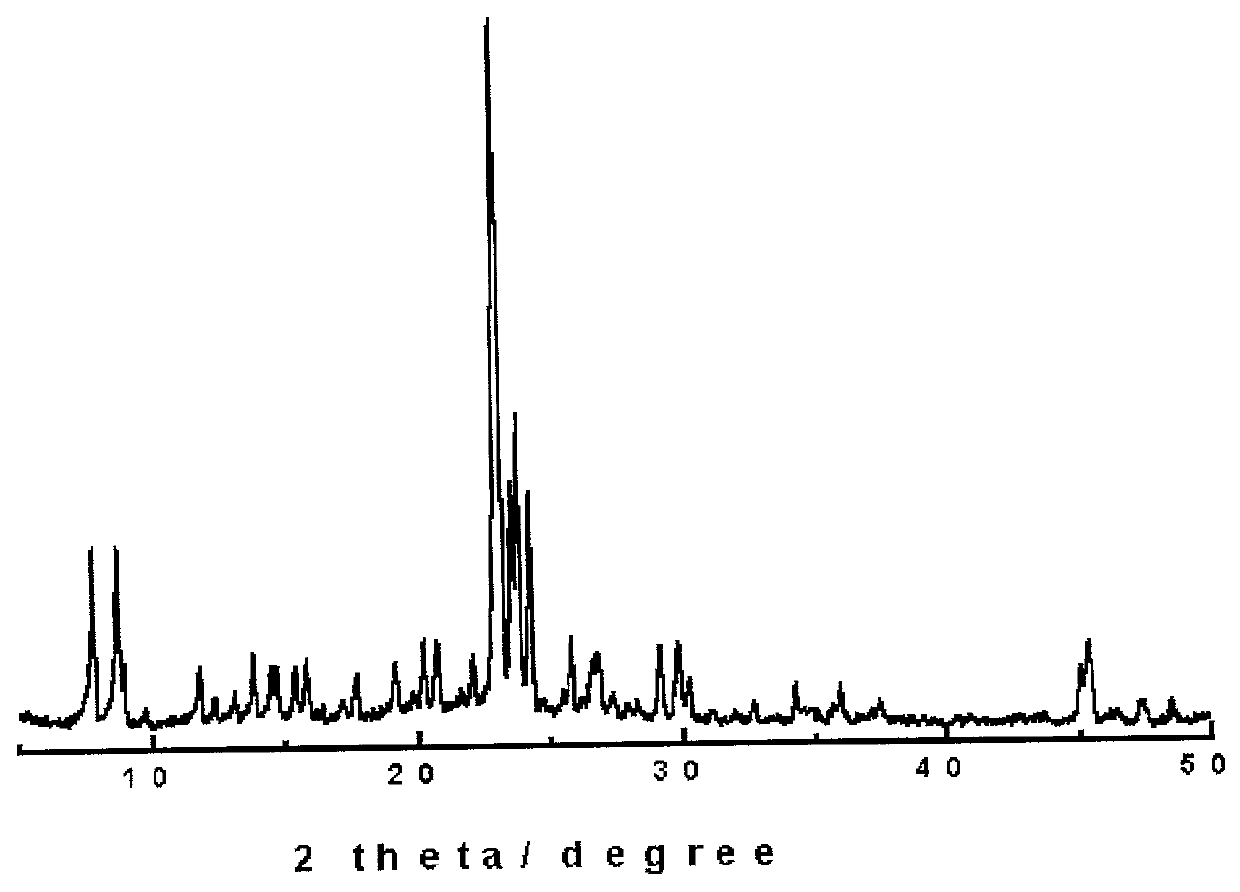

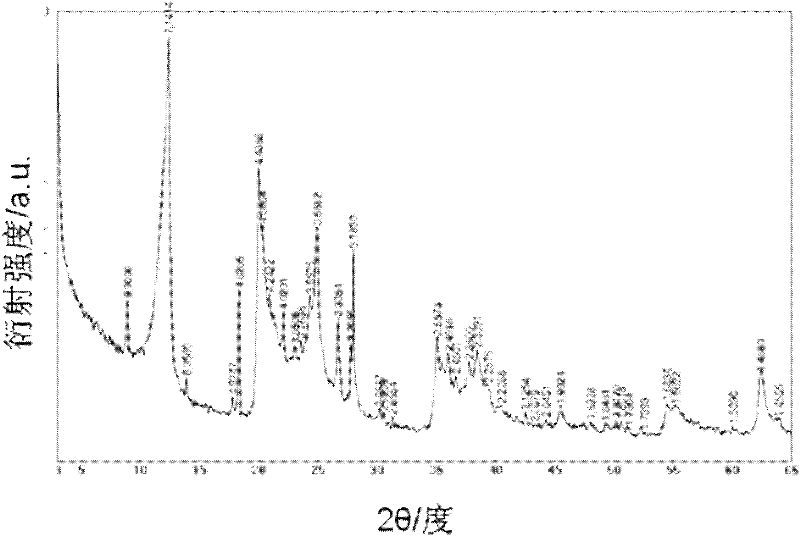

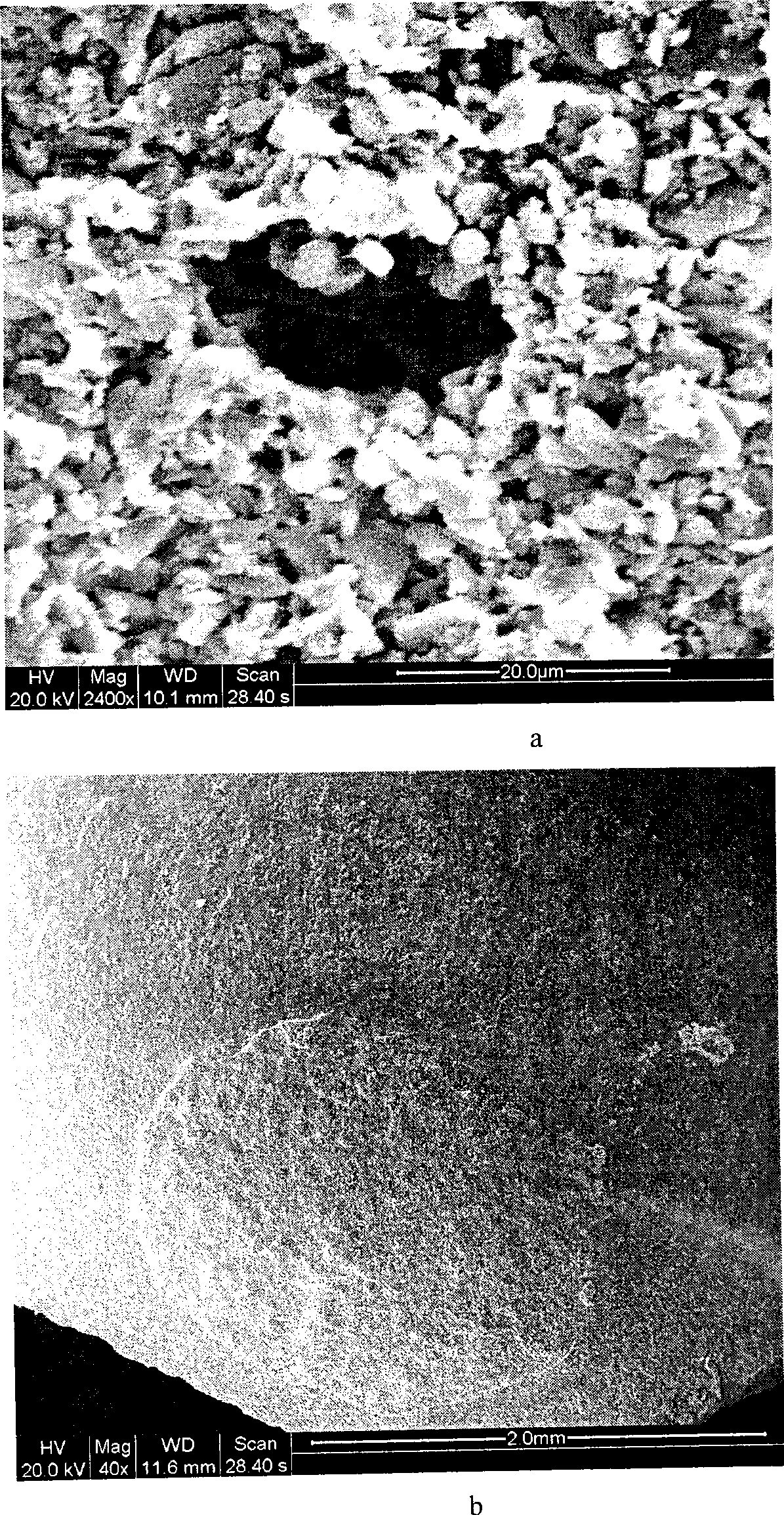

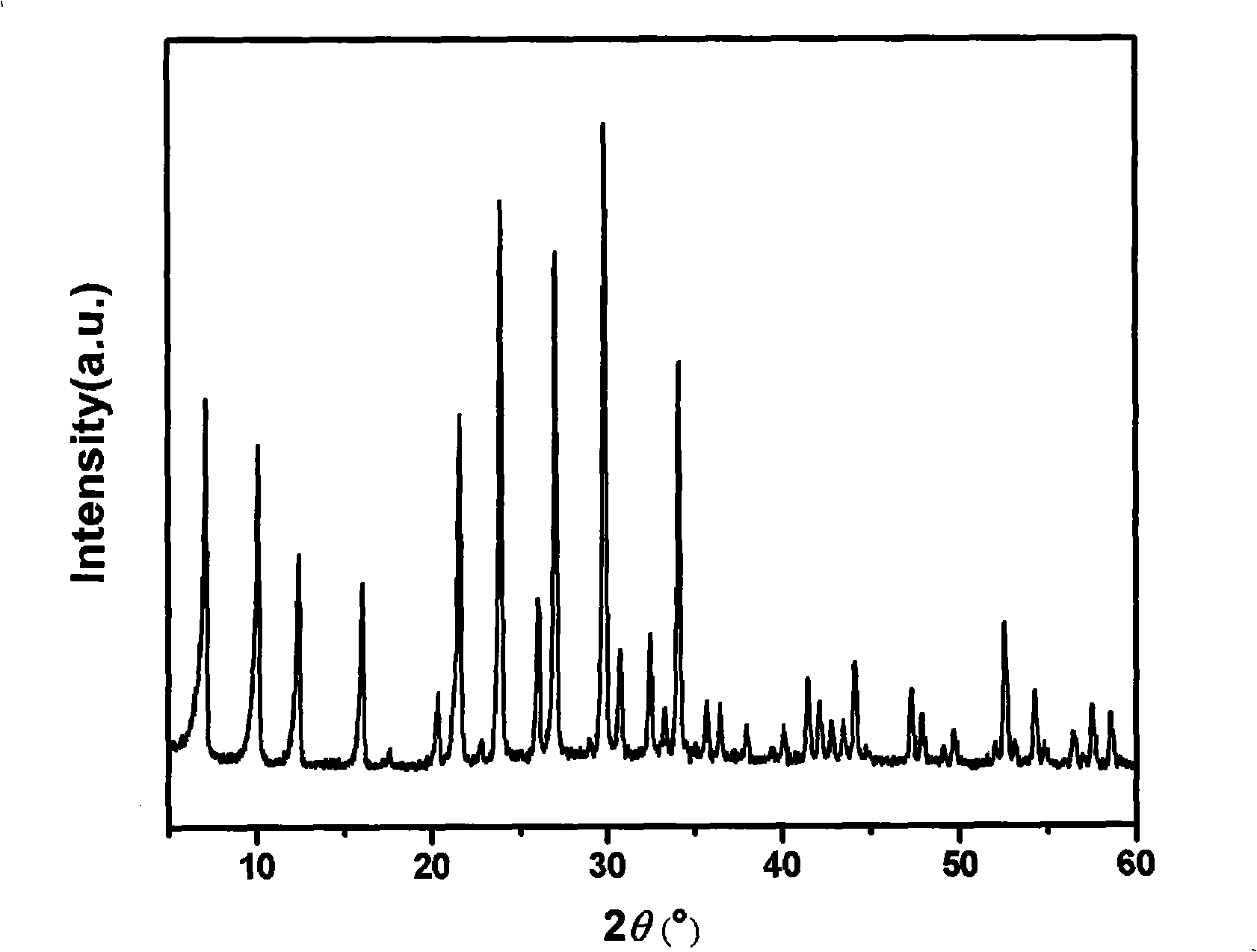

High-temp alkali fusing-hydrothermal crystallizing process for preparing A-type zeolite from coal gangue

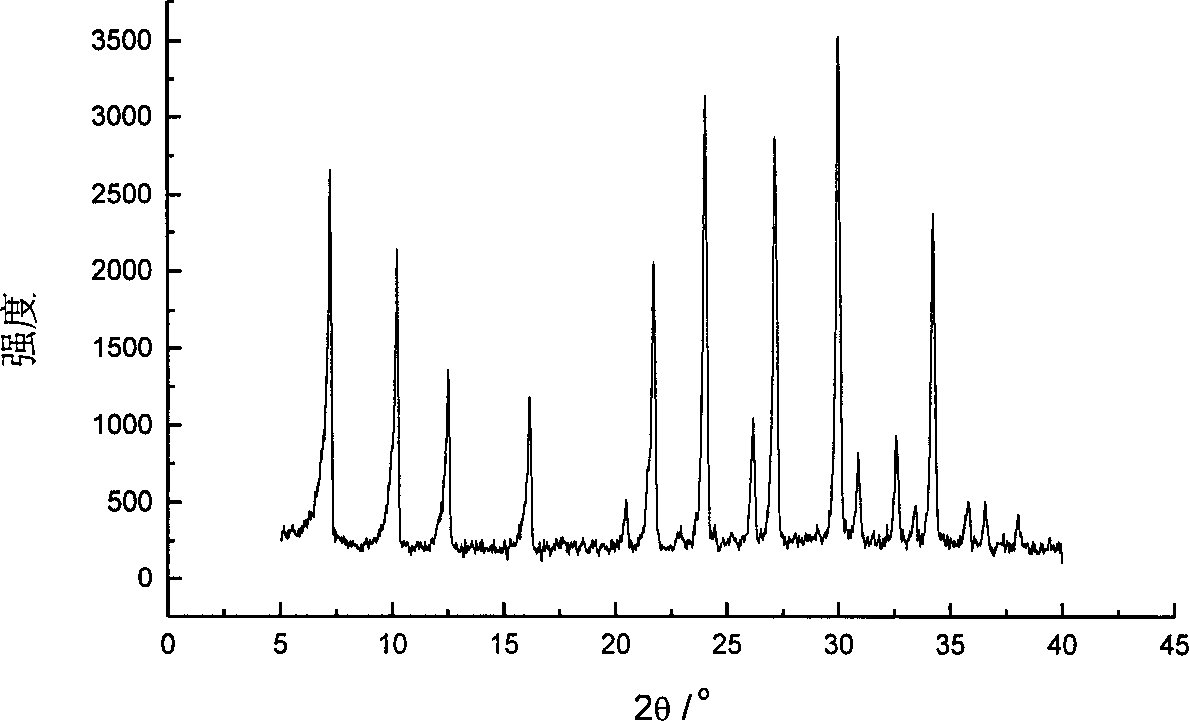

InactiveCN1346794AFully activate active ingredientsHigh crystallinityOther chemical processesAluminosilicate zeolite type-ACrystallinitySilicon

A process for preparing A-type zeolite from coal gangue includes high-temp fusing of coal gangue in alkali flux, adding water and crystallizing. In the process, the Na2O / SiO2, SiO2 / Al2O3 and H2O / Na2O are respectively controlled to be (1-3), (1-3.5) and (30-150). Its advantages are full activation of all active Si and Al components in coal gangue, high crystallinity and high purity.

Owner:FUDAN UNIV

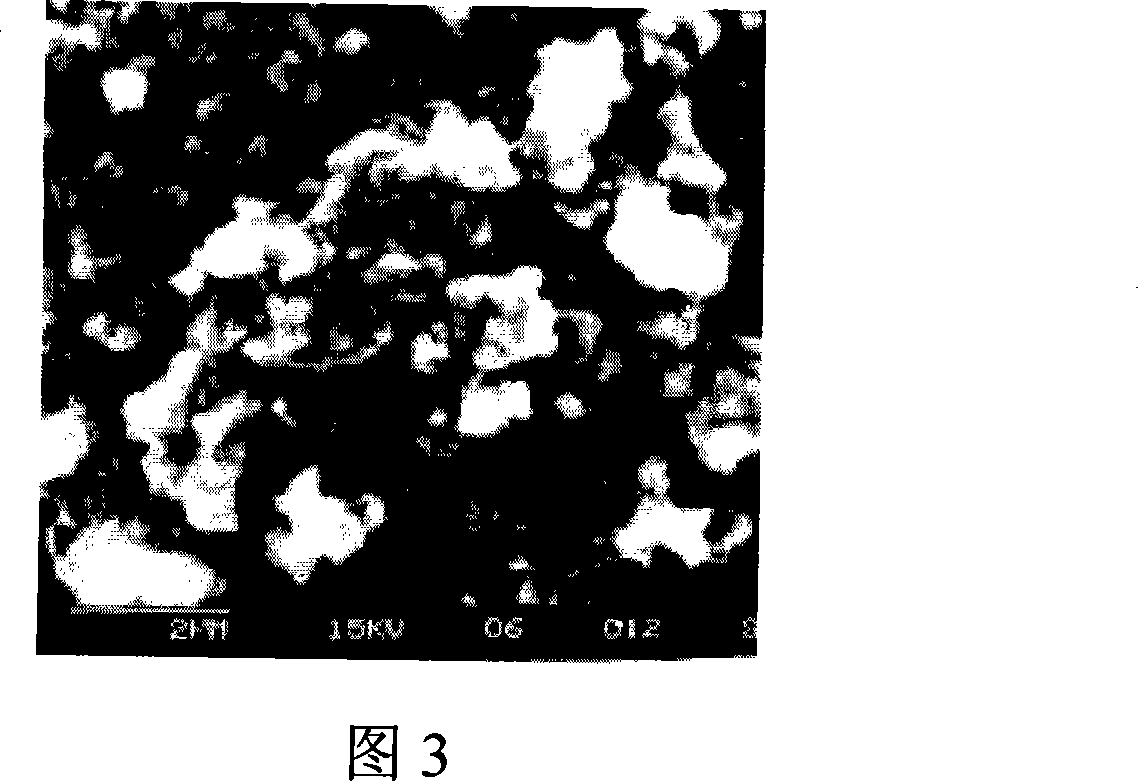

Method for synthesis of 4A molecular sieve with coal ash alkali melting method

InactiveCN101367529AImprove gelationHigh gelation rateAluminosilicate zeolite type-AMolecular sieveMixed materials

The invention discloses a method for synthesizing 4A molecular sieve by adopting the fly ash in alkaline dissolving method; the fly ash with Al2O3 being more than or equal to 36 percent (36 percent to 46 percent), and the mol ratio of the SiO2 / Al2O3 being 1.8 to 2.1 is used to be mixed with alkali according to the mol ratio of Na2O / Al2O3 is 3 to 10, and to be milled and well distributed; the mixed material with the height of each layer being 4 to 8 cm is arranged inside a high-temperature furnace at the temperature of 550 to 800 DEG C to be calcined and activated for 1 to 3 hours. After being dissolved by the water, the mol ratio of H2O / Na2O is controlled to be 30 to 60, and is mixed at the temperature of 50 to 80 DEG C for 1 to 3 hours, and is colloidized, and then is heated to the temperature of 100 plus or minus 10 DEG C to be held quietly for the crystallization for 4 to 6 hours; after the reaction, the material is filtered, and is washed until the pH value is equal to 9 to 11, and is dried to get the 4A molecular sieve. The molecular sieve is white, the calcium exchanging quantity is more than or equal to 310 mg of CaCo3 / g; and the sieving rate is more than or equal to 90 percent. The invention can integrally use the fly ash of the waste pollutant, and has the advantages of high utilization rate, simple process flow procedures, environmental protection, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash

InactiveCN103204518AImprove water retentionIncrease productionSolid waste disposalFaujasite aluminosilicate zeoliteCation-exchange capacityBottom ash

The invention discloses a method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash. The method comprises the following steps of: carrying out decarburization treatment on the coal ash by a screening machine and mixing the treated coal ash with the bottom ash which is milled by a ball mill; adding alkali liquor in a liquid-solid weight ratio of (5:1) to (9:1); reacting for 1-2 hours under the condition of 50r / min-70r / min by stirring, and the reaction temperature being 95 DEG C to 100 DEG C, and crystallizing by stirring for 4-6 hours at the speed of 20 revolutions / minute to 40 revolutions / minute and the crystallizing reaction being 95 DEG C to 100 DEG C; washing and crystallizing until the pH value is 9-10, dehydrating and filtering, and drying for 3-5 hours under the condition of 85 DEG C to 100 DEG C to a dried zeolite product with the content of 76w%-81w%. According to the method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash disclosed by the invention, the synthesis material coal ash is free of any roasting pre-treatment and calcining pre-treatment; the synthesis process is a hydro-thermal synthesis process under normal pressure; and the obtained zeolite has the characteristics of being high in cation exchange capacity, high in specific surface area and the like.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

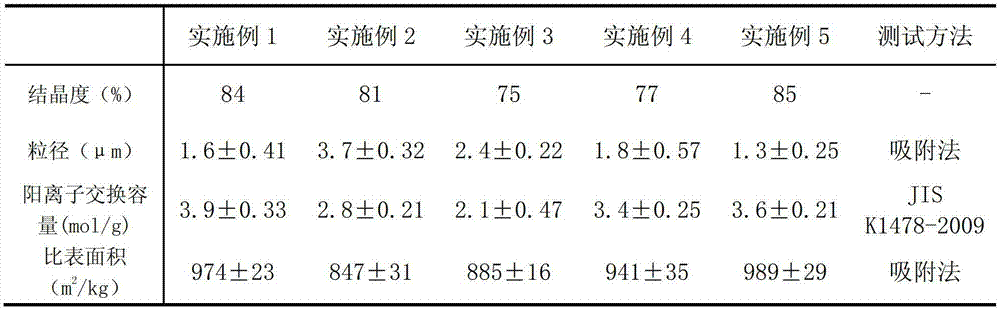

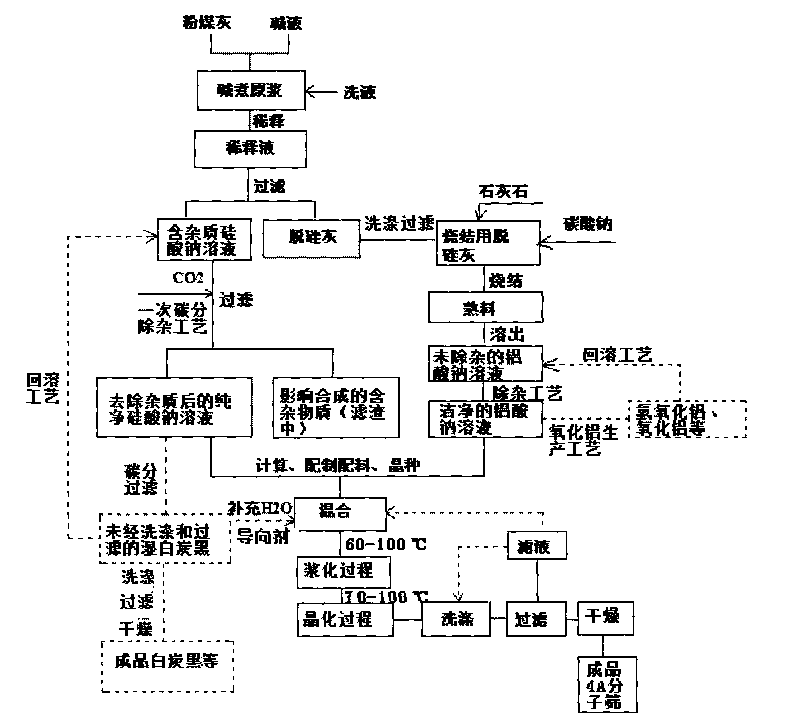

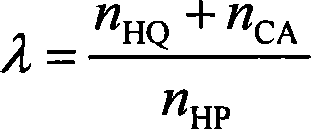

Method for producing 4A molecular sieve

InactiveCN101445254ALower requirementRemoval of Synthetic Affecting FactorsAluminosilicate zeolite type-ASodium aluminateSODIUM SILICATE SOLN

A method for producing a 4A molecular sieve comprises the following steps: (a) an intermediate product sodium silicate solution or a product carbon white obtained in the process of extracting silicon dioxide by a fly ash alkali solution method, (b) an intermediate product sodium aluminate solution or products aluminum hydroxide and aluminum oxide obtained in the process of extracting aluminum oxide by a fly ash soda lime sintering method, (c) NaOH and (d). H2O are taken as raw materials which meet the following mol ratios: Na2O:SiO2=1.6-3.8:1 and SiO2:Al2O3=1.7-2.1:1, and water added is controlled at the mol ratio of H2O:Na2O=30-60:1; and the raw materials are evenly mixed, stirred and gelled at 50-80 DEG C, heated to 90-120 DEG C, kept standing and crystallized for 3-6 hours, filtered, washed and dried to obtain the 4A molecular sieve. The calcium exchange capacity of the produced 4A molecular sieve is not less than 310mgCaCO3 / g, and the sieving rate of a 1.25mm sieve is not lower than 90%.

Owner:PINGSHUO INDAL

Production method of 4-A molecular sieve

InactiveCN101693542AEfficient removalWide variety of sourcesAluminosilicate zeolite type-ASodium aluminateSODIUM SILICATE SOLN

A production method of 4-A molecular sieve is disclosed, wherein raw materials comprise sodium silicate solution which is obtained through resolving intermediate product sodium silicate solution or product white carbon black in alkaline solution or sodium silicate solution with low modulus and low concentration in the manufacturing process of silicon dioxde which is extracted by adopting the coal ash alkali-soluble method, intermediate product sodium aluminate solution or product aluminum hydroxide, and aluminum oxide solution which are obtained in the production process of aluminum oxide through the coal ash desiliconisation sintering method, sodium-hydroxide and water, the components satisfy the following mole proportion conditions: SiO2: Al2O3=1.5-2.5, Na2O: SiO2=1-10, and filled water H2O: Na2O=10-80, the raw materials are mixed, are stirred into glue, and are added with guiding agent, the temperature rises to 70-100 DEG C, the mixed solution is stationarily placed for crystallization, then the soultion is led out, filtered and washed until the pH value is smaller than 11, and finally the solution is dried in 70-80 DEG C for abtaining 4-A molecular sieve.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

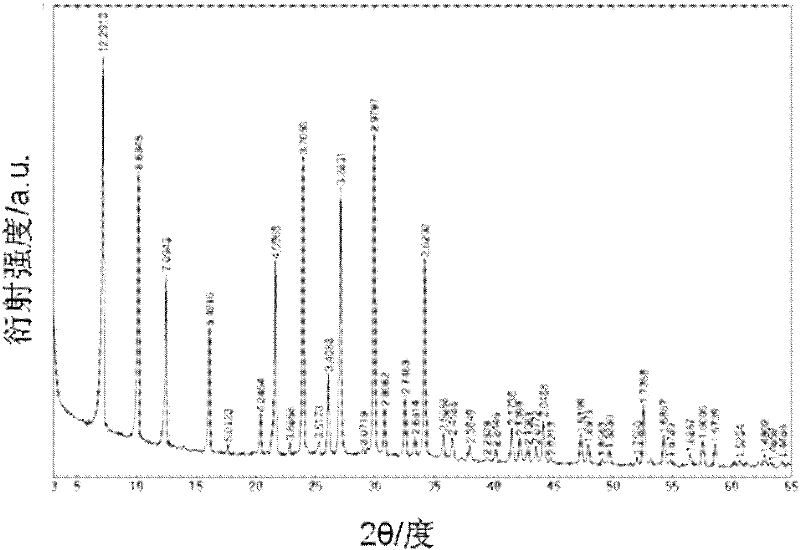

Zeolite molecular sieve and its prepn process with palygorskite as material

InactiveCN101066766AMolecular sieve catalystsAluminosilicate zeolite type-AMolecular sievePalygorskite

The present invention discloses one kind of zeolite molecular sieve and its preparation process with palygorskite as material. The zeolite molecular sieve is prepared through reacting palygorskite and alkali solution in 5-20 times, and the subsequent washing and drying. The prepared zeolite molecular sieve has type controlled through altering the ratio between palygorskite and alkali solution. The process of preparing zeolite molecular sieve with palygorskite as material is simple.

Owner:ZHEJIANG UNIV

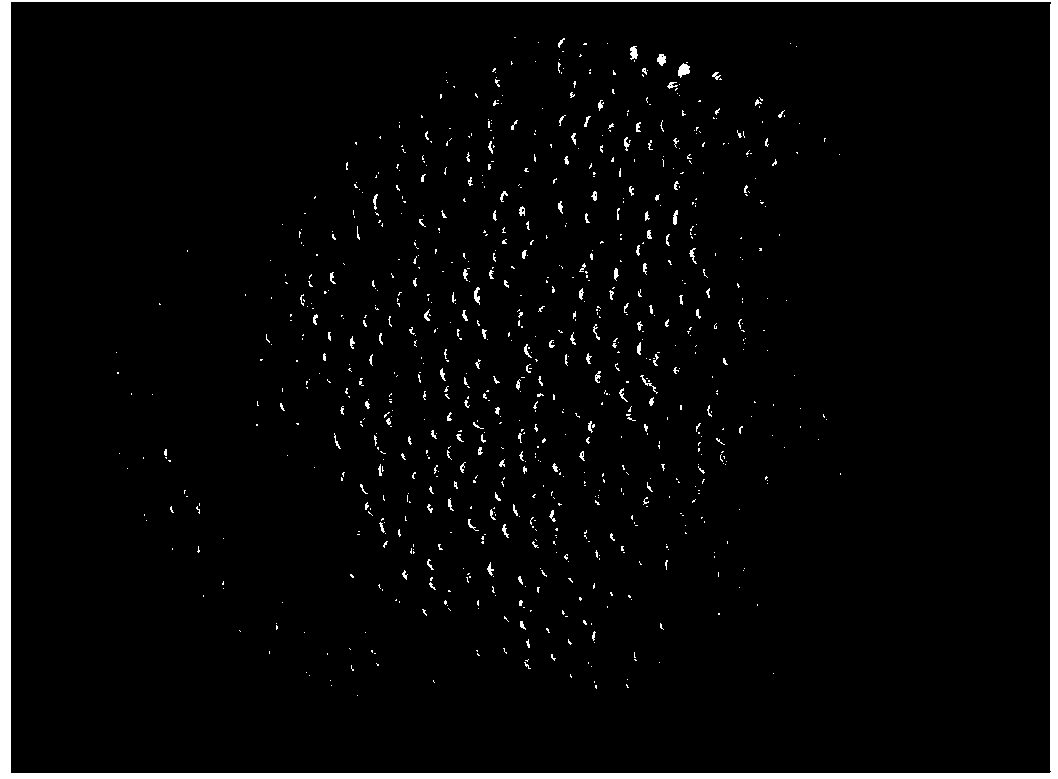

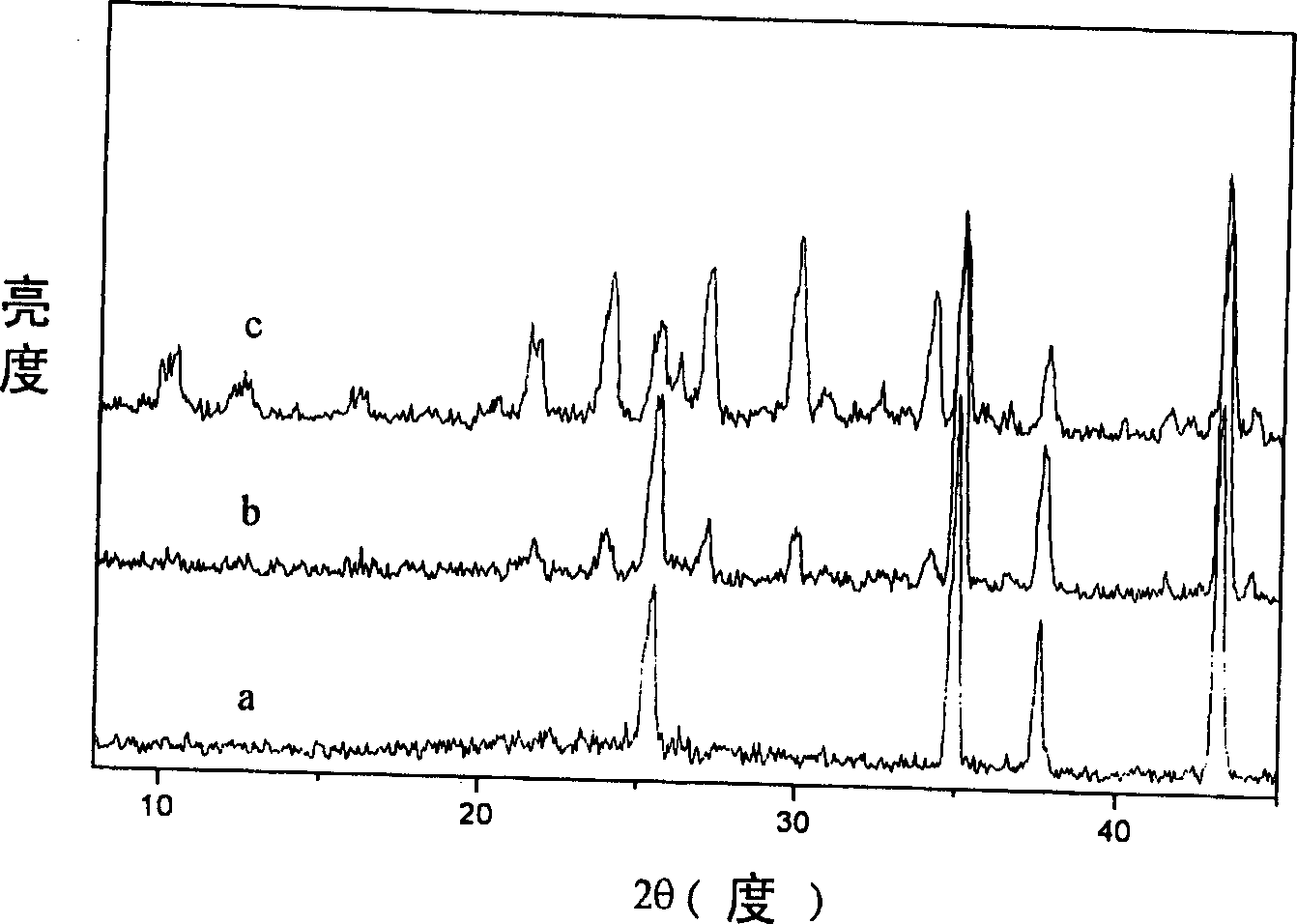

Method for synthesizing molecular sieve film using vacuum crystal method

InactiveCN1467017AEasy to separateGood repeatabilitySemi-permeable membranesAluminosilicate zeolite type-ASolution compositionChemistry

A process for synthesizing A-type molecular sieve membrane by the vacuumizing and coating crystals method includes such steps as introducing a layer of uniform crystal seeds to the surface of base membrane by vacuumizing or compressing method, and synthesizing A-type molecular sieve membrane by hydrothermal synthesis and microwave synthesis, where the used solution contains Na2O, Al2O3, SiO2 and H2O. The resulting molecular sieve membrane features high separation performance and high repeatability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of porous 5A molecular sieve for straight-chain alkane adsorption

InactiveCN104045095AHave diversityGood saturated adsorption capacityOther chemical processesAluminosilicate zeolite type-AAlkaneSilicic acid

The invention discloses a preparation method of a porous 5A molecular sieve for straight-chain alkane adsorption and belongs to the technical field of molecular sieve adsorbents. The preparation method comprises the following steps of adding ethyl orthosilicate into a sodium hydroxide aqueous solution, carrying out stirring for some time, fully dissolving sodium metaaluminate in water, fast mixing the two solutions, carrying out violent stirring to obtain milky colloid, carrying out crystallization on the colloid at a temperature of 80-95 DEG C for 4-6h, carrying out cooling, carrying out filtration, carrying out washing until a pH value is less than 9, carrying out drying by an oven to obtain 4A molecular sieve raw powder, carrying out ion exchange on the 4A molecular sieve raw powder and a calcium chloride solution to obtain the 5A molecular sieve. The 5A molecular sieve has n-decane static saturated adsorption capacity of 0.538g / g and n-pentdecne static saturated adsorption capacity of 0.647g / g. The 5A molecular sieve is prepared from an organic silicon source ethyl orthosilicate replacing an inorganic silicon source sodium silicate so that the channels of the 5A molecular sieve have diversity. The 5A molecular sieve has a good saturation adsorption amount of straight-chain alkanes.

Owner:CHANGZHOU UNIV

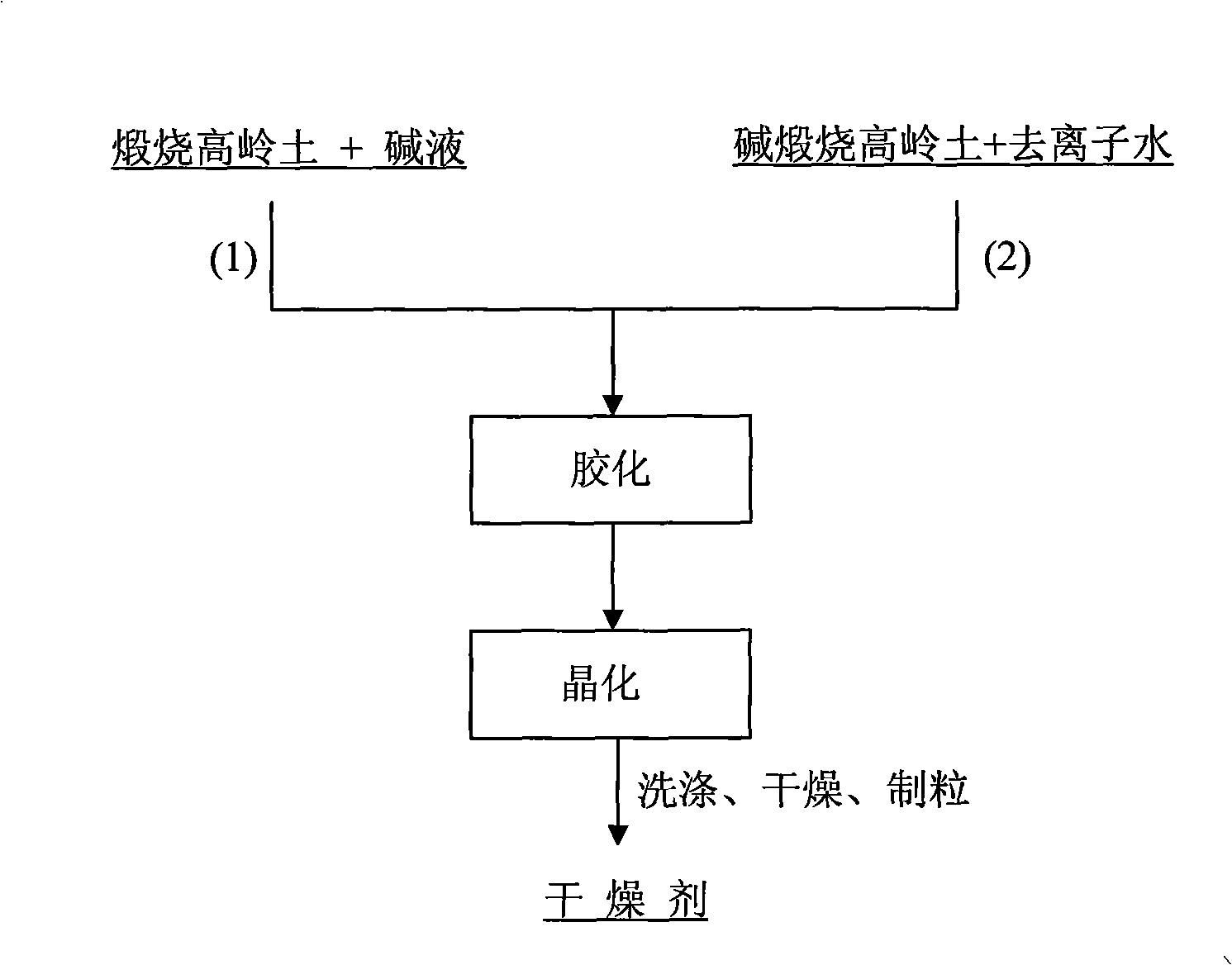

Method for synthesizing 4A molecular sieve drier using kaoline

InactiveCN101406825ASimple processRaw materials are easy to getOther chemical processesDispersed particle separationMolecular sieveChemical industry

The invention discloses a method for preparing a 4A zeolite molecular sieve desiccant with high crystallinity through a raw material of common natural kaolin. The method comprises the following steps: taking kaolin as the raw material, roasting the kaolin by a direct roasting method or a dry-process alkali roasting method, colloidizing, crystallizing, and suction filtrating and cleaning the kaolin through deionized water, and then drying the kaolin; and adding clay mineral bentonite or kaolin crude ore into the kaolin for granulation, and then obtaining the 4A zeolite molecular sieve desiccant after roasting. The method has the advantages that the method has a simple preparation process, raw material available, and loose operating conditions; and the synthesized 4A zeolite molecular sieve has the characteristics of high crystallinity, small particle size, good dispersibility, and high static water adsorption rate and high strength against crushing. The static water adsorption rate of the desiccant reaches 21.5 weight percent, and the strength against crushing reaches 62.1N / particle. The indexes reach the standards of the Department of Chemical Industry.

Owner:CENT SOUTH UNIV

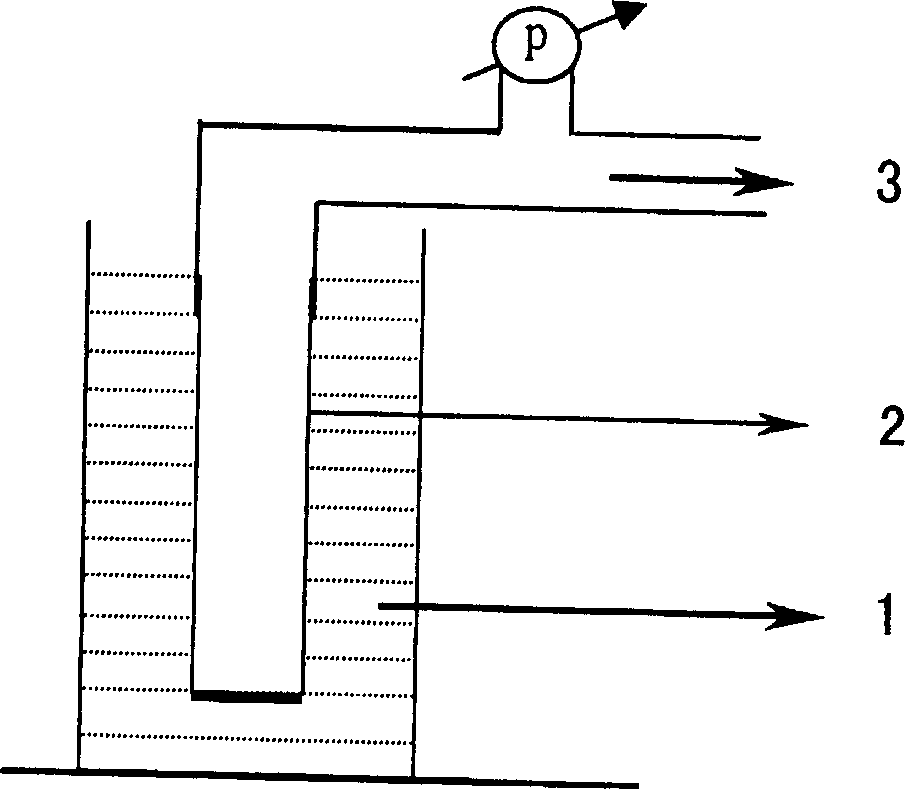

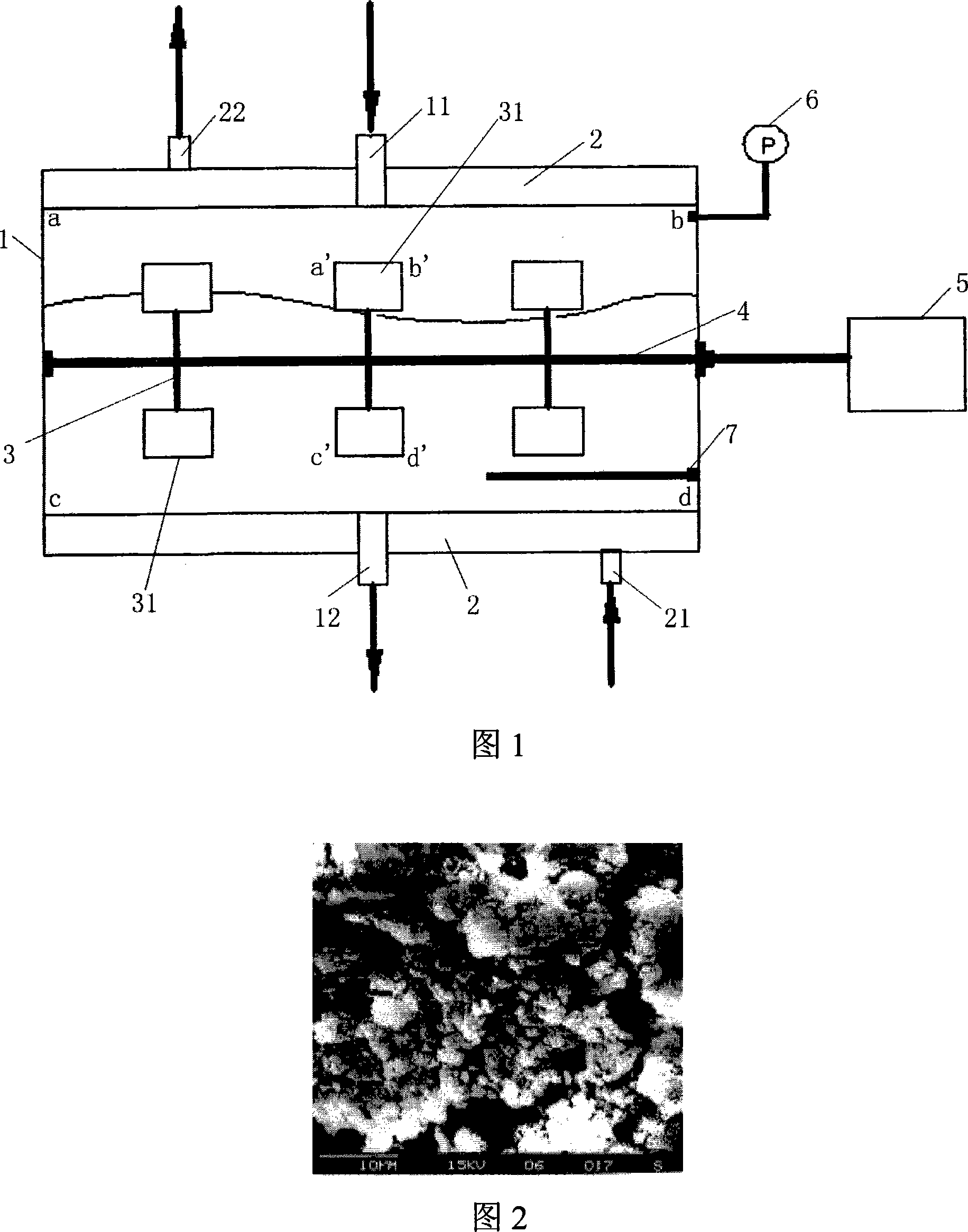

Method for preparing molecular sieve in reaction vessel

InactiveCN101205071AUniform distribution of reaction temperatureEasy to controlFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveMixing effect

The invention discloses a method for producing a molecular sieve in a horizontal reaction vessel. The horizontal reaction vessel of the invention is used for hydrothermal method or sol-gel method and method for composing the molecular sieve relating to liquid and solid mixed system which can be used for composing all microporous molecular sieves, mesopore molecular sieves and microporous-mesopore composite molecular sieves. The invention overcomes the defects of bad mixing effect of the liquid and the solid in compositing the molecular sieve in a vertical reaction vessel and difficulty in controlling pore canal structure, grain diameter and distribution of the product thereof.

Owner:EAST CHINA UNIV OF SCI & TECH

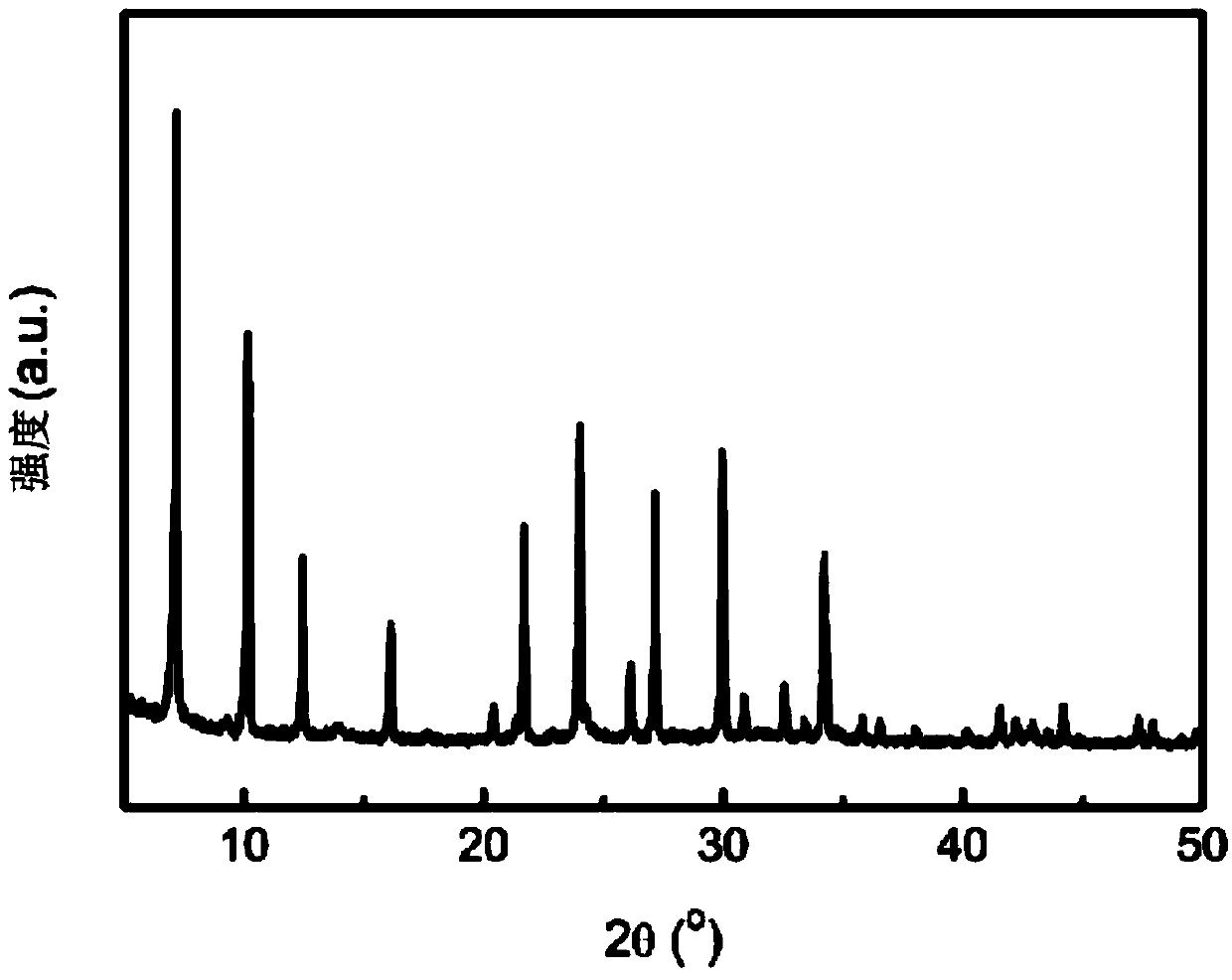

Method for preparing NaA molecular sieve from geopolymer

ActiveCN102583428ASimple processSuitable for large-scale productionAluminosilicate zeolite type-AChemical synthesisAluminum silicate

The invention mainly discloses a method for preparing a NaA molecular sieve from a geopolymer. The method comprises the following steps: with metakaolin or chemically-synthesized aluminum silicate active powder as a solid raw material and sodium potassium silicate or sodium hydroxide solution as an exciting agent, adjusting the ratio of silicon to aluminum in a system by using boehmite; mixing the solid raw material with the alkali exciting agent according to the ratio of silicon to aluminum and the ratio of sodium to aluminum in the raw materials in the composition design of the NaA molecular sieve; stirring the solid raw material and the alkali exciting agent and injecting the mixture into a die; carrying out sealed curing the mixture in a thermostat at the temperature of 60-80 DEG C for 6-24 hours; feeding the cured geopolymer sample into a hydrothermal reactor; and carrying out hydrothermal crystallization on the cured geopolymer sample at the crystallization temperature of 70-110 DEG C for 4-10 hours to obtain the NaA molecular sieve. According to the method disclosed by the invention, due to the utilization of the characteristic that the geopolymer is easily formed, a NaA molecular sieve blocky material can be prepared in situ at one time. Compared with the preparation method for the NaA molecular sieve, the prepared method disclosed by the invention has the advantages of simplicity in operation, low cost and suitability for scale preparation.

Owner:GUANGXI UNIV

Synthetic method of 4A molecular sieve

InactiveCN104211082ALow activation energy consumptionReduce pollutionAluminosilicate zeolite type-AMolecular sieveActivation method

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-intensity molecular sieve and preparation method thereof

InactiveCN102502692AHigh mechanical strengthReduce wear rateFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveHigh intensity

The invention relates to a high-intensity molecular sieve and a preparation method thereof. The method comprises the following steps: uniformly mixing molecular sieve material and a binder so as to obtain molecular sieve quality A; adding structure intensifier into the molecular sieve quality A so as to obtain molecular sieve quality B, and then obtaining the high-intensity molecular sieve through forming, drying, roasting and cooling the molecular sieve quality B in sequence. The molecular sieve prepared by using the method provided by the invention not only has excellent mechanical strengthand also is low in abrasion ratio.

Owner:YANTAI UNIV

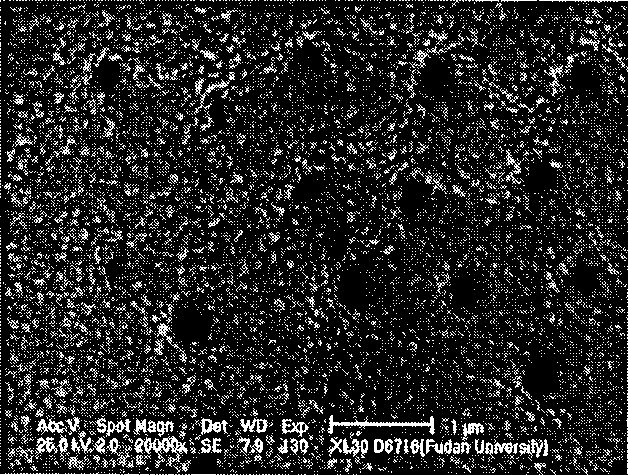

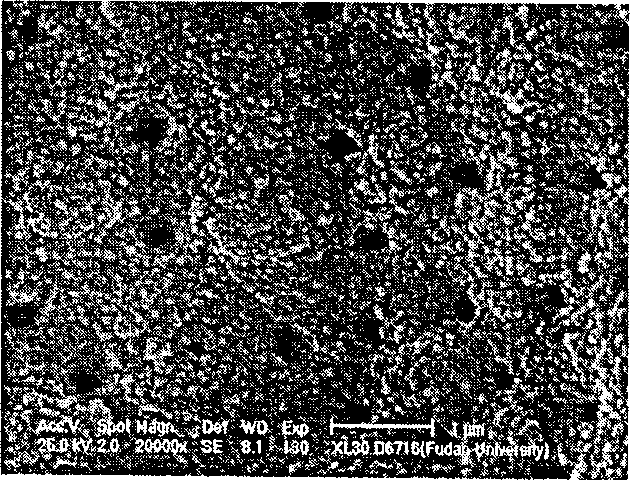

Method for preparing zeolite material in perforation type of multilevel pore canals

ActiveCN101003377AHigh zeolite contentImprove featuresFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-ASorbentSilica gel

This invention discloses a method for preparing multi-level porous cross-flow zeolite material. The method comprises: (1) dispersing zeolite microcrystal in water or inorganic salt solution to form colloidal solution; (2) soaking the multi-level porous cross-flow silica gel material in polyelectrolyte solution so that the surface of the modified backbone is charged; (3) soaking and washing the silica gel material obtained in step 2 in the colloidal solution obtained in step 1 under normal or negative pressure; (4) soaking the silica gel material obtained in step 3in the colloidal solution obtained in step 1 under normal or negative pressure, and performing secondary crystallization by using vapor phase method. The obtained multi-level porous cross-flow property and abundant macropores with high uniformity, and can be used in catalysis and adsorption-separation. It has obvious advantages against normal zeolite molecular sieve on catalyst, adsorbent, separating agent and water treatment.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for synthesizing NaA-type molecular sieve membrane on inner wall of support body

InactiveCN102583430AEasy to prepareEvenly distributedSemi-permeable membranesAluminosilicate zeolite type-AMolecular sieveAdhesive

The invention discloses a method for synthesizing a NaA-type molecular sieve membrane on an inner wall of a support body. The method adopts a way of adding an adhesive to coat seed crystal to synthesize the molecular sieve membrane. Clear liquid, composition of which is similar to that of synthetic liquid for synthesizing the molecular sieve membrane, is prepared to serve as the adhesive, and then the clear liquid is mixed with molecular sieve crystal suspension in certain proportion to prepare seed crystal liquid; the support body is immersed into the seed crystal liquid; the support body is dried after being dipped so as to obtain the support body with the seed crystal; and finally, the molecular sieve membrane is synthesized by a dynamic hydrothermal synthesis method. According to the invention, prepared seed crystal layers are distributed uniformly, the surface of the synthesized molecular sieve membrane is continuous and dense, and the synthesized molecular sieve membrane has an excellent separating property, is good in repeatability and is suitable for large-scale production.

Owner:ZHEJIANG UNIV

Method for preparing molecular sieve

ActiveCN108298553AShorten crystallization timeHigh crystallinityAluminosilicate zeolite type-AMolecular-sieve and base-exchange phosphatesMolecular sieveCrystallinity

The invention discloses a method for preparing a molecular sieve. The method comprises the following steps: preparing a molecular sieve gel, and crystallizing the molecular sieve gel under a gamma rayradiation condition to obtain the molecular sieve. The method greatly shortens the crystallization time of the synthesized molecular sieve and greatly improves the relative crystallinity of the molecular sieve.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

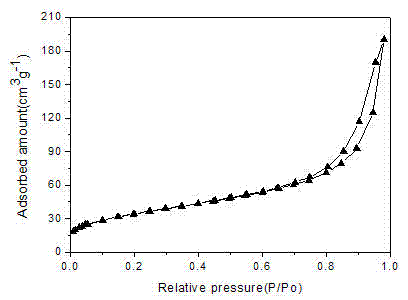

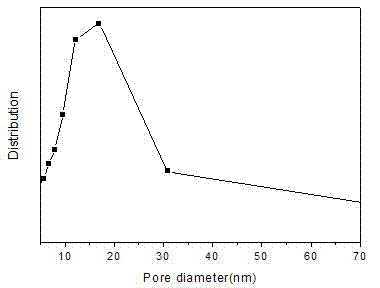

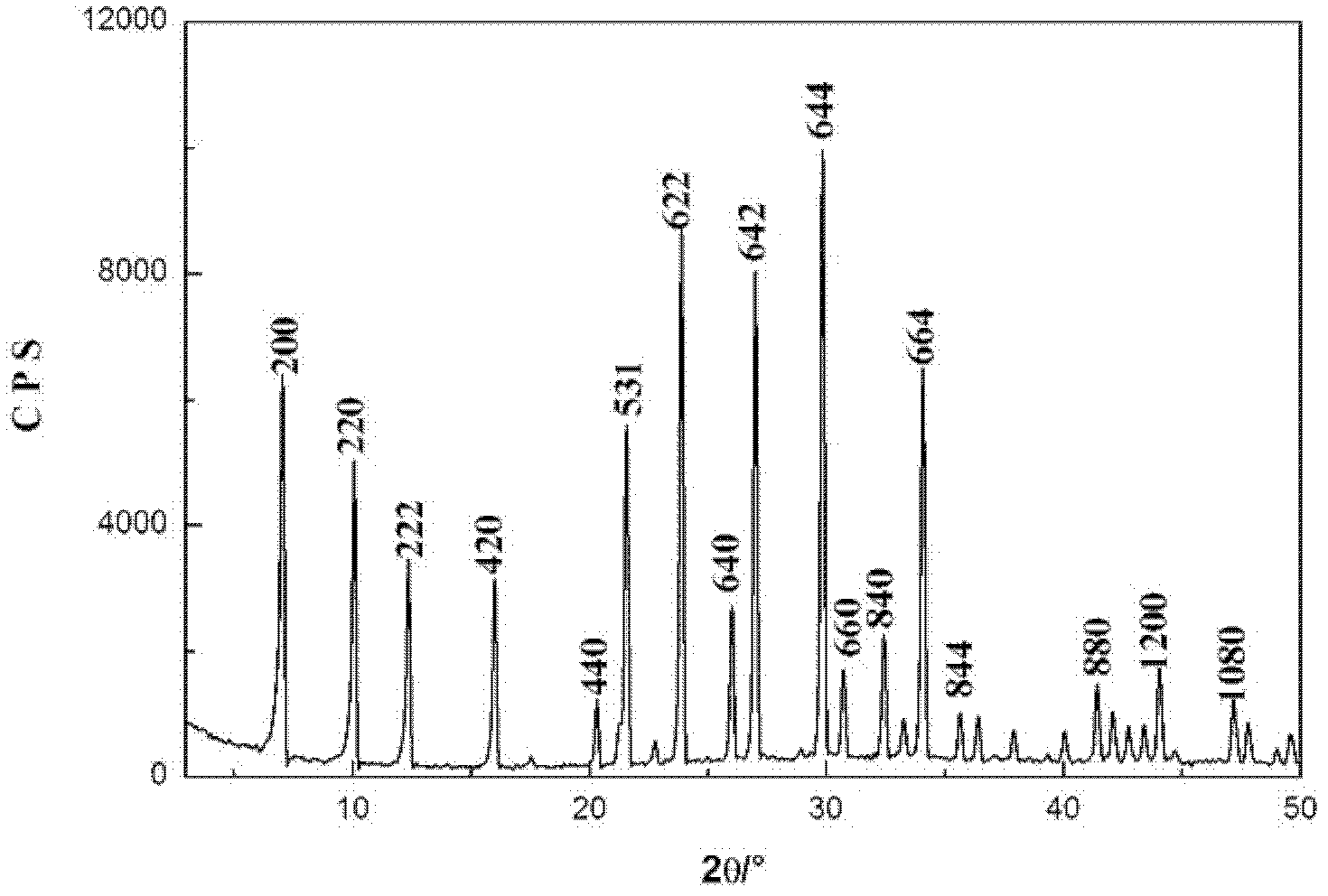

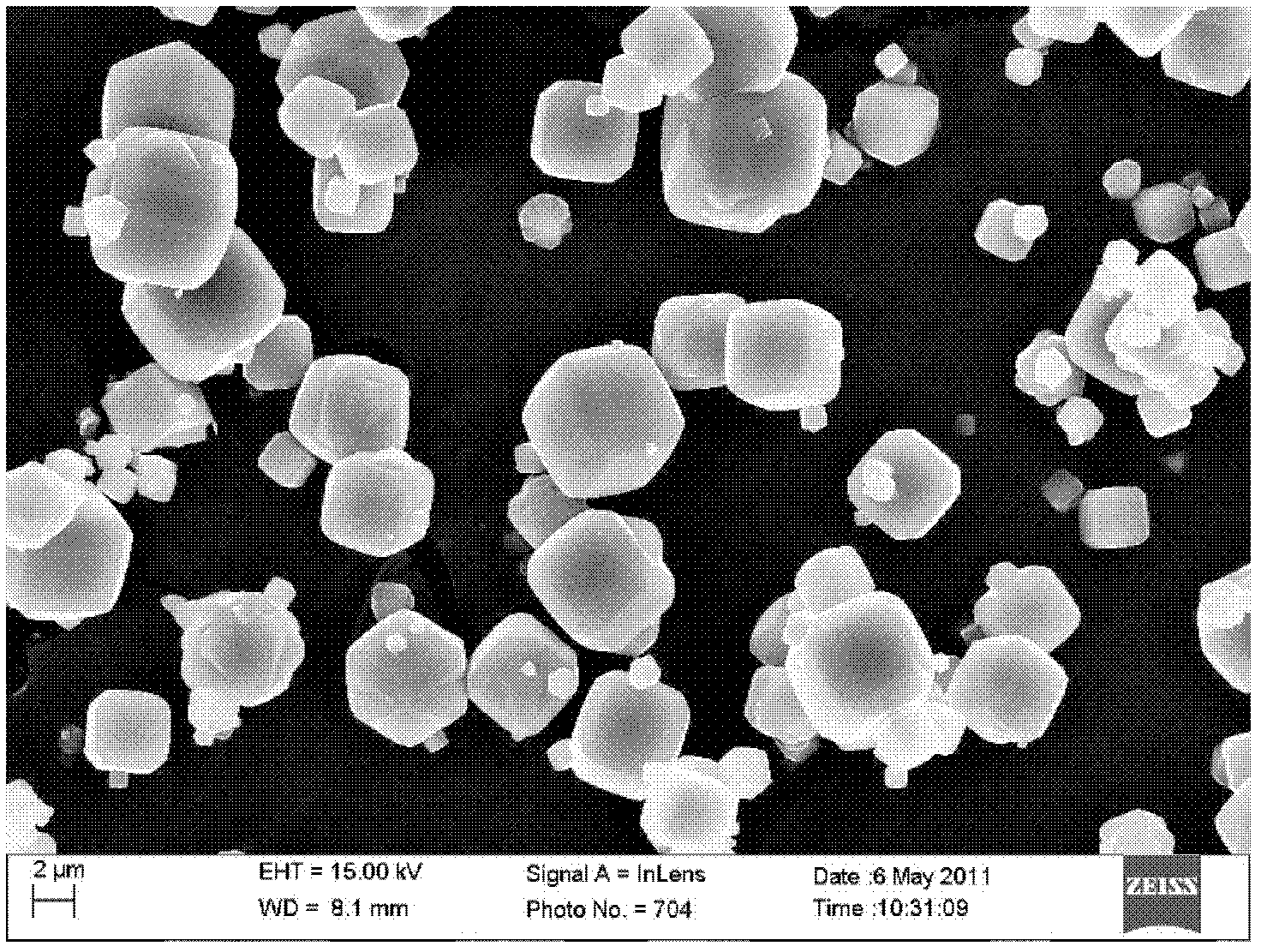

Composite method of mesoporous A type molecular sieve

ActiveCN102874836AImprove adsorption capacityIncrease speedAluminosilicate zeolite type-AMolecular sieveMultiwalled carbon

The invention discloses a composite method of a mesoporous A type molecular sieve. The composite method comprises the following steps: stirring and infusing multiwalled carbon nanotubes on the surface of template agent with silane coupling agent solution; adding the multiwalled carbon nanotubes processed with the silane coupling agent solution into a silicon source while adding another kind of silane coupling agent solution; processing the mixture under a heating condition to impel the mixture to react; transferring the mixture to an aluminum source after the reaction is finished; and removing template agent to obtain mesoporous A type molecular sieve through high temperature calcinations after stirring, crystallization, suction, filtration, cleaning and drying. According to the invention, the process method of the multiwalled carbon nanotubes is novel, the silane coupling agents are various, and the mesoporous A type molecular sieve obtained according to the method is high in heat stability.

Owner:TAIYUAN UNIV OF TECH

Method for synthesizing 4A-type molecular sieve by utilizing aluminum-silicon tailings obtained in process of carrying out potassium extraction on potassium feldspar

The invention relates to a method for synthesizing a 4A-type molecular sieve by utilizing aluminum-silicon tailings obtained in the process of carrying out potassium extraction on potassium feldspar. The method comprises the following steps: uniformly mixing the residual aluminum-silicon tailings obtained in the process of carrying out potassium extraction on potassium feldspar and 2 to 5mol / L of NaOH solution according to a certain ratio and stirring for 1 to 3 hours under the condition of a temperature of 24 DEG C to 26 DEG C; then carrying out hydrothermal crystallization on the mixed materials for 3 to 6 hours under the condition of a temperature of 90 to 100 DEG C and filtering after the crystallization reaction is finished; washing a filter cake to the pH value of 9 to 10 by distilled water; and drying to obtain the 4A-type molecular sieve. According to the invention, the residual aluminum-silicon tailings obtained in the process of carrying out potassium extraction on potassium feldspar replaces conventional chemical raw materials and the raw material cost is obviously reduced; the synthesis process is simple; the synthesized 4A-type molecular sieve has calcium ion exchange capacity of over 310mg; and the CaCO3 / g anhydrous 4A-type molecular sieve accords with the requirements of the 4A-type molecular sieve for a detergent, which are regulated by the light industry standard QB / T1768-2003. An effective approach is provided for efficiently and comprehensively utilizing the potassium feldspar resources by the process.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com