Method for preparing zeolite material in perforation type of multilevel pore canals

A technology of zeolite materials and channels, which is applied in the field of preparation of zeolite materials, can solve the problems of non-penetration, uniformity of zeolite, loading, etc., and achieve the effect of low device requirements, easy external control, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example illustrates the process of using methyl orthosilicate as the silicon source to prepare a through-flow silica gel monolithic column with multi-stage channels.

[0044] Stir 30ml of methyl orthosilicate, 6g of polyethylene glycol and 30ml of 0.01mol / L acetic acid solution evenly, seal it, and stir at 0°C for 50min. The obtained sol was poured into a polytetrafluoroethylene test tube or a glass tube, and aged in a water bath at 30°C for one day to obtain a wet silica gel column. Then soak the silica gel column with 0.01mol / L ammonia water to prepare mesopores. Then soak the cylinder with 0.1mol / L nitric acid solution, distilled water, 30% ethanol / water ethanol solution and Tween 80 for 6 hours. Finally, dry and roast to obtain the multi-stage channel through-flow silica gel monolith material A 1 .

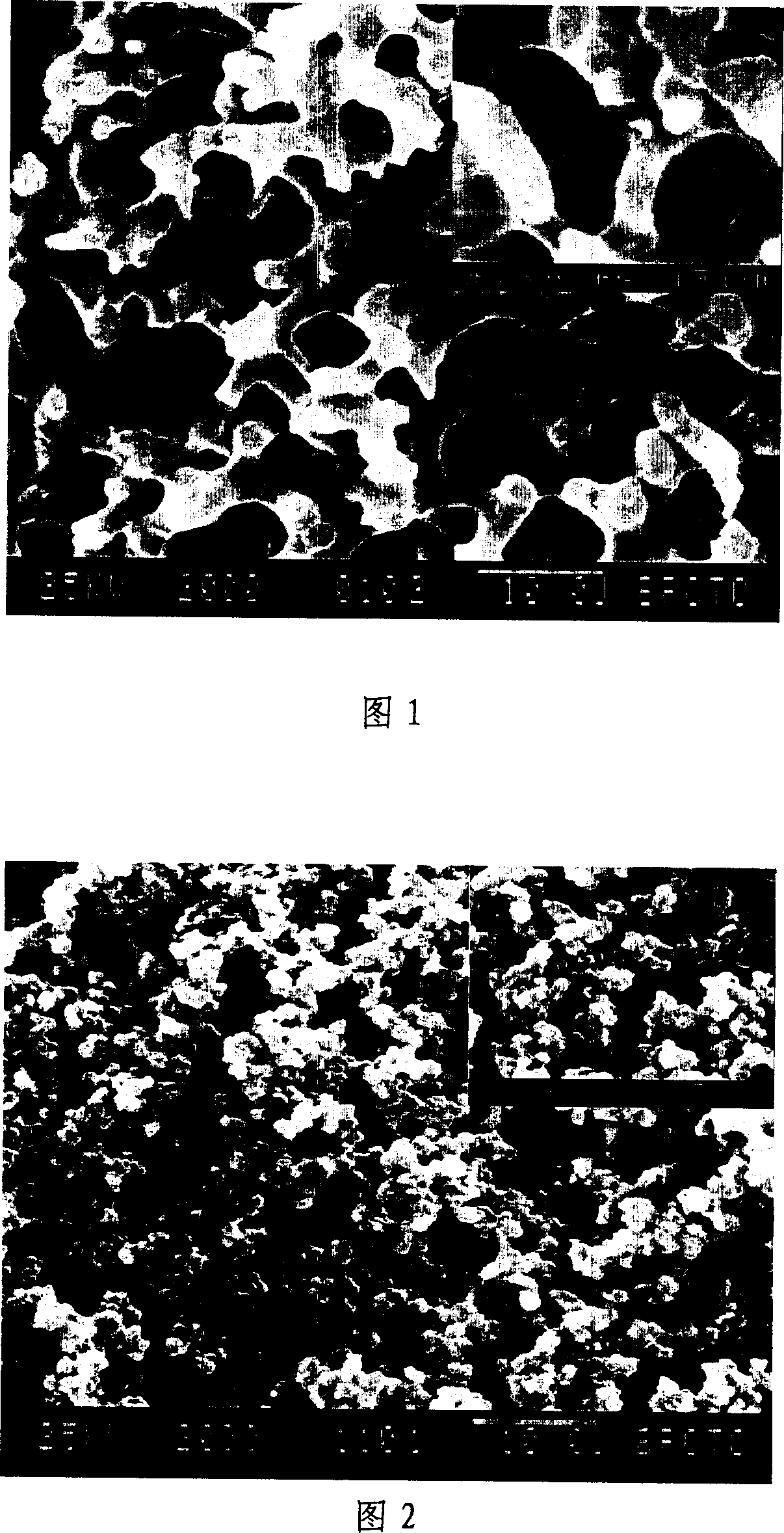

[0045] A 1 The SEM image is shown in Fig. 1, N 2 The adsorption-desorption curve is shown in Figure 12.

Embodiment 2

[0047] This example illustrates the process of preparing a through-flow monolithic column of silica gel with multi-stage channels using water glass solution as a silicon source.

[0048] Mix 20g of water glass solution, 2g of polyvinyl alcohol and 15ml of concentrated nitric acid evenly, pour the resulting sol into a test tube and seal it, place it in a water bath at 40°C for 40 hours, then soak it in deionized water for 4 days, and replace it every 24 hours. Water once, dry and roast at the end Multi-stage channel through-flow type silica gel monolithic material B 1 .

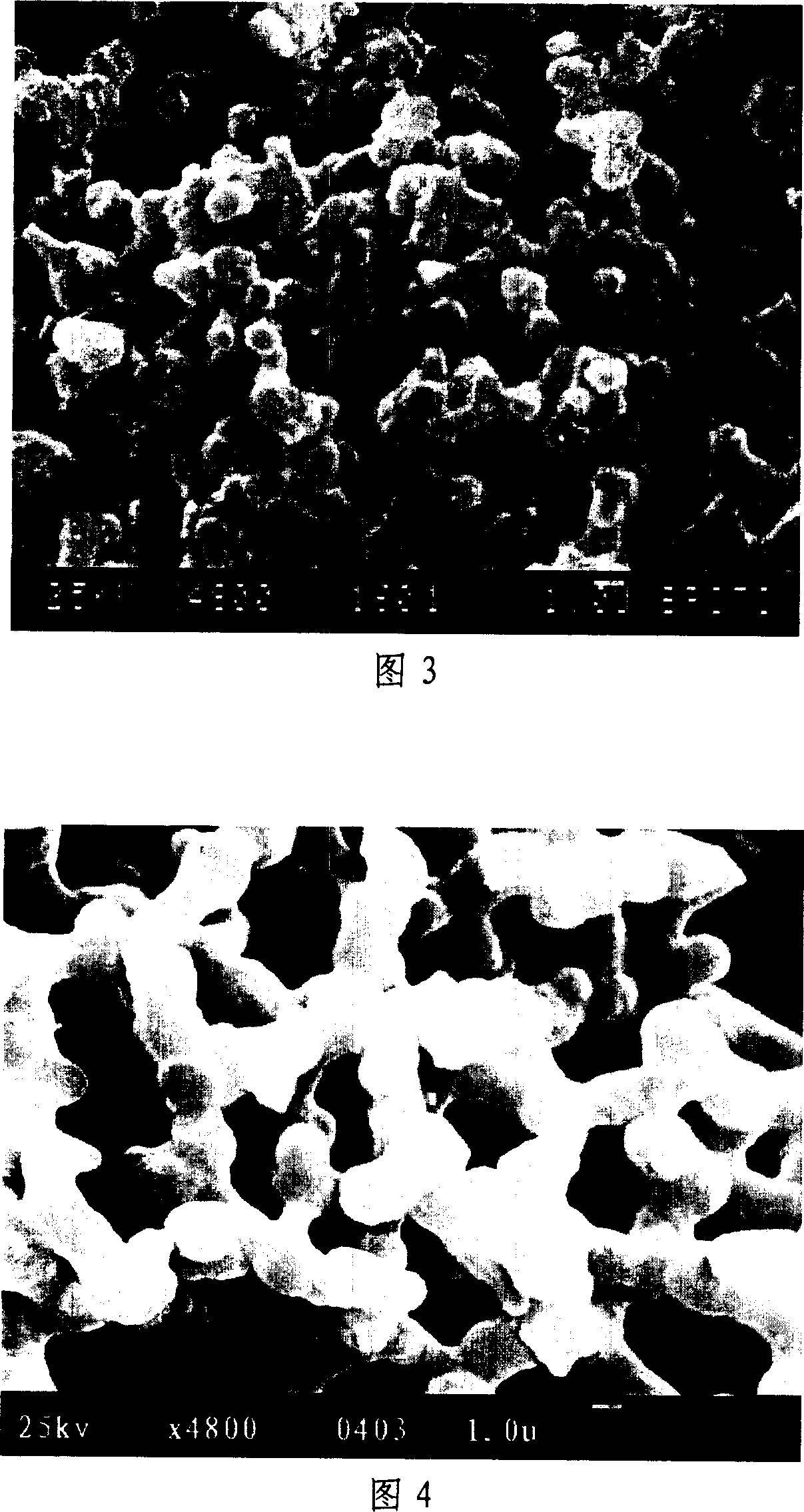

[0049] B 1 The SEM image is shown in Figure 2.

Embodiment 3

[0051] This example illustrates the process of preparing a double-hole silica gel column according to the method of Chinese Patent Application No. 200510073092.7.

[0052] Weigh 4.9737g of polyethylene glycol and pour it into a conical flask, add 52ml of 0.01mol / L acetic acid, and stir until completely dissolved. Measure 28.4ml TMOS into the conical flask, place the conical flask in an ice-water bath and stir vigorously for 30 minutes, then pour the obtained sol into a glass tube and seal it, and place it in a water bath at 40°C for 1-2 hours to gel. Then the wet silica gel column was soaked in water-ethanol solution and kept at 60°C for 24h. Then soak in the ethanol solution of TMOS and keep at 70°C for 72h. Then wash the silica gel column with ethanol and n-heptane at 50°C for 24 hours respectively, and finally dry and roast to obtain the double-hole silica gel column sample C with enhanced hardness. 1 . C 1 In the shape of cylindrical particles with a height of 1 cm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com