Patents

Literature

358results about How to "Increased crush strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

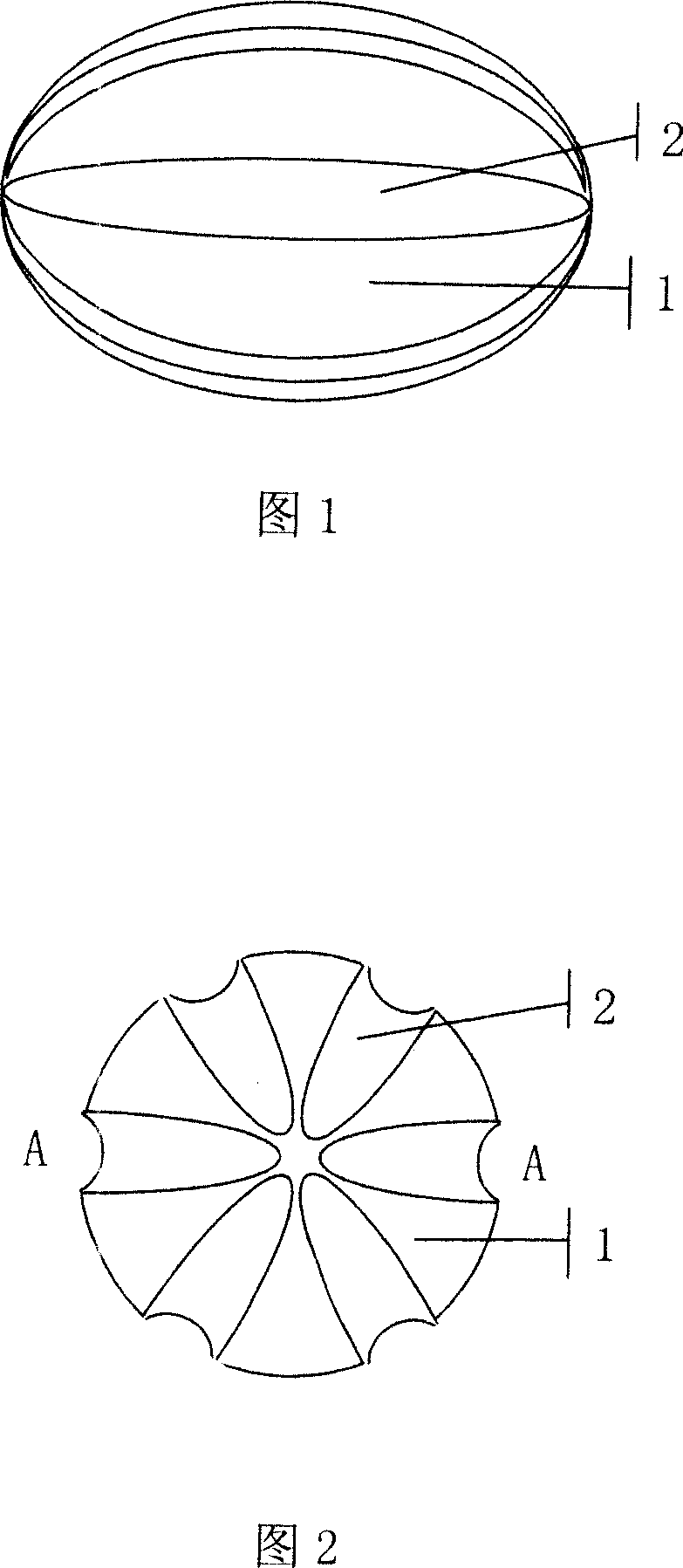

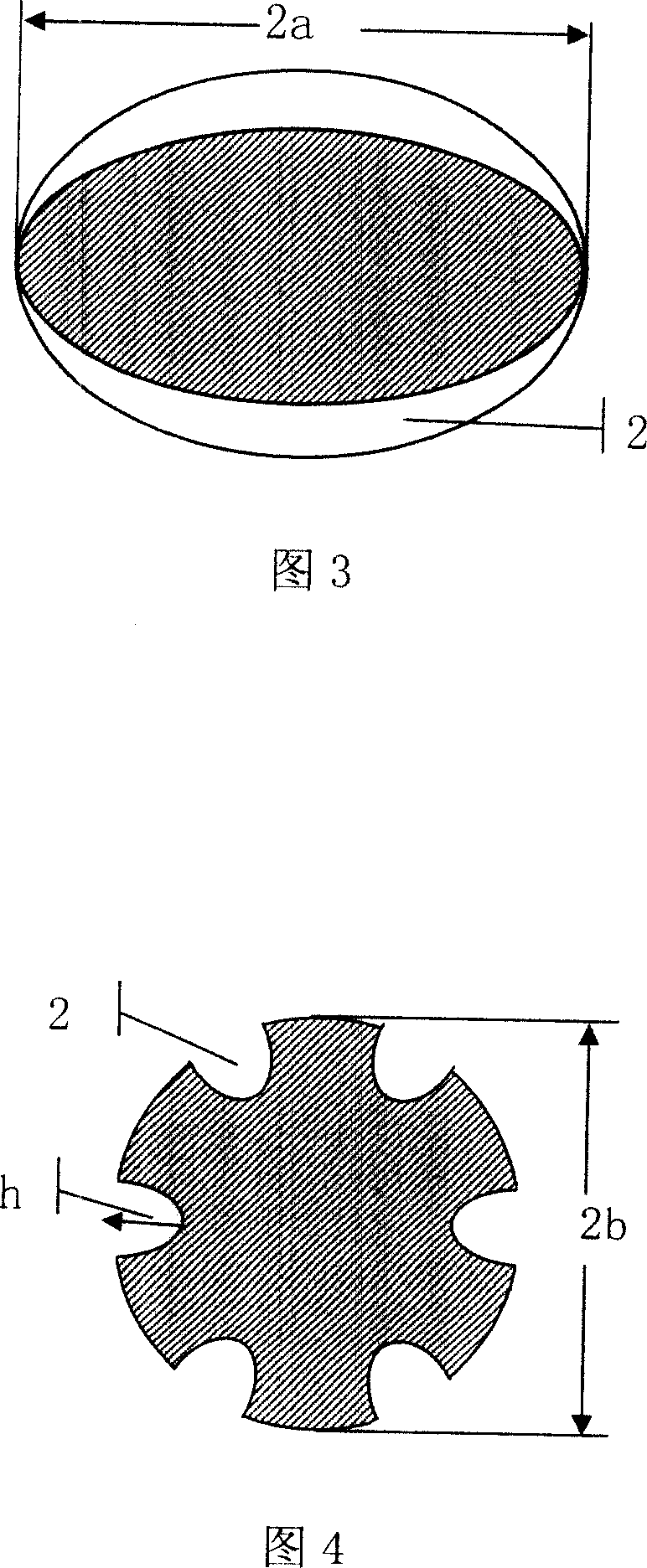

Carrier having a special feature, catalyzer and producing method thereof

ActiveCN101134173AHigh porosityHigh strengthPhysical/chemical process catalystsOil processingSorbent

The present invention is carrier in special shape, catalyst and their preparation process. The carrier is one ellipsoid with the major axis-to-minor axis ratio a / b of 1.05-2.5 and one or several grooves in the major axis direction. The carrier is prepared through pressing the material containing oxide hydrate in a mold to form, and heating the formed matter to convert the oxide hydrate into oxide. The carrier may be applied as adsorbent, catalyst carrier, reactor stuffing, etc. The catalyst prepared with the carrier has relatively great outer surface area and excellent mass transferring process, and may be applied widely in heavy oil processing reaction, etc, especially as hydrogenation activity protectant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

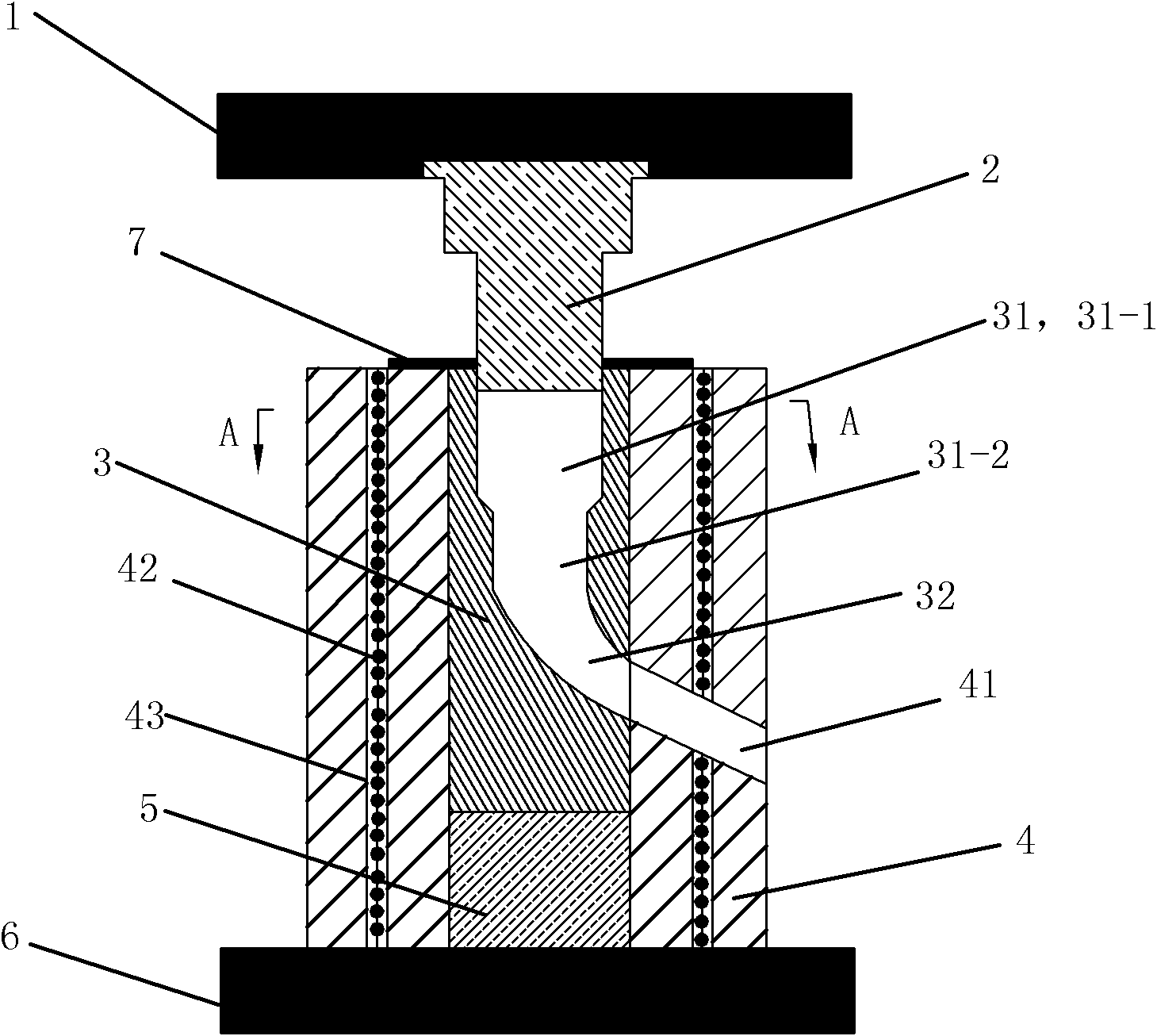

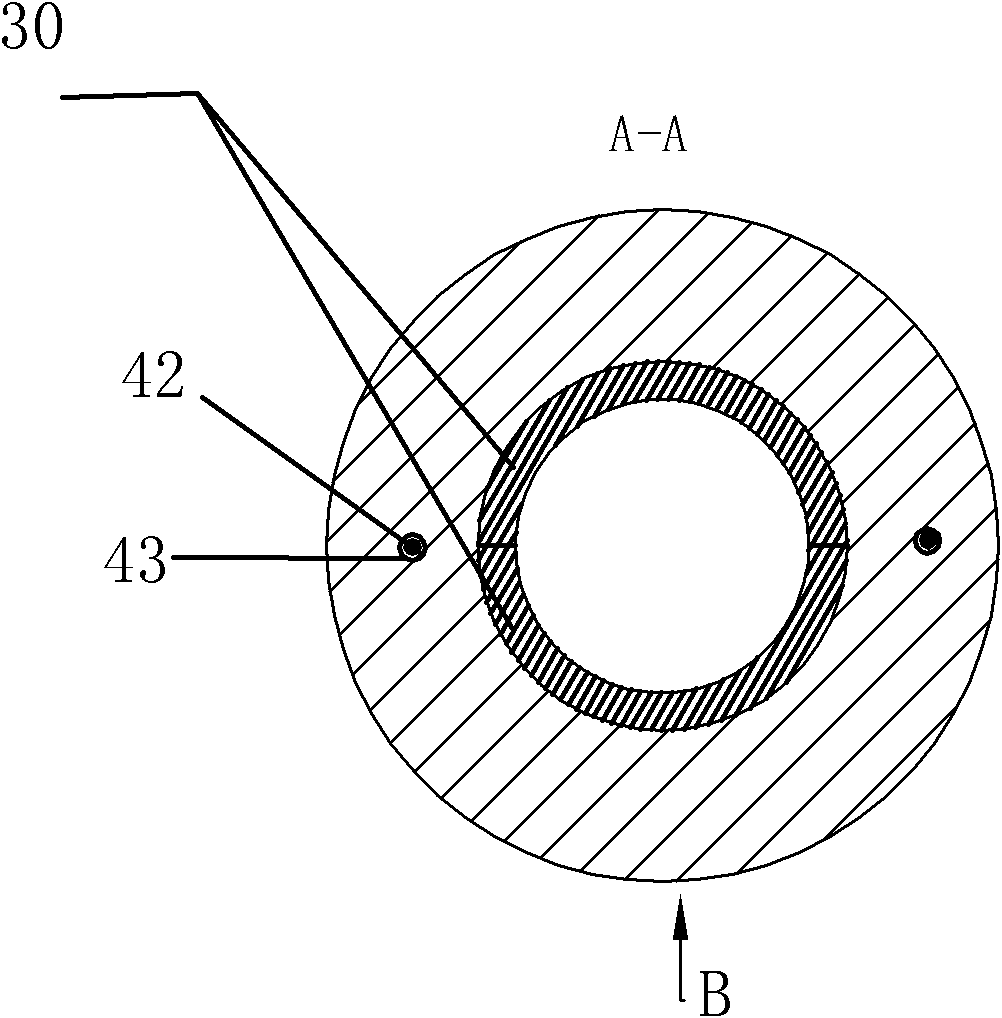

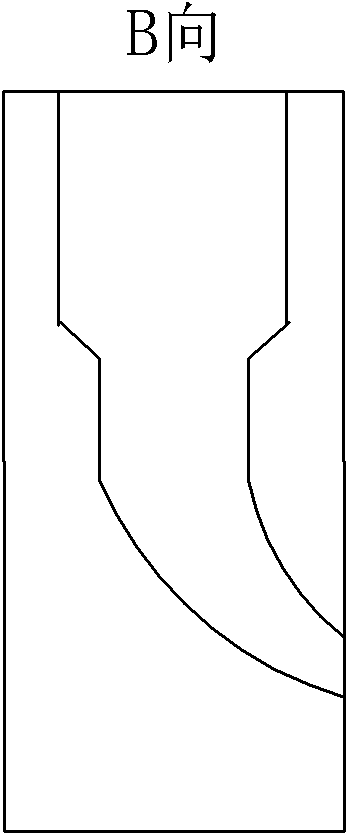

Method and die for forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets

InactiveCN101850376ASmall grain sizeSolve the problem of not being able to continuously prepare large-size semi-solid billetsExtrusion diesSemi solidLarge deformation

The invention discloses a method and a die for the forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets. The preparation method comprises a predeformation process and an isothermal spheroidizing heat treatment process, wherein in the predeformation process, uniform deformation of large deformation amount is realized by the die for the forward extrusion and variable diameter bending extrusion; cutting a magnesium alloy bar stock which is subjected to large deformation by a fixed size; heating the magnesium alloy bar stock cut by the fixed size at the temperature of between 520 and 580 DEG C under the protection of argon, and keeping the temperature of the obtained magnesium alloy bar stock for 10 to 30 minutes; and processing a bending extrusion angle of the die to be over 90 degrees. The method has the advantages of small predeformation resistance, large and uniform deformation, safety, reliability and no three-waste pollution. The grains of the prepared magnesium alloy semi-solid billets have fine size, are uniform and have a shape close to that of a sphere. The method solves the problem that the conventional SIMA method cannot continuously prepare the large-size semi-solid billets and meets the requirements of the semi-solid thixoforming workpieces for large-scale continuous production.

Owner:CHANGZHOU INST OF TECH

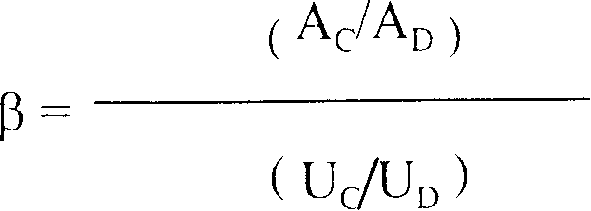

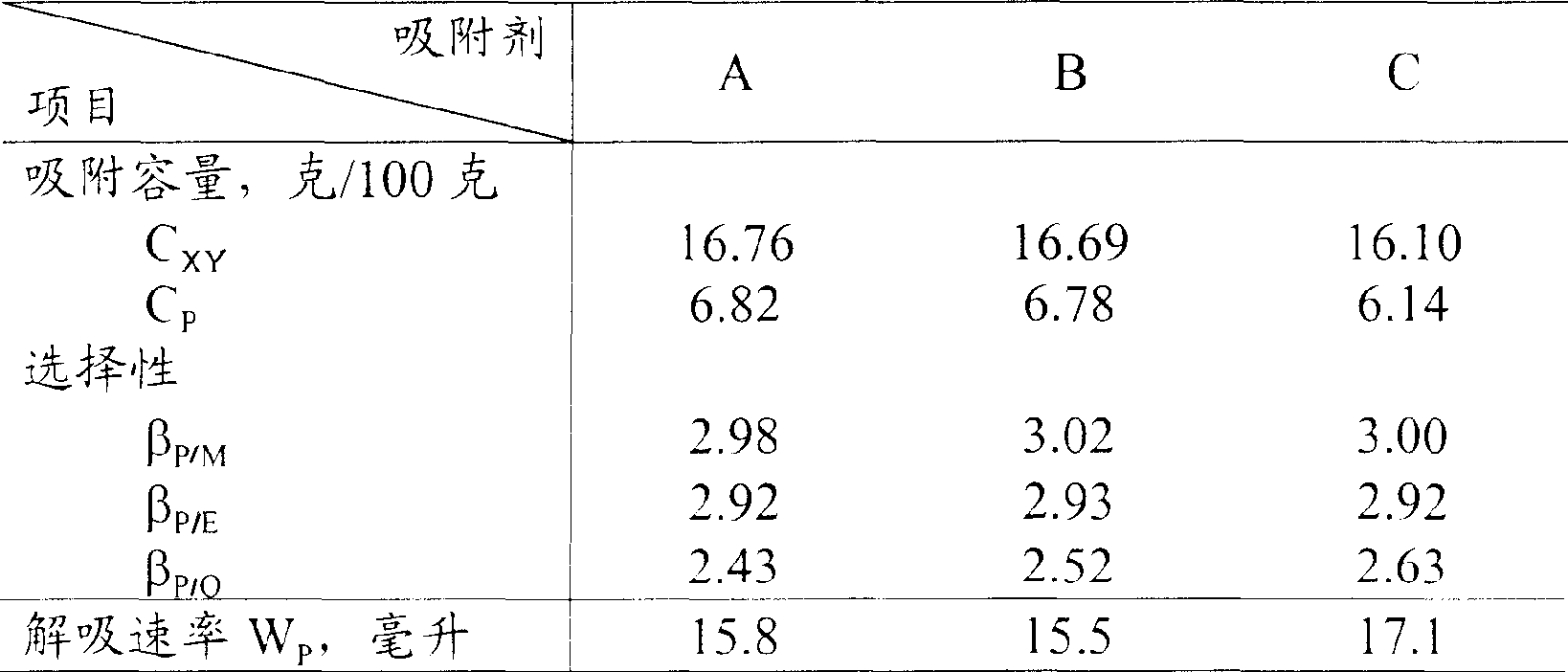

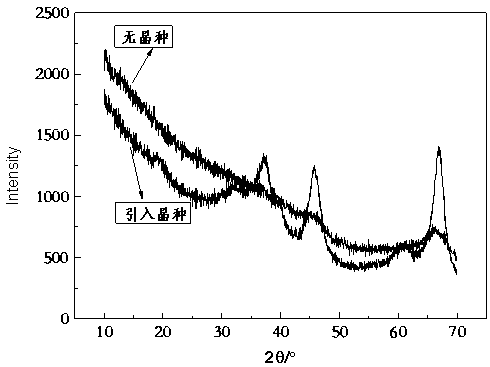

Paraxylene adsorbent and preparing method thereof

InactiveCN1552515AHigh bulk densityIncreased crush strengthOther chemical processesHydrocarbon oils refiningKaoliniteActive component

An adsorbent for adsorbing p-xylene from mixed C8 arylhydrocarbon is composed of the adsorptive active component chosen from Ba or Ba and K exchange X zeolite to Y zeolite (88-95 mass%) and the kaolinite. Its advantages are high adsorption capacity and high adsorption selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

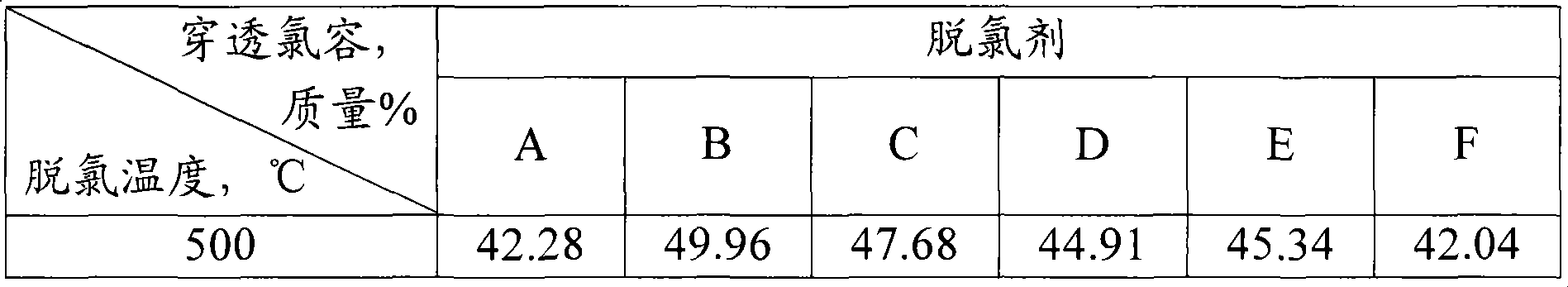

Dechlorination agent and preparation method thereof

ActiveCN103386244AImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

Owner:康健科技(山东)有限公司

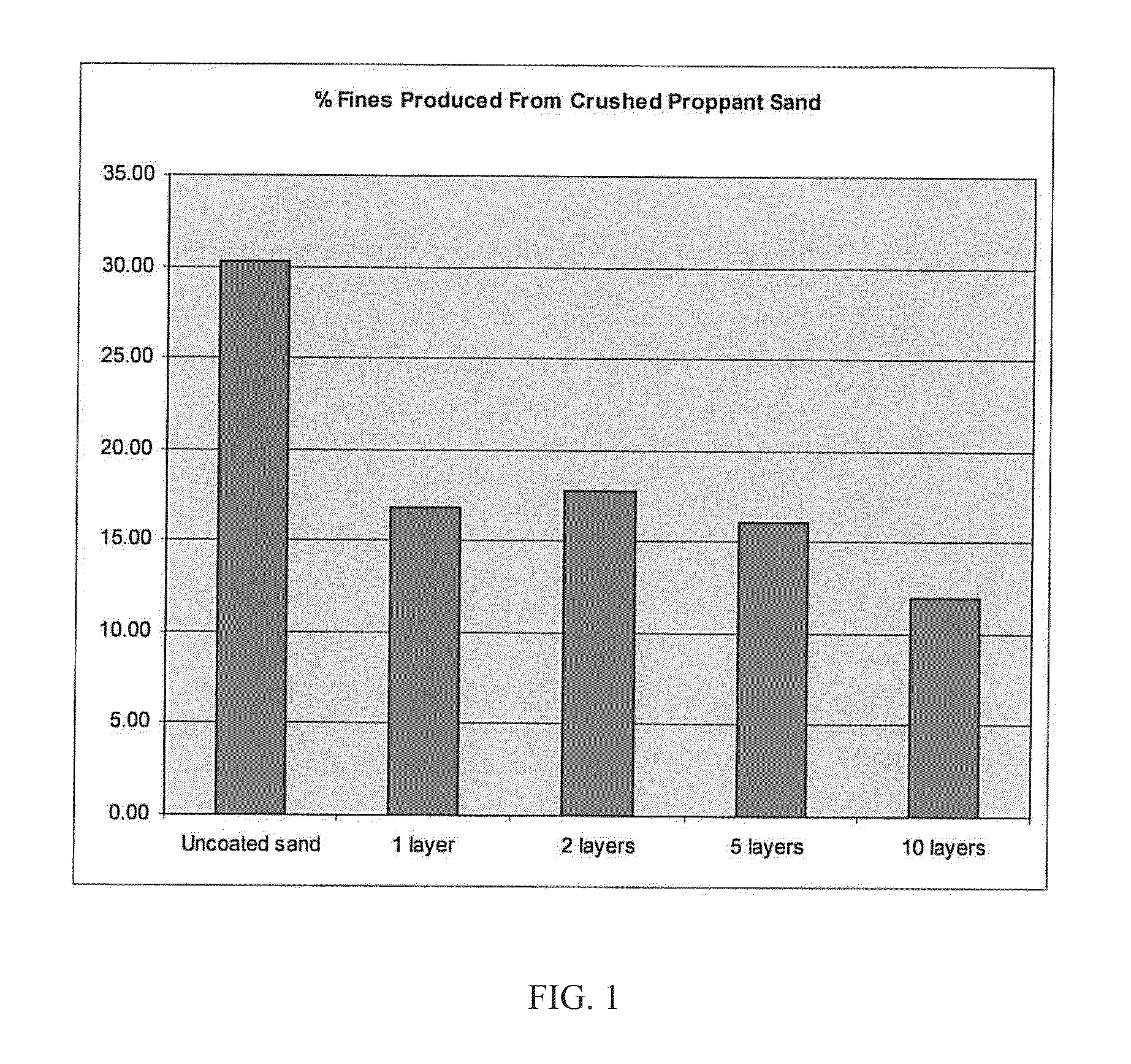

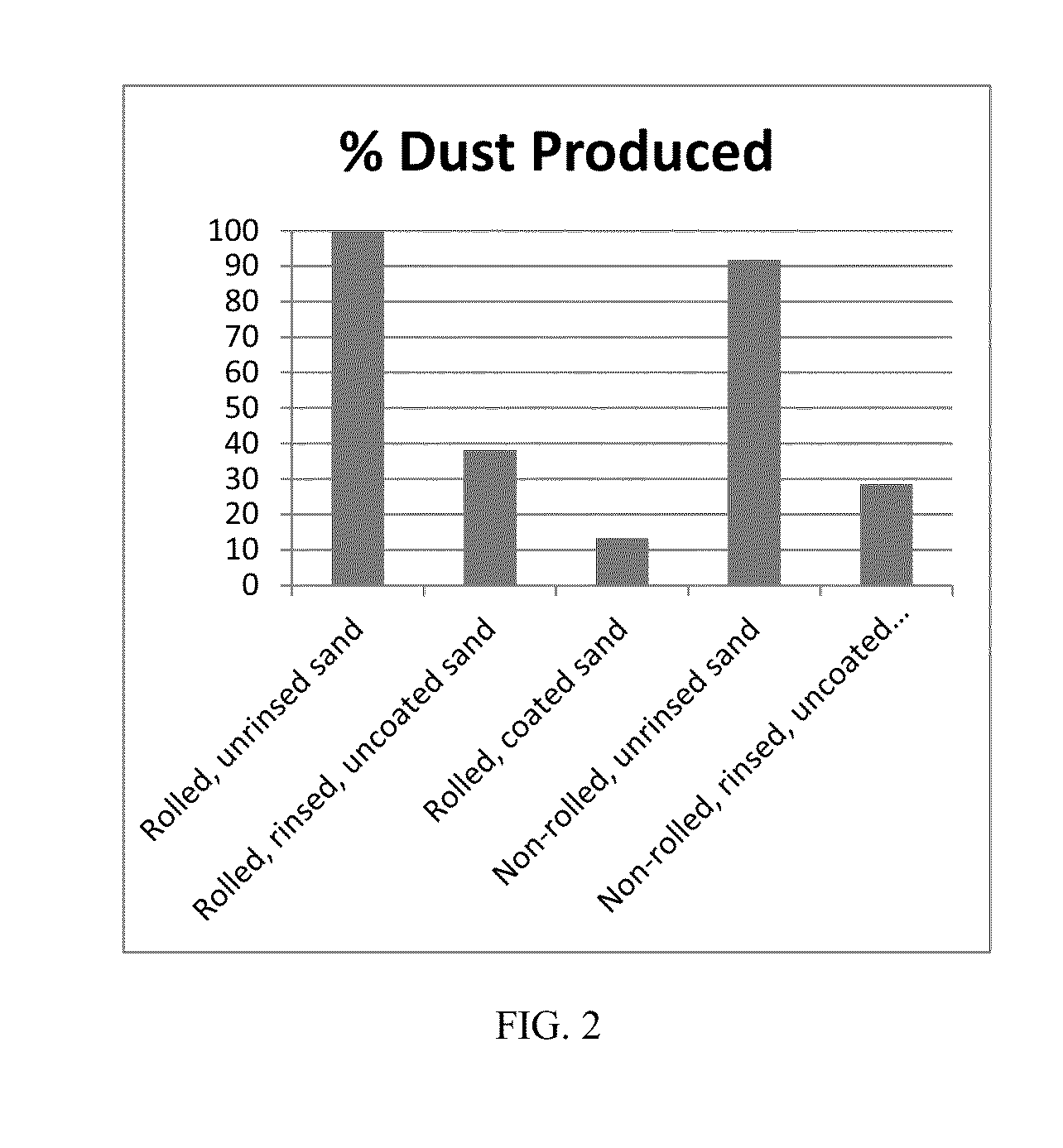

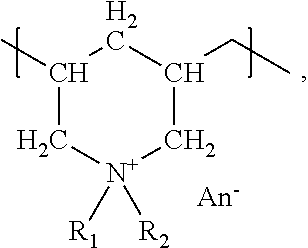

Method of reducing dust with self-assembly composites

ActiveUS20130192835A1Reduce the amount requiredReduce productionMaterial nanotechnologyLiquid surface applicatorsPolyelectrolyteParticulates

Well treatment particulates are coated with polyionic material and a composite is formed comprising multiple layers of polyelectrolyte, each layer composed of polyionic material counter to the polyionic material of the polyelectrolyte layer to which it is adjacent.

Owner:BAKER HUGHES INC

Improved wrapping material for dripping pills of cigarette additive

ActiveCN102485777AQuality assuranceConsistent size uniformityTobacco smoke filtersUltimate tensile strengthGum arabic

The invention discloses an improved wrapping material for dripping pills of a cigarette additive, which belongs to the technical field of cigarettes. The improved wrapping material comprises, by weight, 6 to 20 of sodium alginate, 0.1 to 3 of Arabic gum and 77 to 95 of water. A preparation method for the wrapping material comprises the following steps: uniformly mixing the above-mentioned components in proportion, stirring the components in a reaction pot with a heating interlayer, heating the interlayer to a temperature of 75+-5 DEG C with steam, carrying out insulation for 1 to 2 h after anobtained mixture is melt, standing the melt mixture until foam floats upward and filtering the mixture with temperature maintained to be 75+-5 DEG C so as to obtain a filtrate which is the wrapping material for dripping pills of a cigarette additive. The improved wrapping material provided in the invention guarantees that prepared dripping pills have a uniform size, good circularity, improved crushing strength, increased rubber thickness and enhanced brittleness and enables the product qualification rate and yield of the dripping pills to be improved and product quality of cigarettes to be effectively ensured.

Owner:HUBEI CHINA TOBACCO IND

Method for molding tin-silicon molecular sieve, molded tin-silicon molecular sieve prepared by method and method for preparing dimethyl sulfoxide

ActiveCN104549549AHigh catalytic activityIncreased crush strengthOrganic chemistryMolecular sieve catalystsMolecular sieveSlurry

The invention provides a method for molding a tin-silicon molecular sieve and the molded tin-silicon molecular sieve. The method comprises the following steps: carrying out hydro-thermal treatment on a tin-silicon molecular sieve in an aqueous mixture in a closed container; molding slurry obtained in hydro-thermal treatment to obtain a molded body, and roasting, wherein the aqueous mixture is from a crystallized mother liquor containing silicon molecular sieve, and the crystallized mother liquor contains at least one alkaline template agent. The molded tin-silicon molecular sieve prepared by the molding method has a relatively high catalytic activity and high crushing strength. The invention further provides a method for preparing dimethyl sulfoxide. In the method, the molded tin-silicon molecular sieve is used as a catalyst to obtain high conversion rate of dimethyl sulfide, high effective utilization of an oxidant and high selectivity of dimethyl sulfoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

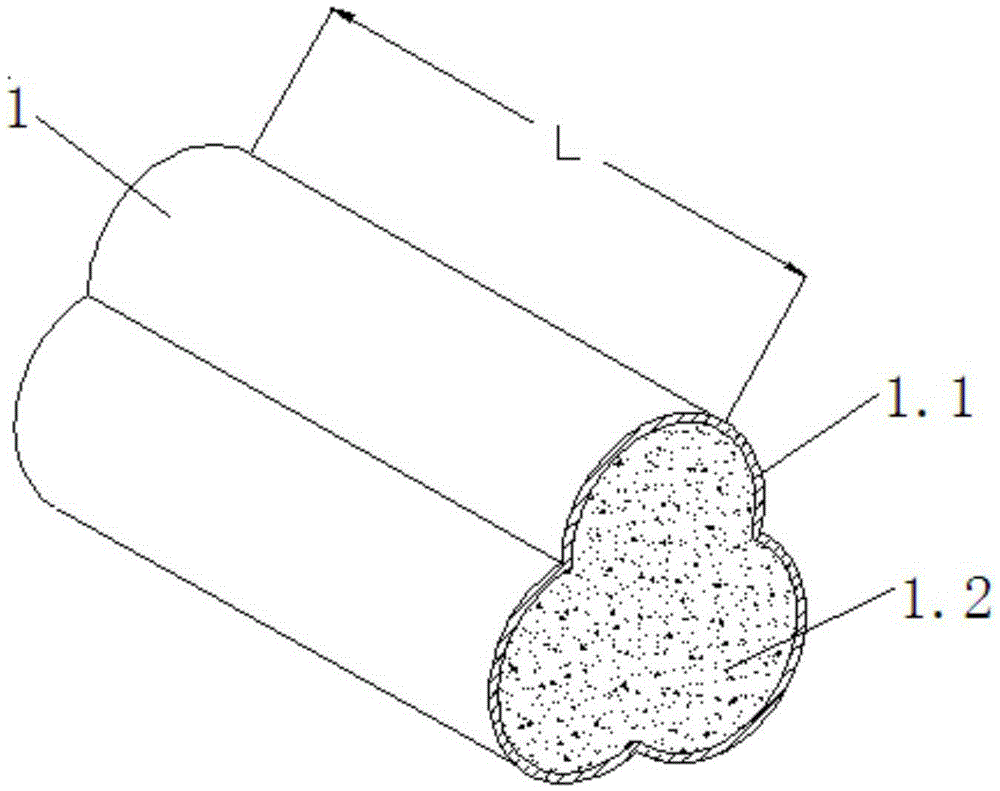

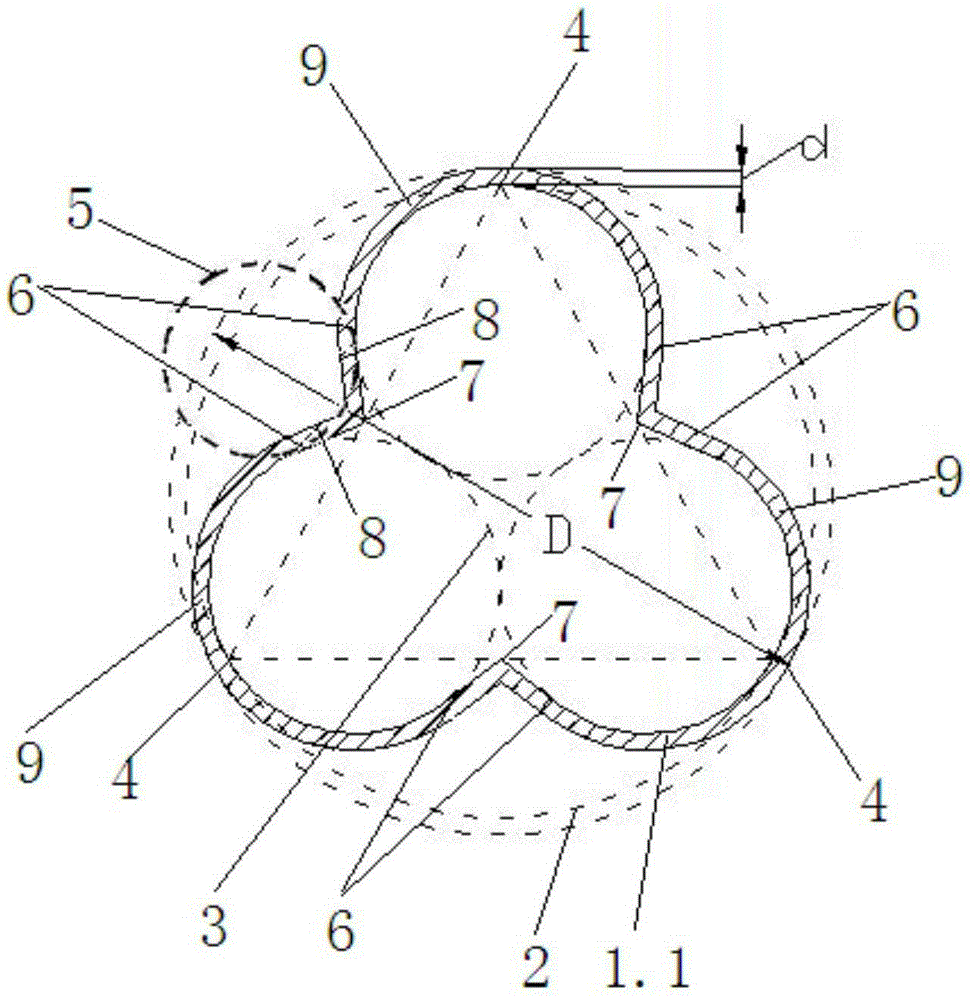

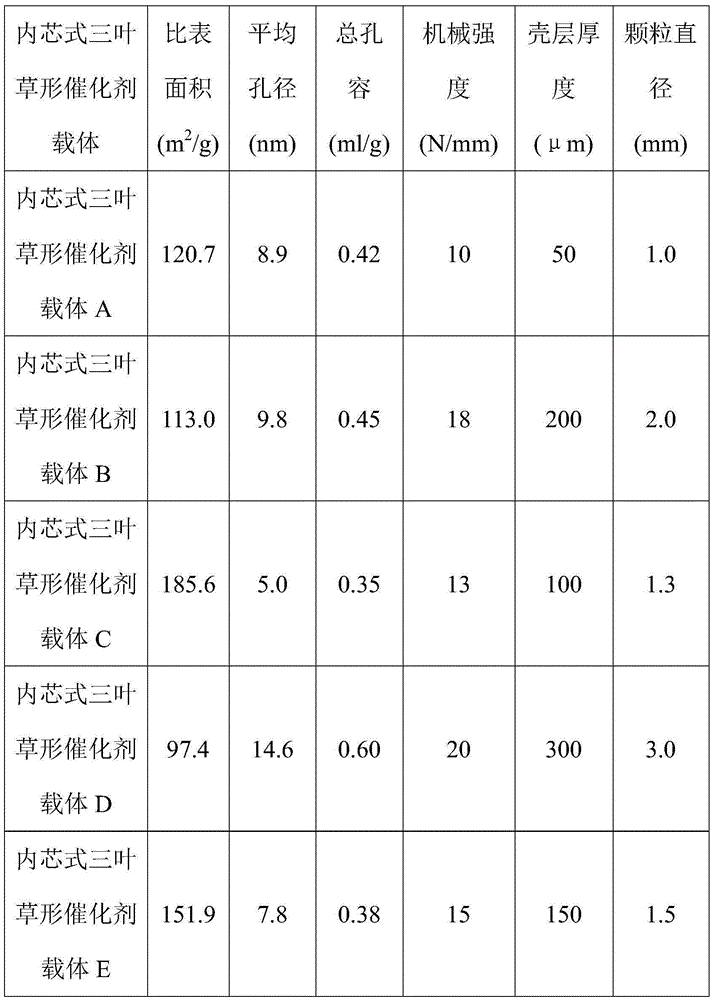

Inner core type cloverleaf-pattern catalyst carrier and preparation method and application thereof

ActiveCN105233880AIncreased crush strengthExtended service lifeCatalyst carriersLiquid hydrocarbon mixture productionEngineeringAqueous solution

The invention discloses an inner core type cloverleaf-pattern catalyst carrier and a preparation method and application thereof. The catalyst carrier comprises a catalyst carrier bar, and the catalyst carrier bar comprises an outer shell and an inner core. The cross section of the outer shell is in a hollow cloverleaf pattern, and the hollow part of the outer shell is filled with the inner core. The outer shell is made of a porous structure material. The inner core is made of a compact structure material, and the specific surface area of the inner core is smaller than 1 m<2> / g. The preparation method includes the steps that 1, Al2O3 powder which is of a porous structure is fully mixed with an aqueous solution containing an extrusion aid and a peptizing agent, so that a material I is obtained; 2, Al2O3 powder which is of a compact structure is fully mixed with an aqueous solution containing an extrusion aid and a peptizing agent, so that a material II is obtained; 3, after the material I and the material II are subjected to extrusion molding, drying and calcining are conducted. The catalyst carrier is applied to preparation of a Fischer-Tropsch synthesis catalyst. The catalyst carrier is high in anti-crush strength, large-scale industrial production can be achieved, the diffusing effect in the Fischer-Tropsch synthesis catalyst prepared through the catalyst carrier is small, methane selectivity is low and C5+ selectivity is high.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Preparation method of hydrotreating catalyst

InactiveCN103055908AImprove denitrification activityReduce dosagePhysical/chemical process catalystsRefining to eliminate hetero atomsPhosphoric acidChemistry

The invention discloses a preparation method of a hydrotreating catalyst. The method consists of: first pulping aluminum hydroxide or alumina into a slurry, adding concentrated phosphoric acid to react so as to obtain a sol; then taking the sol as a binder, kneading the sol with large hole alumina and small hole alumina, and conducting shaping, drying and roasting to obtain an alumina carrier; and then steeping the alumina carrier with an active metal component steeping solution, and carrying out drying and roasting so as to obtain the hydrotreating catalyst. In the invention, phosphorus is introduced into the alumina carrier in the form of a binder, and can play a structural assistant role to improve the active metal dispersity on the alumina carrier. The weak acid amount of the carrier is increased, the amount of strong-medium acid is decreased, and the total acid amount is reduced. Particularly, the corrosive effect of the phosphorus-containing binder on an alumina carrier frame is greatly mitigated, the pore structure and mechanical strength of the alumina carrier and the catalyst can be significantly improved, meanwhile, consumption of the phosphorus-containing sol binder is low, and the preparation process is environment-friendly and pollution-free.

Owner:CHINA PETROLEUM & CHEM CORP +1

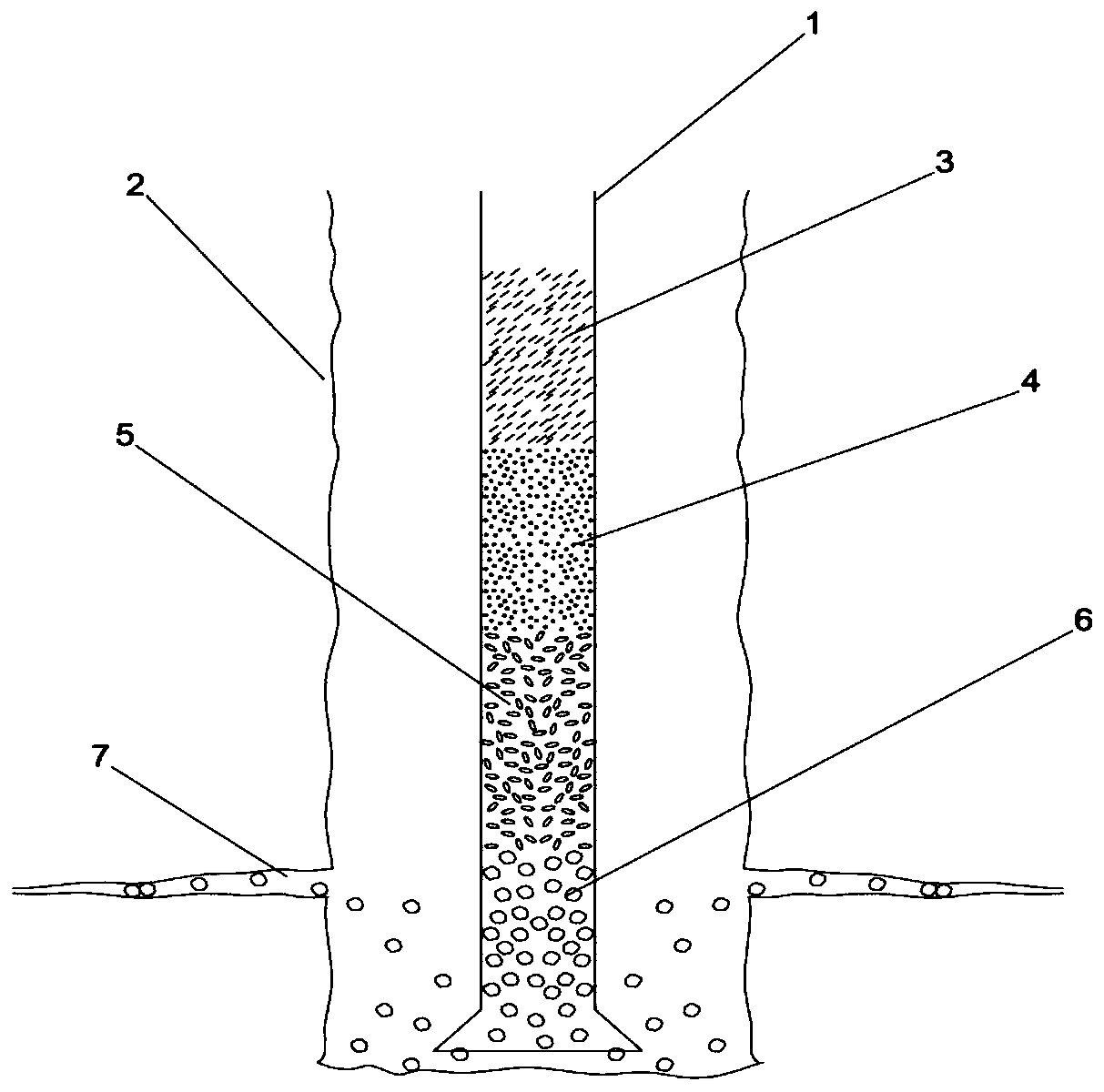

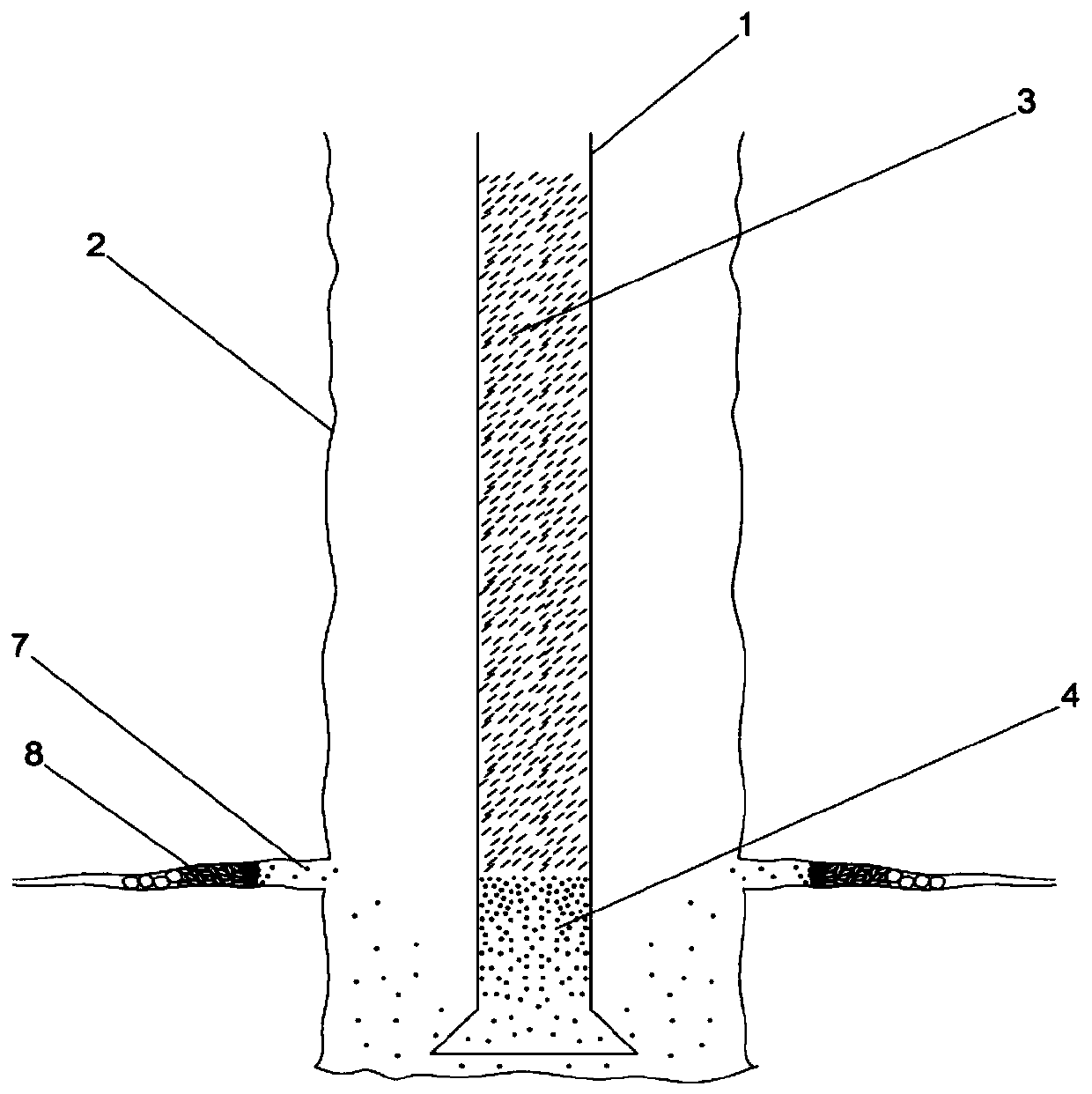

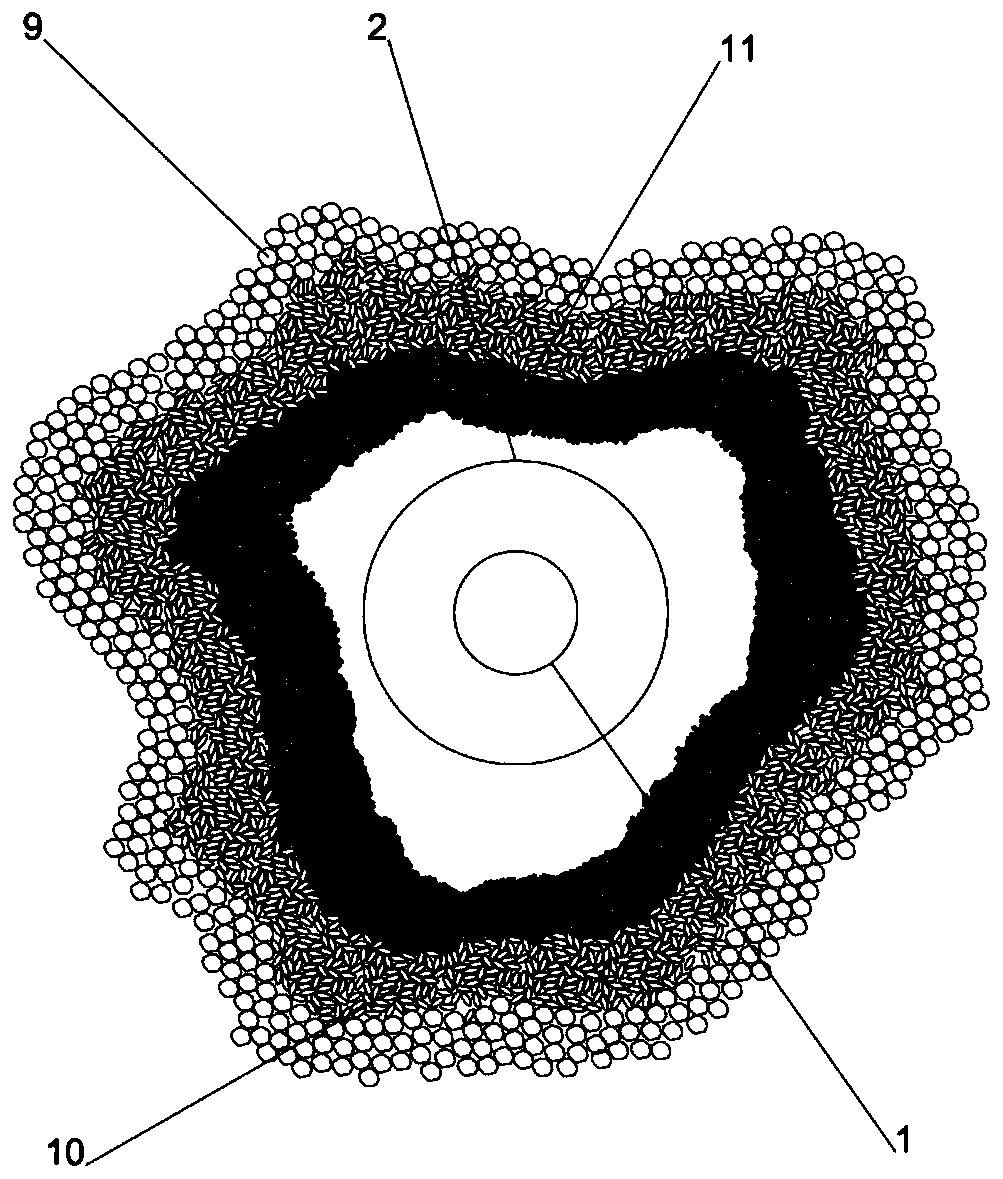

Multistage plug classification plugging method suitable for fissured stratum

The invention relates to a multistage plug classification plugging method suitable for a fissured stratum. The multistage plug classification plugging method includes the steps that first, the averageopening of fissures in the periphery of a well is determined to be D, bridging particles with the particle size being slightly smaller than D are used in first-stage plugging, the average particle size of the bridging particles is denoted as D<1>, the average particle size D<2> of plugging particles used in second-stage plugging is larger than D<1> / 4, and smaller than D<1>, and the particle sizeof each of the following stages of the plugging particles is successively determined through the same method until the average particle size D<n> of the last stage of the plugging particles is small enough to form a dense sealing layer; second, plugging grout only containing the bridging particles with the average particle size being D<1> is first injected through slugs to form a bridging particlelayer; third, plugging grout containing the plugging particles with the average particle size being D<2>-D<n-1> is injected in several times through a plurality of slugs to form a particle filling layer; and fourth, plugging grout with the average particle size of the plugging particles being D<n> is finally injected through the slugs to form the dense sealing layer. According to the multistage plug classification plugging method suitable for the fissured stratum, the principle is reliable, the fissures in the periphery of the well are more effectively sealed, the cost is saved, and the broadapplication prospects are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

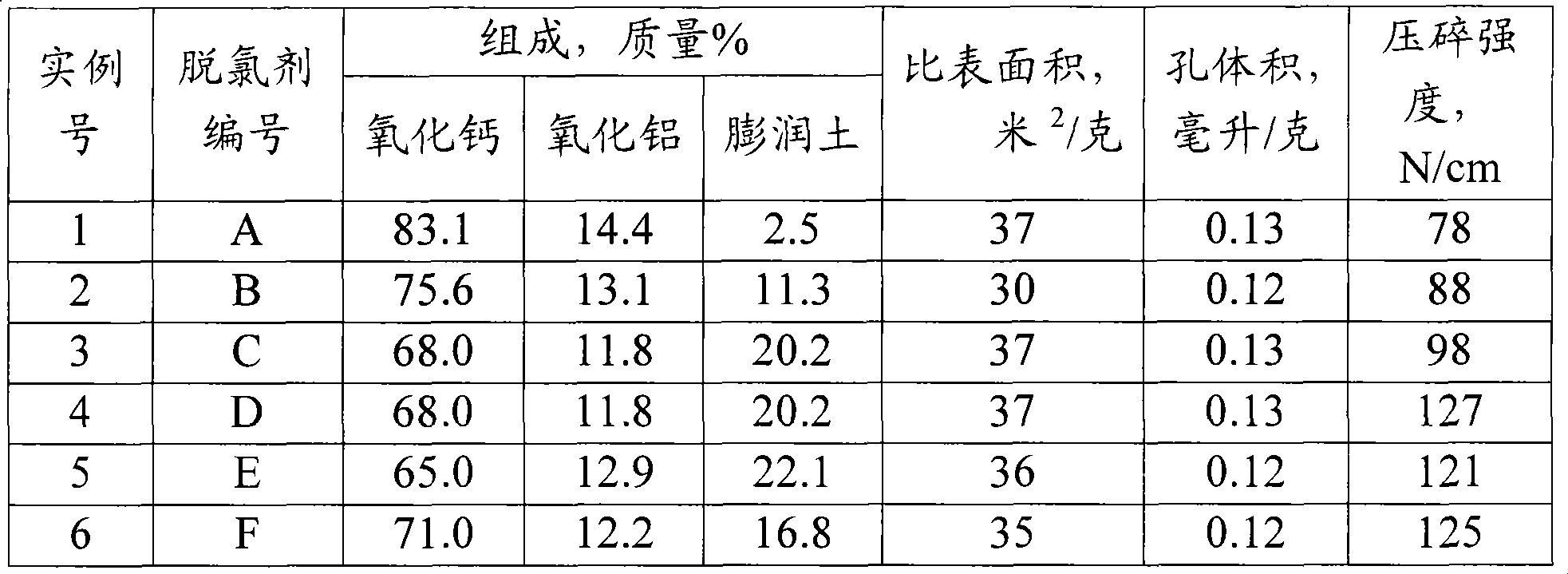

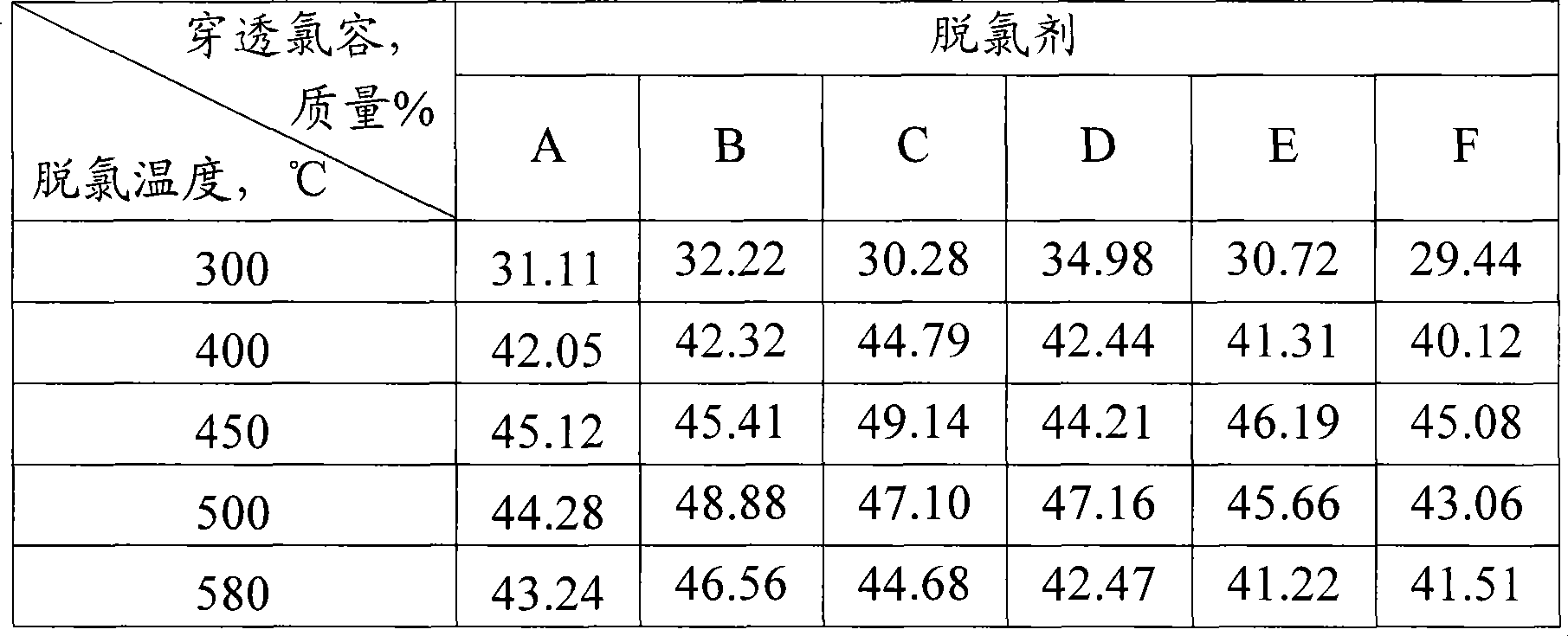

Gas dechlorination agent and preparation method thereof

ActiveCN101422690ALarge specific surface areaLarge pore volumeDispersed particle separationChemistryHydrogen chloride

A gas antichlor comprises 50 to 88 mass percent of alkaline earth oxides, 10 to 40 mass percent of alumina and 2 to 30 mass percent of bentonite. The antichlor can effectively remove the hydrogen chloride in the gas at high temperature, is especially suitable for the dechlorination of a constant reforming and regenerative gas with high water content, is not easy to slime or cake in the process of dechlorination, and has higher crushing strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

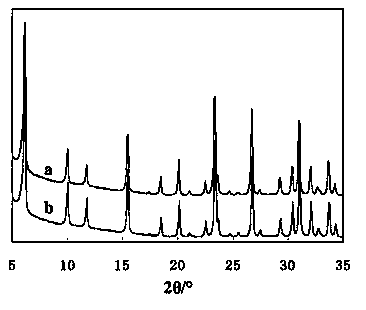

Preparation method for Silicate-1 molecular sieve catalyst, catalyst and method for preparing caprolactam

ActiveCN107335464AImprove conversion rateExtend your lifeLactams preparationMolecular sieve catalystsMolecular sieveNitrogen

The invention discloses a preparation method for a Silicate-1 molecular sieve catalyst, the Silicate-1 molecular sieve catalyst prepared by the method and a method for preparing caprolactam from cyclohexanone oxime. The preparation method for the Silicate-1 molecular sieve catalyst comprises the steps: a. mixing a silicon source, a metal ion source, an organic template agent and water, so as to obtain a colloidal mixture; b. subjecting the colloidal mixture obtained in the step a to hydrothermal crystallization, so as to obtain a crystallized product; c. subjecting the crystallized product obtained in the step b to washing and separating treatment, so as to obtain metal ion containing Silicate-1 molecular sieves; and d. subjecting the metal ion containing Silicate-1 molecular sieves obtained in the step c to forming treatment, roasting treatment and aftertreatment by an alkaline buffer solution of a nitrogen containing compound, and carrying out washing, separating and drying, thereby obtaining the Silicate-1 molecular sieve catalyst containing trace metal ions. By adopting the method, the performance of the Silicate-1 molecular sieve catalyst can be effectively changed; and by applying the catalyst to the production of the caprolactam, an unexpected result can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dust settling fine coke reblending coal coking method and its technology

This invention discloses a coal blending method and its technology of dust removal coking coal powder using as lean agent to substitute clean coal. It collects coke dry quenching environmental dust removal coking coal powder, coke dry quenching technological dust removal coking coal powder, coking ground dust moving station dust removal powder, mixing them homogeneously, and then putting them into stockhouse, and then transporting into dosage bunker by leather belt transport machine, and then transporting to leather belt transport machine equipped with electronic scale by dosage plate, and then quantitively transporting to leather belt transport machine equipped with dust fall equipment, and at last, sending into crusher together with other coal for coking and mixing them homogeneously in blending coal room for coking at coking chamber of coke oven.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Alumina supporter, and preparation method and application thereof

ActiveCN103041870ALarge hole volumeLarge specific surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMaterials scienceAluminium oxide

The invention discloses an alumina supporter and a preparation method thereof. The specific area of the supporter is 170-200 m<2> / g, the pore volume is 0.85-1.0 mL / g, the pores with the diameter of 10-25 nm account for 40-50% of the total pore volume, the pores with the diameter of 100-250 nm account for 25-35% of the total pore volume, and the crushing strength is 200-220 N / cm. The preparation method comprises the following steps: respectively roasting one quasi-boehmite dry gelatine powder at 450-600 DEG C and 700-900 DEG C for 3-5 hours to prepare two alumina dry powders; weighing the two alumina dry powders, evenly mixing with the quasi-boehmite dry gelatine powder (the same quasi-boehmite dry gelatine powder), extrusion aid and peptizator, extruding into strips and molding; and drying and roasting the molded material to obtain the alumina supporter. The alumina supporter has the advantages of large pore volume, proper specific area and proper mechanical strength, has a double pore structure, and thus, is suitable to be used as a hydrogenation protecting agent for heavy oil and a supporter of a demetallization catalyst. In addition, the preparation method is simple, and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

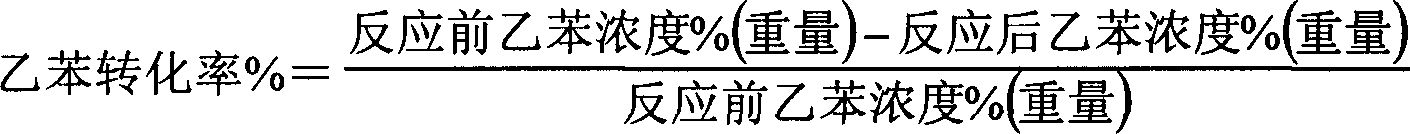

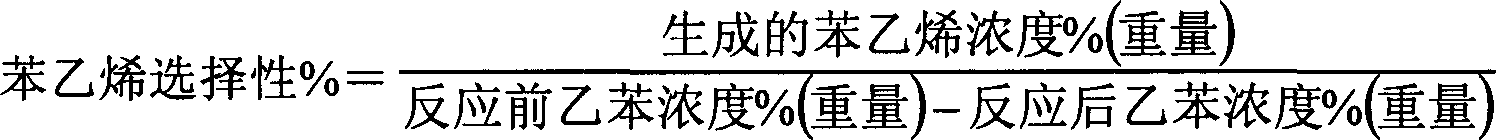

Catalyst for dehydrogenating alkyl arene in preparing alkyl alkenyl arene

ActiveCN1810370AImprove selectivityIncreased crush strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPortland cementAlkyl

The present invention relates to one kind of catalyst for dehydrogenating alkyl arene to prepare alkyl alkynyl arene and aims at raising the selectivity and strength of low potassium catalyst. The technological scheme of the present invention includes replacing Portland cement in the Fe-K-Ce-Mo-Mg-Ca catalyst system with aluminate cement and adding selecting modulation agent. The catalyst system may be used in industrial production to prepare alkyl alkynyl arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

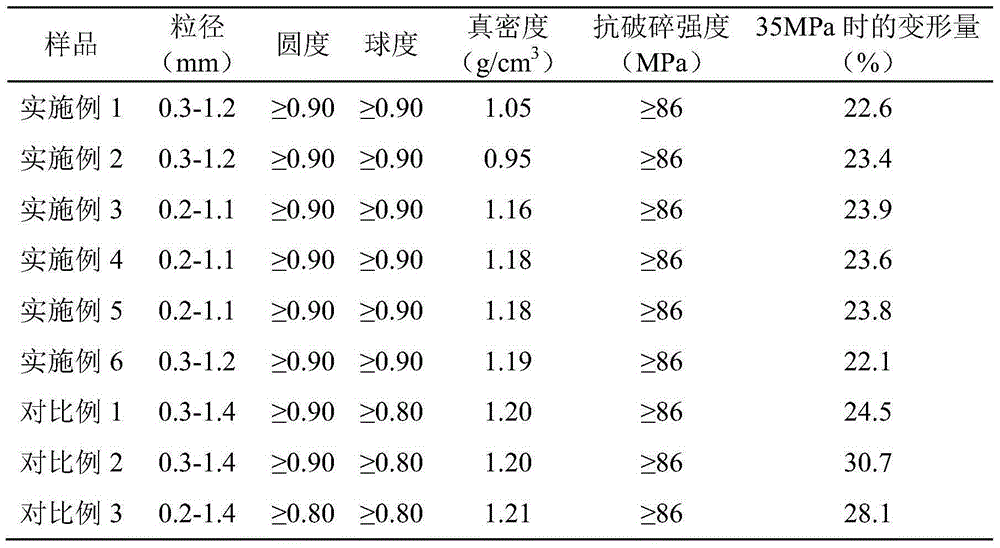

Low-density composite proppant, preparation method and applications thereof

The present invention provides a low-density composite proppant, which is prepared by carrying out a polymerization reaction on an oil phase and an aqueous phase, wherein the oil phase comprises, by weight, 60-90 parts of a monomer, 5-25 parts of a cross-linking agent, 0.01-10 parts of a filler, 0.1-5 parts of an initiator and 0-2 parts of a filler dispersant, and the aqueous phase comprises, by weight, 90-100 parts of water, 0.1-5 parts of a dispersant and 0.1-5 parts of an inorganic salt. The present invention further provides a preparation method of the proppant, wherein the preparation method comprises: uniformly mixing the dispersant, the inorganic salt and the water to obtain the aqueous phase, uniformly mixing the monomer, the cross-linking agent, the initiator, the filler and the optional filler dispersant to obtain the oil phase, mixing the oil phase and the aqueous phase, carrying out a polymerization reaction at a certain temperature to obtain a polymerization product system, and post-treating the obtained polymerization product system. The present invention further discloses applications of the proppant or the proppant prepared according to the method in reservoir fracturing reforming.

Owner:CHINA PETROLEUM & CHEM CORP +1

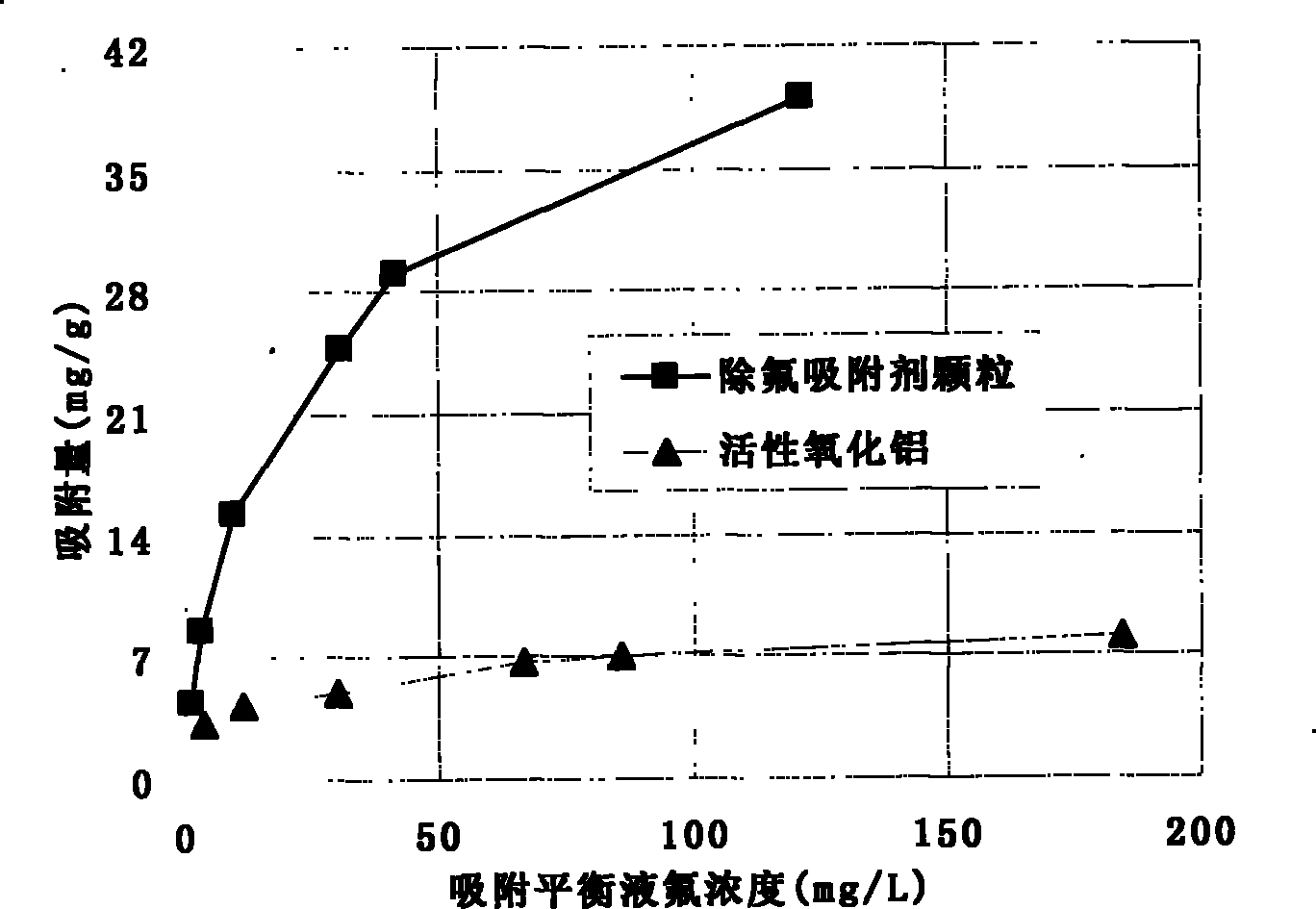

Defluorinating adsorbent and preparation method thereof

The invention provides a defluorinating adsorbent for drinking water, which is a composite metal oxide defluorinating adsorbent and a high polymer material playing a role of adhering absorbent particles. Absorbent powder and a high polymer binder are mixed, extruded, cut and dried to prepare into particles. The defluorinating adsorbent has the characteristics of good ion selectivity, high adsorption capacity, better strength in both dry and wet states, and no crushing or dissolving after being used for a long time.

Owner:北京国中科创环境科技有限责任公司

Compound arsenic-removing adsorbent and preparation method thereof

ActiveCN102114403AHigh ion selectivityGood choiceOther chemical processesGranulation by material expressionSorbentWater flow

The invention provides an arsenic-removing adsorbent for drinking water and a preparation method thereof. The adsorbent contains composite metal oxide and a polymer material binder. The arsenic-removing adsorbent has high adsorption property, high adsorption selectivity on arsenic in the drinking water, and high adsorption capacity; adsorbent particles have high strength in a dry state or in a moist state, and the adsorbent has low breakage rate of the particles and cannot be dissolved out during use; and the adsorbent is used under the conditions of long time and larger change of waterflow pressure.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Arsenic removal adsorbent and preparation method thereof

The invention provides an arsenic removal adsorbent and a preparation method thereof. The adsorbent contains sulfate akaganeite and high-molecular material agglomerant. In the invention, the particles of the arsenic removal adsorbent have high adsorption property to have high adsorption selectivity to arsenic in drinking water, the adsorption capacity is high, the adsorbed particles have large strength under a drying state or a moisture state, the particle crushing rate is low during use, no adsorbent is dissolved out, and the arsenic removal adsorbent is suitable for being used for a long time and under the condition of larger water flow pressure change.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Environment-friendly acrylate grouting material as well as preparation method and application thereof

InactiveCN104177554AImprove water resistanceImprove aging resistancePolymer science(Hydroxyethyl)methacrylate

The invention provides an environment-friendly acrylate grouting material, as well as a preparation method and an application thereof. The material mainly comprises the following components in parts by weight: a main agent, namely 100 parts of methacrylic acid-beta-hydroxyethyl ester, a crosslinking agent which includes 5-30 parts of hydrophilic compound containing a diallyl ether functional group, 1-5 parts of initiator and 0.5-3 parts of accelerant, 0-20 parts of an adjuvant, and a solvent, namely 2-1,000 parts of water. The method comprises the following steps: firstly, mixing the main agent, the crosslinking agent, the accelerant, the adjuvant and a part of solvent evenly to form a solution A in use; then dissolving the initiator into a residual solvent to form a solution B; and finally mixing the solution A with the solution B evenly, and solidifying at room temperature. According to the grouting material disclosed by the invention, the technical problem that the existing organic grouting material cannot be grouted once after being mixed with an inorganic grouting material, and the technical problem that the existing grouting material has poor durability, low strength, poor water solubility, low water expansion rate and high toxicity are solved.

Owner:湖南博旺水电建设有限公司

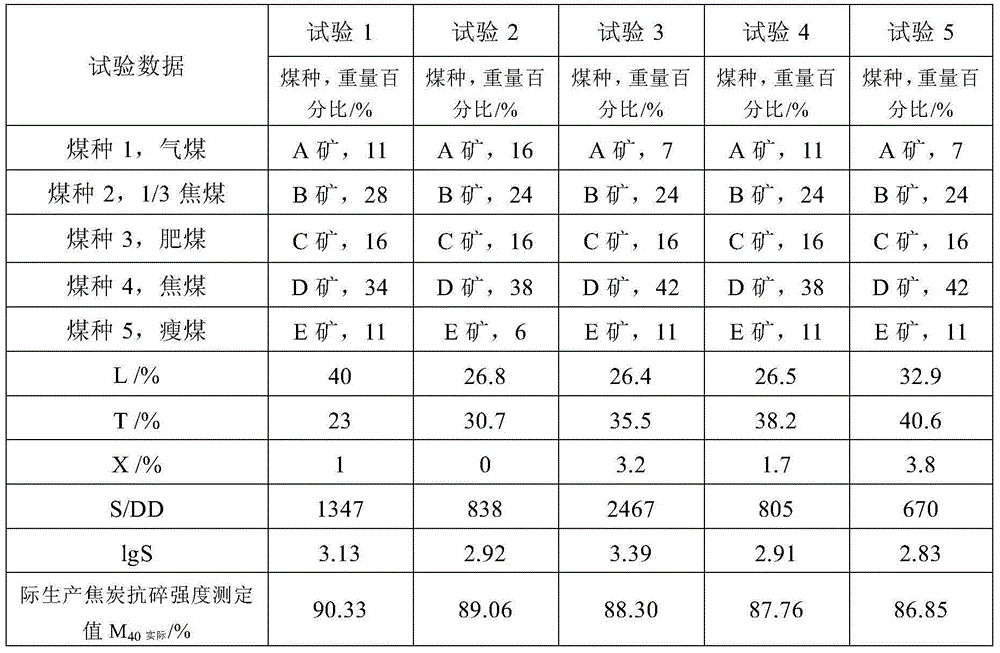

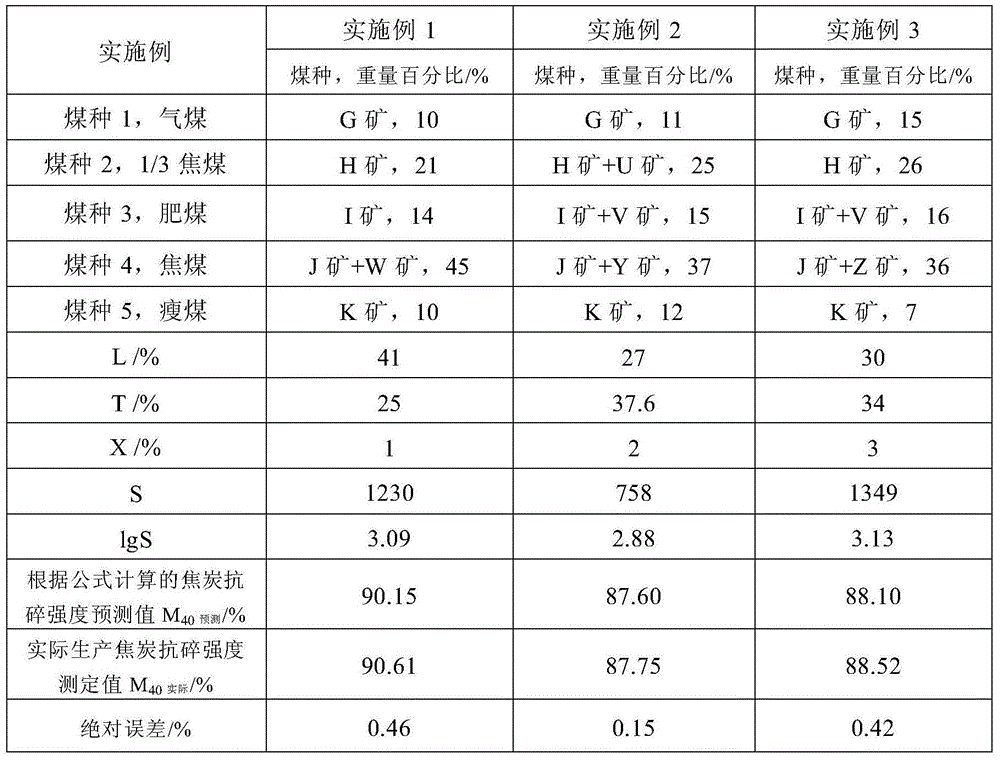

Prediction method of crushing strength of coke for coal blending coking

The invention discloses a prediction method of the crushing strength of coke for coal blending coking. The method comprises the following steps: (1) measuring coking optical textures of all single-grade coals for coking to obtain the sum L of the contents of a coarse grain embedding component, a medium grain embedding component and an incomplete fiber component in coal blending, the sum T of the contents of an isotropic component and a fine grain embedding component as well as the content X of a fiber component; (2) measuring the Gieseler fluidity of the coal blending to obtain a Gieseler plastic flow area S within the temperature range of 450-500 DEG C; (3) setting M40 to be equal to A+B*L+C*T+E*X+F*1gS, wherein M40 represents the crushing strength of the coke, the unit is percent, and A, B, C, E and F are constants; (4) calculating the predicted value of the crushing strength of the coke. According to prediction method, a coal blending coking test does not need to be carried out due to fewer influence factors and a simple predictor formula, and a coal blending scheme is better adjusted according to the predicted results, so that the practice of coal blending coking is effectively guided.

Owner:武汉钢铁有限公司

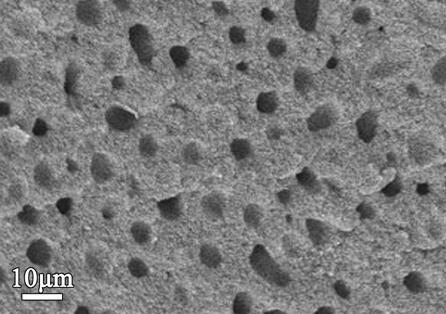

Macroporous alumina and preparation method thereof

ActiveCN110467206AEvenly distributedUniform concentrationCatalyst carriersAluminium oxides/hydroxidesPolyethylene glycolOrganic compound

The invention discloses macroporous alumina and a preparation method thereof. The macroporous alumina of the invention has the properties that the macroporous alumina is a gamma crystalline state, thetotal porosity is 60%-85%, the macropore diameter is 100 nm-1000 nm, the proportion of macropores to the total porosity is 40%-75%, the macropores are evenly distributed and three-dimensionally penetrated, a ratio of the wall thickness to the pore diameter of the macropores is 0.7-3.0, and the side crushing strength is 8-25 N / mm. The preparation method of the macroporous alumina includes the following steps: (1) preparing aluminum sol; (2) evenly mixing inorganic aluminum salts, polyethylene glycol, the aluminum sol obtained in the step (1), organic compounds containing amide groups and a low-carbon alcohol aqueous solution; (3) adding epoxypropane and / or pyridine into the mixture obtained in the step (2), evenly mixing the mixture to obtain gel, and carrying out aging to obtain an agingproduct; and (4) immersing the aging product by using the low-carbon alcohol aqueous solution, carrying out solid-liquid separation, and drying and roasting a solid phase to obtain the macroporous alumina.

Owner:CHINA PETROLEUM & CHEM CORP +1

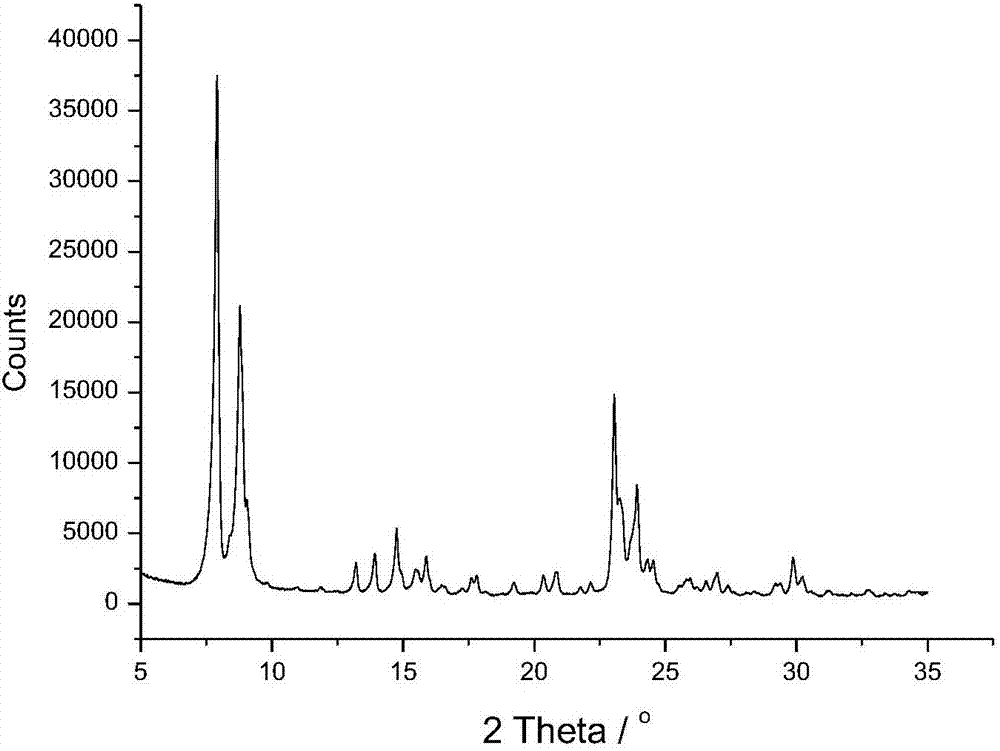

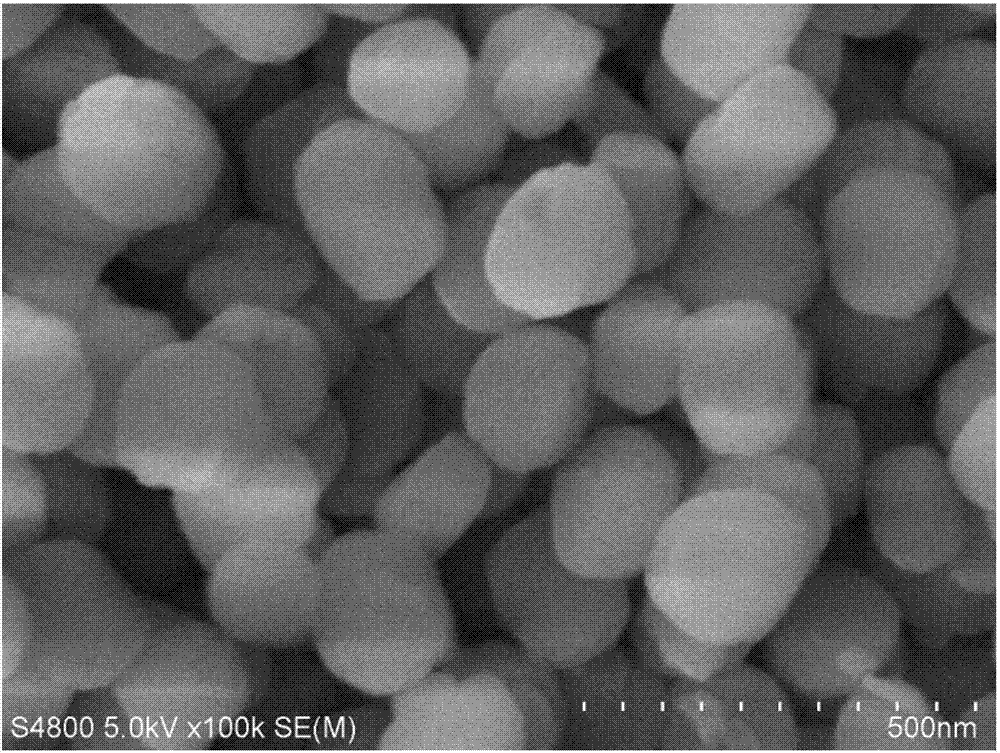

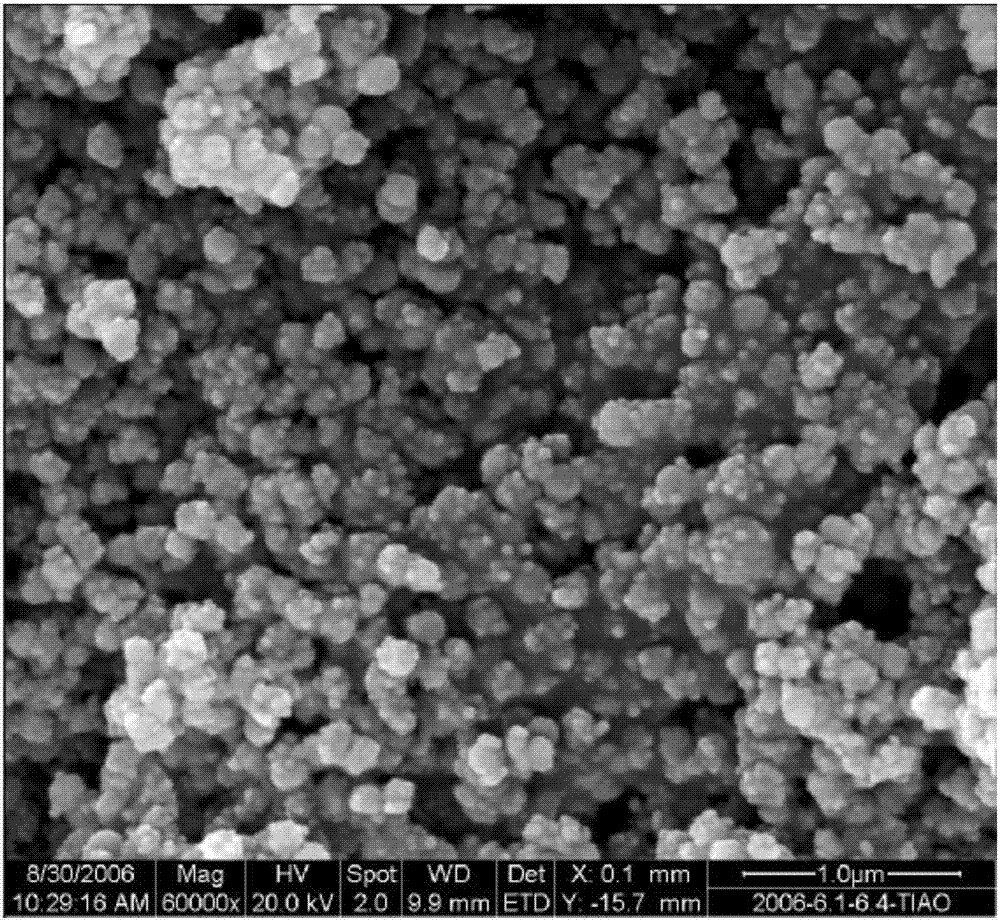

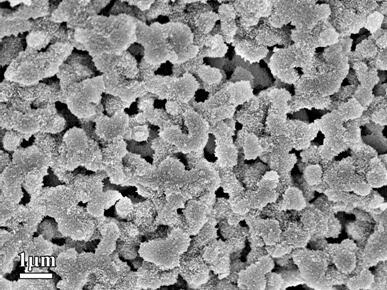

Preparation method of binderless spherical faujasite particles

ActiveCN103508463AHigh zeolite contentIncreased crush strengthCrystalline aluminosilicate zeolitesFaujasiteMixed materials

A preparation method of binderless spherical faujasite particles comprises the following steps: 1, mixing an aqueous solution of sodium silicate with a solution of a peptizing agent at -5-10DEG C to prepare a sol having a pH value of 5.0-8.0, adding the sol into an oil column in a dropwise manner to generate hydrogel beads, collecting the hydrogel beads, washing with water, ageing, drying, and roasting to prepare silica gel beads, wherein the specific surface area and pore volume of the silica gel beads, determined through a BET method, are 200-500m<2> / g and 0.6-1.5mL / g respectively, and the peptizing agent comprises an inorganic acid and an inorganic ammonium salt; 2, uniformly mixing sodium silicate, sodium metaaluminate, sodium hydroxide and water according to a molar ratio of (16-24)Na2O:Al2O3:(15-20)SiO2:(300-500)H2O, and ageing at 0-30DEG C for 10-30h to prepare a liquid phase directing agent; and 3, mixing the silica gel beads with a sodium metaaluminate solution to obtain a mixed material, ageing the mixed material at 30-60DEG C, adding the directing agent prepared in step 2 to the mixed material, heating to 90-110DEG C, crystallizing, washing obtained crystallized products with water, and drying. The method is simple to operate, and the prepared faujasite particles have a high strength and a large adsorption capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

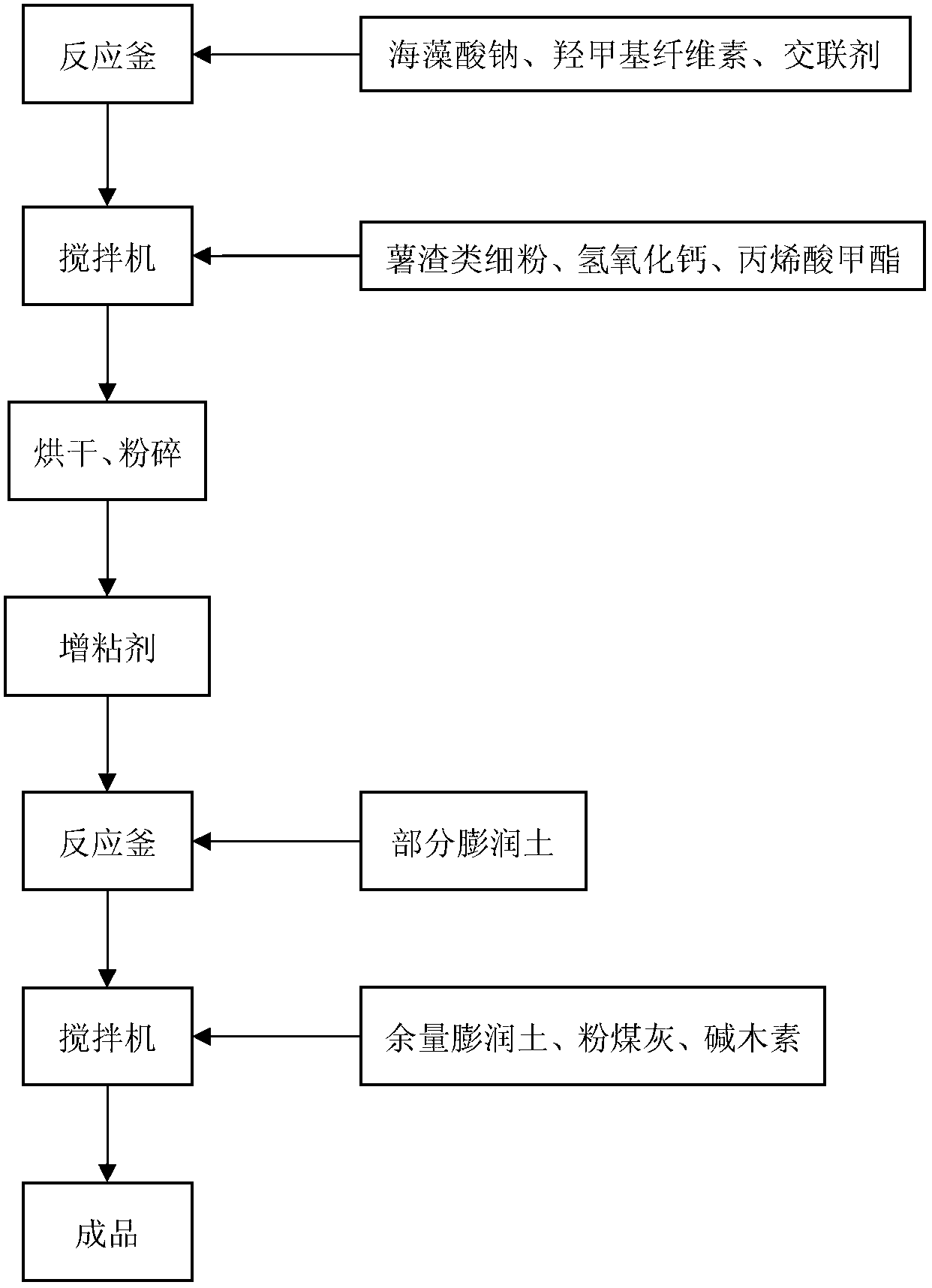

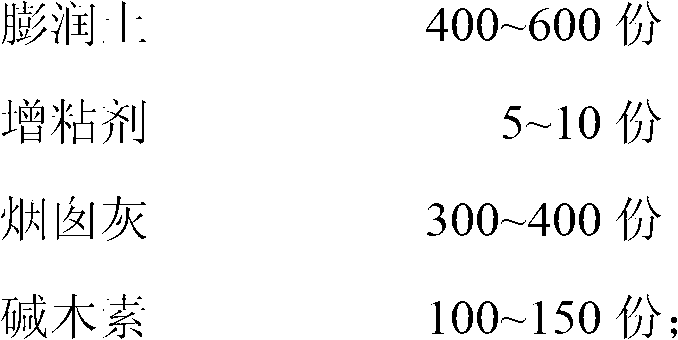

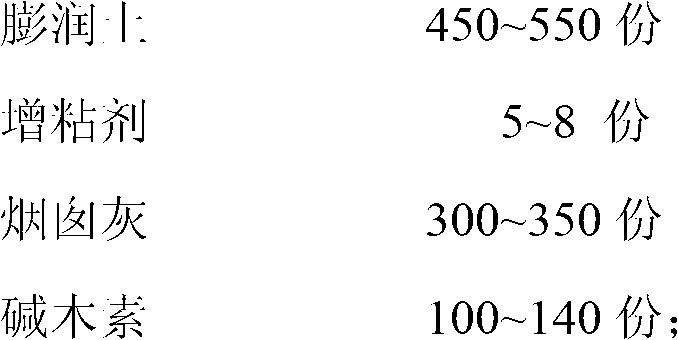

Coal briquette composite crosslinking binder and production method thereof

InactiveCN102796585AMeet the requirements of round-the-clock productionMeet production requirementsSolid fuelsCoal briquetteSodium Bentonite

The present invention discloses a coal briquette composite crosslinking binder, comprising the following components, by weight ratio: 400-600 parts of bentonite, 5-10 parts of tackifier, 300-400 parts of chimney ash and 100-150 parts of alkali lignin, wherein the tackifier is prepared by mixing 1-5 parts of sodium alginate, 1-5 parts of hydroxymethyl cellulose, 2-5 parts of potato residue class fine powder, 0.1-1 part of a crosslinking agent, 0.1-1 part of calcium hydroxide, and 0.05-0.5 parts of methyl acrylate. The production method comprises the steps of: preparing the tackifier, pretreating, mixing, etc. The binder of the present invention is not only strong in water absorption of more than 400 times, but wide in sources of raw materials and low in cost. The coal briquettes added with the binder are high in mechanical strength, good in thermal stability and reactivity, high in water absorption, do not need adding a base when being used, do not need cooking and retting, help to reduce labor intensity of workers, and are free from impacts of northern rain and snow and southern humid weather.

Owner:GUANGXI JINZHUANGJIN ENERGY SAVING TECH

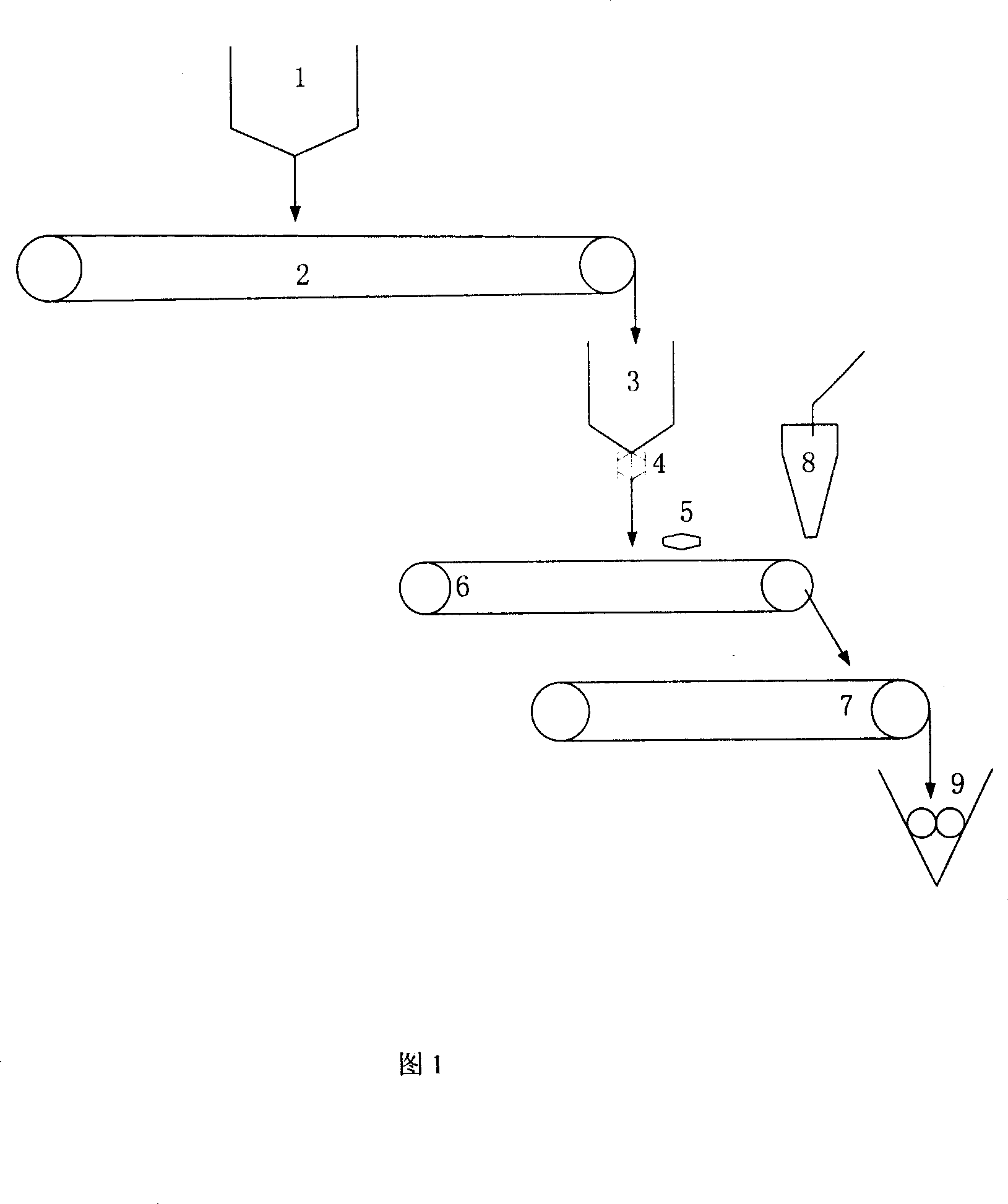

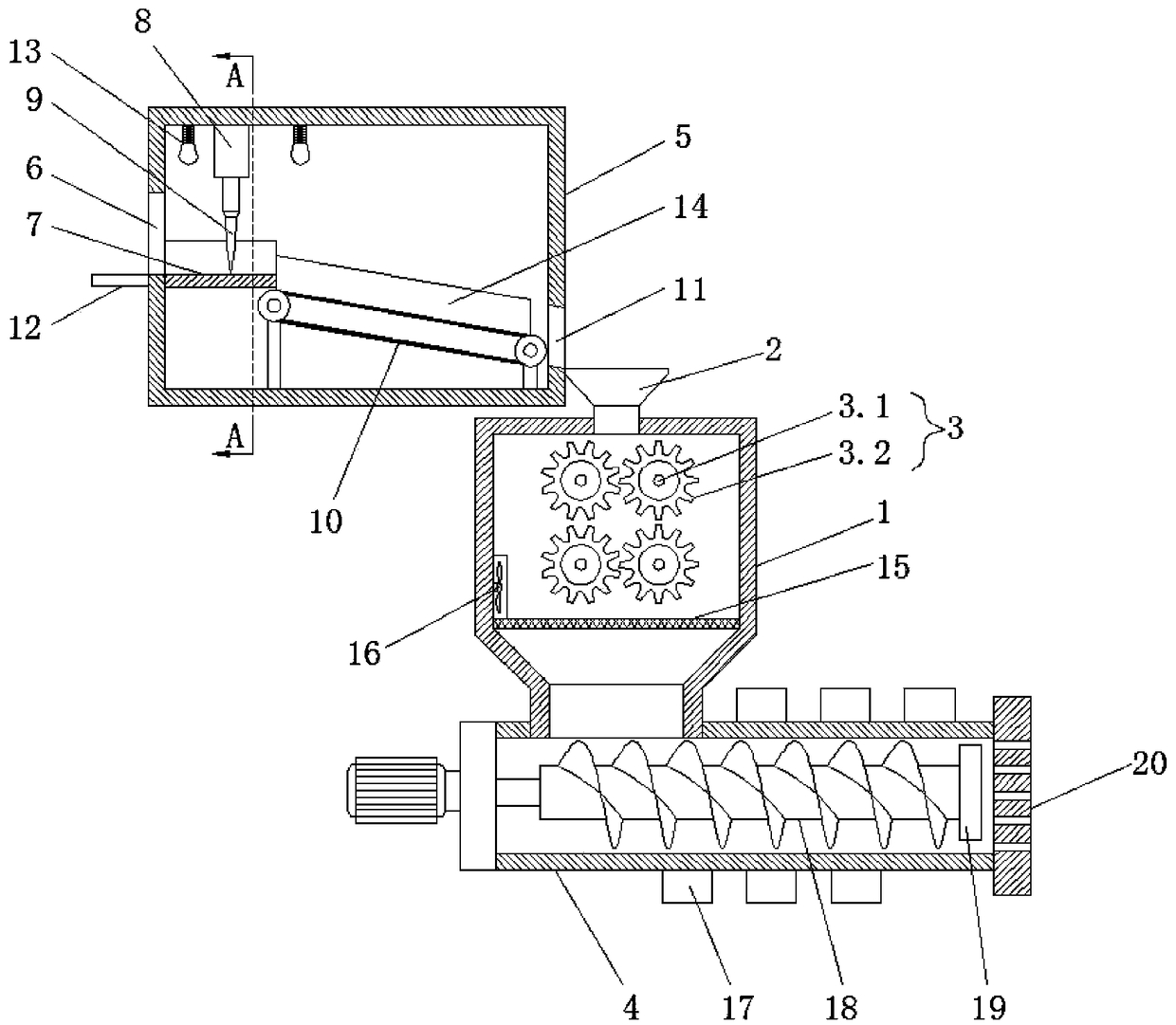

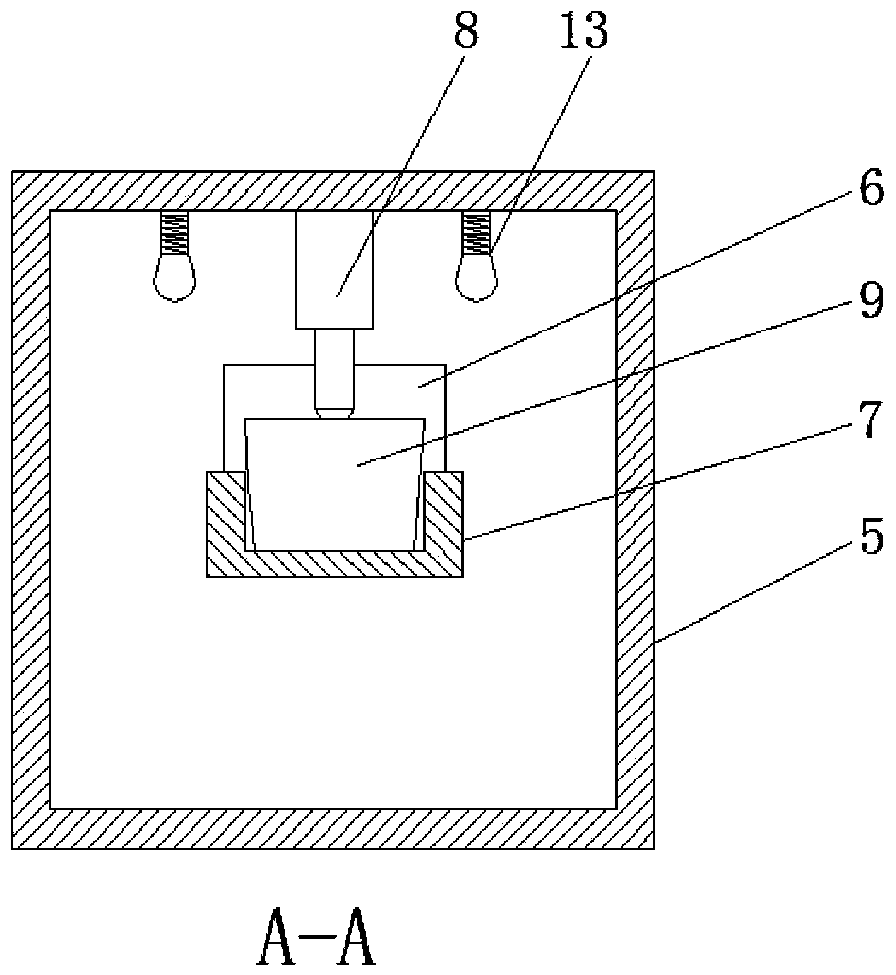

Multi-stage processing system for crop straw and operation method thereof

The invention discloses a multi-stage processing system for crop straw and an operation method thereof, and relates to the technical field of straw processing. The multi-stage processing system for the crop straw comprises a pretreatment machine for cutting straw raw materials into strips, a crusher is arranged below the pretreatment machine, a feeding hopper close to the discharging end of the pretreatment machine is arranged at the top of the crusher, the crusher is internally provided with at least two groups of crushing mechanisms arranged from top to bottom, and the crushing mechanisms are arranged under the feeding hopper. The bottom of the crusher is connected with an extrusion processing machine, the pretreatment machine is used for cutting, the crusher is used for crushing, and the extrusion processing machine is used for extruding. The multi-stage processing system for the crop straw has the advantages that the functions are complete, use safety of equipment is high, and thequality of produced fuel is high.

Owner:河南博顿生物科技有限公司

Environment-friendly biomass composite fuel prepared from sludge garbage and preparation method of environment-friendly biomass composite fuel

InactiveCN106753648AEfficient removalEfficient removal of emissionsBiofuelsSolid fuelsCombustionSludge

The invention relates to an environment-friendly biomass composite fuel prepared from sludge garbage and a preparation method of the environment-friendly biomass composite fuel. The environment-friendly biomass composite fuel is prepared from a biomass raw material, sludge garbage, fire coal, a combustion improver, a catalyst, a desulfuration nitrogen fixing agent, a stabilizer and a dust and harm removal agent. The environment-friendly biomass composite fuel prepared from the sludge garbage has the advantages of quick ignition, strong combustion fire, long combustion resistance, full combustion, high temperature, less dust and the like; meanwhile, under the action of prepared reagents, discharge of toxic and harmful substances is effectively eliminated, and the environmental pollution is avoided; furthermore, combustion is stable and heat is uniformly distributed, so as to prevent slagging of a boiler, prolong the service life of the boiler and reduce the operation cost; particularly in a preparation process, by the combination of the component proportion of the raw materials and a preparation technology which are preferred according to an actual working condition of the boiler, the combustion performance condition can be adjusted, the boiler can realize full-load efficient operation, and the heat efficiency of the boiler and the fuel heat use efficiency are improved; the environment-friendly biomass composite fuel is applicable to being used in a civil boiler and an industrial boiler.

Owner:杨立亮

Catalyst with hydrocarbon dehydrogenation catalysis function, preparation method and application of catalyst and hydrocarbon dehydrogenation reaction method

ActiveCN107661777AIncreased crush strengthHigh porosityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPorosityDehydrogenation

The invention relates to a catalyst with a hydrocarbon dehydrogenation catalysis function, a preparation method and an application of the catalyst and a hydrocarbon dehydrogenation reaction method anddiscloses the catalyst with the hydrocarbon dehydrogenation catalysis function. The catalyst contains a nanocarbon material and inorganic oxide, wherein at least part of inorganic oxide covers at least part of the surface of the nanocarbon material, the inorganic oxide contains at least one basic oxide and at least one metal oxide, the basic oxide is selected from silicon oxide, aluminum oxide and titanium oxide, and metal elements in the metal oxide are selected from group IA metal elements, group IIA metal elements and transition metal elements. The catalyst has higher crushing strength andhigher porosity and is suitable for being used as a catalyst, particularly a catalyst for a hydrocarbon dehydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron bronze composite powder and preparation method thereof

ActiveCN1920074ALow manufacturing costLow impurity contentMetallic material coating processesCopperIron powder

The invention relates the iron bronze composite powder and preparing method. The invention adopts chemical replacement method to form metal powder with bronze coating layer on the iron powder; the tin content is 1-11%, the copper content is 9-49%, and the left is iron, The method has the advantages of saving the cost, and the product has good property and long life. The bruising strength of the product is 28kgf / mm2. The product has not leaded, so the method is not bad for environment and human.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

Plasma-etching-resistant granulated yttrium oxide for hot spraying and preparation method thereof

The invention belongs to the technical field of hot spraying, and particularly relates to plasma-etching-resistant granulated yttrium oxide for hot spraying and a preparation method thereof. The preparation method of the plasma-etching-resistant granulated yttrium oxide for hot spraying comprises the following steps: preparing nano or ultrafine yttrium oxide powder and deionized water or an organic solution into a paste, performing depolymerization and reduction, adding surface activity activator into the paste for preparation, and performing hot expansion balling and high-temperature densification treatment to obtain the granulated yttrium oxide for hot spraying. According to the invention, the surface activity activator is added into the paste before hot expansion balling, so that the prepared granulated yttrium oxide for hot spraying is favorable in spherical degree, and the high-spherical-degree favorable-flowability high-density granulated yttrium oxide for hot spraying can be obtained without later spheroidization, thereby achieving favorable flowability during hot spraying, ensuring that the supply of the granulated yttrium oxide for hot spraying is more stable, and providing a guarantee for obtaining a hot spray coating having a uniform thickness.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com