Defluorinating adsorbent and preparation method thereof

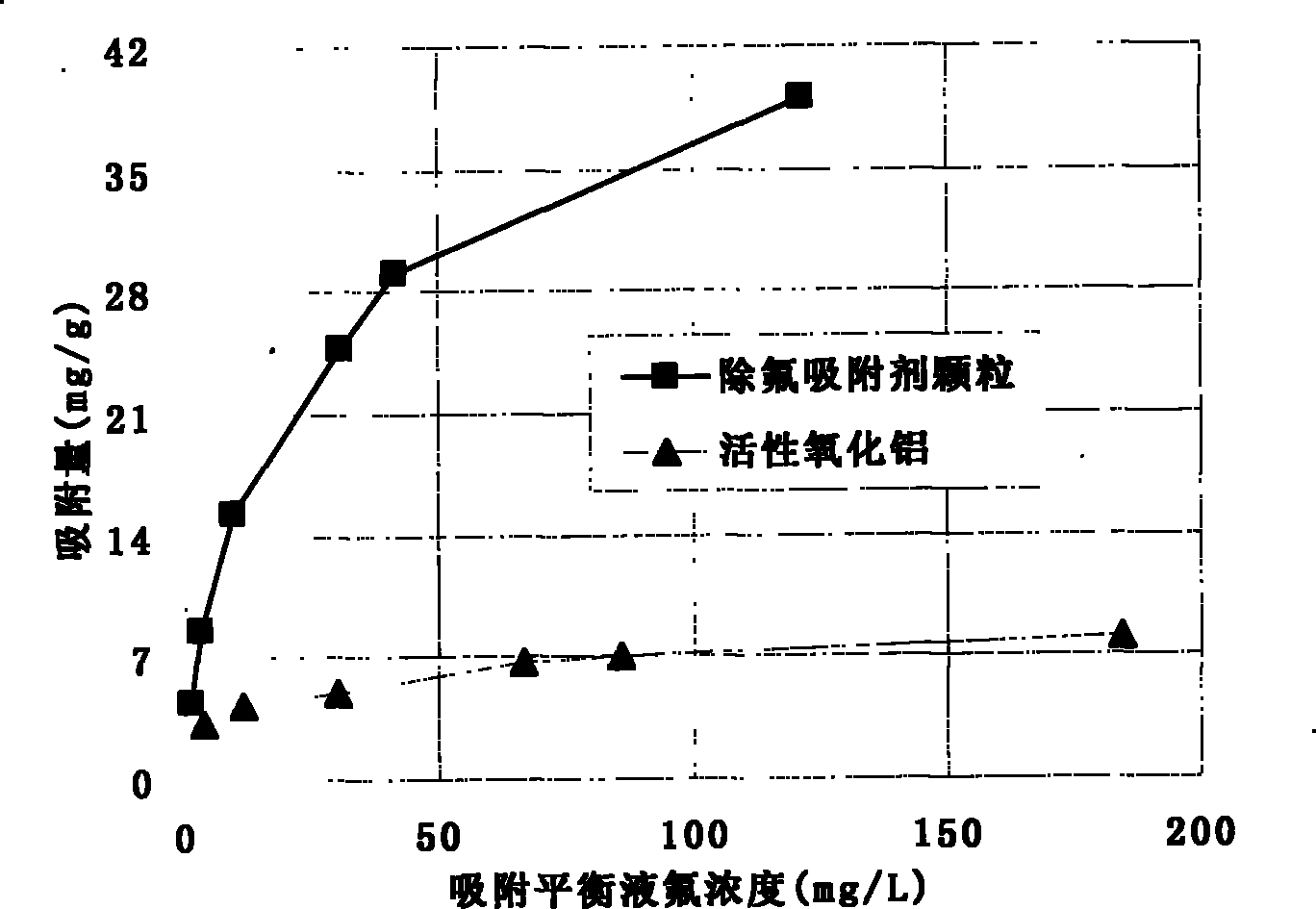

A technology of adsorbent and binder, which is applied in the field of preparation of fluorine-removing adsorbent, and achieves the effect of high pore volume, large specific surface area and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Preparation of composite metal oxide powder

[0066] Manganese nitrate, aluminum nitrate and cerium nitrate are dissolved in water to form an aqueous solution in a molar ratio of Mn: Al: Ce=1:4:1;

[0067] While stirring, add ammonia solution dropwise to the above aqueous solution until the pH of the solution is 9.5; let it stand for 24 hours; wash and separate by centrifugal washing with deionized water until the pH of the effluent is nearly neutral; dry the washed product at 100°C to a constant weight, calcined at 400° C. for 2 hours, and ground to obtain a composite metal oxide defluorination adsorbent powder.

[0068] 2. Preparation of adsorbent particles

[0069] Add the fluorine-removing adsorbent powder and the binder polyacrylate emulsion into a coulter mixer and mix evenly to prepare a mixed material, wherein the polyacrylate emulsion has a solid content of 53%, a concentration of 10%, and a viscosity of 800mPa·s , the pH value is 6.0, and the mass ratio o...

Embodiment 2

[0077] 1. Preparation of composite metal oxide powder

[0078] Dissolving ferric chloride, aluminum sulfate and lanthanum nitrate in a molar ratio of Fe: Al: La = 1: 4: 1 to form an aqueous solution, stirring and mixing at room temperature;

[0079] While stirring, add sodium carbonate solution dropwise to the above aqueous solution until the pH of the solution is 9.0, and let it stand for 24 hours; centrifuge and separate with deionized water until the pH of the effluent is nearly neutral; the washed product is stored at 90°C Dried to constant weight, calcined at 500° C. for 3 hours, and ground to obtain composite metal oxide fluorine removal adsorbent powder.

[0080] 2. Preparation of polymer binder

[0081] In a closed container, under the condition that the stirring rate is 150rpm, the polyvinyl formal powder is dissolved in ethanol, and the air bubbles are released after standing, so that the polyvinyl formal glue solution with a mass percentage concentration of 10% is ob...

Embodiment 3

[0088] 1. Preparation of composite metal oxide powder

[0089] Ferric nitrate, aluminum chloride, and cerium sulfate are dissolved in water to form an aqueous solution in a molar ratio of Fe: Al: Ce=1:6:1;

[0090] While stirring, add sodium hydroxide solution dropwise to the above aqueous solution until the pH of the solution is 9.5, and let it stand for 24 hours; centrifuge and separate with deionized water until the pH of the effluent is nearly neutral; the product after washing is at 95°C Dry at 450° C. for 1 hour, and grind to obtain composite metal oxide fluorine-removing adsorbent powder.

[0091] 2. Preparation of polymer binder

[0092] After dissolving polyvinyl alcohol (2499) in water at 95°C, add small molecular carboxylic acid citric acid and stir to carry out esterification reaction to obtain polyvinyl alcohol citrate binder, wherein the esterification reaction temperature is 70°C, the reaction time is 120min, the weight ratio of polyvinyl alcohol (2499) to wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com