Preparation method of high content glass fiber filled polypropylene battery diaphragm

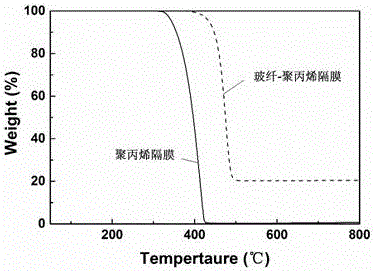

A high-content glass fiber and battery separator technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of poor ion permeability selectivity and the need for improvement of polypropylene separators, etc. Achieve uniform pore size distribution, superior safety performance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

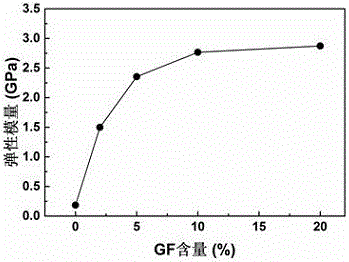

Embodiment 1

[0034] Weigh 100 g of glass fiber into a glass bottle, and use absolute ethanol and ultrapure water to prepare 95% ethanol aqueous solution. Add 1g (1wt%) silane coupling agent (KH-570) into 300mL ethanol aqueous solution, mix well, add to glass fiber, stir with mechanical stirrer for 24h, filter and remove the solution to obtain modified glass fiber. Put the polypropylene (PP) pellets and modified glass fiber (KH570-g-GF) into an electric constant temperature blast oven, and dry at 110°C for 24 hours to remove the moisture in the raw materials. Weigh PP and modified glass fiber at a certain mass ratio (the mass content of KH570-g-GF is 2%, 5%, 10%, and 20% respectively), and then make the modified glass fiber and PP pellets through a high-speed mixer. After the initial mixing of the materials, they were added to an internal mixer for melt blending for 10 minutes, and the extruded materials were crushed into masterbatches using a plastic crushing and granulating machine. Use ...

Embodiment 2

[0045]Weigh 100 g of glass fiber into a glass bottle, and use absolute ethanol and ultrapure water to prepare 95% ethanol aqueous solution. Add 1g (1wt%) of silane coupling agent (KH-550) into 300mL ethanol aqueous solution, mix thoroughly, add to glass fiber, stir with mechanical stirrer for 24h, filter and remove the solution to obtain modified glass fiber. Put the polypropylene (PP) pellets and modified glass fiber (KH550-g-GF) into an electric heating constant temperature blast oven, and dry at 110°C for 24 hours to remove the moisture in the raw materials. The KH550-g-GF and PP raw materials are fed according to the mass ratio of 1:4, and pre-mixed by a high-speed mixer. Add it into an internal mixer for melt blending for 10 minutes, and crush the extruded material into masterbatches using a plastic crushing granulator. Use a torque rheometer for extrusion molding. The die size of the extruder is 10mm×2mm. The die is connected with a drafting machine to draw the sheet in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com