Method for preparing porous film by adopting high molecular weight polyolefin and product and application thereof

A high molecular weight, porous film technology, applied in the direction of electrical components, circuits, battery components, etc., can solve the problems that cannot meet the requirements of power lithium-ion batteries, the distribution of porous film pores, poor pore structure, mechanical properties, high temperature, etc. Low puncture strength and other problems, to achieve the effect of thermal shutdown characteristics and thermal dimensional stability, low cost, high temperature puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

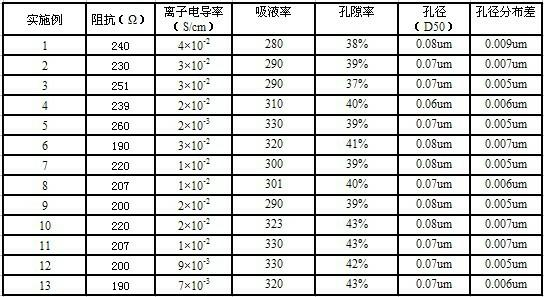

Examples

Embodiment 1

[0032] ①Take the high molecular weight polyolefin A with a weight average molecular weight of 500,000 g / mol and a molecular weight distribution (Mw / Mn) of 10 and the high molecular weight polyolefin B with a weight average molecular weight of 2 million g / mol and a molecular weight distribution of 20 at a ratio of 2:1 Mix together to obtain high molecular weight polyolefin raw materials, then take 1 part of non-polar solvent white mineral oil in parts by weight and soak 9 parts of high molecular weight polyolefin raw materials at a temperature of 50 °C for 6 hours;

[0033] ② Take 100 parts by weight of high molecular weight polyolefin after soaking treatment, mix with 1 part of anti-adhesive agent ABPP05 and 1 part of antioxidant 1010, and mix them in a single-screw extrusion equipment at an extrusion temperature of 230 ° C to prepare co- masterbatch;

[0034] ③On the cast film unit, under the condition of casting sheet temperature of 25°C, the masterbatch is stretched by biax...

Embodiment 2

[0037] Repeat the operation of embodiment 1, the difference is:

[0038] In step ①, the high-molecular-weight polyolefin raw material is only polyolefin A, the non-polar solvent is white mineral oil and paraffin oil mixed in a weight ratio of 1:1, and the weight ratio of the non-polar solvent to the high-molecular-weight polyolefin raw material is 1 : 4. The immersion temperature is 70°C, and the immersion time is 10h; in step ②, 100 parts by weight of soaked high molecular weight polyolefin, 1 part of anti-adhesive agent ABPP05 and 2 parts of antioxidant 1010 are mixed, and passed through double The screw extruder is mixed to prepare the blend masterbatch; in step ③, the longitudinal stretching temperature is 90°C, the longitudinal stretching ratio is 3 times, the transverse stretching temperature is 150°C, and the transverse stretching ratio is 5 times, and the obtained film material The thickness is 40um; in step ④, the non-polar solvent is xylene, the extraction temperatur...

Embodiment 3

[0040] Repeat the operation of embodiment 1, the difference is:

[0041] In step ①, in the high molecular weight polyolefin raw material, the weight ratio of polyolefin A to polyolefin B is 7:1, the non-polar solvent is mixed with xylene and paraffin oil in a weight ratio of 1:1, and the non-polar solvent and The weight ratio of high-molecular-weight polyolefin raw materials is 1:4, the soaking temperature is 90°C, and the soaking time is 14 hours; in step ②, 100 parts by weight of soaked high-molecular-weight polyolefin are taken, 2 parts of anti-adhesive agent ABPP05 and 1 part of antioxidant 1010 is mixed and mixed by an internal mixer to form a blend masterbatch; in step ③, the longitudinal stretching temperature is 100°C, the longitudinal stretching ratio is 4 times, the transverse stretching temperature is 150°C, and the transverse stretching temperature is 150°C. The ratio is 6 times, and the thickness of the obtained film material is 33um; in step ④, the non-polar solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com