Patents

Literature

680 results about "Large pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

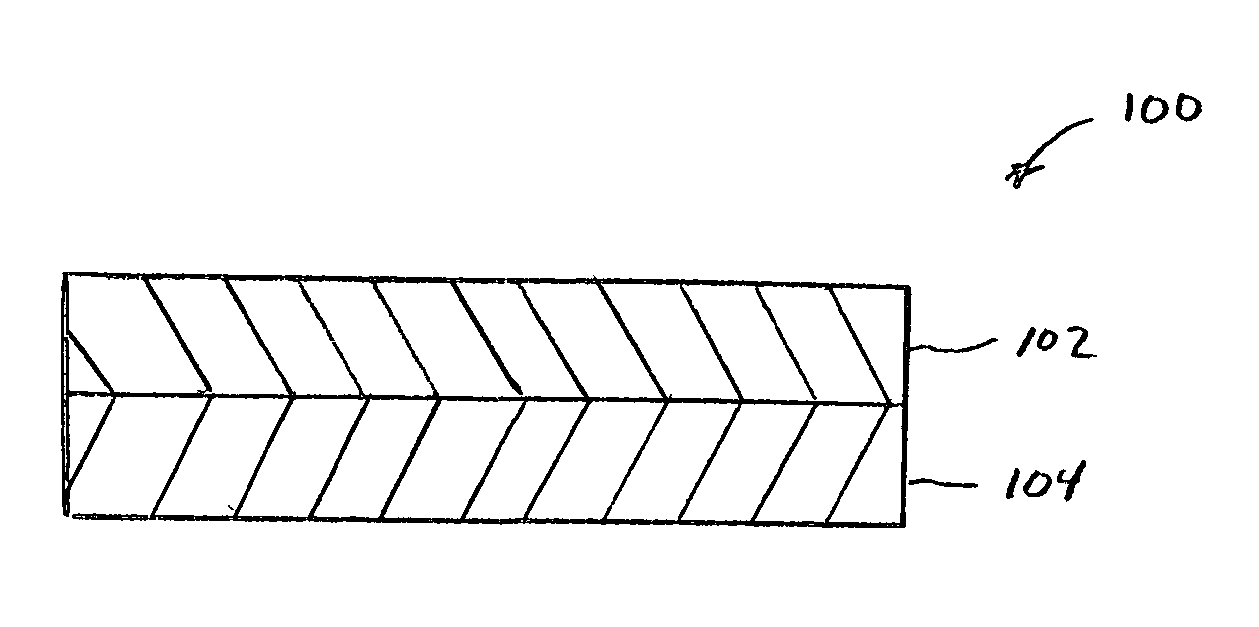

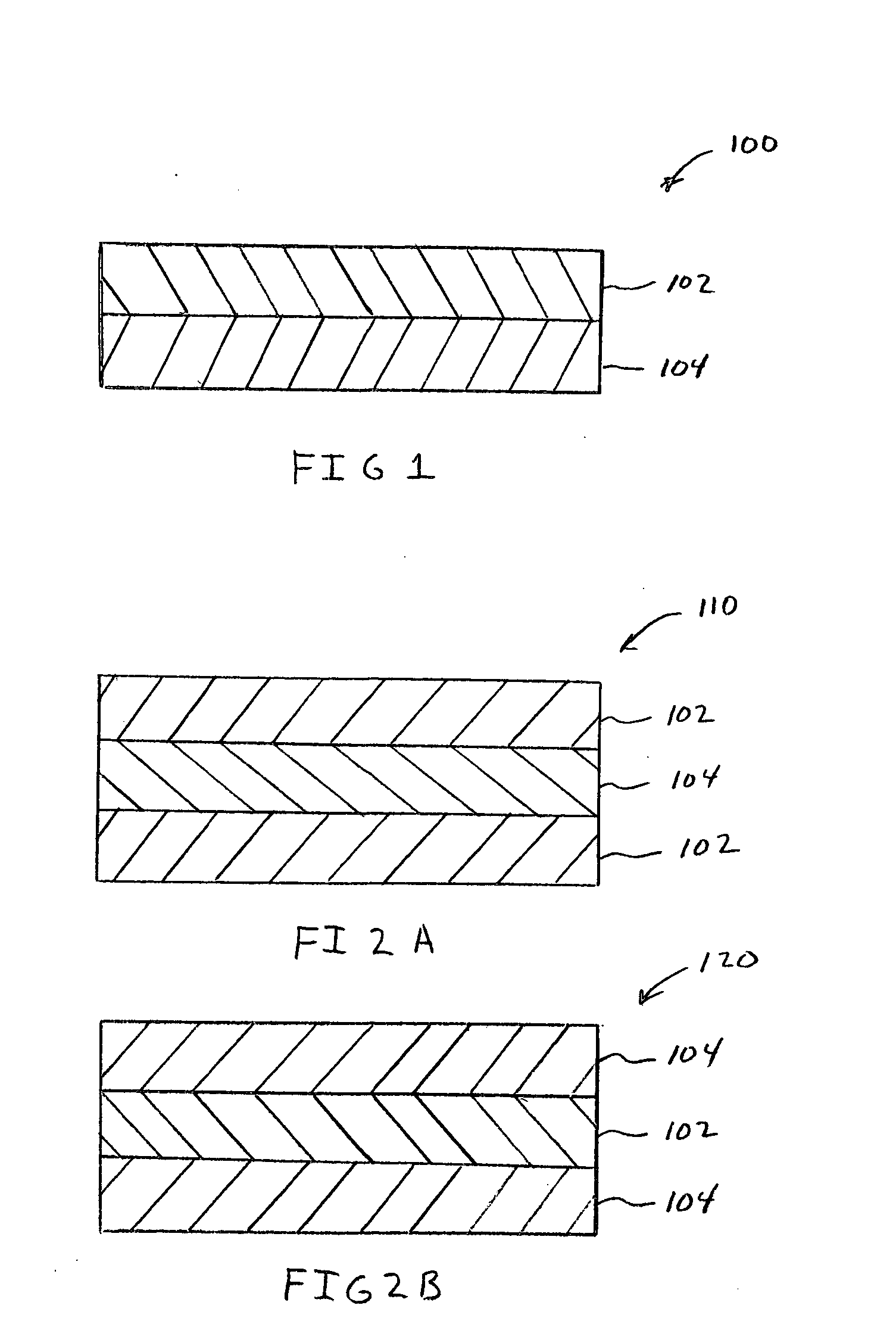

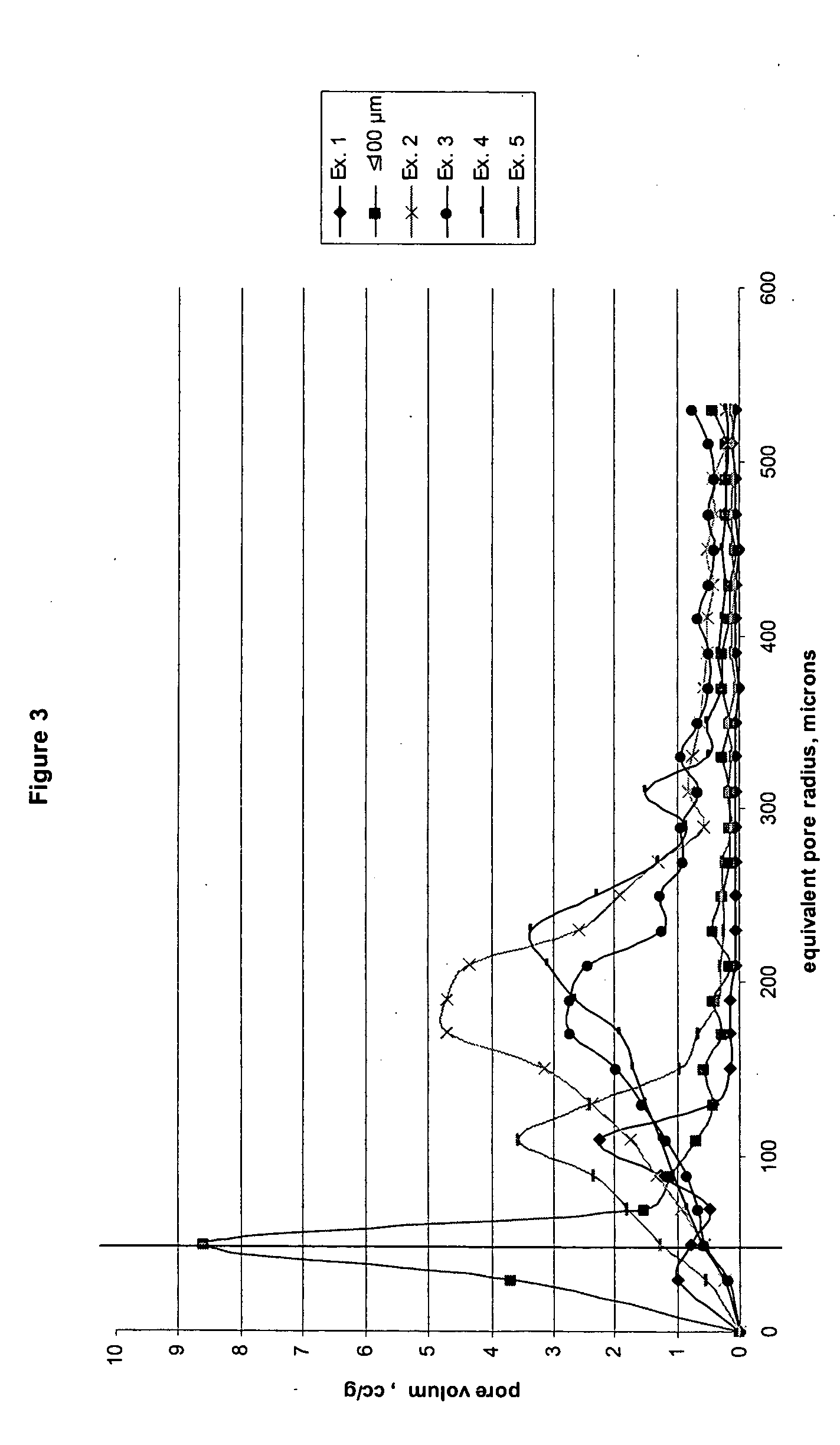

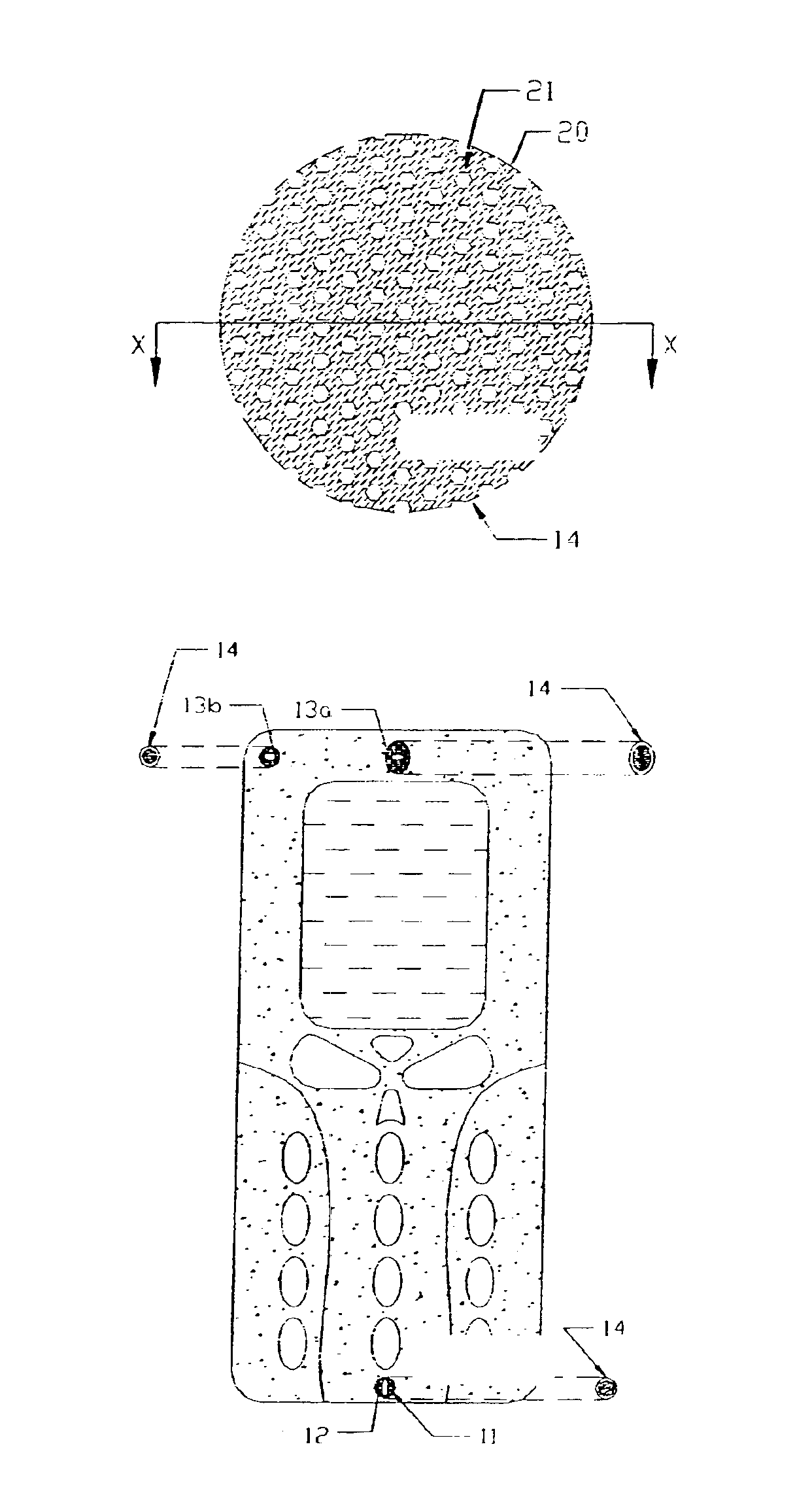

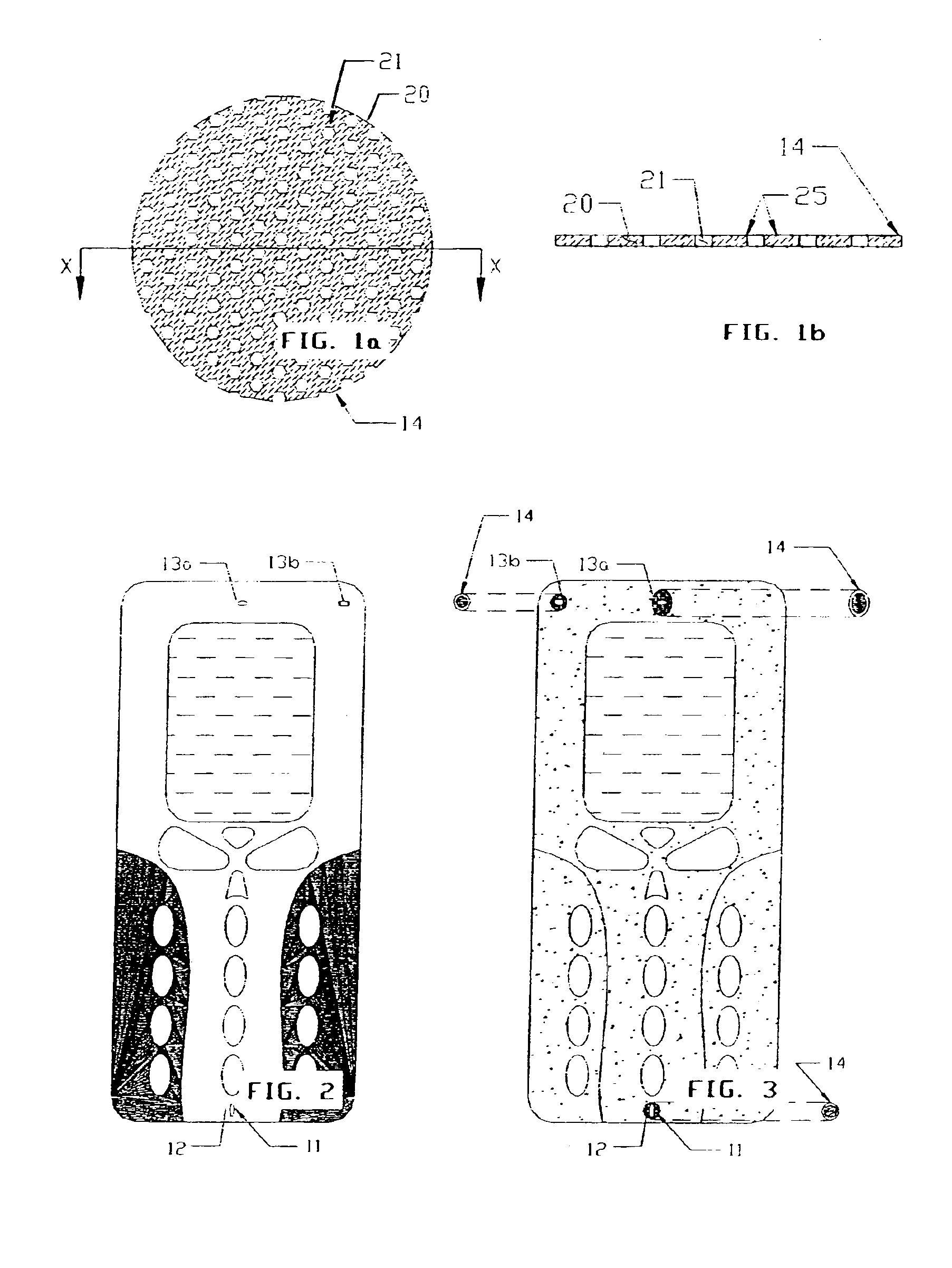

Bimodal pore size nonwoven web and wiper

InactiveUS20050148264A1Easy to cleanQuick releaseCleaning equipmentCleaning using toolsViscous liquidReservoir function

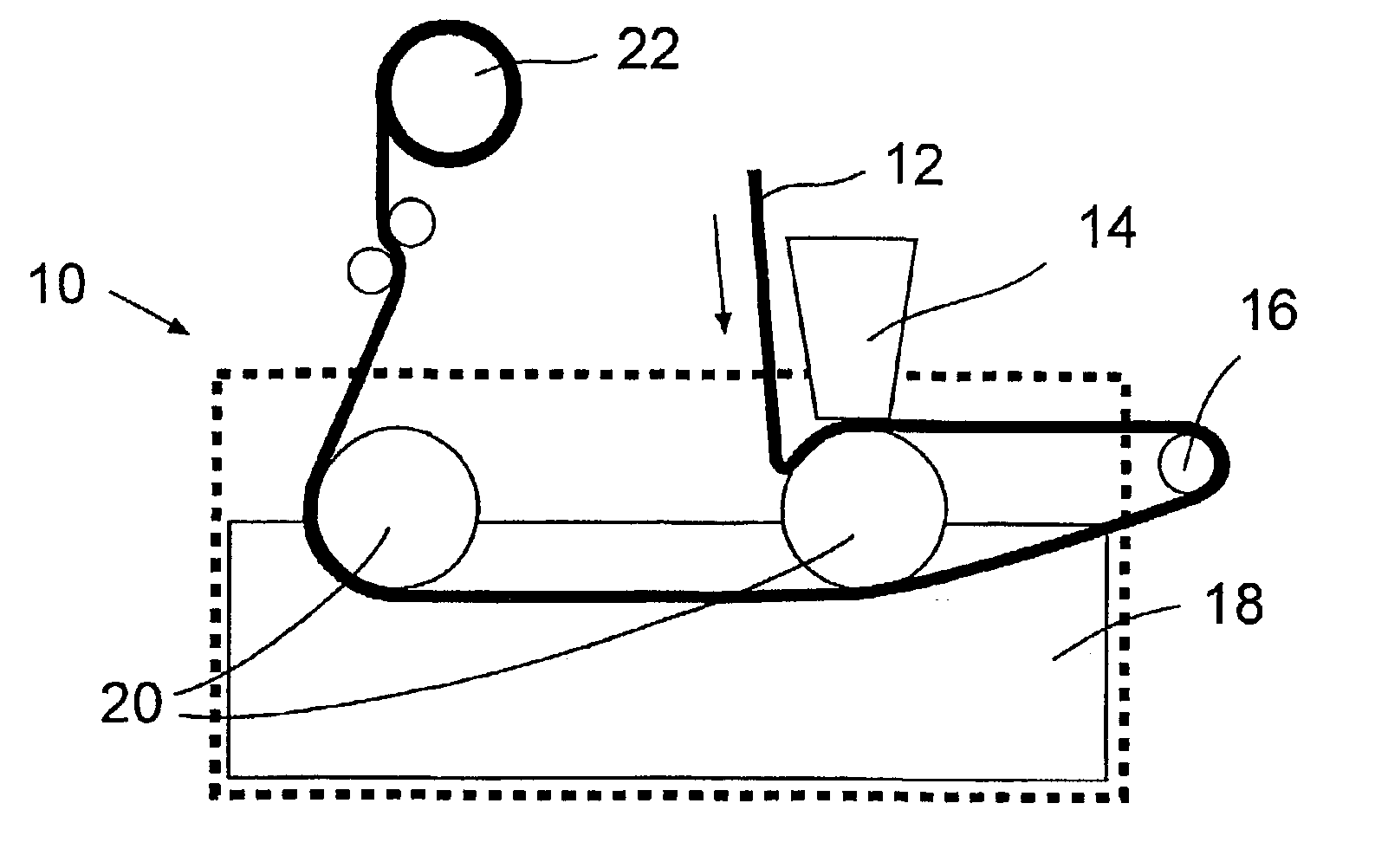

The present invention provides a nonwoven web laminate having at least a bimodal pore size distribution. The laminate has a first layer with pores having a mean equivalent pore radius greater than about 100 μm and a second layer with pores having a mean equivalent pore radius less than about 100 μm. Generally, the first layer has a mean equivalent pore size radius in the range of about 1 μm to about 100 μm and the second layer has a mean equivalent pore size radius in the range of about 100 μm to about 1000 μm. The layer having an average pore size radius greater than 100 μm provides rapid fluid release from the laminate to facilitate cleaning by providing a cleaning solution to solubilize particles or viscous liquids on the surface. In addition, the large pore size allows particles and viscous liquids to be captured and trapped within the pores of the laminate, thereby effectively cleaning the surface to be cleaned. The layer with the small pore size provides a fluid reservoir function by absorbing fluid and holding the fluid in the laminate, or by holding a cleaning fluid to be released during a cleaning operation. The nonwoven web laminate of the present invention is an effective wiper.

Owner:KIMBERLY-CLARK WORLDWIDE INC

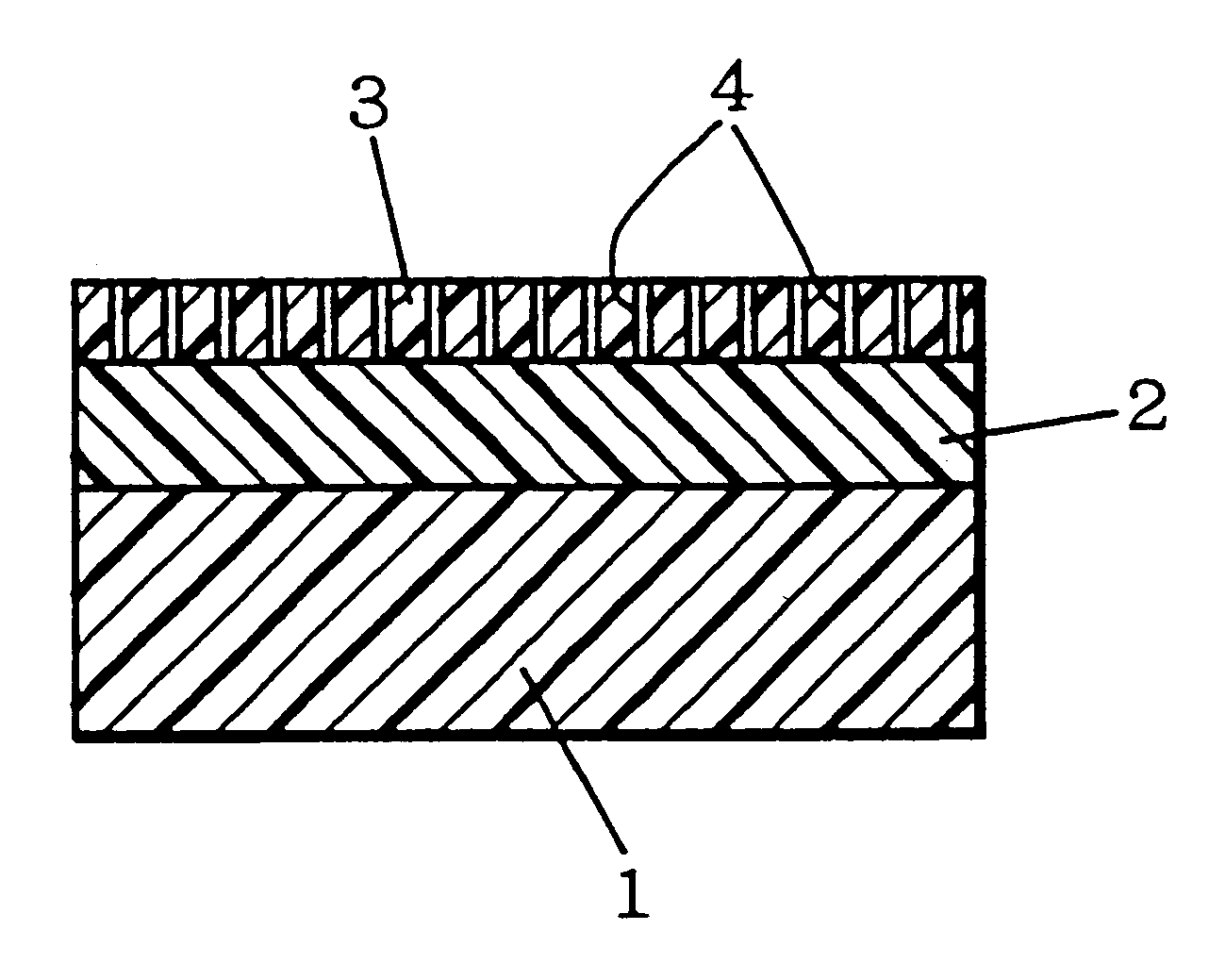

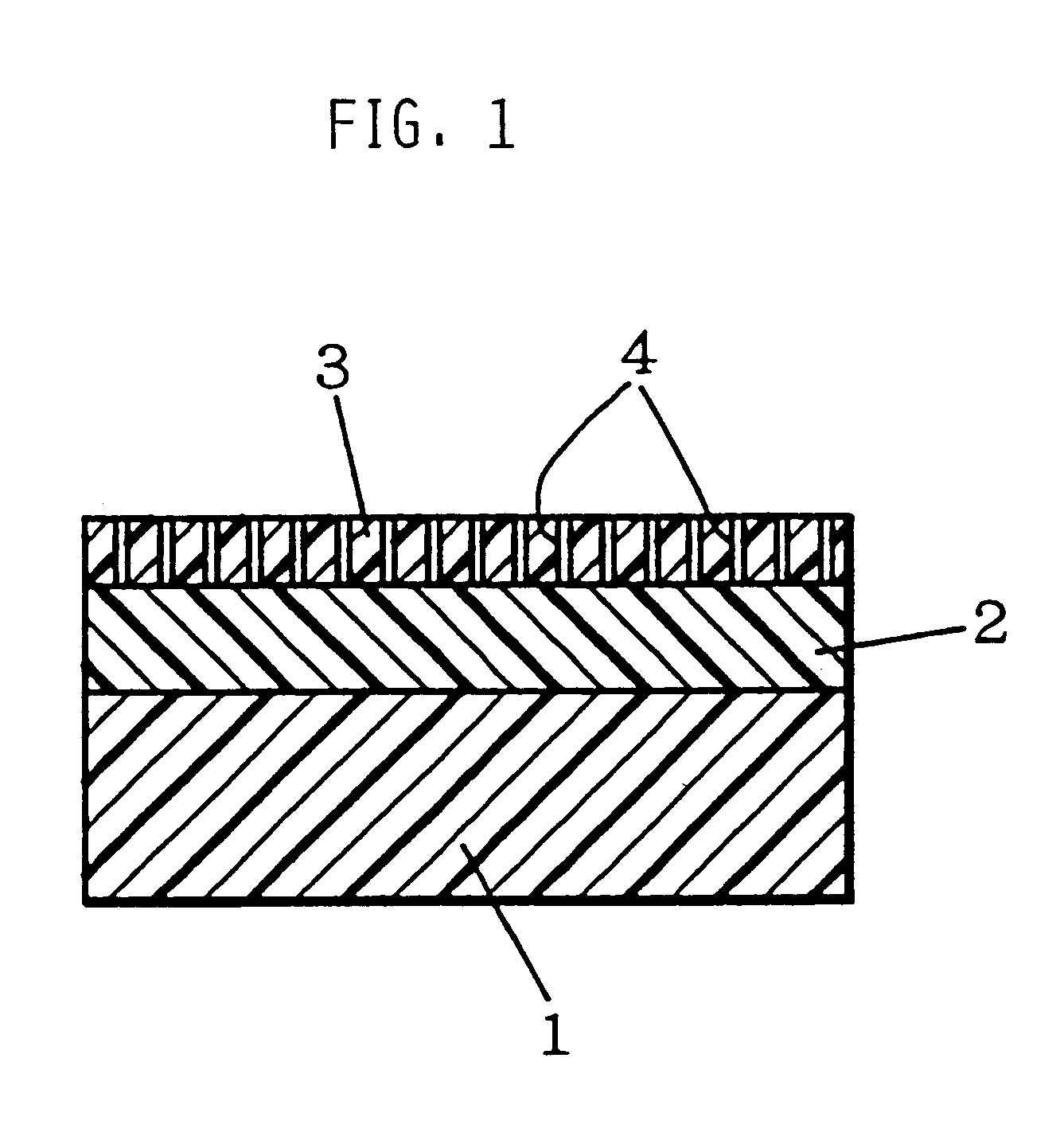

Porous films, process for producing the same, and laminate films and recording sheets made with the use of the porous films

InactiveUS6177181B1High in transparency and ink absorptionImprove waterproof performanceMembranesSemi-permeable membranesBoiling pointOptical transmittance

Porous membranes having a micro phase separation structure and showing a light transmittance at the wavelength of 400 nm of not less than 30% are obtained by the dry phase conversion method comprising drying a coating layer of a dope containing a polymer, a good solvent for the polymer and a poor solvent for the polymer which solvent has a higher boiling point than the good solvent. The polymer includes cellulose derivatives, vinyl-series polymers such as acrylonitrile-series polymers and (meth)acrylic acid ester-series polymers, polysulfone-series polymers, and the like. The porous polymer membranes have a porosity of 10 to 60%, a mean pore size of about 0.002 to 0.35 mum and a maximum pore size of not greater than 0.4 mum. These porous membranes shows not only excellent transparency but also high productivity.

Owner:DAICEL CHEM IND LTD

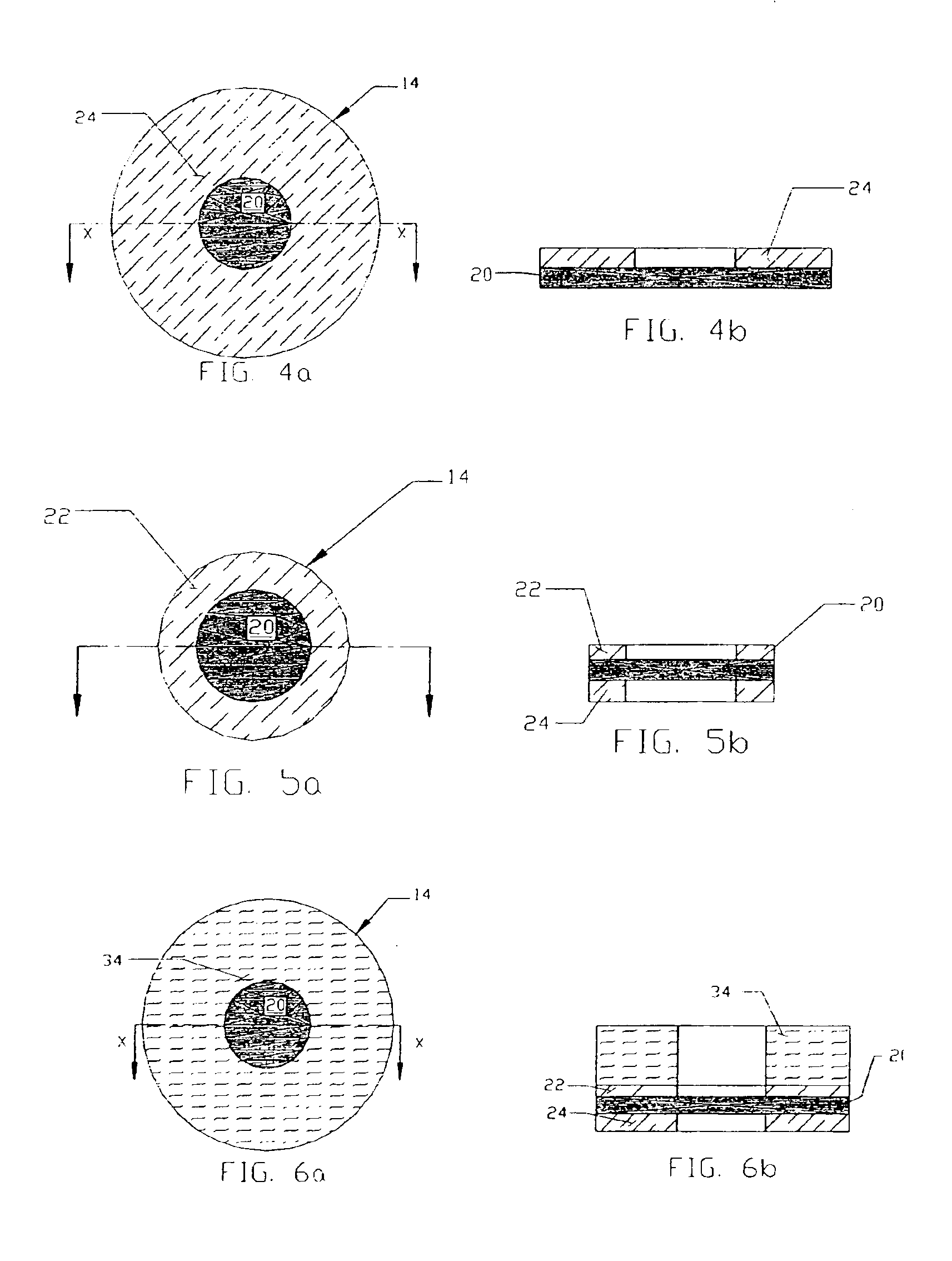

Protective acoustic cover assembly

A protective acoustic cover assembly including a metal foil with perforations, and a treatment on one or more surfaces of said metal foil. The treatment is a hydrophobic or oleophobic treatment, or both. The protective acoustic cover assembly has an average specific acoustic resistance of less than about 11 Rayls MKS from 250-300 Hz, an average specific acoustic reactance magnitude of less than about 1 Rayls MKS from 250-300 Hz, and an instantaneous water entry pressure value of greater than about 11 cm. The perforations of the metal foil preferably have an average maximum pore size of less than about 150 micrometers. The protective acoustic cover assembly further includes an adhesive mounting system, and the preferred metal foil is nickel.

Owner:WL GORE & ASSOC INC

Multi component catalyst and its use in catalytic cracking

A multi component catalyst and catalytic cracking process for selectively producing C3 olefins. The catalyst comprises a first molecular sieve having an intermediate pore size, a second molecular sieve and, optionally a third molecular sieve having a large pore size. At least one of the channels of the second molecular sieve has a pore size index that is less than the pore size index of at least one channel of the first molecular sieve. The process is carried out by contacting a feedstock containing hydrocarbons having at least 5 carbon atoms is contacted, under catalytic cracking conditions, with the multi component catalyst. The catalyst finds application in the cracking of naphtha and heavy hydrocarbon feedstocks.

Owner:EXXONMOBIL CHEM PAT INC

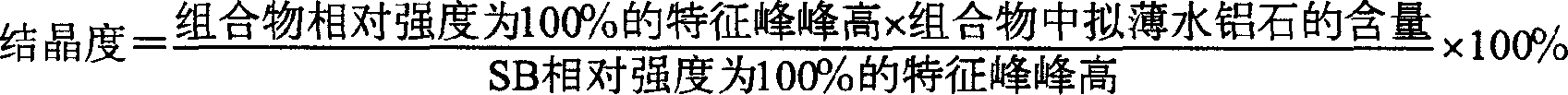

Quasi-thin empholite composition containing organic reaming agent

ActiveCN1611300AReduce crystallinityLarge hole volumeCatalyst activation/preparationRefining to eliminate hetero atomsDiasporeResidual oil

The present invention relates to a pseudothin diaspore composition containing organic pore-expanding agent. Said composition contains 92-99.5 wt% of pseudothin diaspore and 0.5-8 wt% of organic pore-expanding agent, in which the crystallinity of pseudothin diaspore is 10-70%. In the pseudothin diaspore composition provided by said invention the organic pore-expanding agent content is low, after high-temperature calcination the alumina with large pore capacity and large pore diameter can be obtained. Said alumina can be used as carrier material for preparing hydrodemetalization catalyst for heavy oil, residual oil and short residuum specially.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

Gasoline sulfur reduction in fluid catalytic cracking

InactiveUS6852214B1Reduce sulfur contentLow sulfurCatalytic crackingMolecular sieve catalystsOxidation stateGasoline

The sulfur content of liquid cracking products, especially the cracked gasoline, of the catalytic cracking process is reduced by the use of a sulfur reduction additive comprising a porous molecular sieve which contains a metal in an oxidation state above zero within the interior of the pore structure of the sieve. The molecular sieve is normally a large pore size zeolite such as USY or zeolite beta or an intermediate pore size zeolite such as ZSM-5. The metal is normally a metal of Period 4 of the Periodic Table, preferably zinc or vanadium. The sulfur reduction catalyst may be used in the form of a separate particle additive or as a component of an integrated cracking / sulfur reduction catalyst.

Owner:MOBIL OIL CORP +1

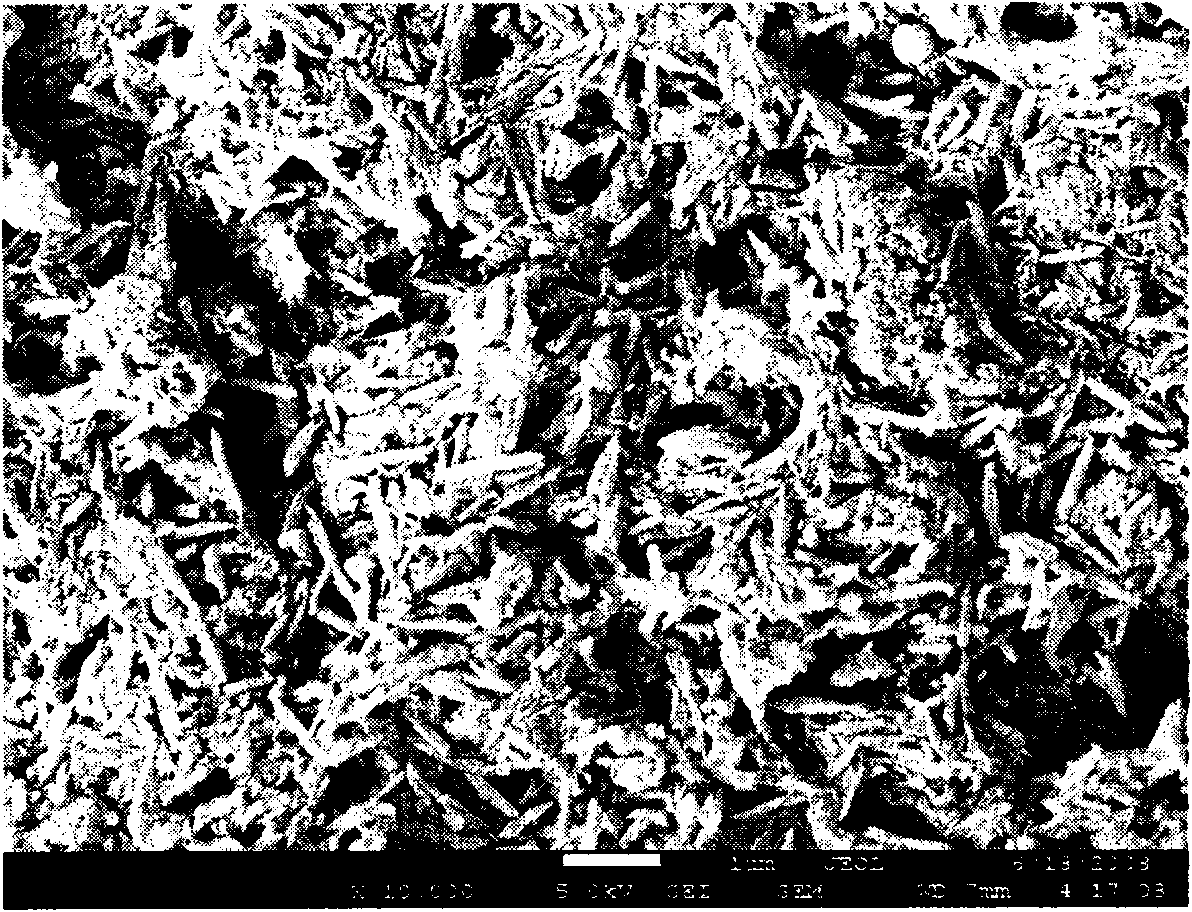

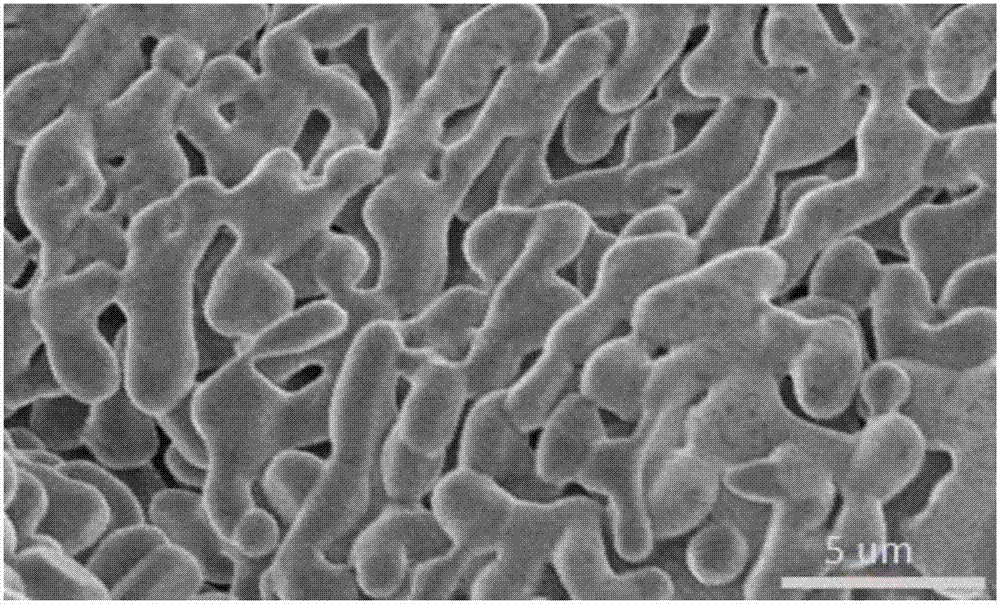

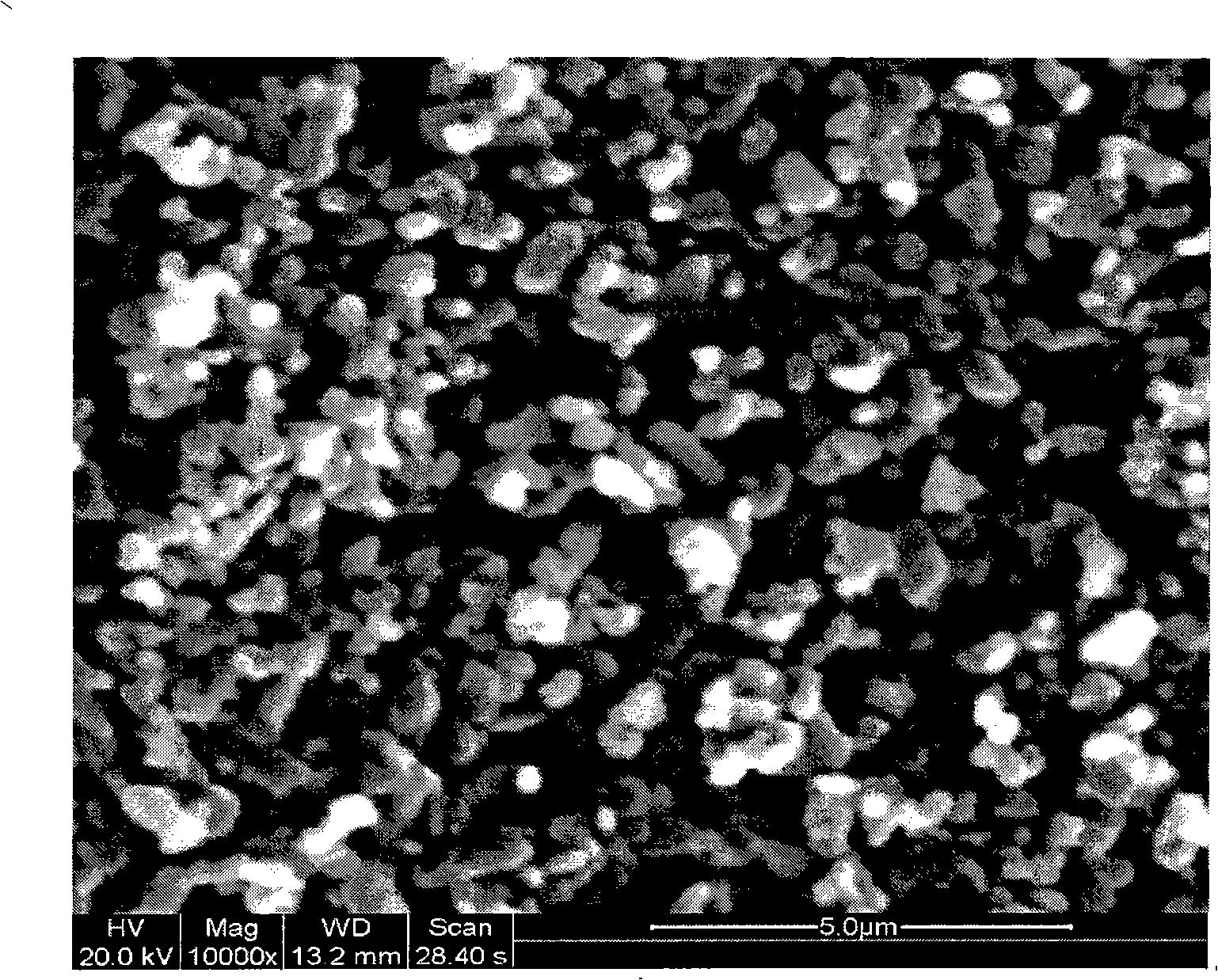

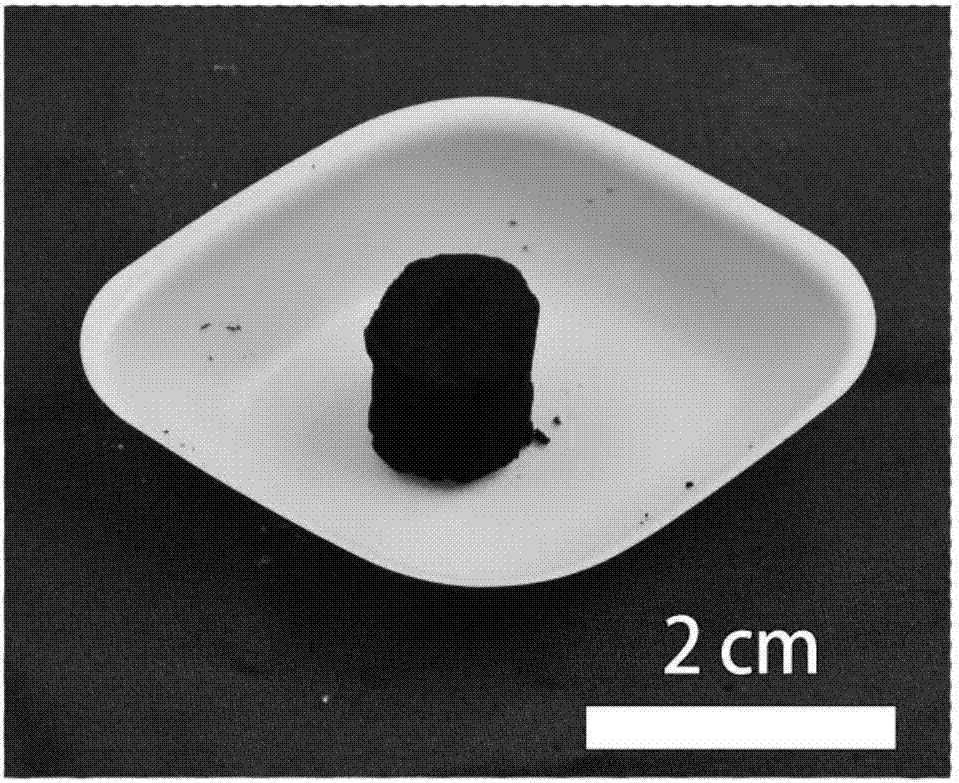

Alumina carrier and preparation method thereof

The invention discloses an alumina carrier and a preparation method thereof. In the alumina carrier, aluminum hydroxide gel prepared by a molten salt supersolubilizing micelle method is taken as a raw material. After a surfactant and a hydrocarbon component contained in the gel are molded and baked, nano-alumina particles formed by removing water from the polymerized aluminum hydroxide still have a basic rod-shaped structure and are piled up in an unordered way so as to form a frame structure. The alumina carrier has the characteristics of large pore volume, large pore diameter, high porosity, large orifice on the outer surface and high pore canal penetrability. In particular for macromolecules, the alumina carrier prevents catalyst inactivation caused by the blocking of an ink bottle-shaped orifice, so that impurity deposition is increased, and the running period of a catalyst is prolonged. The alumina carrier can be applied to a catalytic reaction which contains a macromolecule reactant or a macromolecule product.

Owner:CHINA PETROLEUM & CHEM CORP +1

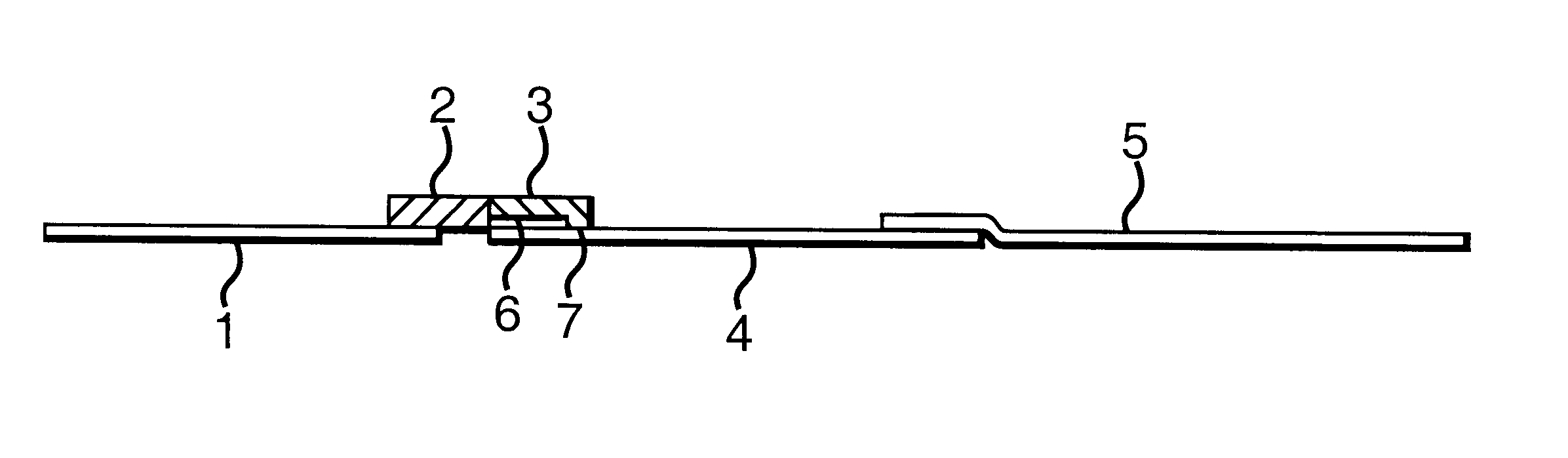

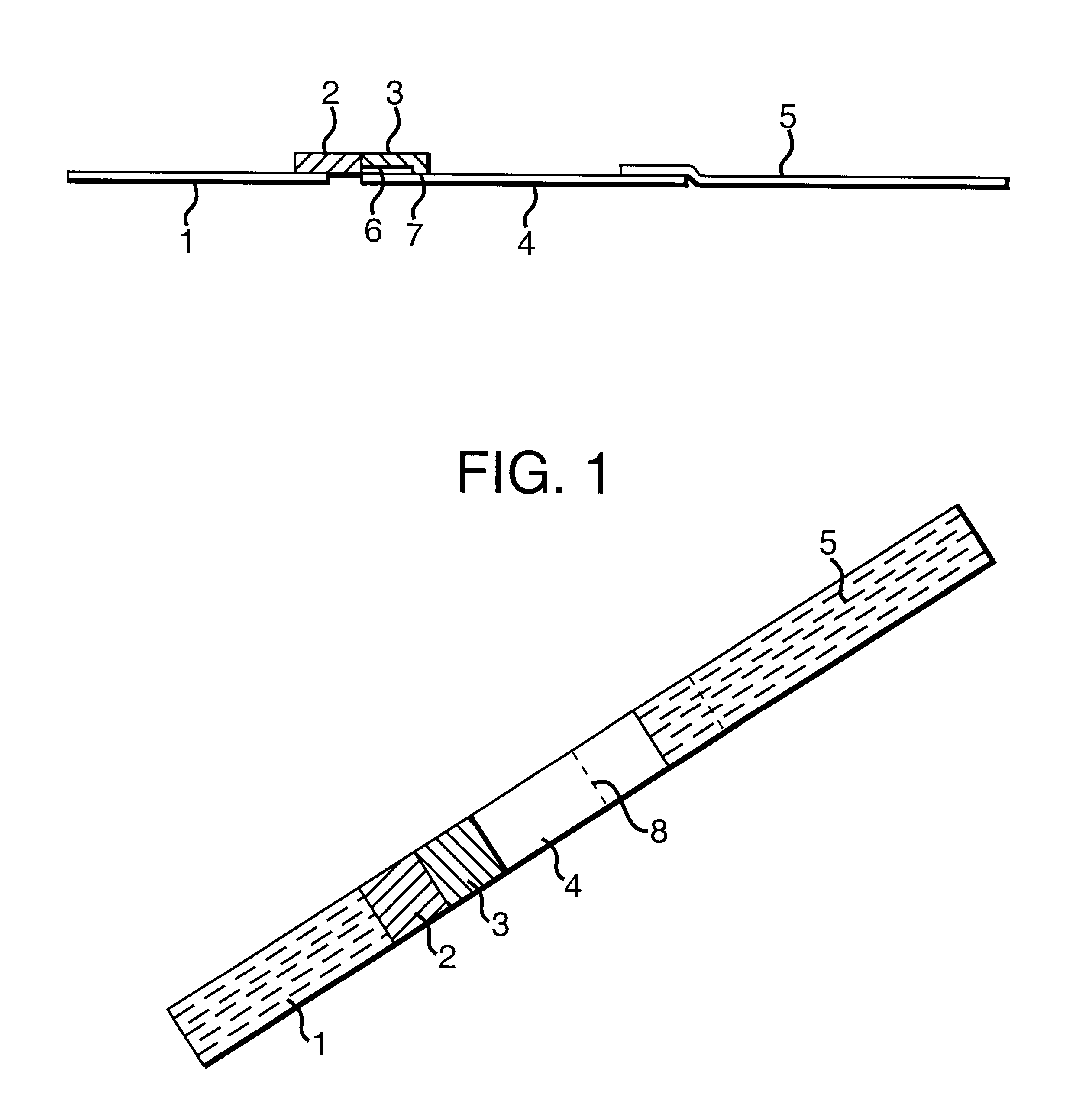

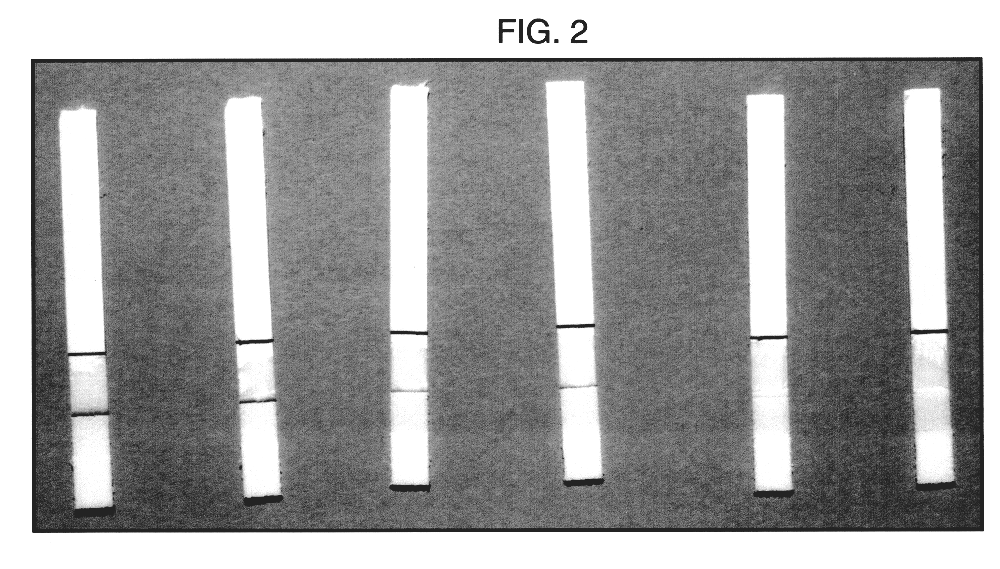

Assay using porosity-reduction to inhibit migration

InactiveUS6472226B1Small sizeConveniently formedBioreactor/fermenter combinationsBiological substance pretreatmentsPorosityAnalyte

Device for assaying an analyte, comprising a labelling zone, where a label can bind to the analyte, in communication with a capture zone, wherein the pore size of the capture zone is such that label which is not bound to the analyte can migrate therethrough, whereas label which is bound to the analyte cannot. During migration from the labelling zone (large pore size) to the capture zone (small pore size), unbound label can pass into and through the capture zone, whereas bound label will be captured at the junction of the labelling zone a the capture zone. The device relies upon the label being smaller than the analyte, such that free label is not retarded by the capture zone. It is particularly suitable for assying analytes such as spermatozoa, which are large in comparison with a label such as a labelled antibody.

Owner:GENOSIS UK

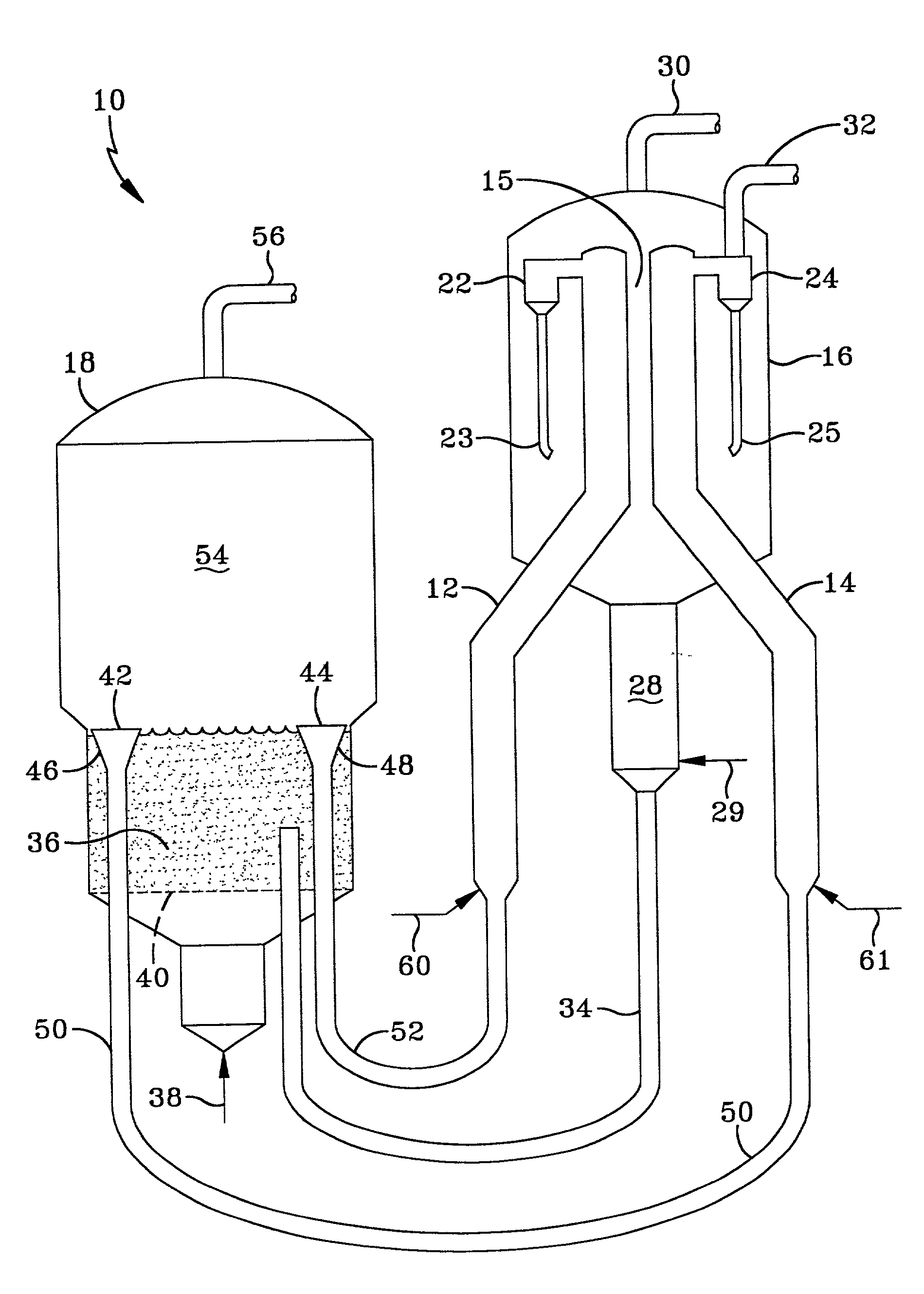

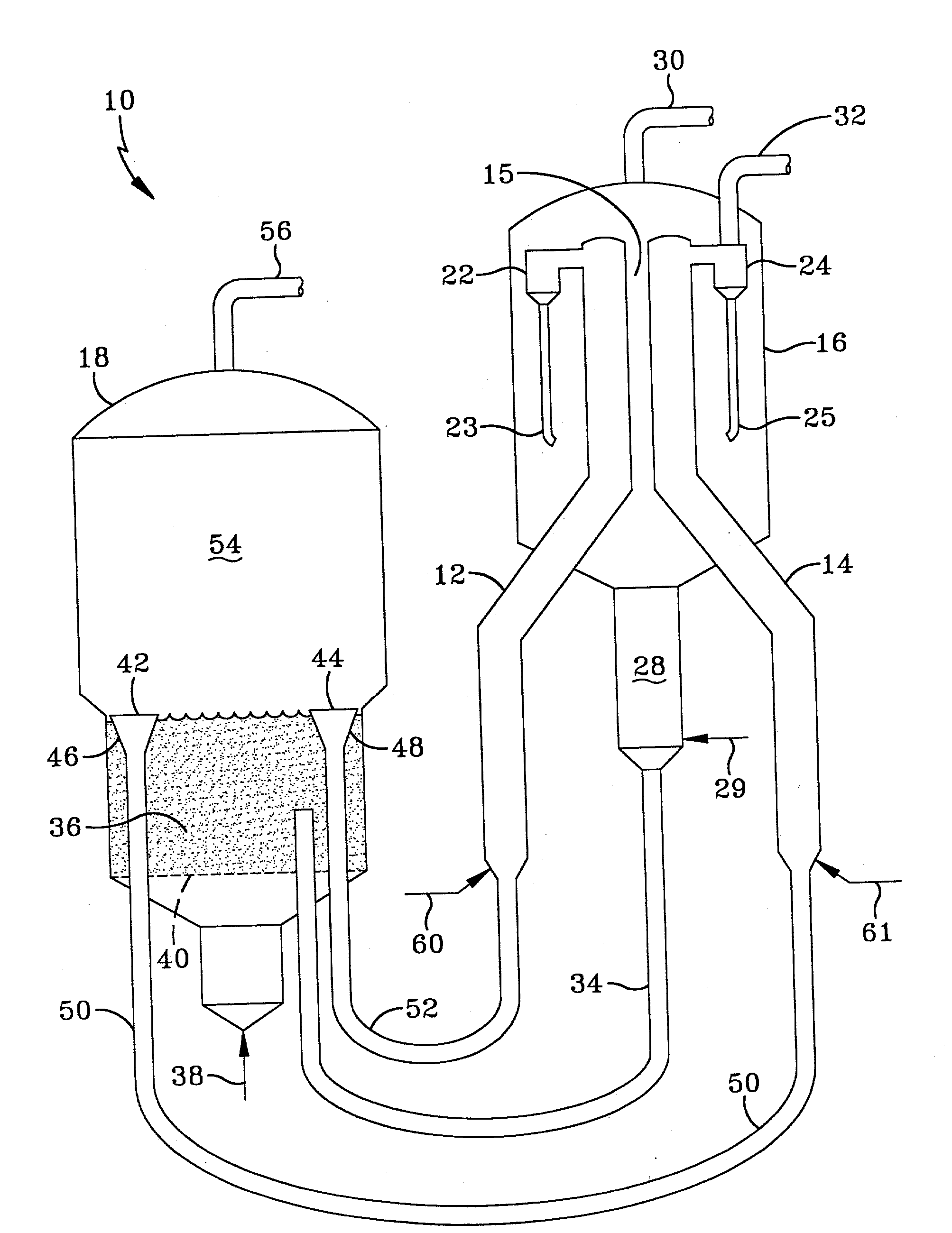

Fluid cat cracking with high olefins production

InactiveUS20020189973A1Maximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300° F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

Nanoscale double-cylindrical-bore filter membrane

InactiveCN107875860AImprove permeabilityLow flow resistanceMembranesSemi-permeable membranesMembrane permeabilityFiltration

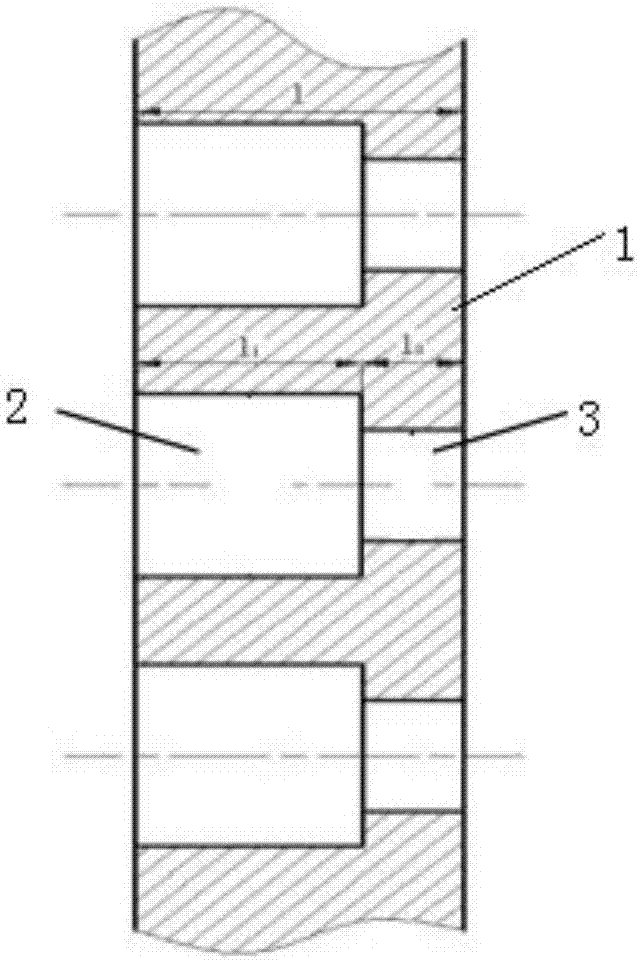

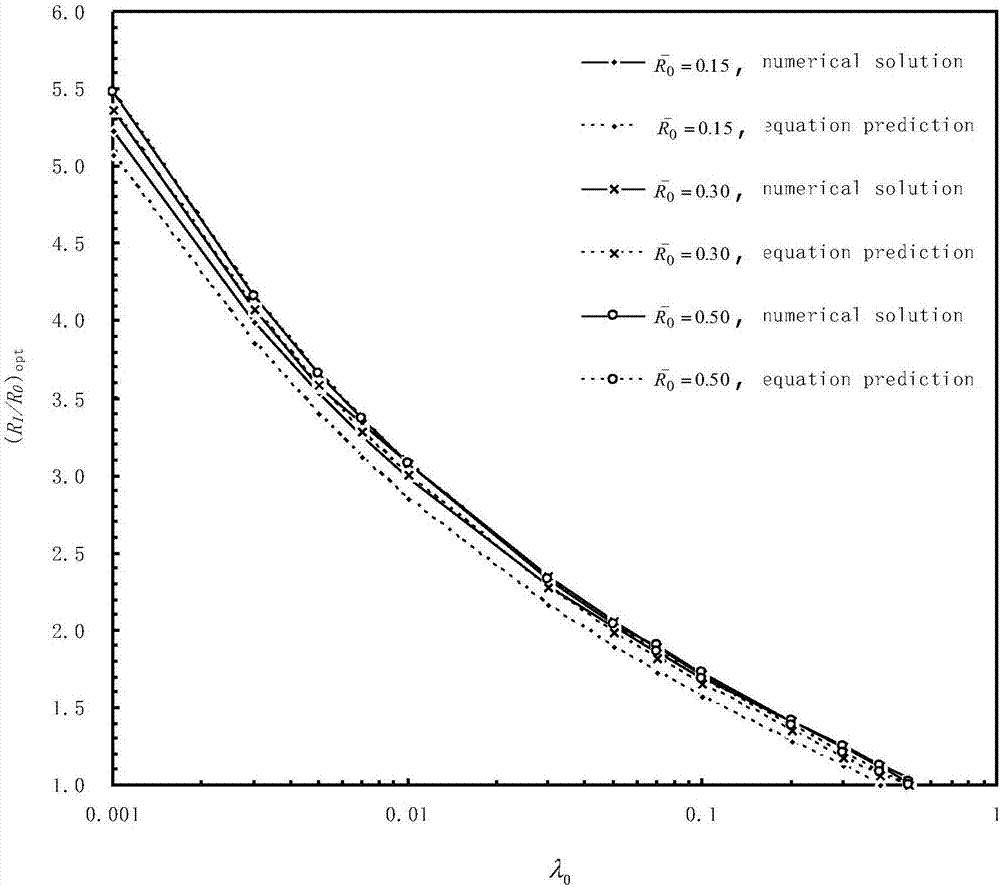

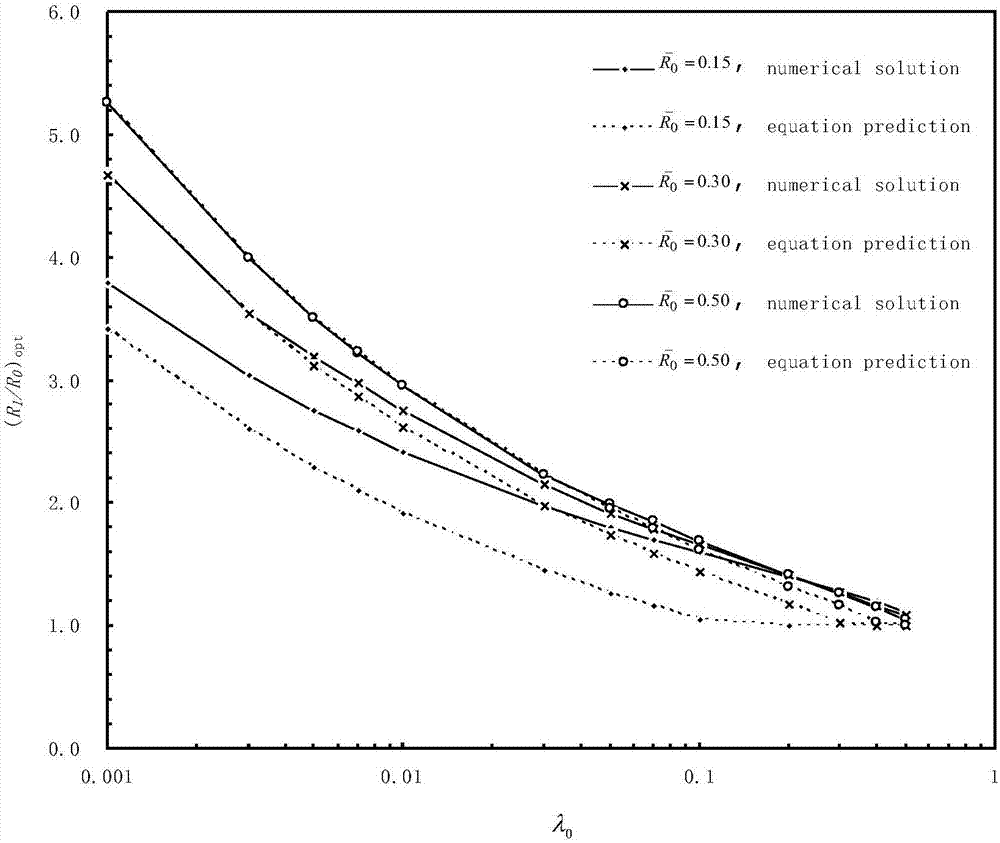

The invention provides a nanoscale double-cylindrical-bore filter membrane. According to the invention, two sides of a layer of a solid material are provided with two cylindrical bores which are in communication; the cylindrical bore with a small bore diameter is a filtration bore with a length of L0, a diameter of 2R0 and a radius of R0; the value of the L0 is determined according to the requirement for strength of the filtration bore; the radius R0 is determined according to the requirements of filtration and is at a nanometer scale; the cylindrical bore with a large bore diameter is a dragreduction bore with a length of L1 and a radius of R1; the value of the L1 is determined according to the requirement for mechanical strength of a filter membrane; R1 is no less than R0; the radius R1is determined according to the requirement for the maximum penetration capacity of the filter membrane; the cylindrical bores are uniformly distributed on the surface of the solid material; and the layer of the solid material is the filter membrane. The filter membrane provided by the invention can realize ultrafine filtration, has excellent penetration capacity, and can meet the requirement formechanical strength during filtration at the same time.

Owner:袁虹娣

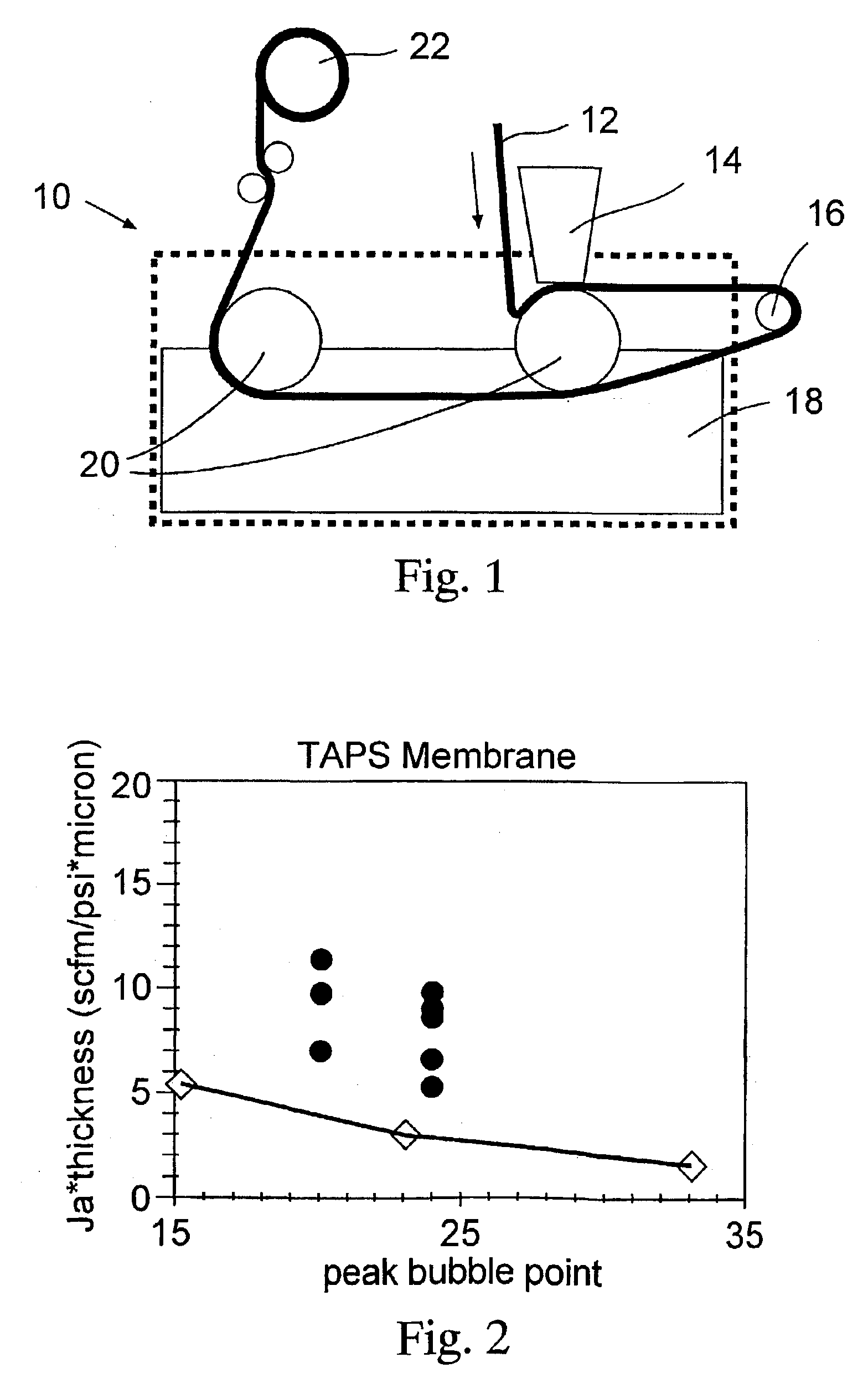

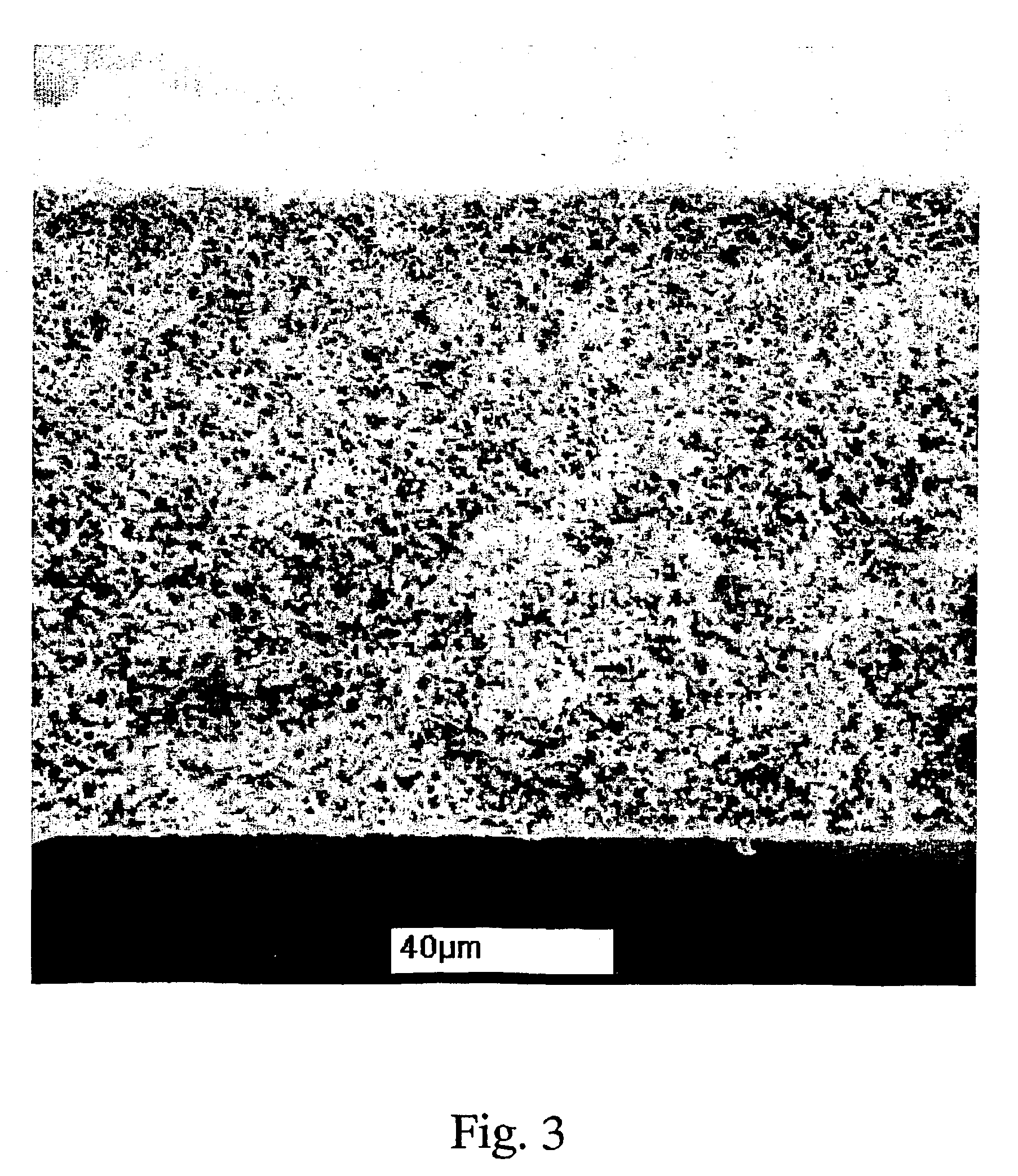

Method of manufacturing membranes and the resulting membranes

InactiveUS6994811B2Different profileLarge apertureSemi-permeable membranesMembranesHollow fibreFiber

This invention provides a process for making microporous membranes from a polymer solution and the membranes therefrom. A thermal assist, such as heating of the polymer solution can be effected subsequent to shaping the solution, such as by forming a film, tube or hollow fiber of the solution under conditions that do not cause phase separation.. In a preferred embodiment, the formed solution is briefly heated to generate a temperature gradient through the body of the formed solution. The polymer in solution then is precipitated to form a microporous structure. The formation of a wide variety of symmetric and asymmetric structures can be obtained using this process. Higher temperatures and / or longer heating times effected during the heating step result in larger pore sizes and different pore gradients in the final membrane product.

Owner:MILLIPORE CORP

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS6652735B2Yield maximizationReduce pointsHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

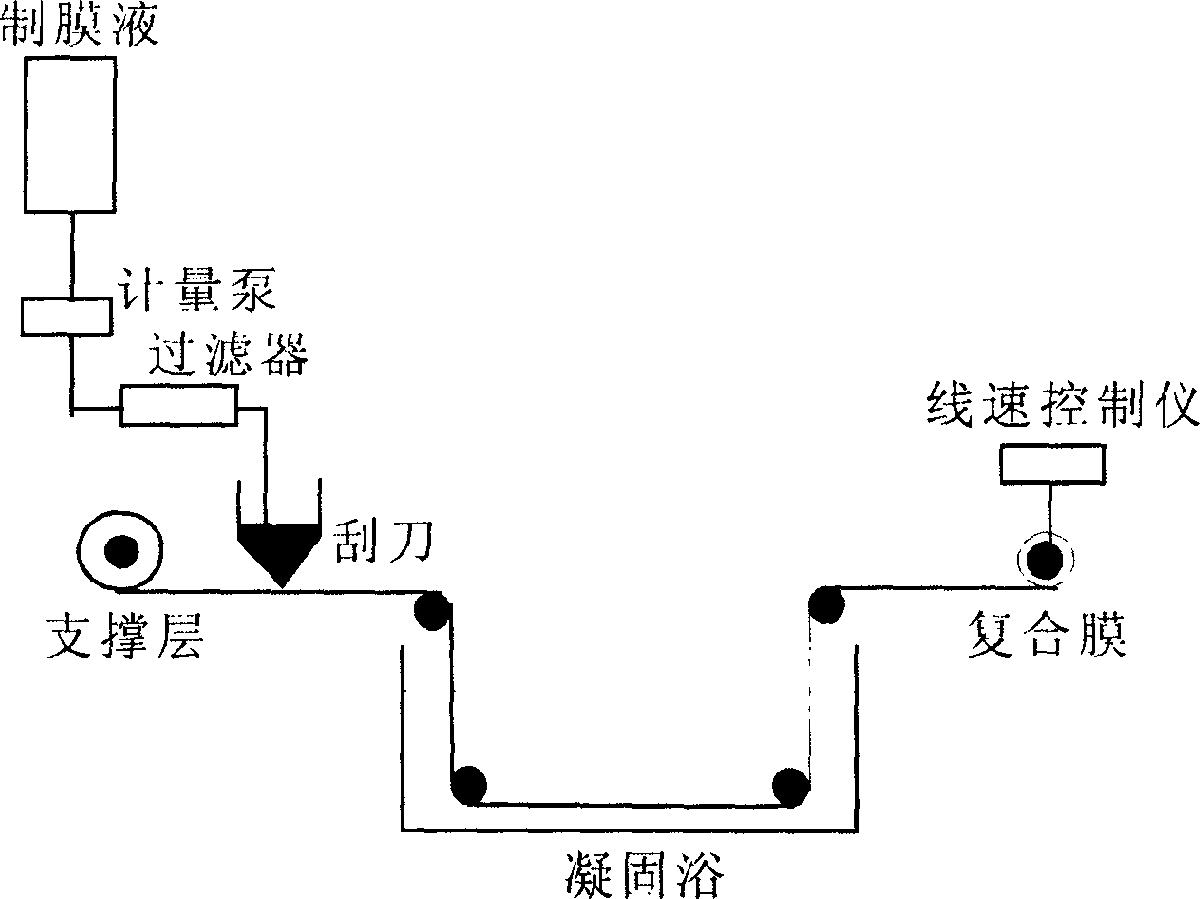

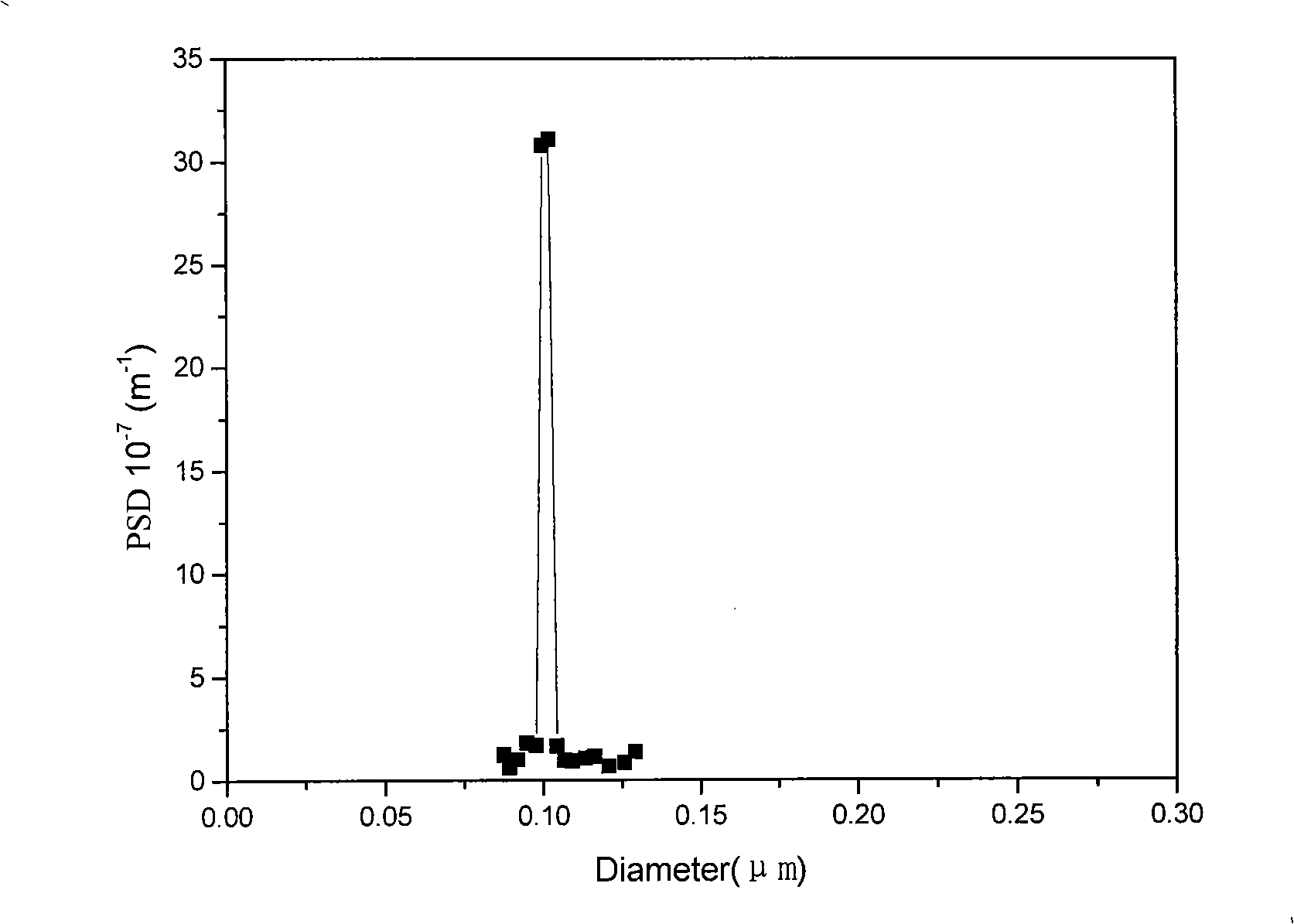

Method for preparing polyvinylidene fluoride flat plate microporous compound film

InactiveCN1621140AReduce energy consumptionEasy temperature controlSemi-permeable membranesComposite filmEngineering

The present invention is preparation process of plate microporous composite polyvinylidene fluoride film. The preparation process includes: mounting the support layer on composite film scraping machine and regulating the cloth speed; regulating the interval between the support layer and the scraper with plug gage; feeding filming liquid into the film scraping machine and coating the liquid to the support layer to form film, running the film in the air for some time, soaking the film in solidifying bath to form the composite film of polyvinylidene fluoride and the support layer. The composite film features large pore size, high strength and high water flux. The composite film is measured to have pore size of 0.1-1.5 micron, pure water flux of 400-2100 L / hr.sq m (at 0.1MPa), thickness of 150-220 microns, radial tensile strength of 35.2 MPa, radial elongation at breaking of 51.92 %, transverse tensile strength of 18.2 MPan and transverse elongation at breaking of 68.7 %.

Owner:ZHEJIANG UNIV

Microporous hydrophilic membrane

ActiveUS20060016748A1High removing abilityGood removal effectMembranesSolvent extractionChemistryHydrophilization

A hydrophilic microporous membrane comprising a thermoplastic resin, having been subjected to hydrophilizing treatment and having a maximum pore size of 10 to 100 nm, wherein when 3 wt % bovine immunoglobulin having a monomer ratio of 80 wt % or more is filtered at a constant pressure of 0.3 MPa, an average permeation rate (liter / m2 / h) for 5 minutes from the start of filtration (briefly referred to as globulin permeation rate A) satisfies the following formula (1) and an average permeation rate (liter / m2 / h) for 5 minutes from the time point of 55 minutes after the start of filtration (briefly referred to as globulin permeation rate B) satisfies the following formula (2): Globulin permeation rate A>0.0015×maximum pore size (nm)2.75 (1) Globulin permeation rate B / globulin permeation rate A>0.2 (2).

Owner:ASAHI KASEI MEDICAL CO LTD

Catalyst for heavy oil fixed bed hydrogenating treatment and its preparation process

The invention relates to a heavy oil fixed-bed hydrotreating catalyst and a preparation method thereof. The catalyst has a large pore size and high activity, is suitable for conversion reactions of macromolecular components such as asphaltene and heavy colloids, and is hydrogenated with conventional heavy and residual oils. The treatment catalyst is used together to obtain a higher rate of impurity removal, especially the rate of carbon residue removal and heavy metal removal is greatly improved. When the catalyst of the present invention is combined with the existing catalyst, it should be installed after the desulfurization catalyst and before the denitrogenation catalyst. It has an ideal treatment effect on various heavy and residual oil raw materials, and is especially suitable for residual oil raw materials with high residual carbon value. Hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing propylene oxide

InactiveUS6211388B1Molecular sieve catalystsOrganic chemistry methodsEthylbenzene hydroperoxideQuaternary ammonium ions

A method for producing propylene oxide by reacting propylene with ethylbenzene hydroperoxide, wherein the reaction is conducted in the presence of a catalyst comprising a titanium-containing silicon oxide and satisfying all of the following conditions (1) to (6):(1) there is at least one peak showing a interplanar spacing (d) larger than 18 Å in X-ray diffraction;(2) an average pore size is 10 Å or more;(3) a pore size of 90% or more of the total pore volume is 5 to 200 Å;(4) a specific pore volume is 0.2 cm3 / g or more;(5) a quaternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by calcination operation:wherein R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms; and(6) The catalyst has been subjected to silylation treatment.

Owner:SUMITOMO CHEM CO LTD

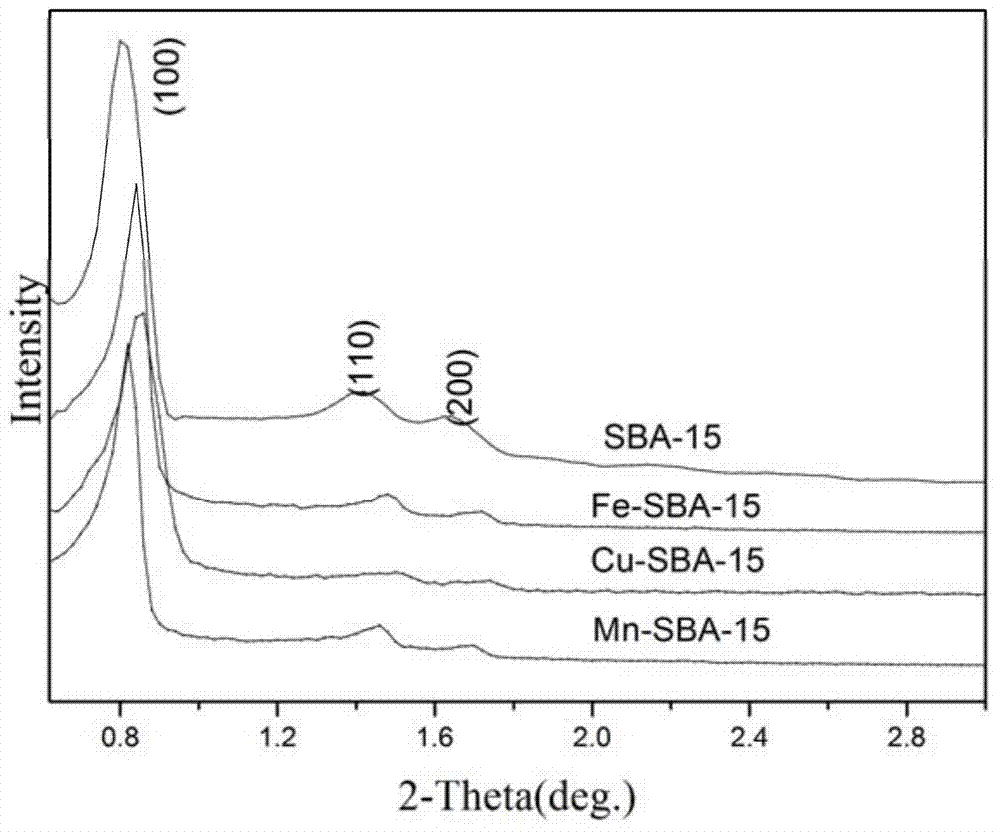

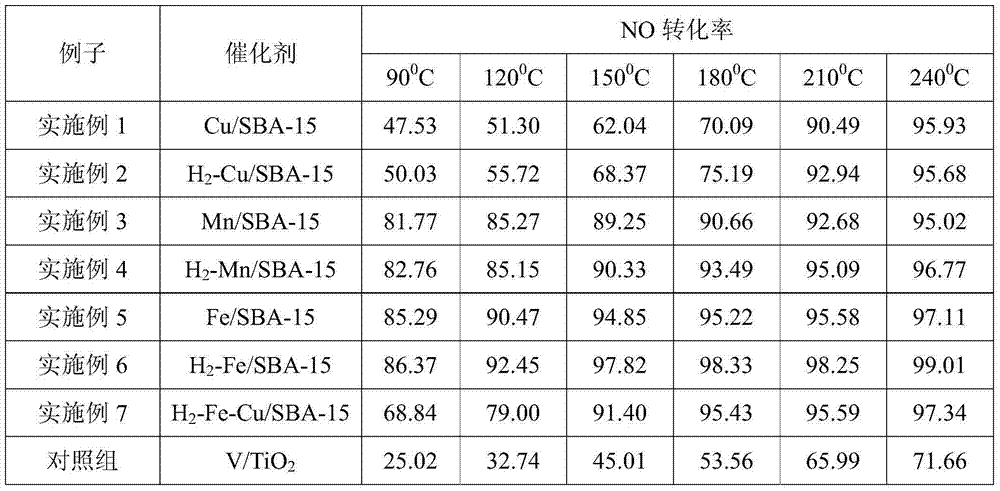

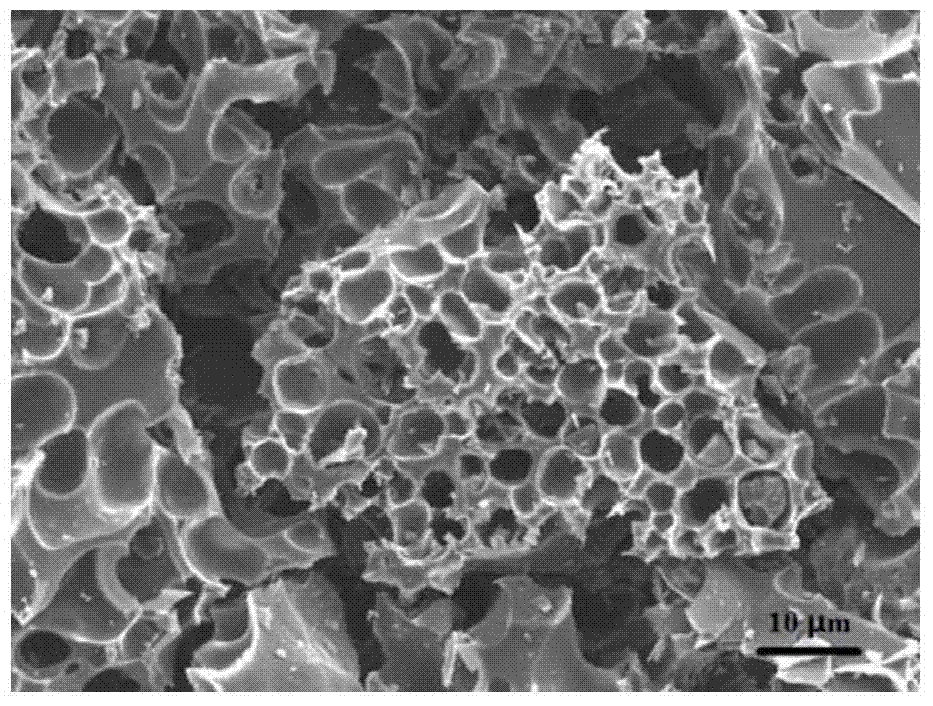

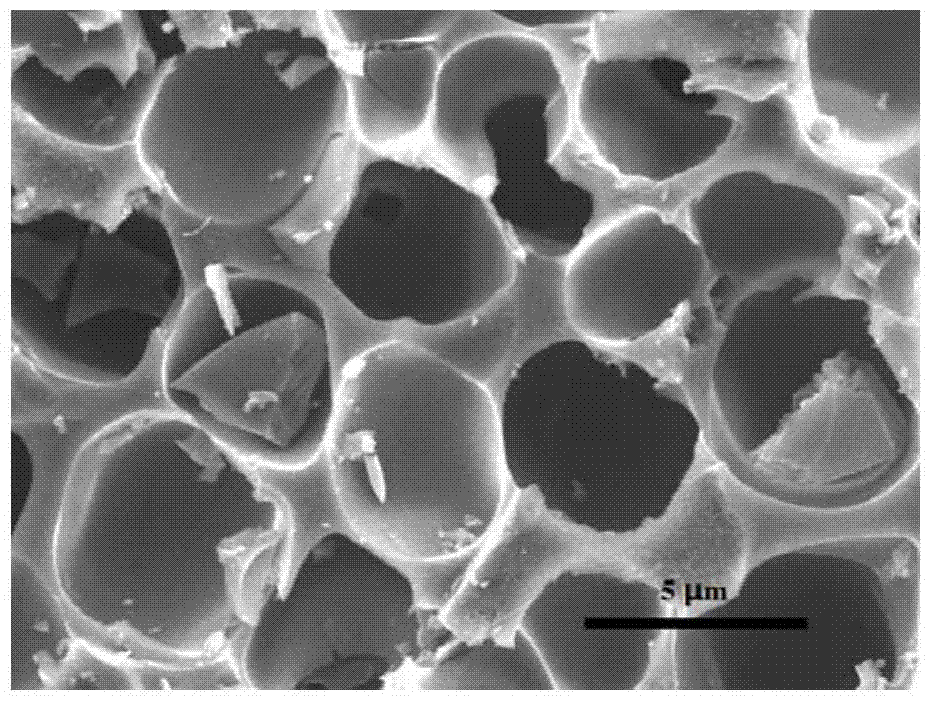

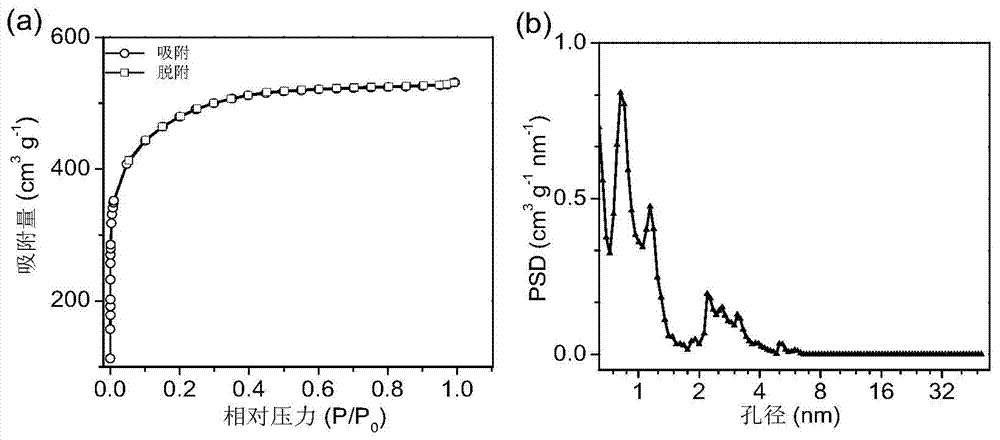

Medium-low temperature SCR denitration mesoporous molecular sieve catalyst and preparation method and application method thereof

InactiveCN104492471AGood dispersionImprove medium and low temperature denitrification efficiencyMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention provides a medium-low temperature SCR denitration mesoporous molecular sieve catalyst and a preparation method and an application method of the medium-low temperature SCR denitration mesoporous molecular sieve catalyst. The catalyst is prepared from active components and a carrier, wherein the active components are one or more of iron, copper and manganese, and the carrier is an SBA-15 silicon dioxide mesoporous molecular sieve and has the characteristics of large specific surface area and uniform pore size distribution. According to the medium-low temperature SCR denitration mesoporous molecular sieve catalyst, the active components can be uniformly dispersed on the surface of the SBA-15, the effective active sites for catalytic reaction can be increased, the denitration efficiency of the catalyst is improved at a medium-low temperature interval of 90 DEG C-240 DEG C, and the catalyst can achieve better denitration effect after H2 reduction activation, and can achieve the denitration efficiency at medium-low temperature up to 80-99%.

Owner:CENT SOUTH UNIV

Preparation method of three dimensional graded porous activated carbon material

The invention relates to a preparation method of a three dimensional graded porous activated carbon material, the method is as follows: a chemical activator itself is used as a template hole forming agent, on the basis of formation of pore channel in the chemical activator, micropores and mesopores are further formed by corrosion, and eventually the three dimensional graded porous activated carbon material simultaneously having macropores, mesopores and micropores is formed. The activated carbon material prepared by the method has a very large specific surface area, a mutually-comunicated porous structure, larger pore size and high conductivity. The material can be widely used as electrode materials, adsorption materials, catalysts, catalyst carriers, hydrogen storage materials, electric adsorption desalting electrode materials and the like of energy storage devices; the preparation method of the three dimensional graded porous activated carbon material has the advantages of simple operation and low cost, and is convenient for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Microporous hydrophilic membrane

ActiveUS7459085B2Good removal effectHigh in quantityMembranesGas treatmentHydrophilizationPolymer science

A hydrophilic microporous membrane comprising a thermoplastic resin, having been subjected to hydrophilizing treatment and having a maximum pore size of 0 to 100 nm, wherein when 3 wt % bovine immunoglobulin having a monomer ratio of 80 wt % or more is filtered at a constant pressure of 0.3 MPa, an average permeation rate (liter / m2 / h) for 5 minutes from the start of filtration (briefly referred to as globulin permeation rate A) satisfies the following formula (1) and an average permeation rate (liter / m2 / h) for 5 minutes from the time point of 55 minutes after the start of filtration (briefly referred to as globulin permeation rate B) satisfies the following formula (2):Globulin permeation rateA>0.0015 ×maximum pore size (nm)2.75 (1)Globulin permeation rate B / globulin permeation rate A>0.2 . (2)

Owner:ASAHI KASEI MEDICAL CO LTD

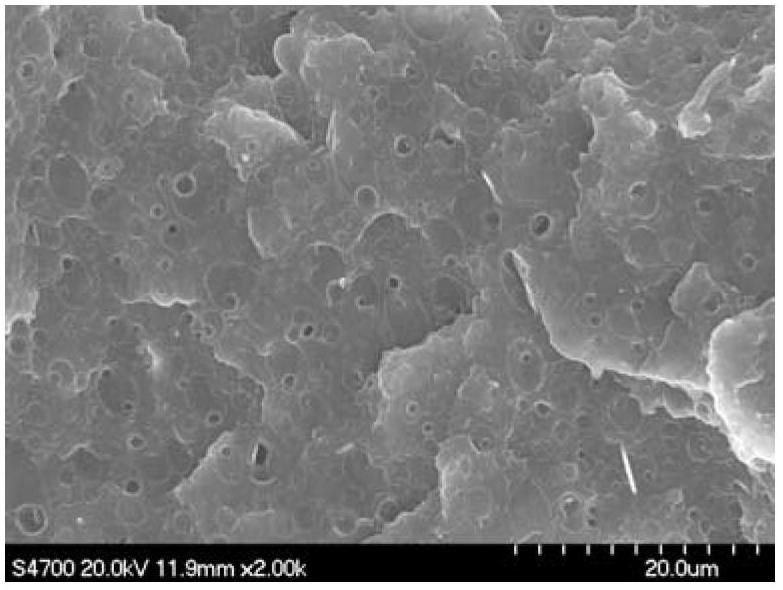

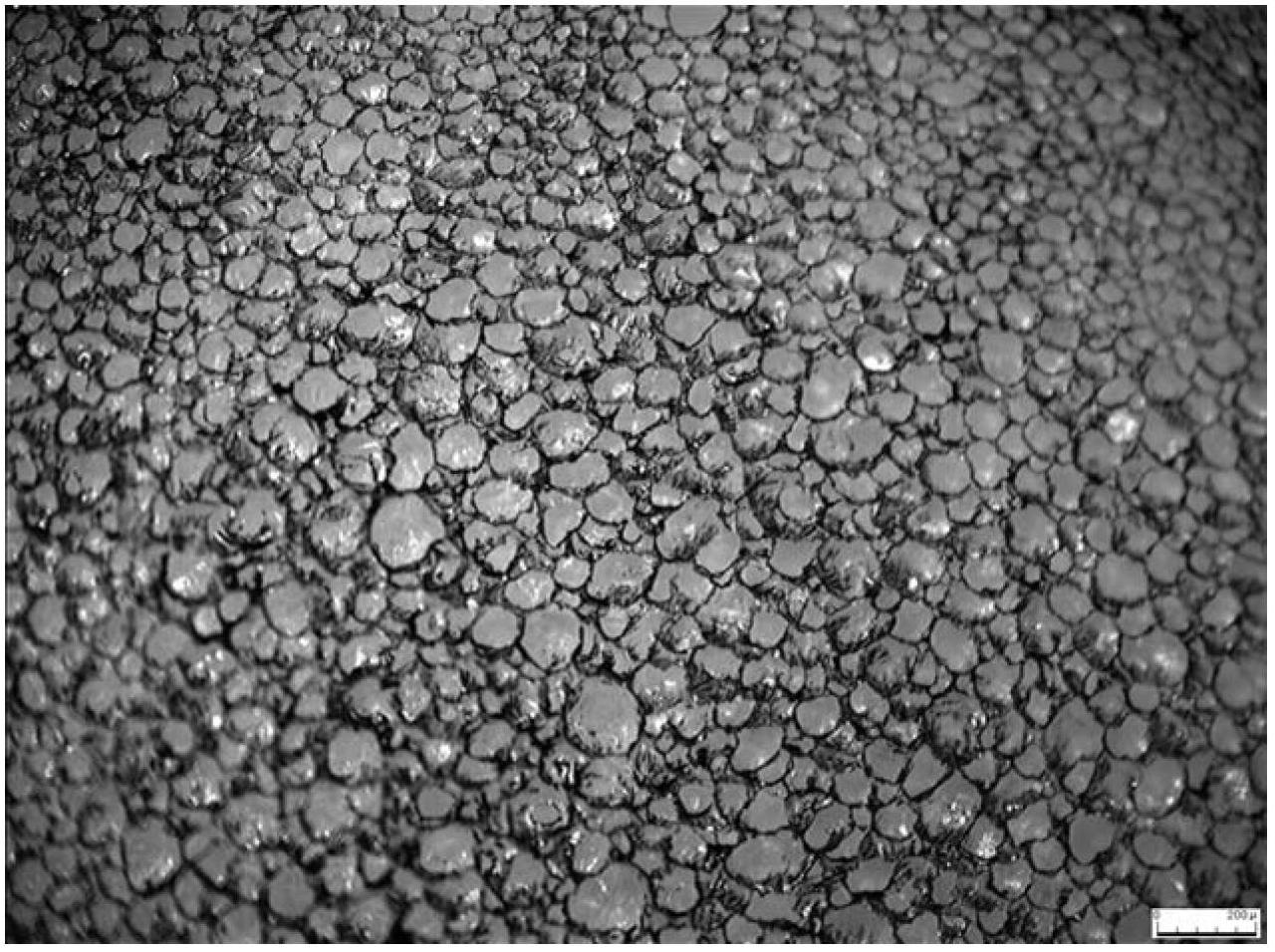

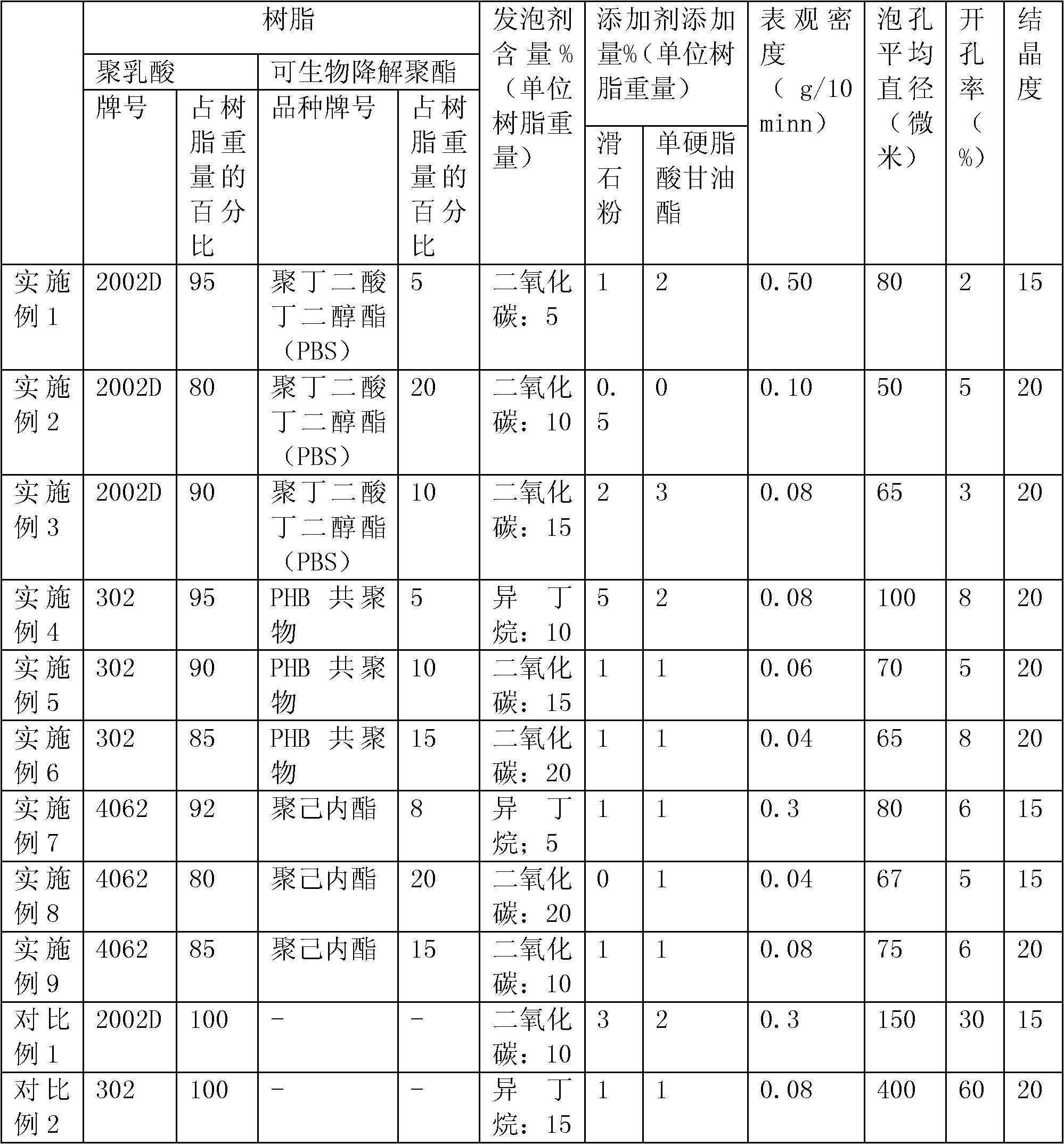

Polylactic acid foamed material and preparation method thereof

The invention relates to a polylactic acid foamed material and a preparation method thereof. The invention solves the technical problems of large pore size, nonuniformity and high porosity in the existing product. The polylactic acid foamed material is prepared by an extrusion foaming method. The polylactic acid foamed material comprises polylactic acid, at least one biodegradable polyester (selected from poly(butylenes succinate), polyhydroxybutyrate, polycaprolactone and copolymer or blend thereof), a physical foaming agent, and at least one processing assistant for foaming. The apparent density of the microporous foamed sheet is 0.05-0.5g / cm<3>, the average pore diameter is not greater than 100 micrometers, and the porosity is not greater than 10%. The invention is mainly used in the fields of food packaging, automobile industry and the like.

Owner:BEIJING UNIV OF CHEM TECH

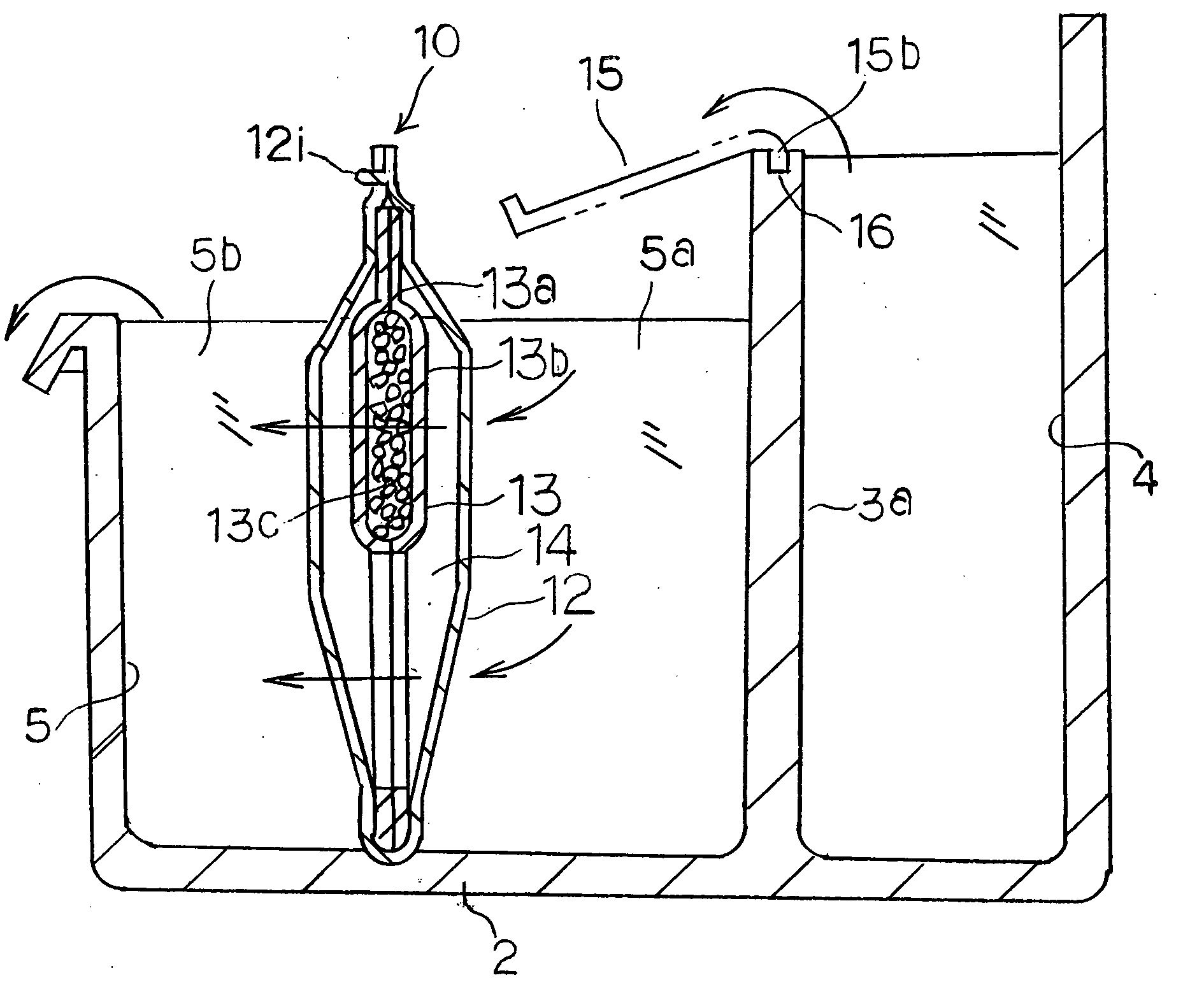

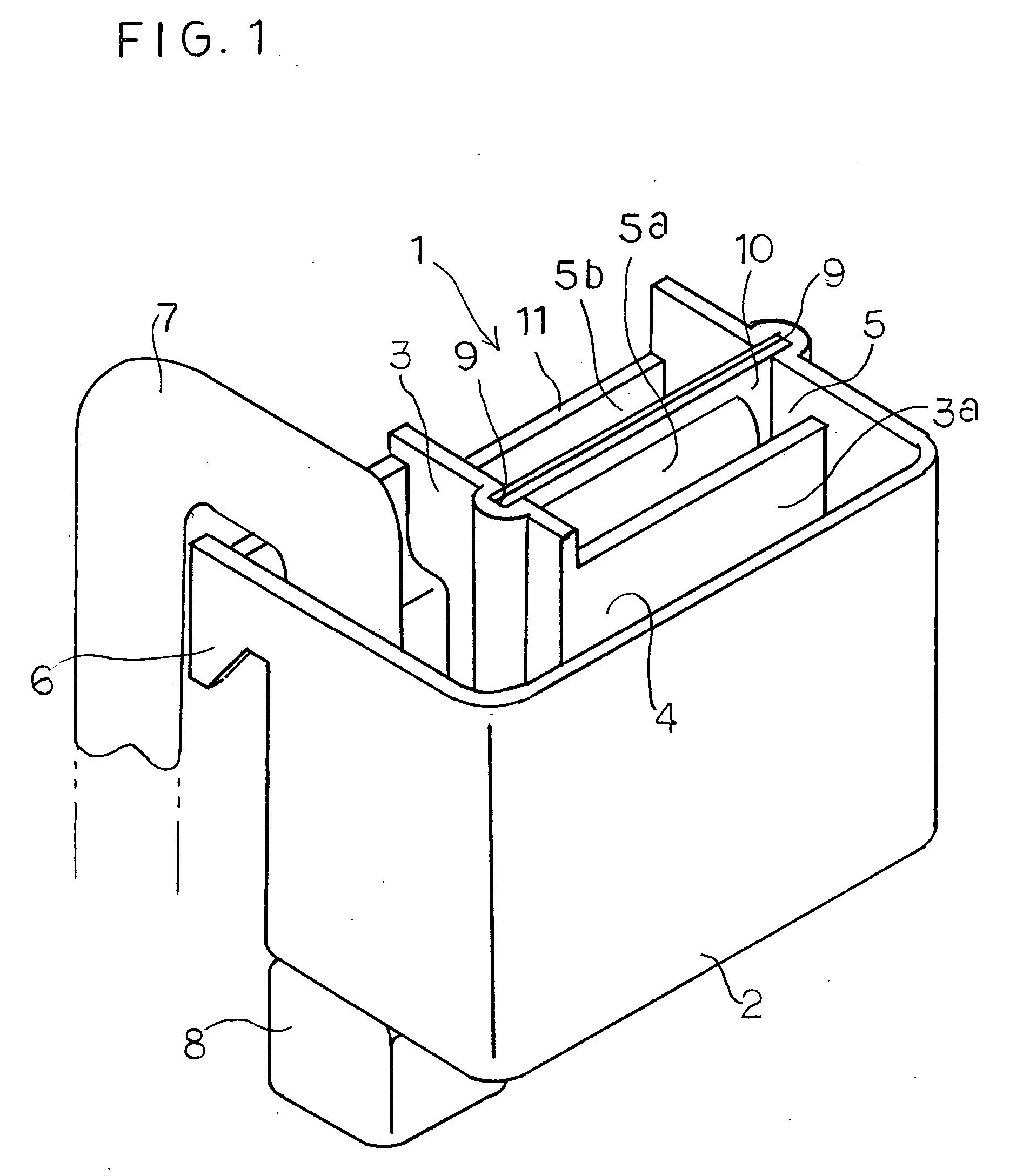

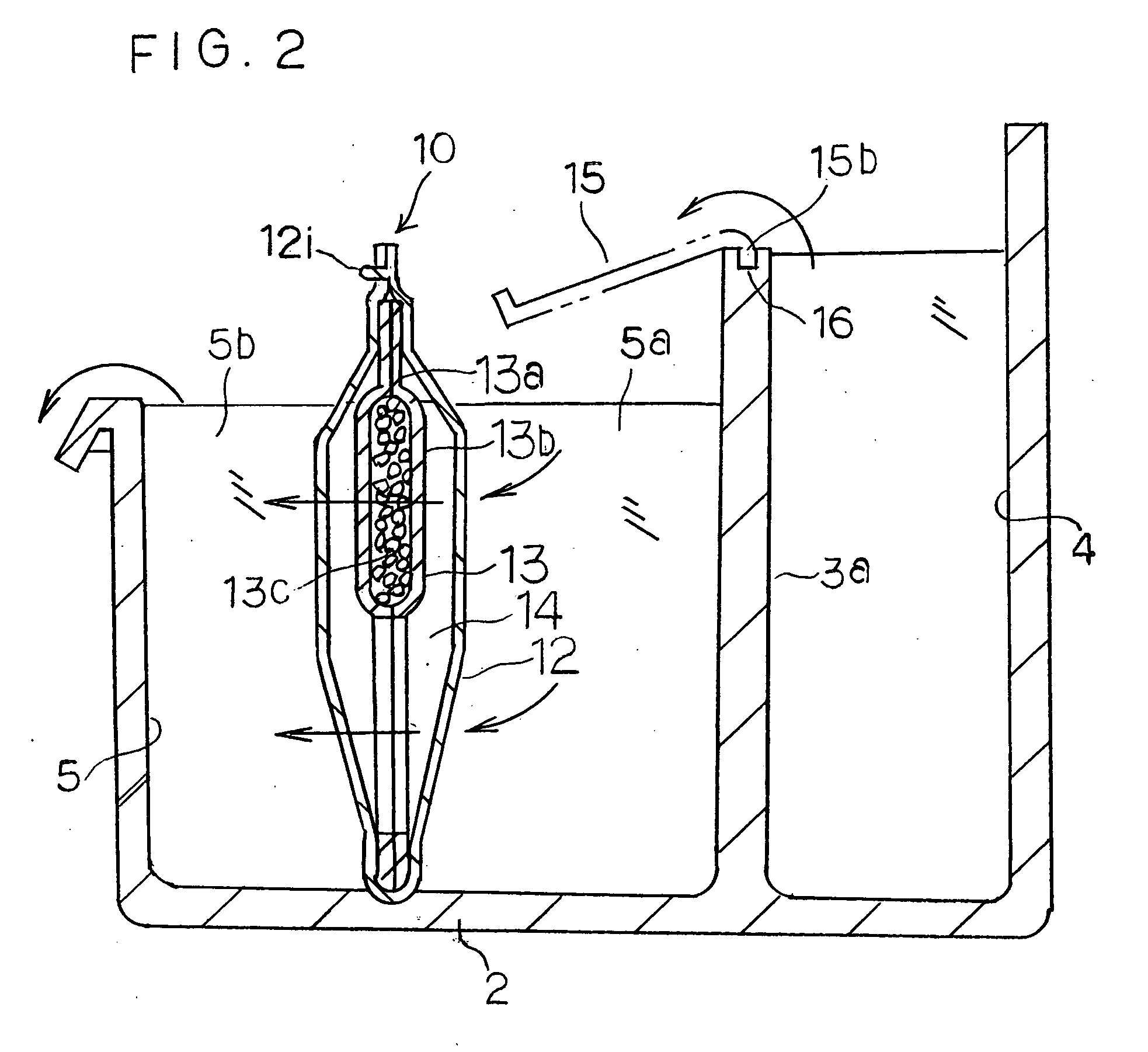

Water tank filter and purifier

InactiveUS20040222137A1Removed satisfactorilyEasy to floatPisciculture and aquariaLoose filtering material filtersInterior spaceEngineering

A water tank filter having a double structure including an inner filter having a small pore size for trapping fine particles of filth from tank water and situated within a hollow outer filter having a large pore size for trapping coarse particles of filth. The inner filter is situated in roughly the upper half of the internal space of the outer filter. Disclosed also is a water tank purifier including the water tank filter. The water tank filter and purifier can effectively remove both coarse and fine particles of filth from a water tank. The filter does not quickly get clogged, and is easy to handle.

Owner:YUGEN KAISHA HOUSEKI NO ANGEL

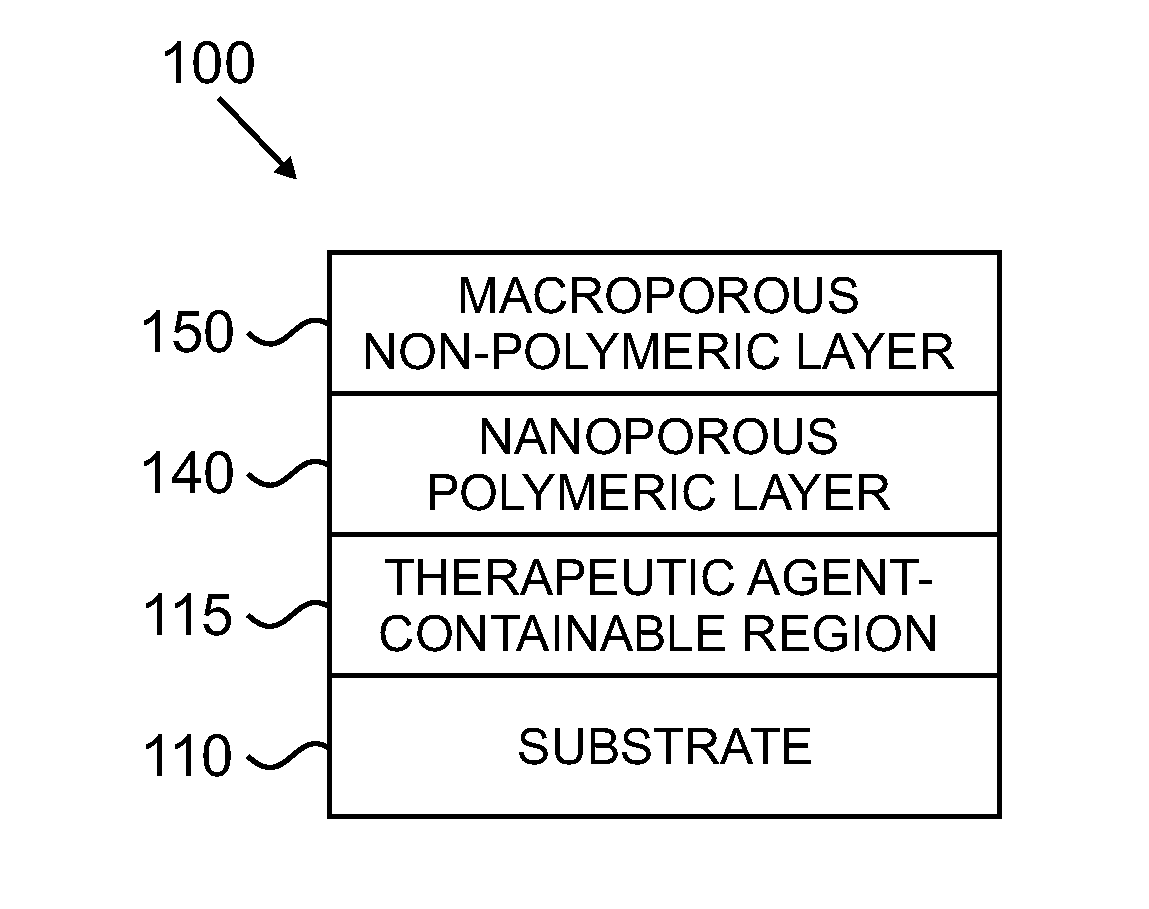

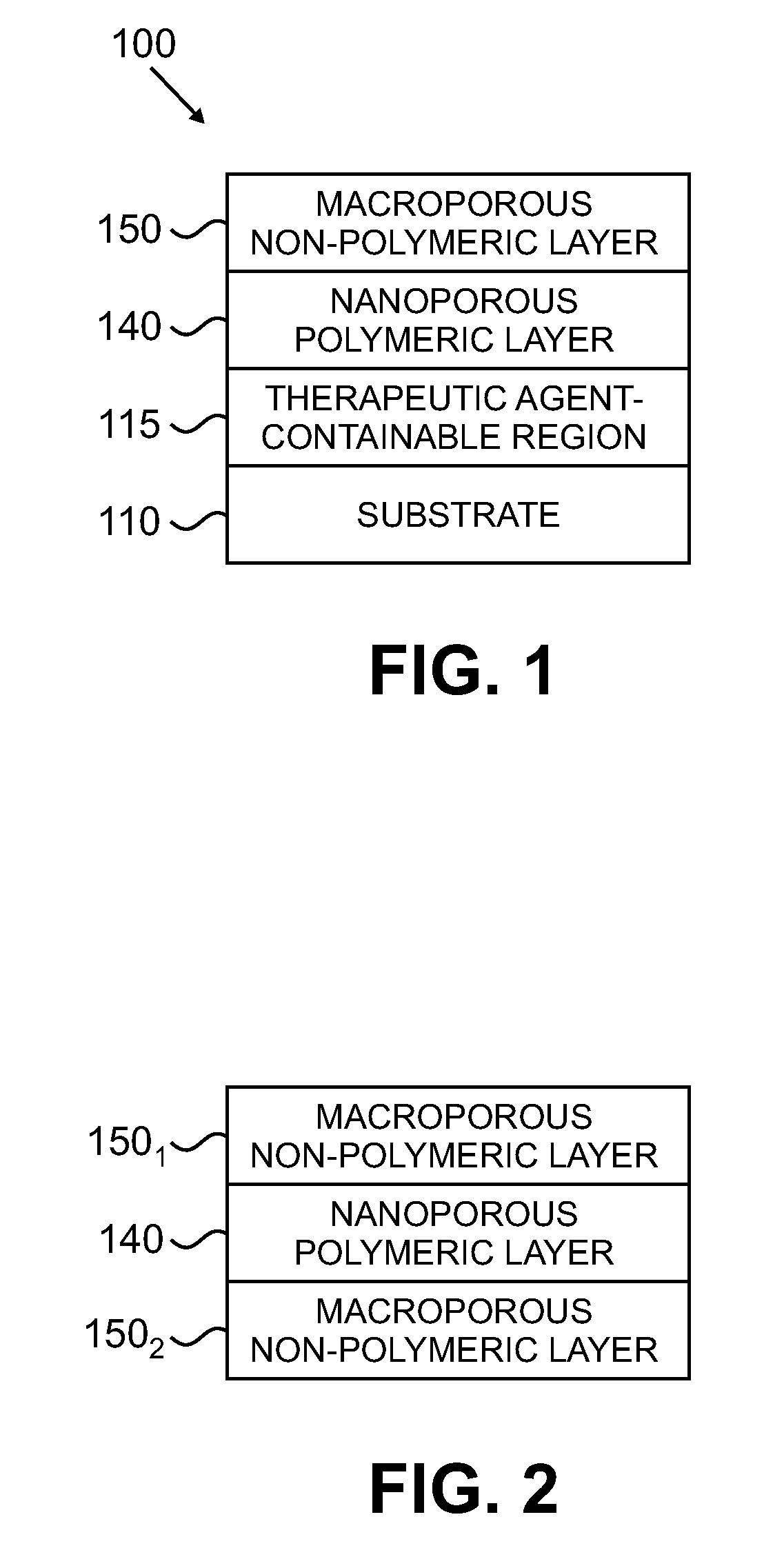

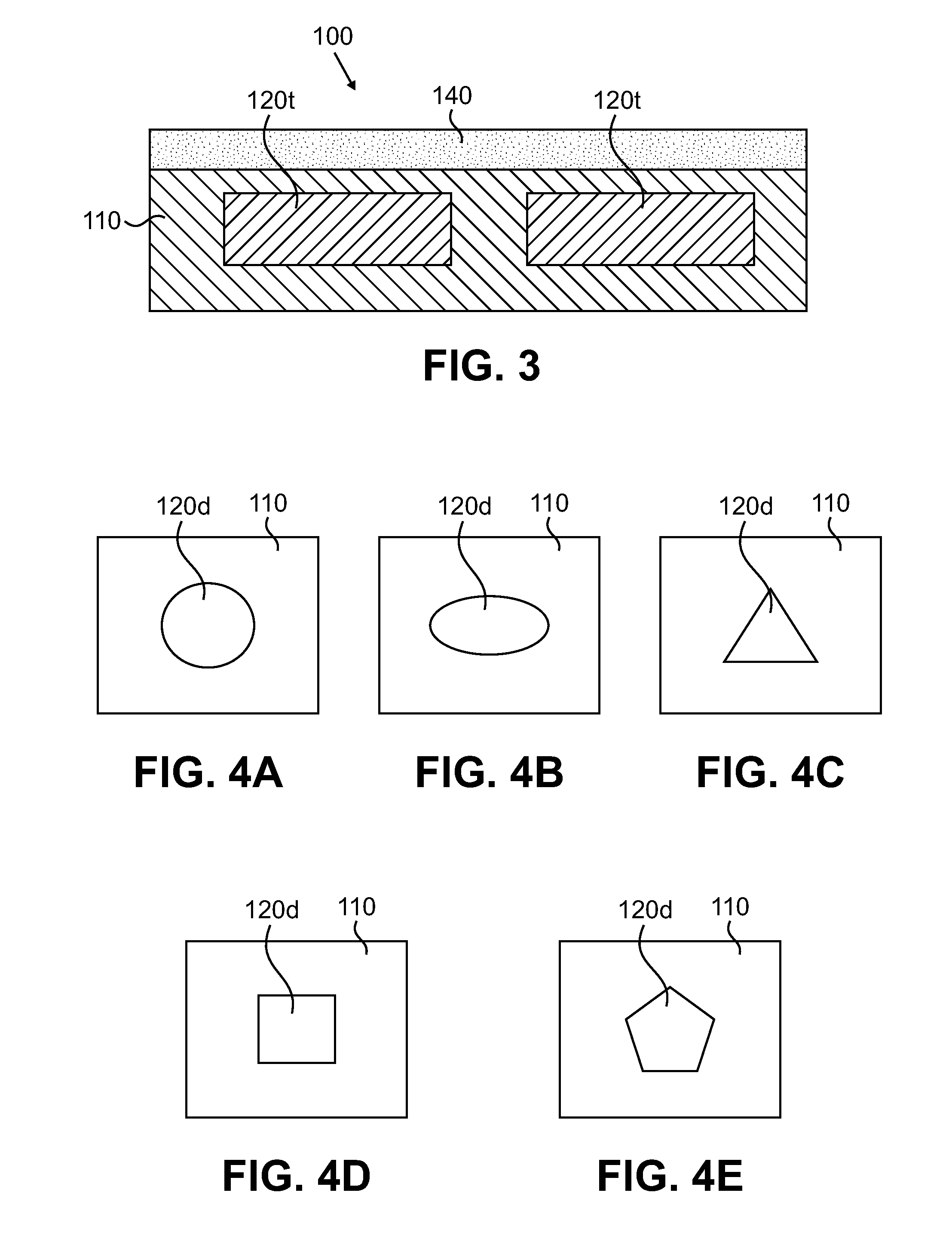

Medical devices having polymeric nanoporous coatings for controlled therapeutic agent delivery and a nonpolymeric macroporous protective layer

An implantable or insertable medical device is provided which contains the following: (a) a substrate, (b) a therapeutic agent-containable region disposed over the substrate, (c) a nanoporous polymeric layer disposed over the therapeutic agent-containable region and (d) a macroporous non-polymeric layer disposed over the nanoporous polymeric layer. The nanoporous polymeric layer largely regulates transport of species between the therapeutic agent-containable region and the exterior of the device. The macroporous non-polymeric layer has a larger pore size than the nanoporous polymeric layer and largely serves to isolate the polymeric material from surrounding tissue during in-situ delivery of the therapeutic agents.

Owner:BOSTON SCI SCIMED INC

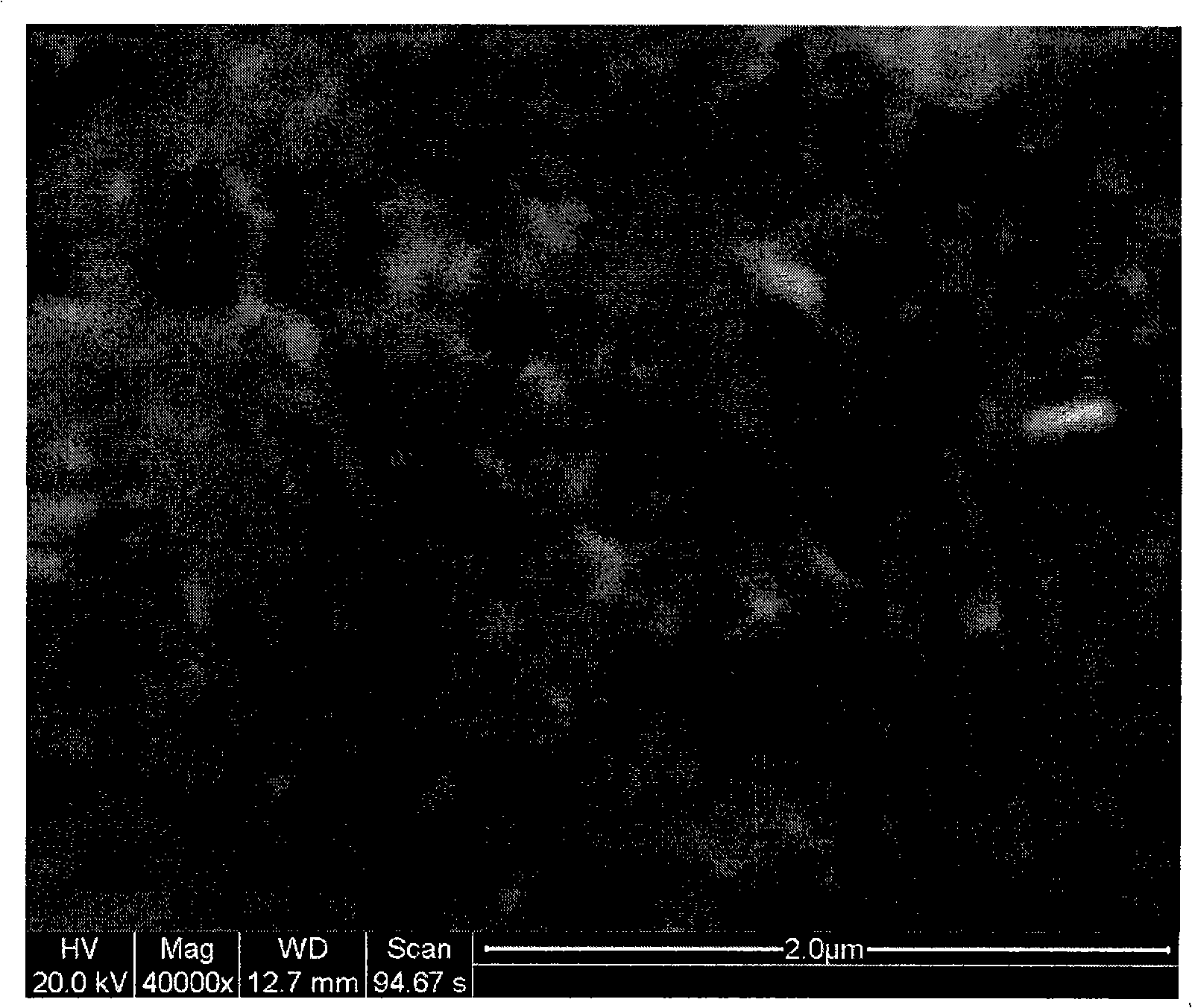

Method for preparing small aperture ceramic film

The invention relates to a method for producing a small-aperture ceramic membrane. The invention can produce a small-aperture ceramic ultrafiltration membrane on the surface of a support with an aperture of 50- 200 nm. The method comprises the following steps: treating the surface of the support with larger pore size with organic solution, covering the surface with coating solution with smaller sole particle size, allowing rapid gelatination of the coating under constant-temperature and constant-humidity conditions, preventing leakage of the sol, sun-drying or oven-drying the coating, and removing organic substances by means of solvent extraction or direct calcination, to obtain the small-aperture ceramic membrane. The produced small-aperture ceramic membrane doesn't be affected by the support. The production cycle of the membrane is short with low cost.

Owner:NANJING UNIV OF TECH

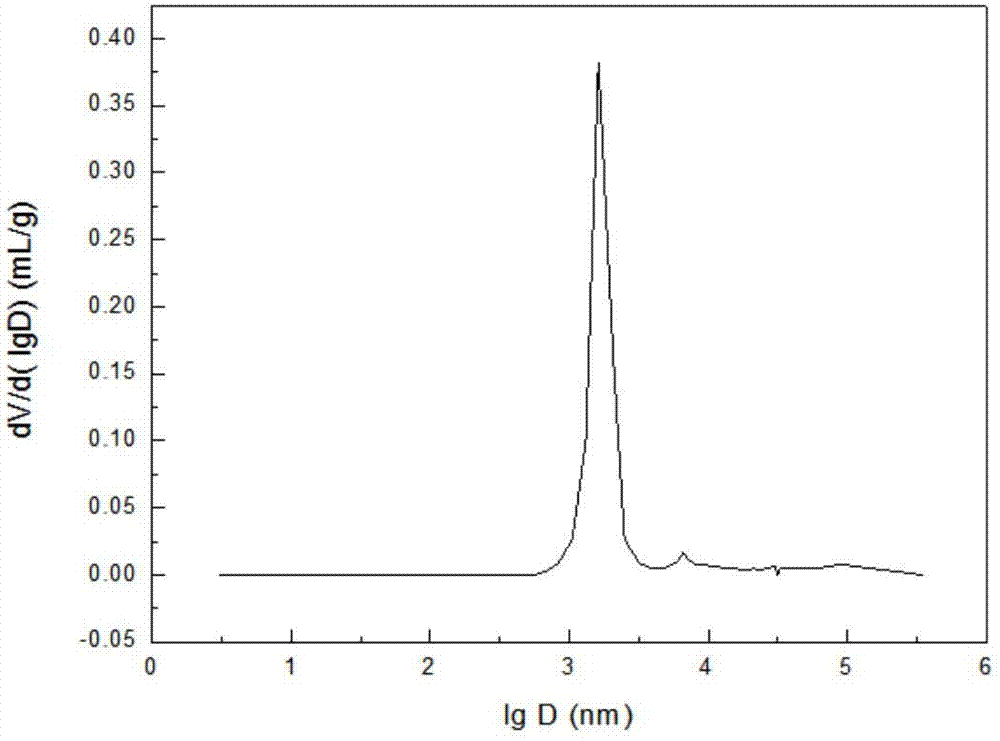

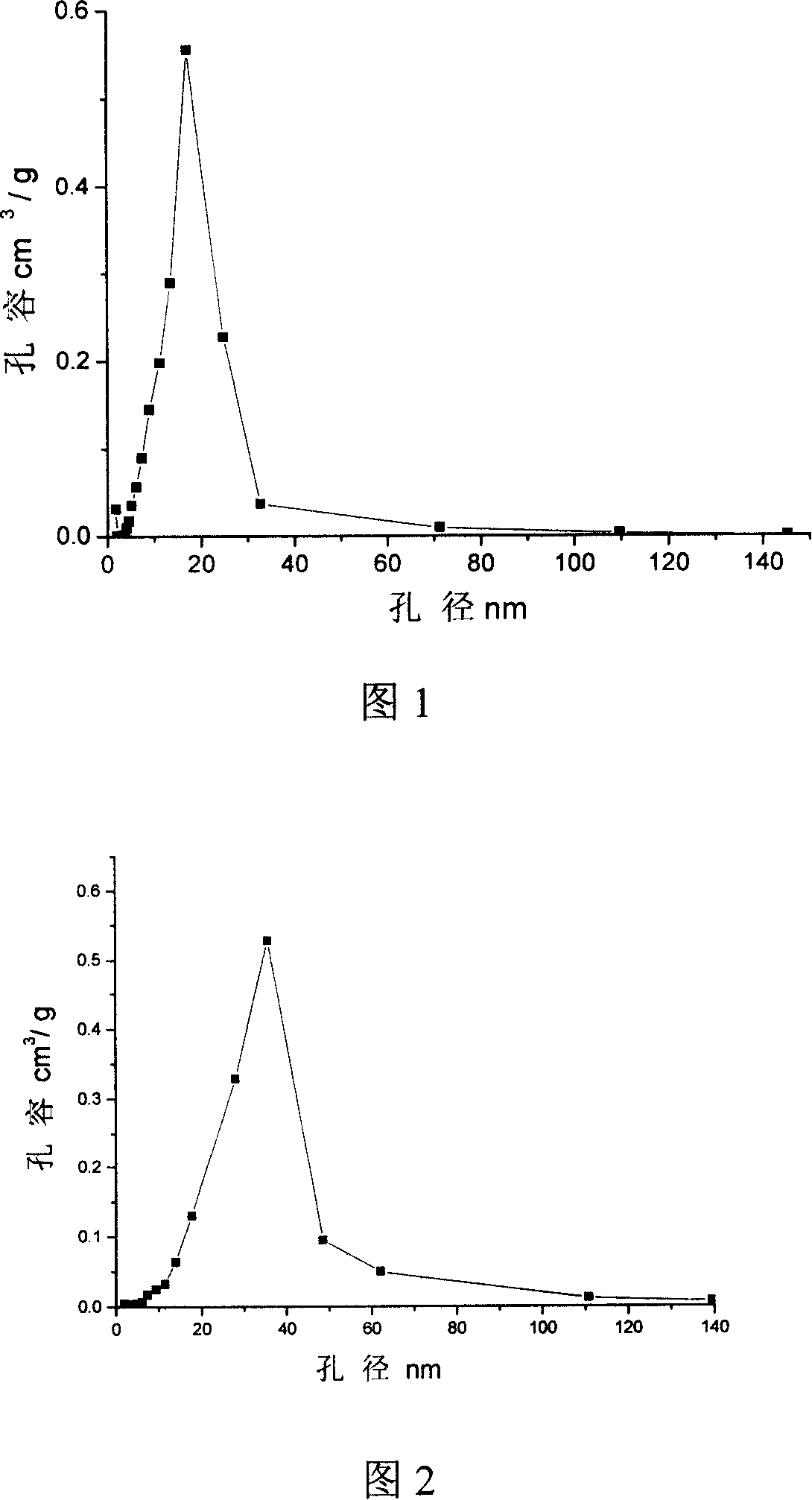

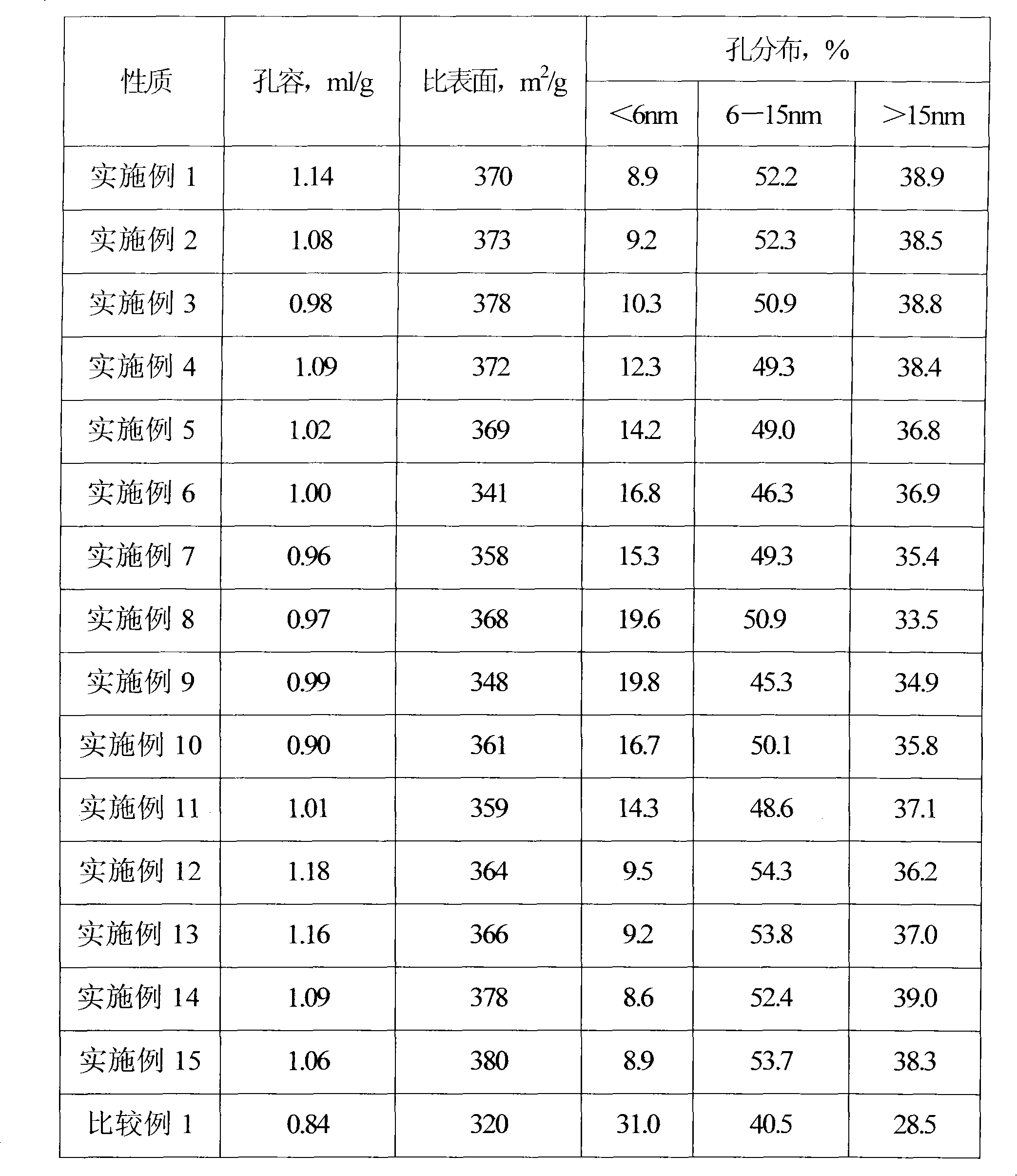

Method for preparing silicon dioxide with large pore volume and large aperture

InactiveCN101112991AImprove precipitation effectOrderly distribution of poresSilicaActive agentWater soluble

The invention relates to a preparation method of large pore volume and large pore diameter silica. With industrial water glass as silica source, water soluble polymer and surfactant as hydrophobic agent and hole forming template, by controlling reaction conditions such as temperature, hydrophobic agent, final ph value, etc., the large pore volume silica products are produced; the pore diameter is narrowly distributed, the pore volume is between 2-2.5cm3 / g and the average pore diameter is between 18-35 nm. Especially, the more optimal three-step heating regulation is more beneficial to the stability of hole forming and hole structure and that the distribution of pore diameter reaches between 25-35nm is more proper to be used as flatting agent.

Owner:BEIJING UNIV OF CHEM TECH

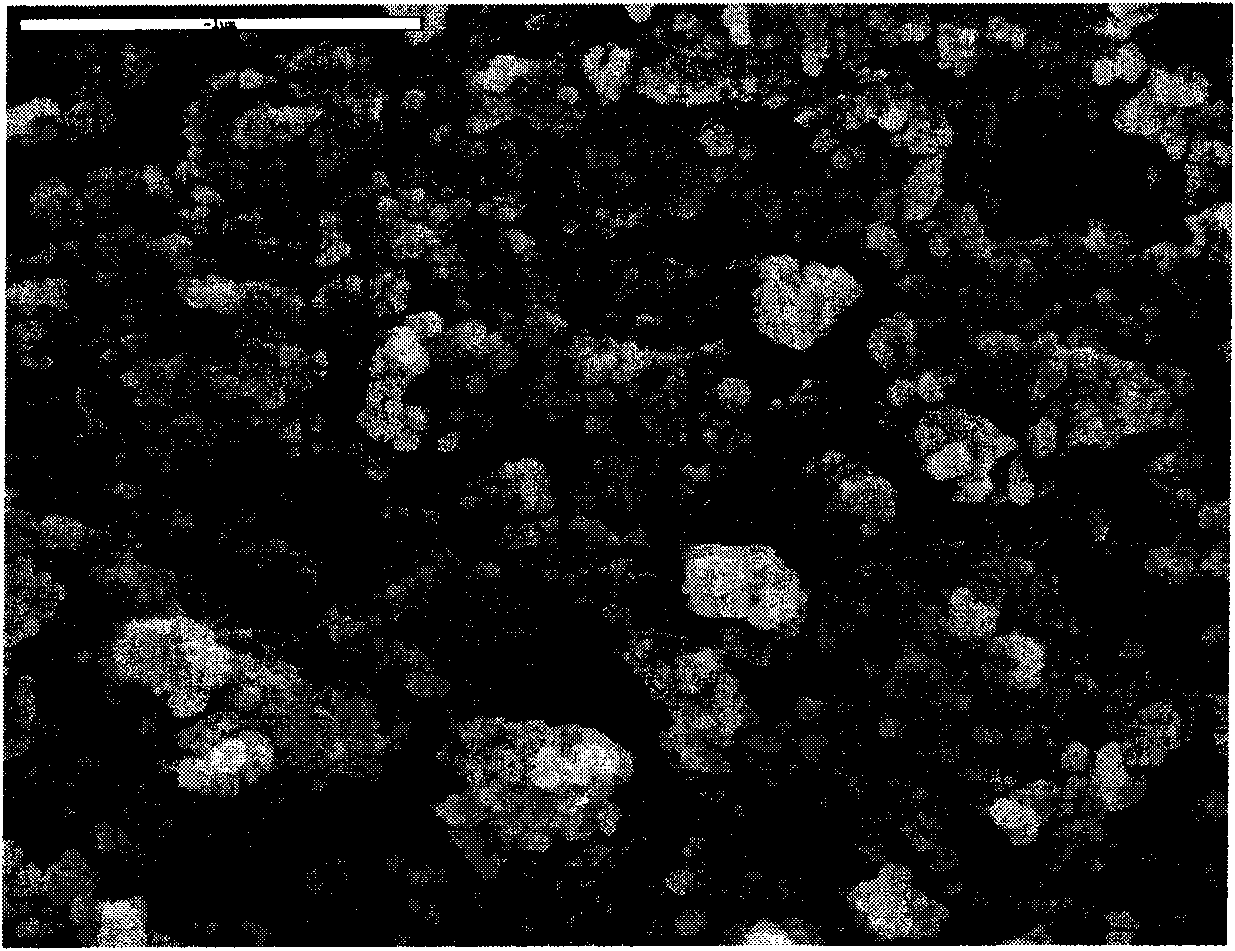

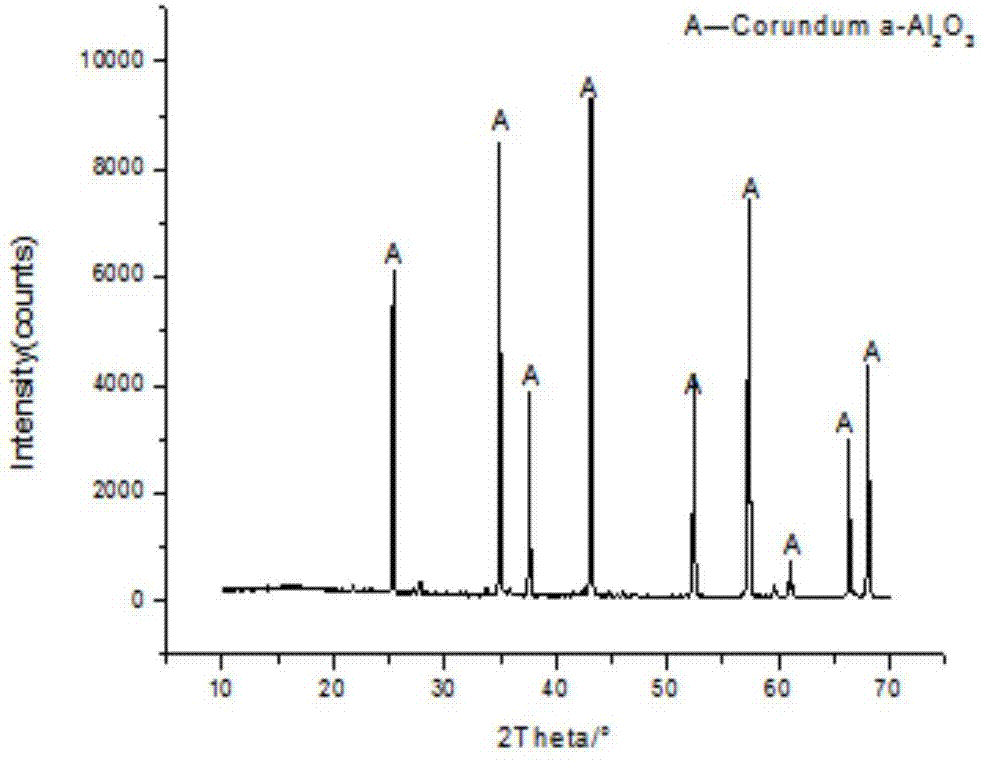

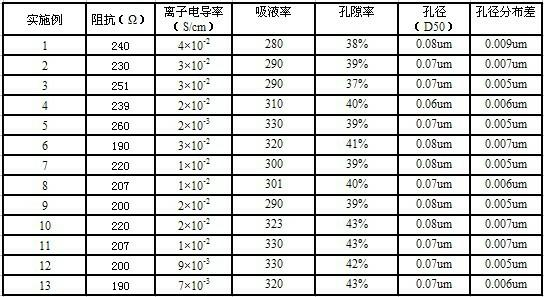

Aluminum hydroxide and preparation method thereof

The invention discloses aluminum hydroxide and a preparation method thereof. The aluminum hydroxide is prepared by a carbonization method and contains over 94 weight percent of pseudo-boehmite. The method comprises the following steps: adding a small amount of organic pore-expanding agent and defoaming agent into aqueous solution of sodium metaaluminate; introducing a mixed gas of air and CO2 into the solution to stir the solution to form one-step gel; generating evenly grained pseudo-boehmite; and roasting the evenly grained pseudo-boehmite to obtain alumina with a large pore volume, a large aperture and concentrated pore distribution. The aluminum hydroxide is suitable to be used as a component of absorbent or catalyst carrier, particularly a component of a heavy oil or residual oil hydrodemetallization catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing porous film by adopting high molecular weight polyolefin and product and application thereof

ActiveCN102153776AHigh mechanical strengthHigh temperature puncture strengthCell component detailsPolymer sciencePolyolefin

The invention discloses a method for preparing a porous film by adopting high molecular weight polyolefin. The method comprises the following steps of: (1) performing soaking treatment on the high molecular weight polyolefin; (2) blending the soaked high molecular weight polyolefin and materials such as thermoplastic resin, auxiliary agent and the like to prepare blended master batch; (3) preparing the obtained blended master batch into a film material; and (4) extracting the film material to obtain the porous film. The porous film has the characteristics of high mechanical strength, high porosity, uniform aperture size, high ion permeability, excellent dielectric property and the like, can be used as a lithium ion battery diaphragm, and has better safety; and the method has simple process and easily controlled conditions, is suitable for mechanized large-scale production, and has low cost and high efficiency.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsCvd grapheneGraphite oxide

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com