Medium-low temperature SCR denitration mesoporous molecular sieve catalyst and preparation method and application method thereof

A technology of mesoporous molecular sieve and application method, which is applied in the field of medium and low temperature SCR denitration mesoporous molecular sieve catalyst, can solve the problem of low medium and low temperature activity, achieve uniform pore size distribution, increase effective active sites, and improve medium and low temperature denitration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

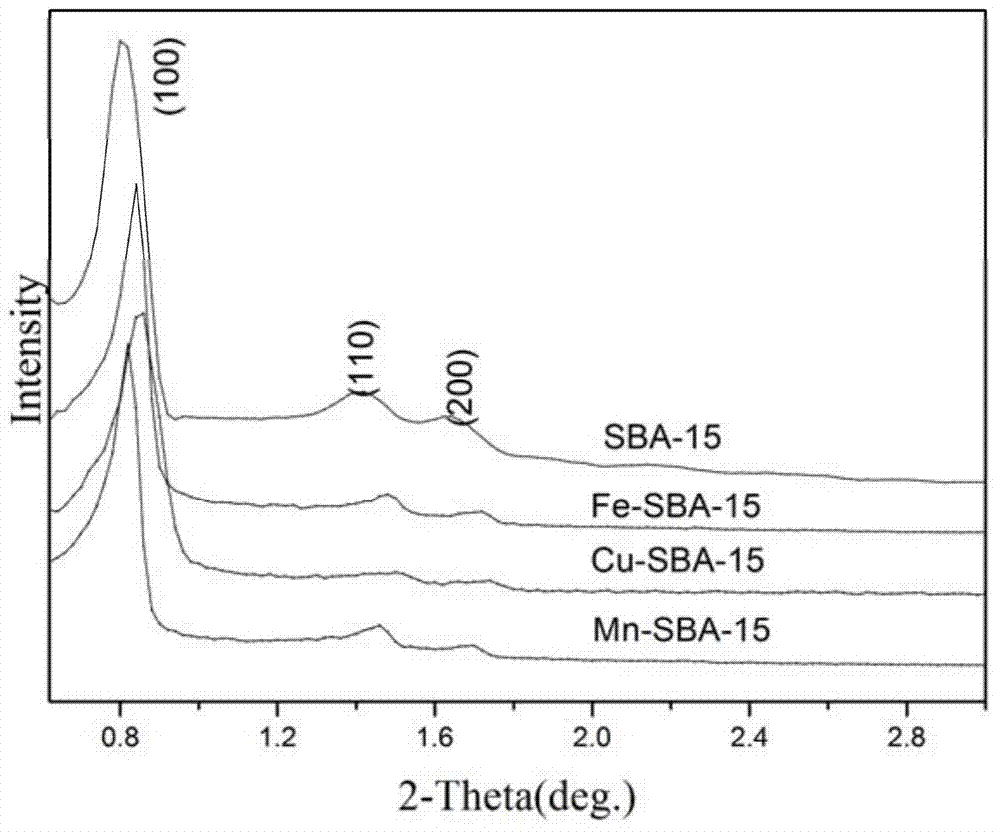

[0028] Preparation of SBA-15:

[0029] Take 4g P123 (polyoxyethylene-polyoxypropylene-polyoxyethylene), 132.45g distilled water, 20ml hydrochloric acid, dissolve P123 in water, stir magnetically until a uniform solution is formed, add 8.4g ethyl orthosilicate, and stir magnetically for 20 hours Transfer to a hydrothermal kettle and crystallize at 100°C for 24h, cool to room temperature and filter, wash the filtrate with distilled water to neutrality, then wash with absolute ethanol, dry the obtained solid, and finally place it in a muffle furnace at 1 The heating rate of ℃ / min was raised to 550 ℃, and the temperature was kept for 5 hours to obtain the mesoporous molecular sieve SBA-15.

Embodiment 1

[0031] Take a certain amount of copper nitrate (mass fraction of copper element 10%) and dissolve it in absolute ethanol, and uniformly impregnate the above solution on 1 g of the above-mentioned treated SBA-15 carrier. Calcined in a furnace to obtain a Cu / SBA-15 denitration catalyst with a copper content of 10%.

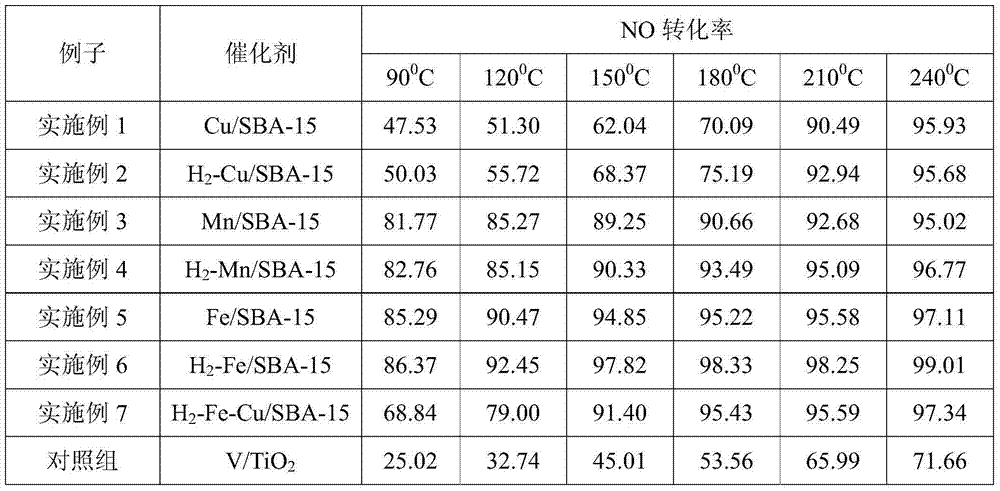

[0032] Get 0.2g of above-mentioned Cu / SBA-15 catalyst packing in the fixed tubular reactor, feed simulated flue gas (1000ppm NO, 1000ppm NH 3 , 5.0%O 2 , N 2 As balance gas), the space speed ratio is 30,000h -1, in the temperature range of 90-240 ℃ to measure the denitrification efficiency of the catalyst, the denitrification efficiency is calculated by the following method:

[0033] α NO = C in - C out C in

[0034] The denitrificati...

Embodiment 2

[0036] The 0.2g Cu / SBA-15 catalyst prepared by embodiment 1 is in the same experimental platform, feeds H in the reactor before use 2 / N 2 (volume ratio of 1:5), activated at 300°C for 1 hour, tested under the same conditions as described in Example 1 after H 2 The denitrification activity of the activated Cu / SBA-15 catalyst (denoted as H 2 -Cu / SBA-15), the denitration efficiency is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com