Method for preparing small aperture ceramic film

A ceramic membrane and small pore technology, which is applied in the field of preparation of small pore ceramic membranes, can solve problems such as large resistance, membrane layer defects, and inability to obtain ceramic membranes, so as to increase membrane flux, reduce membrane resistance, and shorten membrane preparation. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

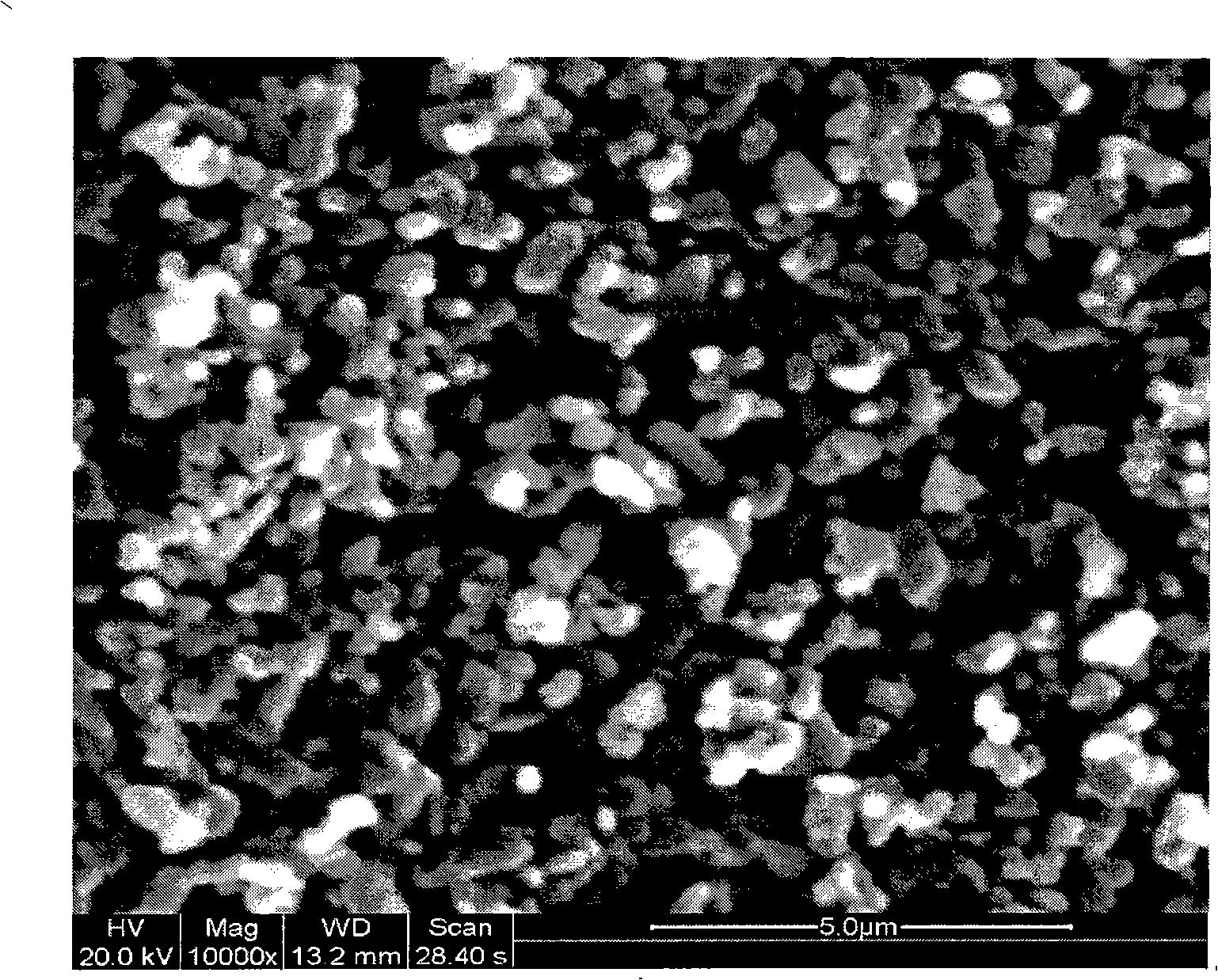

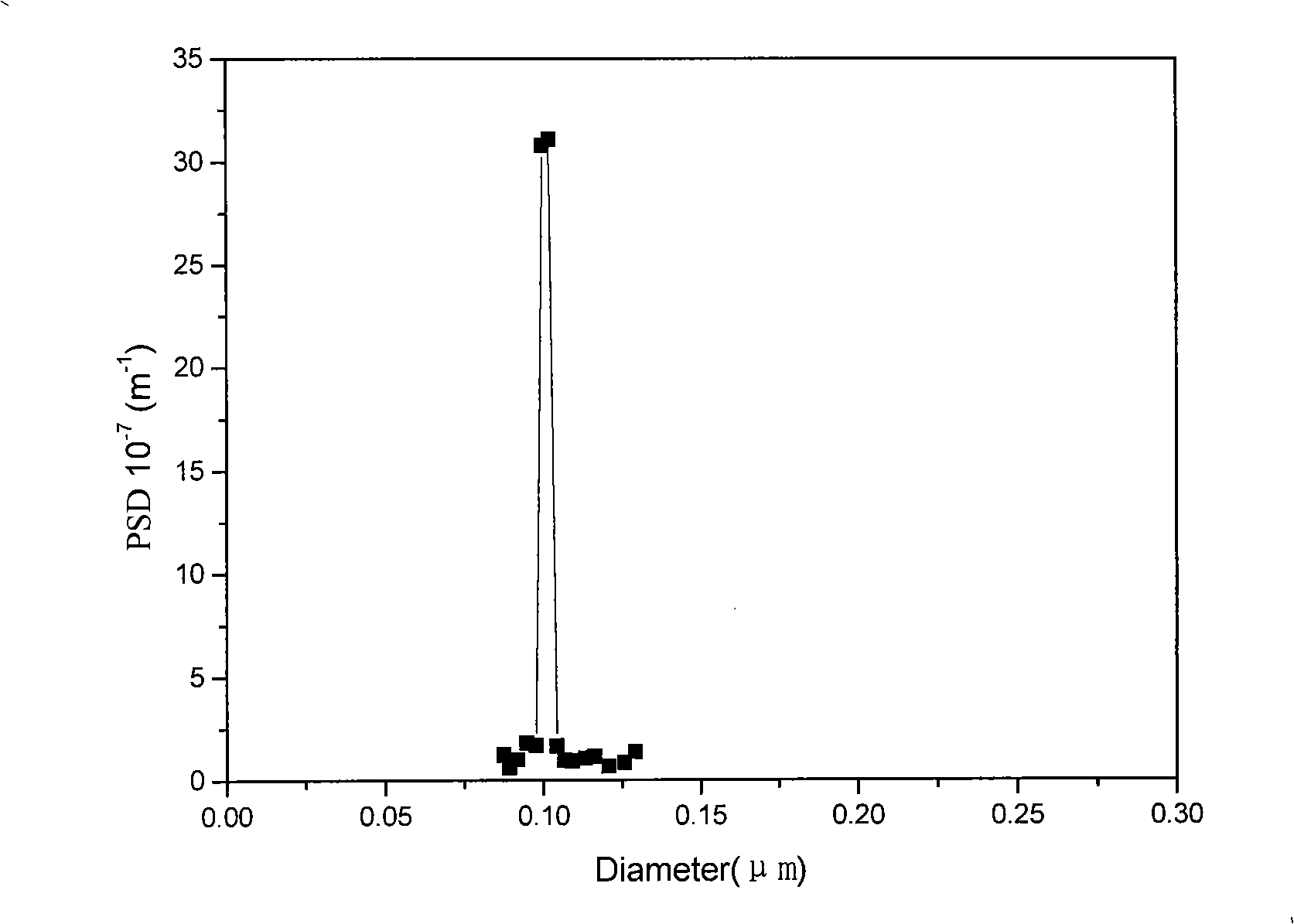

[0024] Titanium content is 1.5mol L -1 , the sol particle diameter is to add MC solution (the mass volume concentration of MC is 50g L -1 ) to prepare a membrane-forming solution, wherein the mass ratio of titanium sol to MC solution is 100:1. Adopt the mode of suction filtration to utilize PVA solution (the mass volume fraction of PVA is 10g L -1 ) to treat the support body (the surface structure pore size is 180nmAl 2 o 3 Ceramic membrane) after coating. After placing the support body containing the surface coating for 7 minutes, place it under constant temperature and humidity conditions with a temperature of 40°C and a humidity of 80% for 0.1 hour, then take it out, the film layer is gelled, and then dry the wet film, and Drying at 60°C and calcining at 400°C can obtain a titanium oxide ceramic film with a pore size of 8nm.

Embodiment 2

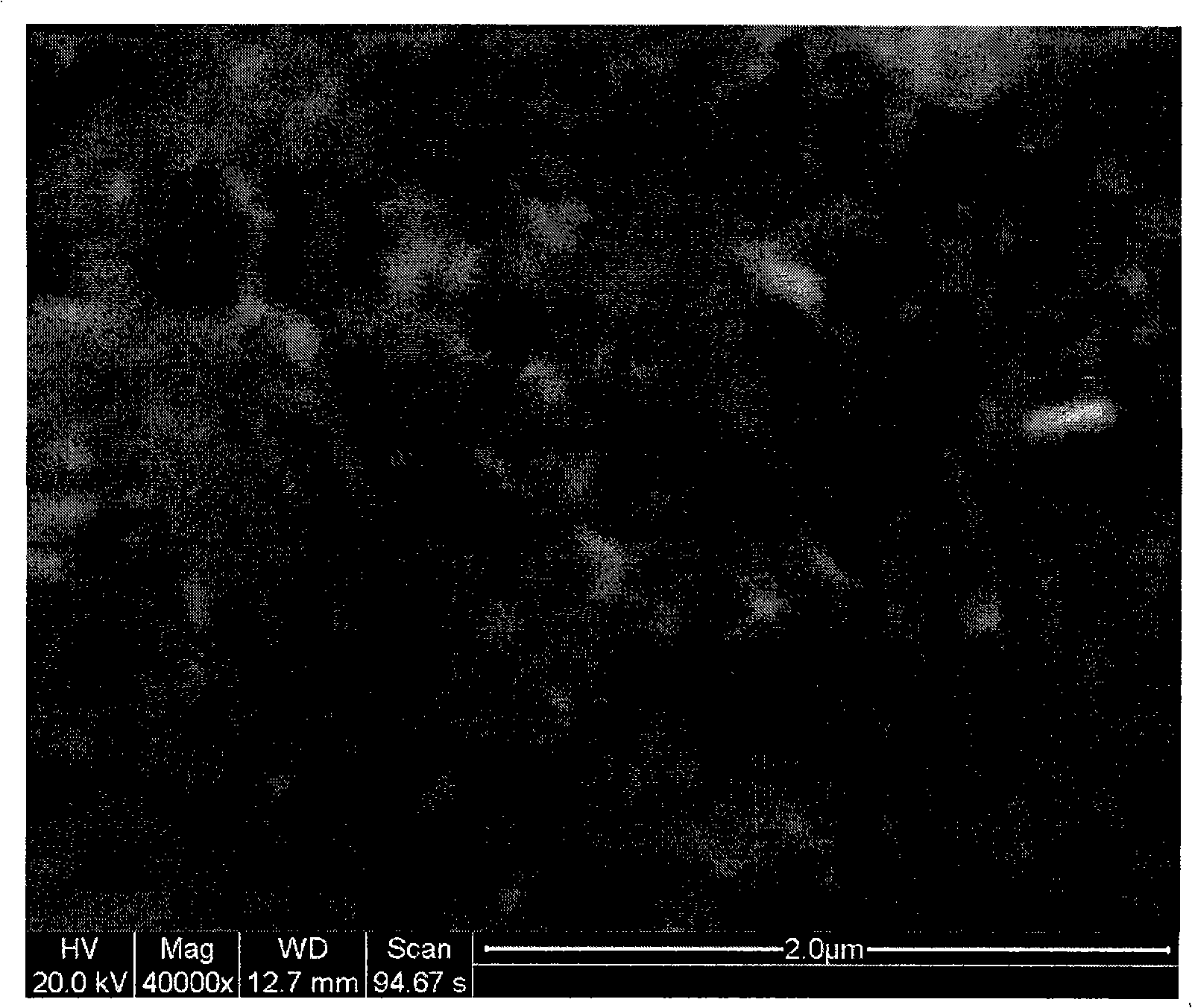

[0026] The content of titanium and aluminum is 1mol L -1 , the sol particle diameter is to add PVA solution (the mass volume concentration of PVA is 100g L in the sol of 8nm -1 ) and dimethylformamide to prepare a membrane solution, wherein the mass ratio of the sol to the PVA solution and the dimethylformamide organic additive is 100:10. Adopt the mode of soaking to utilize MC solution (the mass volume fraction of MC is 150g L -1 ) to coat the surface of the support body (the surface structure pore diameter is 100nm carbon film). After placing the support body containing the surface coating for 20 minutes, place it under constant temperature and humidity conditions with a temperature of 60°C and a humidity of 90% for 10 hours and then take it out. Drying at 40°C and calcining at 600°C can obtain a ceramic composite membrane with a pore size of 18nm.

Embodiment 3

[0028] Silicon content is 0.1mol L -1 , Add PEG solution (the mass volume concentration of PEG is 200g L -1 ) to prepare a membrane-forming solution, wherein the mass ratio of silica sol to PEG solution is 100:0.5. The support body (the pore size is 50nm Al 2 o 3 Ceramic membrane) after coating the surface. After the support body containing the surface coating is placed for 10 minutes, it is placed under constant temperature and humidity conditions of 20°C and 100% humidity for 24 hours, and then the film layer is gelled, and then the wet film is dried and placed in the Drying at 30°C and calcining at 250°C can obtain a ceramic ultrafiltration membrane with a pore size of 1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com