Method for preparing polyvinylidene fluoride flat plate microporous compound film

A technology of polyvinylidene fluoride and composite membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. It can solve the problems of increasing the average pore size and achieve energy saving, easy temperature control and large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

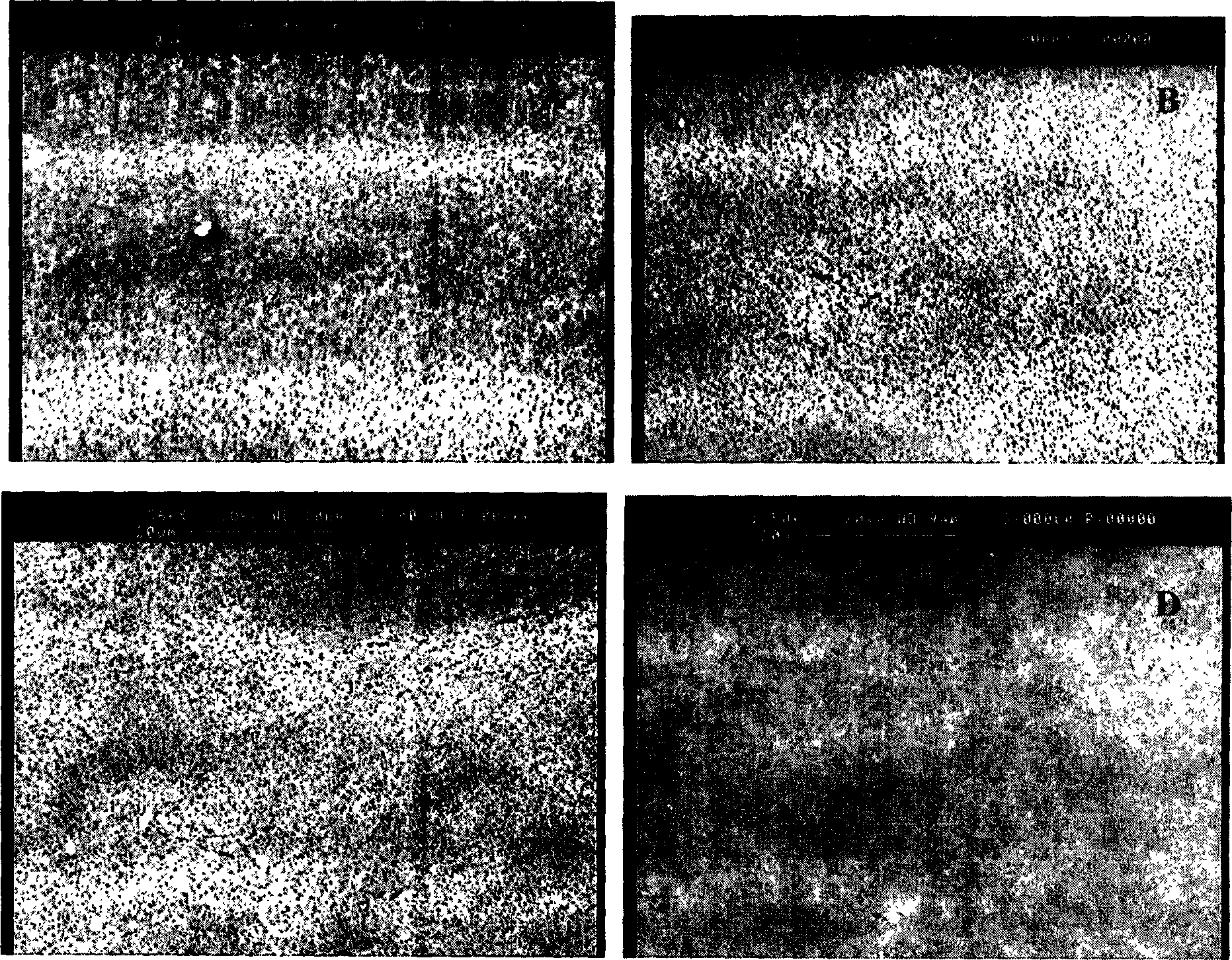

[0036] Effect of Membrane Solution Concentration on Structure and Properties of PVDF Flat Composite Microporous Membrane

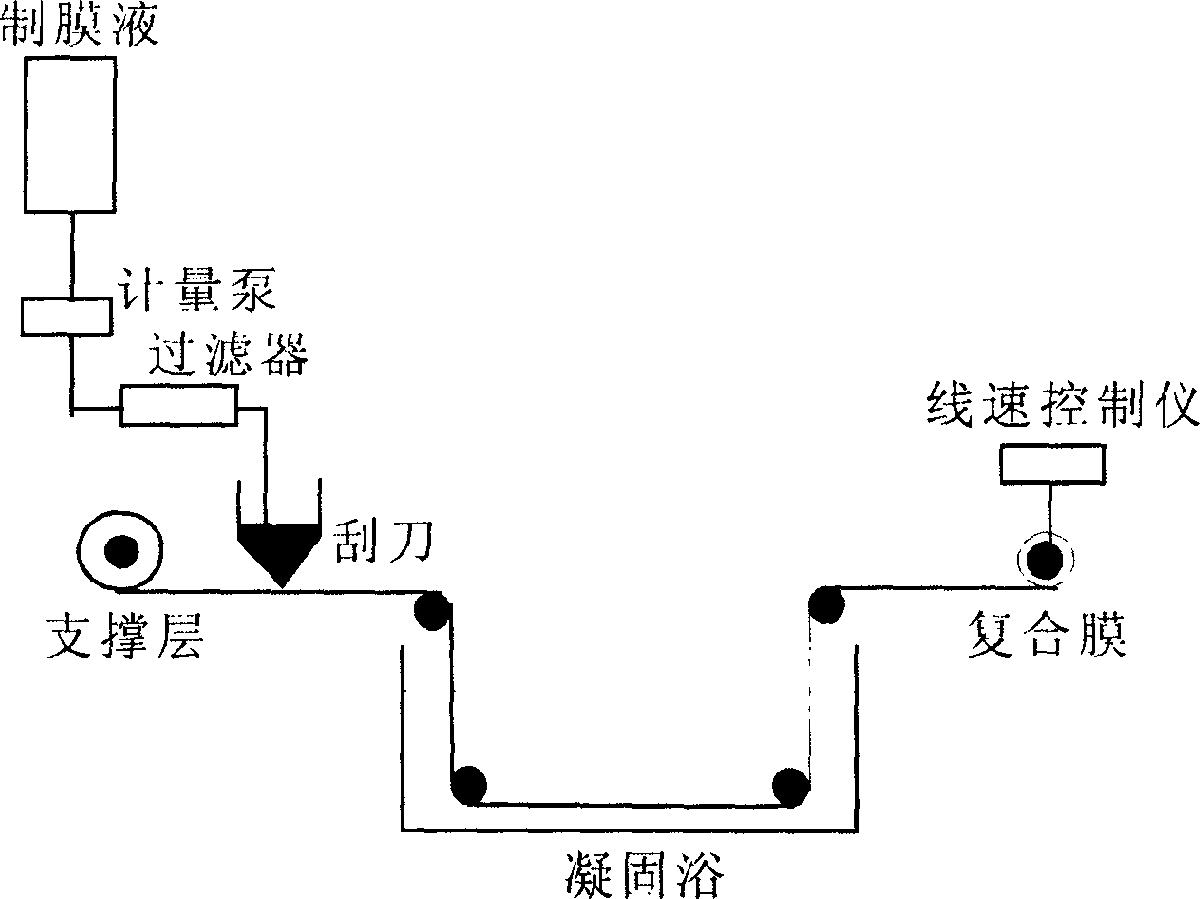

[0037] The proportions are respectively 8 / 5 / 87, 10 / 5 / 85, 12 / 5 / 83, 14 / 5 / 81 (wt%) polyvinylidene fluoride / polyvinylpyrrolidone / N,N-dimethylacetamide Fully stir and dissolve in the flask at about 70°C for 48 hours until the polymer is completely dissolved and the solution remains clear; filter the above-mentioned film-making solution with a Buchner funnel, then perform vacuum degassing for several hours, and stand for use. Install the PET non-woven fabric on the compound scraping film machine, adjust the linear speed controller to control the non-woven fabric's running speed to 1.5m / s; use the plug gauge to adjust the blade thickness between the scraper and the support layer to 150μm; The ambient temperature is 14.5°C. Pour the film-making solution at 25°C into the feed tank, and then scrape the film. The solution is scraped on the support layer, run in the a...

Embodiment 2

[0042] Effect of Support Layer on Membrane Properties

[0043] Polyvinylidene fluoride, polyvinylpyrrolidone, and N,N-dimethylformamide with a mass ratio of 10 / 5 / 85 were fully stirred and dissolved in a flask at about 70°C for 48 hours until PVDF was completely dissolved and the solution remained clear; The membrane solution was filtered with a Buchner funnel, then subjected to vacuum degassing for several hours, and then left to stand for use. Use PET non-woven fabric and polyester as the support layer respectively, install the support layer on the film scraping machine, adjust the line speed controller to control the cloth speed of the support layer to 1.5m / s; adjust the distance between the scraper and the support layer with a plug gauge The thickness of the knife-edge between them is 150 μm; pour the film-making solution at a temperature of 25 °C into the feed tank, and then scrape the film. The solution is scraped on the support layer, run in the air for 5 seconds, and th...

Embodiment 3

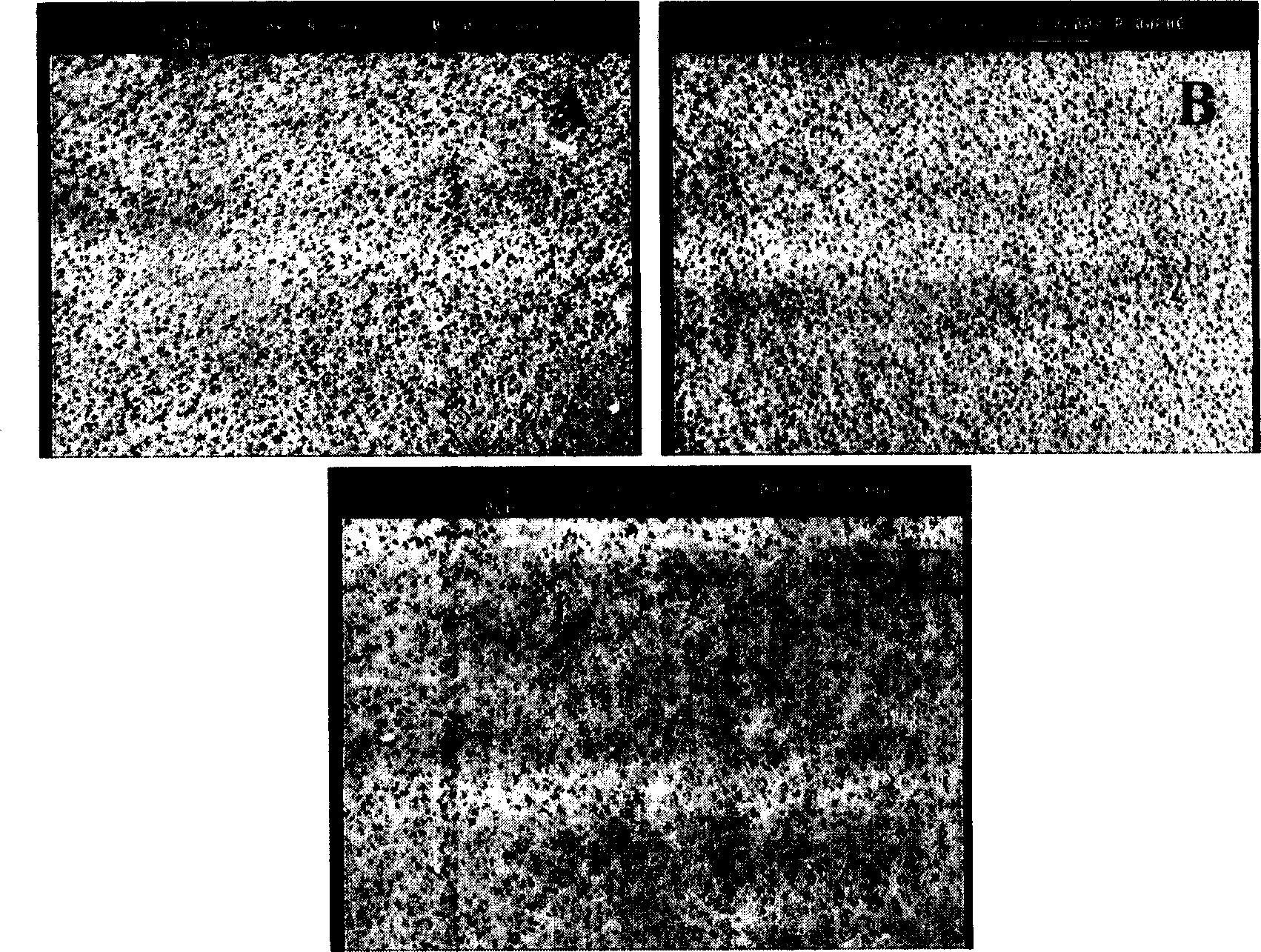

[0047] Effect of Coagulation Bath Temperature on the Structure and Properties of Polyvinylidene Fluoride Flat Composite Membrane

[0048] The preparation of the film-making solution and the scraping process are the same as in Example 1, except that the solvent used is N-methylpyrrolidone, the ambient temperature is 18°C, and the temperatures of the coagulation bath are respectively set at 10°C, 18°C, and 25°C. The measurement of the flux and the characterization by SEM are the same as in Example 1. The thickness, average pore size and water flux of the prepared composite membranes are listed in Table 4. The surface morphology of various membranes is shown in the appendix image 3 .

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com