Patents

Literature

1862 results about "Feed tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In most cases, a feed tank is a large metal or polyethylene tank able to store many gallons of liquid. The tank is generally elevated above the level of the system it is used to feed. This allows the force of gravity to move the liquid from the tank into the rest of the system when a valve on the bottom of the tank is opened.

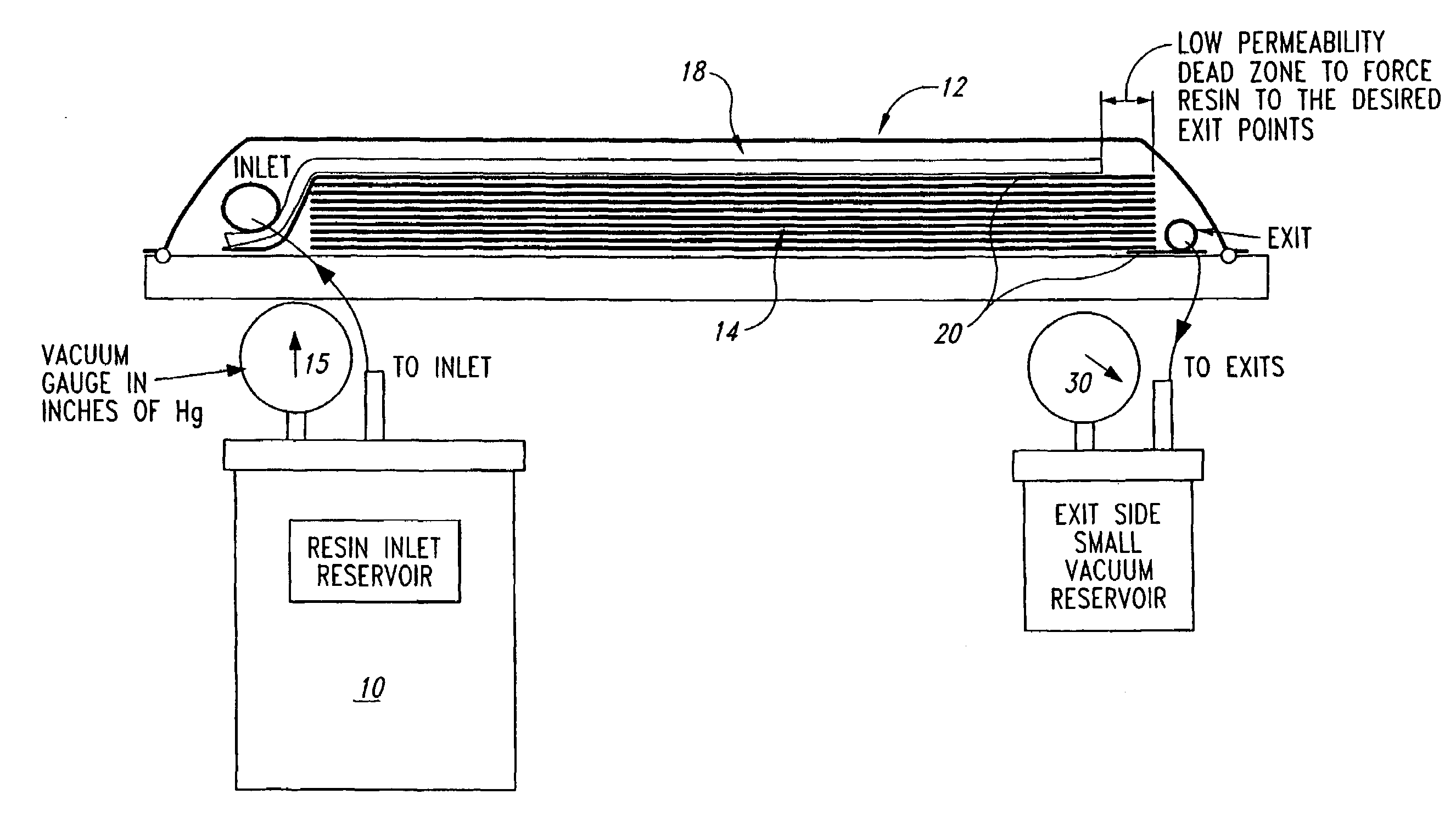

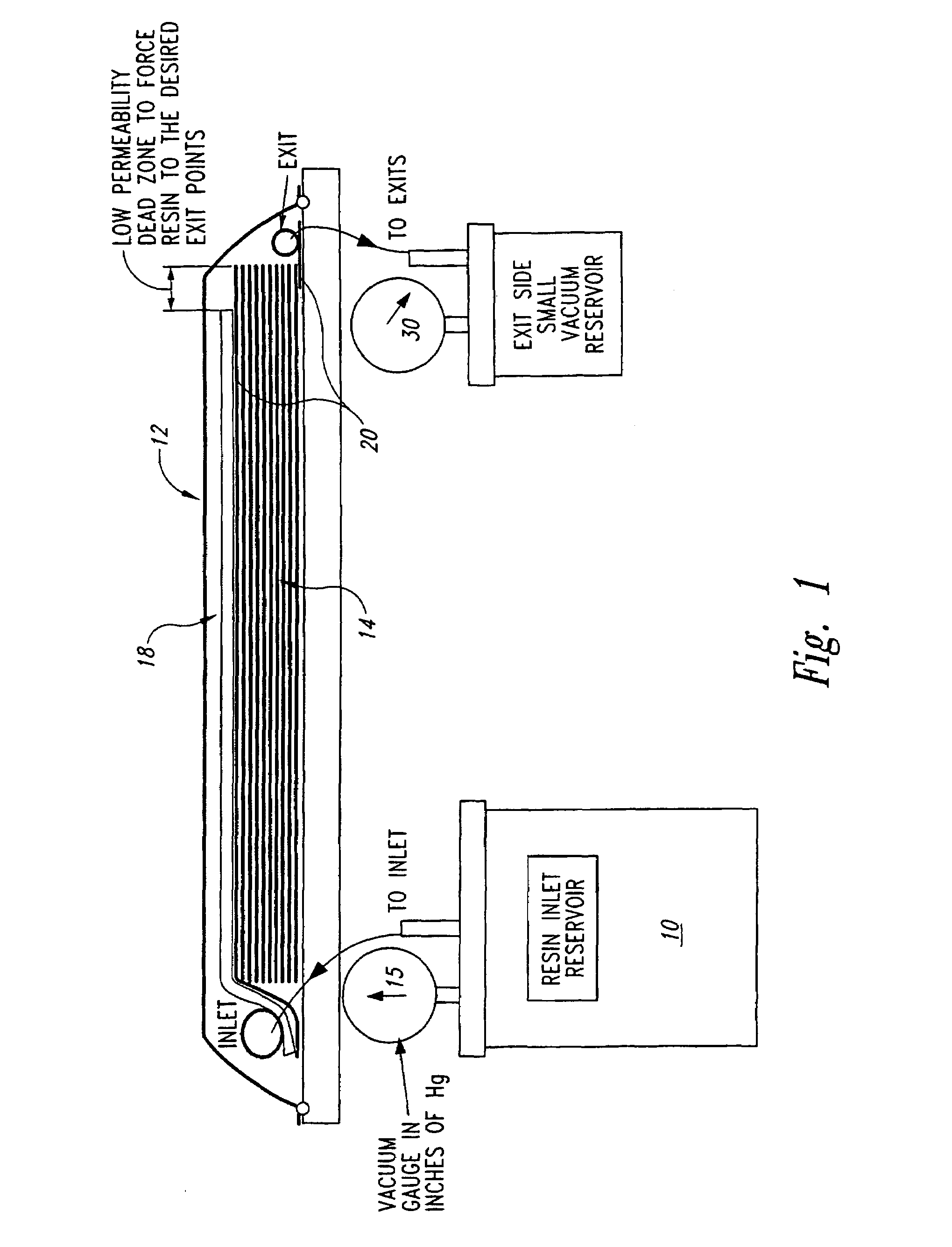

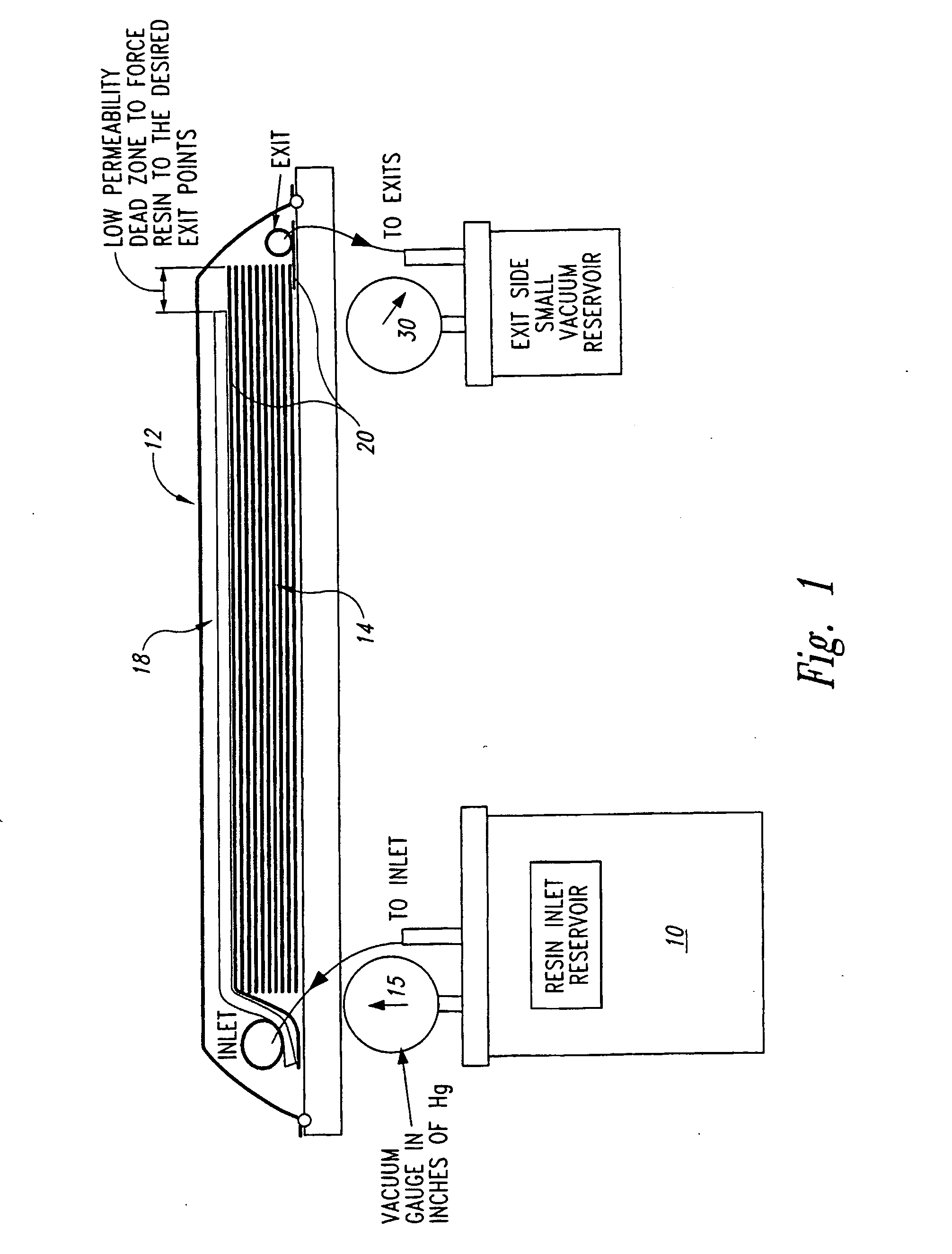

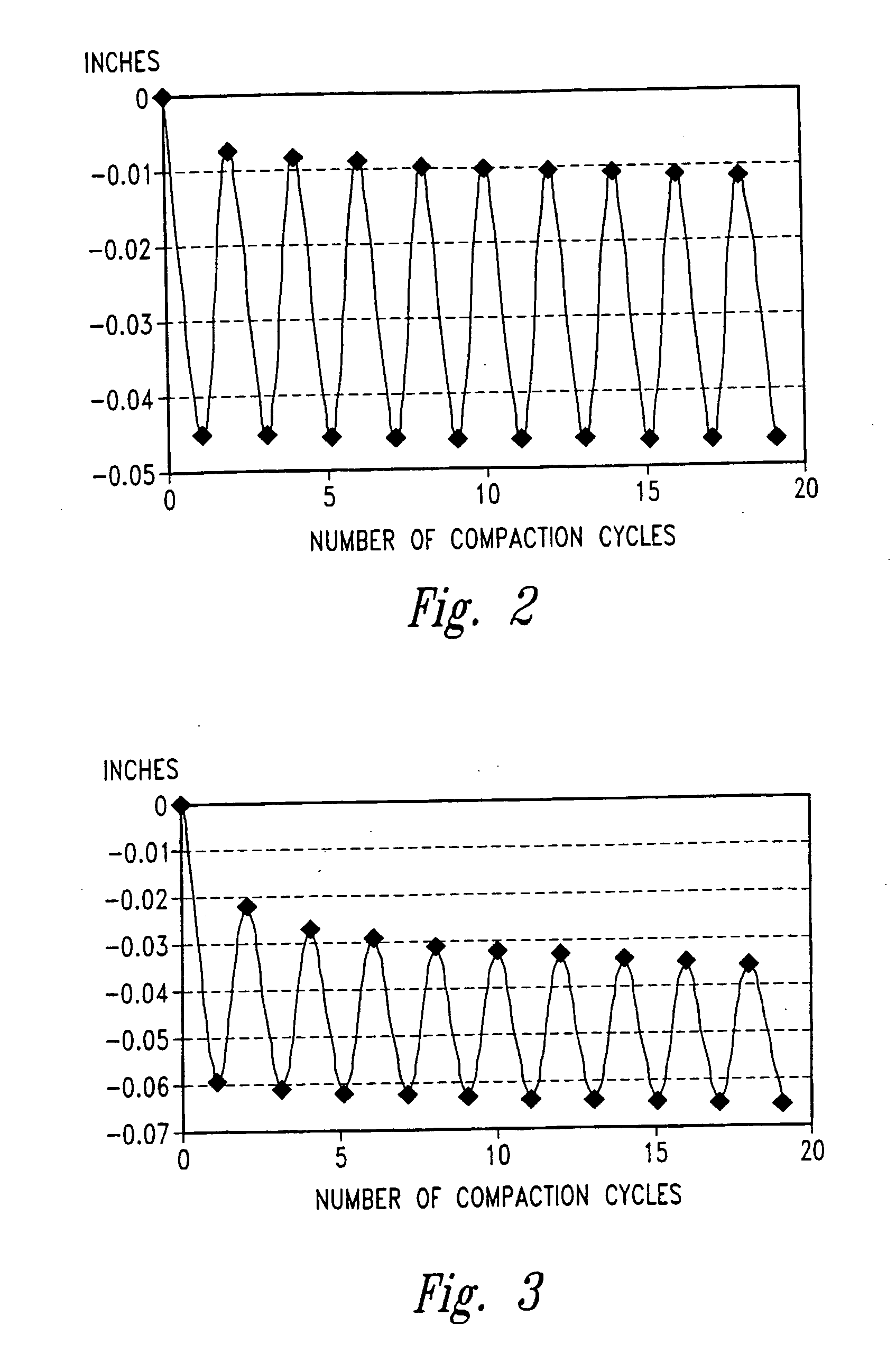

Controlled atmospheric pressure resin infusion process

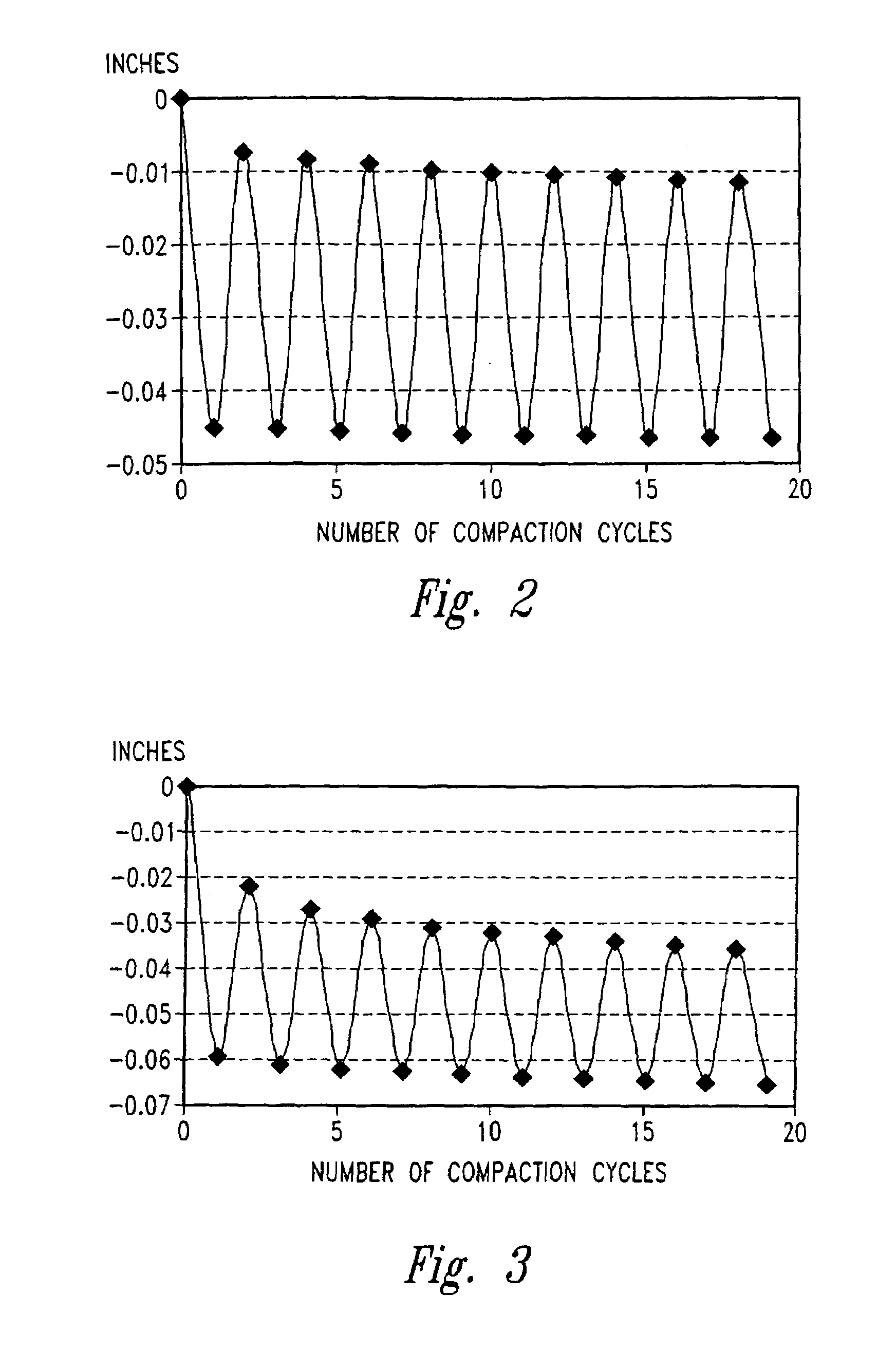

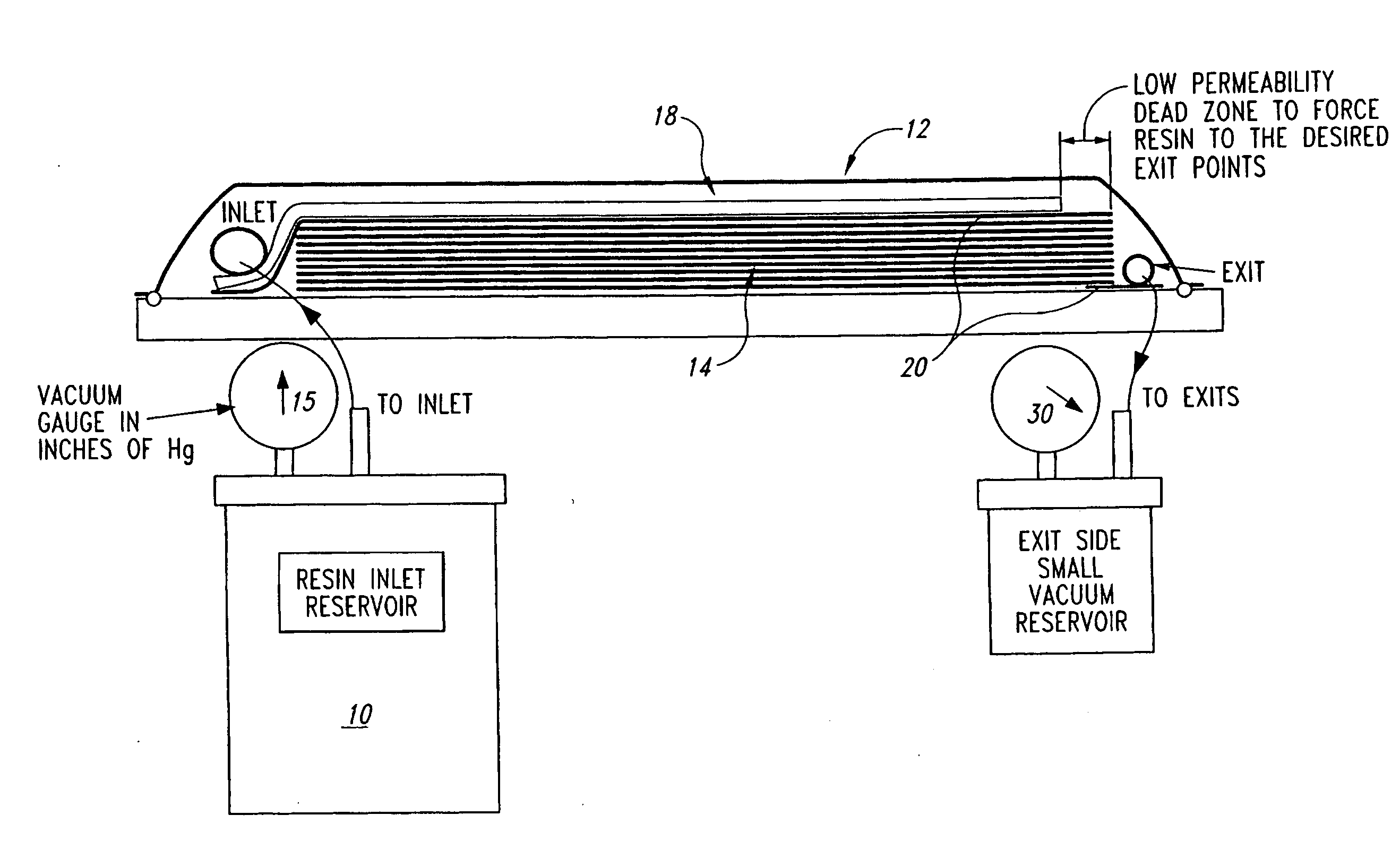

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

Controlled atmospheric pressure resin infusion process

ActiveUS20050073076A1Specific strength of partLow costLaminationLamination apparatusSurface finishEngineering

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

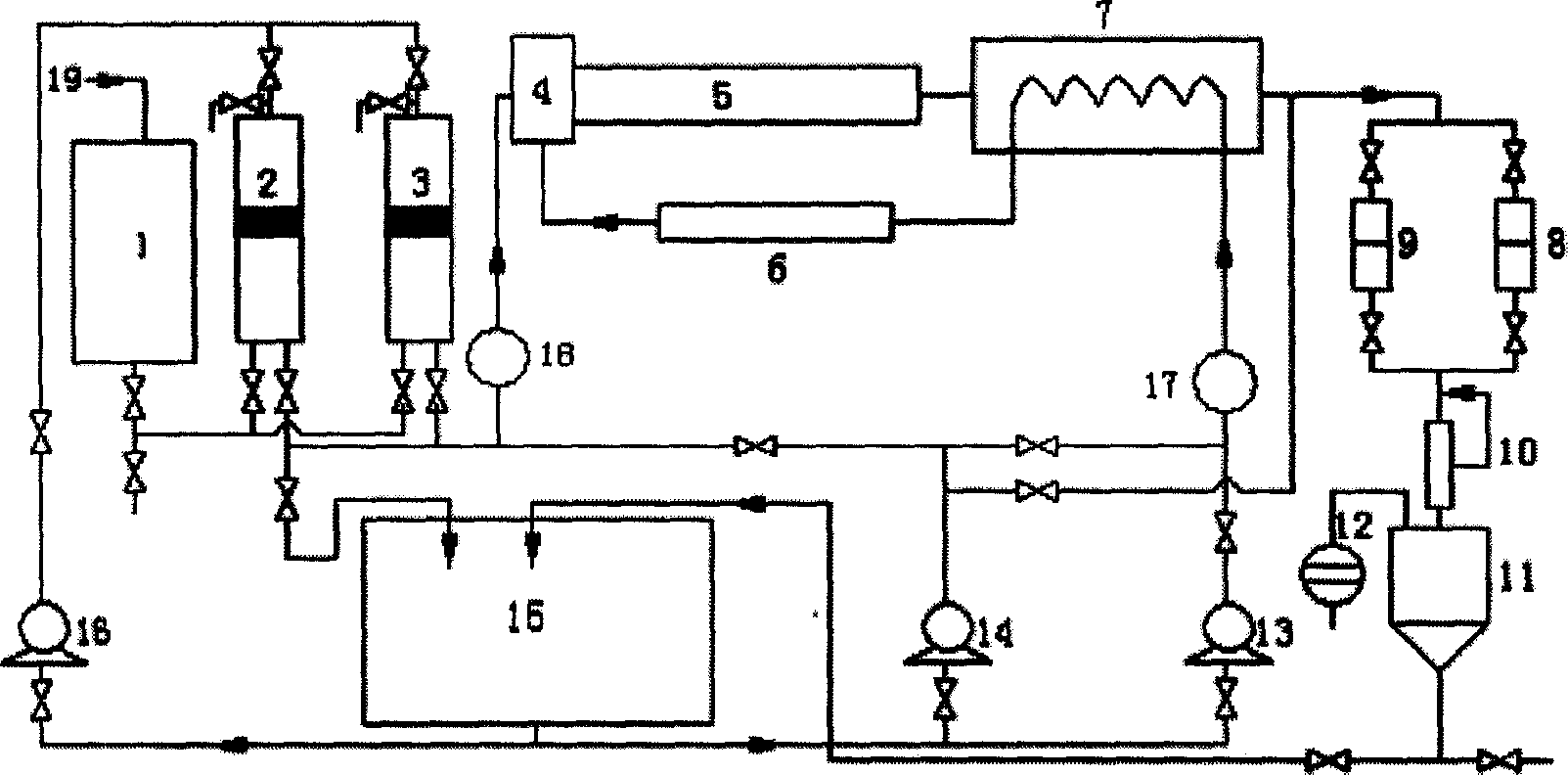

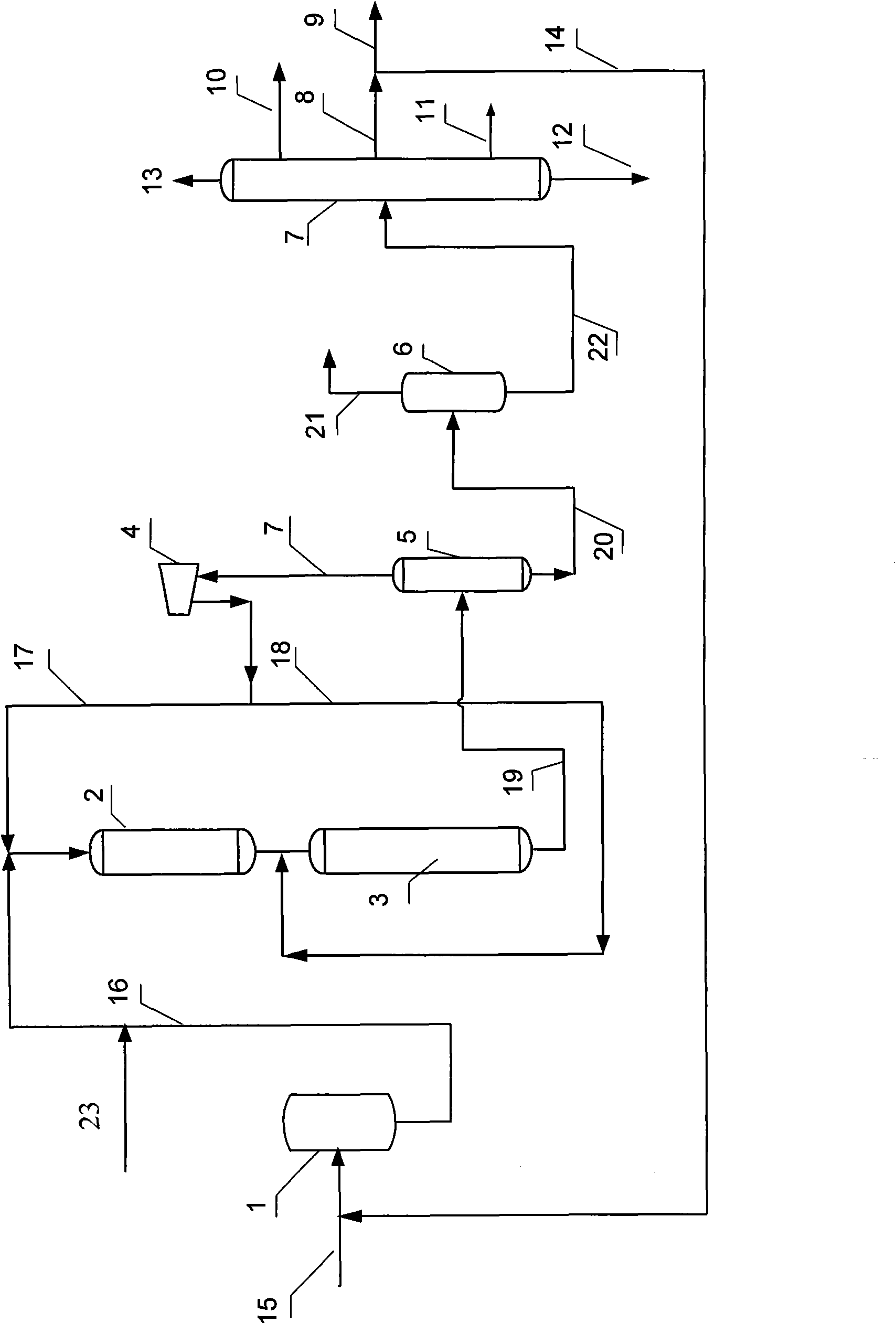

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

ActiveCN1654313AMild reaction conditionsEasy to controlHydrogen productionBulk chemical productionCO2 contentHydrogen content

The present invention discloses one kind of supercritical water catalytic coal and biomass gasifying process and apparatus for producing hydrogen. The apparatus has material feeder with one inlet connected to the outlet of the material pump and the other inlet connected to the outlet of feeding tank, pre-heater with outlet connected to the preheated water inlet and inlet connected to the outlet of inner pipe outlet of the cooler, cooler with inlet connected to the inlet of water pump, water pump with outlet connected to the water tank, cooler jacket with outlet connected to the inlet of the first filter and the inlet of the second filter, and back pressure valve with inlet connected to the outlets of the first filter and the second filter. The present invention has special heating mode for fast heating of the reaction material, raised hydrogen content in the gas product, raised CO2 content in the gas product, and easy separation of CO2 and feeding of CO2 to the processing terminal. The present invention is simple, effective and feasible.

Owner:陕西中核交大超洁能源技术有限公司

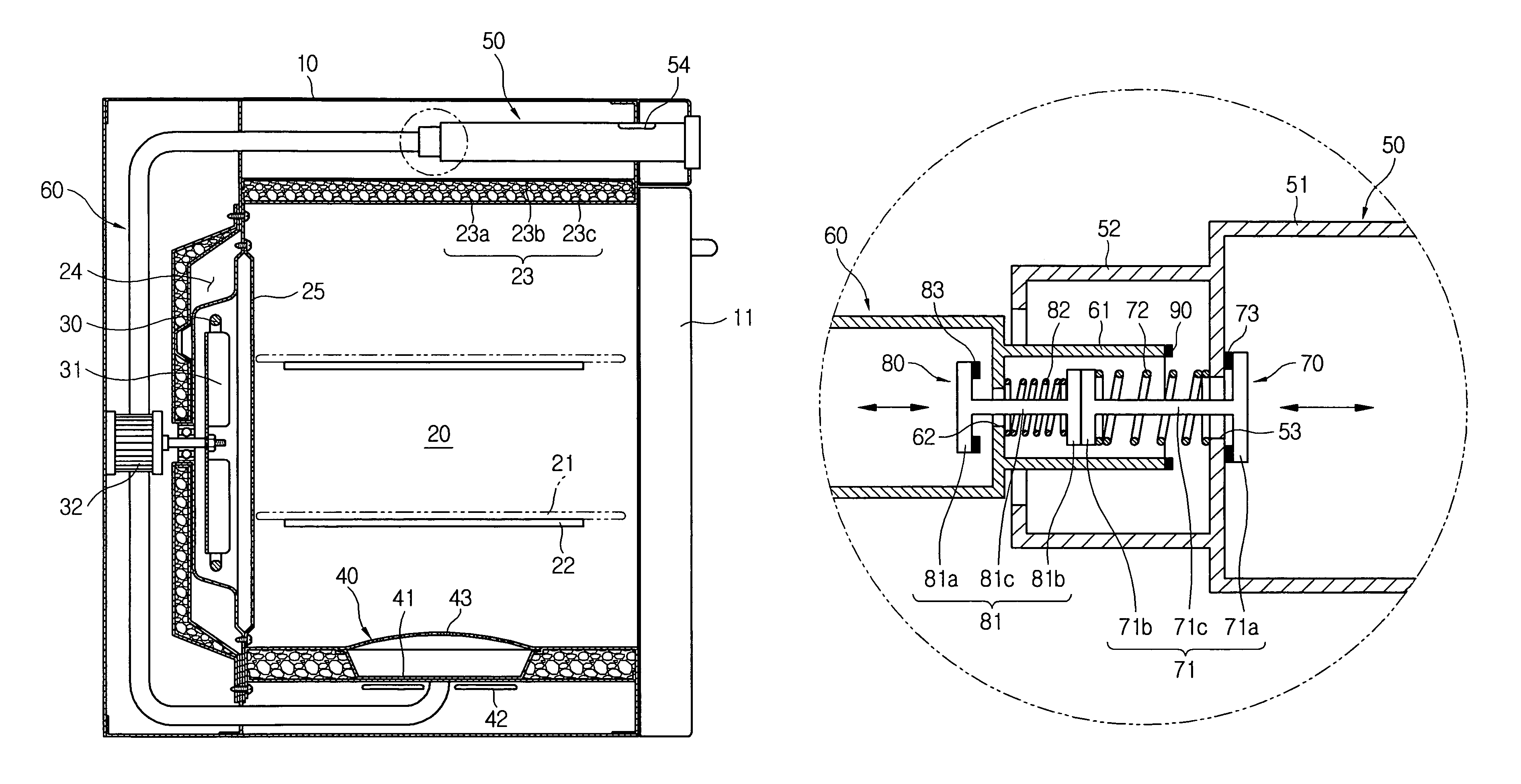

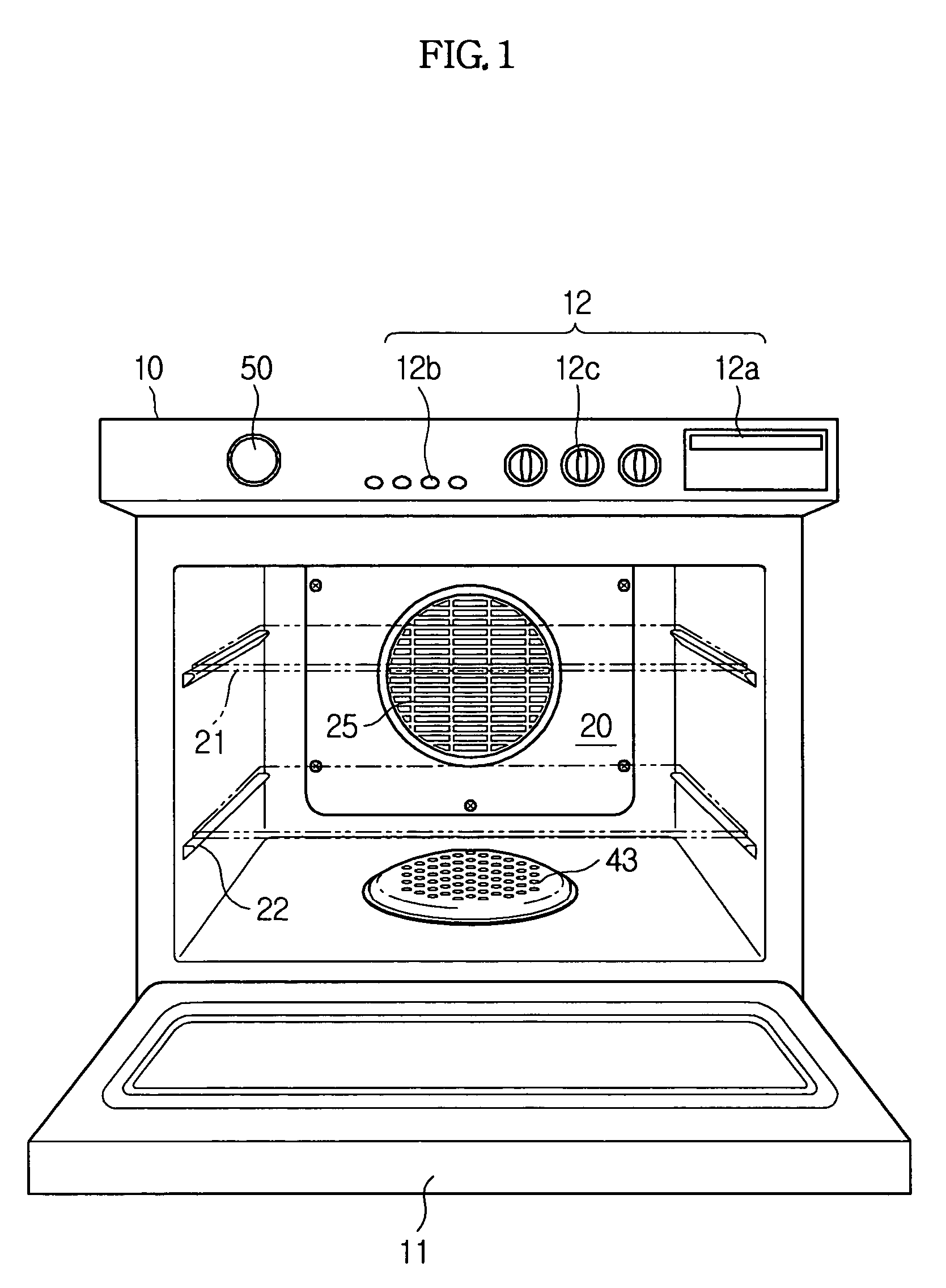

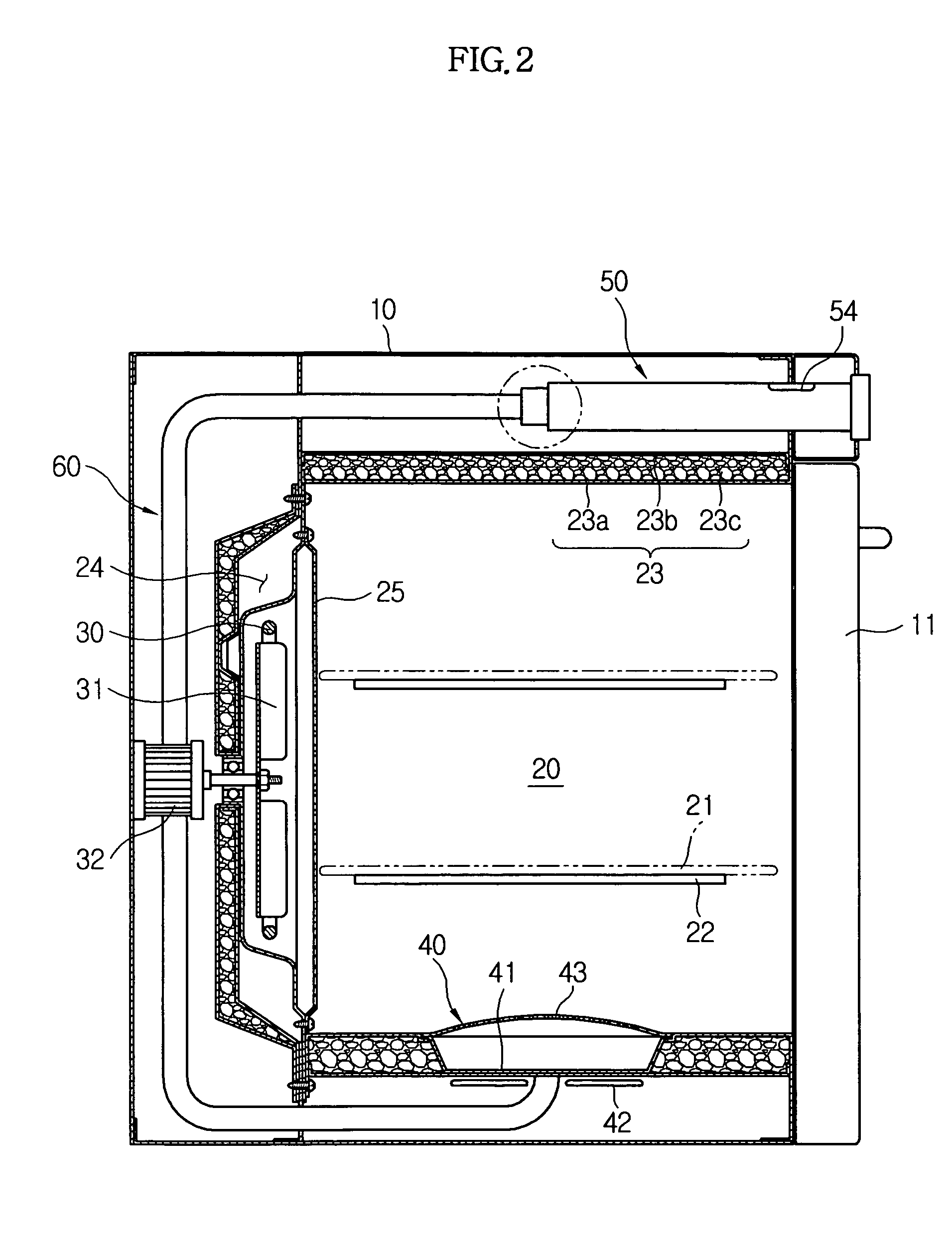

Heating cooker

A heating cooker which prevents leakage of water even when an inlet of the water feed pipe is placed in any direction, and in which a water feed tank is removably coupled to the water feed pipe in any direction. The heating cooker includes a steam generator to supply steam into a cooking cavity defined in the heating cooker, a water feed tank to supply water into the steam generator, a water feed pipe to supply the water from the water feed tank into the steam generator, with the water feed tank removably coupled to the water feed pipe, a first valve to control an outlet provided on the water feed tank to discharge the water from the water feed tank, and a second valve to control an inlet provided on the water feed pipe to draw the water discharged from the water feed tank into the water feed pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

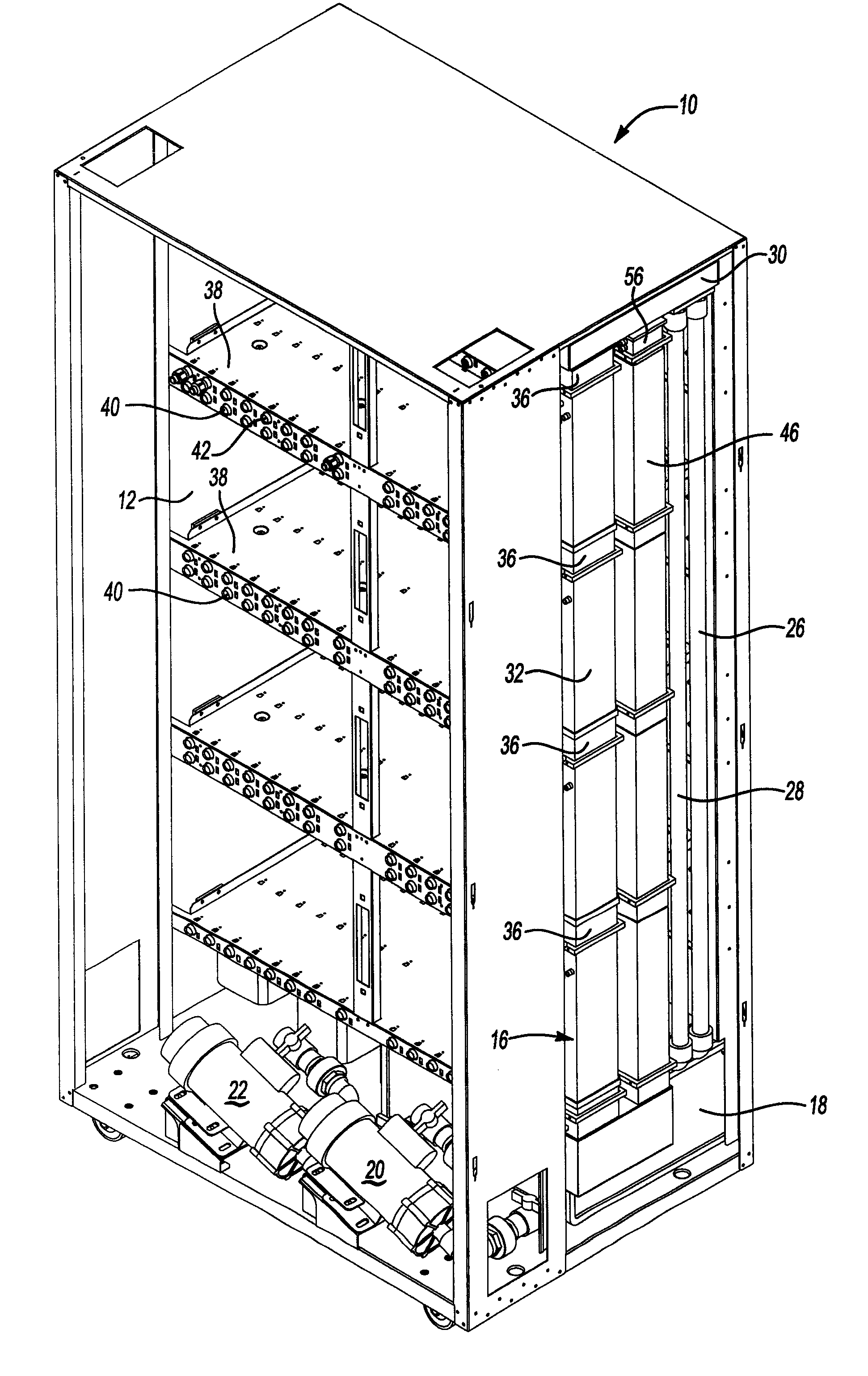

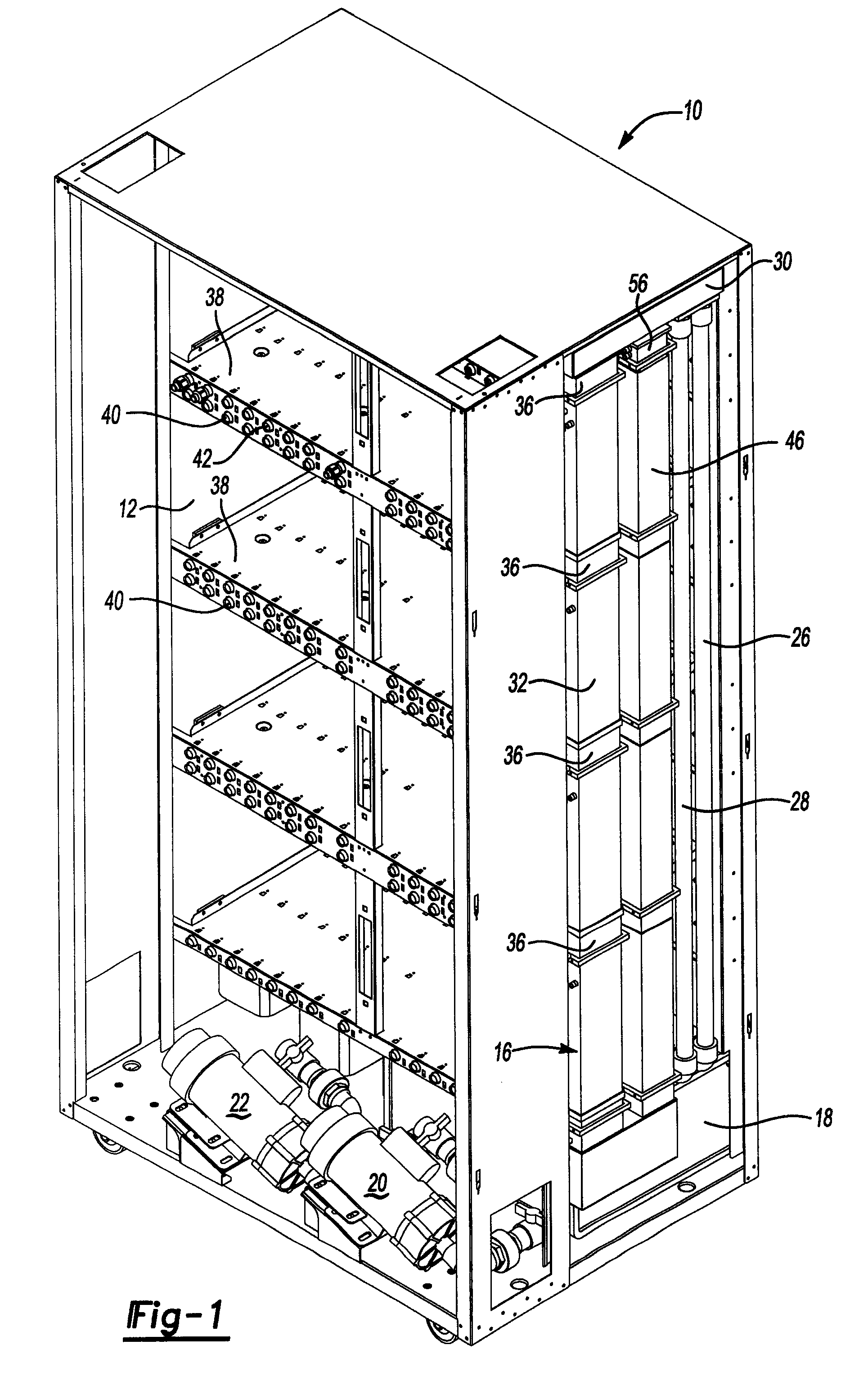

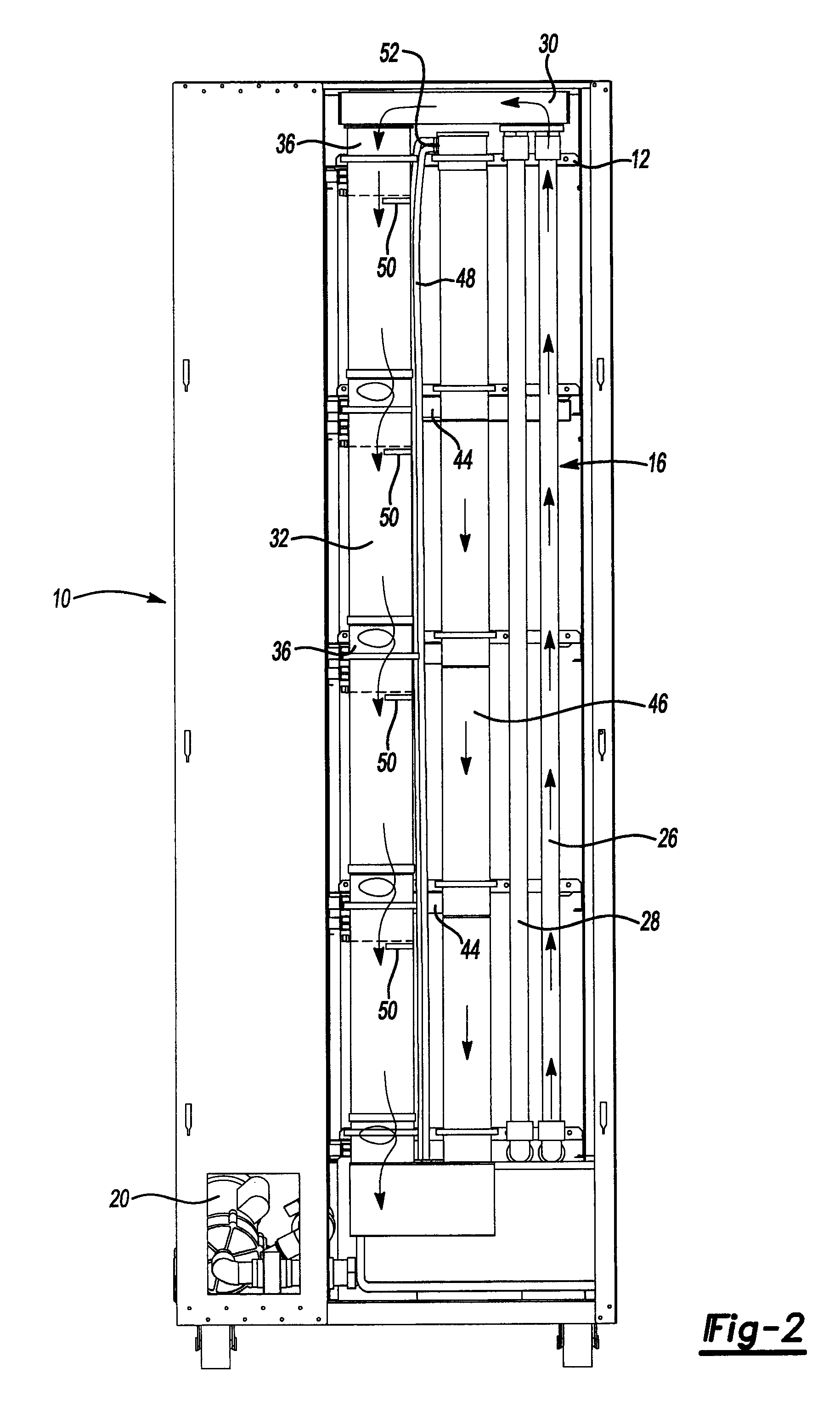

Method and apparatus for liquid cooling computer equipment

ActiveUS8035972B2Prevent leakageMore reliableDigital data processing detailsIndirect heat exchangersEngineeringAtmospheric pressure

A cooling system for cooling computer component with a liquid provided at atmospheric pressure, or low pressure, that flows through channel defined in the computer component. The liquid is pumped from a reservoir to a discharge port, or weir, that is located above the computer component. The liquid flows through an in-feed manifold to diverters that direct the liquid into in-feed tanks located above a row of the computer component. The liquid flows through the channels and flow control orifices to a drain that returns the liquid to the reservoir.

Owner:ORACLE INT CORP

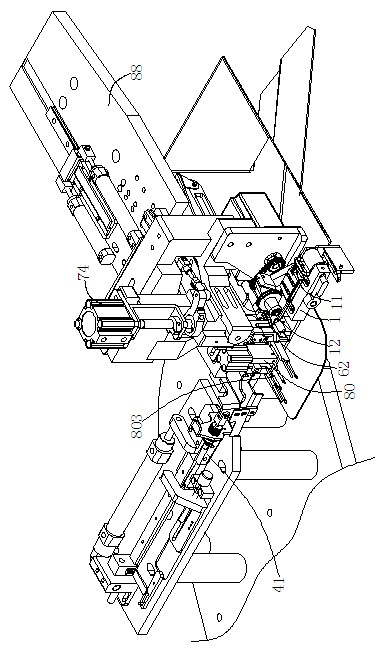

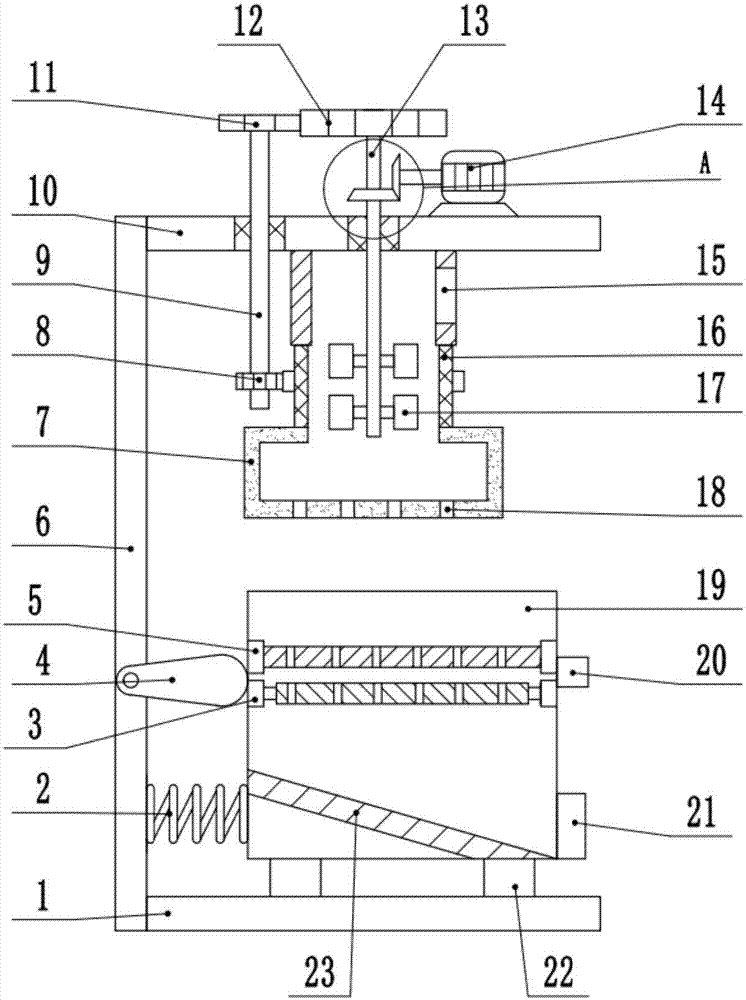

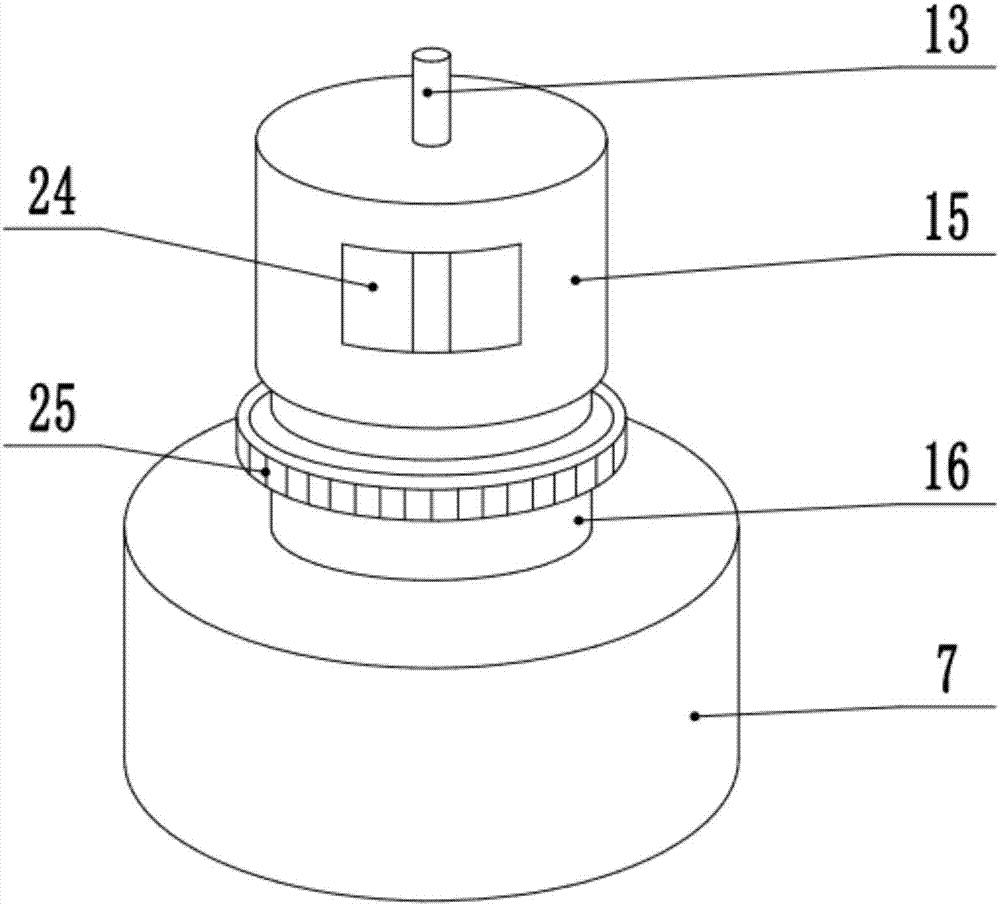

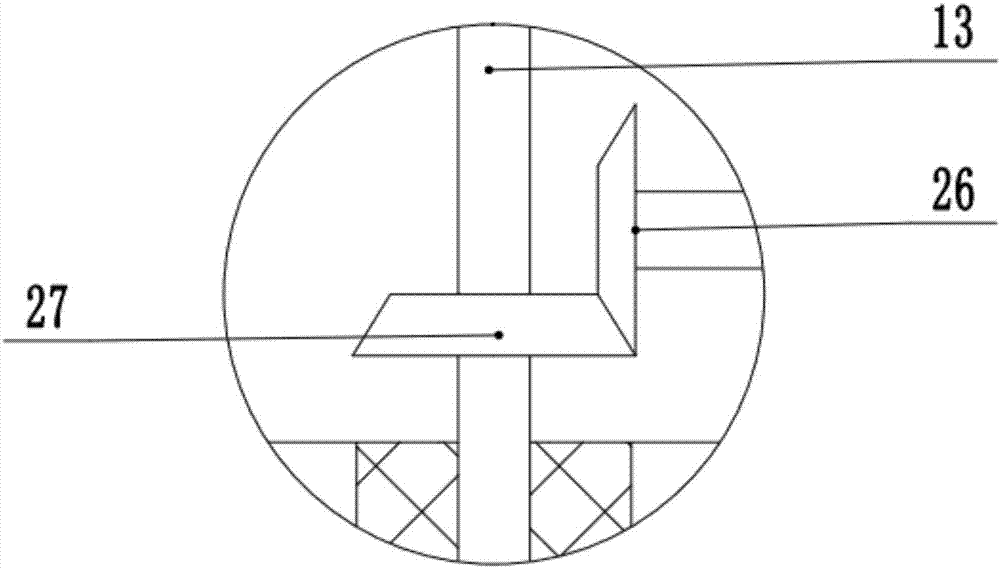

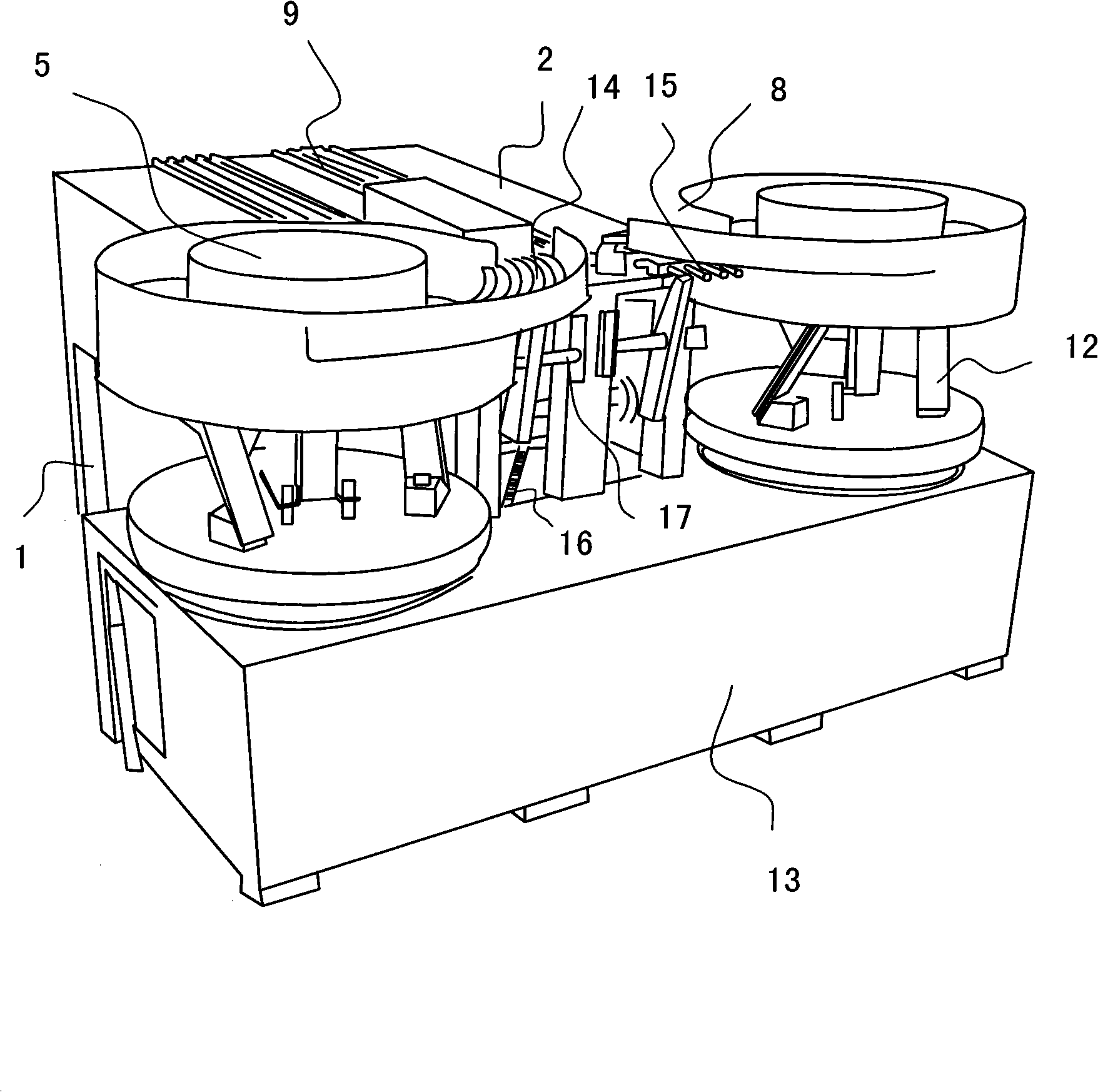

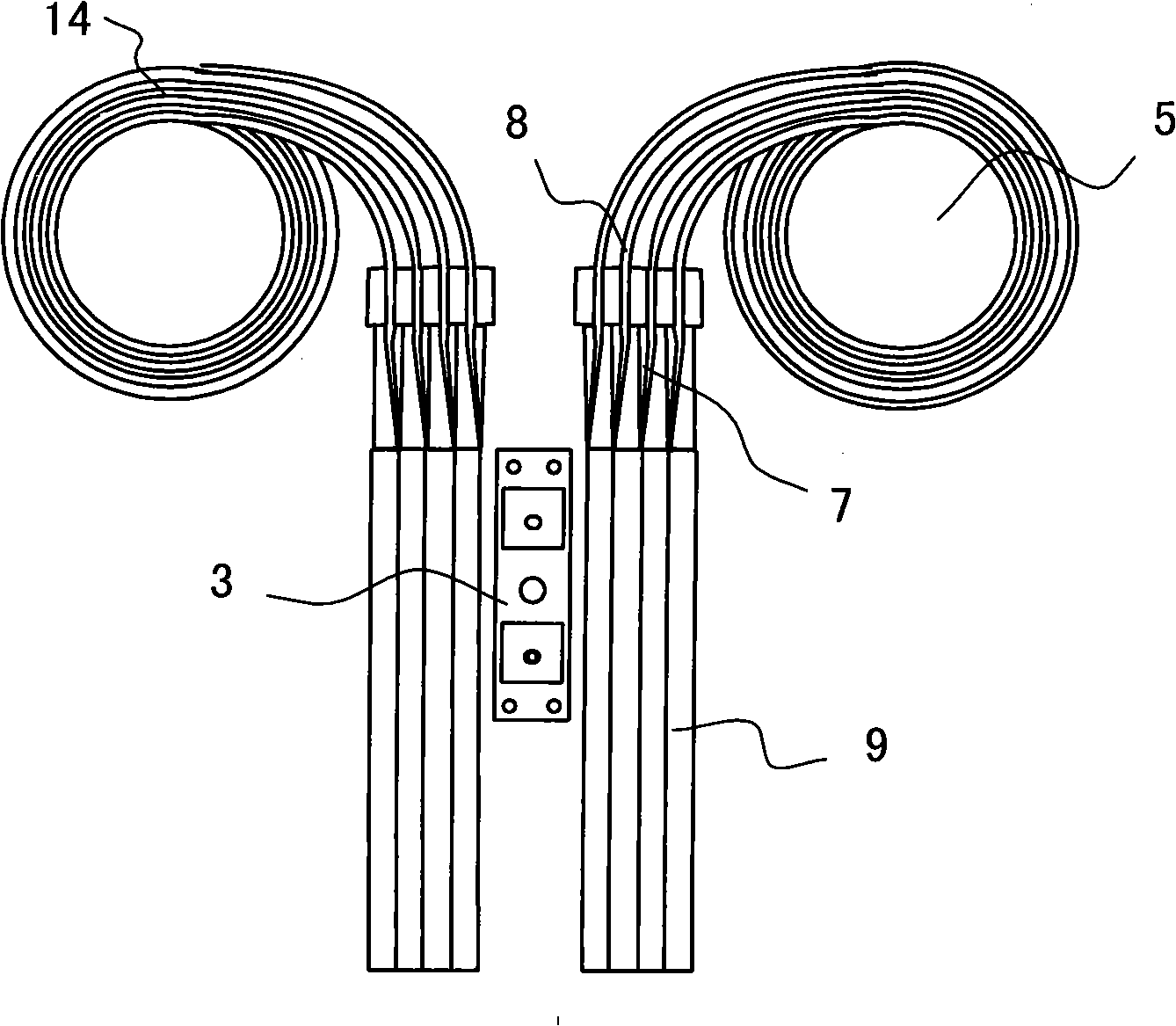

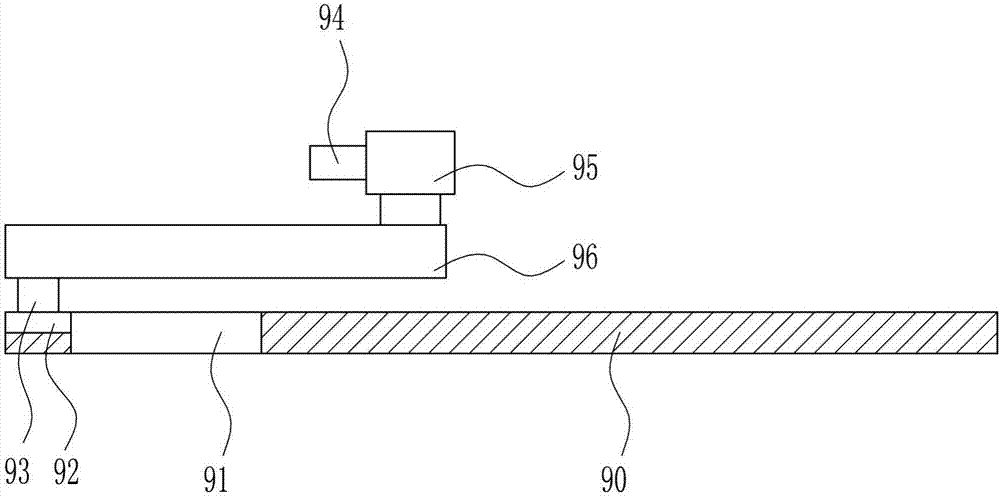

Feeding device for automatic band nailing machine

ActiveCN102493131AEasily adjust the range of motionAdjust the range of motionWorkpiece carriersWork-feeding meansEngineeringFeed tank

The invention discloses a feeding device for an automatic band nailing machine. The feeding device comprises a feeding mechanism for inputting bands, a clamping mechanism used for clamping the heads of the bands in the feeding mechanism and drawing the heads by a set length, a cutter mechanism used for cutting off the bands, and a winding mechanism used for clamping two ends of the bands and winding. The bands are input into a feeding tank through a feeding hole, are conveyed by the feeding tank to pass through a tool rest, a clamping head component can move to the tool rest to clamp the heads of the bands and draw out the bands from the feeding tank by the set length; a telescopic platform of the winding mechanism moves, two winding arms clamp and draw out the two ends of the bands; a cutter cuts off the bands at the outlet of the feeding tank; the two winding arms of the winding mechanism rotate to wind the two ends of the bands; and the telescopic platform continuously moves to feed the wound bands to a sewing area. The feeding device can automatically feed, cut and wind the bands and convey the bands to the sewing area, and has the advantages of convenience for operation, highspeed and high efficiency.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

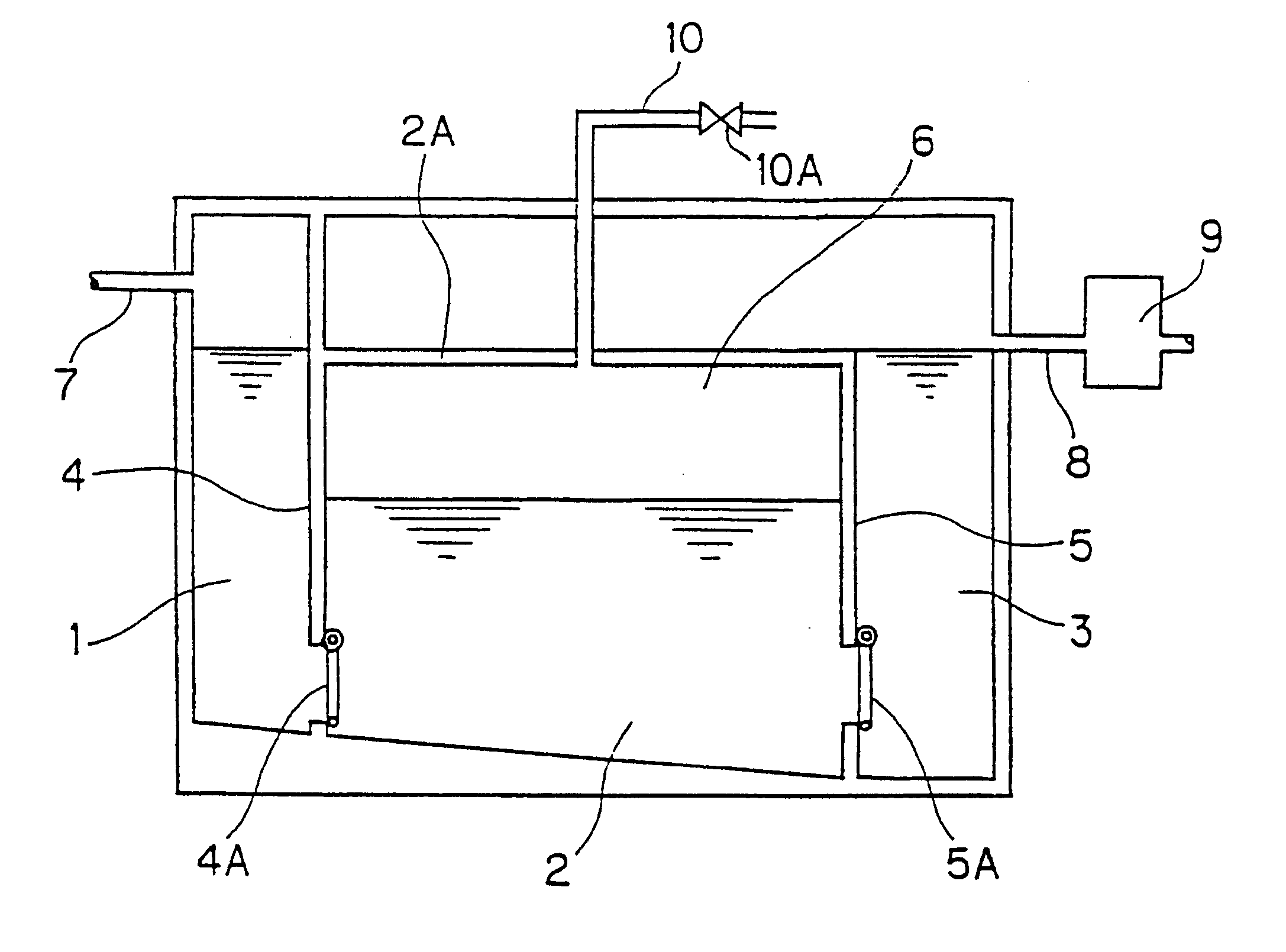

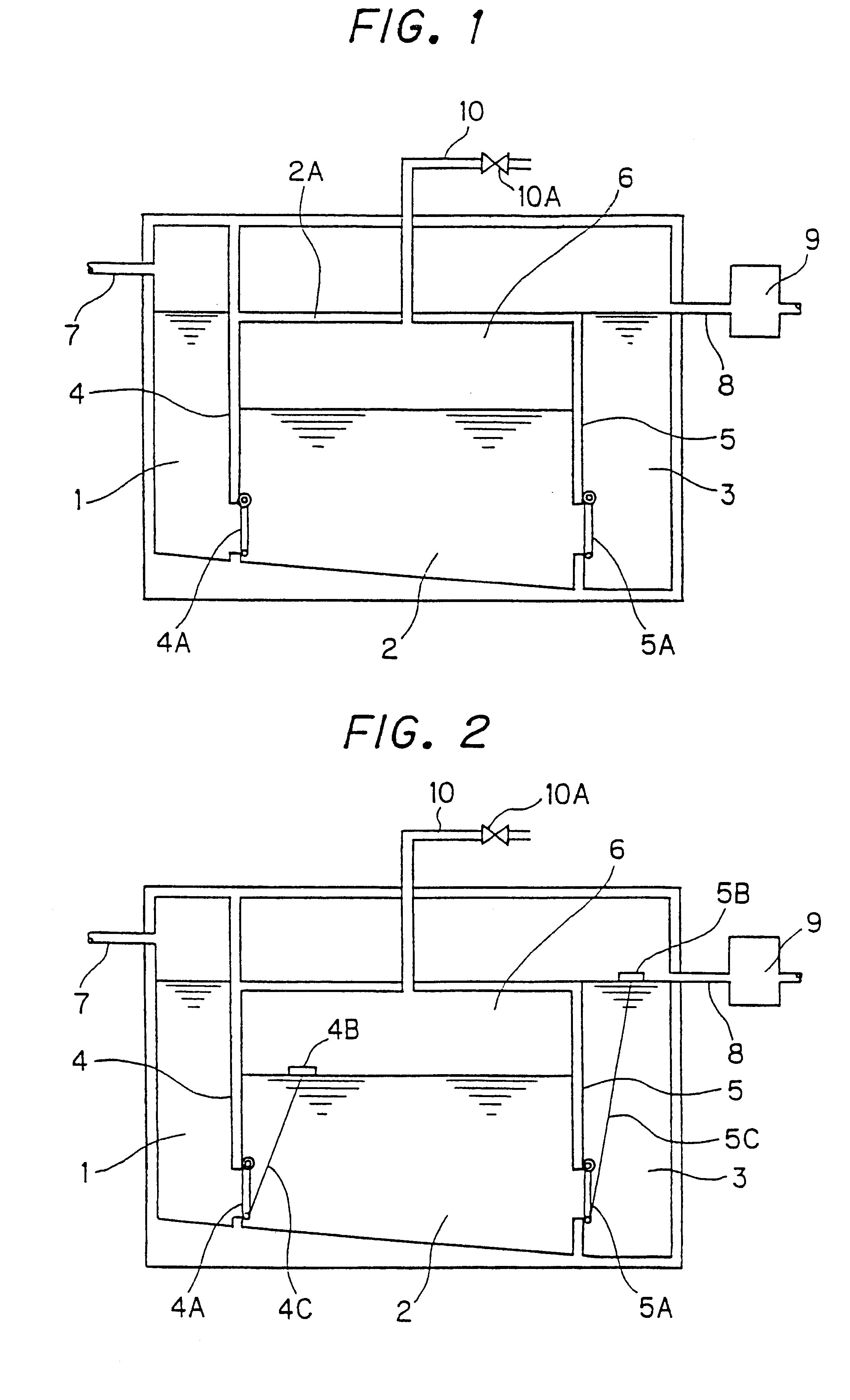

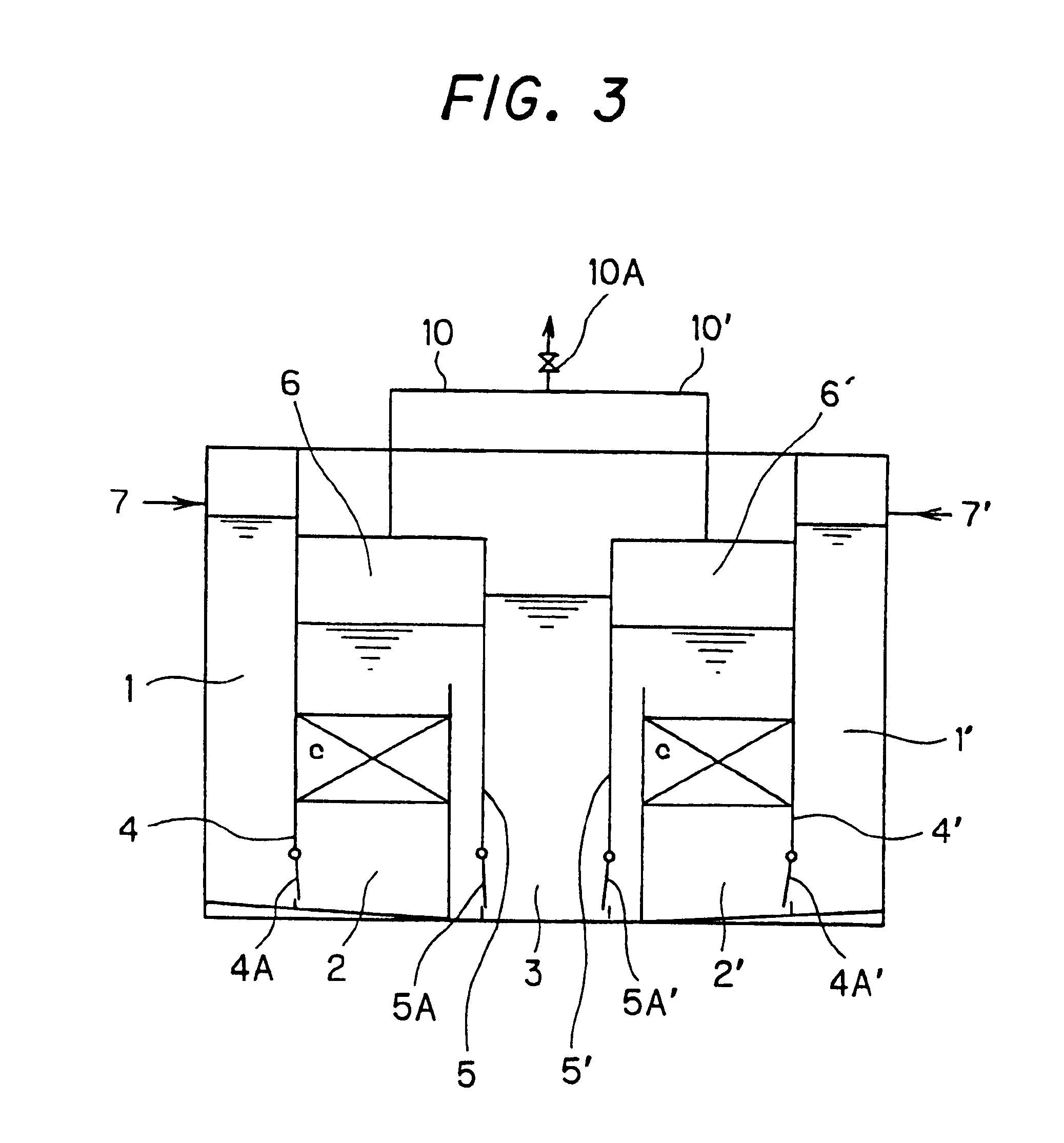

Two-phase type methane fermentation reactor

InactiveUS6660518B1Improve efficiencyLarge capacityBioreactor/fermenter combinationsBio-organic fraction processingMethane fermentationMethane gas

Provided by the invention is a reactor for two-phase methane fermentation of organic waste materials such as livestock excrements which can be operated for a long period with stability. The apparatus comprises an acid fermentation tank (1) connected to a feed tank, a methane fermentation tank (2) partitioned from the acid fermentation tank (1) with a partition wall (4) having a gate valve (4A) and a settling tank (3) partitioned from the methane fermentation tank (2) by a second partition wall (5) having a gate valve (5A) and the space in the upper part of the methane fermentation tank (2) serves as a gas holder (6). The methane gas generated in the methane fermentation tank (2) and collected in the gas holder (6) is taken out from a methane outlet pipeline (10) opening in the canopy of the gas holder (6).

Owner:DAISHIN DESIGN CORP

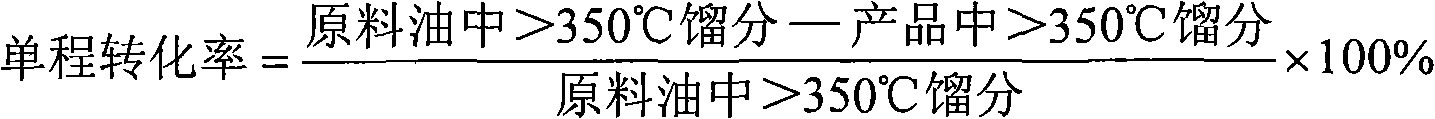

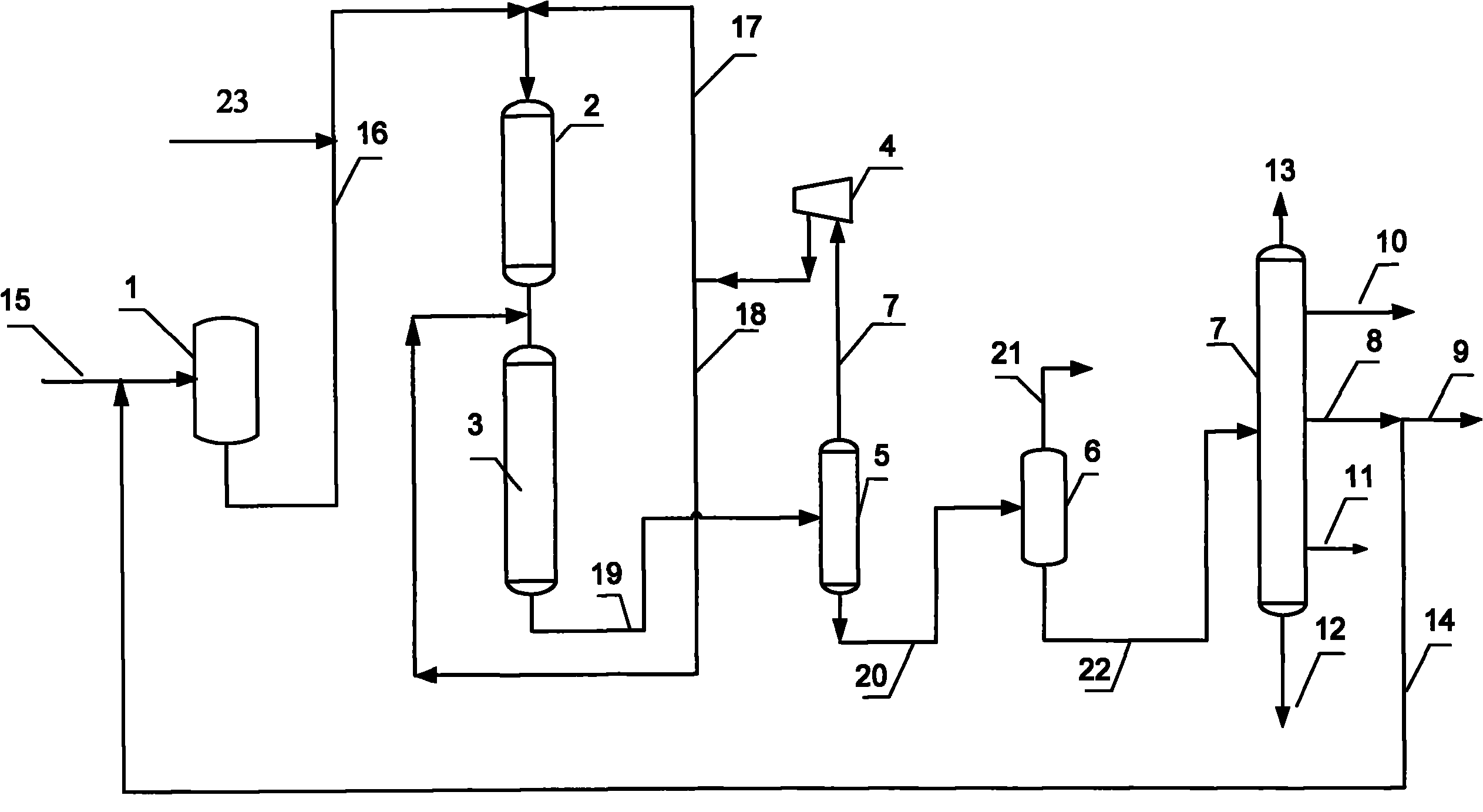

A mid-pressure hydrocracking method for producing jet fuel

ActiveCN102399586AQuality improvementHigh yieldTreatment with hydrotreatment processesKeroseneSmoke point

A mid-pressure hydrocracking method for producing jet fuel is employed under mid-pressure condition; under the control of a certain single- pass conversion, part of kerosene fractions are circulated to a feed tank, and refined, the refined kerosene fractions accounting for 30 percent of the total kerosene fractions. The method of the invention can improve the smoke point of the kerosene fractions and acquire No. 3 jet fuel satisfying GB 6537-2006 standard, and simultaneously acquire maximum high-quality tail oil. The invention has a simple process and low operation cost and equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

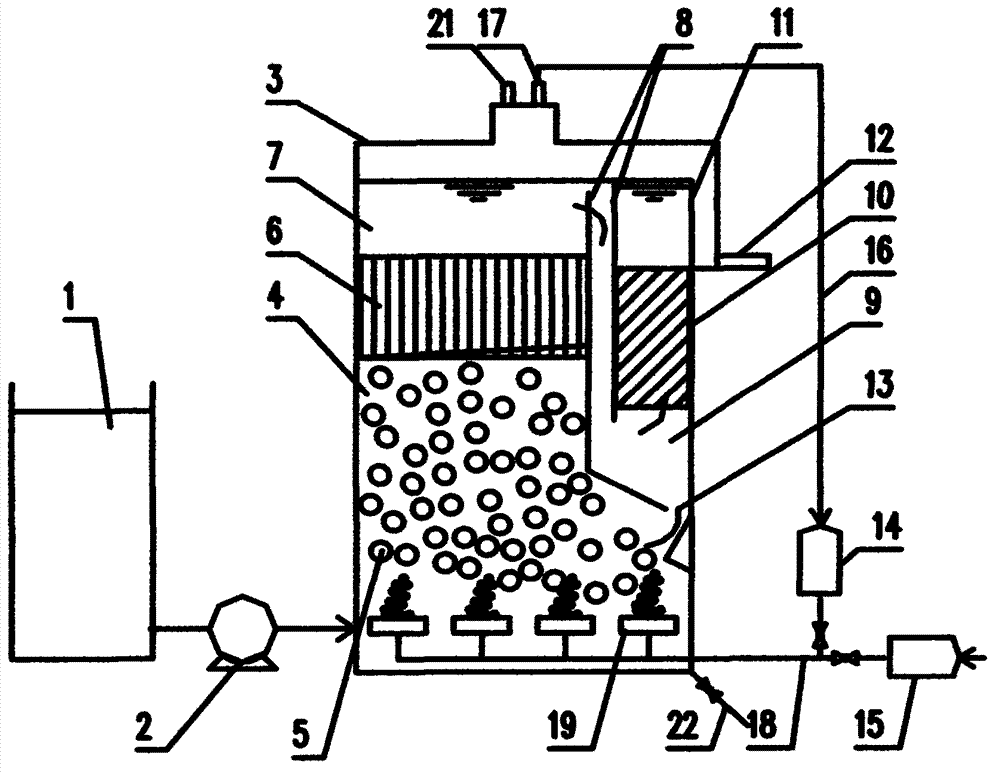

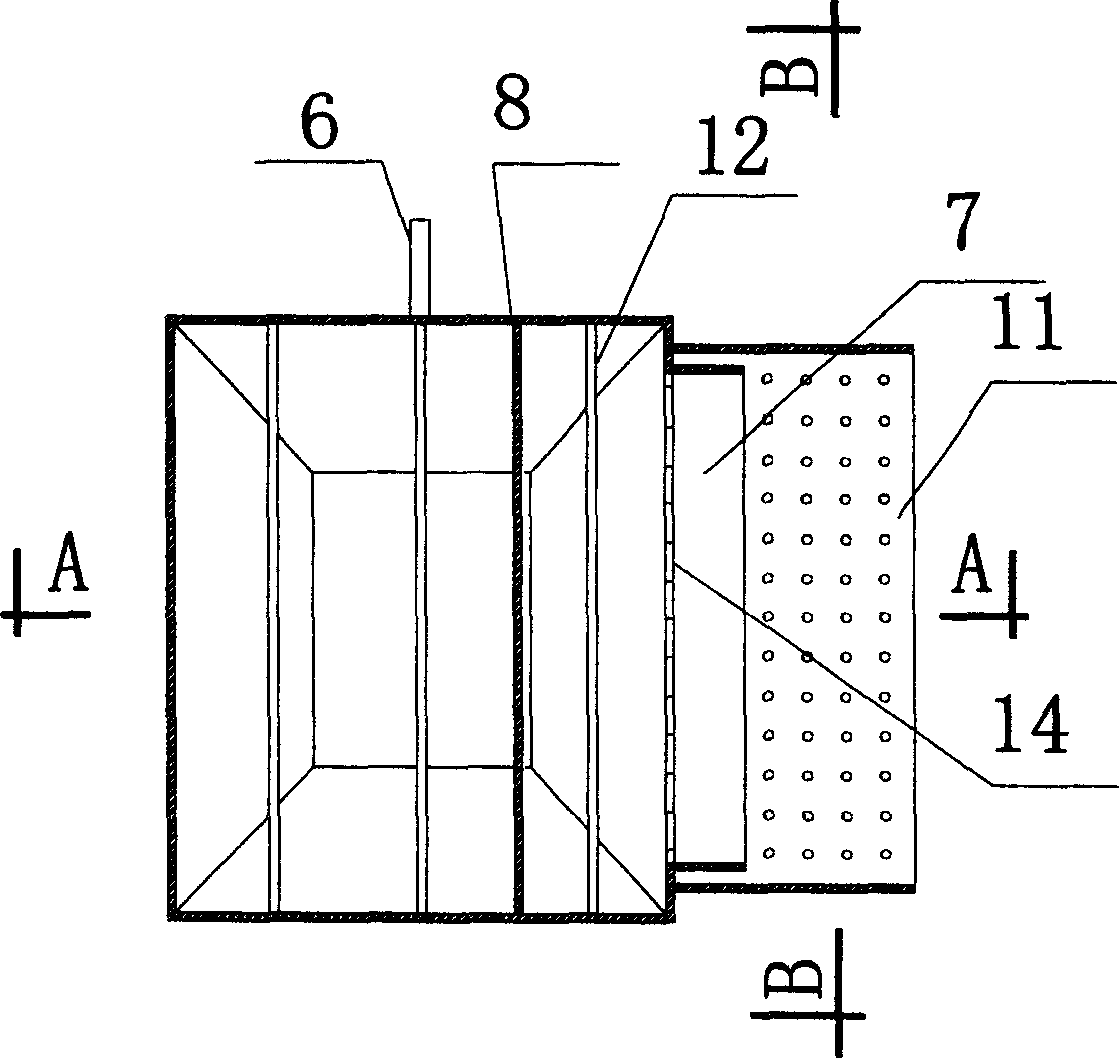

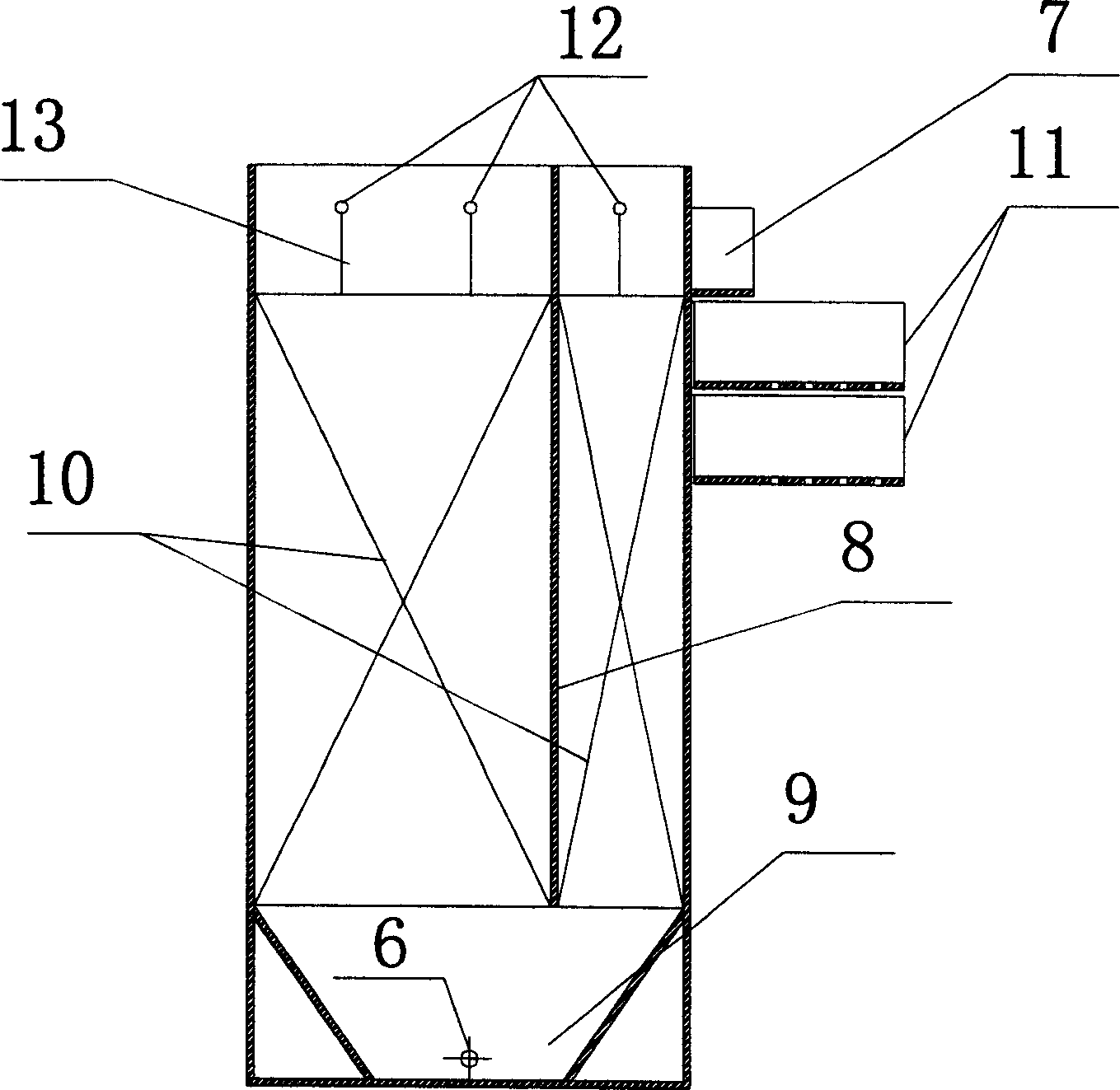

Granular sludge integrated autotrophic nitrogen removal device and operating method thereof

ActiveCN102775027AReduce power consumptionCompact layoutWater contaminantsMultistage water/sewage treatmentNitrogen removalSewage treatment

The invention discloses a granular sludge integrated autotrophic nitrogen removal device, which is provided with a water feed tank and an integrated anammox reactor, wherein the reactor is provided with a shell, a reaction area and a settling area are arranged in the shell, and the reaction area is provided with a microporous aerator, a fixed packing layer and a top area; the settling area is provided with an inclined plate settling area, an overflow weir and a water outlet pipeline; a guide plate and a reflow hole are formed between the reaction area and the settling area; the top of the reaction area has an air return port and an air outlet; and a sludge discharge pipeline is arranged at the bottom of the reaction area. The operating method comprises the following steps of (1) seeding sludge; (2) starting stage; and (3) continuous operation. The device and the method disclosed by the invention are suitable to be used for carrying out side treatment on high-ammonia-nitrogen and low-carbon-nitrogen-ratio digested sludge dewatering liquid in urban sewage treatment plants, and also suitable to be applied to the denitrification treatment of other high-ammonia-nitrogen industrial wastewater. The device and the method disclosed by the invention are perfect in process, simple in operation, agile in control, low in operation cost, good in sewage treatment effect and high in efficiency.

Owner:BEIJING DRAINAGE GRP CO LTD

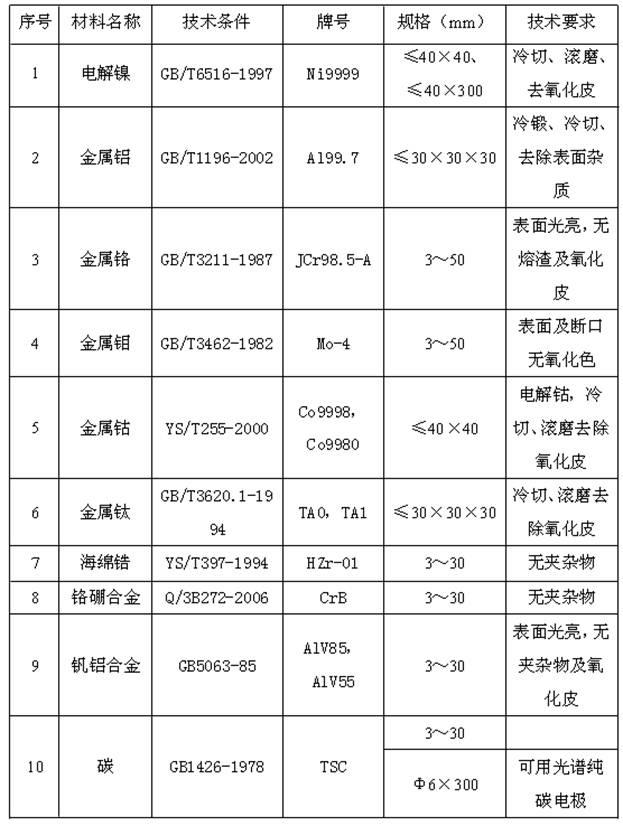

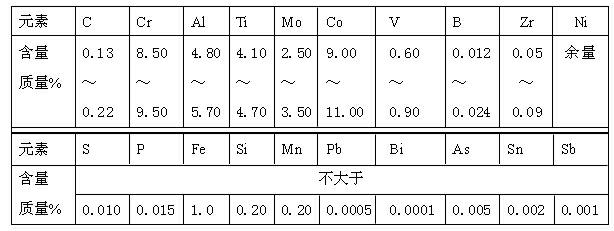

Method for preparing nickel-based alloy by stepwise adding carbon in melting process

The invention discloses a method for preparing a nickel-based alloy by stepwise adding carbon in a melting process, which comprises: adding 66 to 70 percent of the total Ni, 16 to 20 percent of the total C, total Co, total Mo, total Cr and the rest Ni into a crucible in turn, or adding the rest Ni into a feeding tank; adding 16 to 20 percent of total C, the rest C, V-Al, Al, Ti, CrB and Zr into a feeding tank separately, namely, adding 16 to 20 percent of the total C in a refining period, the rest C in an alloying period and V-Al, Al and Ti in turn after the C is melted completely; and performing cold treatment, heating and pouring. In the invention, the technique for adding the C can reduce the gas content of the alloy; and thus, the drawbacks such as looseness caused by high gas content of the alloy in a casting forming process are overcome and the precise control of the alloy elements is realized on the premise that the deoxidation effect of the C is fully played.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

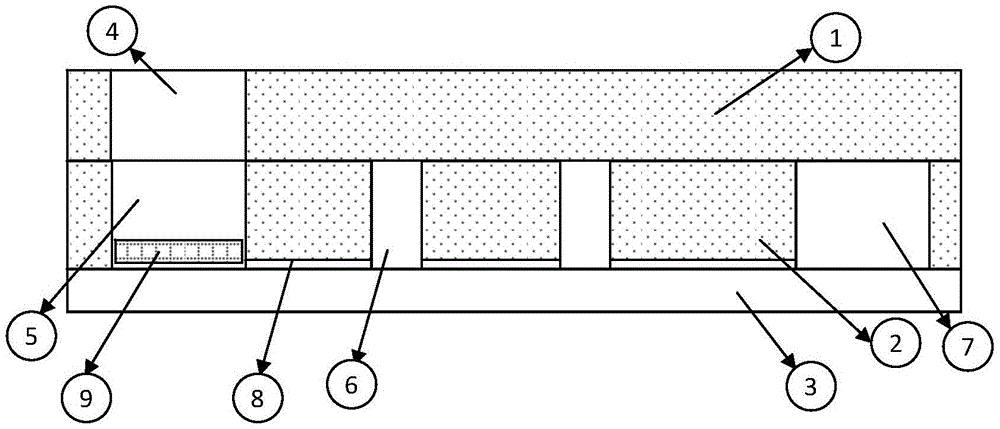

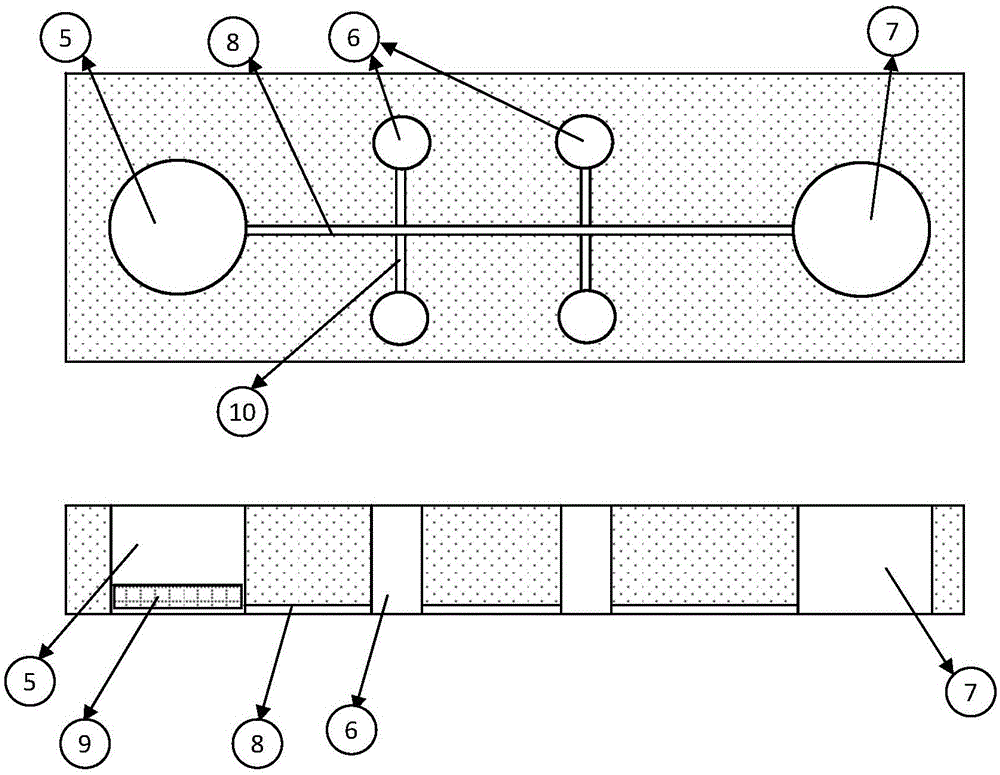

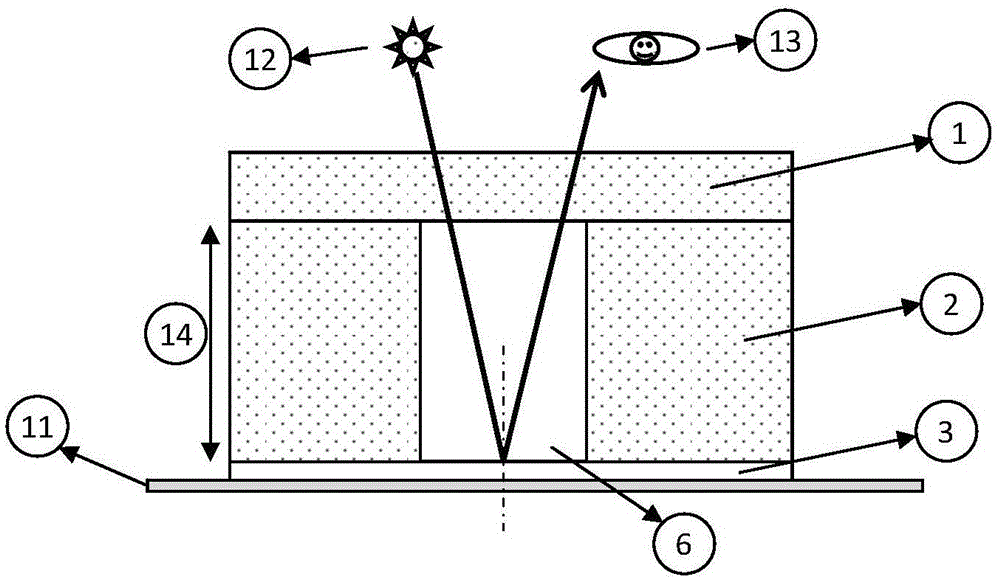

Water quality detecting method and micro-fluidic chip special for water quality detecting method

ActiveCN105115911AReduce volumeEasy to carryColor/spectral properties measurementsBiochemical engineeringWater quality

The invention discloses a water quality detecting method and a micro-fluidic chip special for the water quality detecting method. The micro-fluidic chip comprises an upper-layer cover plate (1), a middle layer (2) and a lower-layer gasket (3) which are overlapped in sequence and in seal fit, wherein a sample feeding hole (4) is formed in the upper-layer cover plate (1); the middle layer comprises a sample feeding tank (5), a reaction chamber (6) and a residual liquid chamber (7); the sample feeding tank (5) and the sample feeding hole (4) are communicated and are corresponding in position; the sample feeding tank (5) and the residual liquid chamber (7) are communicated through a main micro channel (8); the main micro channel (8) extends outwards to form multiple pairs of branch micro channels (10), and the end part of each branch micro channel is communicated with the reaction chamber (6); the lower-layer gasket (3) is made of a transparent material. The micro-fluidic chip can be conveniently used by people, and facilitates the ' Internet +' popularization; a color development chip is separated from a detection device, and is easy to integrate with mobile equipment and Internet of Things; the multi-index detection can be realized.

Owner:TSINGHUA UNIV

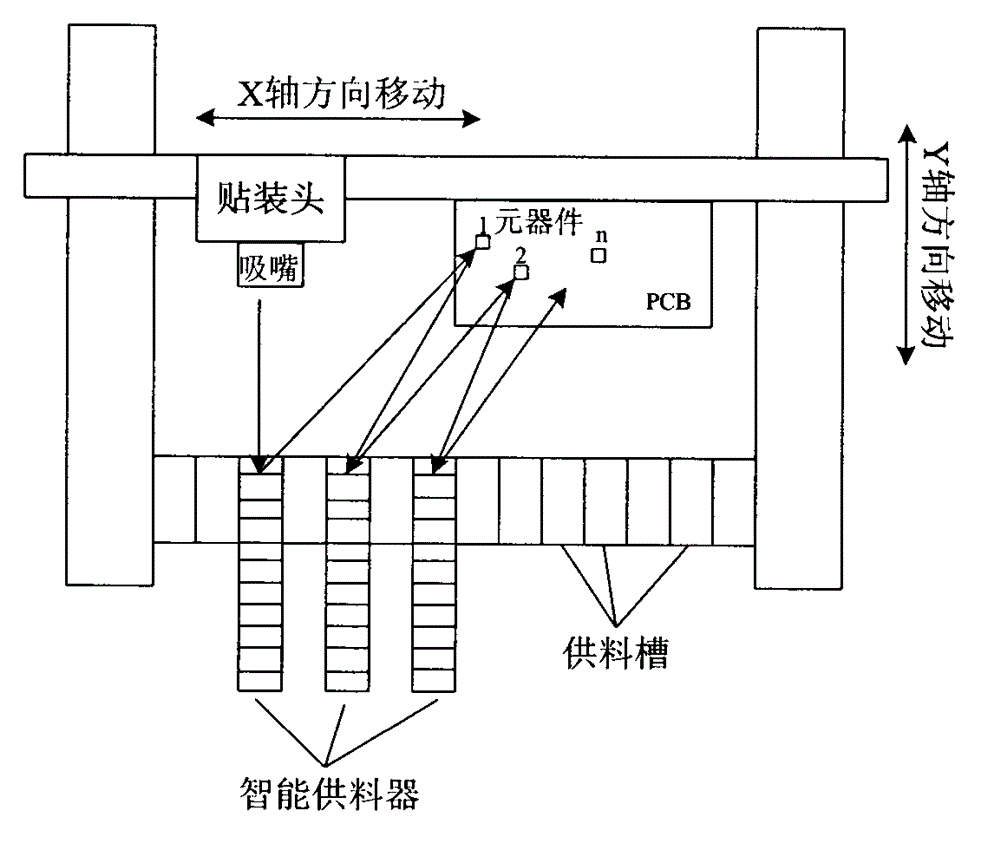

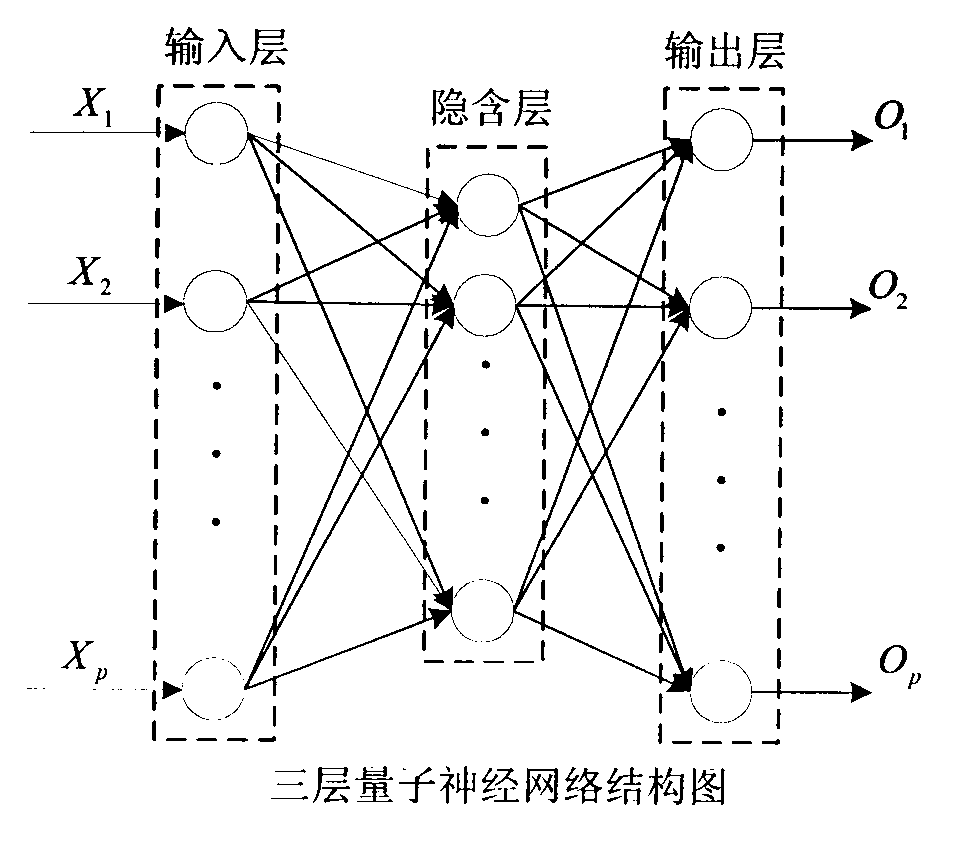

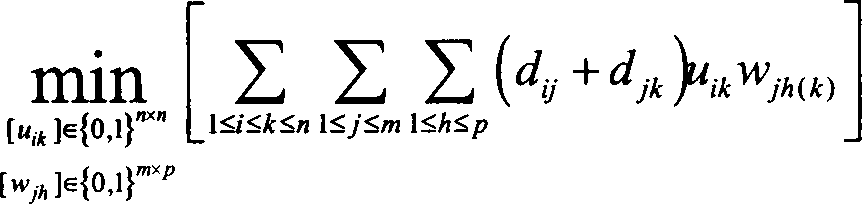

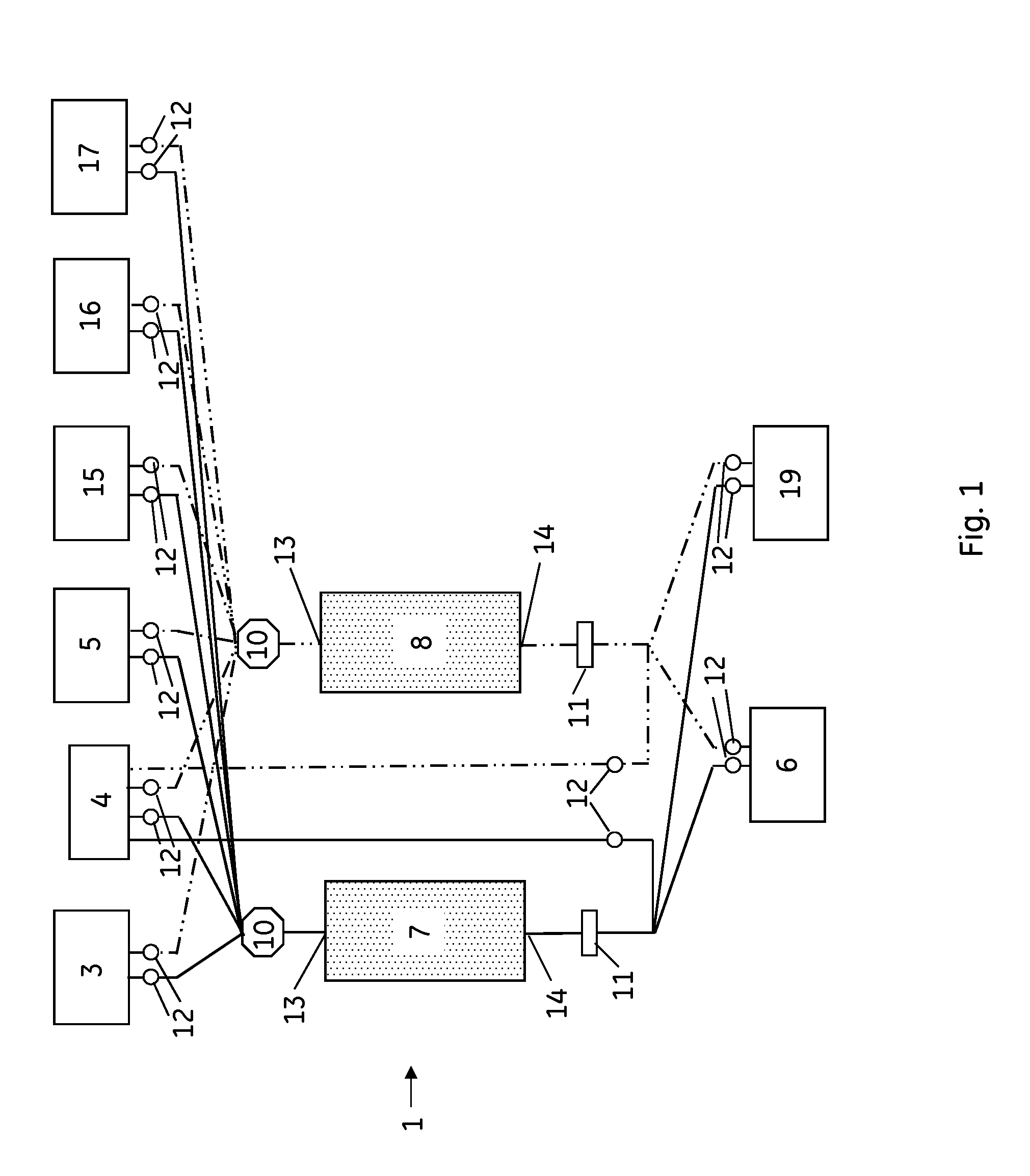

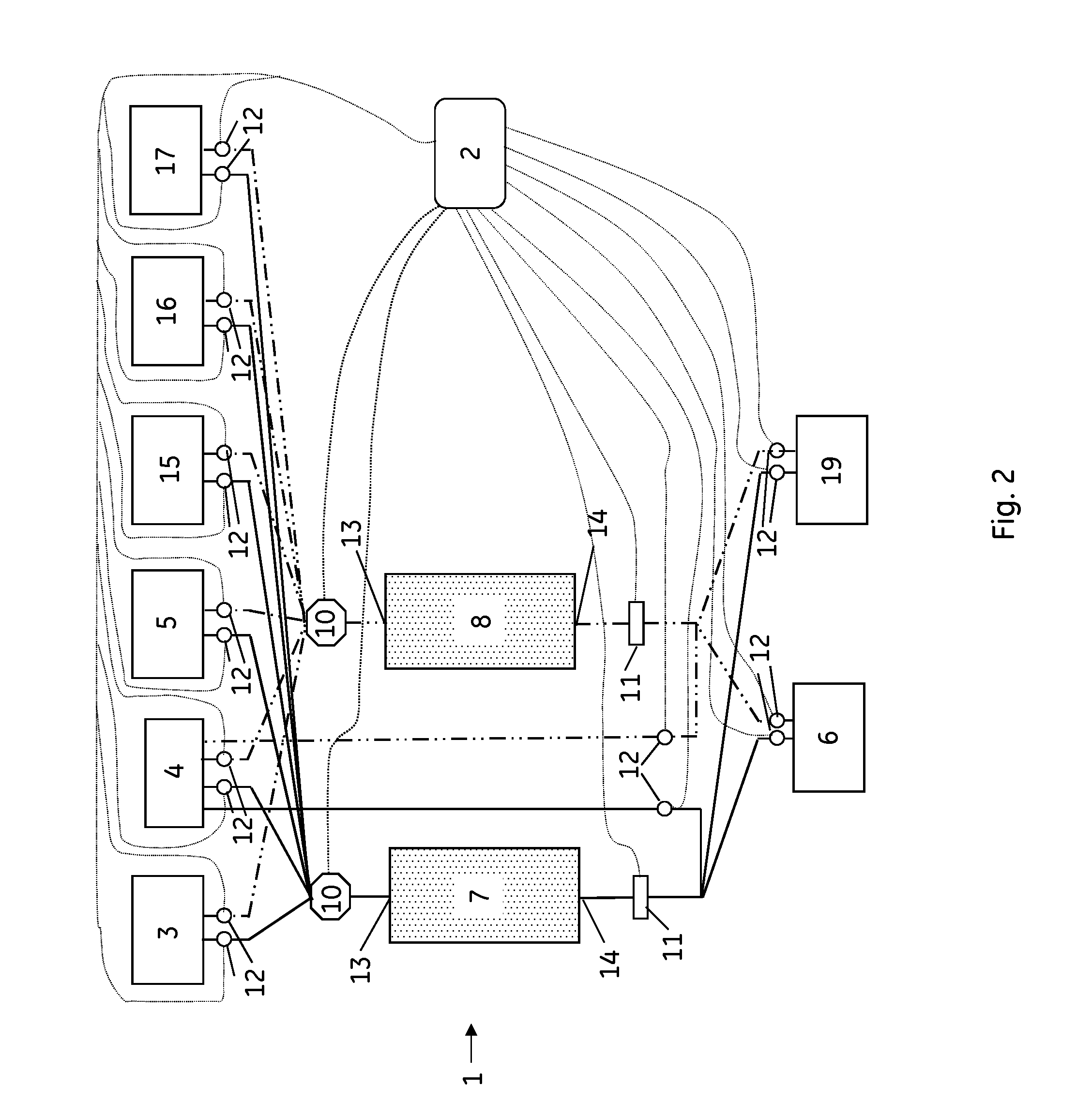

Component mounting and dispatching optimization method for chip mounter on basis of quantum neural network

InactiveCN102883548APlacement time minimizedSave placement timePrinted circuit assemblingBiological neural network modelsMathematical modelOptimal control

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

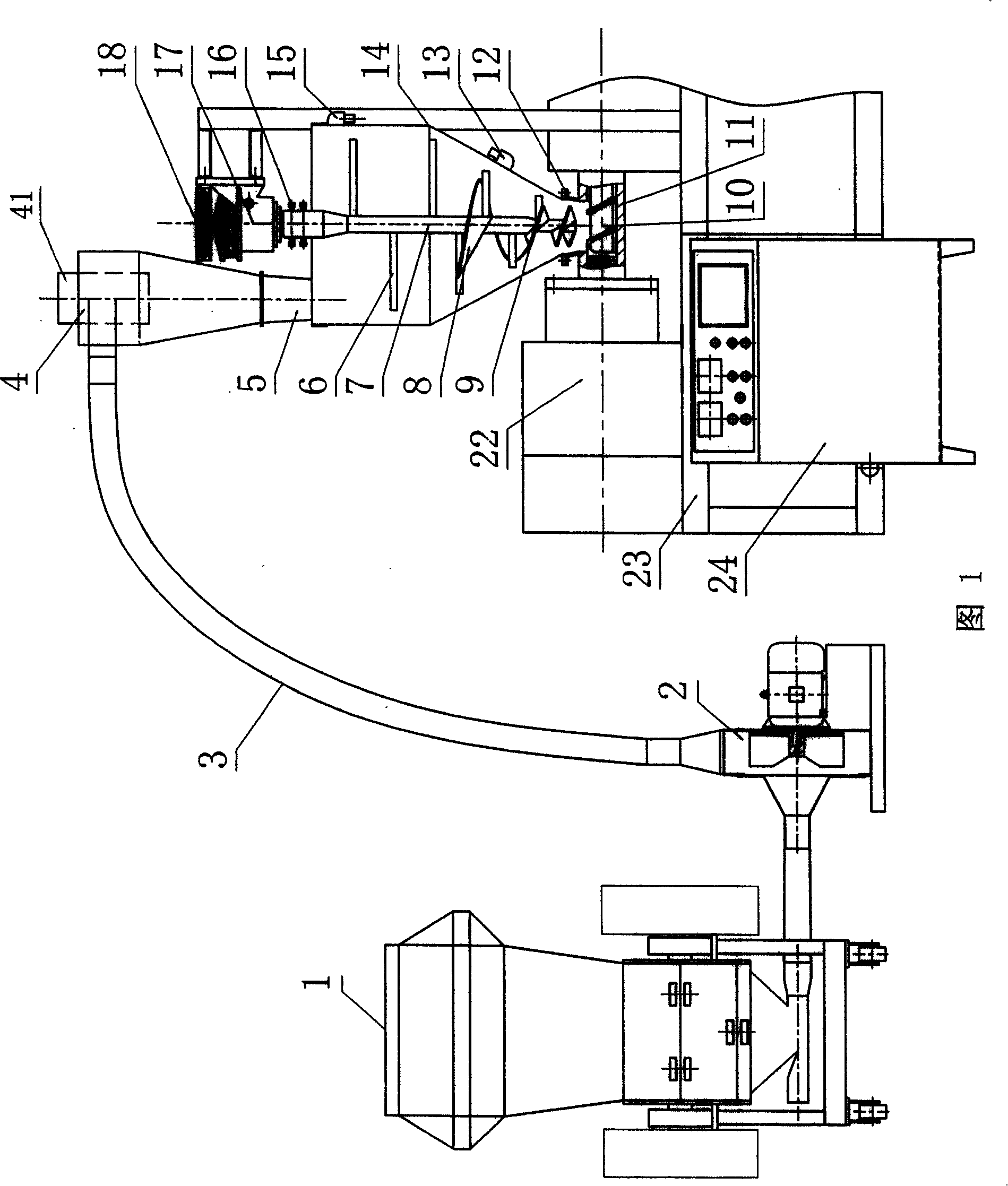

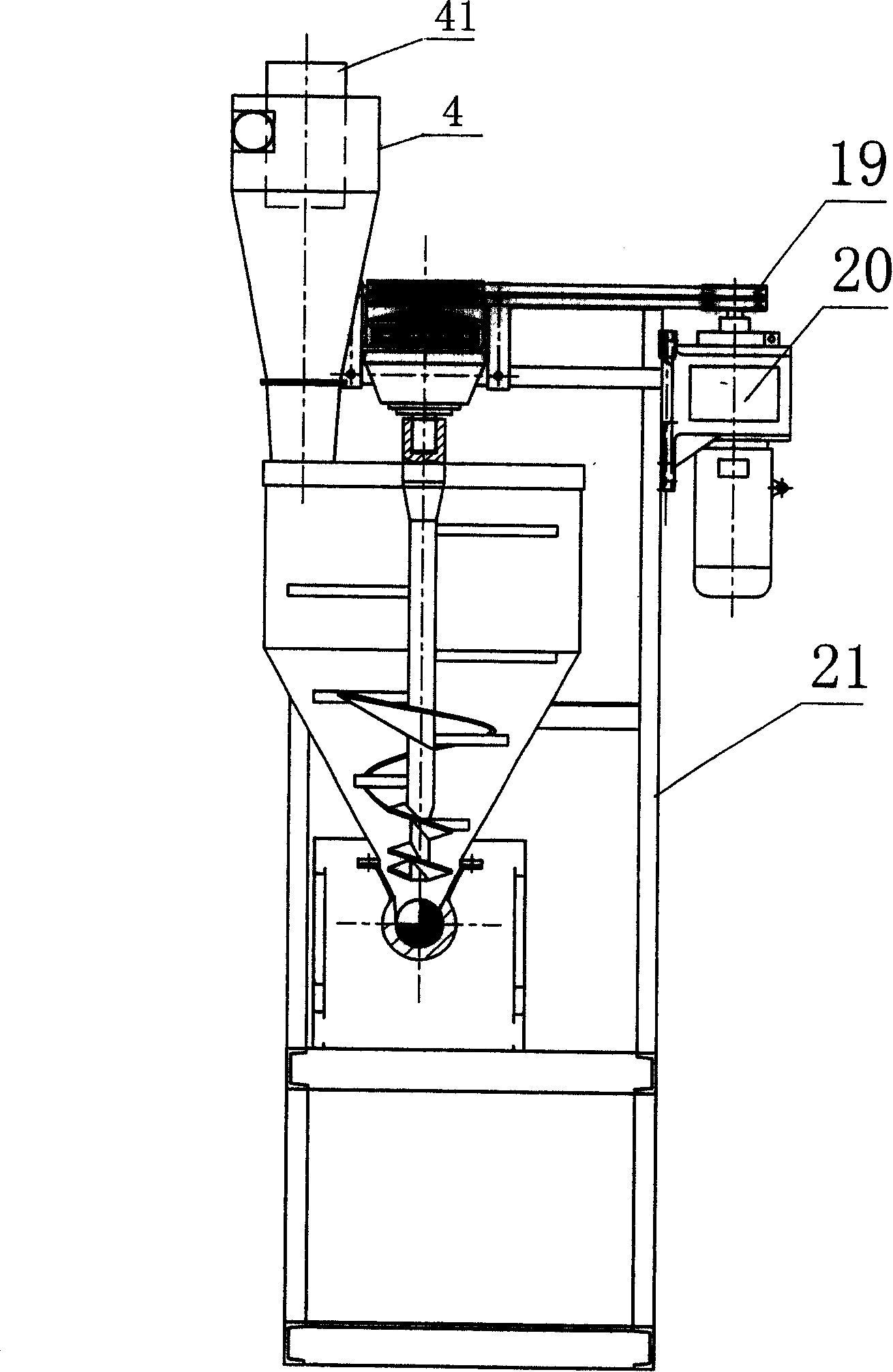

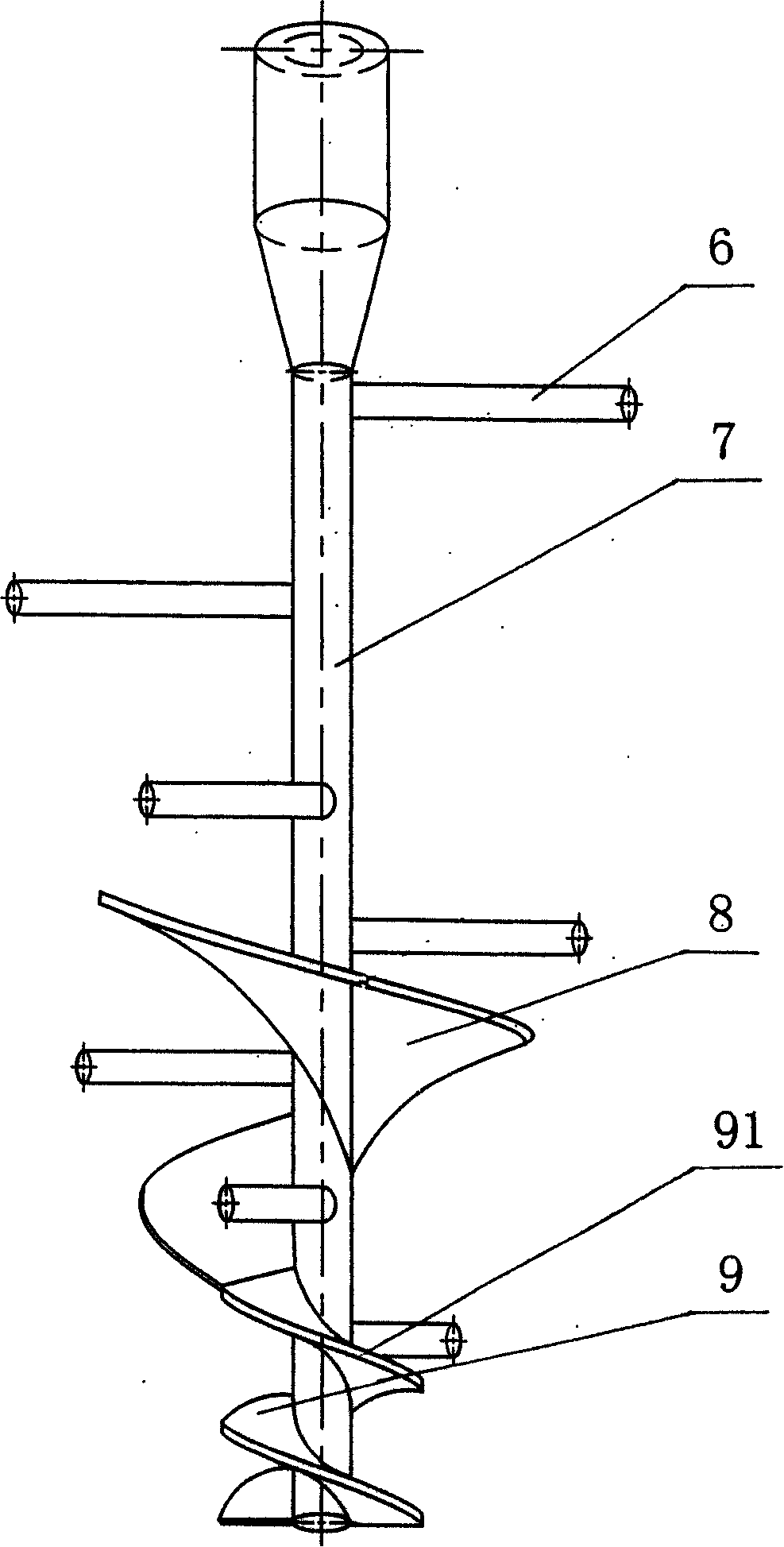

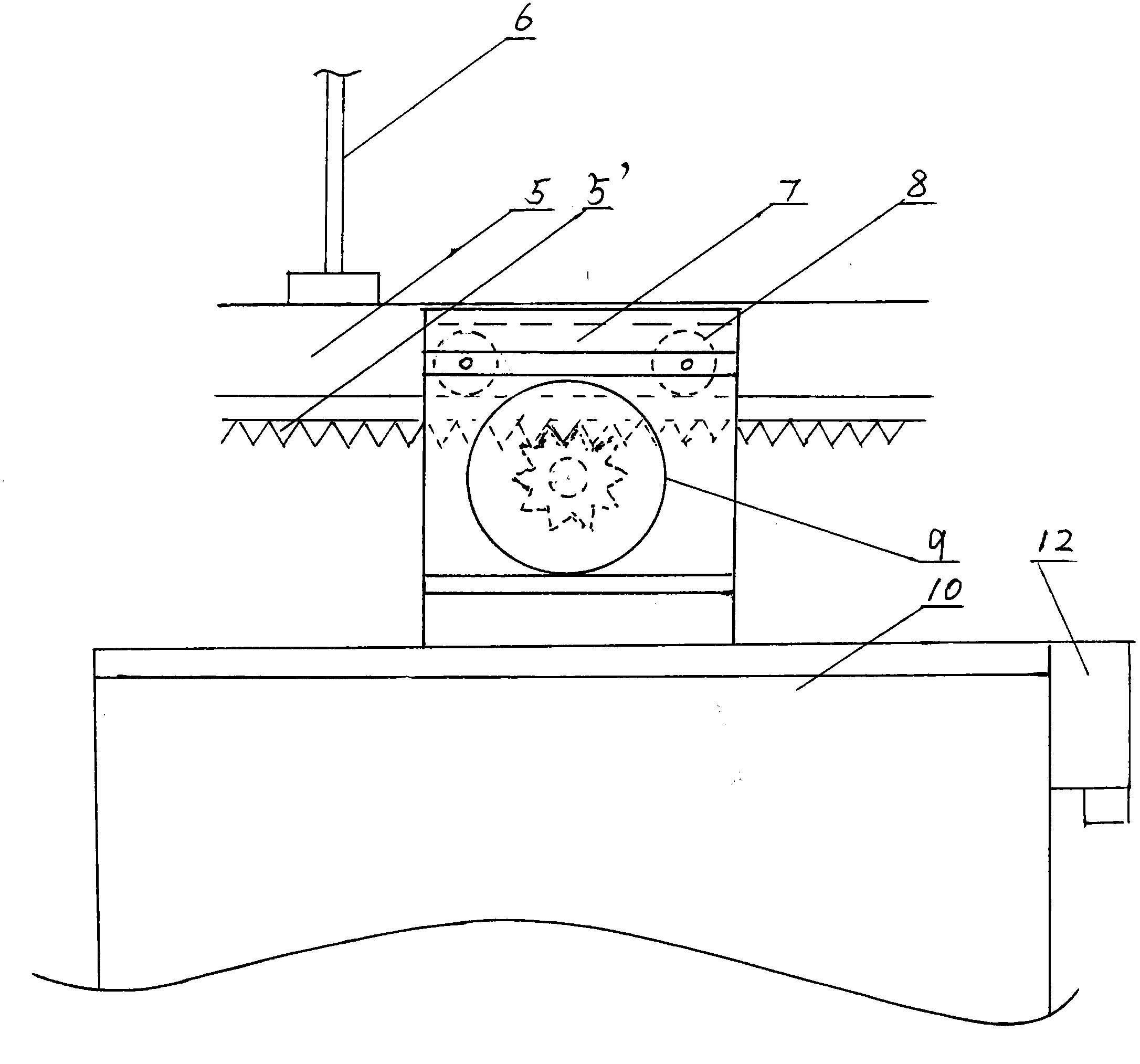

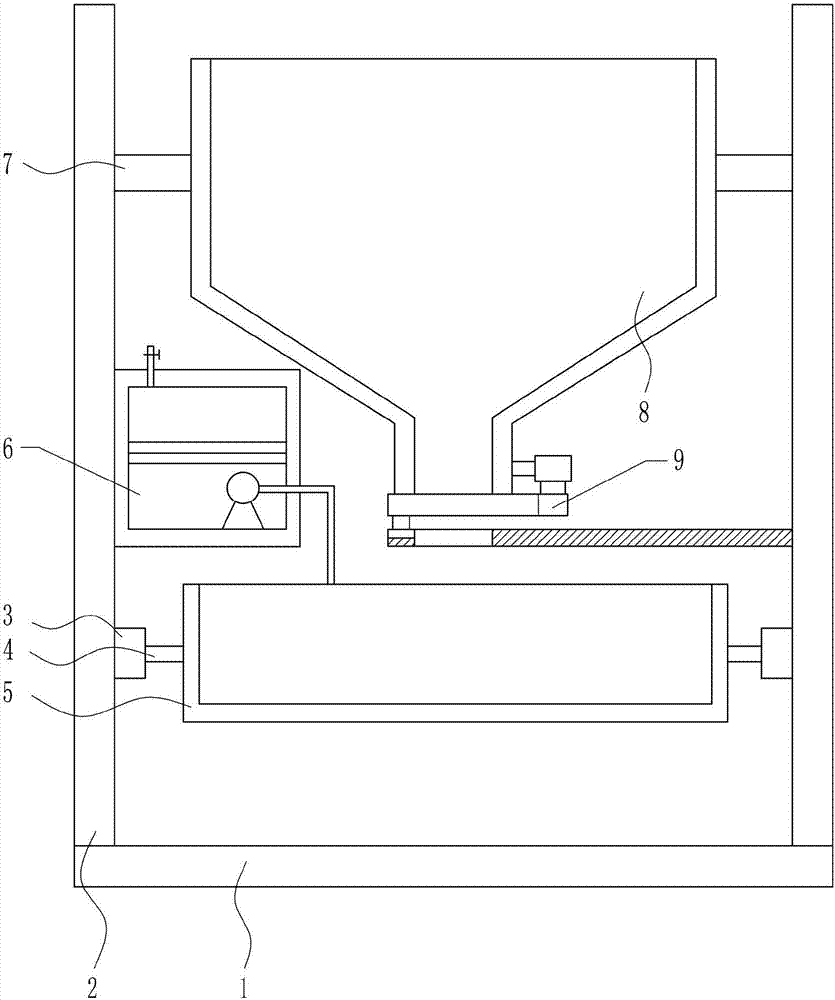

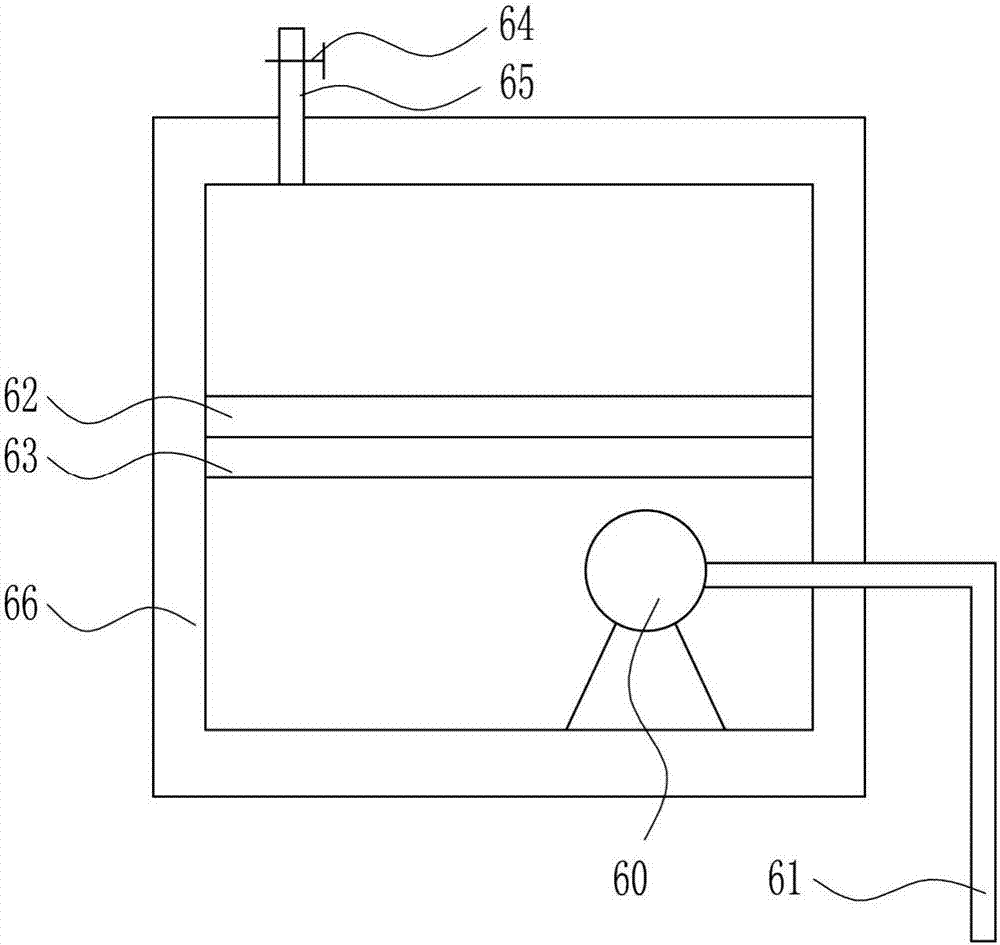

Material feeding system for granulator

InactiveCN101234316AReduce consumptionUniform size, plump and shinyGranulation by material expressionPressure transmissionHelical blade

The invention discloses a granulator feeding system. The material ground by a grinder is sent into a feeding tank which is provided with a sensor through a transmission pipe system, and then the material in the feeding tank is transmitted to a host screw through a stirring mechanism. The pipe system comprises a transmission fan which is connected with the outlet hopper of the grinder, a transmission pipe which is connected with the outlet of the transmission fan and a cyclone separator which is connected with the outlet of the transmission pipe; the stirring mechanism comprises a stirring section and a pressure transmission section; the stirring section is a material mixing rod which is arranged on the upper section of a center shaft, and the pressure transmission section is a structure combining the material mixing rod and a helical blade, which is arranged on the lower section of the center shaft. The helical blade comprises a helical expansion blade and a standard helical pressure plate which is arranged below the helical expansion blade; the front part of the standard helical pressure plate adopts double helix. The granulator feeding system has the advantages of reasonable structure, simple operation, uniform running, stability, reliability, high efficiency of extrusion pelletizing, reducing the production cost and saving energy consumption.

Owner:余姚市绿岛橡塑机械设备有限公司

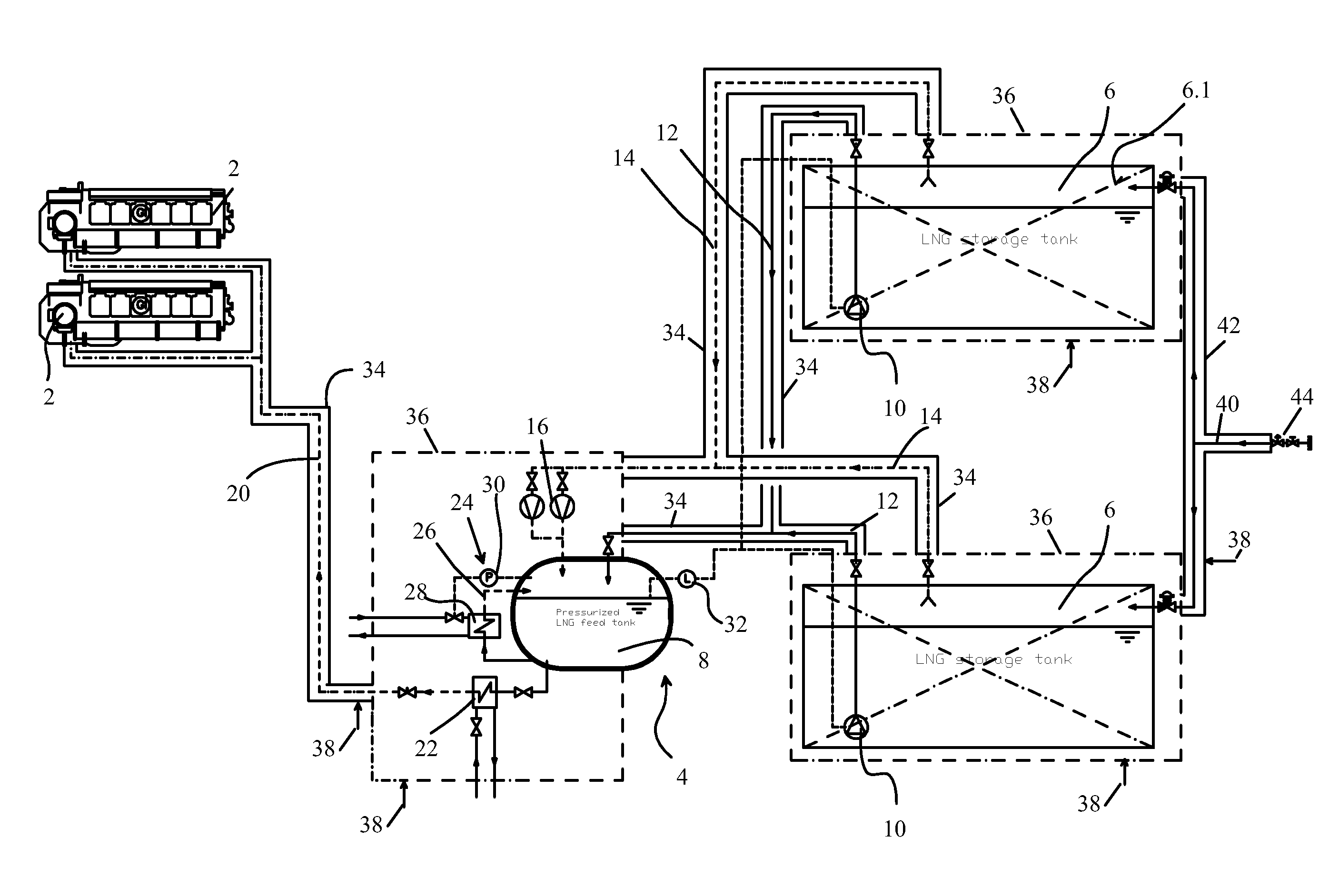

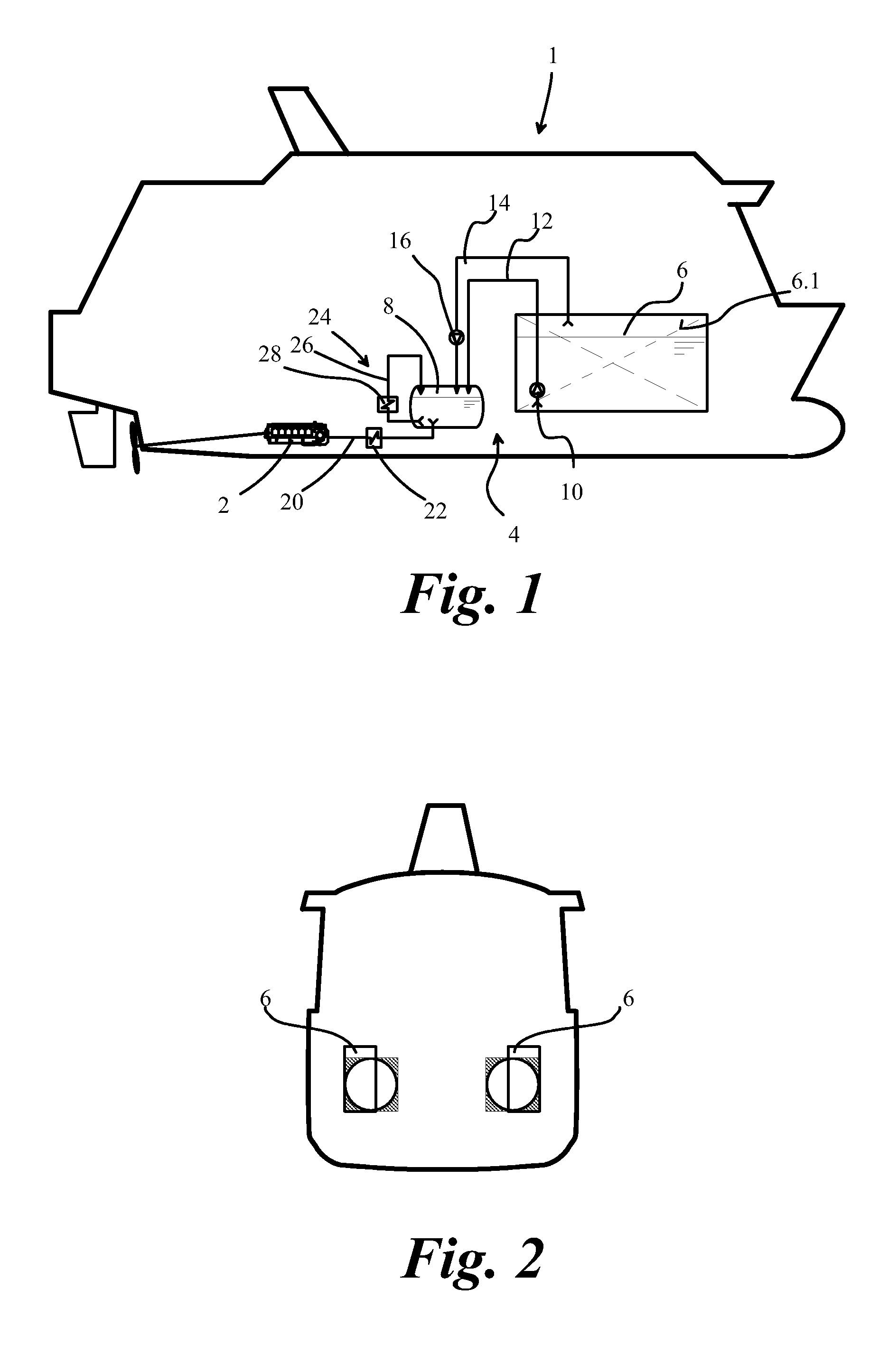

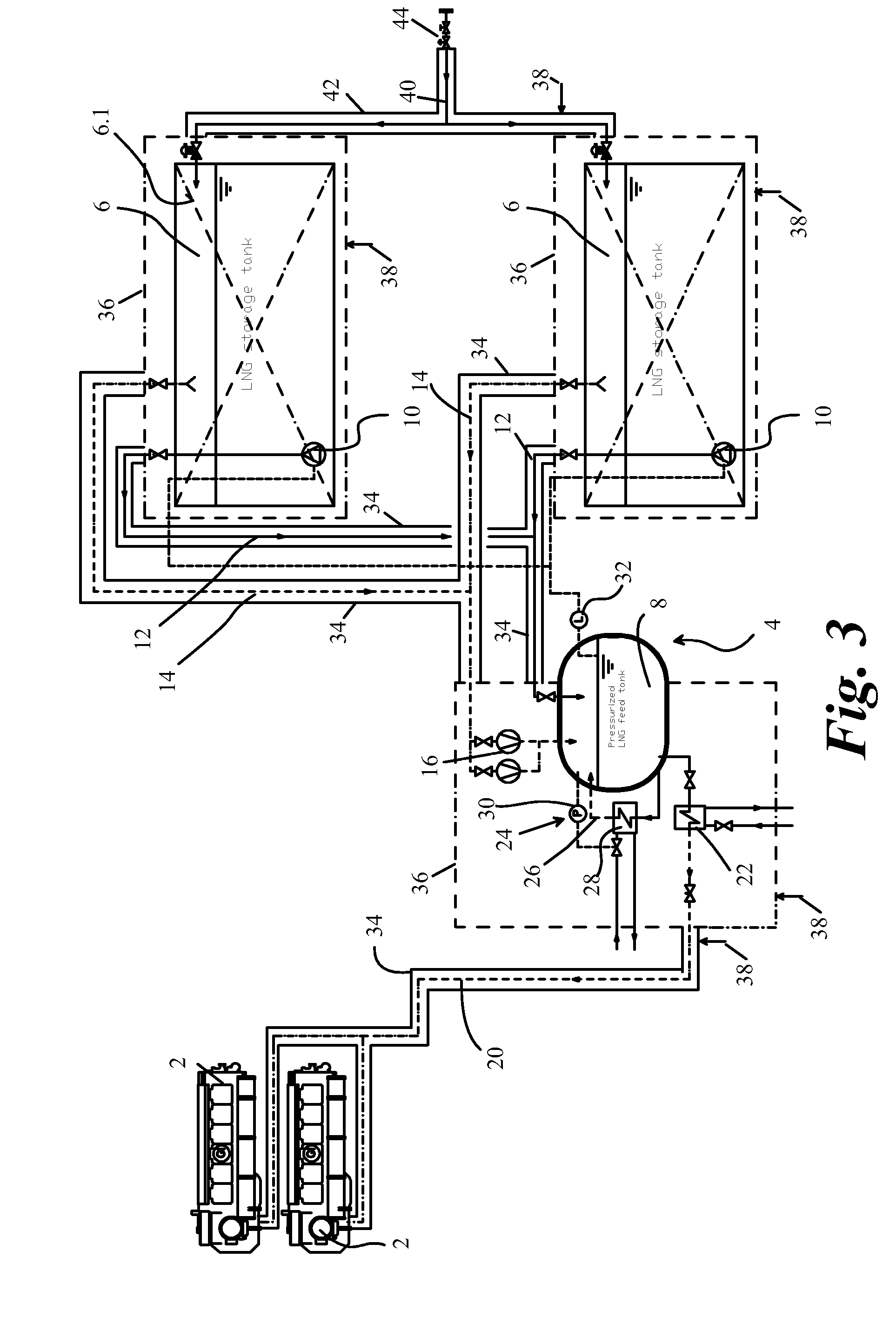

Fuel system for gas driven vessel

ActiveUS20090239426A1Easy to useFuel storage tanksPropulsion based emission reductionInternal combustion piston enginesHydrostatic pressureProduct gas

The invention relates to fuel system for gas driven piston engine in a marine vessel, which gas is stored in at least one fuel storage tank in the vessel as liquefied gas. The fuel feeding system comprises a separate fuel feed tank in which the gas is in liquid phase and at elevated pressure. The gas is also in liquid phase in the fuel storage tank, in which, however, prevails only the hydrostatic pressure caused by the liquid gas.

Owner:WARTSILA FINLAND OY

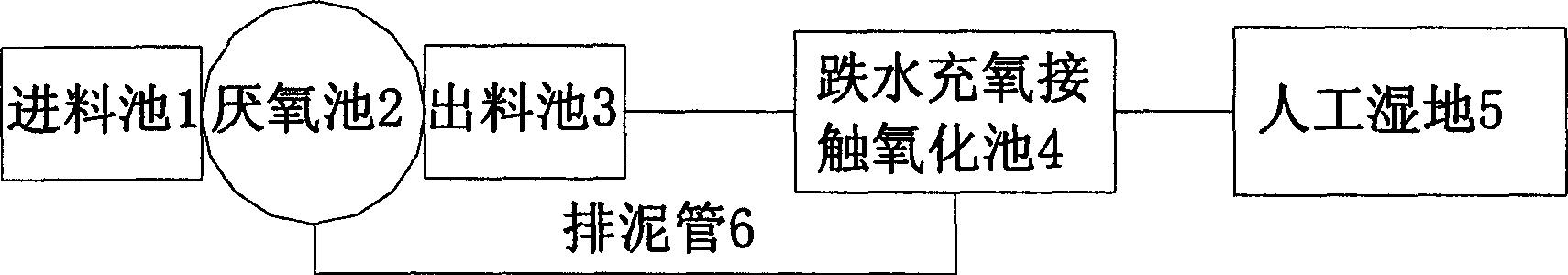

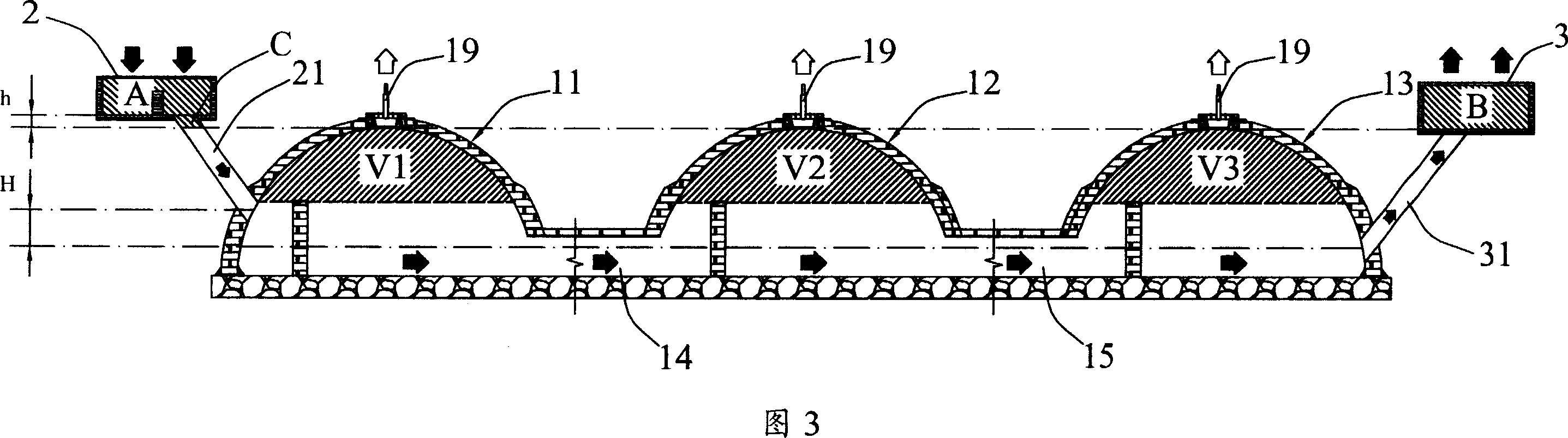

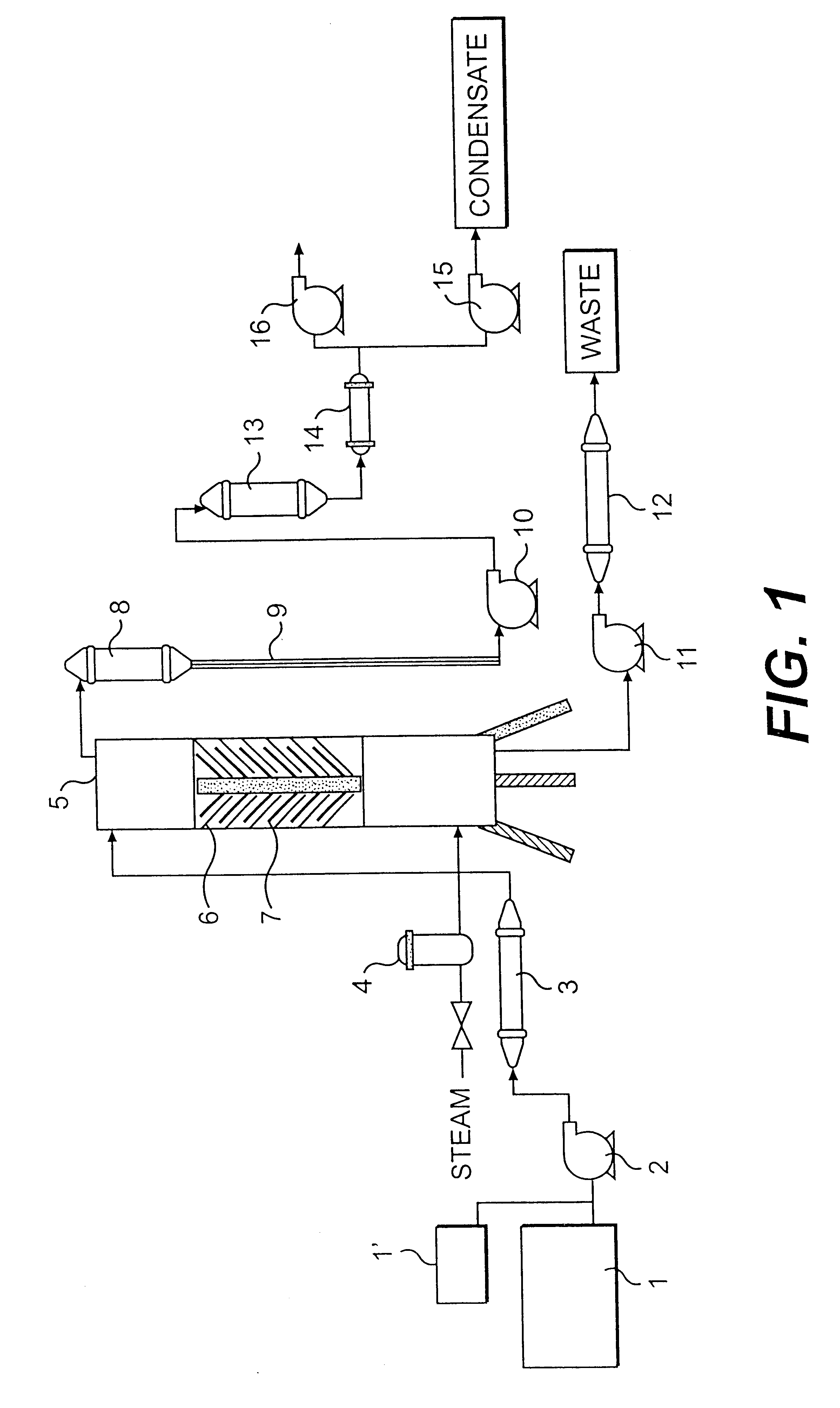

Anoxia, drop aeration, artificial wetland combination type small-scale sewage dephosphorizing and denitrifying method

ActiveCN1789175AReduce power consumptionSimplify complexityWater contaminantsTreatment with aerobic and anaerobic processesConstructed wetlandSludge

A method of phosphorous removal and denitrification for small-sized wastewater combined with anaerobic, dropping oxygenating and artificial wetland, firstly introducing the wastewater into feeding tank(1), then into anaerobic tank(2), and entering into the dropping oxygenating contact oxidation tank through discharging tank(3) by water pump, and finally into the artificial wetland(5); the dropped biological membrane in the dropping oxygenating contact oxidation tank(4) is discharged into anaerobic tank(2) through sludge pipe(6); prolonging the anaerobic tank(2) retention time if the organic matter concentration of the inletting water is high and shortening the retention time if the concentration is low, reducing the organic matter concentration to be below 100mg / l by anaerobic action; the dropping oxygenating contact tank(4) is cascaded to two-tank or four-tank form. The method in this invention reduces the running cost.

Owner:SOUTHEAST UNIV

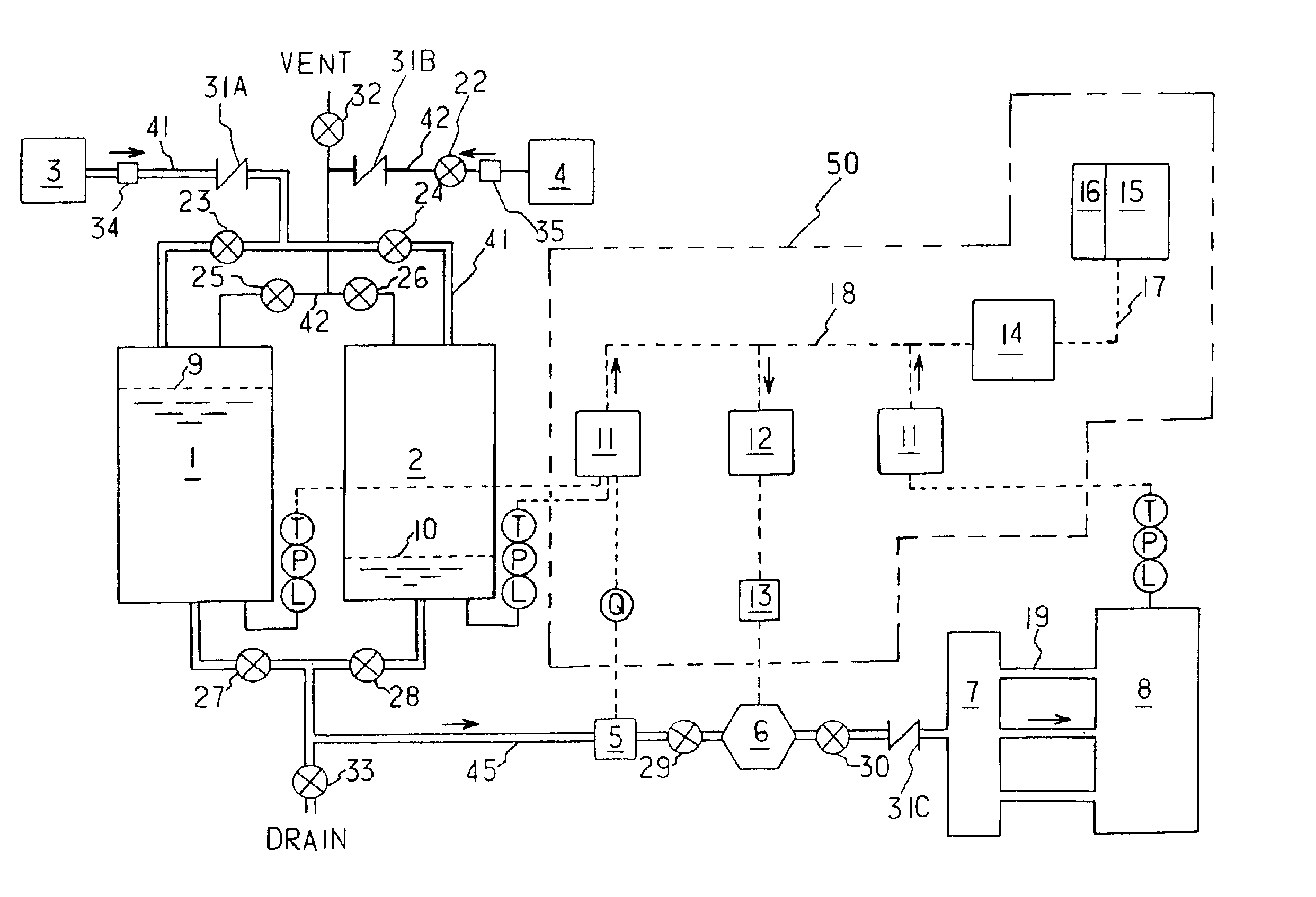

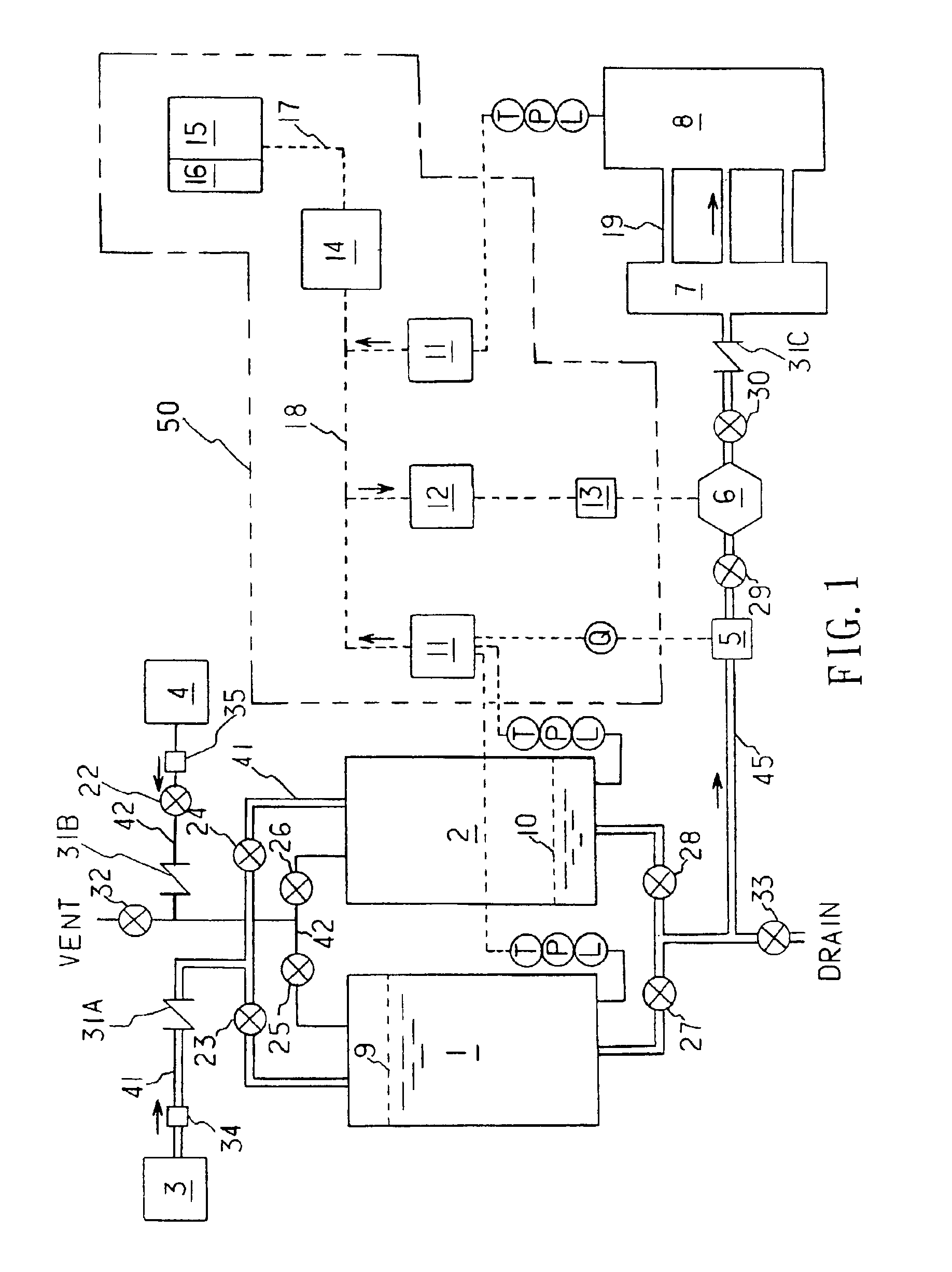

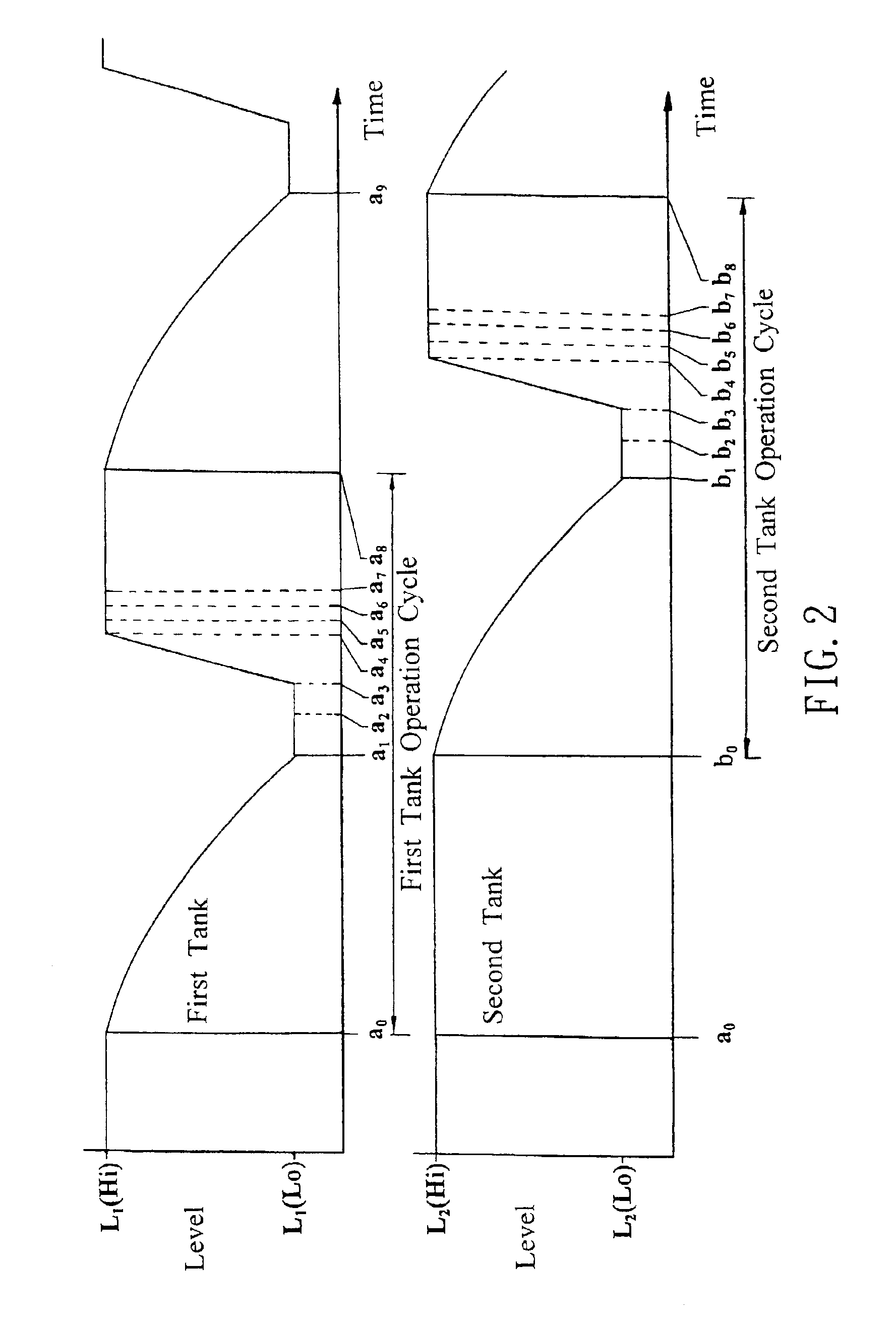

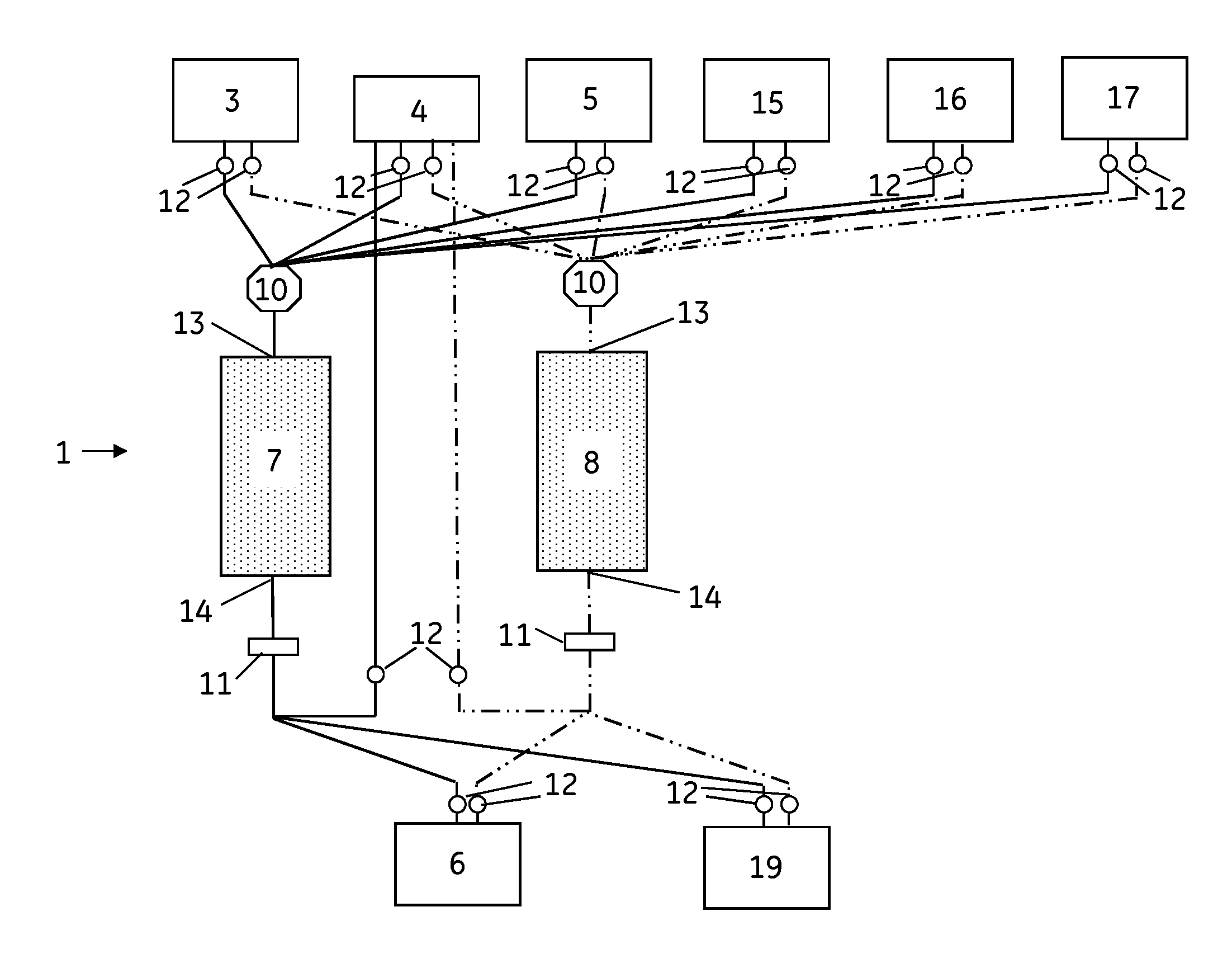

Multifunction passive and continuous fluid feeding system

InactiveUS7100631B2Realize functionEasy to controlOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsEngineeringHigh pressure

The present invention is to provide a kind of multifunction passive and continuous fluid feeding system for external systems, the fluid-feed system including a storing and transmitting component, a measuring and regulating component, and a control unit characterized by: pressurizing from above fluid level surface of the feed fluid tank by high-pressure gas supply source to fulfill the passive fluid feeding function, performing the feed fluid measuring and regulating through the flow meter and flow control valve installed on the transmission pipe lines connecting to the external systems, fulfilling function of continuous fluid feeding by switching between two fluid-feed tanks, and combining the feed fluid requirements of the external systems through the control unit to achieve the multifunction fluid-feed art of automatic operation, continuous fluid feeding, and flow rate controlling. The present invention does not utilize high-head and high-pressure pumps as the driving components, thus it is not only cost-saving but makes easier in coping with various fluid-feed requirements by the external systems, hence, possessing potentials of extending applicability into various industrial fields.

Owner:INST NUCLEAR ENERGY RES ROCAEC

System and process for biopolymer chromatography

A chromatography system for separation of a biopolymer is described, comprising at least one feed tank, at least one hold tank, at least one elution buffer tank, at least one eluate tank, at least two packed bed chromatography columns and for each packed bed chromatography column at least one pump and at least one outlet detector both connected to said each packed bed chromatography column, wherein the feed tank, the hold tank(s), the elution buffer tank and the eluate tank are each connected to the packed bed chromatography columns via a system of valves.

Owner:CYTIVA SWEDEN AB

Blocky coarse sand screening device used in construction sites

InactiveCN107297266AImprove screening efficiencyImprove sand screening effectSievingScreeningEngineeringParticle board

The invention discloses a block coarse sand screening device for a construction site, which comprises a base, a material spreader, a top plate, a first rotating shaft, a second rotating shaft, a feeding barrel and a sand screening barrel; the upper side of the feeding barrel Fixedly installed on the lower side of the top plate, the lower end of the feeding barrel is rotated and installed with a rotating cylinder; the lower end of the rotating cylinder is fixedly connected with a material spreading plate; the feeding barrel is provided with a feeding port; the bottom plate of the material spreading plate A number of discharge holes are evenly opened on the top; the sand screening box is a circular structure with an upper end opening, and the sand screening box is located below the material spreading tray; the inside of the sand screening box is sequentially provided with fixed sieve plates and movable screens from top to bottom. sieve plate. The invention is provided with a particle board, a rotating cylinder and a material spreading plate, and a heating wire is arranged on the inner wall of the rotating cylinder, which can effectively improve the screening efficiency of massive coarse sand and improve the sand screening effect; it is also provided with a fixed sieve plate and a movable The sieve plate can not only control the particle size of the discharged fine sand, but also facilitate the discharge of coarse sand.

Owner:苏天平

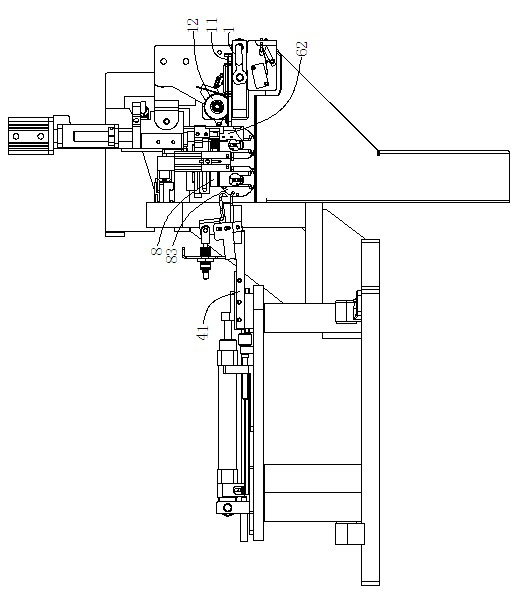

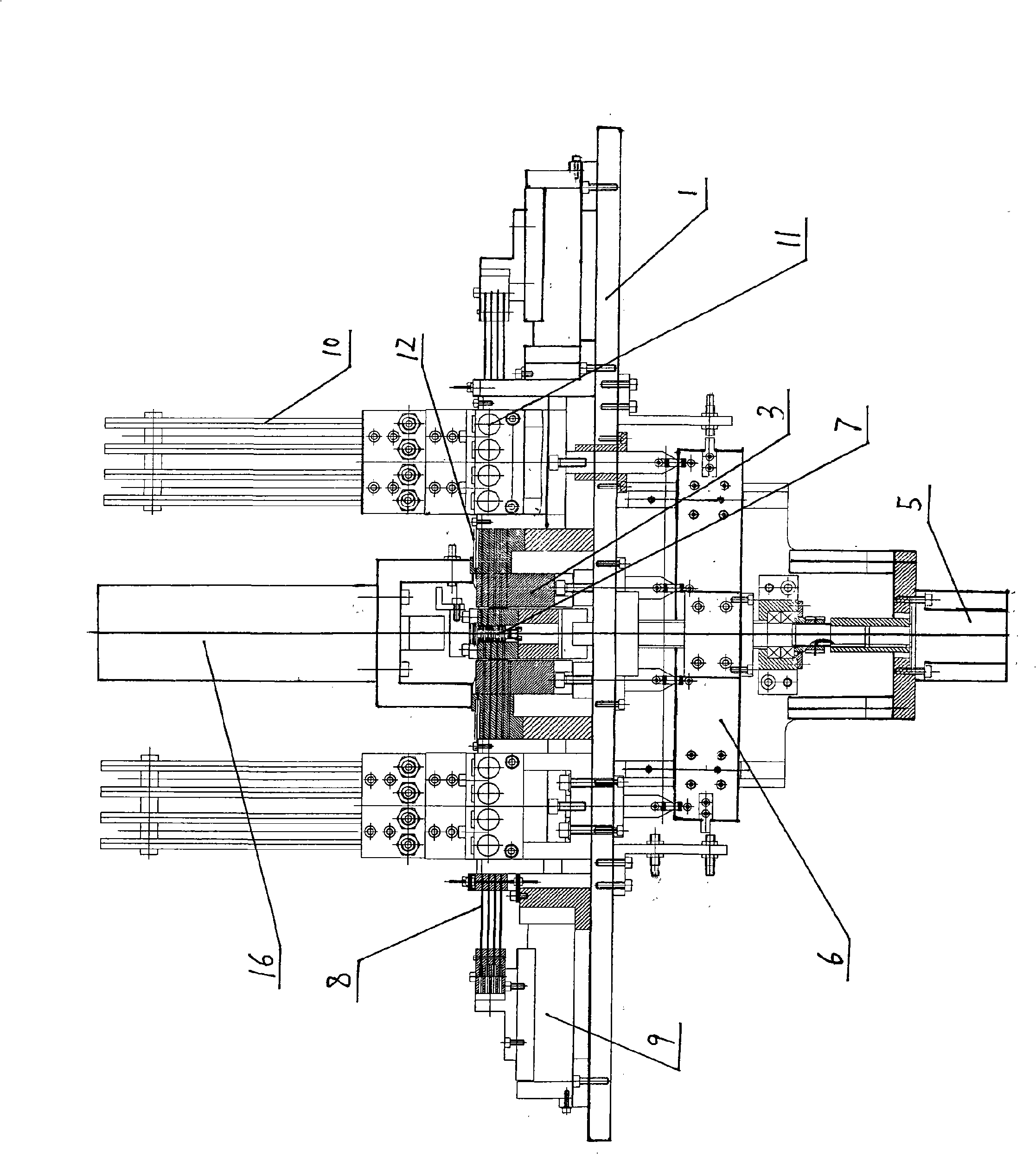

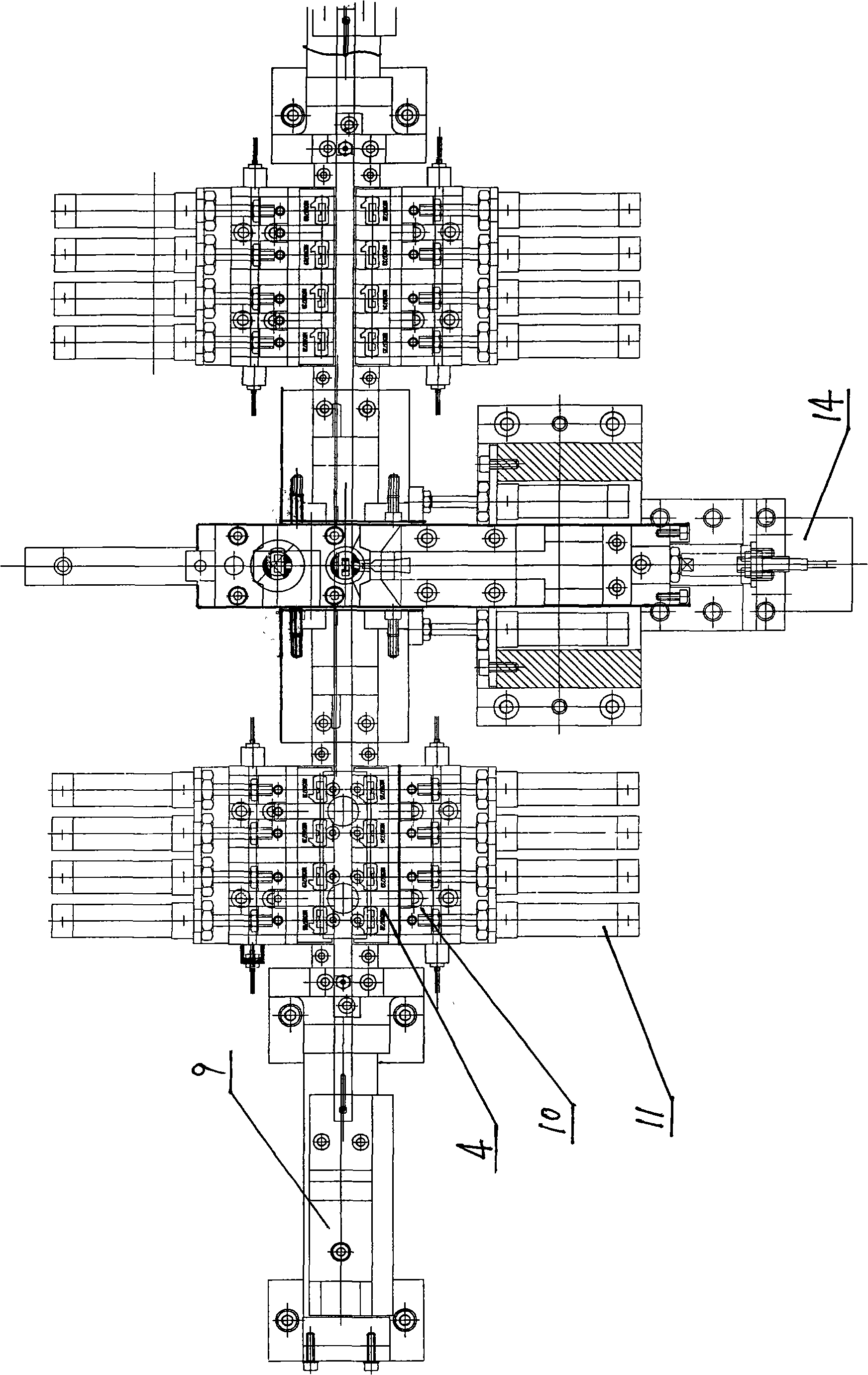

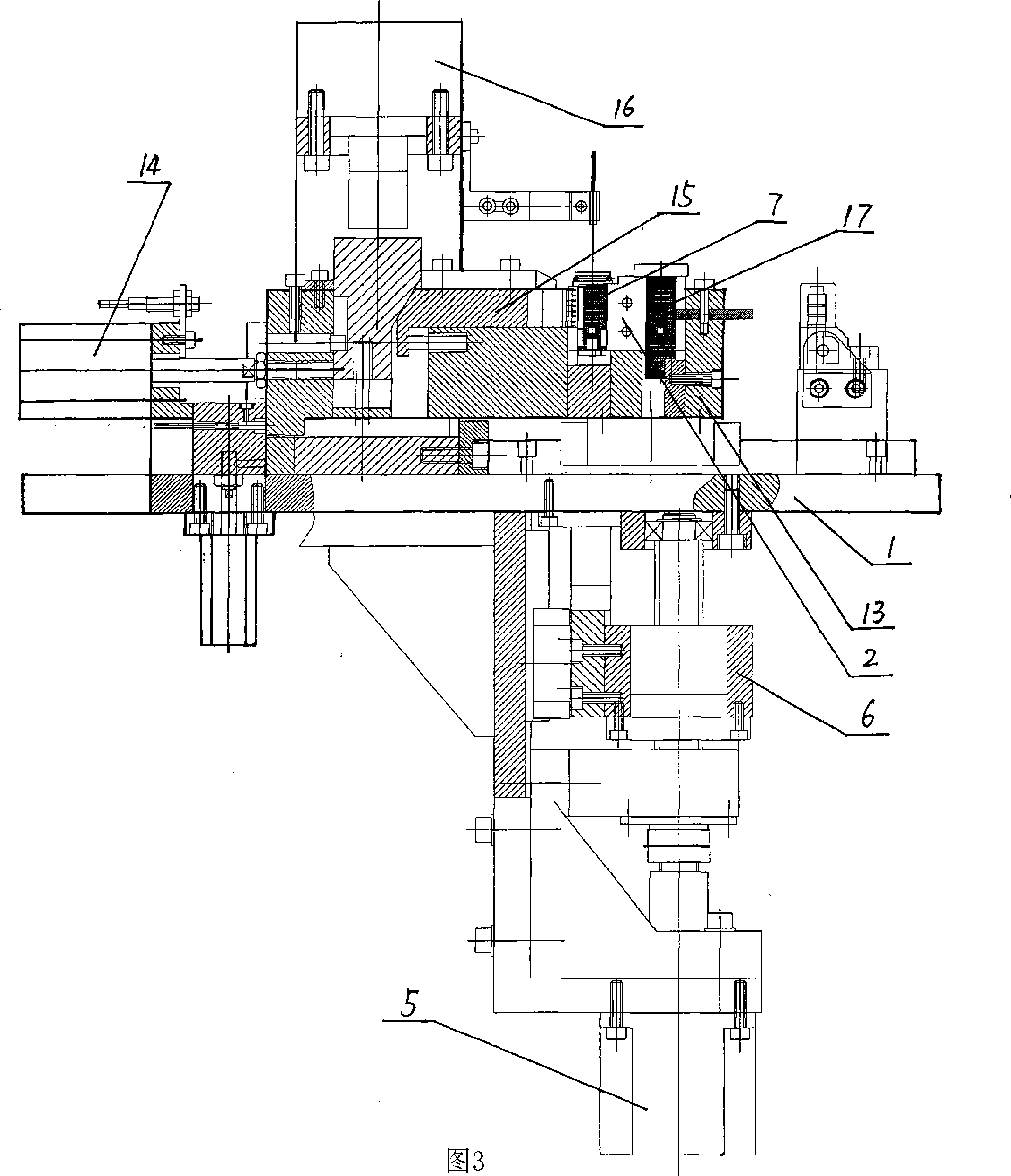

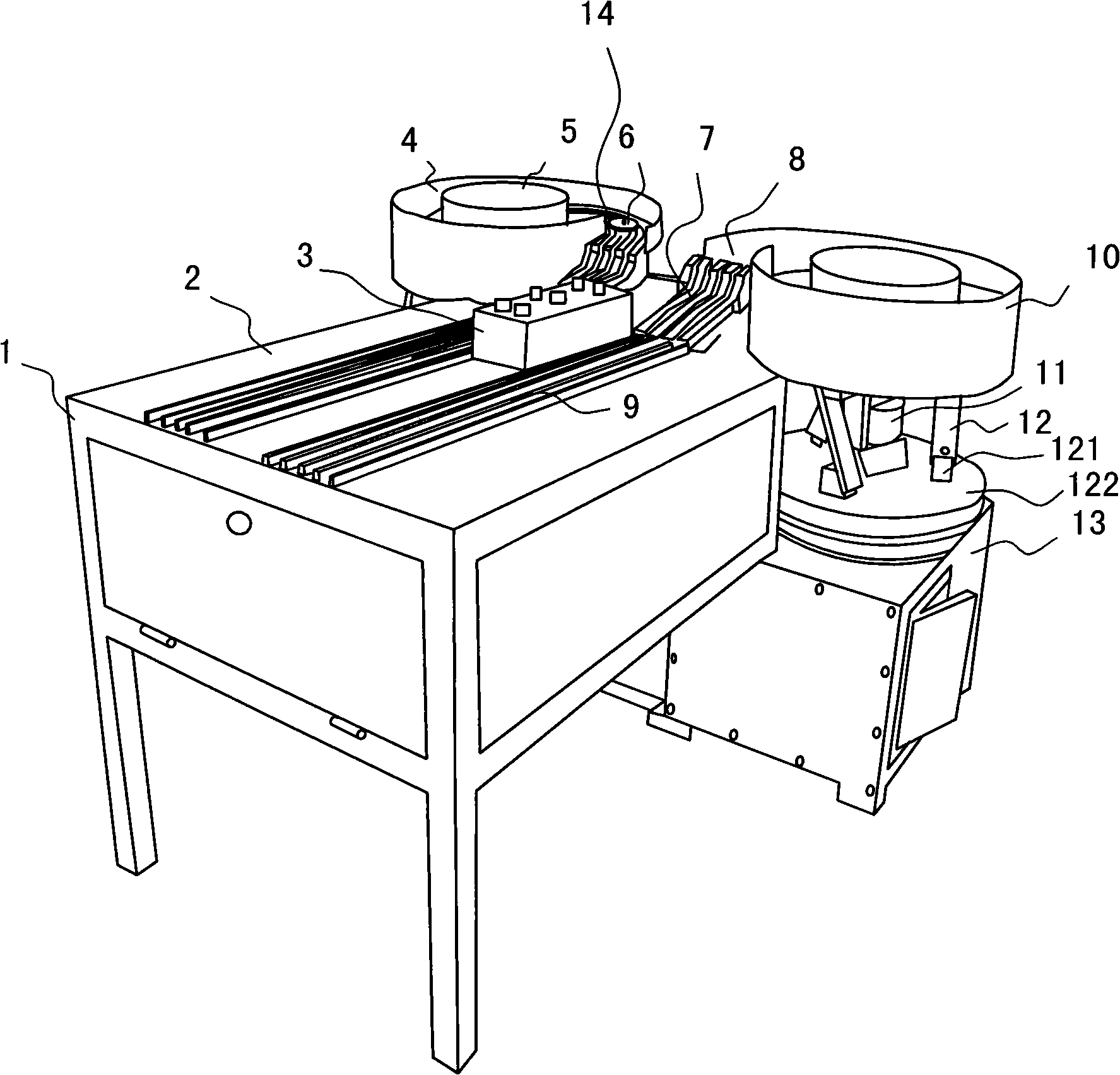

Automobile lock cylinder automatic assembly machine

InactiveCN101513713AAutomated Assembly ScienceNo pollutionAssembly machinesAssembly machineFeed tank

An automobile lock cylinder automatic assembly machine is disclosed in the invention, which includes a frame table, a lock cylinder clamp is installed on the frame table, one side of the lock cylinder clamp is provided with a spring preassemble bin sliding fit with the frame table and a lock plate preassemble bin subsequently. A lifting block capable of vertically moving is slidingly arranged below the frame table and is used for supporting the spring preassemble bin and the lock plate preassemble bin; a horizontal lock plate passage corresponding to the lock plate position of the lock cylinder is disposed in the lock plate preassemble bin; a lock plate push rod is provided in the lock plate passage of the lock plate preassemble bin and is connected with a cylinder disposed outside the lock plate preassemble bin, a lock plate material bin is installed above the rear side of the lock plate preassemble bin, a material feed tank is arranged on the lower end of the lock plate material bin. A charging ram is in slidingly fit with the material feed tank, and a horizontally contraposed lock plate disposed in the lock plate material bin is arranged on the charging ram. The invention replaces the manual assembly method, the assembly efficiency of the automobile lock cylinder can be greatly increased, meanwhile, due to the electric and pheumatic power, environment pollution can be prevented.

Owner:合肥安达数控技术有限责任公司

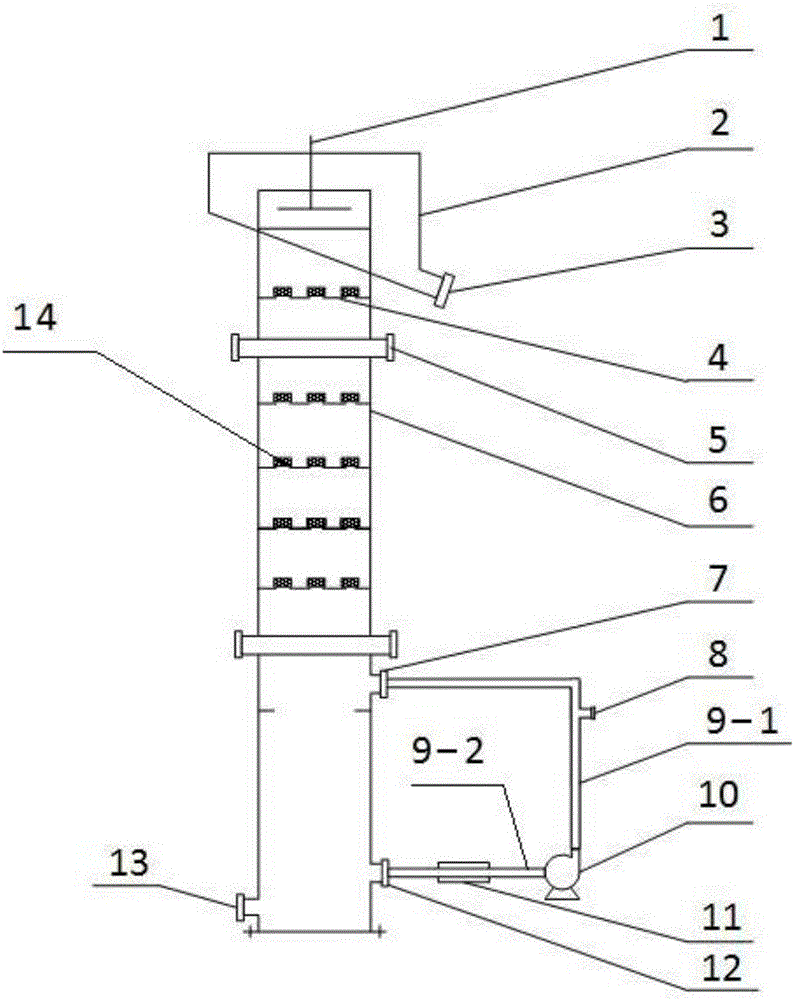

Flotation column separation equipment and separation method

The invention discloses flotation column separation equipment. The flotation column separation equipment comprises a hollow column body. A foam collecting tank, a spraying device and a tailing pipeline are arranged at the top of the column body. A plurality of sieve plates are arranged on the middle-upper portion in the column body. A middling circulating device is arranged on the lower portion of the column body. The middling circulating device comprises a circulating ore pulp outlet, and the circulating ore pulp outlet is sequentially connected with a chemical feeding tank, a middling circulating ore pulp pump, a bubble generator and a circulating ore pulp inlet. A feeding pipe is arranged on the upper portion of the column body. A concentrate pipe is arranged on the lower portion of the column body, and the concentrate pipe is lower than the circulating ore pulp outlet. The invention further provides an ore separation method. According to the flotation column separation equipment and the separation method, the trinity mineralization mode integrating raw ore reverse flow mineralization, middling pipe flow mineralization and middling fluid impact mineralization is adopted, efficient separation of phosphorus ore can be achieved, the production cost is low, and the energy consumption is low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

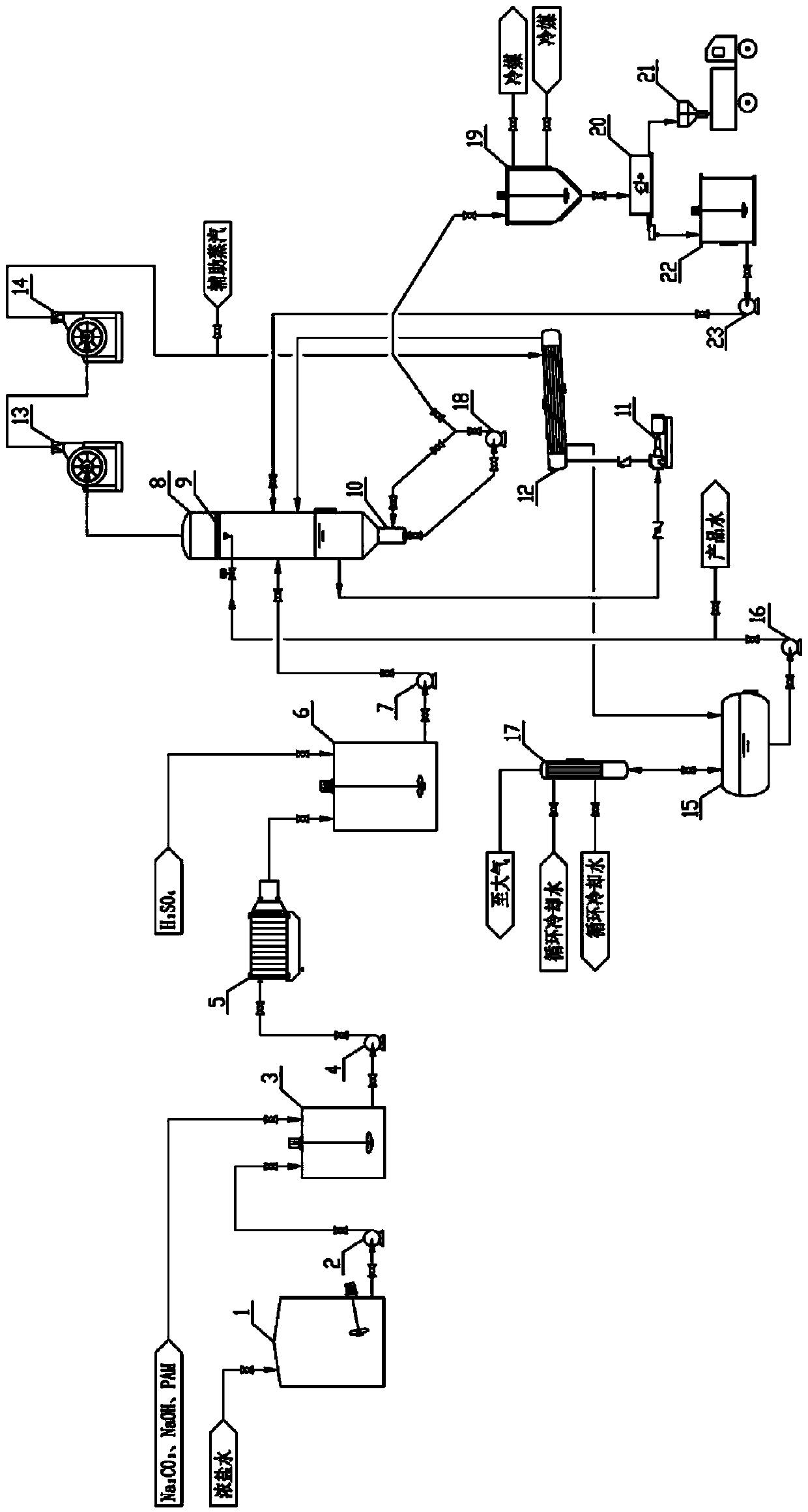

Strong brine evaporating and crystallizing system

ActiveCN103991997AEvaporation crystallization is fully continuousAvoid cloggingMultistage water/sewage treatmentWater/sewage treatment by heatingTotal dissolved solidsEngineering

The invention provides a strong brine evaporating and crystallizing system, which comprises a calcium-magnesium removing reaction tank, a filter press, a feeding tank, a crystallizing separator, a crystallizing heater, a compressor, a thickener, a centrifugal machine and a mother liquor tank, wherein the filter press is connected with the calcium-magnesium removing reaction tank, and the feeding tank is connected with the filter press; the crystallizing separator is connected with the feeding tank, a strong brine inlet and a strong brine outlet of the crystallizing heater are respectively connected with the crystallizing separator; an inlet and an outlet of the compressor are respectively connected with the crystallizing separator and the crystallizing heater; an inlet of the thickener is connected with the crystallizing separator, an outlet of the thickener is connected with the centrifugal machine, and a liquid outlet of the centrifugal machine is connected with the crystallizing separator through the mother liquor tank. The strong brine evaporating and crystallizing system can be used for processing mixed strong brine with TDS (total dissolved solids) concentration of 100-300g / L so as to realize continuous stable running and total recycling of the sewage, solves the problem of water resource shortage in some areas and reduces pollution to the environment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

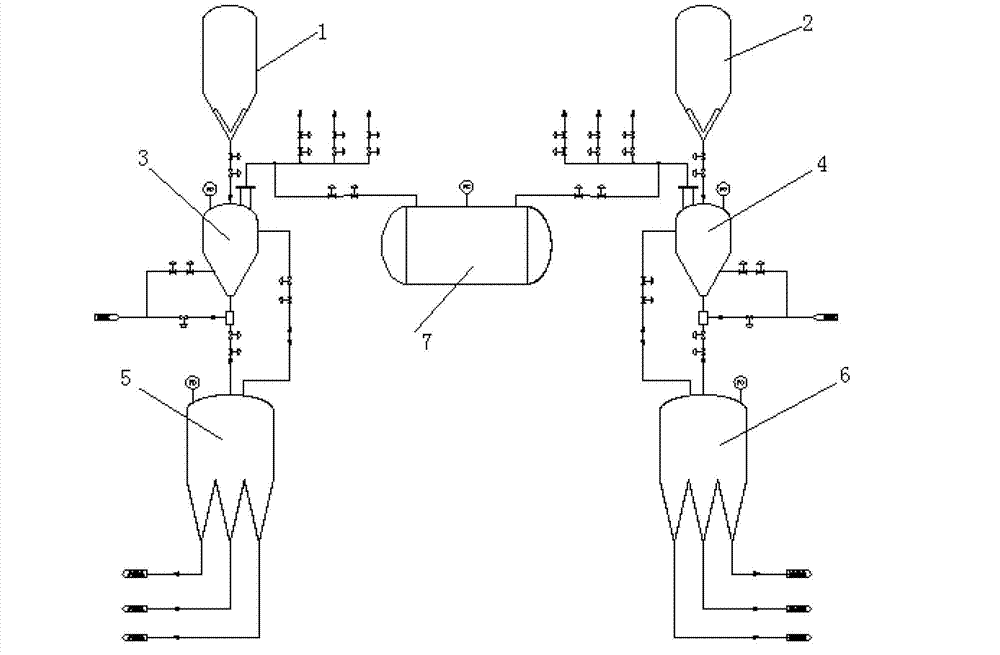

High pressure conveyance gas recovery method

The invention discloses a high pressure conveyance gas recovery method which comprises a first storage tank, a second storage tank, a first locking hopper, a second locking hopper, a first feeding tank, a second feeding tank and a gas coupling tank. After the first feeding tank (second feeding tank) correspondingly receives a batch of power from the first locking hopper (second locking hopper), the first locking hopper (second locking hopper) is separated from the first feeding tank (second feeding tank). The first locking hopper is opened for equalizing pressure with a communication valve of the gas coupling tank, after pressure is balanced, the second locking hopper is opened for equalizing pressure with the communication valve of the gas coupling tank. When pressure of the first locking hopper, the gas coupling tank and the second locking hopper is balanced, the gas coupling tank is isolated, gases are discharged into a powdered coal storage tank so that a filter is used for discharging pressure of the first locking hopper, and meanwhile, pressure conveyance gases are used for punching the second locking hopper. According to the high pressure conveyance gas recovery method, conveyance gases can be partly recycled, energy dissipation is reduced, and recovery use ratio of conveyance gases is 50% compared with a single system.

Owner:ANHUI JINMEI ZHONGNENG CHEM IND

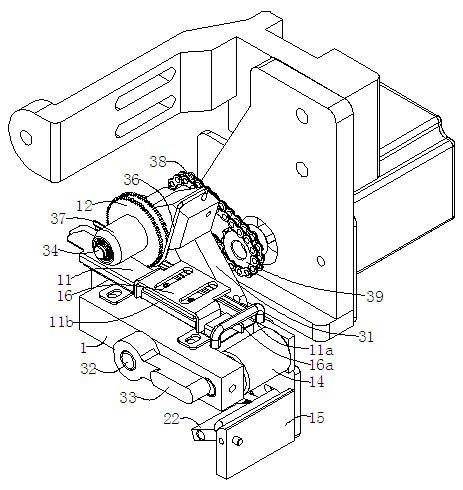

Machine for stringing chain-sheets

InactiveCN101352749AImprove reliabilityAccelerate the natural fall speedMetal chainsButt jointFeed tank

A link plate stringing machine comprises a frame, a hopper, a feeding tank, a monolith tank, a discharge tank and a pushing device, wherein, the hopper takes the shape of a cylinder, the feeding tank is arranged on the periphery of the hopper and integrated with the cylinder body. The monolith is arranged on a vibrating bracket; an discharge outlet of the hopper is communicated with the feeding tank, a plurality of gradually rising spiral feeding rails are arranged in the feeding tank, and clearance is kept between the feeding rails; the monolith tank is composed of a plurality of monolith rails, a step is respectively formed at inlets of the monolith rails and outlets of the corresponding feeding rails, the monolith rail behind the step takes the shape of a tunnel, and the wall of the monolith rail in the shape of the tunnel is provided with gaps in the axial direction; the monolith rails are respectively provided with a pushing rod hole for accommodating the pushing device, the outlets of the monolith rails are butt-jointed with the inlet of the discharge tank. By adopting the link plate stringing working procedure on the frame, the link plate stringing machine has the advantages of solving the existing defects of loose mechanical structure, bad reliability, slow strip stringing speed, low production efficiency and only being applicable to dry strip stringing work.

Owner:郦忠

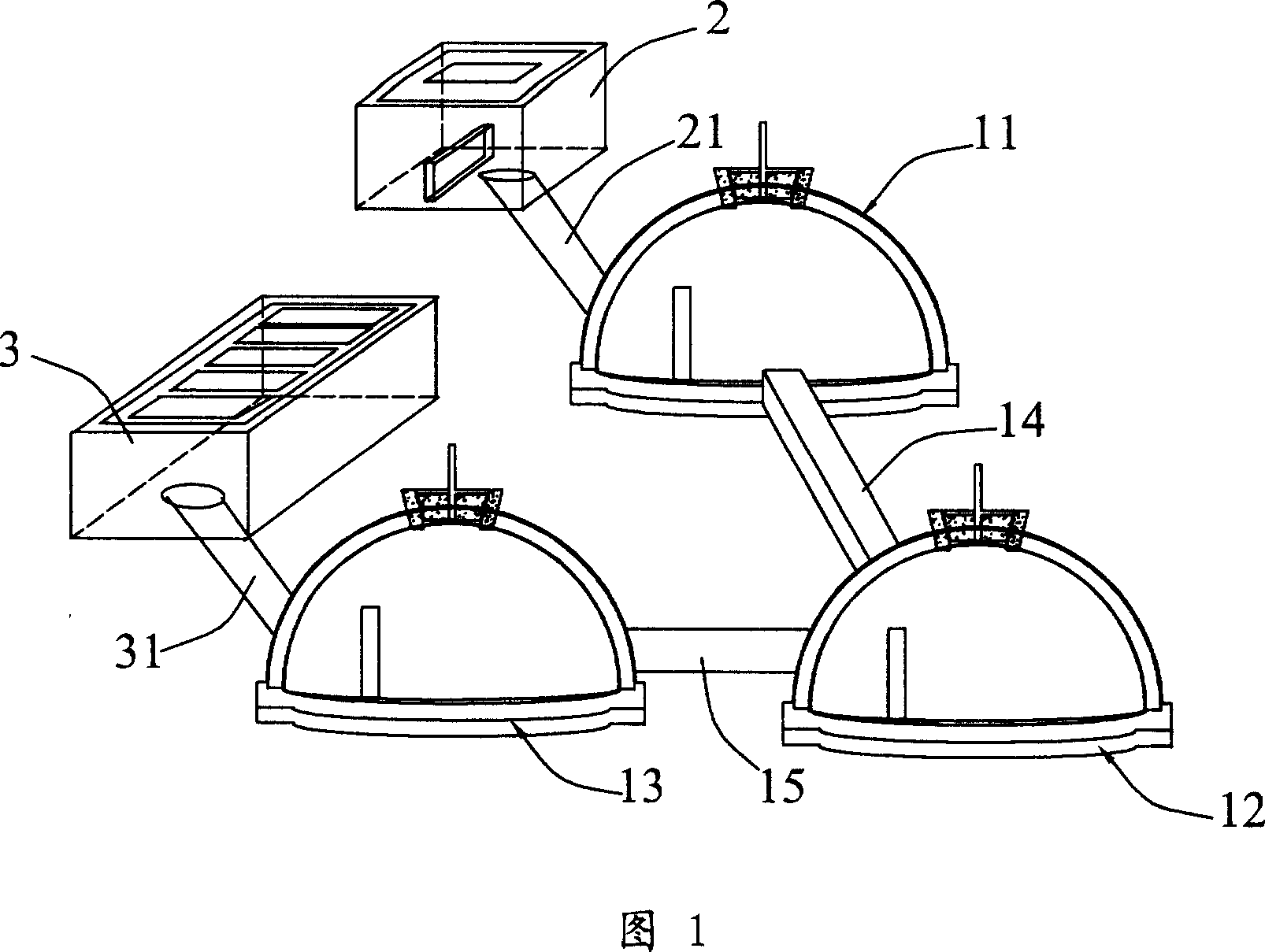

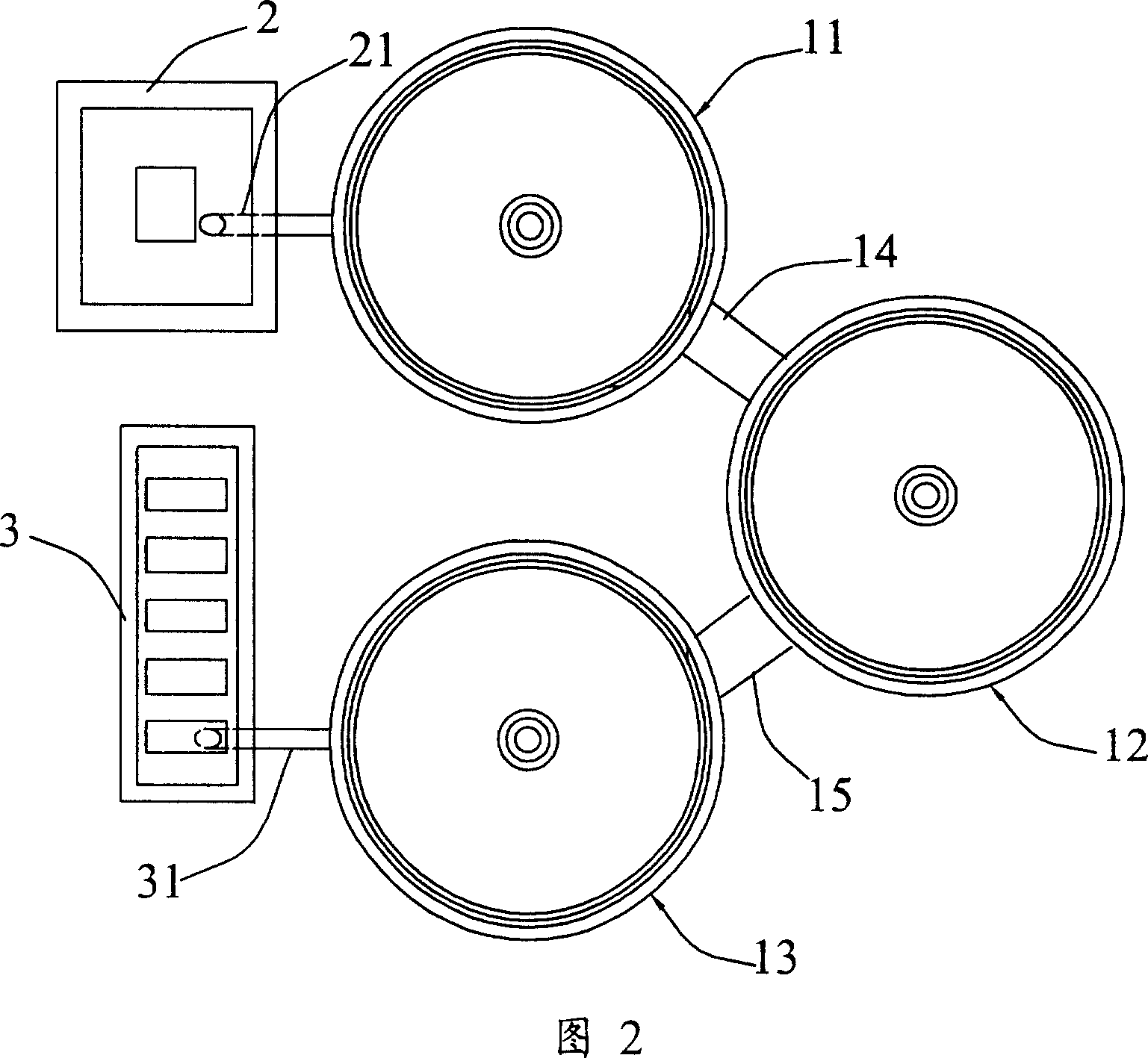

Coupled methane tank

InactiveCN101045901AAchieve purificationIncrease gas capacityGas production bioreactorsWaste based fuelWastewaterSewage treatment

The present invention relates to methane generating apparatus and sewage treating technology, and is especially one kind of coupled methane tank capable of treating great amount of domestic garbage to produce methane through complete degradation. Structurally, the coupled methane tank includes one feeding tank with gas outlet, two or more fermenting tanks, one discharging tank and connecting pipeline to form liquid flow passage. Through stage-by-stage reaction in the fermenting tanks, the present invention produces methane.

Owner:朱涛 +1

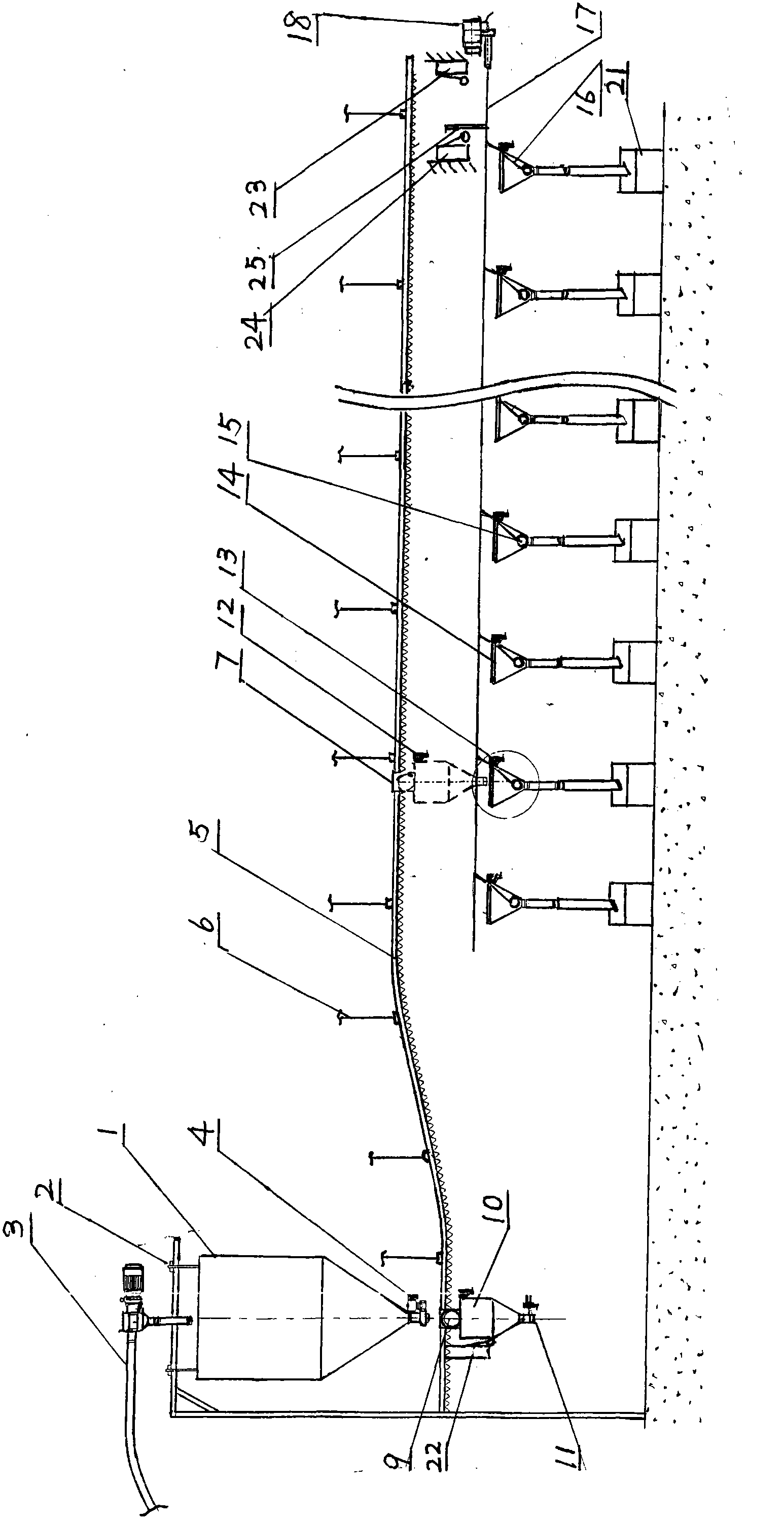

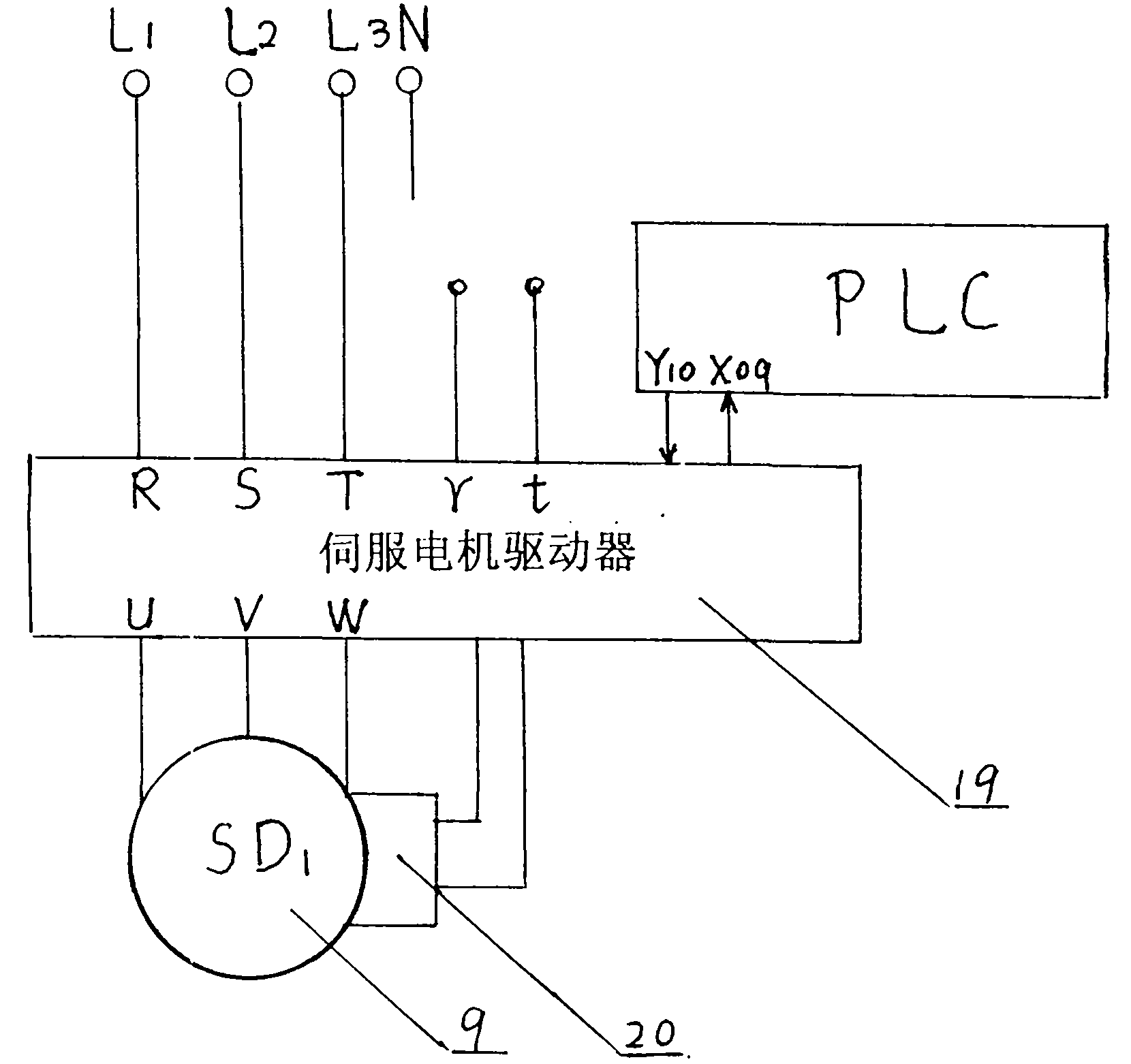

Intellectualized livestock and poultry feeding line capable of realizing precise metering and timed discharge

InactiveCN102792898ABalanced feedingSynchronous feedingAnimal feeding devicesAvicultureEngineeringMechanical equipment

The invention relates to an intellectualized livestock and poultry feeding line capable of realizing precise metering and timed discharge, and belongs to the livestock and poultry breeding mechanical equipment in the farming mechanical field. The feeding line comprises a feed tank, a feed conveying device, a discharge device, feeding tanks and an electric control device, wherein the feed tank is in a hanging state by an electronic scale and a metering sensor; the feed conveying device comprises a feed conveying rail 5 hung along the upside of a row of feeding tanks and a moving hopper 10 for feeding along the rail in a reciprocating manner, and is driven by a servomotor, and the moving hopper is provided with a searching and locating device for automatically searching the corresponding feeding tank; a blanking funnel of the discharge device is provided with a timed blanking control mechanism; and the electric control device comprises a programmable logic controller (PLC) and correlated auxiliary circuits. The feeding line has the benefits that quantitative and timed charging and discharge of the livestock and poultry feeding line are realized, and equalized and synchronous feeding is realized, so that the livestock and poultry grow healthily and rapidly. The feeding line is controlled in an intellectualized manner, the manpower is saved, the production efficiency is improved, the production cost is lowered, and the culture economic benefits are maximally improved.

Owner:GOLDENEST MACHINERY MFG QINGDAO

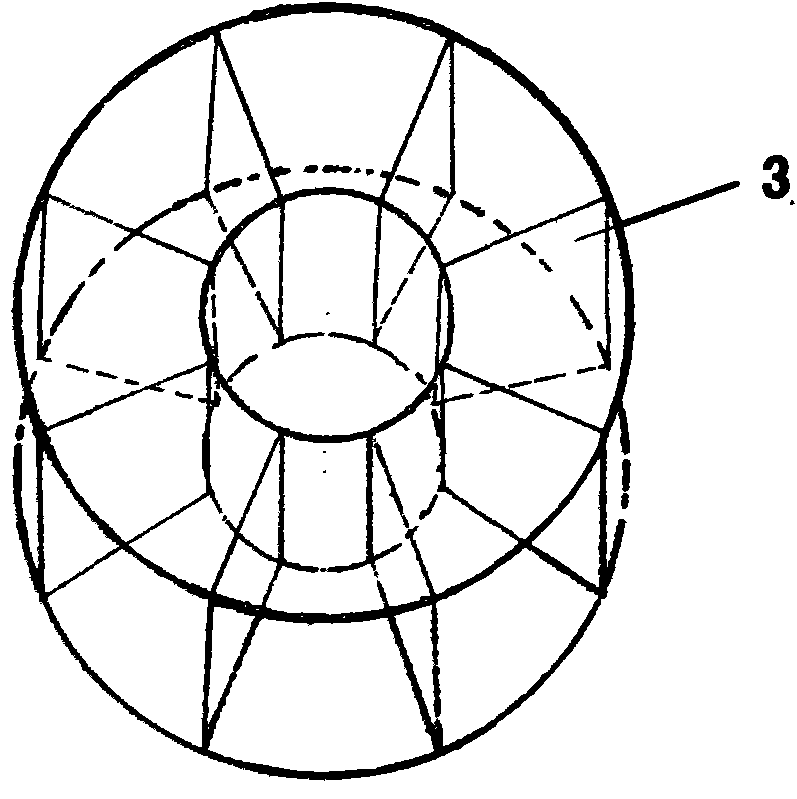

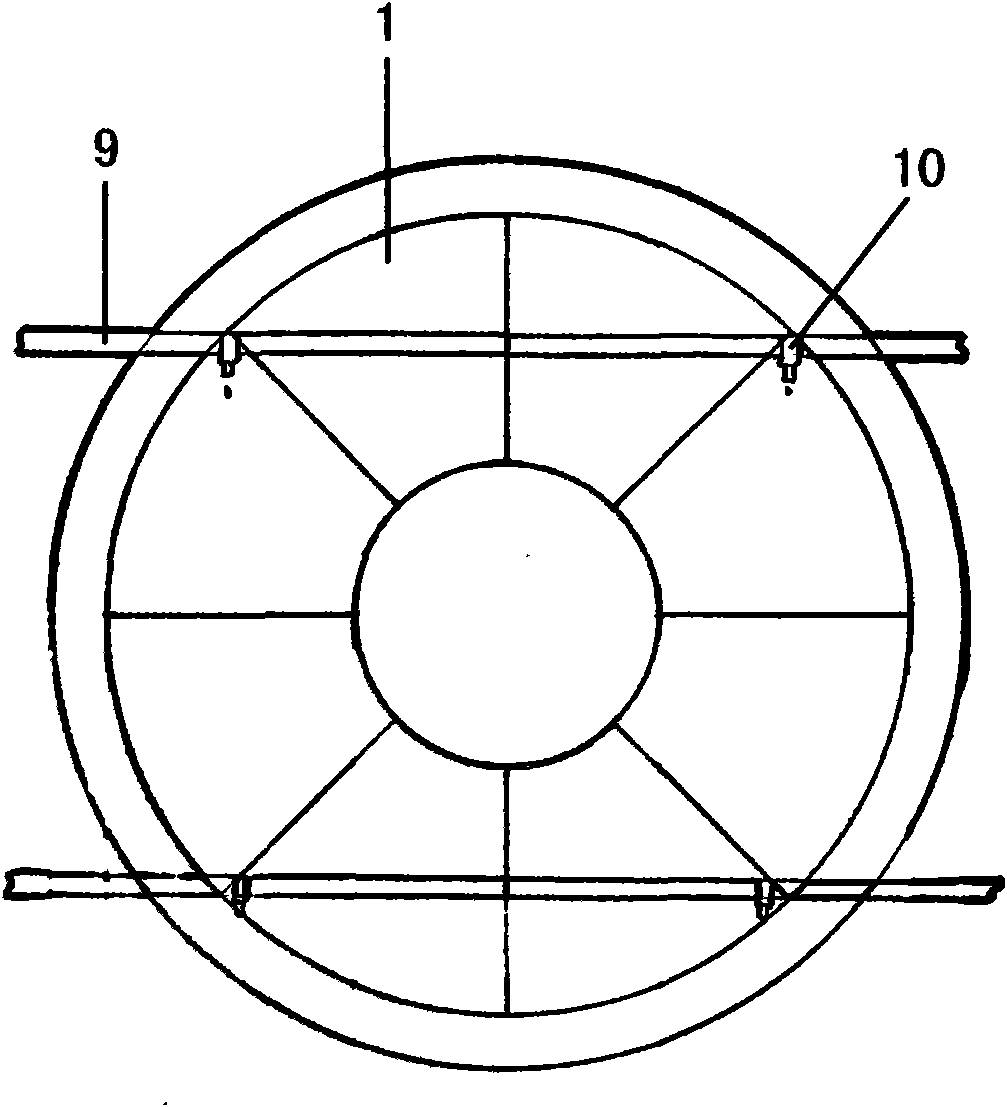

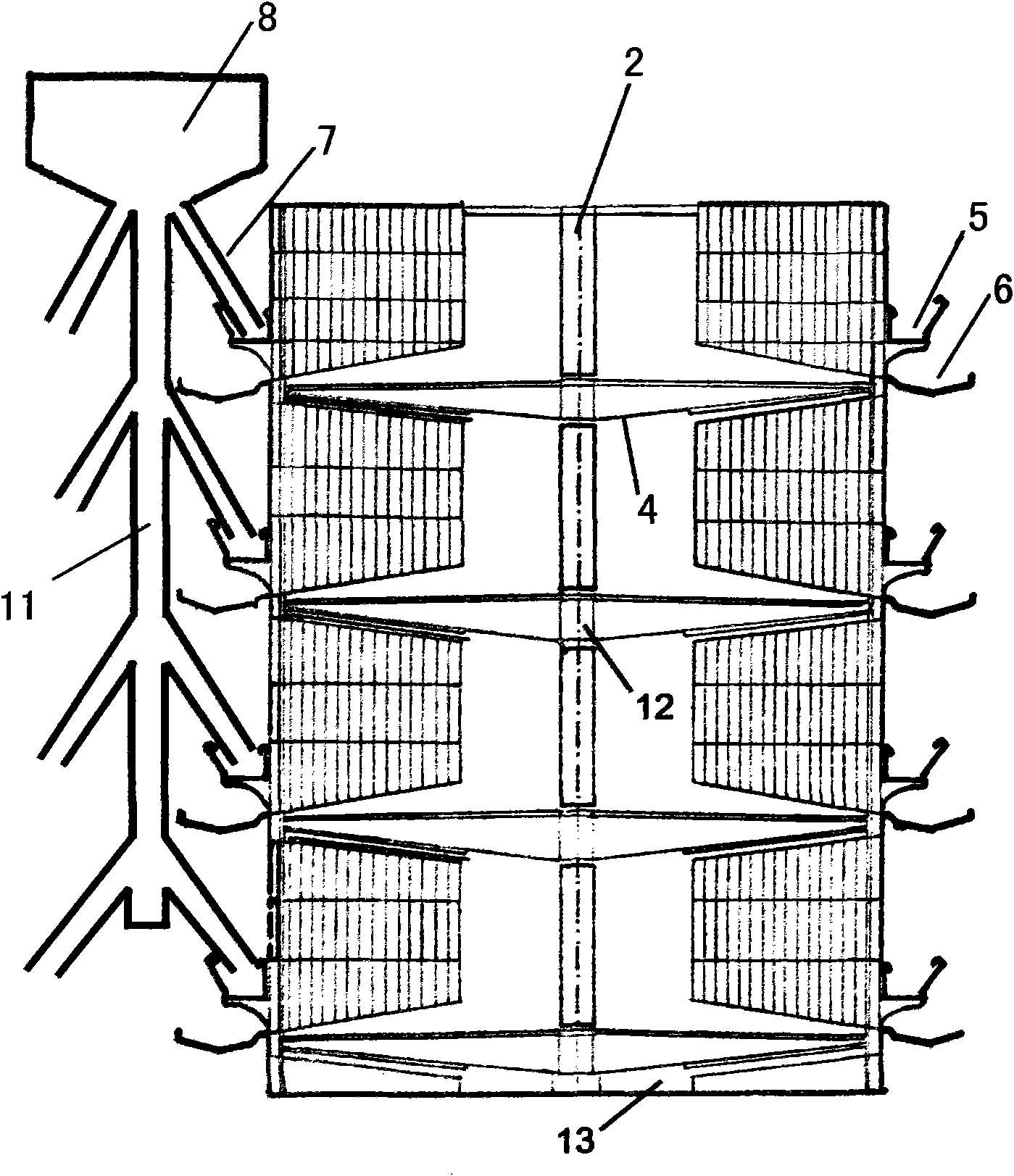

Circular overlapped multilayered cage culture feeding equipment

The invention provides a piece of circular overlapped multilayered cage culture feeding equipment, which comprises a cage body 1, a central stand column 2, a feeding system, a water supply system, and a motor, wherein the cage body 1 has a concentric circle structure; a scraper 4 which is inclined to the center of the circle is arranged on the top of the first layer of the cage body 1; the central stand column 2 is positioned in the center of the circle of the cage body 1 and is connected with the cage body; one end of a feed pipe 7 is connected with the lower part of a feed tank 8, and the other end of the feed pipe 7 is connected with a crib 5 at the periphery of the bottom of the cage body 1; the water supply system is equipped with a water pipe 9 on the top of the cage body 1; and a nipple 10 is arranged on the water pipe 9 for automatically supplying water. The circular overlapped multilayered cage culture feeding equipment is simple, improves the feeding density, can be combined and spliced, saves the manual labor and energy, maximizes the space utilization, integrates feeding, water supply, egg collection, manure clearing and other automatic operation systems, is widely applied to poultry, and achieves the optimized effects on poultry farming and growth under the same illumination and ventilation conditions.

Owner:谢天权

Method of sugar-like flavorous component and method of preparation of perfumery composition or beverage using the resulting flavorous component

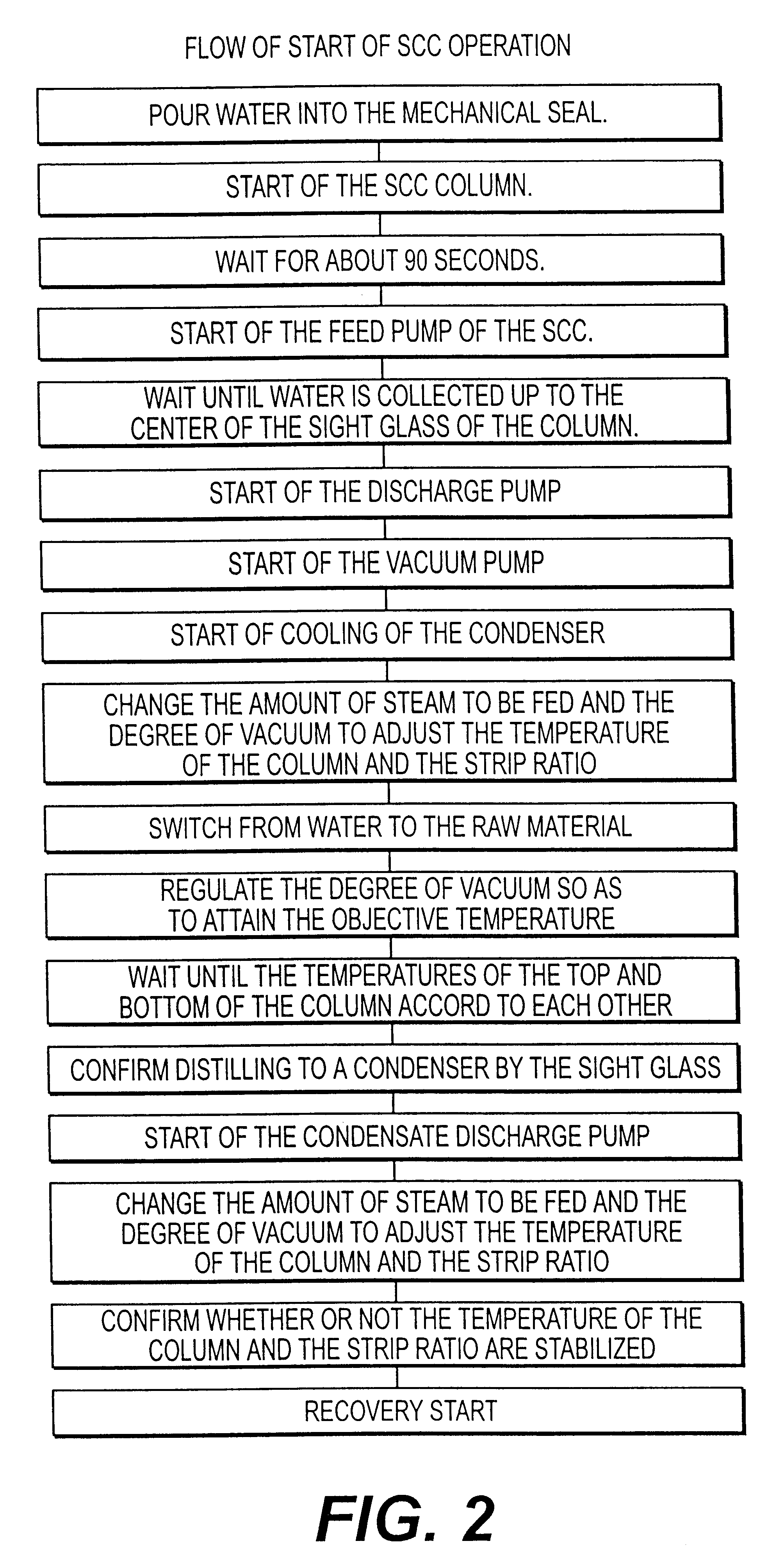

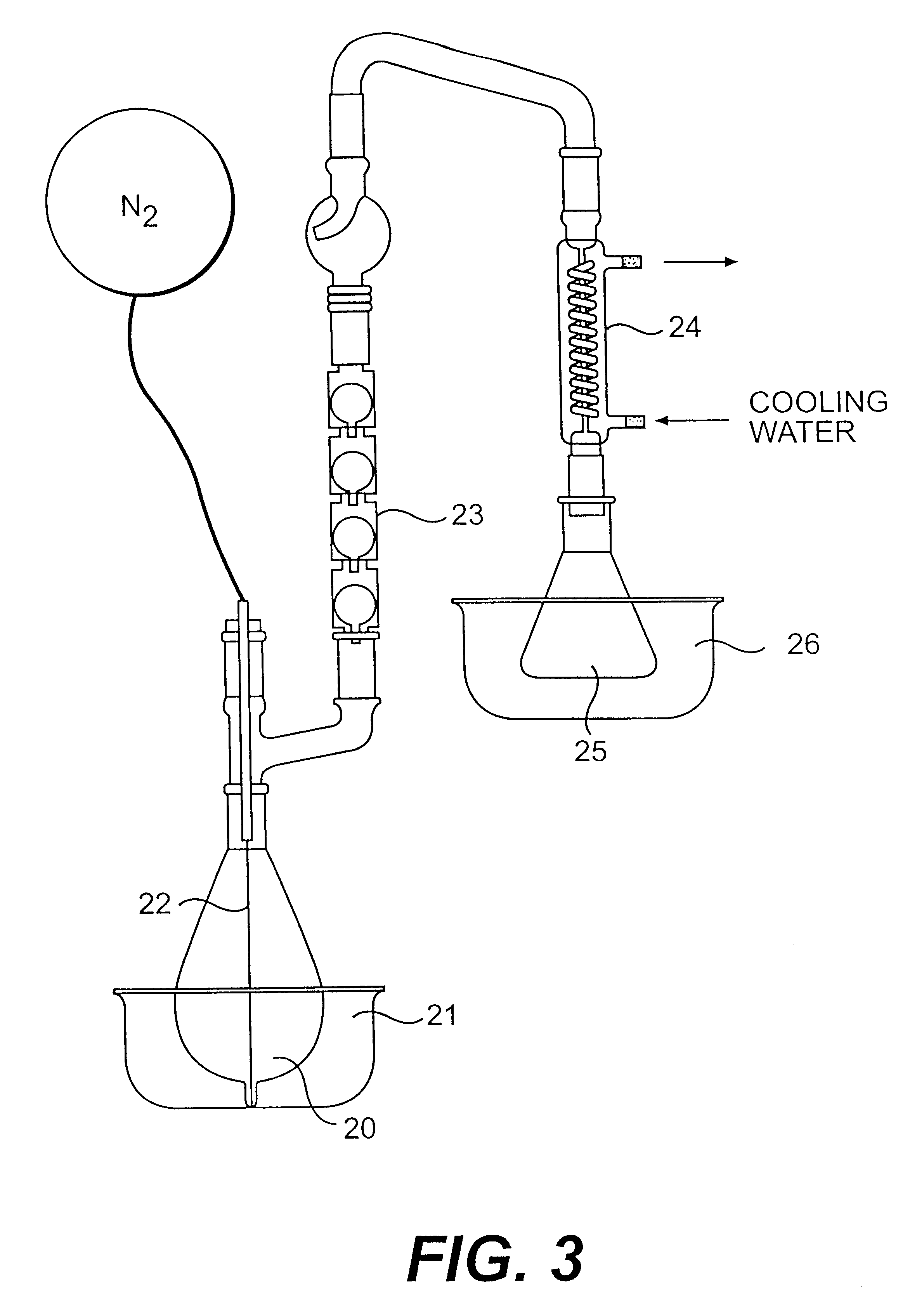

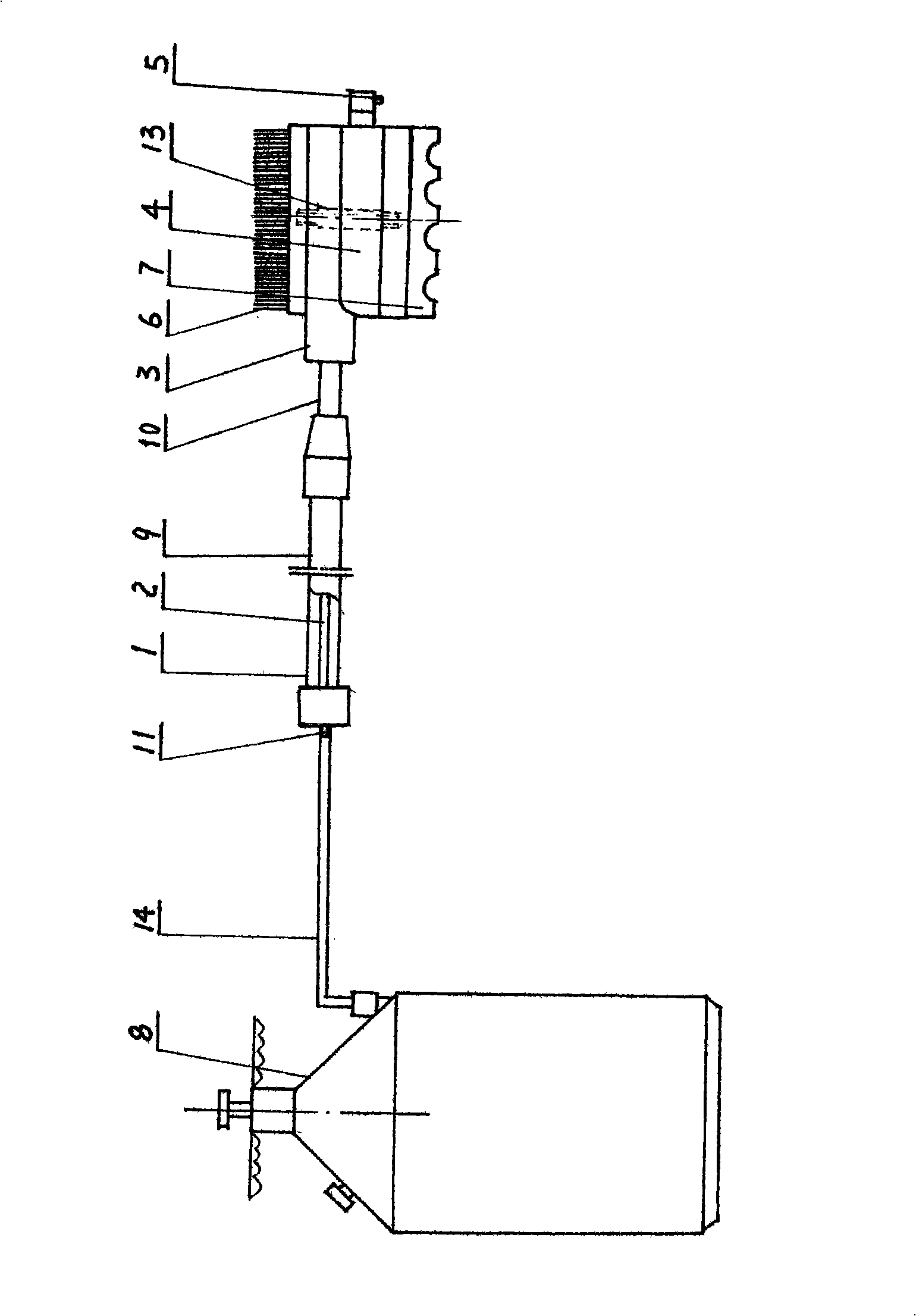

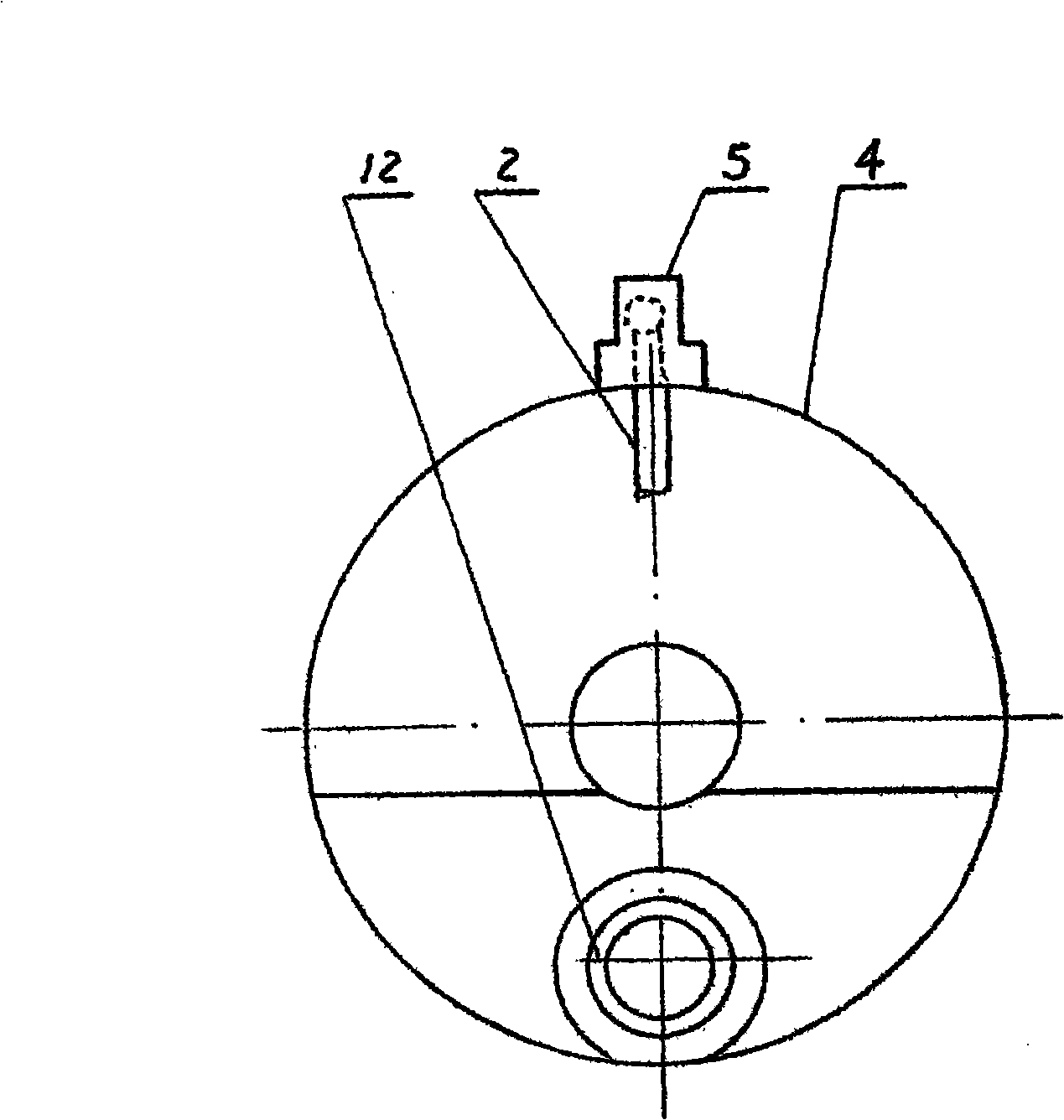

The invention has an object of providing a method of the preparation of a sugar-like flavorous component which imparts a mellow feeling to beverages and flavorous compositions and retains a live flavor even if it is diluted thousands times. The method of the preparation of a sugar-like flavorous component includes steps of adding 1.5 to 3 parts by weight of ion exchange water and 0.02 to 0.05 parts by weight of ethanol to 1 part by weight of molasses in a feed tank, mixing and dissolving these components thoroughly with stirring, and introducing the resulting solution into a spinning cone column (SCC) to treat the solution in the following condition: the temperature in a column: 40 to 60° C., strip rate: 0.5 to 7% and the degree of pressure reduction: 70 to 100 kPa.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Automatic rotating water-injection double-face cleaning device

InactiveCN101337539AReasonable designSimple structureBrushesCleaning apparatus for vehicle exteriorsWater savingArchitectural glass

The invention relates to an autorotation and water spraying double-faced cleaner which is characterized in that a retractable control rod is composed of two hollow sleeves, namely, an outer sleeve and an inner sleeve; an intake pipe passes through the retractable control rod; one end of the intake pipe is connected with a water inlet of the retractable control rod, while the other end passes through a brush holder and is connected with a spray head fixed on a rotation and water spraying component; the brush holder and the water spraying component, as well as the outlines of the brush and a sponge brush are round; the rotation and water spraying component is sleeved on the central shaft of the brush holder; and the brush and the sponge brush are respectively and fixedly connected with threads at two ends of the central shaft. A balancing weight is arranged in the rotation and water spraying component, and a pneumatic feed-tank is connected with a water inlet through a water pipe. The cleaner is characterized by reasonable design, simple structure, convenient use, high efficiency, water saving, time saving and labor saving, thereby reducing intensity of labor, and particularly guaranteeing safe operations in cleaning wall bodies and glass of high-rise buildings. The autorotation and water spraying double-faced cleaner also has the function of assistant extinguishment.

Owner:徐晓平

Feed feeding device for livestock raising

InactiveCN107232078ADrinking water healthConvenient drinking waterAnimal watering devicesAnimal feeding devicesEngineeringFodder

The invention relates to a feeding device, in particular to a feed feeding device for animal husbandry. The technical problem to be solved by the present invention is to provide a feed feeding device for animal husbandry. In order to solve the above technical problems, the present invention provides such a feed feeding device for animal husbandry, which includes a bottom plate, a first bracket, a fixing block, a connecting rod, a first feed trough, a drinking water device, etc.; The first bracket, the lower right side of the first bracket on the left and the lower left side of the first bracket on the right are symmetrically provided with fixing blocks, a connecting rod is arranged between the fixing blocks on the left and right sides, and the first feed is arranged in the middle of the connecting rod Groove, the middle of the right side of the first bracket on the left is provided with a drinking device, and the drinking device is located directly above the first feed trough. The invention achieves the effect that the feeding is orderly, and the water and the feed can be eaten together. In order to prevent the feed from blocking the outlet of the feed box when the feed falls into the first feed tank, people can start the second electric push rod.

Owner:谢陈钗

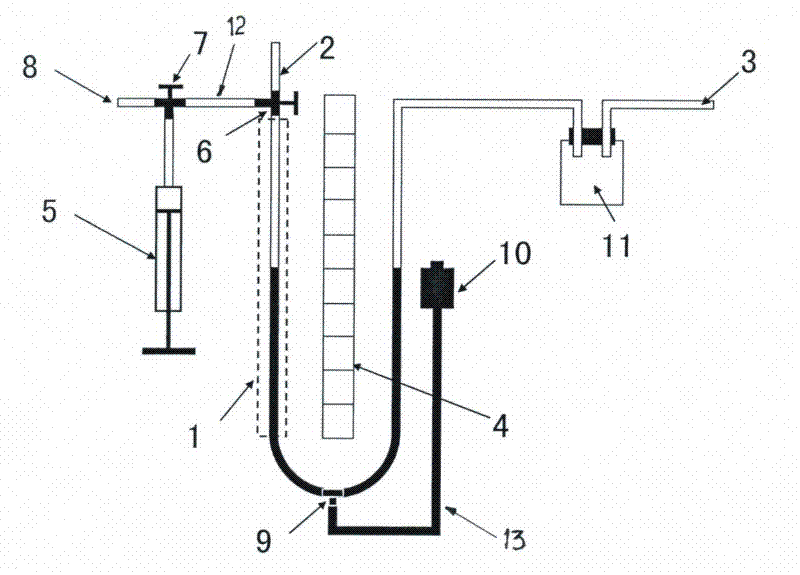

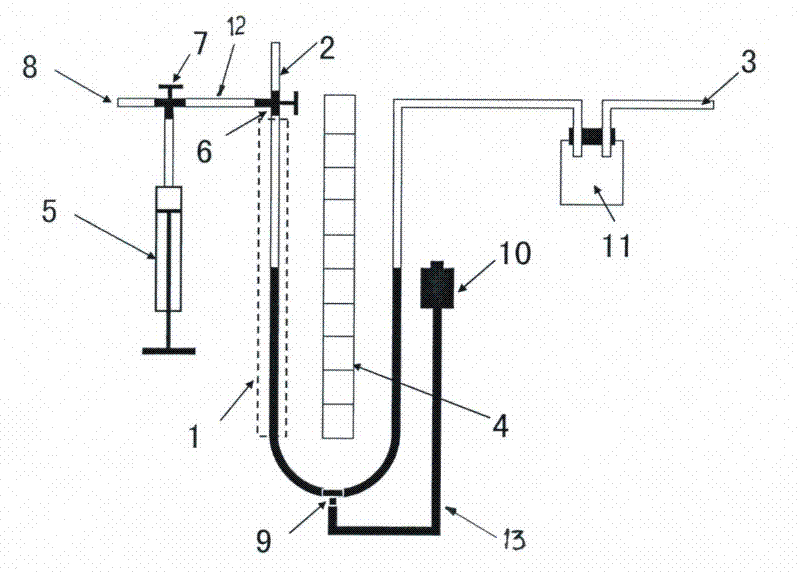

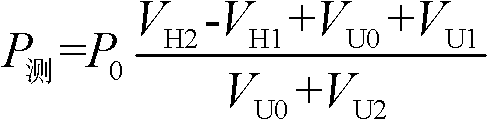

U-shaped pipe pressure meter and pressure measurement method thereof

InactiveCN102252797ANovel measuring methodEasy to measureFluid pressure measurement using pressure-sensitive liquidEngineeringHigh pressure

The invention discloses a U-shaped pressure meter and a pressure measurement method thereof. In the U-shaped pressure meter, the bottom of the U-shaped pressure meter is communicated with a liquid feed tank through a liquid feed pipe; the right pipe section of a U-shaped pipe extends in the horizontal direction into an overpressure overflow protection tank; the left pipe section of the U-shaped pipe is communicated with a high pressure measurement mouth pipe and a horizontal connection pipe, and a three-way valve is arranged at the joint of the left pipe section of the U-shaped pipe, the high pressure measurement mouth pipe and the horizontal connection pipe; the external end of the horizontal connection pipe is communicated with a horizontal escape pipe and a piston air measurement cylinder, and another three-way valve is arranged at the joint of the external end of the horizontal connection pipe, the horizontal escape pipe and the piston air measurement cylinder; and the volume scale is marked on the left pipe section of the U-shaped pipe. The pressure measurement method comprises the following steps of: disconnecting the high pressure measurement mouth pipe and the U-shaped pipe by the three-way valve; connecting high-pressure gas in the U-shaped pipe and the piston air measurement cylinder; and measuring the volume of high-pressure gas in the U-shaped pipe under normal pressure by using the piston air measurement cylinder and calculating to obtain pressure of the high-pressure gas. The invention has the characteristics that the measurement accuracy does not change along with the rise of pressure, and when the measurement pressure is higher, relative error is smaller.

Owner:XIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com