Machine for stringing chain-sheets

The technology of a stringer and chain piece is applied in the field of chain manufacturing equipment, which can solve the problems of slow stringing speed, inability to carry out oil film, wet film stringing operation, low production efficiency, etc., and achieves improved reliability and is conducive to stringing The effect of film speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

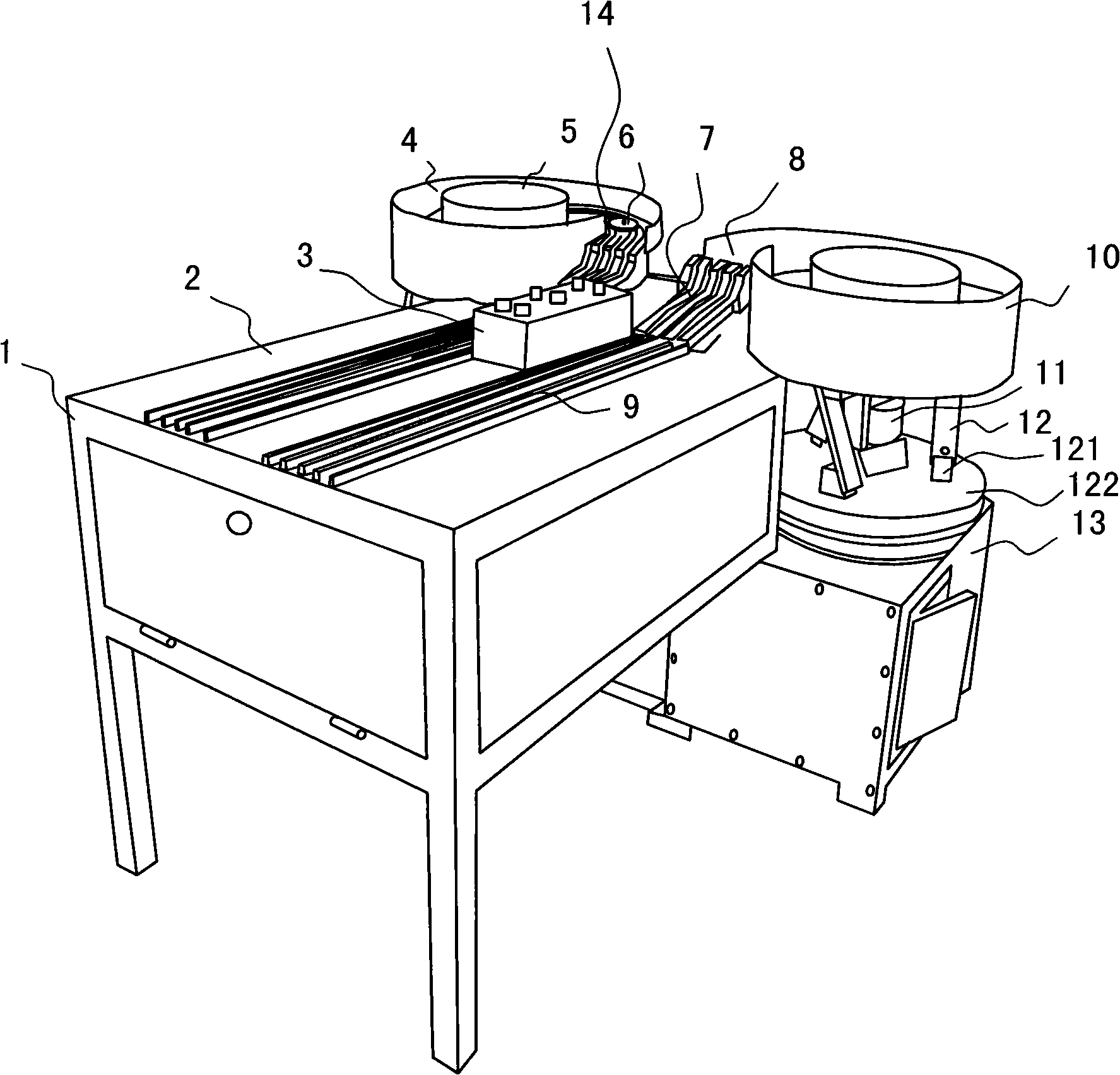

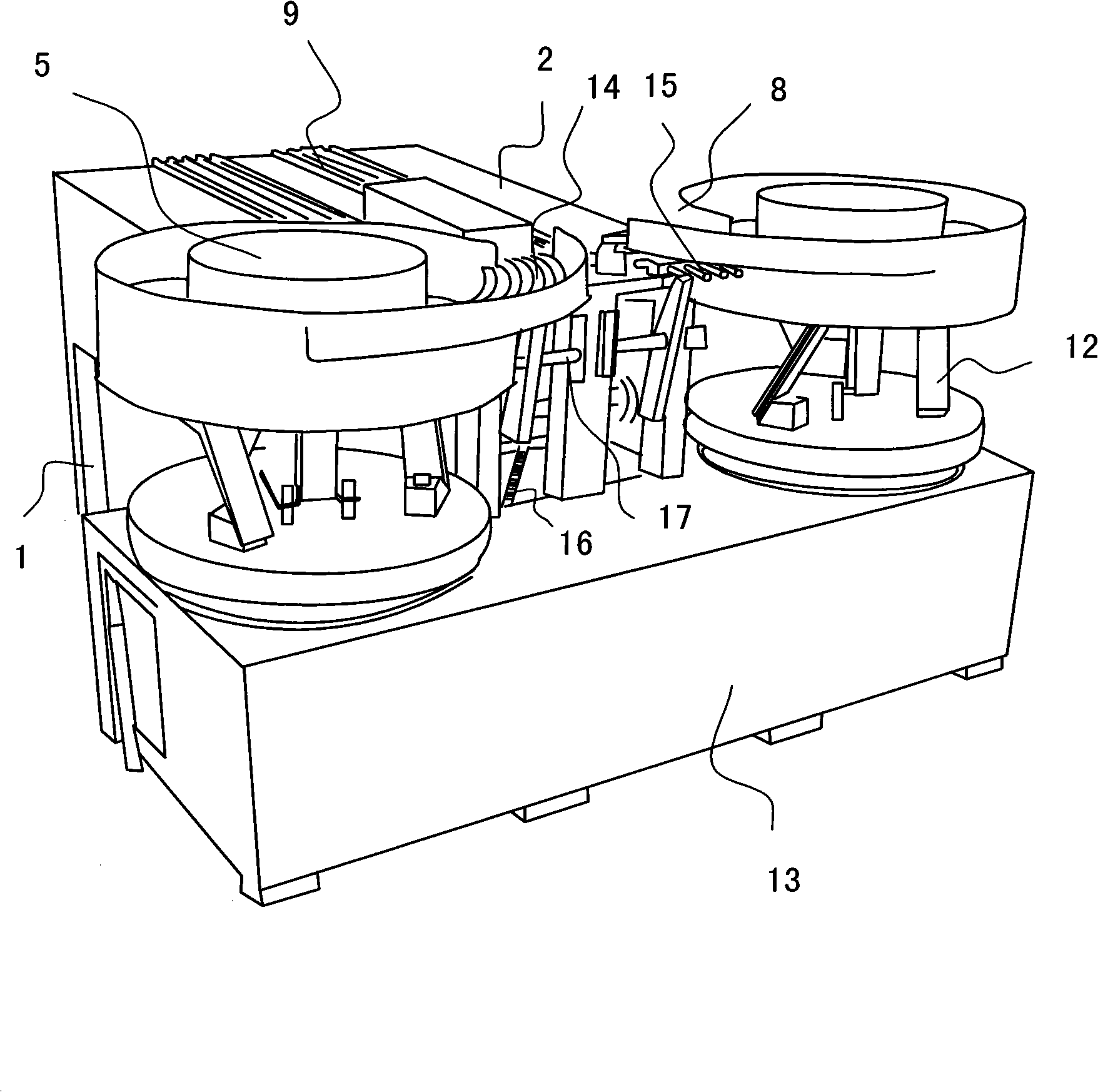

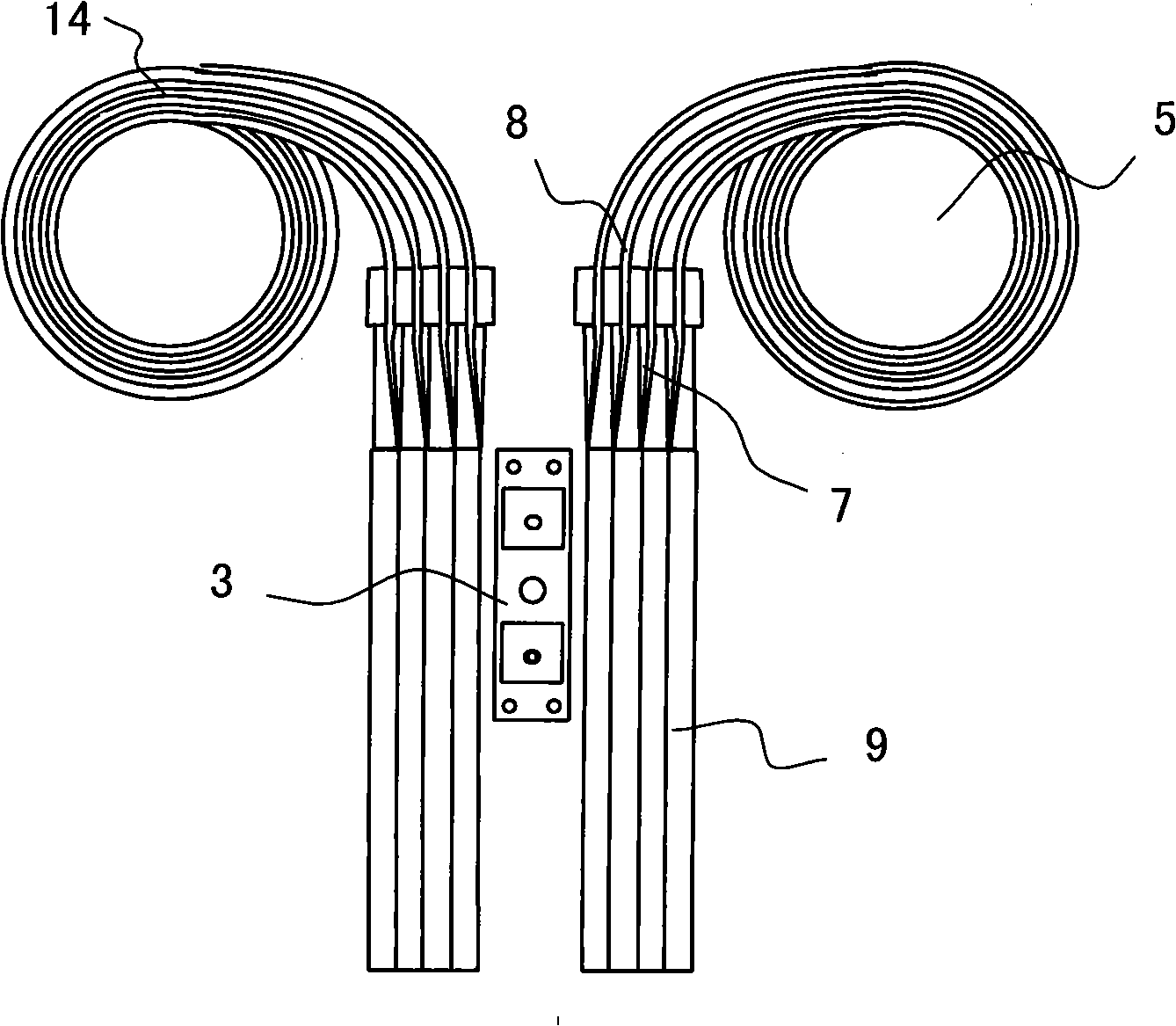

[0021] see figure 1 , and combined with figure 2 . This is a machine that has the function of connecting the inner and outer chains of the chain. Therefore, two sets of chaining mechanisms are symmetrically set on the frame 1. The chain piece needs to be set, corresponding to the difference in parameters such as the size, shape and thickness of the inner chain piece and the outer chain piece.

[0022] Frame 1 front portion is provided with worktop 2, and rear portion is provided with hopper 5, and motor, transmission mechanism are housed in transmission mechanism box 13, certainly, on frame 1, some accessory structures such as toolboxes can be set as required, to facilitate work. There is a discharge chute 9 and an electric control box 3 on the work surface 2, and the electric control box 3 is arranged on the symmetrical middle part of the work surface 2, which is convenient for the operation of the left and right stations.

[0023] As far as a single stringing mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com