Patents

Literature

1228results about "Metal chains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

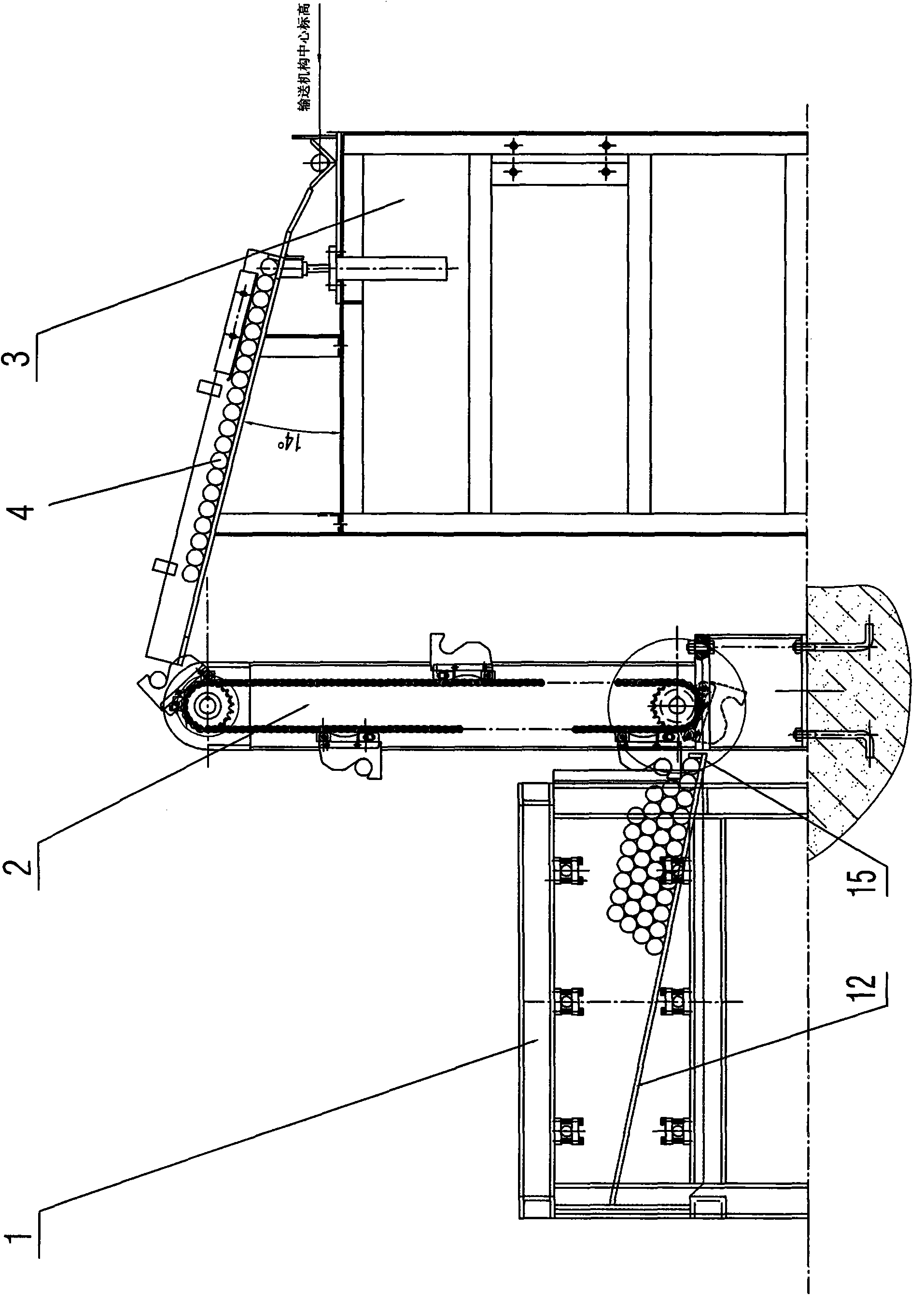

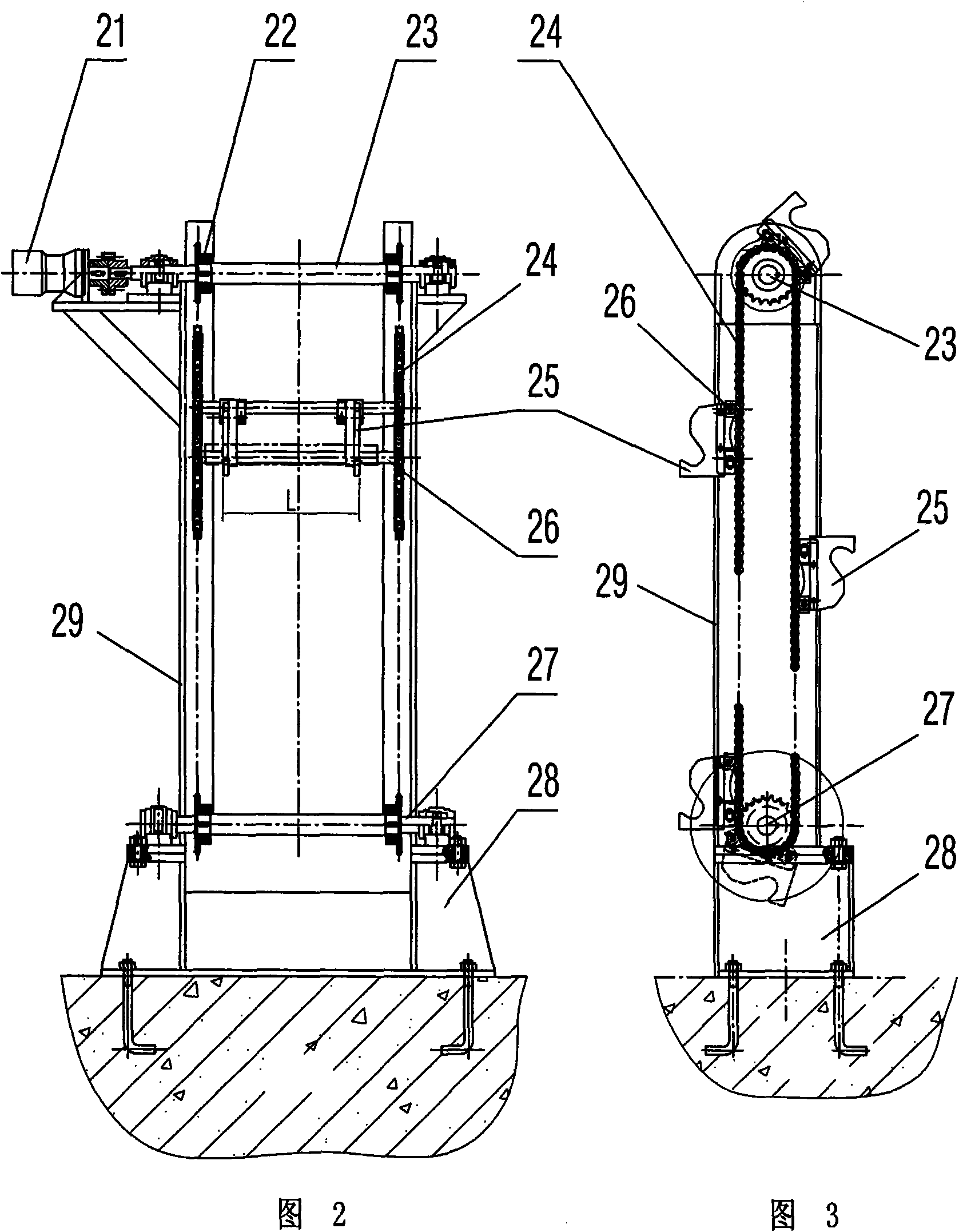

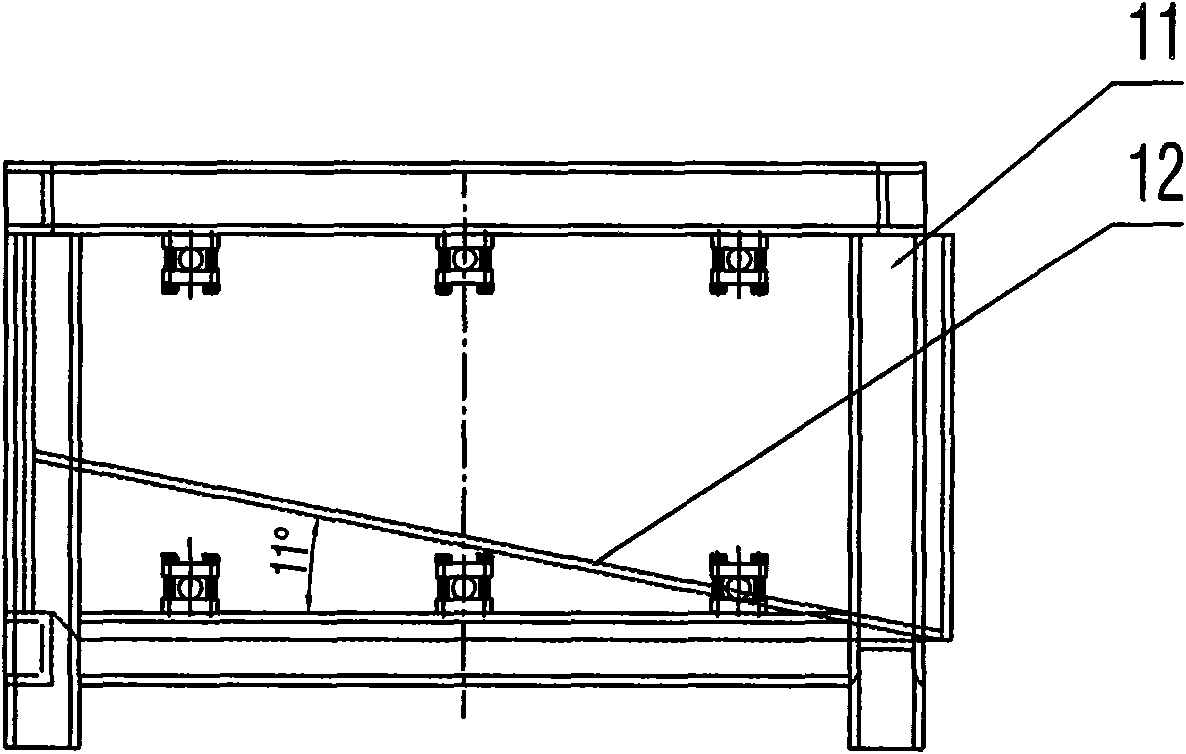

Automatic lifting mechanism for round metal rod

ActiveCN101628658AGuarantee normal productionReduce labor intensityConveyorsControl devices for conveyorsEngineeringAutomation

The invention relates to an automatic lifting feeding and discharging mechanism for a round metal rod, in particular to an automatic lifting mechanism for a round metal rod. According to the technical scheme provided for the mechanism in the invention, a discharge opening of a feed box is connected with a feed end of a lifting feeding machine and a discharge end of the lifting feeding machine is connected with a feed opening of a feeding and discharging machine; in the feed box, an inclined bottom plate of the feed box is arranged on the lower part of the feed box body, the lower end of the inclined bottom plate of the feed box is positioned at the discharge opening of the feed box, and a group of side plate fixing rods are respectively arranged on both the upper part and the lower part of the feed box; the inner ends of the side plate fixing rods are connected with a side regulating plate and the outer ends extend out of a side face of the feed box; and the side regulating plate is positioned on both sides of the inclined bottom plate of the feed box. The mechanism adopts an integrated mechanical, electric and hydraulic automatic lifting mechanism for the round metal rod and has the advantages of high production efficiency, high degree of automation, steady production process and safe reliability.

Owner:王洪军

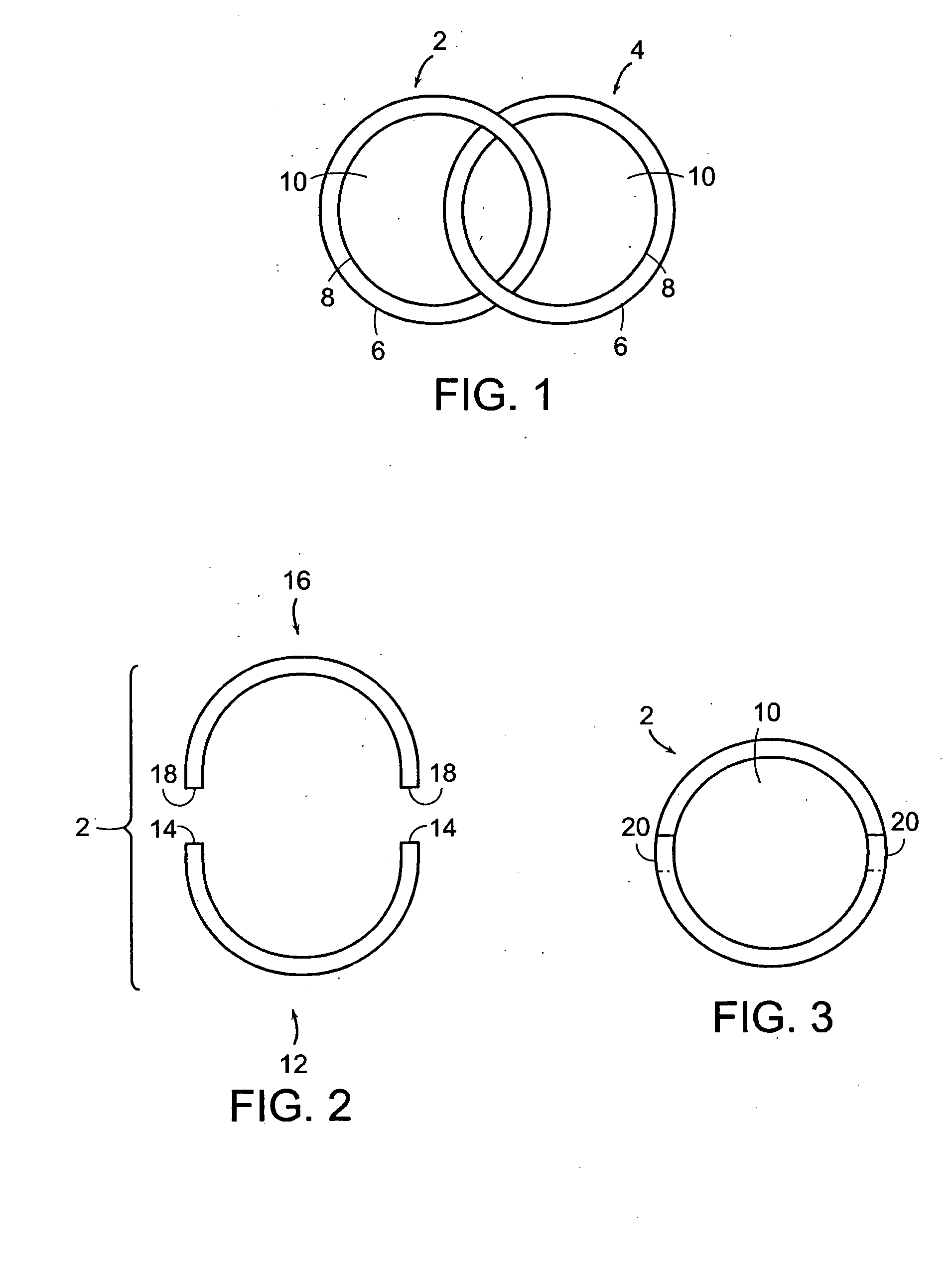

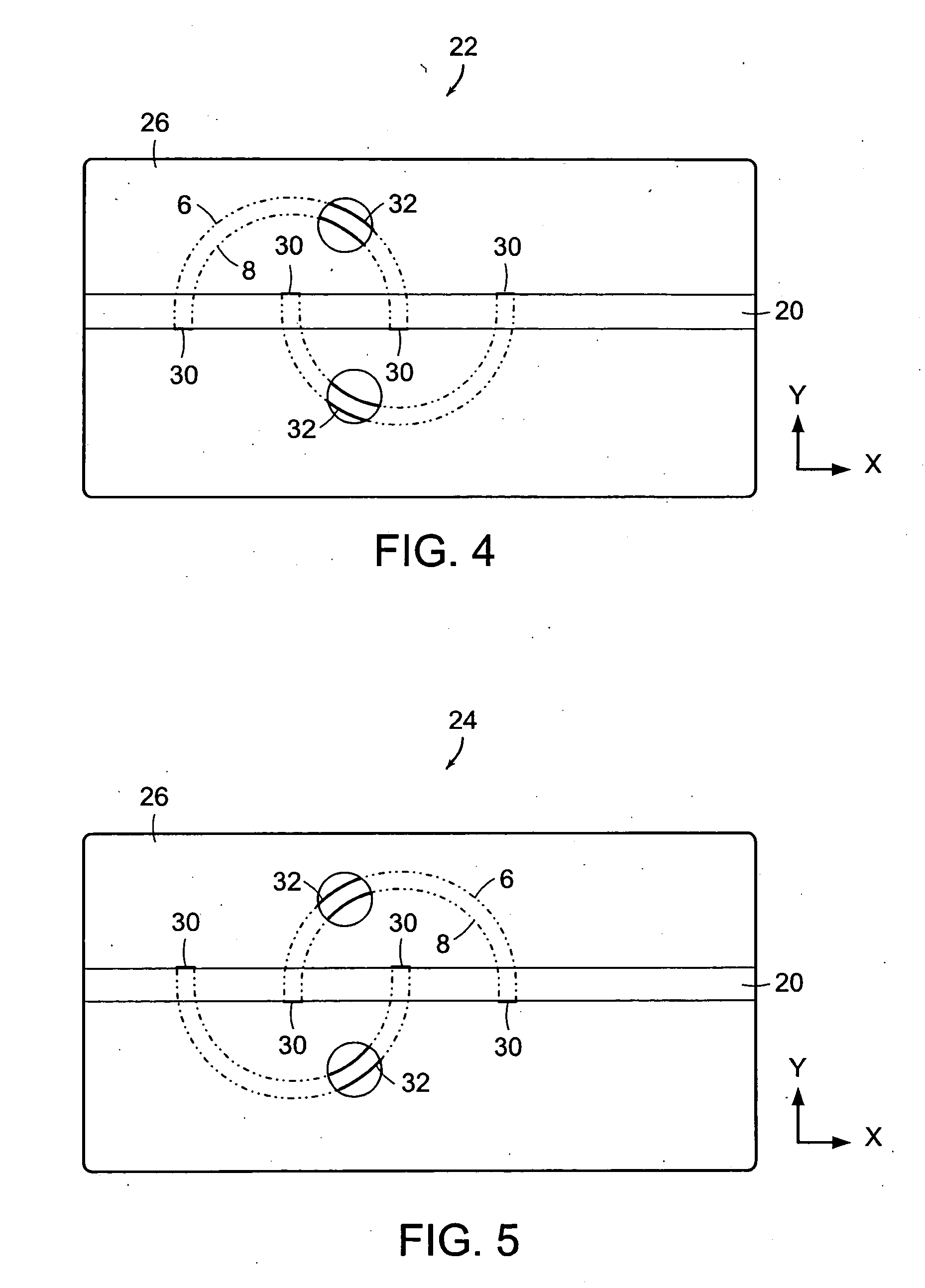

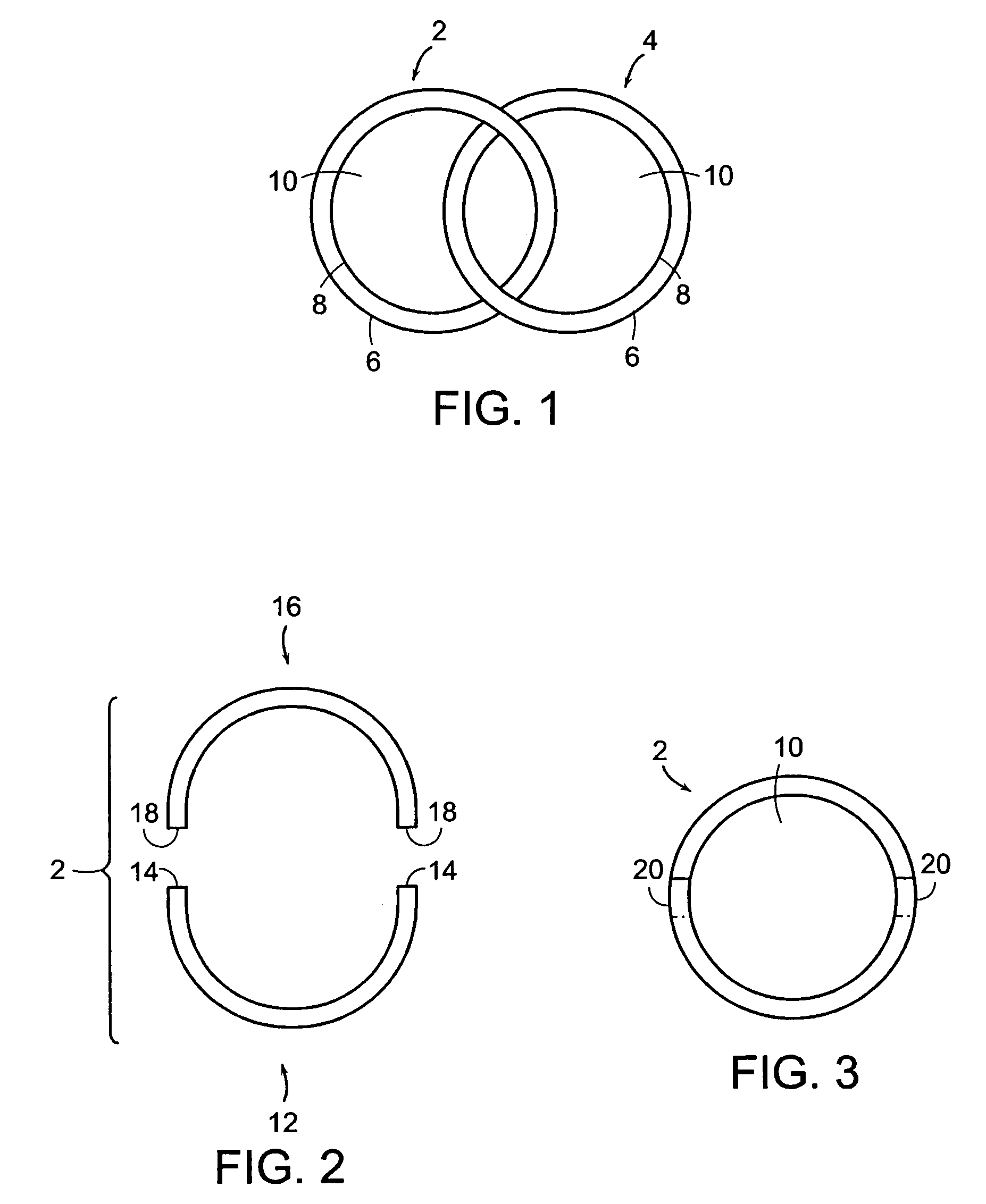

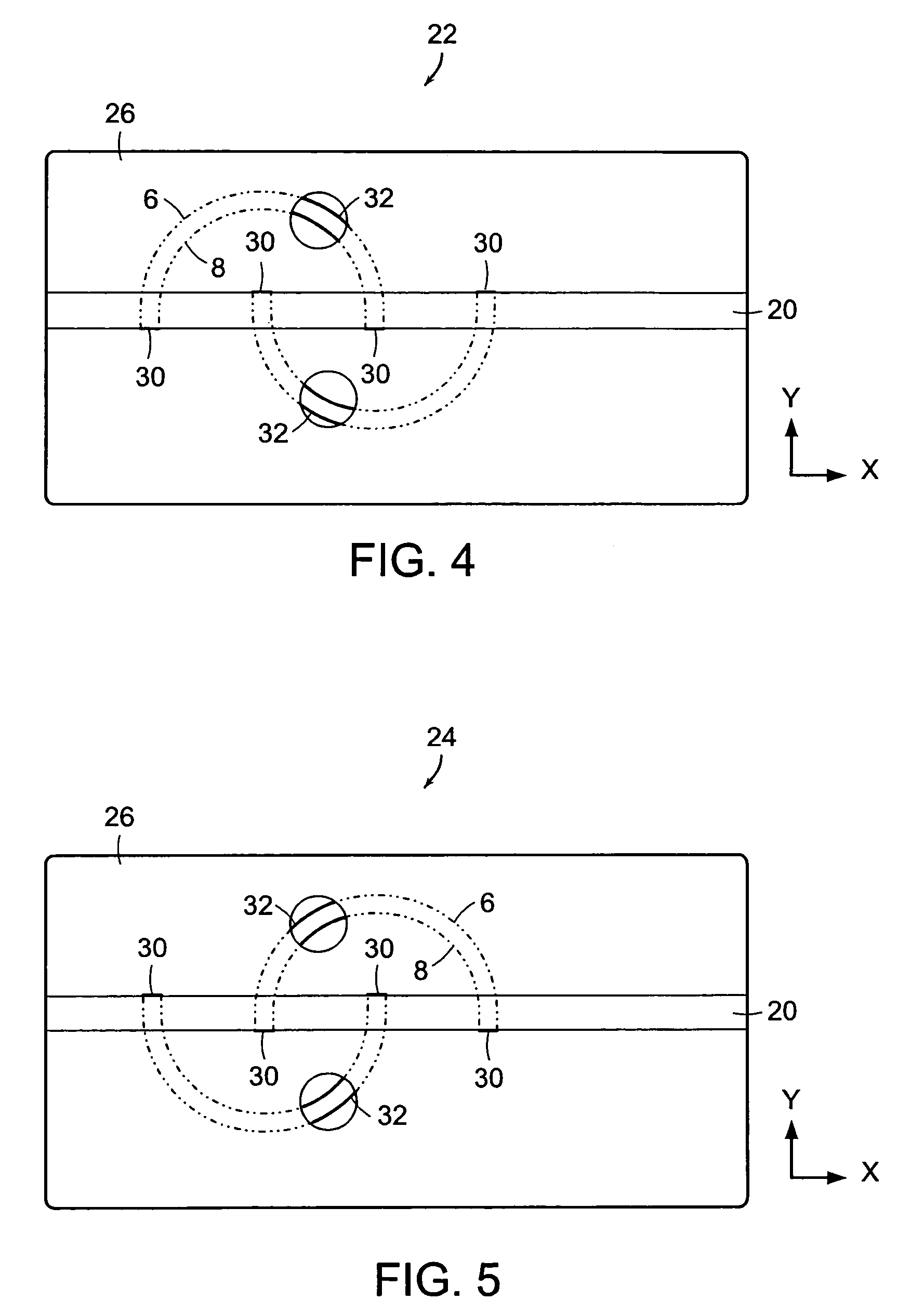

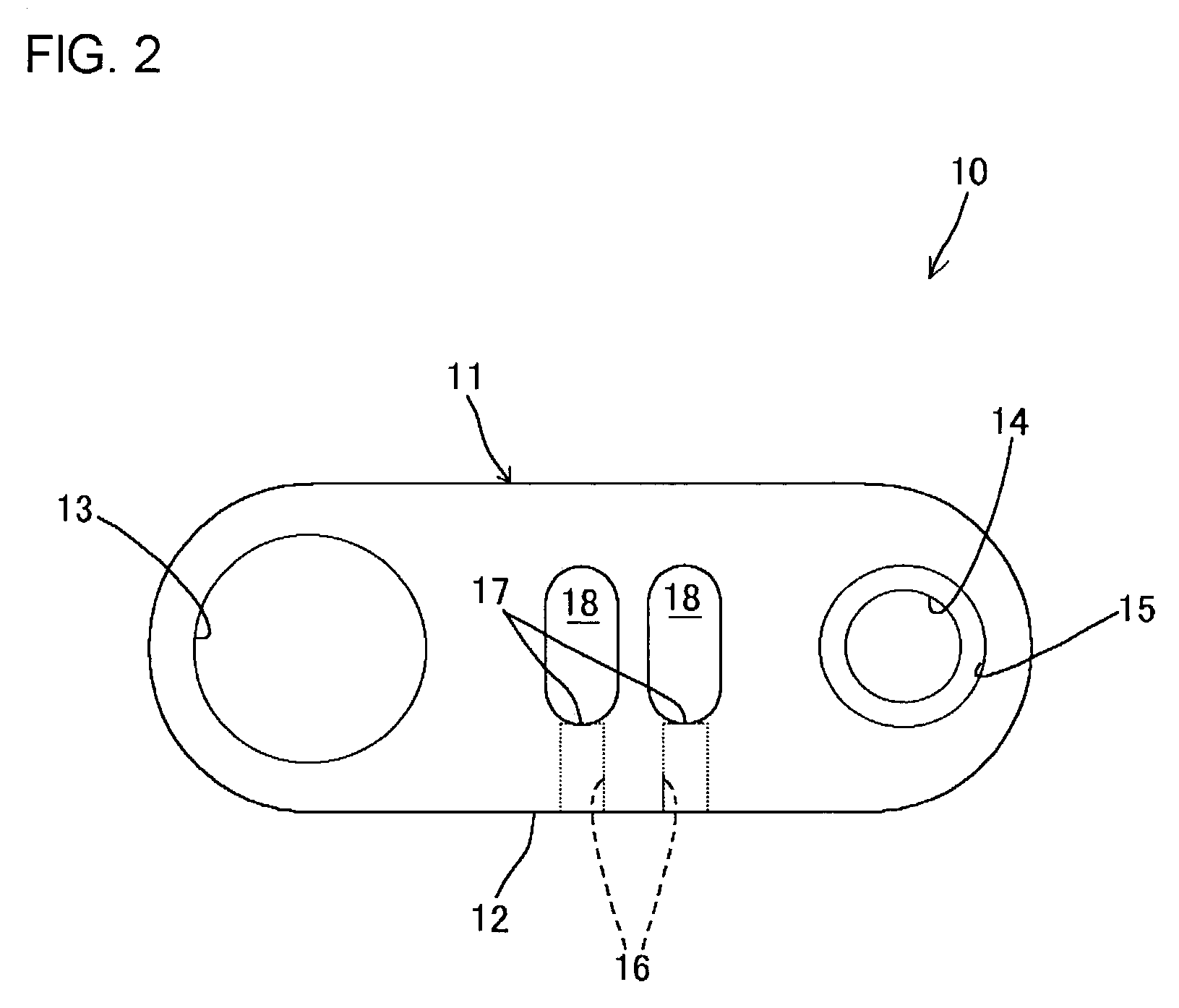

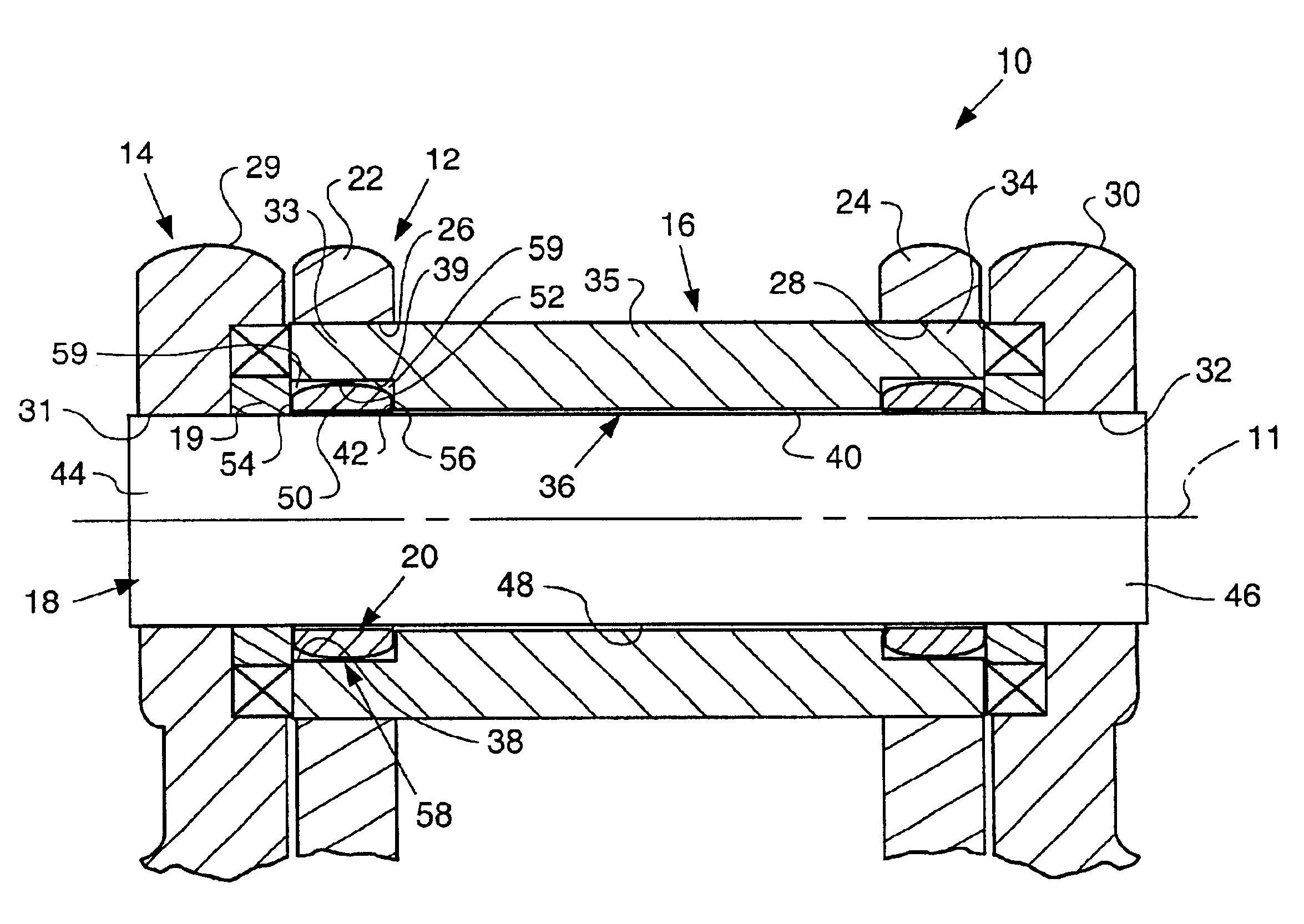

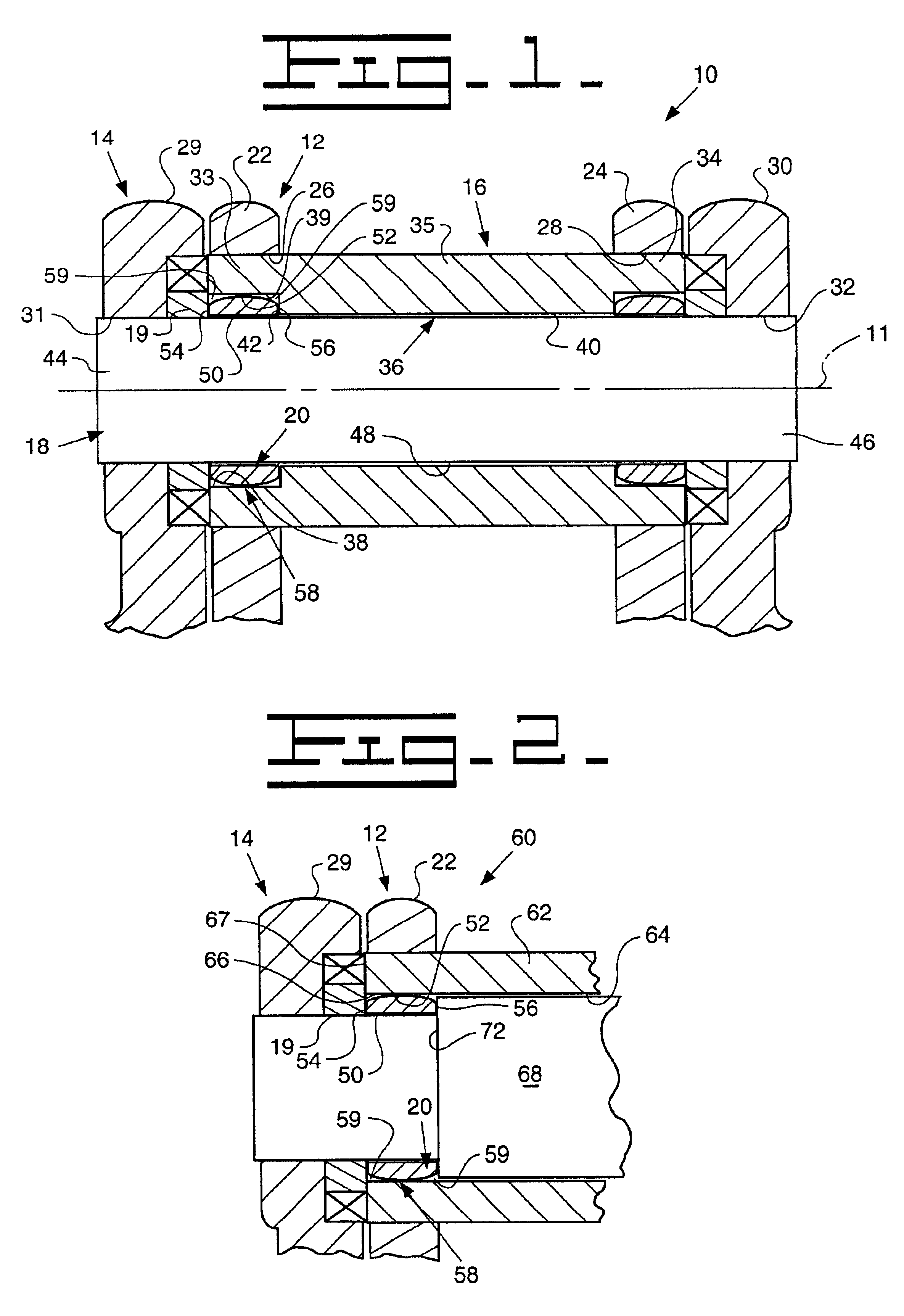

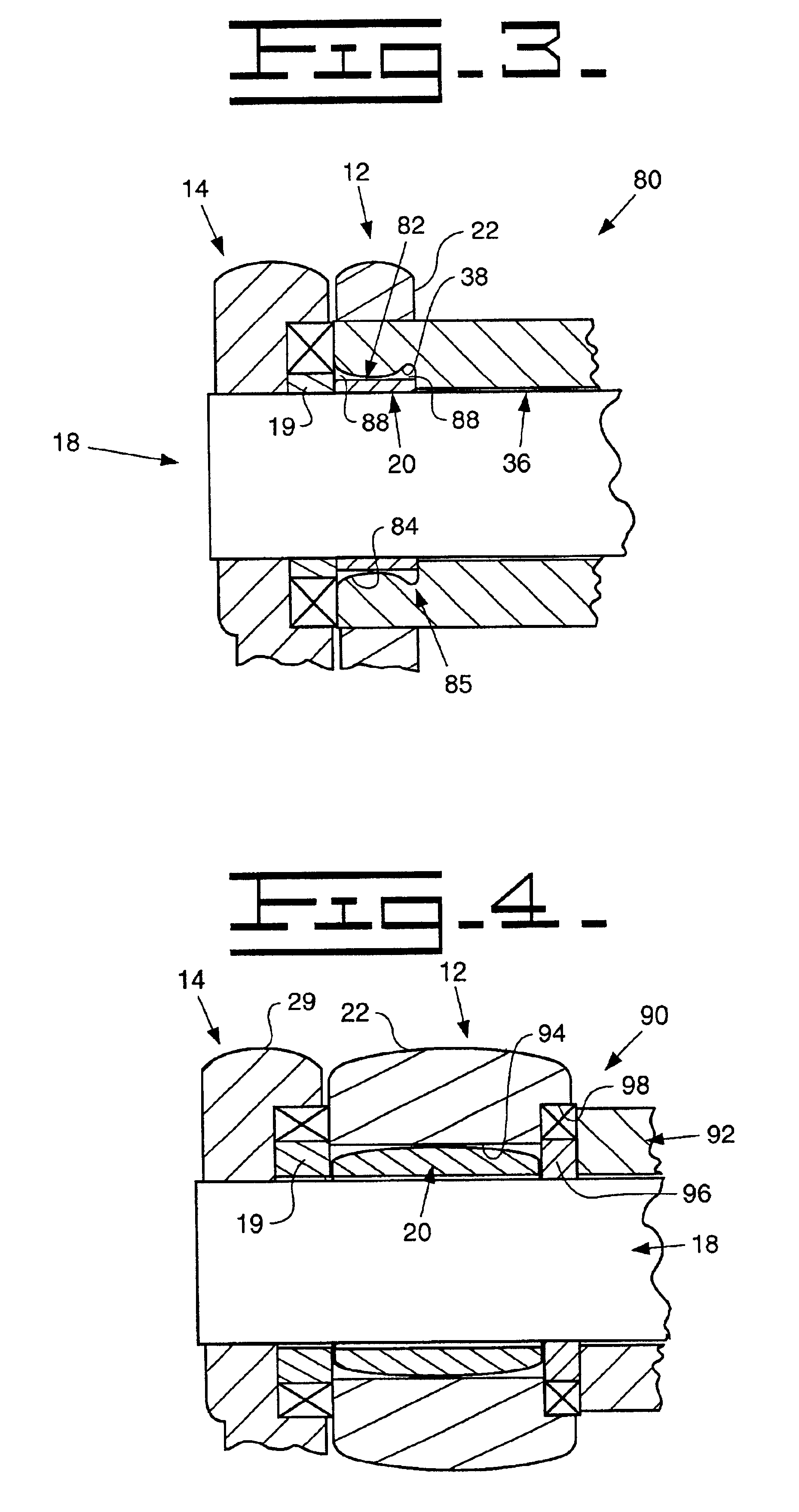

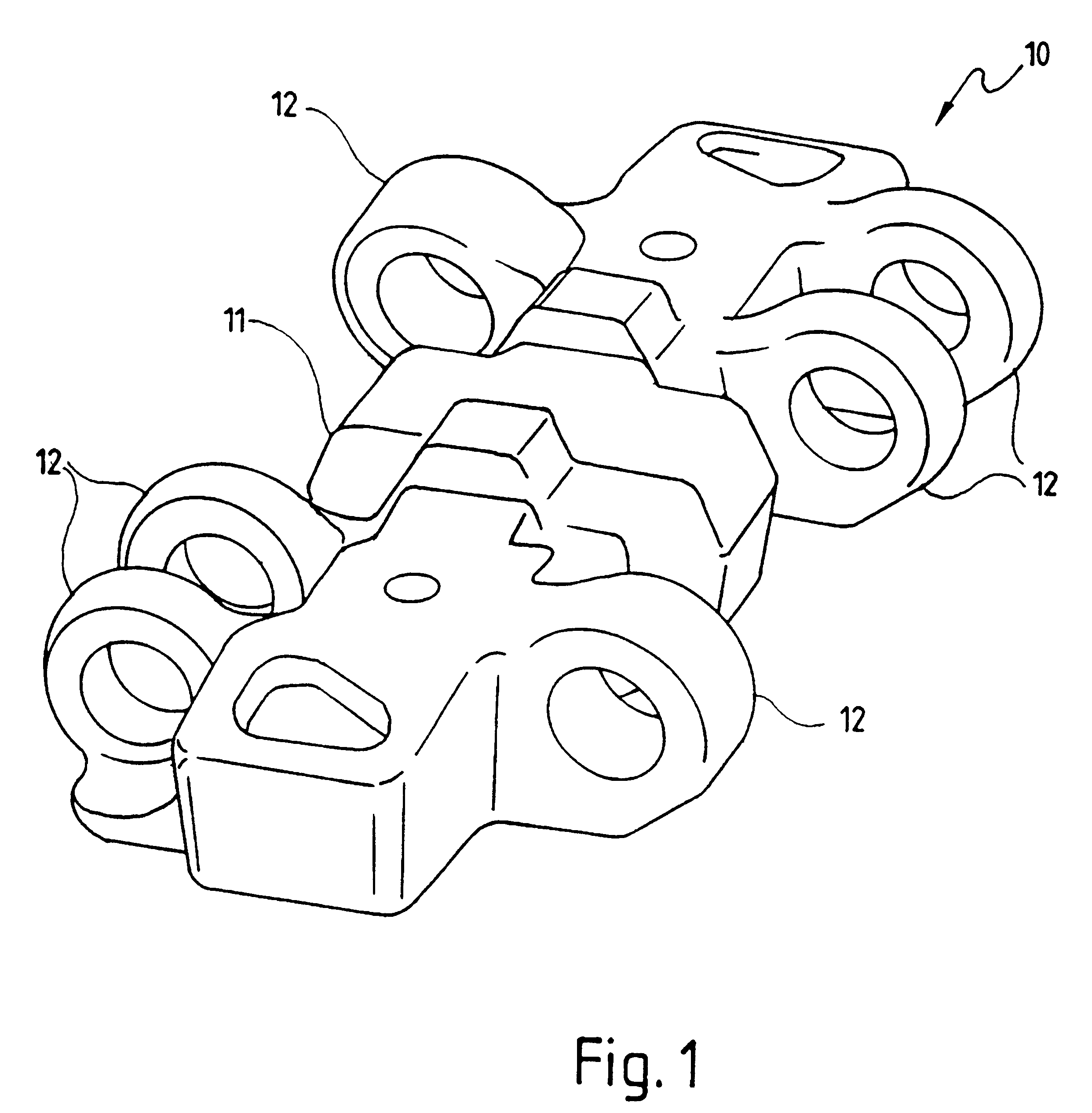

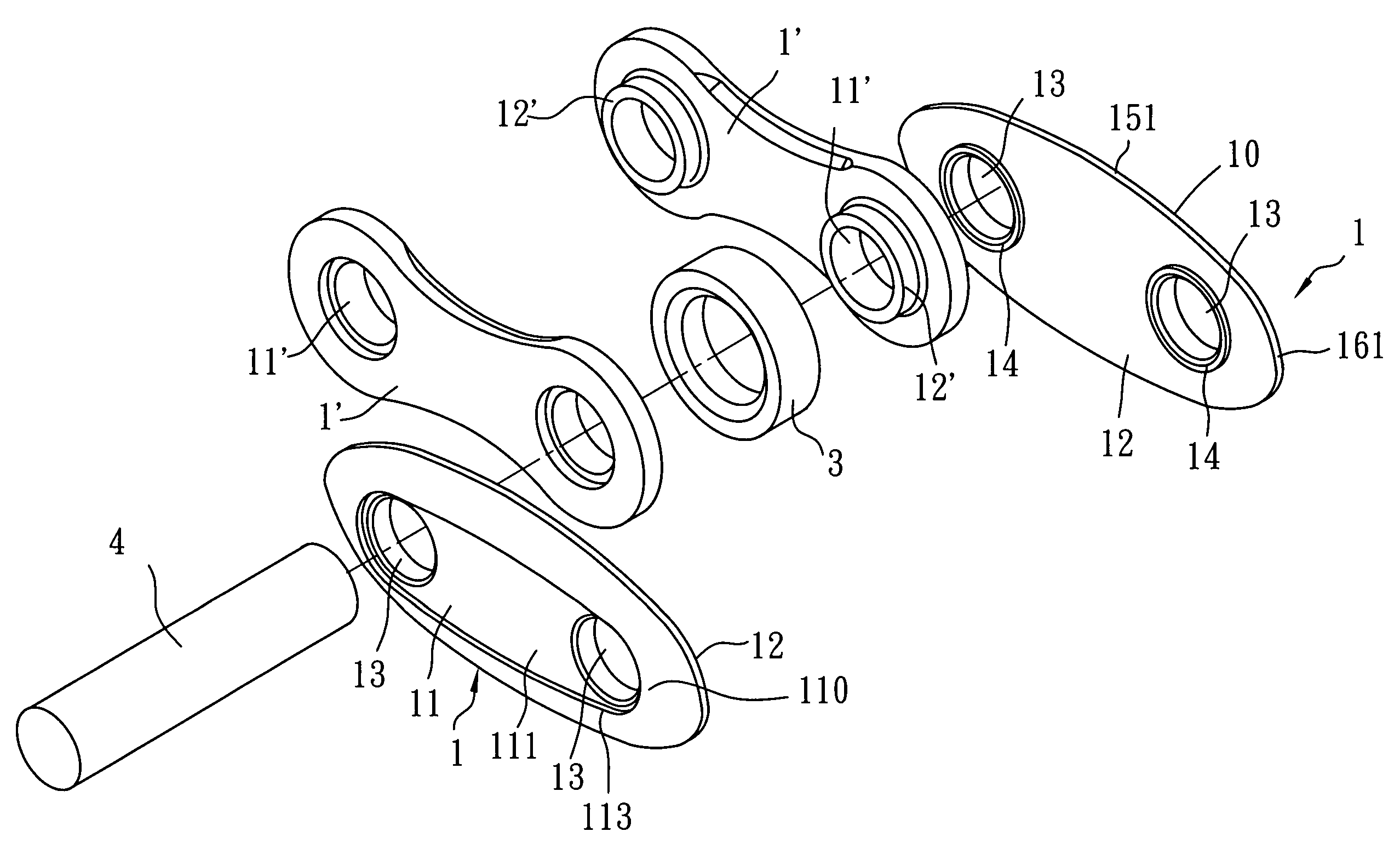

Interlaced compositions and methods of production

Disclosed are methods for producing an interlaced device or composition which includes at least a first and a second interlaced element. Each interlaced element includes a mated first and second part, the first part having two termini and the second part having two termini, and a defined central void through which the other interlaced element passes. The method includes the processing and mating of a first and a second substrate layer, each including a top surface, a bottom surface and a mating zone. The first substrate layer includes a portion corresponding to a first part of a first interlaced element and a first part of a second interlaced element. The second substrate layer includes a portion corresponding to a second part of a first interlaced element and a second part of a second interlaced element. Also disclosed are interlaced devices or compositions.

Owner:CLOZEX MEDICAL LLC

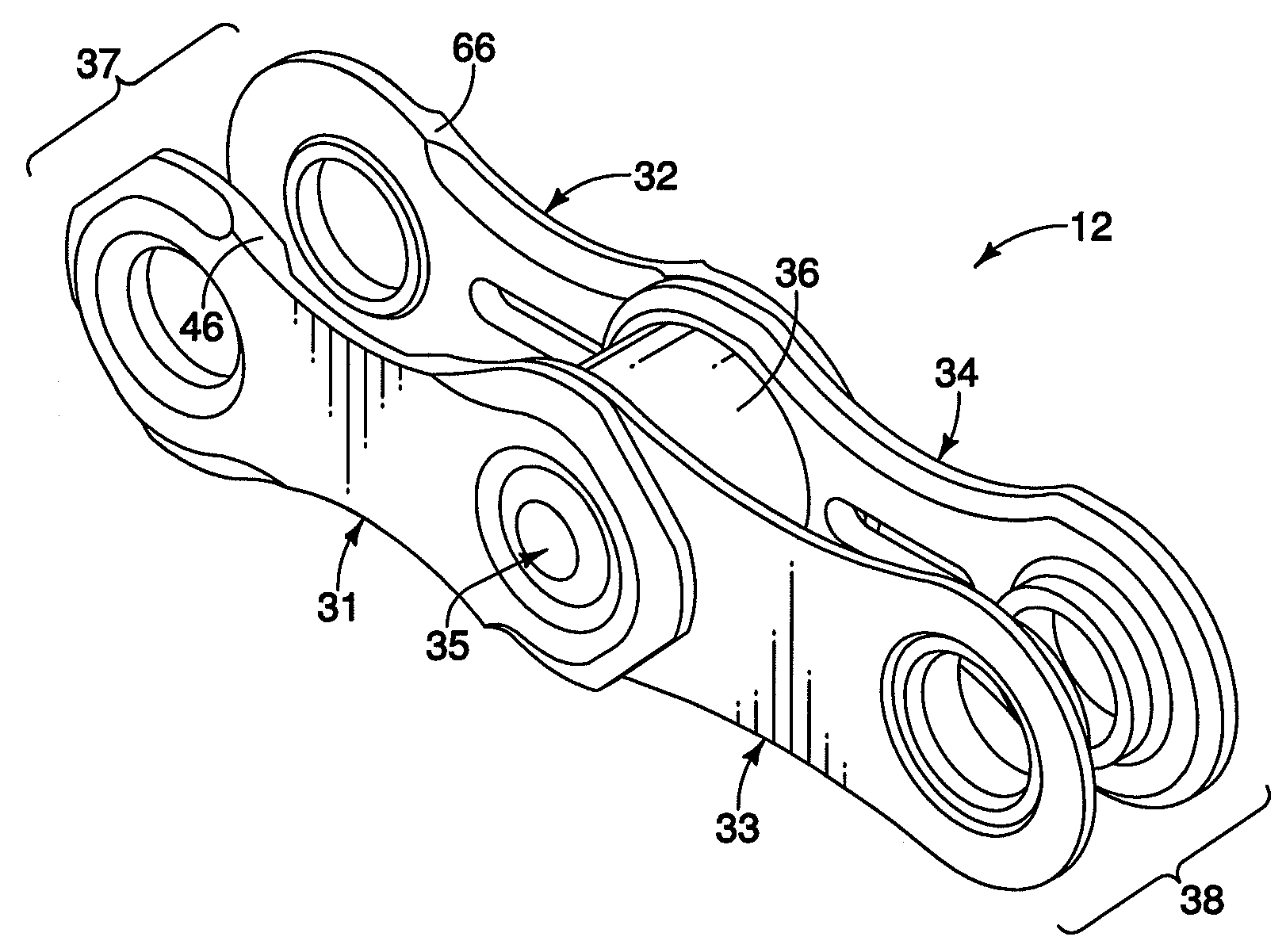

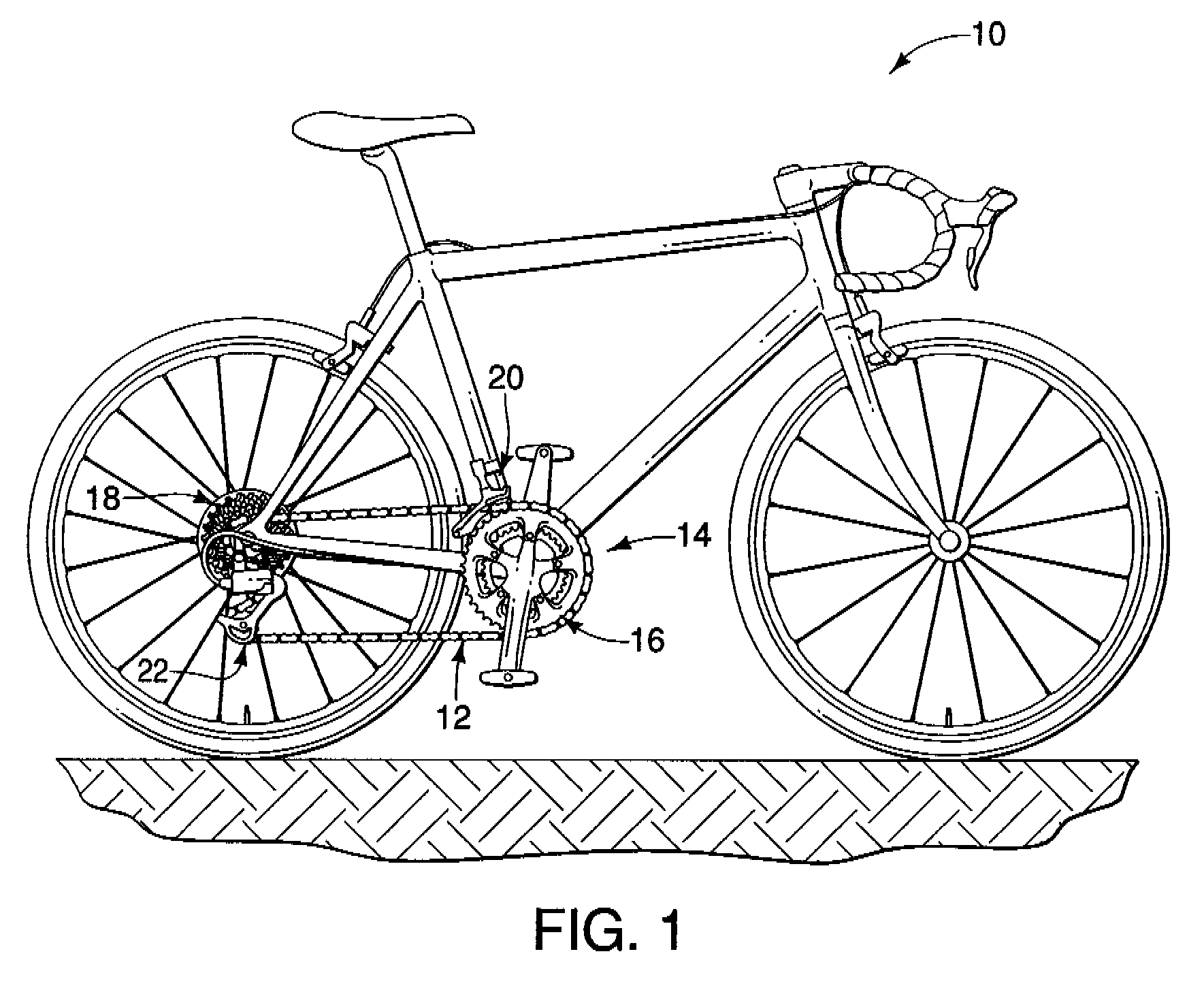

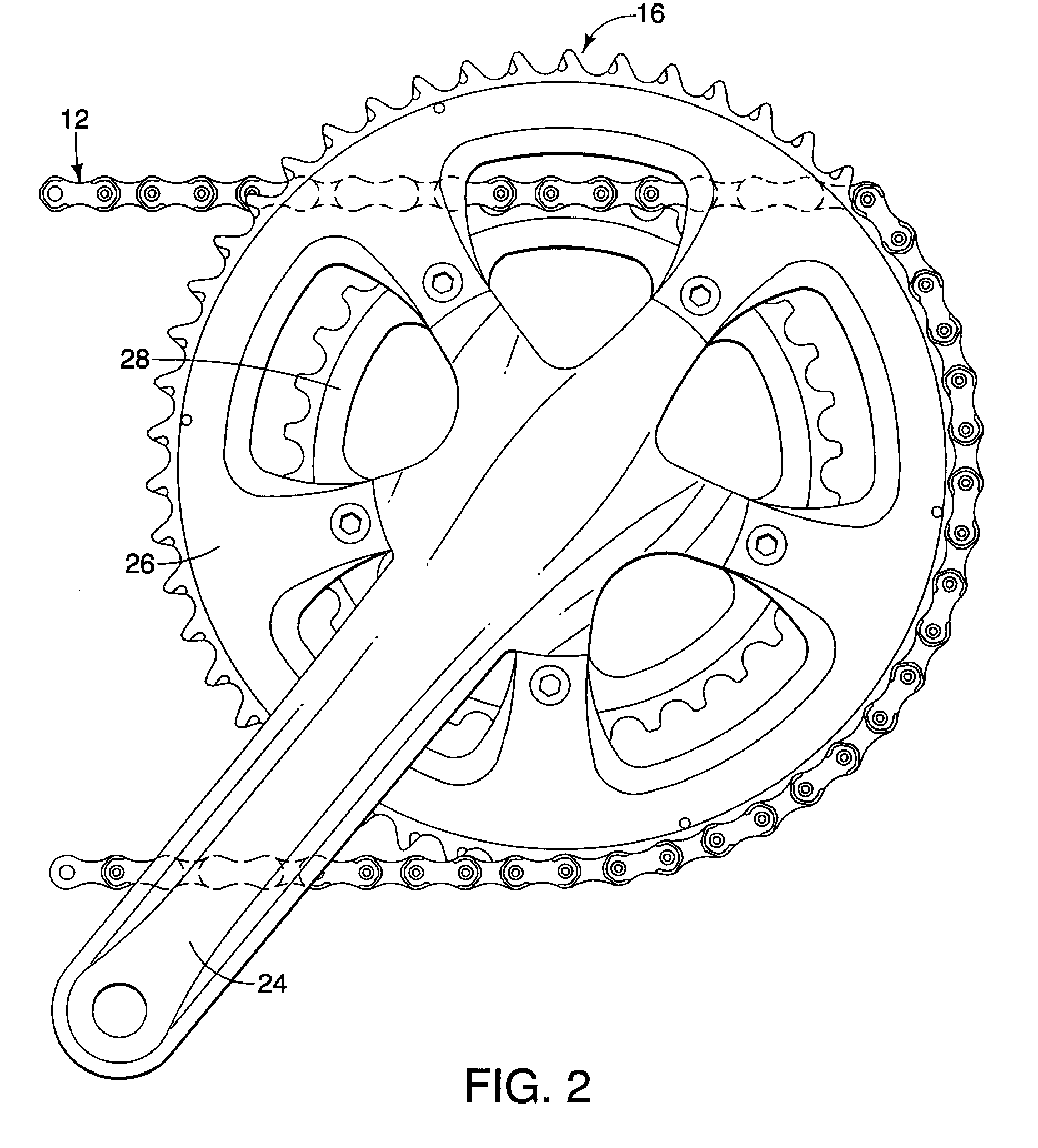

Bicycle chain

A bicycle chain has an outer link with two outer link plates, an inner link formed with two inner link plates and a link pin connecting adjacent ones of the together. The link plates are configured to aid in smoothly shifting a chain moves between sprockets. The outer link plates have the outer link peripheral edges that are shaped differently. One of the outer link plates has an exteriorly facing surface with a first chamfered outer edge portion extending along a section of its outer link peripheral edge at a first end portion and a first reduced area part having a reduced radial dimension with respect to a radial dimension of the first end portion lying along a longitudinal axis. The inner link plates have center connecting portions with different minimum widths.

Owner:SHIMANO INC

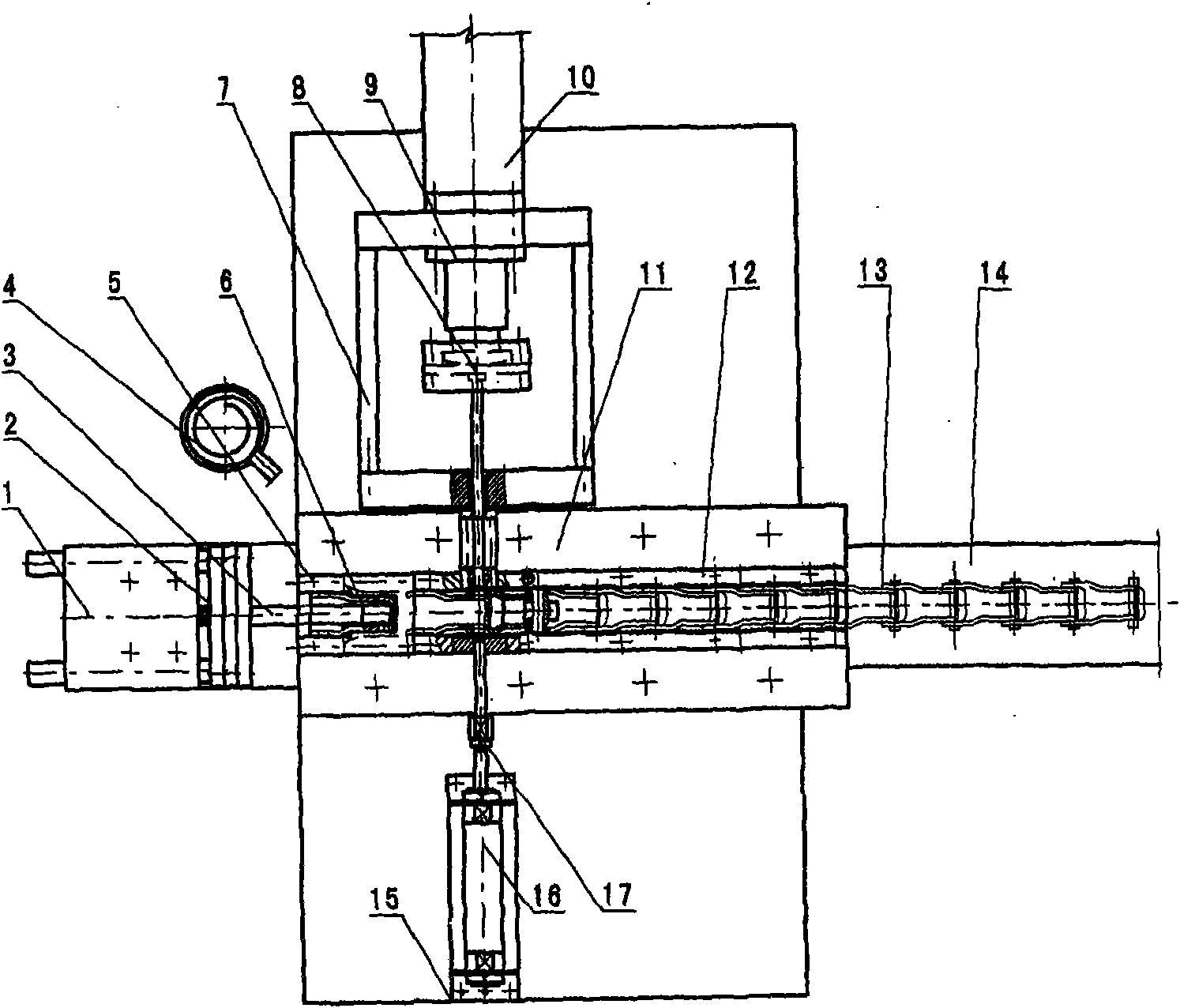

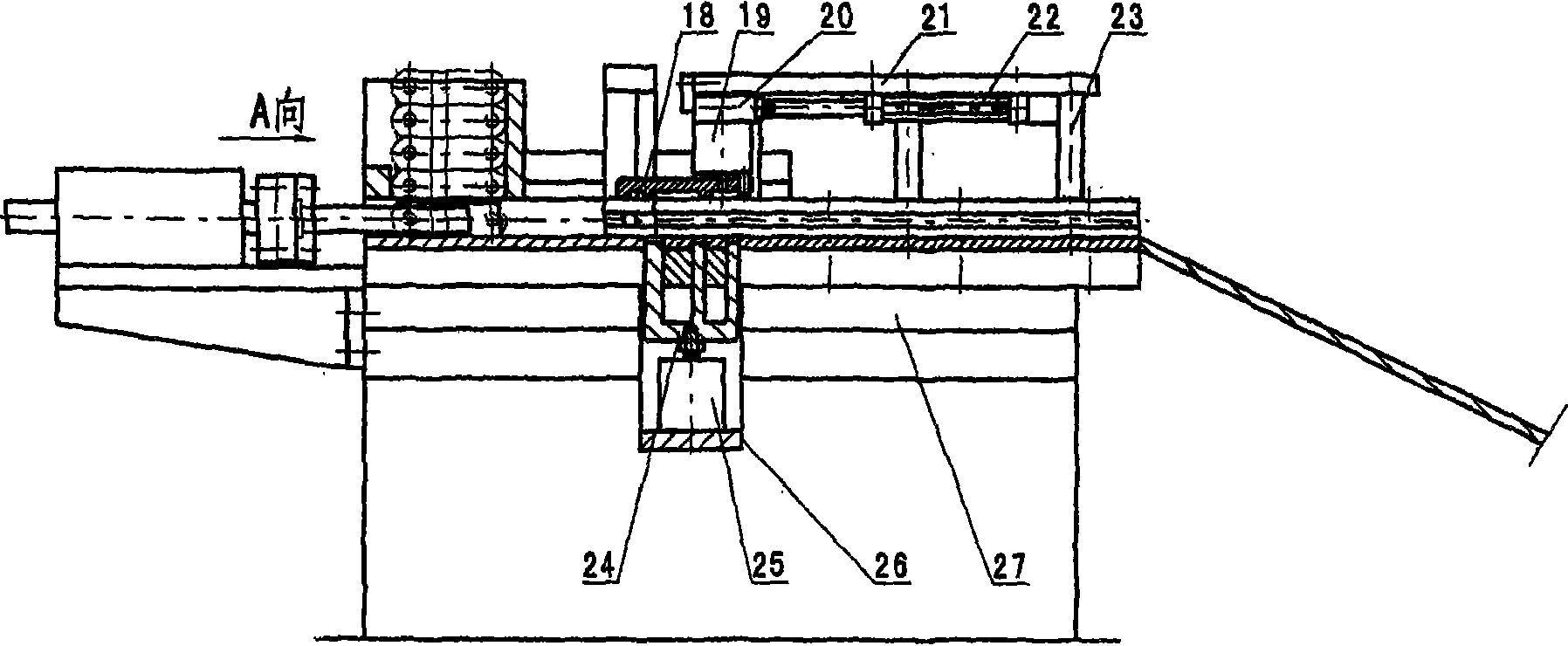

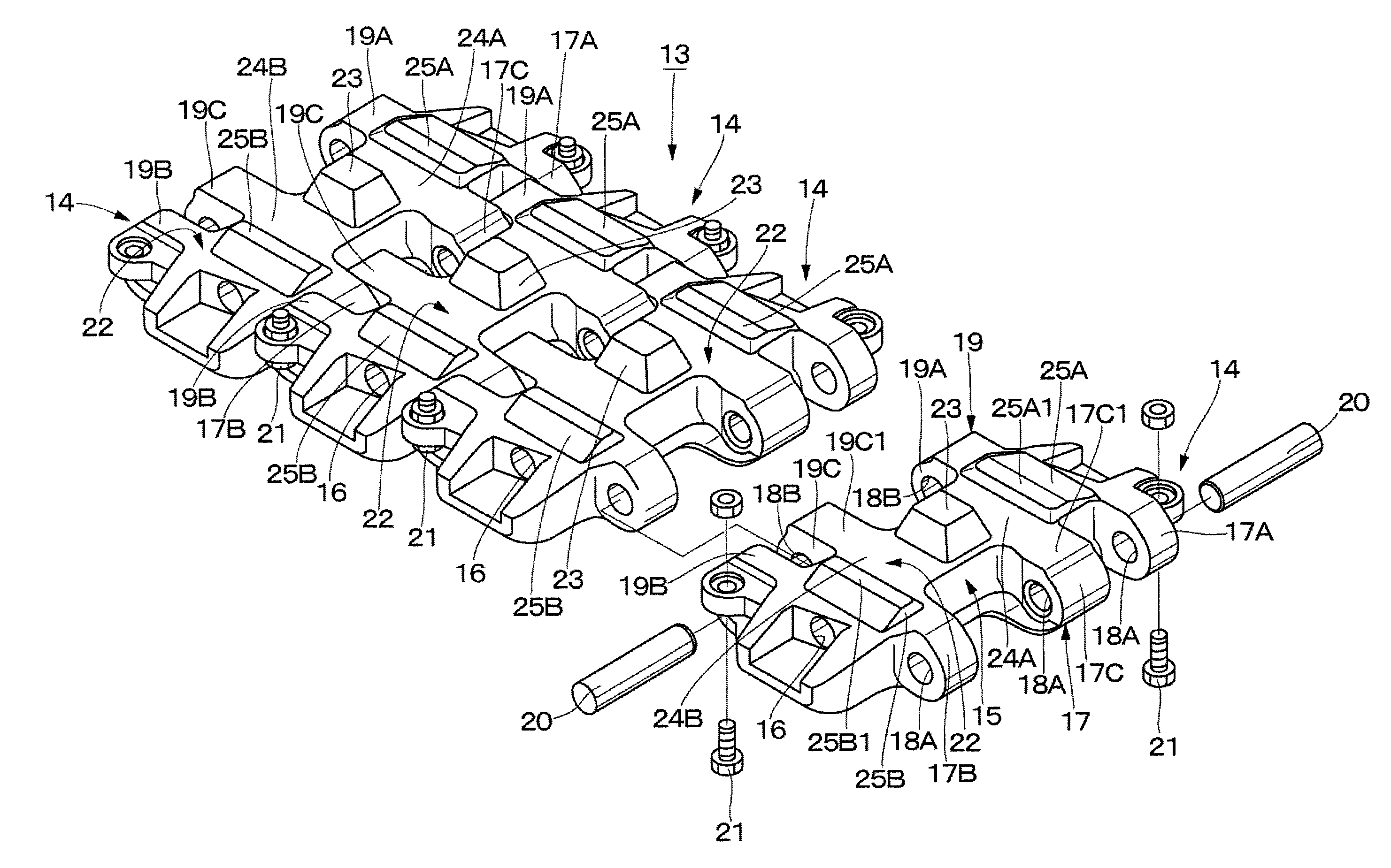

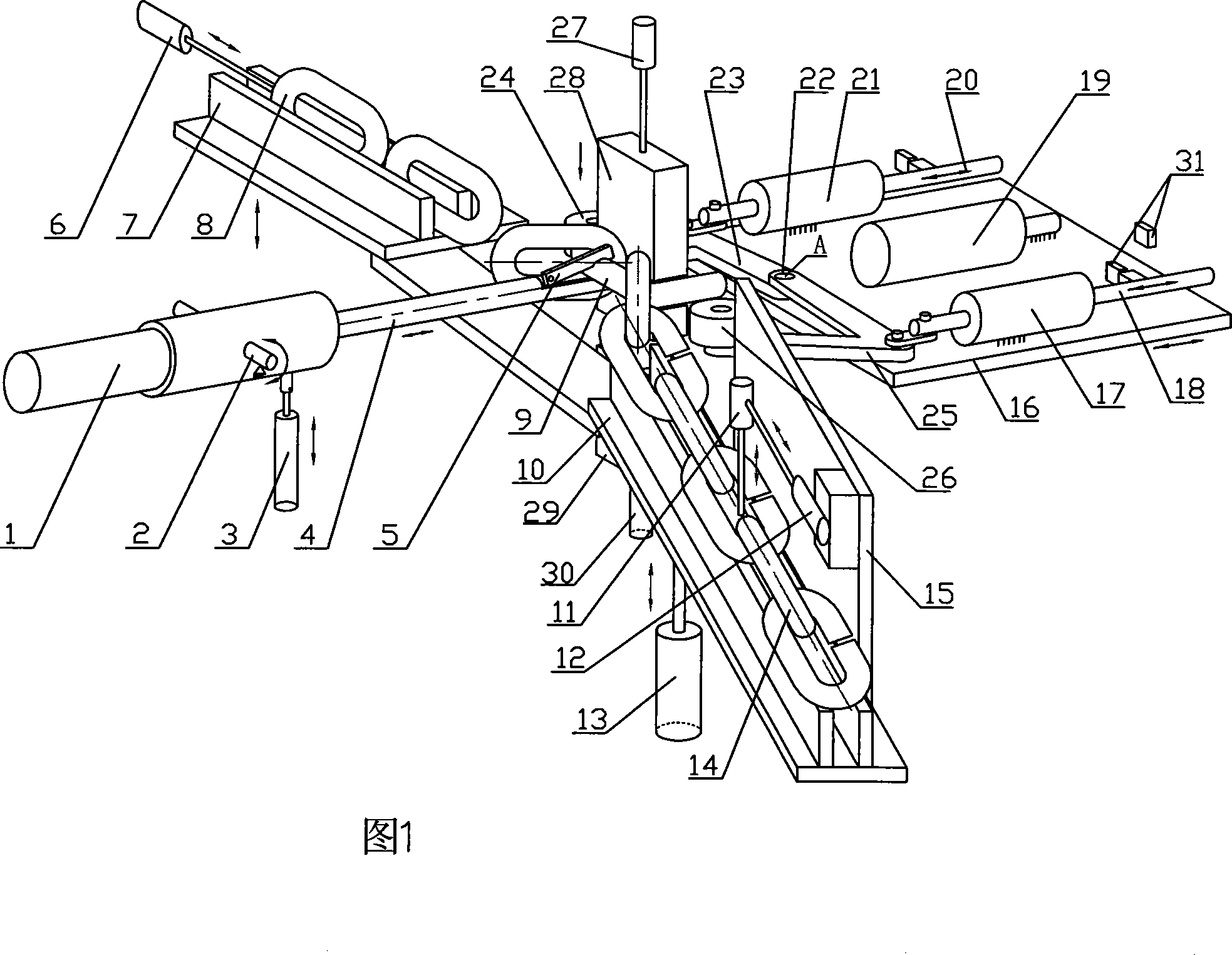

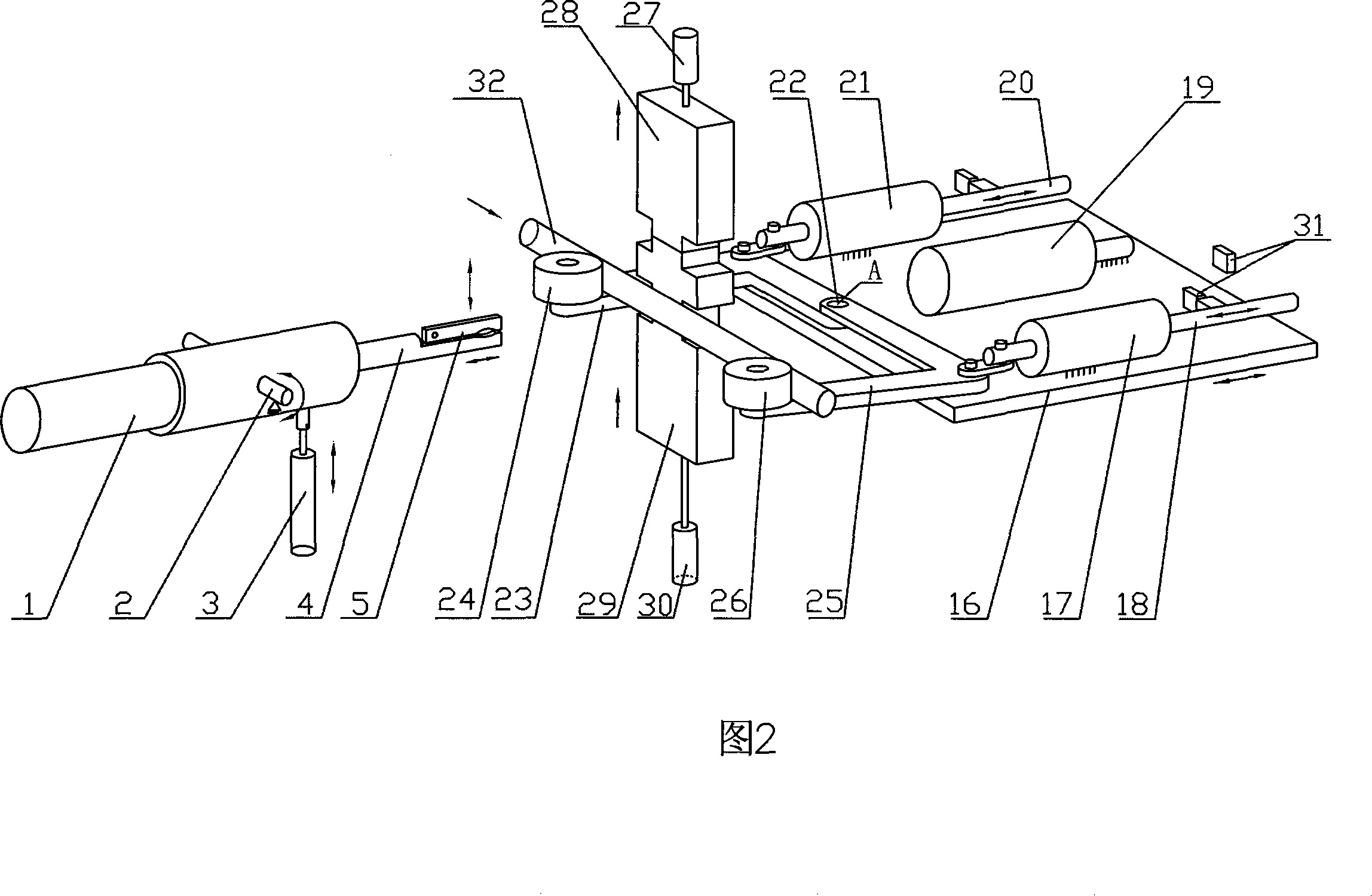

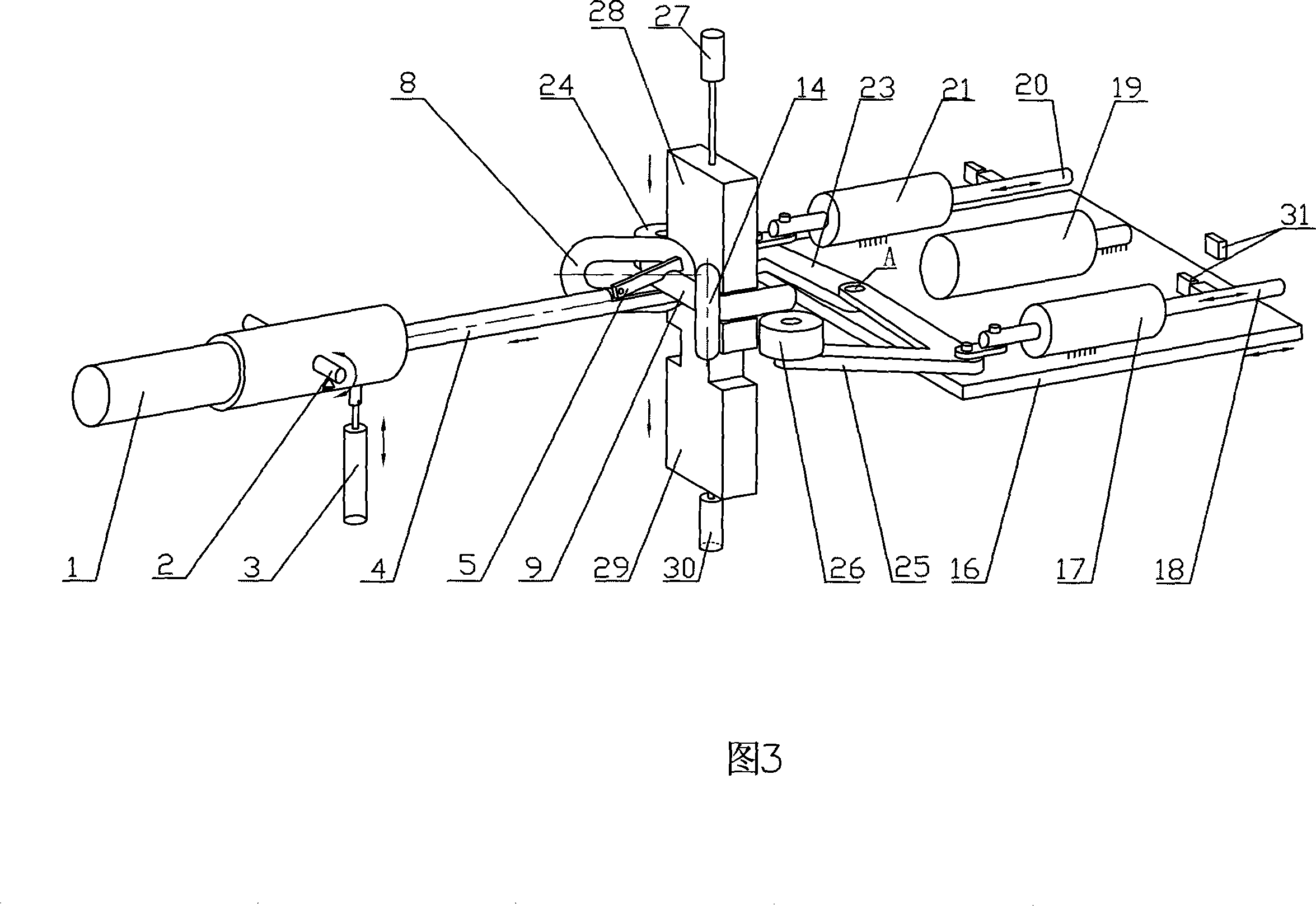

Pintle chain automatic assembly machine

InactiveCN101676049AGood assembly precisionSolve the shortcomings of manual assemblyMetal chainsControl systemEngineering

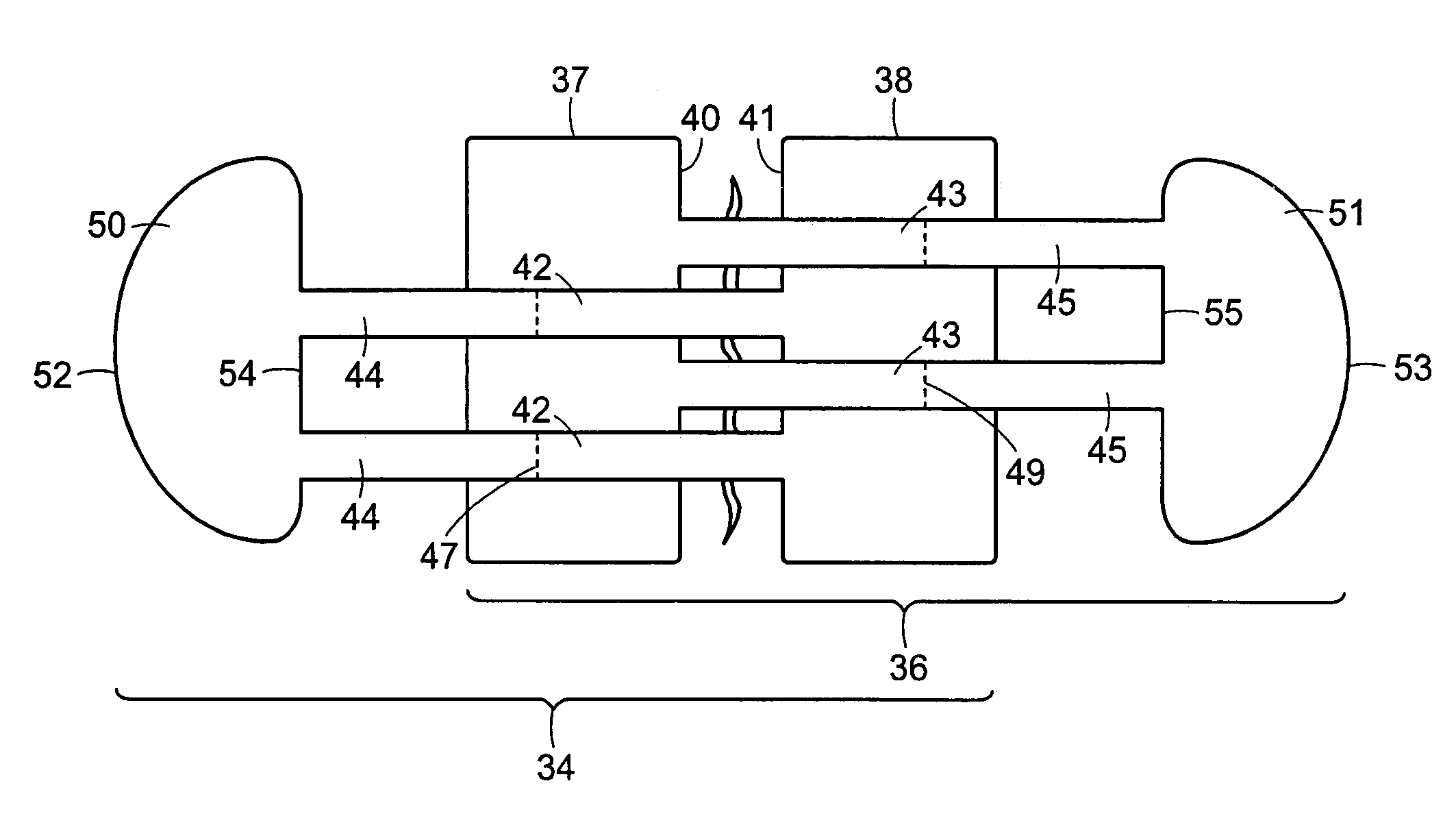

The invention relates to a pintle chain automatic assembly machine, belonging to the technical field of chain manufacturing machinery. The invention aims to provide a pintle chain automatic assembly machine which is suitable for the assembly production process of pintle chains and has good precision control and high production efficiency. The technical key of the pintle chain automatic assembly machine in that the assembly machine comprises a frame, a link plate feeding mechanism, a link plate positioning mechanism, a pin-penetrating mechanism, a chain element moving mechanism, a PLC automaticcontrol system and a discharging plate, wherein the link plate feeding mechanism comprises a double-cylinder feeding air cylinder (1) and a feeding pole (3) which are arranged in the front of the frame (27) and a link plate-feeding box (5); the link plate positioning mechanism comprises a positioning air cylinder (25) and a positioning block (24) which are arranged below the platen of the frame;the chain pin feeding and pin-penetrating mechanism comprises a pin-pressing air cylinder (10) and a pin-introducing air cylinder (16) which are arranged on the two sides of the parallel track of theplaten of the frame and a vibration pin-distributing disk (4), a pin-sending hose (30) and a pin-collecting box (32) which are arranged on the platen of the frame; the chain element moving mechanism comprises a moving air cylinder (22) and a chain element-pressing air cylinder (19) which are arranged above the platen of the frame; the discharging plate (14)is arranged on the backside of the platenof the frame.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

Interlaced compositions and methods of production

InactiveUS7332641B2Suture equipmentsLighting support devicesStructural engineeringMechanical engineering

Disclosed are methods for producing an interlaced device or composition which includes at least a first and a second interlaced element. Each interlaced element includes a mated first and second part, the first part having two termini and the second part having two termini, and a defined central void through which the other interlaced element passes. The method includes the processing and mating of a first and a second substrate layer, each including a top surface, a bottom surface and a mating zone. The first substrate layer includes a portion corresponding to a first part of a first interlaced element and a first part of a second interlaced element. The second substrate layer includes a portion corresponding to a second part of a first interlaced element and a second part of a second interlaced element. Also disclosed are interlaced devices or compositions.

Owner:CLOZEX MEDICAL LLC

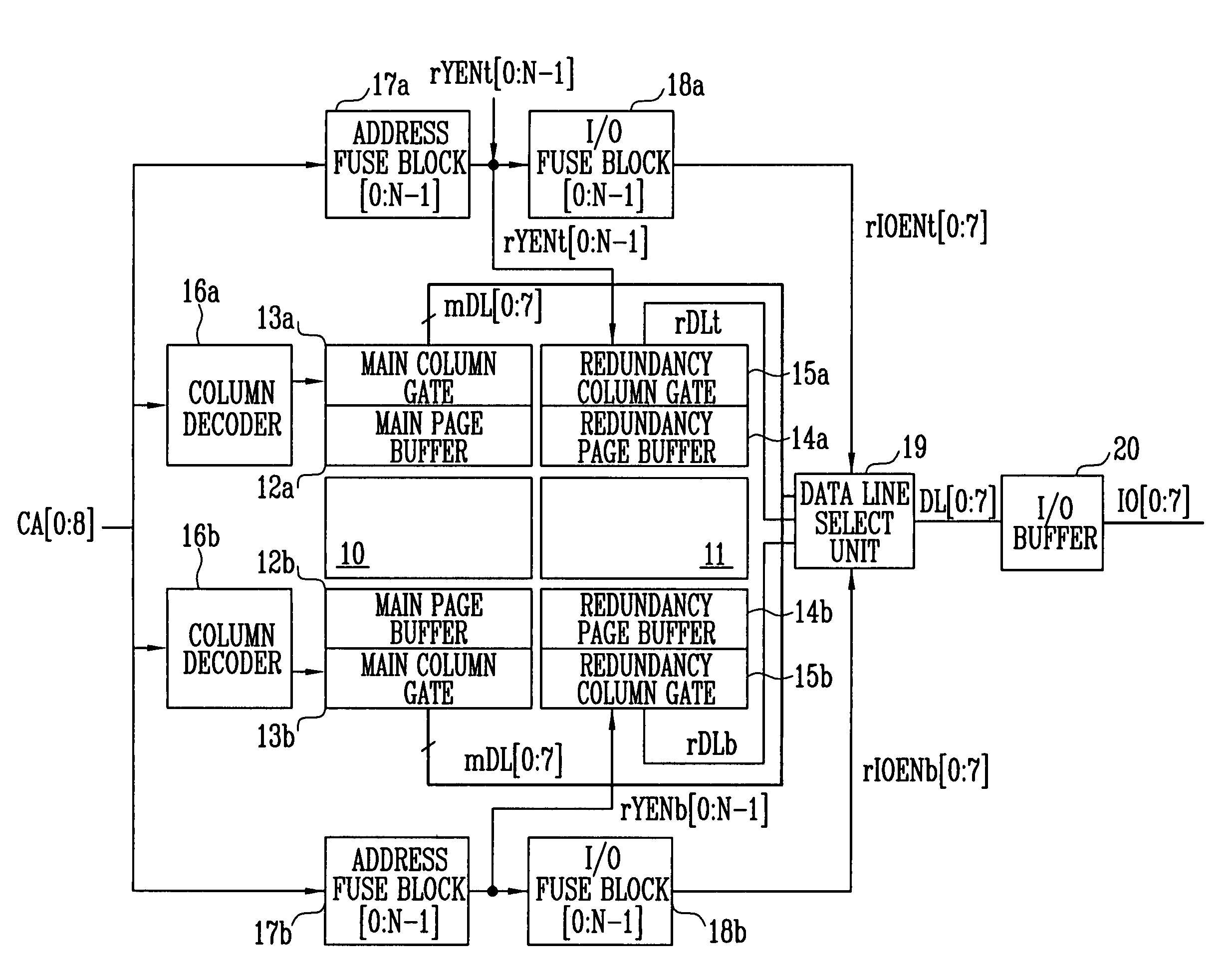

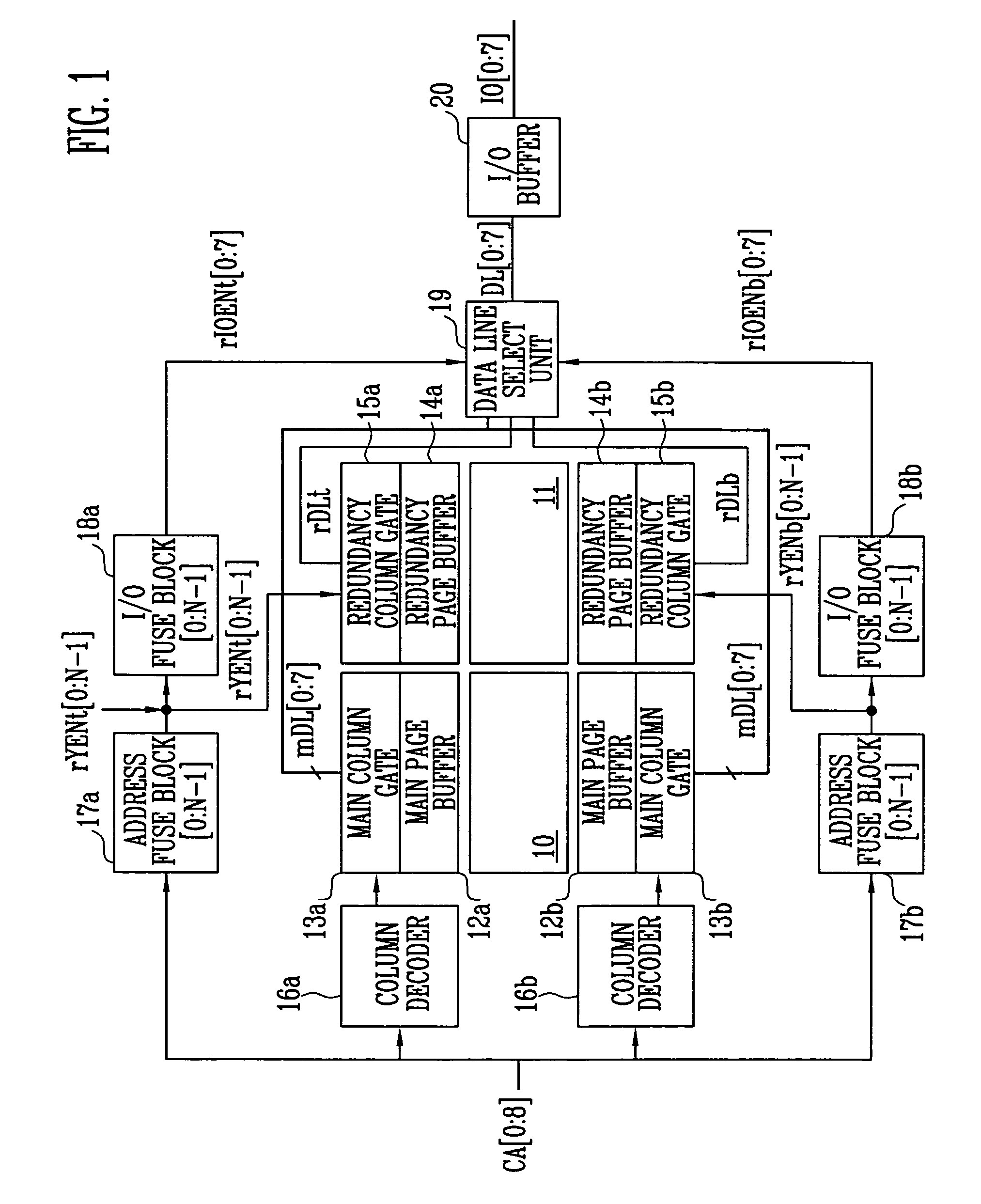

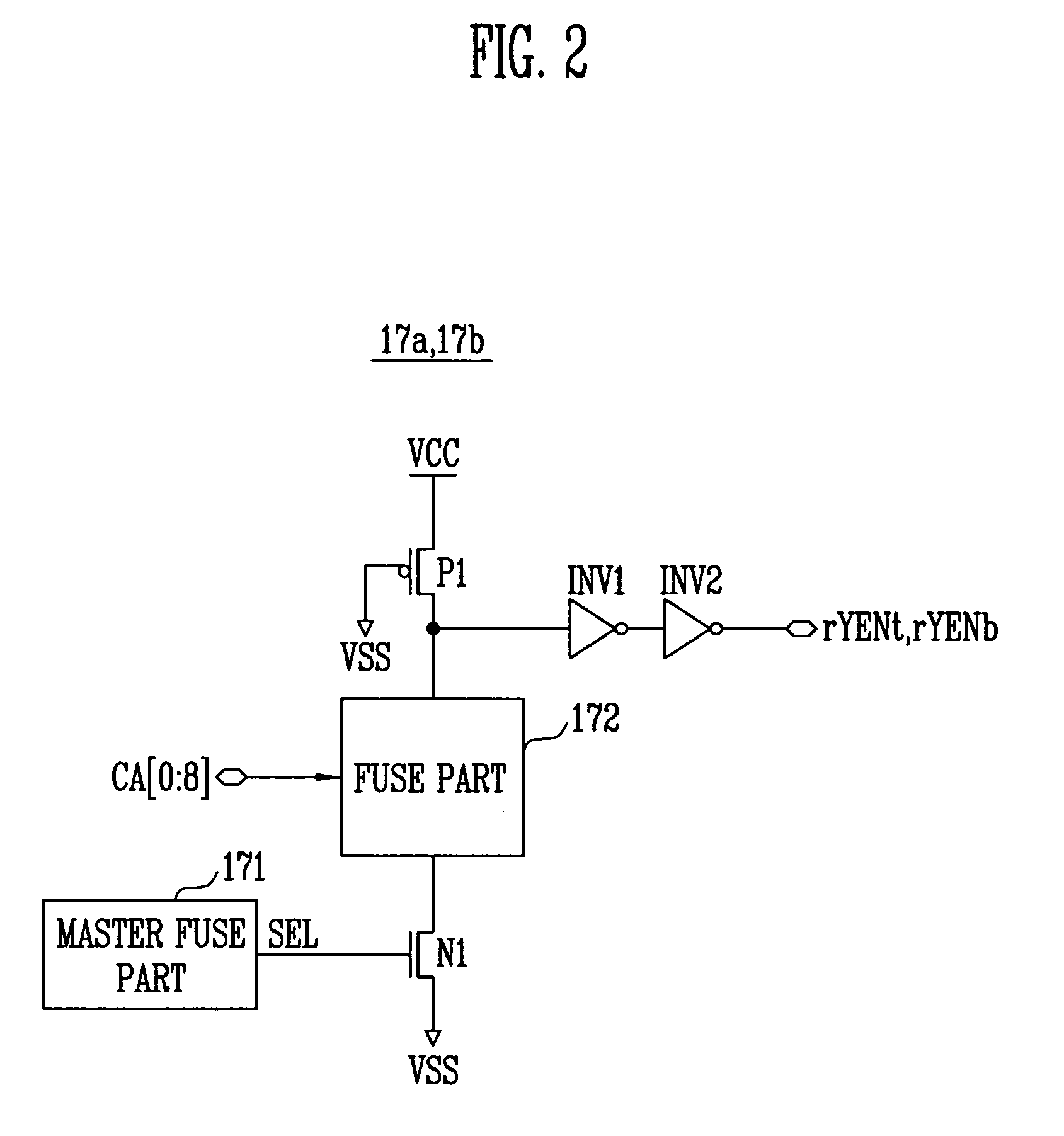

Multi-input/output repair method of NAND flash memory device and NAND flash memory device thereof

A multi-I / O repair method of a NAND flash memory device and a NAND flash memory device thereof are disclosed. A NAND flash memory device is disclosed in which page buffers are positioned at the top and bottom of a main array and a redundancy array and have different data lines. The top / bottom page buffers of the redundancy array are all selected according to an external address and data is transmitted over redundancy data lines, and this data is finally selected through a data line select unit. Accordingly, if main columns having different addresses are to be repaired, they can be replaced with redundancy columns one to one and multi-I / O repair of two main columns having the same address is thus possible.

Owner:STMICROELECTRONICS SRL +1

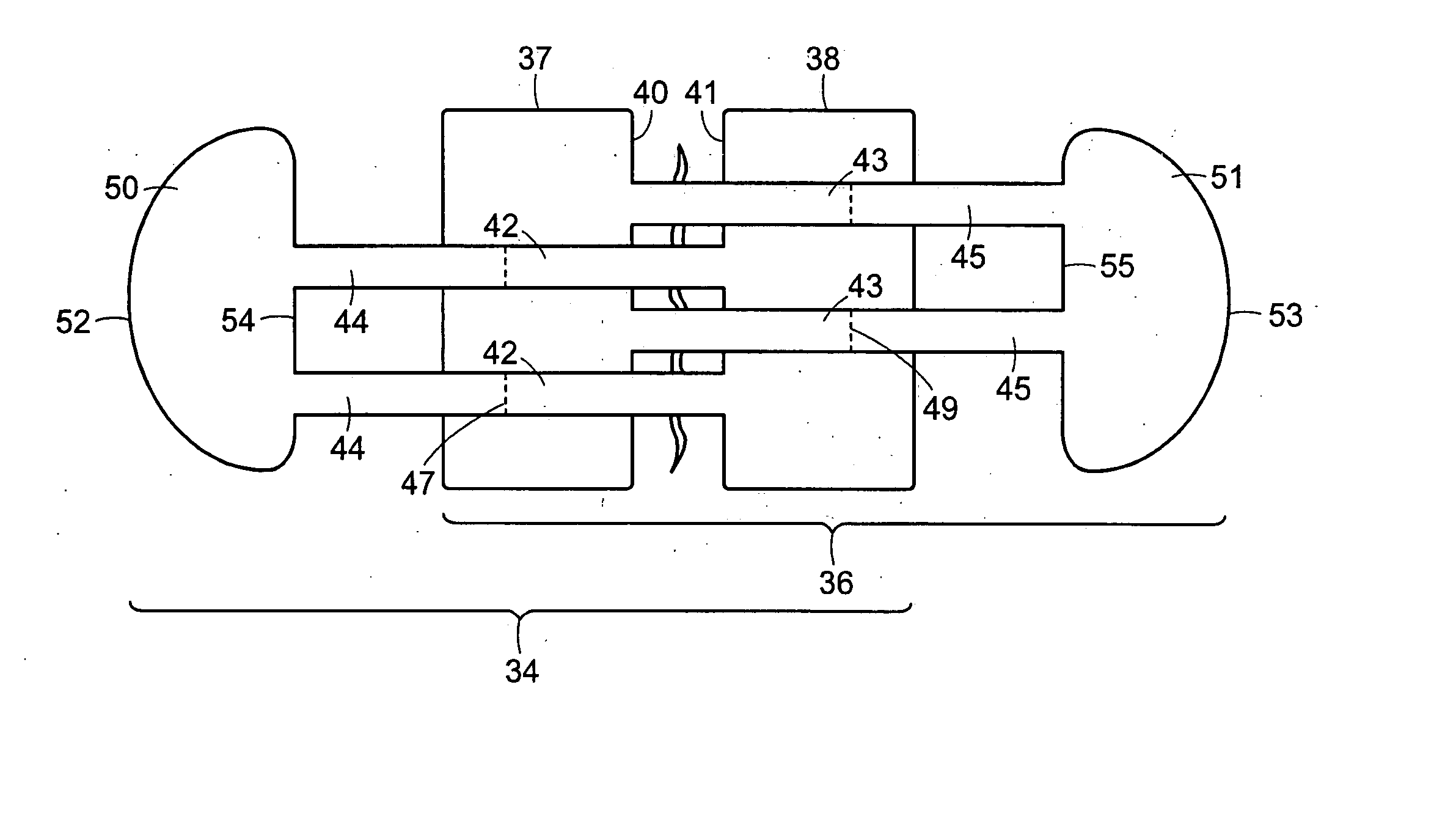

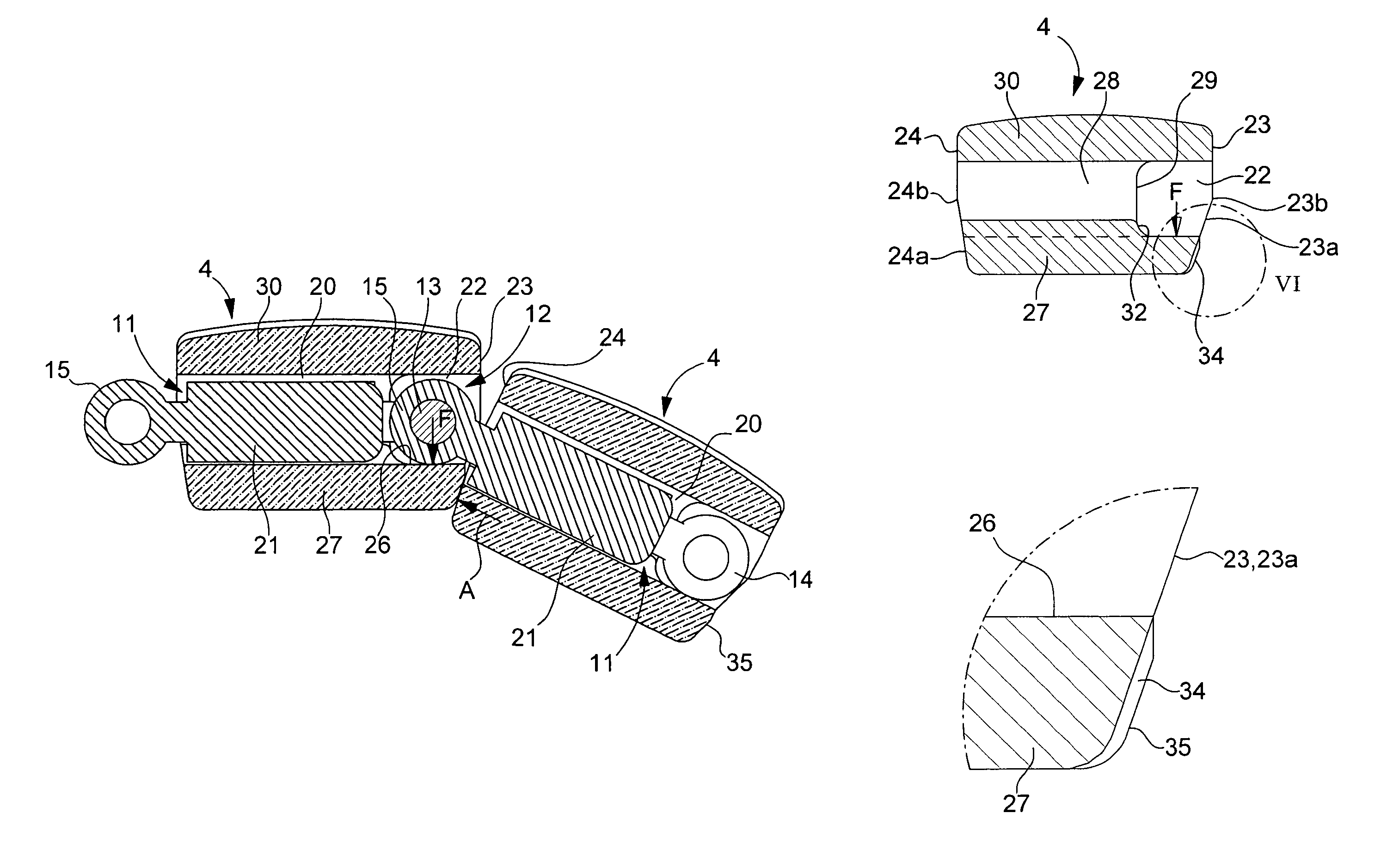

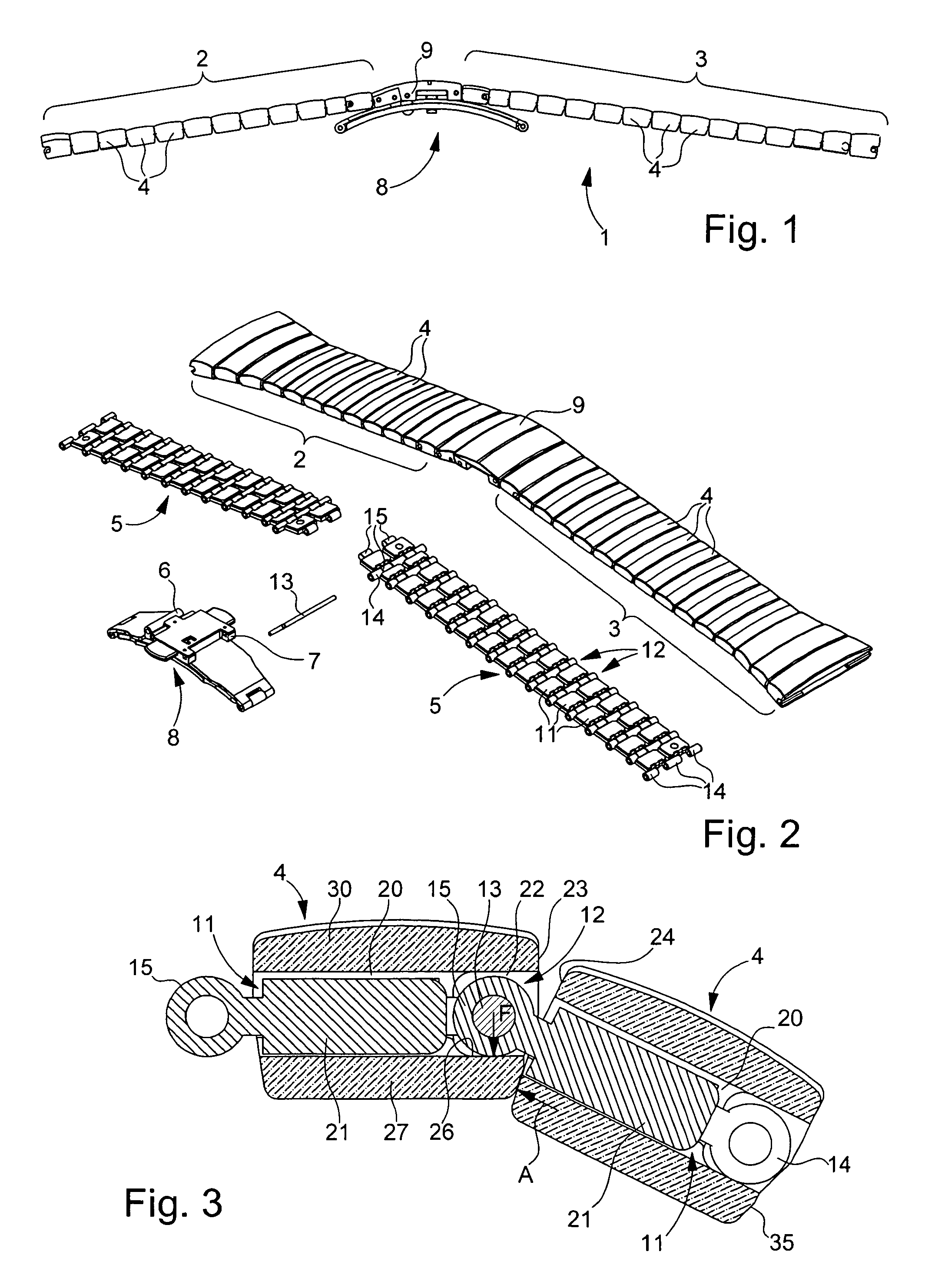

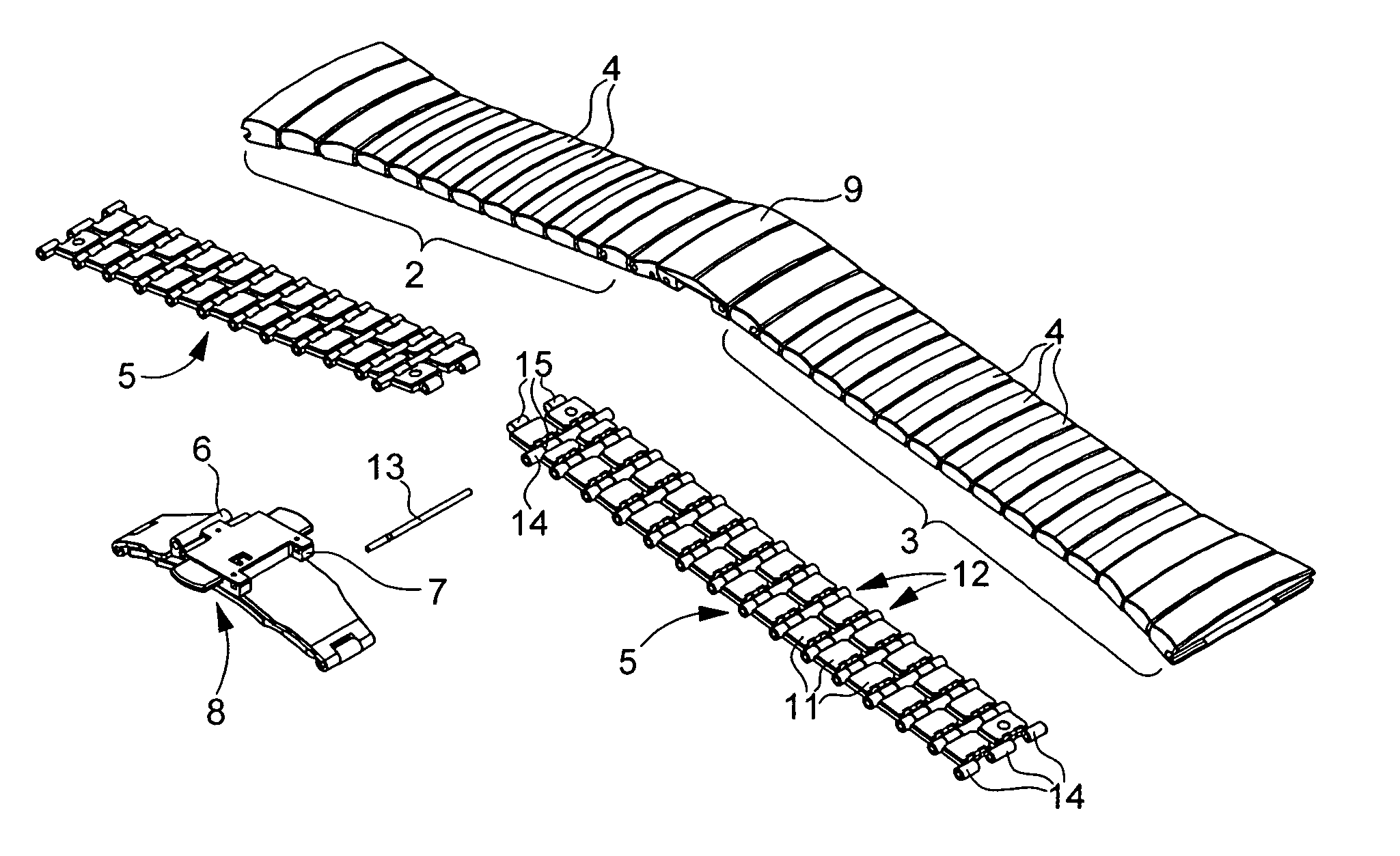

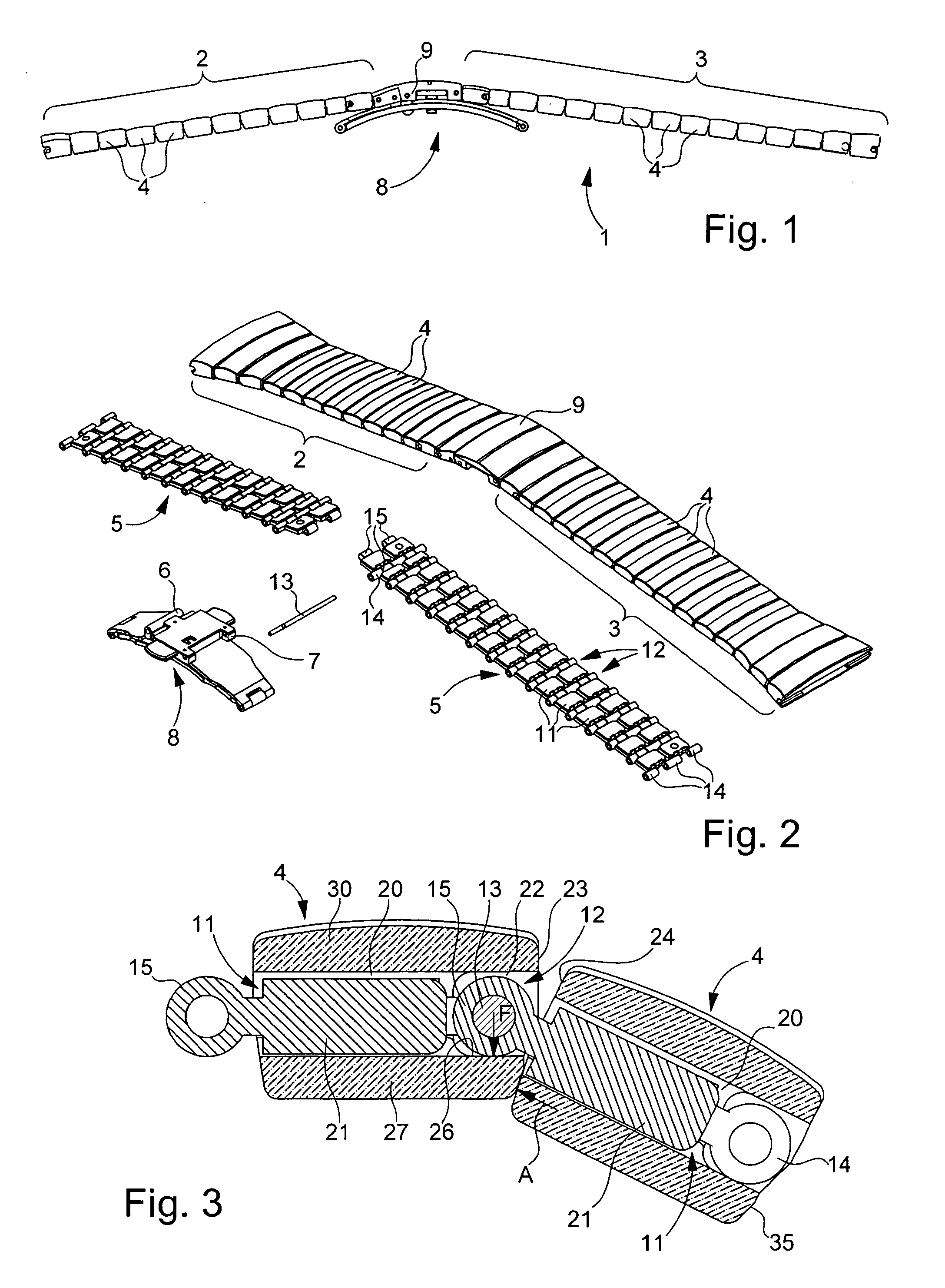

Articulated bracelet including decorative links threaded onto a chain

ActiveUS7013631B2Reduce stressSuppression reductionBraceletsHorseshoeEngineeringMechanical engineering

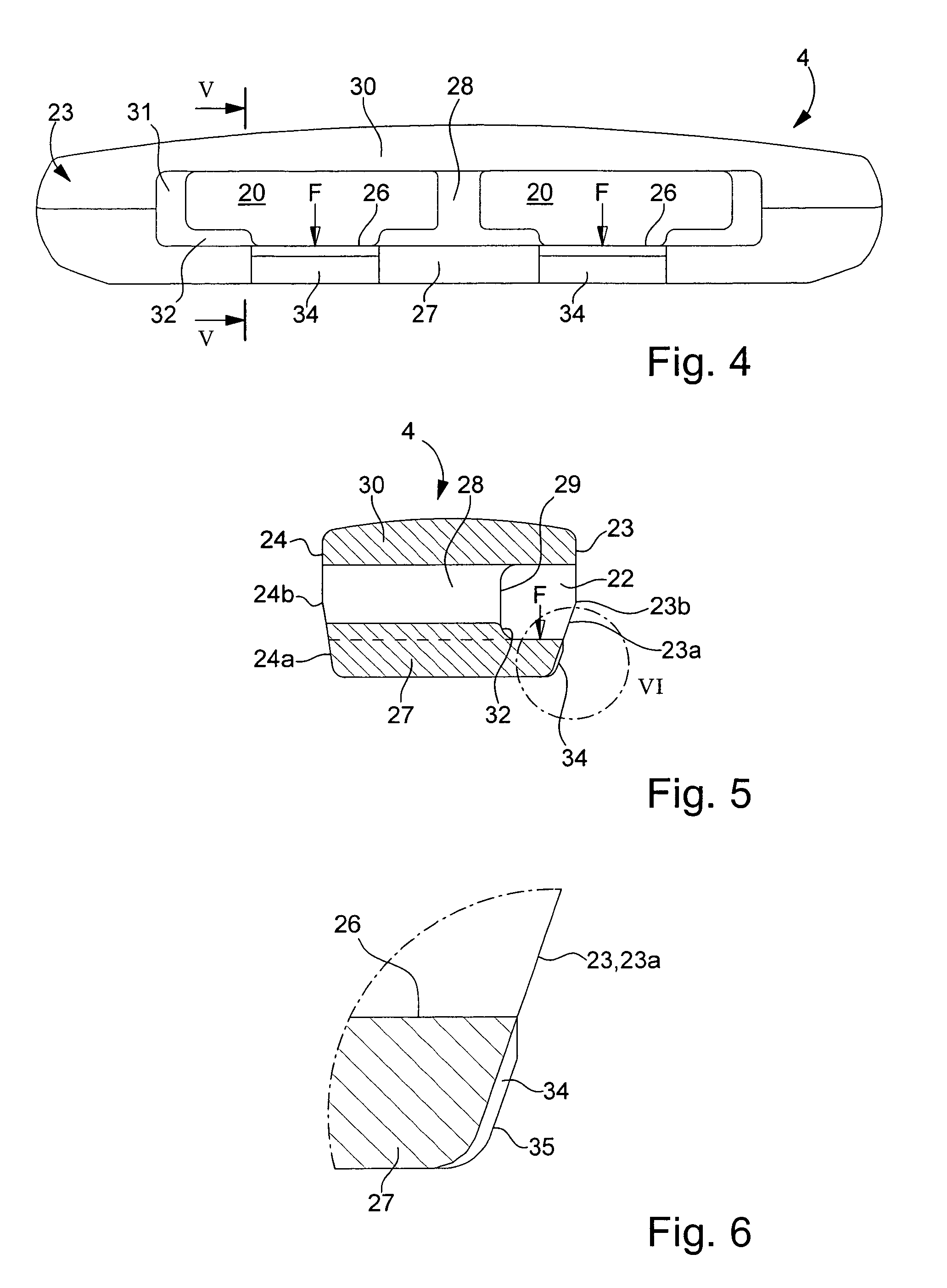

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

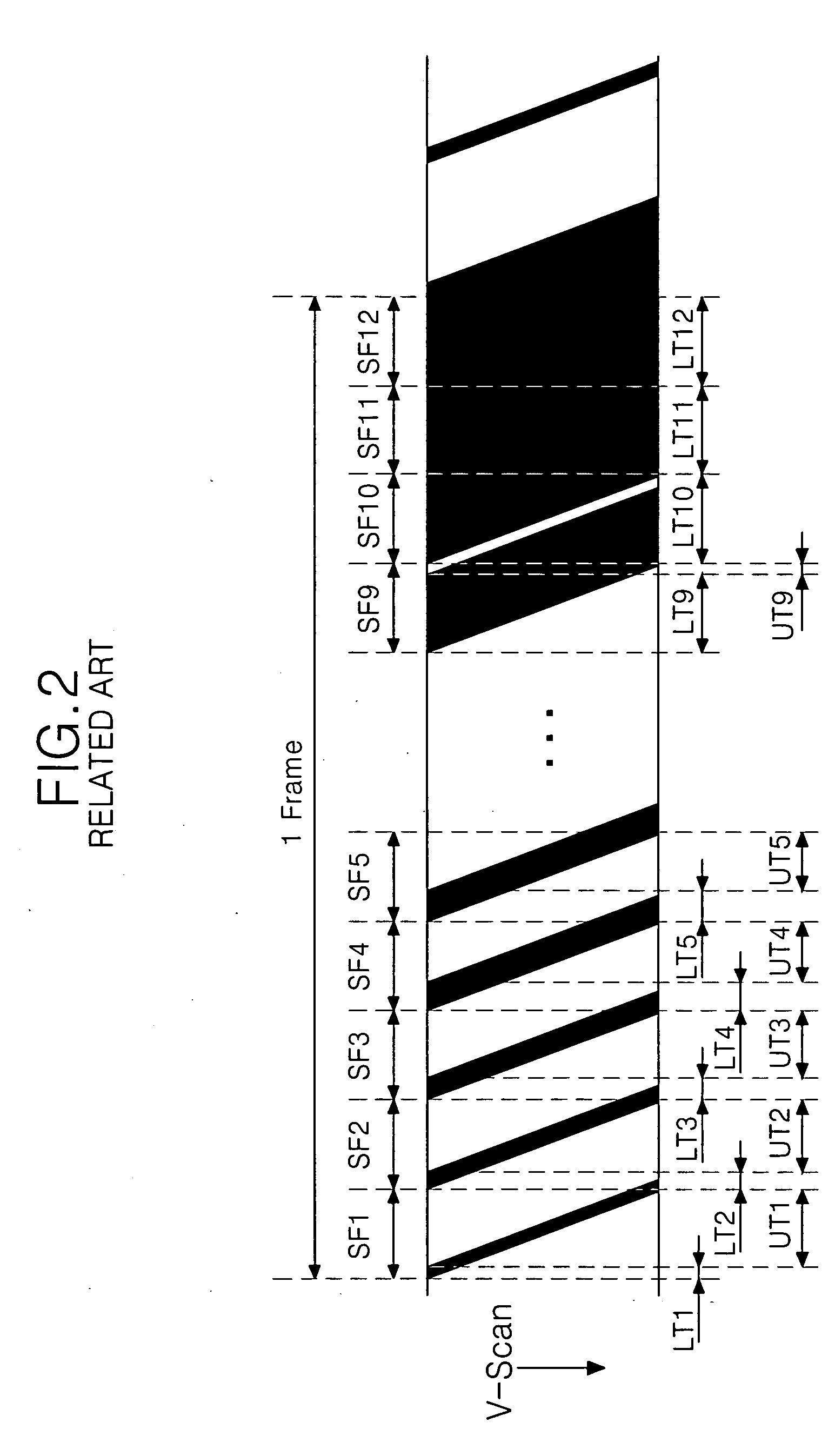

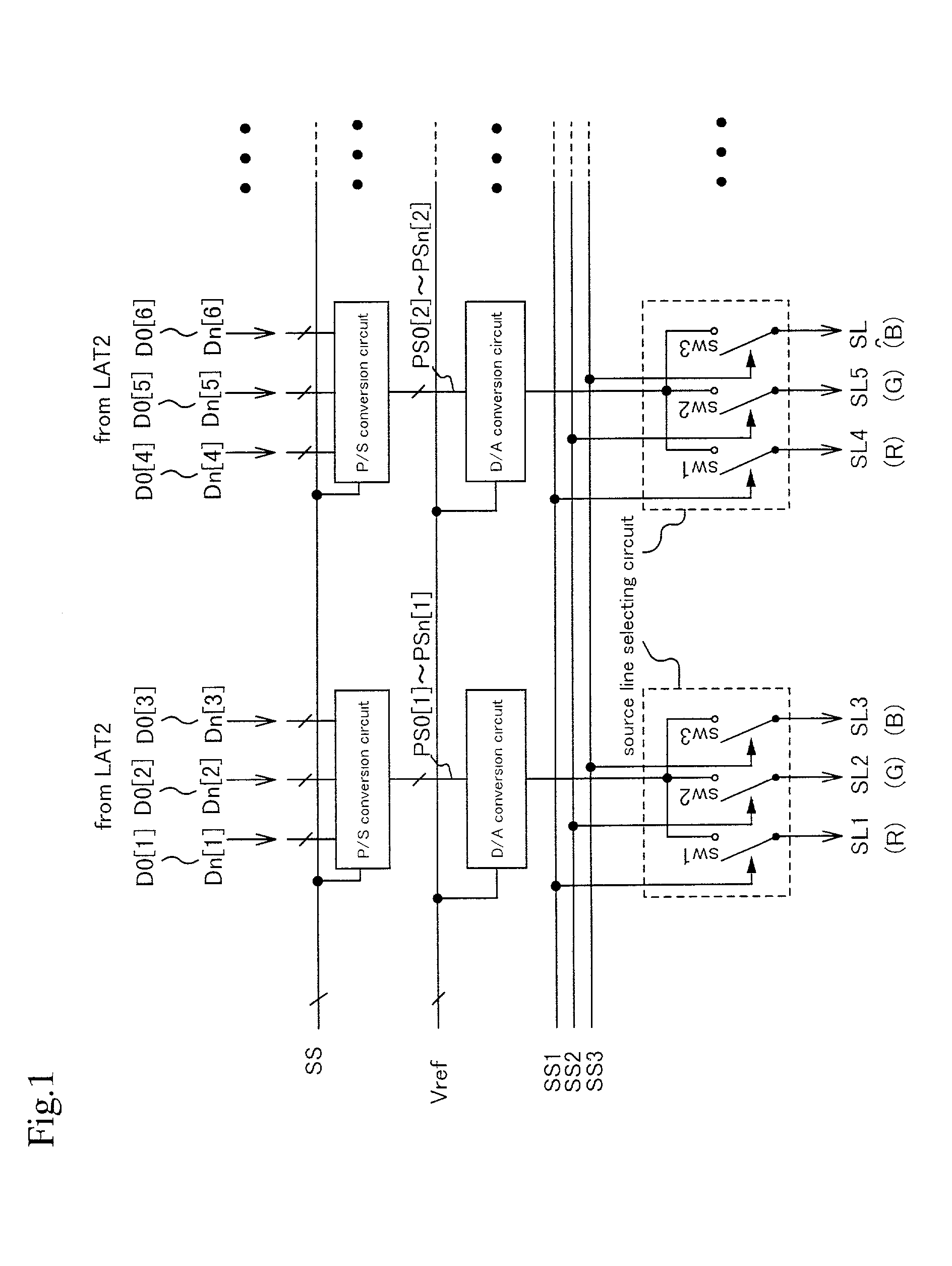

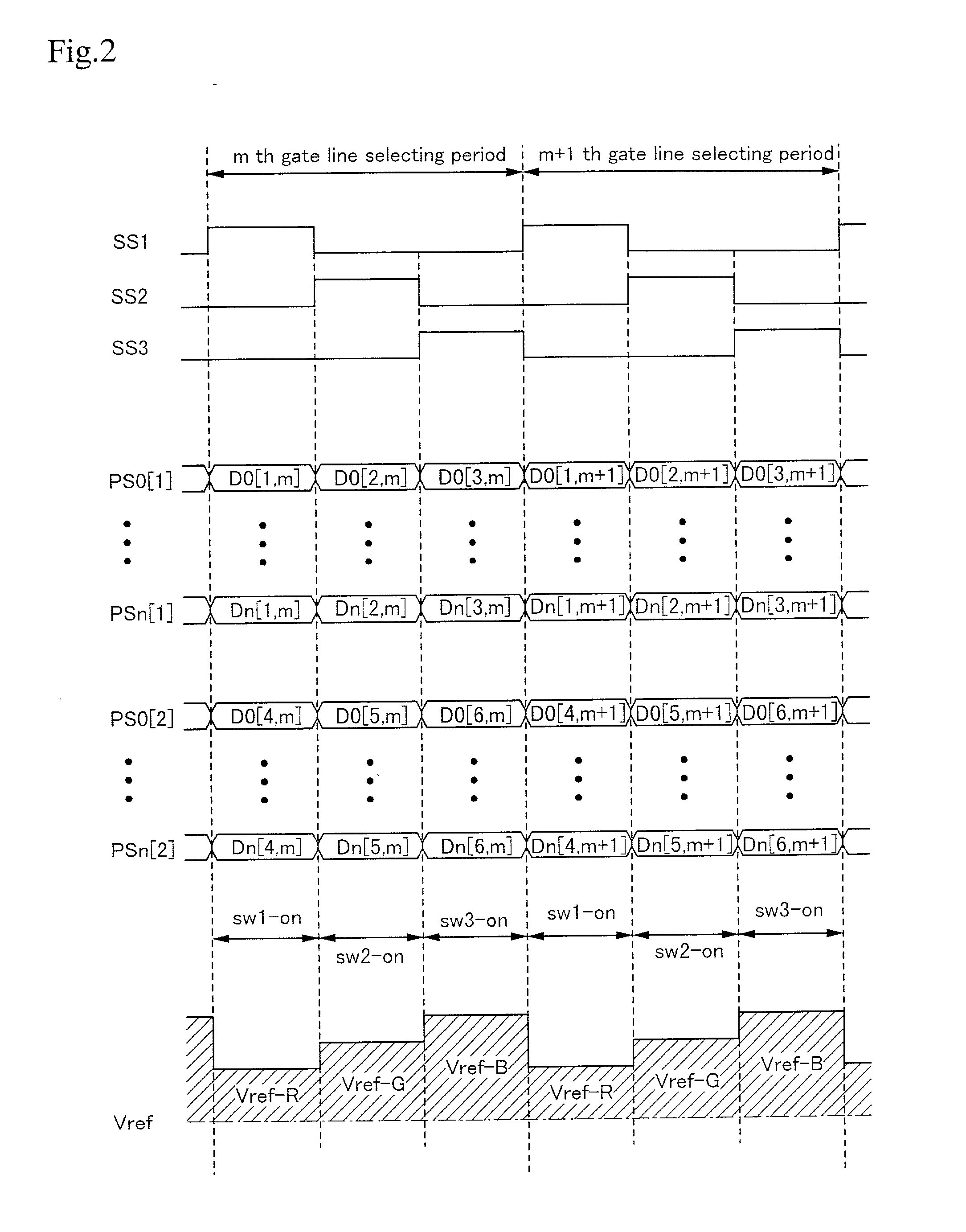

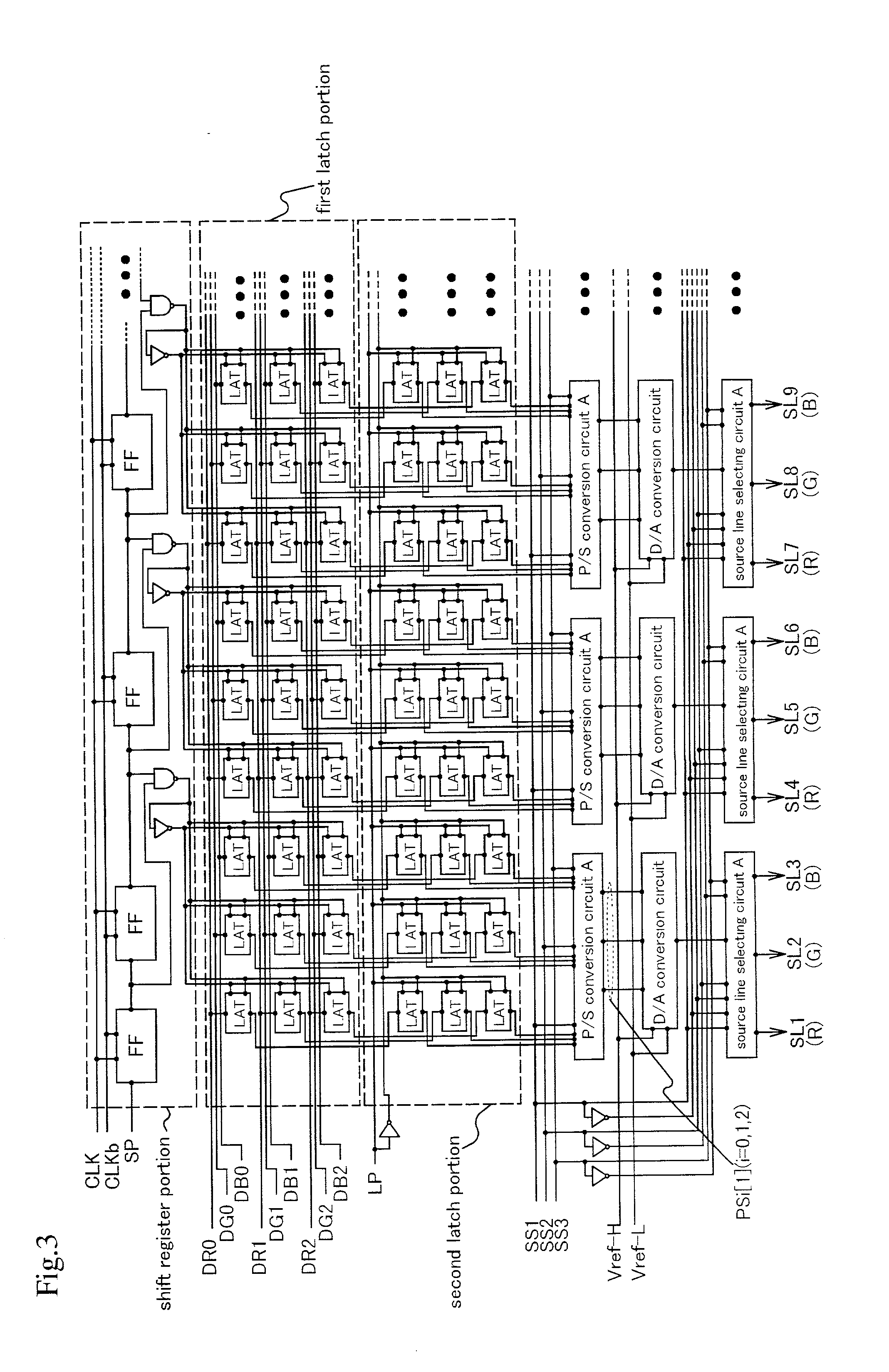

Color image display device, method of driving the same, and electronic equipment

InactiveUS6702407B2Solid-state devicesSemiconductor/solid-state device manufacturingColor imageDisplay device

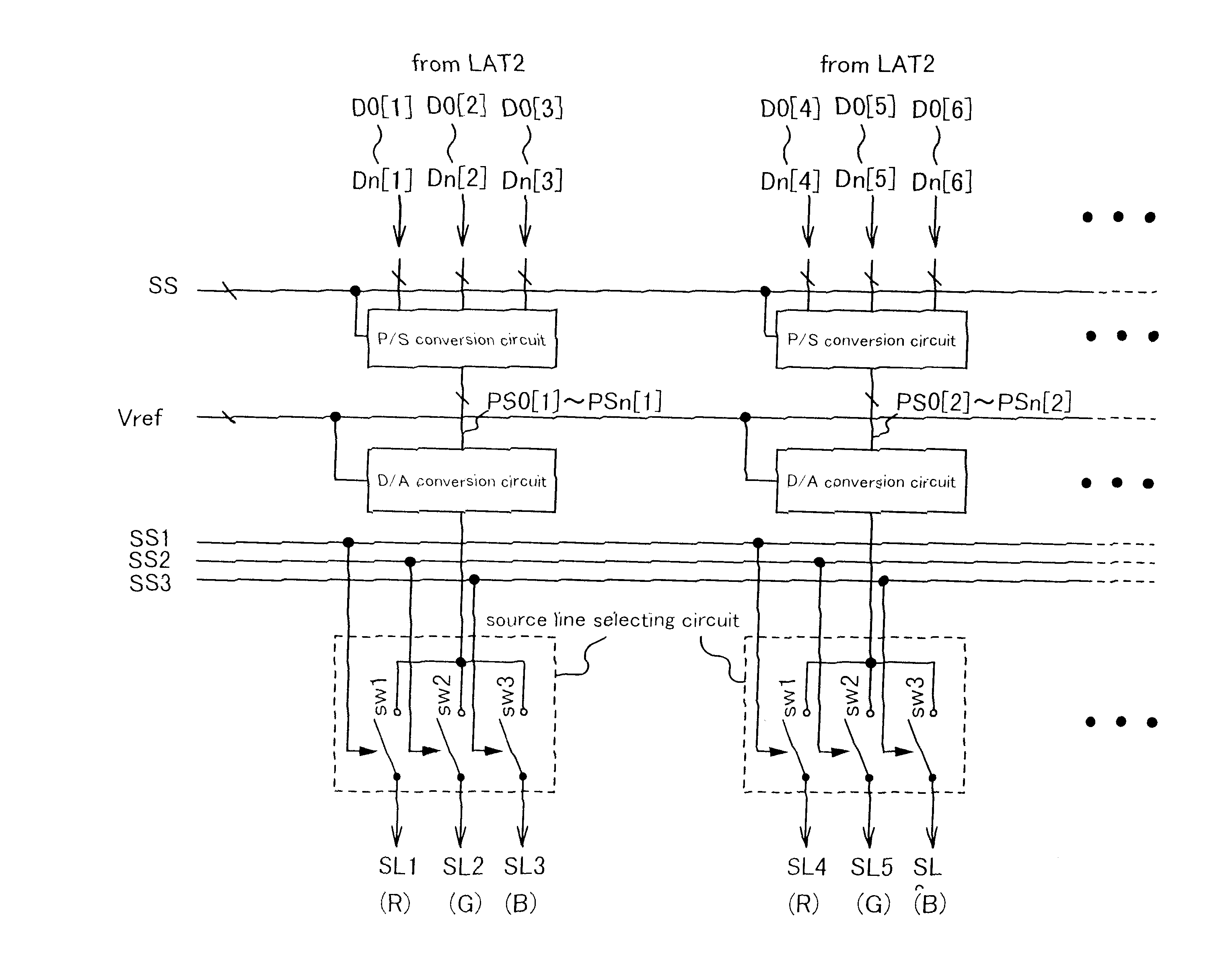

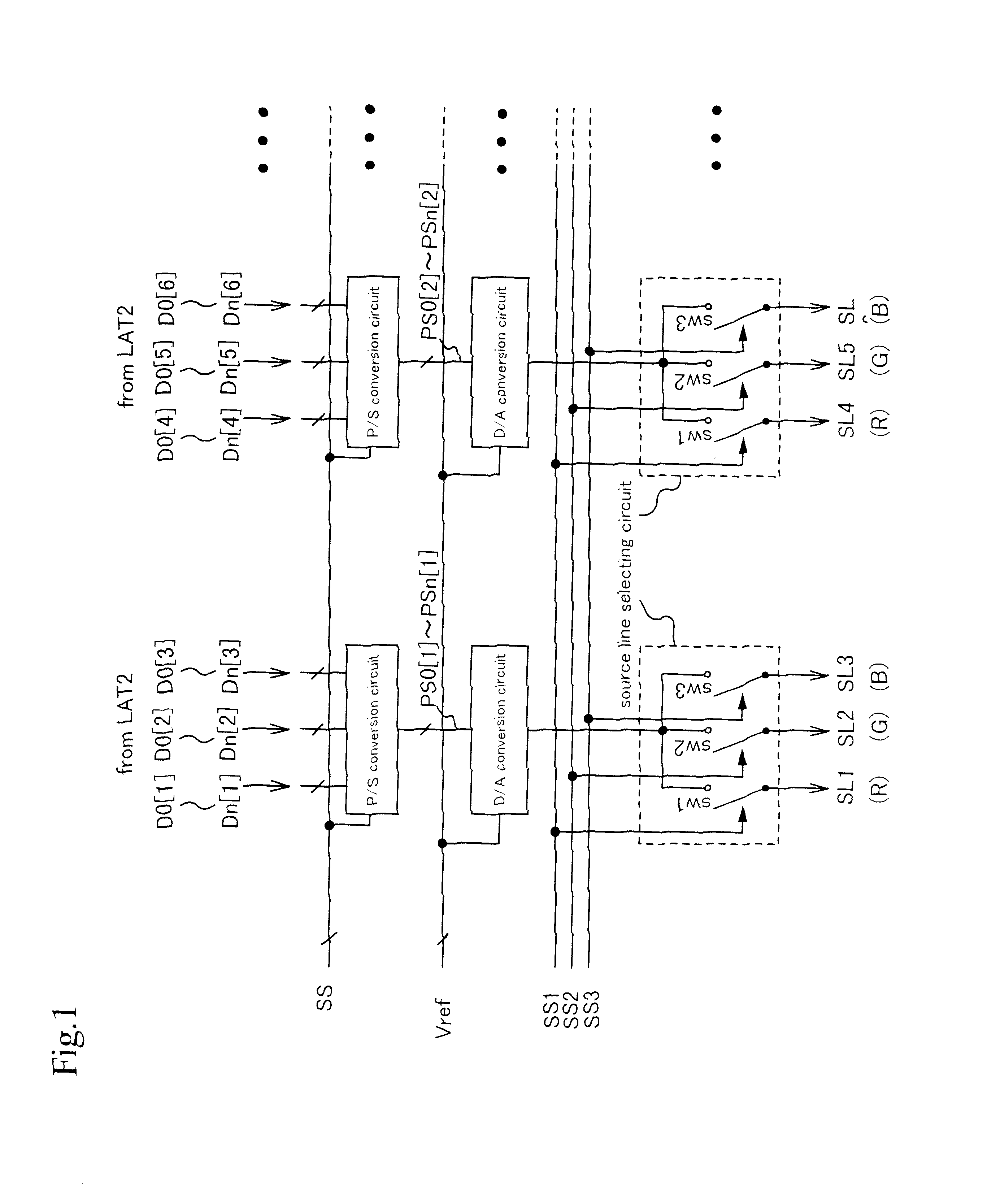

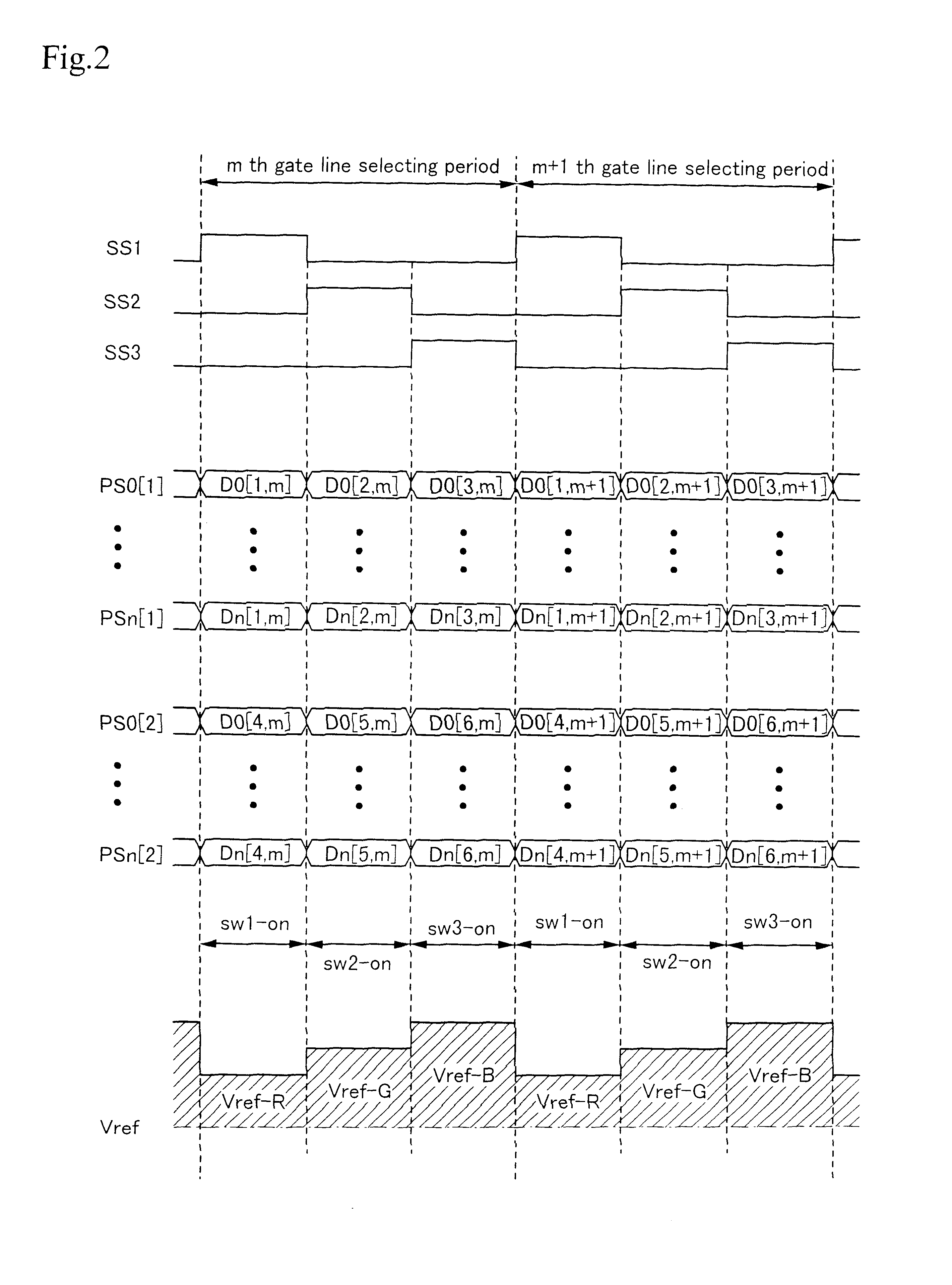

A gray-scale power supply line supplied to a source signal line driving circuit is made only one system, and each of D / A conversion circuits drives source signal lines in which three source signal lines corresponding to RGB are made a unit and the number of which is a multiple of 3. The periods in which respective source line selecting circuits select source signal lines corresponding to respective colors of the RGB are made synchronous with each other, and the power supply voltage applied to the gray-scale power supply line is changed in one horizontal writing period, so that power supply voltages corresponding to R, G and B are respectively applied to the gray-scale power supply line in periods while the source signal lines of R, G and B are respectively selected.

Owner:SEMICON ENERGY LAB CO LTD

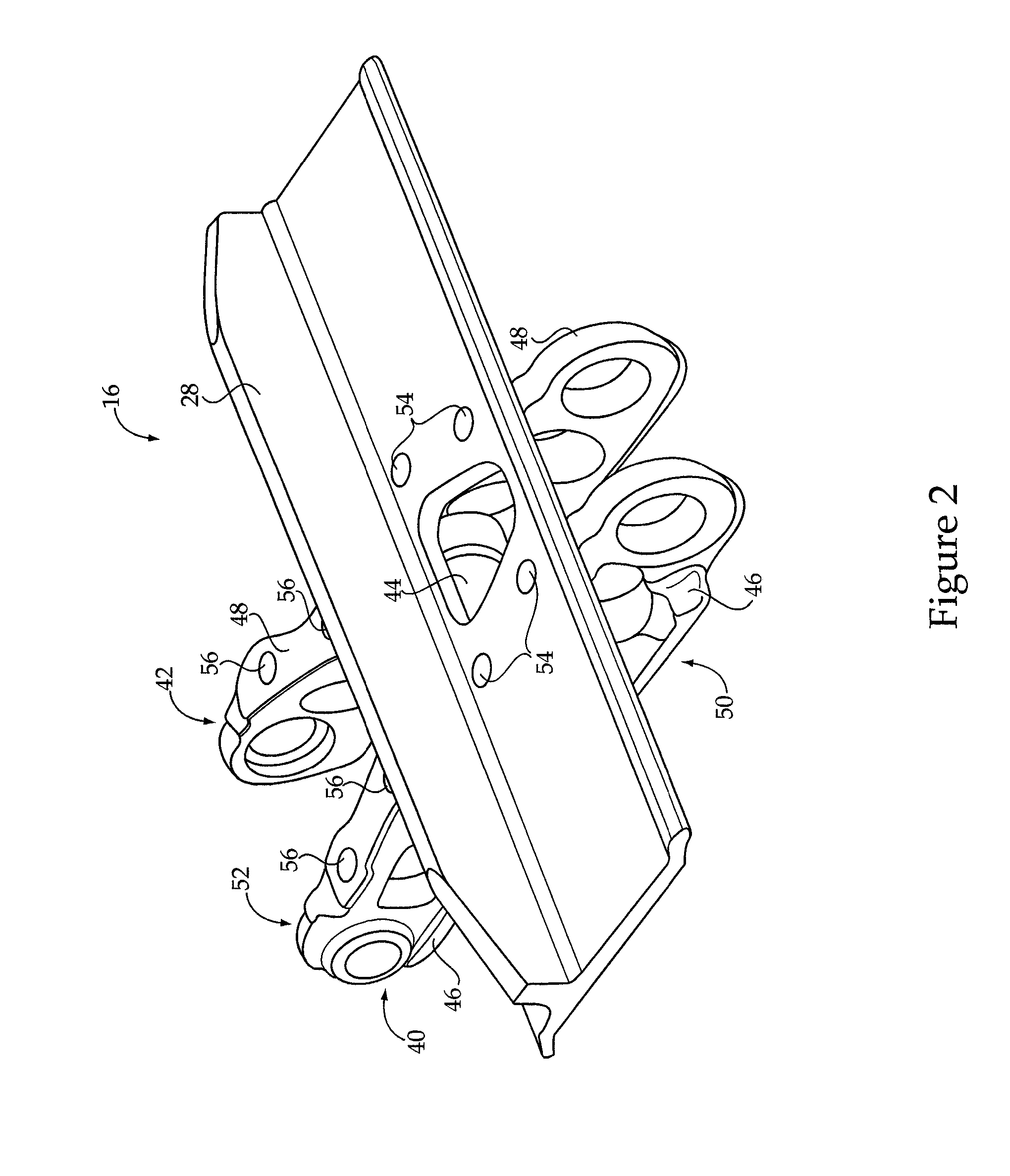

Articulated bracelet including decorative links threaded onto a chain

ActiveUS20050210857A1Reduce stressSuppression reductionBraceletsWrist-watch strapsEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

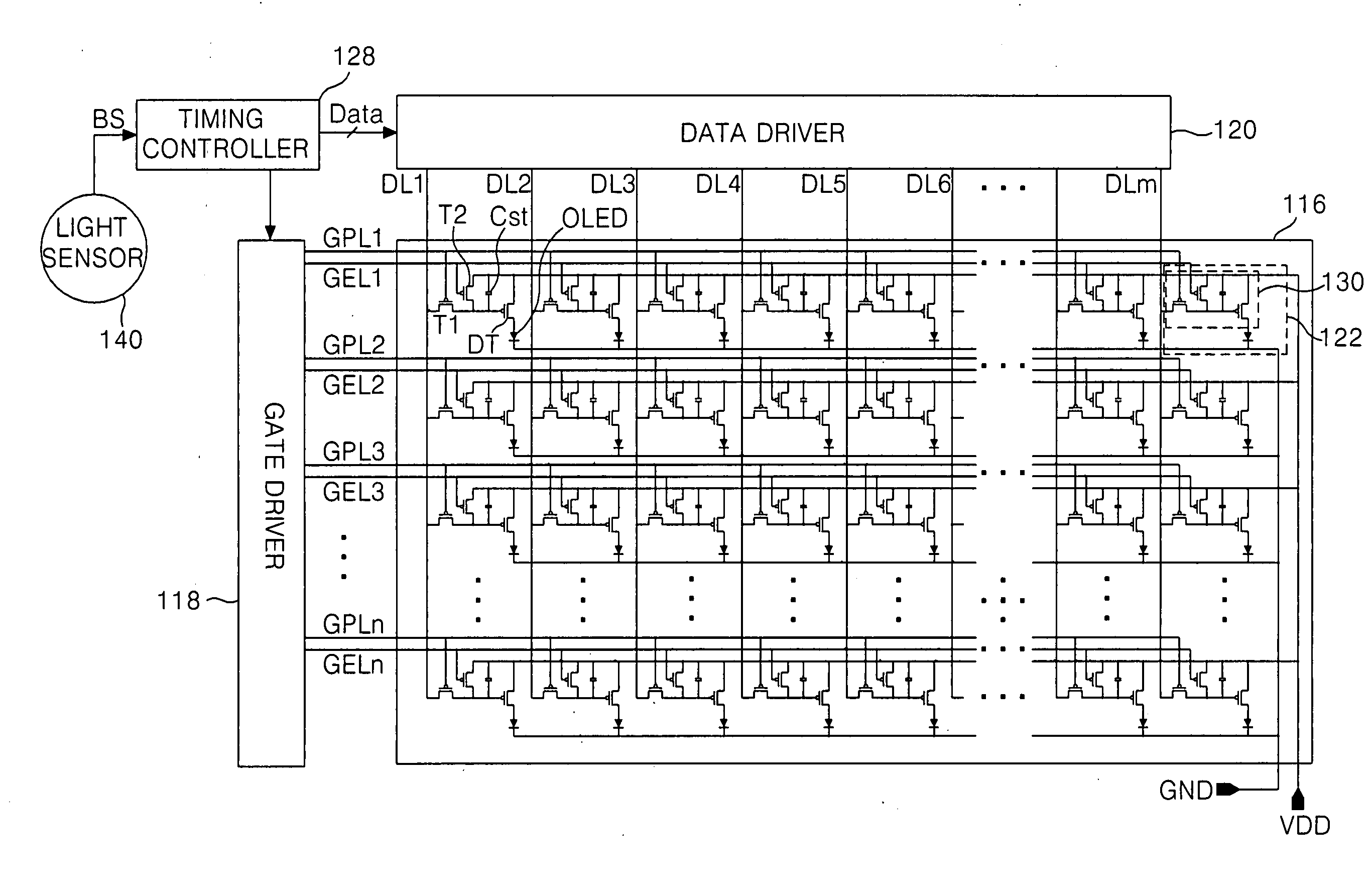

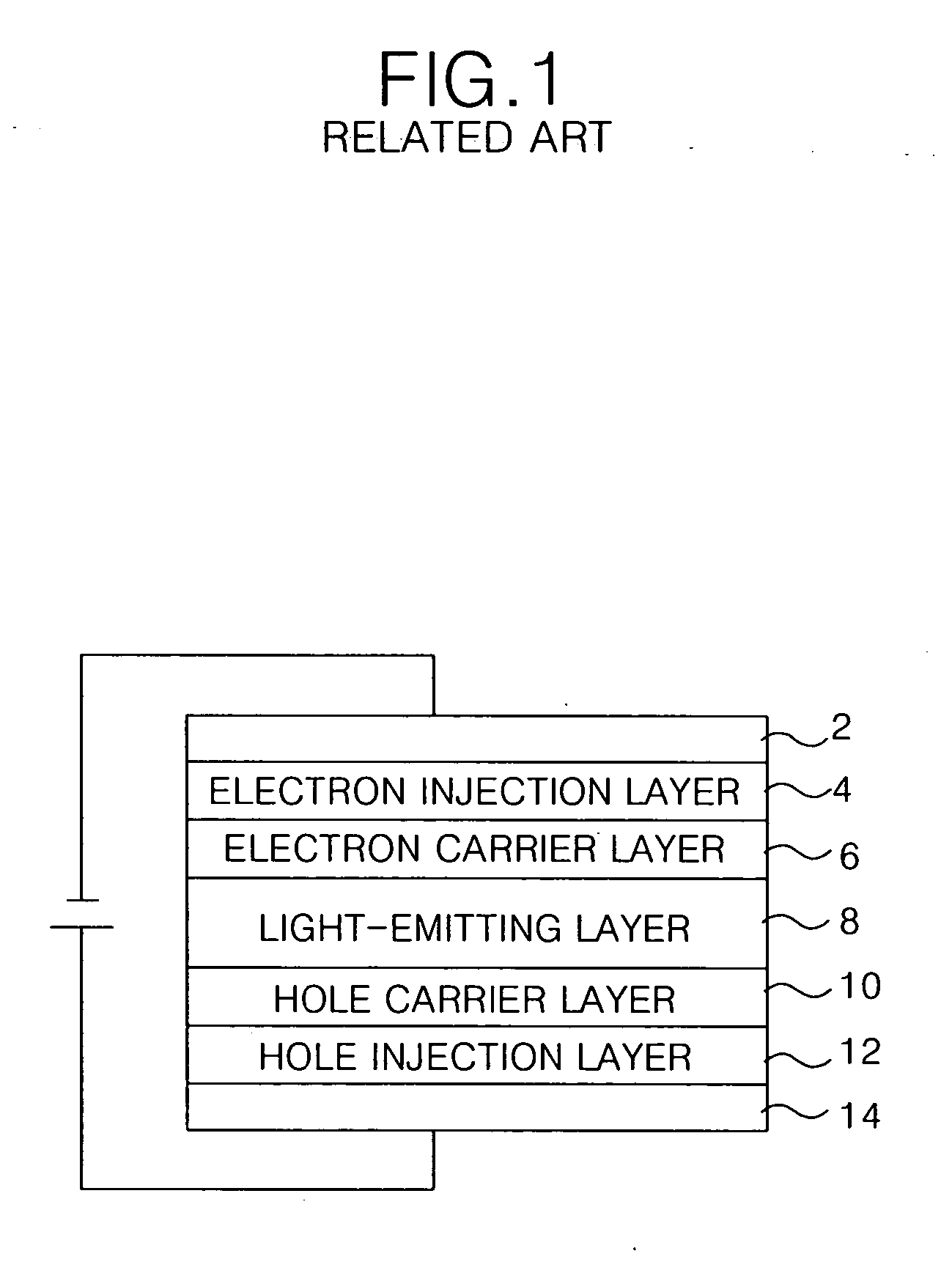

Electro-luminescence display device and method of driving the same

ActiveUS20050243077A1Reduce power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingElectricityDisplay device

An electro-luminescence display device and a method of driving the same for controlling a full white brightness depending upon a brightness of the external environment and thus controlling a brightness mode is disclosed. An electro-luminescence display device according to the present invention comprising: a display panel having pixels light-emitted by a supplied current; a data driver for applying a data voltage corresponding to said current to the pixels; and a timing controller for dividing one frame into a plurality of sub-frames and applying said data voltage corresponding to each of the plurality of sub-frames to the data driver and for controlling an emission time of each frame.

Owner:LG DISPLAY CO LTD

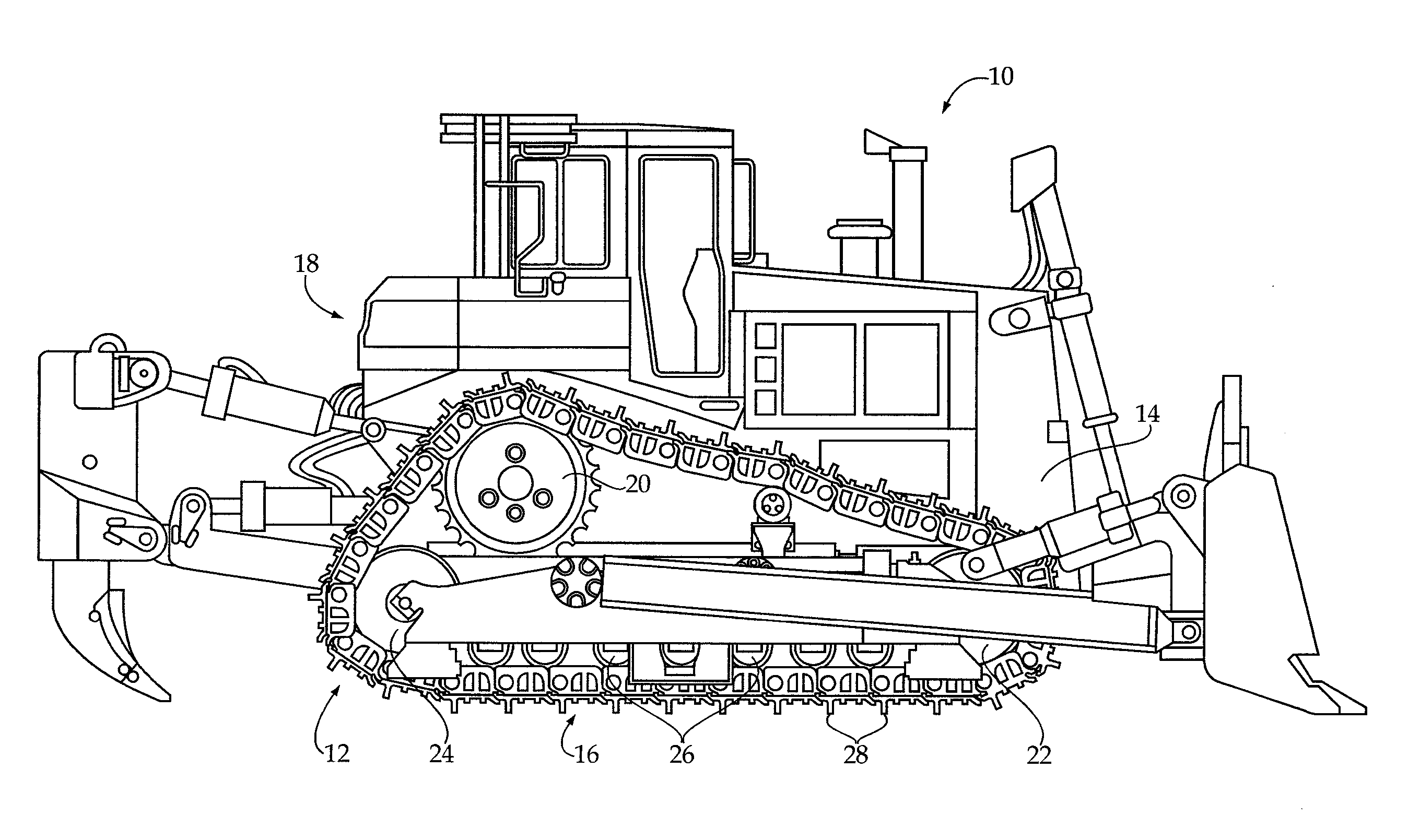

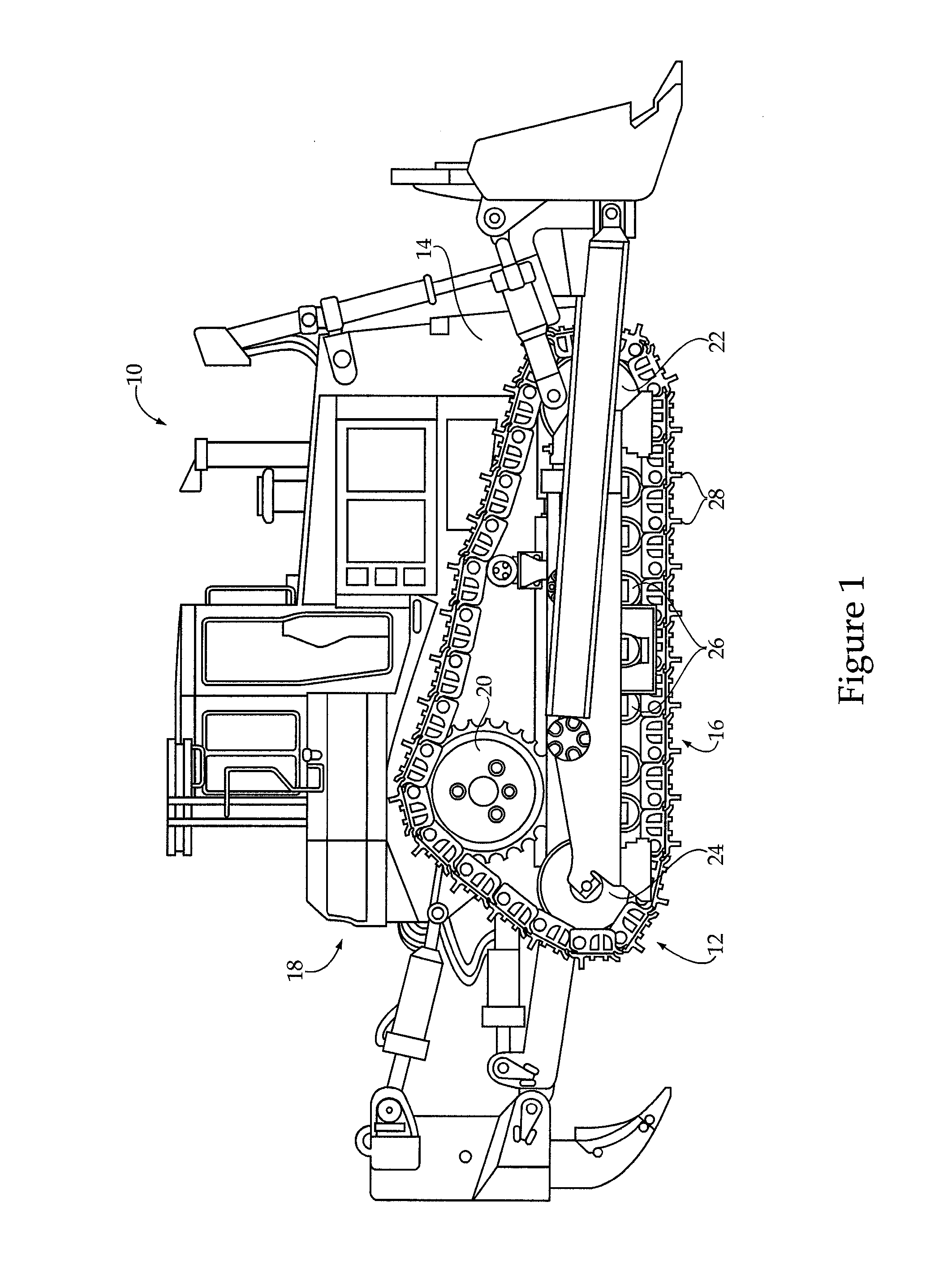

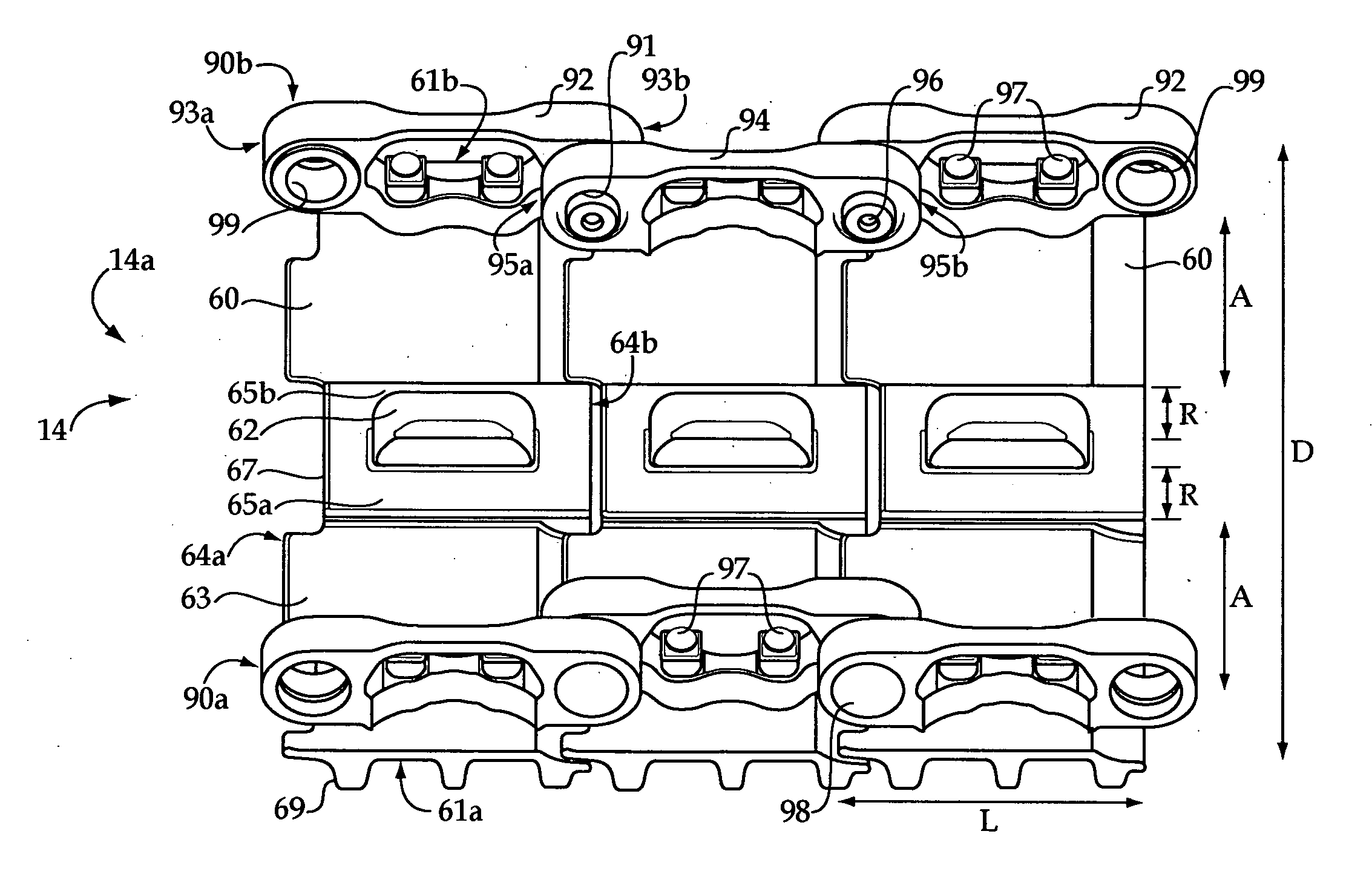

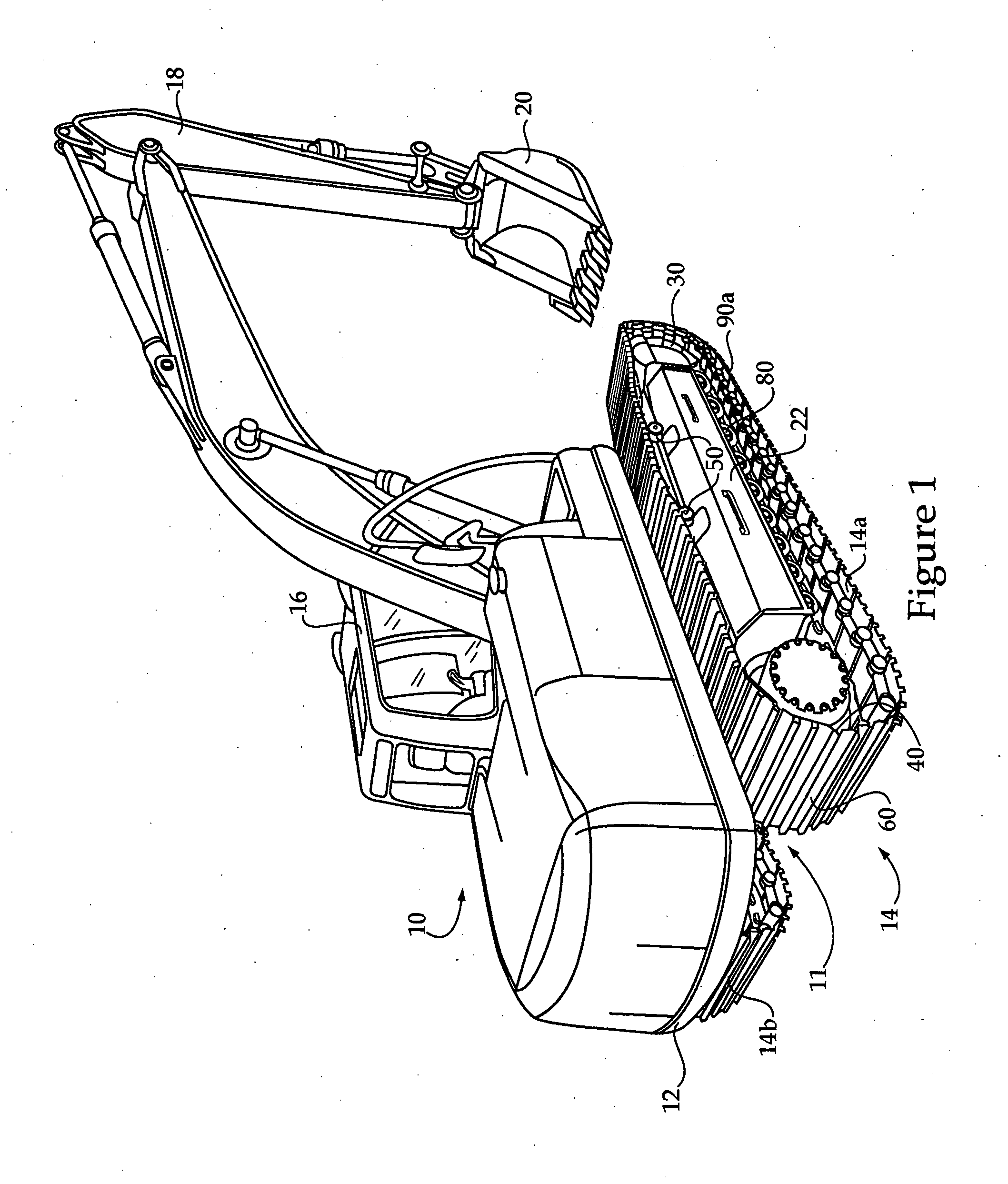

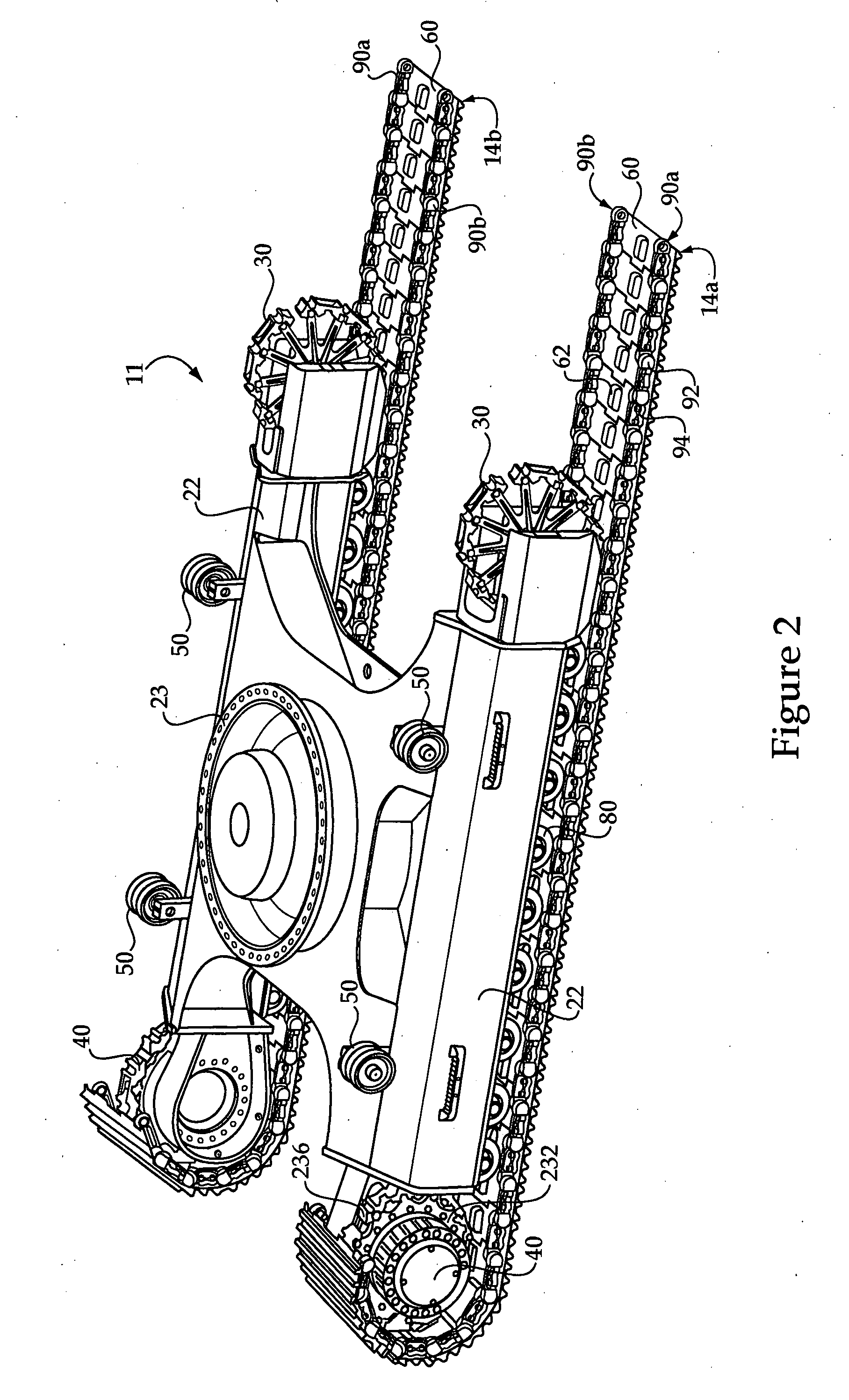

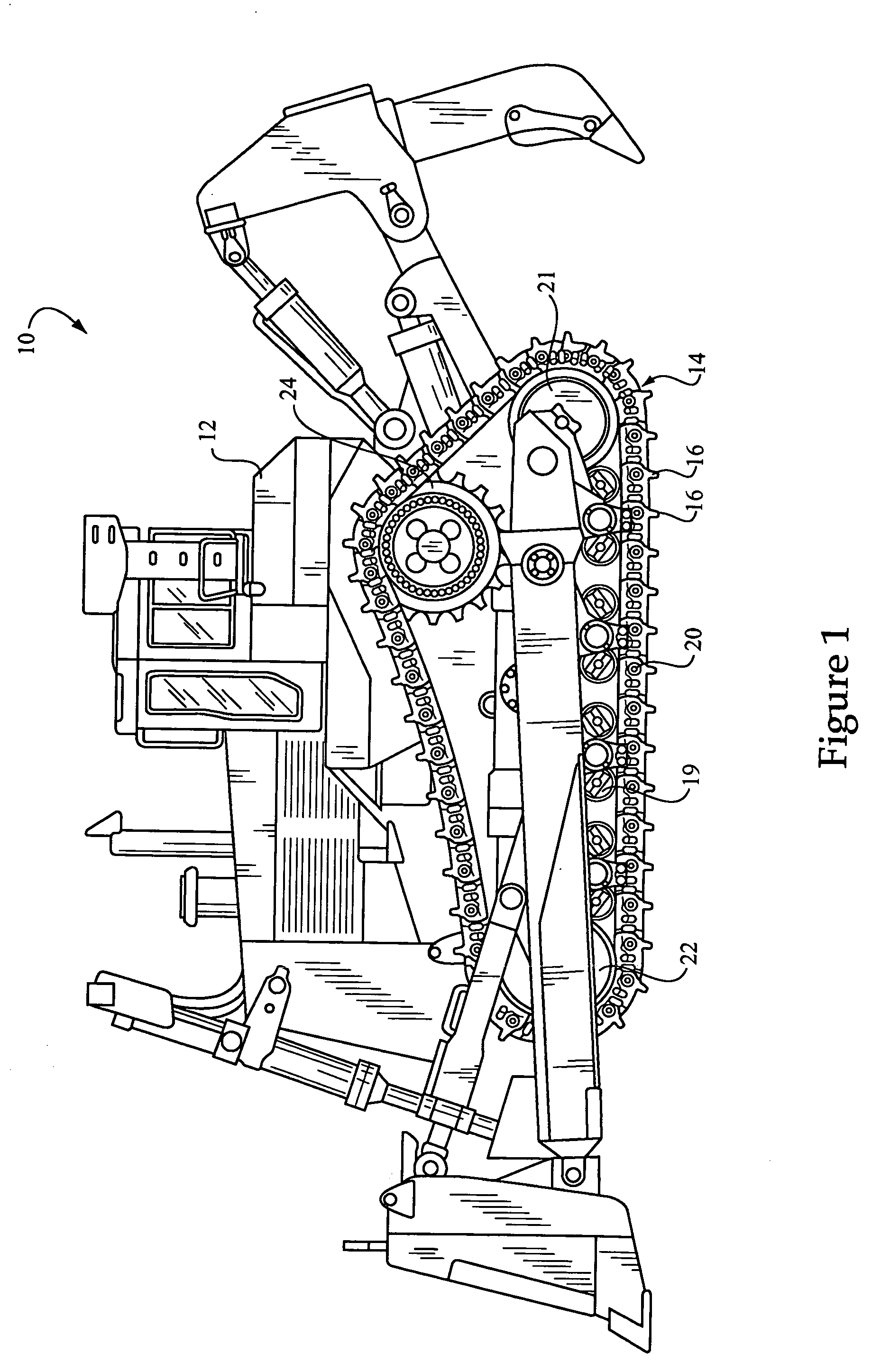

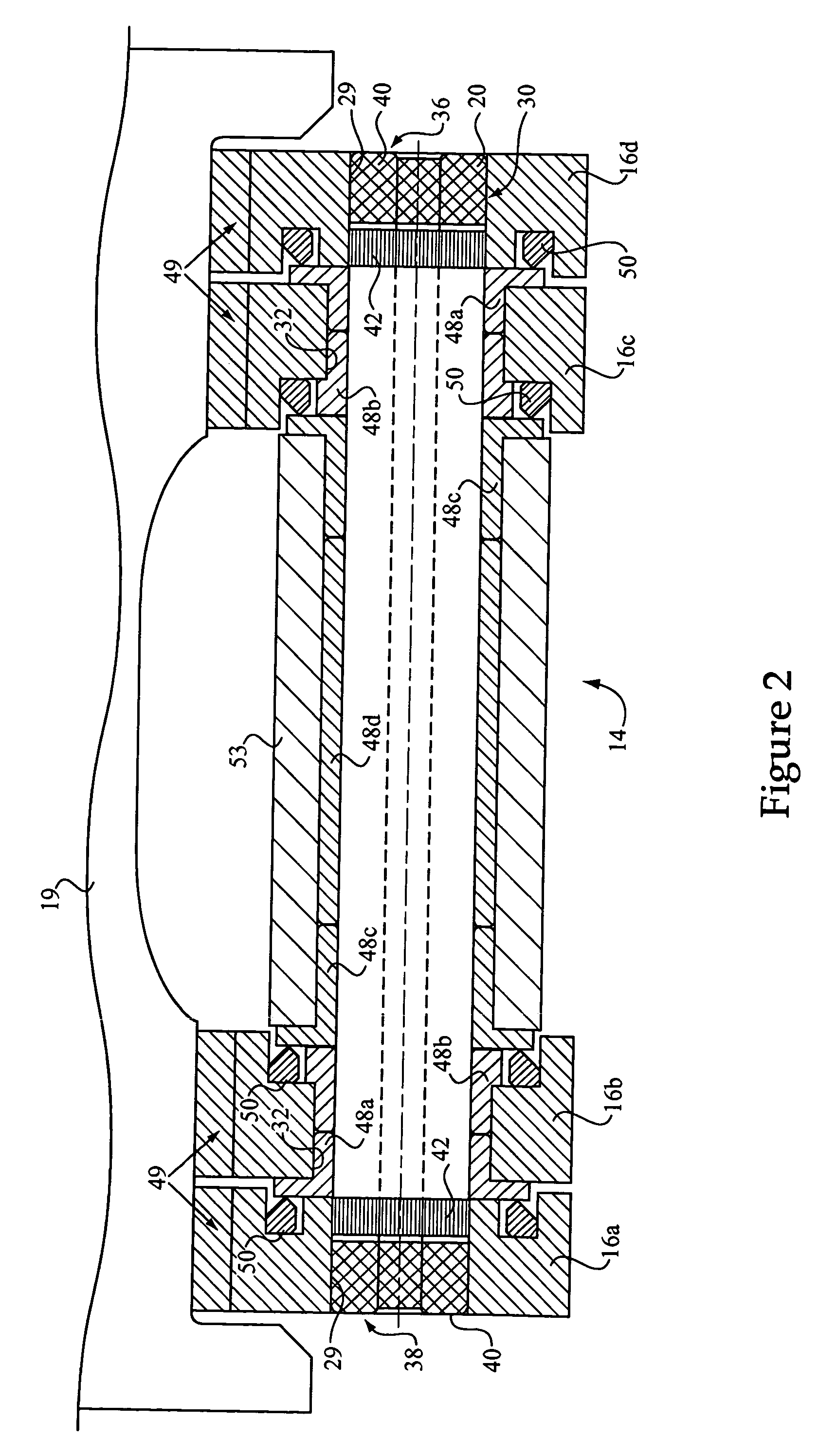

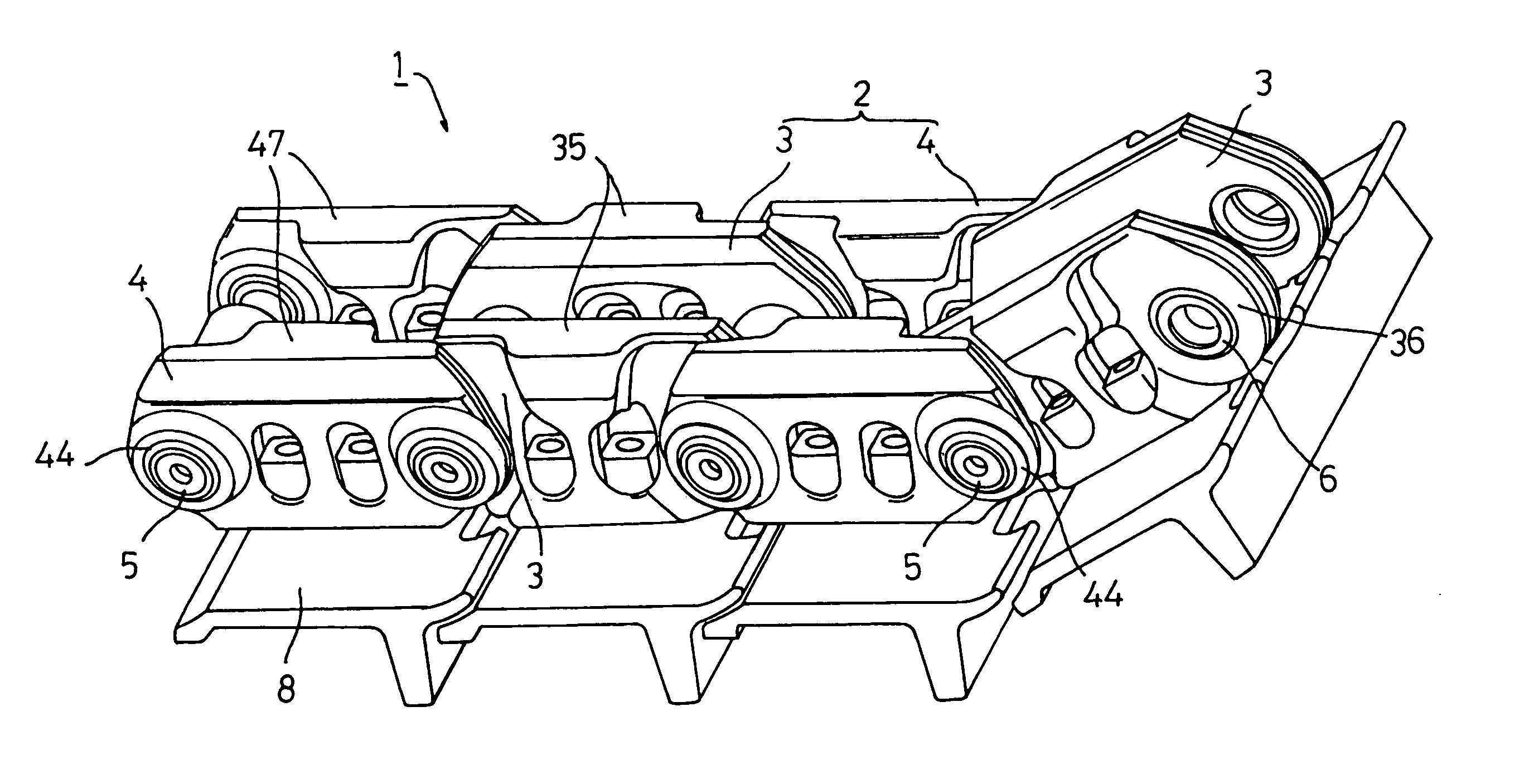

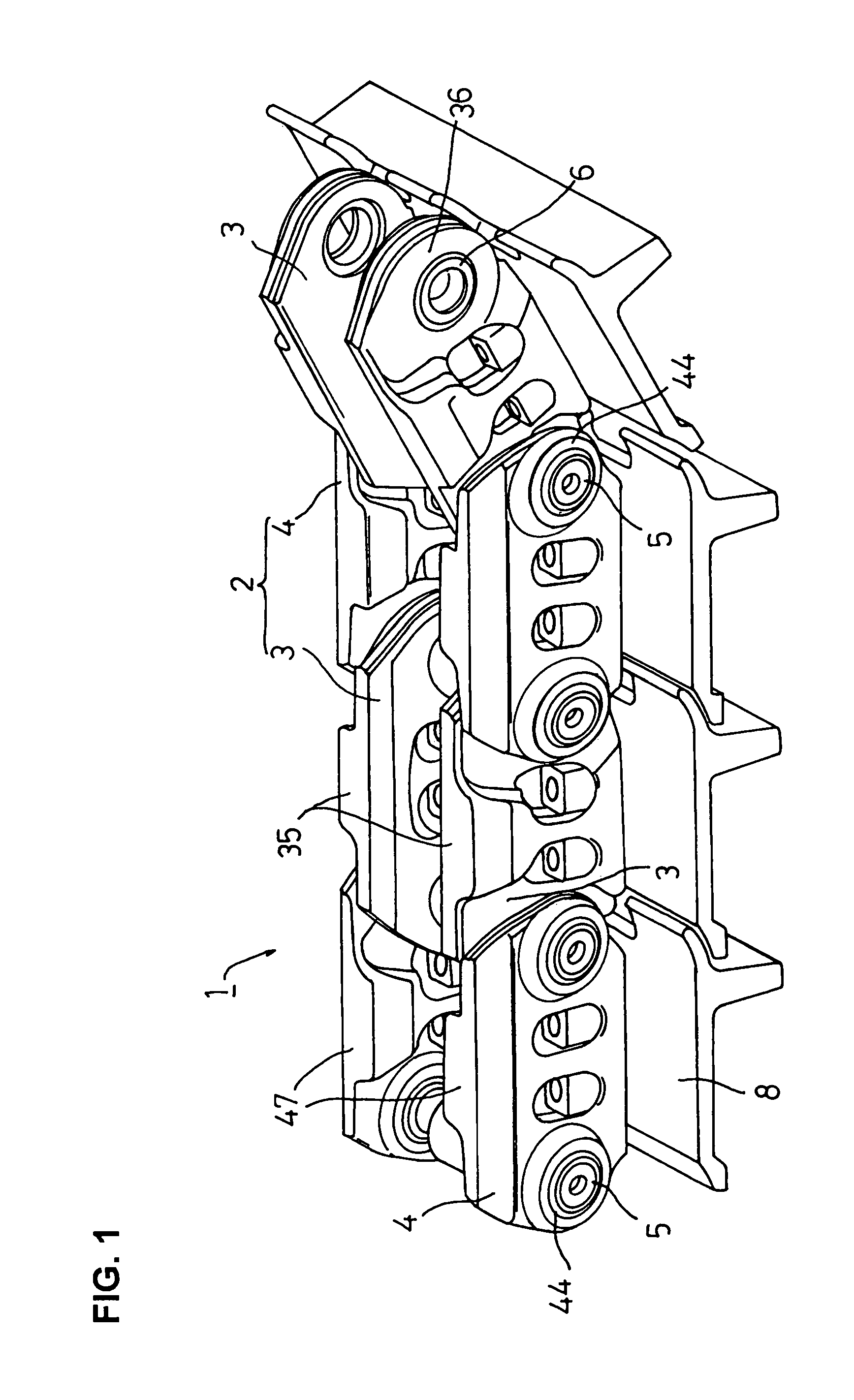

Lobed Bushing For Track Assembly And Track-Type Machine Using Same

ActiveUS20100139993A1Sliding contact bearingsEndless track vehiclesEngineeringMechanical engineering

A lobed bushing is provided for a track assembly of a track-type machine. The track assembly includes a first chain and a second chain coupled together with a track pin. A bushing, defining a longitudinal axis, includes a central bore oriented along the longitudinal axis and extending from a first end of the bushing to a second end of the bushing for receiving the track pin. The bushing includes a first lobe positioned at a first location about the longitudinal axis and a second lobe positioned at a second location about the longitudinal axis that is less than about 180° from the first location. The first end of the bushing has a substantially cylindrical shape.

Owner:CATERPILLAR INC

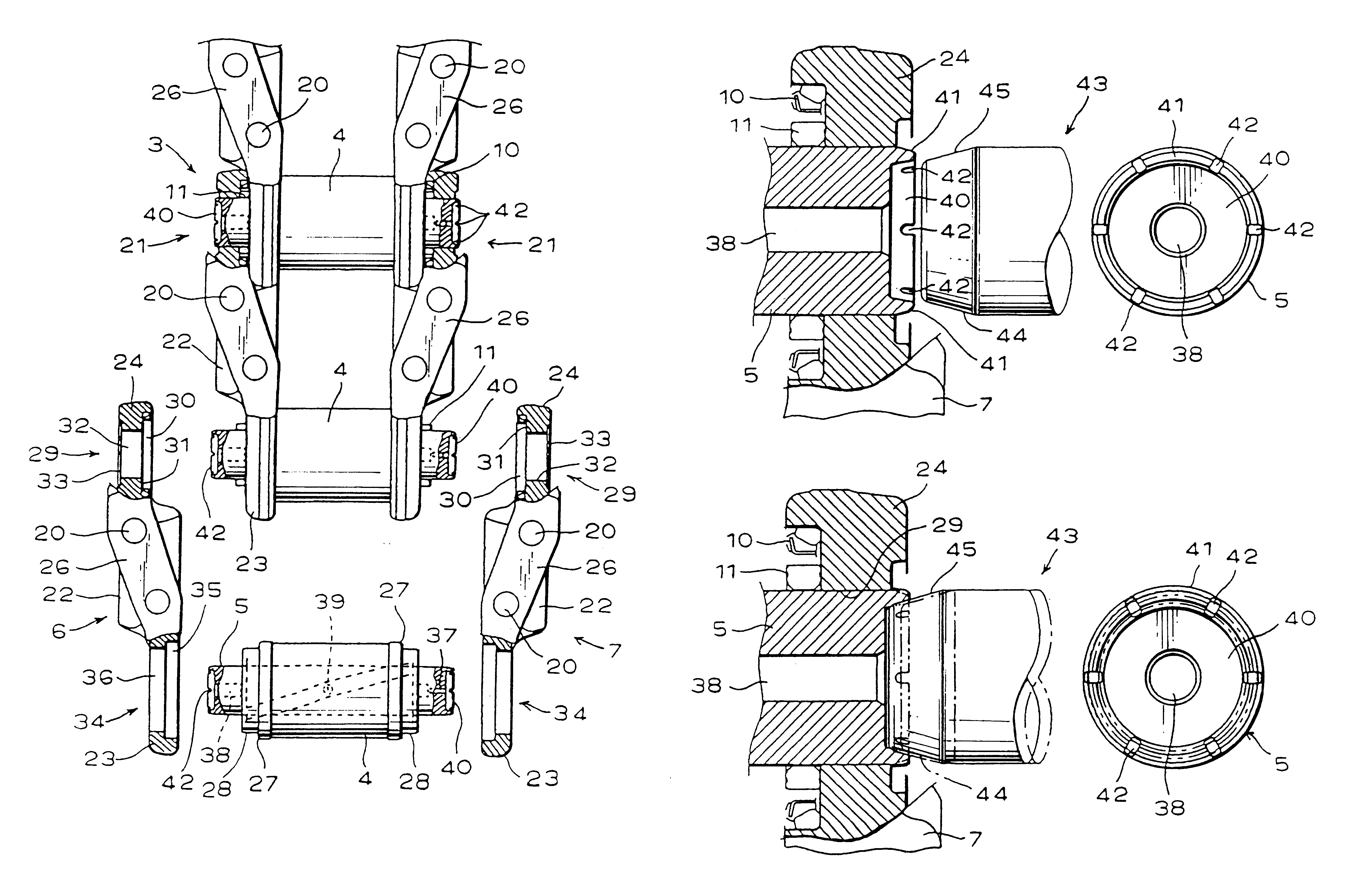

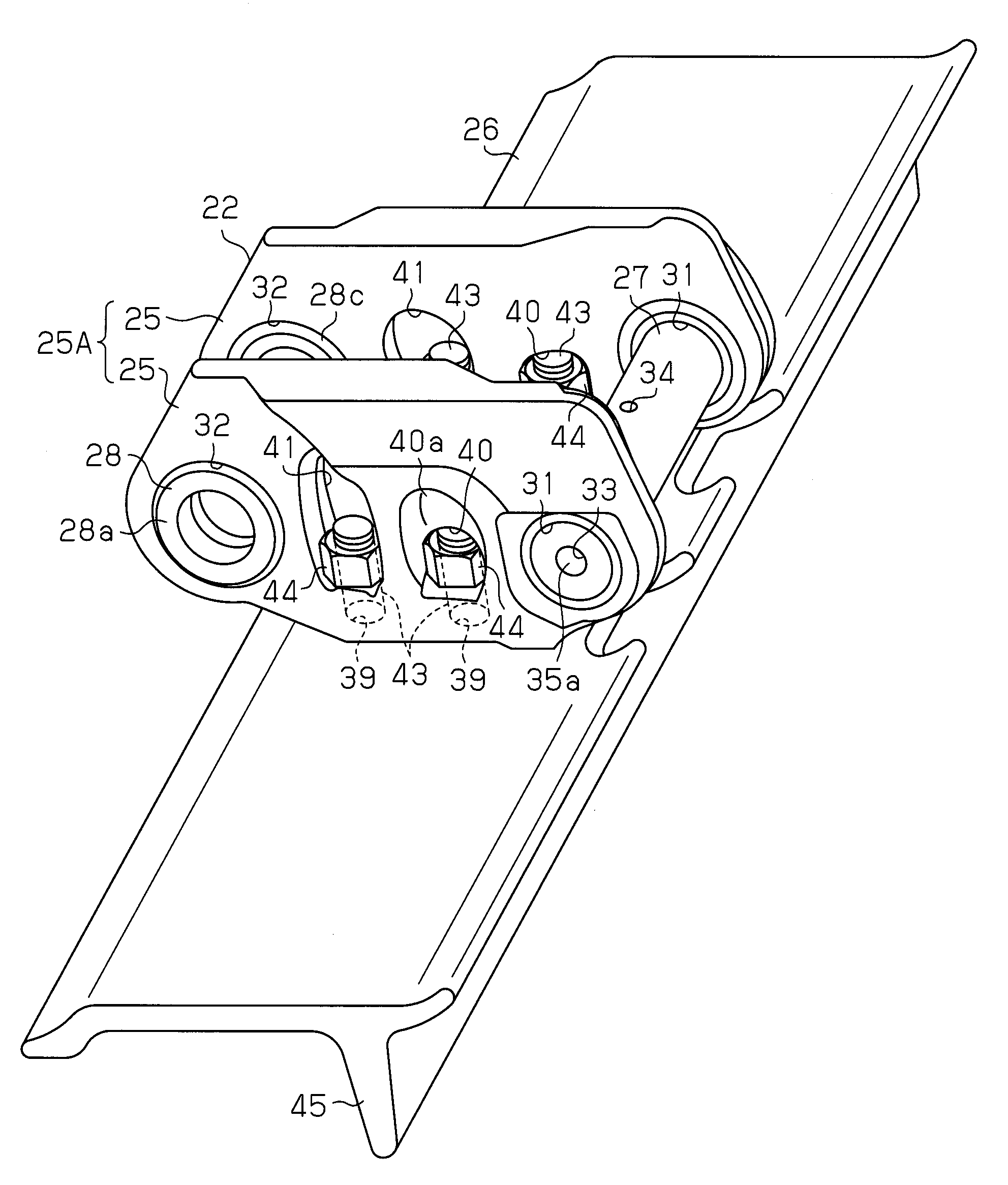

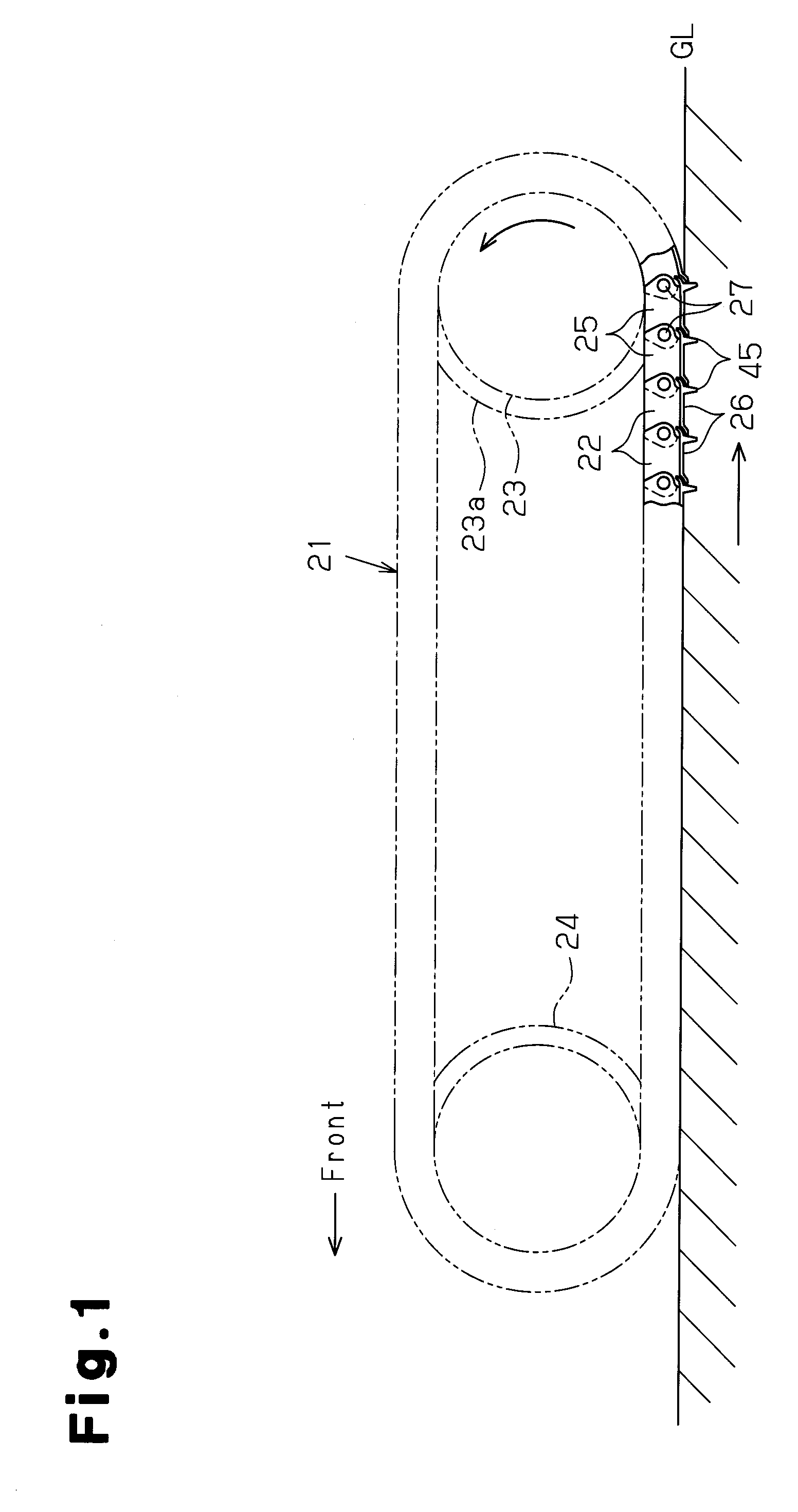

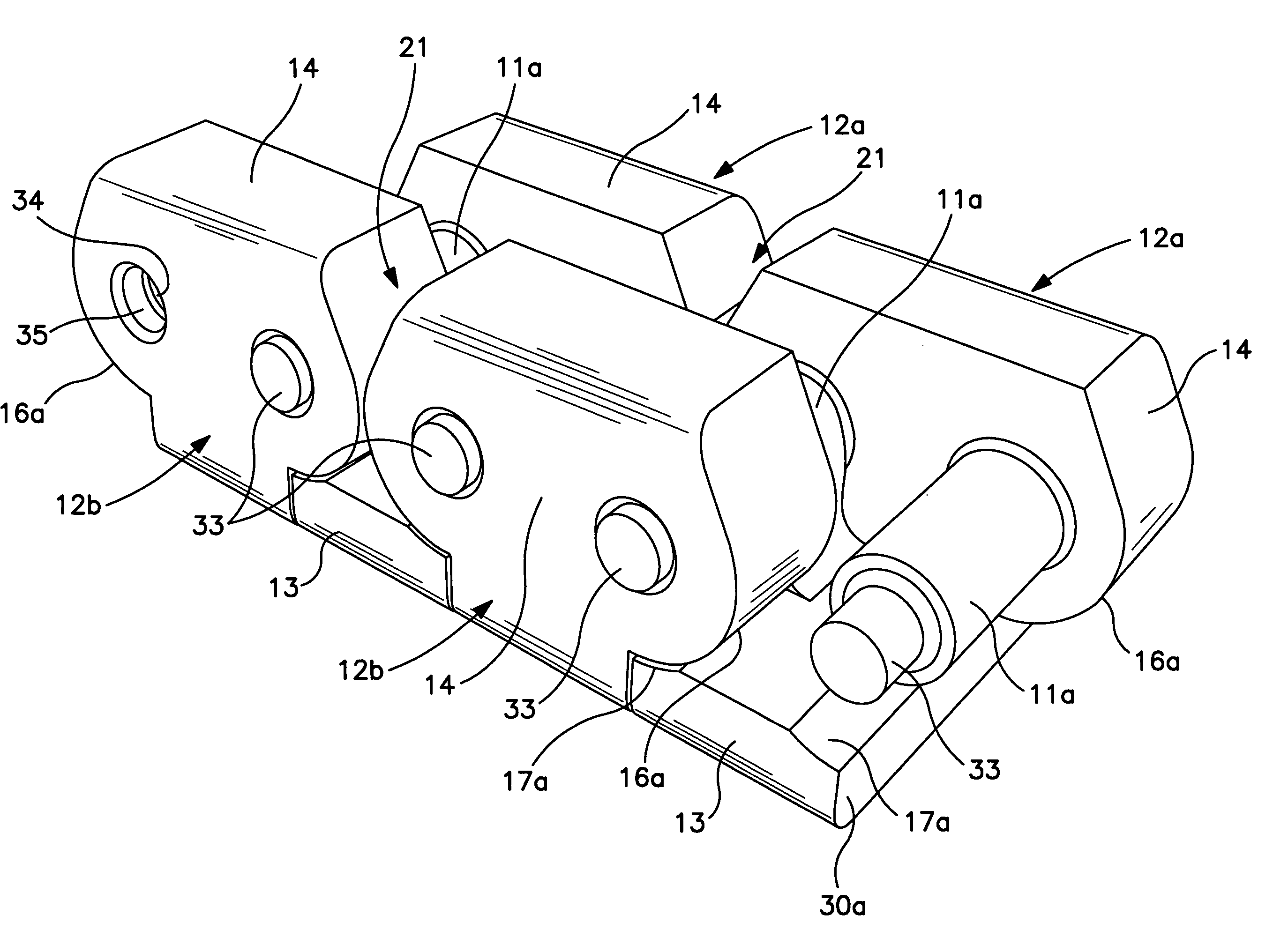

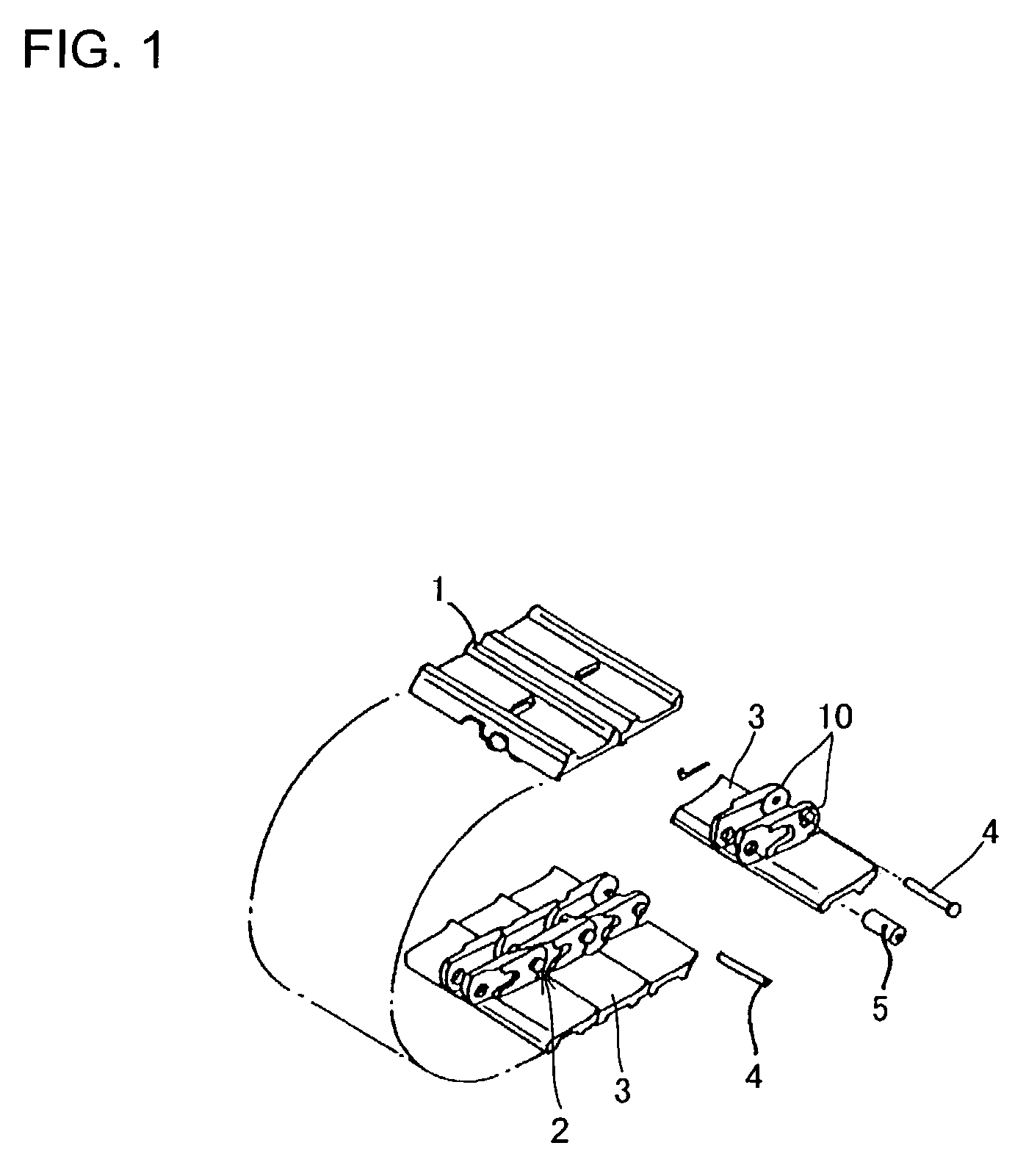

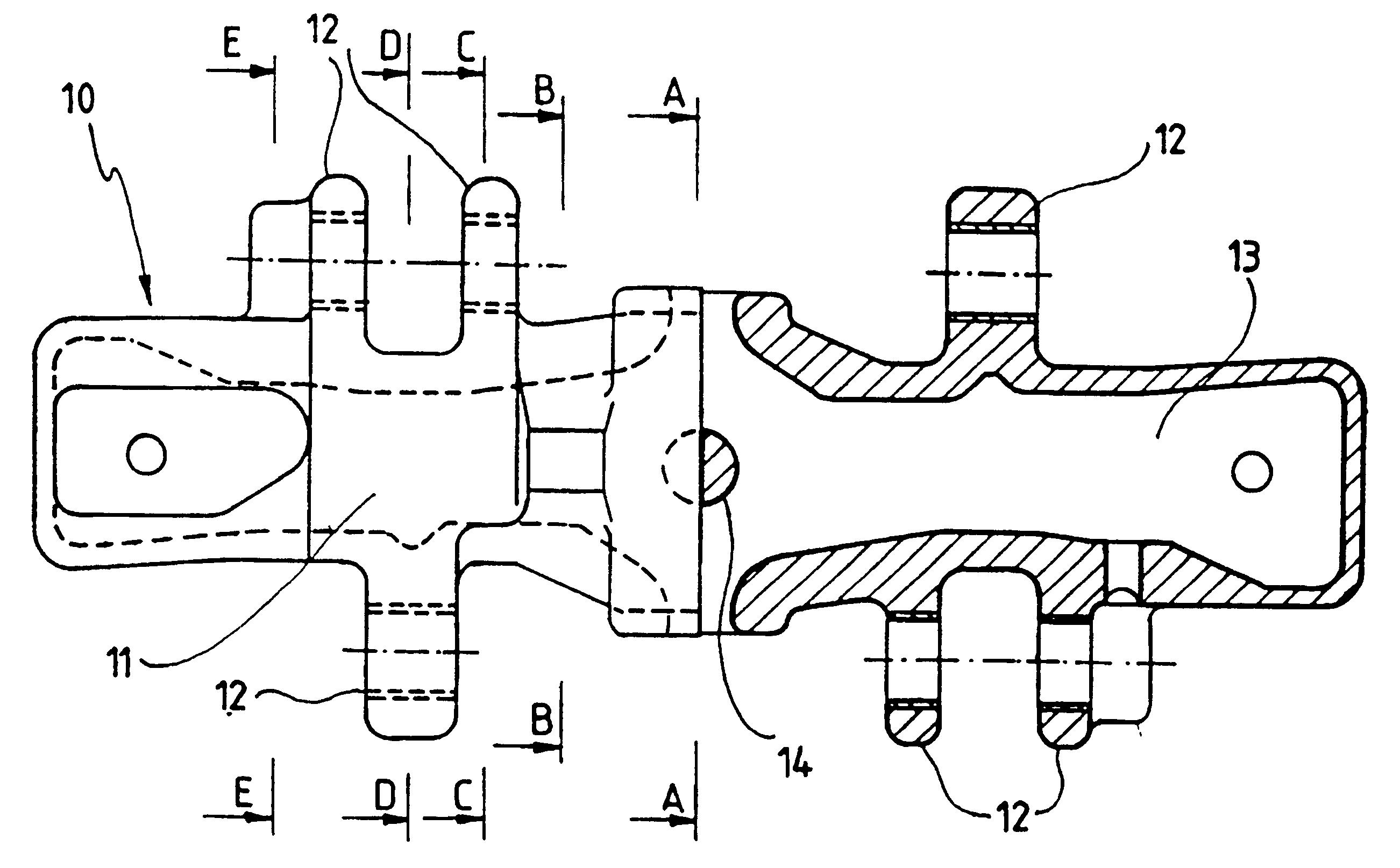

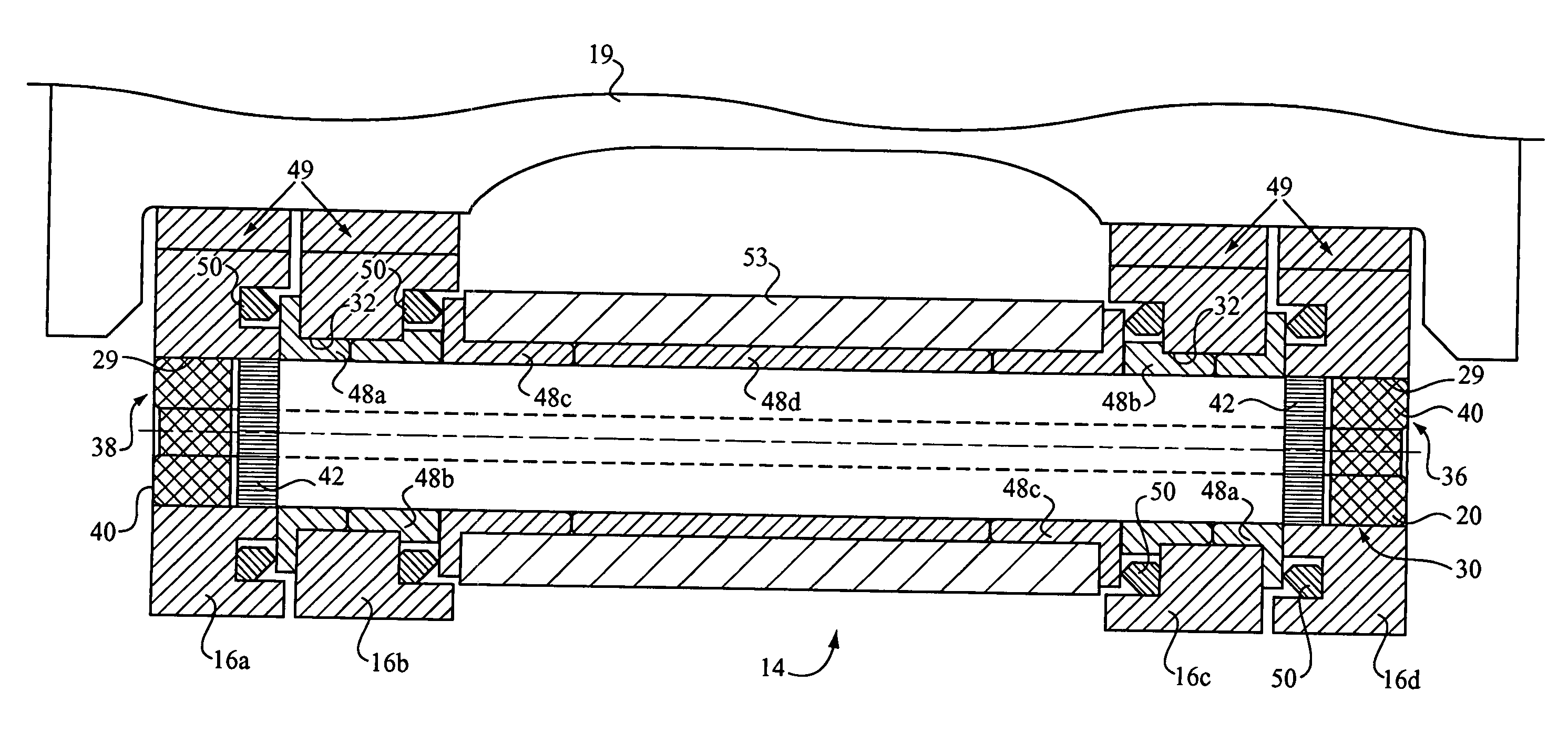

Fixing structure of link and pin of travelling crawler belt, and fixing method thereof

In a travelling crawler belt in which a pair of left and right links are connected by pins respectively press-fitted into the corresponding links, a fixing end surface of the pin or the links is continuously and locally pressed and deformed in an axial direction of the pin from the fixing end surface, along an inner or outer peripheral portion of an opening of a pin-press-fit hole. Then, a part of the opening peripheral portion of the end of the pin or the link is enlarged or reduced in diameter, so that the diametrically increased or reduced portion is retained and fixed to a mating retaining space. With this fixing method, it is possible to easily and strongly couple the links and the pin, and to obtain a fixing structure of the links and the pin for a crawler belt capable of sufficiently securing a holding force of the pin in the axial direction. When the pin is fixed at the time of the assembling of the pin, an existing press can be used without requiring any exclusive machine, and it is possible to easily and reliably assemble the links and the pin for the crawler belt.

Owner:KOMATSU LTD

Color image display device, method of driving the same, and electronic equipment

A gray-scale power supply line supplied to a source signal line driving circuit is made only one system, and each of D / A conversion circuits drives source signal lines in which three source signal lines corresponding to RGB are made a unit and the number of which is a multiple of 3. The periods in which respective source line selecting circuits select source signal lines corresponding to respective colors of the RGB are made synchronous with each other, and the power supply voltage applied to the gray-scale power supply line is changed in one horizontal writing period, so that power supply voltages corresponding to R, G and B are respectively applied to the gray-scale power supply line in periods while the source signal lines of R, G and B are respectively selected.

Owner:SEMICON ENERGY LAB CO LTD

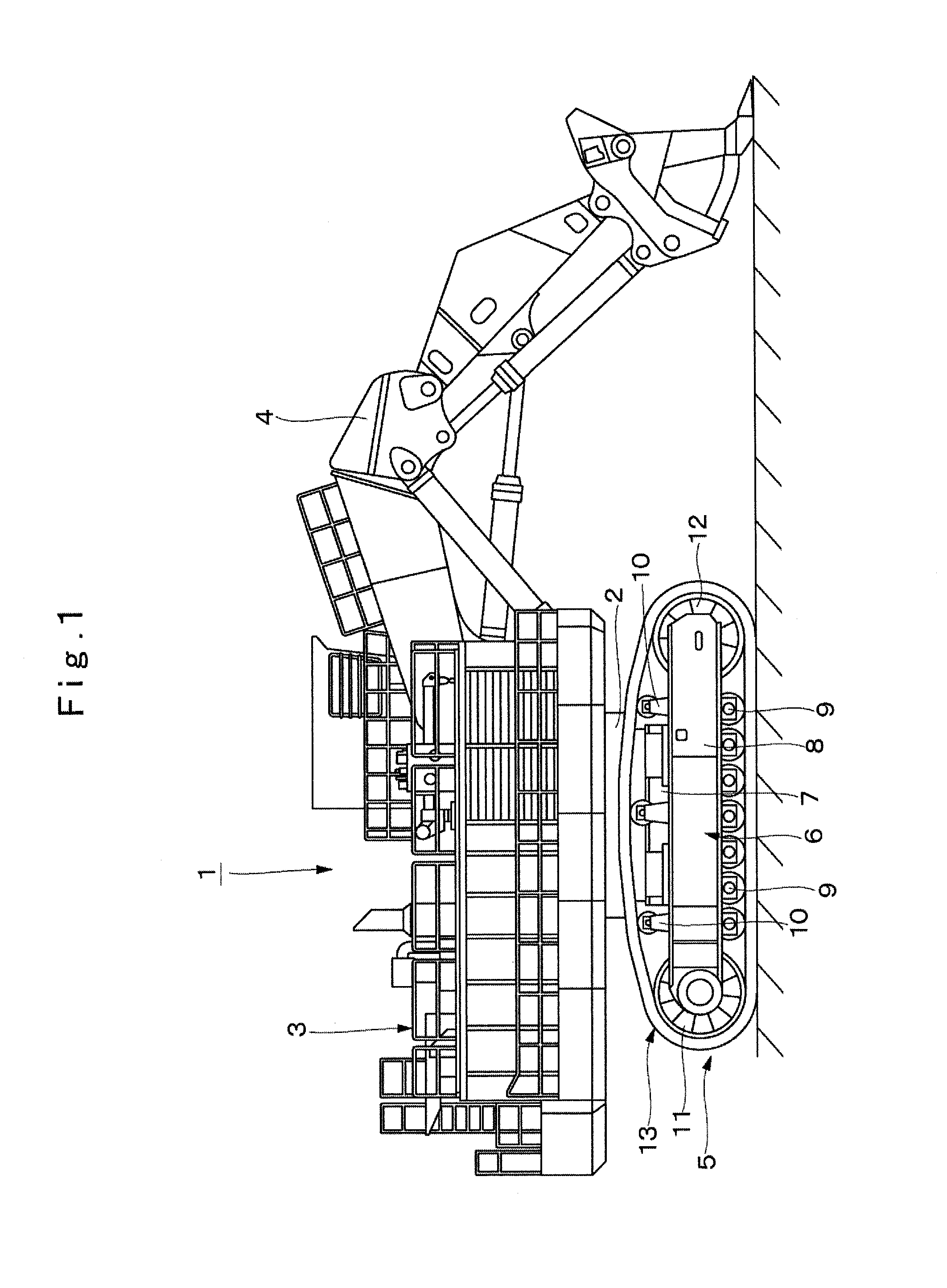

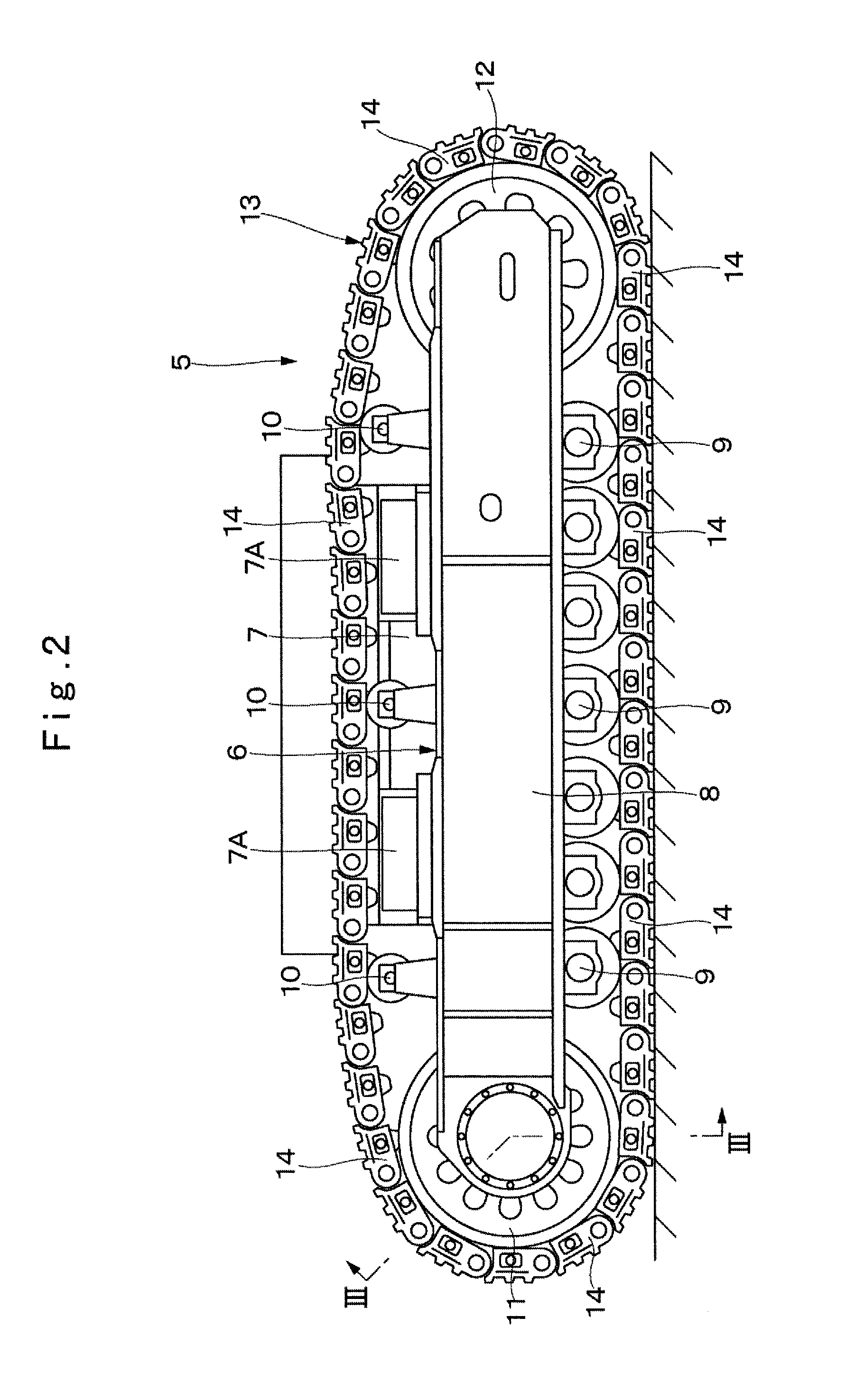

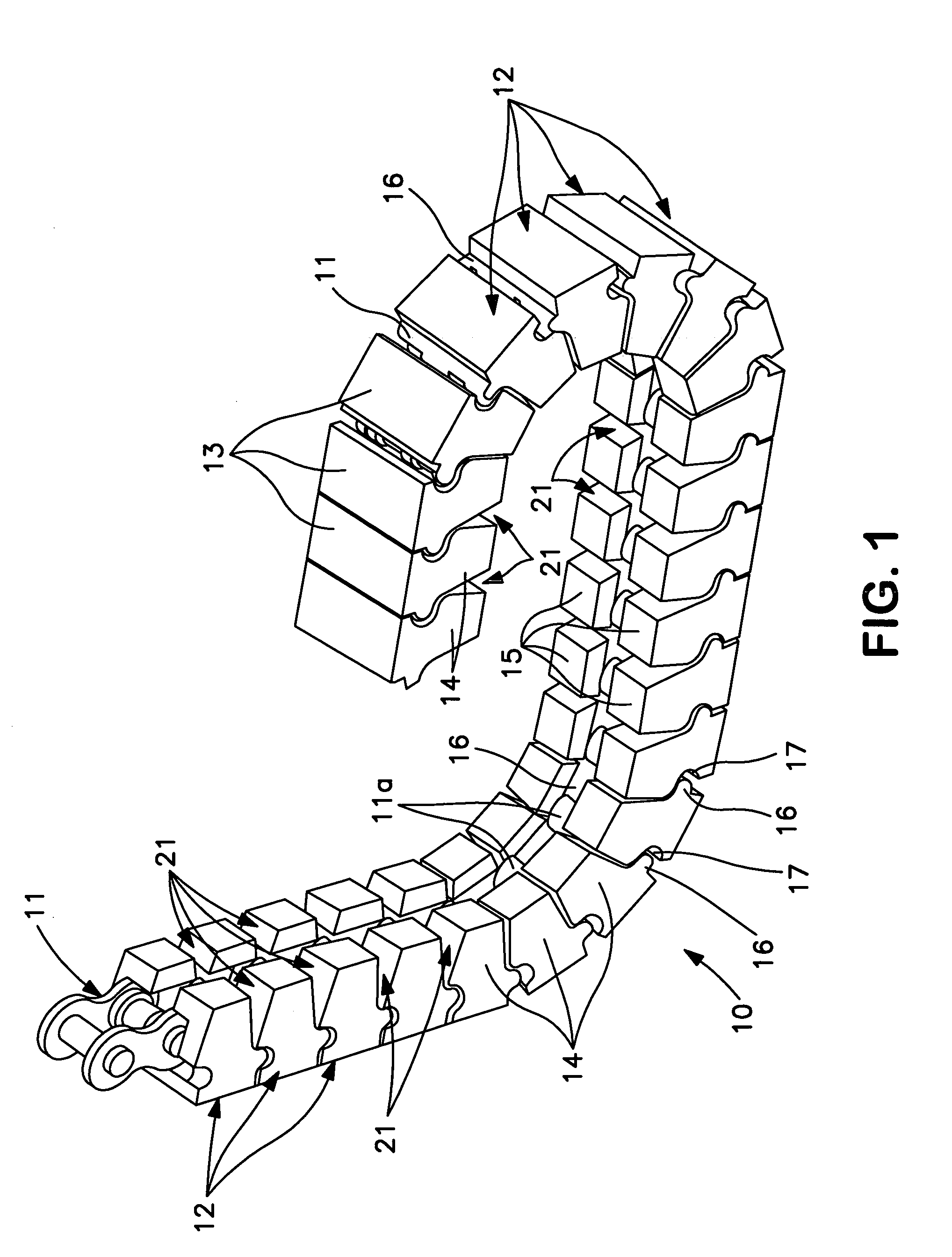

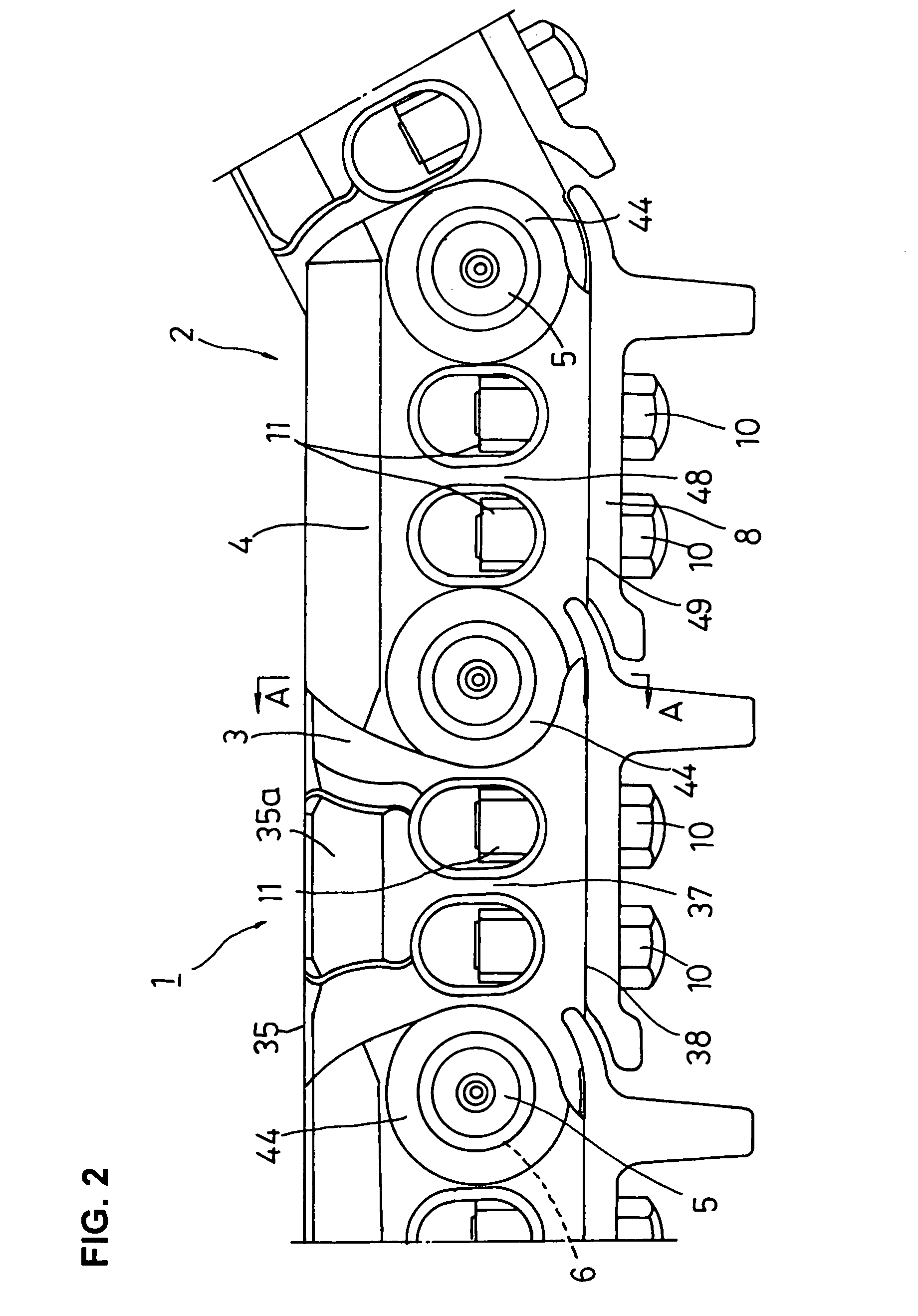

Machine track system and machine track segment

A machine track system includes a track with track shoes each having a footprint, and a ground contact area equal to the footprint, the track shoes being coupled together by a total of two track chains. A first rail and a second rail are located between first and second outboard edges of each of the track shoes, such that track rollers roll directly on the track shoes. The track chains are spaced outboard of the rails, and a guide block configured to engage with an idler and a drive sprocket is positioned between the respective rails. A sprocket and idler for use with the track system includes removable track contacting segments having pockets configured to receive the guide blocks for driving and guiding the track.

Owner:CATERPILLAR INC

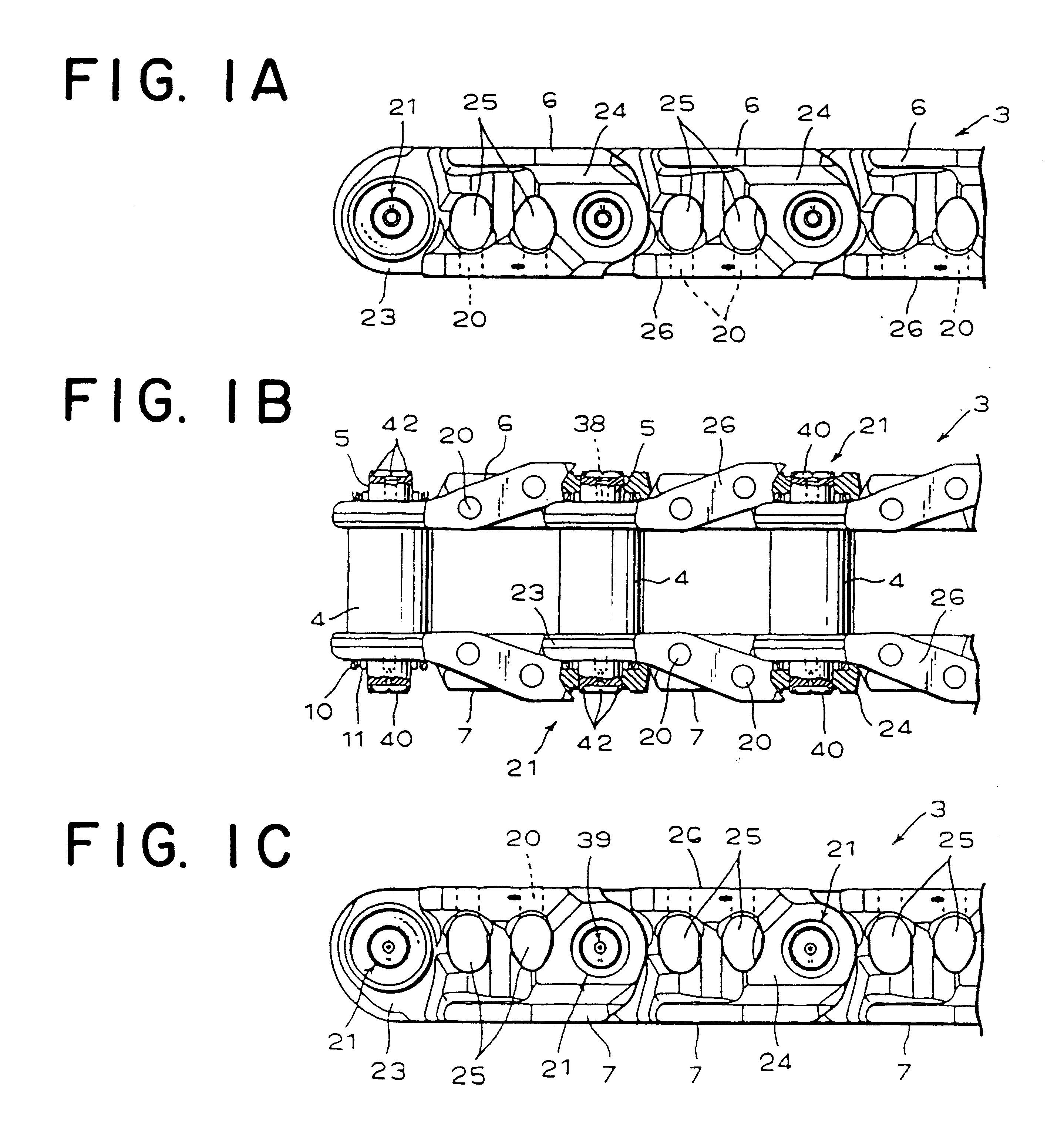

Link for connecting track shoe of crawler belt, assembly for crawler belt, and crawler belt

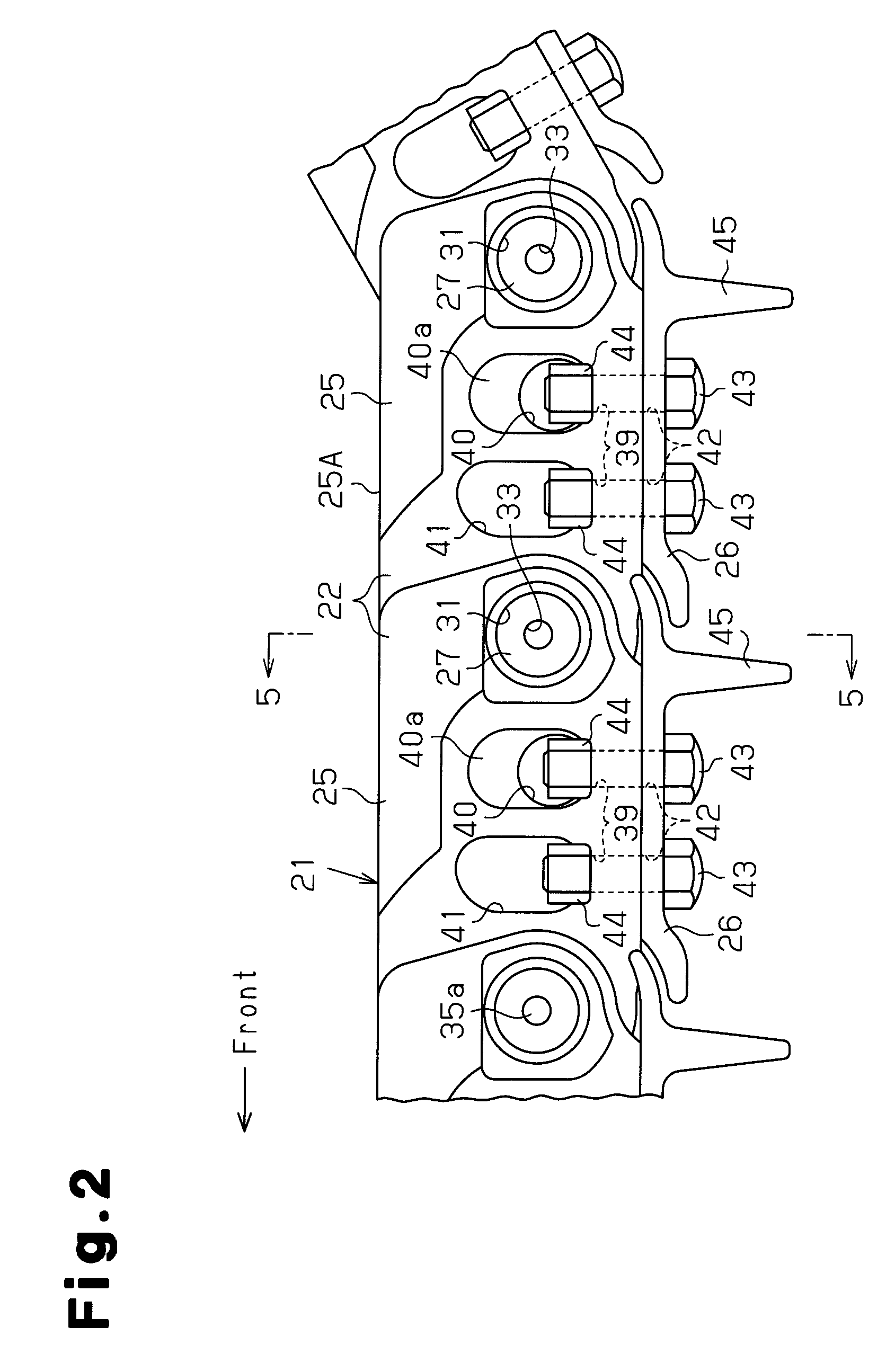

InactiveUS20090026836A1Improve rigidityAvoid stress concentrationGearingEndless track vehiclesEngineeringMechanical engineering

A track shoe connecting link 25 has shaft holes 31, 32 at both end portions. In the track shoe connecting link 25, a plurality of insertion holes 39 are formed between the shaft holes 31, 32, and window holes 40, 41 are formed so as to correspond to each insertion hole 39. A bolt 43 is inserted through each of the insertion holes 39 and a nut 44 is screwed onto a distal end of the bolt 43 in each of the window holes 40, 41. Accordingly, the track shoe connecting link 25 is fixed to a track shoe 26. The area of the window hole 41 that is adjacent to the second shaft hole 32 is greater than the area of the window hole 40. Accordingly, the rigidity of the track shoe connecting link 25 becomes smaller toward the second shaft hole 32.

Owner:KOMATSU LTD

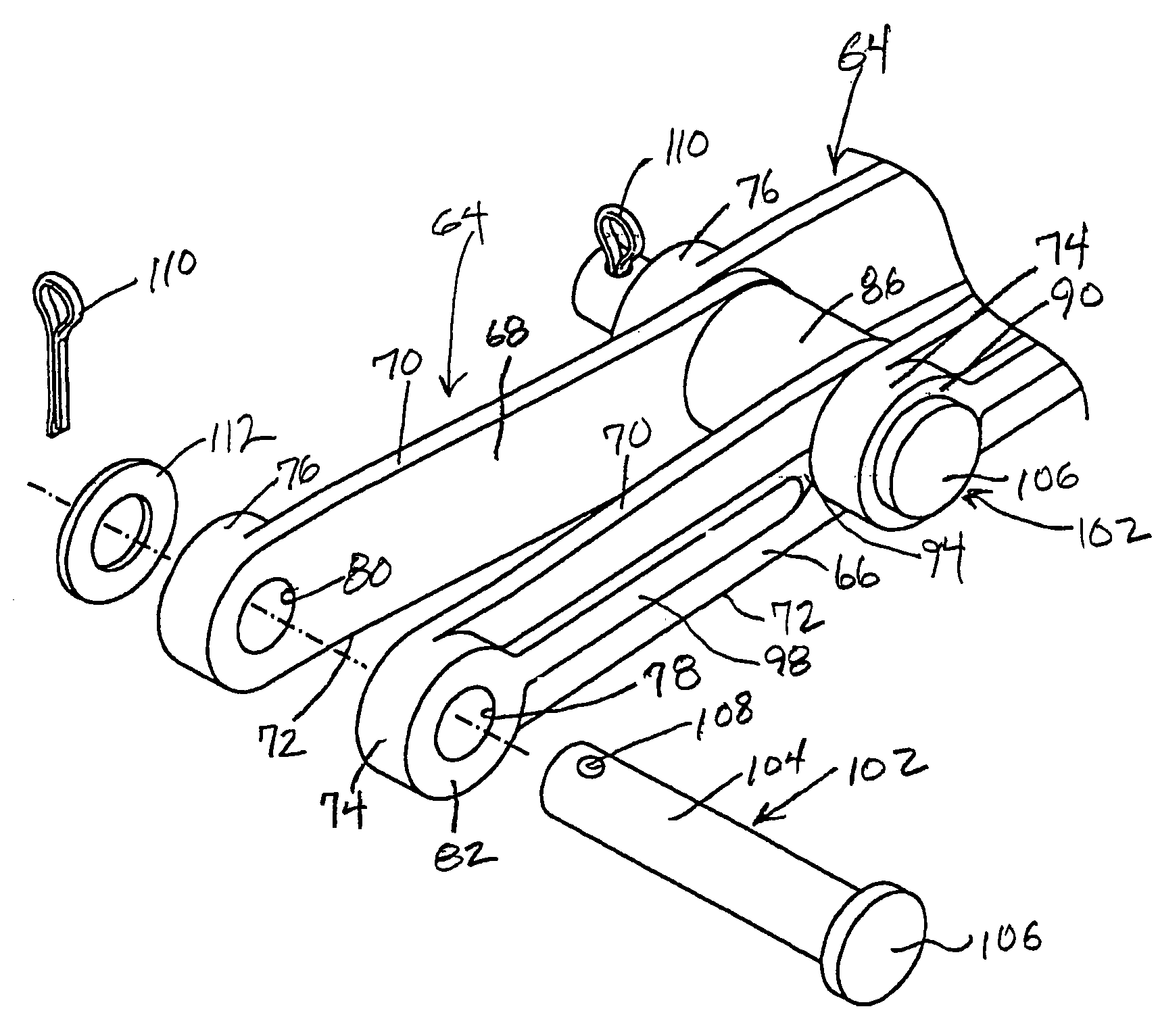

Investment cast, stainless steel chain link and casting process therefor

ActiveUS20070107412A1Reduce tensionEliminate wear and tearFoundry mouldsSedimentation separationFree rotationInvestment casting

An investment cast, stainless steel chain link is provided for chains used in water and wastewater treatment. The chain link comprises a pair of spaced apart, elongated sidebars having forward ends and rearward ends. The forward ends are spread apart and are provided with outwardly and laterally extending bosses having transverse boss pin bores coaxially aligned with each other. The rearward ends are interconnected by a cylindrical barrel having a barrel pin bore extending through each of the sidebars. The sidebars are formed with outwardly and laterally projecting reinforcing ribs extending between the bosses and the barrel pin bore along a substantial length of the sidebars. A freely rotatable chain pin is inserted through aligned boss and barrel pin bores from either end thereof for interconnecting first and second pairs of sidebars. An arrangement is provided for preventing the lateral dislodgement of the chain pin from the sidebars.

Owner:HUMCKE MICHAEL W +1

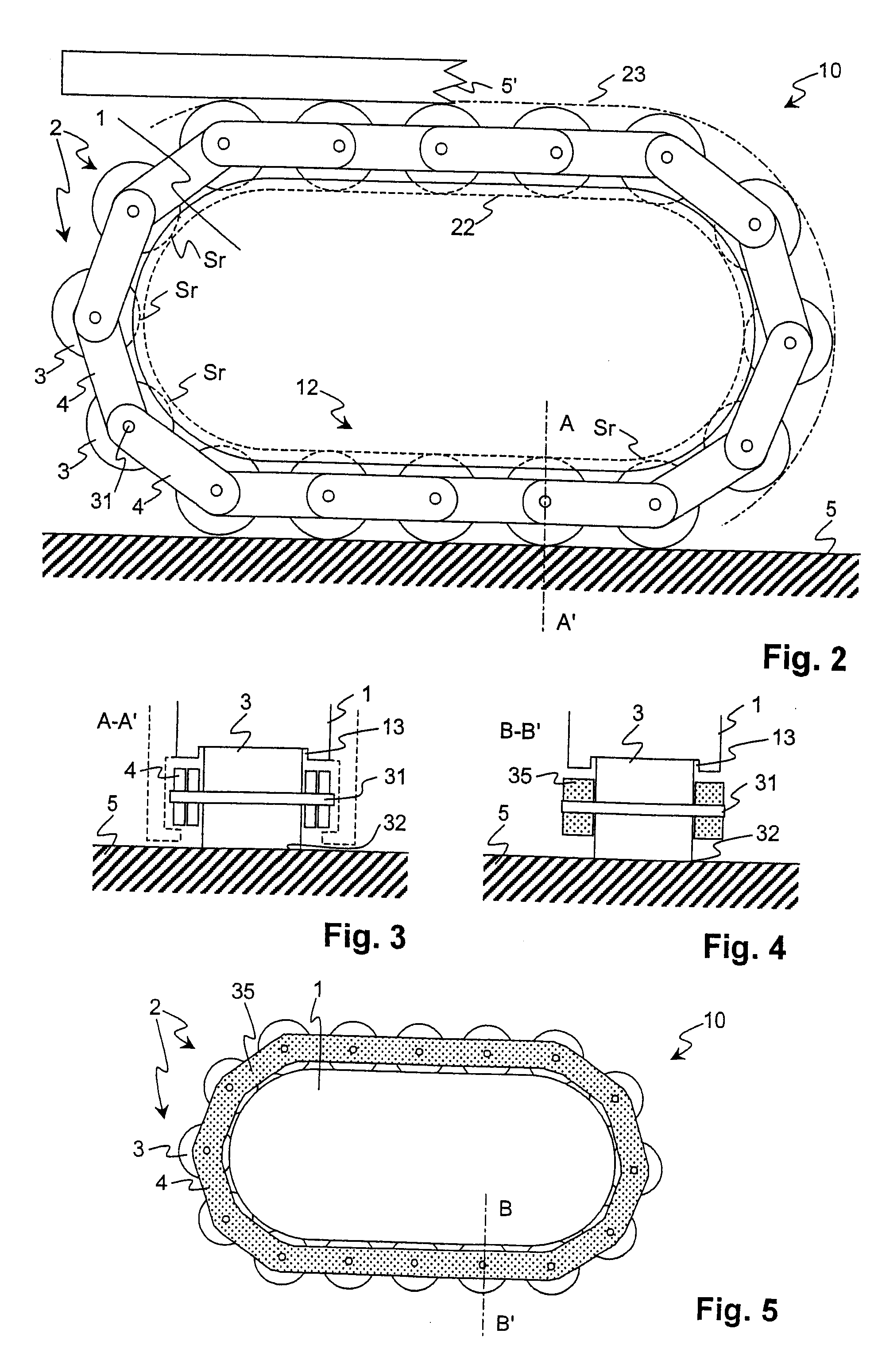

Crawler belt

InactiveUS20150158536A1Improve efficiencyStable trackingEndless track vehiclesMetal chainsGround contactDrive wheel

In each of track links (14) forming a crawler belt (13), an engaging projection (23) engaging to a drive wheel (11) is provided on a drive wheel abutting surface (22) abutting on the drive wheel (11). A fitting groove (27) composed of a bottomed recessed groove is provided on a ground contact surface (26) at the opposite side to the drive wheel abutting surface (22) in the upper-lower direction in a position corresponding to the engaging projection (23). Thereby, at the time of stacking up the track links (14) in the upper-lower direction, the fitting groove (27) of the upper track link (14) can be fitted into the engaging projection (23) of the lower track link (14).

Owner:NIHON KENKI CO LTD

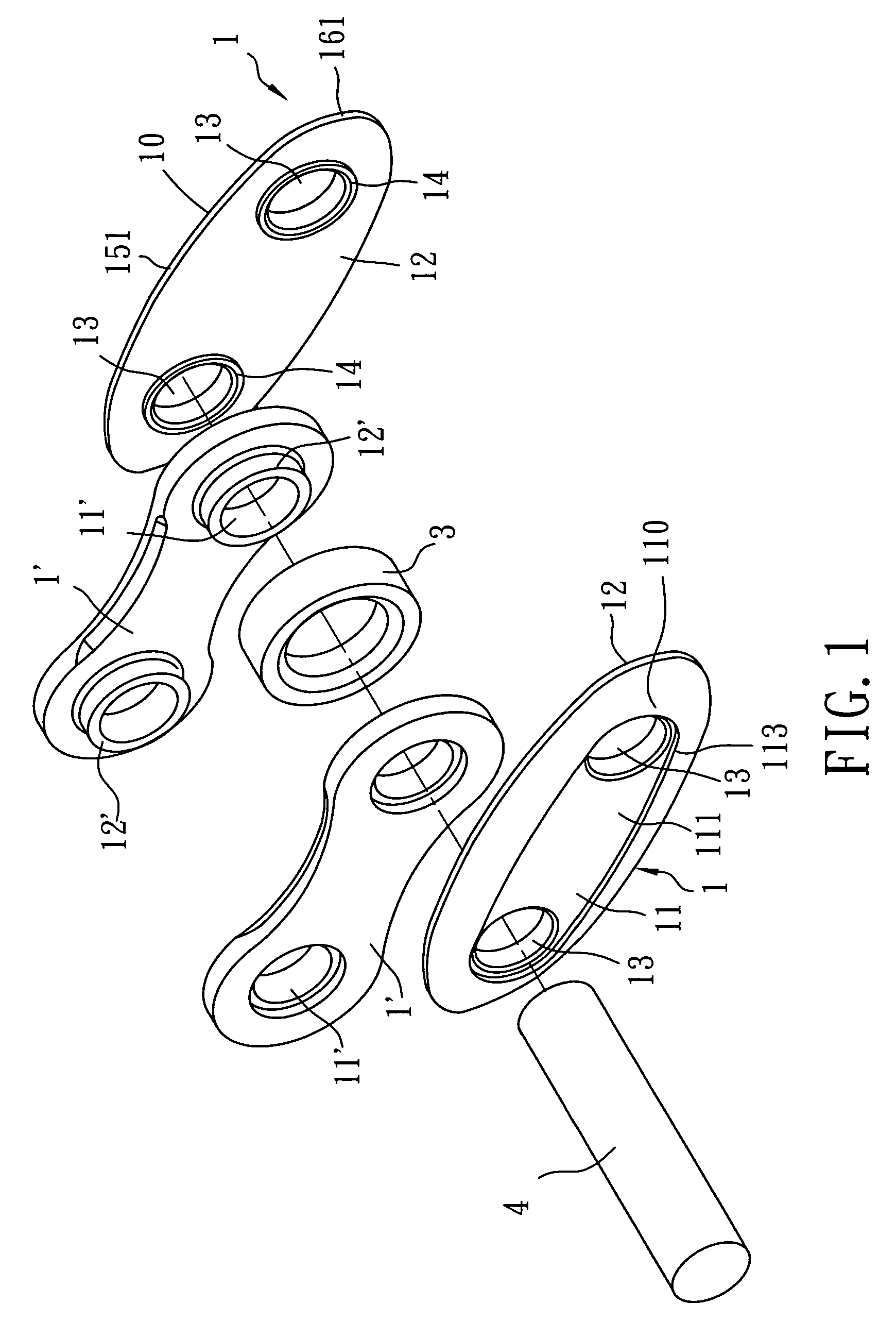

Multi-link connector

Owner:ASSA ABLOY FINANCIAL SERVICES

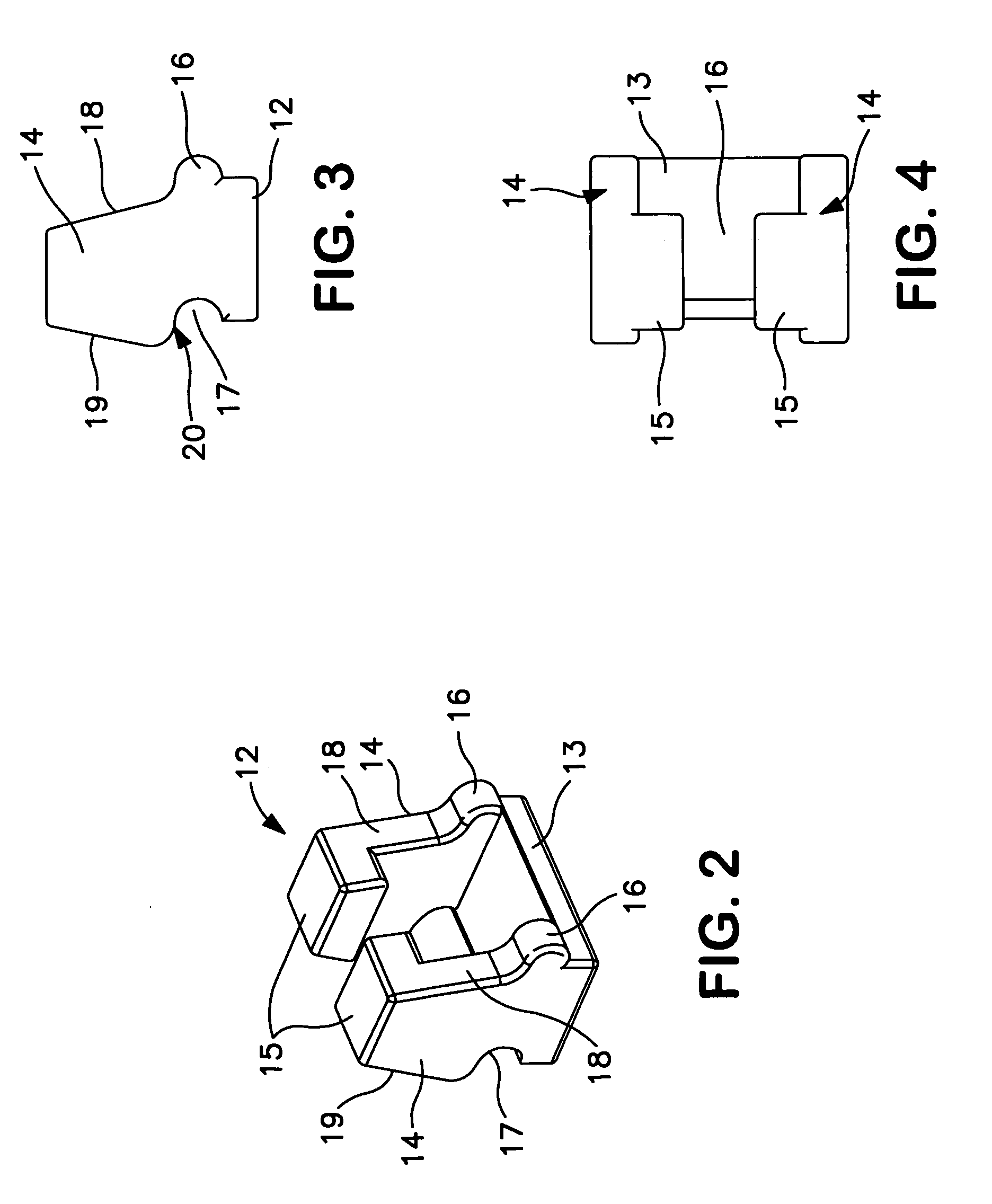

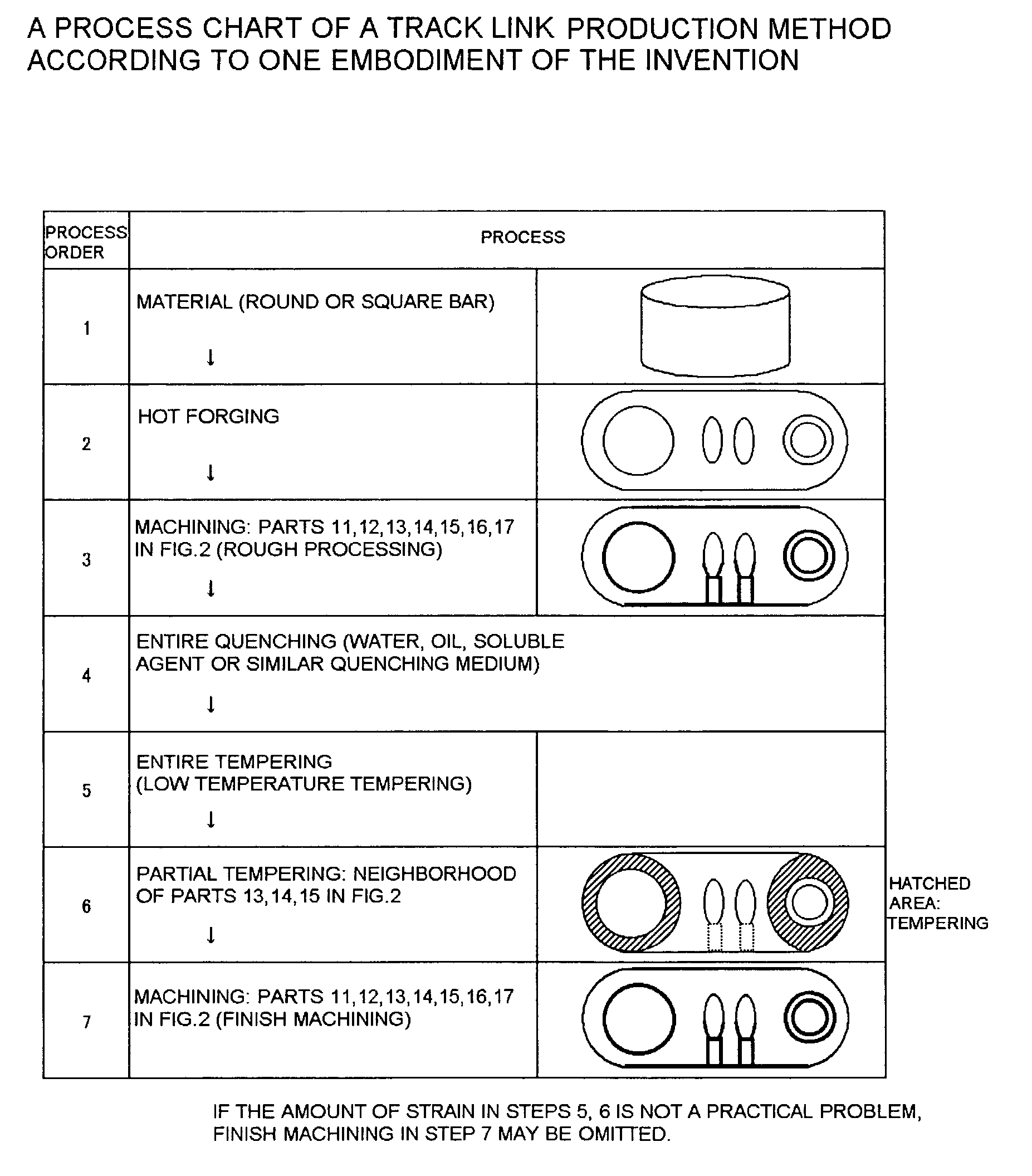

Track link production method and track link produced by the same

InactiveUS7040080B2Delayed failureIncrease pressureConnecting rodsMetal-working apparatusHigh dimensionalMachining process

There are proposed a track link production method capable of providing markedly improved wear life with good cost performance and a track link produced by this method. To this end, the track link production method includes a heat treatment process (Steps 4, 5) of applying quenching and low temperature tempering treatment to a whole link material after hot forging (Step 2), and is designed such that desired machining is applied to the link material (Step 3) before the heat treatment process (Steps 4, 5) and such that after the heat treatment process (Steps 4, 5), tempering (Step 6) and finish machining (Step 7) are sequentially applied to some of the parts which have undergone the machining process, the some parts including at least parts where high dimensional accuracy is required.

Owner:KOMATSU LTD

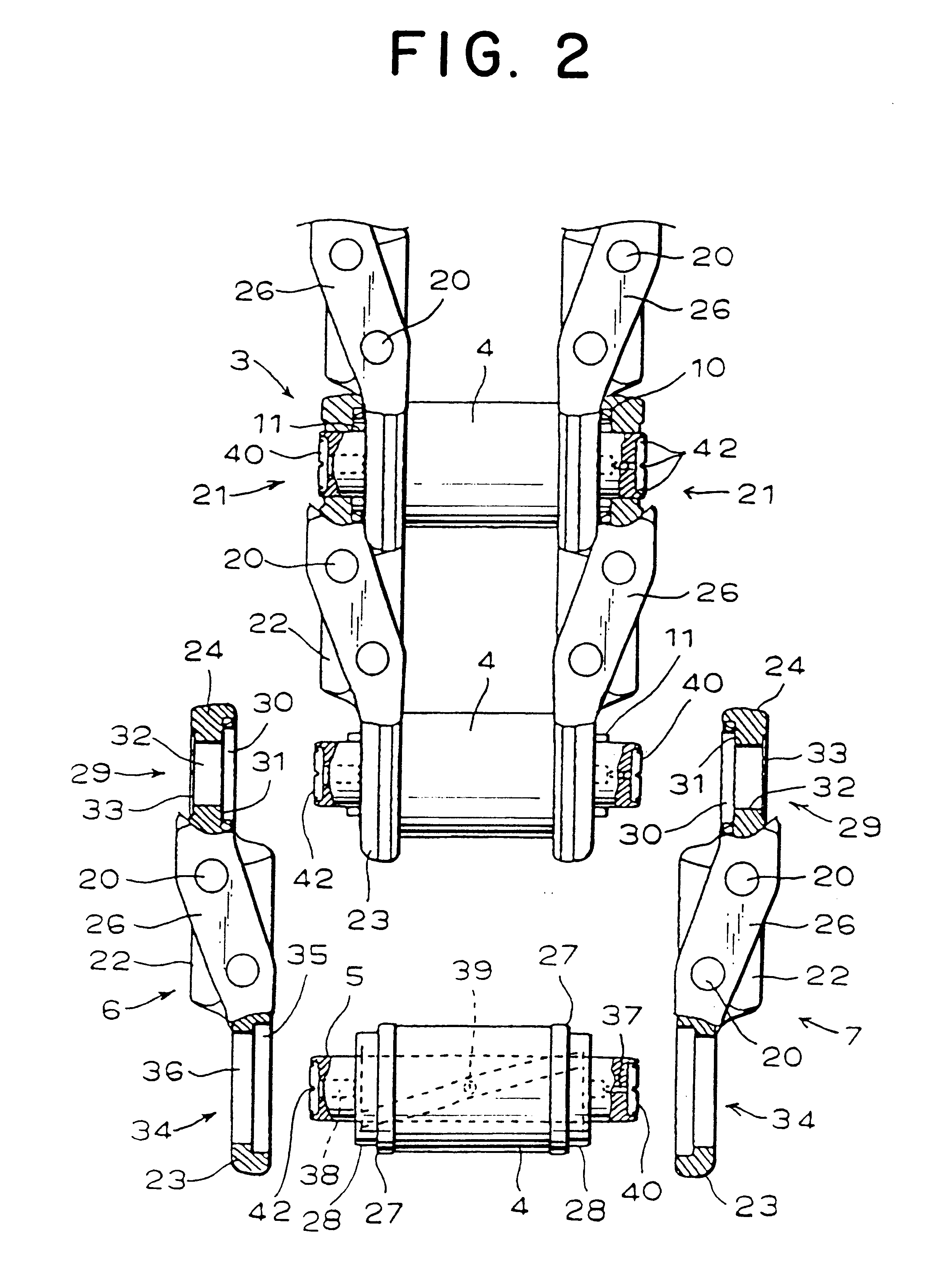

Joint assembly to resist galling

Joint assemblies are useful for connecting one structure to another structure. When the various structures deflect or bend, edge loading occurs therebetween. The subject joint assembly includes a pin positioned between a first and second structure. An insert is free floating positioned around the pin for contacting either of the first or second structures. A crown shaped surface is utilized on the insert at a substantially central location therealong. The crown shaped surface directs forces to the center of the insert to reduce edge loading.

Owner:CATERPILLAR INC

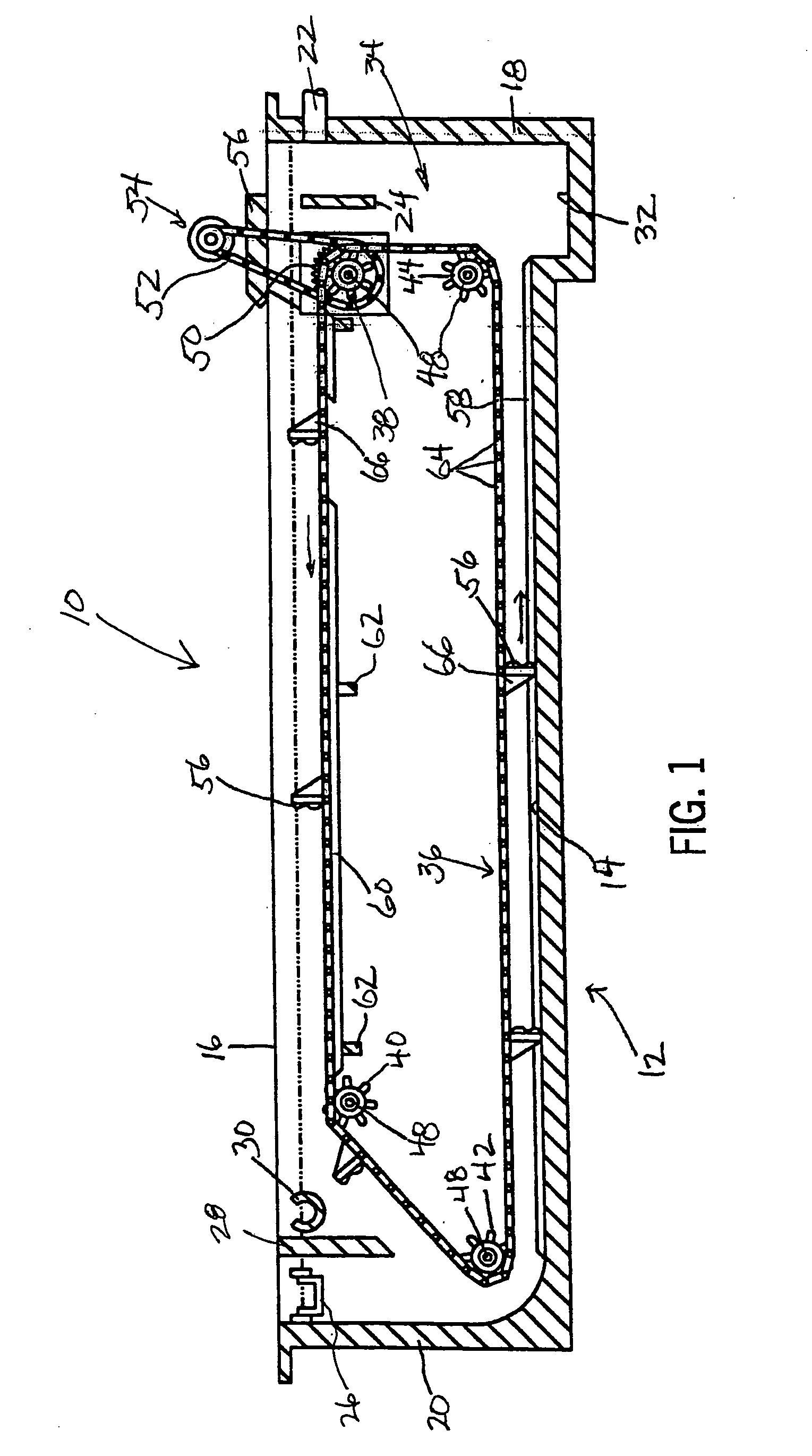

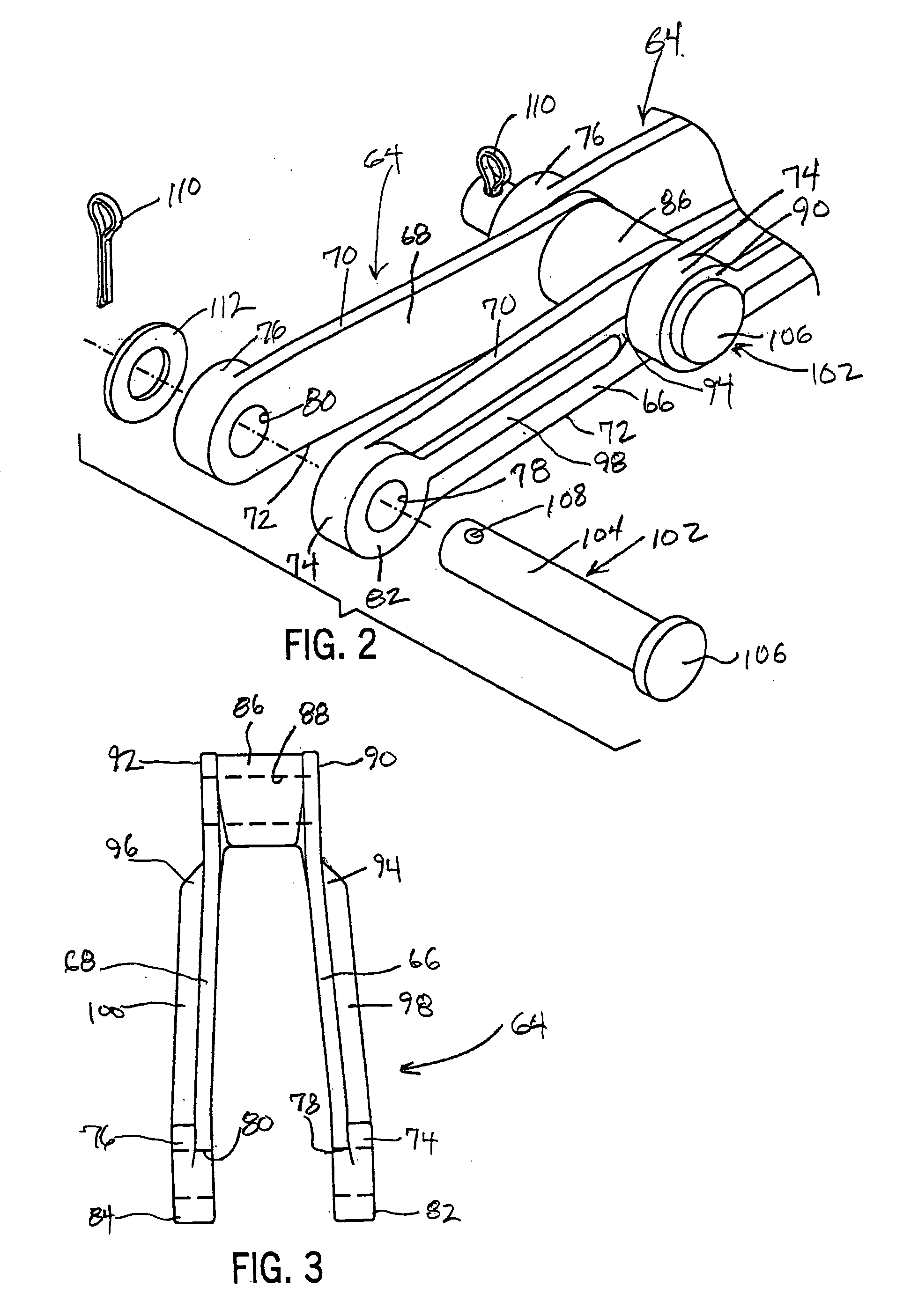

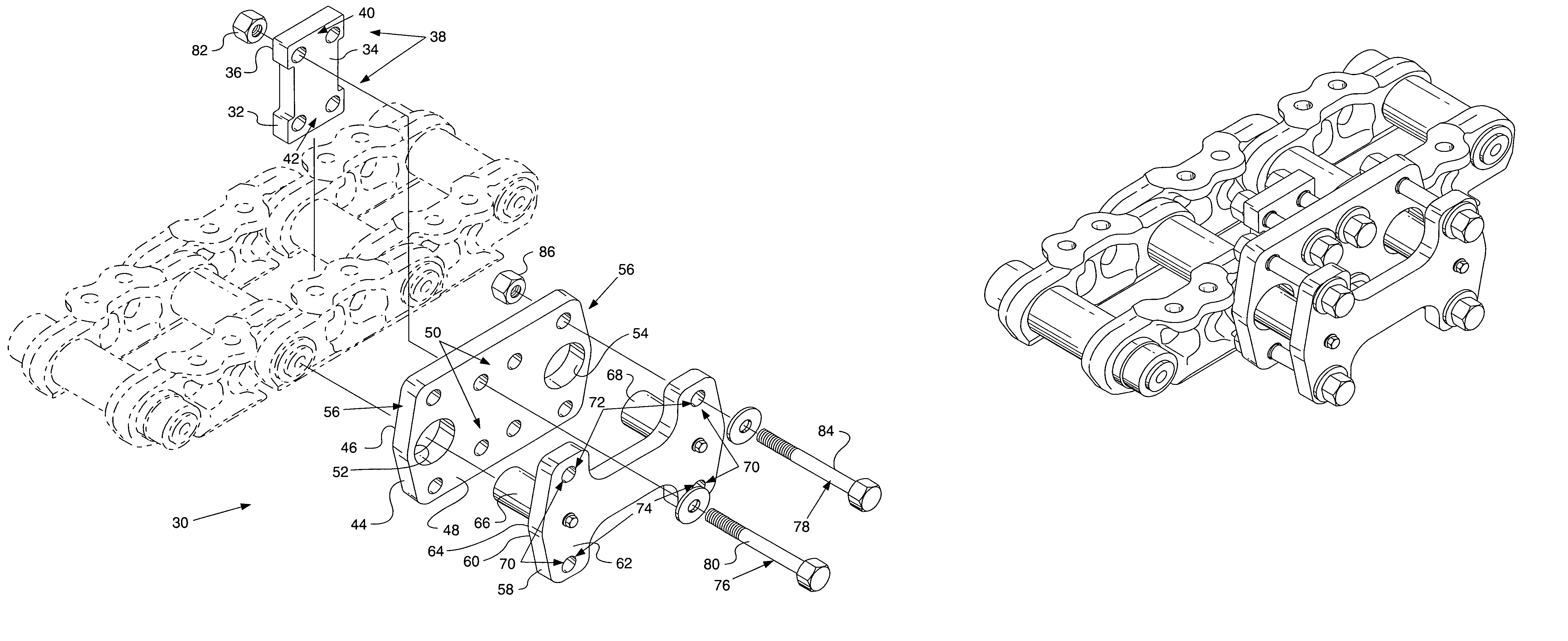

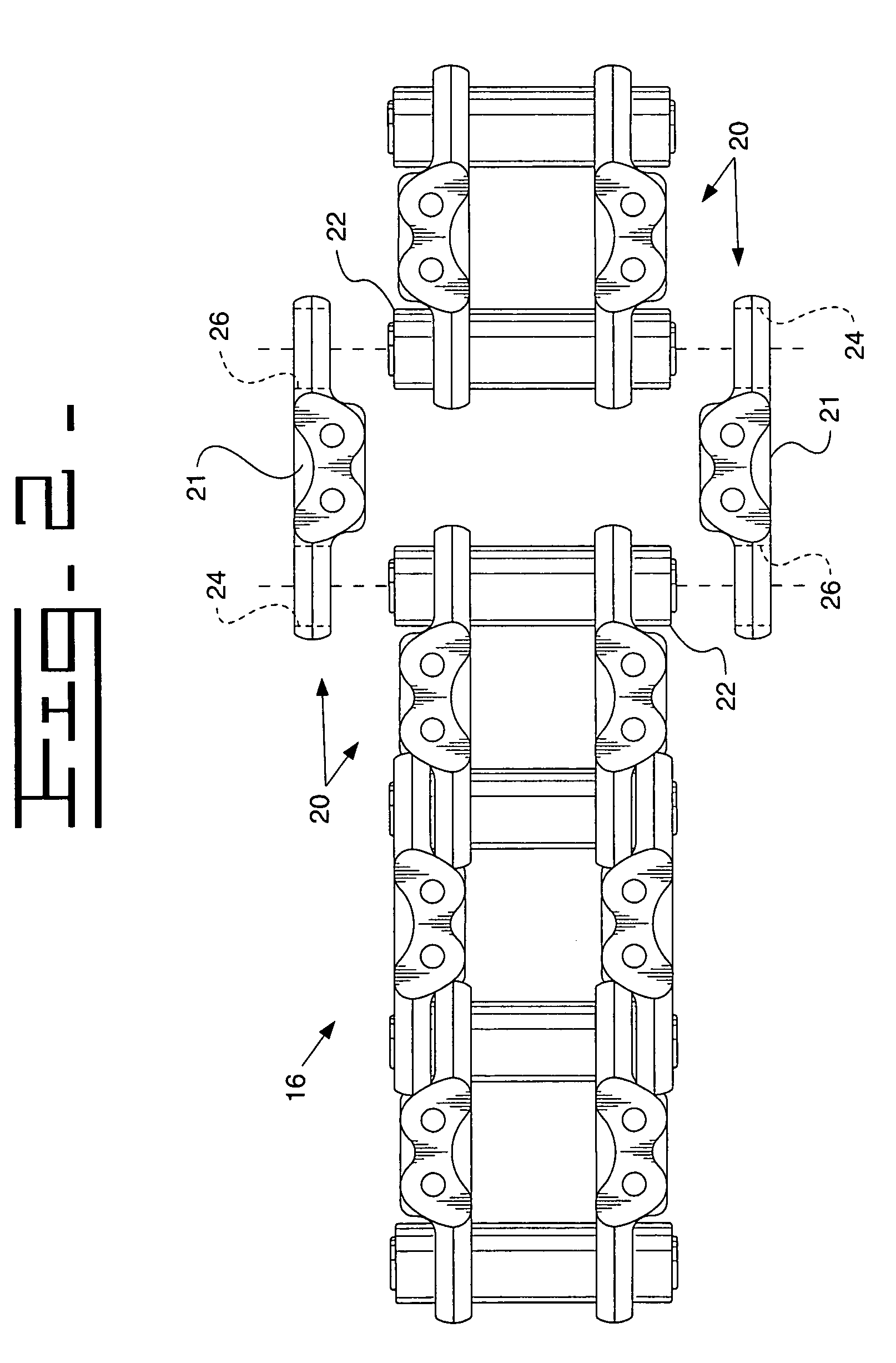

Portable track link disassembly tool

A portable disassembly tool is provided to disassemble a track link assembly from a machine by removing opposed track links from the track link assembly. The portable disassembly tool includes first and second members that are tightly secured to the track link to be removed by a plurality of fasteners. The second member has clearance holes therein to freely receive the ends of the associated track pin assemblies. A third member having spacer members extending therefrom is disposed adjacent to the second member with the spacer members extending into the respective clearance holes into contact with the ends of the track pin assemblies and secured to the second member by a second plurality of fasteners. By alternately tightening the plurality of fasteners, the track link is pulled from the associated track pin assemblies. During the removal of the track link, binding in any direction is overcome.

Owner:CATERPILLAR INC

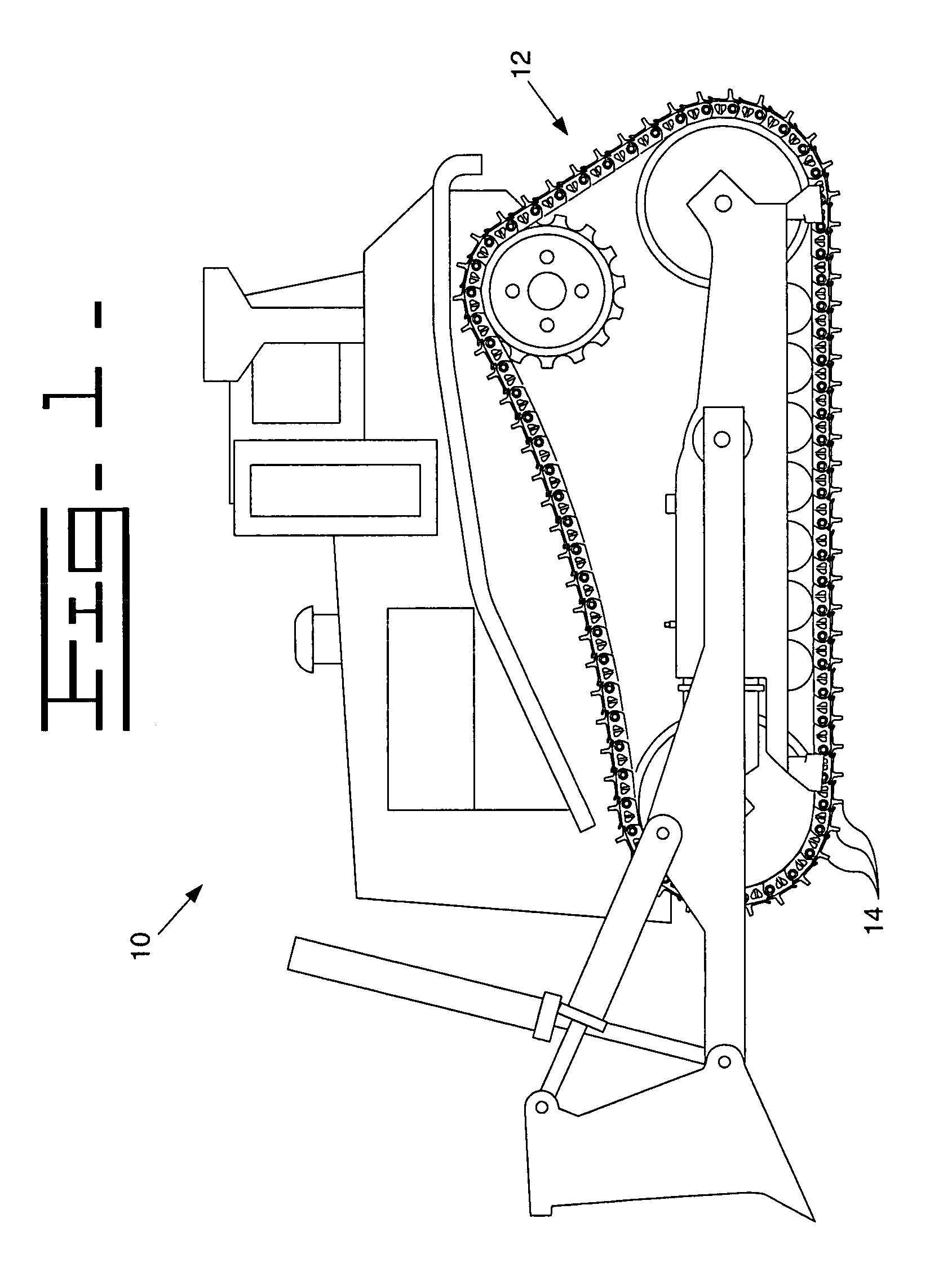

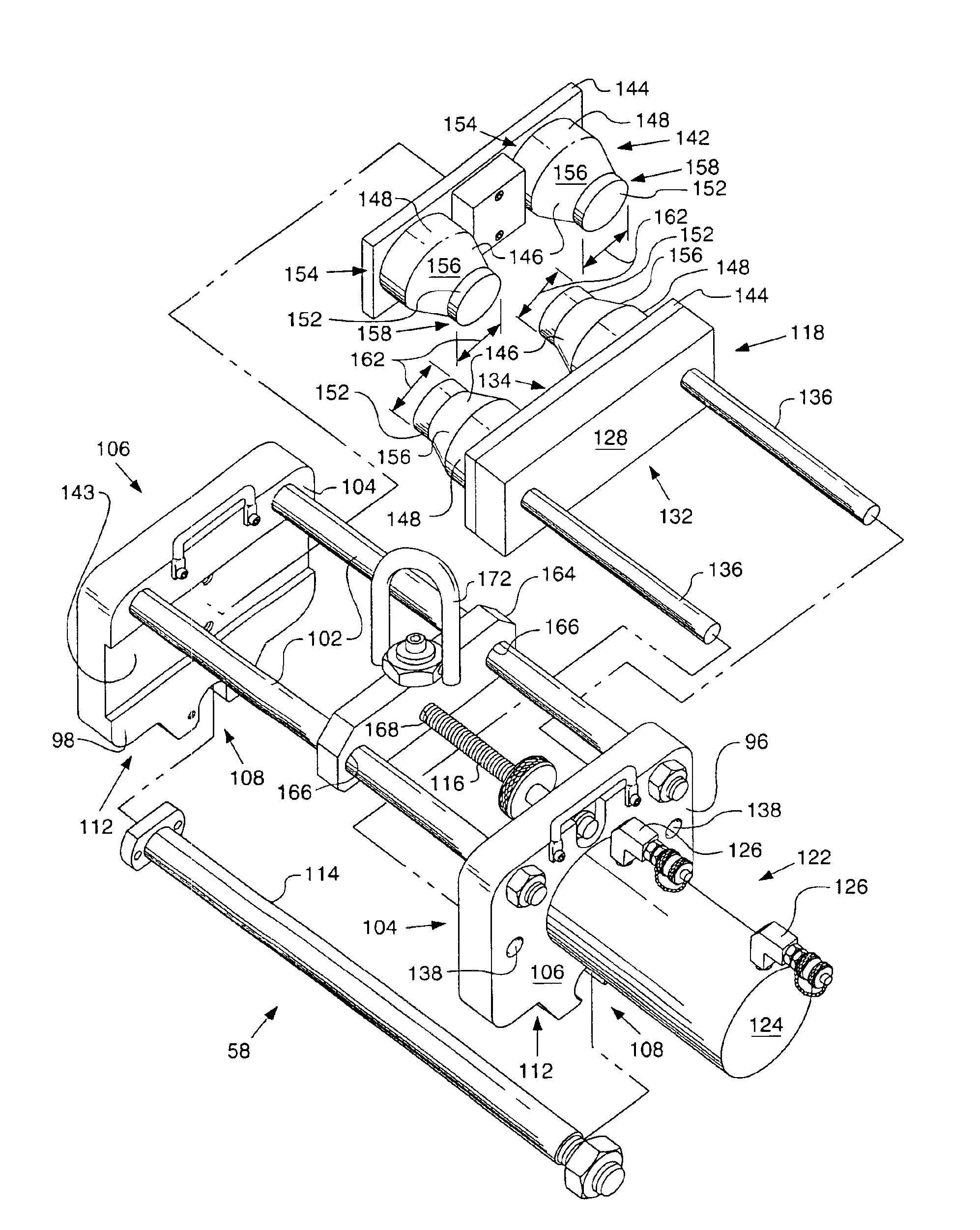

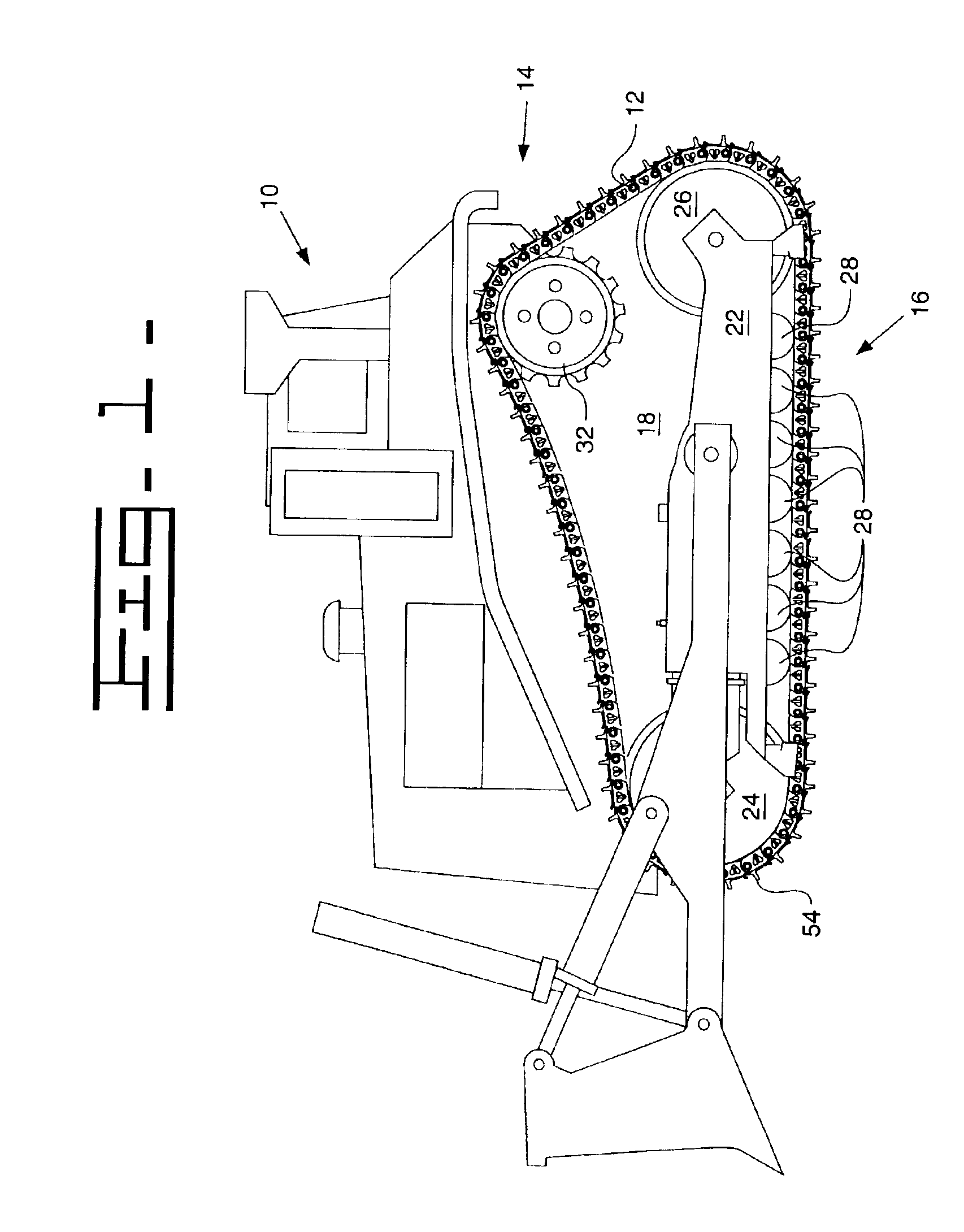

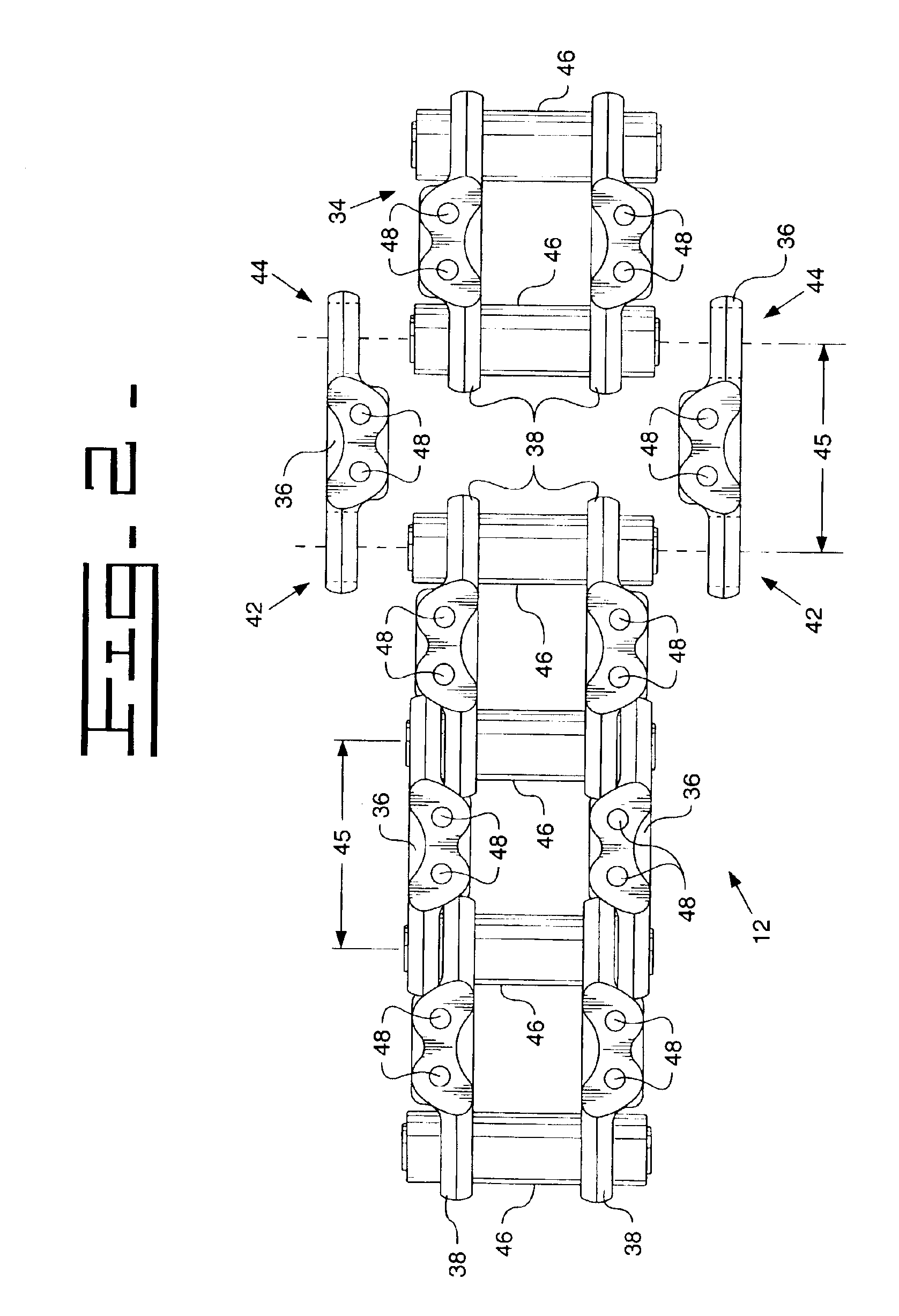

Method and apparatus for installing links on an endless track chain

The present invention provides a portable machine for assembling a track for a track type work machine. A positioning block is provided for alignment of a pair of track pins that are to receive an outer track joint. A portable assembly tool having a pair of contact tools is adapted to receive a pair of outer track joints. The assembly tool is positioned over the positioning block and a hydraulic ram is extended to press each of the outer track links onto the track pins. The present invention is used with track assemblies that do not require master links.

Owner:CATERPILLAR INC

Track shoe

InactiveUS6543863B1High strengthIncrease costSuperstructure subunitsVehicle cleaningMechanical engineering

A track shoe for a crawler track has a hollow body with top and bottom sections and perimeter side walls defining a void therebetween. A supporting pillar is located in the void and extends between the top and bottom sections. The pillar is located in the main loadbearing region of the shoe and bears most of the load on the shoe. This enables the thickness of the side walls to be minimized. The shoe can be manufactured more efficiently by complementing foundry methods.

Owner:BRADKEN RESOURCES

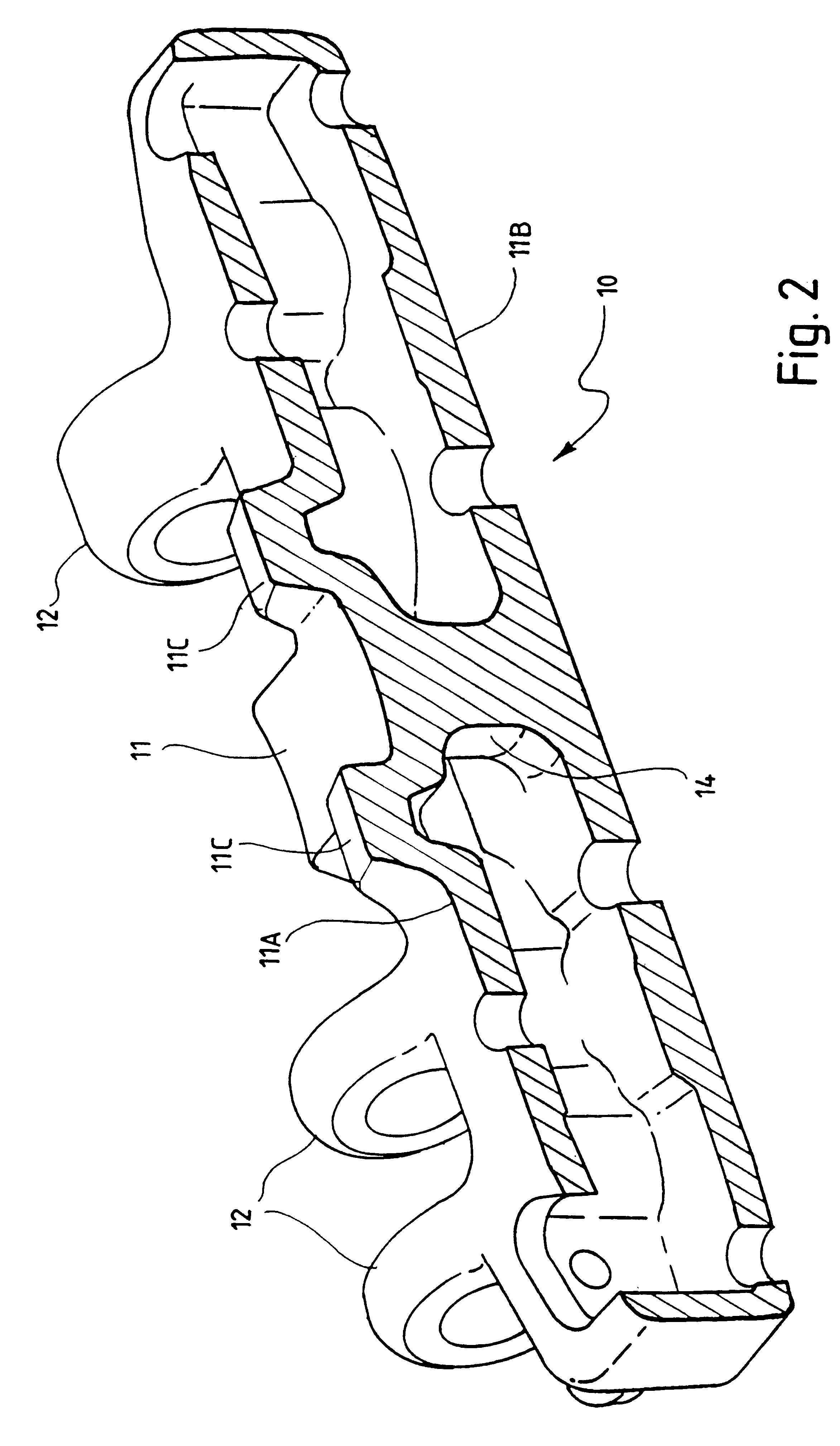

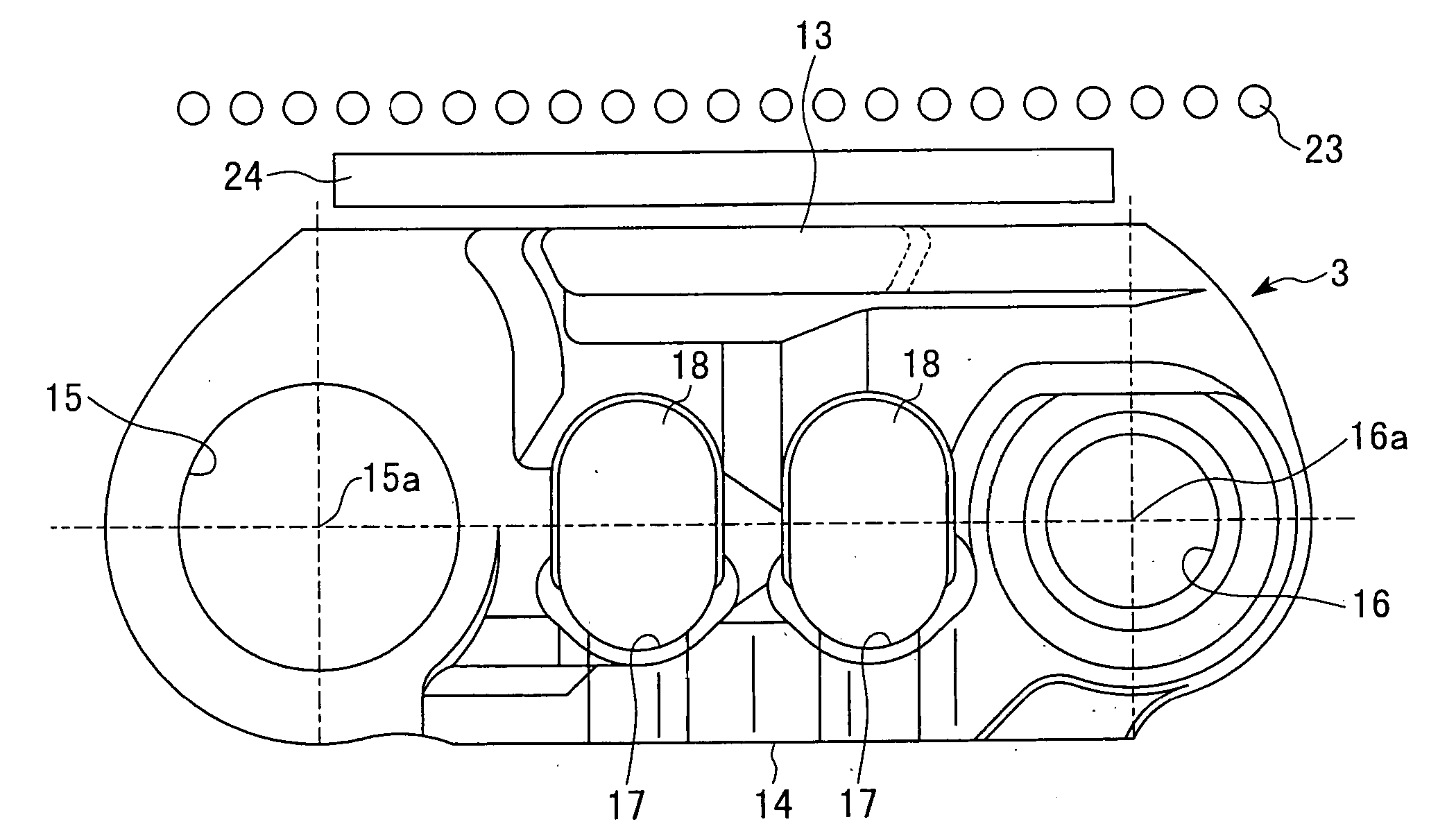

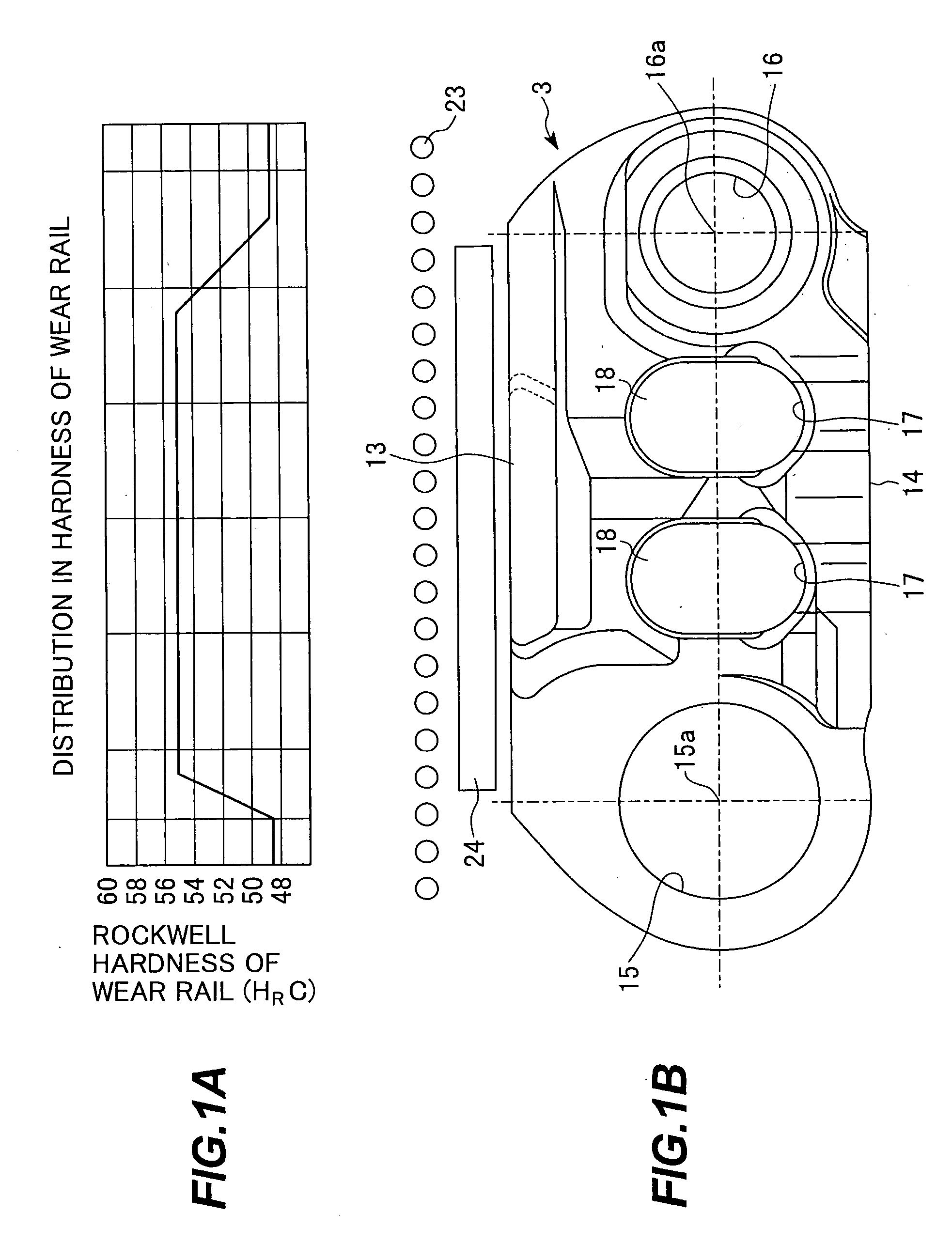

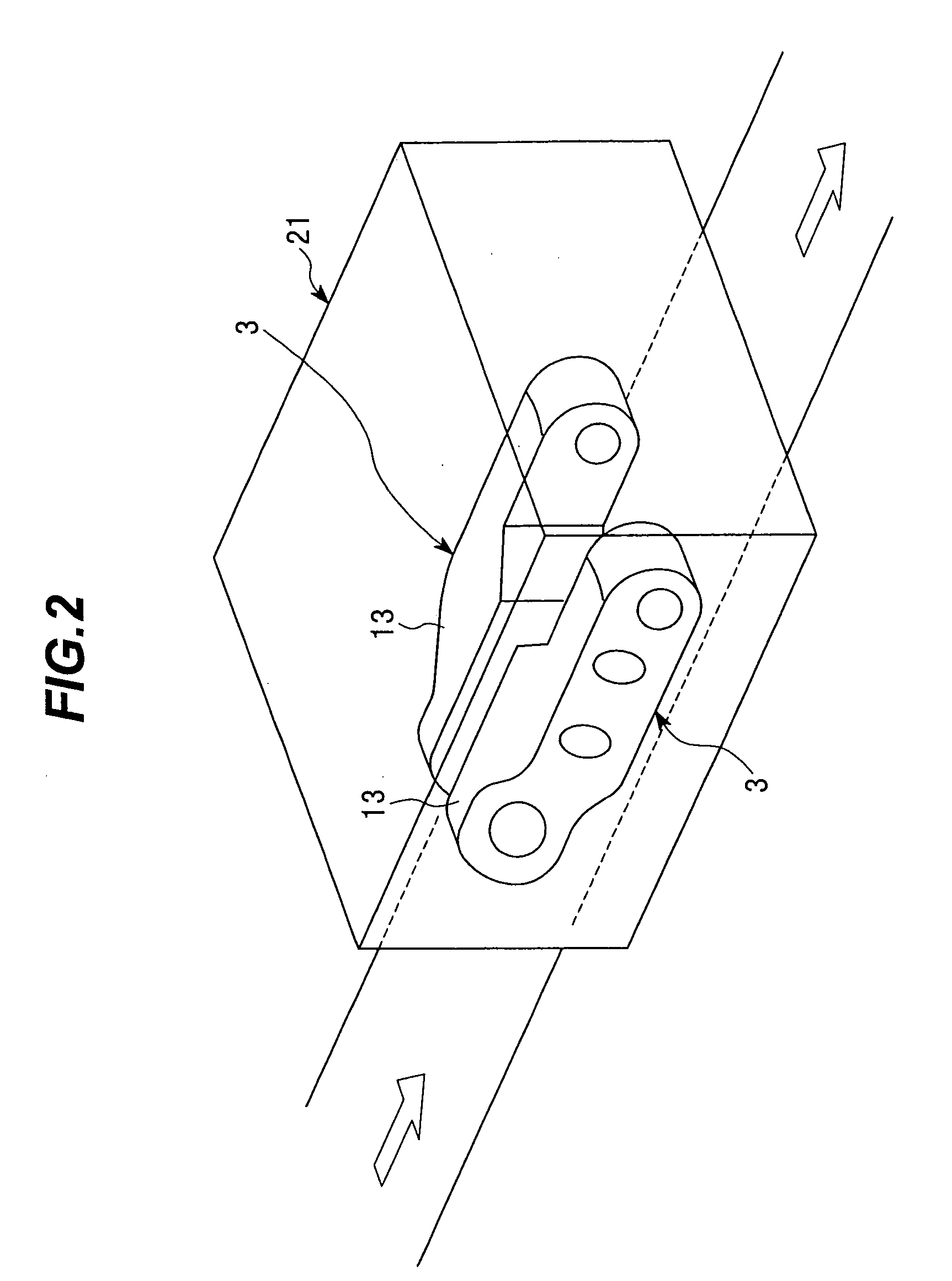

Link and producing method of the same

A link has link connecting bores (15) and (16) at both ends thereof and a wear rail (13) disposed between the upper portions of the link connecting bores (15) and (16). Portions near the ends of the wear rail (13) are designed to have hardness smaller than that of a center portion of the wear rail. Accordingly, the portions near the ends of the wear rail can be abraded easier than the center portion of the wear rail. Since the portions near the ends of the wear rail, in which the portions are easily abraded, are positioned closer to the link connecting bores, abrasion loss in use is smaller than that of the center portion owing to its structure. So, the difference in abrasion amount makes it possible to lower a level irregularity of the wear rail.

Owner:KOMATSU LTD

Machine component configuration for enhanced press fit and press fit coupling method

A machine is provided including a frame and at least one track, such as first and second ground engaging tracks, coupled with the frame. A plurality of pins are provided which each couple together at least two of the links of the tracks and include an outer diameter, a first end and a second end. The first and second ends of the pin may be press fit in first and second bores of first and second links of the tracks, respectively. A non-directional surface finish along a first portion of the length of the pin within the first bore forms a fluid seal with the first bore, whereas a directional surface finish along a different portion of the length of the pin within the first bore inhibits removal of the first end of the pin from the first bore. A method of coupling together machine components via an enhanced press fit is further provided, utilizing a pin having a first surface finish configured to form a fluid seal with a bore of a machine component, and a second surface finish configured to inhibit removal of the pin from the bore.

Owner:CATERPILLAR INC

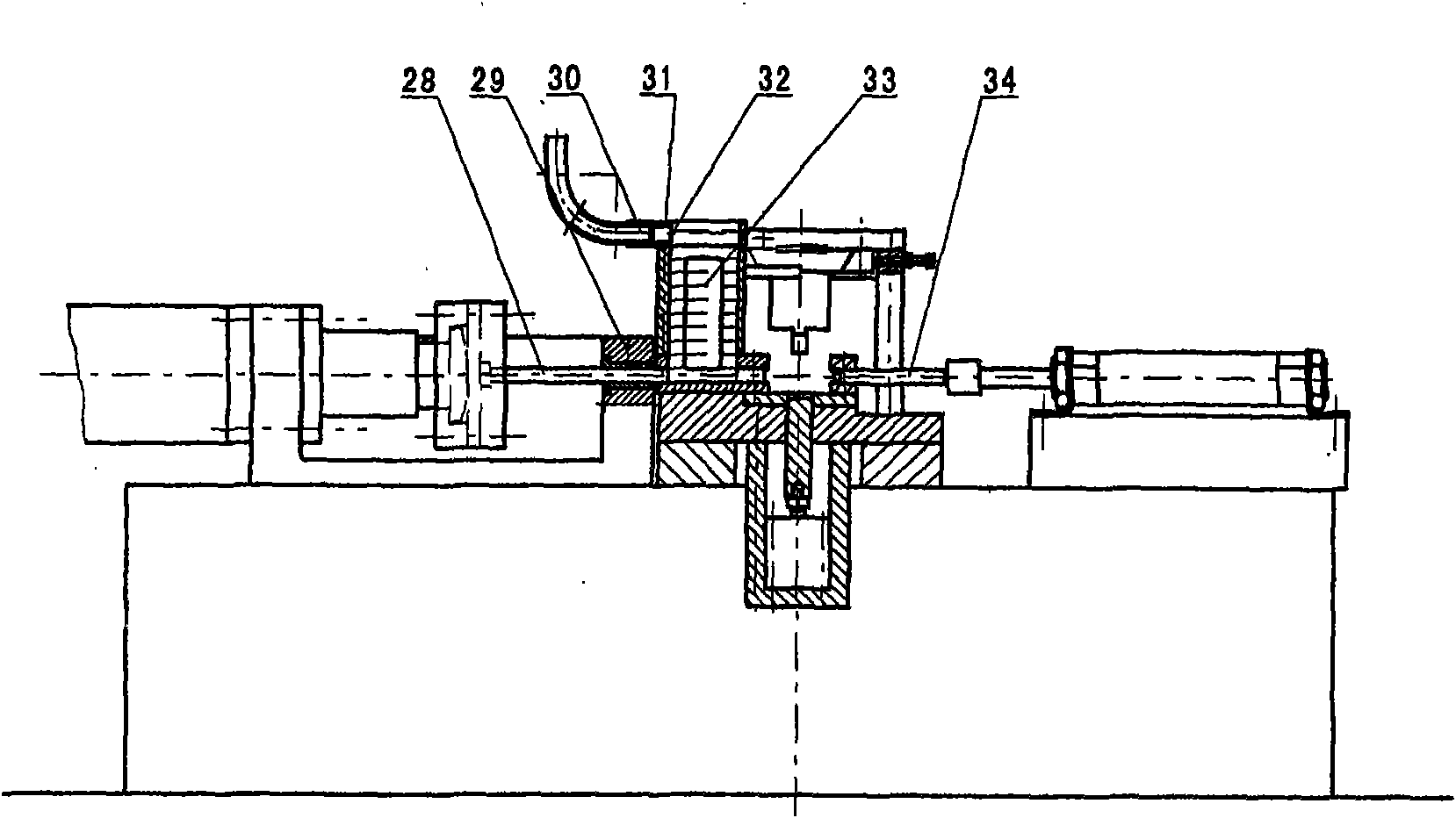

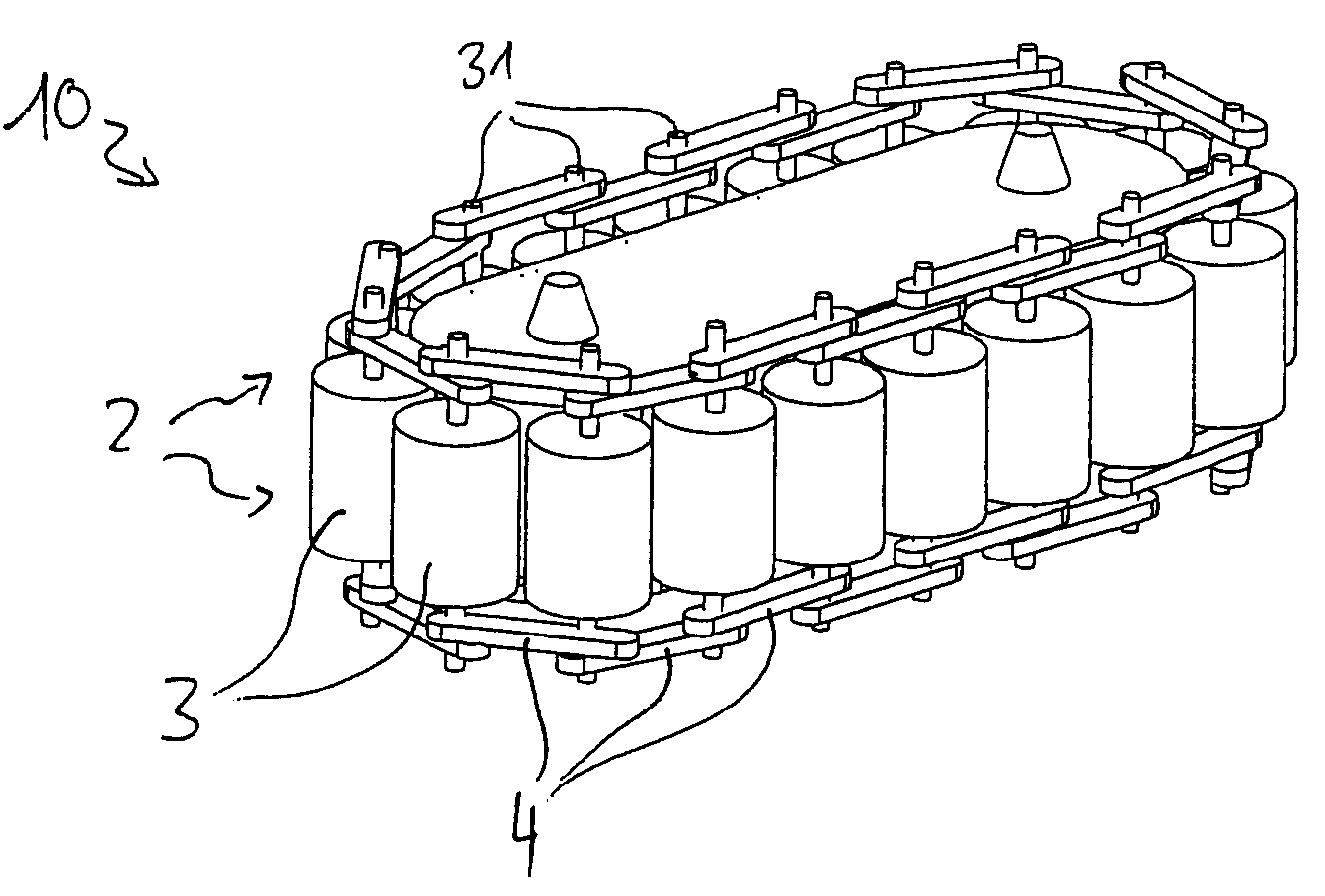

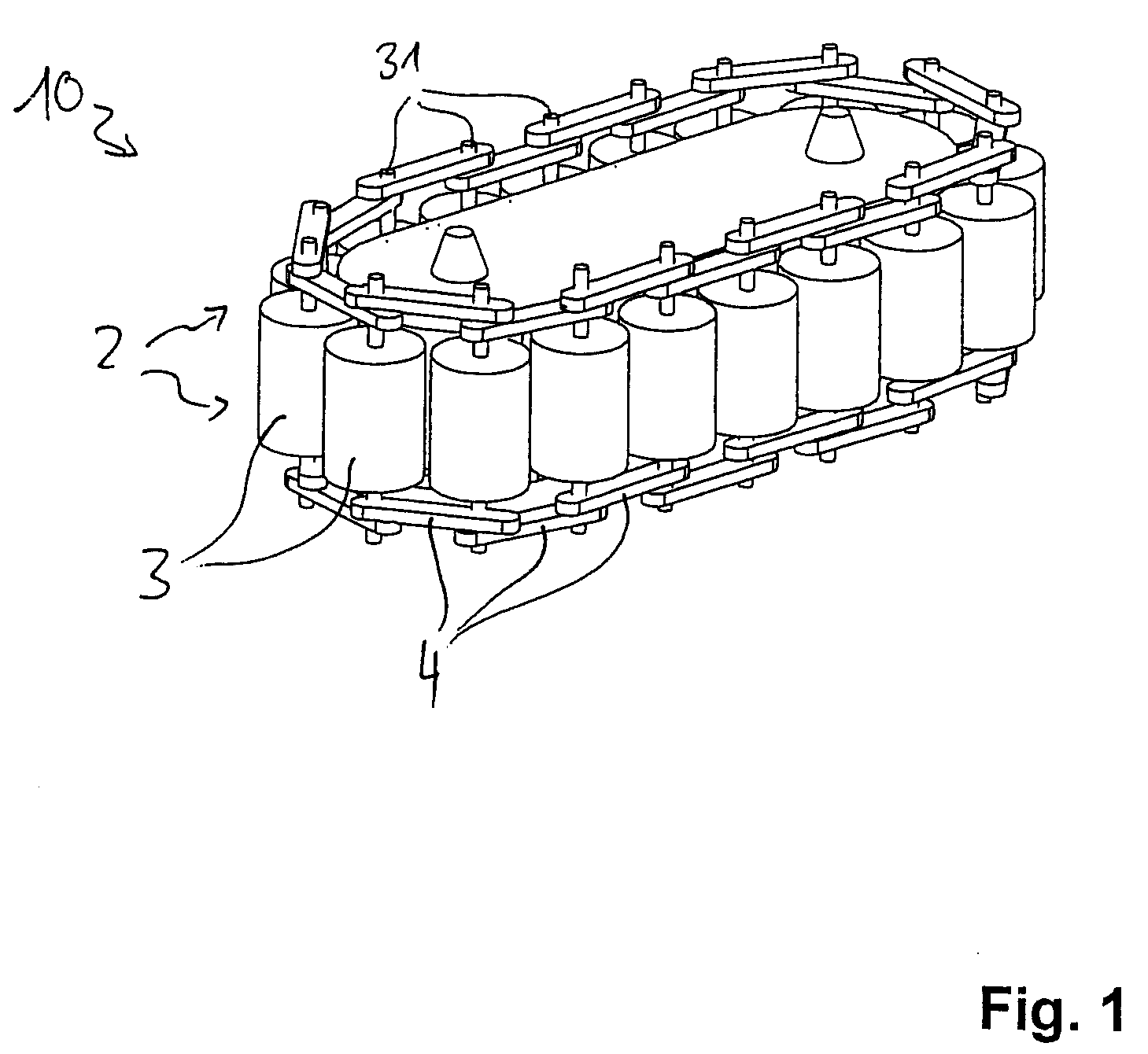

Automatic concatenation knitting-on method and apparatus for metal smith forging circular chain

ActiveCN101157115AReduce labor intensityMechanical properties are not damagedMetal chainsEngineeringBar stock

The invention relates to a production method of a metal chain ring, in particular to an automatic tandem connection and knitting method of a circular ring chain forged with metal and a device thereof. The method has the following steps: a bent ring bar stock is automatically delivered into a chain bending mechanism, and gripped by a mechanical hand, and first bent to be U-shaped under the effect of left and right chain bending rollers; the U-shaped ring penetrates into two knitted and forged rings and is delivered to a core die through the functions of the mechanical hand, a delivering chain inlet and outlet batch bin mechanism, and a core die mechanism; according to the shape of the core die, the U-shaped ring is automatically bent into the circular ring chain with only one step, thereby the tandem connection and the knitting of the circular ring chain is completed. Then an upper core die is elevated and opened, the mechanical hand takes out the well bent ring chain from the core die, the delivering chain inlet and outlet batch bin mechanism lowers and delivers out the well knitted chain, so that the next bent ring bar stock enters into the chain bending mechanism, and automatic repeating and circulation are continued. The invention proposes the automatic tandem connection and knitting method of the circular ring chain forged with metal with mechanical-electric-hydraulic integration and the device thereof, thereby having the advantages of high production efficiency, stable product quality, high degree of automation, and safe and reliable production process.

Owner:王洪军

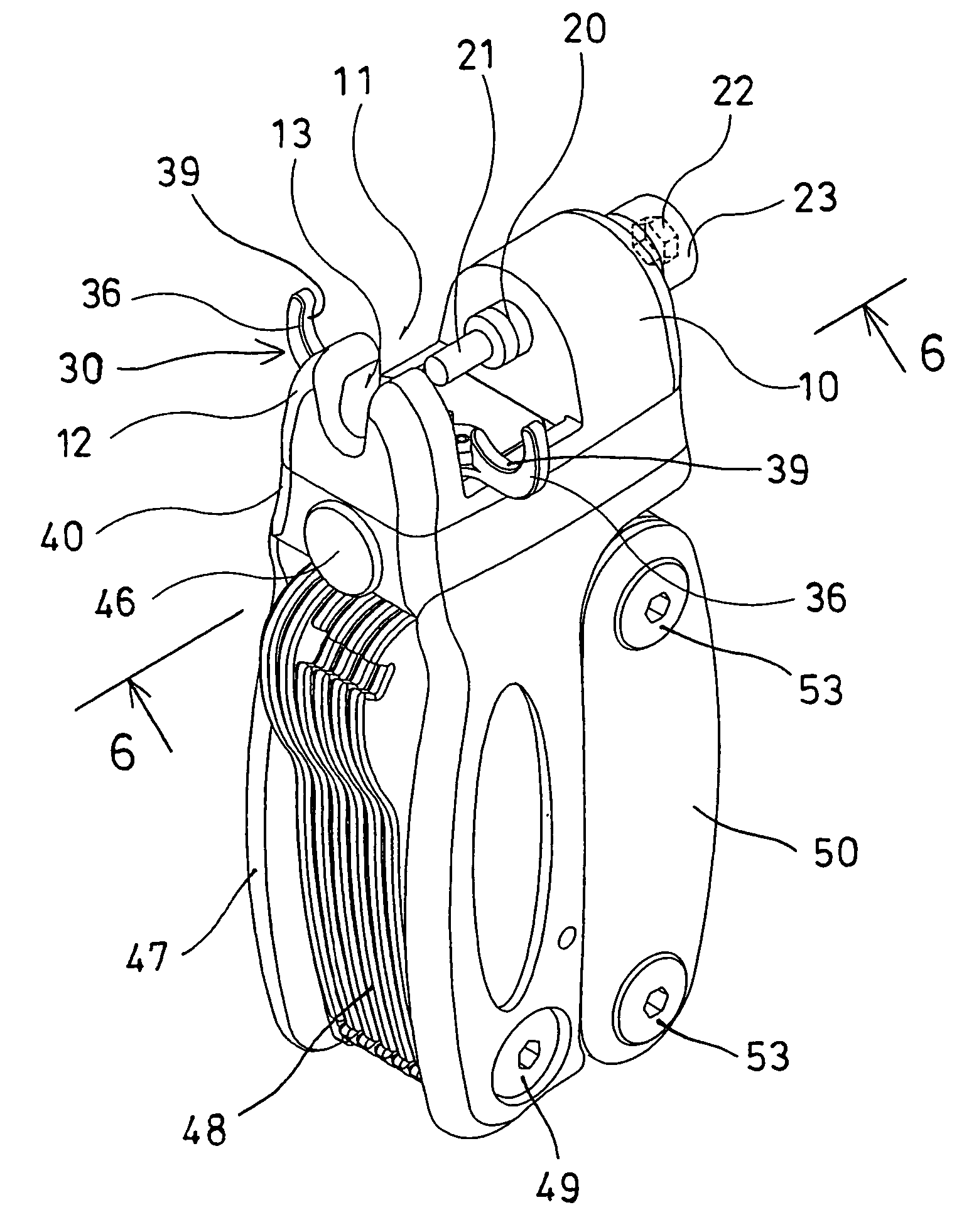

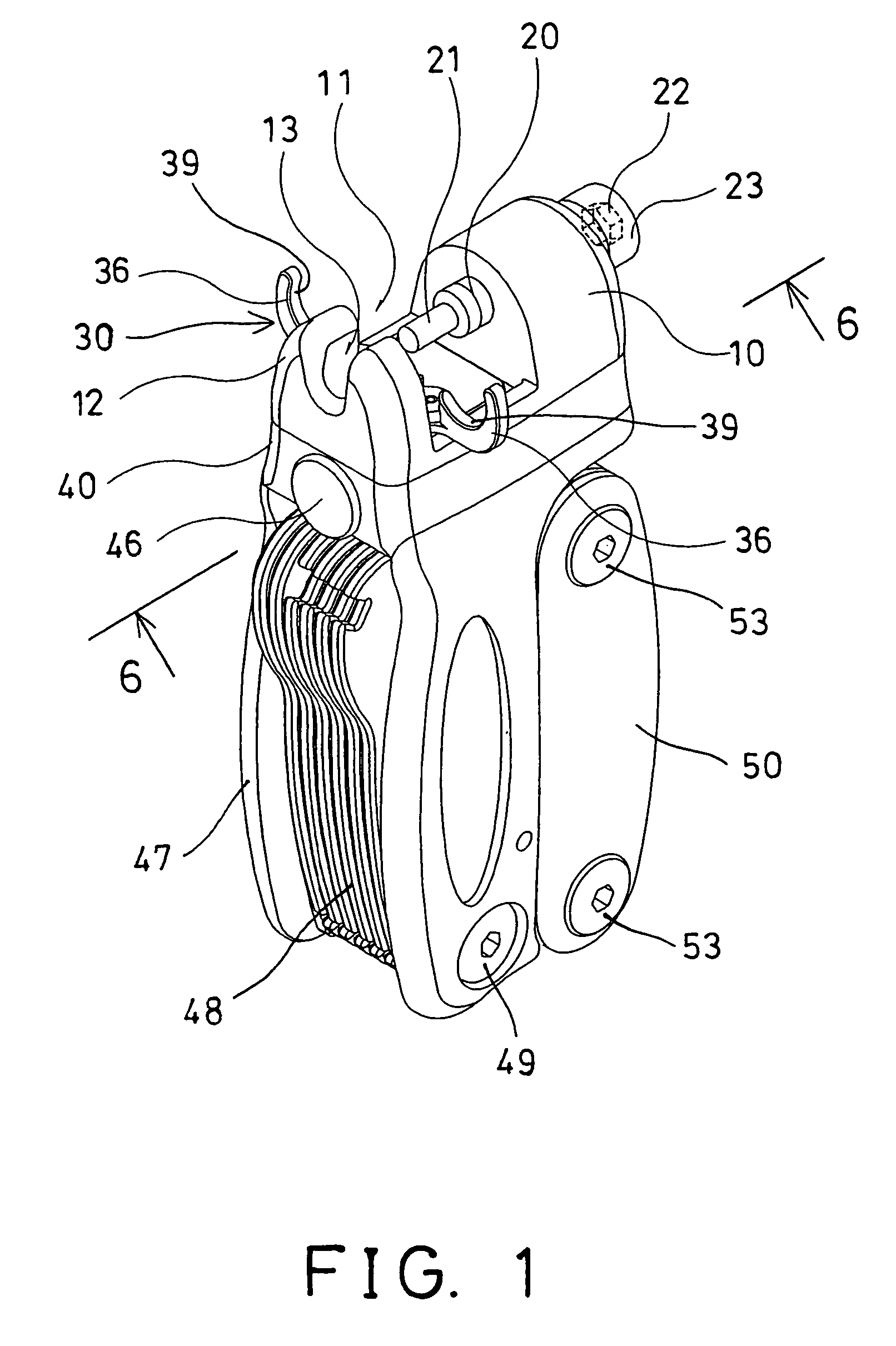

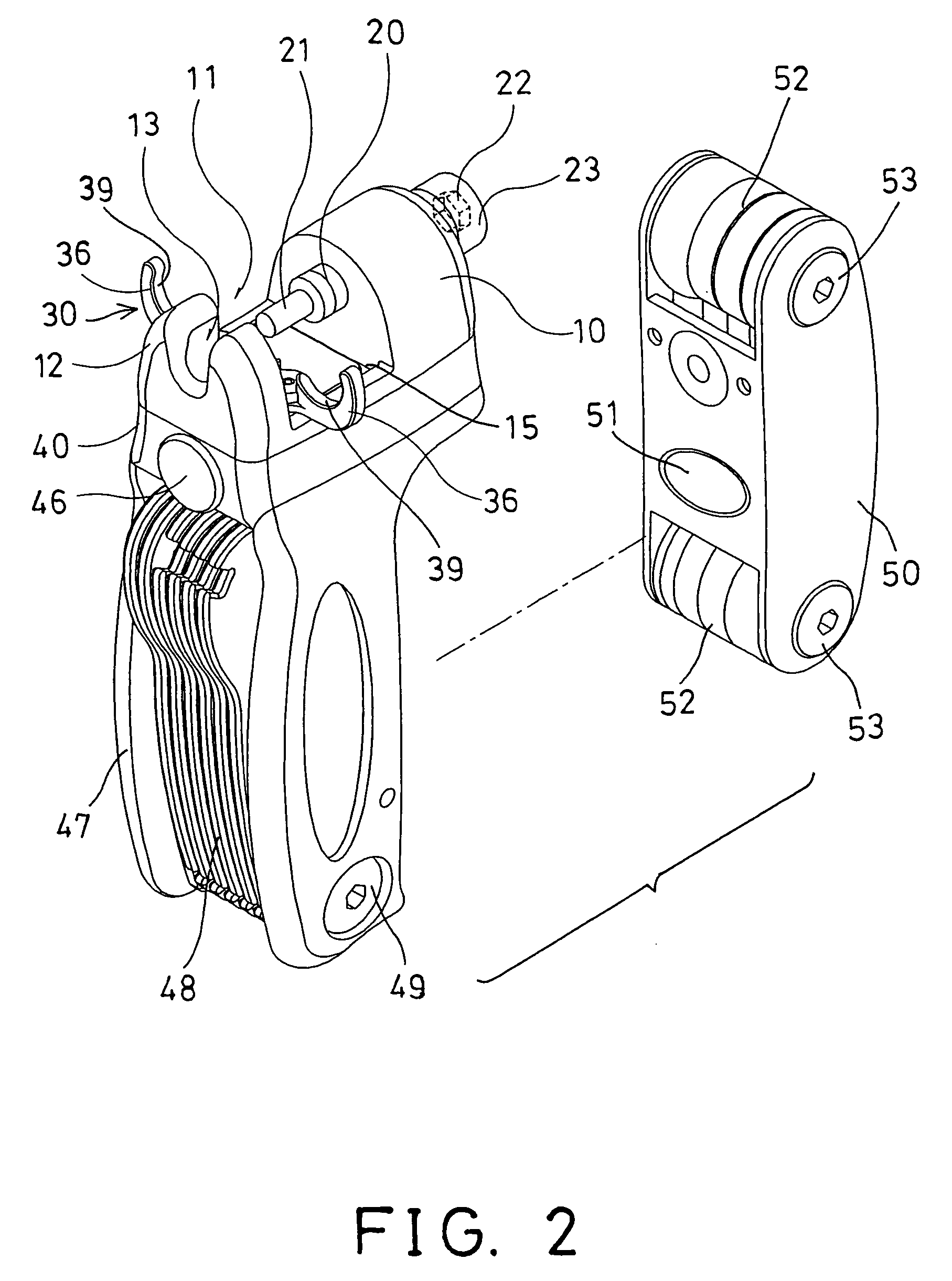

Roller Element

InactiveUS20080078158A1Suitable for utilizationReduce frictionConnecting rodsConveyorsEngineeringMechanical engineering

A roller element (10) is provided which has a central body (1) and a roller unit (2). The roller unit (2) is mounted so as to circulate on a non-circular race (21) about the central body (1) and so as to be mobile with respect to the central body (1) by the rolling movement of the rollers (3) of the roller unit (2) on the central body (1). The rollers (3) are configured as balls or substantially cylindrical elements. A peripheral surface of the rollers (3), for a substantial part, is shaped as a rolling surface that corresponds to the central body (1) and for rolling off on the central body (1). The elements of the roller unit (2) have play in relation to one another and / or the roller unit has play regarding its mobility in relation to the central body (1).

Owner:WRH WALTER REIST HLDG

Chain link remover for cycles

A chain link remover includes a base having an opening formed by an anvil and having a screw hole for threading with a threaded shaft which has a link ejector rod to remove the chain link pin from the chain. A support device is disposed in the base to support the chain in the opening of the base, and to retain the chain between the anvil and the threaded shaft, and thus to allow the chain link pin to be easily disengaged or removed from the chain without holding by the users. The support device includes two pawls to engage with and to support the chain between the anvil and the threaded shaft, with such as resiliences.

Owner:WANG LOPIN

Track comprised or internal and external links

InactiveUS7661774B2Avoid stress concentrationFlexible cuttingGearingTilling equipmentsEngineeringSprocket

In a track with a rotatable bushing which is brought into engagement with a sprocket of a track-type vehicle, it is intended that strength is enhanced rationally by link functionality sharing and by combination of such assigned functional tasks for achieving further improvements in rotatable bushing function. To this end, a first bolt insertion hole provided in a track shoe mount surface of an external link and a second bolt insertion hole provided in a track shoe mount surface of an internal link are arranged on the same straight line, and a straight line connecting the first bolt insertion hole and the second bolt insertion hole is situated at a position more interior than a contact plane of the external link and internal link.

Owner:KOMATSU LTD

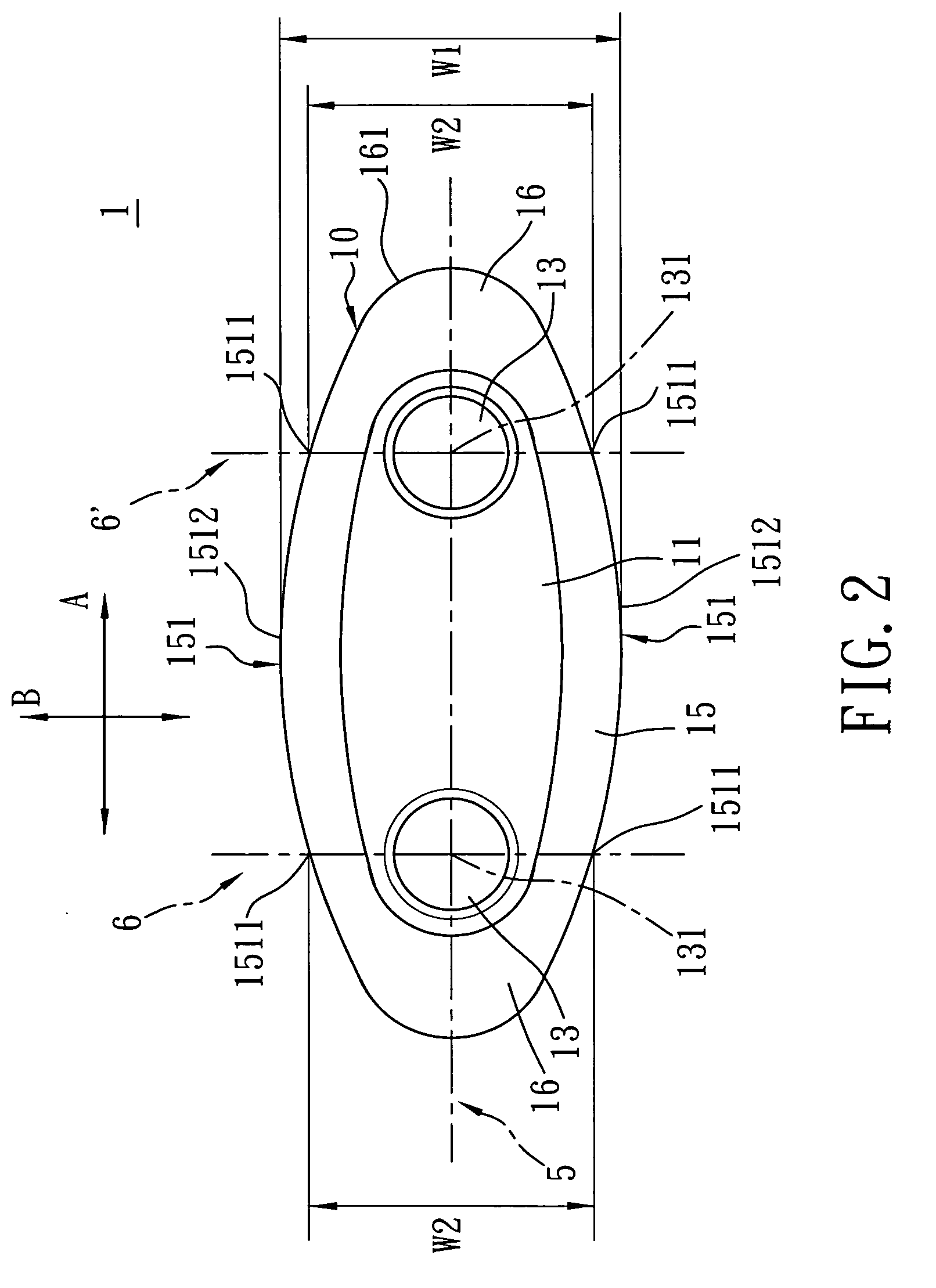

Chain link plate with high strength

A chain link plate includes an elliptical plate body having opposite first and second surfaces, and two mounting holes spaced apart from each other in a longitudinal direction of the plate body and extending from the first surface to the second surface. The plate body has a central longitudinal line that passes through centers of the mounting holes, and two transverse lines that pass respectively through the centers of the mounting holes and that are perpendicular to the central longitudinal line. The plate body has an intermediate juncture portion defined between the transverse lines, and opposite end portions integrally and respectively connected to opposite ends of the intermediate juncture portion. The intermediate juncture portion has a largest width greater than that of each of the end portions.

Owner:KMC CHAIN INDUSTRIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com