Patents

Literature

502results about "Chain links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

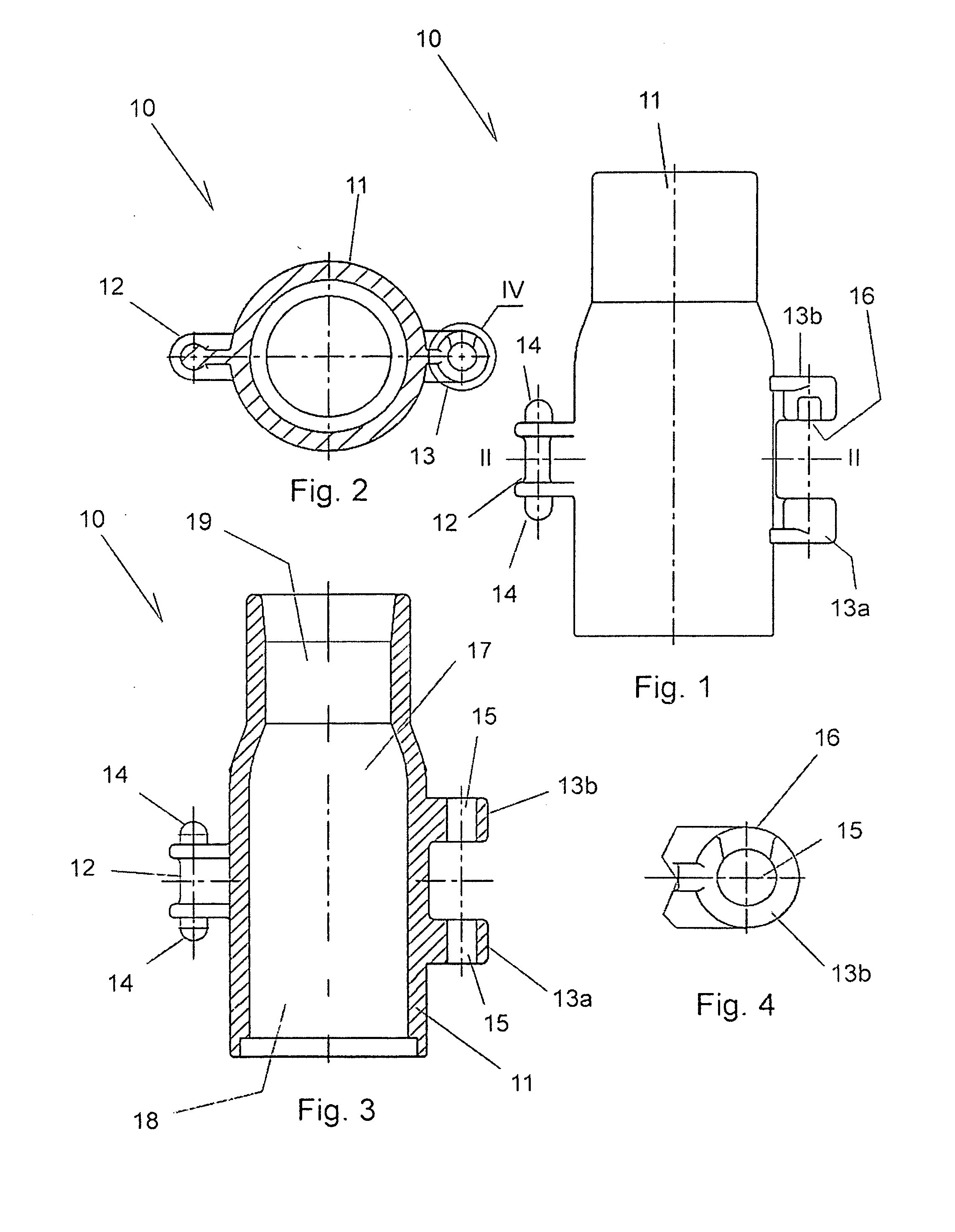

Chain with identification apparatus

InactiveUS7958715B2Low costEasy to identifyDrilling rodsConstructionsSubject matterIdentification device

Owner:NAT OILWELL VARCO LP

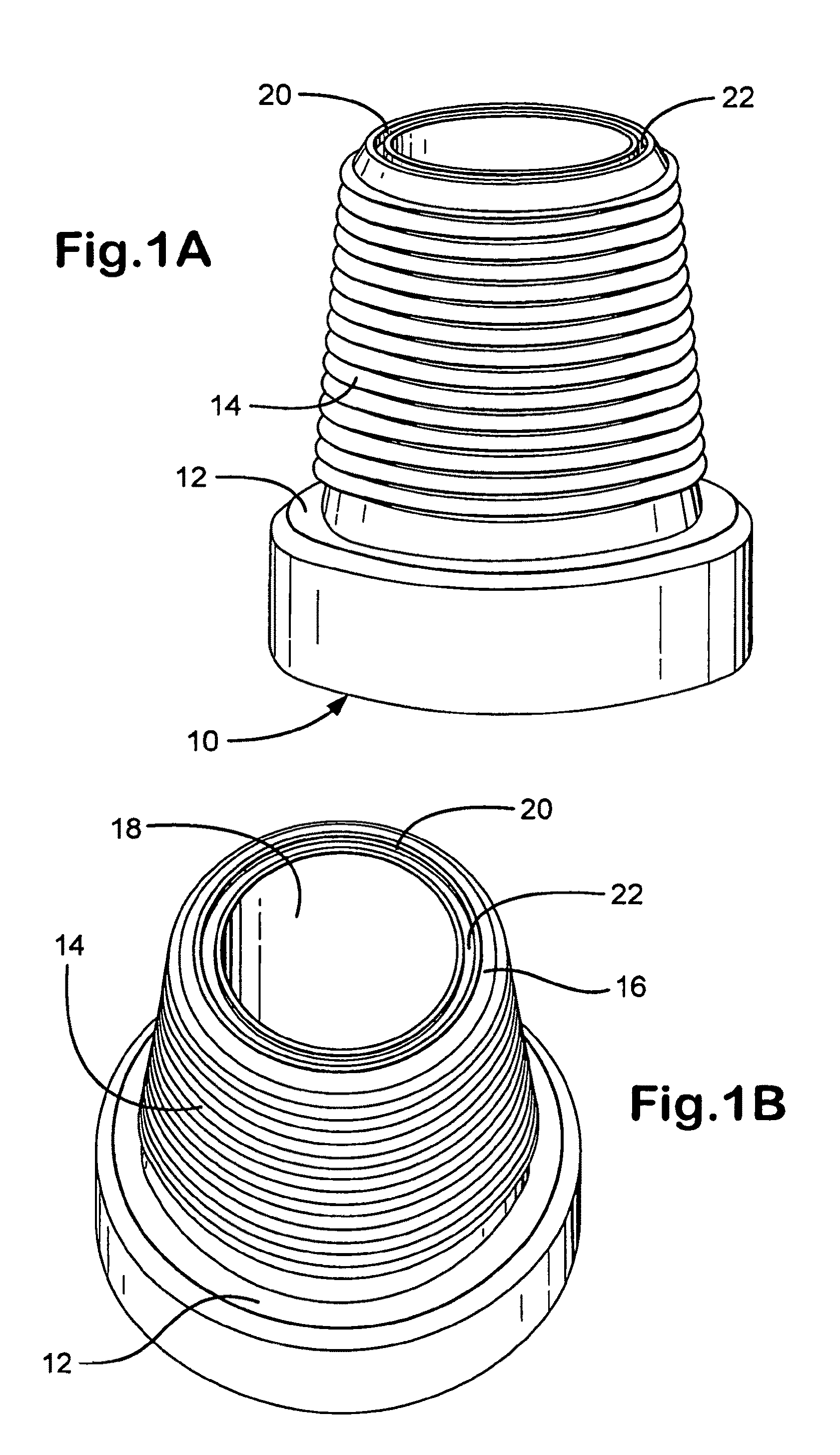

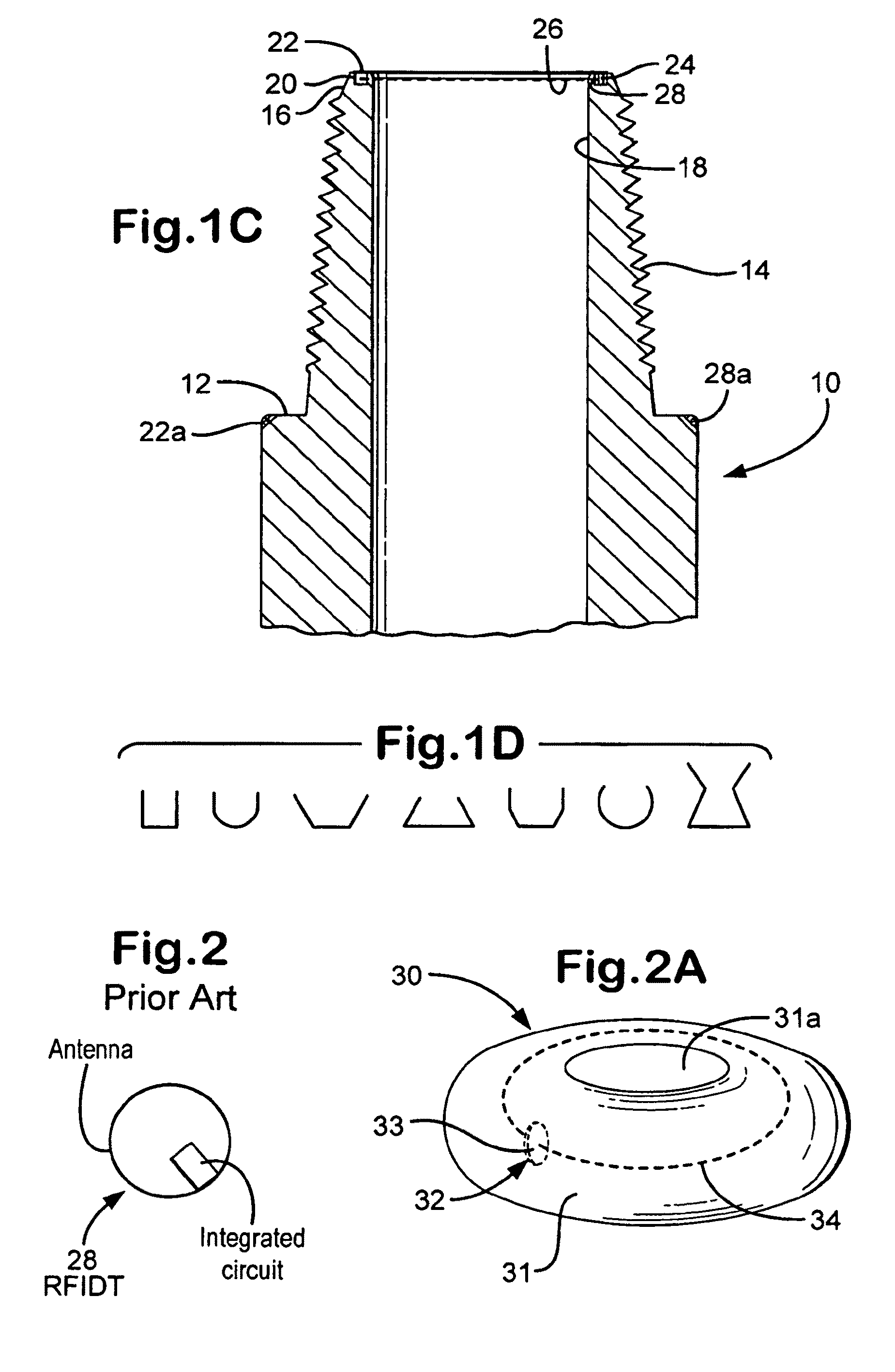

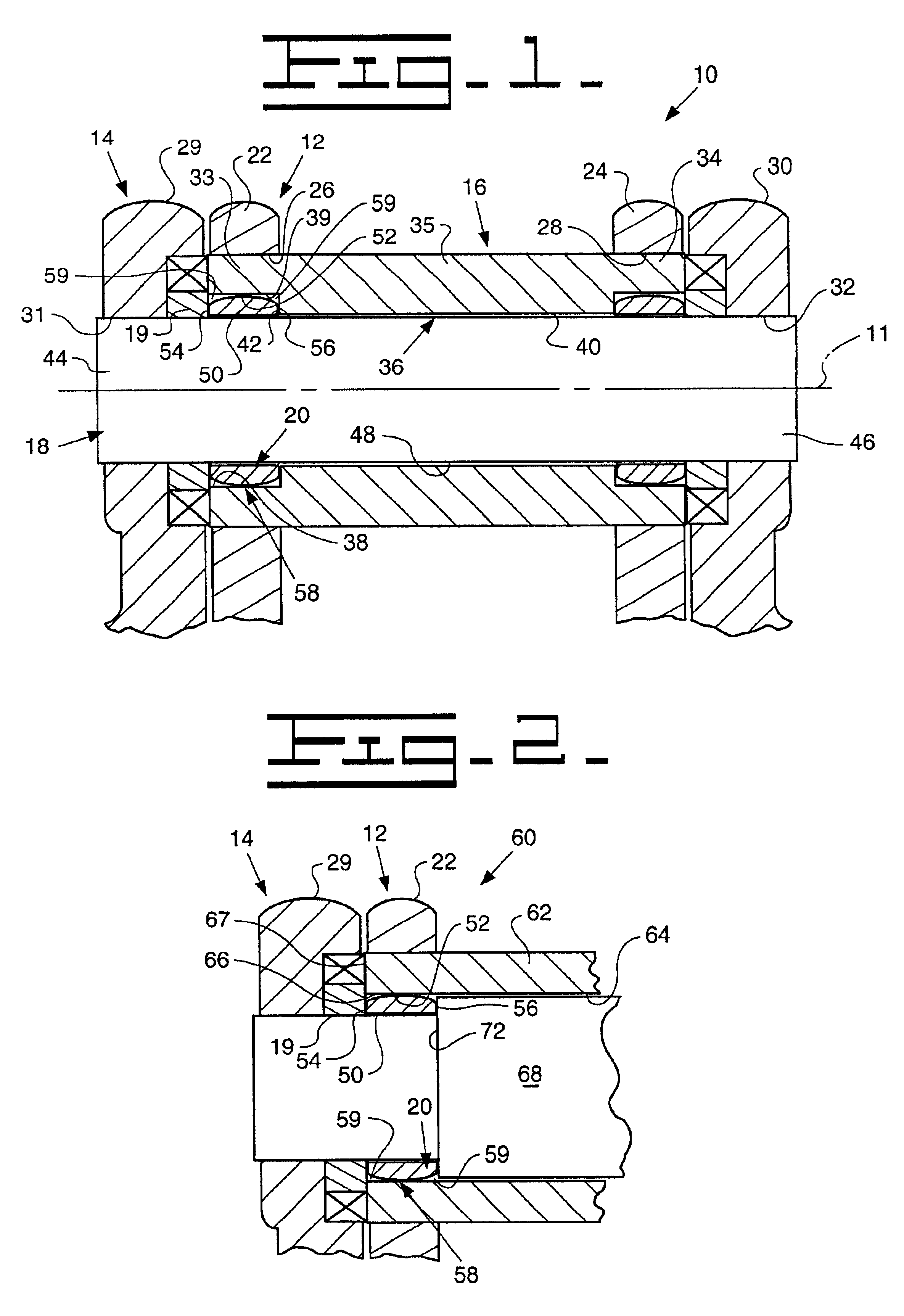

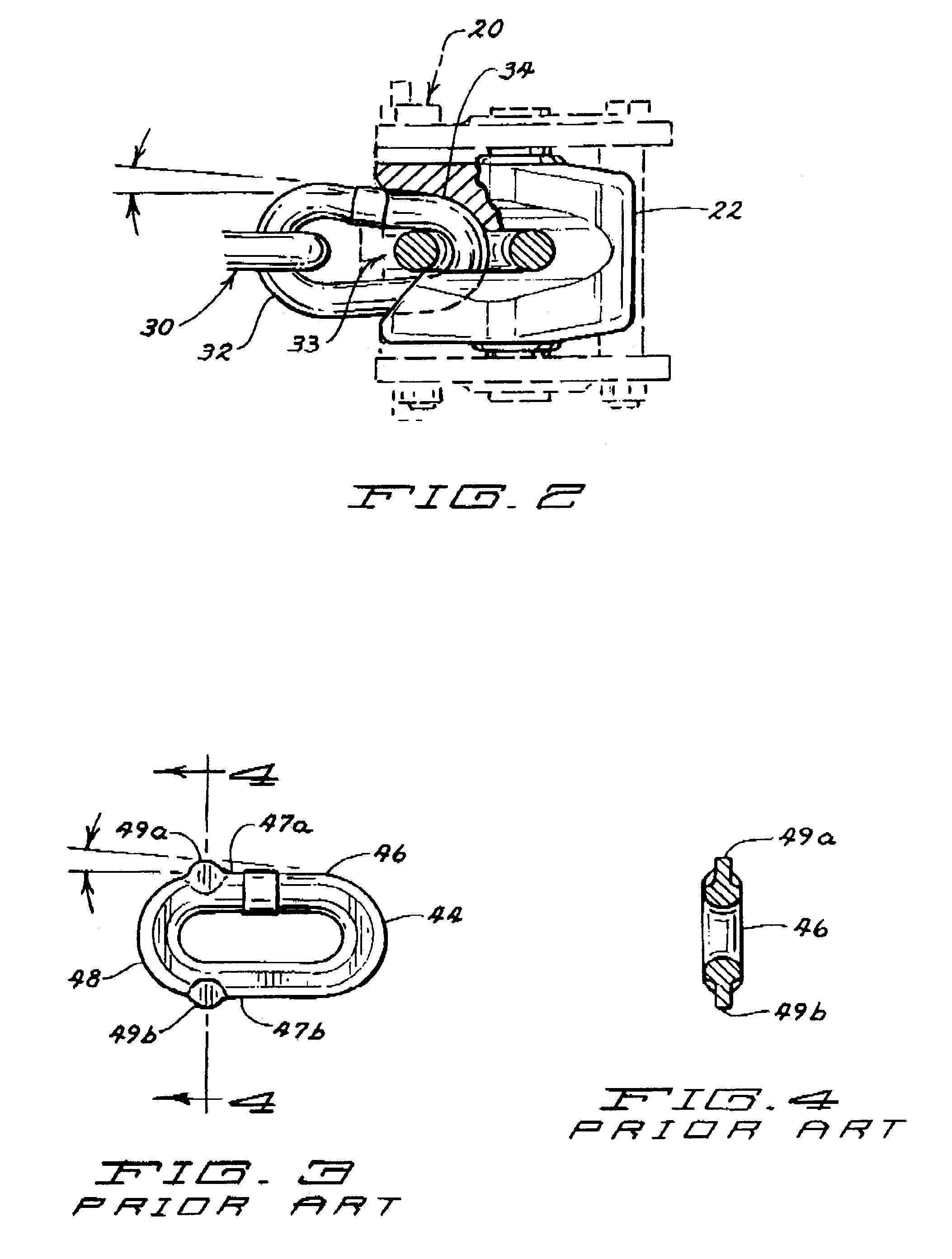

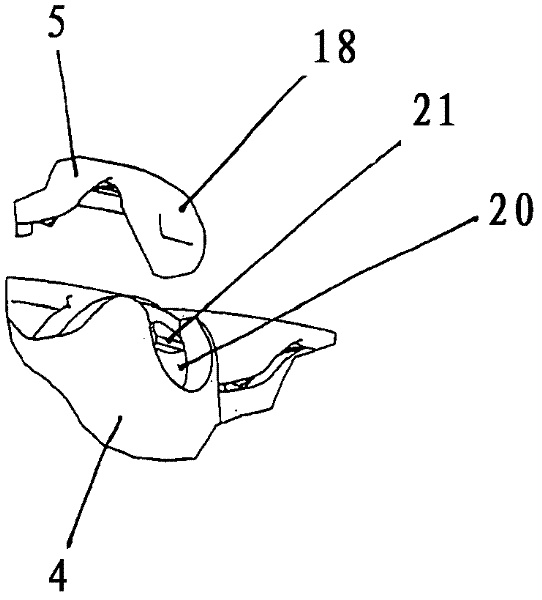

Joint assembly to resist galling

Joint assemblies are useful for connecting one structure to another structure. When the various structures deflect or bend, edge loading occurs therebetween. The subject joint assembly includes a pin positioned between a first and second structure. An insert is free floating positioned around the pin for contacting either of the first or second structures. A crown shaped surface is utilized on the insert at a substantially central location therealong. The crown shaped surface directs forces to the center of the insert to reduce edge loading.

Owner:CATERPILLAR INC

Ammunition chain for toy projectiles

A link for a toy ammunition chain made up of a plurality of links hinged together side-by-side in articulated fashion includes a cylindrical body adapted to receive a soft projectile. A first hinge component extends laterally from the body and has a pair of hinge pins. A second hinge component extends laterally from the body at a position opposite the first hinge component and has a pair of recesses each for pivotally receiving a hinge pin of an adjacent link in the chain.

Owner:BUZZ BEE TOYS

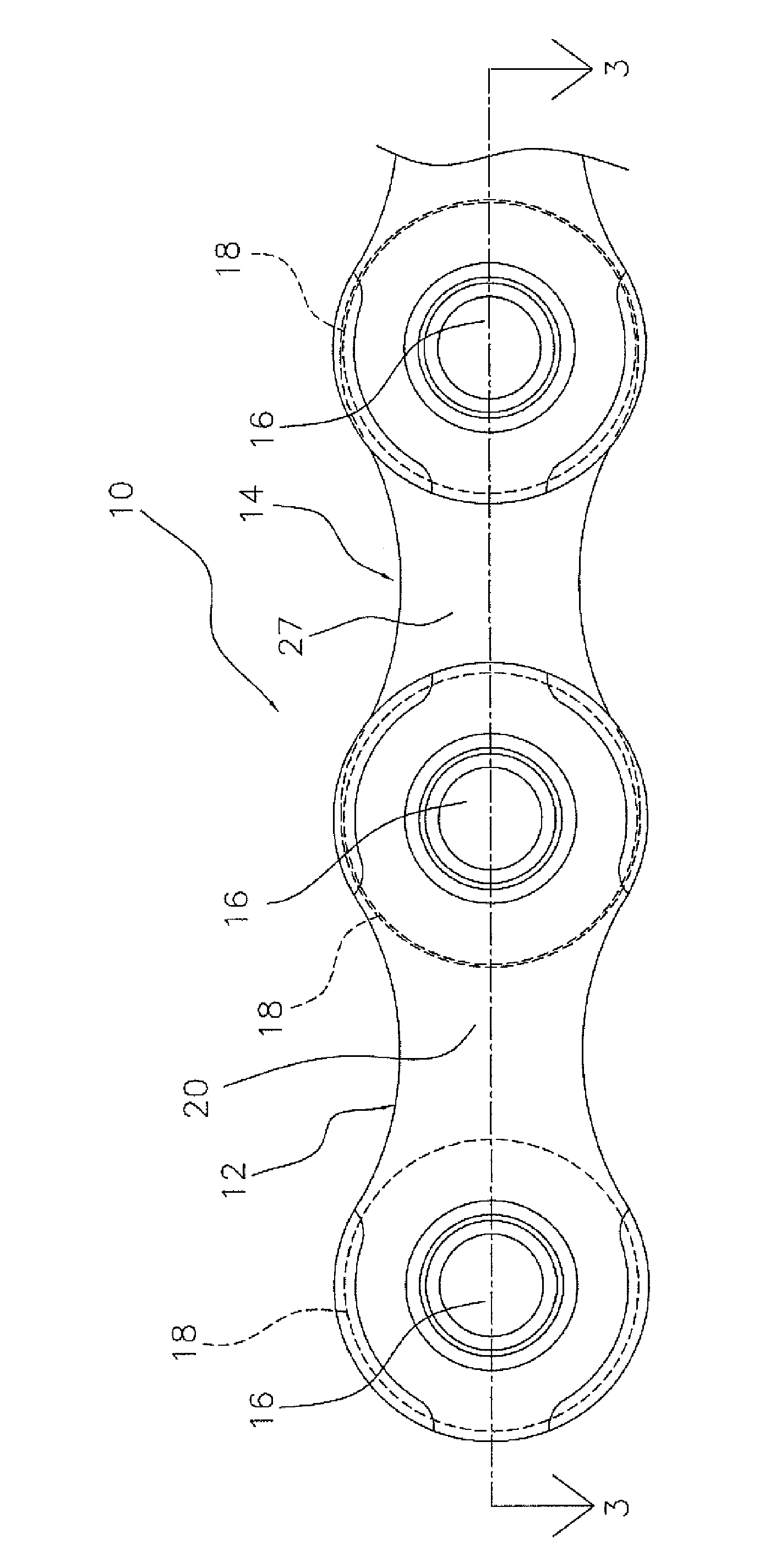

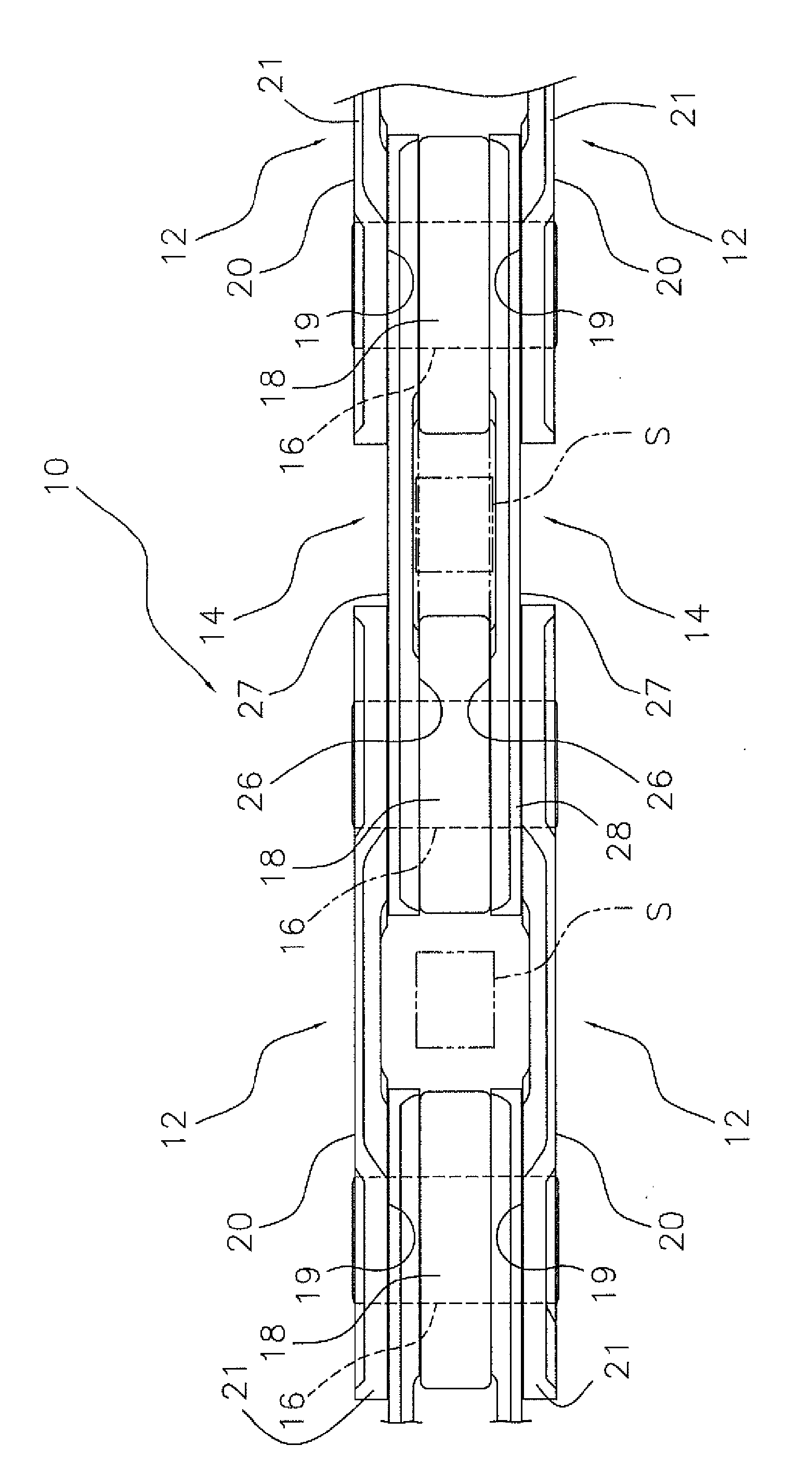

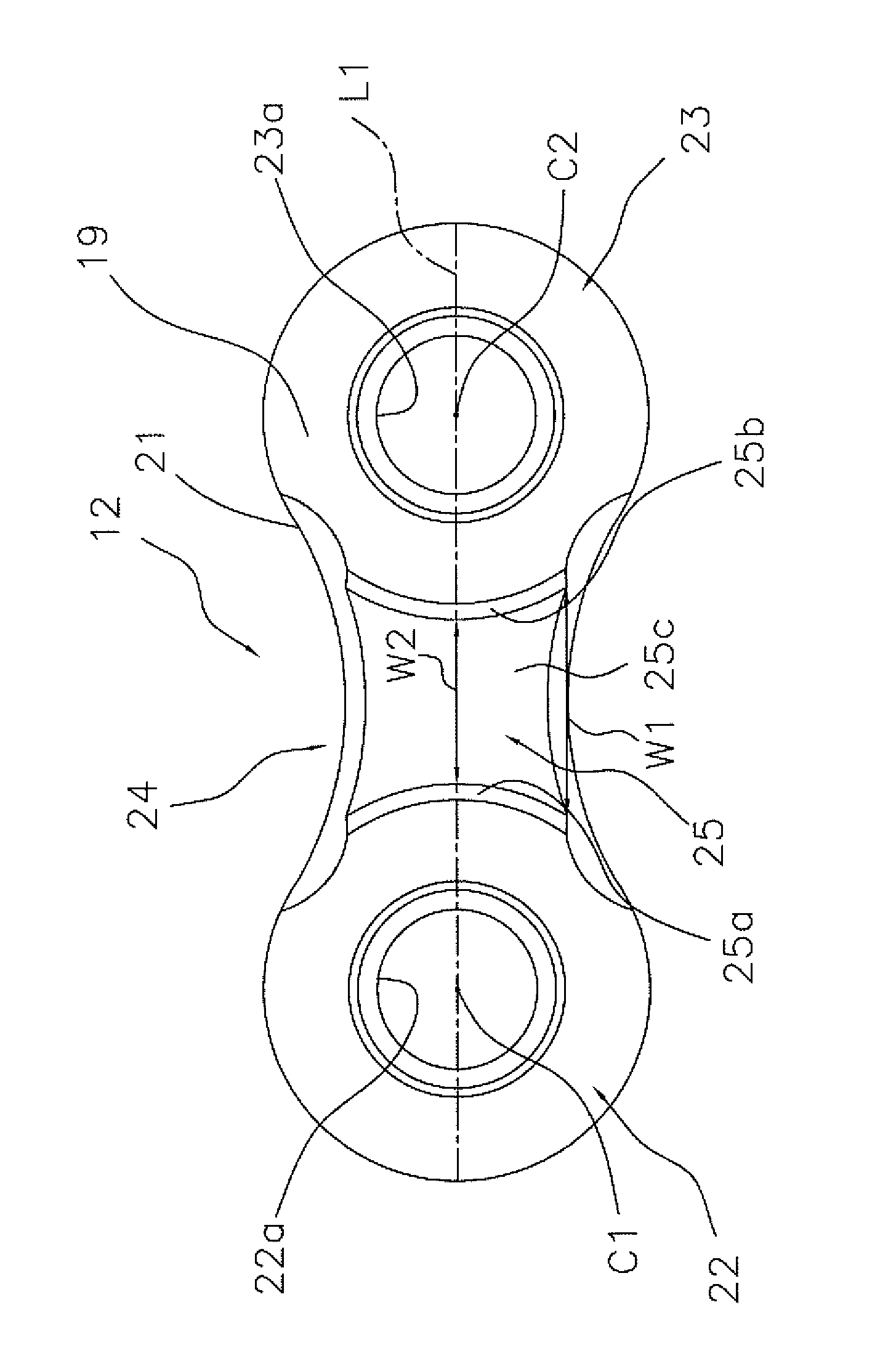

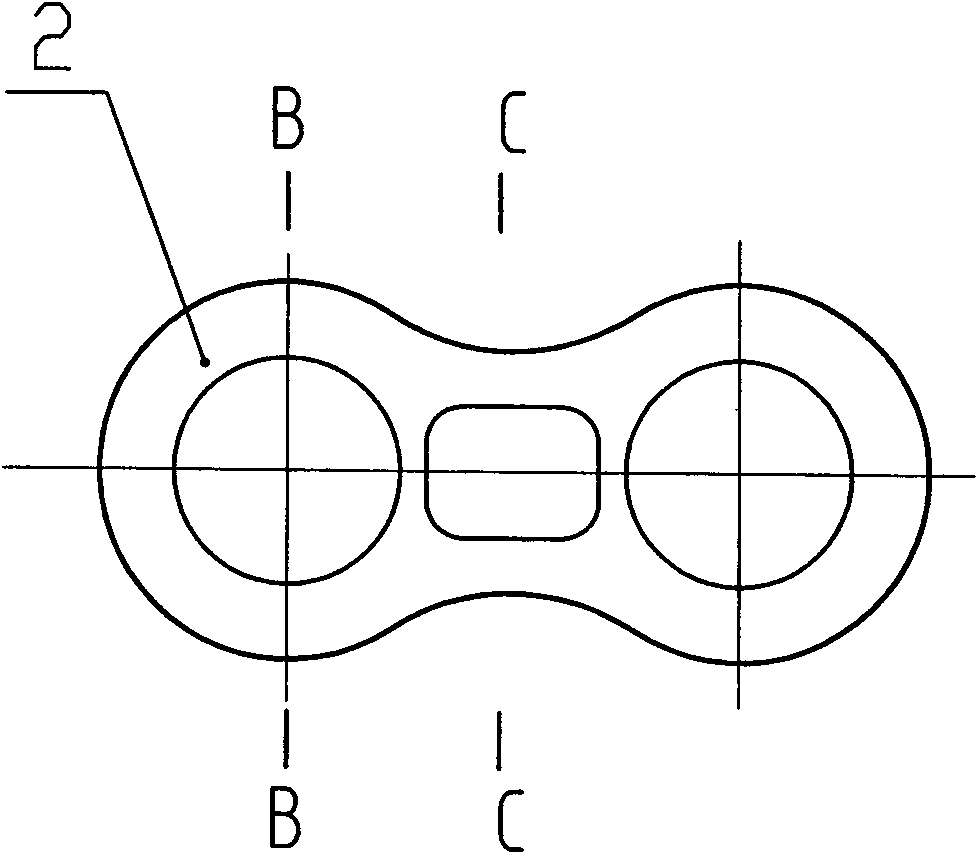

Inner link plate for bicycle chain

An inner link plate is provided for a bicycle chain. The inner link plate has a longitudinal centerline, an inside surface arranged to face another inner link plate when the chain is assembled, an outside surface opposite to the inside surface, and an outer peripheral edge disposed between the inside and outside surfaces. The bicycle inner link plate basically has a first end portion, a second end portion and a connecting portion. The first and second end portions are each provided with a connecting opening. The connecting portion includes a recess disposed on the inside surface of the connecting portion. The recess has a maximum longitudinal width on the outer peripheral edge, and a minimum longitudinal width in a region adjacent the longitudinal centerline. The recess at least extends from the outer peripheral edge to the longitudinal centerline.

Owner:SHIMANO INC

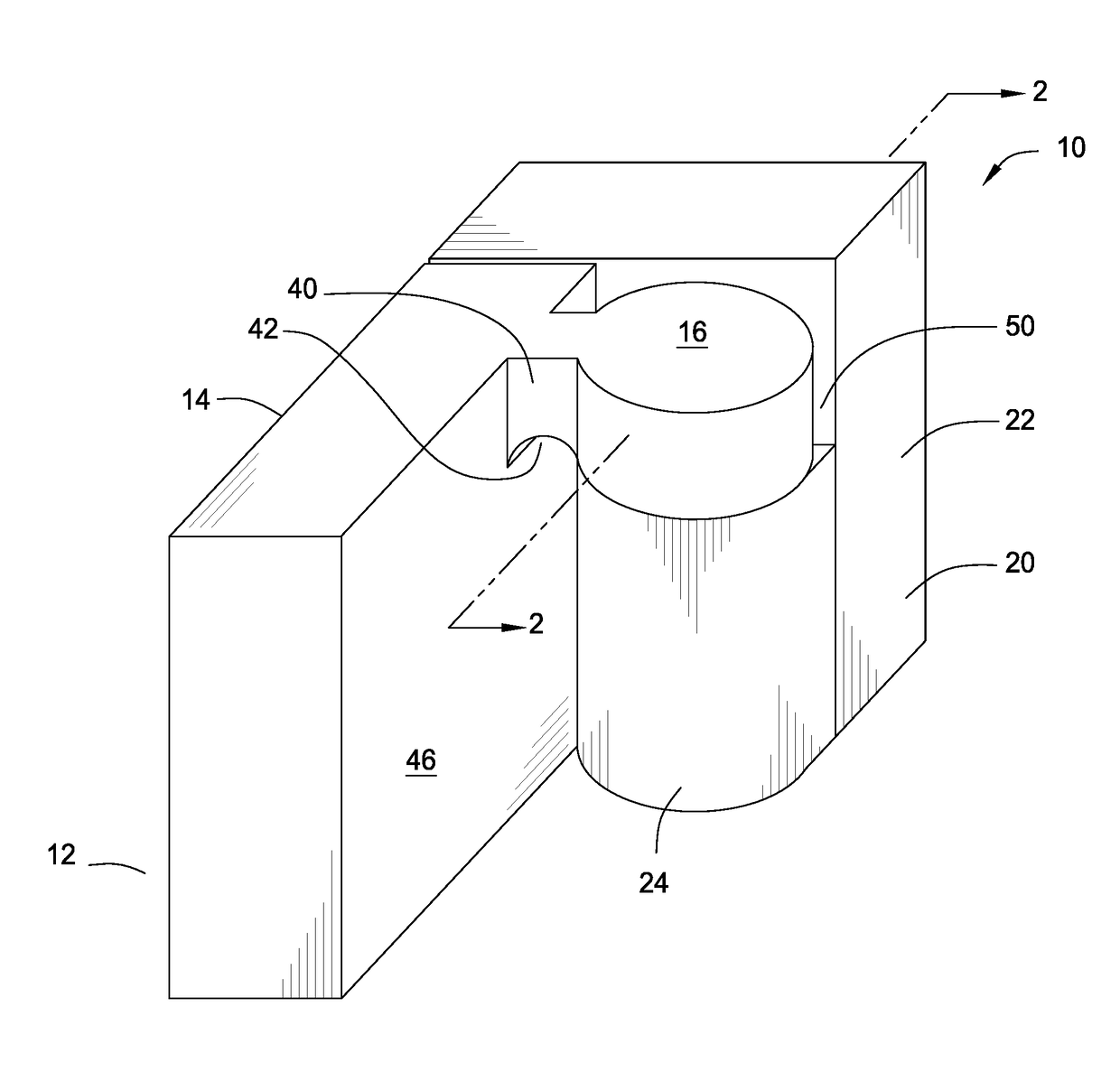

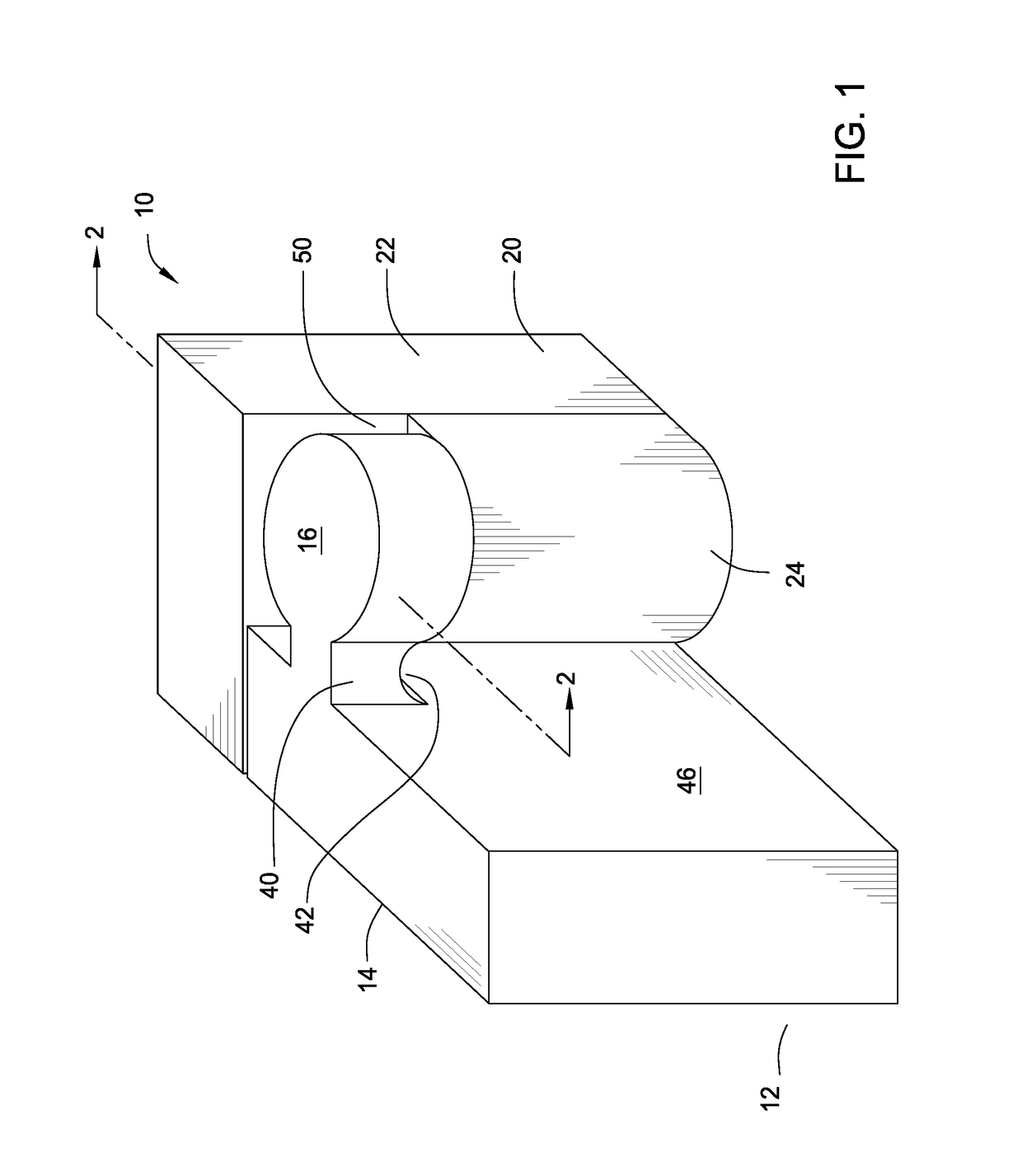

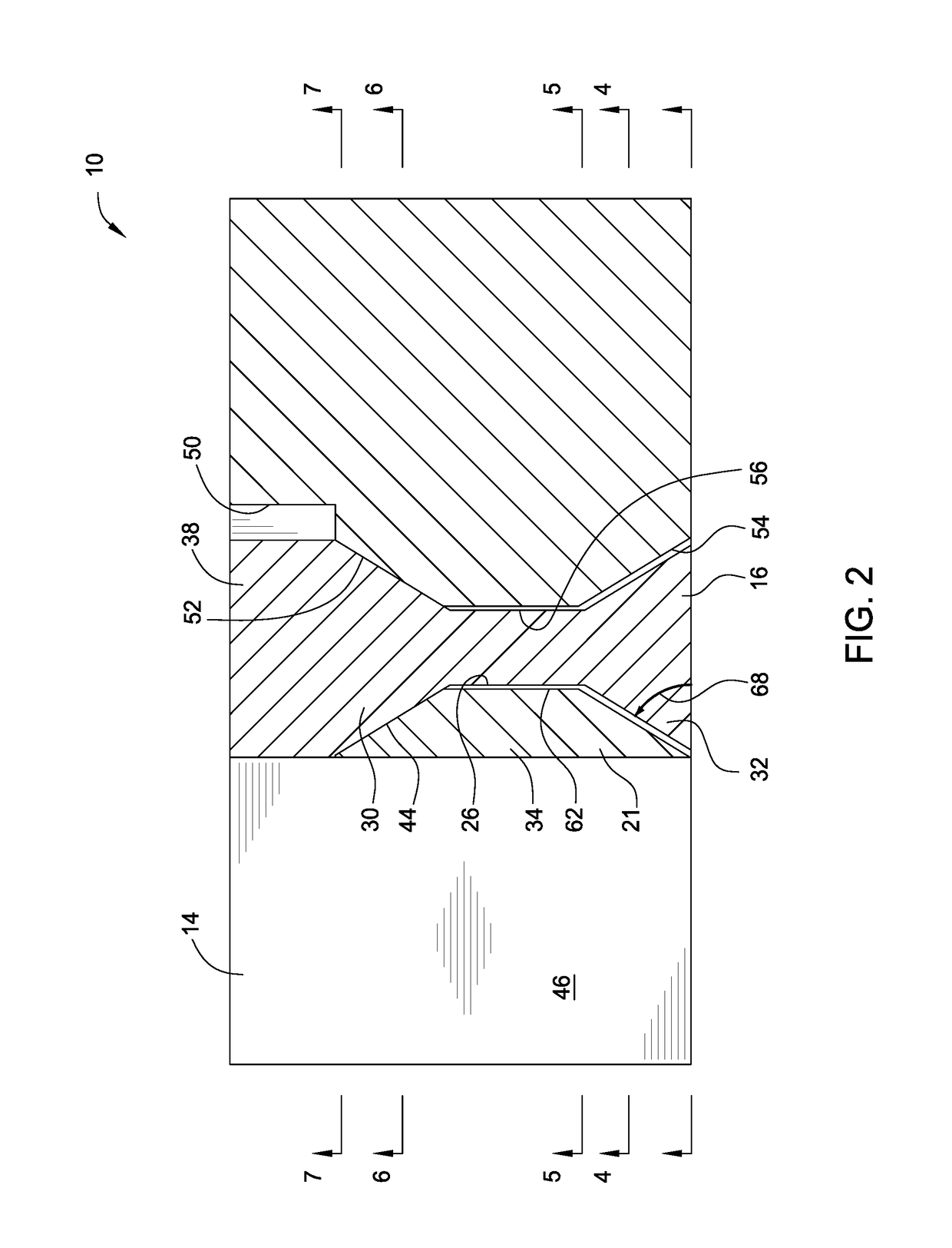

Additive manufactured moveable parts

InactiveUS20170096847A1Improve toleranceSpectales/gogglesAdditive manufacturing apparatusEngineeringMechanical engineering

Owner:UCT ADDITIVE MFG CENT PTE LTD

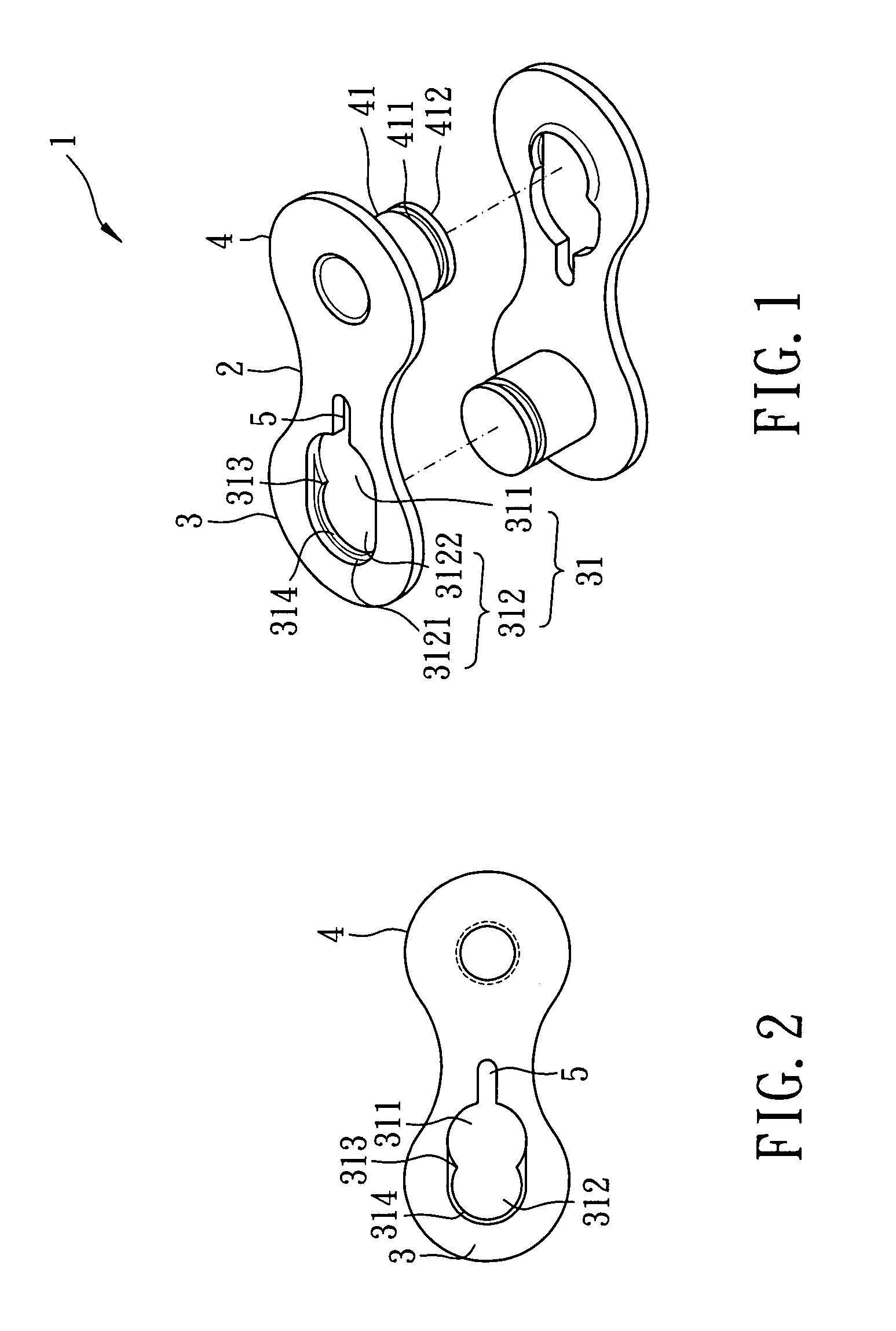

Link plate for a bicycle chain

InactiveUS20090247339A1Simple structureEasy and fast assemblyChain linksDriving chainsEngineeringMechanical engineering

Owner:TIEN HSIN INDS

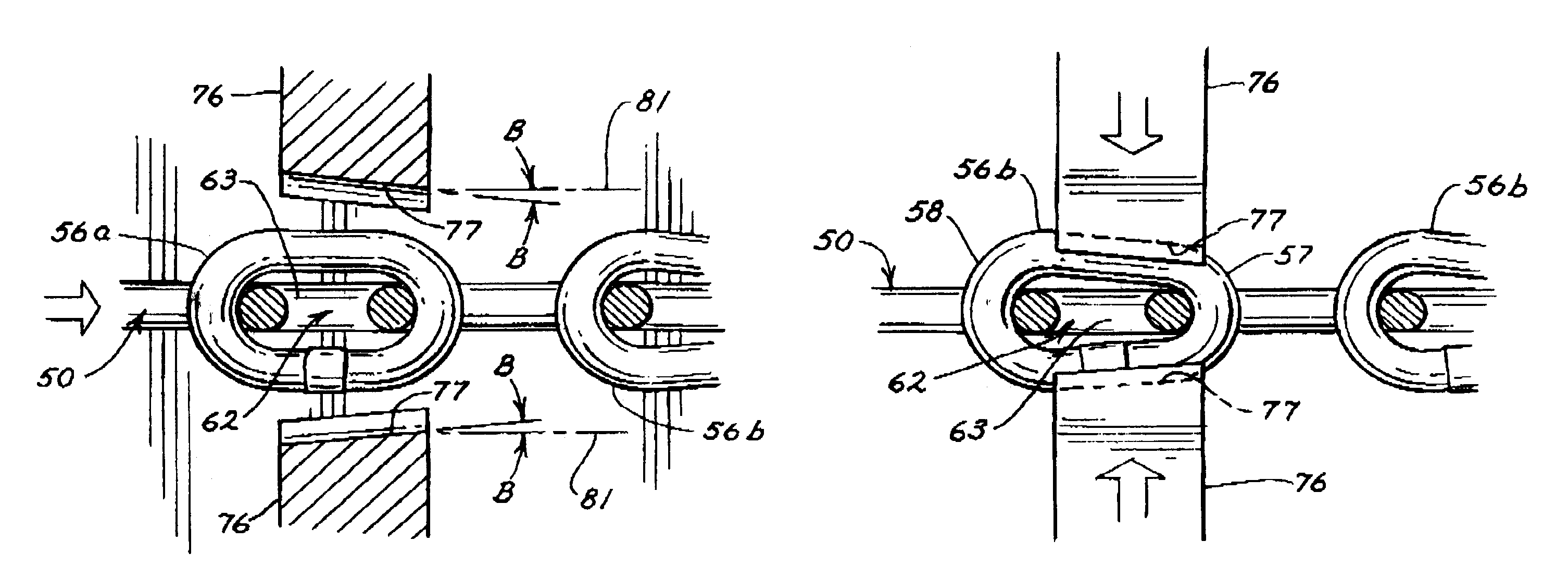

Method of making one-way chain

One-way chain for an aircraft tie-down, as well as a method of making one-way chain. The method preferably includes the steps of providing an unmodified welded chain having a plurality of welded links; feeding the unmodified chain into an automated shaping machine constructed and arranged to shape the welded links in separate shaping events; and individually shaping the welded links to form shaped links in a series of separate shaping events that shape the respective welded links so that a first width of a forward end of the respective shaped link is narrower than a second width of the greatest planar width of a rearward end of the respective shaped link; such that the forward end is sized to fit into a link receiving receptacle of a screw-type binder mechanism and the rearward end will not fit into the link receiving receptacle.

Owner:PEERLESS CHAIN COMPANY

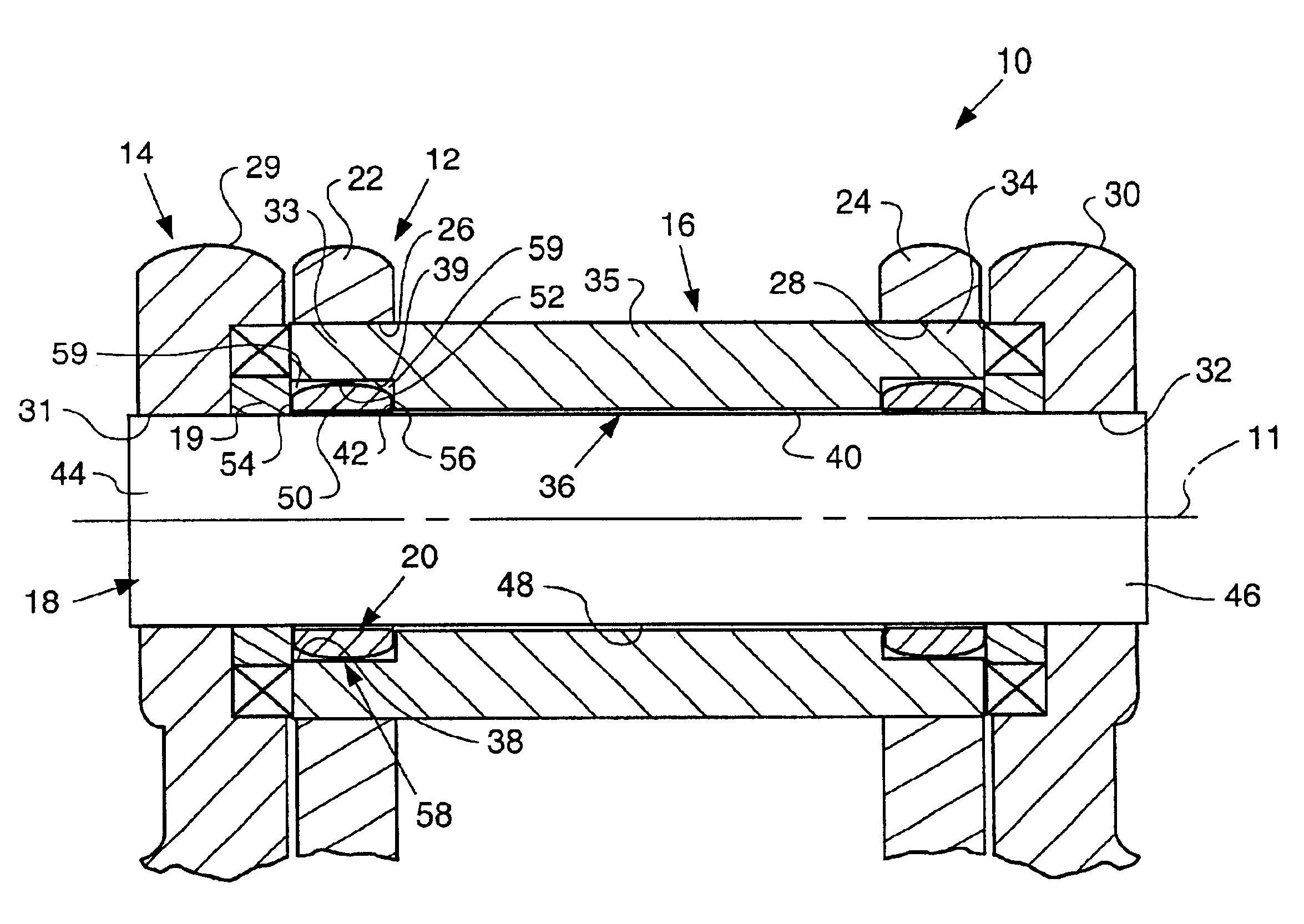

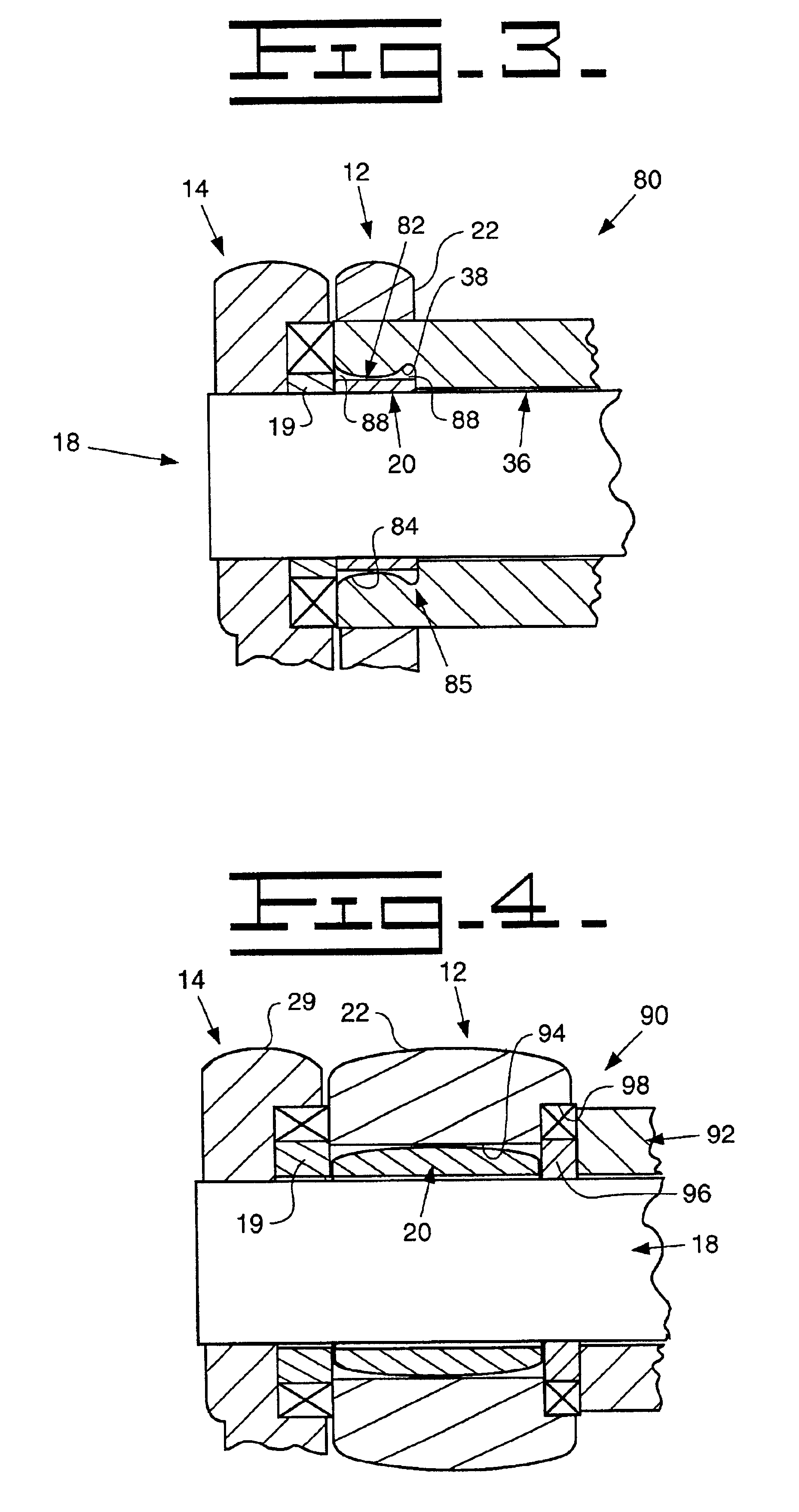

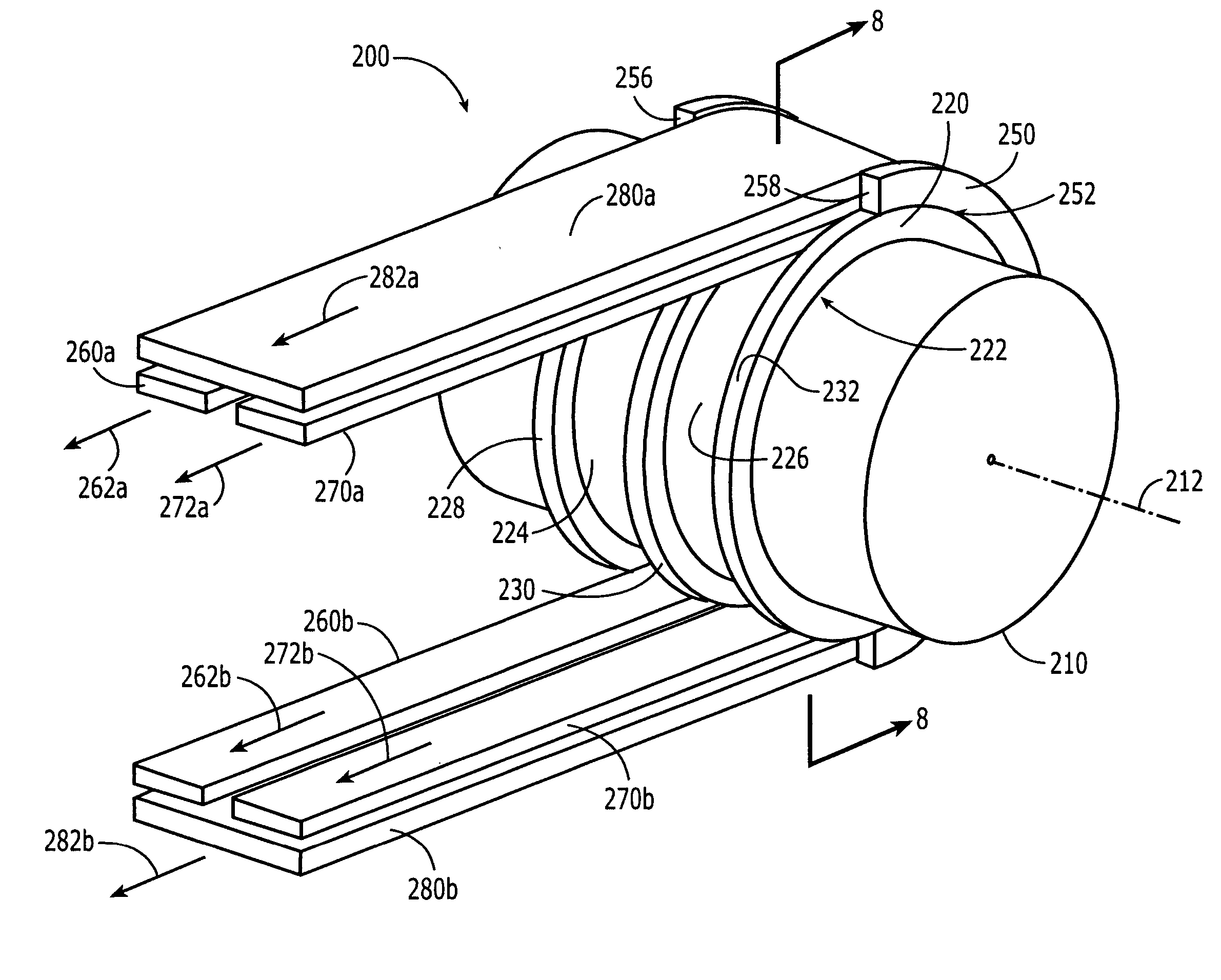

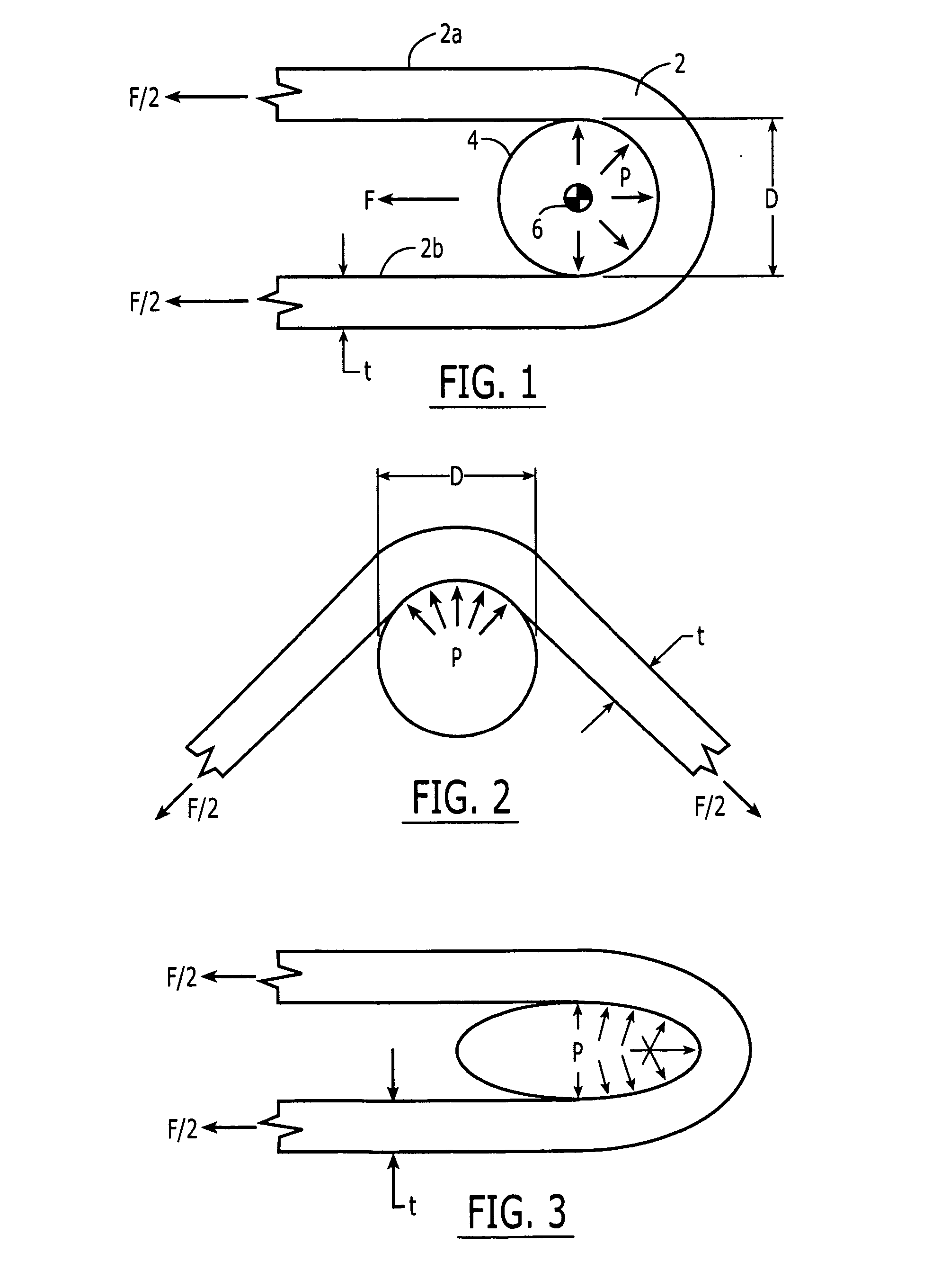

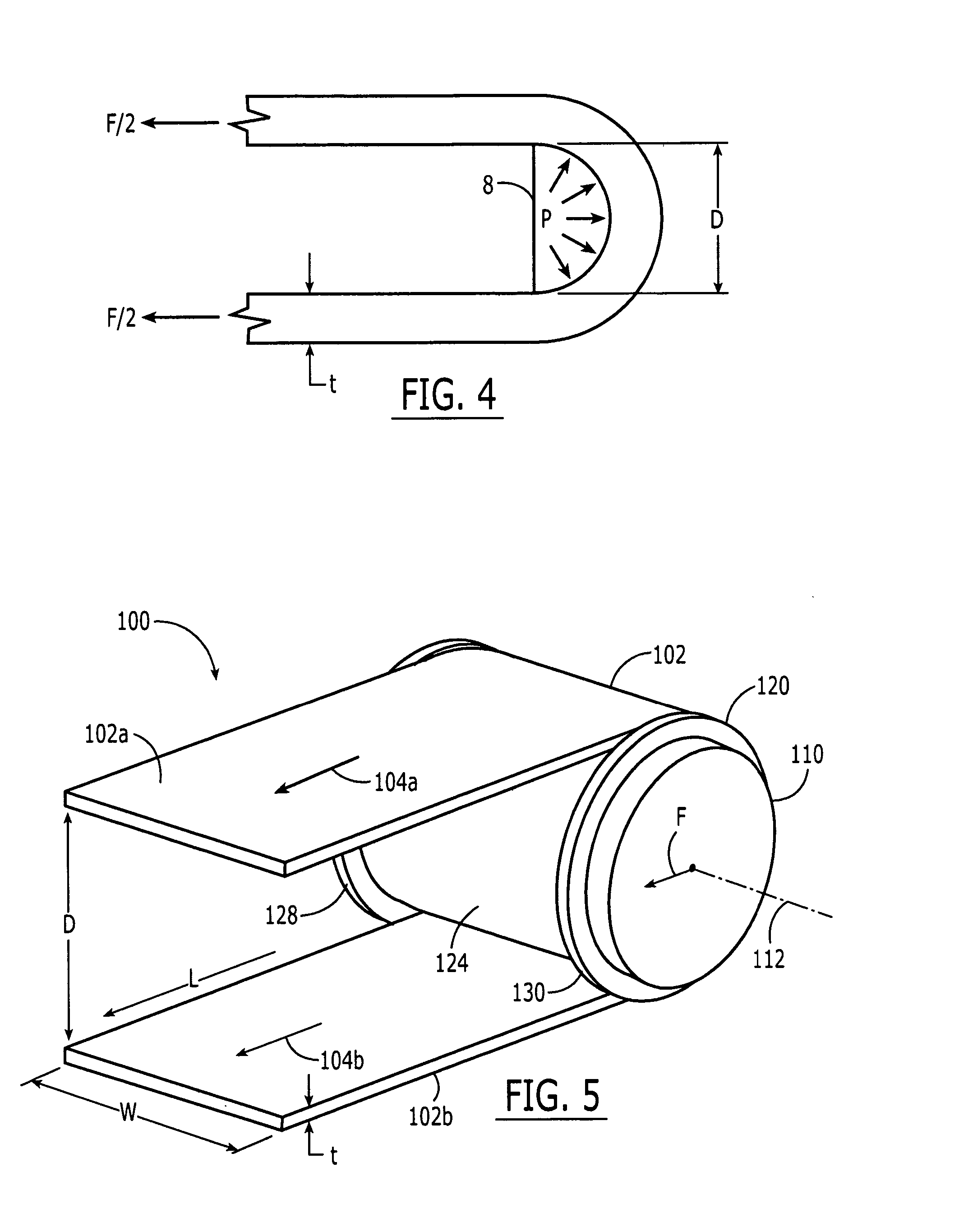

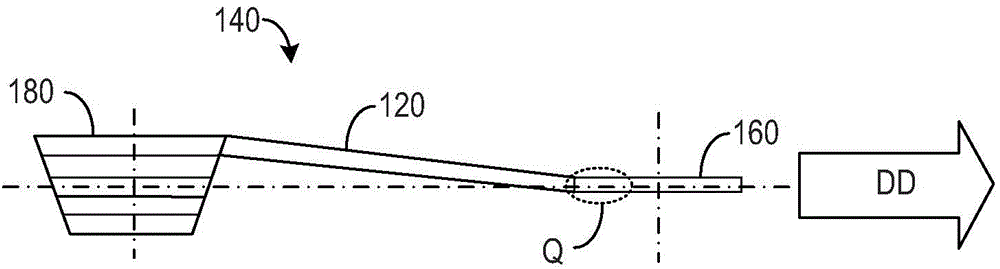

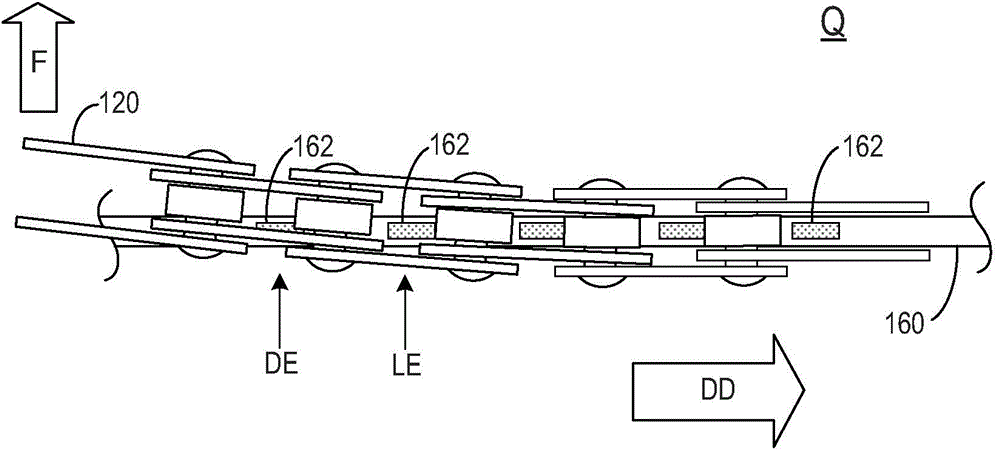

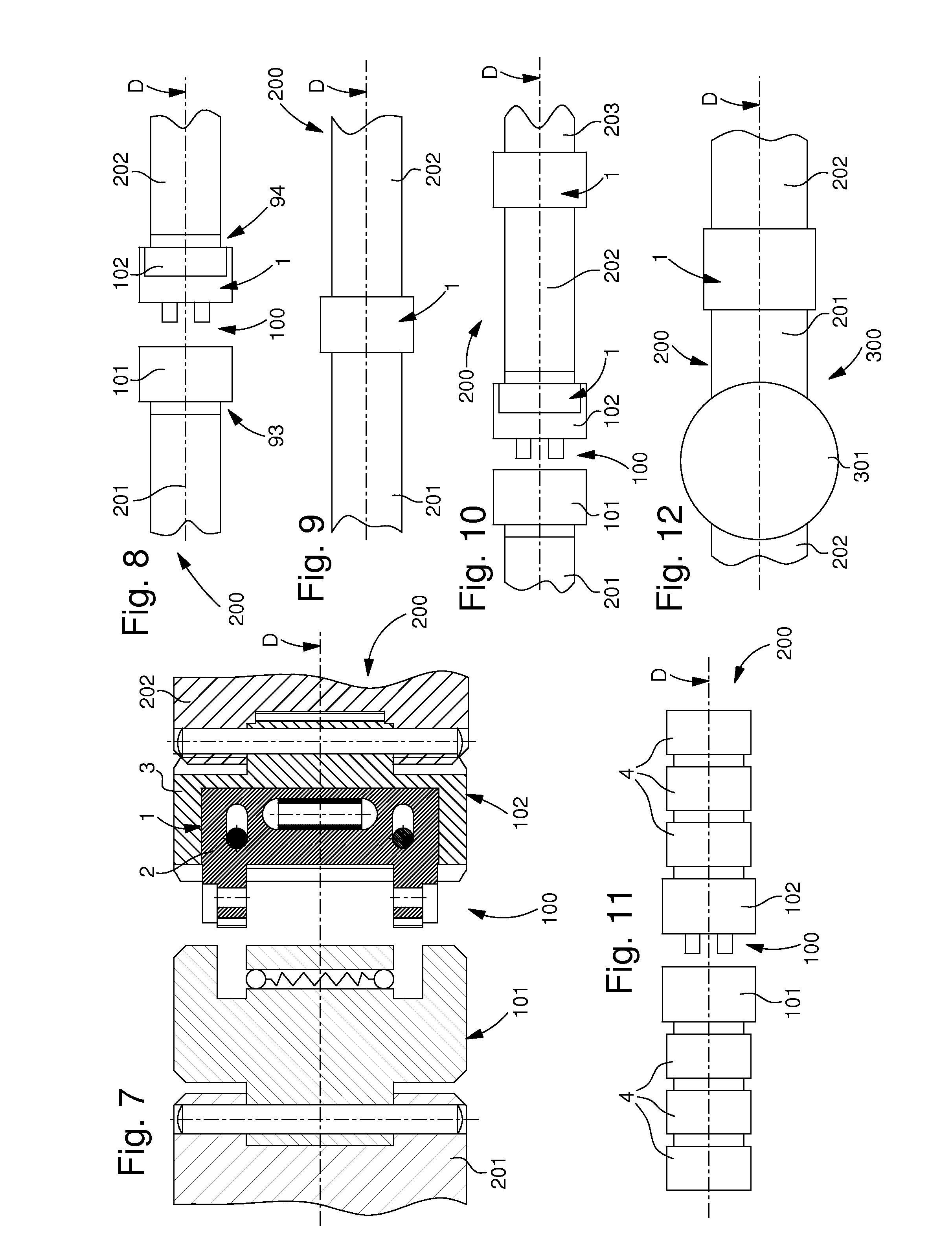

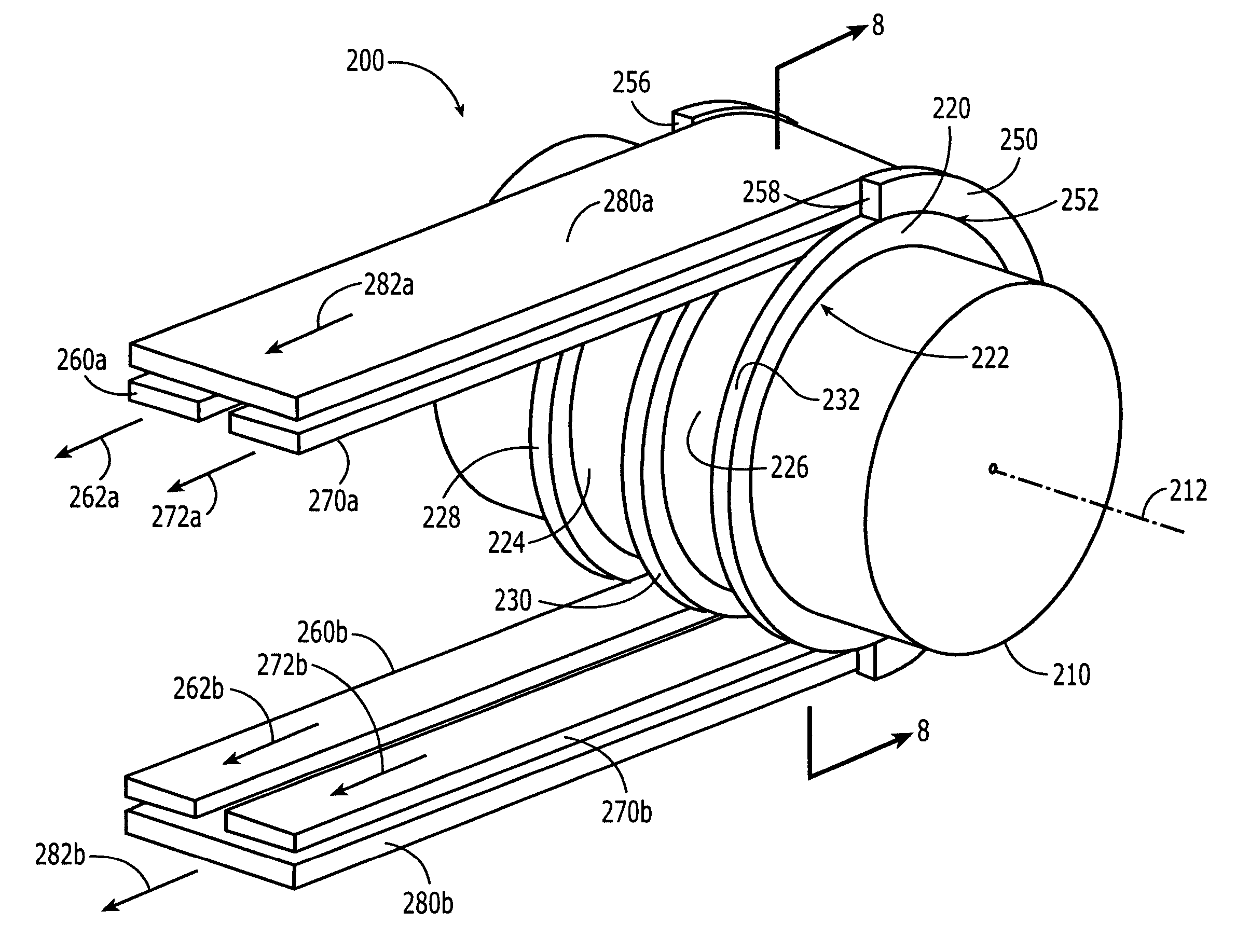

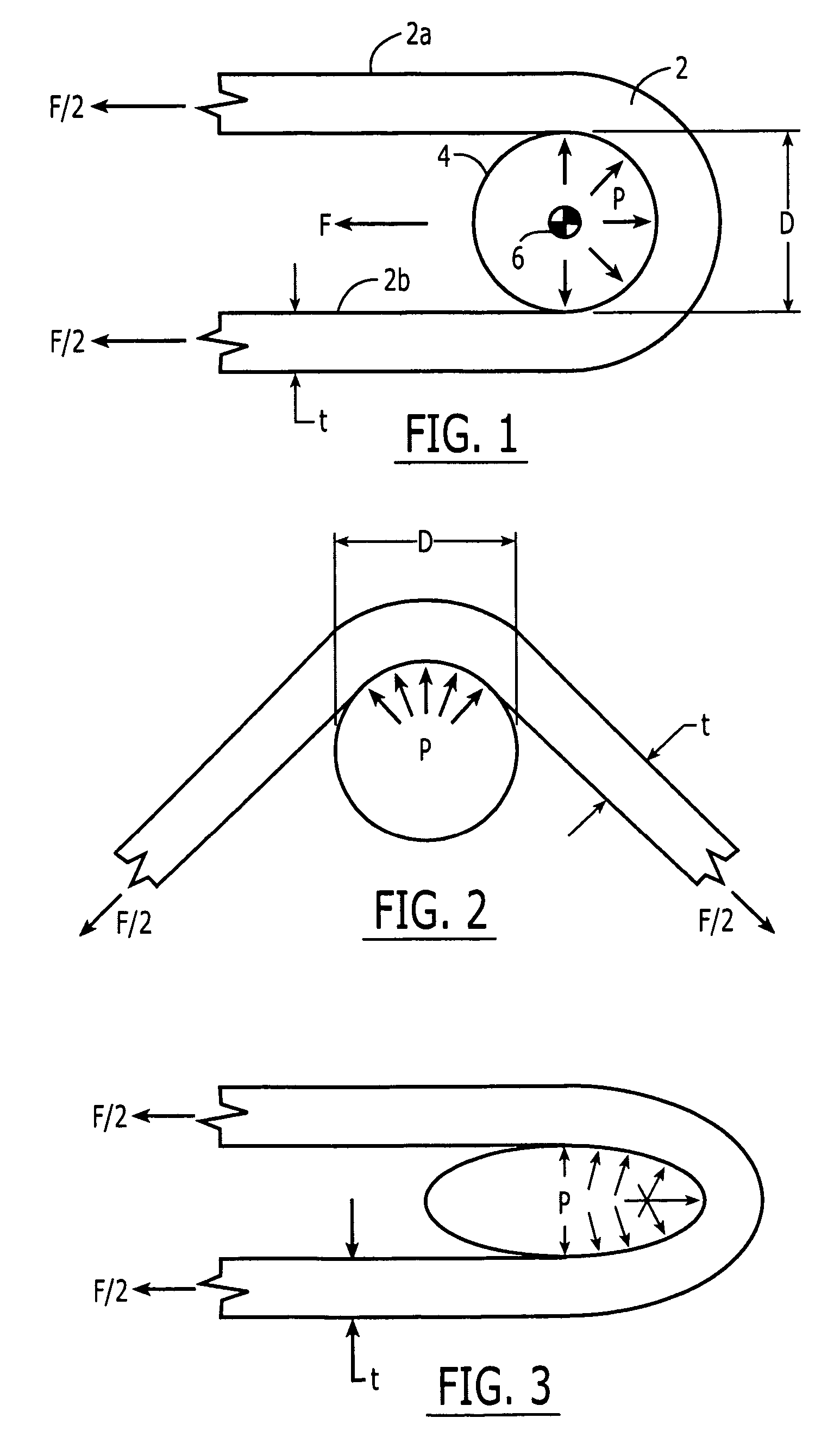

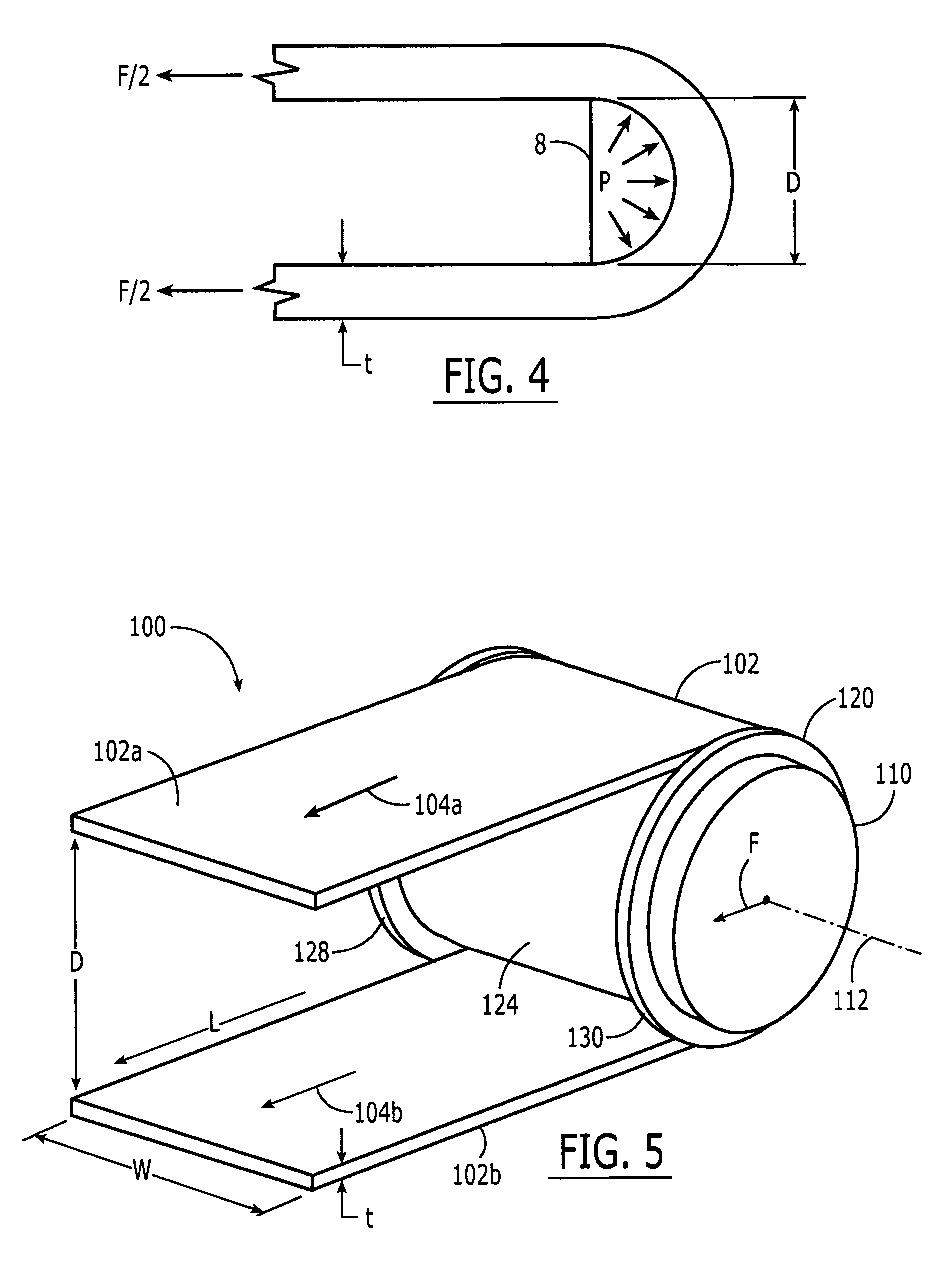

Force transfer assemblies

InactiveUS20070177707A1Ropes and cables for vehicles/pulleyNuclear monitoringEngineeringBearing surface

Force transfer assemblies are provided for transferring forces from tensionable members to receiving structures. The assemblies may include nested thimbles that transfer respective forces from respective tensionable members to receiving structures such as cylindrical members. An outer thimble may transfer force from an outer tensioned member to a receiving structure without causing compression of an inner tensioned member. For example, the outer thimble may transfer forces by way of the inner thimble or to a boss of the receiving structure. Forces from a tensioned member or assembly of tensioned members may be distributed along a cylindrical member by a thimble having a convex bearing surface or by spaced thimbles disposed along the cylindrical member.

Owner:THE BOEING CO

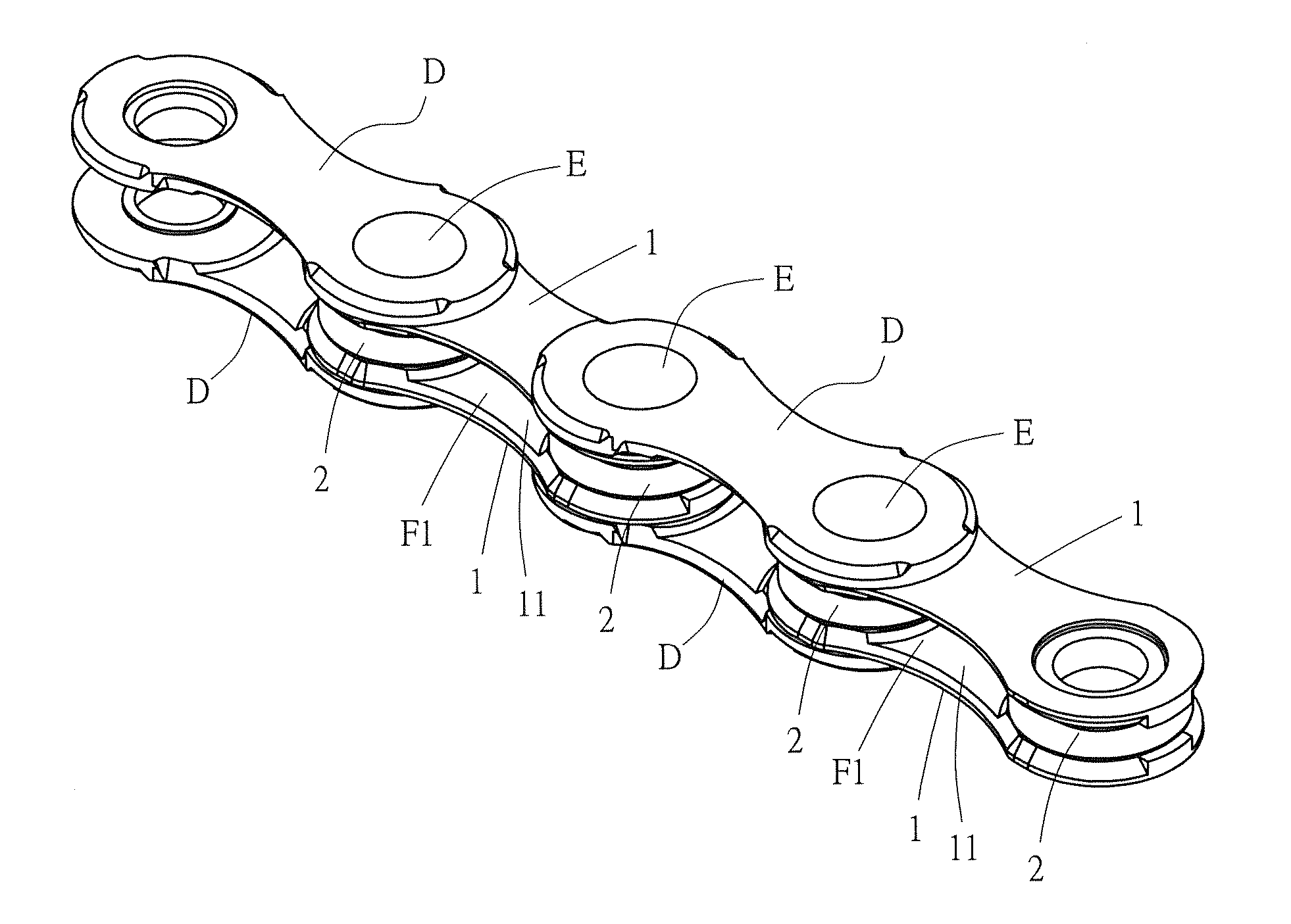

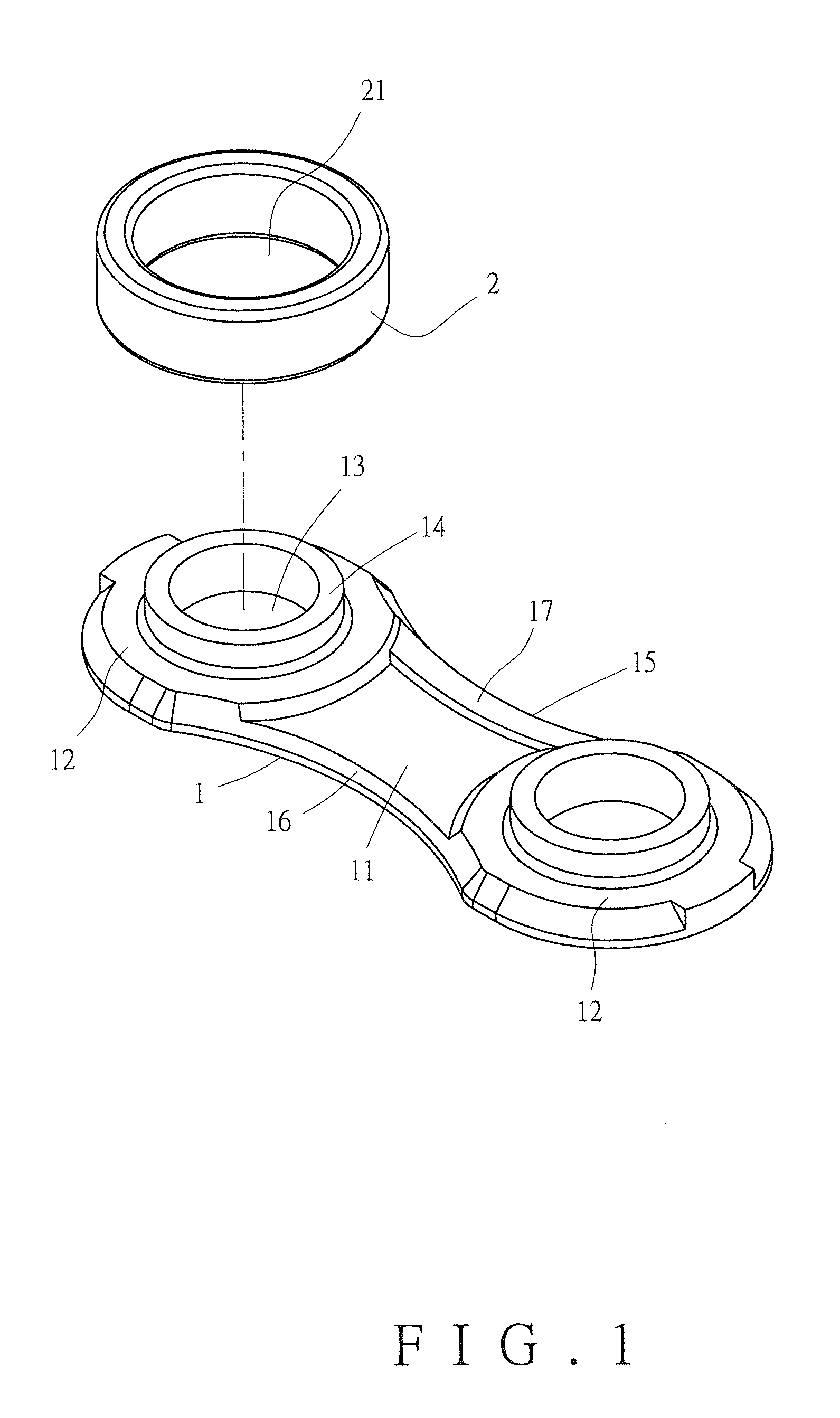

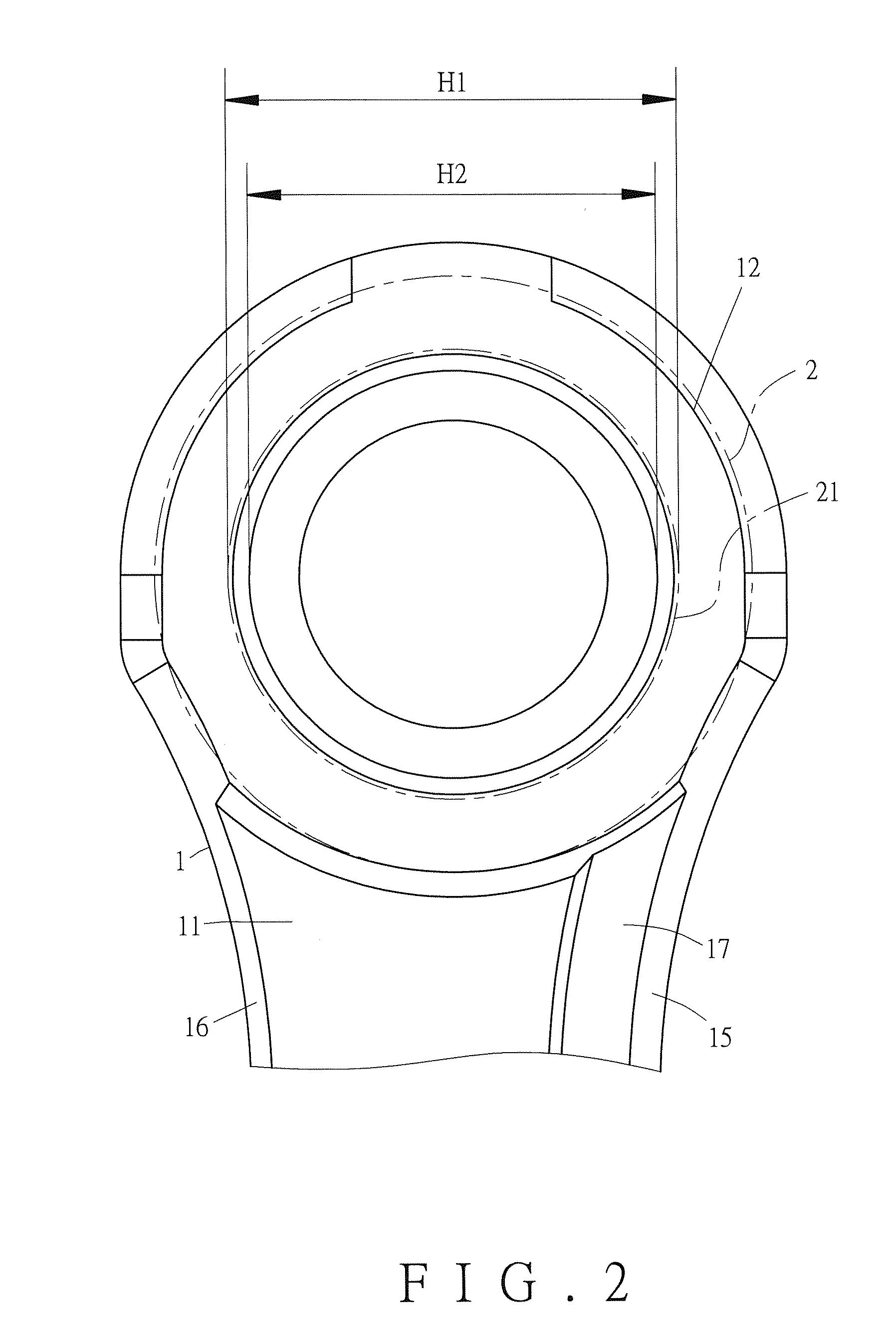

Chain plate structure

ActiveUS20160153526A1Reduce spacingGuaranteed uptimeChain linksDriving chainsMaximum diameterMechanical engineering

A chain plate structure includes a link plate body and a sleeve. The link plate body has an acting surface being provided with a first approach edge, two combining portions, and a limiting block located adjacent to the first approach edge. The limiting block has an altitude higher than an altitude of the acting surface. The sleeve is mounted on the link plate body and has a through hole whose maximum diameter is greater than a maximum diameter of a raised ring peripherally formed on the corresponding one of the combining portions. Therefore, when two of the link plate bodies are combined together, a first space is formed between the acting surfaces of the two aligned link plate bodies. The limiting block serves to limit the first space, while the sleeve is allowed to move on one of the combining portions so as to provide a second space.

Owner:WANG WEN PIN

Energy guiding chain

Owner:IGUS

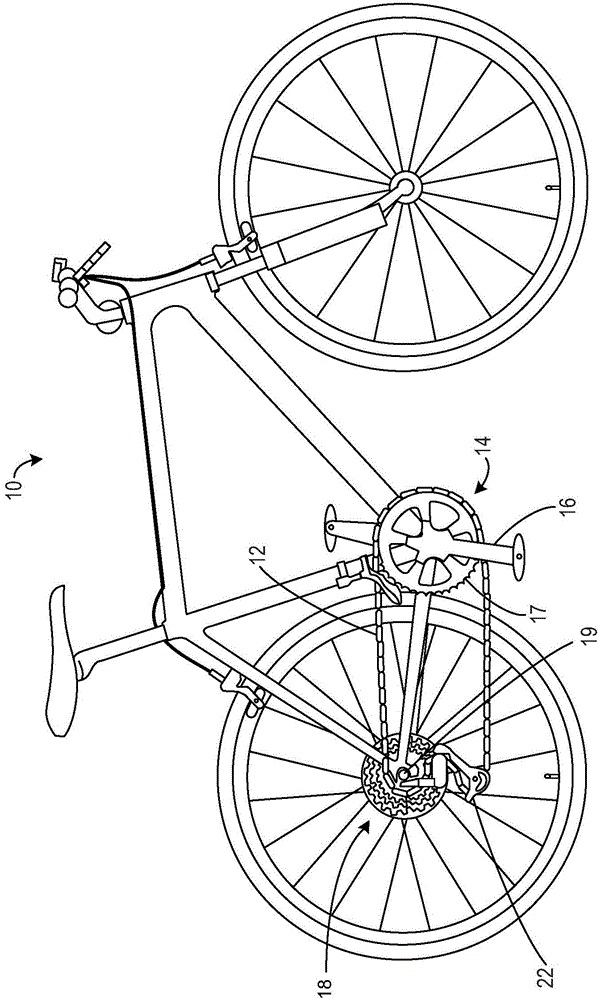

Bicycle chain

Owner:SHIMANO INC

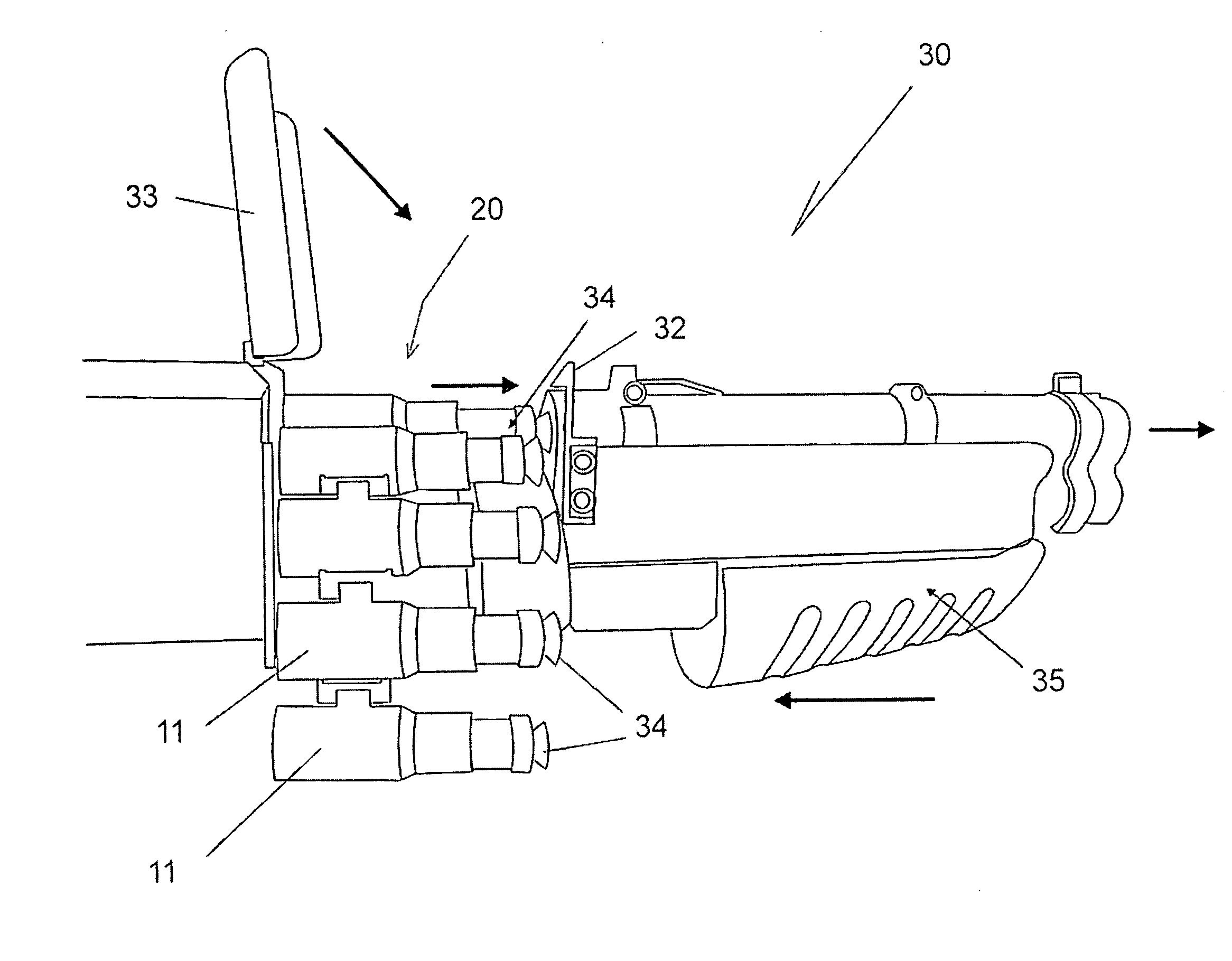

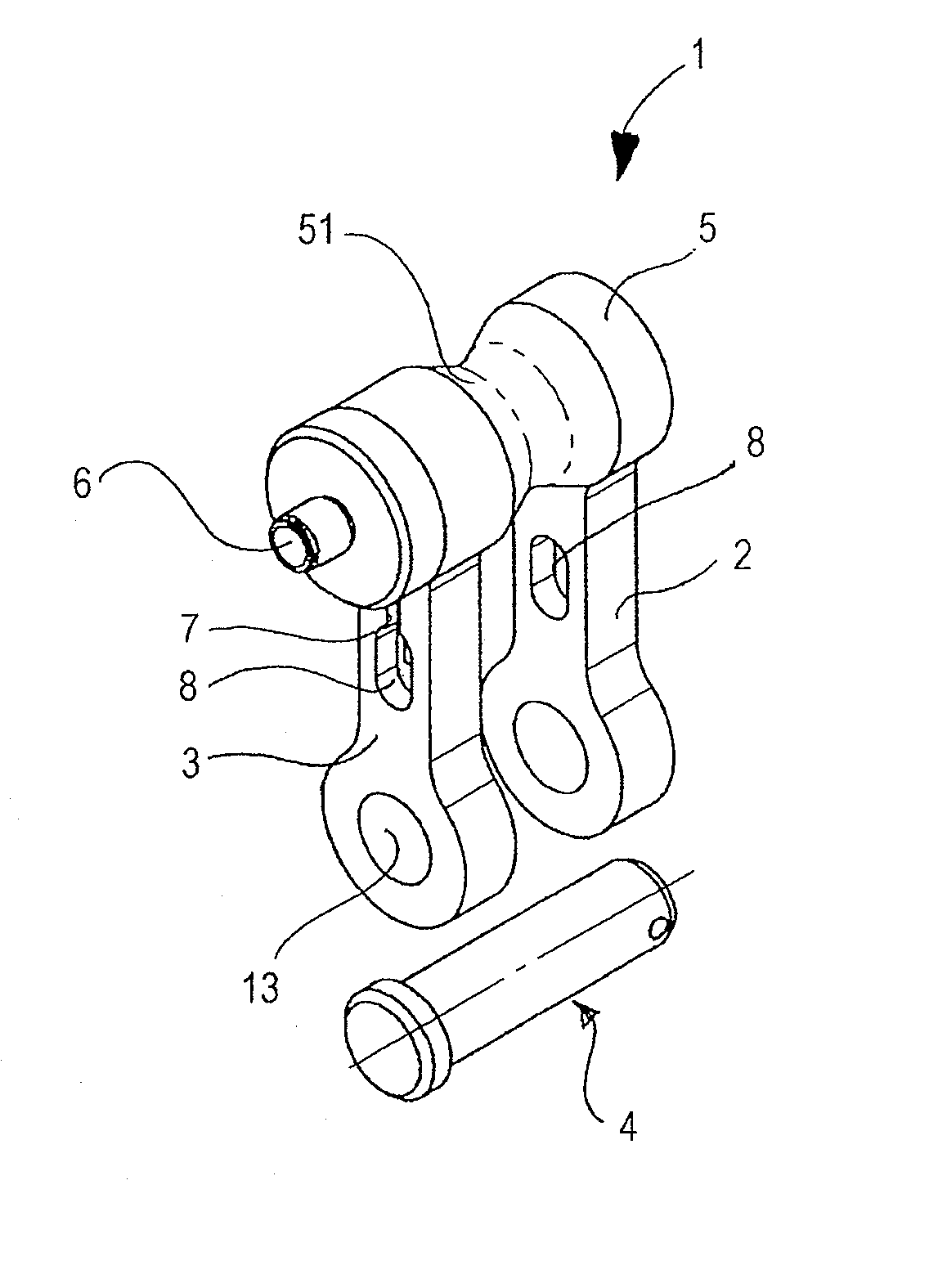

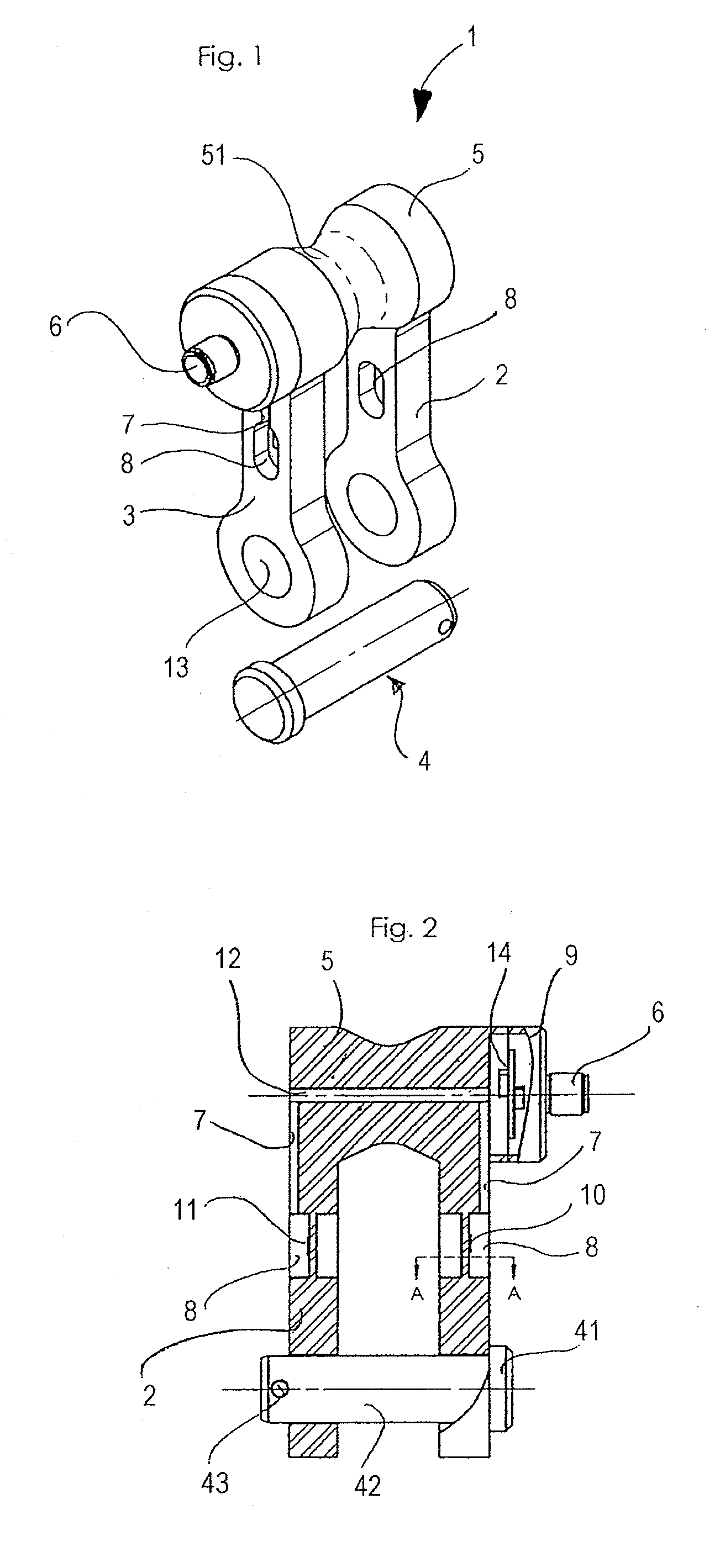

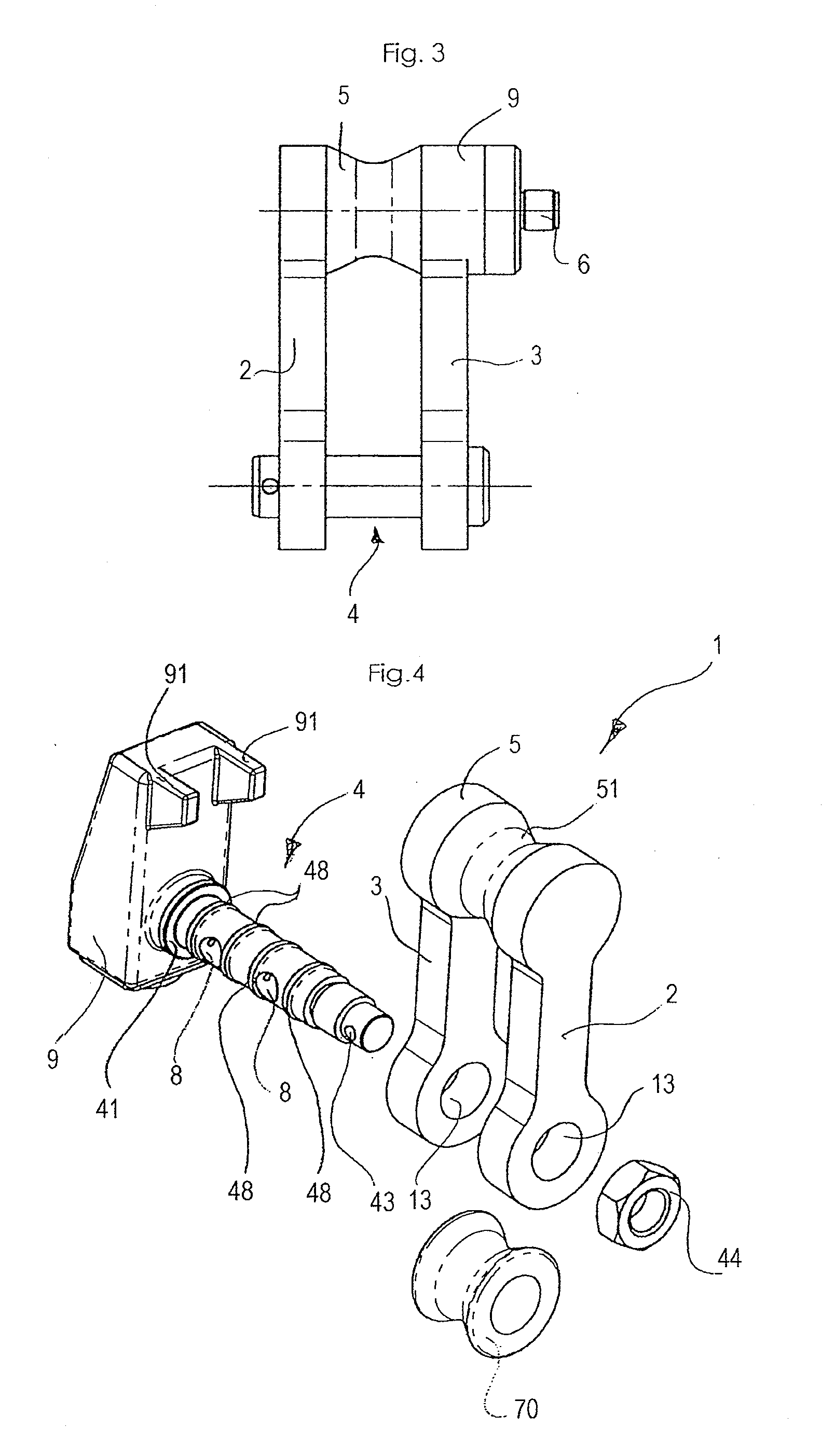

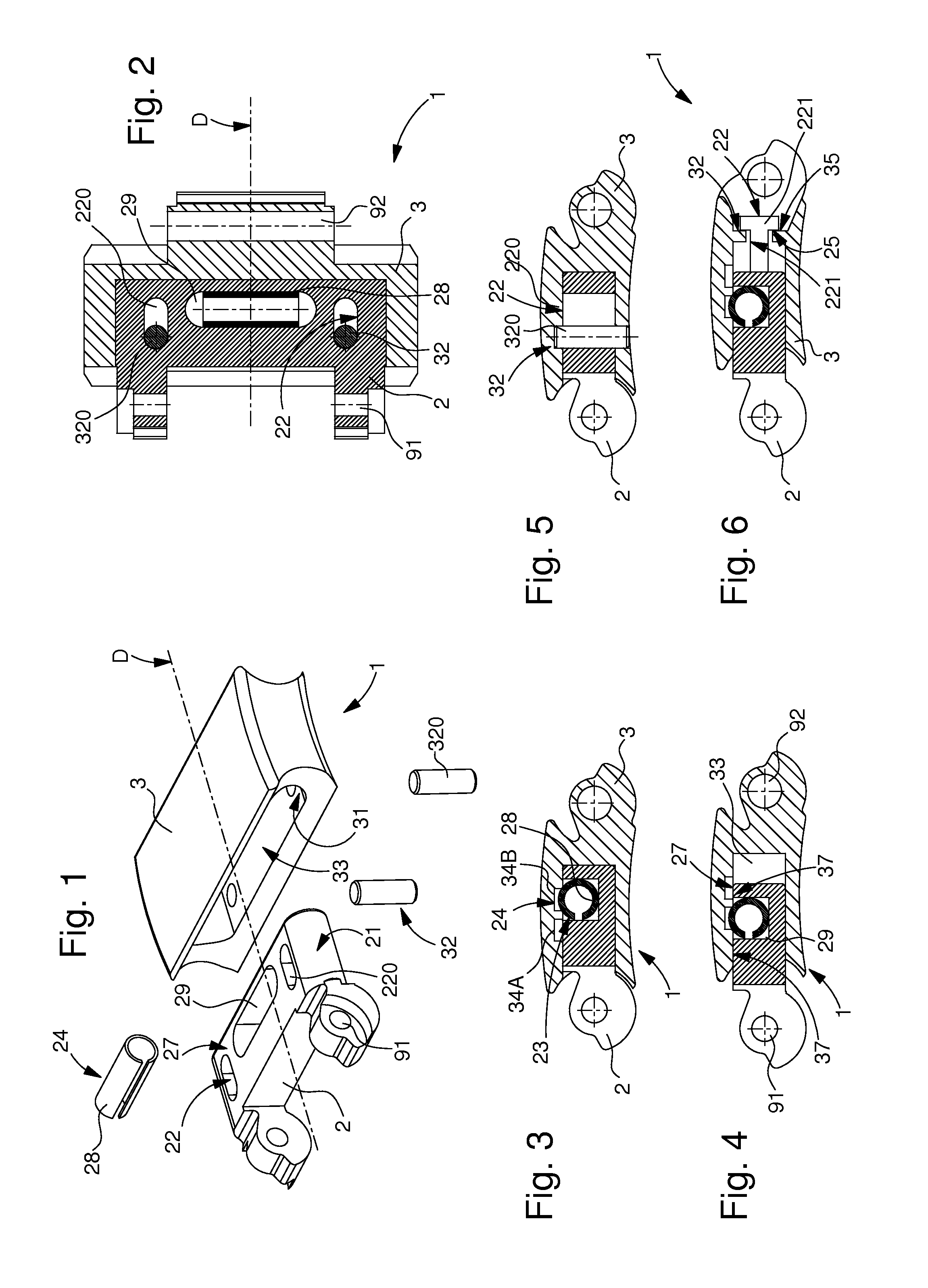

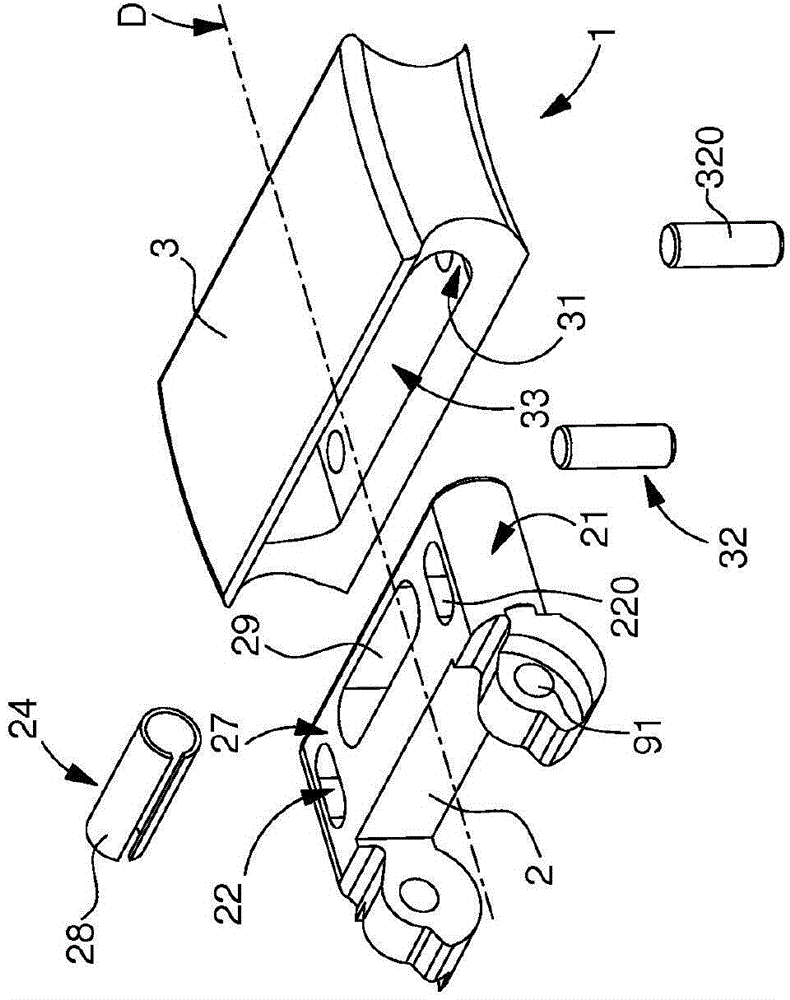

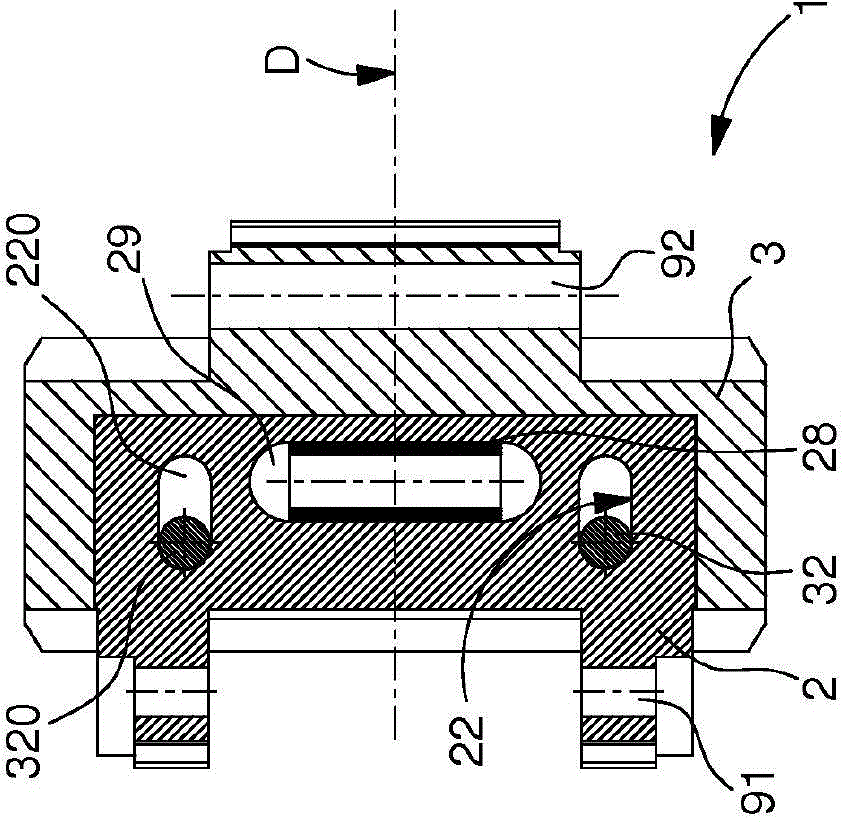

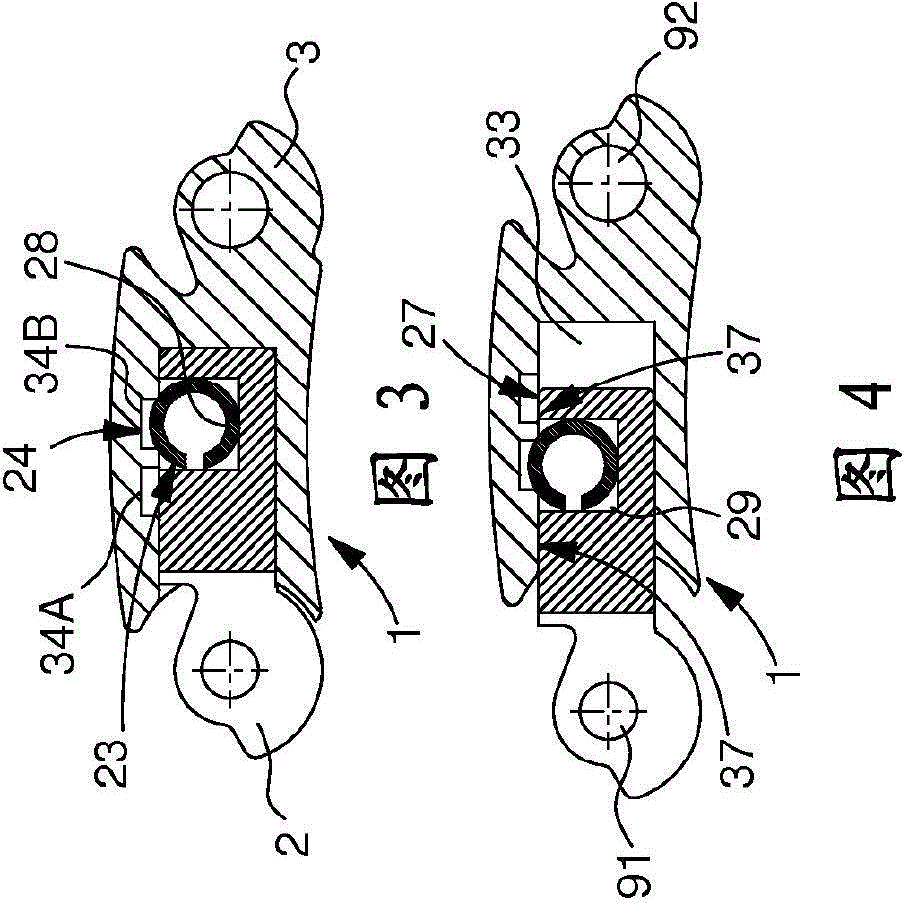

Shackle Assembly

ActiveUS20130067881A1Accurate manufacturing methodReliably repeatable creationShacklesChain linksEngineeringStrain gauge

A shackle assembly includes a shackle body having two shackle arms extending from a bridge portion which is fixed to the two arms and connects the two arms to each other. A shackle pin can be mounted to the shackle arms and connects the two shackle arms in the mounted state. At least one pocket is formed in at least one of the shackle arms and / or the shackle pin, in which pocket a strain sensing element is received and fixedly attached to the bottom or wall of the pocket for detecting a shackle load acting on the shackle assembly. The pocket is a hole going partially through the shackle arm or going partially through the shackle pin, and the strain sensing element is a strain gauge which is attached to the wall or bottom of the hole.

Owner:TECSIS

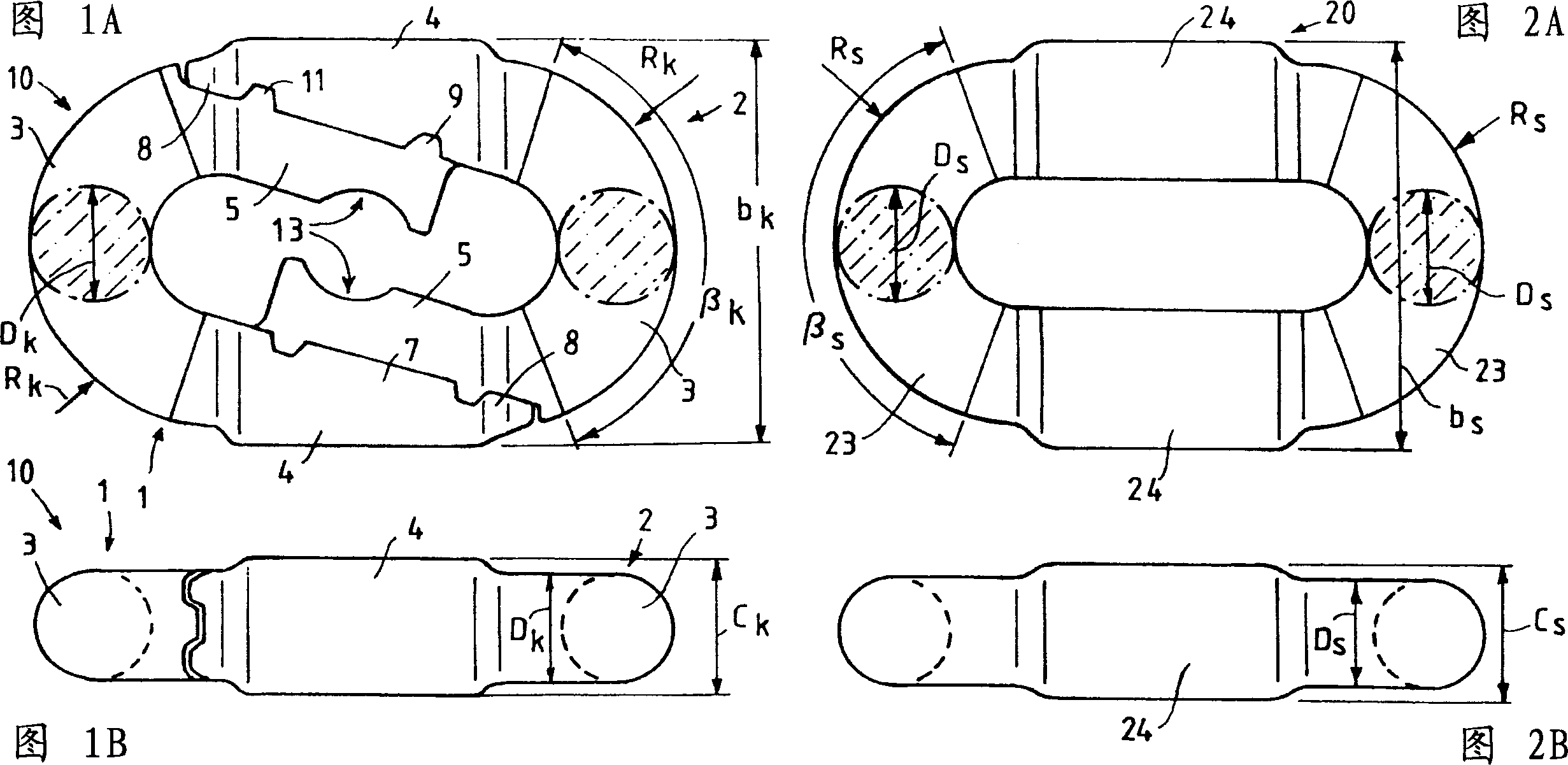

Contact piece of plate link chain for conical disc winding contact part driving device and plate link chain

Owner:SCHAEFFLER TECH AG & CO KG

Adjustable link

Owner:OMEGA SA

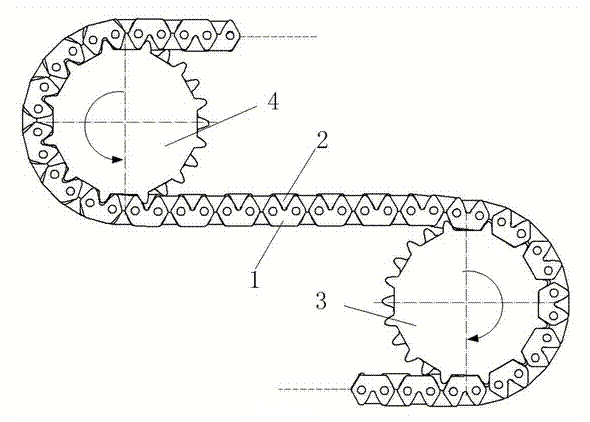

Silent chain complex phase multi-axis transmission mechanism

InactiveCN104728376ASimple structureEasy to replaceGearingPortable liftingDrive wheelTransmitted power

The invention discloses a silent chain complex phase multi-axis transmission mechanism which is composed of a first chain, a second chain, a first driving chain wheel, a second driving chain wheel, a first driven chain wheel and a second driven chain wheel. The needed phase number n is set according to different needs, and in the meshing process of the first driving chain and the first driven chain wheel, the inner side circular tooth profiles of chain plates are meshed with the chain wheel tooth profile of the first driven chain wheel; along with the rotation of the chain wheels, meshing of the chain plates is reduced, the outer side linear tooth profiles of the chain plates begin to be meshed with the chain wheel tooth profiles of the chain wheels, the inner tooth profiles and the outer tooth profiles of the chain plates are meshed with the chain wheels alternately, the meshing process of the chains and the driving chain wheels and the meshing process of the chains and the driven chain wheels are identical, and the chain transmission system is achieved by transmitting power through the driving wheels. The silent chain complex phase multi-axis transmission mechanism is simple in structure, vibration and noise generated by the polygon effect are reduced through the complex phase transmission, and large power and torque can be transmitted; the chain plates of the inner and outer combined meshing mechanism are adopted, the impact between the chain plates and the chain wheels and the polygon effect of the system are reduced, and complex phase multi-axis transmission can be achieved.

Owner:JILIN UNIV

High-strength forged square chain and production method thereof

The invention relates to a high-strength forged square chain and a production method thereof and belongs to the technical field of chain production. The high-strength forged square chain comprises forged rings arranged at intervals; every two forged rings are welded through two forged half chain rings to form a long-chain structure; the high-strength forged square chain is thermally treated. The forged rings and the forged half chain rings are produced with low-alloy steel by means of forging; the low-alloy steel comprises, by weight, 0.021-0.025% of carbon, 0-0.025% of silicon, 1.10-1.40% ofmanganese, 0.40-0.60% of chromium, 0.90-1.10% of nickel, 0.50-0.60% of molybdenum, 0.025-0.050% of aluminum, < / =0.020% of sulfur, < / =0.020% of phosphorus, and the balance of iron and unavoidable impurities.

Owner:山东华源索具有限公司

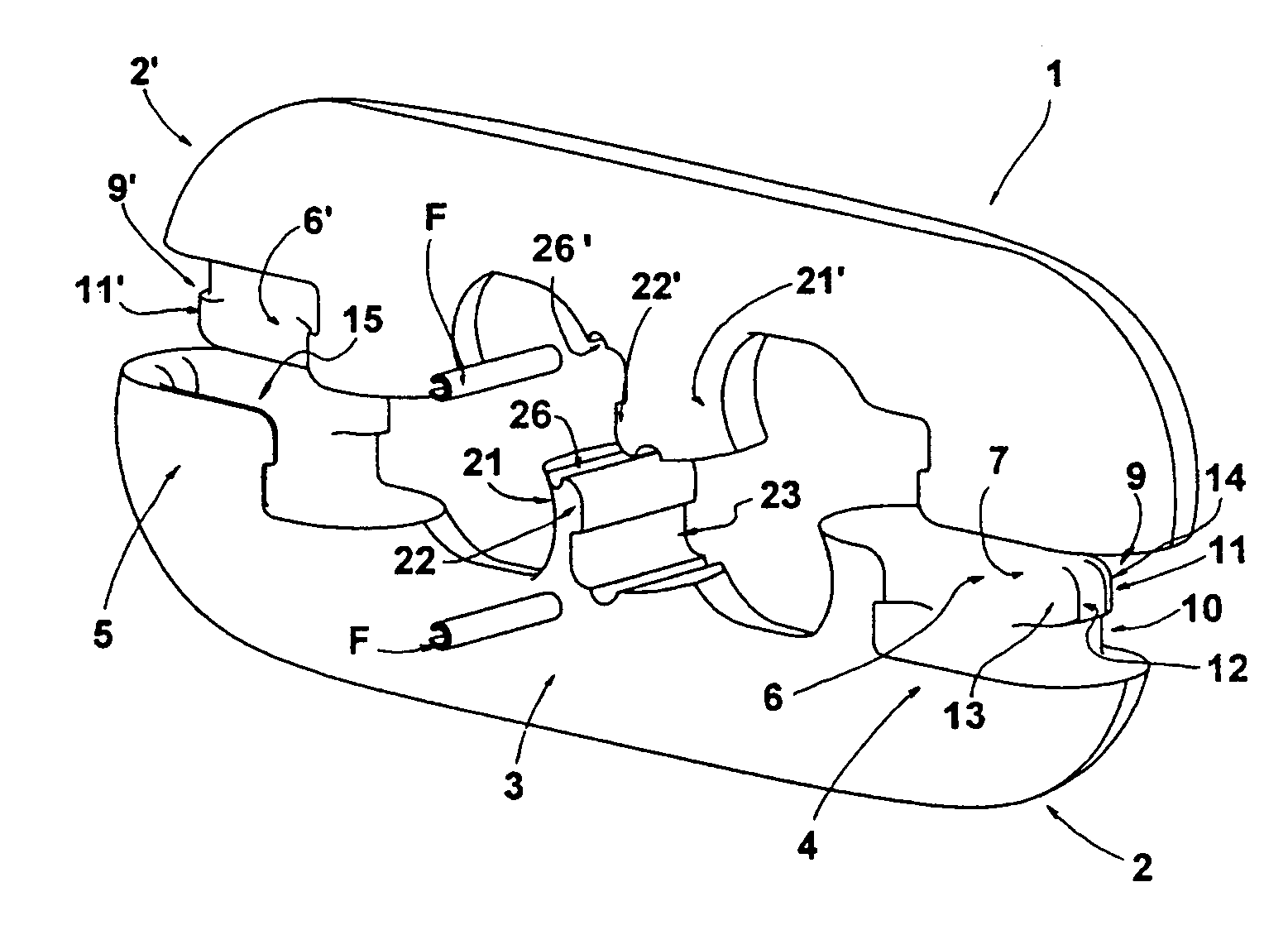

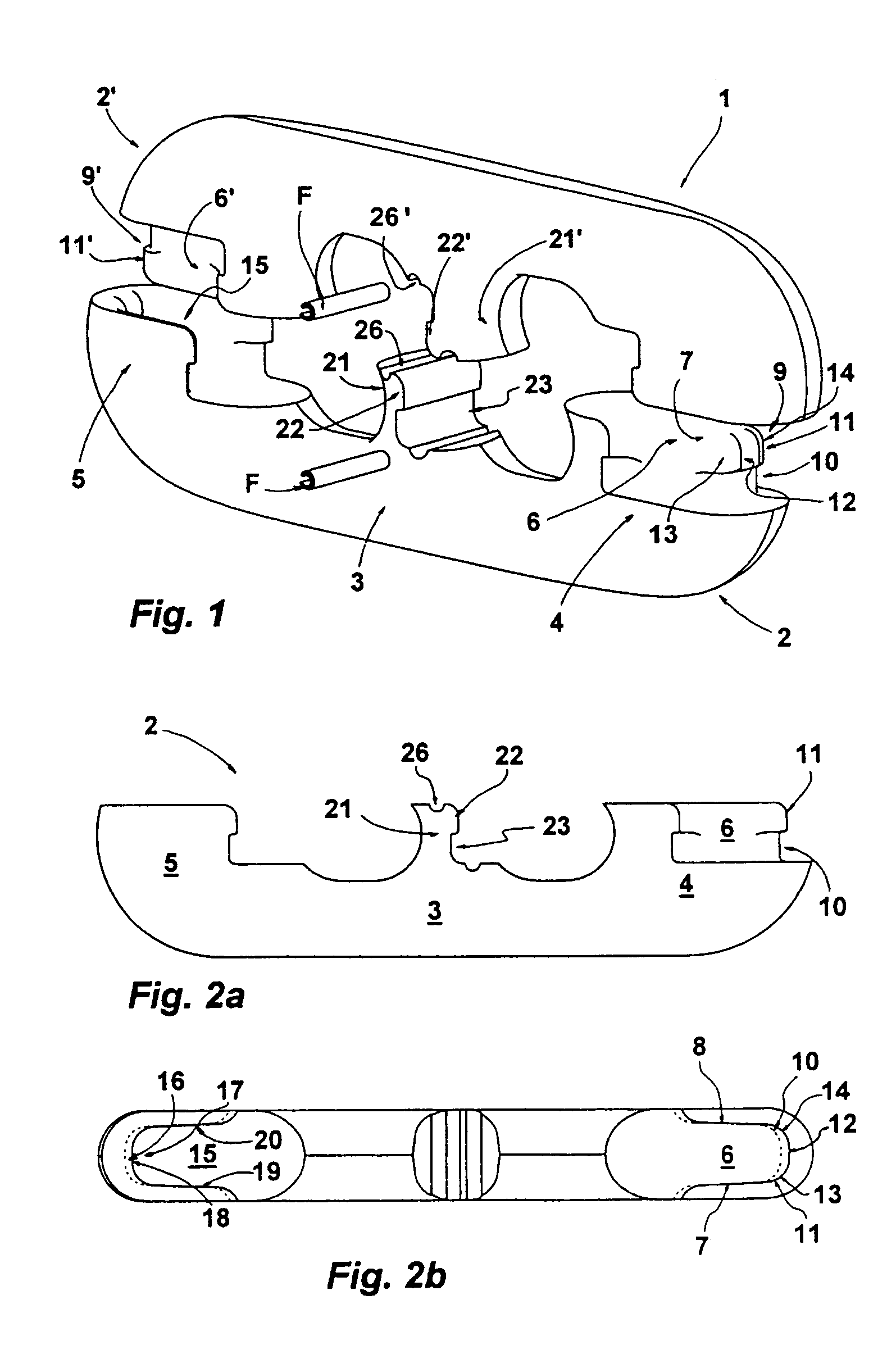

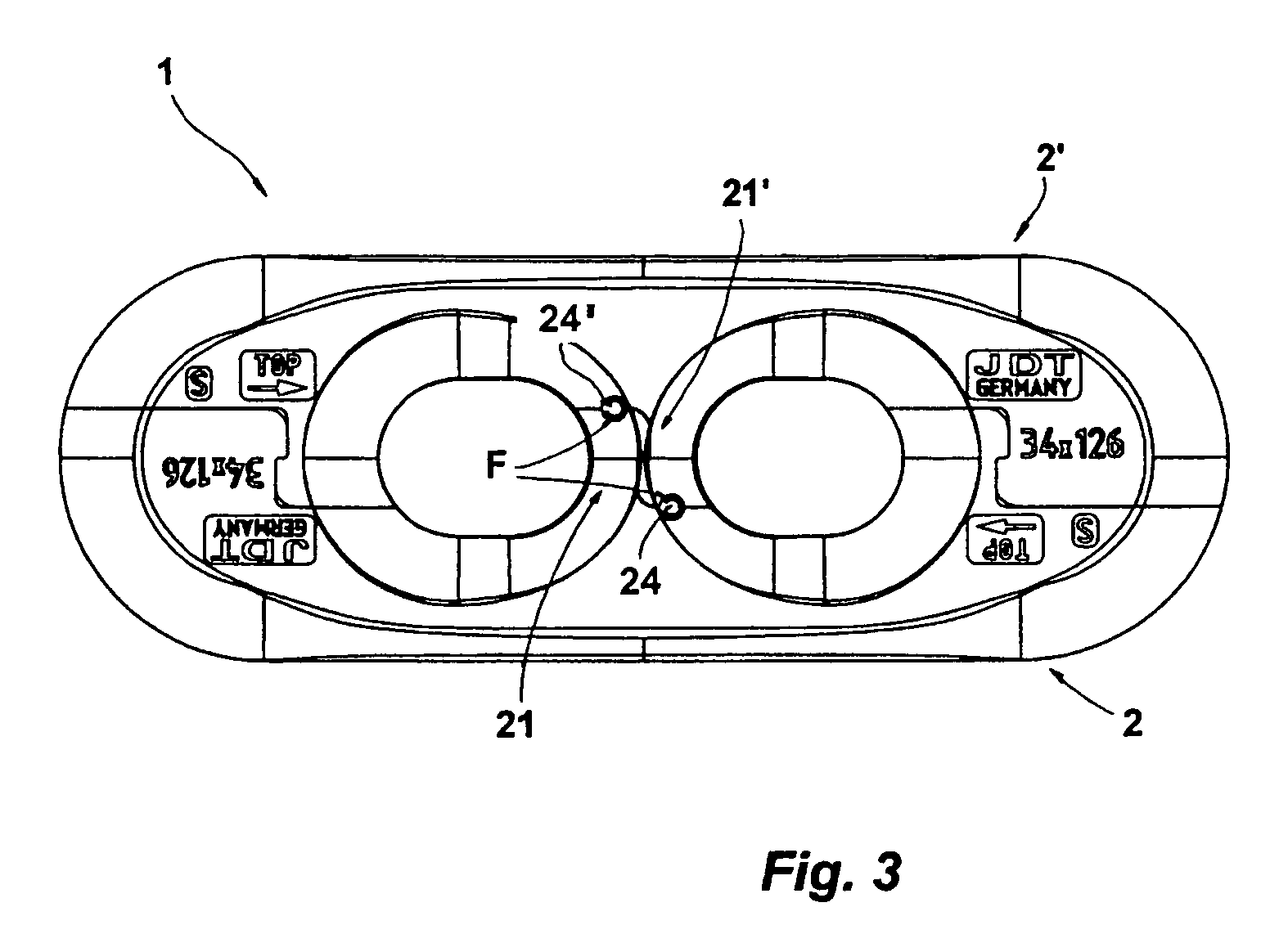

Chain lock

A chain lock for high-strength steel chains has two lock parts that are the same and can be joined together in a rotation-symmetry arrangement with one another, in the longitudinal direction. Each lock part has a longitudinal stay having arc segments that follow it at both ends. There are two coupling elements that are configured complementary to one another and are assigned to the two arc segments of each lock part. One of the elements is configured as a locking stay that follows the longitudinal extension of the lock part, and the other element is configured as a stay accommodation. The locking stay of the one lock part engages in the stay accommodation of the other lock part and rests against the complementary coupling surface of the stay accommodation with its coupling surface formed by the face end in the joining direction. The coupling surfaces comprise a coupling surface segment having a defined width, which has no curvature or only an insignificant curvature pointing in the joining direction.

Owner:J D THEILE

Force transfer assemblies

Force transfer assemblies are provided for transferring forces from tensionable members to receiving structures. The assemblies may include nested thimbles that transfer respective forces from respective tensionable members to receiving structures such as cylindrical members. An outer thimble may transfer force from an outer tensioned member to a receiving structure without causing compression of an inner tensioned member. For example, the outer thimble may transfer forces by way of the inner thimble or to a boss of the receiving structure. Forces from a tensioned member or assembly of tensioned members may be distributed along a cylindrical member by a thimble having a convex bearing surface or by spaced thimbles disposed along the cylindrical member.

Owner:THE BOEING CO

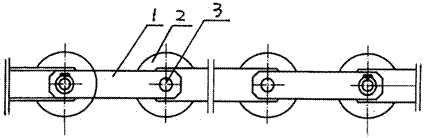

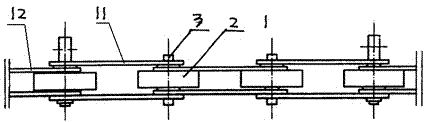

Escalator and light step chain and application thereof

The invention relates to the technical field of escalators, and particularly relates to an escalator and a light step chain and an application thereof. The escalator comprises a step chain and a guide rail, wherein the step chain moves on the guide rail. The step chain comprises a plurality of chain link units, and each chain link unit comprises a roller shaft, a roller, an outer chain piece and an inner chain piece. A first shaft hole is arranged on the outer chain piece, and a second shaft hole is arranged on the inner chain piece. The roller shaft penetrates through the roller, the first shaft hole and the second shaft hole cause the roller to be connected with the outer chain piece and the inner chain piece. The thickness of the outer chain piece is 4mm, the width of the outer chain piece is 35mm, and the pitch is 133.33mm. Compared with the prior art, the step chain has the advantages that the step chain can be applied to the escalator with a lifting height below 5m, the specification is smaller than that of the traditional step chain, materials can be greatly saved, and the manufacture cost of a complete machine is reduced.

Owner:上海爱登堡电梯集团股份有限公司

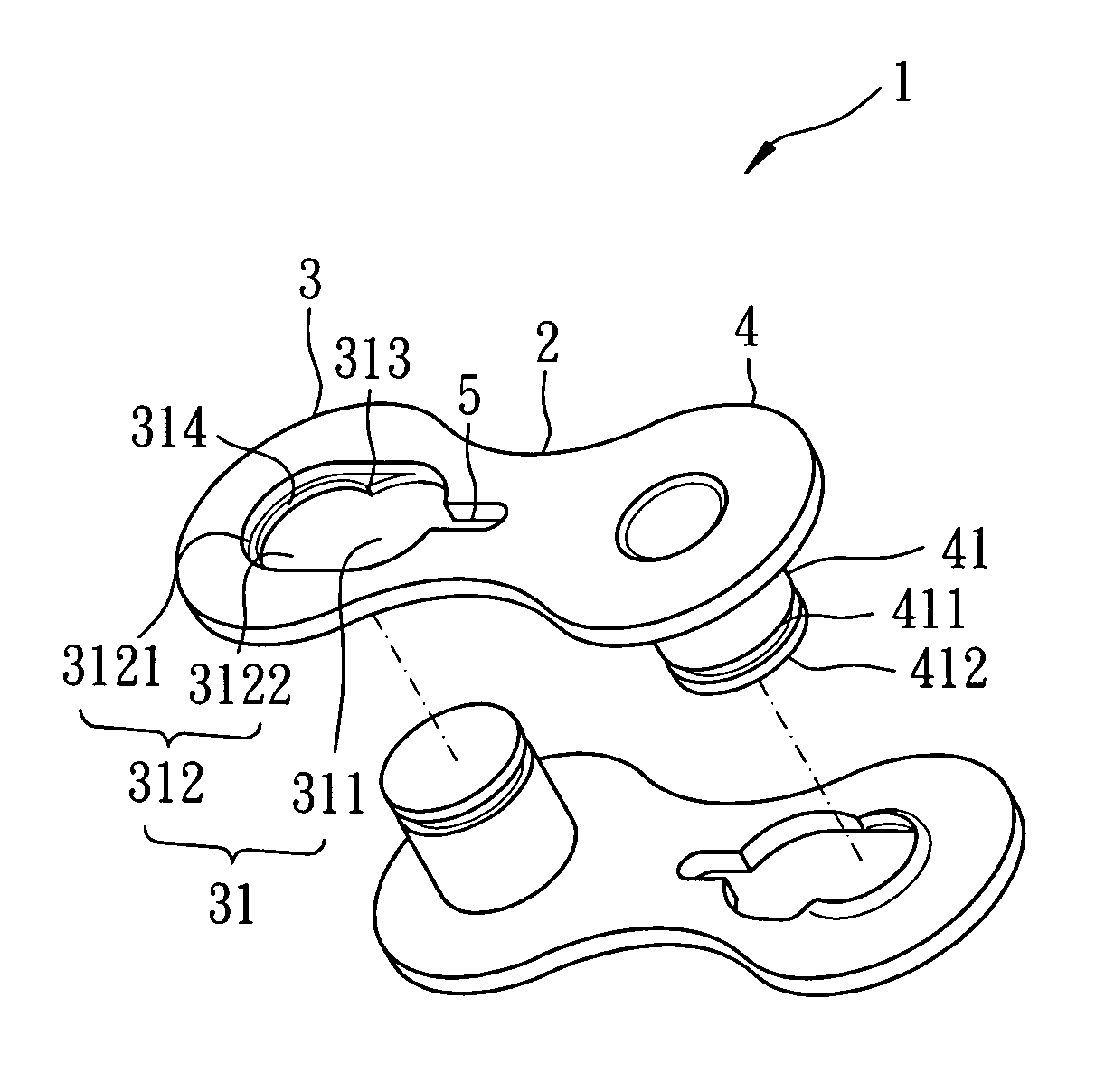

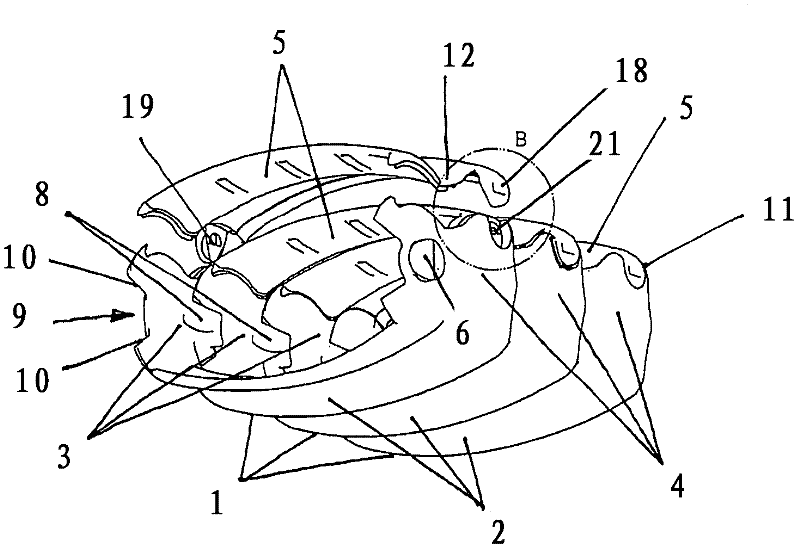

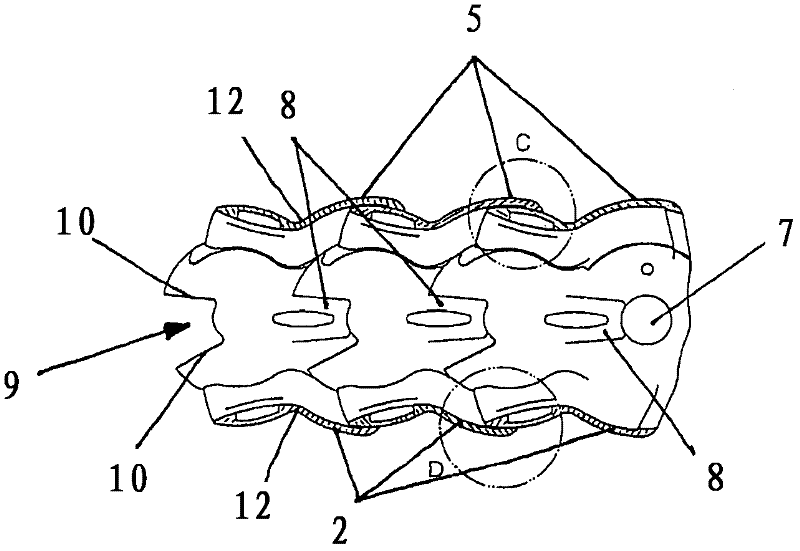

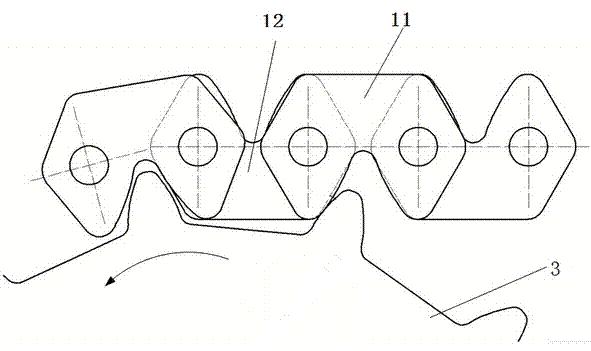

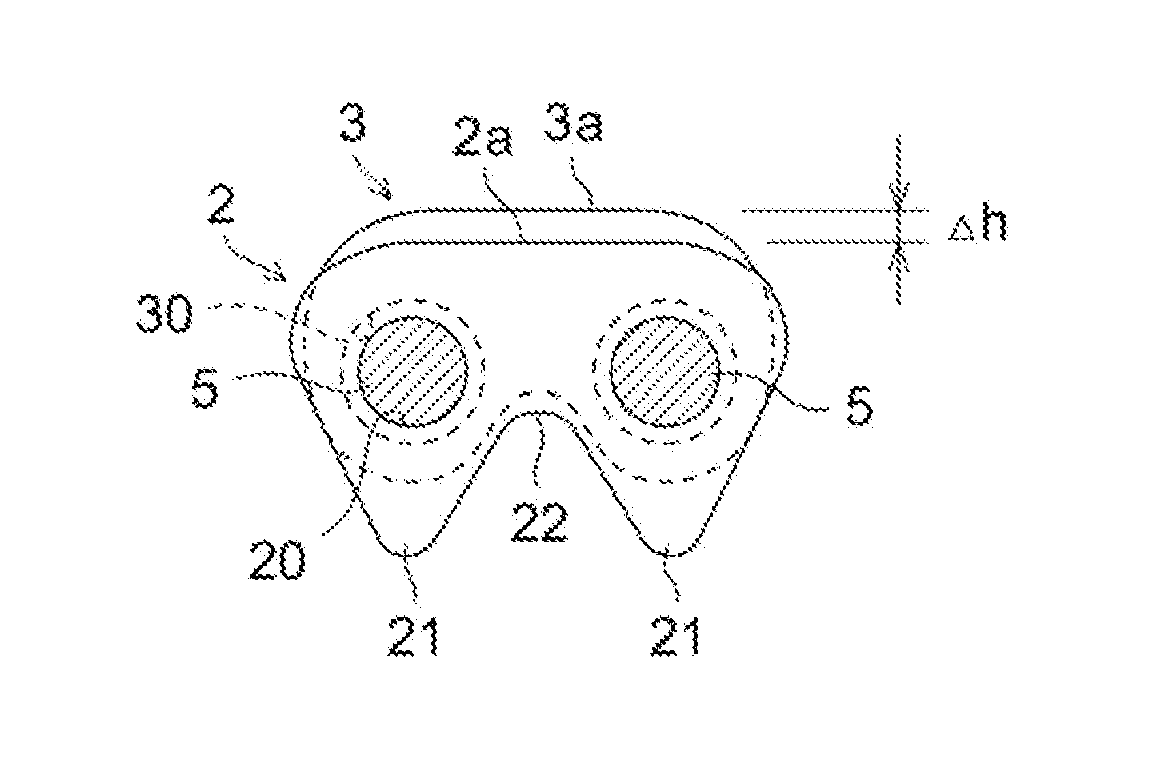

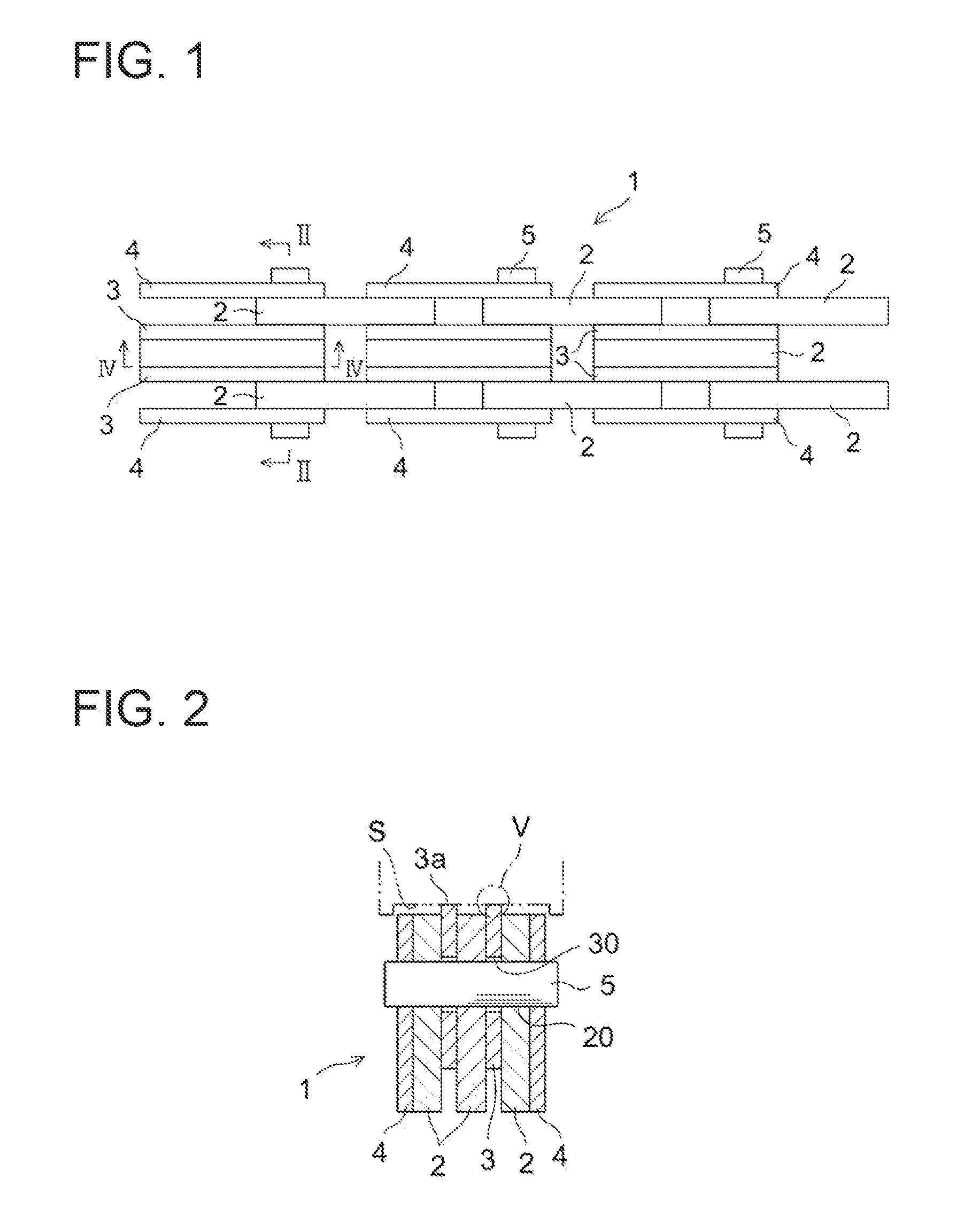

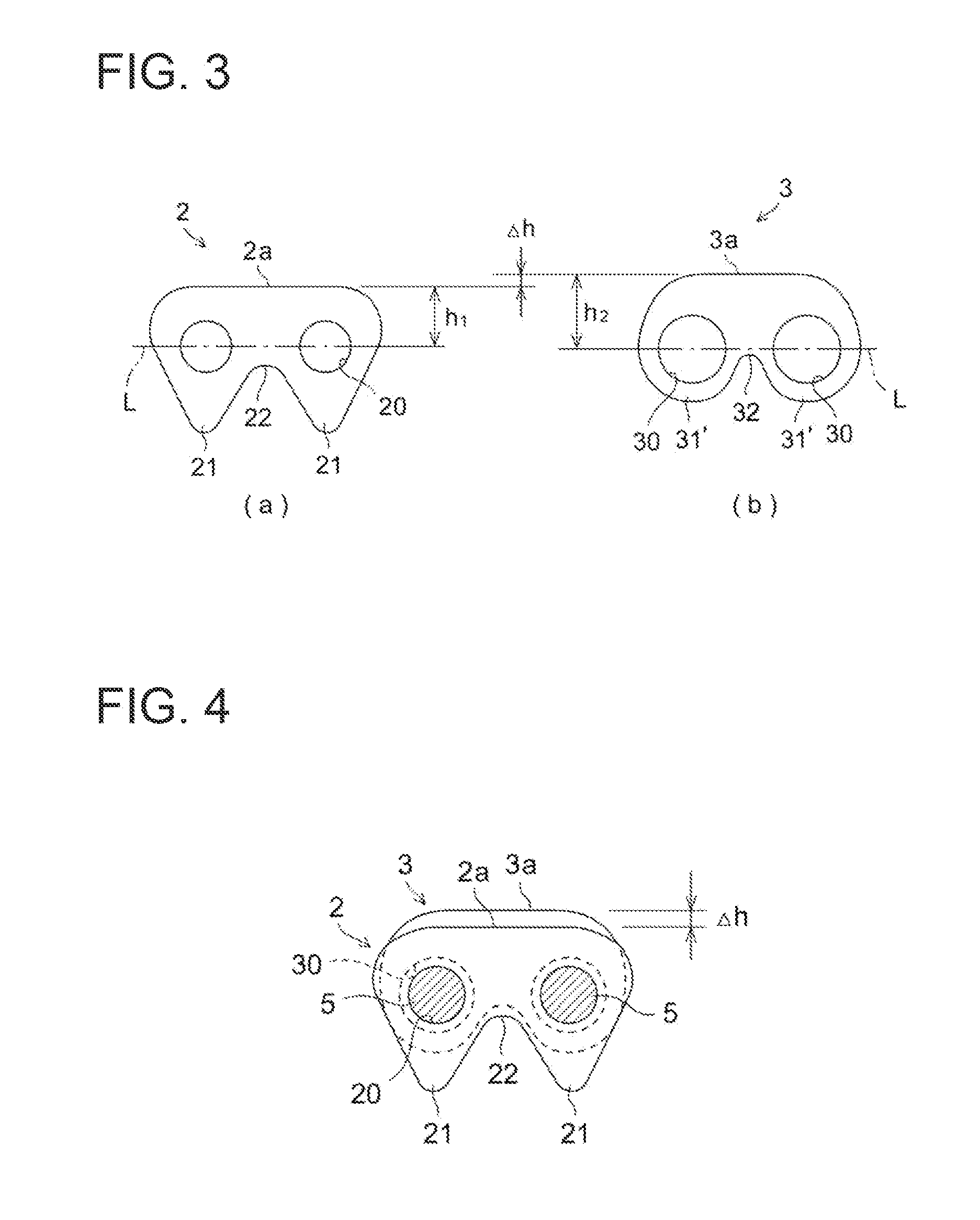

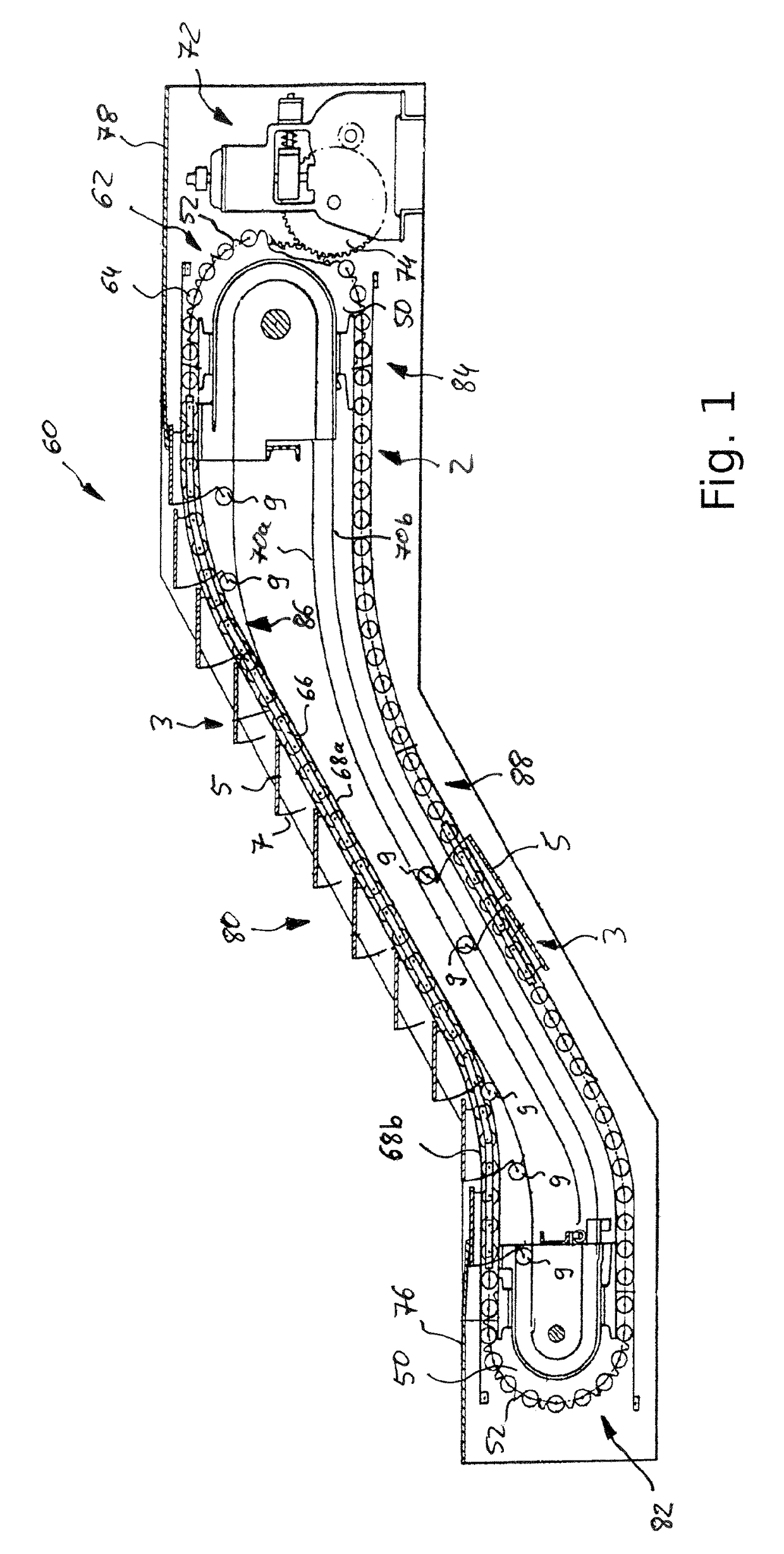

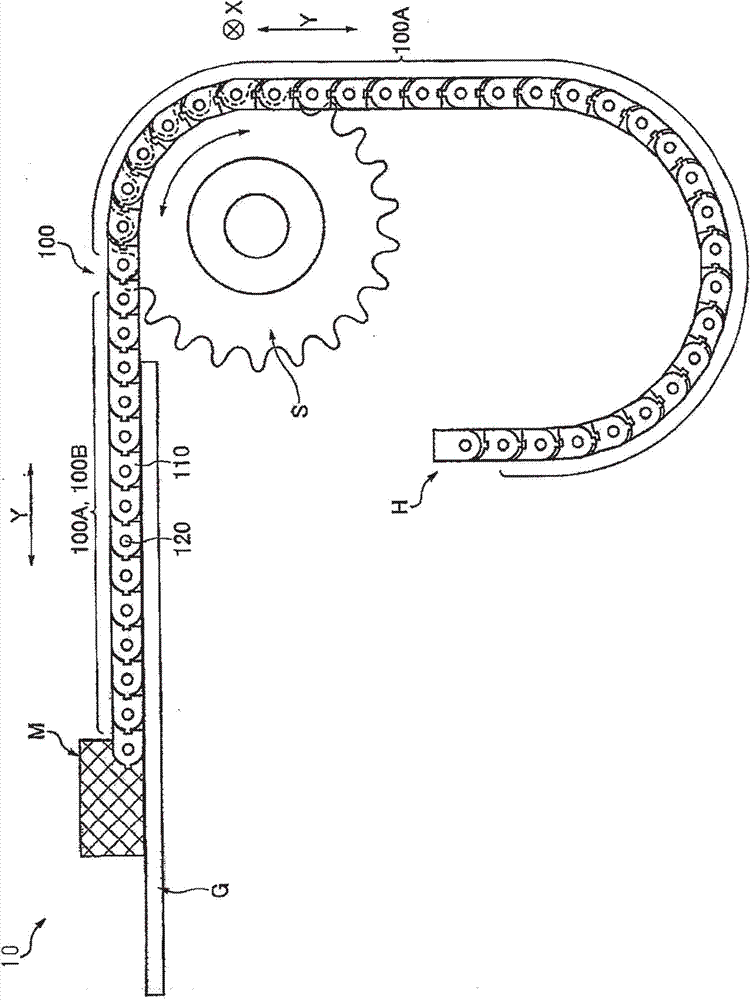

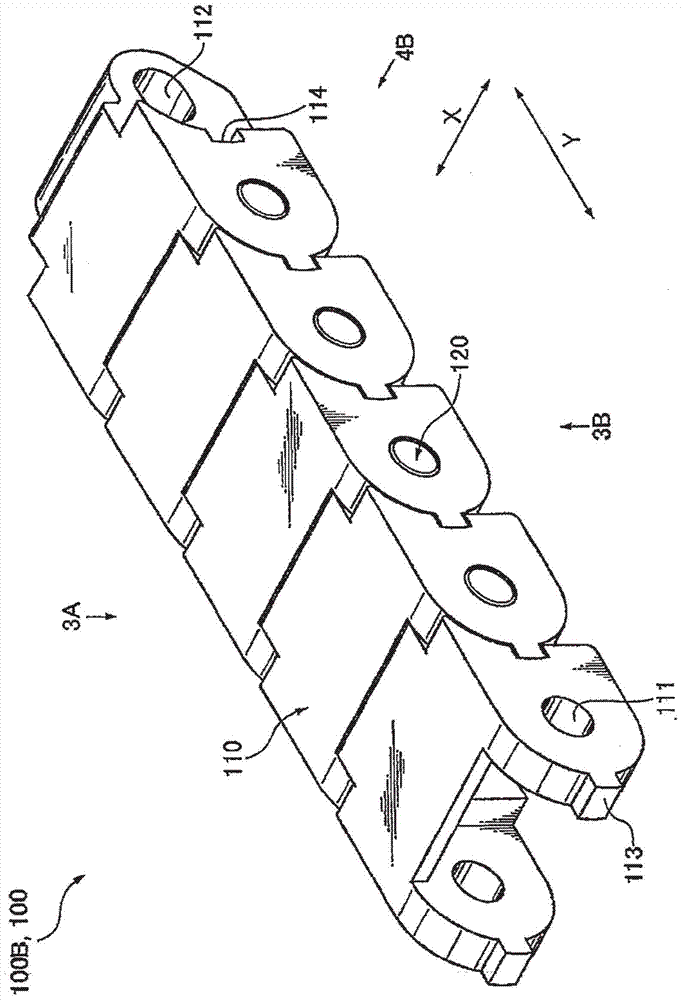

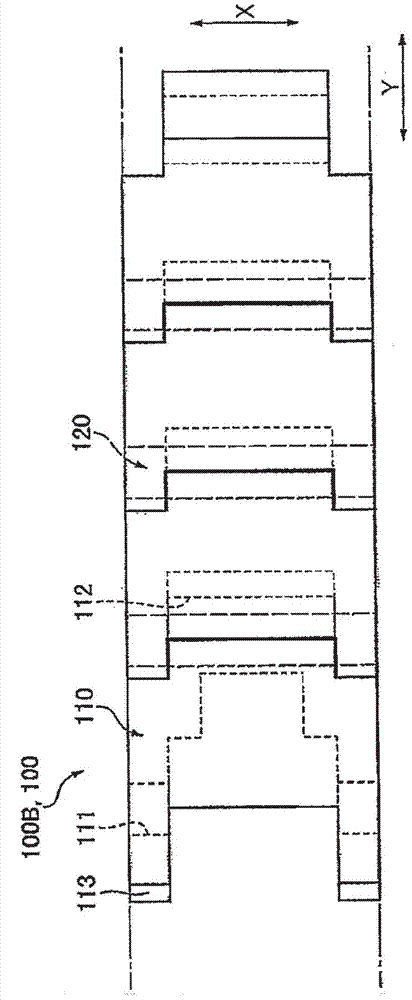

Silent chain

ActiveUS20120157252A1Low costReduce contact surface areaChain linksDriving chainsFriction lossSprocket

To provide a silent chain which makes it possible to further reduce friction loss during operation and to enhance operating efficiency, while also making it possible to reliably prevent assembly errors. A silent chain 1 in which a plurality of links 2 each having a pair of tooth parts 21 which mesh with sprockets and a pair of pin holes 20 are arranged in the lengthwise direction and thickness direction and are linked so as to be able to pivot about one another by linking pins 5 which are inserted into the pin holes 20, and sliding plates 3 are provided. The sliding plates 3 have a pair of pin holes 30 into which the linking pins 5 are inserted, and also have a back surface part 3a which has a greater back surface height h2 than the back surface height h1 of the links 2 and comes into contact with a tensioner arm or chain guide. The sliding plates 3 do not have tooth parts which mesh with the sprockets.

Owner:BORGWARNER INC

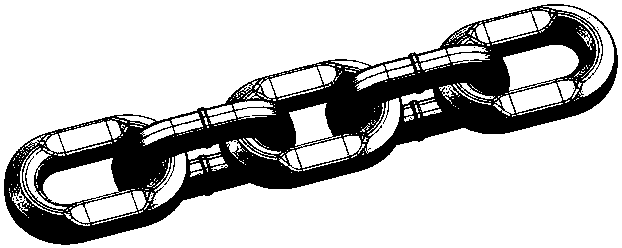

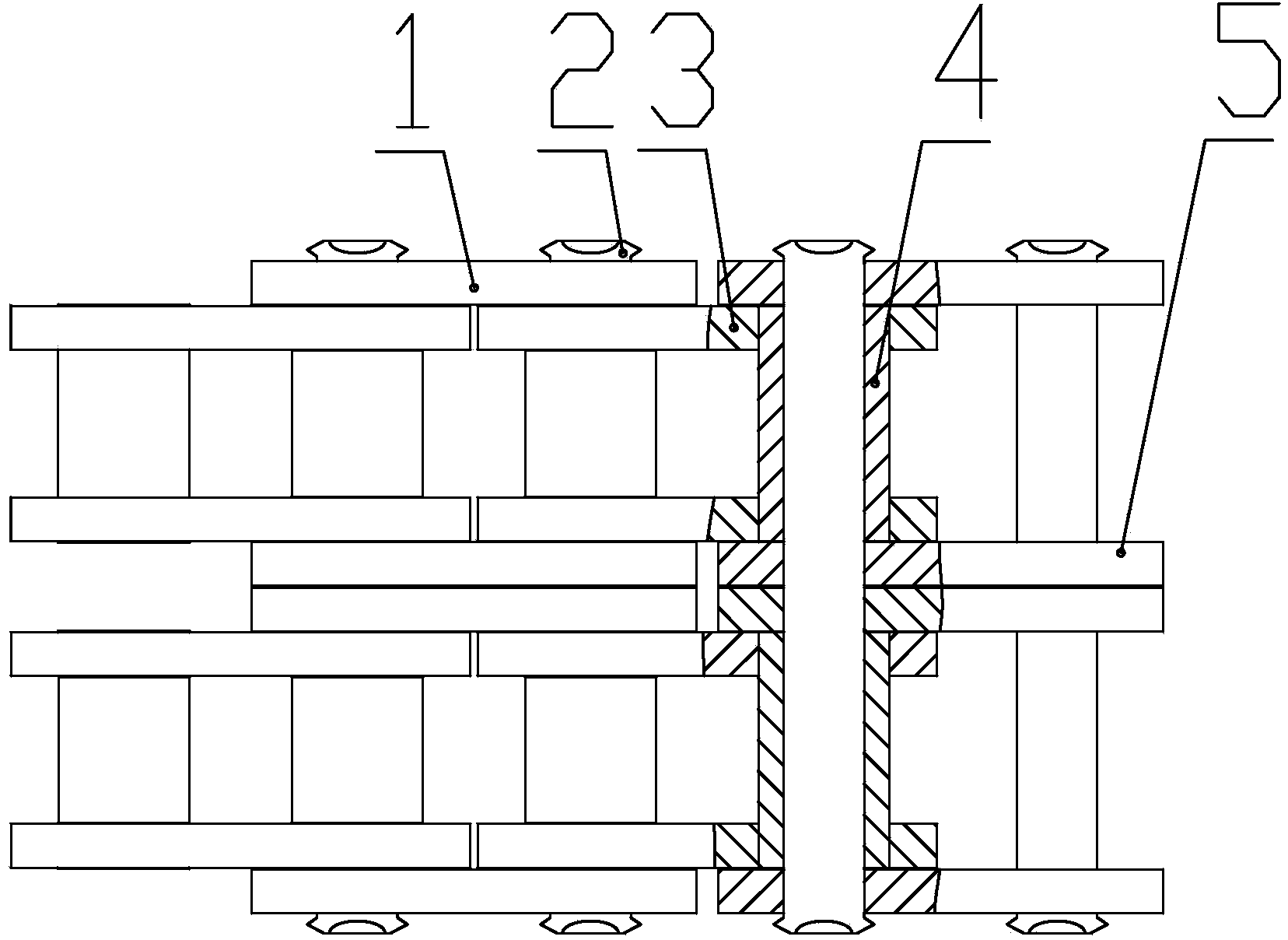

Chain applicable to low temperature environments and production method thereof

ActiveCN103899708ASimple structureImprove stressChain linksDriving chainsInterference fitEngineering

The invention discloses a chain applicable to low temperature environments and a production method thereof. The chain comprises outer link plates, pins, inner link plates, sleeves and middle ink plates, all made of alloy high-quality steel resistant to low temperature. One inner link joint is composed of two inner link plates and two sleeves by interference fitting; one outer pin plate is composed of two middle link plates and one pin by interference fitting. The chain is formed by serially linking the inner link joints and the outer pin plates and covering with end outer link plates and by sequential connecting. The inside of each sleeve is fully coated with low-temperature grease. Two ends of each pin penetrate the corresponding sleeves and the outer link plates and are fixedly locked with square rivets. The outer link plates, the inner link plates and the middle link plates are all in wide-waist structures. The surface of each pin is provided with a high-hardened layer. The chain according to the technical scheme has the advantages that strength of the chain is improved, service life of the chain is prolonged and the chain is well reliable.

Owner:HANGZHOU DONGHUA CHAIN GRP

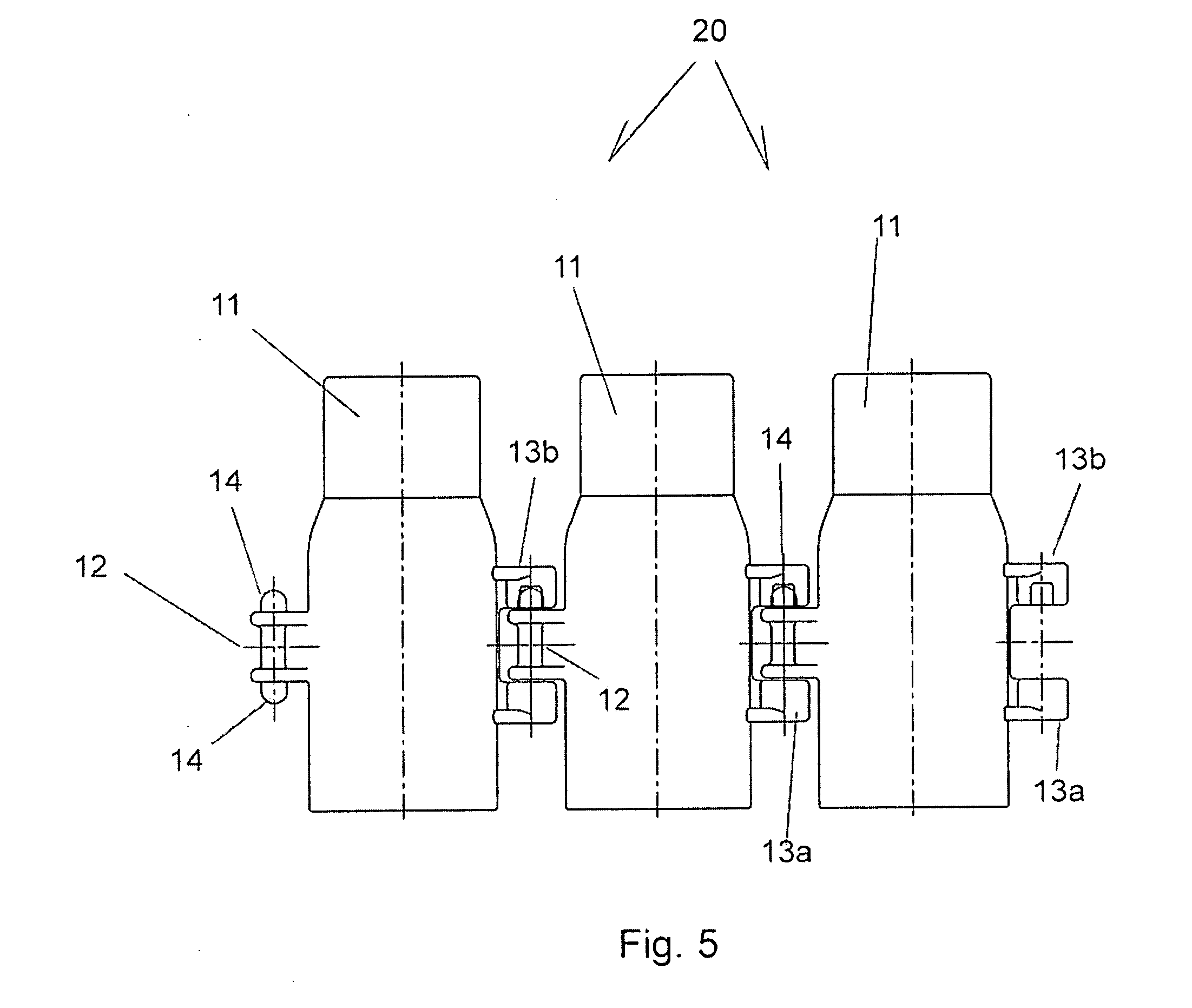

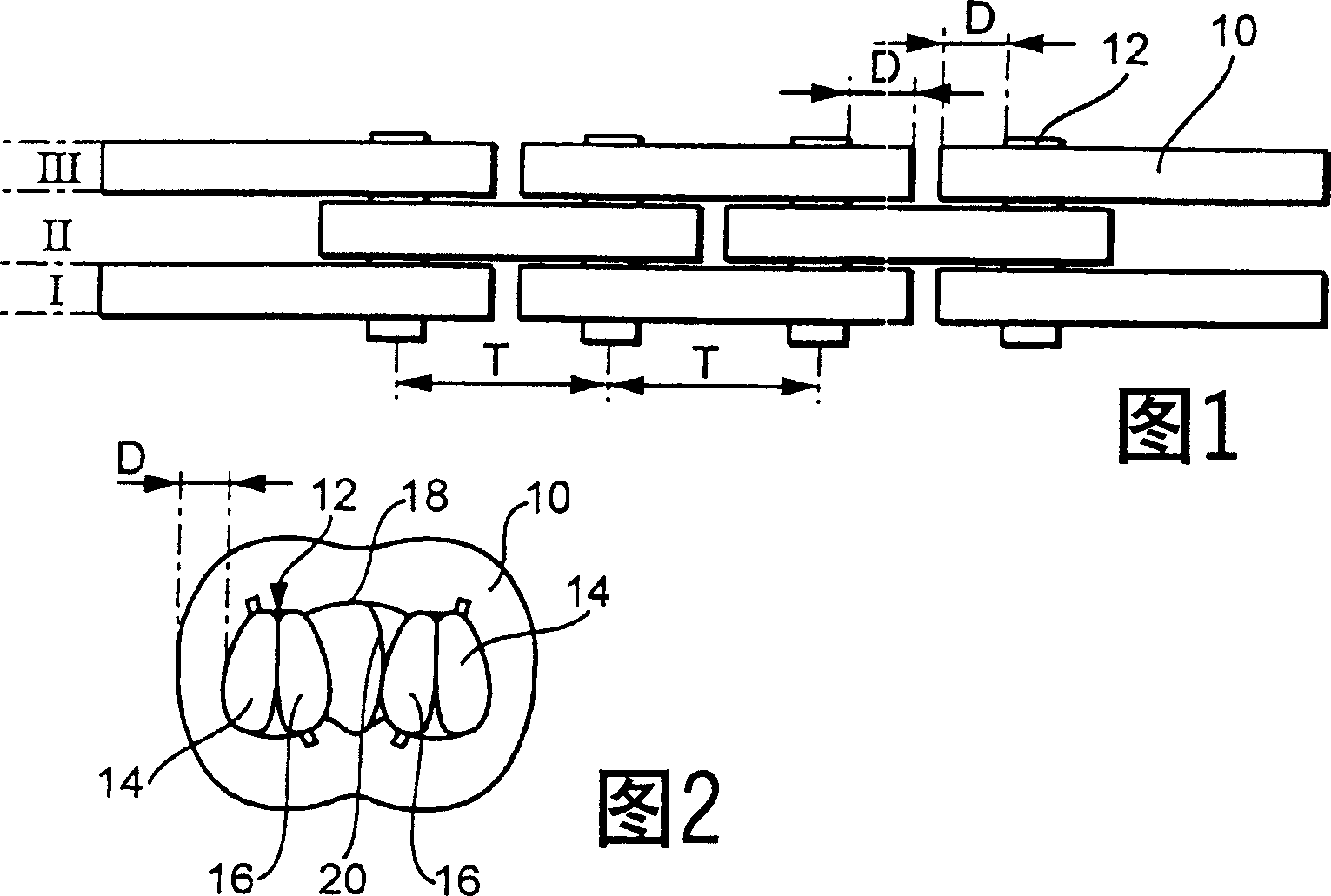

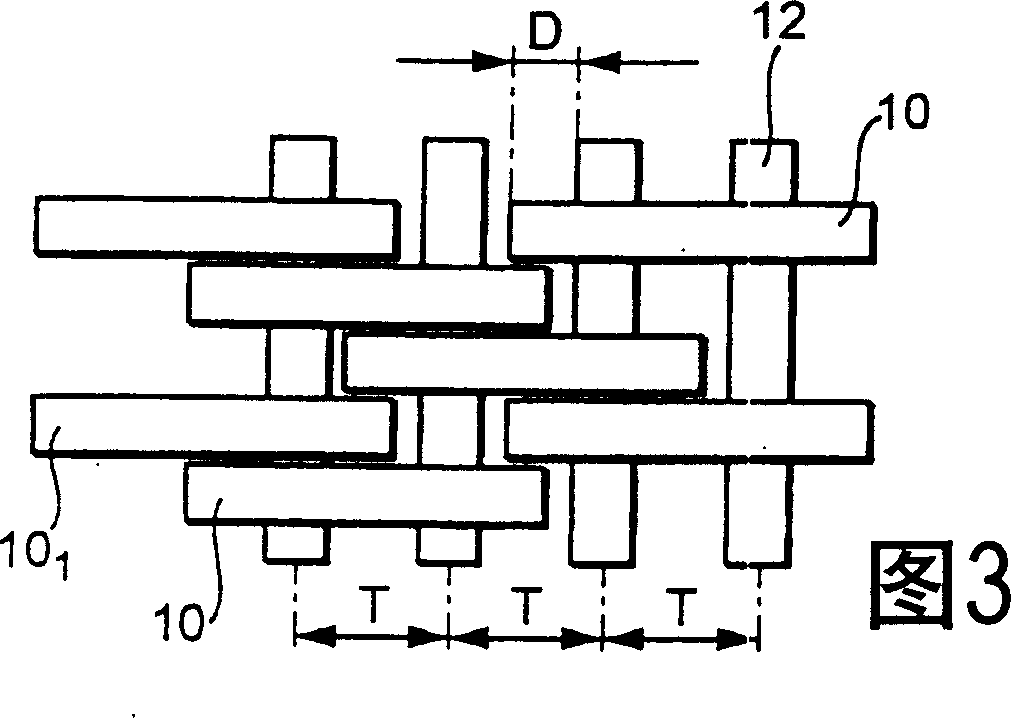

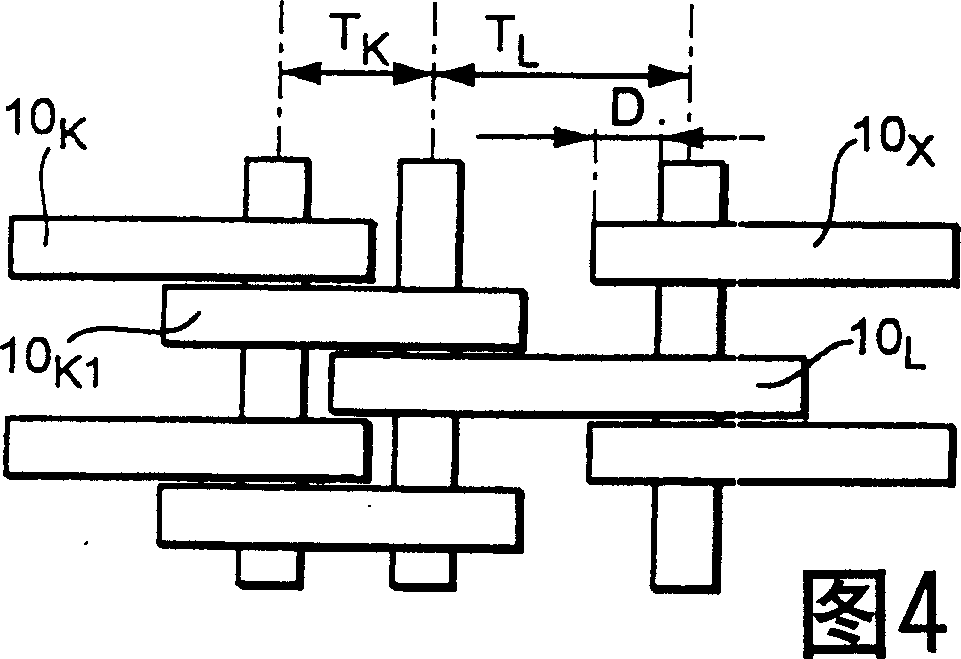

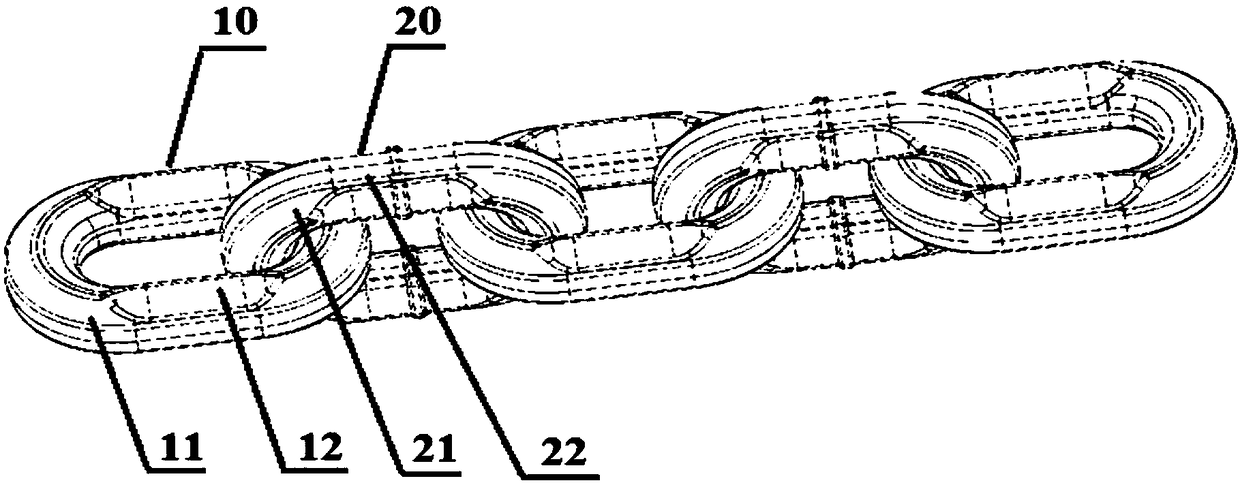

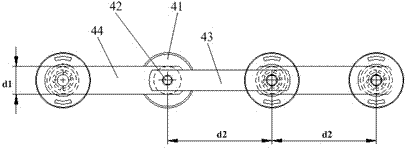

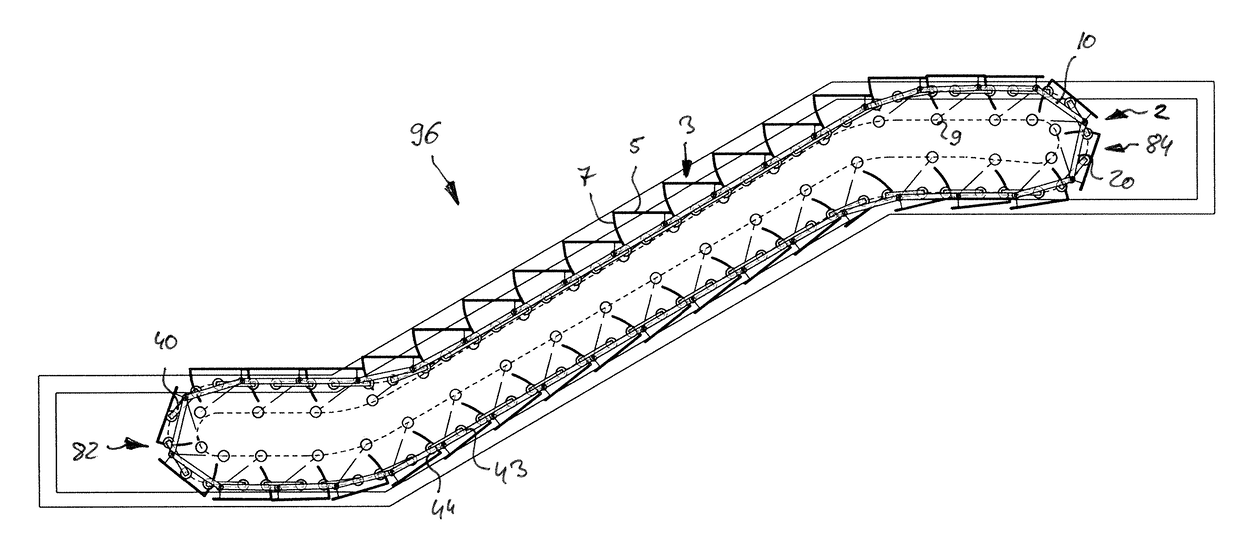

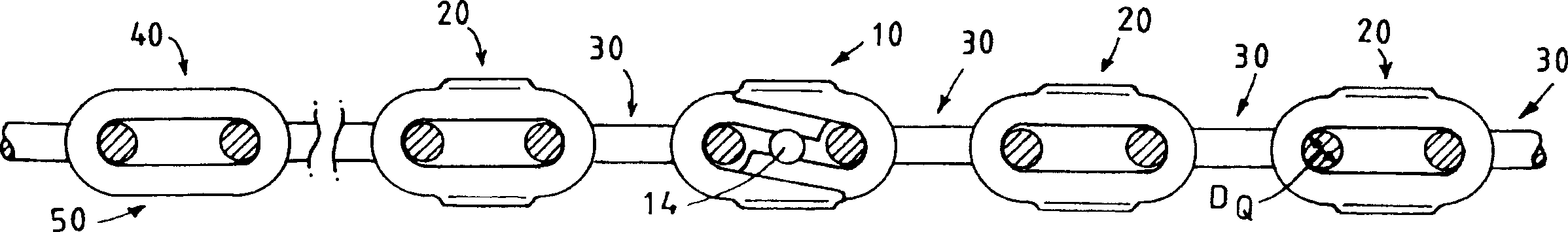

Drive chain and drive chain mechanism and conveyor comprising such a drive chain mechanism

InactiveUS20170275139A1Reduce loadReduce impactChain linksDriving chainsControl engineeringControl theory

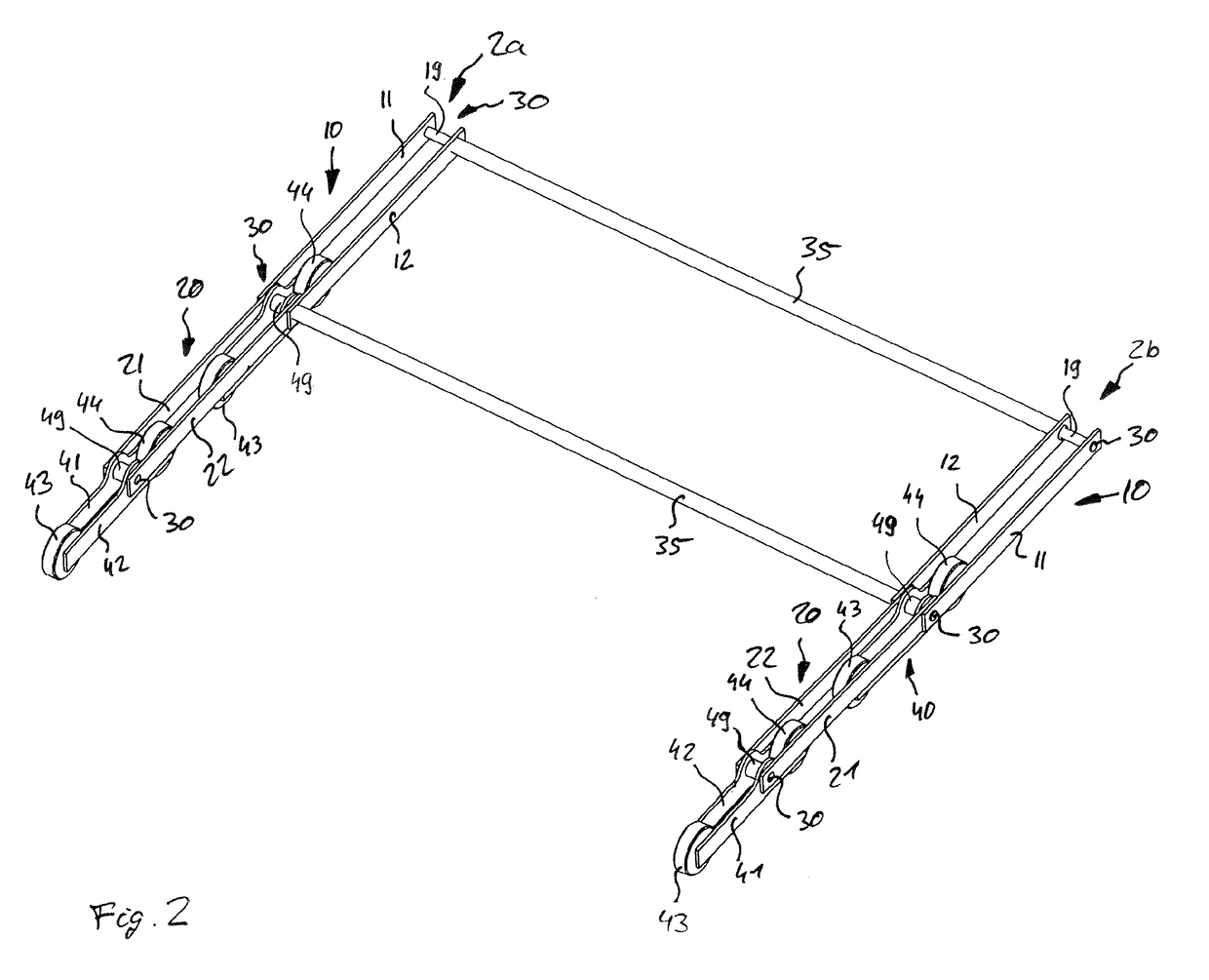

A drive chain (2a, 2b) for a chain drive comprises a plurality of chain links (10, 20) and joints (30) respectively connecting two of the chain links (10, 20) forming the drive chain (2a, 2b). The drive chain (2a, 2b) further comprises a plurality of carrier elements (40), each of said carrier elements (40) being linked to one of the chain links (10, 20) or joints (30) and supporting at least two support / engagement elements (43, 44), which are configured for supporting the drive chain (2a, 2b) and / or for engagement with an appropriate turnaround element (50; 90) for driving the drive chain (2a, 2b).

Owner:OTIS ELEVATOR CO

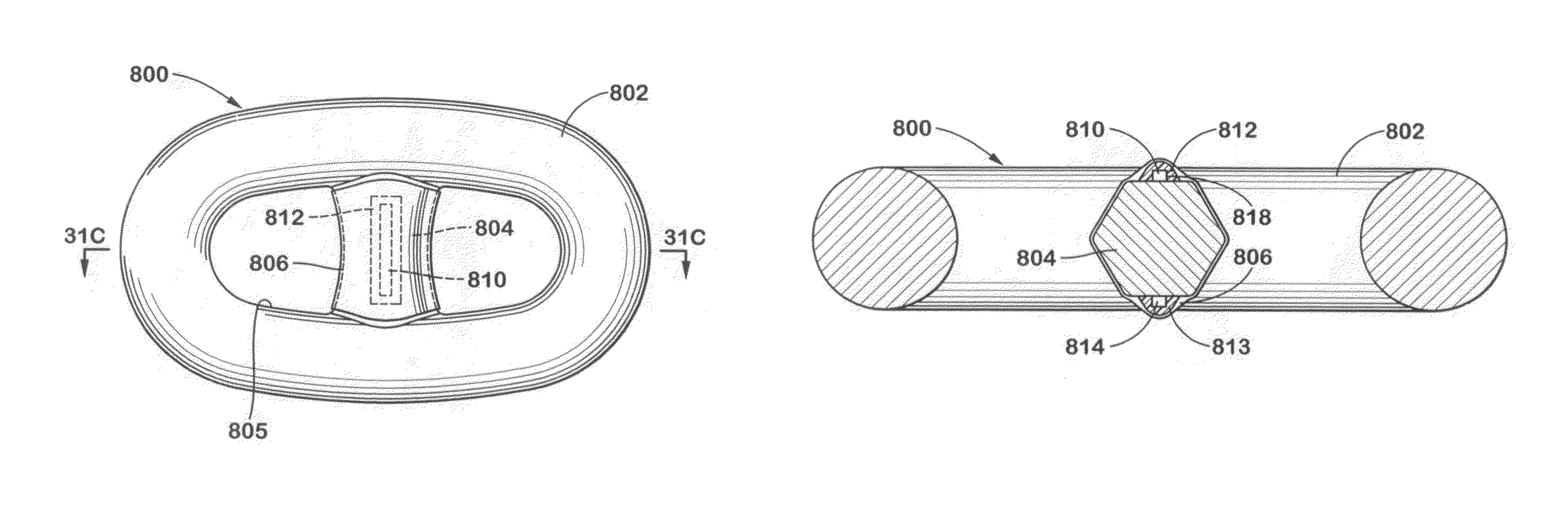

Two-way push-pull chain and reciprocating actuator

Owner:TSUBAKIMOTO CHAIN CO

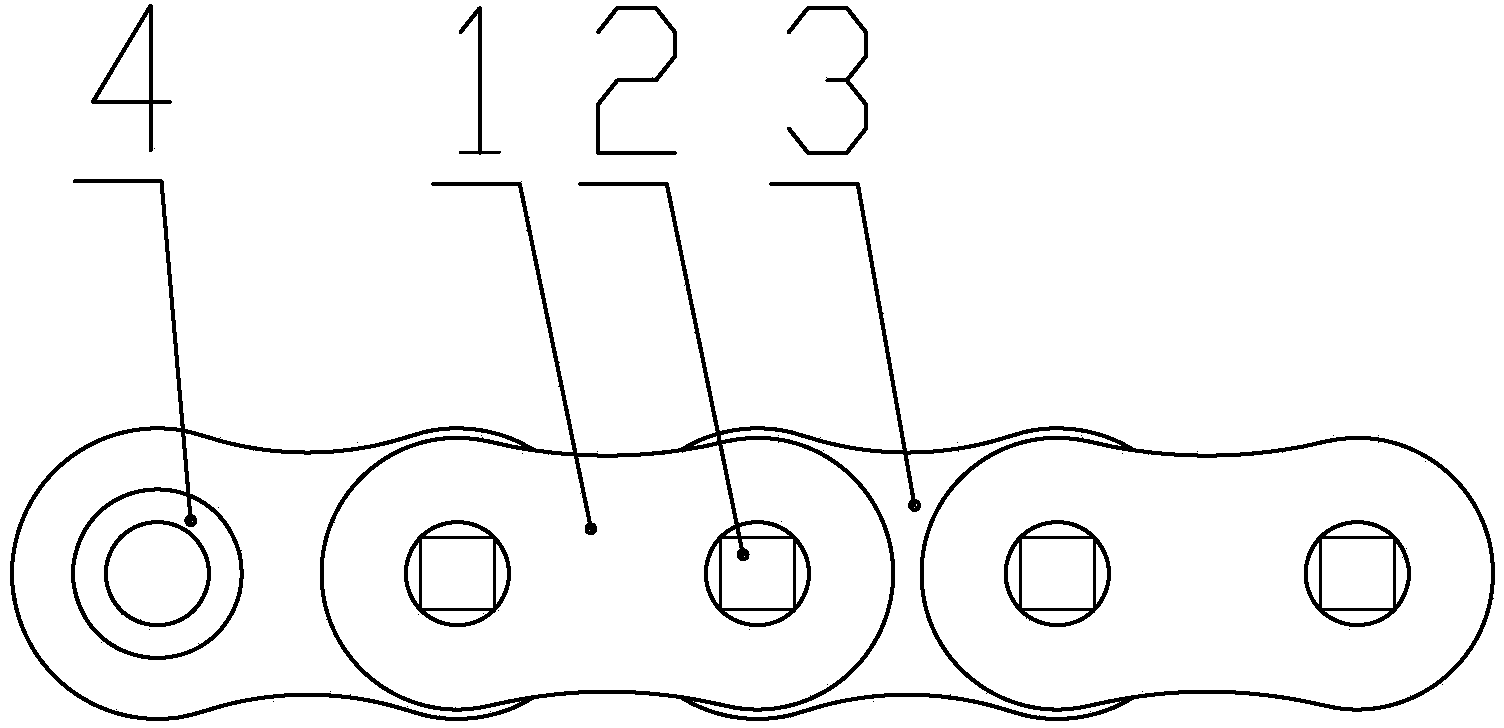

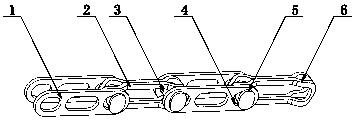

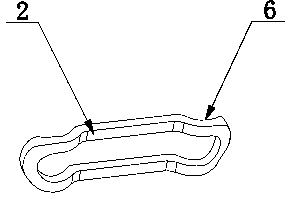

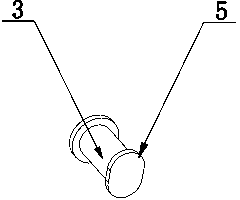

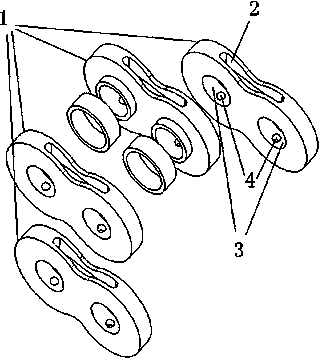

Easy-to-disassemble chain

InactiveCN105221664ASimple structureEasy to assemble and disassembleHauling chainsHoisting chainsEngineeringMechanical engineering

The invention relates to an easy-to-disassemble chain. The easy-to-disassemble chain comprises outer chain plates, inner chain plates and connection shafts, wherein each outer chain plate is a hollowed plate with three long circular through holes; the through holes on the two ends of each outer chain plate are connection holes used for inserting the corresponding connection shafts; each inner chain plate is an long circular ring body; two ends of each ring body are provided with arc-shaped curve parts bending to the same side; each connection shaft is a pin shaft which is provided with a round shaft cap and an long circular shaft cap on the two ends; the end, provided with the long circular shaft cap, of each connection shaft penetrates through the connection holes of the corresponding outer chain plates and the ring bodies of the corresponding inner chain plates, so that the outer chain plates and the inner chain plates are connected to form a chain body; and when the chain is stressed and stretched, the curve parts of every two corresponding inner plates are coincident, and the two corresponding outer chain plates are pressed outwards to cling to the shaft caps on the two ends of the corresponding connection shaft, so that the connection of the chain body is stable. The easy-to-disassemble chain is simple and reasonable in structure; the disassembly and assembly are convenient; and the assembled structure is stable.

Owner:TIANJIN QIANGLI CHAIN

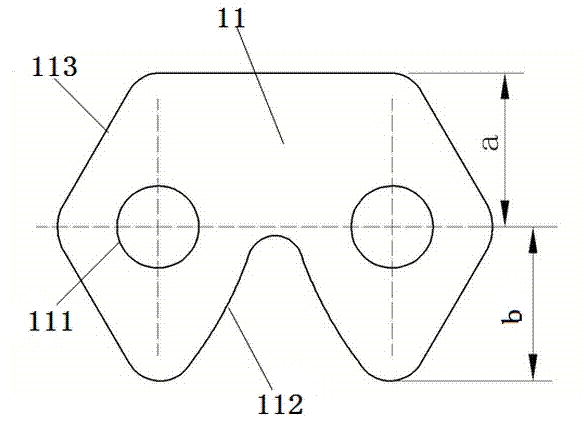

Chain piece capable of storing oil and chain

InactiveCN103758931AReduce lubrication frequencyReduce labor costsChain linksGearing detailsOil storage

The invention discloses a chain piece capable of storing oil. The chain piece comprises a chain piece body which is in a flat shape. The two sides of the chain piece body are respectively provided with an oil storage tank, and the two oil storage tanks are parallel to each other. The chain piece body is further provided with hinge pin holes, and the center symmetry axis of the hinge pin holes is perpendicular to the oil storage tanks. The chain piece body is further provided with oil discharging holes, the first end of each oil discharging hole is communicated with one end of the corresponding oil storage tank, and the second end of each oil discharging hole is communicated with one hinge pin hole. By the adoption of the mode, sponges in the oil storage tanks can store lubricating oil, the lubricating oil enters the hinge pin holes through the oil discharging holes, hence, lubricating frequency is lowered, and human cost is reduced.

Owner:TAICANG SIPUNING PRECISION MACHINERY

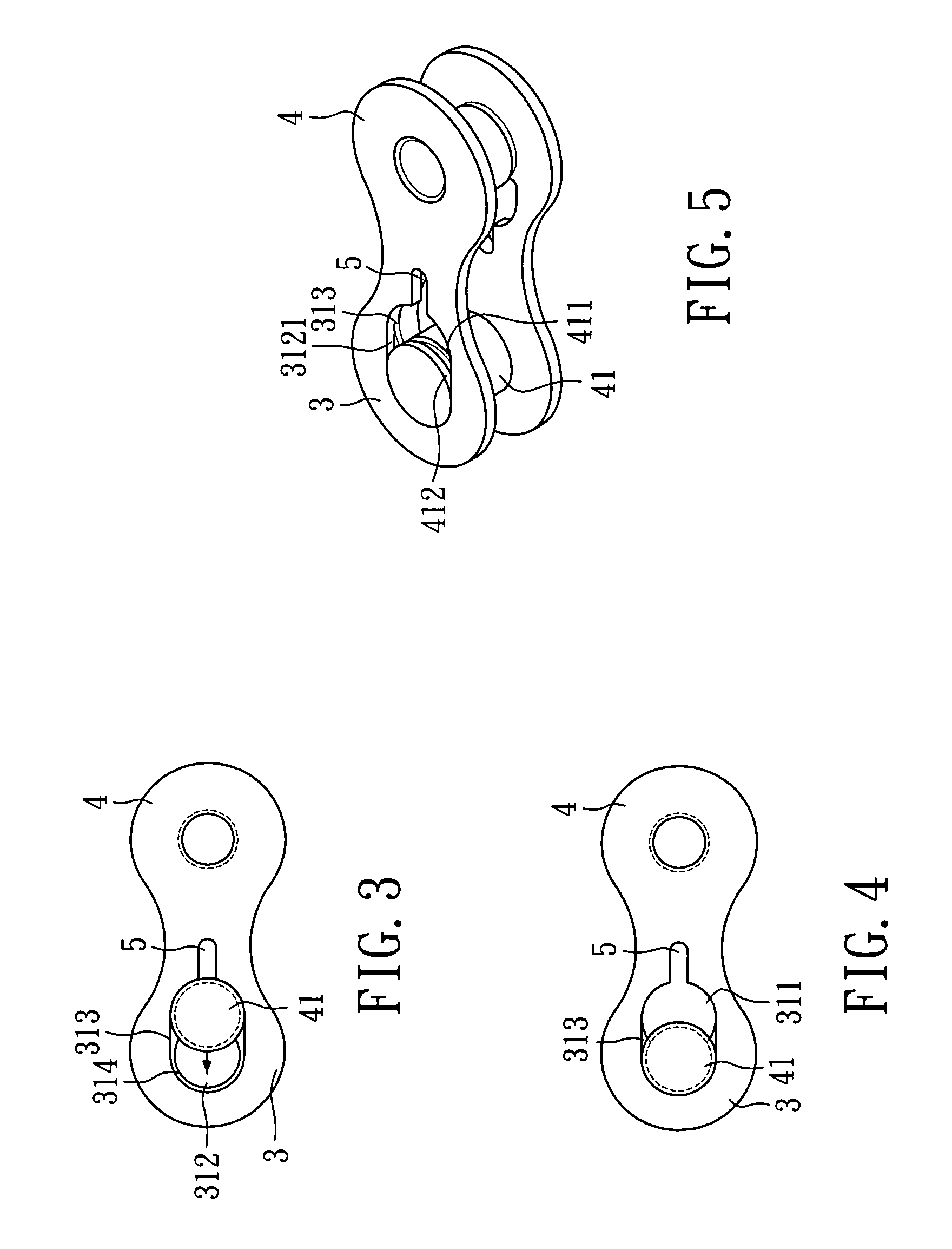

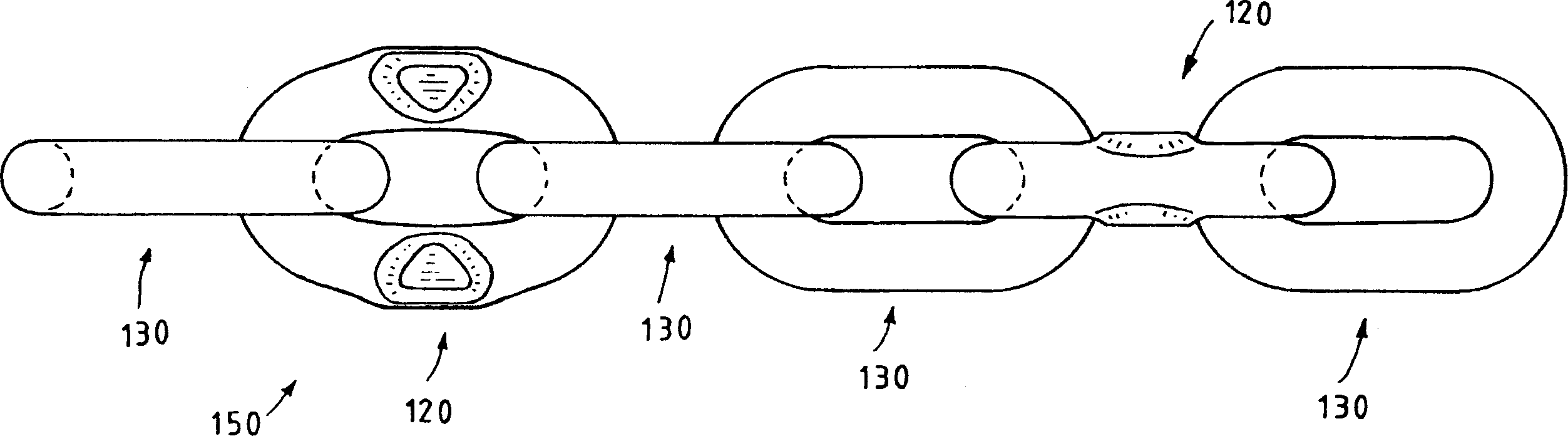

Plane chain strand comprising a chain lock link

The invention relates to a plane chain strand (50) provided with horizontal and vertical normal chain links (30, 40) which are mounted in an alternating manner and which engage into each other in a nondetachable manner with the limbs and arcs thereof. In the chain strand (50), directly in front and directly behind a chain lock link (10), at least one special chain link (20) is mounted in the same position as said chain locking link (10). The limbs of the lock links have the same outer contour, especially the same width and thickness, as the outer limbs of the two lock parts of the chain lock link (10). The wear and tear of the chain lock link (10) of said inventive plane chain strand (50) can be reduced or eliminated in comparison with conventional plane chains, by means of equal or slightly larger previous and subsequent special chain links (20).

Owner:CATERPILLER GLOBAL MINING EURO GMBH

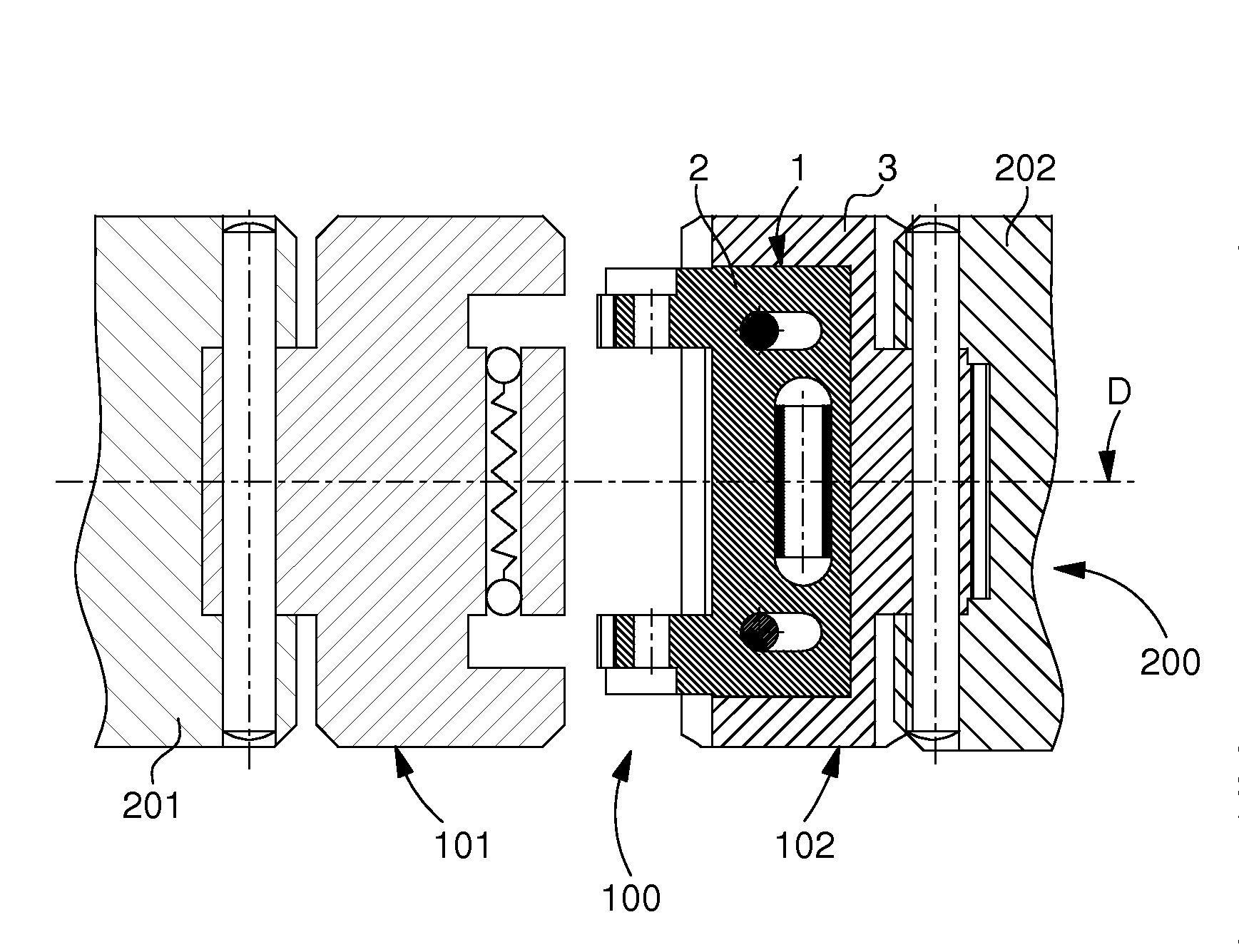

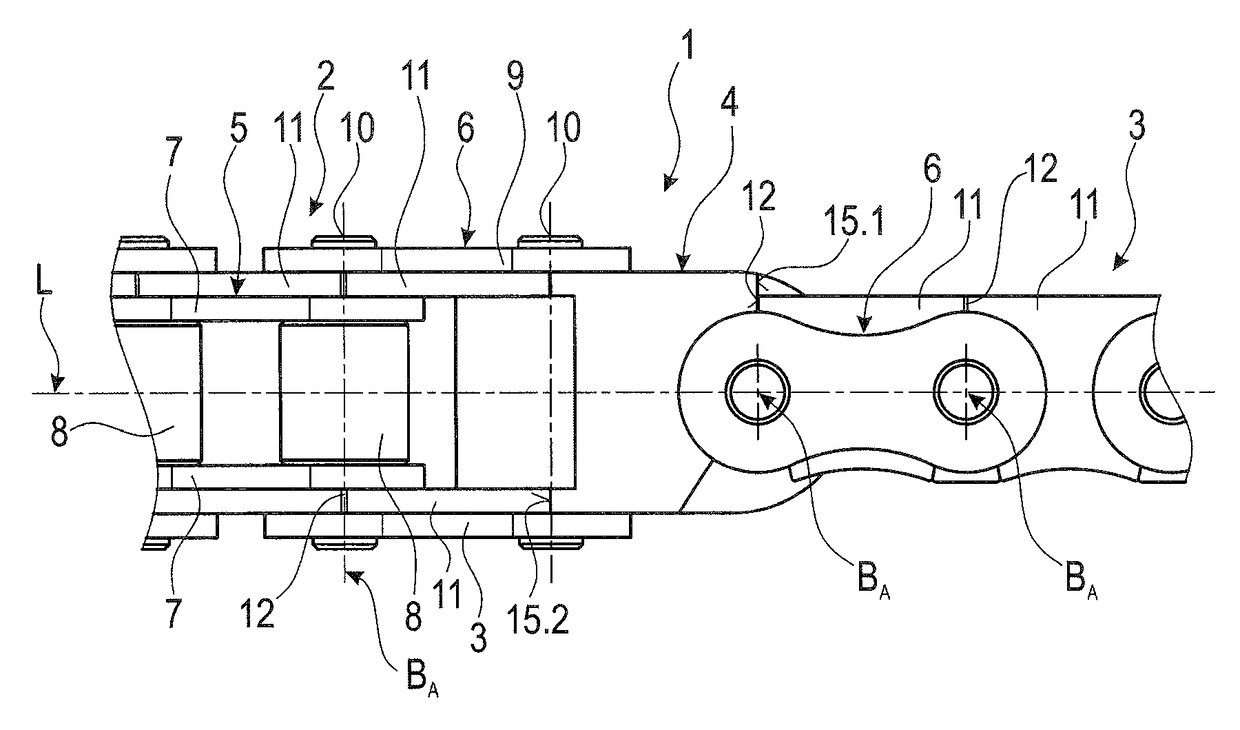

3D push pull chain

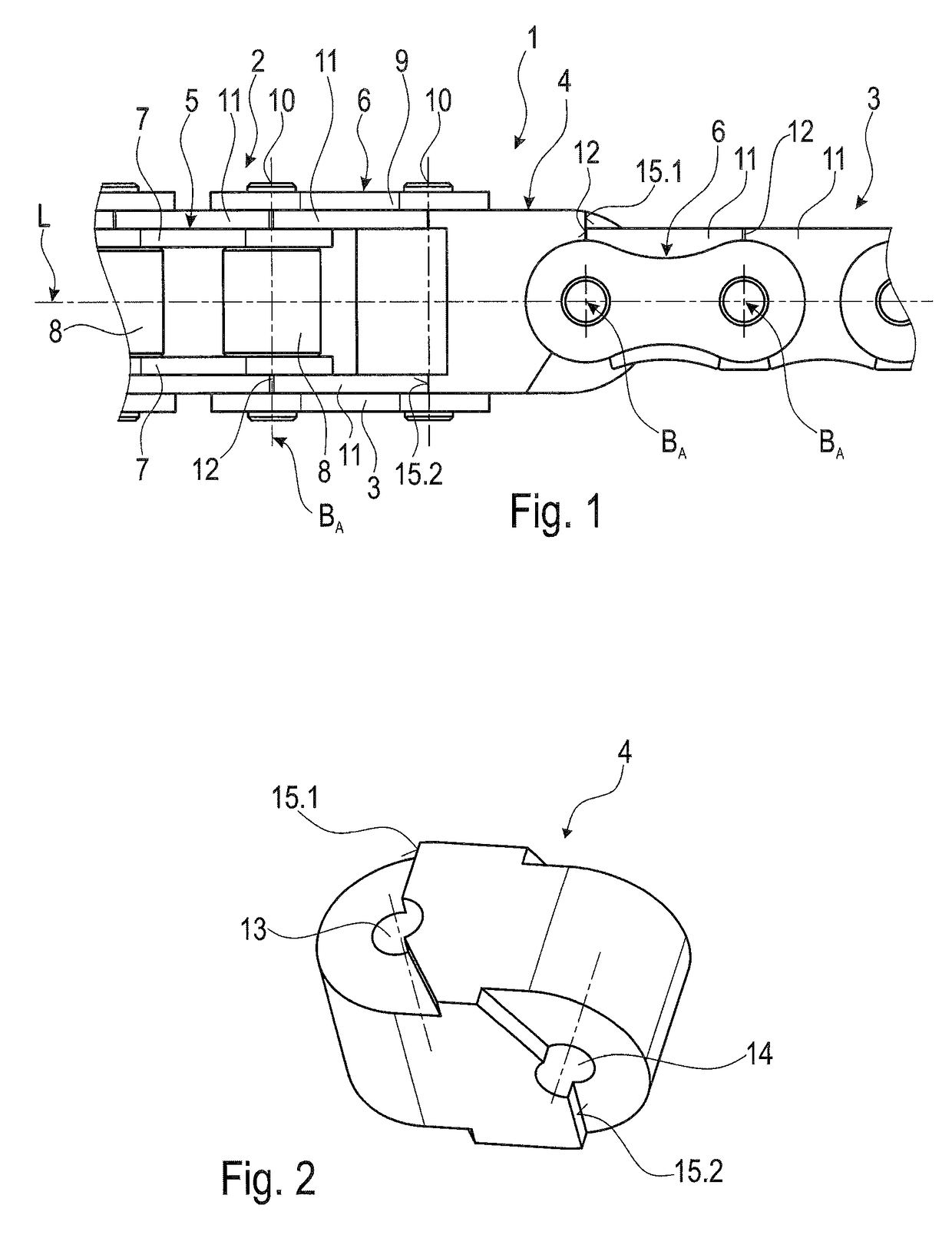

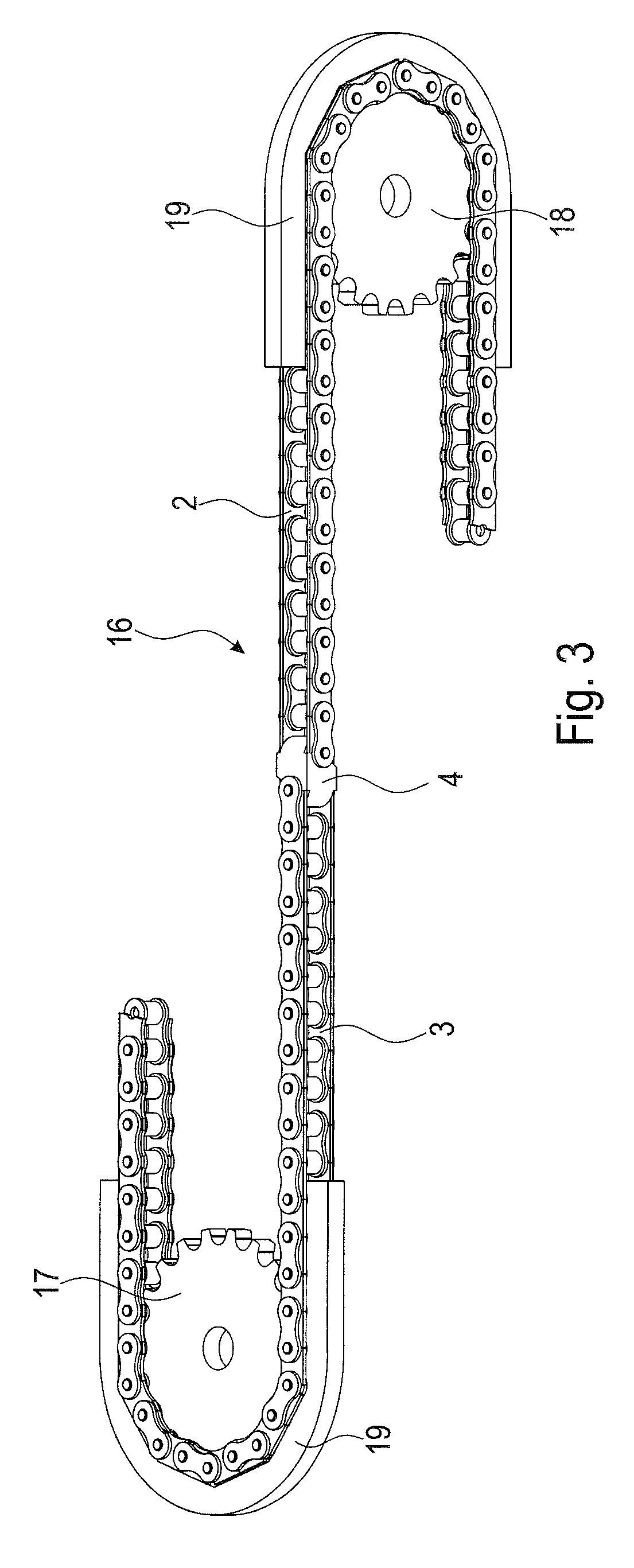

ActiveUS9897180B2Greater storage leewayLevel of flexibilityChain linksDriving chainsPush pullEngineering

A push pull chain is provided with chain links that are connected to each other by respectively one chain joint, designed in a space-efficient manner. The chain joints of a first chain section with their joint axes have a first orientation, whereby the joint axes of the chain joints of a second chain section are arranged in a second orientation that is twisted around the longitudinal axis of the push pull chain or whereby they can be set to this orientation. In addition, a pertaining chain drive is provided.

Owner:IWIS ANTRIEBSSYST

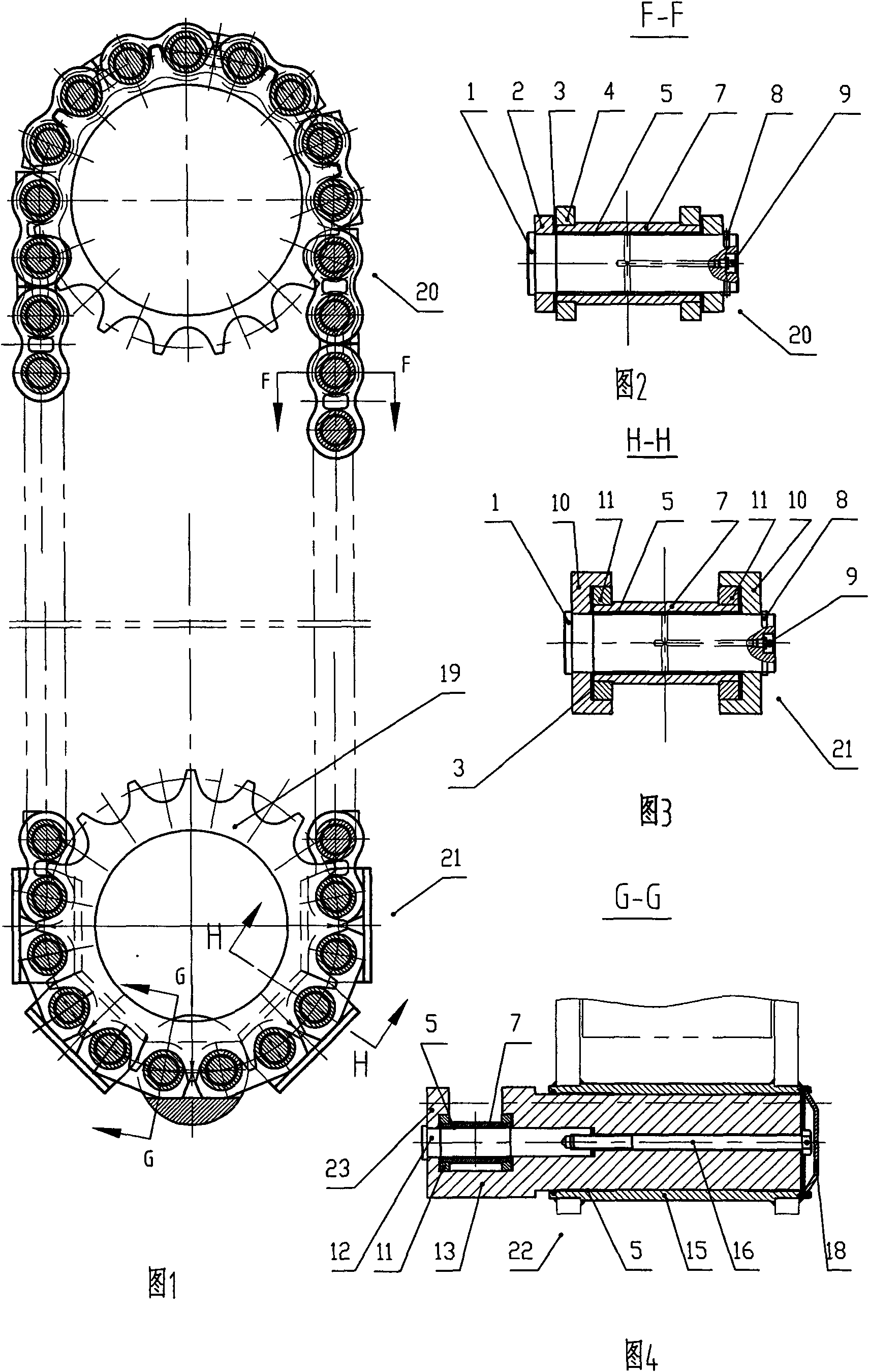

Chain and chain wheel

InactiveCN101614264AAvoid commutation shockSmooth transmissionPortable liftingChain linksCarrying capacityEngineering

The invention relates to a chain transmission mechanism, which is a chain and a chain wheel. The chain comprises a plurality of chain links and is characterized in that the chain also comprises a plurality of specific chain links, a plurality of chain links and a plurality of specific chain links are articulated in series, the structure of the specific chain links comprises a roller, both ends of the roller are sleeved with specific inner chain boards, the specific inner chain boards are positioned in the grooves of specific outer chain boards and are articulated by pin rolls, the outer end face of each specific inner chain board is provided with symmetrical inclined surfaces, the specific outer chain boards are provided with grooves, the two end surfaces of the specific outer chain boards are provided with symmetrical inclined surfaces, the chain has strong carrying capacity and smooth transmission, thus the impact of reversion of chain links suspension loads can be prevented, and the service life is long. The chain wheel is characterized in that the chain wheel comprises a wheel disc, wear layers are attached on the surfaces of a plurality of chain teeth which are fixed on the wheel disc by a position pin and a fixed bolt, the tooth surface strength of the chain wheel is high, the wear resistance is good, the chain tooth can be replaced easily, and the service life is long, therefore the chain wheel is particularly applicable to the utilization in the transmission of chain suspension loads.

Owner:JILIN JIRUI GASOLINEEUM MACHINERY

Adjustable link

Owner:OMEGA SA

Long ring plastic chain

The invention discloses a long ring plastic chain which comprises a plurality of annular chain sections connected in series. The annular chain sections are oval chain sections which can be opened. The long axis of each annular chain section ranges from 5 cm to 7 cm, and the short axis of each annular chain section ranges from 2 cm to 3 cm. When each annular chain section is opened, the opened annular chain section is provided with two ends, the section of one end is inwards concaved to form a concave hole, and the other end protrudes out to form a protruding shaft. The annular chain sections are matched through the cooperation of the concave holes and the protruding shafts to form a closed ring. In addition, the length of the protruding shafts is 2 cm. The long ring plastic chain can be conveniently lengthened or shortened; furthermore, the service life can be prolonged, and materials can be saved.

Owner:WUXI HUIYUAN MECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com