Silent chain complex phase multi-axis transmission mechanism

A multi-axis transmission, toothed chain technology, applied in the direction of transmission chain, transmission device, chain ring, etc., can solve the problems of chain transmission application field limitation, chain transmission system wear, large power and torque, etc., to reduce polygonal effect, ensuring smoothness, reducing the effect of vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

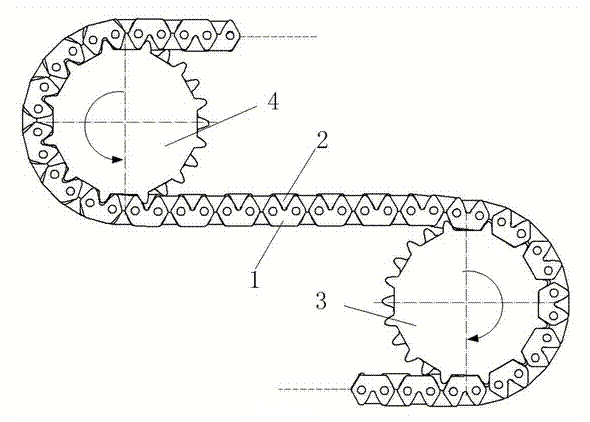

[0020] see Figure 1 to Figure 7 Shown, the present invention is made up of the first chain 1, the second chain 2, the first driving sprocket 3, the second driving sprocket 5, the first driven sprocket 4 and the second driven sprocket 6, the first The hanging chain 1 is meshed and arranged on the first driving sprocket 3 and the first driven sprocket 4, and the second hanging chain 2 is meshed and arranged on the second driving sprocket 5 and the second driven sprocket 6;

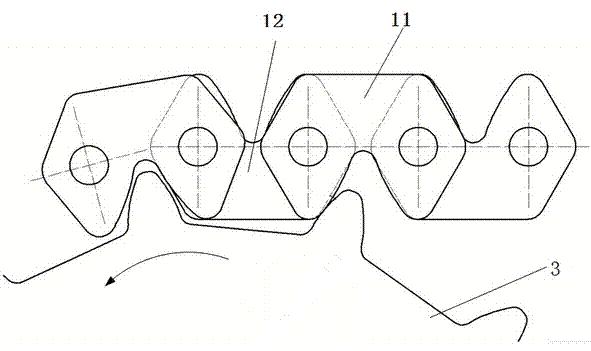

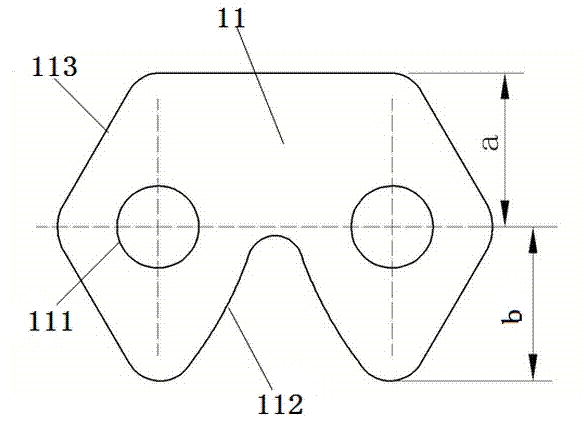

[0021] The first chain 1 has the same structure as the second chain 2, and is composed of several chain plates 11 connected in series in positive and negative directions through pin shafts 12. The chain plate 11 is a wide-waist round pin toothed chain, and the inner diameter of the chain plate hole 111 is slightly larger than The diameter of the pin shaft 12, the inner tooth profile 112 of the chain plate is arc-shaped, and the outer tooth profile 113 is linear, the distance a from the center of the chain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com