Patents

Literature

3391 results about "Chain drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

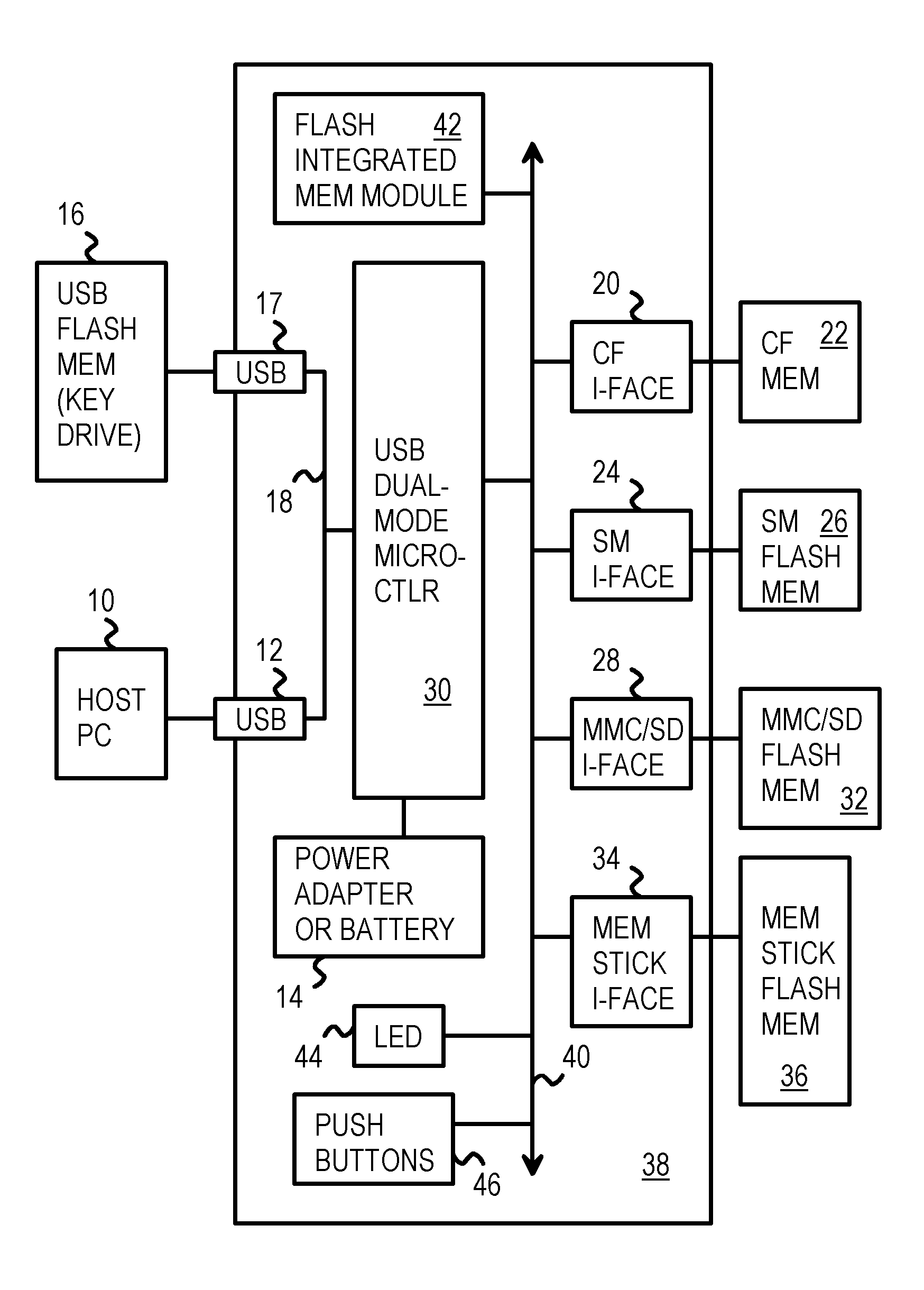

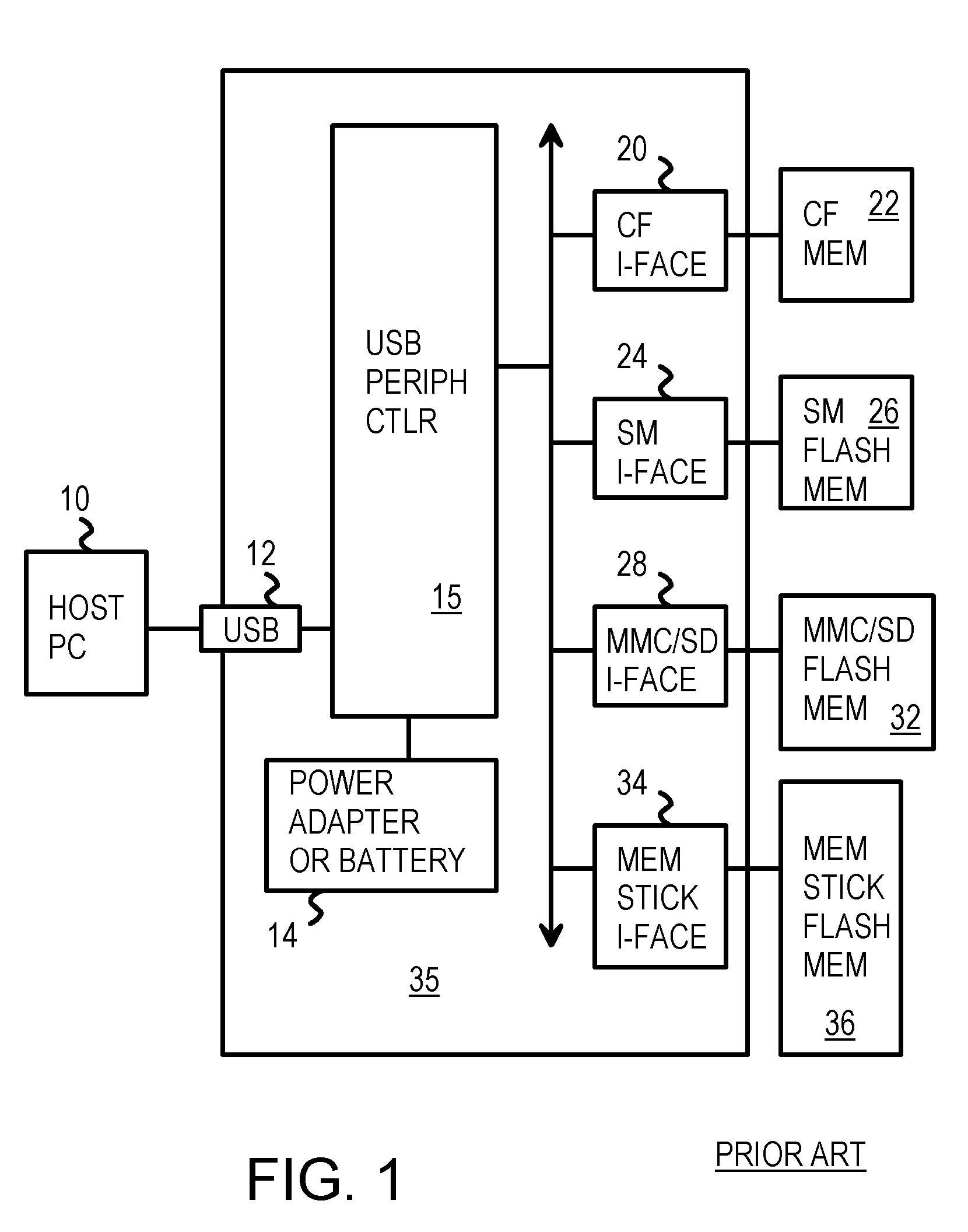

Dual-Mode Flash Storage Exchanger that Transfers Flash-Card Data to a Removable USB Flash Key-Drive With or Without a PC Host

InactiveUS20050160223A1Input/output to record carriersComponent plug-in assemblagesMicrocontrollerOperation mode

A flash-card exchanger has two modes of operation. When a host personal computer (PC) is connected to a Universal-Serial-Bus (USB) connector, the flash-card exchanger operates in a card reader mode, allowing the host to read data from removable flash-memory cards inserted into connector slots of the flash-card exchanger. When the host PC is not connected, a USB flash-memory thumb or key-chain drive can be inserted into a second USB connector. A USB dual-mode microcontroller acts as a USB host, reading data from the removable flash-memory card and writing the data to the USB-memory key drive using USB packets. Since the USB-memory key drive is small and removable, the user can upgrade to larger storage capacities by plugging in a larger-capacity USB-memory key drive. A flash-exchanger program executing on the USB dual-mode microcontroller copies data from an input-output bus and generates USB packets to the USB-memory key drive.

Owner:SUPER TALENT ELECTRONICS

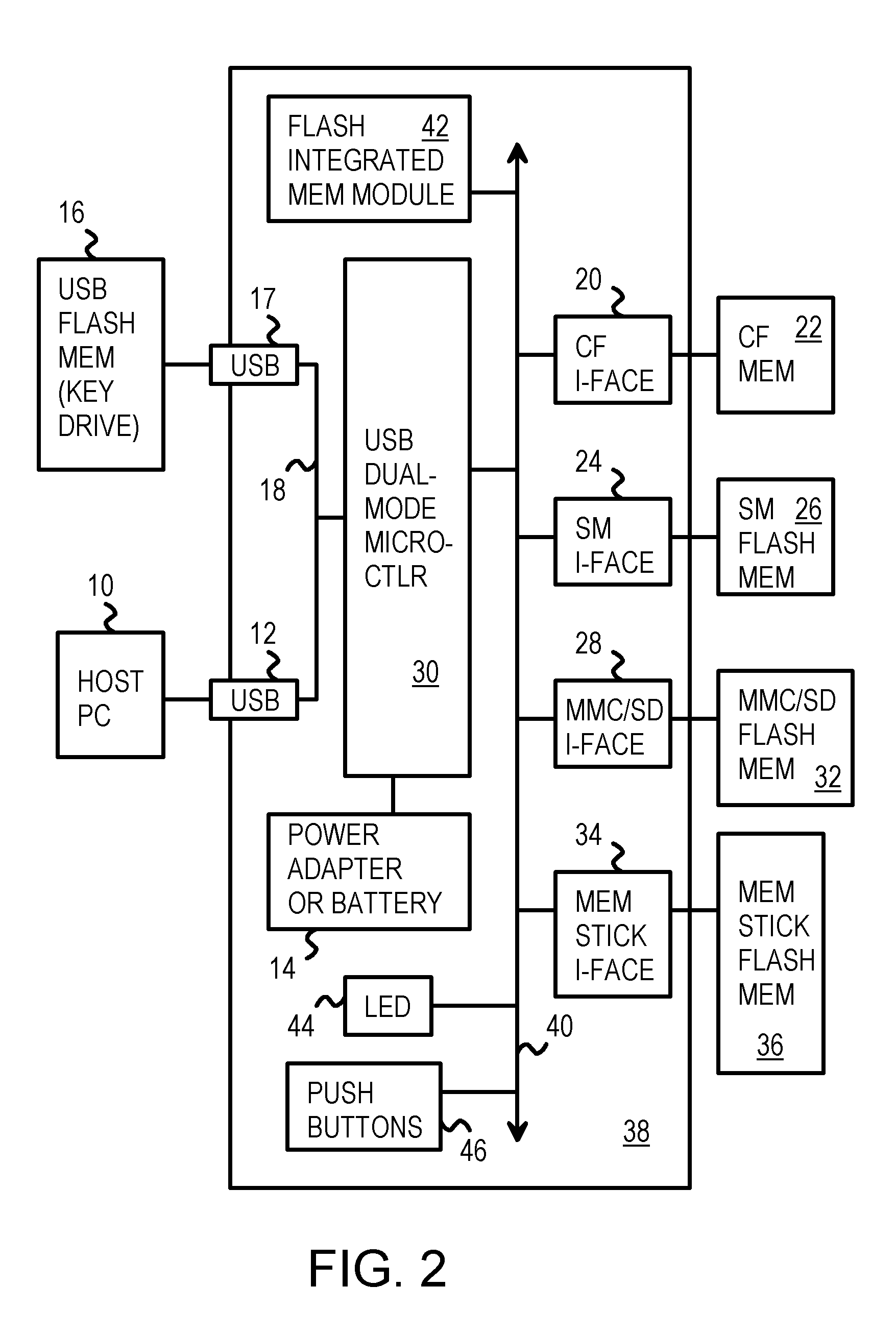

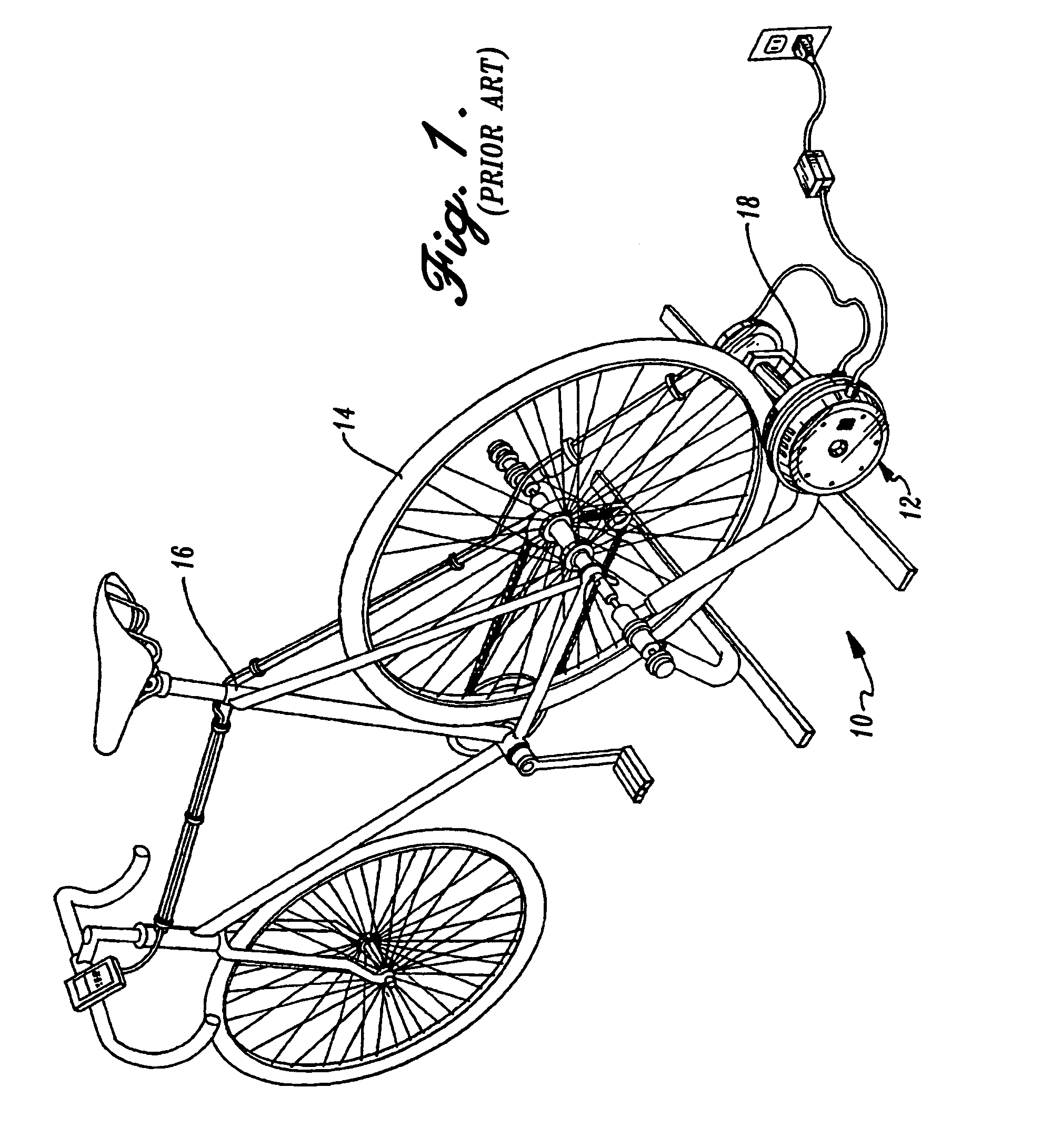

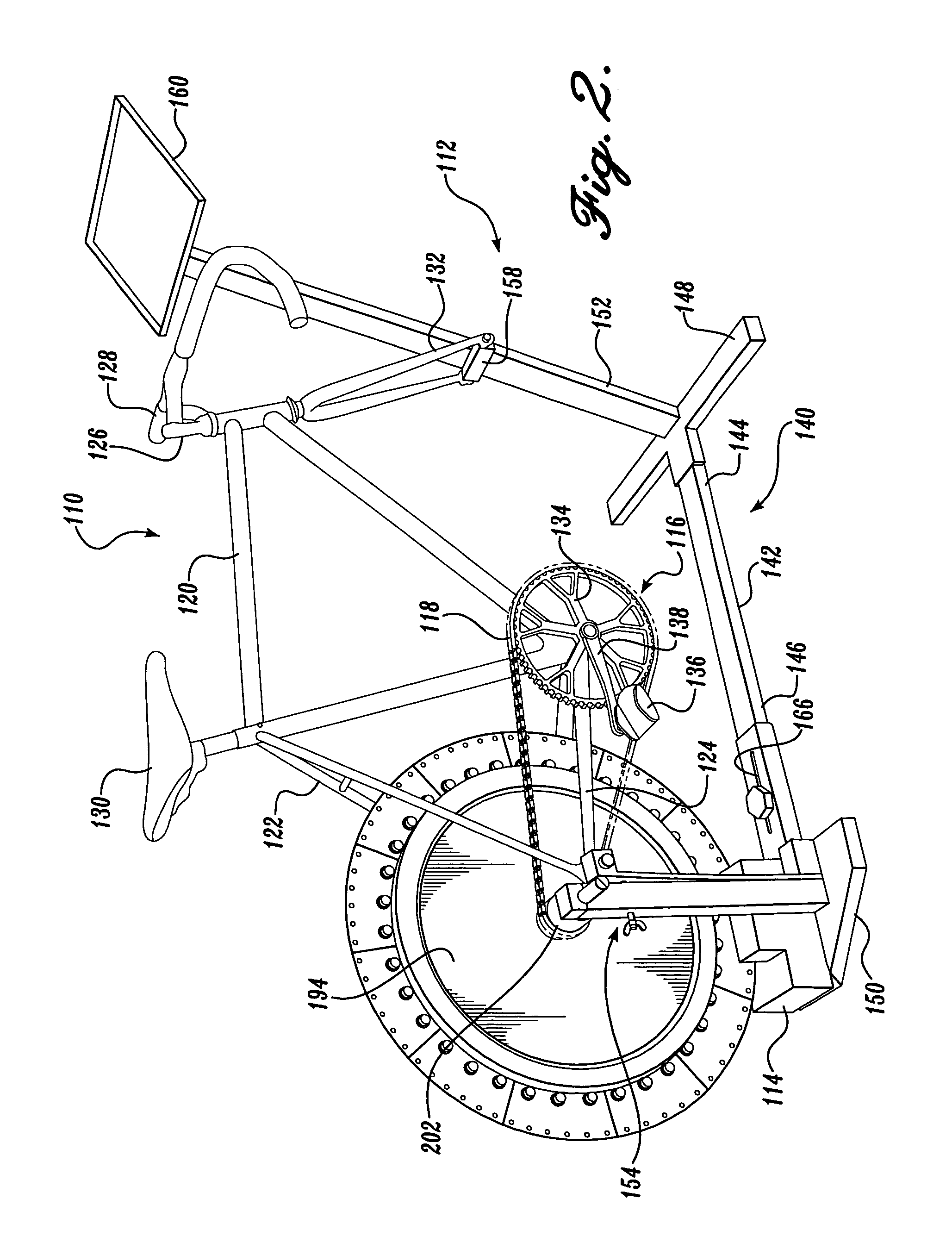

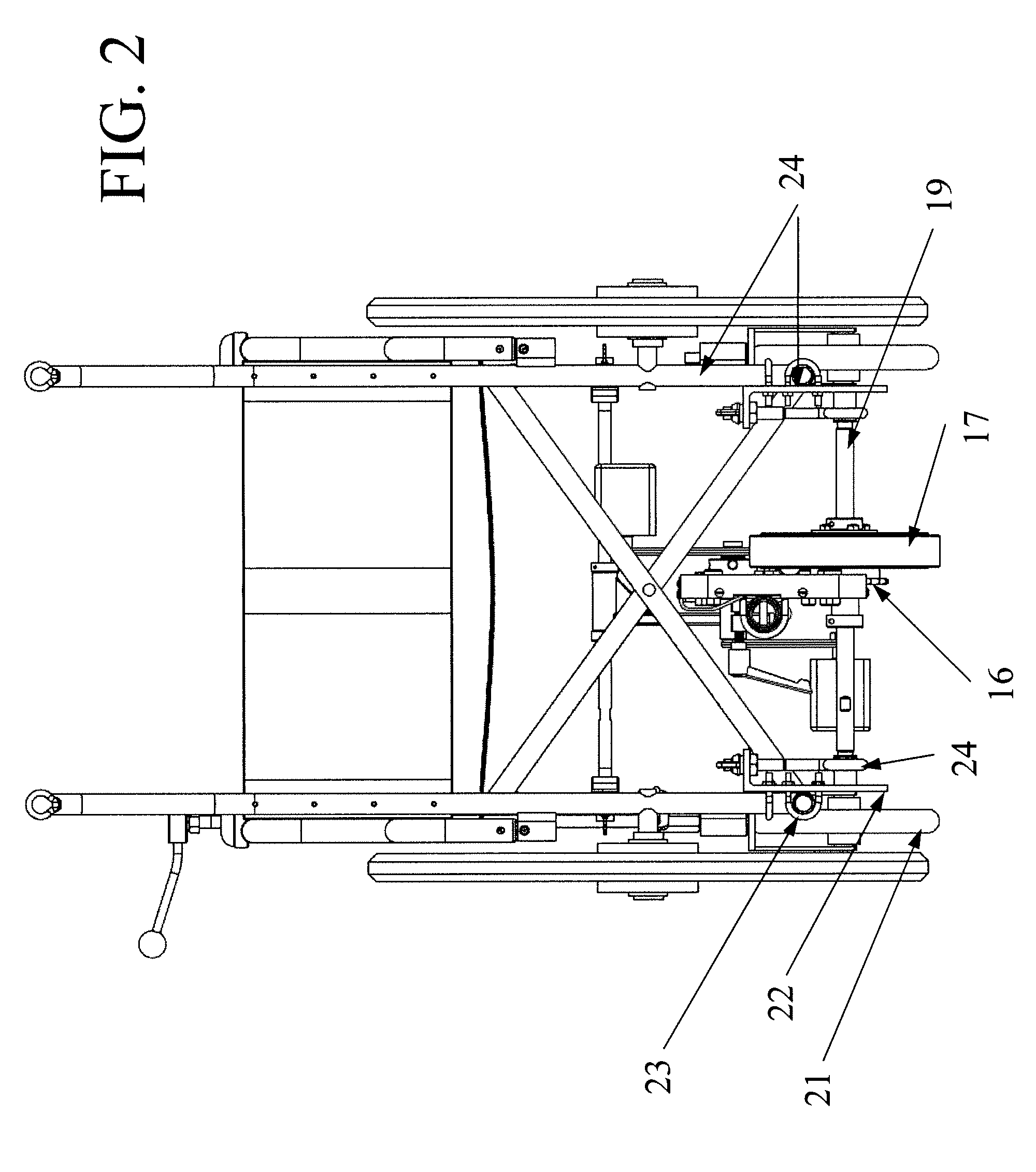

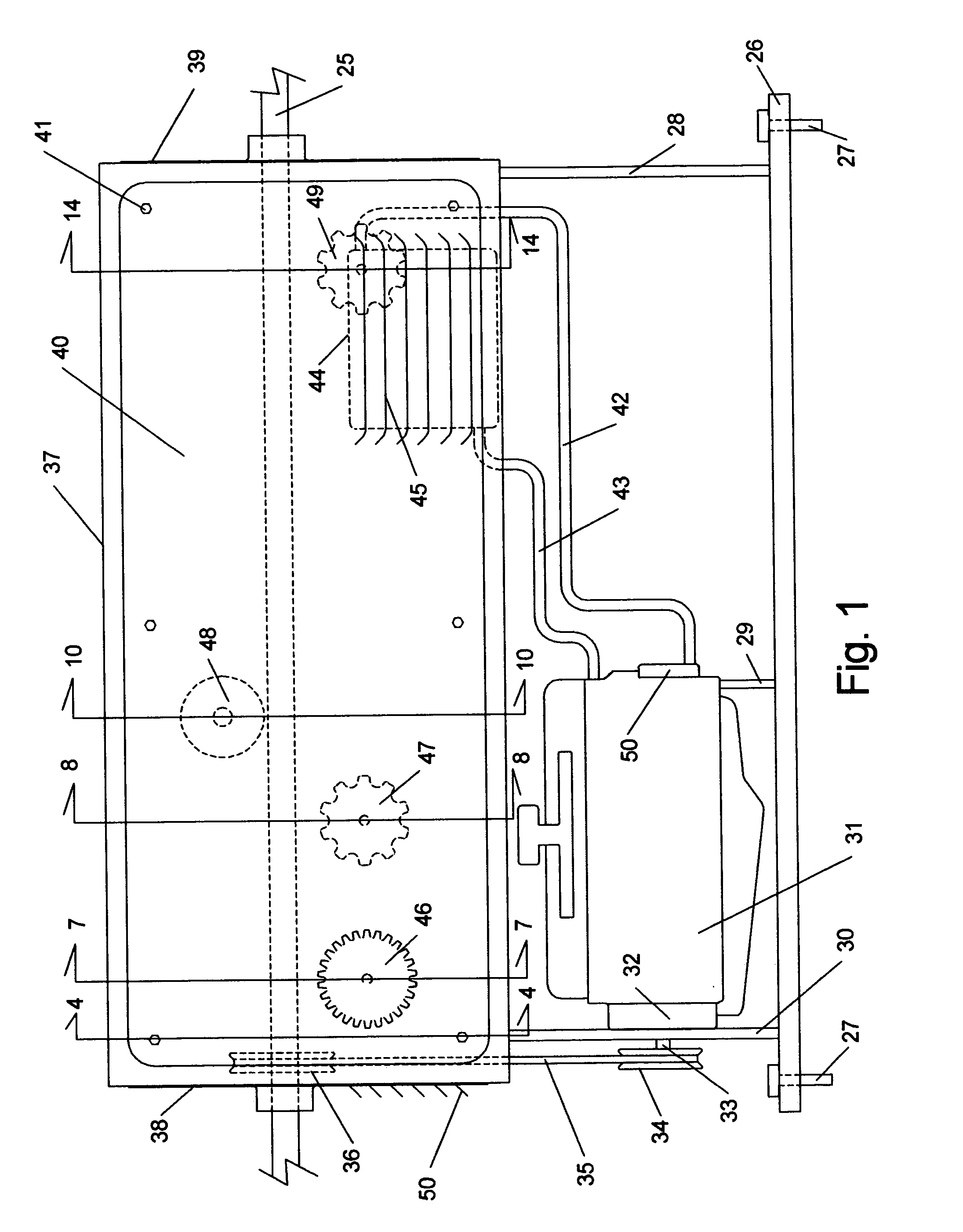

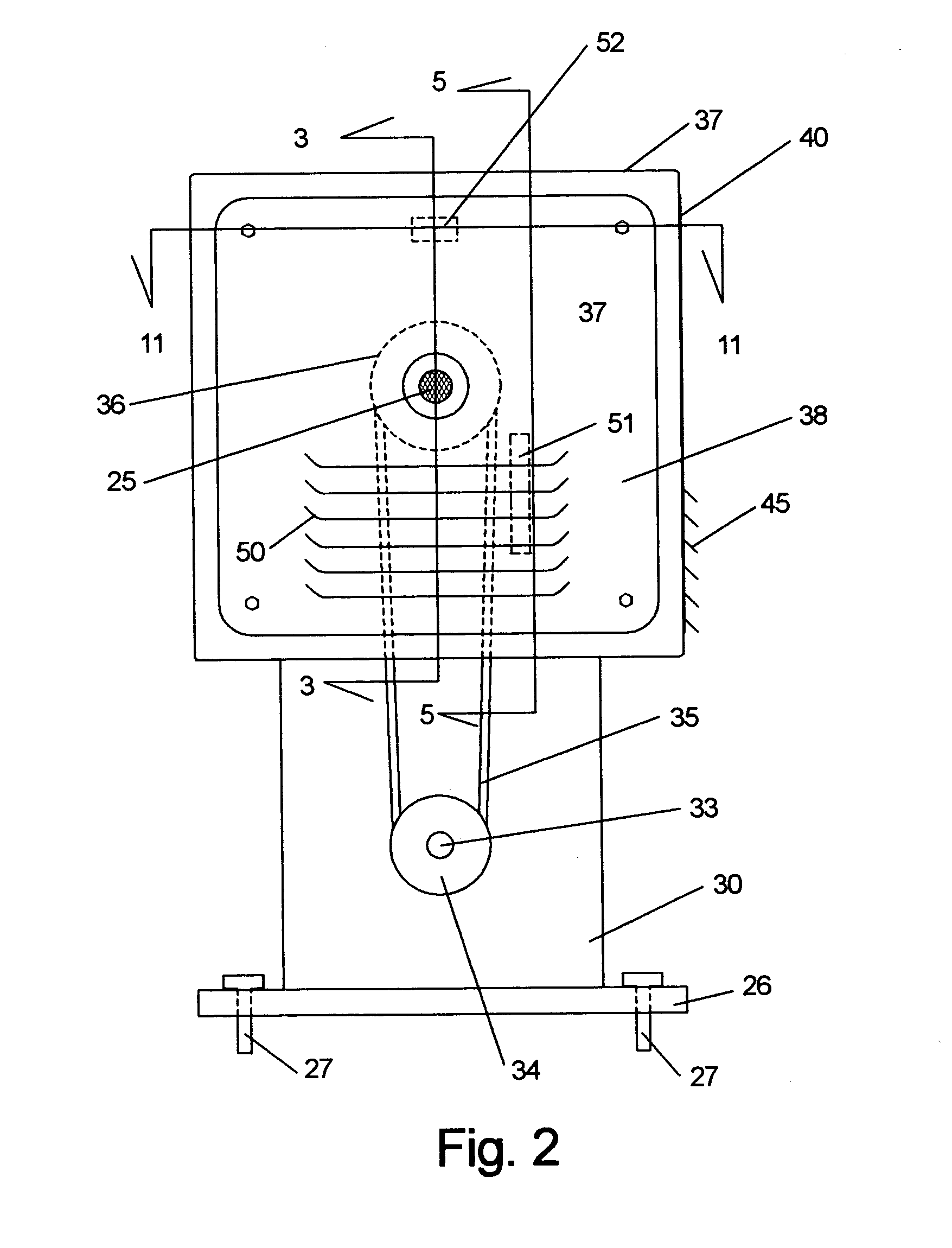

Resistance exercise apparatus and trainer

InactiveUS6945917B1Eliminate frictional lossesMinimum strengthMovement coordination devicesMuscle exercising devicesVehicle frameConductive materials

An apparatus for providing exercise to recreational users and training to professional users comprising a support frame on which a bicycle frame is mounted and a resistance generation unit coupled to the support frame to provide resistance against the pedaling of the user. The resistance unit comprises a magnetic field generation source and a flywheel having an annular ring constructed from a plurality of segments of a non-magnetic, conductive material. The resistance exercise apparatus and trainer utilizes the flywheel to eliminate the need for the conventional rear wheel of a bicycle. The use of the flywheel as part of the resistance generation unit creates a “single-stage” resistance exercise trainer, because the resistance generated on the flywheel is transmitted to the user through a direct chain drive of a conventional bicycle. According to another aspect of the present invention, the resistance exercise apparatus includes a chain tensioning mechanism. The chain tensioning mechanism provides a method of tightening or loosening the tension of the chain to improve the overall efficiency of the chain drive mechanism and prevent the chain from “jumping” off the chain ring during operation.

Owner:RACER MATE

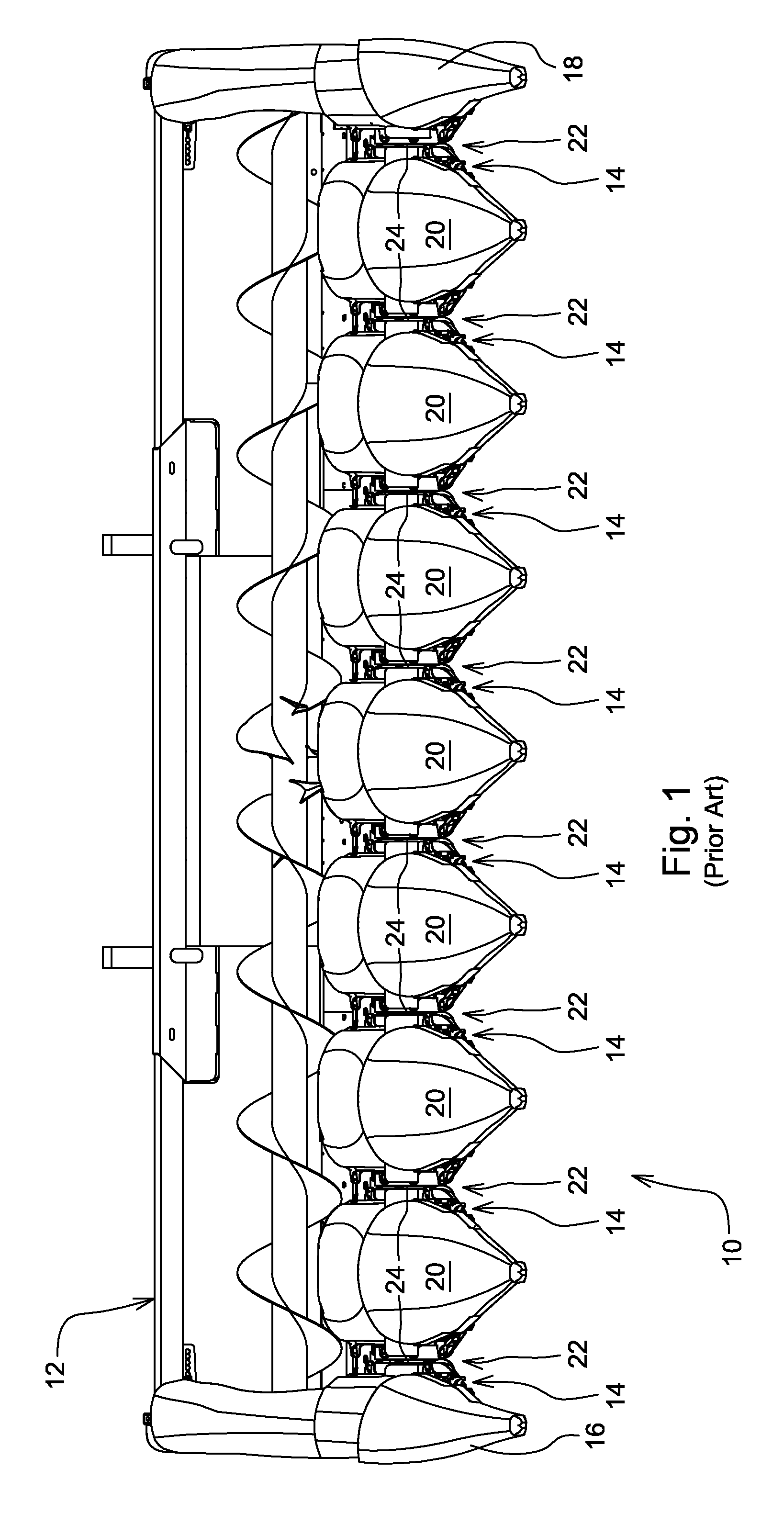

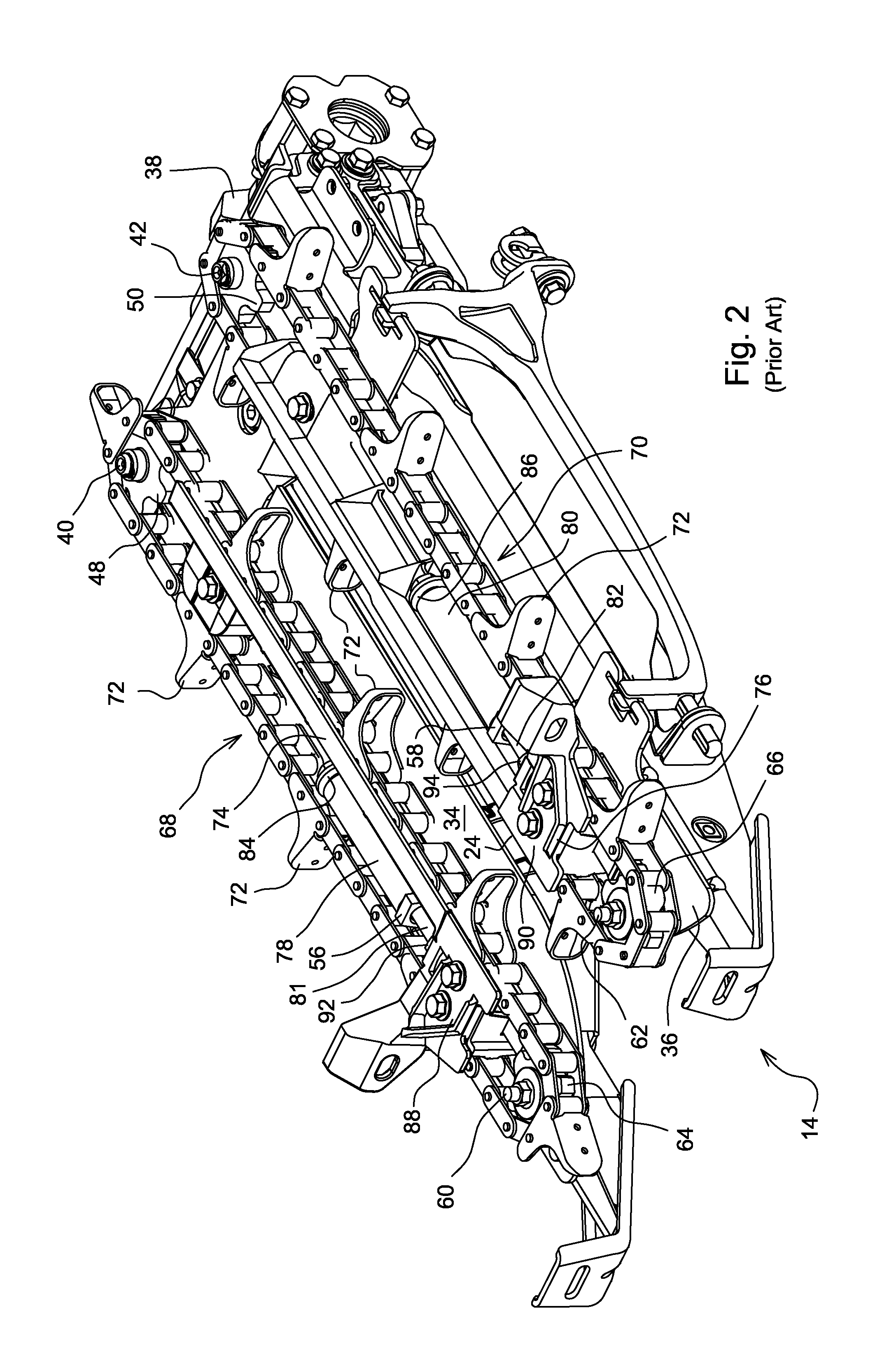

Converting a corn head row unit for harvesting corn stalks in addition to ears

Each row unit of a corn head can easily be converted between a first mode, wherein only ears are harvested, and a second mode, wherein ears together with stalks are harvested. In the first mode, a pair of snapping rolls is mounted for operation beneath each row unit frame for grasping corn stalks and pulling them downwardly through a narrow throat defined by a pair of laterally adjustable deck plates mounted to a top surface of the row unit frame. In the second mode, the snapping rolls are either removed or disabled and at least one stalk cutting disk is mounted on one of a pair of gathering chain drive idler shafts, mounted at the forward end of the row unit frame, for rotating above the frame. The snapping rolls are disabled by adjusting the deck plates toward each other to close the throat.

Owner:DEERE & CO

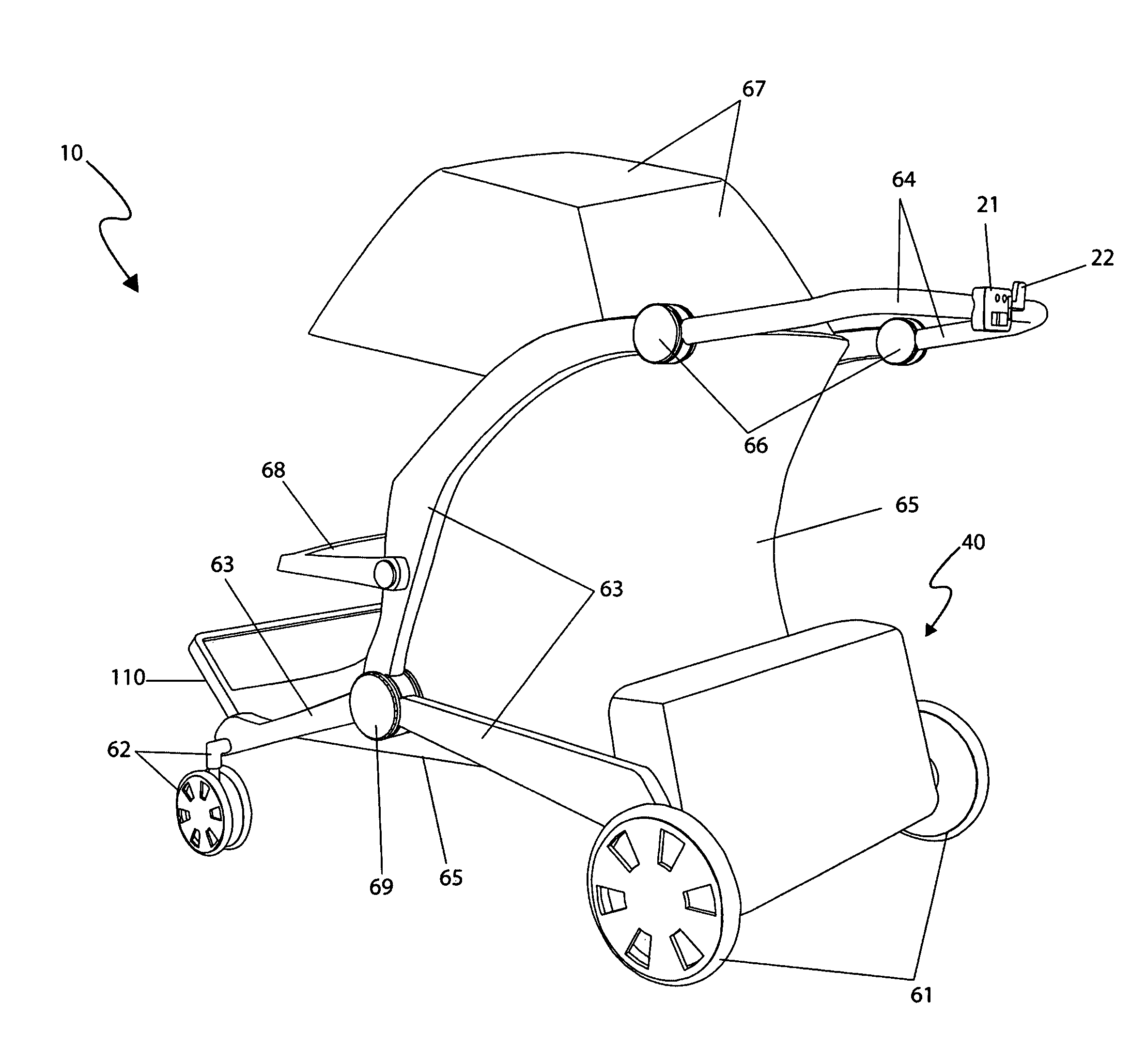

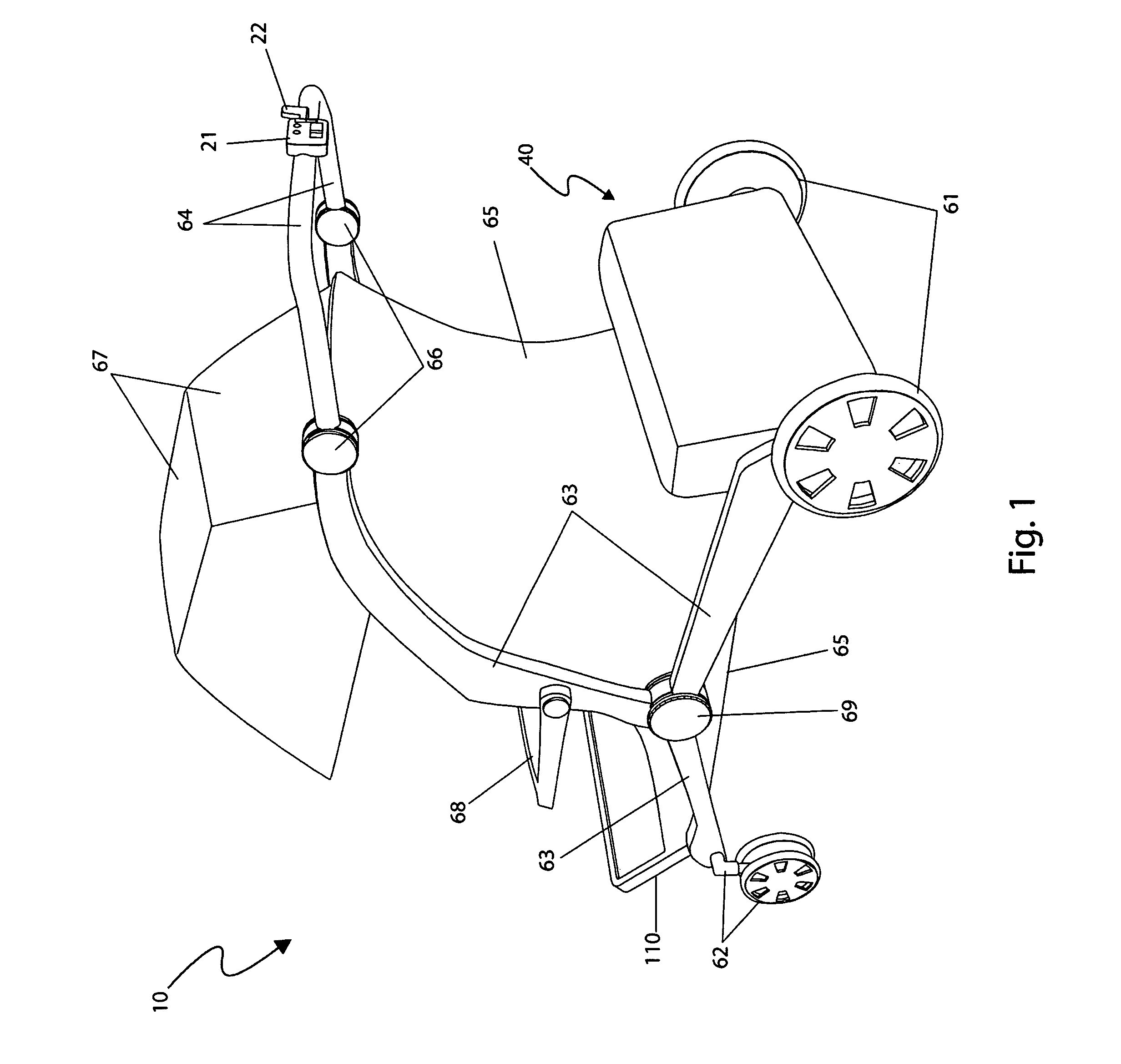

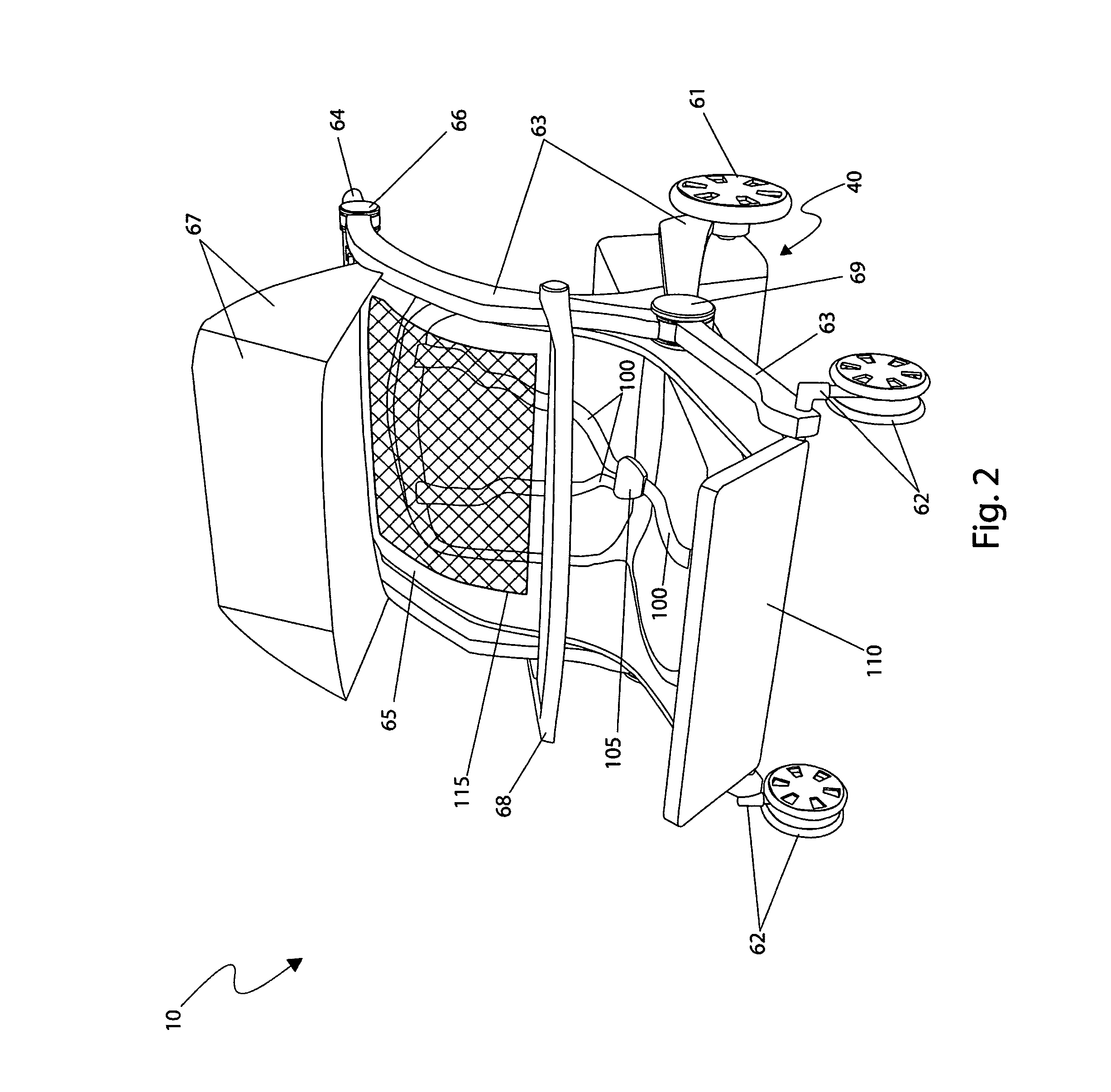

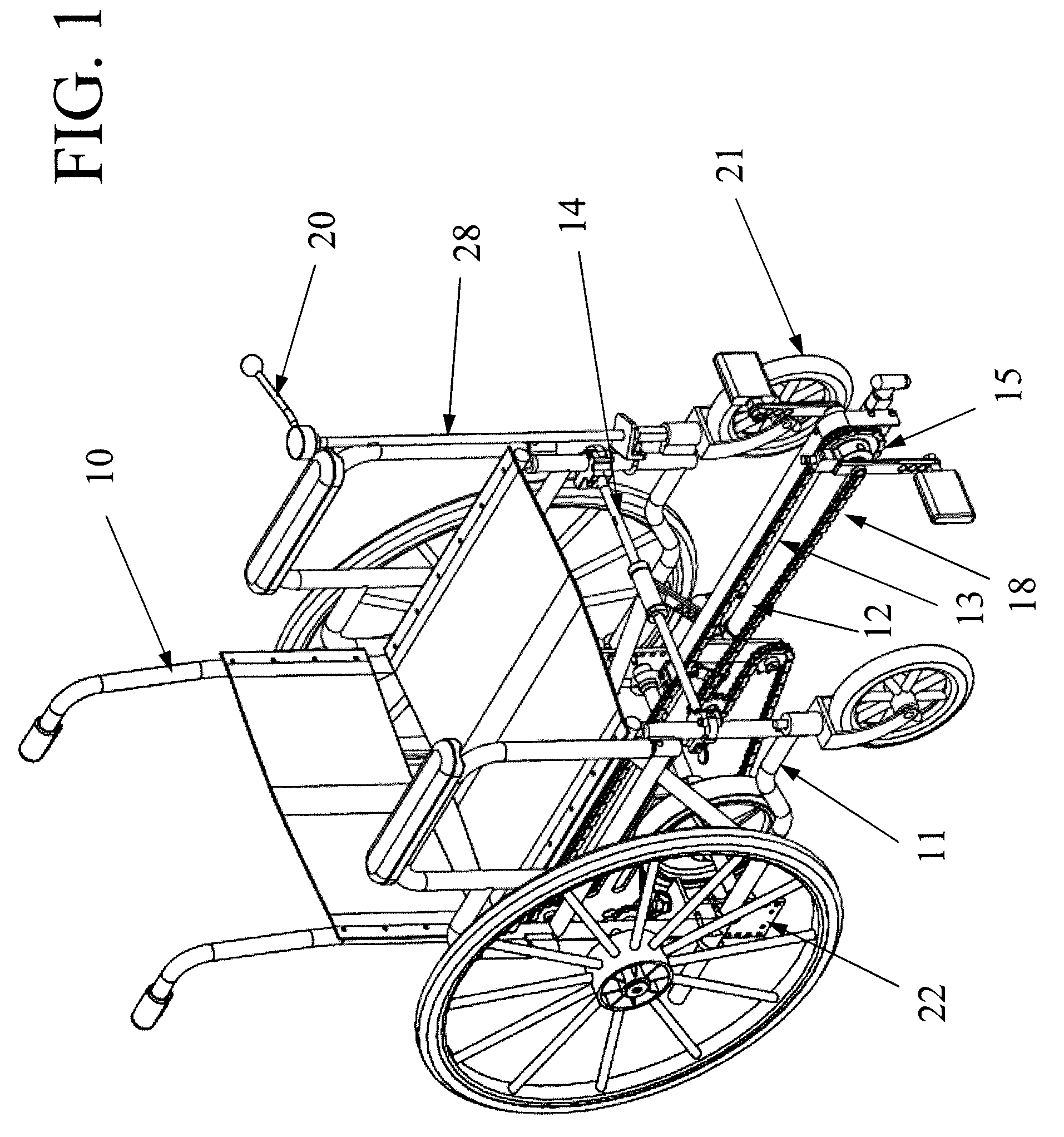

Self-propelled child stroller

InactiveUS8033348B1Weight of the stroller assemblyCarriage/perambulator accessoriesHand cart accessoriesJoystickEngineering

A self-propelled stroller apparatus comprising a motor, a drive train, a braking mechanism, and a set of hand controls, is herein disclosed. Two (2) rear wheels of the stroller are driven by a battery-powered motor utilizing a chain-driven drive train. The motor is controlled by a handlebar-mounted control lever, which when pushed motivates the stroller in a forward direction. During times when the motor and drive train are deactivated, the stroller may be pushed in a normal manner. The apparatus is additionally provided with an emergency braking system to stop or securely park the stroller. The battery is recharged by a normal household outlet and an electrical cord when the stroller is not in use.

Owner:PARKHE HEMIN

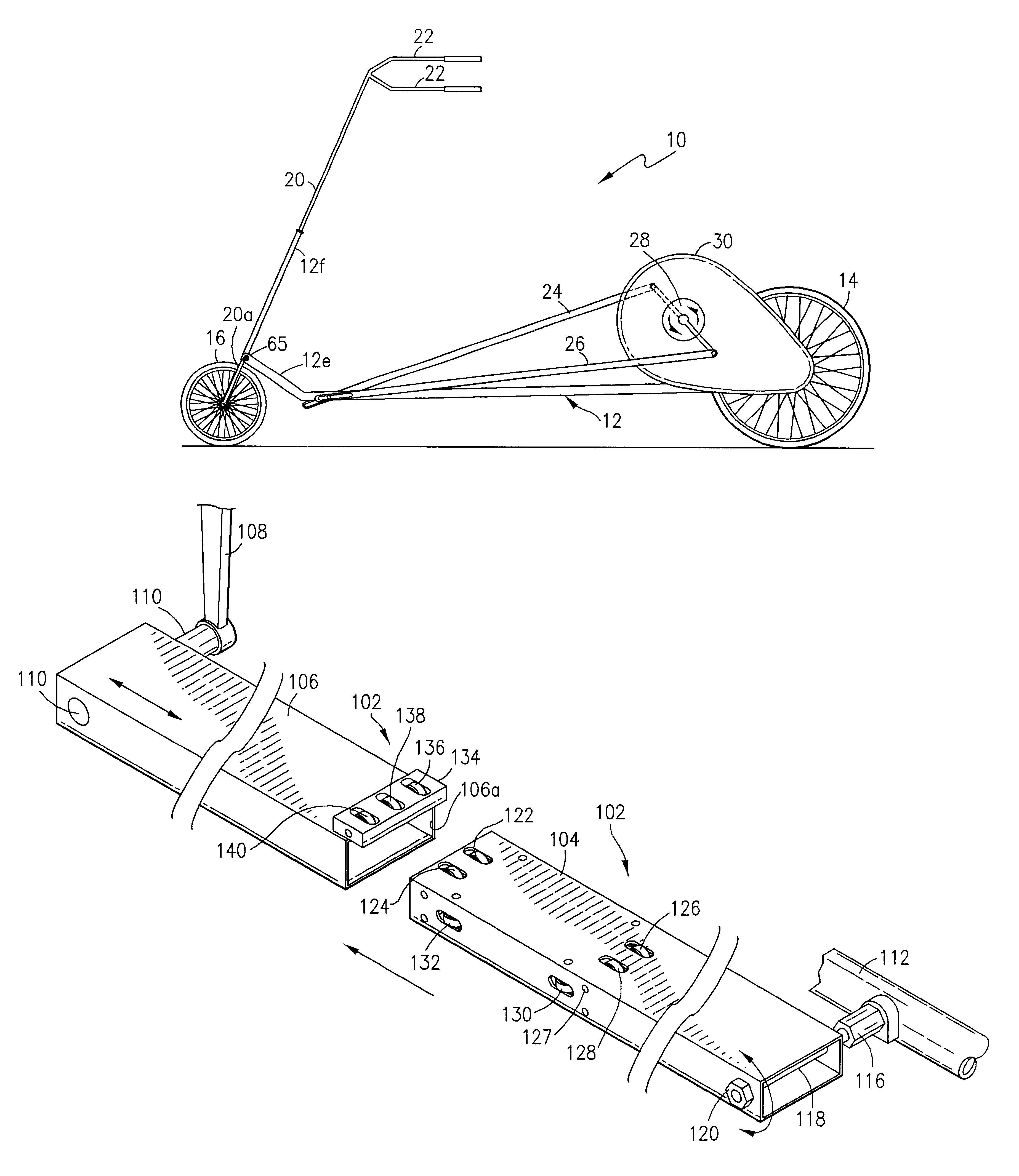

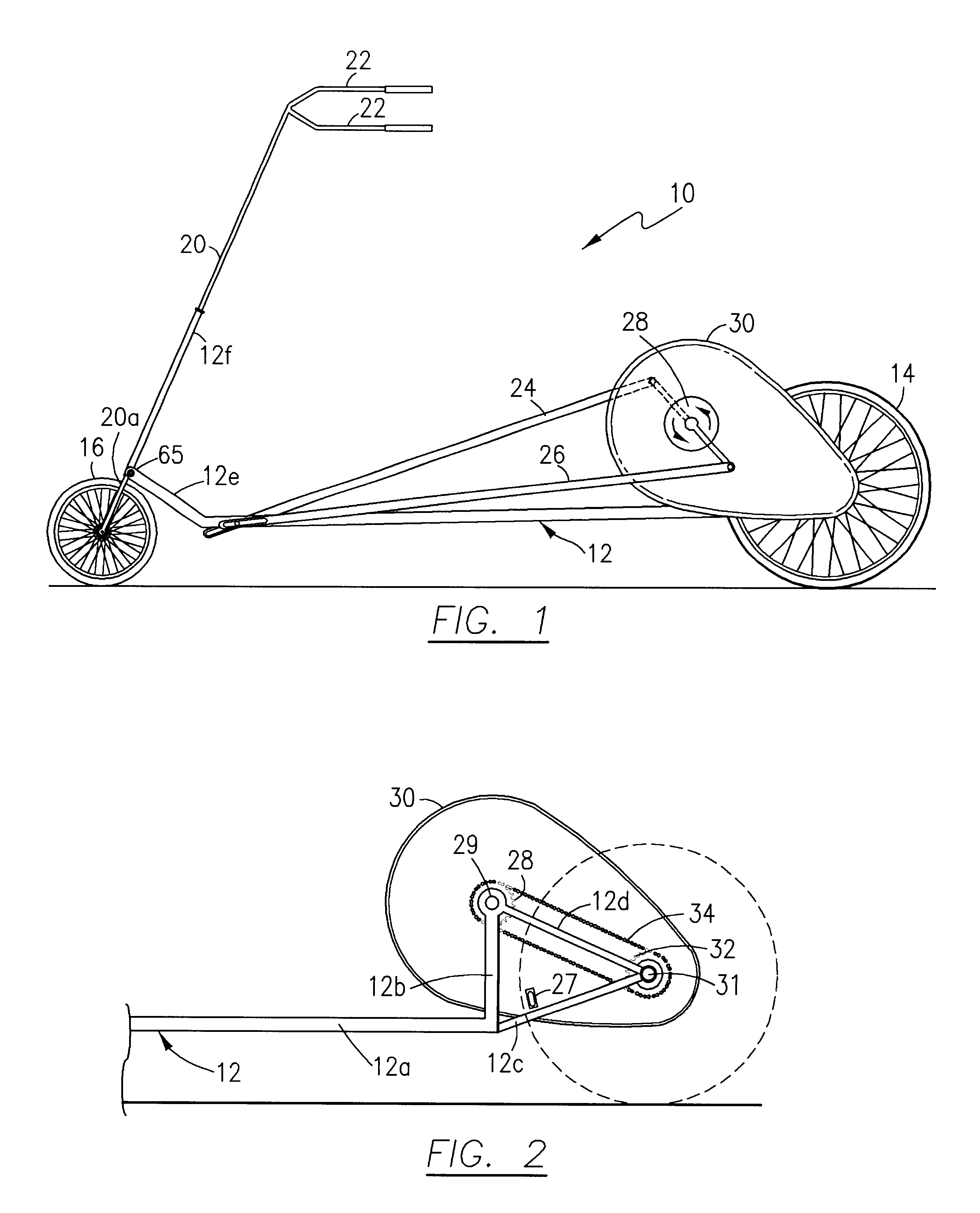

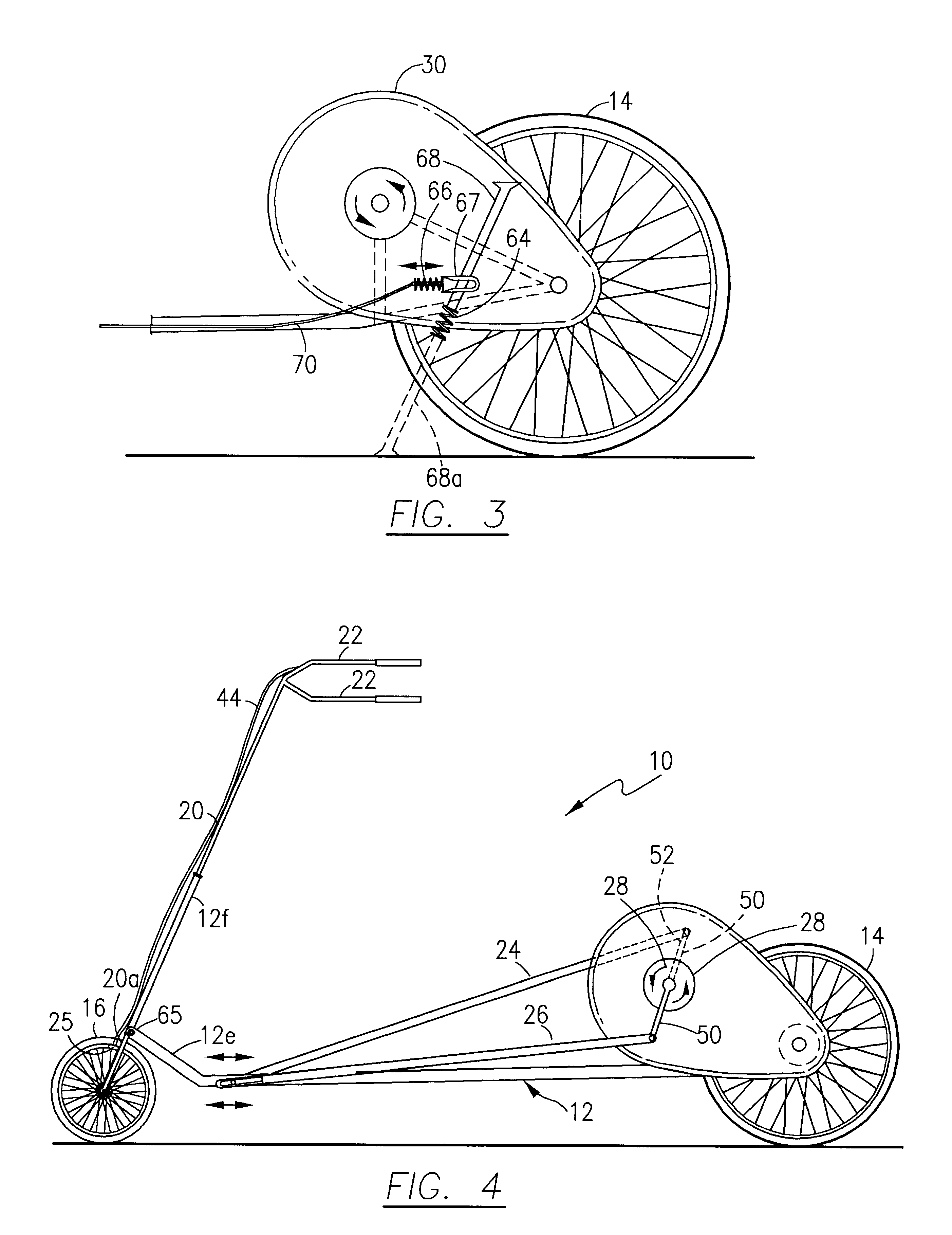

Step-cycle for exercise, recreation, and transport having telescopically movable pedals

A bicycle for providing stair-stepping exercise motion, recreation, and mode of transport comprising a frame that includes a unique triangular rear portion, a pair of wheels, one for the front, one for the back, a chain driven, teardrop-shaped propulsion system, left and right pedals having multiple positions between a horizontal and angular vertical upon which the operator rides, adjustable handle bars for steering, and a safety housing for covering the propulsion and wheel sprockets, chain, braking mechanism, and bike stand. In an alternate embodiment the pedals on each side may be made of telescopic members to provide reciprocal motion so that the forward end of the pedal does not move reciprocally. Also a terrain engaging frame extension is provided below the middle portion of the frame for engaging terrain objects to prevent the pedals from engaging the terrain during activation.

Owner:JANSSEN DEAN R

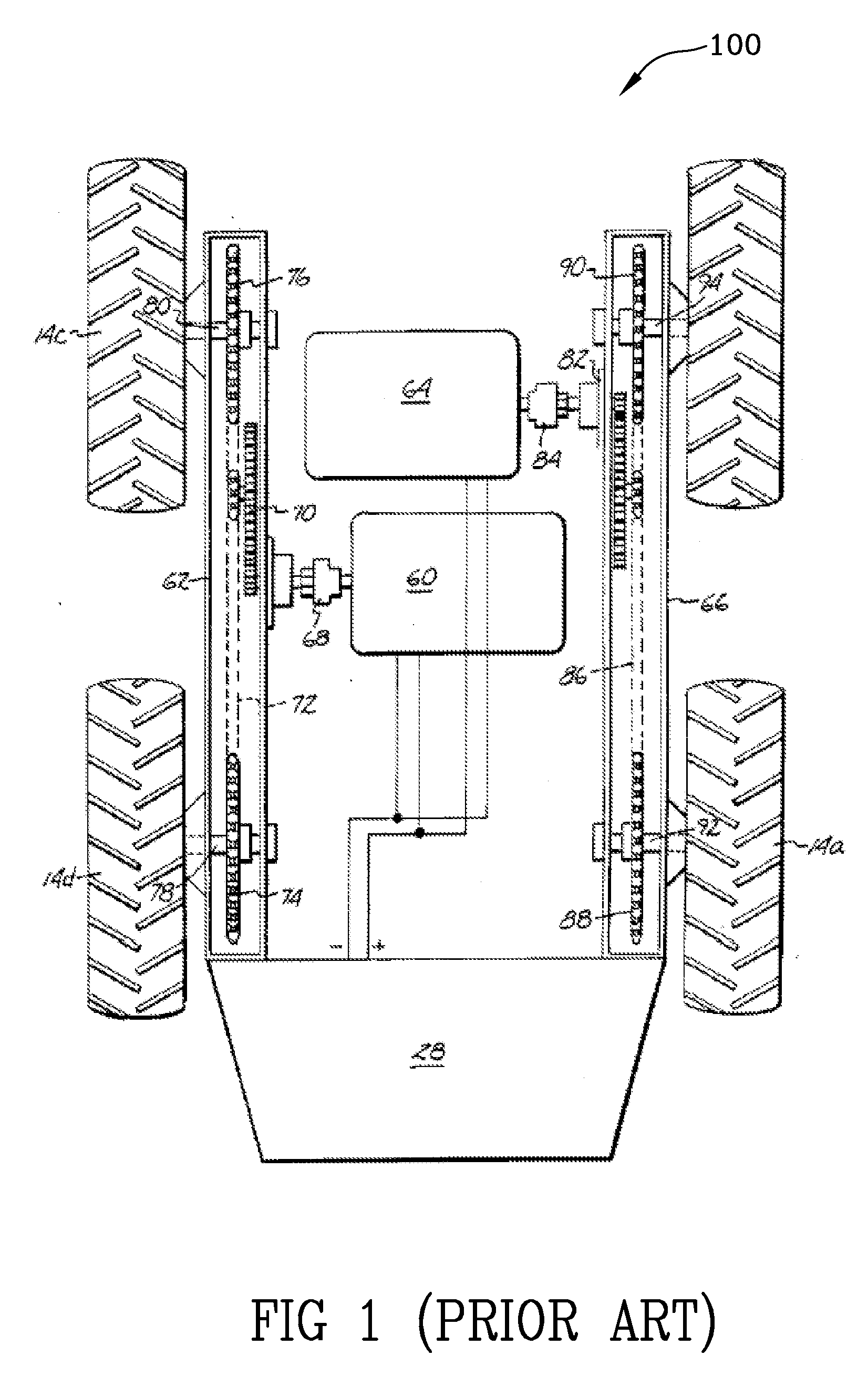

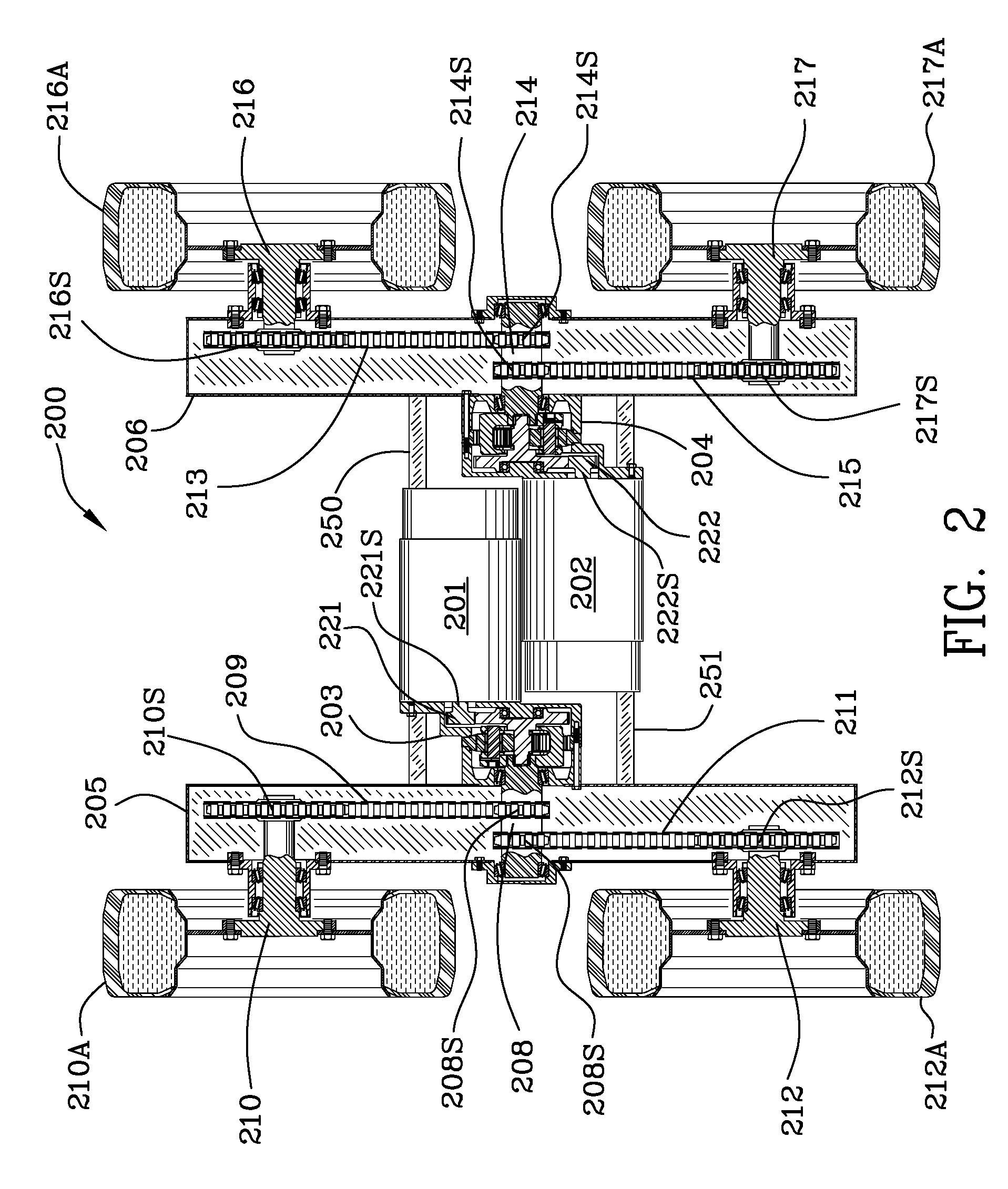

Offset drive system for utility vehicles

ActiveUS20080230284A1Easy to useEfficient production of torqueElectric devicesElectric propulsion mountingGear wheelSprocket

A wheel driven utility vehicle includes a frame and two small volume high speed alternating current electric motors arranged side by side for driving the vehicle. Alternatively high speed direct current, hydraulic or pneumatic direct current motors may be used with suitable controls. Each motor has an output shaft which drives an offset planetary gear reducer. Each offset planetary gear reducer is affixed to the electric motor and includes an output carrier interconnected with an output shaft. Each output shaft includes first and second chain drive sprockets which drive chains interconnected with shafts driving the front and rear wheels respectively. Each offset planetary gear reducer enables use of space saving high speed relatively low-torque alternating current electric motors with attendant large speed reductions. Gear reduction enables the production of sufficient torque at the wheels of the vehicle. Applications in addition to utility vehicles are also specifically contemplated.

Owner:FAIRFIELD MFG CO INC

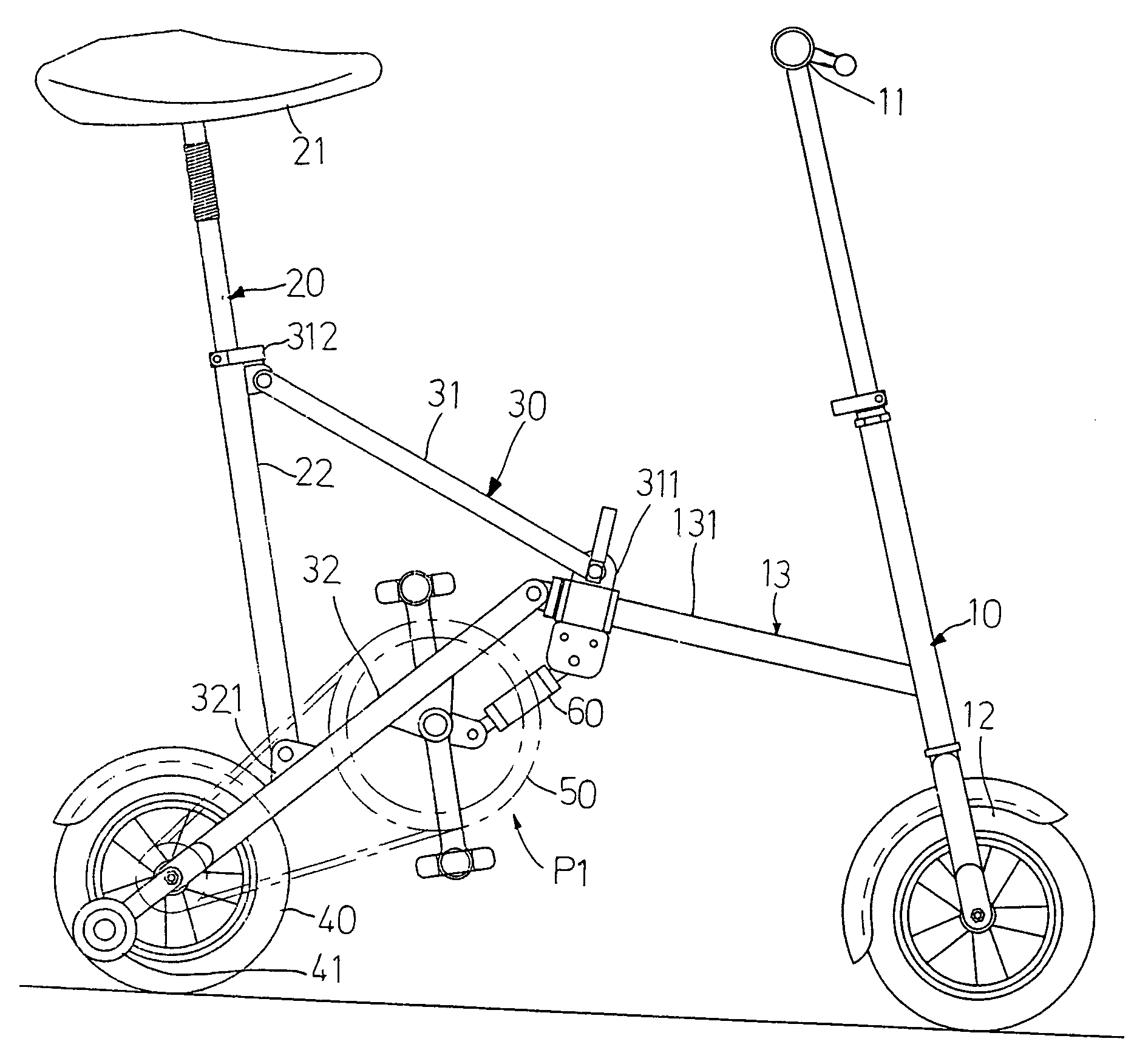

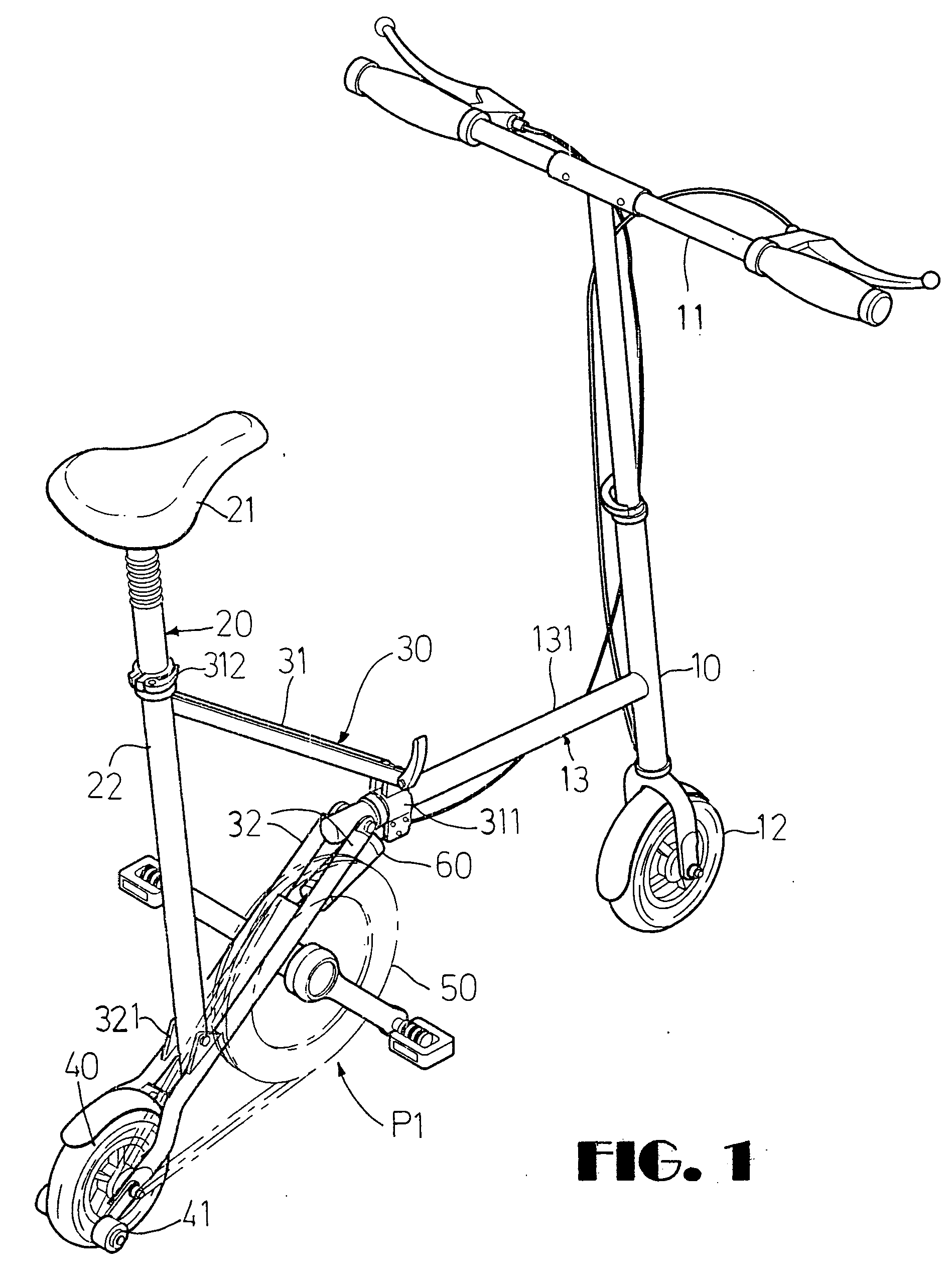

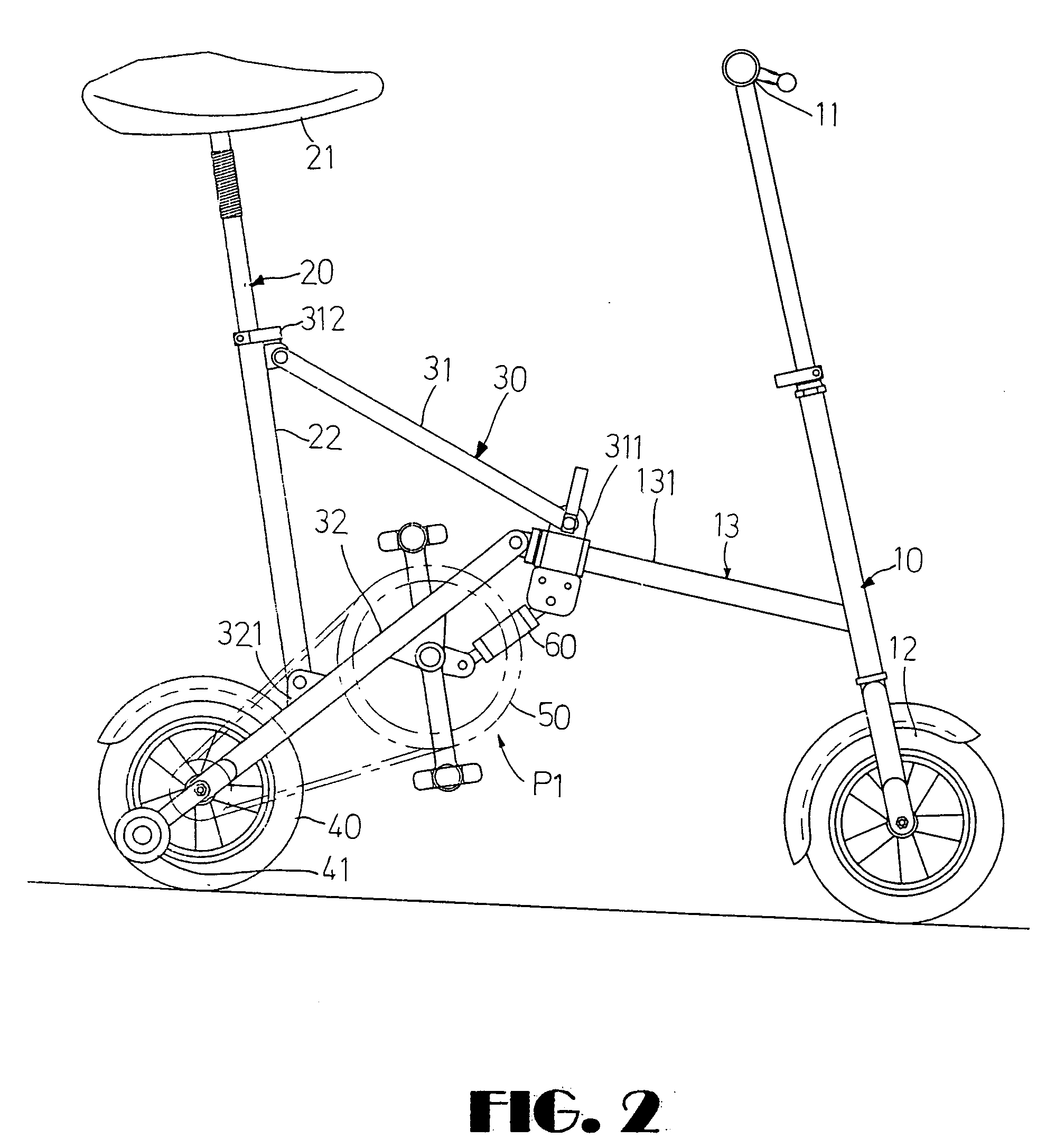

Collapsable bicycle

A collapsable bicycle comprises a link including a first locking device at one end slidably sleeved on and fastened at rear of a crossbar, a second locking device at the other end fastened a seat post at top of a seat tube, two down tubes having one ends pivotably coupled to rear of the crossbar, the down tubes having a pivot point coupled to a bottom end of the seat tube, a rear wheel rotatably coupled to rear of the down tubes, and a chain drive mounted between the rear wheel and the down tubes. Unfastening the quick releases and sliding the first locking device forwardly will move the rear wheel forwardly by pivoting about the rear of the crossbar, move the front wheel rearward, and move the down tubes toward the seat tube by pivoting about the pivot point until the seat tube is engaged with the down tubes.

Owner:WOO MING FENG

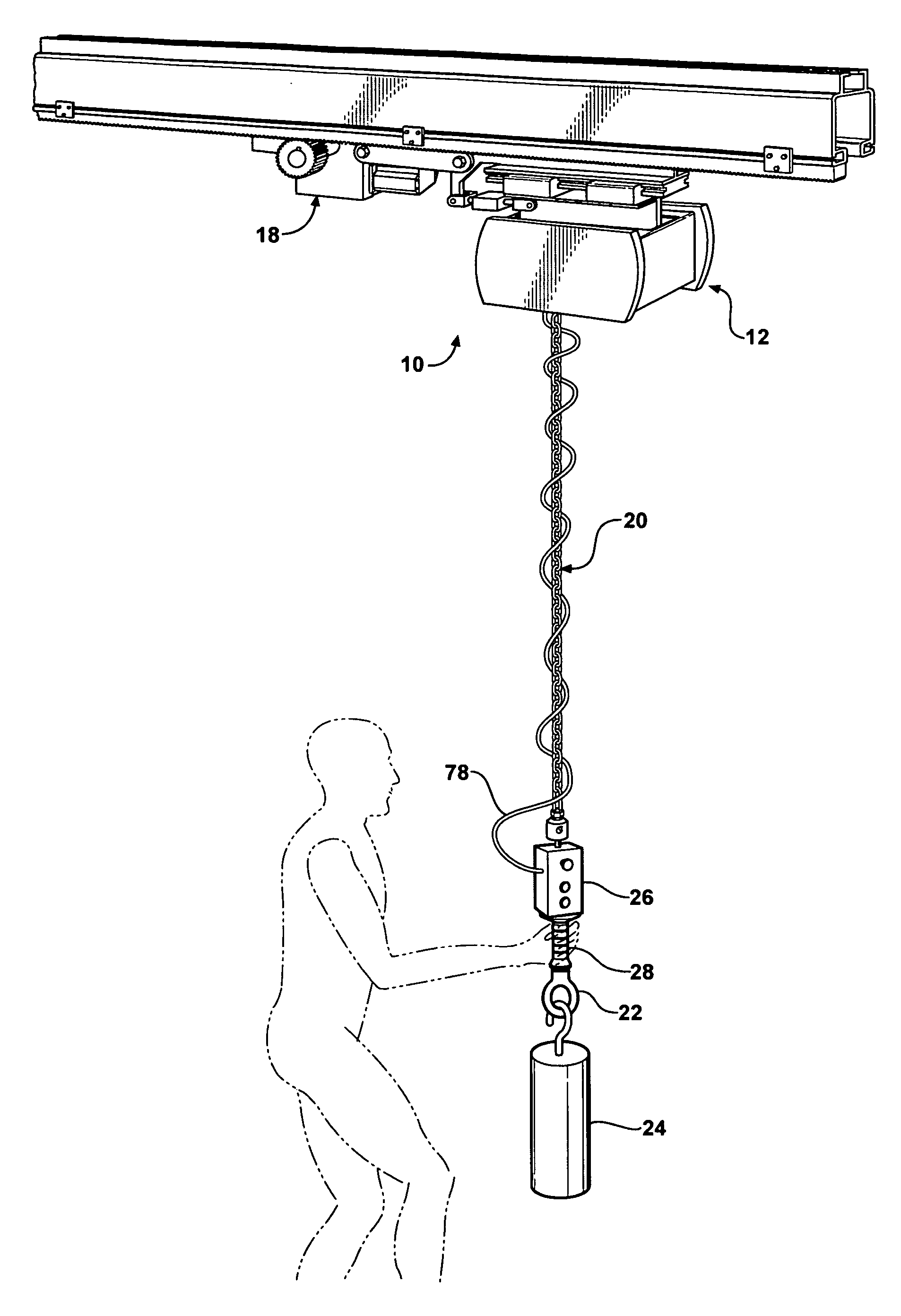

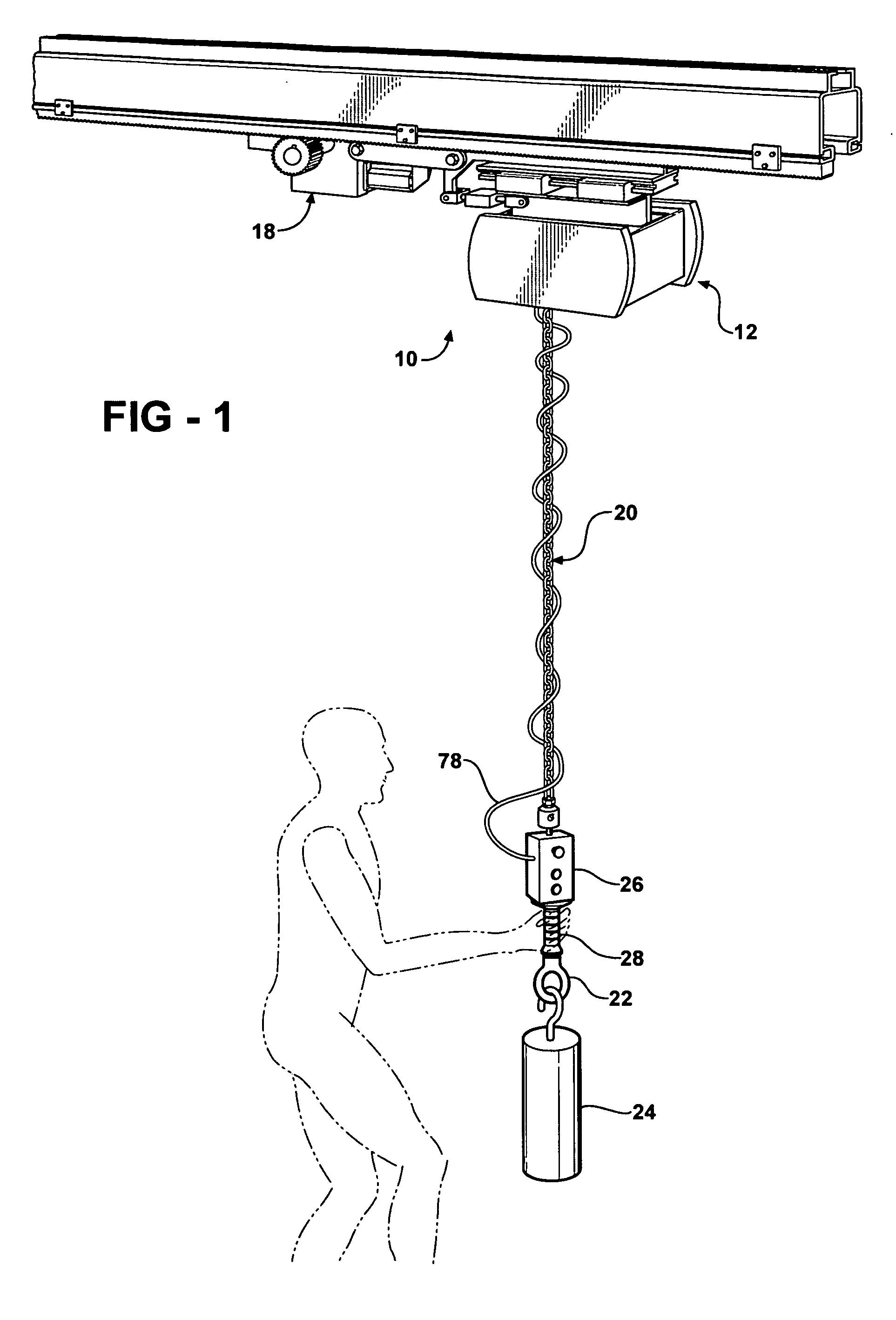

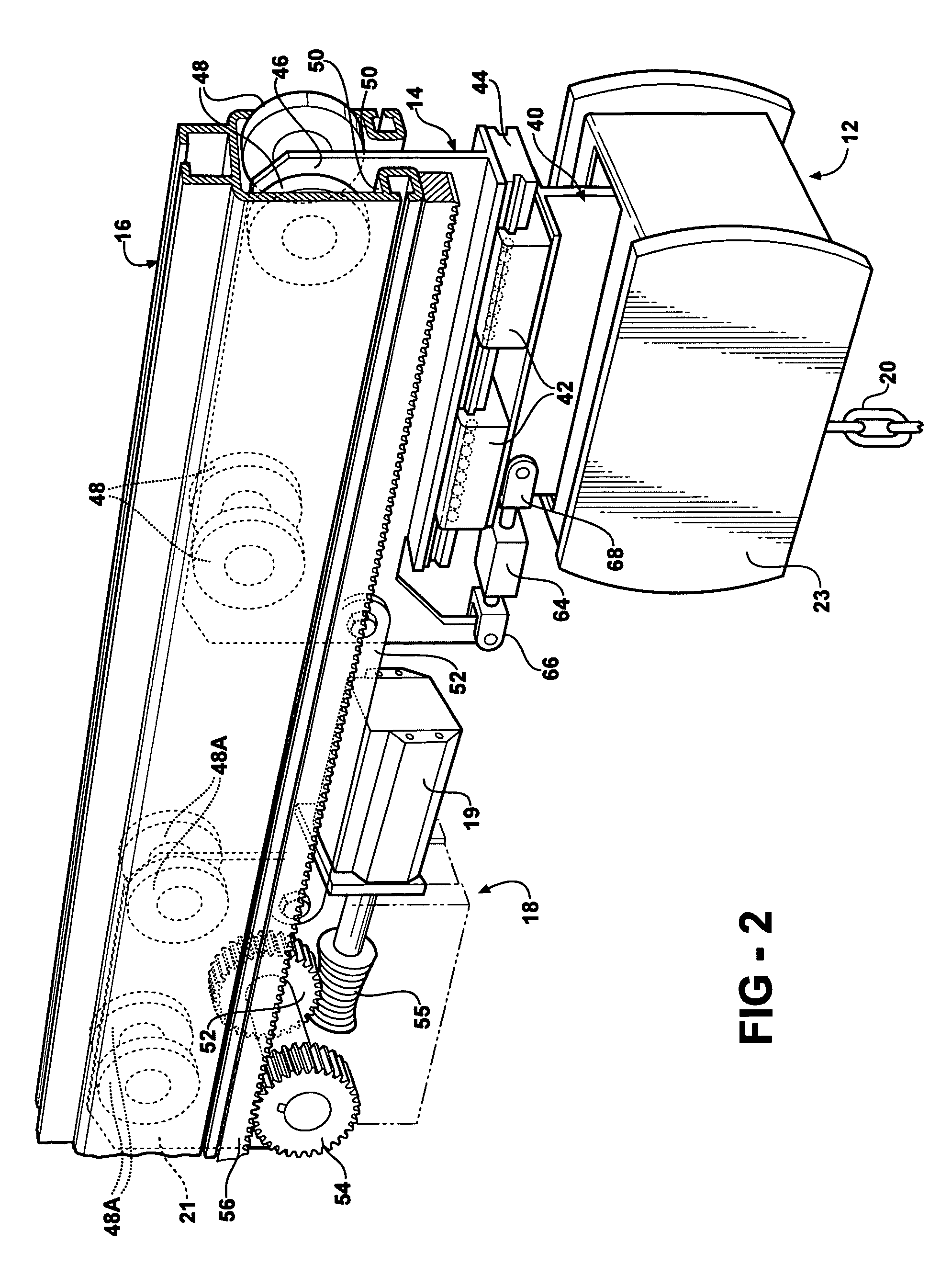

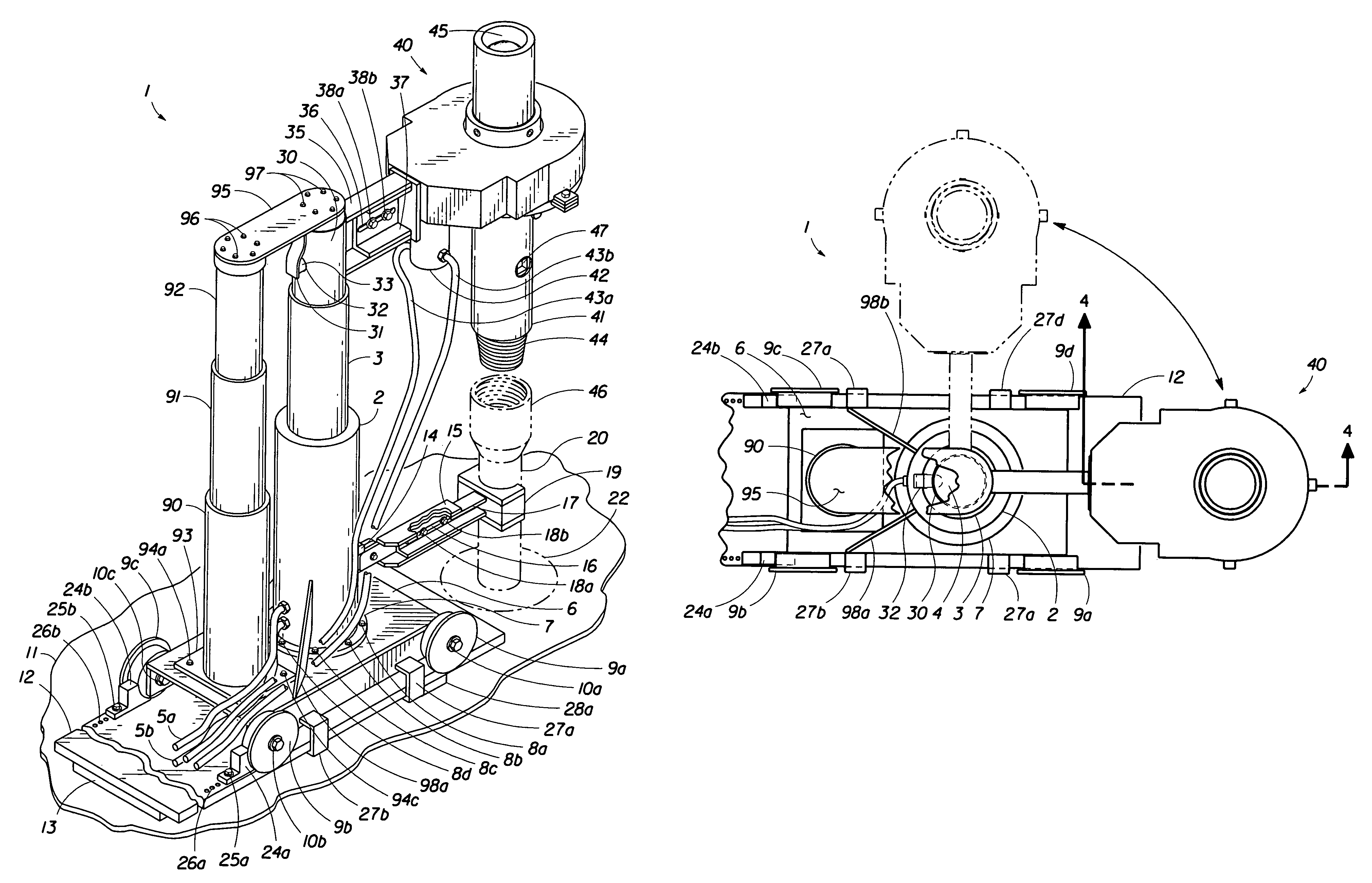

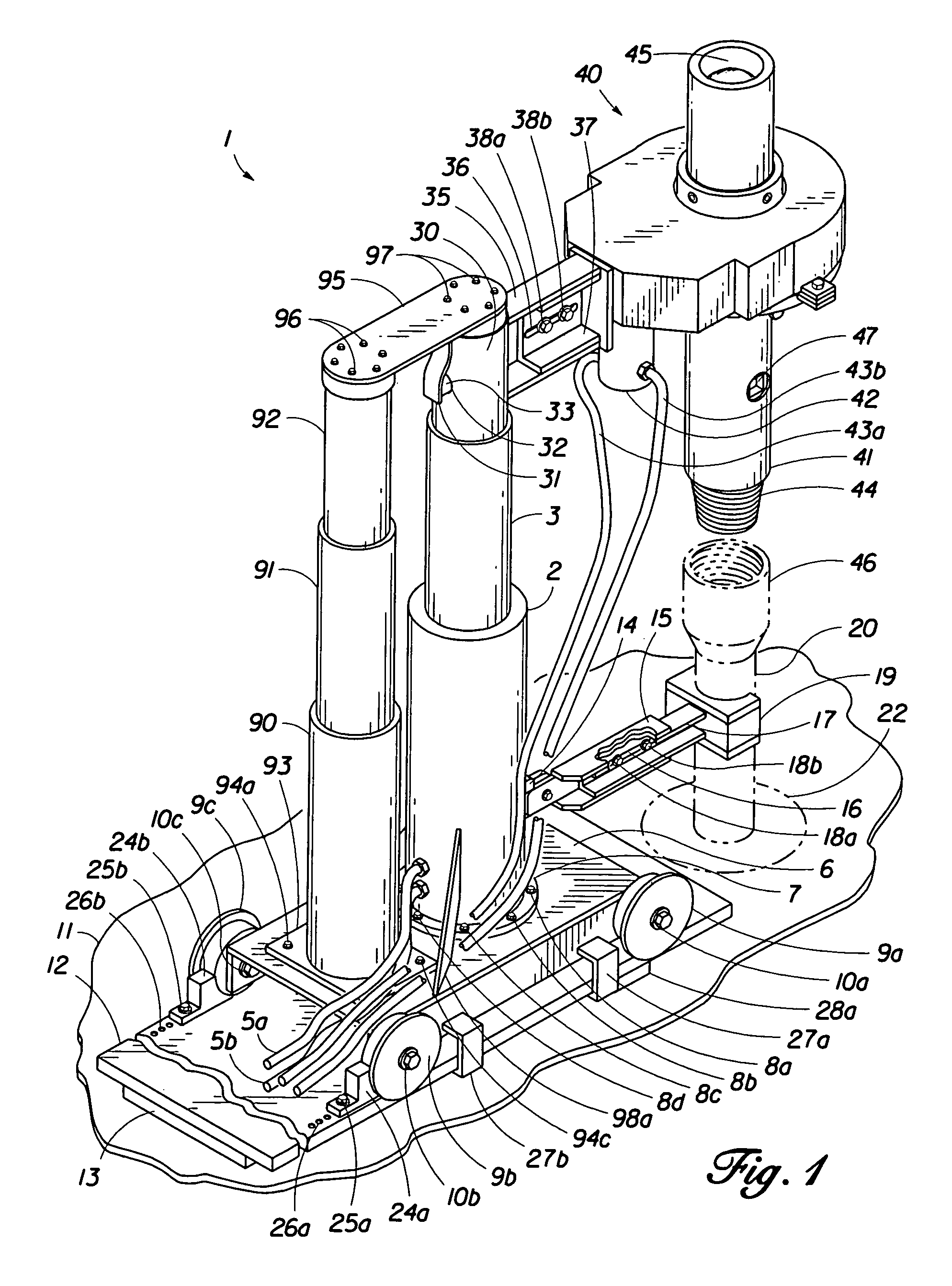

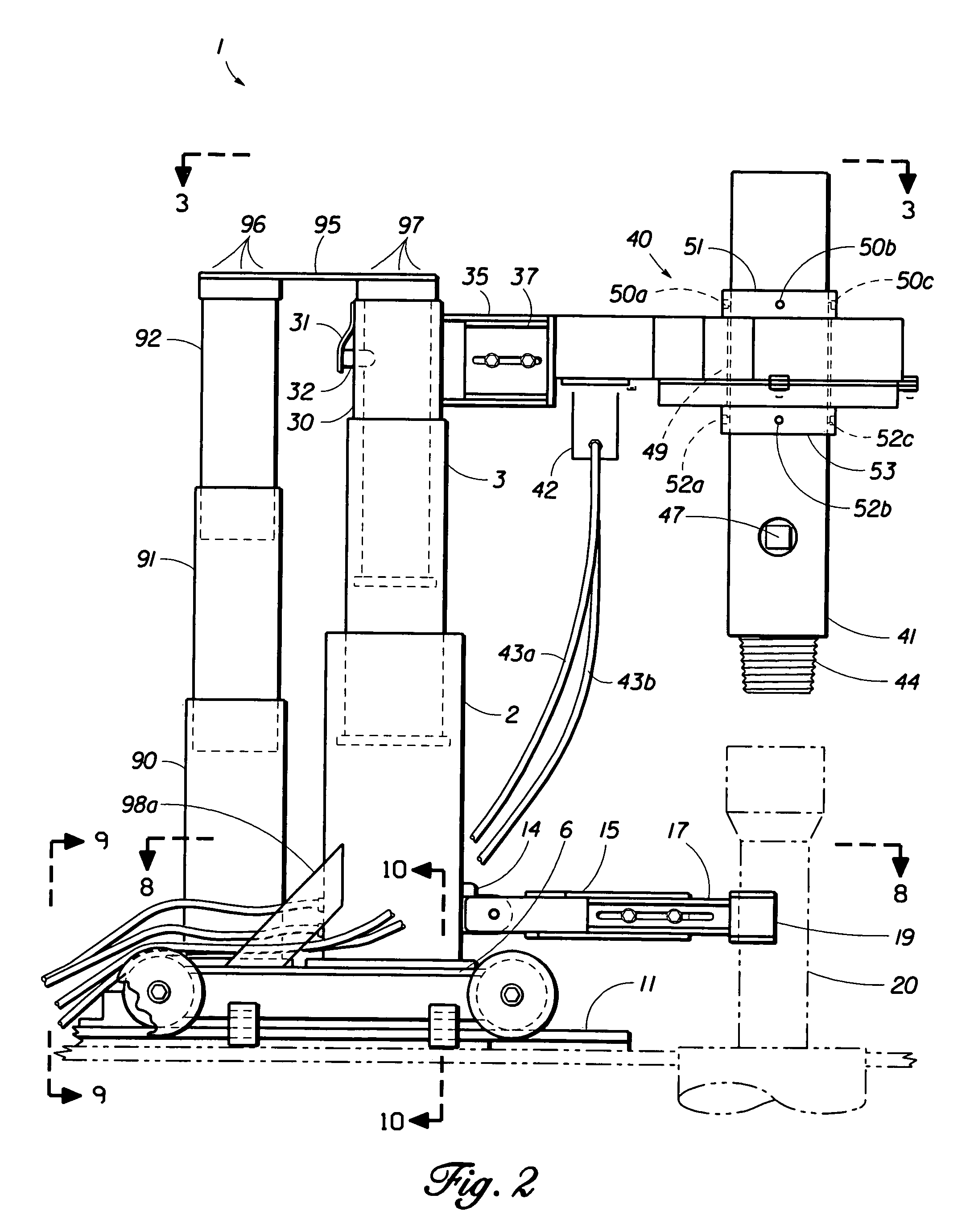

Electric motor driven traversing balancer hoist

ActiveUS20060226106A1Inhibition effectImprove performanceDigital data processing detailsPortable liftingGear wheelElectric machinery

A balancer hoist has an electric servomotor driving irreversible gearing in turn driving a hoist chain drive. A float mode and a manual mode are provided using two independent load sensors for sensing the load weight and force applied to a control grip. A traversing control is produced by a tractor carriage rolling on an overhead rail connected to a trolley also traveling on the rail and supported on upper hoist assembly. A load sensor interconnects the tractor carriage and upon hoist assembly to sense forces created by an operator pulling on the chain, which are used to control an electric motor on the tractor carriage driving a pinion gear engaged with a gear rack on the overhead rail to positively drive the carriage, trolley and upper hoist assembly along the rail. A stationary dual hoist system is also described in which two hoist assemblies are interconnected by a chain and sprockets to provide synchronized operation.

Owner:ZAGUROLI JR JAMES

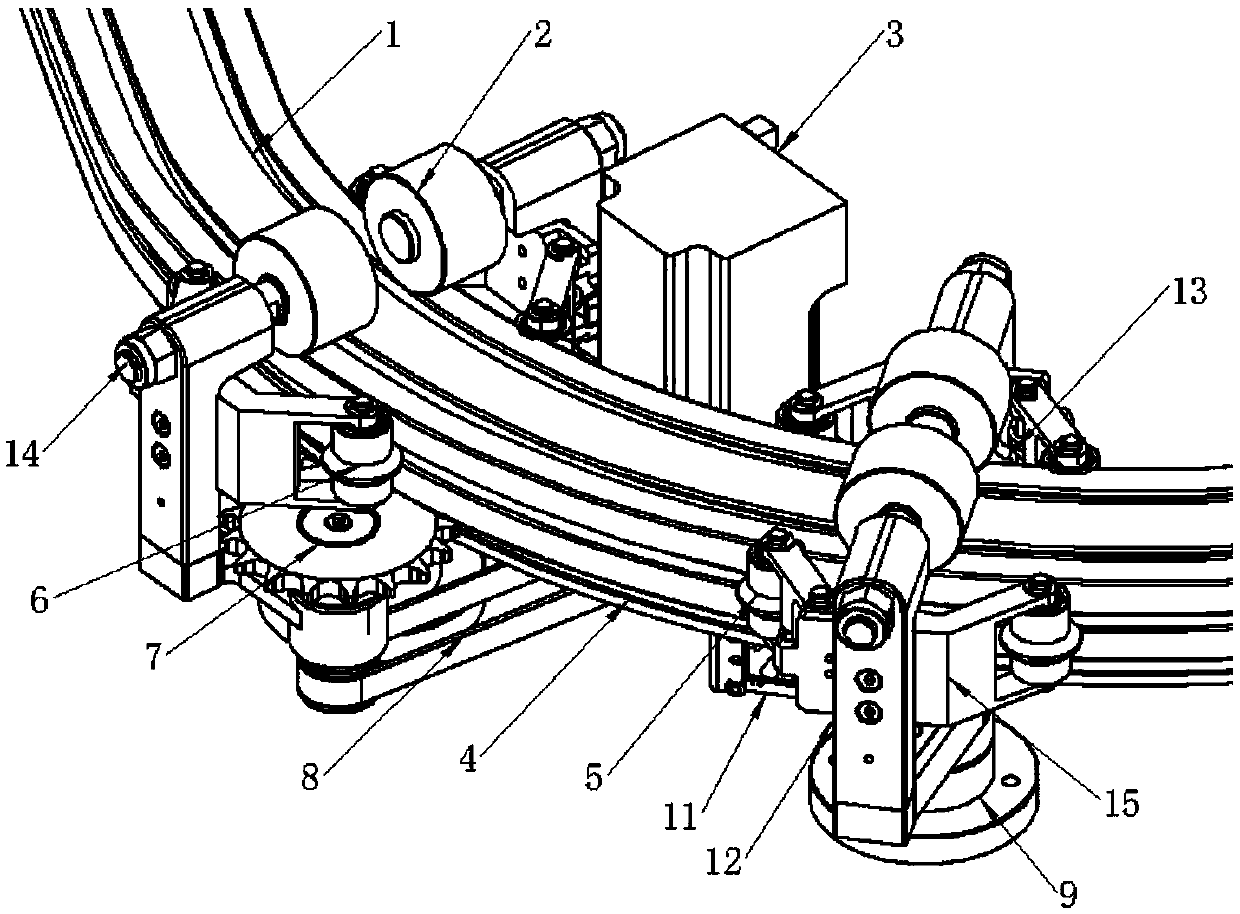

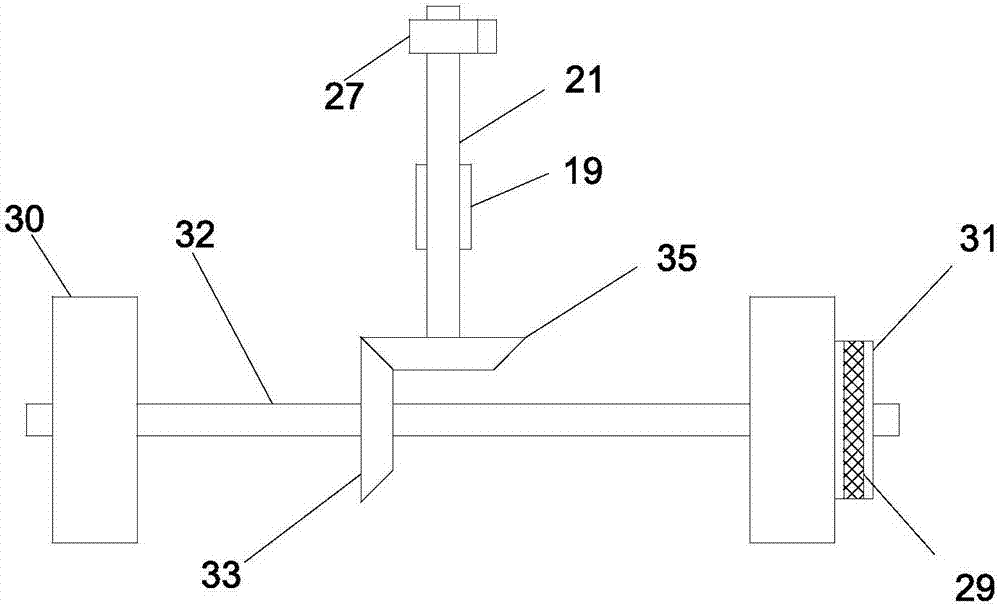

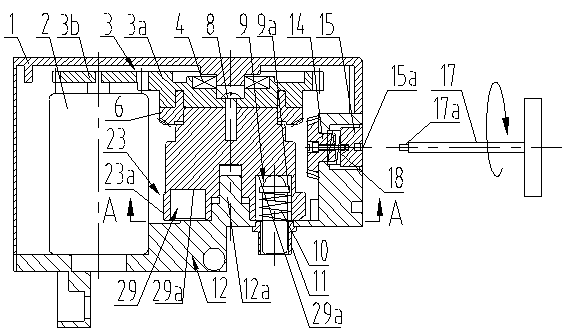

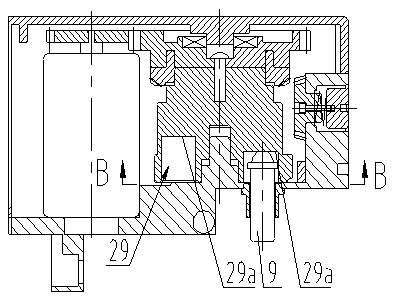

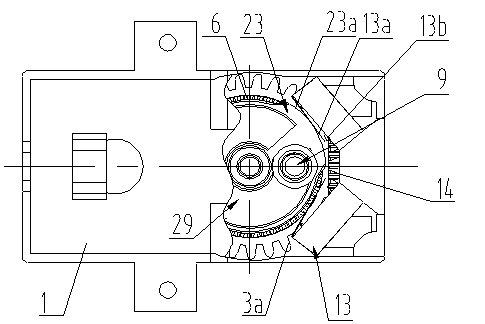

Travelling mechanism of track inspection robot

The invention discloses a travelling mechanism of a track inspection robot. The travelling mechanism comprises a track and a driving mechanism, the driving mechanism moves along the track, and the inspection robot is installed on the driving mechanism; the track comprises an aluminum profile and a chain which is arranged under the aluminum profile in parallel; the driving mechanism comprises suspension arms, a cross beam, a steady wheel set, a chain wheel, a driving motor and a steering device, a U-shaped structure is formed by the two suspension arms and the cross beam, the suspension arms make slideable contact with the aluminum profile through the steady wheel set, the chain wheel is horizontally arranged and rotationally connected with the cross beam, the chain wheel meshes with the chain, a torque input shaft of the chain is fixedly connected with a torque output shaft of the driving motor through a transmission belt, and the driving motor is fixedly connected with the cross beam.In the travelling mechanism, the standard industrial aluminum profile is used as the track, the chain is used as a path, the chain wheel is used as a driving wheel, and a chain-drive mode is adoptedso that precise positioning can be achieved, and turning and climbing can be easily achieved; the steering shaft is adopted as a steering knuckle so that the requirements for small-radius turning canbe met.

Owner:SHENZHEN LAUNCH DIGITAL TECH

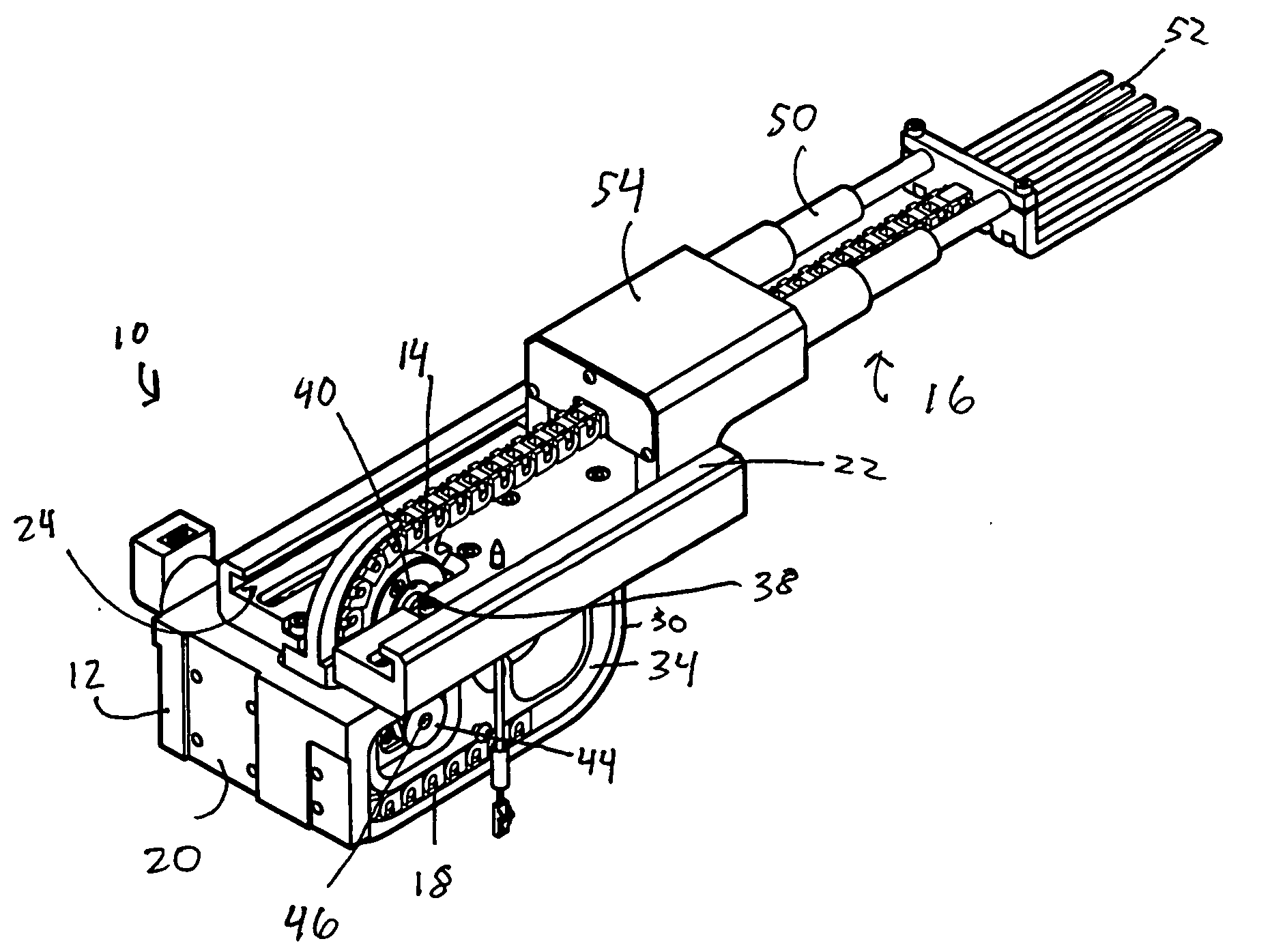

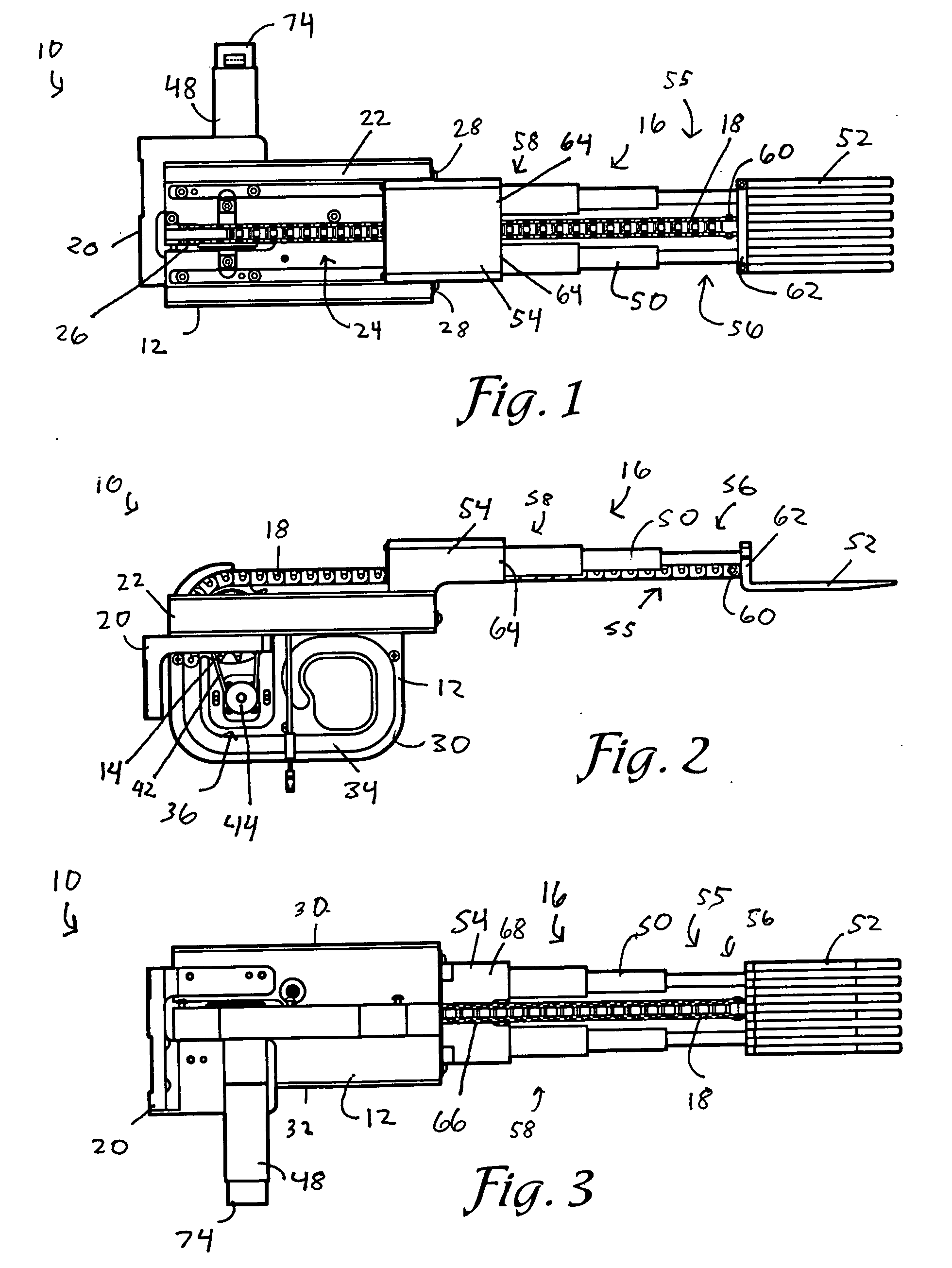

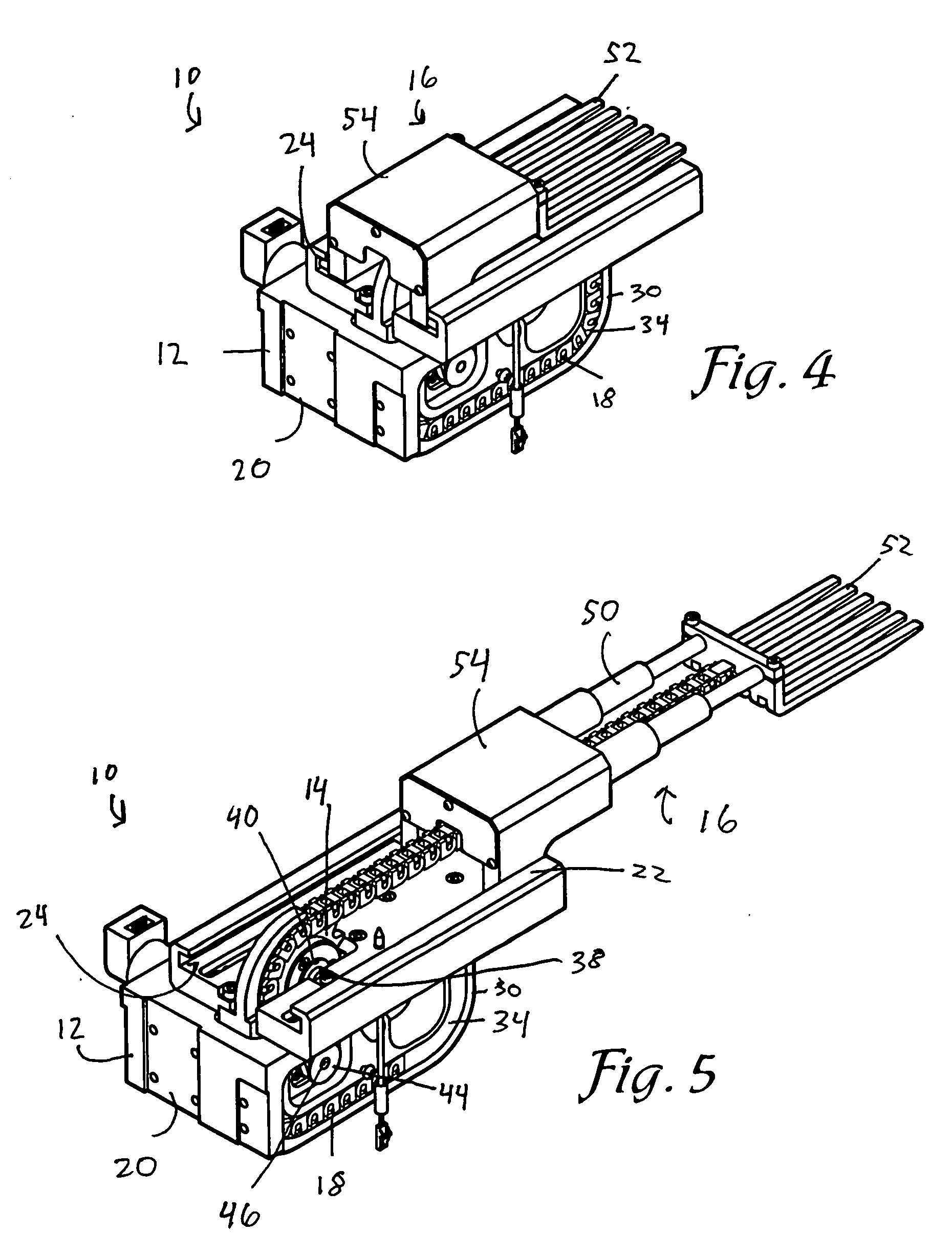

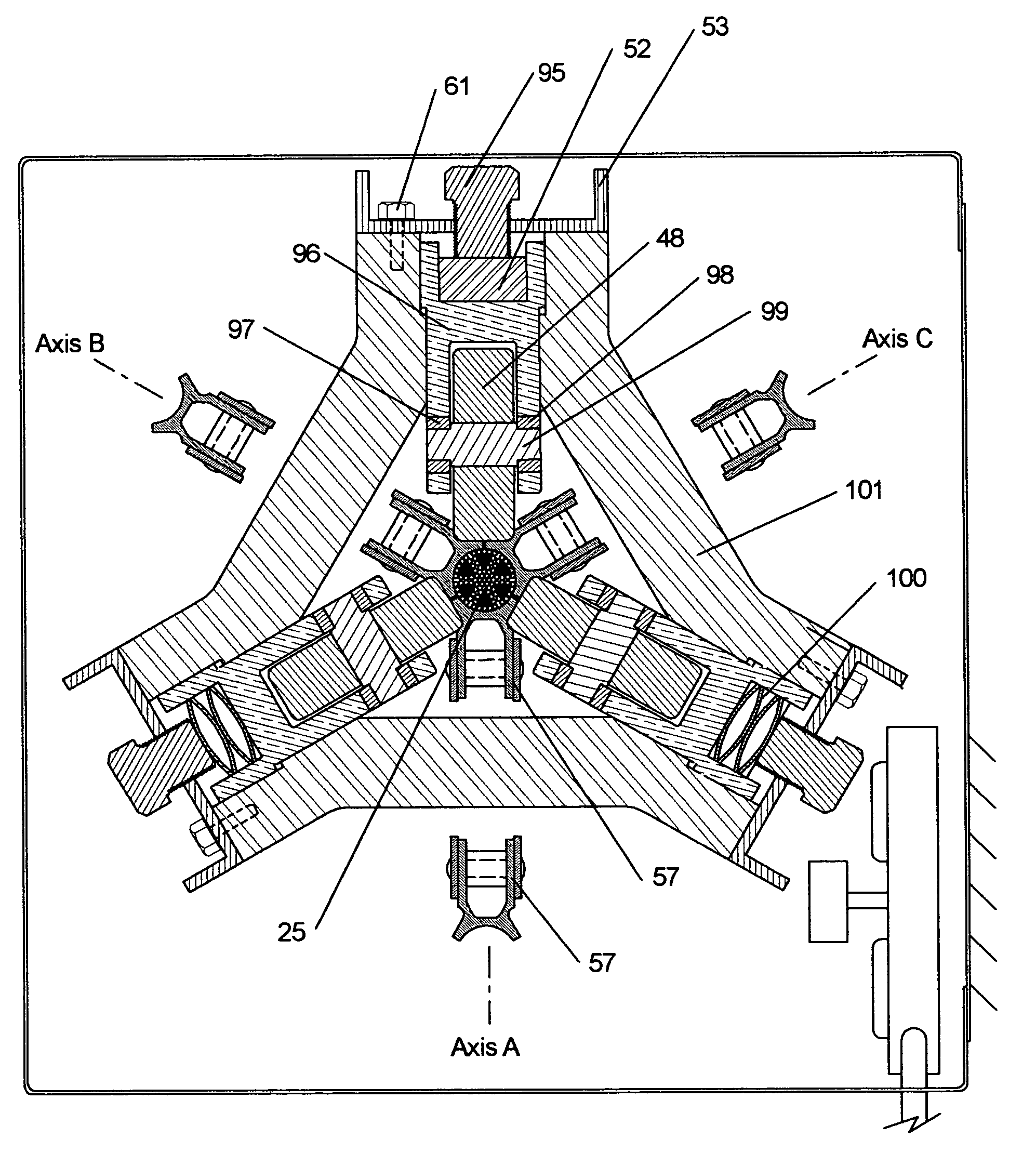

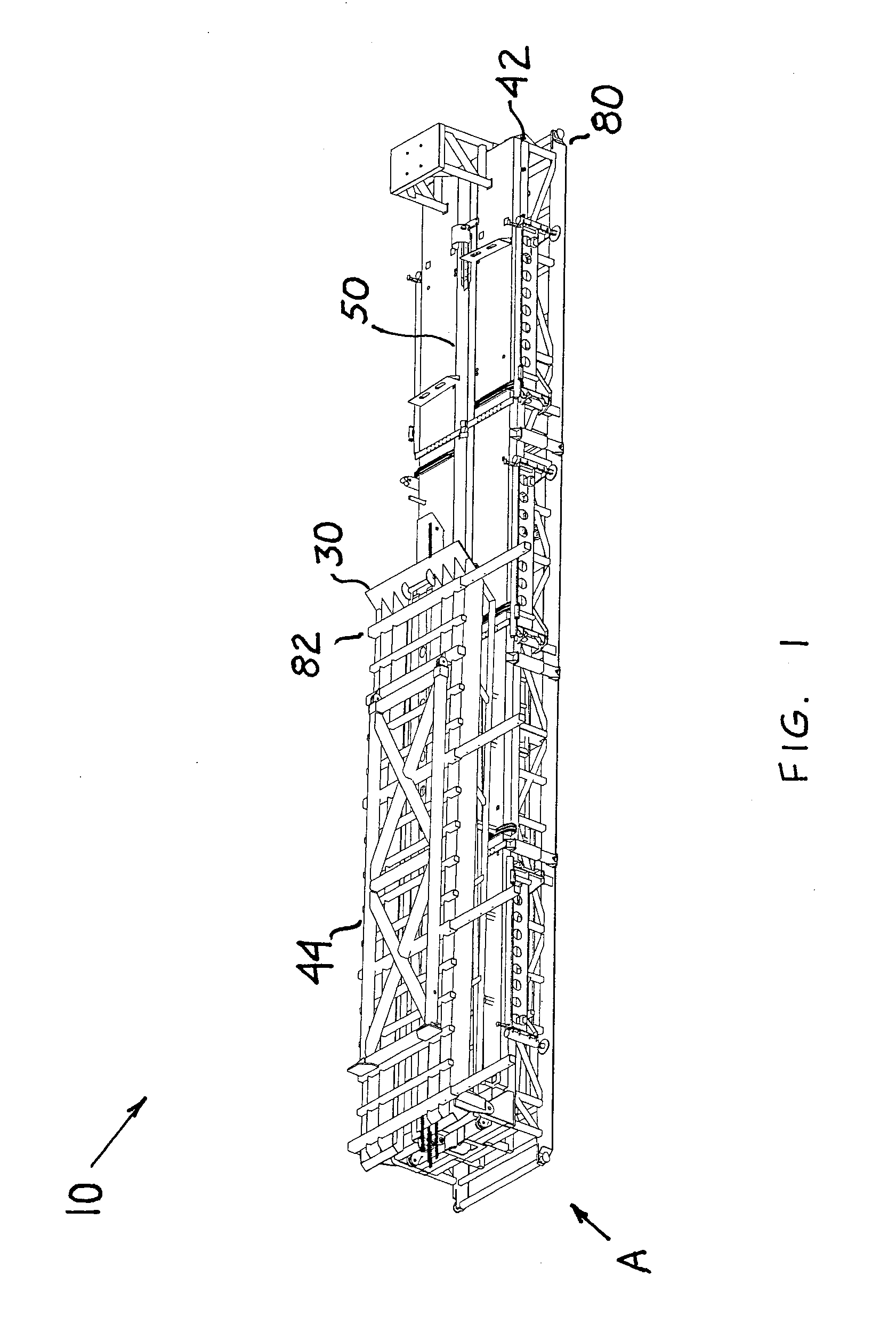

Chain-driven robotic arm

A robotic arm for transporting products in a product storage and dispensing system is disclosed. The robotic arm broadly includes a base operable to couple the arm to the dispensing system; a sprocket coupled with the base; an extendible arm segment coupled with the base; and a chain coupled with the sprocket and the extendible arm segment such that rotation of the sprocket causes movement of the chain and extension of the extendible arm segment. The robotic arm provides a compact and effective retrieval tool that is compatible with closely spaced and densely packed product shelves.

Owner:SCRIPTPRO L L C

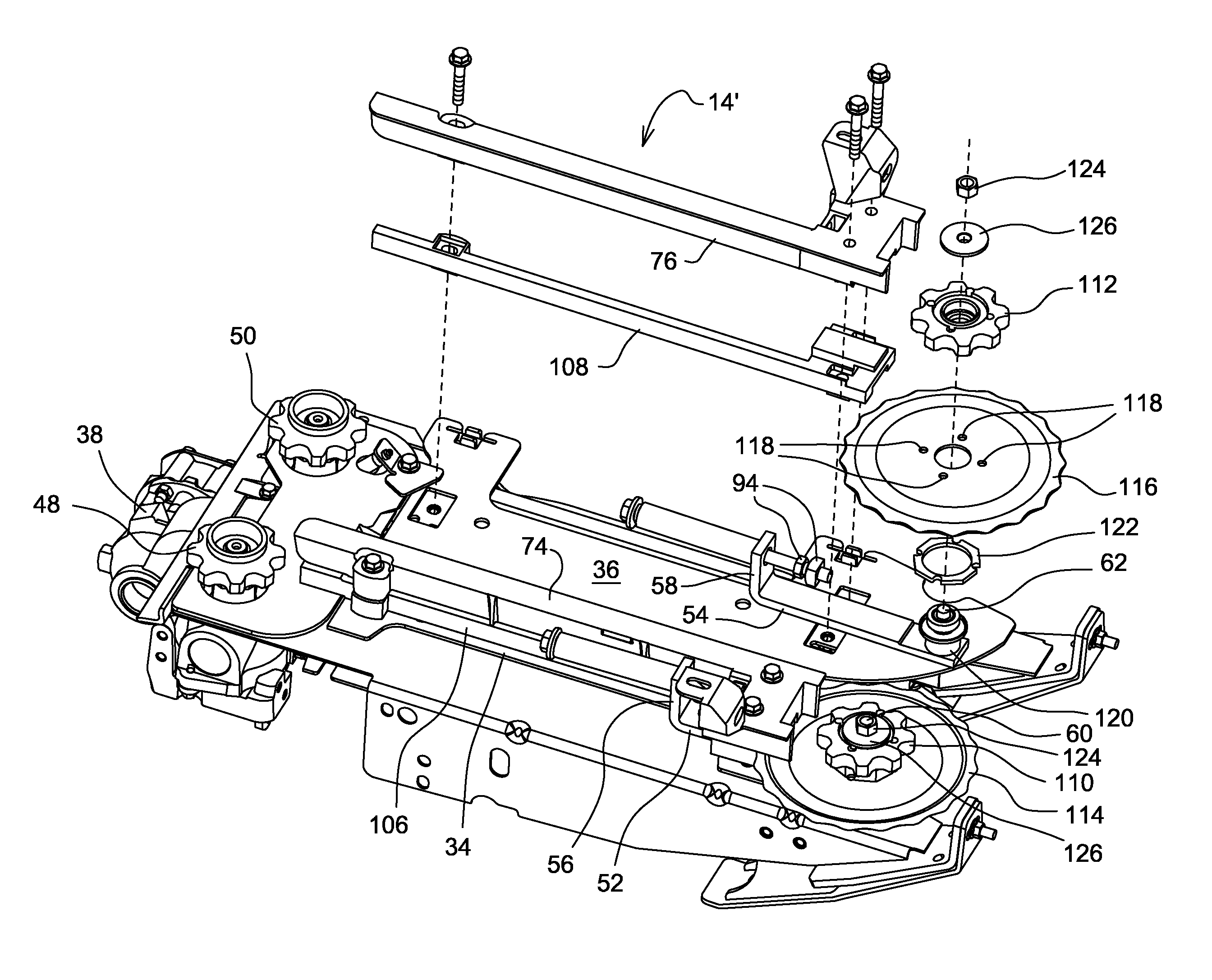

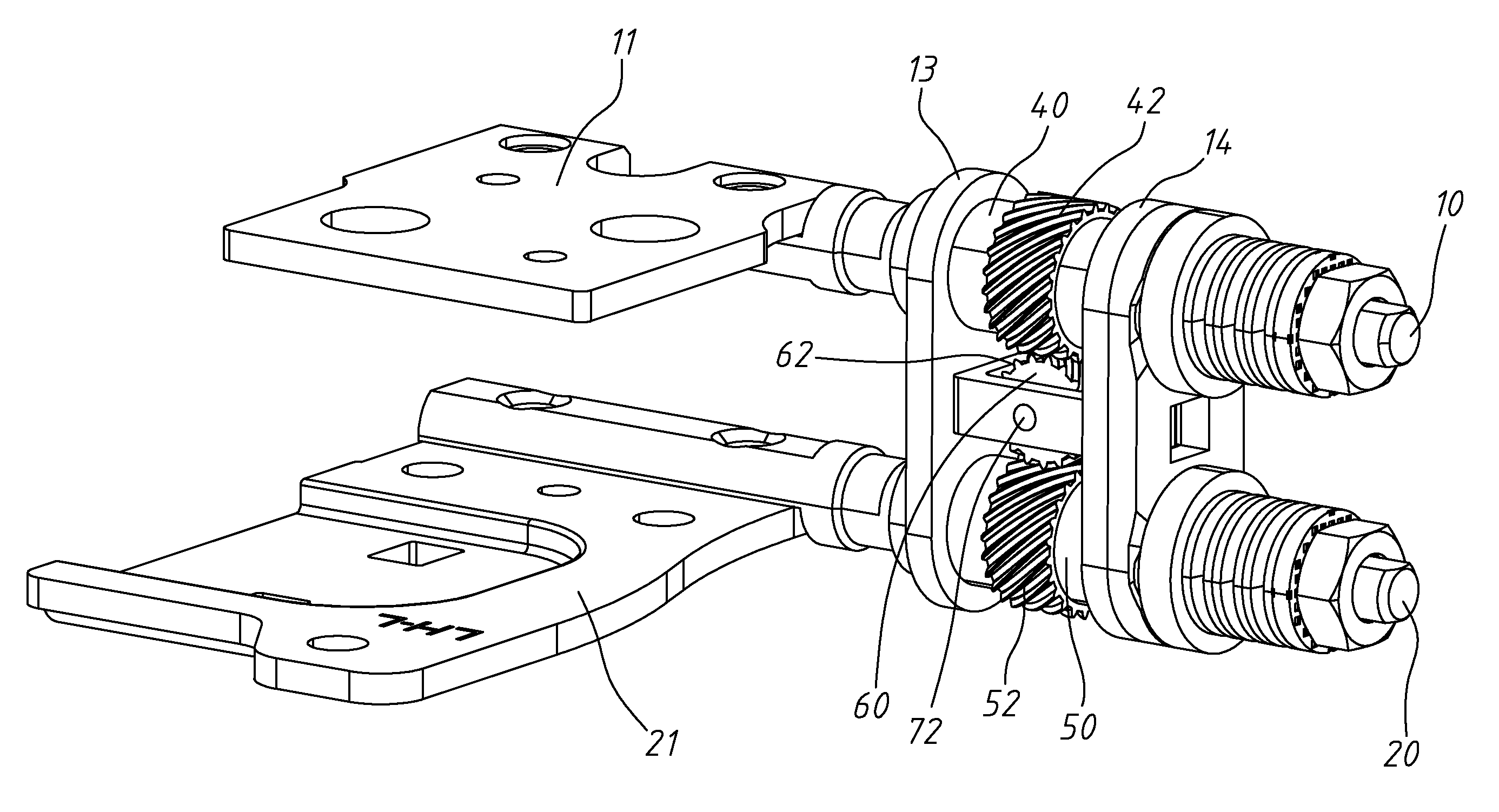

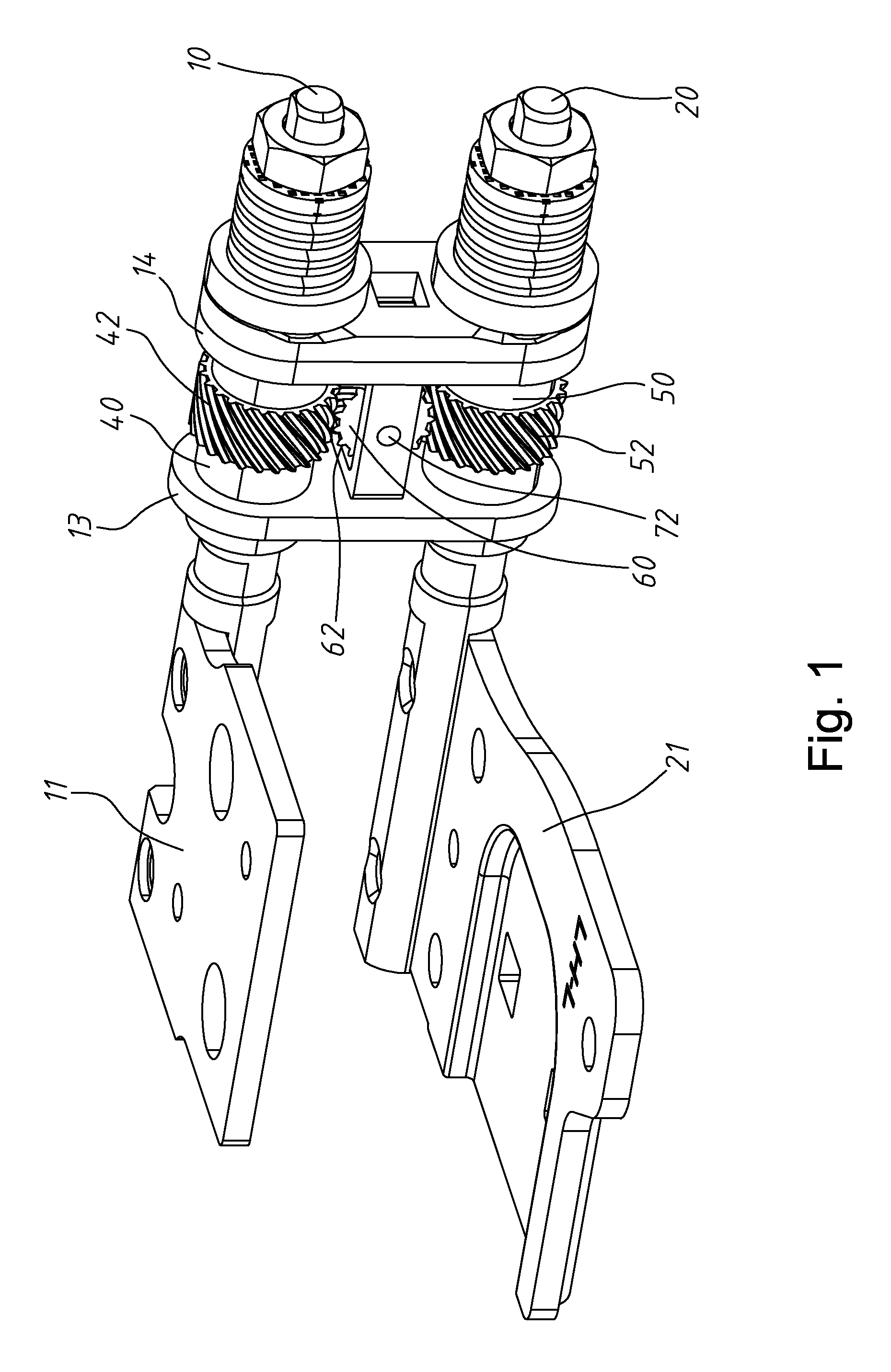

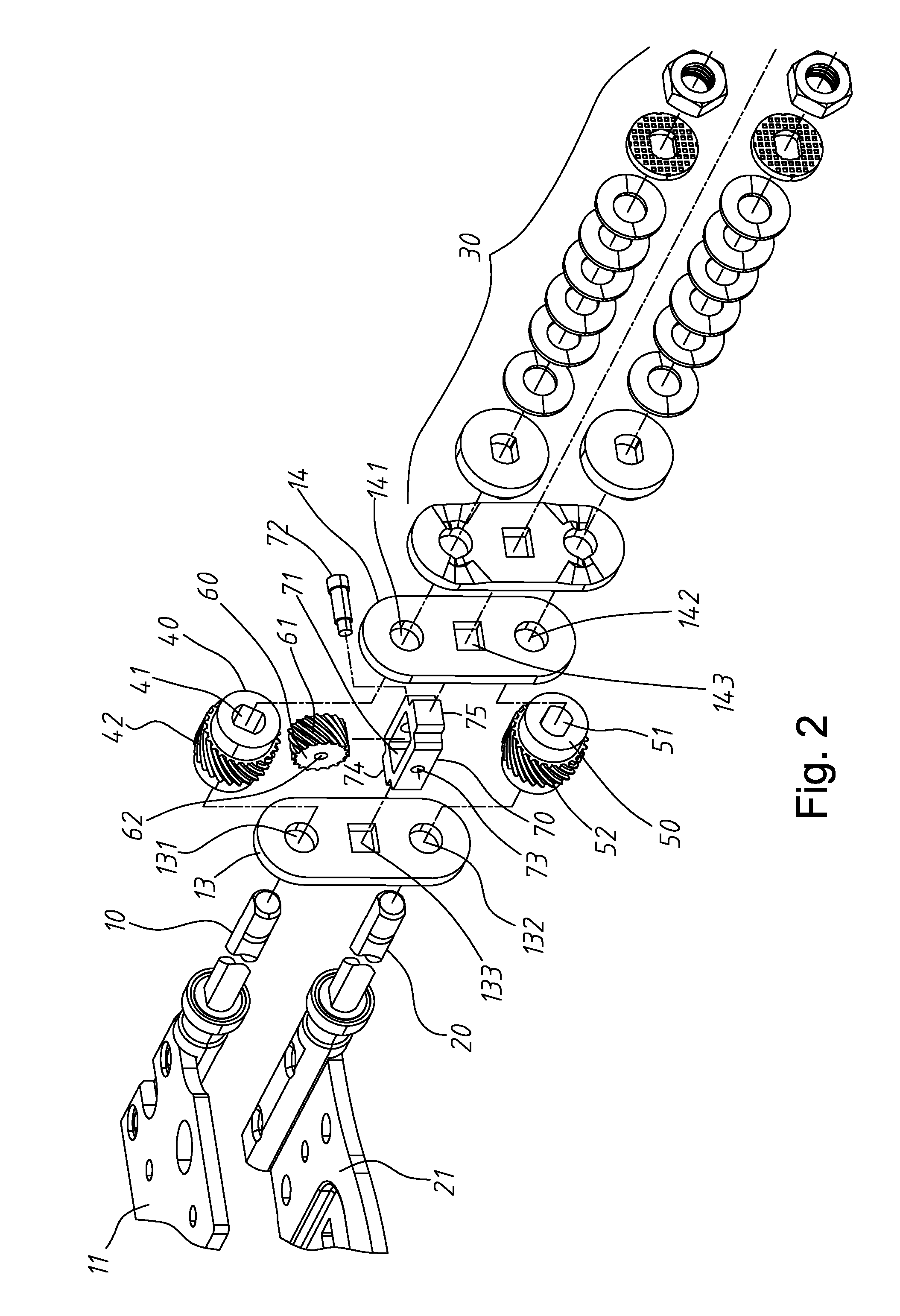

Transmission mechanism for dual-shaft hinge

A transmission mechanism includes a first shaft connected to a first mounting plate; a second shaft connected to a second mounting plate; a first positioning plate through which the first shaft and the second shaft extend rotatably; a second positioning plate, through which the first shaft and the second shaft extend rotatably, spaced from the first positioning plate by a distance; a first gear mounted on the first shaft, disposed between the first positioning plate and the second positioning plate and having a first helical tooth portion; a second gear mounted on the second shaft, disposed between the first positioning plate and the second positioning plate and having a second helical tooth portion having the same tooth profile and helix angle with the first helical tooth portion ; and a middle gear disposed between the first gear and the second gear and having a transmitting helical tooth portion engaging the first helical tooth portion and the second helical tooth portion, wherein the middle gear rotates about an axis skewed with the first shaft and the second shaft.

Owner:LIANHONG TECH

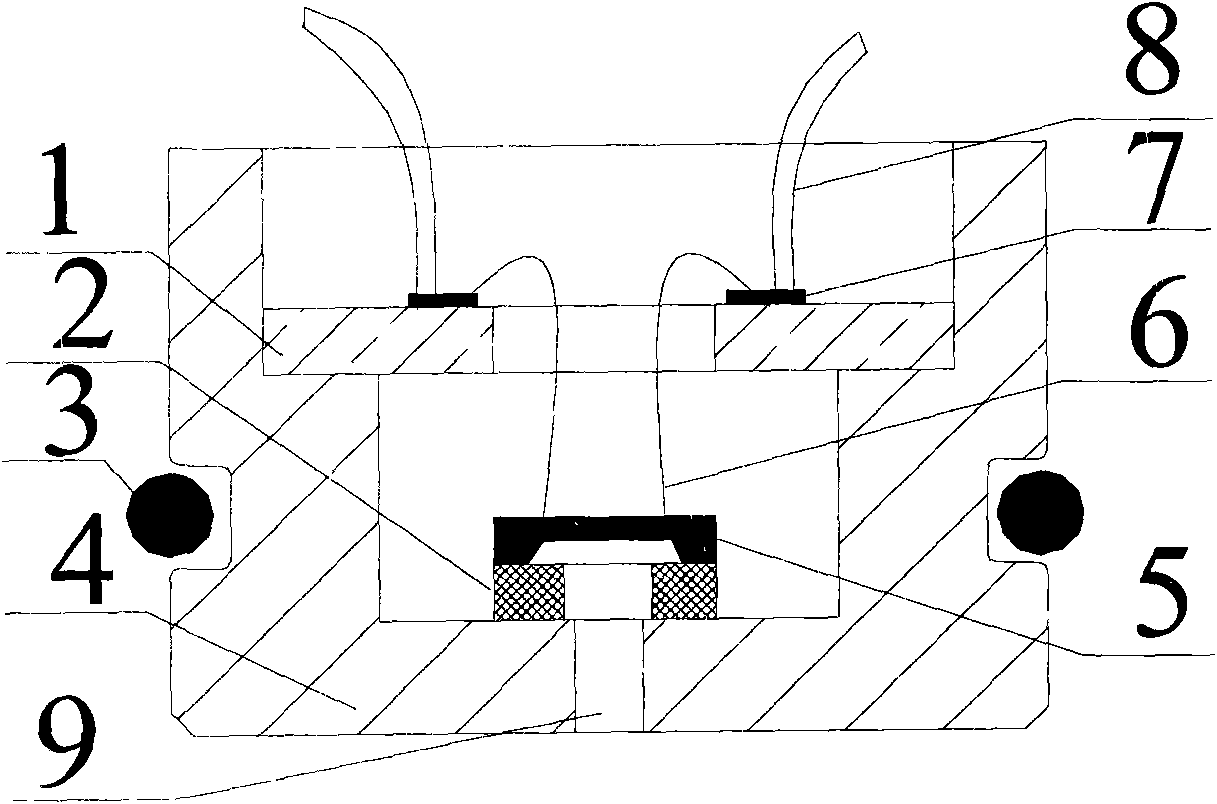

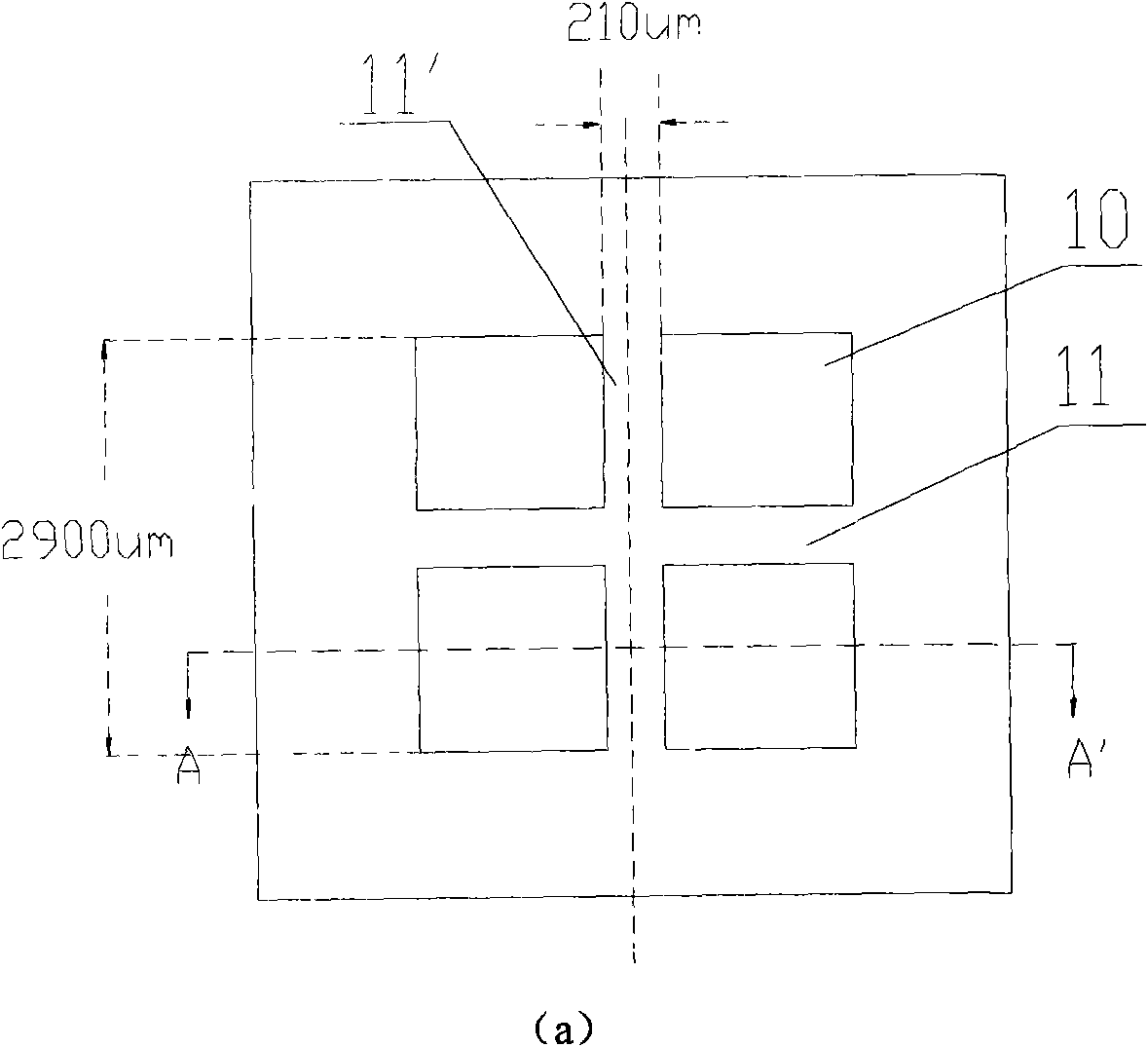

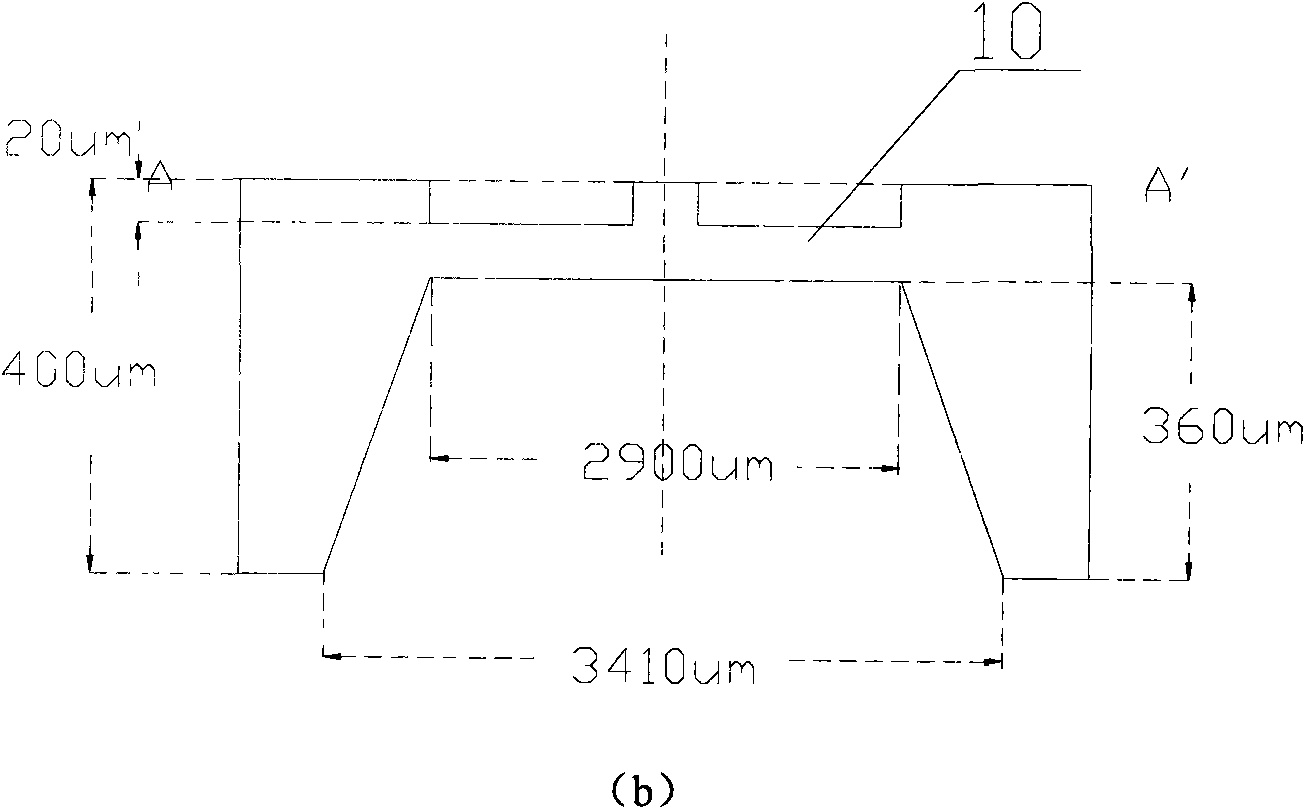

Beam-film combined micro-pressure sensor

InactiveCN101672710AHigh outputReduce hysteresisFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceSilicon membrane

The invention provides a beam-film combined micro-pressure sensor which comprises a base 4; a silicon micro-pressure chip 5 of a (100) crystal face is configured in the base 4; the front of a siliconsheet of the silicon micro-pressure chip 5 is corroded to form beams 11and 11' which are vertical to each other, and the back of the silicon sheet is corroded to form a flat film 10; the beam 11 and the beam 11', as well as beams around the silicon sheet form a beam shaped like a character tian so as to form a beam-film structure; pressure to be measured acts on the back of the back of the siliconsheet 5; a silicon membrane generates stress to cause the changes of resistors on the beams so as to measure a pressure value. The invention integrates the elasticity of a sensor, a sensitive elementand a conversion circuit and greatly reduces the sluggish and repeatability errors of the sensor in the process of measurement, thereby improving the measurement accuracy of the sensor. The inventioncan be widely used in oil logging, industrial automation, chain drive, national defense research and other fields.

Owner:XI AN JIAOTONG UNIV

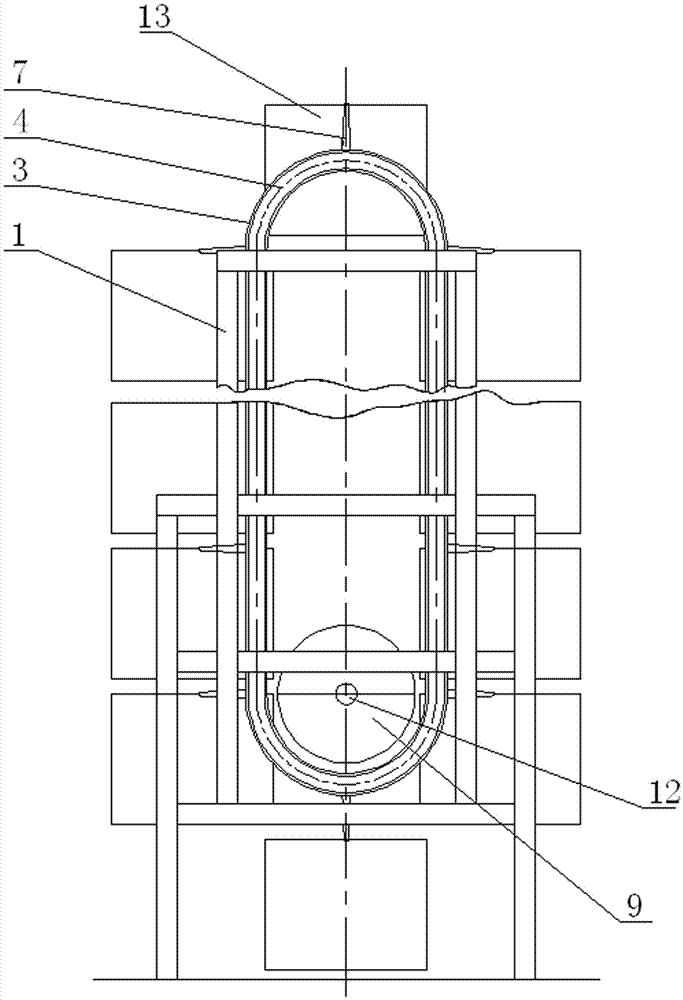

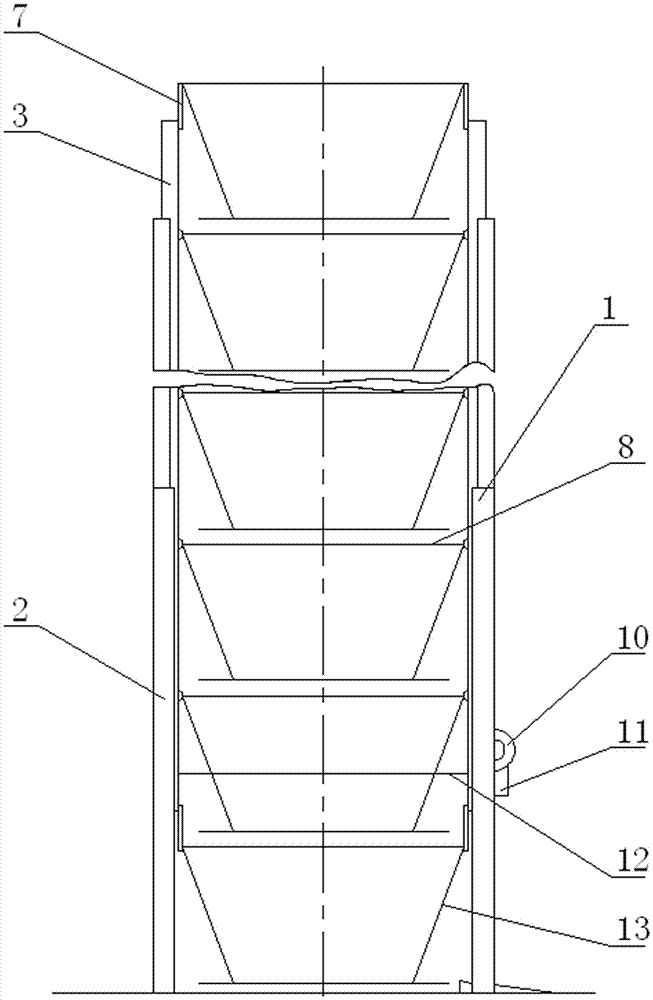

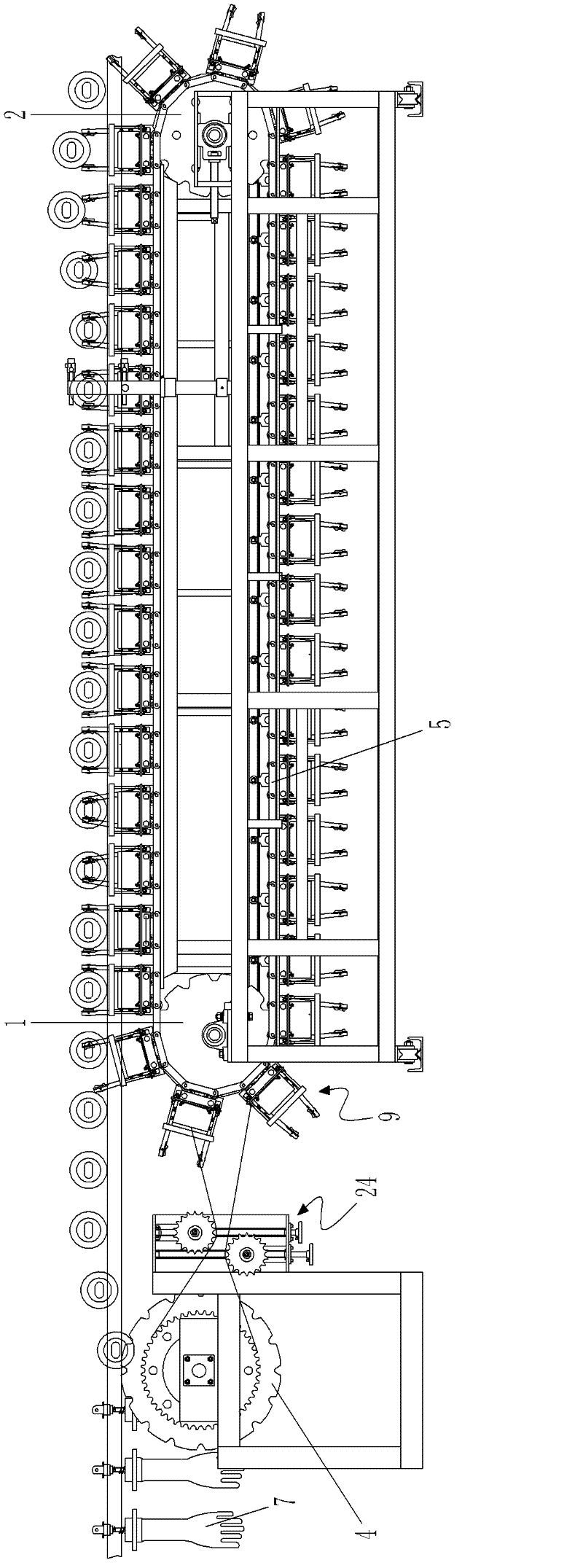

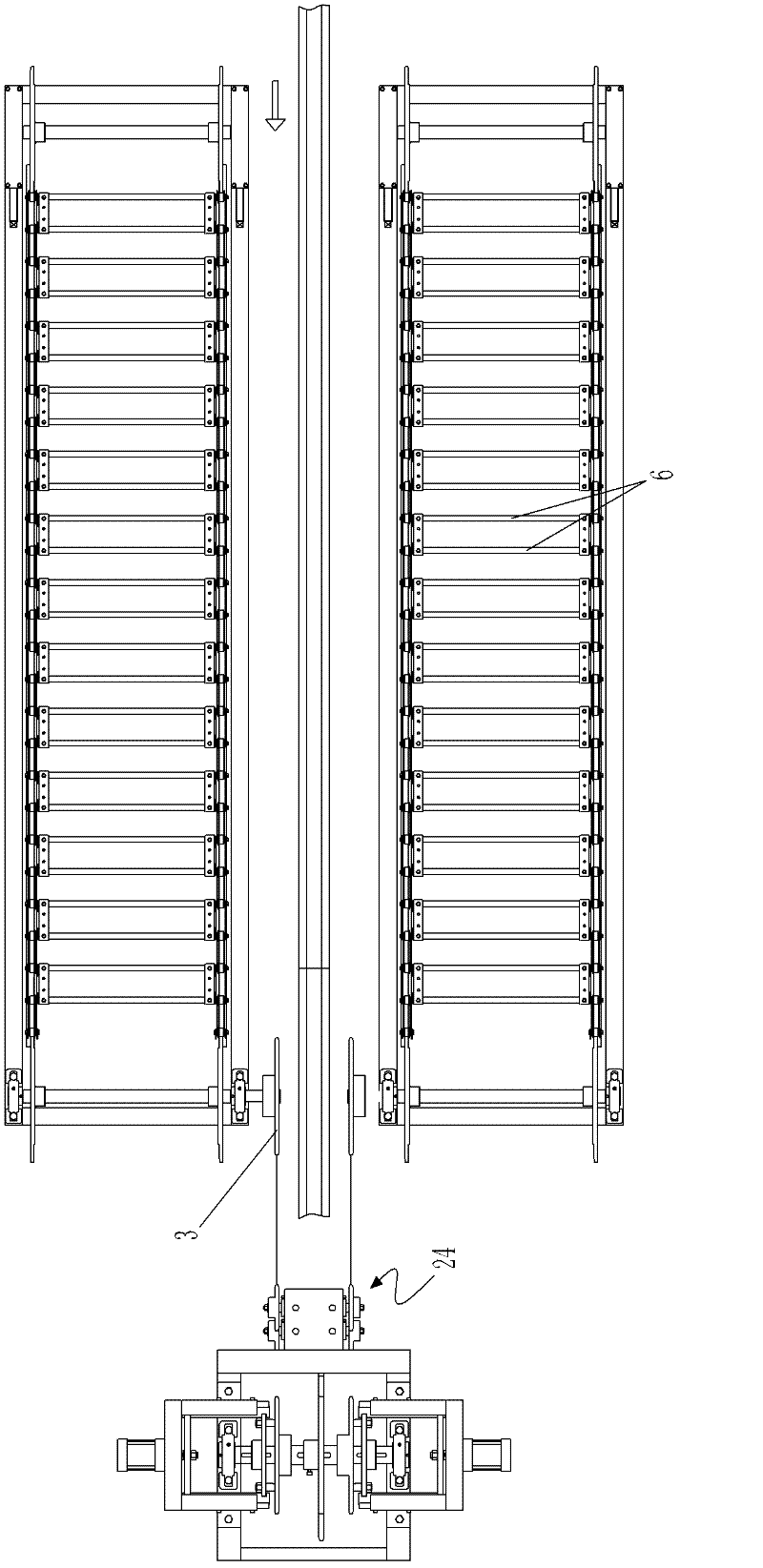

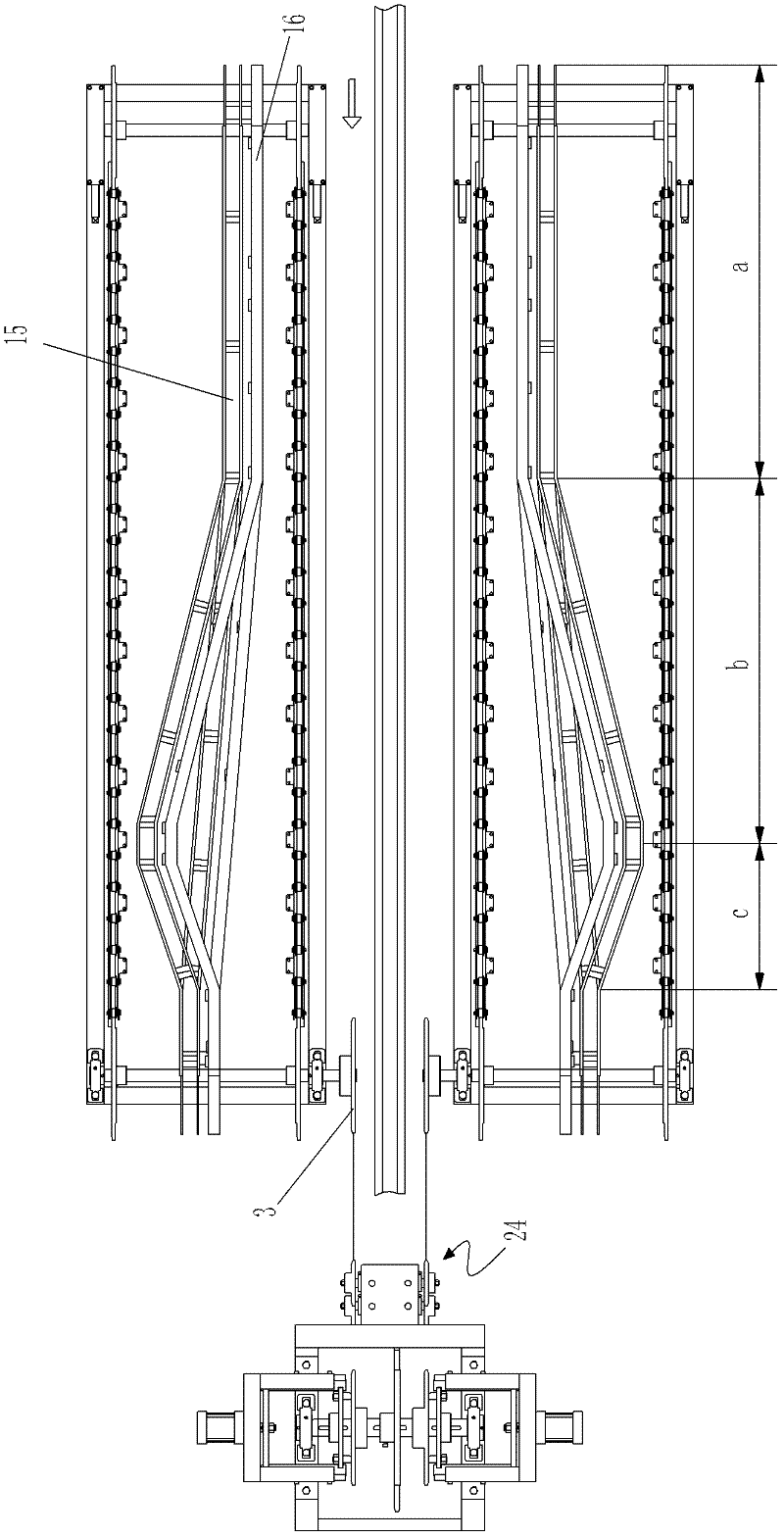

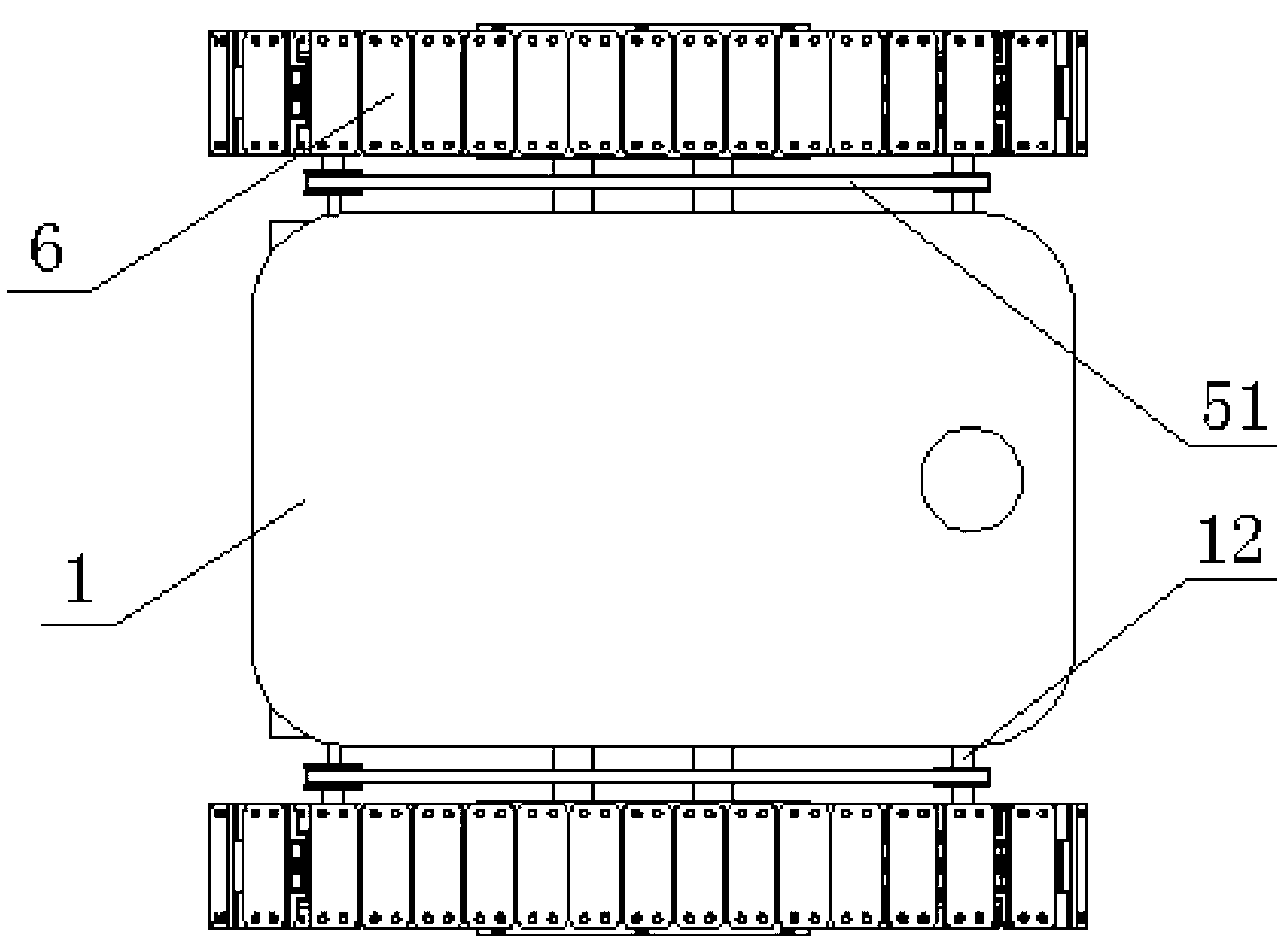

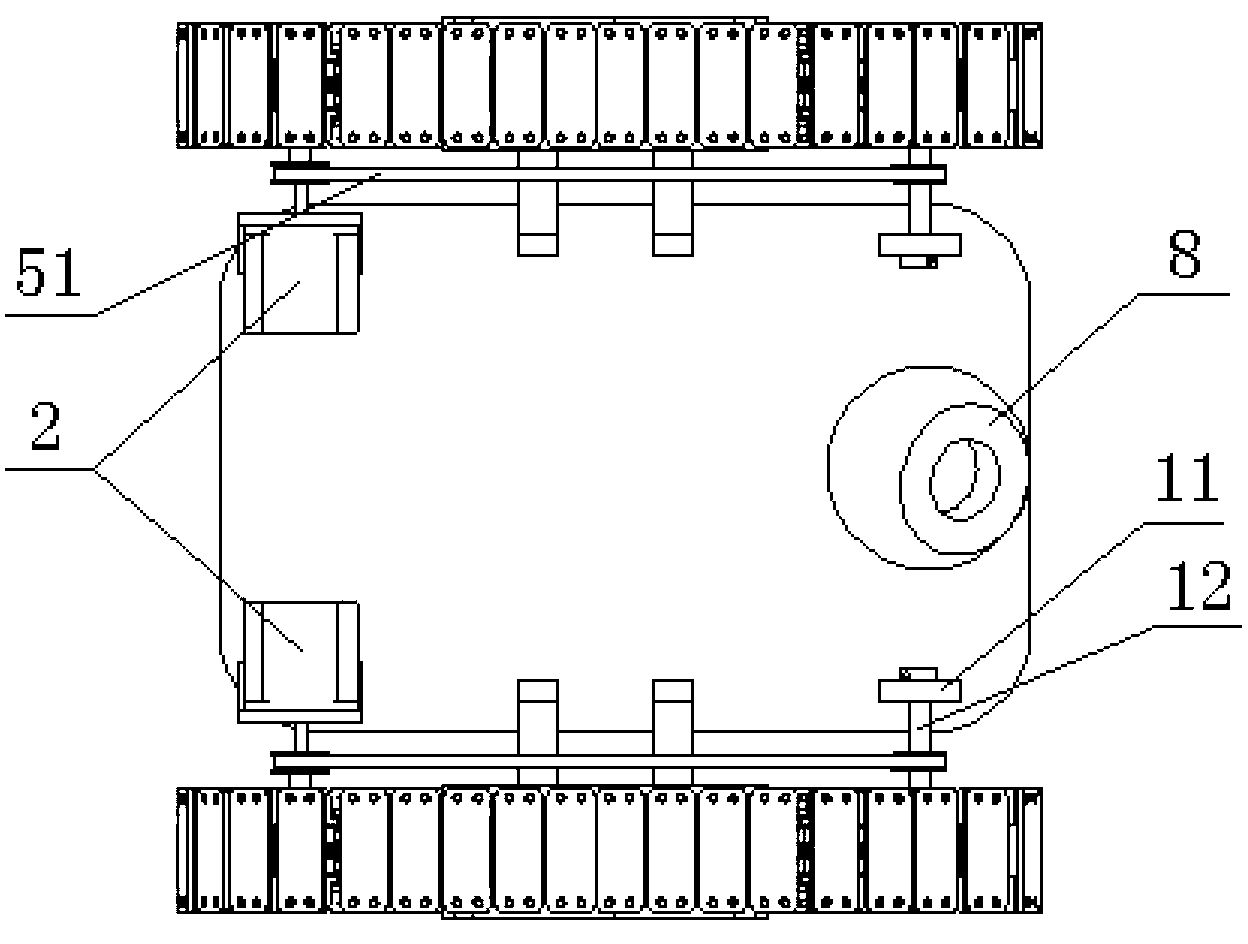

Rail-mounted vertical circulating three-dimensional garage

InactiveCN105442884AAchieve the purpose of accessing the carOutstanding FeaturesParkingsParking spaceEngineering

The invention discloses a rail-mounted vertical circulating three-dimensional garage which comprises a body frame, a basket parking unit and a drive chain wheel. The garage is characterized in that the body frame comprises a front frame and a rear frame, the front frame and the rear frame are each provided with a pair of symmetrical chain wheel track grooves in a fastened mode, an idler wheel trolley chain is installed in each chain track groove, the drive chain wheels are symmetrically installed below the front frame and the rear frame respectively and drive the idler wheel trolley chains respectively to move on the vertical face up and down in a circulating mode, the idler wheel trolley chains drive the basket parking unit to move up and down in a circulating mode, and all the components form the rail-mounted vertical circulating three-dimensional garage. The garage has the advantages of being simple and reasonable in structure, safe, reliable, easy to install, convenient to maintain, small in occupied area, large in parking number, and capable of achieving the purpose of increasing parking lots by improving structural strength of the frame and increasing the structural height.

Owner:何文年

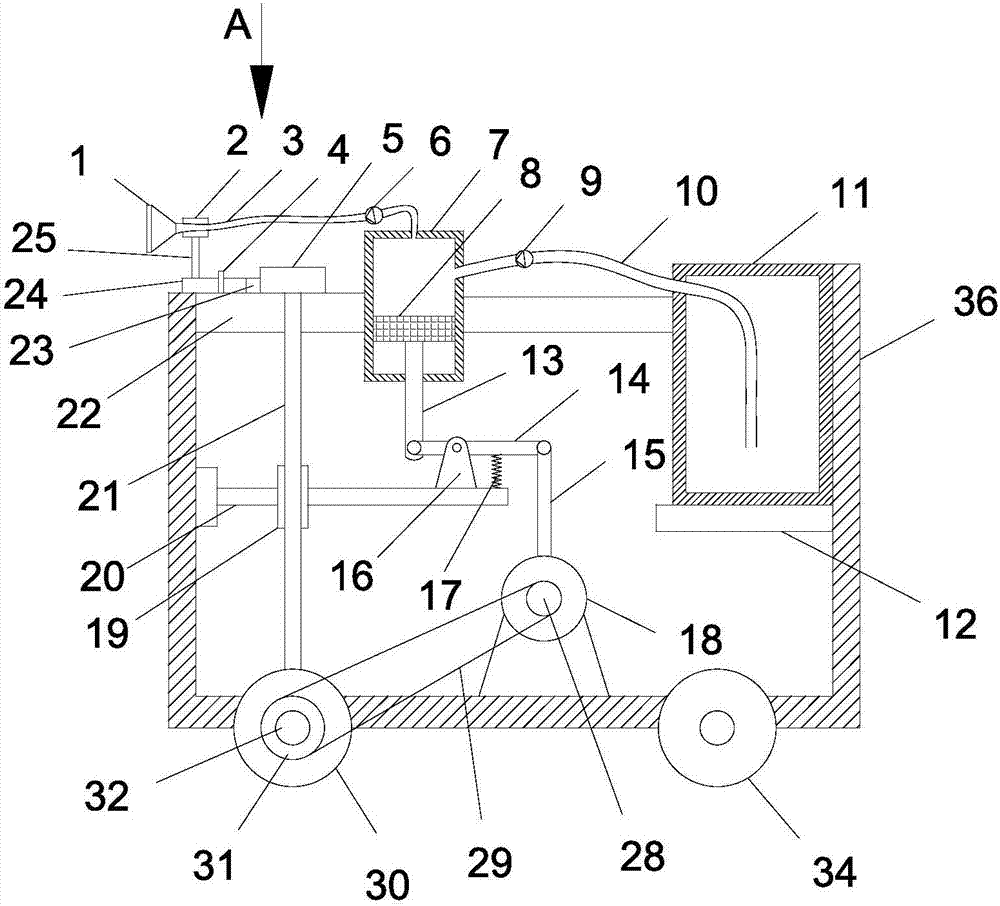

Auto-oscillation sprinkler for building construction

InactiveCN107130555AAchieve horizontal swingLarge range of dust suppressionRoad cleaningDrive shaftArchitectural engineering

The invention discloses an auto-oscillation sprinkler for building construction. The auto-oscillation sprinkler comprises a car body, wherein a front road wheel and a back road wheel are arranged at the bottom of the car body in a rotating manner; a driving chain wheel is in transmission connection with a driven chain wheel through a transmission chain belt; a hinged support seat is fixedly arranged on a fixed plate and is hinged with a lever; the lever is provided with a connecting rod; the upper end of the connecting rod is hinged with the right end of the lever; the lower end of the connecting rod is hinged with the edge of a runner; a piston head is arranged in a water collecting sleeve in a sliding manner; a piston rod is fixedly arranged on the lower side surface of the piston head; a second incomplete gear is coaxially and fixedly arranged at the upper end of a longitudinal drive shaft, is located in a square frame and is meshed with an inner rack; one end, far away from a sprinkler head, of a water outlet hose is tightly connected with the water collecting sleeve; a water tank is filled with clean water; and a suction hose communicates between the water tank and the water collecting sleeve. The auto-oscillation sprinkler is capable of watering the areas in front of the car body and on the left and right of the car body in the advancing process, and is wider in dust fall range and better in dust removal effect.

Owner:吴佳雯

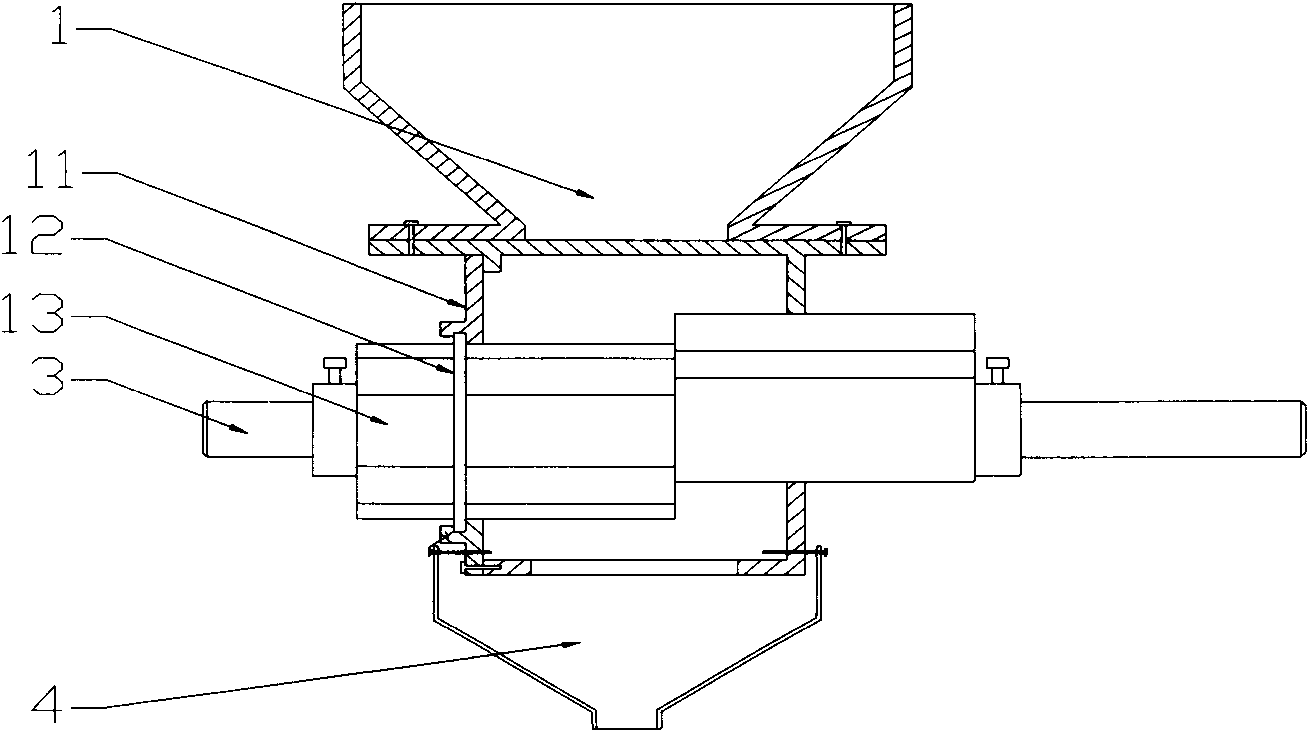

Fertilizer applicator

InactiveCN101611668AImprove handlingEasy to disassembleFertiliser distributersClutch controlGear wheel

The invention discloses a fertilizer applicator which solves the technical problem existing in the prior matching fertilizer applicators. The invention adopts the following technical scheme: the rotating power of the fertilizer applicator is generated by driving a driven shaft by a driving shaft of a gear box; a chain drives a spindle gear of the fertilizer applicator and a fertilizer applicator spindle to rotate; the power transmission of the fertilizer applicator adopts electromagnetic type clutch for clutch control; a semicircular shaft with a flat surface is adopted for the spindle of the fertilizer applicator; a fertilizer wheel club shift ring is mounted outside a fertilizer applicator shell; the upper section of a blanking vessel is a plastic tube; and the iron portion of the lower section is divided into an upper funnel-shaped part and a lower tubular part. The invention has the advantages that the power transmission of the fertilizer applicator adopts electromagnetic clutch for clutch control, which is convenient to operate the fertilizer applicator; the fertilizer wheel club shift ring is mounted outside the fertilizer applicator shell, which is favorable for dismounting and maintaining; the iron portion at the lower part of the blanking vessel is divided into the upper funnel-shaped part and the lower tubular part, thereby ensuring smoothness at the top part when the height of an opener is adjusted to avoid blockage.

Owner:ZHUANGHE AGRI MECHANIZATION TECH PROMOTION STATION

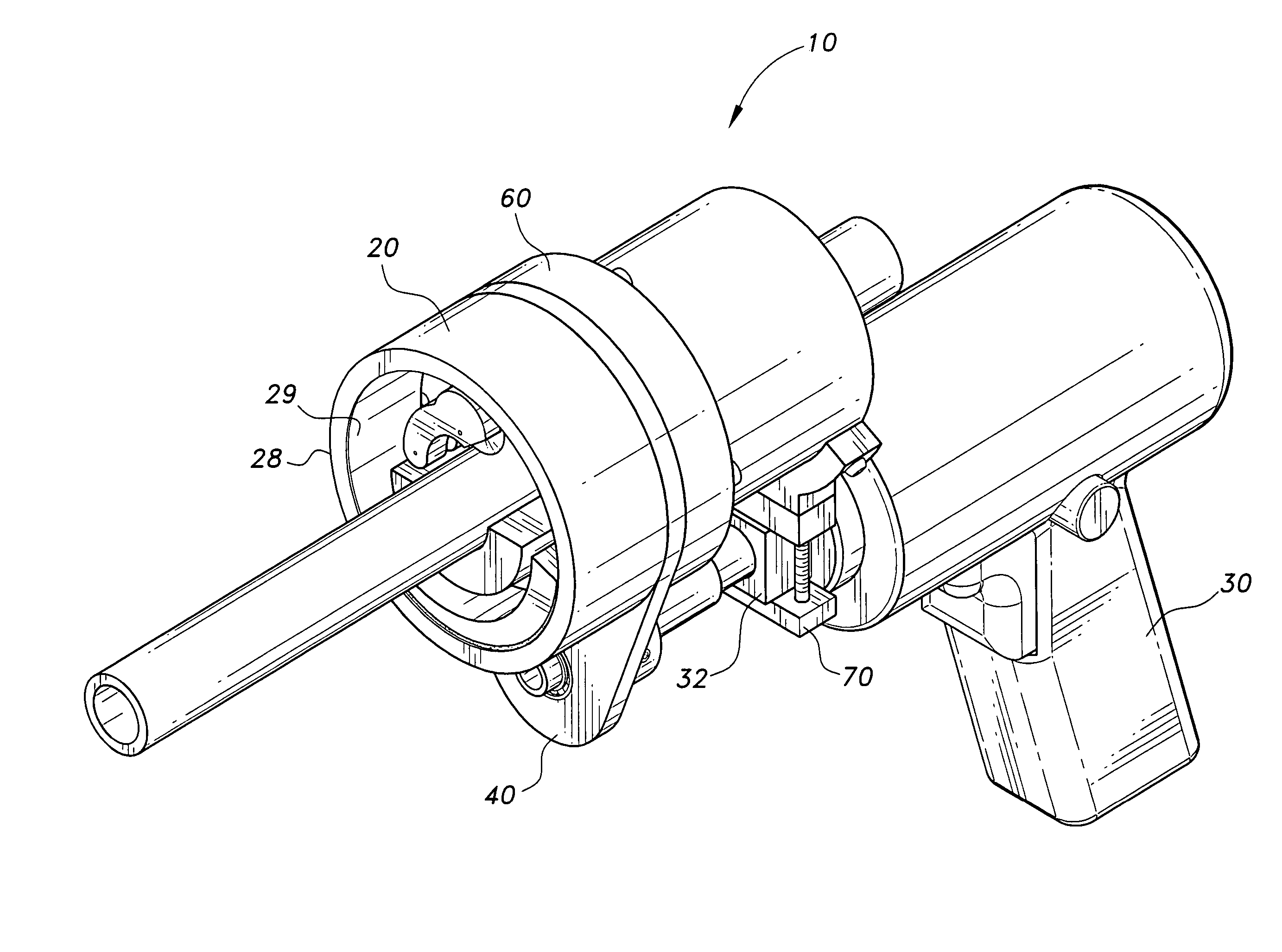

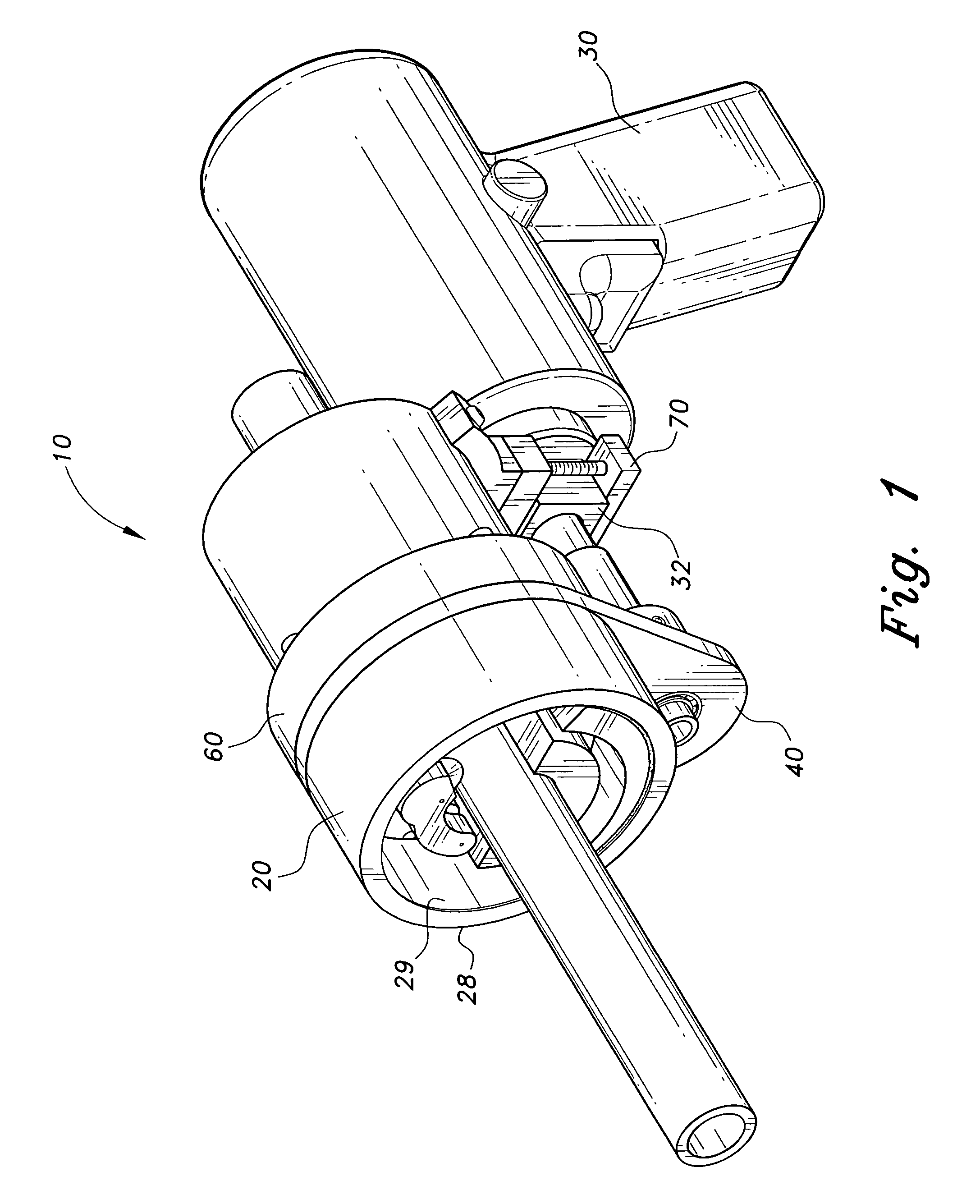

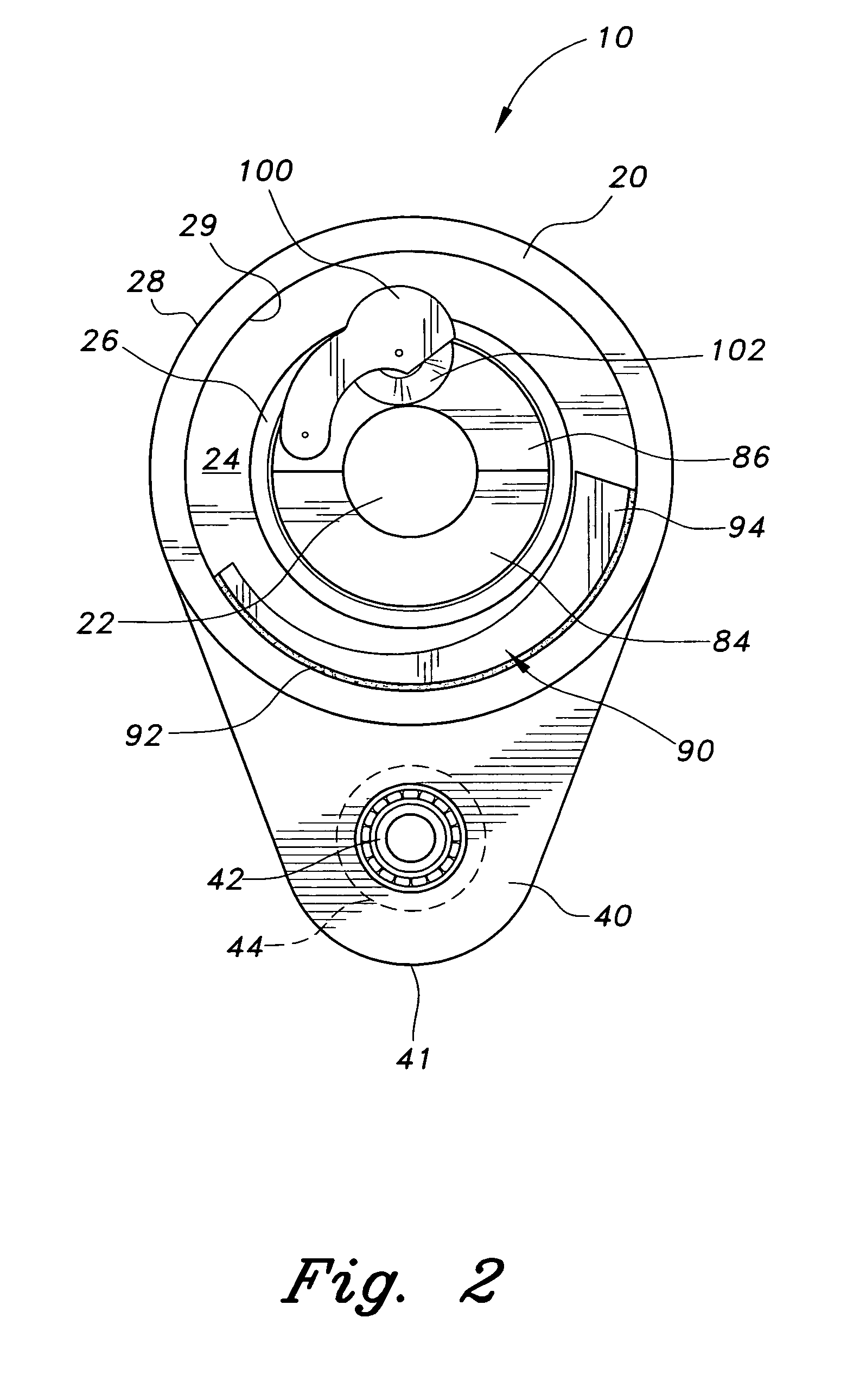

Powered tubing cutter

InactiveUS7152325B2Increase production speedPortable power-driven toolsTube shearing machinesDrive shaftHand held

The powered tubing cutter is a hand held, mechanical device driven by a motor for cutting tubing / piping. The device comprises a housing, a drive plate, a main drive shaft, a cutting assembly having a cutting blade, a cam plate and a chain drive secured to a motor housing, having a handle, by a mounting bracket. The chain drive is powered by the motor, which causes the main drive shaft to rotate. The cutting assembly is pivotally secured to a pin on the main drive shaft. The pipe / tube to be cut is placed into the hole in the center of the housing and the main drive shaft. As the cutting assembly rotates with the main drive shaft the cam plate forces the cutting blade into cutting engagement with the tube / pipe.

Owner:GREEN CARROLL D +1

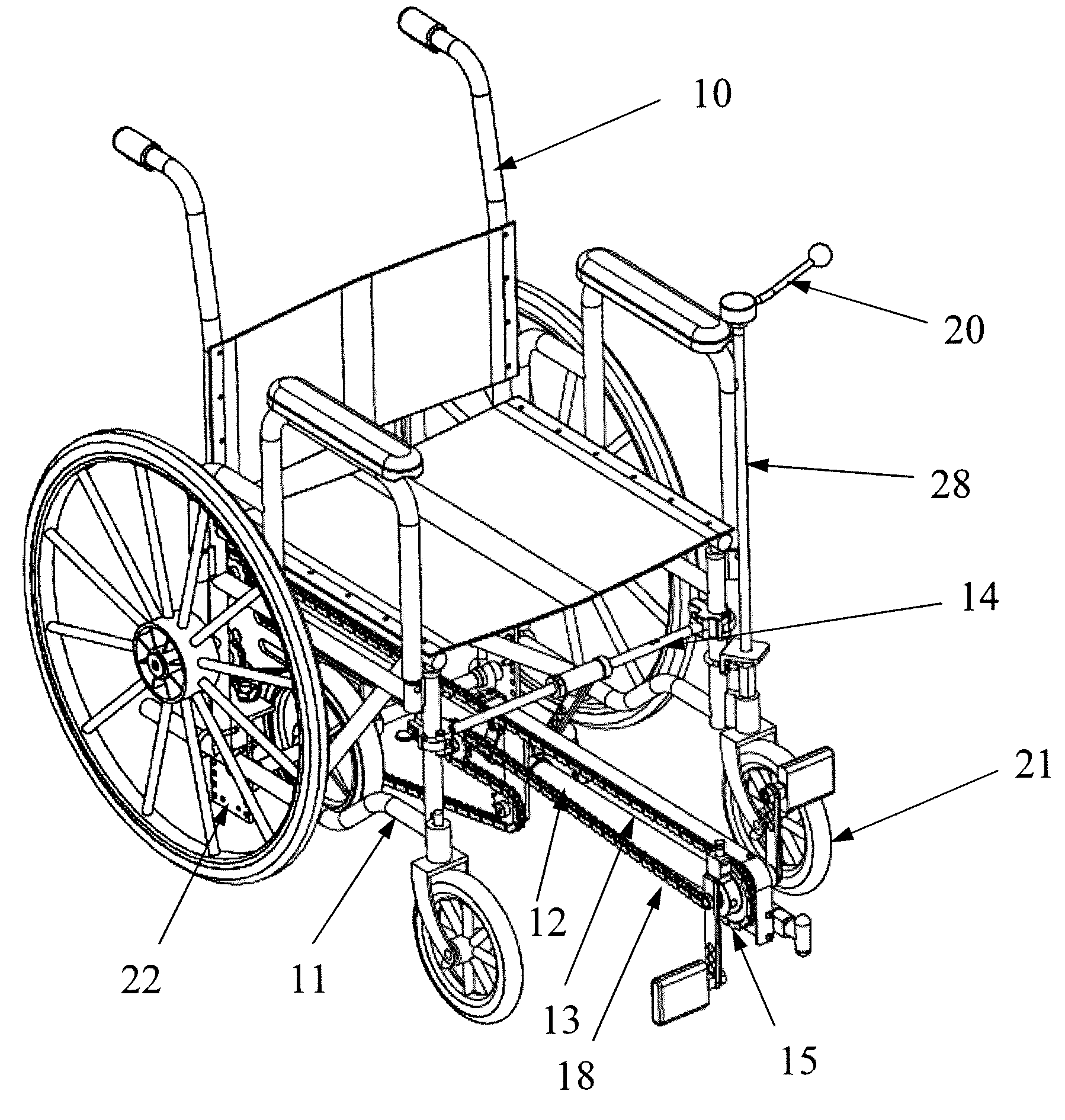

Wheelchair propulsion and exercise attachment

InactiveUS20080246246A1Easy height adjustmentWheelchairs/patient conveyanceRider propulsionDrive wheelChain length

A propulsion and exercise device for attaching to a conventional wheelchair having: at least one drive wheel operably interposed between the rear set of wheelchair wheels. A telescoping mast may connect the drive wheel axle to pedals to permit the pedals to be selectively moved from a stowed position to an extended position for use. Power is transmitted from the pedals to the drive wheel through a chain drive that passes over idler sprockets that maintain the chain length during adjustment of the telescoping mast.

Owner:PAT PENDING MARKETING

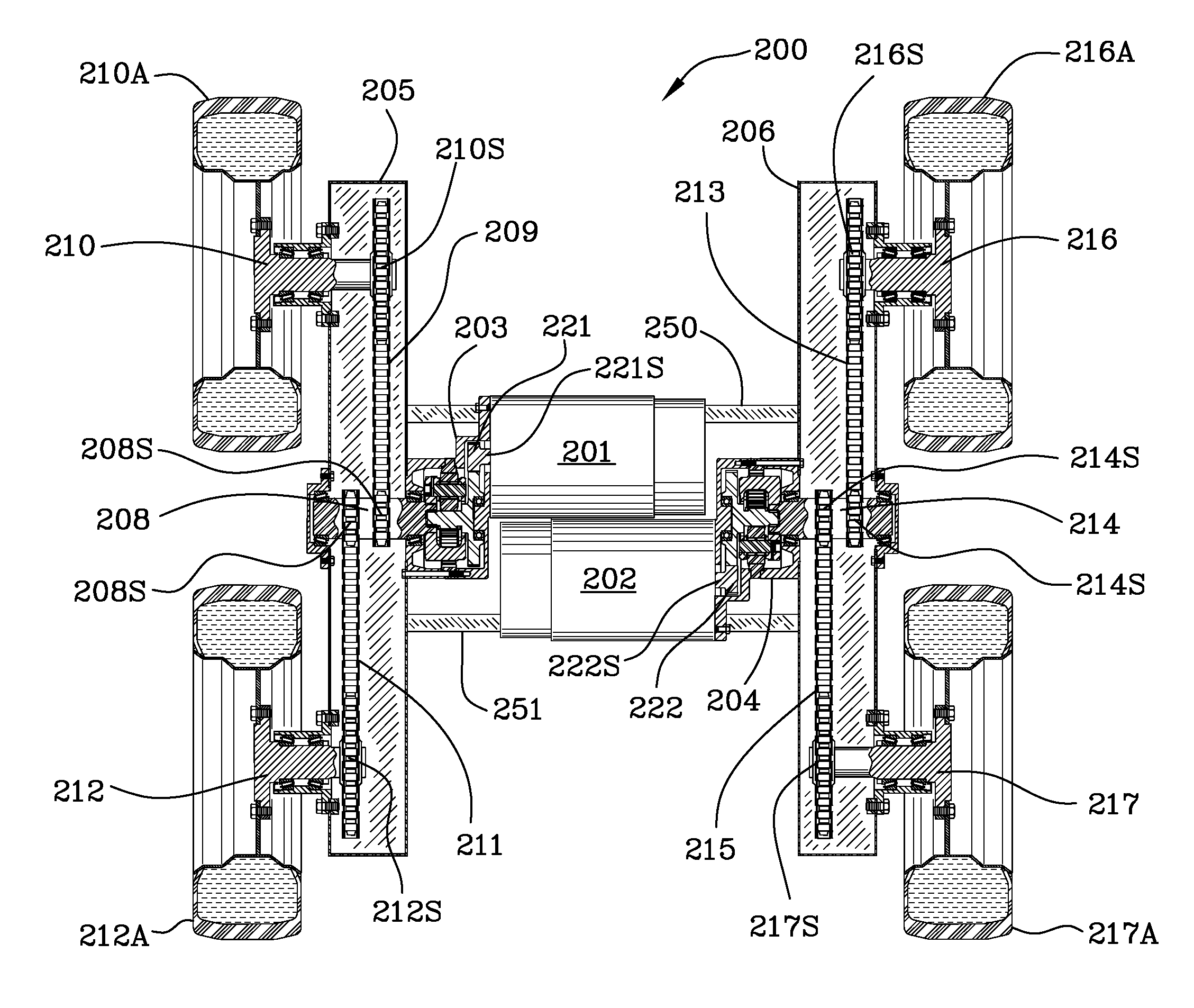

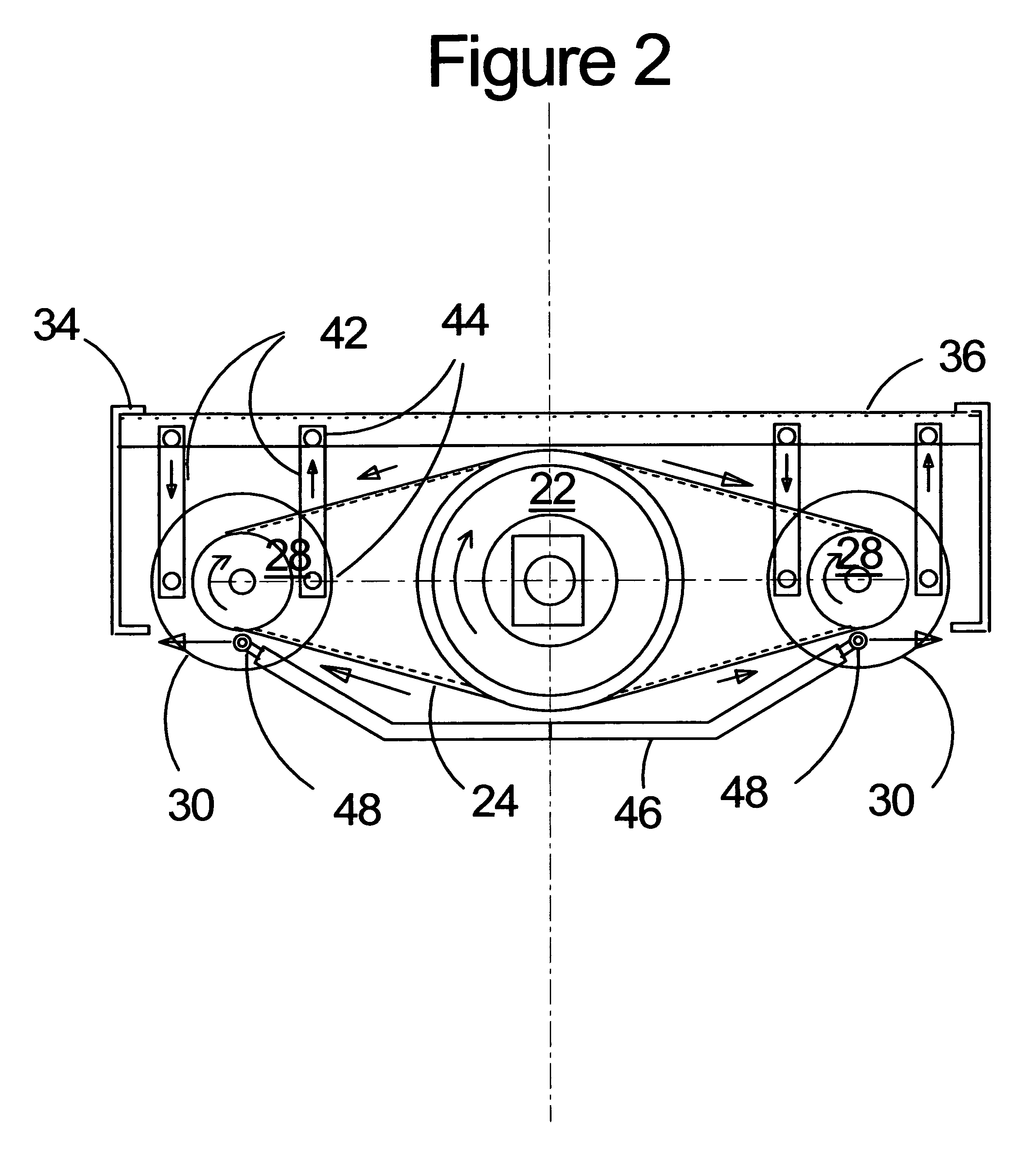

Balanced Belt or Chain Drive for Electric Hybrid Vehicle Conversion

InactiveUS20090000836A1Force balanceShorten speedElectric propulsion mountingElectric machinesCombustionDrive shaft

A drive assembly is described which can apply a pure torque to a driven member while allowing for limited motion of the driven member in the radial direction. This drive assembly is particularly suitable for converting an Internal Combustion (IC) vehicle to an IC-electric hybrid vehicle comprising installation of two electric motors coupled to a drive shaft of the vehicle via the drive of this invention such that the electric motors can provide some or all of the mechanical power required to propel the vehicle while accepting some relative motion between the existing vehicle drive shafts and the chassis and imposing minimal radial force on the drive shaft.

Owner:KYDD PAUL HARRIMAN

Cable traction apparatus and method

InactiveUS7021510B2High strengthDistributes forcePipe laying and repairPortable liftingPull forceNormal force

Owner:ELLINGSON DAVID IRWIN

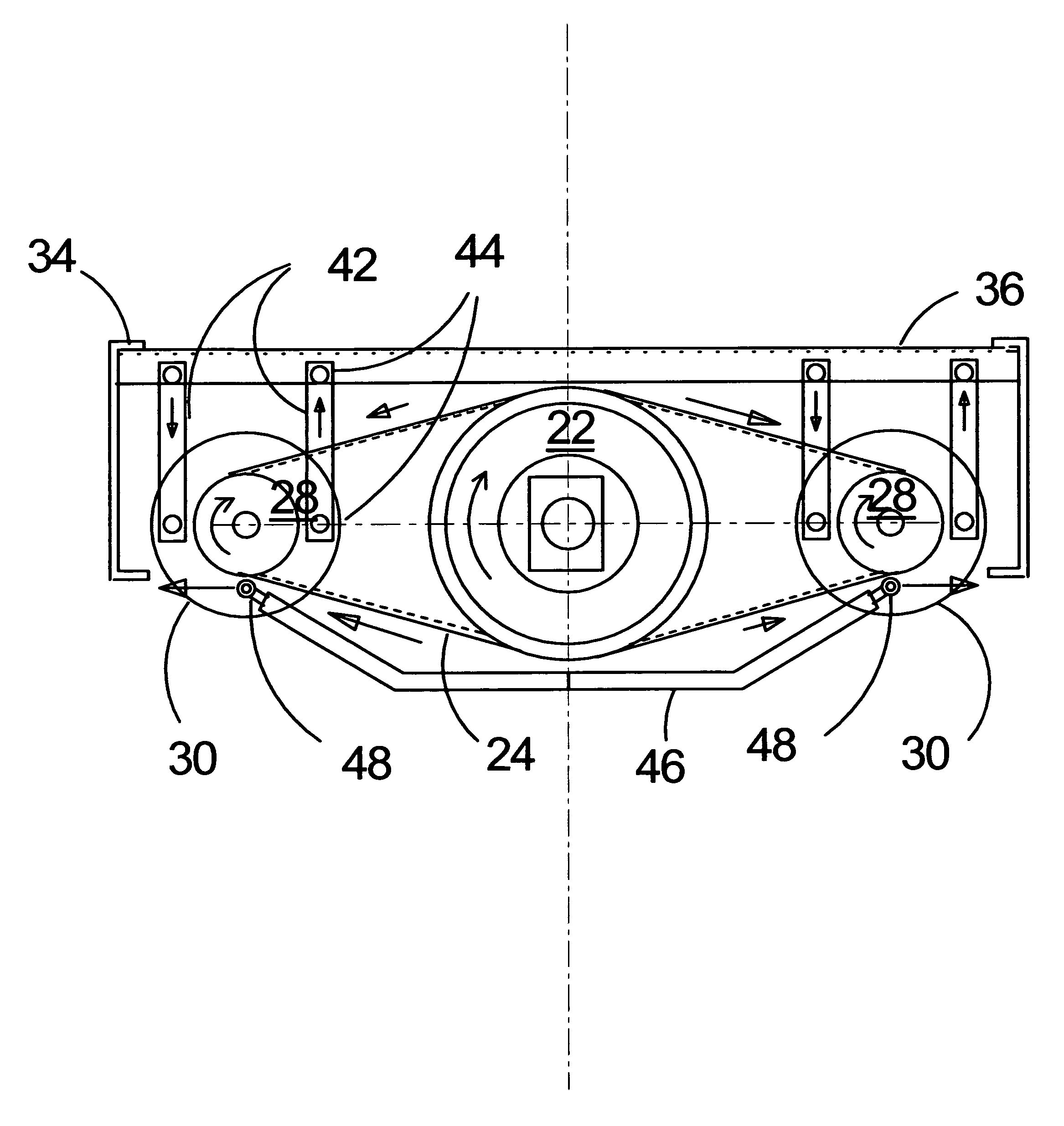

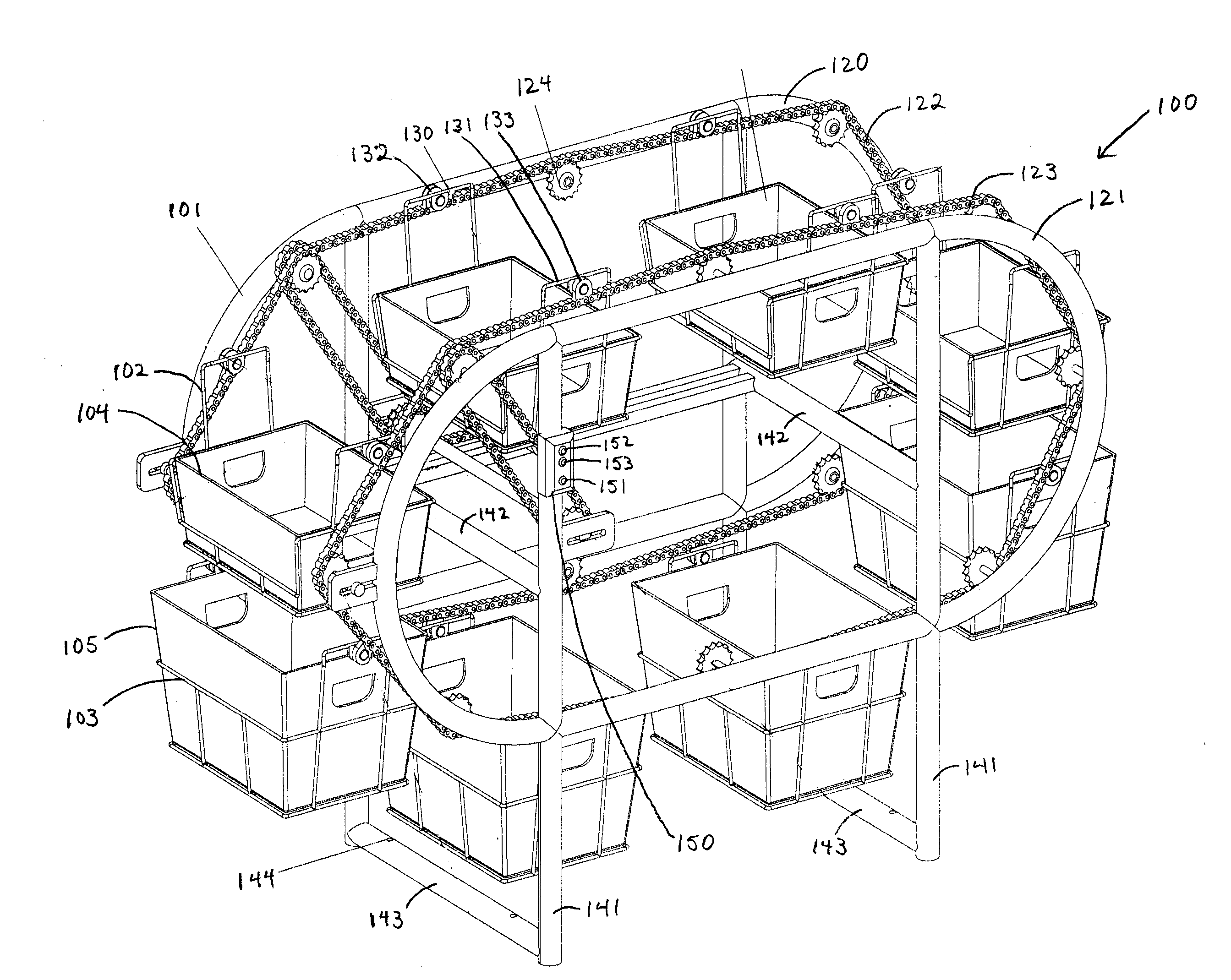

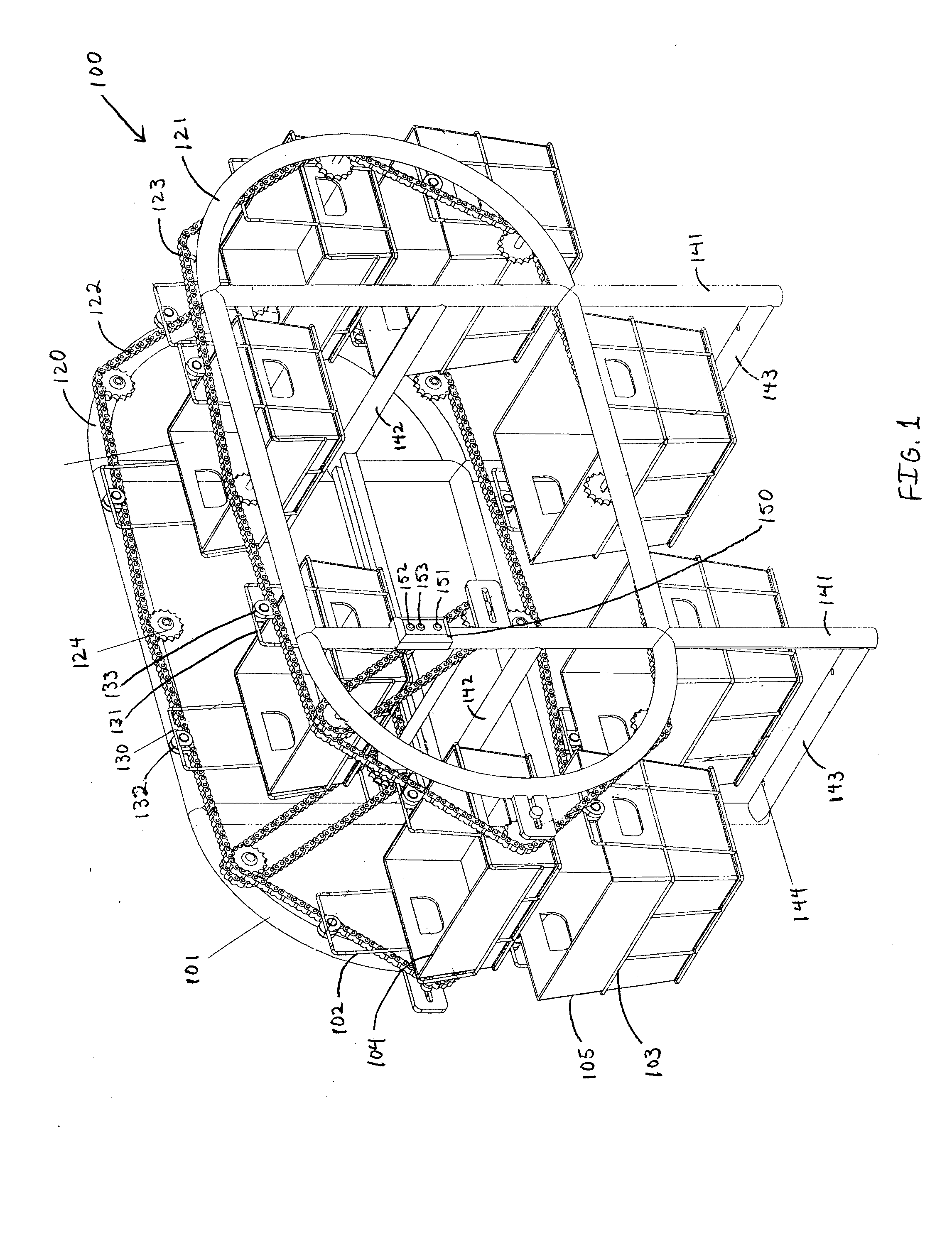

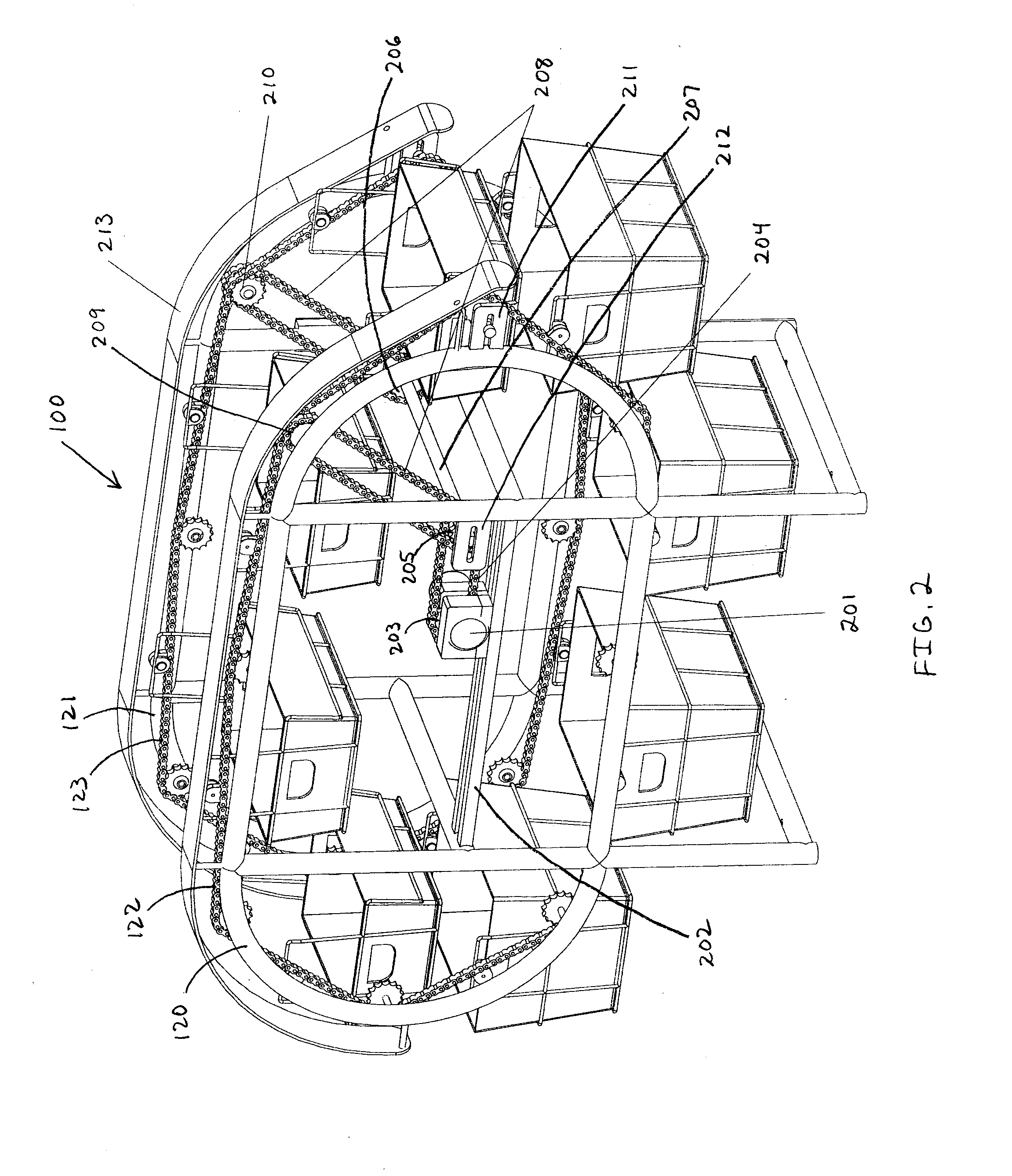

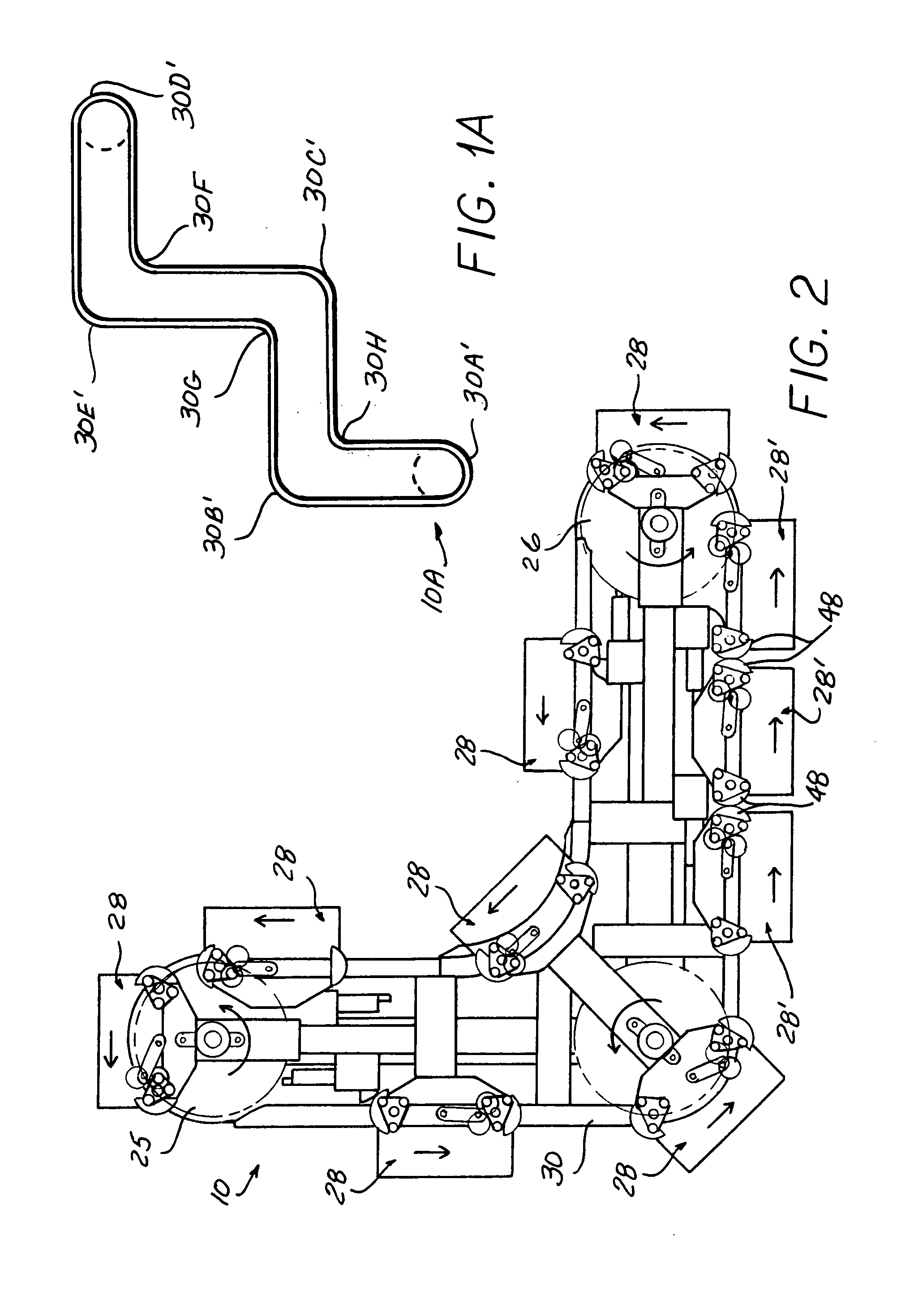

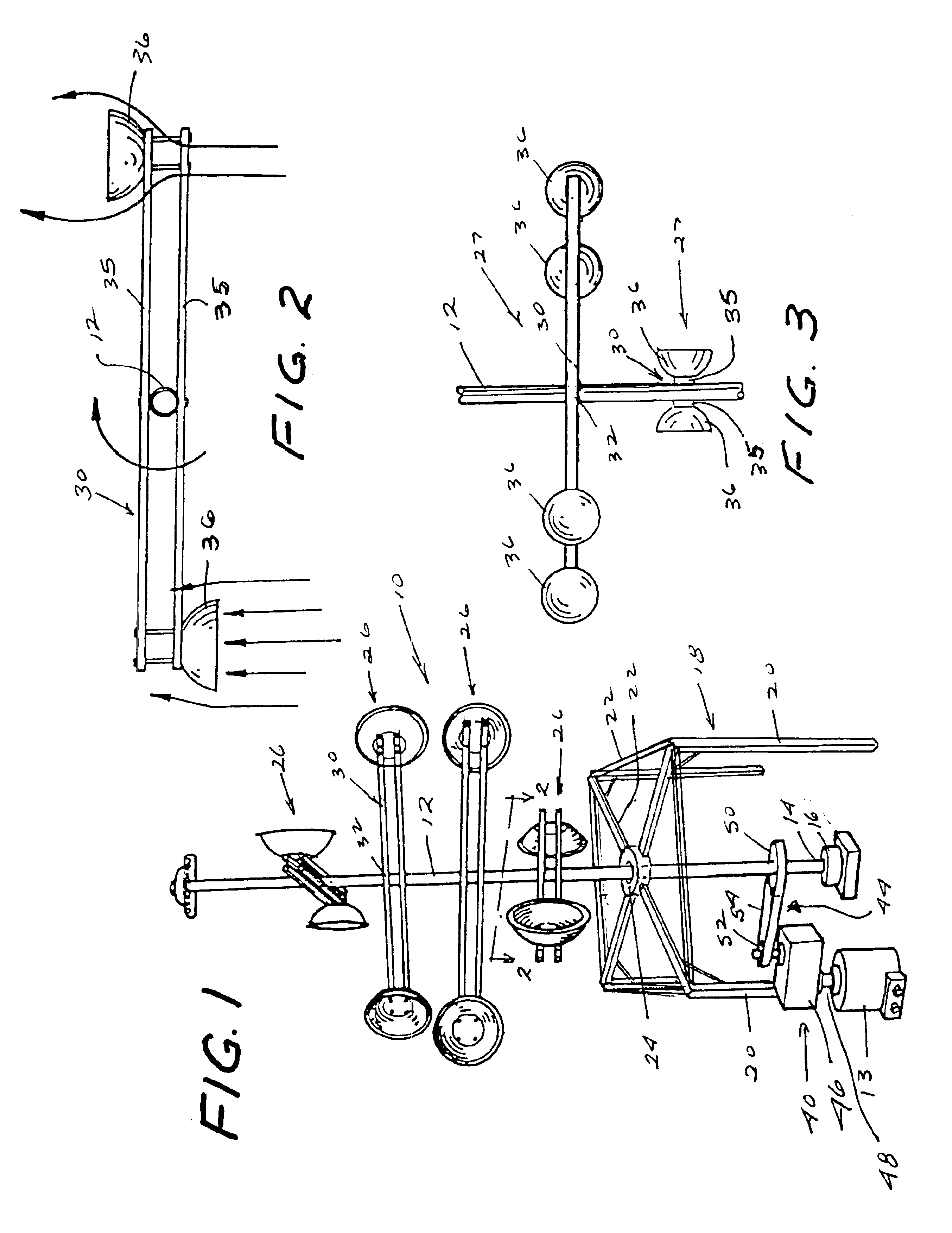

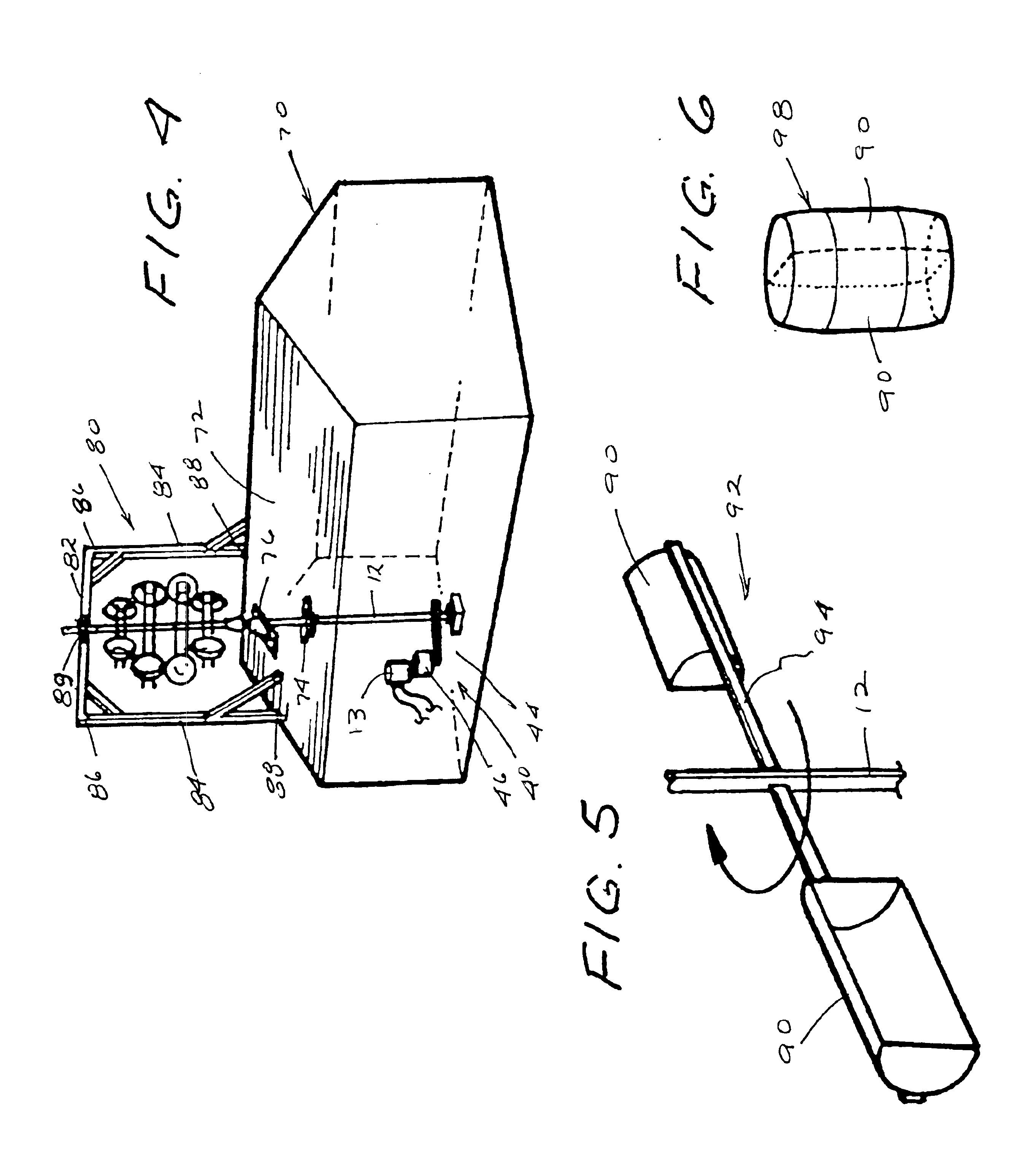

Postal-Go-Round

InactiveUS20080298943A1Stable supportReduces physical demandConveyorsLoading/unloadingEngineeringSprocket

An apparatus is provided for assisting a user in loading and unloading storage bins and goods to and from the back of a vehicle. The apparatus includes two chain drive supports that are elliptical in shape and positioned vertically and parallel to each other. Two chain drives rotate around sprocket guides attached to the two chain drive supports. Multiple bin carriers are attached on two sides to the two chain drives, and each bin carrier is capable of receiving a storage bin. A support stand that supports the chain drive supports attaches to the vehicle floor via floor mounts. A motor is attached to the support stand and drives a plurality of parallel chain drives, which in turn drive the two chain drives in unison to cause the bin carriers to rotate around each other in an ellipsis.

Owner:SIEGEL CYNTHIA L

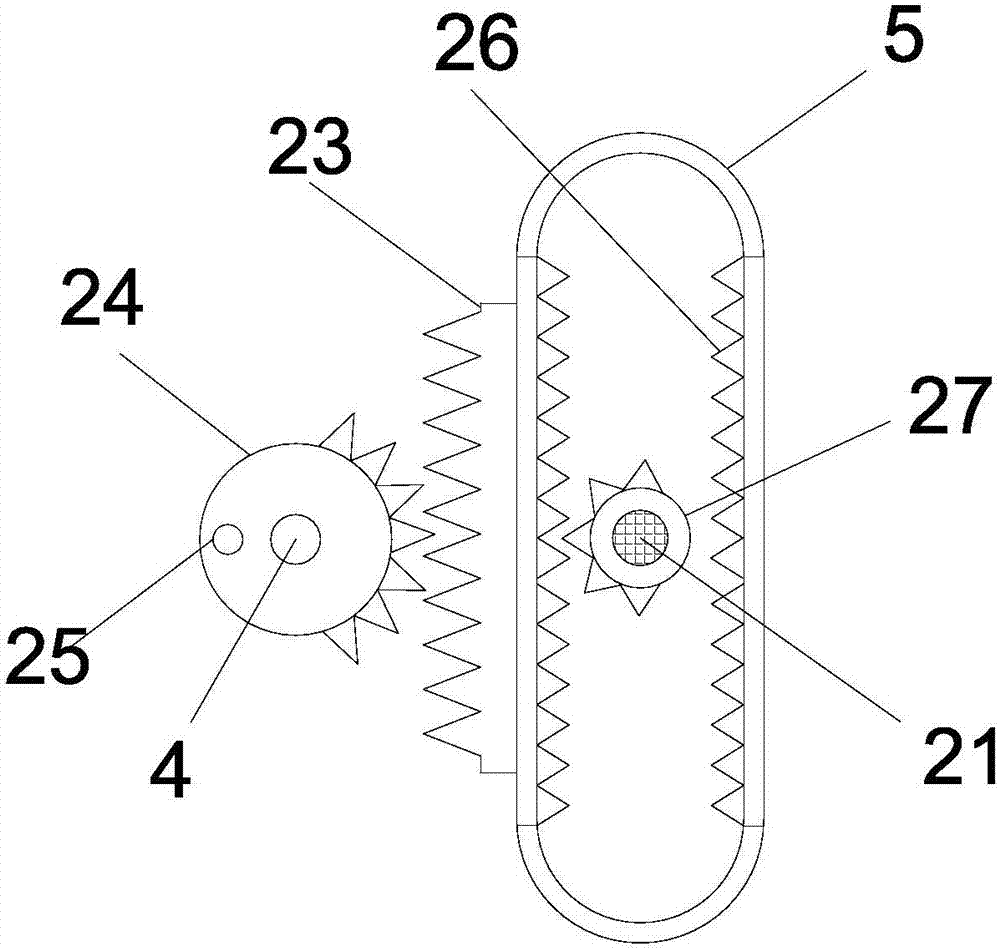

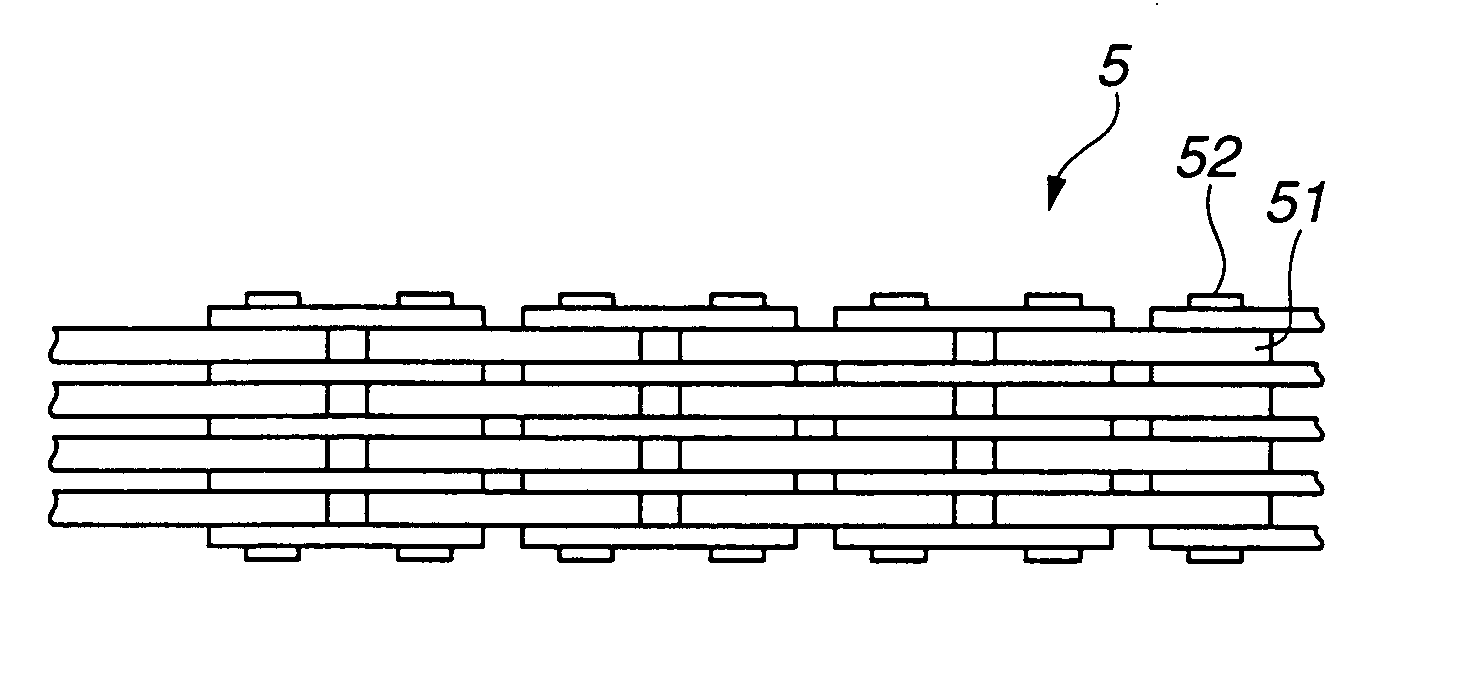

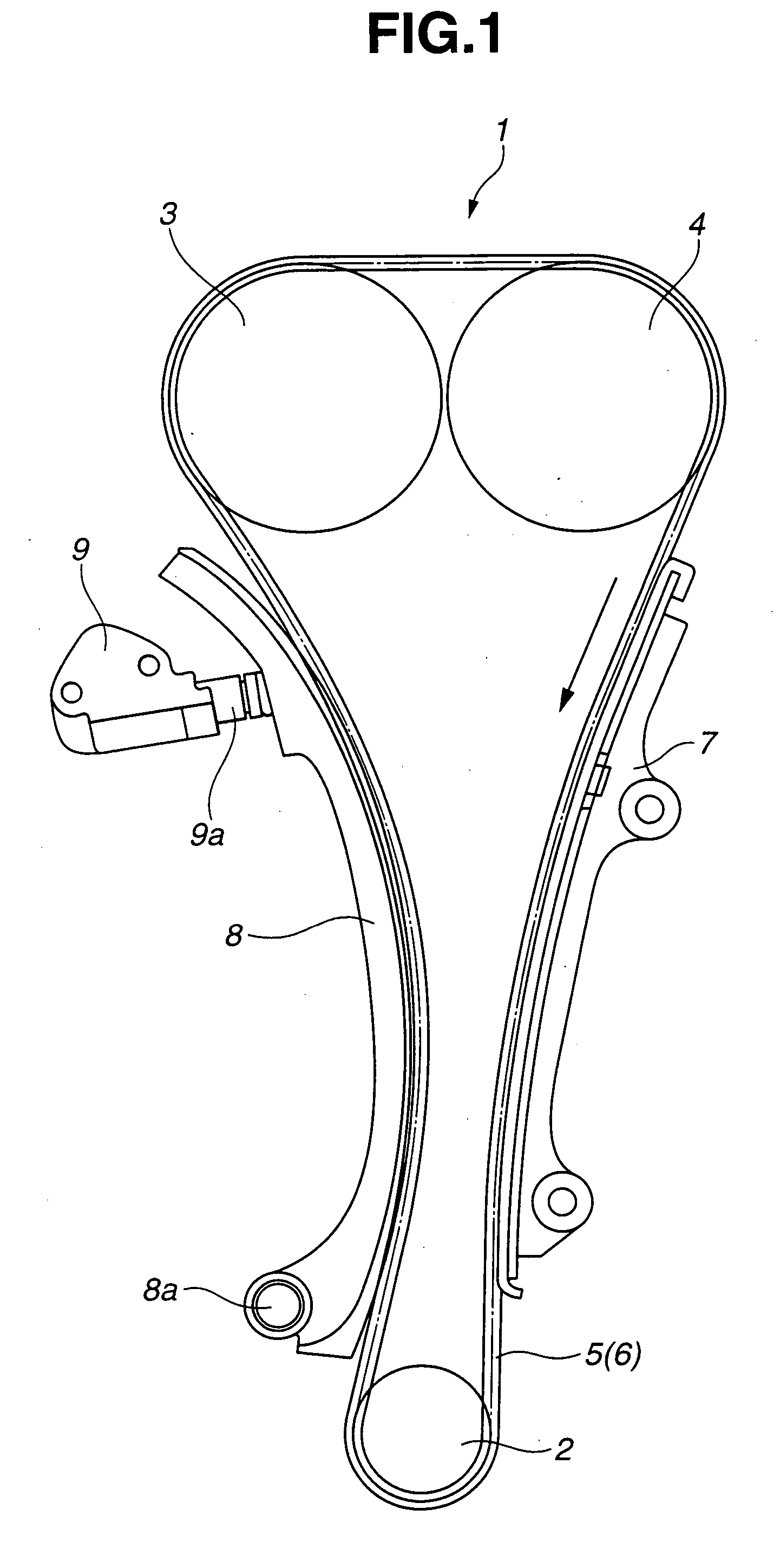

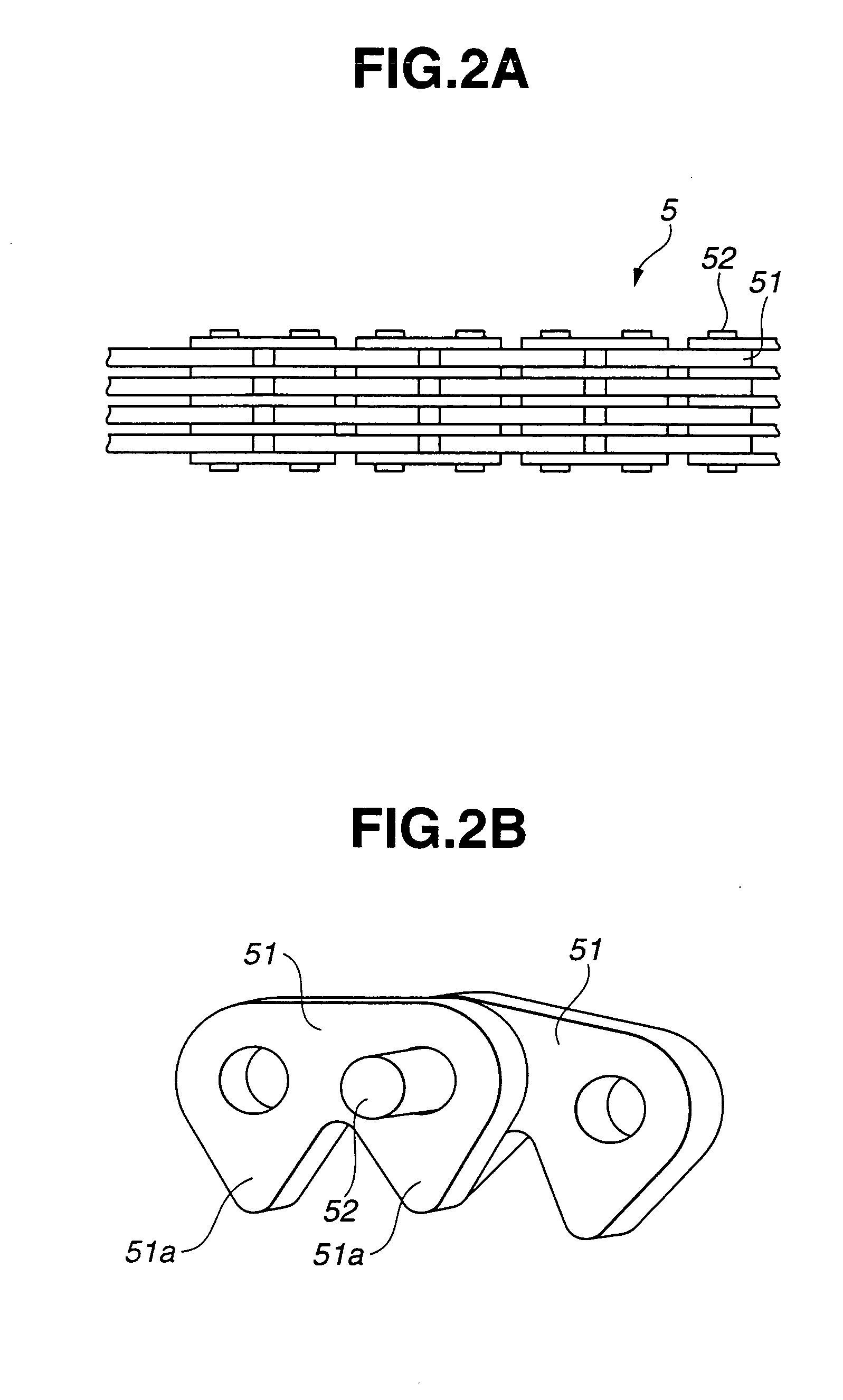

Chain drive system

InactiveUS20050037879A1Avoid excessive frictional resistanceAvoid excessive wearConnecting rod bearingsV-beltsCarbon coatingHydrogen content

A chain drive system includes a drive sprocket, a driven sprocket and a chain looped over the drive sprocket and the driven sprocket. The chain and the sprocket having respective sliding surfaces slidable relative to each other in the presence of lubricating oil, and any adjacent chain components of the chain having respective sliding surfaces slidable relative to each other in the presence of lubricating oil. At least one of the sliding surfaces between the chain and the sprocket and at least one of the sliding surfaces between any adjacent chain components have hard carbon coatings formed on base portions thereof. Each of the hard carbon coatings has a hydrogen content of 10 atomic % or less.

Owner:NISSAN MOTOR CO LTD

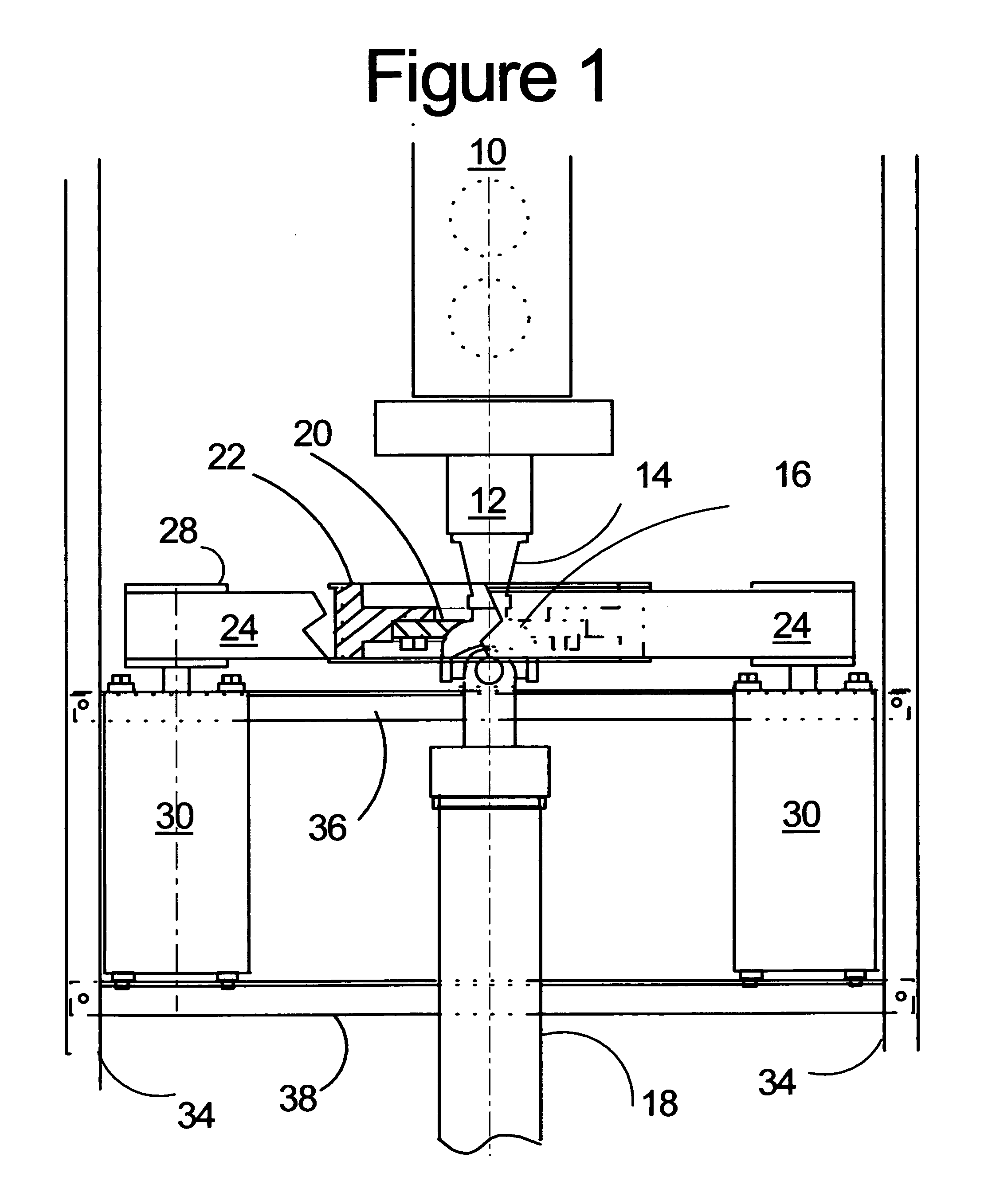

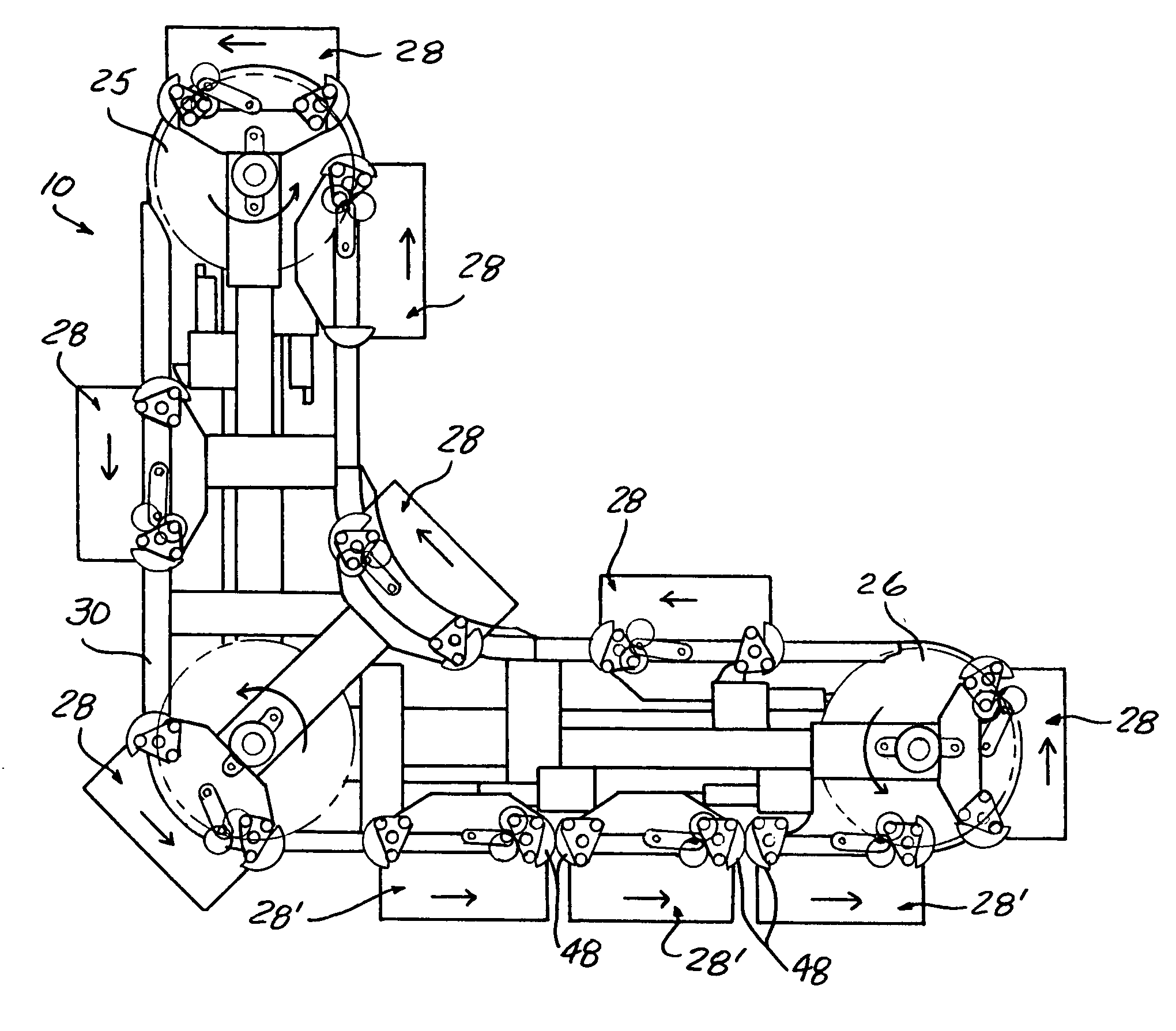

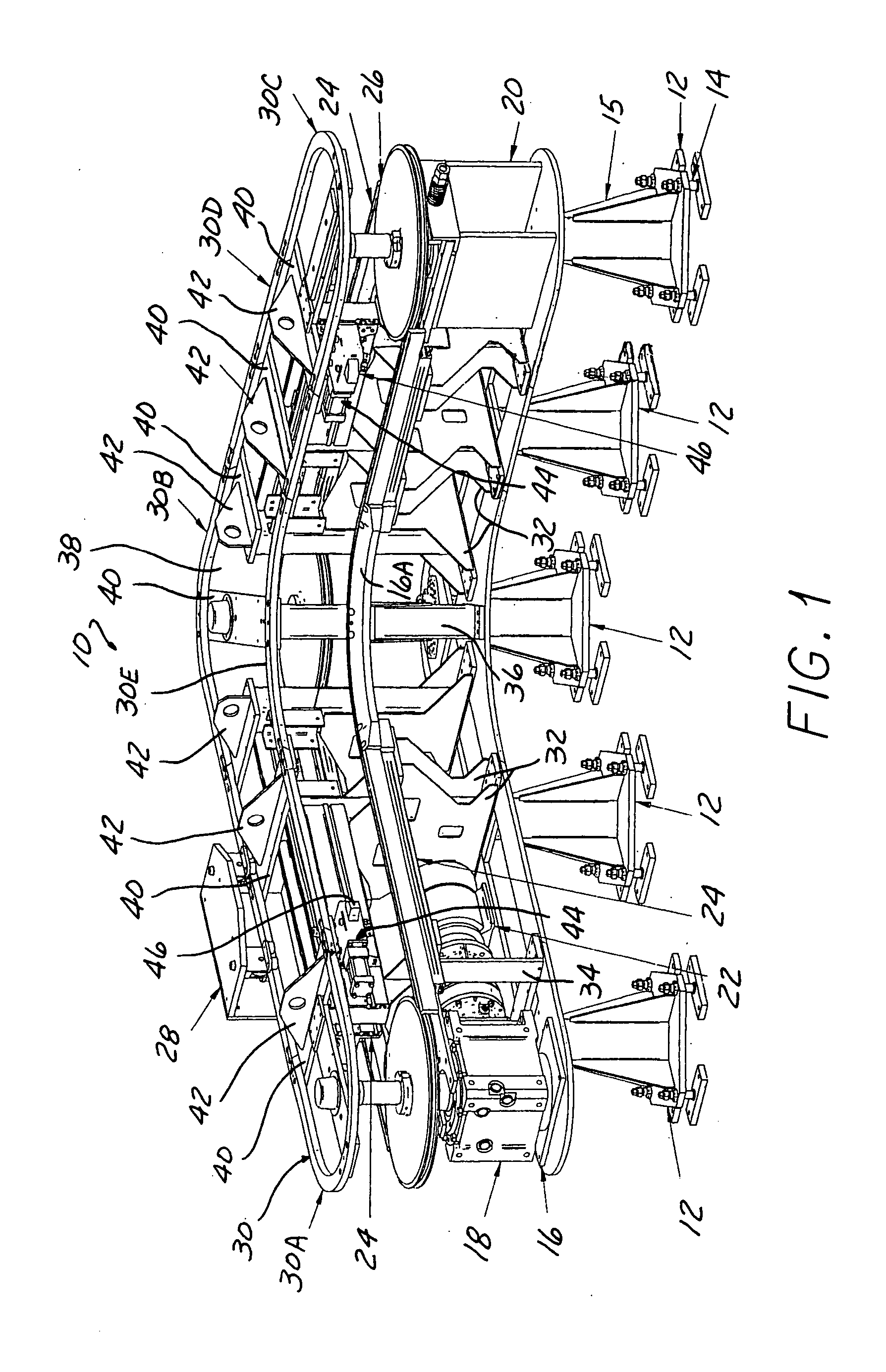

Pallet conveyor with chain drive recirculating in a horizontal plane

ActiveUS20050247546A1Simplified and reliableEliminate spaceMetal working apparatusConveyor partsClosed loopEngineering

A conveyor using a drive chain to drive pallets along a closed loop path on a track lying in a horizontal plane through inside and outside turns so that the conveyor may transport parts along non aligned stations. An advance and a return run extend parallel to each other and are closely spaced to minimize the floor space required. The drive chain is engaged by two spaced apart sprockets engaging a respective side of the drive chain, the sprockets mounted to the pallet on a pivoted bar spring biased to urge the sprocket teeth into engagement with the chain. The sprocket bar is pivotally mounted to one end of the swing bar which has an opposite end connected to the pallet to allow the chain and pallet to move together along the track and negotiate inside and outside turns. The chain is guided in a chain guide channel through inside turns, and on sprockets around the outside turns. A pair of friction brake rollers are included, each attached to one of the sprockets and are normally in firm contact with each other to brake the sprockets and carry the pallet along with the chain, which friction brake rollers slip when the pallet is arrested by a stop mechanism to be allowed to accumulate, the sprockets then able to rotate and the chain allowed to continue to circulate past the stopped pallet. The pallets extend alongside the chain and track to allow vertical mounting of parts on a side plate of the pallet or alternatively on a horizontal top plate. Alternatively, the swing bars can each be connected to the chain by one of a series of pins connected to the drive chain and pivotally received in the swing bar end in a synchronous nonaccumulating conveyor.

Owner:ROBERTS SINTO A MICHIGAN

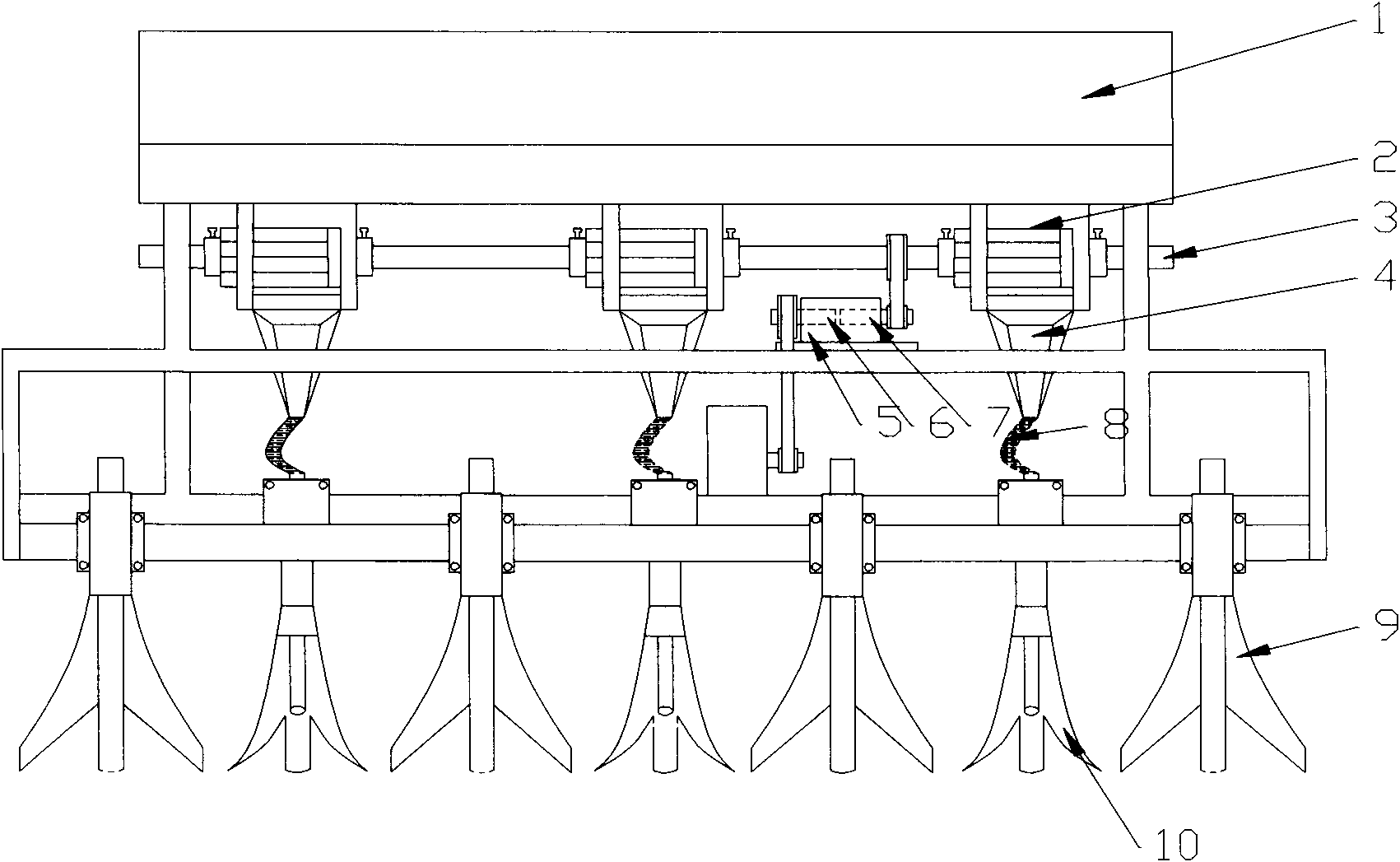

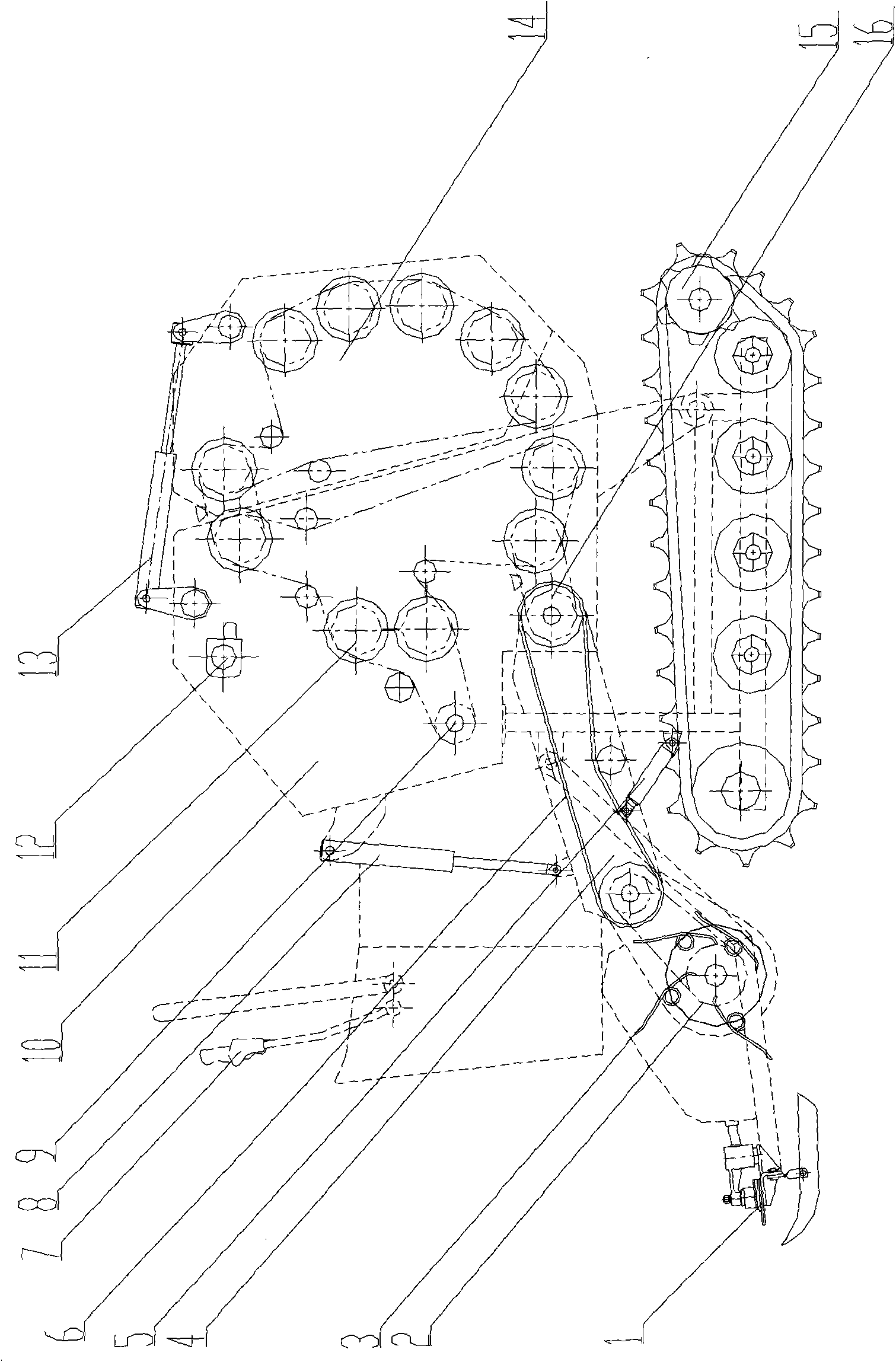

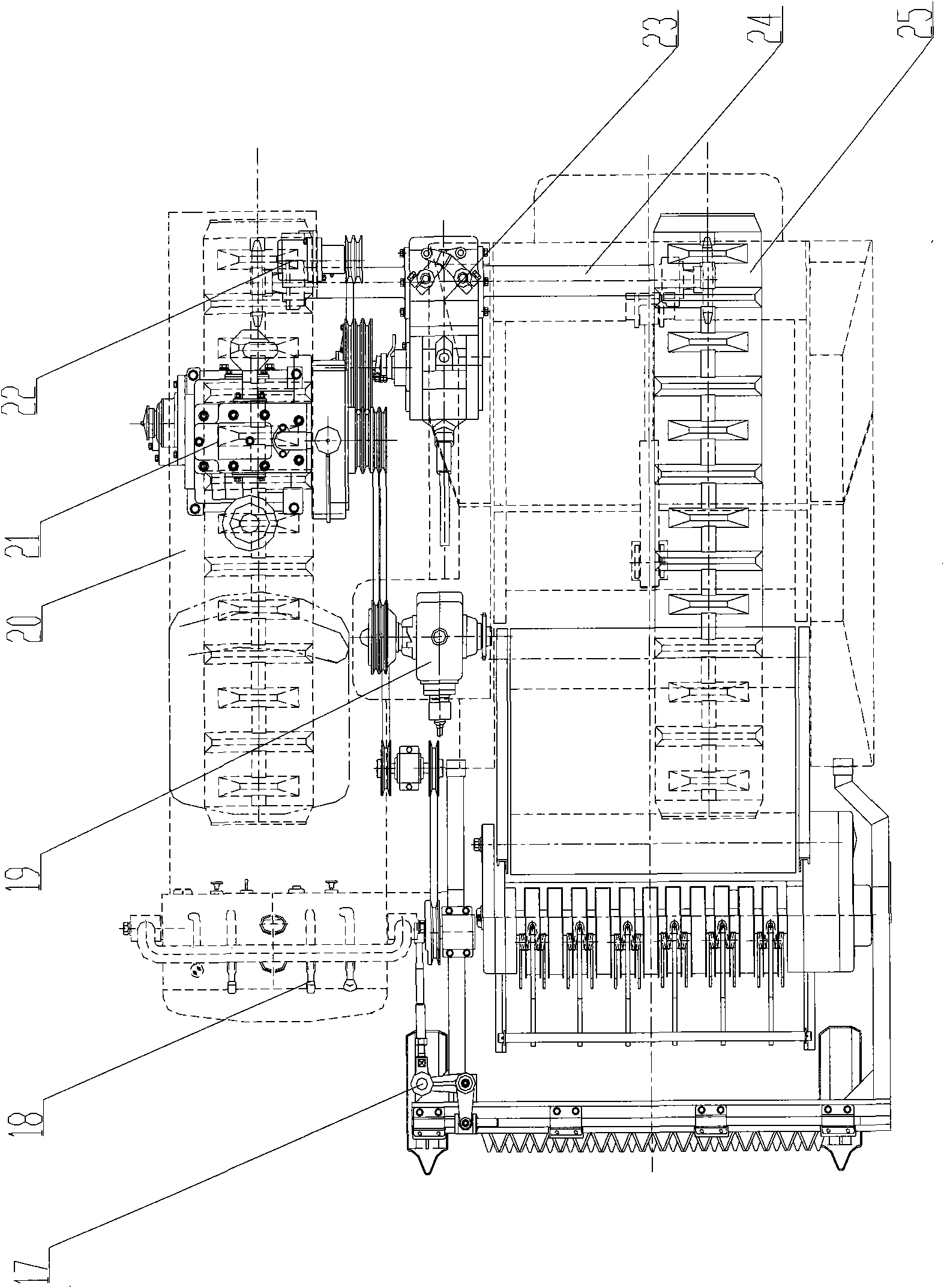

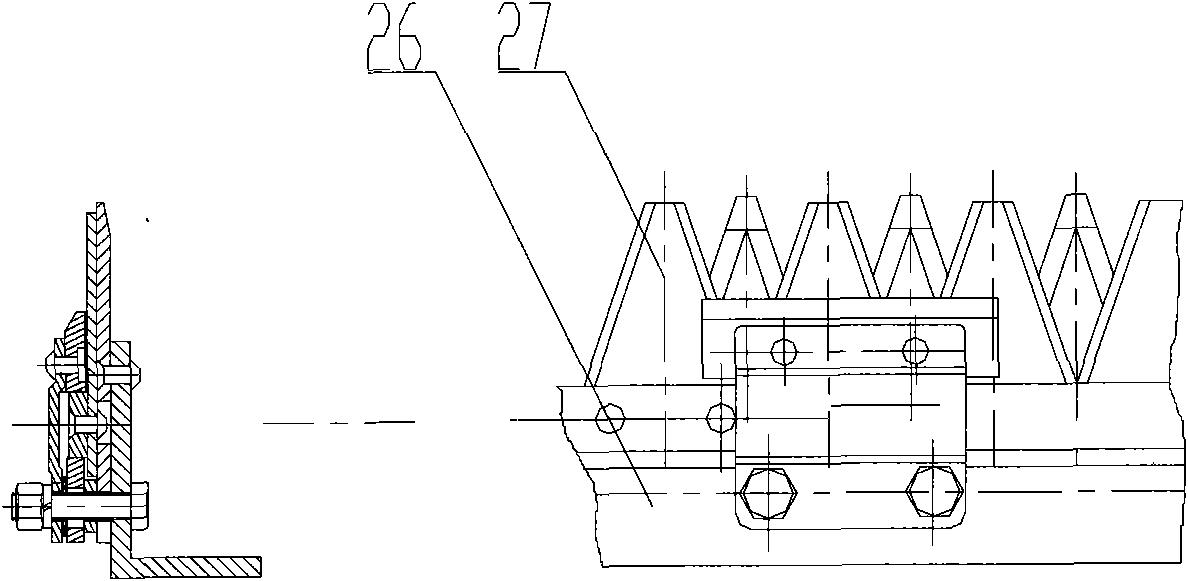

Method for cutting, picking up and bundling straw stalks and device thereof

InactiveCN101622927AImprove work efficiencyReduce labor intensityLoadersAgricultural undercarriagesAgricultural engineeringControl theory

The invention discloses a method for cutting, picking up and bundling straw stalks and a device thereof. The invention is characterized of adopting a self propelled chassis which takes a rubber track as a walk part, and installing a set of device for cutting, picking up and bundling the straw stalks especially for recycling the straw stalks on the chassis. The device for cutting, picking up and bundling the straw stalks adopts the self propelled chassis which takes the rubber track as the walk part; the chassis is provided with a stander; the stander is provided with an engine; the output shaft of the engine is provided with two sets of belts; one set of belt is connected with a walk speed changer by a rubber belt; the other set of rubber belt on the engine is connected with a work speed changer of the device for cutting, picking up and bundling the straw stalks; one end of the output shaft of the a work speed changer is provided with a belt wheel and is connected with the device for cutting, picking up and bundling the straw stalks by the belt; and the output shaft of the other end of the work speed changer is connected with a device for picking up and bundling by means of chain drive.

Owner:株洲联合收割机有限公司

Hydraulic flow control system with an internal compensator sleeve

InactiveUS7341109B1Shorten the length of timeImprove securityDrilling rodsFluid removalControl systemEngineering

A compensator sleeve assembly for use with a hydraulic extension system used to handle safety valves designed to shut off high pressure upward flow through drill pipe or tubing. The compensator sleeve assembly, amounted on an adjustable arm slide, has a steel sleeve for holding the safety valve, an arrangement of circumferentially space-apart spring sets which allow the safety valve to “float” and tilt from the vertical in any direction and a hydraulic-powered chain drive belt for rotating the safety valve.

Owner:SYDNEY PERTH L L C

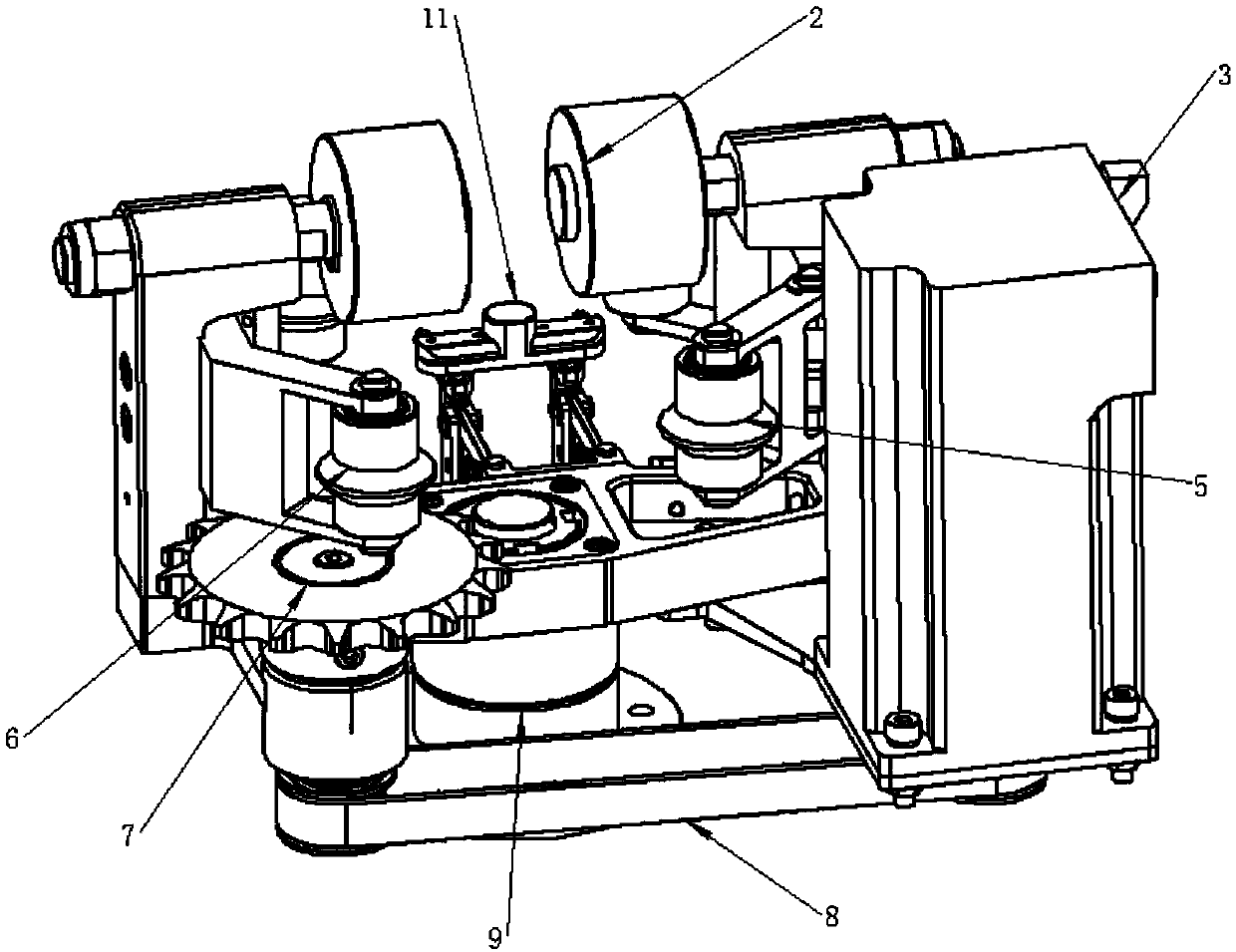

Glove demolding machine

InactiveCN102514136AGuaranteed uptimeEliminate unforeseen influence factorsCoatingsEngineeringSprocket

The invention discloses a glove demolding machine, which comprises a driving unit, a demolding unit, a guiding unit and a side blowing unit, wherein the demolding unit comprises a gripper assembly capable of seizing or loosening a hand mold or glove; the driving unit comprises a driven sprocket, a first chain disc pair and a second chain disc pair, the driven sprocket is driven by a main shaft of a glove machine, the first chain disc pair and the second chain disc pair are in chain driving connection by a chain respectively, and a plurality of pairs of guide bars are arranged between two chains; the guiding unit comprises a circular translation rail and a circular lifting and descending rail, the circular translation rail is used for controlling the gripper assembly to move along a pair of guide bars, the circular lifting and descending rail is used for controlling the gripper assembly to seize or loosen the hand mold or glove, and one segments, which are used for controlling the gripper assembly to move toward the direction close to a glove conveying line, are respectively arranged at ends of the upper parts of the circular translation rail and the circular lifting and descending rail, so that semi-falling glove is separated from a gripper and a blow-falling mechanism in the prior art is replaced. The device is more stable in operation, eliminates the unpredictable influencing factors caused by the gas blow-falling mechanism, reduces the outage maintenance frequency and improves the production efficiency.

Owner:ZHANGJIAGANG PIONEER AUTOMATION MACHINERY EQUIP

Horizontal wind generator

A horizontal wind generator comprises a horizontal windmill drivingly coupled to an electrical generator. The windmill includes a vertical drive shaft mounted for rotation in a base, with a plurality of wind drive units being mounted in wind catching positions at spaced axial locations along the drive shaft. The drive units comprise oppositely facing wind catching elements mounted on opposite sides of crossbars or frames non-rotatably attached to the pole. Multiple wind drive units are spaced along the pole and angularly displaced from adjacent units at regular intervals around the pole. Two or four spaced drive units are particularly desirable. Wind catcher elements formed of cup shaped bowls or split barrels are particularly effective and are inexpensive. The wind generator is drivingly attached to an electrical generator through a gear box and belt or chain drive mechanism. The horizontal windmill rotates the electrical generator within its desired speed range without any governor or speed control.

Owner:HORJUS THOMAS W

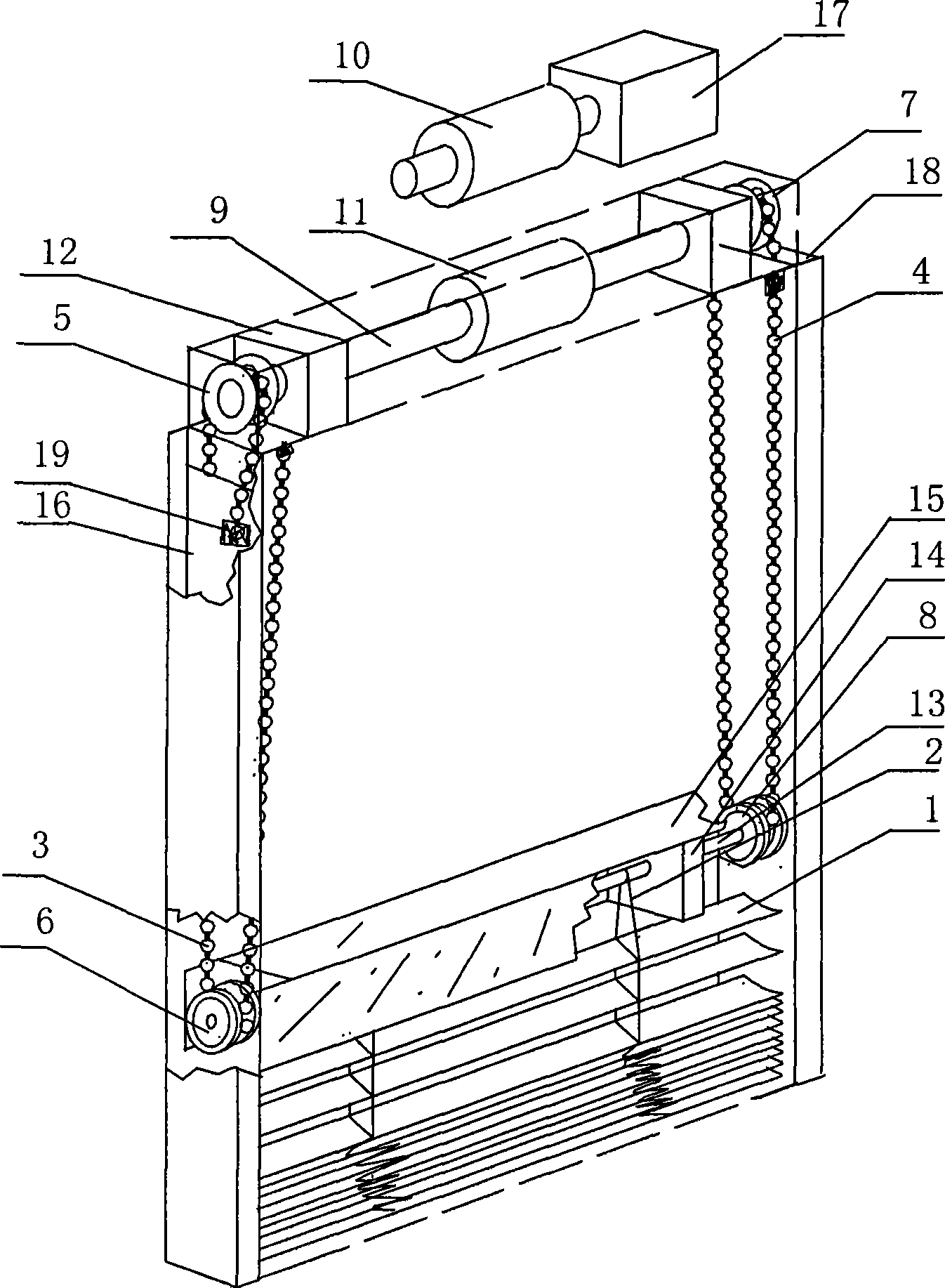

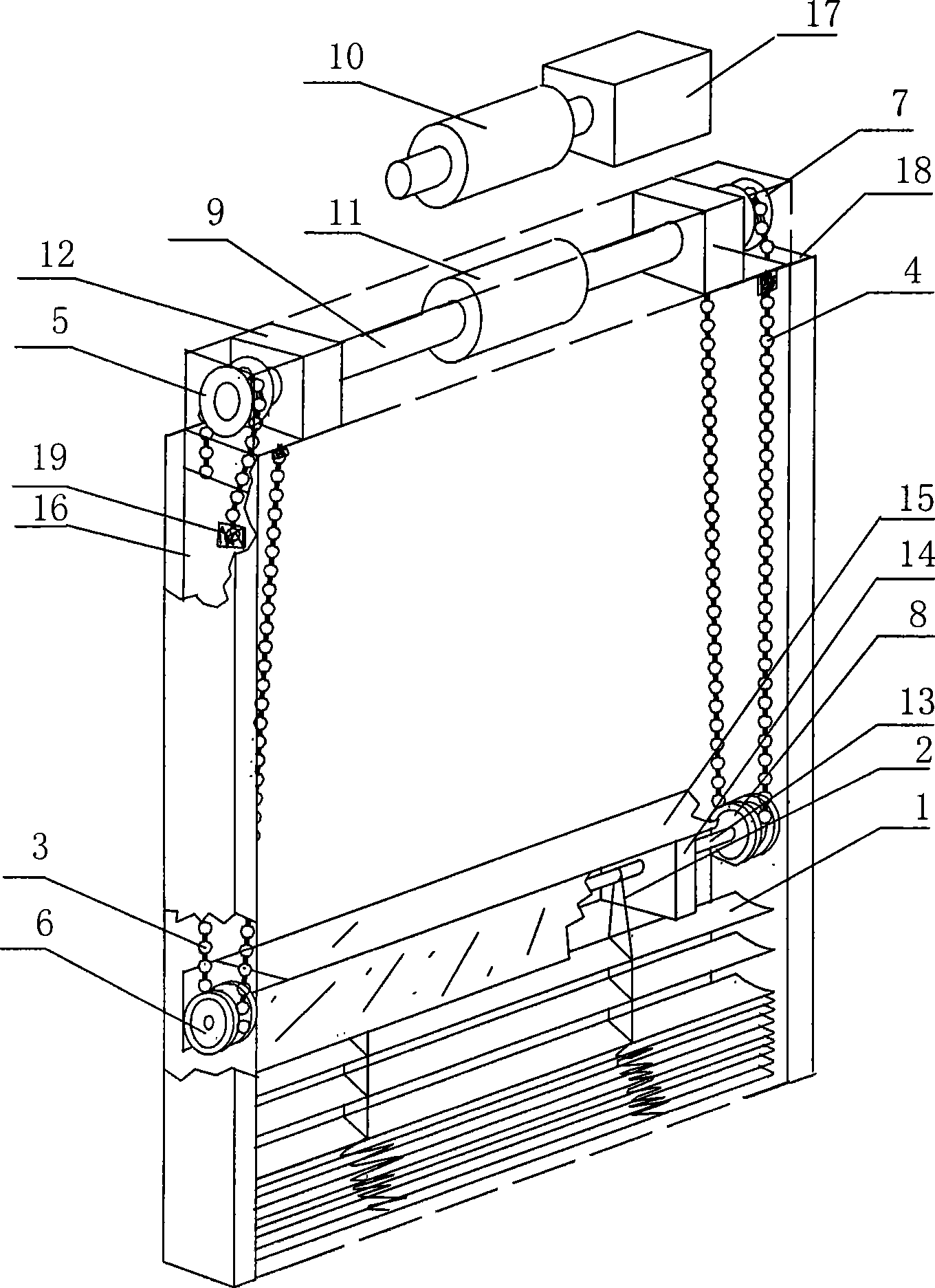

Chain drive of bottom-fixed blind curtain

InactiveCN101392625BEasy to useDeflection synchronous controlDoor/window protective devicesDrive shaftSprocket

The invention provides a chain drive mechanism for a bottom-positioned venetian blind, which consists of a left metal chain, a right metal chain, a left upper sprocket wheel, a right upper sprocket wheel, a left lower friction wheel, a right lower friction wheel, a drive shaft, a trip shaft, a support, a moving groove and a chain chute, wherein one end of the left metal chain is fixed on the leftupper part of a window frame, while the other end is a free end; after the left metal chain rounds the left lower friction wheel and the left upper sprocket wheel, the left metal chain is freely suspended in the chain chute; one end of the right metal chain is fixed on the right upper part of the window frame, while the other end is a free end; after the right metal chain rounds the right lower friction wheel and the right upper sprocket wheel, the right metal chain is freely suspended in the chain chute; the left lower friction wheel and the right lower friction wheel are arranged on two ends of the trip shaft; the trip shaft passes through the support and is supported by the support; the support is connected with the moving groove; the left upper sprocket wheel and the right upper sprocket wheel are arranged on two ends of the drive shaft; and when a power system of the venetian blind starts to run, the whole drive mechanism of the venetian blind starts to work. The chain drive mechanism has the advantages of simple and easy operation and convenient use.

Owner:北京开悦合美窗帘窗科技有限公司

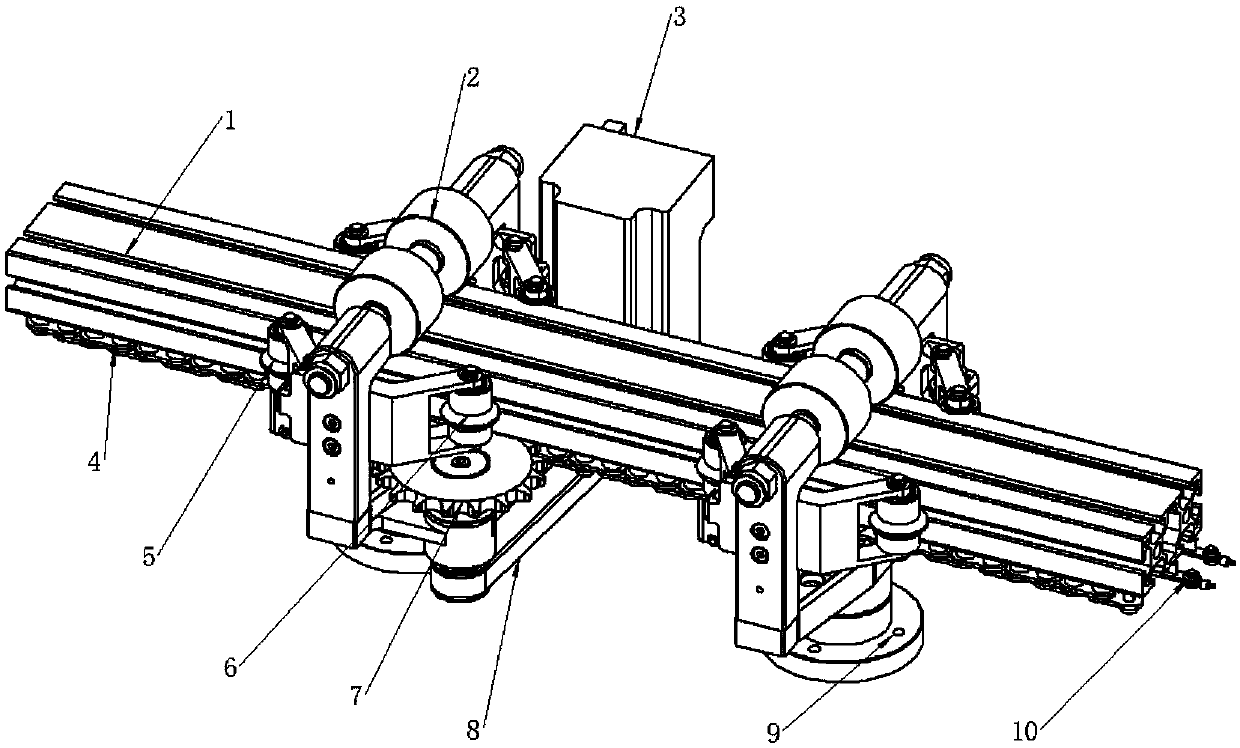

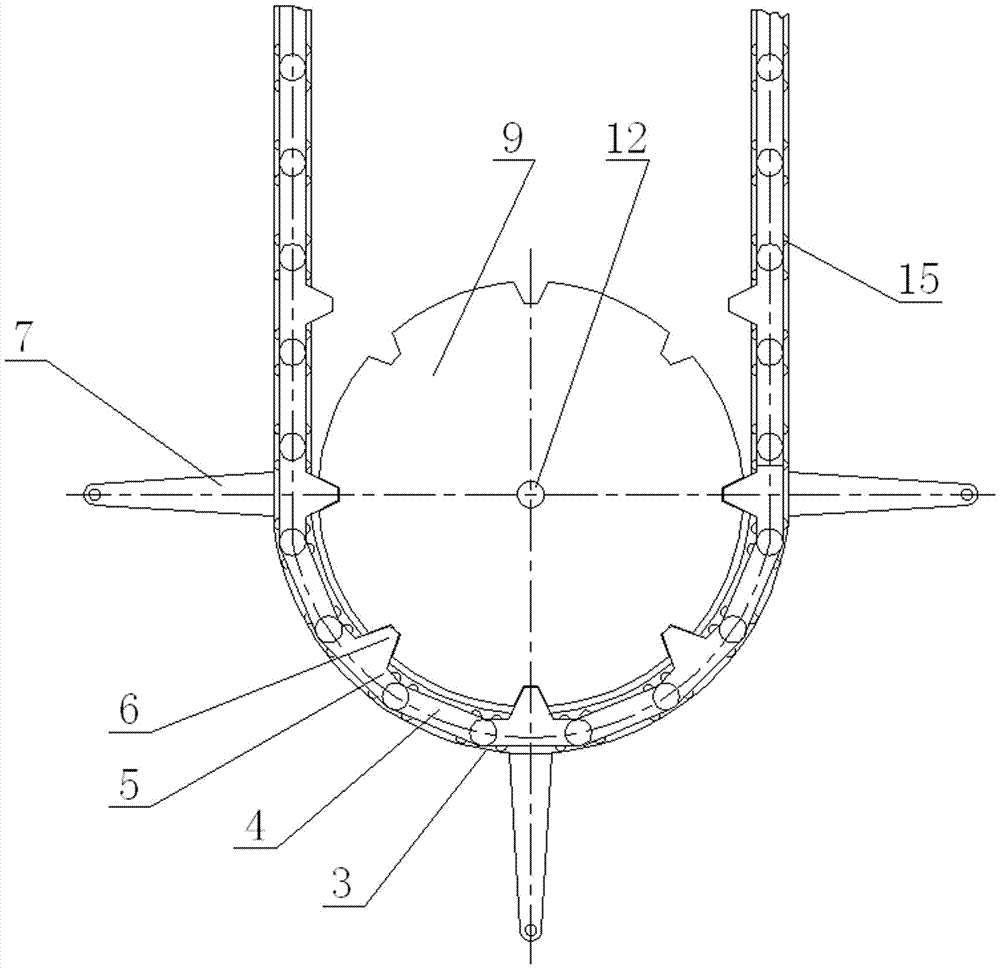

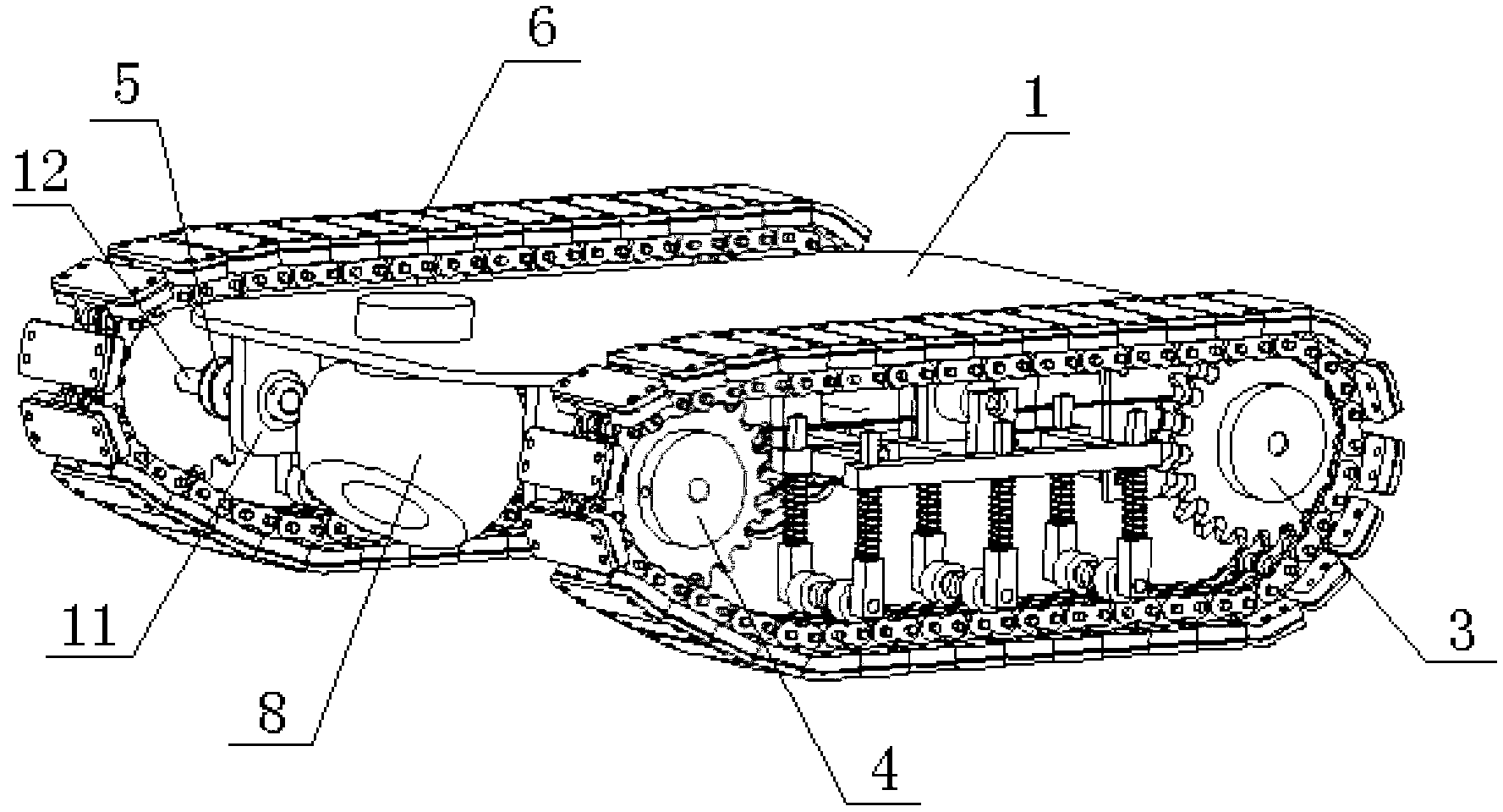

Curved surface self-adaption magnetic adsorption wall-climbing robot

The invention discloses a curved surface self-adaption magnetic adsorption wall-climbing robot, which includes a vehicle body and chain driving assemblies arranged on the two sides of the vehicle body, wherein each chain driving assembly includes a driving motor, a driving chain wheel and a driven chain wheel; each driving motor is fixedly mounted at the bottom of the vehicle body; the driving chain wheels are coaxially and fixedly mounted on driving shafts of the driving motors; and the driven chain wheels are coupled at the bottom of the vehicle body. The curved surface self-adaption magnetic adsorption wall-climbing robot is characterized in that a magnetic chain is arranged between each driving chain wheel and each driven chain wheel; and self-adaption mechanisms are fixedly mounted on the two sides of the vehicle body respectively, and each self-adaption mechanism is positioned on the magnetic chain on the same side where the self-adaption mechanism is arranged. The curved surface self-adaption magnetic adsorption wall-climbing robot has the advantages that the self-adaption mechanisms arranged on the inner sides of the magnetic chains can better clung to and fit with the warped curved surface when the wall-climbing robot walks on a steel curved surface or a warped wall surface, so that the magnetic adsorption area is enlarged, the adsorption efficiency is improved, and the exercise safety performance of the wall-climbing robot is improved, and as lifting wheels arranged on connecting racks can be used for tensioning the magnetic chains, chain slippage and dropping can be prevented during the movement of the wall-climbing robot, and the wall-climbing robot can adapt to and climb the wall with an upright even inverted warped curved surface.

Owner:NINGBO UNIV

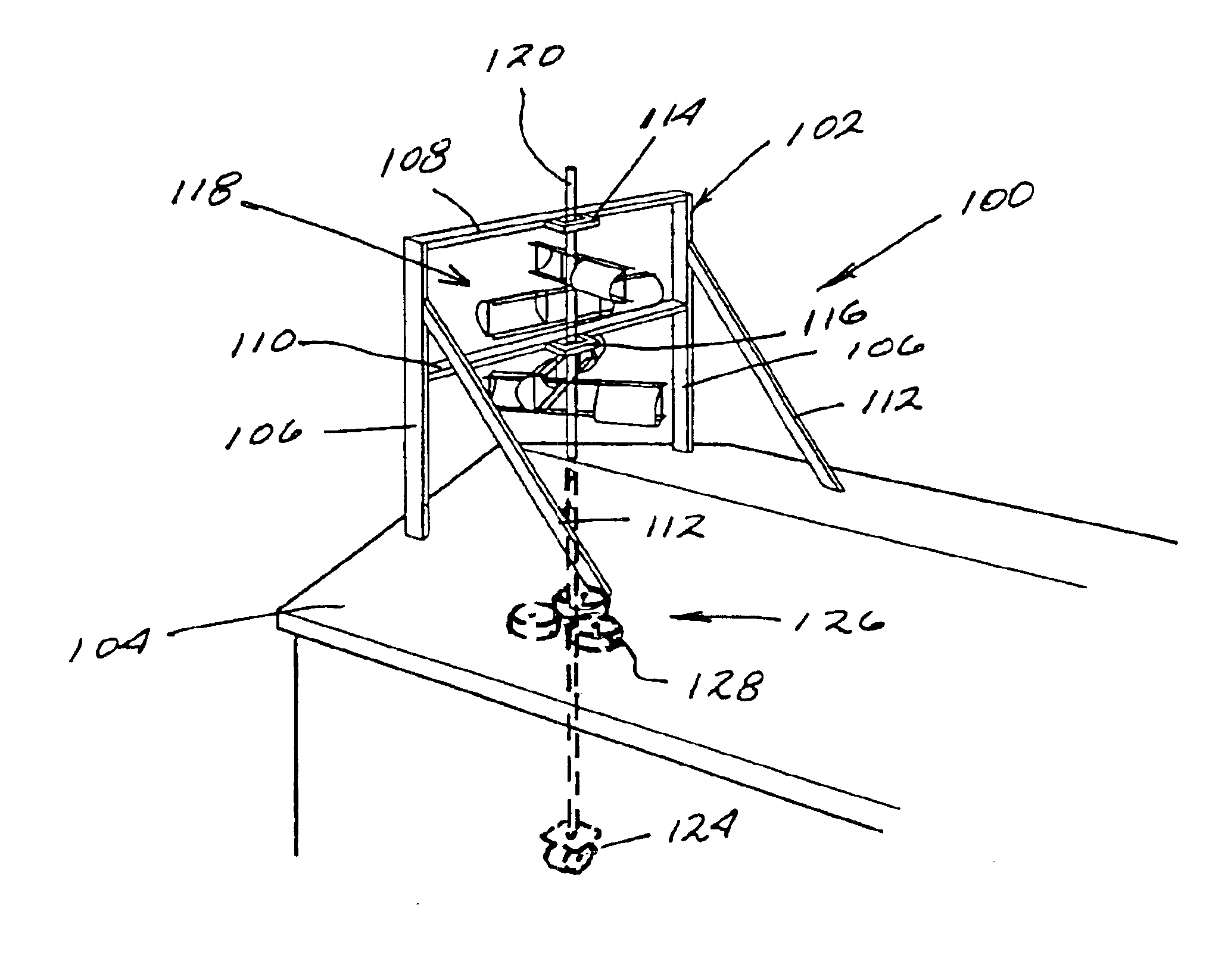

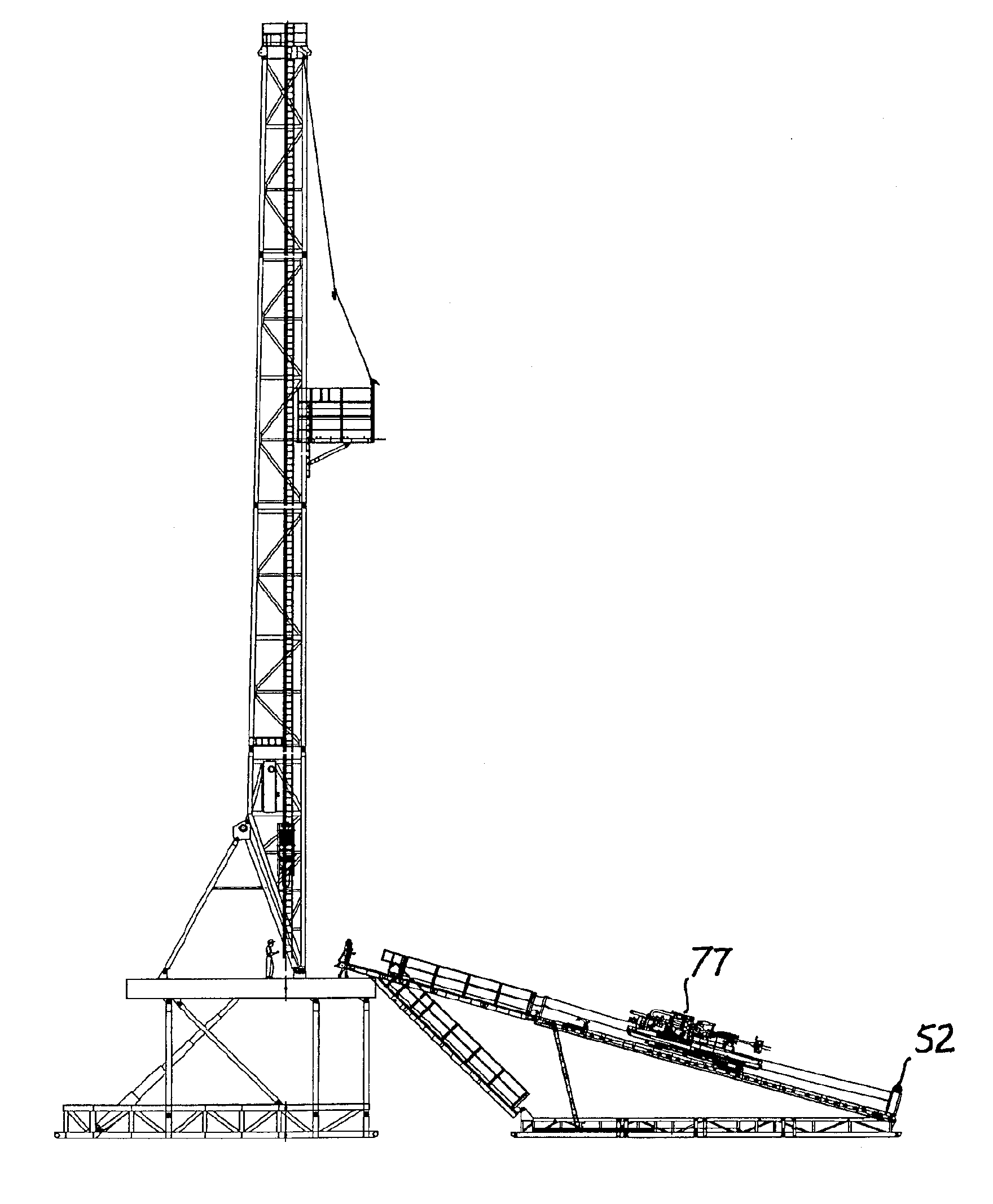

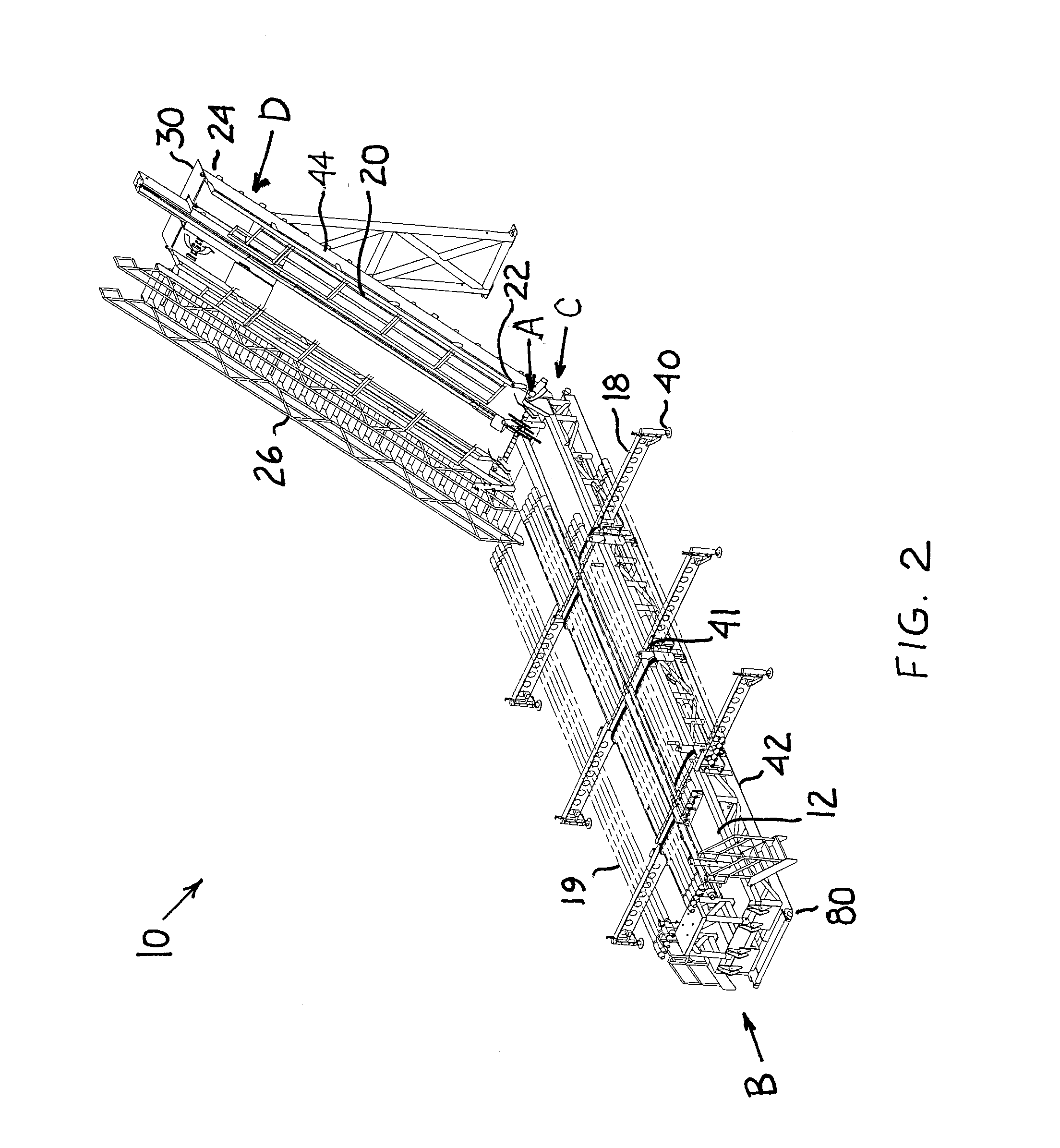

Apparatus for delivering drill pipe to a drill rig

An apparatus for delivering drill pipe has a support frame, a catwalk platform, and a slide platform that are pivotally connected together. A drill pipe rack, a chain drive, and a kicker direct the drill pipe to and from the catwalk platform. A hydraulically actuated piston lifts the catwalk platform and slide platform into alignment to create a single inclined delivery platform extending from the ground to the rig floor. A powered means lifts or lowers the drill pipe along the delivery platform.

Owner:COAX TECH

Locking device for charging plug and charging socket of electric vehicle

ActiveCN102709754AAchieve lockingRealize the unlocking actionCoupling device detailsComputer hardwareElectric machinery

The invention relates to a locking device for a charging plug and a charging socket of an electric vehicle. The locking device comprises a shell, a motor, a transmission chain, a lock disk, a lock pin, a lock pin spring, micro switches, a micro switch cam and a lock pin cam, wherein the lock disk is connected to the interior of the shell in a rotating way; the motor is arranged on one side of the lock disk in the shell; the transmission chain is in transmission connection with the motor and the lock disk; the micro switch cam and the lock pin cam are arranged on the lock disk, and rotate coaxially with the lock disk; the cam surface of the micro switch cam is pressed against the micro switches, so that the micro switches finish 'opening' and 'closing' action; the lock pin spring is connected to the lock pin; the cam surface of the lock pin cam is pressed against one end part of the lock pin; and the lock pin axially moves under the rotation of the lock pin cam and the elasticity of the lock pin spring. The locking device has the advantages that the charging plug and the charging socket are used for safe charging in a locked state, and an electrical signal is provided for control over the metering, charging and background maintenance management of a system, so that unattended charging is realized, and great convenience is brought to a charging station.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com