Beam-film combined micro-pressure sensor

A technology of micro-pressure sensor and beam membrane, which is applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problems affecting the linearity of the sensor signal, and achieve the effects of optimizing the sensor output, improving the sensitivity, and improving the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

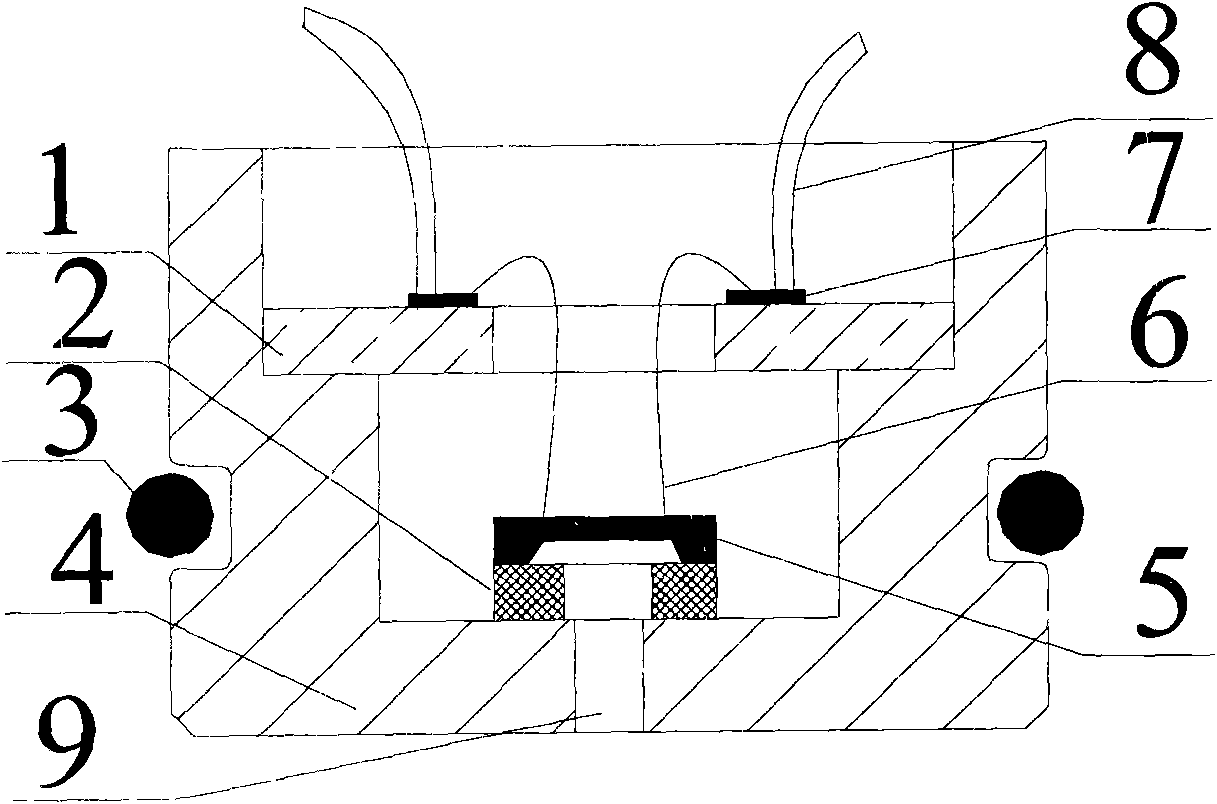

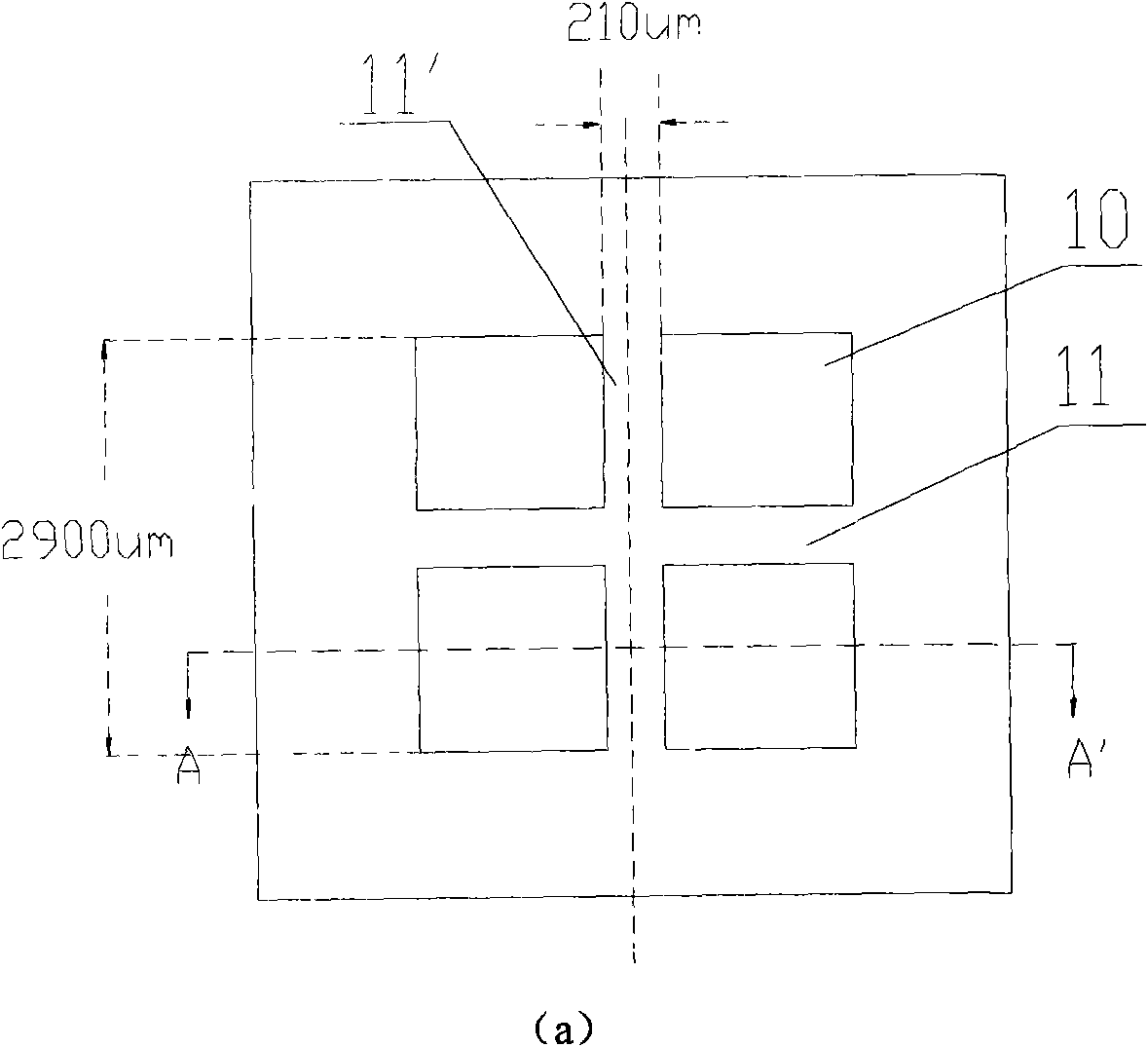

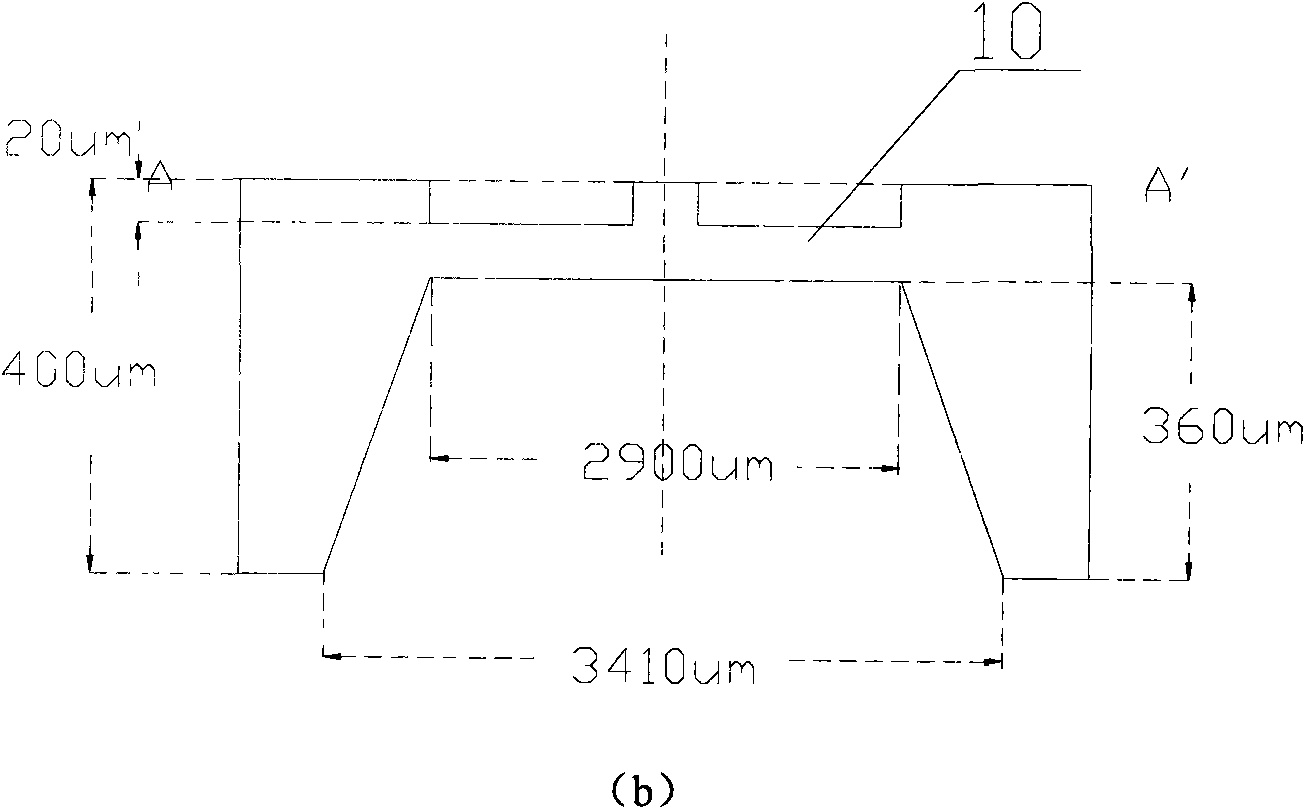

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] refer to figure 1 , the present invention includes a base 4 configured with a cavity, the cavity of the base 4 communicates with the air inlet 9 on the base 4, and the circuit adapter board 1 is sequentially arranged in the cavity of the base 4, and the circuit transfer board 1 is arranged in sequence. The connecting plate 1 and the base 4 are firmly bonded by epoxy resin, and a (100) crystal surface full-silicon micro-press chip 5 is arranged in the cavity of the base 4, and the full-silicon micro-press chip 5 and the PYREX7740 glass ring 2 pass through Electrostatic bonding is sealed together, the hole 2 of the glass ring is aligned with the air inlet 9 and glued with epoxy resin, and the pressure soldering blocks 12, 13, 14, 15 and 16 on the all-silicon micro-press chip 5 are connected with the circuit The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com