Patents

Literature

104 results about "Drill line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

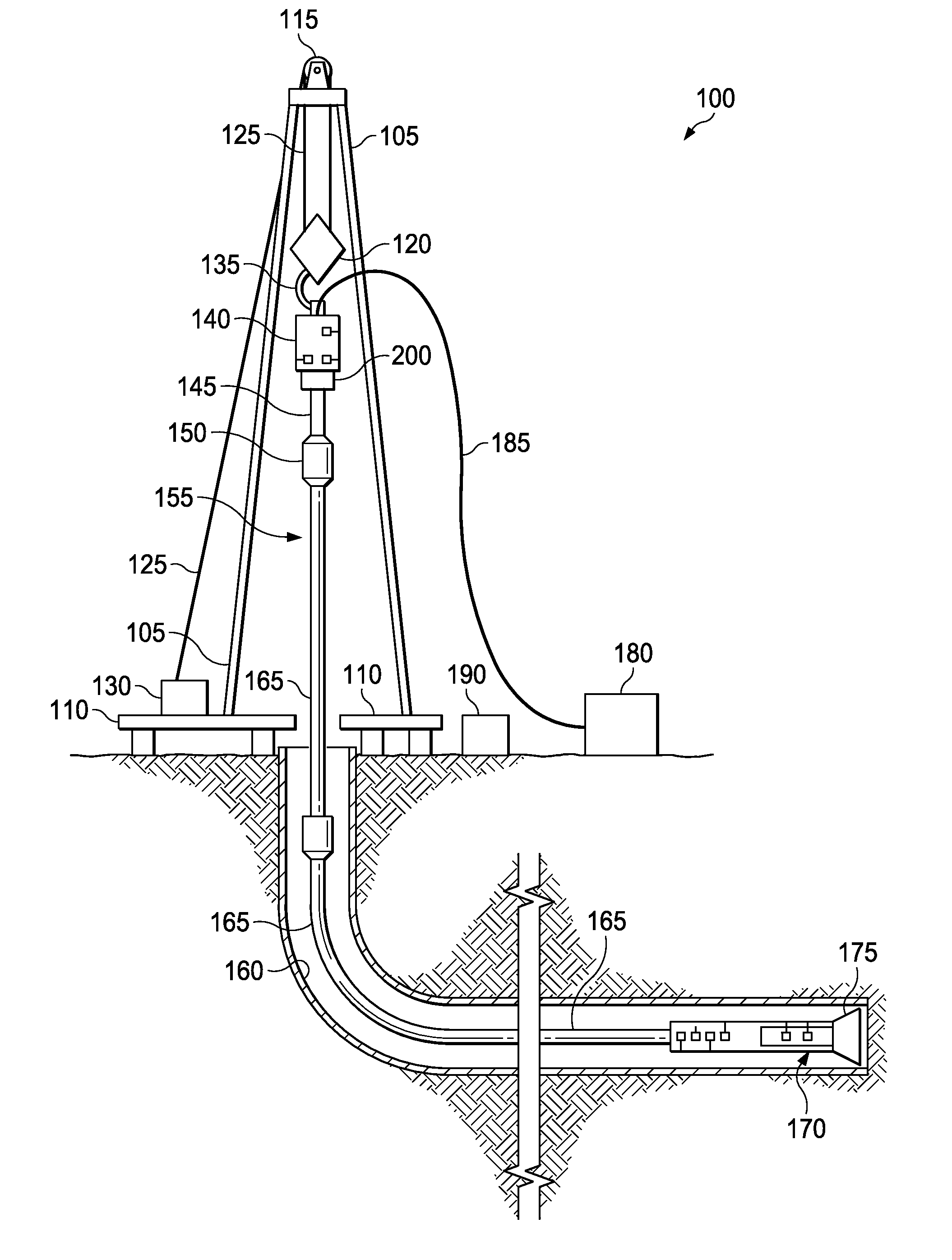

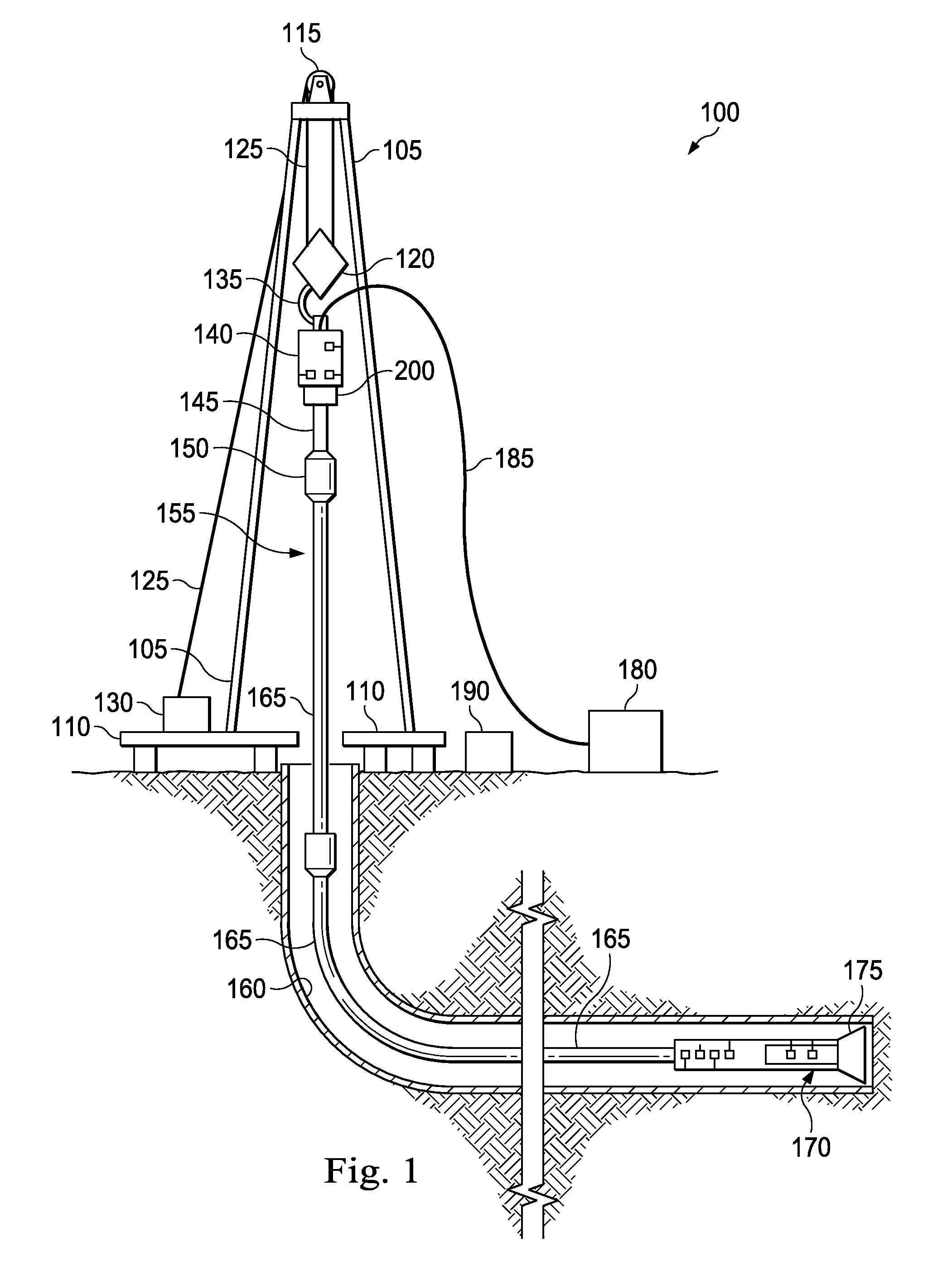

In a drilling rig, the drill line is a multi-thread, twisted wire rope that is threaded or reeved through in typically 6 to 12 parts between the traveling block and crown block to facilitate the lowering and lifting of the drill string into and out of the wellbore.

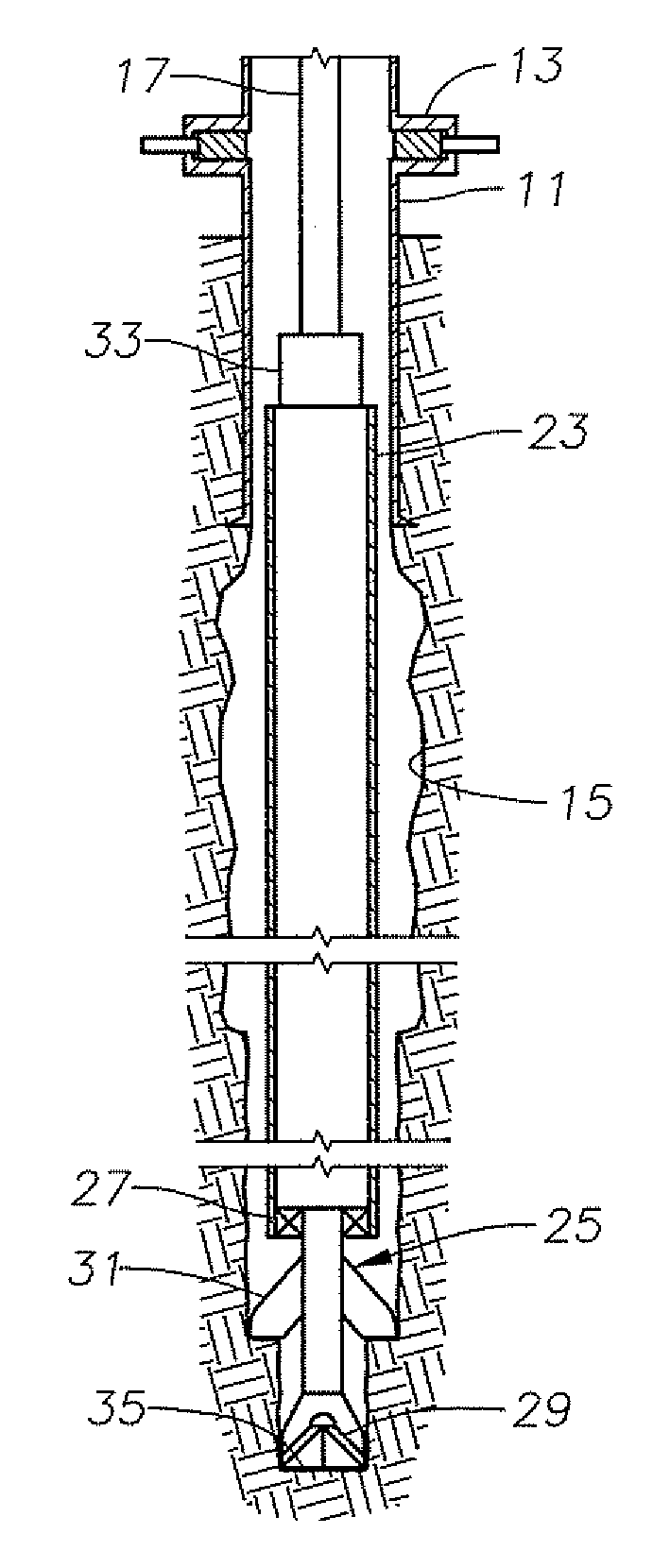

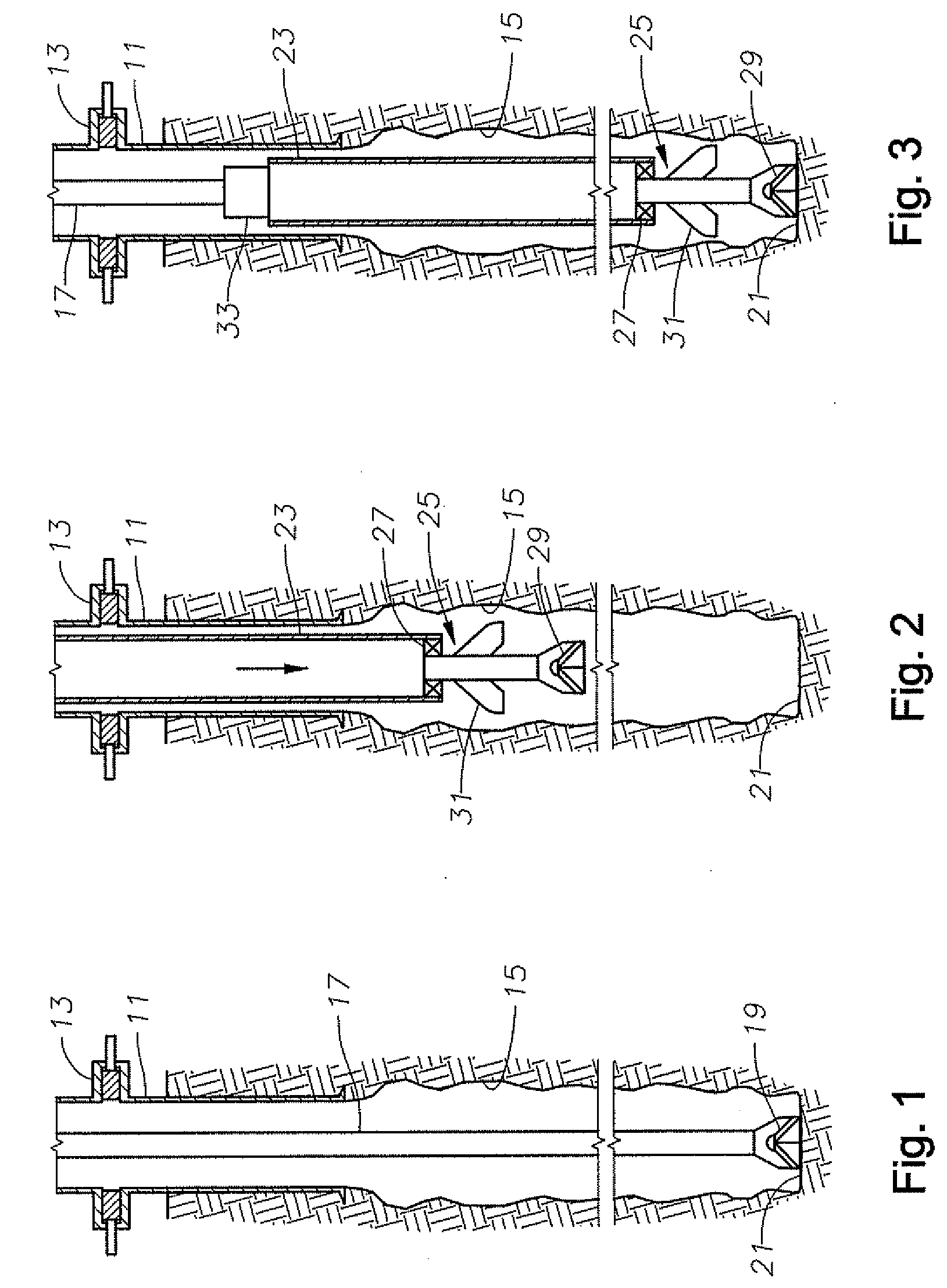

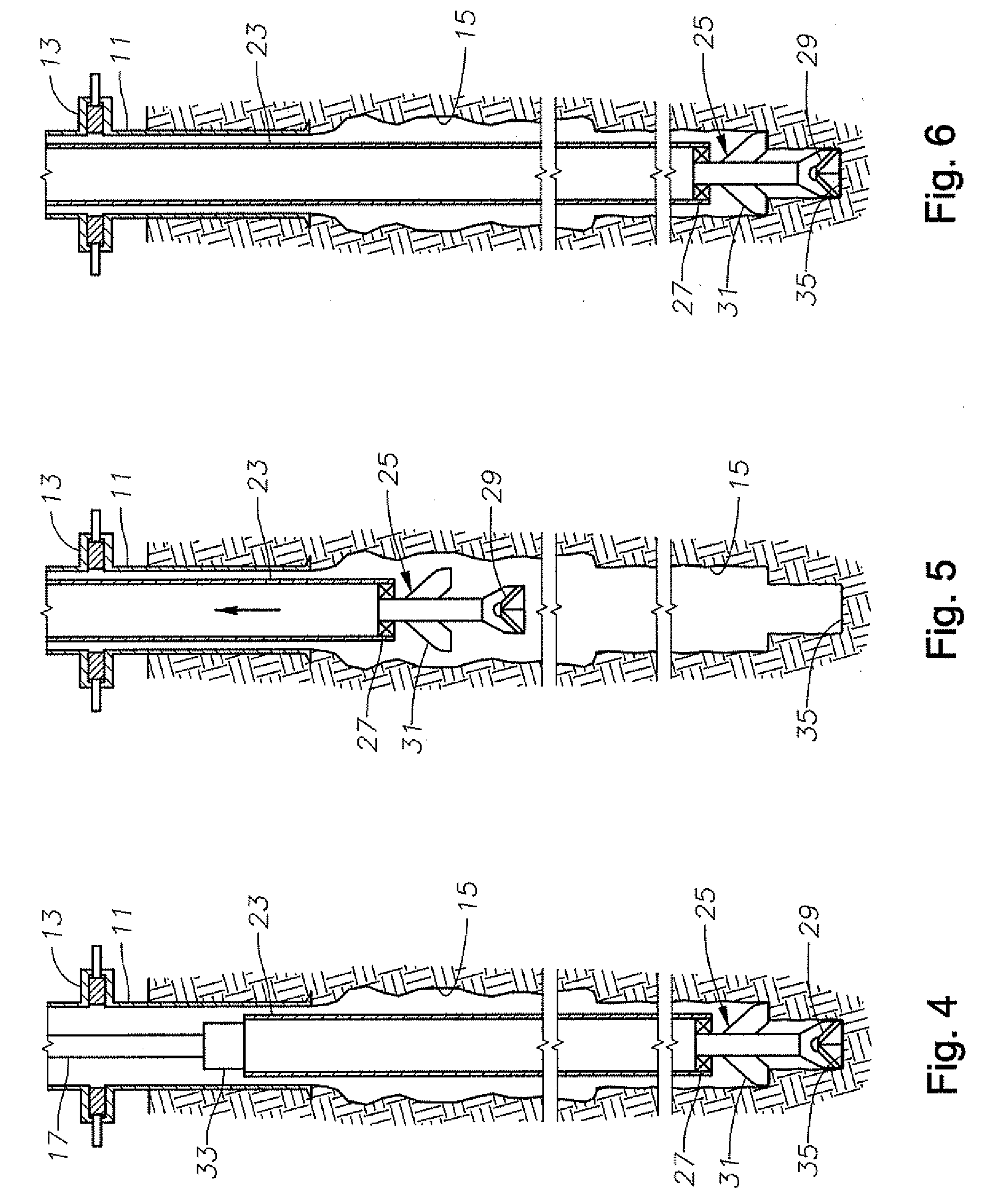

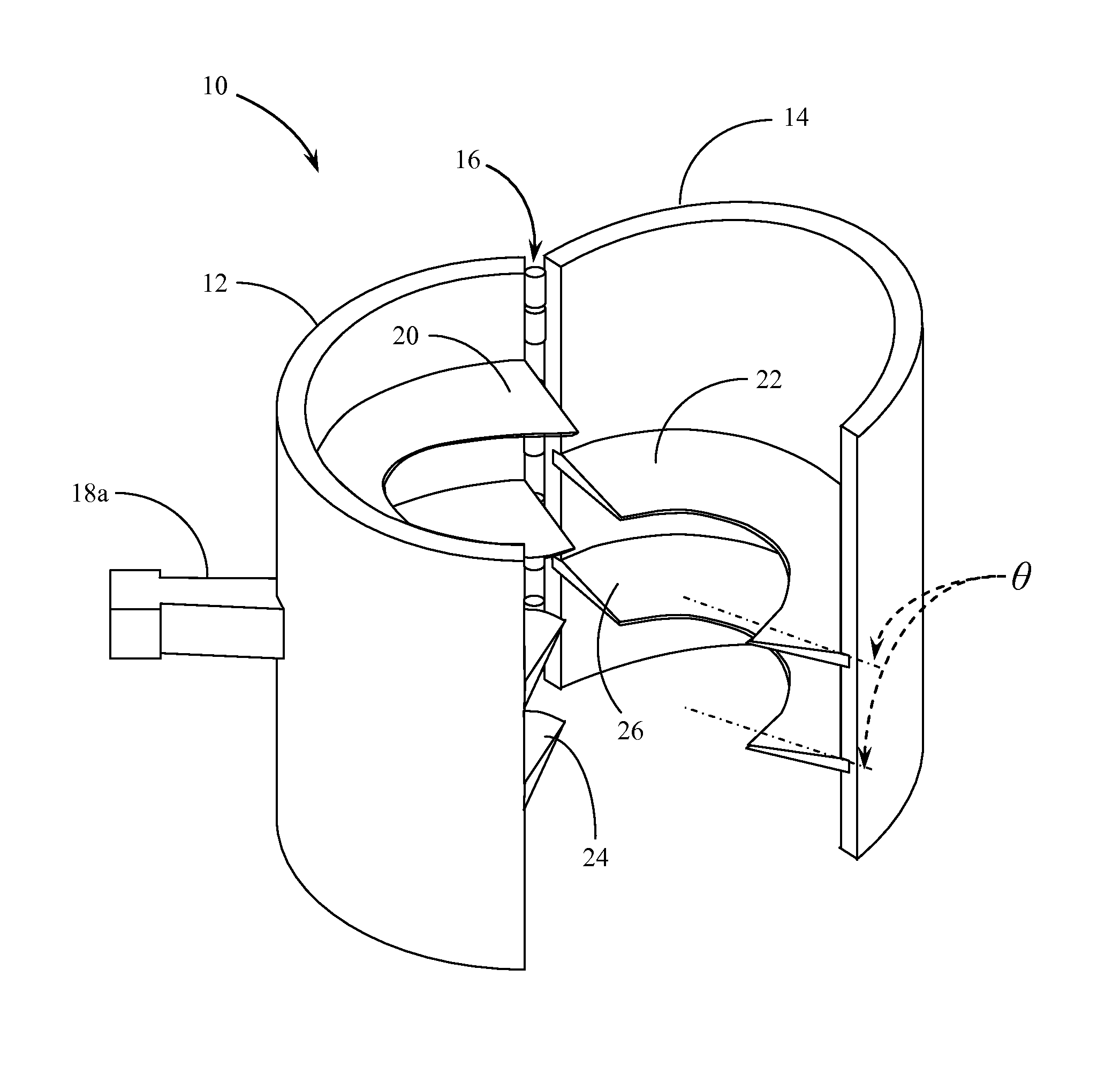

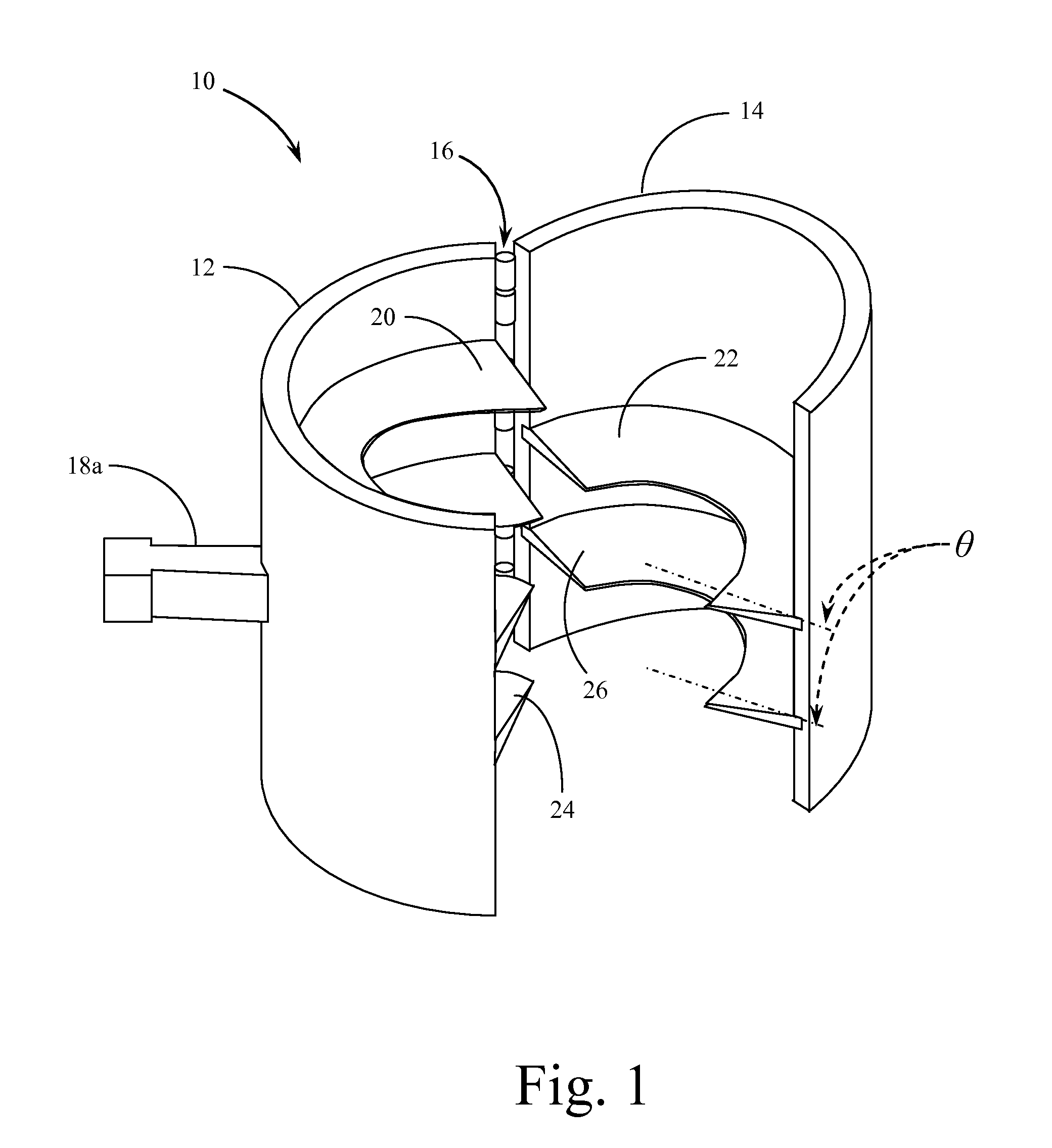

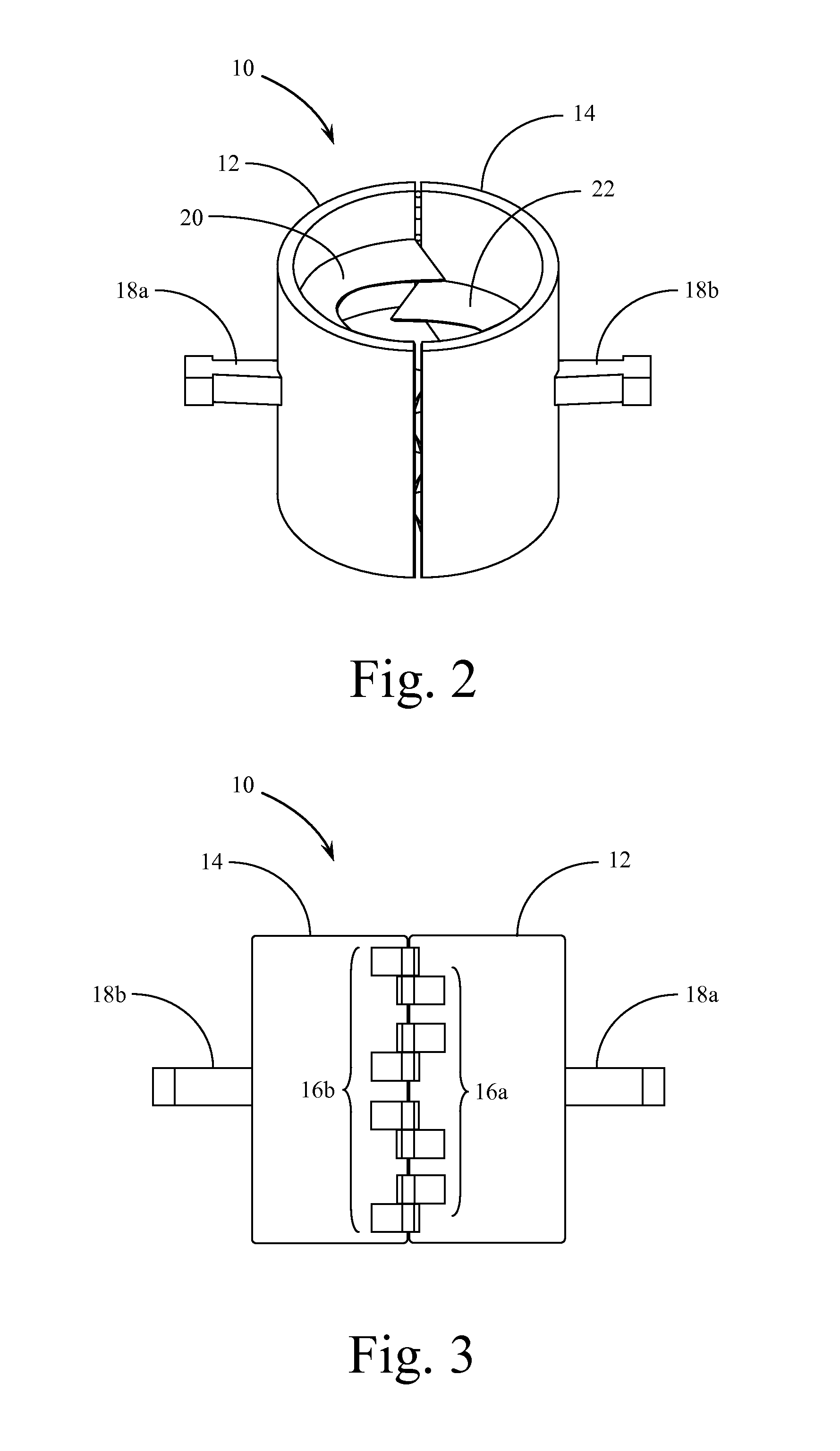

Liner drilling method

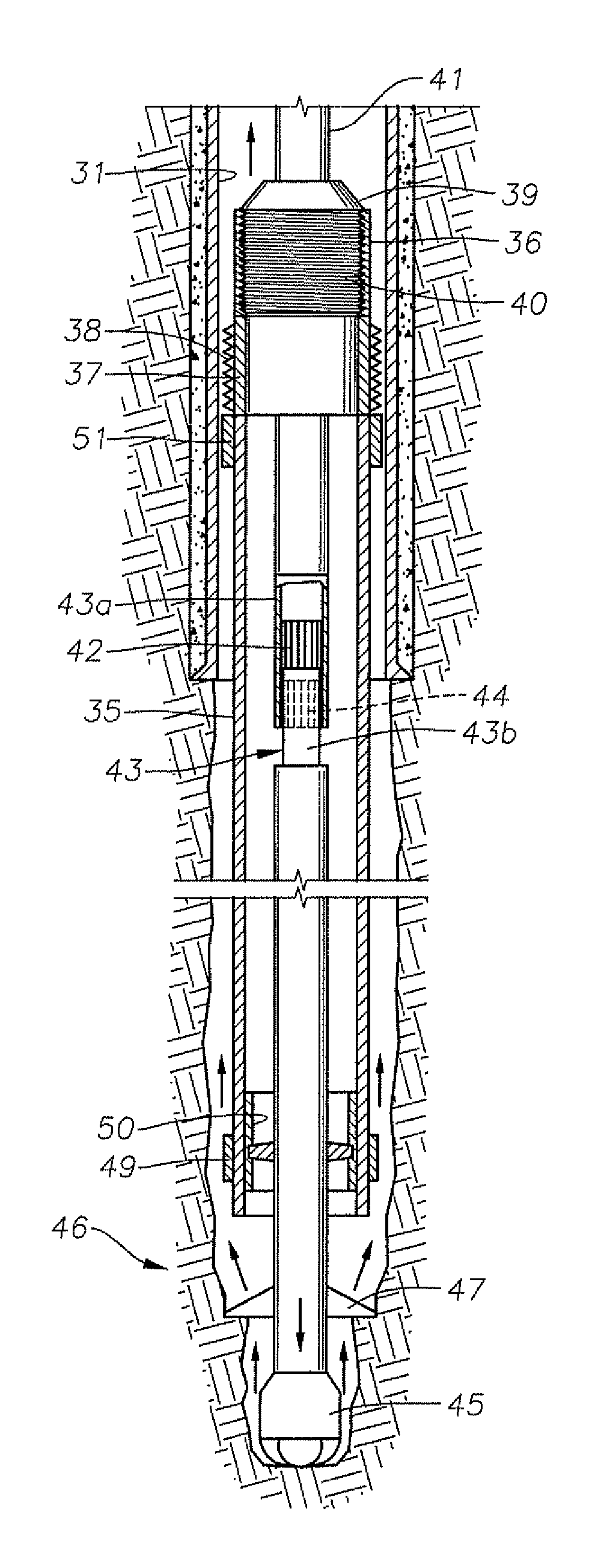

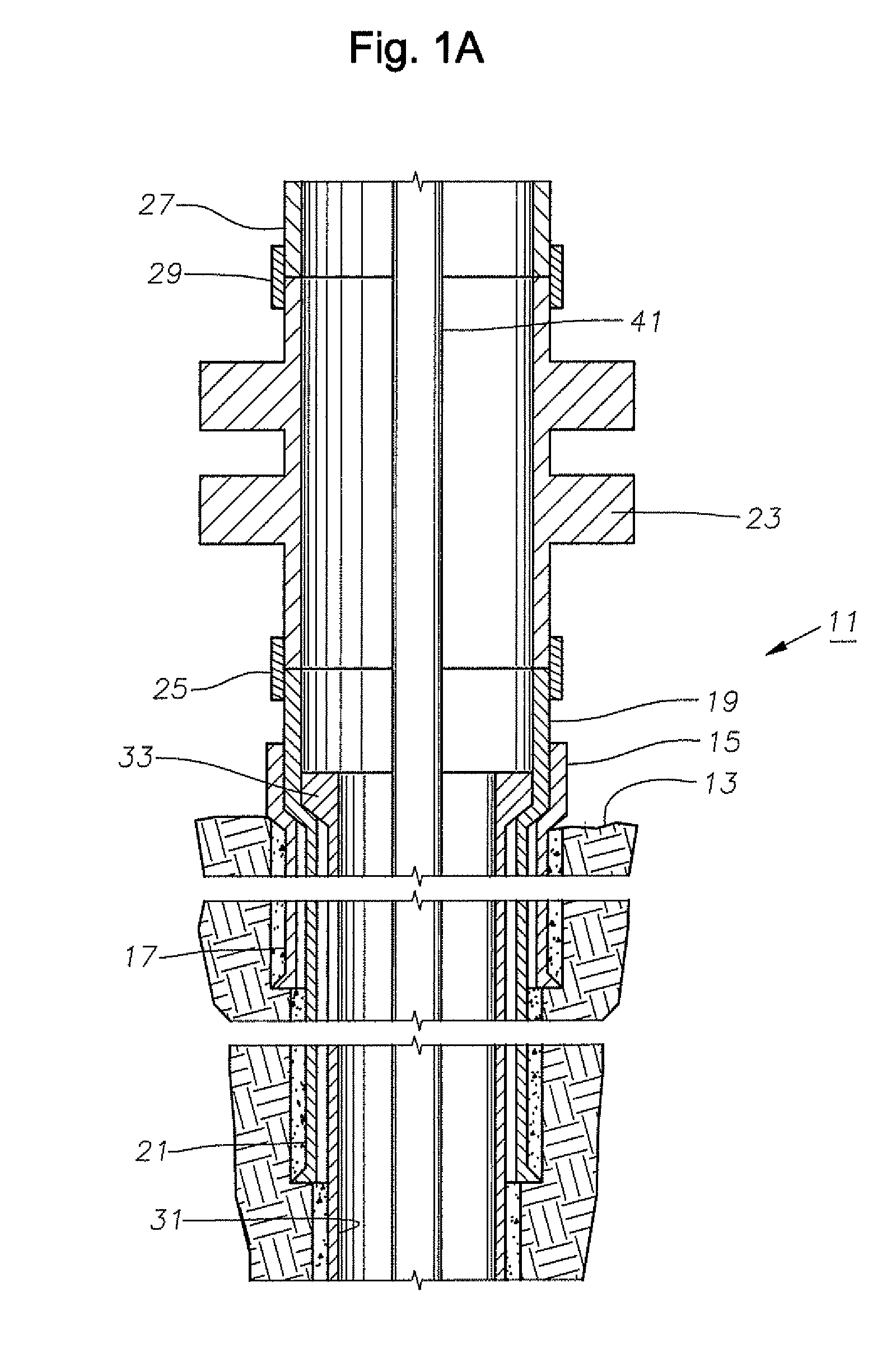

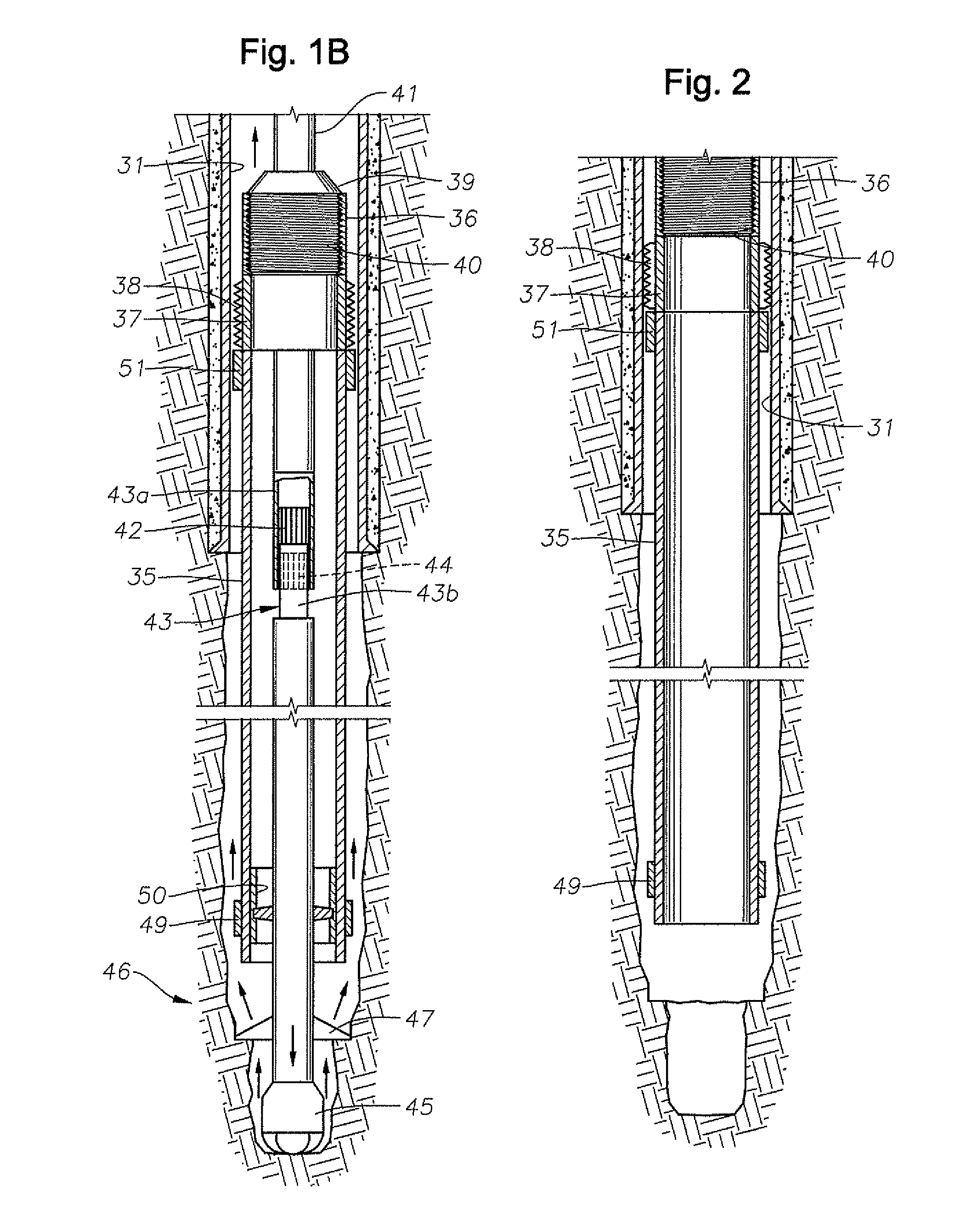

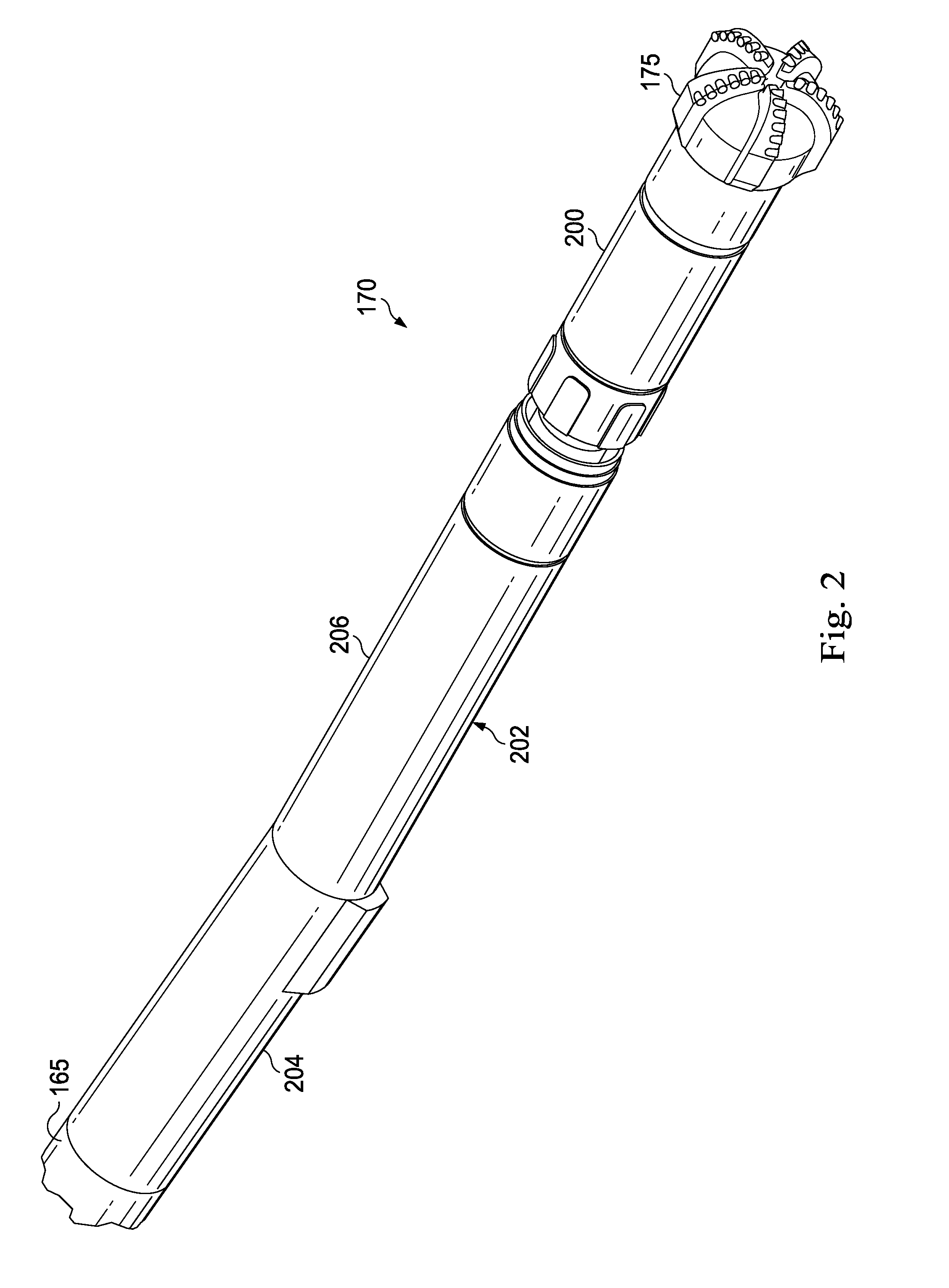

An installation system for installing a liner in a well includes drilling while simultaneously running the liner. A string of drill pipe with a bottom hole assembly including a drill bit on a lower end is lowered into the liner while the liner is suspended at the rig floor. The bottom hole assembly engages a lower sub of the liner for torque transmission. A running tool secured to the drill pipe engages the upper sub such that the running tool supports the weight of the liner and transmits torque. The drill pipe and liner are rotated to drill deeper into the wellbore. The liner hanger can be set to engage the casing, then released and reset at a different point.

Owner:SCHLUMBERGER TECH CORP

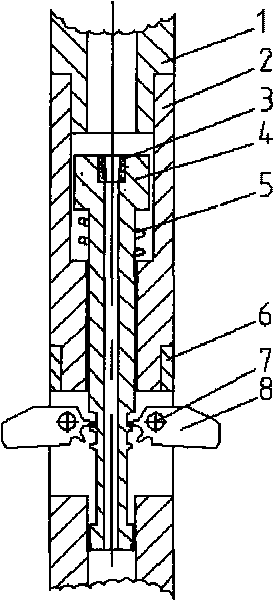

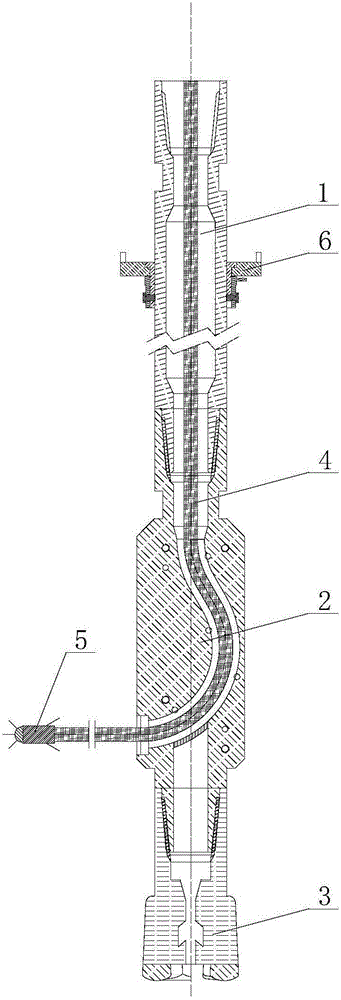

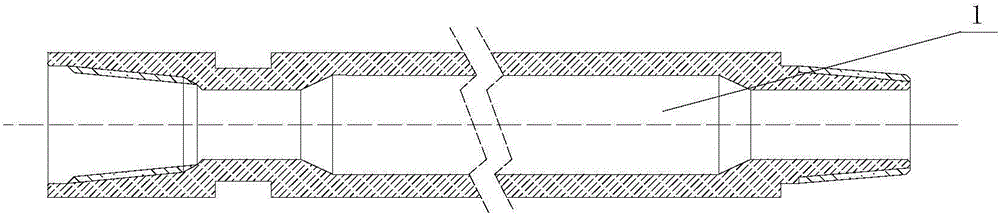

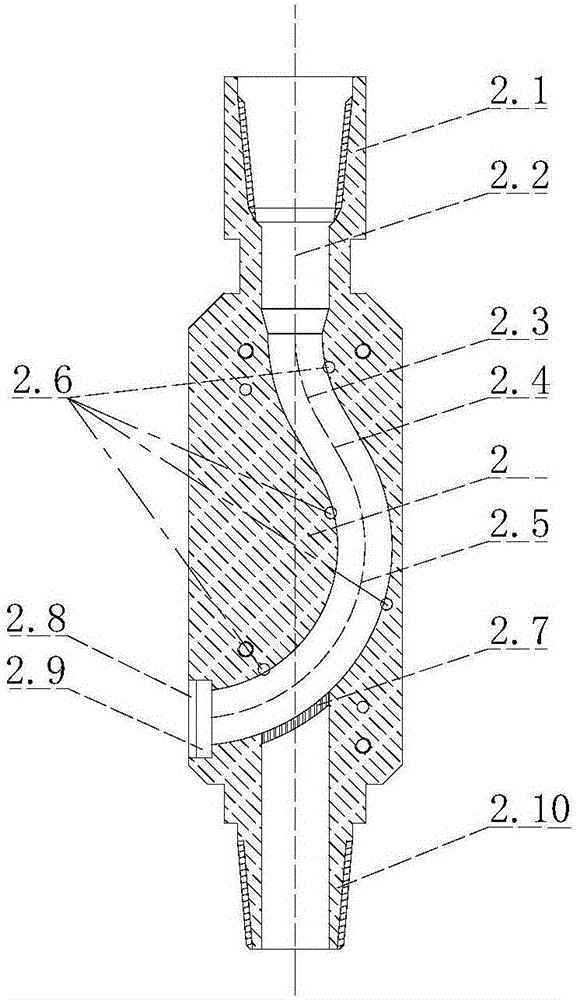

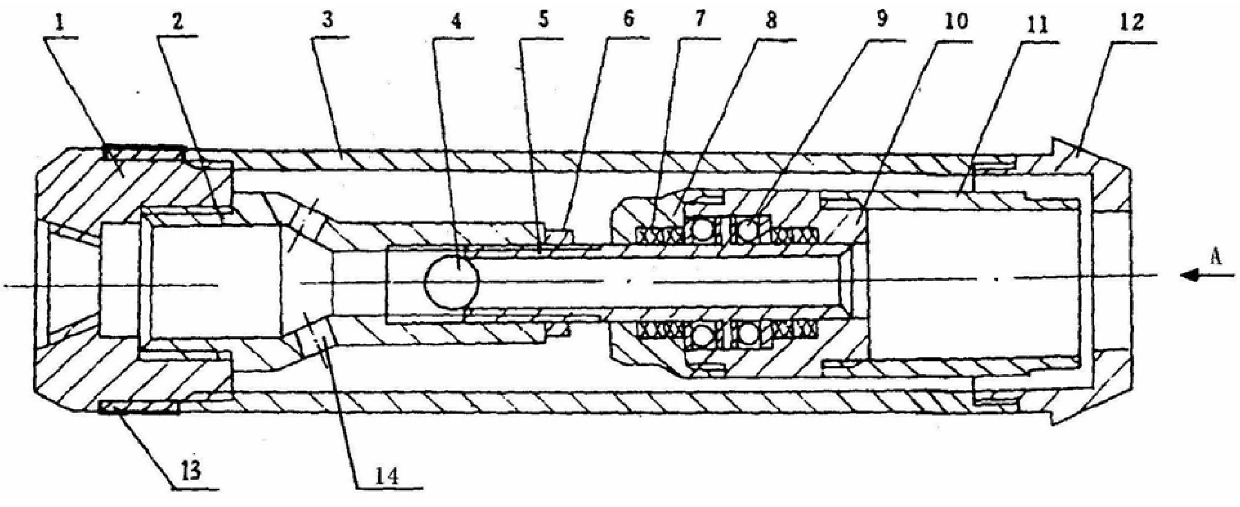

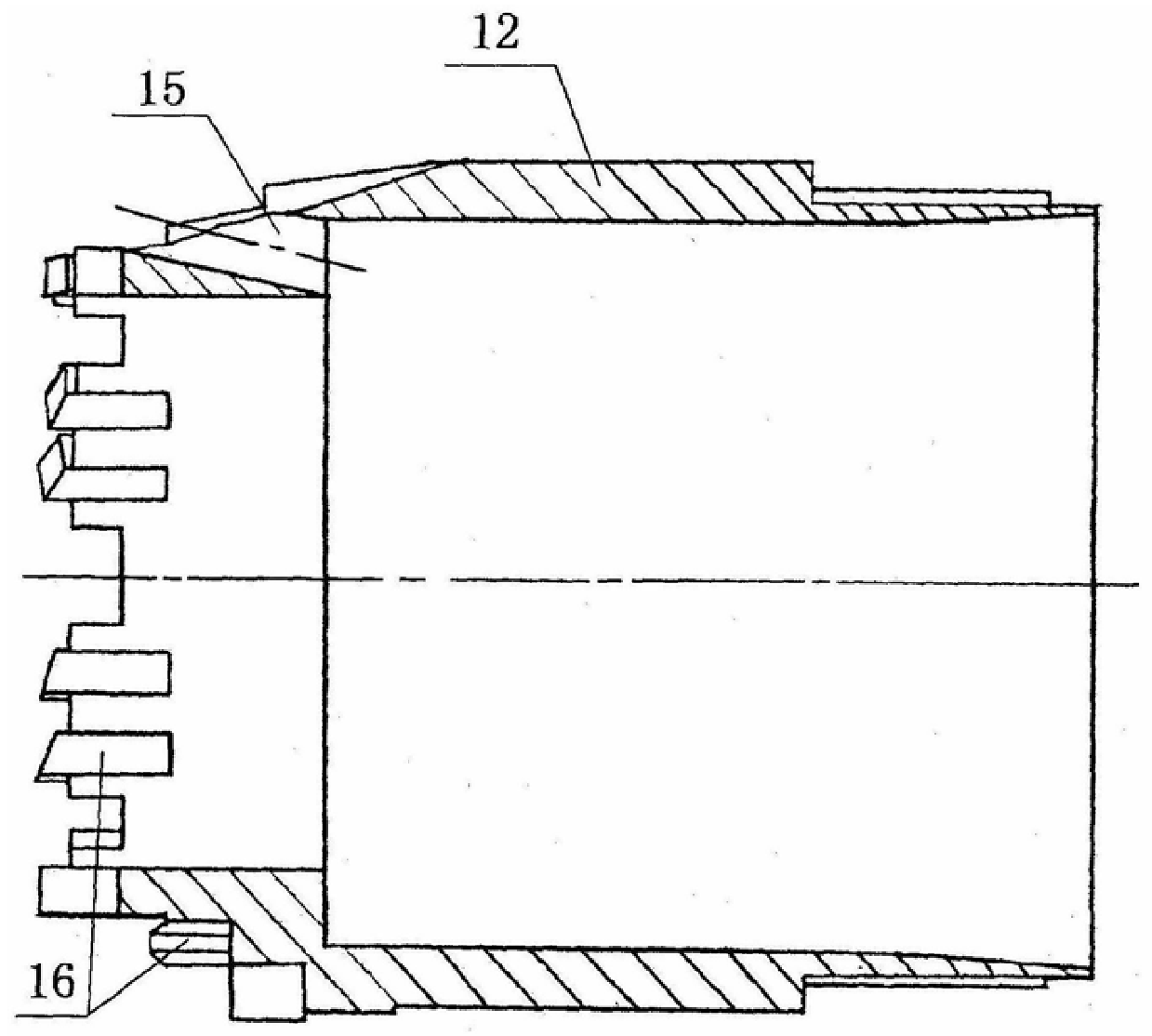

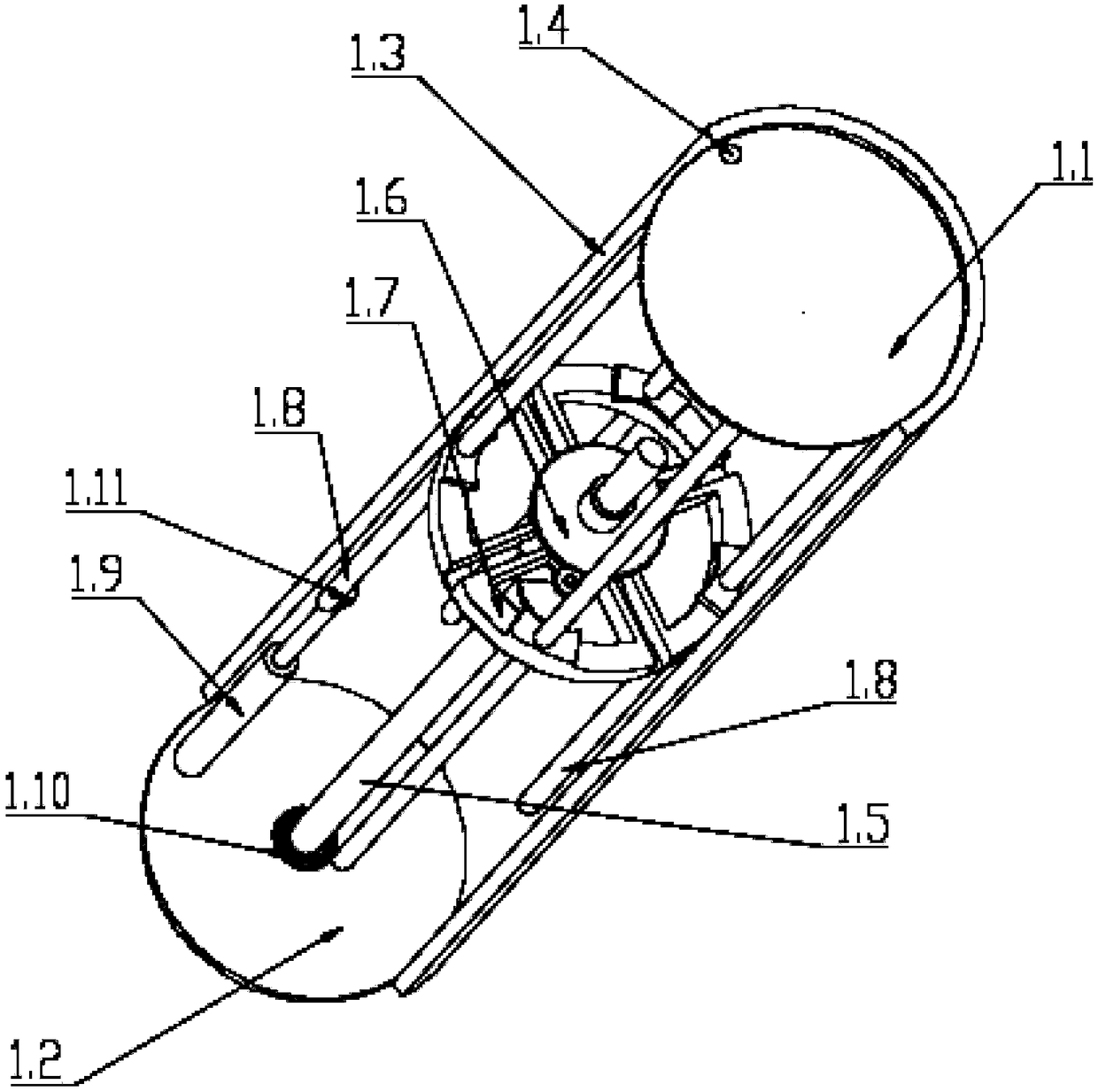

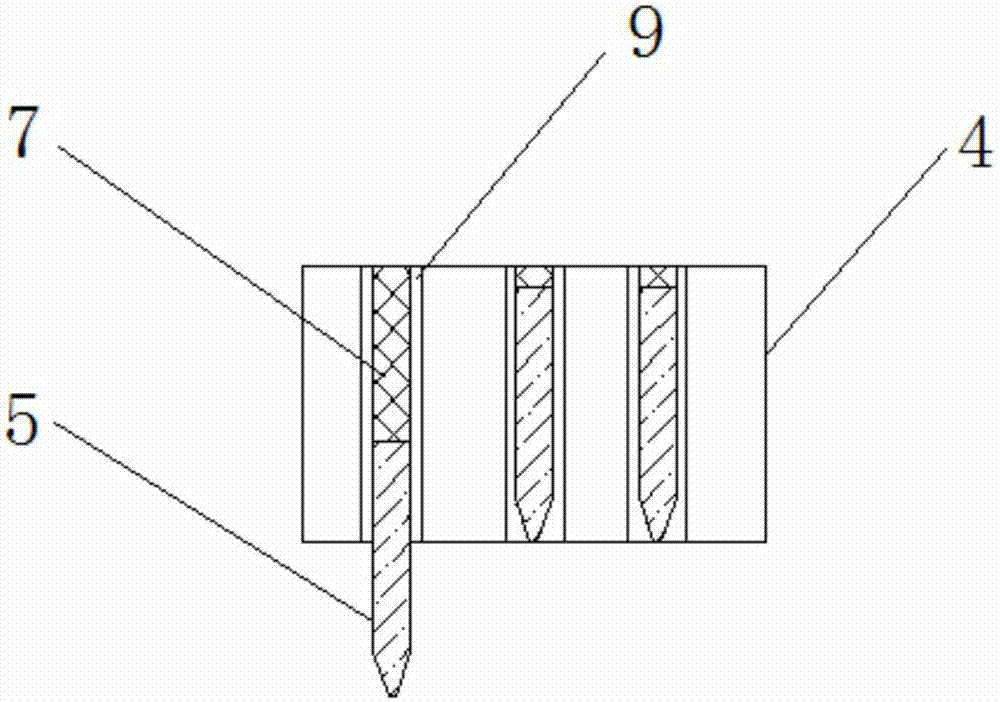

Drill-following reamer

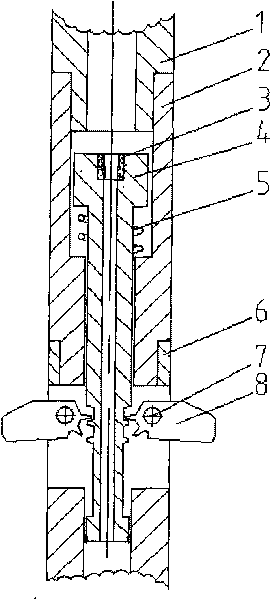

A drill-following reamer comprises an upper joint, a reamer body, a piston nozzle, a piston, a compression spring, a blade, a pin shaft and a limit stop. The upper part of the whole set of device is connected with a drilling tool through the upper joint, while the lower part is connected with a drill bit through a screw thread. During drill-following reaming operation, the liquid piston nozzle pumped on the ground produces pressure drop to push the piston to move downwards, a groove on the piston pushes a gear structure on the blade to rotate the blade outwards by using the pin shaft as the center when the piston moves downwards till the blade is limited by the limit stop, and then the blade is expanded to reach the maximum outside diameter to start the drill-following reaming operation. 78.6 percent of drill hole expansion rate can be achieved by using the drill-following reamer, so the drill hole expansion rate is high; the blade has the mechanical locking function and is not retracted due to the extrusion of the well wall, so the diameter of the reamed drill hole is regular; and because the drilling and the reaming are carried out at the same time, the drilling cost is saved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

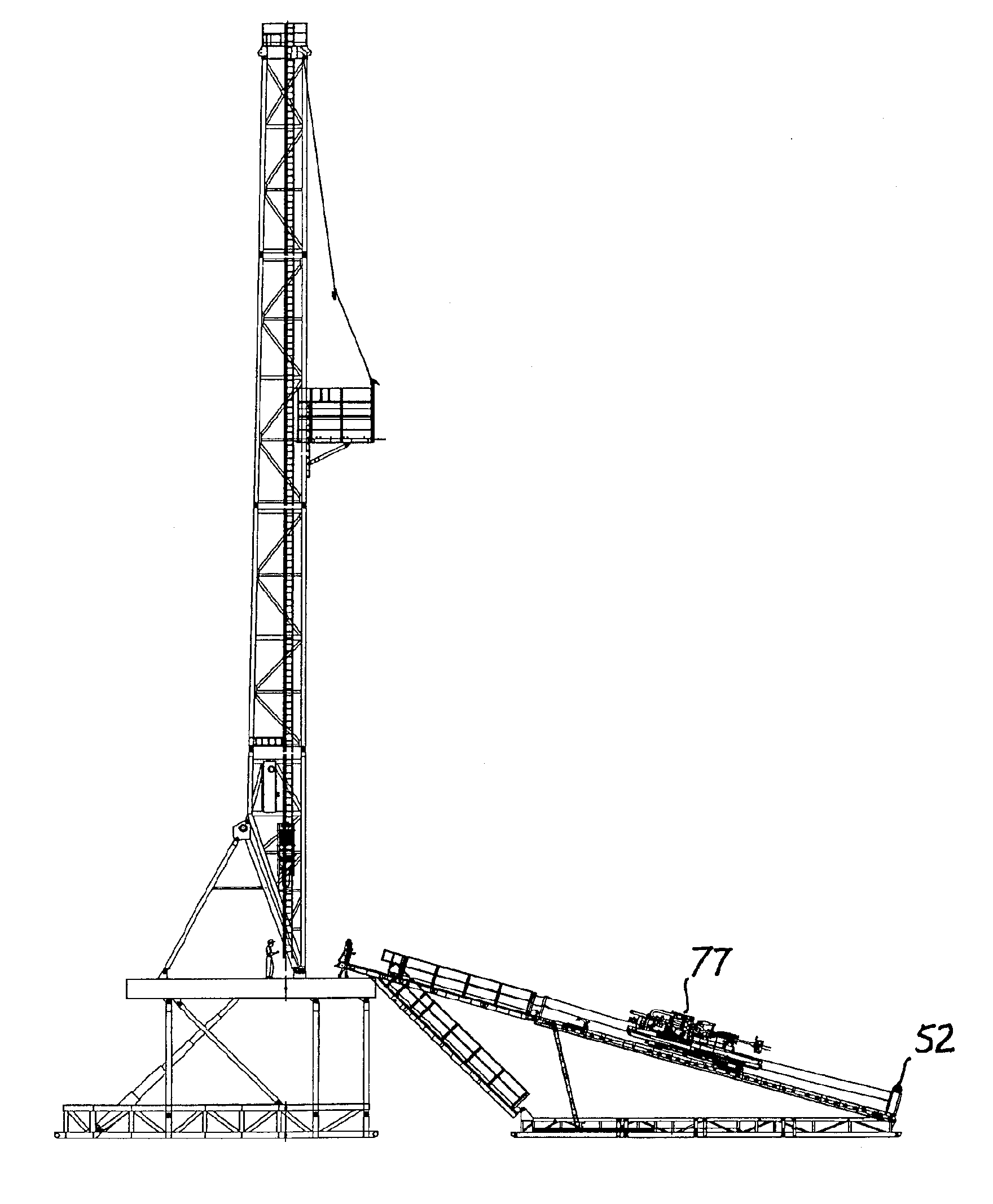

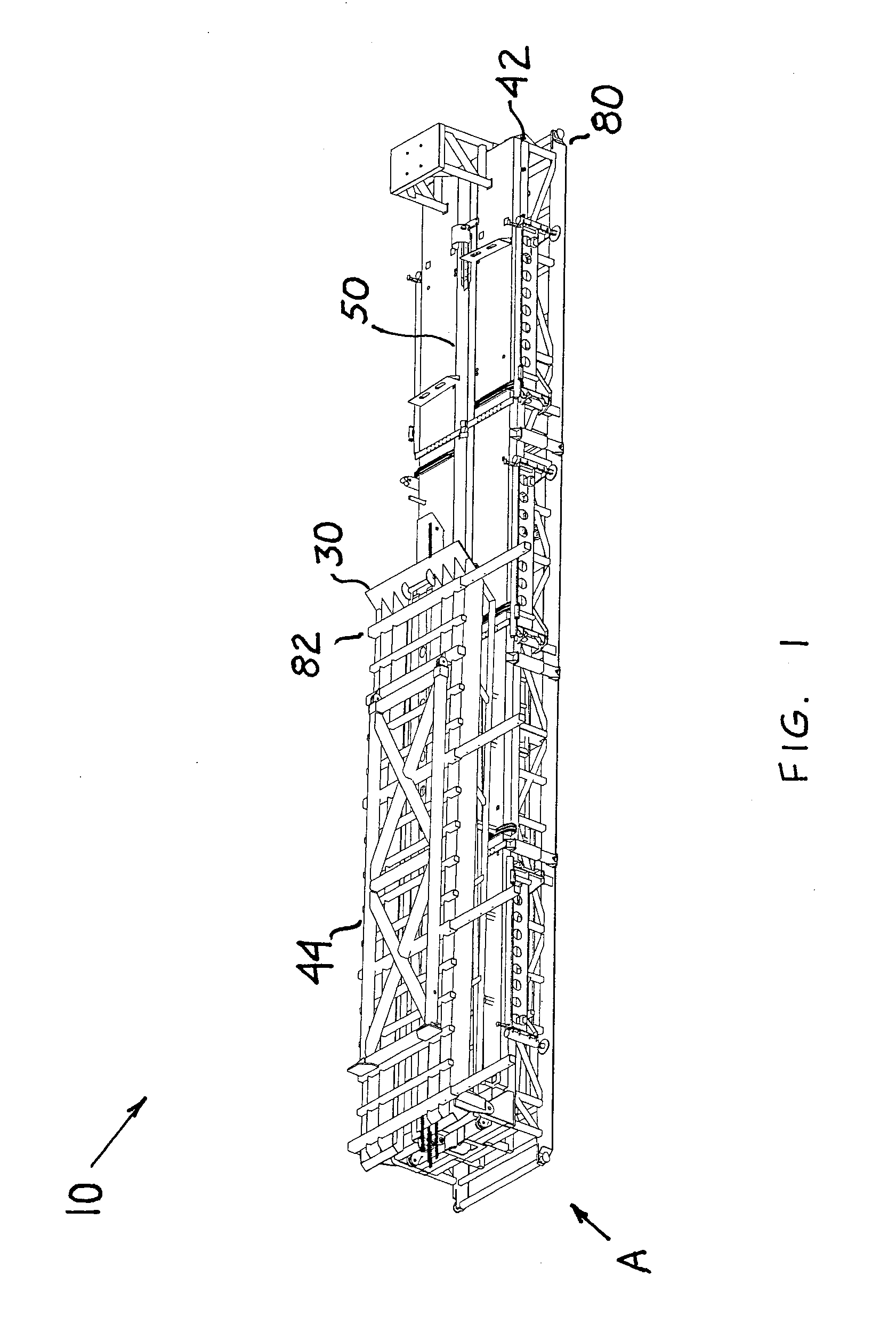

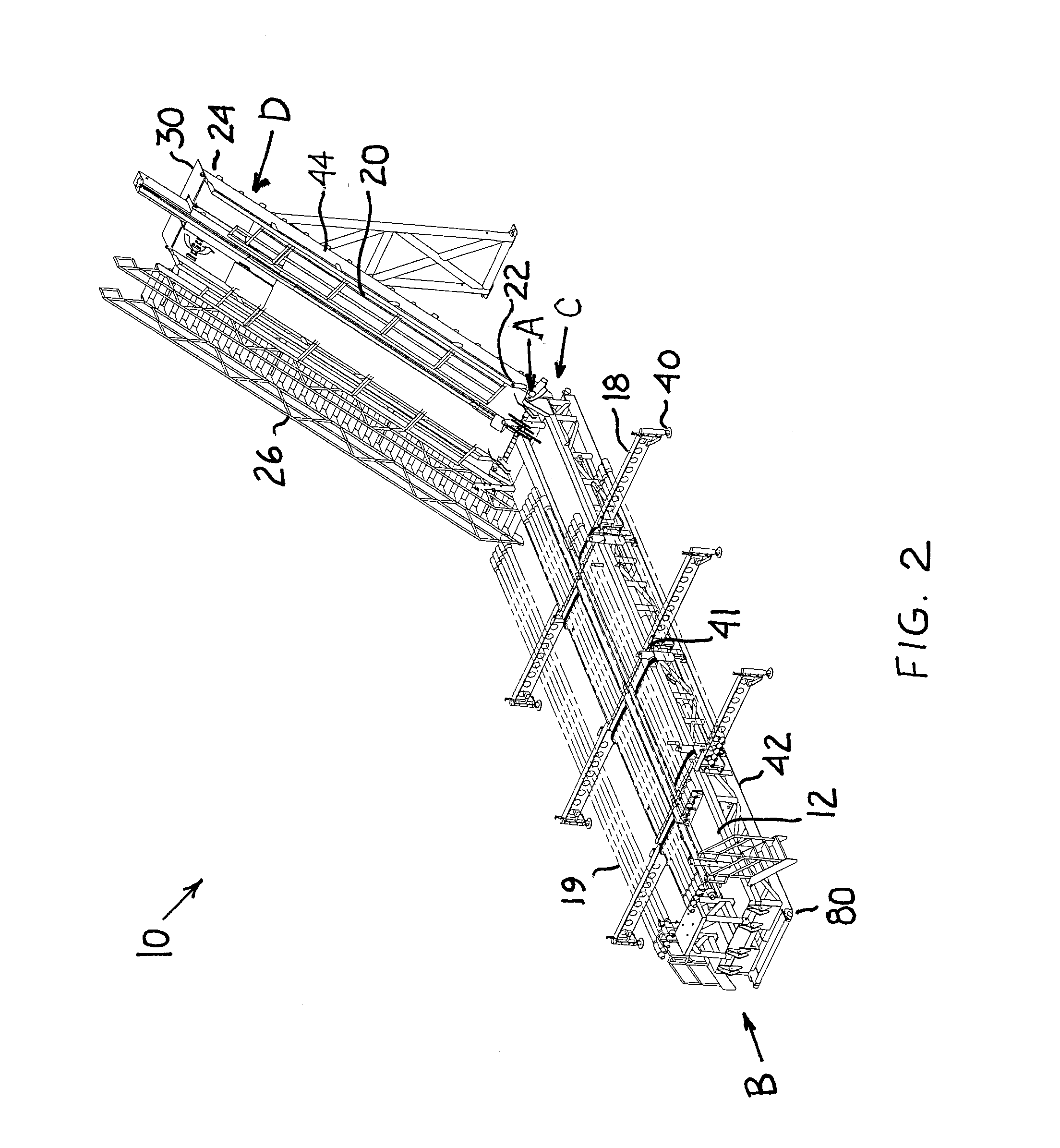

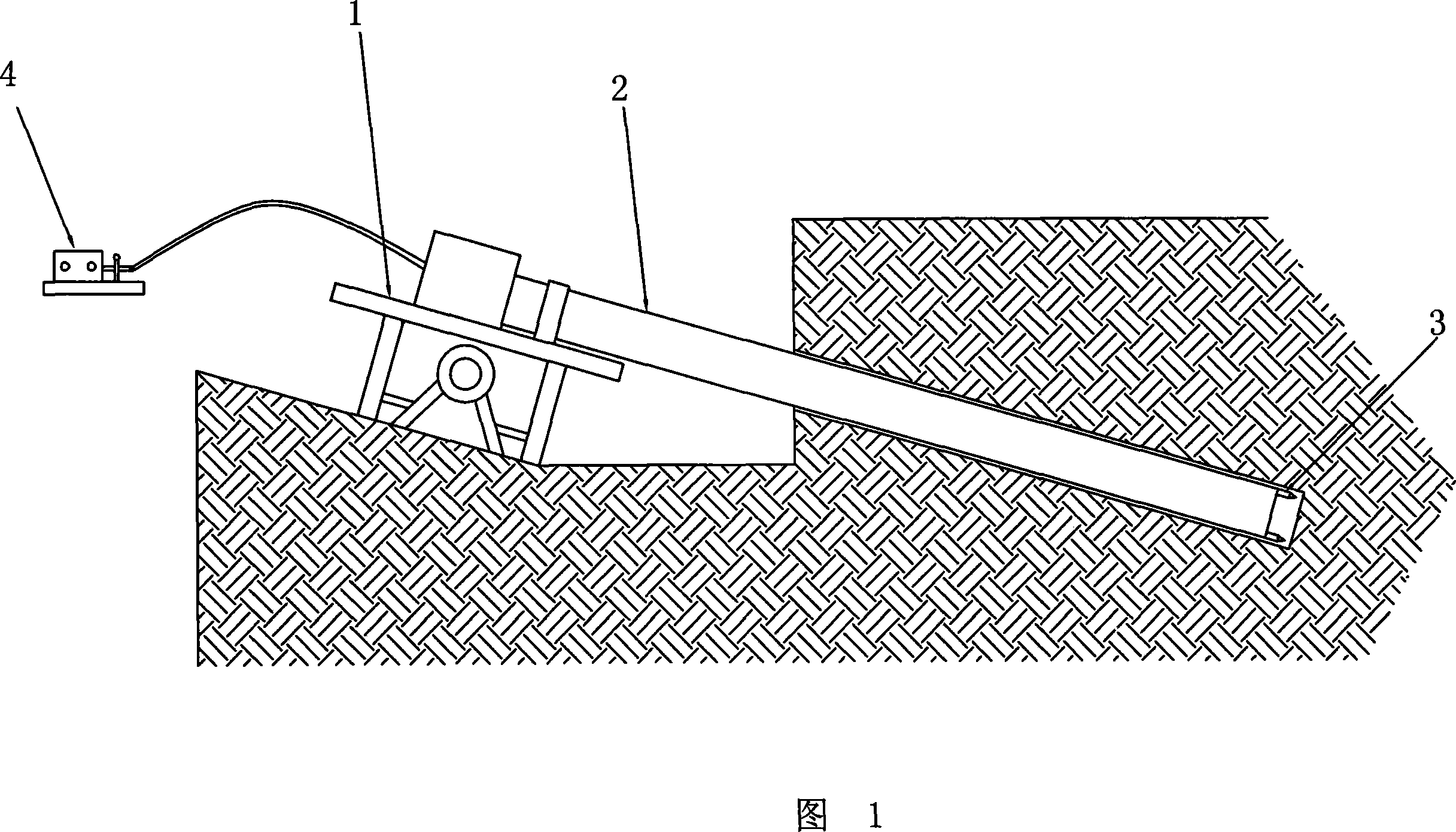

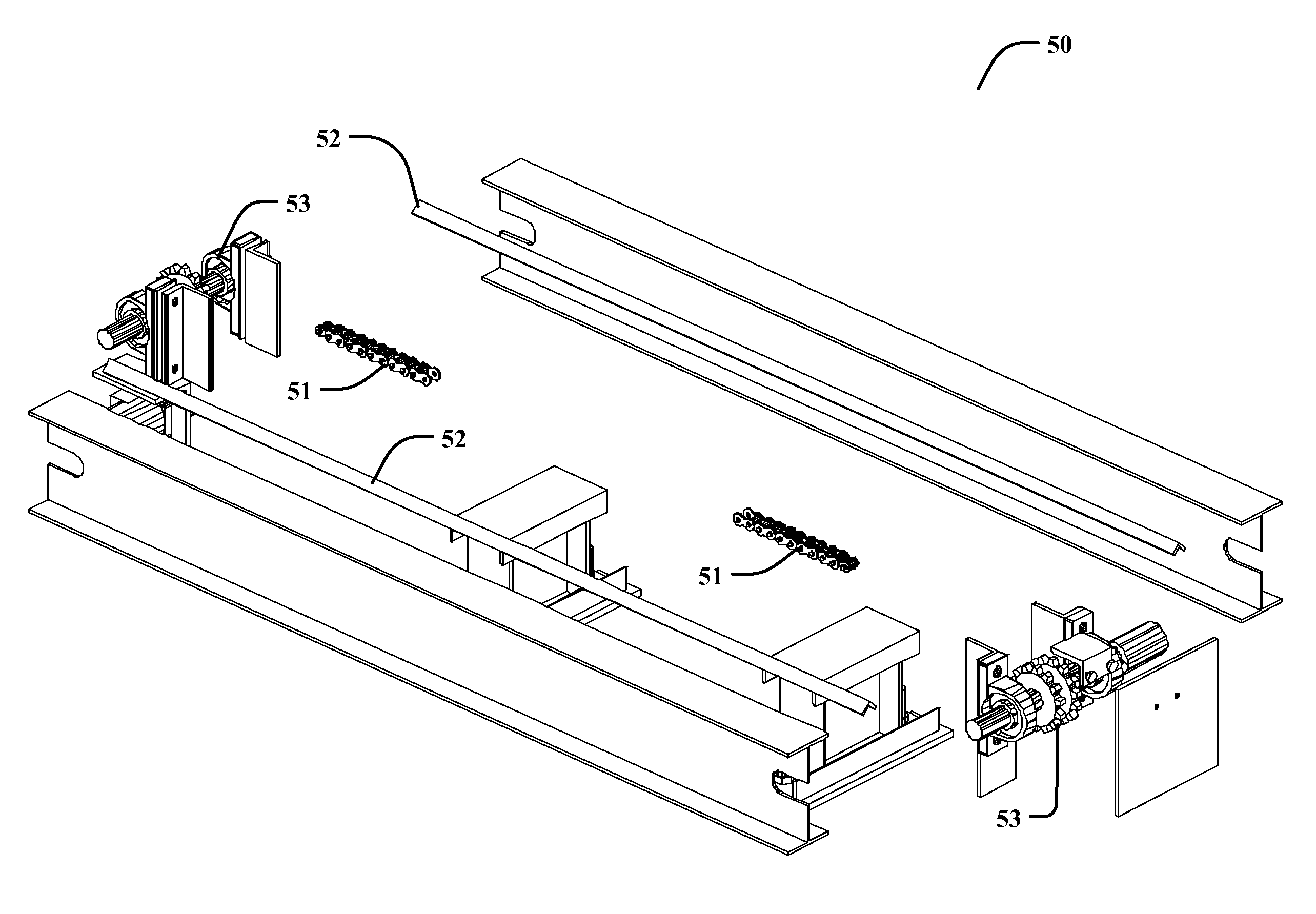

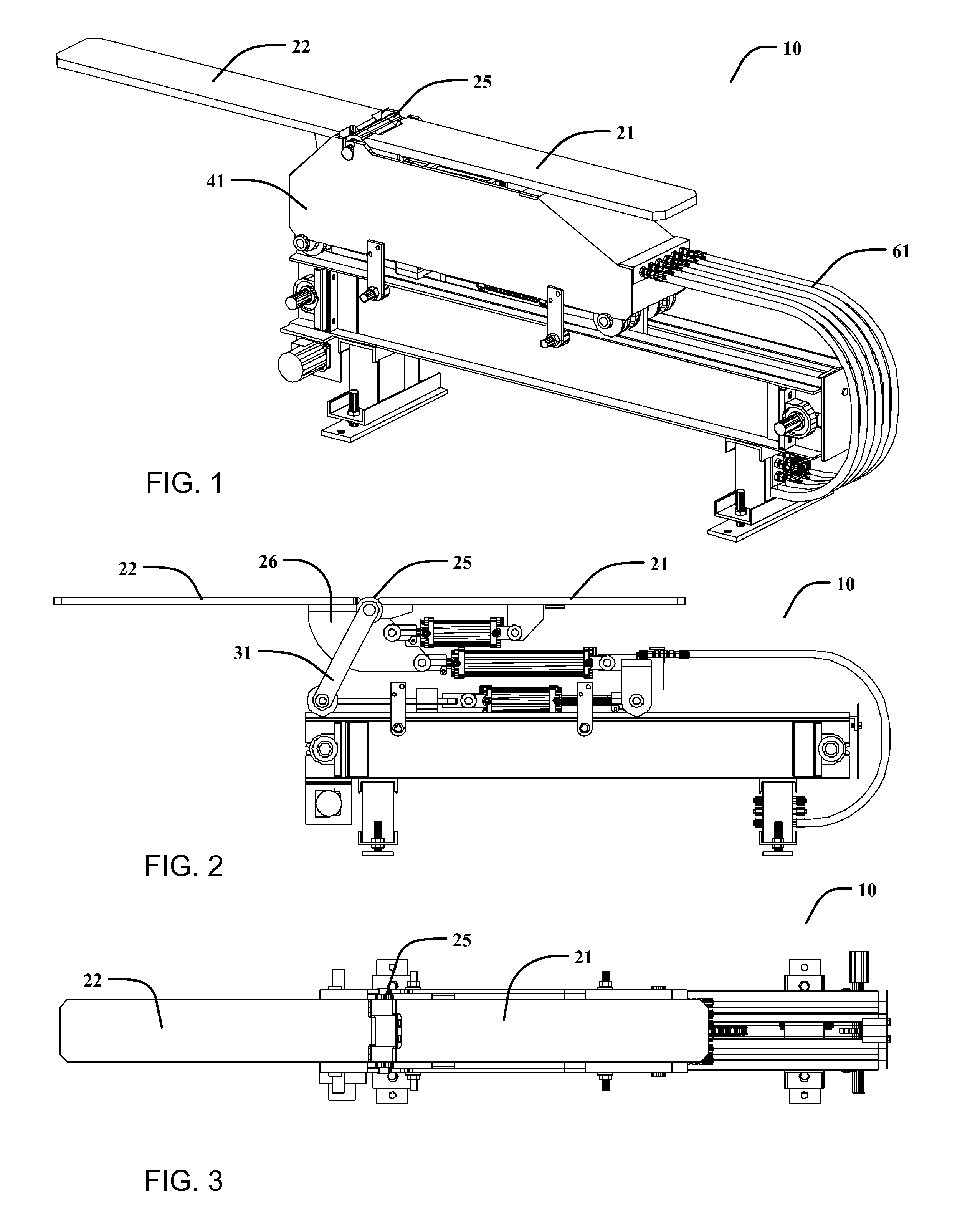

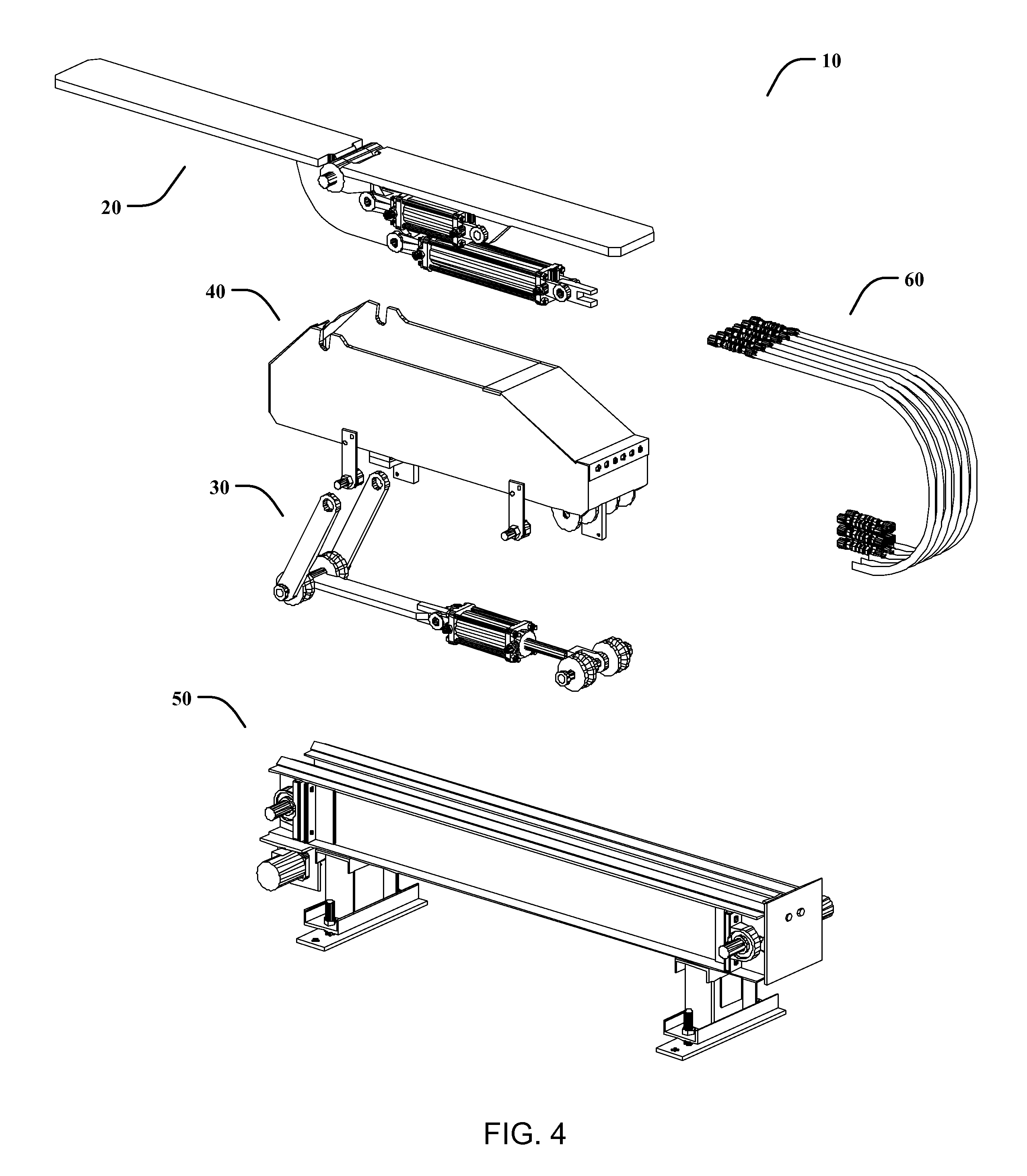

Apparatus for delivering drill pipe to a drill rig

An apparatus for delivering drill pipe has a support frame, a catwalk platform, and a slide platform that are pivotally connected together. A drill pipe rack, a chain drive, and a kicker direct the drill pipe to and from the catwalk platform. A hydraulically actuated piston lifts the catwalk platform and slide platform into alignment to create a single inclined delivery platform extending from the ground to the rig floor. A powered means lifts or lowers the drill pipe along the delivery platform.

Owner:COAX TECH

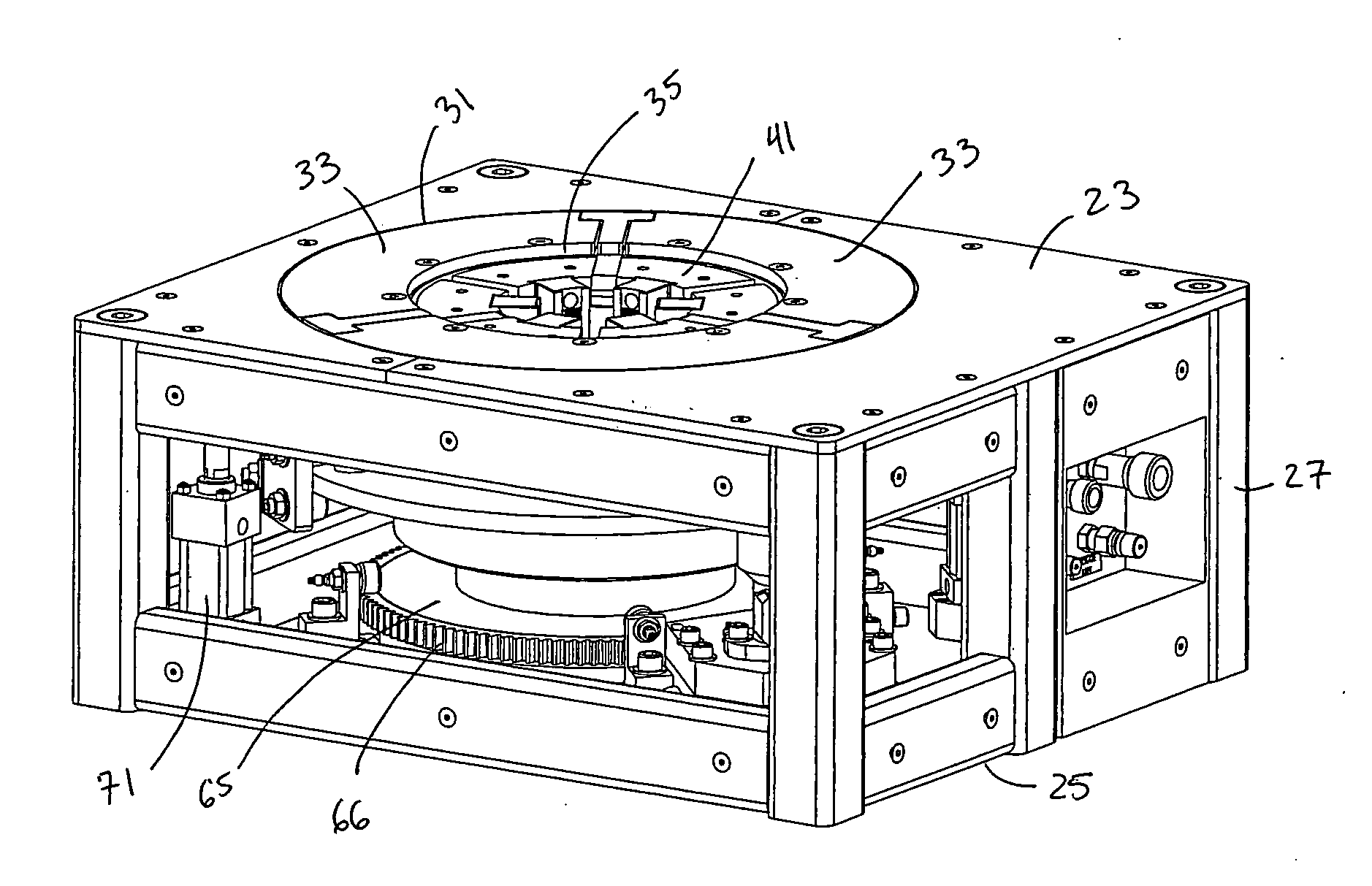

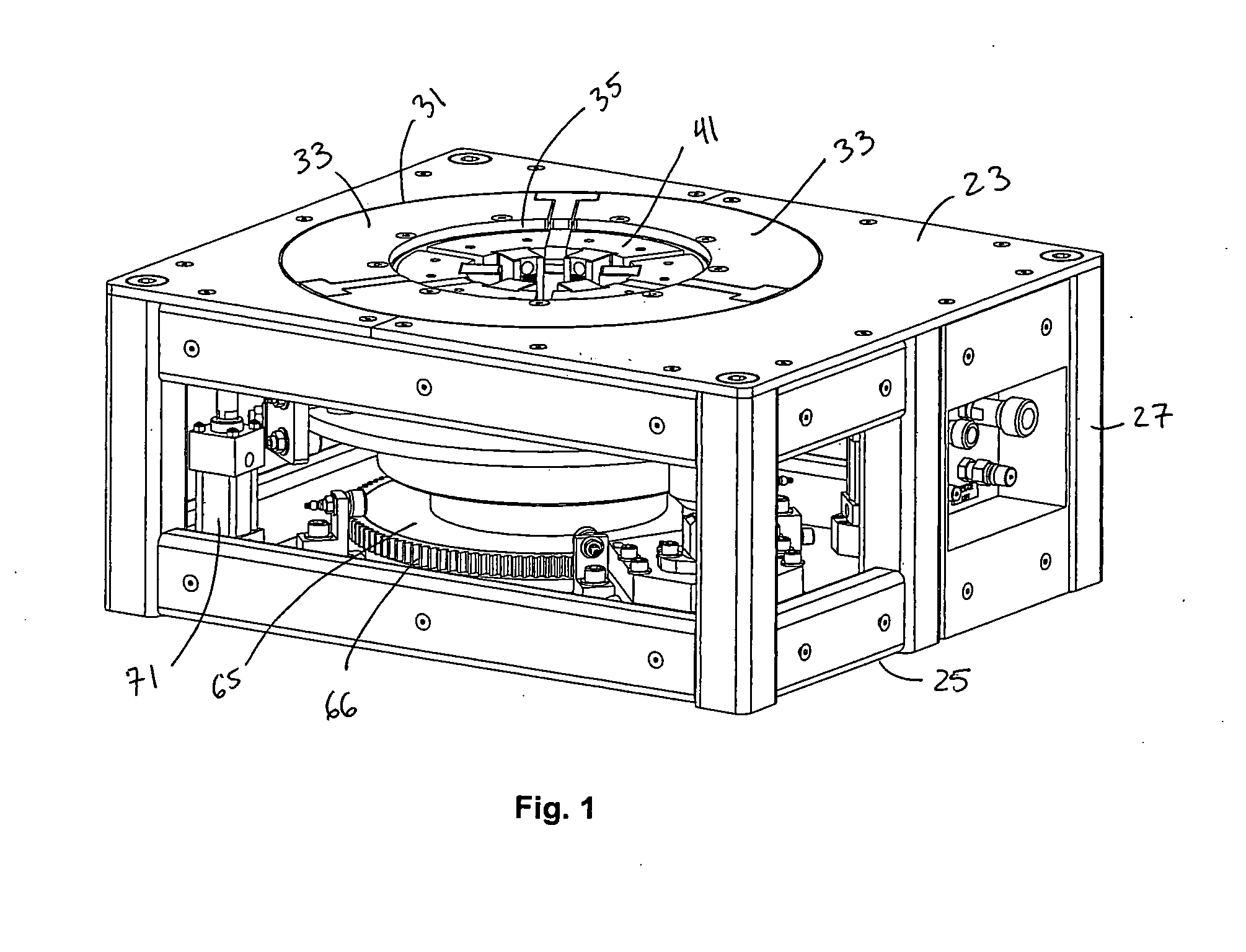

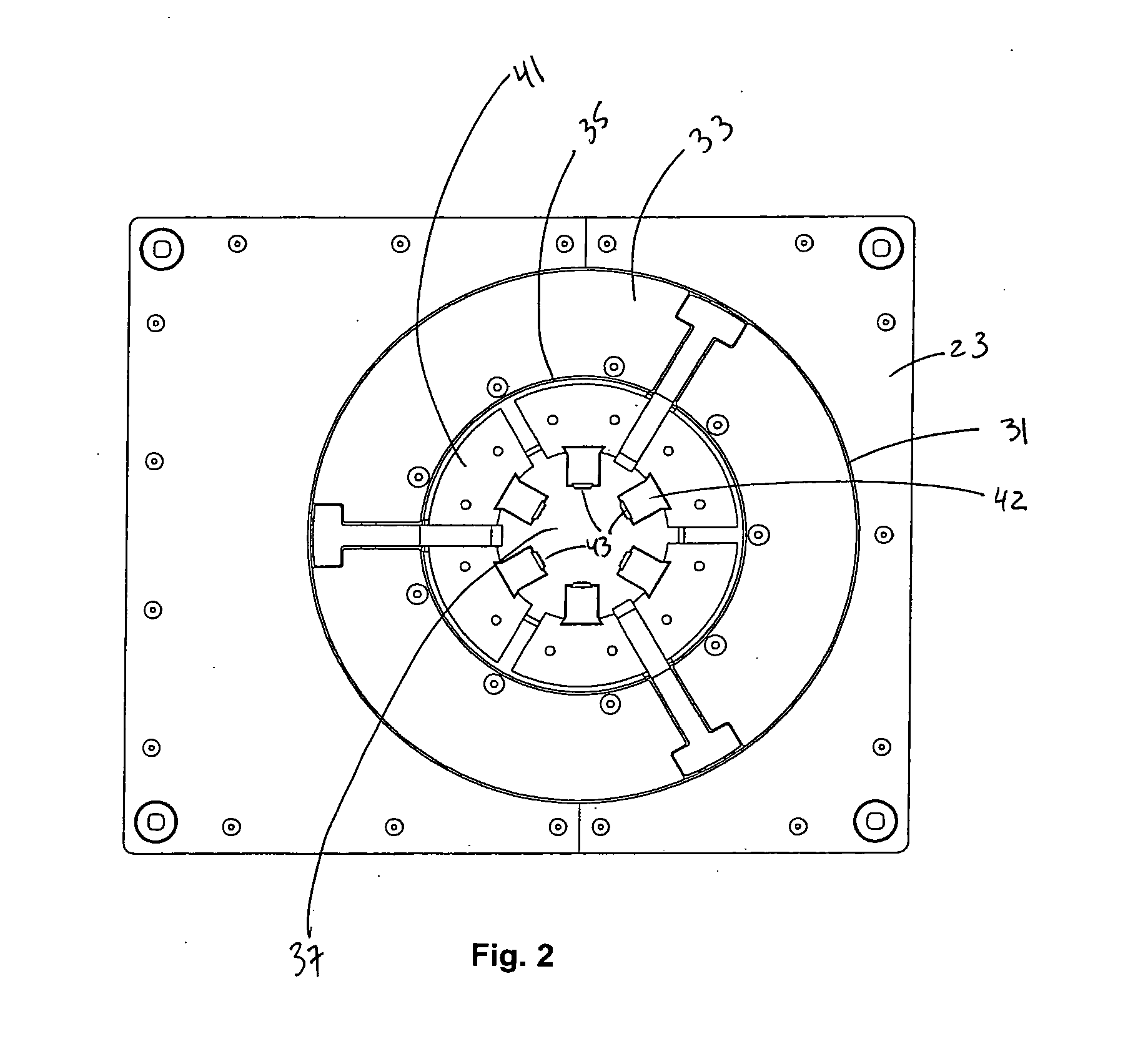

Mouse hole support unit with rotatable or stationary operation

InactiveUS20080202813A1Easy to set upConsiderable timeDrilling rodsConstructionsManual insertionDrill line

The present invention provides improved methods and apparatus for supporting and engaging drill pipe in a mouse hole that allows for multiple drill pipe sections to be attached together before being attached to an existing drill string. The present invention is designed to allow for engagement and disengagement of drill pipe sections of various diameters without the need for manually inserting or removing support shims or slips. Embodiments of the invention provide for rotation of the engaged drill pipe sections to assist in connection to another drill pipe section. These features allow for speedy set up and attachment of drill pipe sections during drilling operations. The support unit of the present invention is also portable, and may be retrofitted into an existing drill rig platform.

Owner:XTECH INDS

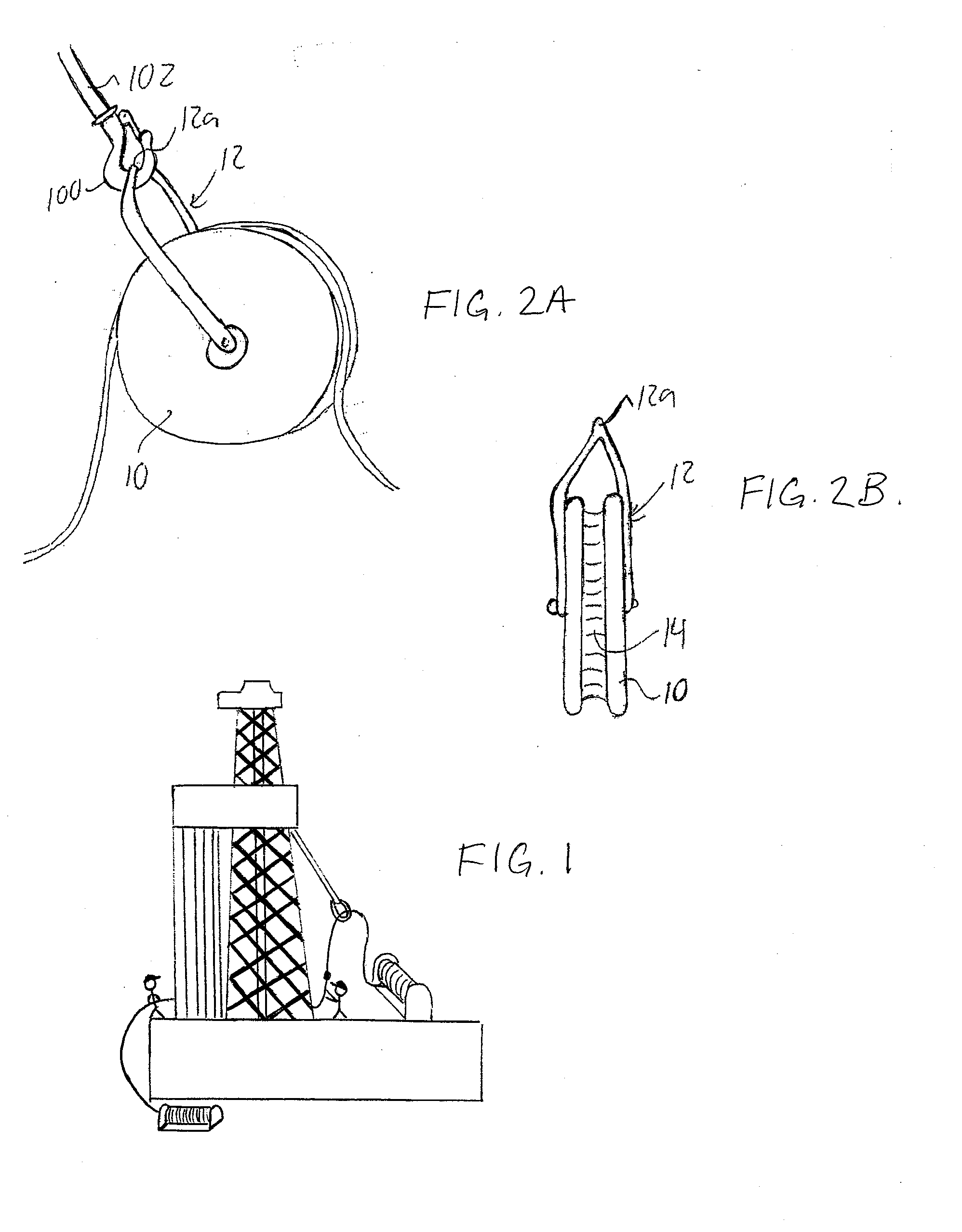

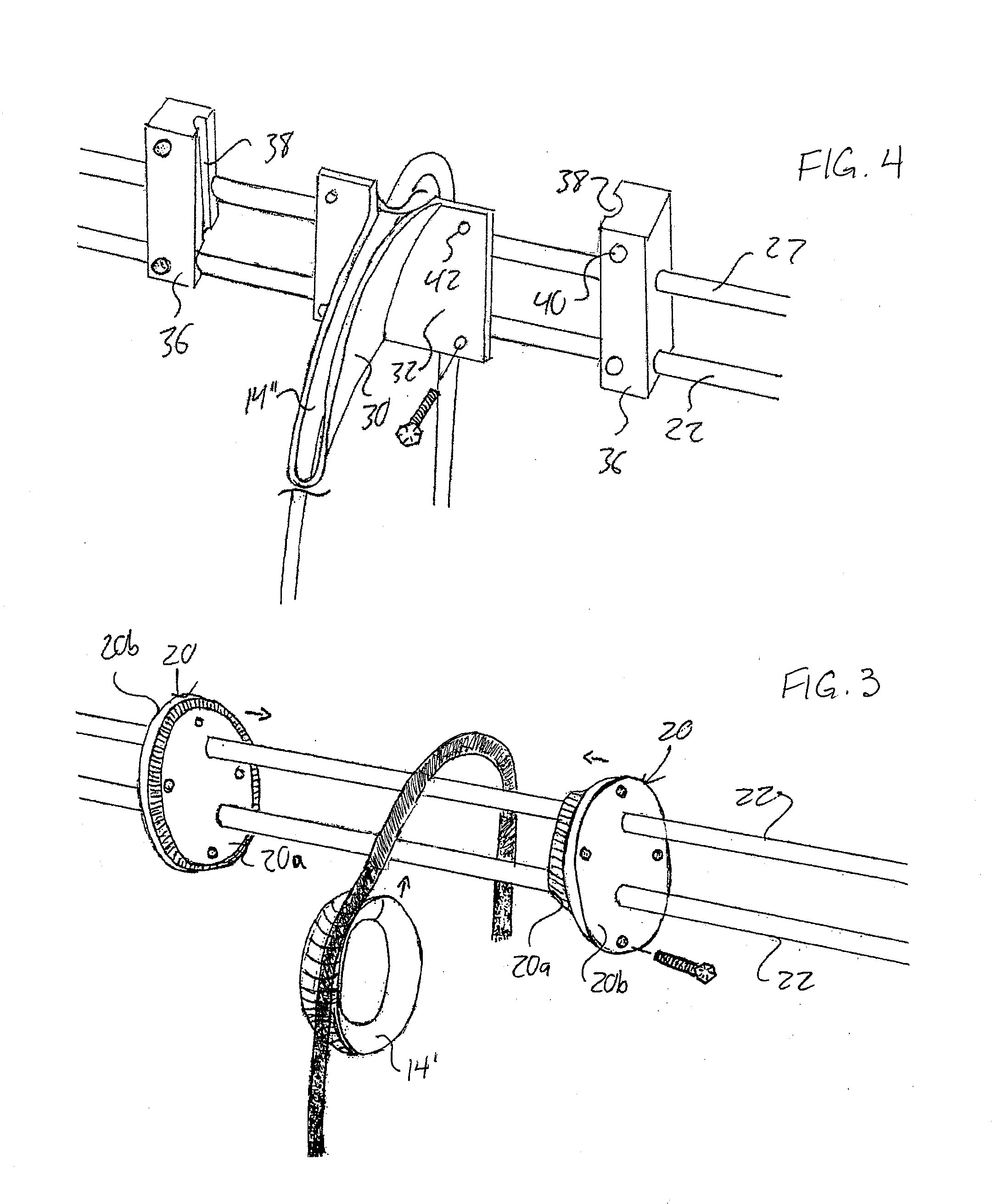

Replaceably Lined Cable Guides and Tensioning Roller for Drill Line Slip and Cut Operations on a Drilling Rig

Cable guides for overhead support of drill line on a drilling rig during a slip and cut operation feature replaceable liners of wear material supported by a re-usable base. A tensioning roller added to the draw-works resides outward from the periphery of the draw-works drum and is spring-biased toward same into order to force the incoming drill line against the periphery of the drum.

Owner:URQUHART JESSE

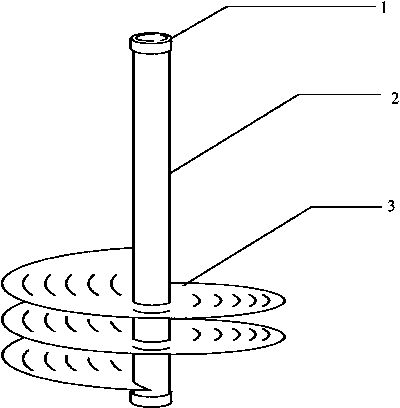

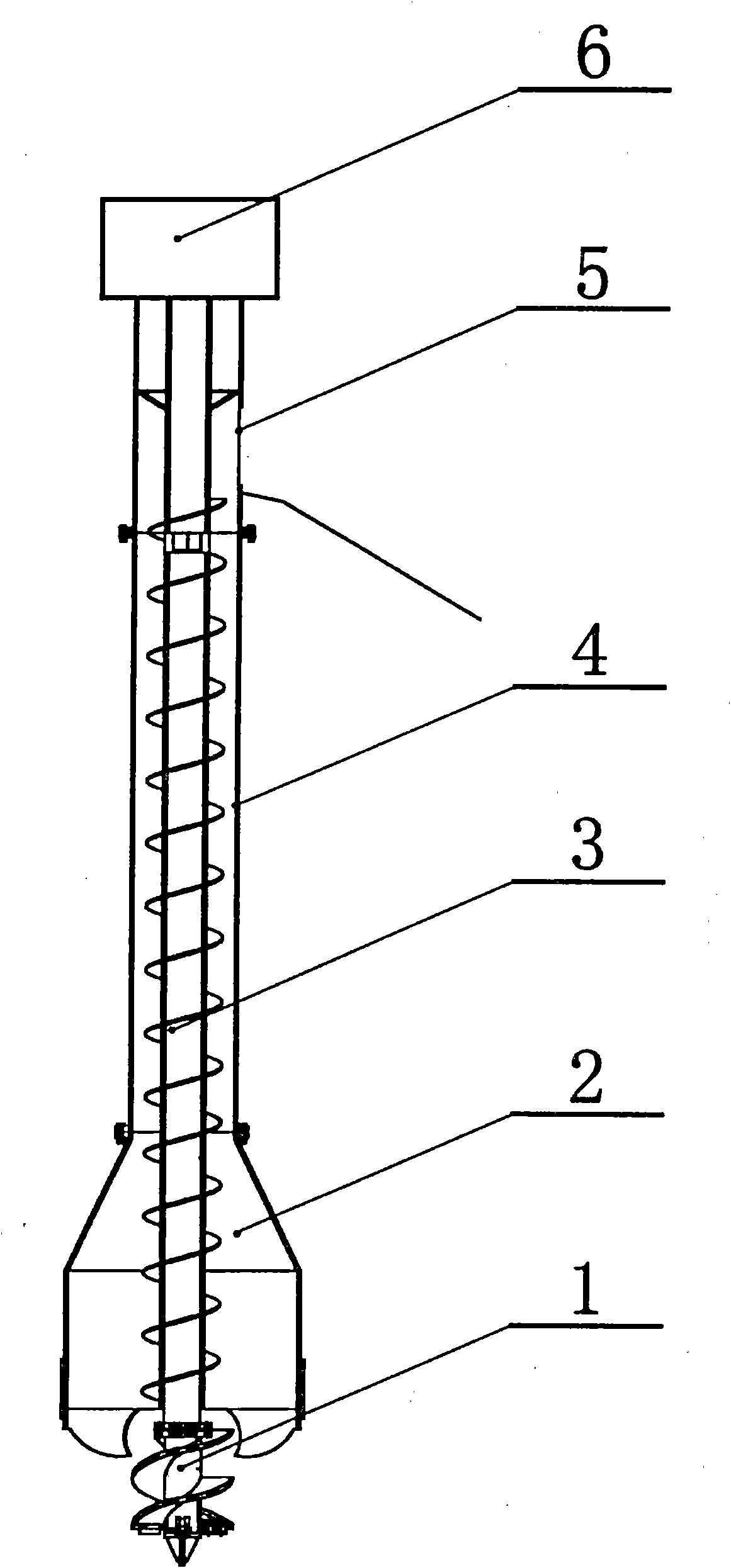

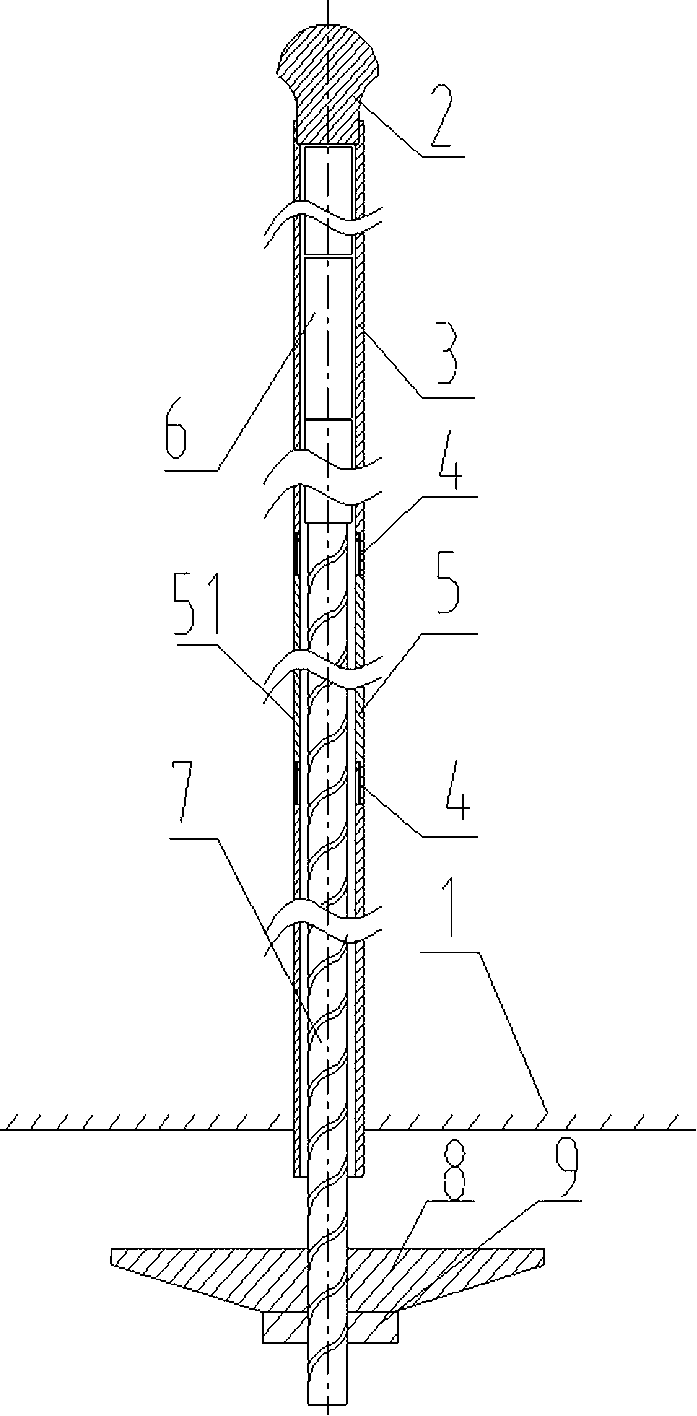

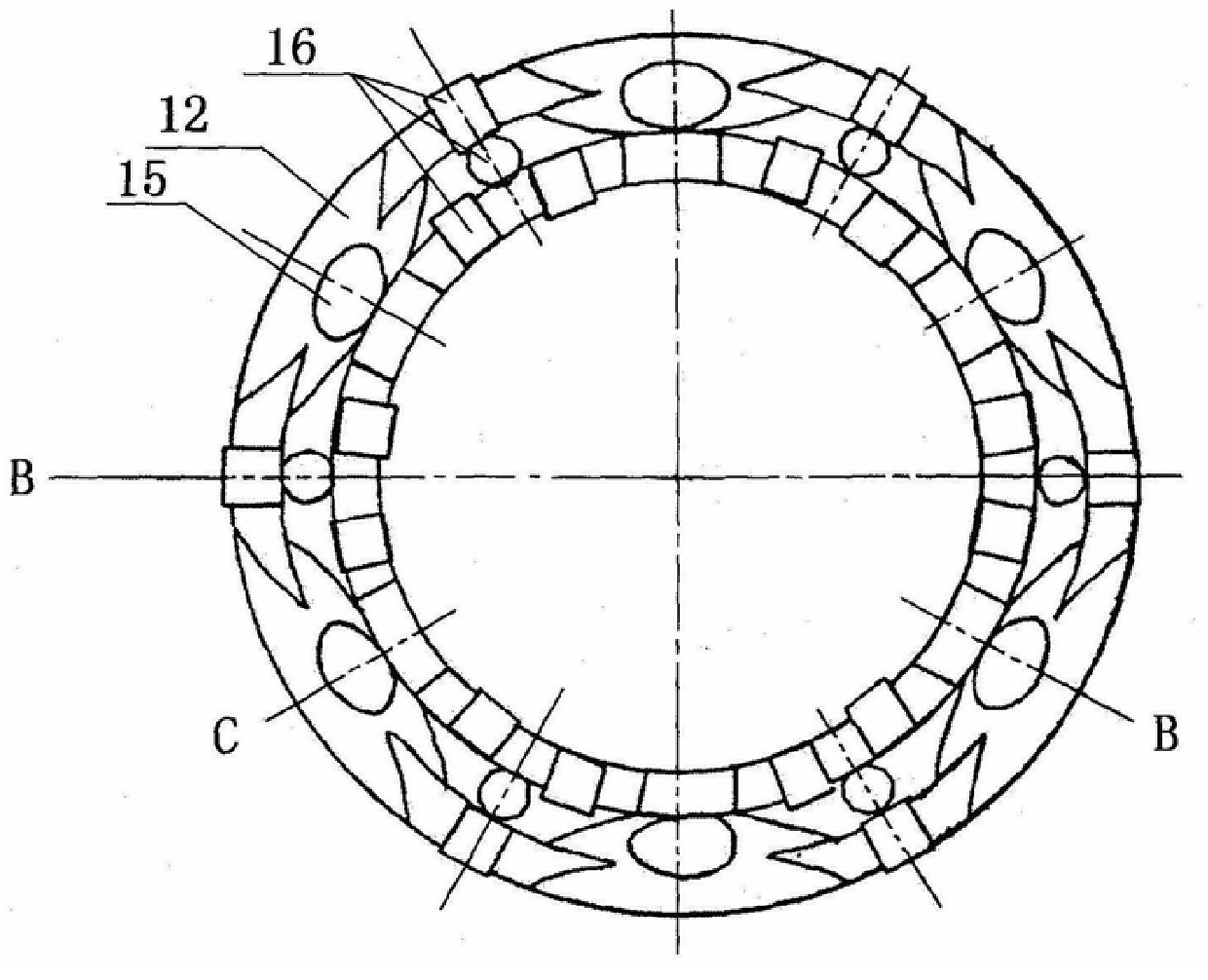

Filling pile spiral hoisting slurry drill pipe

InactiveCN104074478AHigh practical valueSmooth dischargeDrilling rodsDrilling casingsSpiral bladeStructural engineering

The invention discloses a filling pile spiral hoisting slurry drill pipe, which comprises a section or a plurality of sections of hollow drill pipes and drill pipe joints connected with the hollow drill pipes, wherein spiral blades are arranged on the outer surfaces of the hollow drill pipes; every two sections of hollow drill pipes are connected through the drill pipe joints; and a slurry spraying opening is formed in a connecting part of the first section of hollow drill pipe and a drill bit. Generally, The spiral blades are welded onto a hollow drill hole and are arranged at the lower section of the hollow drill pipes; and the length of the spiral blades is 1 / 4 to 1 / 2 of the total length of the hollow drill pipes, and the diameter of the spiral blades is smaller than the diameter of the drill bit. During the construction, the spiral blades rotate in the positive direction along the drill pipes; the upward hoisting force is generated on slurry at the lower section of a pile hole, and mud blocks in the slurry; and meanwhile, downward thrust is generated on the drill pipes. The drill pipe has the effects of connecting the drill bit and transmitting the drill bit and also has the effect of hoisting the slurry, so that the practical value of the drill pipe is improved.

Owner:SHANGHAI SHANSHUN CIVIL ENG TECH +1

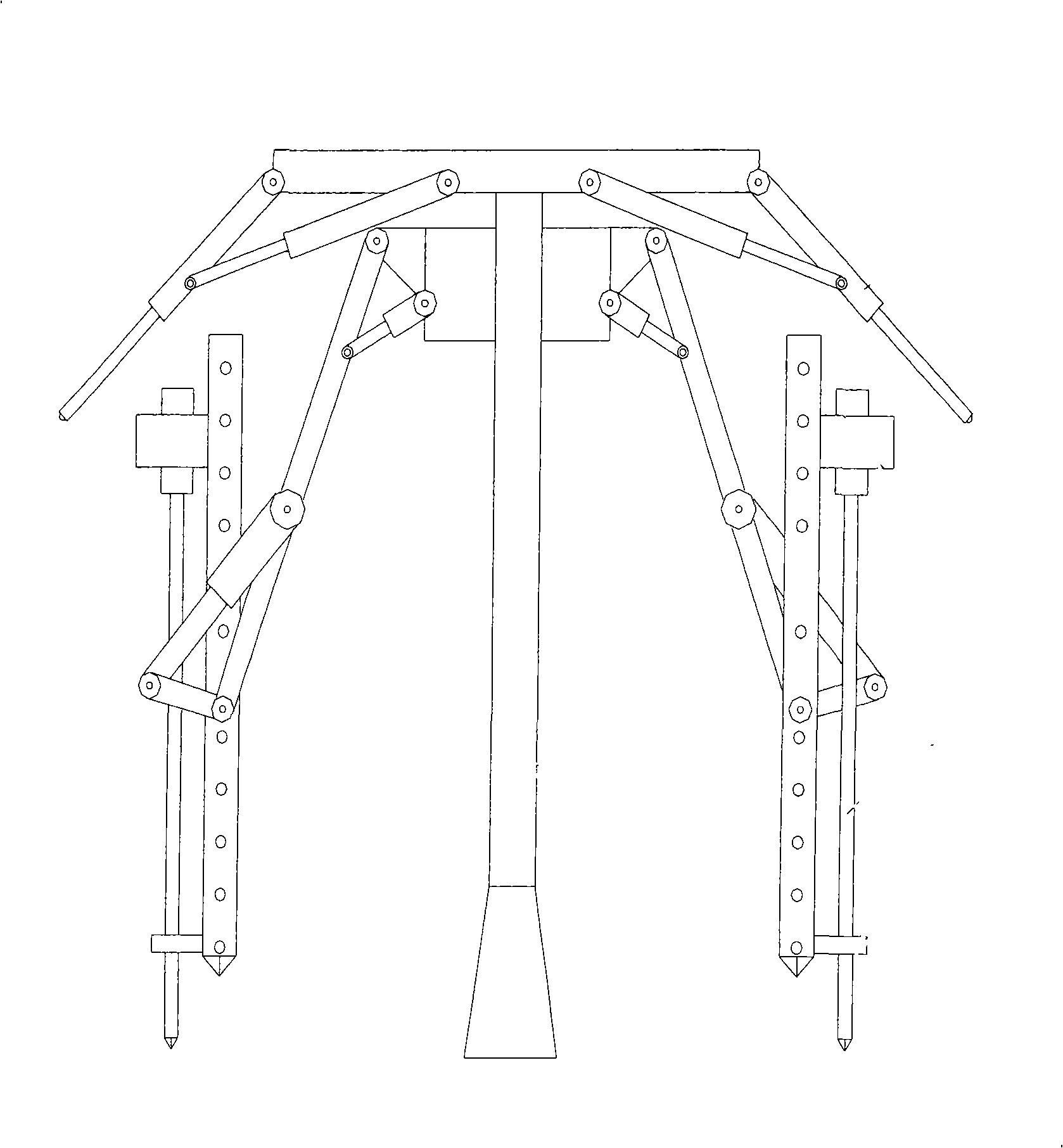

Vertical shaft soft rock special drill construction technique

InactiveCN101298830AImprove drilling efficiencyDerricks/mastsDrilling machines and methodsEngineeringDrill line

The invention claims a sub-vertical soft rock drilling construction technology, the technology steps as follows: (1), descend the FJD umbrella shaped boring frame, (2), install compressed air pipeline after descending the FJD umbrella shaped boring frame, sending the compressed air to the compressed air distributing device on the FJD umbrella shaped boring frame and a cylinder of the pneumatic supporting arm of the FJD umbrella shaped boring frame,(3),open the control valve of the pneumatic supporting arm, strut the FJD umbrella shaped boring frame, (4) install the TMY6 type diving drill on each umbrella rod of the FJD umbrella shaped boring frame through the vertically set drill fixing rack, (5) install the drill rod, the drill bit and the reamer, (6) open the control valve of the TMY6 type diving drill, start the TMY6 type diving drill, (7) open the control valve of the rising and falling cylinder, and the rising and falling cylinder drives the drill to move downwards, (8), lastly reverse the control valve of the rising and falling cylinder to make the rising and falling cylinder drive the drill to move upwards, to take out the drill from the drill hole, and finish drilling. Compared with the impact drilling manner, the drilling efficiency of the technology is improved over 25%.

Owner:中煤第一建设有限公司第四十九工程处

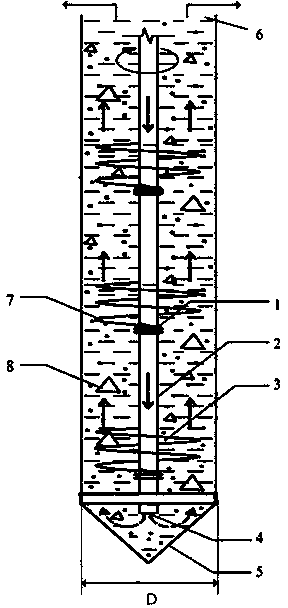

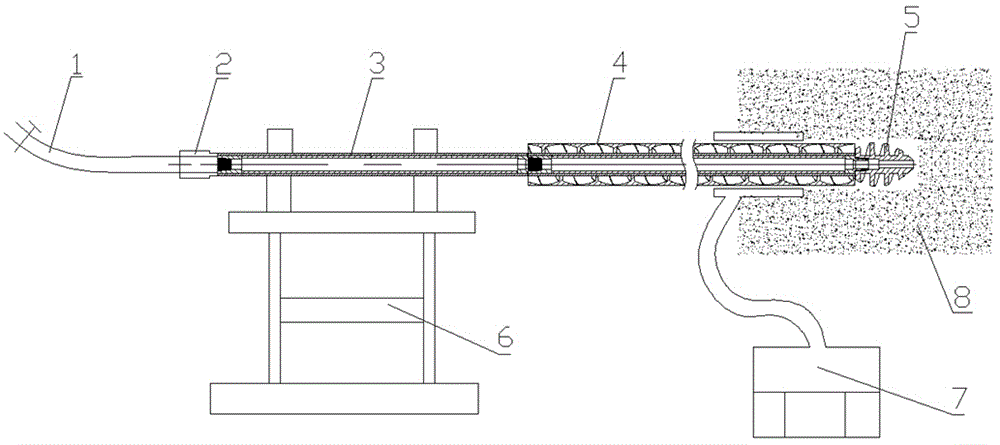

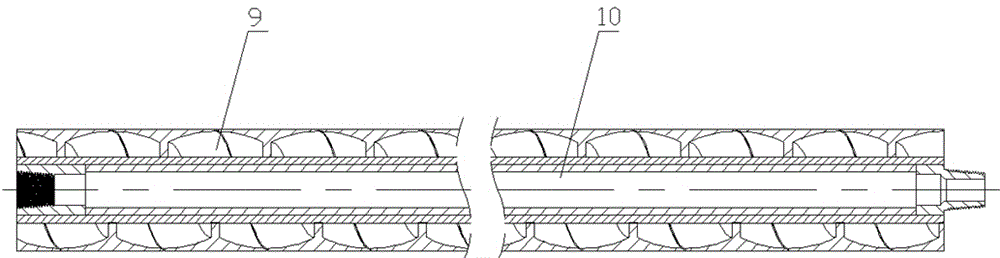

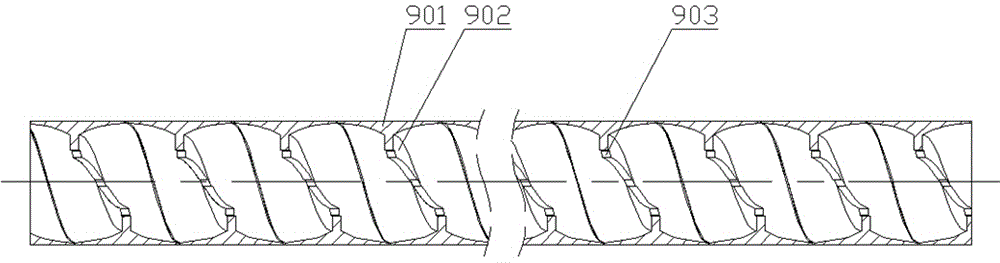

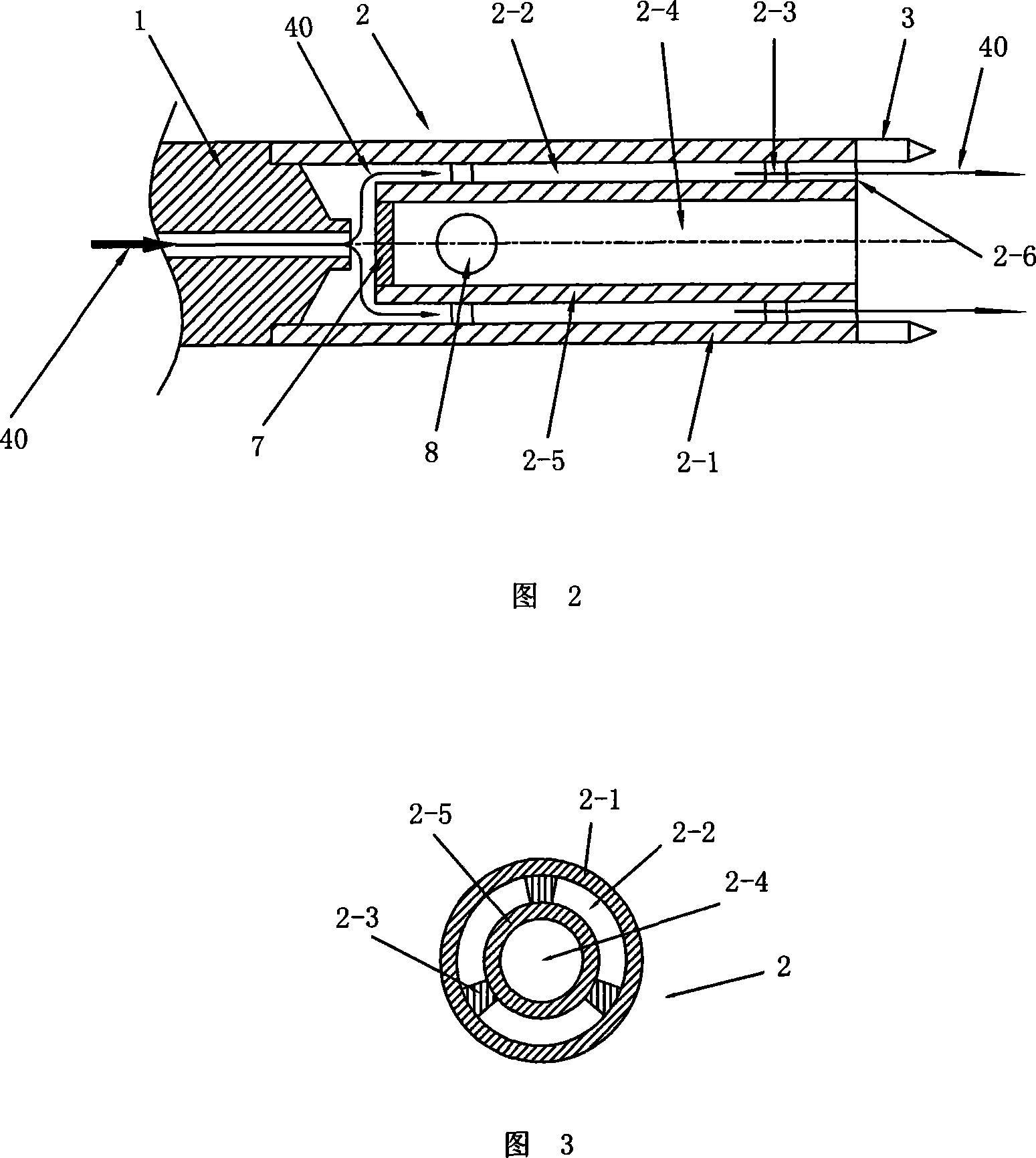

Closed type helical hole-protecting drill and using method thereof for drilling of soft coal bed

ActiveCN104314482ALow rotational resistanceIncreased drilling depthDrill bitsDrilling rodsDischarge efficiencySlag

The invention discloses a closed type helical hole-protecting drill and a using method thereof for drilling of a soft coal bed. The closed type helical hole-protecting drill comprises a closed type helical hole-protecting drill pipe and a helical slag-guiding drill bit, and the helical slag-guiding drill bit is mounted at the front end of the closed type helical hole-protecting drill pipe. The closed type helical hole-protecting drill is mainly applied to the drilling engineering of the soft and breaking coal rock layer. The using method includes mounting and connecting a drill, the closed type helical hole-protecting drill pipe, the helical slag-guiding drill bit and an orifice slag discharging device, starting the drill, breaking and drilling the coal bed by the helical slag-guiding drill bit, guiding drillings into the helical slag discharging space of the closed type helical hole-protecting drill pipe along slag-guiding helical grooves of the drill bit, and discharging the drillings out of the hole through friction of helical blades. The closed type helical hole-protecting drill is novel in design, and is provided with a hole protecting function via structural innovation of the helical blades, the drillings are discharged within in the protected space and prevented from being influenced by deformation and collapse of drilled holes, and the defect that a conventional casing drill is high in drilling resistance, low in slag discharging efficiency and the like is overcome.

Owner:HENAN POLYTECHNIC UNIV

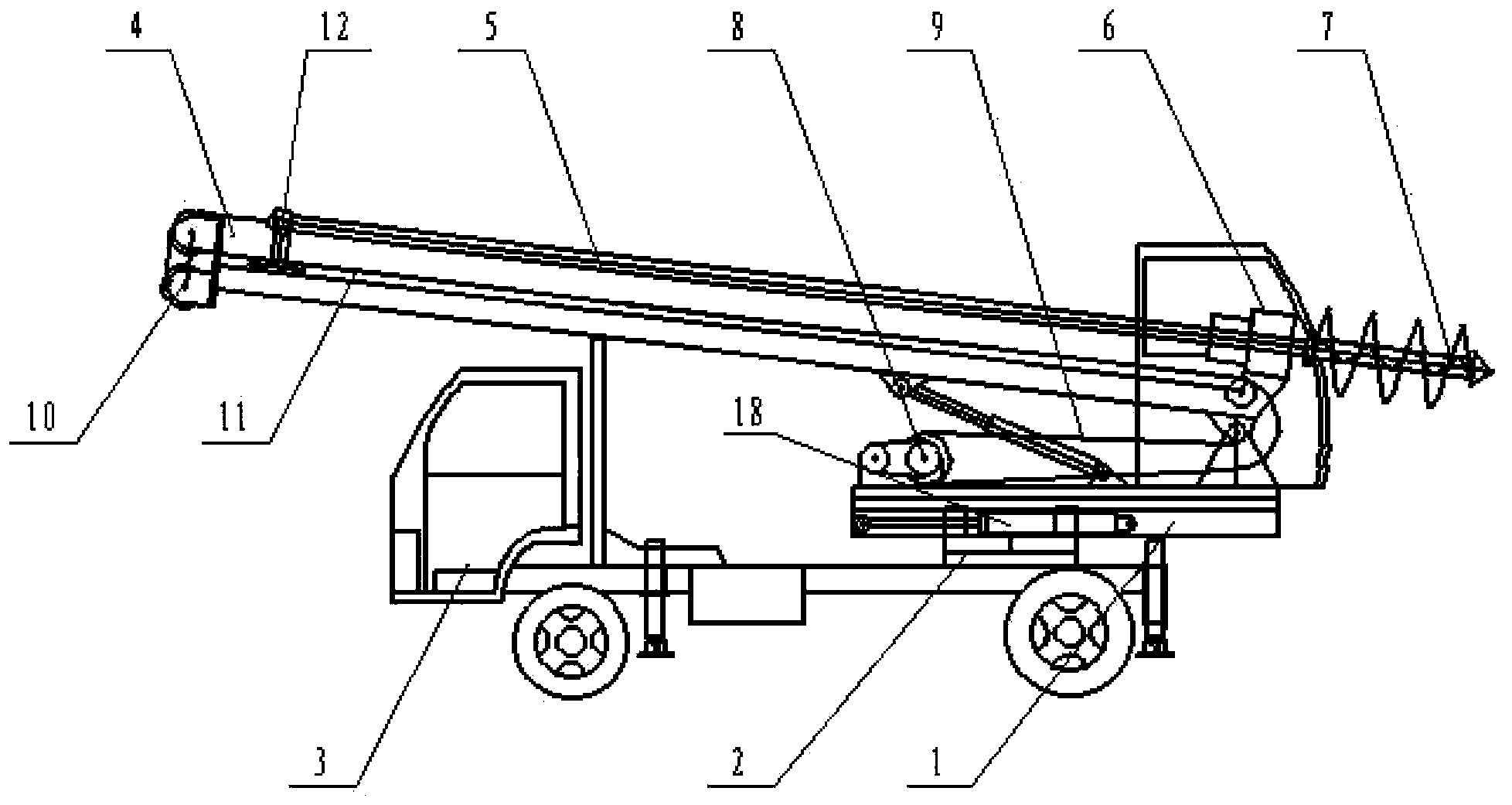

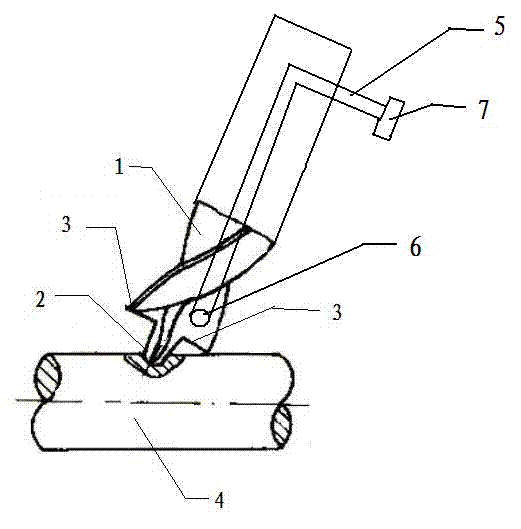

Coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit

ActiveCN105089500AEasy to useEasy to processLiquid/gas jet drillingDirectional drillingDrill lineTree shaped

The invention relates to a coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit. The drilling unit comprises drill rod, a guider, a drill bit, a high-pressure hose, a self-propelled drill bit and a dial. The drill rod is in threaded connection with the front end of the guider. The drill bit is in threaded connection with the tail end of the guider. The drill rod, the guider and the drill bit are used in cooperation, and the two steps of broaching and guider feeding-in can be finished at the same time. After broaching is finished, the high-pressure hose and the self-propelled drill bit are used for drilling tree-shaped drill holes in a coal seam. The distribution uniformity of the tree-shaped drill holes is controlled by the dial. The main effect of the drilling unit is to drill main holes of the tree-shaped drill holes of the coal seam and the tree-shaped drill holes, and uniform permeability increase of the coal seam is achieved. The drilling unit is simple in structure, convenient to operate and suitable for drilling the tree-shaped drill holes in the gas extraction process of the low-air-permeability coal seam.

Owner:CHONGQING UNIV +1

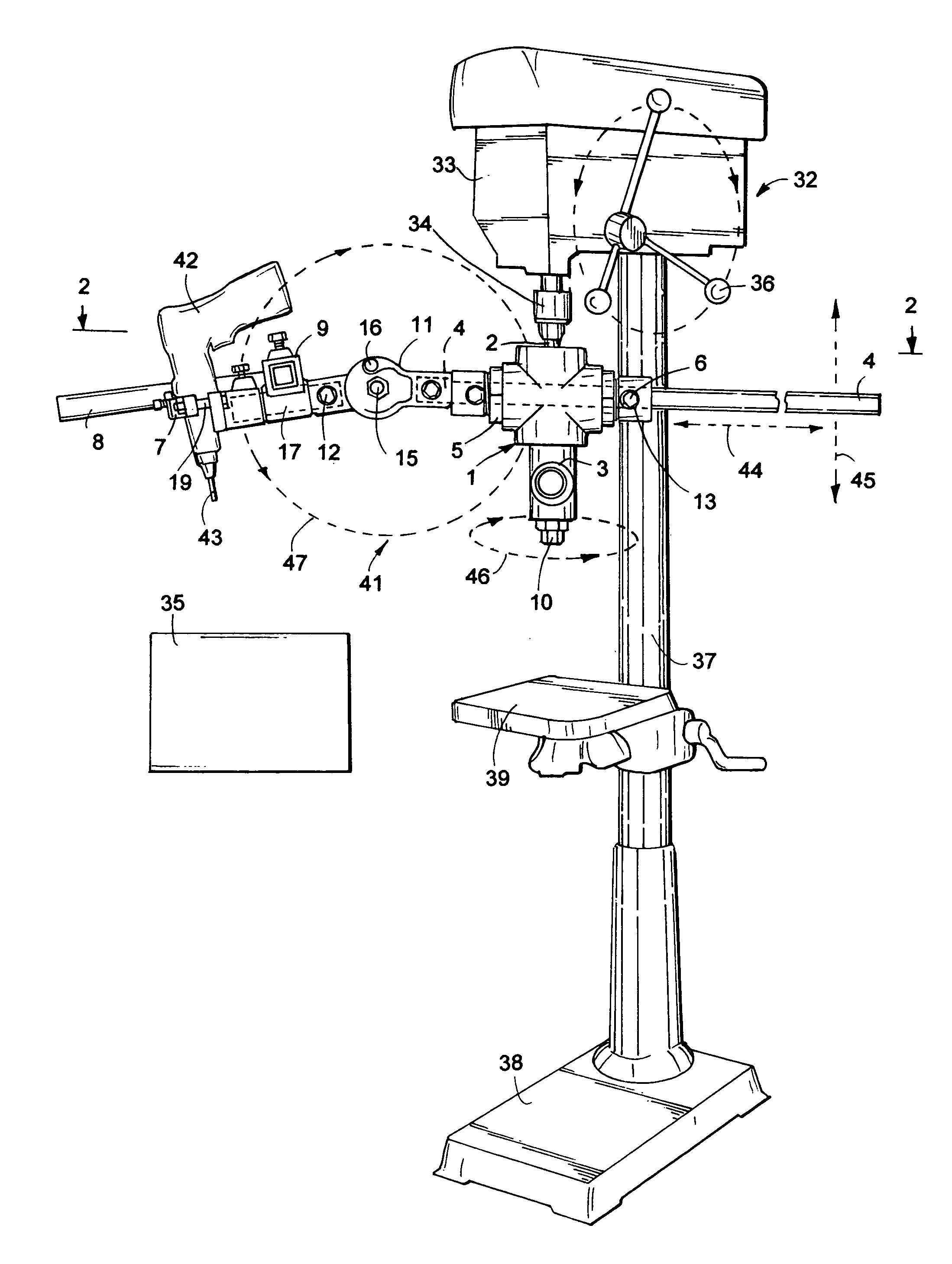

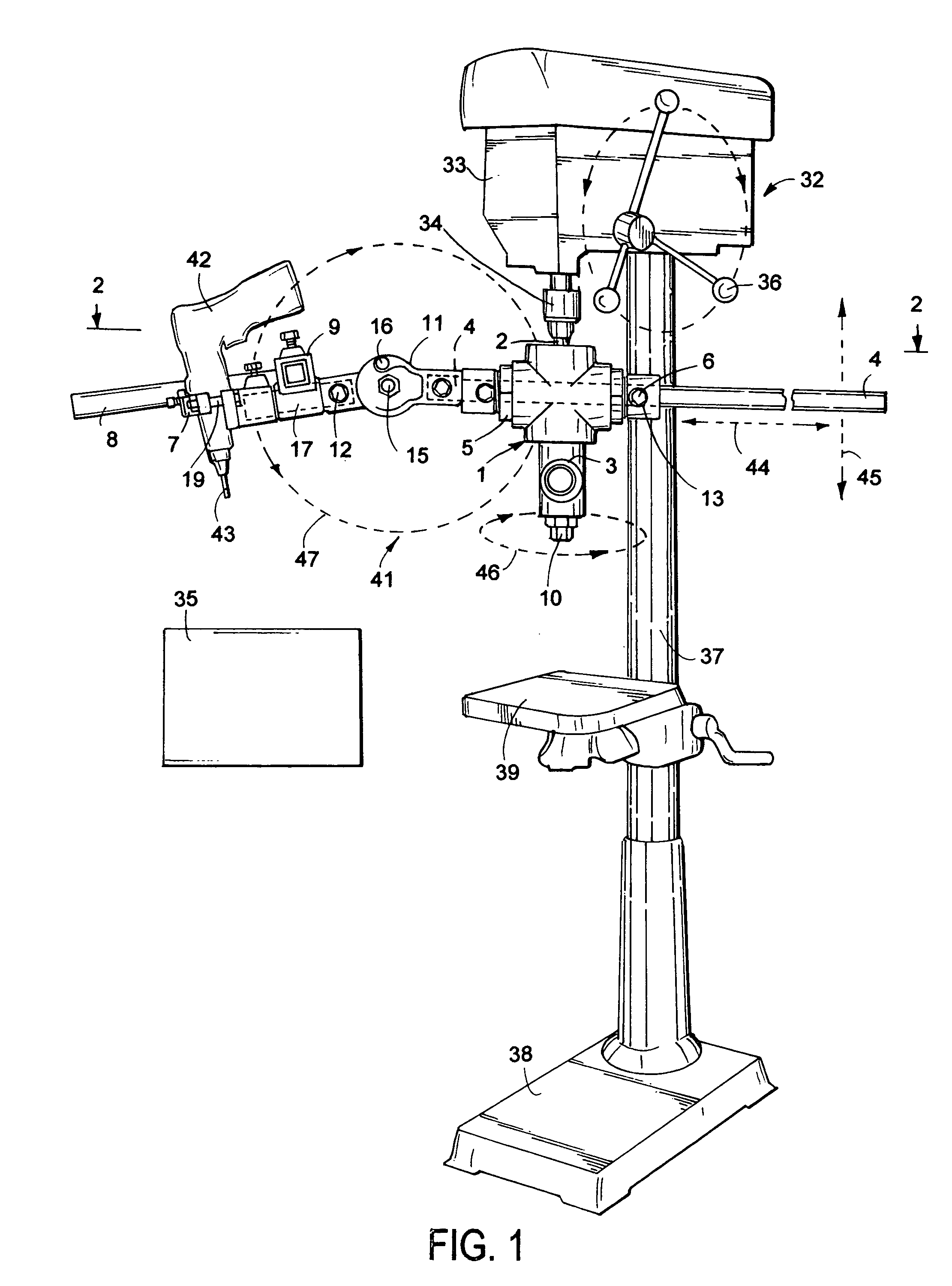

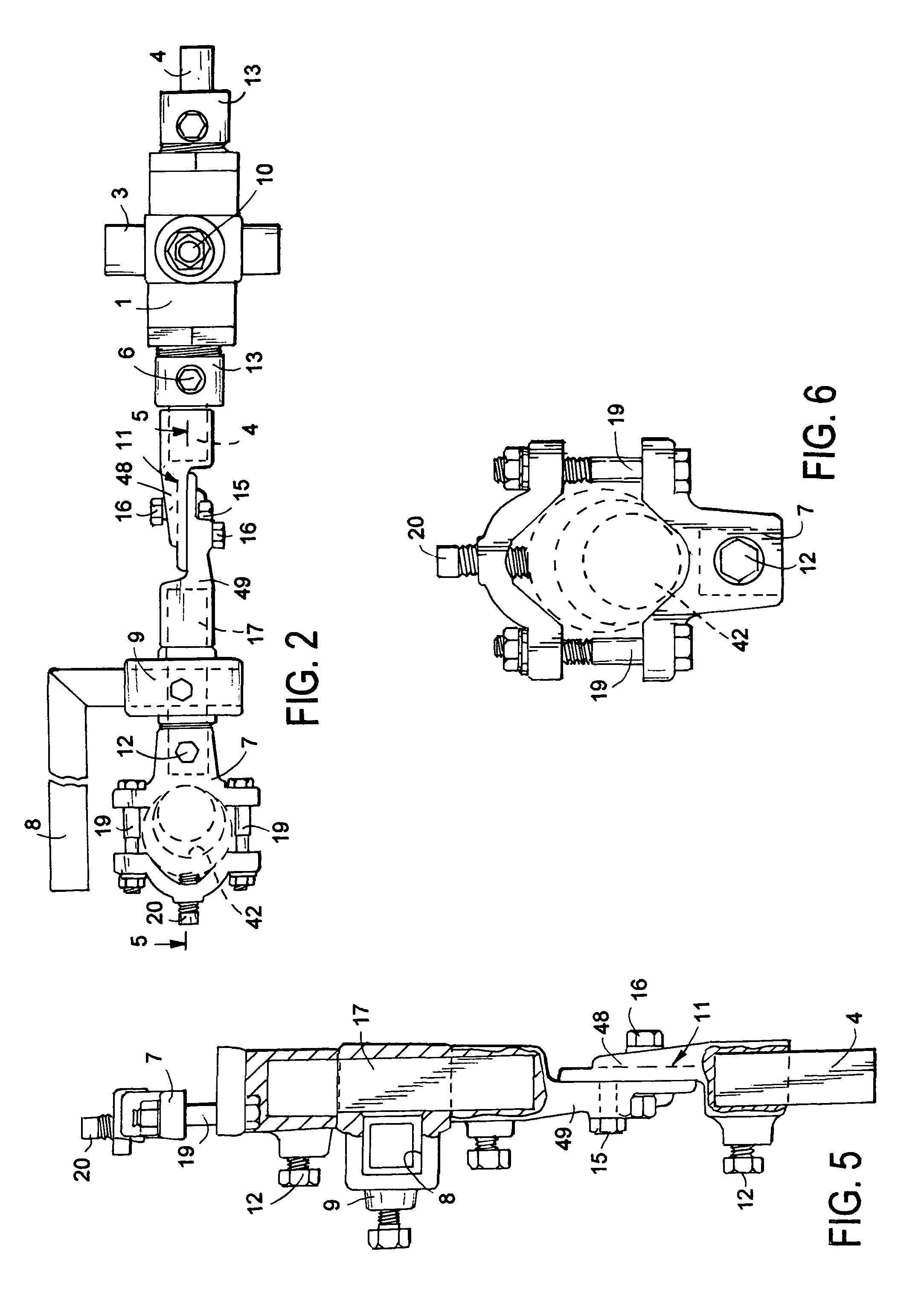

Off-set drill guide assembly and method of drilling holes in a workpiece

InactiveUS7862265B1Drilling/boring measurement devicesThread cutting machinesPortable powerEngineering

An off-set drill guide assembly useable with a conventional drill press or bench vice and portable power tool to drill holes in a workpiece has a body chucked to the drill press supporting a horizontal slide connected to the power tool with an adapter to locate the power tool off-set from the drill press beyond the normal range of the drill press. The body and power tool are moved downward to drill holes in a workpiece.

Owner:CLARK BRUCE A

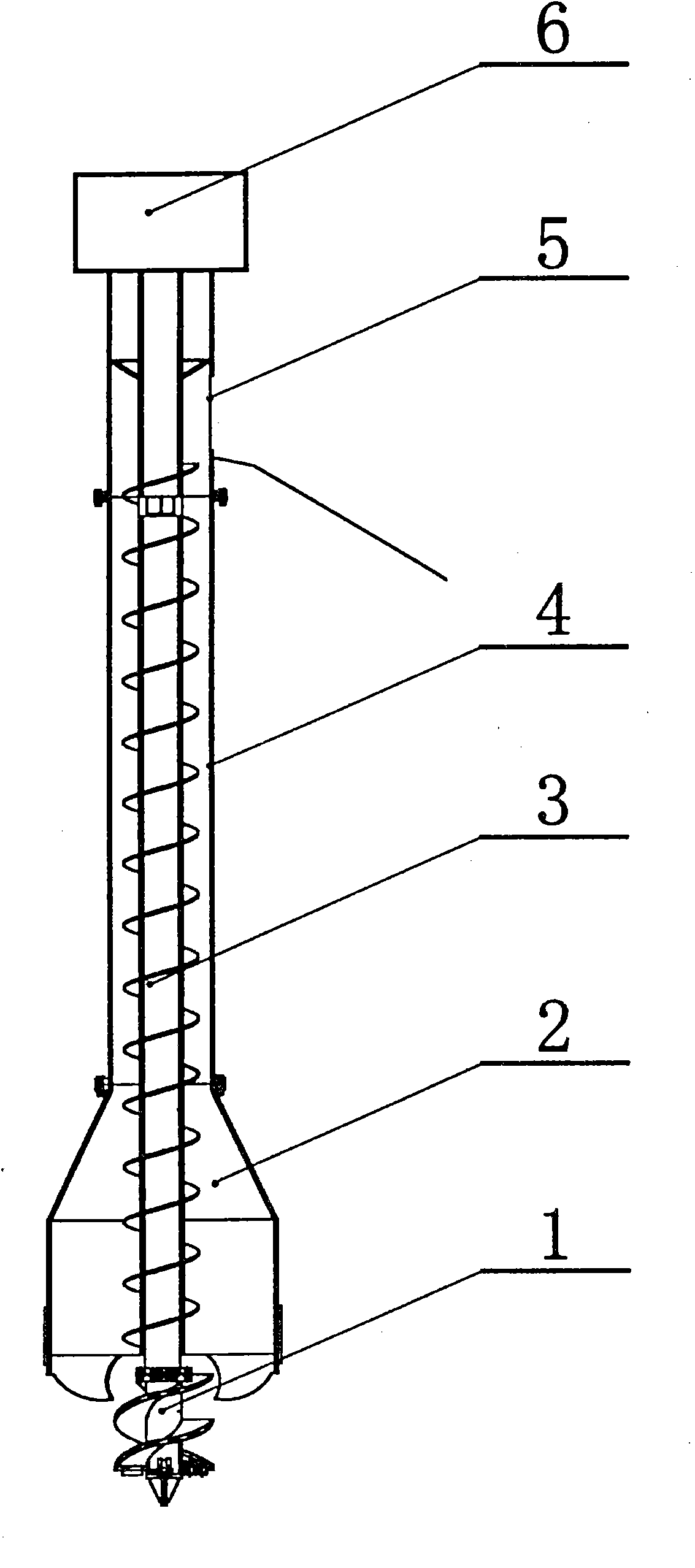

Compound rotary drilling rig drilling mechanism

The invention relates to a compound rotary drilling rig drilling mechanism which is provided with a long tube shape coat drill pipe of which the upper part is provided with a mud discharging port. The lower end of the coat drill pipe is fixedly connected with a heavy-calibre drill by a flange bolt; a spiral drill pipe coaxially rotating is arranged in the coat drill pipe; the bottom end of the rotary drill pipe is connected with a guiding drill; the coat drill pipe and the spiral drill pipe are in sectioned connection structure; two ends of the coat drill pipe and the spiral drill pipe are respectively provided with a quick-change connector capable of quickly splicing and installing; the upper part of the spiral drill pipe is connected with a motor; and meanwhile, the motor is meshed and connected with the gear on the coat drill pipe in a driving mode. The compound rotary drilling rig drilling mechanism has the construction function of a common drilling mechanism, can conveniently adjust the length of the drill pipe and carry out heavy-calibre drilling construction, can pump drilled mud and sand out of the drill pipe, effectively improves progress of works, solves the problem of poor stability caused by an over-high rotary drilling rig and is convenient to transport the rotary drilling rig.

Owner:毛杰

Method for drilling anchor rod hole and anchoring anchor rod in broken roof

The invention provides a method for drilling an anchor rod hole and anchoring an anchor rod in a broken roof. The method includes the following steps that (1) the depth of a drill hole and the length of the anchor rod are determined according to supporting parameters of the anchor rod of broken surrounding rocks, and then two hollow tubular drill rods are connected according to the depth of the drill hole, or a connecting rod is arranged between the threaded ends of the two drill rods in a connected mode to form a combination drill rod; (2) the end, provided with a square inner buckle, of one drill rod is connected with a drill bit in a sleeved mode, and the end, provided with a square inner buckle, of the other drill rod is connected to a drill rig for drilling; (3) the drill rig is dismantled, the drill rods are exposed, and then a cement cartridge is sent to the bottom of a drill rod center hole through the anchor rod; (4) the anchor is pushed into the cement cartridge through the drill rig, the drill rod connected with the drill bit in the sleeved mode is withdrawn, and after 20-30 minutes, an arch supporting plate and a spherical nut are mounted at the end, extending out of the surrounding rocks, of the anchor rod. According to the method, the drill rods and the connecting rod are of a hollow tubular structure, and protective holes of the drill rods and the connecting rod avoid a hole collapse before anchoring the anchor rod; the cement cartridge is used as an anchoring agent, so that the anchoring is prevented from loosing efficacy.

Owner:阜宁县龙创科技服务有限公司

Offshore Casing Drilling Method

A method of casing drilling a portion of an offshore well includes running a casing string with a drill bit assembly attached to it into a previously drilled portion of the well. Before the drill bit assembly reaches bottom, the operator attaches drill pipe to the casing string and lowers the casing string on the drill pipe. When the drill bit is at bottom, an upper end of the casing string should be below the blowout preventer. The operator then performs casing drilling by rotating the drill pipe. When at a desired depth for the casing string, the operator pulls the drill pipe from the well and lifts the casing string up until its upper end is at the rig floor. The operator then runs the casing string back into the well but using casing in this instance. The operator then cements the casing string.

Owner:SCHLUMBERGER TECH CORP

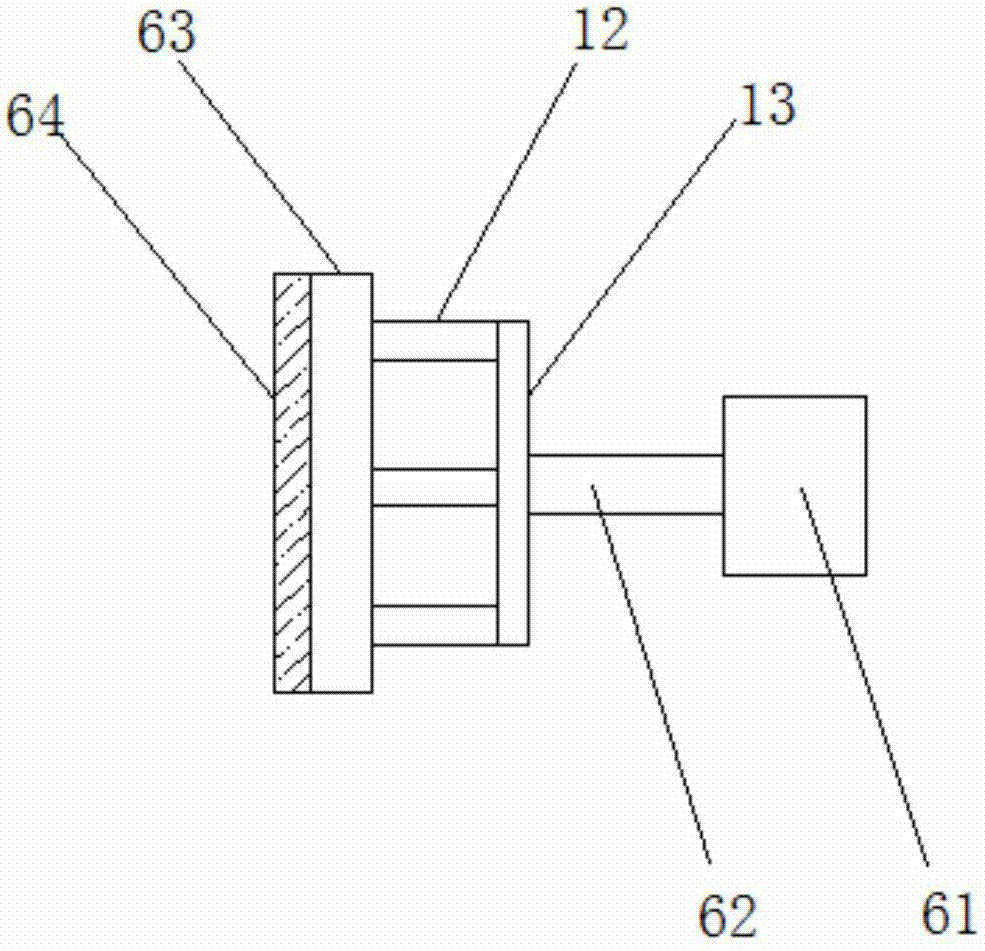

Inverted type drilling machine and operating method for machining fine drill holes

InactiveCN106077734AAvoid the effects of skewnessImprove distributionBoring/drilling componentsBoring/drilling machinesEngineeringDrill line

The invention relates to the field of machining devices, in particular to an inverted type drilling machine and an operating method for machining fine drill holes. The inverted type drilling machine comprises a base, a stand column, a feed supporting plate, a guide sleeve, a drill rod box and a drilling tool. A cooling hole of the drilling tool is a through hole. The cooling hole of the drilling tool and an inner hole of the drill rod box are located on the same center line during installation. A motor used for driving the drill rod box to rotate is arranged in the base. The inverted type drilling machine and the operating method for machining fine drill holes have the beneficial effects that the drilling tool is perpendicularly installed on the drill rod box, the direction of the gravity of the drilling tool coincides with the direction of a drill hole, the situation that deflection of the drill hole is caused under the effect of the gravity of a drill bit is avoided, and the machining precision can be improved easily; and the drilling tool is perpendicularly installed on the drill rod box, scrap iron generated in the drilling process can automatically fall to be discharged from a V-shaped groove of the drill bit under the effect of self weight, the requirements for the oil supply pressure and flow of a cooling system are lowered correspondingly, heat dissipation in the drilling process is facilitated, and energy can be saved easily.

Owner:黄大勇

Rockbolt construction drill method and tube component for rockbolt construction drill

InactiveCN101089357ASimple structureImprove efficacyDrilling rodsDrilling casingsDrill lineHigh pressure

The present invention relates to an anchor rod construction drilling method. Said method adopts drilling machine to drive tubular member whose front end is equipped with drill bit and make it rotation drive forwards, on the tubular member a flow-guiding channel is set, said flow-guiding channel can be used for transferring fluid to the drill bit; the described fluid or high-pressure fluid passed through the flow-guiding channel and transferred to the drill bit can be passed through said tubular member or fluid outlet or nozzle which is set on the drill bit and is perpendicular to the axis direction of drilled hole and flowed out, and can be used for acting on the hole wall of drilled hole, cleaning the hole wall of anchor hole and broaching the hole.

Owner:曾庆义

Clamp-On Drill String Wiper

A clamp-on wiper that facilitates the cleaning of external surfaces of sections of a drill string or drill pipe to remove earth, drilling mud, and other solid / liquid compounds while the drill string is being handled on a drilling platform. The pipe wiper includes a split cylinder with two halves hinged together, each with a handle. Internal to each half cylinder are a number of half circle flexible squeegees that conform to the outside diameter of the drill string when the device is closed. The device may be handled by an individual and positioned around the pipe without the need for access to the end of the drill string. The user may close and hold the pipe wiper around the pipe while the drill string is moving upward so as to wipe liquid and solid debris from the pipe as it is raised.

Owner:MACHICEK DAVID

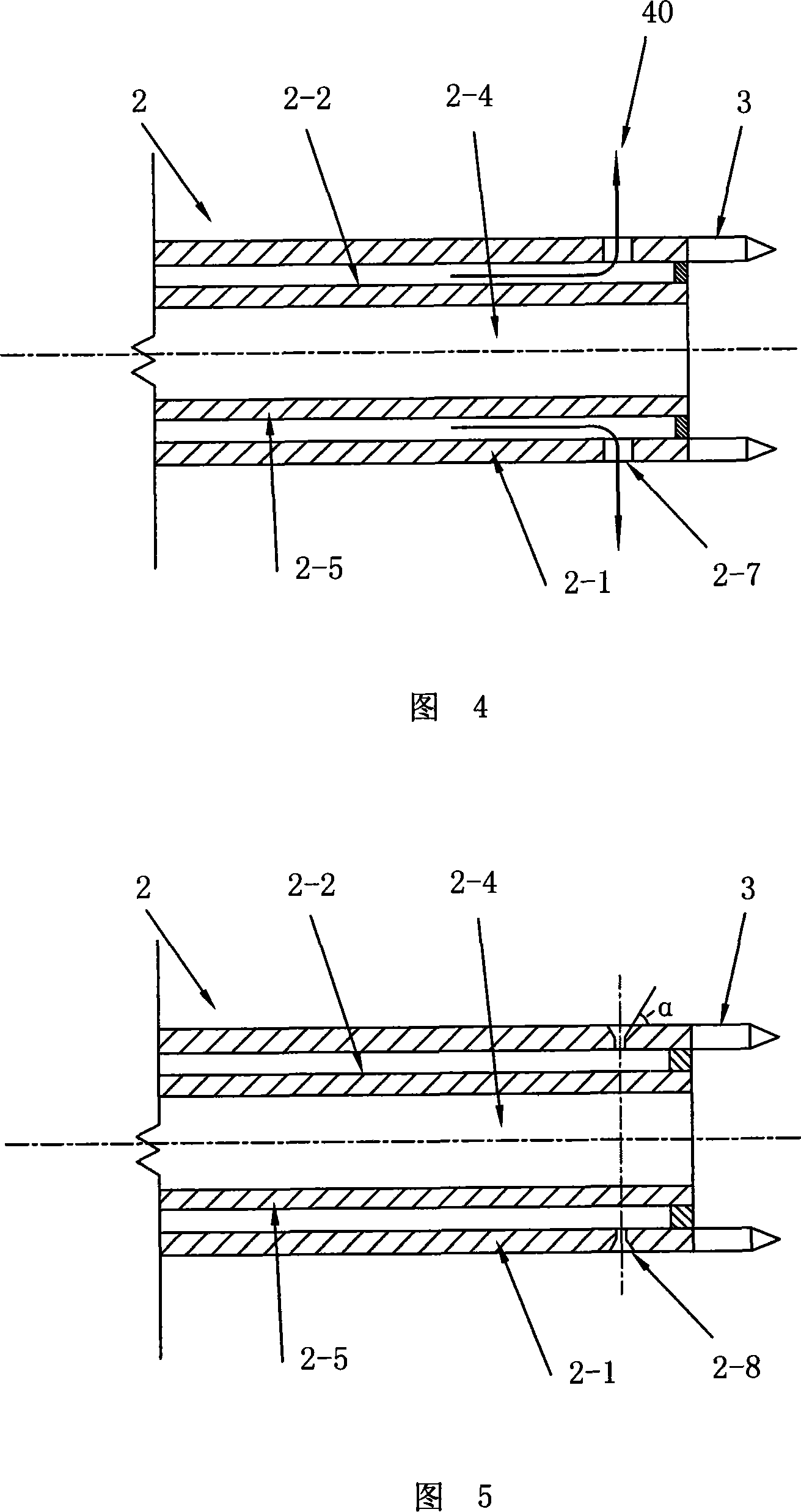

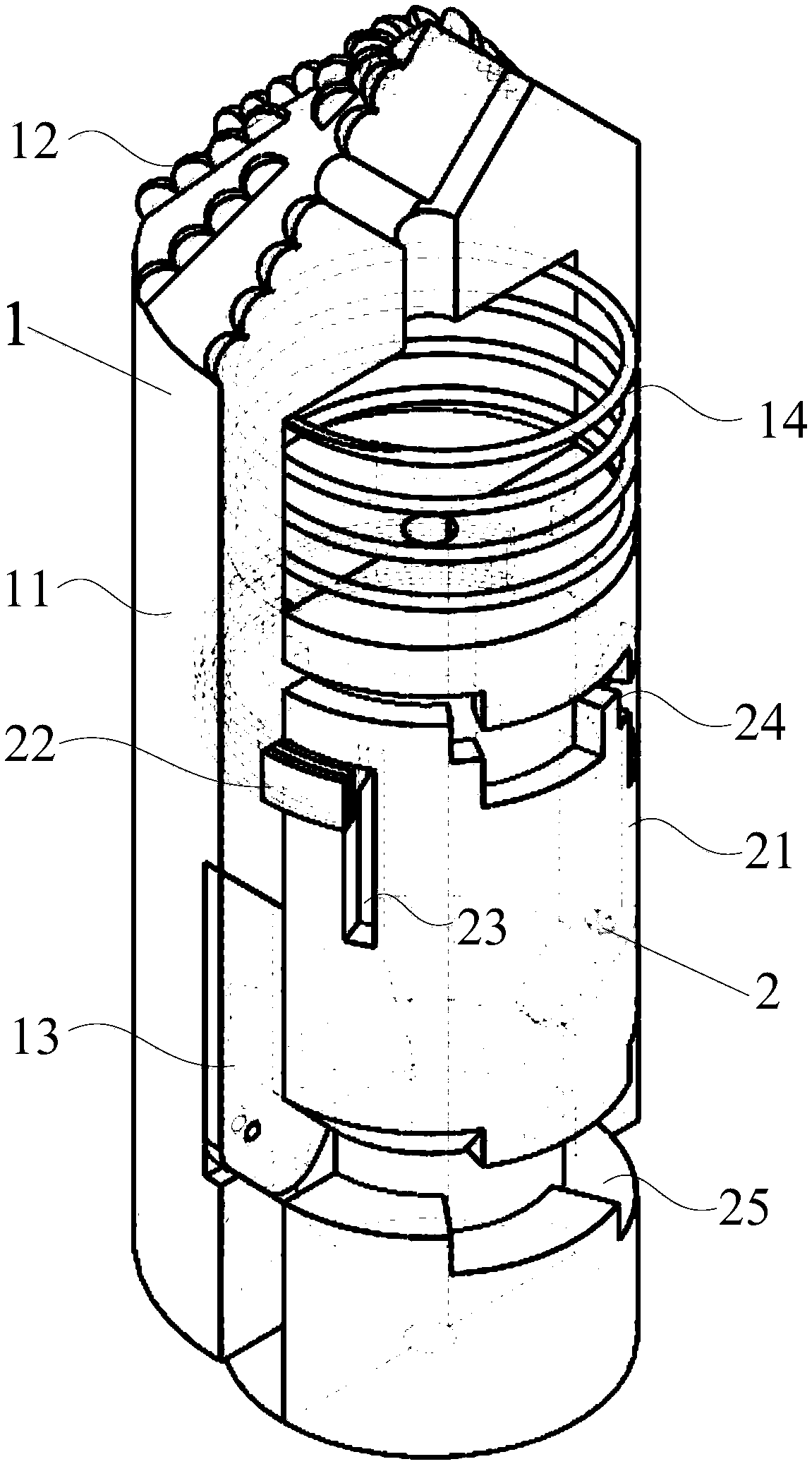

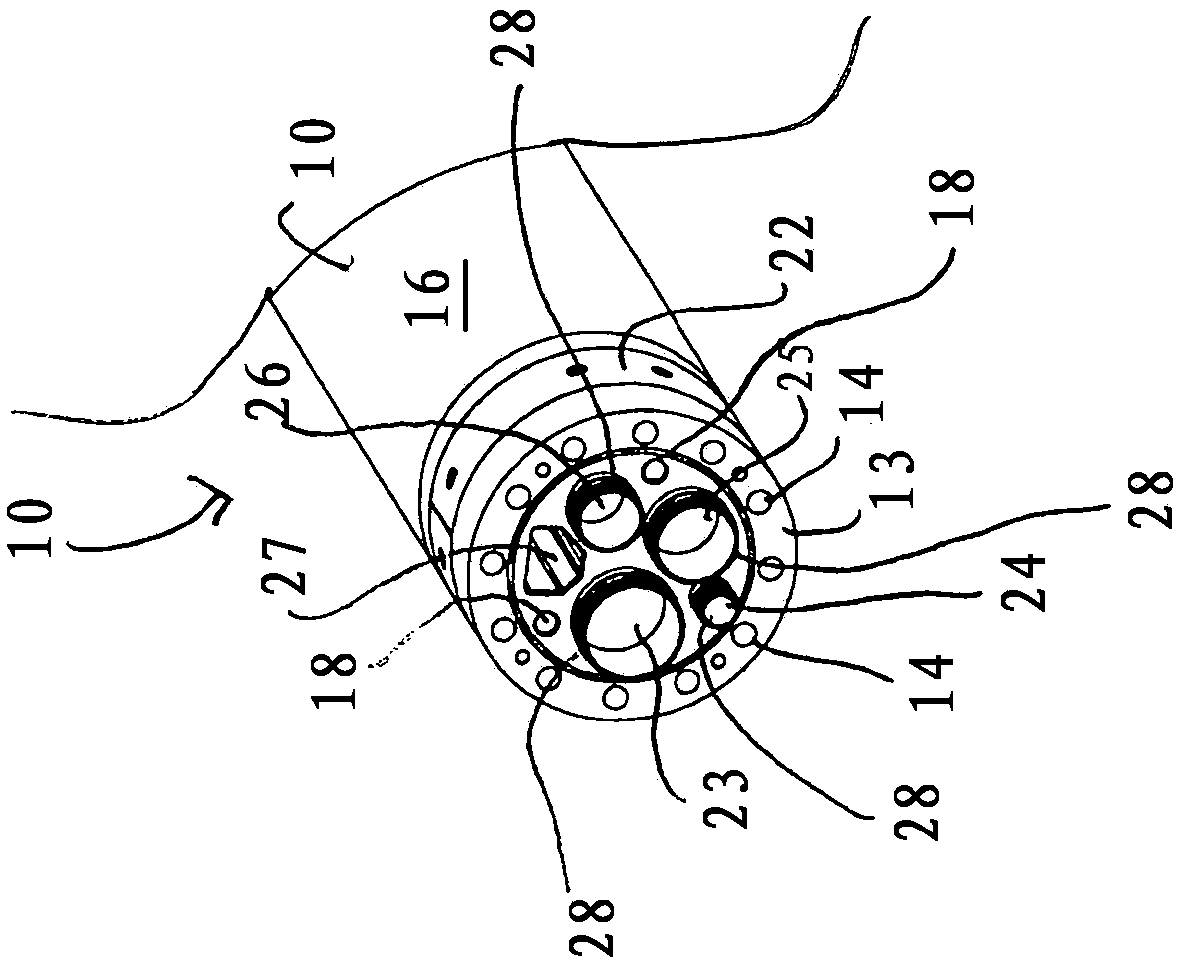

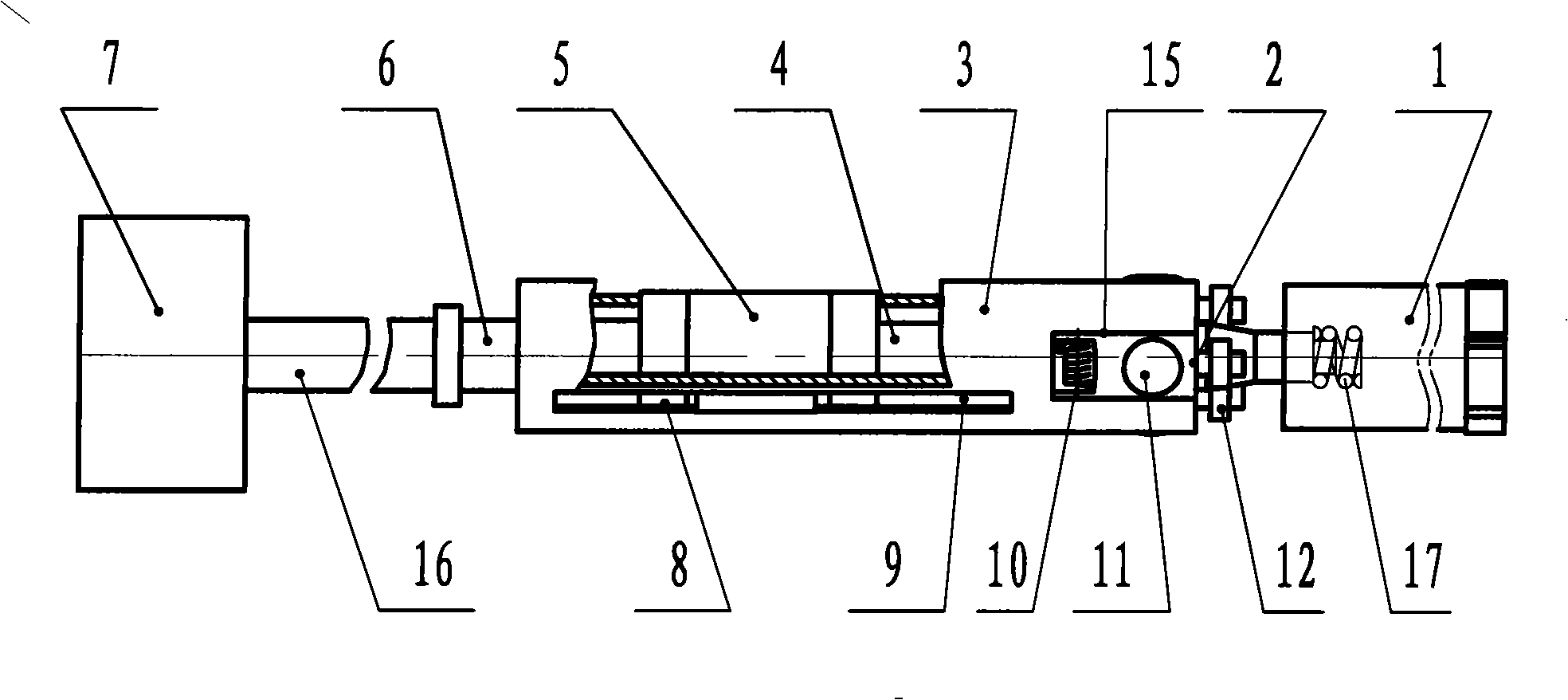

Double tube single action core drilling tool

ActiveCN106507861BGuarantee the quality of the projectMeet the requirements of geological prospectingDrill bitsCore removalPorosityDouble tube

The invention belongs to a drilling tool, and specifically discloses a double-tube single-action core drilling tool. The lip surface of the drill bit is stepped from the inner ring to the outer ring along its radial direction, and the rest of the lip surface of the drill bit is tapered. ; The axis of the water eye and the drill bit intersects in the inner cavity of the drill bit; the connecting end of the cross mandrel and the water distribution joint is provided with a ball-throwing check valve. The bottom lip surface of the drill bit of the present invention adopts a stepped tapered structure, which has a pressing effect on the larger gravel towards the hole wall, avoids the wear and tear of the core by the larger gravel, and has good rotation stability and guiding performance of the drilling tool. It is beneficial to protect the core and prevent the hole from being inclined; after the ball-throwing check valve throws the ball, the flushing fluid flows from the drill pipe through the gap between the inner and outer pipes to the water hole of the side-spray drill bit and then flows to the bottom of the hole, avoiding the impact of the liquid flow on the core in the pipe Direct erosion; the average recovery rate of rock core is increased from 40.30% to 91%, and the high-quality porosity is increased from 17.40% to more than 90%, which meets the requirements of geological prospecting.

Owner:核工业二一六大队

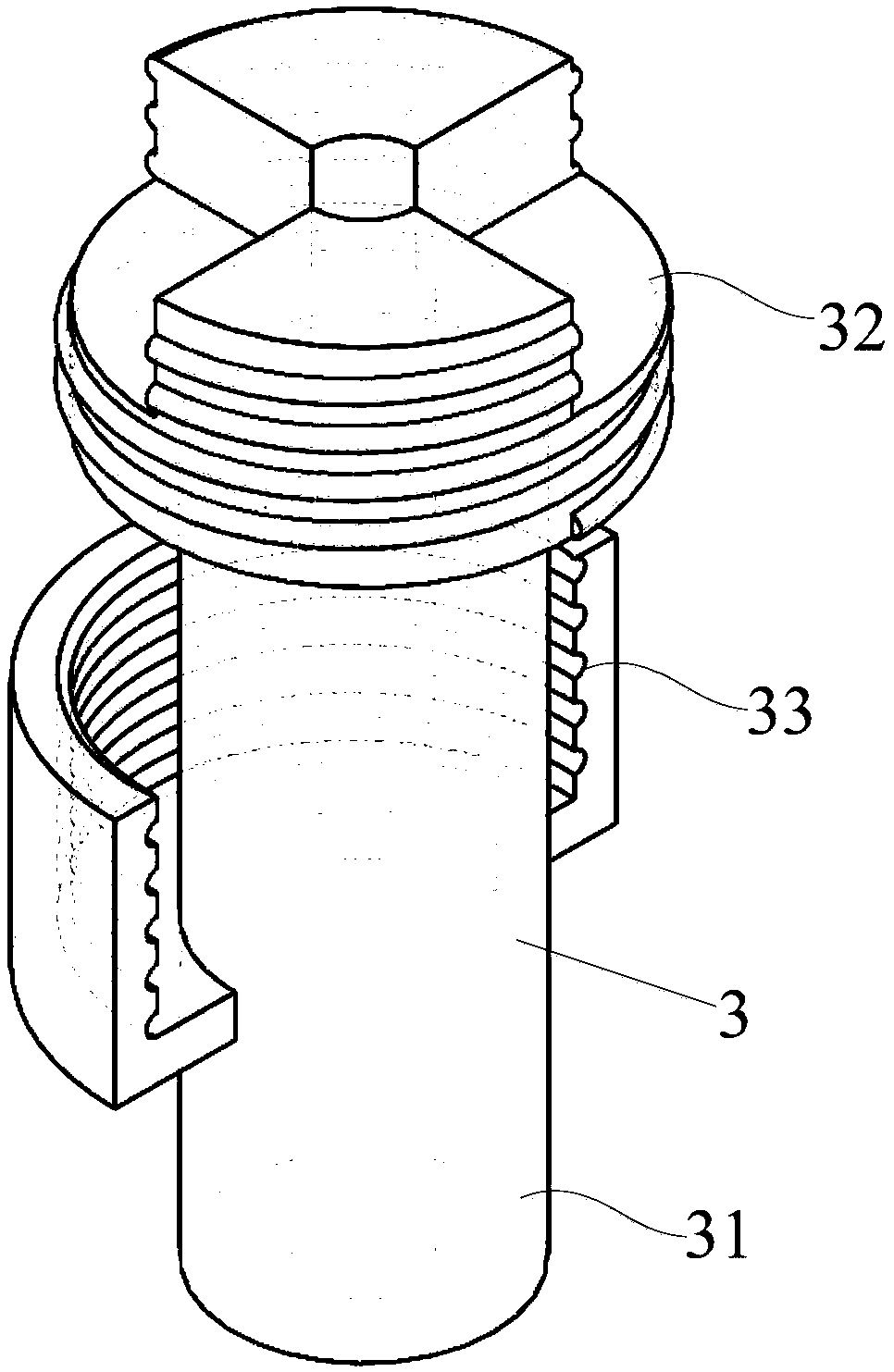

Diameter-adjustable type drill and segmented chambering method

PendingCN109681123AAvoid overall overheatingEasy to installDrill bitsDrilling rodsDrill lineDrill bit

The invention provides a diameter-adjustable type drill and a segmented chambering method, relates to the technical field of mining drills and aims at solving the technical problem that drills need tobe replaced when drilling bore diameters are changed. The drill structurally comprises a drilling mechanism, a bore diameter adjusting mechanism and a drill stem mechanism, wherein the drilling mechanism comprises an outer drill tube, drilling blades, chambering blades and a spring, the drilling blades are arranged at the end part of the outer drill tube, and the chambering blades are hinged to alateral wall of the outer drill tube; the bore diameter adjusting mechanism comprises an inner drill spindle and a one-way bearing, the one-way bearing is fixed to an inner wall of the outer drill tube, a limiting pin is arranged on an inner side of the one-way bearing, and the limiting pin slides in a vertical guiding groove which is formed in the inner drill spindle; the drill stem mechanism comprises a rod body, end heads and a screw cap, butt joint grooves are formed in the end heads at the two ends of the rod body, and the screw cap is arranged at one end of the rod body. When the drillis utilized to drill holes, the bore diameter sizes can be adjusted by adjusting the drilling direction of a drill stem, and the purpose of segmented chambering in the same drill hole is achieved. Thediameter-adjustable type drill disclosed by the invention has the advantages of high drilling efficiency, convenience in construction and the like.

Owner:SHANDONG TANGKOU COAL

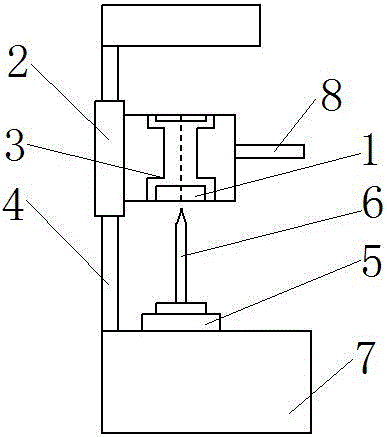

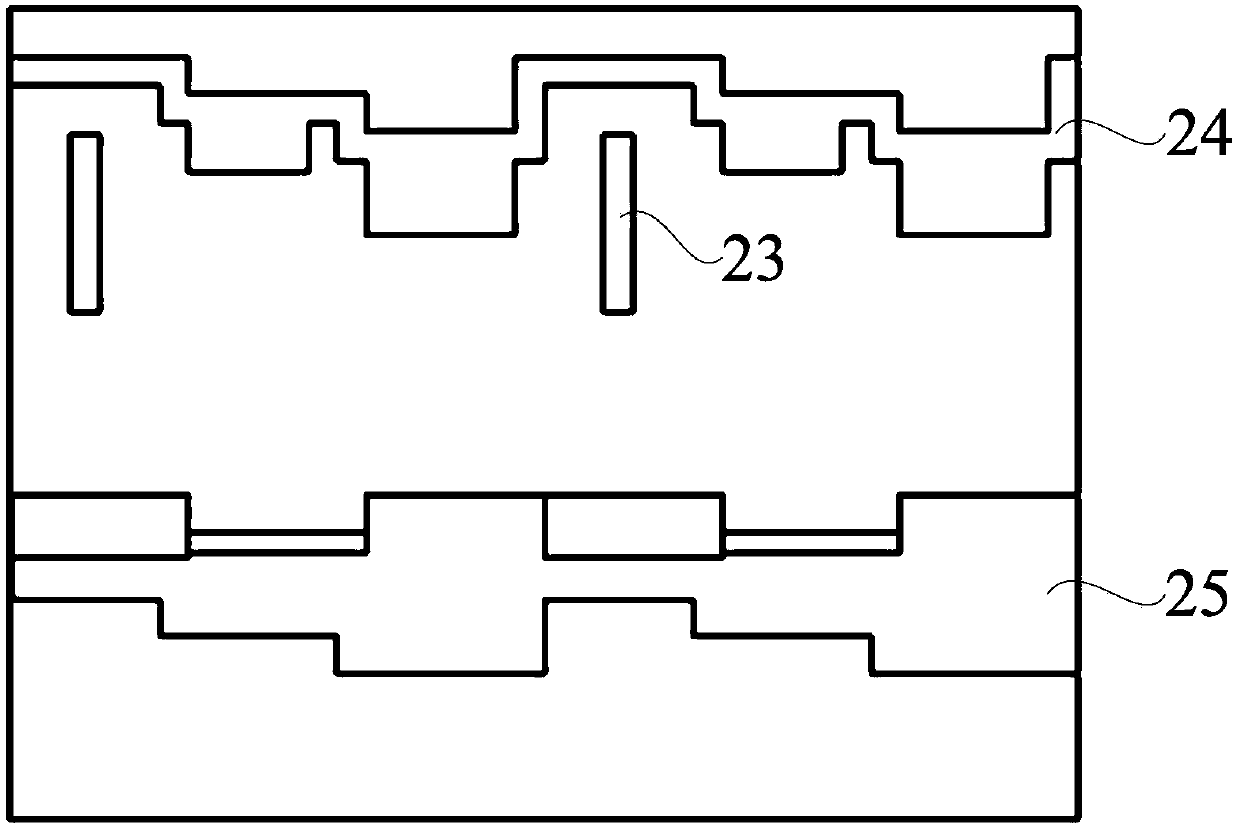

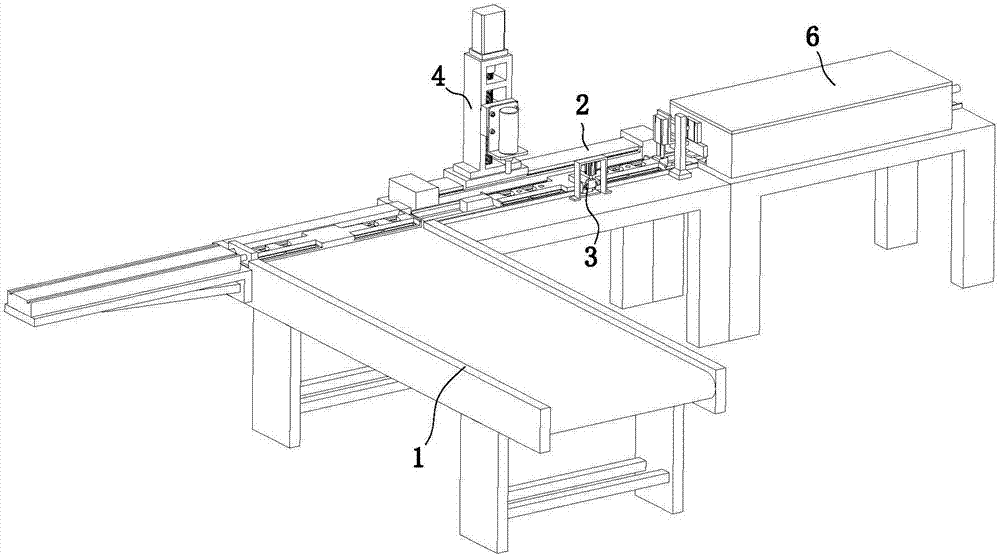

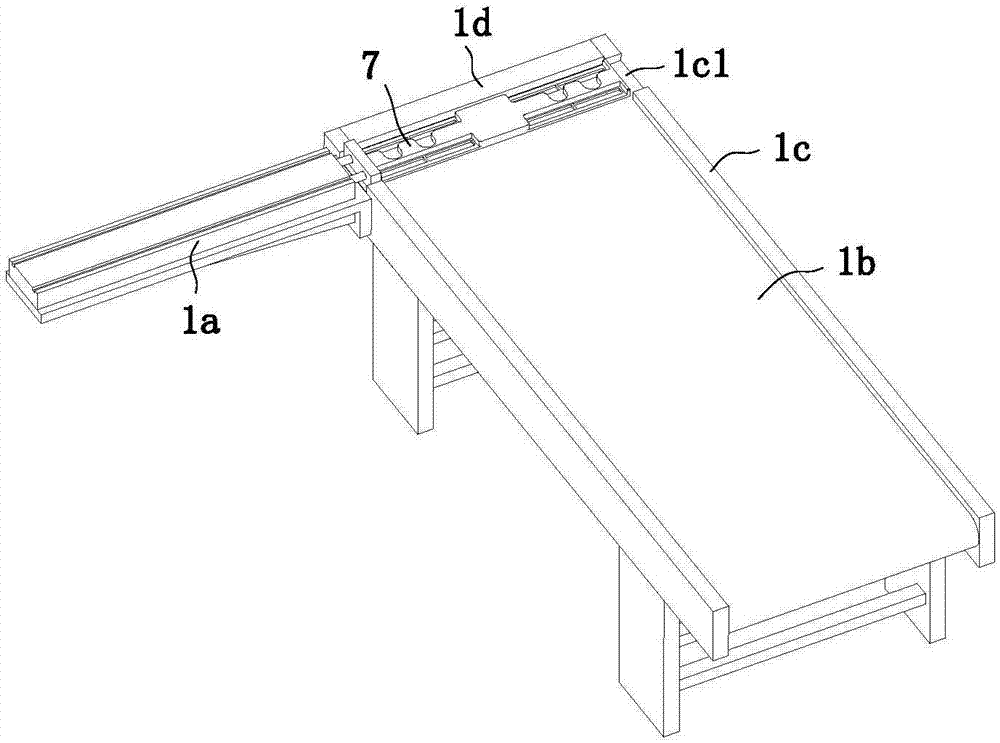

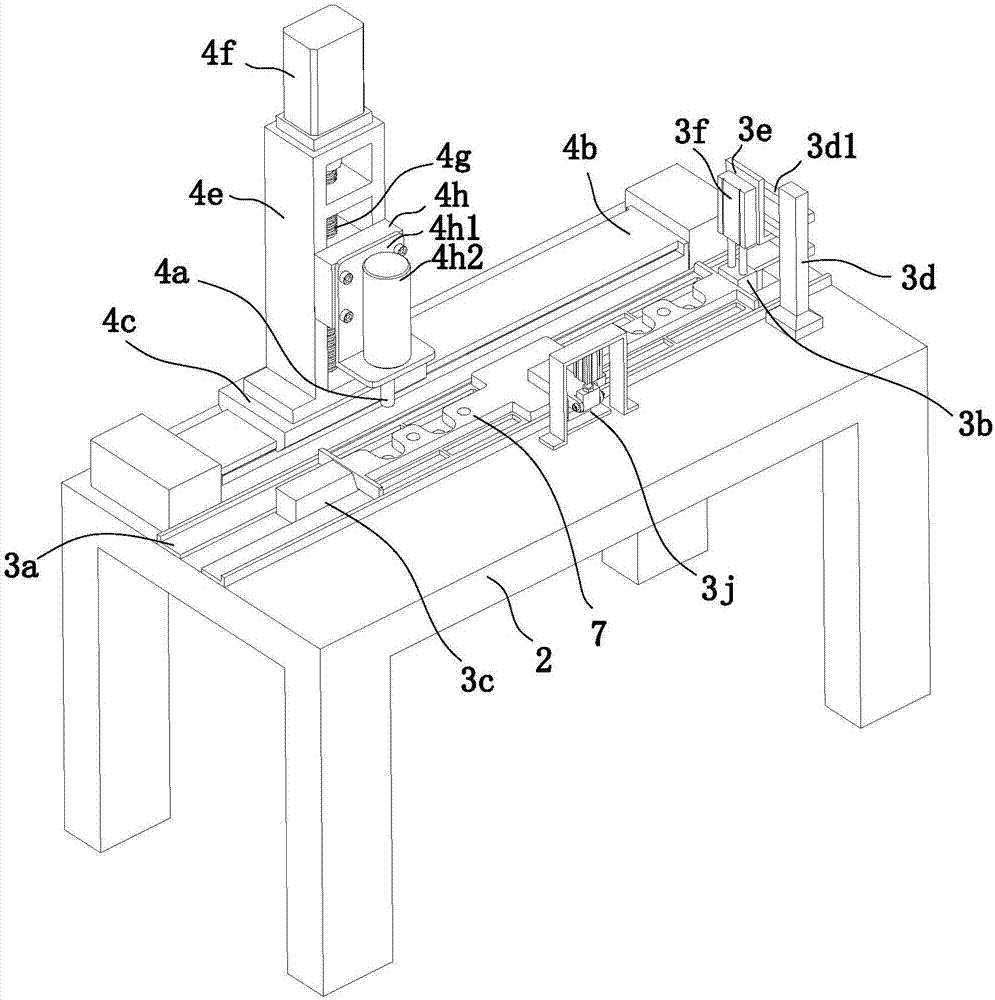

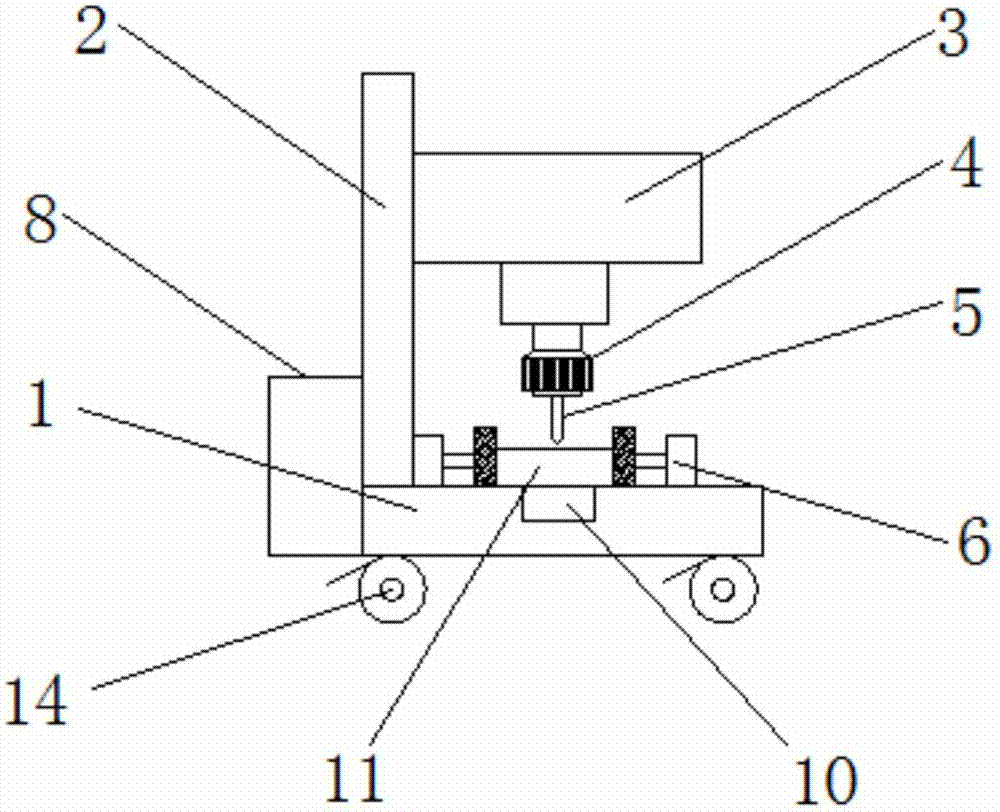

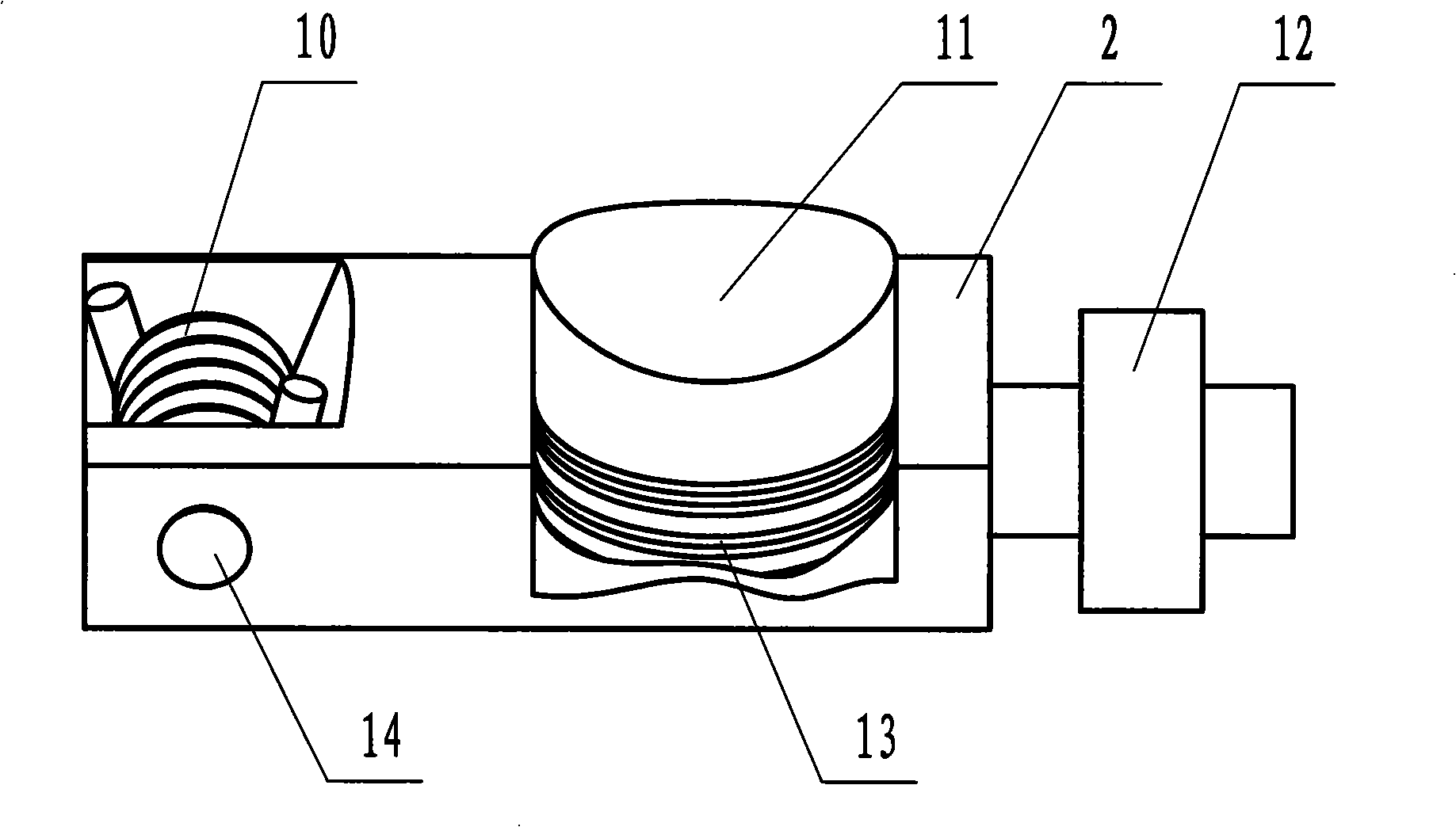

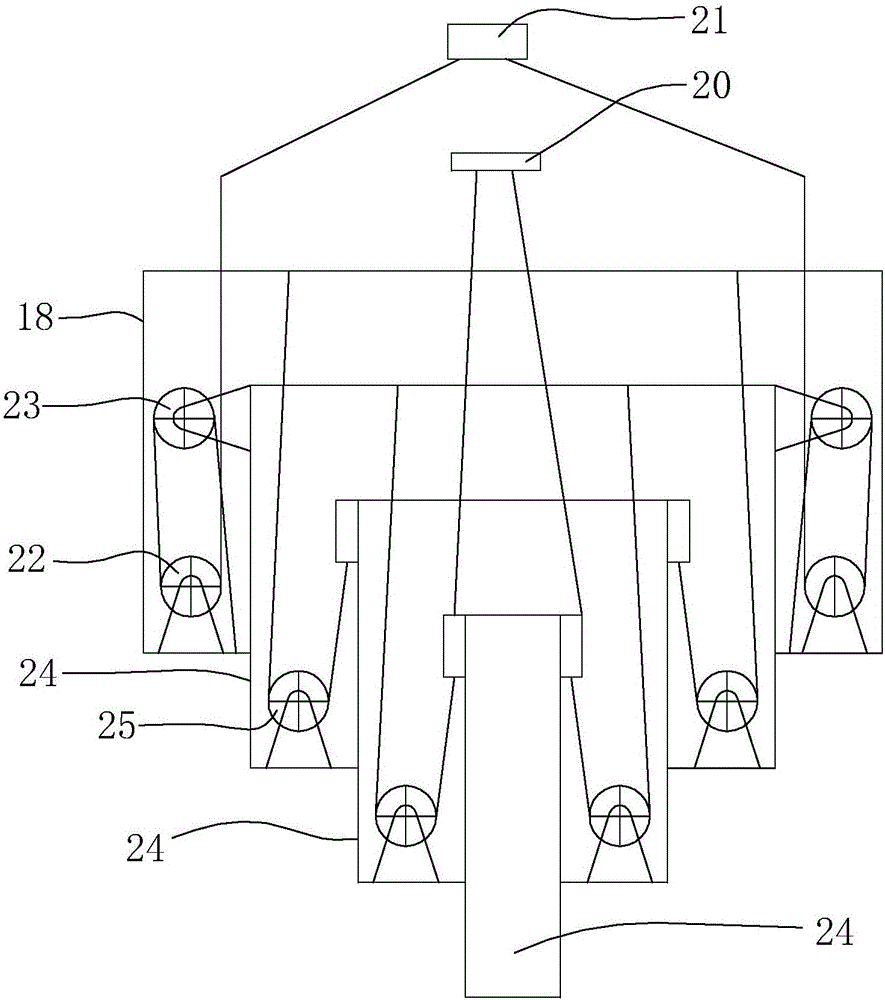

Drilling mechanism of full-automatic drilling production line for communication base station inner support

InactiveCN107234267AImprove processing efficiencyReduce labor costsPositioning apparatusMetal working apparatusProduction lineEngineering

The present invention relates to the field of communication base stations, in particular to a drilling mechanism for a fully automatic drilling production line for the internal support of a communication base station, including a processing platform on which is provided with a first slideway and a device that can move up and down in the vertical direction and can A drill bit reciprocating on the extension line of the slideway, the processing platform is also provided with a traversing drive device and a lifting device, the drill bit is installed on the lifting device, and the lifting device is installed on the traversing drive device. In the present invention, the drill bit used for drilling and the second drive motor that drives the drill bit to rotate are fixedly installed on a lifting device, and the lifting device is generally installed on the slide table of the electric cylinder, and the drill bit is driven to lift and move by the electric cylinder and the lifting device. The rows of holes on the workpiece are processed sequentially, which effectively improves the processing efficiency and saves labor costs.

Owner:WUHU JINYI MACHINERY

Structural Profile Rotator

ActiveUS20120177475A1Damage to materialRotate a structural profile quickly and easilyBuilding constructionsLarge fixed membersEngineeringOverhead crane

An apparatus is disclosed for rotating a structural profile quickly and easily on a single spindle drill line without the use of a crane. The apparatus has two arms which can lay flat or create any angle less than 180 degrees between the two. The apparatus can move horizontally along the drill line and can lift the structural profile vertically for movement and during rotation. This will allow a drill machine operator to rotate large and heavy structural profiles on a drill line and position them with the datum blocks in order to drill the different sides without the need for an overhead crane or other lifting device and

Owner:OCEAN MACHINERY INC A FLORIDA

Drill string with aluminum drill pipes, bent housing, and motor

Methods and apparatuses include drilling a bore hole in a horizontal direction with a drill bit, a bent housing portion, and a mud motor by rotating the drill bit, the bent housing portion, and the mud motor with drill pipe comprising an aluminum pipe section. The methods and apparatuses also include stopping rotation of the drill pipe and performing a slide by rotating the drill bit with the mud motor to advance the drill bit, the bent housing portion, the mud motor, and the drill pipe in the borehole so that the aluminum pipe section moves axially along the bore hole in the horizontal direction. The methods and apparatuses also include continuing to drill the bore hole by rotating the drill bit, the bent housing portion, and the mud motor with the drill pipe.

Owner:RYAN DIRECTIONAL SERVICES

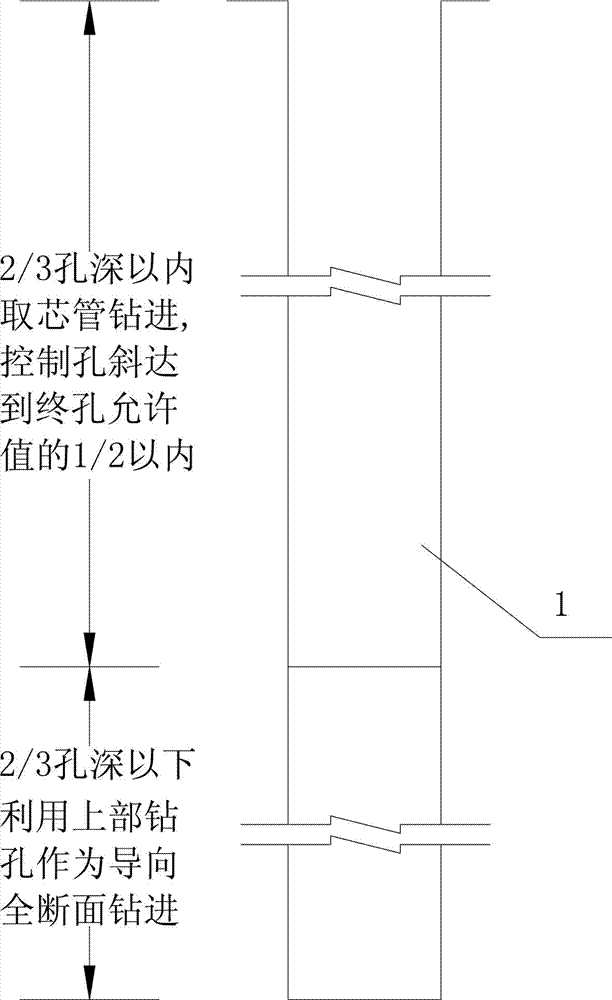

Hole deviation control method for drilling in deep hole curtain grouting

Disclosed is a hole deviation control method for drilling in deep hole curtain grouting. Before spud-in, four corners of a rig substructure is anchored by expansion bolts, the rig abdomen is fixed by a draw bar, so that the rig body can be guaranteed to be stable during the drilling process; during the drilling, a long drilling tool is used for core drilling for the construction within 2 / 3 of the hole depth of the drill hole along with the gradual increase of the hole depth, and the drill hole deviation within 2 / 3 of the hole depth is controlled to be within 1 / 2 of a designed permissible value; and under 2 / 3 of the hole depth, a three-wing clad sheet or a diamond roller bit is used for drilling on the whole section without coring, and the accurate drill hole drilled on the upper portion is used as a guide to finish the drilling. According to the method, the long drilling tool is used for drilling the upper portion of the drill hole, the accurate drill hole drilled on the upper portion is used as a guide for the lower portion, the three-wing clad sheet or the diamond roller bit is used for drilling on the whole section without coring, so that an offset distance at the bottom of the drill hole is not larger than 2.0m.

Owner:GEZHOUBA GROUP FOUND ENG

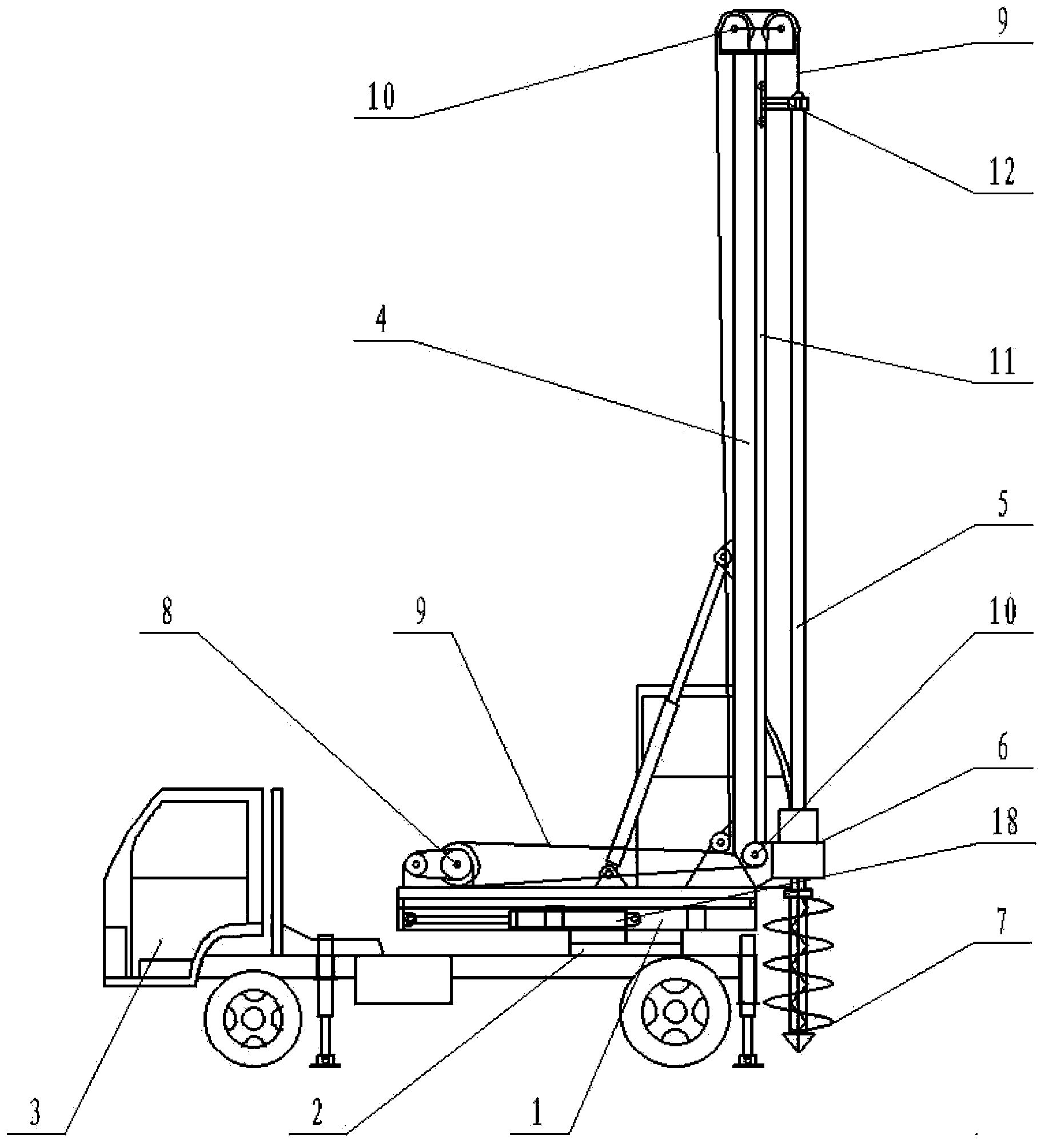

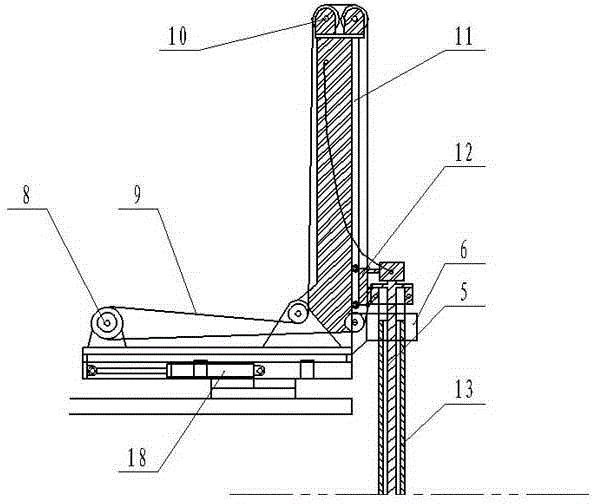

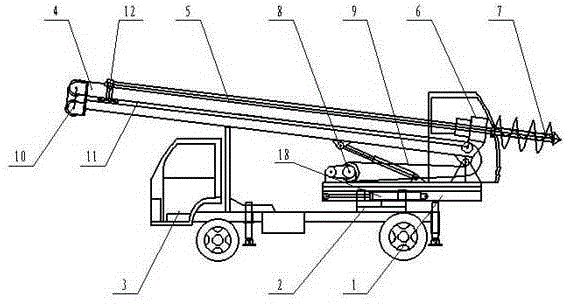

Rotary drilling rig

ActiveCN103510852AReduce frictional resistanceReduce energy consumptionDrilling machines and methodsEngineeringDrill line

The invention discloses a rotary drilling rig. The rotary drilling rig comprises a driving device, a workbench, a stand column, a drill pipe, a rotary power head, a drill bit, a winch, steel wire ropes and a pulley. The stand column and the winch are installed on the workbench, the steel wire ropes wind the winch, the outer side of the stand column is provided with a sports car track which is provided with a drill pipe sports car, the two ends of the drill pipe sports car are fixedly connected with the steel wire ropes respectively, the directions of the steel wire ropes at the two ends are changed through the pulley at the lower end of the stand column so that the steel wire ropes can be connected with the winch, and the steel wire ropes are driven by the winch to move up and down along the sports car track. The drill pipe is fixedly installed on the drill pipe sports car. Due to the fact that the stand column is provided with the sports car track and the drill pipe sports car, and direction changing is carried out through the pulley at the lower end of the stand column, a lever structure is formed, the weight of the whole car can be born by the drill pipe sports car with the pulley as a panel point, enough downwards pressure is given to the drill pipe and the drill bit through the drill pipe sports car, and the rotary drilling rig can fast and efficiently drill a hole in hard soil.

Owner:覃炳德

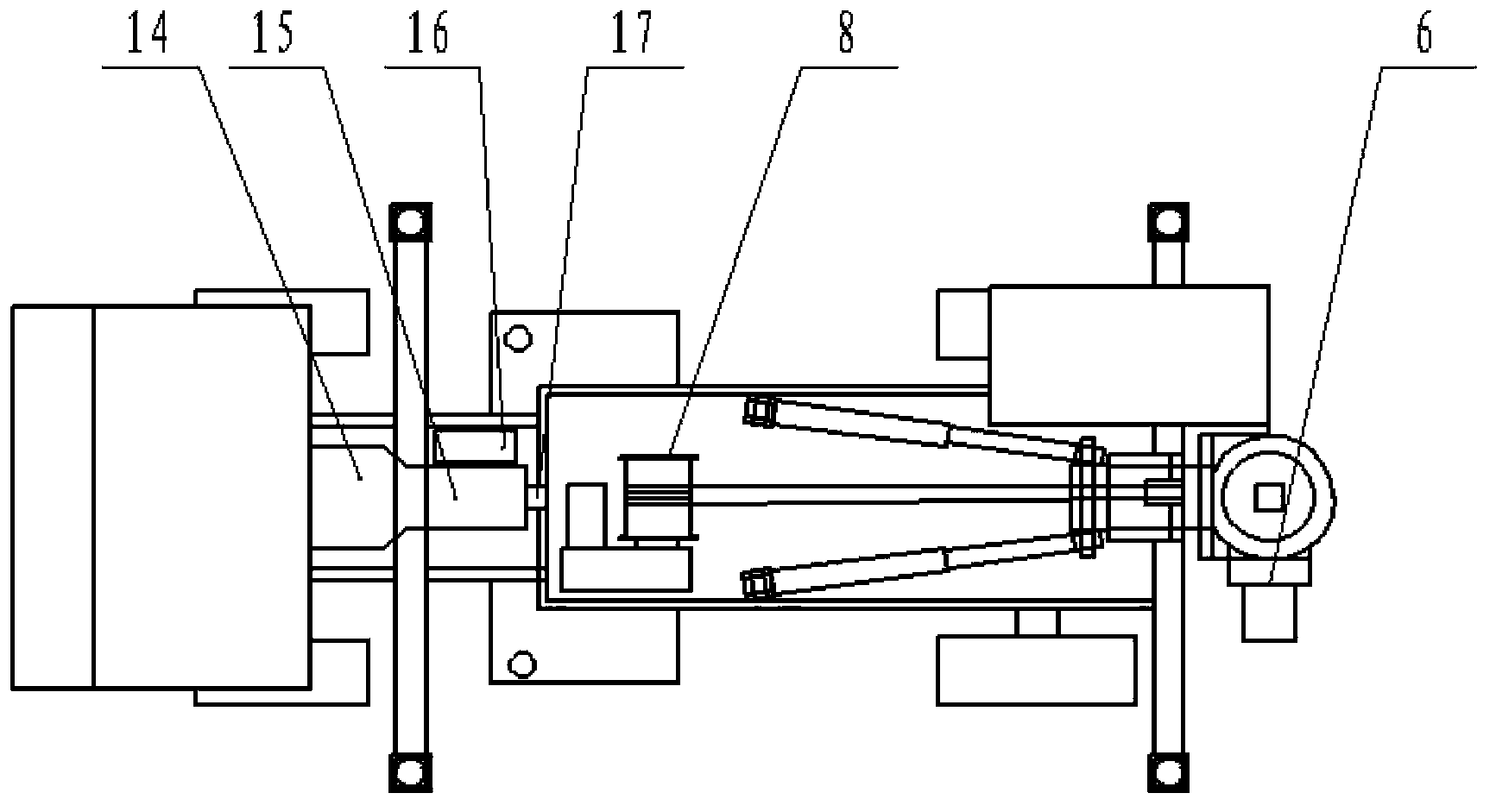

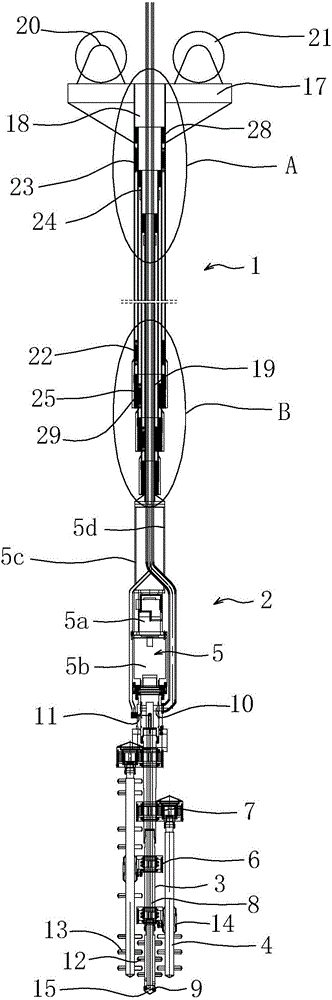

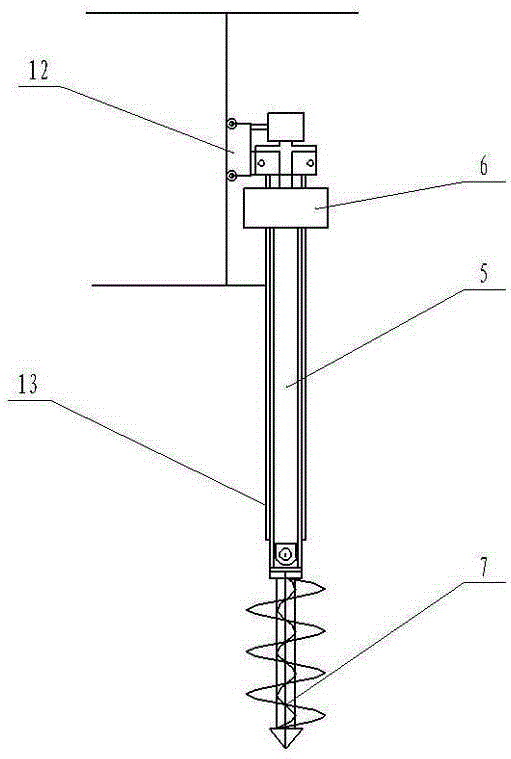

Automatic drill pipe loading device applied to downhole hydraulic drilling rig and having drill pipe storage function

ActiveCN108843249ADoes not affect the structural formSimple structureDrilling rodsDerricks/mastsHydraulic cylinderEngineering

The invention discloses an automatic drill pipe loading device applied to a downhole hydraulic drilling rig and having a drill pipe storage function. The automatic drill pipe loading device comprisesa mechanical device and a power system, wherein the mechanical device comprises a drill pipe box and a manipulator mechanism; multiple drill pipes can be stored in the drill pipe box for one time; a geneva mechanism rotates for a proper angle and a drill pipe is pushed out by a hydraulic cylinder, the manipulator mechanism clamps the drill pipe and takes the drill pipe out, the drill pipe is overturned by a swing cylinder to a drilling coaxial position of the drilling rig and conveyed to the drilling rig in a sliding manner through a linear driving mechanism, and finally, automation of a drillpipe loading process is completed. Automatic loading and unloading of the drill pipes can be finished, original functions of a drill carriage are not changed, functions of the drill carriage are expanded, and automation degree of the drill carriage is improved.

Owner:CHINA UNIV OF MINING & TECH

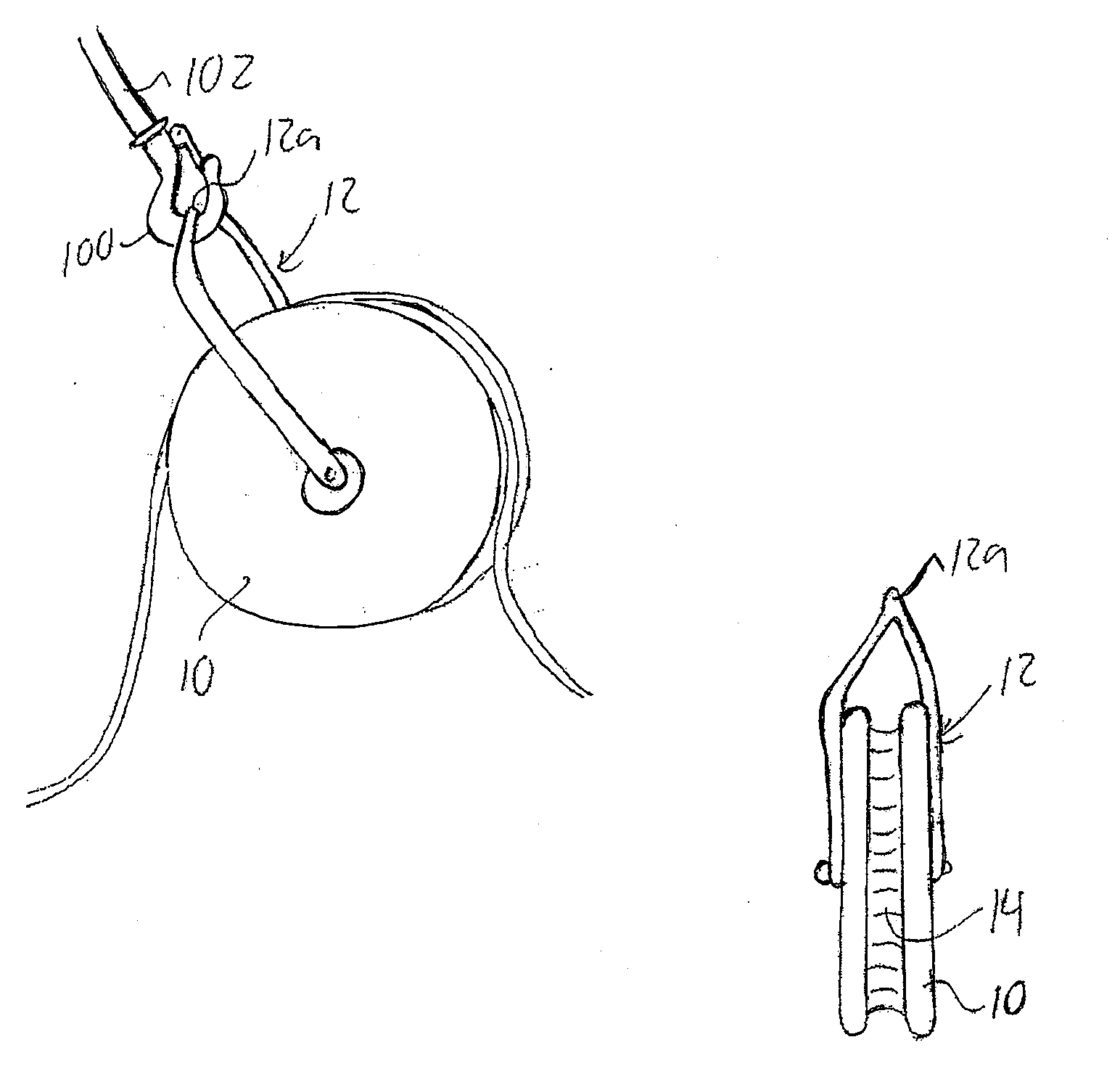

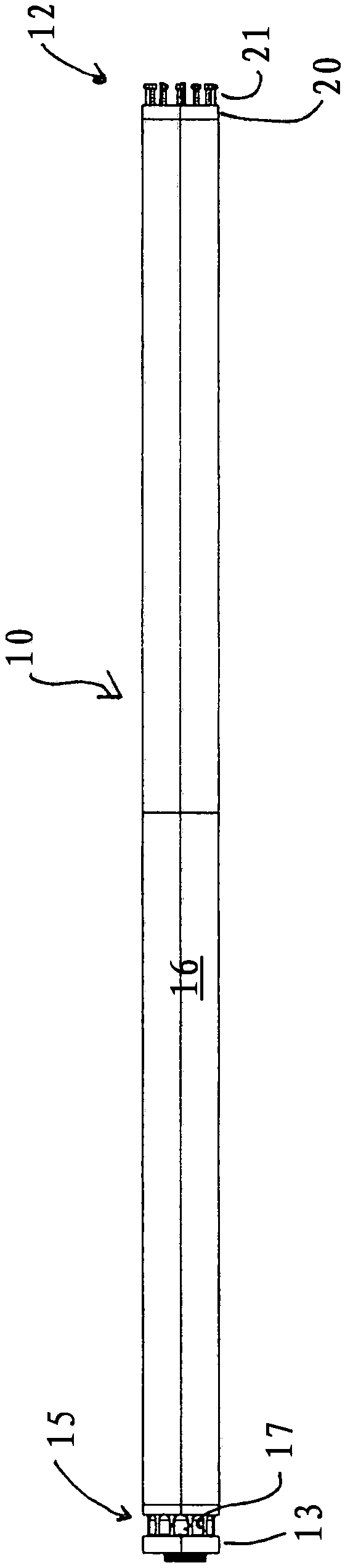

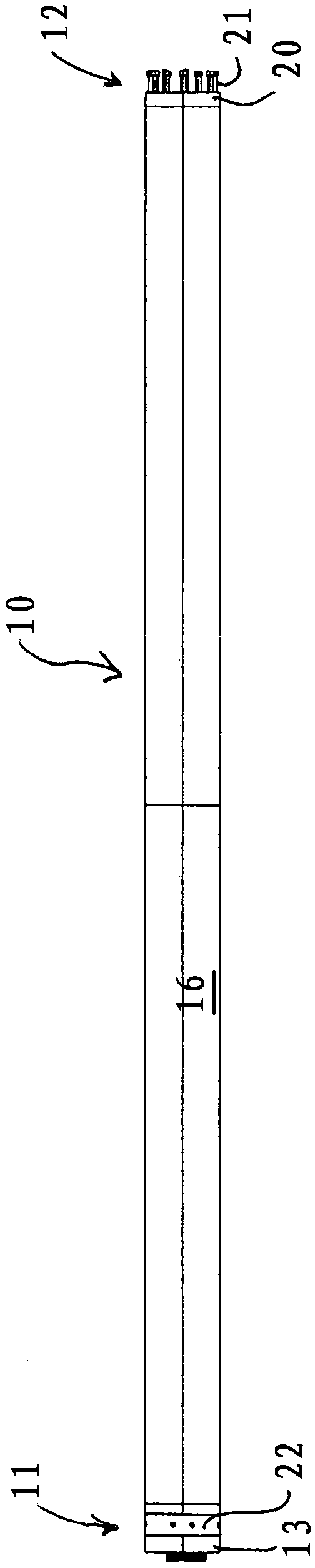

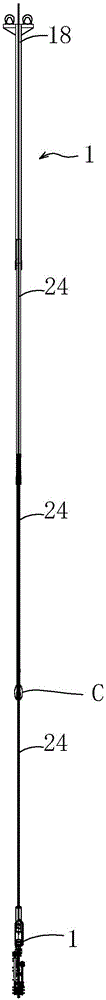

Drill pipe, and system and method for laying a pipeline

PendingCN108779664AOmit or reduce stitchingShorten installation and commissioning timeDrilling rodsConstructionsClassical mechanicsEngineering

The invention relates to a drill pipe (10) for use during the creation of a borehole in a ground (100) from a starting point (101) to a target point (102) along a predetermined drill line, in particular for the near-surface laying of underground cables or electric underground cables in the ground (100). The invention is characterized in that the borehole is gradually created by means of a drillingdevice (103, 106) that has a drilling tool for loosening the ground when the drill pipes (10) are advanced, each end of the drill pipe having at least one connection section (11, 12) for detachably connecting it to a further element of a drill string (110) in a tensile resistant manner; in that the drill pipe (10) has at least one element (21) for producing a tensile-resistant connection to a corresponding element of an advance device for advancing the drill pipe into and / or retracting it from the borehole; and in that an outer wall of the drill pipe is made in one piece. The invention further relates to a device (103) for moving at least one drill pipe into a borehole or out of the same, and to a system and a corresponding method.

Owner:HERRENKNECHT AG

Drilling machine with multiple drill bits

The invention discloses a drilling machine with multiple drill bits, comprising: a workbench, a sliding rod, a drilling mechanism and a clamping part; the sliding rod is vertically fixed on the upper surface of the workbench, the drilling mechanism is arranged on the sliding rod, and the working At least two matching clamping parts are arranged on the upper surface of the table; the drilling mechanism includes: a drilling box, a drill bit fixing part and a drill bit; the drilling box is slidably arranged on the sliding rod, and the drill bit fixing part and the drilling The output shaft of the motor in the box is connected, and the lower surface part of the drill bit fixing part is recessed inward to form a plurality of drill bit grooves, the bottom of each drill bit groove is provided with a telescopic column, and the lower end of each telescopic column is connected with a drill bit, and the drill bit can be retracted. into or out of the drill slot. The drilling machine with multiple drill bits overcomes the problem that the drilling machine in the prior art needs to replace different drill bits to drill different apertures, and the process of replacing the drill bits is cumbersome, which seriously affects the work efficiency.

Owner:芜湖凝鑫机械有限公司

Short distance speed-increasing type hard rock deep borehole drilling device

InactiveCN101319596AAccurate straightnessPrecise ApertureConstructionsRotary drillingLow speedShortest distance

The invention discloses a near-distance acceleration device for drilling deep holes in hard rock, which belongs to the field of drilling machines. An accelerator is arranged close to a drill bit; one end of the accelerator is an input shaft which is connected with a drilling machine; the other end of the accelerator is provided with an output shaft which is connected with the drill bit. The outside of the accelerator is provided with a sleeve; one end of the sleeve which is close to the drill bit is provided with a supporting hole wall and a movable jack catch used to fix the sleeve; the jack catch is provided with a bearing which contacts and is matched with the output shaft; a sliding key on the accelerator is matched with a sliding keyway on the sleeve; through holes which are communicated are arranged in the input shaft, the output shaft and the accelerator and communicated with the inside of the drill bit. The drilling device accelerates the drill bit only at the positions close to the drill bit in the deep holes, so that the drill bit can rotate and cut in the deep holes at high speed; the input shaft and a drill pipe rotate at low speed, so the drill pipe and the drill bit do not shake dramatically, which can not only ensure the liberality of the holes and the precision of the aperture, but also prolong the service life of the drill bit and improve the drilling efficiency.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Inclined drill bit with suction device

The invention relates to an inclined drill bit with a suction device. The inclined drill bit comprises a twist drill, a central drill tip is ground at the top end of the twist drill, left and right outer edges are formed between the central drill tip and the twist drill and used for cutting a workpiece, an L-shaped suction channel from top to bottom is arranged inside the twist drill, a suction hole at the lower end of the L-shaped suction channel is arranged on the chip groove of the twist drill, and the upper end of the L-shaped suction channel is connected with the suction device after penetrating through the twist drill. The suction device is of a pump pipe. The inclined drill bit is firstly drilled into the workpiece by the central drill tip so as to play a role in centering, and then the outer edges are used for cutting, thus reducing the radial cutting component force of the edge at the outer side, guaranteeing the quality of drill holes, and avoiding damage to the workpiece and the drill bit by sucking the chips by virtue of the suction device in time. The inclined drill bit is simple in structure and convenient to manufacture, ensures the quality of drill holes as well as the quality of the workpiece and avoids damage to the drill bit.

Owner:JIANGSU TIANGONG TOOLS CO LTD

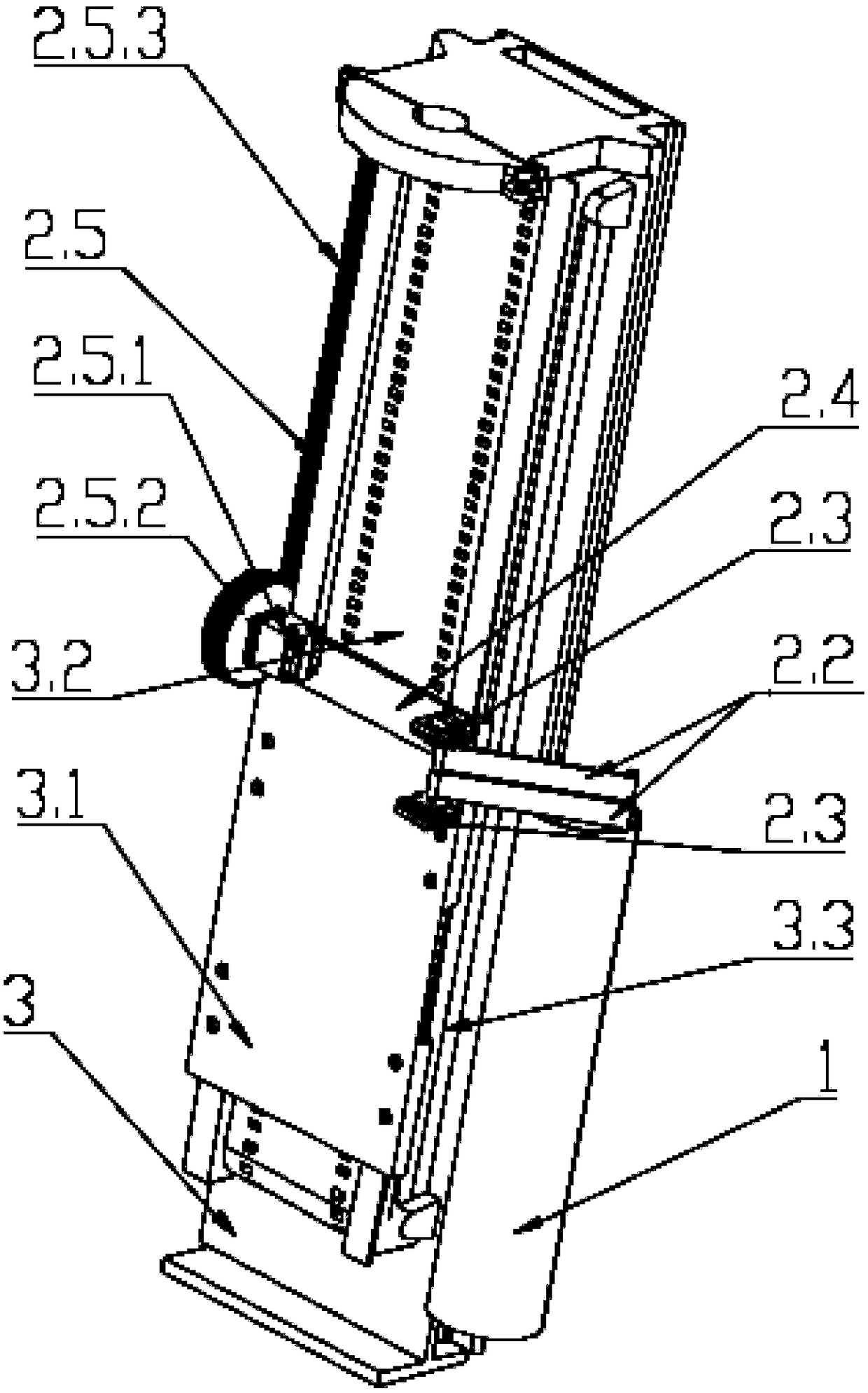

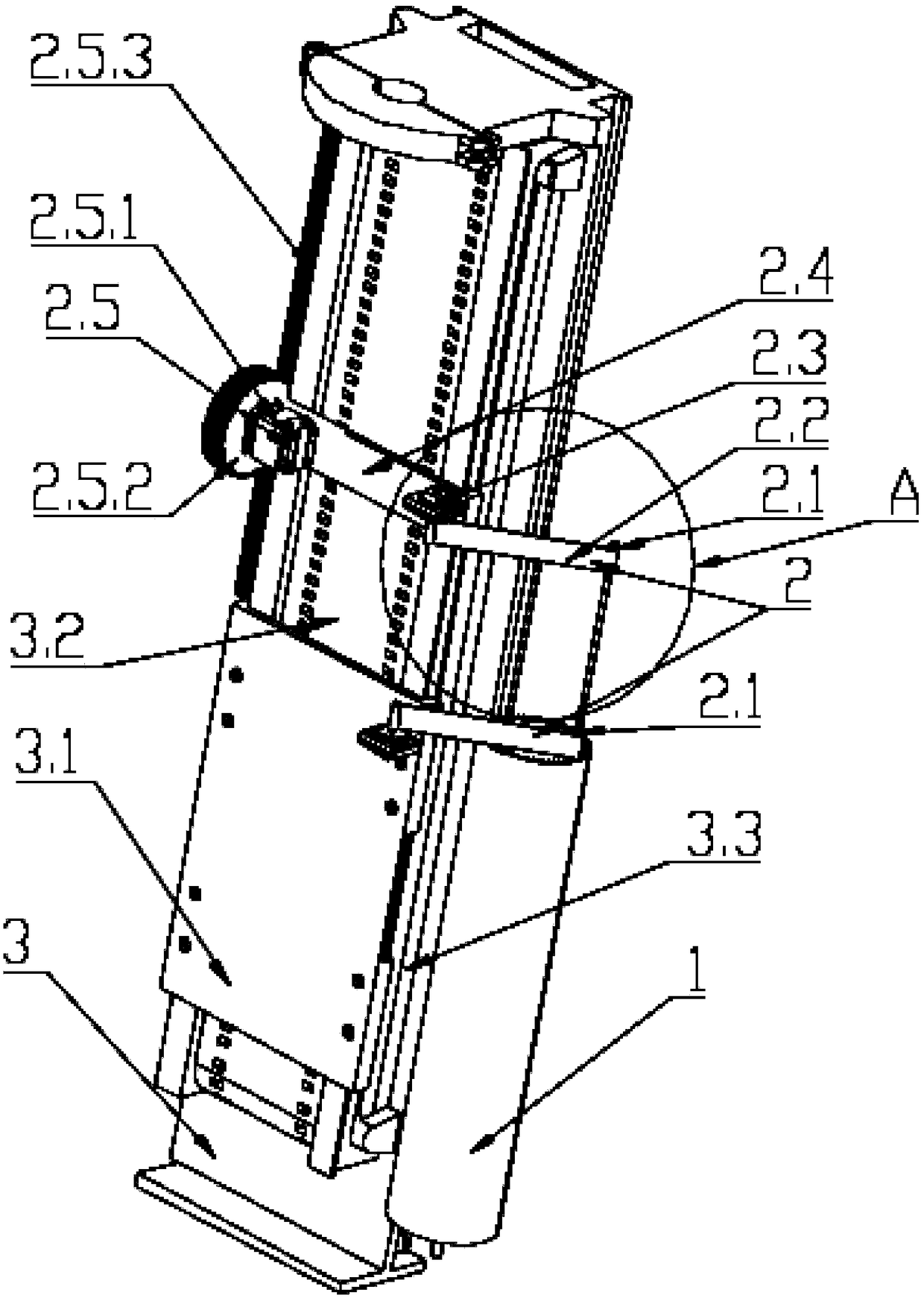

Telescopic drill pipe

InactiveCN106401464AWon't blockShorten the timeDrilling rodsBorehole drivesReciprocating motionDrill line

The invention belongs to the technical field of buildings, and relates to a telescopic drill pipe. The telescopic drill pipe comprises a drill pipe mechanism and a drill bit mechanism fixedly arranged on the end part of the drill pipe mechanism, wherein the drill pipe mechanism can move back and forth in the axial direction to change length of the drill pipe mechanism; the drill bit mechanism comprises a primary drill pipe which can rotate in the circumferential direction and a plurality of secondary drill pipes which are arranged around the primary drill pipe; and the rotation direction of at least one secondary drill pipe is the same with that of the primary drill pipe, and the rotation direction of at least one secondary drill pipe is reverse to that of the primary drill pipe. The drill pipe mechanism and the drill bit mechanism are combined to form the telescopic drill pipe, so that the telescopic drill pipe can automatically drill downwards without external force, and therefore, time of connecting drill pipes is reduced; and the telescopic drill pipe is very convenient and quick, is high in drilling speed, can drill to target depth and is returned to the middle without stop, so that guniting hole blockage is not caused by stop.

Owner:周兆弟

Sleeve type drilling rod

The invention discloses a rotary drilling rig. The rotary drilling rig comprises a driving device, a workbench, a stand column, a drill pipe, a rotary power head, a drill bit, a winch, steel wire ropes and a pulley. The stand column and the winch are installed on the workbench, the steel wire ropes wind the winch, the outer side of the stand column is provided with a sports car track which is provided with a drill pipe sports car, the two ends of the drill pipe sports car are fixedly connected with the steel wire ropes respectively, the directions of the steel wire ropes at the two ends are changed through the pulley at the lower end of the stand column so that the steel wire ropes can be connected with the winch, and the steel wire ropes are driven by the winch to move up and down along the sports car track. The drill pipe is fixedly installed on the drill pipe sports car. Due to the fact that the stand column is provided with the sports car track and the drill pipe sports car, and direction changing is carried out through the pulley at the lower end of the stand column, a lever structure is formed, the weight of the whole car can be born by the drill pipe sports car with the pulley as a panel point, enough downwards pressure is given to the drill pipe and the drill bit through the drill pipe sports car, and the rotary drilling rig can fast and efficiently drill a hole in hard soil.

Owner:覃炳德

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com