Clamp-On Drill String Wiper

a drill string wiper and clamping technology, which is applied in the direction of fluid removal, sealing/packing, and borehole/well accessories, etc., can solve the problems of inability to be handled directly by workers, fixed on the rig, and inconvenient to clean, etc., to facilitate the cleaning of external surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

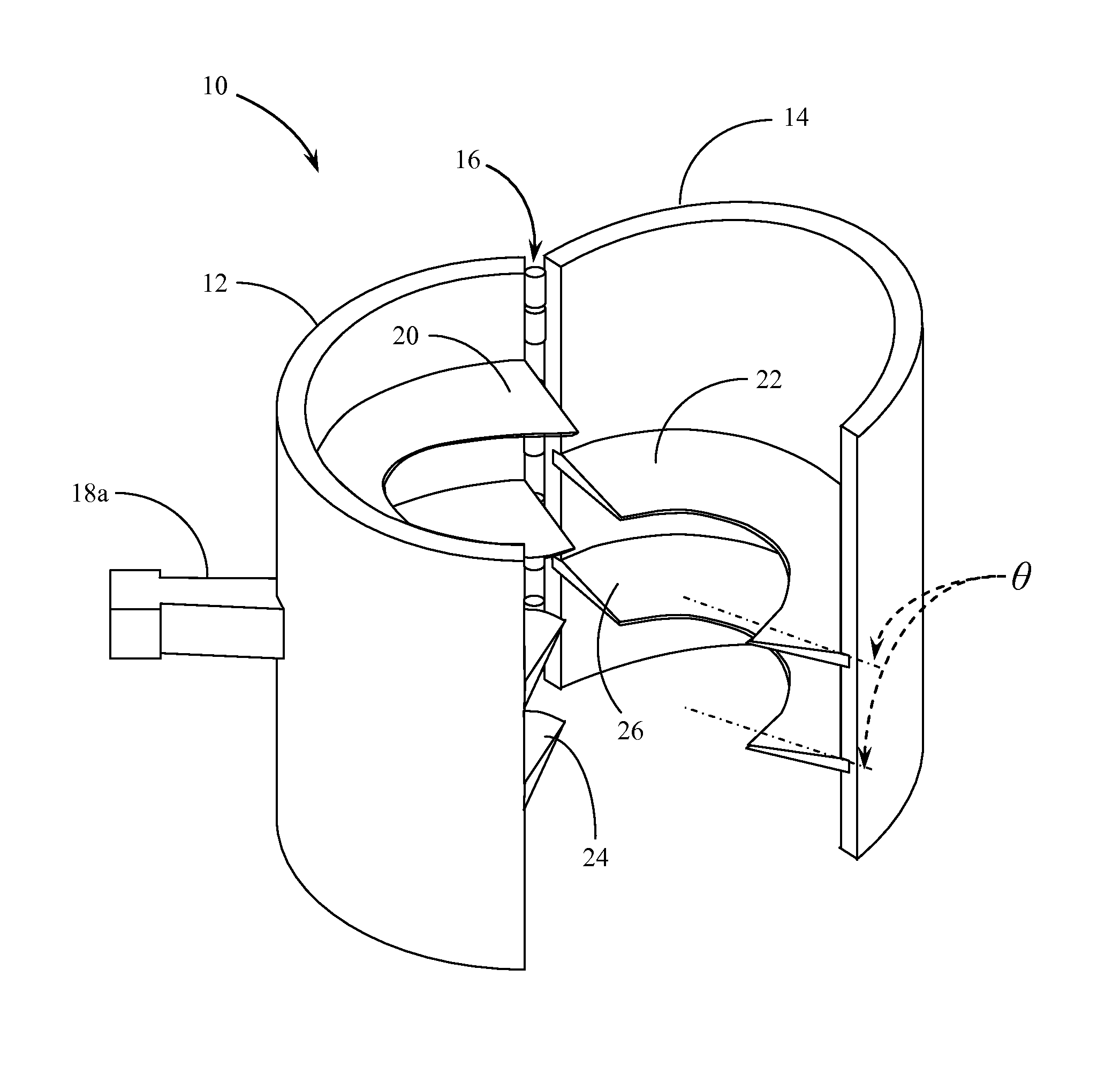

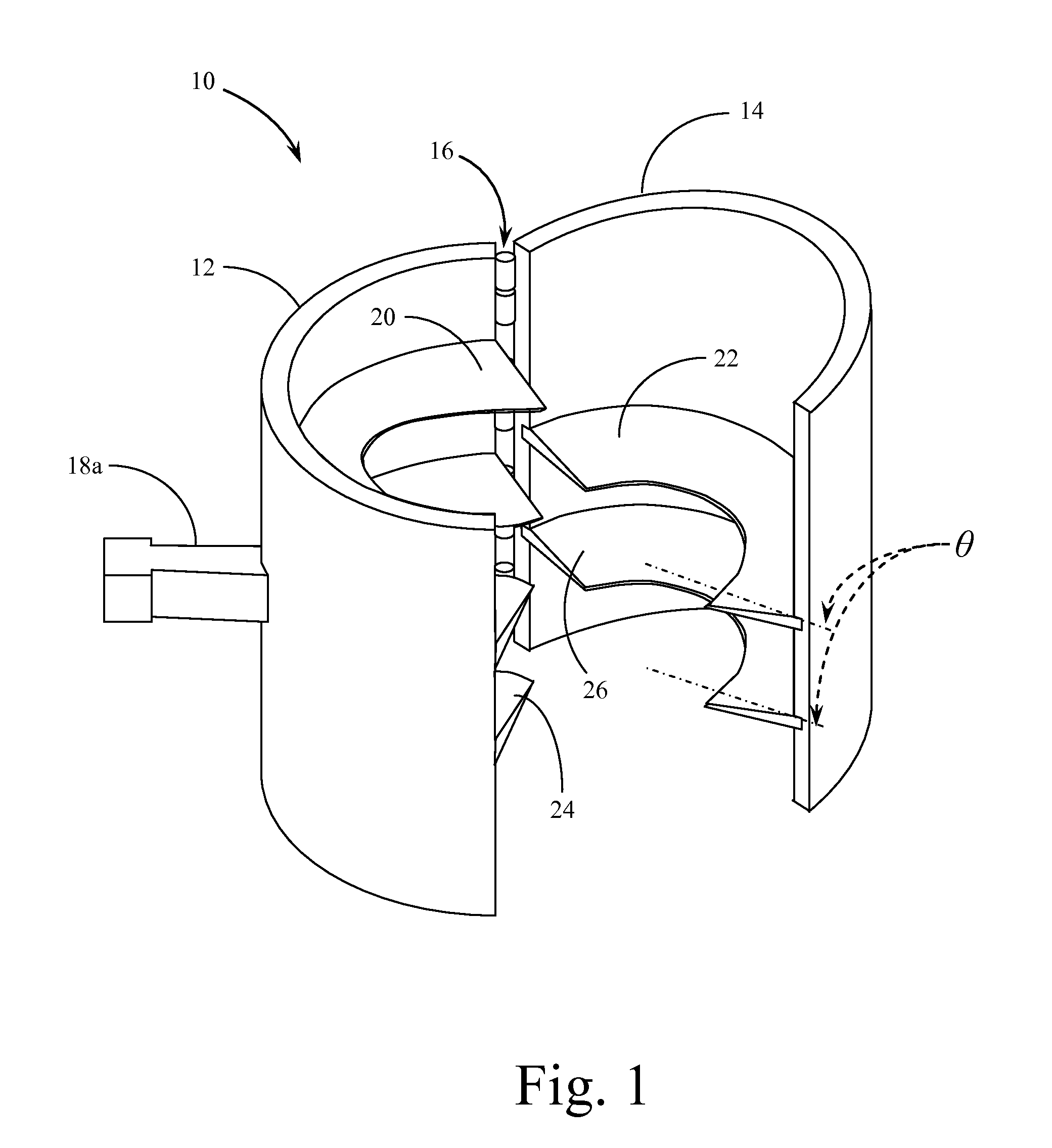

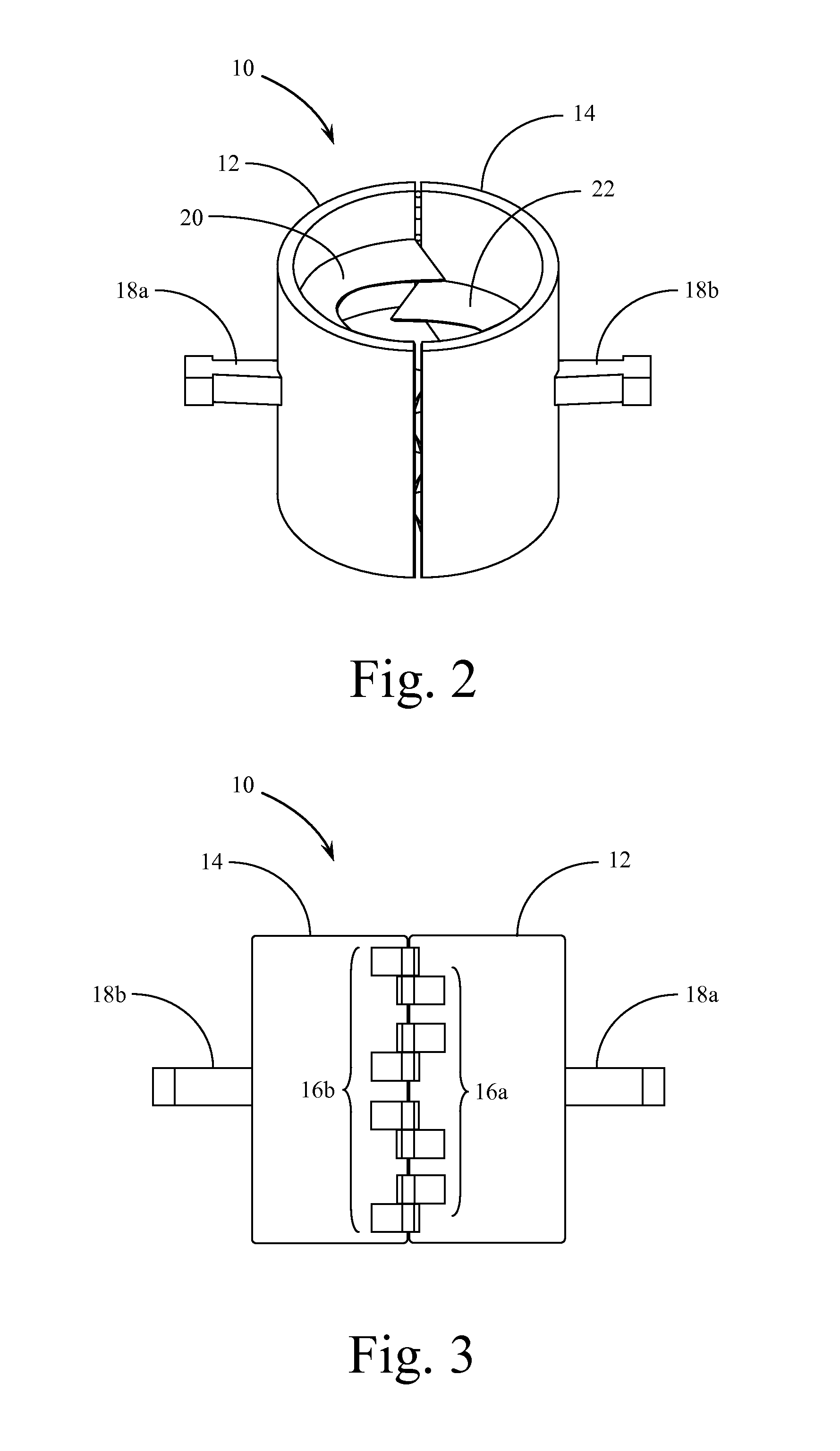

[0017]Reference is made first to FIG. 1 for a perspective view of the wiper device of the present invention shown in a partially open configuration apart from the drill string or drill pipe. The perspective view shown in FIG. 1 provides the orientation of the device that would be required for the placement and positioning of the wiper onto a drill string or drill pipe. Pipe wiper 10 is generally constructed of two half cylindrical shells, first half shell 12 and second half shell 14. These half cylindrical shells are connected to each other through hinge array 16. In a preferred embodiment of the invention, the two half shells 12&14 are constructed from a cylindrical section of large PVC pipe that is split longitudinally with the two resulting half cylinders attached one to the other with hinge array 16.

[0018]Positioned on the outside face of each of first half shell 12 and second half shell 14 are first side handle 18a and second side handle 18b (18b not shown in the view of FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com