Vertical shaft soft rock special drill construction technique

A construction technology, soft rock technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve problems such as slow drilling speed, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

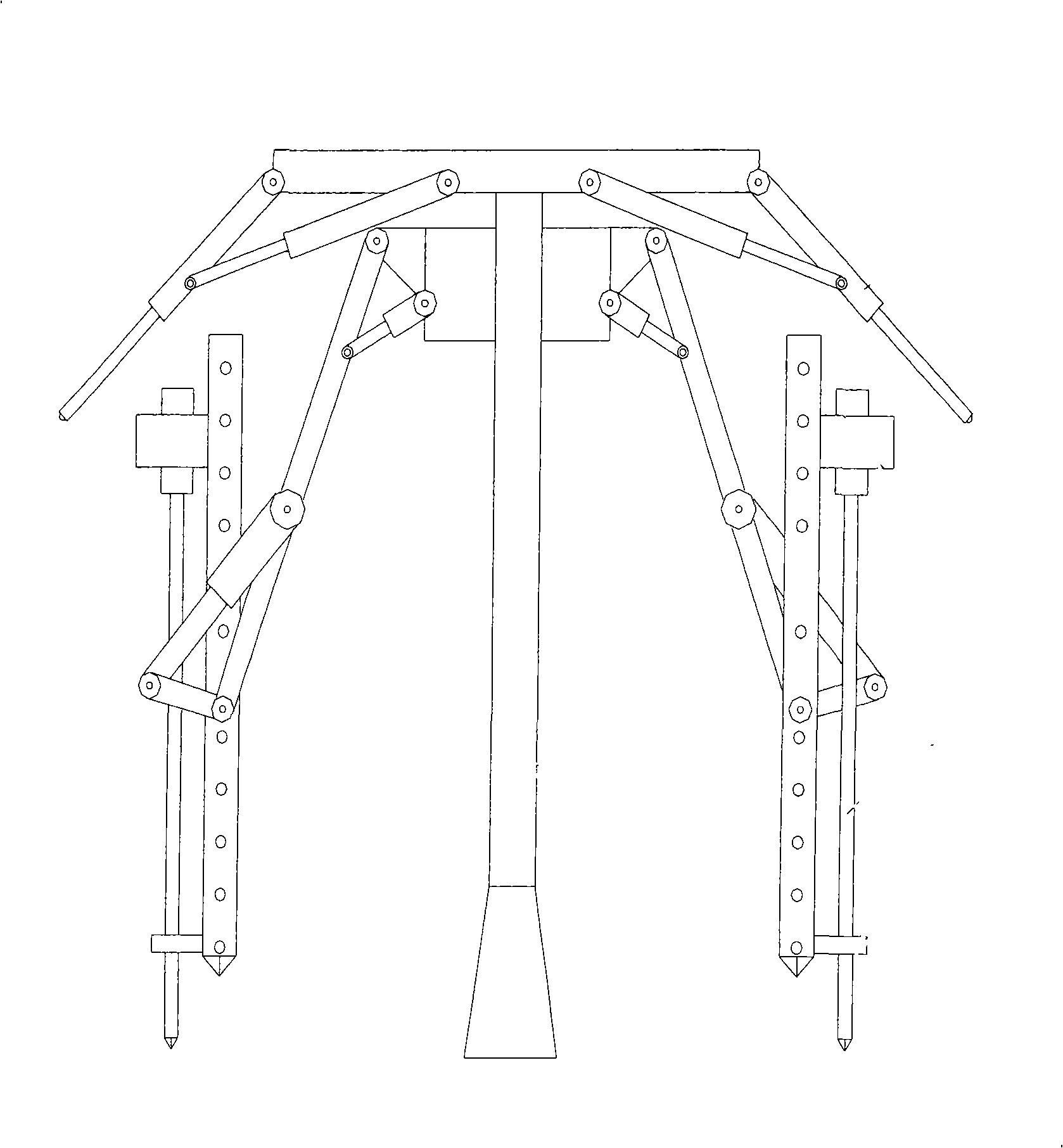

[0026]A special drilling construction technology for vertical shaft soft rock, the construction steps mainly include drilling frame downhole, moving drill downhole, spud drilling, auxiliary work in the drilling process and recovery of downhole drilling frame, and the process steps are: ( 1) First, put the FJD umbrella drill rig down the well, (2), install the compressed air pipeline after the FJD umbrella drill rig goes down the well, and send the compressed air to the compressed air distribution device on the FJD umbrella drill rig and the FJD umbrella drill rig (3), open the control valve of the pneumatic support arm, and spread the FJD umbrella drill stand, (4), install the TMY6 down-the-hole drilling rig through the vertical drilling rig fixing frame On each umbrella bar of the FJD umbrella drill stand, (5), install the drill pipe, drill bit and reamer, (6), open the TMY6 type down-the-hole drilling machine control valve, start the TMY6 type down-the-hole drilling machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com