Drilling machine for metal pipe tapping

A technology for metal pipes and drilling machines, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc. It can solve the problems of poor pipeline firmness, low drilling efficiency, and affecting drilling quality, etc., to achieve Easy to adjust position and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

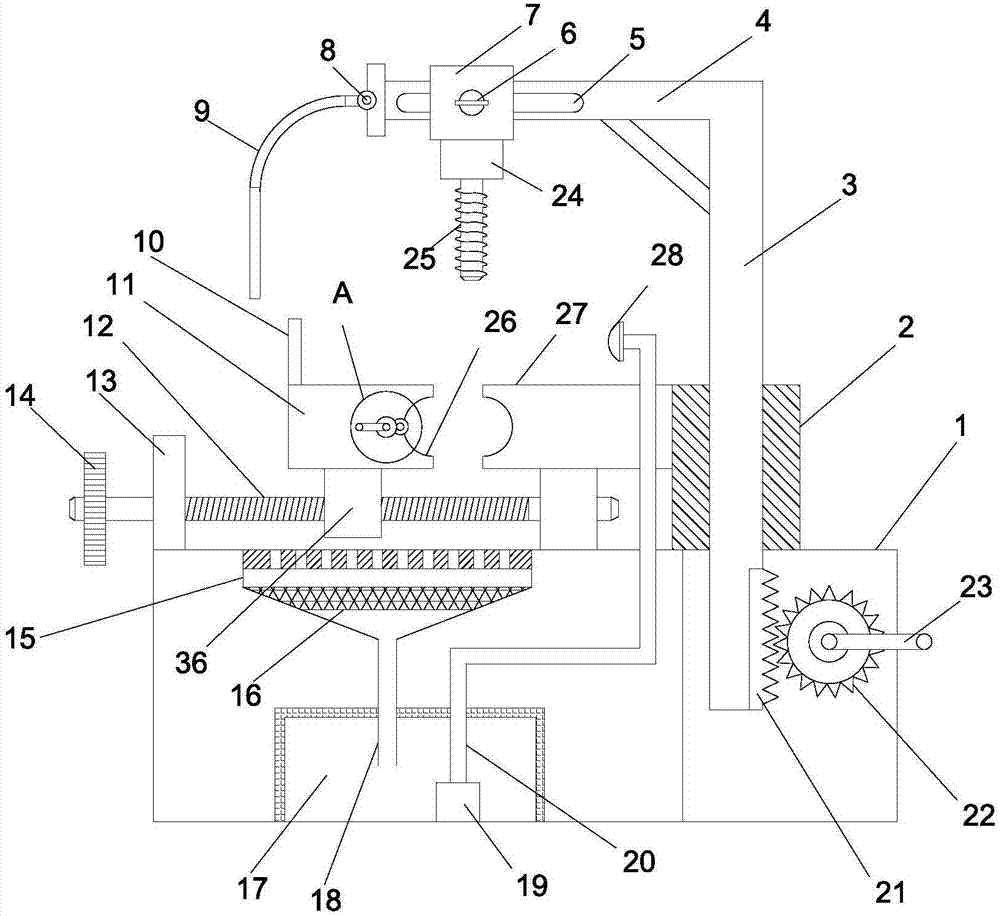

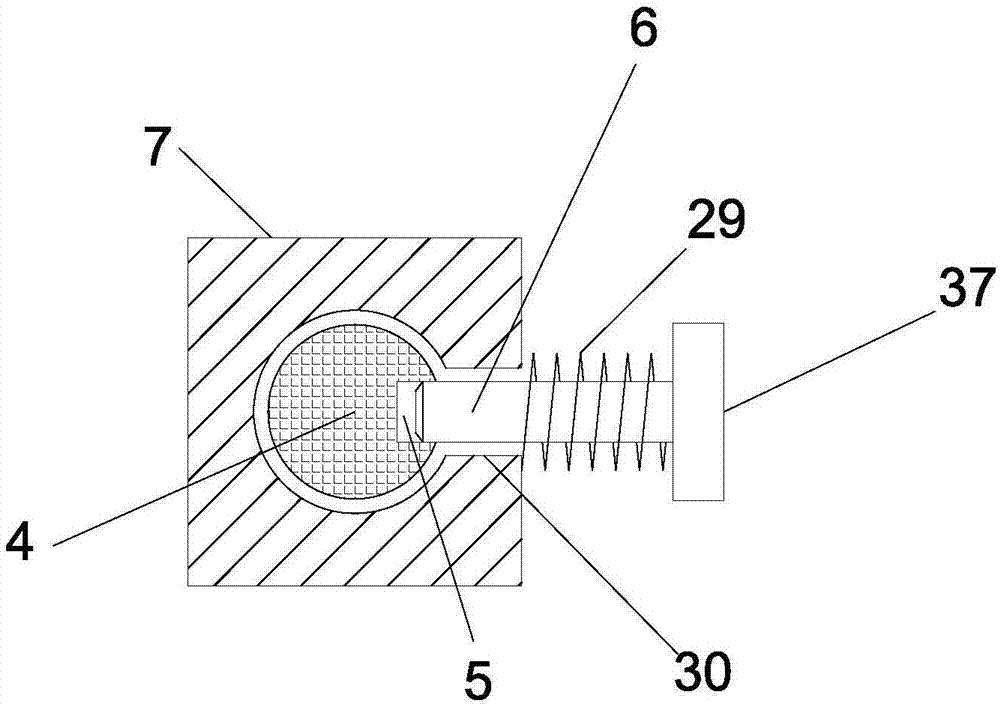

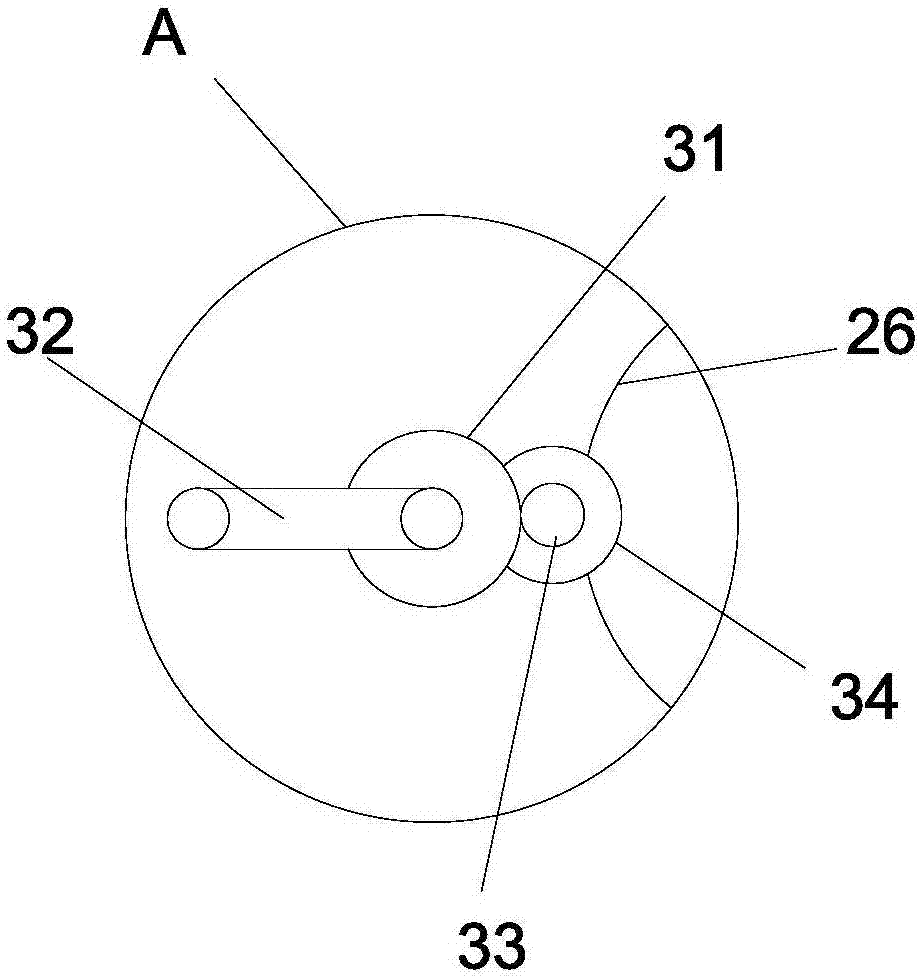

[0026] see Figure 1-5 , a drilling machine for drilling metal pipes, comprising a body 1, characterized in that, the bottom of the body 1 is provided with a liquid storage tank 17, and the liquid storage tank 17 is filled with cooling liquid; the body 1 is provided with a sleeve 2, the sleeve A column 3 is slidably installed on the tube 2, a spur rack 21 is provided at the bottom of the column 3, a drive gear 22 is provided on the right side of the column 3, the drive gear 22 is meshed with the spur rack 21, and the drive gear 22 is fixedly installed with a first Rocker 23; the left side of the sleeve 2 is fixedly equipped with a right pressure block 27, the body 1 is fixedly equipped with a support 13, the support 13 is horizontally provided with a lead screw 12, the left end of the lead screw 12 is fixedly equipped with a hand wheel 14, and The bar 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com