Patents

Literature

51results about How to "Easy drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drilling machine for metal pipe tapping

InactiveCN107159922AEasy to fixAvoid compromising drilling qualityPositioning apparatusMaintainance and safety accessoriesGear wheelEngineering

The invention discloses a drilling machine for metal pipe tapping. The drilling machine comprises a main body; a sleeve is arranged on the main body; a stand column is slidingly mounted on the sleeve; a straight rack is arranged at the lower part of the stand column; a driving gear is arranged on the right side of the stand column; a right pressing block is fixedly mounted on the left side of the sleeve; a bracket is fixedly mounted on the main body; a lead screw is horizontally arranged on the bracket; a hand wheel is fixedly mounted at the left end of the lead screw; a sleeve block sleeves the lead screw; arc grooves are respectively formed in the right side surface of the left pressing block and the left side surface of the right pressing block; a leakage pipe is arranged at the bottom of a liquid collecting tank, and extends into a liquid storage box; a conveying pimp is arranged at the bottom of the liquid storage box; a conveying pipe is arranged at an outlet end of the conveying pump; and a nozzle is arranged at one end, far from the conveying pump, of the conveying pipe. A metal pipe is driven to rotate through rotation of a rotating roller, so that multiple places of the side surface of the pipe are conveniently drilled, and the drilling efficiency is improved; cooling liquid sprayed by the nozzle can cool a drill bit to prevent damage of the drill bit due to overheating; and meanwhile, the cooling liquid can be recycled, so that the waste of the cooling liquid is prevented.

Owner:惠安县长信机电科技有限公司

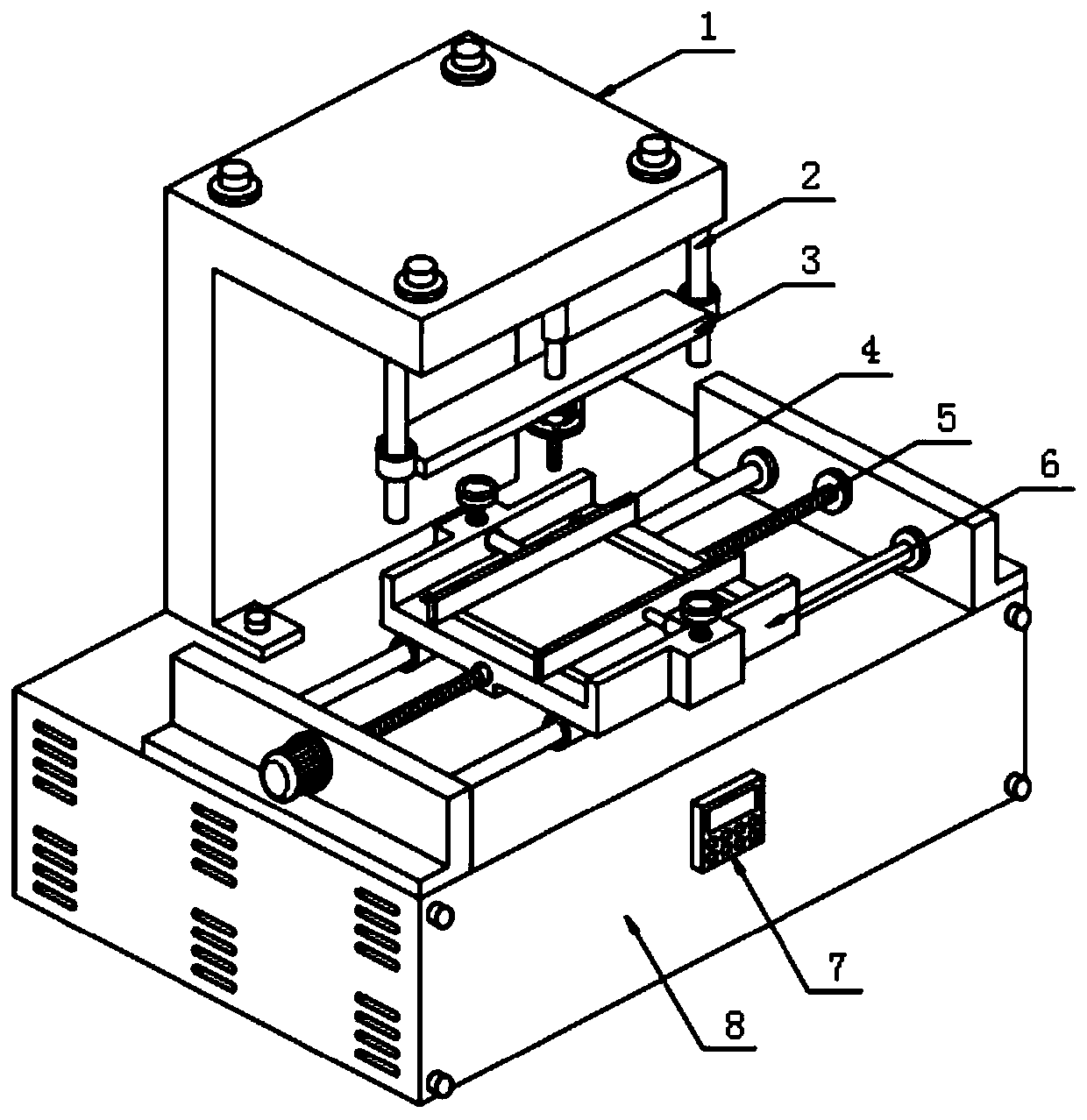

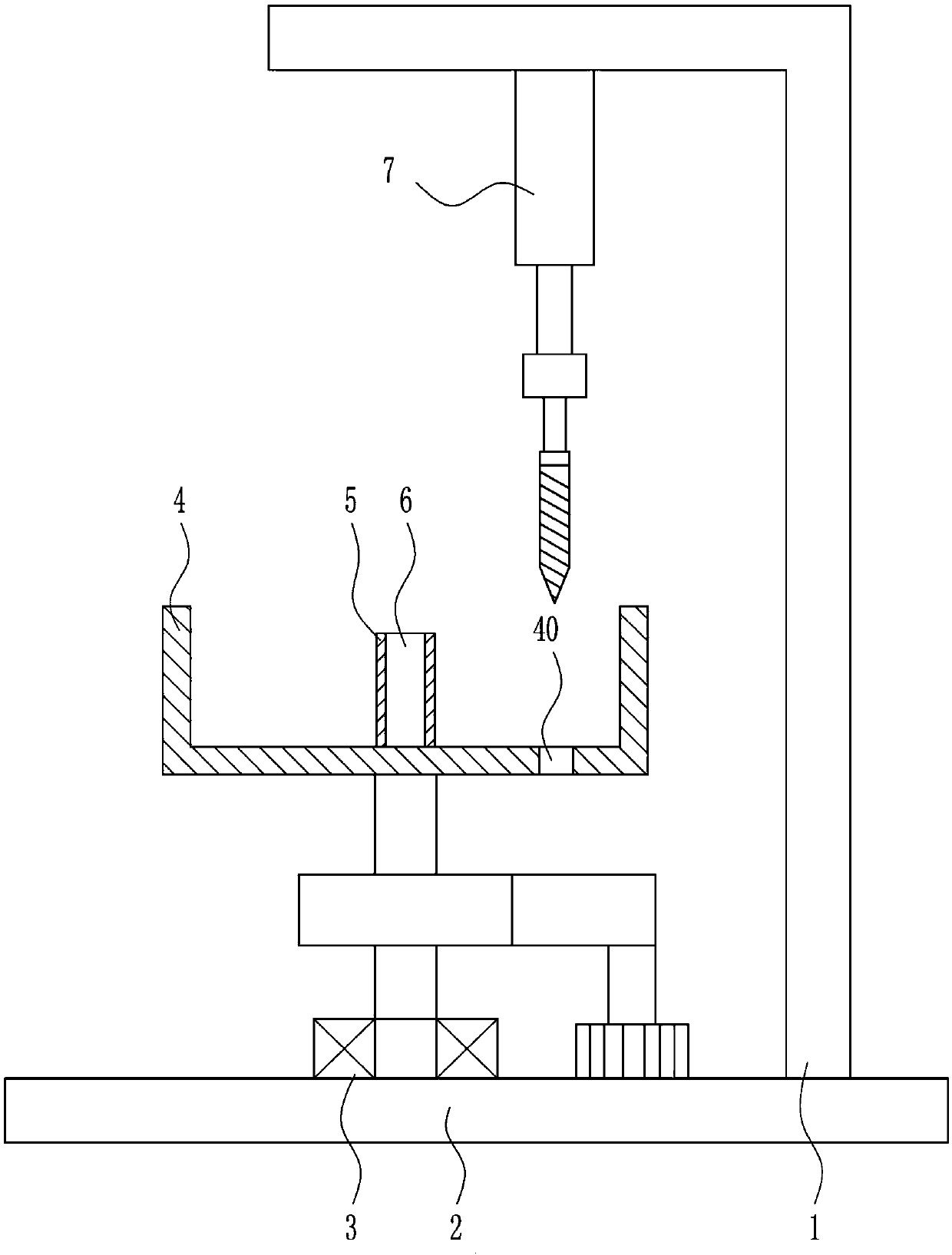

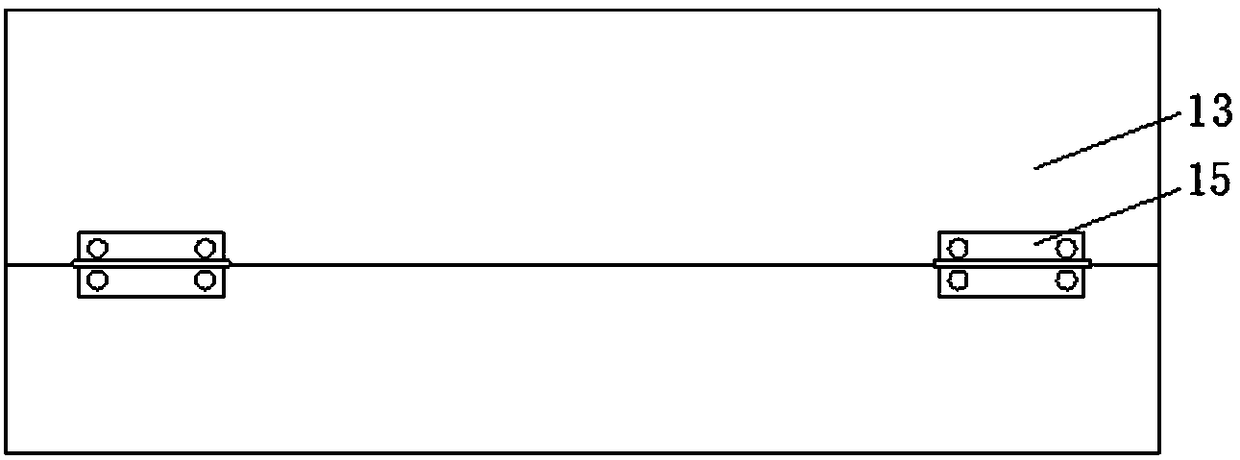

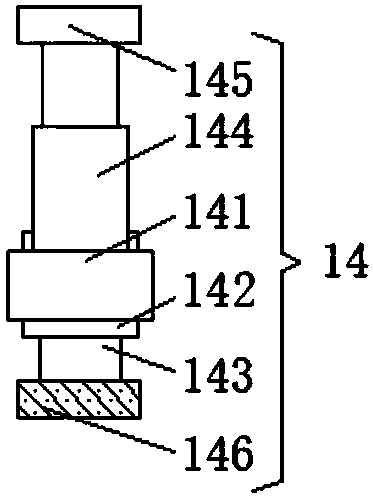

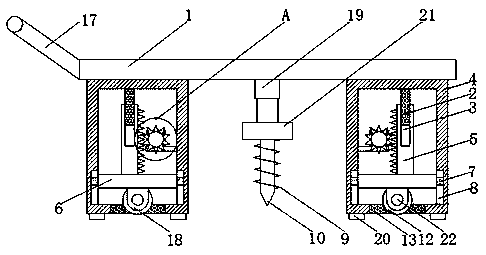

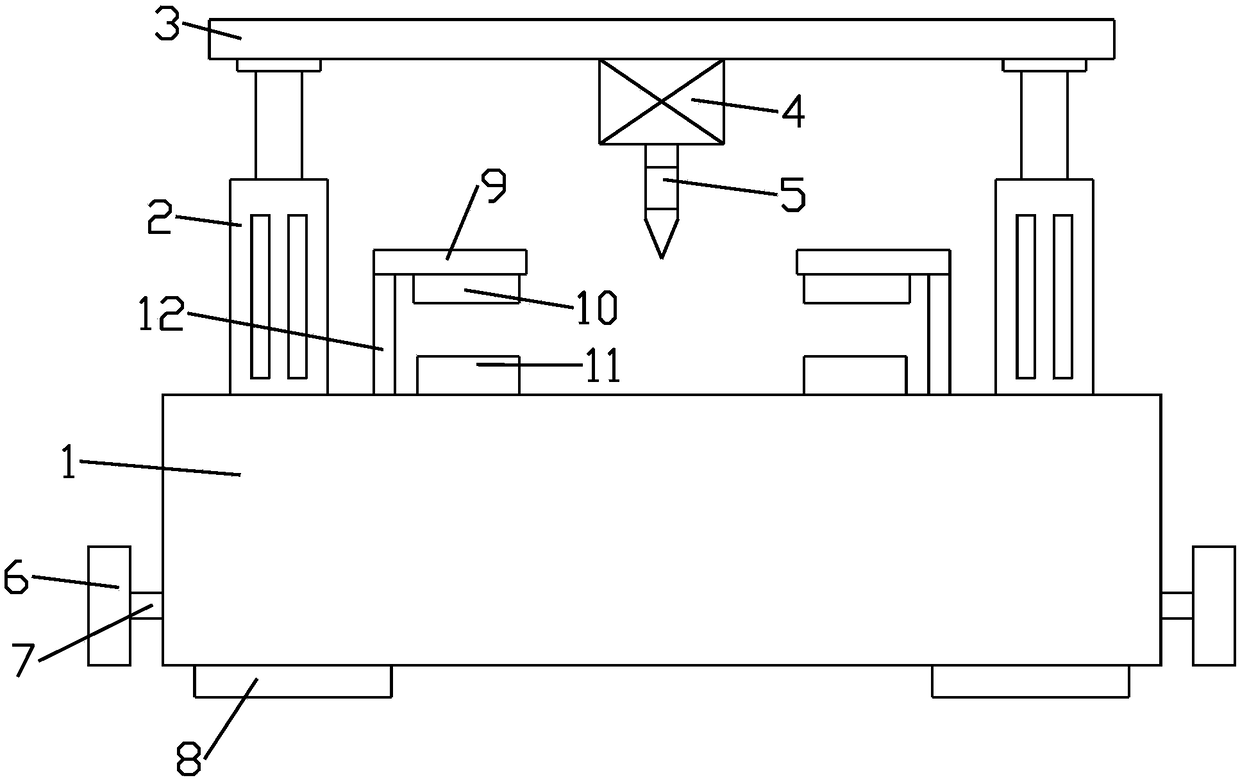

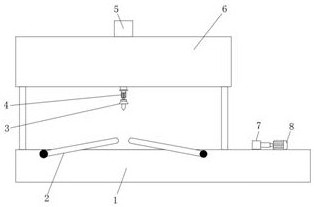

Positioning type drilling device capable of easily adjusting drilling position

InactiveCN111347080AEasy drillingConvenient processing needsFeeding apparatusPositioning apparatusControl switchMachining

The invention relates to the technical field of plate drilling, and discloses a positioning type drilling device capable of easily adjusting the drilling position. A limiting ring is movably connectedto the outer part of a limiting rod in a sleeve mode, a motor is fixedly connected to the bottom of an installing plate, a drill bit is connected to the driving end of the motor, a control switch isfixedly connected to the front surface of a workbench, a driving assembly is arranged on the front side of a supporting table, a placing table is connected to the upper part of the driving assembly, asliding groove is formed in the upper surface of the placing table, and a first clamping assembly and a second clamping assembly are further arranged at the two ends of the placing table. According to the positioning type drilling device capable of easily adjusting the drilling position, a plate on the driving assembly can be driven by the driving assembly to transversely move left and right, different positions on the plate can be conveniently drilled, actual machining requirements are met, a user can conveniently clamp the to-be-drilled plate by arranging the first clamping assembly and thesecond clamping assembly, and the problem that the machining precision is reduced due to shaking in the drilling process is solved.

Owner:江丽平

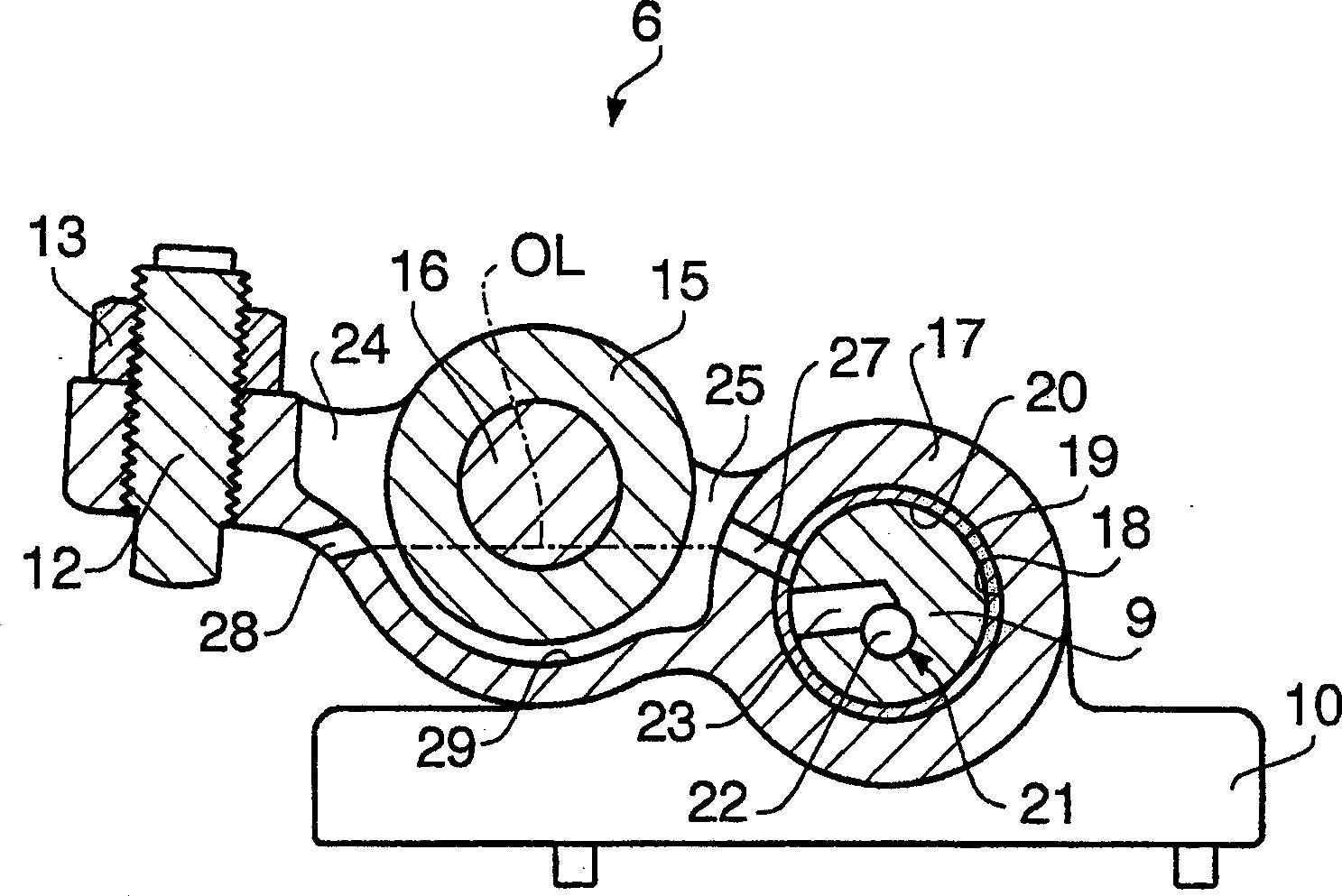

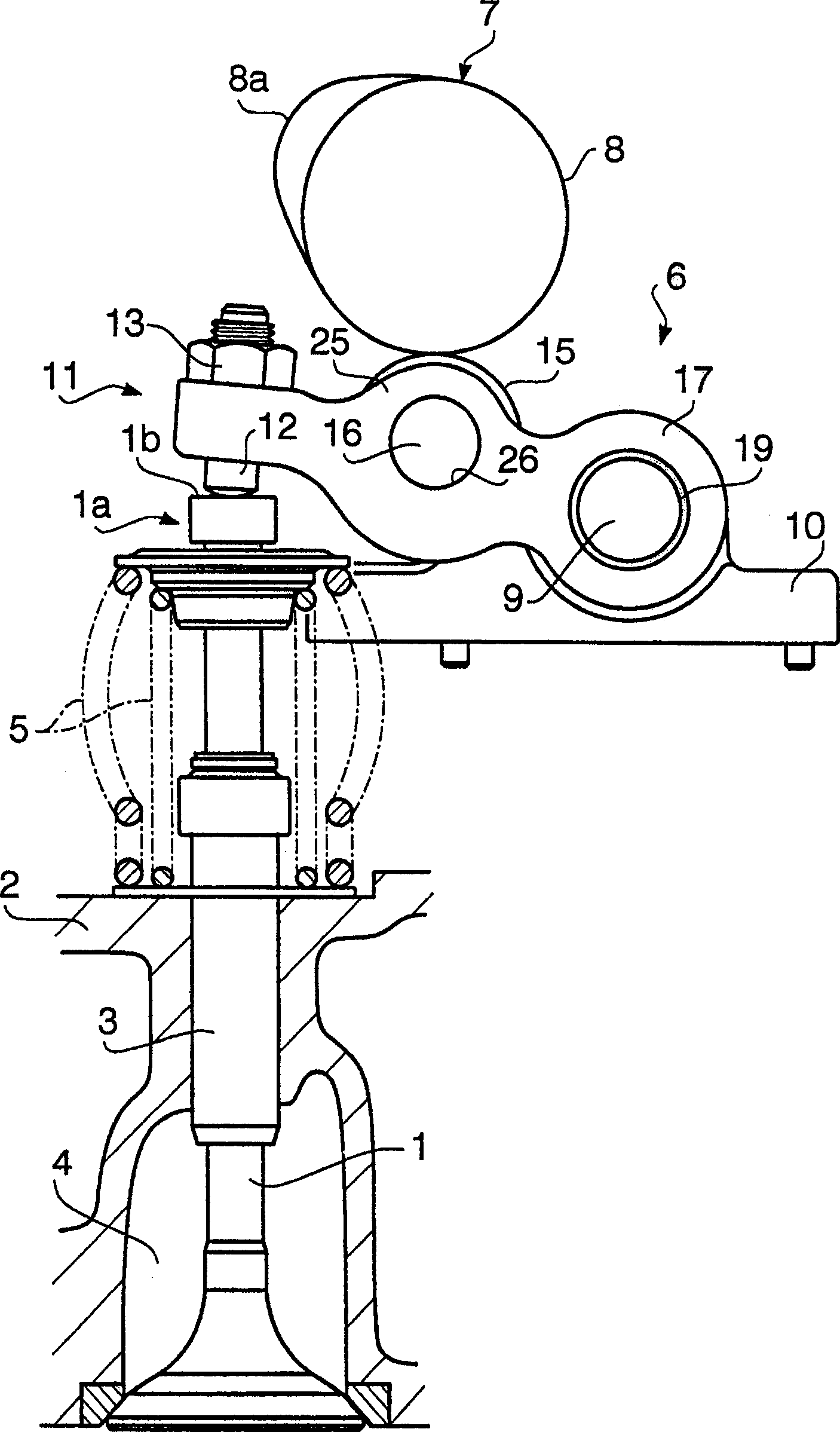

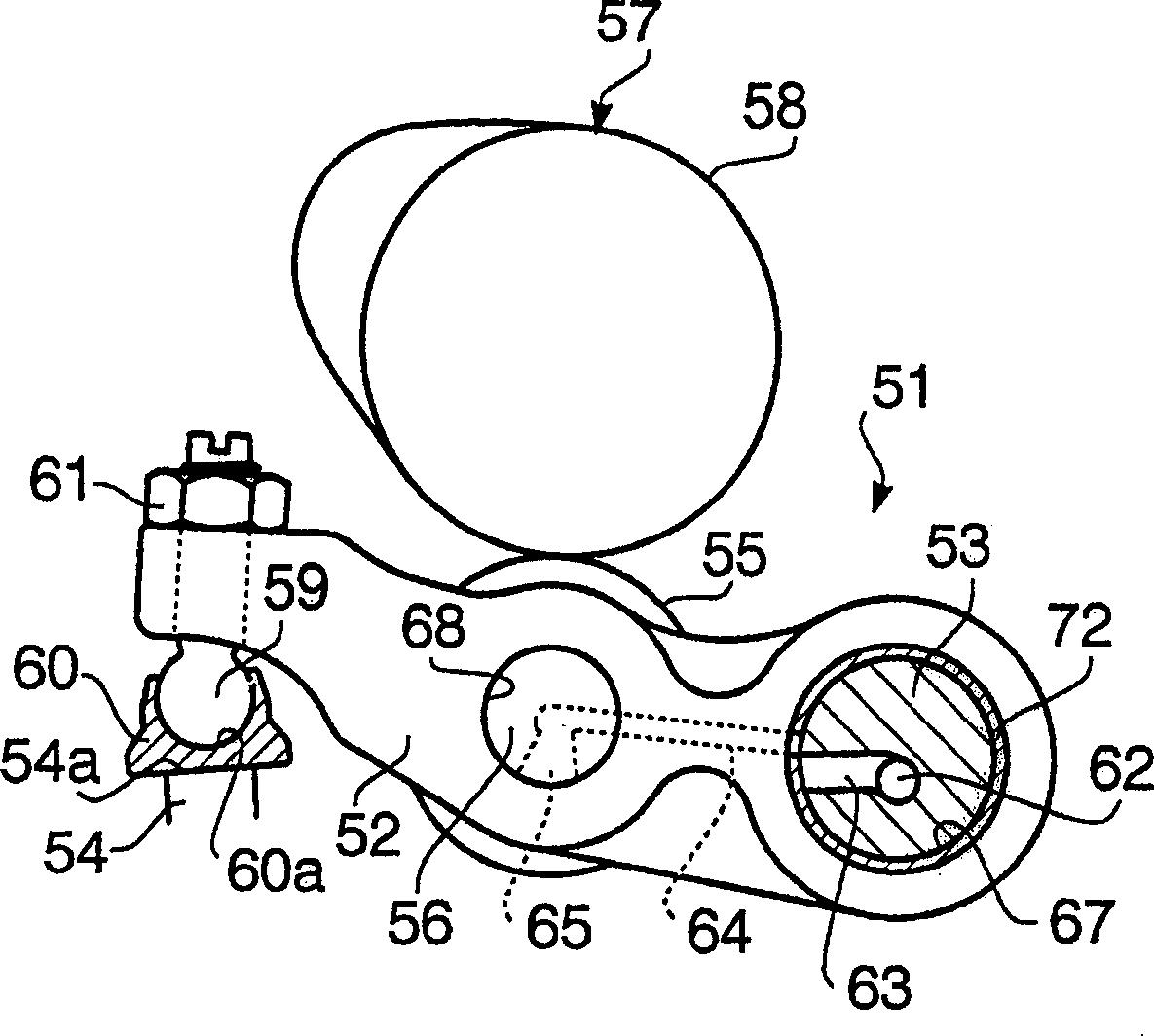

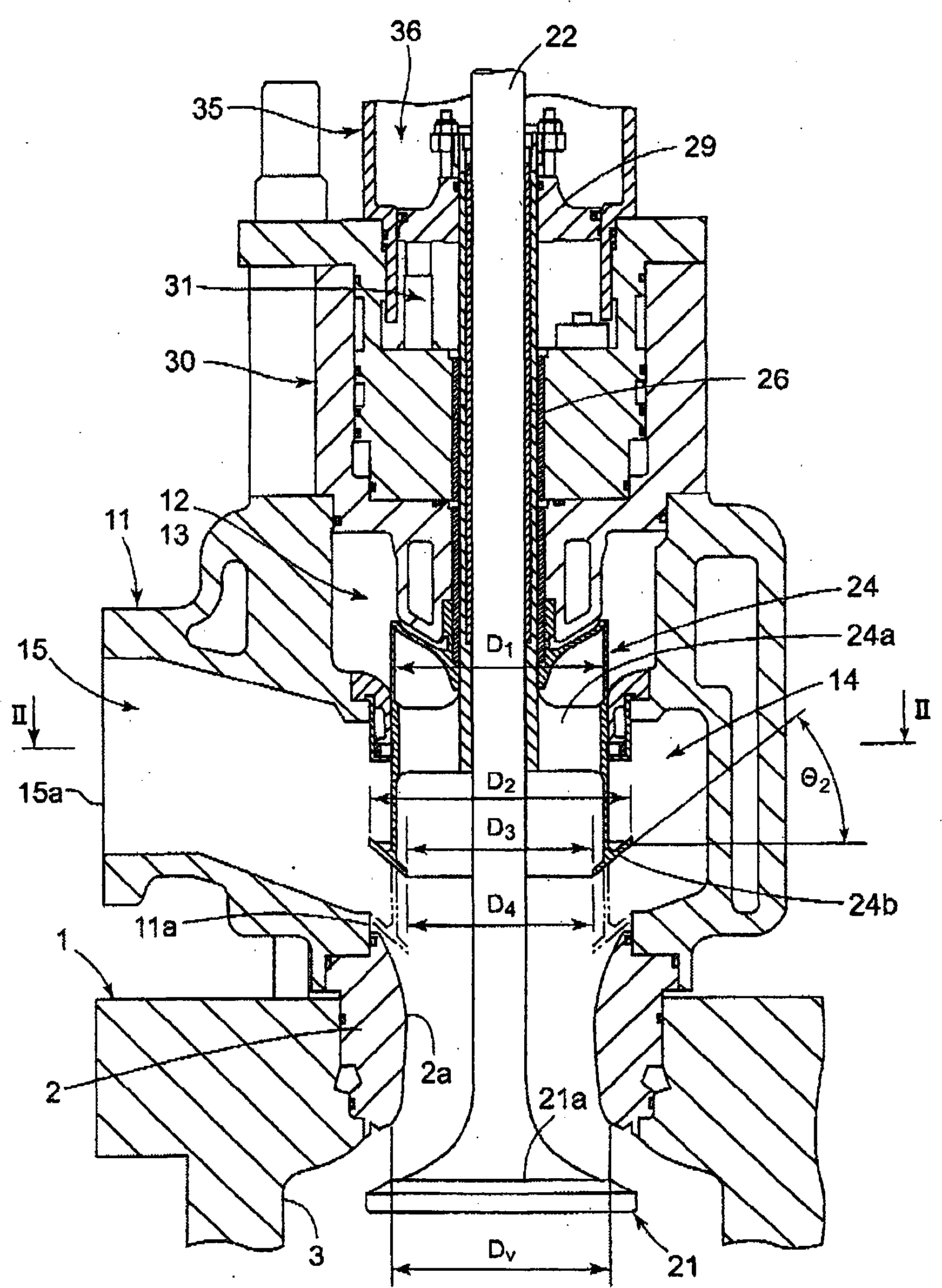

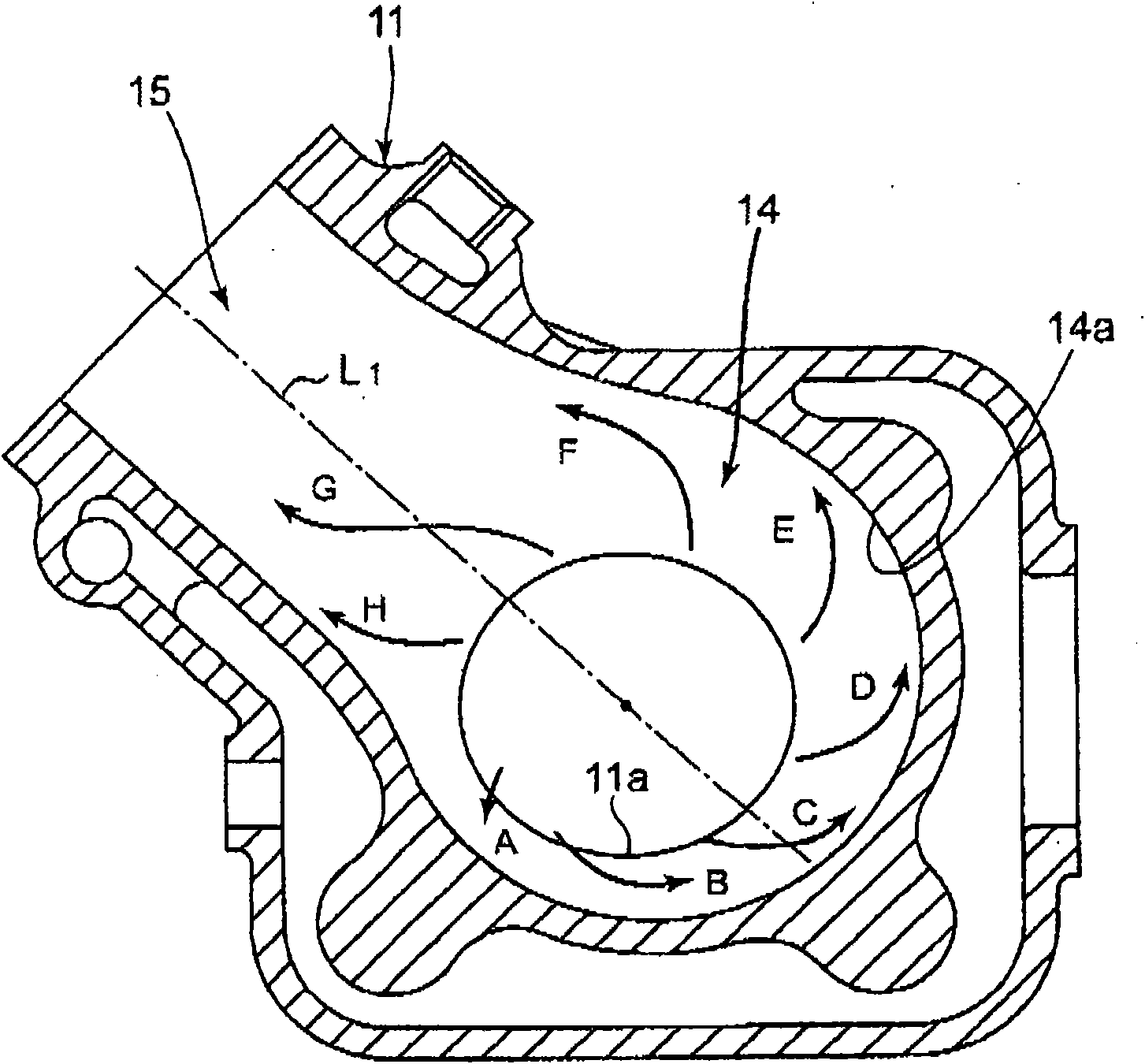

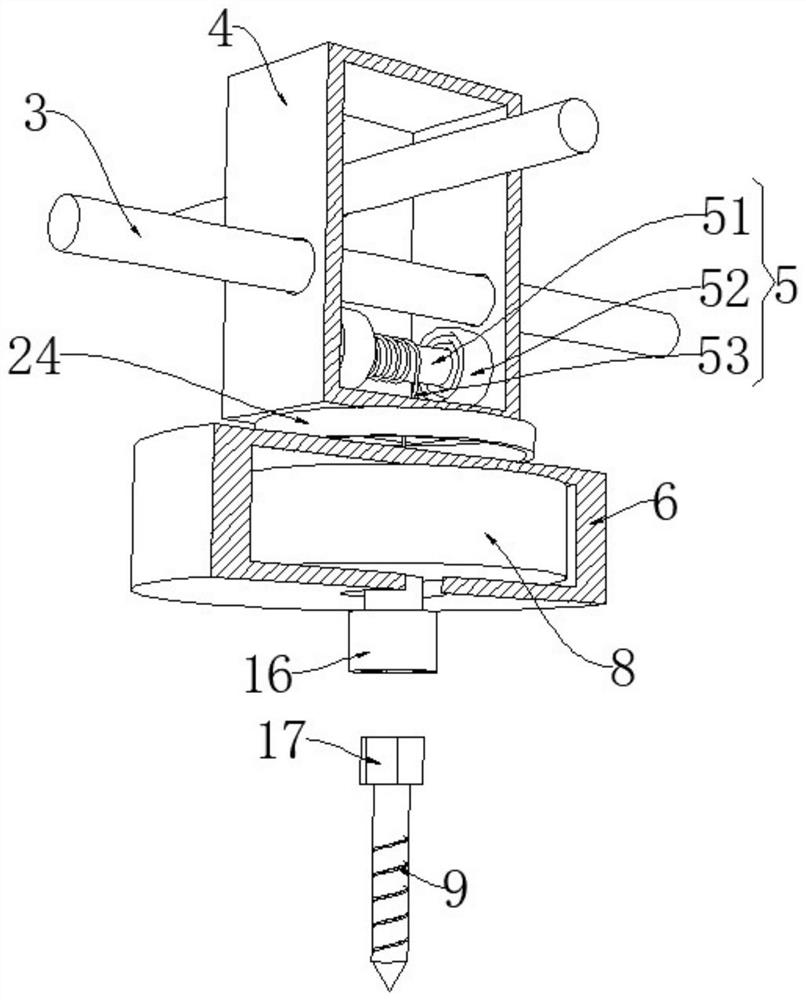

Rocker arm of IC engine

InactiveCN1386960AEliminates problems with poor lubricationEasy drillingValve arrangementsLubrication of auxillariesEngineeringCam

The invention relates to a rocker arm for an internal combustion engine, which prevents abnormal wear of friction surfaces around the rocker arm and prevents poor lubrication when the engine is started at low temperature after a long-term shutdown, thereby improving reliability. A bag-shaped oil storage tank (24) opening upwards is arranged at the middle part of the rocker arm main body (17). A roller (15) and a roller pin (16) are arranged in the oil storage tank (24), and when the engine is stopped, they are immersed in lubricating oil in the oil storage tank (24). With the engine stopped, lubricate the area between the roller (15) and the roller pin (16). In addition, when the engine is restarted after a long-term shutdown, the area between the roller (15) and the cam (8) is lubricated with the lubricating oil adhered to the roller (25) until the lubricating oil rises. When the rocker arm (6) swings downward, lubricating oil in the oil storage tank (24) is supplied from the lubricating oil discharge passage (28) by spraying toward the shaft end of the valve.

Owner:ISUZU MOTORS LTD

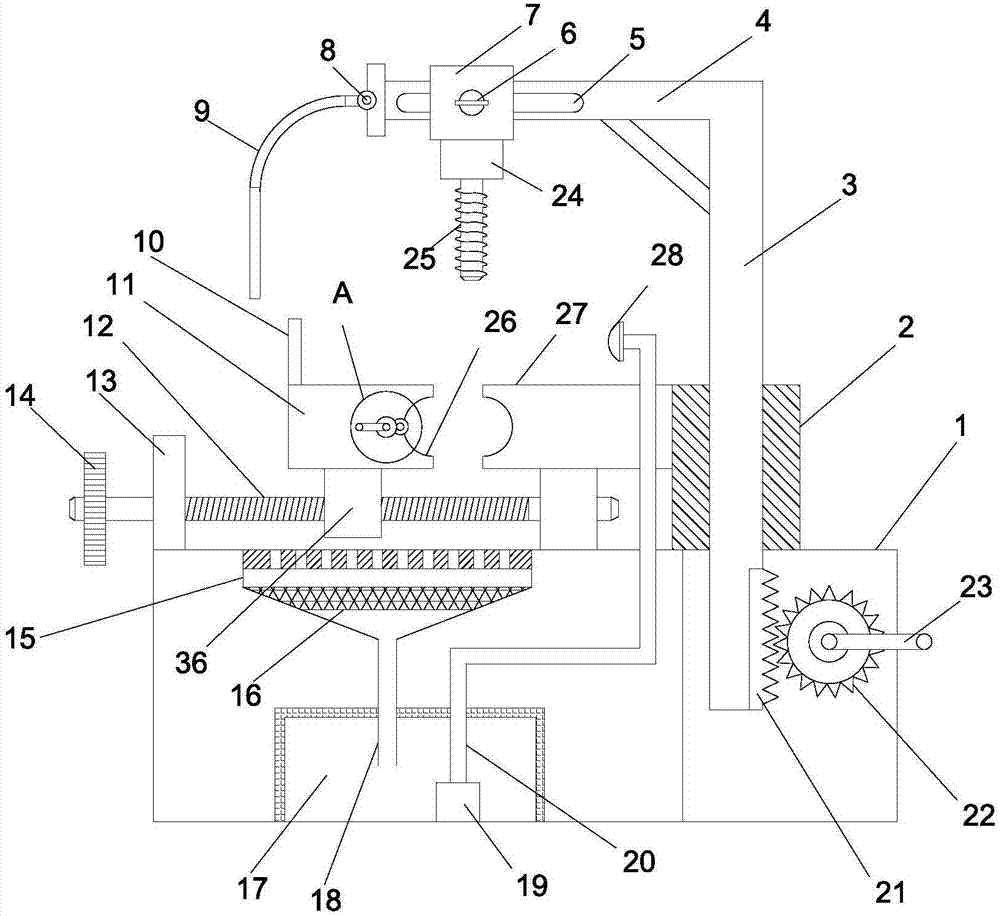

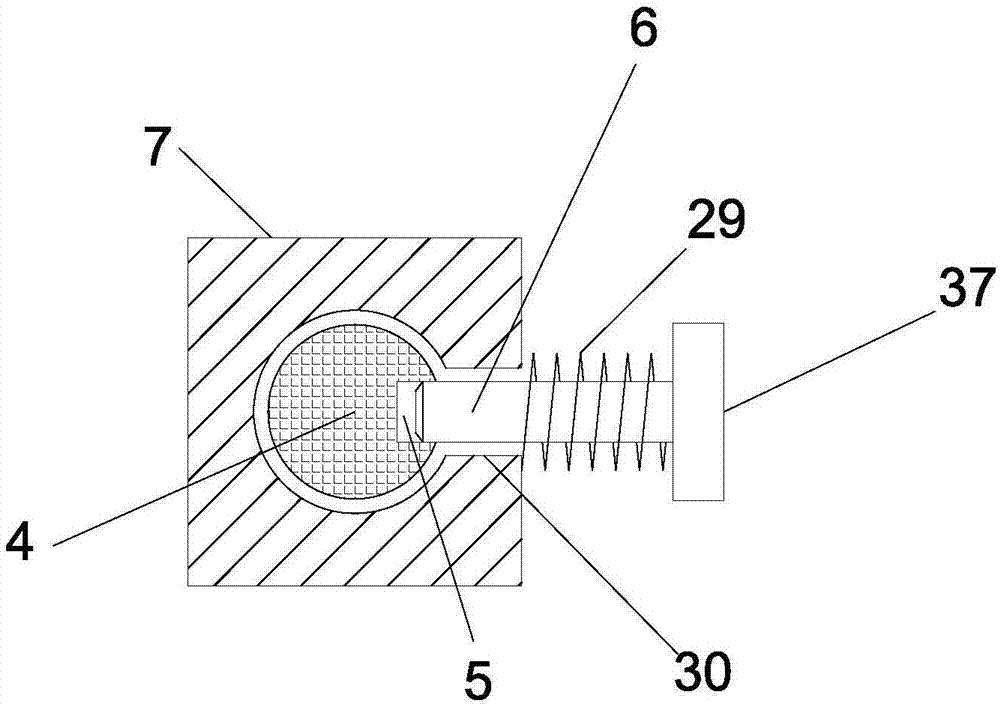

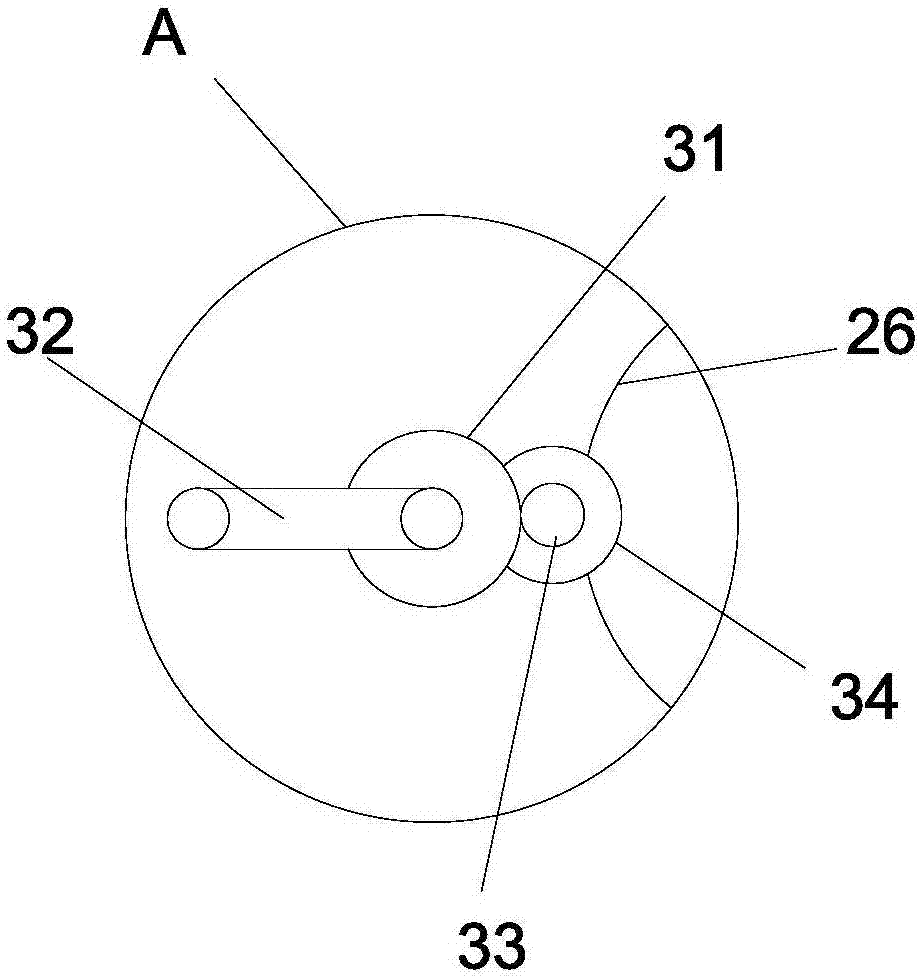

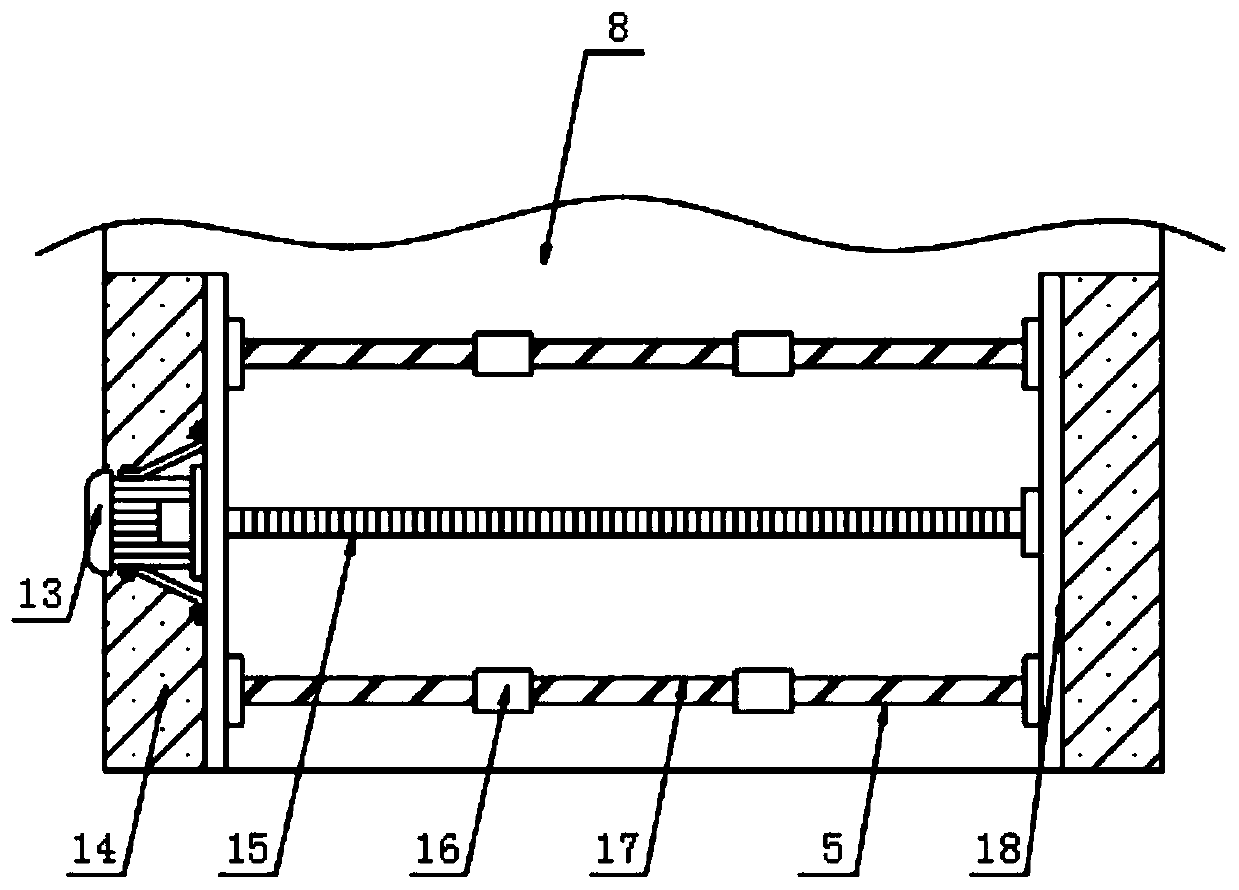

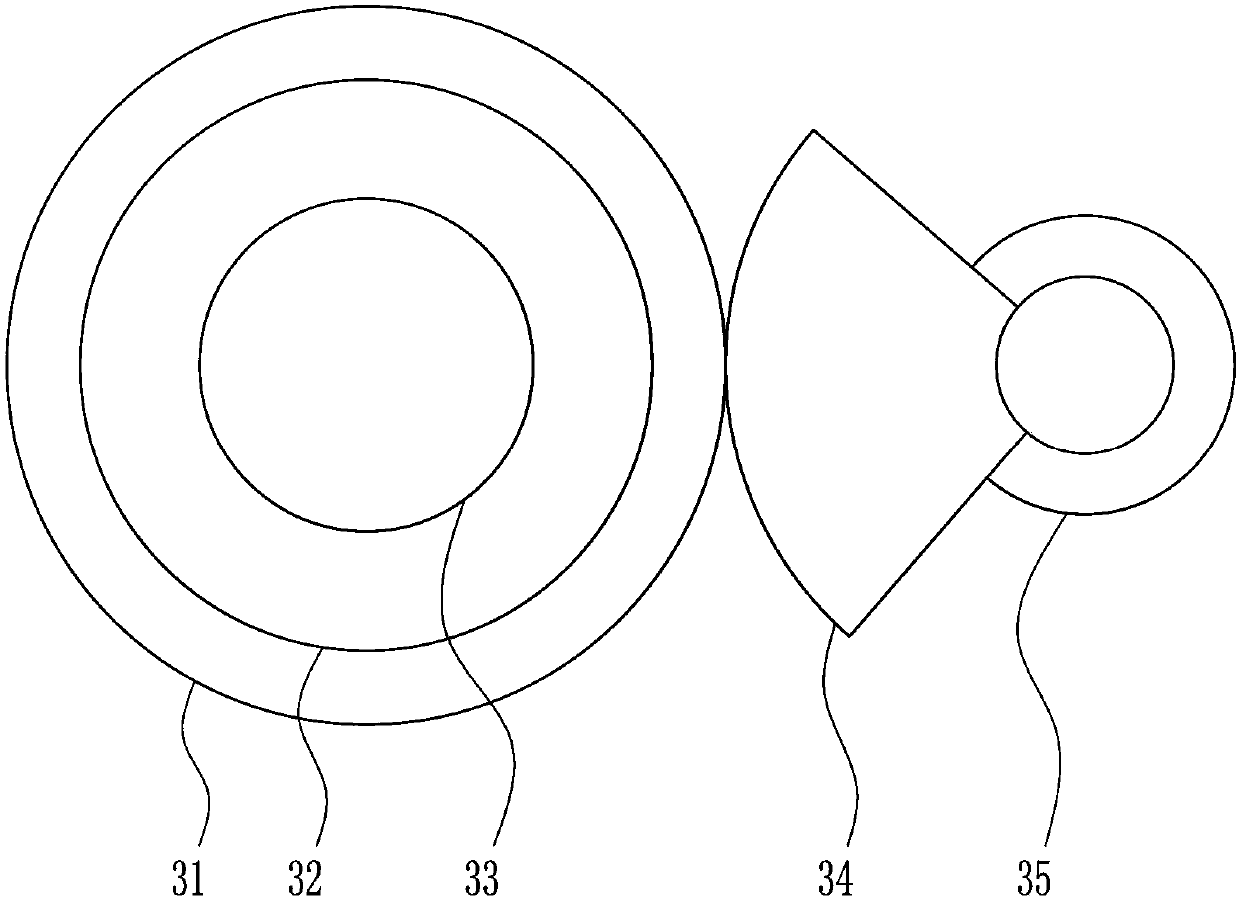

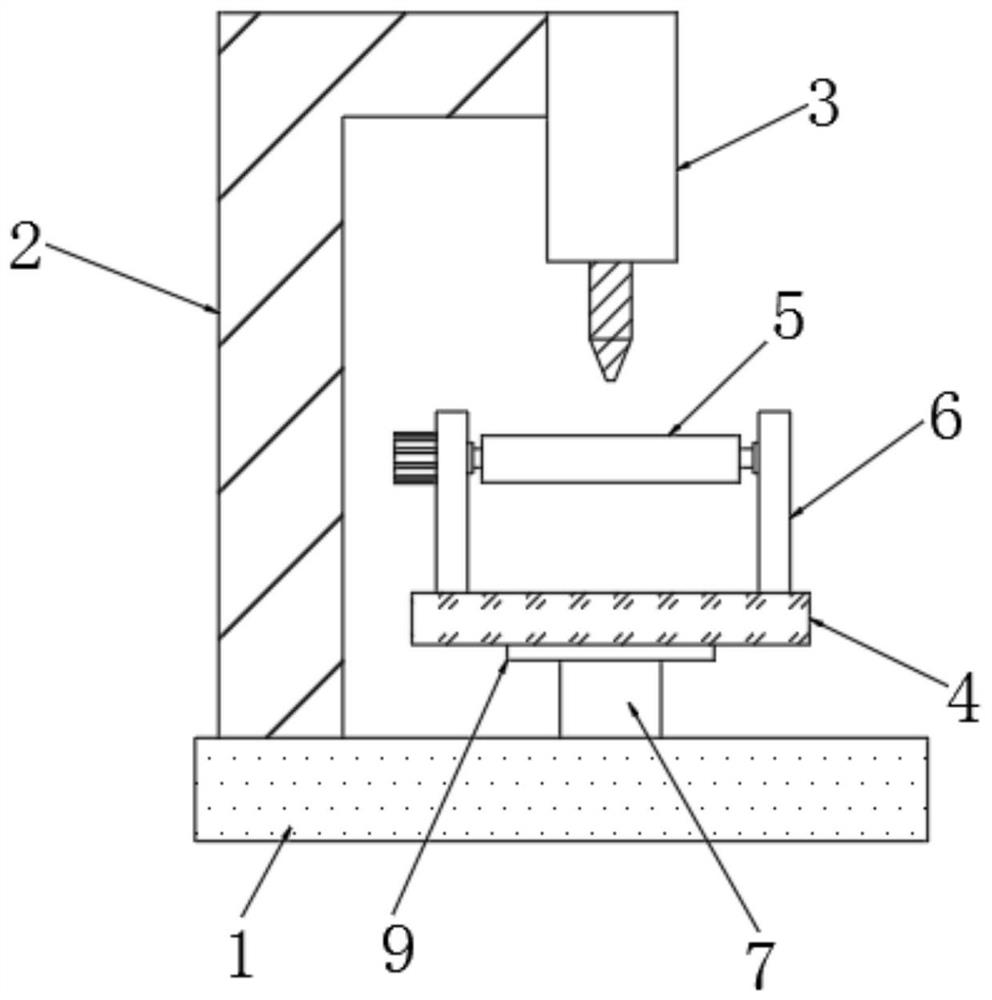

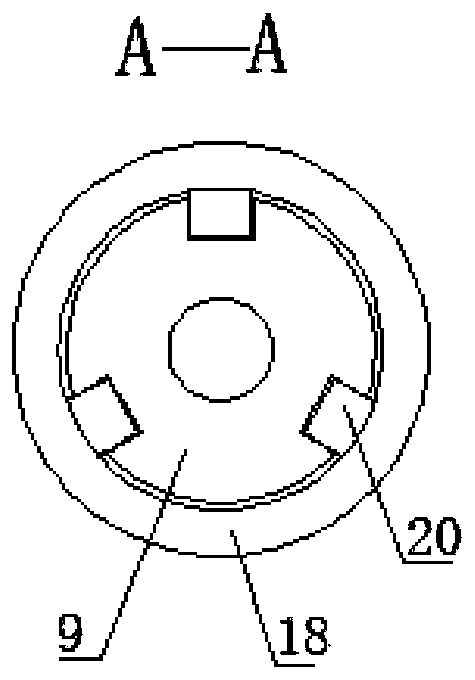

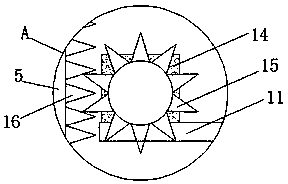

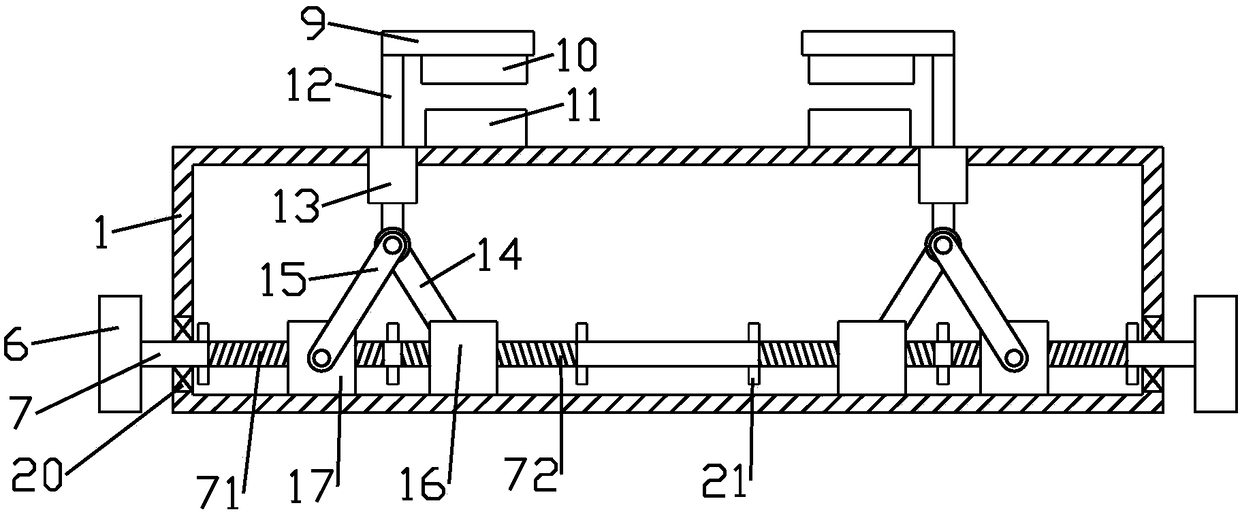

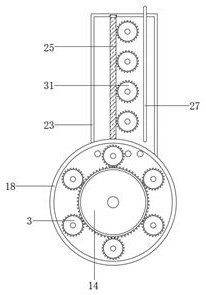

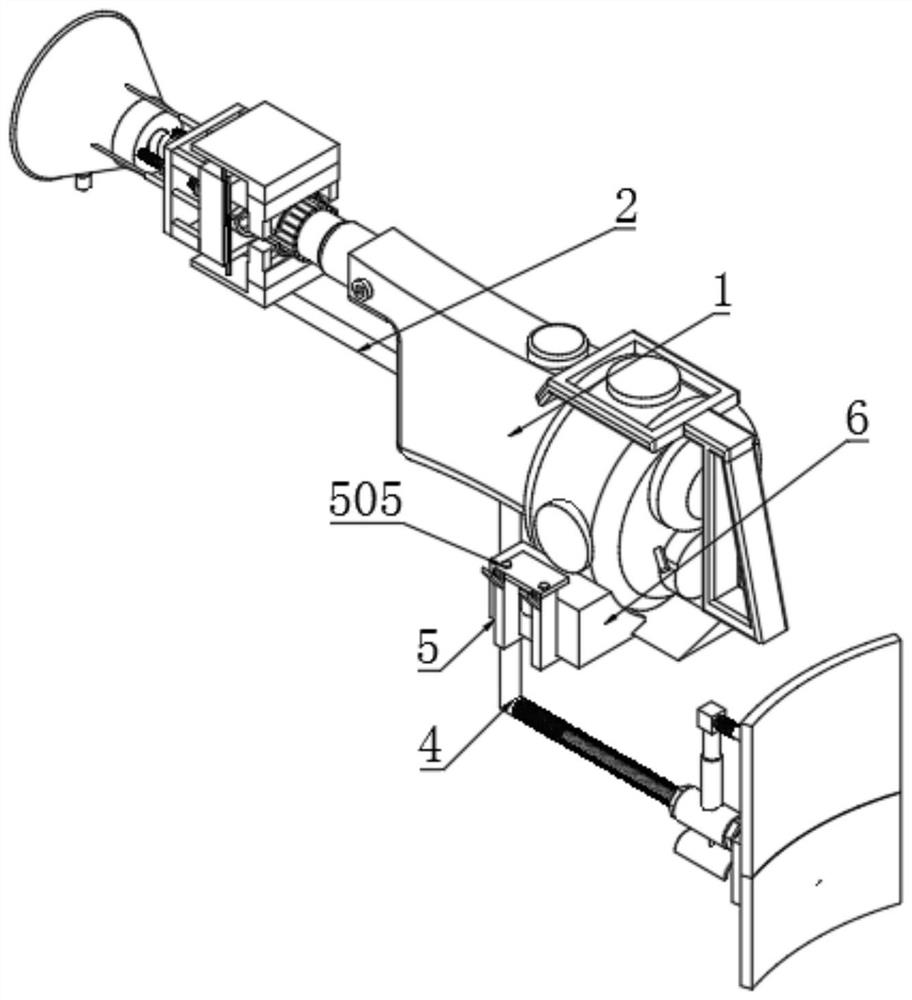

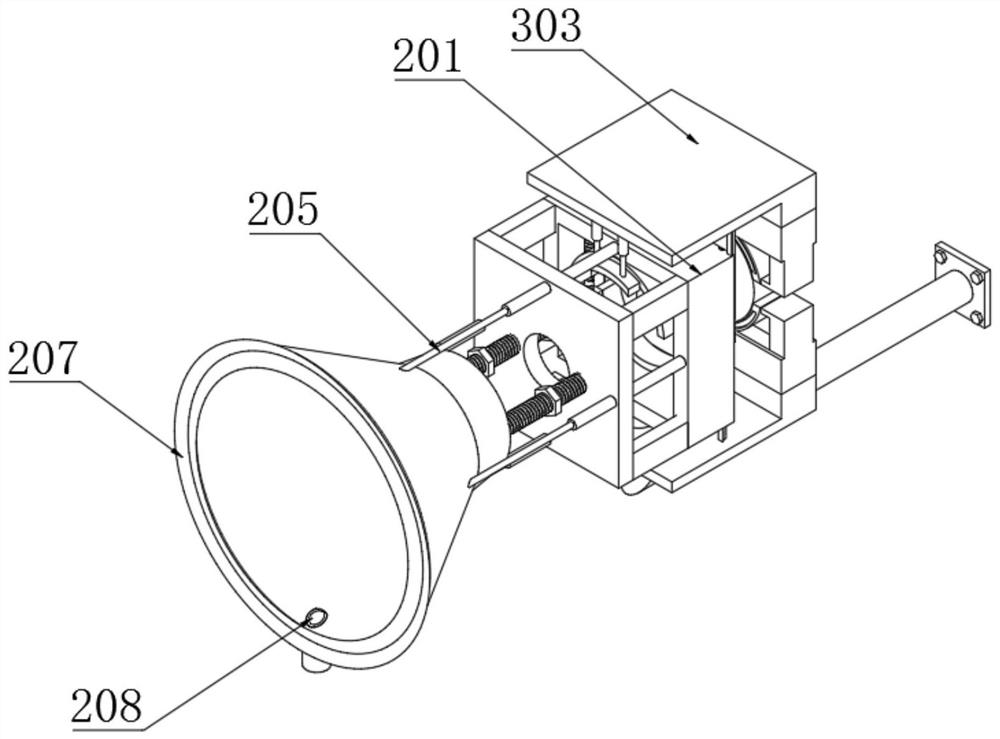

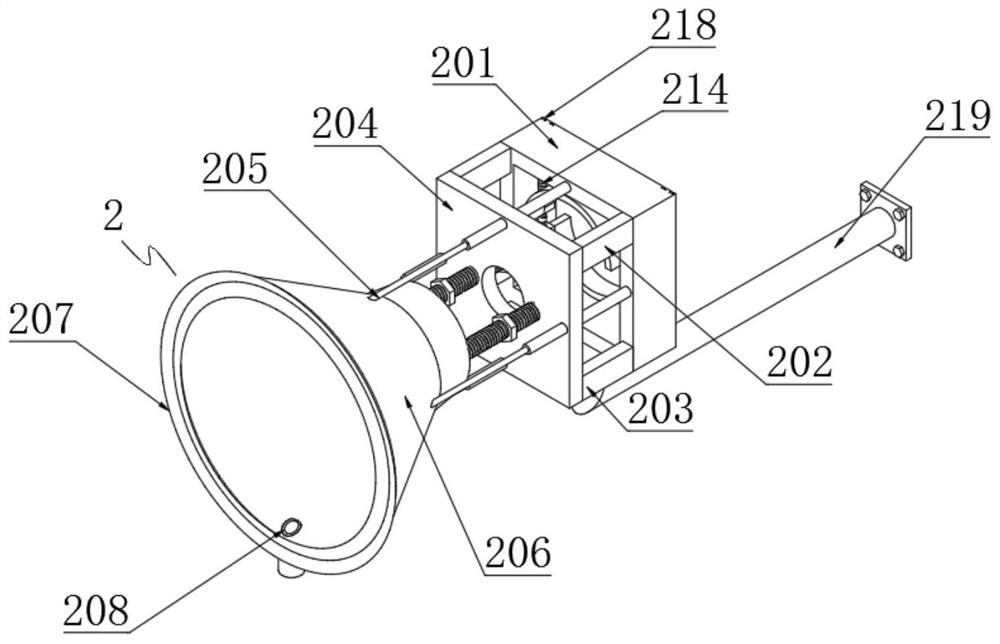

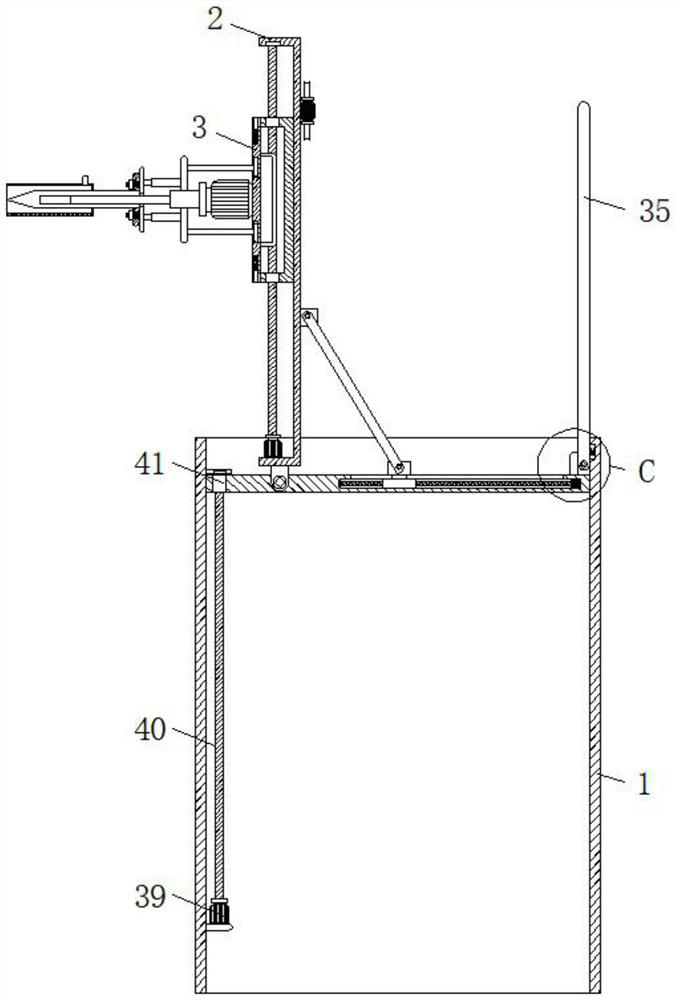

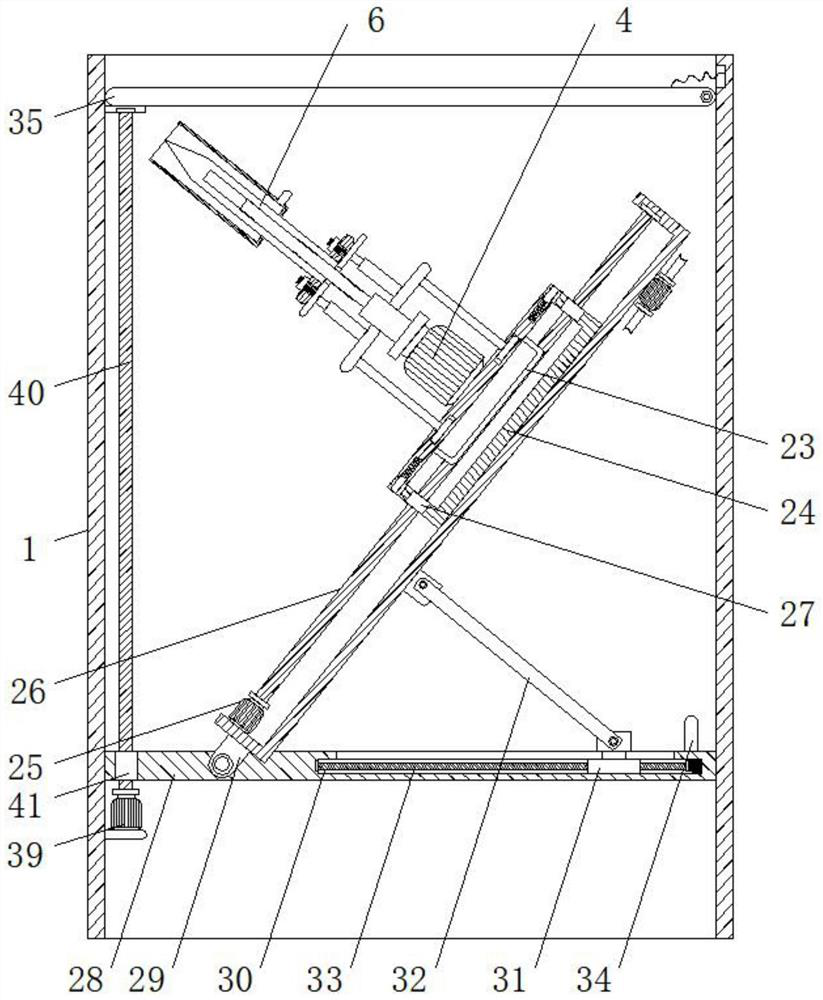

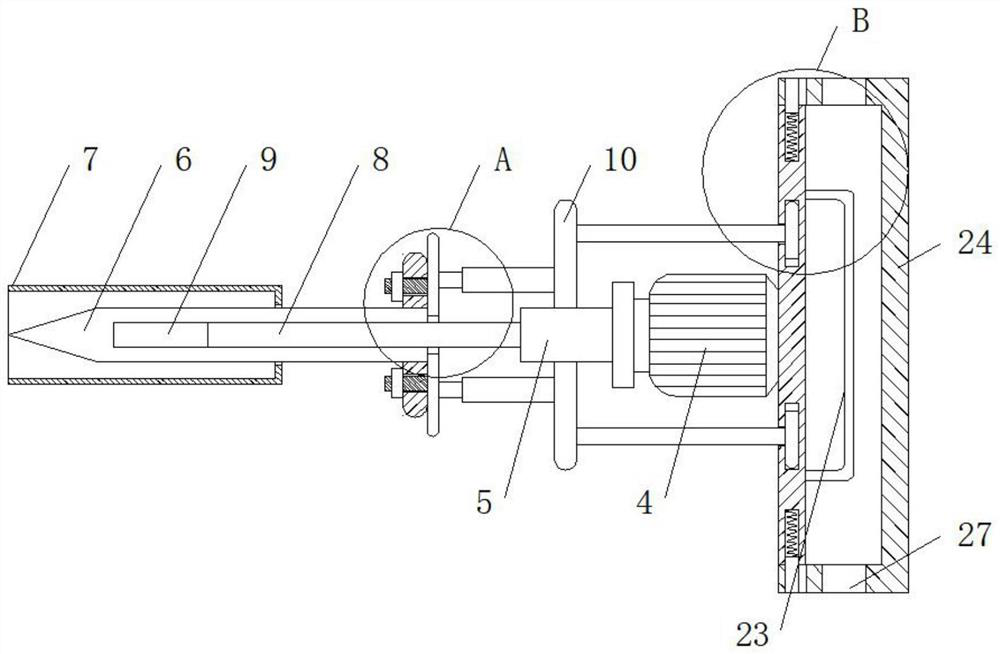

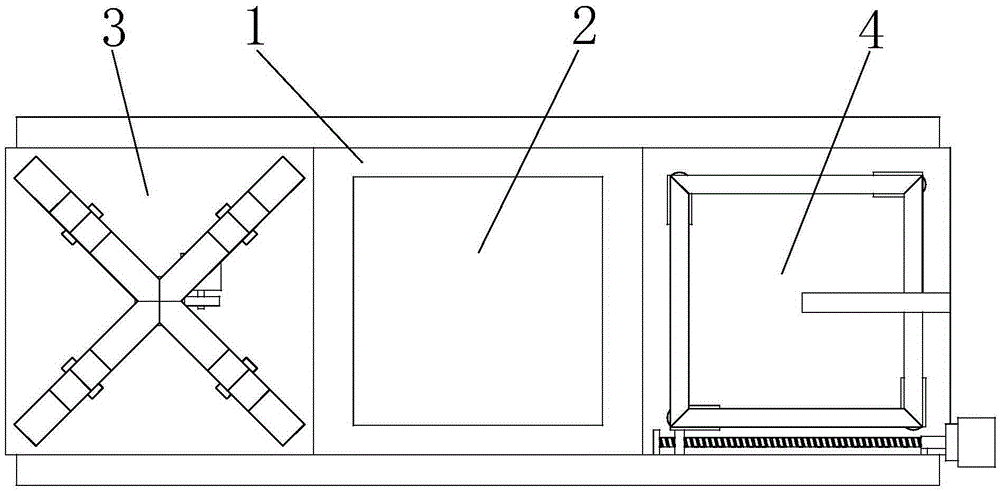

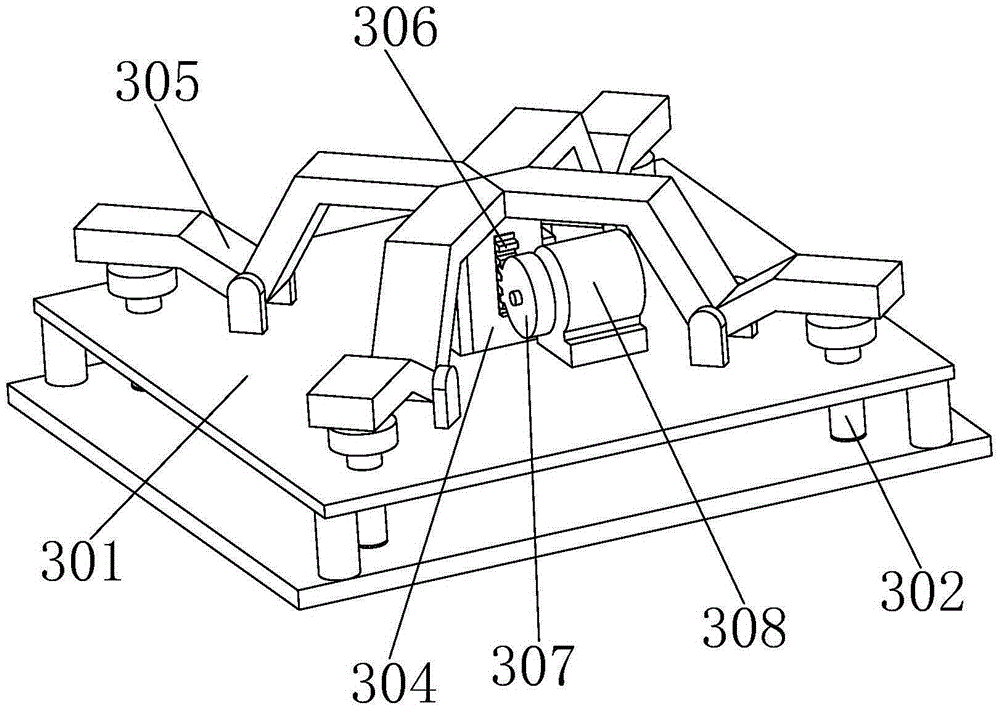

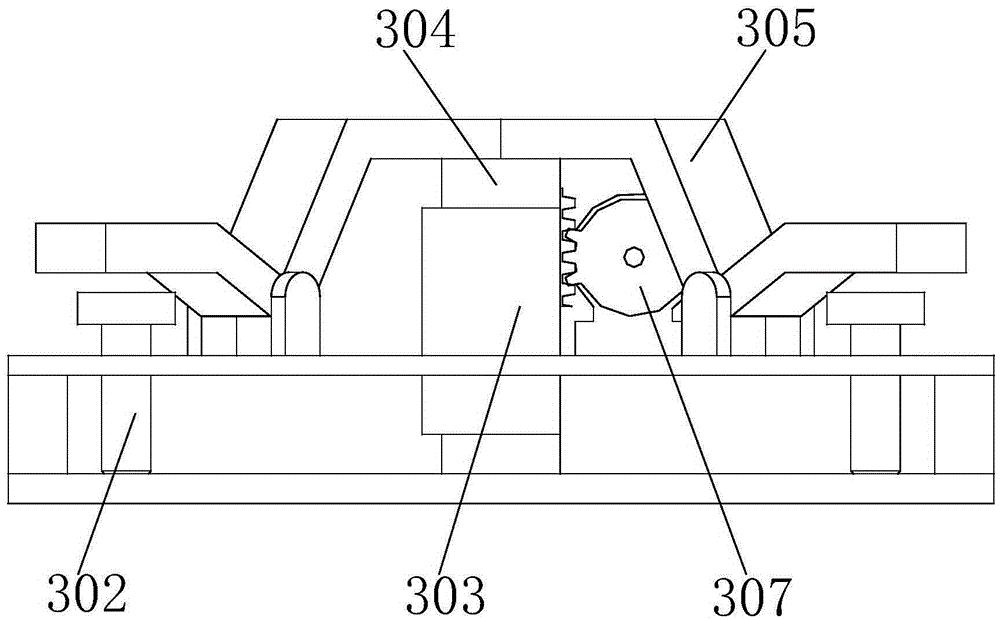

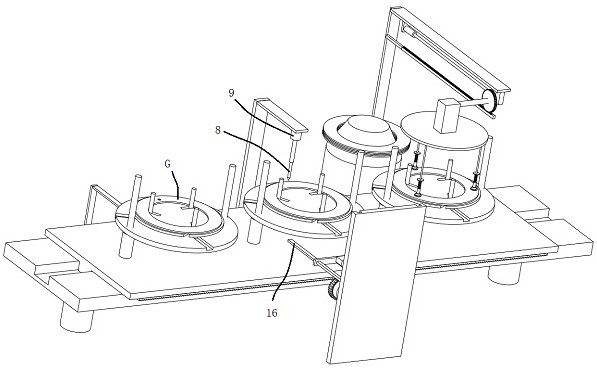

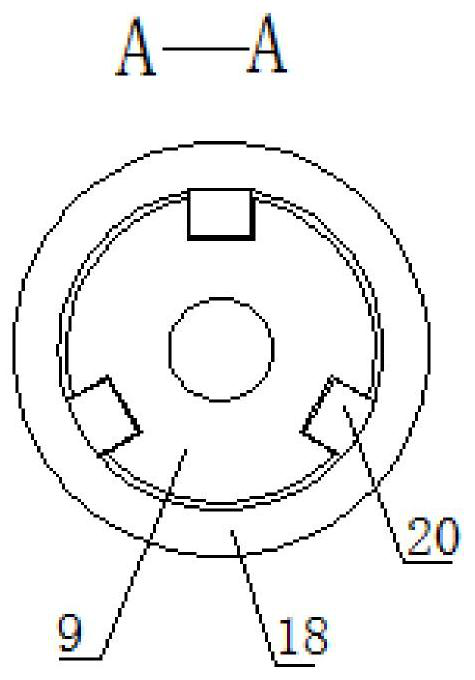

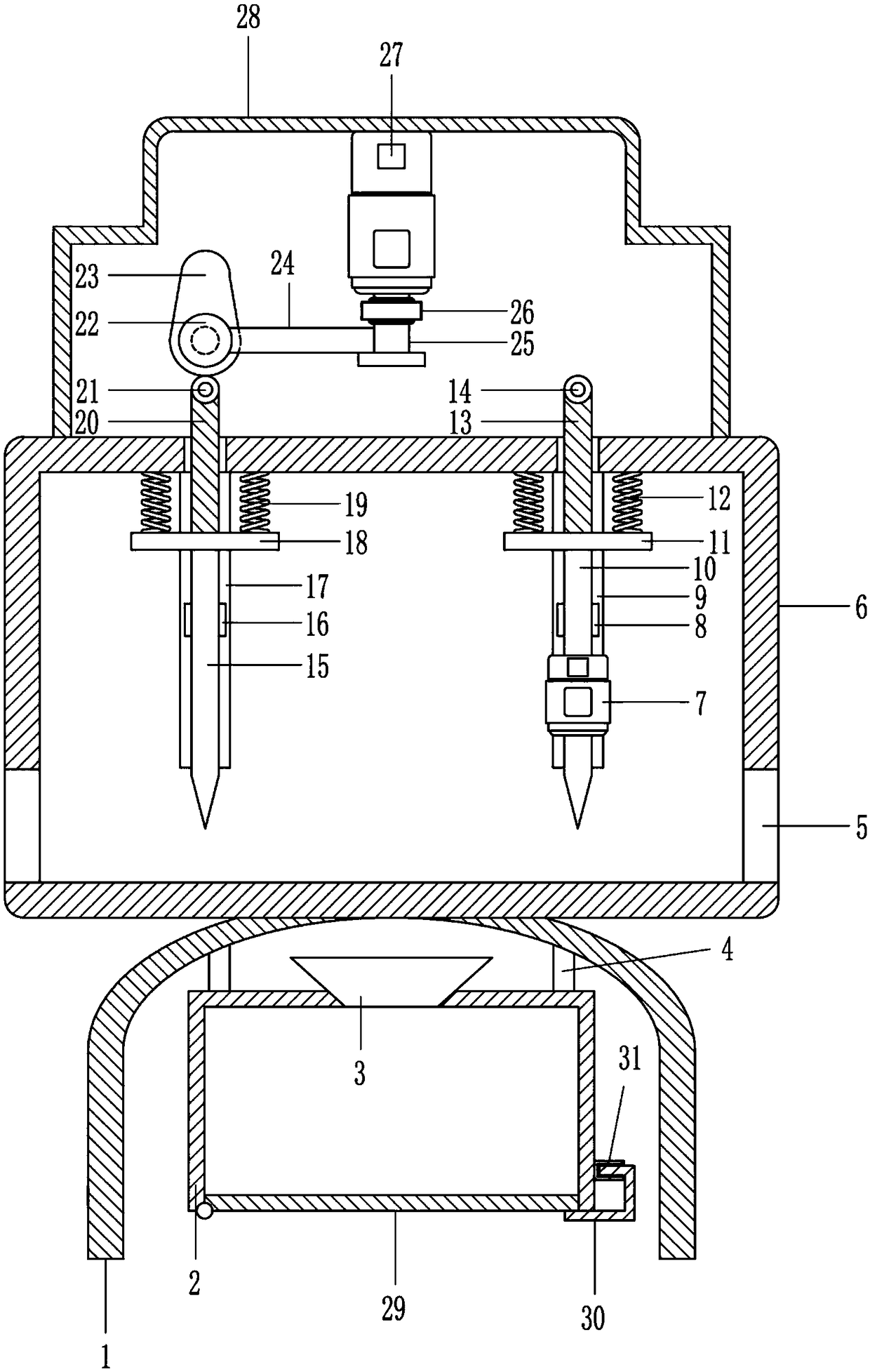

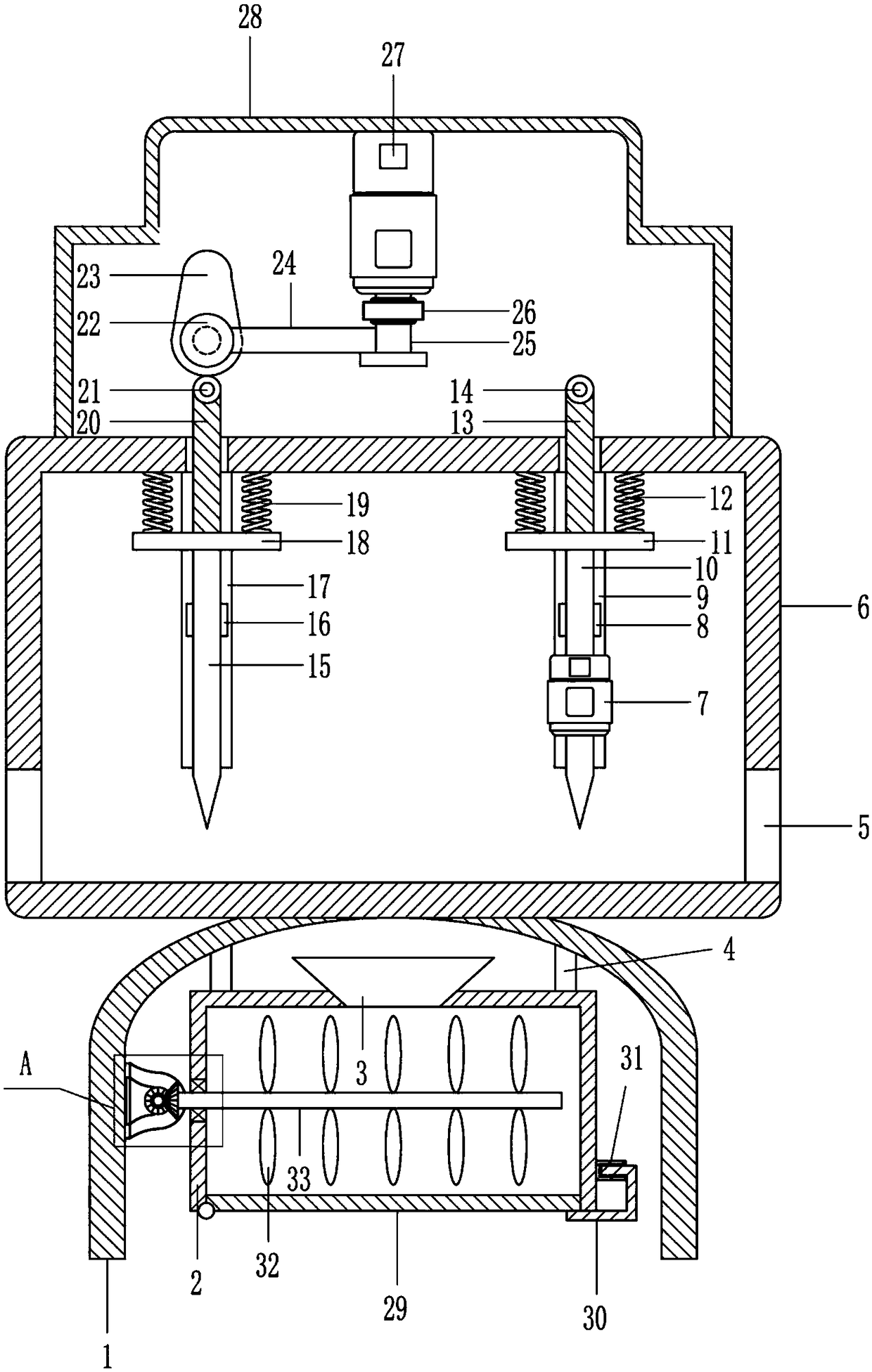

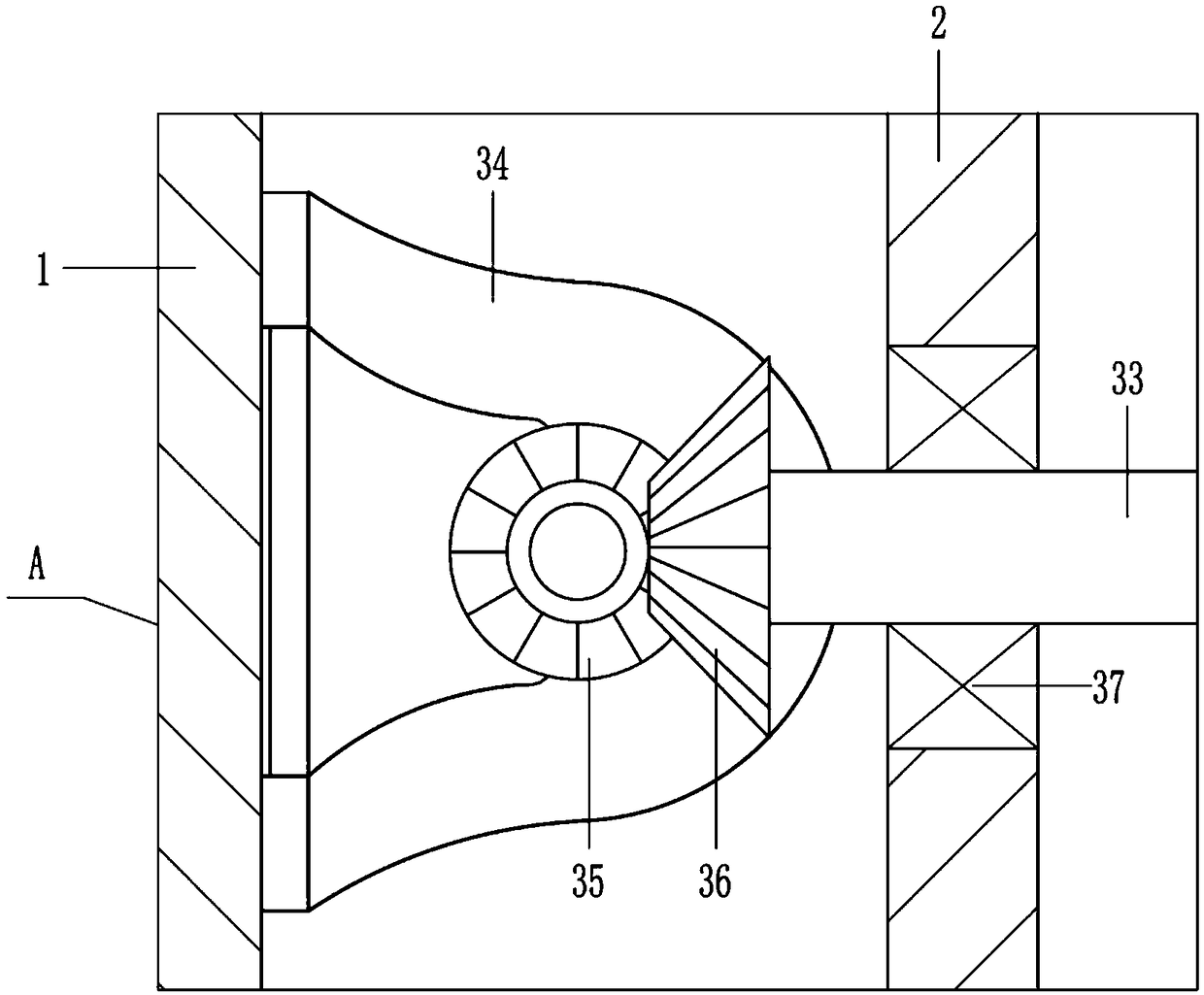

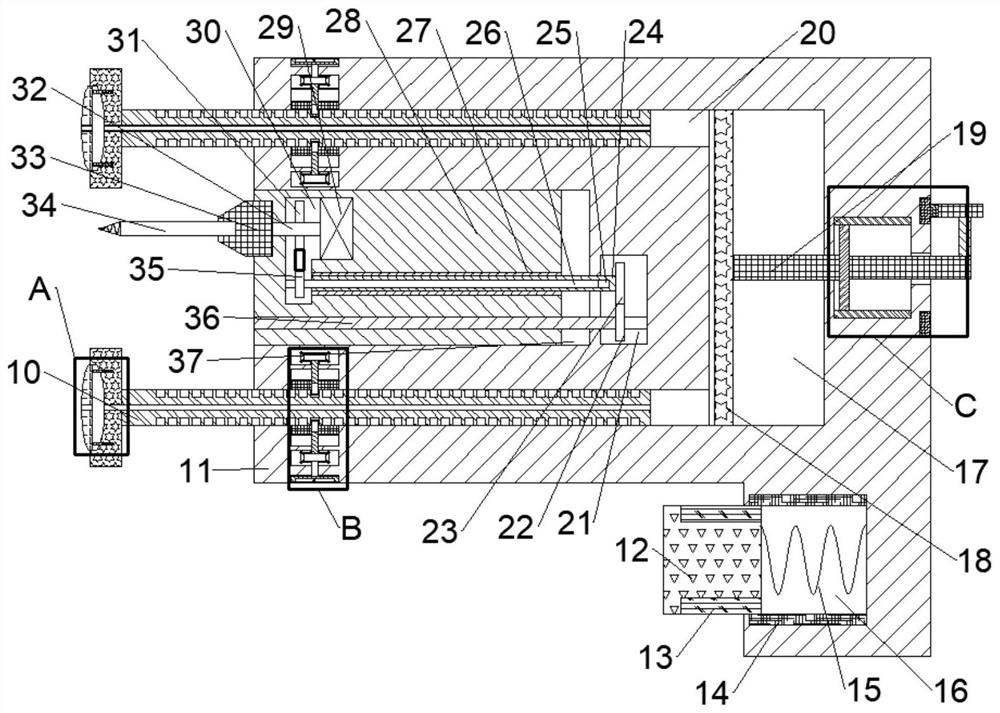

Drilling device for water pump impeller machining

InactiveCN107552828AEasy drillingGuaranteed hole symmetryPositioning apparatusMetal-working holdersImpellerEngineering

The invention relates to a drilling device, in particular to a drilling device for processing water pump impellers. The technical problem to be solved by the present invention is to provide a drilling device for processing water pump impellers. In order to solve the above-mentioned technical problems, the present invention provides such a drilling device for water pump impeller processing, including brackets, etc.; There is a fixed shaft, the periphery of the fixed shaft is provided with a rubber pad, the top right side of the base is connected with a bracket, the inner top of the bracket is provided with a drilling mechanism, the drilling mechanism is set on the upper right side of the placement frame, and the bottom right side of the placement frame is opened. first via. The invention achieves the effects of high safety and high working efficiency. The first drill bit and the second drill bit rotate together to ensure the symmetry of the drilled hole and improve the working efficiency at the same time. The process is more stable and the drilling is more precise.

Owner:杜海燕

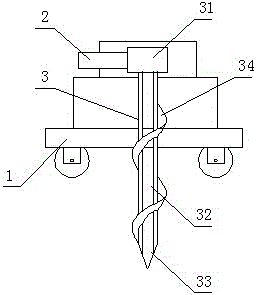

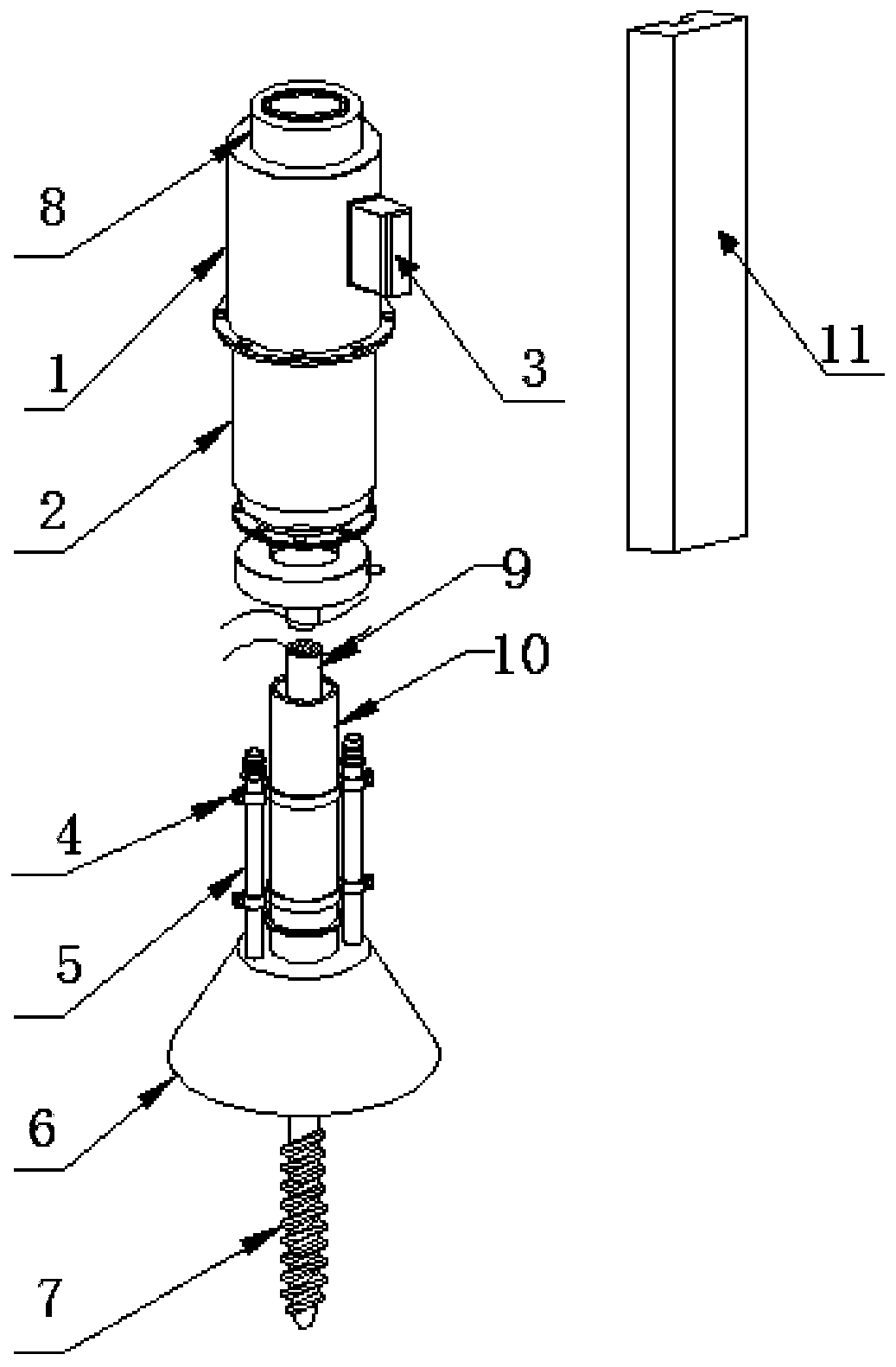

Chinese yam harvesting machine

The invention discloses a Chinese yam harvesting machine which comprises a movable rack, a transmission mechanism and a drilling mechanism. The transmission mechanism and the drilling mechanism are arranged on the movable rack. The drilling mechanism is formed by connecting a rotating head, a hollow drill rod and a hollow drill bit in a sleeving mode. The rotating head is connected with the transmission mechanism in a drive mode. The upper end of the hollow drill rod is connected with the rotating head in a clamping mode, and the lower end of the hollow drill rod is connected with the hollow drill bit in a clamping mode. The hollow drill rod is provided with a plurality of segments which are vertically connected with each other in a sleeving mode. A spiral wing is arranged on the outer side of each segment of the drill rod. According to the Chinese yam harvesting machine, multi-segment combination is adopted for the hollow drill rod, Chinese yam in different depths can be dug, and the land can be dug easily and operation is easy and convenient to conduct in the use process.

Owner:融安县辉煌农产品种养专业合作社

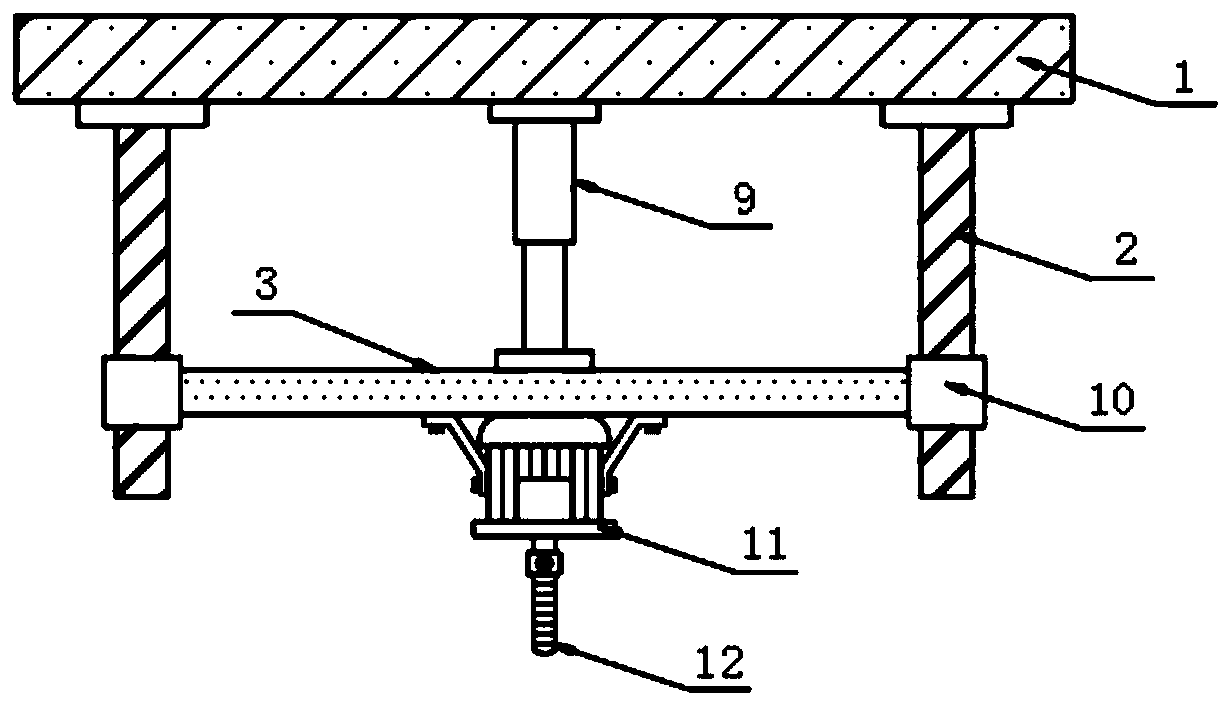

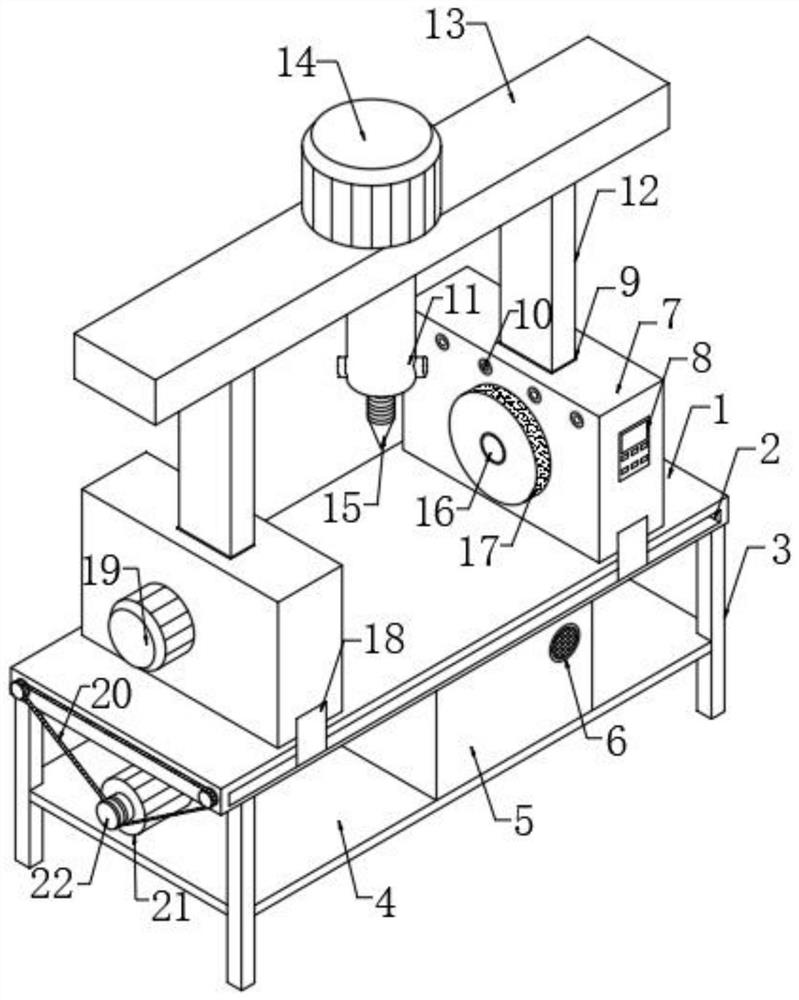

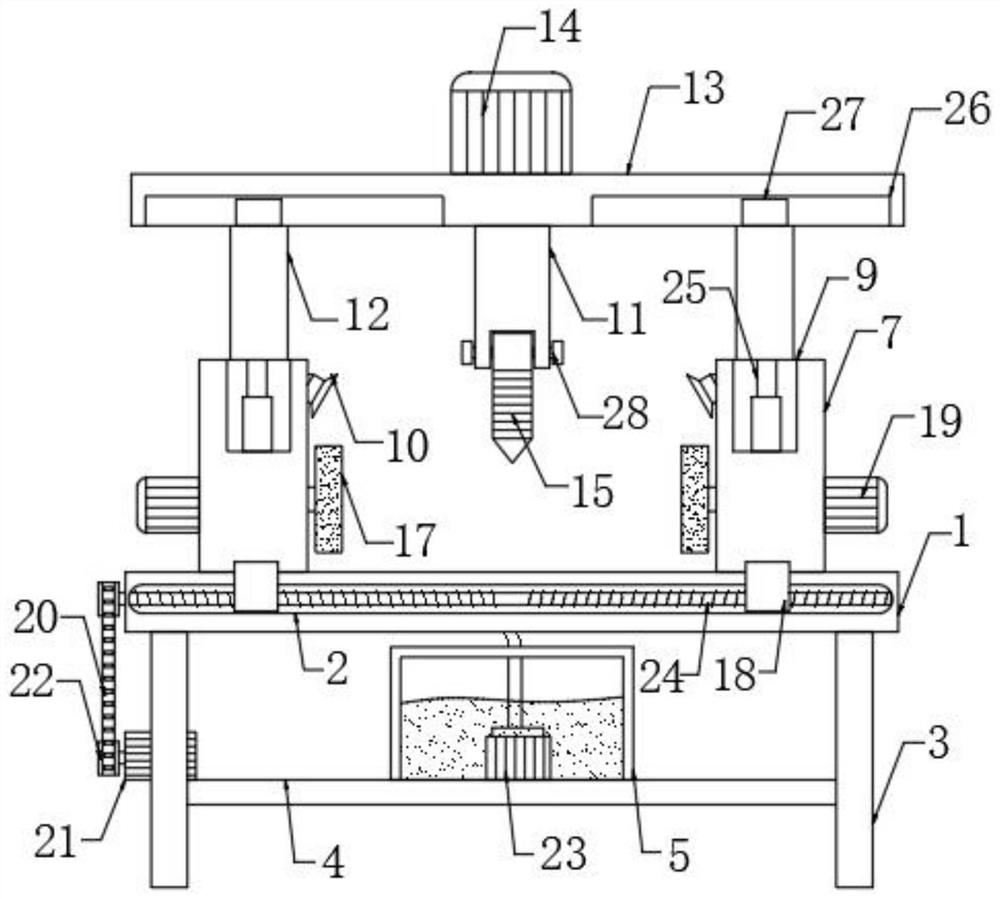

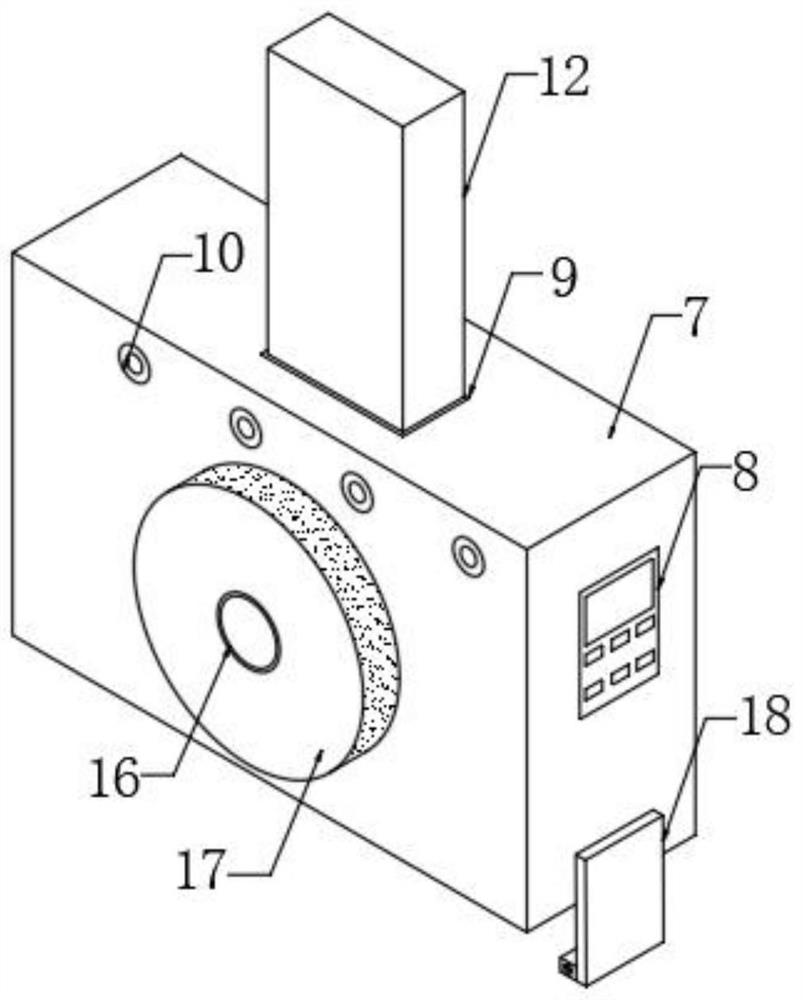

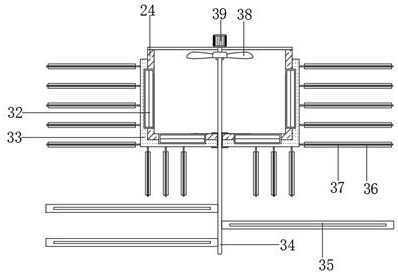

Multifunctional machining table for hardware machining

PendingCN112775771AEasy drillingEasy to grindGrinding drivesFeeding apparatusElectro hydraulicDrill hole

The invention discloses a multifunctional machining table for hardware machining. The multifunctional machining table comprises a machining table body, grooves are formed in the two sides of the machining table body, lead screws are connected to the groove walls of the two sides of each groove in a penetrating and inserting mode through embedded bearings, two connecting blocks are connected to the surfaces of the two lead screws in a threaded mode, and a fixing block is fixedly arranged between the two connecting blocks aligned in position. Mounting grooves are formed in the top ends of the two fixing blocks correspondingly, electric hydraulic cylinders are fixedly mounted at the bottoms of the two mounting grooves correspondingly, and supporting rods are fixedly mounted at the telescopic ends of the two electric hydraulic cylinders correspondingly. The supporting rods are driven to ascend and descend through the mounted electric hydraulic cylinders, a sleeve is driven to ascend and descend through ascending and descending of the supporting rods, a drill bit is driven to ascend and descend through ascending and descending of the sleeve, a hardware workpiece is conveniently drilled through ascending and descending of the drill bit, and the hardware workpiece is conveniently polished through mounted grinding wheels; and during polishing treatment, water in a water tank is sprayed to a polishing portion through a water pump, so that sweeps generated during polishing are conveniently cleaned away.

Owner:张家港市瑞寅精密机械有限公司

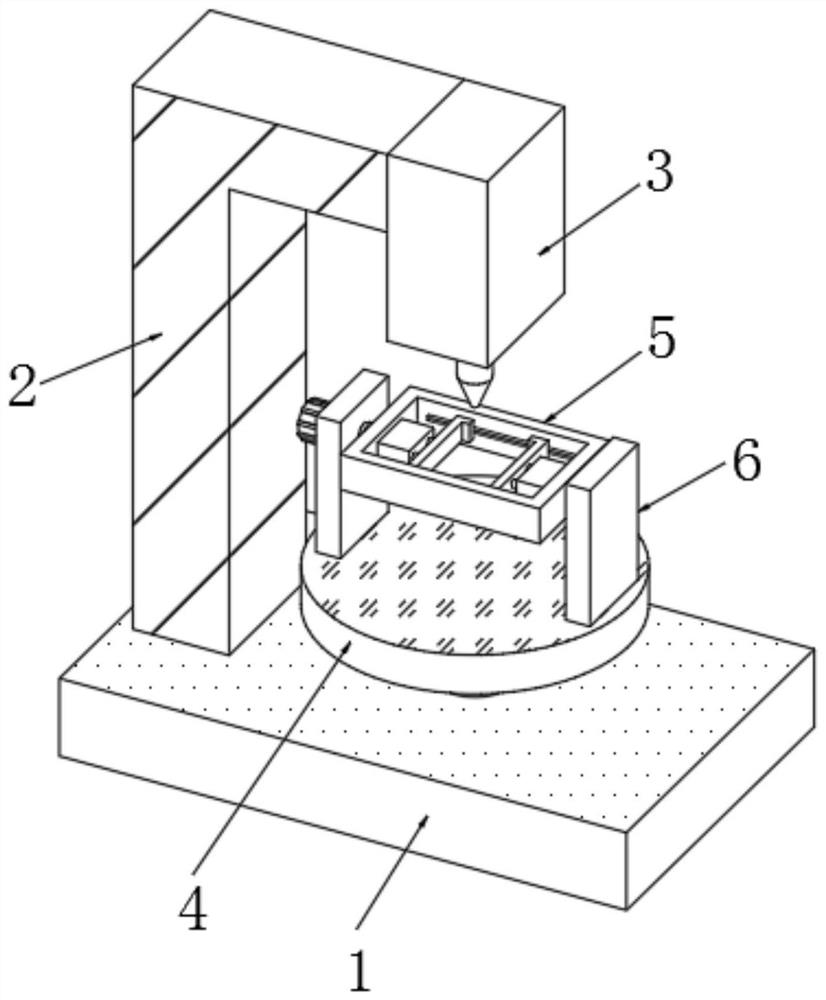

Drilling equipment for hydraulic valve part machining treatment

InactiveCN111872439APracticalImprove drilling accuracyWork clamping meansLarge fixed membersPhysicsDrill hole

The invention discloses drilling equipment for hydraulic valve part machining treatment, and relates to the technical field of hydraulic valve machining. The drilling equipment comprises a base, a rotary disc is arranged above the base, a fixing mechanism is arranged above the rotary disc, a turnover mechanism is arranged at the outer side of the fixing mechanism, and the turnover mechanism is used for driving the fixing mechanism to turn over. The drilling equipment for hydraulic valve part machining treatment is reasonable in structure and easy to operate, through the arranged fixing mechanism, fixing work of hydraulic valve parts can be directly achieved, convenience is provided for drilling work of the drilling equipment, the fixing mechanism can be suitable for fixing treatment of parts of different sizes, the practicability is high, and the drilling precision is effectively improved; and through the arrangement of the turnover mechanism, rotation of the fixing mechanism can be achieved, so that turnover of two to-be-machined parts is achieved, through an arranged rotating mechanism, rotation of the rotary disc can be achieved, rotation of the machined parts is achieved, the automation degree of the parts is improved, and the safety of the device in the using process is guaranteed.

Owner:常德华俊机械设备制造有限公司

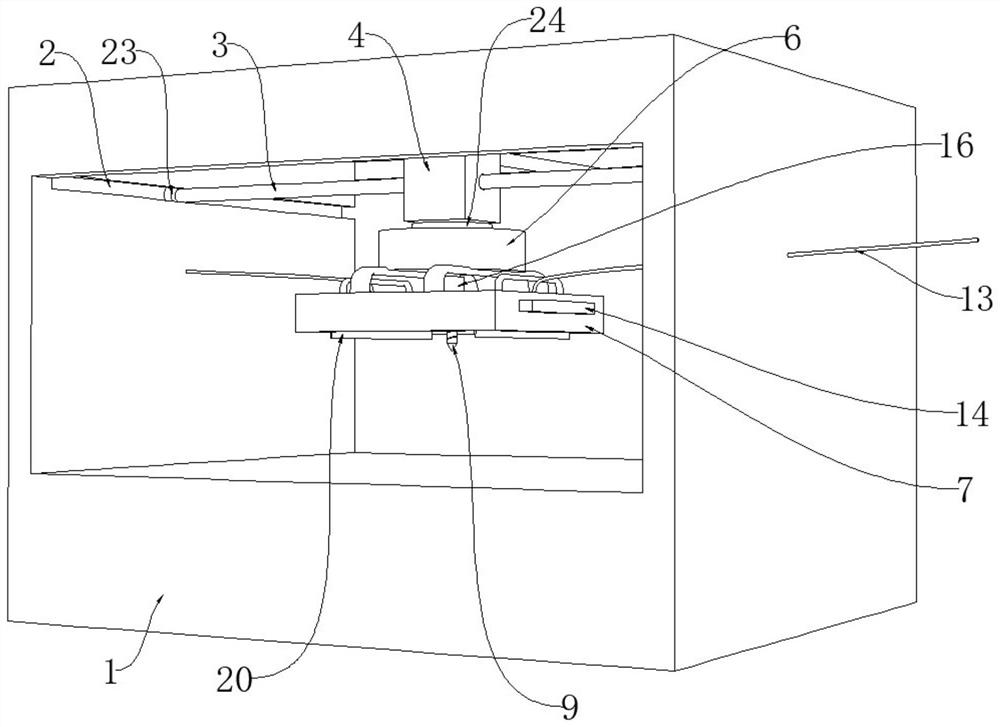

3D printing equipment machining device facilitating scrap removal

ActiveCN108162055AEasy to cleanIncrease productivityMetal working apparatusGear wheelElectric machinery

The invention discloses a 3D printing equipment machining device facilitating scrap removal. The 3D printing equipment machining device comprises a bottom plate. The lower surface of the bottom plateand a machine body of a double-shaft motor are fixedly connected. First gears are fixedly connected to the surfaces of two output shafts of the double-shaft motor. The two first gears are engaged withtwo second gears through two chains correspondingly. The two chains are located in two through holes formed in the upper surface of the bottom plate. The two second gears are fixedly connected to thesurface of a first rotation shaft. According to the 3D printing equipment machining device facilitating scrap removal, through the arrangement of the double-shaft motor, the first gears, the second gears, the first rotation shaft, a bearing plate, a first motor, a thread column and a thread barrel, when scraps on the bearing plate need to be removed, work of the double-shaft motor can be controlled, the front side of the bearing plate can ascend, the scraps slide down from the bearing plate, the situation that the speed of drilling of components by workers is influenced can be avoided, and accordingly, the production efficiency of a 3D printer is improved.

Owner:神木市晨立科技有限公司

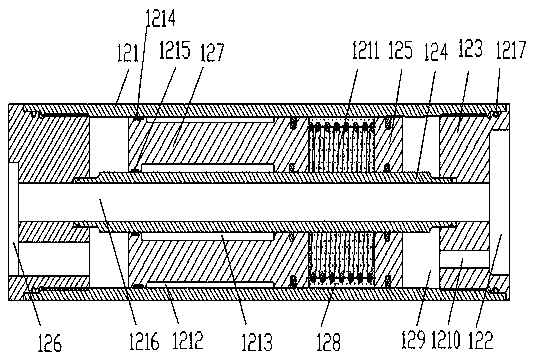

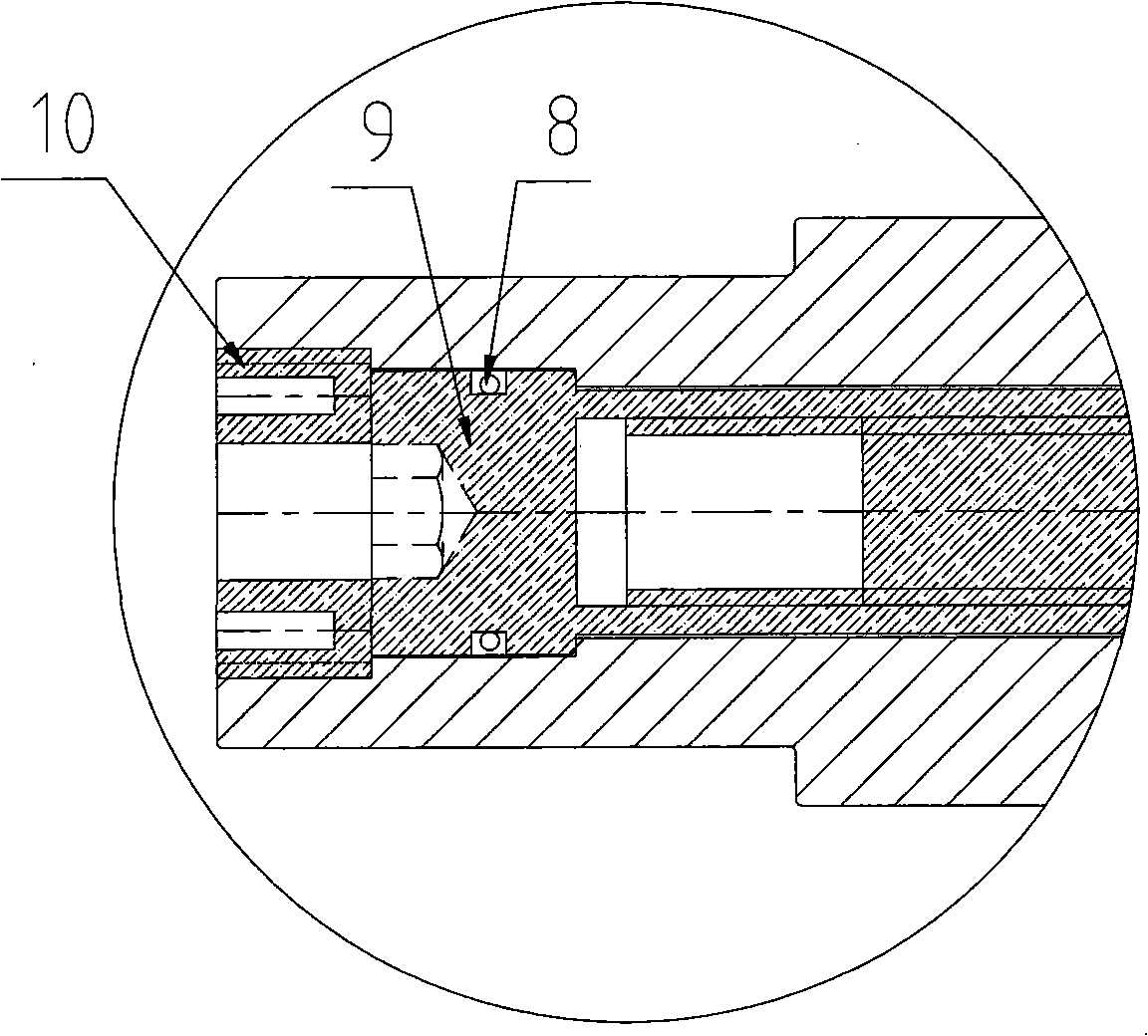

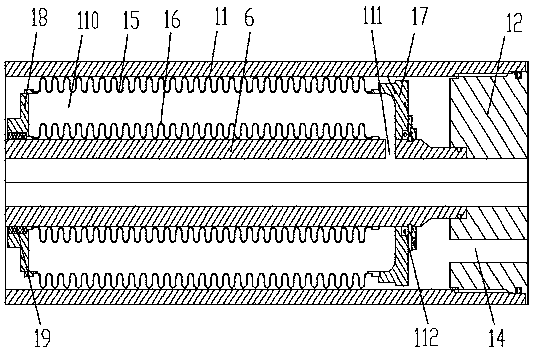

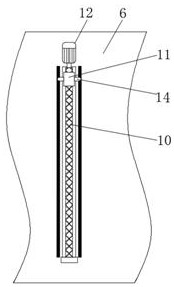

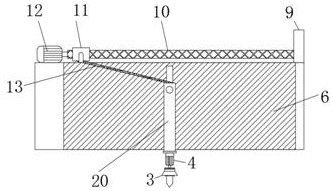

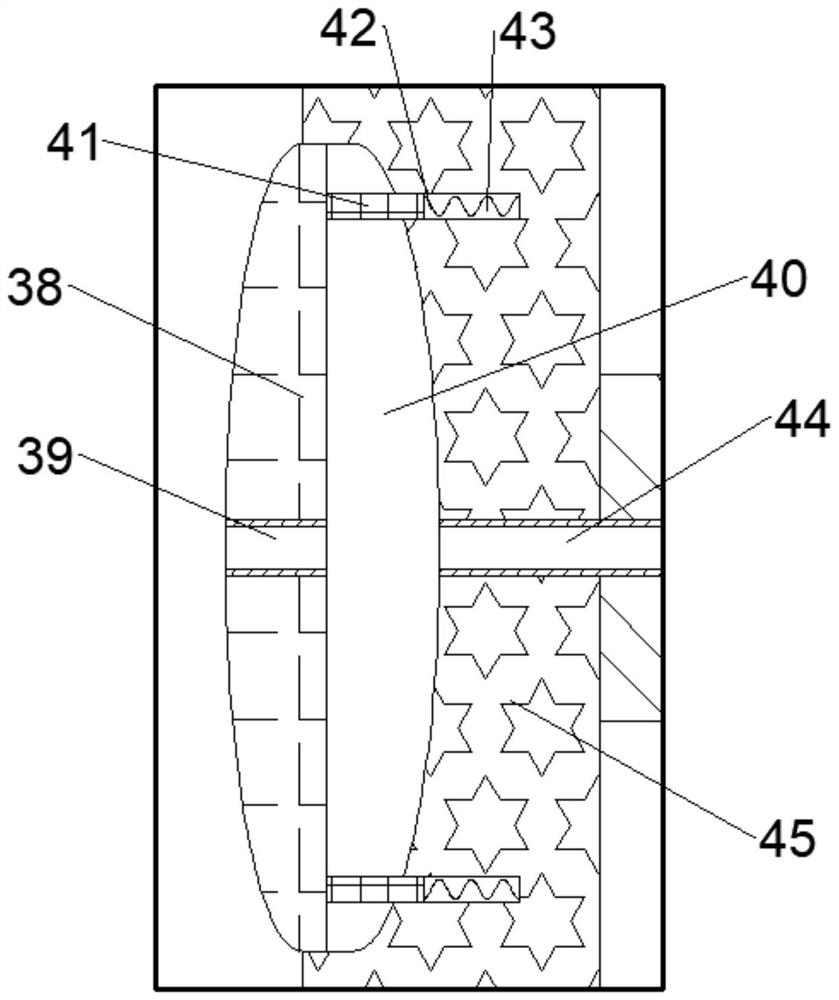

Drilling and hole-flushing integrated device for coal mine gas extraction

ActiveCN110645038AFor multifunctional useImprove efficiencyDrill bitsFlushingElectric machineryCoal mine methane

The invention discloses a drilling and hole-flushing integrated device for coal mine gas extraction. Switching between drilling and hole flushing can be conveniently realized, when a high-pressure hole flushing pipe is connected with a hole flushing high-pressure jet liquid supply pump, and a high-pressure hole flushing medium can pass through an adjustment protection assembly to enable the frontend of a high-pressure nozzle to extend out of the front end of a drill bit, so that the high-pressure medium can be sprayed for hole flushing; when a drilling motor performs the drilling operation, the high-pressure nozzle can be hidden in the inner cavity of the drill bit through the adjustment protection assembly under the function of external pressure, so that the high-pressure nozzle is protected, the efficiency of drilling and hole flushing is effectively improved, and the drilling and hole flushing operations of coal mine gas extraction are facilitated; and drilling is carried out, a cooling liquid can be introduced into the drill bit to protect the drill bit, and the drilling capacity is improved, high-pressure hole flushing is simple and convenient, the operation can be completedonly need to connect the high-pressure hole flushing pipe in a threaded mode, switching is simple and fast, and fast drilling and hole flushing operations of a coal mine are realized.

Owner:LULIANG UNIV

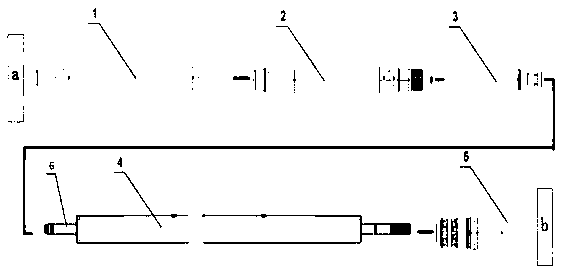

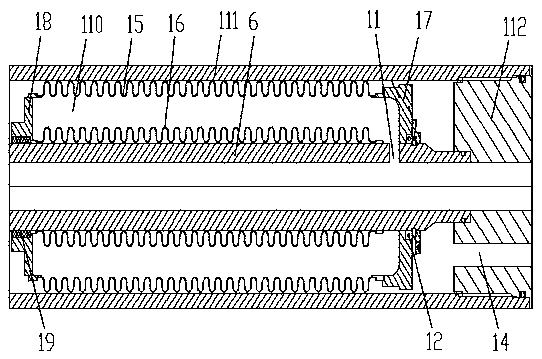

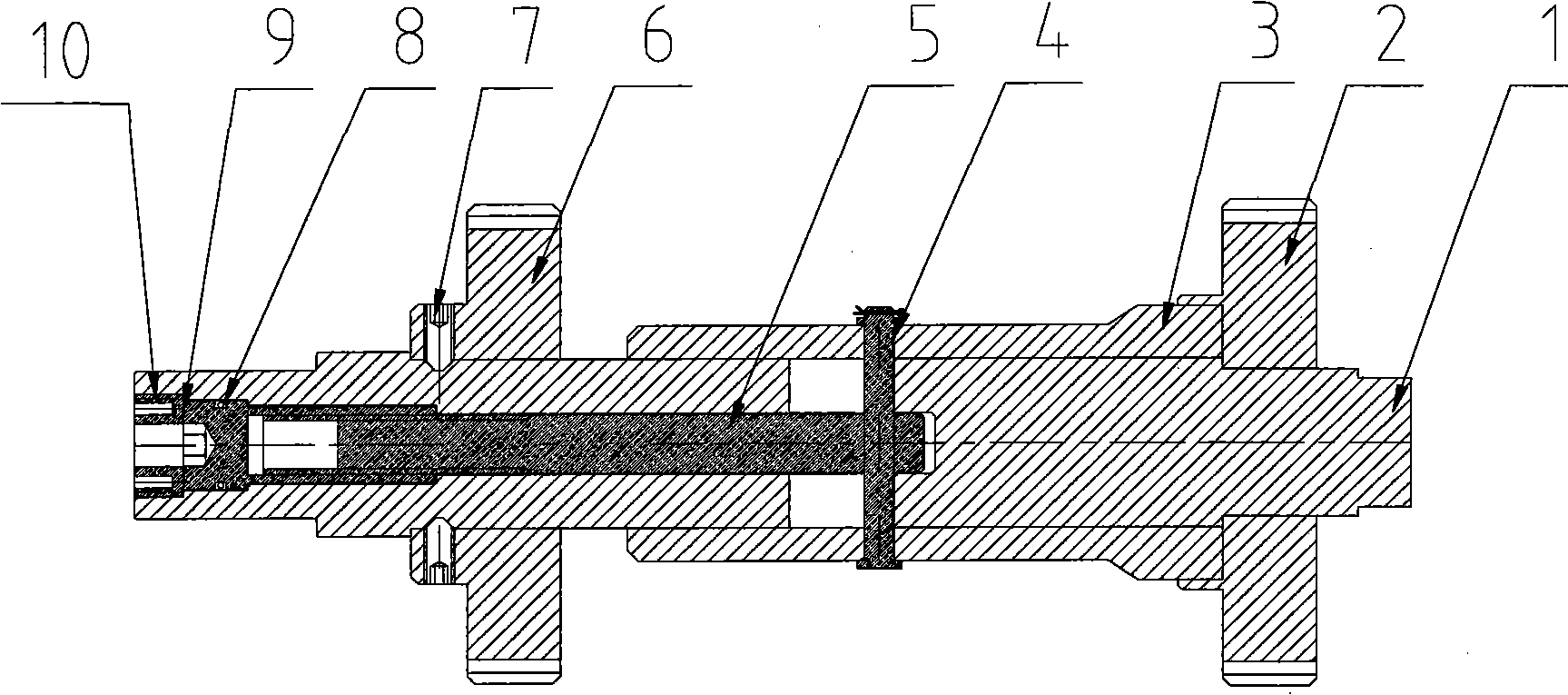

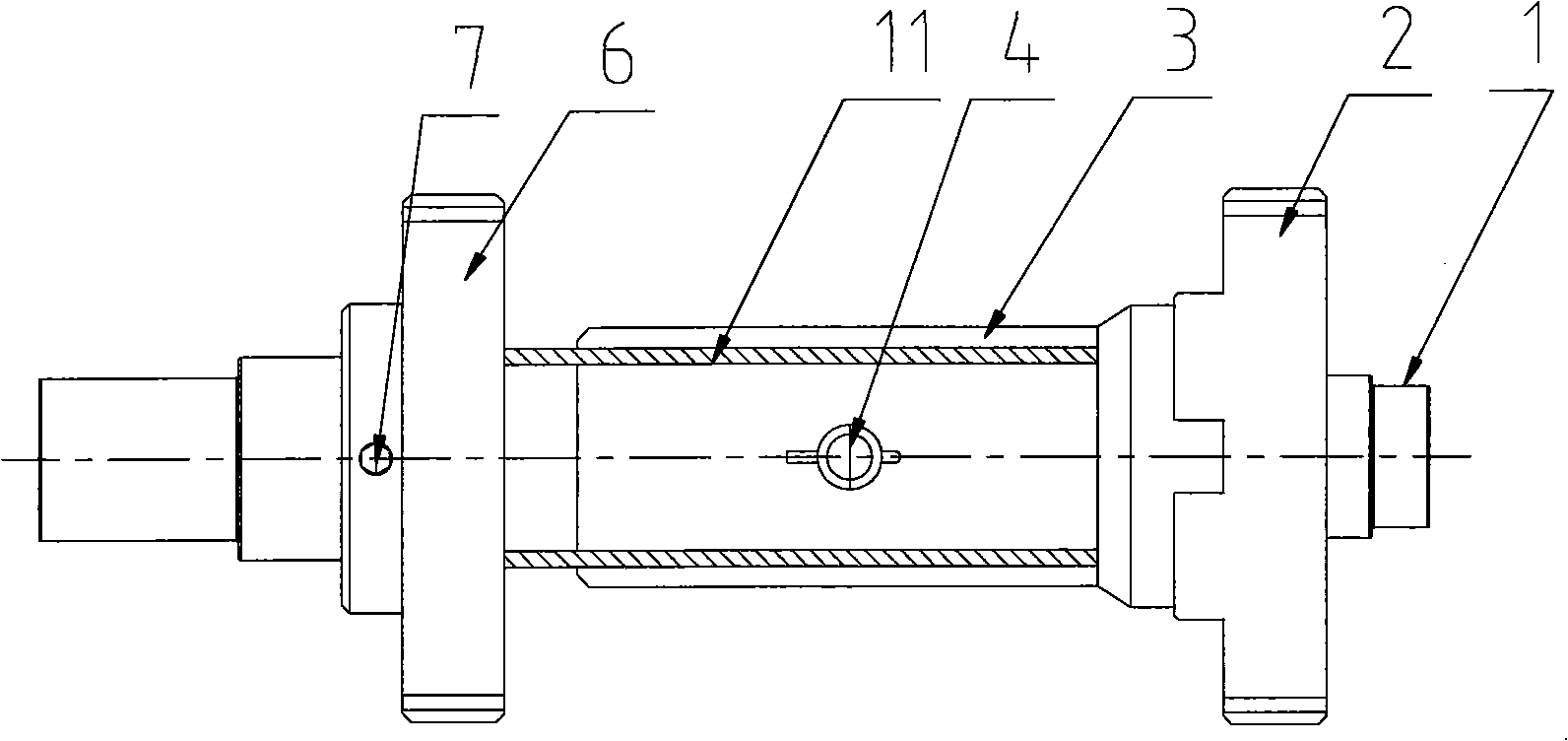

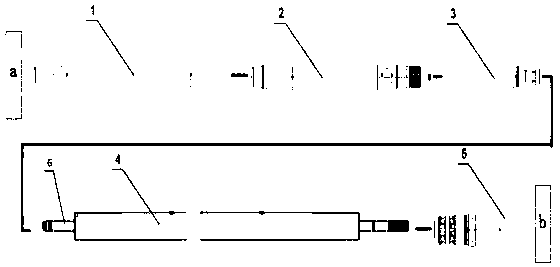

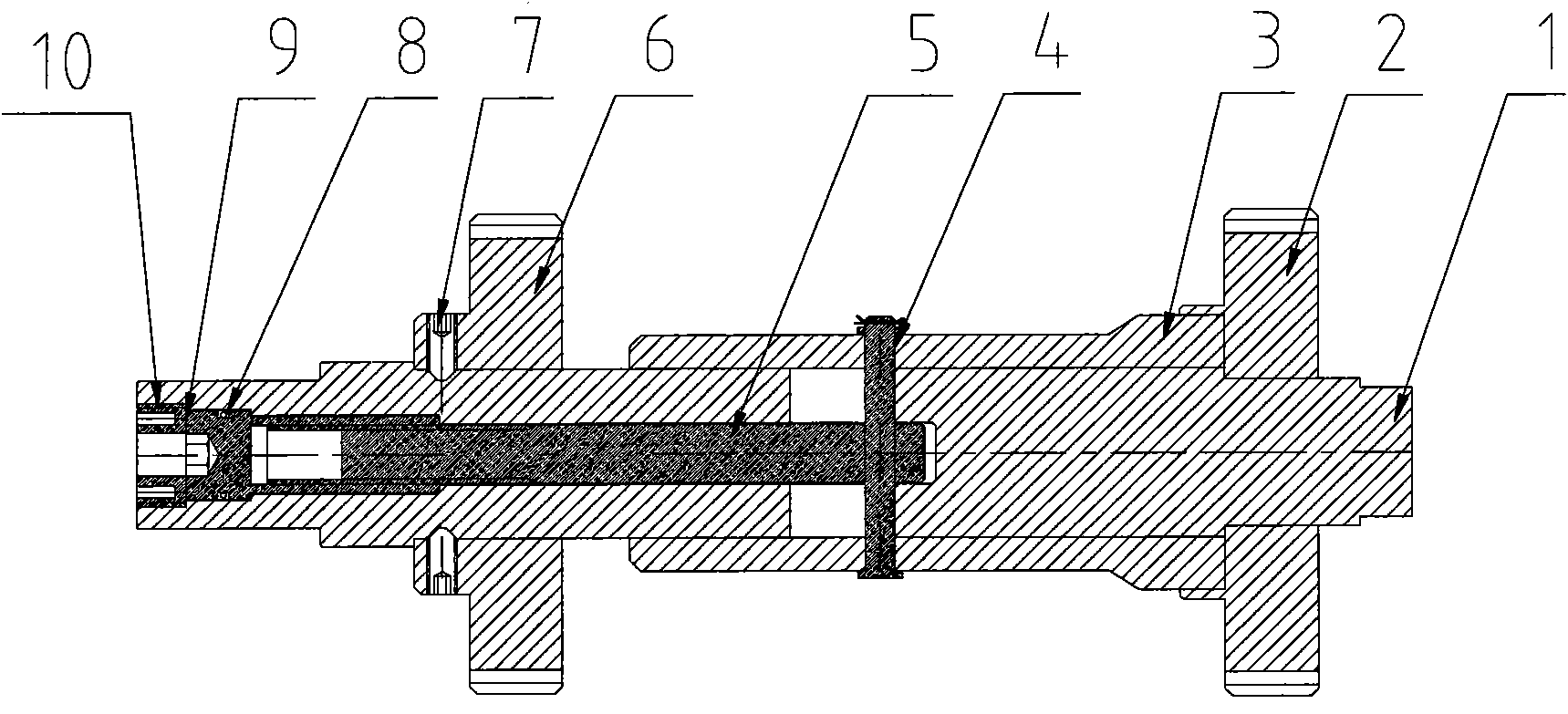

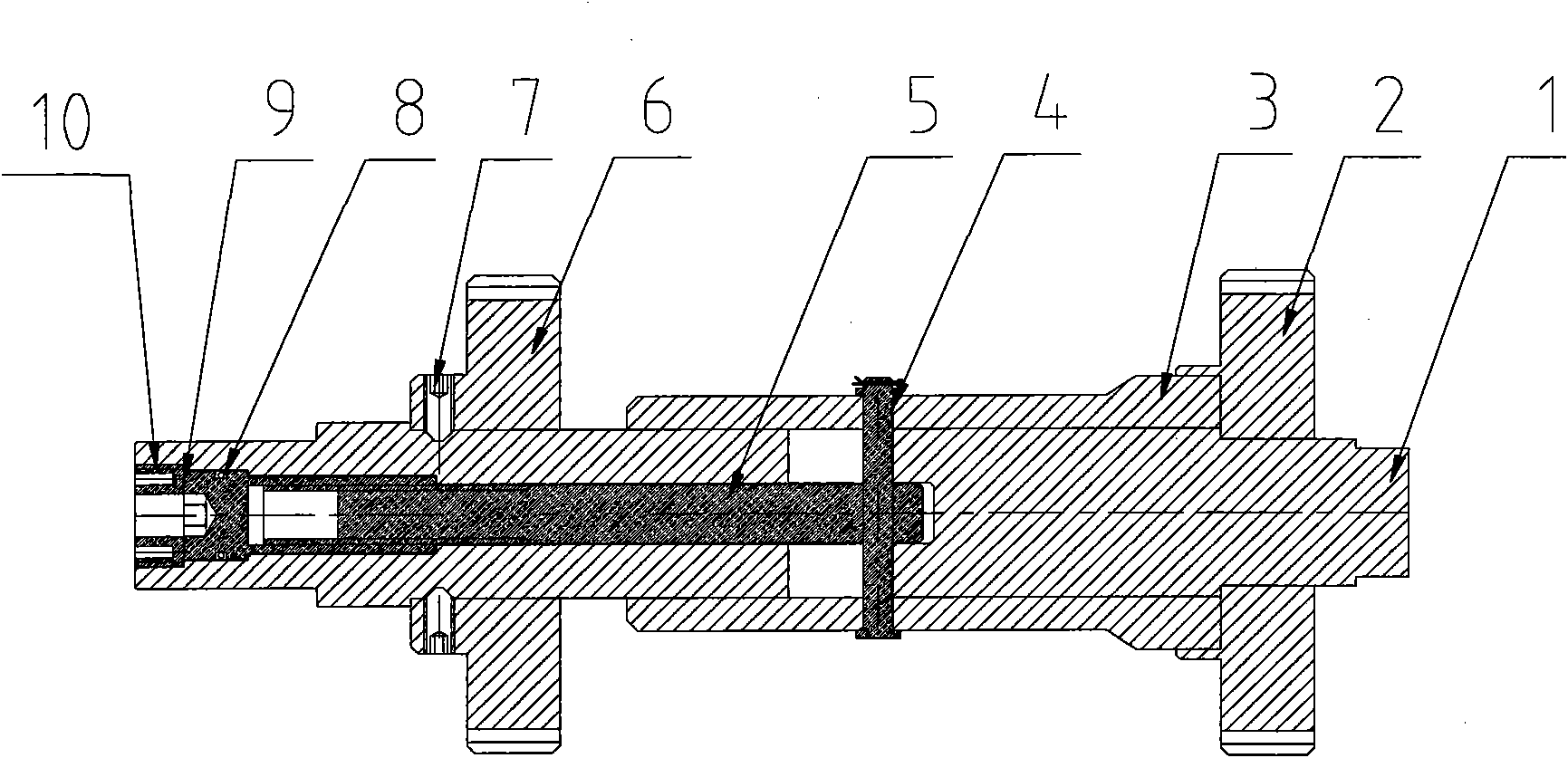

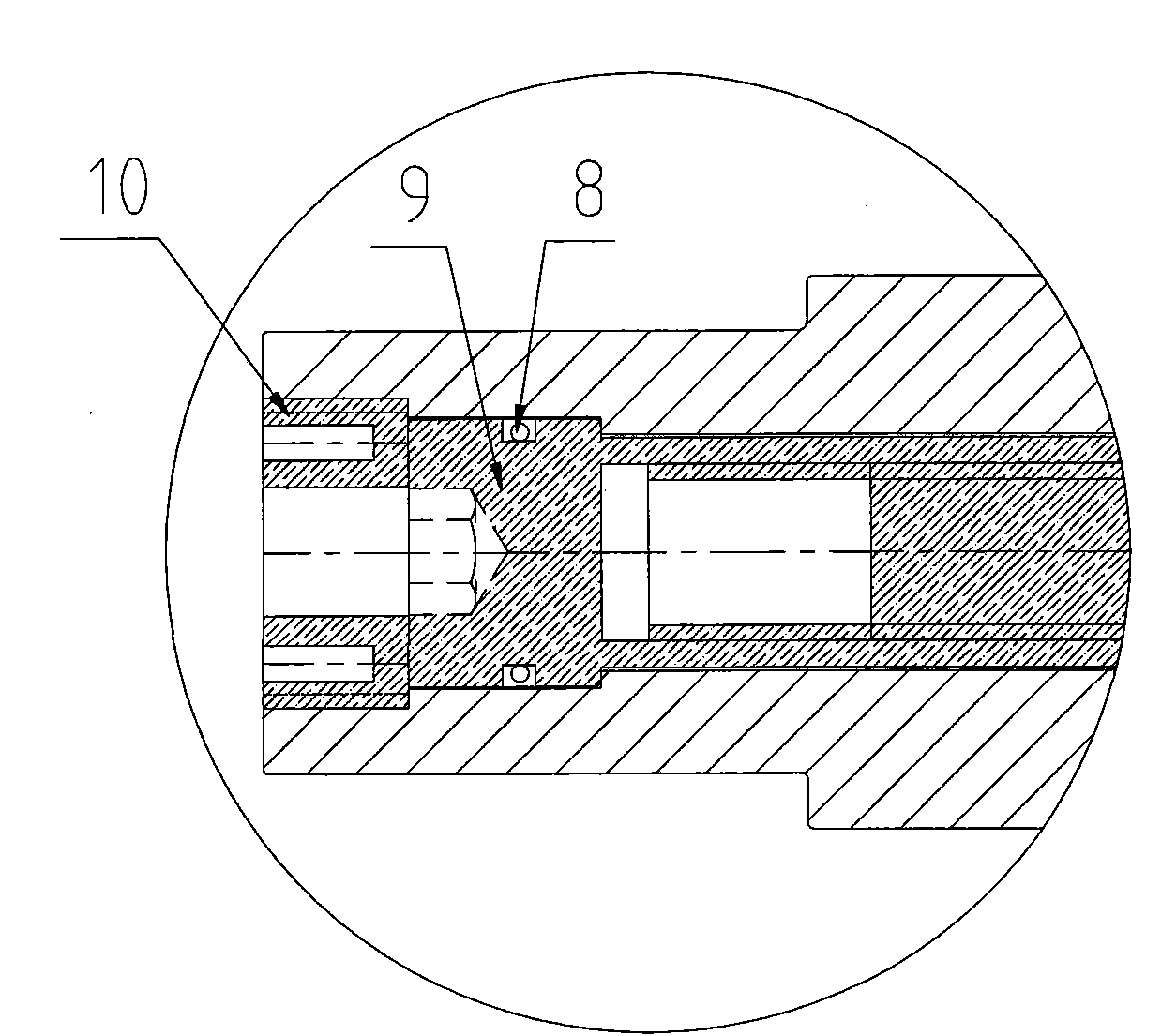

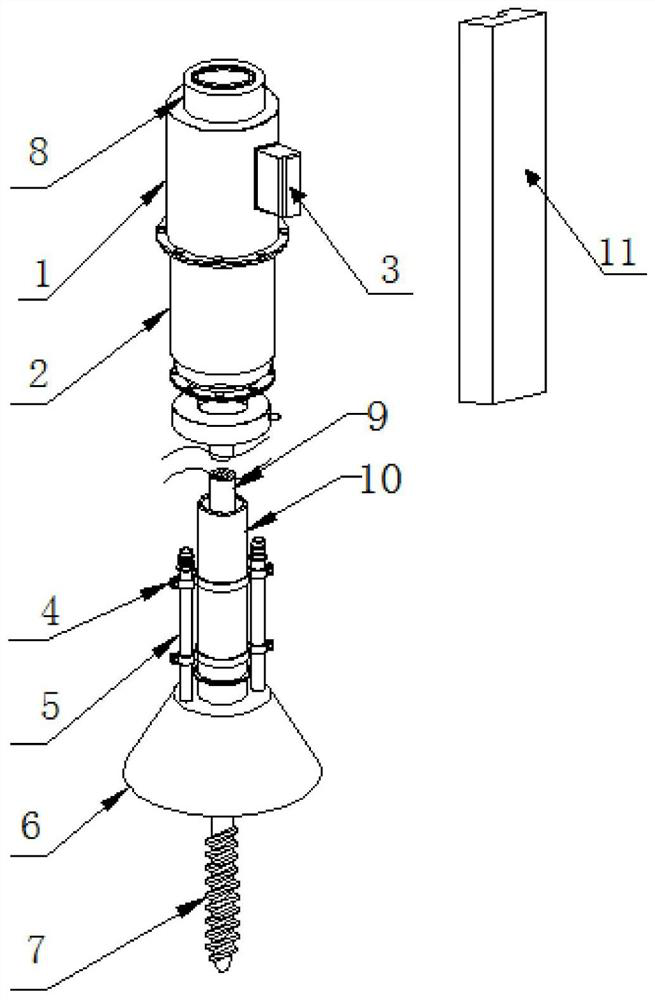

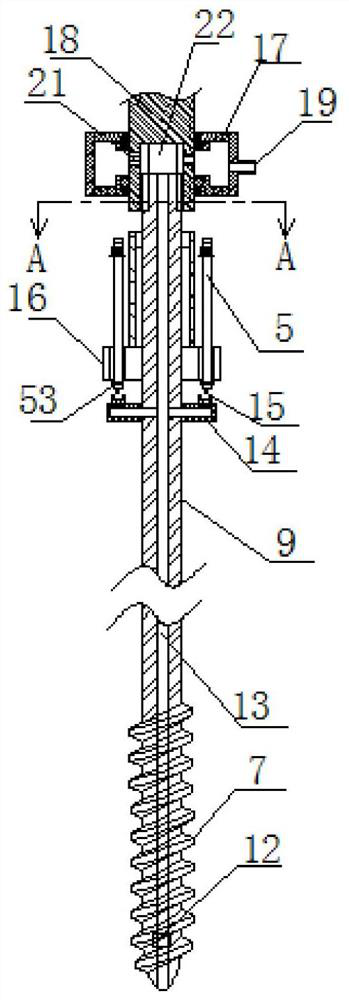

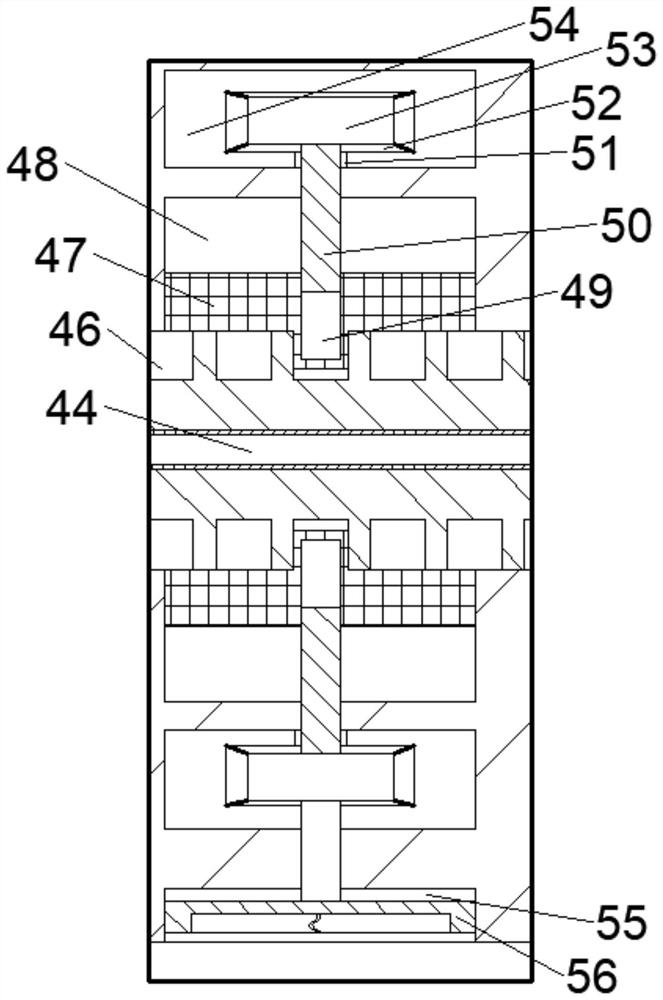

Underground drilling tool motor

ActiveCN105507808AReduce positioning impactAvoid accidentsPipe elementsBorehole drivesGyroscopeWell drilling

The invention discloses an underground drilling tool motor and relates to the technical field of underground well drilling. The underground drilling tool motor comprises a protector (1), an instrument cabin (2), an upper part sealing device (3), a permanent magnet motor (4), a lower part sealing device (5) and a main shaft (6), wherein the main shaft (6) is connected in a sectional manner and penetrates through the protector (1), the instrument cabin (2), the upper part sealing device (3), the permanent magnet motor (4) and the lower part sealing device (5) in the sectional manner. With the adoption of the underground drilling tool motor, automation of a well drilling process can be effectively realized; vibration is reduced and influences on positioning of a gyroscope are reduced, so that other equipment is relatively reliable; and the underground drilling tool motor has a relatively high temperature adaption capability and a relatively high well drilling efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

Pit digging machine convenient to move for planting fruit seedlings

InactiveCN108476663AEasy to moveThe digging process is stablePlantingFurrow making/coveringEngineeringSeedling

The invention discloses a pit digging machine convenient to move for planting fruit seedlings. The pit digging machine comprises a fixing plate body, box bodies are fixedly connected to the four corners of the bottom face of the fixing plate body respectively, an electric push a rod is fixedly connected to the middle of the bottom face of the fixing plate body, a first motor is fixedly connected to an output end of the electric push rod, a rotating rod is fixedly connected to an output end of the first motor, and rotating blades are fixedly connected to the outer surface of the rotating rod; supporting plates are fixedly connected to the inner side walls, close to the rotating rod, of the boxes respectively, and second motors are fixedly connected to the upper surfaces of the supporting plates respectively. According to the pit digging machine convenient to move for planting the fruit seedlings, by mounting rolling wheels in the box bodies, the rolling wheels can move up and down; in this way, the rolling wheels are moved upward when a pit is dug, and fixing blocks on the bottom faces of the box bodies touch the ground, so that the whole machine does not move; by moving the rollingwheels downwards and making the rolling wheels touch the ground, the machine can be moved conveniently, manpower is saved, and the work efficiency is improved.

Owner:XISHAN XIANFENG FAMILY FARM

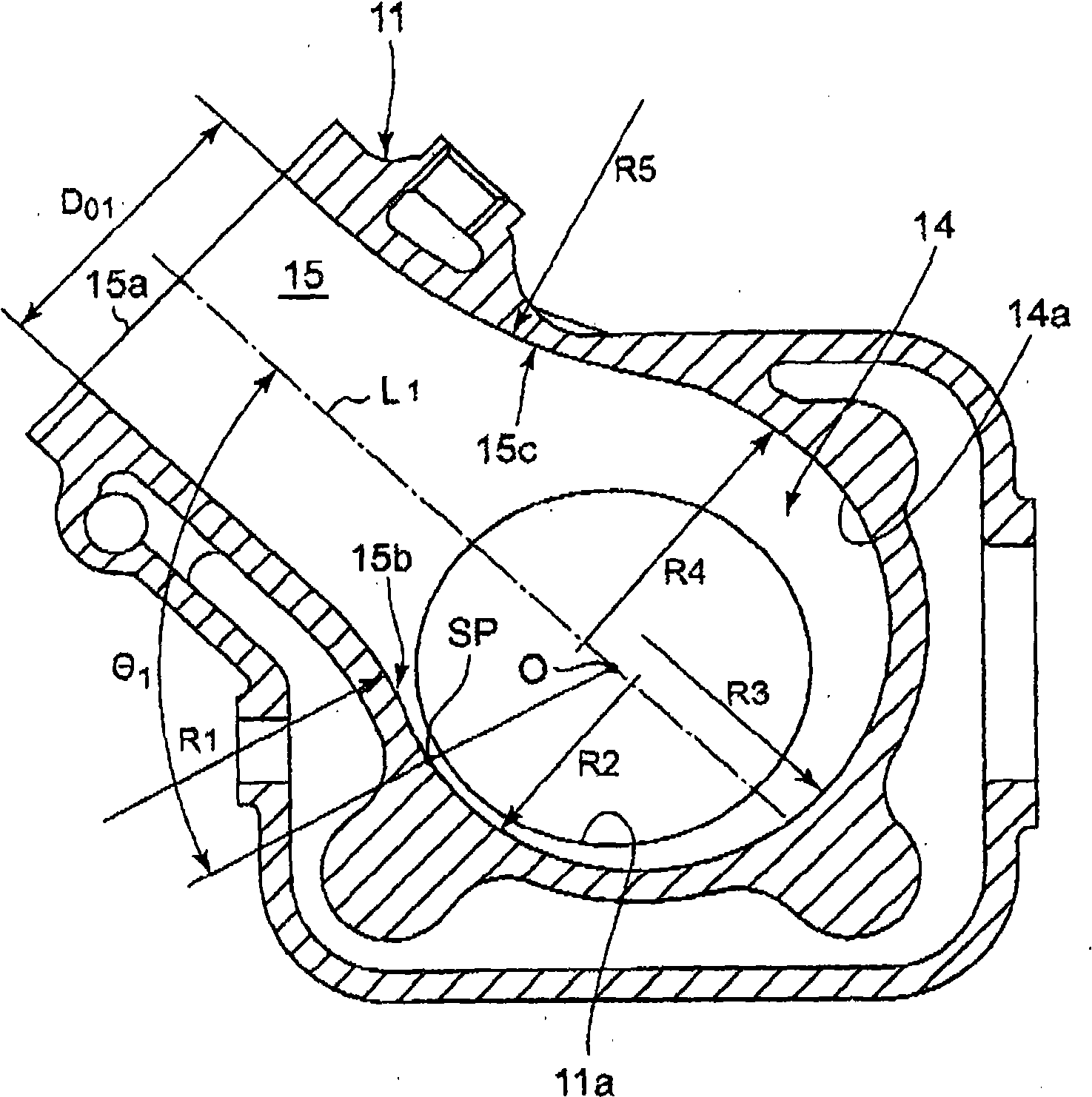

Structure of exhaust gas separation device of internal combustion engine

InactiveCN101818700AEasy drillingEasy to removeInternal combustion piston enginesCylinder headsHydraulic cylinderLower limit

According to the invention, the burnup of an internal combustion engine is improved and the reliability and work efficiency is increased. A low-temperature chamber (14) has a section area from a predetermined position as a starting point to a low-temperature exhaust channel inlet in a scroll shape gradually enlarged in a gas rotating direction. Rectification plates (17, 18) for guiding the high-temperature gas guided into a high-temperature chamber into a high-temperature exhaust channel are arranged on the inner wall surface (12a) of the high-temperature chamber. A hydraulic type zero point position controlling device (52) for defining the lower limit position of an accessory valve air piston and controlling the zero point limiting position of an accessory valve (25) is arranged in a hydraulic cylinder body (40) forming a plurality of hydraulic cylinders (43). the hydraulic cylinder body (40) is formed by an external hydraulic cylinder body (41) and an inner hydraulic cylinder body (42), the plurality of hydraulic cylinders (43) and a first hydraulic channel (65) are formed in the inner hydraulic cylinder body, a second hydraulic channel (69) is formed between the external hydraulic cylinder body and the inner hydraulic cylinder body, and third hydraulic channels (61, 62, 63) are formed in the external hydraulic cylinder.

Owner:MITSUI ENG & SHIPBUILD CO LTD

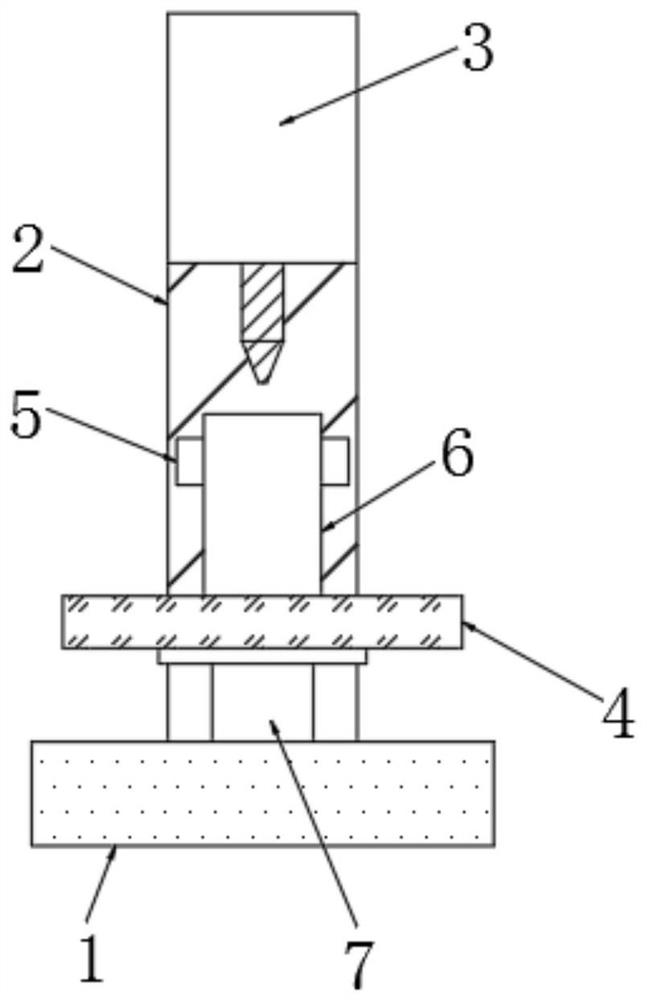

Drilling processing device for plate-shaped novel material

InactiveCN108406359ARealize drilling operationsEasy drillingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a drilling processing device for a plate-shaped novel material. The drilling processing device comprises a supporting box base, hydraulic telescopic cylinders, a drill bit, a rotary rod, a clamping block and pressure rods, wherein the tops of the two ends of the supporting box base are fixedly equipped with the hydraulic telescopic cylinders for driving a supporting beam toperform lifting motion; the bottom end of the middle part of the supporting beam is fixedly equipped with a drilling motor for driving the drill bit to rotate at a high speed; two supporting blocks are symmetrically and fixedly mounted on the top plate of the supporting box base; supporting sleeves are symmetrically arranged on the top plate of the supporting box base; the pressure rod is arranged on each supporting sleeve in an up-down sliding penetrating mode; the top end of each pressure rod is fixedly equipped with a pressure plate; the lower surface of the end part of each pressure plateis fixedly equipped with a clamping block; and the two clamping blocks are positioned above the two supporting blocks separately. The drilling processing device is simple and reasonable in structure,is convenient to operate, is used for clamping and fixing the plate-shaped novel material conveniently, is good in fixing effect, is convenient to use, is beneficial for drilling processing operationof the plate-shaped novel material, and is suitable for being popularized and used.

Owner:林翔

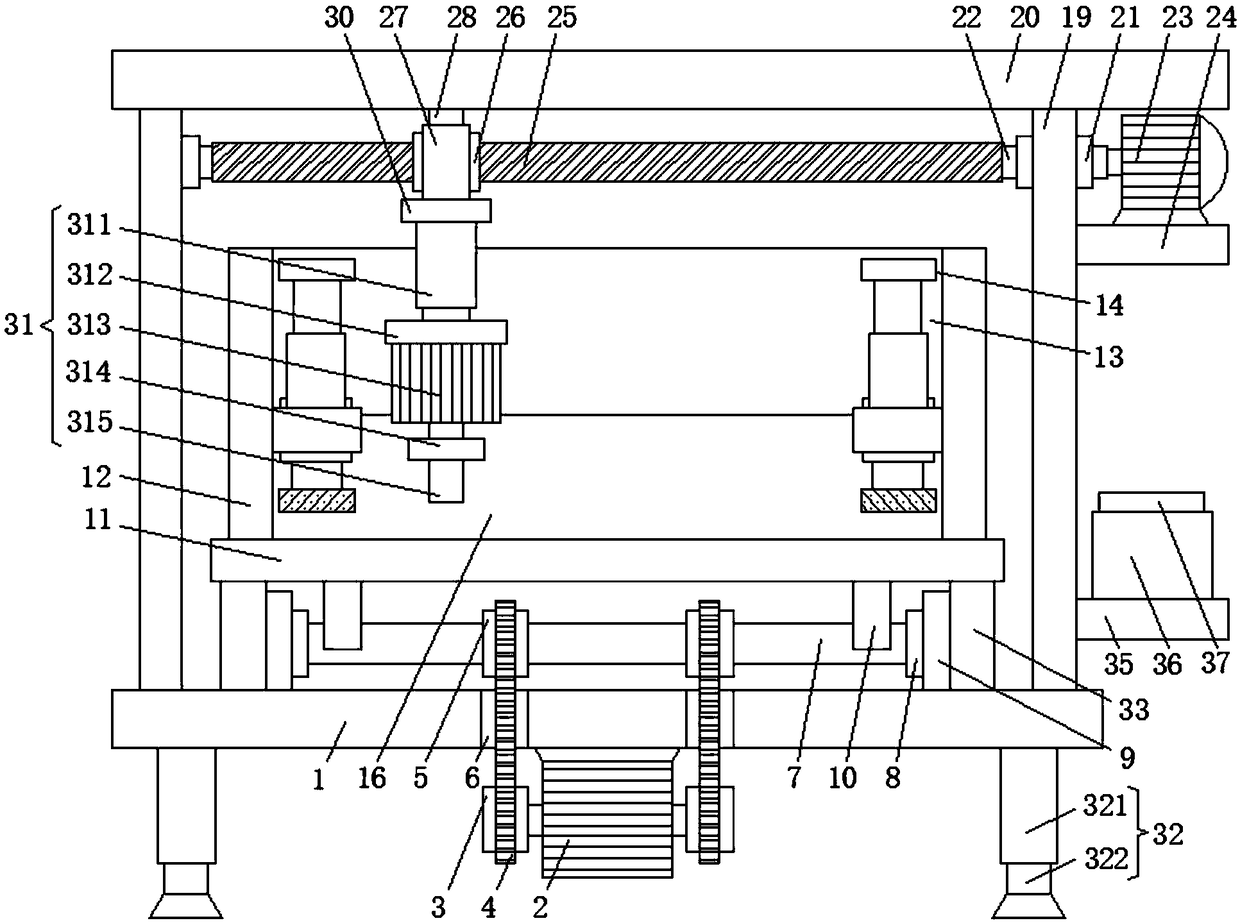

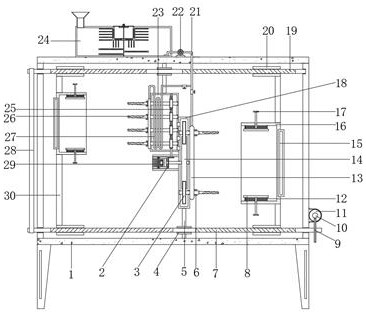

Batch drilling equipment for machining

PendingCN112139535AEasy DrillingGuaranteed stabilityMaintainance and safety accessoriesBoring/drilling machinesElectric machineMachining process

The invention belongs to the technical field of machining, particularly relates to batch drilling equipment for machining, and provides the following scheme for solving the problems that most of drilling equipment in the traditional machining process is simple in design, a single-hole one-by-one machining operation mode is generally adopted, and the machining efficiency is not high. The equipmentcomprises a frame with supporting legs welded to the four corners of the outer wall of the bottom, connecting frame rods are vertically welded to the inner walls of the two ends of the frame, a framebox and a mounting cylinder box are fixed to the opposite sides of the connecting frame rods through bolts correspondingly, and the opposite sides of the frame box and the mounting cylinder box are fixedly connected through bolts; and a rotating motor is fixed to the outer wall of one side of the mounting cylinder box through a bolt, and an output shaft of the rotating motor is in key connection with a driving fluted disc. By means of drilling holes formed in the ends of a first rotating rod and a second rotating rod, rapid drilling of strip-shaped and annularly-distributed holes in a workpiece is facilitated, and the machining efficiency of the device is improved.

Owner:杨晓成

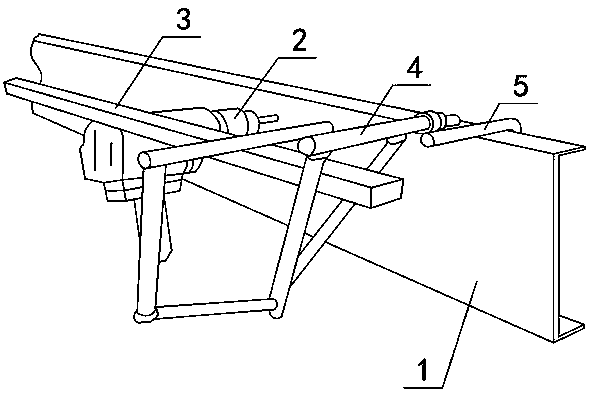

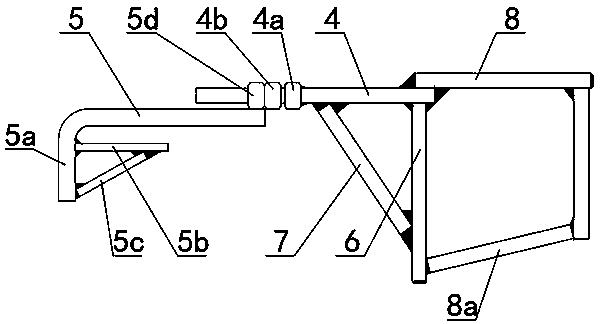

Auxiliary fixture for drilling for automobile chassis beam

PendingCN110340405ALabor savingReduce shakingPortable drilling machinesManufacturing technologyEngineering

The invention discloses an auxiliary fixture for drilling for an automobile chassis beam, and relates to the technical field of vehicle manufacturing. The auxiliary fixture for drilling for the automobile chassis beam comprises a clamping element hooked onto the chassis beam and a brace rod used for being abutted against the clamping element and pressing an electric drill, wherein the clamping element comprises a main rod; a hook rod is connected to the front end of the main rod; a vertical rod is vertically connected to the rear end of the main rod; a first reinforcing rod is connected between the main rod and the vertical rod; and a triangular hole allowing the brace rod to penetrate through is encircled by the main rod, the vertical rod and the first reinforcing rod. According to the auxiliary fixture for drilling for the automobile chassis beam, the quality of drilling a bottom hole in the chassis beam can be improved, the incompletion of a thread during the subsequent tapping is avoided, and the firmness of the subsequent installation for a lower hanging element is enhanced.

Owner:衡阳泰豪通信车辆有限公司

Unrestraint assembly method of plug-in type bundled bracket

The invention provides a unrestraint assembly method of a plug-in type bundled bracket. The steps of preassembly-splitting-reset-splitting-reset are performed for a composite sandwich layer consisting of a bundled bracket, a middle frame and inner and outer reinforced plates; in the process, a technological cover is used for replacing a cover; on the basis of determining a positioning hole, a drill plate is guided to finish precise reaming positioning of a connecting hole near the side of the cover; the precisely reamed connecting hole near the side of the cover serves as positioning standard to determine the positions of remainder connecting holes; and finally, the unrestraint plug-in assembly of the bundle bracket is finished. The method prevents the limitation of the operation space caused by the cover, brings convenience for the drilling of the connecting hole near the side of the cover, realizes unrestraint drilling of the connecting holes in the bundled bracket, uses the precisely reamed connecting hole near the side of the cover as standard to prevent the positioning error caused by the use of a transition fit positioning shaft pin, and guarantees precise reset of the composite sandwich layer after the splitting; and the unrestraint assembly method is provided to the plug-in type bundled bracket.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO +1

Building construction drilling machine with correction function

InactiveCN113715176AEasy to fixGuaranteed uptimeWorking accessoriesStone-like material working toolsPunchingArchitectural engineering

The invention discloses a building construction drilling machine with a correction function. The building construction drilling machine with the correction function comprises a punching machine base body, a limiting protection mechanism is fixedly installed on the edge of one end of the punching machine base body, positioning clamping mechanisms are symmetrically installed on the two sides of the back face of the limiting protection mechanism, a protection bearing mechanism is welded to the bottom of one end of the punching machine base body, an oil tank is installed at the bottom end of the punching machine base body, and a supporting assembly is installed at the position, corresponding to the bottom end of the oil tank, of the bottom end of the punching machine base body. Through the limiting protection mechanism, secondary fixing of a drill bit can be facilitated, so that connection between the drill bit and a punching machine is more stable, and shaking of the drill bit in the operation process is reduced; and meanwhile through an outer conical cover, the stability between the punching machine and a wall is improved, so that shaking of the punching machine during operation is reduced, operation of the drilling machine is facilitated, interference of shaking of the punching machine during operation on drilling of the wall is reduced, and drilling treatment on the wall is facilitated.

Owner:邵燕

Drilling device with cleaning function for circuit board processing and using method

PendingCN114800685AEasy to moveEasy drillingDirt cleaningPrinted circuit manufactureDust controlThreaded rod

The invention discloses a circuit board processing drilling device with a cleaning function and a using method, and belongs to the technical field of drilling, the circuit board processing drilling device comprises a working box, guide grooves are formed in the periphery of an inner cavity of the working box, sliding rods are slidably connected to inner cavities of the guide grooves, and the surfaces of the sliding rods are sleeved with box bodies; through cooperation of a sliding rod and a box body, the box body can move freely in the working box in the horizontal direction, meanwhile, through cooperation of a traction shrinkage assembly, a drill bit is moved up and down, drilling treatment can be conveniently conducted on circuit boards at different positions in the working box, and then through a dust collection pipe and a hose, the dust collection efficiency is improved. Chippings generated by drilling of a drill bit are conveniently discharged out of a working box, the surface of a circuit board is smooth and clean during drilling, meanwhile, a driving assembly is used for driving a positive and negative threaded rod to rotate, a movable frame is conveniently moved during drilling, comprehensive dust removal is conducted on the top of the circuit board, and the working efficiency is improved. The problem that a traditional drilling device for circuit board machining cannot synchronously remove dust is solved.

Owner:SHENZHEN BOMIN ELECTRONICS

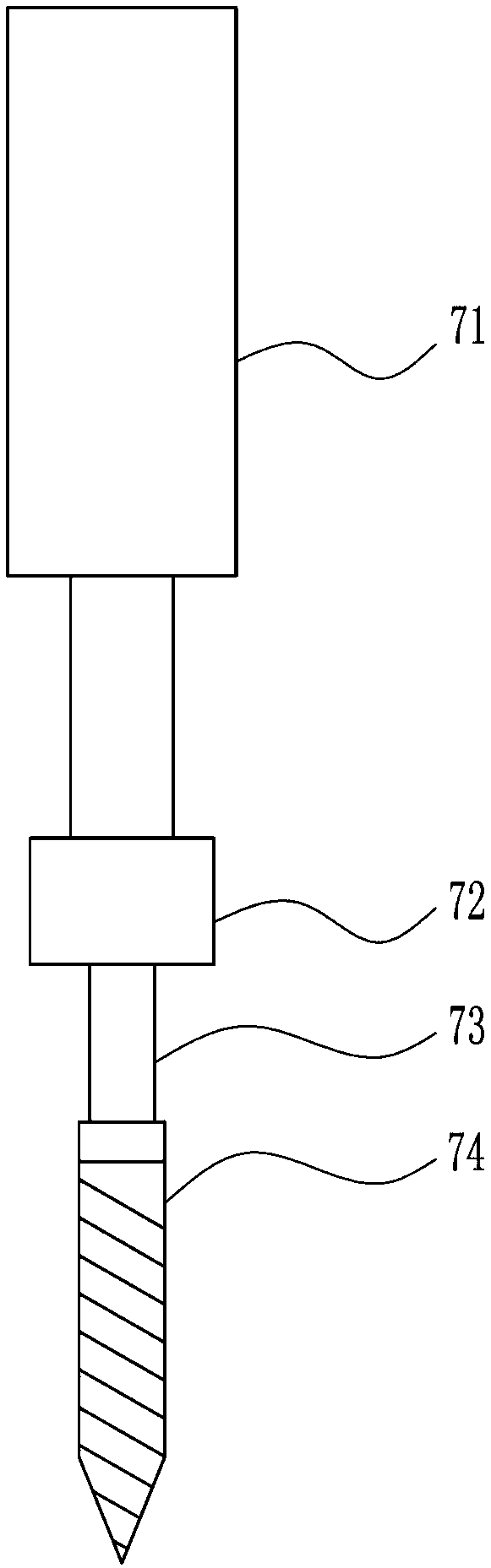

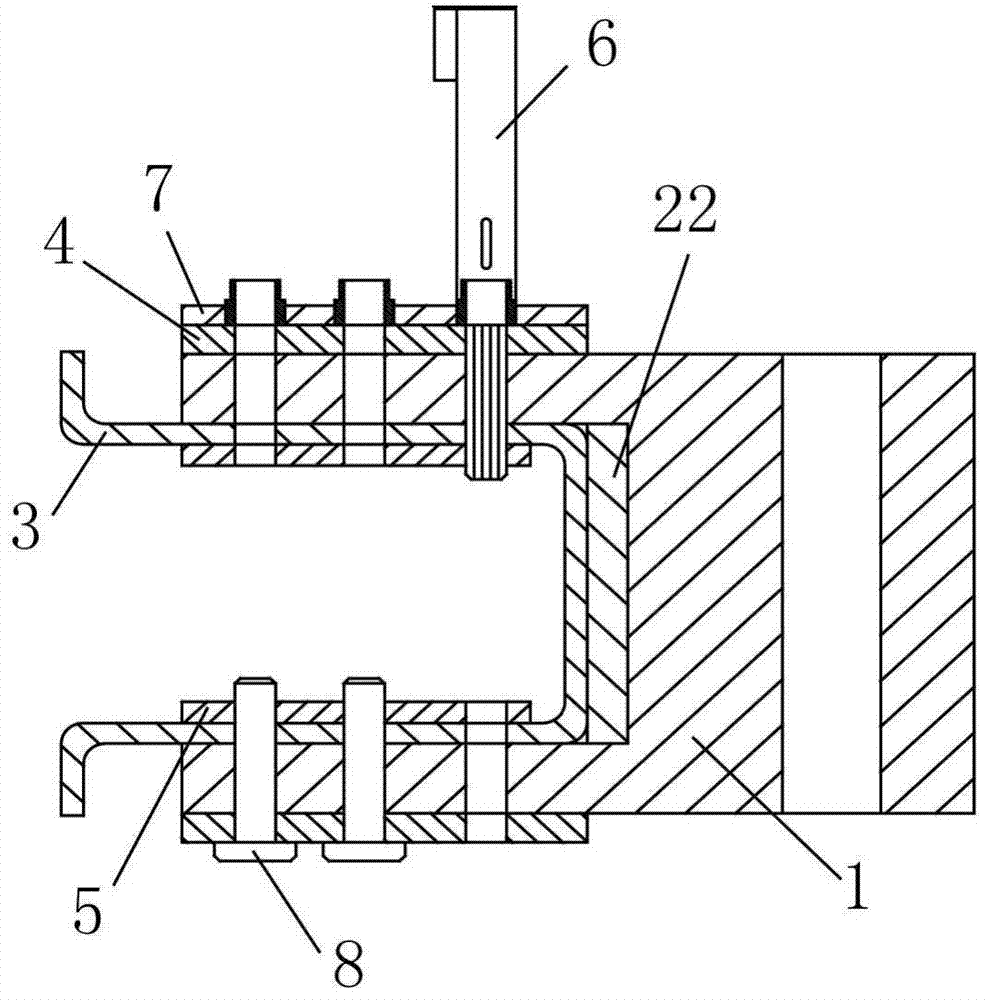

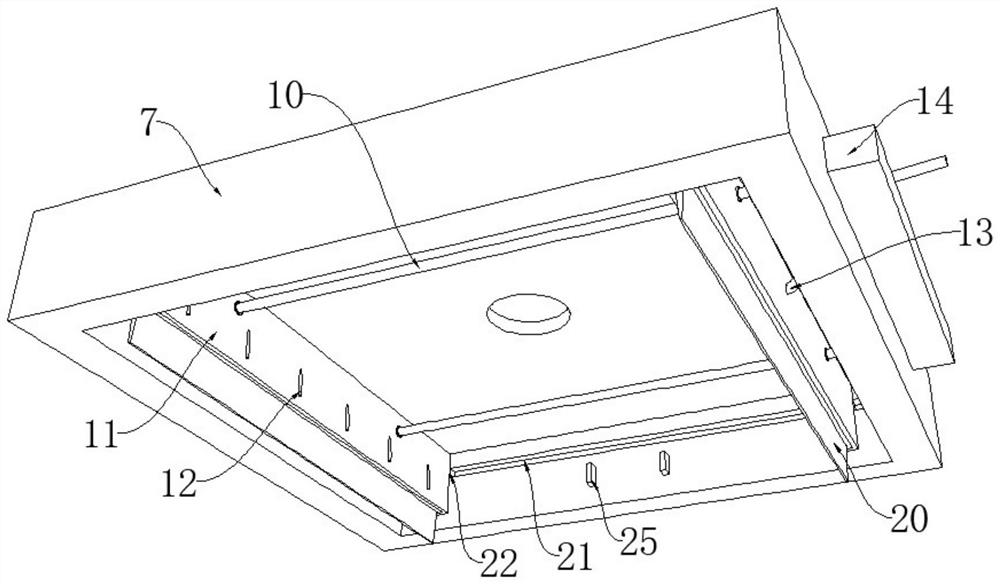

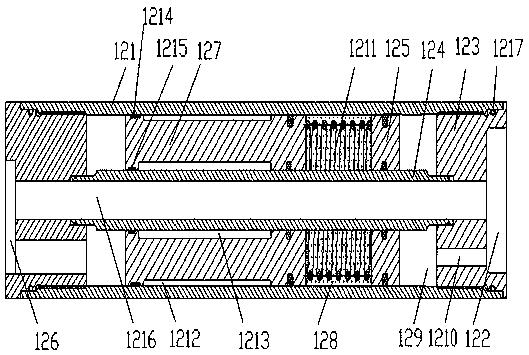

Clutch mechanism and transmission device of hole opening machine using clutch mechanism

InactiveCN101639101ASimple structureReduce volumeMechanical actuated clutchesToothed gearingsDrive shaftClutch

The invention discloses a clutch mechanism and a transmission device of a hole opening machine using the clutch mechanism. The clutch mechanism comprises a clutch sleeve, a clutch mechanism main shaftformed by a clutch mechanism driving section and a clutch mechanism driven section, a clutch mechanism driving gear, a clutch mechanism driven gear and a connecting component and the like. The invention can be used in the transmission device of the hole opening machine; the periphery of a transmission shaft of the transmission device is provided with one or more clutch mechanisms; by operating the clutch mechanism, the clutch mechanism driven gear of each clutch mechanism is meshed with one corresponding driven gear on the transmission shaft; and the clutch mechanism driving gear on the clutch mechanism is meshed with the driving gear sleeved on the transmission shaft. The clutch mechanism has accurate position for clutch switching, safety and reliability. When being applied in the hole opening machine, the invention can easily realize multigear variable transmission feeding, avoid misoperation accident, is safe, reliable and durable and has low cost.

Owner:贾亮亮

Downhole drill motor

ActiveCN105507808BReduce positioning impactAvoid accidentsPipe elementsBorehole drivesGyroscopeWell drilling

The invention discloses an underground drilling tool motor and relates to the technical field of underground well drilling. The underground drilling tool motor comprises a protector (1), an instrument cabin (2), an upper part sealing device (3), a permanent magnet motor (4), a lower part sealing device (5) and a main shaft (6), wherein the main shaft (6) is connected in a sectional manner and penetrates through the protector (1), the instrument cabin (2), the upper part sealing device (3), the permanent magnet motor (4) and the lower part sealing device (5) in the sectional manner. With the adoption of the underground drilling tool motor, automation of a well drilling process can be effectively realized; vibration is reduced and influences on positioning of a gyroscope are reduced, so that other equipment is relatively reliable; and the underground drilling tool motor has a relatively high temperature adaption capability and a relatively high well drilling efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

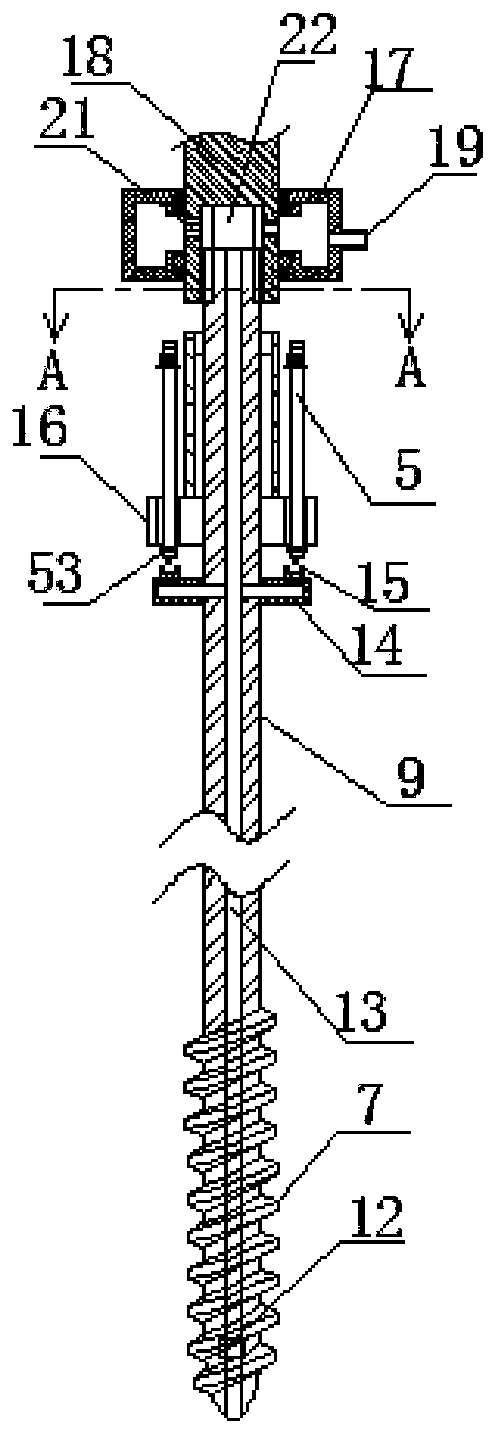

Depth-adjustable drilling device facilitating bone residue collection for orthopedics department

The invention discloses a depth-adjustable drilling device facilitating bone residue collection for the orthopedics department, relates to the technical field of medical instruments, and provides the following scheme aiming at the problem that an existing drilling device cannot collect bone residues: the drilling device comprises a protective shell, a loading block located above the protective shell, and a mounting block located in the loading block; a fixing assembly used for fixing the position of the loading block is arranged on the protective shell, a first stepping motor is fixed to the outer side of the mounting block, the output end of the first stepping motor is in transmission connection with a driving shaft, a drill bit is arranged at the other end of the driving shaft, and a connecting assembly used for being connected with the drill bit is arranged on the driving shaft. According to the orthopedic bone drilling device, a doctor can conveniently conduct drilling treatment on bones of an orthopedic patient, the drilling component can be flexibly adjusted, chippings generated during drilling can be collected, the working performance is high, and use is convenient.

Owner:HUAINAN UNITED UNIVERSITY

Separating device for dismounting tiles

The invention relates to a separating device for dismounting tiles. The device comprises a transverse slideway, a positioning slot, a punching device and a cutting device; the punching device comprises a double layer frame, hammer nails are slidably installed on the double layer frame, a guide sleeve is arranged in the center of the double layer frame, a main hammer is slidably installed on the guide sleeve, pressing handles are connected with the main hammer in a hinged mode, and all the pressing handles are located over the handle nails; the end face, located at one side, of the main hammer is provided with a rack, the rack is meshed with a gear, and the gear is connected with a hammering motor. The cutting device comprises a lower layer plate, an upper layer plate is arranged on the lower layer plate, mouth-shaped slideways are formed in the lower layer plate and the upper layer plate respectively, each mouth-shaped slideway is internally provided with cutting knives, a hinge seat is installed at the upper end of each cutting knife, a connecting rod is arranged above each cutting knife, a driving rack is installed at the upper end of each hinge seat, a vertical plate is welded to any hinge seat, the vertical plates are connected with a ball screw and a polished rod respectively, and the ball screw is connected with a cutting driving motor. According to the separating device for dismounting the tiles, punching is conducted in the first place, then mouth shape cutting and sliding are conducted, and the efficacy of separating the tiles is achieved.

Owner:盐城中咏投资发展有限公司

Drilling device capable of conveniently fixing workpiece

ActiveCN114570967AGuaranteed fixed centerEasy drillingPositioning apparatusMetal-working holdersPhysicsDrill hole

Owner:LANZHOU INST OF TECH

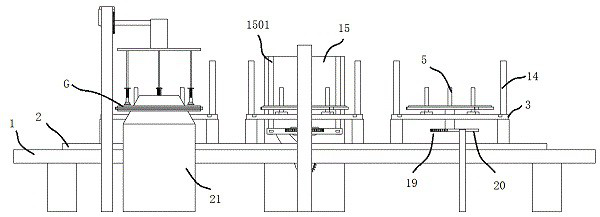

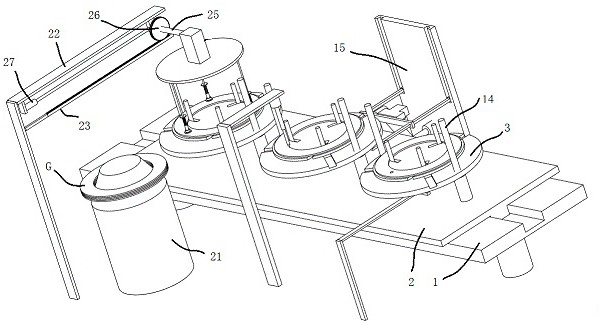

Polishing processing system of high school mathematical teaching models

InactiveCN107855872AEasy to polishEasy drillingGrinding machinesBoring/drilling machinesPunchingMathematical model

The invention relates to a polishing processing system of high school mathematical teaching models. The polishing processing system comprises a base plate. A left hydraulic device and a right hydraulic device are installed on the left side and the right side of the upper portion of the base plate correspondingly. A left hydraulic telescopic column and a right hydraulic telescopic column are connected to the upper portion of the left hydraulic device and the upper portion of the right hydraulic device correspondingly. A left hinge column and a right hinge column are installed on the upper portion of the left hydraulic telescopic column and the upper portion of the right hydraulic telescopic column correspondingly. A lower transverse plate is connected to the left hinge column and the righthinge column through hinges. A supporting table is installed on the upper portion of the lower transverse plate. A slide way is installed on the upper portion of the supporting table. A motor supportis installed on the upper portion of the slide way. A lower motor is installed on the upper portion of the motor support. The right side of the upper portion of the lower transverse plate is connectedwith a supporting column. A sleeve is installed on the upper portion of the supporting column. By means of the device, punching processing can be effectively conducted for the high school mathematical teaching models, polishing is facilitated, polishing and hole drilling processing at different angles are also facilitated, the use effect is improved, and the polishing processing system is conveniently used according to requirements.

Owner:华蓥市双河第四初级中学

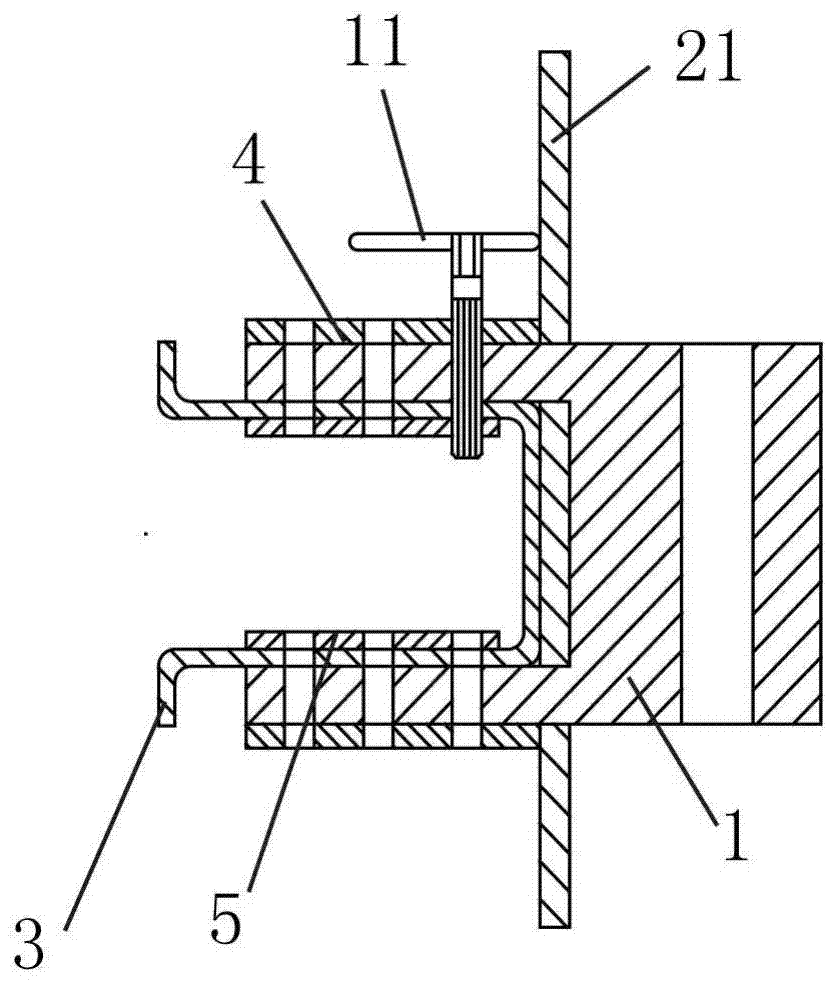

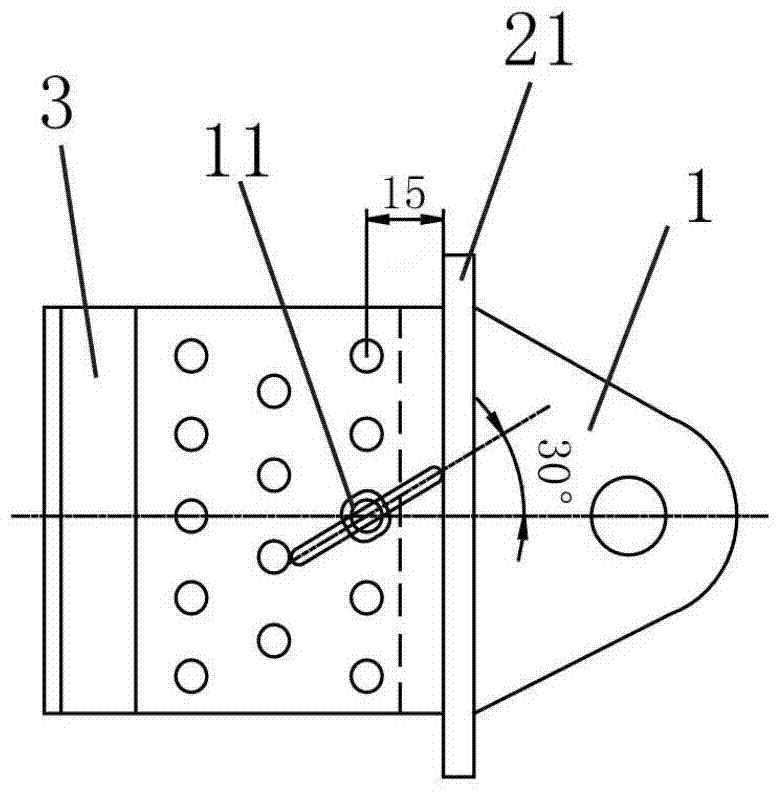

Drilling process equipment for machine base for electric drum special motor

ActiveCN103990835BStable and reliableImprove work efficiencyDrill jigsProcess equipmentElectric machine

The invention relates to a machining fixture, that is, a machine base drilling process fixture for a special motor of an electric drum. It consists of a box with an open side. There is a sleeve fixed horizontally in the box. One end of the fastening shaft in the sleeve is connected to the side wall of the box, and the other end is inserted with a baffle, which is back connected through a nut; It is a drilling template, which has a plurality of guide holes corresponding to the drilling of the motor frame. There is a joystick supported at both ends on the drilling template, and there are two cams arranged at intervals on the joystick. The corresponding cam on the template has a cam hole for the cam to enter below the drilling template. This tooling saves time and labor for installing workpieces, improves work efficiency, and ensures the stability and reliability of parts. Ensure personal safety. Using this tool is more than five times more efficient than the original alignment, scribing, dotting, and drilling work hours.

Owner:JIAN JIAXIN GENERAL MASCH CO LTD

Clutch mechanism and transmission device of hole opening machine using clutch mechanism

InactiveCN101639101BSimple structureReduce volumeMechanical actuated clutchesToothed gearingsGear wheelDrive shaft

The invention discloses a clutch mechanism and a transmission device of a hole opening machine using the clutch mechanism. The clutch mechanism comprises a clutch sleeve, a clutch mechanism main shaft formed by a clutch mechanism driving section and a clutch mechanism driven section, a clutch mechanism driving gear, a clutch mechanism driven gear and a connecting component and the like. The invention can be used in the transmission device of the hole opening machine; the periphery of a transmission shaft of the transmission device is provided with one or more clutch mechanisms; by operating the clutch mechanism, the clutch mechanism driven gear of each clutch mechanism is meshed with one corresponding driven gear on the transmission shaft; and the clutch mechanism driving gear on the clutch mechanism is meshed with the driving gear sleeved on the transmission shaft. The clutch mechanism has accurate position for clutch switching, safety and reliability. When being applied in the hole opening machine, the invention can easily realize multigear variable transmission feeding, avoid misoperation accident, is safe, reliable and durable and has low cost.

Owner:贾亮亮

Engineering machinery iron casting drilling waste chip recycling device

InactiveCN113560633AFastener setEasy drillingPositioning apparatusBoring/drilling componentsElectric machineryProcess engineering

The invention relates to the technical field of iron casting machining, in particular to an engineering machinery iron casting drilling waste chip recycling device. The device comprises a base, a top seat is fixedly installed at the top end of the base through a supporting rod, a strip-shaped through hole is formed in the top seat in the vertical direction, and an adjusting mechanism is installed at the position, at the strip-shaped through hole, of the top end of the top seat. One end of the adjusting mechanism penetrates through the top seat at the strip-shaped through hole and is connected with a first motor, and an output shaft of the first motor is vertically downward and fixedly connected with a cutter fixing table. According to the waste chip recycling device, an iron casting can be well fixed and clamped in the treatment process, and then the iron casting can be conveniently drilled in cooperation with the cutter fixing table, the first motor and the adjusting mechanism; and chips generated in the drilling process of the iron casting can be effectively adsorbed and collected, so that the top surface of the base is cleaned, and the utilization efficiency of the iron casting is improved.

Owner:射阳中路机械制造有限公司

An integrated device for drilling and washing holes for gas pumping in coal mines

ActiveCN110645038BFor multifunctional useImprove efficiencyDrill bitsFlushingElectric machineryCoal mine methane

The invention discloses a drilling and hole-flushing integrated device for coal mine gas extraction. Switching between drilling and hole flushing can be conveniently realized, when a high-pressure hole flushing pipe is connected with a hole flushing high-pressure jet liquid supply pump, and a high-pressure hole flushing medium can pass through an adjustment protection assembly to enable the frontend of a high-pressure nozzle to extend out of the front end of a drill bit, so that the high-pressure medium can be sprayed for hole flushing; when a drilling motor performs the drilling operation, the high-pressure nozzle can be hidden in the inner cavity of the drill bit through the adjustment protection assembly under the function of external pressure, so that the high-pressure nozzle is protected, the efficiency of drilling and hole flushing is effectively improved, and the drilling and hole flushing operations of coal mine gas extraction are facilitated; and drilling is carried out, a cooling liquid can be introduced into the drill bit to protect the drill bit, and the drilling capacity is improved, high-pressure hole flushing is simple and convenient, the operation can be completedonly need to connect the high-pressure hole flushing pipe in a threaded mode, switching is simple and fast, and fast drilling and hole flushing operations of a coal mine are realized.

Owner:LULIANG UNIV

Multifunctional leather product production and processing equipment

ActiveCN109207647AOperation saves time and effortImprove cutting efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusBiochemical engineeringDrilling machines

The invention relates to the field of leather product production, in particular to multifunctional leather product production and processing equipment. According to the multifunctional leather productproduction and processing equipment, the functions of cutting and drilling are achieved simultaneously, operation saves the time and labor, and the cutting and drilling efficiency can be effectivelyimproved. The multifunctional leather product production and processing equipment comprises a supporting frame, a waste box, a feeding hopper, vertical columns, a treatment frame, a drilling machine,a first sliding block, a first sliding rail, a moving rod, a first fixing plate, a first elastic piece and the like; the supporting frame is fixedly connected to the bottom of the treatment frame; thetop of the waste box is fixedly connected with the inner top wall of the supporting frame through the vertical columns; and the feeding hopper is fixedly connected to the top of the waste box. The effects that the functions of cutting and drilling are achieved simultaneously, operation saves the time and labor, and the cutting and drilling efficiency can be effectively improved are achieved.

Owner:江门市百佳皮具制品有限公司

Anti-shaking labor-saving handheld electric drill device

InactiveCN112828346AEasy drillingGood drilling locationPortable drilling machinesBoring/drilling componentsDrill holeDrill bit

The invention discloses an anti-shaking labor-saving handheld electric drill device which comprises a handheld shell. A moving groove with a leftward opening is formed in the left end face of the handheld shell; a moving block is slidably mounted in the moving groove; connecting grooves with leftward openings are symmetrically formed in the upper side and the lower side of the moving groove; and supporting blocks are slidably mounted in the connecting grooves. According to the anti-shaking labor-saving handheld electric drill device provided by the invention, the pressing force needing to be applied to an electric drill gun can be reduced when an operator conducts drilling through a handheld electric drill, so that the operator can conduct drilling more easily, the drilling position can be better guaranteed during drilling, and the situation that the drilling position deviates due to shaking of the handheld gun caused by shaking of a drill bit during handheld drilling is prevented.

Owner:广州瑞杰智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com