Downhole drill motor

A technology of drilling tools and permanent magnet motors, which is applied to drilling driving devices, mechanical equipment, electric components, etc. in the wellbore, can solve the problems of automation and intelligence of difficult drilling operations, cumbersome installation of axial clearance, and small use range of drill bits, etc. problem, to reduce the influence of gyroscope positioning, high drilling efficiency, and the effect of reducing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] As a preferred embodiment of the present invention, this embodiment discloses,

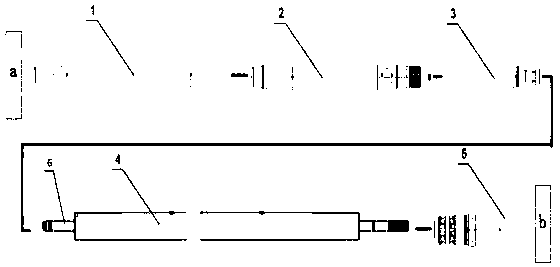

[0045] A motor for downhole drilling tools, including a protector 1, an instrument cabin 2, an upper sealing device 3, a permanent magnet motor 4, a lower sealing device 5, and a main shaft 6; the main shaft 6 is connected in segments, and the segments penetrate the protector 1. Instrument cabin 2, upper sealing device 3, permanent magnet motor 4 and lower sealing device 5; the upper sealing device 3 is connected with the permanent magnet motor 4 and fixed on the upper part of the permanent magnet motor 4; the lower sealing device 5 is connected with the permanent magnet motor The magnetic motor 4 is connected and fixed at the lower part of the permanent magnet motor 4; the protector 1 balances the internal and external pressure of the drilling motor; the instrument cabin 2 detects the drilling motor signal and communicates with the ground in real time.

[0046] When the motor works undergr...

Embodiment 2

[0048] As another preferred embodiment of the present invention, this embodiment discloses: a downhole drilling tool motor, including a protector 1, an instrument cabin 2, an upper sealing device 3, a permanent magnet motor 4, a lower sealing device 5 and a main shaft 6; The main shaft 6 is connected in sections, and sections run through the protector 1, the instrument cabin 2, the upper sealing device 3, the permanent magnet motor 4 and the lower sealing device 5; the upper sealing device 3 is connected with the permanent magnet motor 4 and fixed on the upper part of the permanent magnet motor 4; the lower sealing device 5 is connected to the permanent magnet motor 4 and fixed on the lower part of the permanent magnet motor 4; the protector 1 balances the internal and external pressure of the drilling tool motor; the instrument cabin 2 detects The motor signal of the drilling tool and the real-time communication with the ground. When the motor is working underground, it is ne...

Embodiment 3

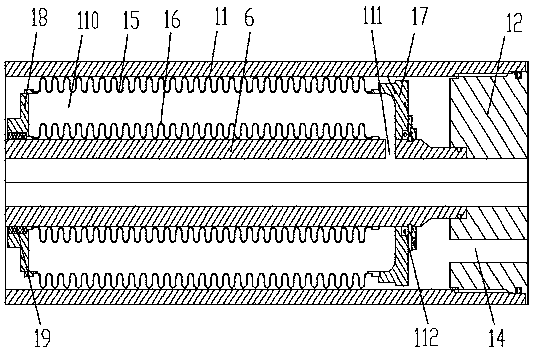

[0050] As another preferred embodiment of the present invention, in this embodiment, the specific structure of the protector is disclosed. In this embodiment, the protector 1 includes a protector housing I11 and a protective device fixed on the protector housing I11. The base 12; the main shaft 6 is located in the protector housing I11 and fixed on the base 12, the base 12 has an oil hole I14, and a bellows assembly is arranged between the protector housing I11 and the main shaft 6, and the bellows The assembly includes an outer bellows 15, an inner bellows 16, a fixed seat 17, a movable seat 18 and a guide ring 19 connected to the movable seat 18. The guide ring 19 is slidably connected to the main shaft 6, and the fixed seat 17 is fixed on the main shaft 6. Above, one end of the outer bellows 15 is connected to the fixed seat 17, the other end is connected to the movable seat 18, the inner bellows 16 is connected to the movable seat 18, the outer bellows 15, the inner bellows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com