Rocker arm of IC engine

A technology of internal combustion engine and valve mechanism, which is applied in the field of rocker arm, can solve the problems of multi-time, etc., and achieve the effects of preventing abnormal wear, low cost, and easy drilling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

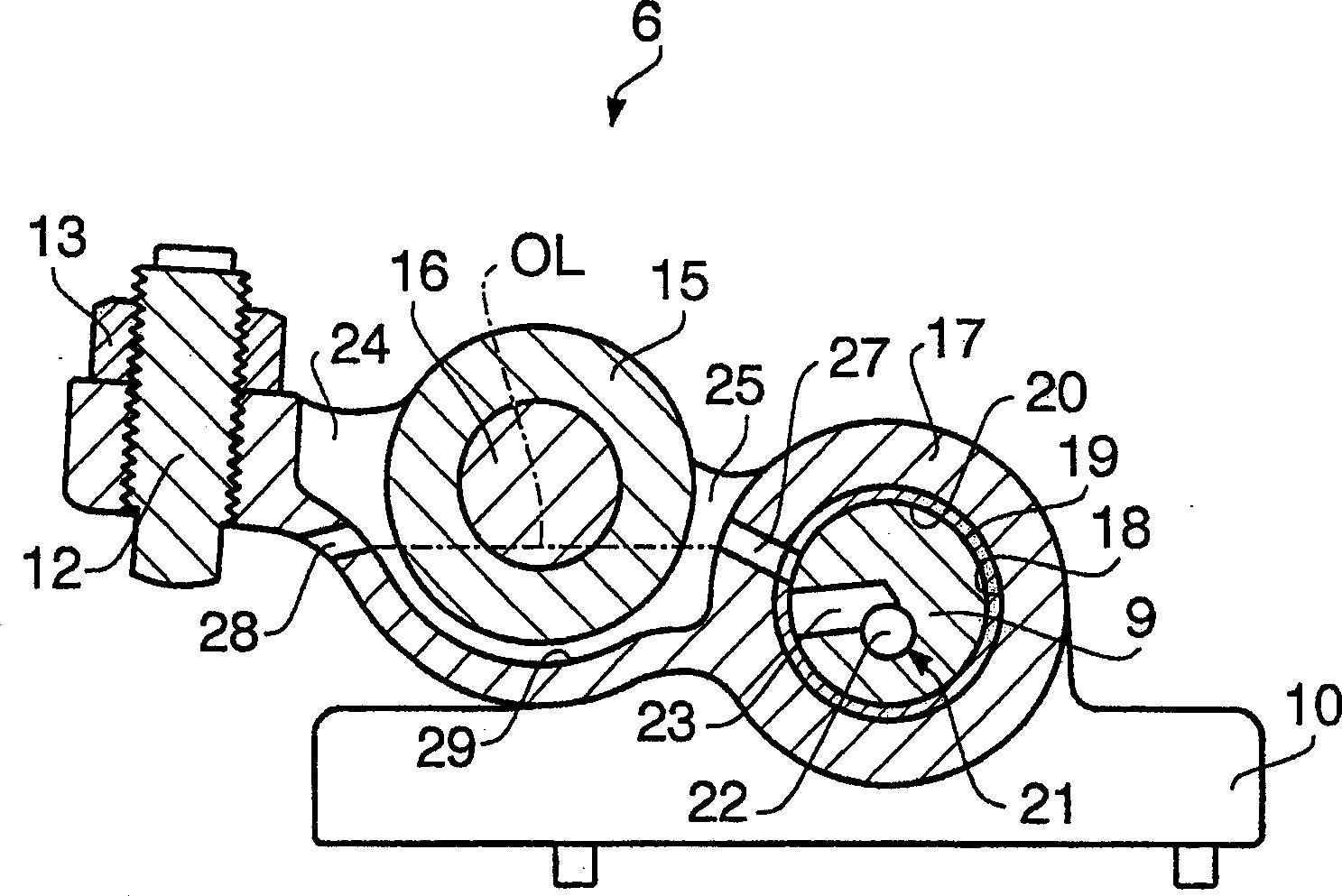

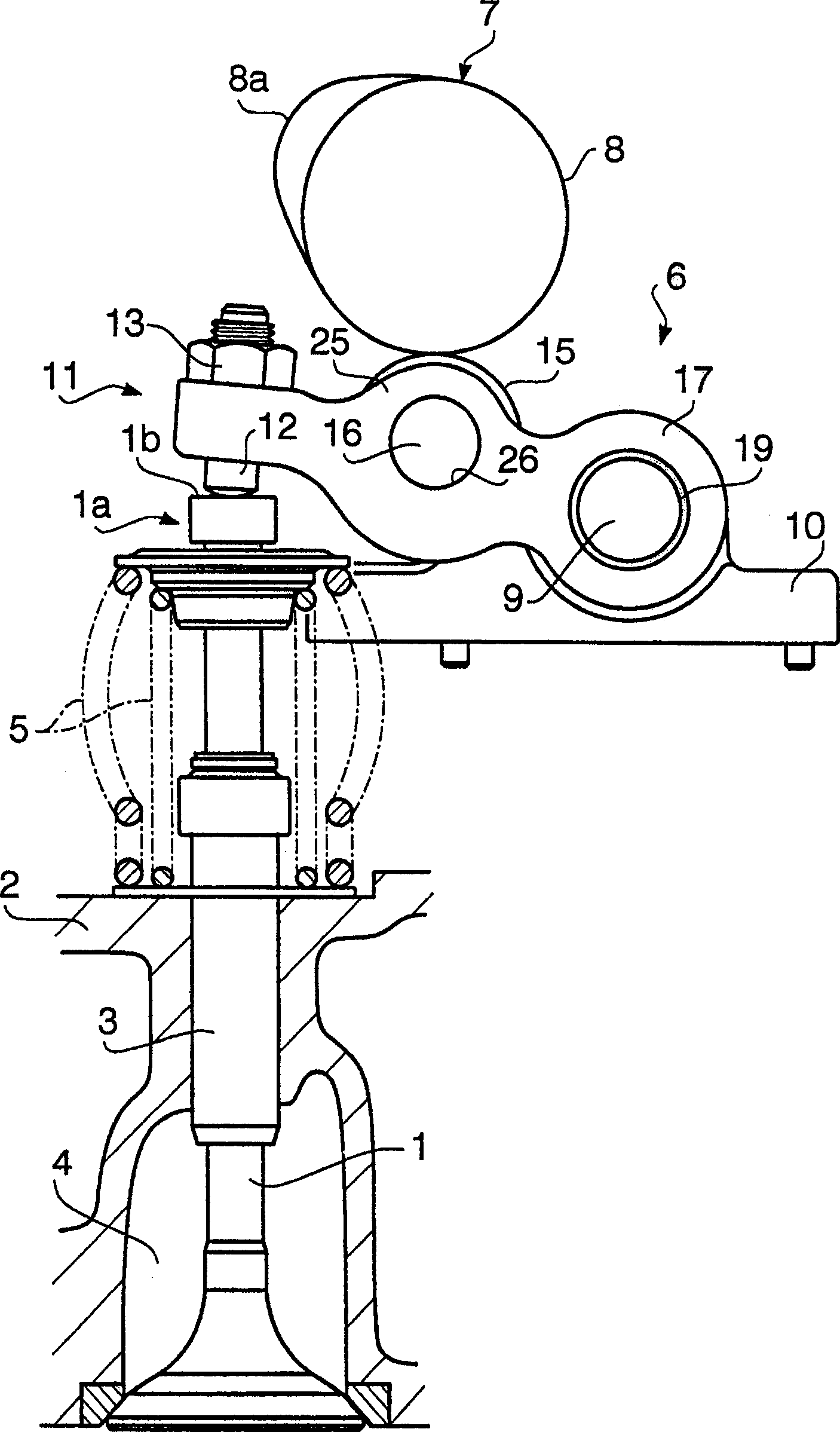

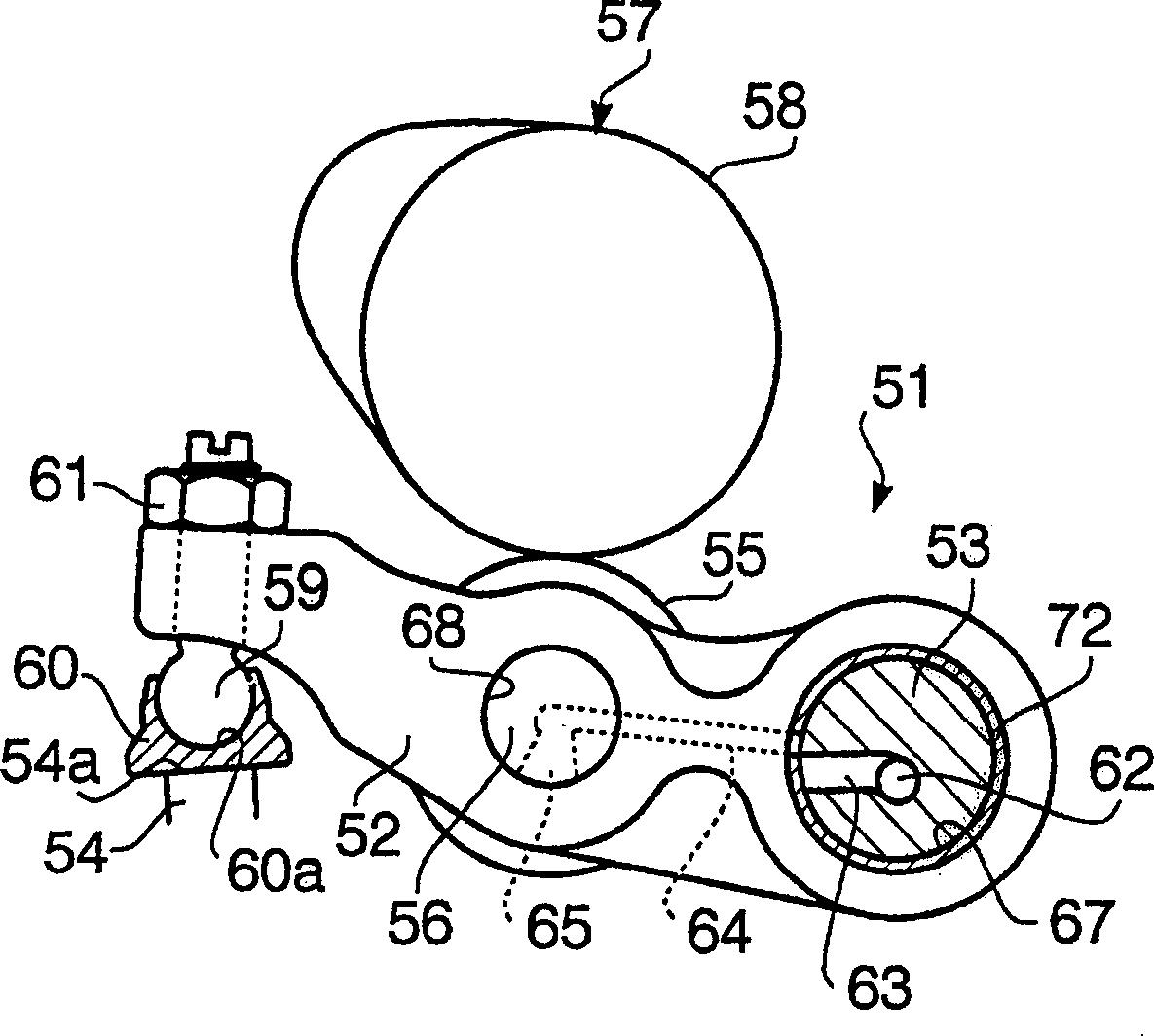

[0030] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] figure 2 A valve mechanism of an internal combustion engine according to the present invention is shown. The valve 1 constituting the intake or exhaust valve is supported in a valve guide 3 fixed in a cylinder head 2 so that the valve can move up and down and open and close the valve constituting the intake or exhaust port. A channel 4 inlet or outlet. The valve 1 is always driven upward by a valve spring 5, in other words, it is in the closed state of the valve; a shaft end 1a is pressed down by the rocker shaft 6, so that the valve is pressed down and the valve is opened. . The rocker arm 6 is positioned below a cam 8 of a camshaft 7 and is connected to the valve 1 in order to increase the amount by which the cam 8 lifts.

[0032] A rocker shaft 9 is fixed on the cylinder head 2 via a boss 10 so that it cannot rotate. One end of the rocker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com