Engineering machinery iron casting drilling waste chip recycling device

A technology of construction machinery and recycling device, applied in the field of iron casting processing, can solve the problems of waste of resources, reduction of workpiece quality, influence of workbench, etc., and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

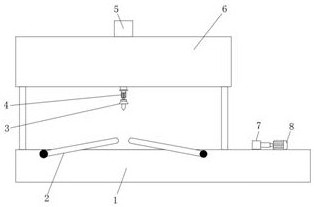

[0028] Both sides of the base 1 are provided with two sets of circular grooves, and a fixed mechanism 2 is connected to the circular grooves in rotation. The fixed mechanism 2 includes an L-shaped clamping rod 15, and the lower part of the vertical arm of the L-shaped clamping rod 15 The side close to the side wall of the base 1 is fixedly equipped with connecting ear pieces inserted in the circular groove on the base 1, and the lower part of the vertical arm of the L-shaped clamping rod 15 is provided with a threaded through hole pointing to the direction of the base 1. And a clamping screw 16 is connected to the internal thread of the threaded through hole. During use, the L-shaped clamping rod 15 is deflected so that its horizontal support arm is placed on the upper surface of the cast iron, and the clamping screw 16 is screwed in, thereby The L-shaped clamping rod 15 clamps and fixes the iron casting, which facilitates the subsequent drilling process;

Embodiment 2

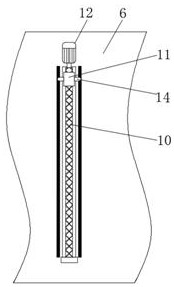

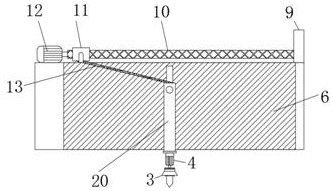

[0030] The adjustment mechanism 5 includes a fixed plate 9 and a second motor 12 fixedly installed on both sides of the bar-shaped opening on the top seat 6, and the output shaft of the second motor 12 is concentrically connected with a reciprocating lead screw 10 that is rotatably connected with the fixed plate 9. The outer threaded sleeve of the lead screw 10 is provided with a threaded sleeve 11, and both sides of the threaded sleeve 11 are fixedly equipped with L-shaped guide rods 14, and the top of the top seat 6 is provided with two sets of bar-shaped guides parallel to the reciprocating screw 10. Slot, the vertical support arm of L-shaped guide rod 14 is slidingly connected with top base 6 in the guide groove, and the bottom end of threaded sleeve 11 is connected with the deflection rod 13 inserted into the inside of the bar-shaped opening on top base 6. The seat 6 is provided with vertical guide grooves on both sides of the strip-shaped opening, and the telescopic rod 2...

Embodiment 3

[0035] One side of the top of the base 1 is provided with a collection tank, and the top of the base 1 is fixedly installed on both sides of the collection tank with a push rod motor 8 whose output shaft points to the horizontal direction, and one end of the output shaft of the push rod motor 8 is fixedly connected with an adsorption mechanism 7 The inside of the adsorption mechanism 7 is provided with an electromagnet.

[0036] After the iron castings are drilled, start the push rod motor 8 to make the adsorption mechanism 7 move horizontally, and energize the electromagnet inside the adsorption mechanism 7, and then absorb the iron filings scattered on the upper surface of the base 1. After completion, the adsorption mechanism 7 is returned to the upper side of the collection tank, and the electromagnet is powered off, so that the absorbed iron filings fall into the collection tank for collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com