Patents

Literature

32results about How to "Realize drilling operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

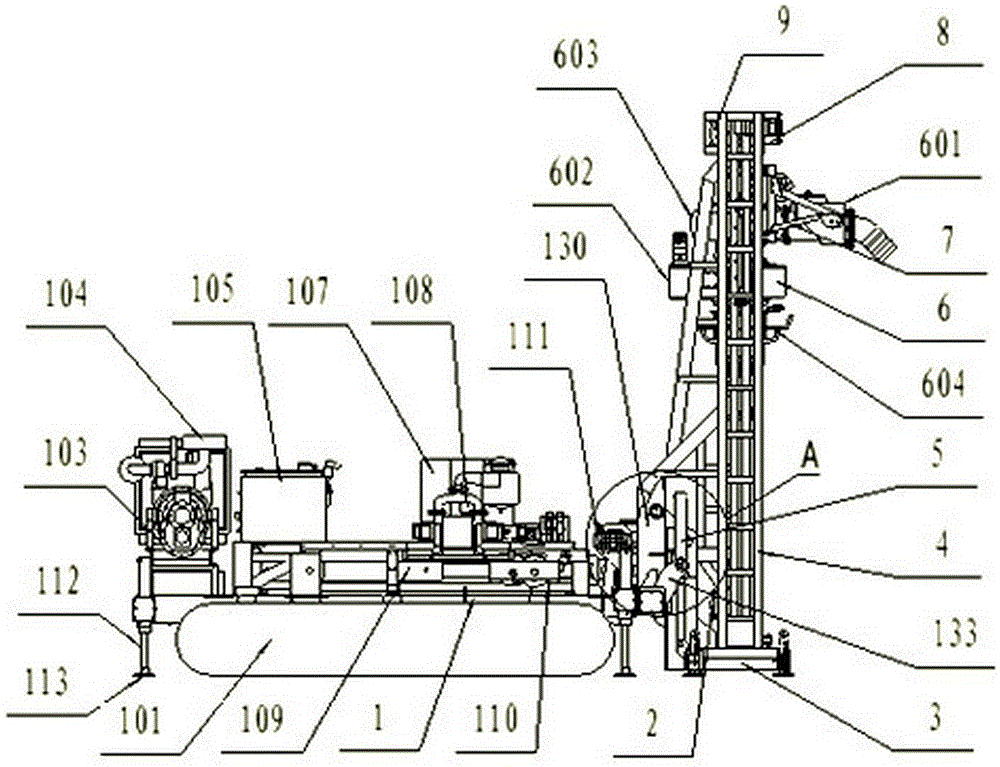

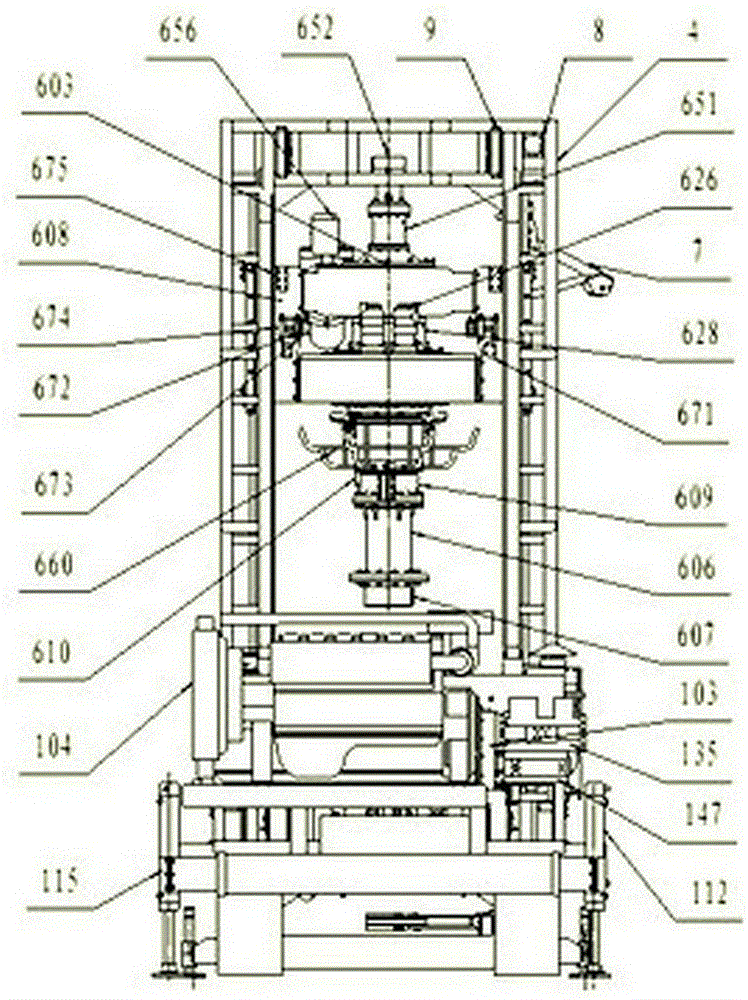

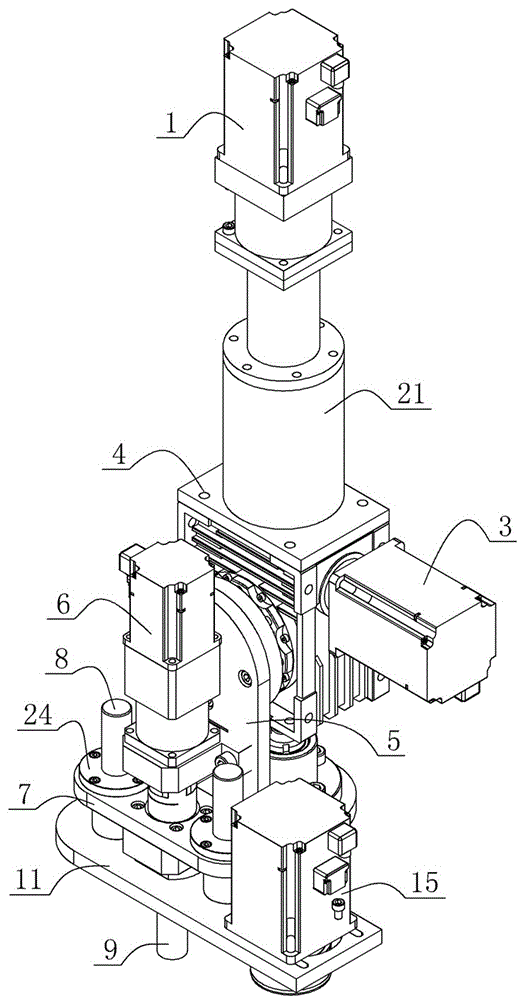

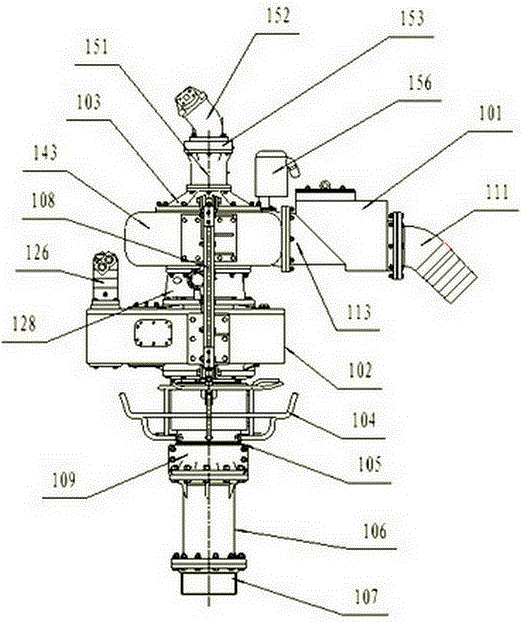

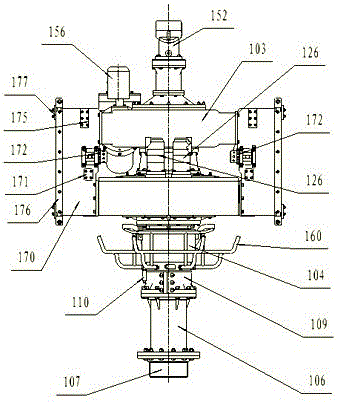

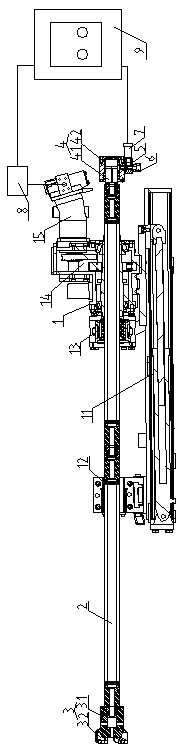

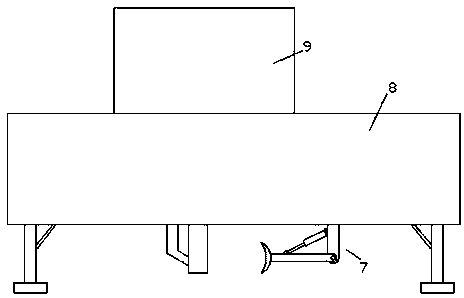

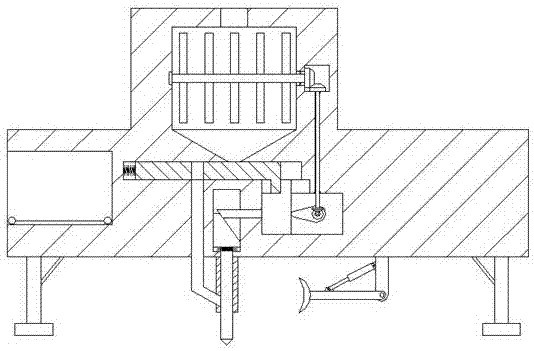

Fully hydraulic reverse circulation drilling machine

InactiveCN105064915AAdapt to the working environmentReduce noiseDrill bitsDrilling rodsGear wheelWinch

The invention provides a fully hydraulic reverse circulation drilling machine, which comprises a walking mechanism, a chassis assembly, a work table frame assembly, a main frame, a main frame turning oil cylinder, a swinging rod assembly, a winch assembly, a drill pipe, a dismounting device, a hydraulic system, a power take-off assembly, an impact drill bit, a rotating wing drill bit, a power assembly and an oil cylinder pulley assembly. A diesel engine or electric power is used for driving; hydraulic motors and oil cylinders are used as executing mechanisms; and the whole process operation of the drilling machine is realized through a hydraulic transmission and control system. The two hydraulic motors and a gear reducer are used for forming a power head to drive a drilling tool to rotate; the hydraulic motors adopt a serial connection or parallel connection mode; and the drill pipe realizes different rotating speeds and can adapt to different-geological-condition and different-hole-diameter operations. The oil cylinders are used for controlling the oil pipe feeding and lifting the drilling tool, so that the power head can vertically move along with the drilling tool and can realize floating, suspension stop and pressurized drilling; the drill pipe can be automatically dismounted and mounted; and the impact drill bit and the rotating wing drill bit are used for realizing the hole drilling of holes with the hole diameter being 2 to 3m and the hole depth exceeding 200m in the pebble bed, the hard rock stratum and the stratum containing large-diameter rock blocks.

Owner:王乐康

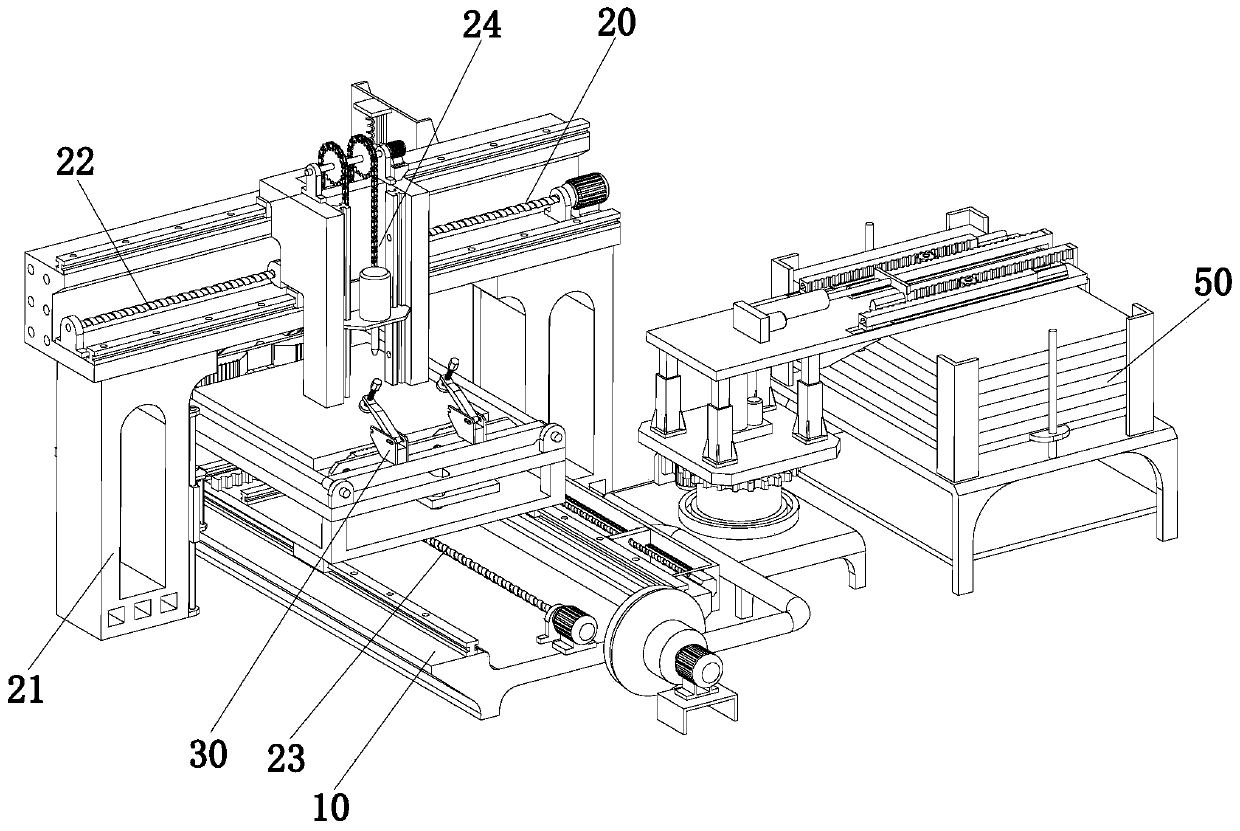

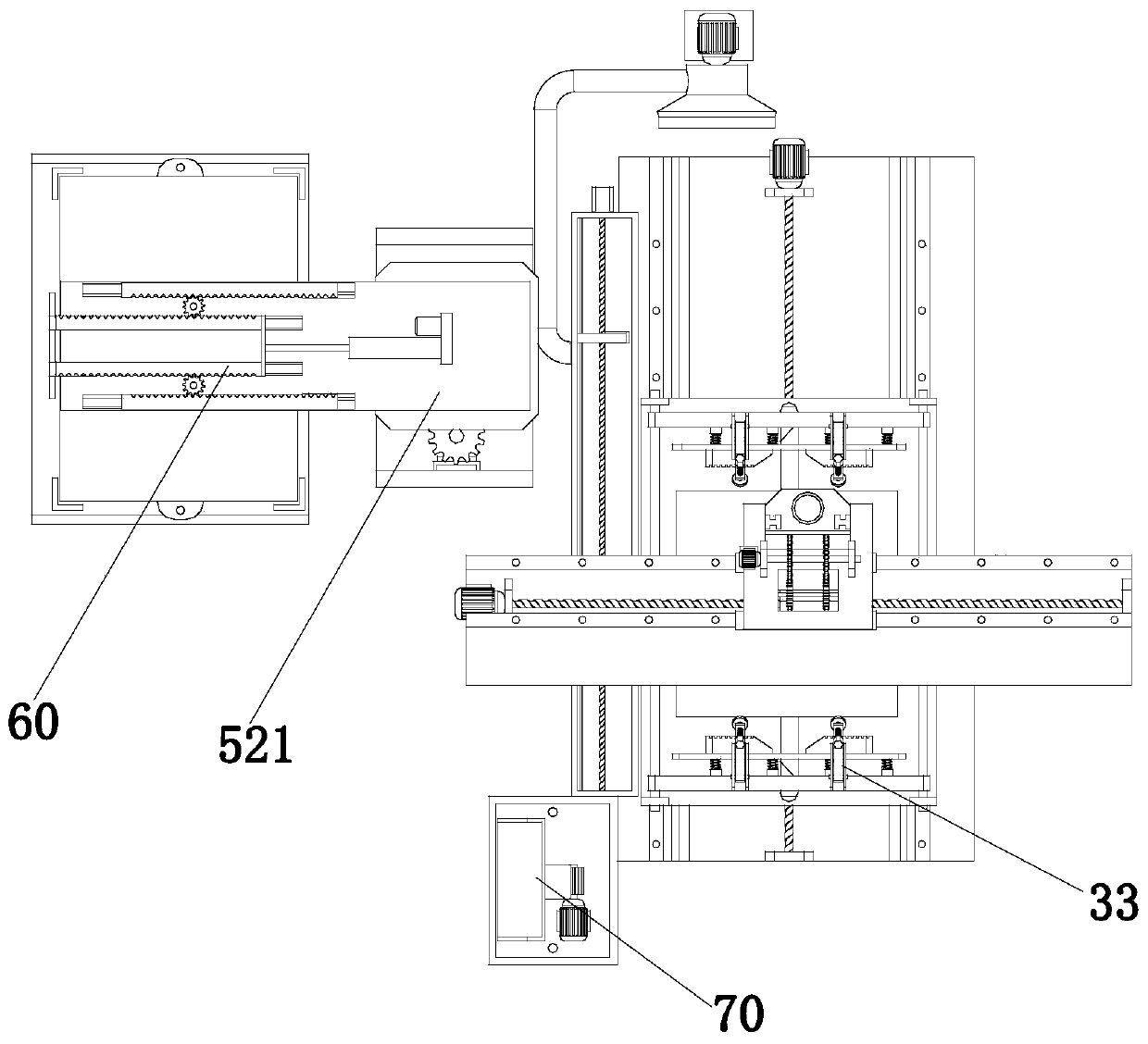

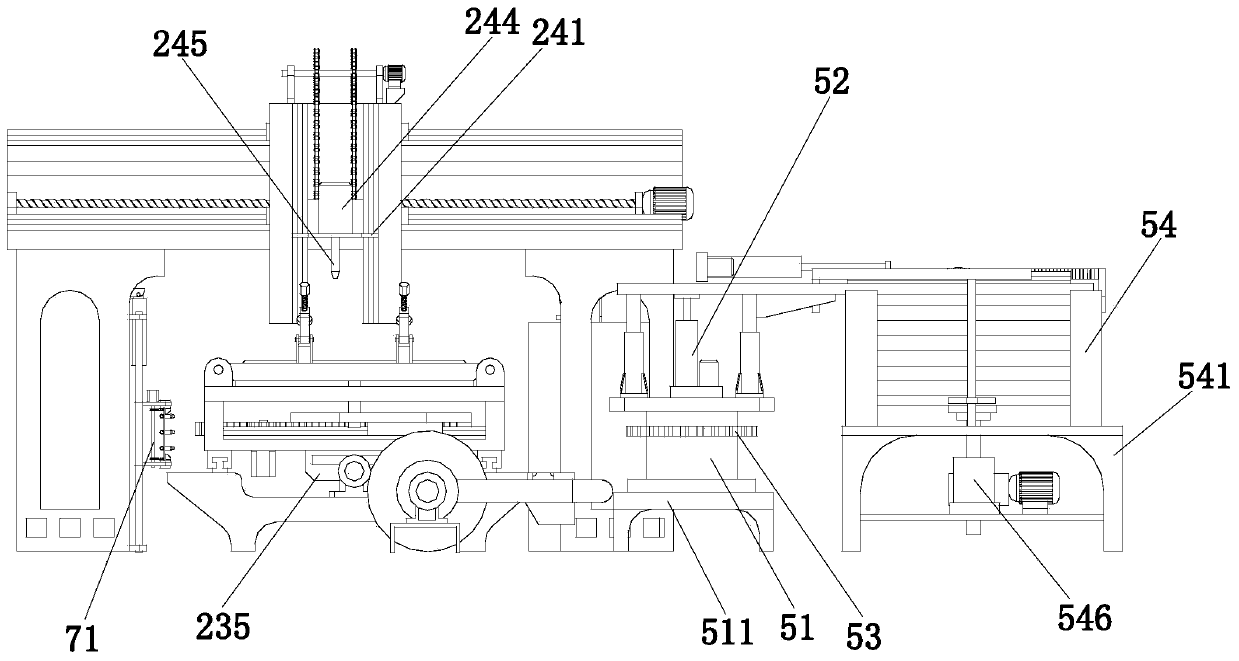

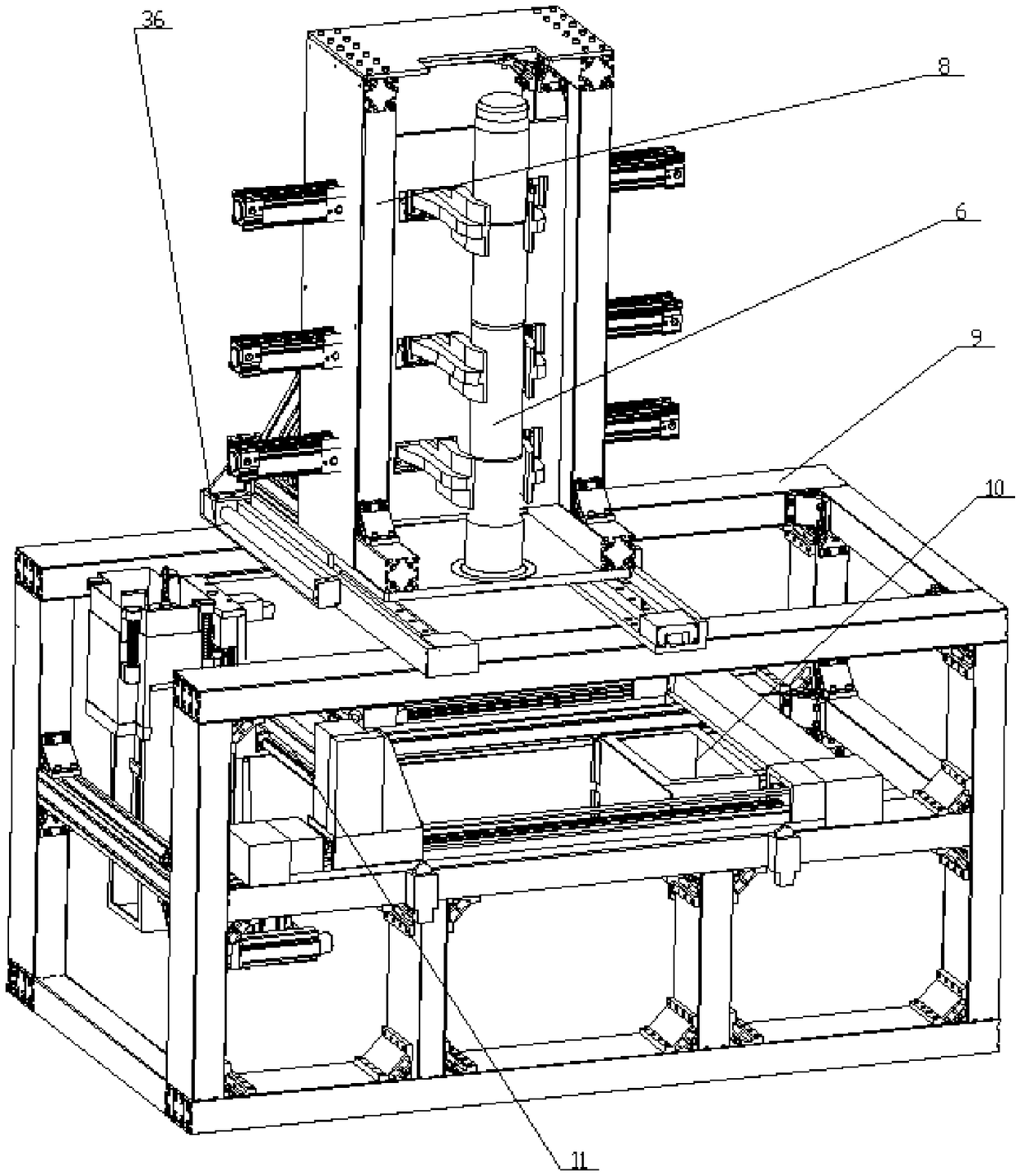

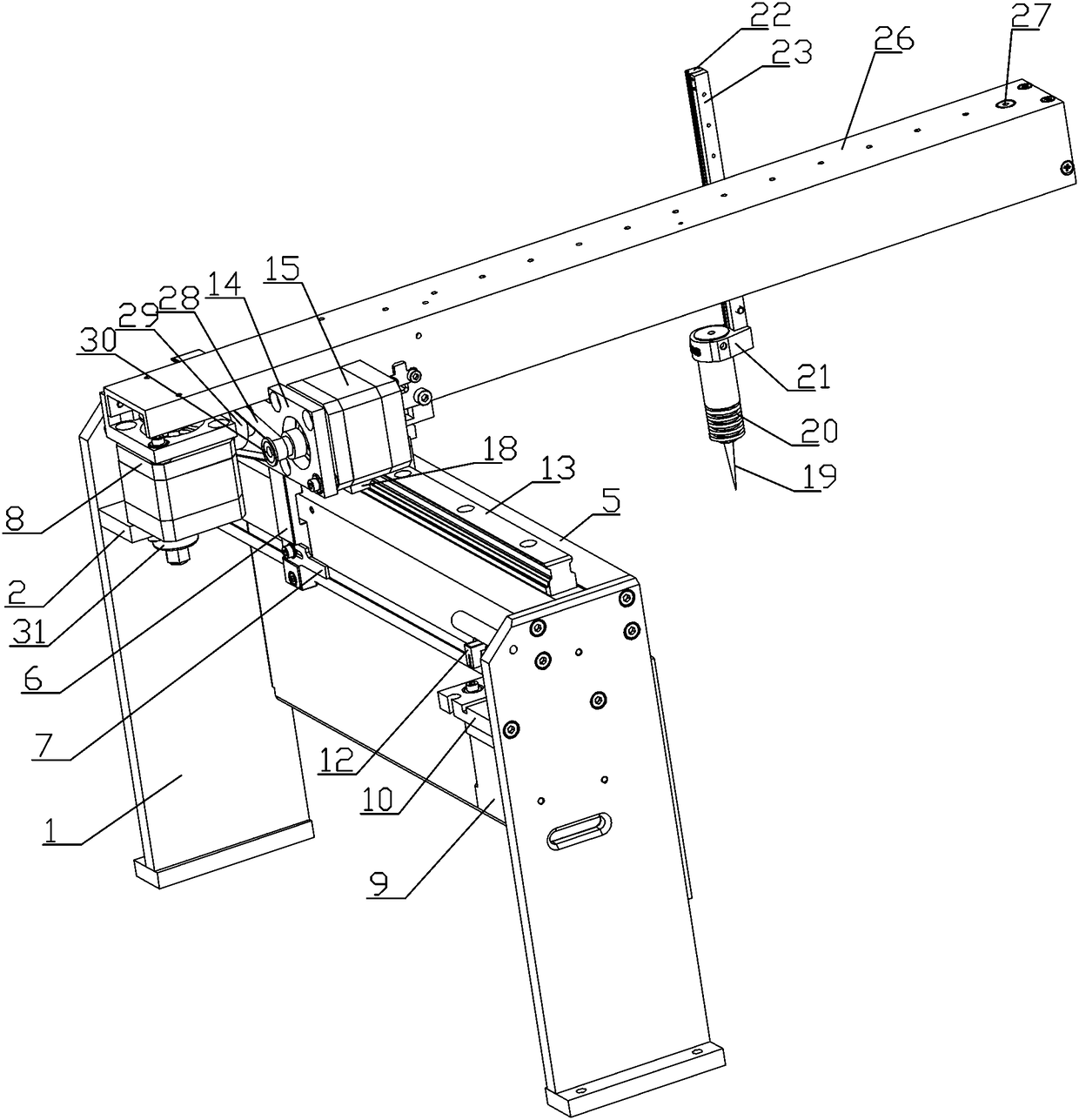

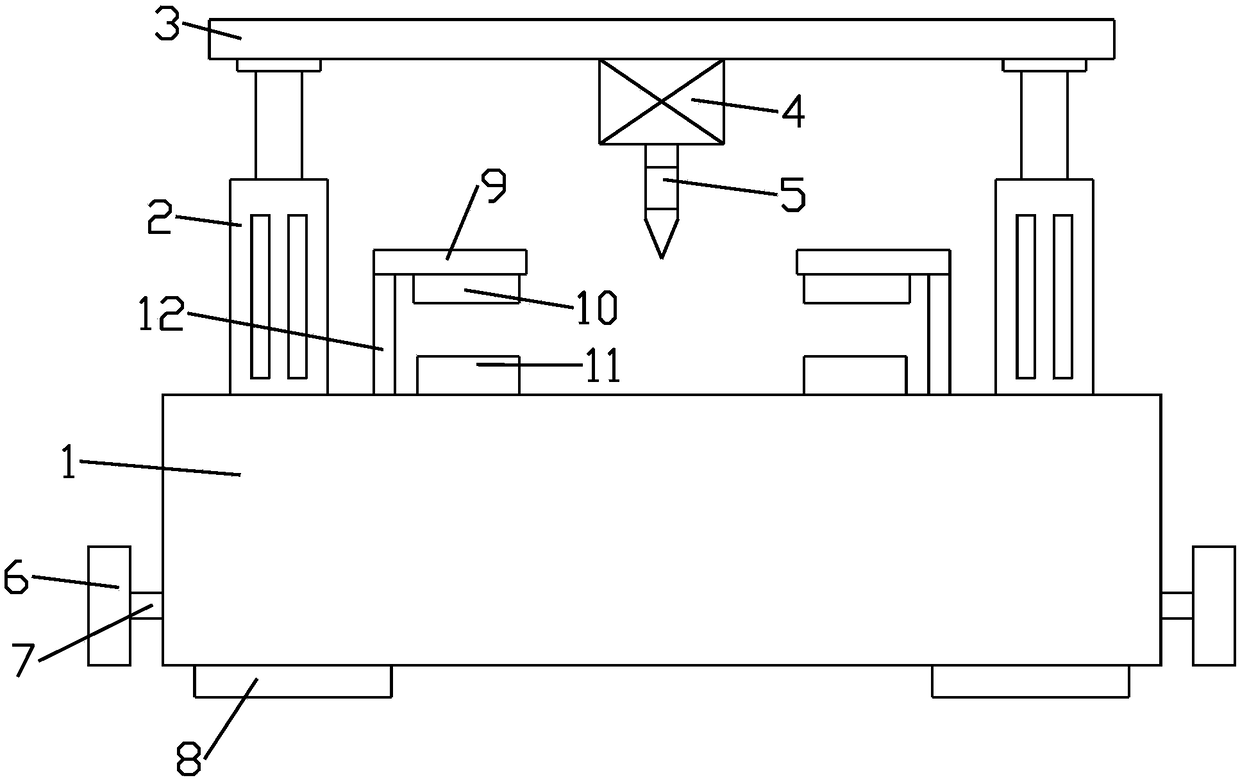

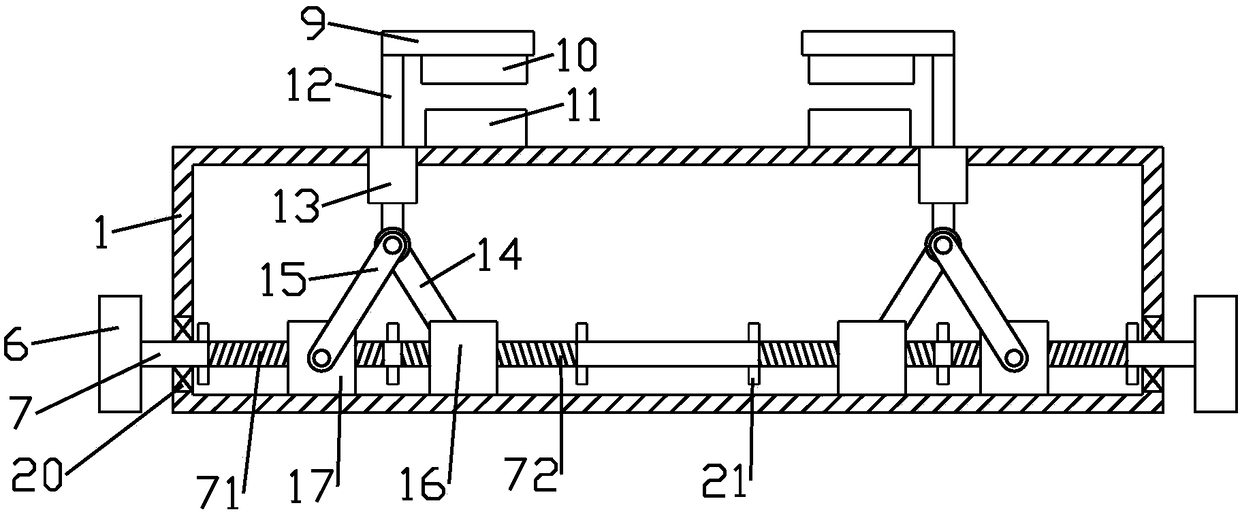

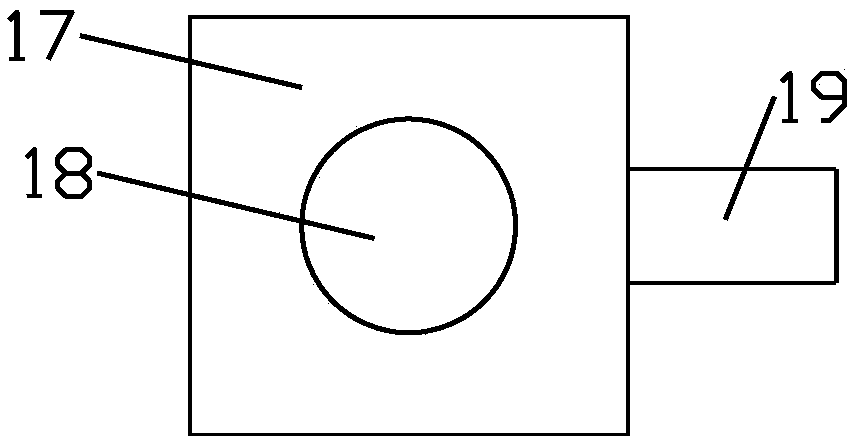

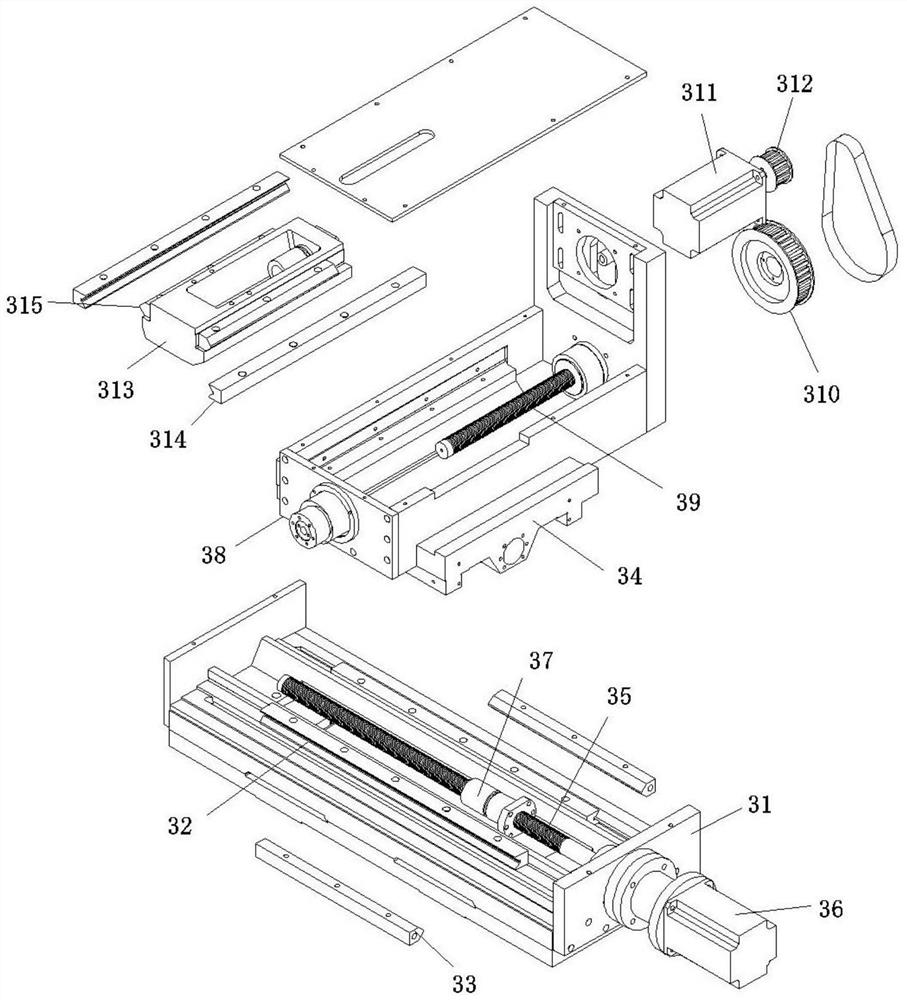

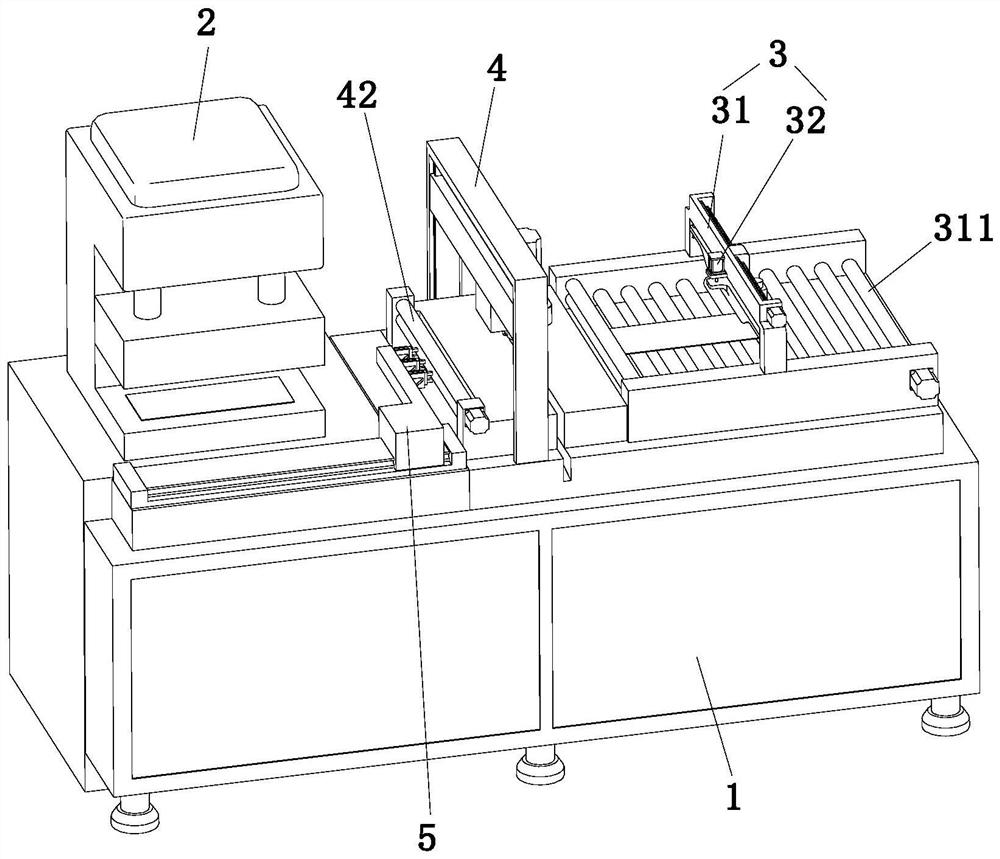

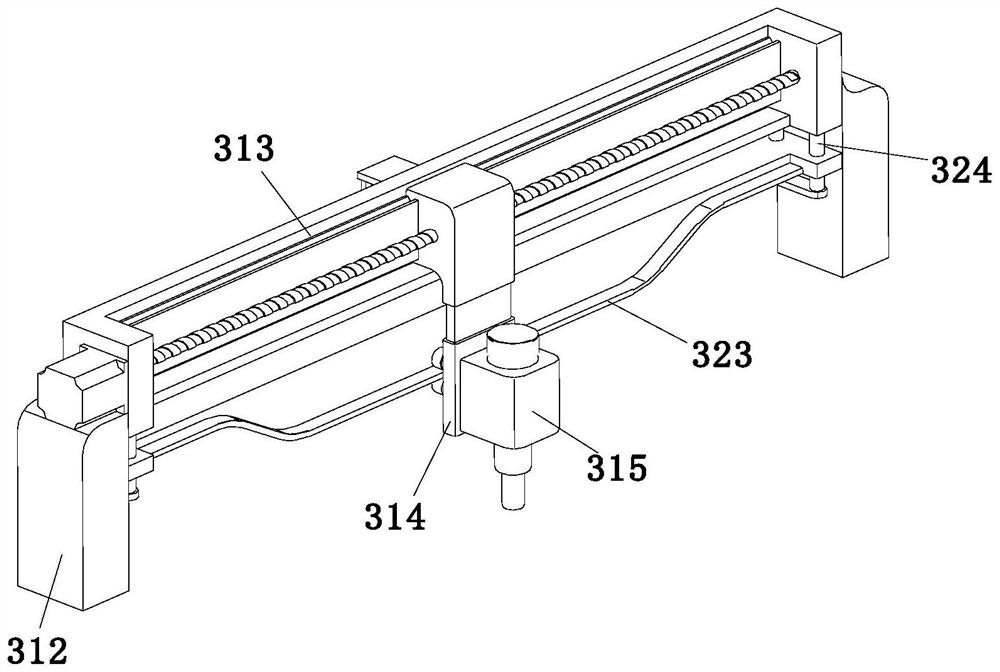

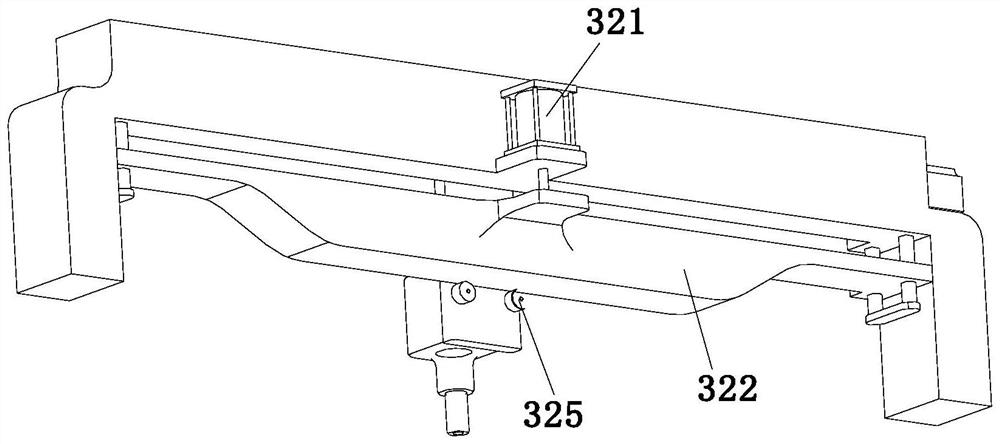

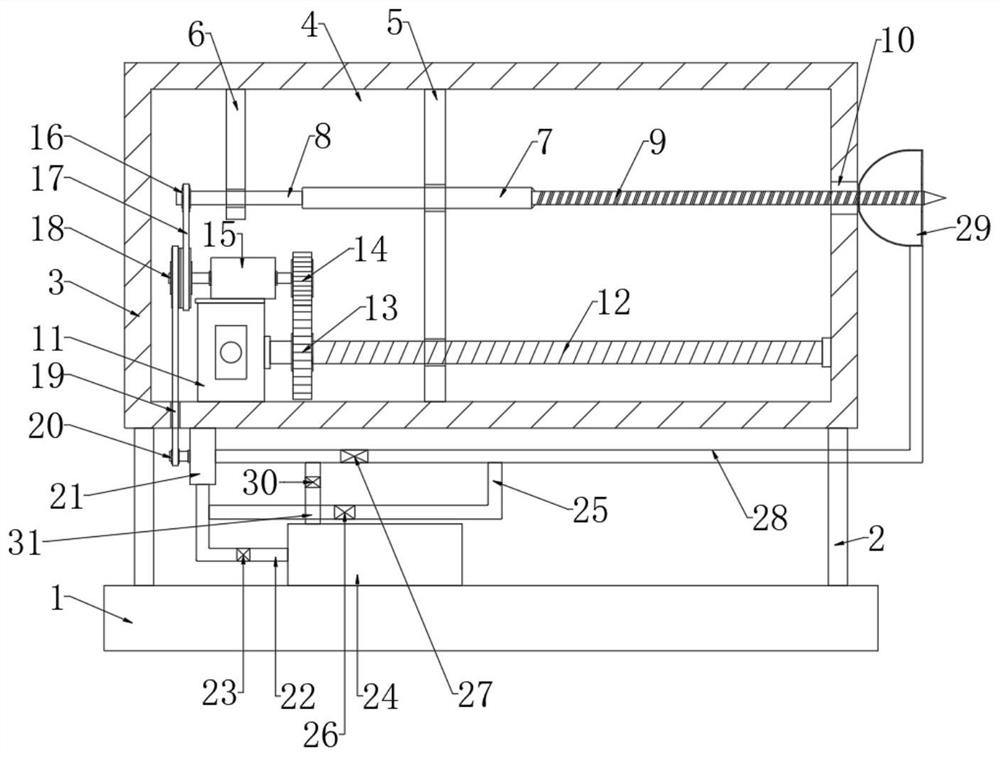

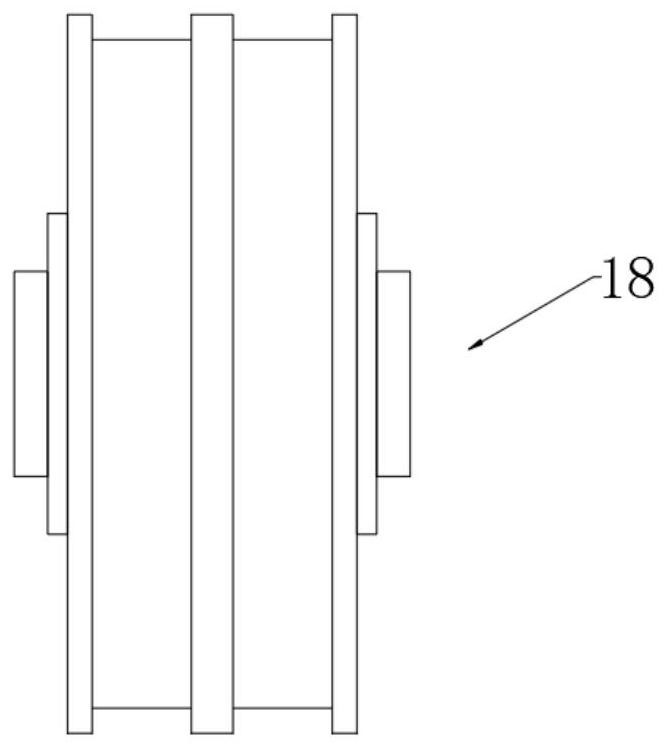

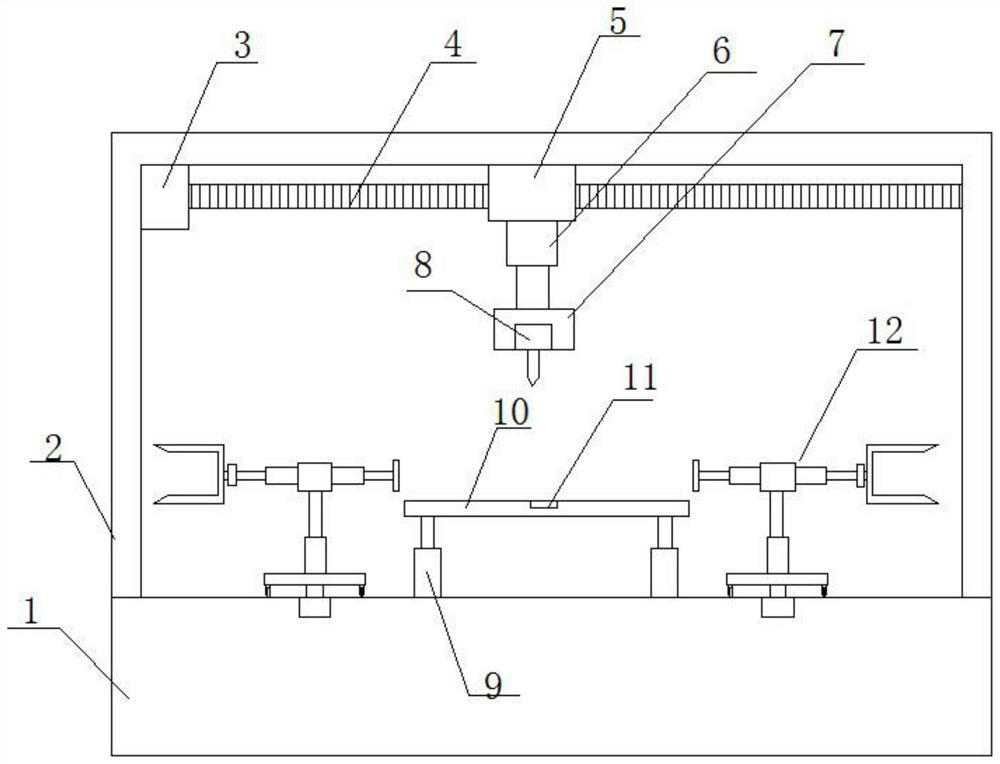

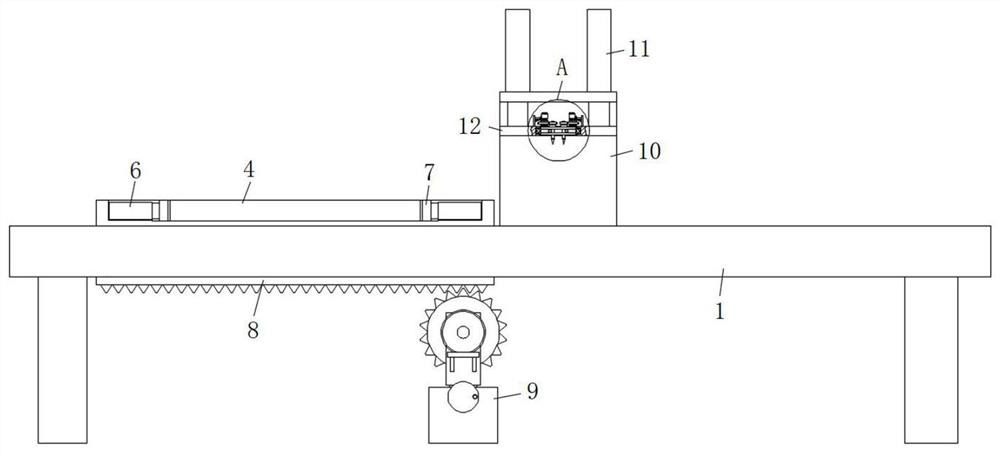

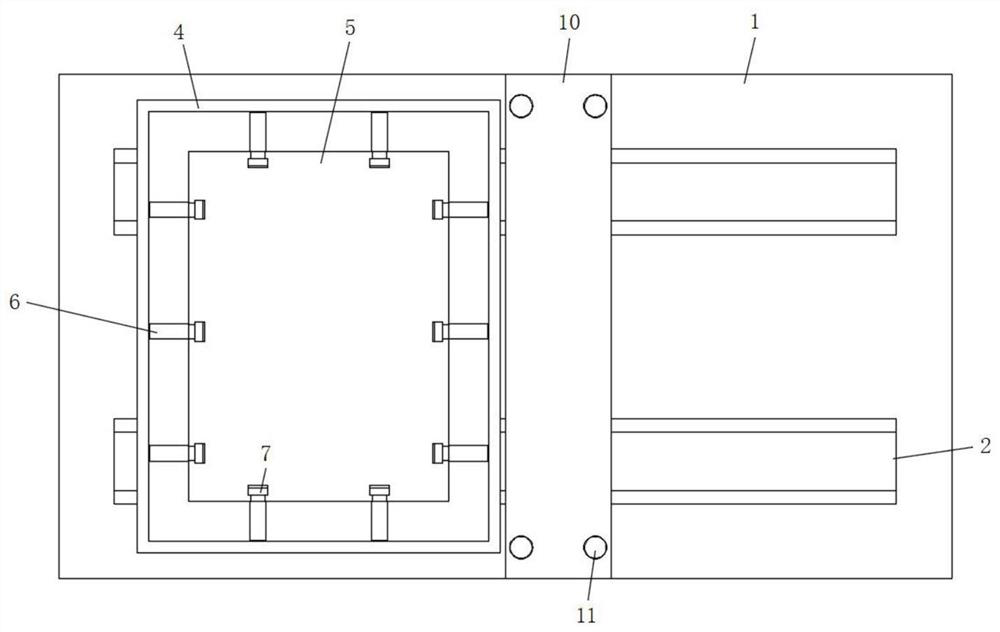

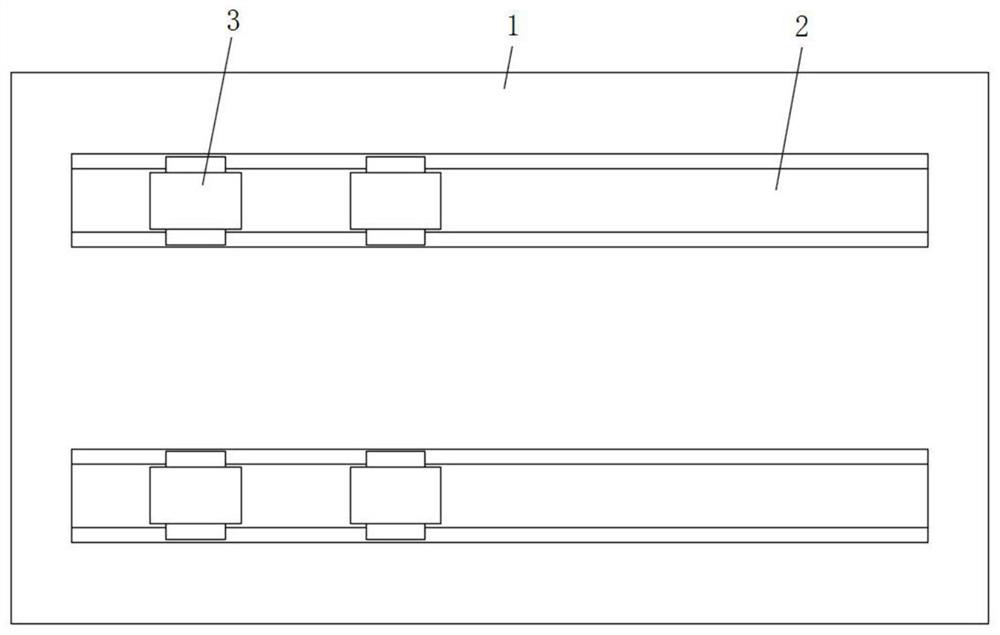

Full-automatic wooden door processing center

InactiveCN110421651ARealize drilling operationsRealize automatic feeding processStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringPortal frame

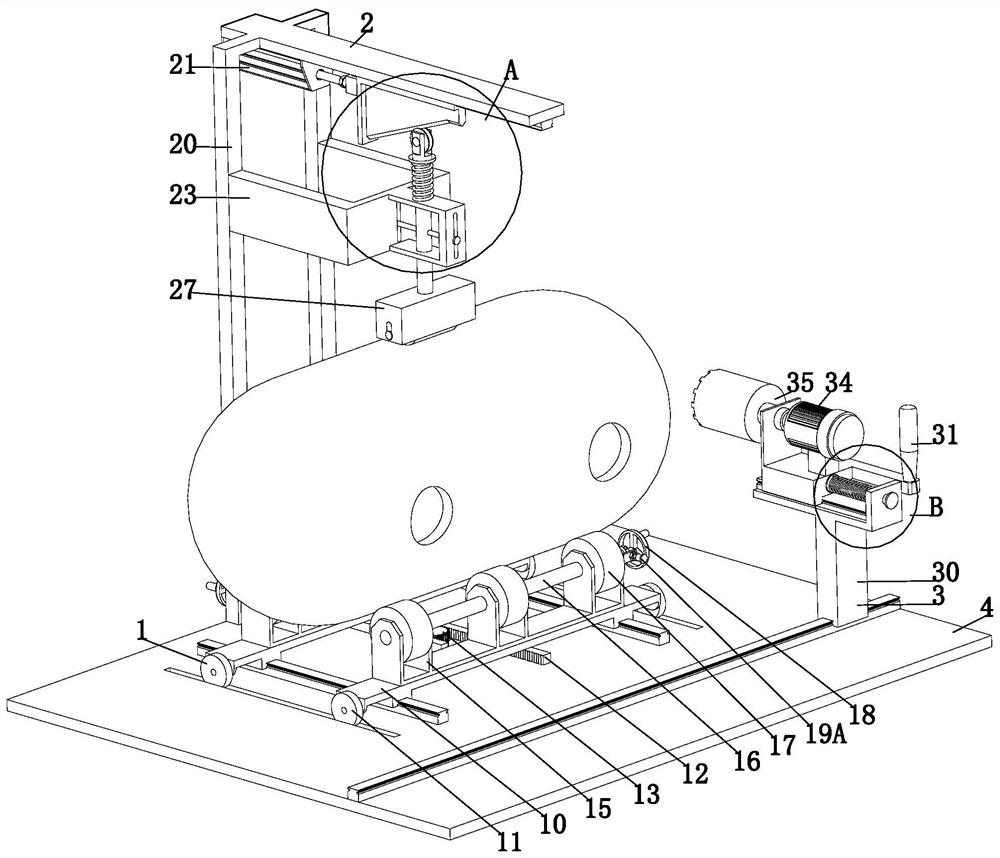

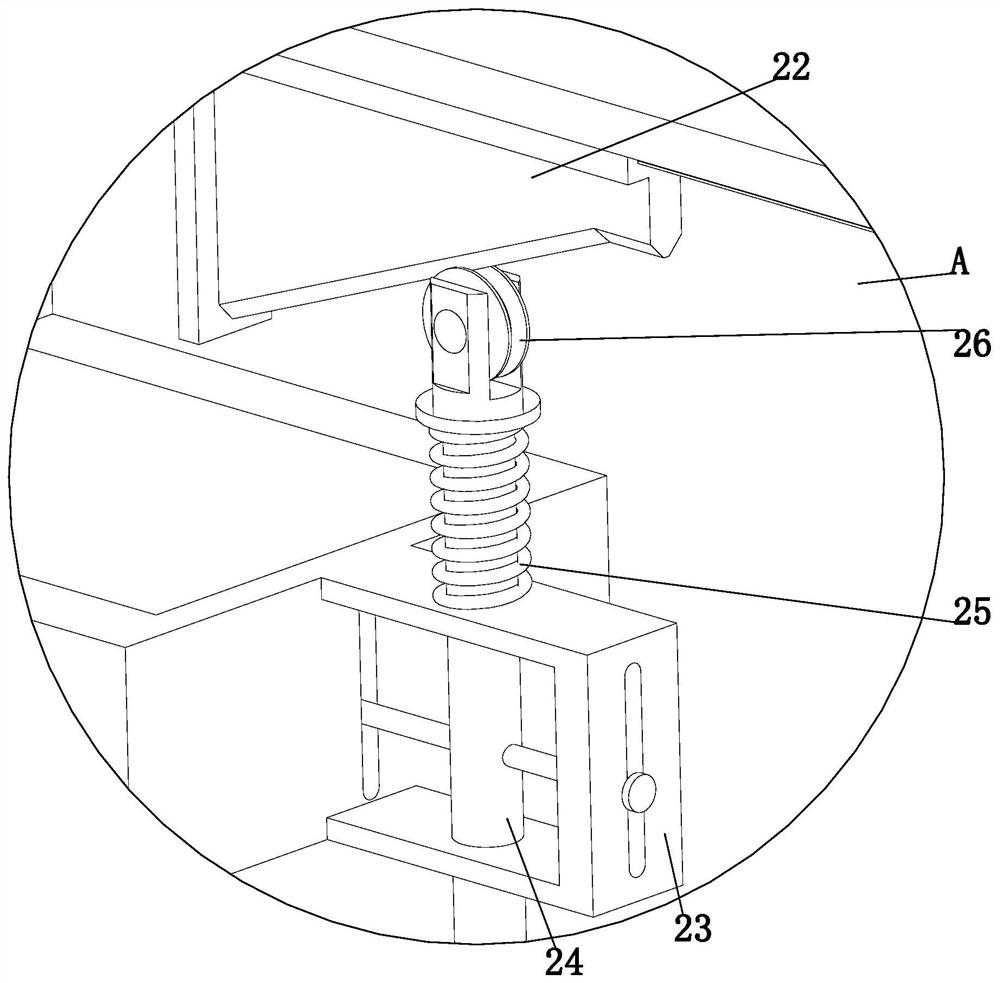

The invention discloses a full-automatic wooden door processing center, and belongs to the technical field of wood board processing equipment. The processing center comprises a base, a three-axis moving mechanism, a wooden door limiting mechanism, an automatic wooden door feeding mechanism and a chip cleaning and compressing mechanism, wherein a sliding table is arranged above the base; the three-axis moving mechanism comprises a portal frame, an X-axis moving mechanism, a Y-axis moving mechanism and a Z-axis moving mechanism; the Y-axis moving mechanism is arranged on the X-axis moving mechanism; the wooden door limiting mechanism comprises a supporting plate, a position adjusting component and two moving strips, and two pressing components are arranged at the top of each moving plate. Limiting operation on wooden doors with different widths can be achieved by the wooden door limiting mechanism, the wooden doors can be automatically stored and sequentially fed by the automatic woodendoor feeding mechanism, manual feeding is not required, and blowing of chips on a material moving table and compression of the chips are achieved by the chip cleaning and compression mechanism.

Owner:惠州捷耀数控机械有限公司

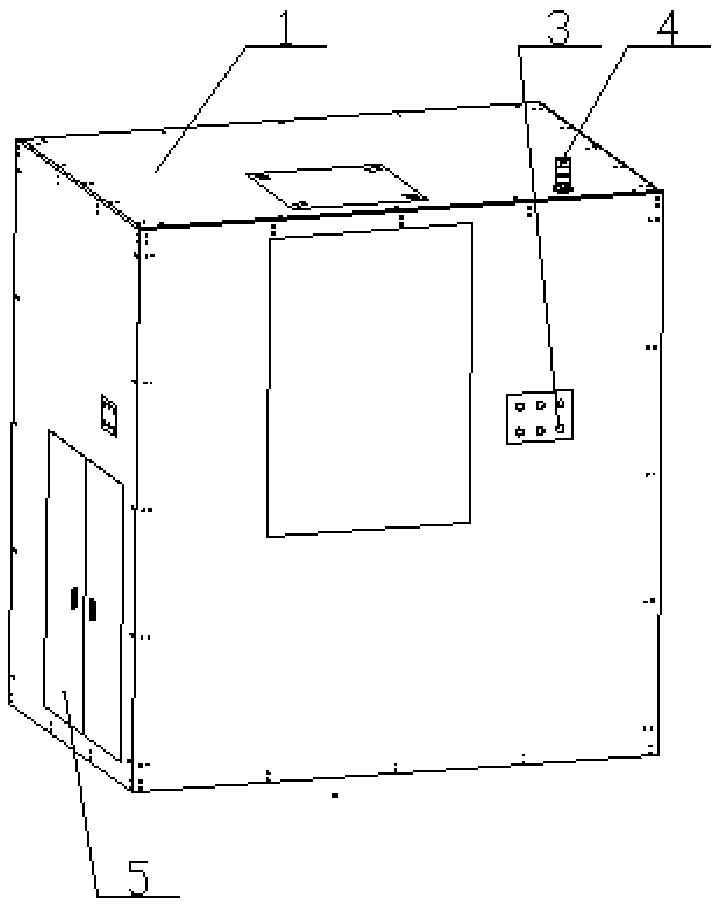

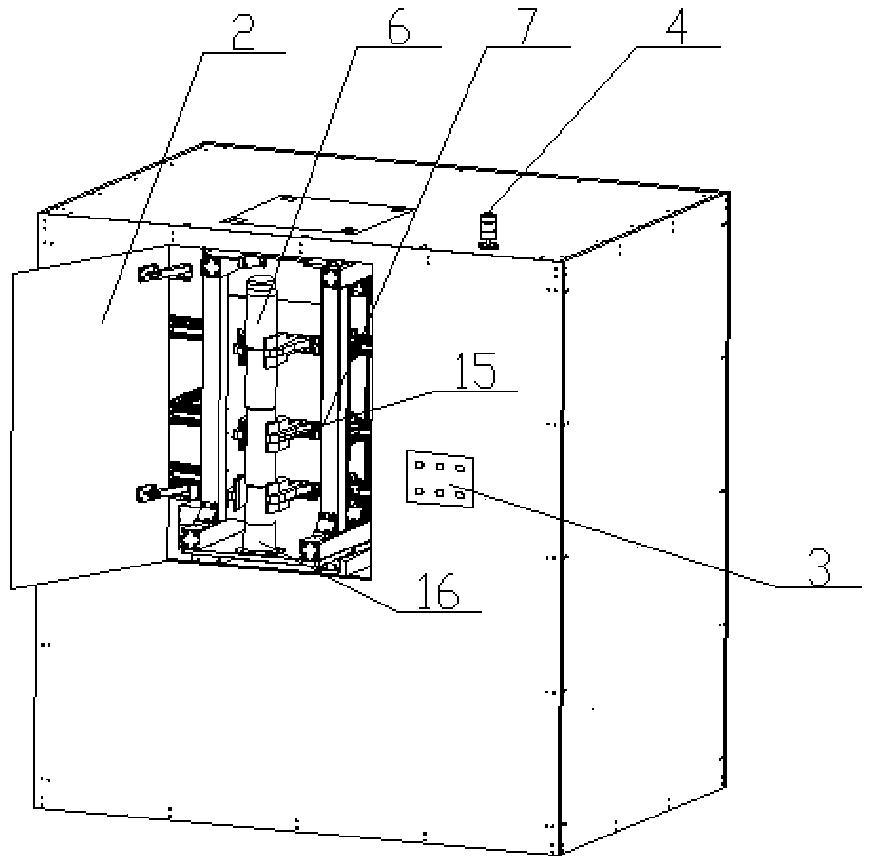

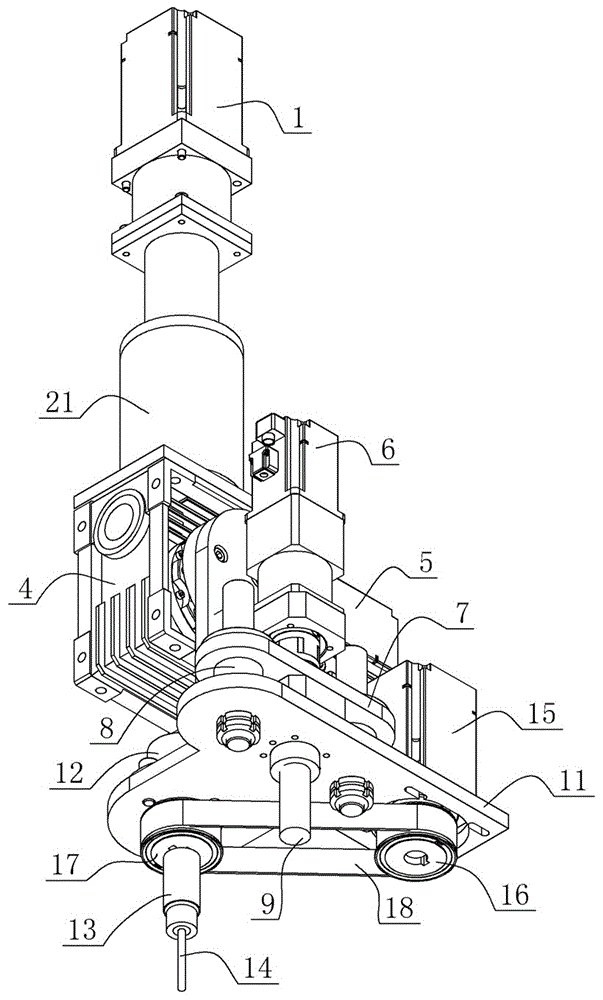

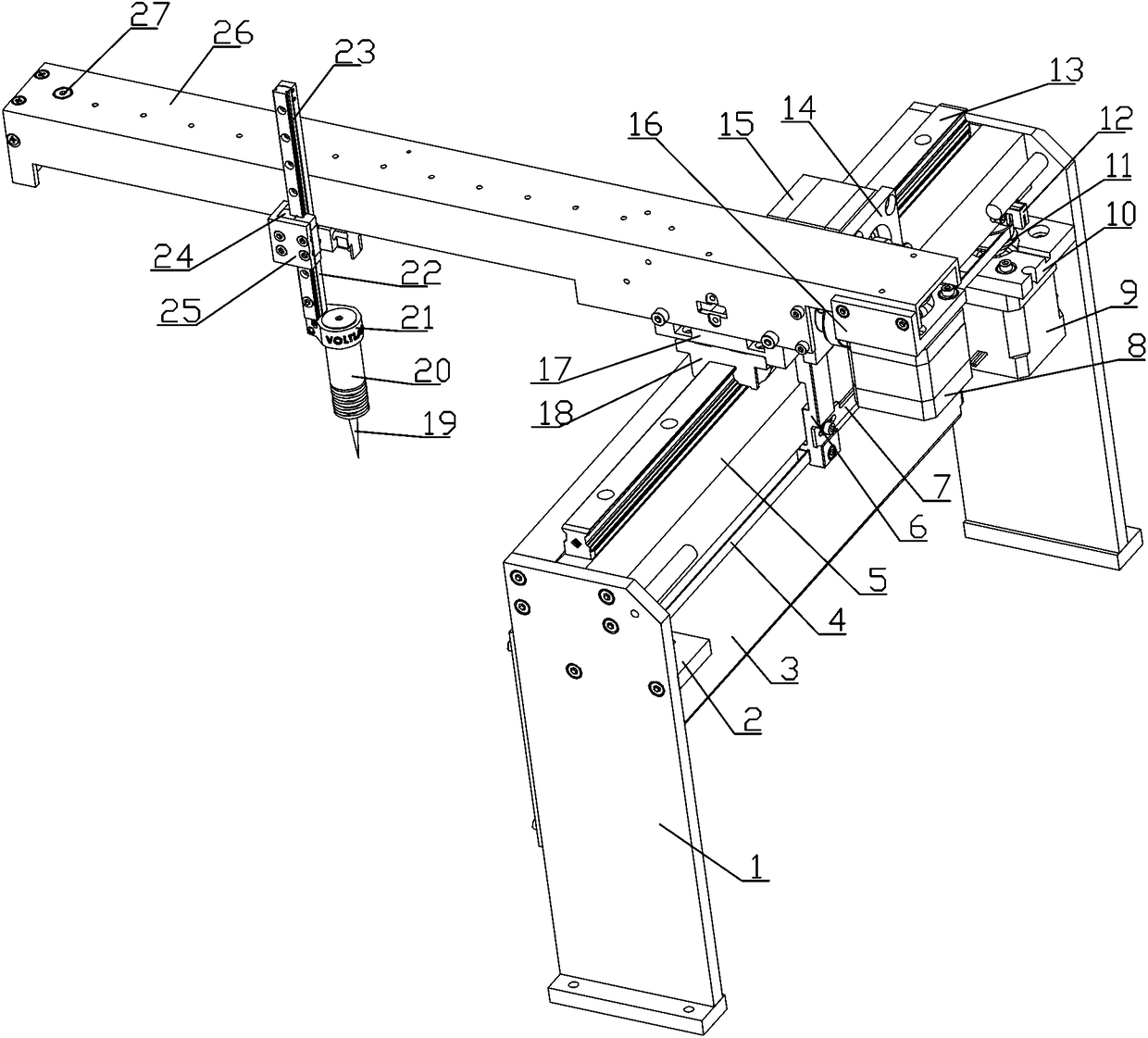

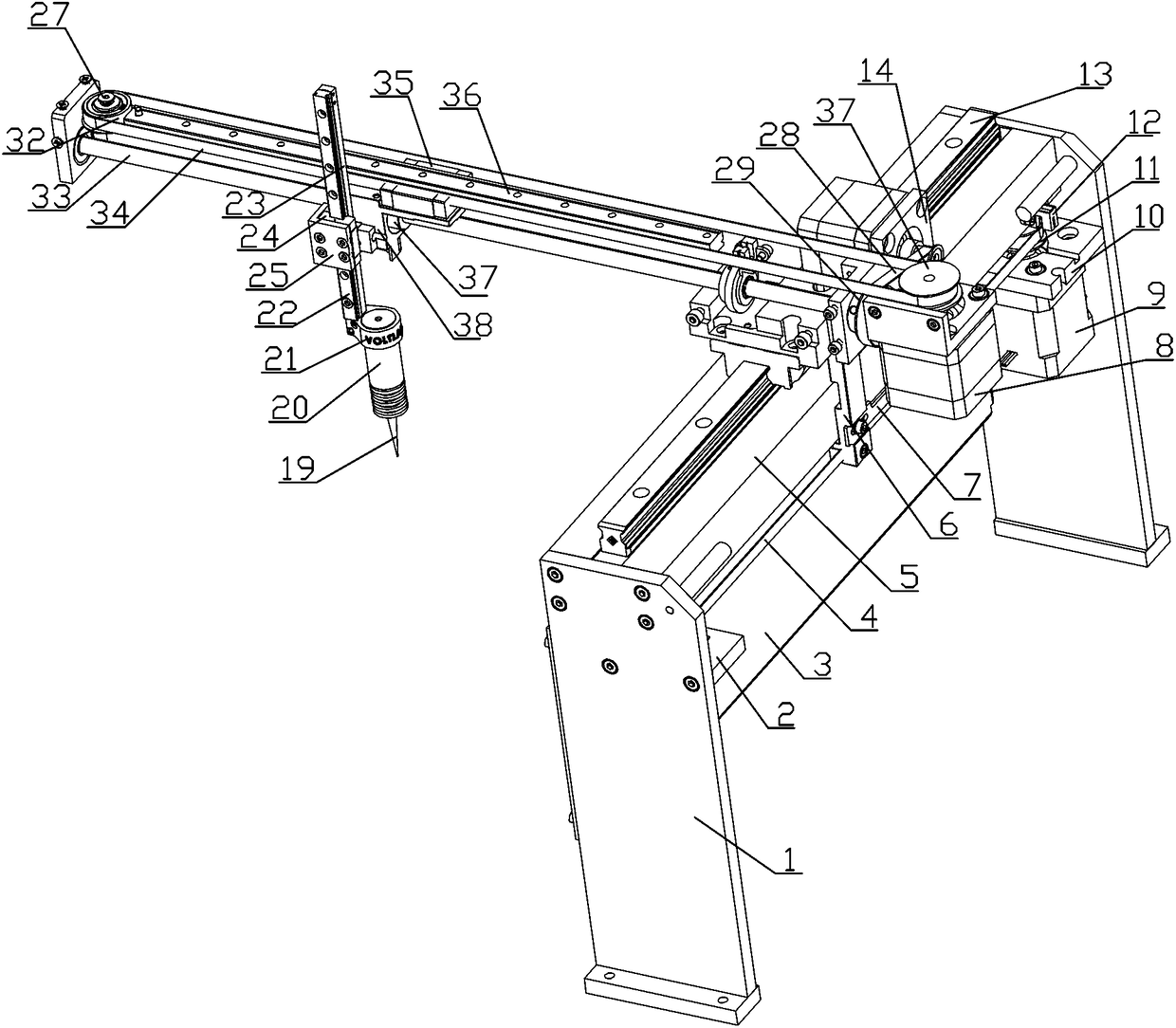

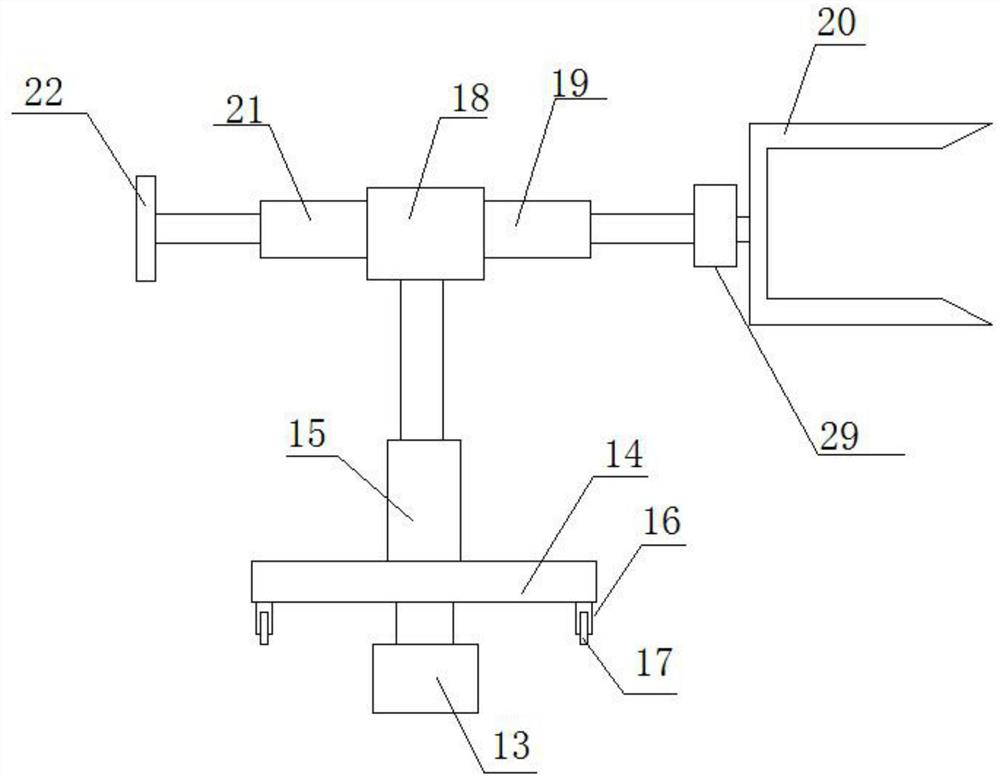

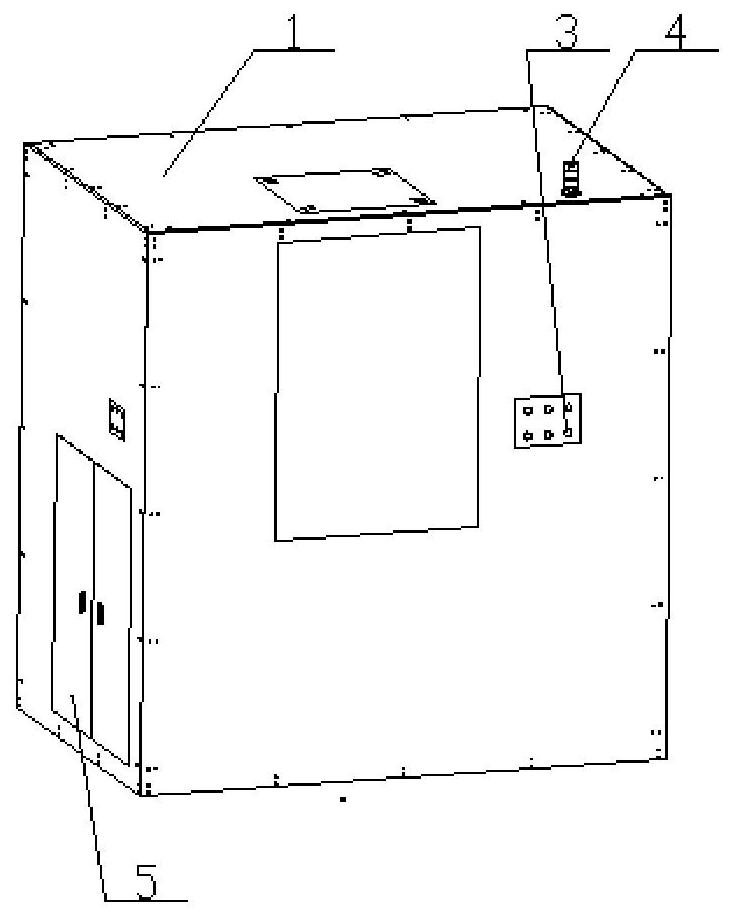

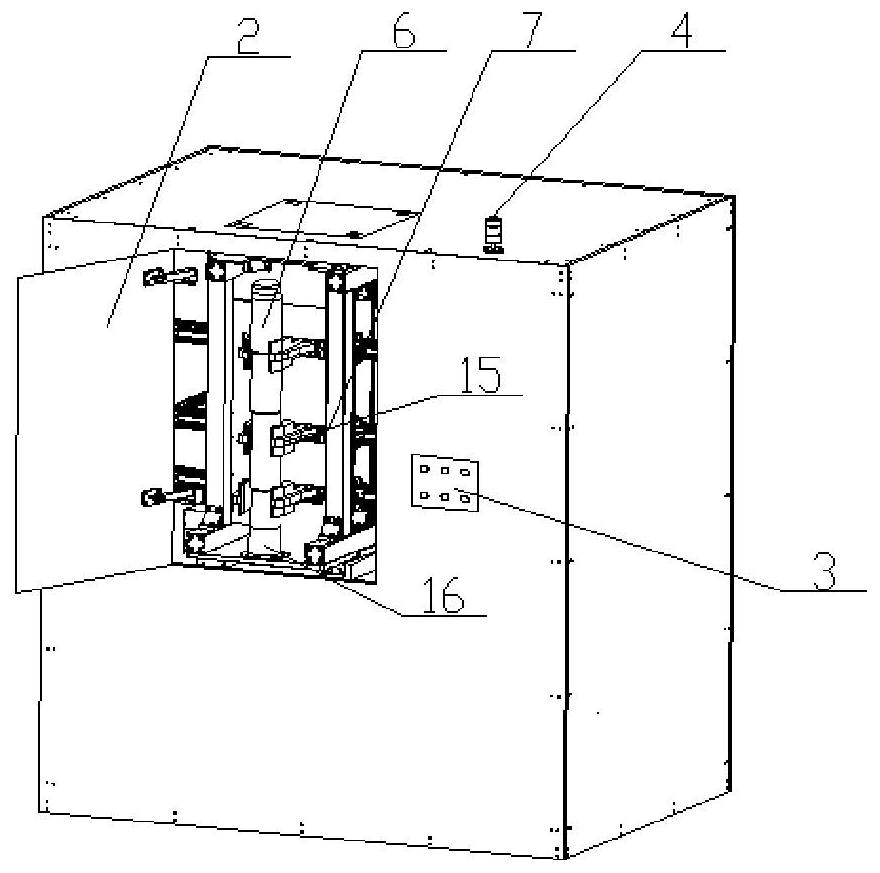

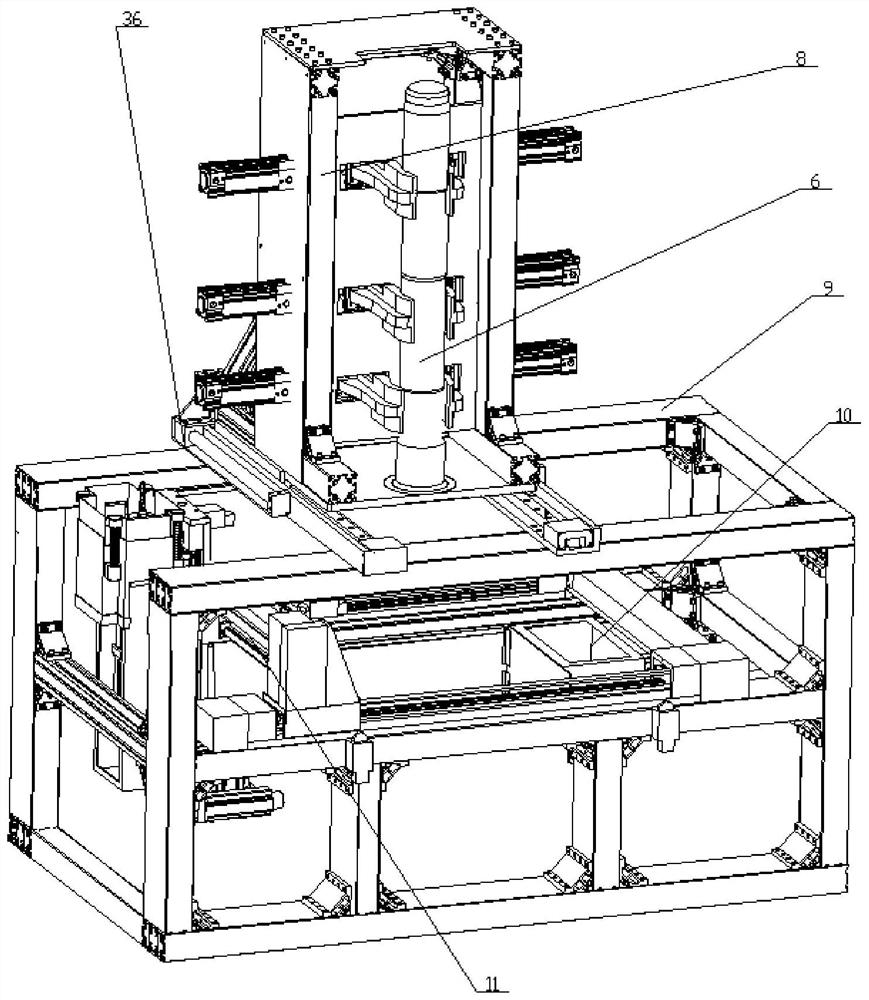

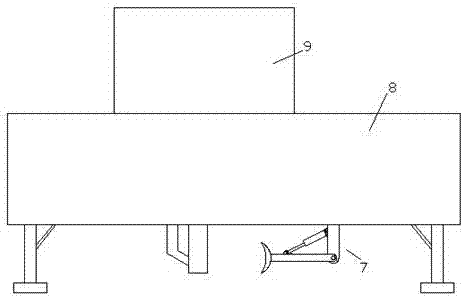

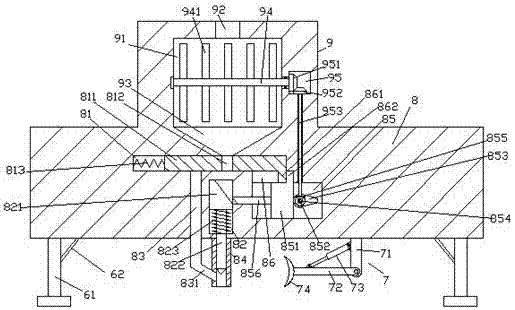

Drilling and shaping device of a coated explosive column

ActiveCN108994949ARealize drilling operationsDirt cleaningMetal working apparatusRectangular coordinatesEngineering

The embodiment of the invention provides a drilling and shaping device of a coated explosive column. The device is characterized by comprising an explosion-proof cabinet, a holding jaw assembly, a camera shooting assembly, a rectangular coordinate mechanism, and a drill bit assembly; the explosion-proof cabinet is a protective structure of the device, arranged on the outermost side of the device in a sleeving mode and used for supporting structures inside the device; the holding jaw assembly comprises a holding jaw unit and a driving mechanism of the holding jaw unit, the holding jaw unit is used for clamping the explosive column, the holding jaw assembly is fixedly arranged on the upper plane of the lower framework; the camera shooting assembly comprises a camera shooting unit and a driving mechanism of the camera shooting unit, the camera shooting unit is used for image acquisition, analysis and identification, and acquiring the position of a silver wire of the explosive column, thecamera shooting assembly is fixedly arranged on the lower side of the holding jaw unit and is arranged inside the lower framework; the rectangular coordinate mechanism is arranged on the lower framework; the drill bit assembly is arranged on the rectangular coordinate mechanism; the rectangular coordinate mechanism drives the drill bit assembly to move to the mark point coordinate position of a drill hole, and drive the drill bit assembly to rotate and carry out axial feed to drill the explosive column.

Owner:SHANGHAI AEROSPACE CHEM ENG INST

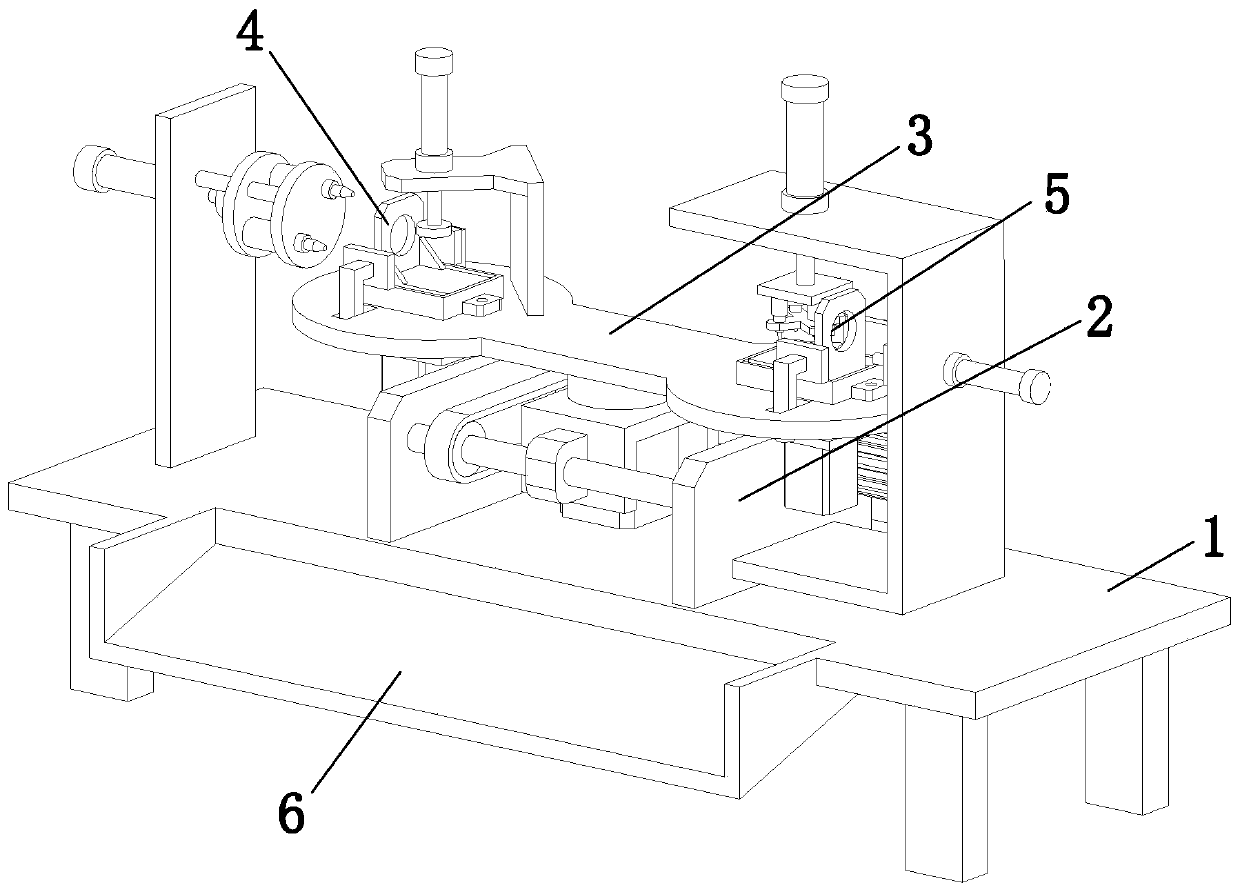

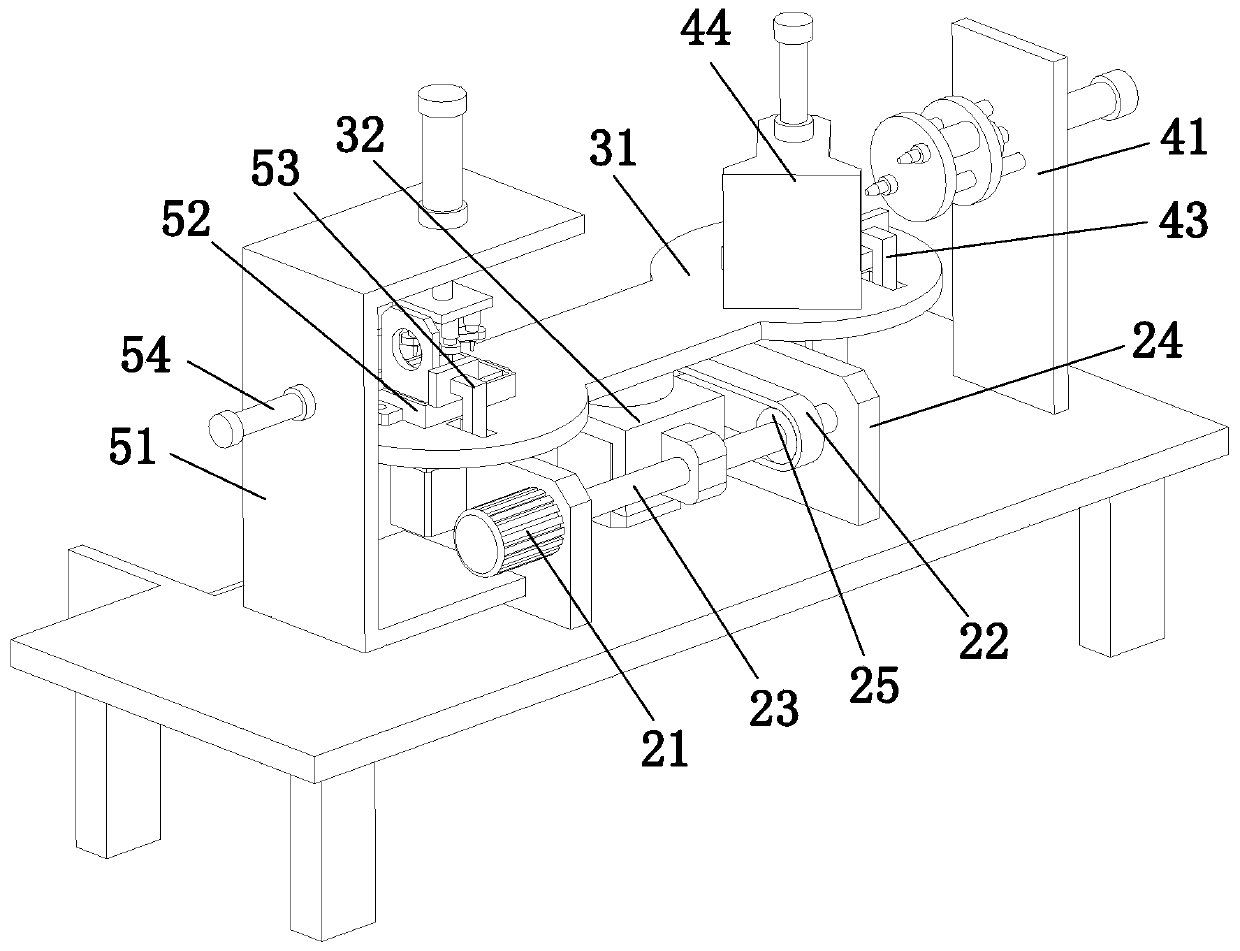

Perforation drill bit for lunch box die

InactiveCN106064247AReduce labor intensityImprove drilling efficiencyFeeding apparatusDriving apparatusDrive motorDrill bit

The invention discloses a perforation drill bit for a lunch box die. The perforation drill bit comprises a rotary movement mechanism, a swing movement mechanism, an advance-retreat movement mechanism and a drill bit drive mechanism, wherein a drill bit drive motor is capable of driving the drill bit to rotate through arranging a driven belt wheel on a drill bit shaft for fixing the drill bit and arranging a drive belt wheel on an output shaft of the drill bit drive motor, thus perforation working for the lunch box die is realized. The drill bit can be driven to carry out ascending and descending actions under the drive effect of an advance-retreat motor through arranging the advance-retreat motor on a fixing plate and fixing a lead screw on an output shaft of the advance-retreat motor, thus perforation and retreat of the drill bit are completed. The perforation drill bit for the lunch box die, which is disclosed by the invention, can automatically complete automatic perforation working for the lunch box die, replaces previous manual perforation, reduces the labour intensity, increases the perforation working efficiency, reduces the cost, has a remarkable beneficial effect, and is suitable for being popularized and applied.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

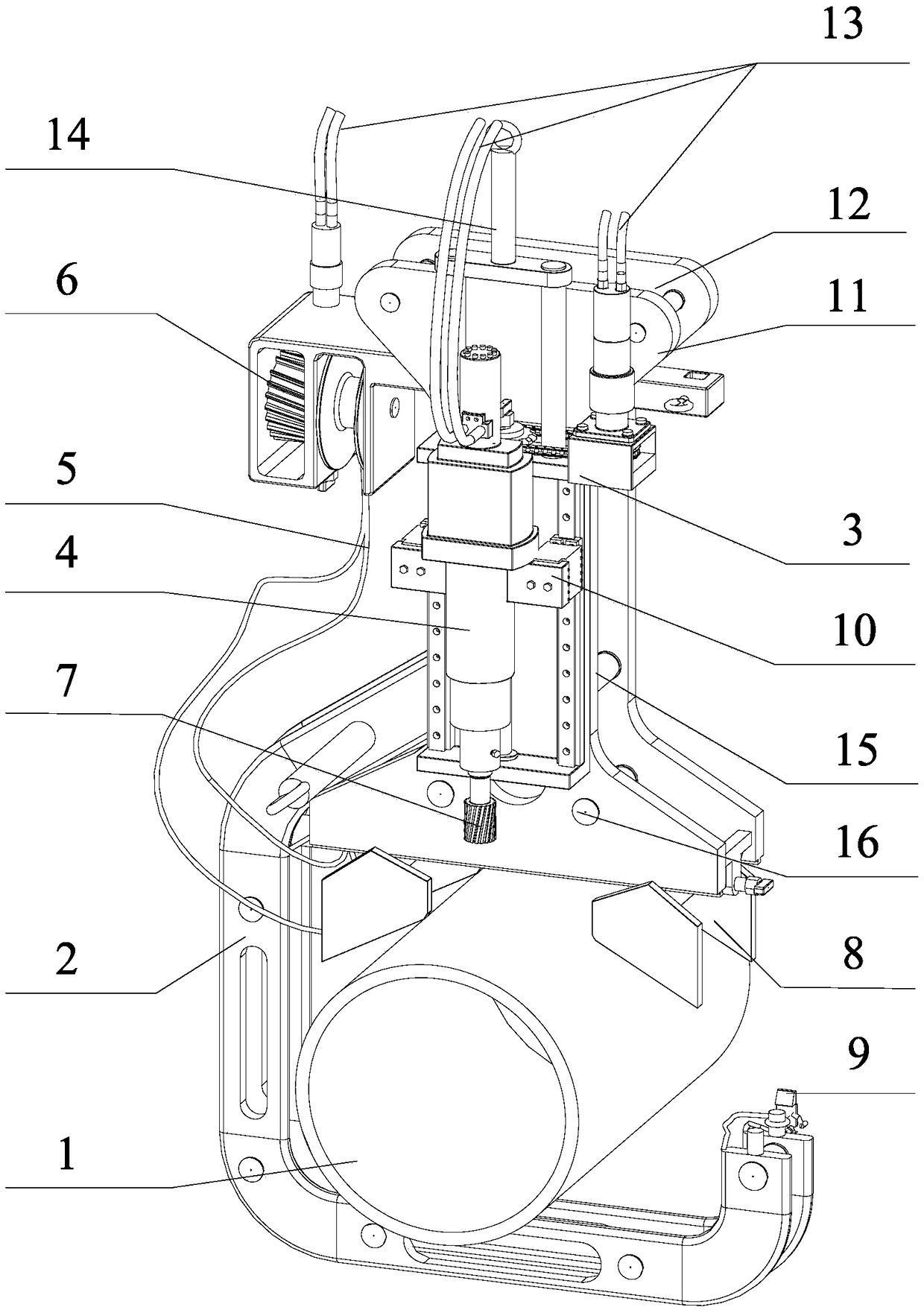

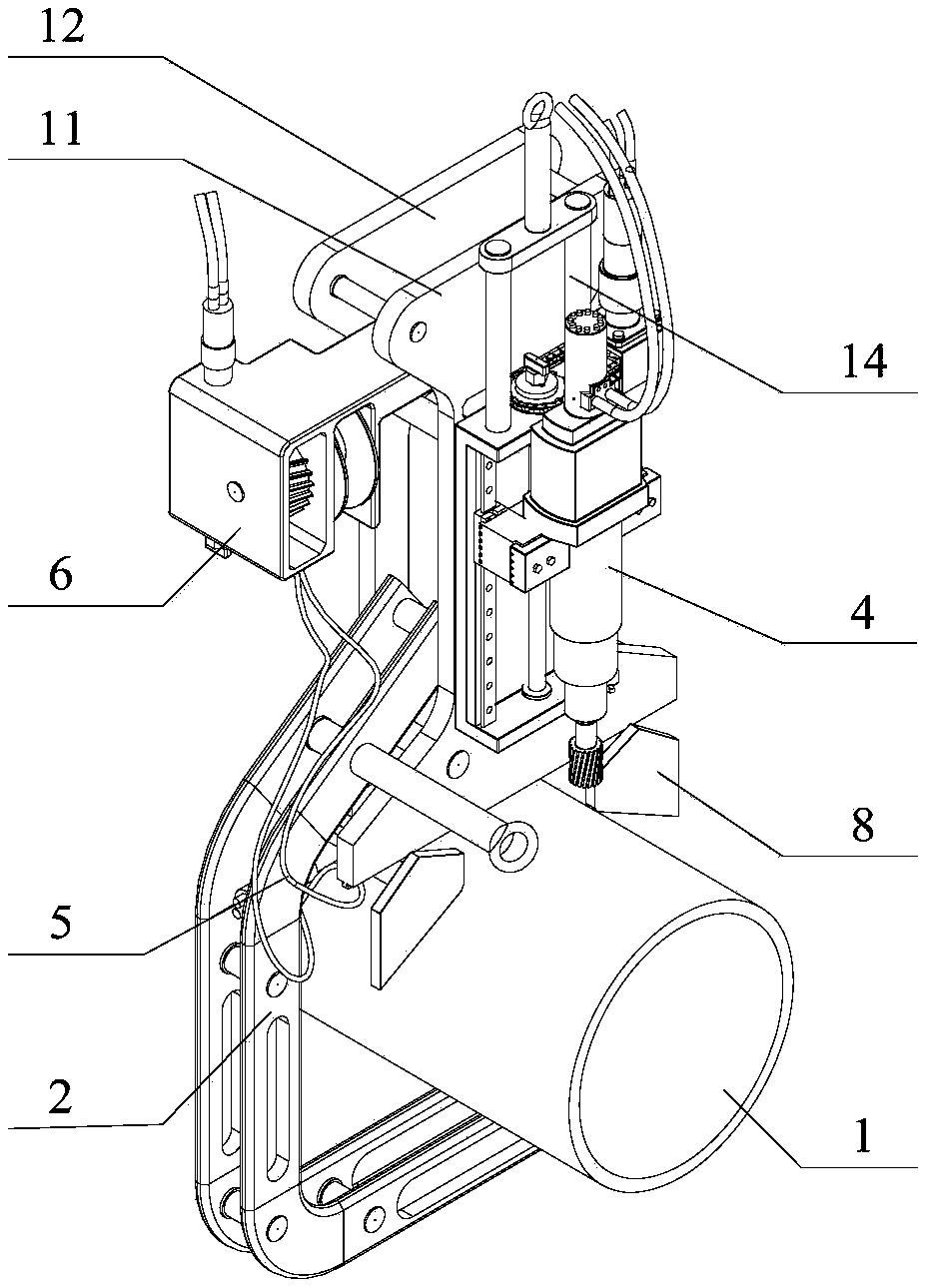

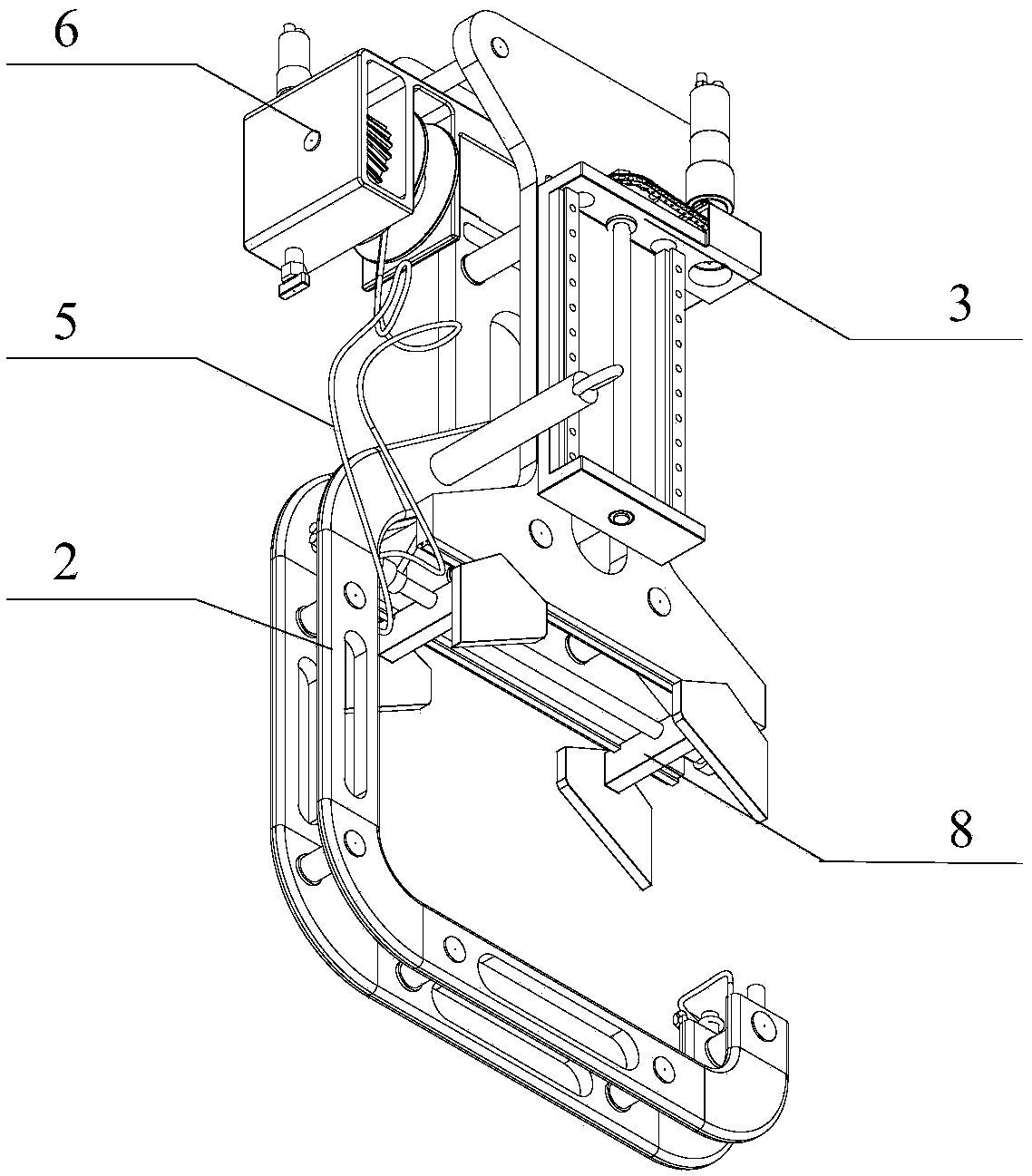

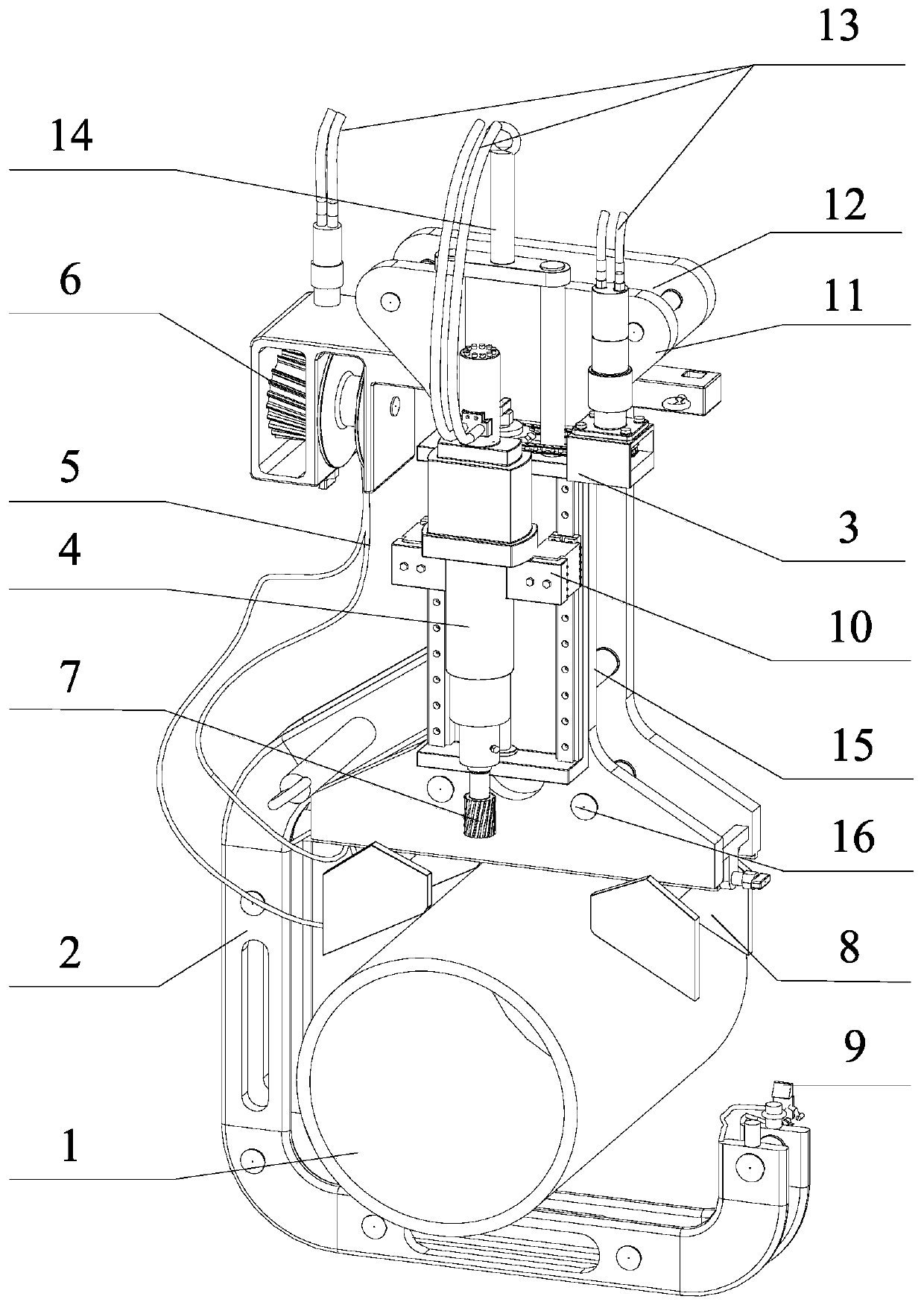

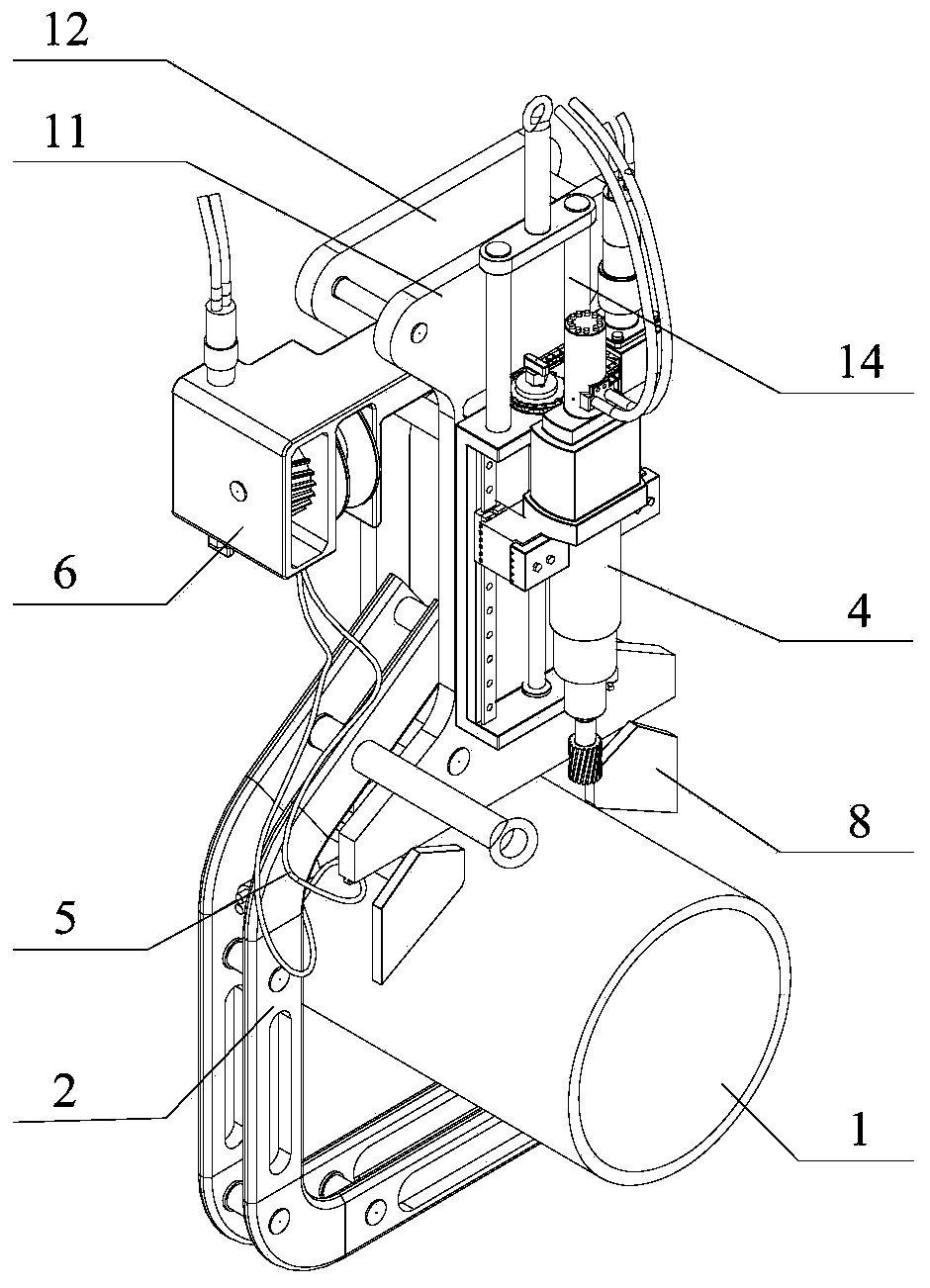

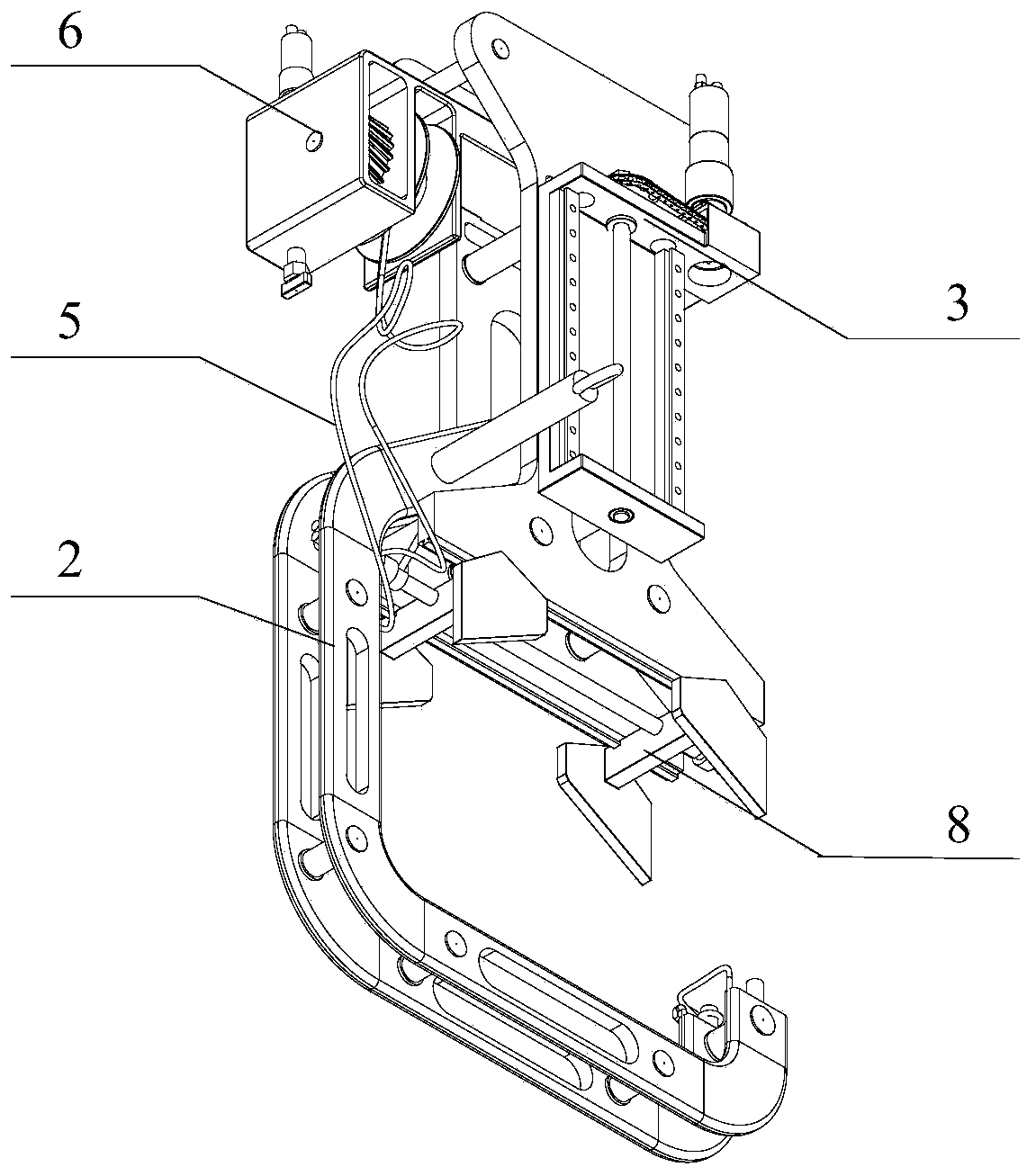

Underwater pipeline automatic drilling machine

ActiveCN109047854ARealize drilling operationsConvenient for underwater workBoring/drilling machinesAutomatic controlWorking environment

The invention provides an underwater pipeline automatic drilling machine. The underwater pipeline automatic drilling machine comprises a steel wire rope guiding mechanism, a feeding driving mechanism,a drilling driving mechanism, a clamping mechanism, a pipeline positioning mechanism and an upper and lower bracket, wherein the upper and the lower support form a machine body main body part througha pin shaft, the steel wire rope guide mechanism, the pipeline positioning mechanism, the feeding driving mechanism and the drilling driving mechanism are arranged on the body part of the machine body. The underwater pipeline automatic drilling machine are used for achieving drilling work of pipelines with different sizes at one time; the system can be automatically controlled and can be operatedby an ROV, the pipeline positioning mechanism, a steel wire rope tightening mechanism can select different driving modes under different working conditions, the application is flexible, and underwater operation is facilitated; and the underwater pipeline automatic drilling machine can adapt to the narrow working environment of the seabed pipeline and the ground space.

Owner:HARBIN ENG UNIV

Building template automatic drilling machine and operating method

InactiveCN108655445AReduce labor intensityImprove drilling efficiencyFeeding apparatusBoring/drilling machinesEngineeringSlide plate

The invention provides a building template automatic drilling machine and an operating method. A transverse beam is fixed to the tops of rack plates; a transverse sliding rail is installed at the topof the transverse beam; a sliding block is installed on the transverse sliding rail in a sliding fit manner; a transverse sliding plate is fixed to the top of the sliding block; a vertical connectingplate is installed on the side wall of the transverse sliding plate and is connected with a transverse power device; the transverse power device is used for driving the transverse sliding plate to move; a longitudinal motor mounting plate is fixed to the side wall of the transverse sliding plate; a cantilever box body horizontally arranged is installed on the longitudinal motor mounting plate; a longitudinal sliding mechanism used for providing longitudinal movement is installed in the cantilever box body; a vertical lifting mechanism used for providing lifting movement is installed on the longitudinal sliding mechanism; and a drilling device used for drilling is installed at the tail end of a lifting sliding rail of the vertical lifting mechanism. The automatic drilling machine can be used for automatic drilling of a building template, so that the drilling efficiency and the drilling quality are further improved effectively.

Owner:湖北绿筑装配科技有限公司

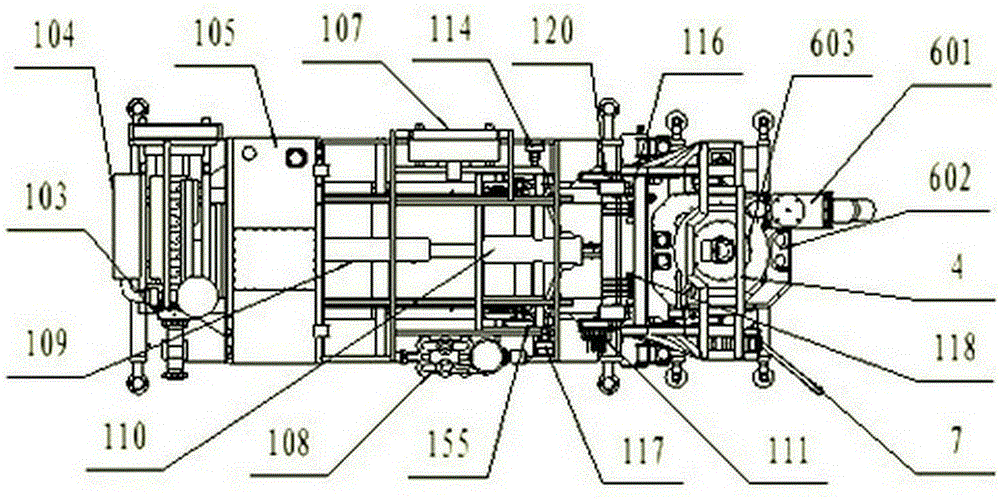

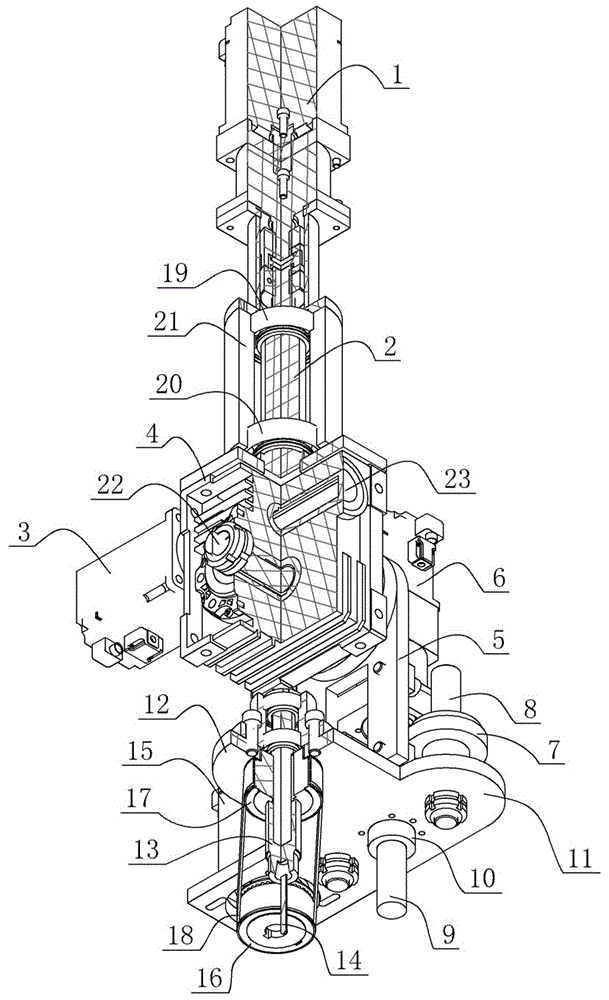

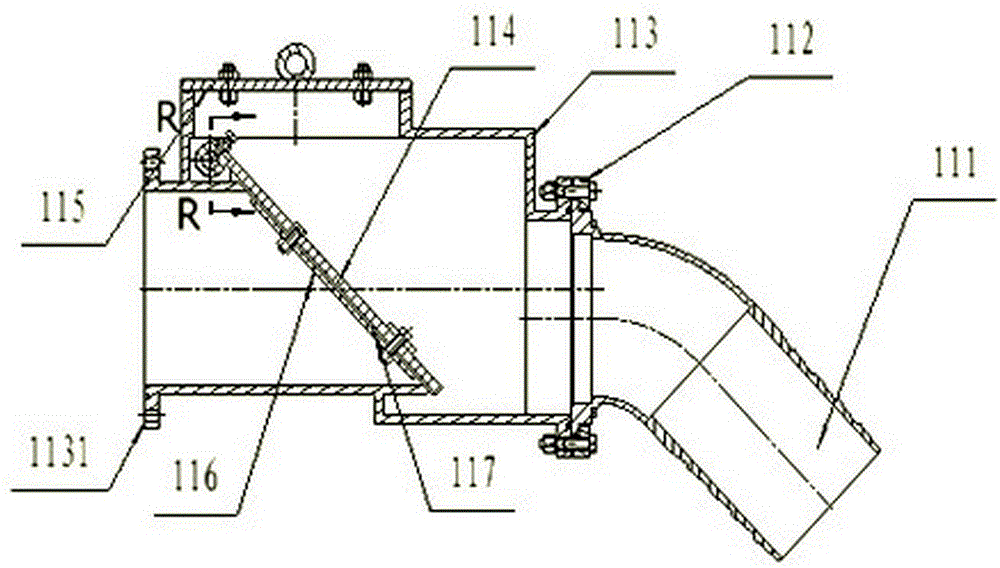

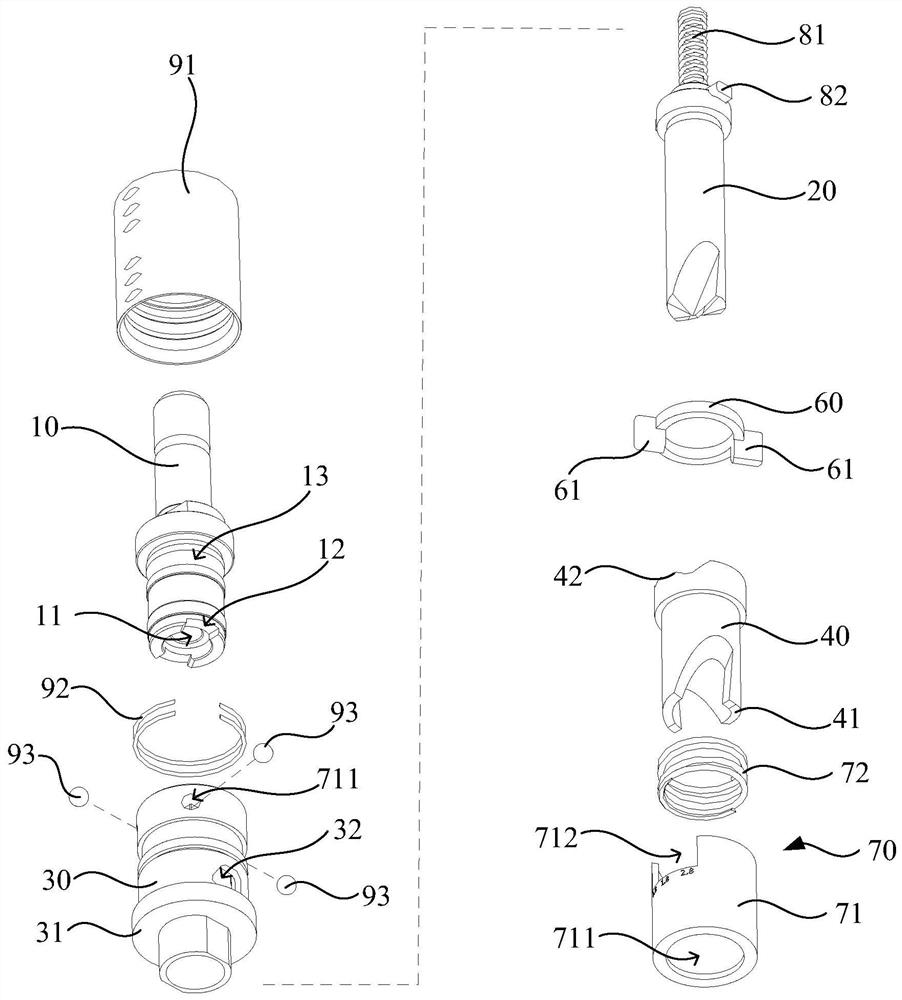

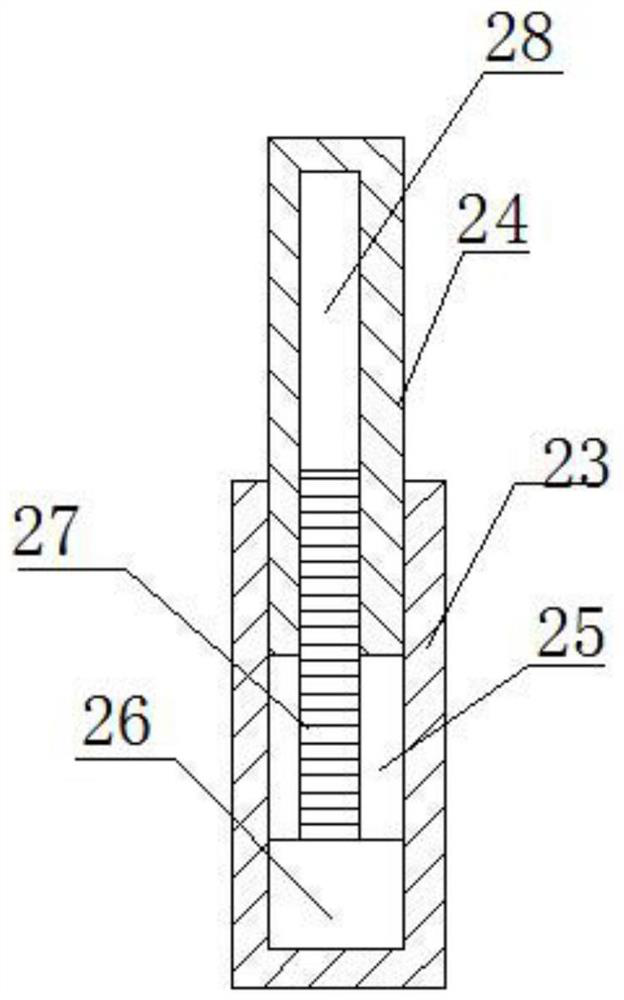

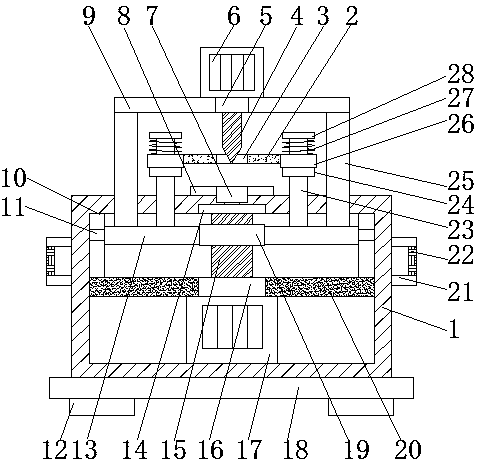

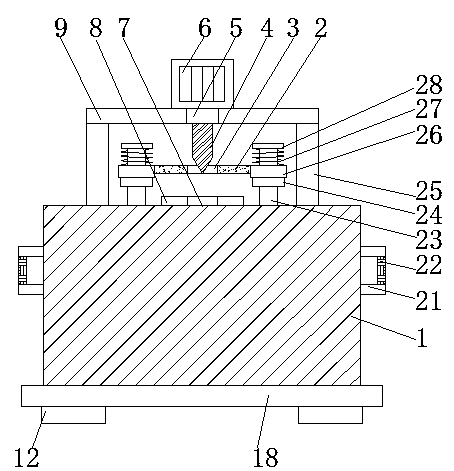

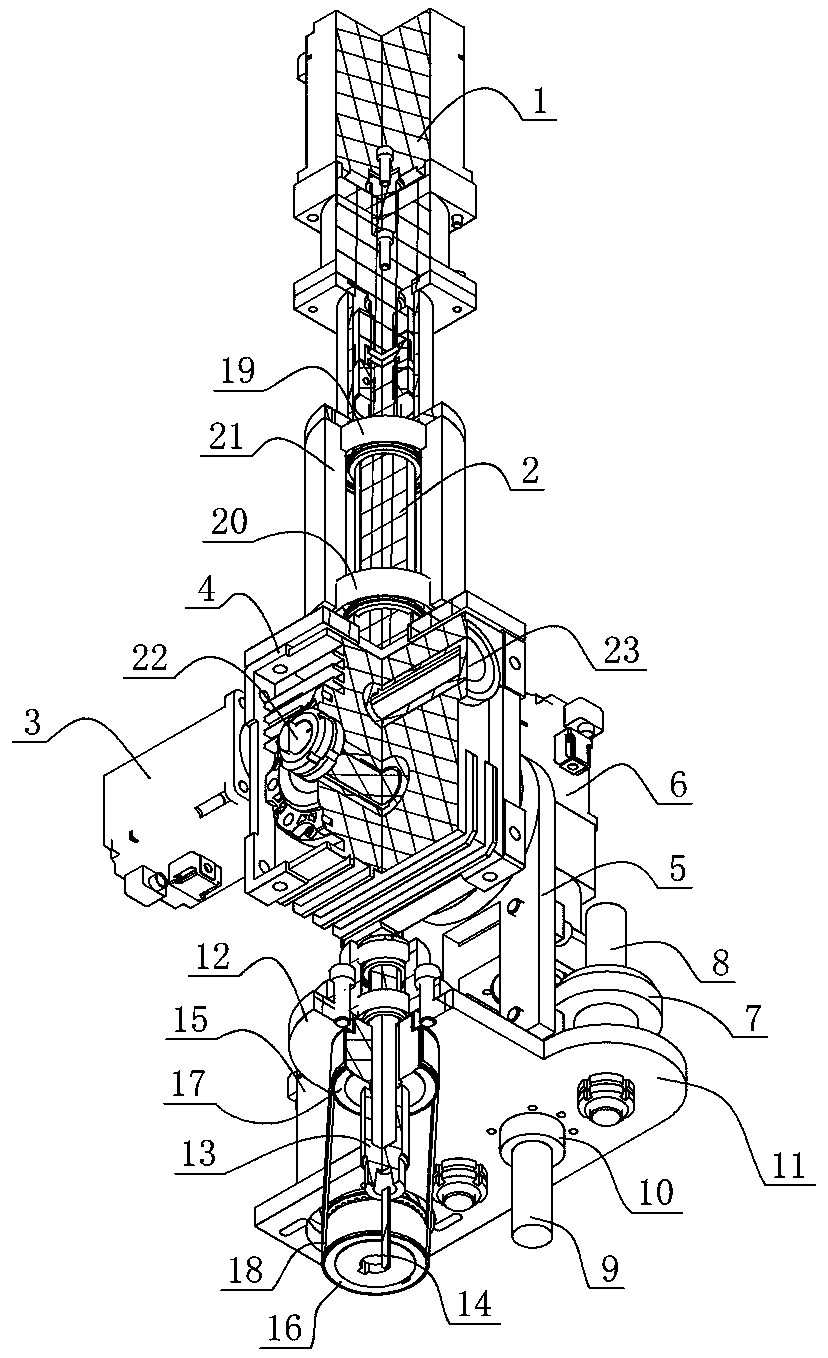

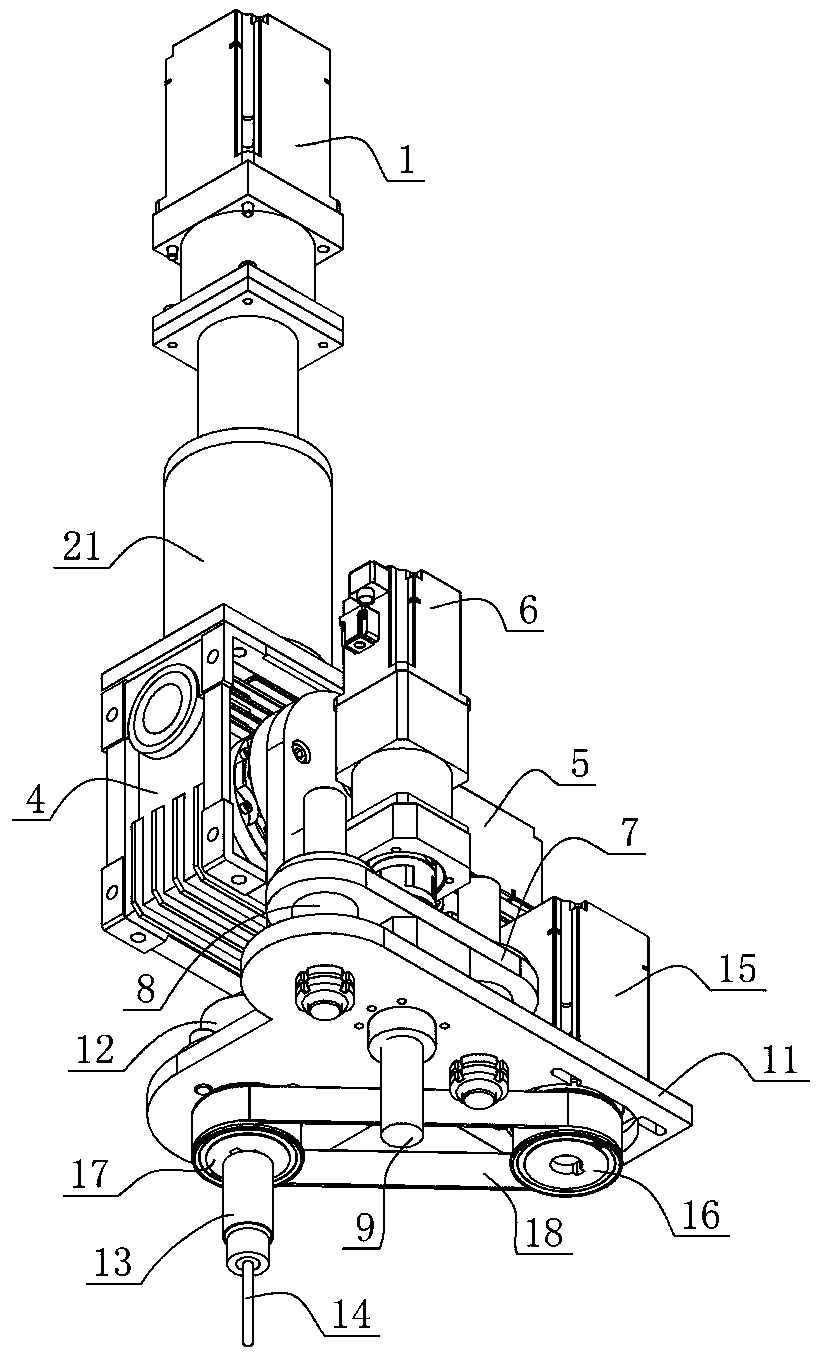

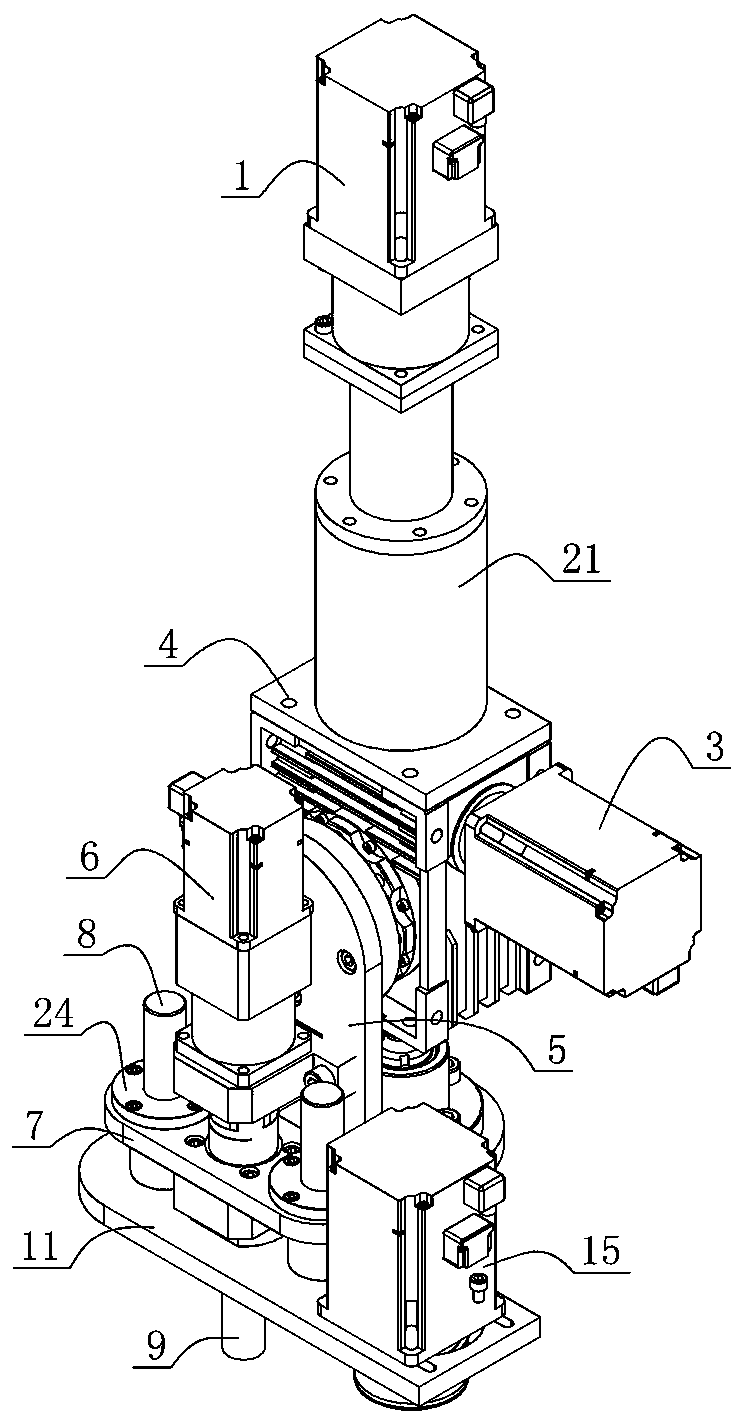

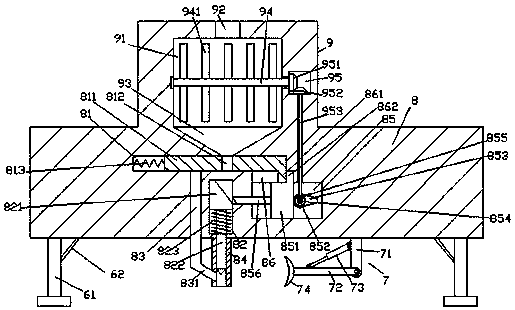

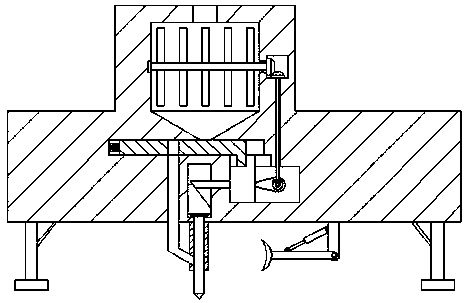

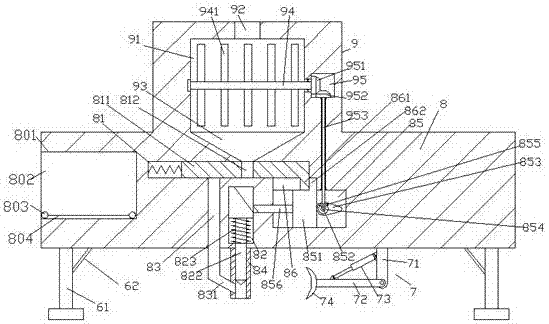

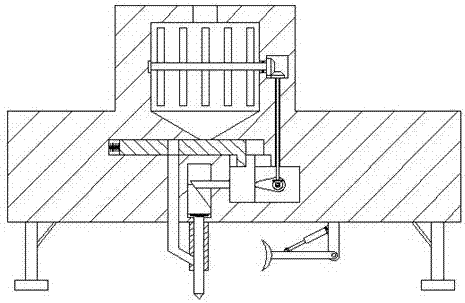

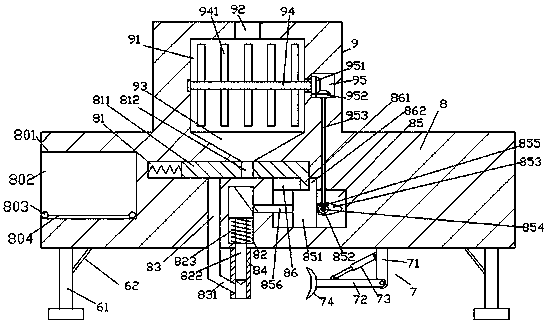

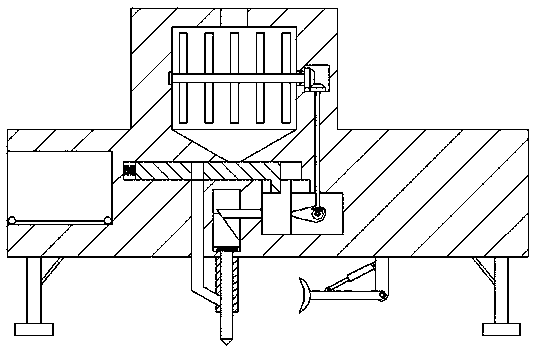

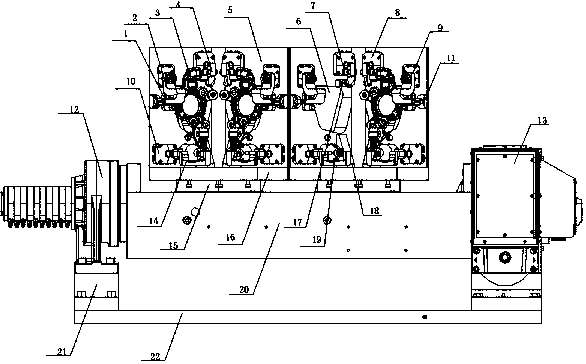

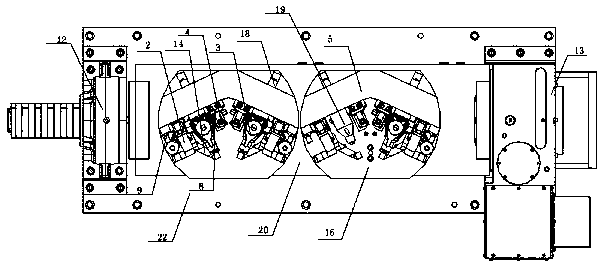

Power assembly of full-hydraulic reverse circulation drilling machine

The invention provides a power assembly of a full-hydraulic reverse circulation drilling machine. The power assembly comprises a residue discharge chamber, a reduction gearbox assembly, a mud pump assembly, a rotary connector subassembly, a shaft spacer, a spindle connecting rod, a main fastener, an assembly connecting plate subassembly, a spindle driving clamp slip and a stop pin subassembly. The power assembly has the advantages that two hydraulic motors are serially connected with each other or are connected with each other in parallel, so that two different rotational speeds can be implemented by a reduction gearbox, and the power assembly is adaptive to operation under different geological and aperture conditions; torque of drilling pipes can be changed along with change of the geological conditions of operation, and accordingly energy can be saved; a hydraulic system can be regulated, so that overload protection effects can be realized for drilling machine operation; the vacuumizing time can be shortened owing to sealing structures of the reduction gearbox and mud pumps; the hydraulic motors can be controlled by the hydraulic system and can drive the reduction gearbox with gears to directly drive drilling tools to rotate; flow of hydraulic pumps can be regulated, so that the rotational speeds and the lifting speeds of the drilling pipes and flow parameters of the mud pumps can be regulated; the power assembly is provided with rotary connector mechanisms, so that hole drilling operation can be implemented by impact drill bits or drill bits with rotor wings, and hole drilling operation on the scales larger than 200 meters can be implemented.

Owner:王乐康

Drilling processing device for plate-shaped novel material

InactiveCN108406359ARealize drilling operationsEasy drillingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a drilling processing device for a plate-shaped novel material. The drilling processing device comprises a supporting box base, hydraulic telescopic cylinders, a drill bit, a rotary rod, a clamping block and pressure rods, wherein the tops of the two ends of the supporting box base are fixedly equipped with the hydraulic telescopic cylinders for driving a supporting beam toperform lifting motion; the bottom end of the middle part of the supporting beam is fixedly equipped with a drilling motor for driving the drill bit to rotate at a high speed; two supporting blocks are symmetrically and fixedly mounted on the top plate of the supporting box base; supporting sleeves are symmetrically arranged on the top plate of the supporting box base; the pressure rod is arranged on each supporting sleeve in an up-down sliding penetrating mode; the top end of each pressure rod is fixedly equipped with a pressure plate; the lower surface of the end part of each pressure plateis fixedly equipped with a clamping block; and the two clamping blocks are positioned above the two supporting blocks separately. The drilling processing device is simple and reasonable in structure,is convenient to operate, is used for clamping and fixing the plate-shaped novel material conveniently, is good in fixing effect, is convenient to use, is beneficial for drilling processing operationof the plate-shaped novel material, and is suitable for being popularized and used.

Owner:林翔

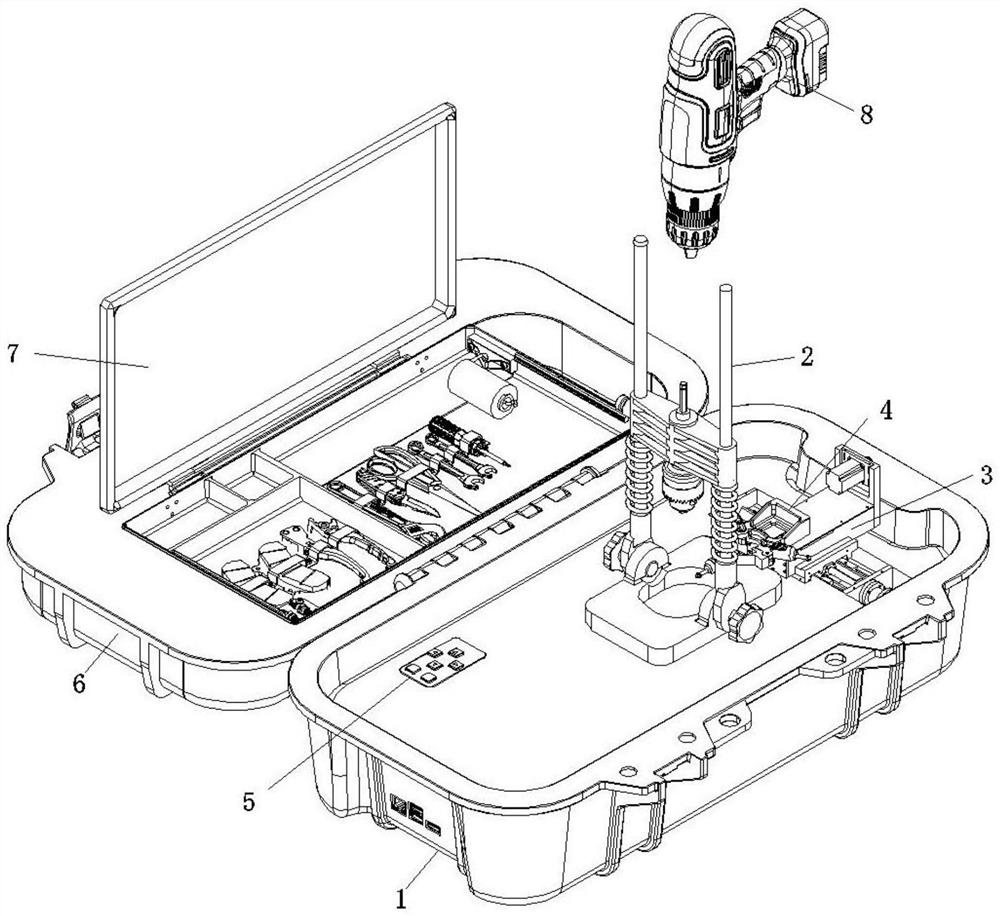

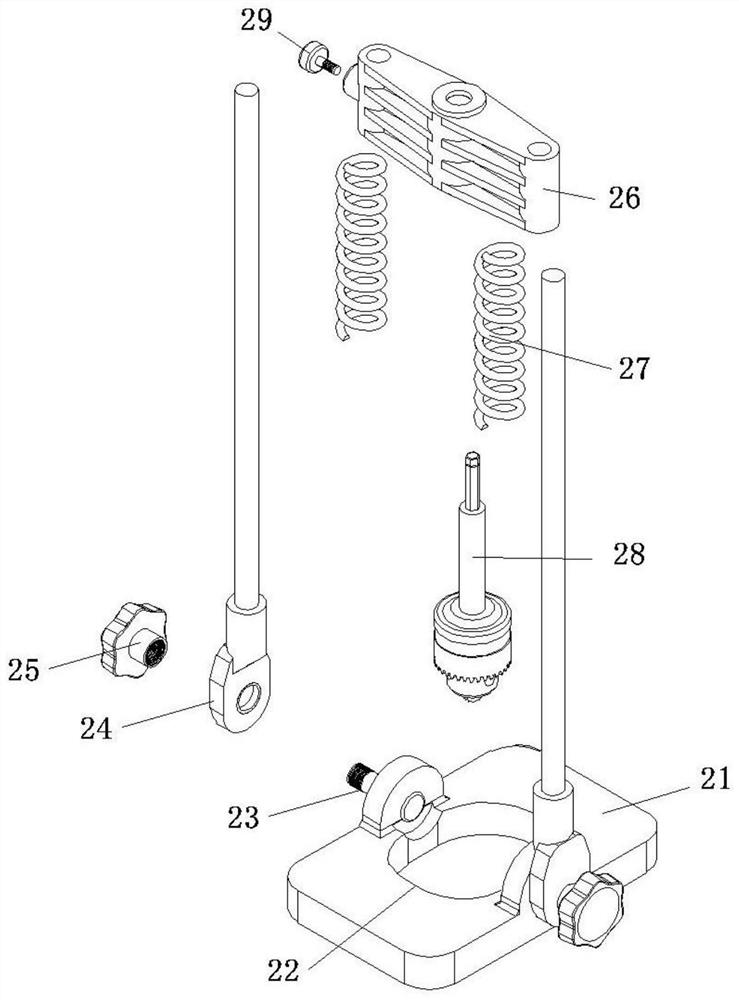

Auxiliary drilling device for hardware

InactiveCN112658741ARealize drilling operationsRealize integrationFeeding apparatusPositioning apparatusControl engineeringToolbox

The invention discloses an auxiliary drilling device for hardware. The auxiliary drilling device comprises a box body, an auxiliary drilling mechanism, a moving mechanism, a fixing mechanism, a control button, a top cover, a tool box and a wireless drill; the auxiliary drilling mechanism is arranged on the inner side of the box body; the moving mechanism is embedded in the inner side of the box body and located on the right side of the auxiliary drilling mechanism; the fixing mechanism is arranged at the top end of the moving mechanism; the control button is embedded in the rear left part of the top end of the box body; the top cover is hinged to the rear side of the box body; the tool box is embedded in the top end of the top cover; and the wireless drill may be disposed on the inner side of the box body. The auxiliary drilling device for hardware is integrated with the tool box and is convenient to carry, meanwhile, hardware workpiece drilling is more stable, the drilling quality is improved, automatic moving of hardware workpieces can be achieved, the moving precision of the hardware workpieces is improved, and operation is easy.

Owner:路志廷

Automatic cutting, drilling and stamping integrated device for automobile buckles

InactiveCN113211081ALow cost requirementsReduced operating requirementsOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringTransfer mechanism

The invention discloses an automatic cutting, drilling and stamping integrated device for automobile buckles, and relates to the technical field of machining. The automatic cutting, drilling and stamping integrated device comprises a workbench and a stamping mechanism arranged beside the workbench, the workbench is provided with a cutting mechanism, a drilling mechanism and a transferring mechanism, and the cutting mechanism comprises a cutting assembly and an adjusting assembly. The adjusting assembly is installed at the upper end of the cutting assembly. The drilling mechanism comprises a drilling table, a traction assembly, a moving assembly, a drilling assembly, a protection assembly and a blowing assembly, the traction assembly is arranged at the tail end of the drilling table, the moving assembly is installed in the middle of the drilling table, and the drilling assembly is installed on the moving assembly. The protection assembly and the blowing assembly are both arranged at the lower end of the drilling assembly and matched with each other, and the transferring mechanism is located between the stamping mechanism and the traction assembly. According to the automatic cutting, drilling and stamping integrated device for the automobile buckles, waste chips generated during drilling can be treated in a centralized mode, the influence on the workshop environment and equipment is avoided, the product quality is improved, and the production efficiency is improved.

Owner:胡定良

Drilling equipment with dustproof function for municipal building

PendingCN112720866AAchieve drillingPrevent leakageWorking accessoriesStone-like material working toolsArchitectural engineeringStructural engineering

The invention discloses drilling equipment with a dustproof function for a municipal building. The drilling equipment comprises a base, four supporting columns are fixedly connected to the base, the upper ends of the four supporting columns are jointly and fixedly connected with a box body, a mounting cavity is formed in the box body, a servo motor is fixedly connected to the inner bottom of the mounting cavity, a screw rod is fixedly connected to the output end of the servo motor, the other end of the screw rod is rotationally connected with the inner wall of the mounting cavity, a vertical plate is slidably connected into the mounting cavity, the screw rod penetrates through the vertical plate and is in threaded connection with the vertical plate, a first hollow rod rotationally connected with the vertical plate is arranged on the vertical plate in a penetrating mode, and one end of the first hollow rod is fixedly connected with a drill bit. The drilling equipment is reasonable in structure, drilling operation on the municipal building can be achieved through one servo motor, dust generated in the drilling process can be removed, the wall surface can be protected, and safety guarantee is provided for the body of a worker.

Owner:廖冬花

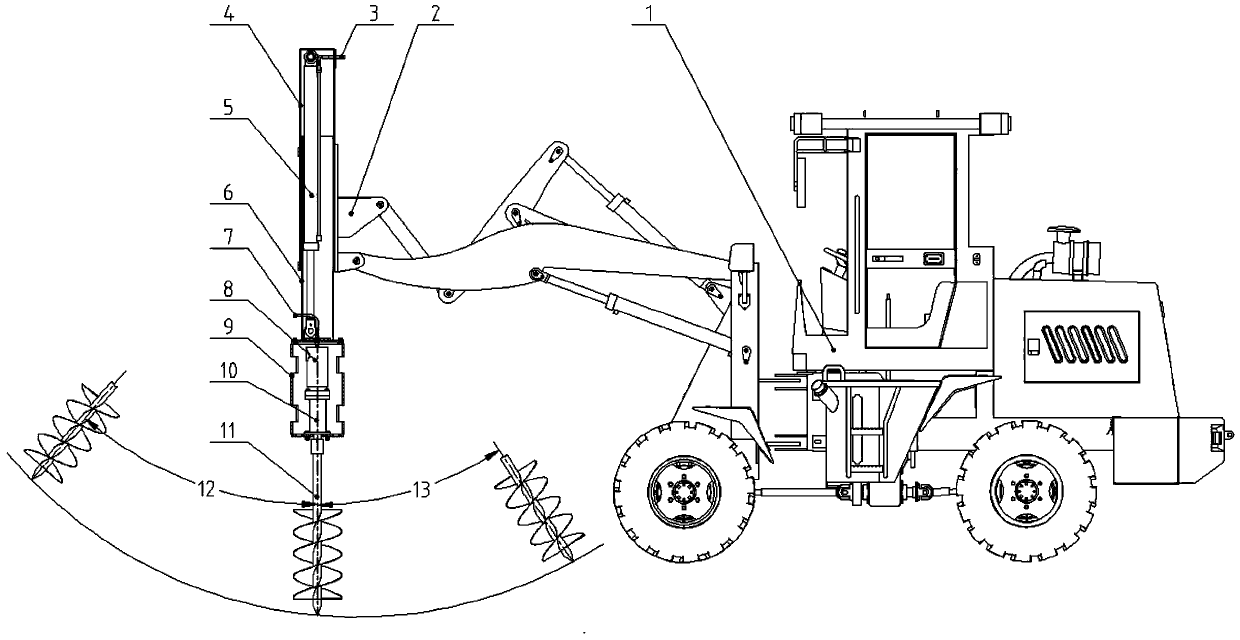

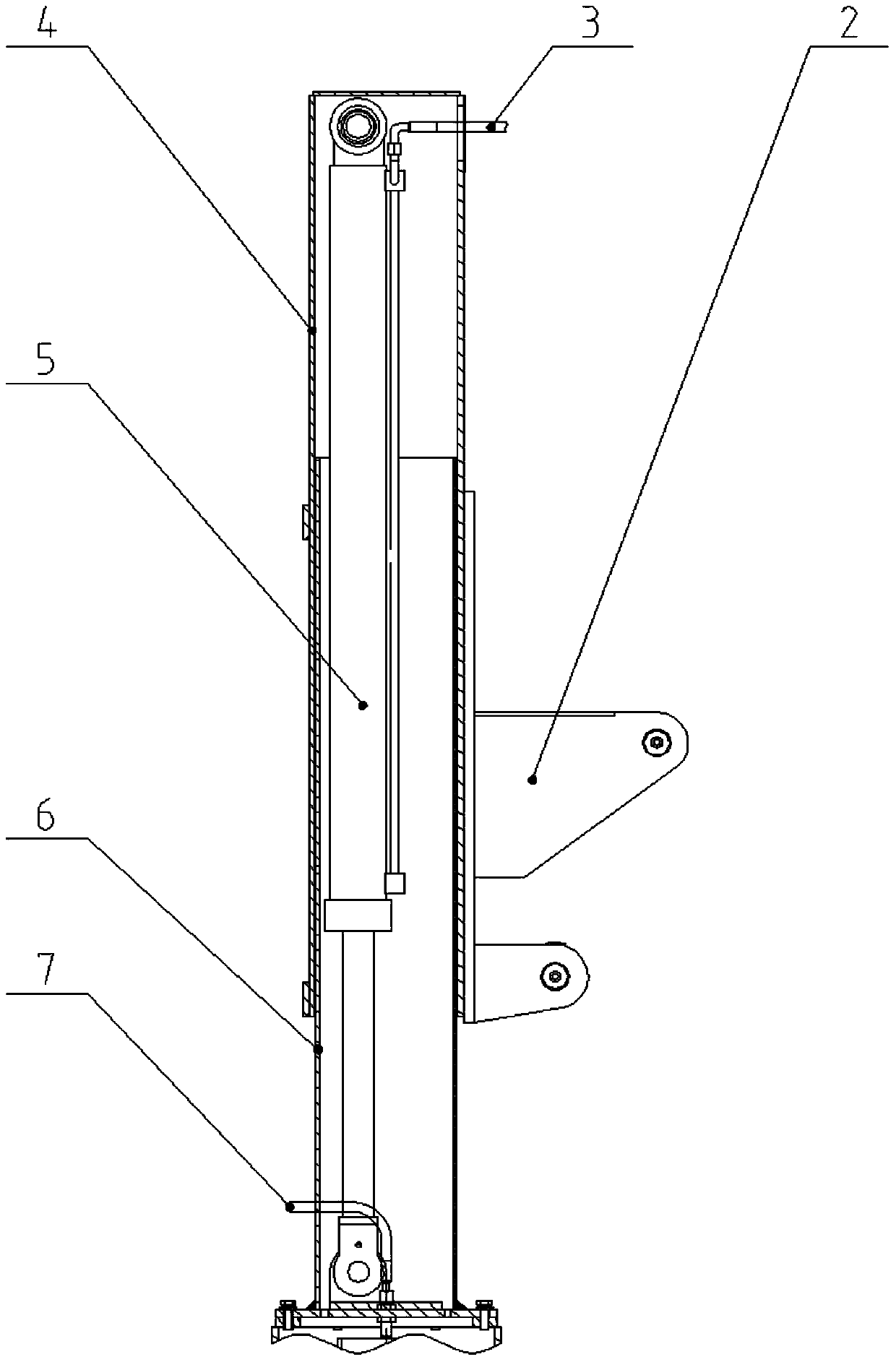

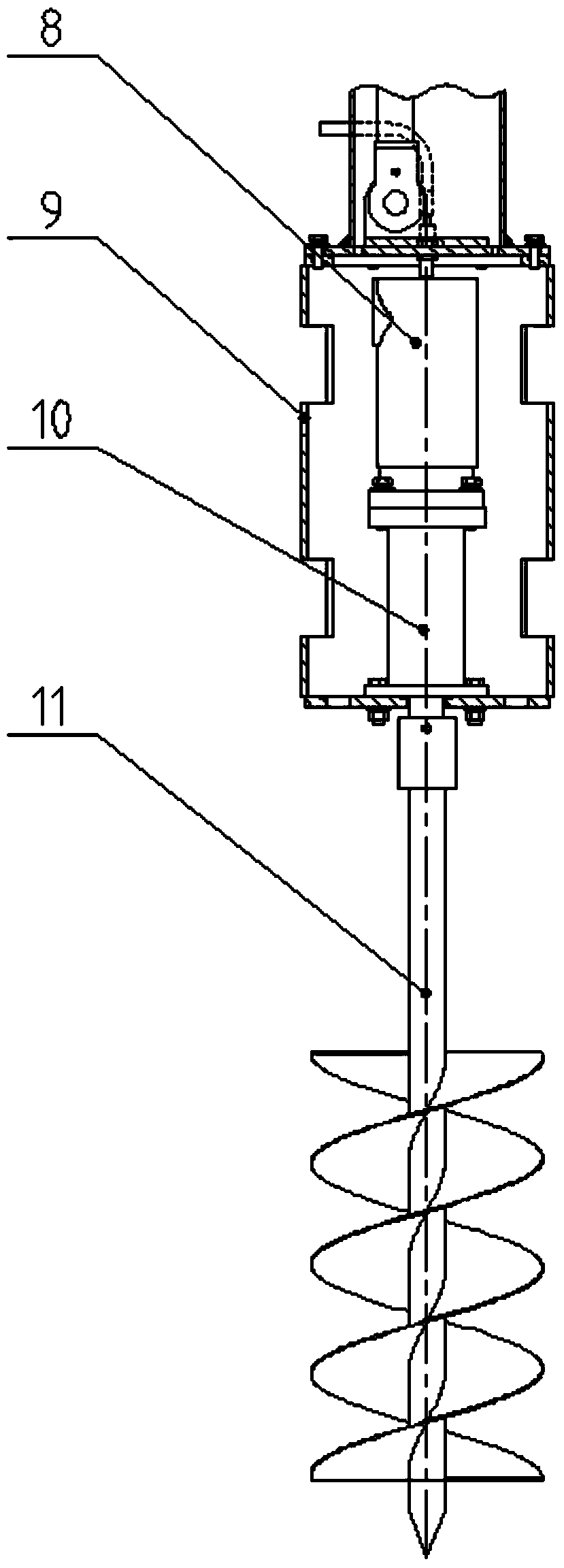

Straight-line directional hole digger

InactiveCN104047546ADirectional DrillingRealize straight line drillingDirectional drillingHydraulic motorPetroleum engineering

The invention discloses a straight-line directional hole digger. The straight-line directional hole digger comprises a loader body and a hole digging device, wherein the hole digging device comprises a connecting support, a fixed sleeve, a telescopic oil cylinder, a sliding sleeve, a hydraulic motor, a supporting drum base, a connecting shaft assembly and a drill bit, the connecting support is connected with the loader body through a hinge pin, the connecting support is welded to the fixed sleeve, a sliding sleeve is arranged in the fixed sleeve, the telescopic oil cylinder is arranged in the sliding sleeve, the base of the telescopic oil cylinder is connected with an oil cylinder fixing base of the fixed sleeve through a hinge pin, the rod end of the telescopic oil cylinder is connected with the sliding sleeve through a hinge pin, the sliding sleeve is fixedly connected with the supporting drum base, the supporting drum base is fixedly connected with the connecting shaft assembly, and the connecting shaft assembly is fixedly connected with the hydraulic motor. The straight-line directional hole digger solves the problem that when the hole digger is used for digging a hole, the hole is oval and not a straight line and the problem that the drill bit and a drill stem are prone to being bent if the hole digging depth is too large, the service life of the drill steam is greatly prolonged, and the quality of the hole and the hole drilling and digging efficiency are improved.

Owner:JIANGSU SIDA HEAVY IND

Multi-axis drilling machine for machining PVC plate

InactiveCN108214662ARealize drilling operationsImprove work efficiencyMetal working apparatusEngineeringMulti axis

The invention relates to the field of multi-axis drilling equipment, in particular to a multi-axis drilling machine for machining a PVC plate. The multi-axis drilling equipment comprises a workbench,a multi-axis drilling device and a positioning bearing device, wherein the multi-axis drilling device is arranged on the workbench, the positioning bearing device is arranged on the workbench, and themulti-axis drilling device is installed on the workbench in a vertical state; the multi-axis drilling device comprises a positioning frame, a multi-axis drilling component and a multi-axis driving component, wherein the positioning frame is arranged on the workbench, the multi-axis drilling component is installed on the workbench, and the multi-axis driving component is arranged on the positioning frame and is used for driving the multi-axis drilling component to rotate; the positioning bearing device comprises a bearing positioning component and a bearing driving component, wherein the beating positioning component is arranged on the workbench and located under the multi-axis drilling component, the bearing driving component is arranged on the workbench and is used for driving the bearing positioning component to move in the vertical direction, and the bearing positioning component is in transmission connection with the bearing driving component. According to the multi-axis drillingmachine, drilling operation is carried out on the PVC plate, manual output is reduced, and the working efficiency of drilling is improved.

Owner:云和县东泽阀门有限公司

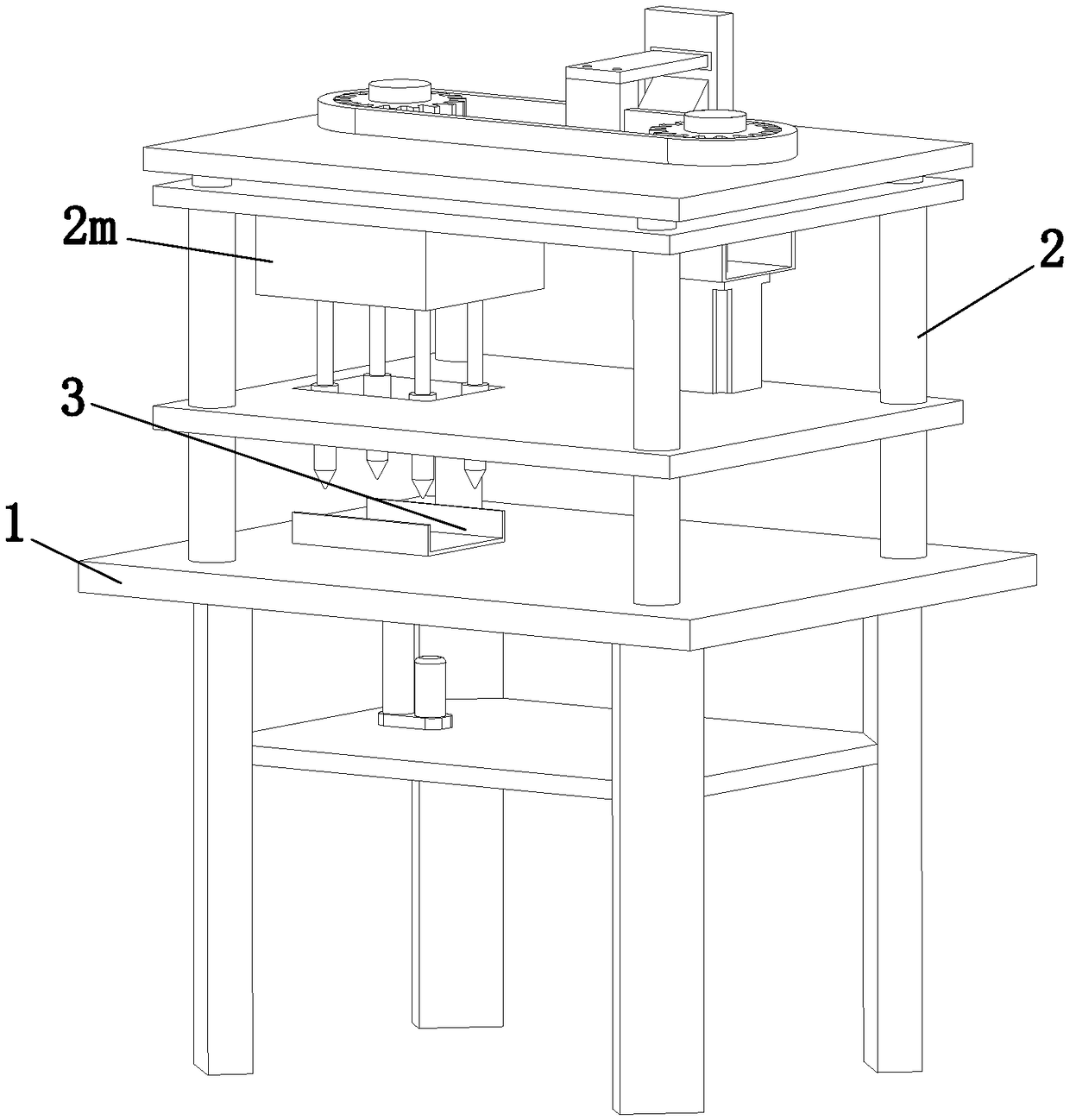

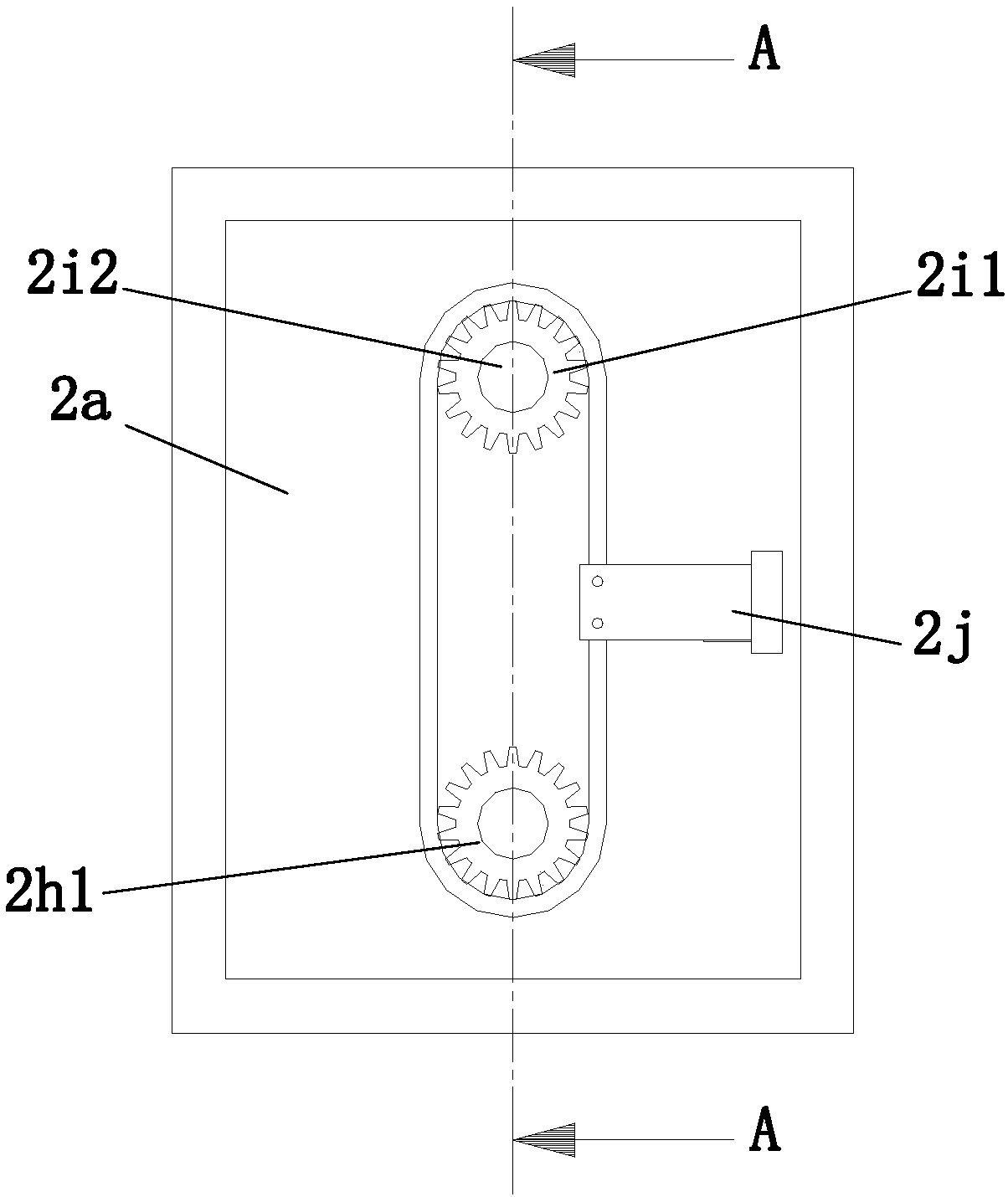

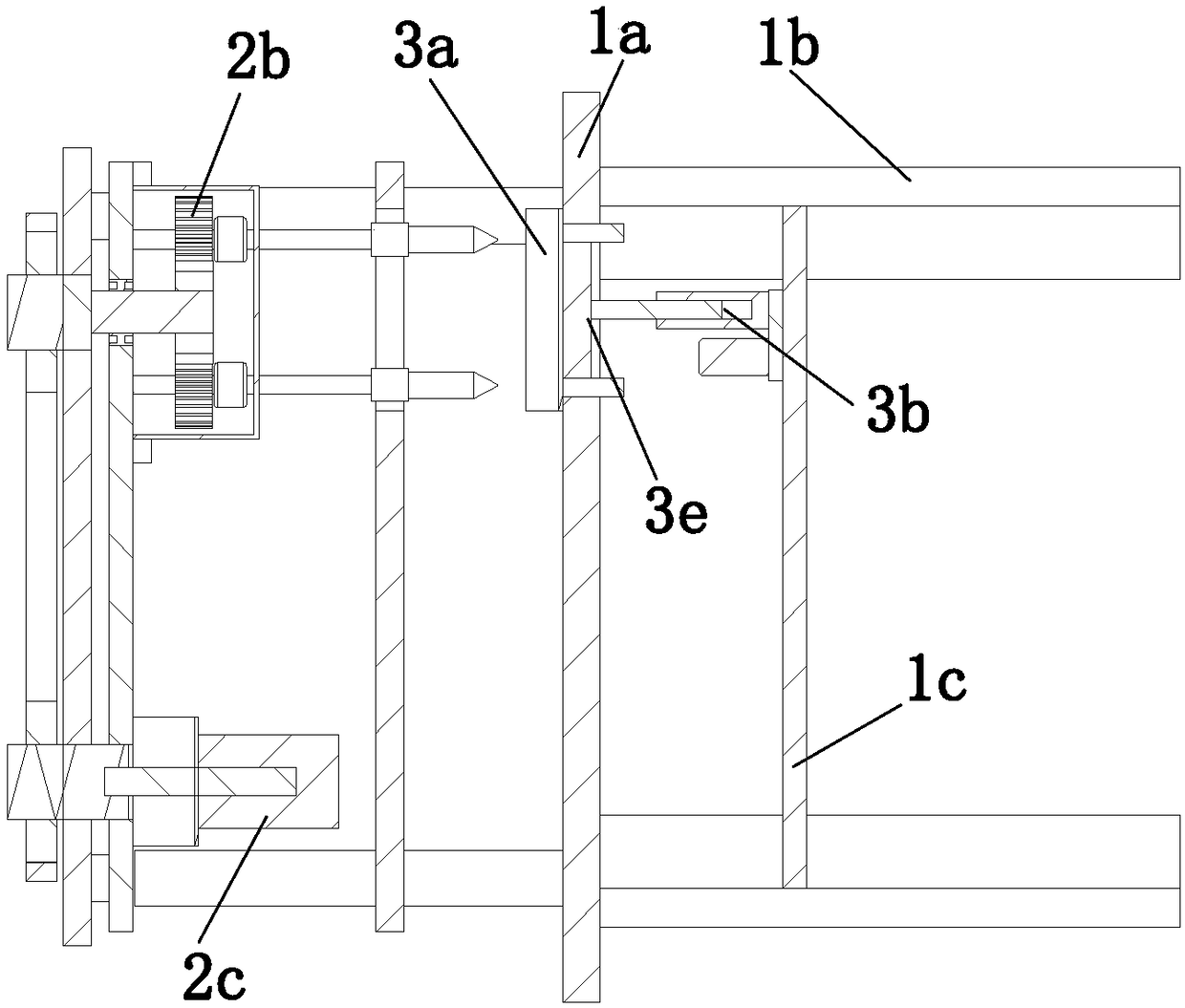

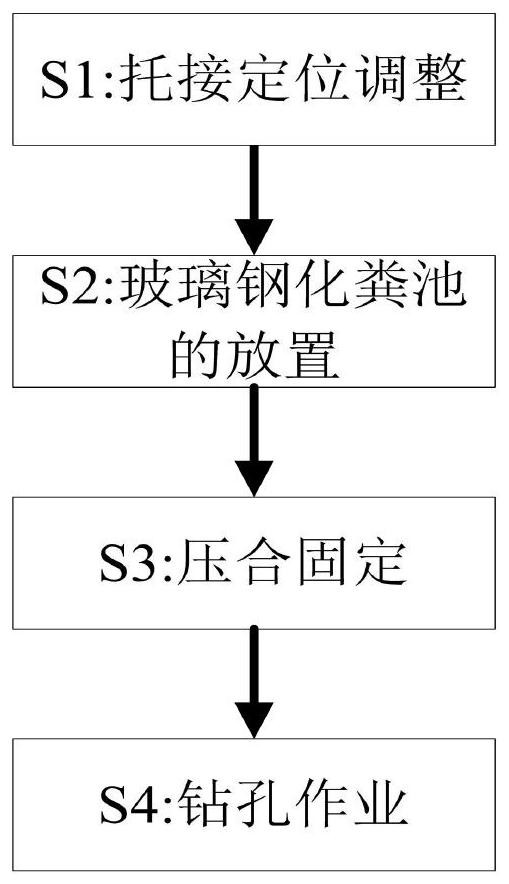

Manufacturing and processing method of glass fiber reinforced plastic septic tank

ActiveCN112776073AQuality assuranceImprove hole efficiencyGeneral water supply conservationMetal working apparatusGlass fiberEngineering

The invention provides a manufacturing and processing method of a glass fiber reinforced plastic septic tank, which comprises a transposition mechanism, a rolling press-fit mechanism, a trepanning mechanism and a bottom plate, wherein the transposition mechanism is installed on the bottom plate; the rolling press-fit mechanism is arranged directly above the transposition mechanism; the rolling press-fit mechanism is installed on the bottom plate; the trepanning mechanism is arranged on the outer side of the rolling press-fit mechanism; and the trepanning mechanism is mounted on the bottom plate in a sliding fit manner. The problems that when trepanning operation is conducted on the glass fiber reinforced plastic septic tank nowadays, a scaffold needs to be built manually to climb to the position above a tank body for drilling operation, and the labor intensity of manual operation is increased; traditional drilling equipment cannot be centrally positioned, so that a drilled hole slips, drill bits with different diameters are inconvenient to replace, drilled waste cannot be removed after drilling is finished, a next hole site cannot be quickly moved and positioned after drilling is finished, and the position of the glass fiber reinforced plastic septic tank cannot be rotated and moved, therefore, the drilling position cannot be quickly aligned.

Owner:河南四通精密模具有限公司

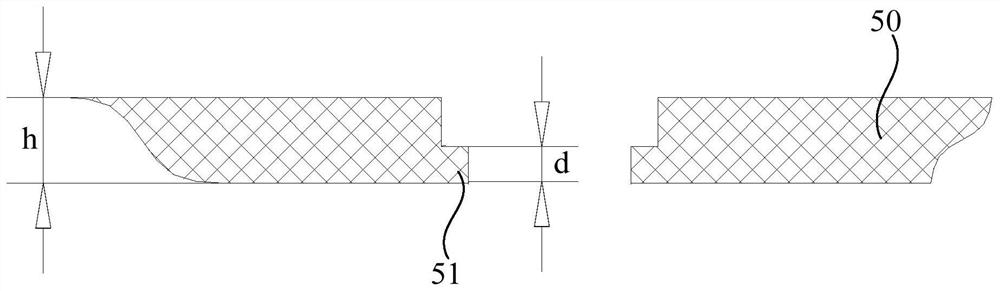

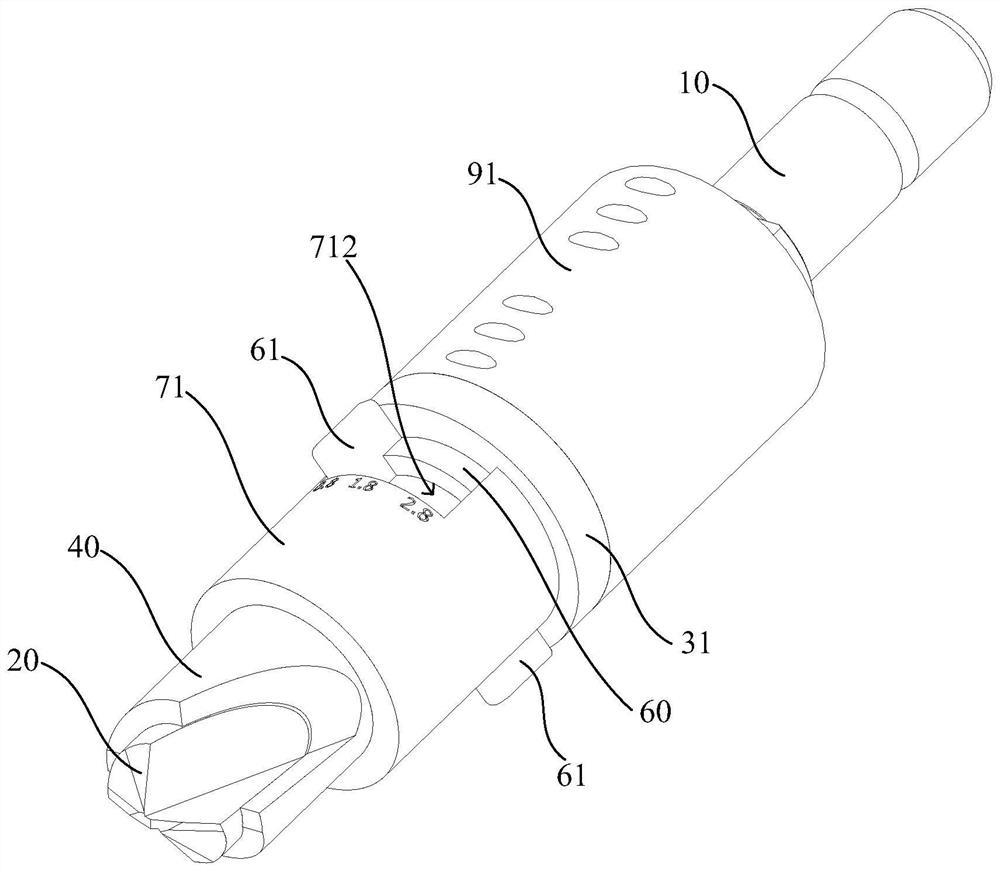

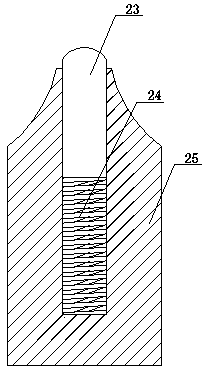

Skull drill bit capable of adjusting bone pad thickness

The invention relates to a skull drill bit capable of adjusting the bone pad thickness. The skull drill bit capable of adjusting the bone pad thickness comprises a connecting column, an inner drill bit, a transmission sleeve and an outer drill bit, wherein one end of the inner drill bit is in clutch fit with the connecting column, a first drilling surface is arranged at the other end of the innerdrill bit, and the inner drill bit synchronously drives the transmission sleeve to rotate while rotating; the transmission sleeve synchronously drives the outer drill bit to rotate when rotating, anda first through hole is formed in the transmission sleeve; the outer drill bit is provided with a second through hole; the inner drill bit is arranged in the first through hole and the second throughhole; the first drilling surface is located outside the outer drill bit; and the outer drill bit is adjustably arranged on the transmission sleeve in the axial direction of the outer drill bit, and asecond drilling surface is arranged at the end, away from the connecting column, of the outer drill bit. According to the skull drill bit capable of adjusting the bone pad thickness, the position of the outer drill bit can be adjusted according to the thickness d of a bone pad required to be formed by drilling, so that the skull tapper of the same model can adapt to drilling operation of skulls with different thicknesses h and can adapt to drilling operation of skulls of different people or different parts of the skull, the safety performance is guaranteed, and the cost is reduced.

Owner:CHONGQING XISHAN SCI & TECH

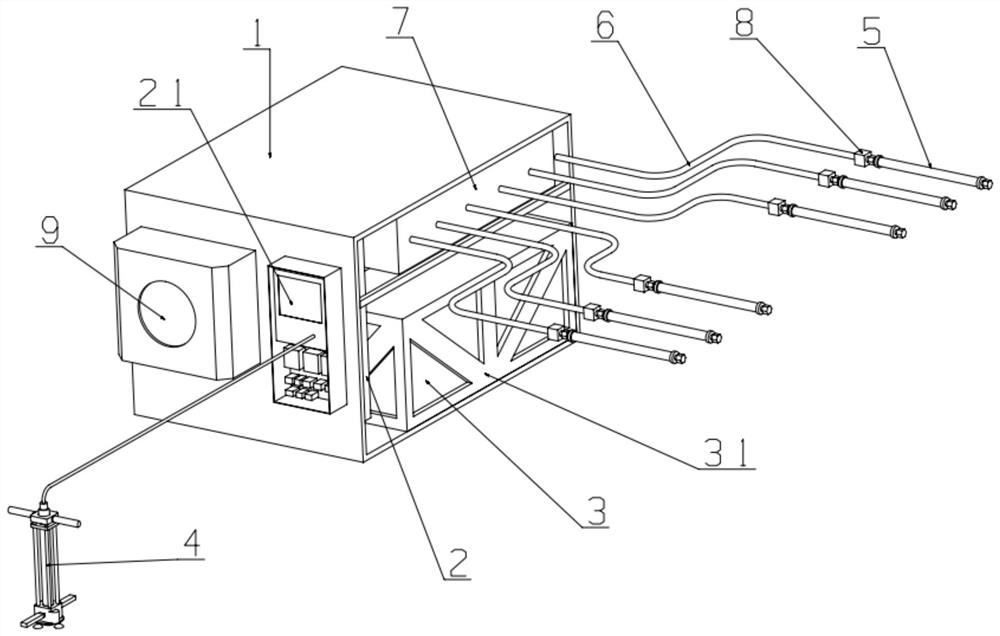

Underground tunnel drill rig device based on forced water spray for limiting fire explosion and drilling method

PendingCN110424910ARealize drilling operationsEasy to debugFlushingFire extinguisherUnderground tunnelWater flow

The invention relates to an underground tunnel drill rig device based on forced water spray for limiting a fire explosion and a drilling method. The underground tunnel drill rig device comprises an underground tunnel drill rig device body, a first main part, a second main part and a controller (9). The underground tunnel drill rig device body is provided with a drill rig (1) and a water injector (4), the first main part is arranged on the drill rig (1) and used for controlling the work state of the drill rig (1), the second main part is arranged in the water injector (4) and used for collecting water flow signals in the water injector (4), and the controller (9) is set to be connected with the first main part and the second main part and used for processing signals. By means of the secondmain part, it is achieved that water flow signals of the water injector (4) serve as basic signals; by means of the first main part and the controller (9), control over the drill rig (1) is achieved;by means of the underground tunnel drill rig device body, drilling work is achieved; and thus the phenomenon that drilling work is carried out in the situation that no water is injected is avoided, and the safety performance of coal mine underground drilling work is improved.

Owner:SHANDONG XIANGDE ELECTROMECHANICAL

An energy-saving drilling device for mechanical parts

ActiveCN109623495BRealize drilling operationsPracticalMeasurement/indication equipmentsFeeding apparatusElectric machineryEngineering

The invention relates to the technical field of drilling devices, in particular to an energy-saving drilling device for mechanical parts, which includes a workbench, a machine cover is arranged on the upper side of the workbench, a first motor is arranged on the upper left side of the inside of the machine cover, and the first motor The output end of the first threaded rod is provided with a first threaded rod, the first threaded rod is provided with a sliding seat, the lower side of the sliding seat is provided with a first telescopic device, the lower end of the first telescopic device is provided with a motor seat, and the motor seat is provided with A drilling motor is installed, and a second expansion device is symmetrically arranged in the middle of the upper side of the workbench. A part placement plate is arranged on the upper end of the second expansion device, and a pressure is embedded in the upper side of the part placement plate. For the sensor, the upper side of the workbench is symmetrically provided with clamping mechanisms located on the left and right sides of the part placement plate. The structural setting of the device can select the working mode according to the weight of the parts, and the work can be realized by using the minimum energy, which is energy-saving, environment-friendly and highly practical.

Owner:宁波斯凯勒智能科技有限公司

An industrial automatic drilling equipment

ActiveCN108705323BImprove stabilityPrevent slidingLarge fixed membersPositioning apparatusElectric machineryScrew thread

Owner:浙江甬岭数控刀具有限公司

An automatic drilling machine for underwater pipelines

ActiveCN109047854BRealize drilling operationsConvenient for underwater workBoring/drilling machinesWorking environmentMachine

The invention provides an underwater pipeline automatic drilling machine. The underwater pipeline automatic drilling machine comprises a steel wire rope guiding mechanism, a feeding driving mechanism,a drilling driving mechanism, a clamping mechanism, a pipeline positioning mechanism and an upper and lower bracket, wherein the upper and the lower support form a machine body main body part througha pin shaft, the steel wire rope guide mechanism, the pipeline positioning mechanism, the feeding driving mechanism and the drilling driving mechanism are arranged on the body part of the machine body. The underwater pipeline automatic drilling machine are used for achieving drilling work of pipelines with different sizes at one time; the system can be automatically controlled and can be operatedby an ROV, the pipeline positioning mechanism, a steel wire rope tightening mechanism can select different driving modes under different working conditions, the application is flexible, and underwater operation is facilitated; and the underwater pipeline automatic drilling machine can adapt to the narrow working environment of the seabed pipeline and the ground space.

Owner:HARBIN ENG UNIV

Efficient drilling equipment for brush plate machining

The invention discloses efficient drilling equipment for brush plate machining. The equipment comprises a workbench, first mounting grooves are formed in the front side and the rear side of the top face of the workbench in a penetrating mode, first mounting blocks are slidably connected to the inner walls of the first mounting grooves, a working disc is fixedly connected to the top faces of the four first mounting blocks through screws, a fixing groove is formed in the top face of the working disc, first electric telescopic rods are fixedly connected to the side walls of the fixing groove through screws, extrusion blocks are fixedly connected to the output ends of the first electric telescopic rods through screws, a toothed bar is further fixedly connected between the bottom faces of the two first mounting blocks at the front end and the rear end, a driving mechanism is further arranged on the lower side of the middle of the workbench, and a mounting frame is further fixed to the middle of the top face of the workbench. The efficient drilling equipment is reasonable in design and stable in device operation; synchronous drilling operation of a plurality of bristle planting holes can be completed at a time, so that the working efficiency of brush plate drilling machining is greatly improved; and the bristle planting holes at different intervals are convenient to adjust during drilling, and then the application range of the device is greatly widened.

Owner:安徽三和刷业股份有限公司

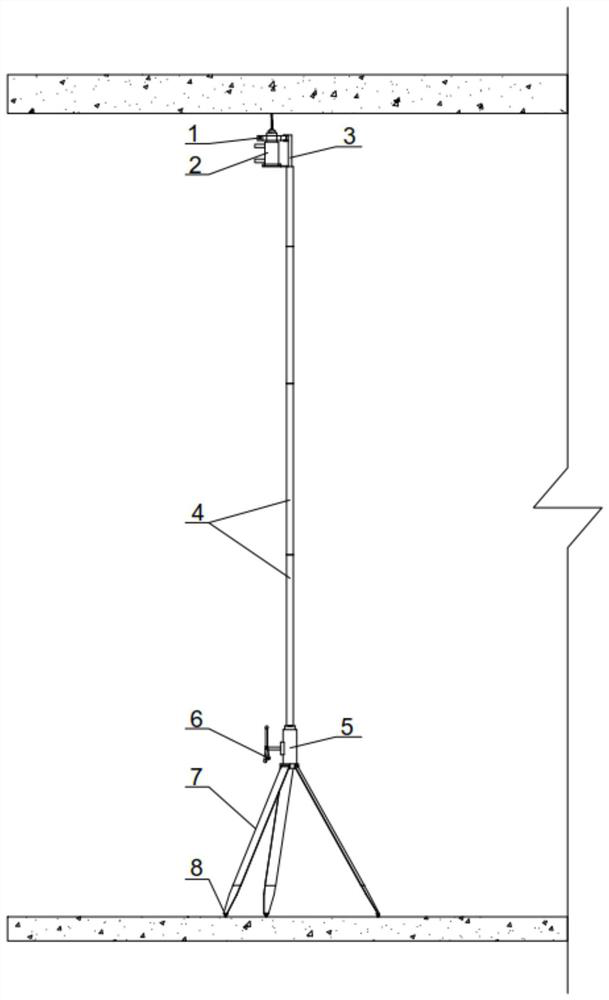

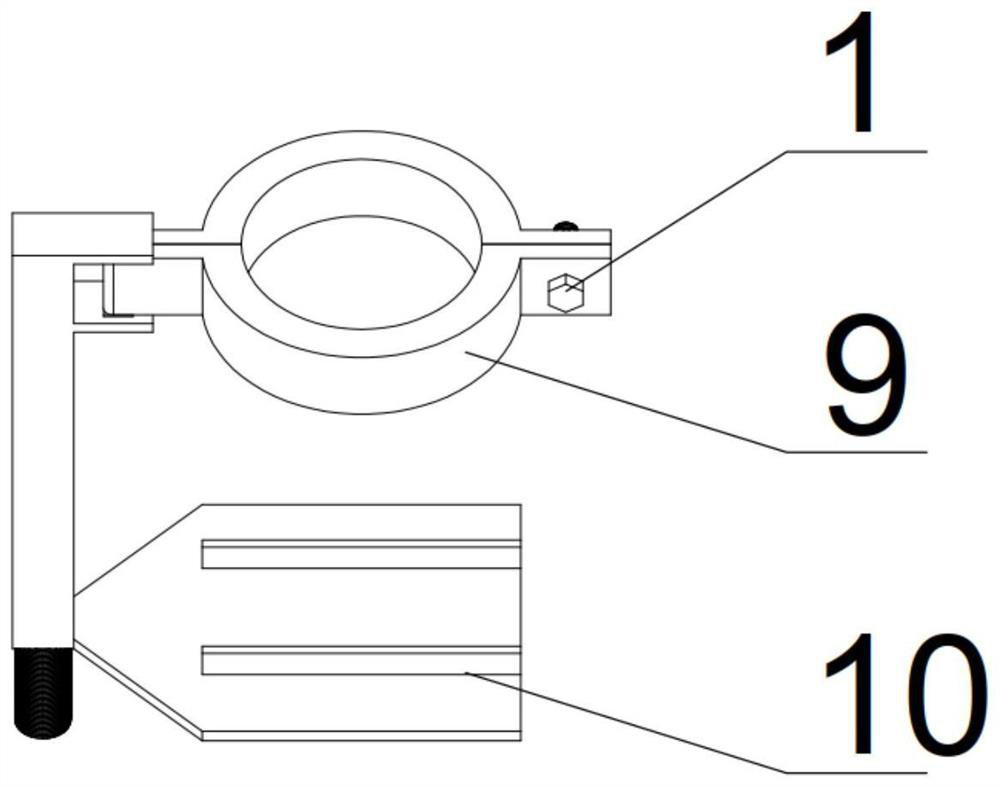

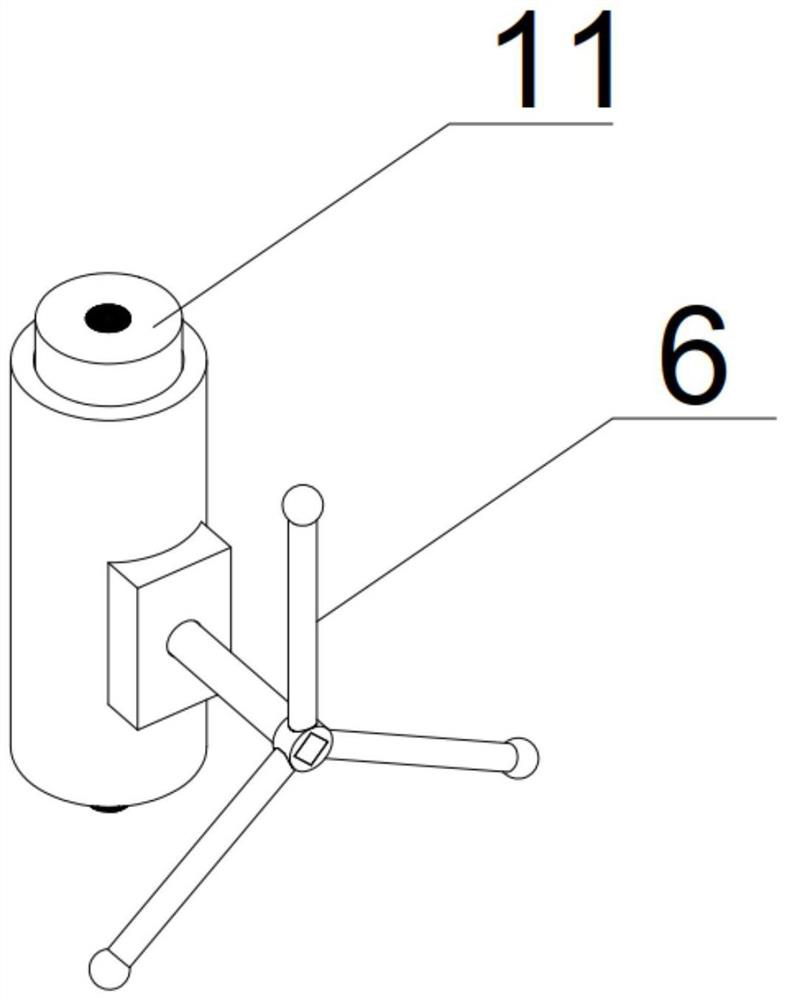

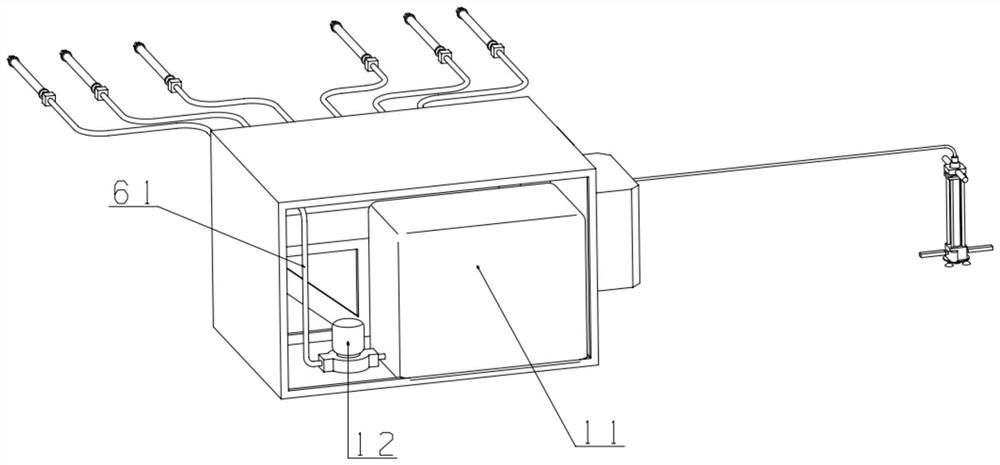

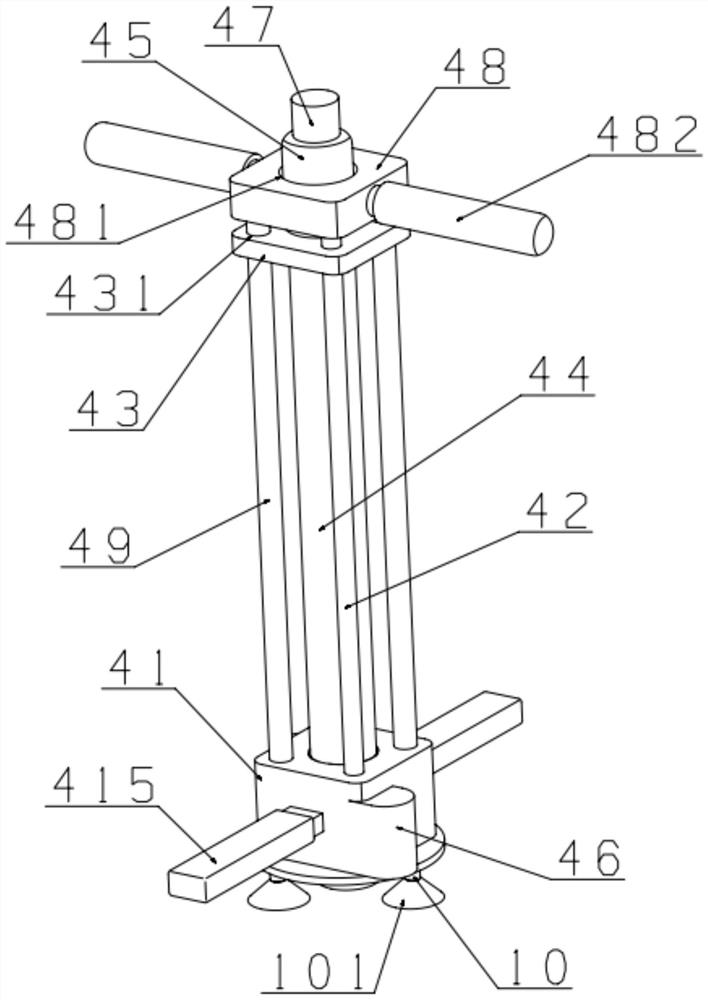

Adjustable and detachable drilling machine support device

PendingCN112963100AEasy to assembleRealize drilling operationsDerricks/mastsScrew threadIndustrial engineering

The invention relates to an adjustable and detachable drilling machine support device suitable for drilling construction of a high-rise floor. The support device structurally comprises a drilling machine fixing platform, a plurality of extension rods, a hydraulic lifting support and a tripod, the drilling machine fixing platform comprises a drilling machine body bayonet, a drilling machine supporting jig frame and a fixing bolt, the fixing bolt is installed on the drilling machine body bayonet in a threaded mode and used for fixing the drilling machine, the drilling machine makes contact with the drilling machine supporting jig frame, and the lower end of the drilling machine fixing platform is in spiral connection with the extension rods. A plurality of the extension rods are spirally connected with the drilling machine fixing platform and the hydraulic lifting support through external threads and internal threads which are respectively arranged at the two ends of the extension rods. The two ends of the hydraulic lifting support are respectively and spirally connected with the extension rods and the tripod through the arranged external threads and the internal threads. The device has the advantages of being easy to assemble, convenient to carry, convenient to operate and suitable for multiple terrains.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

A fast food box mold punching drill bit

InactiveCN106064247BRealize drilling operationsReduce labor intensityFeeding apparatusDriving apparatusDrive motorEngineering

The invention discloses a perforation drill bit for a lunch box die. The perforation drill bit comprises a rotary movement mechanism, a swing movement mechanism, an advance-retreat movement mechanism and a drill bit drive mechanism, wherein a drill bit drive motor is capable of driving the drill bit to rotate through arranging a driven belt wheel on a drill bit shaft for fixing the drill bit and arranging a drive belt wheel on an output shaft of the drill bit drive motor, thus perforation working for the lunch box die is realized. The drill bit can be driven to carry out ascending and descending actions under the drive effect of an advance-retreat motor through arranging the advance-retreat motor on a fixing plate and fixing a lead screw on an output shaft of the advance-retreat motor, thus perforation and retreat of the drill bit are completed. The perforation drill bit for the lunch box die, which is disclosed by the invention, can automatically complete automatic perforation working for the lunch box die, replaces previous manual perforation, reduces the labour intensity, increases the perforation working efficiency, reduces the cost, has a remarkable beneficial effect, and is suitable for being popularized and applied.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

A big data server

InactiveCN107505992BImprove work efficiencyRealize drilling operationsDigital processing power distributionJoint cavityEngineering

The invention discloses a big data server. The big data server comprises a base and a storage box arranged at the top of the base, wherein a storage cavity is formed in the storage box, the bottom of the storage cavity is provided with a back taper cavity, which extends downwards to the base, in a mutual communication mode, a conduction cavity is formed in the portion, at the right side of the storage cavity, of the storage box, a first taper turning wheel is arranged in the conduction cavity, a stirring shaft which is arranged to extend to the left side is fixedly arranged at the left end of the first taper turning wheel, the left extension segment of the stirring shaft penetrates through the portion, between the conduction cavity and the storage cavity, of the storage box and is connected with the storage box in a rotary mode, the left extension tip of the stirring shaft extends into the storage cavity and is connected with the left inner wall of the storage cavity in a rotary mode, the bottom of the back taper cavity is provided with a first slide-joint slot, which is arranged to extend to the left side and the right side, in a mutual communication mode, a slide-joint cavity is formed in the portion, below the first slide-joint slot, of the base, and a guide-joint pipe which is arranged to extend up and down is arranged in the portion, at the left side of the slide-joint cavity, of the base. The big data server is simple in structure and convenient to operate.

Owner:广东联结电子商务有限公司

Fast big data server

ActiveCN107466178AImprove work efficiencySimple structureCasings/cabinets/drawers detailsClamping/extracting meansEngineeringBig data

The invention discloses a fast big data server comprising a base body and a storage box arranged on the top of the base body. A storage cavity is formed inside the storage box; and an inverted-cone-shaped cavity that extends downwardly to the base body is formed in the bottom of the storage cavity. A conduction cavity is formed in the storage box at the right of the storage cavity; a first tapered rotating wheel is arranged in the conduction cavity; a stirring shaft extending to the left side is fixedly arranged at the left end of the first tapered rotating wheel; the left-side extending segment of the stirring shaft penetrates the storage box between the conduction cavity and the storage cavity and is in through connection; and the left-side extending tail of the stirring shaft extends into the storage cavity and is in through connection with the inner wall of the left side of the storage cavity. Besides, a first sliding groove extending left and right is formed in the bottom of the inverted-cone-shaped cavity in a mutual connection manner; a sliding cavity is formed in the base body below the first sliding groove; and a guiding pipe extending up and down is arranged in the base body at the left side of the sliding cavity. The fast big data server having a simple structure is operated conveniently.

Owner:广东联结电子商务有限公司 +1

Directional variable flow type hydraulic fracturing system and method

PendingCN113931628AImprove intelligenceImprove securityConstructionsDisloding machinesEngineeringHydraulic fracturing

The invention relates to the field of rock breaking equipment, and particularly discloses a directional variable flow type hydraulic fracturing system. The directional variable flow type hydraulic fracturing system comprises a water tank, a pressure pump, a main controller, a storage battery, a distribution valve, a drilling device and expanders. The invention further discloses a directional variable flow type hydraulic fracturing method using the directional variable flow type hydraulic fracturing system. According to the directional variable flow type hydraulic fracturing system and method, the drilling device is used for drilling a rock wall and collecting hardness data of the rock wall at the same time, the main controller is used for calculating to form the fracturing critical pressure intensity at each fracturing point, then the needed fracturing critical pressure intensity of the expanders at each fracturing point is calculated according to the set time sequence, the main controller controls the flow in the expanders by controlling the distribution valve, and therefore the effect of controlling the fracturing time sequence by controlling the pressure intensity is achieved. The system can adjust measures to local conditions, on-site calculation and deployment are achieved, the intelligence is high, judgment can be carried out without human experience, the safety is high, and the error rate is low.

Owner:GUANGXI NEWHARBOR ENG CO LTD

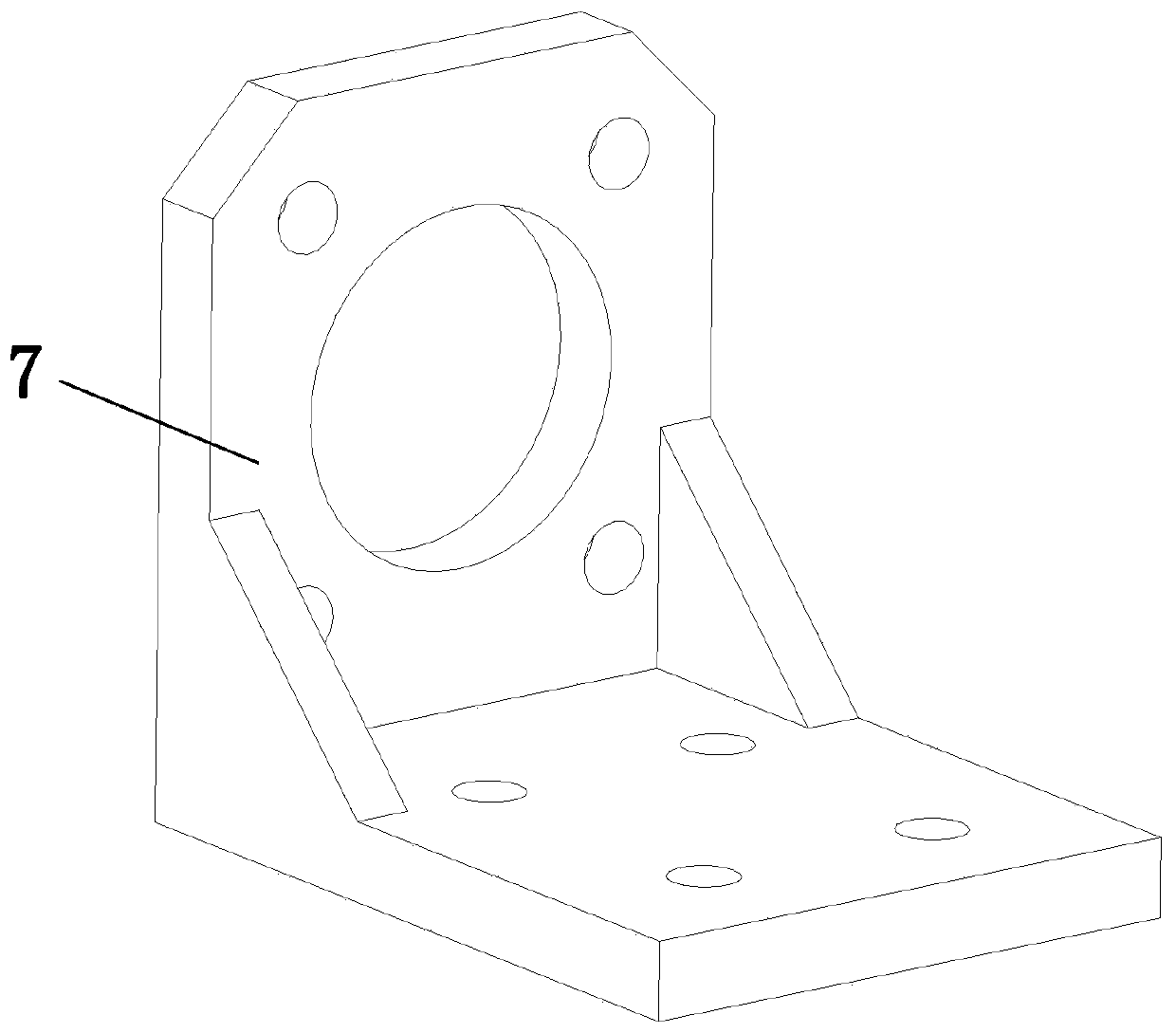

Waste recycling mechanism for machining motor bracket parts

InactiveCN111283240AReduce manual laborIncrease productivityPositioning apparatusMetal working apparatusElectric machineryMechanical equipment

The invention relates to the technical field of mechanical equipment, and discloses a waste recycling mechanism for machining motor bracket parts. The waste recycling mechanism comprises a workbench,a rotating device, a bearing device, a first drilling device and a second drilling device, the rotating device is fixed at the top of the workbench, the first drilling device and the second drilling device are located at the two ends of the bearing device respectively, the first drilling device comprises a first drilling assembly, a first bearing die holder, a first limiting assembly and a first abutting assembly, the second drilling device comprises a second drilling assembly, a second bearing die holder, a second limiting assembly and a second abutting assembly, and a material guide plate isarranged on the workbench. According to the waste recycling mechanism, the purpose that manual cleaning is not needed can be achieved, manual labor is reduced, and the production efficiency is improved; the whole drilling machining operation of the bracket is achieved, and the practicability of the equipment is improved; and alternate and synchronous machining operation requirement of the brackets in two rectangular mounting frames is met, and the production efficiency is further improved.

Owner:惠州市奥科伟业精密五金有限公司

A device for drilling and shaping coated grains

ActiveCN108994949BRealize drilling operationsDirt cleaningMetal working apparatusRectangular coordinatesEngineering

Owner:SHANGHAI AEROSPACE CHEM ENG INST

Big data server

InactiveCN107505992AImprove work efficiencyRealize drilling operationsDigital processing power distributionJoint cavityEngineering

The invention discloses a big data server. The big data server comprises a base and a storage box arranged at the top of the base, wherein a storage cavity is formed in the storage box, the bottom of the storage cavity is provided with a back taper cavity, which extends downwards to the base, in a mutual communication mode, a conduction cavity is formed in the portion, at the right side of the storage cavity, of the storage box, a first taper turning wheel is arranged in the conduction cavity, a stirring shaft which is arranged to extend to the left side is fixedly arranged at the left end of the first taper turning wheel, the left extension segment of the stirring shaft penetrates through the portion, between the conduction cavity and the storage cavity, of the storage box and is connected with the storage box in a rotary mode, the left extension tip of the stirring shaft extends into the storage cavity and is connected with the left inner wall of the storage cavity in a rotary mode, the bottom of the back taper cavity is provided with a first slide-joint slot, which is arranged to extend to the left side and the right side, in a mutual communication mode, a slide-joint cavity is formed in the portion, below the first slide-joint slot, of the base, and a guide-joint pipe which is arranged to extend up and down is arranged in the portion, at the left side of the slide-joint cavity, of the base. The big data server is simple in structure and convenient to operate.

Owner:广东联结电子商务有限公司

A big data server cabinet drilling device

InactiveCN107466178BImprove work efficiencyRealize drilling operationsCasings/cabinets/drawers detailsClamping/extracting meansEngineeringBig data

The invention discloses a fast big data server comprising a base body and a storage box arranged on the top of the base body. A storage cavity is formed inside the storage box; and an inverted-cone-shaped cavity that extends downwardly to the base body is formed in the bottom of the storage cavity. A conduction cavity is formed in the storage box at the right of the storage cavity; a first tapered rotating wheel is arranged in the conduction cavity; a stirring shaft extending to the left side is fixedly arranged at the left end of the first tapered rotating wheel; the left-side extending segment of the stirring shaft penetrates the storage box between the conduction cavity and the storage cavity and is in through connection; and the left-side extending tail of the stirring shaft extends into the storage cavity and is in through connection with the inner wall of the left side of the storage cavity. Besides, a first sliding groove extending left and right is formed in the bottom of the inverted-cone-shaped cavity in a mutual connection manner; a sliding cavity is formed in the base body below the first sliding groove; and a guiding pipe extending up and down is arranged in the base body at the left side of the sliding cavity. The fast big data server having a simple structure is operated conveniently.

Owner:广东联结电子商务有限公司 +1

Tooling fixture for processing steering knuckle

PendingCN110587342AImprove processing efficiencyClamp firmlyPositioning apparatusMetal-working holdersPulp and paper industryEngineering

The invention discloses a tooling fixture for machining a steering knuckle. The tooling fixture for machining the steering knuckle comprises a station bottom plate, a machining vertical plate and twogroups of clamping mechanisms, wherein the machining vertical plate is fixed on the station bottom plate, the machining vertical plate is of a V-shaped structure, the two groups of clamping mechanismsare symmetrically arranged on the inner sides of the machining vertical plate respectively, and the clamping mechanisms comprise first pressing oil cylinders, second pressing oil cylinders and thirdpressing oil cylinders; and the power output end of each first pressing oil cylinder is connected with one end of a second pressing block, the power output end of each second pressing oil cylinder isconnected with one end of a first pressing block, and the power output end of each third pressing oil cylinder is connected with one end of a third pressing block. By adopting the technical scheme, the steering knuckle to be machined is clamped through the V-shaped machining vertical plate, two steering knuckle workpieces can be machined simultaneously on the machining vertical plate, and the machining efficiency is greatly improved; the three-point positioning is carried out through every three pressing oil cylinders, so that the clamping of the steering knuckle workpieces is firmer and morestable, and the machining precision is better.

Owner:杭州卫东数控机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com