Fully hydraulic reverse circulation drilling machine

A reverse circulation, full hydraulic technology, applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve problems such as unstable movement, high equipment cost, and impact on drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

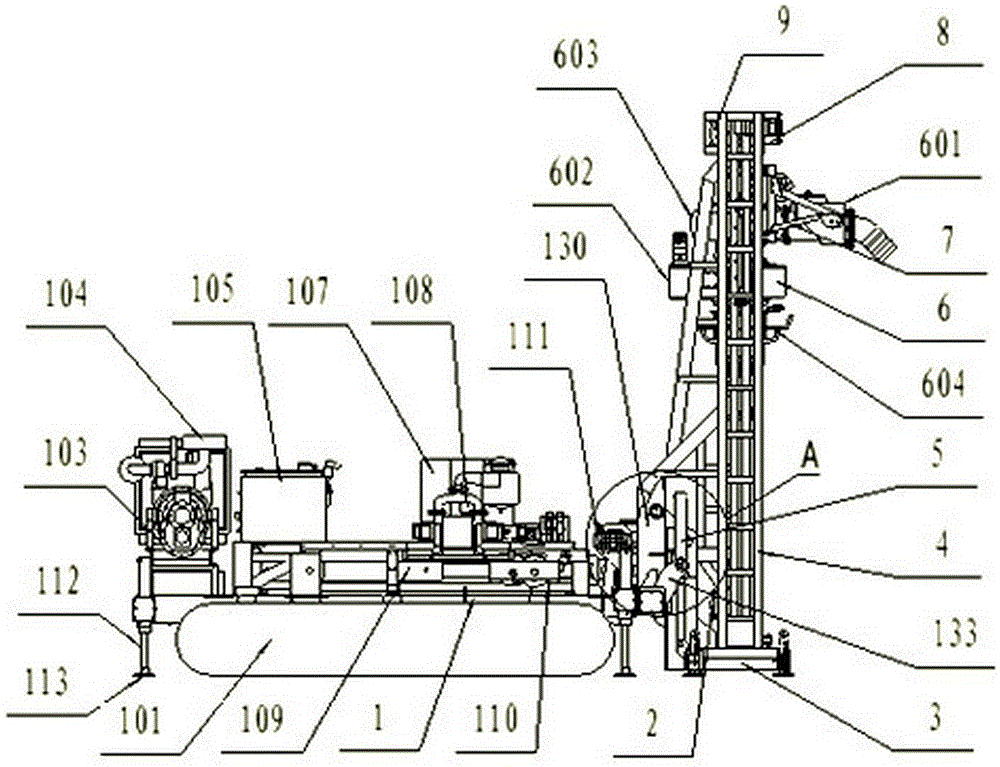

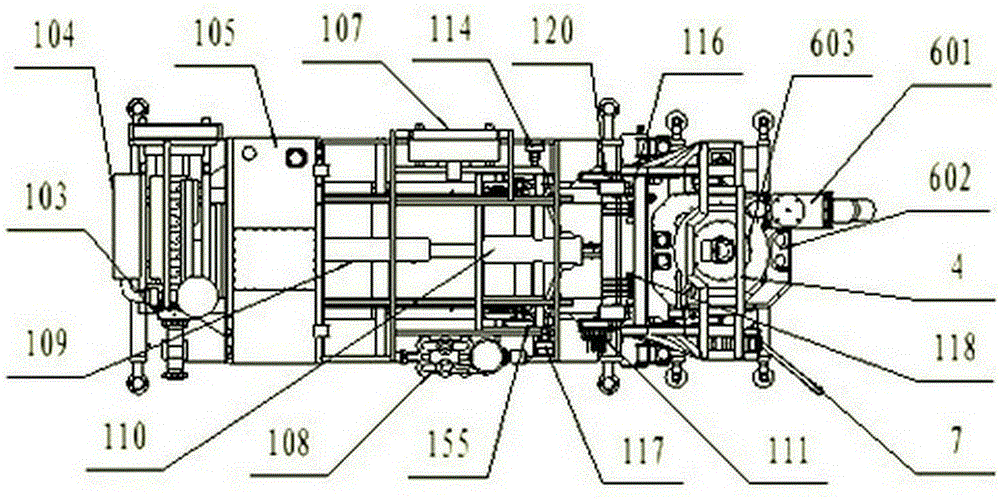

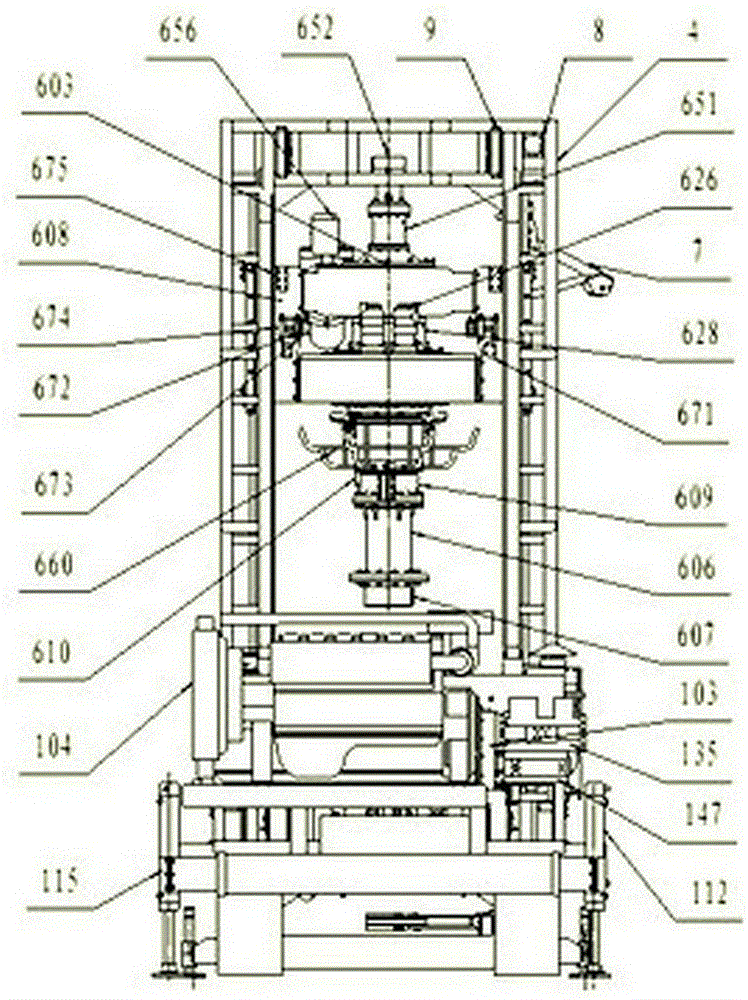

[0307] Example 1 A fully hydraulic reverse circulation drilling rig, including a traveling mechanism 101, a chassis assembly 1, two lower pulley assemblies 2, a workbench assembly 3, a main frame 4, two main frame turning cylinders 5, a swing rod assembly 7, a hinge Car assembly 8, two upper pulley assemblies 9 ( Figure 1-4 ), cylinder pulley assembly 110, drill pipe 13 ( Figure 78-79 ), remover 16 ( Figures 116-118 ),Hydraulic system( Figure 120 ); also includes power take-off assembly 103 ( Figure 22-24 ), impact drill 14 ( Figures 80-88 ), rotor bit 15 ( Figure 89-114 ), the power assembly (referred to as the power assembly) 6 and the cylinder pulley assembly 110 containing the swivel joint assembly;

[0308] Walking mechanism 101 Welded under the chassis assembly 1, it adopts vehicle-mounted self-propelled mechanism or crawler self-propelled mechanism to adapt to different working environments;

[0309] Chassis component 1 It is a welded assembly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com