Patents

Literature

426results about How to "Speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

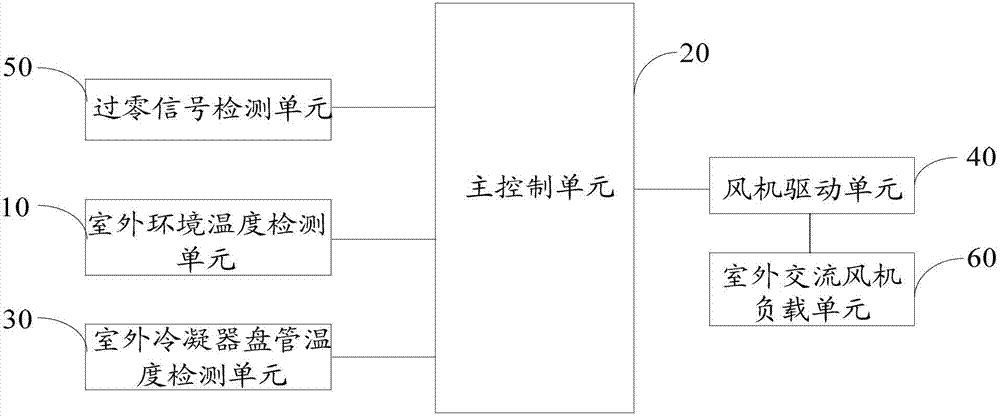

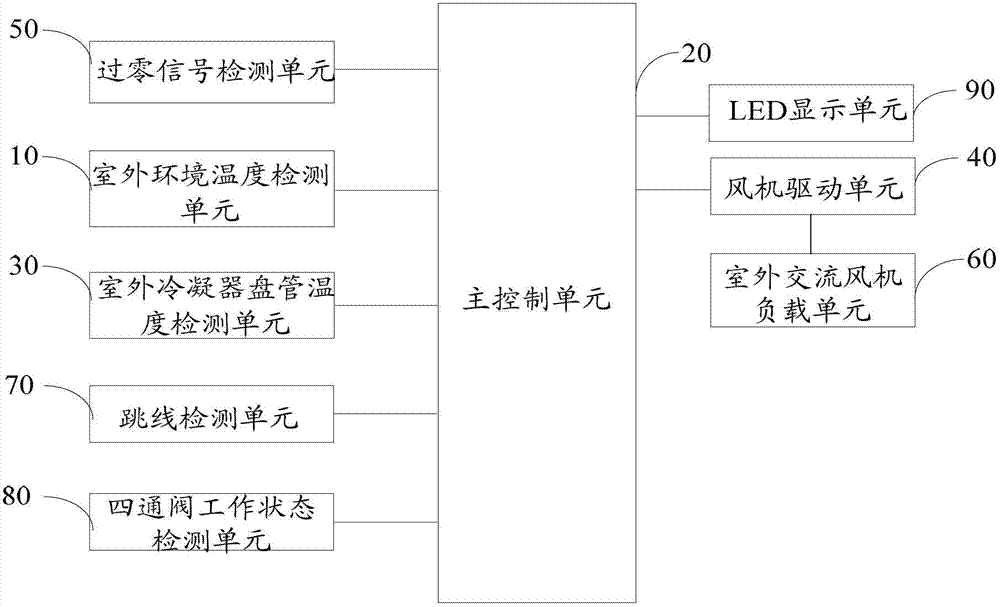

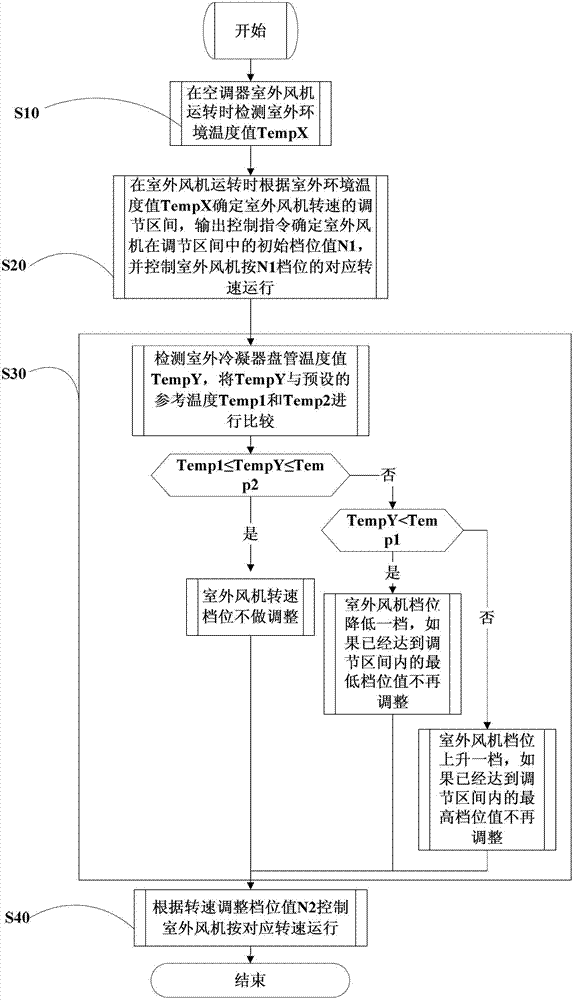

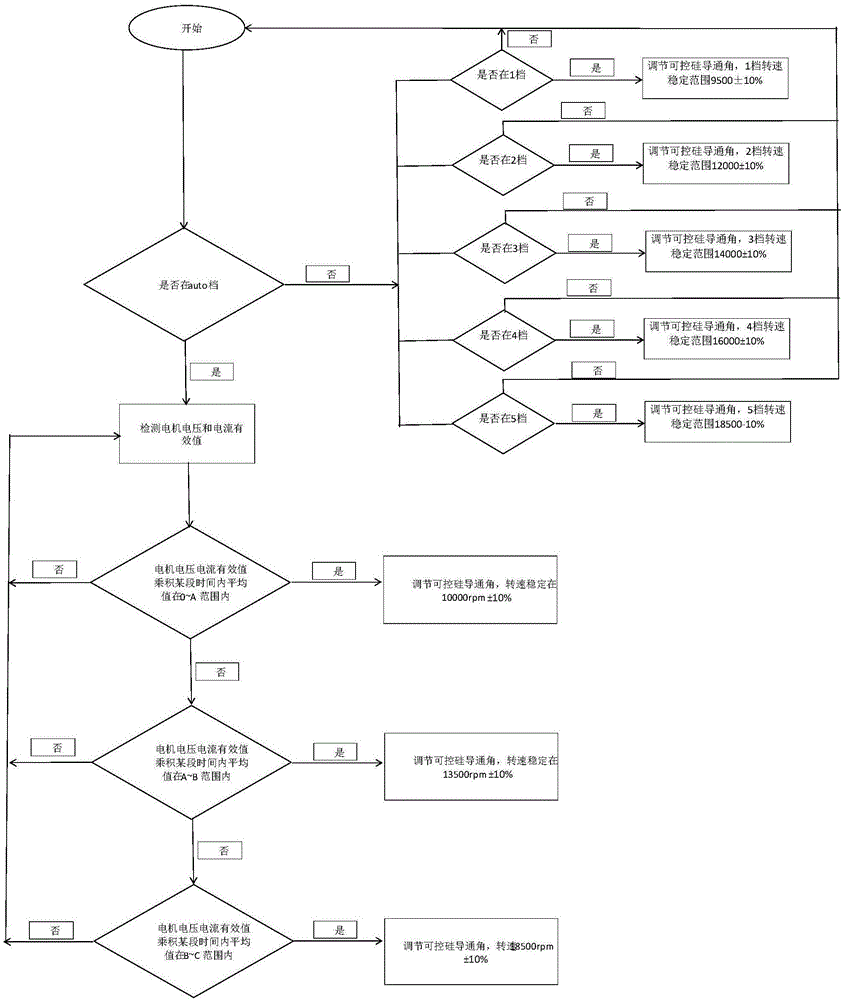

Control circuit and control method of air-conditioner outdoor draught fan and air-conditioner

ActiveCN103175285ASolve the cooling effectTroubleshoot problems that can damage your compressorMechanical apparatusSpace heating and ventilation safety systemsEngineeringOutdoor temperature

The invention discloses a control circuit of an air-conditioner outdoor draught fan. The control circuit comprises an outdoor temperature measurement detecting unit, a condenser pipe temperature detecting unit, a main control unit and a draught fan drive unit. The outdoor temperature measurement detecting unit is used for detecting outdoor environment temperature values when the air-conditioner outdoor draught fan is operated; the condenser pipe temperature detecting unit is used for detecting outdoor condenser coil pipe temperature values when the air-conditioner outdoor draught fan is operated, the main control unit is used for confirming a adjustment range of the rotating speed of the outdoor draught fan according to the outdoor environment temperature values, confirming the initial gear values in the adjustment range of the outdoor draught fan, comparing the outdoor condenser coil pipe temperature values with preset reference temperature, confirming rotating speed adjustment gear values in the adjustment range of the outdoor draught fan, and outputting corresponding rotating speed commands to the draught fan drive unit according to the initial gear values or adjustment gear values; and the draught fan drive unit drives the outdoor draught fan load according to the control commands to adjust the outdoor draught fan to operate in a corresponding speed. The invention further provides an air-conditioner containing the control circuit and a control method of the air-conditioner outdoor draught fan. The control circuit of the air-conditioner outdoor draught fan is low in cost and more stable in system.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

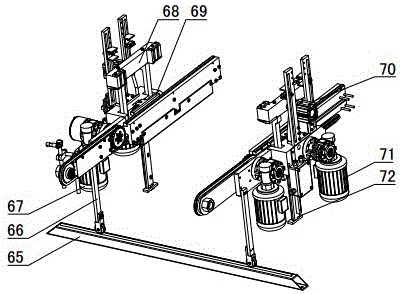

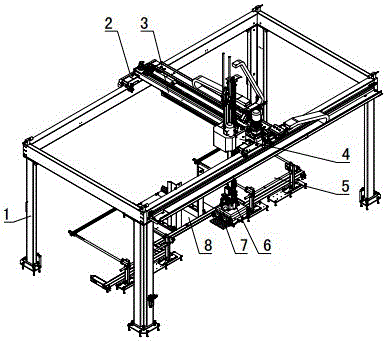

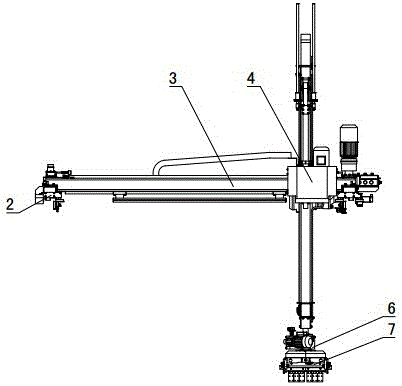

Tile stacking device and tile stacking and palletizing device

ActiveCN106276293AAdjustable spacingLow costStacking articlesDe-stacking articlesEngineeringMechanical engineering

Owner:山东爱而生智能科技有限公司

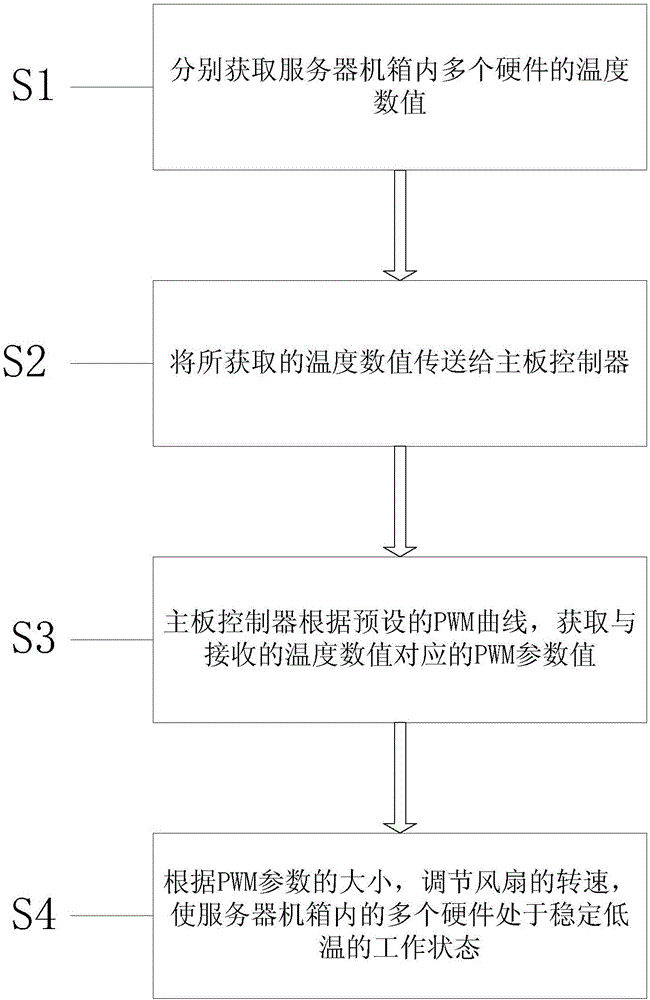

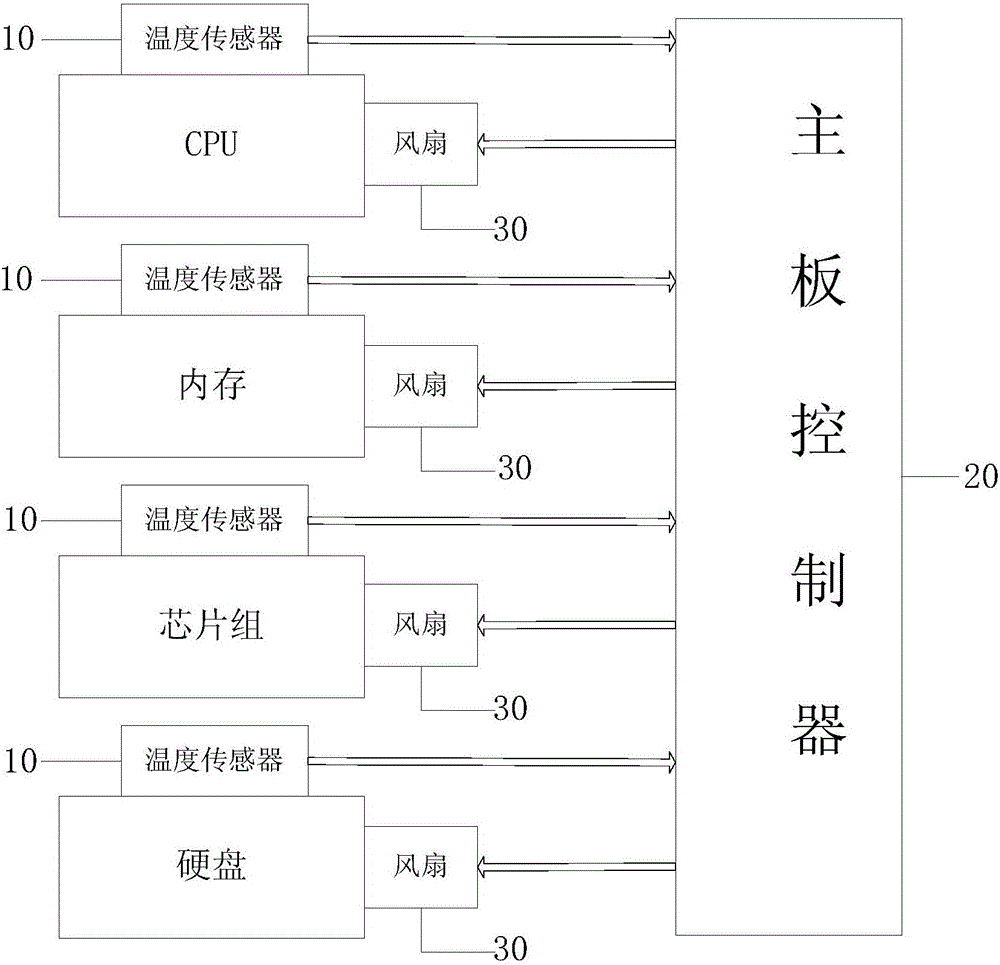

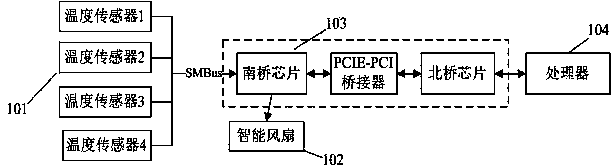

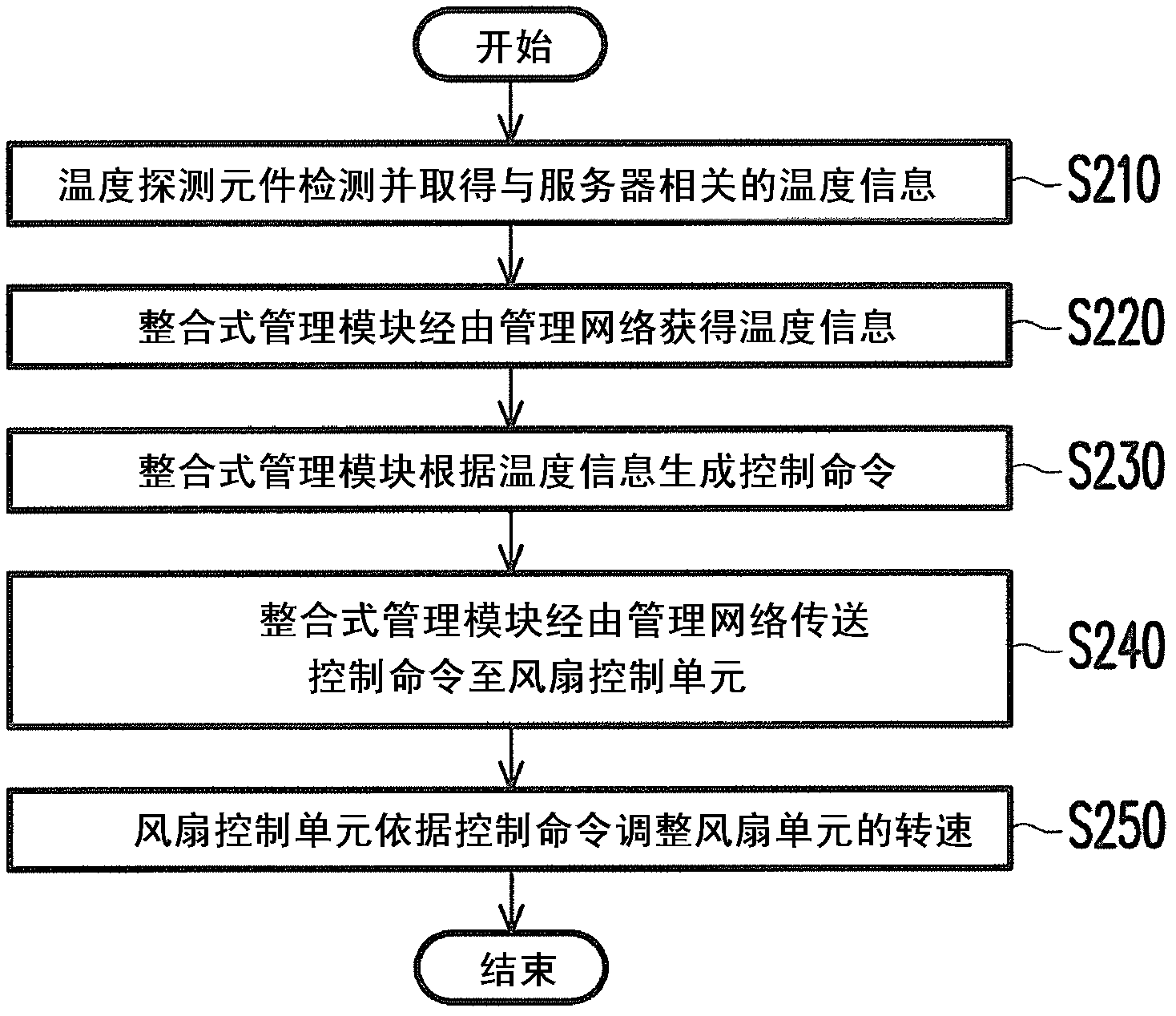

Intelligent server heat dissipation management method

PendingCN106292960ASpeed adjustmentDigital data processing detailsEnergy efficient computingNoise reductionComputer science

The invention discloses an intelligent server heat dissipation management method. The method comprises steps as follows: temperature values of multiple pieces of hardware in a server case are acquired respectively; the acquired temperature values are transmitted to a mainboard controller; the mainboard controller acquires PWM parameter values corresponding to the received temperature values according to a preset PWM curve; the rotation speed of fans is adjusted according to the magnitude of PWM parameters, so that the multiple pieces of hardware in the server case are in a stable and low-temperature work state. Besides, the invention further provides an intelligent server heat dissipation management device. The method and the device have the benefits as follows: the rotation speed of the corresponding fan is adjusted automatically according to heat generated by the hardware in the server case; when the temperature of the hardware is higher, the rotation speed of the fans can be automatically increased, and heat dissipation is accelerated; when the hardware generates less heat, the fans can keep the lower rotation speed, and the purposes of energy consumption reduction and noise reduction can be achieved.

Owner:深圳市云海麒麟计算机系统有限公司

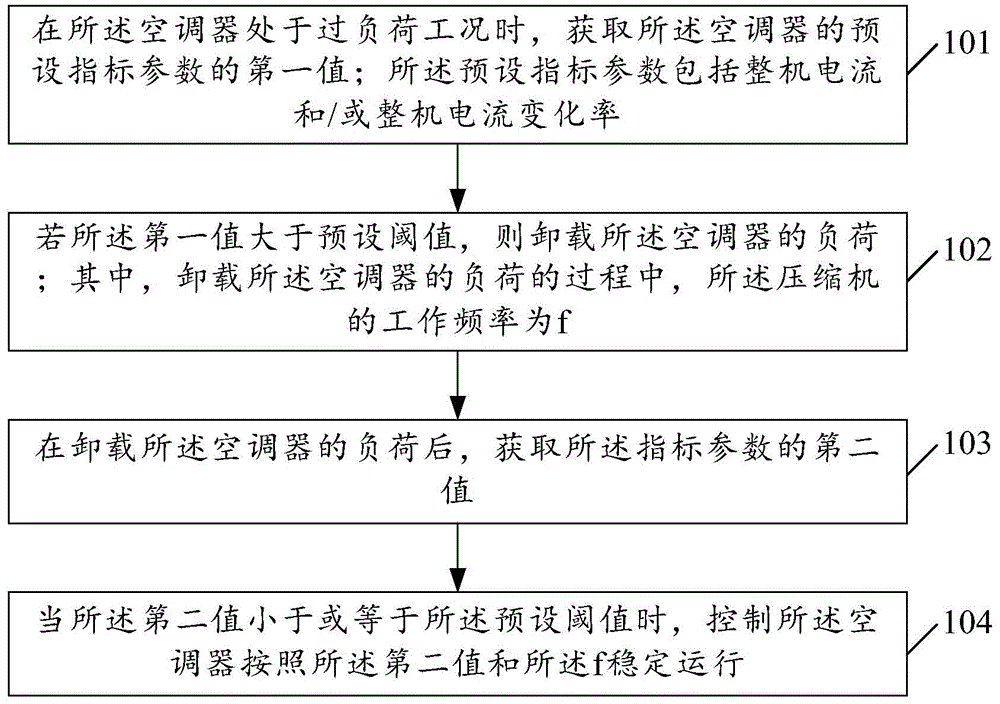

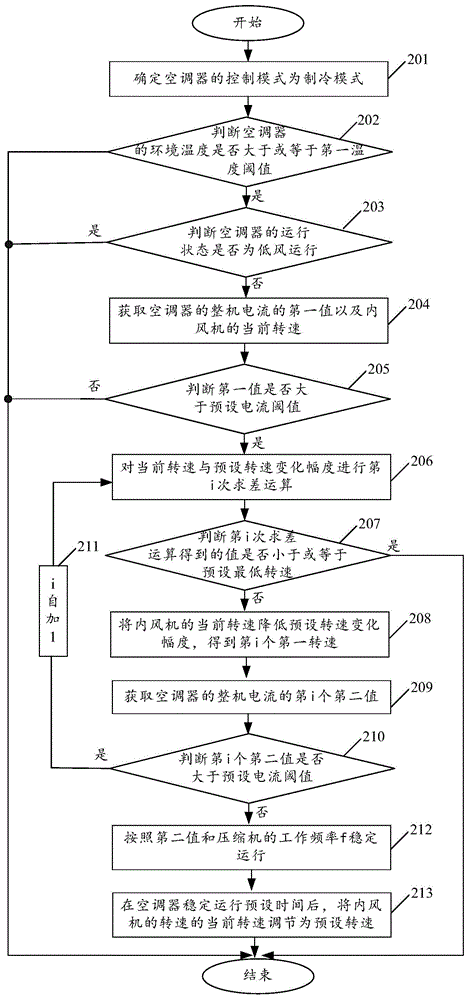

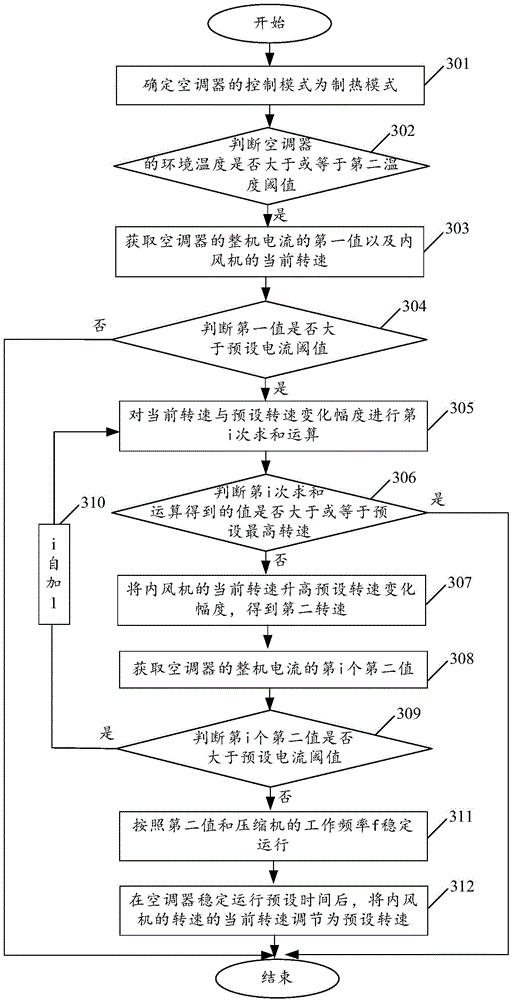

Method and device used for controlling air conditioner and air conditioner

InactiveCN105091185ASpeed adjustmentExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsPower flowControl theory

The embodiment of the invention discloses a method and a device used for controlling an air conditioner and the air conditioner, pertaining to the technical field of control technology for air conditioners. Therefore, service lifetime of the air conditioner is increased while the experience effect of a user is improved. The air conditioner comprises a compressor having working frequency of f and an inner fan. The method for controlling the air conditioner provided by the embodiment comprises following steps: acquiring first value of a pre-set index parameter, comprising machine current and / or rate of change for machine current, of the air conditioner when the air conditioner is in the working condition of excess load; unloading loads of the air conditioner if the first value is greater than the pre-set threshold value; acquiring second value for the index parameter after unloading loads of the air conditioner; and controlling the air conditioner to stably operate according to second value and f when the second value is smaller than or equal to the pre-set threshold value. When the loads of the air conditioner are unloaded, working frequency of the compressor is f.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

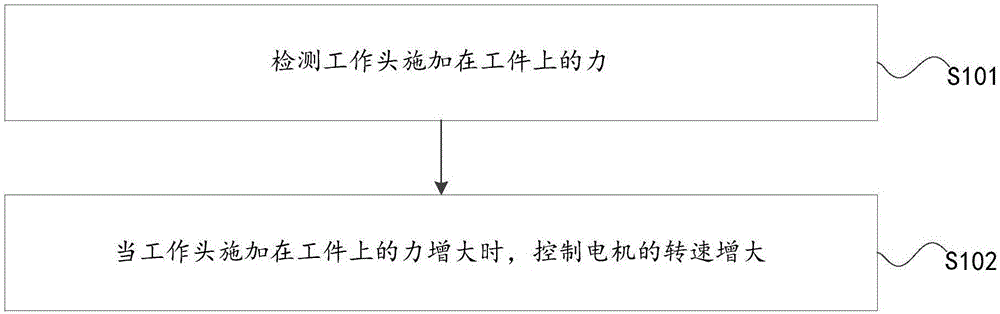

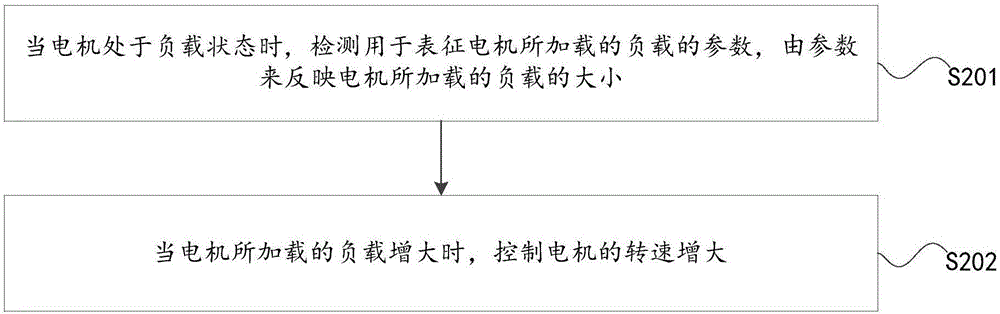

Electric tool, and control method and device thereof

InactiveCN106487286ASpeed adjustmentAssociation with control/drive circuitsSingle motor speed/torque controlEngineeringPower tool

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

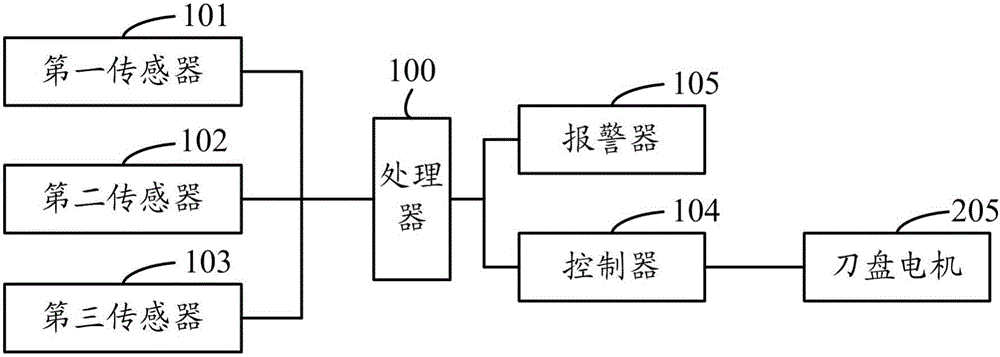

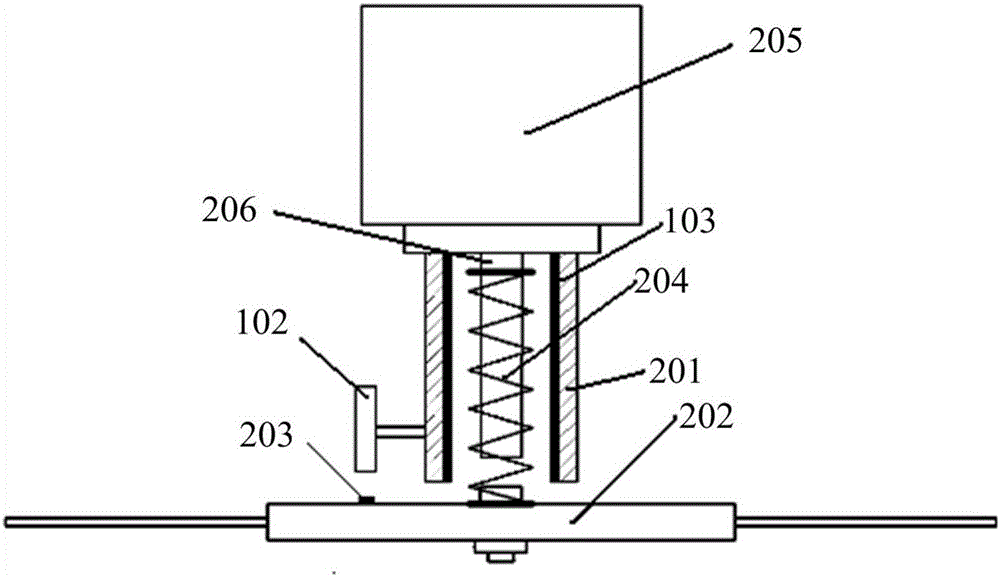

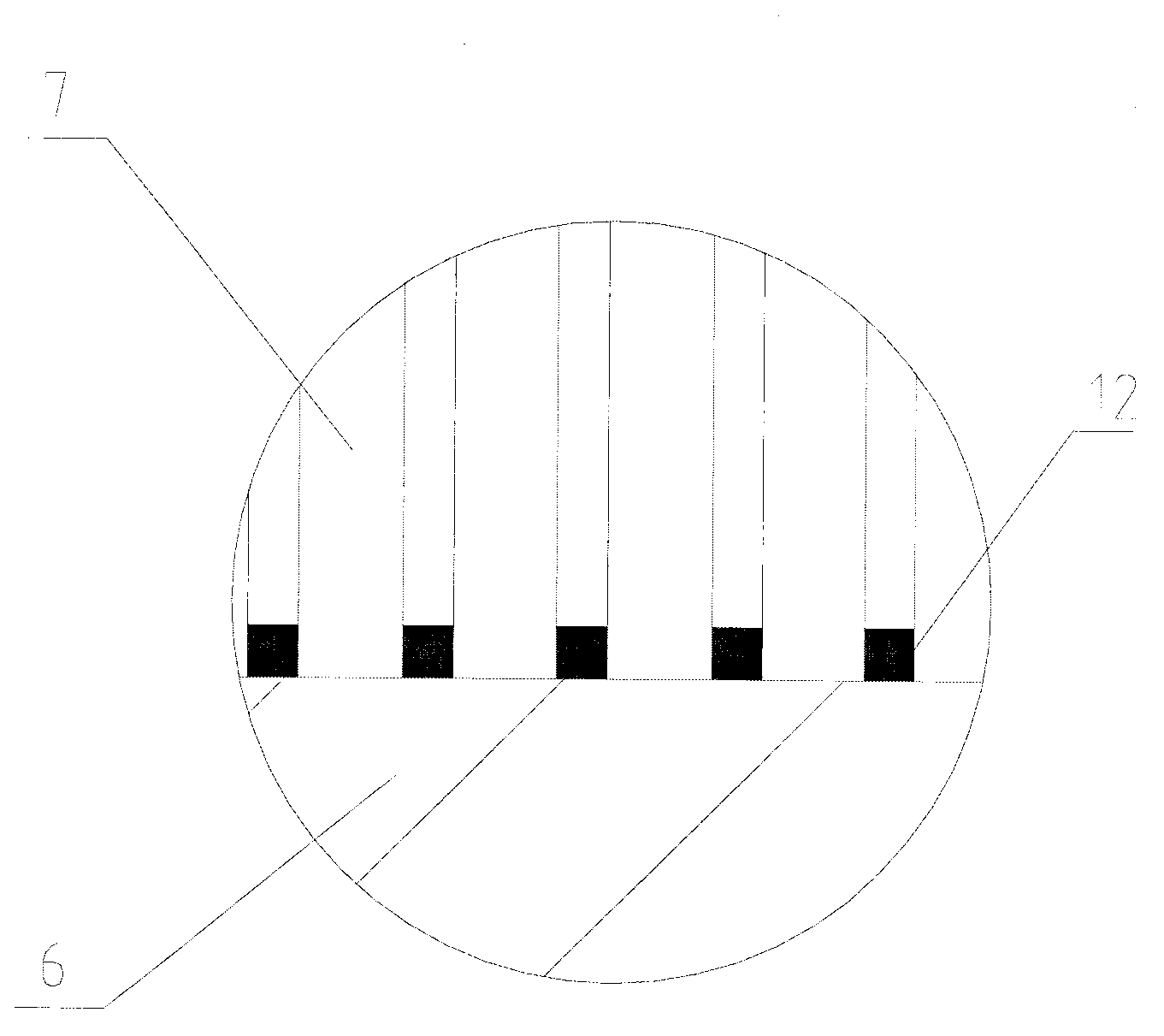

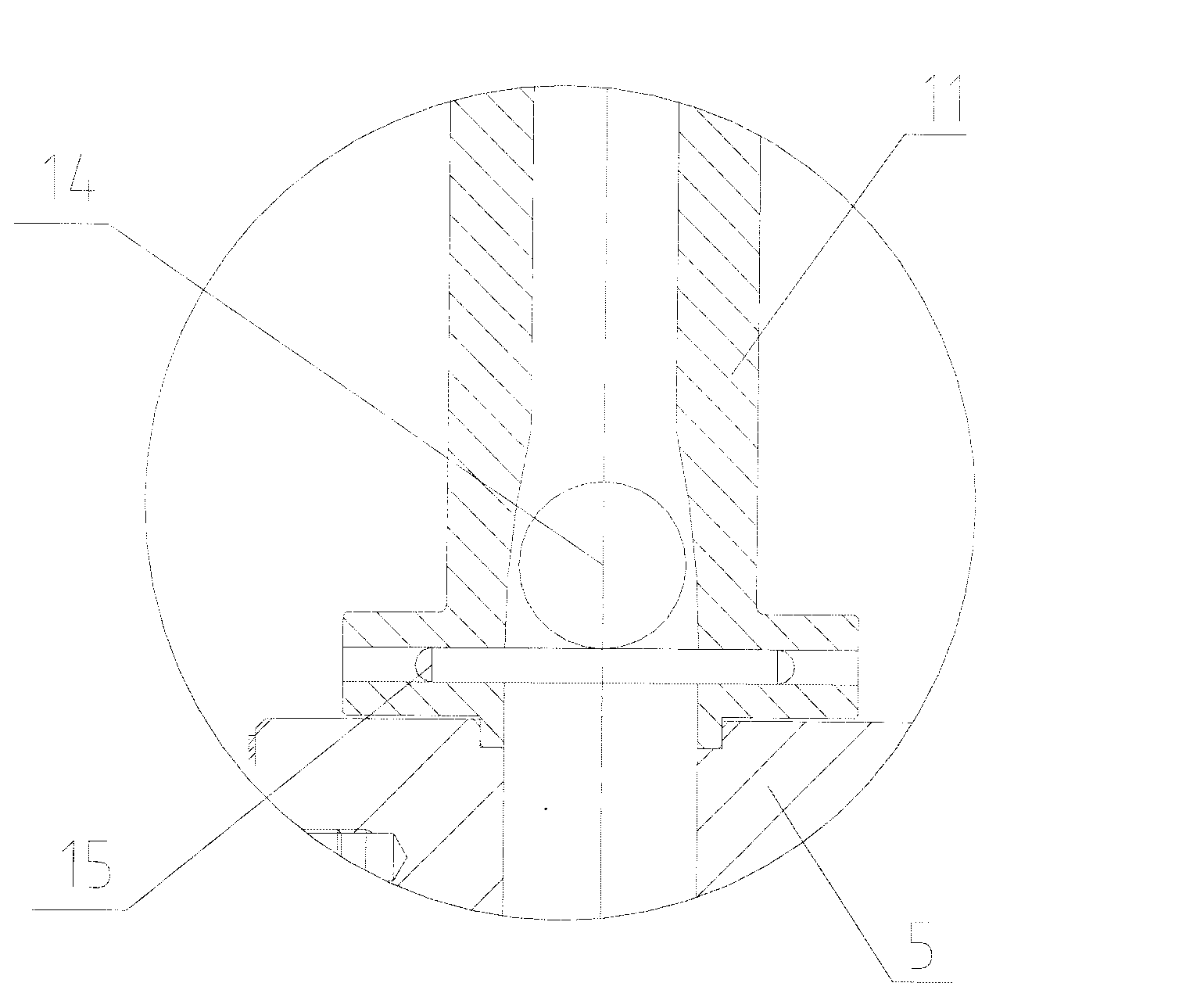

Hand-pushing-type electric-mowing-machine control system

The invention discloses a hand-pushing-type electric-mowing-machine control system, and belongs to the field of weeding machine control. The hand-pushing-type electric-mowing-machine control system is used for solving the problem that the proportion of the traveling speed of the hand-pushing-type electric mowing machine and the rotating speed of a cutter disc can not be adjusted. The hand-pushing-type electric-mowing-machine control system comprises a first sensor, a second sensor, a third sensor and a processor, wherein the first sensor is arranged on a wheel of a mowing machine and used for converting the obtained traveling speed into a first signal and sending the first signal to the processor; the second sensor is arranged on the outer side of a sleeve and used for converting the obtained rotating speed of the cutter disc into a second signal and sending the second signal to the processor; the third sensor is arranged on the inner side of the sleeve and used for obtaining deformation pressure of a spring arranged in the sleeve, converting the deformation pressure into a third signal and sending the third signal to the processor; the processor sends the pulse width to a cutter disc motor of the mowing machine through a controller according to the third signal to stop the cutter disc motor from rotating; the processor adjusts the rotating speed of the cutter disc through the controller and the cutter disc motor of the mowing machine according to the traveling speed of the mowing machine and the rotating speed of the cutter disc.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

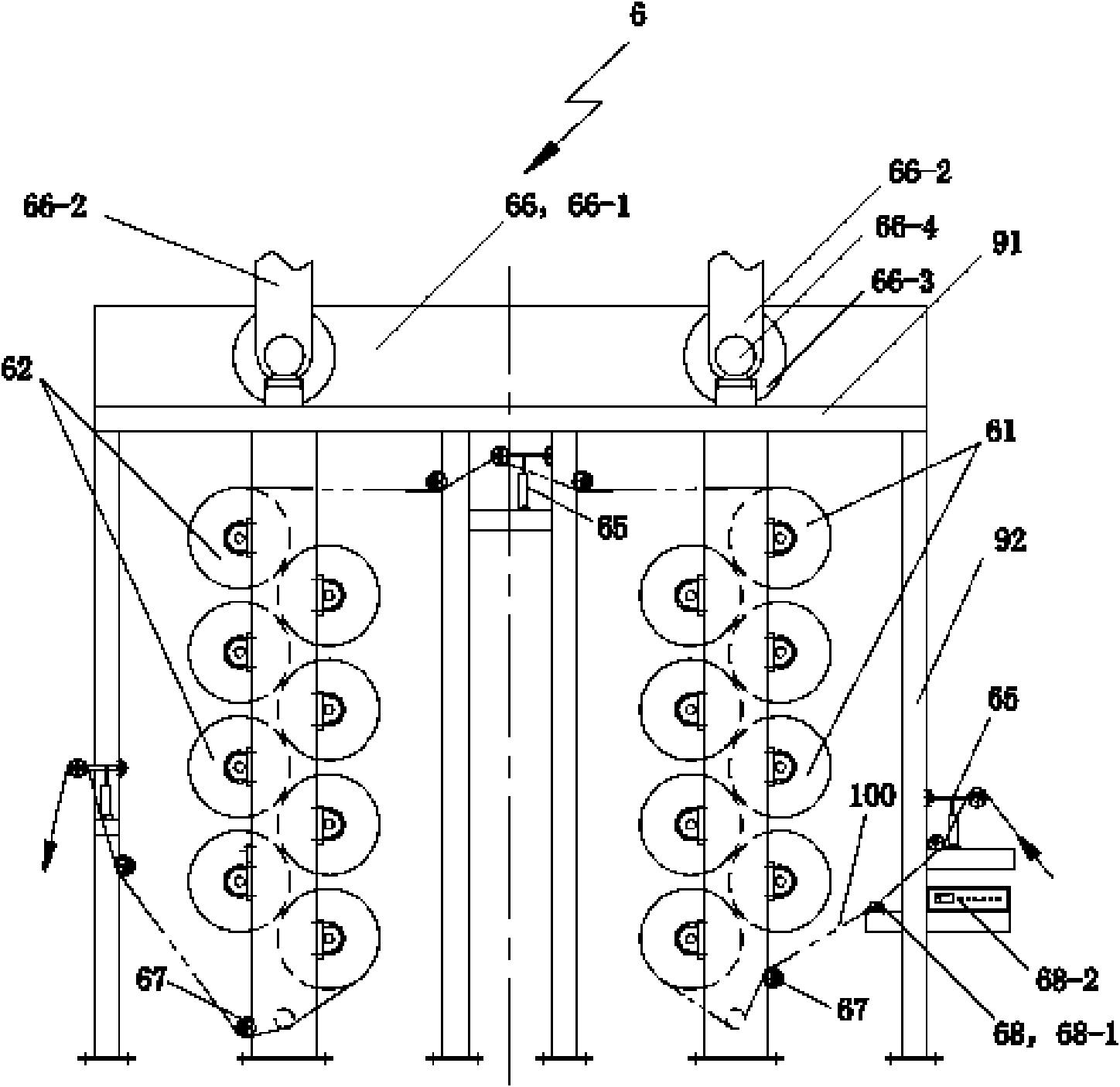

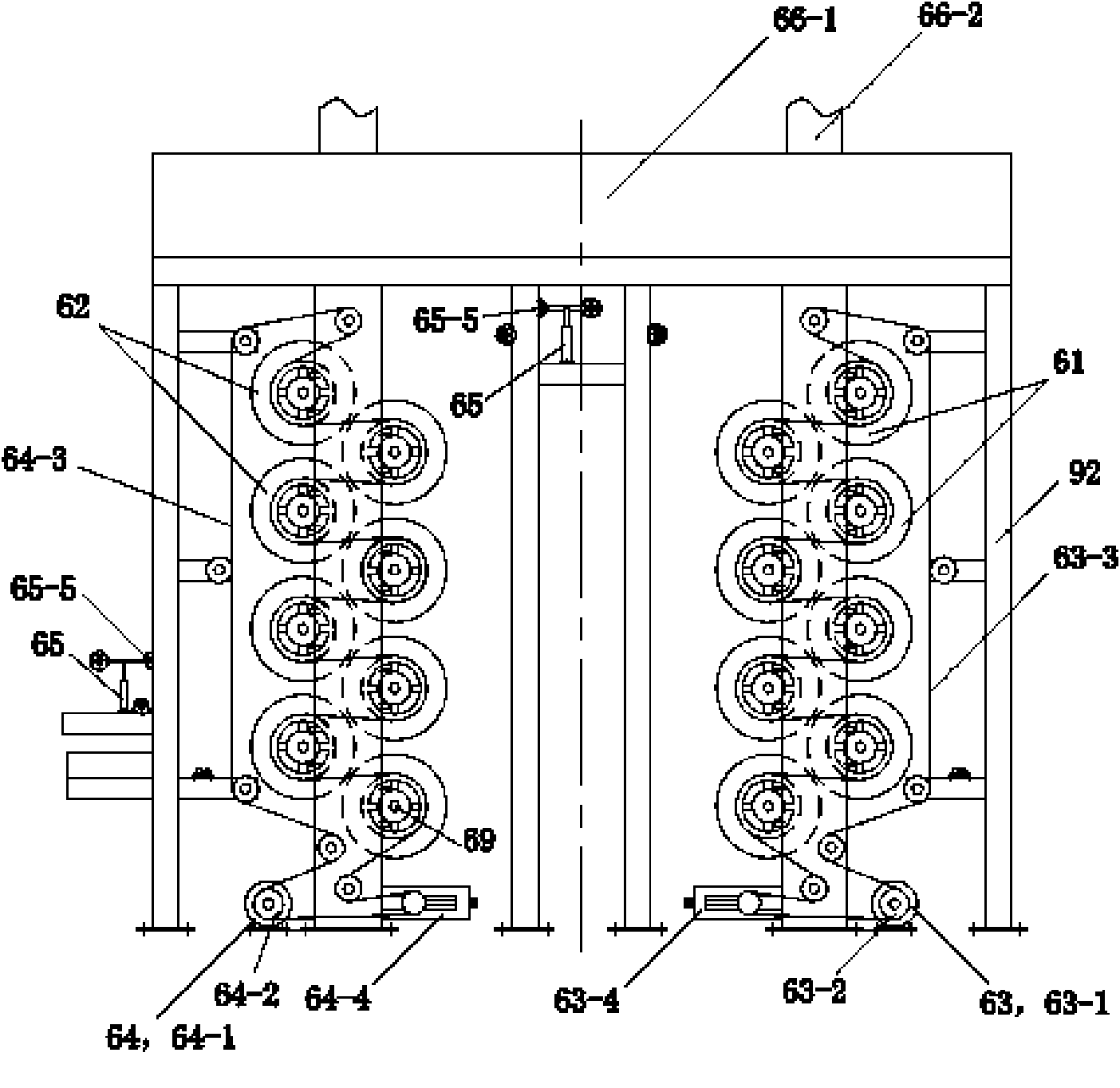

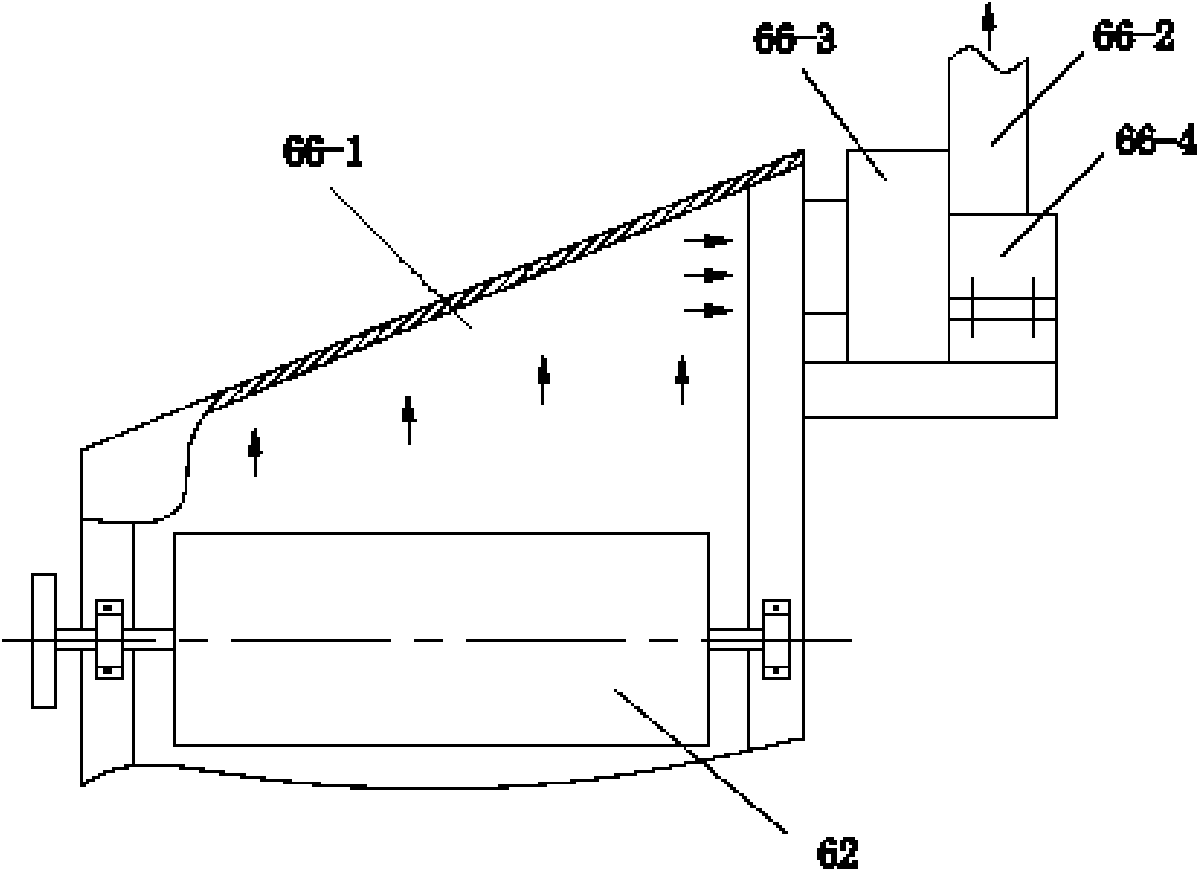

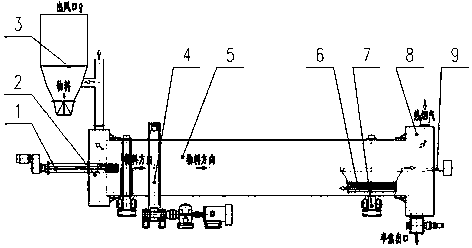

Steam drying device of continuous pigment dyeing padding mangle

InactiveCN101598489ASpeed adjustmentReduce speedDrying solid materials with heatDrying gas arrangementsPulp and paper industryDrying time

The invention relates to a steam drying device of a continuous pigment dyeing padding mangle, which comprises steam drying cylinders, drying transmission mechanisms, a second humidity-discharging device, a water ratio detecting device and an electric cabinet which are arranged on a second mangle frame, wherein the steam drying cylinders are divided into two groups; and the drying transmission mechanisms are divided into two groups correspondingly. During operation, the drying transmission mechanisms drive a fabric to advances sequentially to be dried on the steam drying cylinders. If the water ratio detecting device detects that a water ratio is overhigh, the electric cabinet can be operated in an automatic or a manual mode to reduce the rotating speed of a transmission motor to increase drying time; and otherwise, the rotating speed of the transmission motor is increased to reduce the drying time. Because two groups of steam drying cylinders are adopted to achieve a high advancing speed of the fabric, the steam drying device of the continuous pigment dyeing padding mangle improves the drying efficiency and has a high processing capacity of the drying fabric.

Owner:常州慧杰电气技术有限公司

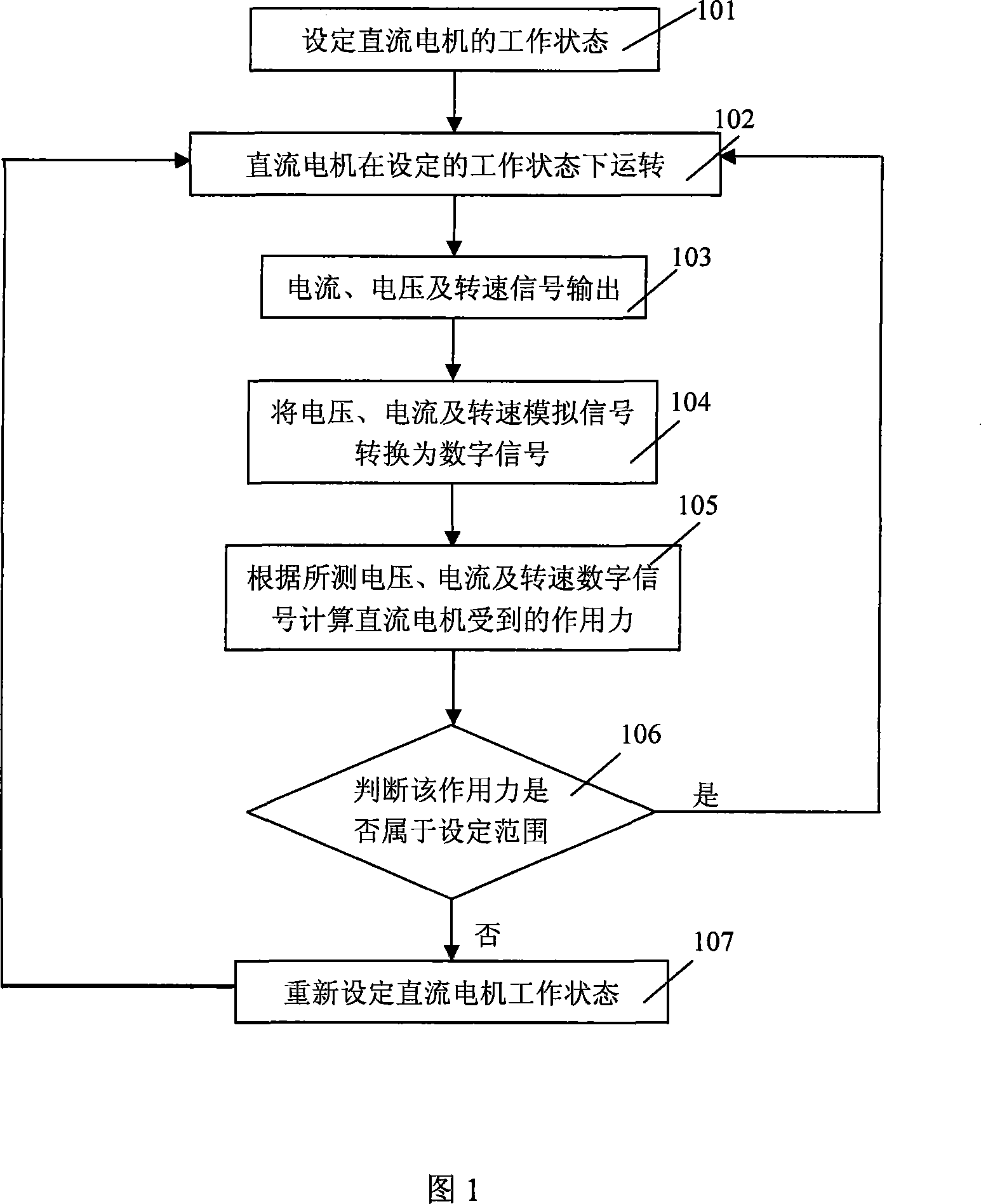

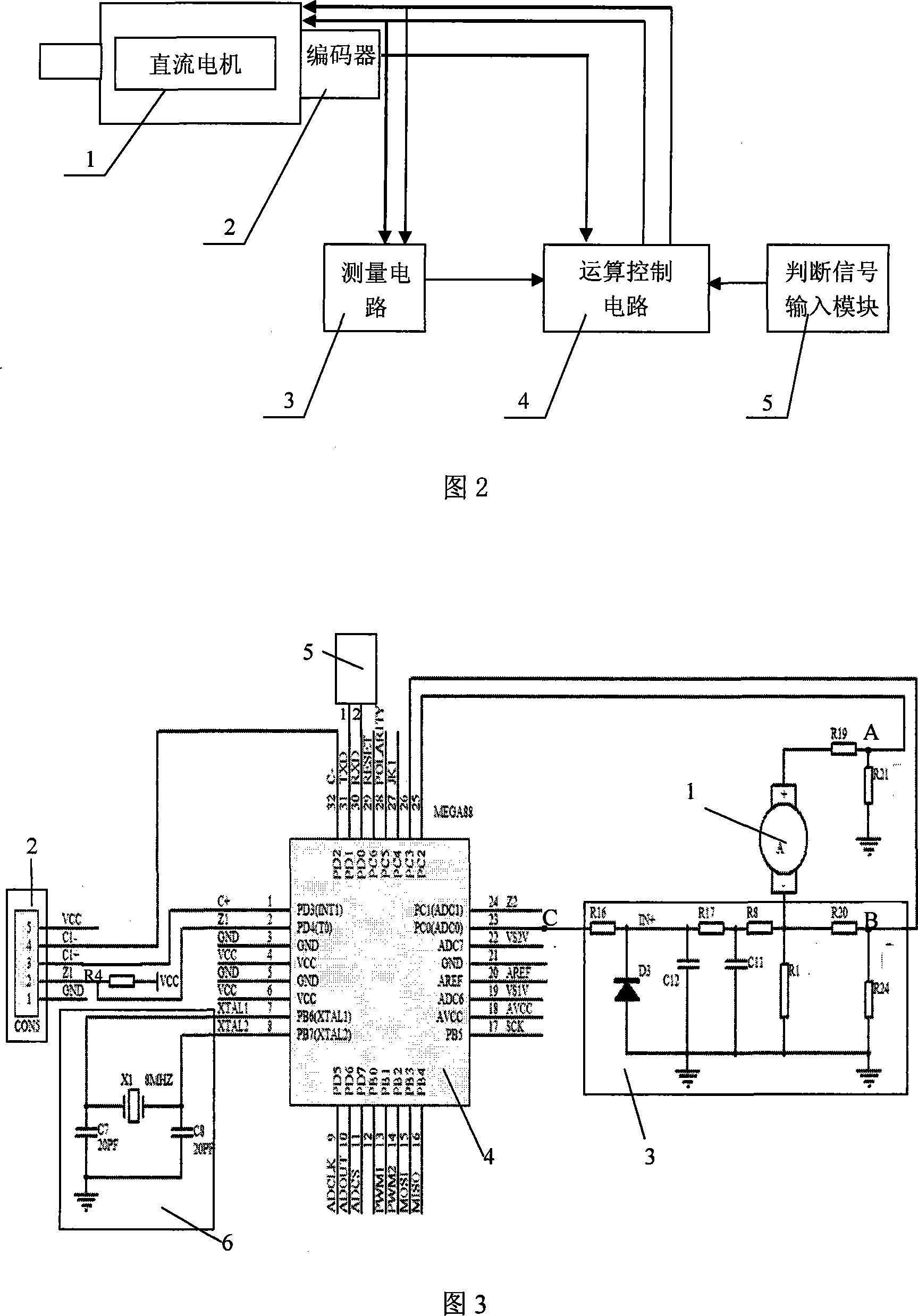

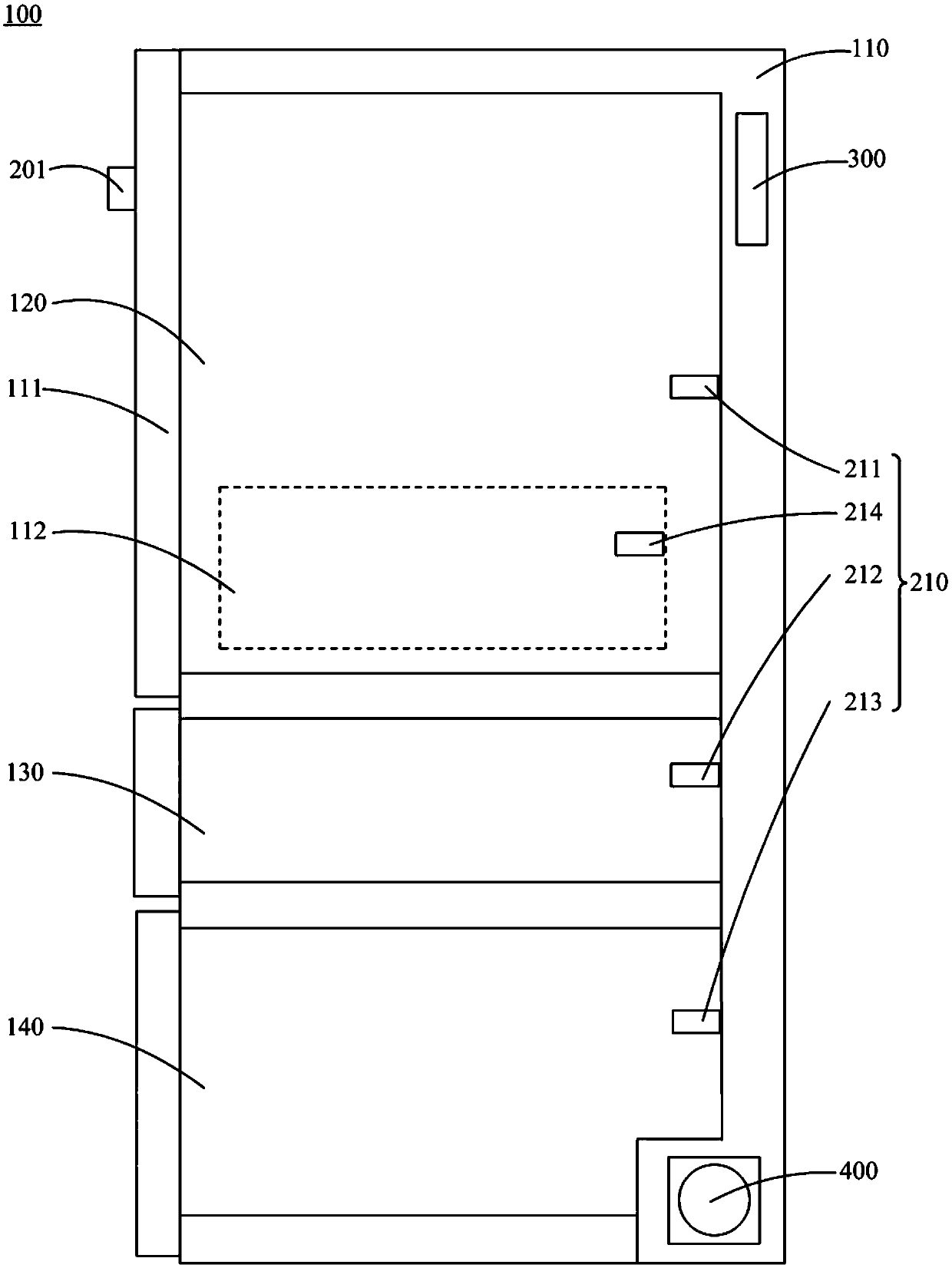

Measurement control method taking DC electric machine as force measuring device and realizing device thereof

ActiveCN101135596AAvoid harmSpeed adjustmentForce measurementDynamo-electric machine testingElectric machineAnalog signal

The method comprises: setting the working state of DC motor under the exogenic action; the DC motor runs at said workings state; detecting the analog signal of the voltage v, current i and rotate speed n to be detected, and converting said analog signal into digital signals; according to the testing signal, calculating the value of exogenic action suffered by the DC motor; detecting the acting force suffered by the DC motor to decide if it is in a preset range, and adjusting the working state of the DC motor. The invention also reveals a DC motor thereof used for measuring the acting force suffered by the DC motor and adjusting the working state of the motor.

Owner:南京康龙威康复医学工程有限公司

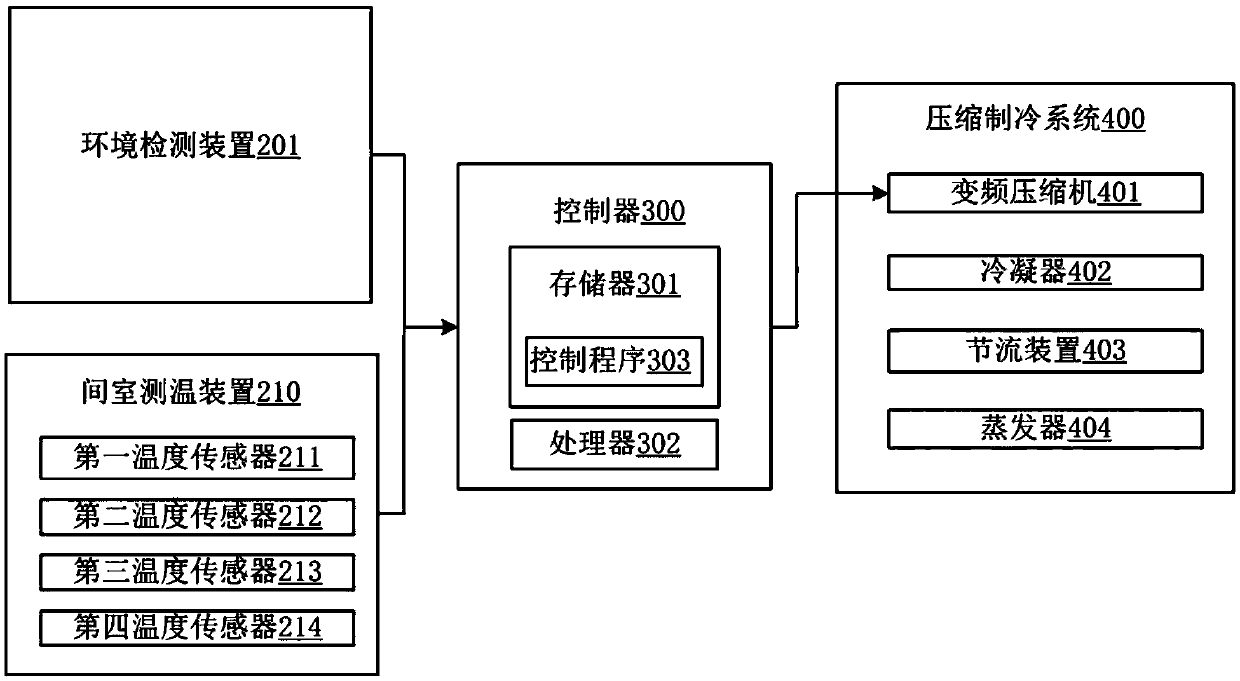

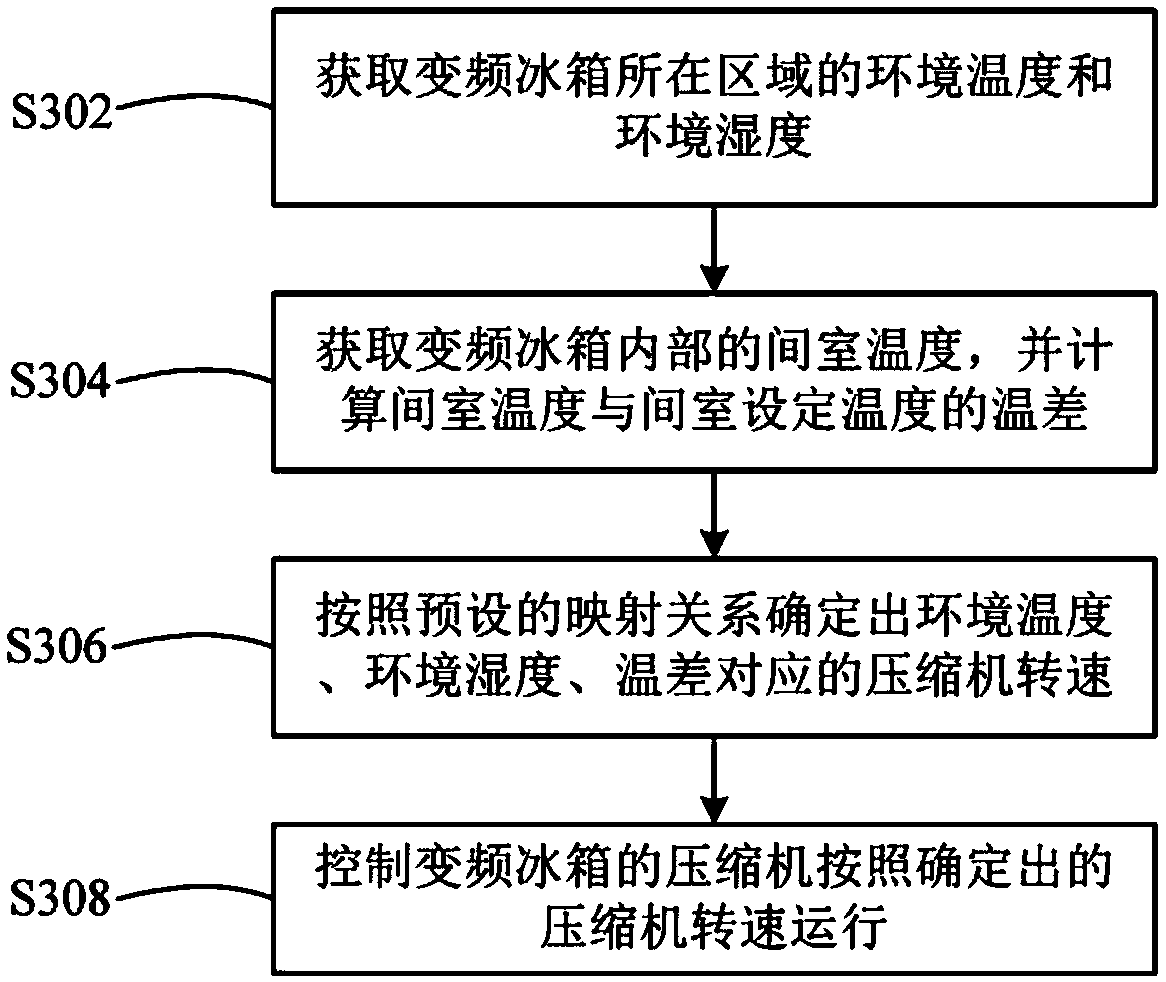

Refrigerator and control method thereof

ActiveCN110953792AImprove efficiencyReduce energy consumptionLighting and heating apparatusDomestic refrigeratorsPhysicsMechanical engineering

The invention provides a control method for an inverter refrigerator. The control method comprises the steps: the environment temperature and the environment humidity of an area where the inverter refrigerator is located are obtained; the temperature of a chamber in the inverter refrigerator is obtained, and the temperature difference between the temperature of the chamber and the set temperatureof the chamber is calculated; the compressor rotating speed corresponding to the environment temperature, the environment humidity and the temperature difference is determined according to a preset mapping relationship, wherein the mapping relationship specifies rotating speed values corresponding to an environment temperature numerical range, an environment humidity numerical range and a temperature difference numerical range; and the compressor of the inverter refrigerator is controlled to operate according to the determined rotating speed of the compressor. The invention further provides arefrigerator.

Owner:HAIER SMART HOME CO LTD

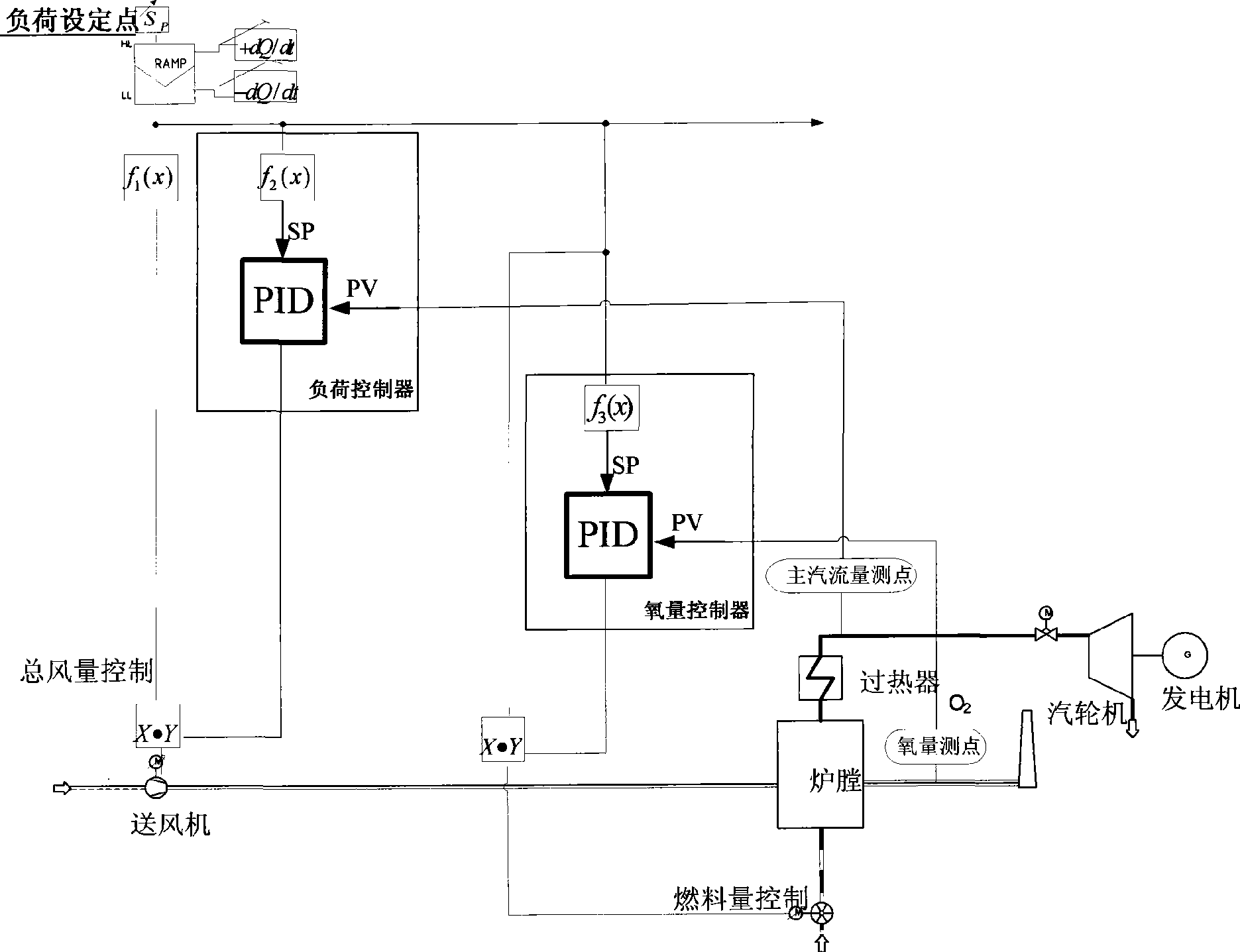

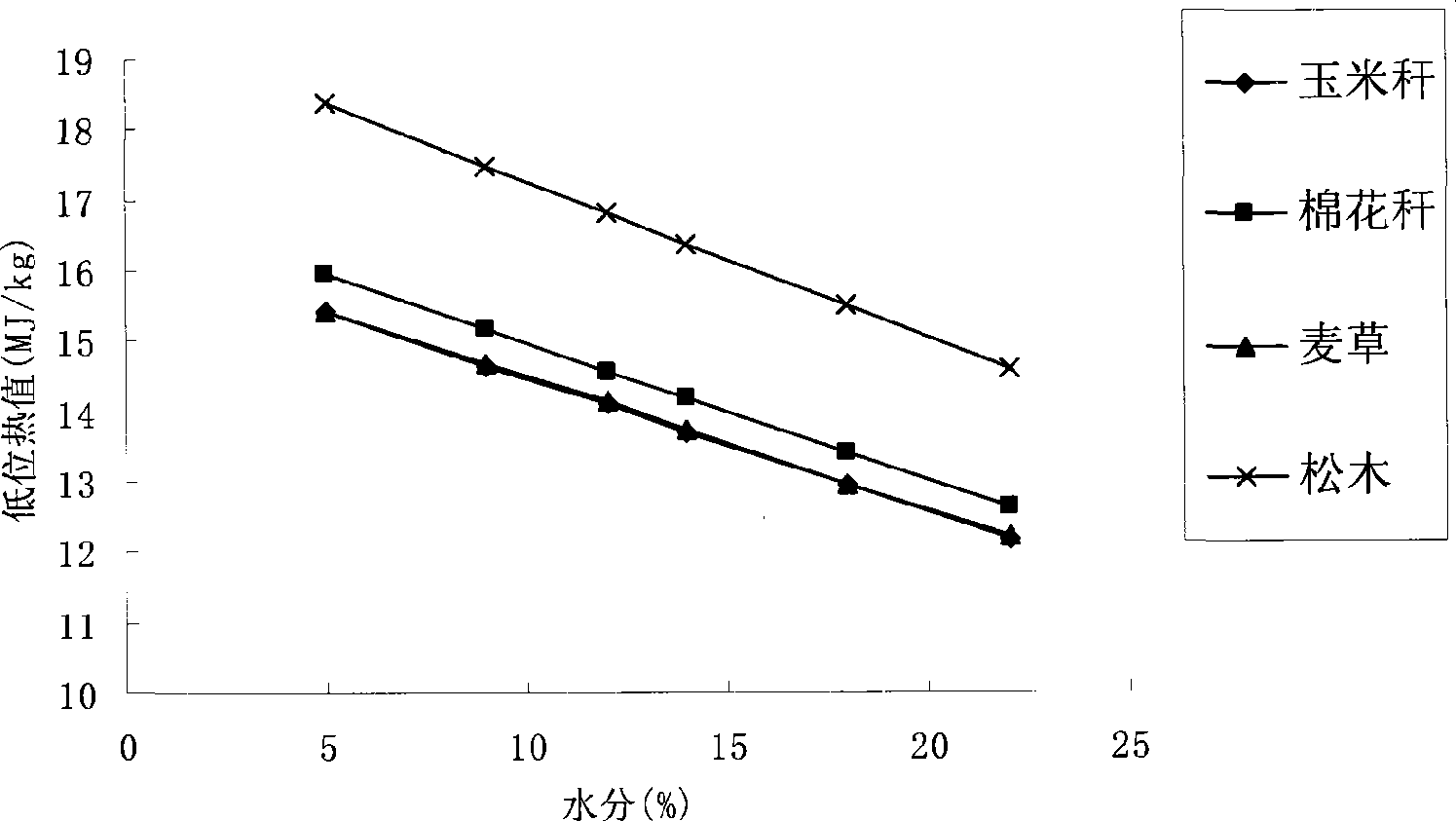

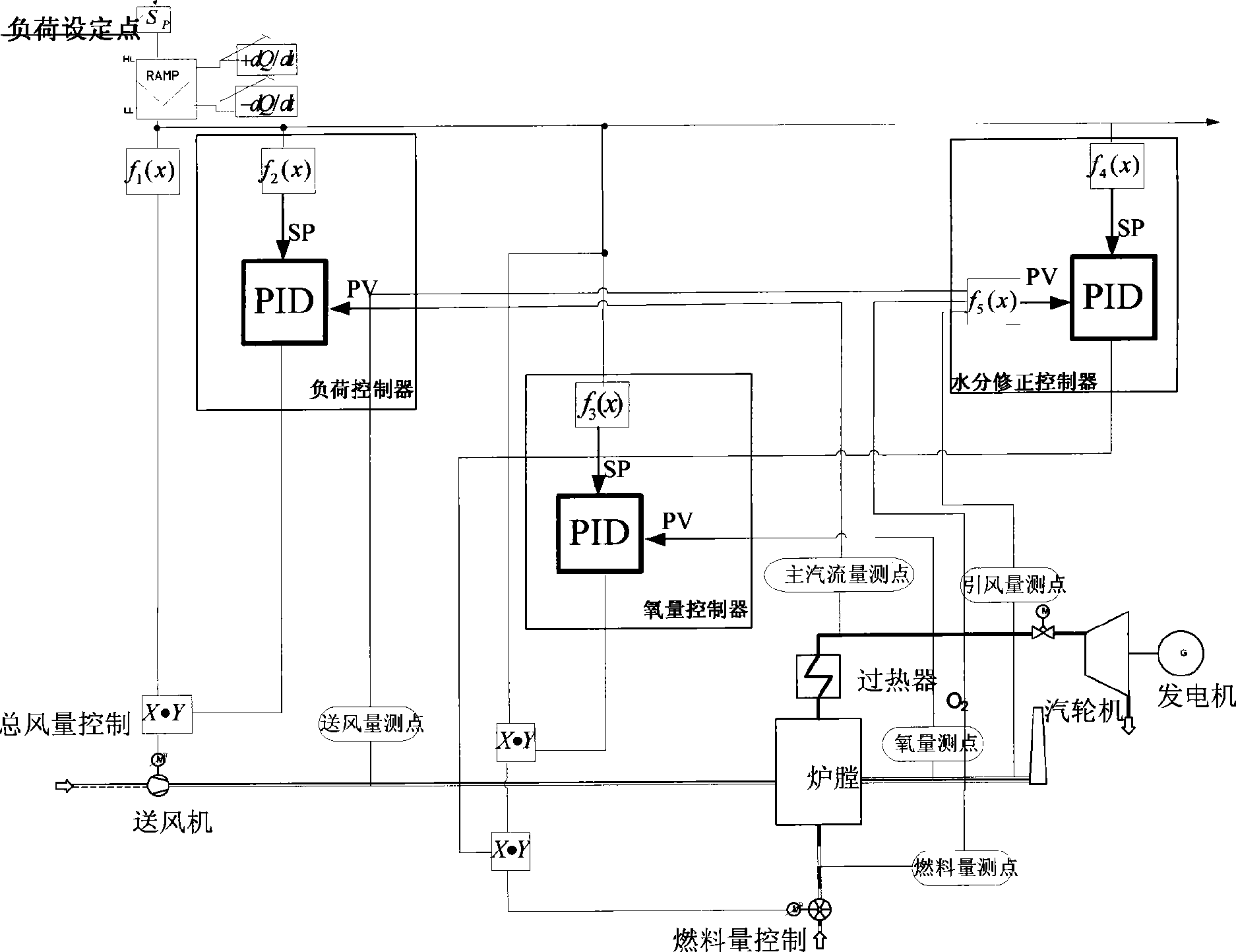

Method for correcting and controlling impacts of water content in fuel on loads of boiler

Water content in a biomass fuel is a greatest impact factor with most frequent change of fuel properties, largest range of fluctuations and greatest impacts on loads of a boiler, the invention discloses a method for correcting and controlling the impacts of the water content in the biomass fuel on the loads of the boiler, a curve is firstly calibrated according to the change of low heat value of the fuel along with the water content, then the water content in the fuel is obtained by calculation according to air supply volume, feeding quantity and air induction volume obtained by actual measurement, and heat which can be provided by the fuel put into a furnace chamber is further obtained according to the calibrated curve. The heat is taken as a feedback value of a controller, the heat needed by the boiler under the operation loads is taken as a set value of the controller, the correction coefficient of the water content in the fuel is obtained by the PID operation, and the rotational speed of a feeding machine is corrected. The method eliminates the fluctuations of the loads of the boiler along with the water content of the fuel, ensures the safe and stable operation of the boiler and improves the operation efficiency of the boiler by realizing the real-time and accurate control of the amount of the biomass fuel.

Owner:CHINA ELECTRIC POWER RES INST +1

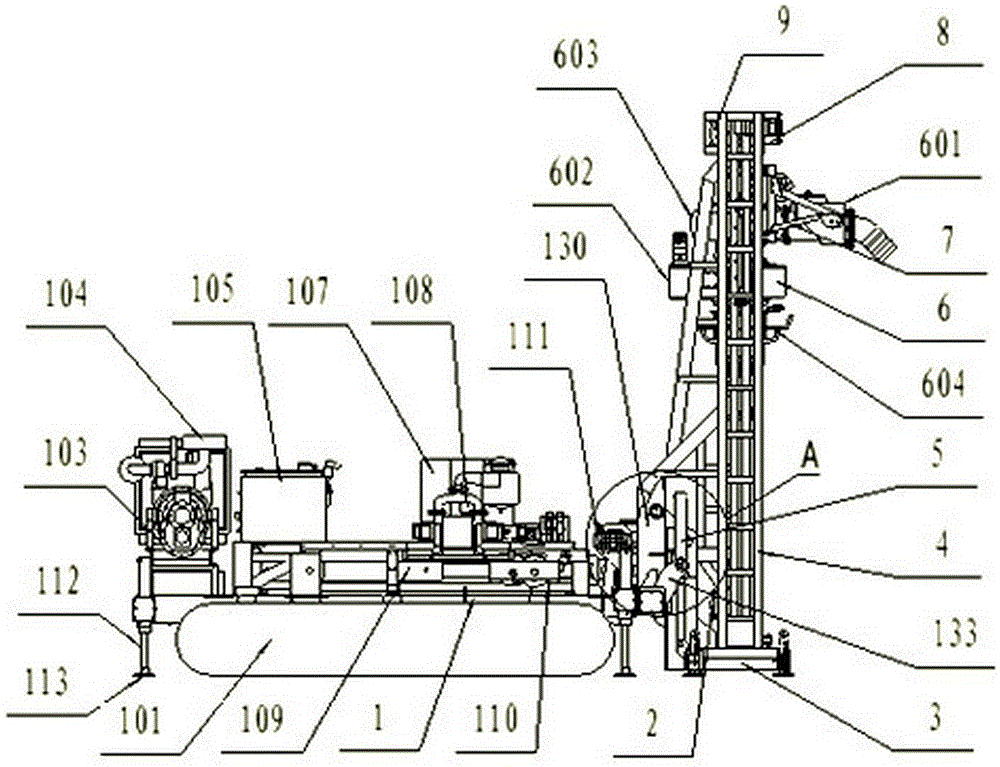

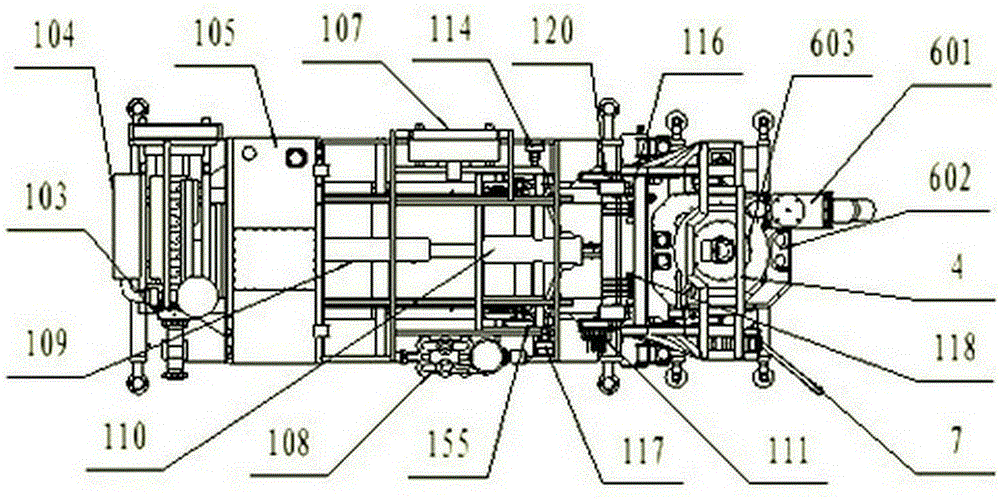

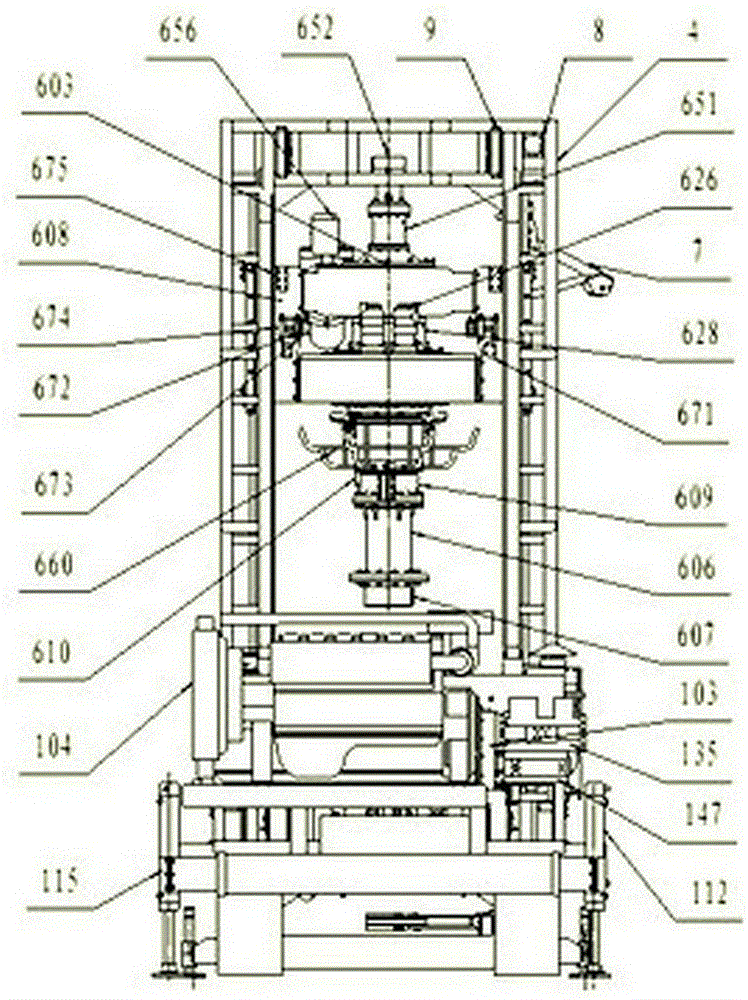

Fully hydraulic reverse circulation drilling machine

InactiveCN105064915AAdapt to the working environmentReduce noiseDrill bitsDrilling rodsGear wheelWinch

The invention provides a fully hydraulic reverse circulation drilling machine, which comprises a walking mechanism, a chassis assembly, a work table frame assembly, a main frame, a main frame turning oil cylinder, a swinging rod assembly, a winch assembly, a drill pipe, a dismounting device, a hydraulic system, a power take-off assembly, an impact drill bit, a rotating wing drill bit, a power assembly and an oil cylinder pulley assembly. A diesel engine or electric power is used for driving; hydraulic motors and oil cylinders are used as executing mechanisms; and the whole process operation of the drilling machine is realized through a hydraulic transmission and control system. The two hydraulic motors and a gear reducer are used for forming a power head to drive a drilling tool to rotate; the hydraulic motors adopt a serial connection or parallel connection mode; and the drill pipe realizes different rotating speeds and can adapt to different-geological-condition and different-hole-diameter operations. The oil cylinders are used for controlling the oil pipe feeding and lifting the drilling tool, so that the power head can vertically move along with the drilling tool and can realize floating, suspension stop and pressurized drilling; the drill pipe can be automatically dismounted and mounted; and the impact drill bit and the rotating wing drill bit are used for realizing the hole drilling of holes with the hole diameter being 2 to 3m and the hole depth exceeding 200m in the pebble bed, the hard rock stratum and the stratum containing large-diameter rock blocks.

Owner:王乐康

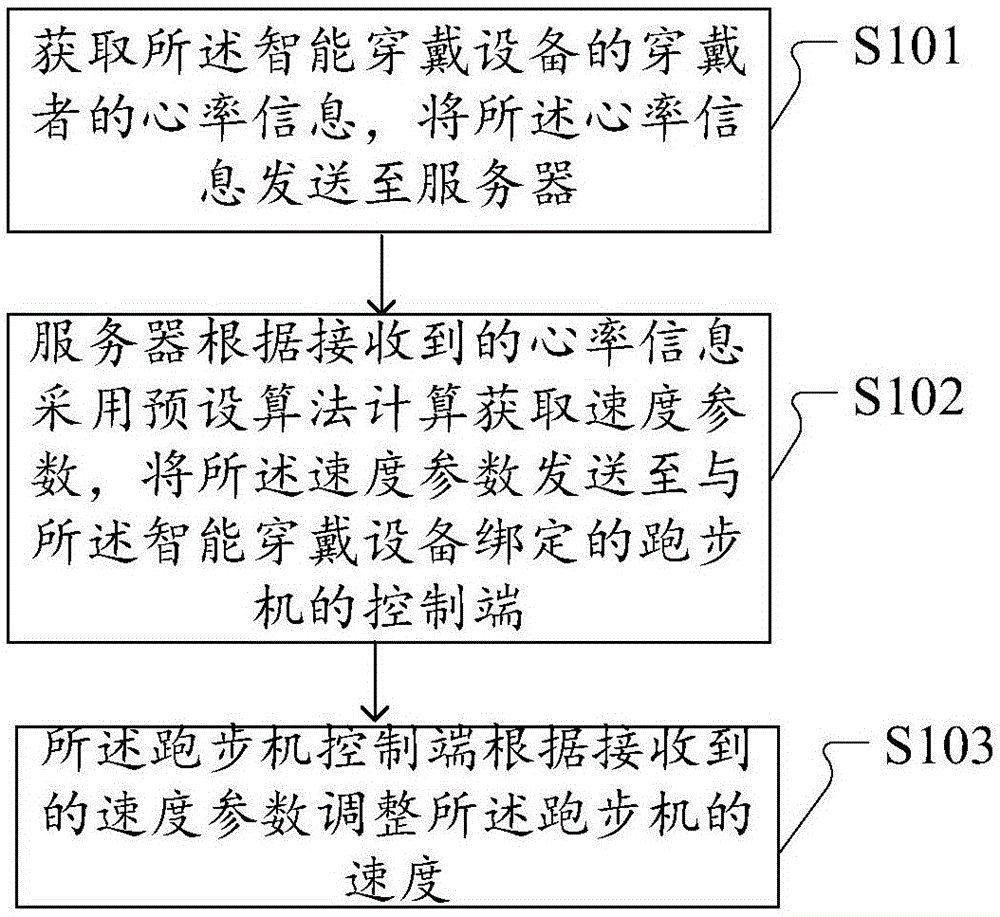

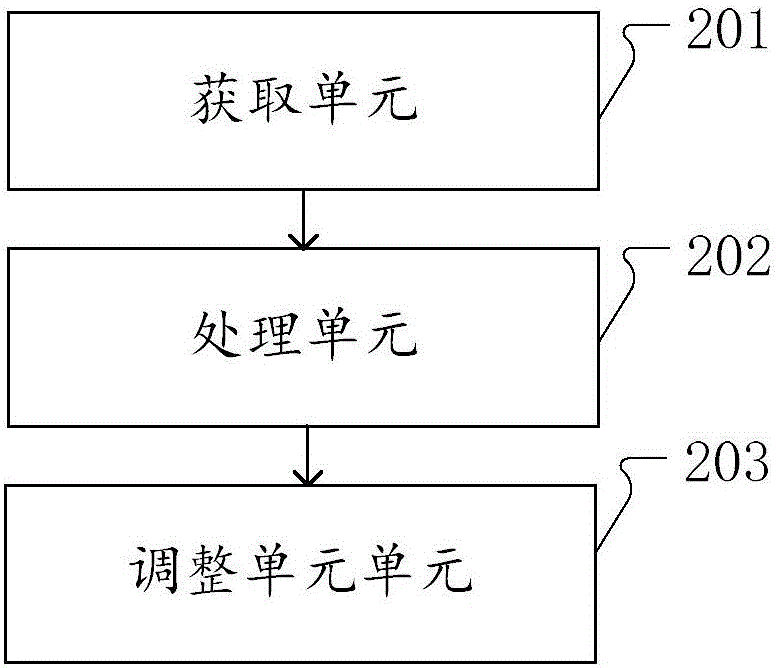

Method and device for adjusting speed of treadmill, intelligent equipment and treadmill

InactiveCN106474667ARetrofit costs are not too highIncreased renovation costsMovement coordination devicesCardiovascular exercising devicesComputer scienceIntelligent equipment

The invention discloses a method and a device for adjusting a speed of a treadmill, intelligent equipment and the treadmill. The method comprises the following steps: acquiring heart rate information of a wearer of intelligent wearing equipment and transmitting the heart rate information to a server; calculating and acquiring, by the server, a speed parameter by using a preset algorithm according to the received heart rate information, and transmitting the speed parameter to a control end of the treadmill bound to the intelligent wearing equipment; adjusting the speed of the treadmill according to the received speed parameter by the control end of the treadmill. The above method can be used to achieve the intelligent and automatic adjustment of the speed of the treadmill and makes it easier for a user to use; the finally obtained speed parameter is calculated by the server, thereby cutting out cumbersome steps for calculation by the user, while avoiding problems of errors and the like caused by calculation by the user; therefore, the method not only saves a trouble of calculation by the user, but also makes user's exercise more scientific and reasonable.

Owner:HANGZHOU LIANLUO INTERACTIVE INFORMATION TECH CO LTD

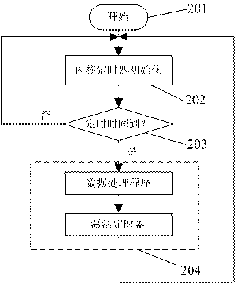

Method for detecting and controlling temperatures of processor

InactiveCN103995766AControl speedSpeed adjustmentHardware monitoringTemperature control using electric meansControl signalPwm signals

The invention provides a method for detecting and controlling the temperatures of a processor. The method includes the steps of firstly, initializing a kernel timer for initializing the structure of the timer, setting the cycle of the timer, designating the interrupt processing function of the timer and inserting the timer into a timer global array; secondly, calling the interrupt processing function of the timer when timeout of the timer occurs, reading data of a temperature sensor, and processing the read temperature data so as to determine a PWM control signal; thirdly, reactivating the kernel timer in the timer interrupt processing function so as to conduct the next time of temperature collection and so as to adjust the rotating speed of a fan. The temperature data collected by the temperature sensor connected to a south bridge chip are read periodically through the kernel timer, after software filtering is conducted on the temperature data, corresponding control information is generated according to the interval where the processed temperature data are located and is then transmitted to the south bridge chip so that the south bridge chip can be controlled to output corresponding PWM signals, and therefore the aims of adjusting the rotating speed of the fan and controlling the temperatures of the processor are achieved. According to the method, the temperatures of the processor are collected and controlled through basic elements on a main board, software filtering is conducted on the temperature data, and control accuracy is improved.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

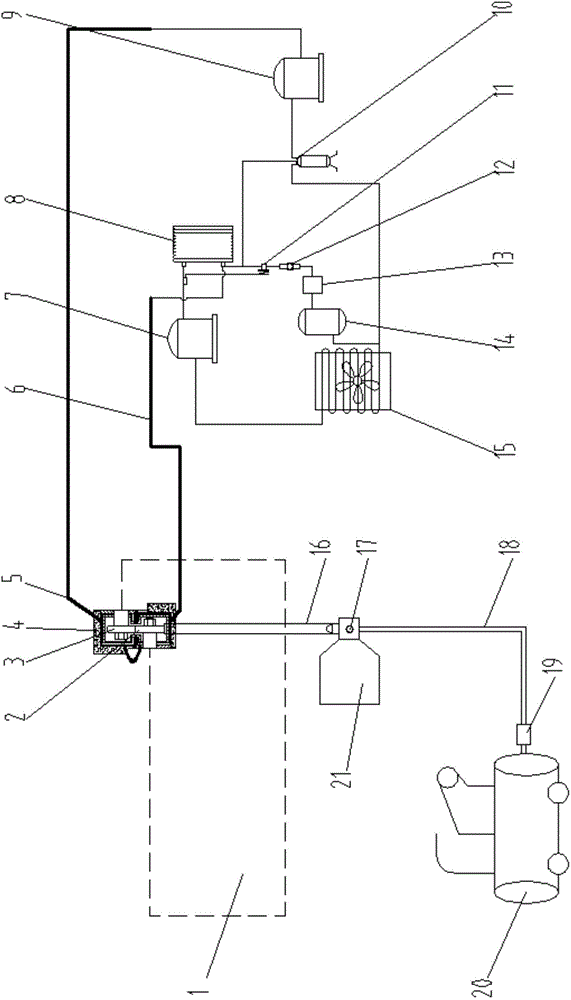

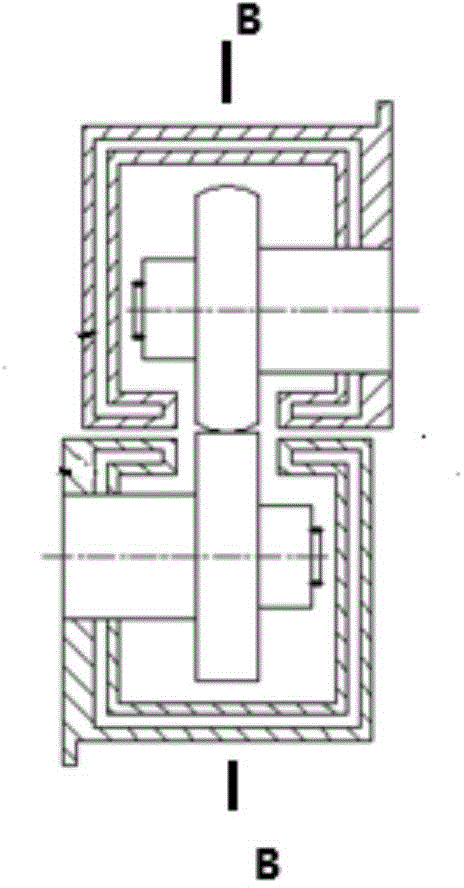

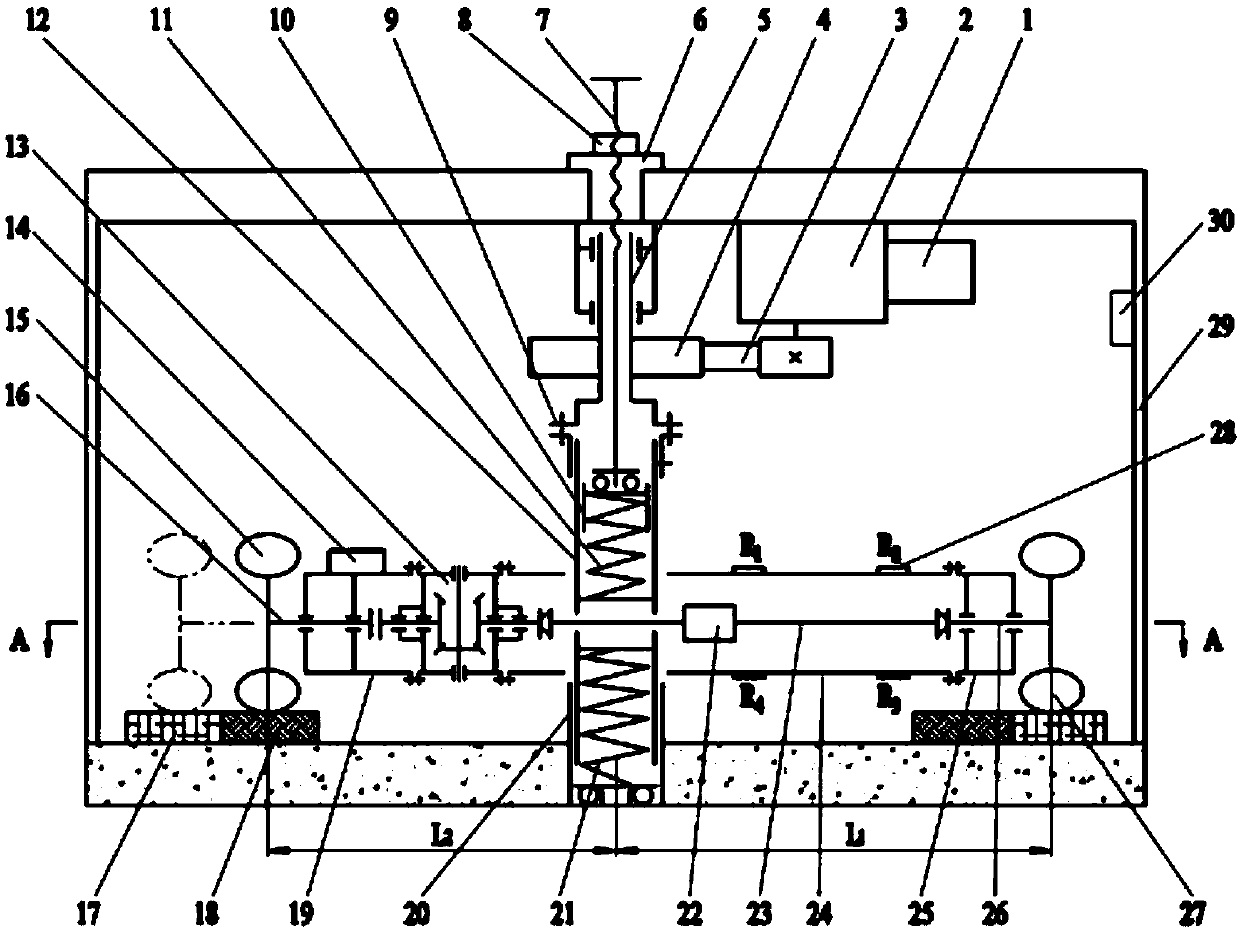

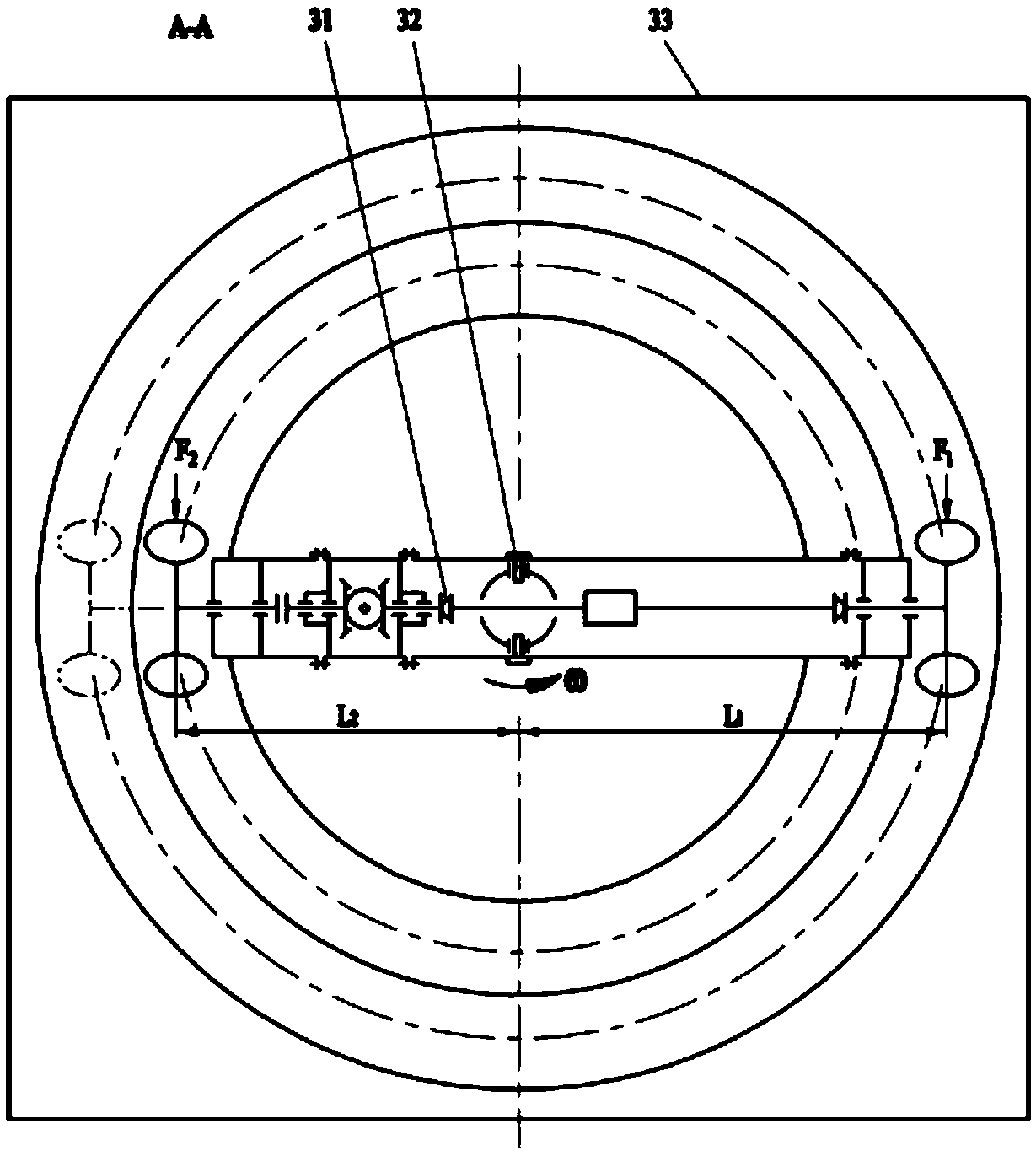

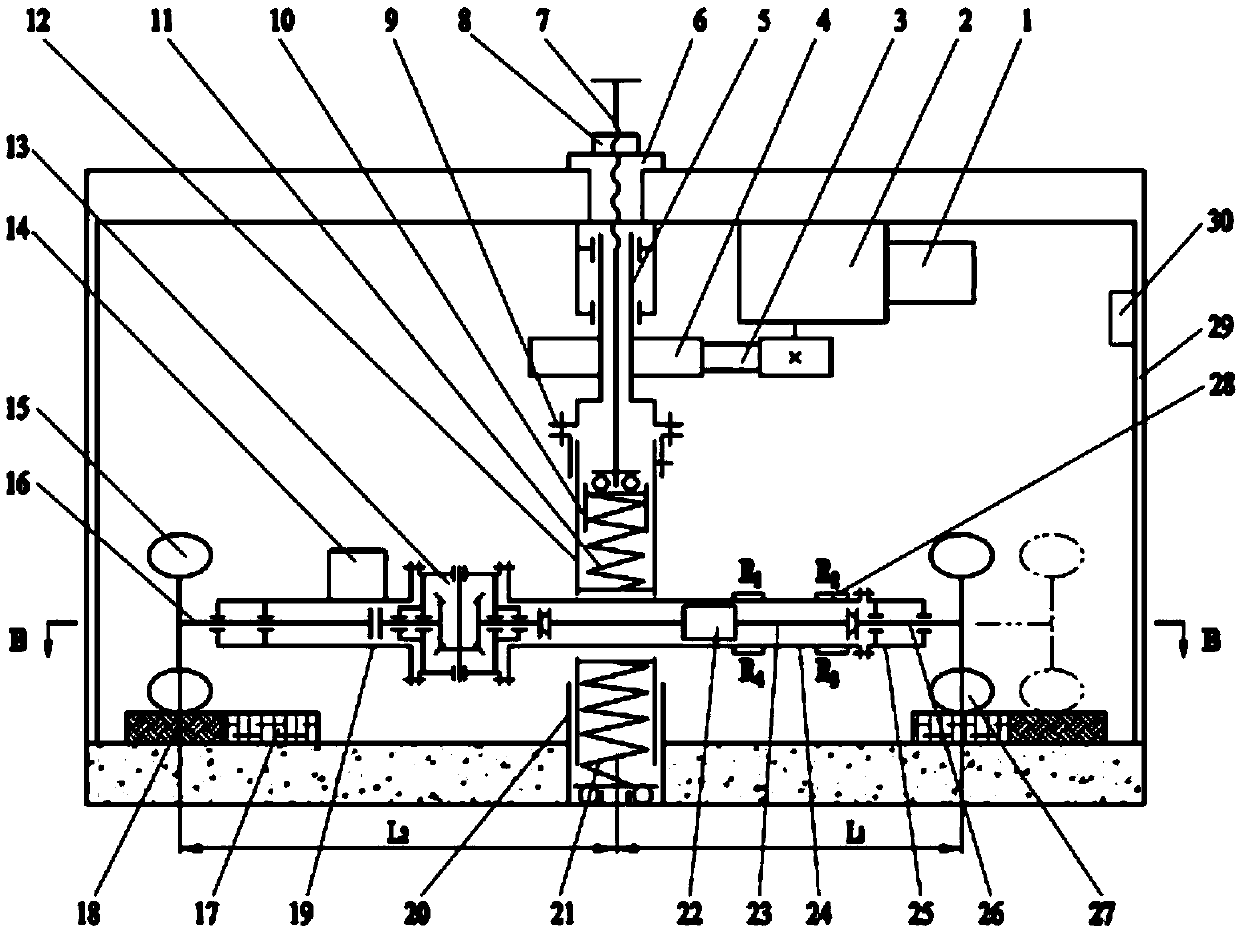

High-cold wind-sand environment wheel rail abrasion simulation experimental device

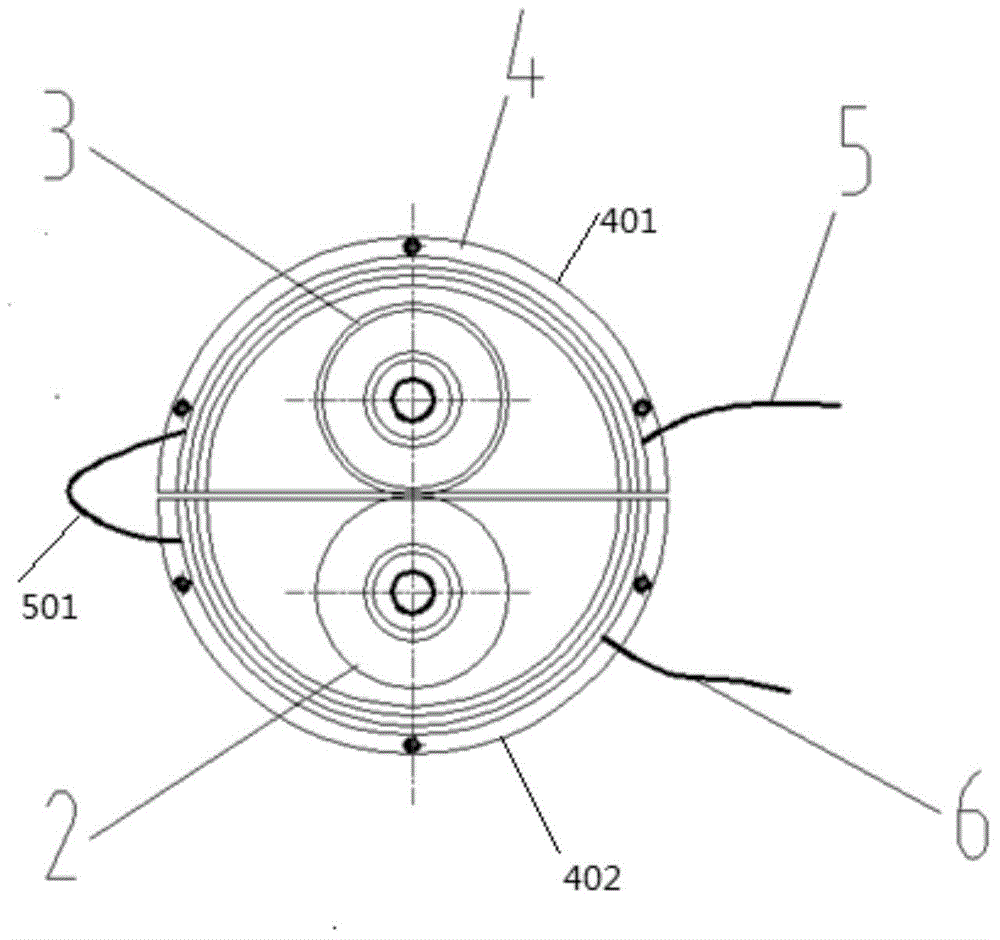

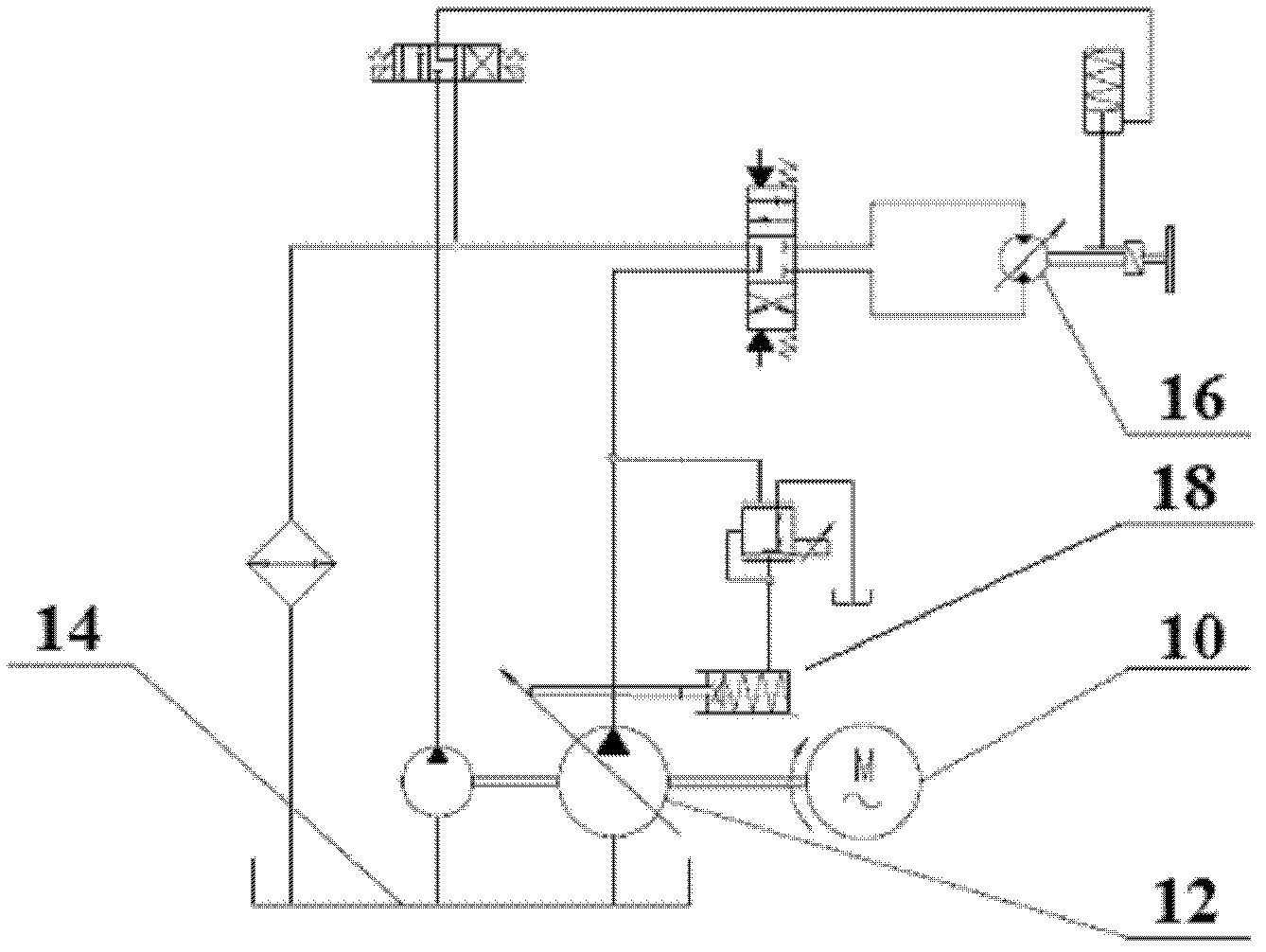

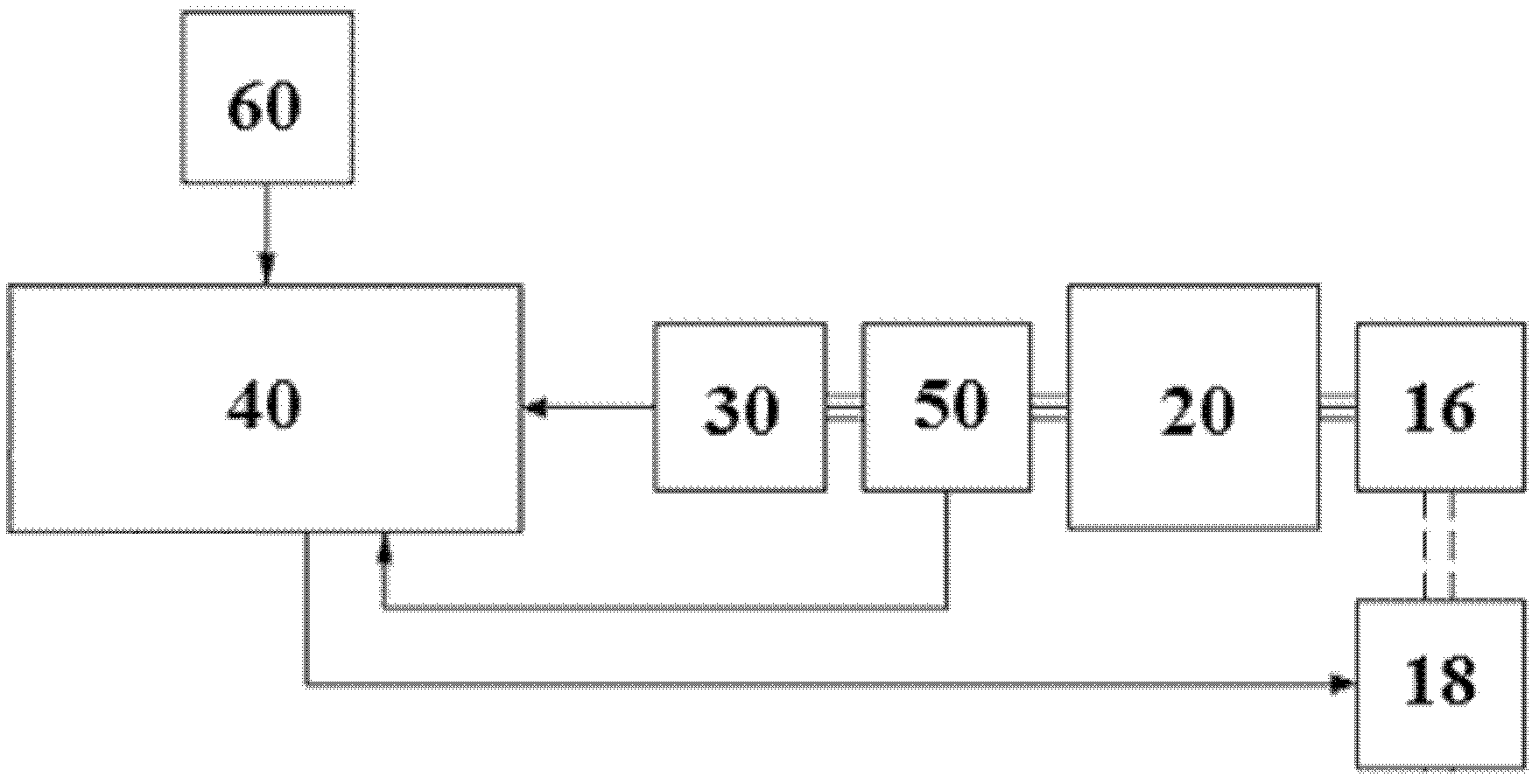

ActiveCN104634685AFacilitate conductionReduce the temperatureInvestigating abrasion/wear resistanceFriction torqueEngineering

The invention discloses a high cold wind sand environment wheel rail abrasion simulation experimental device. The high cold wind sand environment wheel rail abrasion simulation experimental device consists of a wheel rail rolling abrasion test rack and a wheel rail rolling abrasion simulation auxiliary system. A low-temperature cavity wind-sand environmental cavity (4) is communicated with a wind-sand simulation control unit by virtue of a sand conveying pipe (16); the low-temperature cavity wind-sand environmental cavity (4) is a double-layer cavity which is made of a copper alloy and is provided with an upper part and a lower part, namely an upper cavity (401) and a lower cavity (402); a refrigerant connecting pipe (501) is connected to the upper cavity (401) and the lower cavity (402); an upper refrigerant pipe (5) is used for inputting refrigerant prepared by a low-temperature cavity unit into the upper cavity (401), and a lower refrigerant pipe (6) is used for conveying the refrigerant of the lower cavity (402) back to the low-temperature cavity unit. By adopting the high-cold wind-sand environment wheel rail abrasion simulation experimental device, a high-cold wind-sand environment can be simulated, the interactive relationship of factors such as temperature, wind-sand conditions, applied load, rotation speed of a test piece, slide difference, an impact angle, friction torque, experiment time, post experiment forms and the like can be accurately and reliably analyzed, and reliable experimental data can be provided for researching a wheel rail abrasion mechanism and building a measure for alleviating the abrasion.

Owner:SOUTHWEST JIAOTONG UNIV

Control device for winching mechanism and winching mechanism test platform

ActiveCN102381652AReal-time speed detectionSpeed adjustmentMachine part testingWinding mechanismsElectricityHydraulic motor

A winching mechanism test platform is disclosed, and comprises a winching mechanism which comprises a hydraulic driving system for driving the winching mechanism, wherein the hydraulic driving system comprises a hydraulic motor and a proportional solenoid associated with the hydraulic motor. The test platform further comprises a rotate speed detector coupled with the winching mechanism for detecting the rotate speed of the winching mechanism and outputting corresponding rotate speed signals; a controller electrically coupled with the winching mechanism and configured to receive the rotate speed signal from the rotate speed detector and compare the detected rotate speed with preset standard one, to generate corresponding control signals according to the comparison result and output the control signal to the proportional solenoid so as to adjust the output power of the hydraulic motor by adjusting the openness of the solenoid to control the rotate speed of the winching mechanism to be matched with the standard rotate speed.

Owner:ZOOMLION HEAVY IND CO LTD

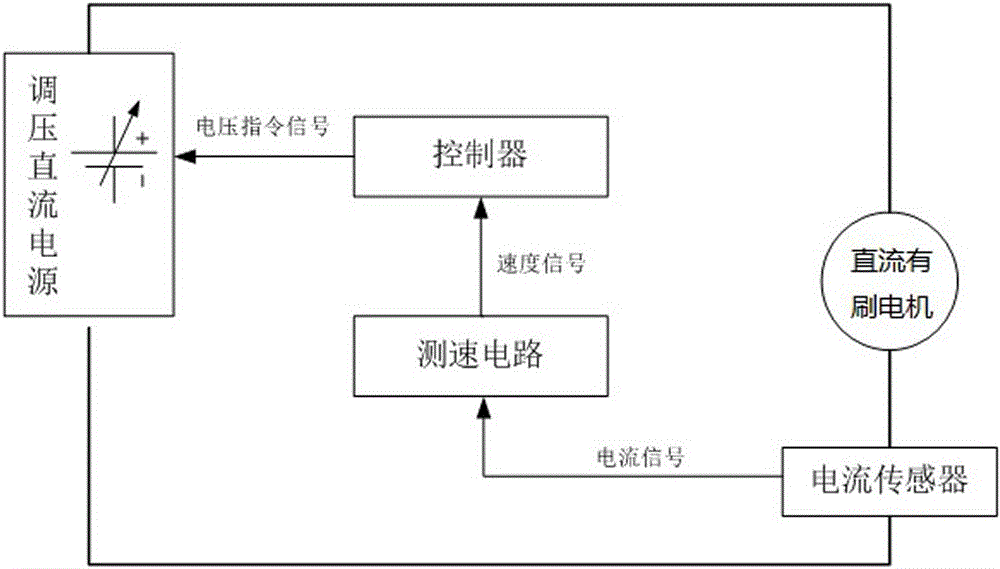

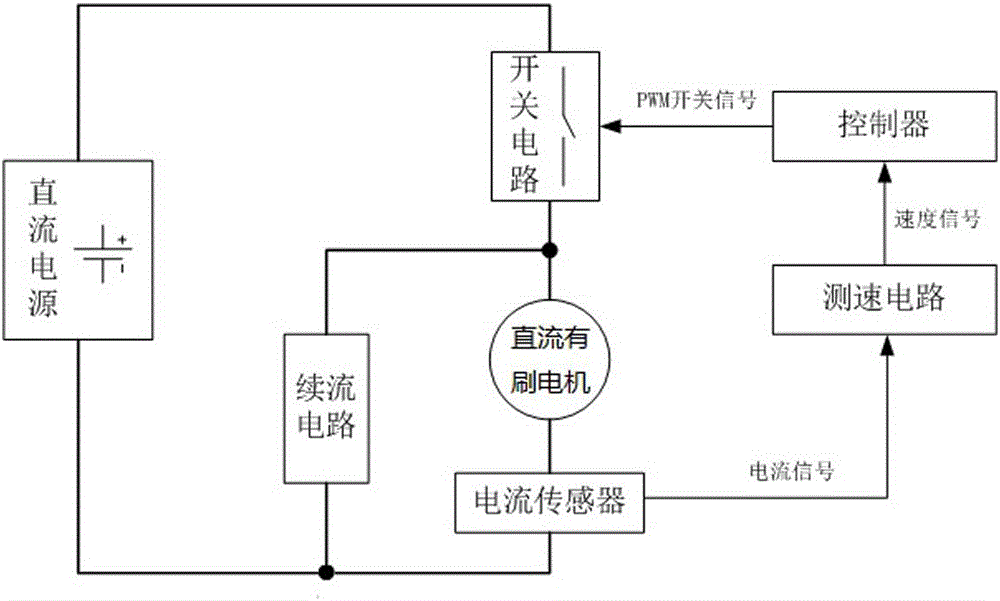

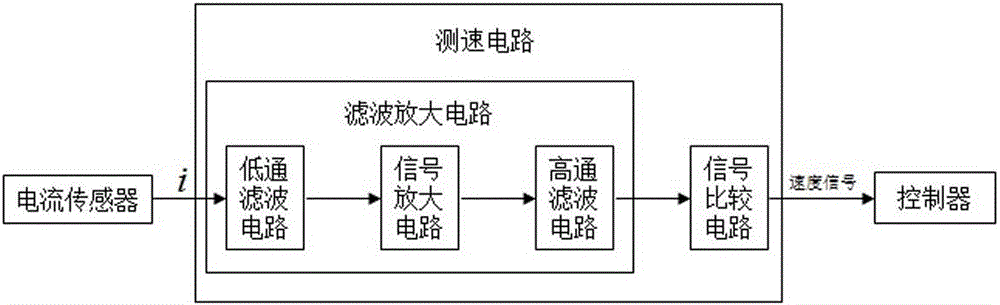

Speed regulation device and speed regulation method of DC brush motor

InactiveCN105680744ARev easySpeed adjustmentField or armature current controlPower flowSquare waveform

The invention relates to a speed regulation device and speed regulation method of a DC brush motor. The speed regulation device and the speed regulation method are characterized in that a current signal of the DC brush motor is acquired by a current sensor; the current signal is filtered and amplified by a filtering amplification circuit; the current signal is converted to a high-low alternating square wave speed signal by a single comparison circuit; the rotational speed of the motor is obtained through calculation by a controller according to the period or the frequency of the speed signal combined with the number of mica plates in a motor commutator; and finally, an instruction signal is sent to an adjustable power supply from the controller, and the purpose of adjusting the rotational speed of the motor is achieved by controlling the DC voltage amplitude of the motor. With the speed regulation device and the speed regulation method, the speed of the motor can be measured and adjusted by single circuit combination, an extra large-scaled device is not needed, and the speed regulation device and the speed regulation method are relatively low in cost; and moreover, no limitation is generated to an application environment and a mechanical structure of the motor, the speed measurement result is more accurate, and the rotational speed of the motor can be adjusted and controlled better.

Owner:JIANGSU REYA ELECTRIC

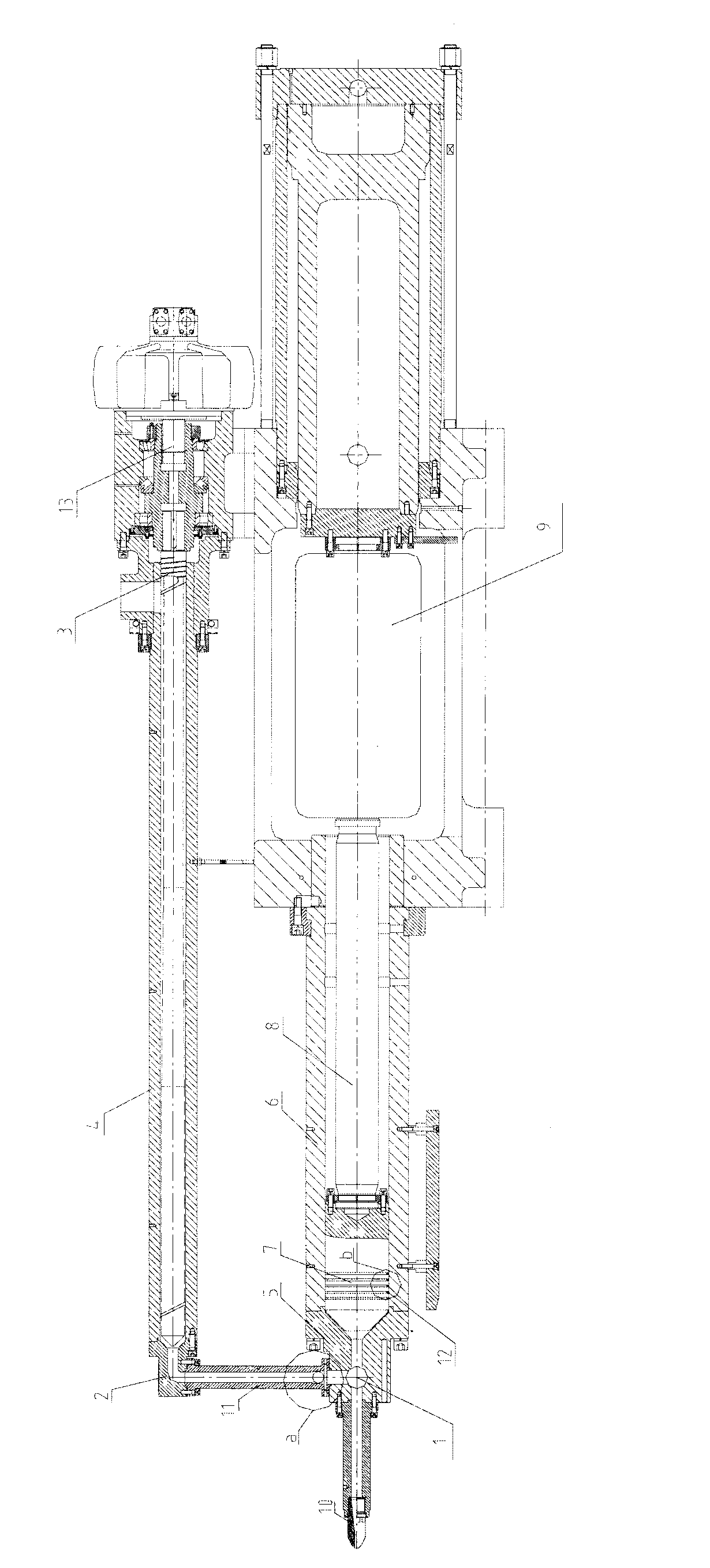

Extrusion large-injection amount injection moulding device and use method thereof

InactiveCN102909836AMeet the needs of large injection volumeImprove versatilityElectro hydraulicEngineering

The invention discloses an extrusion large-injection amount injection moulding device and a use method of the extrusion large-injection amount injection moulding device. The extrusion large-injection amount injection moulding device comprises a pre-injection material storage mechanism, an injection mechanism, a nozzle (10) and a three-way valve (1), wherein the pre-injection material storage mechanism comprises a charging barrel (2) before preplastication, a screw (3) and a preplastication charging barrel (4); the screw (3) is arranged in the preplastication charging barrel (4); the injection mechanism comprises a pre-injection charging barrel (5), an injection charging barrel (6), a piston rod (8) sheathed with a piston (7) and an electro-hydraulic system; the piston rod (8) is arranged in the injection charging barrel (6); the electro-hydraulic system (9) is connected with the piston rod; both the pre-injection material storage mechanism and the injection mechanism are connected with the nozzle by the three-way valve; and processes, such as a preparation stage, a preplastication stage and an injection moulding stage are carried out. According to the invention, the requirement of big injection amount can be satisfied, the phenomenon that a corresponding injection machine type needs to be designed according to the injection amount can be avoided, the extrusion large-injection amount injection moulding device has the advantages of good generality, wide applicable range, energy saving and high efficiency, and the injection efficiency is improved.

Owner:TEDERIC MACHINERY +1

Mower

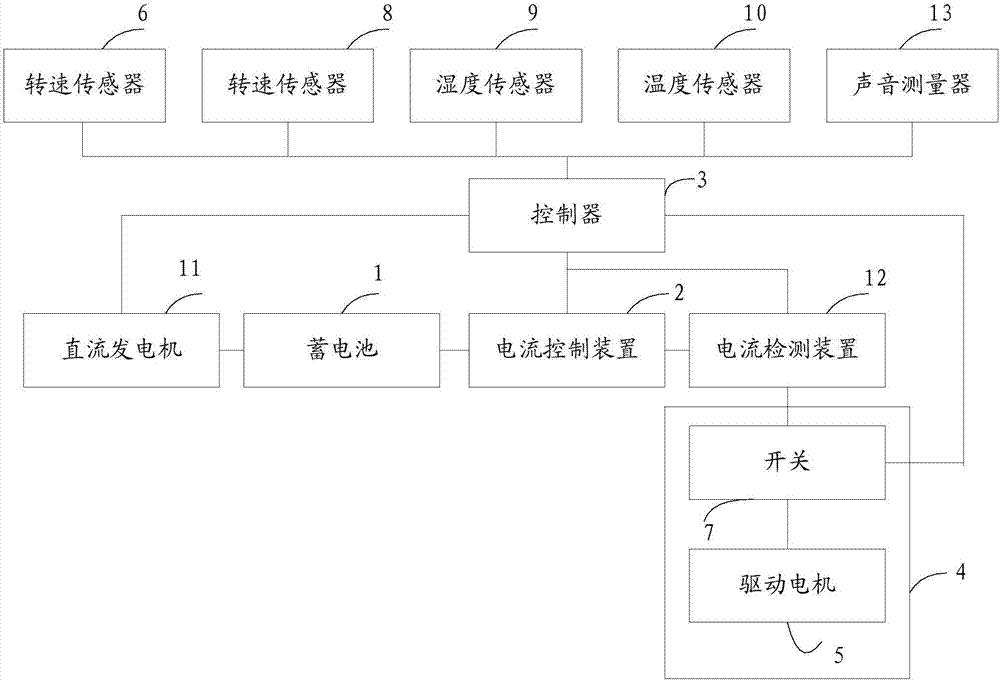

PendingCN106856799AIncrease input currentAdjust the input currentMowersField or armature current controlMotor speedElectric machine

The invention provides a mower. The mower comprises a storage battery, a current control device, a controller and mowing equipment, wherein the storage battery is electrically connected with the mowing equipment through the current control device; the mowing equipment comprises a driving motor, and the driving motor comprises a rotation speed sensor which is arranged on an output shaft of the driving motor; the rotation speed sensor is connected with the current control device through the controller; the controller is used for obtaining a rotation speed value of the rotation speed sensor, and when the rotation speed value is smaller than a preset rotation speed threshold value, the output current of the current control device is increased. The mower has the advantages that the mowing efficiency is high, the output power of the mower can be intelligently adjusted, the rotation speed of the driving motor is adjusted, the waste of energy is avoided, and the energy-saving and environment-friendly effects are realized.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

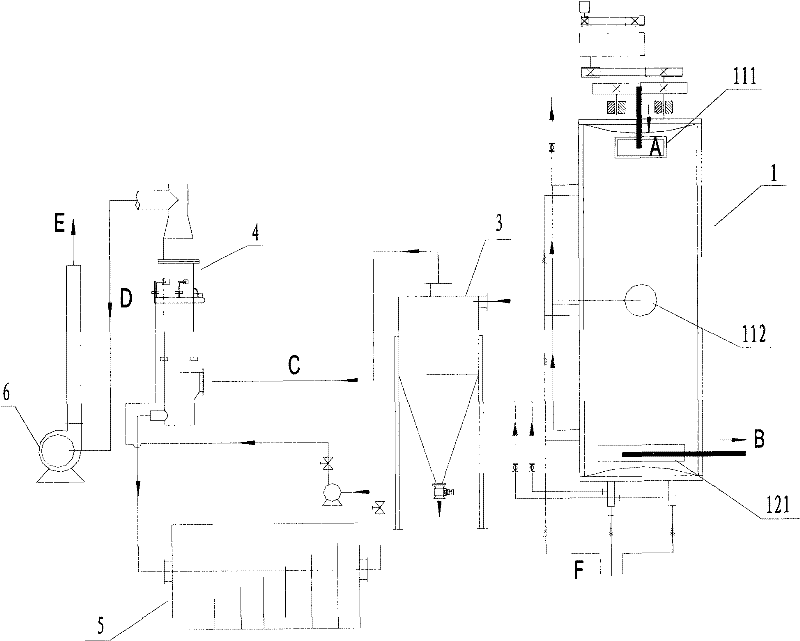

Sludge drying process and equipment

InactiveCN102295398ASmall starting currentImprove winding capacitySludge treatment by de-watering/drying/thickeningWater contentPre treatment

The invention relates to a sludge drying process and equipment. The process is: pretreat the sludge with high moisture content until the moisture content is lower than the set value, keep the temperature of the sludge constant, and input it into the sludge drying equipment, in which the sludge is continuously discharged to the It is pushed by the mouth, and the sludge is heated to above 120°C, accompanied by continuous stirring and crushing, and at the same time, the water vapor volatilized from the sludge is continuously drawn out by the air-inducing equipment until the sludge with the required moisture content is produced. The sludge is discharged from the drying equipment. The sludge drying equipment is produced for the improvement of the traditional hollow paddle dryer. The process of the present invention is simple and easy to operate, runs smoothly, and can make the degree of sludge drying more controllable, the sludge treatment capacity is larger, and there is no risk of secondary pollution; the equipment of the present invention has simple structure, stable operating performance, and high efficiency. High, and can achieve the goal of energy saving and emission reduction, it is expected to be widely used in the field of environmental protection and in chemical, pharmaceutical, food and other industries.

Owner:SUZHOU ZILI CHEM EQUIP

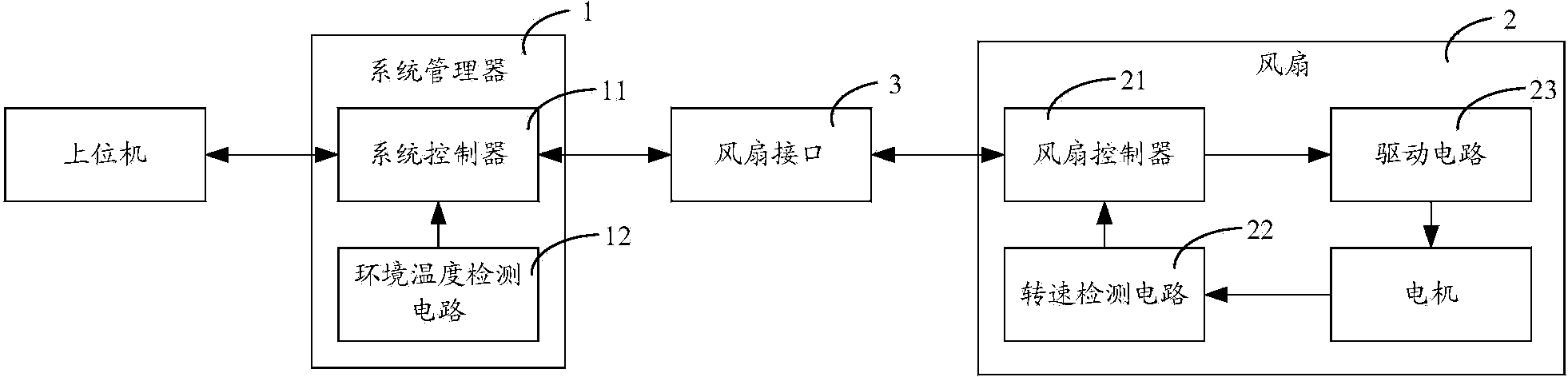

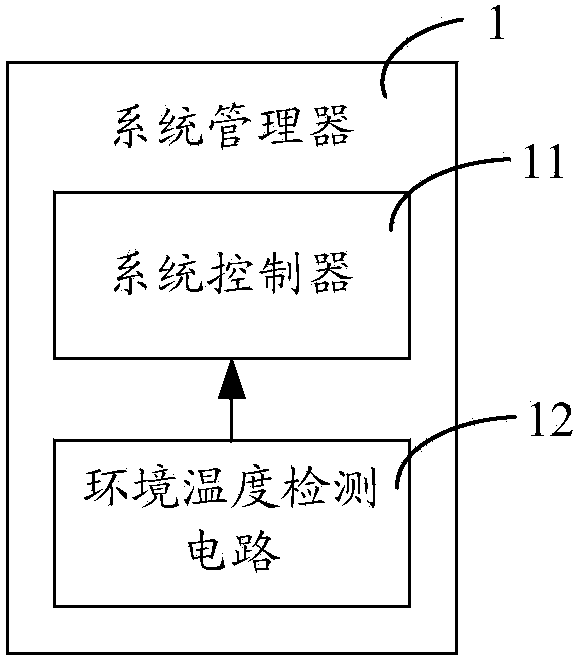

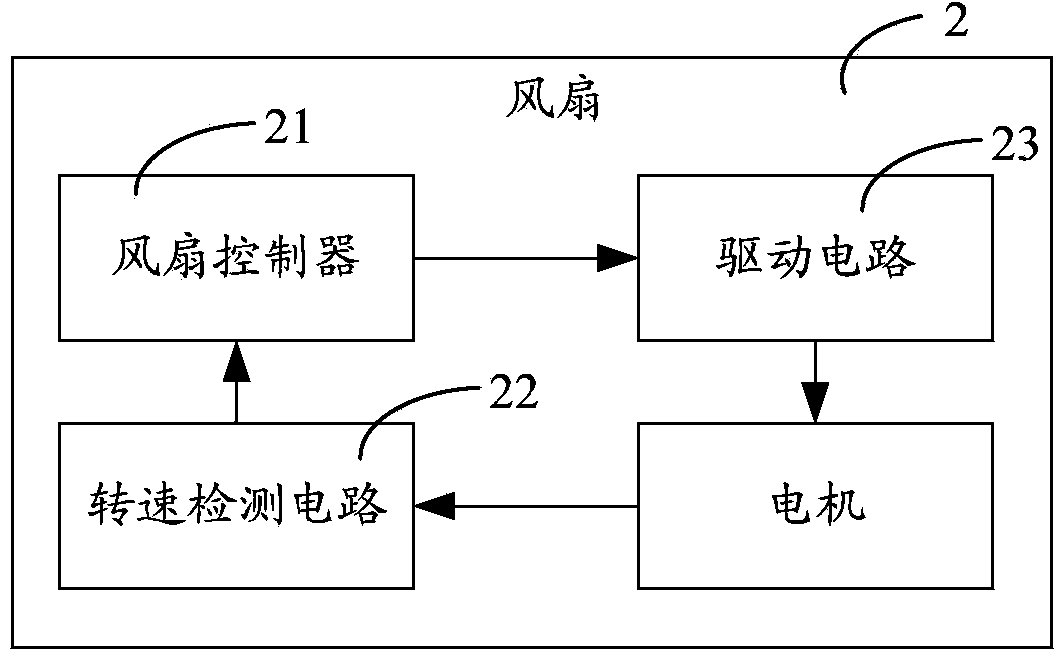

Fan control system, system management device and fans

ActiveCN103644136ASpeed adjustmentMeet thermal requirementsPump controlPump installationsSystems managementControl system

The invention applies to the field of communication devices, and discloses a fan control system, a system management device and fans. The fan control system comprises the system management device, one or more fan interfaces and one or more fans, wherein the system management device is connected with one fan through one fan interface and comprises a system controller; each fan comprises a drive circuit, which is used for driving a motor, and a fan controller. Therefore, the system controller can send a specification selection command to the fan controller according to the heat dissipation requirements of different communication devices so as to switch to a matched fan specification; under the fan specification, the system controller sends a speed regulation command to the fan controller to further control the fan rotating speeds, so as to realize accurate control. According to the invention, the heat dissipation requirements of different communication devices are effectively satisfied; the fan rotating speed can be further regulated according to work environments at different temperatures; the practicability is high; humanization is achieved.

Owner:HUAWEI TECH CO LTD

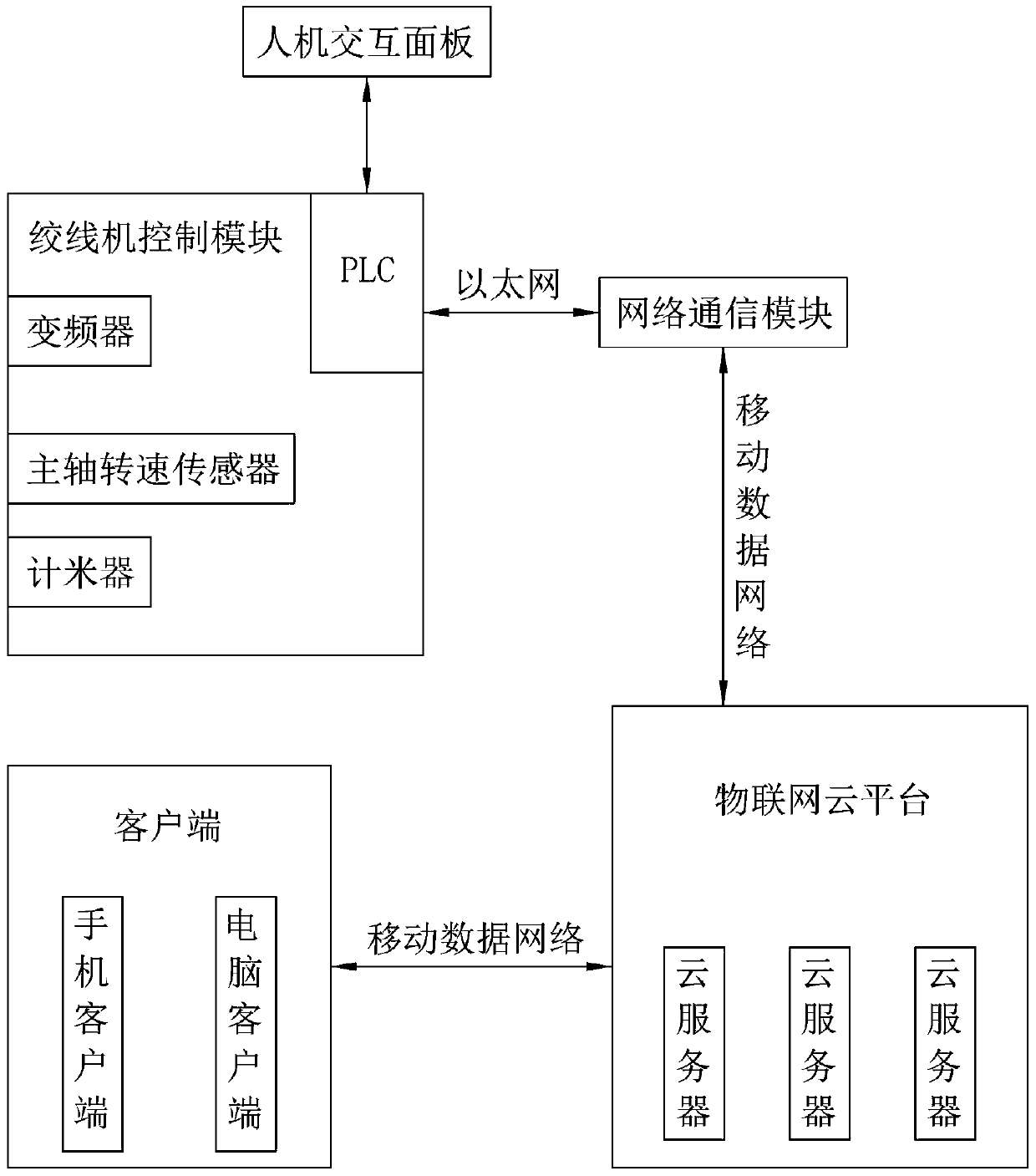

Internet of Things monitoring system for stranding machine

InactiveCN110177149ARealize the function of long-distance monitoring of the twisting machineImprove detection efficiencyTransmissionProgramme control in sequence/logic controllersMachine controlComputer module

The invention discloses an Internet of Things monitoring system for a stranding machine, and relates to the technical field of Internet of Things. The problem that the monitoring efficiency is low issolved. Technical key points are as follows: the system comprises a stranding machine control module, a network communication module, an Internet of Things cloud platform and a client. The network communication module is in communication connection with the stranding machine control module through the Ethernet; the network communication module is in communication connection with the Internet of Things cloud platform through a mobile data network; and the stranding machine control module sends working parameter information to the Internet of Things cloud platform through the network communication module, wherein the working parameter information comprises set main shaft rotating speed information, winding drum rotating speed information, a single-branch wire diameter M, a stranding number S, set meter number information, stranding tension information, stranding distance information, finished meter number information and stranding wire diameter information. The function of remotely monitoring a plurality of stranding machines can be realized, and an operator does not need to walk to a control panel of the stranding machine for monitoring and controlling, so that the effect of improving the detection efficiency is achieved.

Owner:GUANGZHOU HONGHUI ELECTRICIAN & MACHINERY

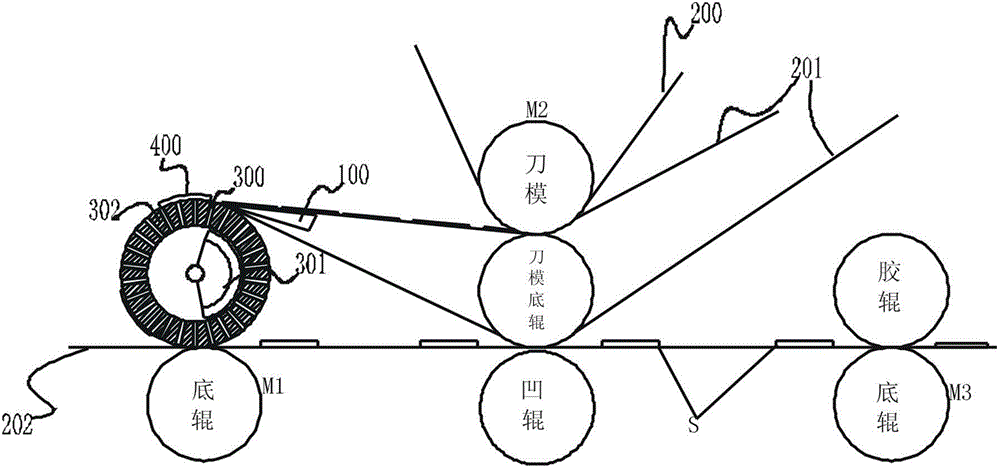

Continuous asynchronous transfer-paste film cutting technology

ActiveCN104960033AIncrease resourcesSave resourcesMetal working apparatusEngineeringMechanical engineering

The invention relates to a continuous asynchronous transfer-paste film cutting technology, thus improving cutting product material utilization rate, and realizing seamless connection; the film cutting technology comprises raw material cutting, splicing and shaping cutting a splicing overlapping portion; the raw material cutting step comprises an asynchronous cutting device including a cutting roller set and an absorption roller set; the cutting roller set comprises a knife mold and a knife mold bottom roller in a lower position; the knife mold is connected with a first servo motor; the absorption roller set comprises a hollow roller and is driven by a second servo motor; absorption holes are uniformly arranged on a periphery of the hollow roller; a plug-hole sector pad is arranged in the hollow roller and connected with a negative pressure inhalation device; one side of the absorption roller set is provided with a triangle separating piece; the second servo motor has bigger speed than that of the first servo motor, and a speed proportion is adjustable. The continuous asynchronous transfer-paste film cutting technology saves cost and knife resources, and is applied to electronic product outer film cutting technology.

Owner:SHENZHEN HADESHENG PRECISION TECH

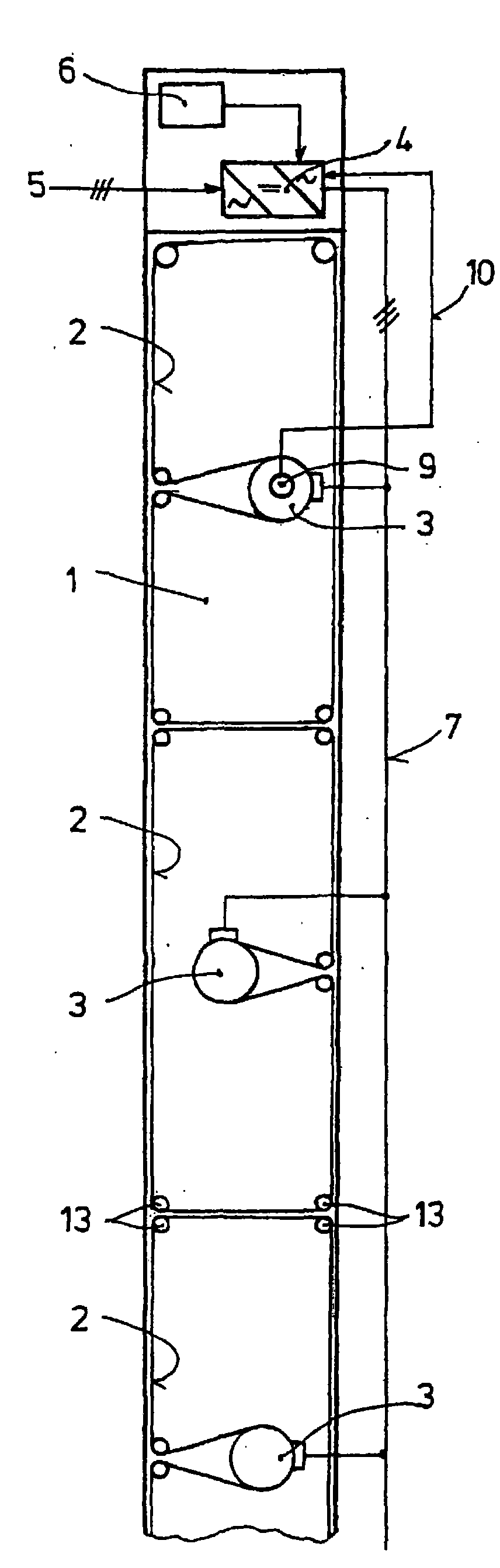

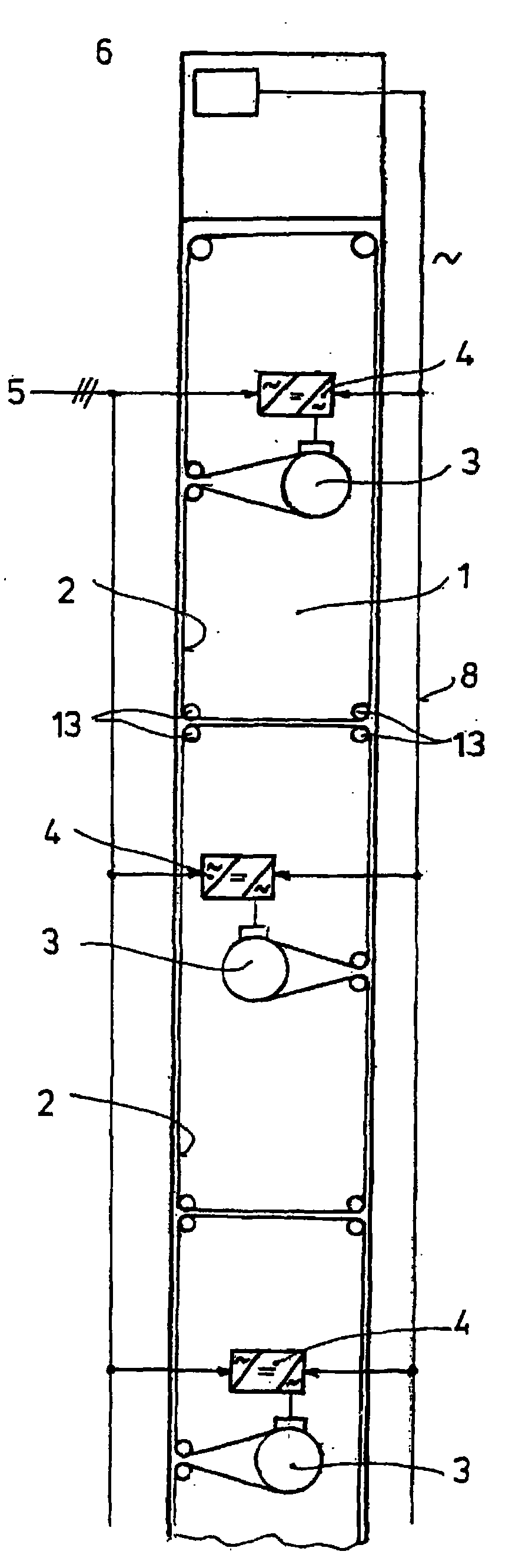

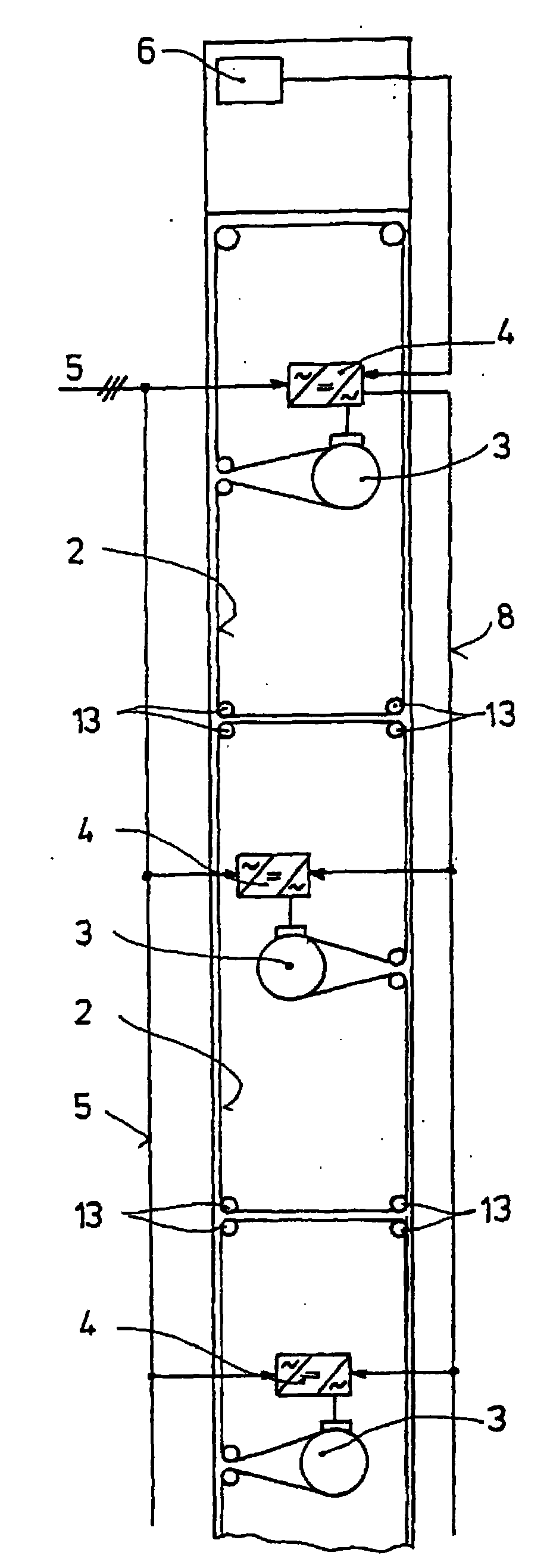

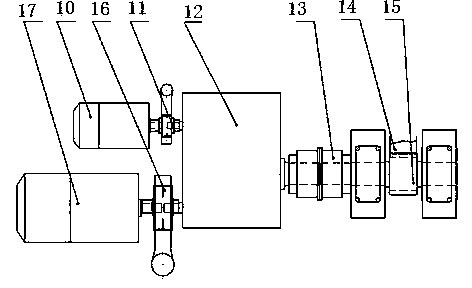

Drive device for the spindles of a ring spinning machine

In order to ensure the synchronous operation of the tangential belt driving the spindles of a ring spinning machine in sections, the electric drive motors (3) of the tangential belts (2) are configured as synchronous motors. They are supplied via a common frequency converter or individual frequency converters (4). The supply frequency is transmitted to the individual frequency converters by means of the machine controller (6) in the form of the desired spindle rotational speed.

Owner:OERLIKON TEXTILE GMBH & CO KG

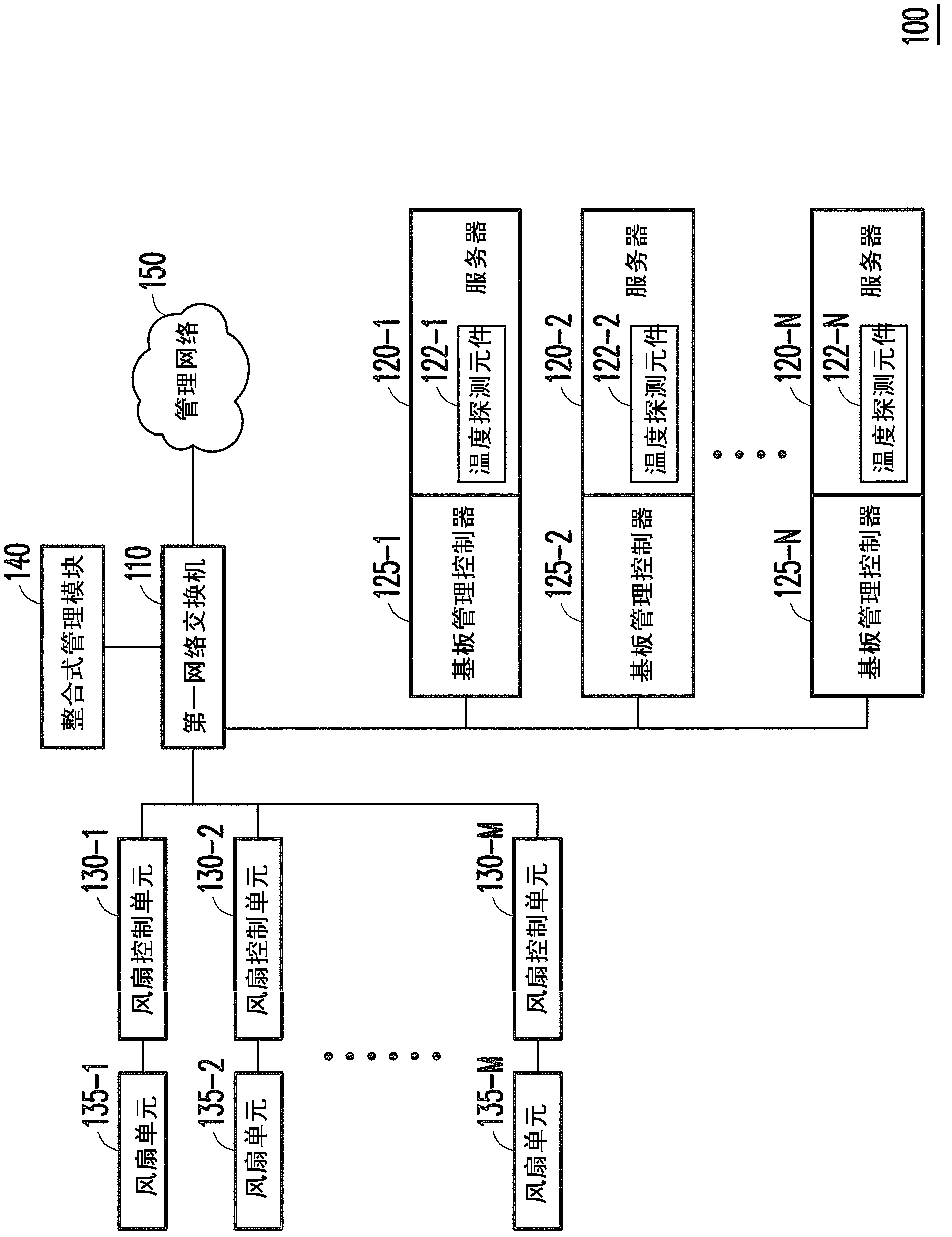

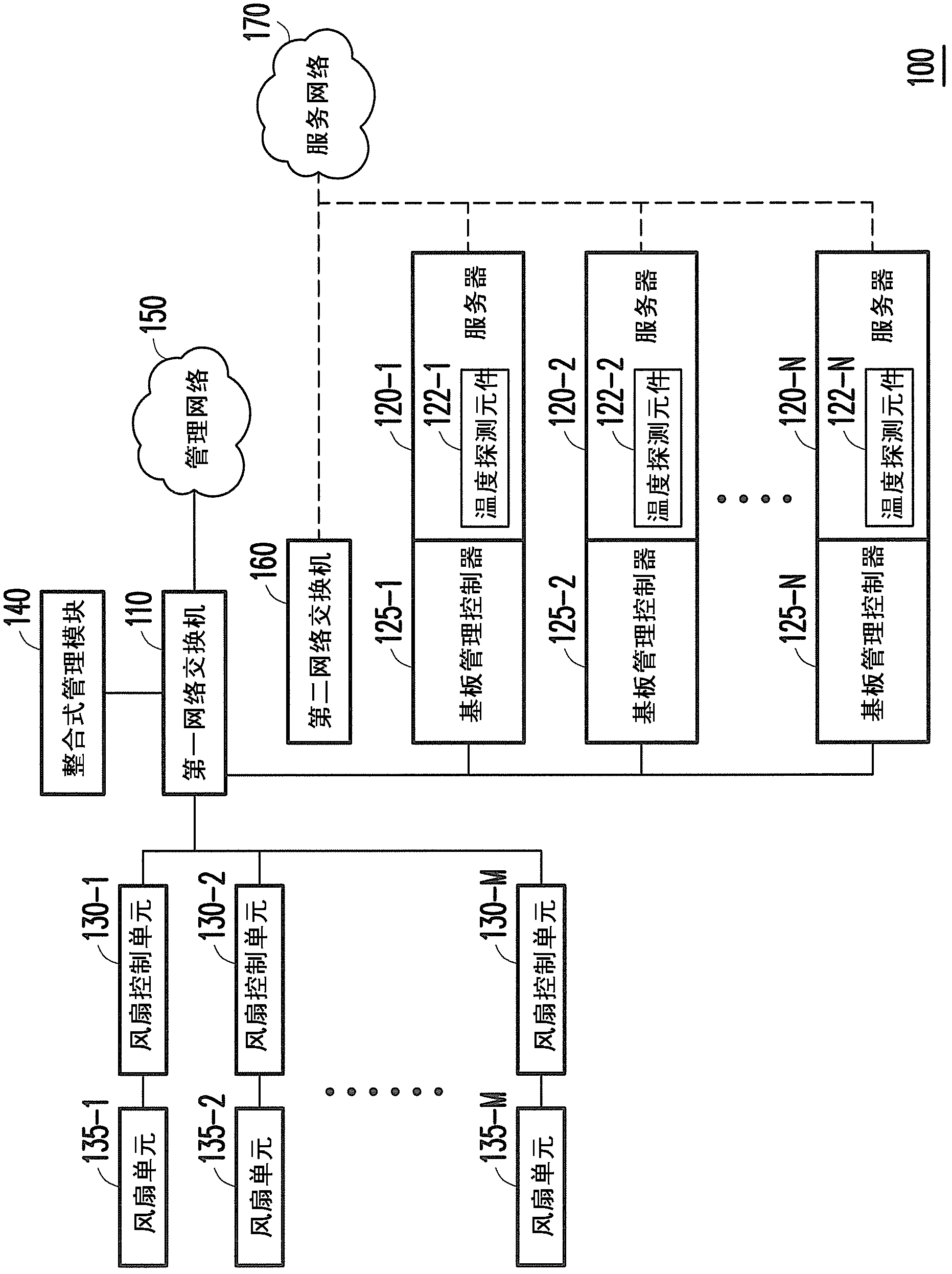

Server rack system of managing rotating speeds of fan

InactiveCN103138974ASpeed adjustmentElectrical apparatus contructional detailsData switching networksComputer moduleNetwork switch

Owner:INVENTEC PUDONG TECH CORPOARTION +1

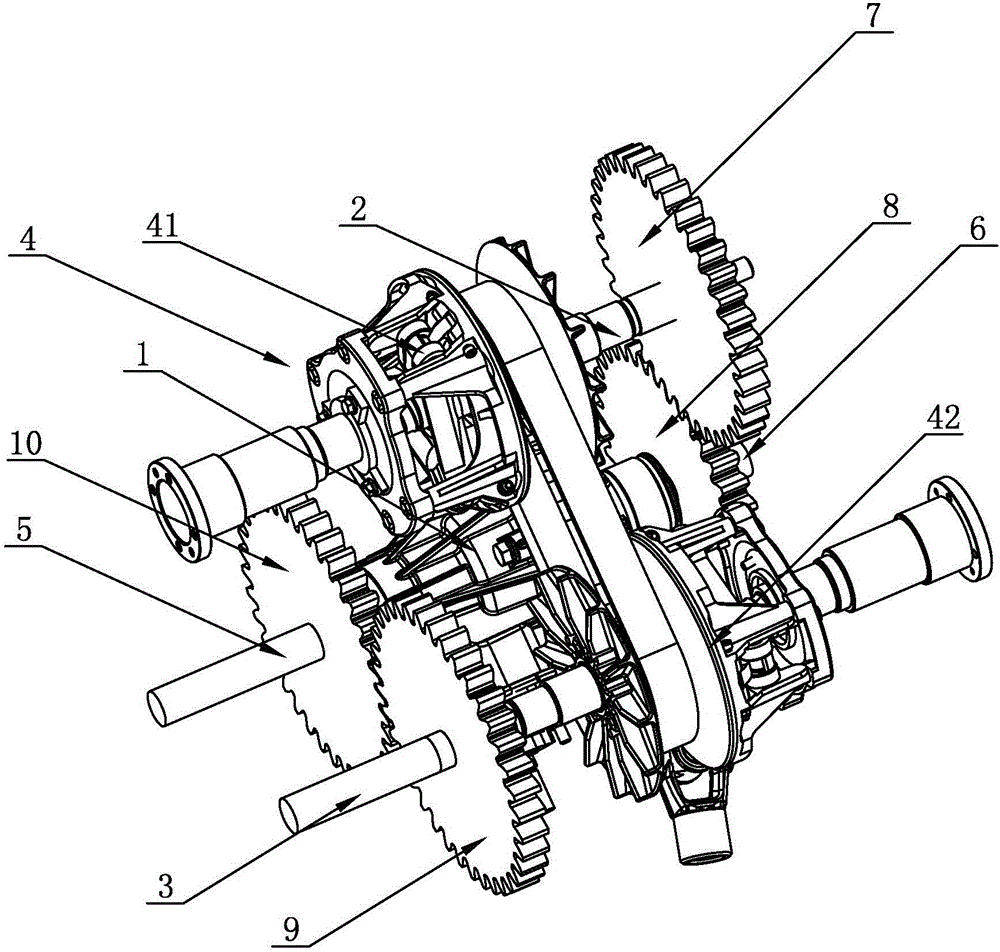

Continuously variable steering mechanism for tracked vehicle

ActiveCN106246847AMake a left turnImprove securityVehicle sub-unit featuresTransmission elementsDrive shaftEngineering

The invention relates to a continuously variable steering mechanism for a tracked vehicle. The continuously variable steering mechanism for the tracked vehicle comprises a differential mechanism, a right transmission shaft, a left transmission shaft and a continuously variable transmission used for regulating rotational speeds of the right transmission shaft and the left transmission shaft; the differential mechanism is connected with a left half shaft and a right half shaft; the right half shaft of the differential mechanism is in linkage matching with the right transmission shaft; the right transmission shaft rotates to drive the right half shaft of the differential mechanism to rotate; the left half shaft of the differential mechanism is in linkage matching with the left transmission shaft; the left transmission shaft rotates to drive the left half shaft of the differential mechanism to rotate; and the rotational speed ratio of the right half shaft of the differential mechanism and the right transmission shaft is equal to that of the left half shaft of the differential mechanism and the left transmission shaft. With adoption of the technical scheme, the invention provides the continuously variable steering mechanism for the tracked vehicle, in which the rotational speeds of the left and right half shafts of the differential mechanism are continuously and accurately regulated through the continuously variable transmission, thus accurate turning of a track is realized, the high-speed driving safety of the tracked vehicle is improved.

Owner:傅江标 +2

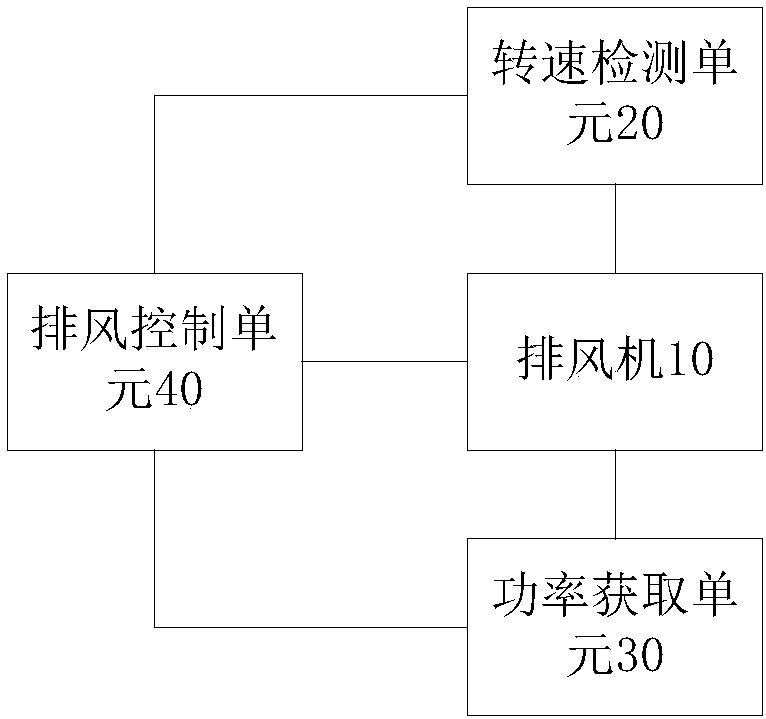

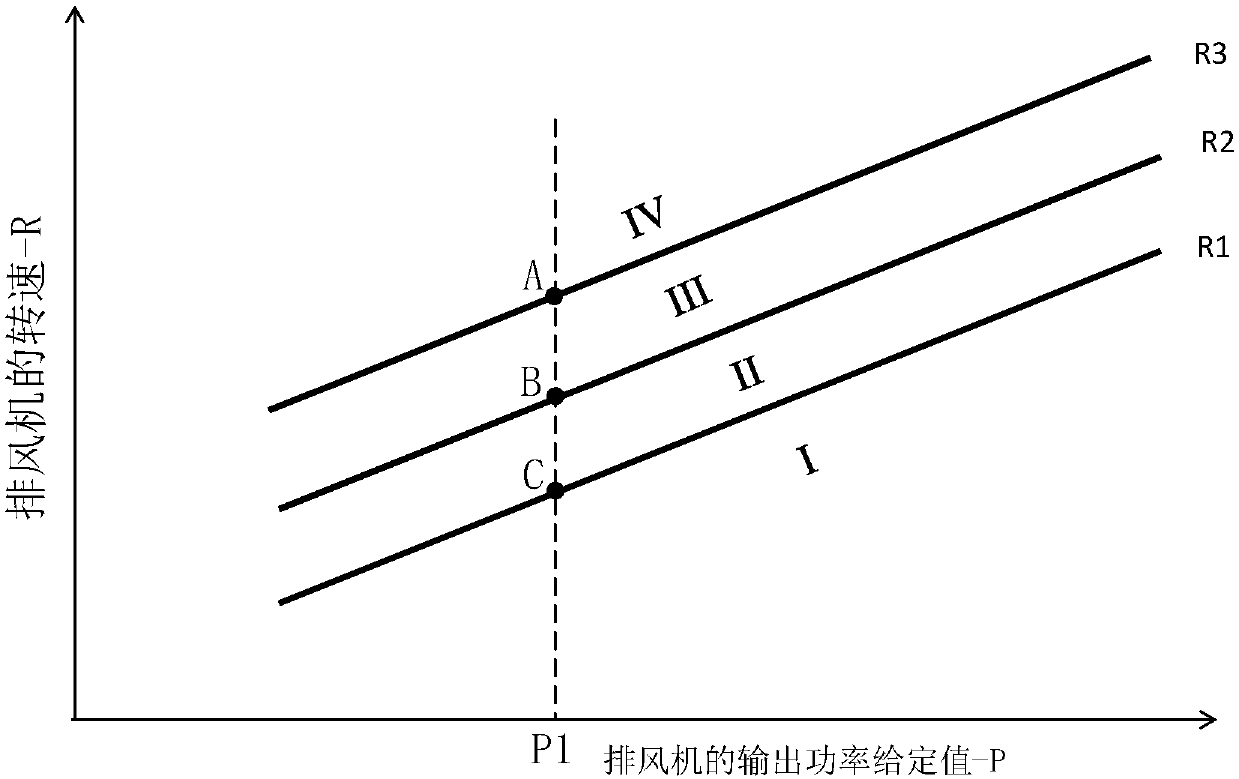

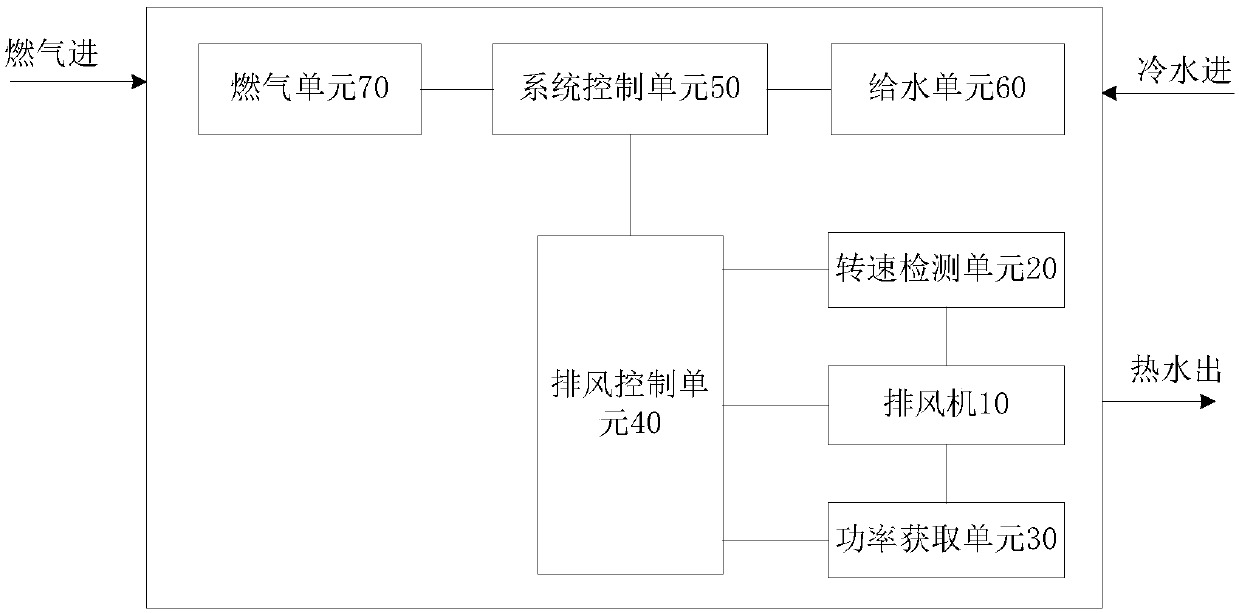

Gas water heater and safety control system and method thereof

InactiveCN107781999AEnsure safe and reliable operationQuick responseFluid heatersAir supply regulationTuyereWater heater

The invention discloses a gas water heater and a safety control system and method thereof. The system comprises an exhaust fan for exhausting waste gas produced by the gas water heater during burning,a rotary speed detecting unit for detecting the rotary speed of the exhaust fan, a power obtaining unit for obtaining an output power given value of the exhaust fan, and an exhausting control unit connected with the exhaust fan, the rotary speed detecting unit and the power obtaining unit and used for judging the air outlet air pressure situation of the exhaust fan according to the rotary speed of the exhaust fan and the output power given value of the exhaust fan and regulating the output power given value of the exhaust fan according to the air outlet air pressure situation of the exhaust fan. The system can ensure that the gas water heater has good burning conditions and ensure safe and reliable operation of the gas water heater, is high in response speed and lower in cost, can providemore accurate air volume and improves the control accuracy.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG

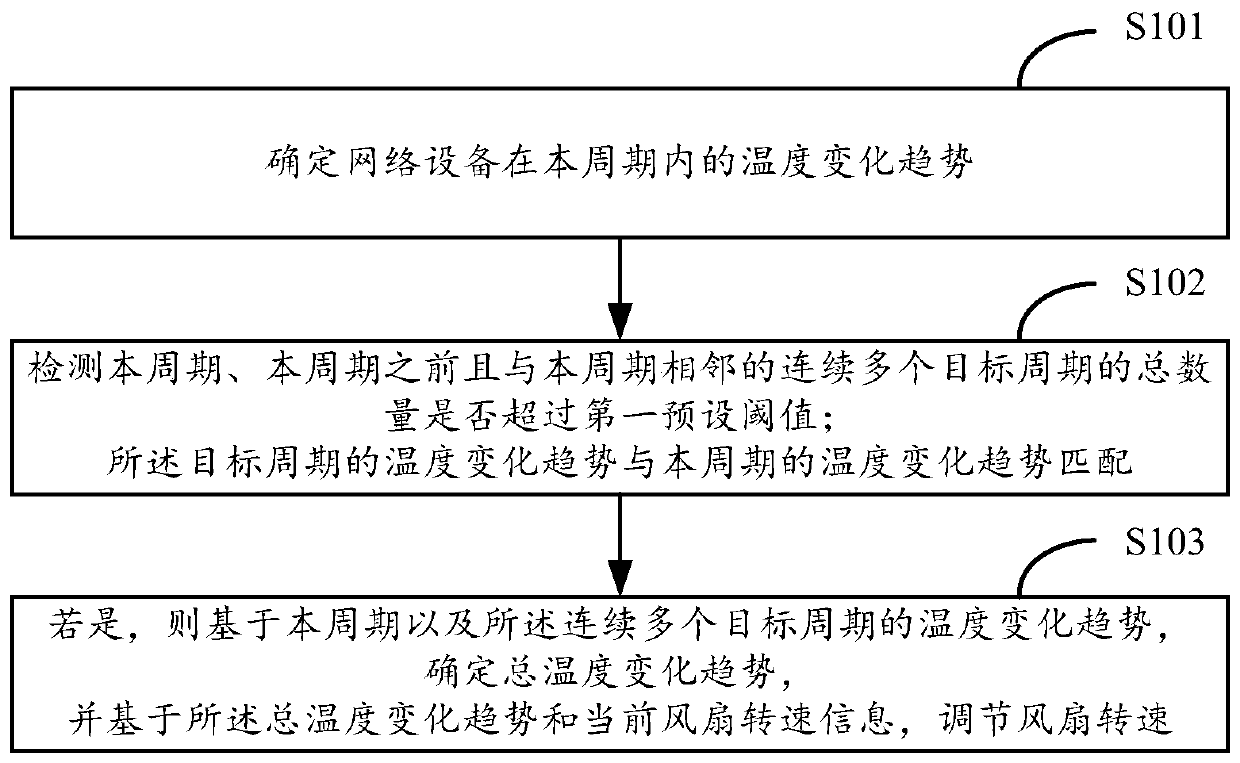

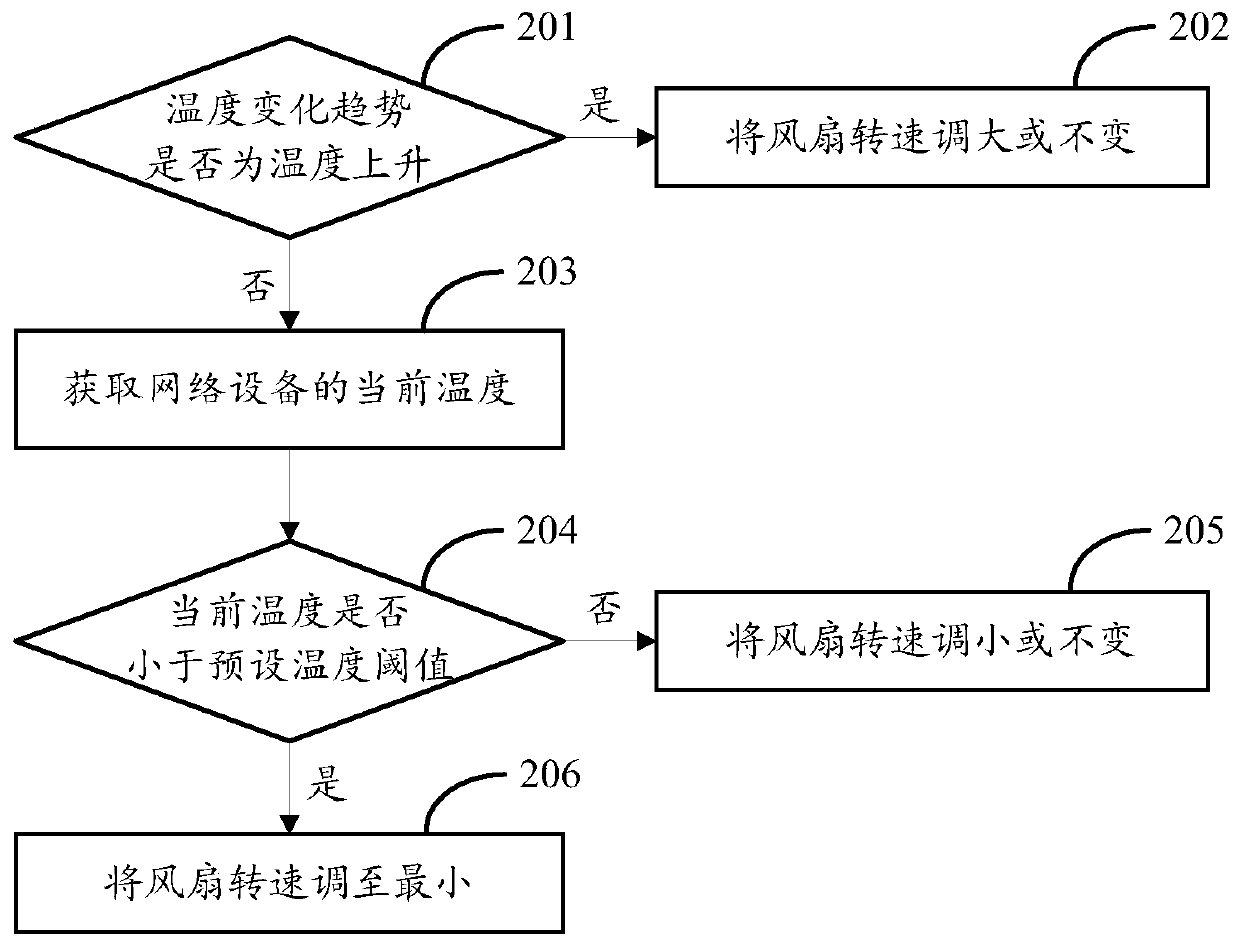

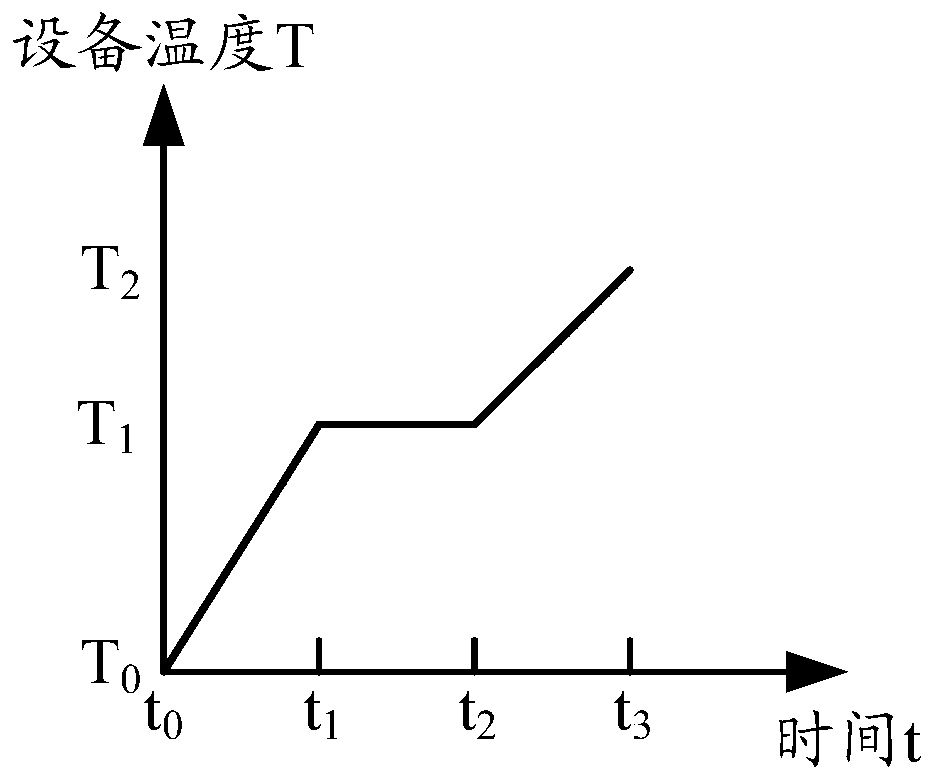

Method and device for fan speed regulation

ActiveCN111503038ASpeed adjustmentAvoid frequent speed adjustmentsPump controlModifications using gaseous coolantsEquipment temperatureThermodynamics

The invention provides a method and a device for fan speed regulation. The method comprises the steps that a network device periodically detects the temperature of the network device, determines the temperature change trend in each period, and determines the number of continuous periods which are matched with the temperature change trend of the period and are adjacent to the period at the end of each period; and if the total number of the continuous periods matched with the temperature change trend exceeds a preset threshold value, the rotating speed of a fan is regulated according to the total temperature change trend of the continuous periods and current rotating speed information of the fan. Through the method, the network device can determine the temperature change trend of the networkdevice when the temperature change of the network device is stable, and the rotating speed of the fan is regulated according to the temperature change trend so that electric energy waste caused by always adjusting the rotating speed of the fan to the maximum can be avoided, and the frequent speed regulation, caused by the network device temperature fluctuation, of the fan can be avoided.

Owner:HANGZHOU DPTECH TECH

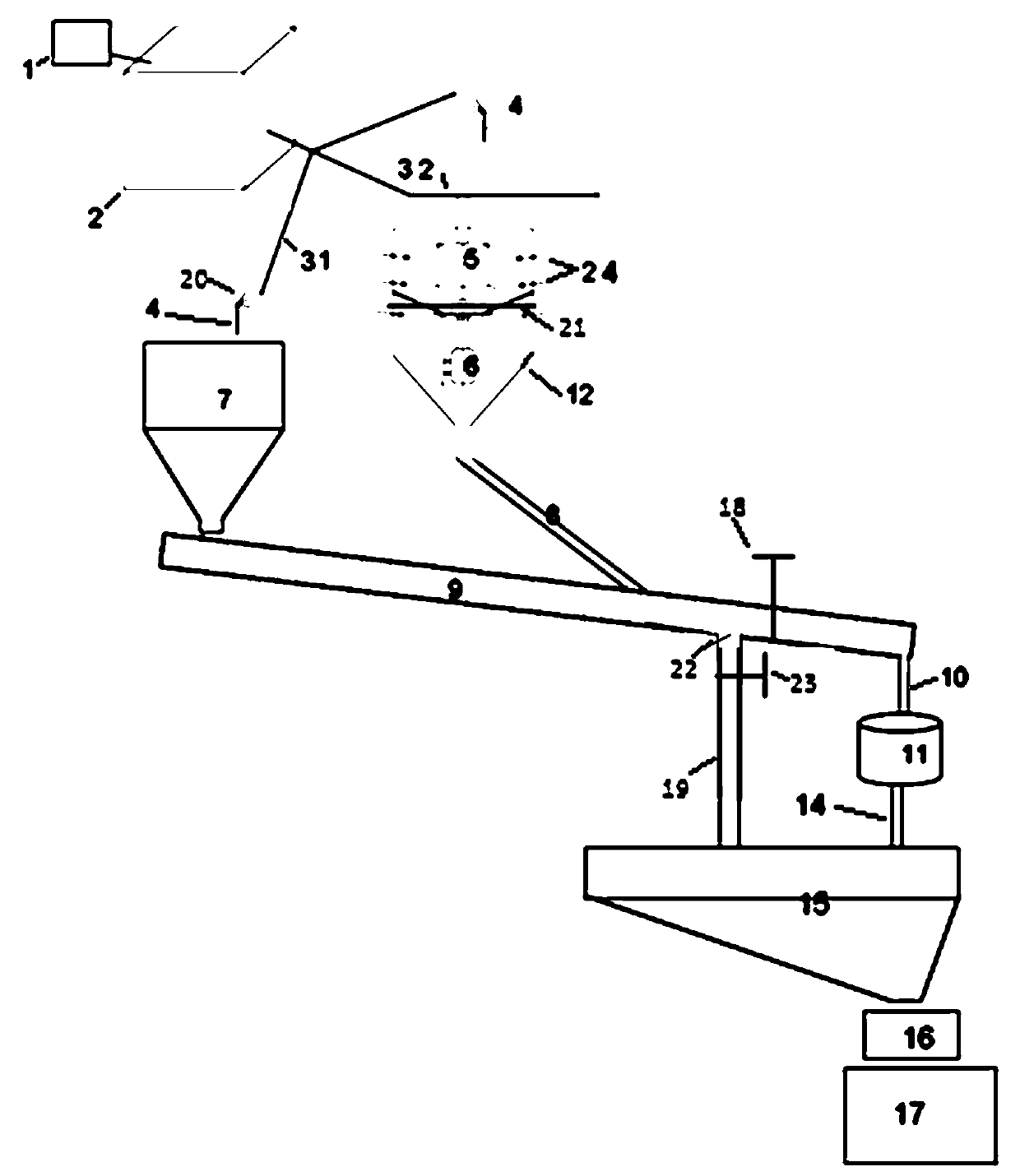

System and method for producing fracturing propping agent by taking red mud as raw material

The invention discloses a system and a method for producing a fracturing propping agent by taking red mud as a raw material. The system comprises a charging machine, a high temperature furnace, a swing-out device, a blanking bin, a tempering furnace and screening equipment, wherein the high temperature furnace is connected with the blanking bin or the swing-out device; dosing is performed by taking inorganic solid wastes as raw materials; and the product is prepared by performing high-temperature melting in the high temperature furnace and molding in a molding device. The method comprises the following steps: (1) dosing, namely mixing pure red mud or red mud with one or more of fluorite, silica sand, potassium (or sodium) feldspar and dolomite; (2) mixing and performing wet grinding, namely mixing and performing wet grinding on the prepared materials; (3) drying and granulating; (4) melting the granulated materials in the high temperature furnace; (5) molding the granulated materials into propping agent granules by utilizing the molding device; and (6) screening, weighing and packaging the propping agent granules by virtue of the screening equipment. The system and the method are high in product yield, high in production efficiency and low in cost.

Owner:JINGANG NEW MATERIALS

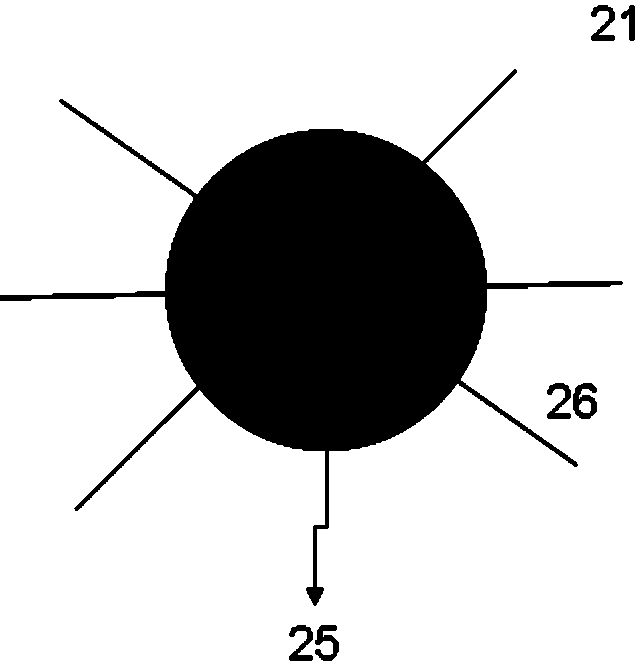

Test device and method for researching friction characteristics between tire and actual pavement

PendingCN109612929AExtended service lifeEliminate the influence of other additional loads such as centrifugal forceUsing mechanical meansVehicle tyre testingWear patternRoad surface

The invention discloses a test device and method for researching friction characteristics between a tire and an actual pavement, and belongs to the technical field of detecting equipment. Actual working conditions of the tire with load running on different pavements are well simulated through mechanical structures such as a loading sleeve, a loading sleeve base, a rotary arm and a rack, the test device and method for researching friction characteristics between the tire and the actual pavement can be used for testing a friction factor between the tire and the pavement and researching wear pattern between the tire and the pavement, compression amount of a loading spring can be adjusted through a loading screw according to requirements, and thus a test load is adjusted; meanwhile tire running speed is adjusted through a transmission system; changing is conducted on a slip rotary rate or a slip shift rate between the tire and a pavement through adjusting a connected relation between a tested wheel and an auxiliary wheel, multiple kinds of running conditions of the tire on the pavement are simulated, data such as the load, a rotate speed and a torque are detected in real time through asensor, and thus the friction factor between the tested tire and the tested pavement is obtained by formula calculation.

Owner:西安凯德液压机电有限责任公司

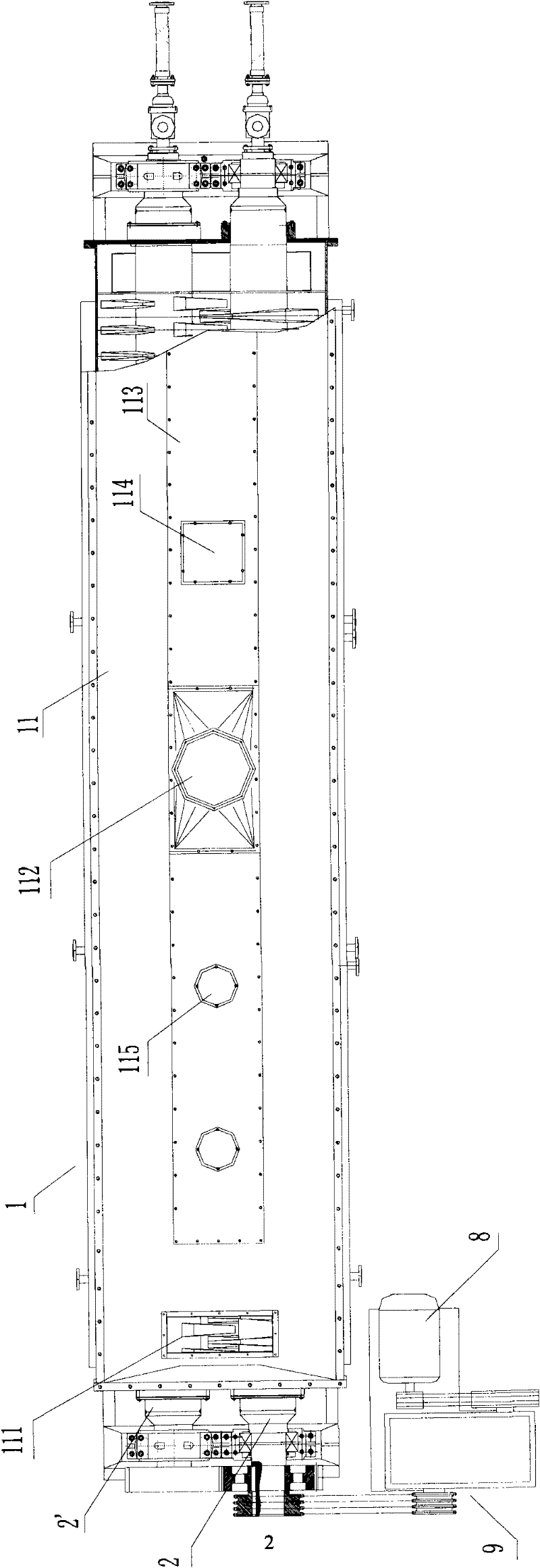

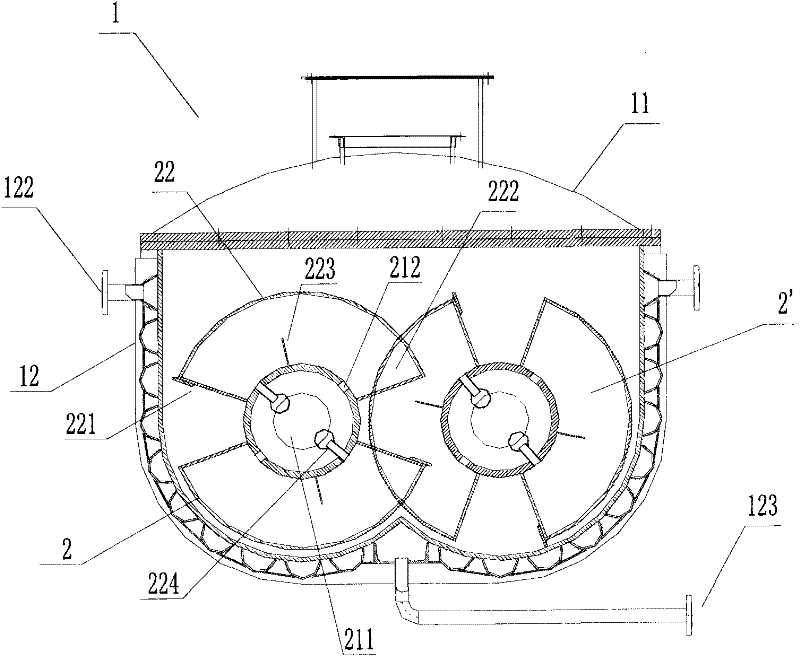

Multitube heating rotary pulverized coal pyrolysis system

InactiveCN104017592ARealize large-scale pyrolysisAchieve recyclingIndirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention discloses a multitube heating rotary pulverized coal pyrolysis system, including a feeder, an outlet gas gathering and distribution box, a preheater, a transmission mechanism, a rotating cylinder body, a heating pipe, a riding wheel device, an air inlet gas gathering and distribution box and a gas guiding device. The rotating cylinder body supports on the riding wheel device, and is driven by the transmission mechanism; a feed end of the rotating cylinder body is provided with the outlet gas gathering and distribution box, and a discharging end of the rotating cylinder body is provided with the inlet gas gathering and distribution box; The rotating cylinder body is provided with the heating pipe, both ends of the heating tube are respectively connected with the inlet gas gathering and distribution box and the outlet gas gathering and distribution box; the feeder is connected with the charging end of the rotating cylinder body through the gas gathering and distribution box; the gas guiding device is connected with the discharge end of the rotating cylinder through the gas inlet gathering and distribution box; and the feeder is installed on the upper part of the preheater, and is connected with the gas outlet gathering and distribution box. The invention realizes the scale pyrolysis of pulverized coal, and creates conditions for improving the comprehensive utilization and economic value of pulverized coal.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com