Continuous asynchronous transfer-paste film cutting technology

An asynchronous, die-cutting technology, applied in metal processing, etc., can solve problems such as backward transmission technology, easy-to-failure die-cutting stability, etc., and achieve the effects of saving tool resources, simple processing, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

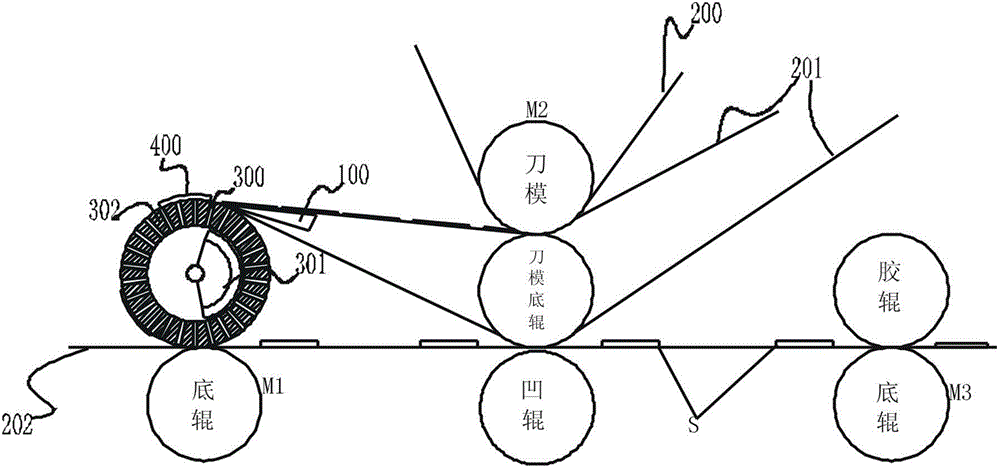

[0011] combine figure 1 , which describes the specific implementation of the invention in detail, but does not limit the claims in any way.

[0012] In a continuous asynchronous transfer die-cutting process of the present invention, the die-cutting process includes raw material cutting, splicing, and forming and cutting the overlapped joints, wherein the raw material cutting process includes asynchronous cutting equipment, The asynchronous cutting equipment includes a cutting roller group M2 and an adsorption roller group M1. The side of the adsorption roller group M1 is provided with a triangular separation block 100. The cutting roller group M2 includes a knife mold and a bottom roller of the knife mold below; Cutting knives are set at the interval and driven by the first servo motor; the adsorption roller group M1 includes a hollow roller body 302 and is driven by the second servo motor, and there are adsorption holes 300 evenly distributed around the periphery of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com