Measurement control method taking DC electric machine as force measuring device and realizing device thereof

A DC motor, measurement and control technology, applied in the direction of measuring device, motor generator test, force measurement, etc., can solve the problems of difficult determination of threshold value, high cost, complex structure of controller and device, etc., to prevent abnormal working state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

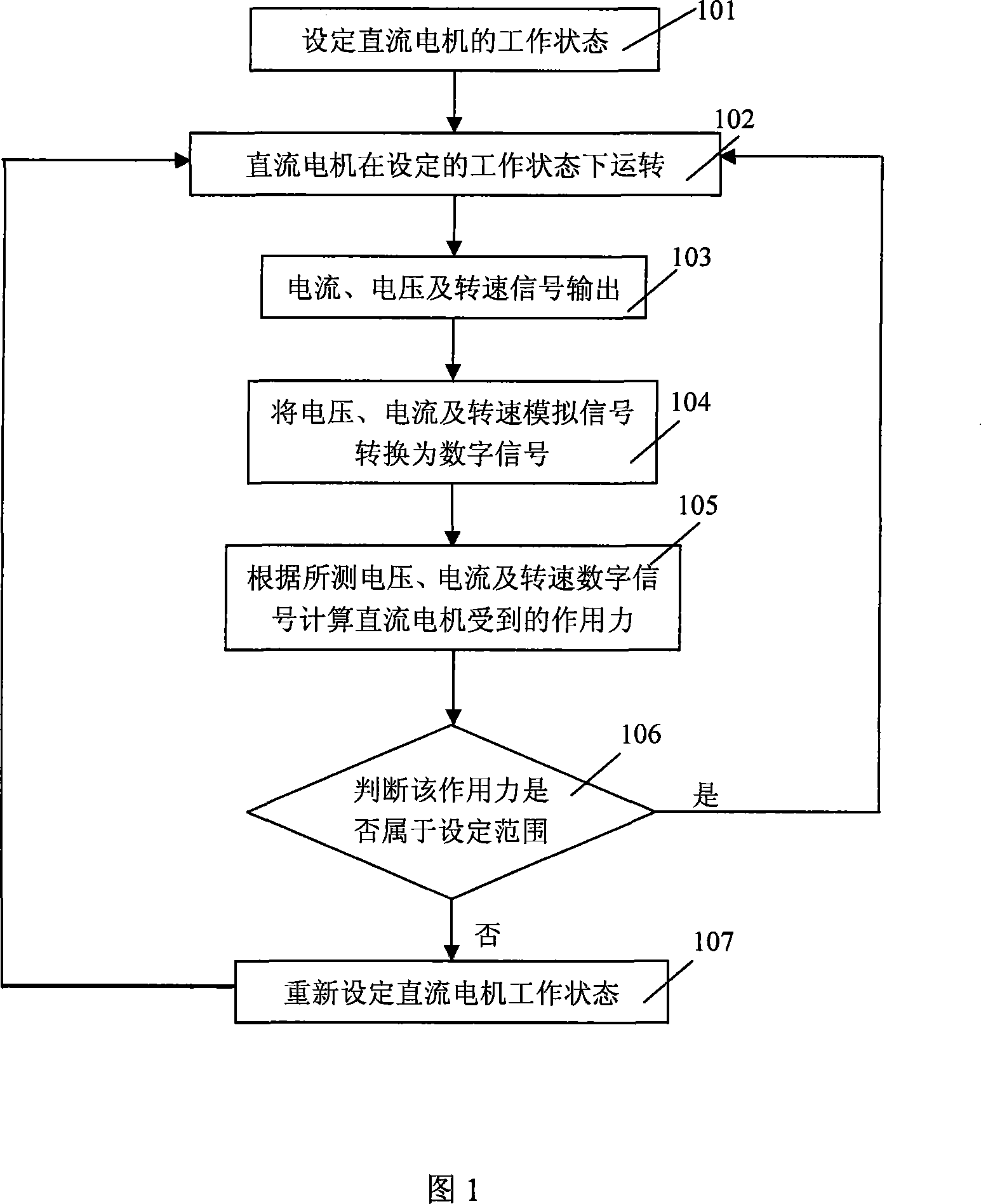

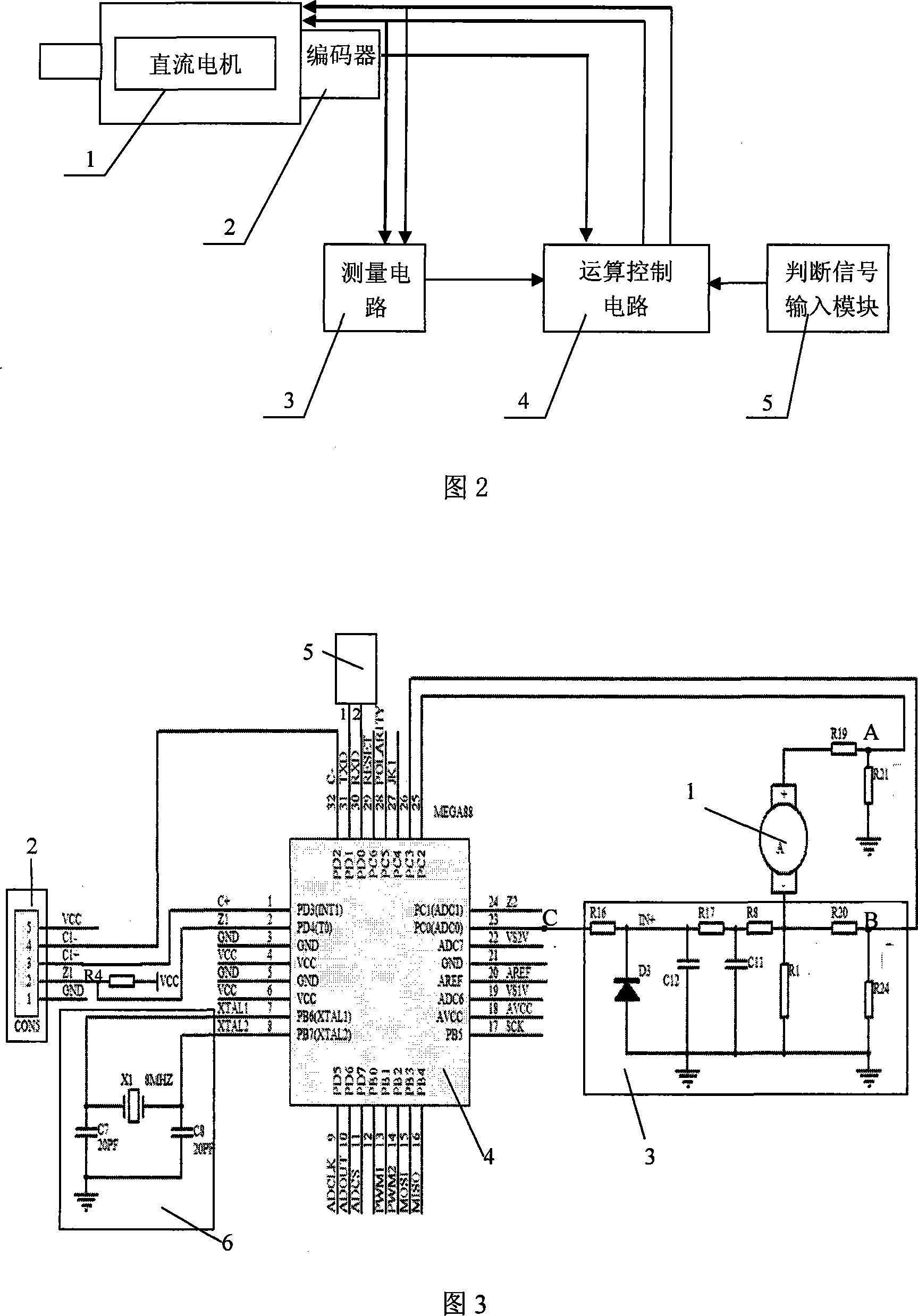

[0027] Referring to Fig. 1 and Fig. 2, describe in detail the measurement control method of the present invention, in step 101, set the operating state of DC motor 1 under the action of external force by digital circuit integrated chip 4 according to the output value of judging signal input module 5; Step 102, the DC motor 1 rotates at a certain speed under the set working state; step 103, directly output the analog signals of the voltage v and current i of the DC motor 1 running under the action of external force, and the encoder 2 converts the DC motor 1 speed The signal n is directly sent to the digital circuit integrated chip 4; step 104, through the measuring circuit 3, the analog signal of the voltage v and current i of the DC motor 1 running under the action of external force is converted into a signal that meets the requirements of the digital circuit integrated chip; step 105 , the operation control circuit 4 calculates the numerical value of the external force that th...

Embodiment 2

[0033] Combined with the purpose and working principle of the present invention, it can be further applied to electric bicycles for medical rehabilitation. The DC motor is connected with the pedal through the electric bicycle rotating arm, and the electric bicycle rotating arm and the pedal are connected by a movable hinge, and the DC motor is controlled by the realization device of the present invention. By judging the working mode selected by the signal input device, the user can control the motor to drive the pedal to rotate at a speed of ten circles per minute. At the same time, the digital circuit integrated chip measures in real time the force exerted by the motor on the DC motor when the user steps on it: when the detected force changes within the set force value range, the device can slow down or increase it according to the user's force condition. The speed of the motor is to improve the rehabilitation effect; when the user's leg has cramps or stiffness and other bad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com