Mechanical self-adaptive auxiliary docking platform

A docking platform and self-adaptive technology, applied in the workbench, metal processing equipment, metal processing and other directions, can solve the problem of the misalignment of the geometric center of the slide rail and the chute, the complex cost of the multi-degree-of-freedom docking platform, the damage of the workpiece and the docking body, etc. problems, to achieve the effect of sensitive adaptive ability, easy operation control and assembly and disassembly maintenance, and avoid injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

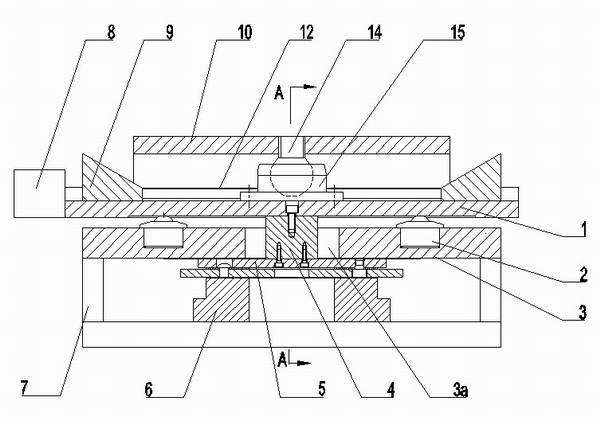

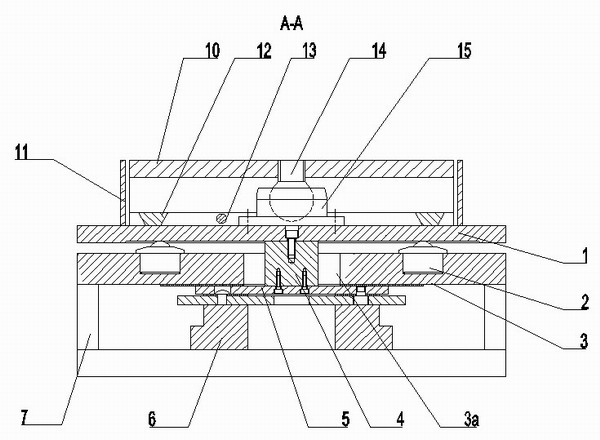

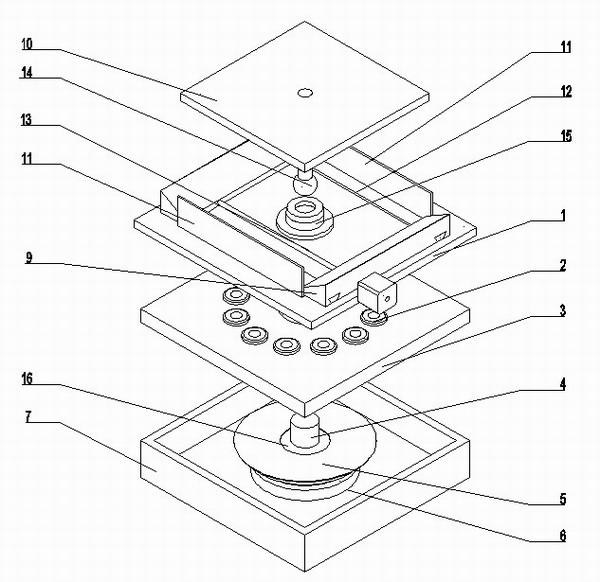

[0016] like figure 1 , figure 2 and image 3 The mechanical adaptive auxiliary docking platform shown includes a translation mechanism and a rotation mechanism; the translation mechanism consists of a support plate 1, a universal ball 2, a bottom plate 3, a connecting column 4, a connecting plate 5, an electromagnetic brake 6 and a base 7, wherein the electromagnetic brake 6 is installed in the base 7, the connecting plate 5 is fixed on the electromagnetic brake 6, the connecting column 4 is fixed on the connecting plate 5, and the bottom plate 3 is located on the Above the connecting plate 5, and the base plate 3 is supported on the base 7, a connection through hole 3a is opened on the base plate 3, a group of universal balls 2 is fixed on the base plate 3, and the group of universal balls 2 is fixed on the base plate 3. The balls 2 are evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com