Patents

Literature

98 results about "Wear pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

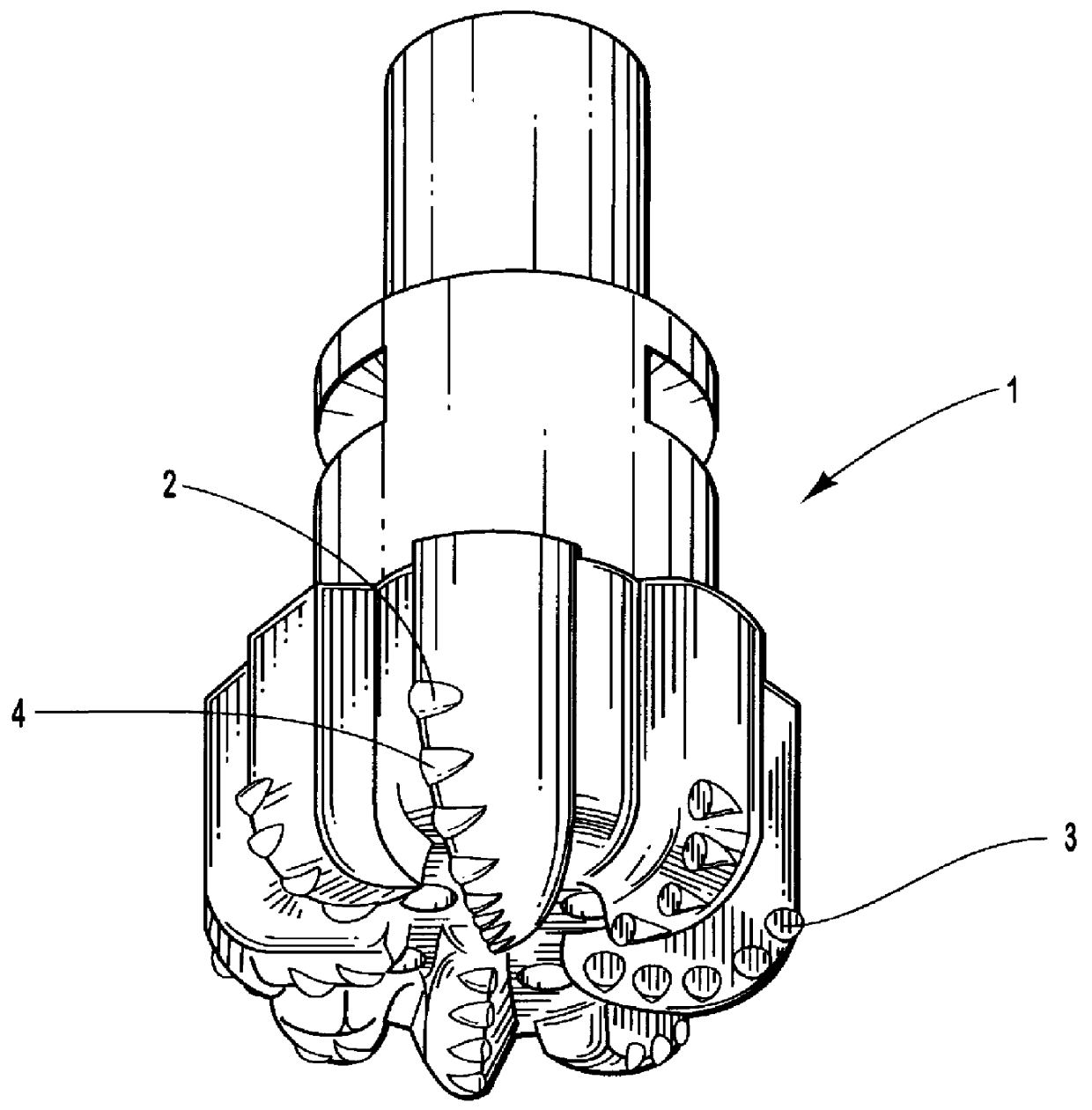

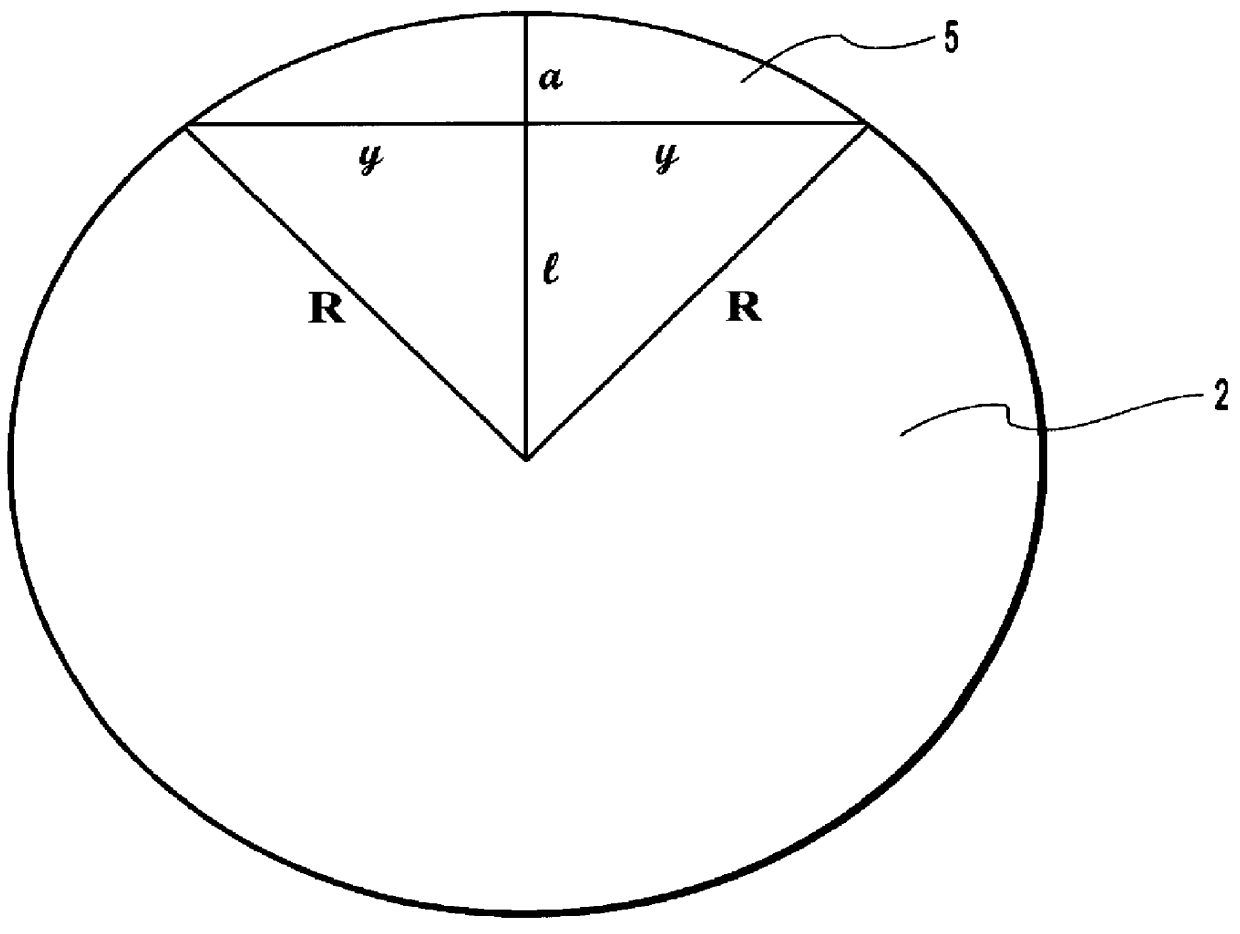

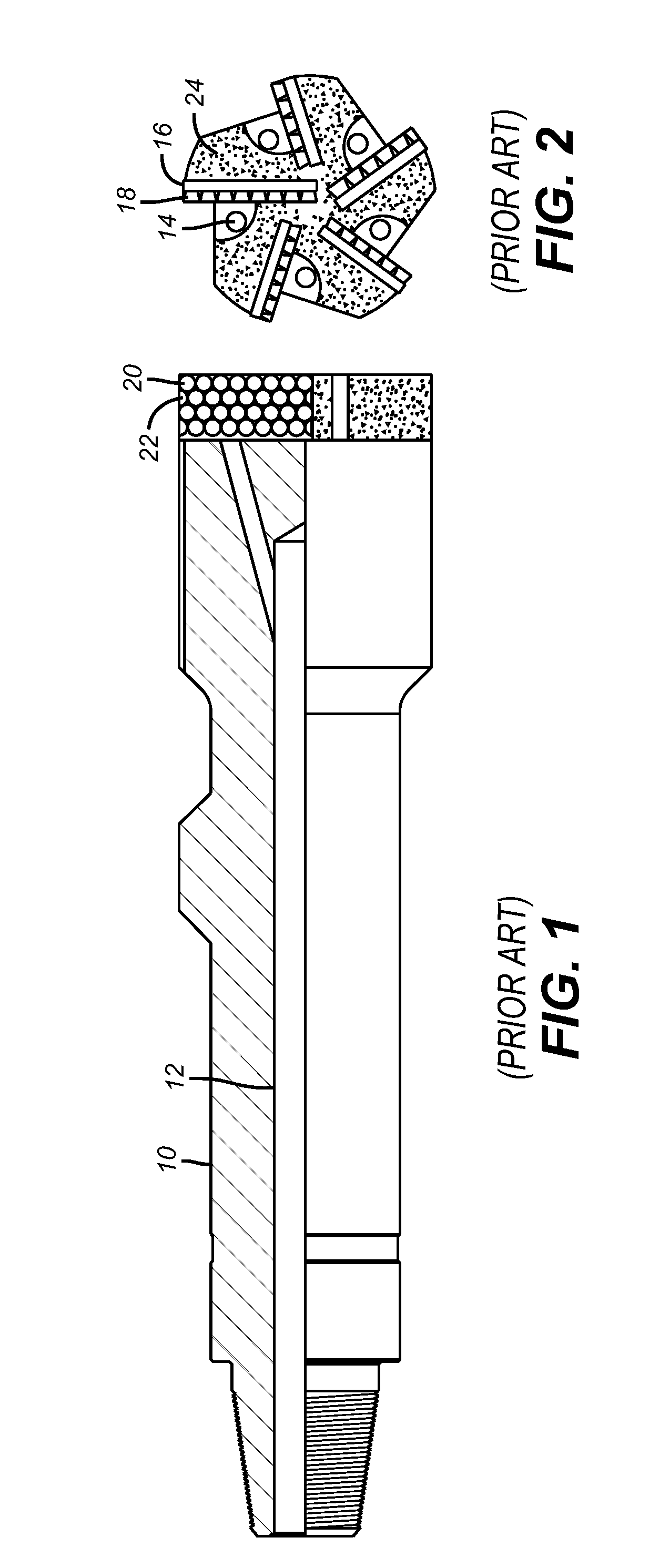

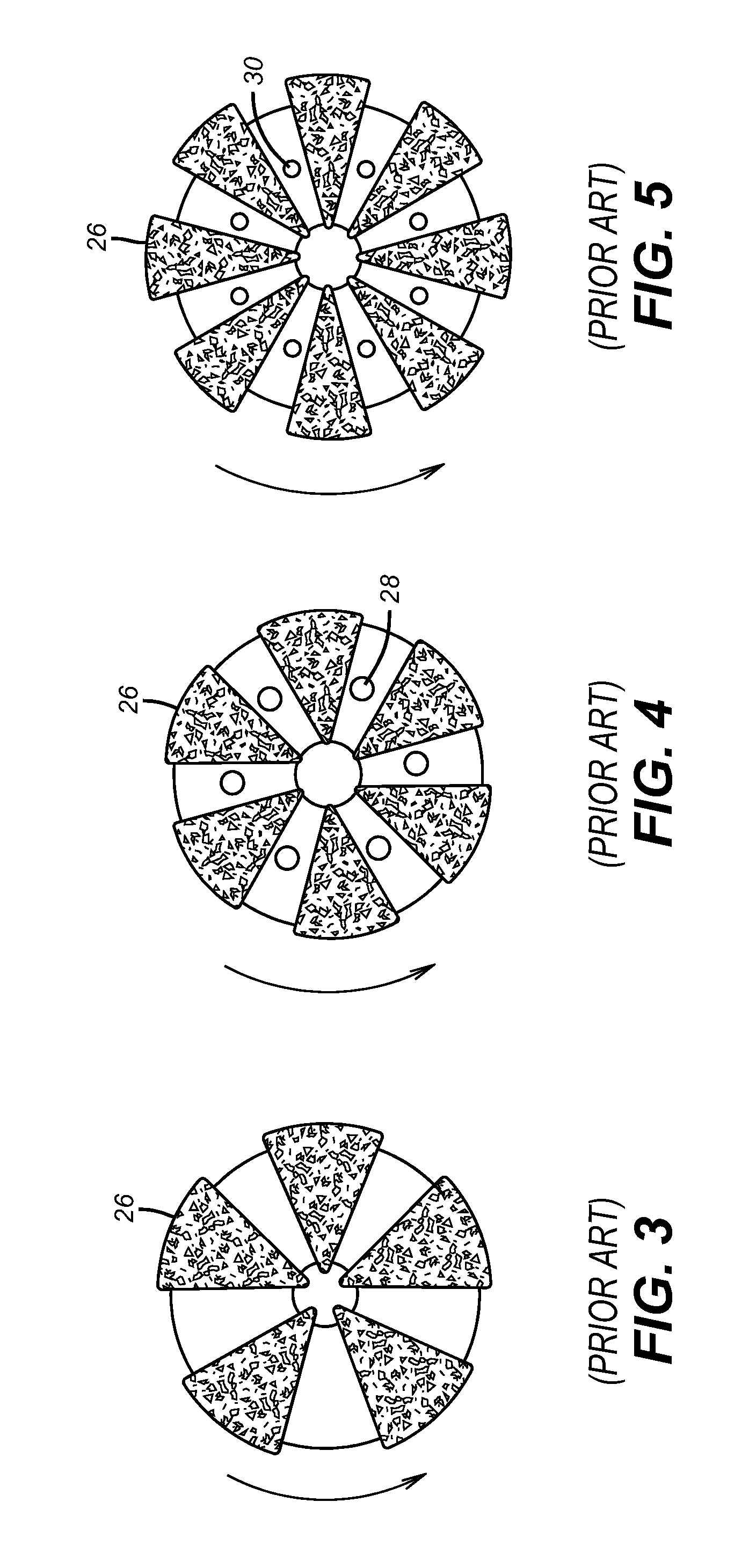

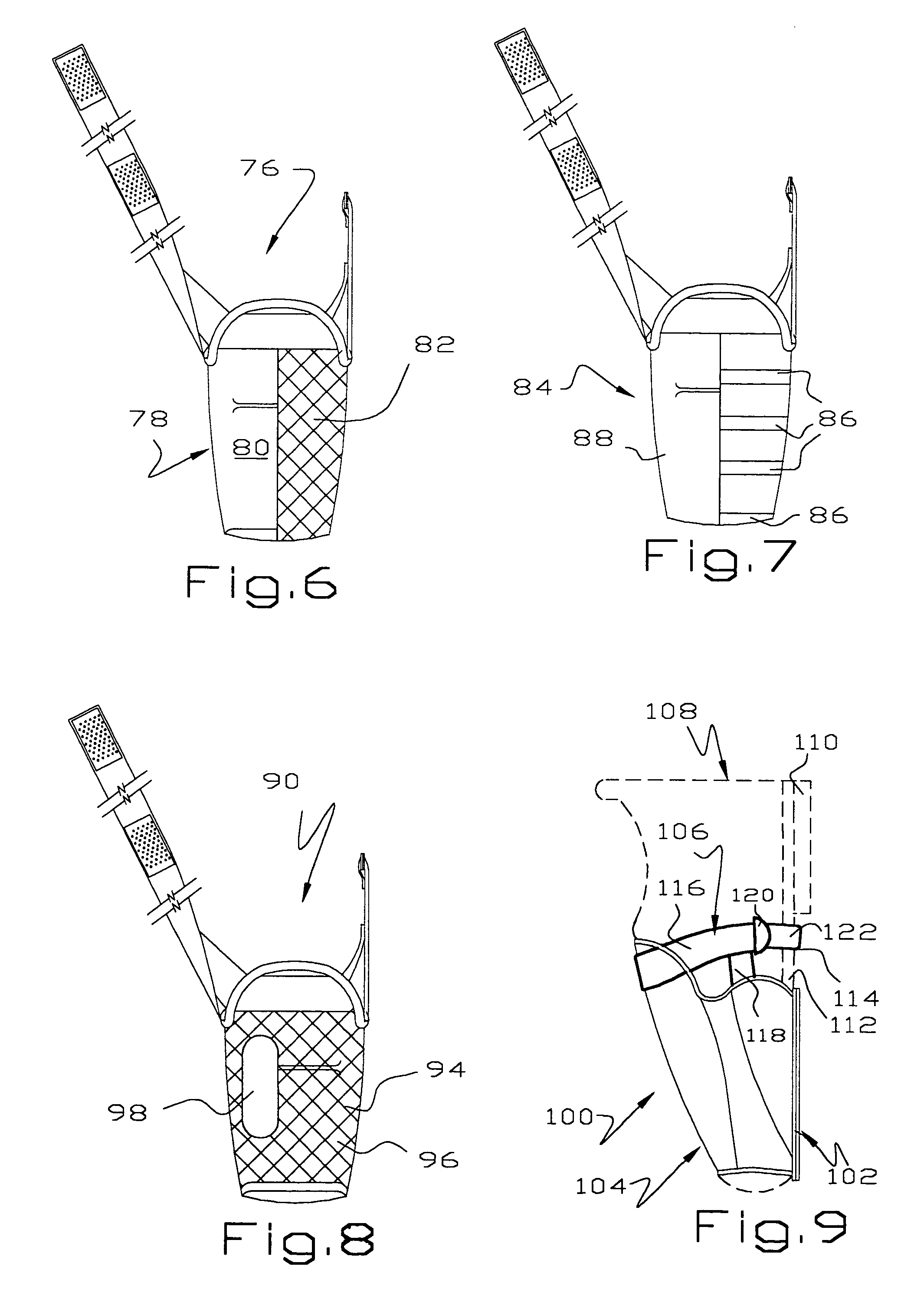

Cutter with polycrystalline diamond layer and conic section profile

InactiveUS6068071AReduce wearReduce actionDrill bitsConstructionsWear patternPolycrystalline diamond

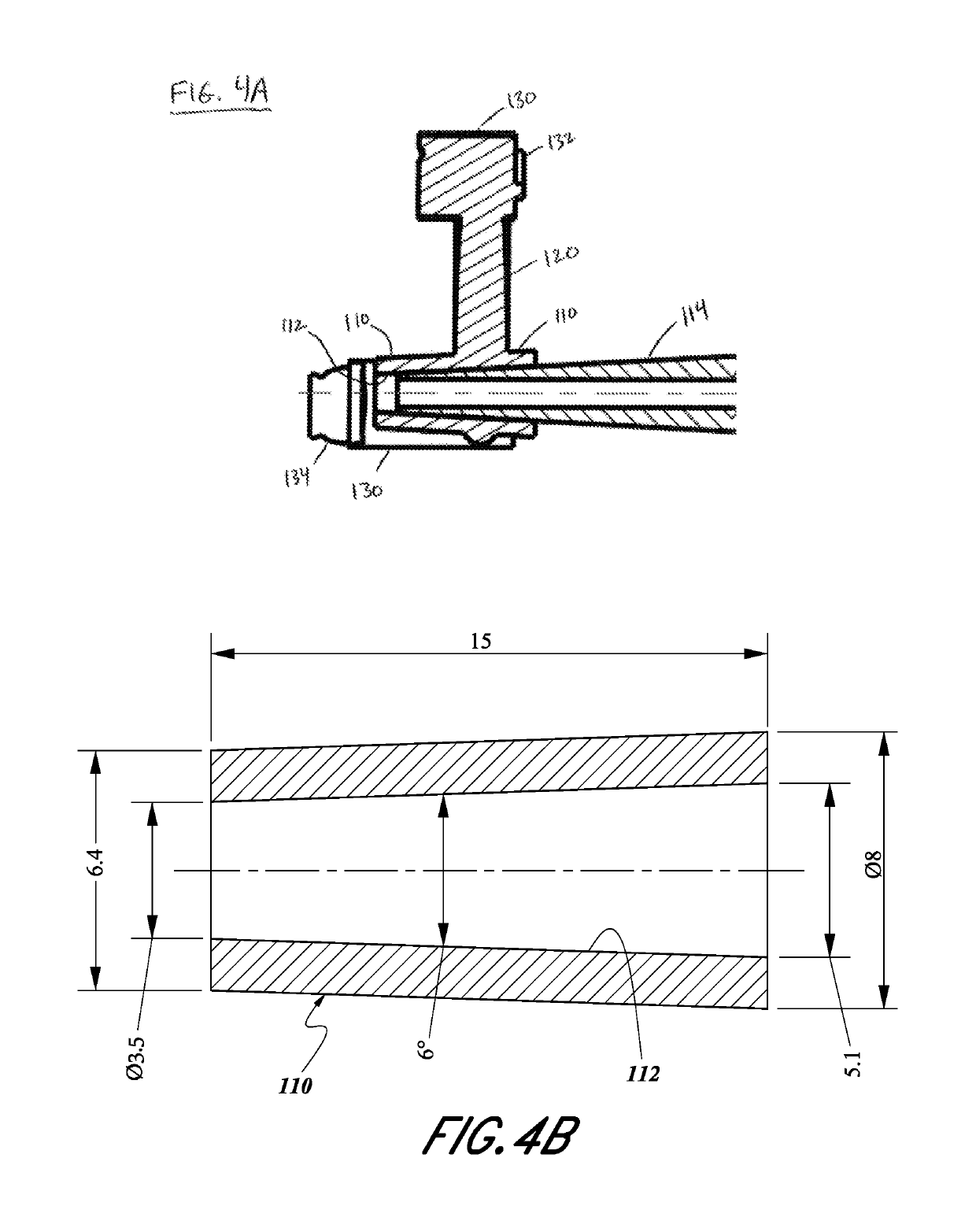

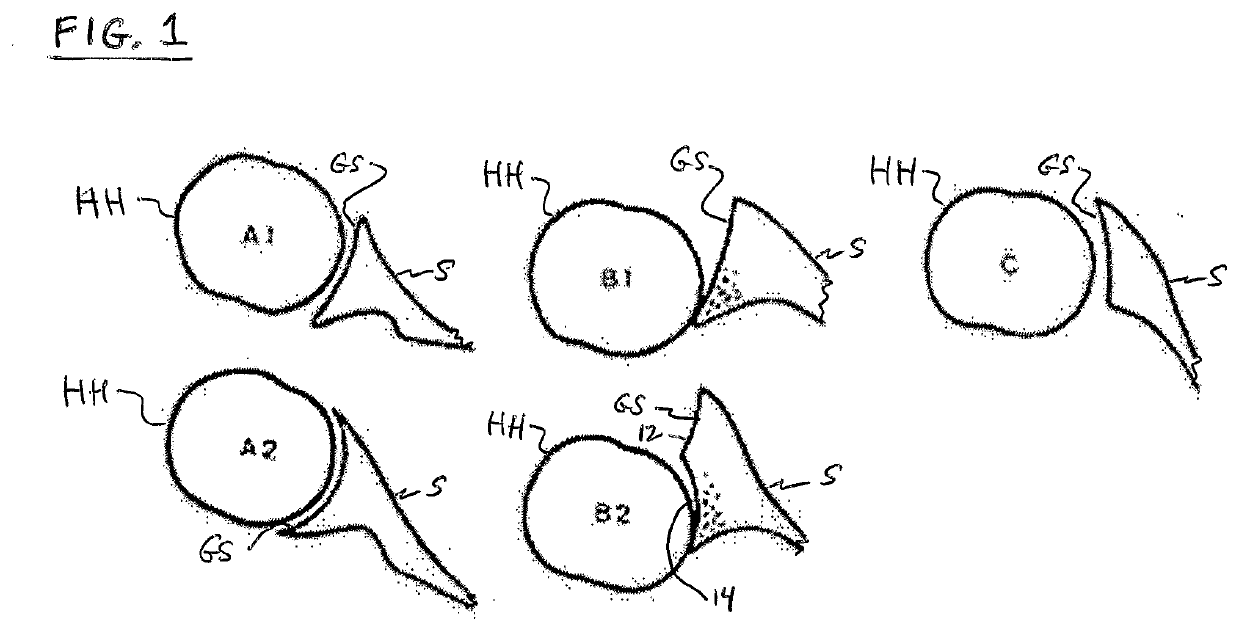

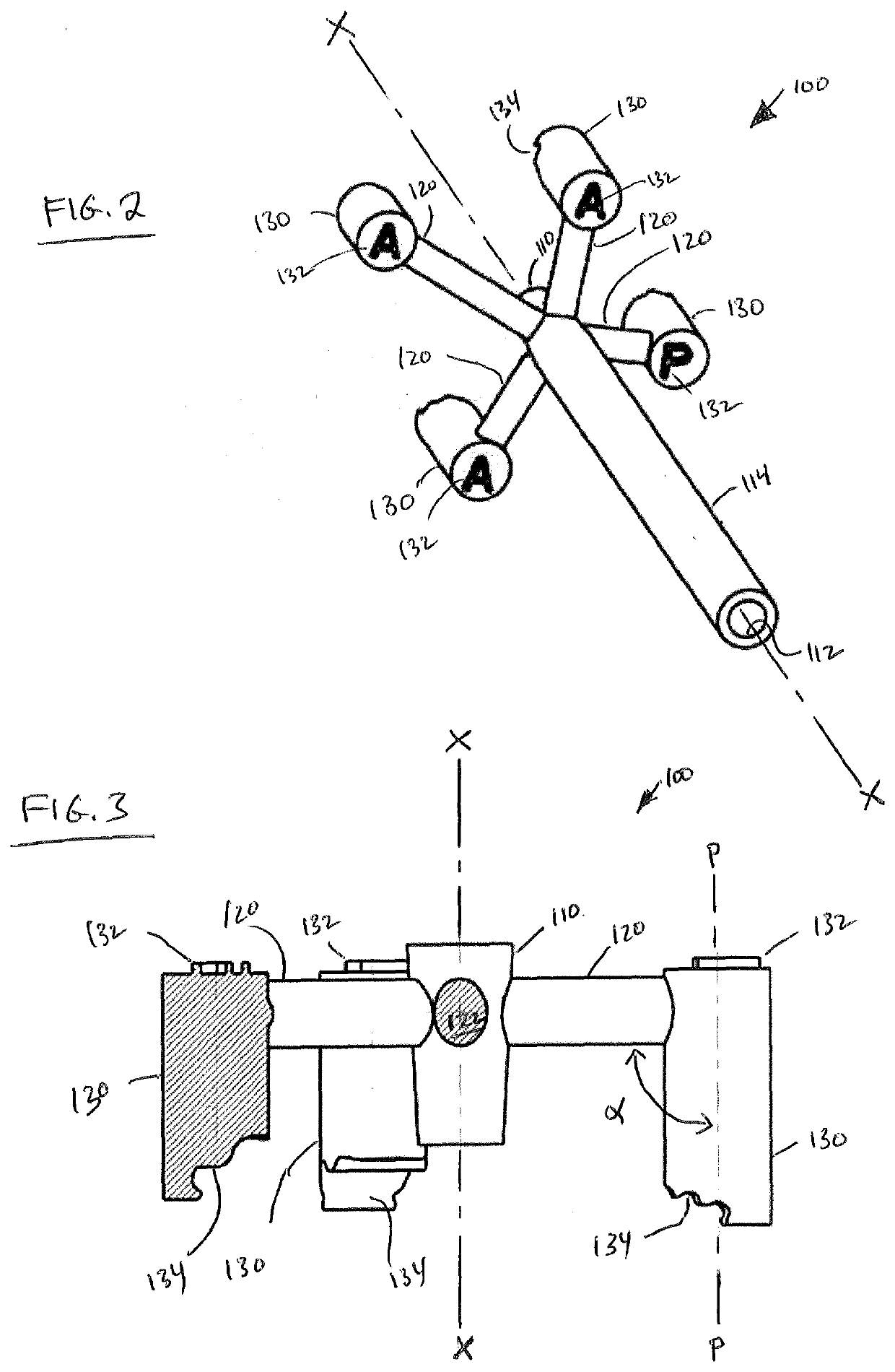

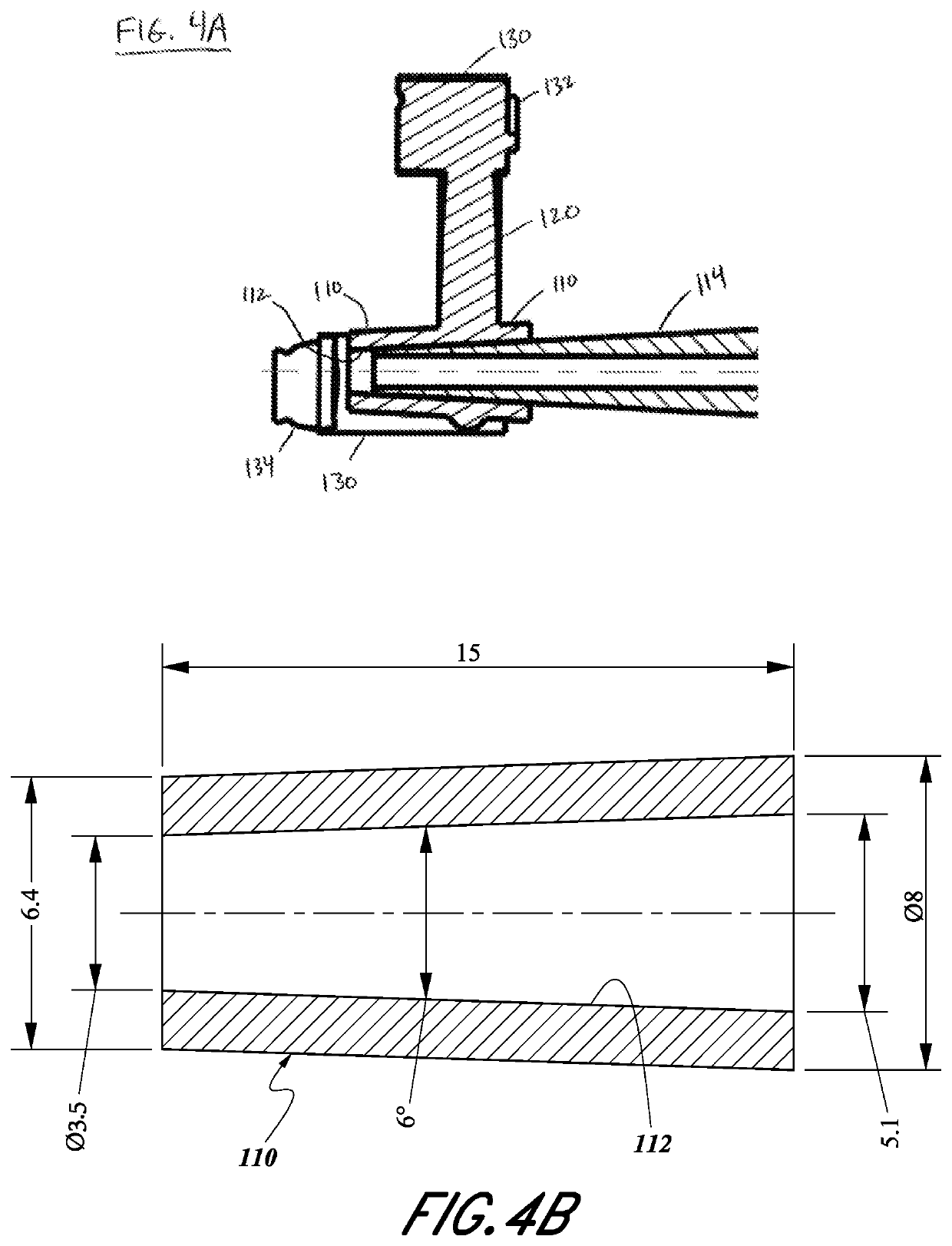

Polycrystalline diamond cutter (PDC) designs which substantially improve the penetration rate of fixed cutter drill bits while simultaneously reducing the wear on the bit during drilling operations are disclosed. The designs are based upon the observation that: 1) the wear pattern of a PDC is roughly a conic section and is parallel to bit rotation, and 2) the cutting surface is perpendicular to the rotation of the bit. The inventive PDC designs provide cutting action both perpendicular and parallel to the direction of bit rotation.

Owner:US SYNTHETIC CORP

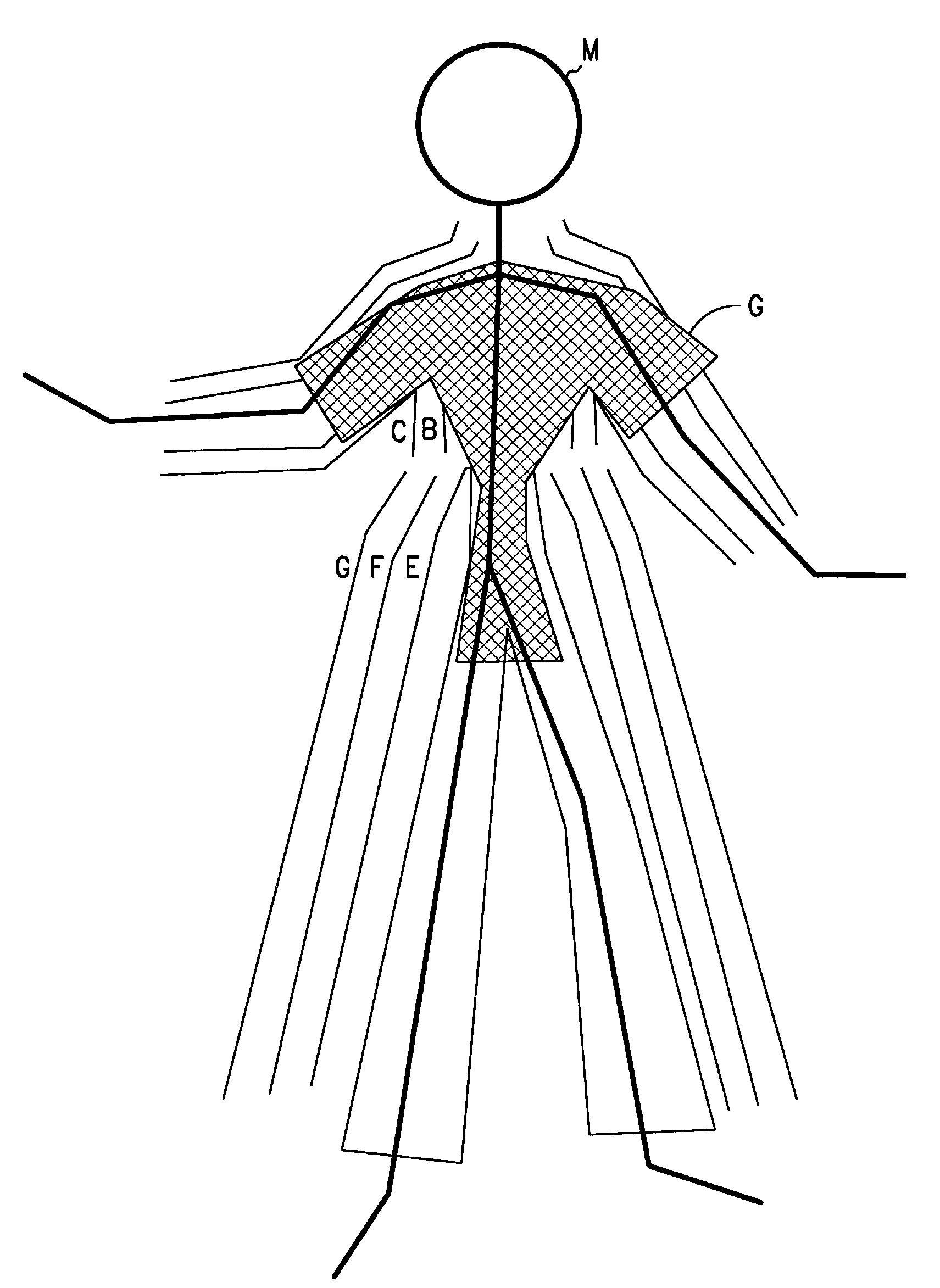

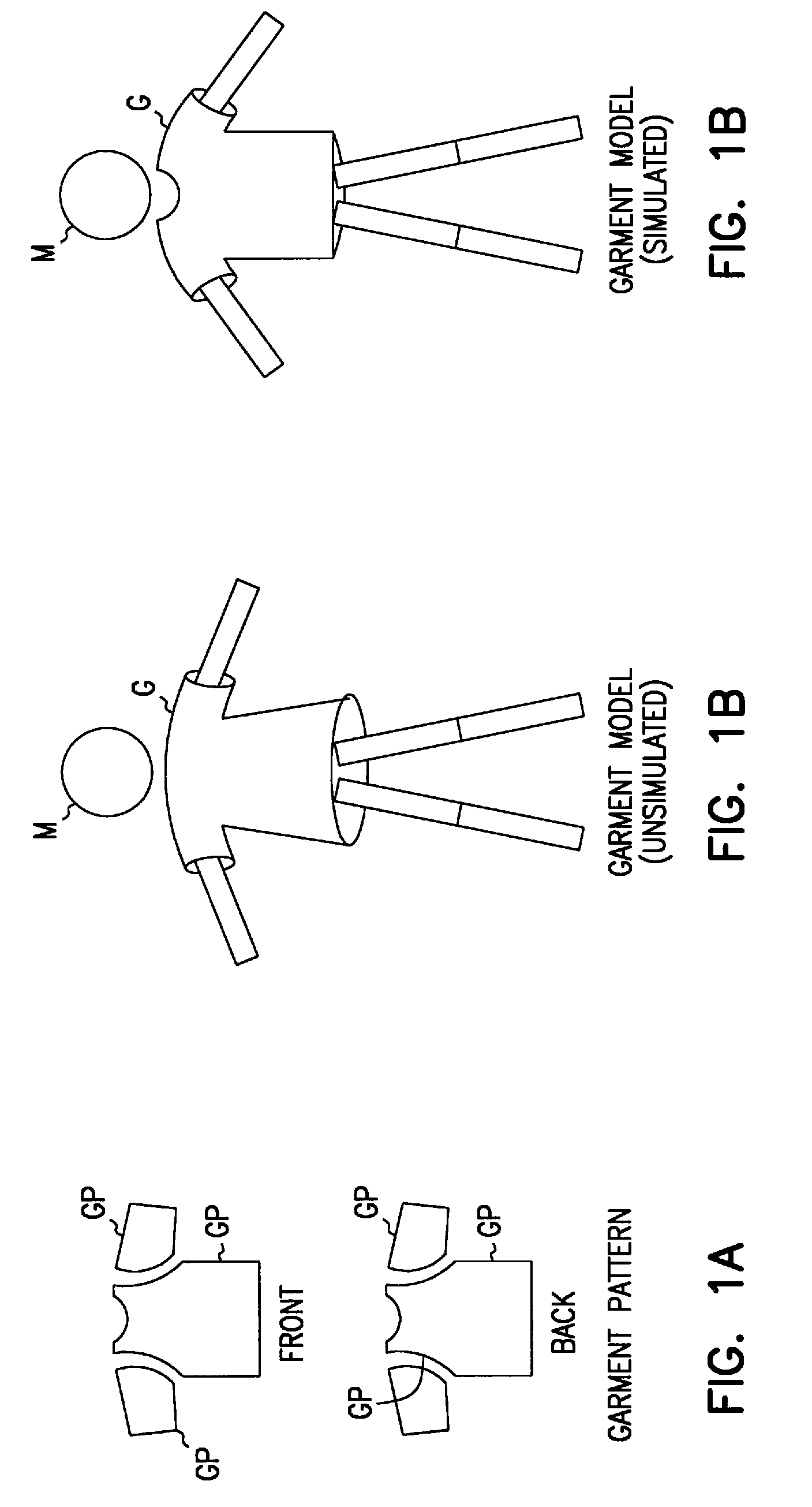

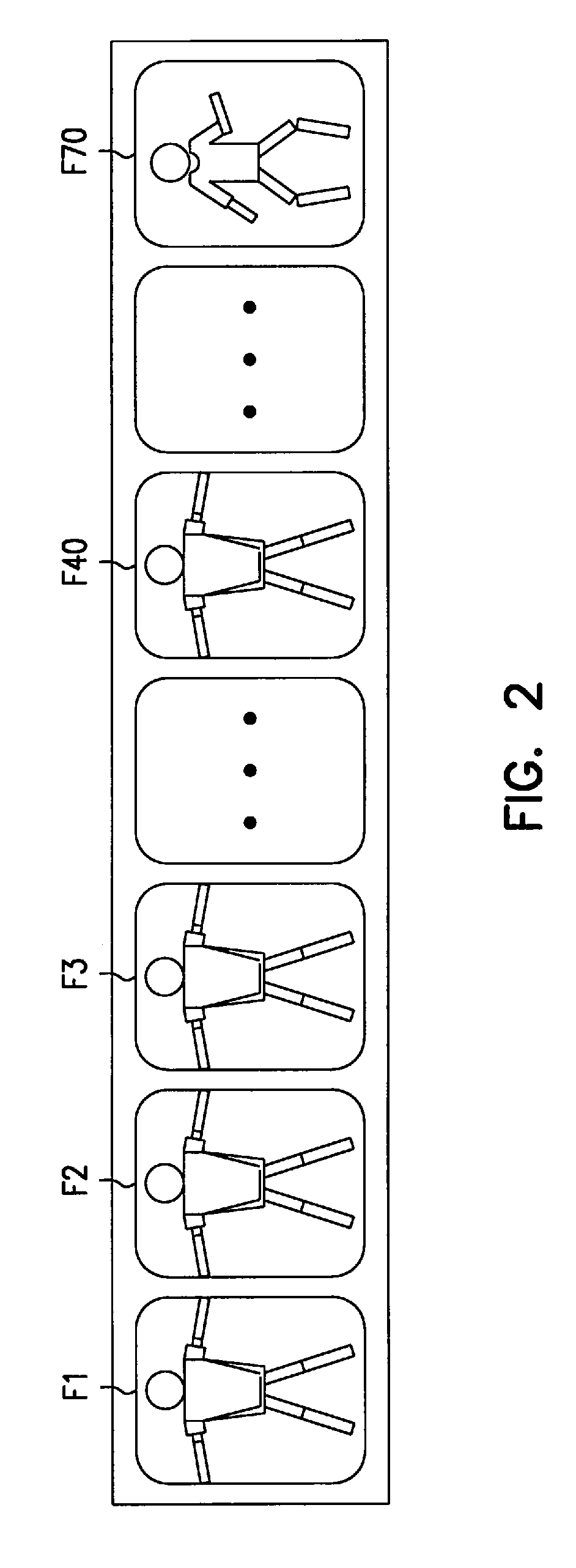

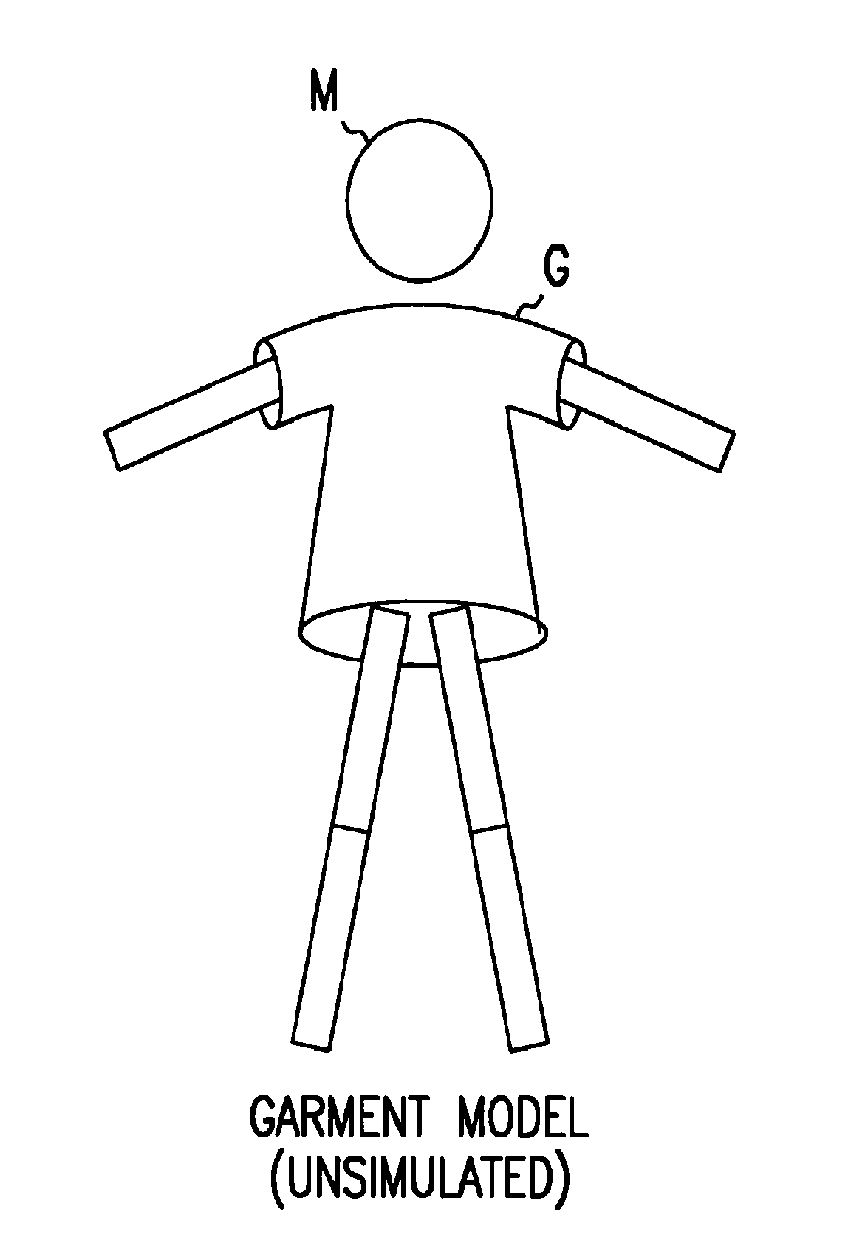

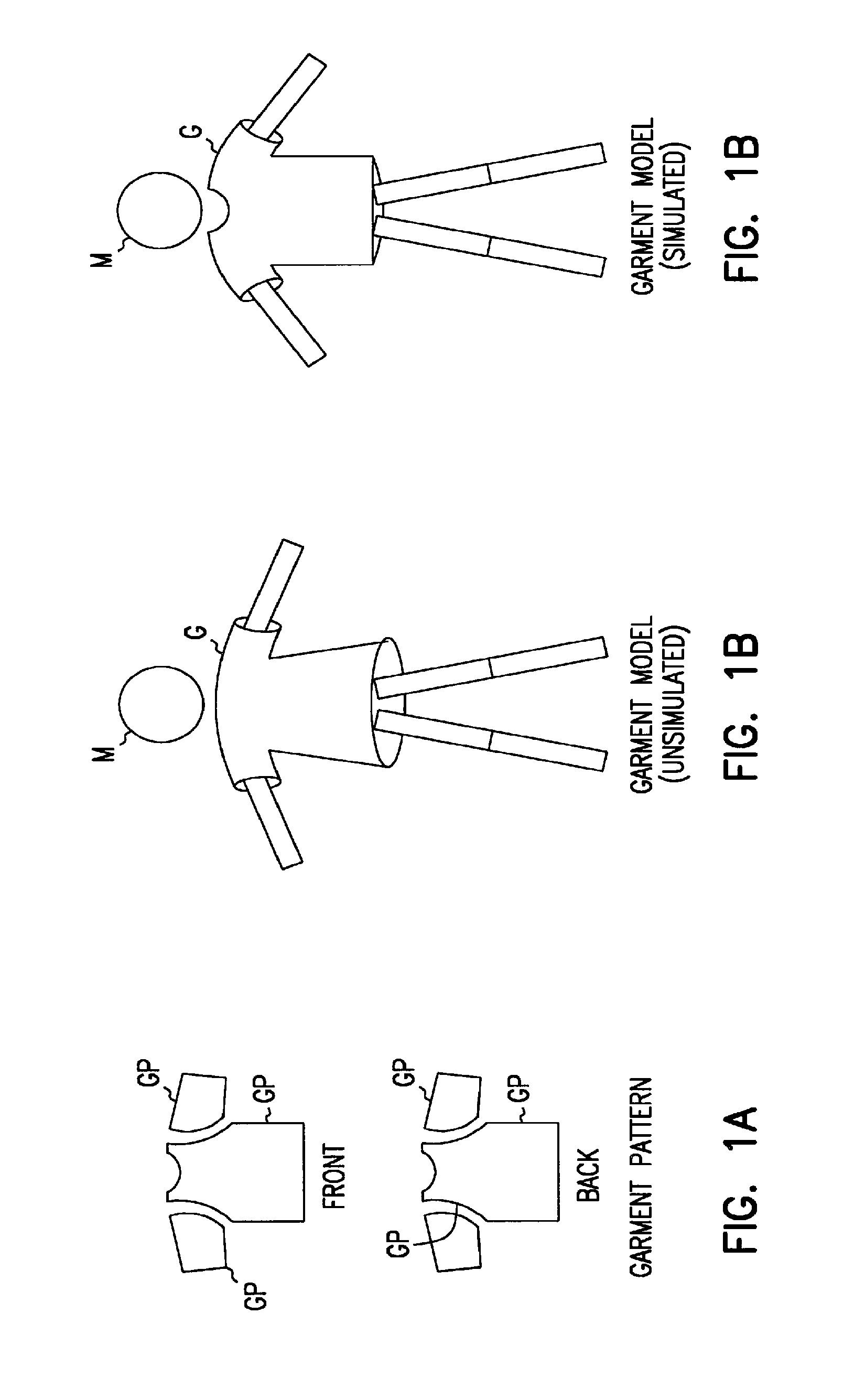

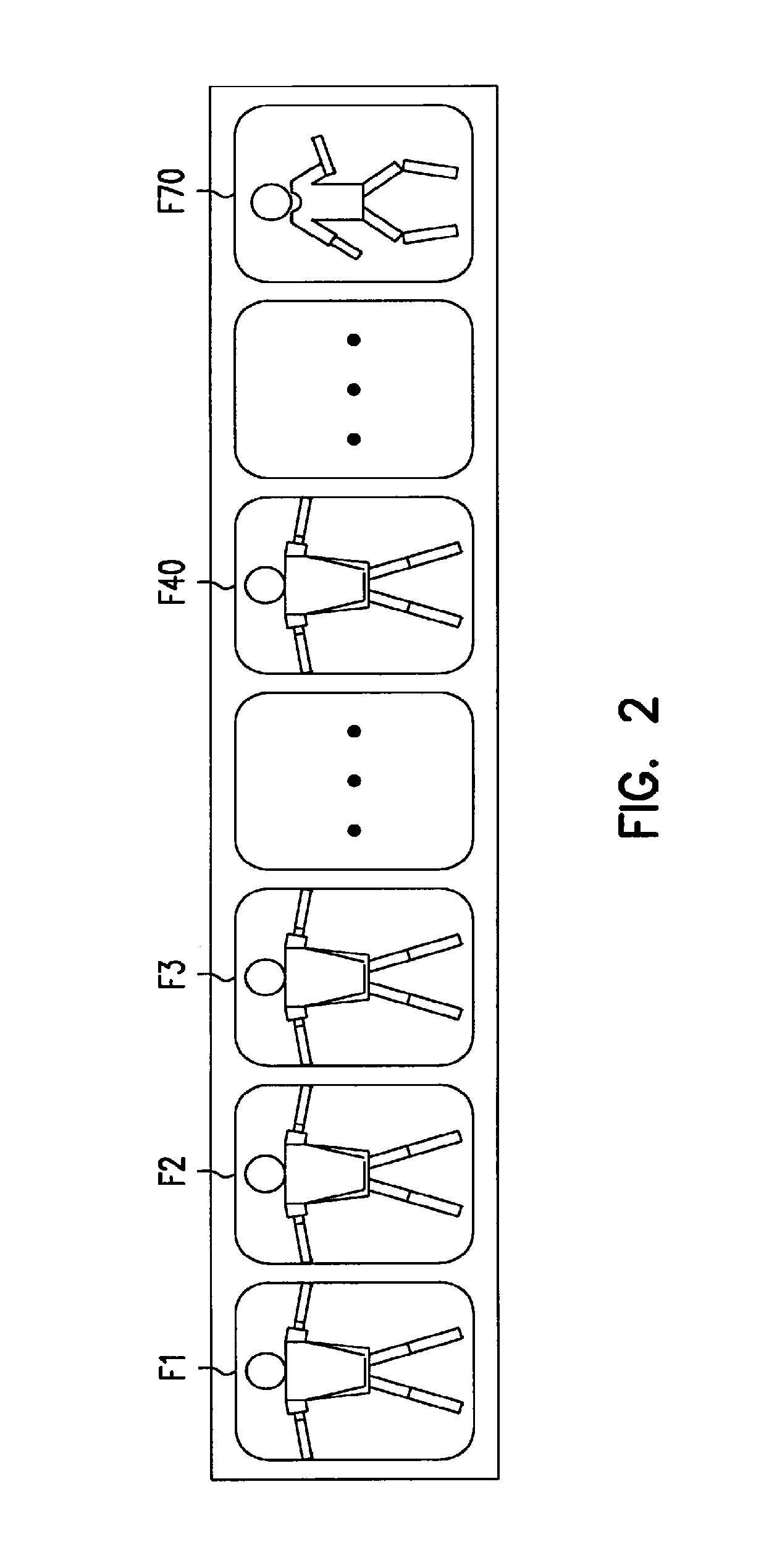

System and method for displaying selected garments on a computer-simulated mannequin

InactiveUS7663648B1Effective imagingImprove matchDigital computer detailsCathode-ray tube indicatorsWear patternEngineering

A method and system for providing a computer-simulated environment for displaying a selected mannequin wearing a combination of selected garments. In one aspect, three-dimensional scenes containing mannequin and garment objects are created within a three-dimensional modeling environment, and a simulation is performed using a cloth simulator within the modeling environment to model the construction, draping, and collision of the garment with the mannequin. Rendering frames corresponding to a variety of garments, mannequins, garment dimensions, garment styles, wearing patterns, viewing angles, and other parameters, are then generated from which images can be rendered and displayed in accordance with user requests.

Owner:MY VIRTUAL MODEL

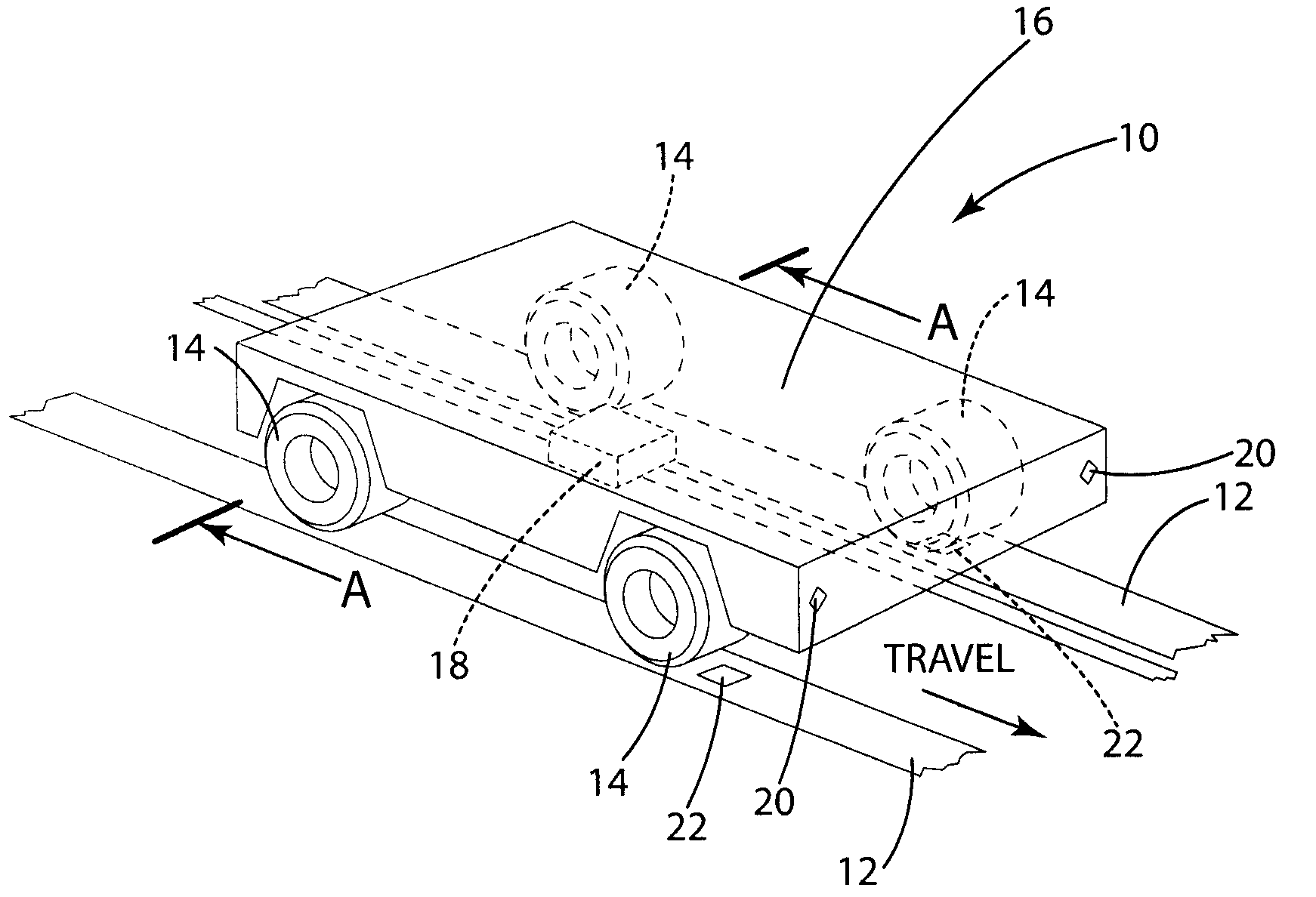

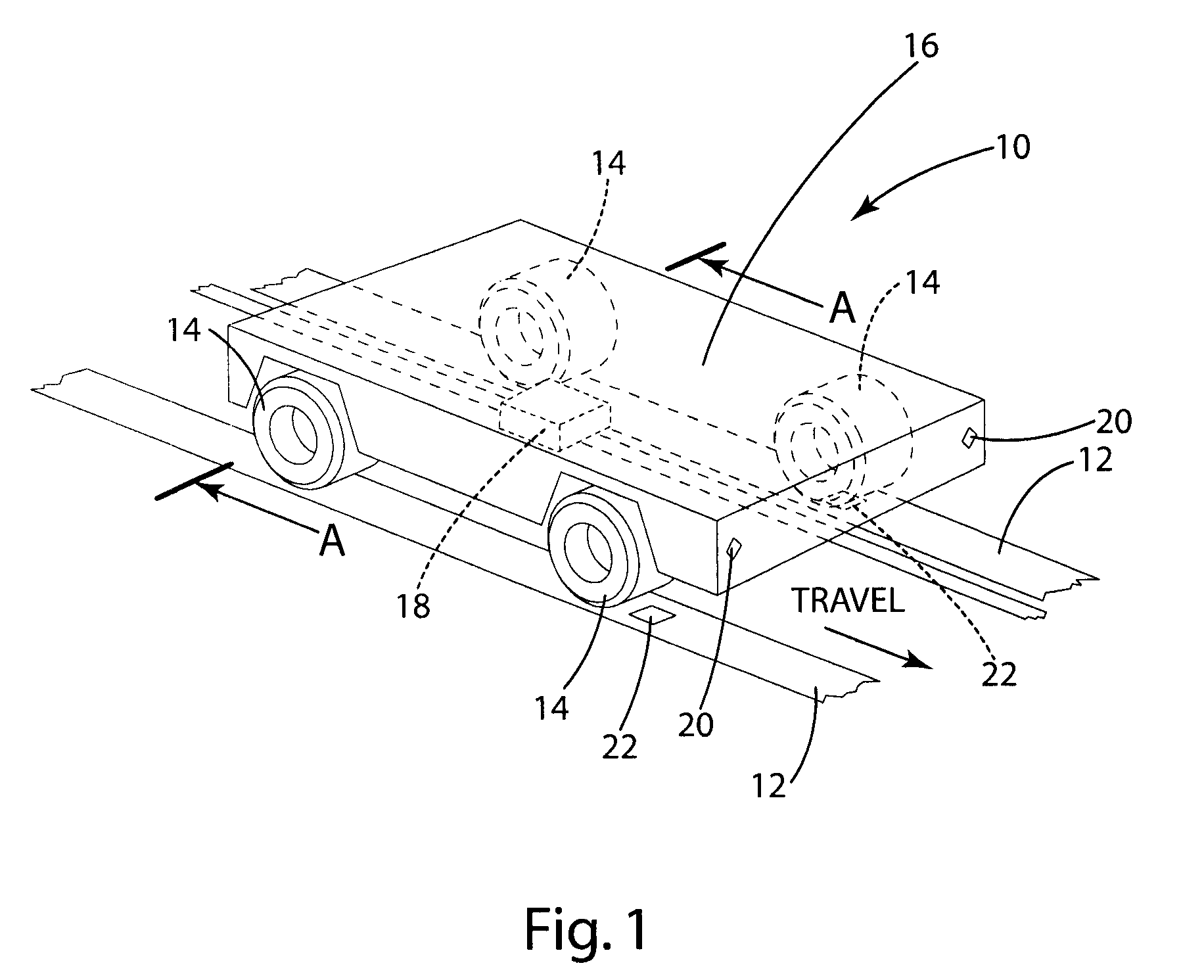

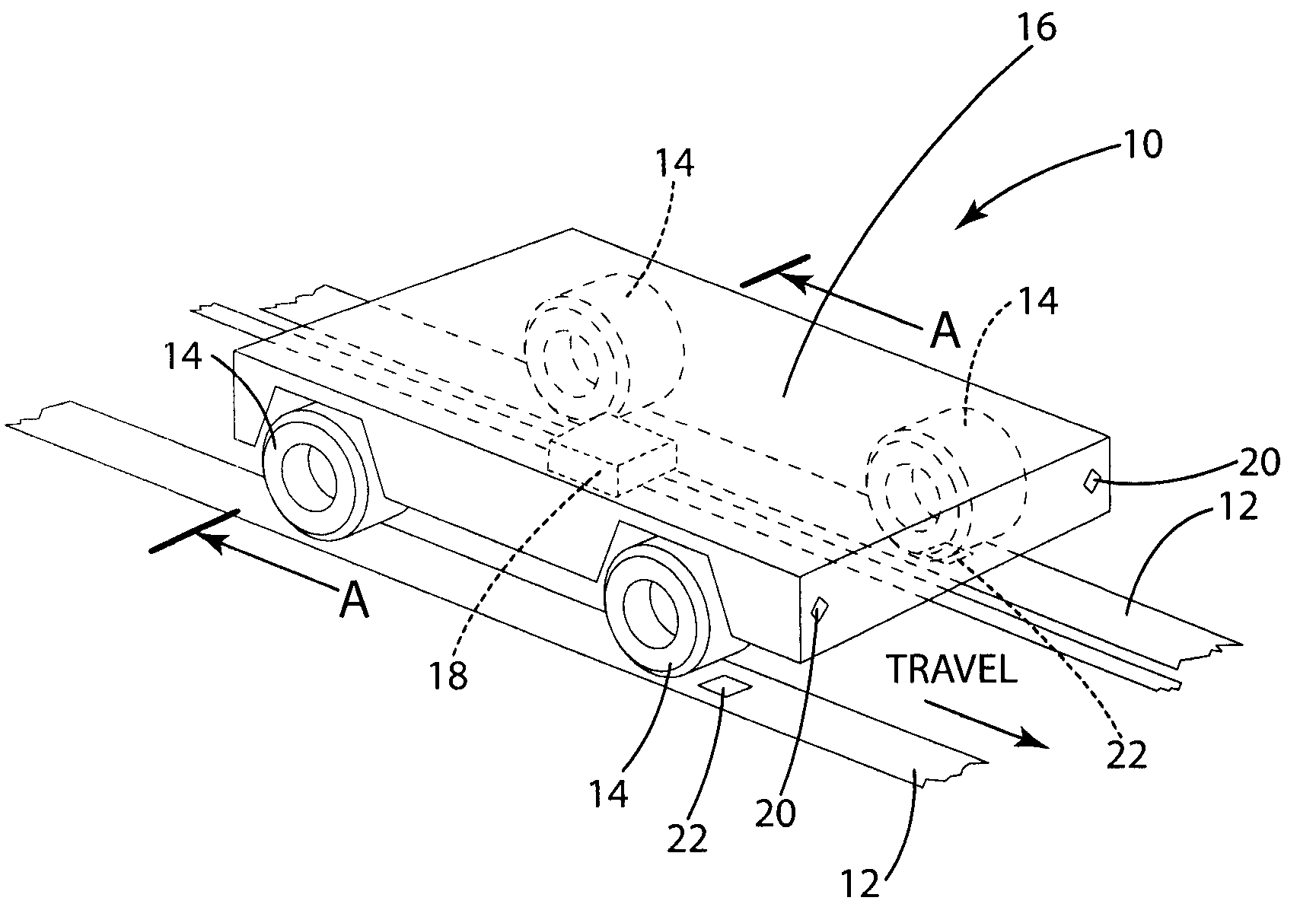

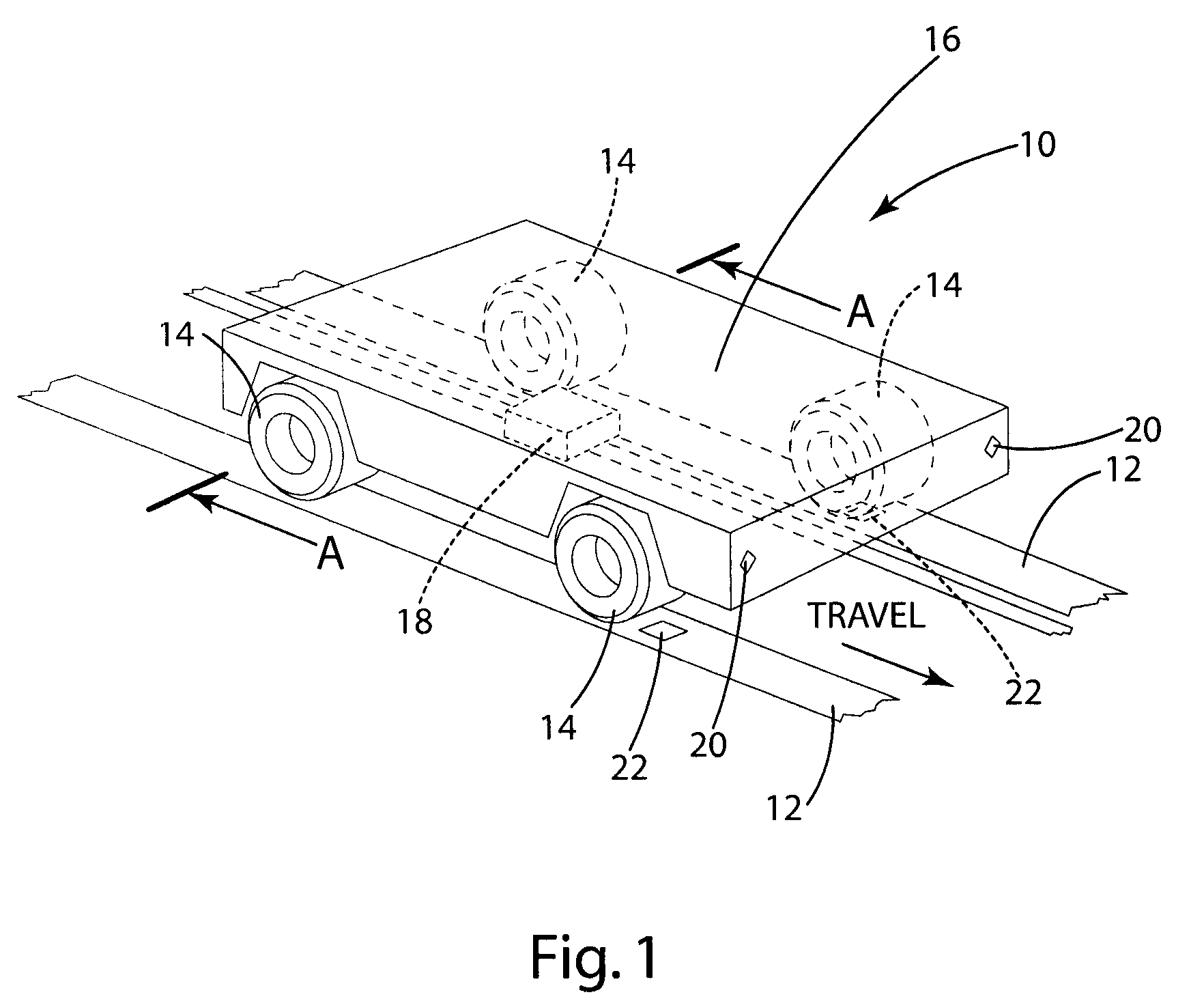

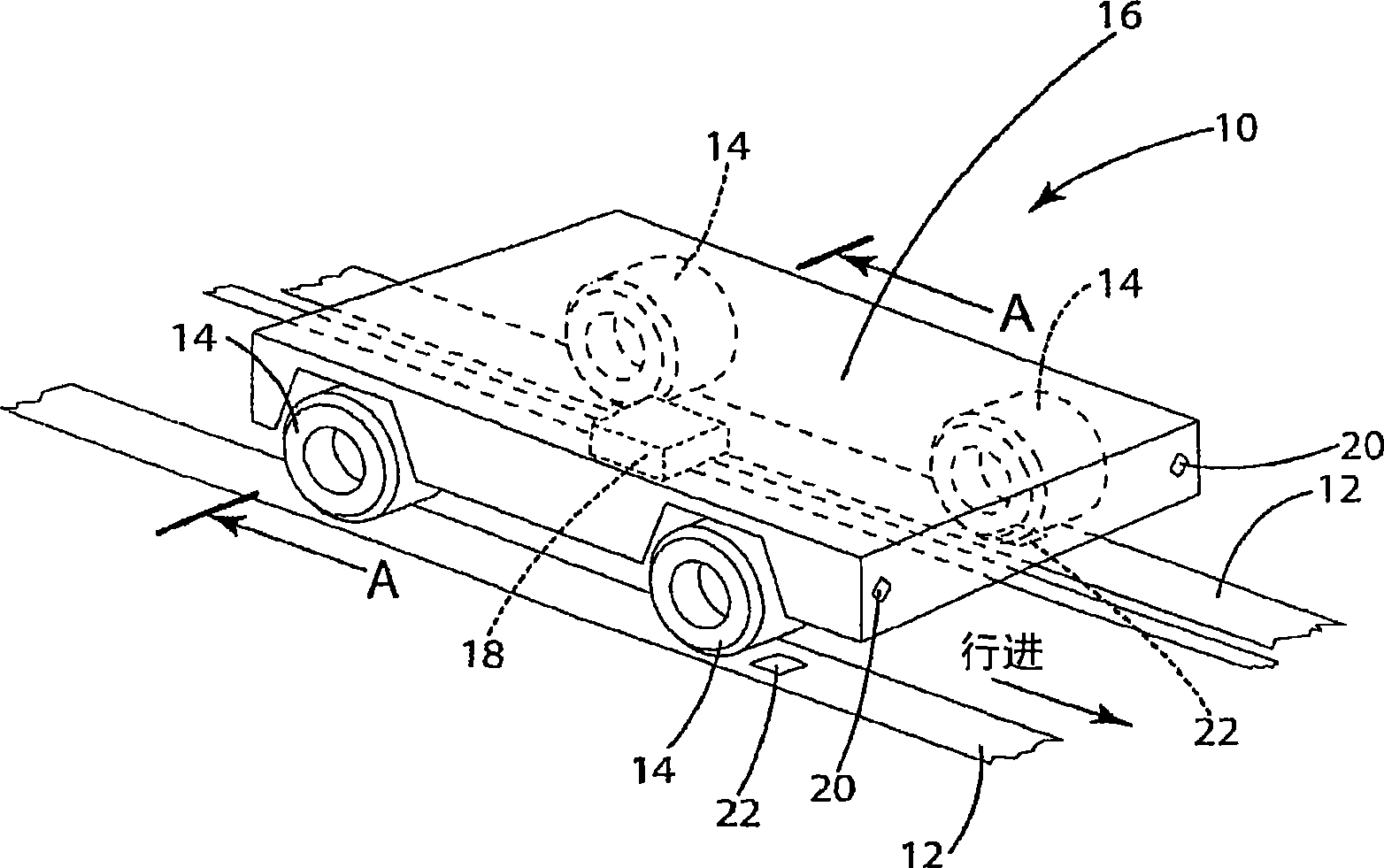

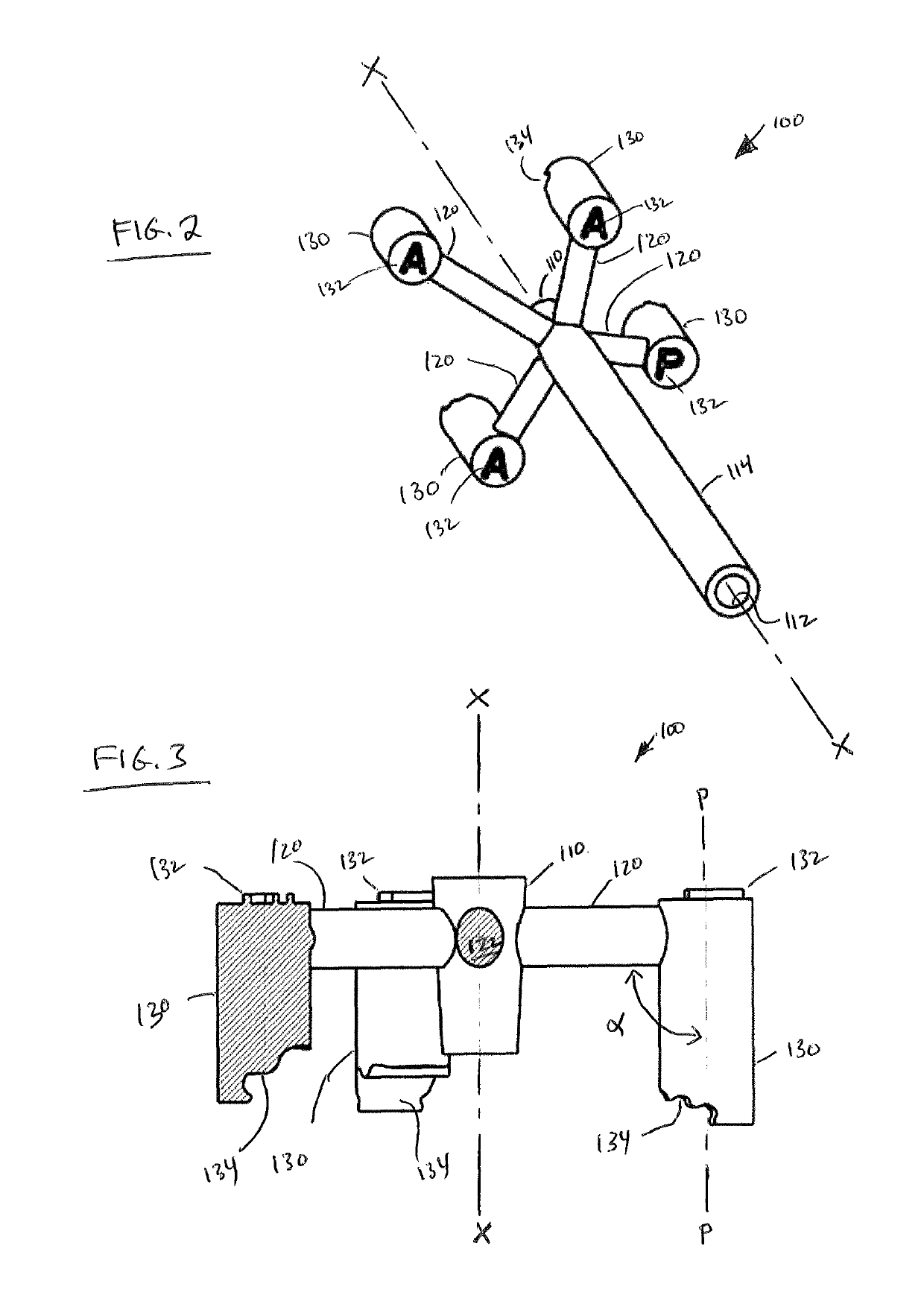

Variable path automated guided vehicle

InactiveUS20070179690A1Efficient transportWear minimizationNavigation instrumentsVehicle position/course/altitude controlWear patternAutomated guided vehicle

An automated guided vehicle and a method of controlling an automated guided vehicle which are capable of varying the travel path of the automatic guided vehicle in order to reduce wear patterns created in the floor of the material handling facility. The travel path of the AGV is varied by intentionally applying a deviation from a selected predetermined route along which the AGV is traveling.

Owner:JERVIS B WEBB INT CO

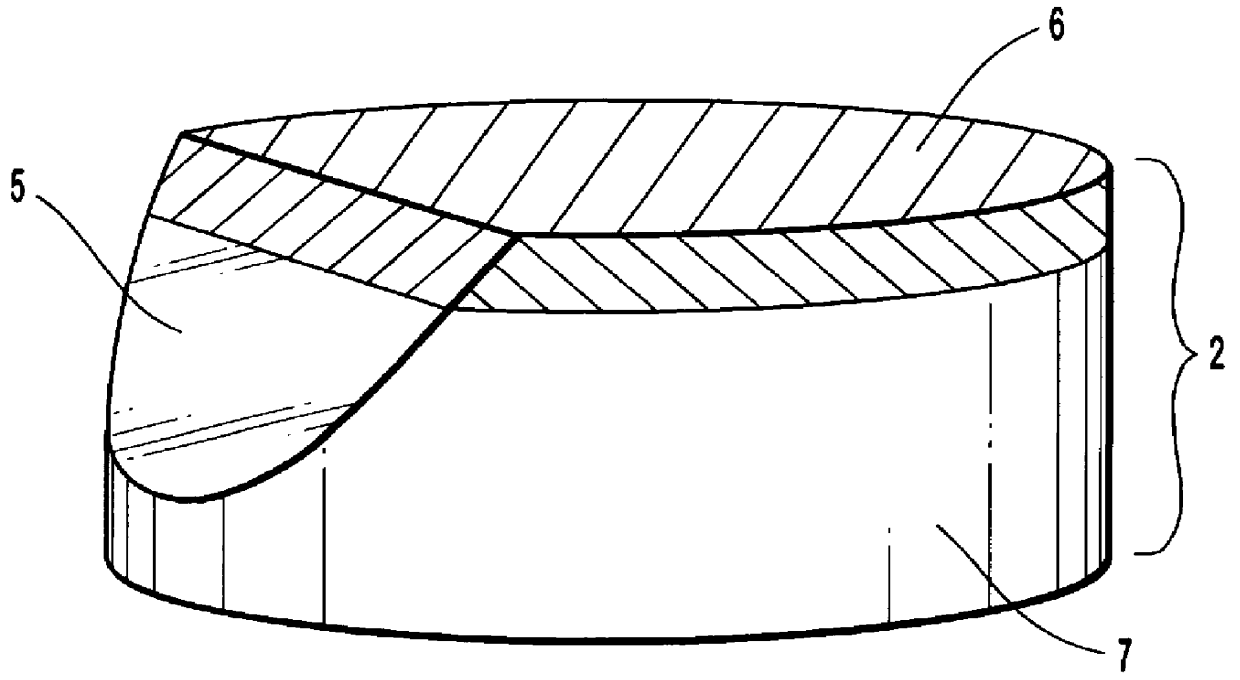

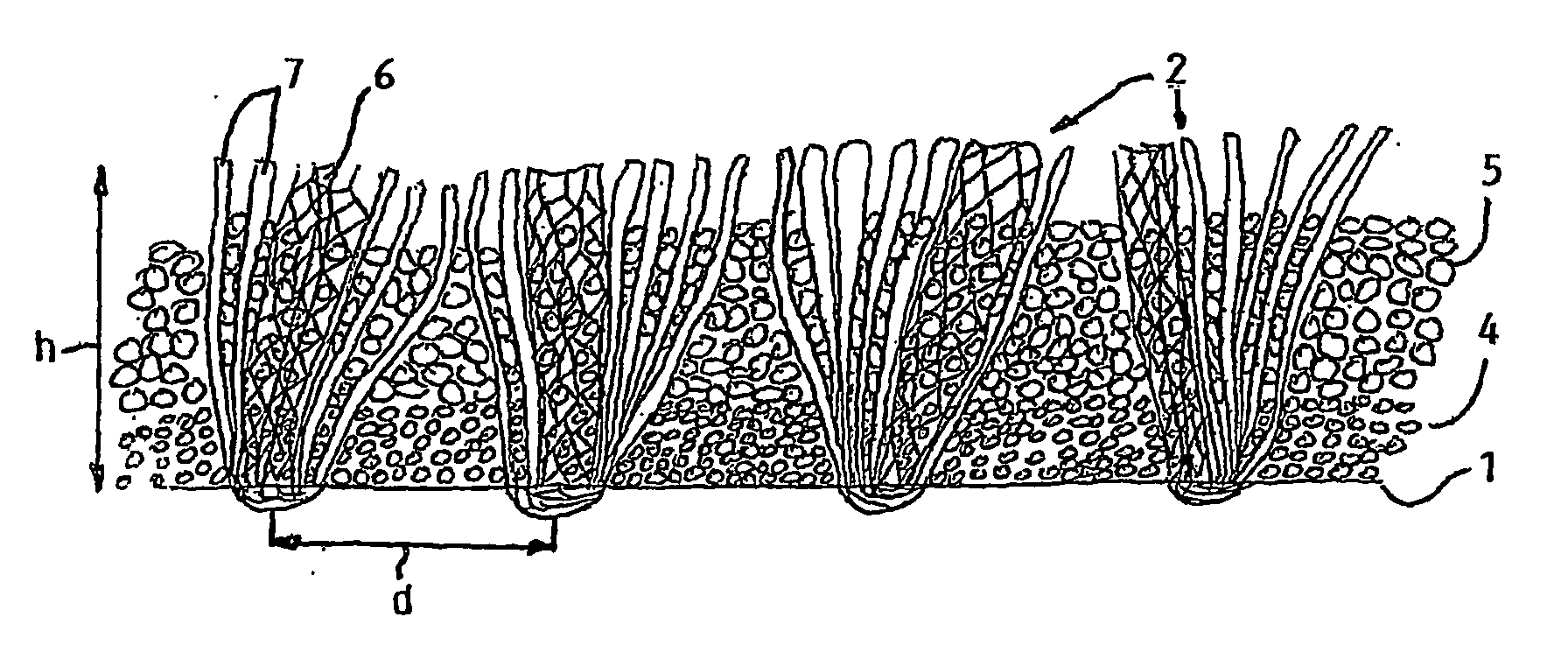

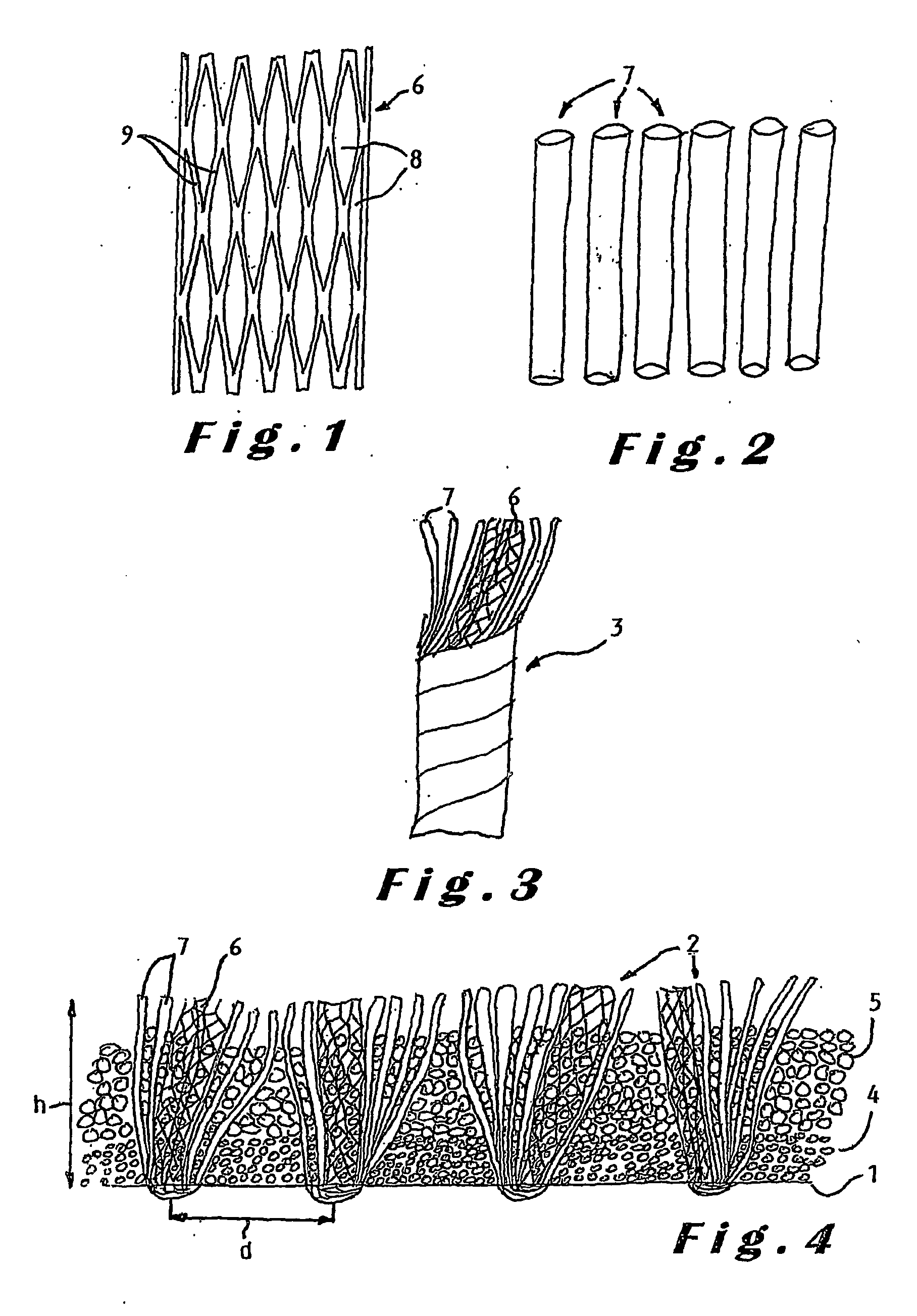

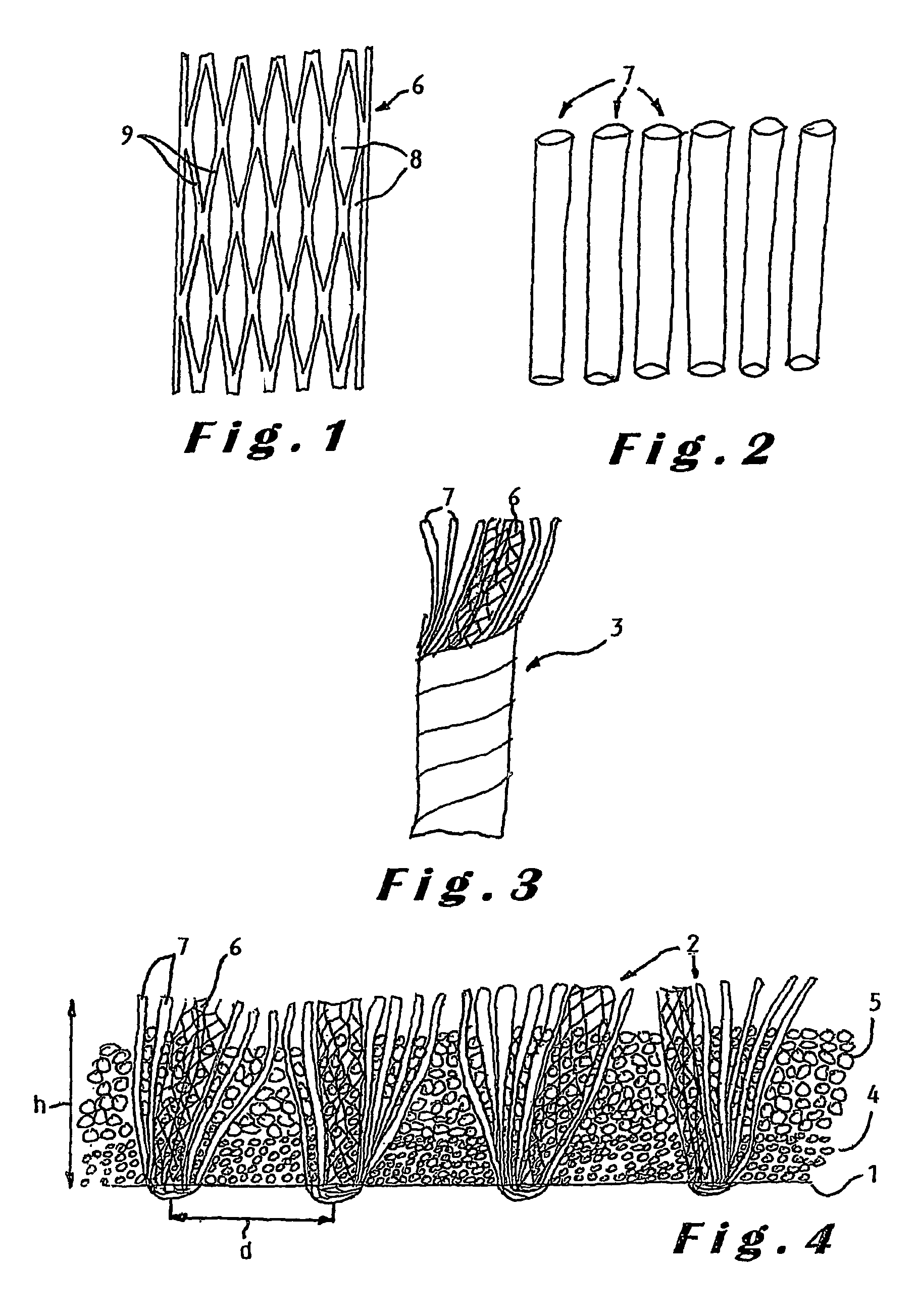

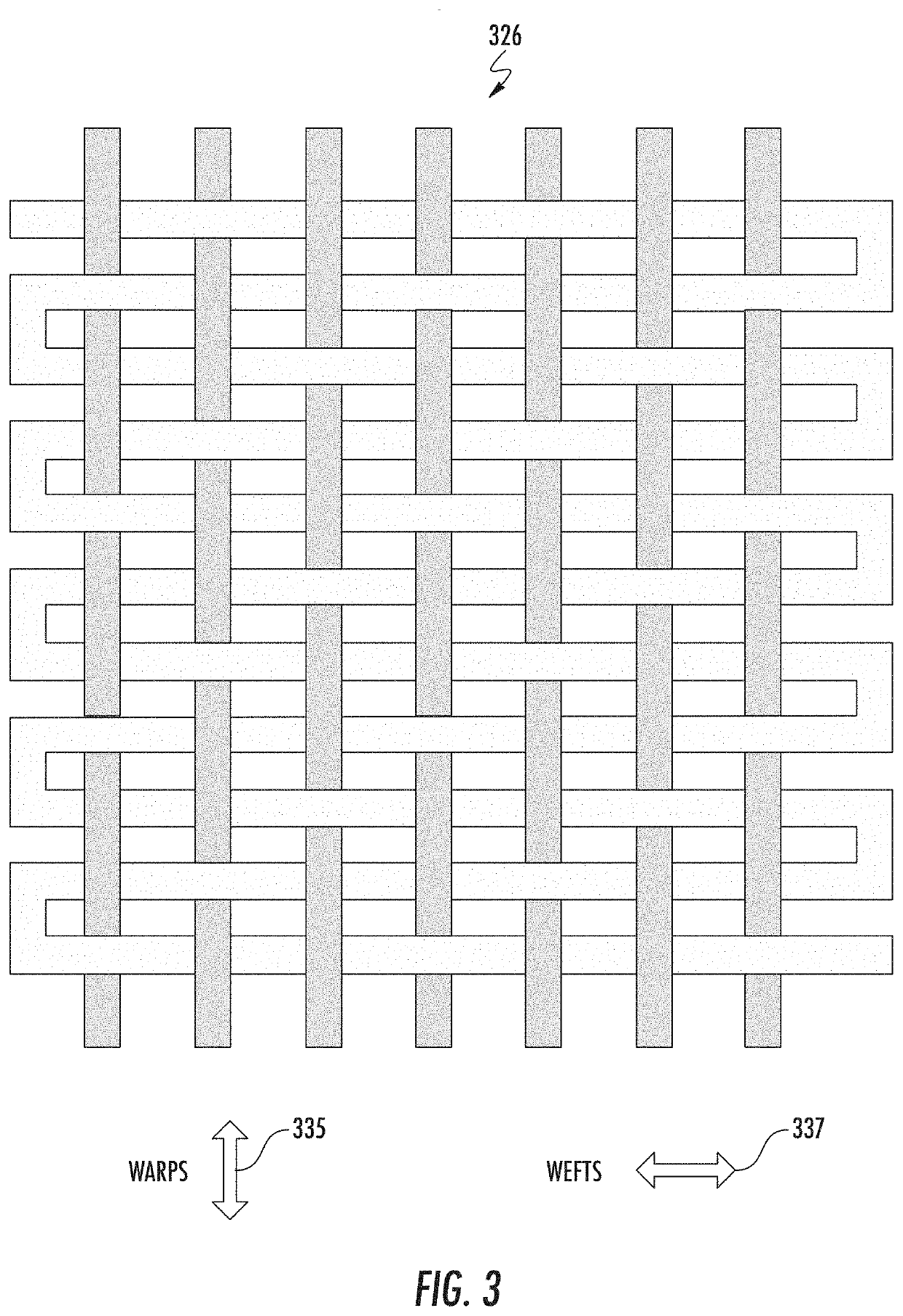

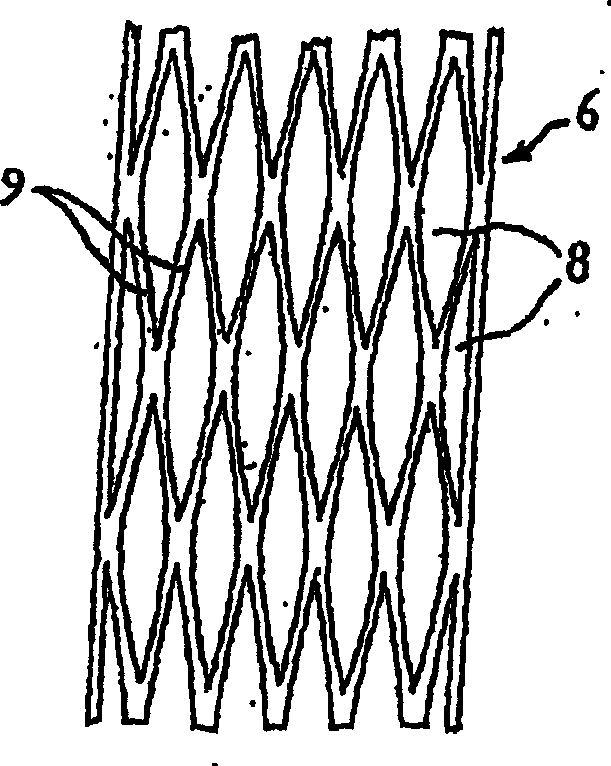

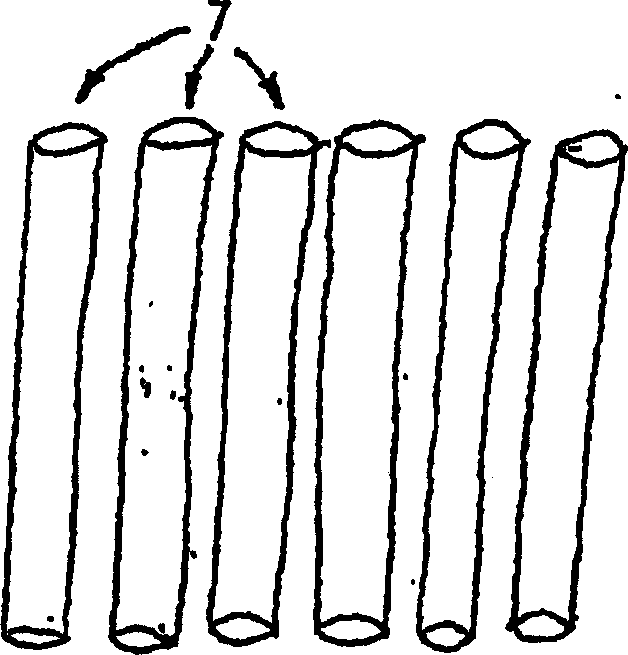

Synthetic turf

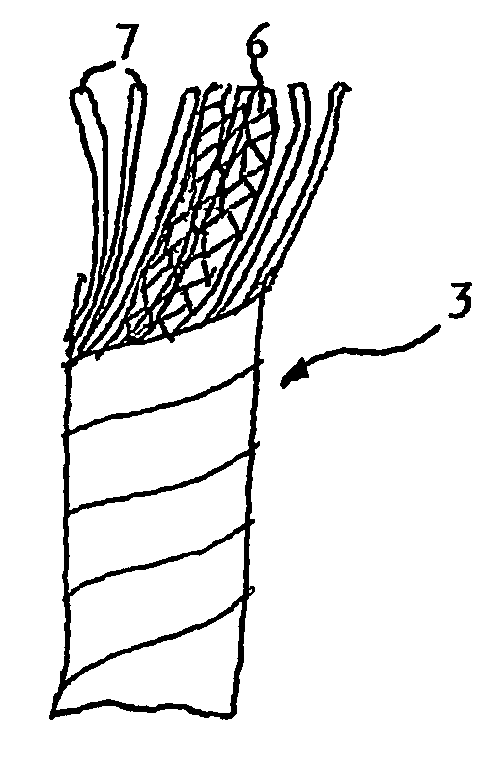

InactiveUS20060093783A1Increase elasticityEasy to recycleDead plant preservationArtificial flowers and garlandsInfillWear pattern

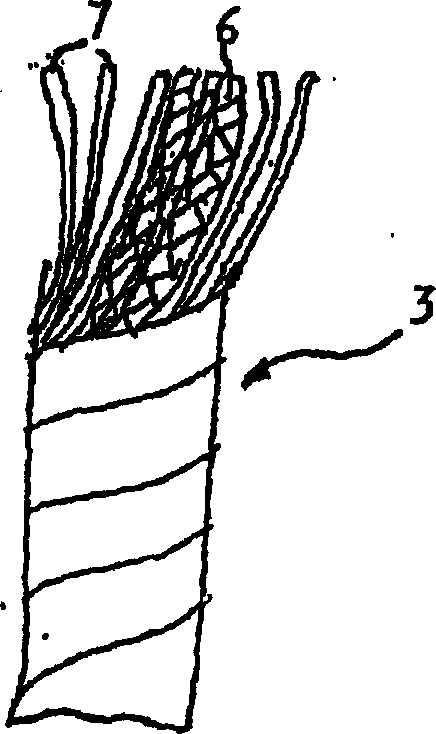

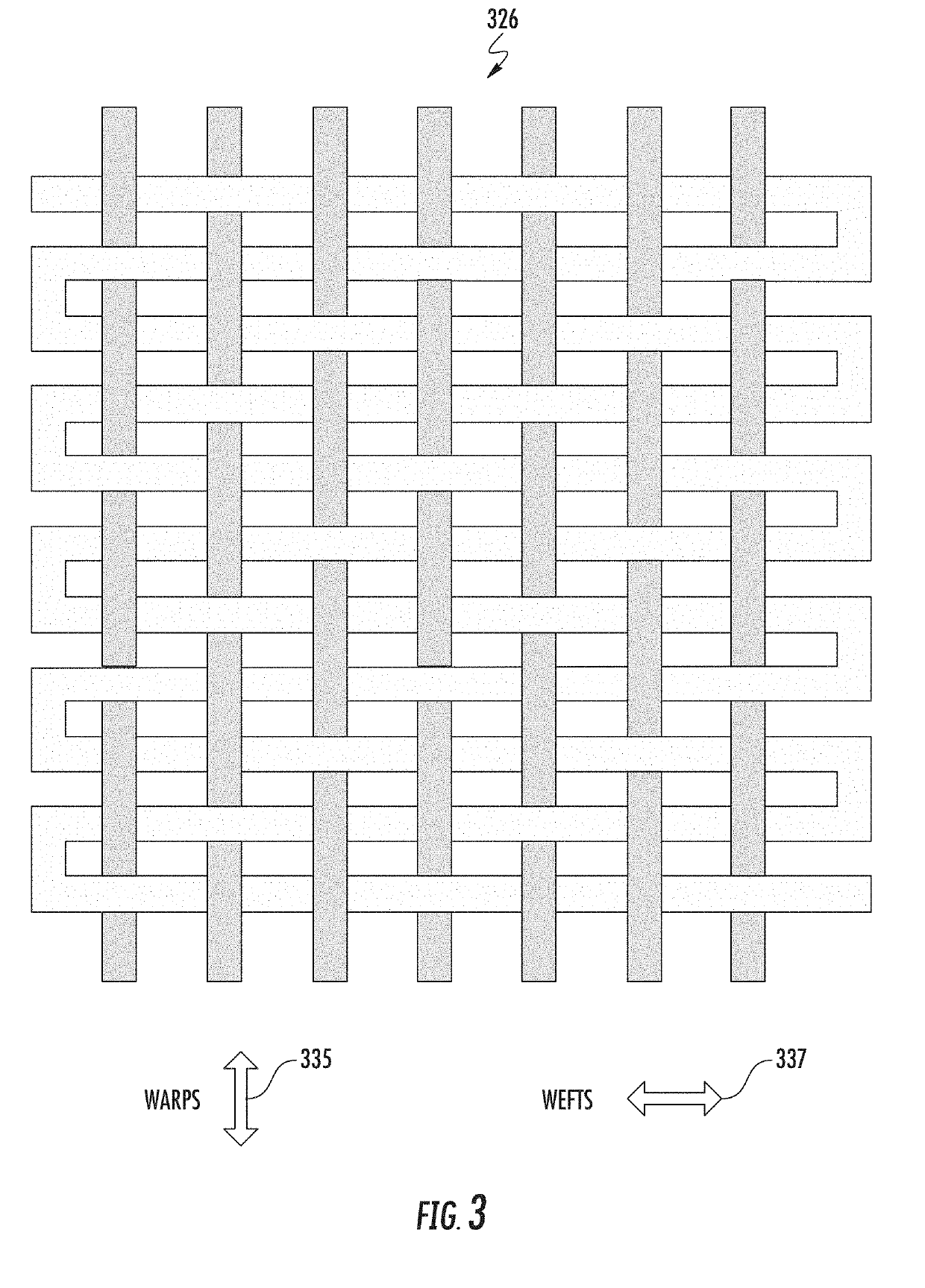

The present invention provides new types of synthetic turf. The synthetic turf includes a pile fabric having a backing (1) and tufts (2) projecting therefrom. In one embodiment, at least a number of the tufts are made of a composite yarn formed by at least one fibrillated yarn (6) together with a number of individual filament yarns (7), in particular with so-called monofilament or monotape yarns. The fibrillated yarn and the individual filament yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. In another embodiment, at least a number of the tufts are made of a composite yarn formed by monotape yarns twisted together with a number of the monofilament yarns. The monofilament and monotape yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. The combination of a fibrillated yarn and individual filament yarns or the combination of monofilament and monotape yarns in a composite yarn allows immediate achievement of the look of natural grass, that is, without post-fibrillation, and avoids any visible difference in wear pattern between the different types of yarns. In another embodiment, the invention also provides improved particulate material for use as infill material for top-dressing a synthetic turf.

Owner:DOMO ZELE

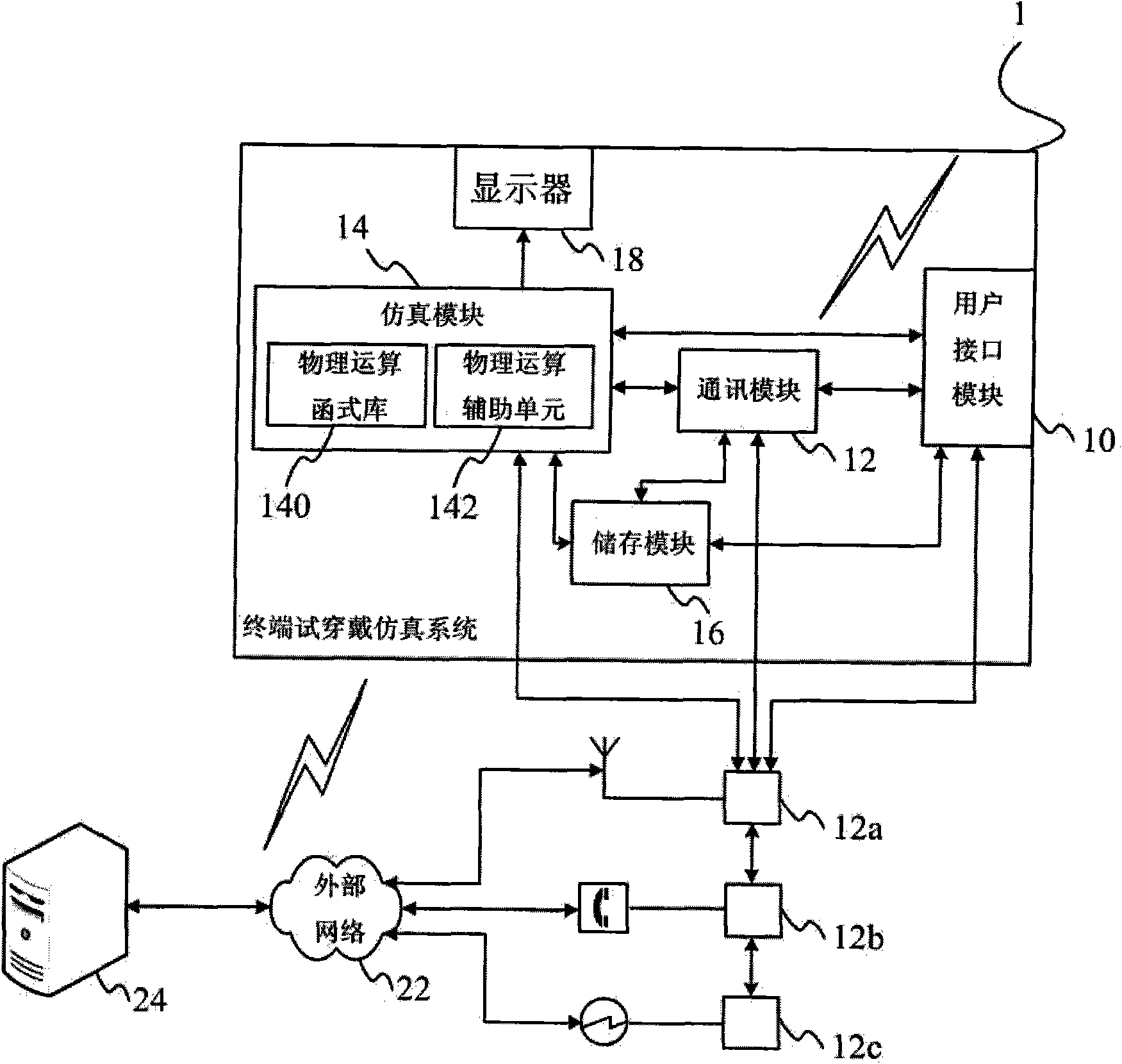

Terminal try-on simulation system and method for generating try-on image

The invention provides a terminal try-on simulation system and a method for generating a try-on image, which are used for respectively generating a 3D body model and a 3D commodity model based on body established model information and commodity established model information. The commodity established model information is relevant to a wearable object. The 3D body model and the 3D commodity model are integrated into a stereoscopic image of a 3D try-on model, and the stereoscopic image is displayed on a display. The user judges whether the wearable object fits a body or not and estimates an actual wearing pattern according to the stereoscopic image displayed on the display, and different stereoscopic image effects are formed by the combination of different 3D commodity models.

Owner:杨政宪

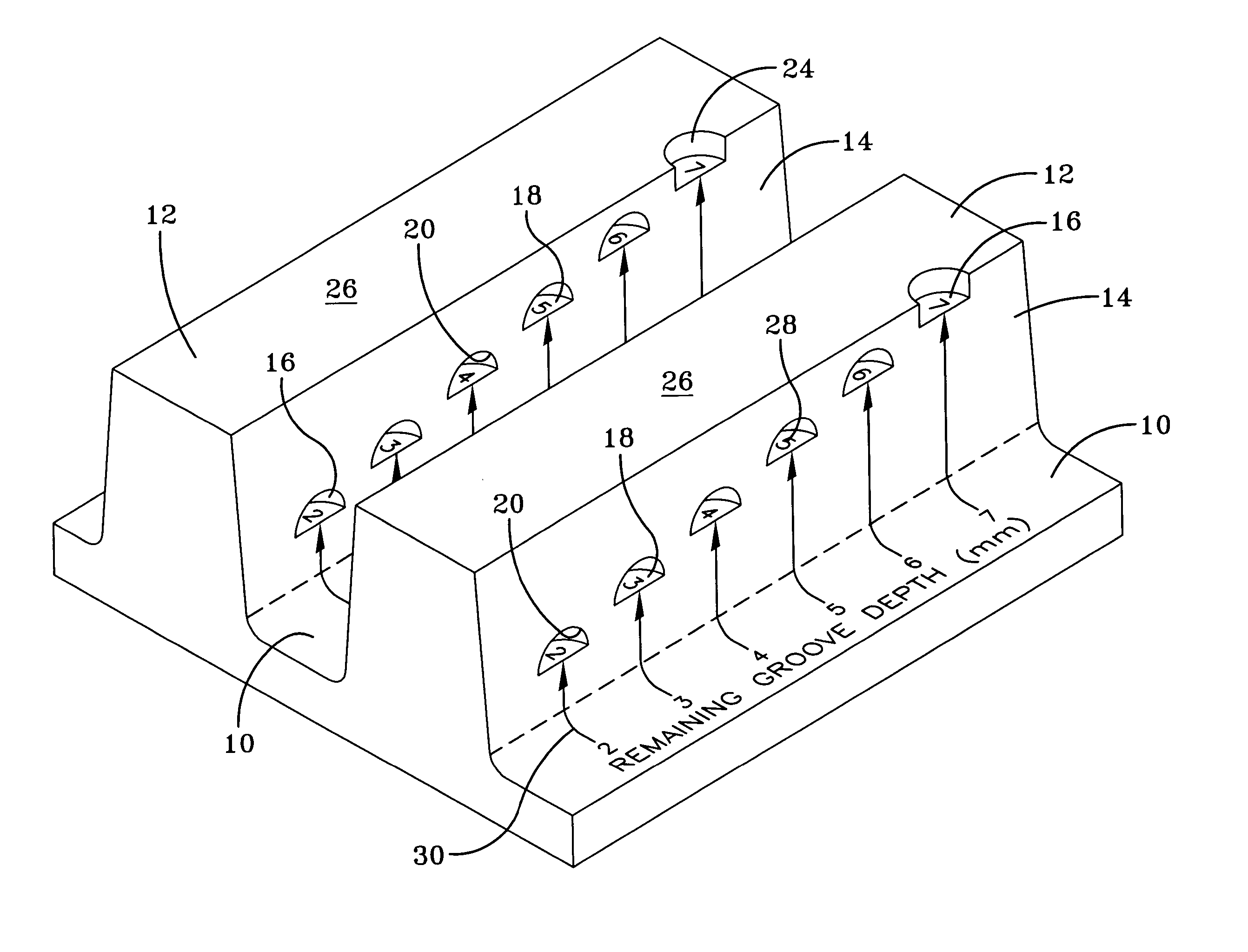

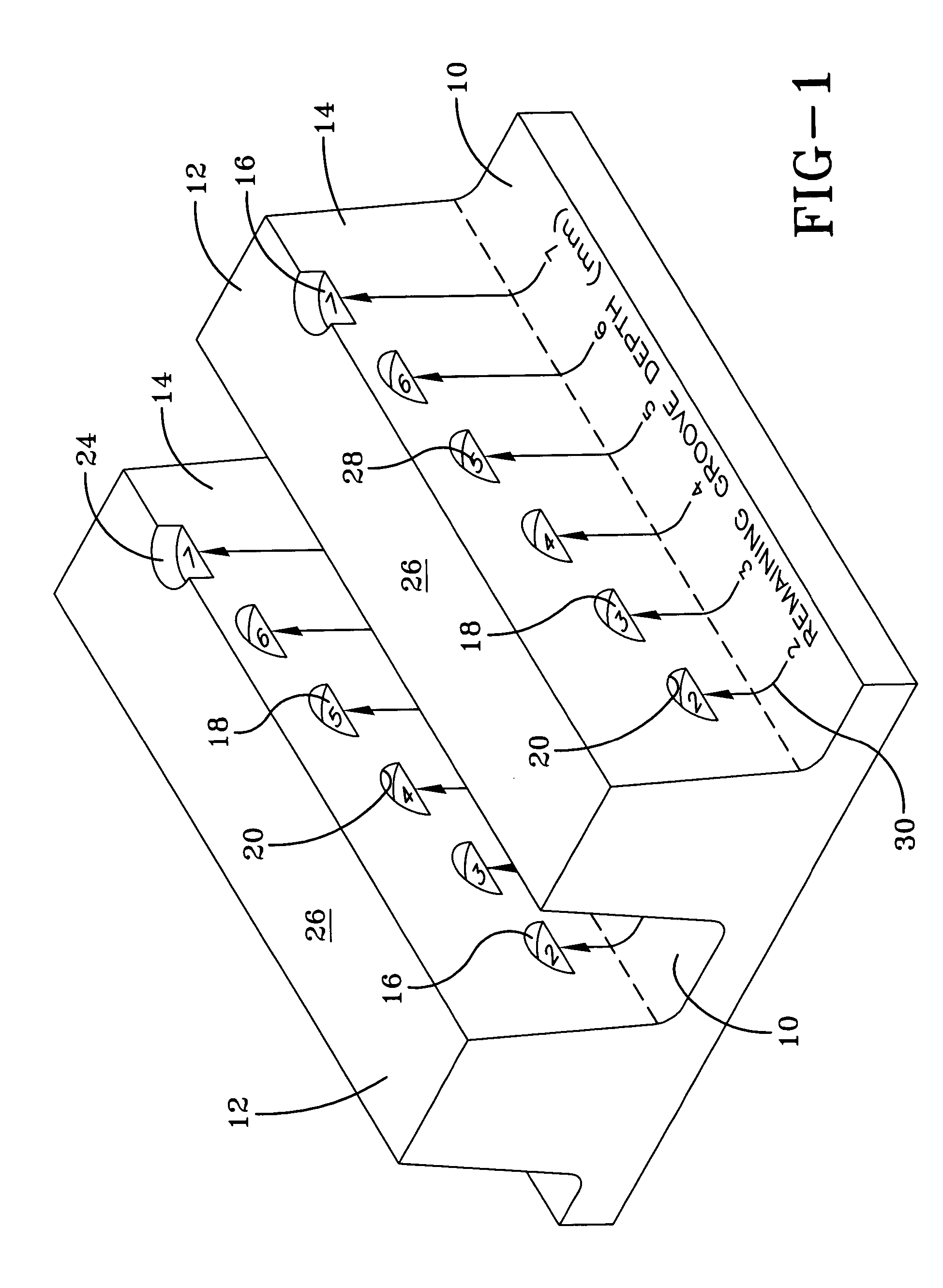

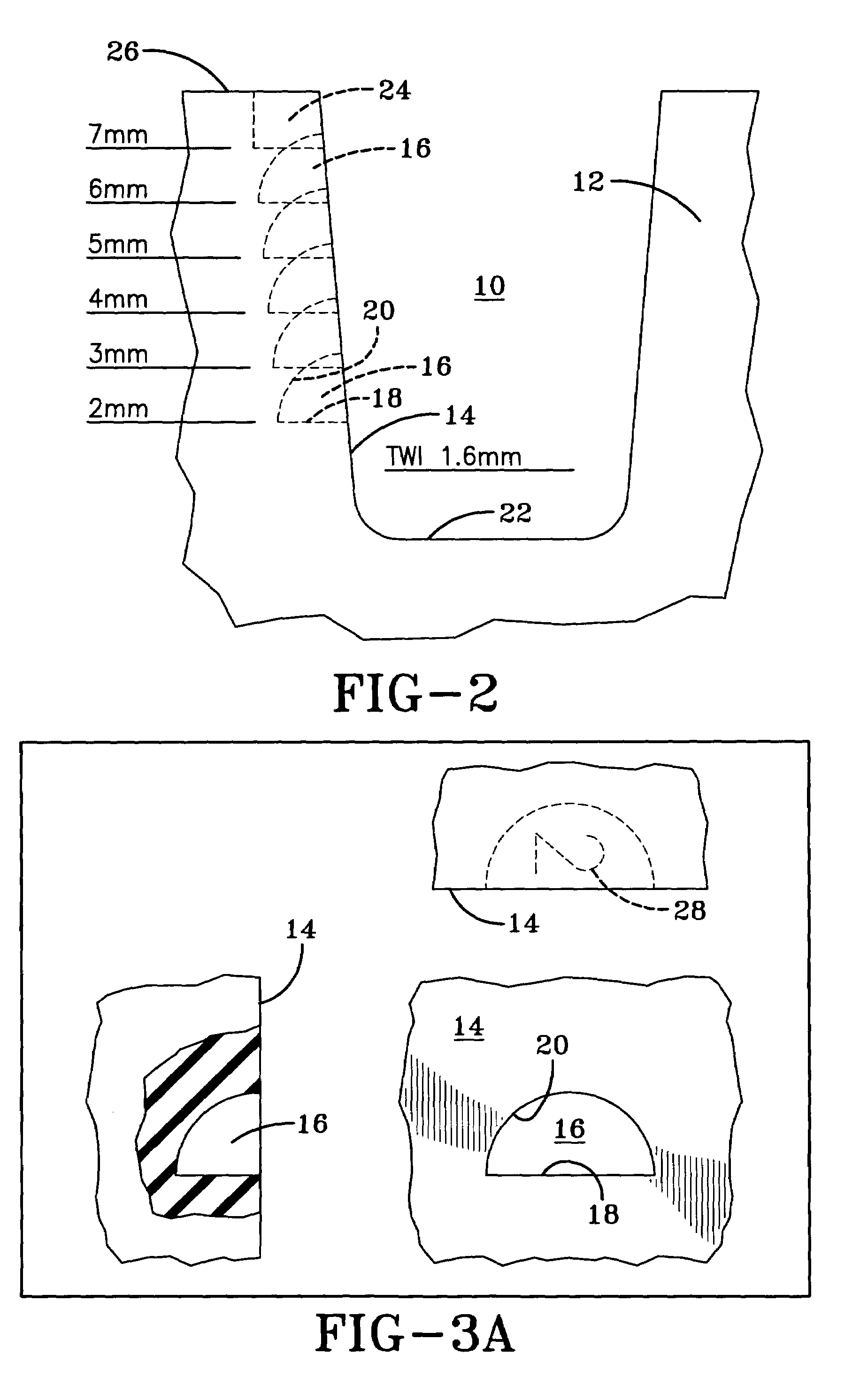

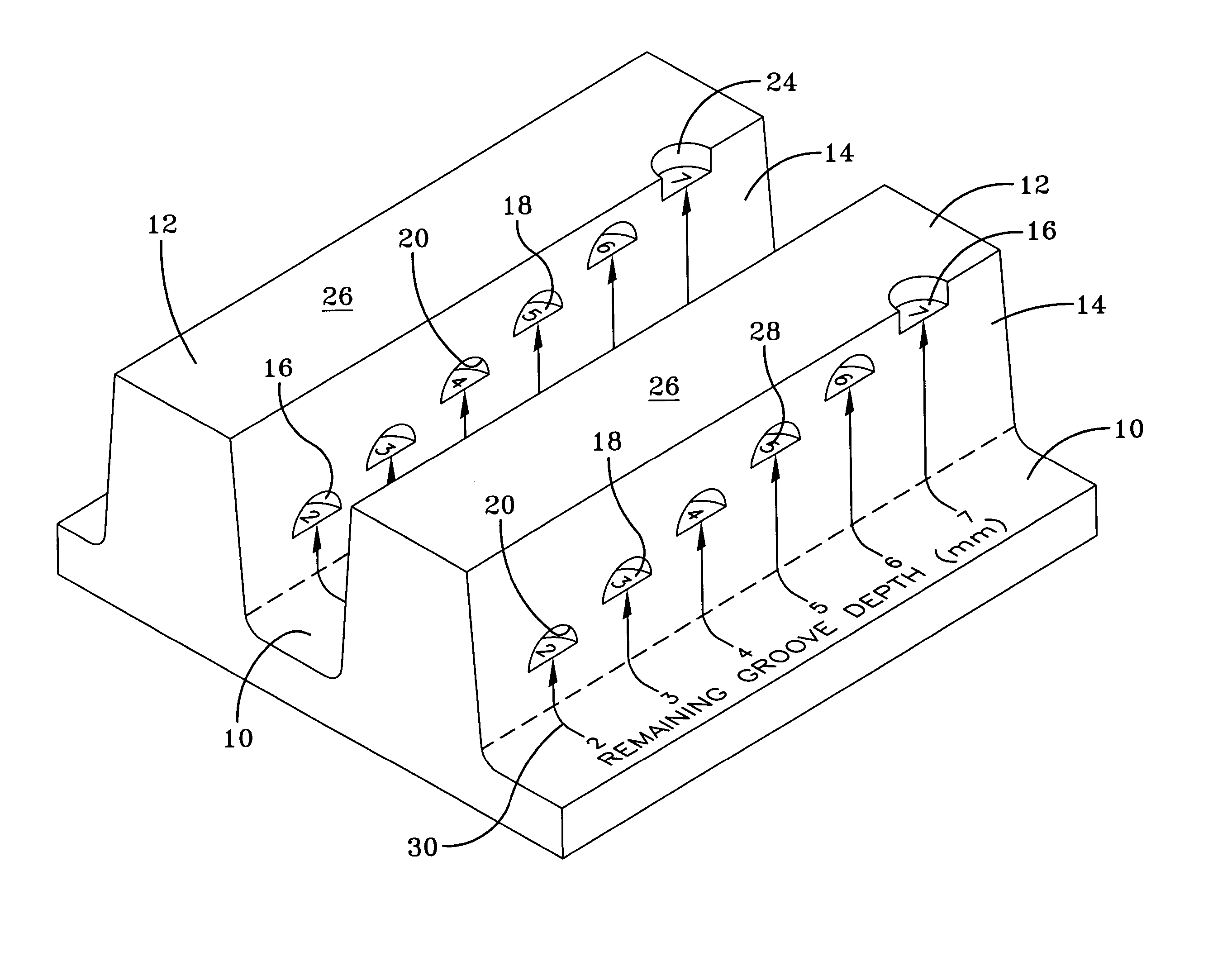

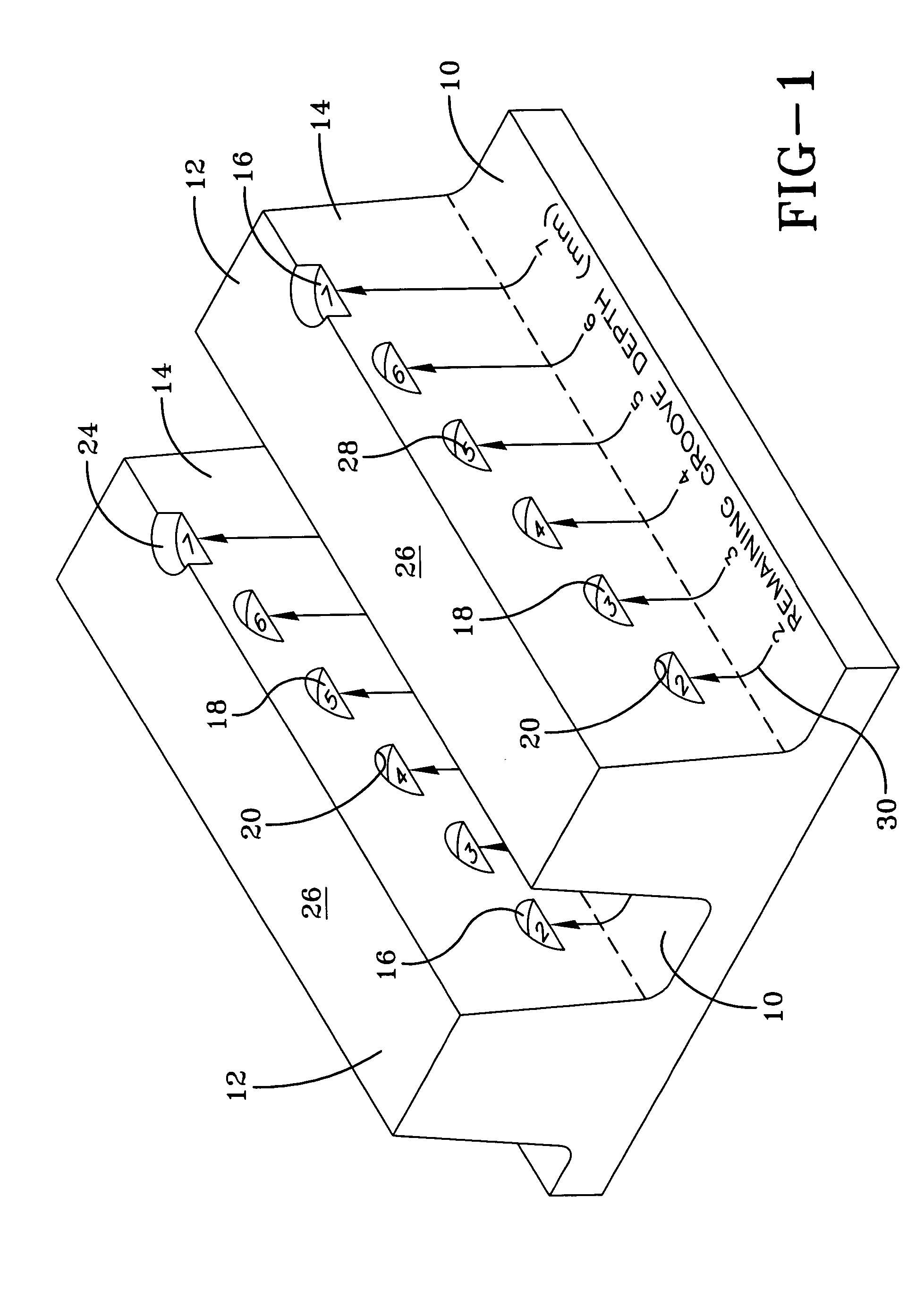

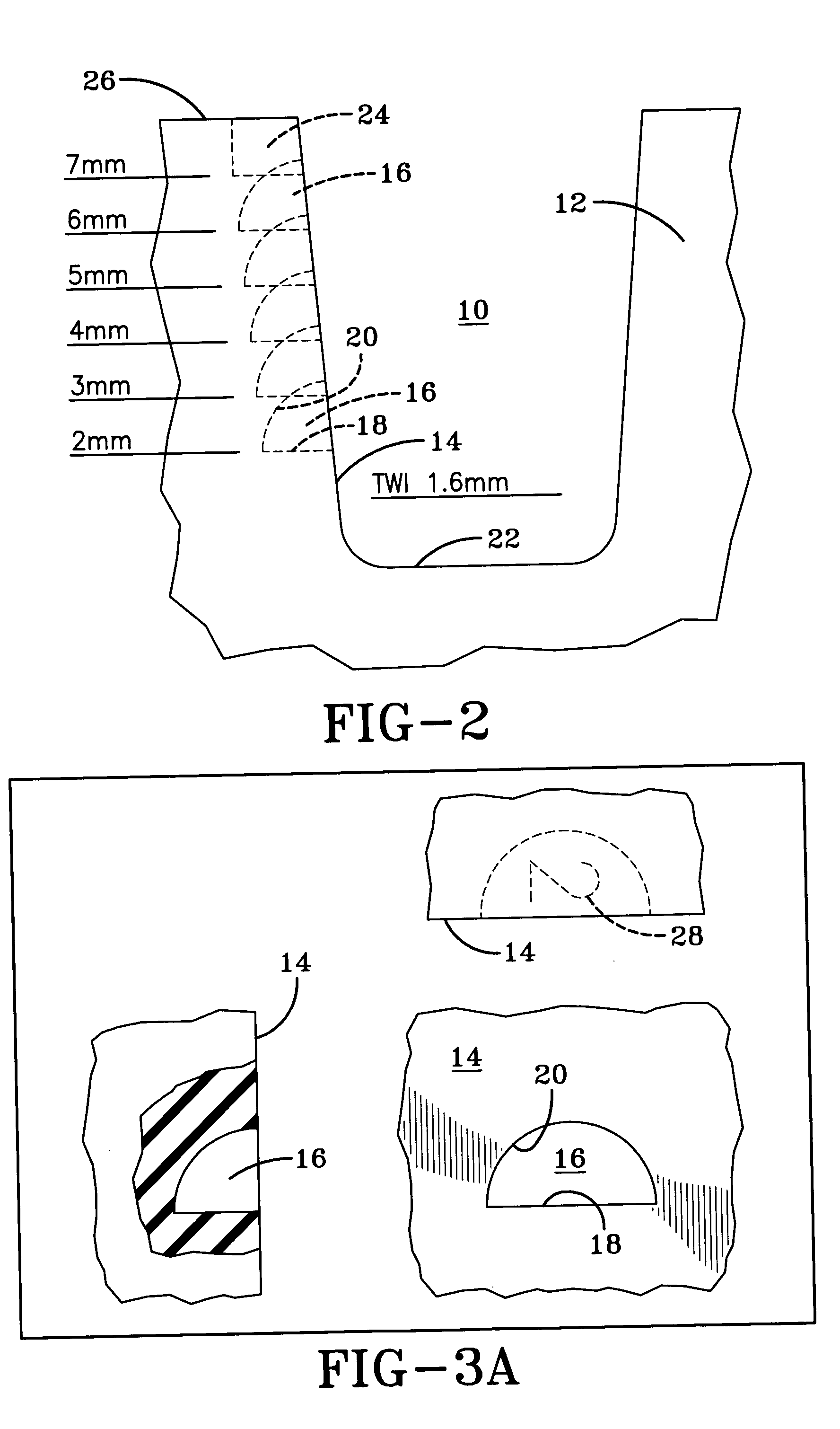

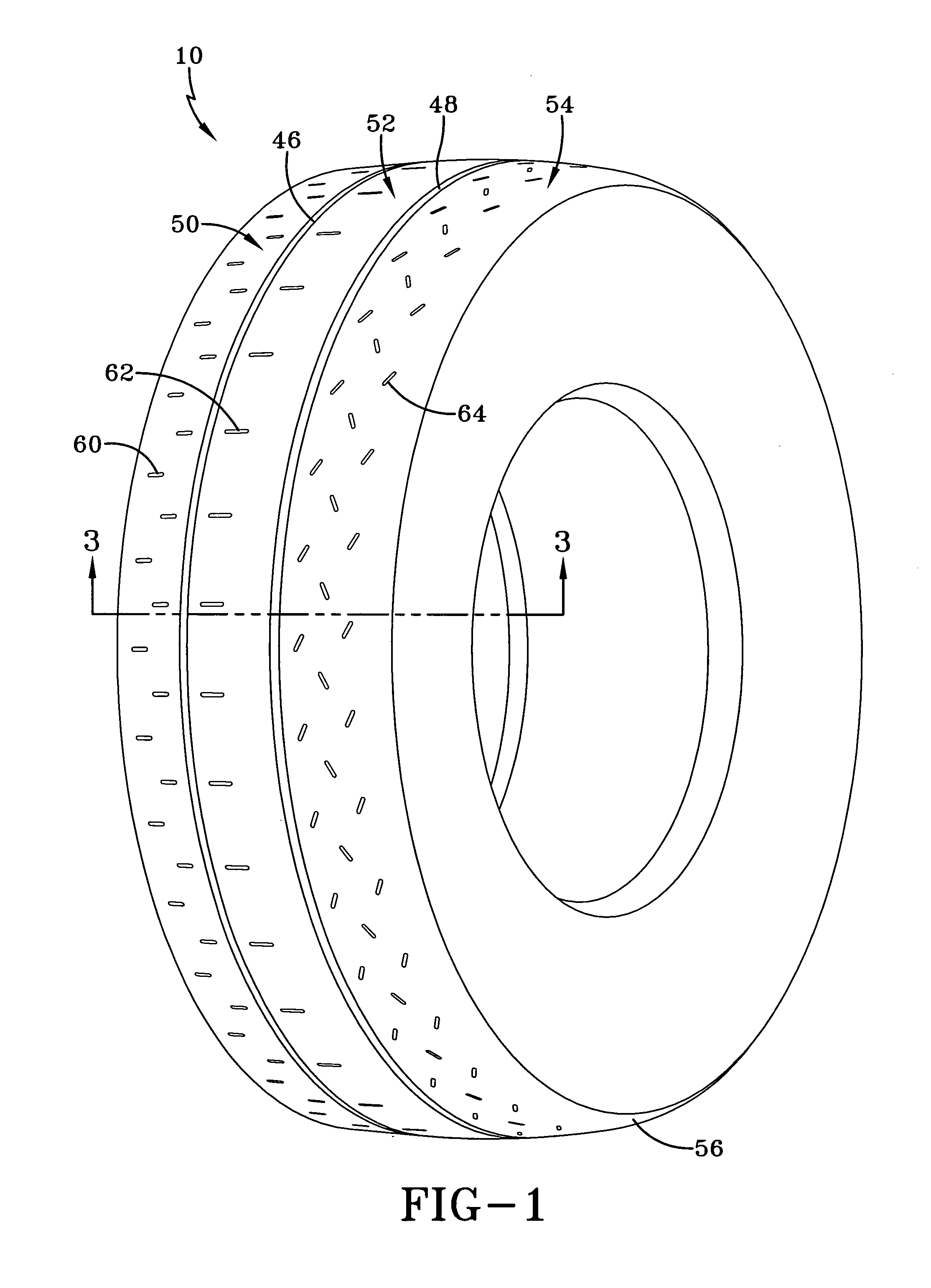

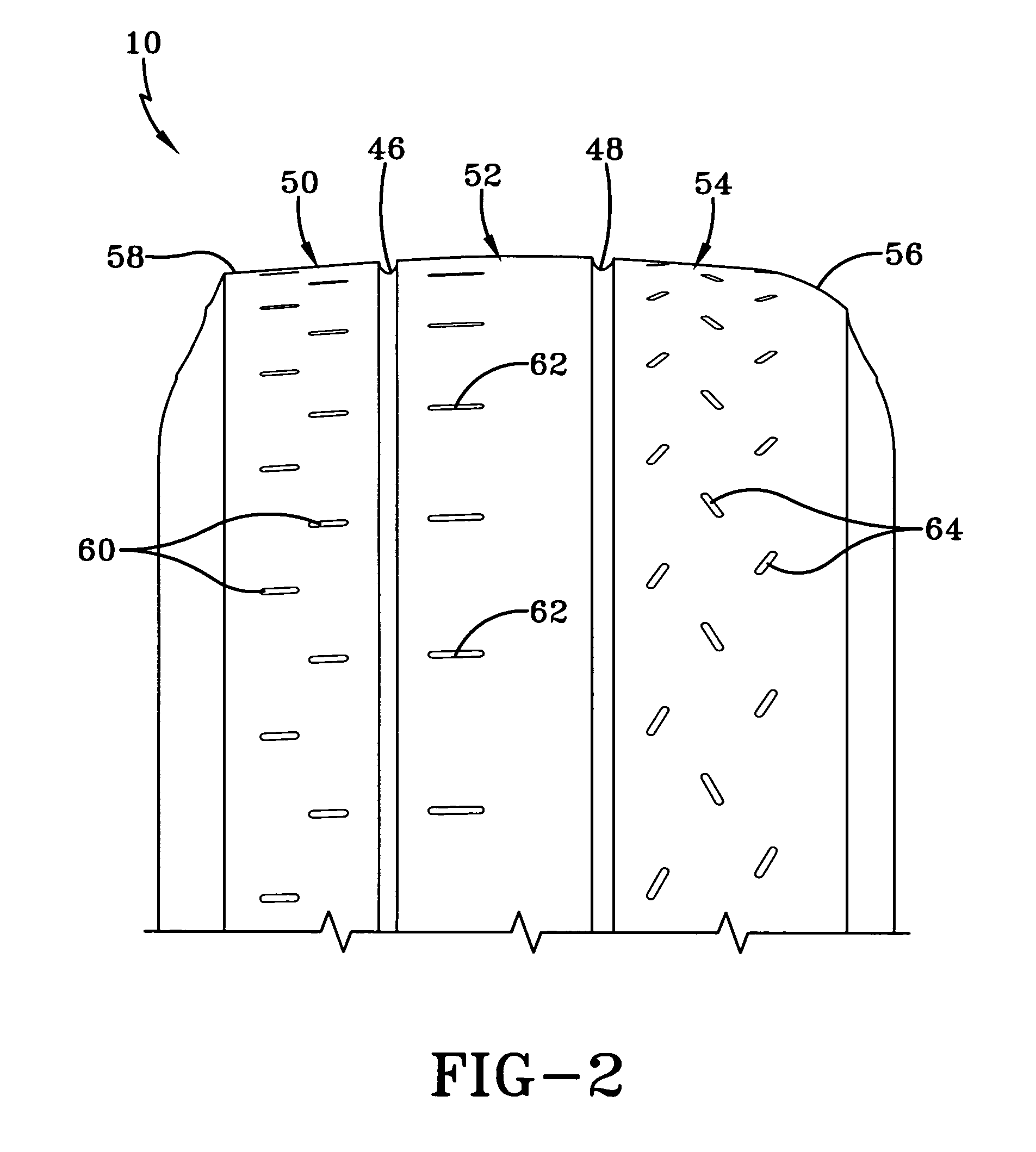

Progressive tire tread wear indicator

Owner:THE GOODYEAR TIRE & RUBBER CO

Progressive tire tread wear indicator

A tire tread has at least one cavern formed in the sidewall of the traction elements of the tire. The cavern has a base with information therein to indicate the state of wear of the tire and a ceiling that is progressively worn away as the tread wears. Multiple caverns may be formed in the traction elements. If arranged in a series at progressively increasing or decreasing radial heights, the remaining tread life is communicated to an operator. If the caverns are located in different locations of the tread, relative wear patterns of the tire can also be indicated.

Owner:THE GOODYEAR TIRE & RUBBER CO

Variable path automated guided vehicle

InactiveUS7991521B2Efficient transportWear minimizationVehicle fittingsNavigation instrumentsWear patternAutomated guided vehicle

An automated guided vehicle and a method of controlling an automated guided vehicle which are capable of varying the travel path of the automatic guided vehicle in order to reduce wear patterns created in the floor of the material handling facility. The travel path of the AGV is varied by intentionally applying a deviation from a selected predetermined route along which the AGV is traveling.

Owner:JERVIS B WEBB INT CO

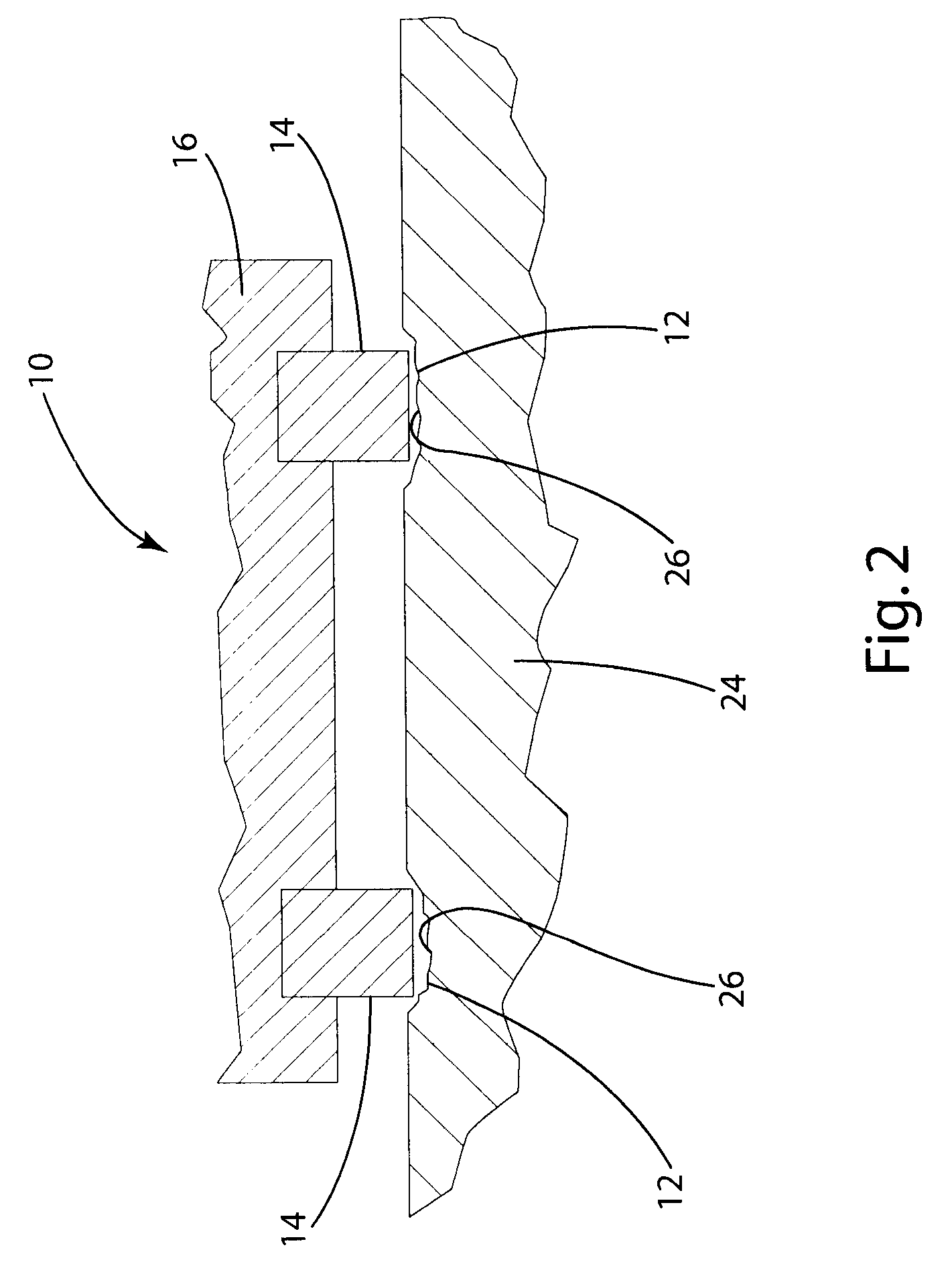

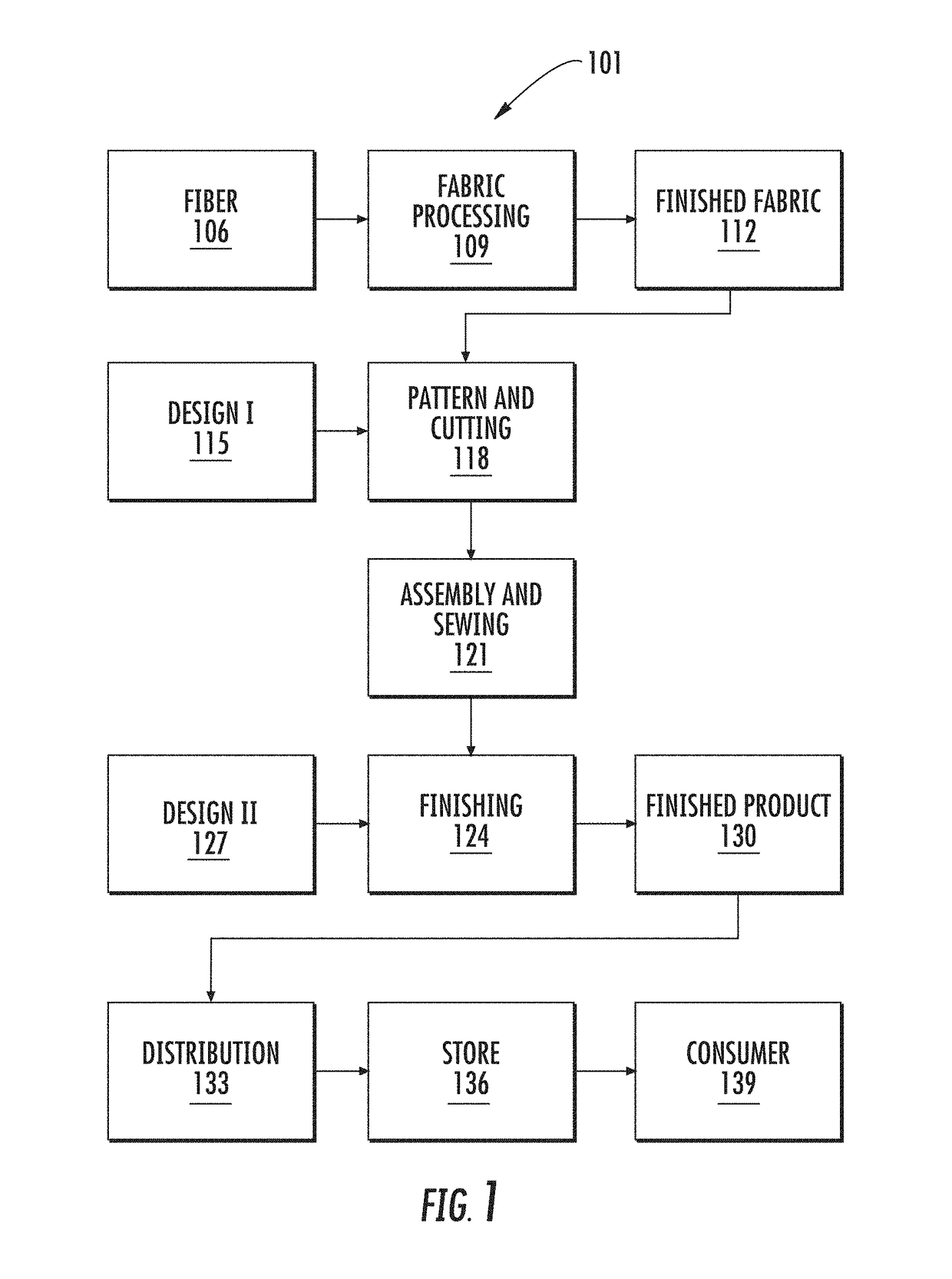

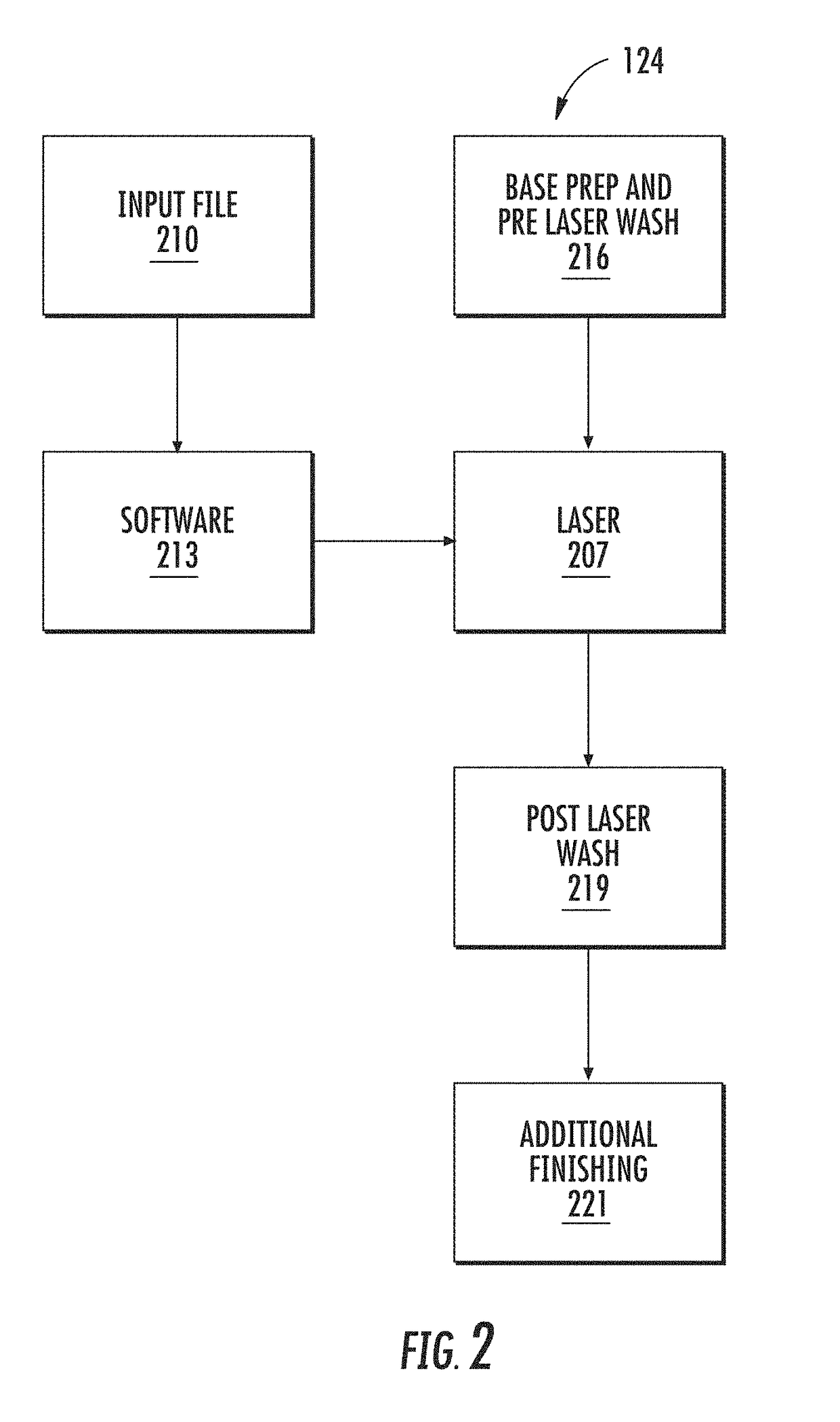

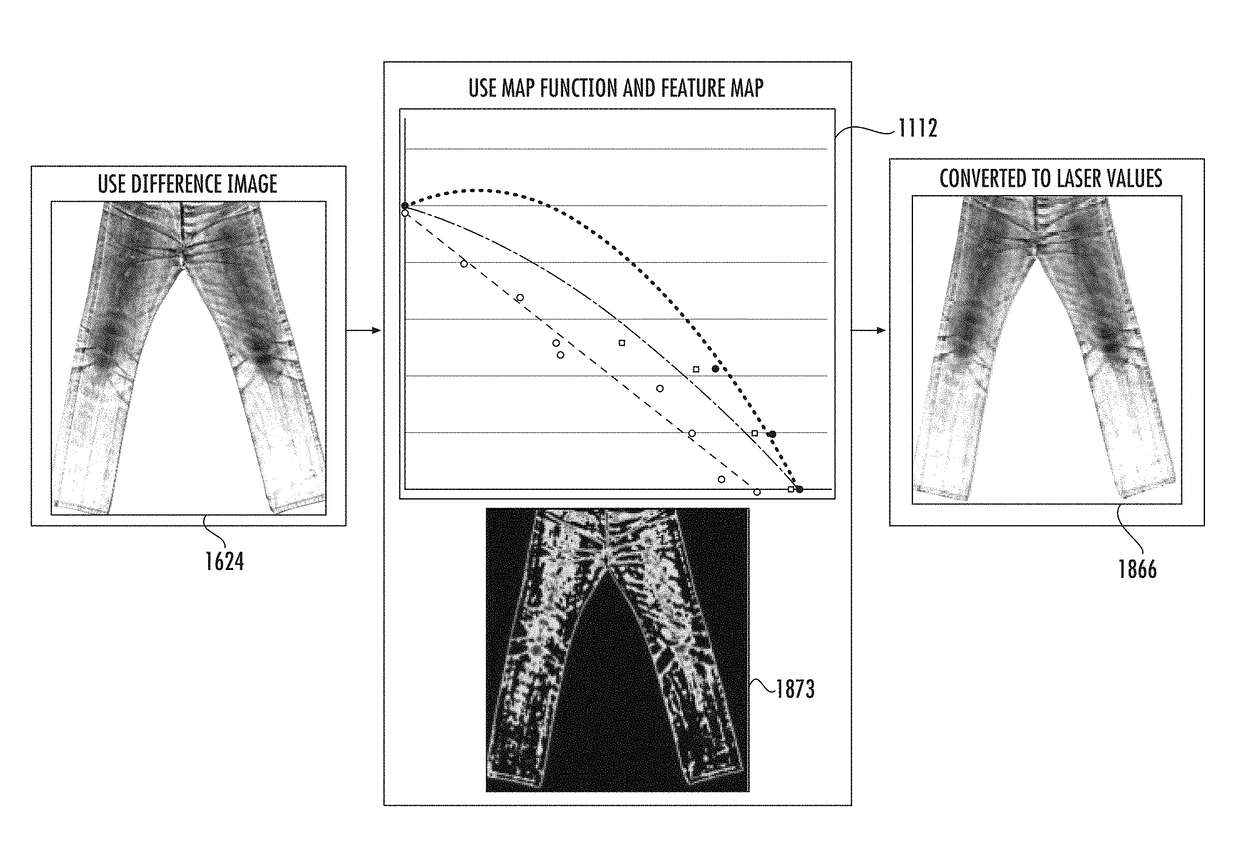

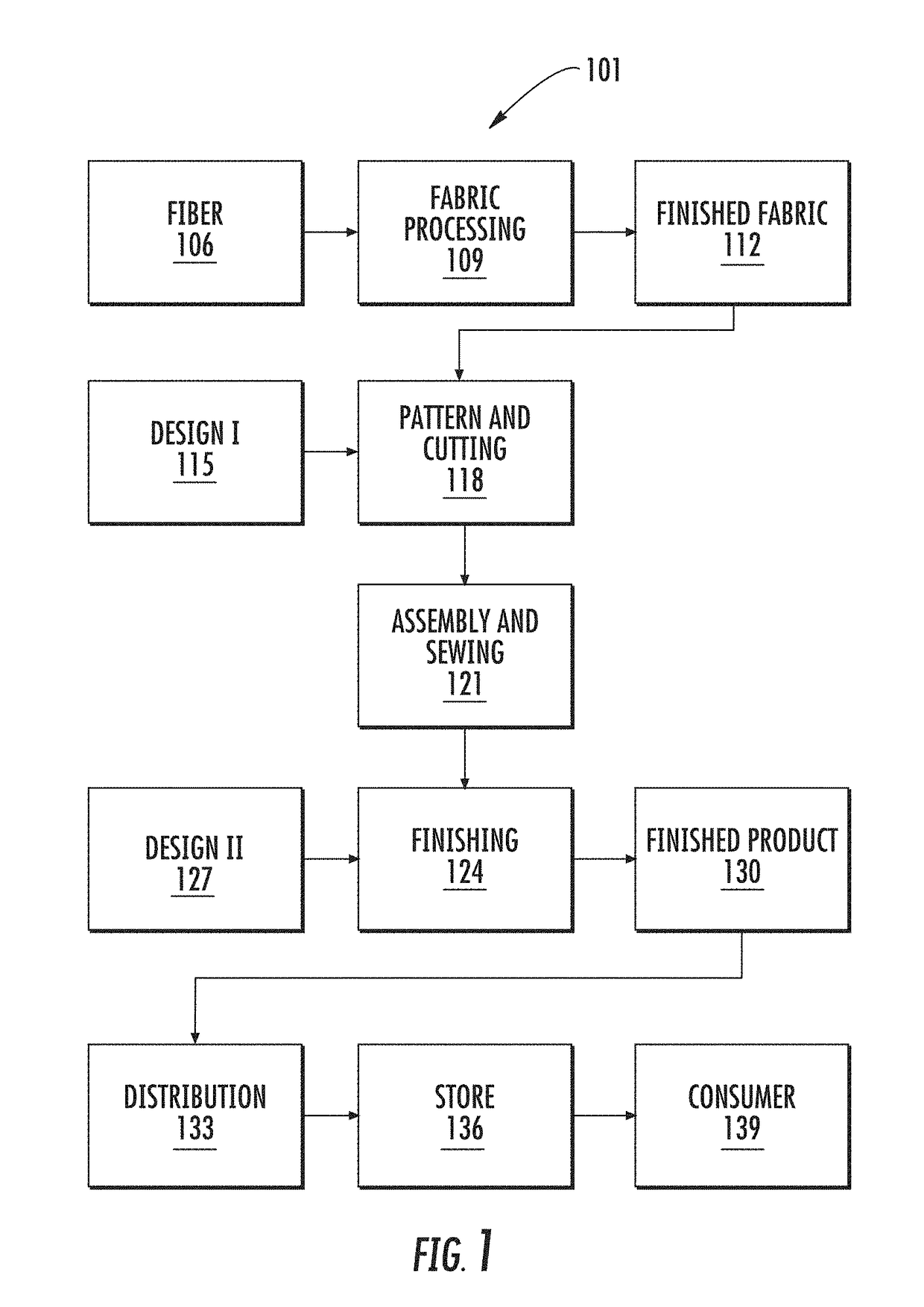

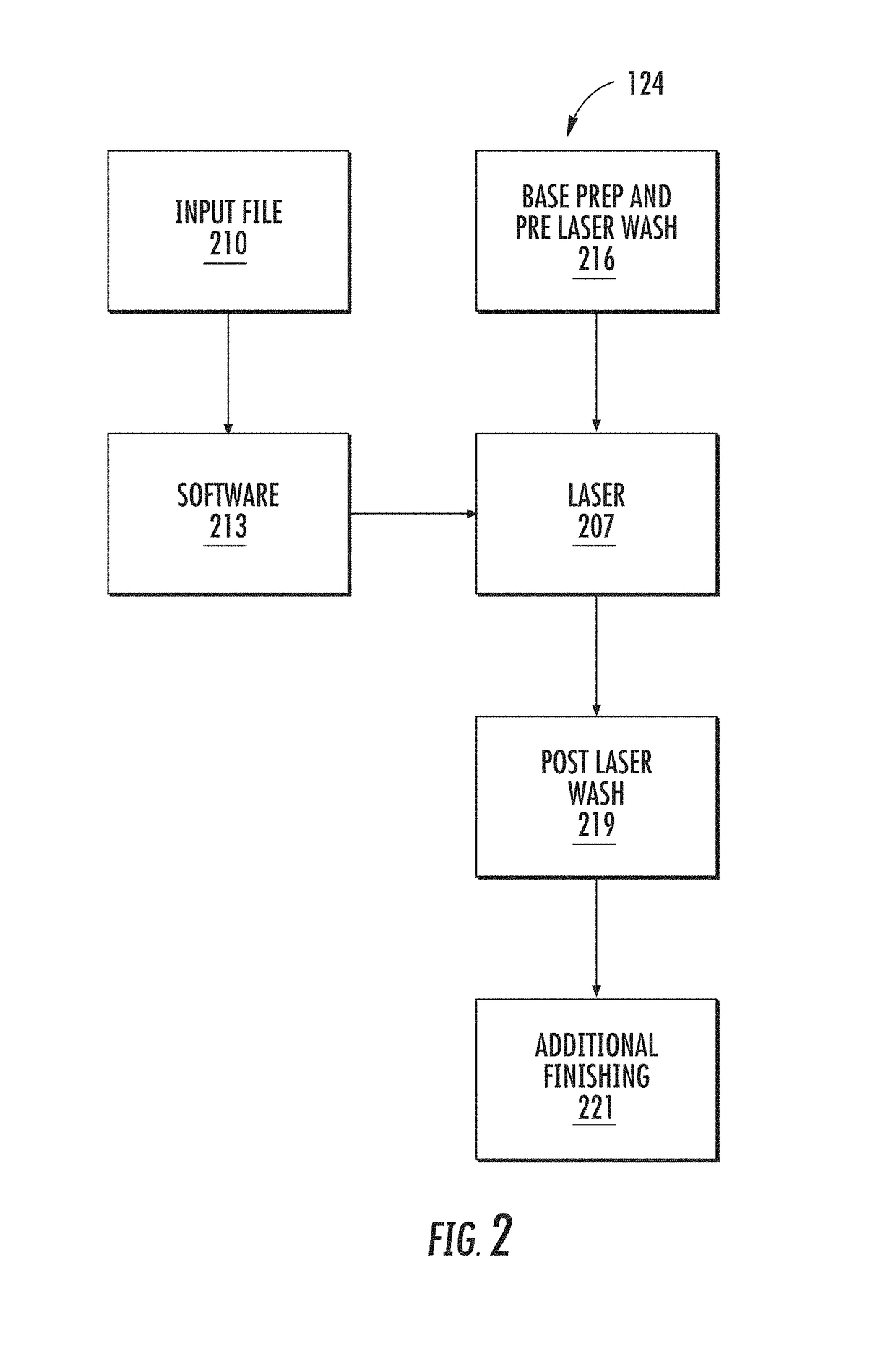

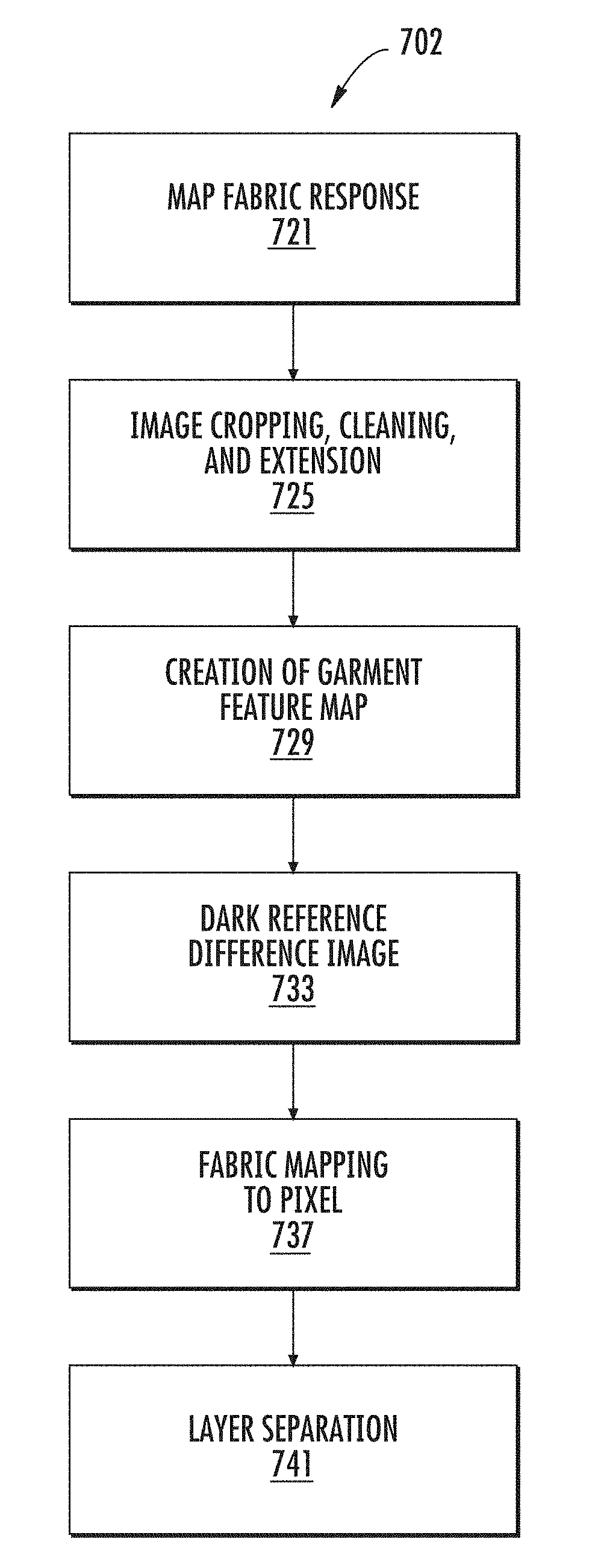

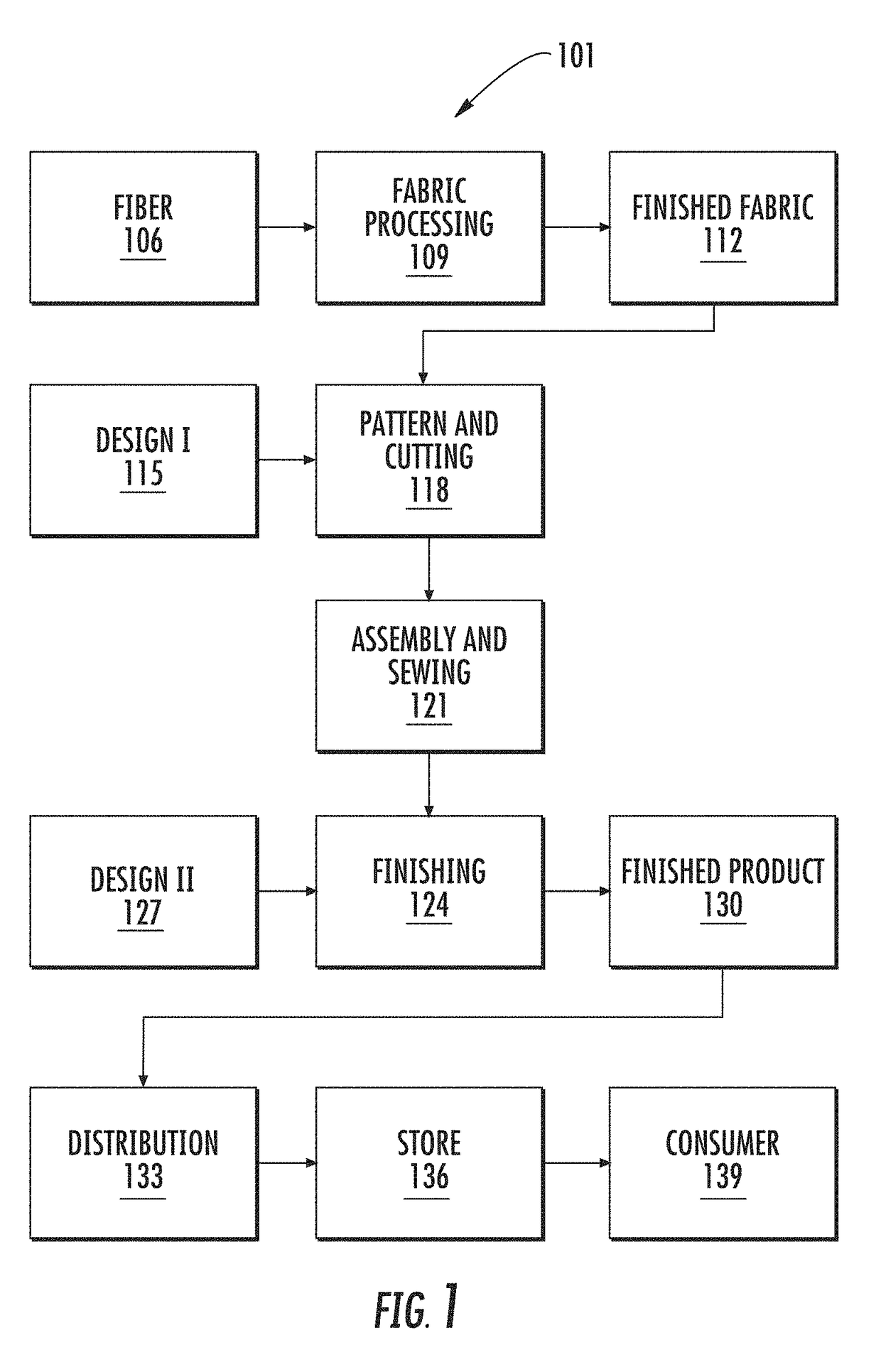

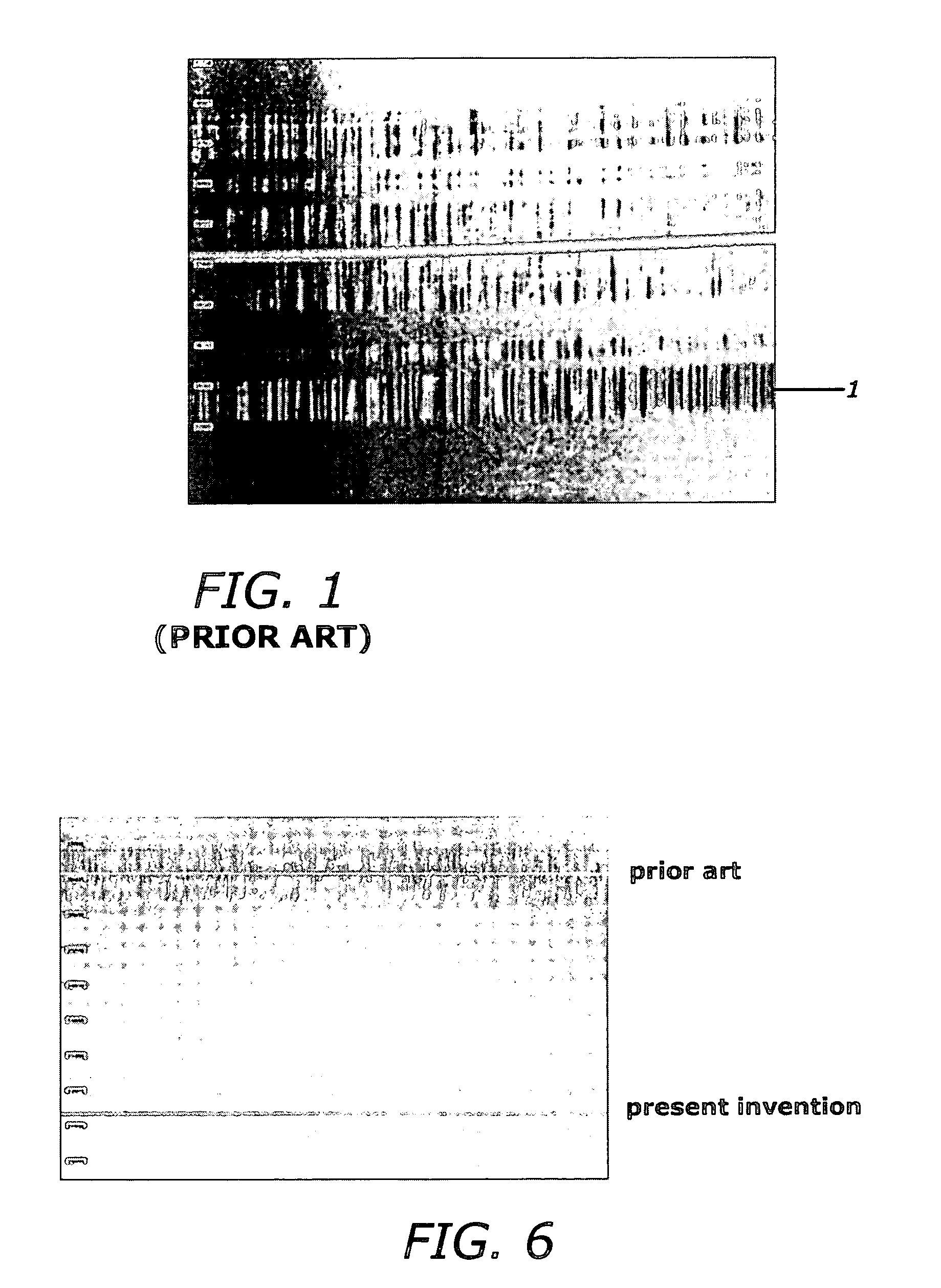

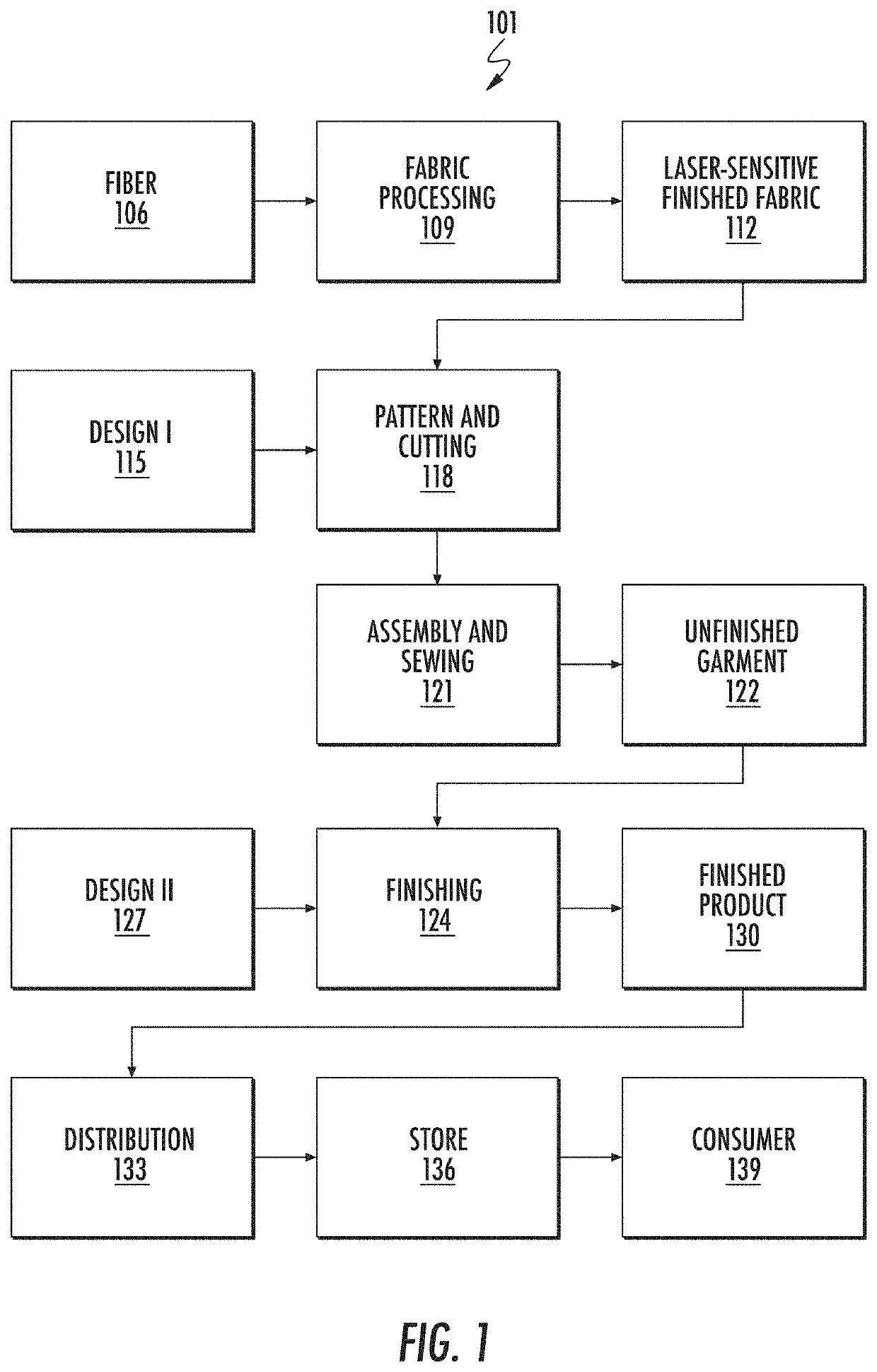

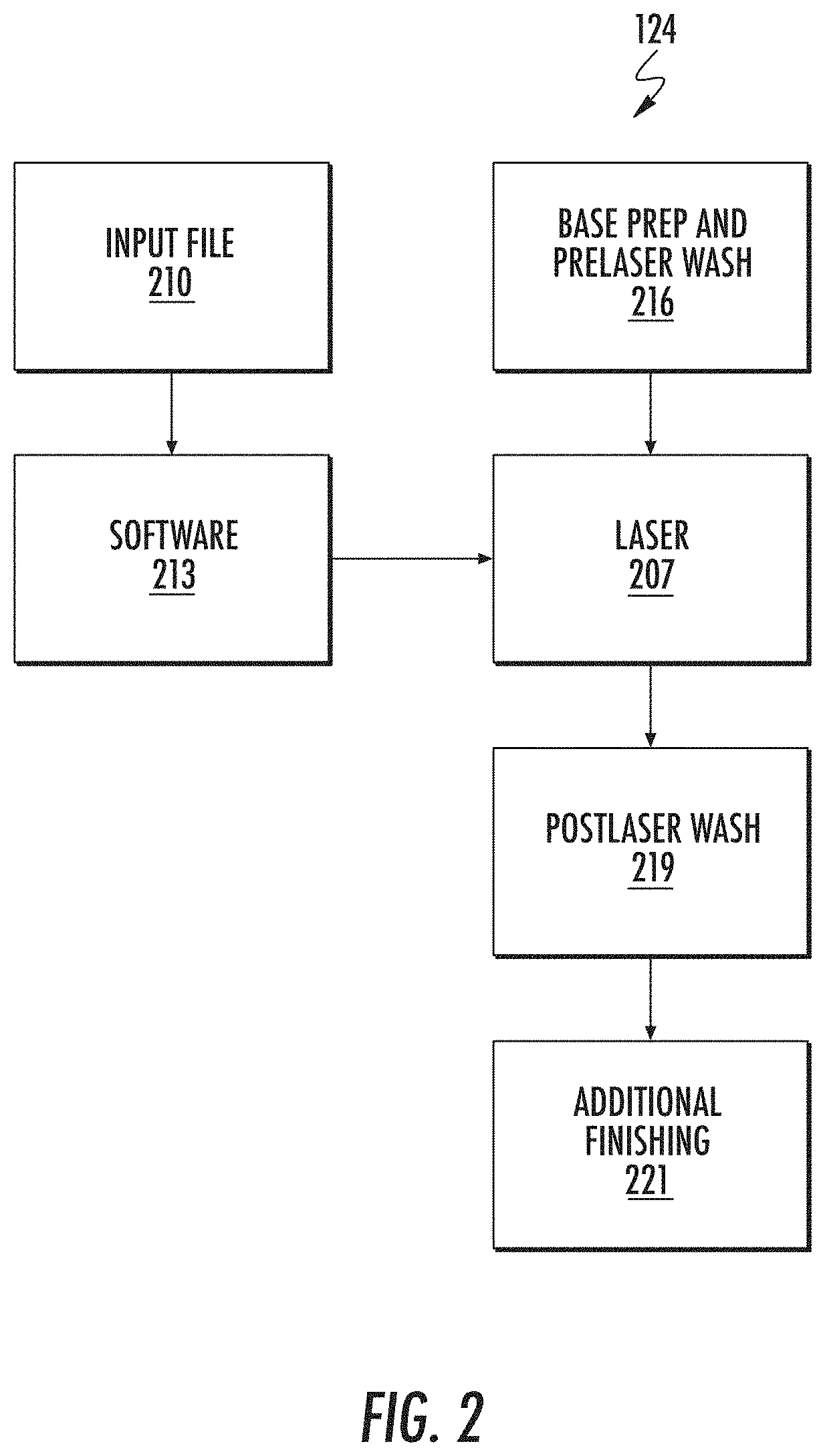

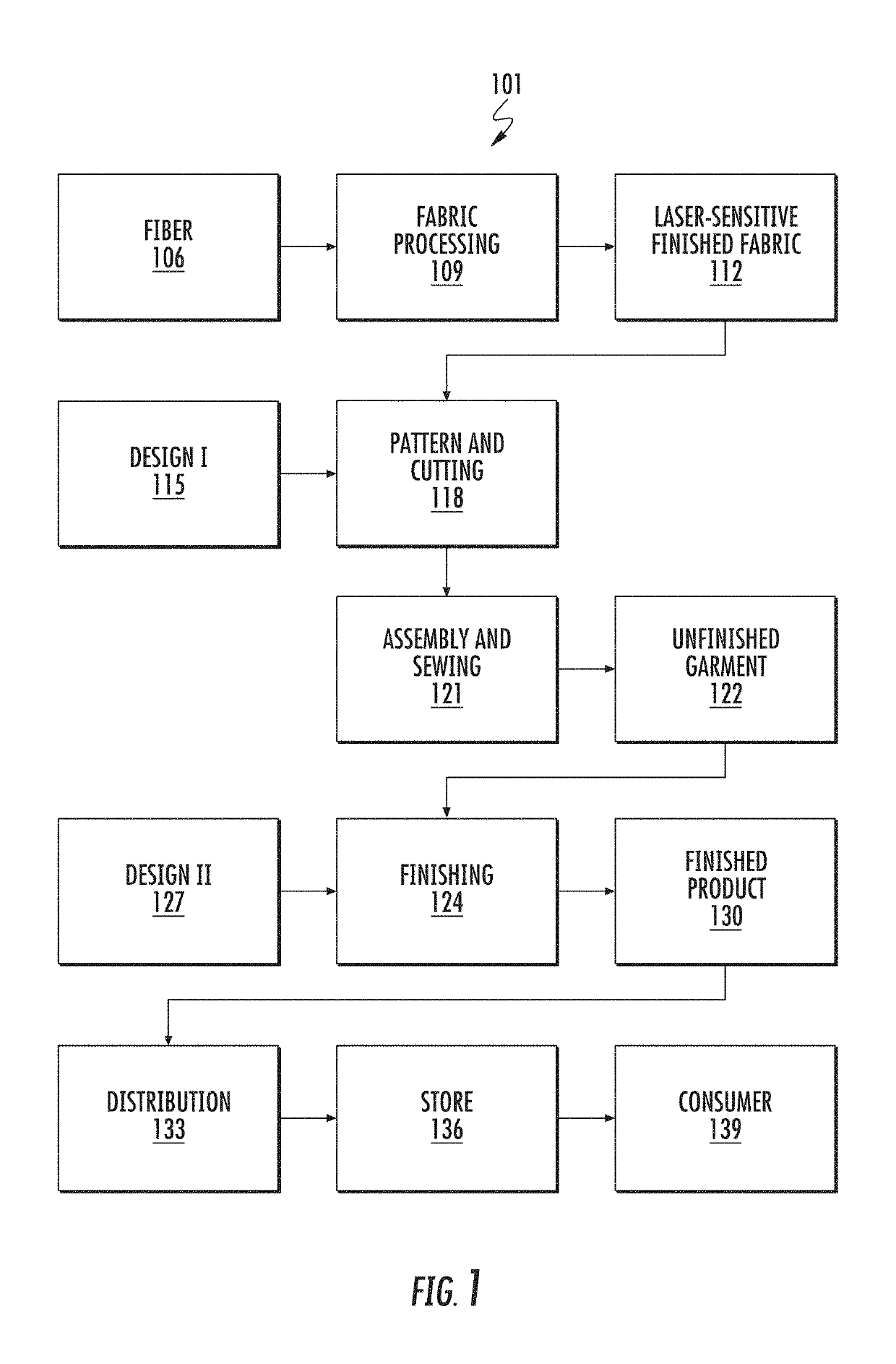

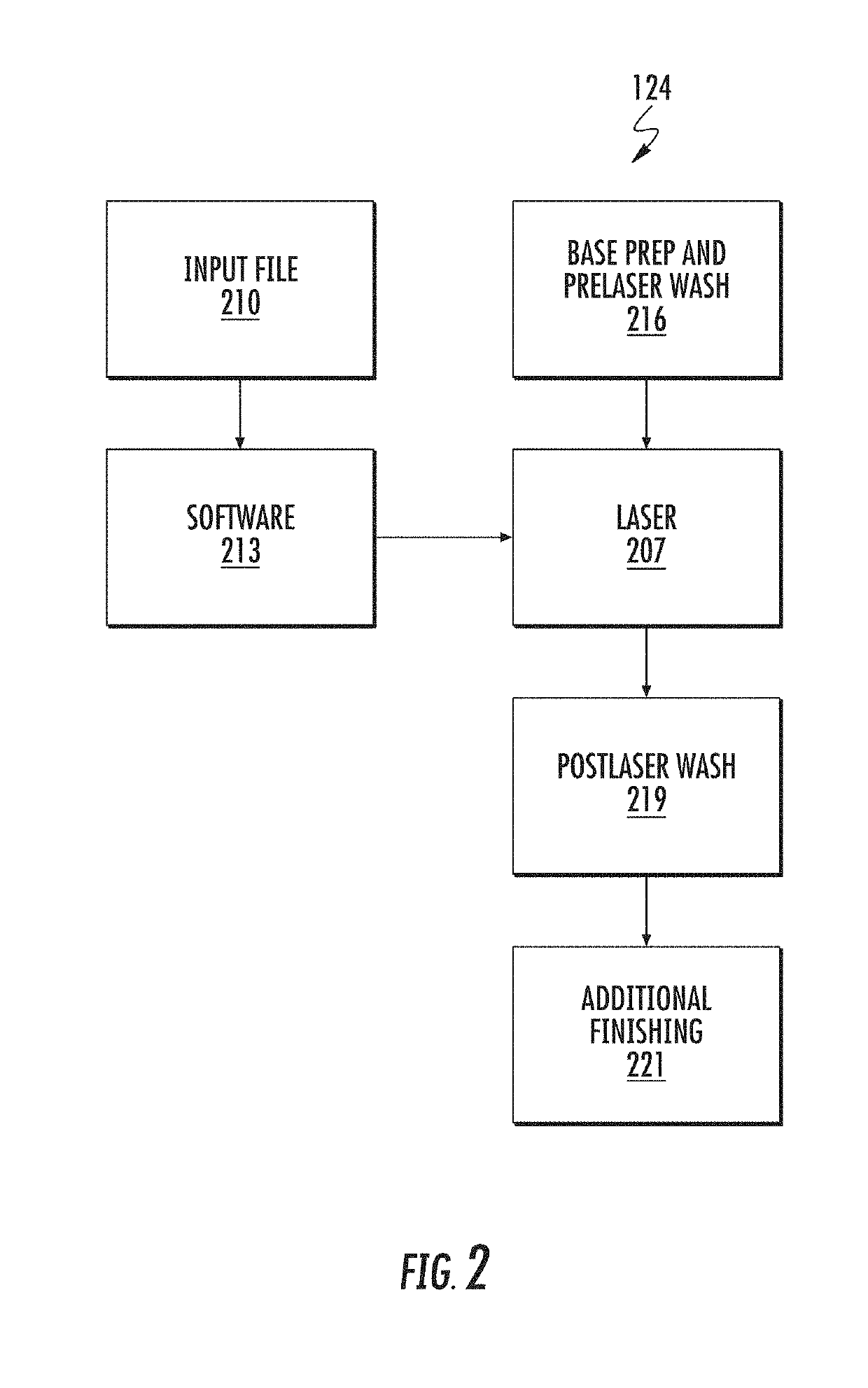

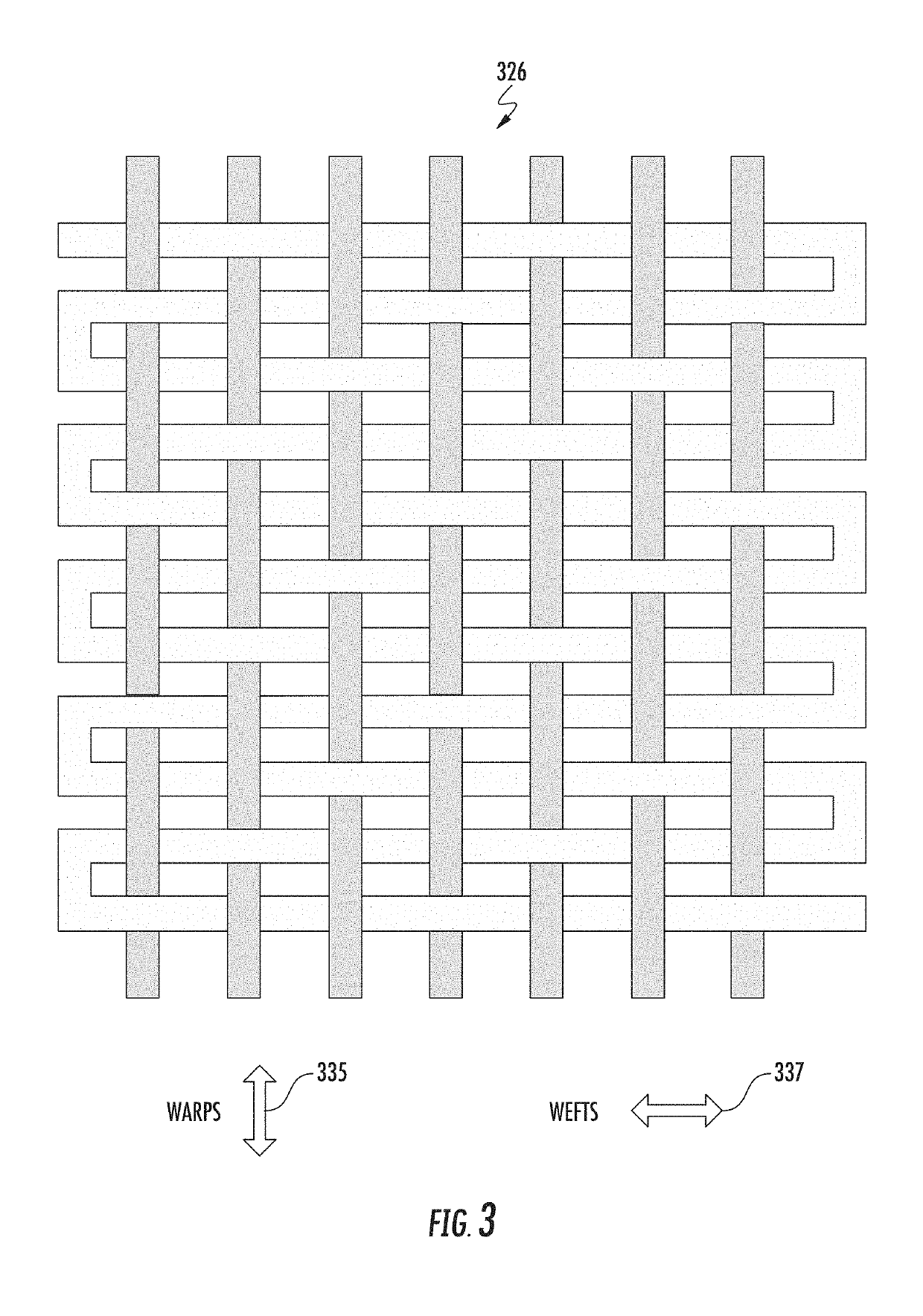

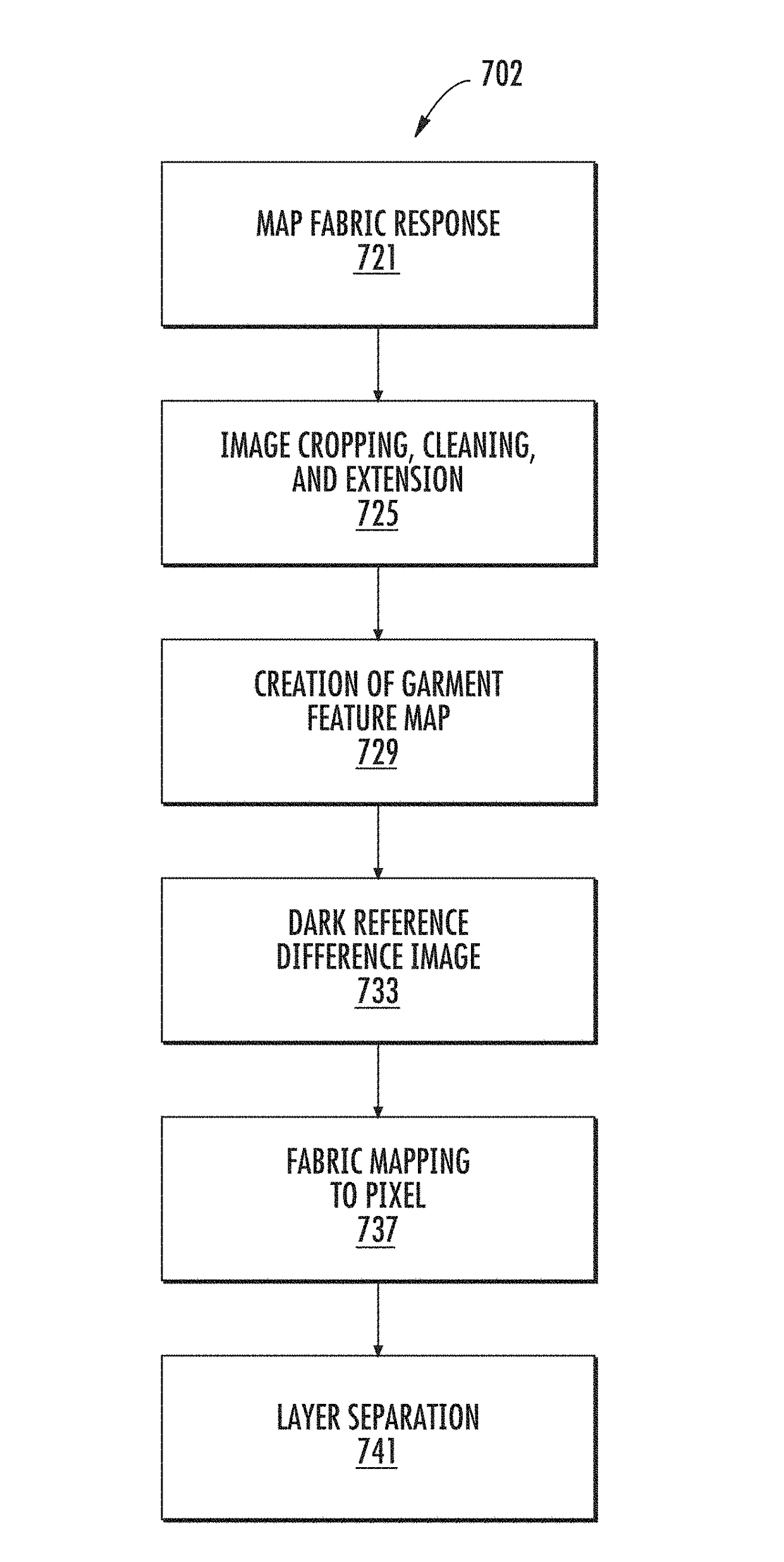

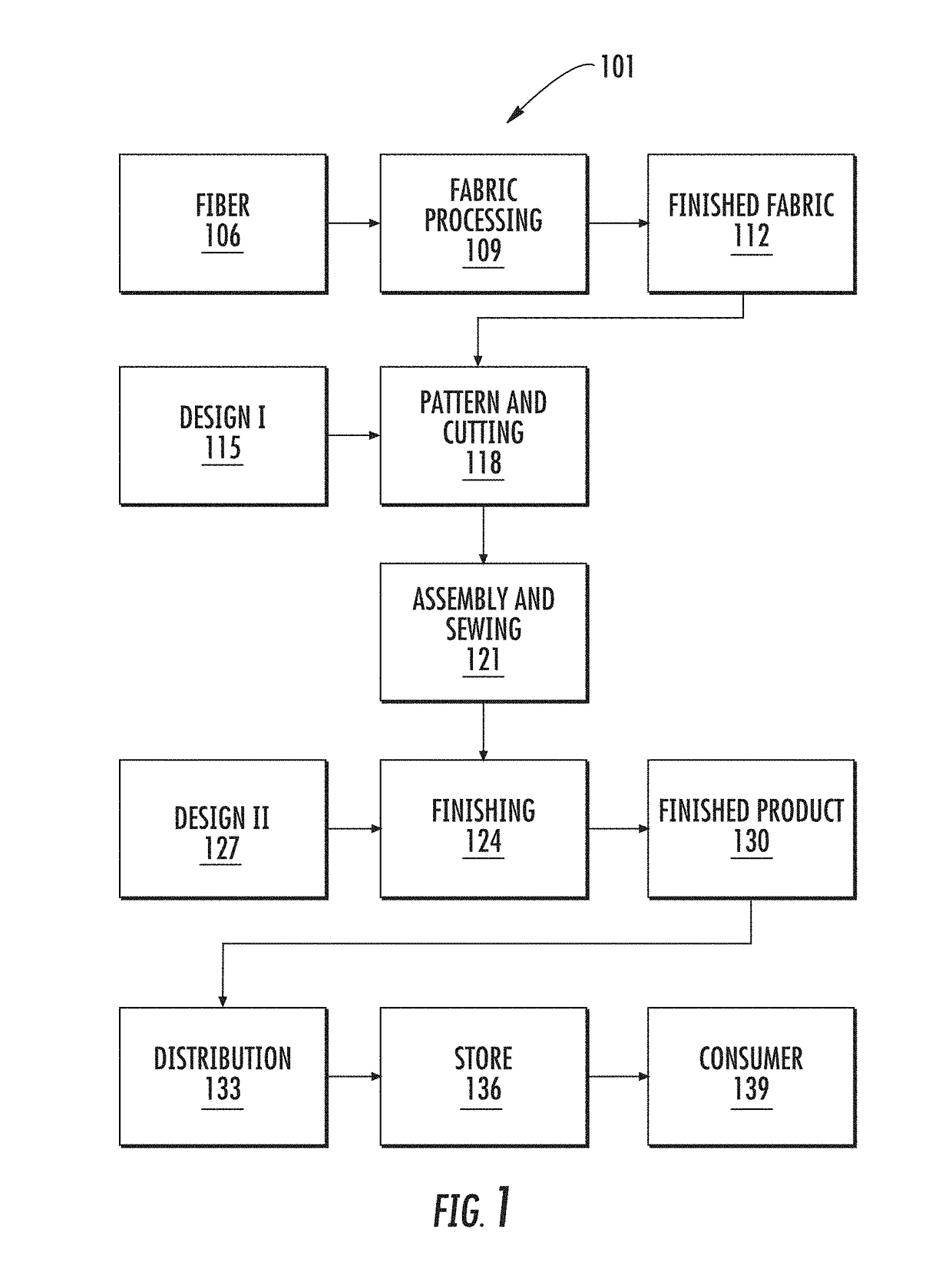

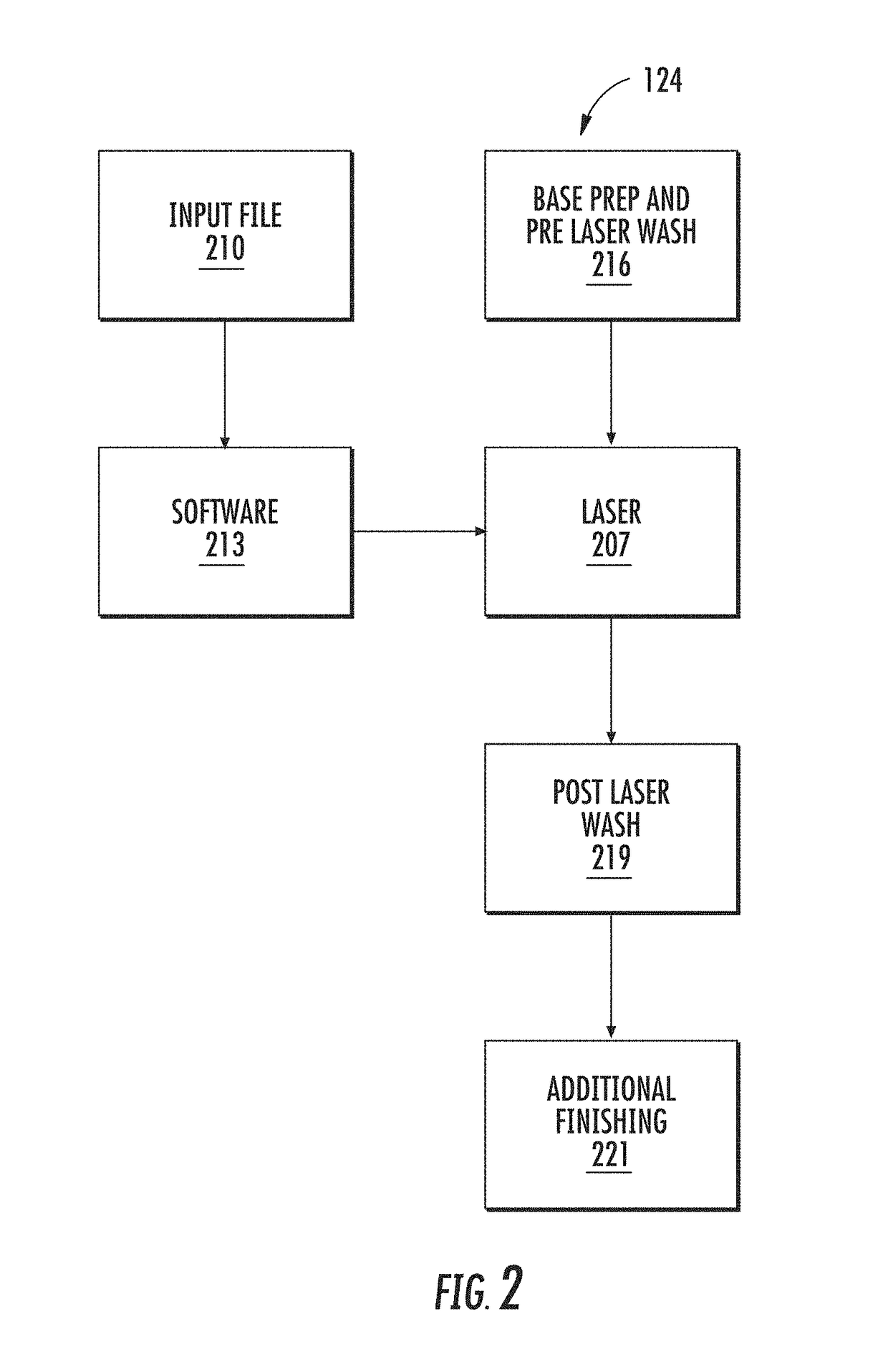

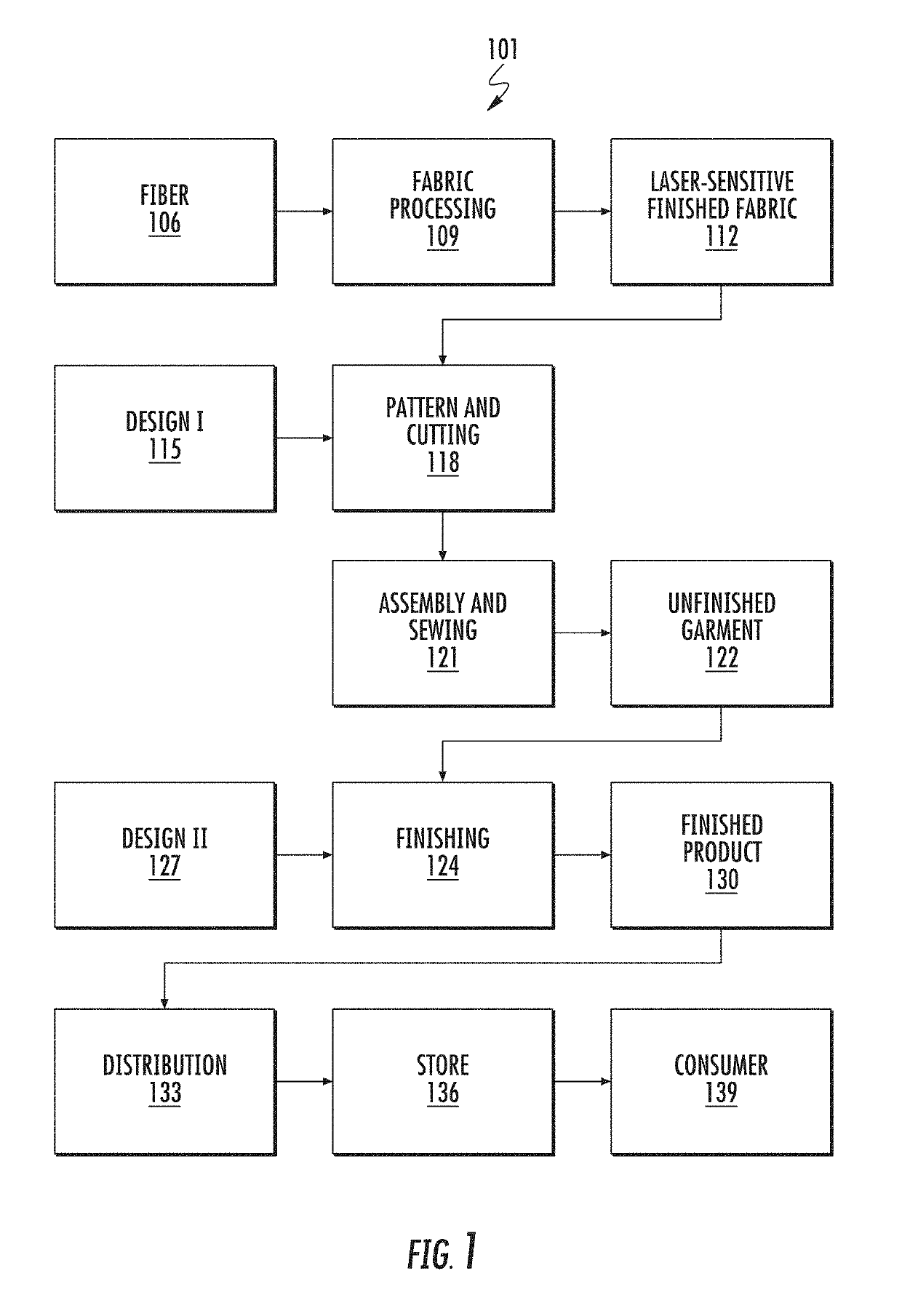

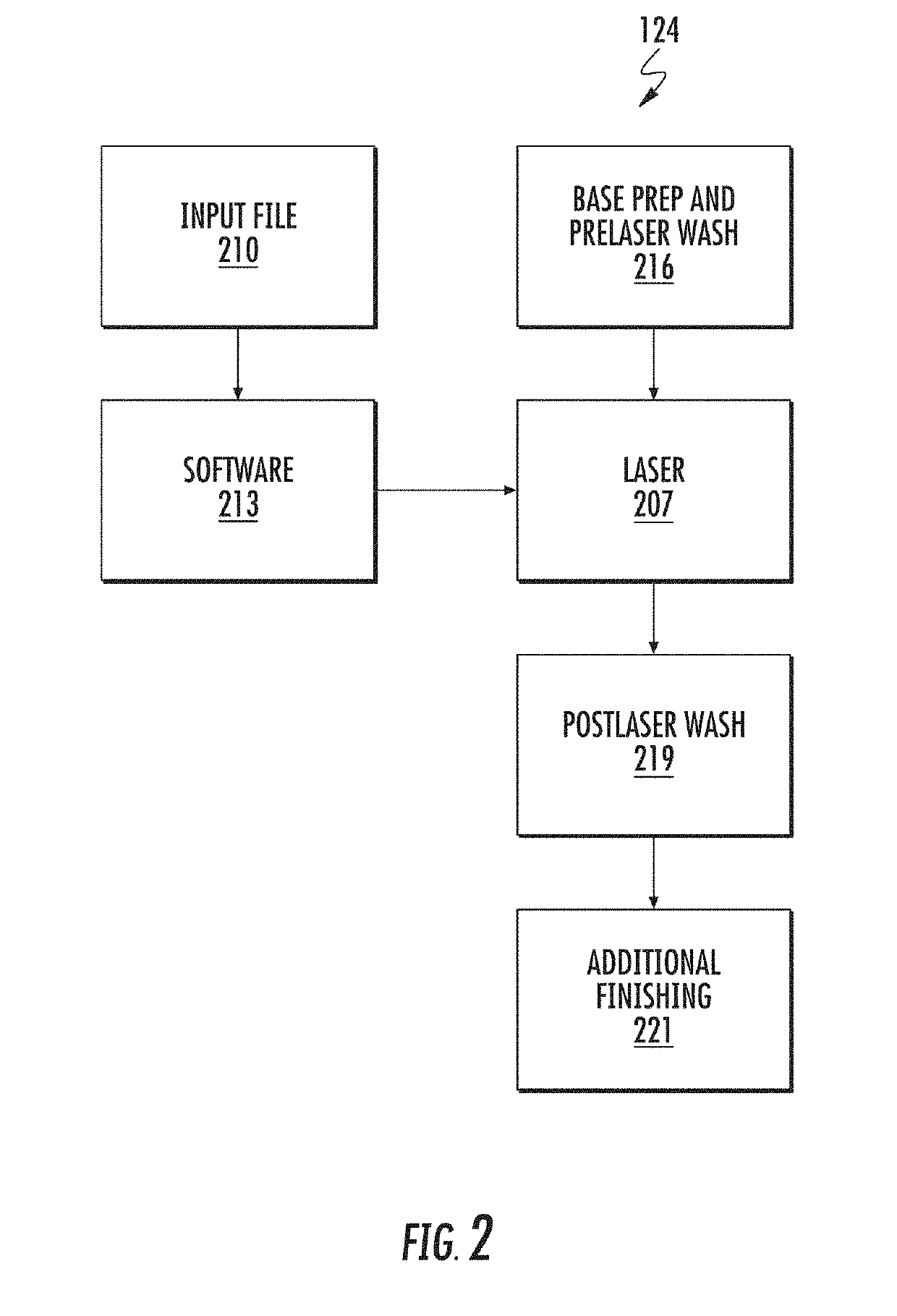

Laser Finishing of Apparel

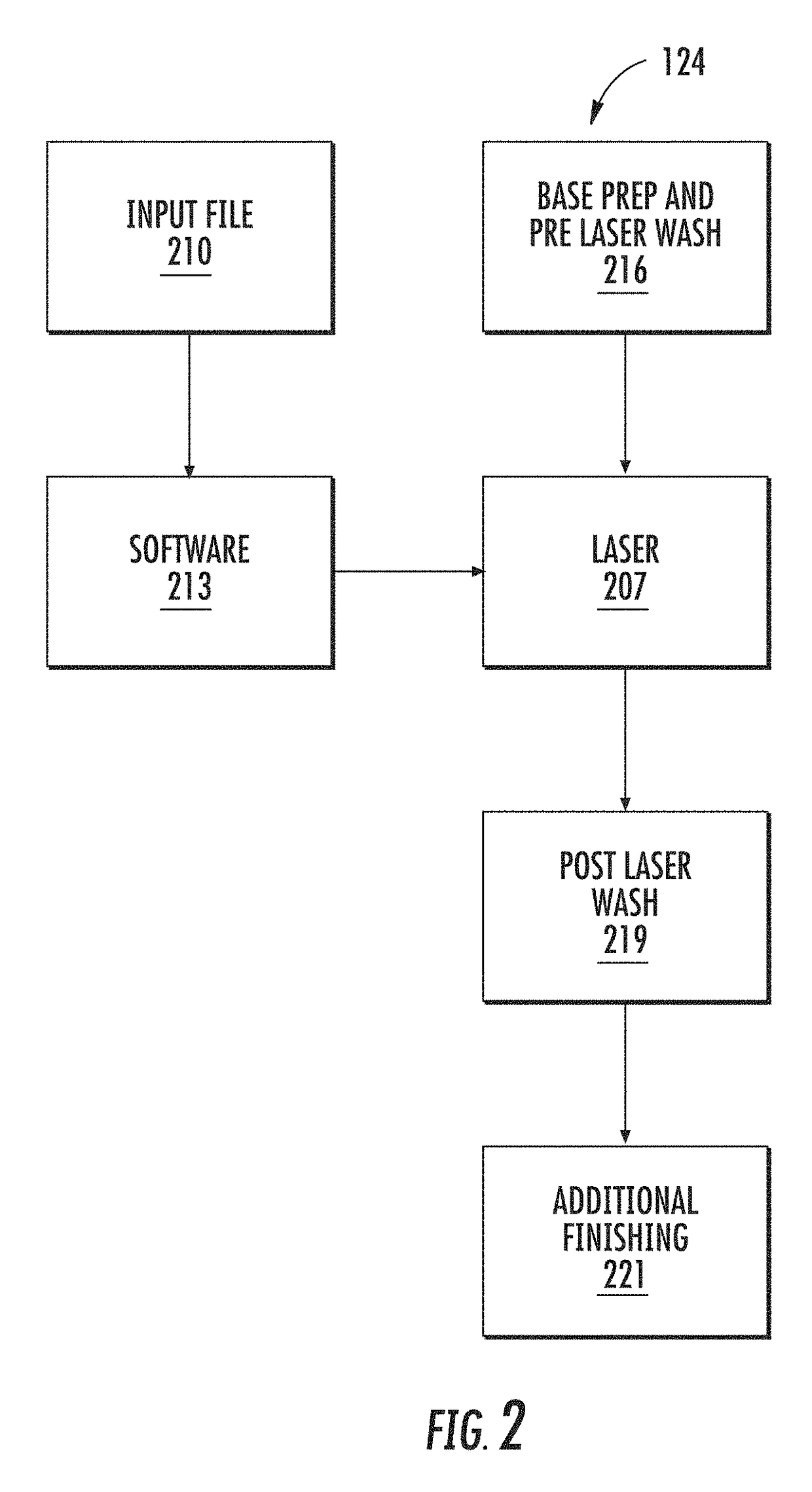

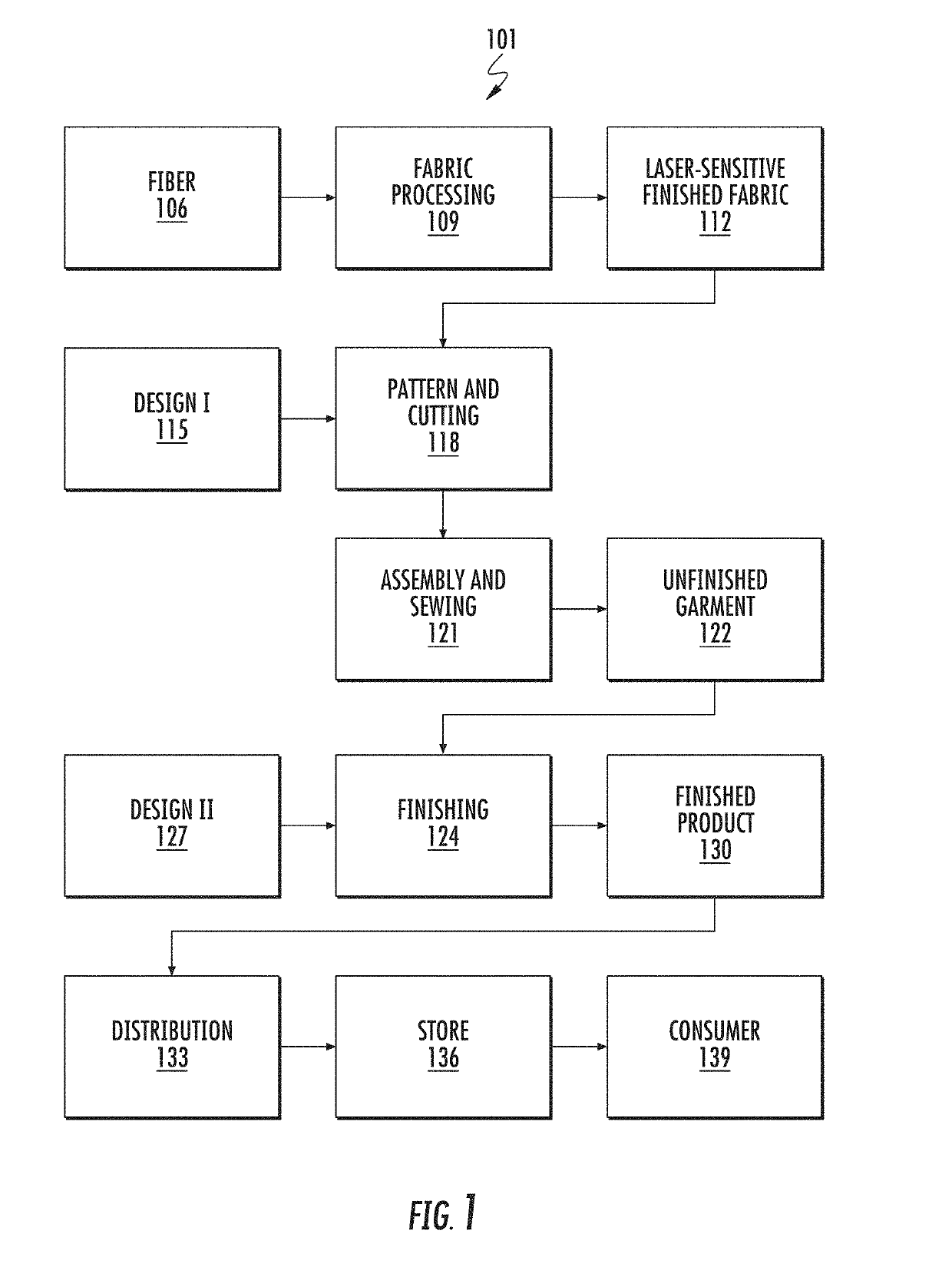

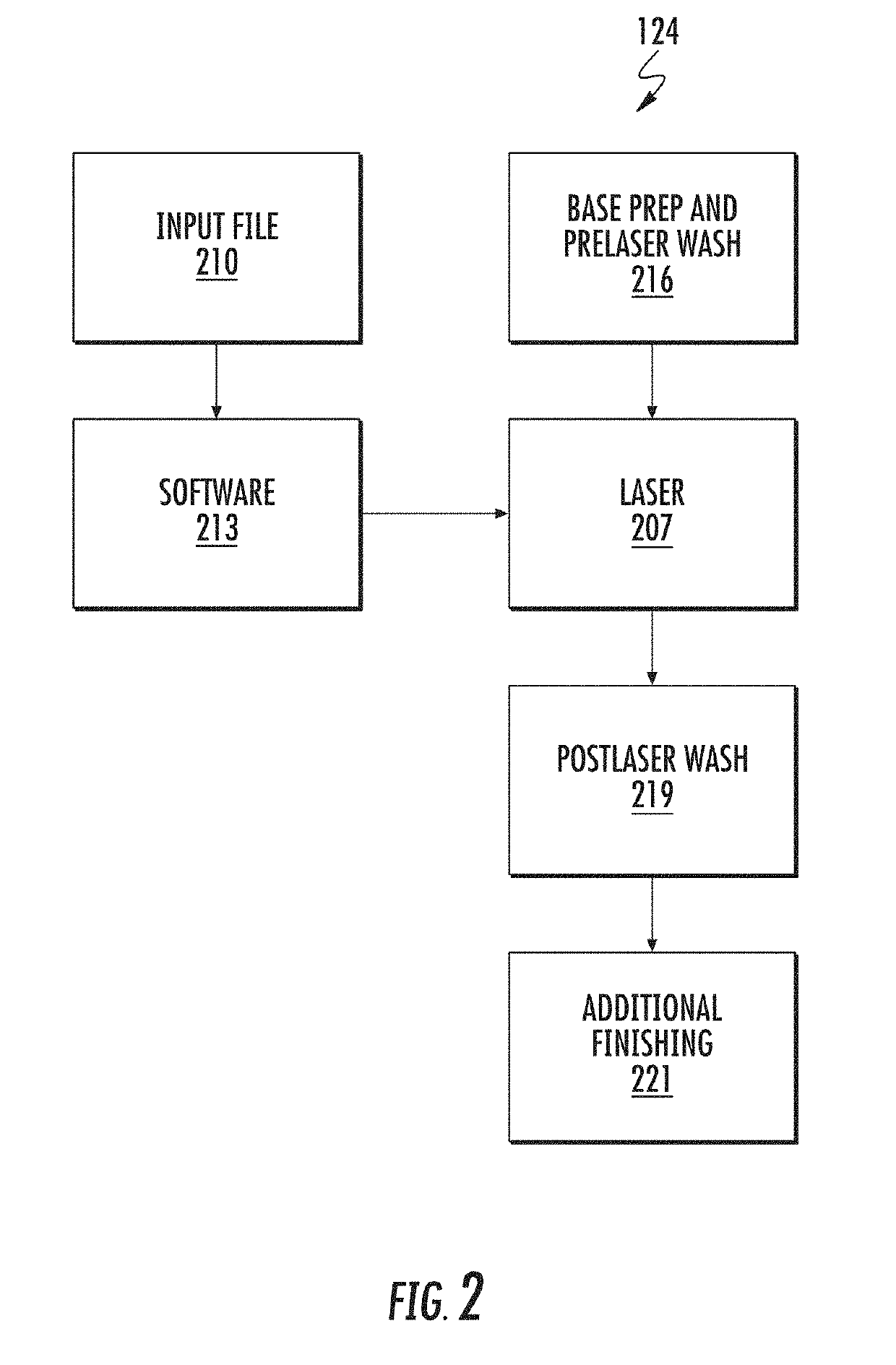

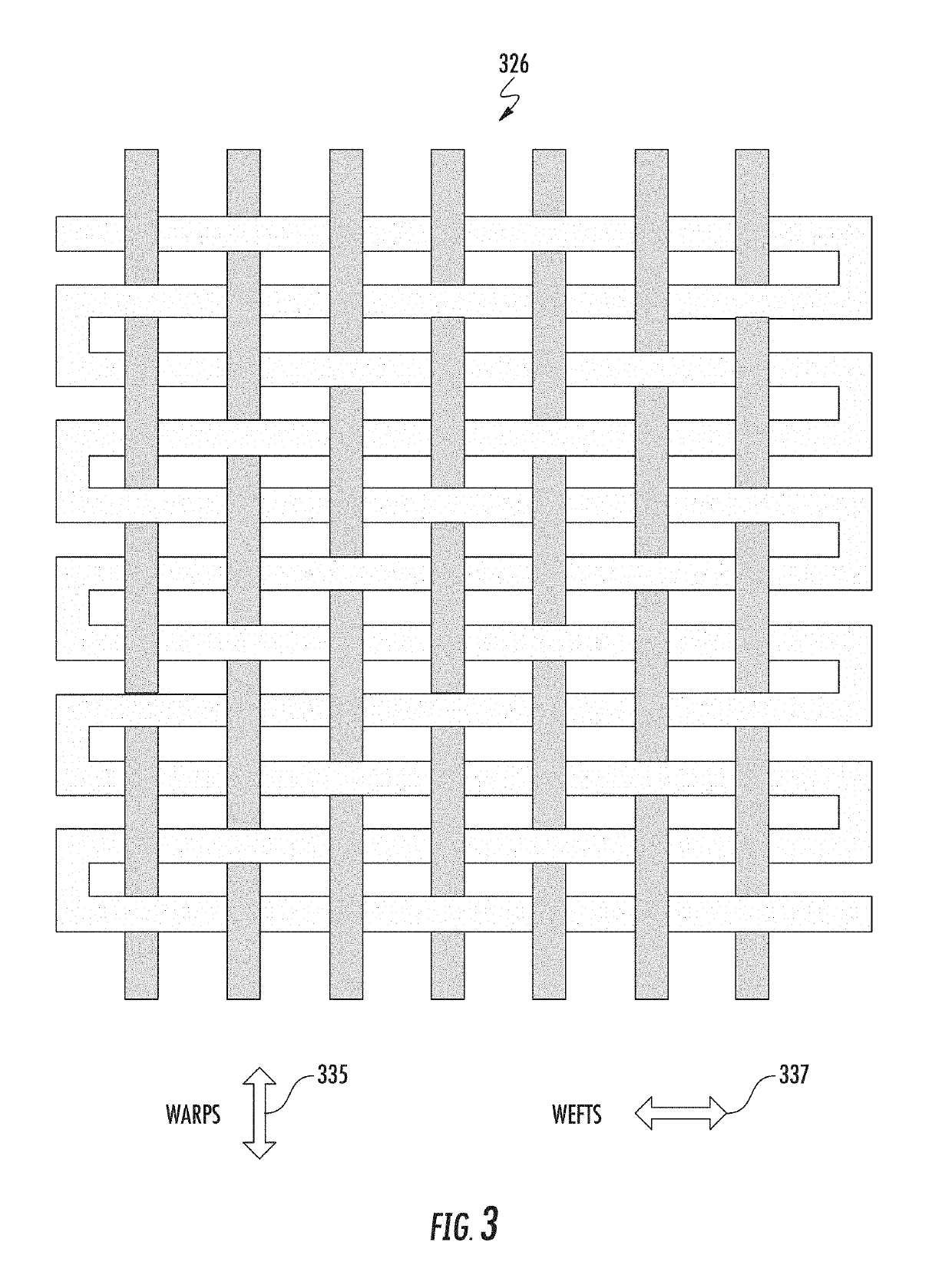

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

Laser finishing of apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

Variable path automated guided vehicle

An automated guided vehicle and a method of controlling an automated guided vehicle which are capable of varying the travel path of the automatic guided vehicle in order to reduce wear patterns created in the floor of the material handling facility. The travel path of the AGV is varied by intentionally applying a deviation from a selected predetermined route along which the AGV is traveling.

Owner:JERVIS B WEBB INT CO

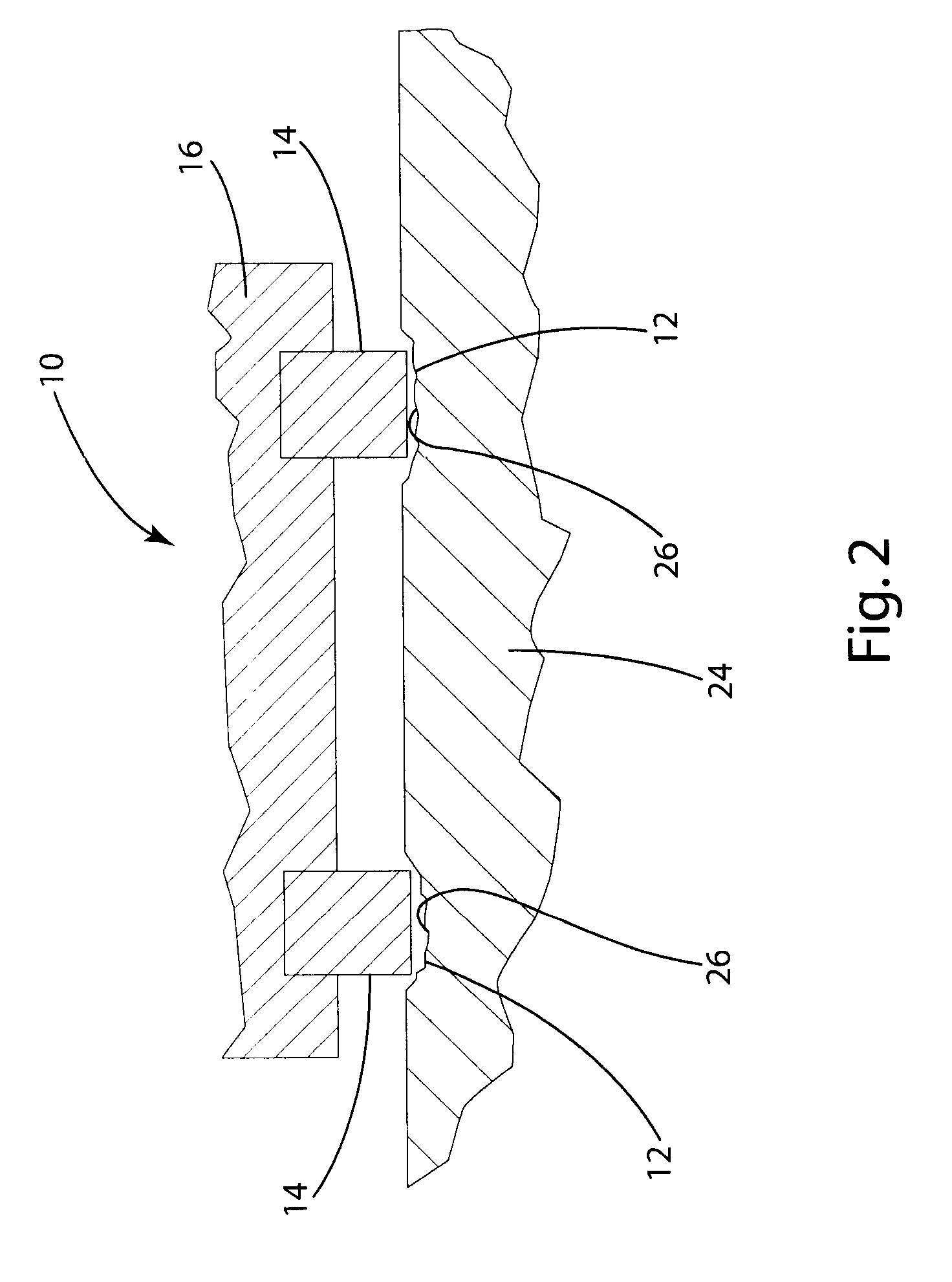

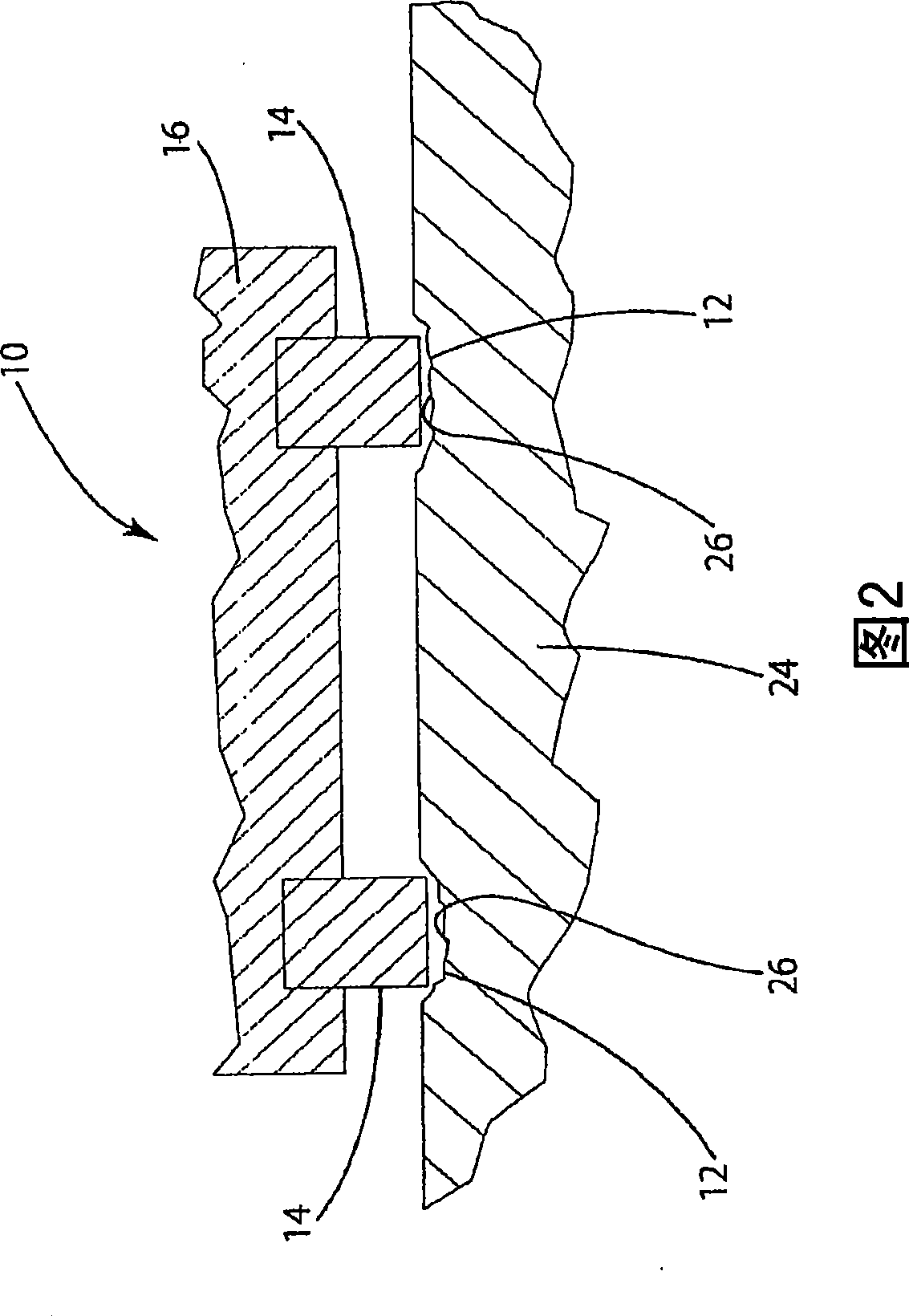

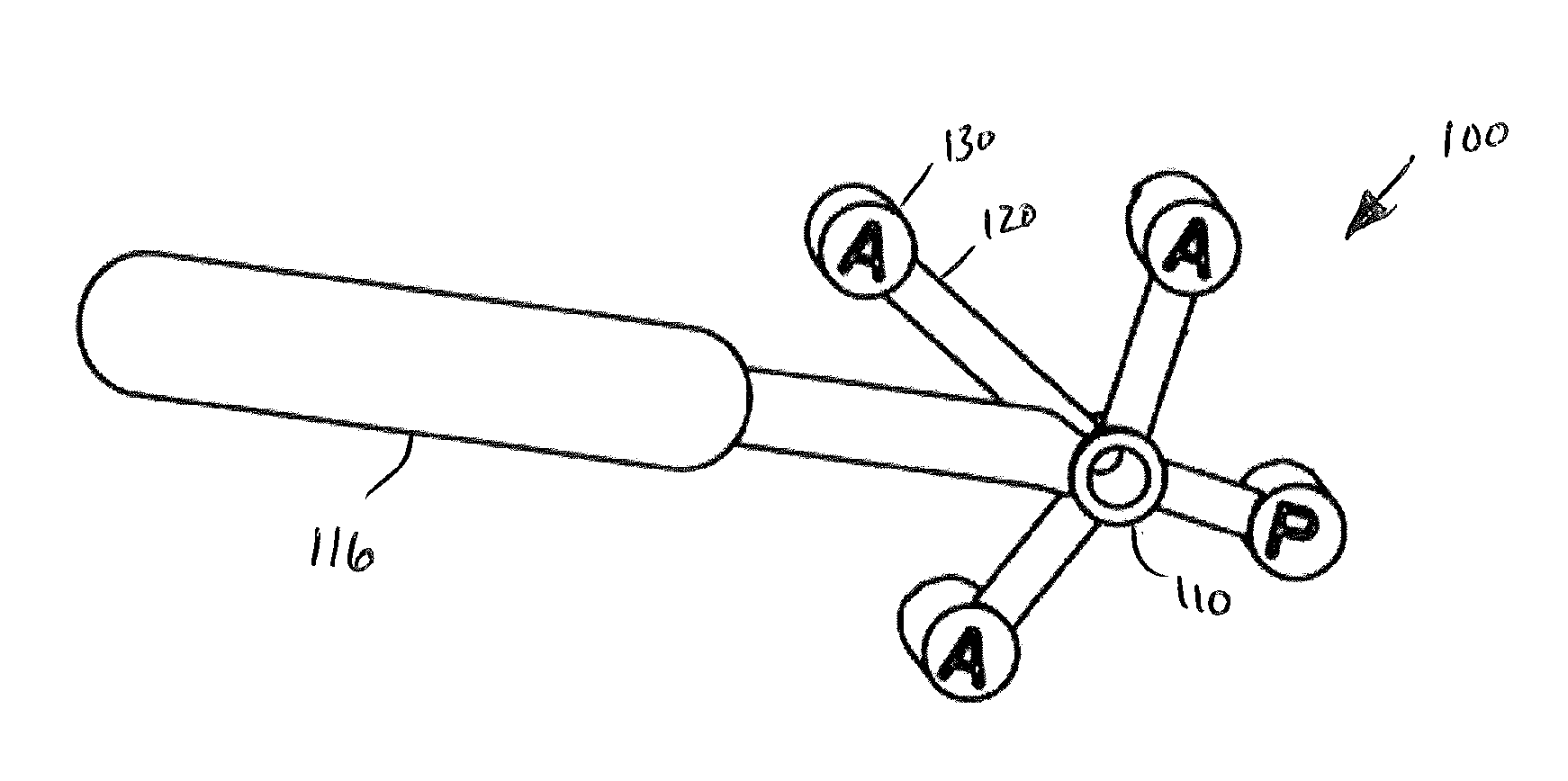

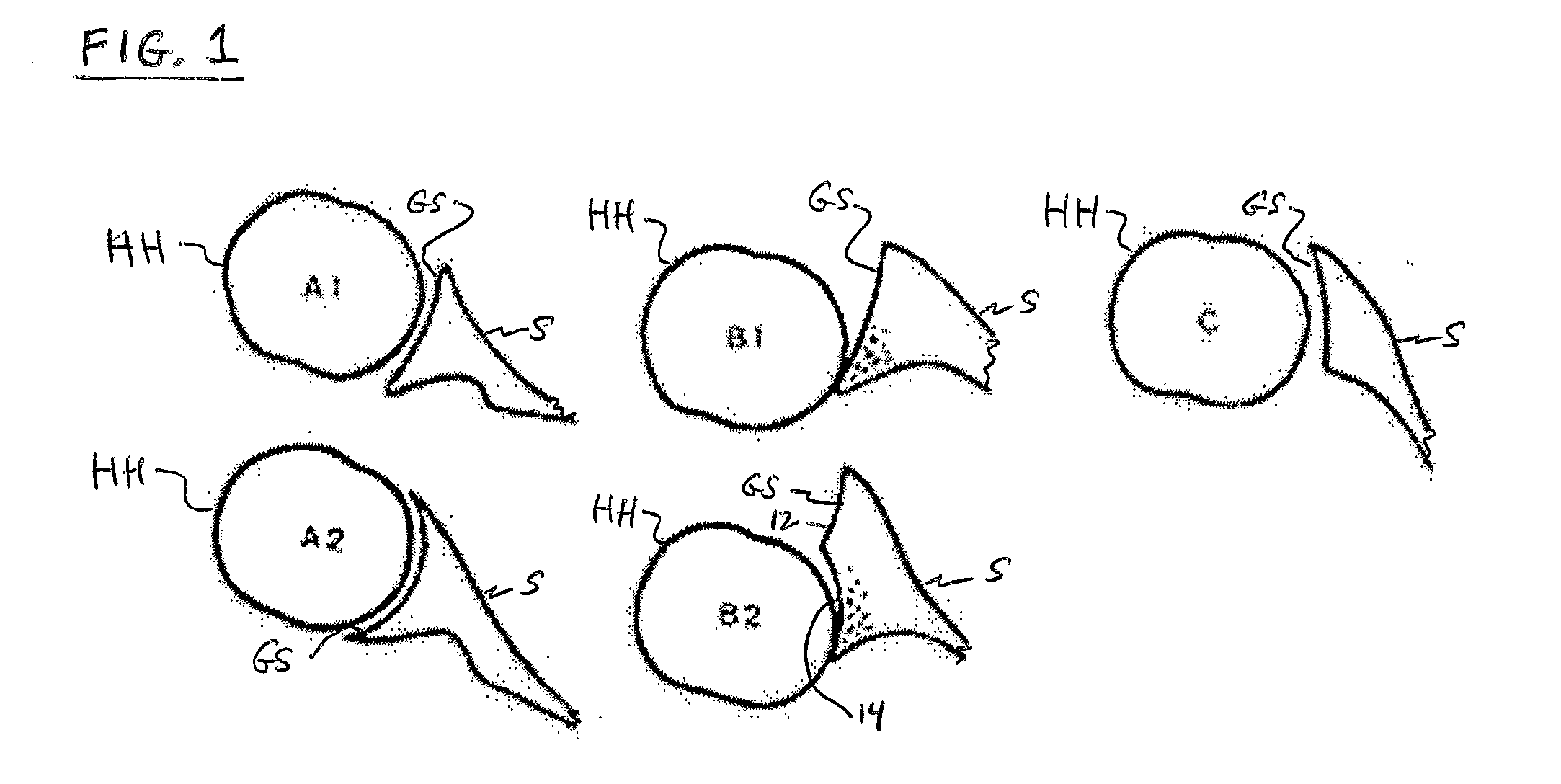

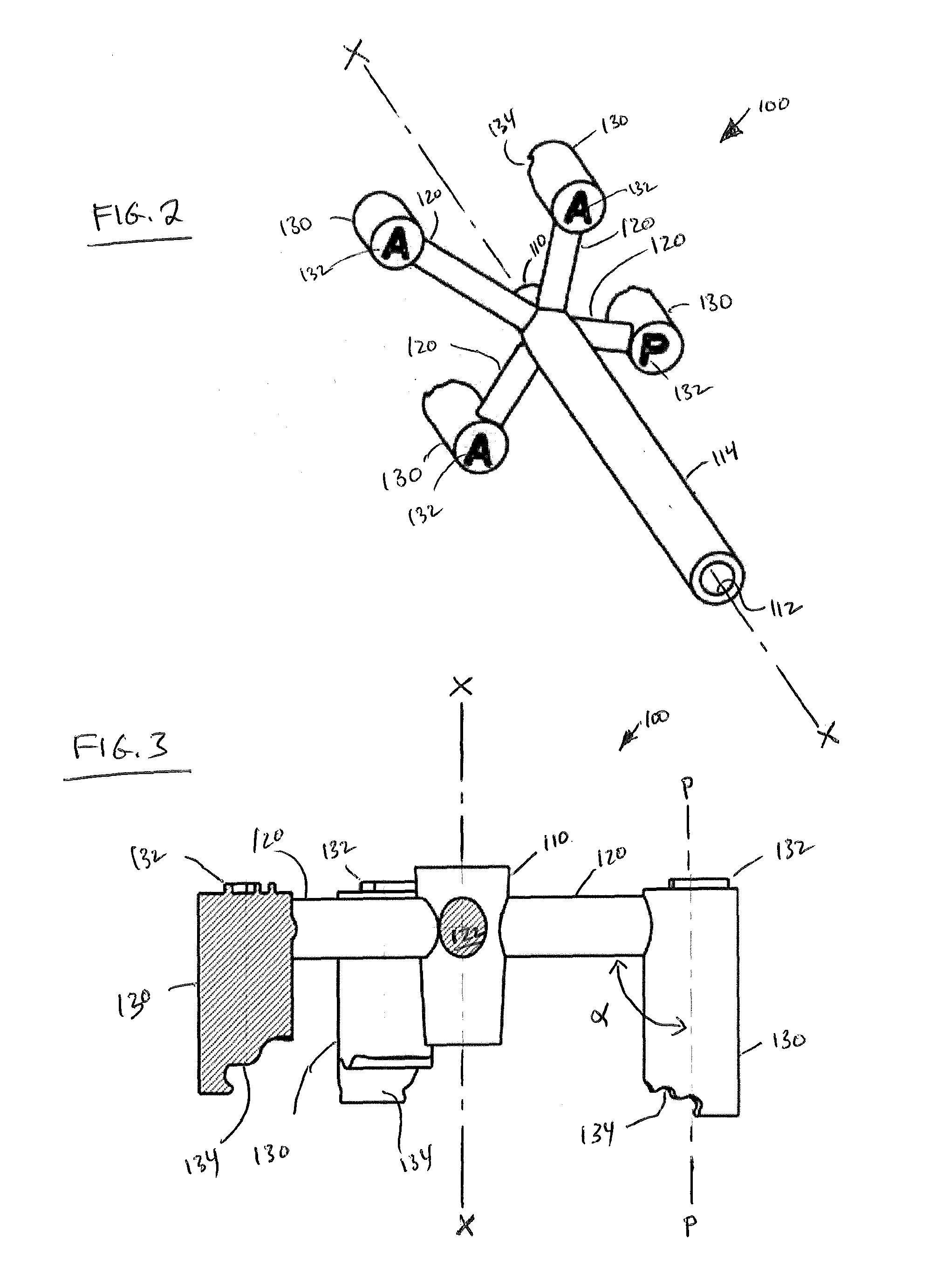

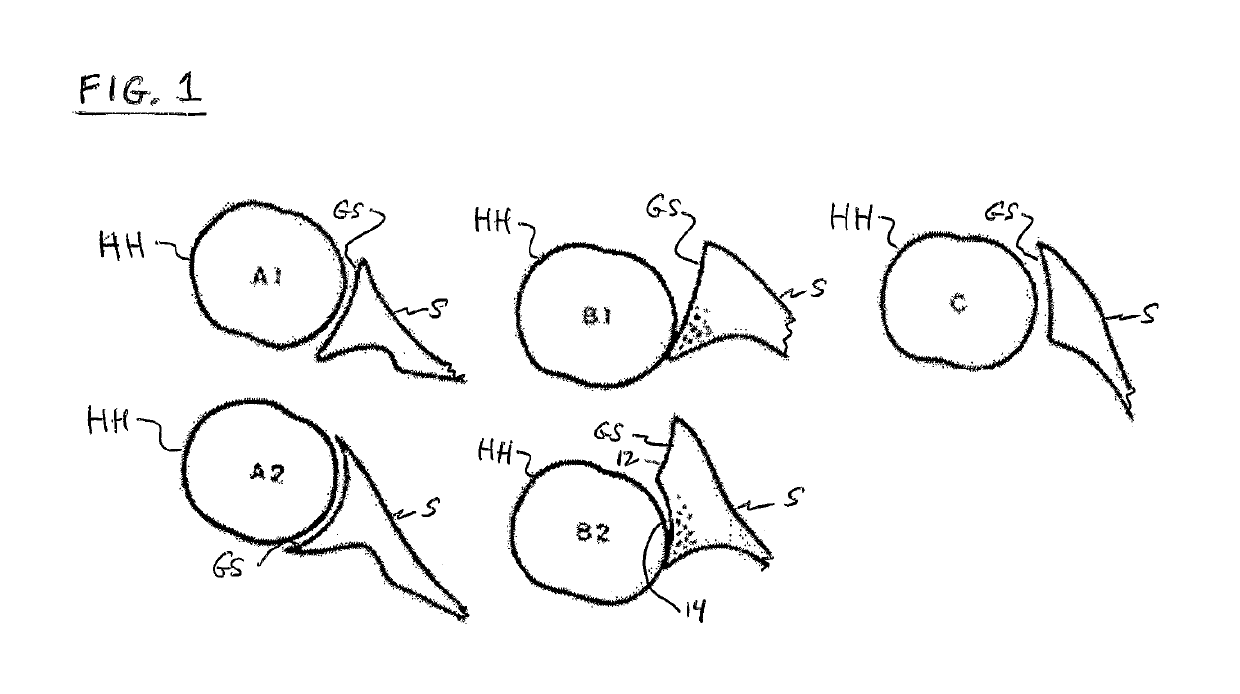

Shoulder patient specific instrument

A patient specific glenoid guide is provided to facilitate properly aligned implantation of a glenoid prosthesis into a patient. The guide shape is designed preoperatively based on the unique configuration of the scapula of the patient. The guide orientation is chosen preoperatively based on one or more of the bone structure of the patient, the wear pattern of the patient's glenoid cavity, the anchoring means of the glenoid prosthesis, or other aspects.

Owner:TORNIER SA SAINT ISMIER

Synthetic turf

InactiveUS7399514B2Less differenceSmall coefficient of frictionDead plant preservationArtificial flowers and garlandsInfillWear pattern

The present invention provides new types of synthetic turf. The synthetic turf includes a pile fabric having a backing (1) and tufts (2) projecting therefrom. In one embodiment, at least a number of the tufts are made of a composite yarn formed by at least one fibrillated yarn (6) together with a number of individual filament yarns (7), in particular with so-called monofilament or monotape yarns. The fibrillated yarn and the individual filament yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. In another embodiment, at least a number of the tufts are made of a composite yarn formed by monotape yarns twisted together with a number of the monofilament yarns. The monofilament and monotape yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. The combination of a fibrillated yarn and individual filament yarns or the combination of monofilament and monotape yarns in a composite yarn allows immediate achievement of the look of natural grass, that is, without post-fibrillation, and avoids any visible difference in wear pattern between the different types of yarns. In another embodiment, the invention also provides improved particulate material for use as infill material for top-dressing a synthetic turf.

Owner:DOMO ZELE

System and method for displaying selected garments on a computer-simulated mannequin

InactiveUS20100302275A1Effective imagingImprove matchCathode-ray tube indicatorsVisual presentationWear patternDimensional modeling

A method and system for providing a computer-simulated environment for displaying a selected mannequin wearing a combination of selected garments. In one aspect, three-dimensional scenes containing mannequin and garment objects are created within a three-dimensional modeling environment, and a simulation is performed using a cloth simulator within the modeling environment to model the construction, draping, and collision of the garment with the mannequin. Rendering frames corresponding to a variety of garments, mannequins, garment dimensions, garment styles, wearing patterns, viewing angles, and other parameters, are then generated from which images can be rendered and displayed in accordance with user requests.

Owner:MY VIRTUAL MODEL

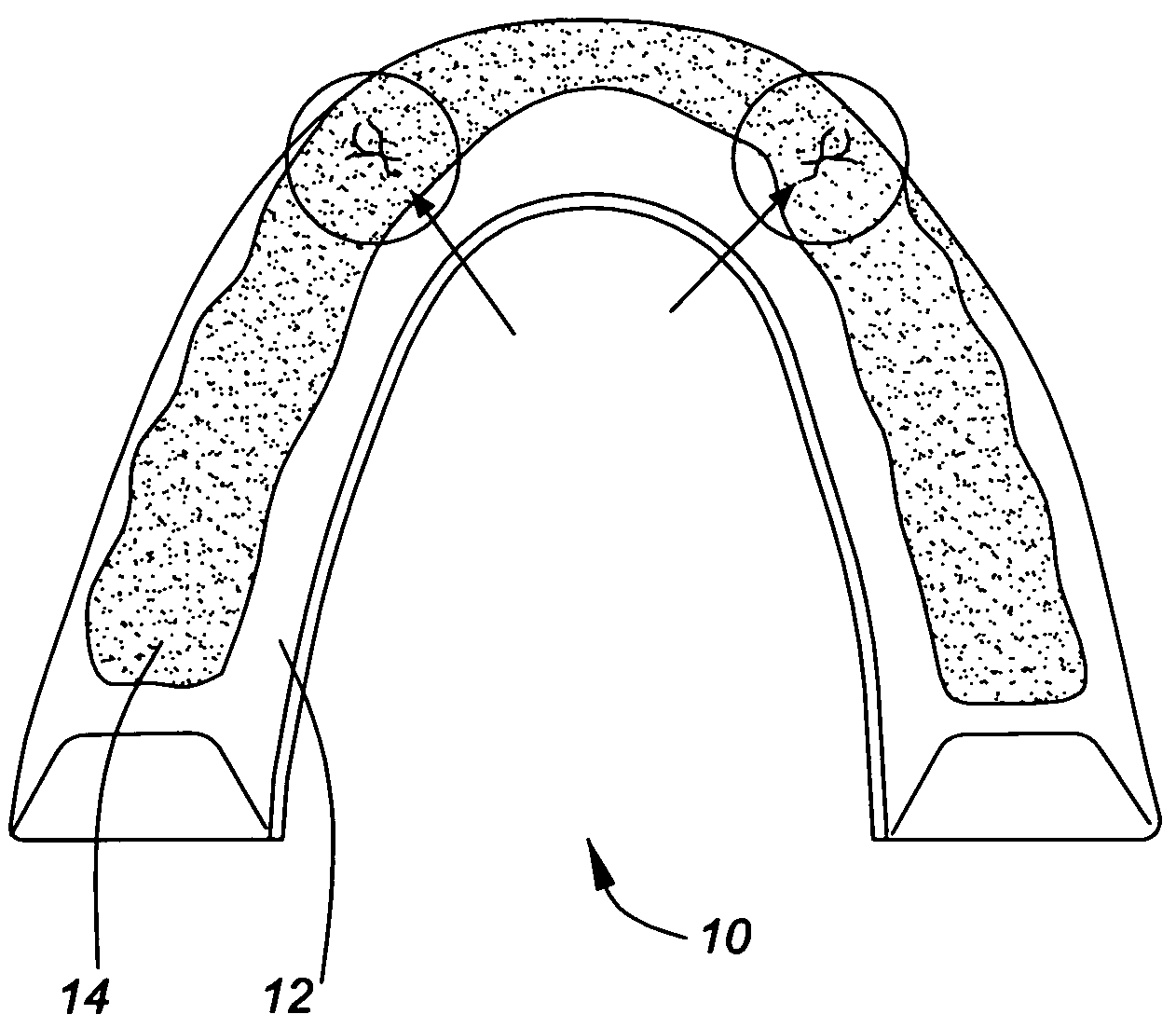

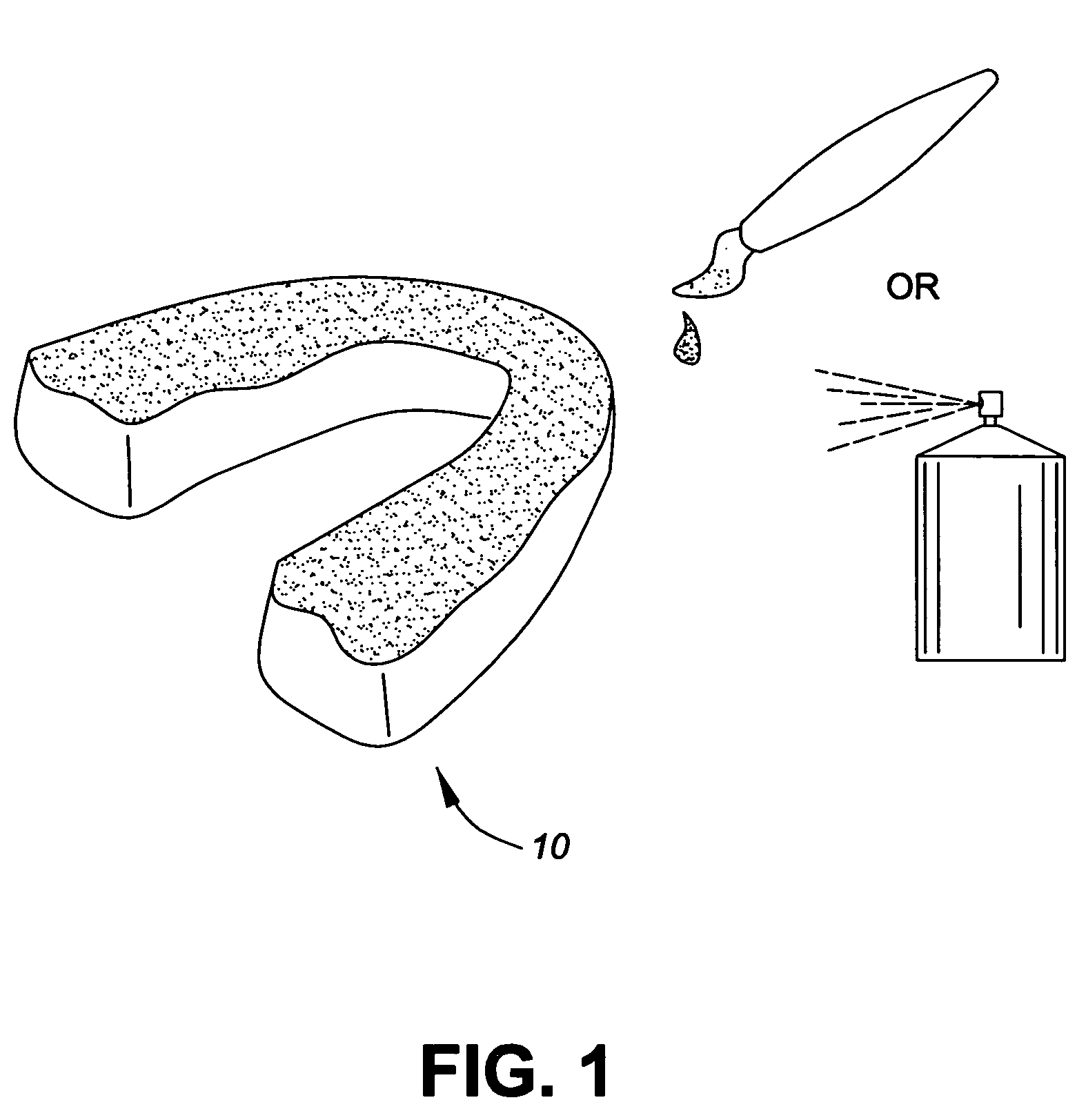

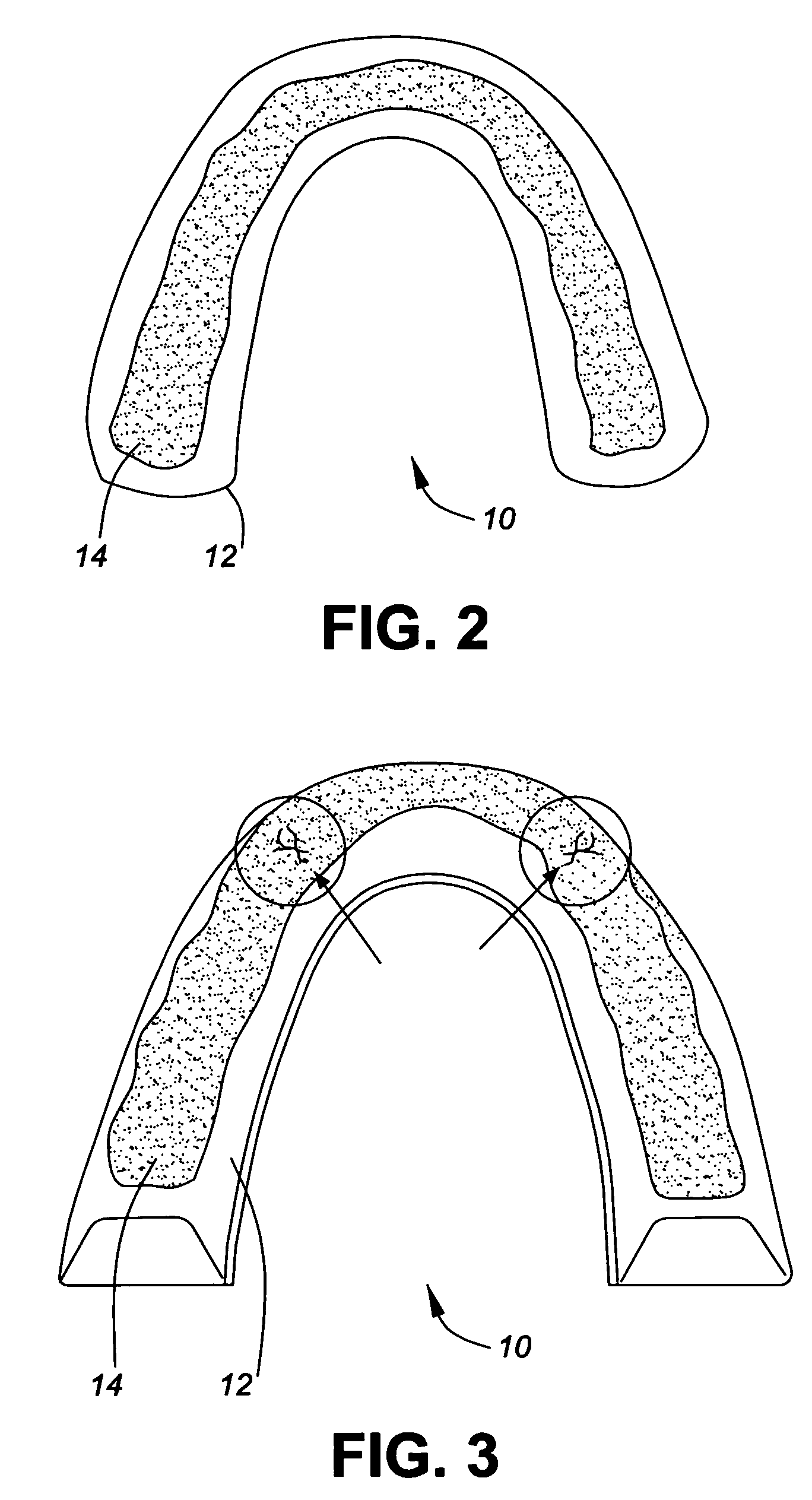

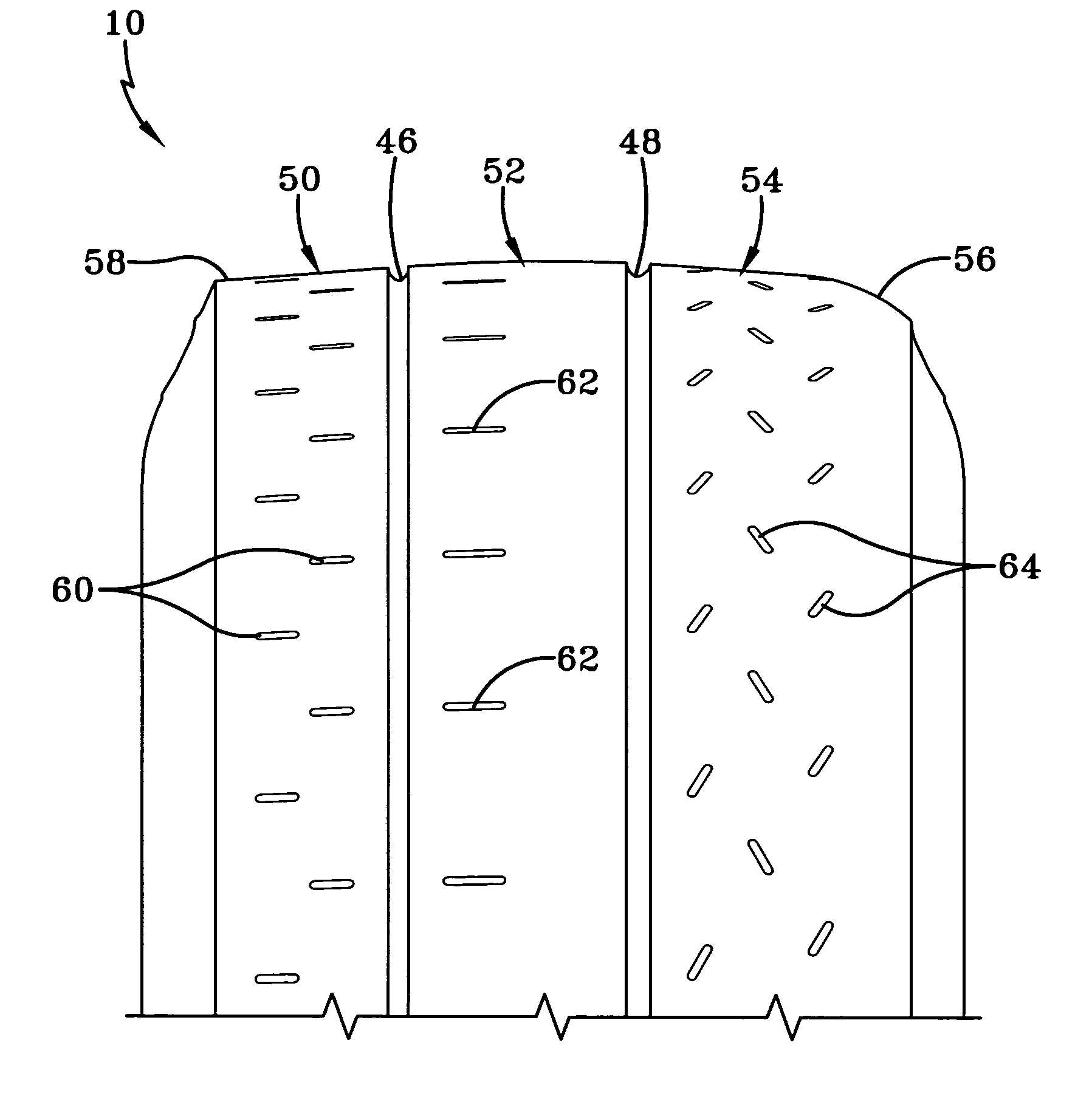

Bruxism appliance and method of forming

A bruxism appliance and a method of forming a bruxism appliance is described for providing a patient and a dentist with a visual indication of the degree of bruxism by the patient. The invention teaches the application of an abradable composition to the non-retaining / opposing dentition contacting surfaces of the appliance in order that specific wear patterns can be observed on the appliance following use by a patient.

Owner:ZUK MICHAEL YAR

Asymmetric truck racing tire

InactiveUS7140410B2Reduce distanceImprove gripSpecial tyresPneumatic tyre reinforcementsWear patternEngineering

An improved truck racing tire includes three belts and reduced tread and undertread thickness for weight reduction. An asymmetric shoulder design is provided and circumferential grooves having wear indicia therein at a preselected depth are incorporated into the tread to divide the tread into plural ribs. Notches are formed within the tread ribs in circumferential patterns of distribution at a depth equivalent to the depth of groove tread wear indicators. The tread is constructed of a relatively softer compound in the cap and a relatively harder compound in the base. The boundary between the cap and the base is at a depth corresponding to the notch depth and the wear indicators within the grooves to provide a further indication and confirmation of wear pattern and magnitude.

Owner:THE GOODYEAR TIRE & RUBBER CO

Using Laser to Create Finishing Pattern on Apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

Laser Finishing Design Tool with Image Preview

ActiveUS20190129604A1Texturing/coloringLaser beam fibre treatmentWear patternUltimate tensile strength

A tool allows a user to create new designs for apparel and preview these designs before manufacture. Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. Based on a laser input file with a pattern, a laser will burn the pattern onto apparel. With the tool, the user will be able to create, make changes, and view images of a design, in real time, before burning by a laser. Input to the tool includes fabric template images, laser input files, and damage input. The tool allows adding of tinting and adjusting of intensity and bright point. The user can also move, rotate, scale, and warp the image input.

Owner:LEVI STRAUSS & CO

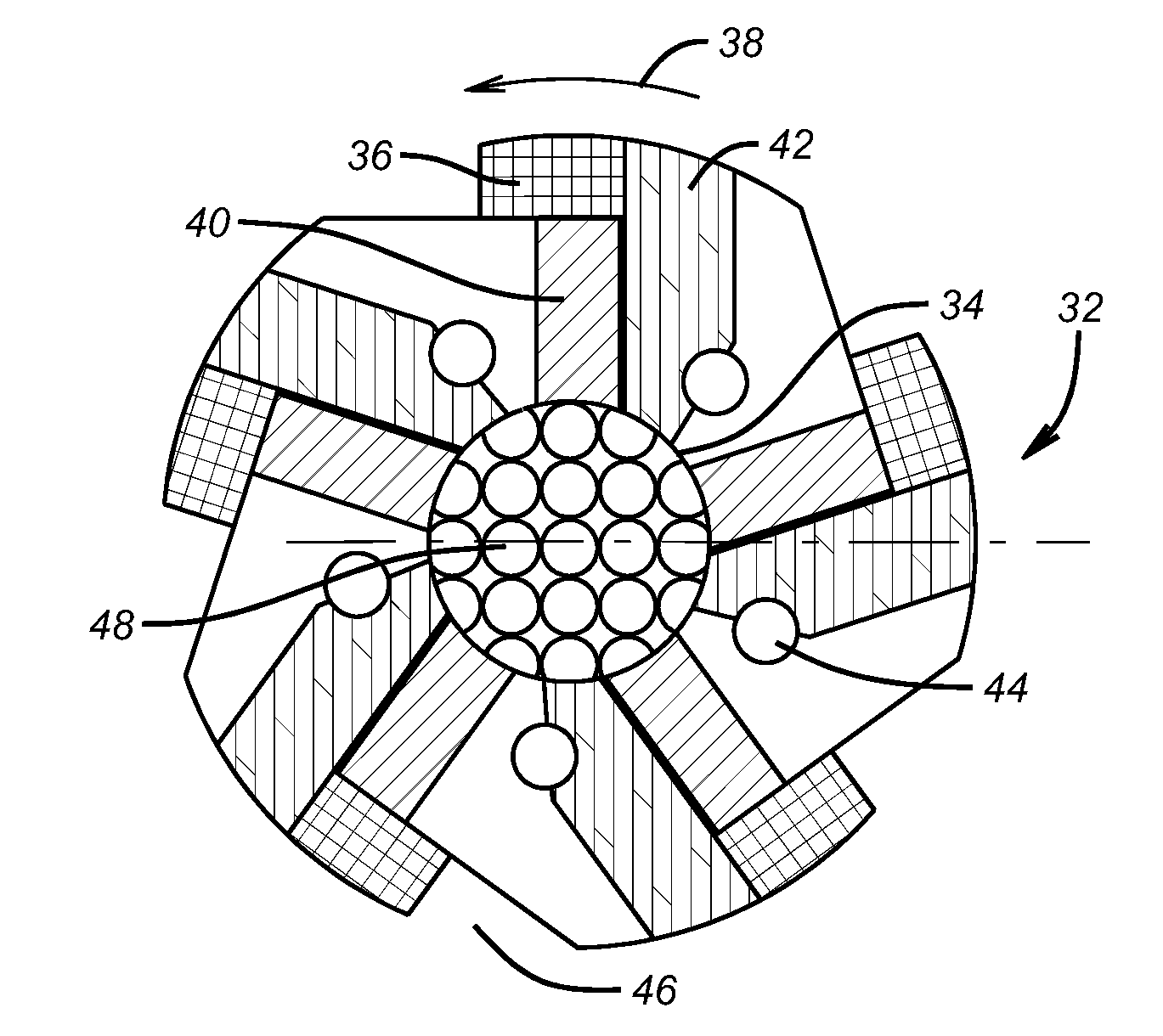

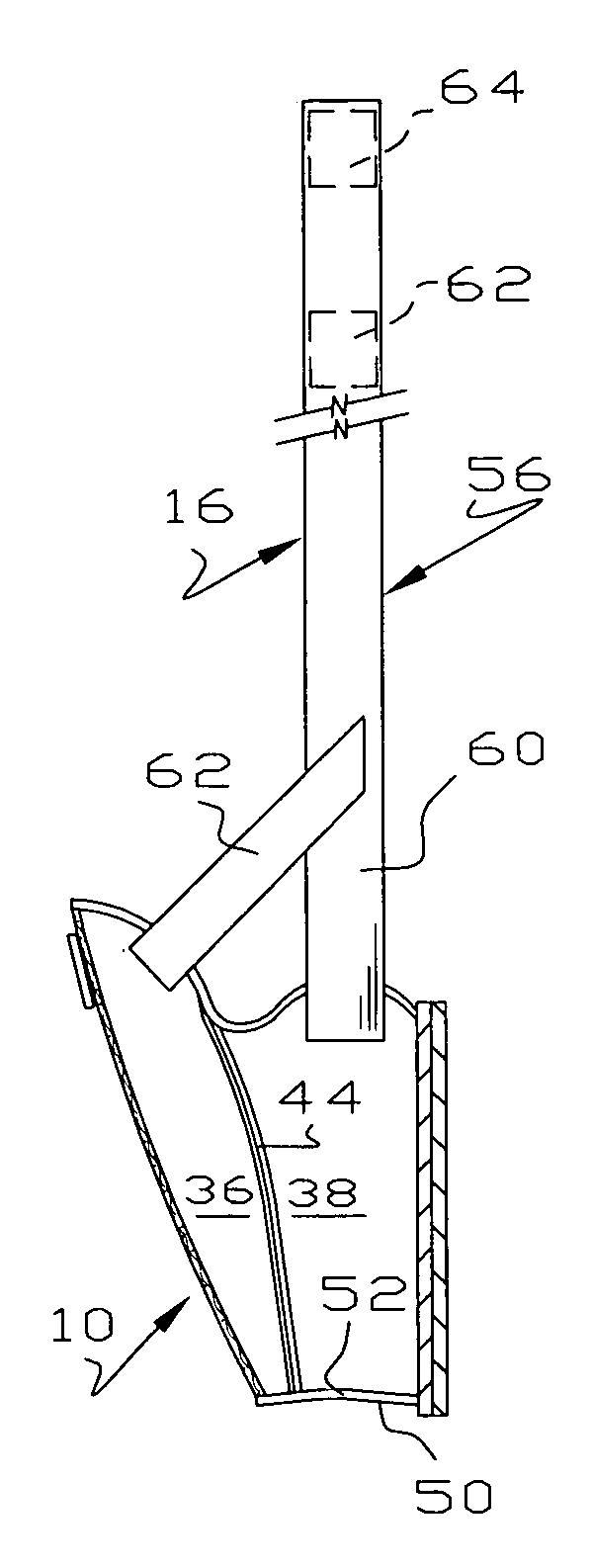

Subterranean Cutting Tool Structure Tailored to Intended Use

ActiveUS20120073880A1Improve wear resistanceGood temperature bond strengthDrill bitsConstructionsWear patternWear resistant

A mill cutting structure is differently configured in three zones. Those zones are the center, the outer edge and in between. At the center has highly wear resistant material that has good temperature bond strength and high impact resistance. The outer periphery can have a material that is highly resistant to wear and impact. In between can be inserts such as used in the Metal Muncher® mills using sintered carbide shapes that resist tracking and create a chipping rather than a grinding action. The shapes should have high edge retention capability and shapes such as a double sided pyramid can be used. The wear patterns of prior designs are addressed to allow longer and faster milling of the fish.

Owner:BAKER HUGHES INC

Footwear protector

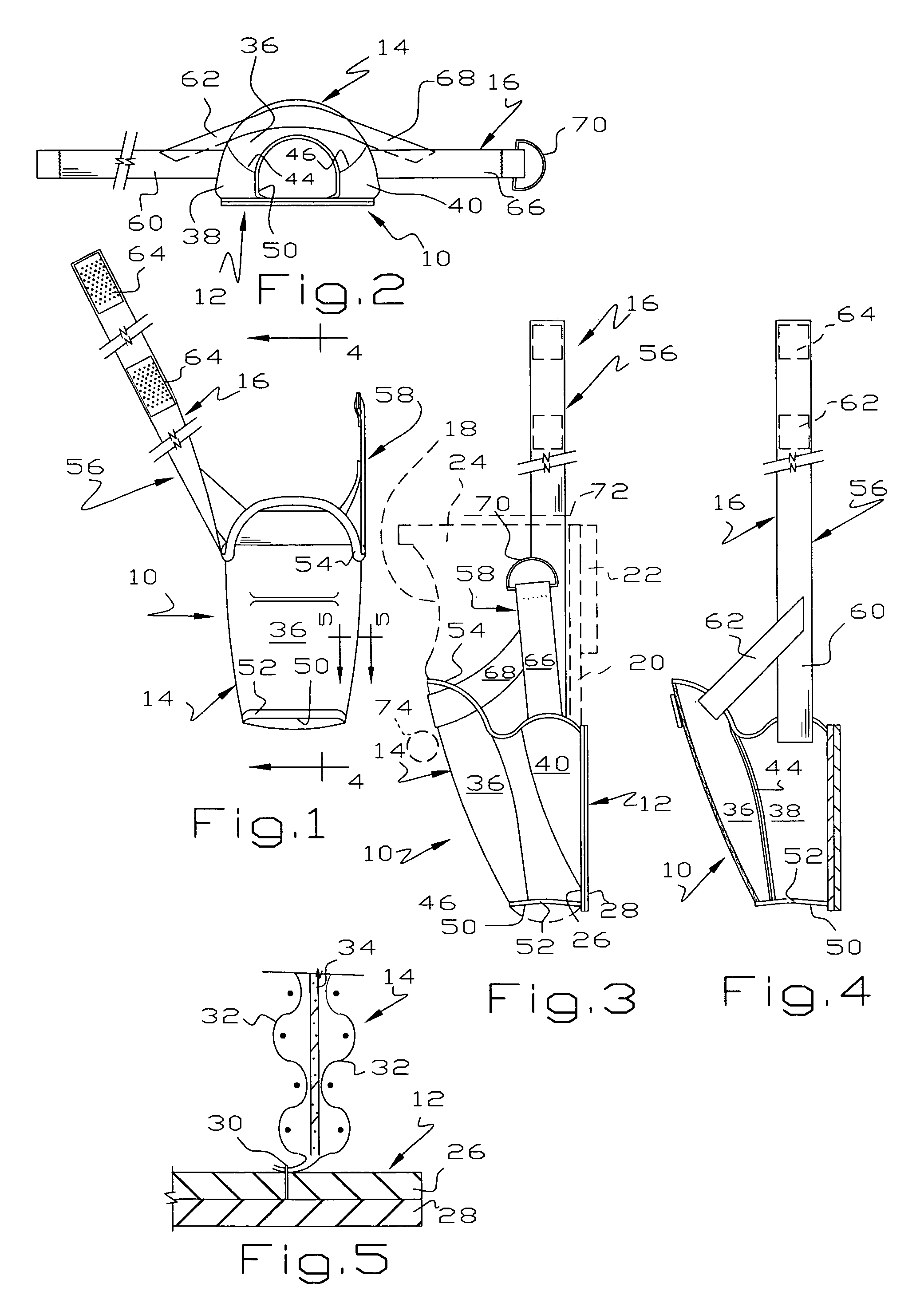

A device for protecting footwear of a motorcycle rider comprises a sole of a water impermeable material, an upper of bodily flexible material and an adjustable strap for securing the device to footwear of the rider. The device is typically worn on the left foot of the rider because motorcycle transmissions are shifted by the left foot, leaving a characteristic wear pattern on the left shoe or boot of the rider. The upper allows substantial air movement around the rider's footwear and may be partially or wholly insulated with a foam layer in the upper. Some embodiments provide greater air circulation and less insulation. Two types of adjustable straps are shown.

Owner:LUTZ CELESTE V +1

Shoulder patient specific instrument

A patient specific glenoid guide is provided to facilitate properly aligned implantation of a glenoid prosthesis into a patient. The guide shape is designed preoperatively based on the unique configuration of the scapula of the patient. The guide orientation is chosen preoperatively based on one or more of the bone structure of the patient, the wear pattern of the patient's glenoid cavity, the anchoring means of the glenoid prosthesis, or other aspects.

Owner:TORNIER SA SAINT ISMIER

Shoulder patient specific instrument

A patient specific glenoid guide is provided to facilitate properly aligned implantation of a glenoid prosthesis into a patient. The guide shape is designed preoperatively based on the unique configuration of the scapula of the patient. The guide orientation is chosen preoperatively based on one or more of the bone structure of the patient, the wear pattern of the patient's glenoid cavity, the anchoring means of the glenoid prosthesis, or other aspects.

Owner:TORNIER SA SAINT ISMIER

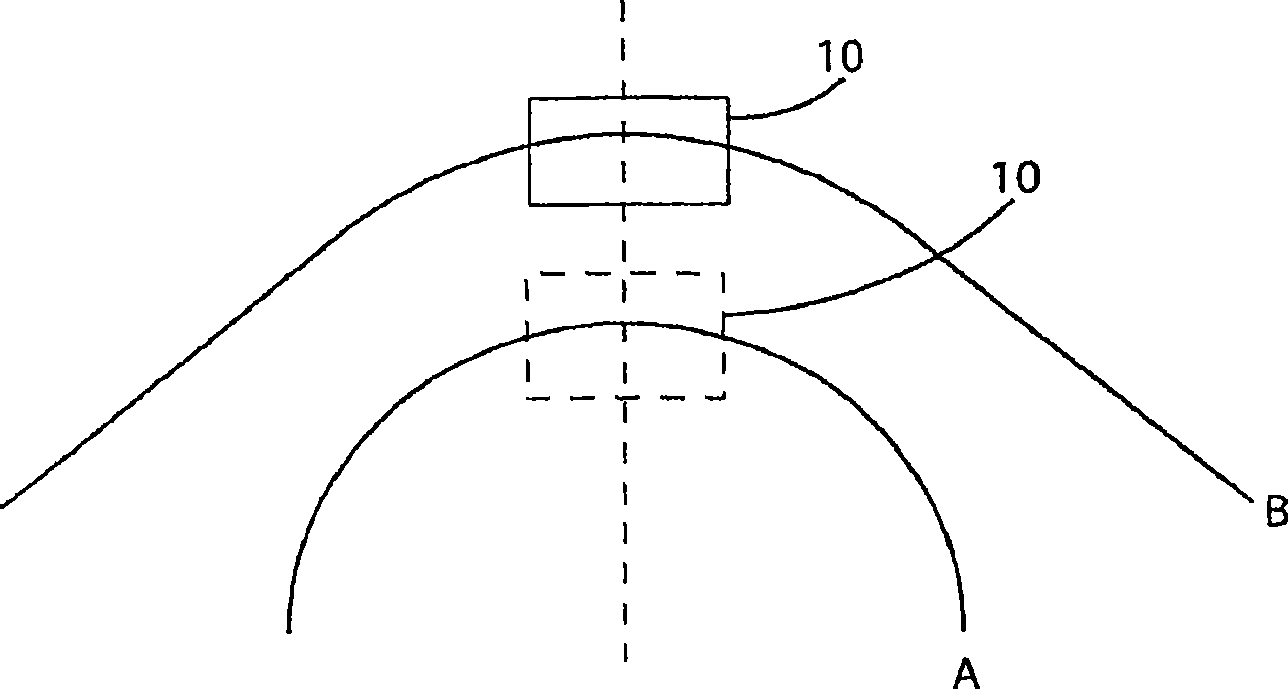

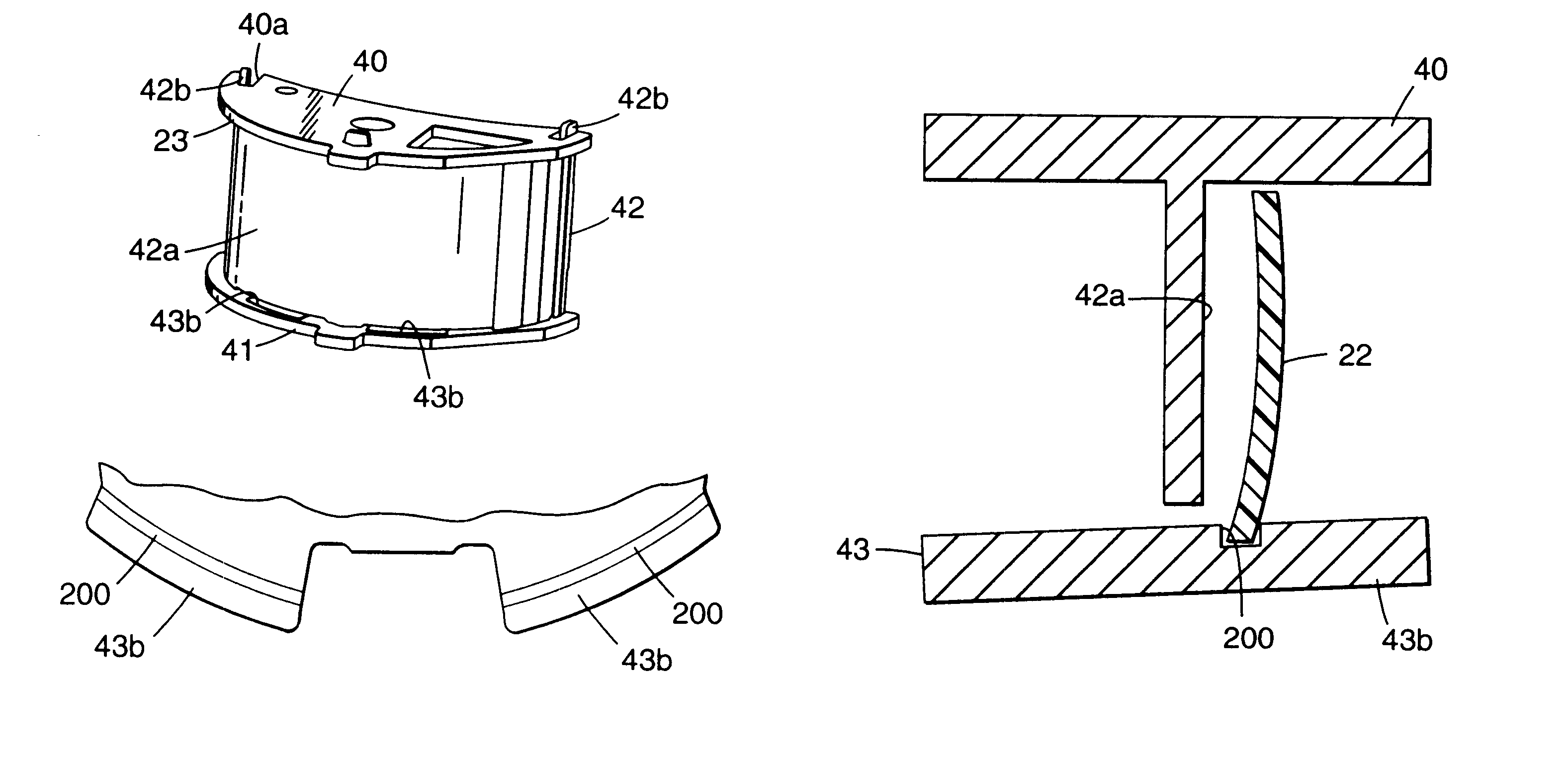

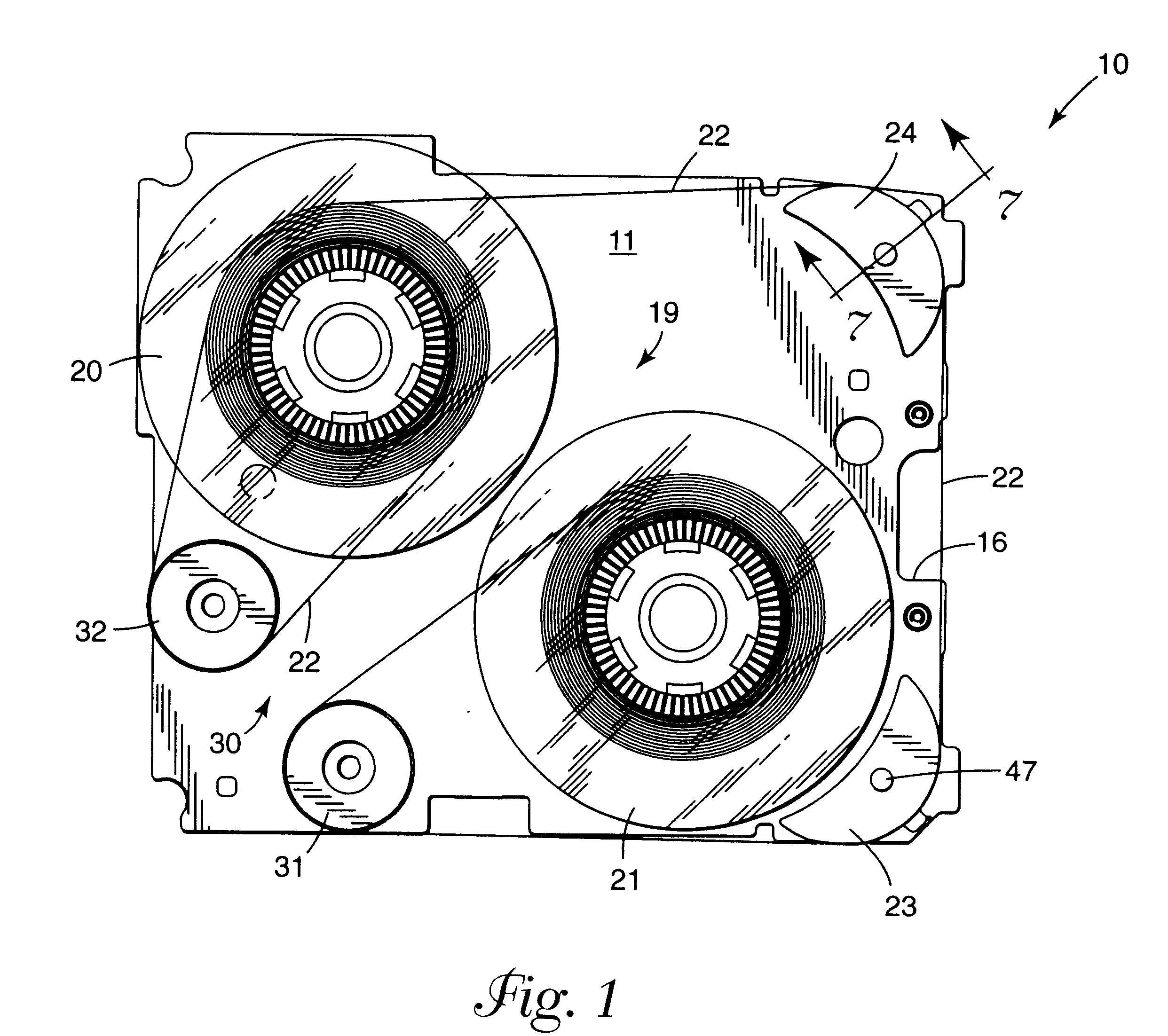

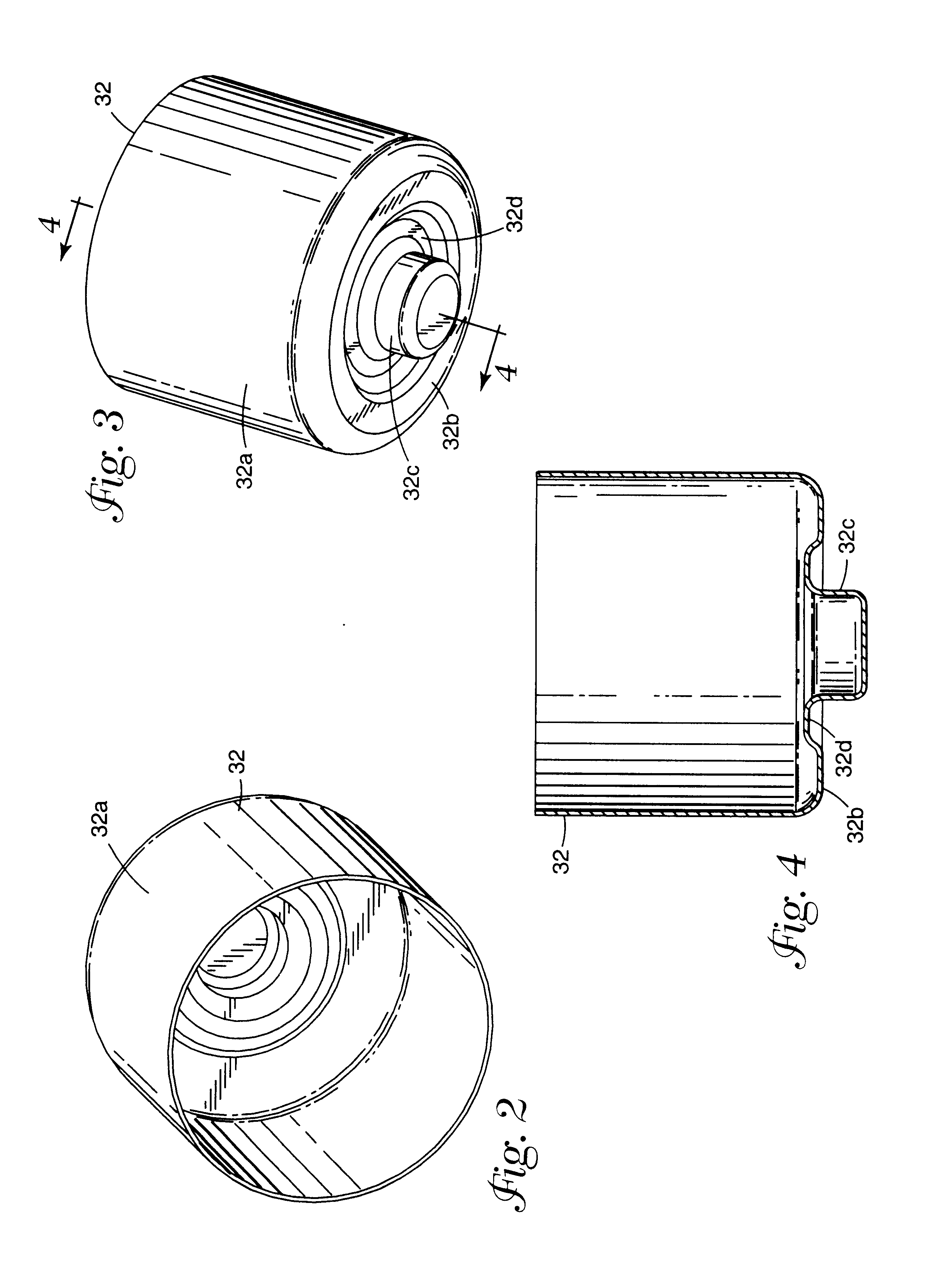

Data storage tape cartridge with guide having wear pattern

A data storage tape cartridge (10) includes two tape guides (23, 24). The tapes guides (23, 24) have a foil (43, 143, 243) which is constructed from material which causes a wear pattern (200) to be formed in the foil (43), thereby removing localized forces and spreading out the forces and thereby decreasing the tape pressure.

Owner:IMATION

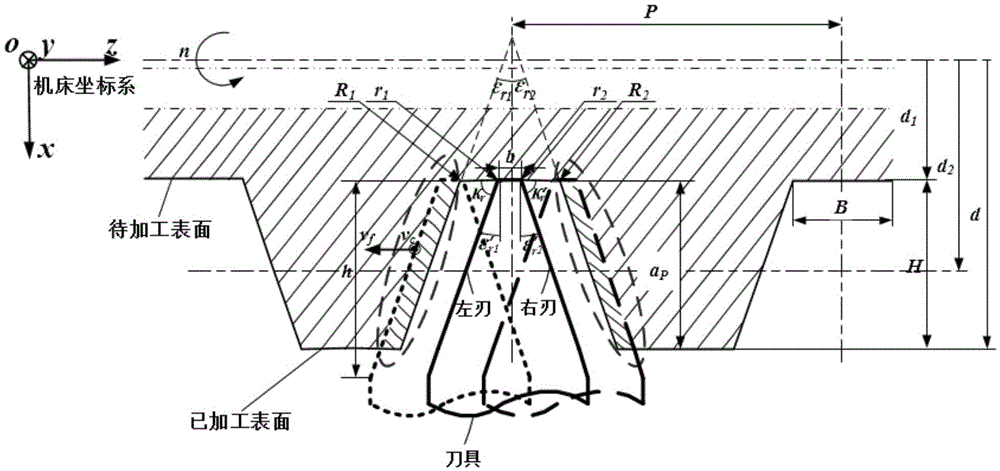

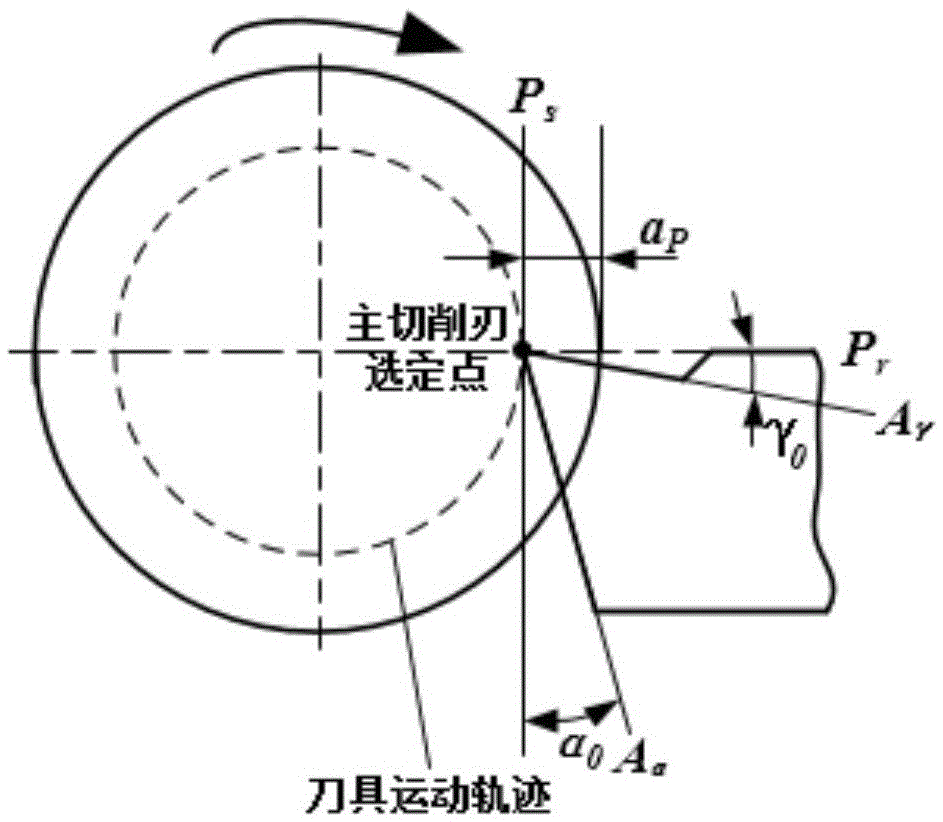

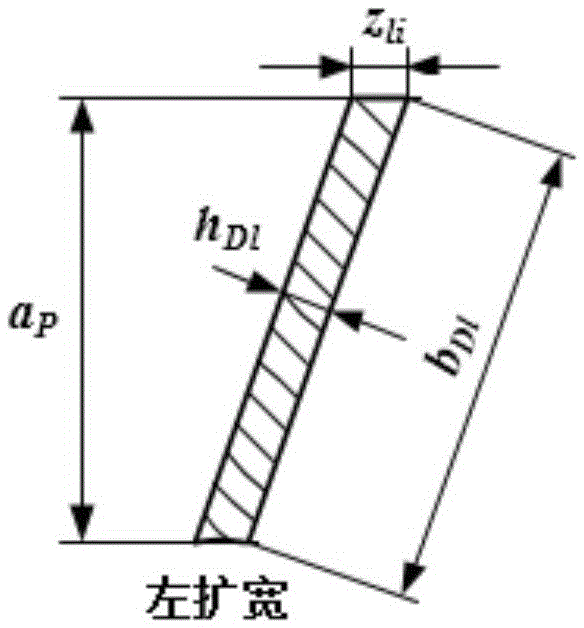

Axial layered cutting method for turning coarse-pitch threads, tool wear testing method and force-heat load calculating method of tool wear

InactiveCN105643024ADimensional accuracy does not existGuaranteed dimensional accuracyAutomatic control devicesThread cutting machinesWear patternHeat load

The invention discloses an axial layered cutting method for turning coarse-pitch threads, a tool wear testing method and a force-heat load calculating method of tool wear for eliminating principle errors caused by radial layered cutting of the coarse-pitch threads. The axial layered cutting method for turning the coarse-pitch threads, the tool wear testing method and the force-heat load calculating method of tool wear are technically characterized in that through the cutting method, a testing tool with a left cutting edge and a right cutting edge is used for axially turning a left thread surface and a right thread surface of a coarse-pitch test piece in a layered mode, wear tests of the tool turning the coarse-pitch threads are conducted through the cutting method, the wear pattern of the tool turning the coarse-pitch threads is obtained, the influence of tool wear on thread machining surfaces is revealed, then a finite element analytical model of the tool is reconstructed according to the flank wear data of the tool and the blunt round radius measurement data of the cutting edges, analysis and calculation of the temperature field and the stress field of the tool are carried out, and the force-heat load change characteristic on the tool wear condition is obtained.

Owner:HARBIN UNIV OF SCI & TECH

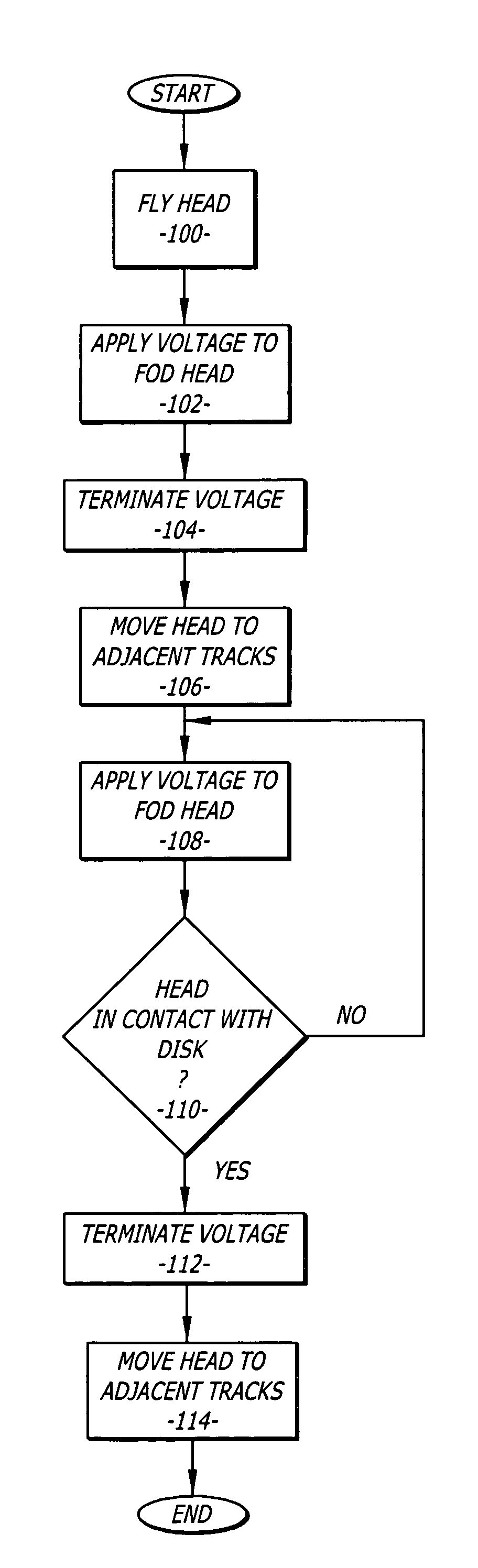

Clearance sweep test

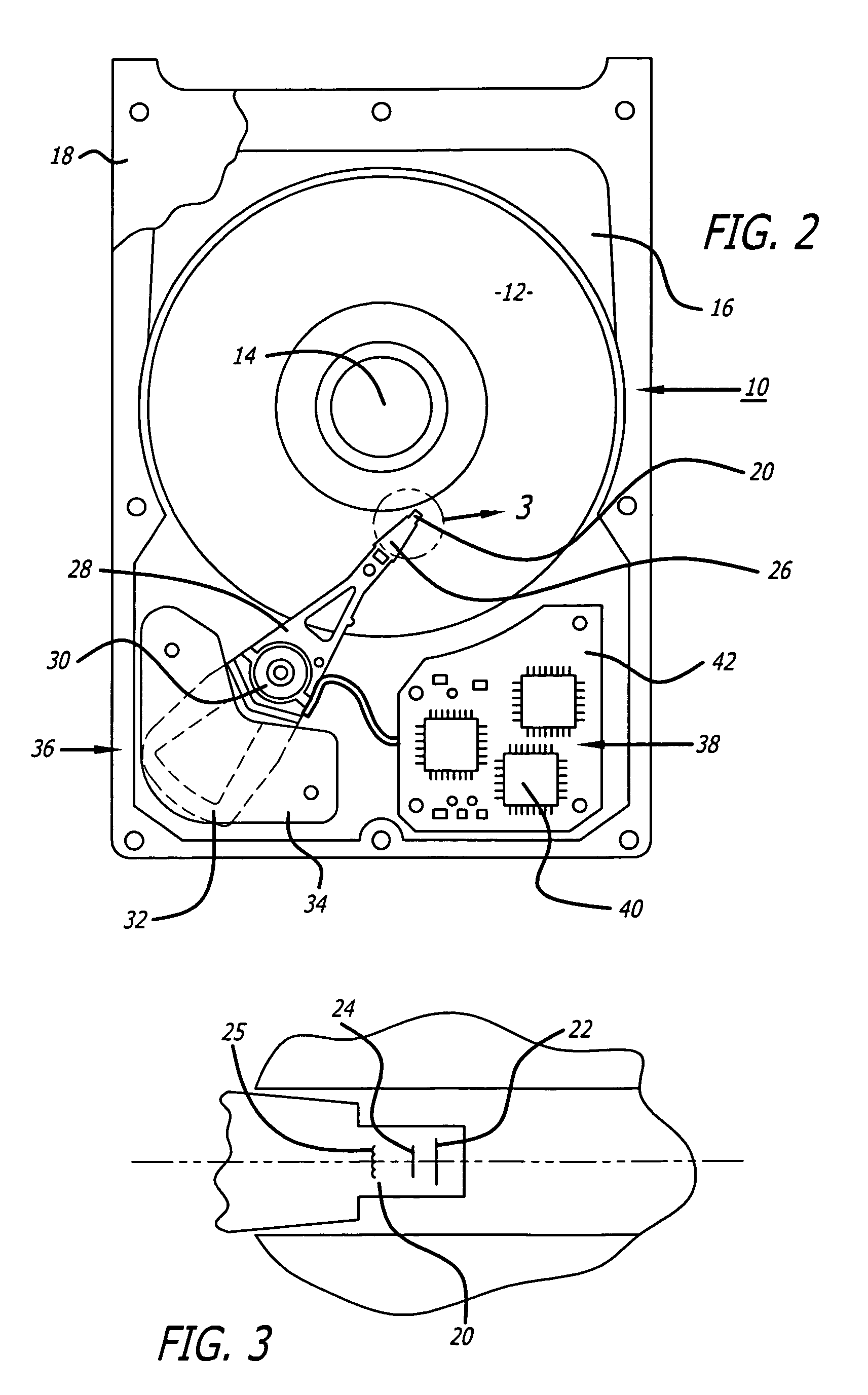

InactiveUS7301719B1Filamentary/web record carriersRecord information storageHard disc driveWear pattern

A calibration method for a fly on demand head of a hard disk drive. The method includes the steps of flying a head over a test track of a disk that is covered with a lubricant. A voltage is applied to a heating element of the head to move the head closer to the disk. The fly height of the head is then determined. The voltage can be incrementally varied until the head makes contact with the disk. This sequence can cause a modulated wear pattern in the lubricant of the disk. The voltage is terminated and the head is allowed to fly over the test track. The head is also moved to adjacent tracks on either side of the test track. A pressure gradient of the flying head moves the lubricant about the disk to mitigate the modulated wear pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Laser Finishing Design Tool

A computer system of a finishing center, such as a mobile finishing center, includes a tool that allows a customer to preview or create new designs for apparel before purchase and before laser finishing. Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. Based on a laser input file with a pattern, a laser will burn or ablate the pattern onto apparel. With the tool, the customer will be able to preview, create, make changes, and view images of a design, in real time, before purchase and burning or ablation by a laser. Input to the tool can include fabric template images, laser input files, and damage input. In an implementation, the customer or another user can also move, rotate, scale, and warp the image input.

Owner:LEVI STRAUSS & CO

Using Neural Networks in Laser Finishing of Apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes using machine learning to create or extract a laser input file for wear pattern from an existing garment. Machine learning can be by a generative adversarial network, having generative and discriminative neural nets. The generative adversarial network is trained and then used to create a model. This model is used generate the laser input file from an image of the existing garment with the finishing pattern. With this laser input file, a laser can re-create the wear pattern from the existing garment onto a new garment.

Owner:LEVI STRAUSS & CO

Laser Finishing System for Apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

Synthetic turf

The present invention provides new types of synthetic turf. The synthetic turf includes a pile fabric having a backing (1) and tufts (2) projecting therefrom. In one embodiment, at least a number of the tufts are made of a composite yarn formed by at least one fibrillated yarn (6) together with a number of individual filament yarns (7), in particular with so-called monofilament or monotape yarns. The fibrillated yarn and the individual filament yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. The combination of a fibrillated yarn and individual filament yarns or the combination of monofilament and monotape yarns in a composite yarn allows immediate achievement of the look of natural grass, that is, without post-fibrillation, and avoids any visible difference in wear pattern between the different types of yarns. In another embodiment, the invention also provides improved particulate material for use as infill material for top-dressing a synthetic turf.

Owner:DOMO ZELE

Laser Finishing Design Tool with Damage Assets

A tool allows a user to create new designs for apparel and preview these designs before manufacture. Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. Based on a laser input file with a pattern, a laser will burn the pattern onto apparel. With the tool, the user will be able to create, make changes, and view images of a design, in real time, before burning by a laser. Input to the tool includes fabric template images, laser input files, and damage input. The tool allows adding of tinting and adjusting of intensity and bright point. The user can also move, rotate, scale, and warp the image input.

Owner:LEVI STRAUSS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com