Patents

Literature

292results about How to "Small coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

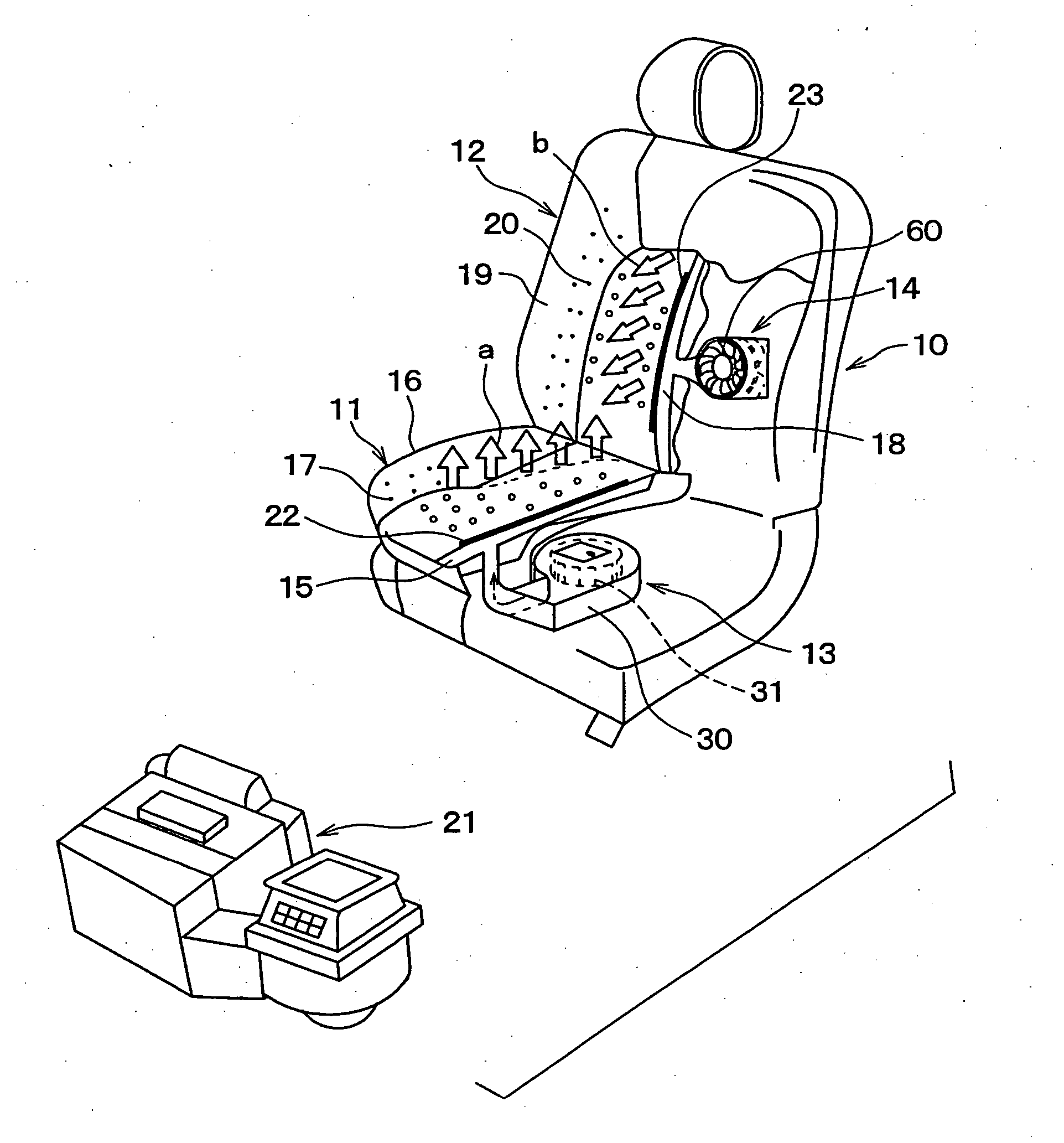

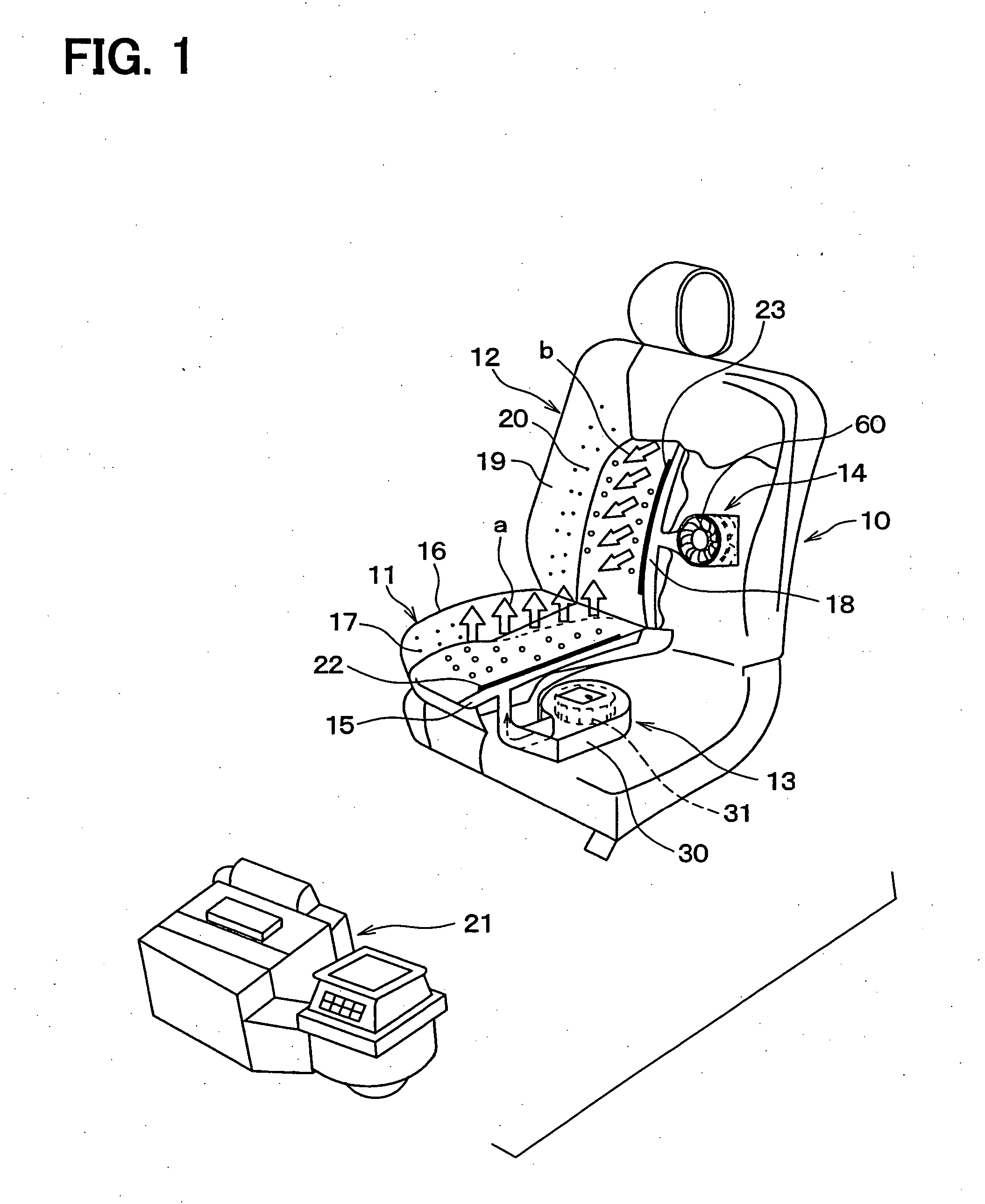

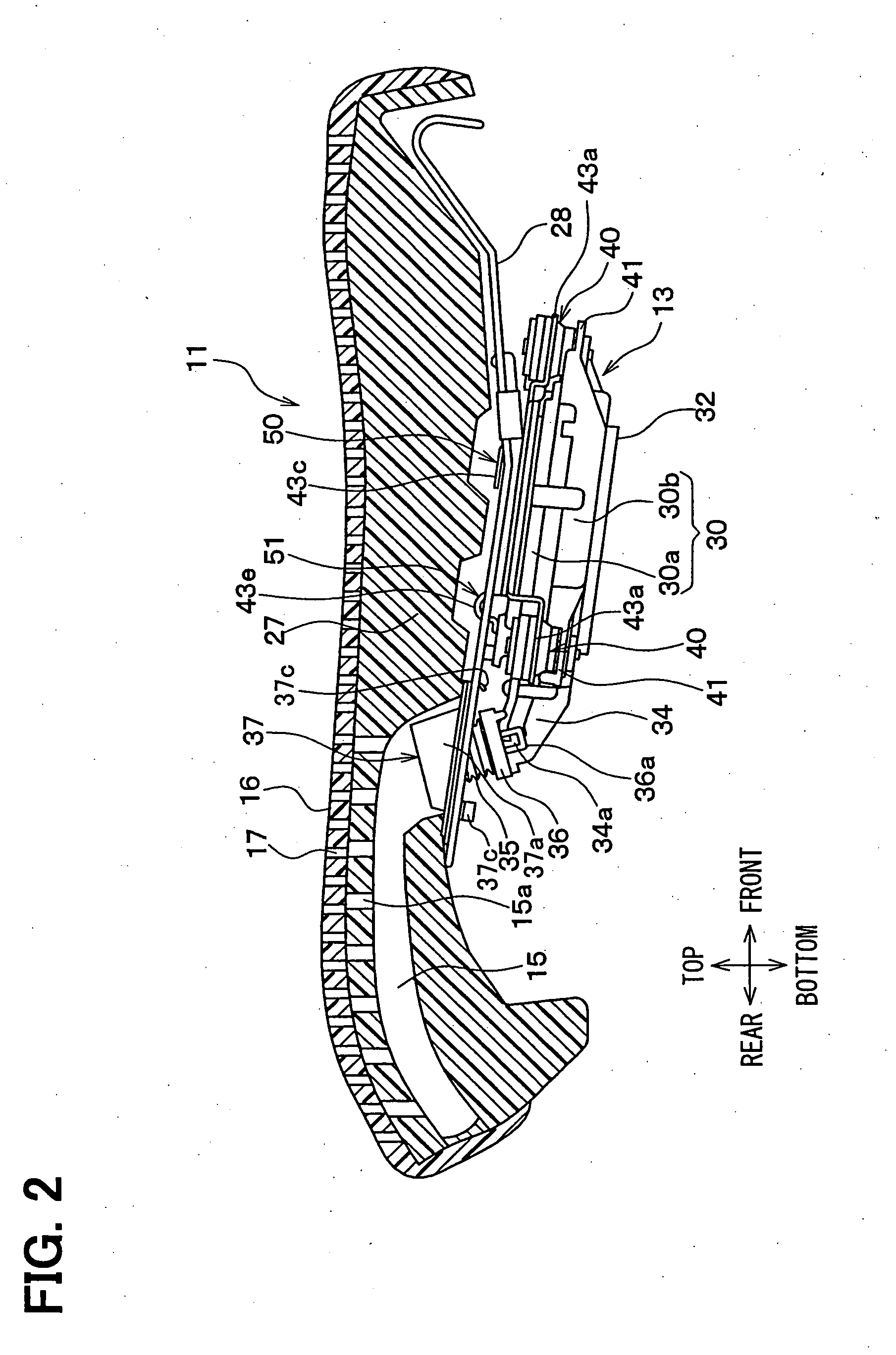

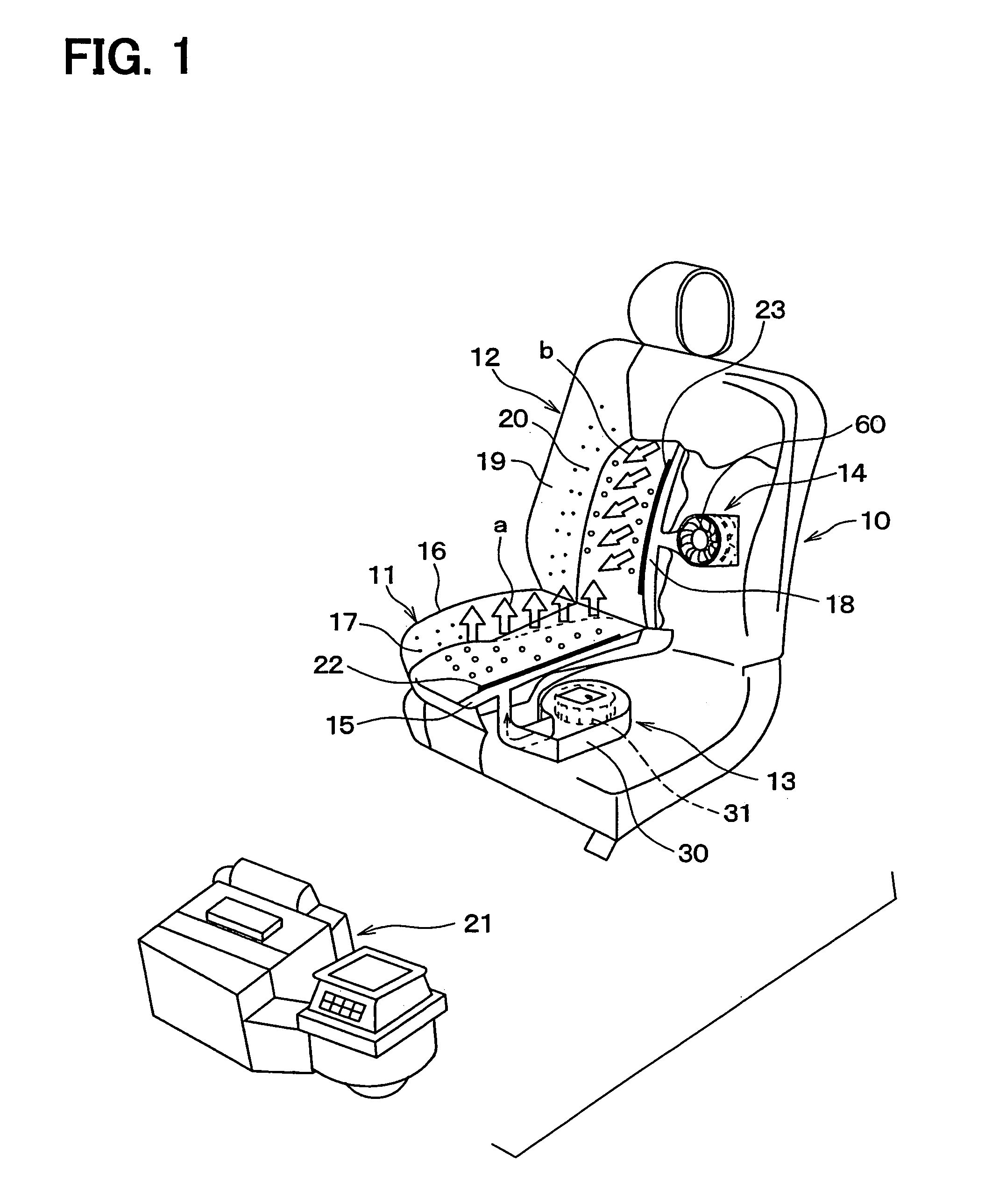

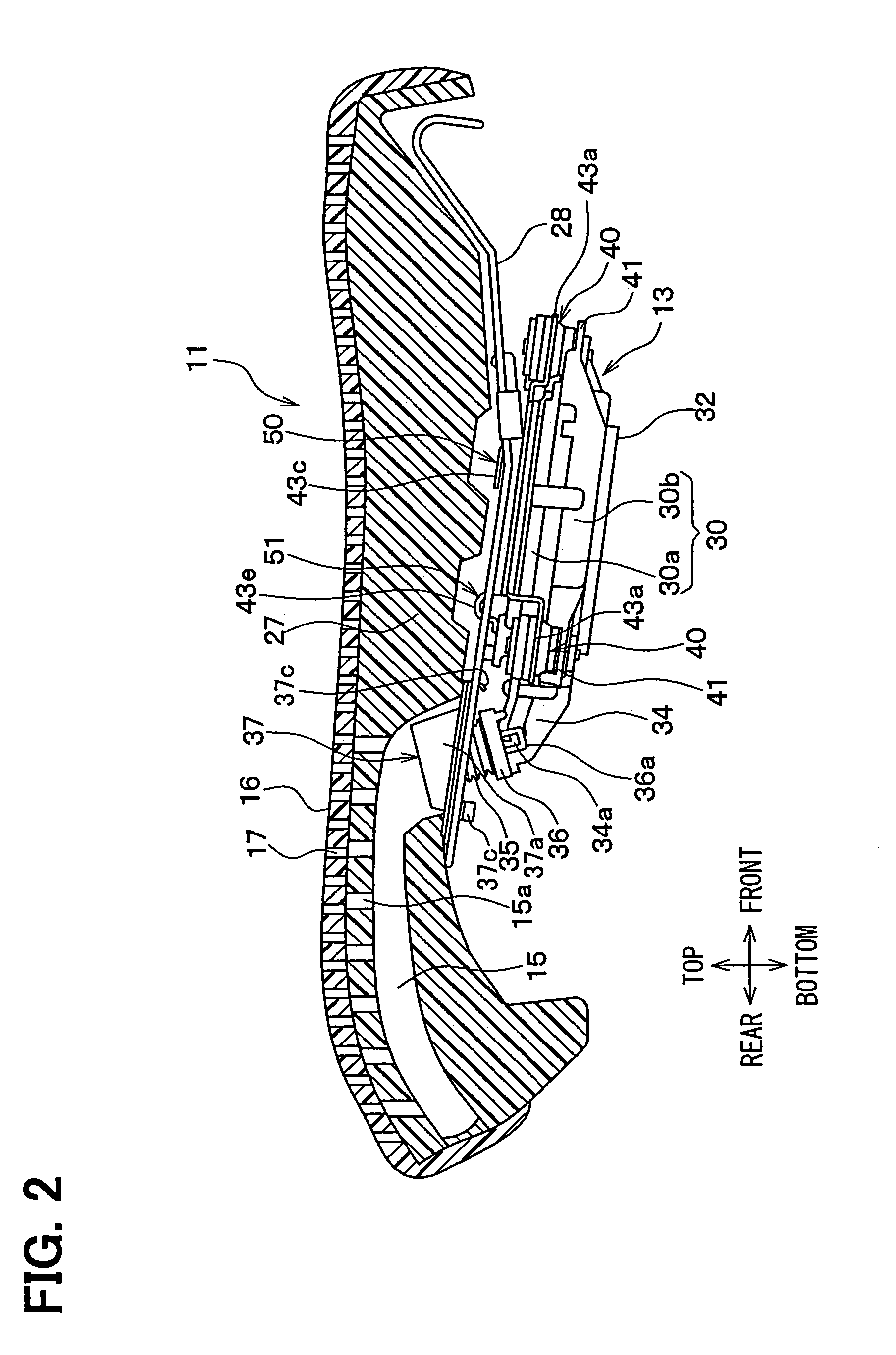

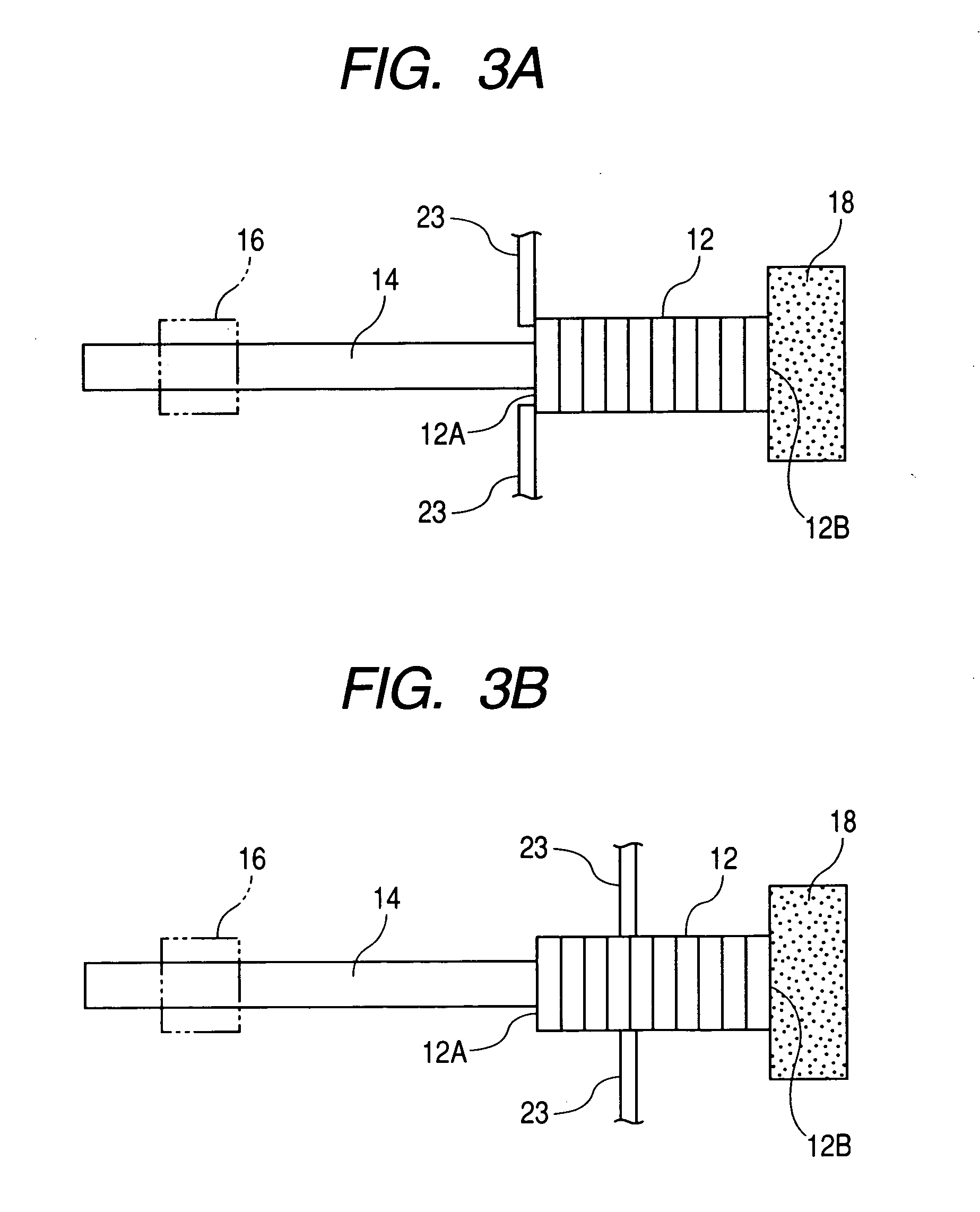

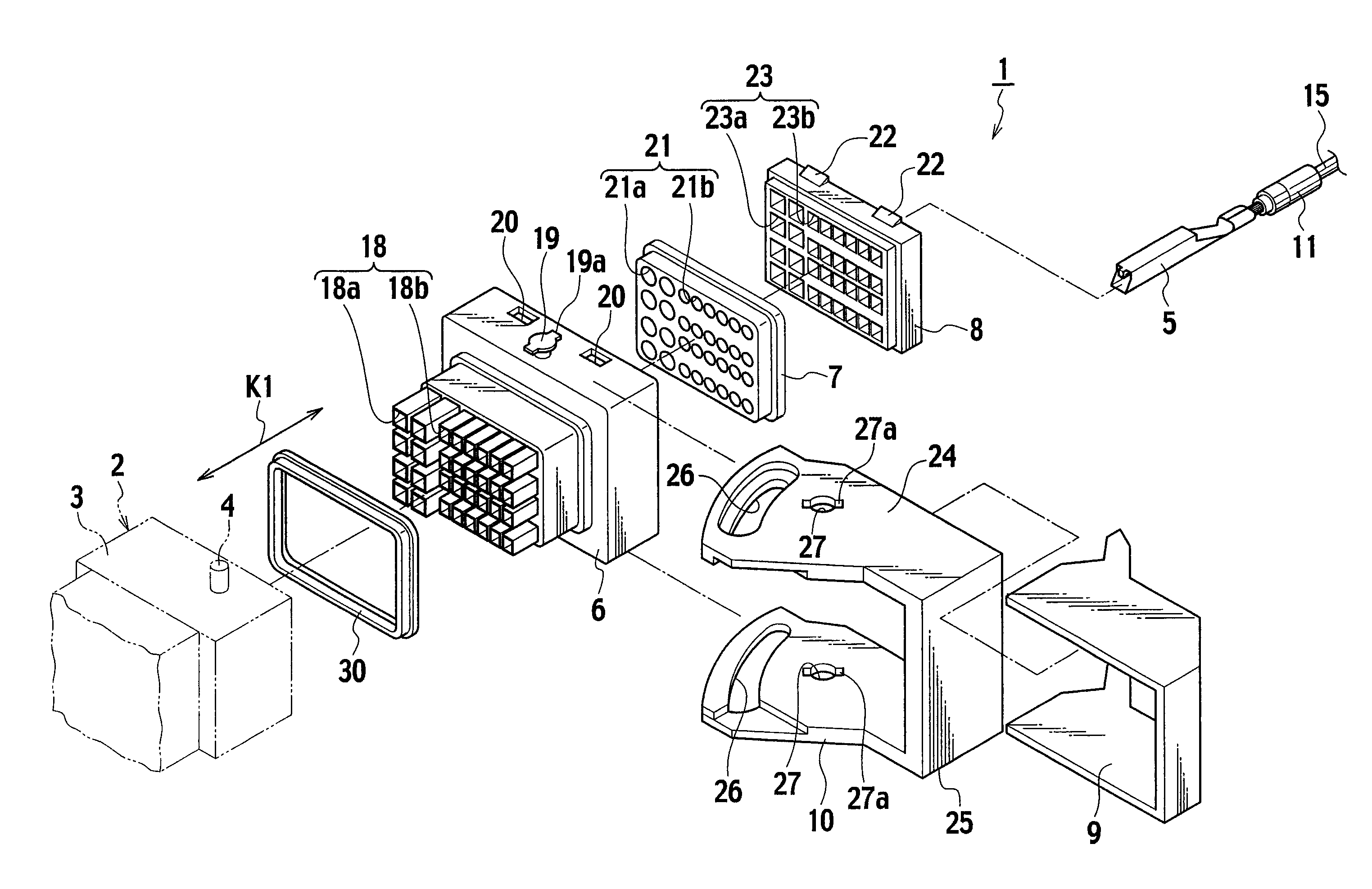

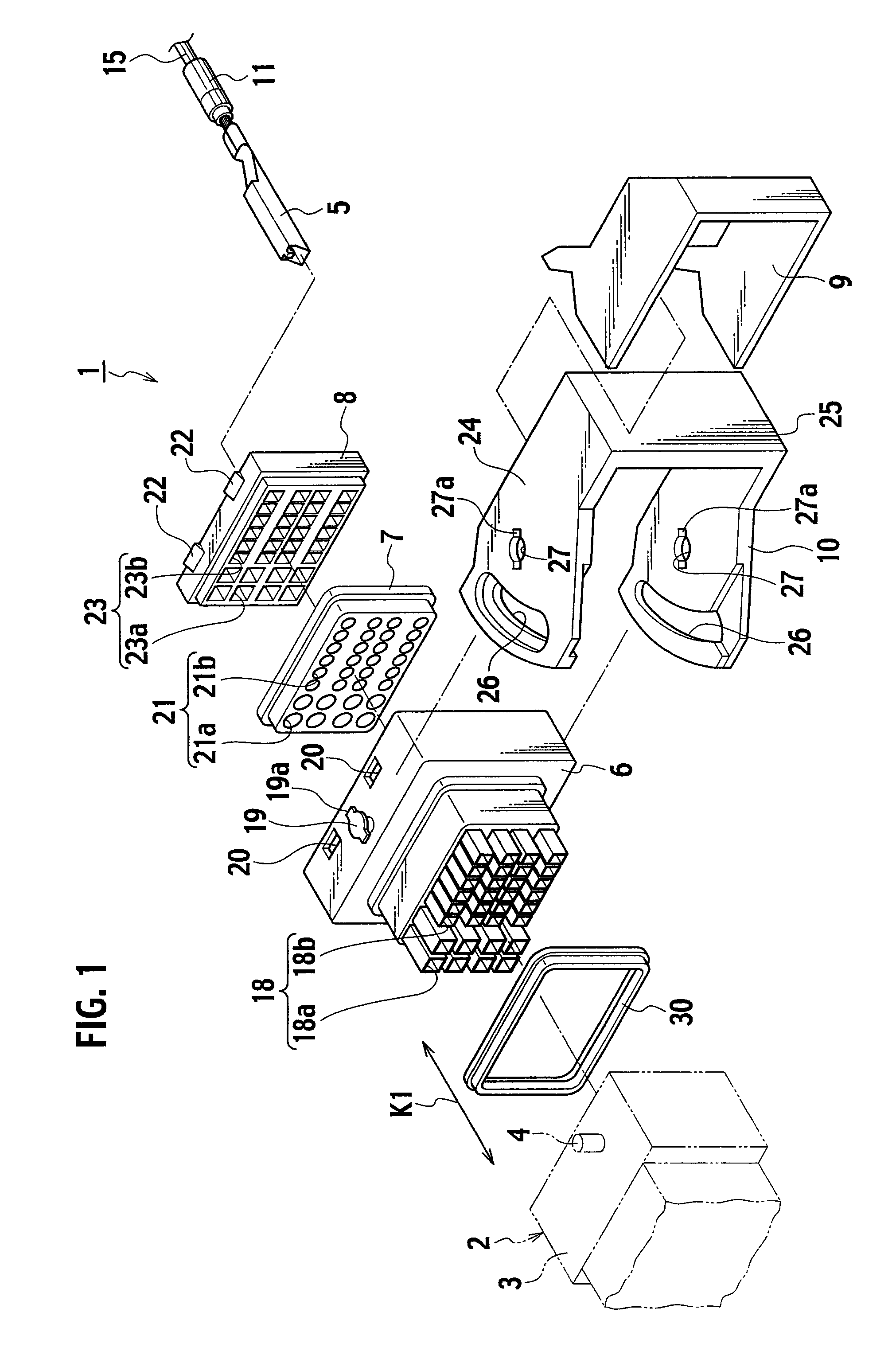

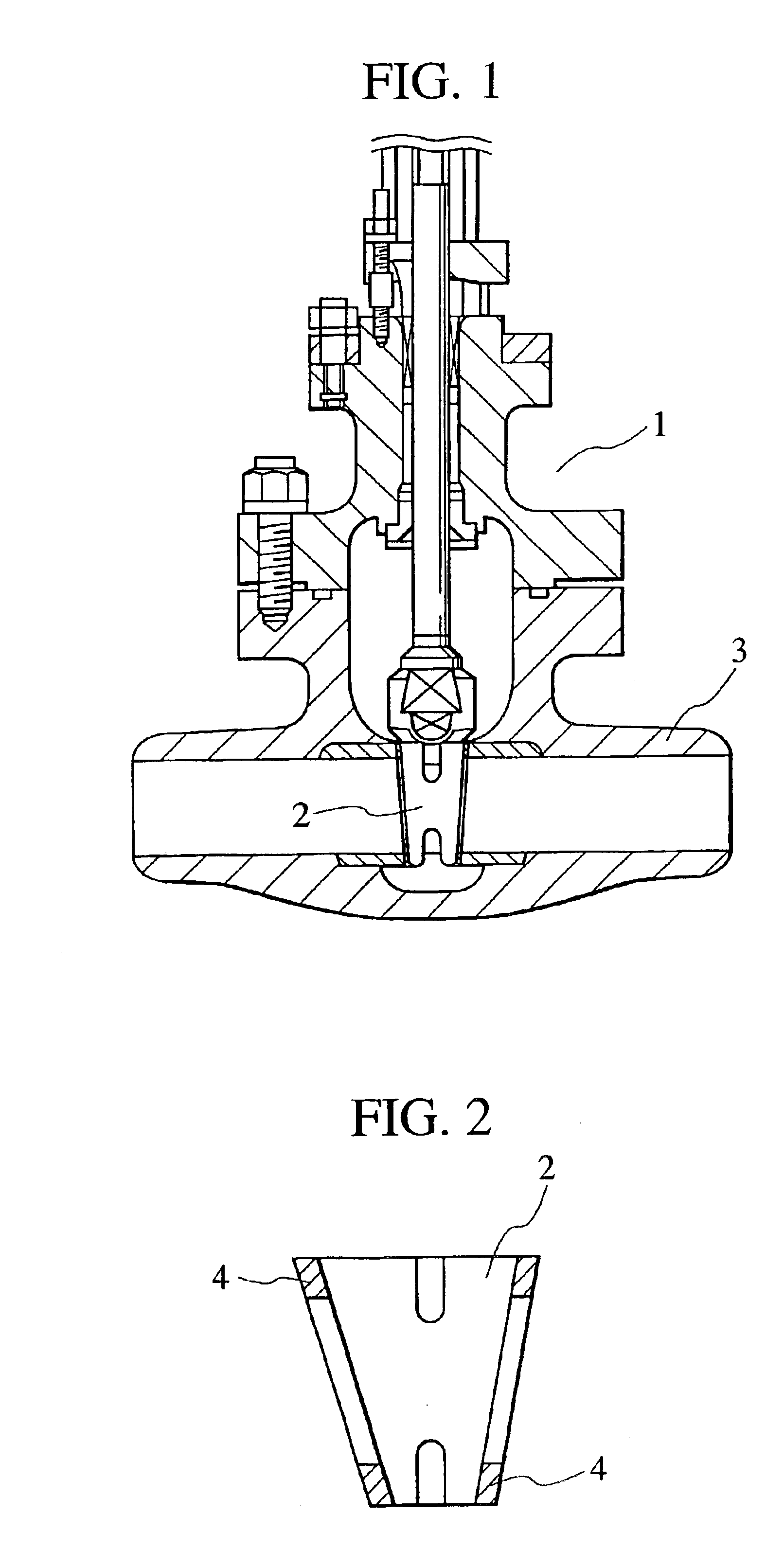

Seat air conditioner for vehicle

InactiveUS20060138812A1Large capacityAbsorption of relative displacement of the blower unitVehicle seatsAir-treating devicesEngineeringAir blower

A seat air conditioner for a vehicle seat includes a blower unit which has a blower fan and an air discharge duct, a vibration isolation unit arranged between the blower unit and a cushion member of the seat, and an accordion duct which is arranged between the air discharge duct and an air passage defined in the cushion member. The blower unit is disposed at an opposite side to the cushion member with respect to seat spring members of the seat. Air blown by the blower fan flows toward a plurality of blowing-out openings formed at a surface cover member of the seat, through the air discharge duct, the accordion duct and the air passage formed in the cushion member.

Owner:DENSO CORP

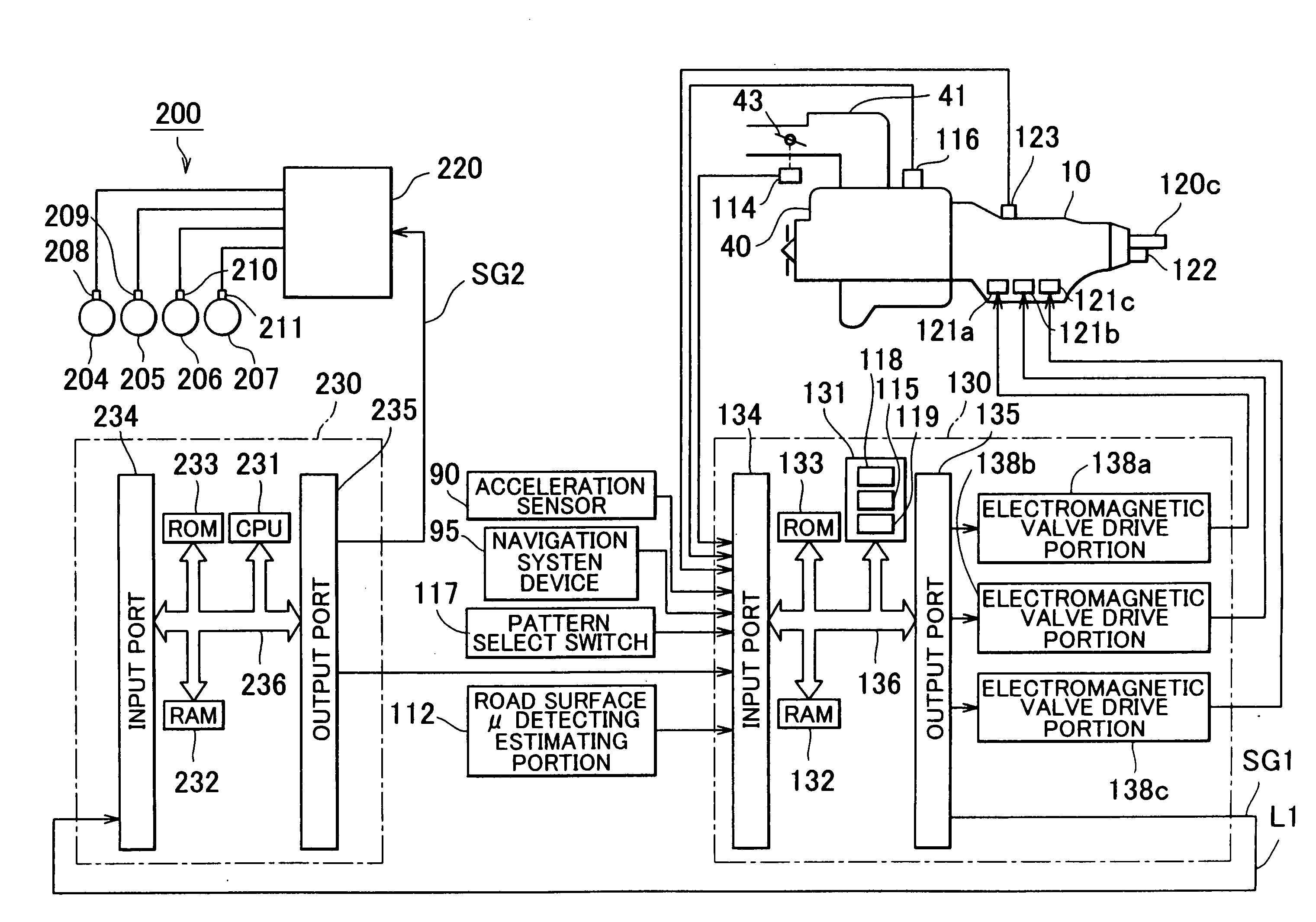

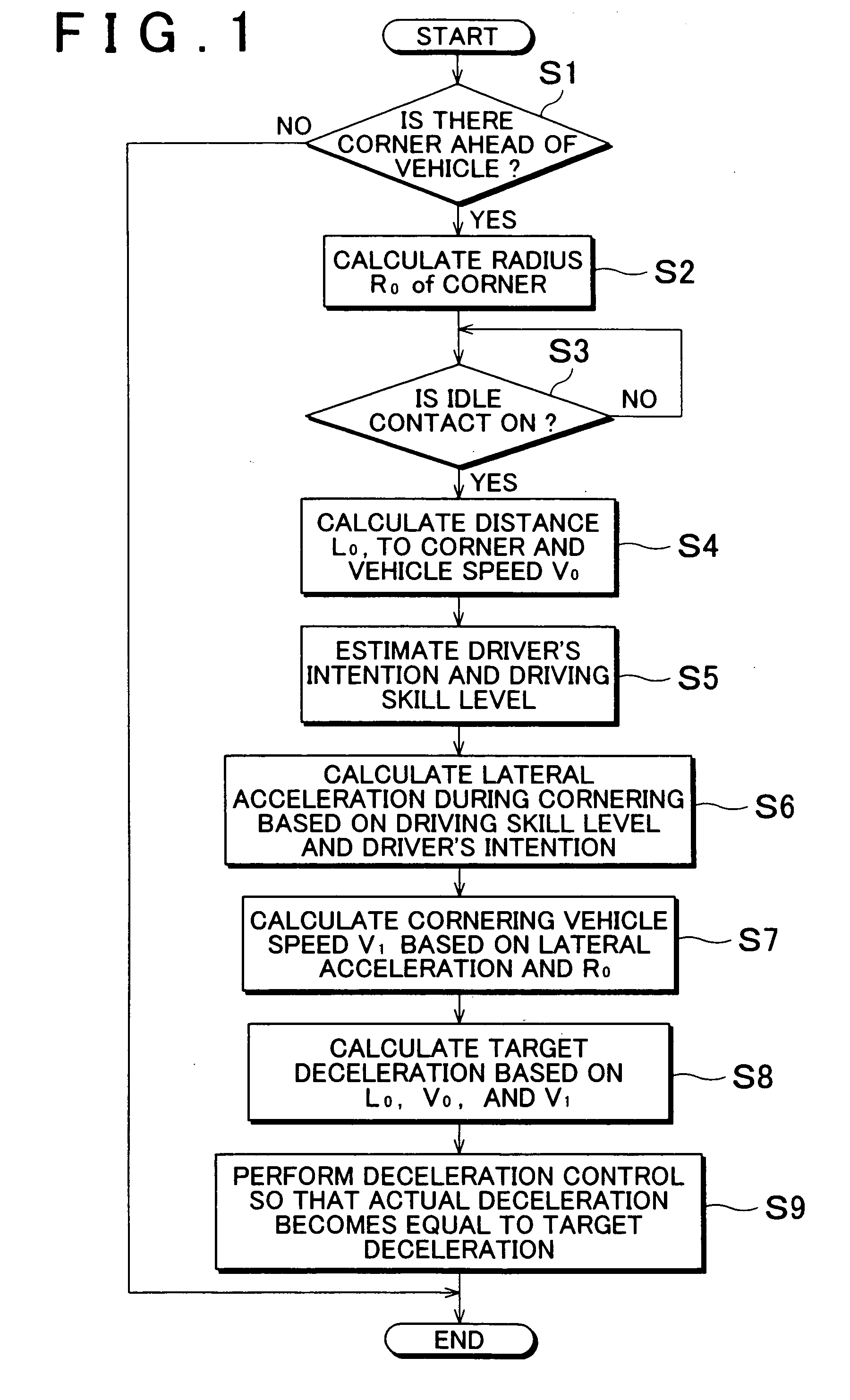

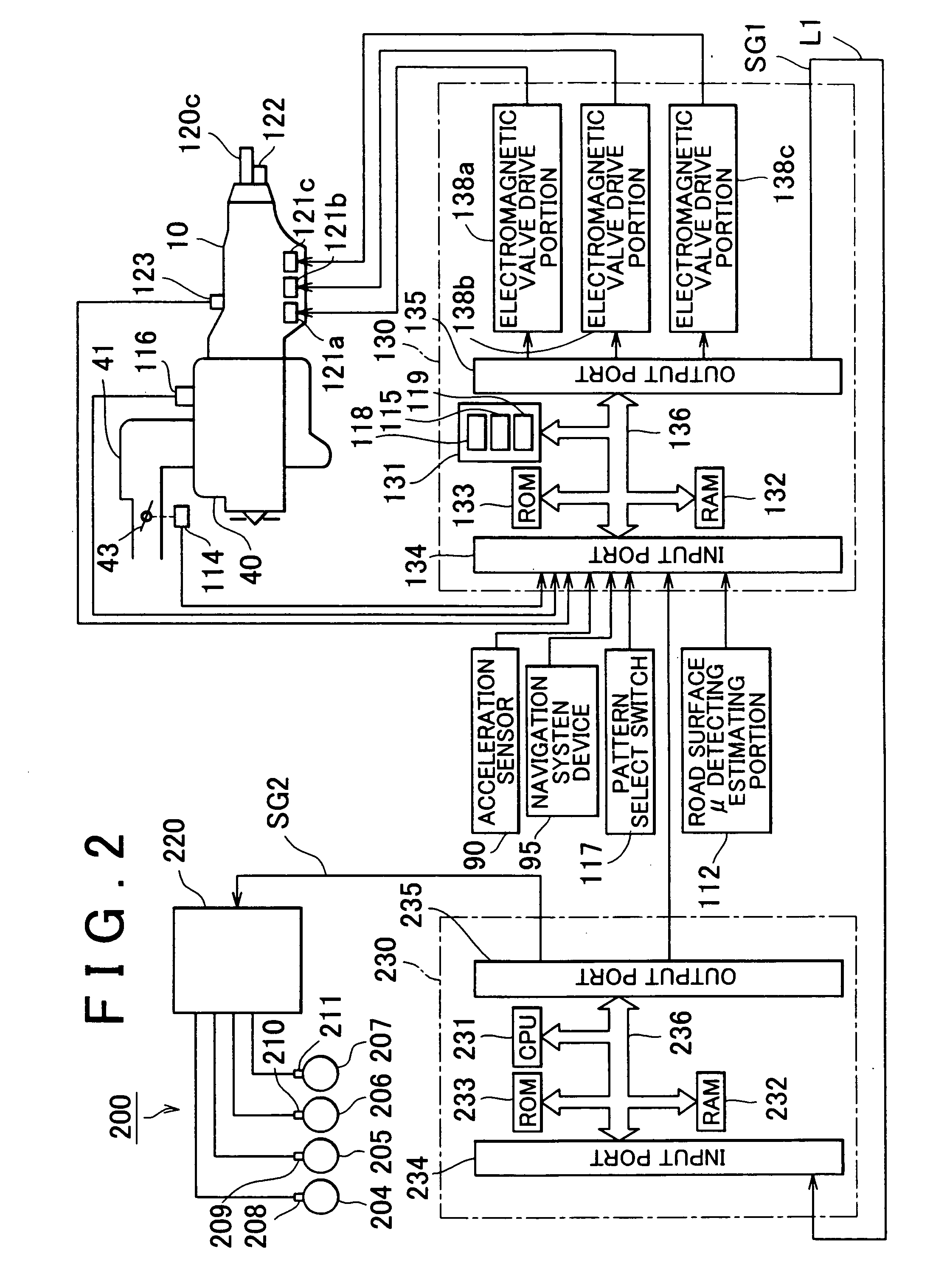

Deceleration control apparatus and deceleration control method for vehicle

InactiveUS20050234626A1Feel comfortableSmall coefficient of frictionHand manipulated computer devicesVehicle body stabilisationDriver/operatorEngineering

A target deceleration for running on a curved road ahead of a vehicle is obtained, based on a driver's intention which is input or estimated, and a driver's driving skill level which is input or estimated; and deceleration control is performed so that deceleration applied to the vehicle becomes equal to the target deceleration. In a case where the driver's intention is to cause the vehicle to respond to driving operation relatively quickly, the target deceleration may be set to a relatively small value; and in a case where the driving skill level is relatively high, the target deceleration is set to a relatively small value. Further, the target deceleration is decided based on a state of a road where the vehicle runs.

Owner:TOYOTA JIDOSHA KK

Seat air conditioner for vehicle

InactiveUS7261372B2Large capacityAbsorption of relative displacement of the blower unitVehicle seatsAir-treating devicesEngineeringVibration isolation

A seat air conditioner for a vehicle seat includes a blower unit which has a blower fan and an air discharge duct, a vibration isolation unit arranged between the blower unit and a cushion member of the seat, and an accordion duct which is arranged between the air discharge duct and an air passage defined in the cushion member. The blower unit is disposed at an opposite side to the cushion member with respect to seat spring members of the seat. Air blown by the blower fan flows toward a plurality of blowing-out openings formed at a surface cover member of the seat, through the air discharge duct, the accordion duct and the air passage formed in the cushion member.

Owner:DENSO CORP

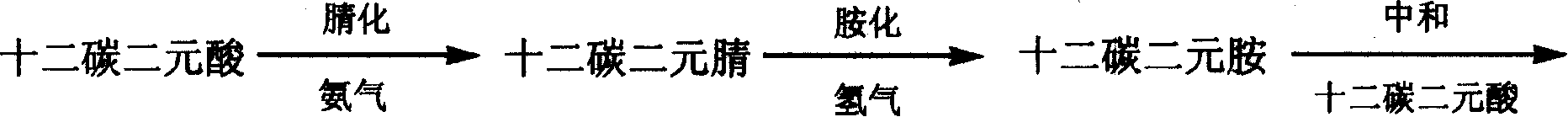

Corrosion-resisting wear-resisting powder coating for metal

The present invention provides a new type anti-corrosion wear-resisting coating material for metal. Said coating material is made of petroleum fermentation nylon-1212 as base material and adding epoxy resin, solidifying agent, wear-resisting agent, lubricating agent, leveling agent, chemical inhibitor, optical stabilizing agent and pigment. Said coating material has excellent elasticity and flexibility, and has the good water-proofing property, impact resistance and can raise service life of machines, so that it has extensive application.

Owner:ZHENGZHOU UNIV

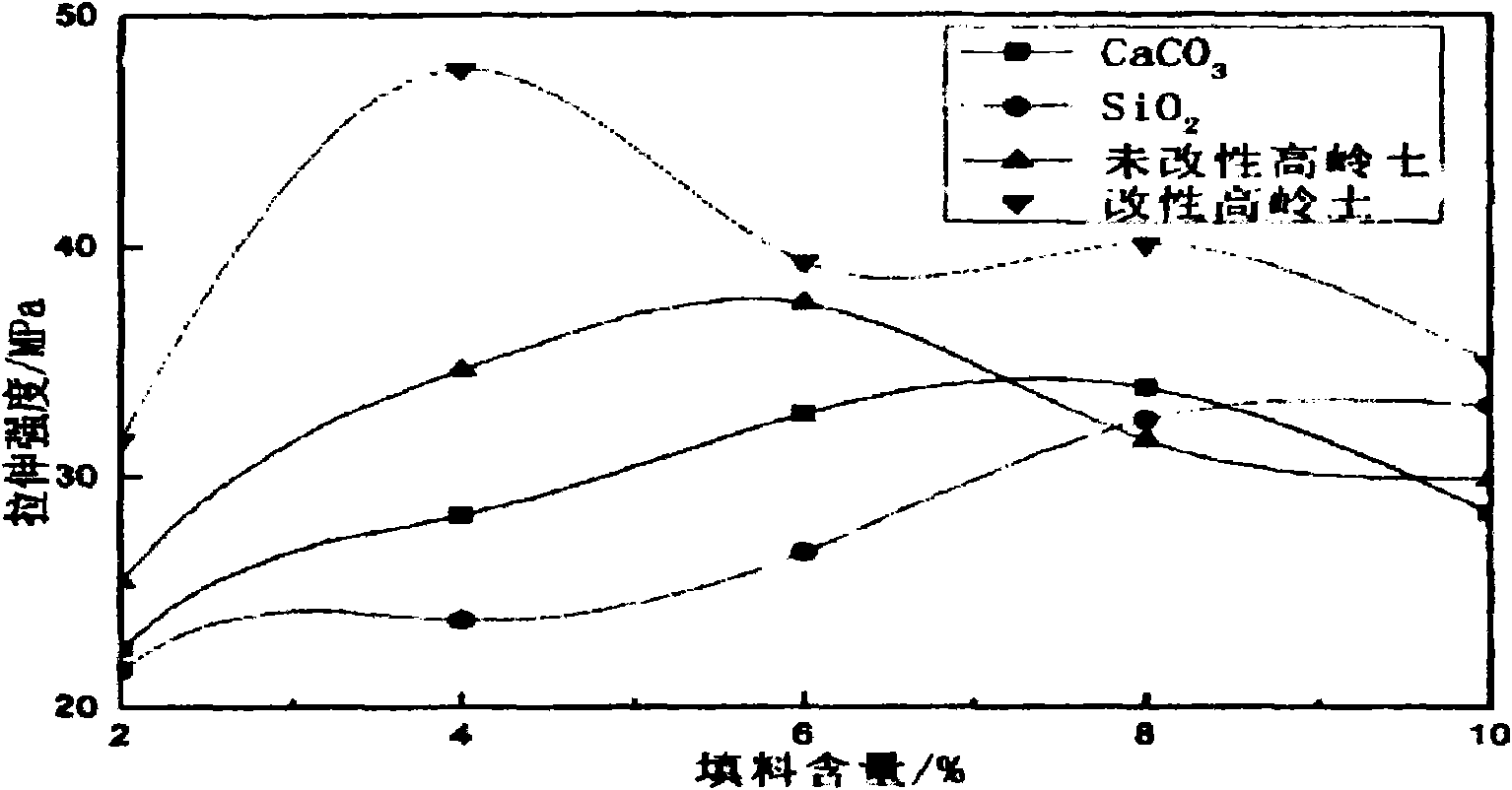

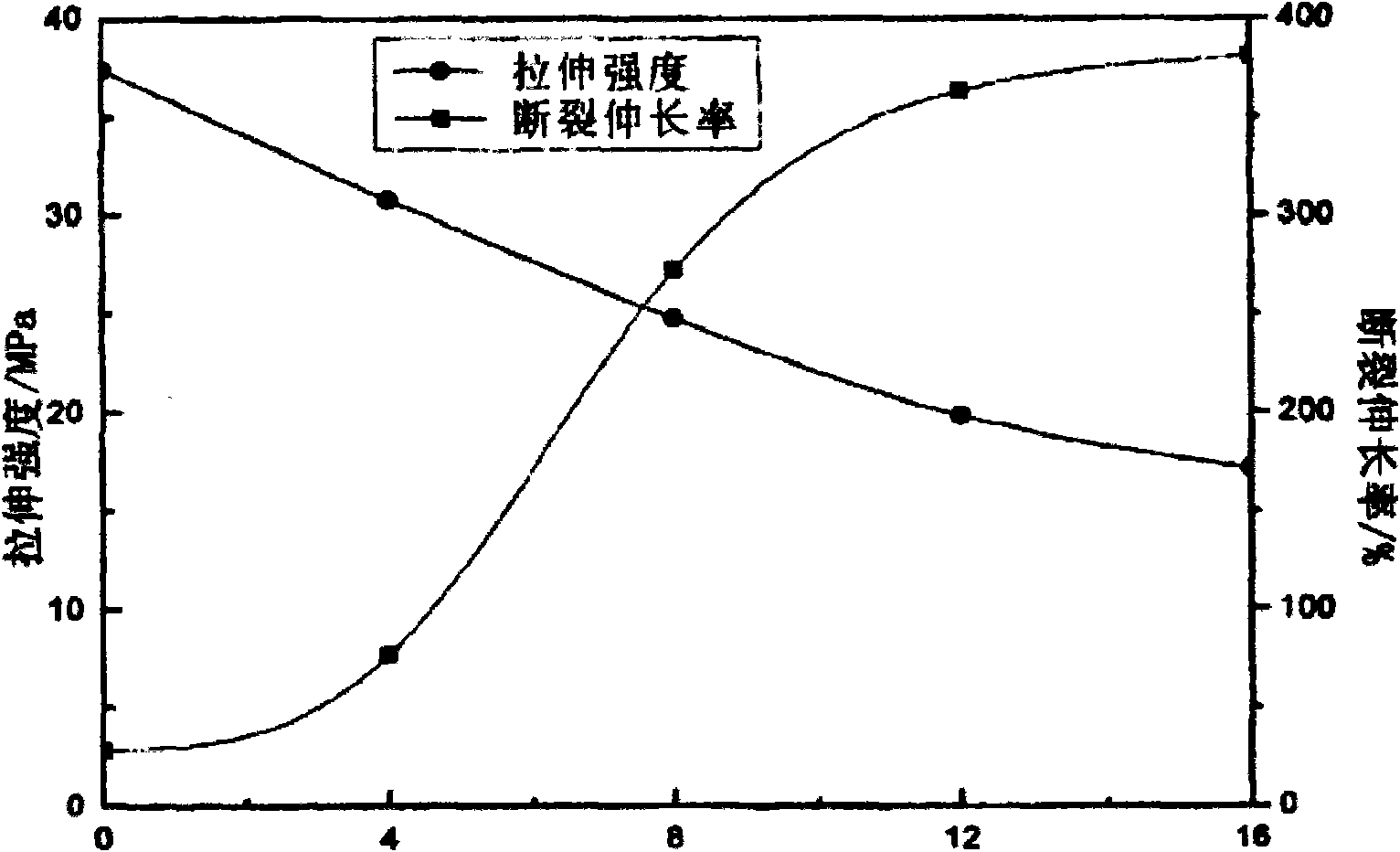

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

Aqueous dull finishing coat, preparation method and use method thereof

InactiveCN101717603AGood chemical resistanceHigh hardnessPolyurea/polyurethane coatingsDefoaming AgentsMaterials science

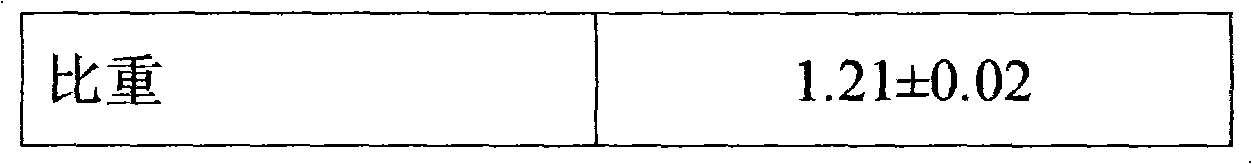

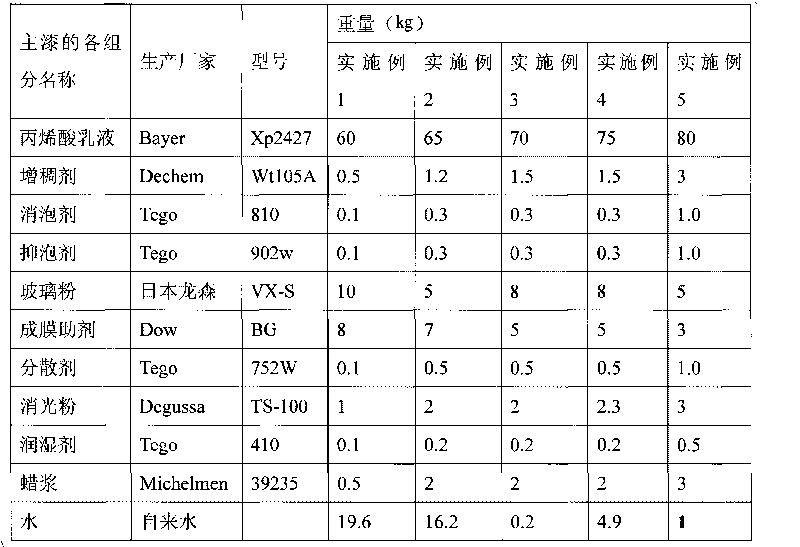

The invention relates to an aqueous dull finishing coat with scratch resistance, a preparation method and a use method thereof. Main varnish is prepared from the following components in parts by weight: 60-80 parts of acrylic acid emulsion, 0.5-3 parts of thickening agent, 0.1-1.0 part of defoaming agent, 5-10 parts of glass powder, 0.1-1.0 part of foam inhibitor, 3-8 parts of filming auxiliary agent, 0.1-1.0 part of dispersant, 0.1-0.5 part of wetting agent, 1.0-3.0 parts of extinction powder, 0.5-3.0 parts of wax pulp and 1-20 parts of water; a curing agent of the aqueous dull finishing coat is mixed by 80 parts by weight of aliphatic polyisocyanate and 20 parts by weight of propylene glycol methyl ether acetate; and the ratio of curing agent NCO to main varnish OH is 2.5. The main varnish is prepared by the steps of adding the acrylic acid emulsion into a container, adding the thickening agent, the defoaming agent, the foam inhibitor and the dispersant under stirring, and dispersing at 500RPM for 5-8 minutes till being uniform; afterwards, after adding the extinction powder, the glass powder and the wax pulp under stirring, dispersing at 1000RPM for 15 minutes till the fineness is not more than 25mum; and then, adding the wetting agent, the filming auxiliary agent and the water, dispersing at 500RPM for 10 minutes till being uniform and filtering by a sieve with 100 meshes so as to obtain the aqueous dull finishing coat. The aqueous dull finishing coat is used by mixing in the weight mixture ratio of the main varnish to the curing agent to tap water being 100:50:20. A varnish film has very good hardness, toughness, scratch resistance, abrasion resistance and weather resistance, can be recoated without blanching and has especially good chemical resistance.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

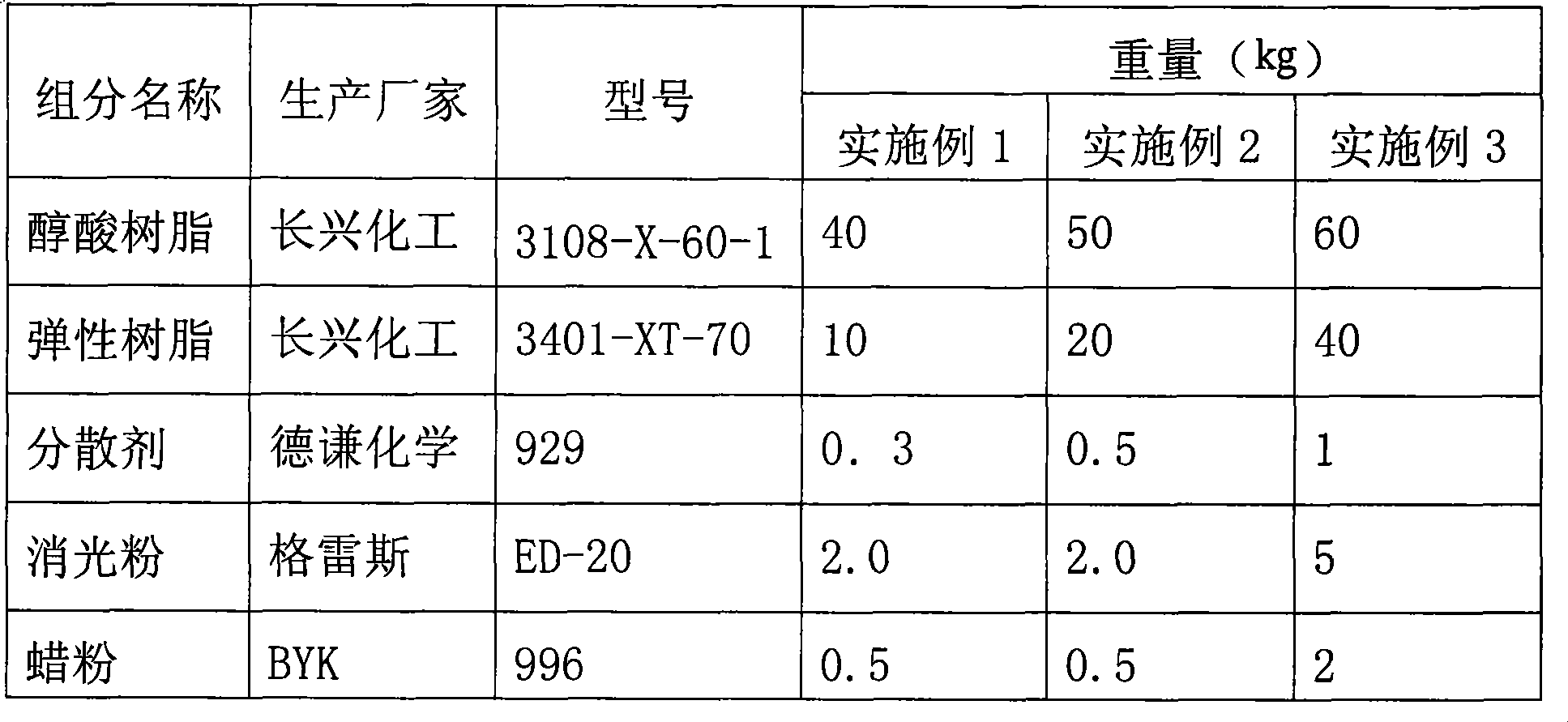

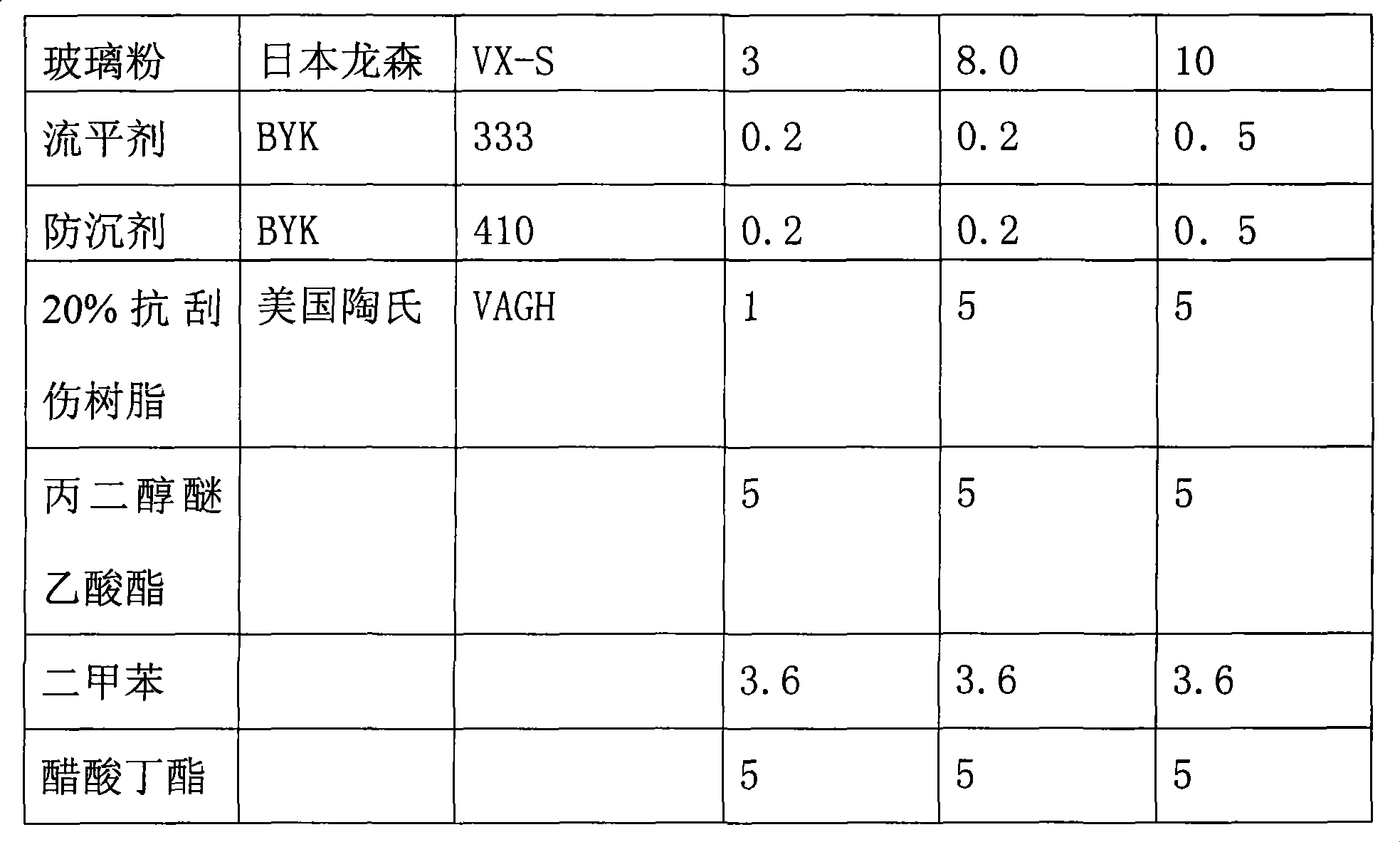

Polyurethane transparent matt topcoat, preparation method and use method thereof

ActiveCN101381581AFeel smoothGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxLow speed

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

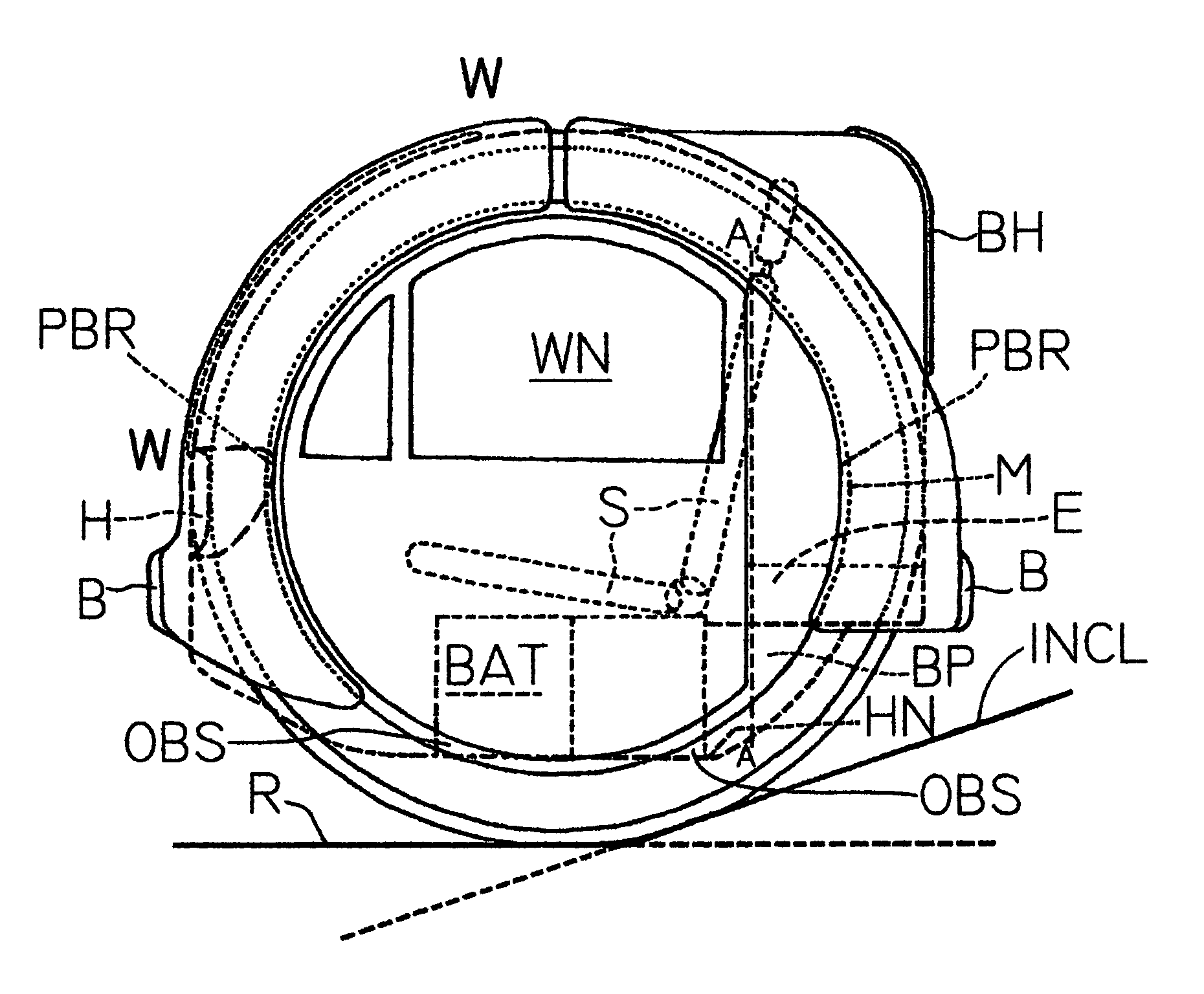

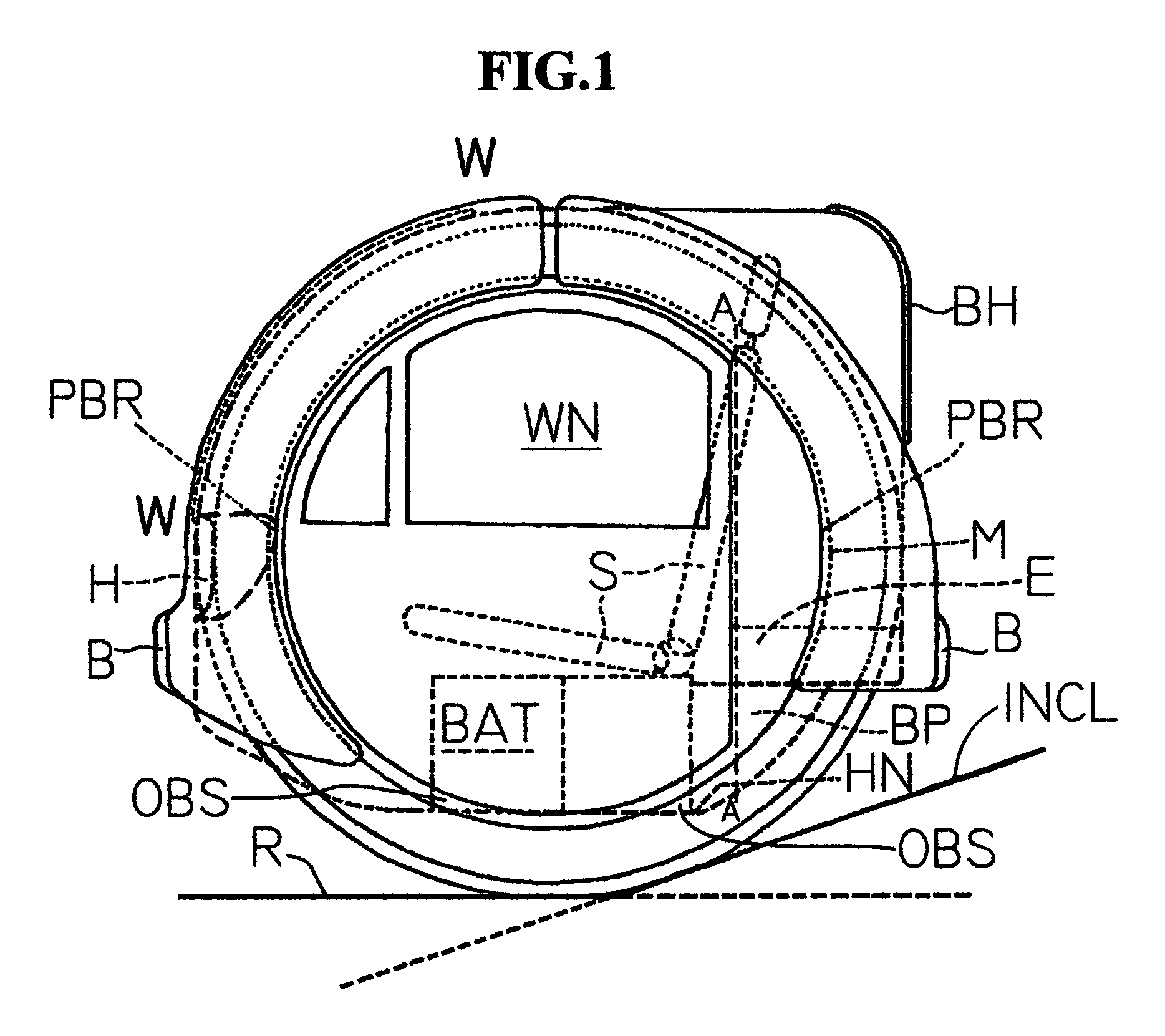

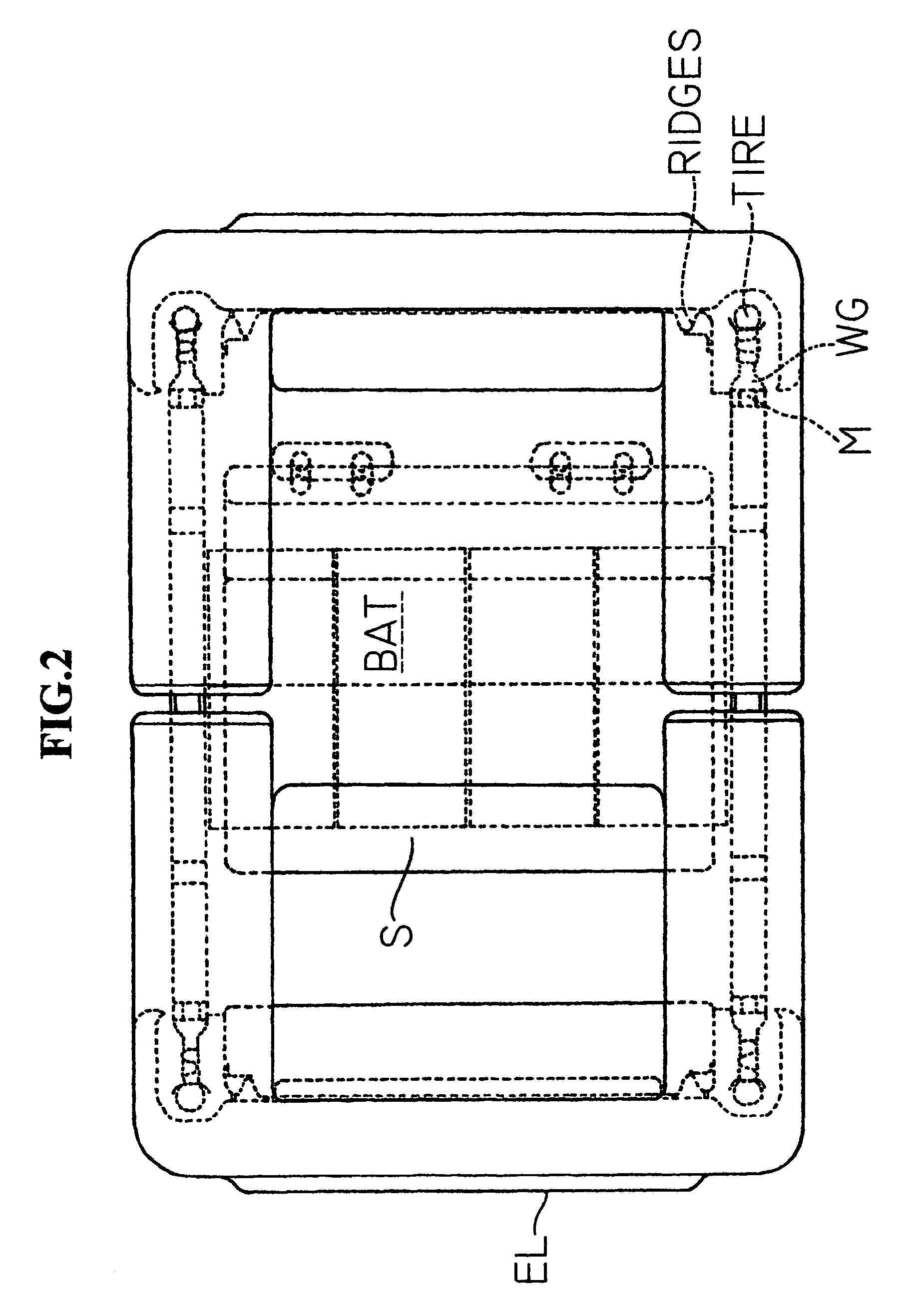

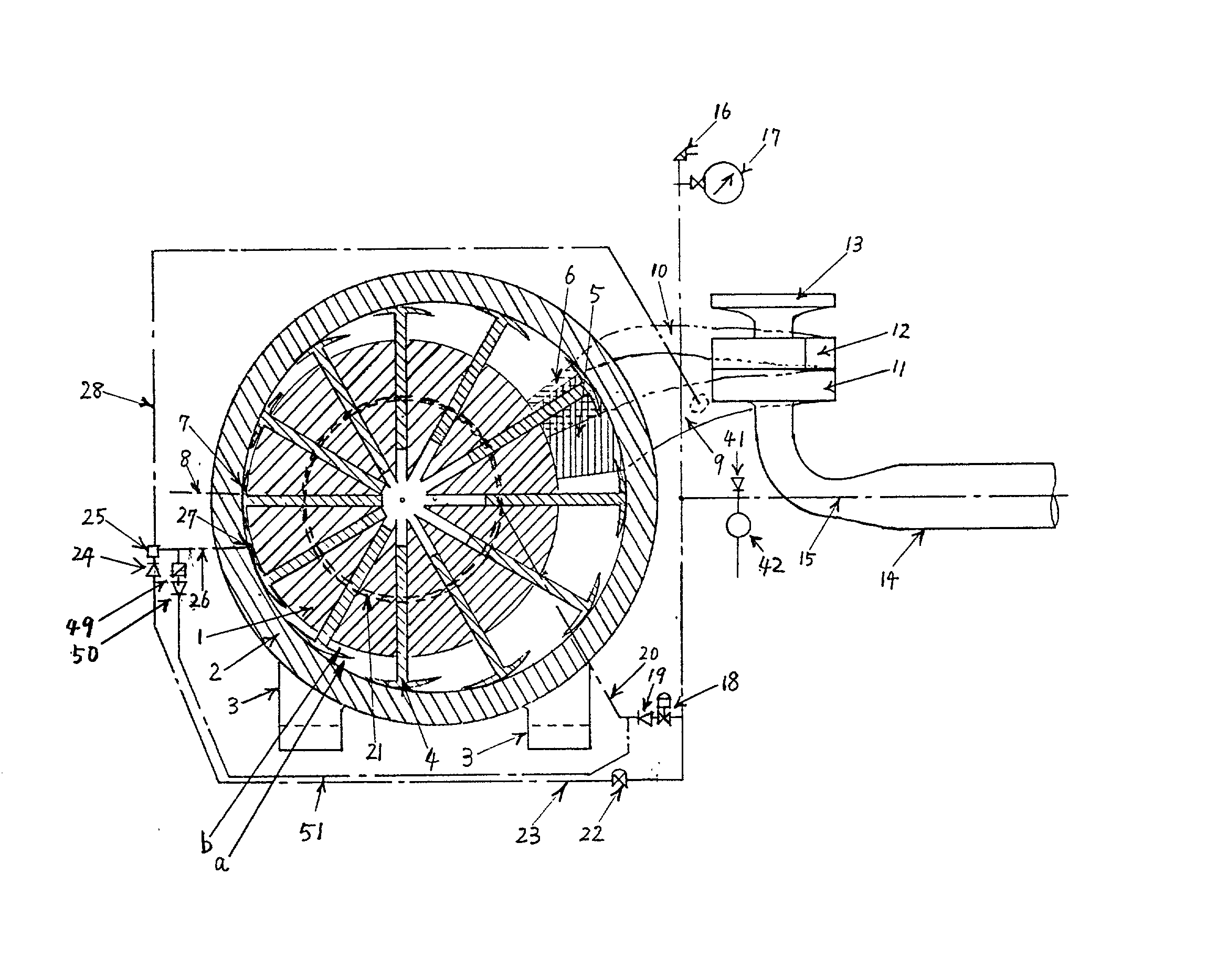

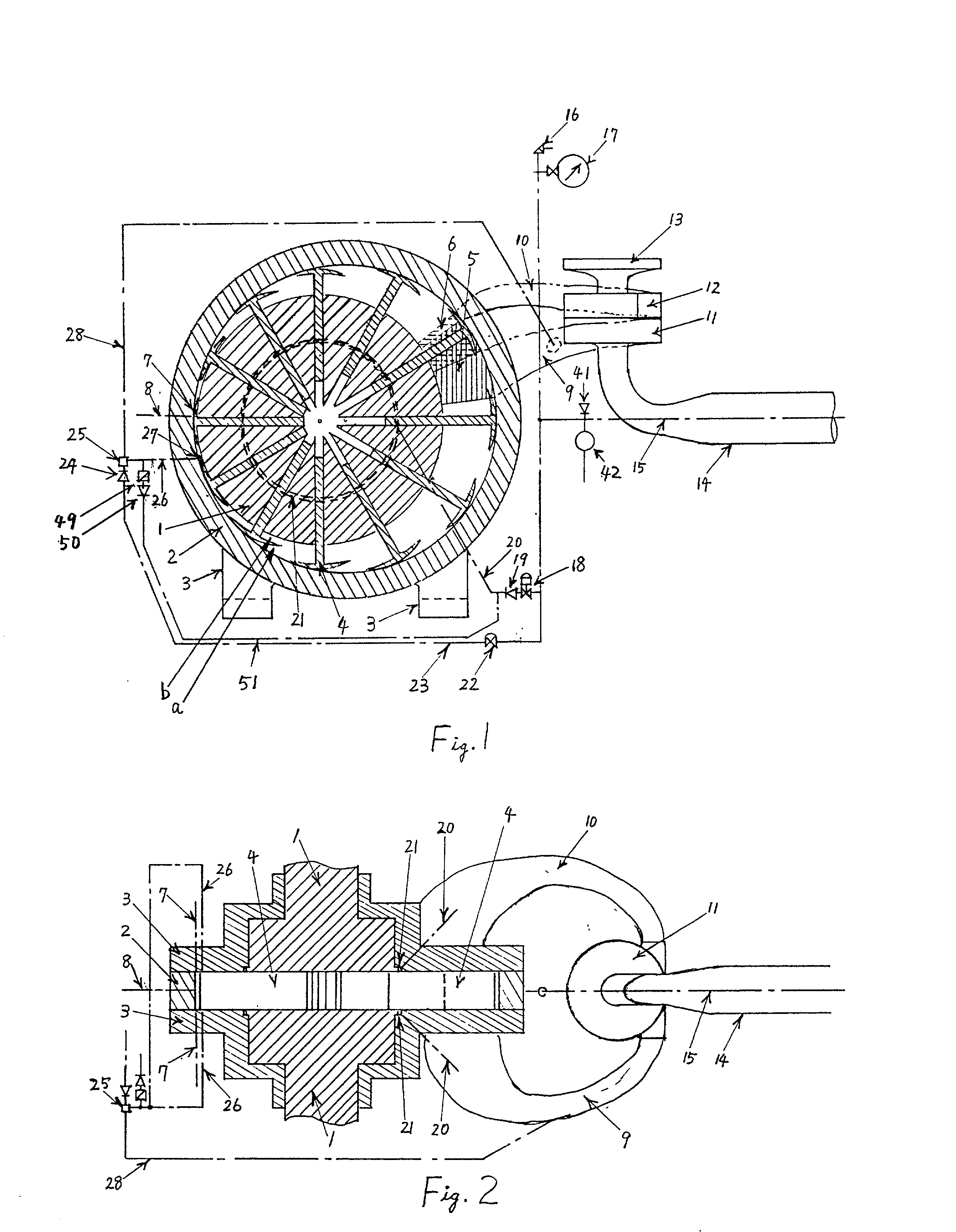

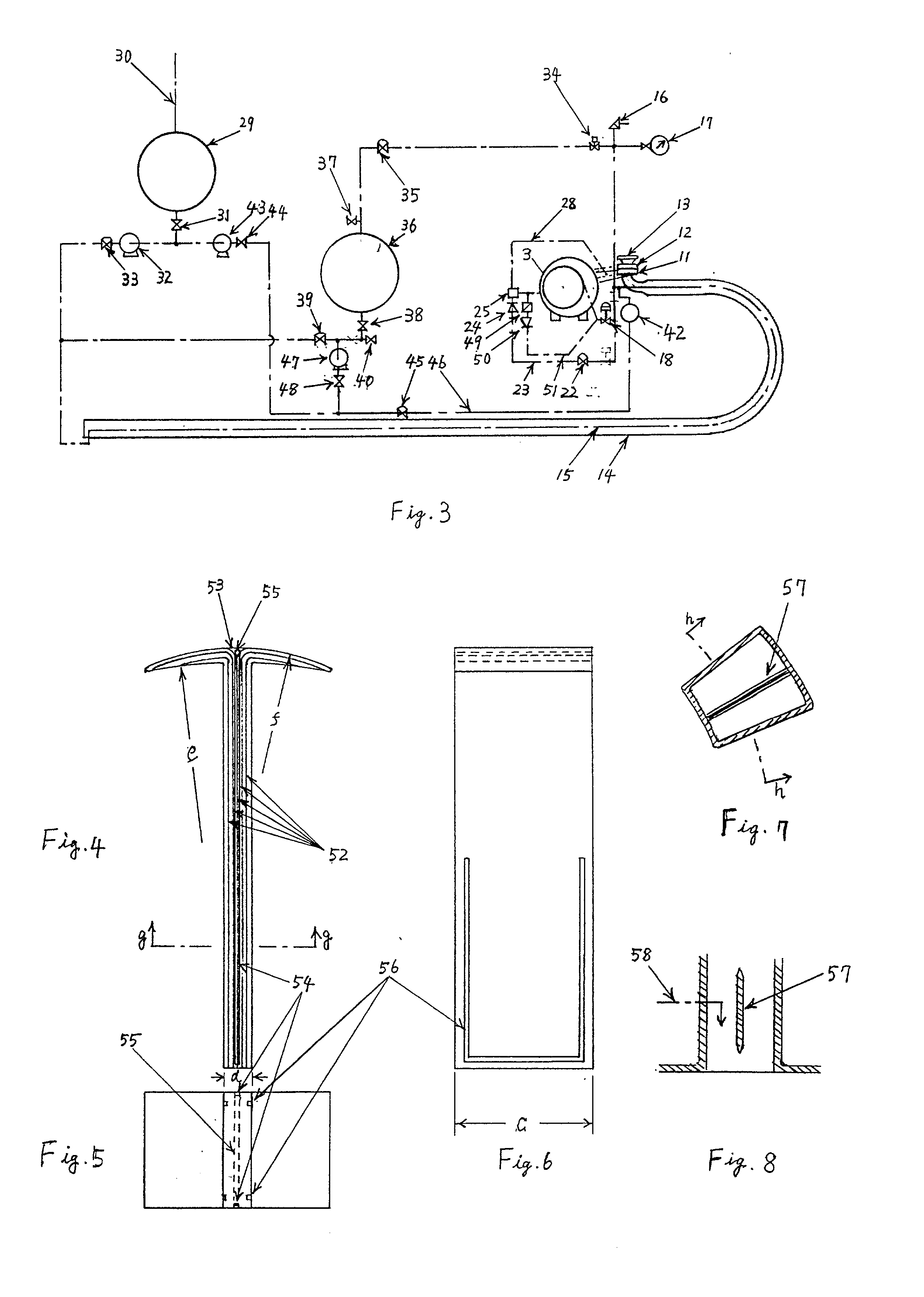

Electric motor vehicle with passenger opening through ring motor

InactiveUS7017696B2Increase the diameterReduce in quantityUnicyclesElectric machinesElectric power systemEngineering

A two-wheel electric vehicle with ringlike, large, powered parallel wheels, in which at least one ringlike wheel is driven by a large toroidal electric motor. The fully circular rotor of the large toroidal electric motor is integrated with the hub of the ringlike wheel, while the circular or semi-circular toroidal stator is joined to the body of the two-wheel electric vehicle, the ringlike wheel and the toroidal electric motor having a common bearing. The electric power source to drive the toroidal electric motor is located near the ground-facing portion of the vehicle body. An opening is formed in the internal circular area of the toroidal stator, to allow the entry and exit of the passengers of the vehicle. A similar small vehicle with parallel, coaxial wheels allows the occupant of the small vehicle to travel, seated either facing the conventional front or the rear of the small vehicle.

Owner:PAL ANADISH KUMAR

Metal ceramic and its preparation method

The invention discloses the Ti(C,N) based metal ceramics and its preparation method. The weight ratio of each constituent of the metal ceramics is as following Ti30-65, W8-25, Ta1.0-15.0, Zr 0.1-5.0,Nb0-10, Cr0-1.0 V 0-5.0 etc as well as C and N as the rest. The powder of ceramics of carbonitride with multiple elements in duplex type of two or more different element combinations is mixed with the powder of carbide of Ti, W, Ta, Nb, V, Zr etc. and / or powders of carbide of their solid solution as well as the powders of Co, Ni, Mo. The metal ceramics are made from the admixture through the procedures of ball mill crushing, pressure moulding, vacuum dewaxing and vacuum sintering. With the good wear resistance being kept, the metal ceramics possesses high intensity and toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

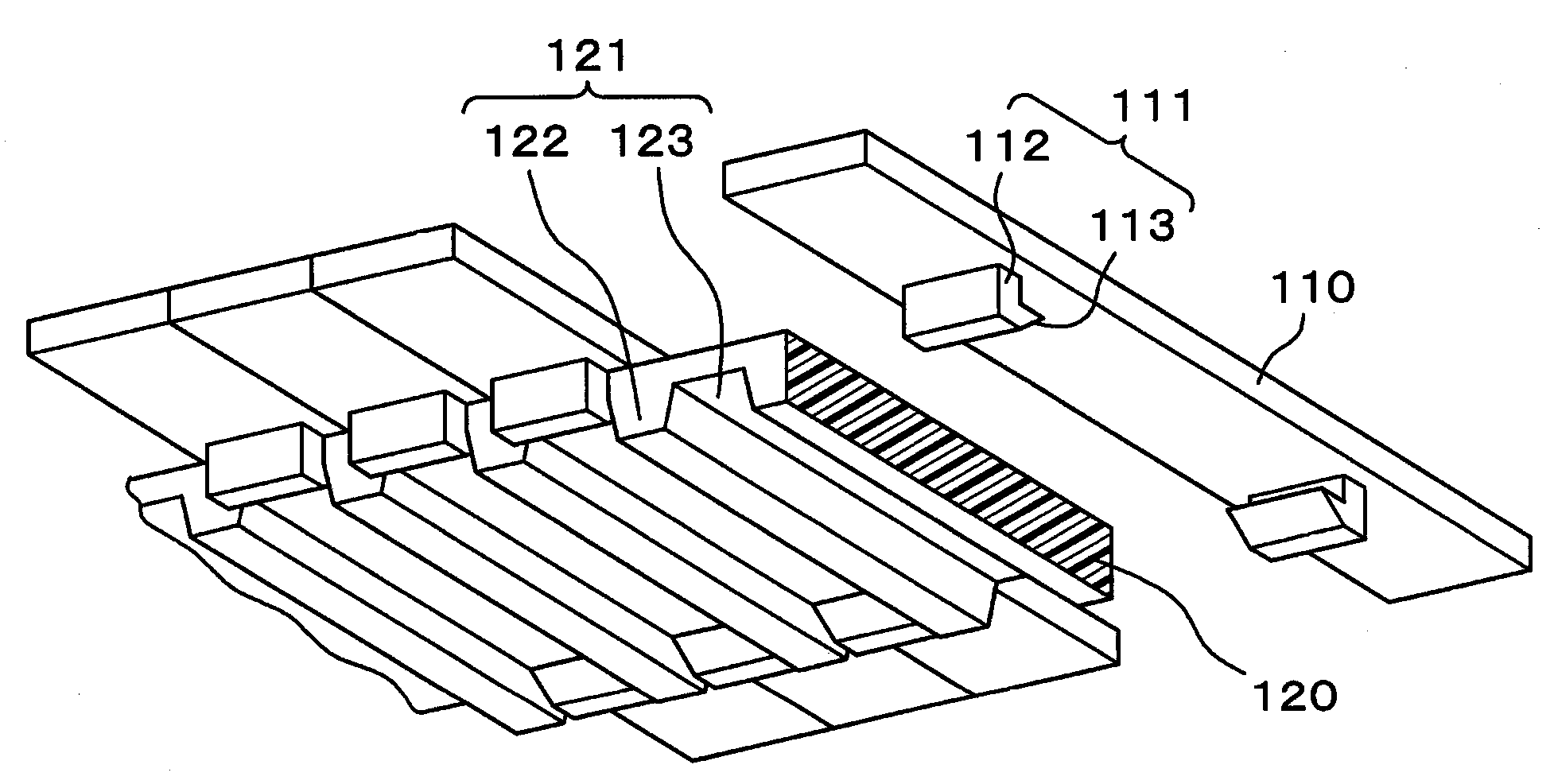

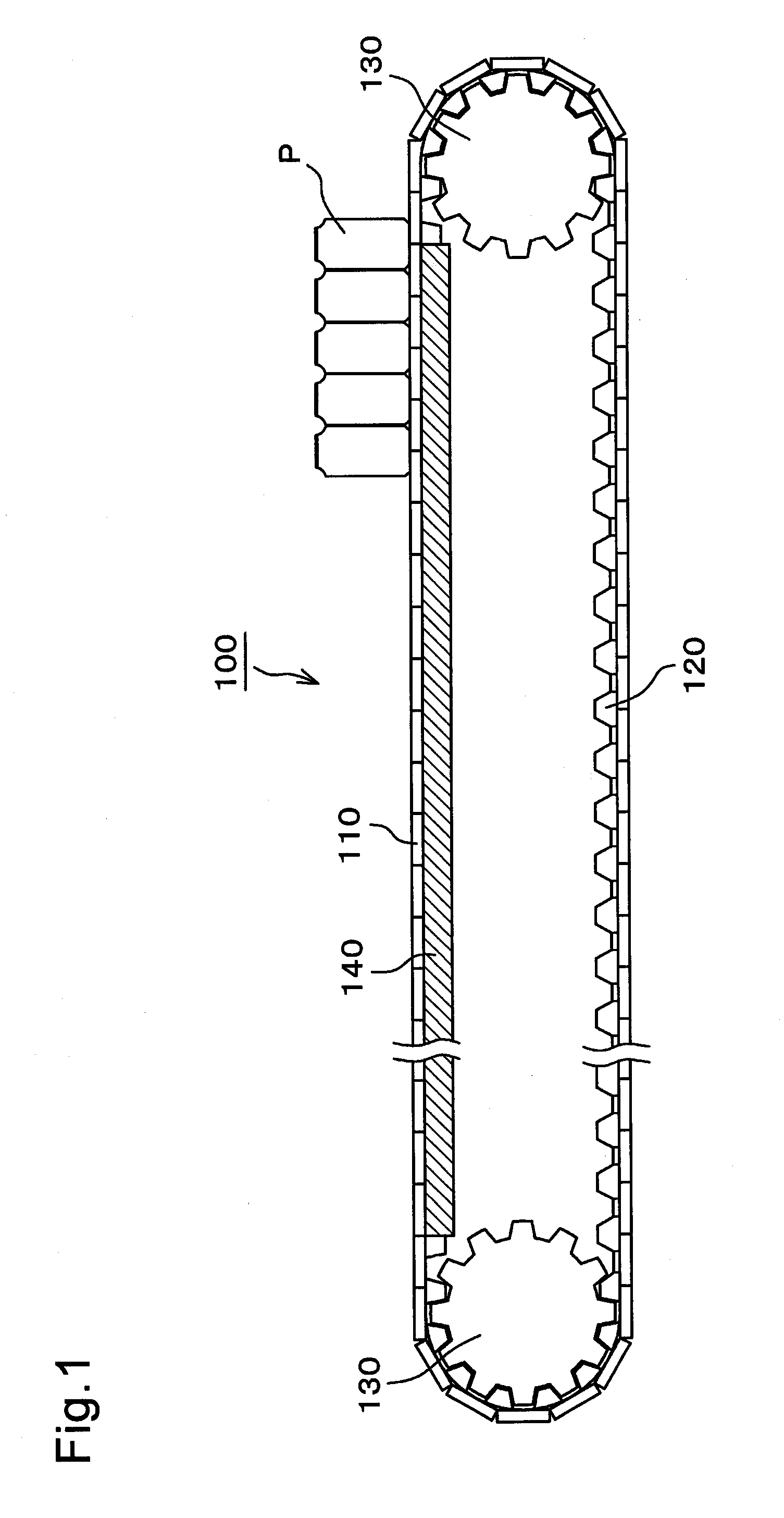

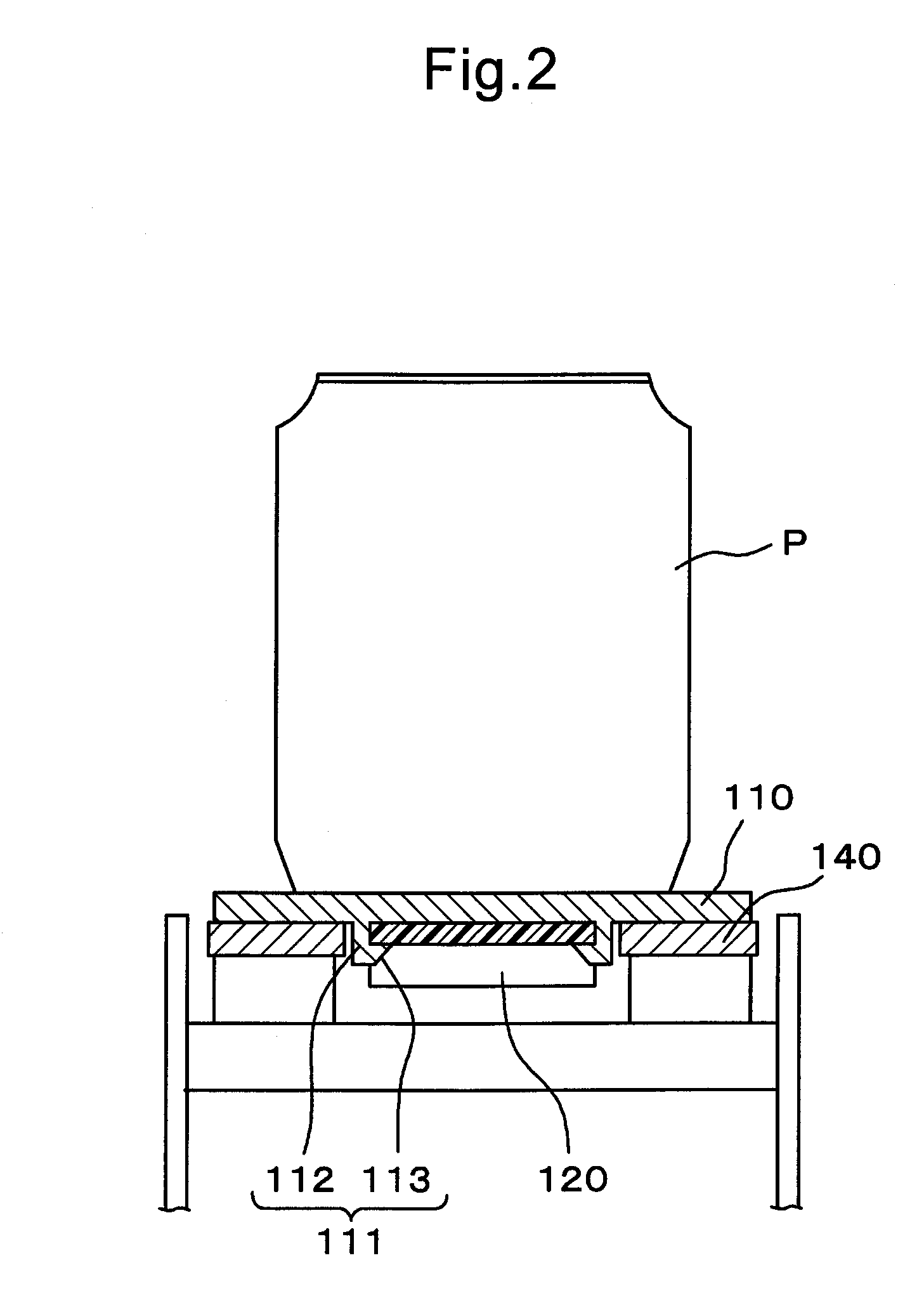

Top plate conveyor device

InactiveUS20090133993A1Reduce noiseReduce vibrationRollersRotary conveyorsMechanical engineeringToothed belt

A top plate conveyor device, in which vibrations and noises are reduced, and the structure is simple and the production assembly and handling are easy. Top plates 110 are removably provided on a rubber toothed belt 120 by engagement members 111 provided on the back surfaces of the top plates 110, and engagement members 111 include sandwiching portions 112 which sandwich the toothed belt 120 from both outer sides in the width direction and terminate in pawl portions 113, which snap-connect the top plates to the toothed belt 120.

Owner:TSUBAKIMOTO CHAIN CO

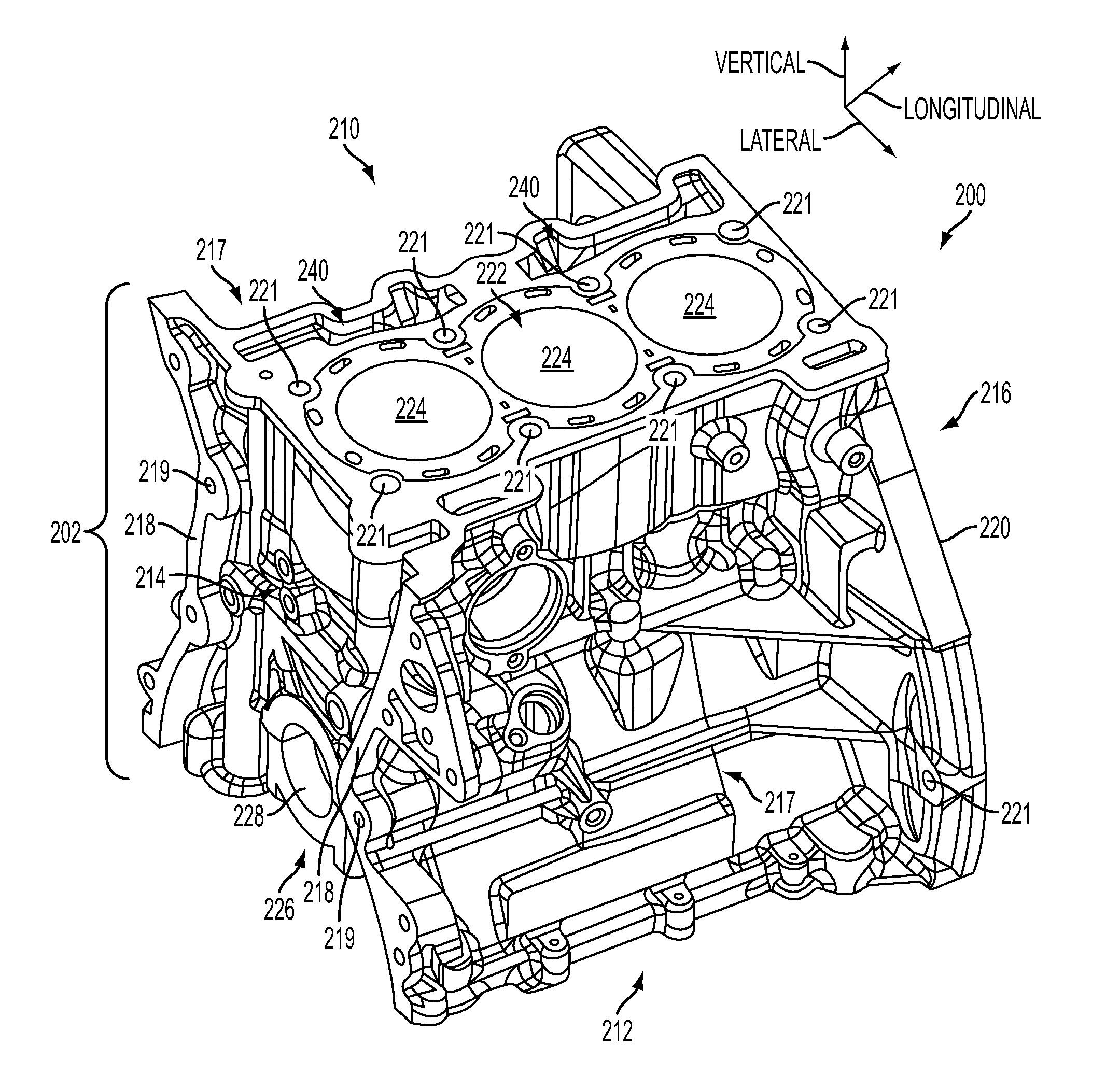

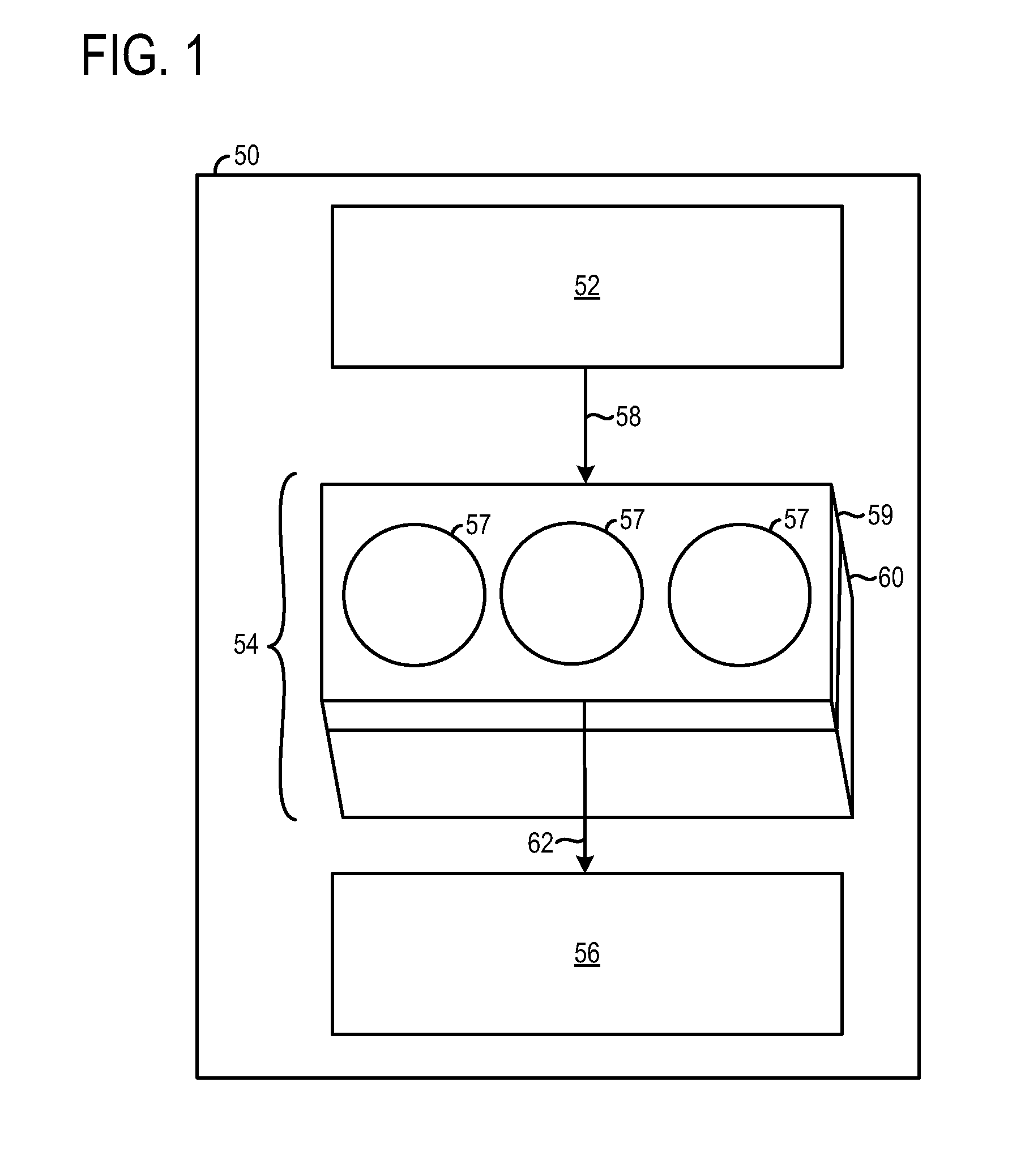

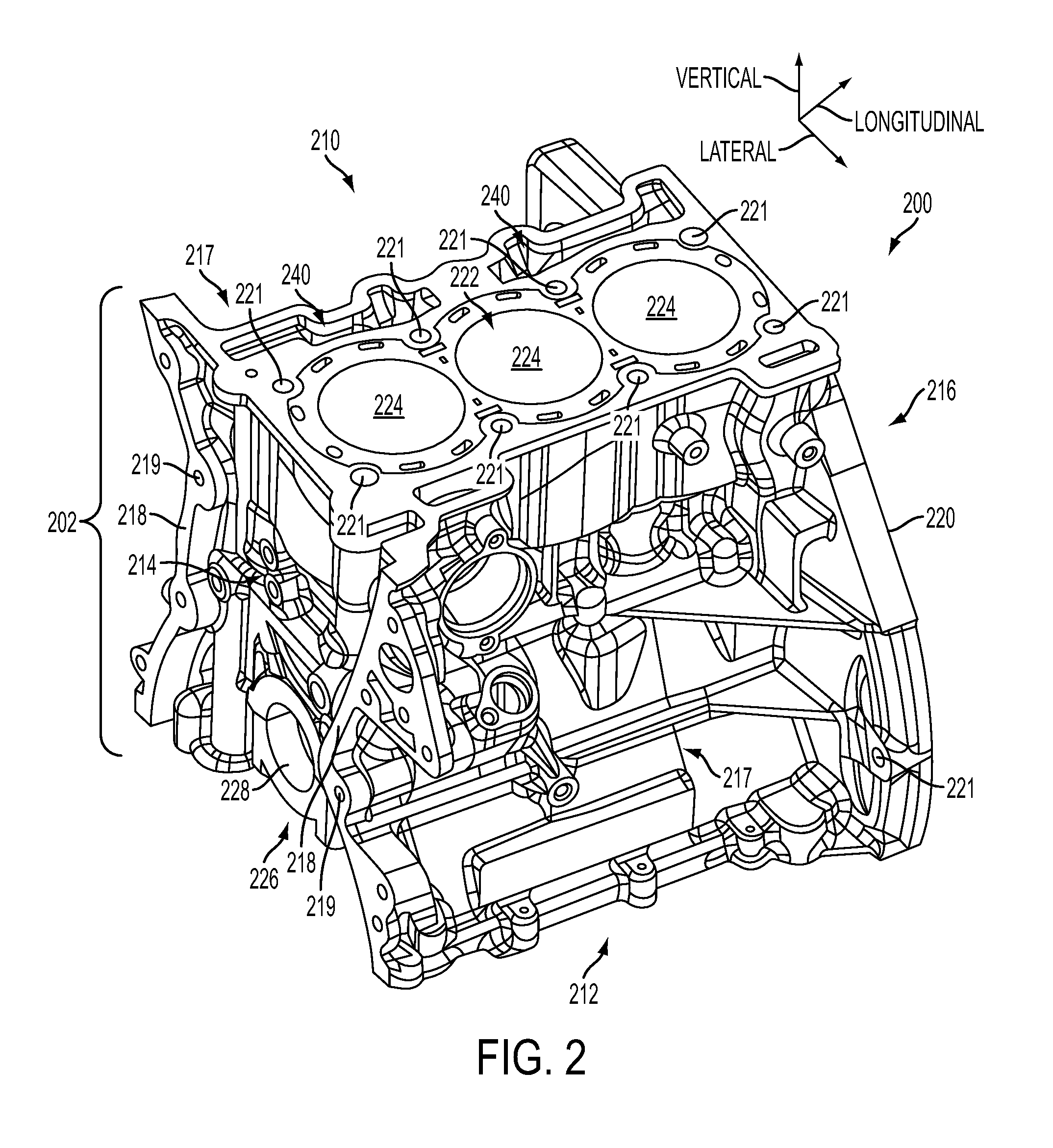

Engine having composite cylinder block

ActiveUS20150159581A1Strength to weight ratio is relatively lowMore susceptible to corrosionCasingsCylinder headsEngineeringWater jacket

An engine is provided. The engine includes a thermo-molded composite cylinder block including a front engine cover attachment interface and a transmission attachment interface. The engine further includes a cylinder liner comprising a different material than a composite cylinder block and integrally molded with the composite cylinder block, the cylinder liner defining a portion of a boundary of a cylinder and including a top deck at least partially extending across a water jacket cavity surrounding the cylinder.

Owner:FORD GLOBAL TECH LLC

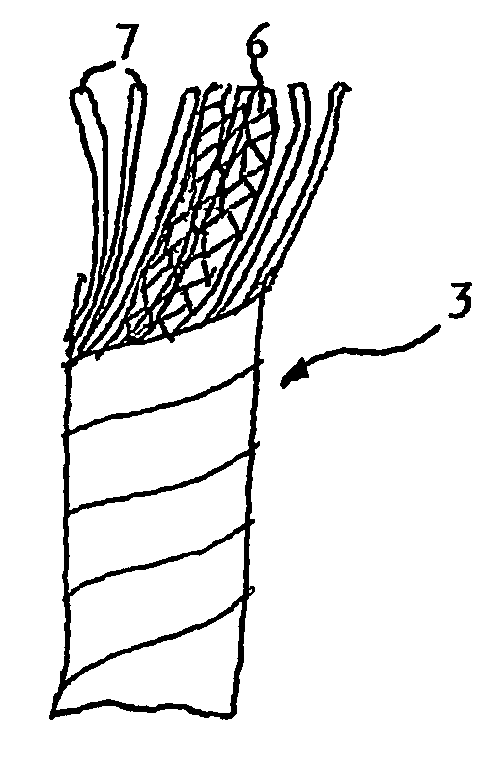

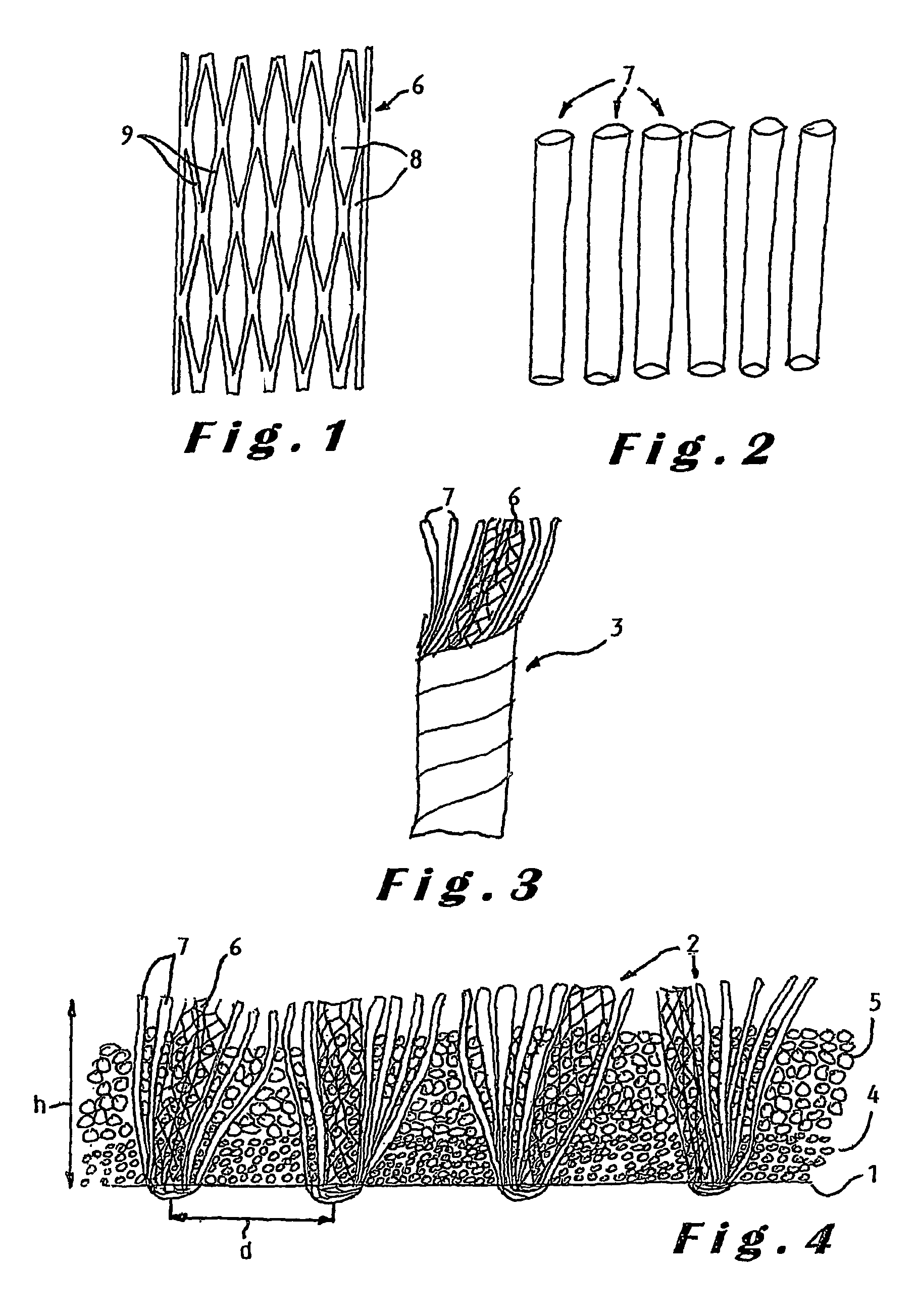

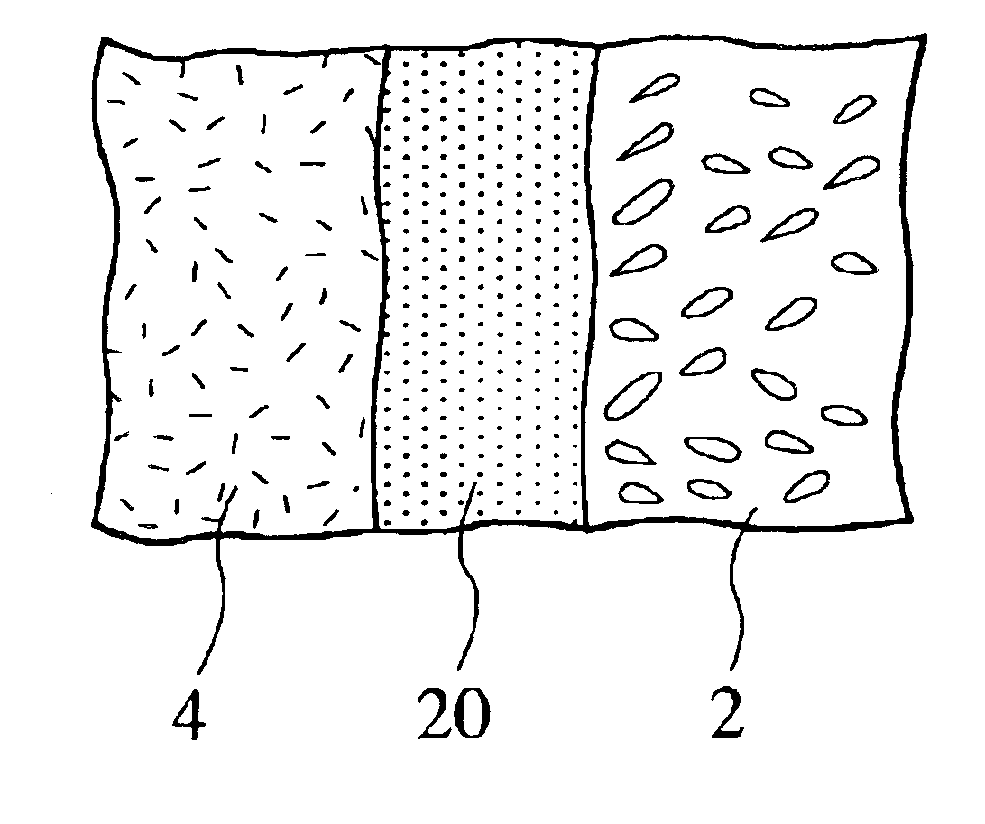

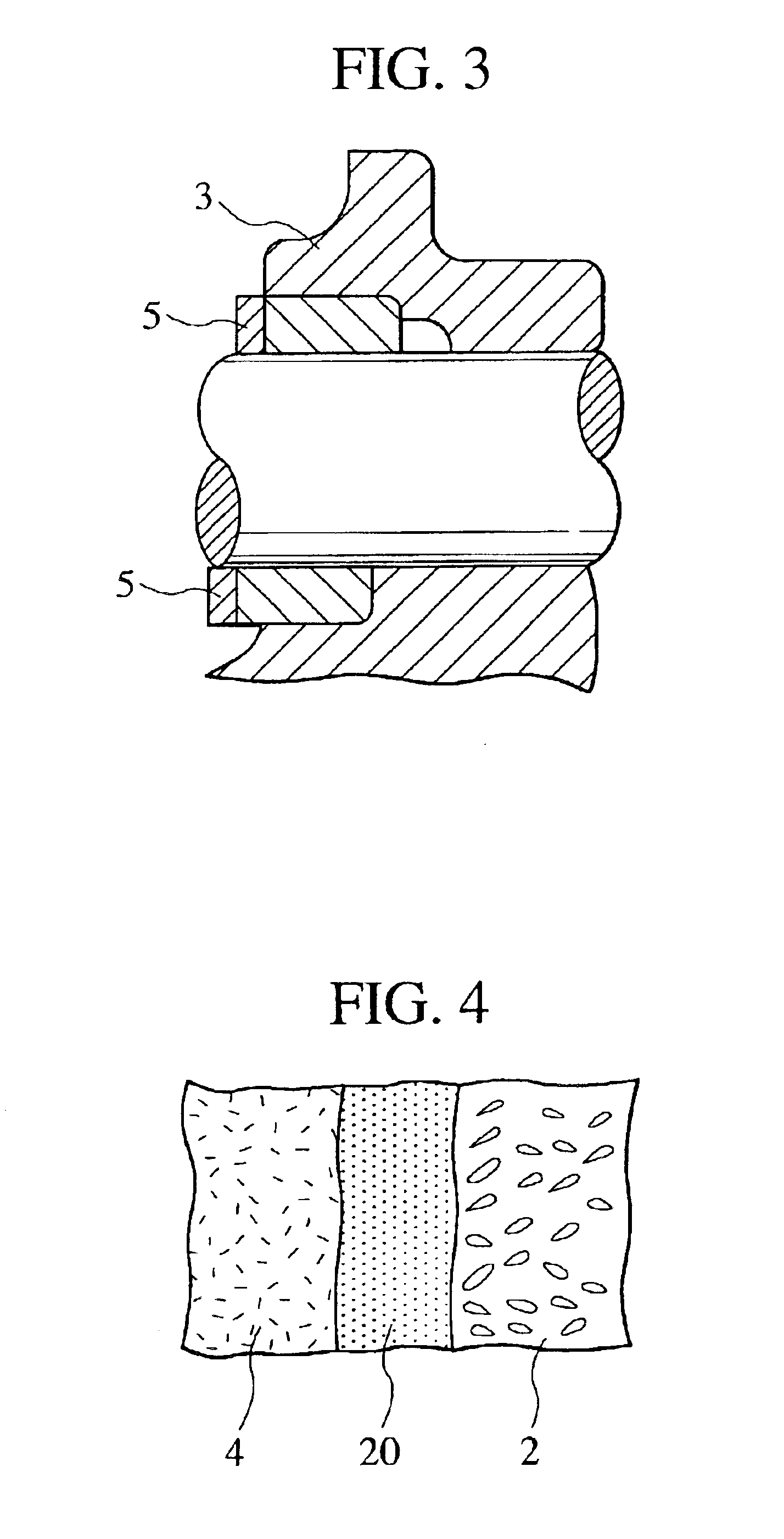

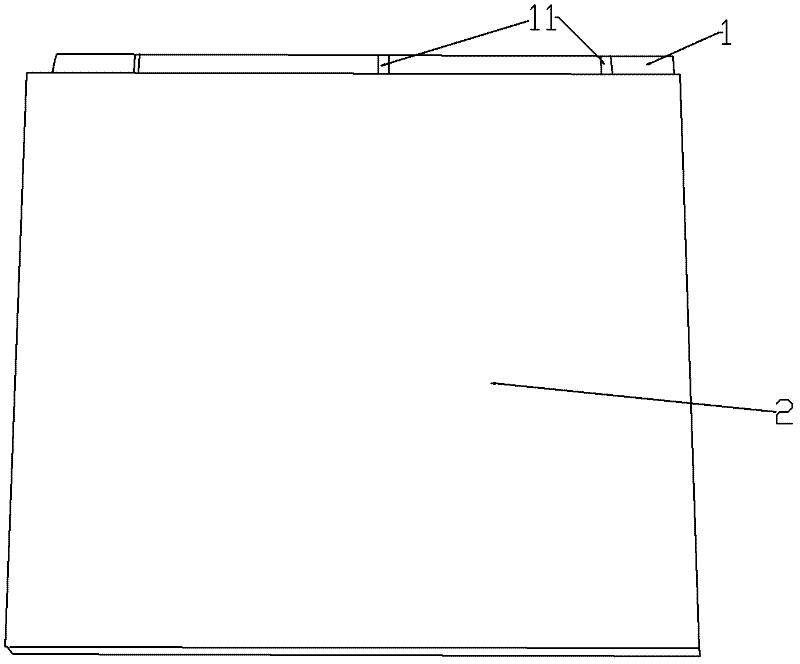

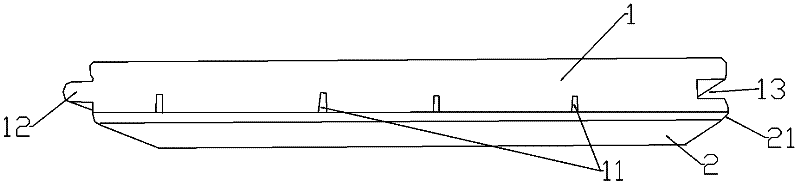

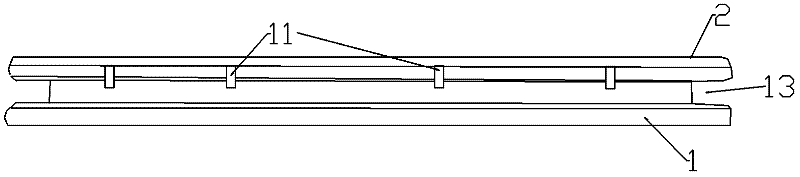

Synthetic turf

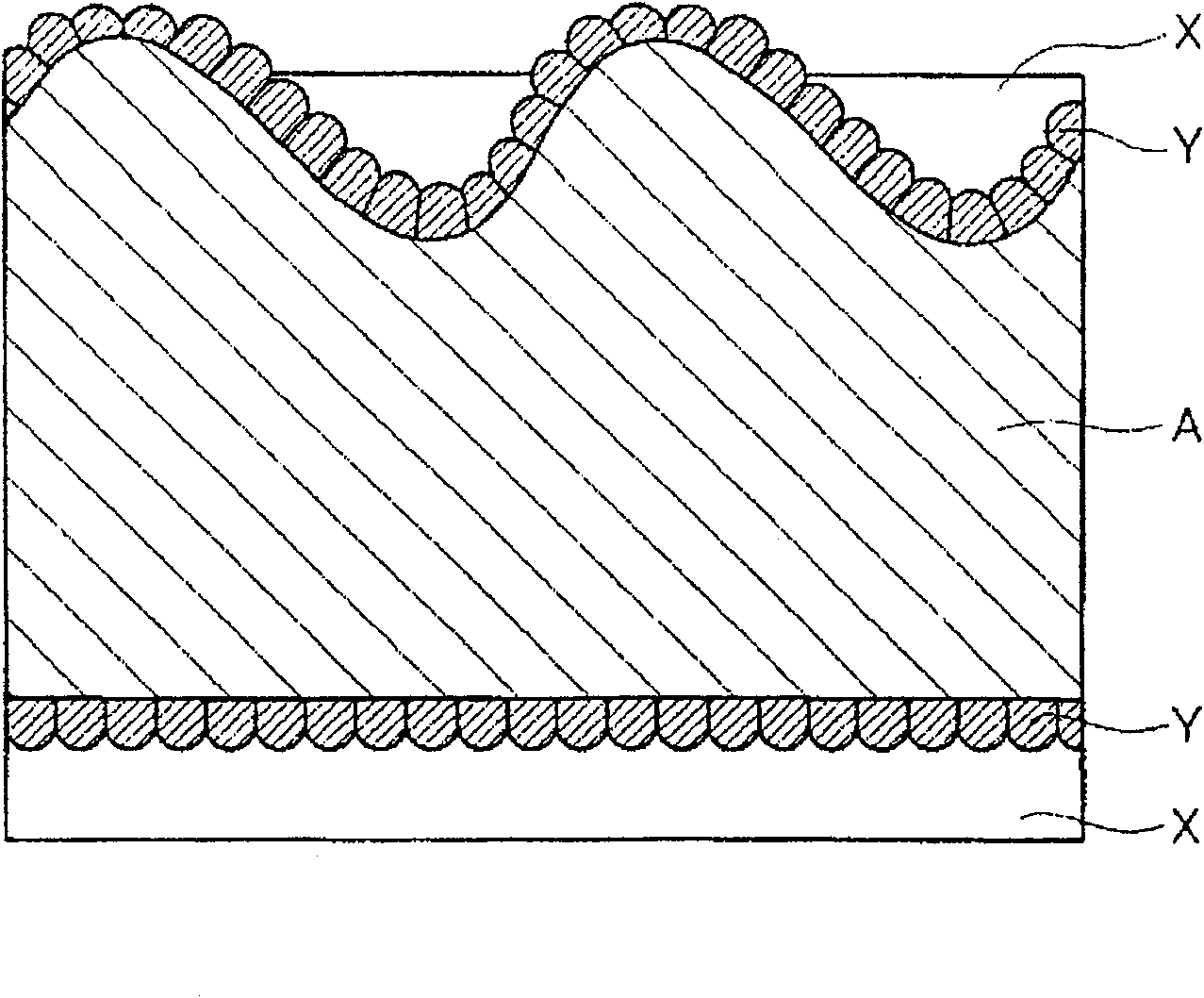

InactiveUS7399514B2Less differenceSmall coefficient of frictionDead plant preservationArtificial flowers and garlandsInfillWear pattern

The present invention provides new types of synthetic turf. The synthetic turf includes a pile fabric having a backing (1) and tufts (2) projecting therefrom. In one embodiment, at least a number of the tufts are made of a composite yarn formed by at least one fibrillated yarn (6) together with a number of individual filament yarns (7), in particular with so-called monofilament or monotape yarns. The fibrillated yarn and the individual filament yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. In another embodiment, at least a number of the tufts are made of a composite yarn formed by monotape yarns twisted together with a number of the monofilament yarns. The monofilament and monotape yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. The combination of a fibrillated yarn and individual filament yarns or the combination of monofilament and monotape yarns in a composite yarn allows immediate achievement of the look of natural grass, that is, without post-fibrillation, and avoids any visible difference in wear pattern between the different types of yarns. In another embodiment, the invention also provides improved particulate material for use as infill material for top-dressing a synthetic turf.

Owner:DOMO ZELE

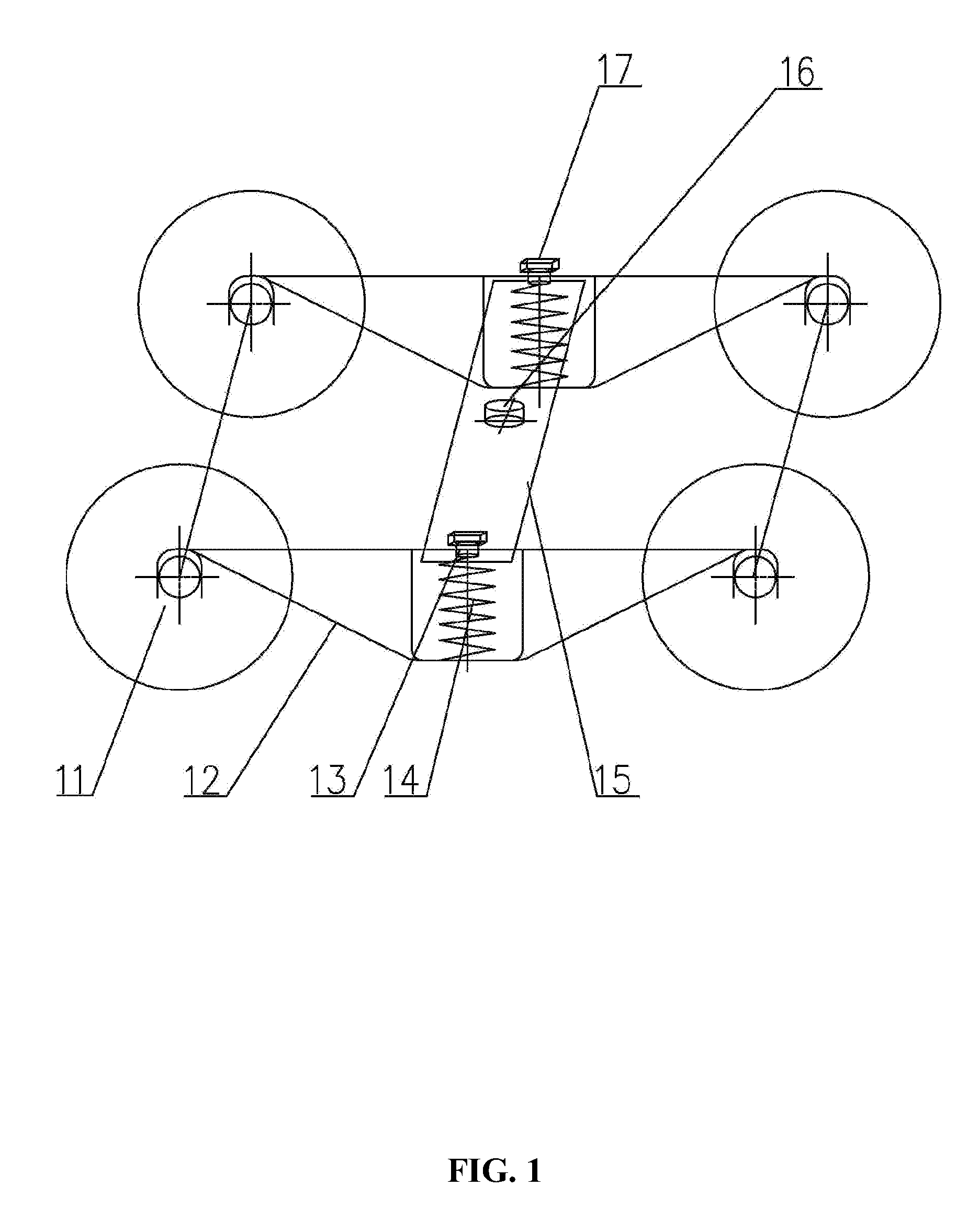

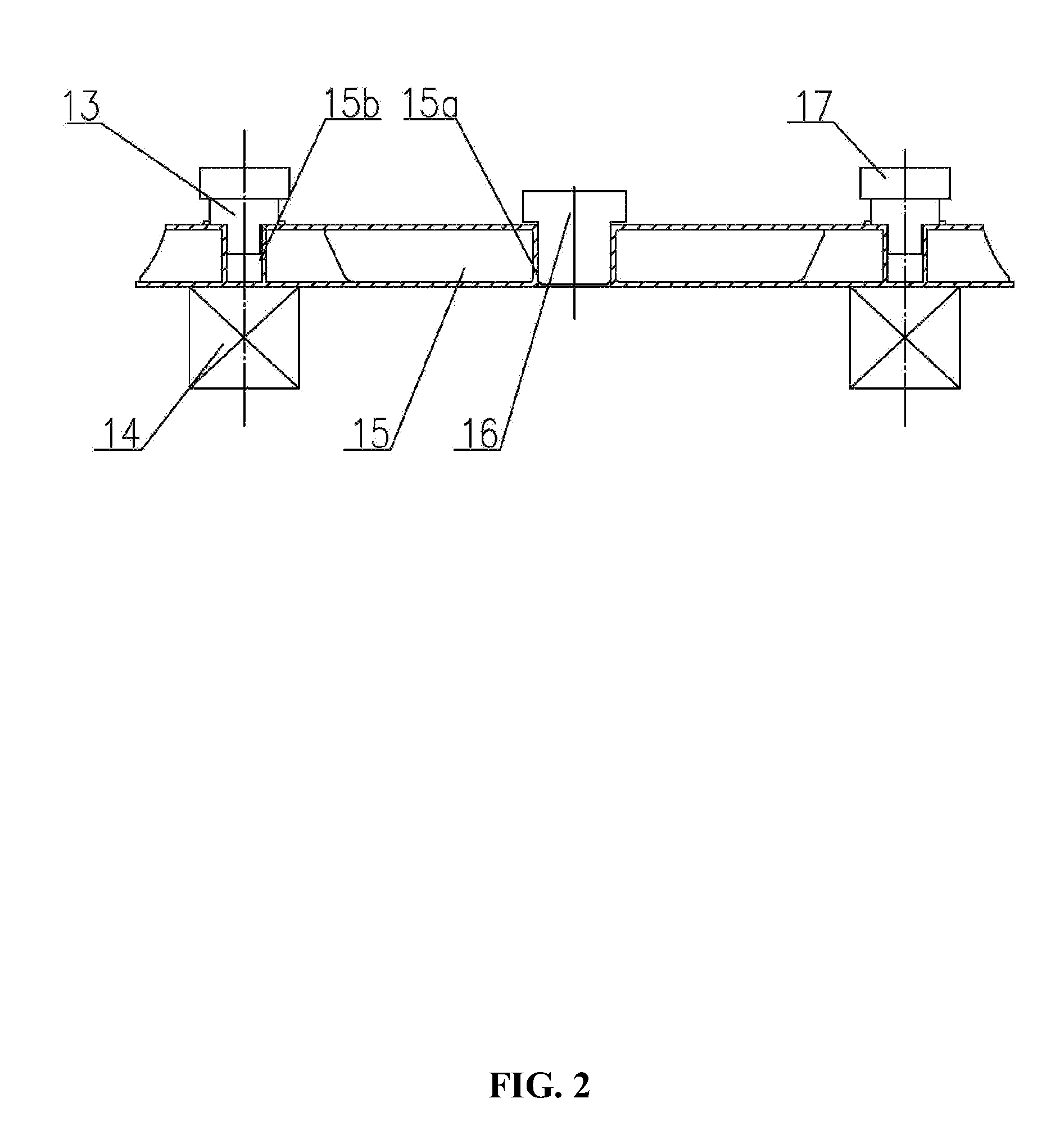

Railroad car wheel truck

ActiveUS20130055922A1Light weightThe stress state is reasonableBogiesBogie-underframe connectionsHorizontal forcePilot hole

A wheel truck for a railroad car, including: a front wheel pair assembly and a rear wheel pair assembly; two side frame assemblies, each side frame assembly including a square box and journal-box guides; two spring suspension devices; and a bolster assembly including two ends disposed on the two spring suspension devices, respectively. The bolster assembly includes a pilot hole in the center and two mounting holes on the two ends, the pilot hole is rotationally matched with a cylindrical upper center plate of a car body for transmitting vertical and horizontal forces from the car body, and the two mounting holes are disposed above the two spring suspension devices, respectively. Each mounting hole receives a lower side bearing, and the lower side bearing is matched with a corresponding upper side bearing disposed on each side of the car body for transmitting the vertical load from the car body.

Owner:CRRC YANGTZE CO LTD

High wear-resisting composite material of strenthen polytetrafuoro ethylene and fiber rod stone kind clay and preparation process and application thereof

The invention is a high-wearability attapulgite clay reinforced polytetrafluorethylene composite, composed of attapulgite clays and polytetrafluorethylenes, and its characteristic: the content of the attapulgite clays is 20-1 wt% and that of the polytetrafluorethylenes is 80-99 wt%. Compared with existing techniques, the composite has lower friction coefficient and excellent wearability and mechanical property, applied in self-lubricating wearable parts in many fields, such as aviation, spaceflight, machinery, electronics, automobiles, home appliances, office, communications, etc. For the parts without considering oil stain pollution, after the composite are processed by oil dipping, it can obtain better wearability and lower friction coefficient.

Owner:上海高分子材料研究开发中心

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

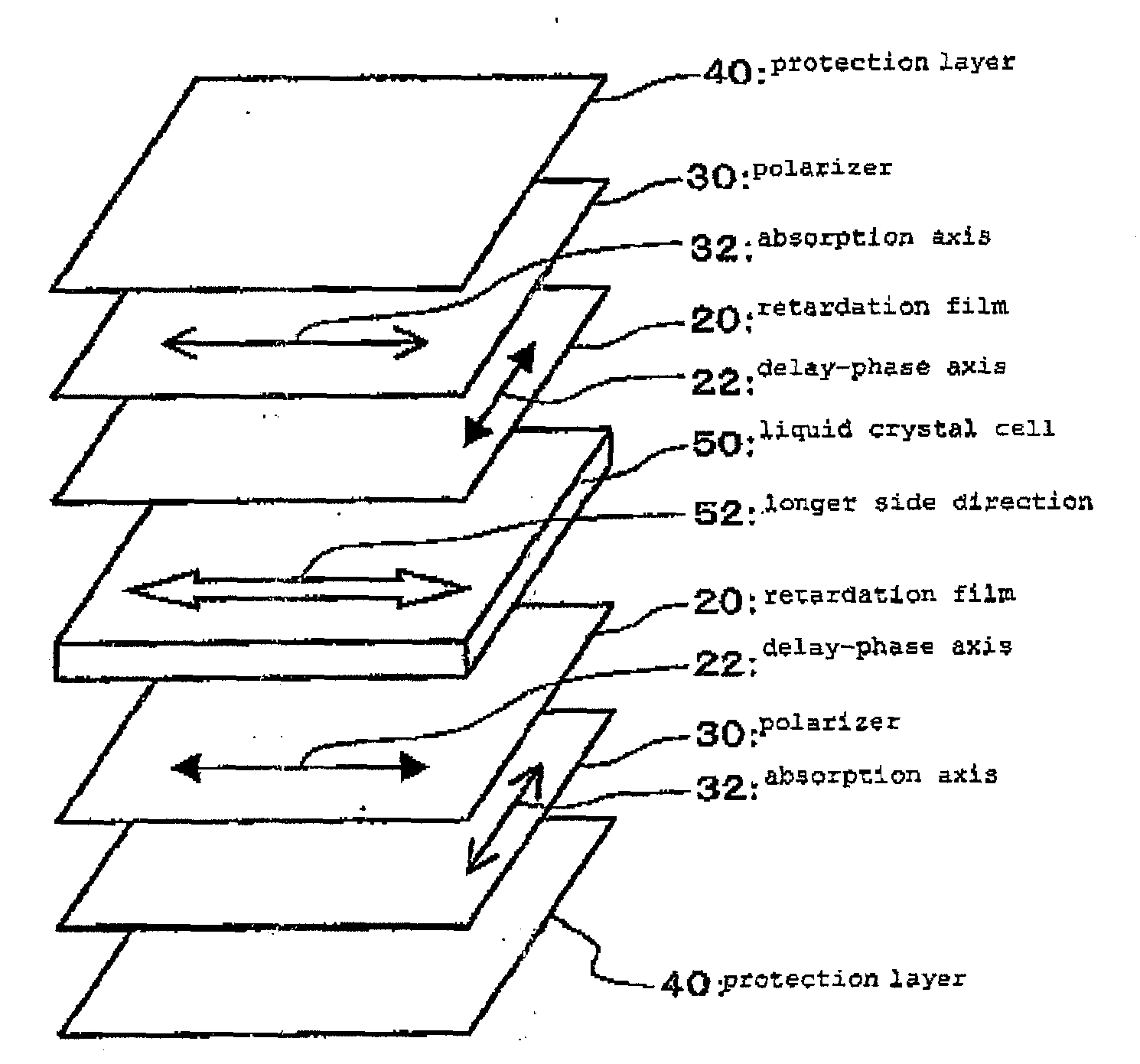

Composite polarizing plate and liquid crystal display using the same

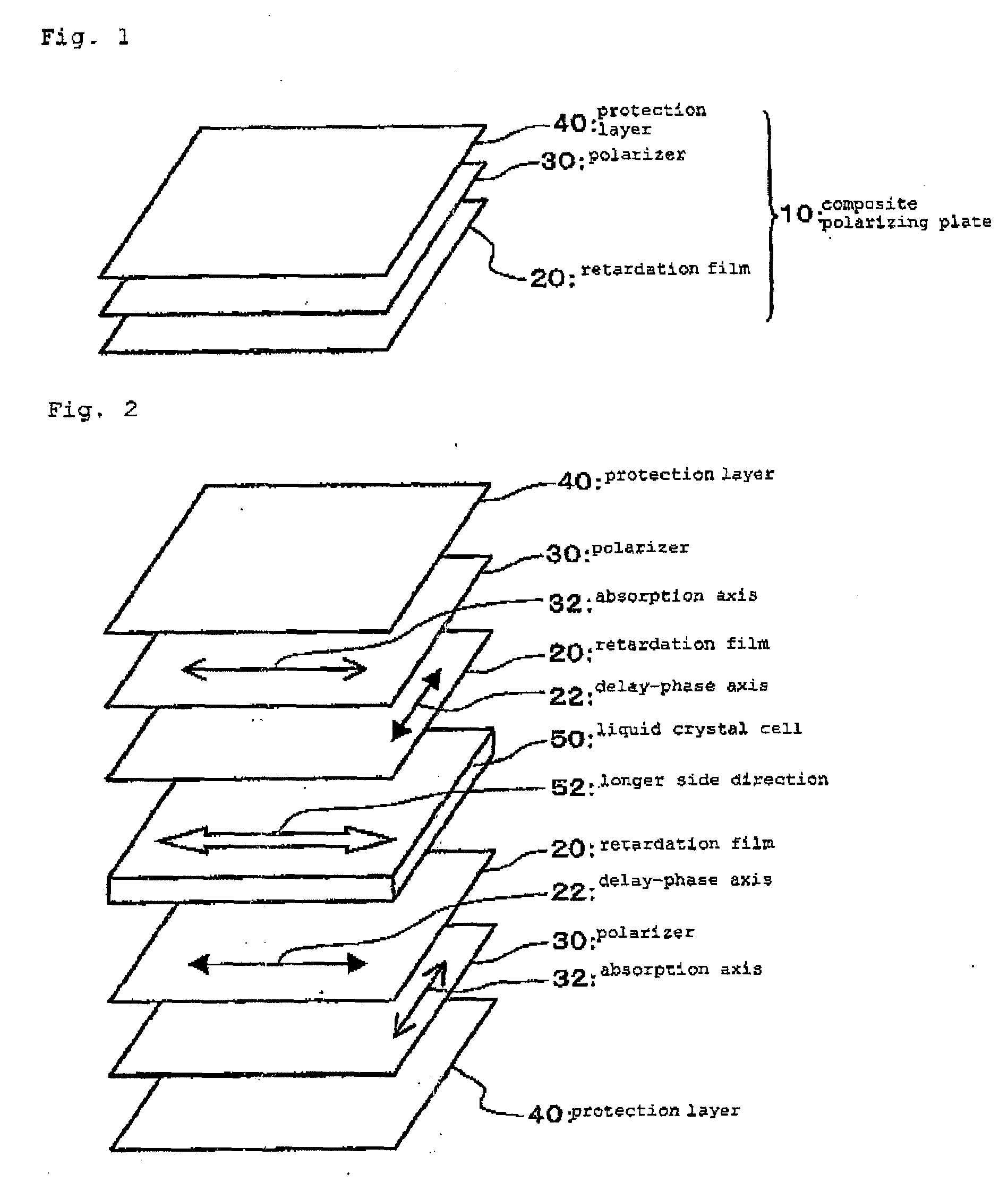

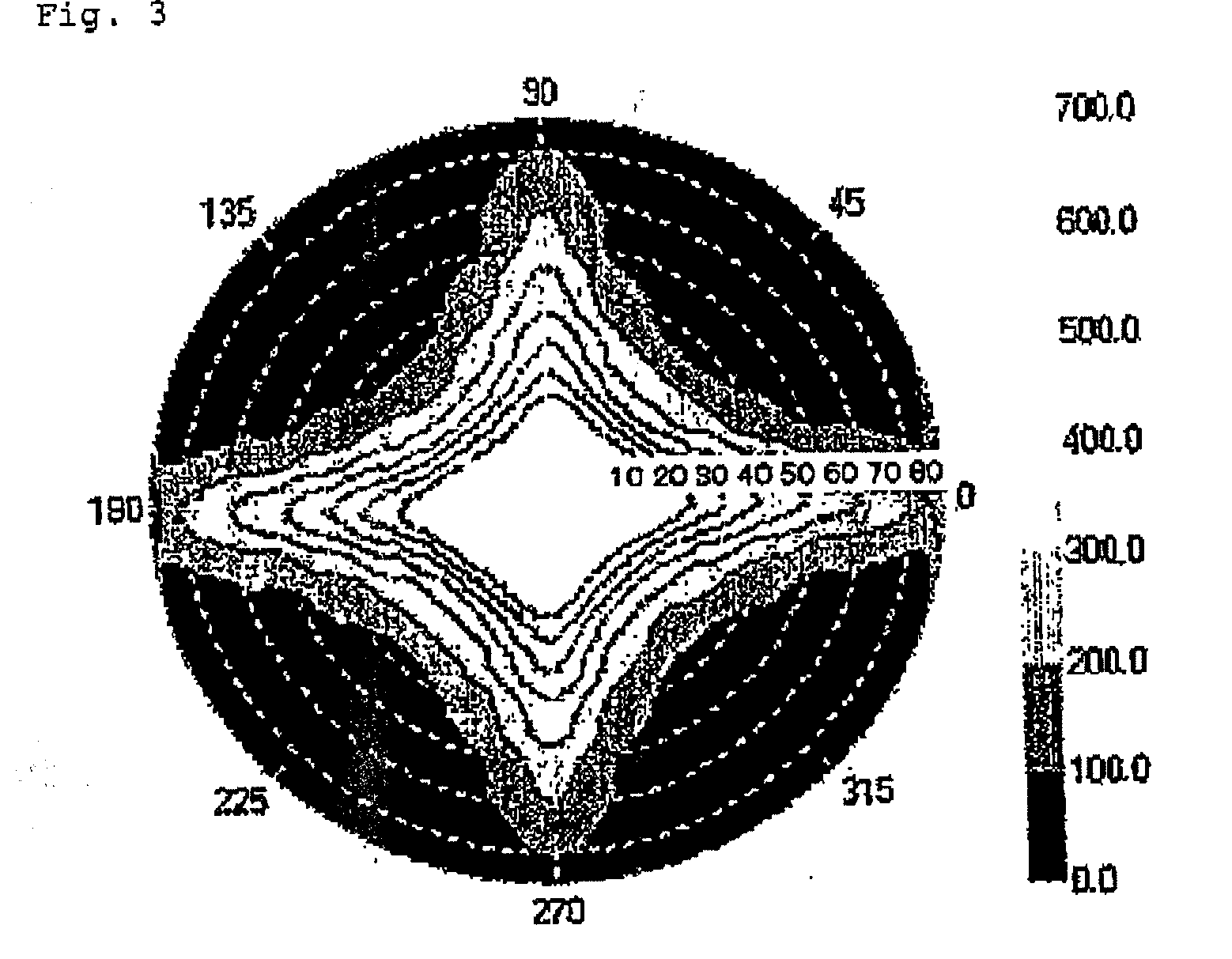

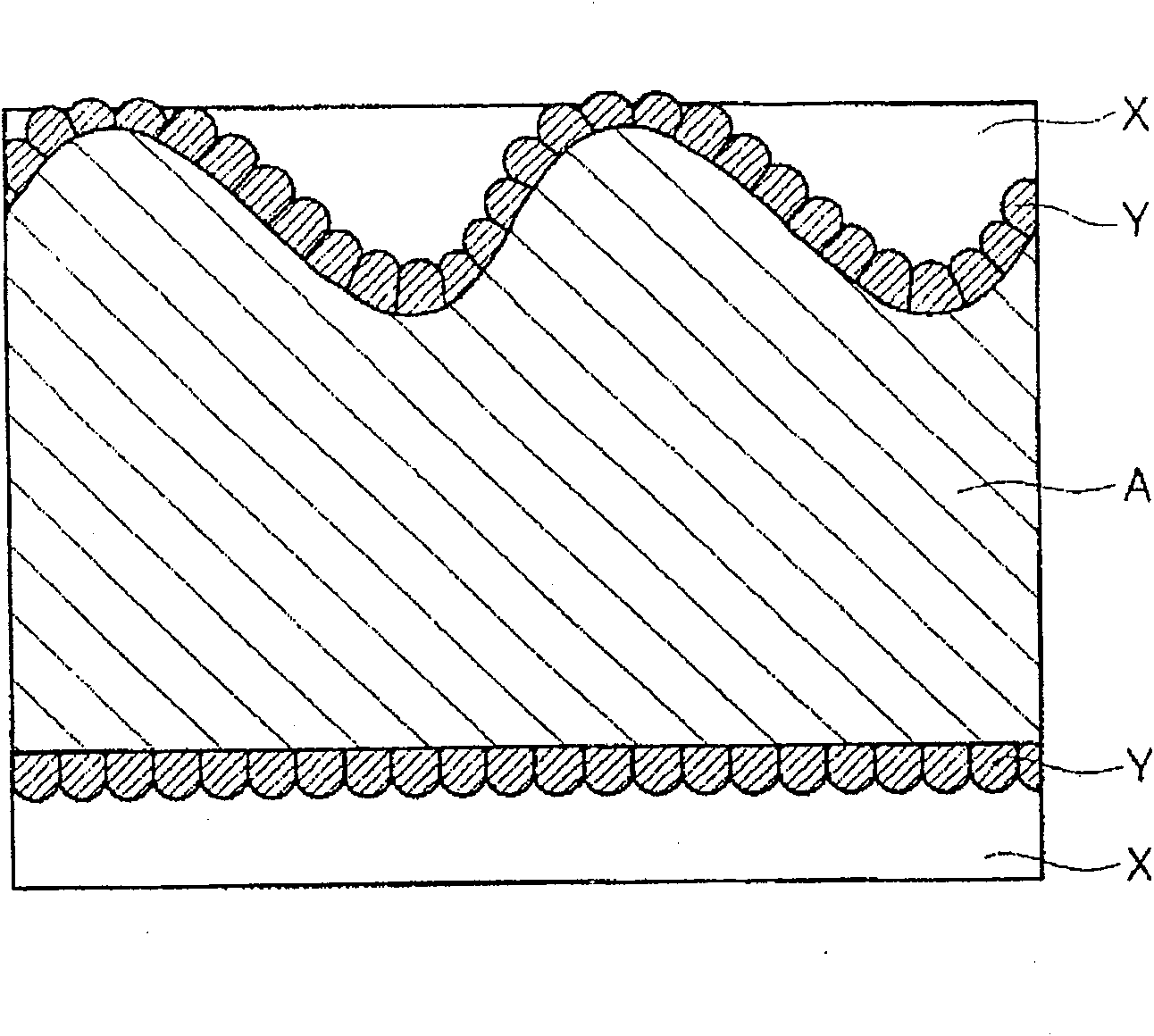

InactiveUS20090066888A1Suppression of deteriorationSuppression of decompositionPolarising elementsNon-linear opticsPolyvinyl alcoholPolarizer

Disclosed is a composite polarizing plate wherein a transparent protection layer (40) is formed on one side of a polarizer (30) which is composed of a polyvinyl alcohol resin and a retardation film (20) composed of a polypropylene resin is bonded to the other side of the polarizer (30), which is opposite to the side on which the transparent protection layer (40) is formed. The retardation film (20) composed of a polypropylene resin may be made of a homopolymer of propylene, or alternatively made of a copolymer with another monomer which mainly consists of propylene. A liquid crystal display is obtained by arranging this composite polarizing plate on at least one side of a liquid crystal cell (50).

Owner:SUMITOMO CHEM CO LTD

Metal-ceramic cutting tool material and its preparation method

The invention discloses the Ti(C,N) based metal ceramics and its preparation method. The weight ratio of each constituent of the metal ceramics is as following Ti30-65, W8-25, Ta1.0-15.0, Zr0.1-5.0, Nb0-10, Cr0-1.0 etc as well as C and N as the rest. The powder of ceramics of carbonitride with Multiple elements in duplex type of two or more different element combinations is mixed with the powdersof carbide of Ti, W, Ta, Nb, V, Zr etc. and / or powders of carbide of their solid solution as well as the powders of Co, Ni, Mo. The metal ceramics are made from the admixture through the procedures of ball mill crushing, pressure moulding, vacuum dewaxing and vacuum sintering. With the good wear resistance being kept, the metal ceramics possesses high intensity and toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

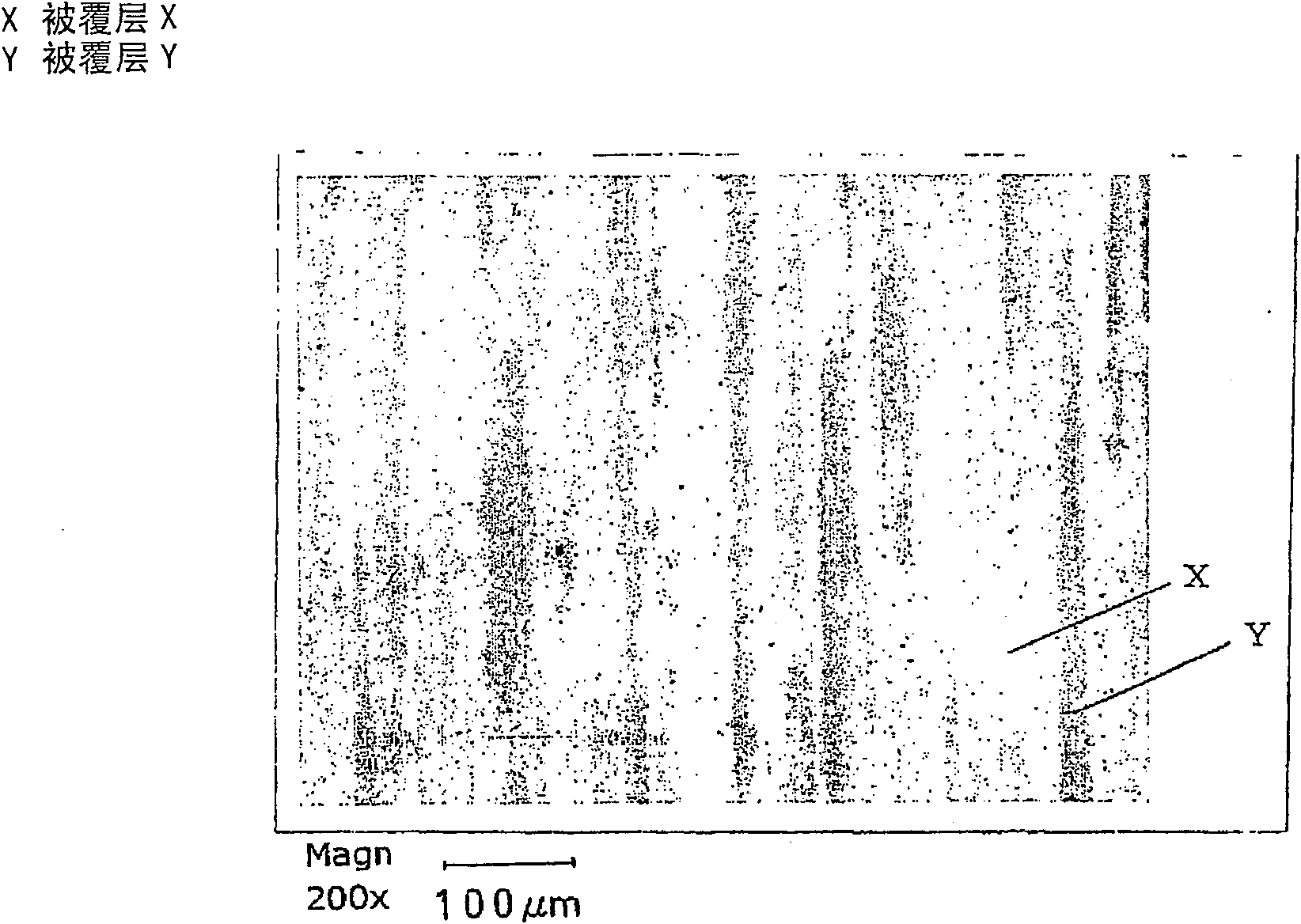

Conductive material for connecting part and method for manufacturing the conductive material

ActiveCN100583309CImprove reliabilitySmall coefficient of frictionSingle bars/rods/wires/strips conductorsCoupling contact membersConductive materialsAlloy

In a conductive material, on the surface of a base material composed of a Cu plate strip, a Cu-Sn alloy covering layer, which contains a Cu of 20-70at% and has an average thickness of 0.1-3.0[mu]m, and an Sn covering layer having an average thickness of 0.2-5.0[mu]m are formed in this order, and a part of the Cu-Sn alloy covering layer is exposed from the surface of the Sn covering layer at an exposing area rate of 3-75%. Reflow process is performed to the material surface, and preferably, the arithmetic average roughness Ra at least in one direction is 0.15[mu]m or more, the arithmetic average roughness Ra in all the directions is 3.0[mu]m or less, and the average thickness of the Cu-Sn alloy covering layer is 0.2[mu]m or more. The conductive material is manufactured by forming an Ni plating layer, and further, a Cu plating layer and an Sn plating layer as needed on the roughened base material surface, then by performing reflow process.

Owner:KOBE STEEL LTD

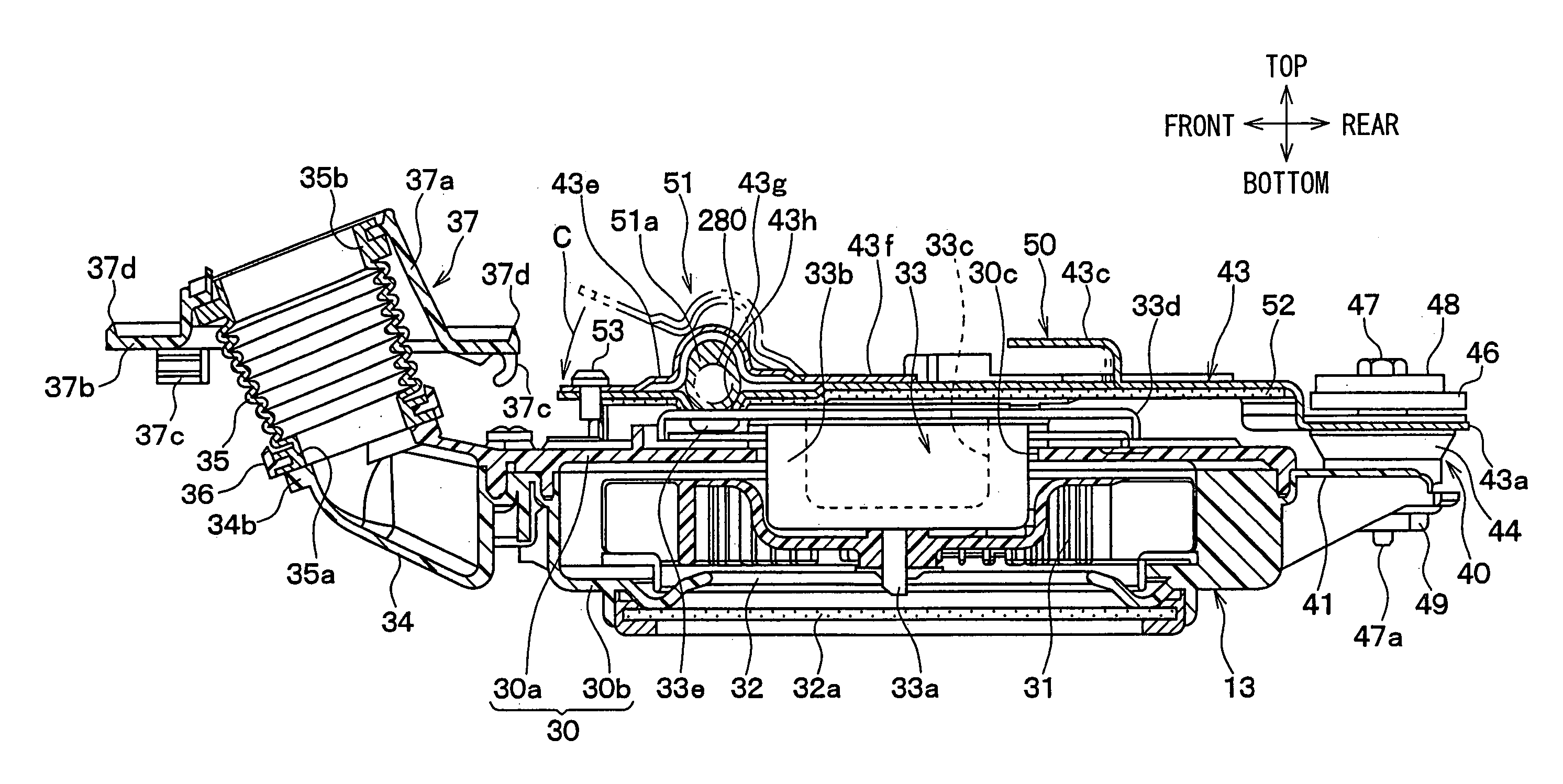

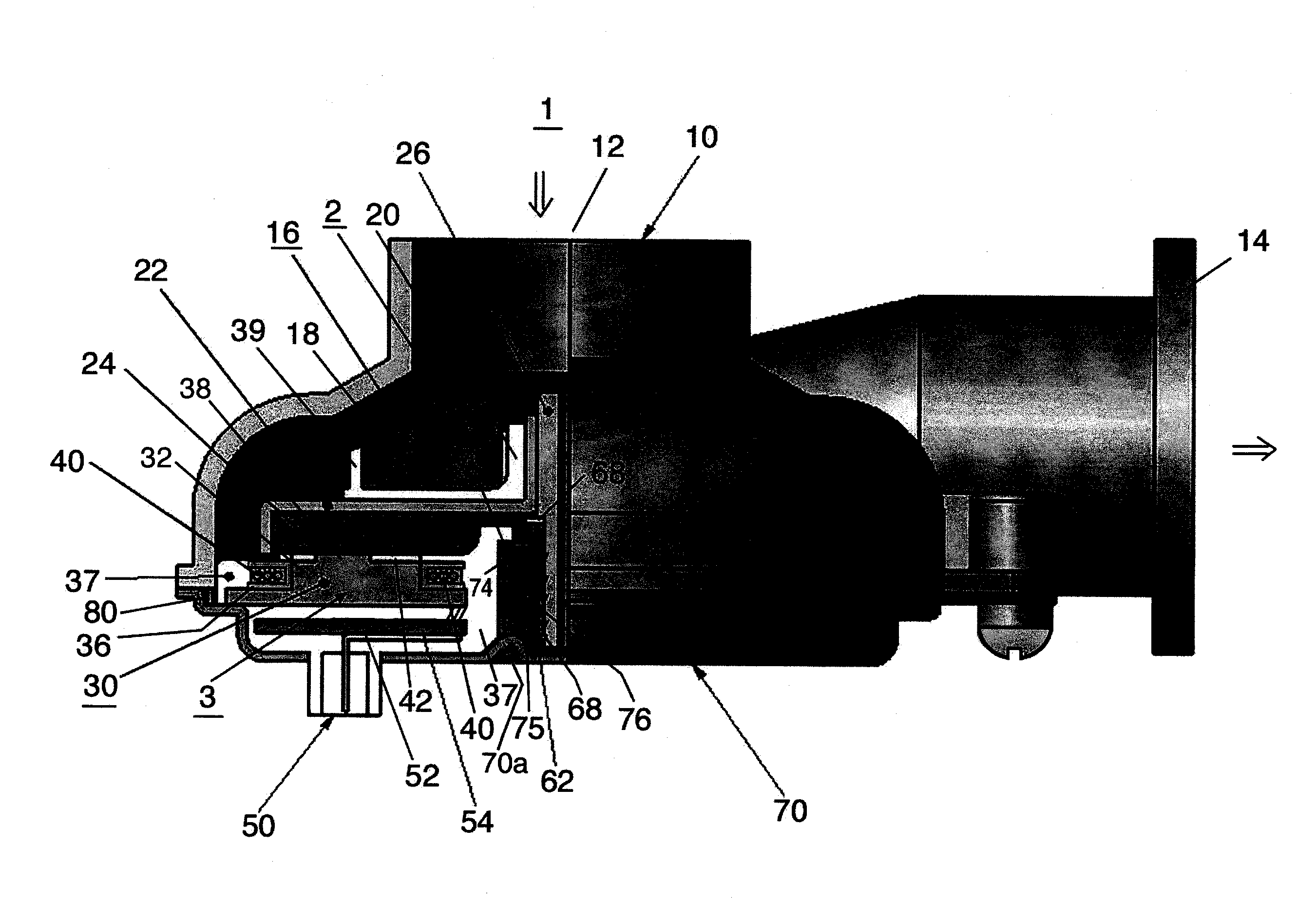

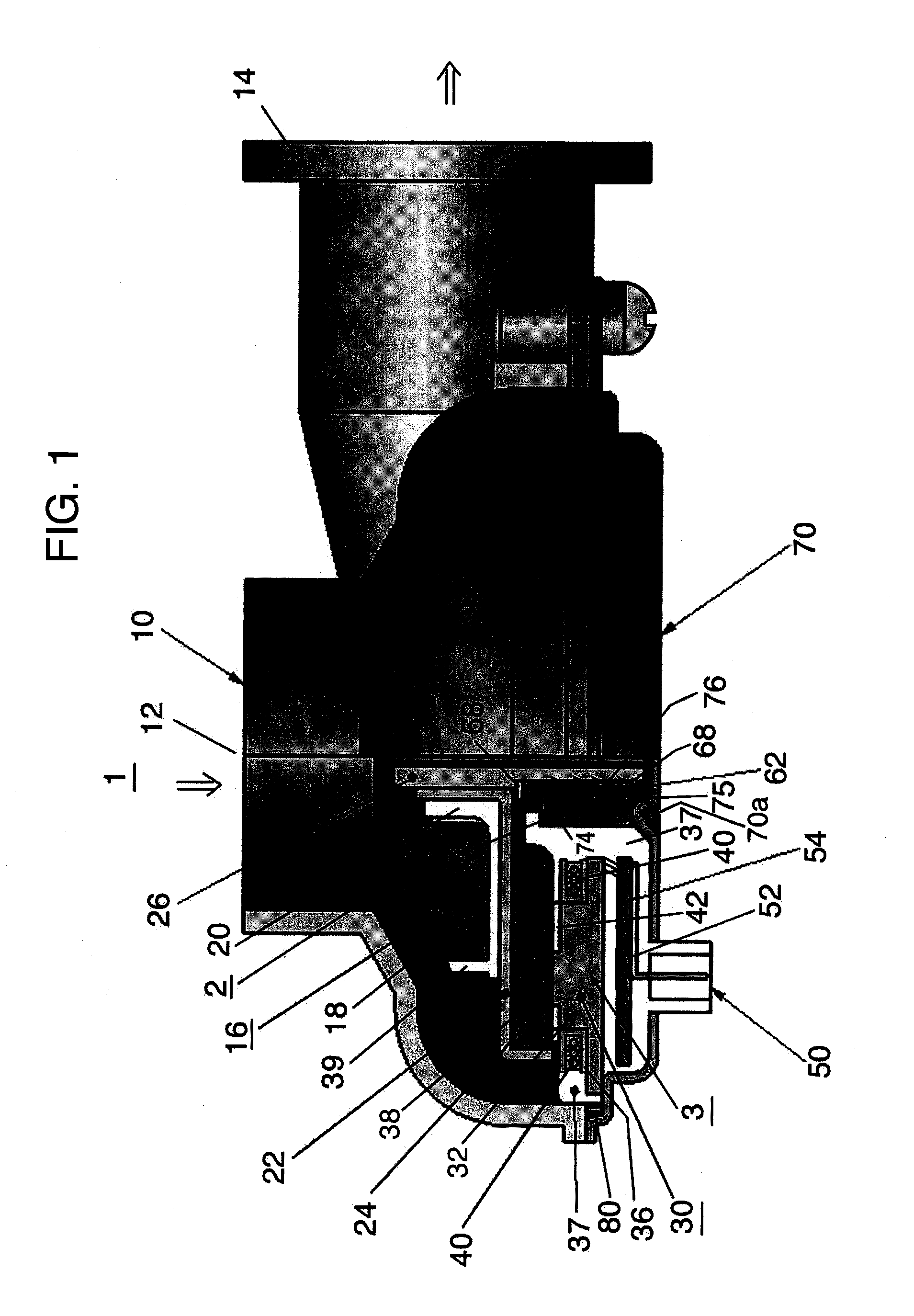

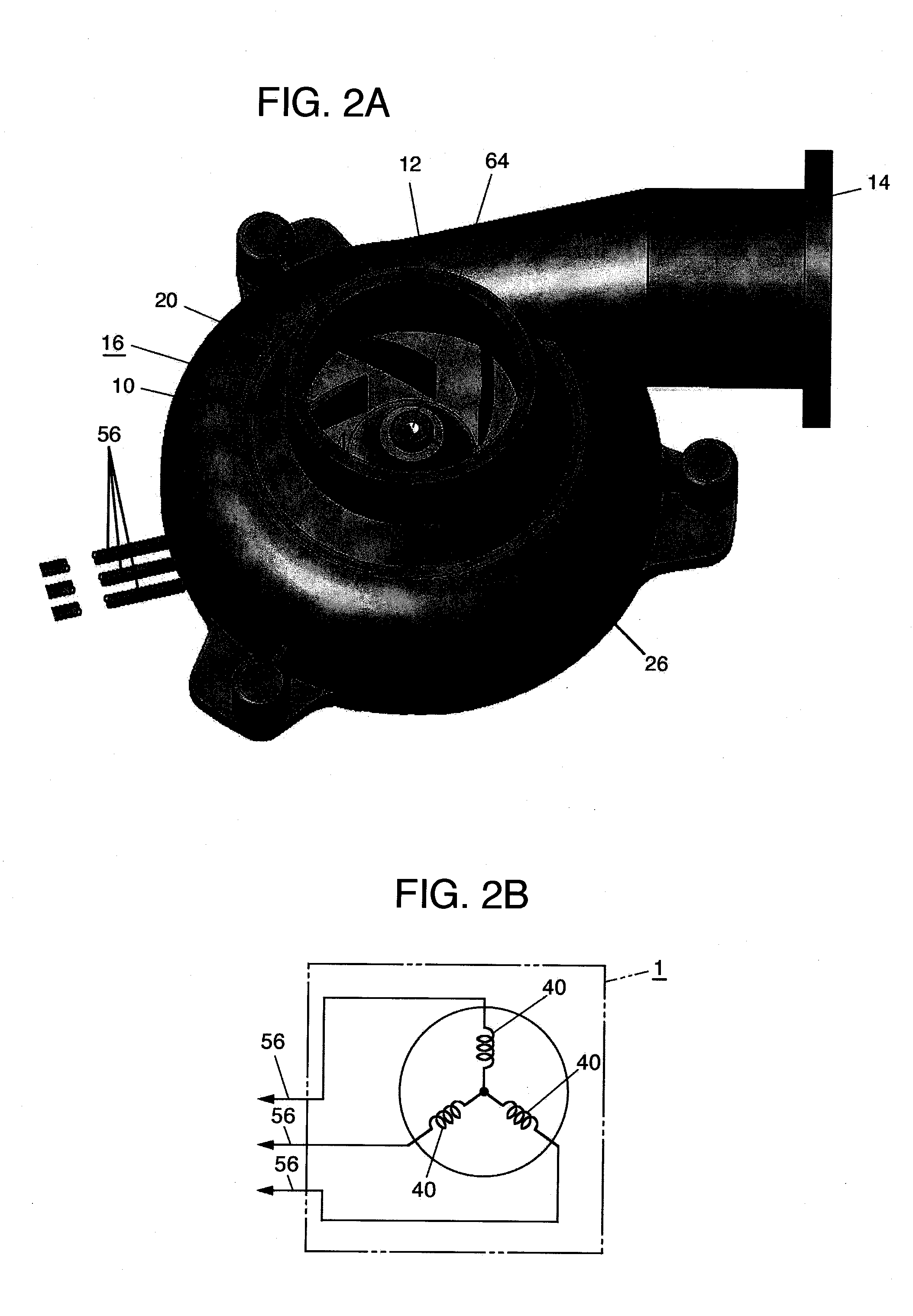

Flattened Brushless Motor Pump and Vehicle Electric Pump Unit Using Flattened Brushless Motor Pump

InactiveUS20080226474A1Simple configurationImprove featuresPositive displacement pump componentsBlade accessoriesBrushless motorsEngineering

The flattened brushless motor pump sucks liquid from suction port and discharges liquid from discharge port by rotating rotary shaft of flattened brushless motor flattened brushless motor has a stator unit having cores around which a plurality of armature coils are wound and terminals electrically connected to the armature coils, and being formed by molding the cores and the terminals with resin in a watertight manner a rotor unit having magnets disposed facing the cores via a gap, rotary shaft and a yoke fixed to the rotary shaft and holding the magnets, wherein an in-water bearing for sliding the rotary shaft by a water film.

Owner:YAMAMOTO ELECTRIC

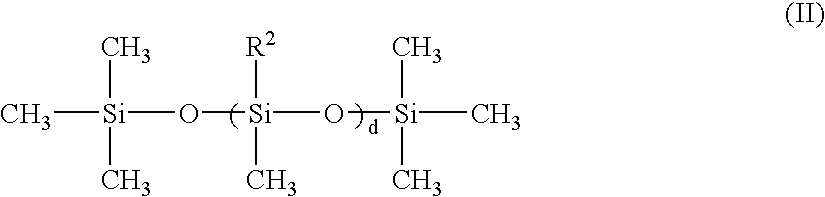

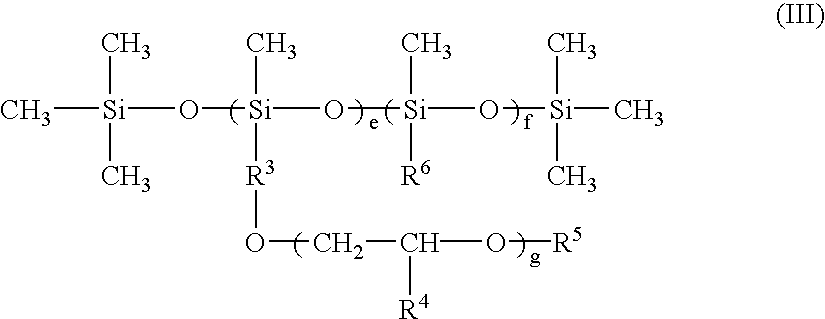

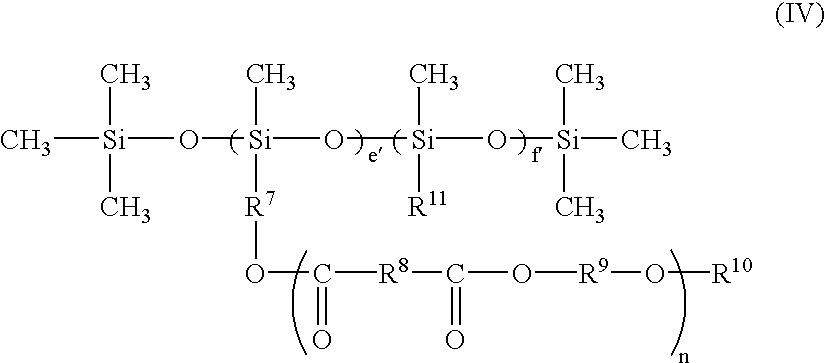

Preparation of wear resistant thermoplastic alkene complex

The invention relates to a method for preparing wear-resistant thermoplastic olefin hydrocarbon compound, which comprises: first, chemical grafting modification is carried out on thermoplastic olefin hydrocarbon polymer in an initiation system by silane coupling agent under the condition that peroxide initiator exists, thus leading the thermoplastic olefin hydrocarbon polymer to take along alkoxy or chloro-silane branched chain; polysiloxane which has super high molecular weight and H+ active group on at least one end is mixed together with the thermoplastic olefin hydrocarbon polymer which is processed by grafting modification in a melt extrusion way, so that hydrogen bond connection is formed between the polysiloxane with super high molecular weight and the polymer silane branched chain to obtain the thermoplastic olefin hydrocarbon compound. The method greatly improves the compatibility between the polysiloxane with super high molecular weight and the thermoplastic olefin hydrocarbon compound, thus the adding quantity of the polysiloxane can be increased by about ten times, and the long-term wearing resistance of the products can be improved. After being rubbed for 10,000 times, the product has the friction depth being about half of the traditional technical product added with wear resistant addition agent, and the static state friction coefficient and the dynamic friction coefficient being 10% more than the traditional blending technical product.

Owner:SHANDONG DAWN POLYMER CO LTD

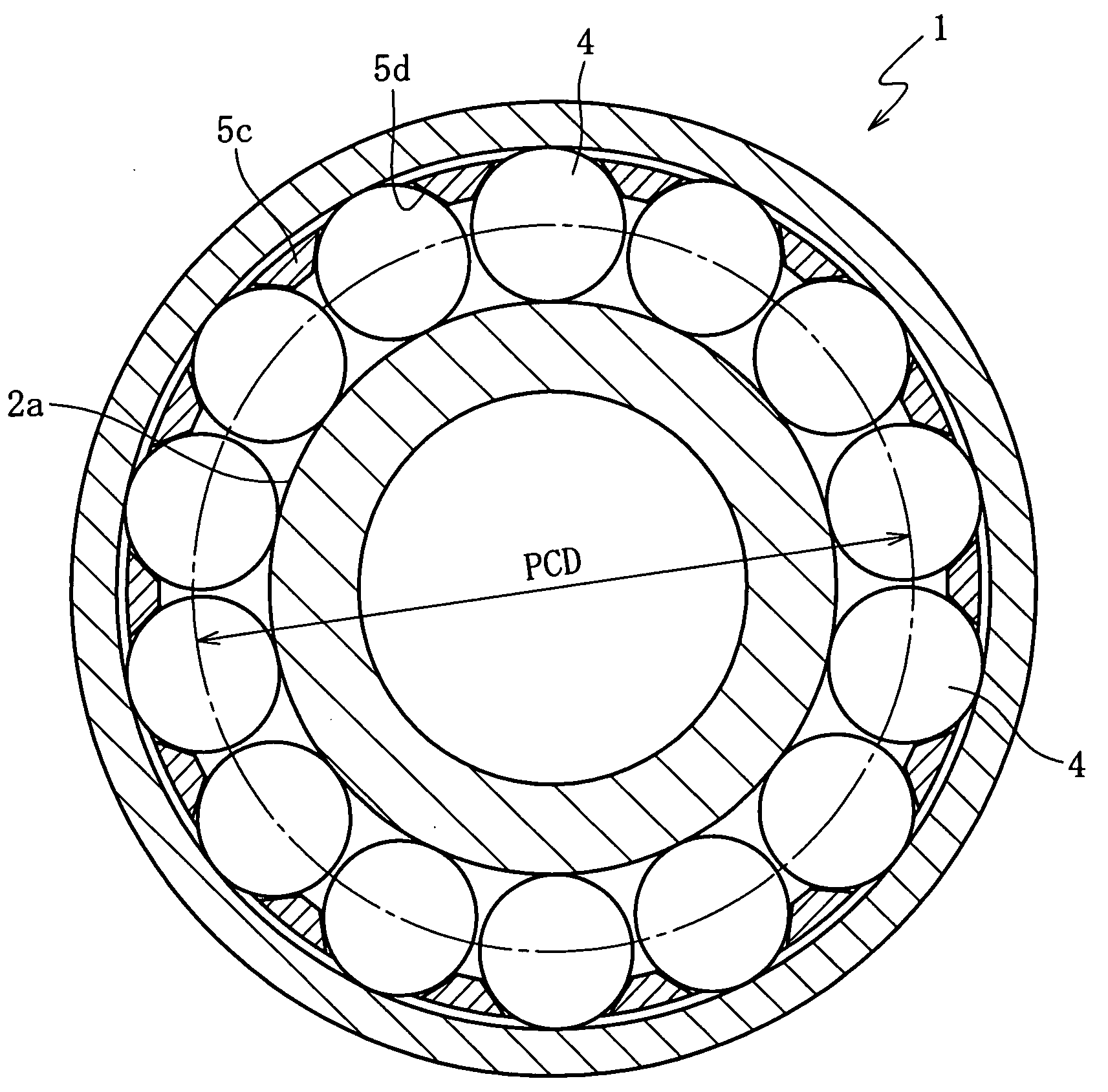

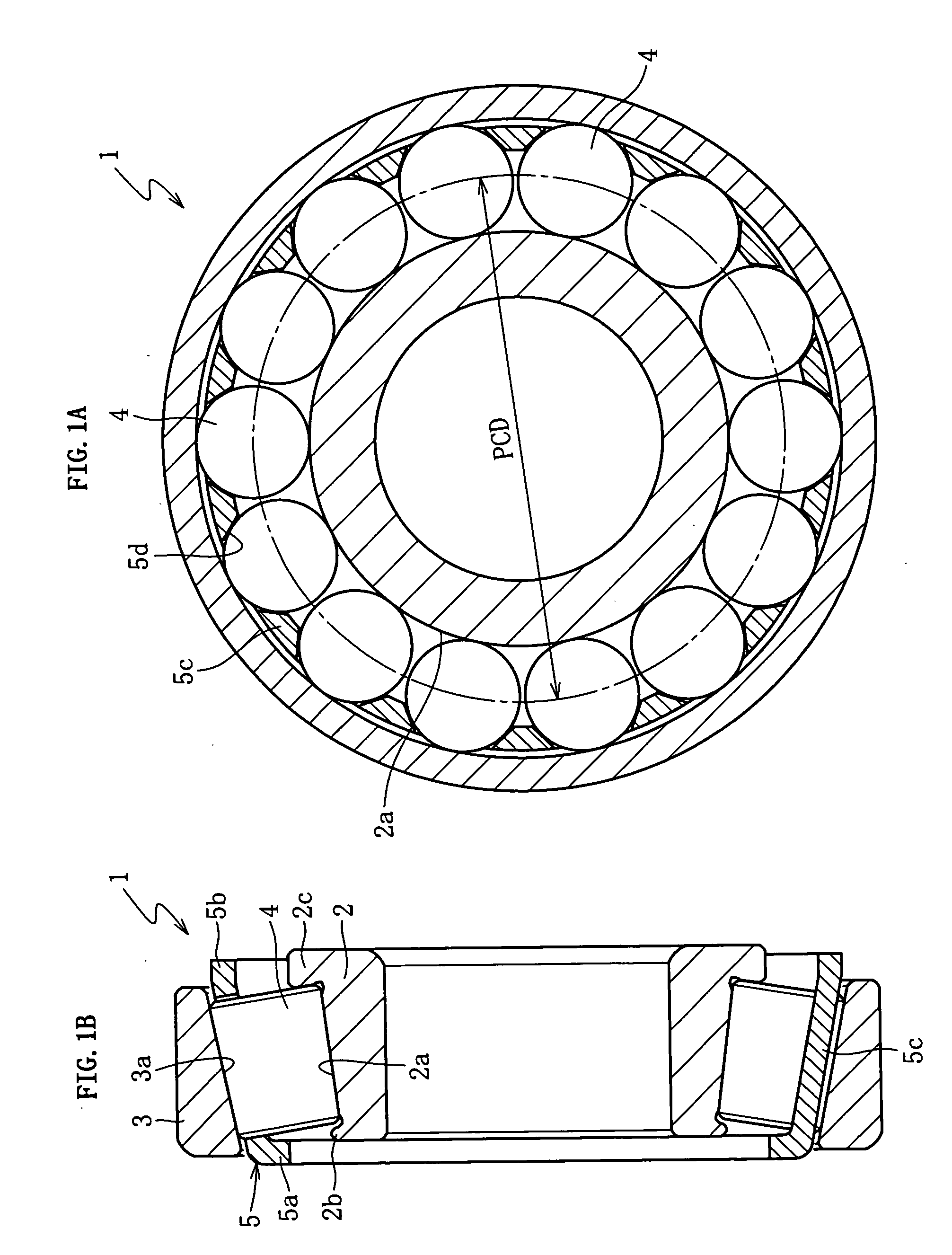

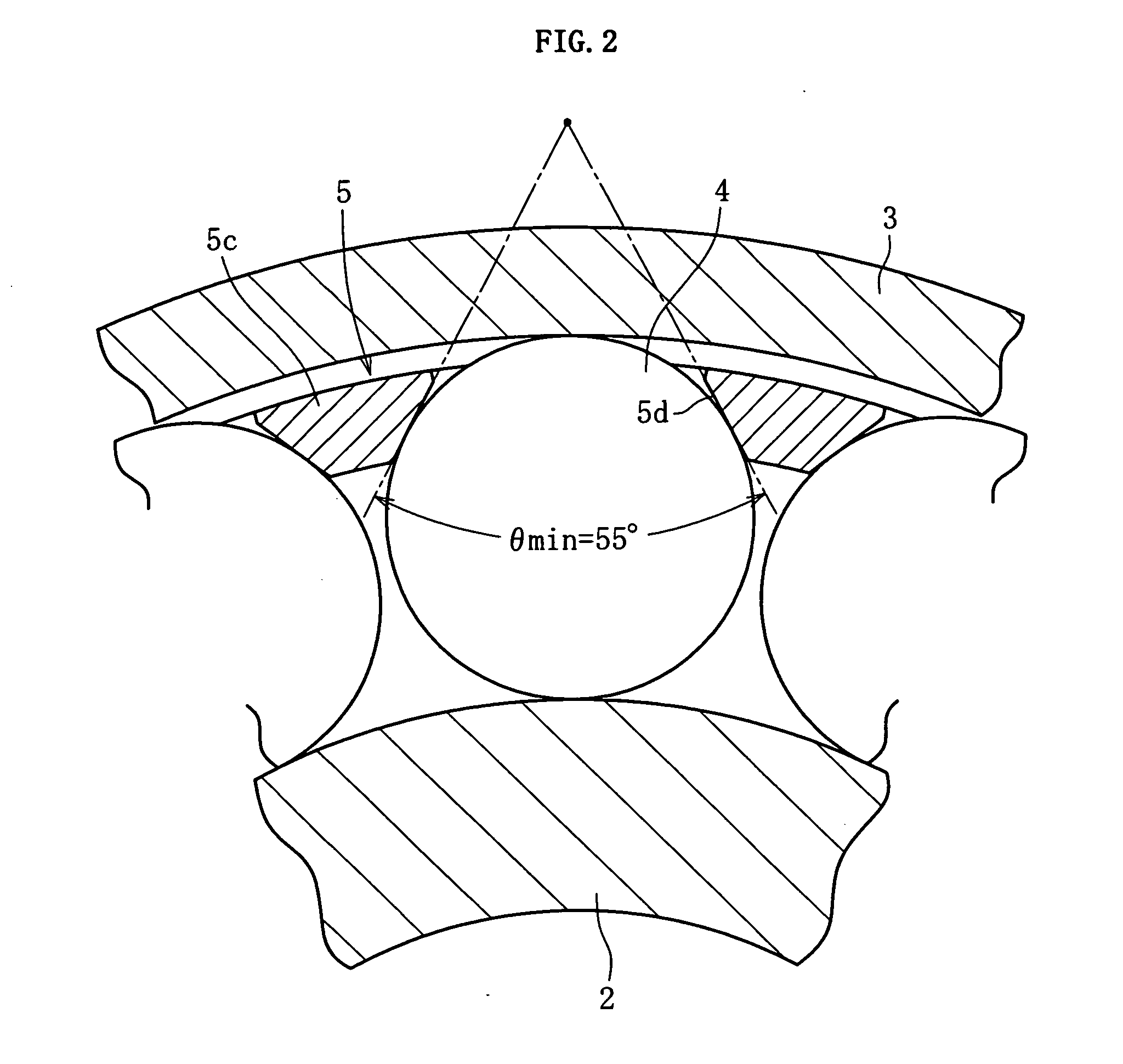

Tapered roller bearing

InactiveUS20090016664A1Avoid failureAmount of oil is smallRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing includes: an inner ring; an outer ring; a plurality of tapered rollers which are rollably disposed between the inner ring and the outer ring; and a retainer which retains the tapered rollers at predetermined circumferential intervals. In this tapered roller bearing, a roller coefficient {γ=(the number of rollers×average roller diameter) exceeds 0.94, a number of indentations having a micro recess-like shape are randomly provided at least on a surface of the tapered roller, a surface roughness parameter Ryni of the surface having the indentations falls within a range of 0.4 μm≦Ryni≦1.0 μm, and an Sk value is −1.6 or less.

Owner:NTN CORP

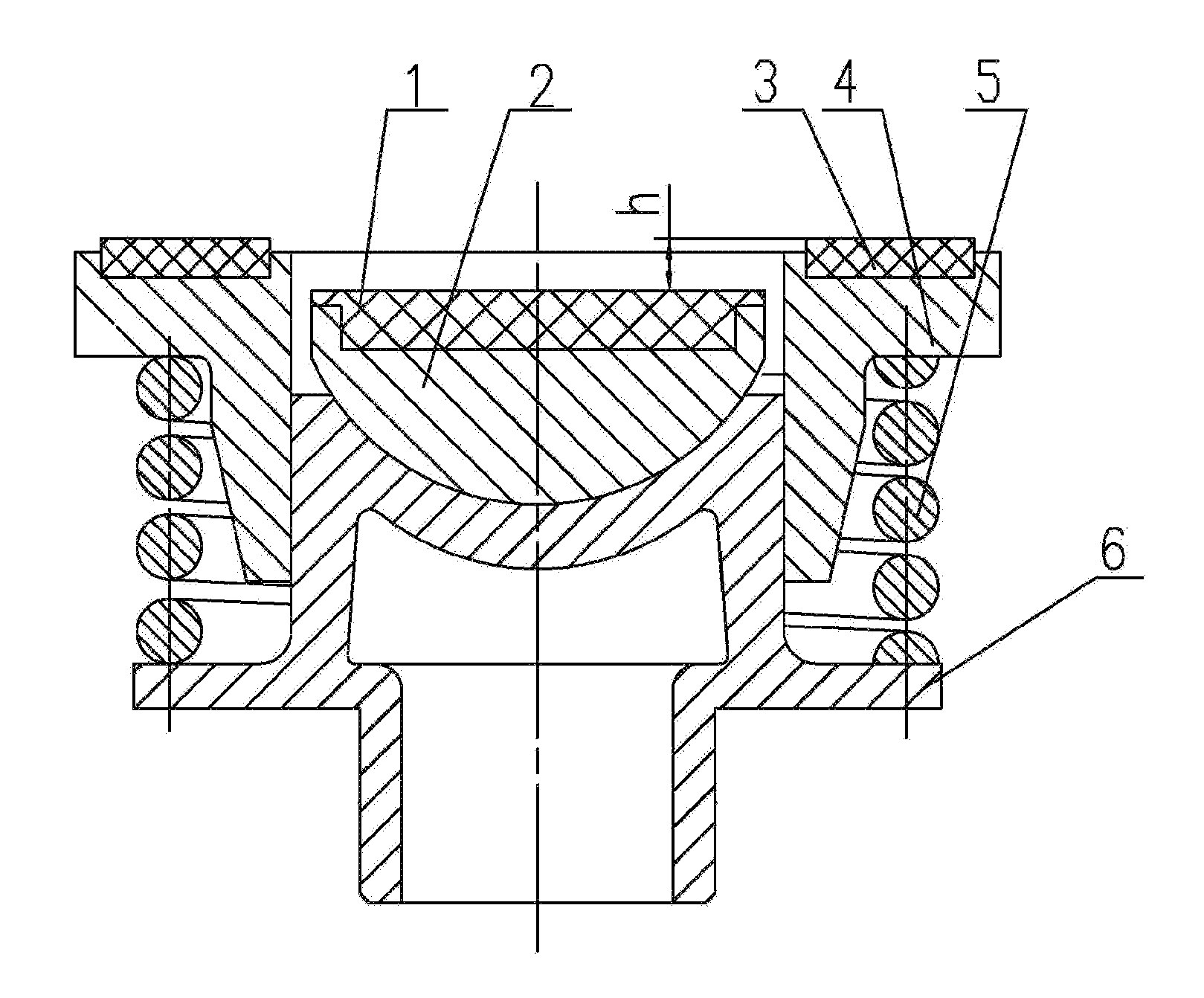

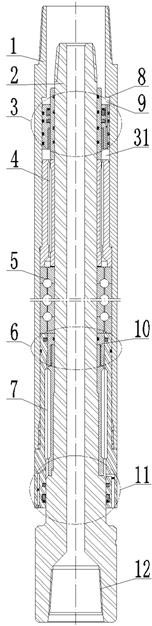

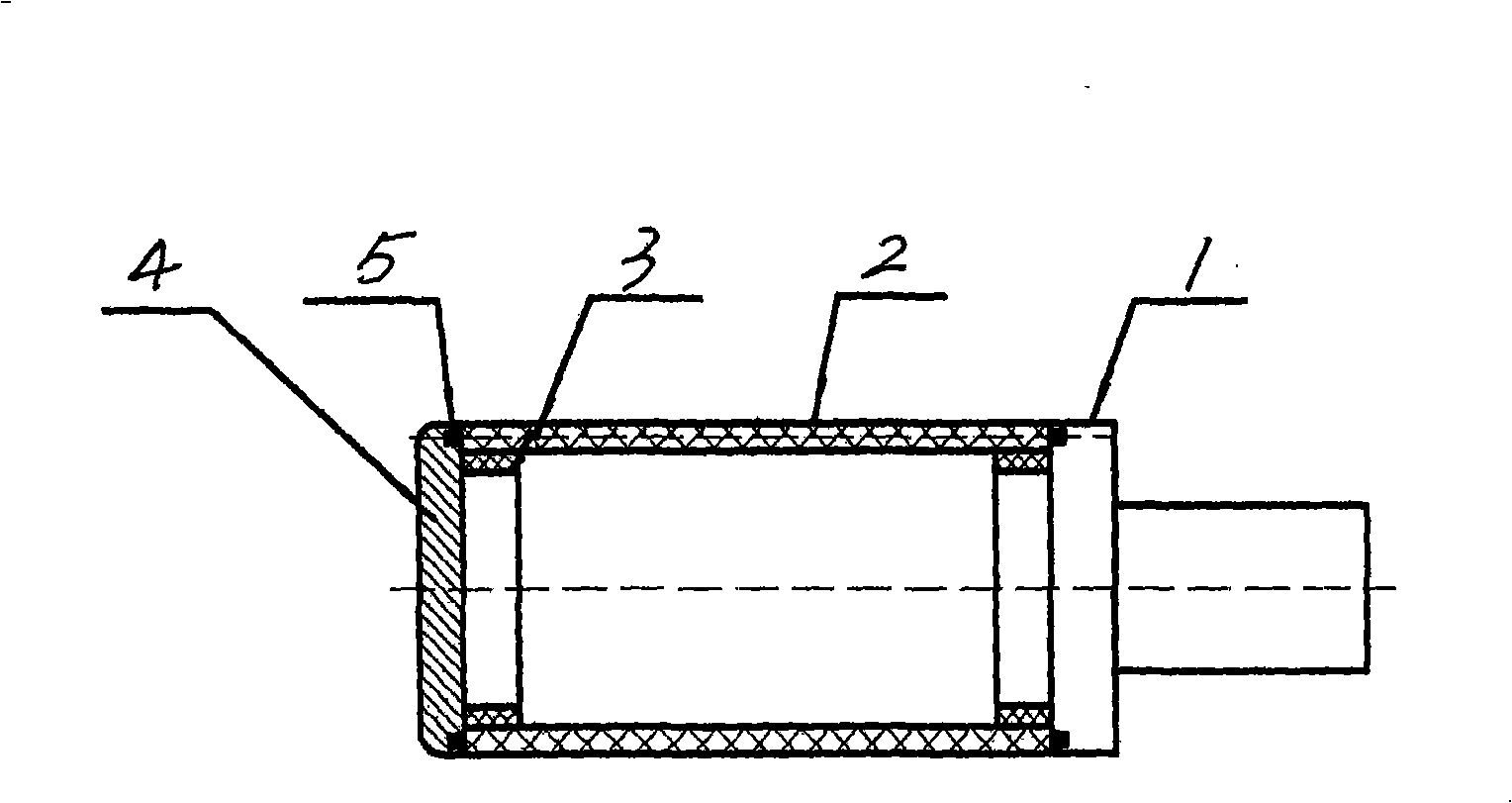

An oil-sealed cavity pressure-balanced screw drilling tool transmission shaft assembly

InactiveCN102296928AImprove the lubrication effectGood sealing pressureEngine sealsDrilling rodsEngineeringPressure balance

The invention relates to a driving shaft assembly of a screw drilling tool capable of maintaining the pressure balance of an oil seal chamber for oil and gas drilling. The technical solution is: oil seal chamber pressure balance screw drilling tool transmission shaft assembly includes upper seal assembly, middle seal assembly and lower seal assembly, etc.; upper seal assembly and middle seal assembly, middle seal assembly and lower seal assembly The cavity between the sealing assemblies is filled with lubricating oil; the upper sealing assembly includes the annular cavity, the piston cylinder and the upper sealing check valve, etc., and the lower sealing device includes the flow channel, the piston chamber, the piston and the lower sealing check valve. Valves, etc.; the balance between the pressure in the sealing cavity and the external drilling fluid pressure is controlled by the up and down sliding of the piston cylinder and the piston, and the opening and closing of the upper sealing check valve and the lower sealing check valve. The invention has the advantages of good sealing performance, long service life, high temperature and high pressure resistance, small friction coefficient and simple structure, and can be used in gas drilling and mud medium drilling with high temperature and strong vibration.

Owner:SOUTHWEST PETROLEUM UNIV

Driving mechanism

InactiveUS20060238074A1Efficiently contractionEfficiently elongationPiezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingGraphite compositeActuator

A driving mechanism comprises: (i) an actuator comprising: an electro-mechanical conversion element; and a driving member which moves according to the elongation or contraction of the electro-mechanical conversion element; and (ii) a driven member frictionally engaged with the driving member, wherein the actuator which allows the driven member to move along the driving member, and the driving member is a graphite composite.

Owner:FUJI PHOTO OPTICAL CO LTD

Reciprocating vane type rotary internal combustion engine (vane engine)

InactiveUS20030121494A1Coefficient of friction be smallGood lubricationInternal combustion piston enginesEngine componentsLubricationChamber pressure

On the reciprocating bane of a reciprocating vane type rotary internal combustion engine (vane engine), big centrifugal force is generated by a high-speed rotation and is opposed to combustion pressure, and force equal to or more than seal action force to be necessary for vanes tip is added to the case inside, and friction loss becomes big. For get the force to support centrifugal force and to make this friction loss small, a vane tip cross-section vertical to a rotating axis is formed in a pick-shaped so as to generate gas bearing action force greatly. In addition, in order to raise a hydrostatic pressure in neighborhood of tangent line of both the outside curved surface of vanes tip and the case inside, and to get the multiplication effect that raise a hydrodynamic pressure in the vanes tip, gas supply hole is established parallel to the rotating axis in the midsection of the vanes tip. Therein, porous matrix or great many minute holes connect between the gas supply hole and outside curved surface of the vanes tip. High pressure air, combustion pressure gas or steam is provided to gas supply hole, then, it is spouting out from outside curved surface of it, and get a high hydrostatic pressure and raise a hydrodynamic pressure. Furthermore, because there is not the first steam for lubrication searing in a start, steam reservoir and pressurization pump is established. Therein, compress the air in the steam reservoir by press-fitting water in steam reservoir, then it is used to lubrication searing. After an engine began to move in start or activation, till pressure of revitalization vapor by exhaust becomes proper, as method to get the high pressure gas for lubrication searing, part of the combustion gas which is pulled out from the second steam supply-cum-combustion gas pulling out port, which established a little to the bottom dead point from the center point of the front side vane toward rotating, this vane which combustion chamber pressure of this engine, in which continued fuel injection and combustion (make the best use of characteristic of this engine), become maximum, is connected with the first steam supply pipe for lubrication searing through a filter and a check valve. Fuel injection in neighborhood of the top dead point is difficult to avoid the surface of a wall adhesion, because combustion chamber is so flat. As substitute for it, I devised a method to do vaporization of fuel or injection on the part which close late of air supply port near the bottom dead point, so as to vaporized or injected fuel mix with supply air without loss and so as not to join the air to pass without dropping in.

Owner:YOSIKANE IKITAKE

Plunger for high abrasion-proof displacement pump

ActiveCN101403381ASmall coefficient of frictionImprove wear resistancePositive displacement pump componentsPlungersGas phaseMetallic materials

The invention provides a plunger used for a positive-displacement pump, which is formed by embedding metallic and non-metallic materials and has good wear-resisting property. The plunger comprises a plunger core body which is manufactured by Ni-Cr stainless steel and provided with a connecting end head; the plunger core body is coated with a shell prepared by a SIC material; a sealing adhesive layer is arranged between the connecting end head of the plunger core body and the contacting surface of the shell; the end head of the plunger core body is also provided with a plug to plug the end head. The surface of the plunger adopts a gas-phase permeation SIC shell with high hardness, and has very small friction coefficient and good wear-resisting property and good self-lubricity; after being used by the positive-displacement pump, the wear-resisting property of the plunger is higher than the metallic plunger by more than 5 times, thereby being applicable to be used by the positive-displacement pump with high reciprocating frequency and short stroke; simultaneously, the anti-corrosion property of gas-phase permeation SIC material also solves the anti-corrosion property of the plunger, thereby prolonging the service life of the plunger, guaranteeing that the plunger can operate normally in any serious environment and being applicable to be used in highly corrosive mediums.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Black magnetic acicular composite particles for magnetic recording medium and magnetic recording medium using the same

InactiveUS20030027018A1Flat surfaceSmall light transmittanceMagnetic materials for record carriersSynthetic resin layered productsMetal particleCobalt

A magnetic recording medium using black magnetic acicular composite particles produced by forming a single carbon black coat between the surface of magnetic acicular cobalt-coated iron oxide particle or magnetic acicular metal particle and a coating comprising at least one organosilicon compound, in an amount of from more than 10 to 40 parts by weight based on 100 parts by weight of the magnetic acicular particles, exhibits not only a smooth surface, a smaller light transmittance and a lower surface electrical resistivity value, but also a small friction coefficient and an excellent running durability.

Owner:TODA IND

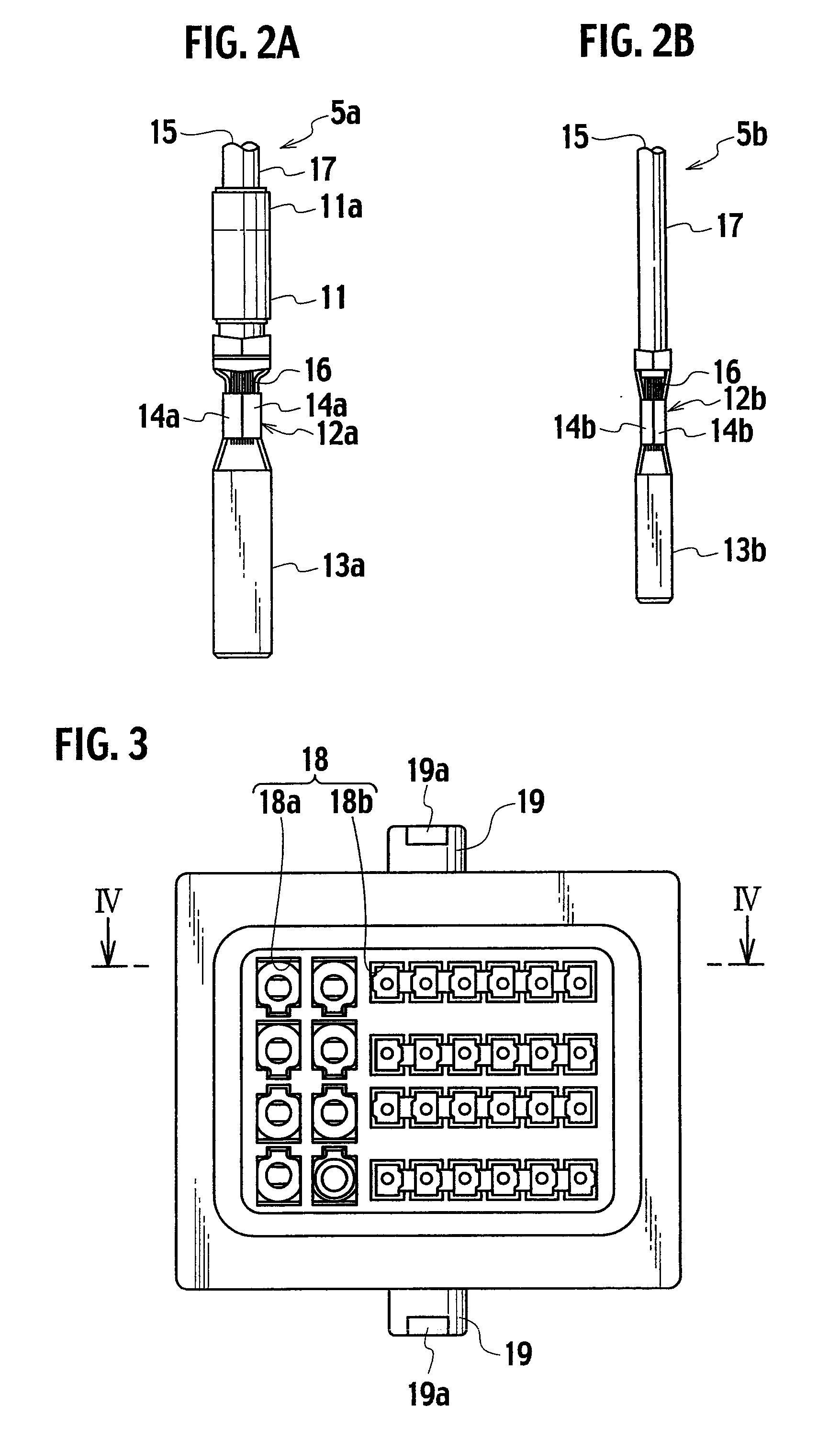

Waterproof Connector

ActiveUS20090017659A1Preventing situationAvoid separationSecuring/insulating coupling contact membersCouplings bases/casesElectric wire

In a waterproof connector, a mat seal and a rear grid are attached to a rear side of a connector housing. These mat seal and rear grid include terminal insertion openings and electric wire insertion openings, respectively, which communicate with terminal receiving chambers. Wire tubes are fitted to electric wires to which large female terminals are crimped, and are brought into elastically intimate contact with inner walls of large terminal insertion openings of the mat seal. Moreover, each of the wire tubes includes a protruding portion that protrudes rearward from the large terminal insertion opening of the mat seal and is located in the large electric wire insertion opening.

Owner:YAZAKI CORP

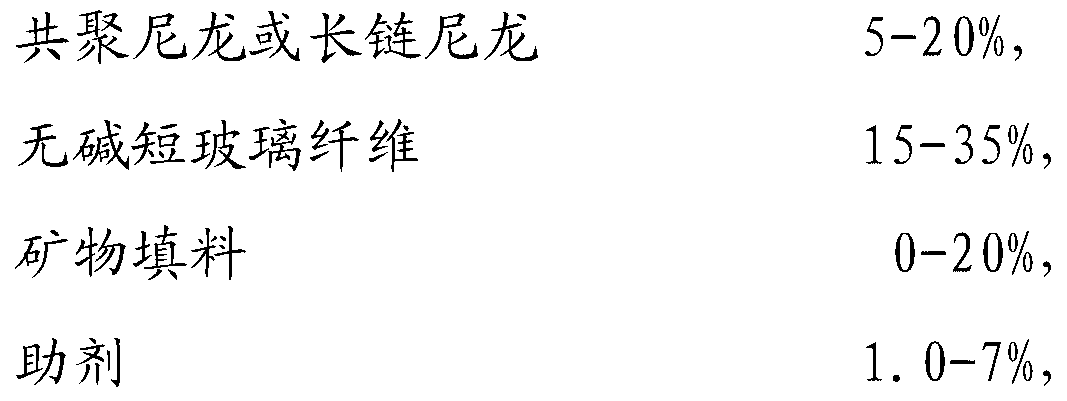

Special nylon 66 composition for automobile engine hood and preparation method thereof

The invention provides a special nylon 66 composition for an automobile engine hood. The composition contains the following components by weight percent: 18-79% of nylon 66, 5-20% of copolymer nylon or long-chain nylon, 15-35% of alkali-free short glass fiber, 0-20% of mineral filler and 1.0-7% of auxiliaries, wherein the copolymer nylon is a polymer which is prepared through reaction, dehydration and polymerization of two or more monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon6 / 66 copolymer, a nylon 6 / 12 copolymer and a nylon 6 / 10 copolymer; and the long-chain nylon is a polymer which is prepared through polymerization of monomers with carbon contents greater than or equal to 10 in polymer monomer units and other monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon 11, a nylon 12 and a nylon 1010. The invention provides the special nylon 66 composition for the automobile engine hood and a preparation method thereof. The composition has the beneficial effects that the composition has quite high impact resistance and super strength and excellent chemical properties and dimensional stability; and products have smooth and clean surfaces and are cheap.

Owner:辰东意普万新材料(广东)有限公司

Valve and manufacturing method thereof

InactiveUS6959916B2High mechanical strengthIncrease strength resistancePipe supportsSlide valveCobaltWear resistance

A valve which is cobalt-free excellent in wear resistance and seizure resistance manufactured by forming valve seats for a valve disc and a valve body with a nickel base alloy in which silicide particles or boride particles of small particle size are finely dispersed, and the valve seat is bonded to the valve disc or the valve body by way of an insert material comprising a nickel base alloy of a lower melting point by transient liquid phase diffusion bonding.

Owner:HITACHI LTD

Solid wood foor

InactiveCN102561654AReduce harmDisperse impactWood layered productsFlooringSolid woodPolyvinyl chloride

The invention discloses a solid wood floor which is characterized by comprising a single-layer solid wood board and a PVC (Polyvinyl Chloride) board, wherein the PVC board is fixedly connected with the solid wood board; the back of the solid wood board is formed into unit area blocks through uniformly spaced grooves; the solid wood board has the water content of 5-8% and the thickness of 8-20mm after being dried in vacuum at the temperature of 40-60 DEG C; the thickness of the PVC board is 2-5mm; and the depth of each groove is 1 / 5-1 / 2 that of the solid wood board. The solid wood floor is simple in structure, stable in size, non-deformable, warp-proof, dampproof, waterproof, environment friendly, capable of absorbing sound, preventing noise, conducting heat and preserving heat, suitable for floor heating, small in coefficient of thermal expansion, stable, simple and rapid in installation and construction and capable of being used after 24h if being adhered by using special environment friendly floor glue.

Owner:GUANGZHOU PANYU KANGDA BOARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com