Preparation process, product and application of new plastic

A preparation process and plastic technology, applied in conductors, electrical components, circuits, etc., can solve the problems of poor toughness and poor temperature resistance, and achieve the effects of good compatibility, good thermal stability and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a process for preparing a novel plastic, which includes the following steps:

[0045] 1. Prepare raw materials, including the following specifications of raw materials:

[0046] (1) TPU raw material specifications are:

[0047]

[0048]

[0049] (2) PVC raw material: use resin powder with K=75, P=1700 as PVC substrate;

[0050] 2. Weighing ratio;

[0051] 3. Add PVC powder, stabilizers, fillers, plasticizers, flame retardants, antioxidants, anti-ultraviolet agents, and other auxiliaries to the kneader, knead at high speed, then pre-plasticize, and control the temperature to 175°C. Pre-plasticized mixture;

[0052] 4. High temperature melting plastic TPU, high temperature melting plastic TPU;

[0053] 5. The pre-plasticized mixture is mixed with TPU particles, and the gradient temperature is controlled to squeeze into a gel. The temperature is controlled at 170°C to 180°C; specifically including:

[0054] (1) Preheat the equipment. The internal mixer is heat...

Embodiment 2

[0059] Examples 2 and 3 provide a new type of plastic. The preparation process steps are basically the same as those of Example 1. The difference lies in the raw material composition ratio, see Table 1:

[0060] Table 1 The raw material ratio of each embodiment

[0061]

[0062]

[0063] The new plastic prepared by the above-mentioned embodiments of the present invention has high wear resistance, high elasticity, easy recovery, high flame retardant, anti-ultraviolet, anti-freezing damage at northern low temperature, good thermal stability, environmental protection, soft hand feeling, anti-sticking, etc. After testing, its performance is shown in Table 2:

[0064] Table 2 Performance Test Table

[0065]

[0066]

[0067] The novel plastic prepared in the embodiment of the present invention is applied to the preparation of outer coverings of wires and cables.

Embodiment 4

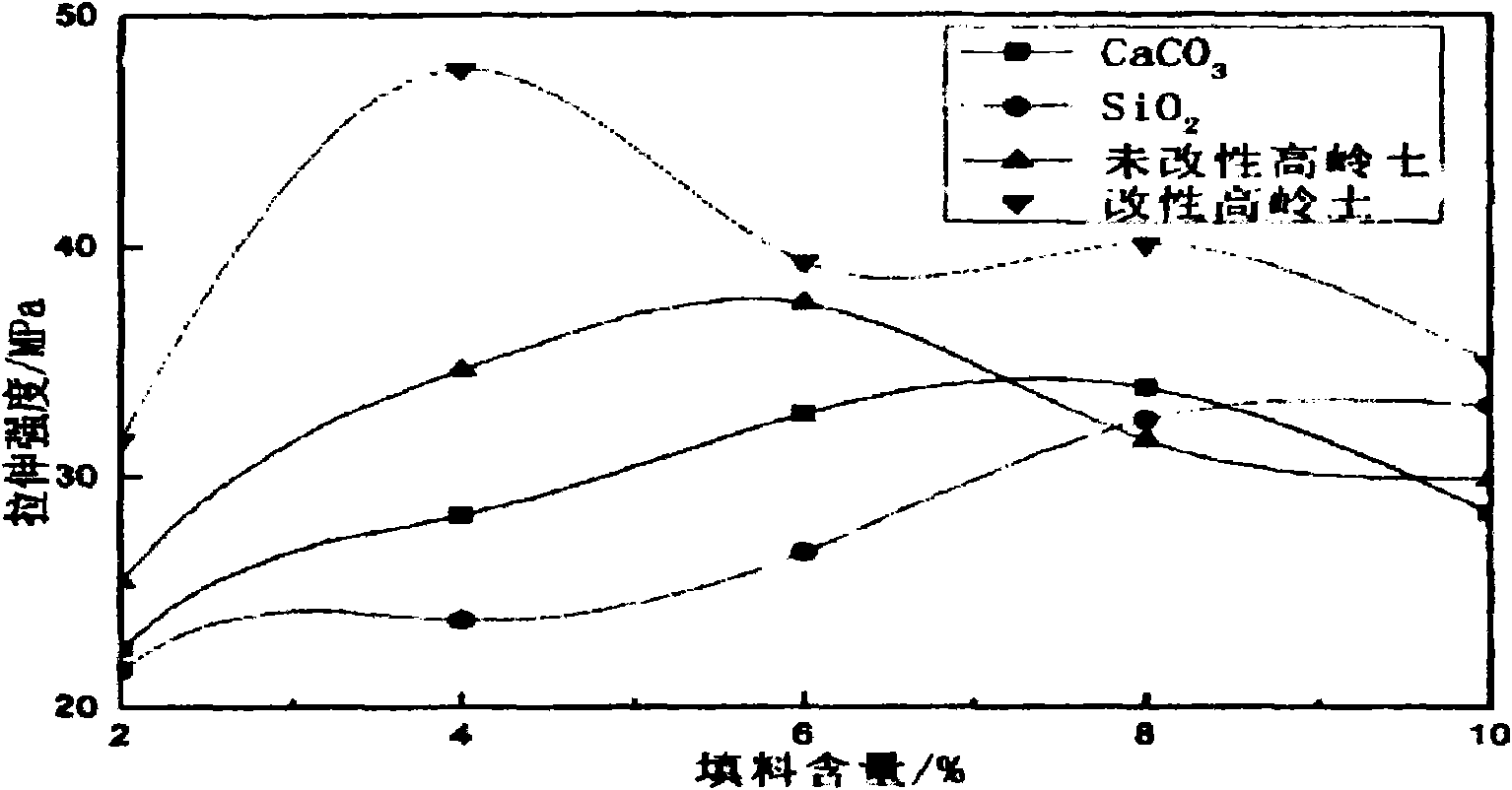

[0069] This example provides a new type of plastic. The preparation process steps are basically the same as those of Example 1. The difference is that different fillers (CaCO 3 , SiO 2 , Modified kaolin, unmodified kaolin) and composition ratio, perform performance analysis, see the results figure 1 :

[0070] by figure 1 As can be seen from the table, choose CaCO 3 And controlling its content to 4% is the highest tensile strength of the blend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com