Aqueous dull finishing coat, preparation method and use method thereof

A matte surface, water-based technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low hardness, furniture surface damage, paint film is easy to be scratched, etc., achieve good chemical resistance, improve scratch resistance damage, excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

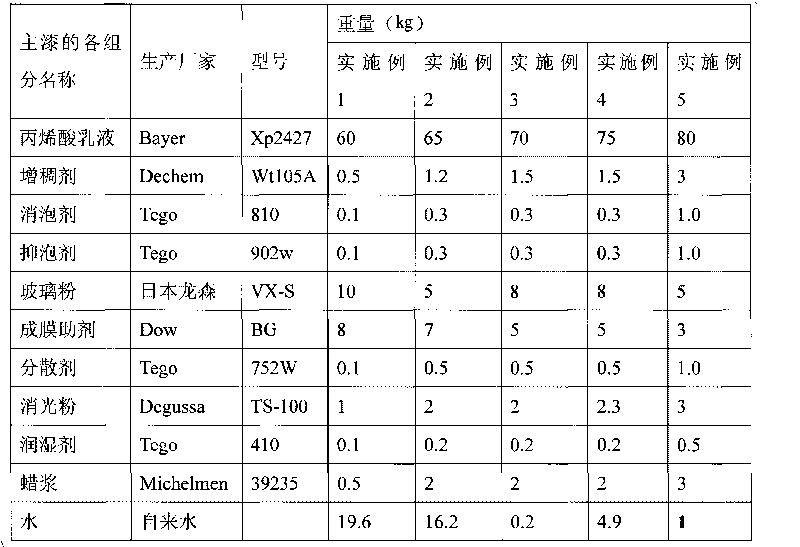

[0054] One. preparation embodiment 1 anti-scratch water-based matt finish paint main paint, step is as follows:

[0055] Take each component according to the weight listed in "Example 1" in Table 1, first add acrylic emulsion and dispersant to the production container, disperse at 500RPM for 3-5 minutes until uniform, add thickener, defoamer, Foam suppressor, disperse at 500RPM for 3-5 minutes until uniform, then add matting powder and glass powder under stirring state, disperse at 1000RPM for 10-15 minutes to fineness≤25μm, finally add wetting agent, wax slurry, water and synthetic Membrane aid, disperse at 500RPM for 10-15 minutes until uniform, and filter through 100 mesh to obtain scratch-resistant water-based matte finish paint.

[0056] 2. Preparation of supporting curing agent: take 80Kg of hydrophilic aliphatic polyisocyanate of XP2451 type hexamethylene diisocyanate of Bayer Company, 20Kg of propylene glycol methyl ether acetate, and add the two kinds of raw materials...

Embodiment 2

[0060] With each component weight listed in "embodiment 2" in table 1, repeat the method (only each component weight changes) described in above-mentioned example 1, make the anti-scratch water-based matte finish paint main paint; Repeat example Components, weight and preparation method of the curing agent in 1 to obtain the curing agent, mix the main paint with the curing agent and water in a weight ratio of 100:50:20 (NCO / OH=2.5), then let stand for 10 minutes, then Carry out construction and drying according to the method described in example 1, then obtain the scratch-resistant water-based matt finish paint film.

[0061] The routine performance test results are shown in the corresponding data of "Example 2" in Table 2.

Embodiment 3

[0063]With each component weight listed in "embodiment 3" in table 1, repeat the method described in above-mentioned example 1 (only each component weight changes), make the anti-scratch water-based matt finish paint main paint; Repeat example Components, proportions and preparation methods of the curing agent in 1 to obtain the curing agent, mix the main paint with the curing agent and water in a weight ratio of 100:50:20 (NCO / OH=2.5), and then let it stand for 10 minutes. Then carry out application and drying according to the method described in Example 1, and then obtain a scratch-resistant water-based matte finish paint film.

[0064] The routine performance testing results are shown in the corresponding data of "Example 3" in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com