An oil-sealed cavity pressure-balanced screw drilling tool transmission shaft assembly

A technology of balancing screw and transmission shaft, which is applied in the direction of engine seal, driving device for drilling in wellbore, drill pipe, etc., can solve the problems of economic loss, low drilling efficiency, inability to meet use requirements, frequent tripping and drilling, etc. Small torque, simple structure, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

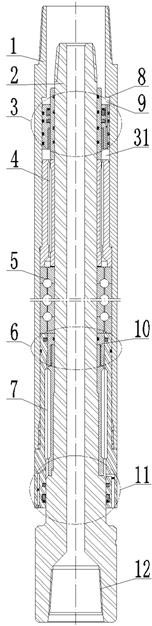

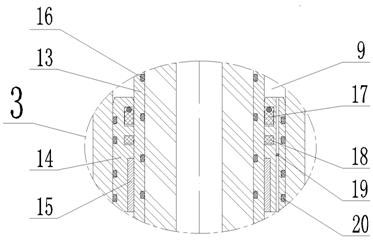

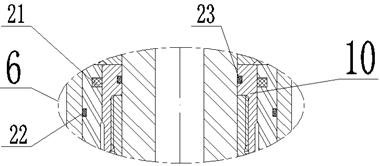

[0017] Such as figure 1 As shown, an oil seal chamber pressure balance screw drilling tool transmission shaft assembly of the present invention is composed of a housing 1, a transmission shaft 2, an upper seal assembly 3, an upper radial bearing group 4, a thrust bearing group 5, an intermediate seal Assembly 6, lower radial bearing group 7, support sleeve 10, lower seal assembly 11 and lower end thread 12, etc. Its structural features are: shell 1 and transmission shaft 2 cooperate to form annular cavity 9 and annular cavity cavity 31; the upper sealing assembly 3 is installed between the annular cavity 9 and the annular cavity 31, and the upper radial bearing group 4, the thrust bearing group 5, the support sleeve 10 and the lower The radial bearing group 7; the middle sealing assembly 6 is installed on the upper end of the lower radial bearing group 7, and the lower sealing assembly 11 is installed on the lower end of the lower radial bearing group 7; the lower end thread 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com