Polyurethane transparent matt topcoat, preparation method and use method thereof

A polyurethane and transparent technology, applied in the field of polyurethane paint, can solve the problems of furniture surface damage, paint film surface is easy to be scratched, etc., and achieve the effect of improving scratch resistance, smooth hand feeling and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

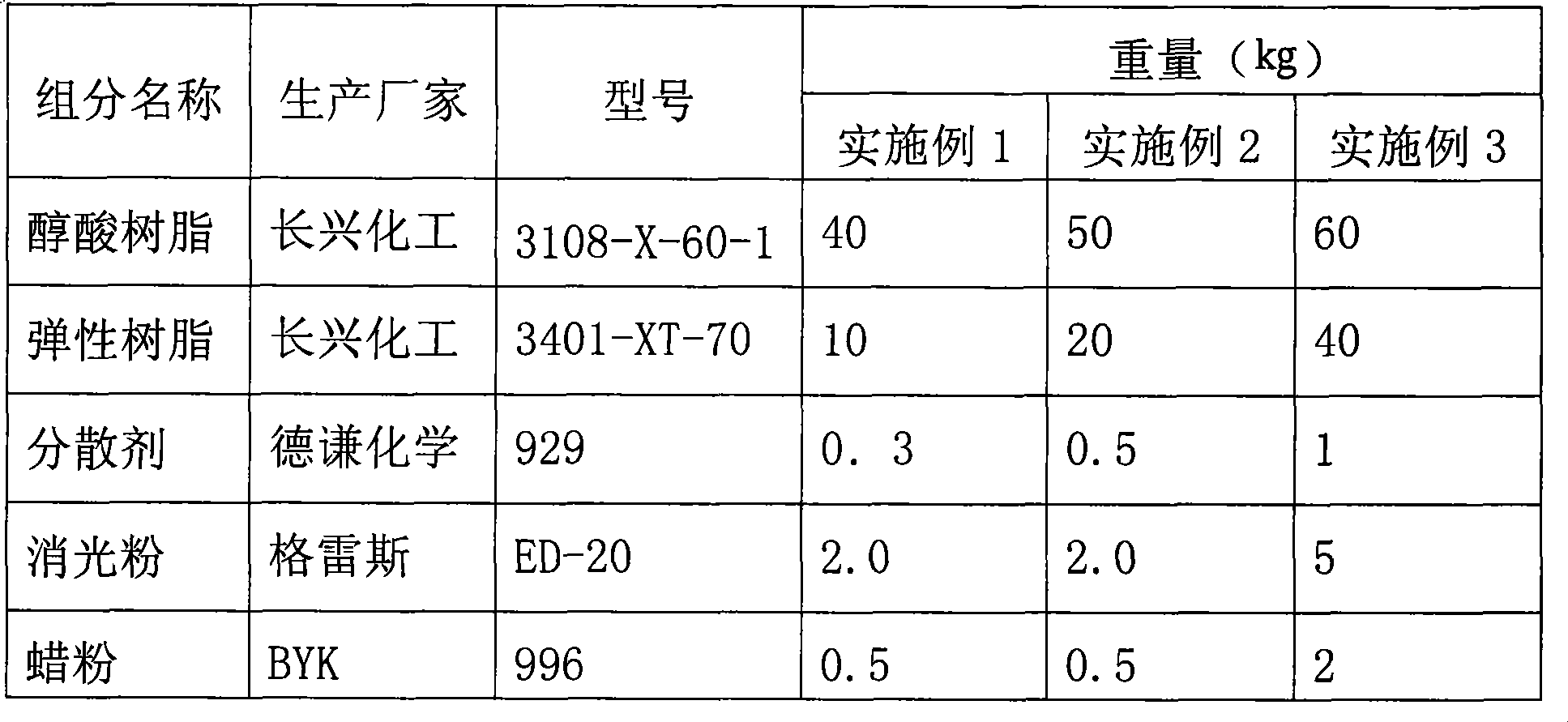

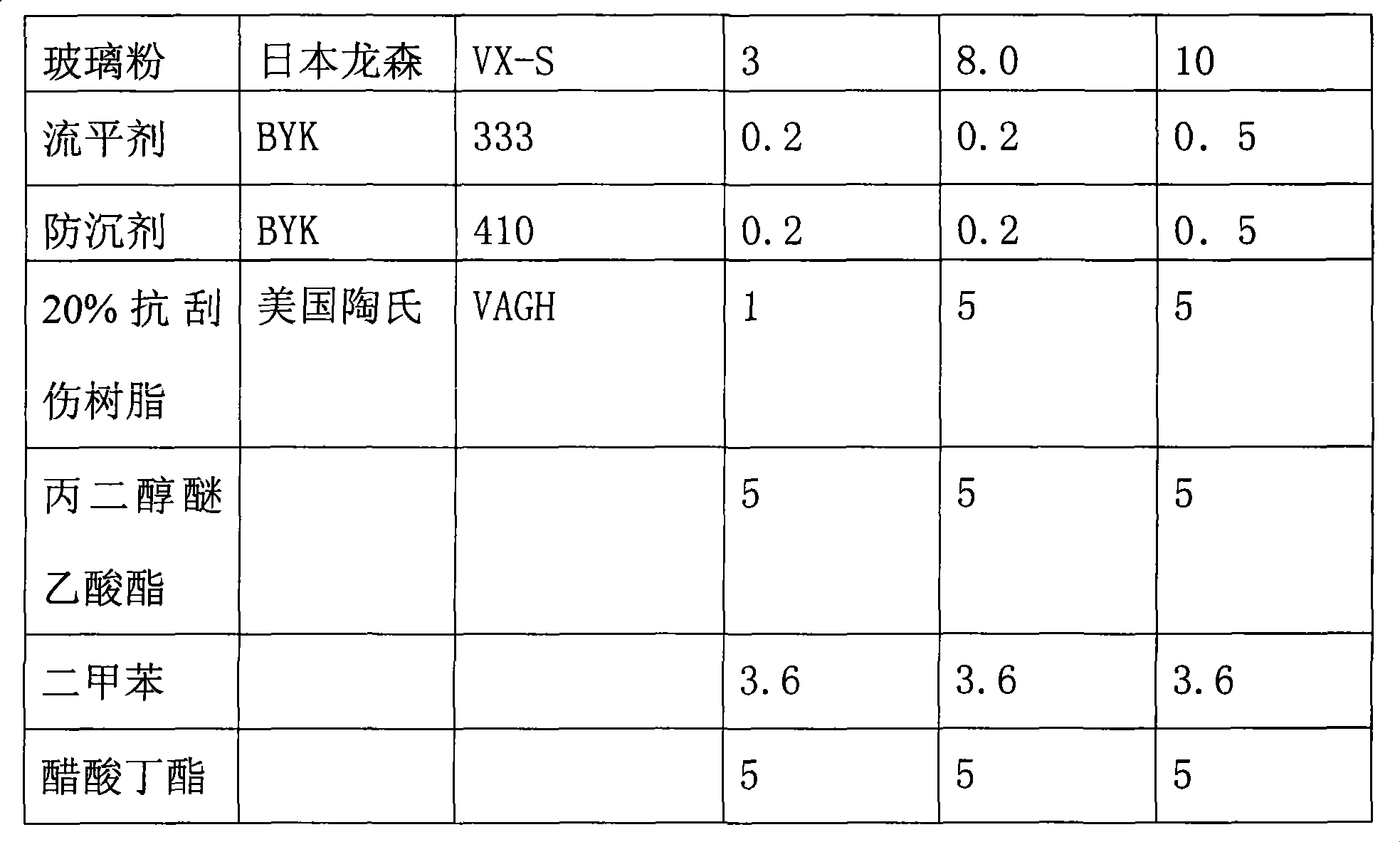

[0061] Preparation of polyurethane anti-scratch transparent matte finish paint main paint of the present invention:

[0062] Step 1: First prepare 20% anti-scratch resin solution. Add xylene and butanone into the container at a ratio of 1:1, add anti-scratch resin VAGH while stirring, disperse at 800 RPM for 30 minutes until completely dissolved, and obtain VAGH solution with a weight percentage of 20% for use;

[0063] Step 2: Add alkyd resin, elastic resin, and dispersant sequentially according to the weight ratio shown in Example 1 of Table 1, and disperse at 500RPM for 3 to 5 minutes until uniform, while stirring, add matting powder, glass powder, wax powder, 1000RPM Disperse for 15 minutes until the fineness is ≤25um, then add leveling agent, anti-sedimentation agent, butyl acetate, propylene glycol ether acetate, xylene in order by weight, and disperse evenly for 10 minutes at 800RPM.

[0064] Step 3: Take 5Kg of the 20% VAGH resin solution obtained in the above step 1,...

Embodiment 2

[0078] With the weight of each component listed in Example 2 in Table 1, repeat the method described in Example 1 (only the weight of each component changes), prepare the main paint of polyurethane anti-scratch transparent matt finish paint; repeat in Example 1 The components, proportions and preparation methods of curing agent and diluent are prepared to obtain curing agent and diluent; mix the main agent with curing agent and diluent according to the ratio of 100:50:60 and let it stand for 10 minutes, and then follow the steps in Example 1. The above method is used for construction and drying to obtain the polyurethane anti-scratch transparent matte finish paint film.

[0079] The routine performance test results are shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0081] With the weight of each component listed in Example 3 in Table 1, repeat the method described in Example 1 (only the weight of each component changes), prepare the main agent of polyurethane anti-scratch transparent matte finish paint; repeat in Example 1 Components, proportions and preparation methods of curing agent and diluent Prepare curing agent and diluent; mix the main agent, curing agent and diluent uniformly according to 100:50:60, and then carry out construction and preparation according to the method described in Example 1 Dried to obtain a polyurethane anti-scratch transparent matte topcoat film.

[0082] The routine performance test results are shown in the corresponding data of Example 3 in Table 2.

[0083] Table II

[0084] serial number Test items Example 1 Example 2 Example 3 1 Viscosity (KU / 25℃) 63 81 90 2 gel time >4 hours >4 hours >4 hours 3 Drying time (minutes) 95 90 100 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com