Patents

Literature

53results about How to "High count" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

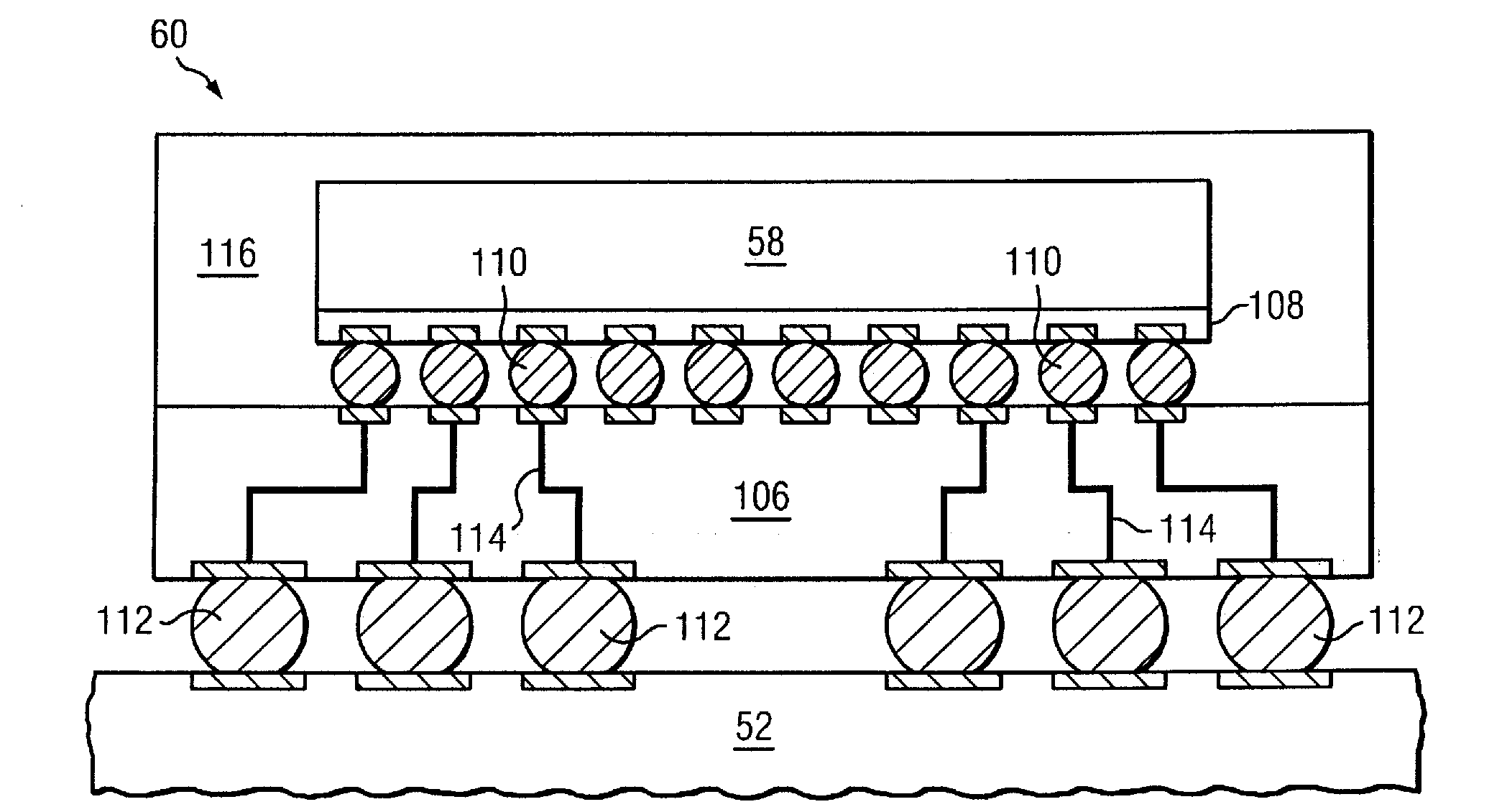

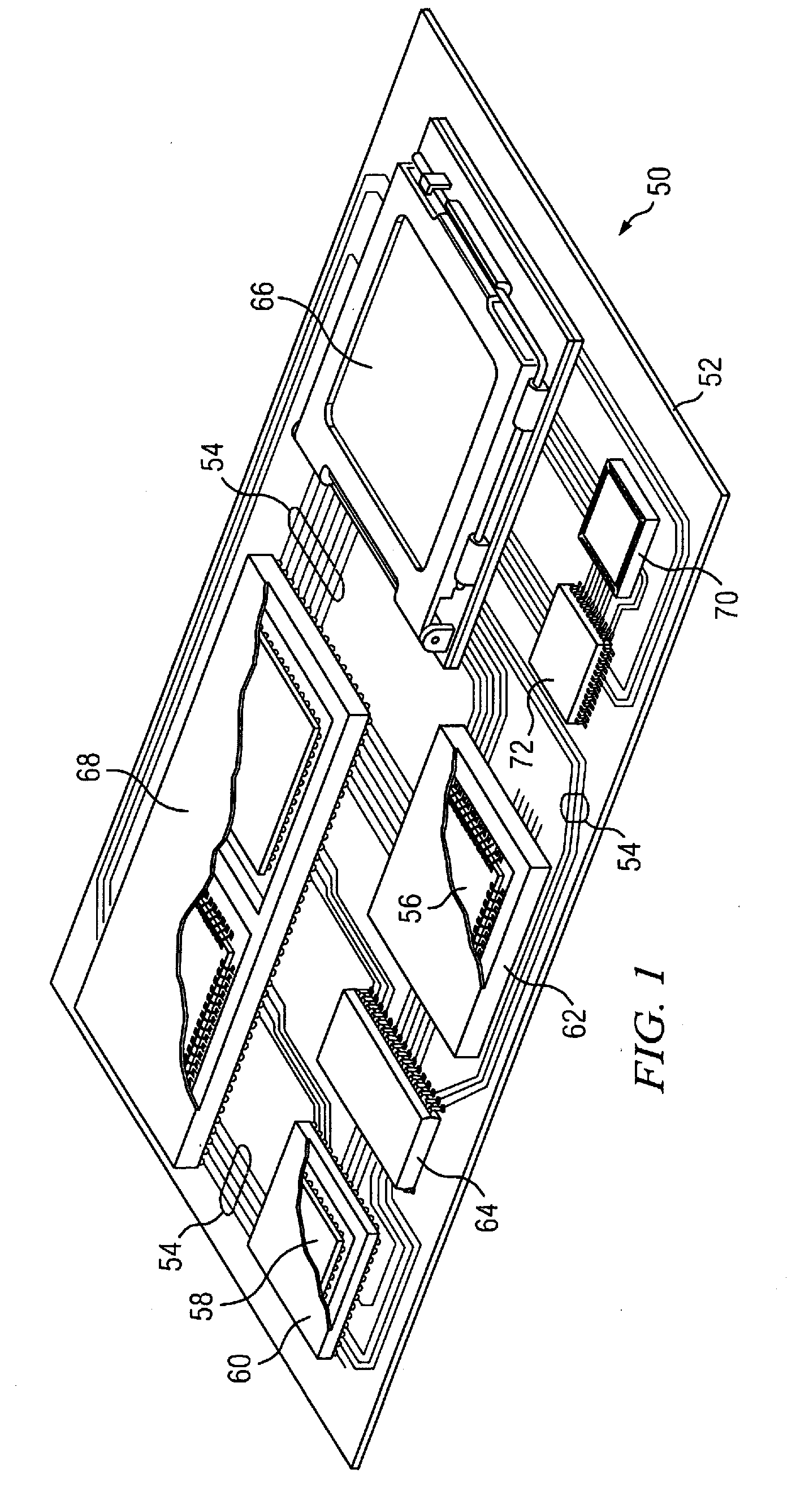

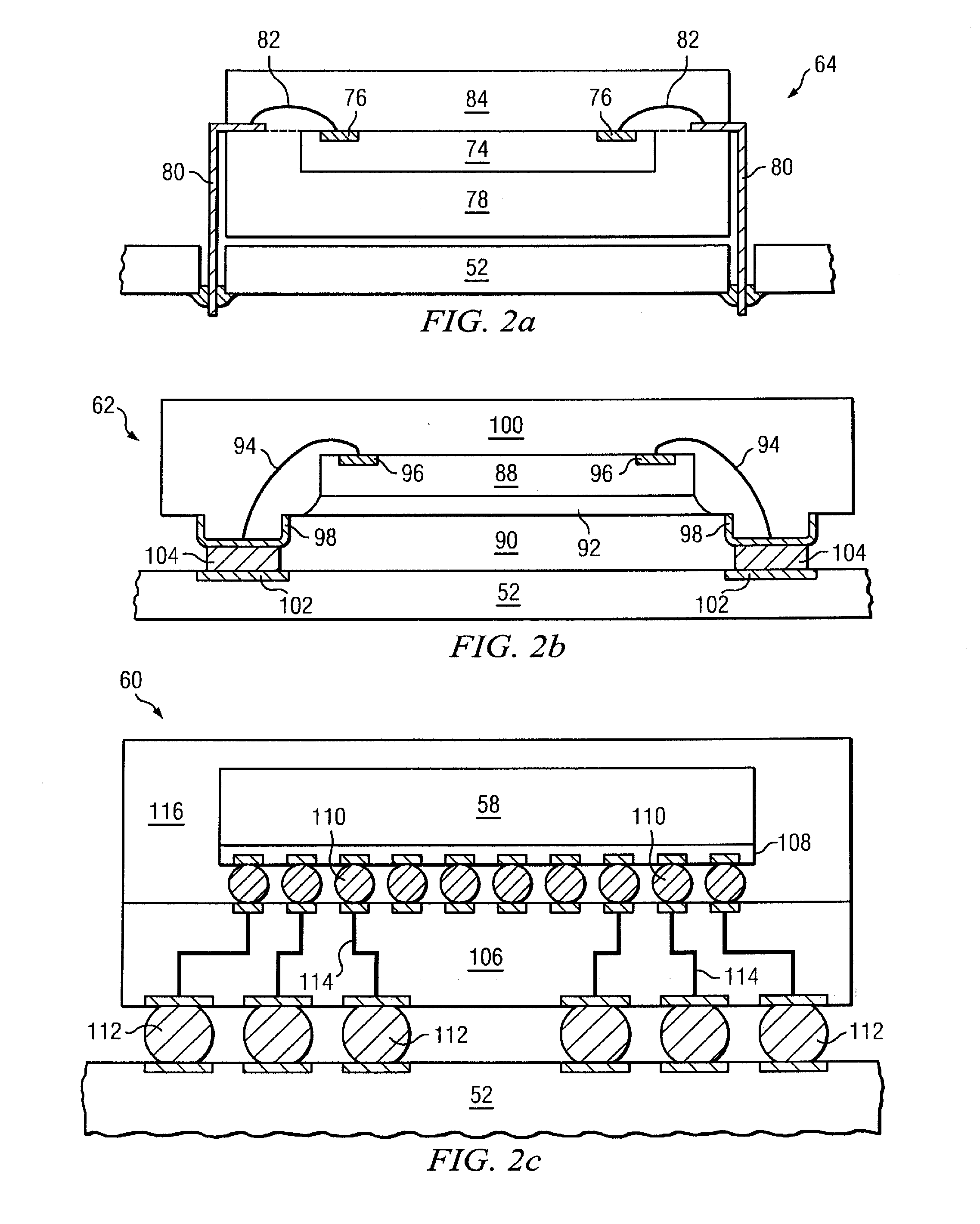

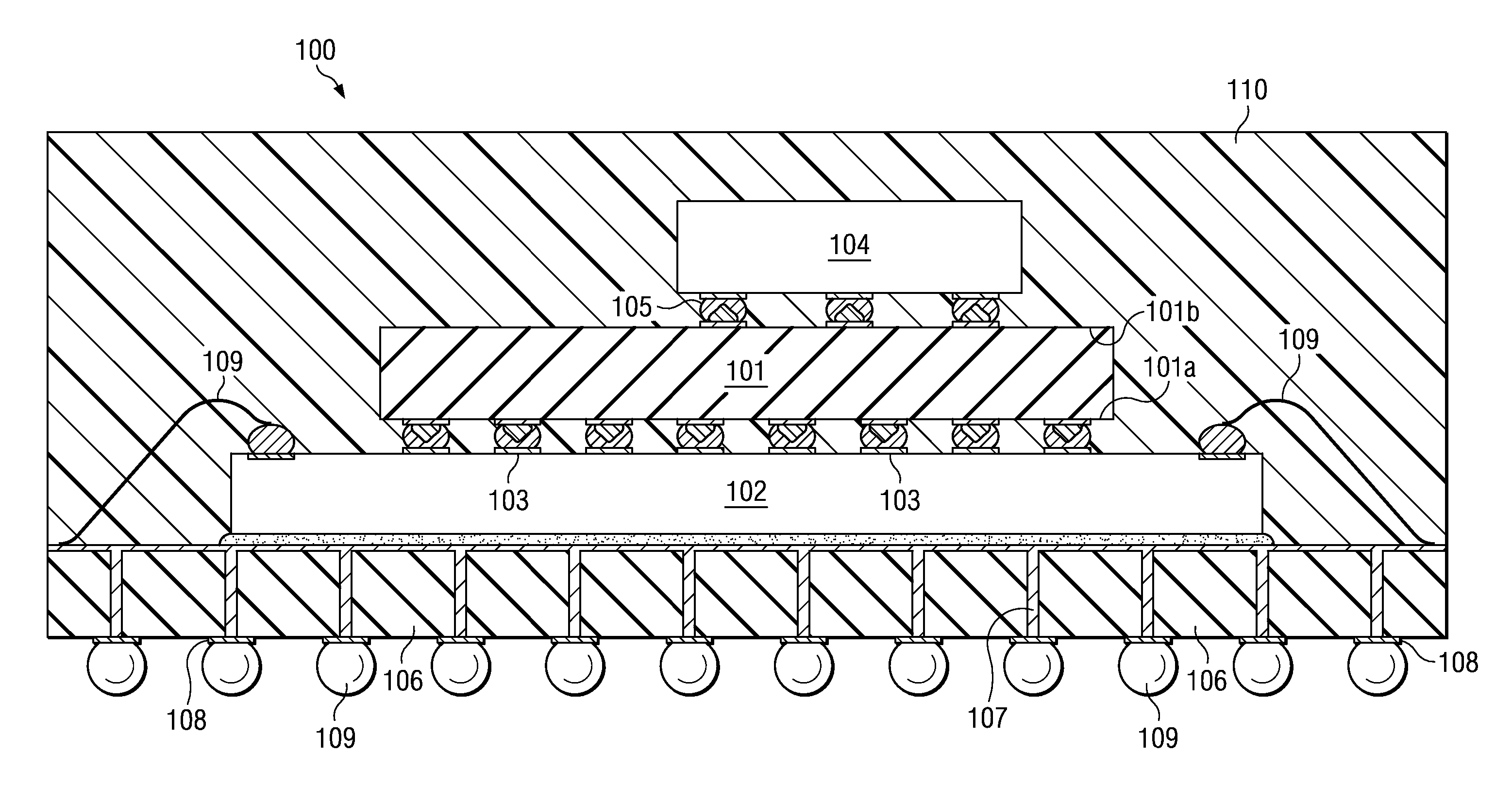

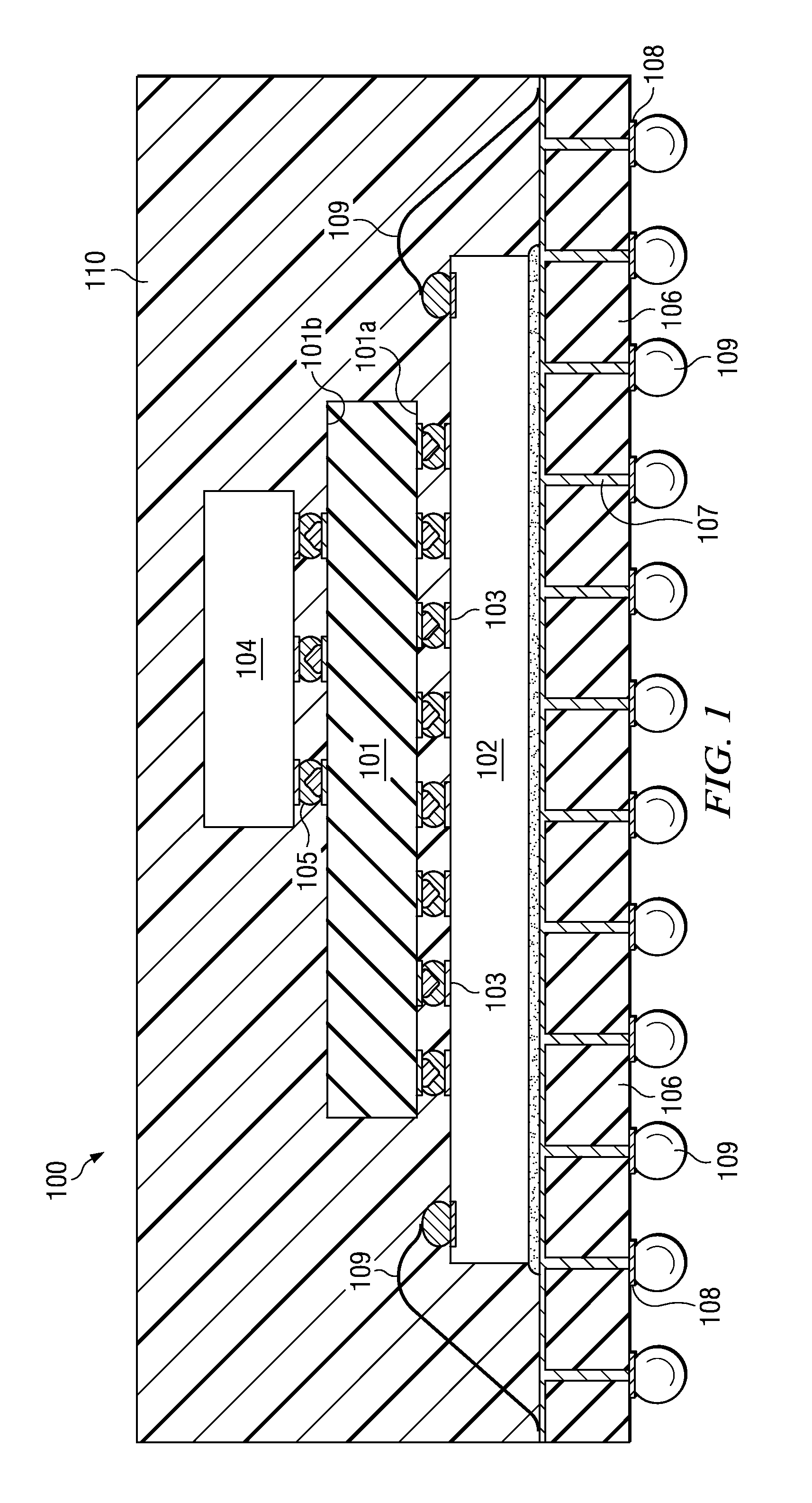

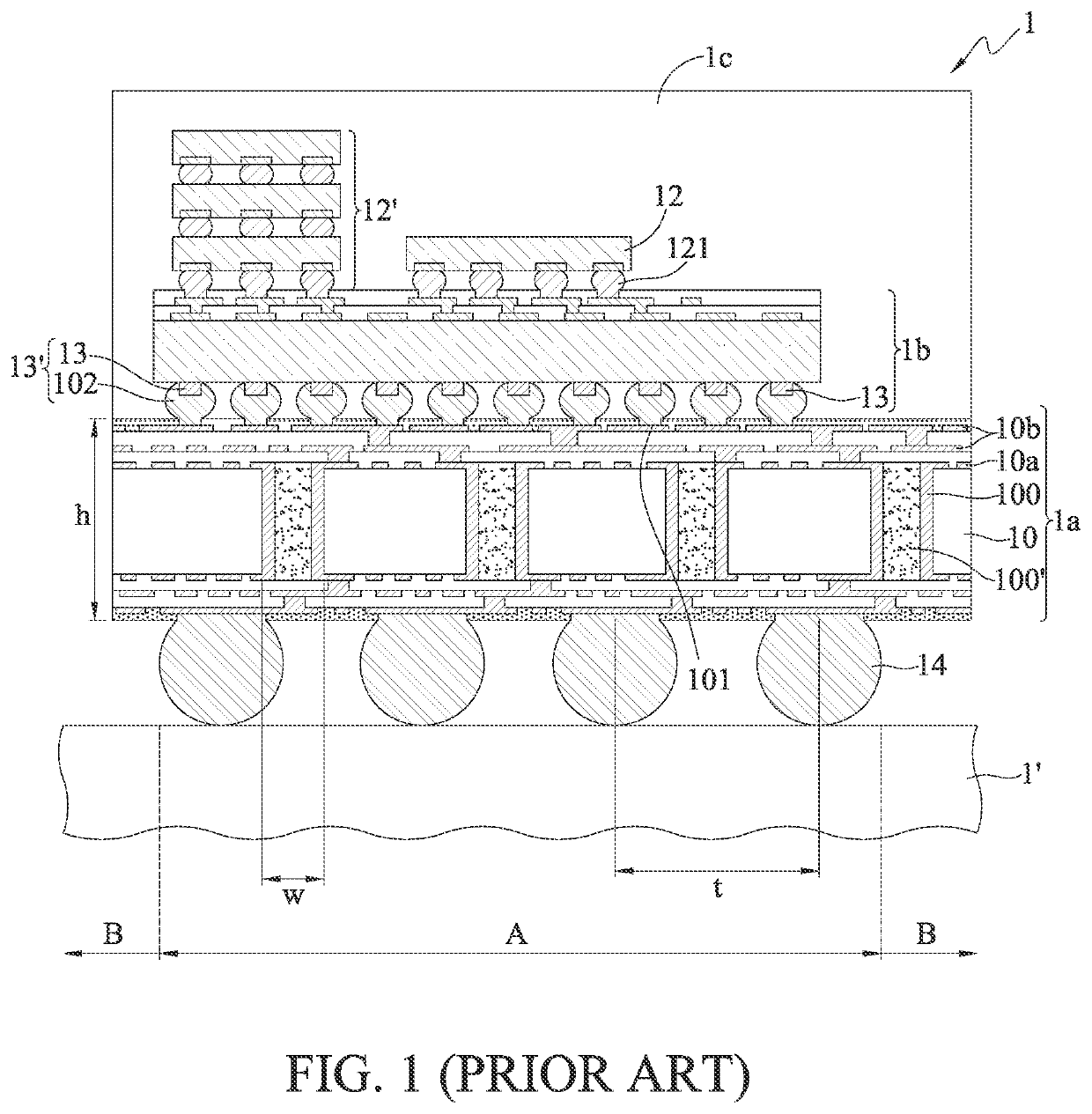

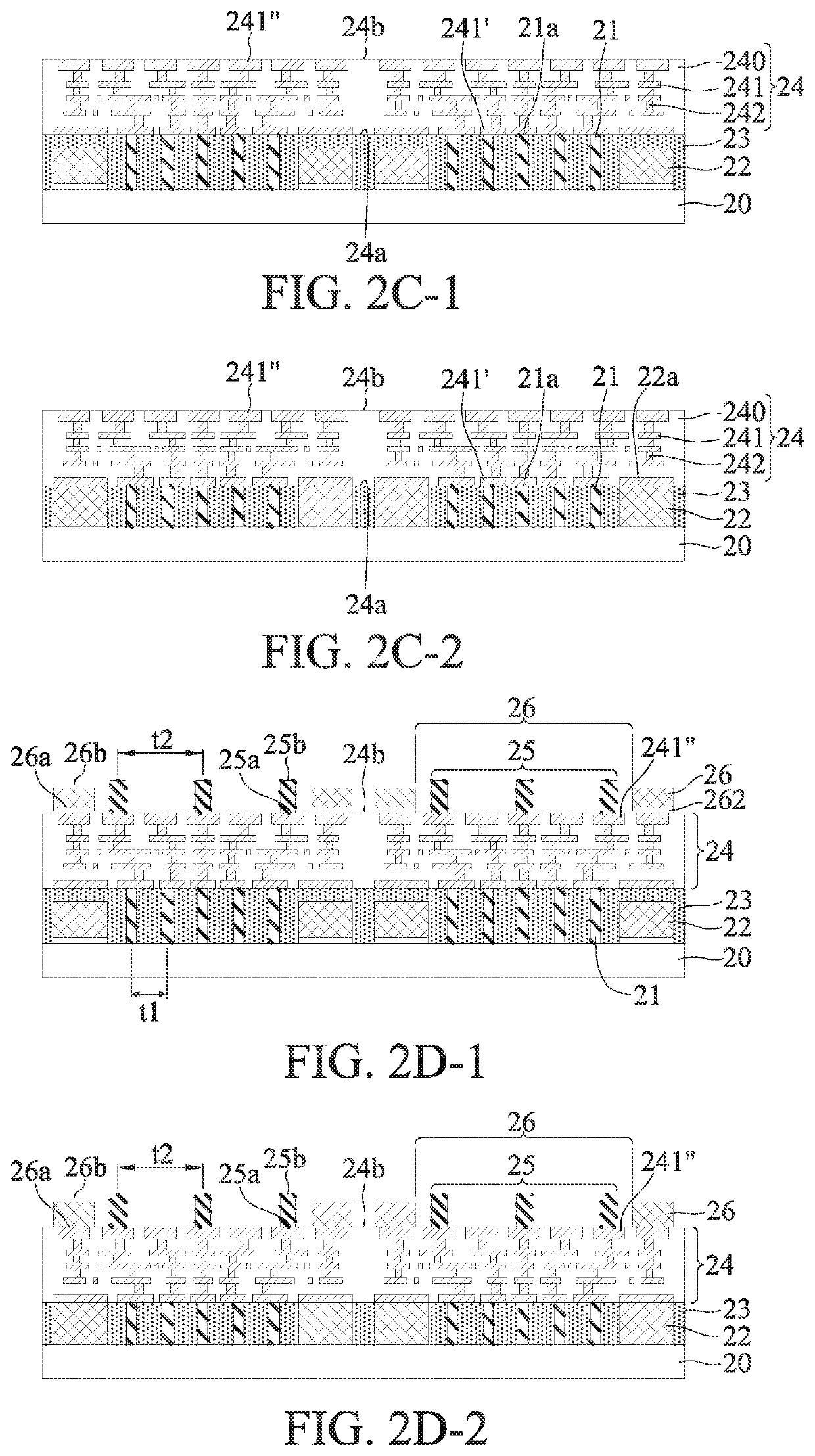

Semiconductor Device and Method of Dual-Molding Die Formed on Opposite Sides of Build-Up Interconnect Structures

ActiveUS20110037169A1High countSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

Owner:STATS CHIPPAC LTD

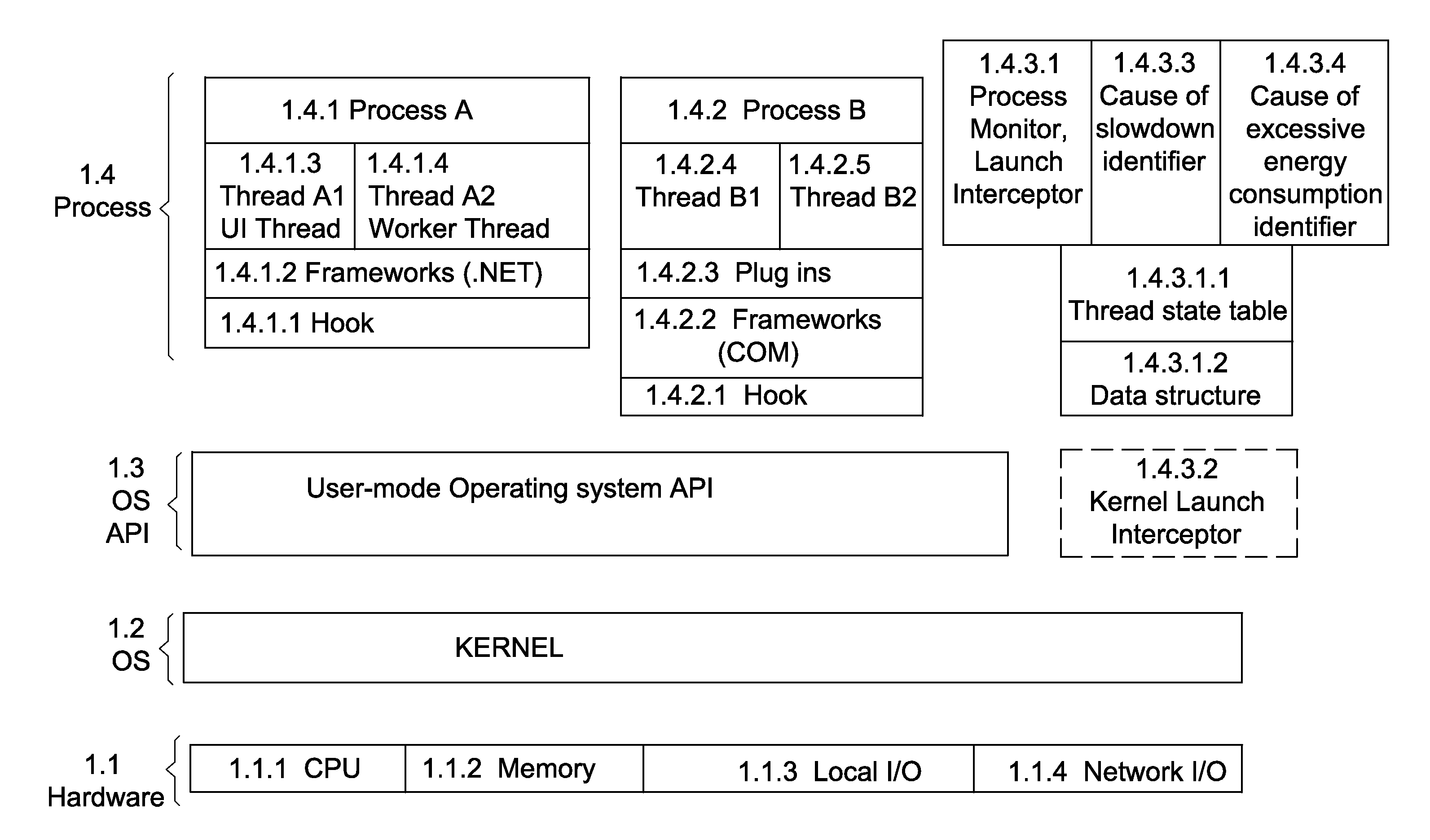

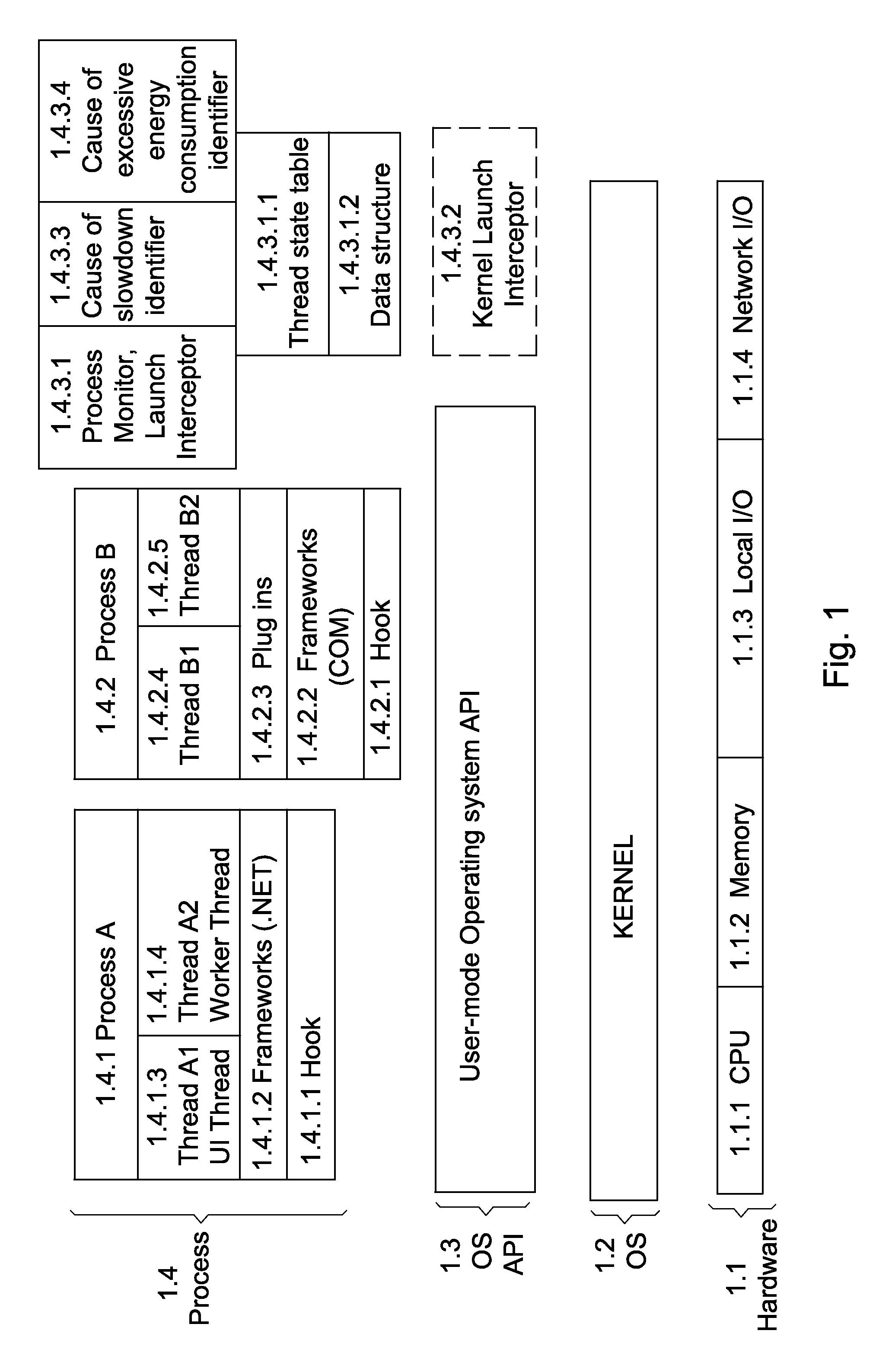

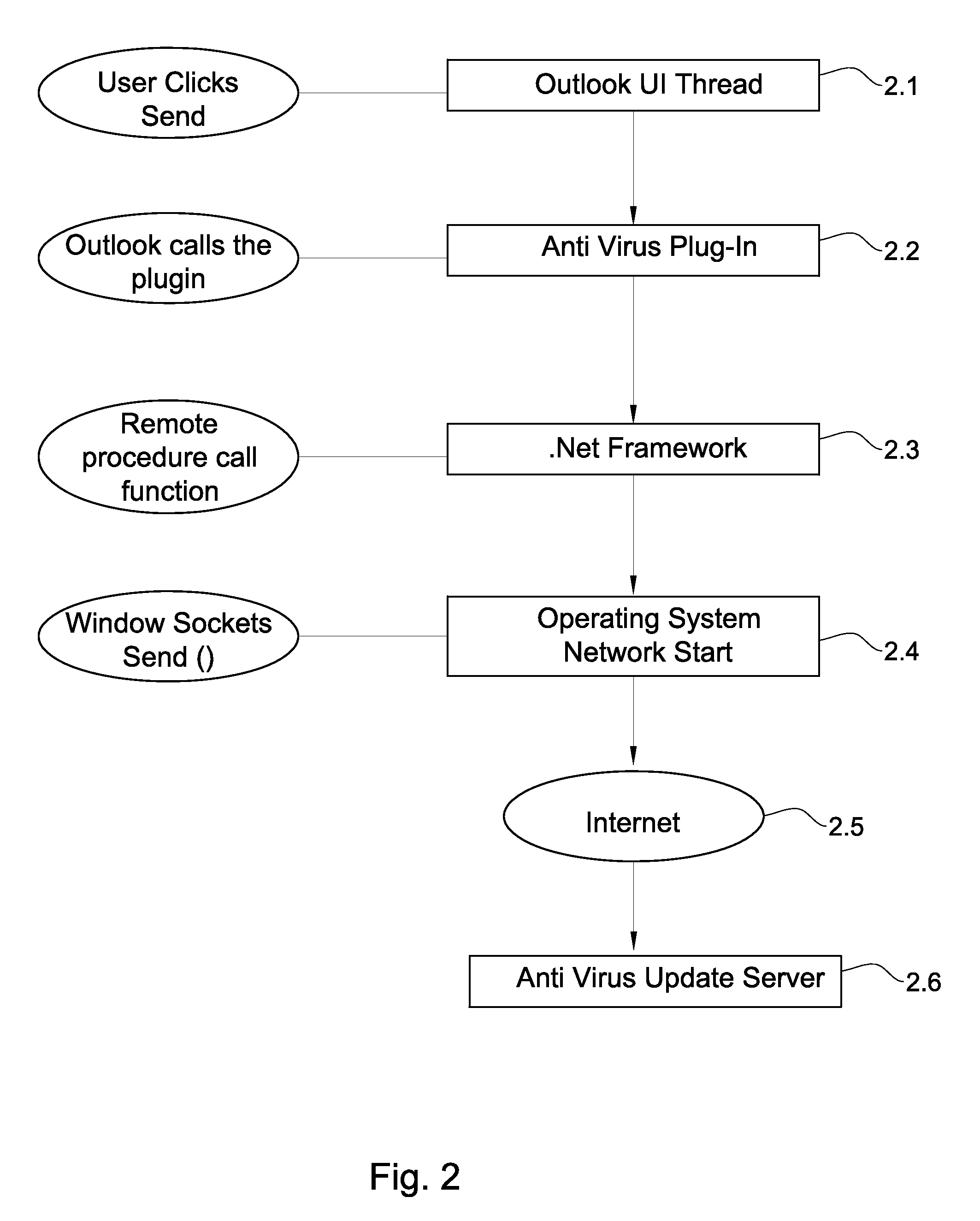

Real time monitoring of computer for determining speed and energy consumption of various processes

ActiveUS20130024731A1Excessive energy consumptionHigh countEnergy efficient ICTSoftware testing/debuggingComputer resourcesReal-time computing

The presently disclosed subject matter includes a system and method which enable to identify one or more causes for excessive energy consumption in a computer executing one or more processes. Information indicating that consumption of a computer-resource of at least one of said processes is greater than a predefined threshold is obtained and one or more threads of said at least one process which are in running state are identified. Thread performance information of at least one thread in running state is collected and used for identifying one or more functions that are the cause for said state of the respective thread. The identified functions are associated with their respective modules in order to identify one or more modules of said process, which are the cause for said excessive energy consumption.

Owner:ATERNITY LLC

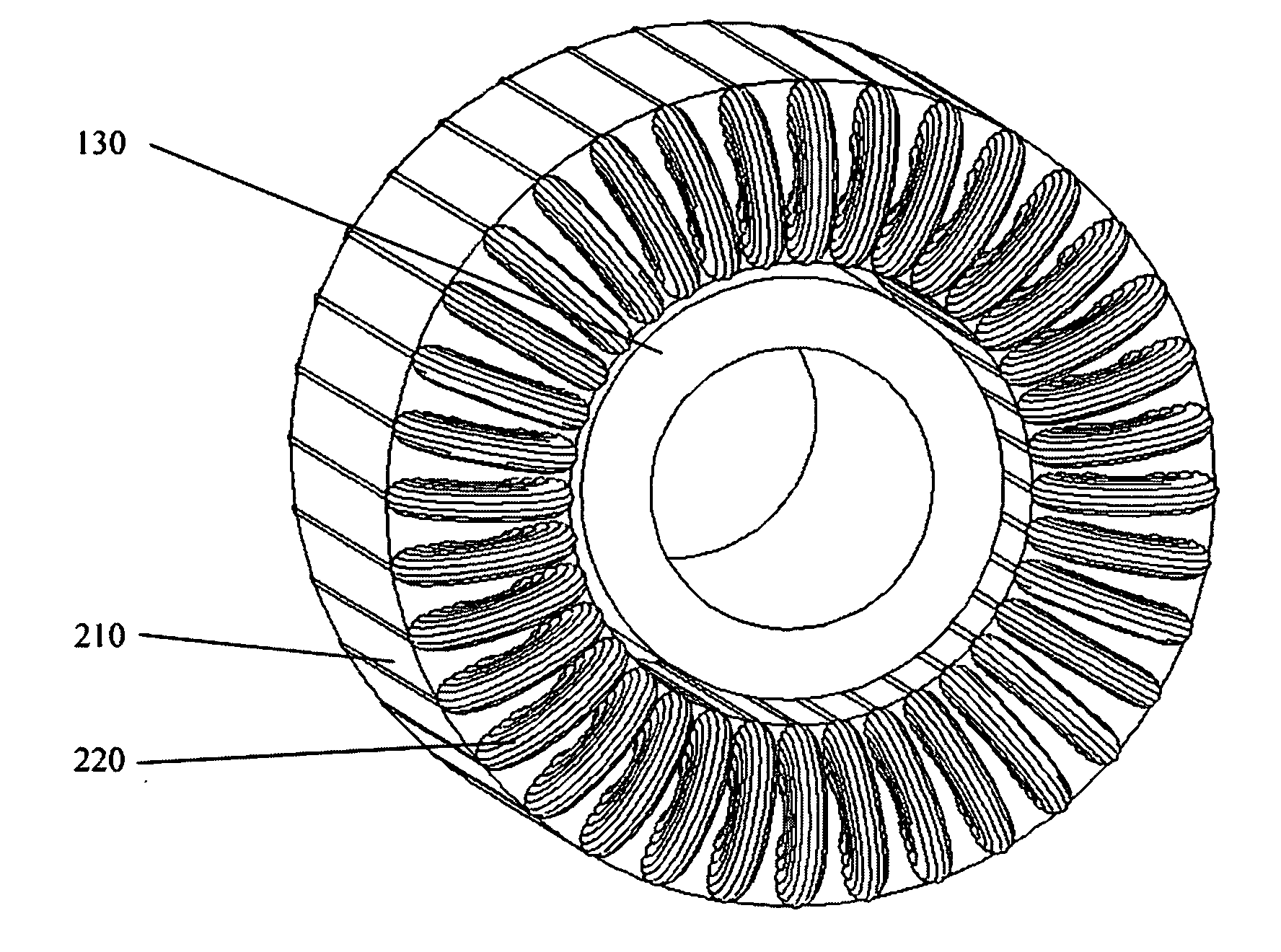

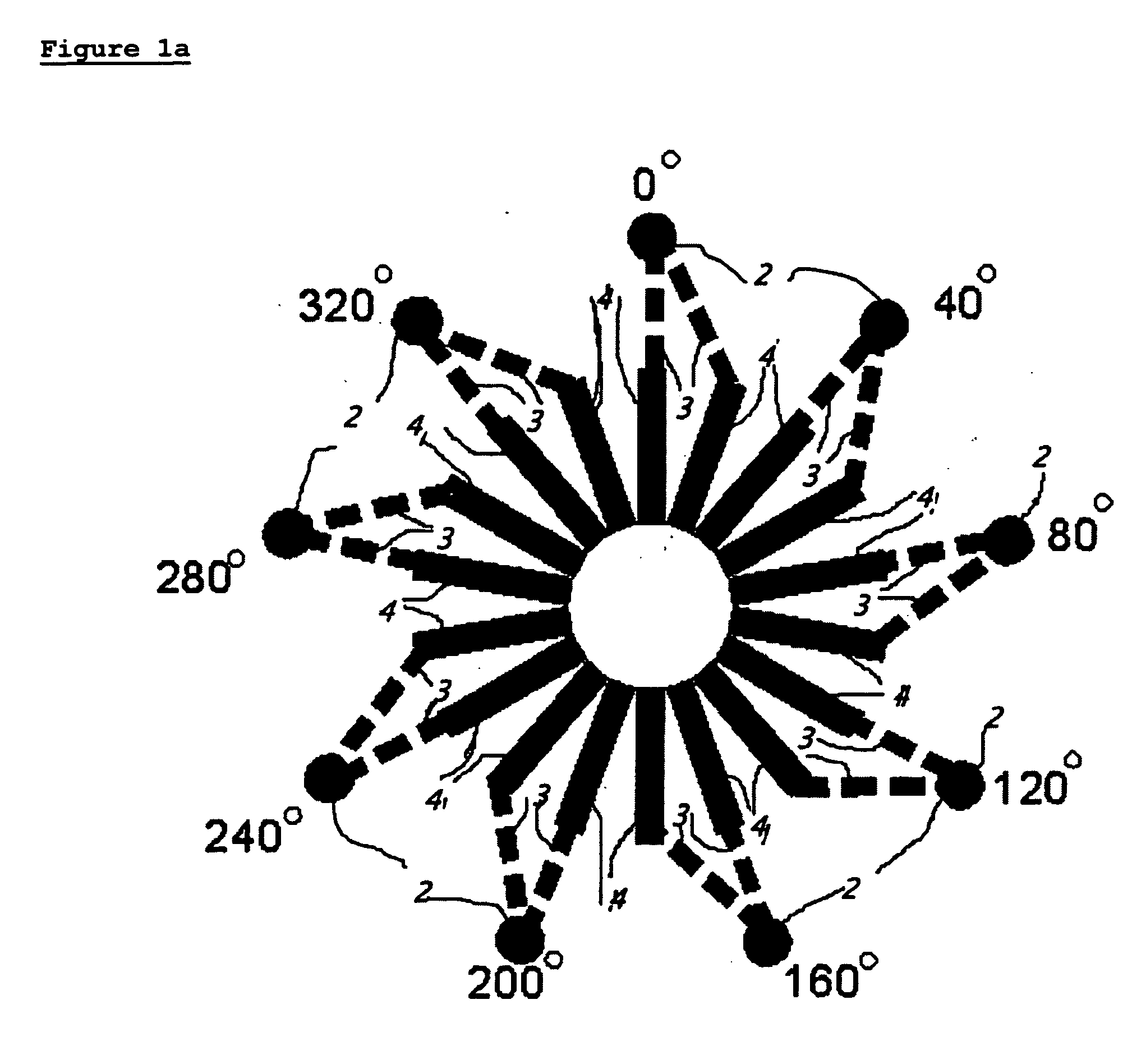

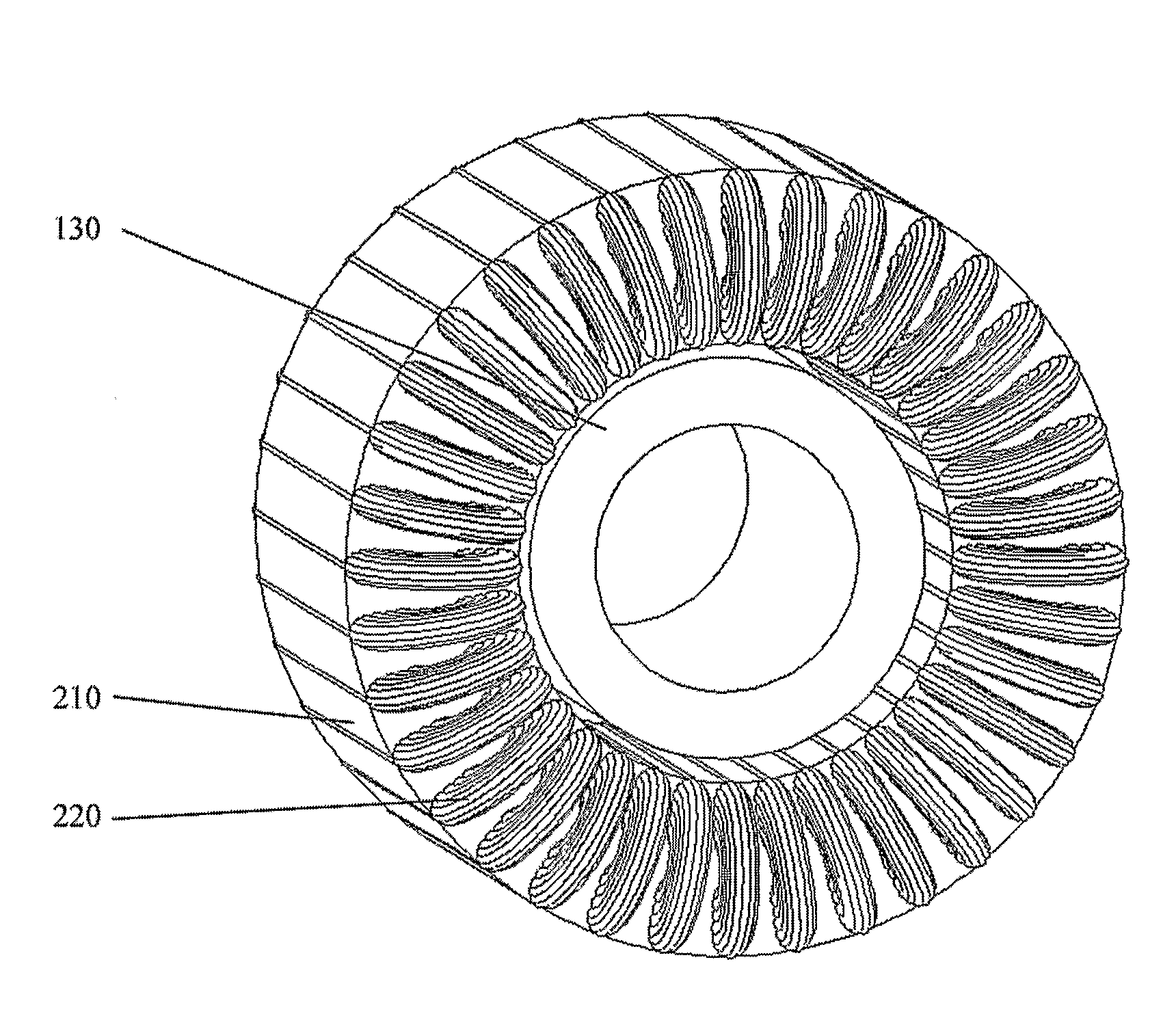

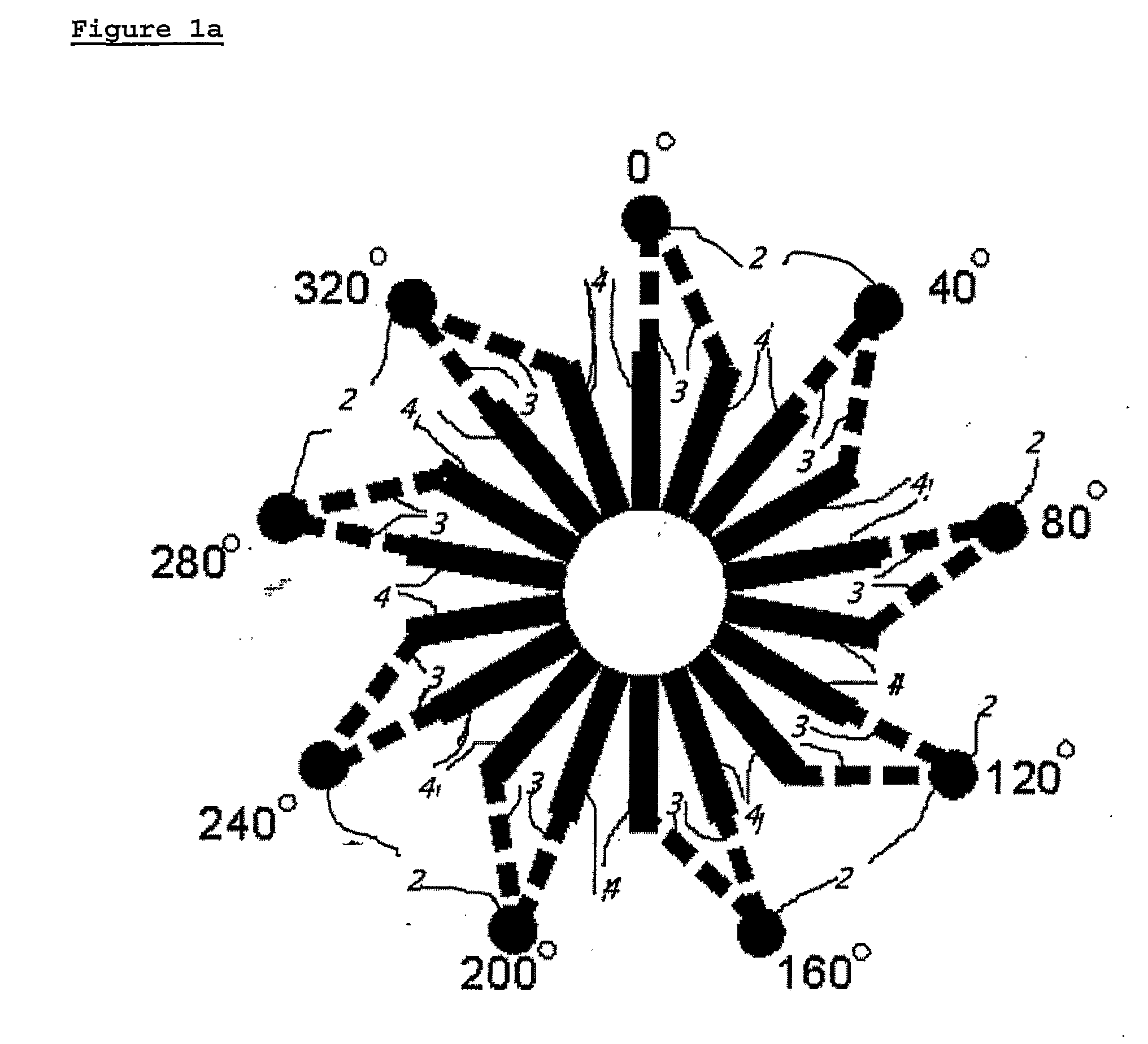

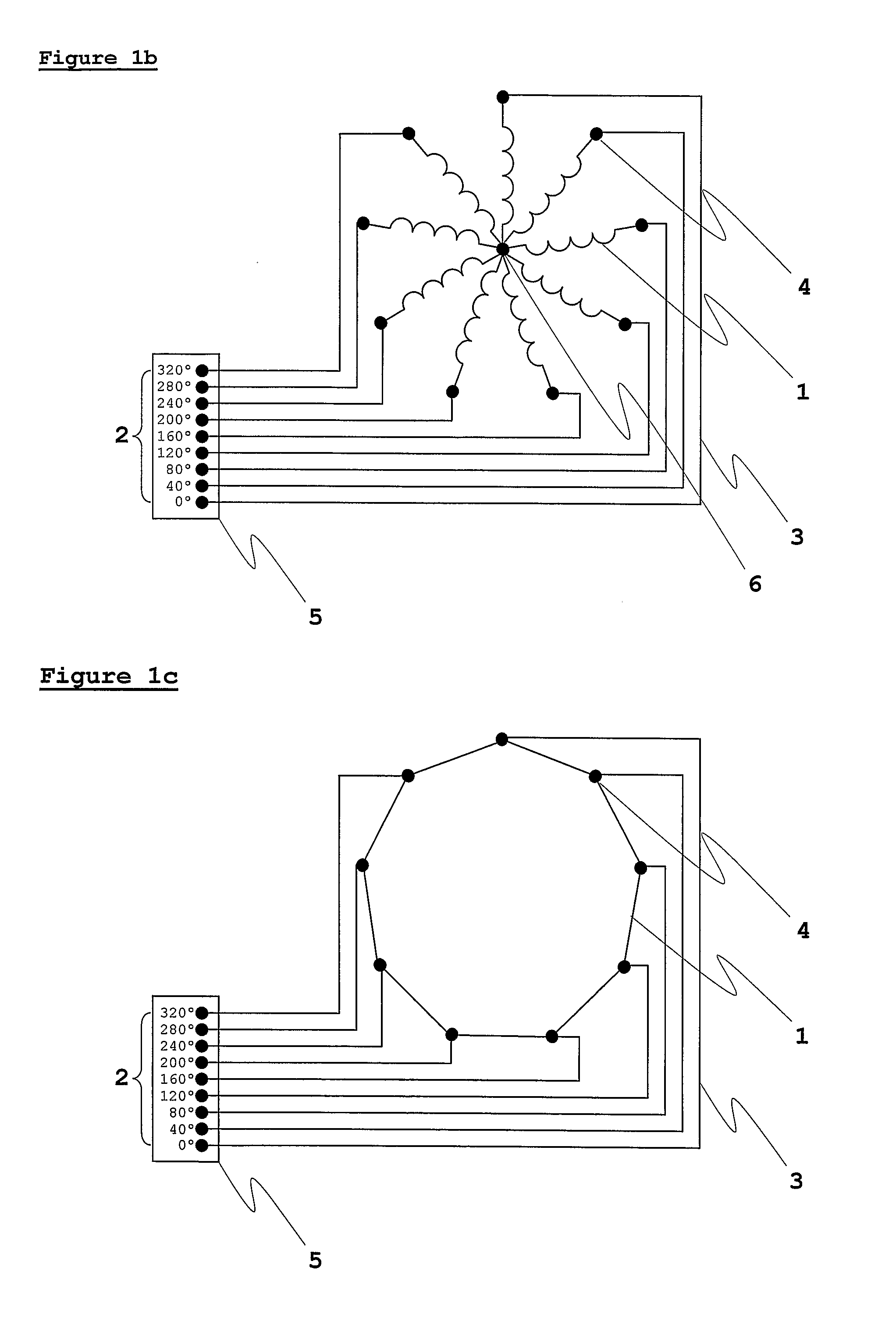

Hub motors

InactiveUS20060273686A1Raise countIncrease surface areaSingle-phase induction motor startersSynchronous motors startersDrive wheelStator coil

The present invention discloses small compact motor systems which may be located inside a vehicle drive wheel, and which allow a drive motor to provide the necessary torque with reasonable system mass. The motor systems of the invention utilize polyphase electric motors, and are preferably connected to appropriate drive systems via mesh connections, to provide variable V / Hz ratios. In one embodiment the stator coils are wound around the inside and outside of the stator. In a further embodiment, the machine contains a high number of phases, greater than three. In a further embodiment, the phases are connected in a mesh connection. In a further embodiment, each half-phase is independently driven to enable second harmonic drive for an impedance effect. Improvements are apparent in efficiency and packing density.

Owner:BOREALIS TECH LTD

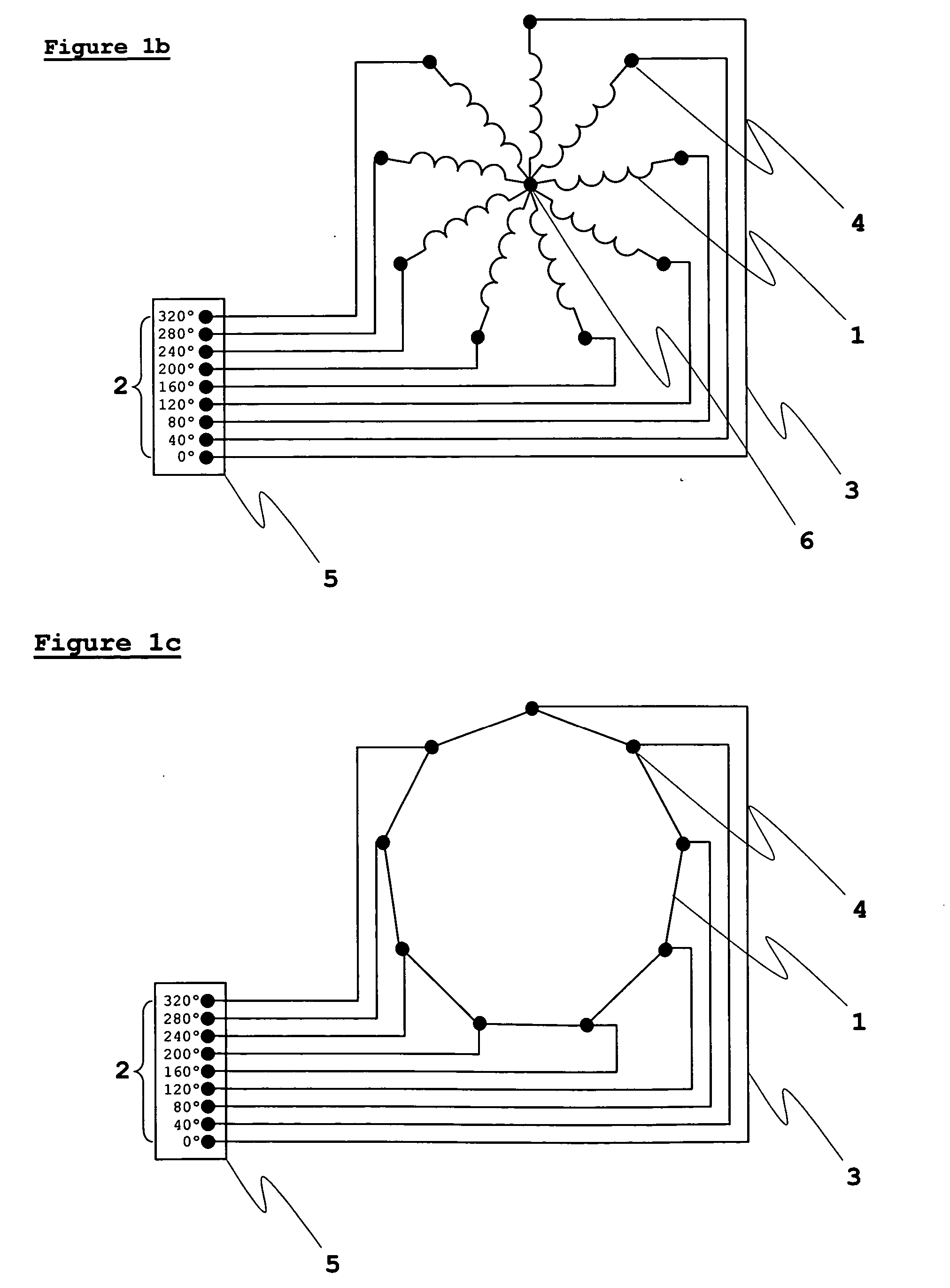

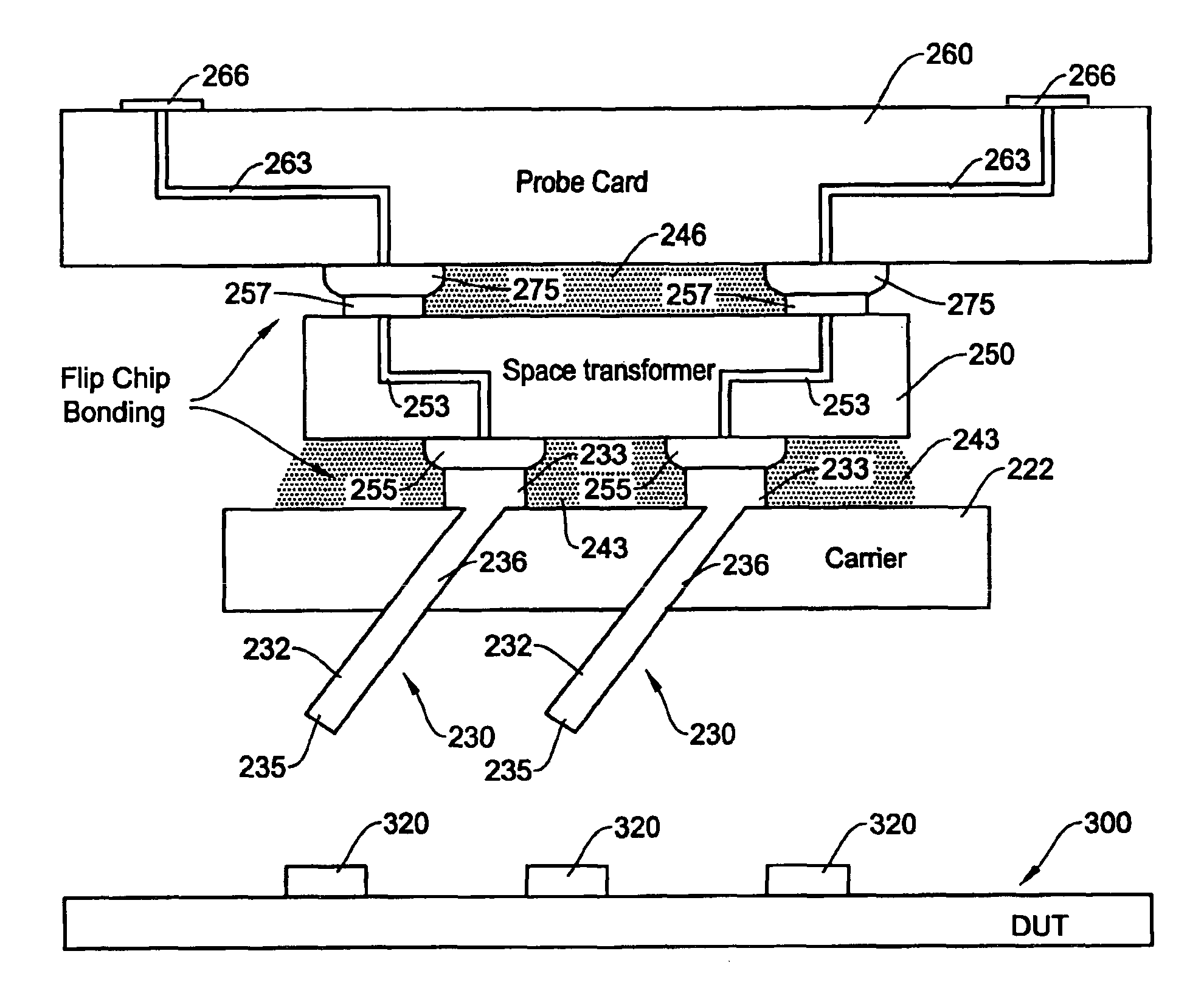

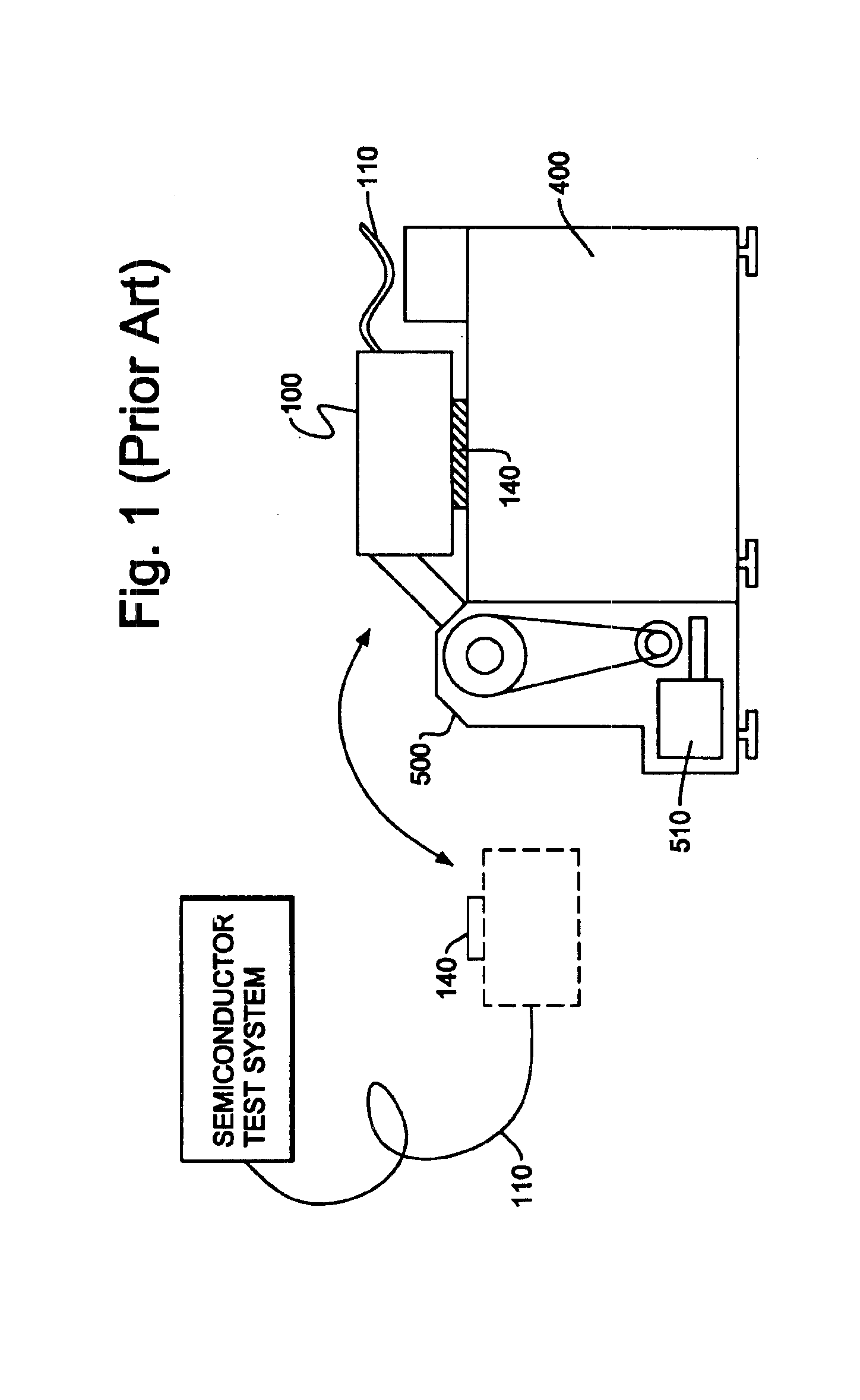

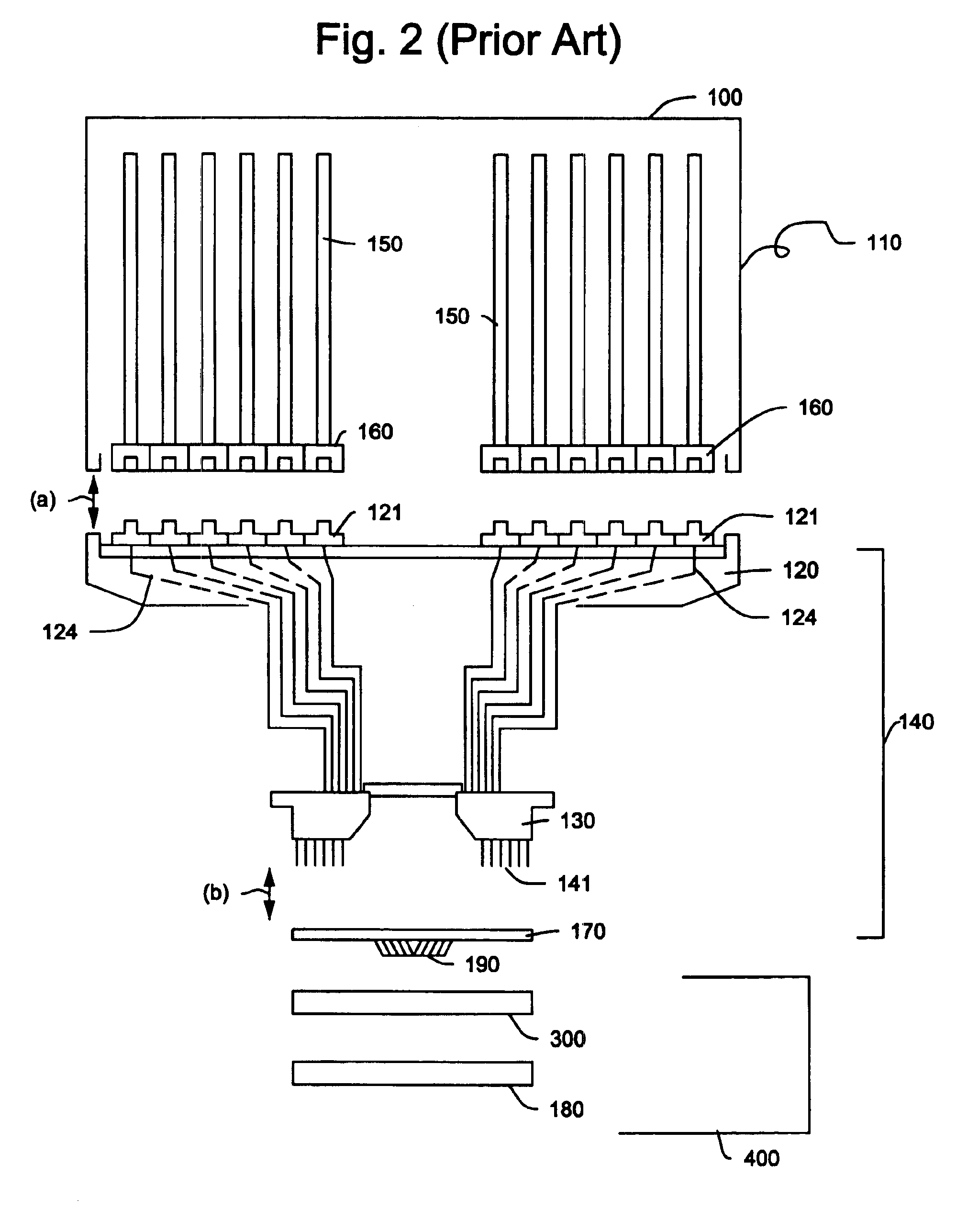

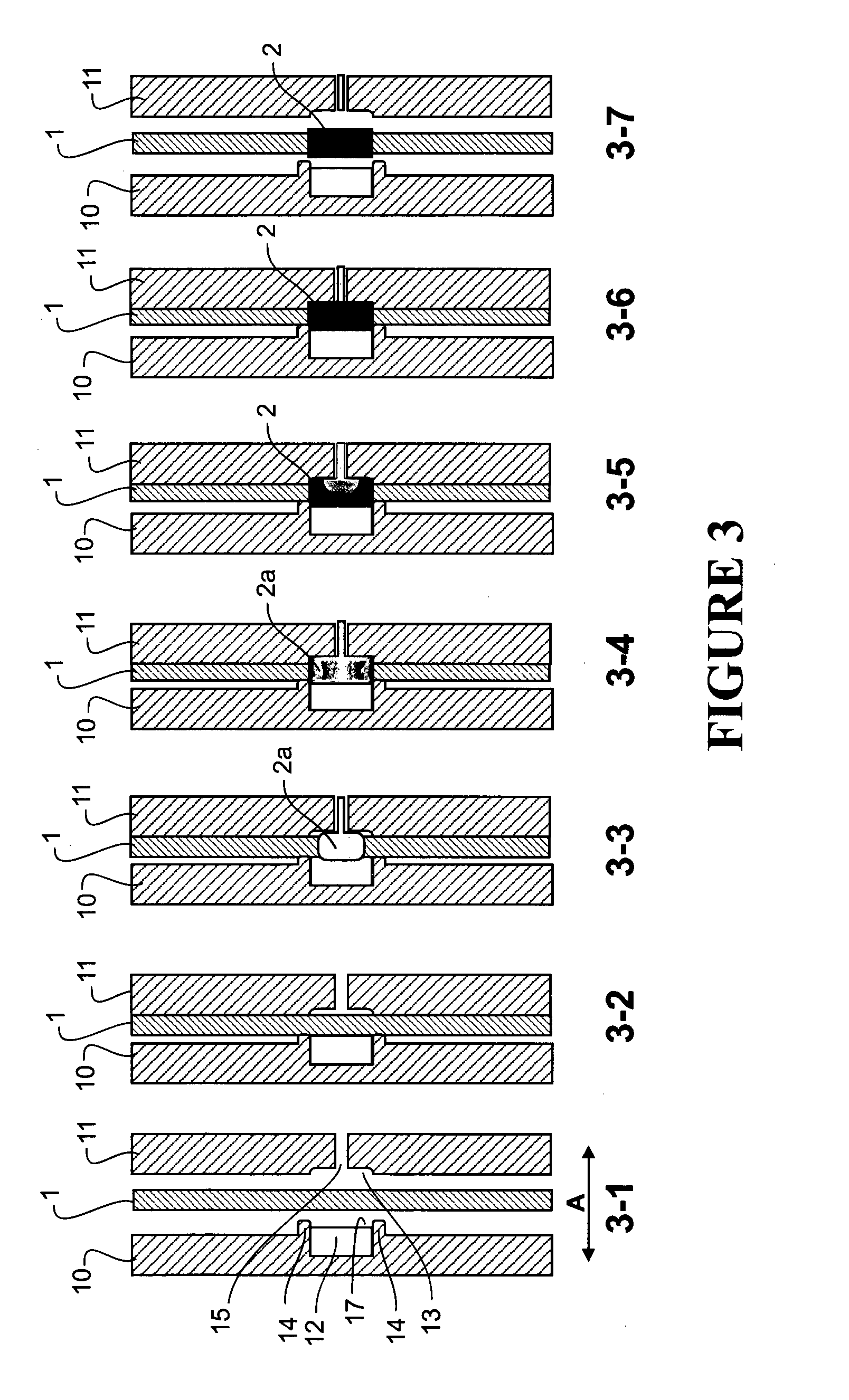

Contact structure and production method thereof and probe contact assembly using same

InactiveUS6917102B2High spring rateHigh countElectrical measurement instrument detailsSemiconductor/solid-state device detailsContactorAdhesive

A contact structure for establishing electrical connection with contact targets. The contact structure is formed of a contactor carrier and a plurality of contactors attached to a contactor carrier. The contactors are inserted in diagonal through holes on the contactor carrier and attached to the contactor carrier through adhesives. The contactor has a top end having a flat top surface, a straight diagonal beam integral with the top end and configured by an upper beam portion and a lower beam portion, and a lower end at an end of the lower beam portion to contact with a contact target. A length of the upper beam portion and a length of the lower beam portion are about the same. A probe contact assembly using the contact structure is also disclosed which incorporates a flip chip bonding technology to interconnect the components therein.

Owner:ADVANTEST CORP

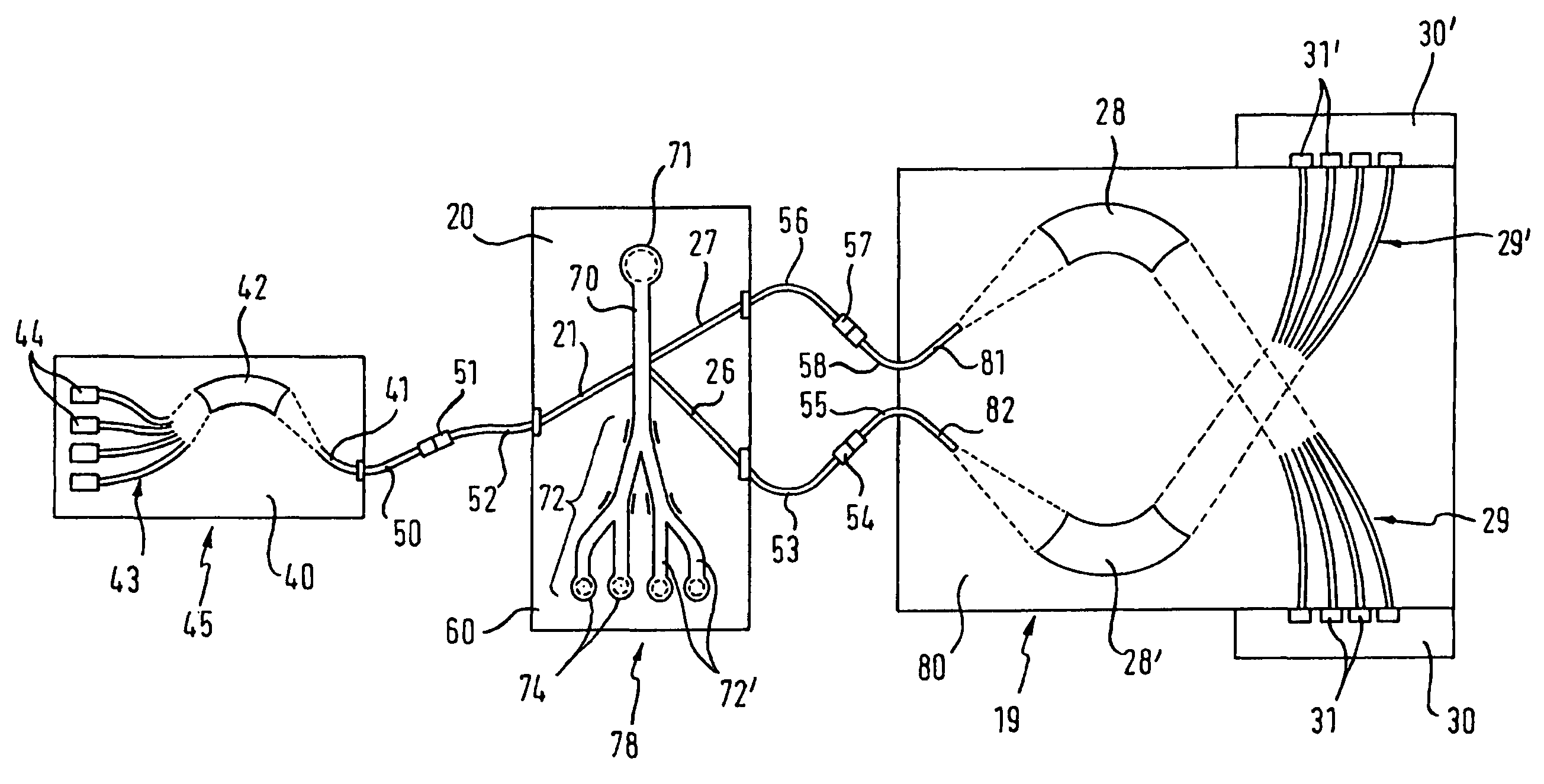

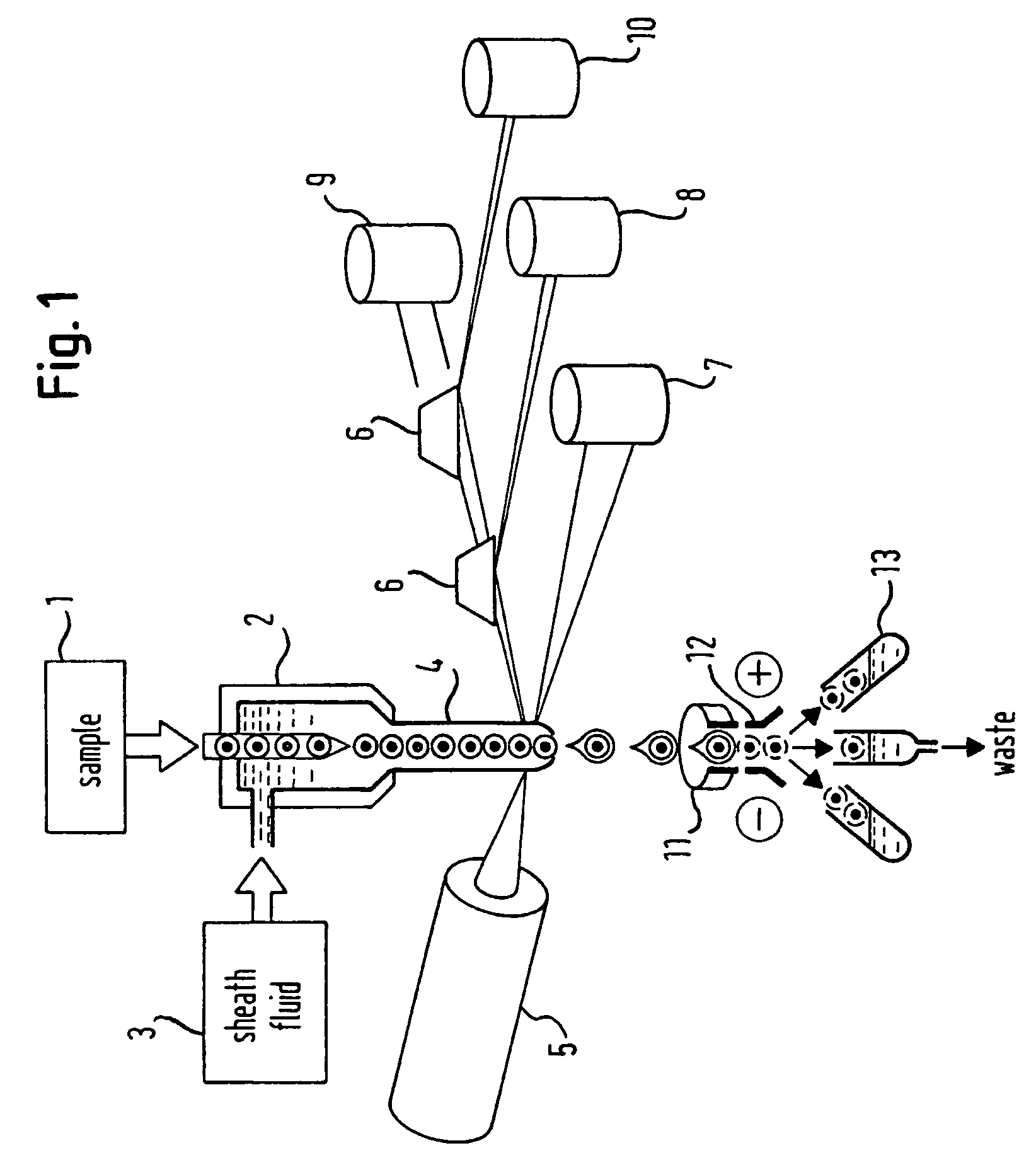

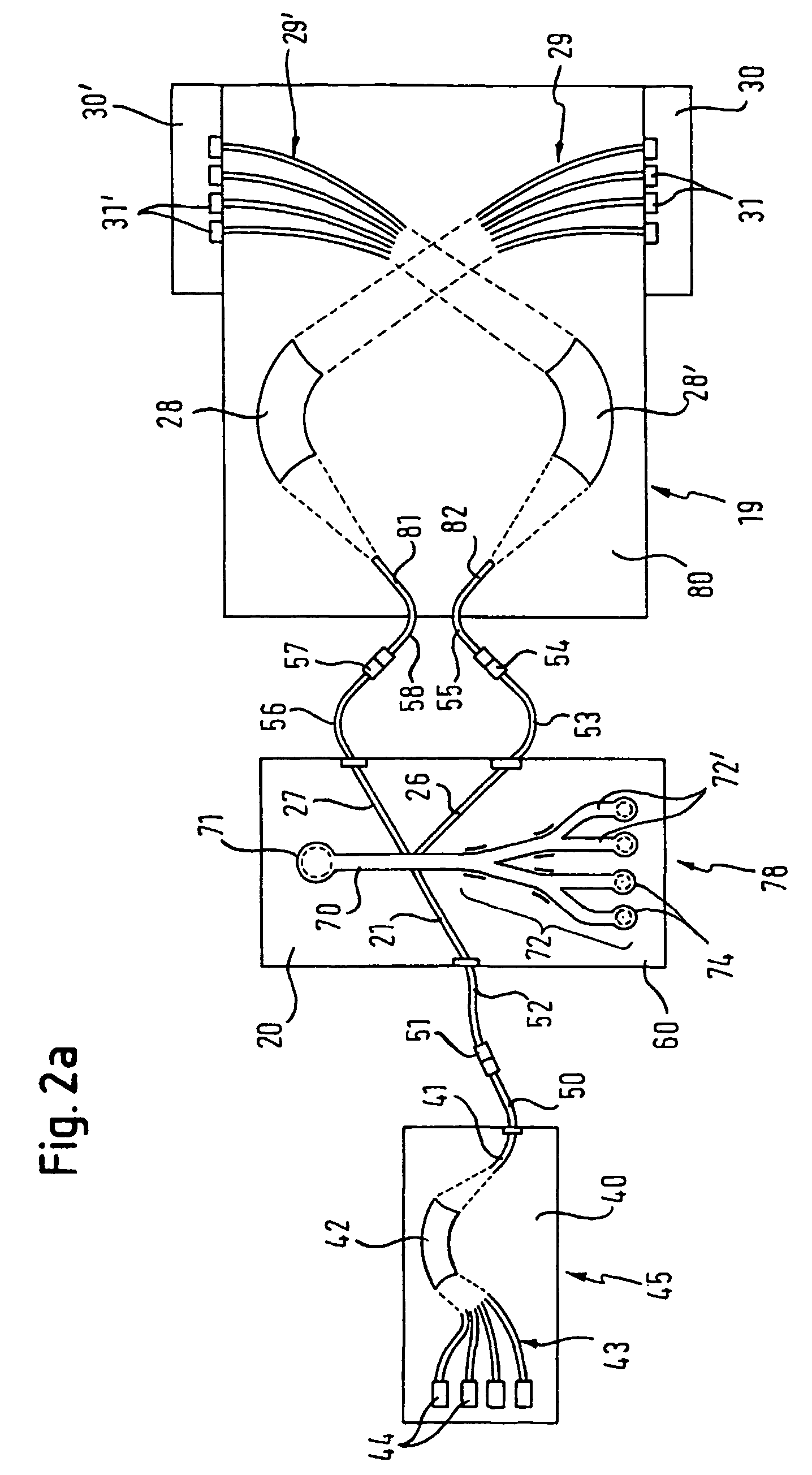

Device and method for investigating analytes in liquid suspension or solution

InactiveUS7245379B2Small sizeEasy to adaptBioreactor/fermenter combinationsBiological substance pretreatmentsAnalytePlanar substrate

Owner:PROIMMUNE

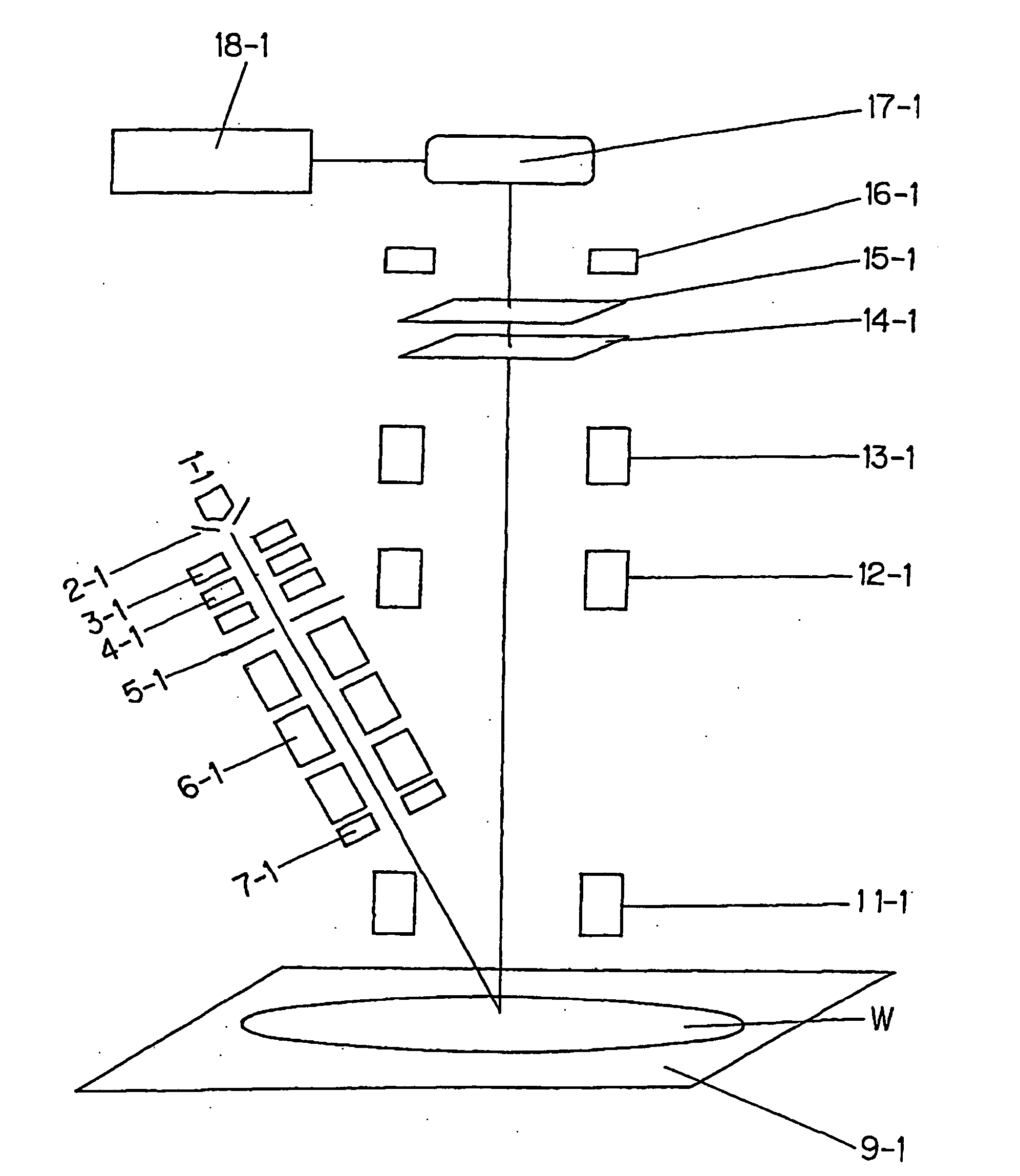

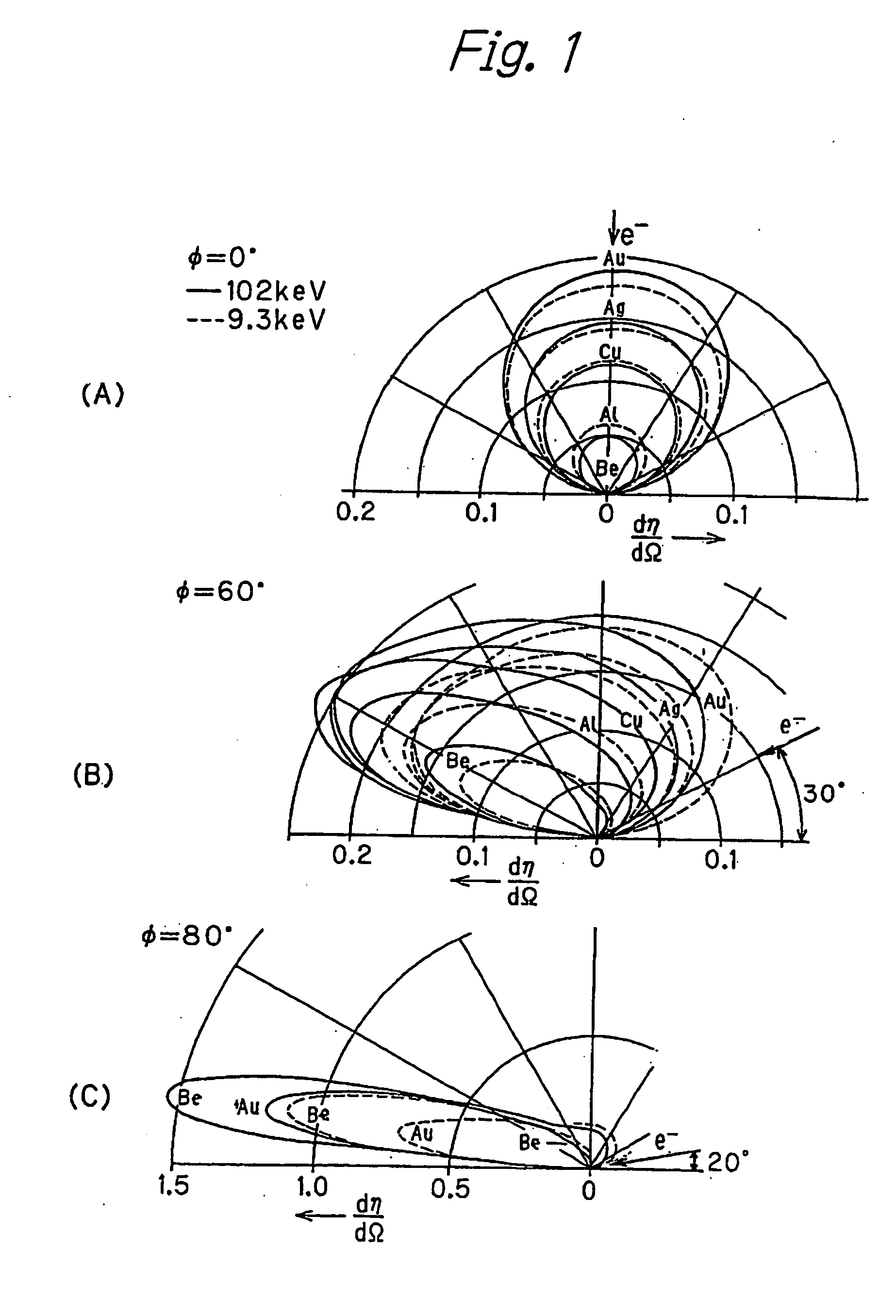

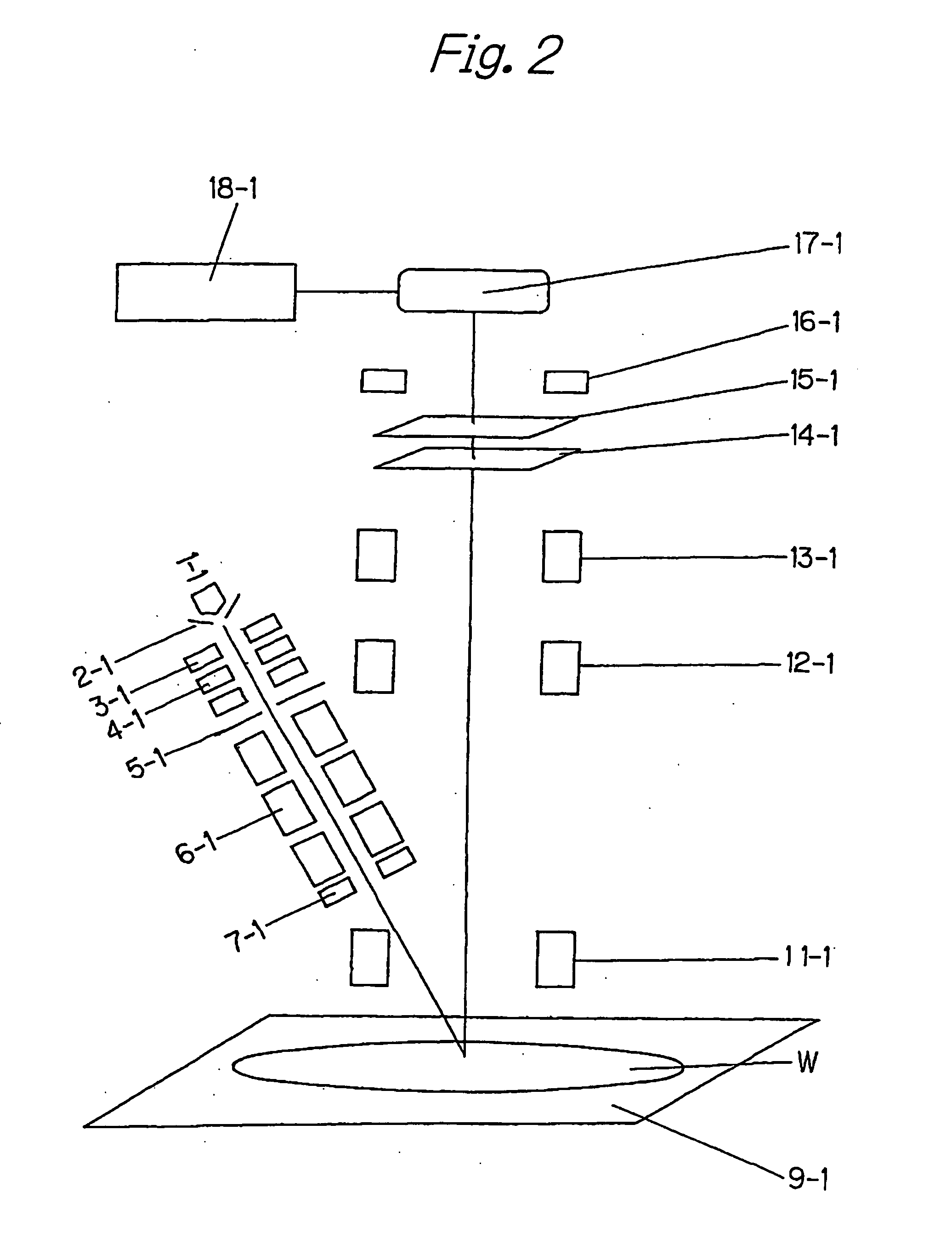

Electron beam apparatus

ActiveUS20050253066A1Increase brightnessExtended service lifeMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingHigh flux

An electron beam apparatus is provided for evaluating a sample at a high throughput and a high S / N ratio. As an electron beam emitted from an electron gun is irradiated to a sample placed on an X-Y-θ stage through an electrostatic lens, an objective lens and the like, secondary electrons or reflected electrons are emitted from the sample. The primary electron beam is incident at an incident angle set at approximately 35° or more by controlling a deflector. Electrons emitted from the sample is guided in the vertical direction, and focused on a detector. The detector is made up of an MCP, a fluorescent plate, a relay lens, and a TDI (or CCD). An electric signal from the TDI is supplied to a personal computer for image processing to generate a two-dimensional image of the sample.

Owner:EBARA CORP

Ultra fine soft wool yern and its production method

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

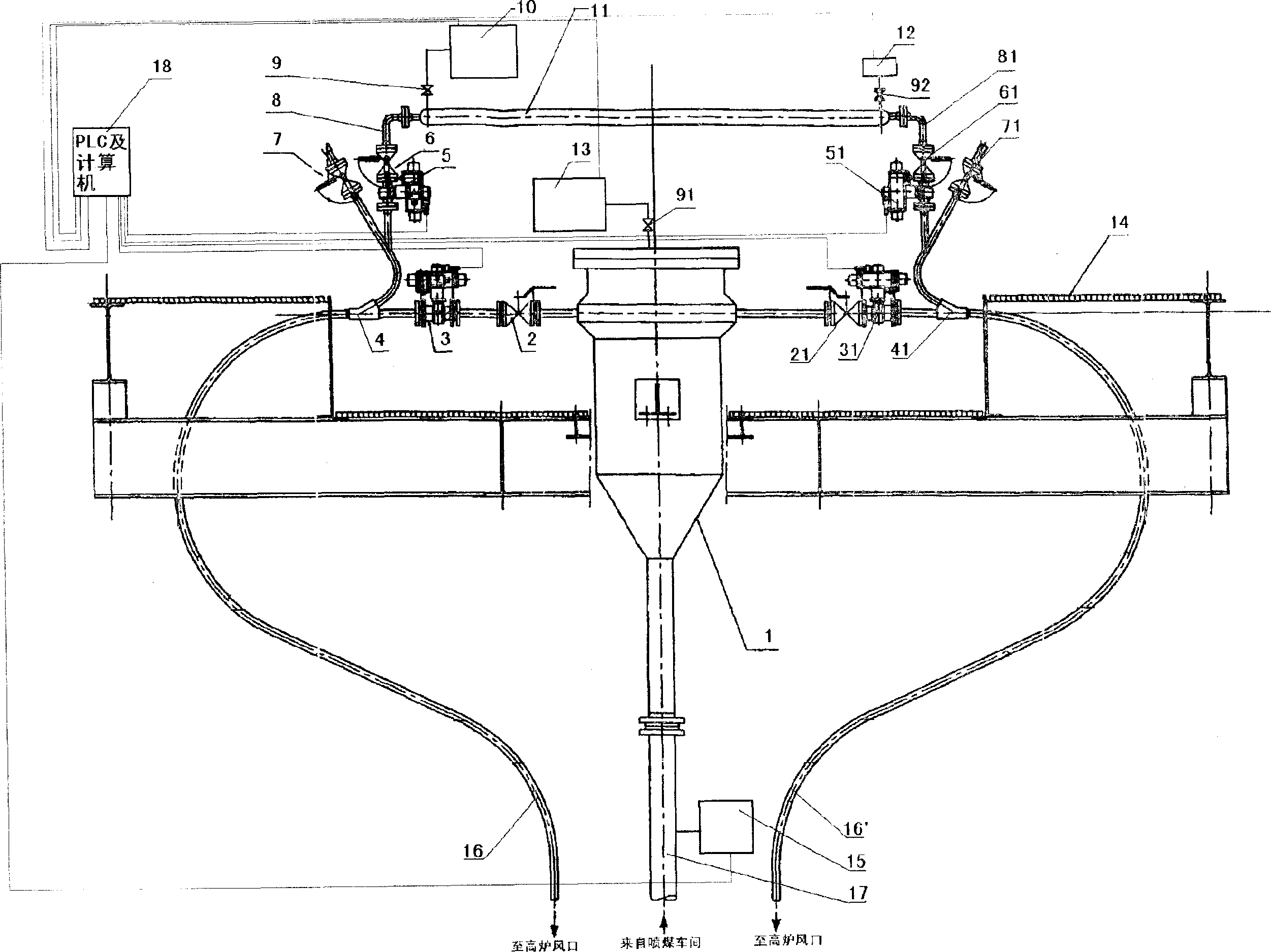

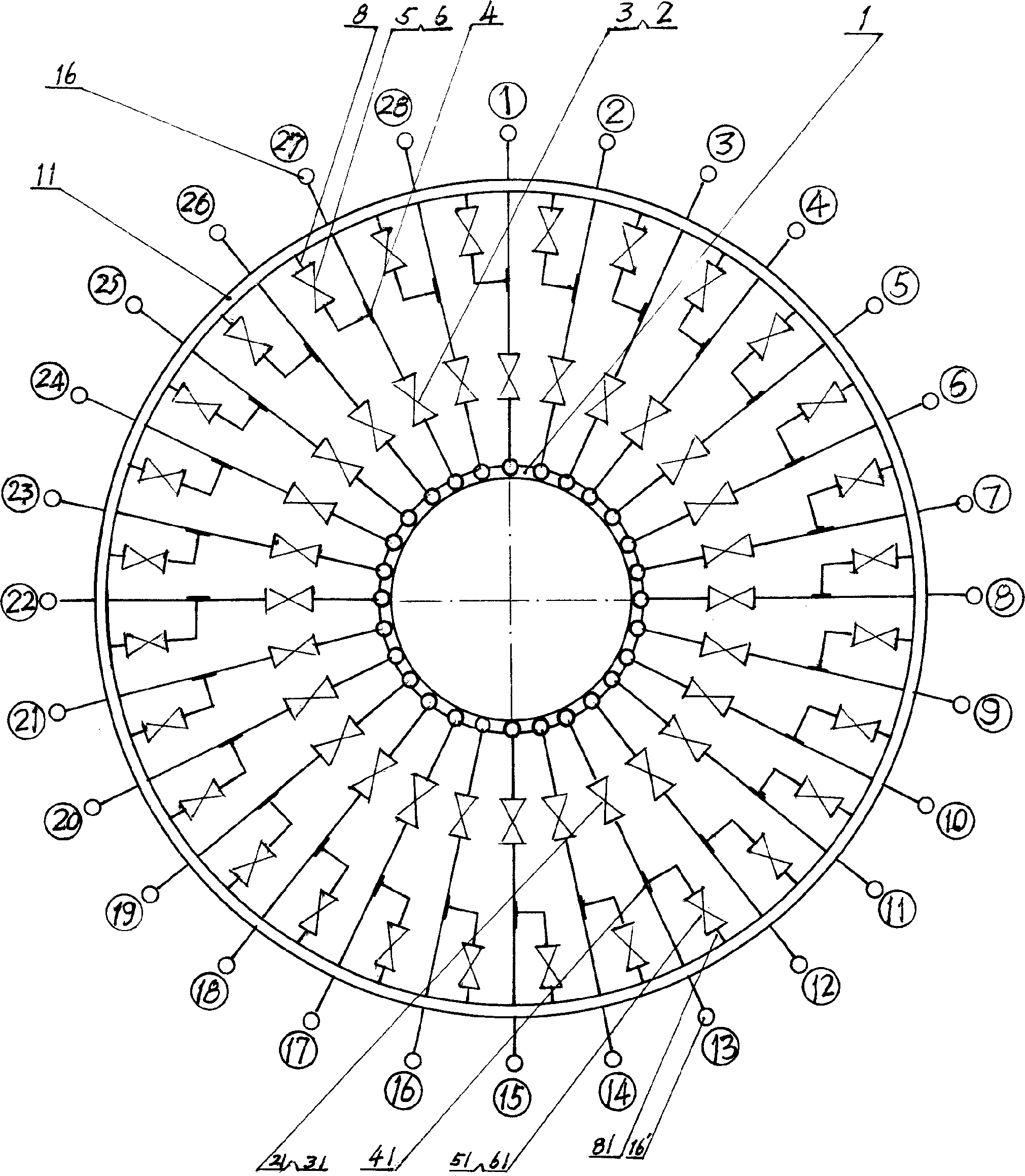

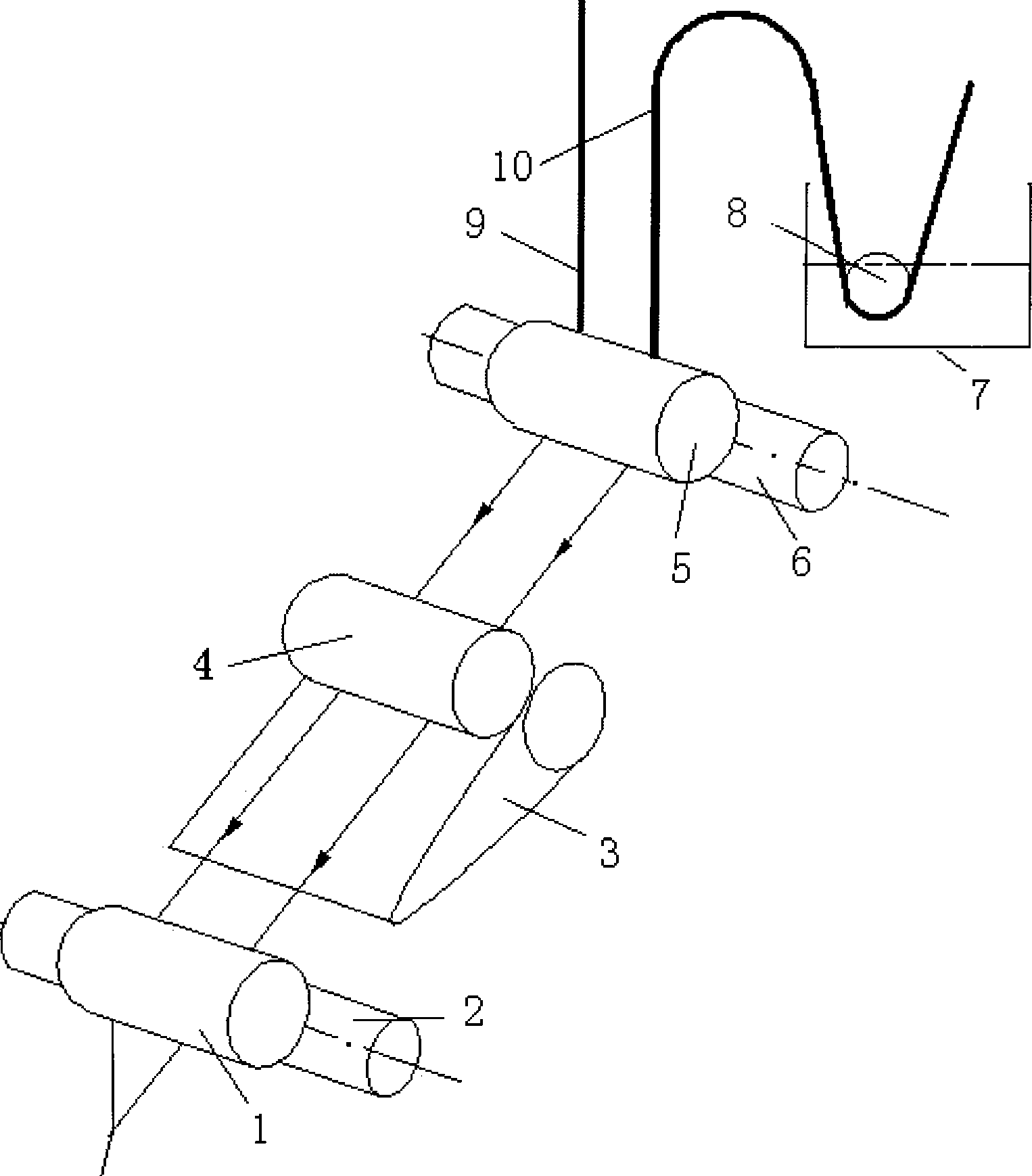

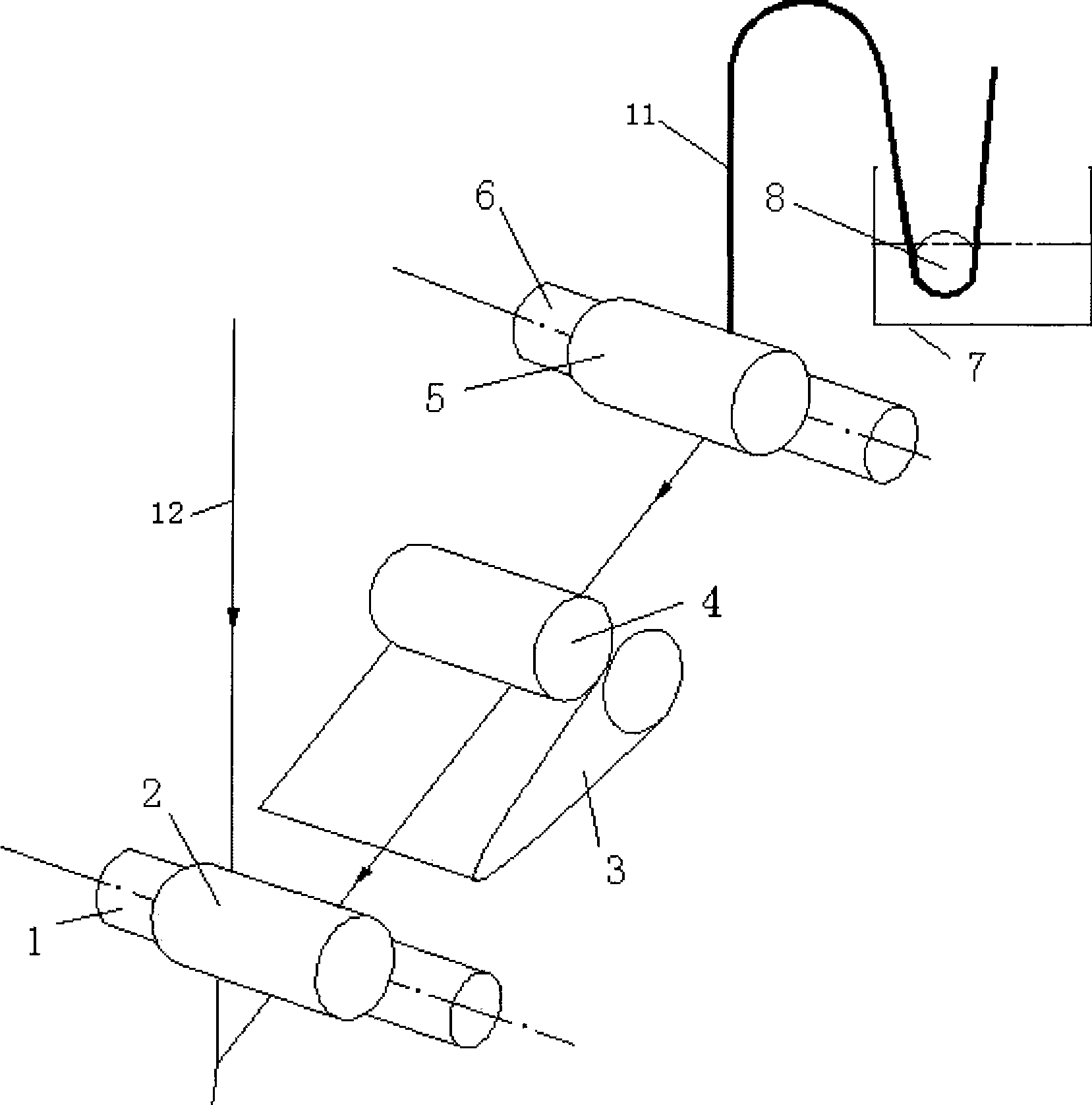

System for automatic monitoring clogging of metallurgy high furnace coal fines lance

ActiveCN1908192AHigh countCycle automatic unblockingComputer controlBlast furnace componentsMonitoring systemEngineering

the invention discloses a self-monitoring system of blocked metallurgical high-furnace coal powder, which comprises the following parts: distributor 1, coal spraying hand ball valve 2 or 21, coal spraying aerating ball valve 3 or 31, blowing aerating ball valve 5 or 51, blowing hand ball valve 6 or 61, blowing compressing air ring-shaped pipe 11 and blowing pressure detecting device 10, main coal transmitting pipe 17, coal spraying branch pipe 16 or 16' and computer 18 or PLC cabinet. when the coal powder is blown in the high-furnace vent, which blowing aerating ball valve 5 or 51 is closed and the coal spraying aerating ball valve 3 or 31 is opened; when the coal spraying branch pipe 16 or 16' is blocked, the coal spraying aerating ball valve 3 or 31 is closed for a while and the blowing aerating ball valve 5 or 51 is opened to remove the blocked coal powder in the 16 or 16'; the screen of computer 18 displays each opening and closing condition of each ball valve, which can monitor each spraying gun condition remotely.

Owner:湖南华菱涟源钢铁有限公司

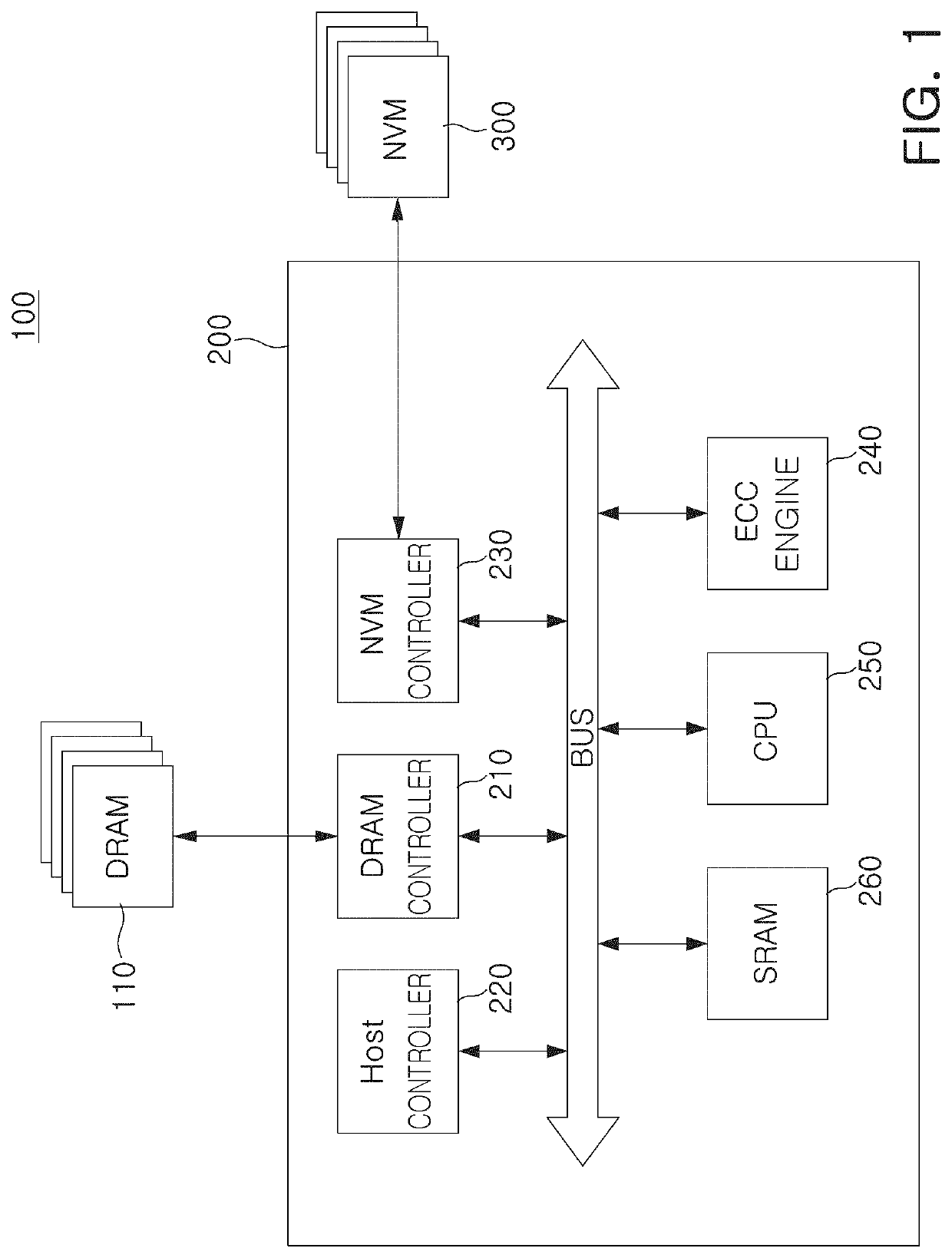

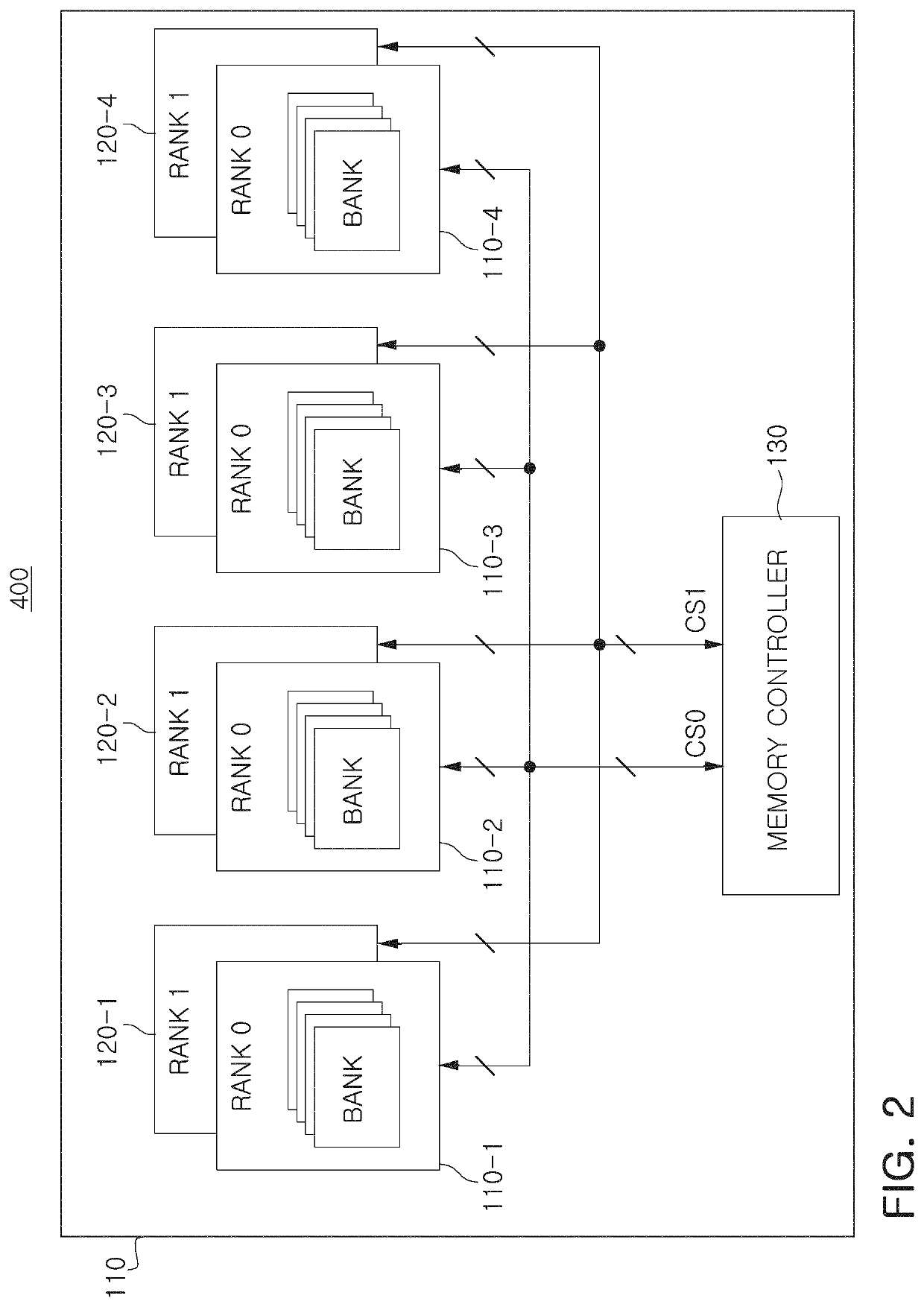

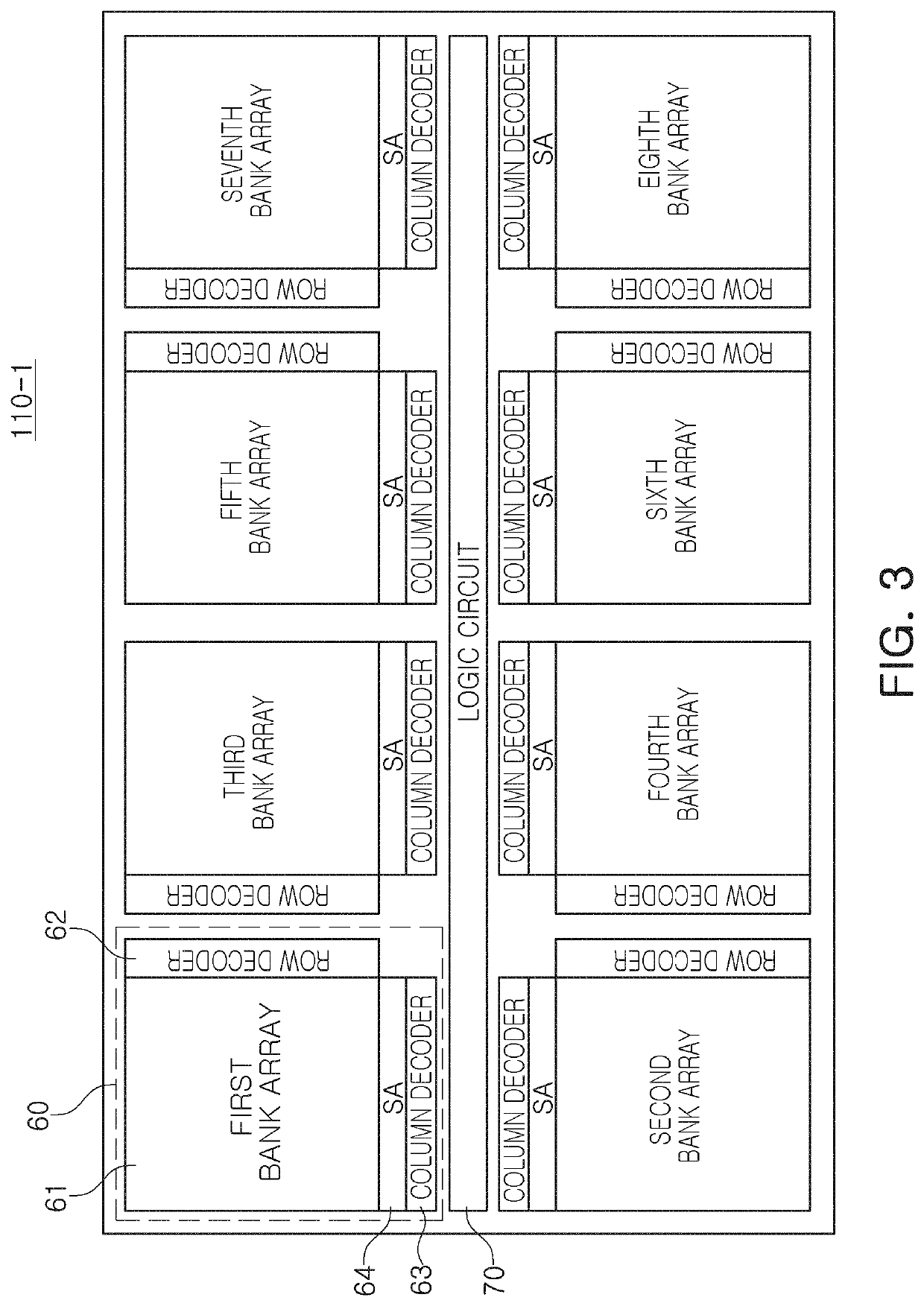

Memory systems for performing failover

ActiveUS20210026732A1High countDigital storageNon-redundant fault processingMemory controllerStorage cell

A memory system includes a plurality of memory devices, each of the plurality of memory devices including a plurality of memory cells, and at least one of the plurality of memory devices including a backup region, and a memory controller configured to store data to be stored in a plurality of selected memory cells in the plurality of selected memory cells and the backup region, the plurality of selected memory cells being connected to a selected word line of a selected memory device among the plurality of memory devices, and replace the selected word line with a redundancy word line to which a plurality of redundancy memory cells among the plurality of memory cells are connected in response to a correctable error correction code (CECC) occurring in at least one of the plurality of selected memory cells.

Owner:SAMSUNG ELECTRONICS CO LTD

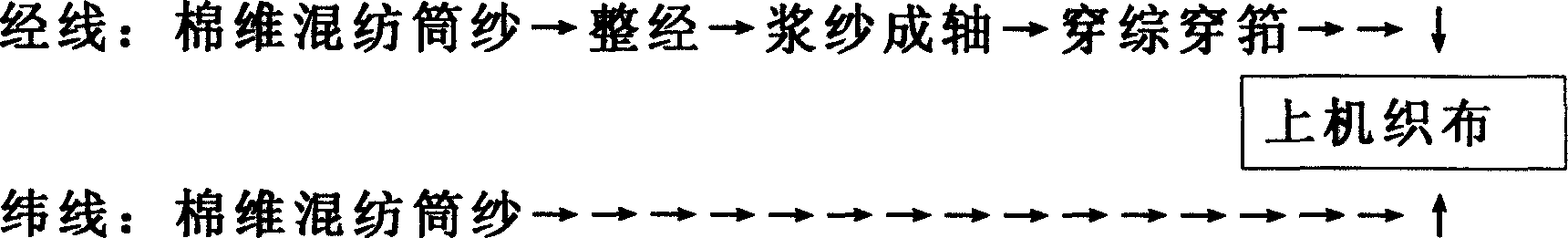

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

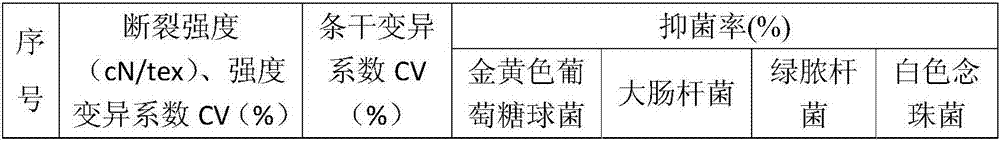

Semi-fine spinning rabbit hair yarn and method of processing the same

InactiveCN101368329AStay Styled and OrnamentalQuality improvementBiochemical fibre treatmentYarnLower intensityHydrogen peroxide

The invention discloses semi-worsted rabbit hair yarn and a processing method thereof, belonging to treatment and processing field of animal fiber, in particular relates to a semi-worsted rabbit hair yarn product which is processed by taking natural rabbit hair as material through the processes of oxidation treatment by hydrogen peroxide and modification treatment by 1398 neutral subtilisin, and a processing method thereof. The processing method includes the following steps: materials pretreatment; oxidation and enzyme treatment; combining the hair and adding oil for health preserving; three times of drawing; roving; spinning; and winding. The invention successfully solves the problem of small friction coefficient, small crimp frequency, low intensity and low cohesion on rabbit hair, which leads to poor spinnability on rabbit hair fiber, and provides a high quality and high yarn count half-worsted rabbit hair yarn product which takes rabbit hair as material, and the processing method thereof. The half-worsted rabbit hair yarn provides high quality material for weaving, knitting, sewing, broidering and tufting industries, and the rabbit hair product is free from hair falling and pilling, thus maintaining the characteristics of rabbit hair.

Owner:山东恒泰纺织有限公司

Method for preparing flax fiber in high cleavage degree

InactiveCN1687491ANo change in propertiesIncrease the degree of splittingVegetable materialYarnBleach

Preparation method of linen fiber of high fission belongs to the domain of weave. The stuff is come unglued by enzyme first, then oxygen bleach it in common pressure, acid and alkali neutralization, drying it and make linen fiber in wet condition. It improves the fission of the fiber and doesn't change its characteristic. The fission increases from 400 - 600 to more than 2000. The cohesion performance and spinnability of the fiber is improved. Blended yarn is high, can reach more than 160N.

Owner:无锡鼎球绢丝纺有限公司

Yarn for hemp/cotton blended high-grade underwear fabric and processing method of yarn

InactiveCN105803608AImprove flexibility and spinnabilityWell spreadGrip property fibresYarnHemp fiberYarn

The invention provides a processing method of yarn for hemp / cotton blended high-grade underwear fabric. The processing method is characterized by comprising the steps that hemp fibers and cotton fibers are pretreated respectively, the pretreated hemp fibers and the pretreated cotton fibers are blended, and then the blended fibers are subjected to cotton opening and scutching, cotton carding, combing, drawing, roving and spinning in sequence. The processing method solves the problem that high-count hemp blended yarn is difficult to produce, the count of the hemp / cotton blended yarn is increased to 70 S-120 S, and the requirement for producing the hemp / cotton blended high-grade underwear fabric is met.

Owner:DONGHUA UNIV +1

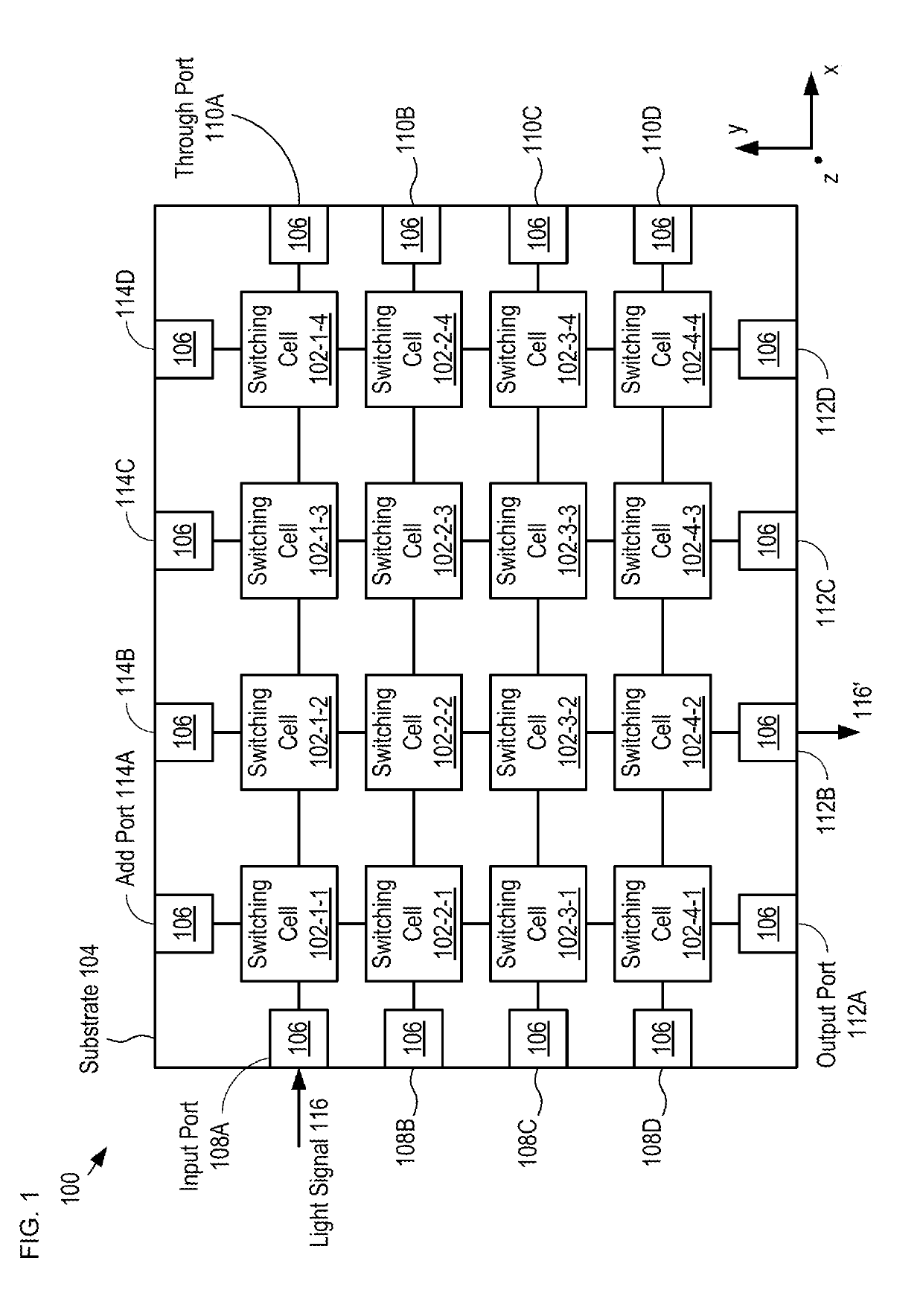

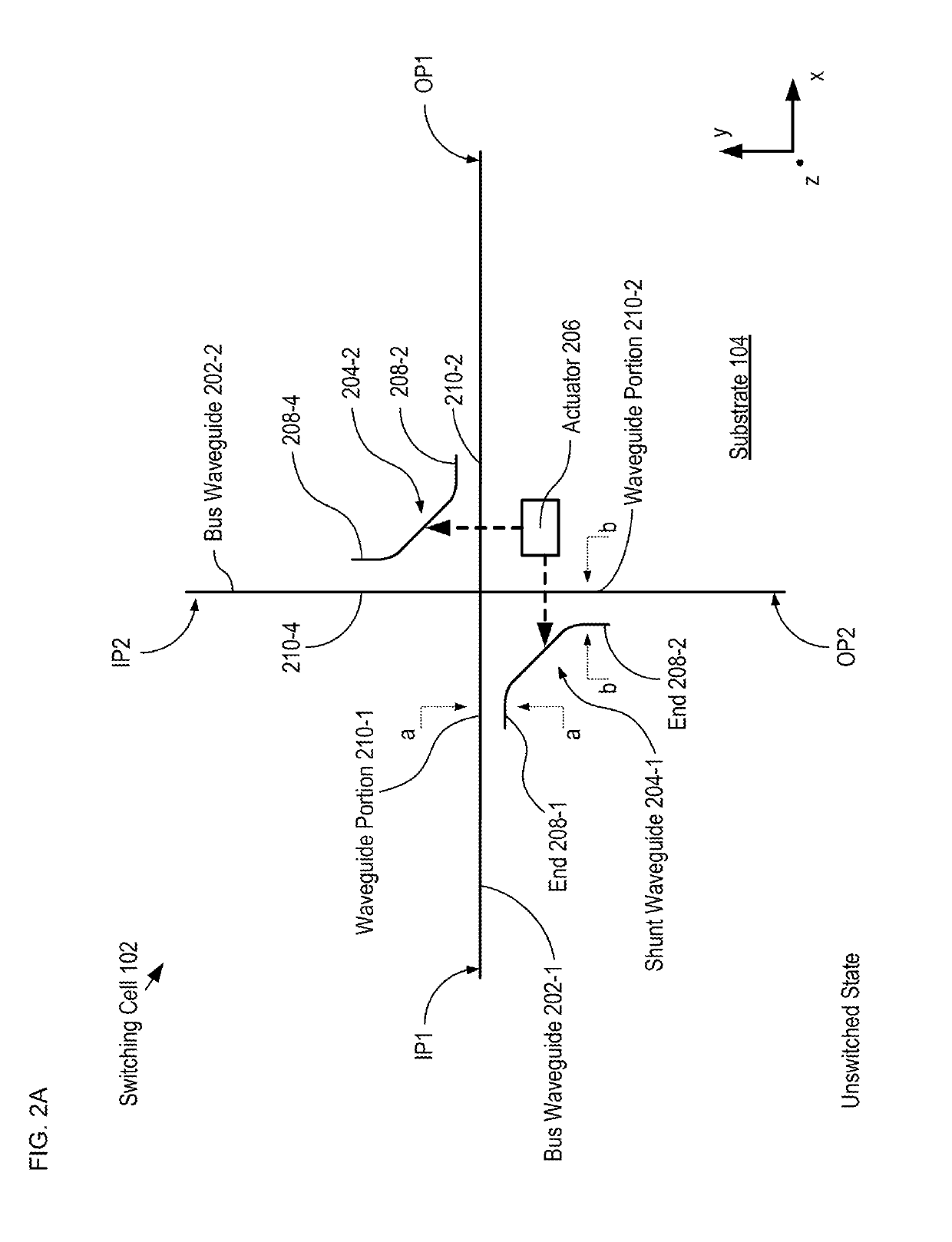

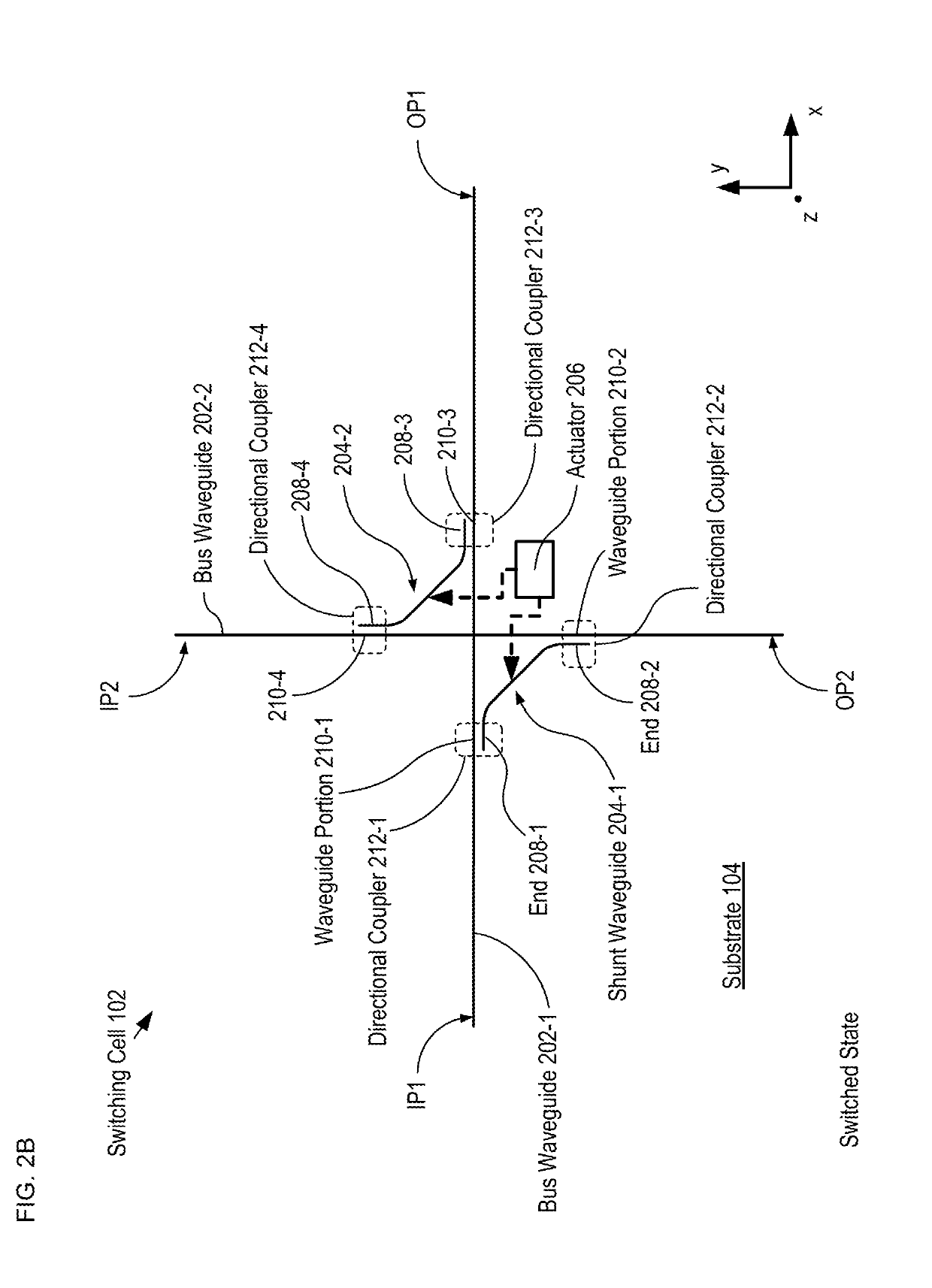

Silicon-photonics-based optical switch with low polarization sensitivity

ActiveUS20190253775A1Low polarization dependenceHigh countMultiplex system selection arrangementsWavelength-division multiplex systemsPhysicsOptical switch

A polarization-independent optical switching system capable of rerouting light signals is disclosed. The system includes a plurality of switching cells, each including a pair of bus waveguides that are formed in different planes above a substrate. Each bus waveguide supports low-loss propagation of both the TE- and TM-polarization modes and are optically decoupled when the switch is in an unswitched state. In its switched state, a shunt waveguide that also supports low-loss propagation of both polarization modes is moved into proximity with both bus waveguides to form a pair of adiabatic directional couplers that enable the light signal to evanescently couple between each bus waveguide and the shunt waveguide. As a result, the path of a light signal through the switching cell is reconfigured.

Owner:RGT UNIV OF CALIFORNIA

Method for producing ramie cotton blended yarn by using cotton-spinning equipment

This invention discloses a method for producing gunny-cotton blend yarn with a cotton spinning device including the following steps: pretreatment of fine dry gunny, cleaning cotton, combing cotton, fine combing, merging slivers, roving, spinning and winding process, which is advantaged that hemp yarn number is high reaching to 60-80 British yarn with 55-80% hemps, dry yarn is increased greatly and faults are reduced greatly.

Owner:CHANGSHANZHAOZHOU TEXTILE

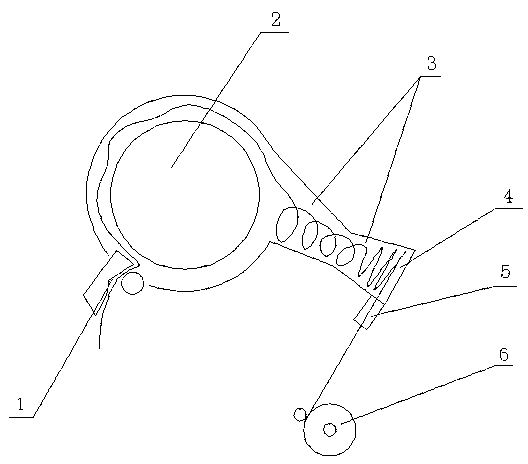

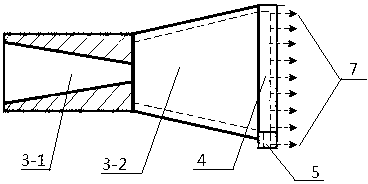

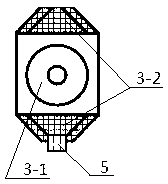

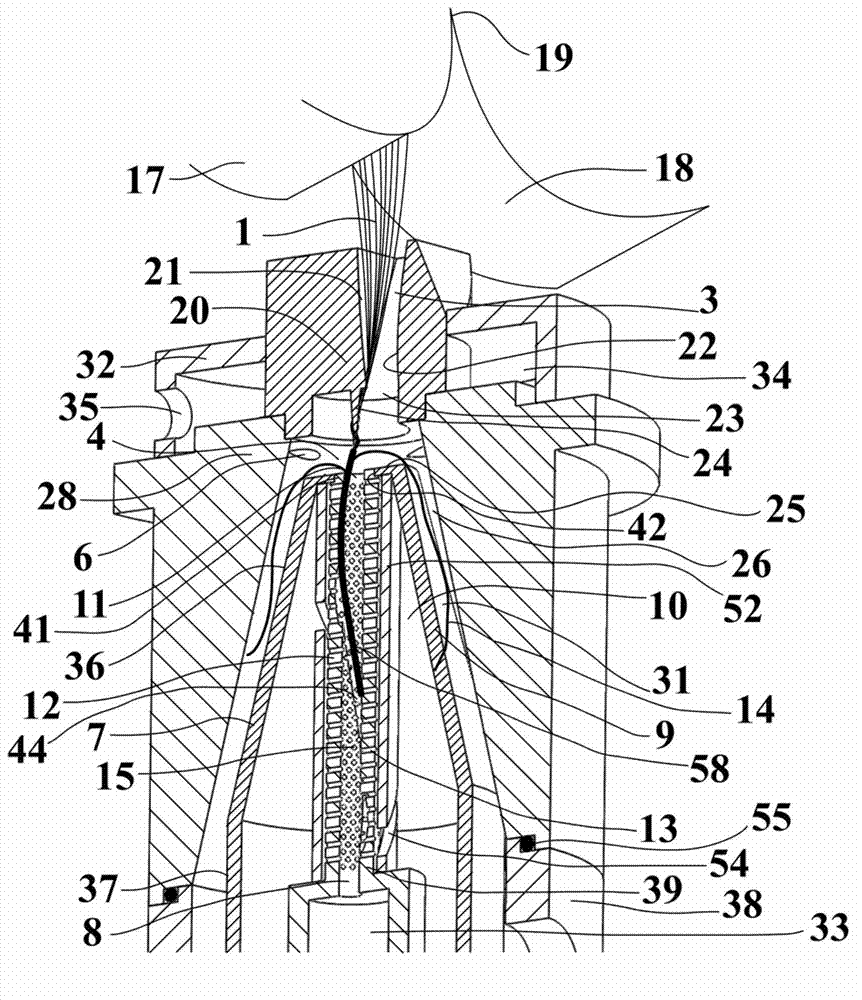

One-step spinning machine capable of conducting entwisting clockwise and one-step spinning method

ActiveCN103060963ACompactReduce power lossContinuous wound-up machinesOpen-end spinning machinesSteel platesYarn

The invention provides a one-step spinning machine capable of conducting entwisting clockwise and a one-step spinning method. The one-step spinning machine comprises a carding roller, a cover, a fiber feeding mechanism, a yarn winding mechanism and an air sucking device. The one-step spinning machine is characterized in that an irregular-shaped pipe formed by a conical pipe and a trapezoid pipe is arranged below the carding roller. The trapezoid pipe is formed by defining two trapezoid steel plates and two trapezoid mesh plates, and a U-shaped fiber cohesion area formed by a semi-circular-arc mesh plate is arranged at the outlet end of the trapezoid pipe so as to achieve cohesion of fiber in the irregular pipe. One side of the cohesion area is connected with a rotation flow entwisting pipe in butting mode, and the inner diameter of the rotation flow entwisting pipe and the U-shaped cohesion area form a straight smooth yarn channel. Compressed air enters along an air inlet hole of a lateral wall of the rotation flow entwisting pipe to form forward rotation flow to finish entwisting of strips and push the yarn to move forward. Fiber is fully separated, stretched, becomes parallel and is combined evenly on one device, and the one-step spinning machine is simple and compact in structure, convenient to machine and manufacture and low in cost. The one-step spinning method achieves purposes of high speed, high yield, high efficiency and high quality.

Owner:吴江赴东扬程化纤有限公司

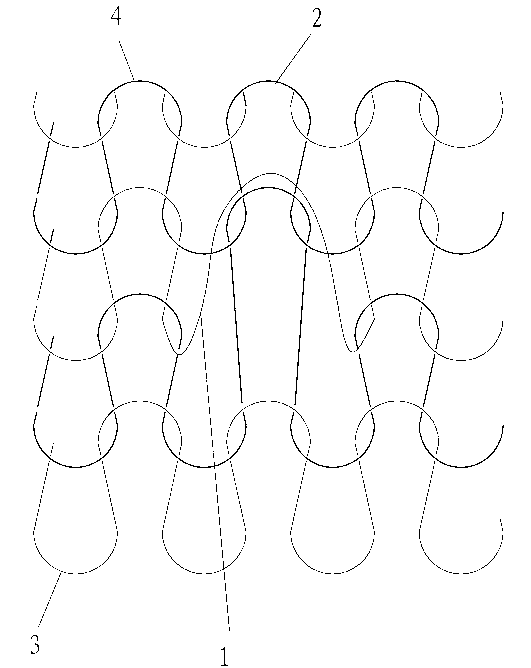

Wool and true silk blended knitted fabric

The invention provides a wool and true silk blended knitted fabric which is formed by blending wool yarns and true silk yarns and comprises multiple closed coils, wherein each coil is provided with an unclosed dangling arc; the stitch number of each dangling arc is one; the wool yarns and the true silk yarns are in side-to-side setup, so as to form transverse striations; and the weight ratio of the wool yarns to the true silk yarns is (5:1)-(10:1). According to the wool and true silk blended knitted fabric, wool is mercerized, so that the wear comfort and pilling resistance of the fabric are improved; by virtue of combination of a proper amount of true silk fibers, the spinnability of the yarns is greatly improved, the count and weaving density of the yarns are effectively improved, and the purpose of reducing the fabric thickness is achieved; and the finished fabric preserves the characteristics of good heat insulating capability and fluffiness of the wool, also has the advantages of good hygroscopicity and glossiness of the true silk, and simultaneously has the characteristics of ultrathin property, hydrophile, comfort of wear and no pilling.

Owner:POLARGOOSE CLOTHING

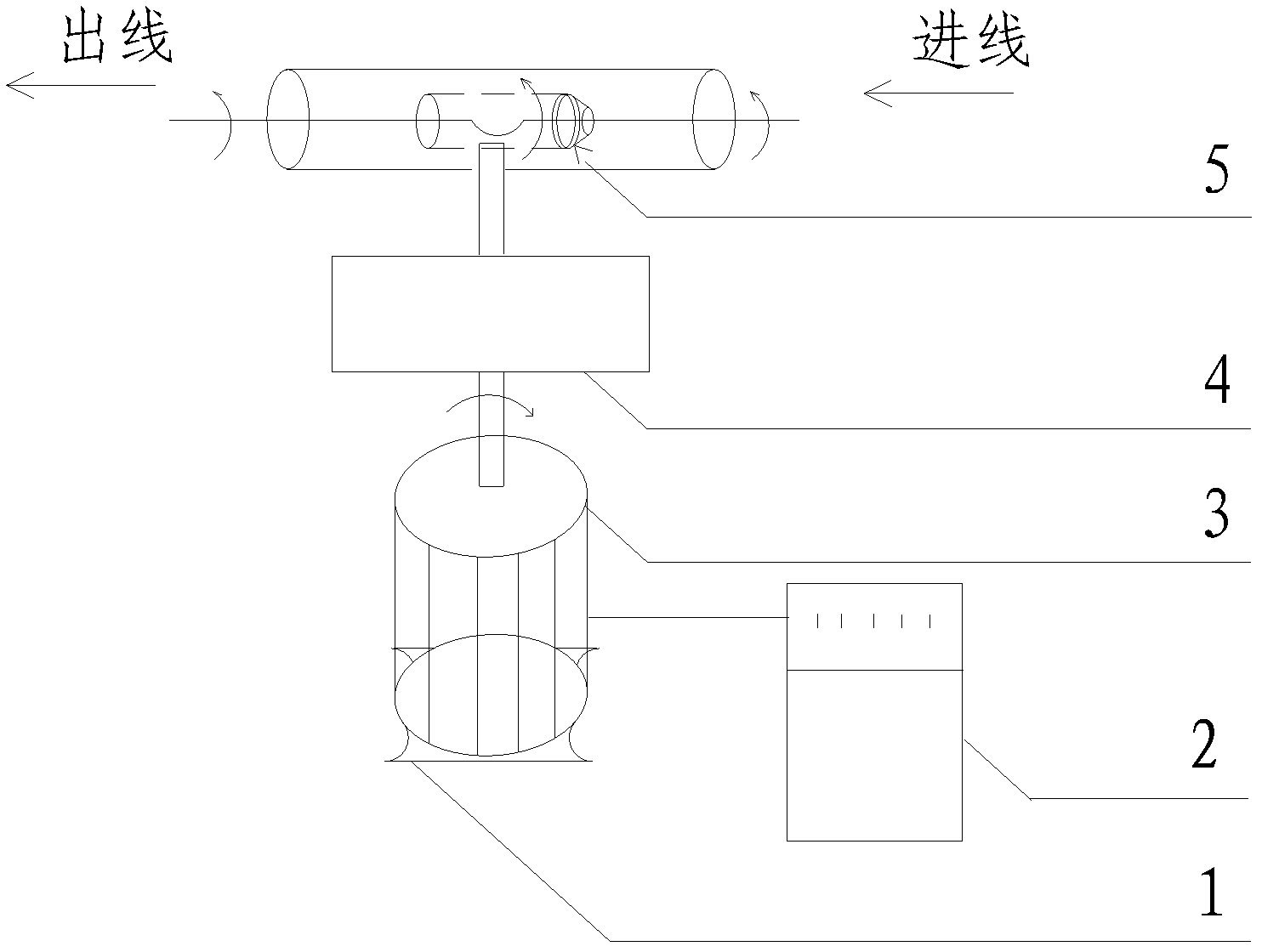

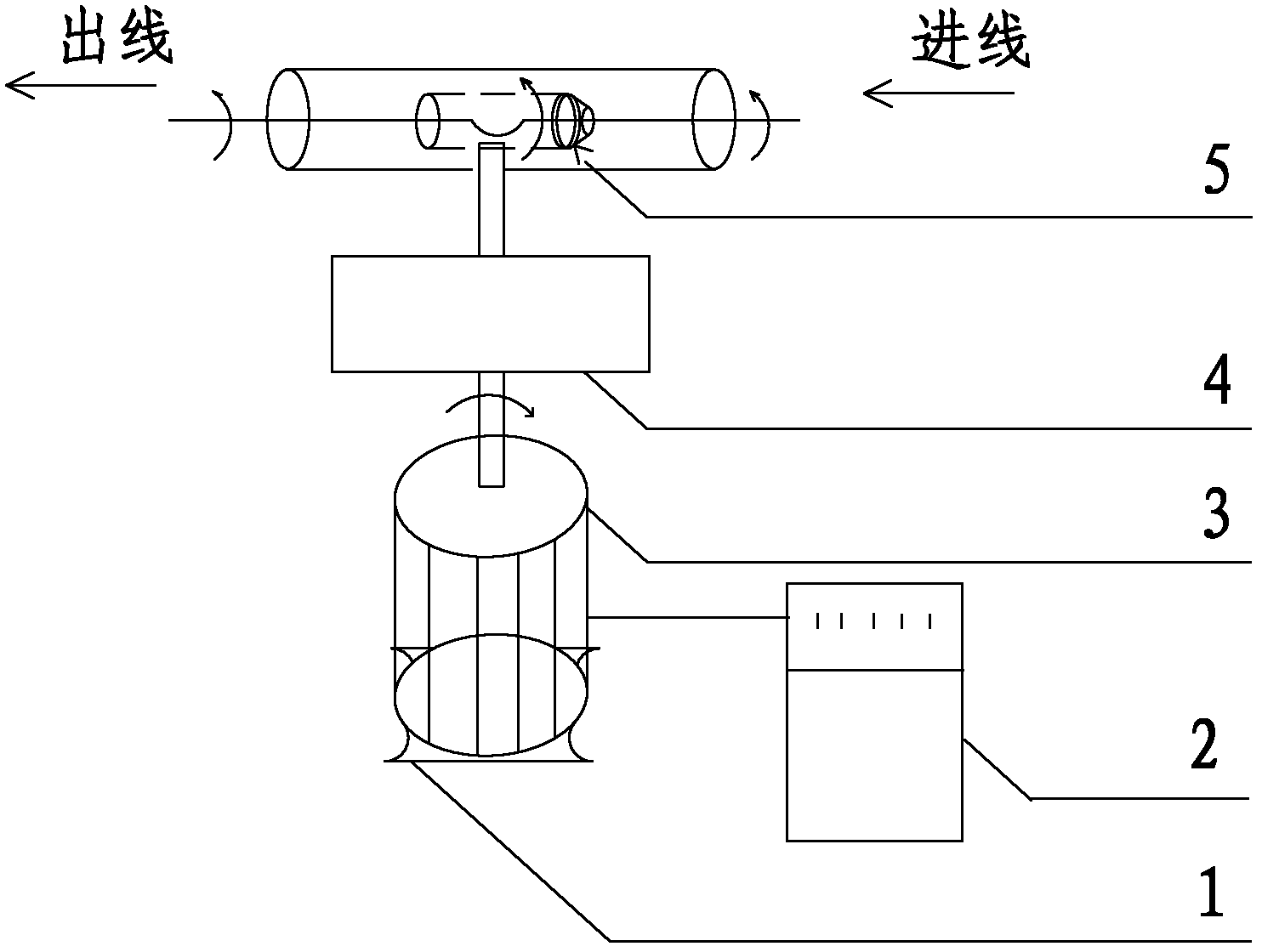

Untwisting drawing device

The invention discloses an untwisting drawing device which comprises a miniature high-speed motor, a speed control and display system, a rotation direction converter and an untwisting drawing device, wherein the miniature high-speed motor is connected with the speed control and display system; the miniature high-speed motor is also connected with the untwisting drawing device through the rotation direction converter; the untwisting drawing device comprises a fixed cylinder, a ball bearing, a rolling shaft, rolling shaft switching teeth and switchers; the inside of the fixed cylinder is connected with the rolling shaft by the ball bearing to form an integer; multiple rolling shaft switching teeth are formed on the rolling shaft; and multiple switchers are arranged at the middle of the rolling shaft. According to the device, the count limit of yarn in the existing spinning technique can be overcome, the count of the yarn is increased by an after-spinning drawing manner without being limited by fiber types and spinning manners, the chemical or wet treatment is not needed, and the yarn subjected to untwisting drawing is softer and has low torque.

Owner:WUHAN TEXTILE UNIV

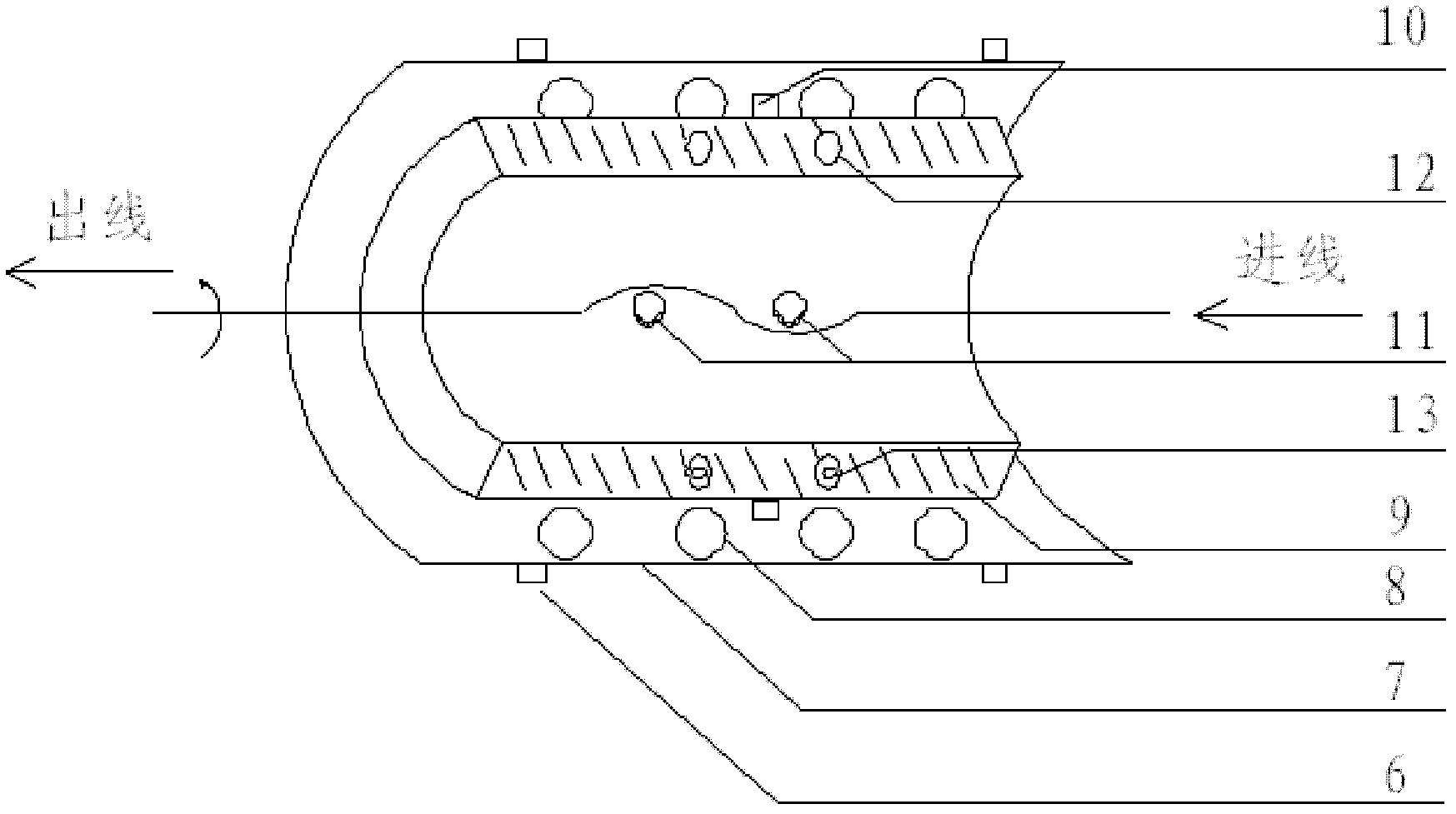

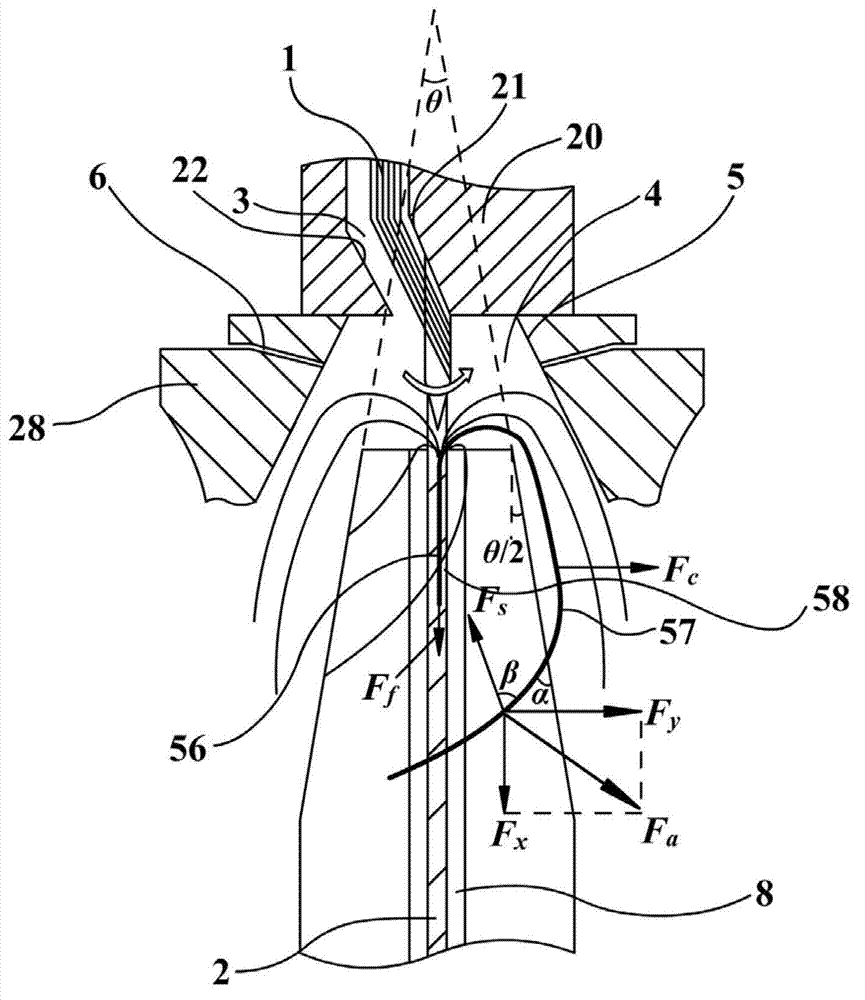

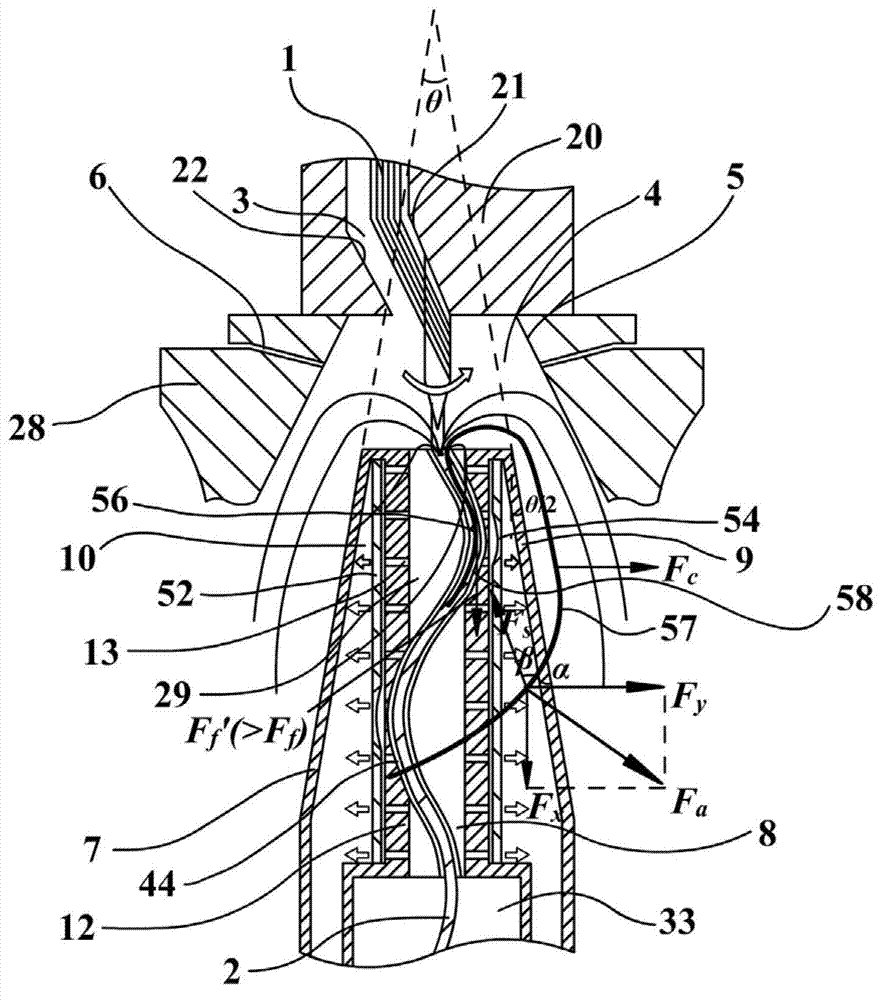

Air injection vortex spinning device with pumping component

InactiveCN102926054AReduce false twistReduce lossesContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to an air injection vortex spinning device with a pumping component. A section, which closes to an inlet of a yarn-guiding channel, of the yarn-guiding channel is a minor diameter section, and the diameter of the minor diameter section is small. A section, which closes to an outlet of the yarn-guiding channel, of the yarn-guiding channel is a major diameter section, and the diameter of the major diameter section is big. A yarn-guiding cone is hollow, and the shape of a cavity of the hollow portion inside the yarn-guiding cone is generally the same with the shape of an outer outline. Small holes communicated with the yarn-guiding channel and the cavity are arranged on the side wall of the minor diameter section, and the small holes are evenly distributed on the side wall of the minor diameter section. A screwy groove is formed in the inner wall of the minor diameter section of the yarn-guiding channel, and a screwy shape of the groove shares the same axis with an axial direction of the yarn-guiding channel. A plug-in module is placed inside the cavity of the minor diameter section of the yarn-guiding channel, the plug-in module is generally of a round tube shape, and the inner diameter of the plug-in module is larger than the external diameter of the minor diameter section. A screwy gap communicated with the tube wall is arranged on the side wall of the plug-in module, and the screwy gap is matched with the groove. According to the air injection vortex spinning device with the pumping component, fiber loss is reduced by utilizing pumping and inhalation of flow, yarn evenness is improved, yarn twist is increased, and finer yarns with a compact structure can be produced.

Owner:DONGHUA UNIV

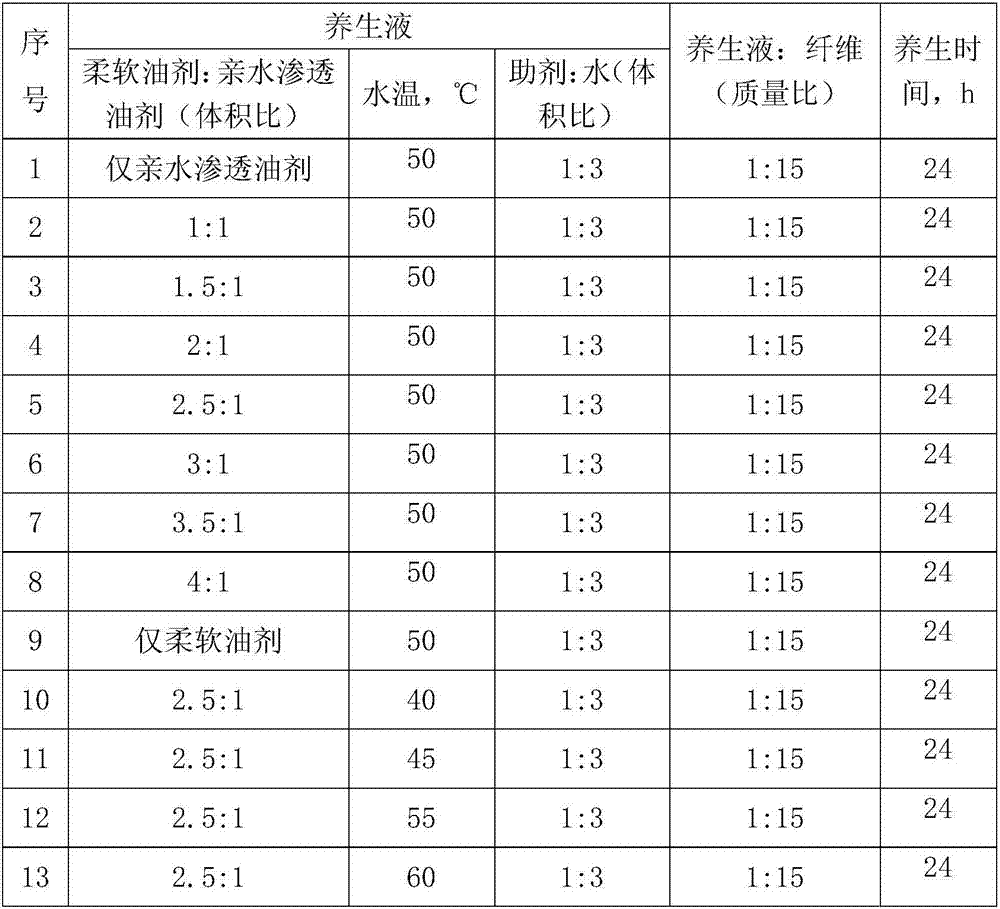

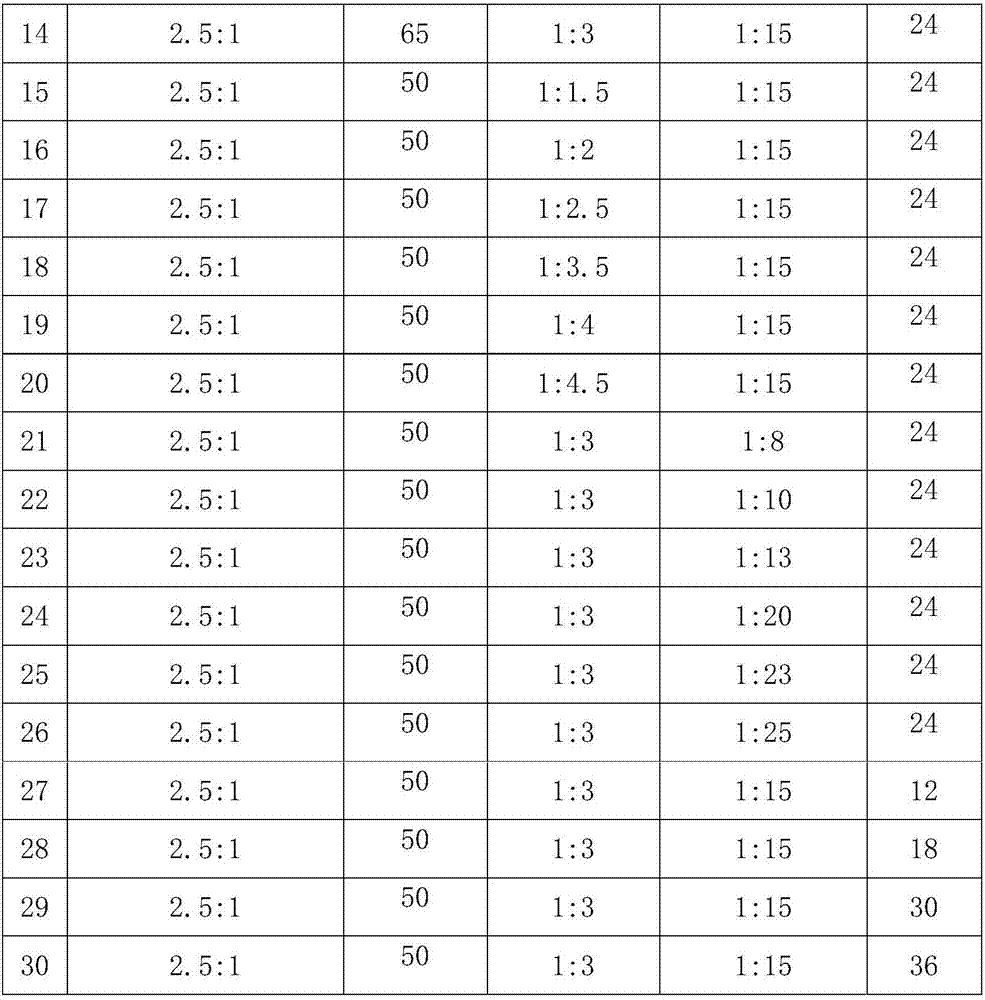

Yakwool yarns and preparation method thereof

InactiveCN106757610AMeet the requirements of spinnabilityHigh countYarnAnimal fibresYarnWater soluble

The invention provides a preparation method of yakwool yarns. The preparation method comprises the following steps: mixing yakwool with a health maintaining auxiliary and then covering tightly to obtain health maintaining yakwool; mixing the health maintaining yakwool with water-soluble fiber and then carding to obtain a mixture card sliver; drawing the mixture card silver to obtain fiber drawn sliver; roving the fiber drawn sliver to obtain rough yarn; performing fine spinning of the rough yarn to obtain one-ply yarn; doubling multiple one-ply yarns to obtain plied yarns; twisting the plied yarns to obtain a finished product of yarn; and washing the finished product of yarn to obtain yakwool yarns. In the preparation method provided by the invention, the doping fiber added in a spinning process can be removed to obtain pure yakwool fiber. Moreover, by adding and removing water-soluble fiber in the middle process, the count of the yakwool fiber can be increased.

Owner:西藏圣信工贸有限公司 +2

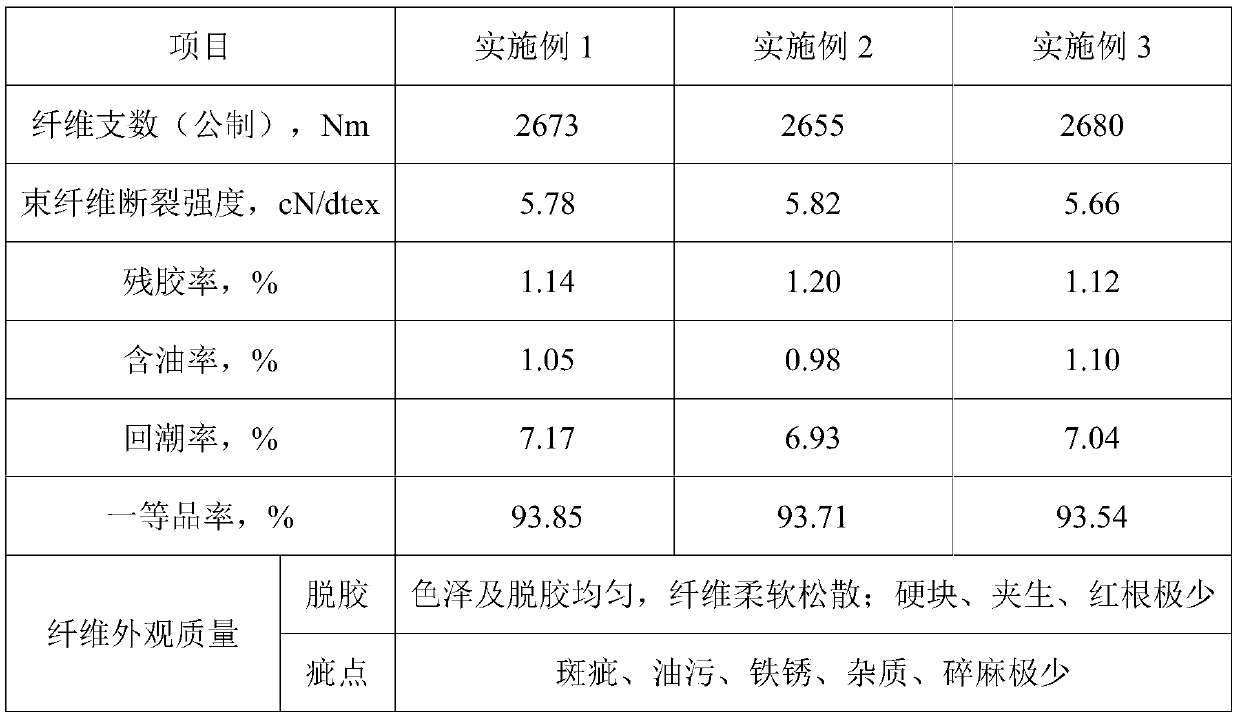

Preparation method of ramie fibers for high-count textile fabric

InactiveCN110453294ALess residual glueHigh degumming rateFibre treatment to obtain bast fibreChemistrySodium silicate

The invention relates to a preparation method of ramie fibers for a high-count textile fabric. The preparation method comprises the steps of 1) preimpregnation, wherein raw ramie is immersed in a presoak containing sodium hydroxide for preimpregnation, taken out and dehydrated to obtain a preimpregnated material; 2) steam explosion, wherein the obtained preimpregnated material is subjected to steam explosion to obtain a steam explosion material; 3) boiling off, wherein the obtained steam explosion material is placed in a degumming solution for heat preservation and boiling off to obtain a boiling-off material; the degumming solution comprises water and the following components of sodium hydroxide, sodium sulfite, sodium metasilicate, sodium tripolyphosphate and sodium dodecyl benzene sulfonate; 4) ultrasonic ramie washing, wherein the obtained boiling-off material is placed in water for ultrasonic immersion washing to obtain a water washing material; 5) aftertreatment. The residual gumratio of the obtained ramie fibers reaches 1.2% or below, residual gum is less, and the degumming rate is high; the fiber count is high and reaches 2655 Nm or above, and fibrils of the high-count rawramie are fully released; the loss of strength is less; the first-grade product rate reaches 93.54% or above, the quality is high, and the ramie fibers are fluffy and soft, and suitable for producingthe high-count light ramie textile fabric.

Owner:北京知淘科技有限责任公司

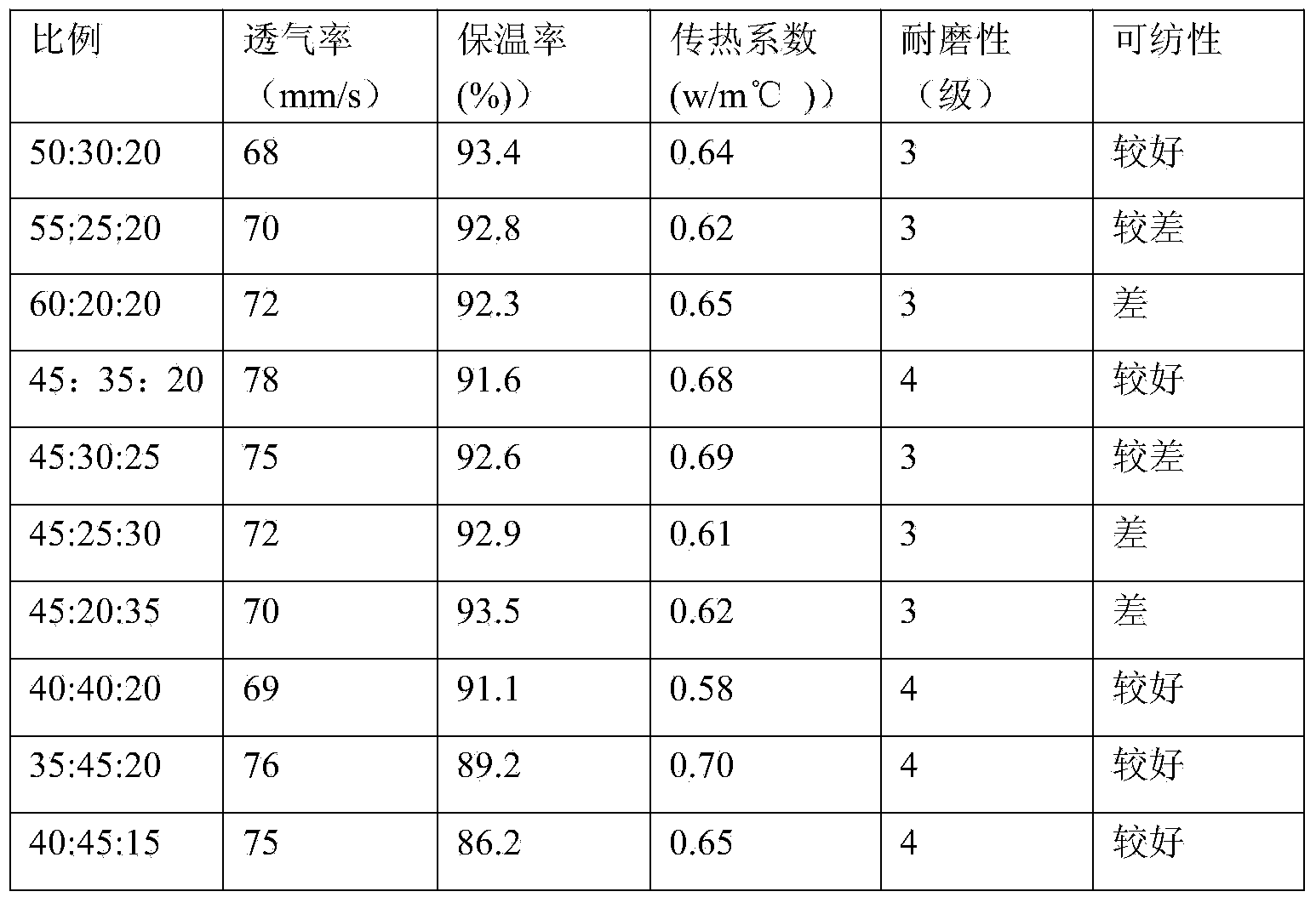

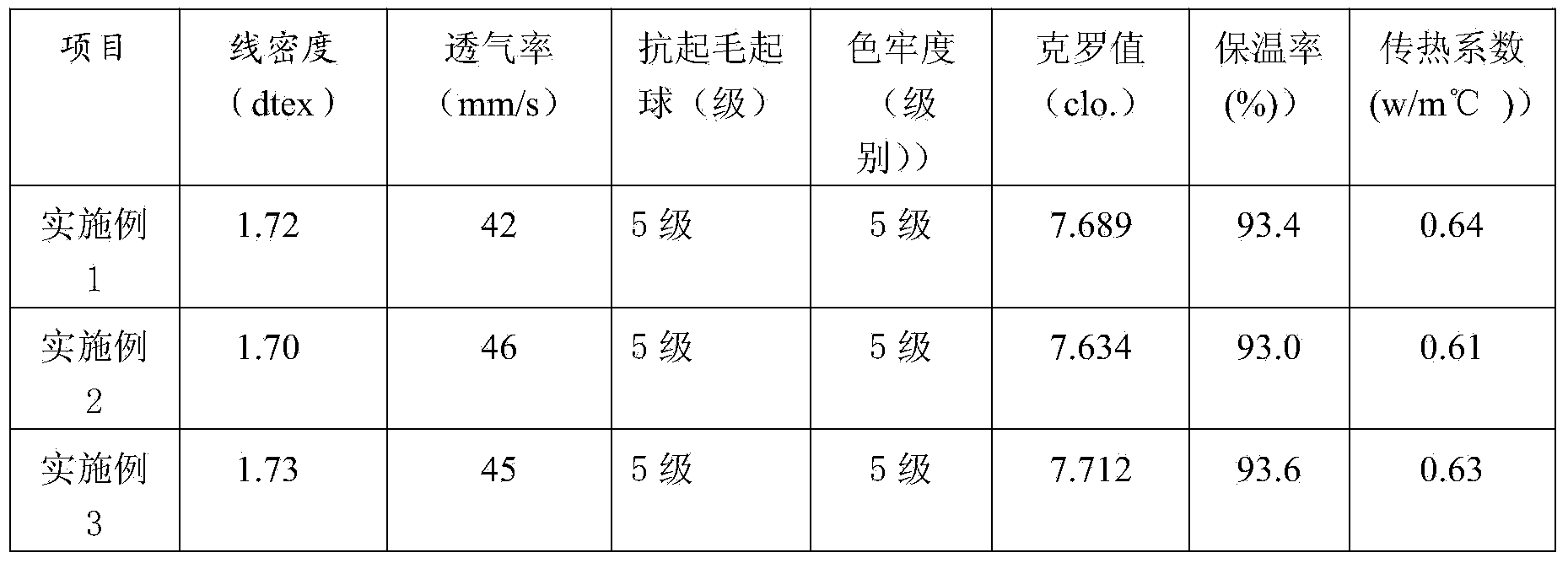

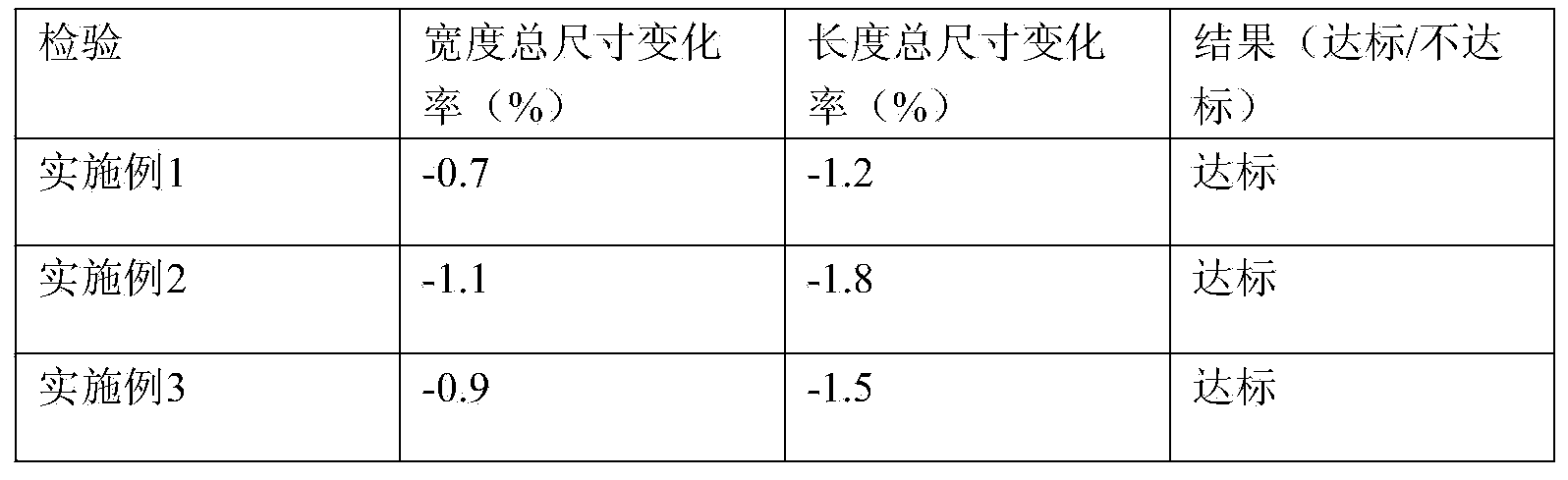

Warmth knitted fabric and preparation method thereof

InactiveCN104385752ANatural drape feels goodGood breathability and water absorptionLayered productsClothingsYarnAdditive ingredient

Owner:HUZHOU NEW ZHONGHU KNITTED CLOTHING MAKING

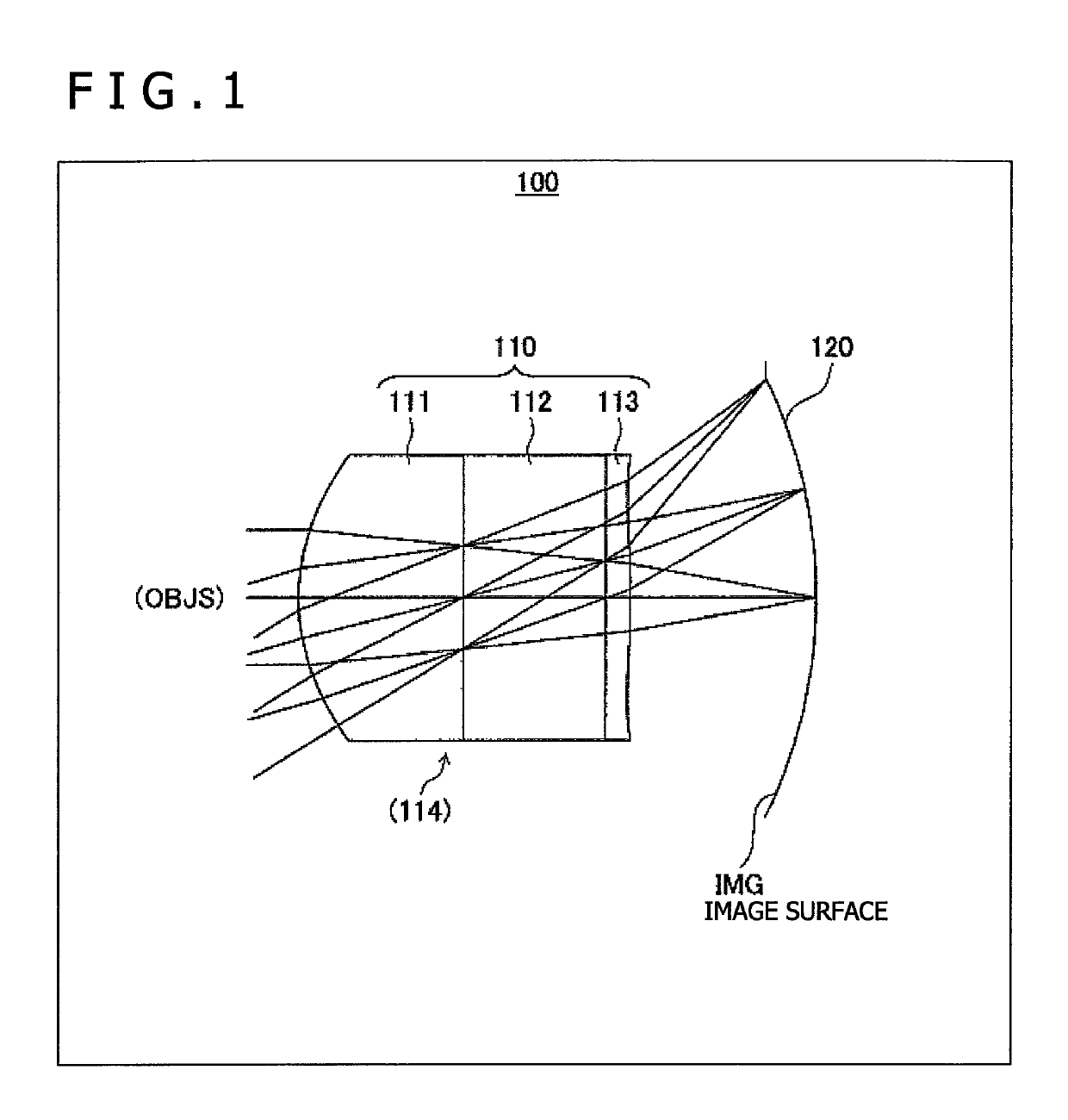

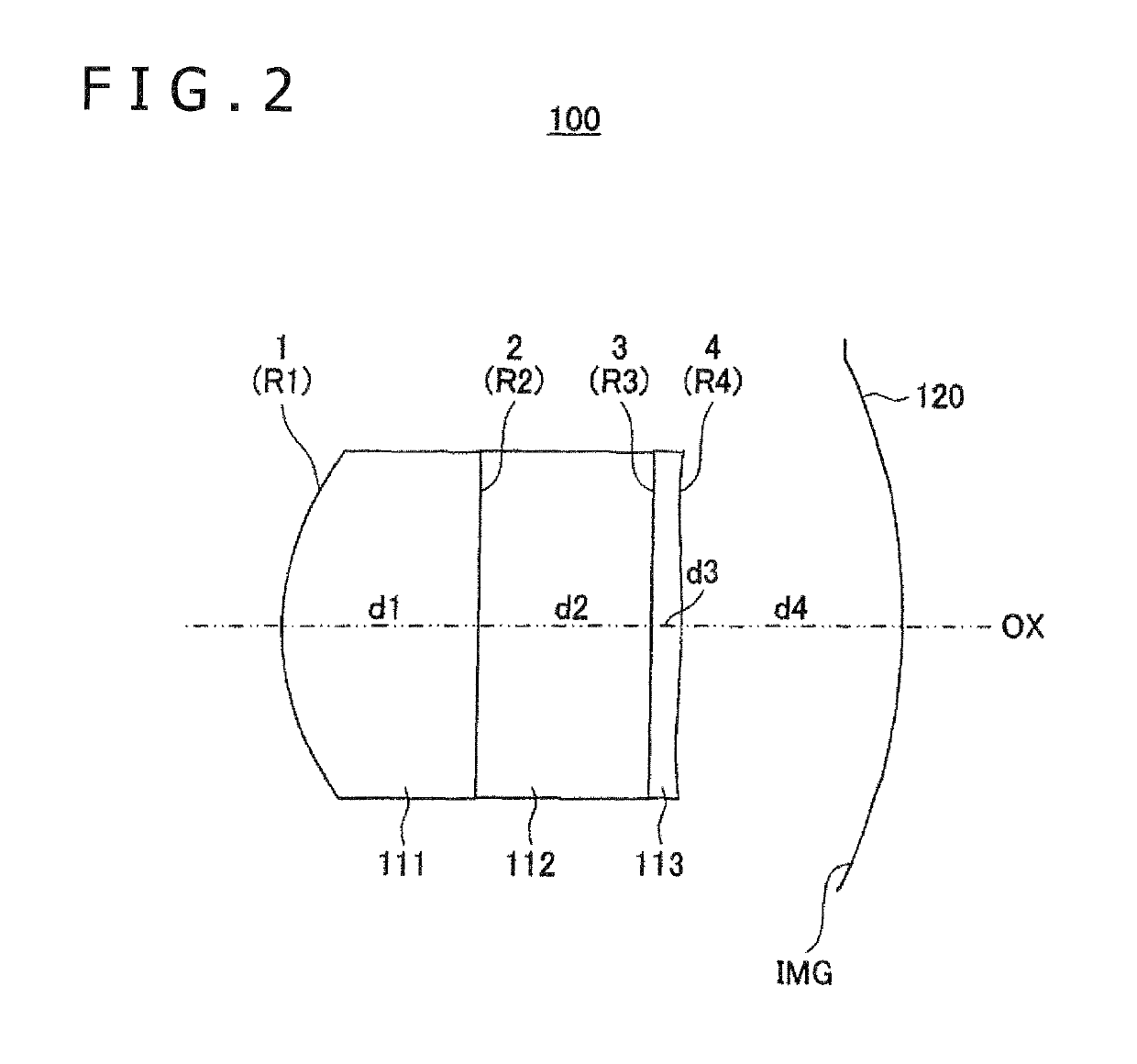

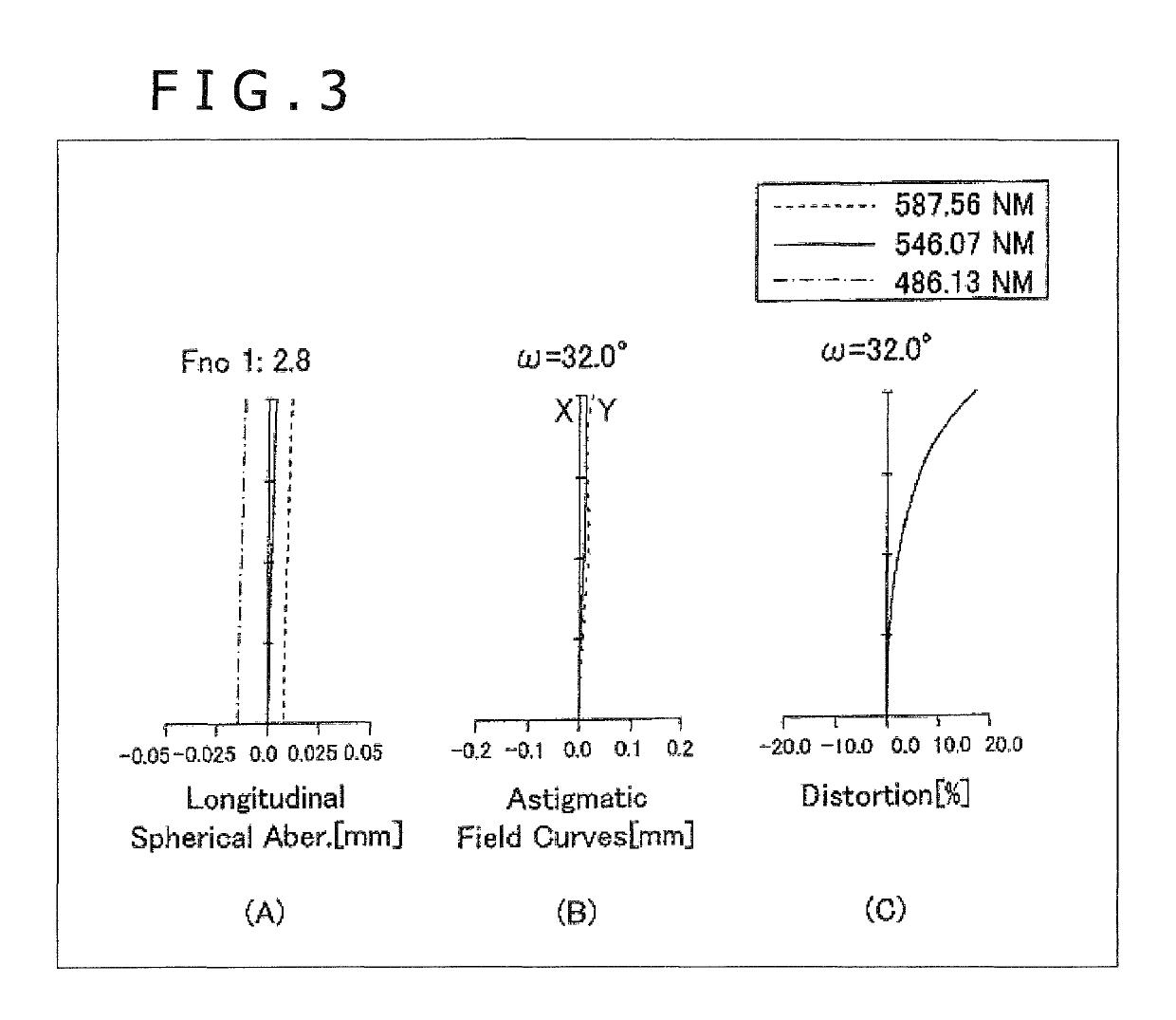

Imaging device and electronic apparatus

InactiveUS10330888B2Raise countSmall sizeTelevision system detailsColor television detailsSignal processing circuitsElectron

An electronic apparatus includes an imaging device and a signal processing circuit for performing signal processing on an output signal of the imaging device. The imaging device includes one group of lenses, and an imaging element on which an image is formed through the lenses, and the lenses include a first lens having an object side surface in a convex shape projecting to an object side, a transparent body, and a second lens, the first lens, the transparent body, and the second lens being arranged in order from the object side to an image surface side without an air being interposed between the first lens, the transparent body, and the second lens, and the imaging element is curved so as to have a concave surface facing the object side.

Owner:SONY CORP

Processing method of cotton and copper alginate blended yarn

The invention relates to a processing method of cotton and copper alginate blended yarn and belongs to the technical field of yarn manufacturing processes. Copper alginate fiber and cotton are pretreated respectively, and after the copper alginate fiber and the cotton are mixed evenly, mixed fiber is sequentially subjected to opening picking, carding, combing, drawing, roving and spinning, wherein the opening picking process comprises the steps that the mixed fiber sequentially passes through a bale plucker, a mixing opener, a roller card wire opener, a vibration cotton feeding box and a single beater scutcher to be treated, the roller card wire opener and all beater screens of the single beater scutcher are sealed; a half holding and beating gauge is adopted, and in the carding process, controllable half-hold licker-in opening is adopted; needle teeth small in working angle and low in density are adopted in carding machine card clothing. When applied to processing of the copper alginate fiber and cotton mixed yarn, the method has the advantages that the mixed yarn is less in hairiness, high in strength, less in nep, good in yarn levelness and the like.

Owner:浙江吉麻良丝新材料股份有限公司 +2

Production method for ultra fine soft wool yern

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

Motor Winding

InactiveUS20080129137A1Raise countIncrease surface areaDynamo-electric brakes/clutchesMotor/generator/converter stoppersStator coilEngineering

The present invention is an electrical rotating apparatus comprising stator coils wound around the inside and outside of the stator. In a further embodiment, the machine contains a high number of phases, greater than three. In a further embodiment, the phases are connected in a mesh connection. In a further embodiment, each half-phase is independently driven to enable second harmonic drive for an impedance effect. Improvements are apparent in efficiency and packing density.

Owner:BOREALIS TECH LTD

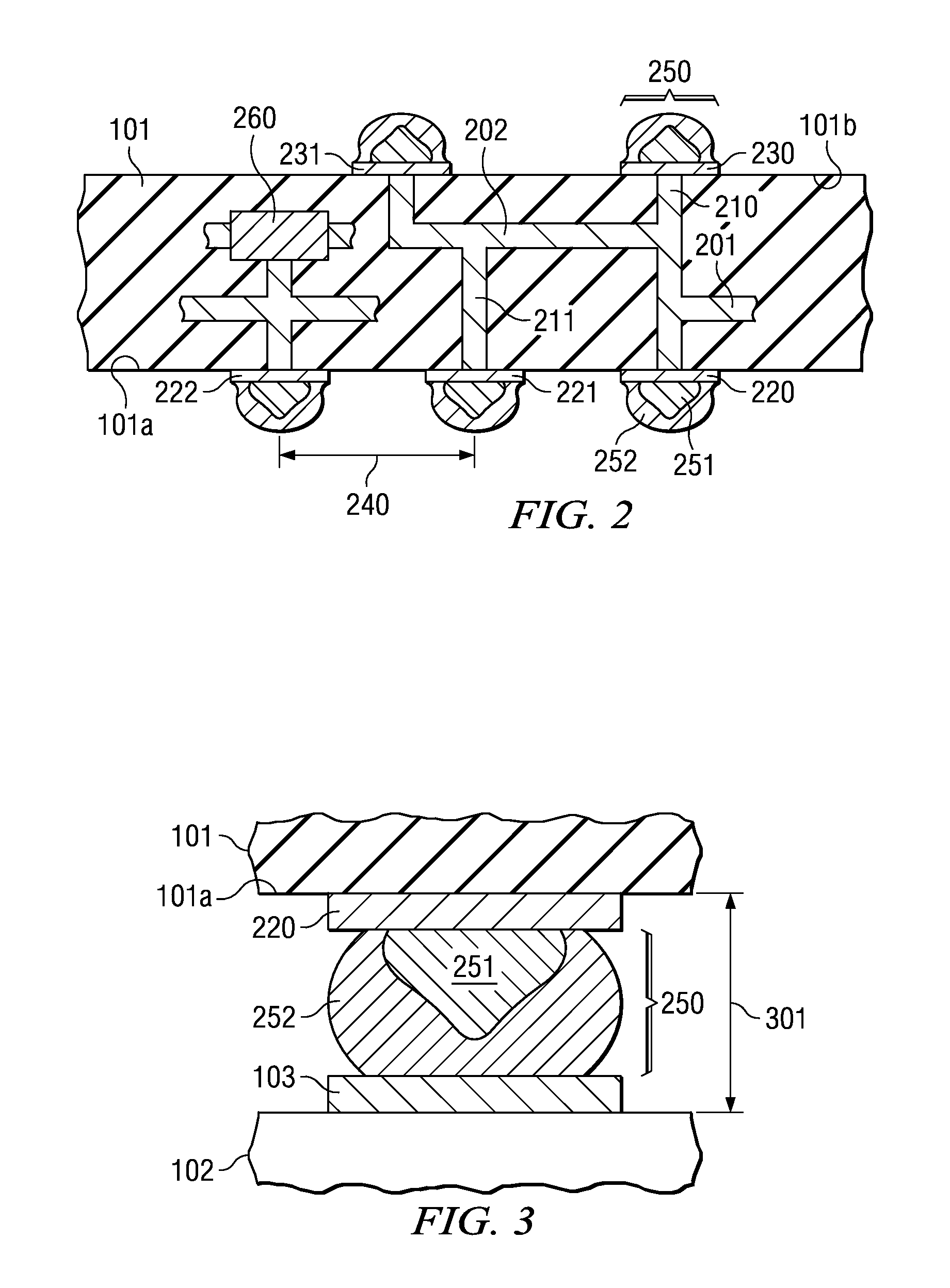

Gold-bumped interposer for vertically integrated semiconductor system

InactiveUS20070210426A1High product reliabilityHigh countSemiconductor/solid-state device detailsSolid-state devicesPhysicsContact pad

A semiconductor system (100) enabled by an interposer (101) with non-reflow metal studs (251), preferably gold, coated with reflow metals (252), preferably solder. The studs are on exit ports (220, 230, etc) of the interposer surface; selected exit ports may be spaced apart by less than 125 μm center to center. A first electrical device (102), such as one or more semiconductor chips with contact pads matching the locations of the interposer exit ports, contacts the studs on one interposer surface. A second electrical device (104), such as a semiconductor chip, a passive component, or both, is attached to the other interposer surface. A carrier (106) supports the first device and provides electrical connections (109) to external parts.

Owner:TEXAS INSTR INC

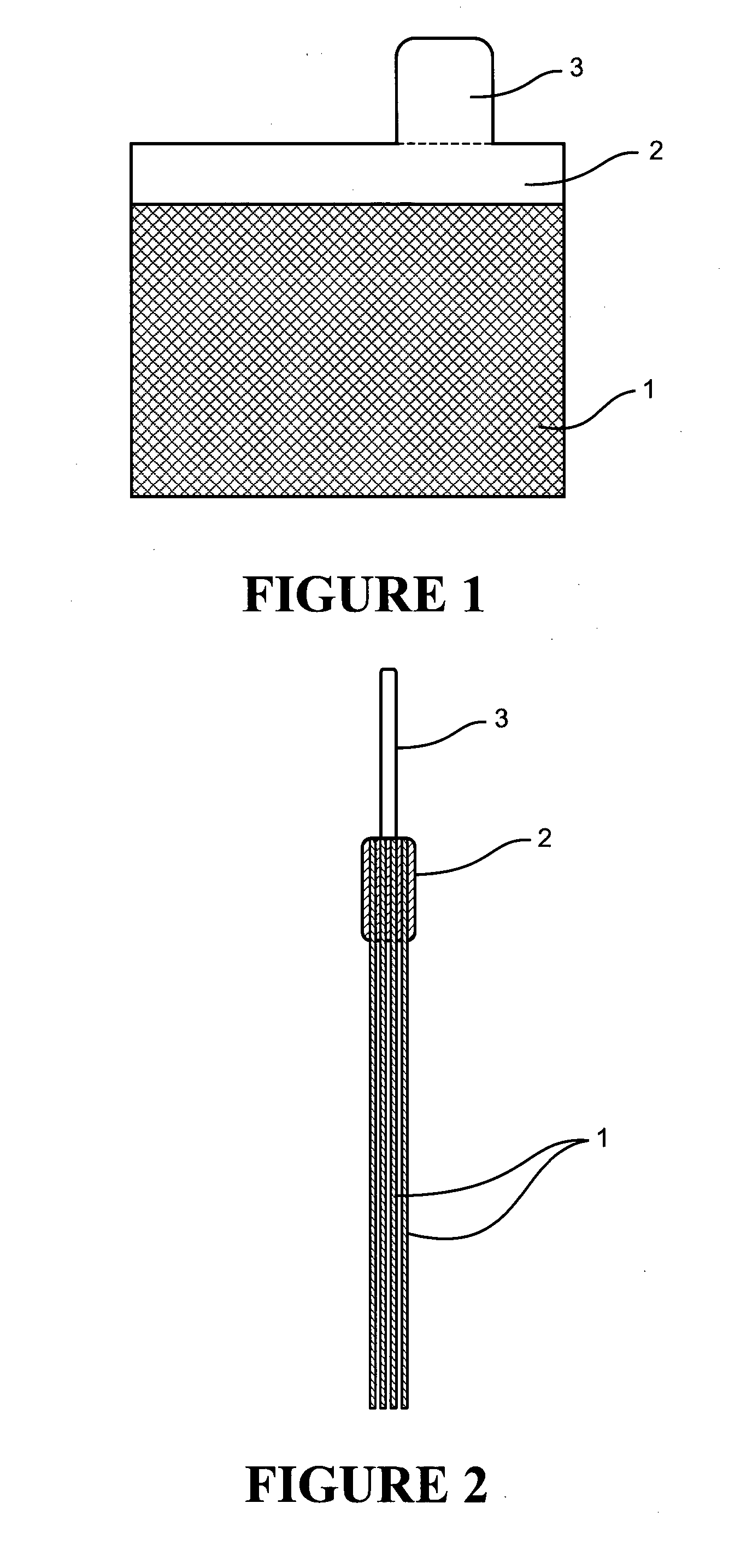

Method for Forming an Electrical Connection to a Conductive Fibre Electrode and Electrode So Formed

ActiveUS20150255783A1High countReduce porosityFinal product manufactureElectrode carriers/collectorsElectrically conductiveExternal connection

A method for forming an electrical connection to a microscale electrically conductive fibre material electrode element, such as a carbon fibre electrode element of a Pb-acid battery, comprises pressure impregnating into the fibre material an electrically conductive lug material, such as molten Pb metal, to surround and / or penetrate fibres and form an electrical connection to the fibre material and provide a lug for external connection of the electrode element. Other methods of forming a lug for external connection are also disclosed.

Owner:ARCACTIVE LTD

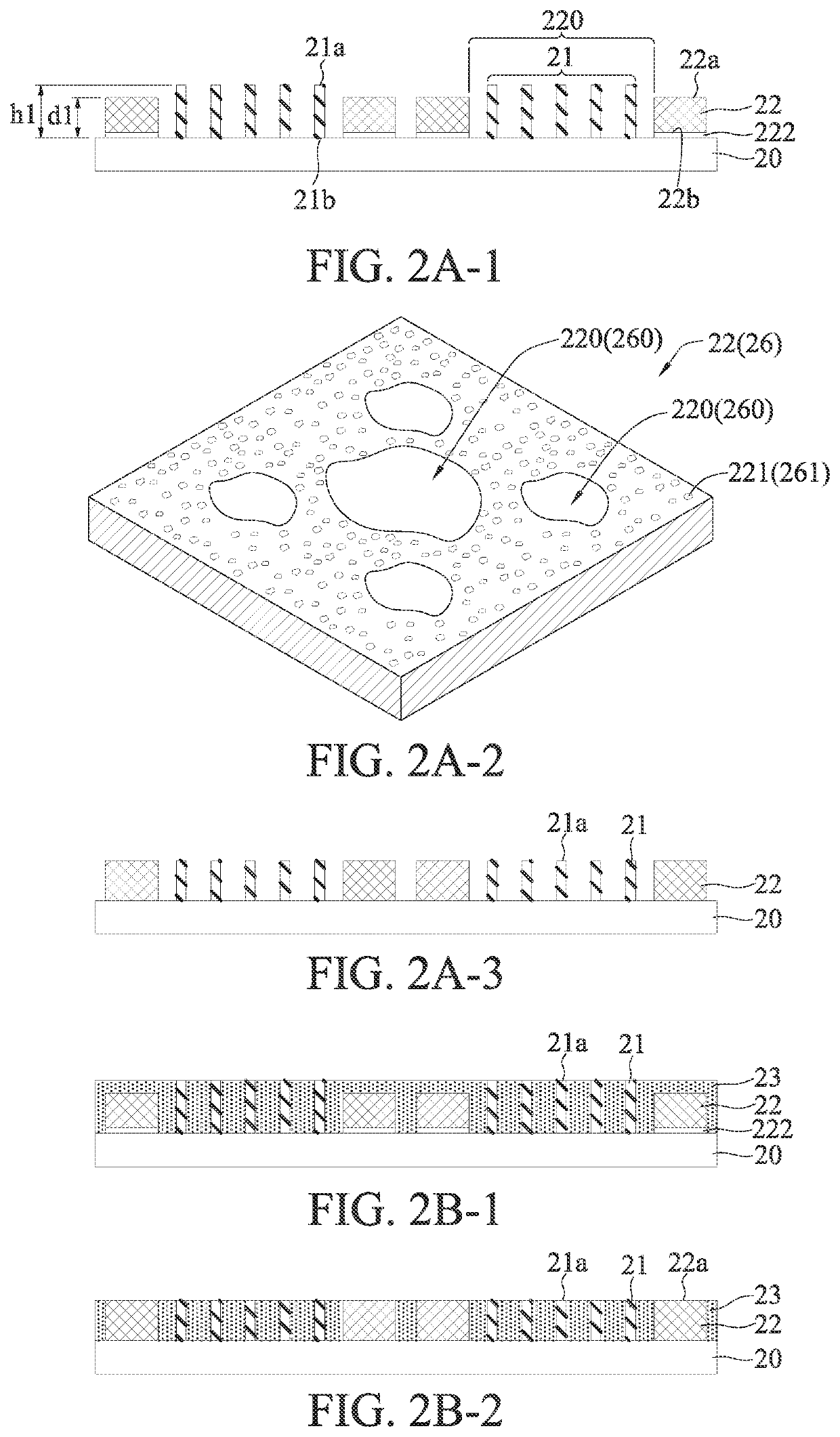

Intermediate substrate and fabrication method thereof

ActiveUS20220285257A1Improve reliabilityHigh countSemiconductor/solid-state device detailsPrinted circuits stress/warp reductionHemt circuitsEngineering physics

An intermediate substrate is provided with a plurality of conductive posts and support members arranged at opposite sides of a coreless circuit structure and insulating layers encapsulating the conductive posts and the support members. Through the arrangement of the support members and the insulating layers, the intermediate substrate can meet the rigidity requirement so as to effectively resist warping and achieve an application of fine-pitch circuits.

Owner:PHOENIX PIONEER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com