System for automatic monitoring clogging of metallurgy high furnace coal fines lance

An automatic monitoring system and pulverized coal technology, which is applied in the general control system, control/regulation system, blast furnace, etc., can solve the problems of peeping device, peeping device blockage, difficult application, cable and detector damage, etc., to improve support Number, improve pertinence, and avoid long-term blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

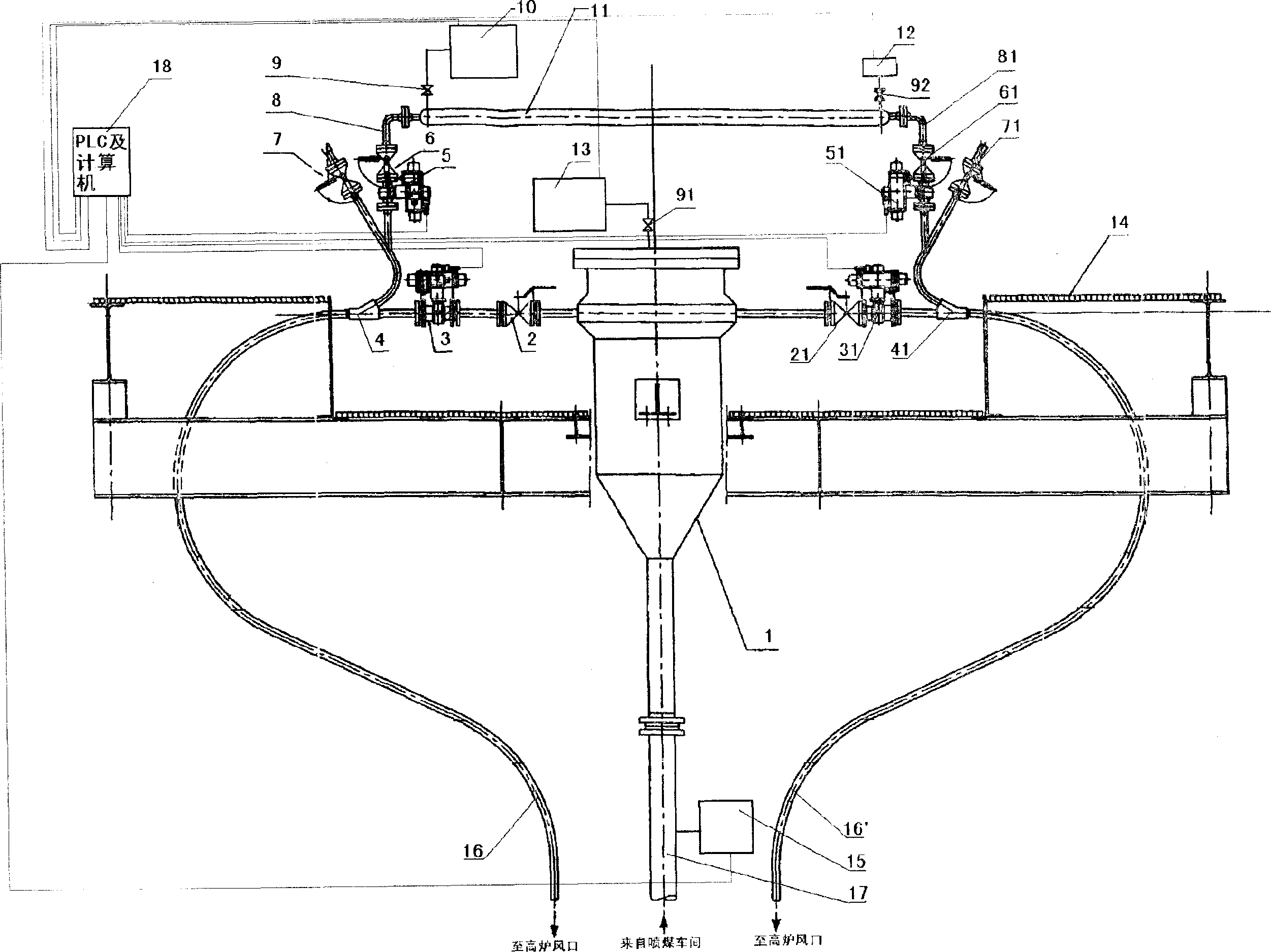

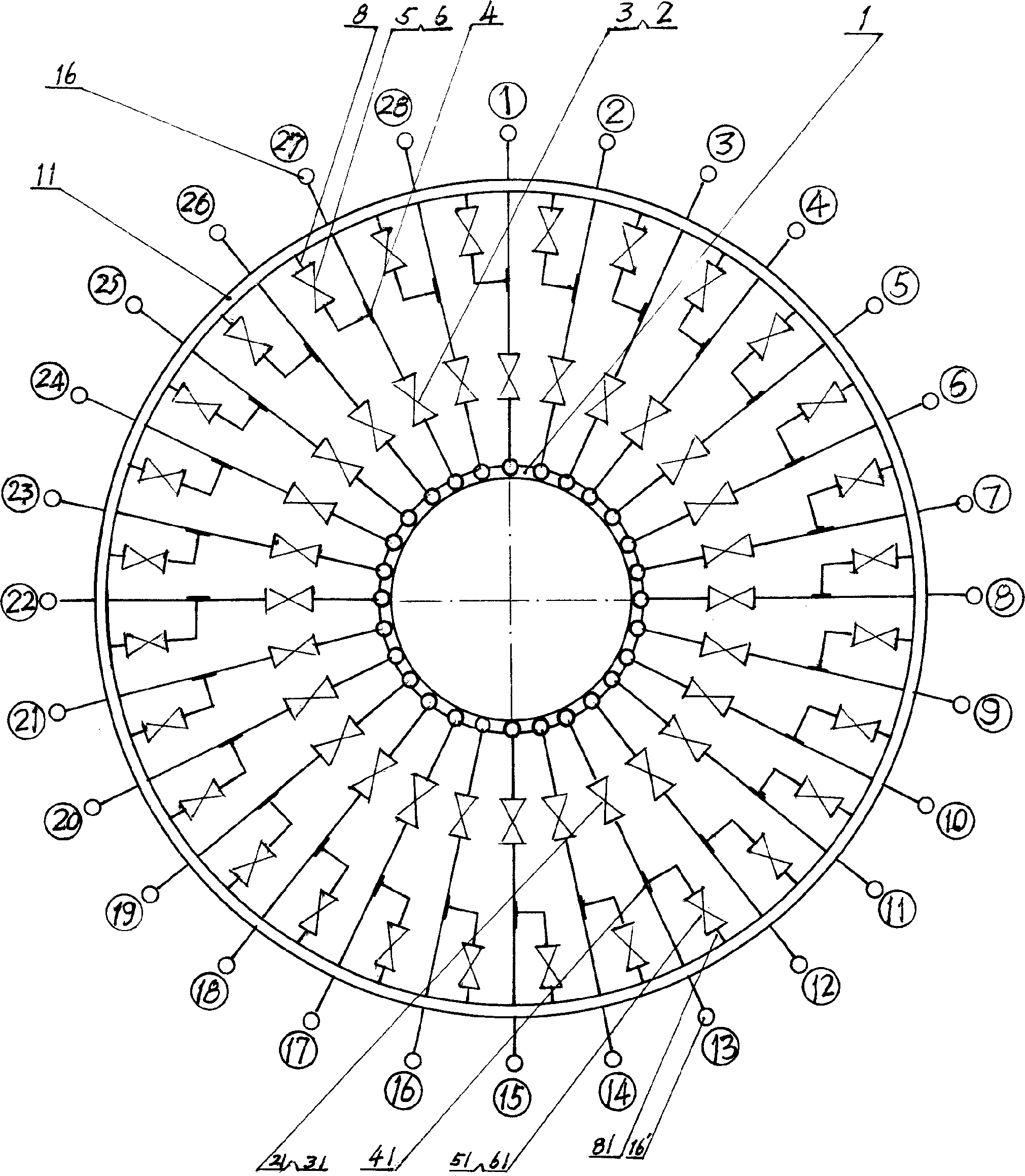

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The metallurgical blast furnace pulverized coal spray gun blockage automatic monitoring system consists of distributor 1, coal injection manual ball valve 2 or 21, coal injection pneumatic ball valve 3 or 31, thick wall tee 4 or 41, purge pneumatic ball valve 5 or 51, purge Manual ball valve 6 or 61, manual drain valve 7 or 71, purge branch pipe 8 or 81, manual ball valve 9 or 91 or 92, purge pressure detection device 10, purge compressed air ring pipe 11, blast pressure controller 12, distribution It is composed of device pressure detection device 13, support 14, surface temperature measuring thermocouple 15, coal injection branch pipe 16 or 16', coal conveying main pipe 17, computer 18 and corresponding connection lines, which include signal lines and control lines. Taking the axis of the distributor 1 as the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com