Patents

Literature

1840 results about "Pressure controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

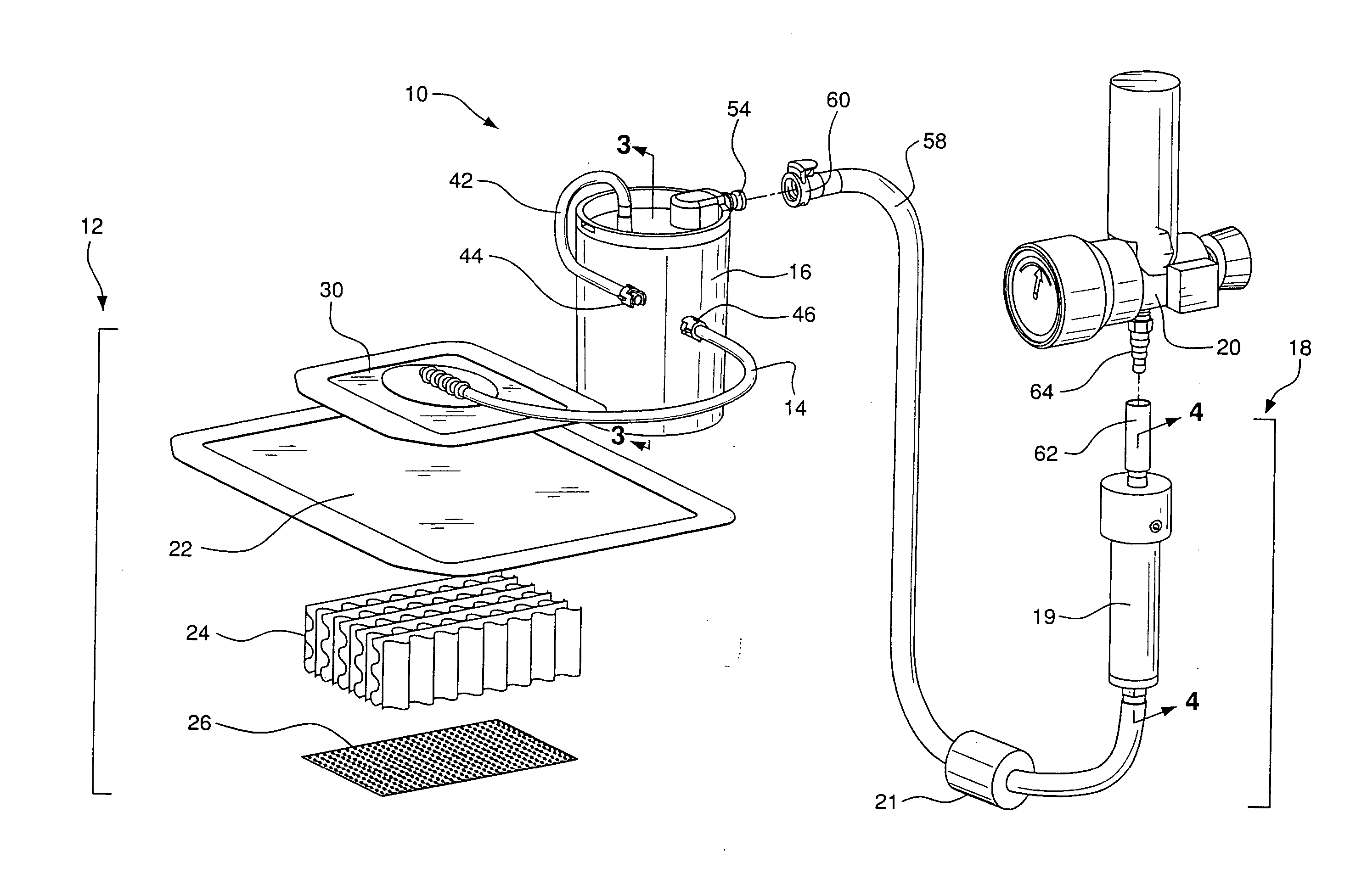

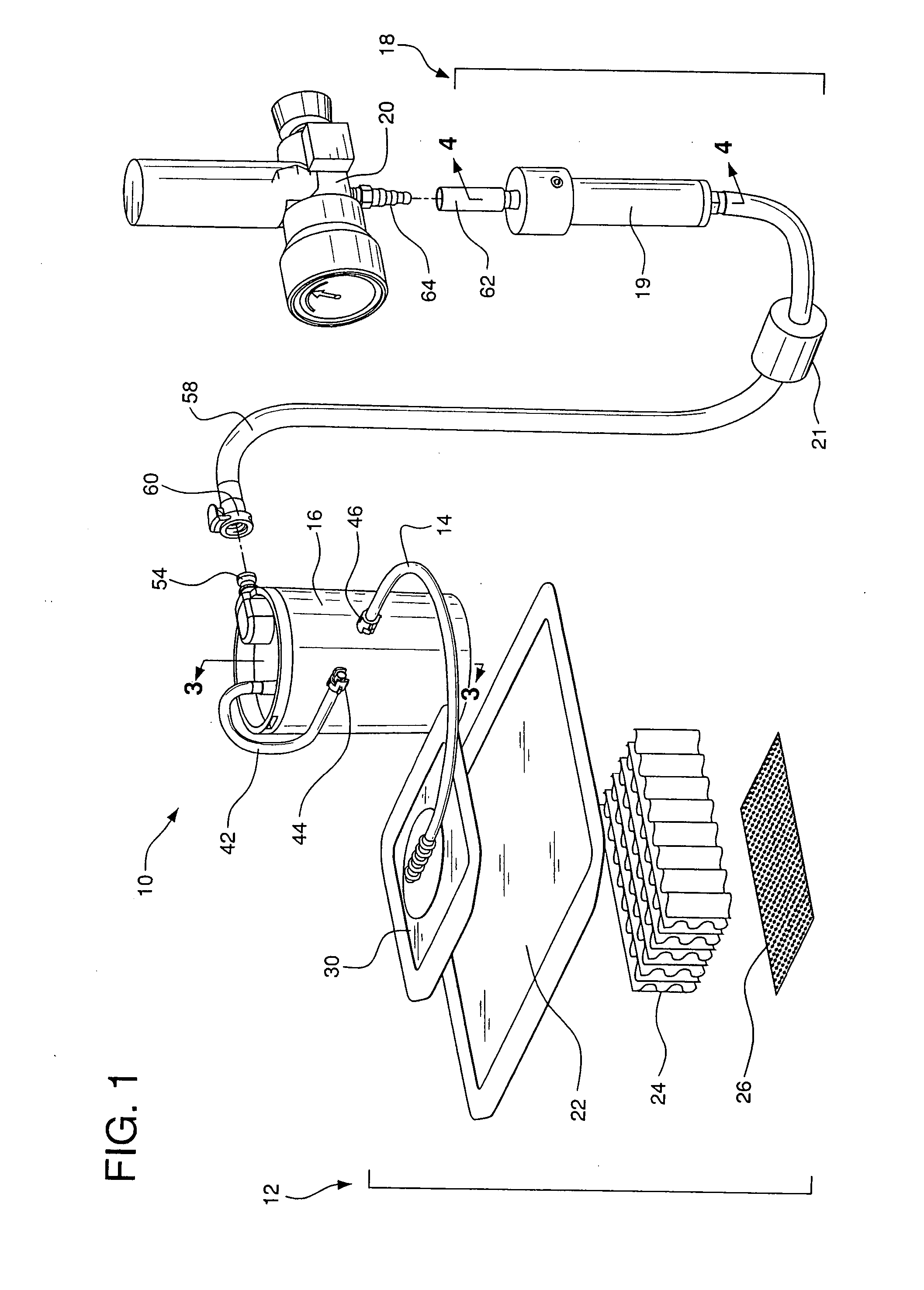

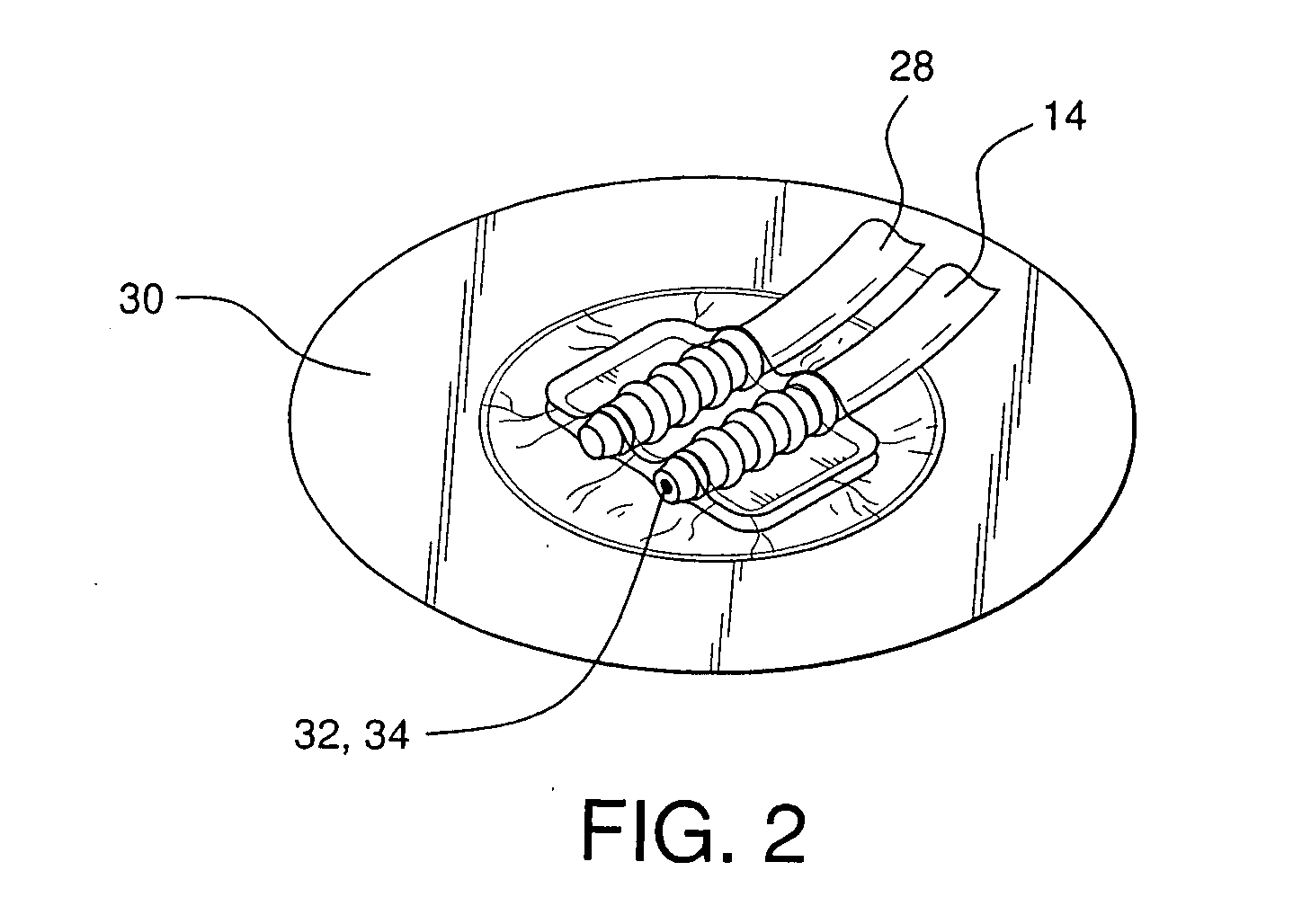

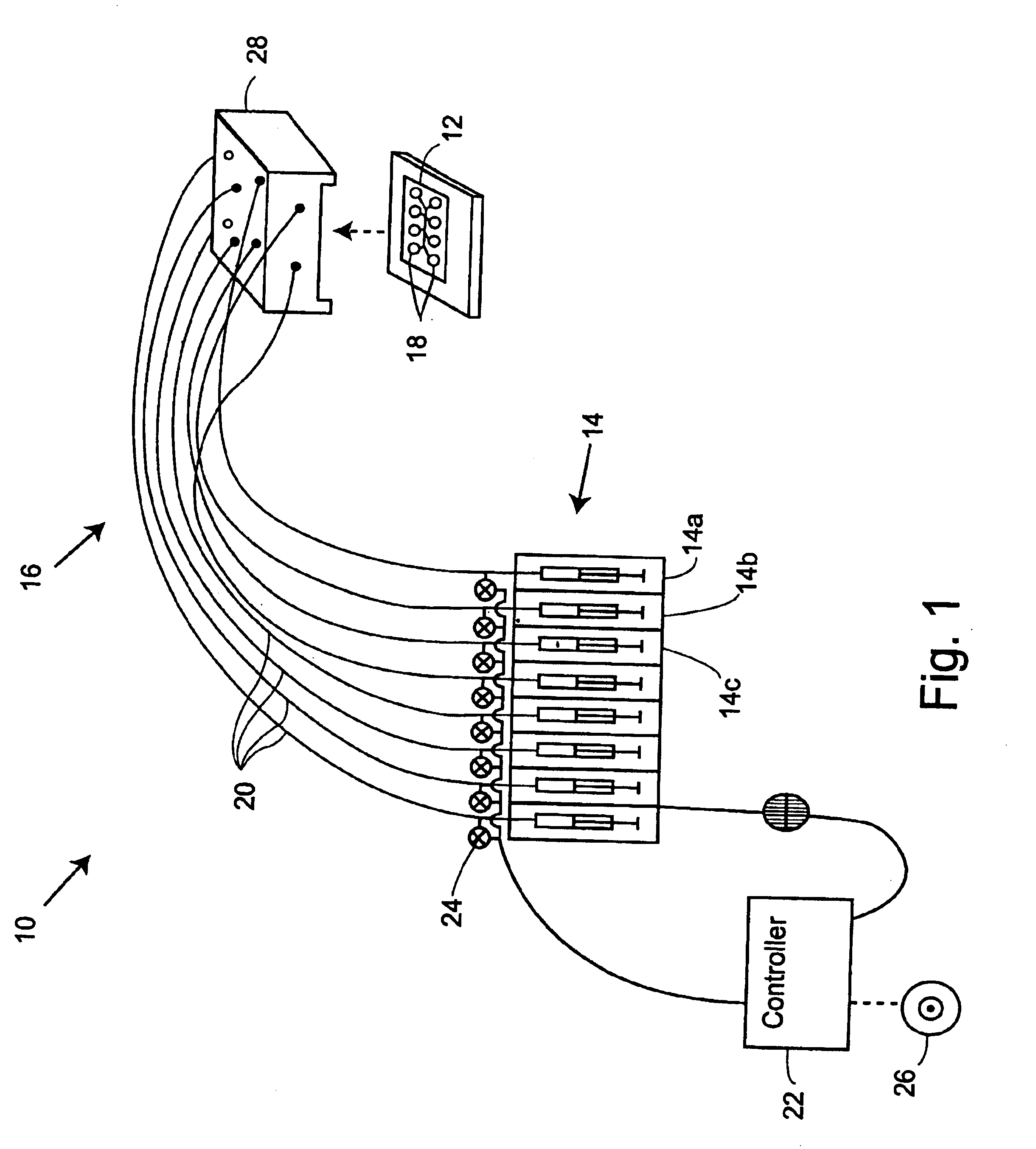

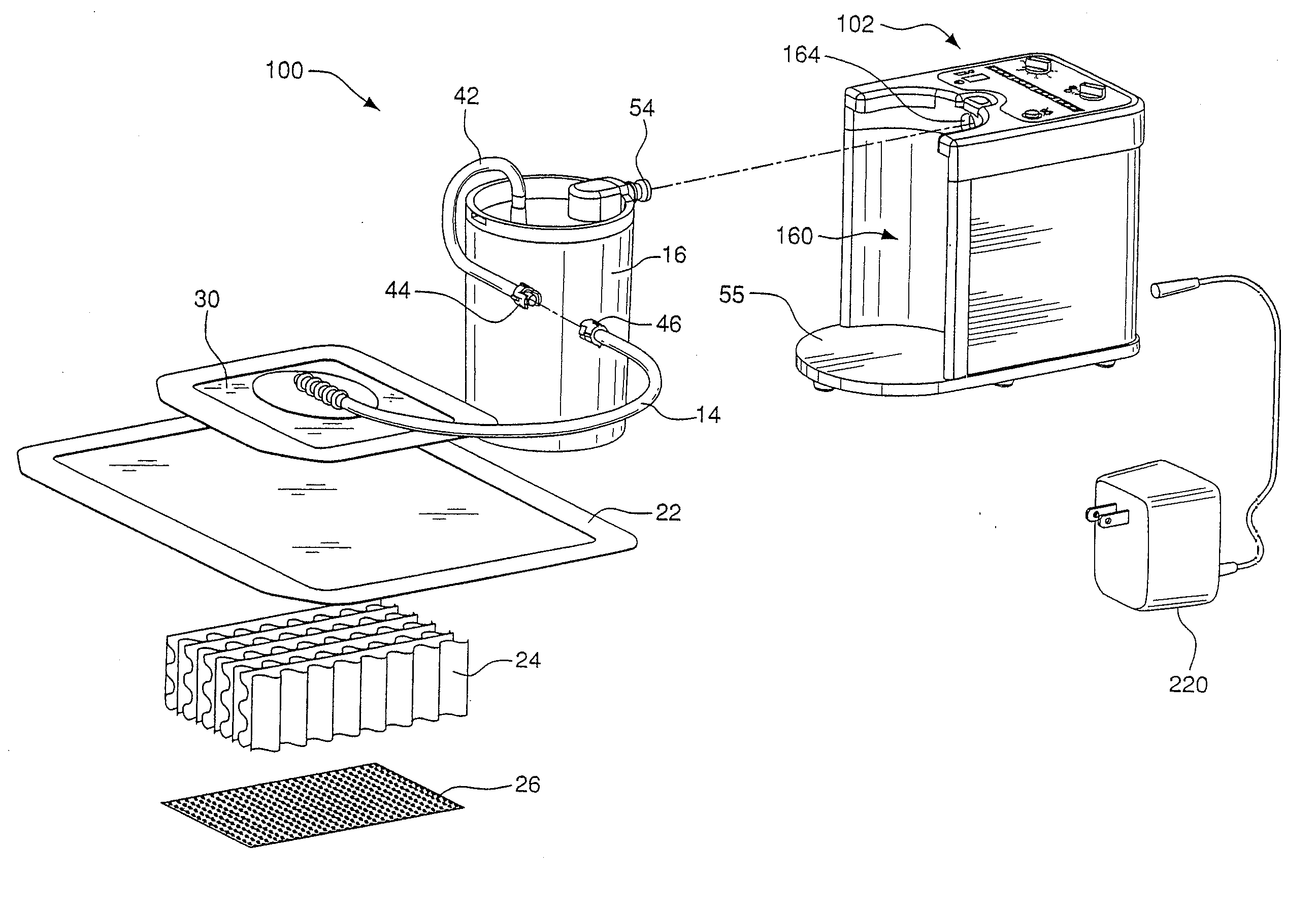

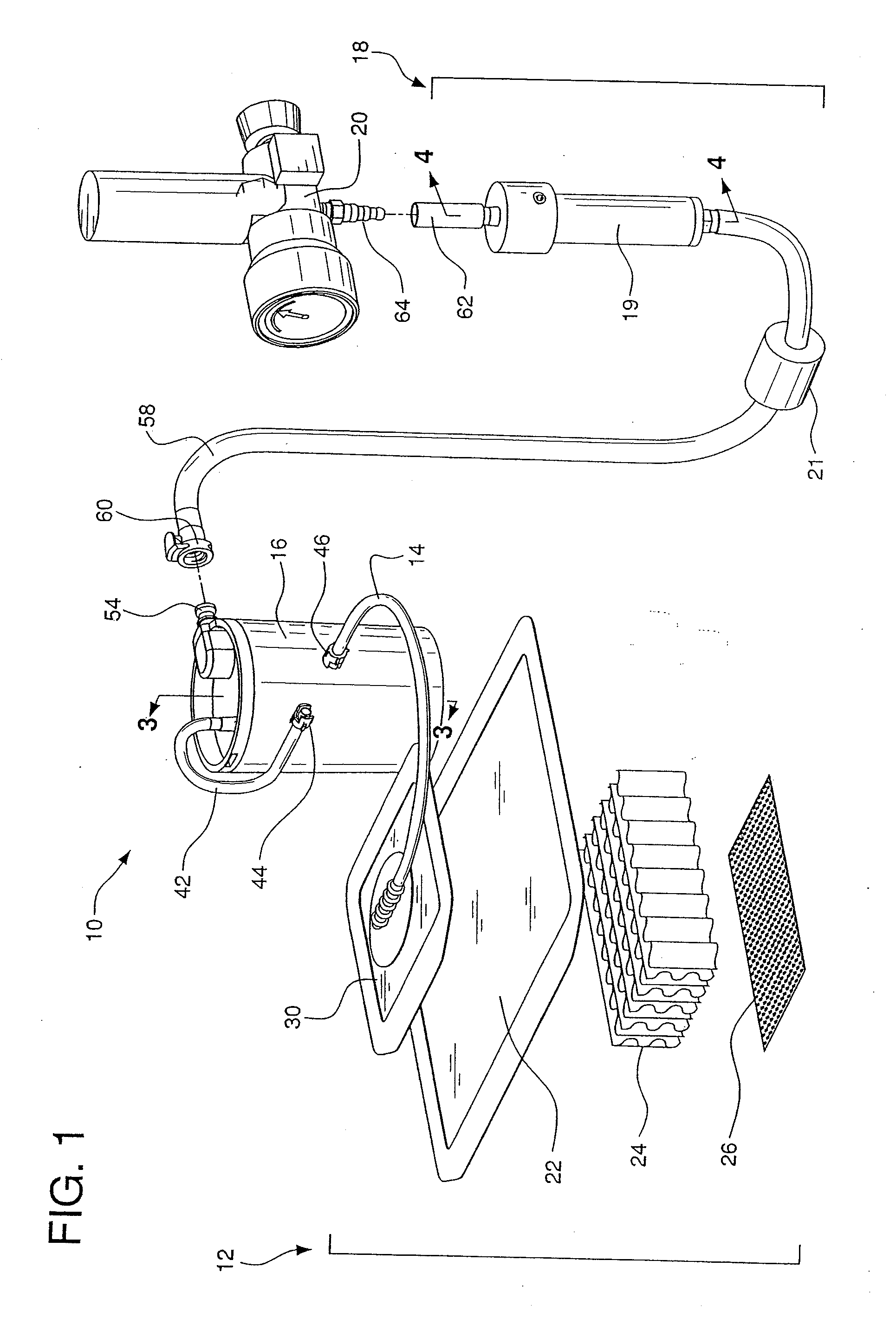

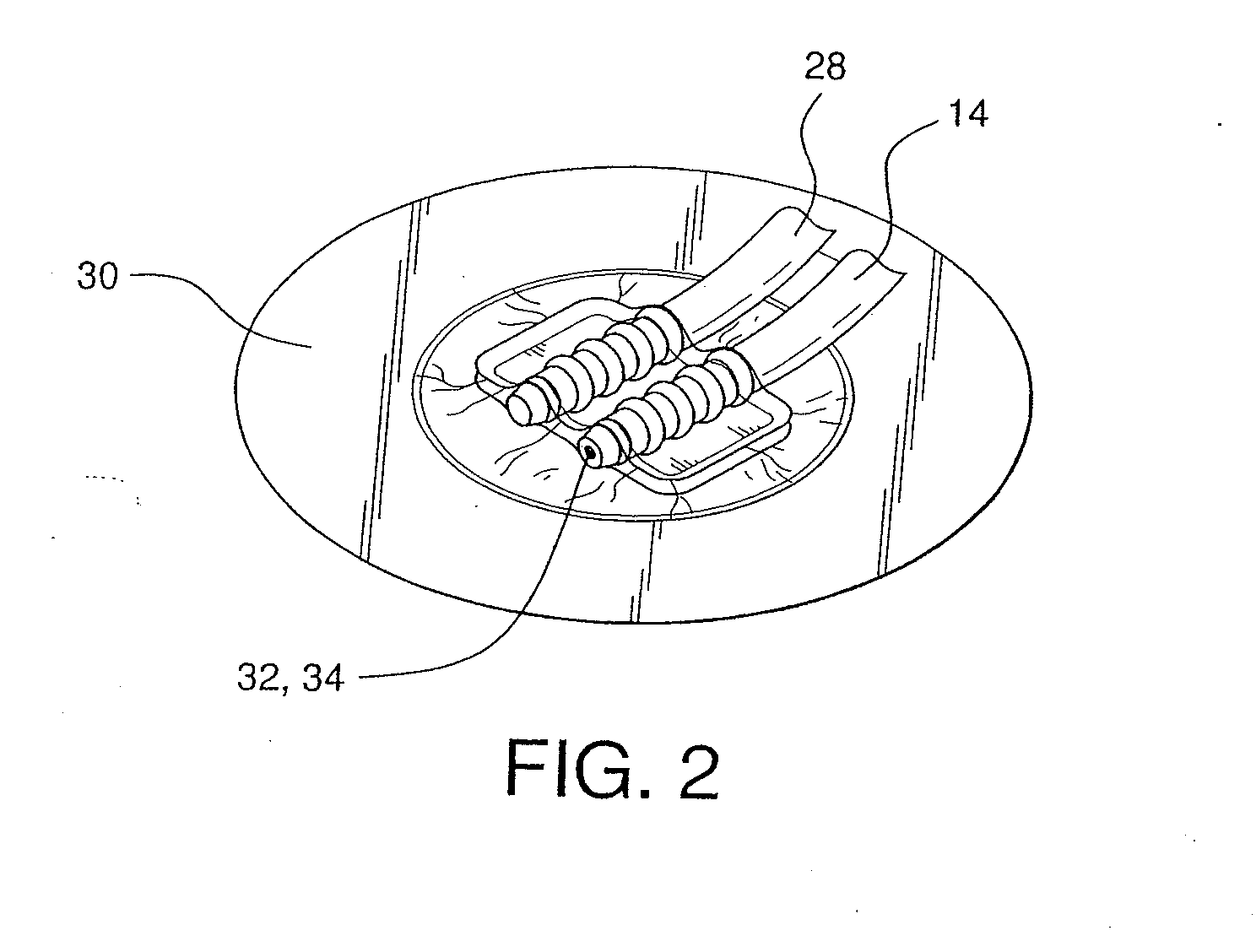

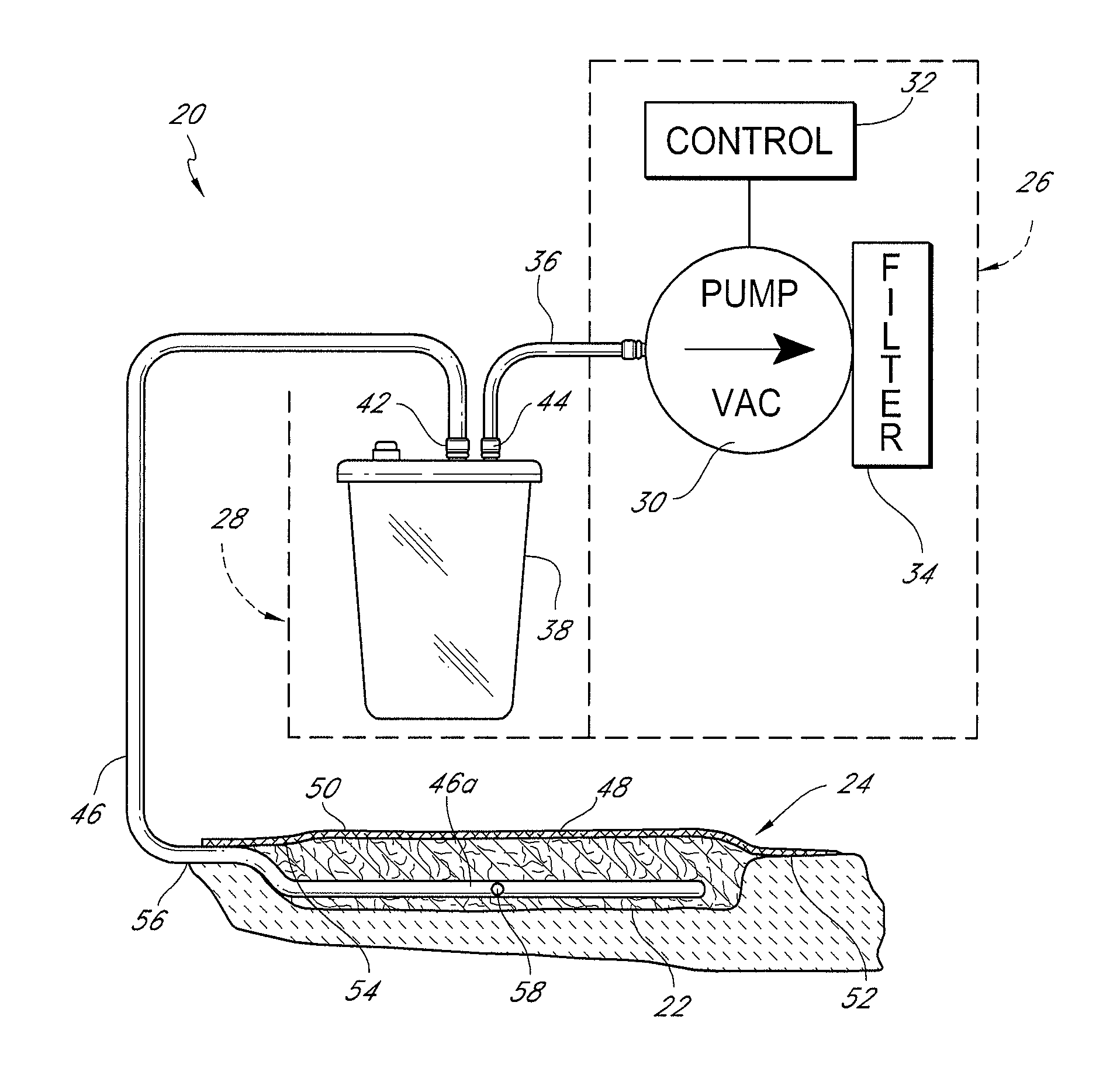

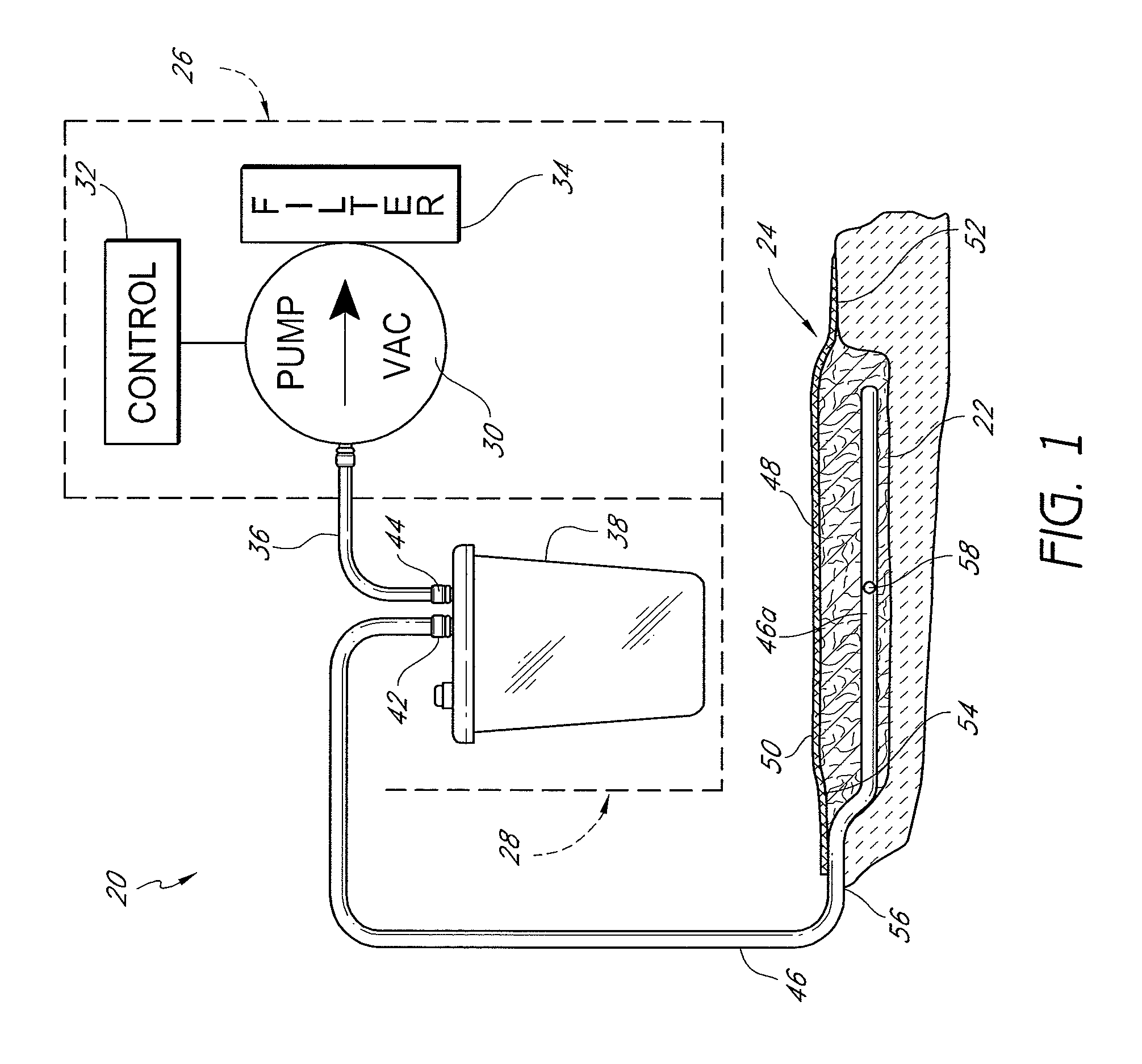

Pump system for negative pressure wound therapy

ActiveUS20070219532A1Reduce the possibilityTrend downWound drainsMedical devicesLevel sensorEngineering

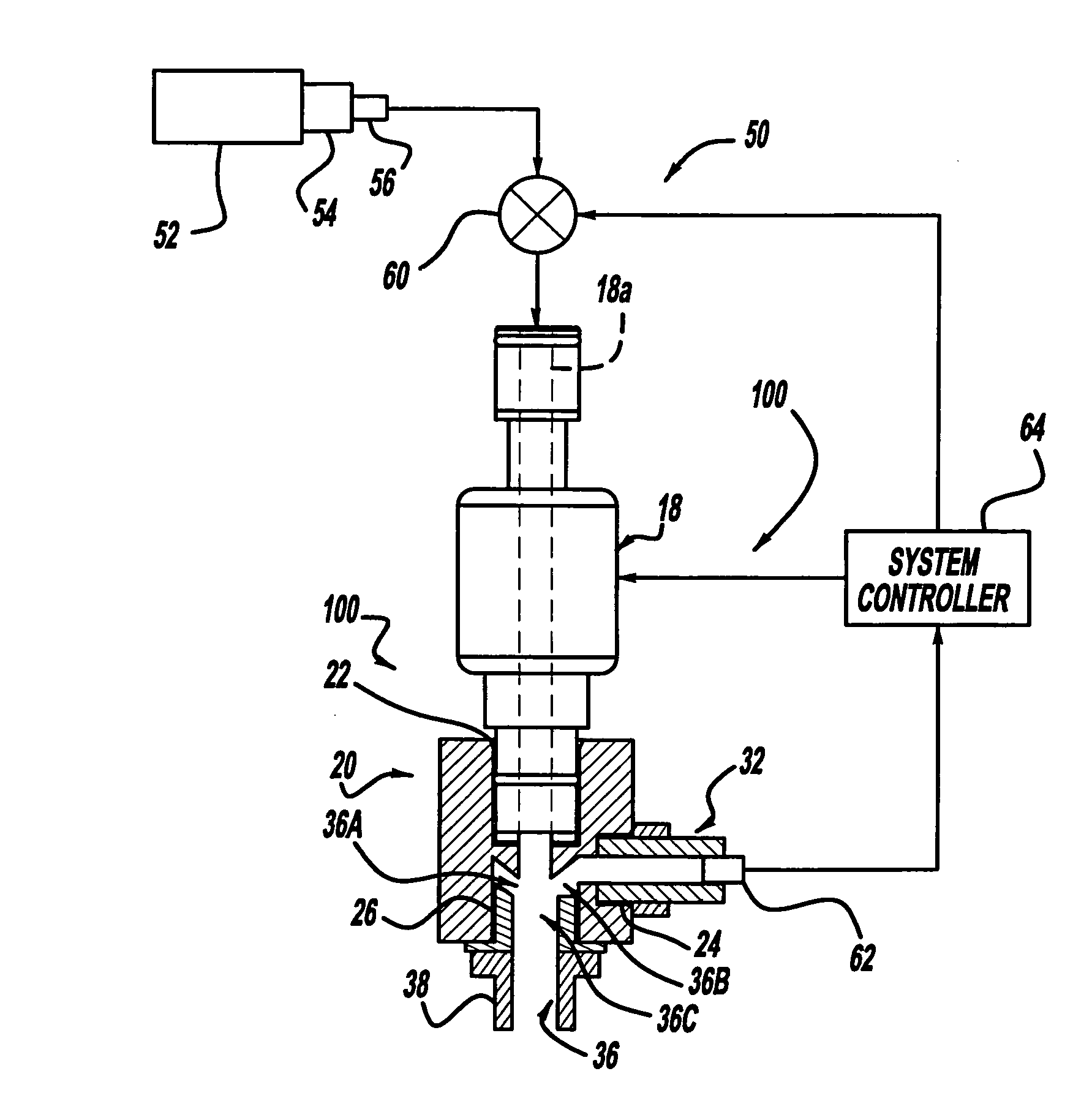

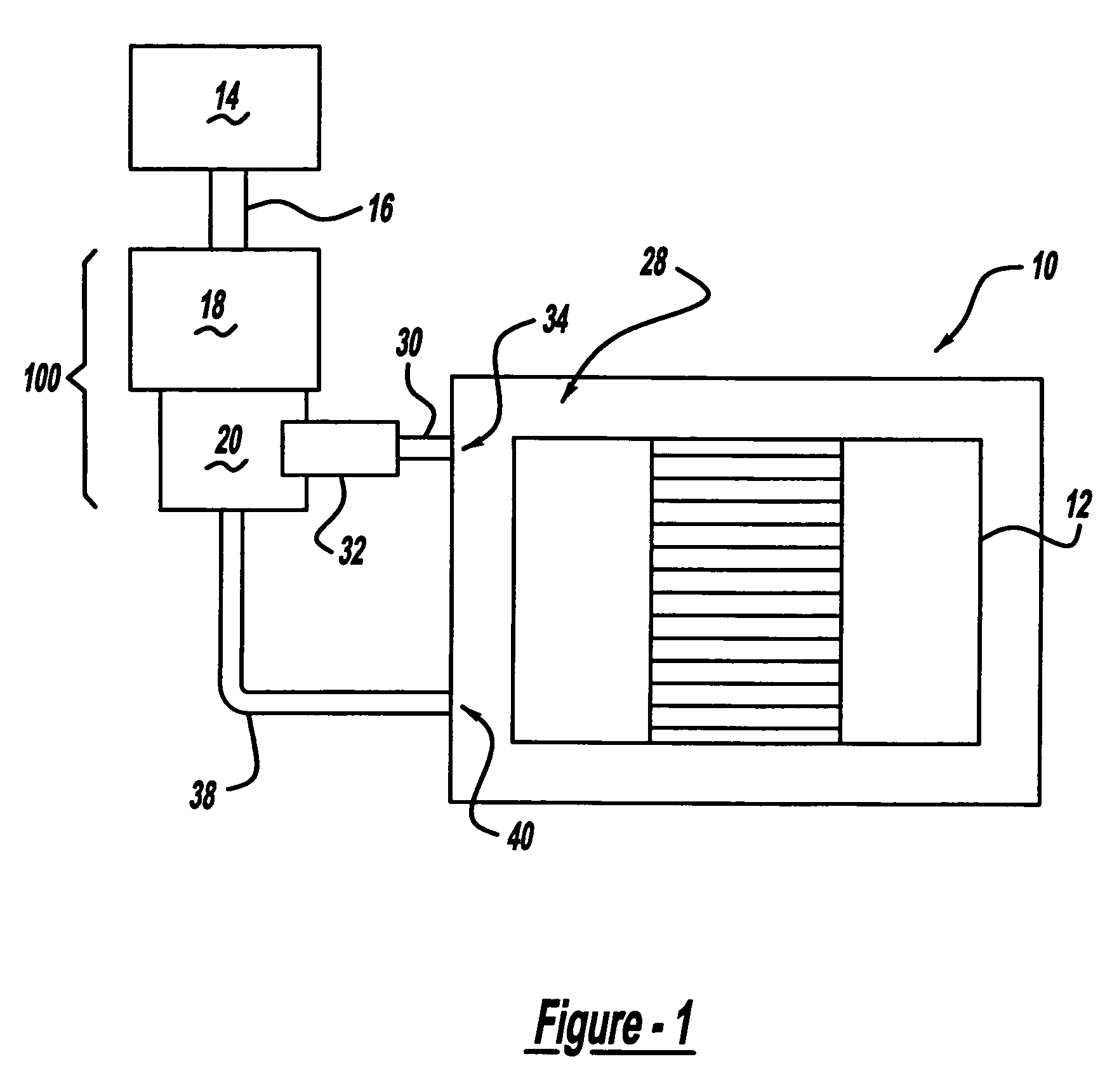

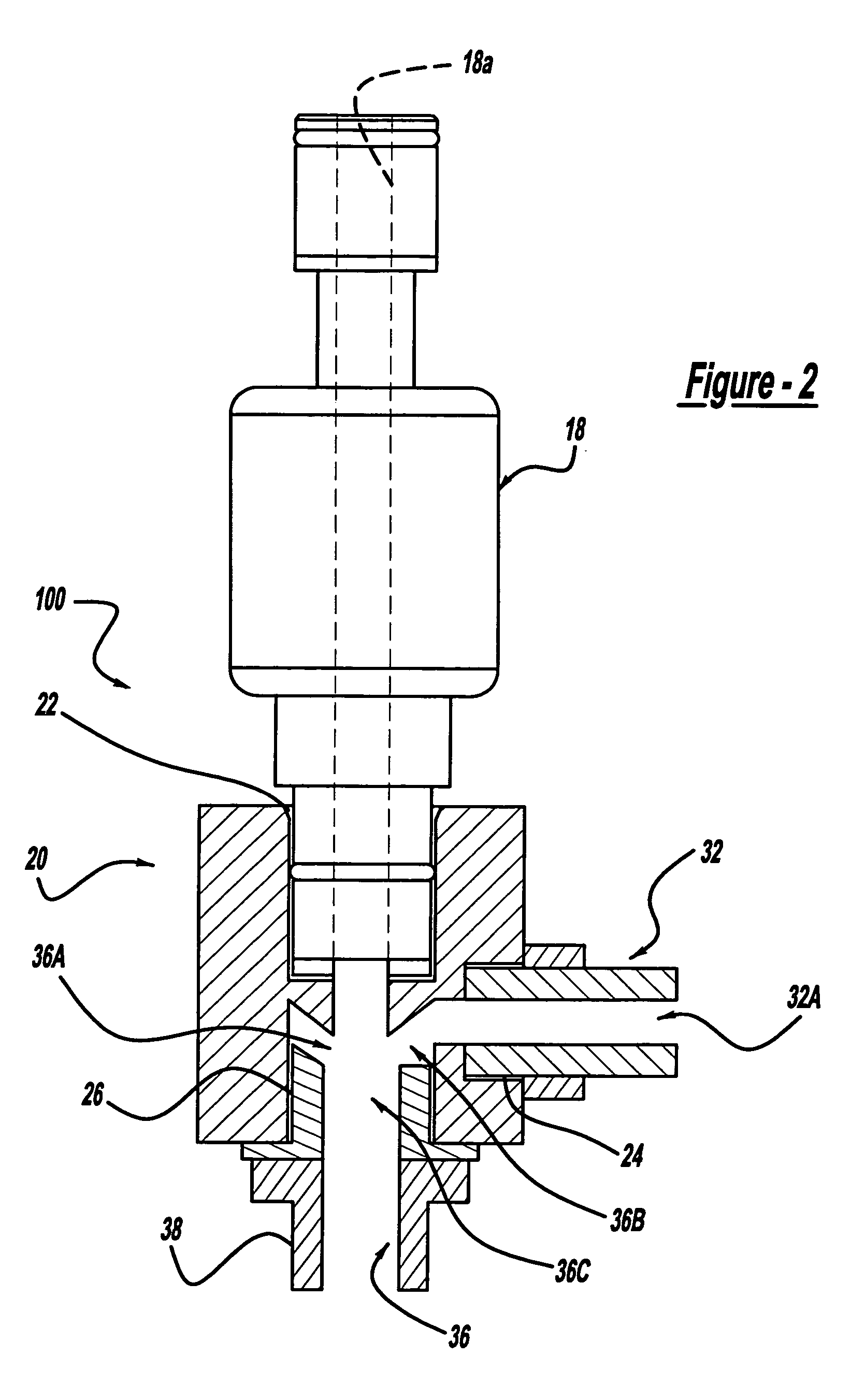

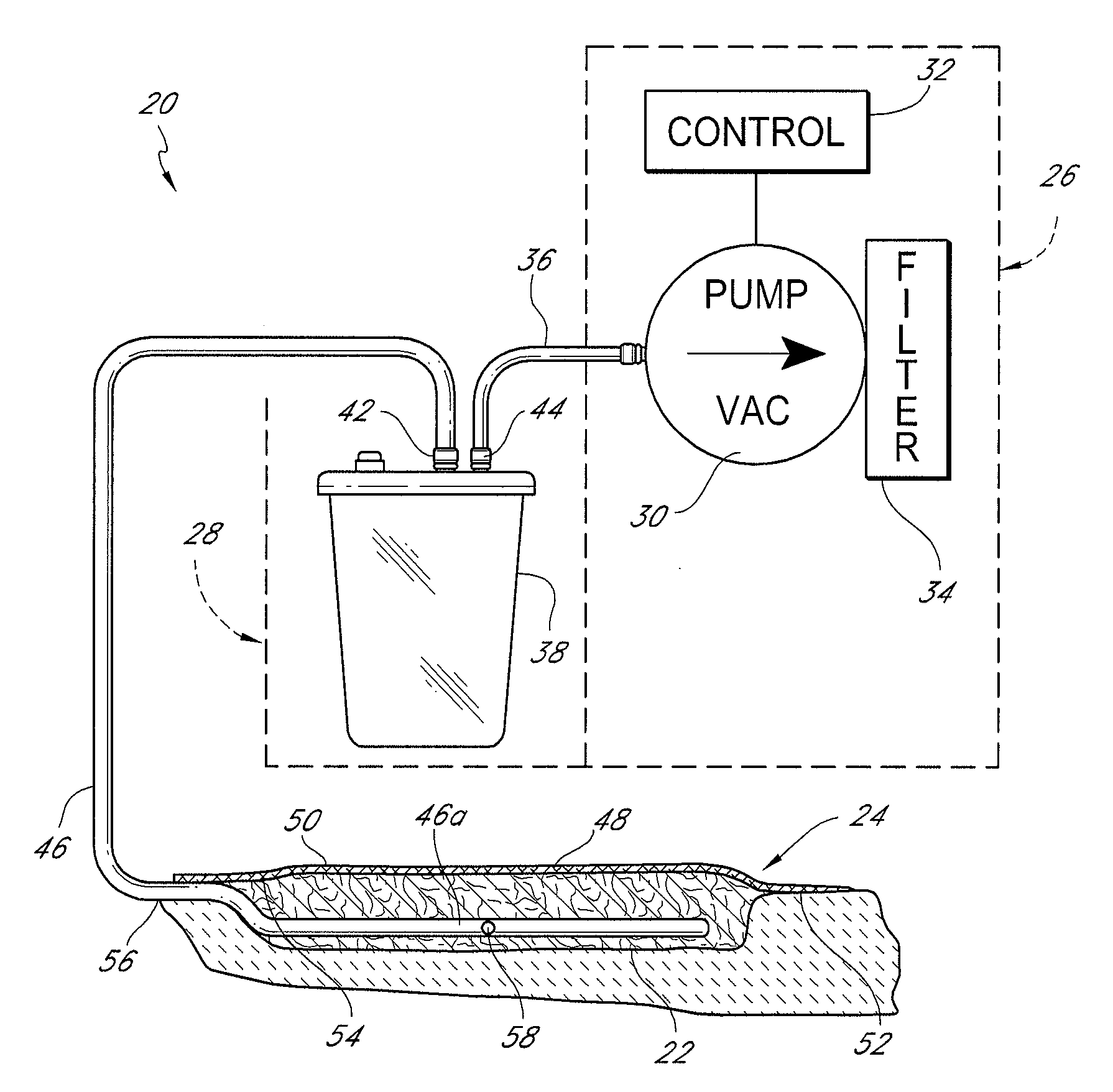

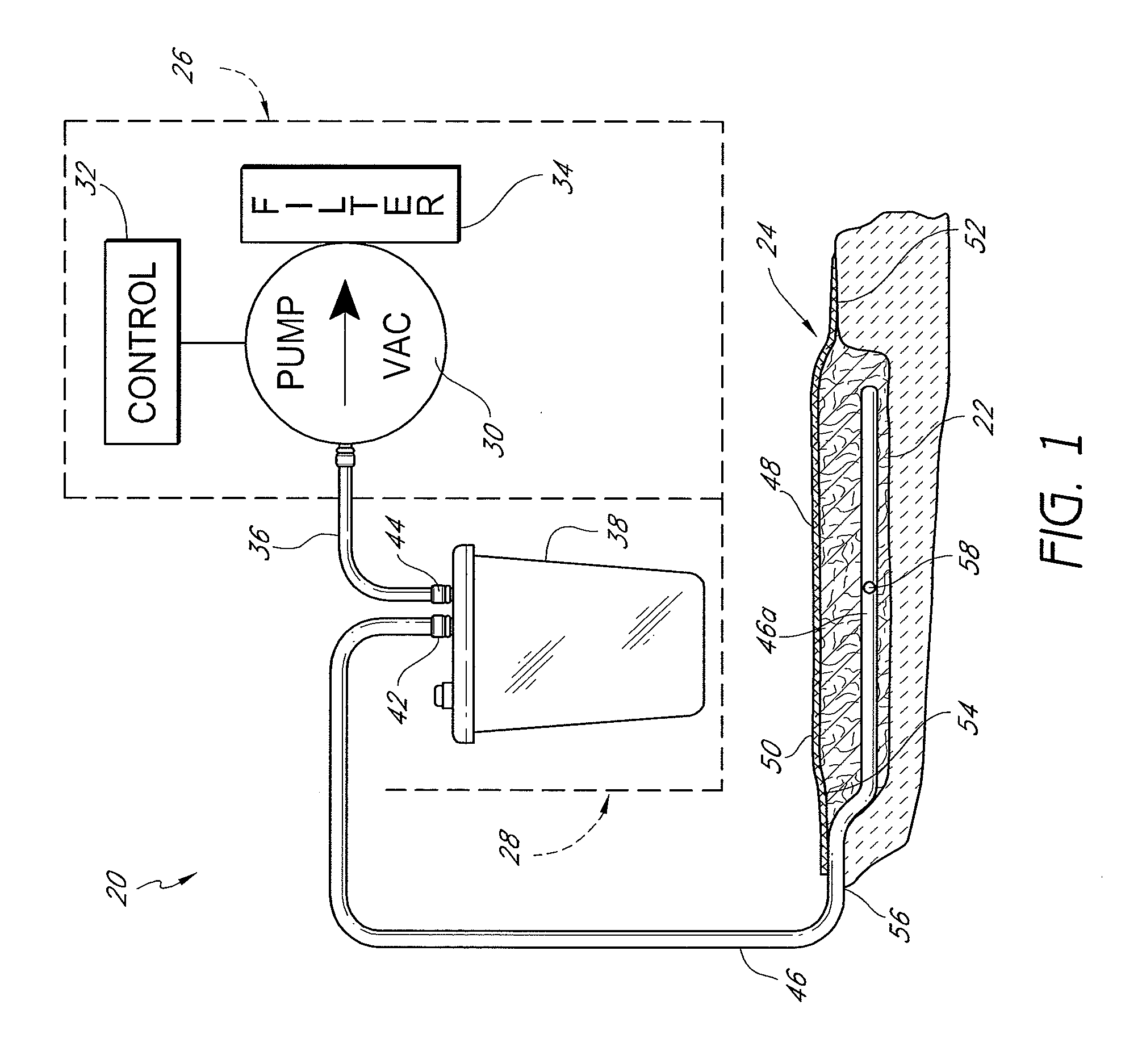

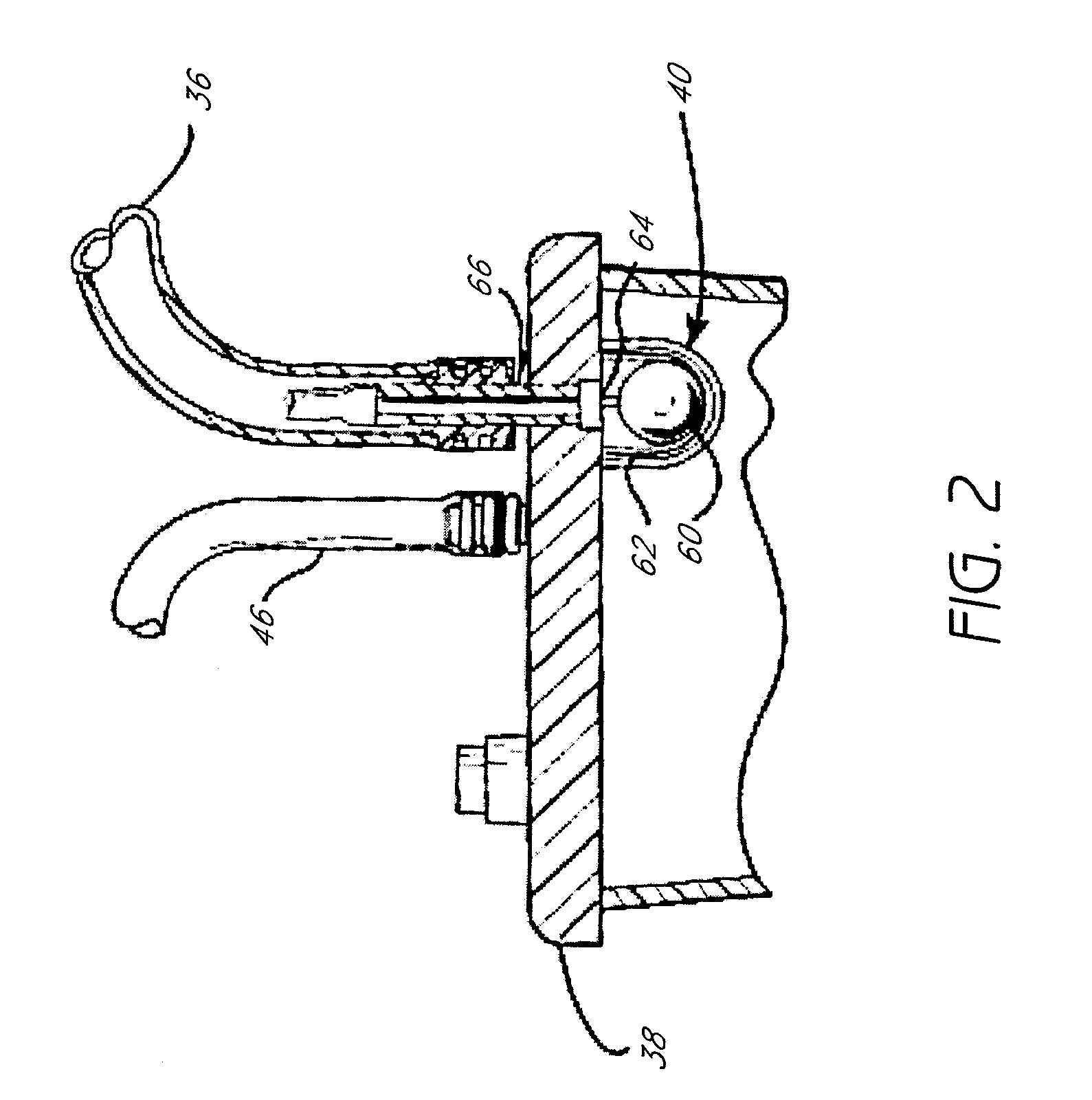

A pump system for applying negative pressure to a wound, including a flow monitor capable of detecting a deviation from a reference airflow rate provided by a controlled leak to determine whether the system is operating normally or abnormally, and a flow status annunciator to indicate a normal operating condition or whether an abnormal condition is a leak or an occluded line in the system. The pump system further includes a pressure controller for regulating operation of a pump to control pressure in the system at a range around a user-selected setpoint. The pump system may also include a waste collector and a level sensor for detecting when the collector is full.

Owner:PAUL HARTMANN AG

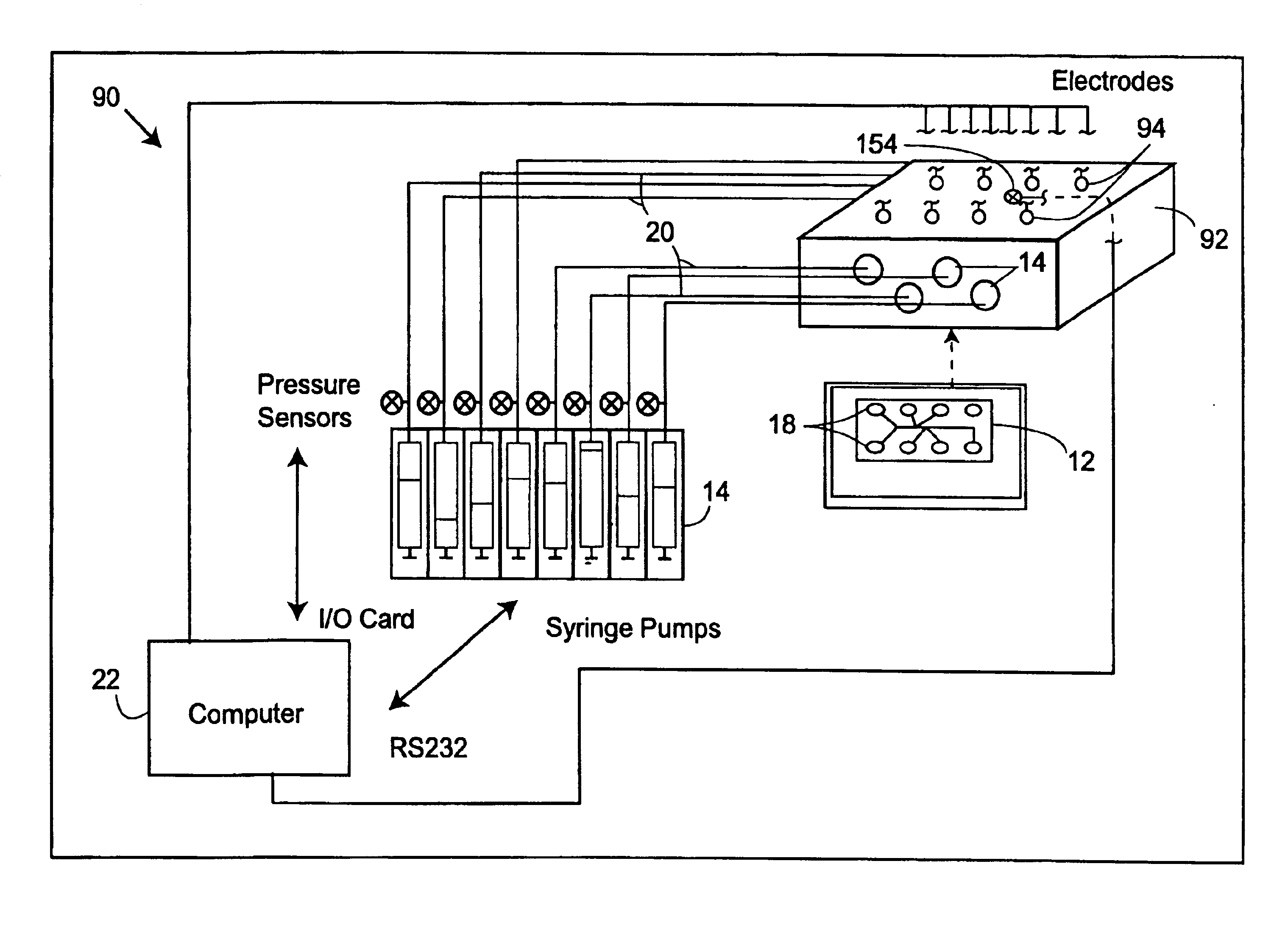

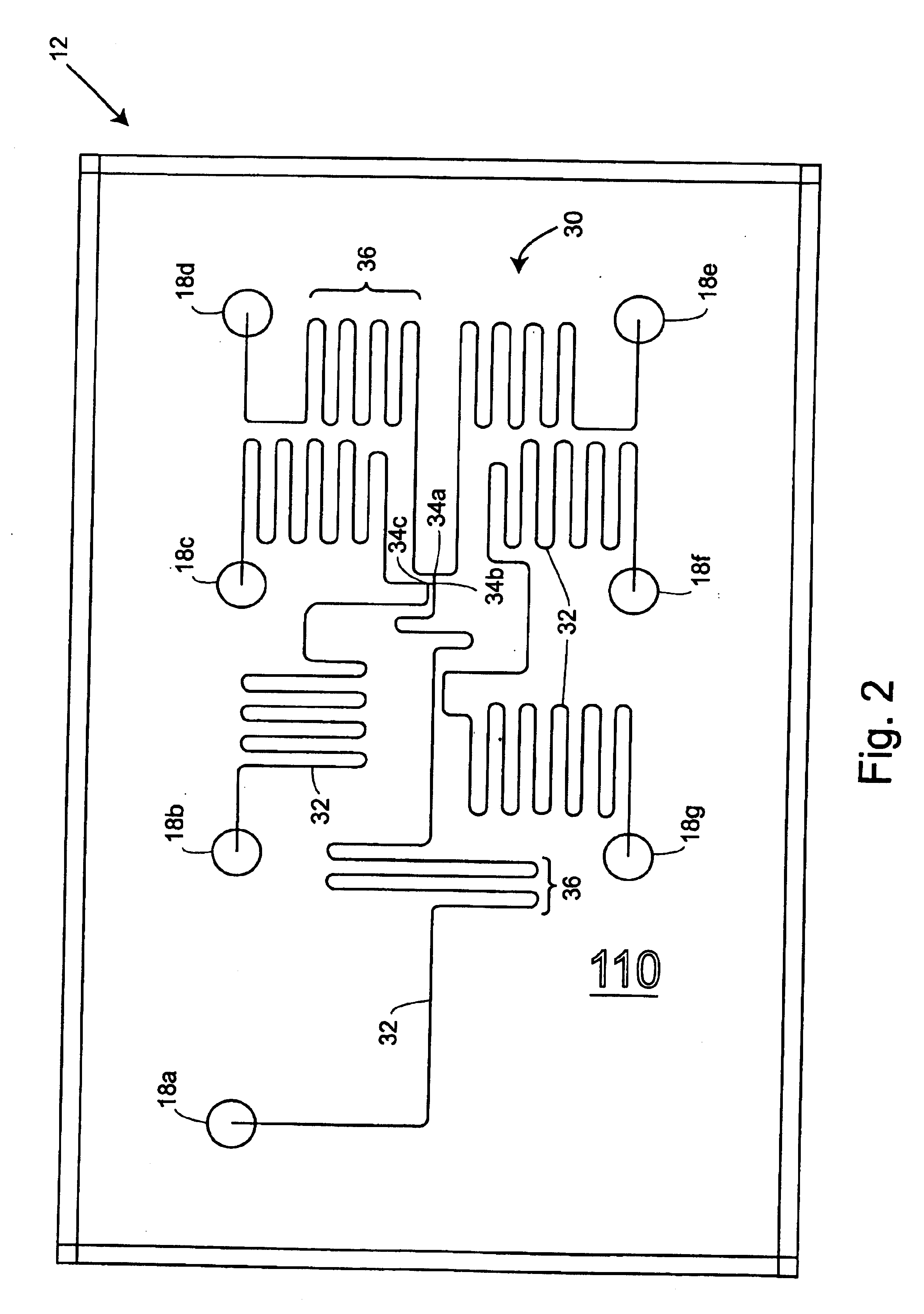

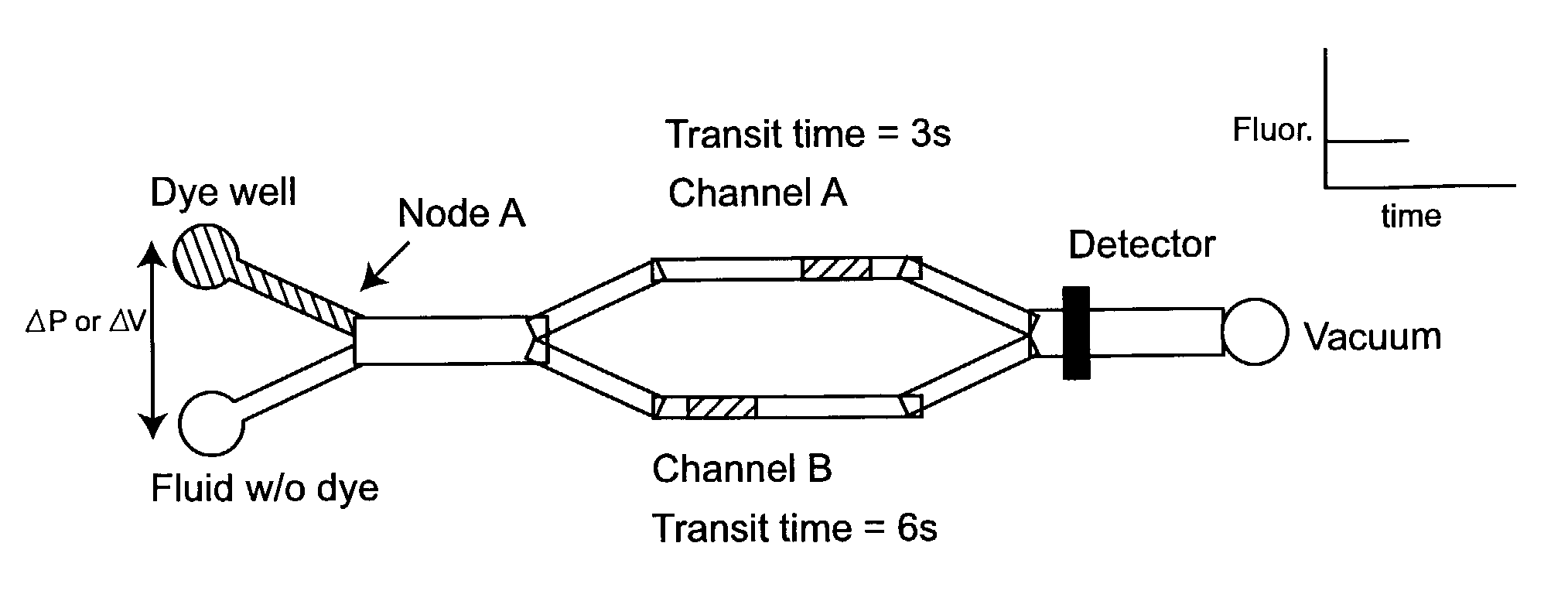

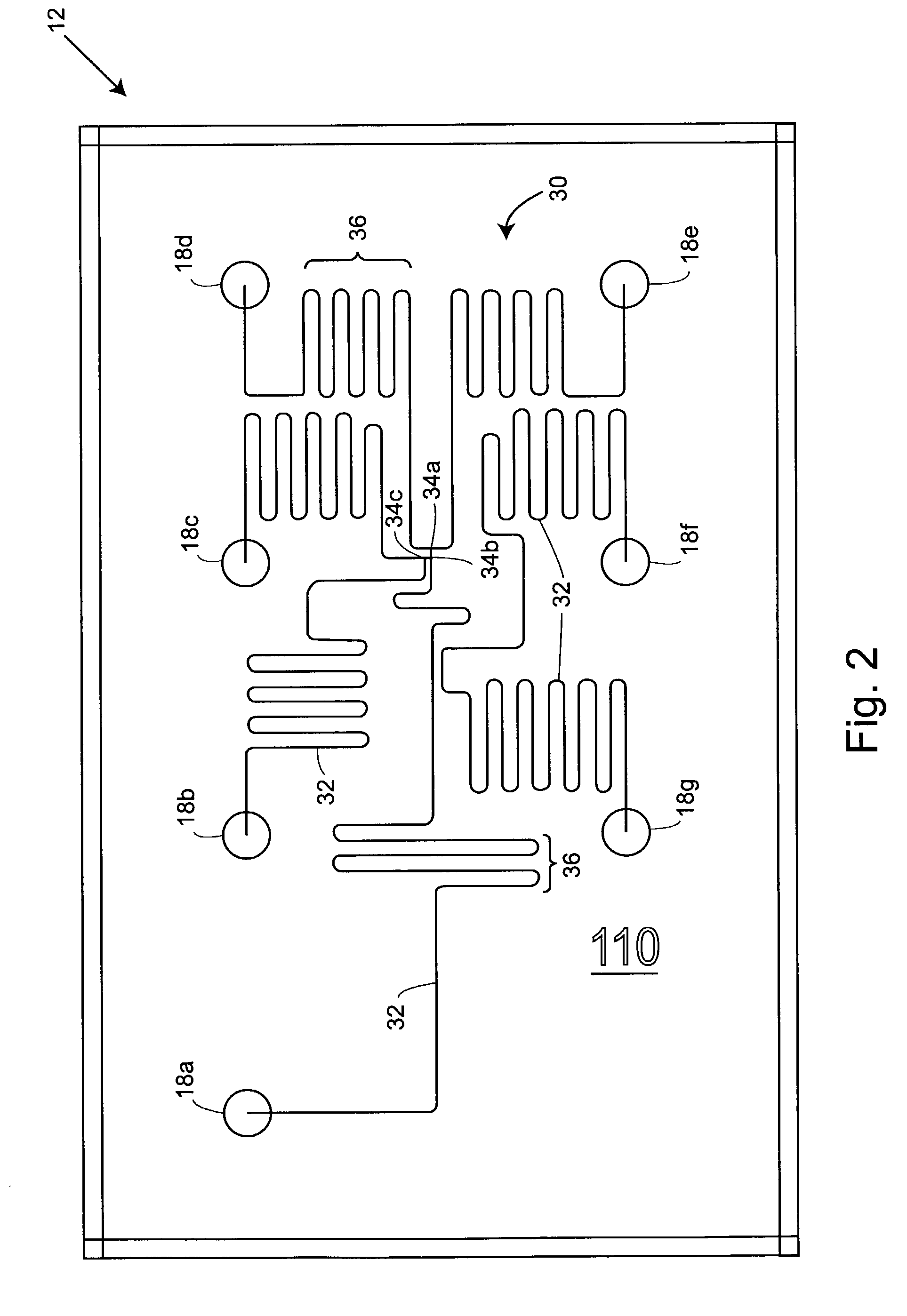

Multi-reservoir pressure control system

InactiveUS6915679B2Sufficient oscillationAccurate and stable and reliable assayAnalysis by electrical excitationLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

Pump system for negative pressure wound therapy

ActiveUS7857806B2Minimize the possibilityReduce the possibilityWound drainsMedical devicesControl systemLevel sensor

Owner:PAUL HARTMANN AG

Pump system for negative pressure wound therapy

InactiveUS20110077605A1Minimize the possibilityReduce the possibilityMedical devicesIntravenous devicesControl systemLevel sensor

A pump system for applying negative pressure to a wound, including a flow monitor capable of detecting a deviation from a reference airflow rate provided by a controlled leak to determine whether the system is operating normally or abnormally, and a flow status annunciator to indicate a normal operating condition or whether an abnormal condition is a leak or an occluded line in the system. The pump system further includes a pressure controller for regulating operation of a pump to control pressure in the system at a range around a user-selected setpoint. The pump system may also include a waste collector and a level sensor for detecting when the collector is full.

Owner:PAUL HARTMANN AG

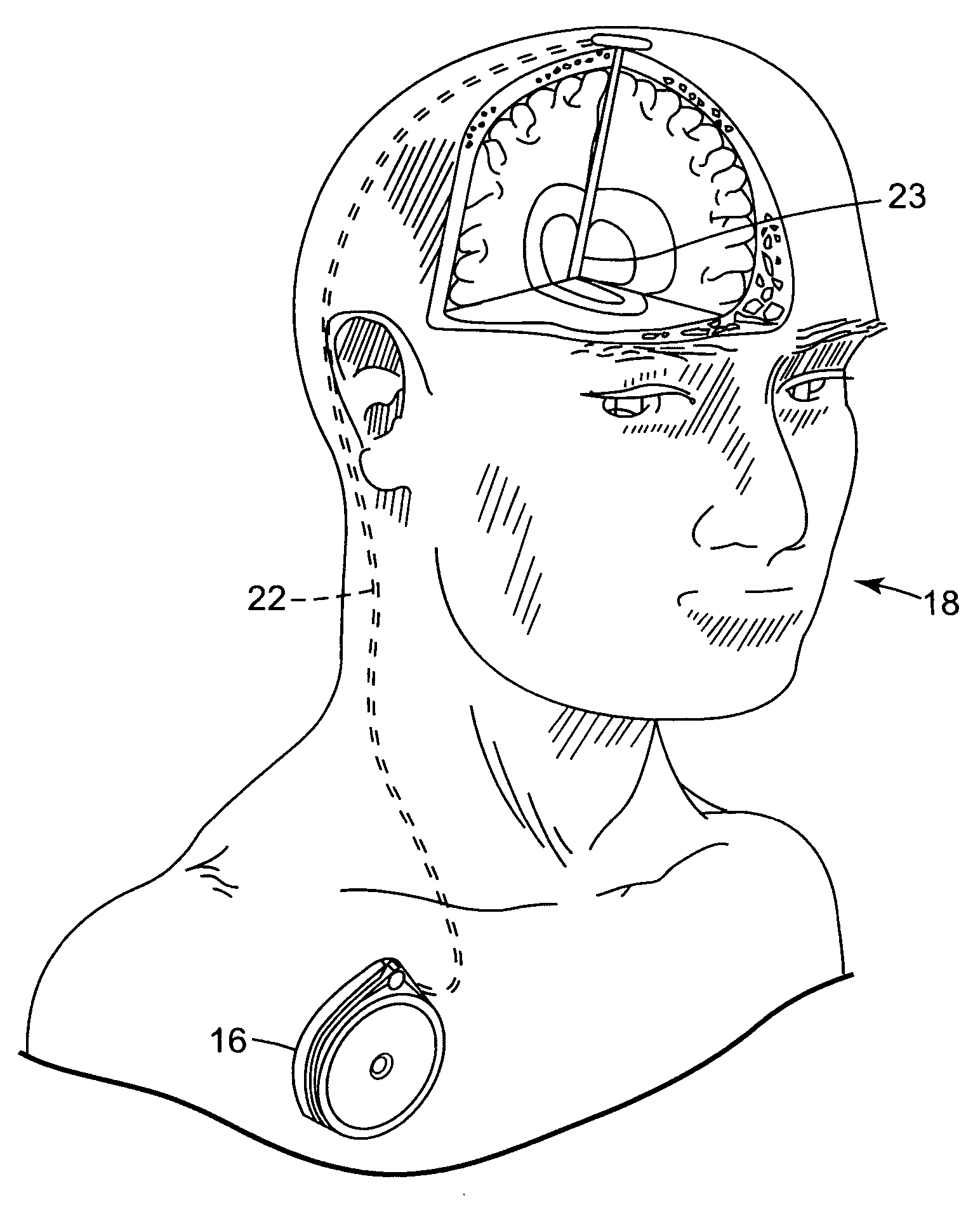

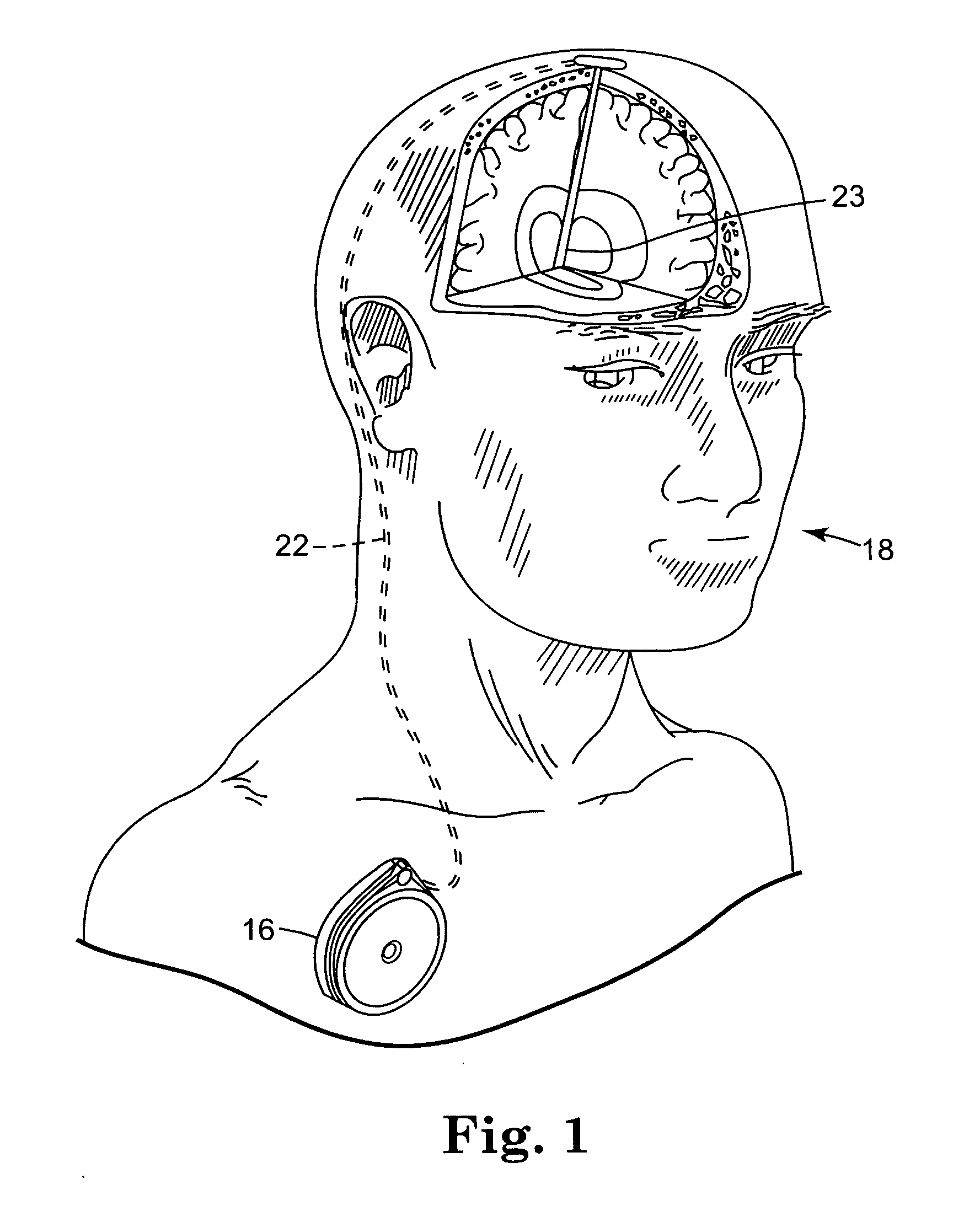

Pressure sensing in implantable medical devices

ActiveUS20050075624A1Detection malfunctionReduce pressureFluid pressure measurement by electric/magnetic elementsMedical devicesPressure controllerBiomedical engineering

An implantable medical device for delivering a therapeutic substance to a delivery site in a patient. A reservoir holds a supply of the fluid therapeutic substance. A catheter has a proximal end, a delivery region and a lumen extending from the proximal end to the delivery region. The proximal end of the catheter is operatively coupled to the reservoir. The delivery region of the catheter is adapted to be placed proximate the delivery site in the patient. The therapeutic substance is adapted to be delivered through the lumen to the patient. A sensing device is operatively coupled with the lumen of the catheter being capable of detecting a pressure of the therapeutic substance in the lumen. A controller is operatively coupled to the sensing device, the controller being capable of taking an action in response to the pressure in the lumen.

Owner:MEDTRONIC INC

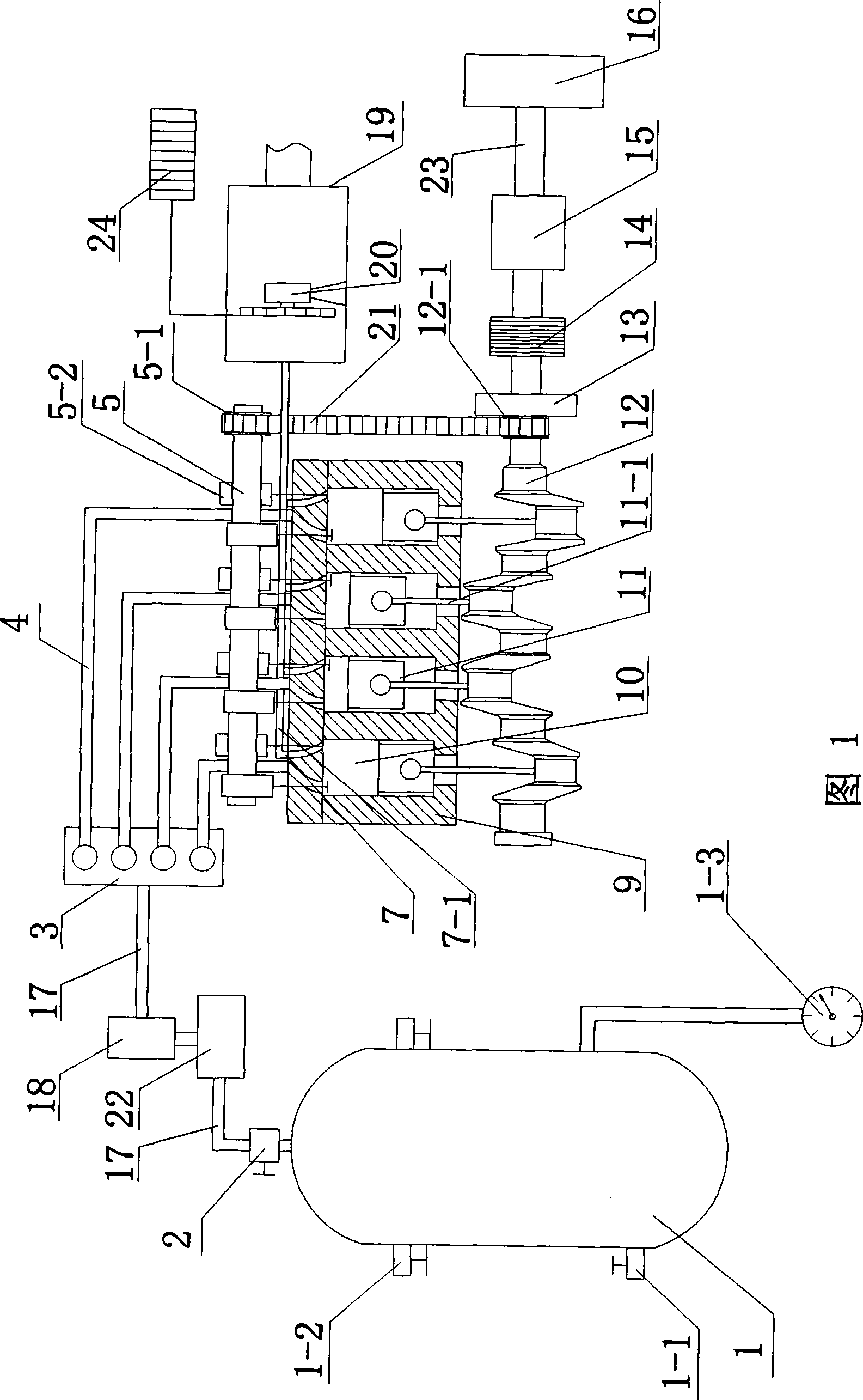

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

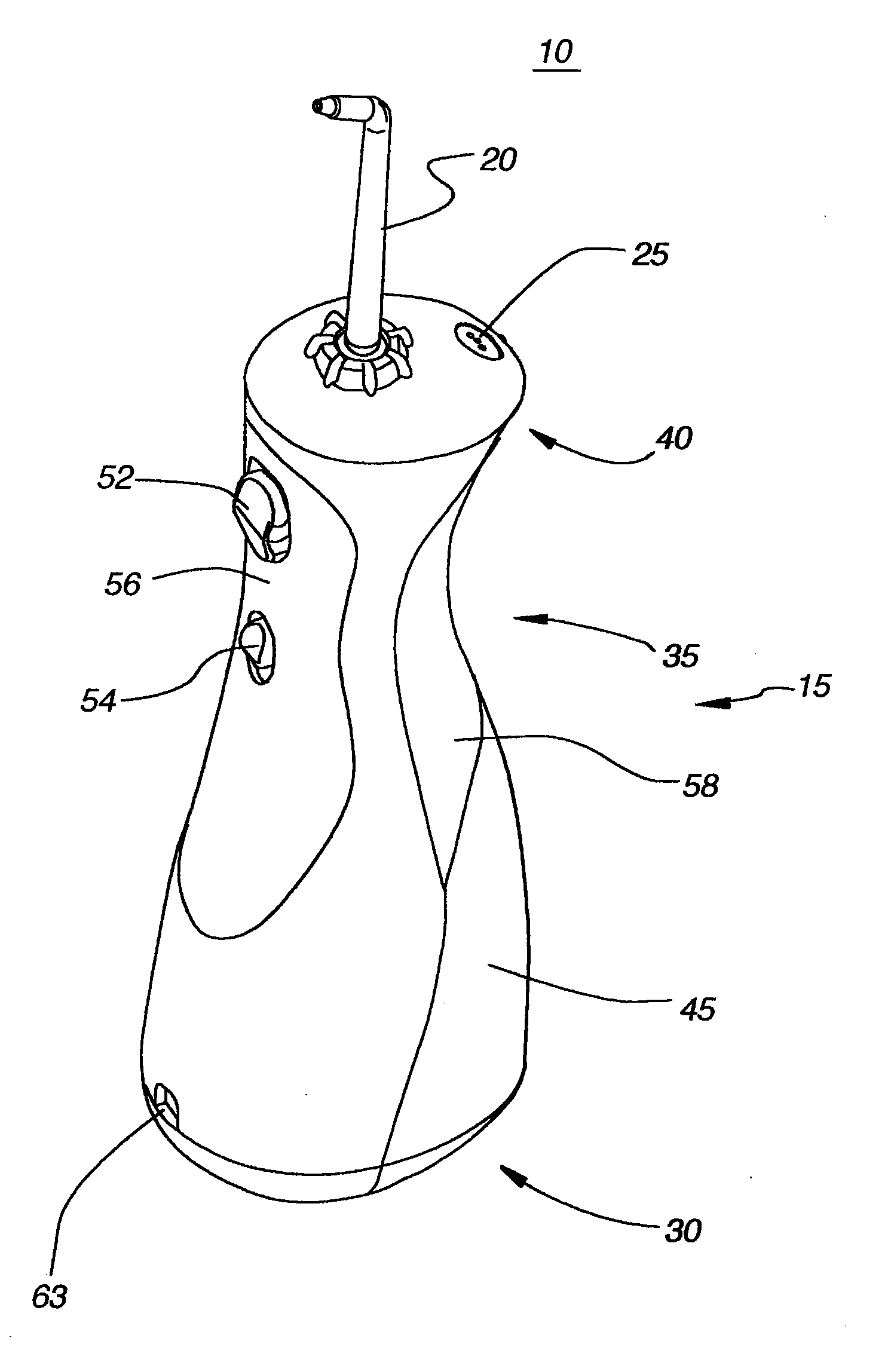

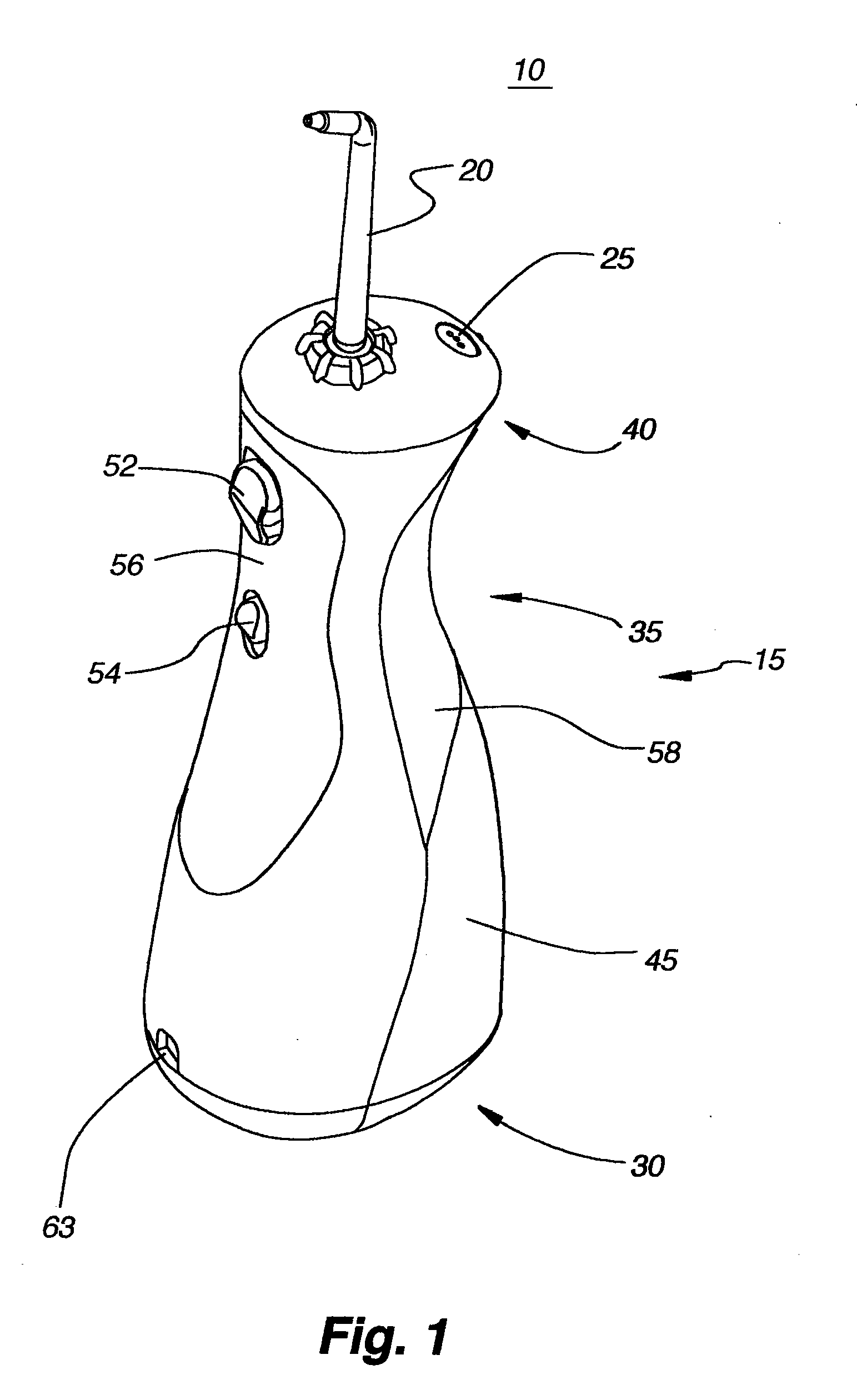

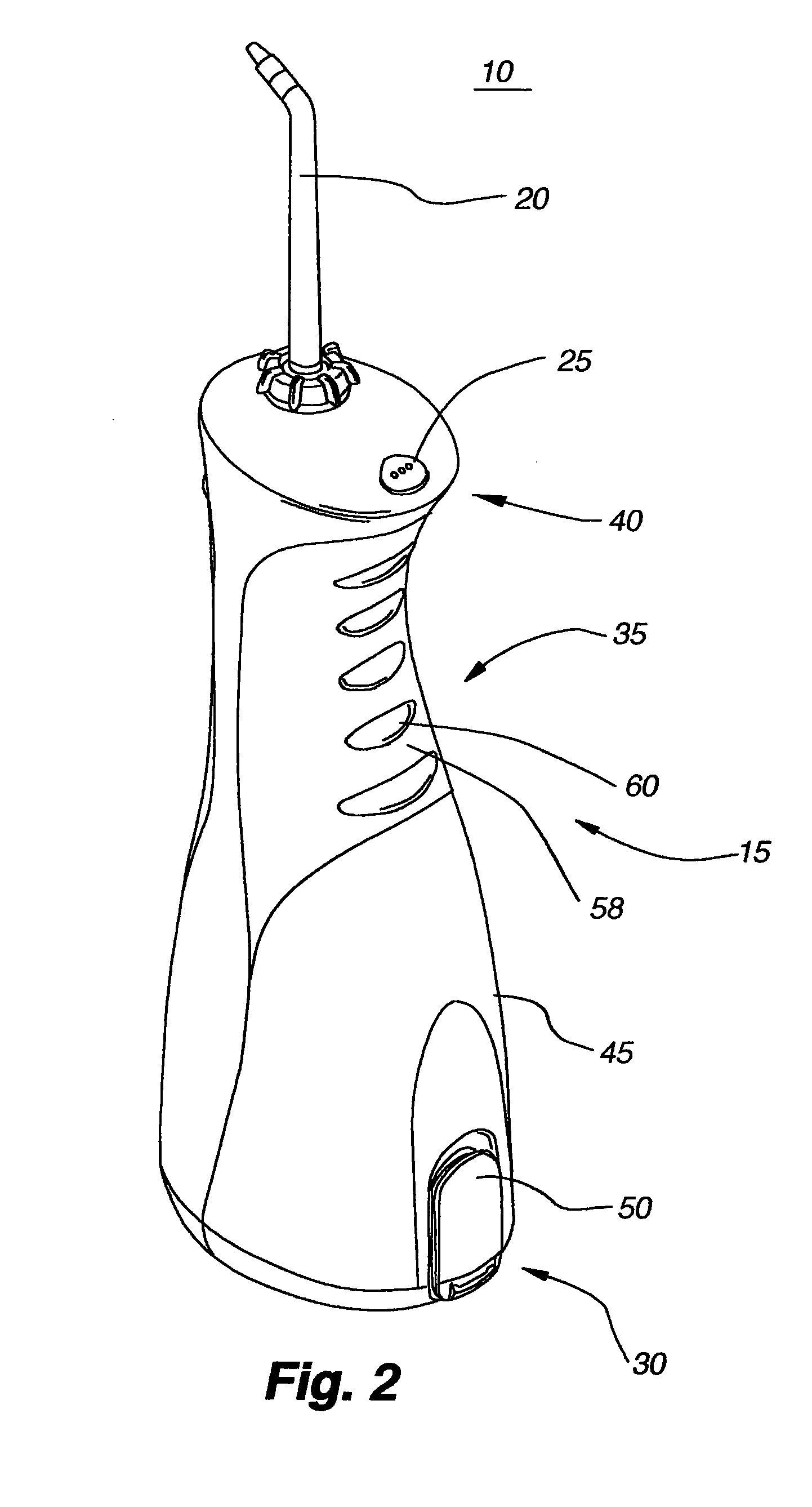

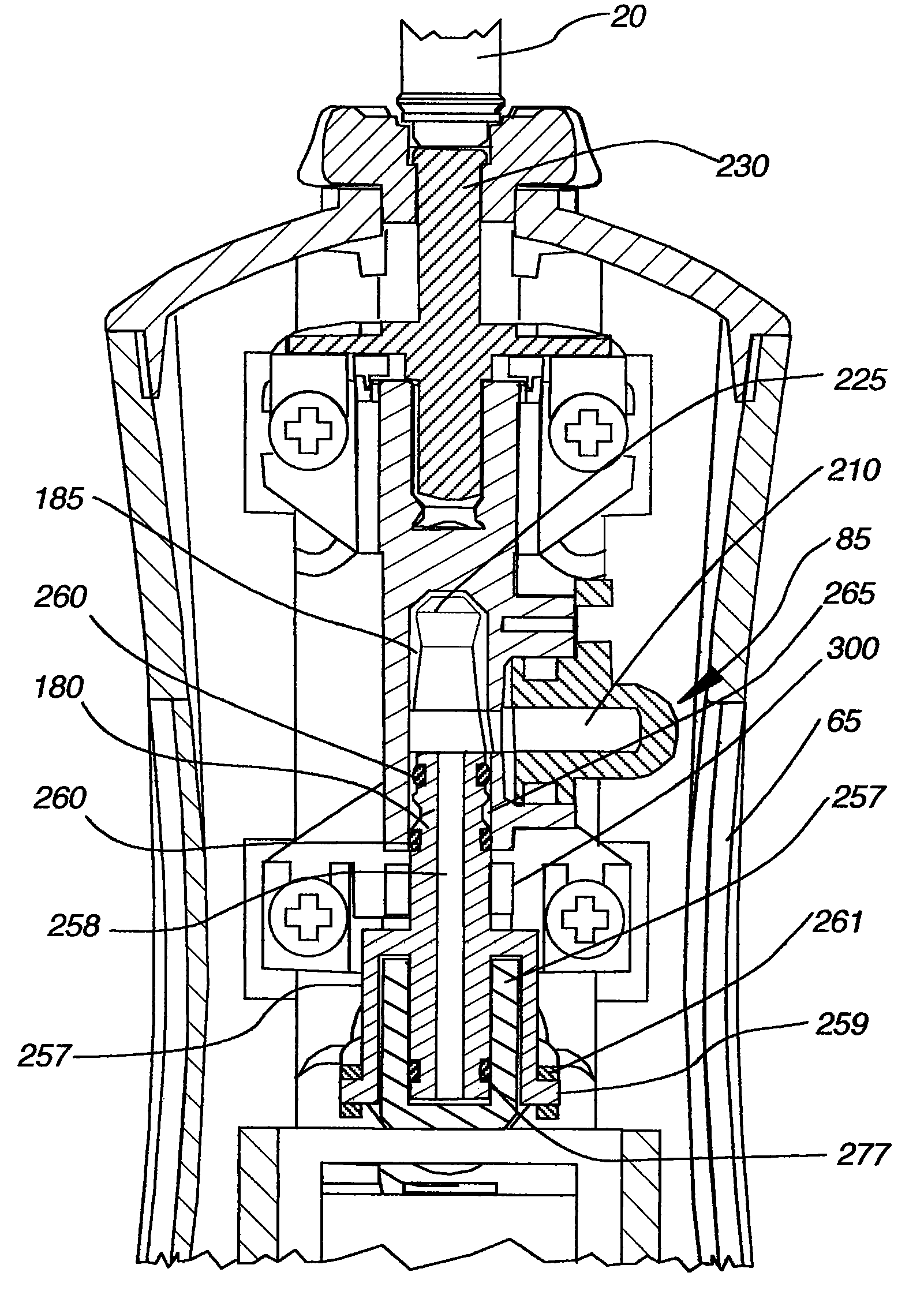

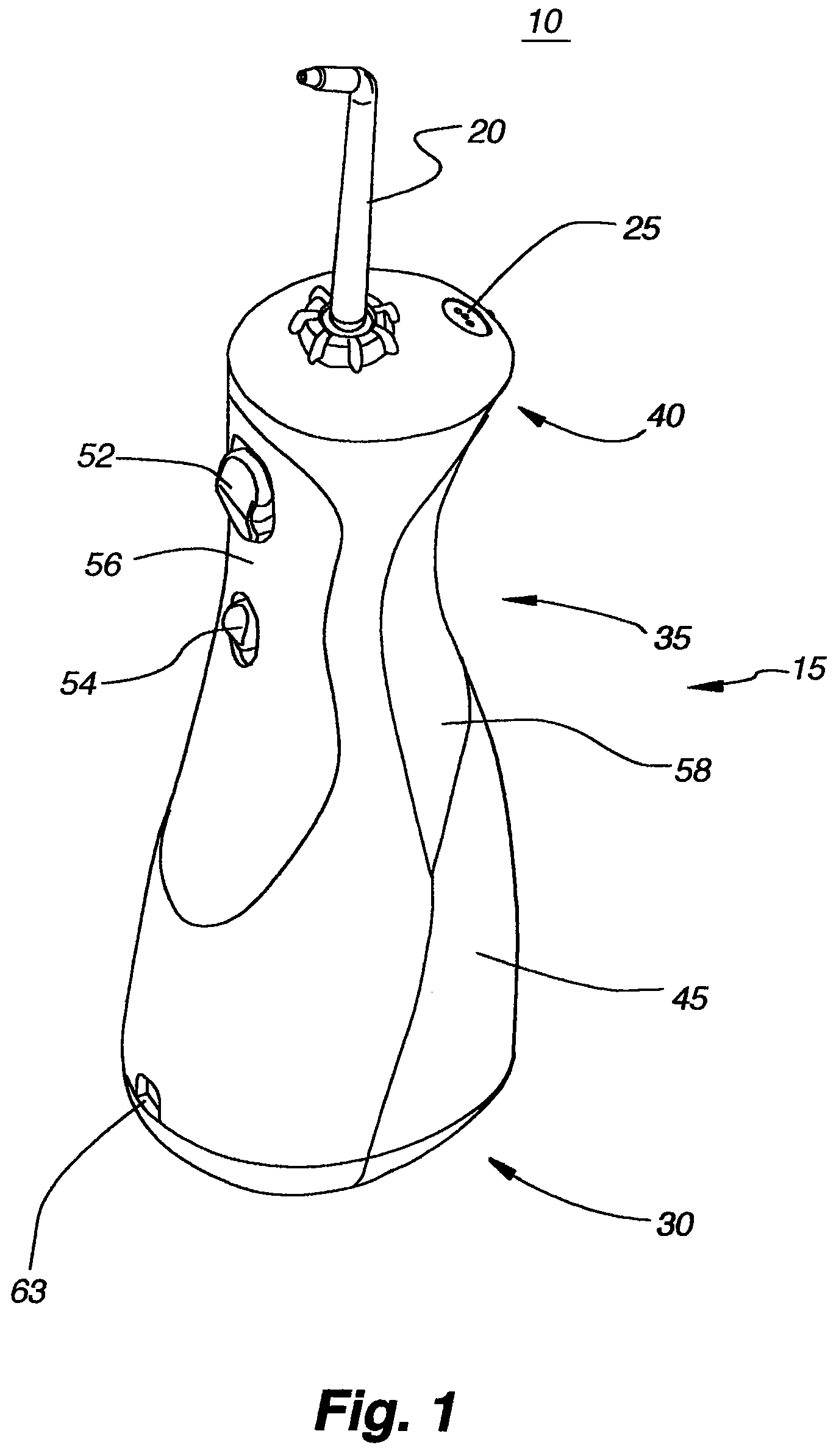

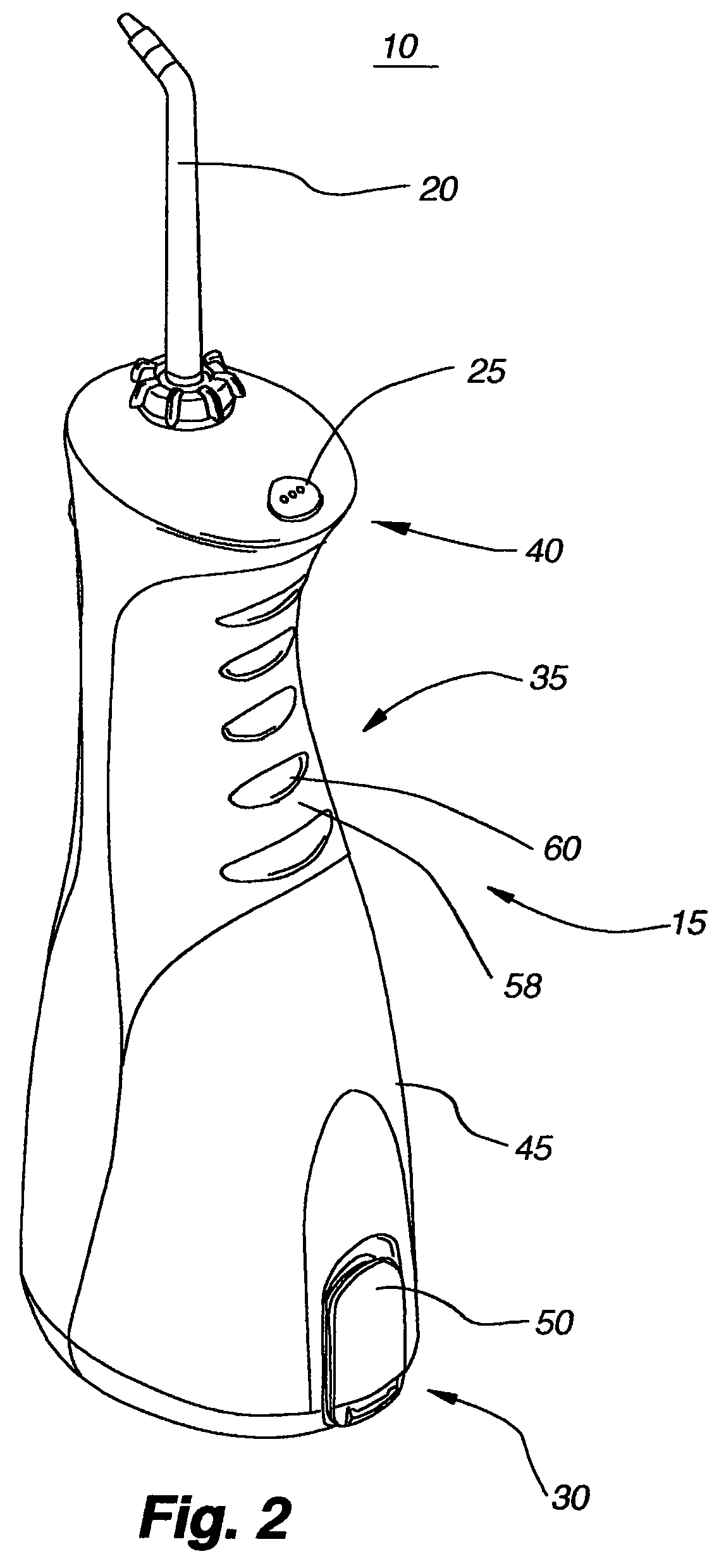

Oral irrigator

The present invention is an oral irrigator comprising a pump, a discharge nozzle and a pressure control. The pump has a generally constant operating speed and feeds the discharge nozzle. The pressure control is adapted to modify a discharge pressure at the nozzle without a significant change in pump speed. The pressure control modifies a level of fluid flow restriction between the pump and the nozzle. The modification of the level of fluid flow restriction is accomplished by modifying aspects of a fluid flow path extending through the pressure control. The aspects modified include the diameter, length and / or number of direction changes of the fluid flow path.

Owner:WATER PIK INC

Oral irrigator

The present invention is an oral irrigator comprising a pump, a discharge nozzle and a pressure control. The pump has a generally constant operating speed and feeds the discharge nozzle. The pressure control is adapted to modify a discharge pressure at the nozzle without a significant change in pump speed. The pressure control modifies a level of fluid flow restriction between the pump and the nozzle. The modification of the level of fluid flow restriction is accomplished by modifying aspects of a fluid flow path extending through the pressure control. The aspects modified include the diameter, length and / or number of direction changes of the fluid flow path.

Owner:WATER PIK INC

Auxiliary powered negative pressure wound therapy apparatuses and methods

ActiveUS8323264B2Meet growth needsPromote quick completionWound drainsMedical devicesWound dressingElectrical battery

Owner:SMITH & NEPHEW PLC

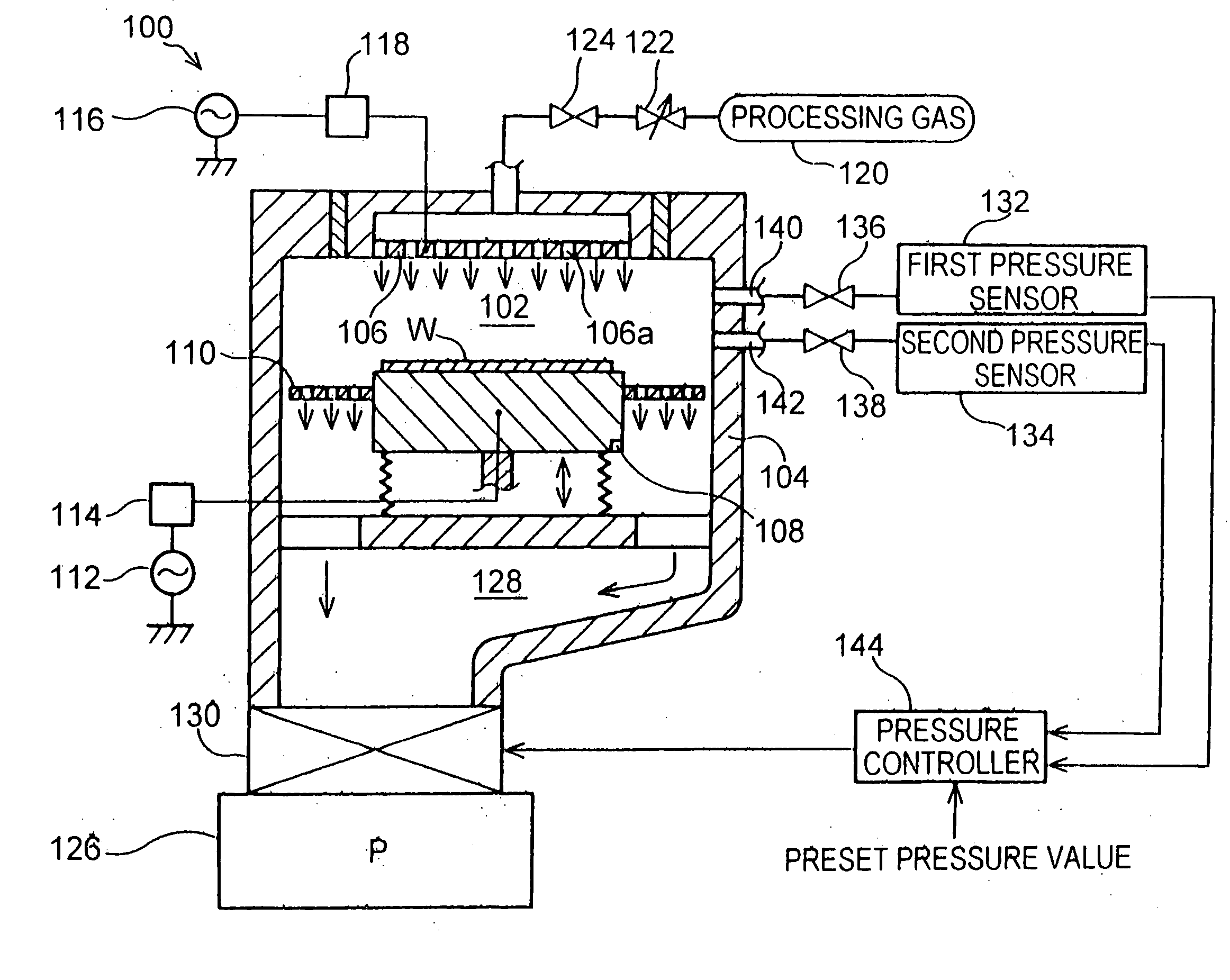

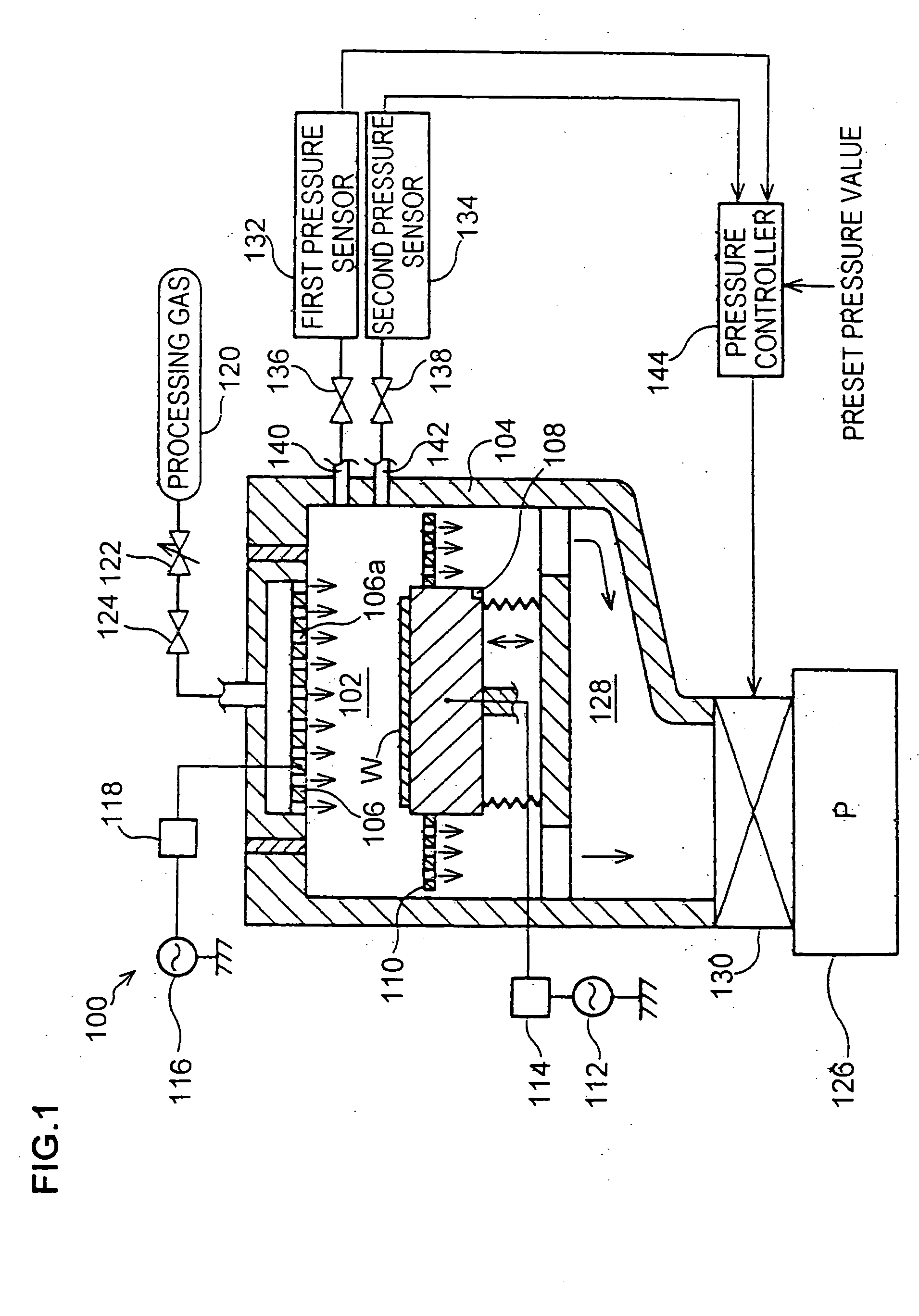

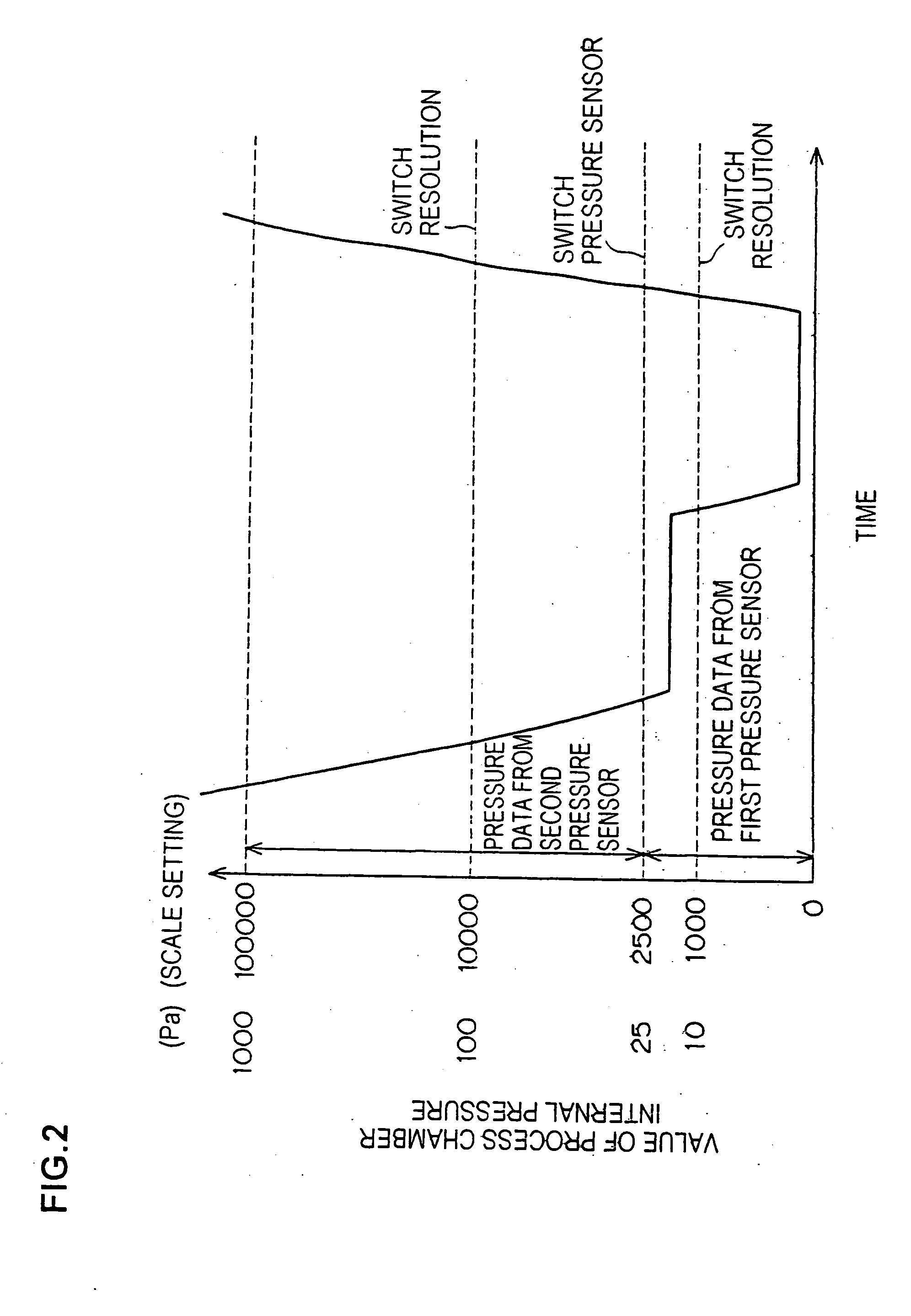

Pressure control method and processing device

InactiveUS20050176258A1Level of control performanceOptimize dataElectric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionEngineering

First and second pressure sensors 132 and 134 that perform pressure detection over different pressure detection ranges from each other detect the pressure within a process chamber 102 of an etching device 100. A pressure controller 144 selects optimal pressure data in correspondence to the pressure inside the process chamber from the pressure data provided by the first and second pressure sensors 132 and 134. It also analyzes the selected pressure data at a resolution selected in correspondence to the pressure inside the process chamber 102 and thus obtains pressure data achieving a predetermined data density. The pressure controller 134 controls a pressure control valve 130 so as to ensure that the pressure data match preset pressure data.

Owner:TOKYO ELECTRON LTD

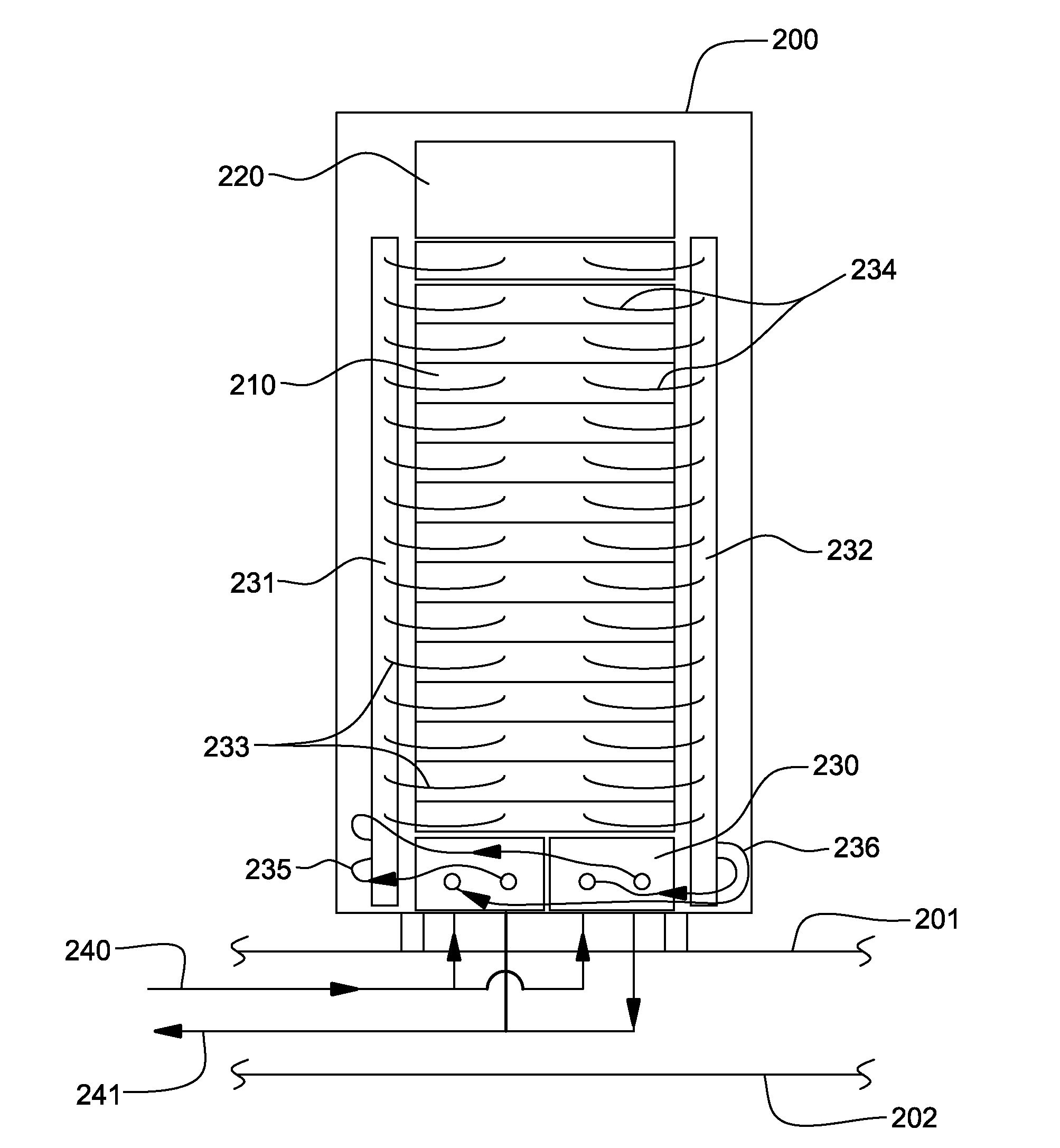

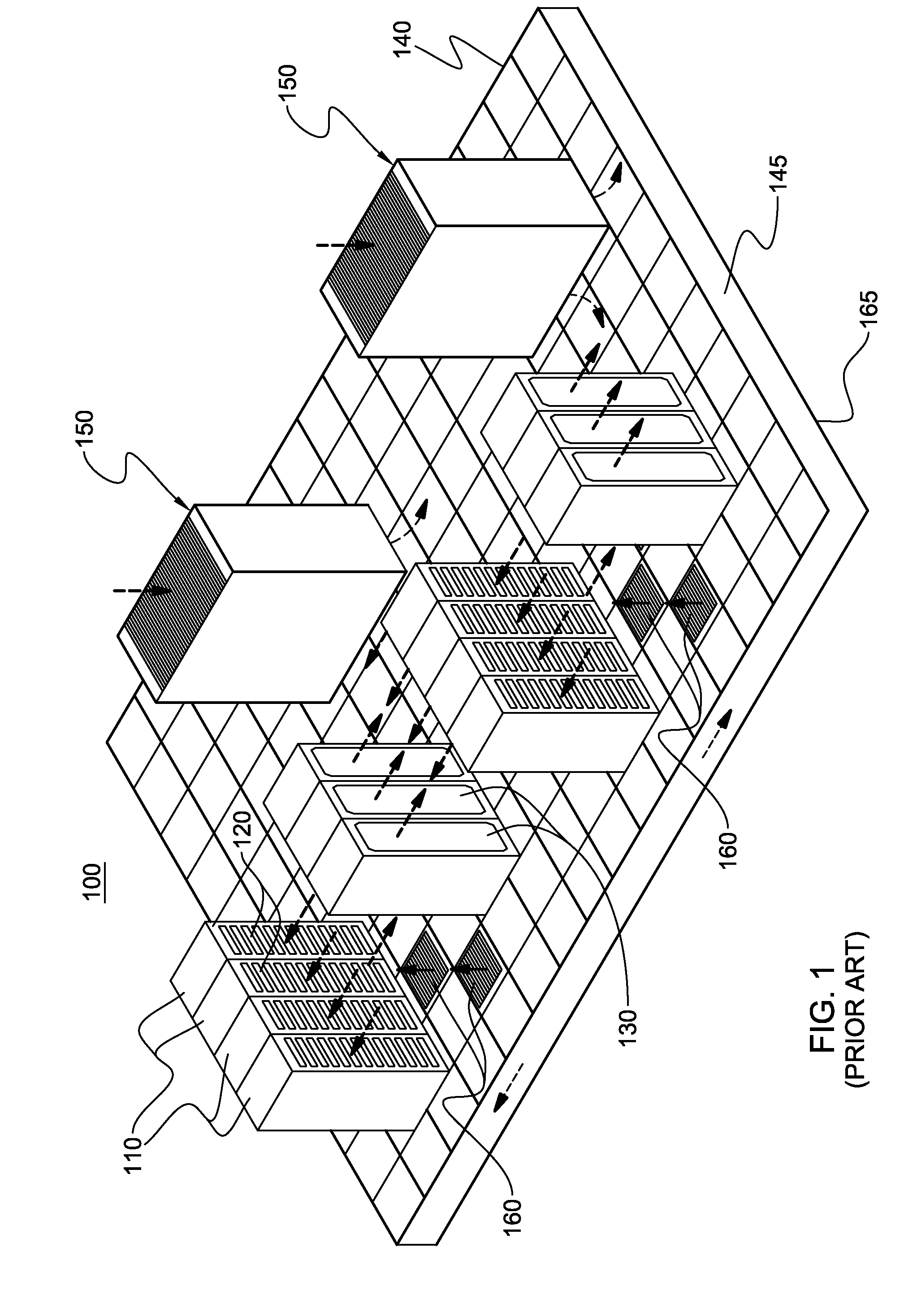

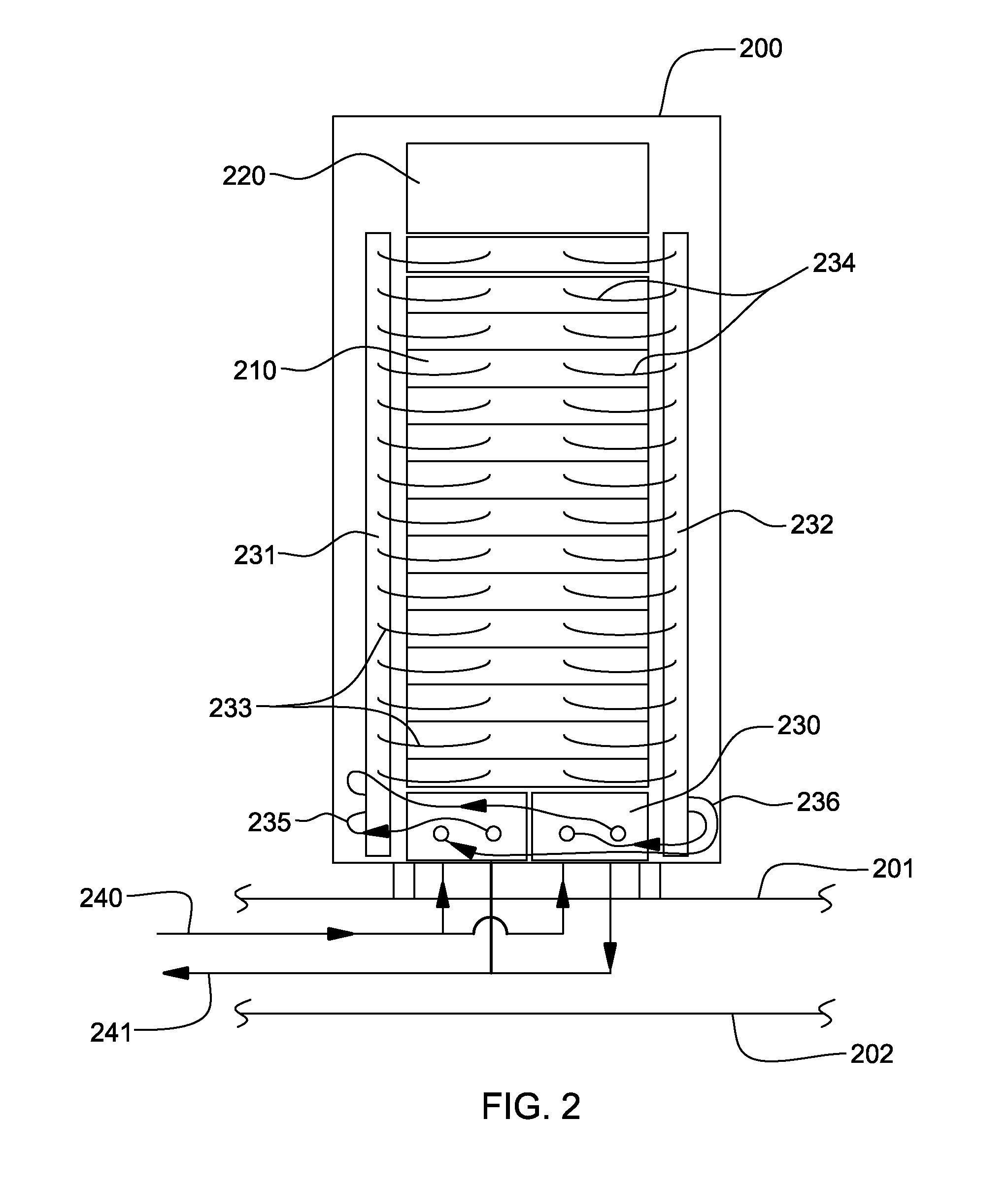

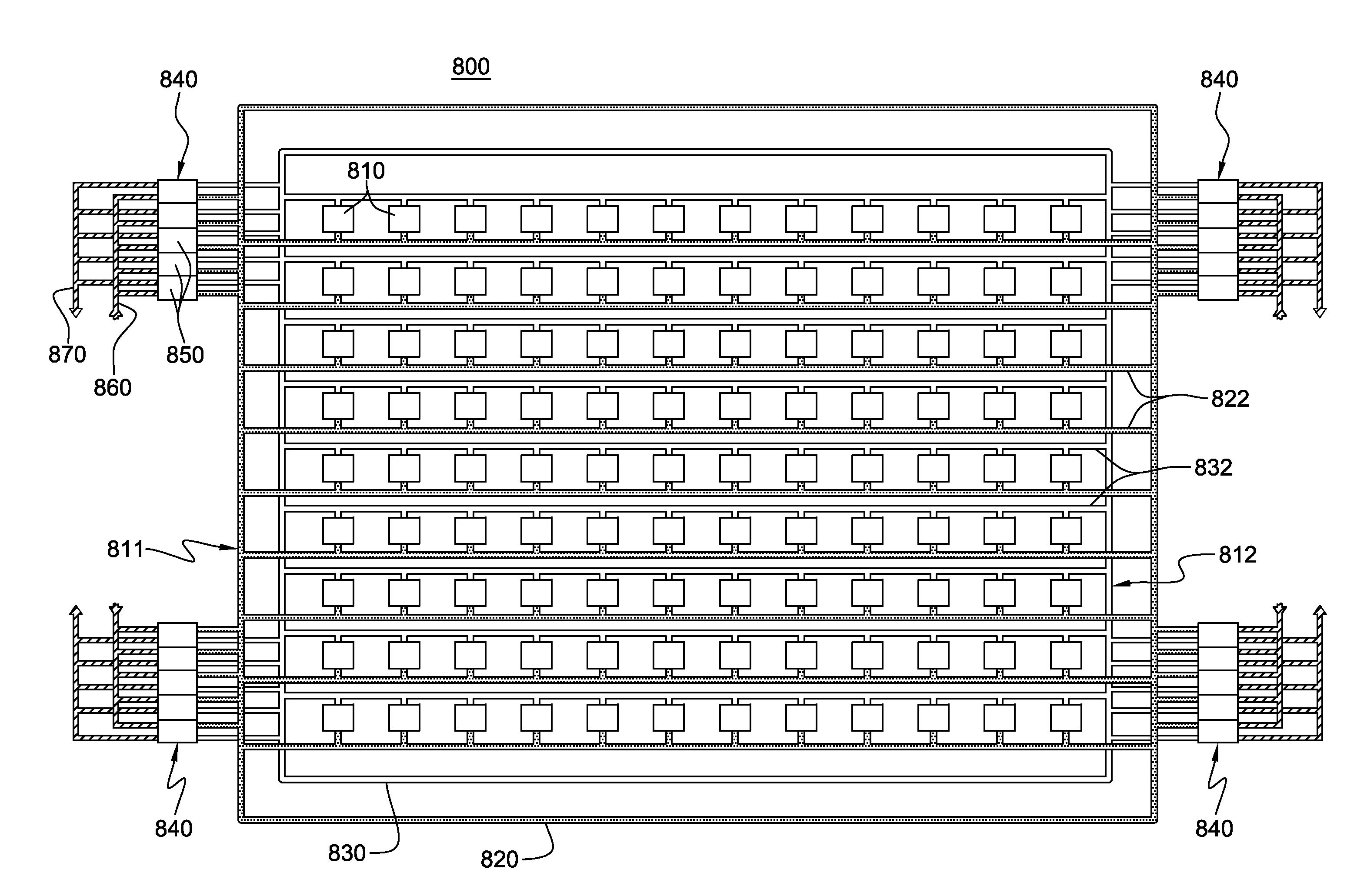

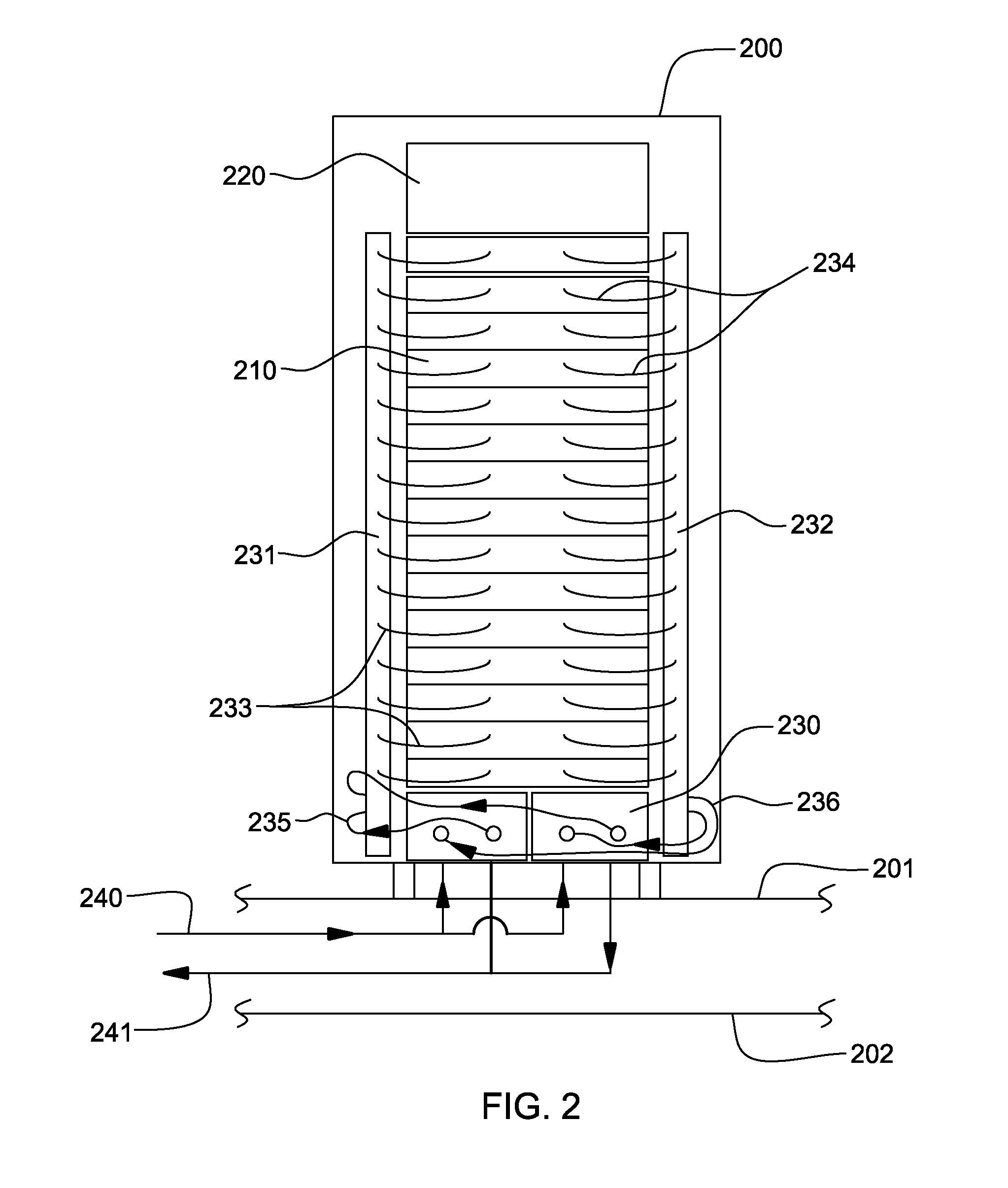

Cooling system and method minimizing power consumption in cooling liquid-cooled electronics racks

InactiveUS20110060470A1Reduce power consumptionOvercomes shortcomingMechanical power/torque controlEnergy efficient ICTControl flowPower dissipation minimization

A cooling system and method are provided for facilitating cooling of a liquid-cooled electronics rack. The cooling system includes a coolant flow controller, a modular cooling unit and a pressure controller. The flow controller is associated with a respective electronics rack and controls flow of coolant through that electronics rack based on its changing cooling requirements. The cooling unit includes an adjustable coolant pump for facilitating supply of coolant to the rack. The pressure controller is associated with the cooling unit for controlling pressure of coolant at an output of the cooling unit via control of pump speed of the pump. Responsive to adjusting coolant flow through the electronics rack, the pressure controller automatically adjusts pump speed of the adjustable pump to maintain pressure about a constant coolant pressure set point at an output of the cooling unit, thereby conserving power while still cooling the liquid-cooled electronics rack.

Owner:IBM CORP

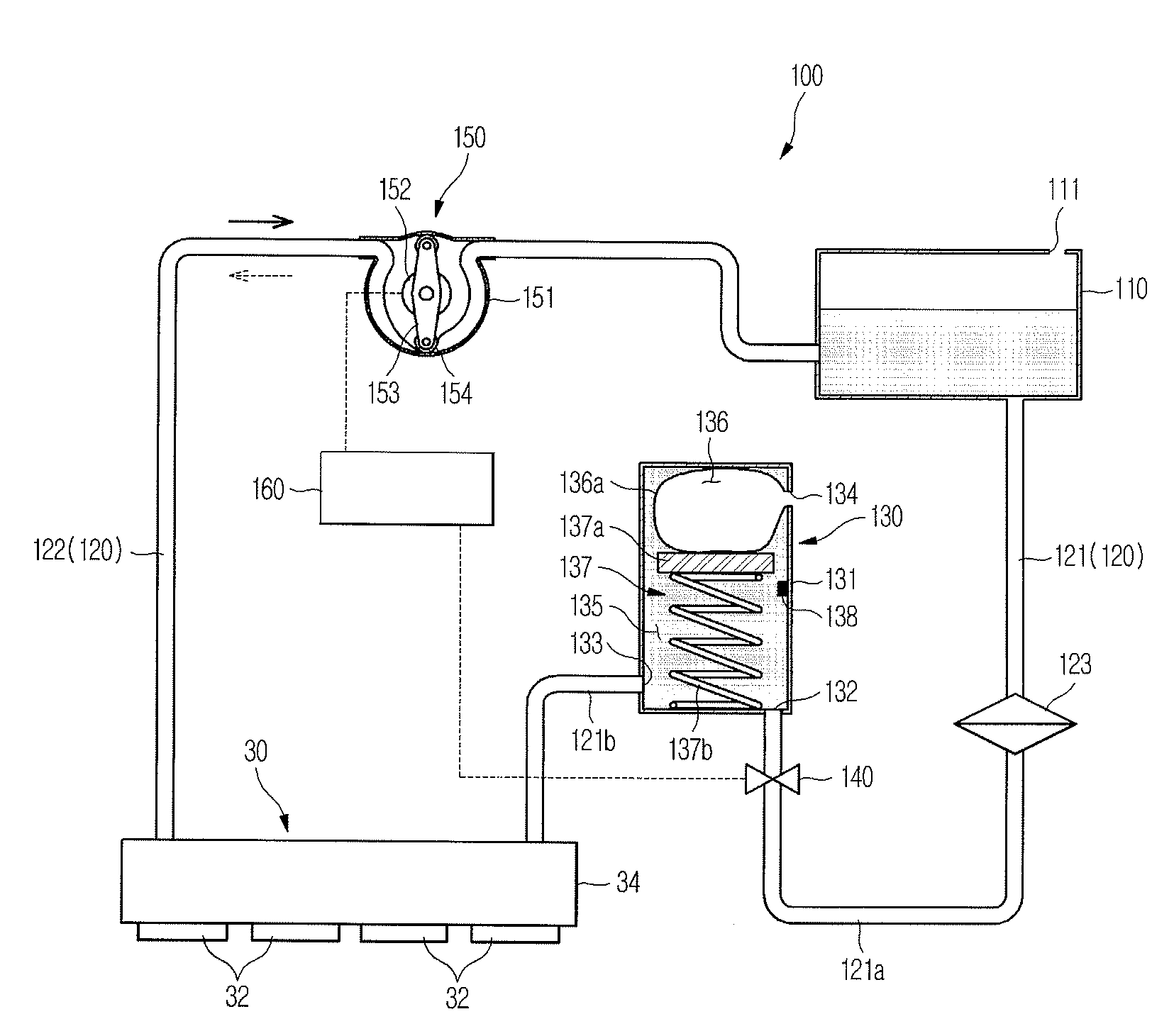

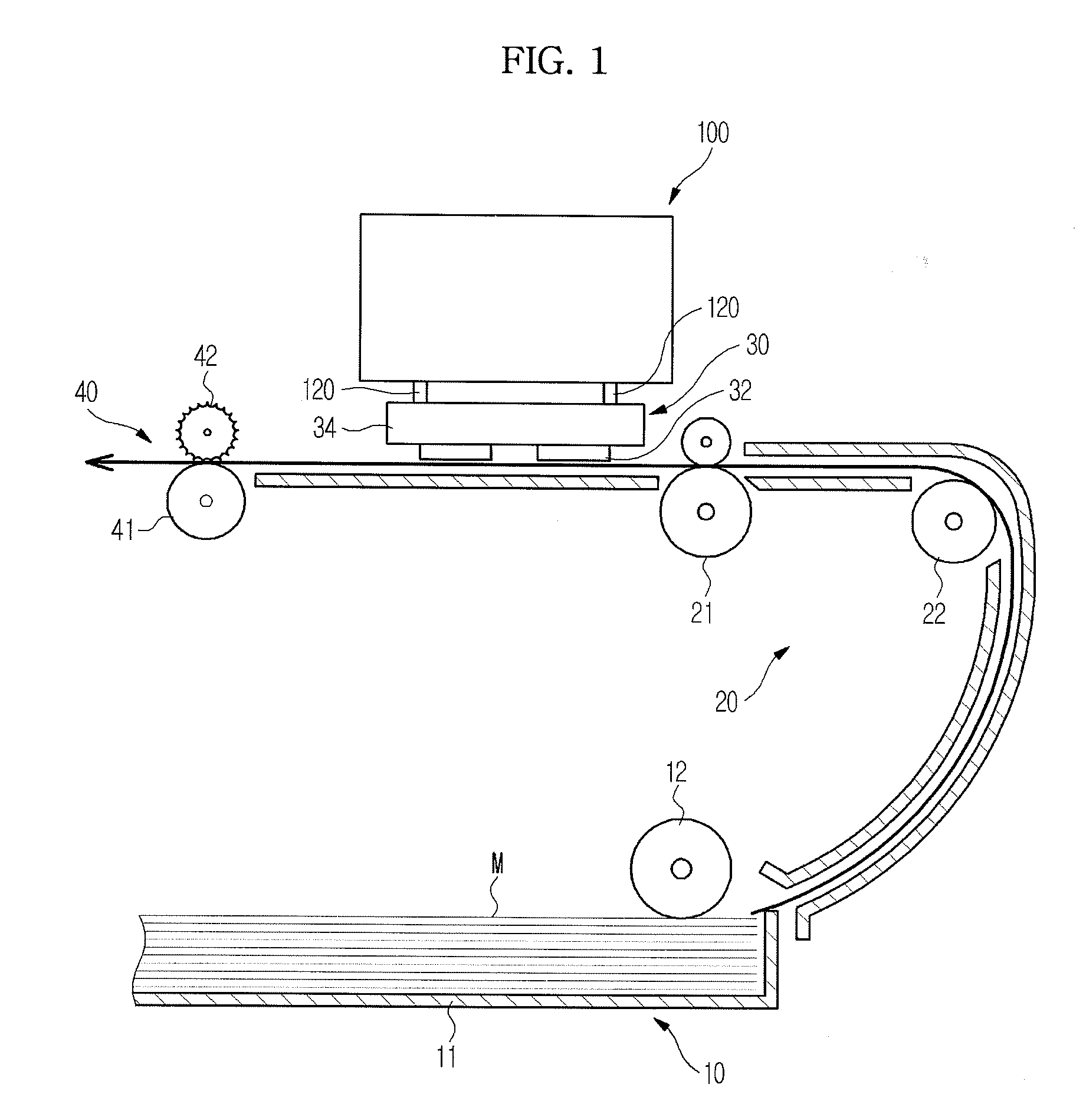

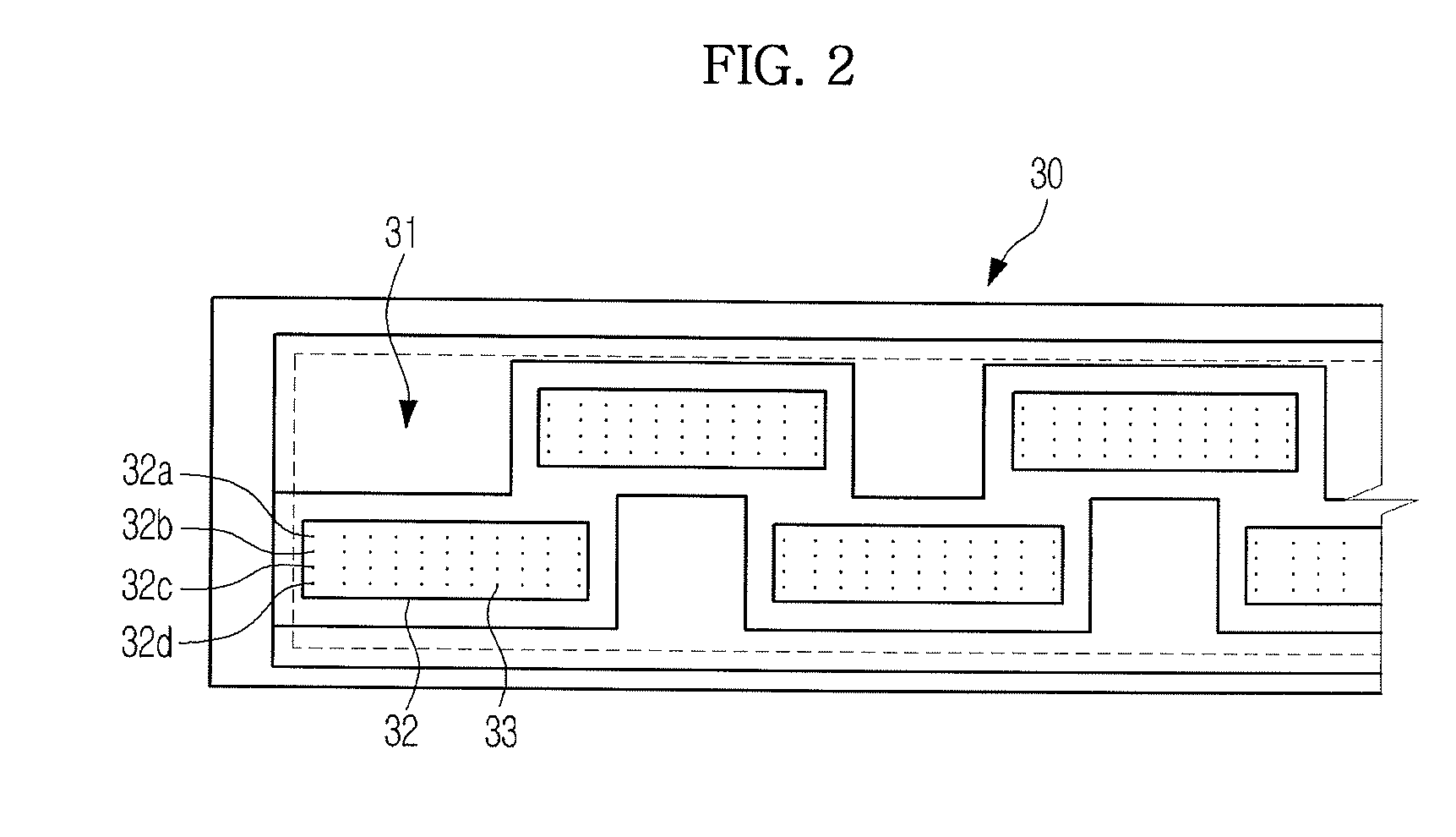

Ink jet image forming apparatus

InactiveUS20080297546A1Simple structureMinimize impactOther printing apparatusImage formationEngineering

An ink jet image forming apparatus, which is improved in a structure of an ink supply device so as to minimize an influence due to a pressure loss generated in an ink flow passage, is provided. The ink jet image forming apparatus includes a print head to eject an ink to a printing medium, an ink tank to store the ink, an ink circulation passage through which the ink circulates between the ink tank and the print head, a pressure controller which has an ink storage unit communicating with the ink circulation passage and an air storage unit communicating with external air, a valve mounted in the ink circulation passage between the ink tank and the pressure controller, a pump mounted in the ink circulation passage and pumps the ink, and a control unit to control operations of the valve and the pump.

Owner:S PRINTING SOLUTION CO LTD

Microfluidic viscometer

InactiveUS7040144B2Determine viscosityVolume/mass flow measurementFlow control using electric meansFluid transportEngineering

Microfluidic devices, systems, and methods measure viscosity, flow times, and / or pressures, other flow characteristics within the channels, and the measured flow characteristics can be used to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems, electrokinetic systems and / or other fluid transport mechanisms can generate the flow, controllably mix fluids, and the like.

Owner:CAPLIPER LIFE SCI INC

Combination of injector-ejector for fuel cell systems

ActiveUS7320840B2Efficient drawingReactant parameters controlCell component detailsHydrogenFuel cells

A fuel cell system including a combined injector / ejector system. The pressure of a hydrogen gas being injected into the fuel cell system by the injector acts as a pump that draws an anode exhaust gas being carried by the ejector back into the fuel cell system. The respective gases mix together in proximity to the ejector prior to being introduced back into the fuel cell system. A pressure controller can be provided to control the pressure of the hydrogen gas applied to the injector to more effectively draw the anode exhaust gas. In this manner, the need for a separate pump for the ejector, and the energy required for its operation, is eliminated or at least lessened, thus increasing the overall energy efficiency of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cooling system and method minimizing power consumption in cooling liquid-cooled electronics racks

InactiveUS8583290B2Reduce power consumptionOvercomes shortcomingEnergy efficient ICTMechanical power/torque controlControl flowCoolant flow

A cooling system and method are provided for facilitating cooling of a liquid-cooled electronics rack. The cooling system includes a coolant flow controller, a modular cooling unit and a pressure controller. The flow controller is associated with a respective electronics rack and controls flow of coolant through that electronics rack based on its changing cooling requirements. The cooling unit includes an adjustable coolant pump for facilitating supply of coolant to the rack. The pressure controller is associated with the cooling unit for controlling pressure of coolant at an output of the cooling unit via control of pump speed of the pump. Responsive to adjusting coolant flow through the electronics rack, the pressure controller automatically adjusts pump speed of the adjustable pump to maintain pressure about a constant coolant pressure set point at an output of the cooling unit, thereby conserving power while still cooling the liquid-cooled electronics rack.

Owner:IBM CORP

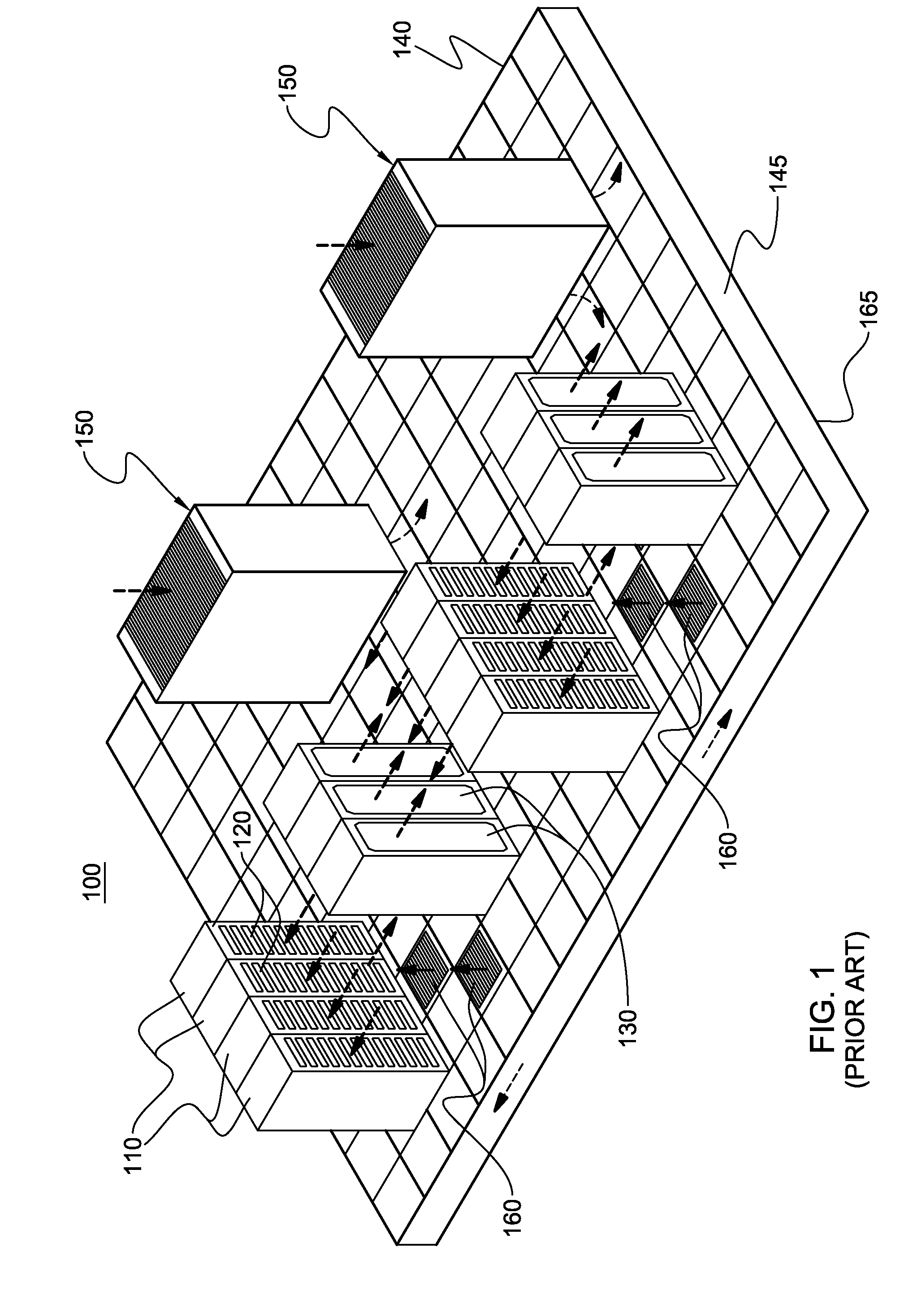

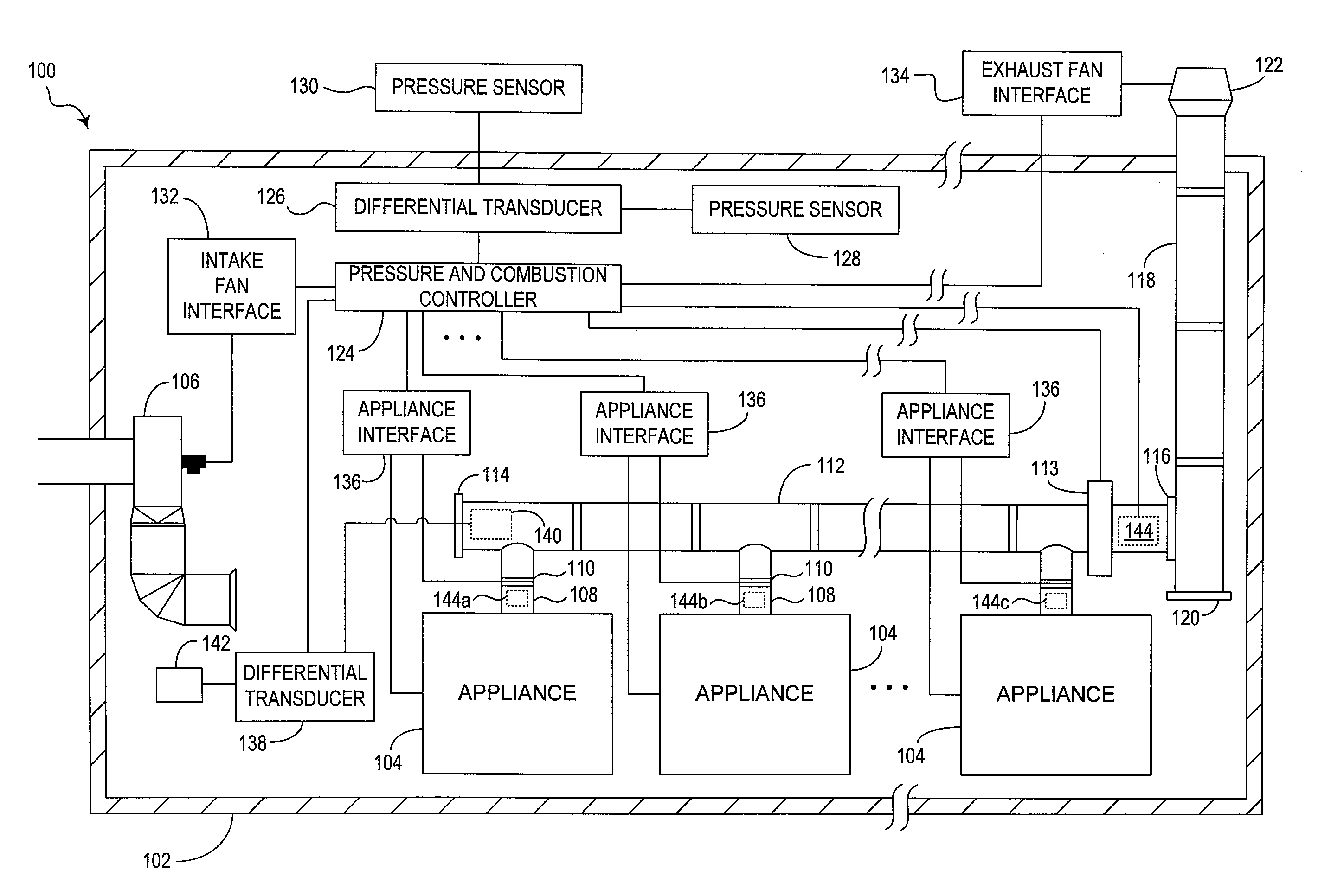

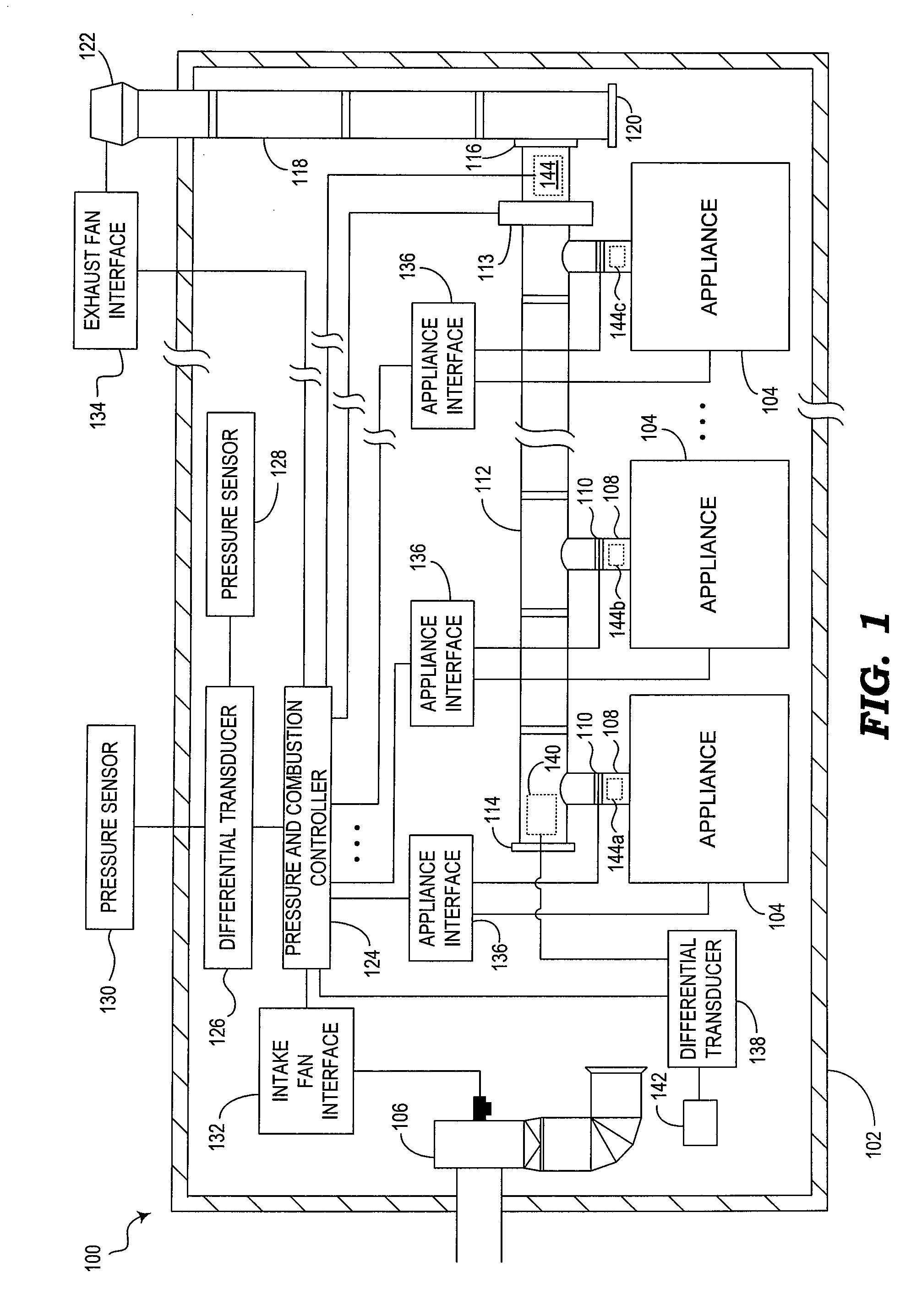

Pressure Controller for a Mechanical Draft System

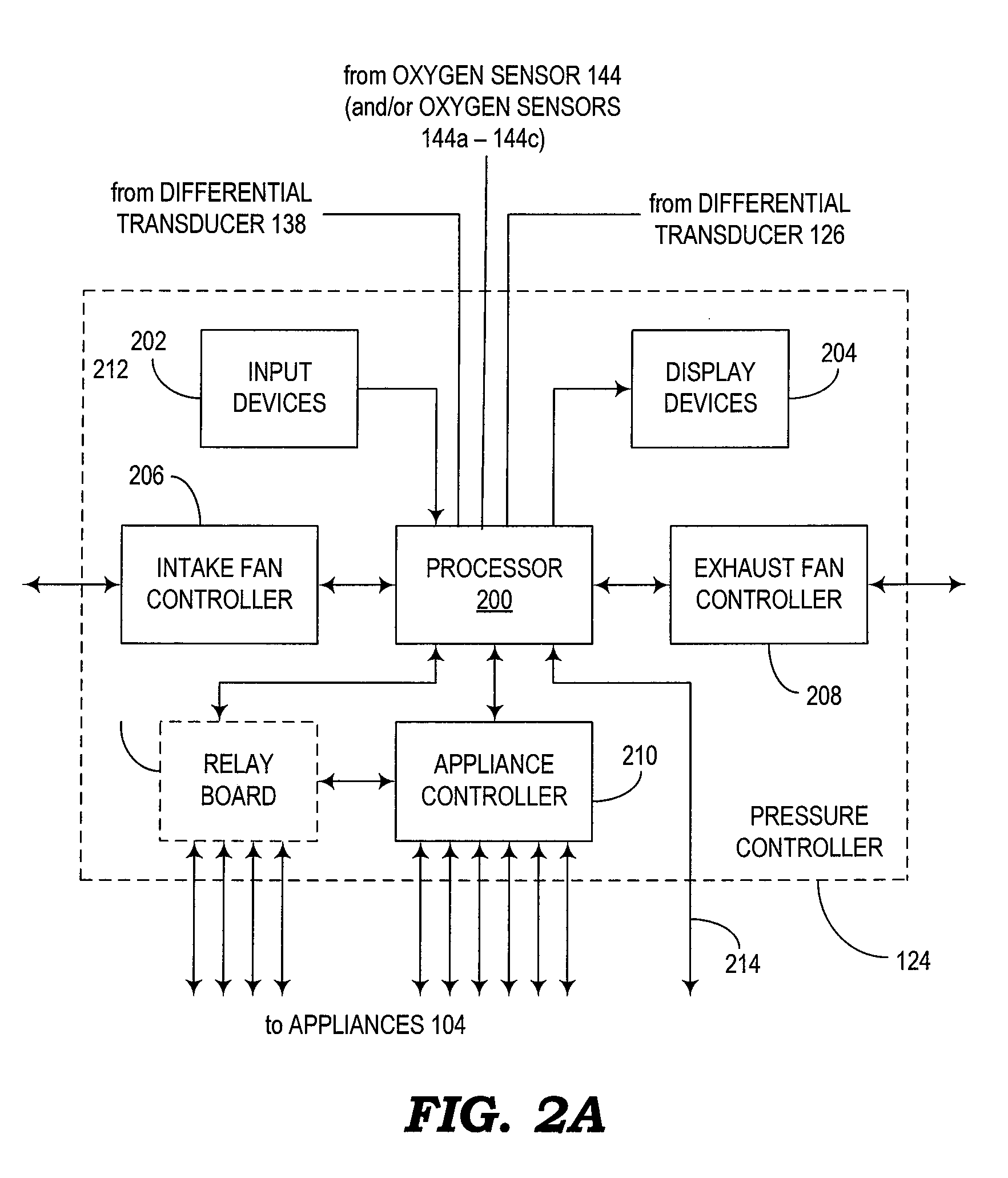

InactiveUS20070209653A1Mechanical apparatusAir supply regulationDifferential pressureAtmospheric pressure

Systems and method for controlling the flow of air through a mechanical draft system are disclosed herein. A pressure controller for controlling air pressure comprises an appliance controller configured to control the operation of a plurality of appliances, an intake fan controller configured to control the speed of an intake fan, and an exhaust fan controller configured to control the speed of an exhaust fan. The pressure controller also includes a processor configured to receive a differential pressure signal and to control the operation of the appliances, the speed of the intake fan, and the speed of the exhaust fan in response to the differential pressure signal.

Owner:ENERVEX

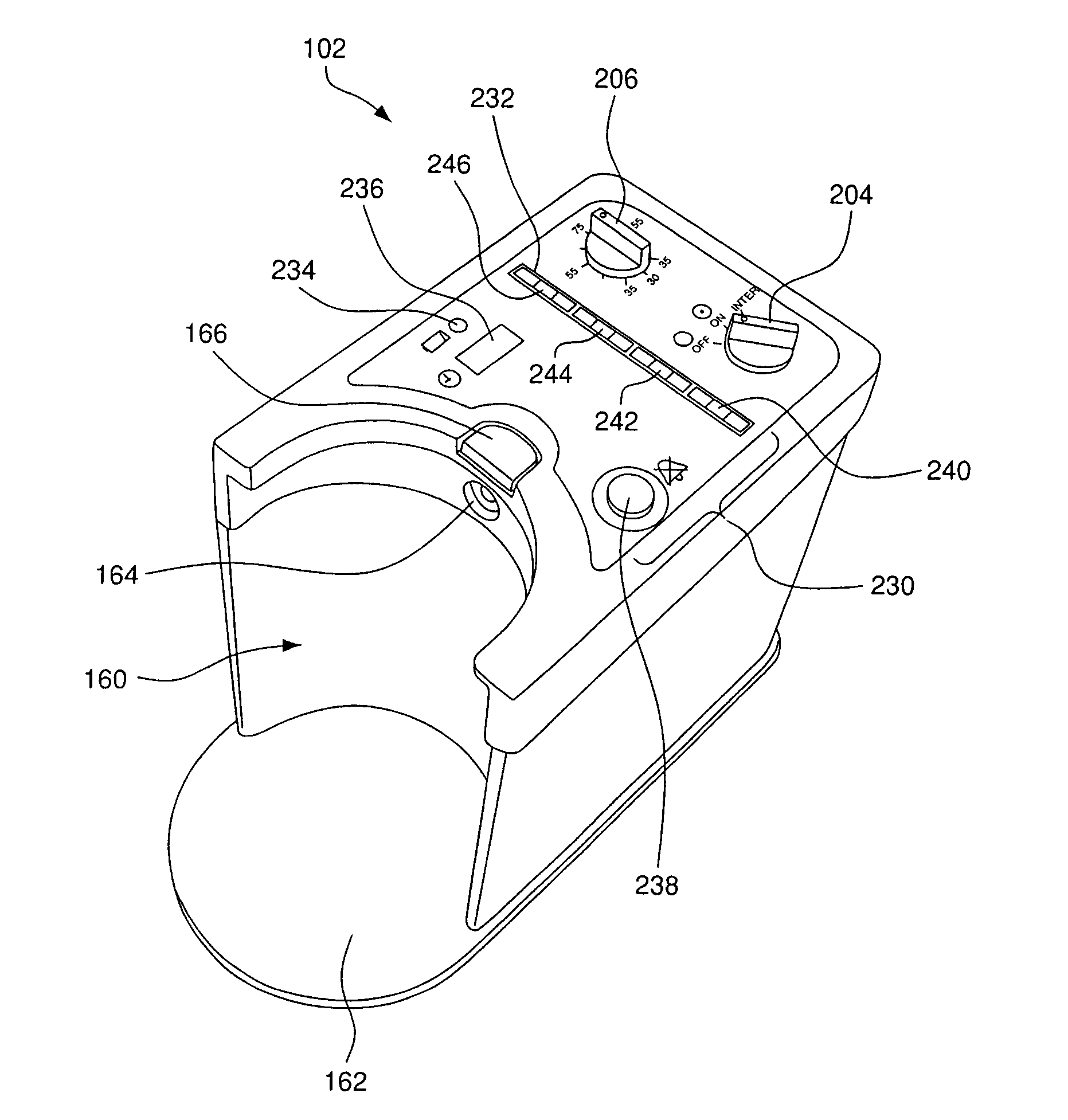

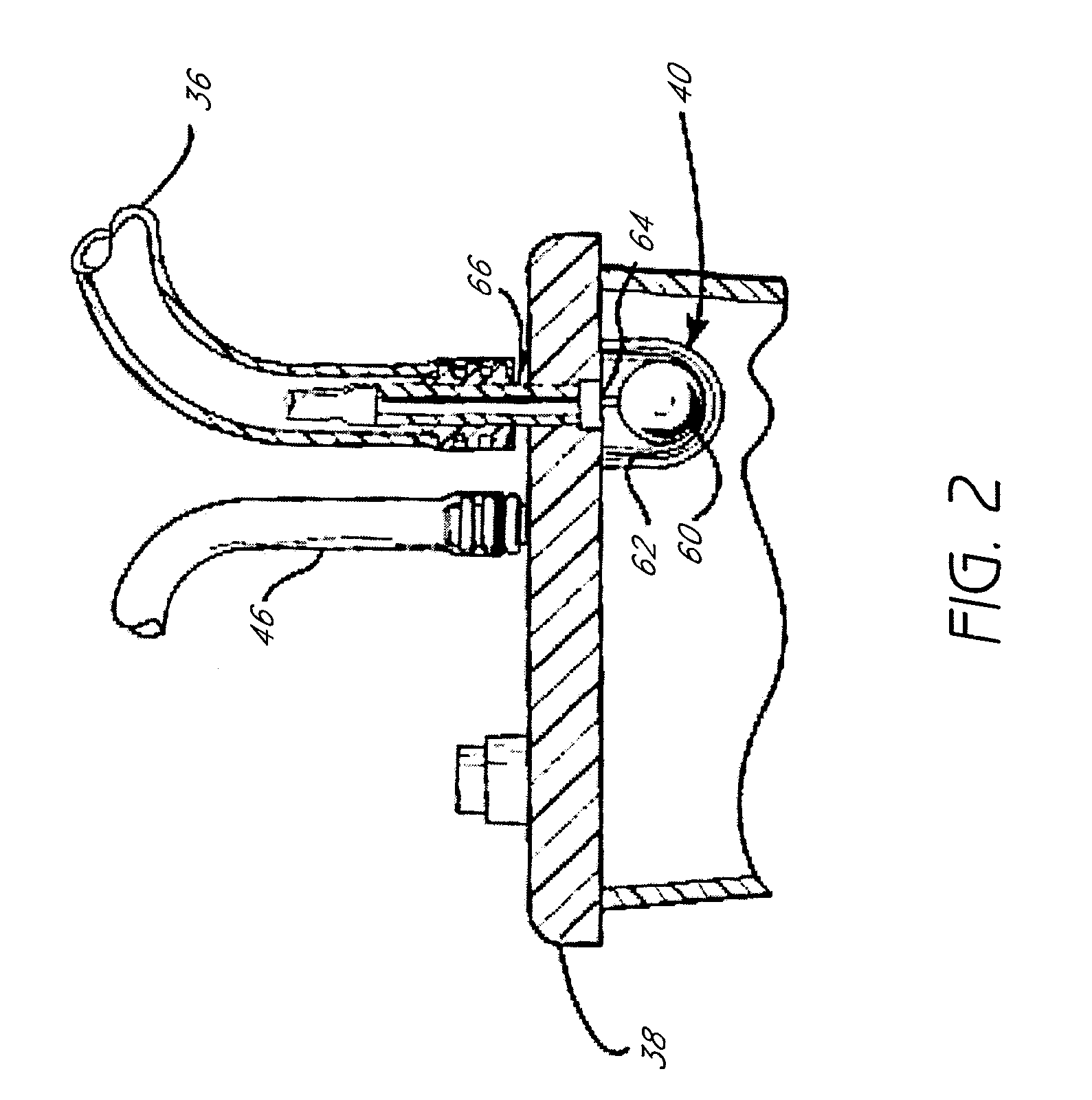

Auxiliary powered negative pressure wound therapy apparatuses and methods

ActiveUS20100042074A1Meet growth needsPromote quick completionWound drainsMedical devicesWound dressingElectrical battery

A negative pressure wound therapy apparatus that can include a wound dressing, a fluid collection device, a vacuum pump comprising a pump motor, and tubing can be powered by auxiliary power sources such as high efficiency batteries, photovoltaic panels or cells, fuel cells, combustion generators, human powered generators, or other mechanical, electrical, or chemical power sources such as hand operated dynamos or wound springs, or any combination of the foregoing. Additionally, the apparatus can include a high efficiency pressure controller for controlling the output of the vacuum pump. In some embodiments, the pressure controller can control the pump without using a processor, and can have other features such as an intermittent delay function and an anti-stall mechanism to reduce the energy consumption of the apparatus.

Owner:SMITH & NEPHEW INC

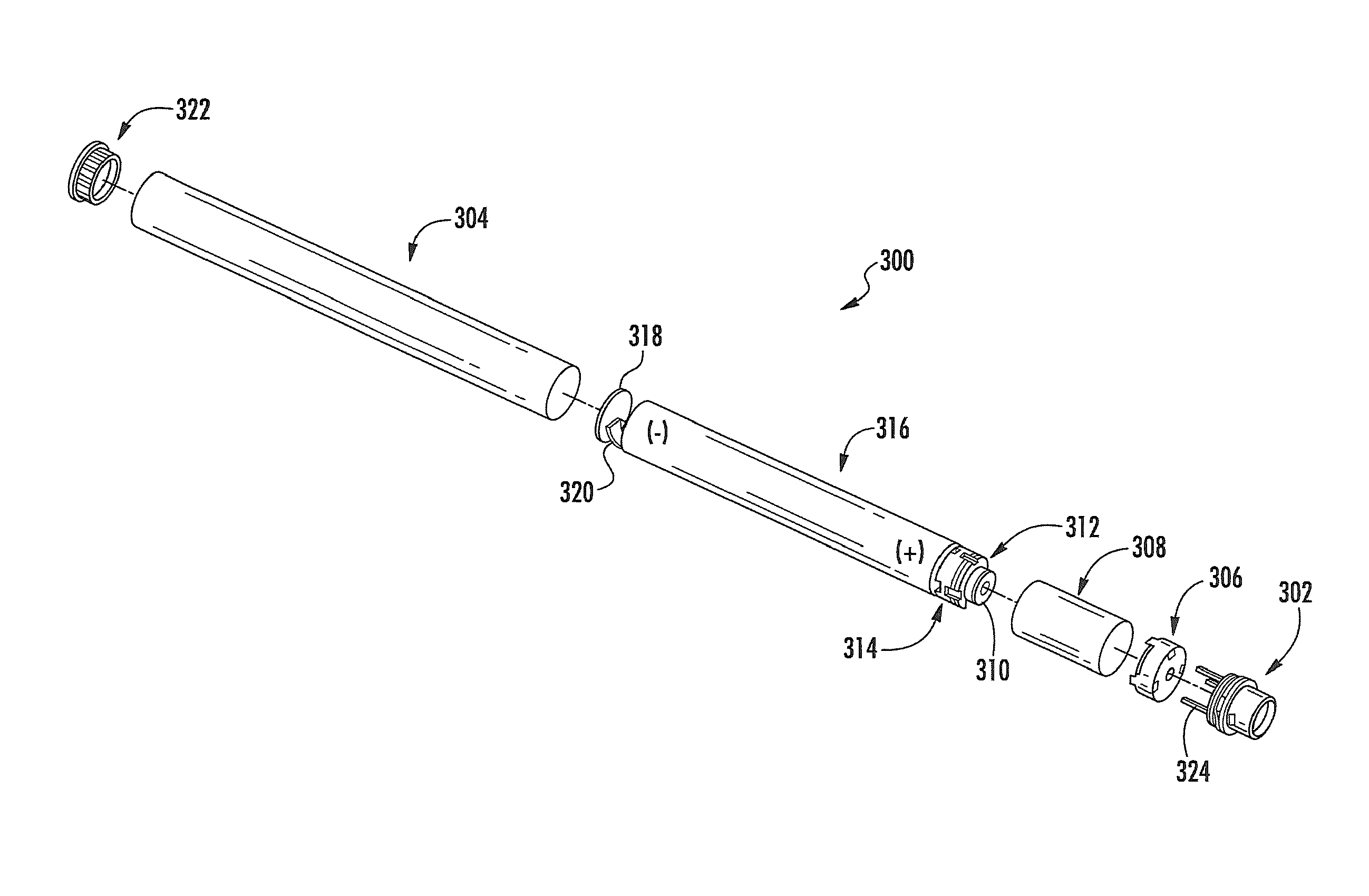

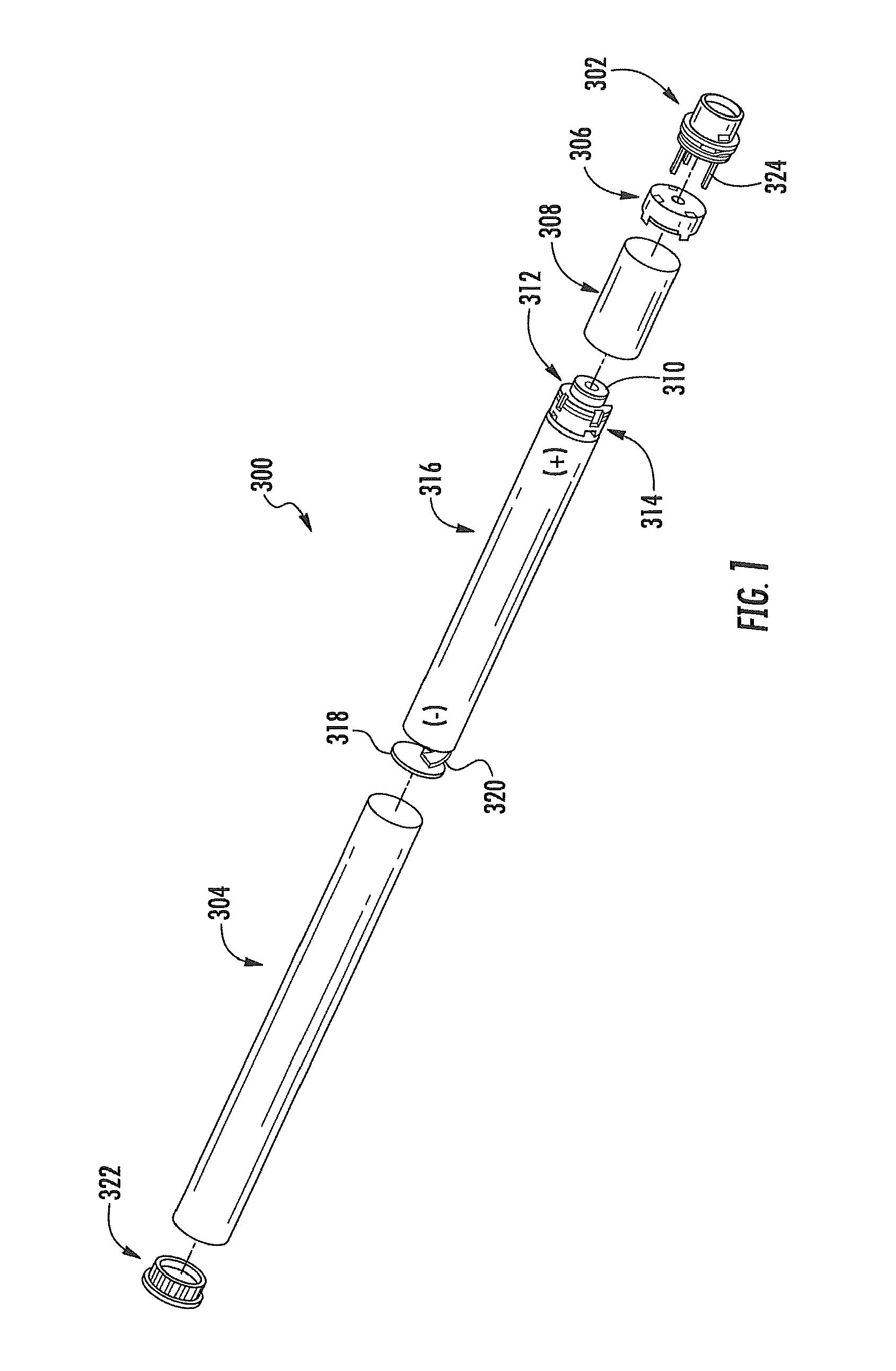

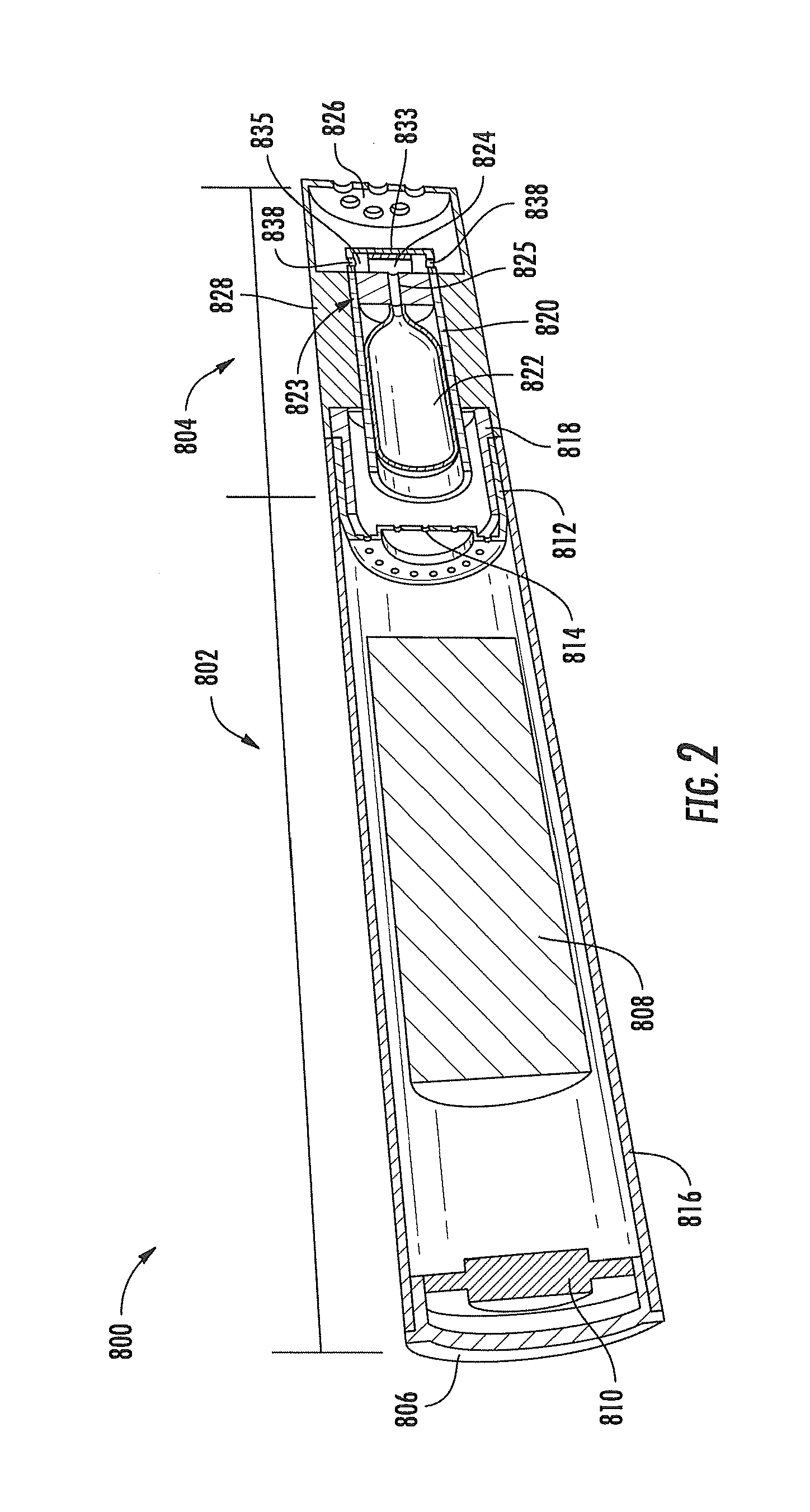

Aerosol Delivery Device Including a Pressure-Based Aerosol Delivery Mechanism

The present disclosure relates to aerosol delivery devices. The aerosol delivery devices include mechanisms configured to deliver an aerosol precursor composition from a reservoir to an atomizer including a heating element to produce a vapor. A pressure controller may control dispensing of the aerosol precursor composition from the reservoir based on a pressure differential between a first pressure within the reservoir and a second pressure proximate the atomizer. The first pressure within the reservoir may be substantially equal to atmospheric pressure. Alternatively, the first pressure within the reservoir may be greater than atmospheric pressure.

Owner:RAI STRATEGIC HLDG INC

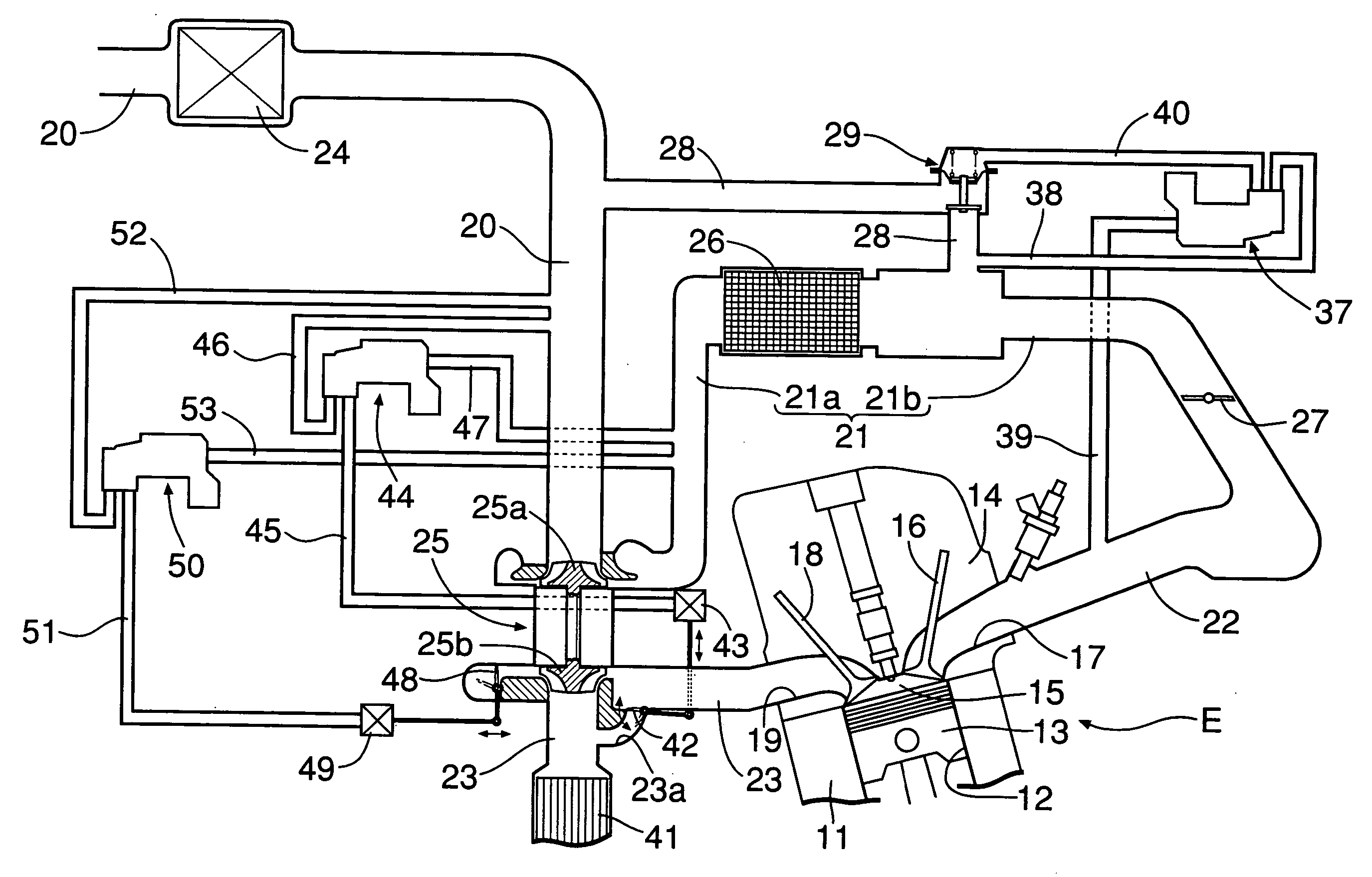

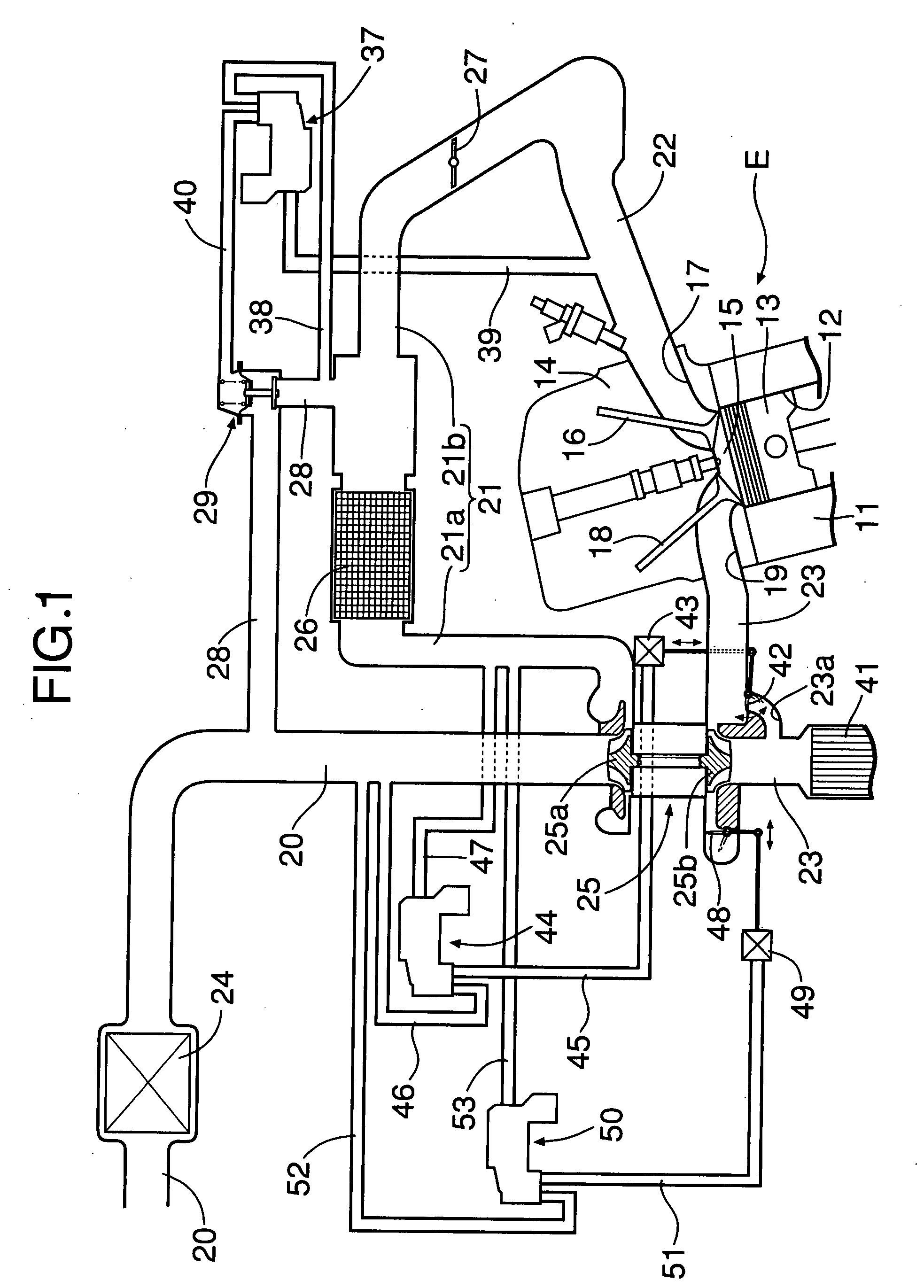

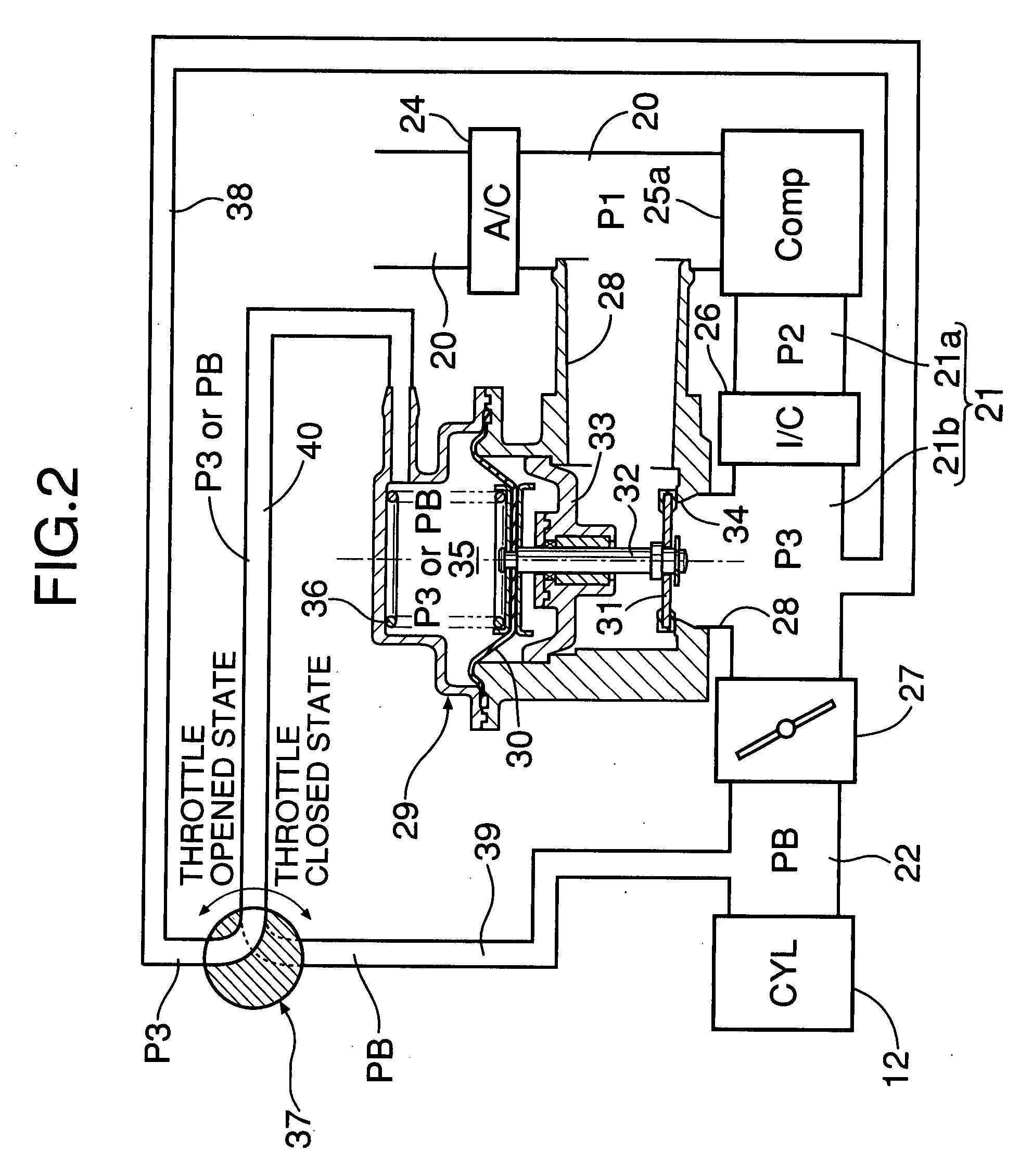

Failure detecting device for supercharging-pressure control means in supercharging device of engine

InactiveUS20080022679A1Accurate detectionHigh frequencyElectrical controlInternal combustion piston enginesWastegateResponse delay

When an engine load QC is equal to or larger than a predetermined value, an acceleration-state determiner determines that a turbine is in an acceleration state, and a supercharging-pressure-control-state determiner determines that supercharging-pressure controller (a bypass valve, a wastegate, and a variable flap) of a turbocharger are in a maximum supercharging pressure control state (a closed valve state), i.e., when a delay coefficient α of the turbocharger calculated by a delay-coefficient calculator on the basis of an actual supercharging pressure πc and a convergent value πc* of a supercharging pressure calculated by a convergent-value calculator indicates a value peculiar to the turbocharger, a failure of the supercharging-voltage controller is determined on the basis of the delay coefficient α. Thus, it is possible to secure a high failure detection accuracy, and increase a frequency of performing failure detection even when the engine load QC suddenly changes to cause a delay in a response of the supercharging pressure πc.

Owner:HONDA MOTOR CO LTD

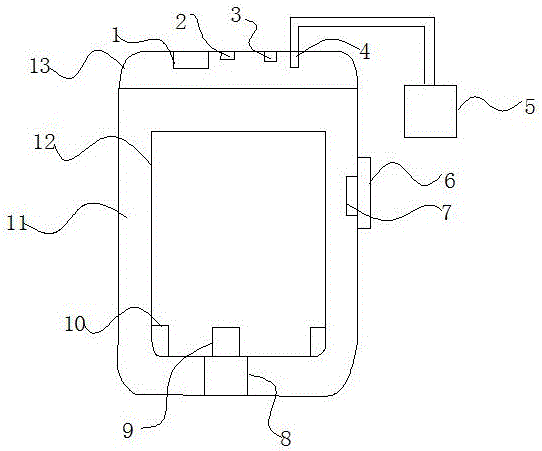

Novel electric cooker

ActiveCN106213979AAppropriate soaking timeEasy cookingCooking-vessel lids/coversWarming devicesMicrocontrollerMicrocomputer

The invention discloses a novel electric cooker which comprises a pot body, a pot cover and a liner, wherein the liner is placed in the pot body; and the pot cover is disposed on the pot body and used in cooperation with the pot body. The novel electric cooker is characterized by comprising a temperature controller, a pressure controller, a moisture measurement device and a single-chip microcomputer, wherein the single-chip microcomputer is disposed on the inner wall of the pot body and connected to the temperature controller, the pressure controller and the moisture measurement device; the temperature controller comprises a heater and a temperature sensor, and the heater is disposed on the bottom of the outer wall of the liner; the temperature sensor is disposed on the inner wall of the pot cover; the pressure controller comprises an adjustable steam micro-pressure valve and a pressure sensor, and the adjustable steam micro-pressure valve is disposed on the pot cover; the pressure sensor is disposed on the inner wall of the pot cover; and the moisture measurement device comprises a moisture measurement instrument. According to the invention, rice can be soaked for a proper period, and accurate control of temperatures and pressures can be achieved, so that the best rice cooking effects can be achieved.

Owner:GUANGDONG LIANJIANG YILAIDUN CO LTD

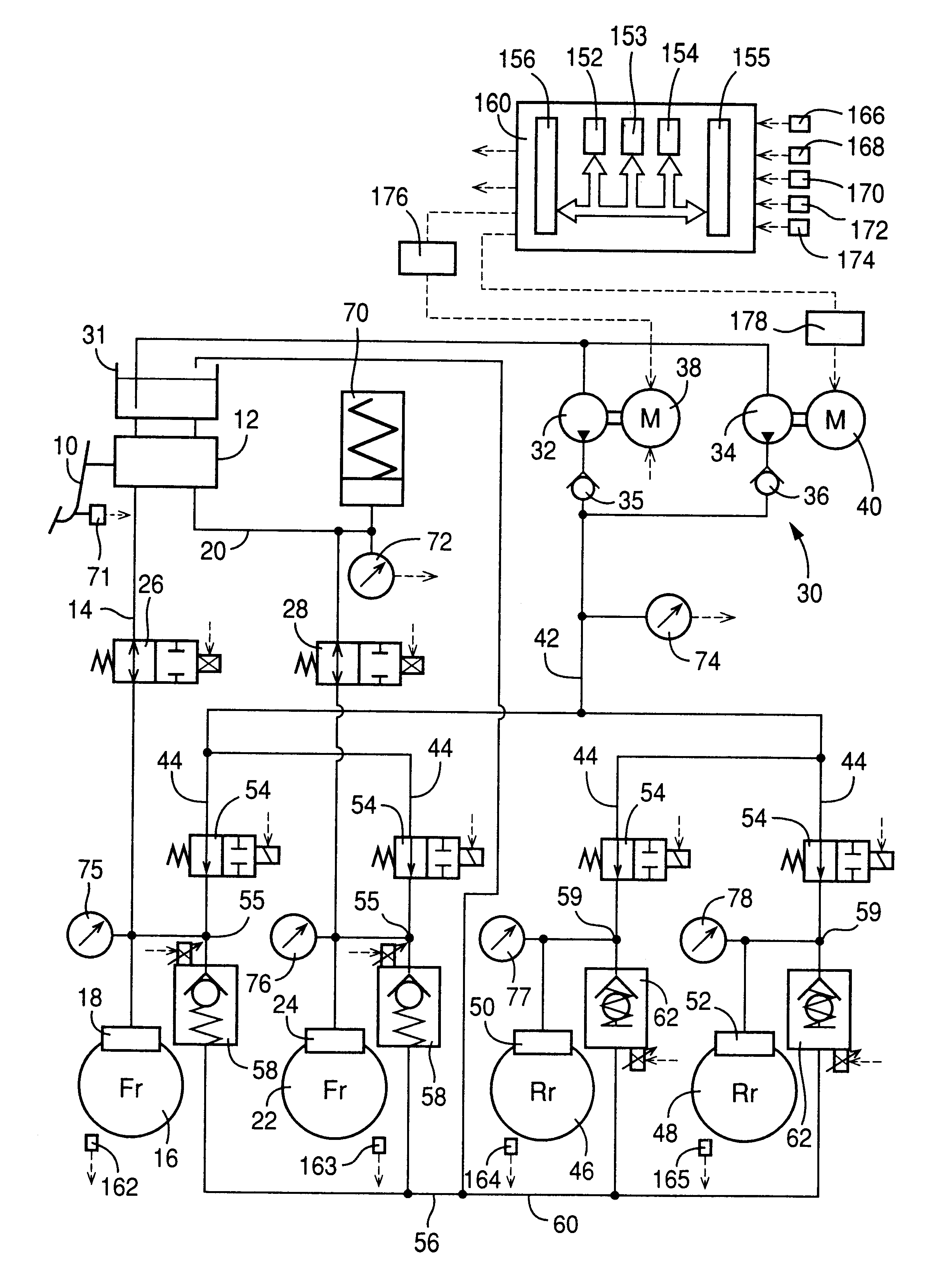

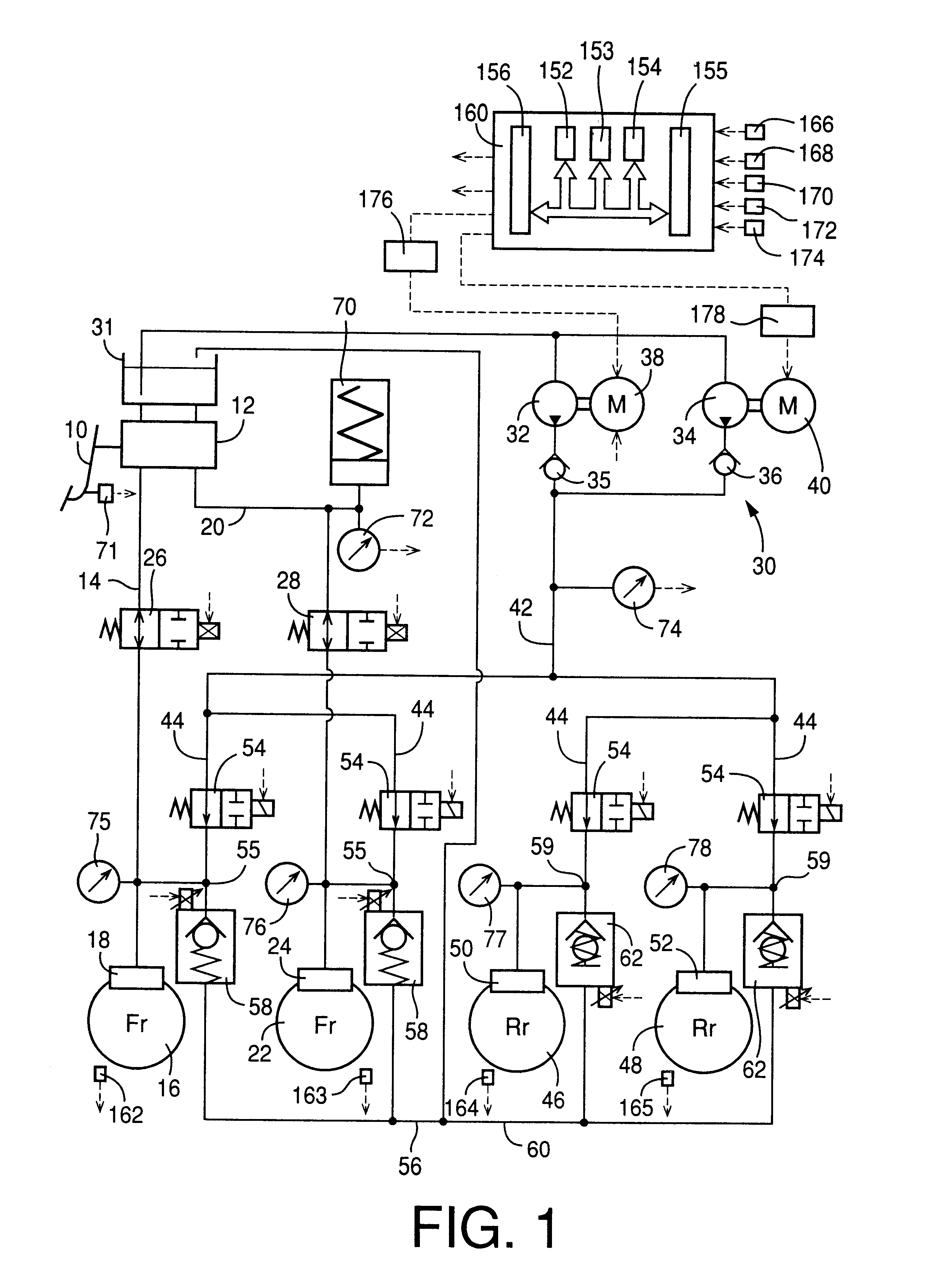

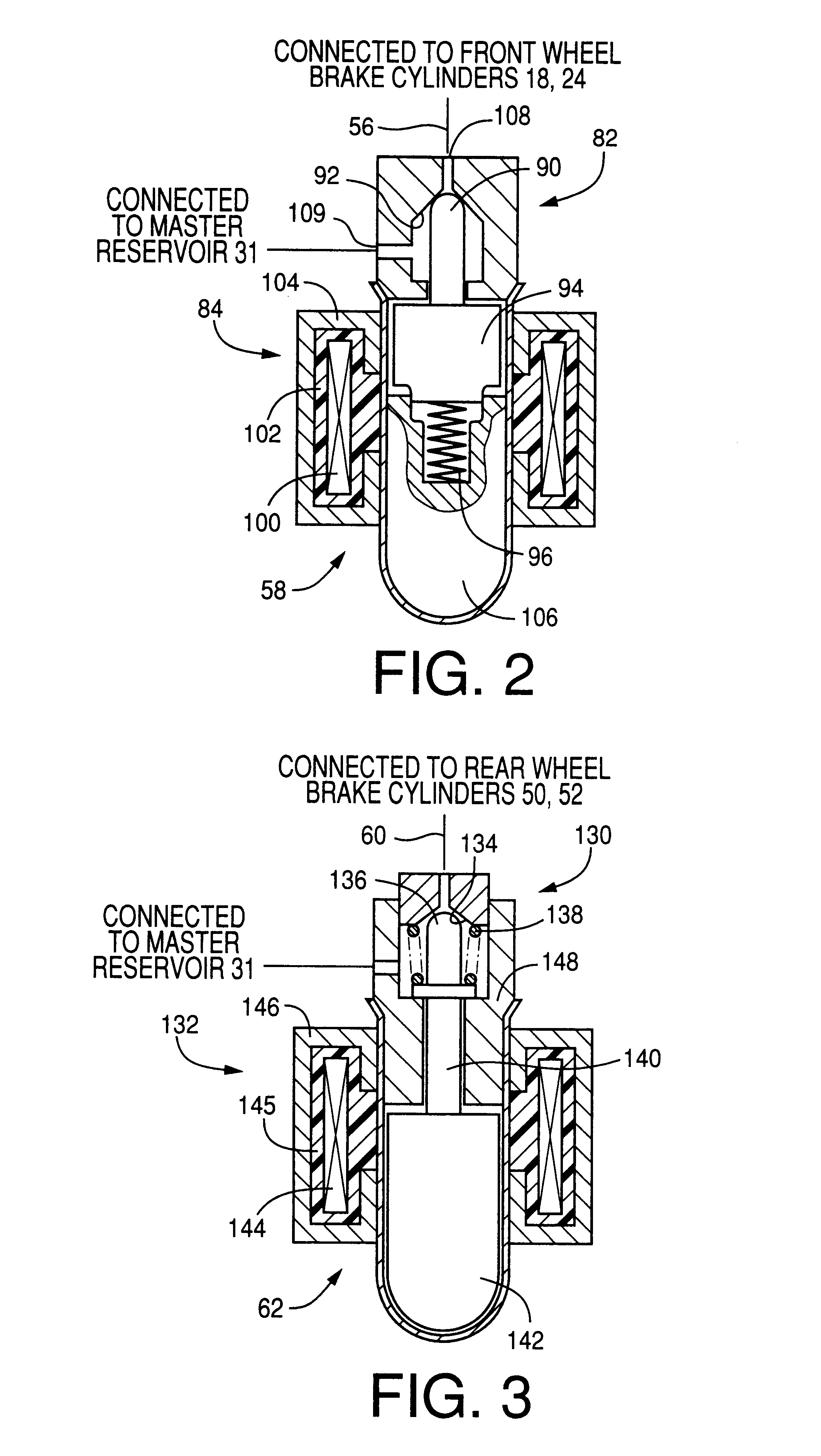

Apparatus for increasing brake cylinder pressure by controlling pump motor and reducing the pressure by controlling electric energy applied to control valve

Hydraulic pressure control apparatus for controlling a pressure of a brake cylinder pressure, including a pump device connected to the brake cylinder and including at least one set of a pump for delivering a pressurized fluid to the brake cylinder and a pump operating electric motor, a low-pressure source for storing the fluid discharged from the brake cylinder, a solenoid-operated pressure control valve disposed between the low-pressure source and the brake cylinder and operated with an electric energy applied thereto, for controlling the brake cylinder pressure depending upon the electric energy, and a controller including a pressure increase control device for increasing the brake cylinder pressure by controlling the electric motor, and a pressure reduction control device or reducing the brake cylinder pressure by controlling the electric energy applied to the control valve.

Owner:TOYOTA JIDOSHA KK

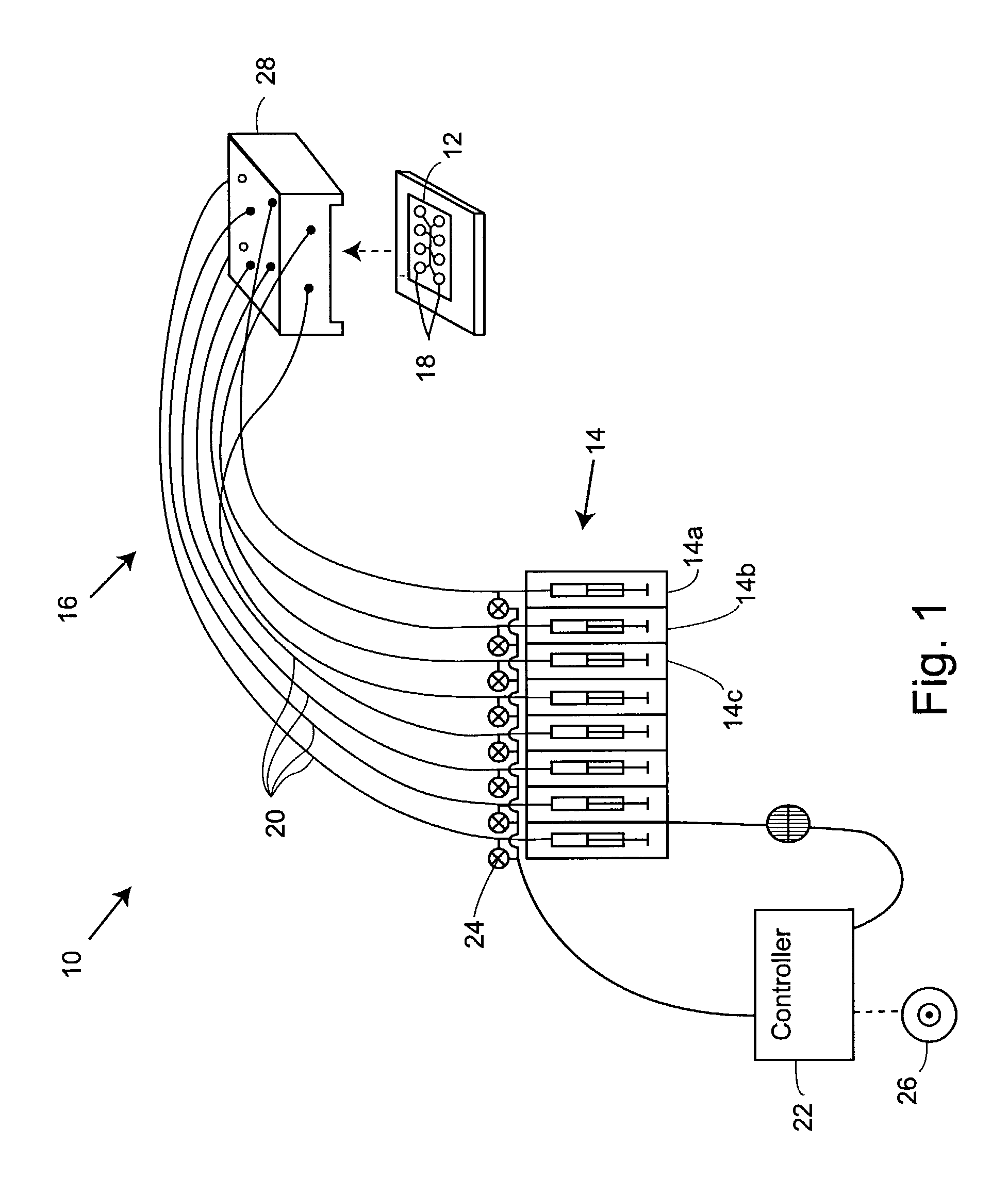

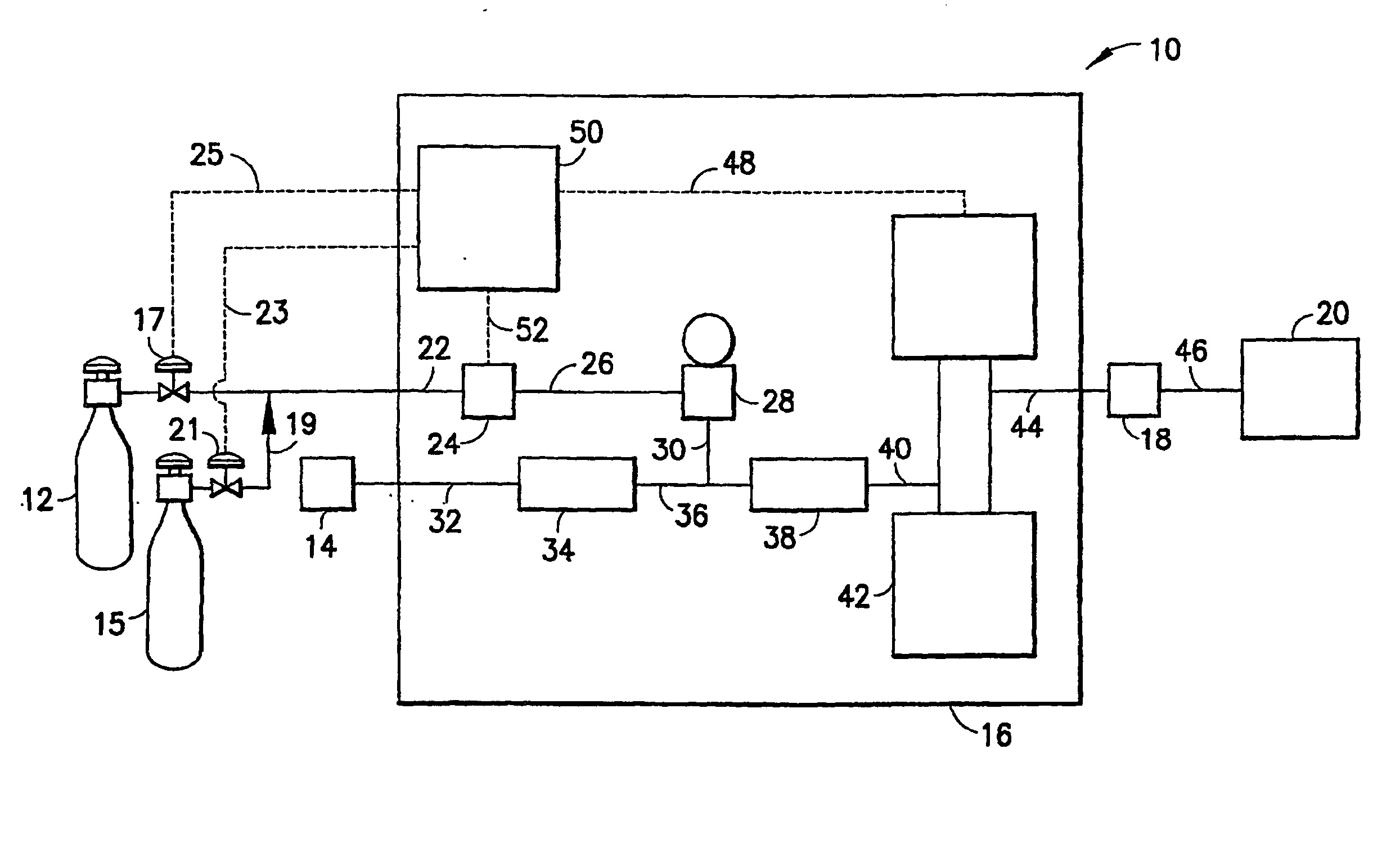

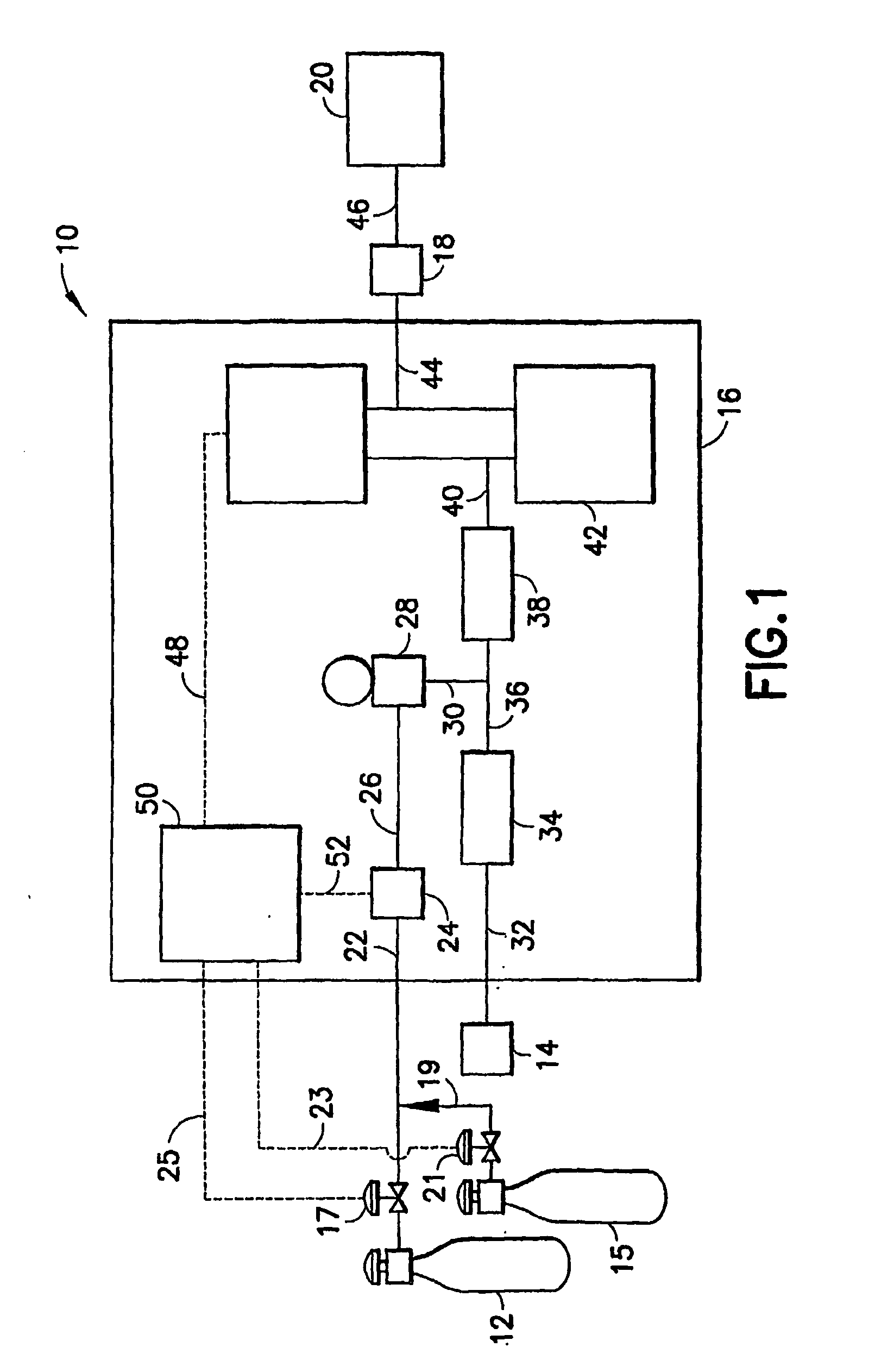

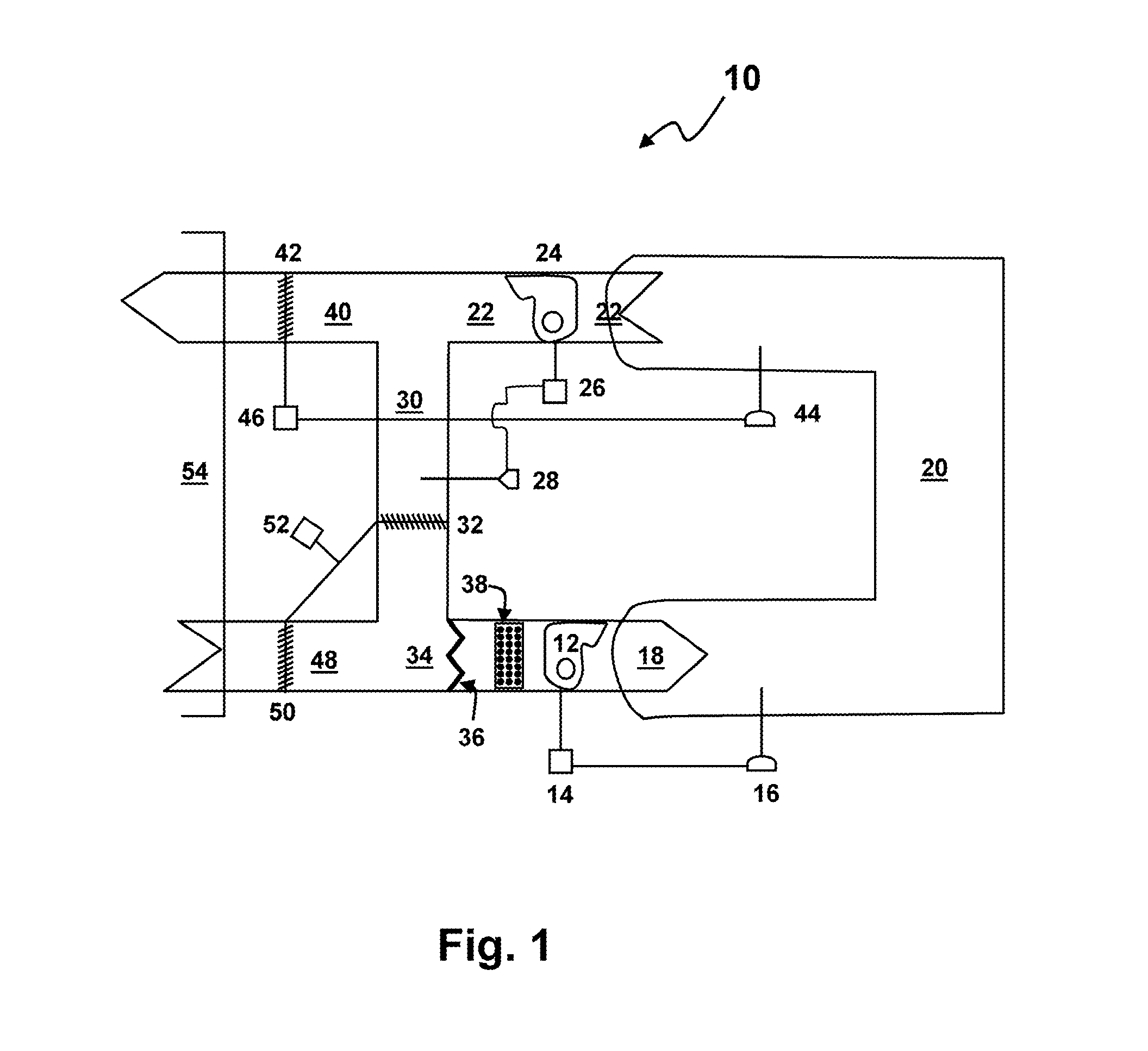

Apparatus and process for integrated gas blending

InactiveUS20100224264A1Keep the pressureFrozen sweetsSemiconductor/solid-state device manufacturingDiluentEngineering

A system (10) for delivery of dilute fluid, utilizing an active fluid source (12), a diluent fluid source (14), a fluid flow metering device (24) for dispensing of one of the active and diluent fluids, a mixer (28) arranged to mix the active and diluent fluids to form a diluted active fluid mixture, and a monitor (42) arranged to sense concentration of active fluid and / or diluent fluid in the diluted active fluid mixture, and responsively adjust the fluid flow metering device (24) to achieve a predetermined concentration of active fluid in the diluted active fluid mixture. A pressure controller (38) is arranged to control flow of the other of the active and diluent fluids so as to maintain a predetermined pressure of the diluted active fluid mixture dispensed from the system. The fluid dispensed from the system then can be adjustably controlled by a flow rate controller, e.g., a mass flow controller, to provide a desired flow to a fluid-utilizing unit, such as a semiconductor process tool. An end point monitoring assembly is also described, for switching fluid sources (12, 15) to maintain continuity of delivery of the diluted active fluid mixture.

Owner:ENTEGRIS INC

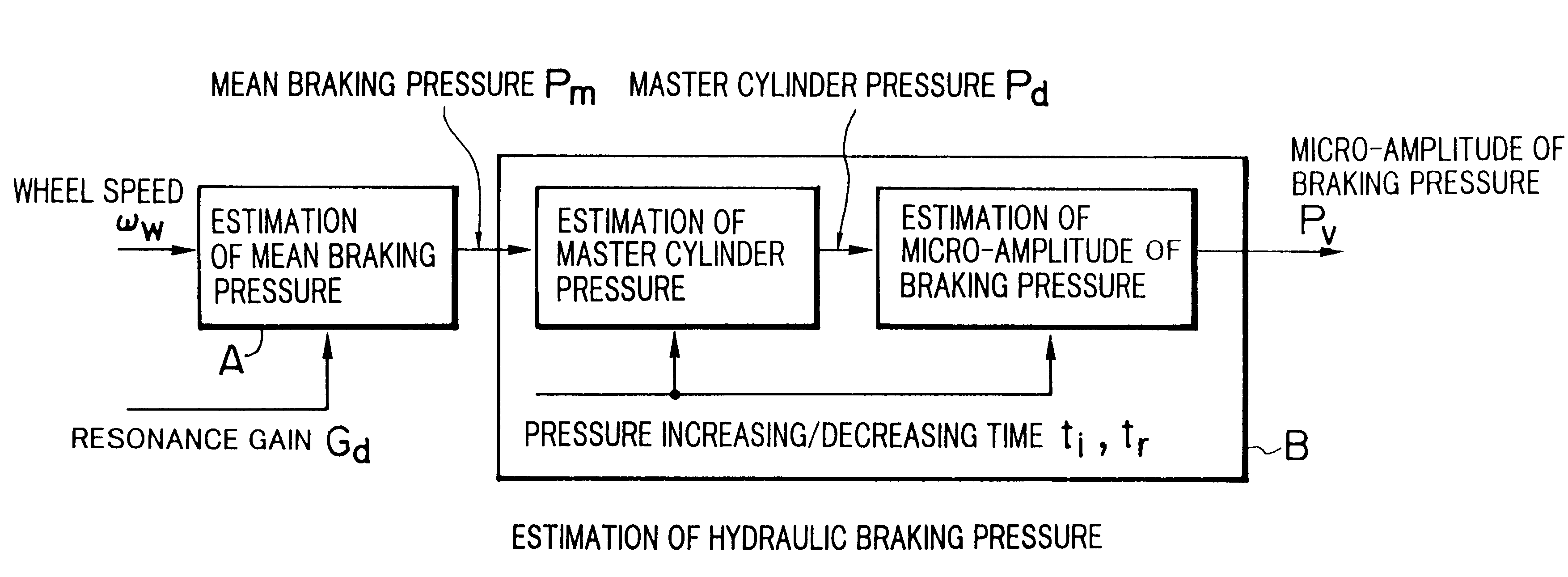

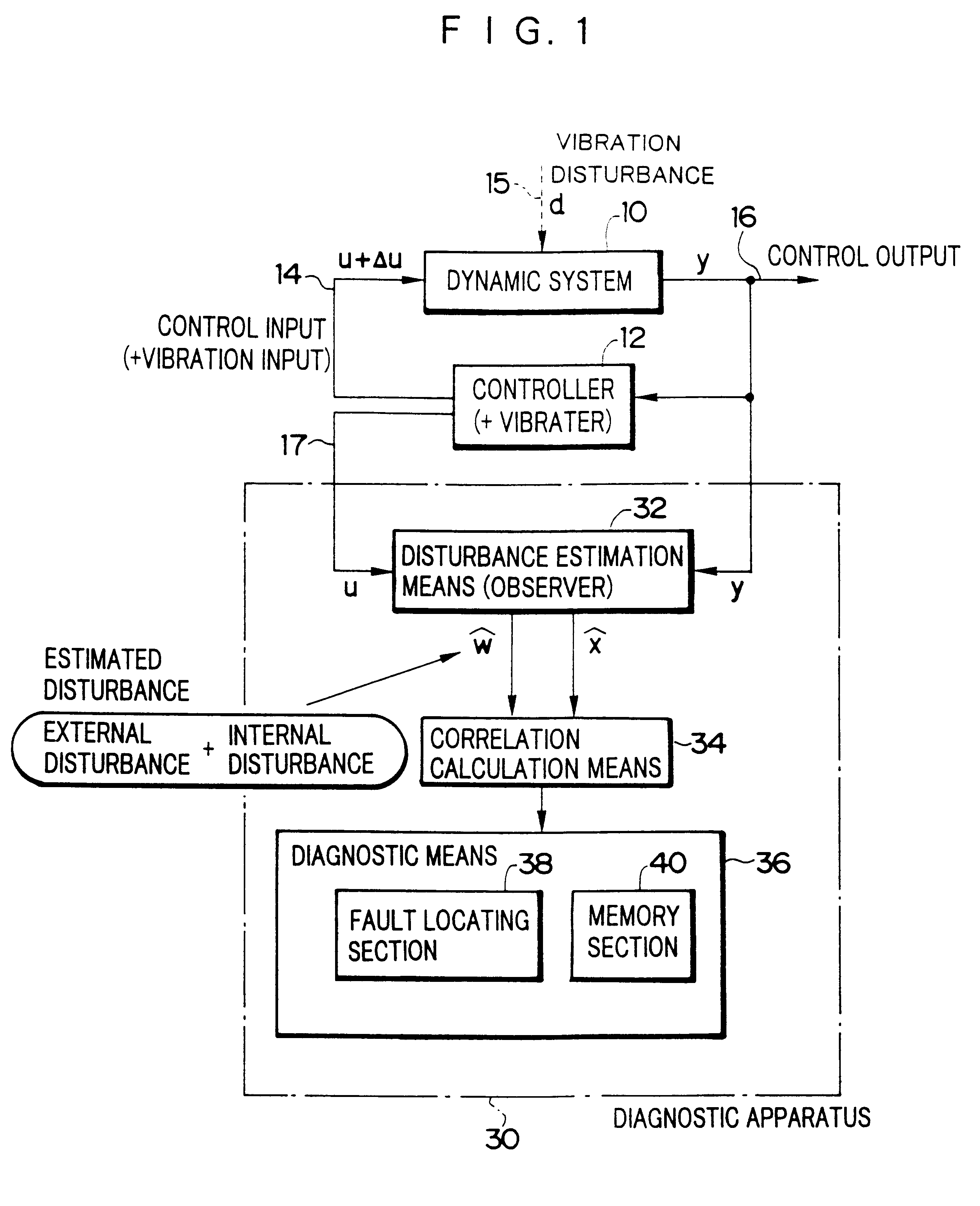

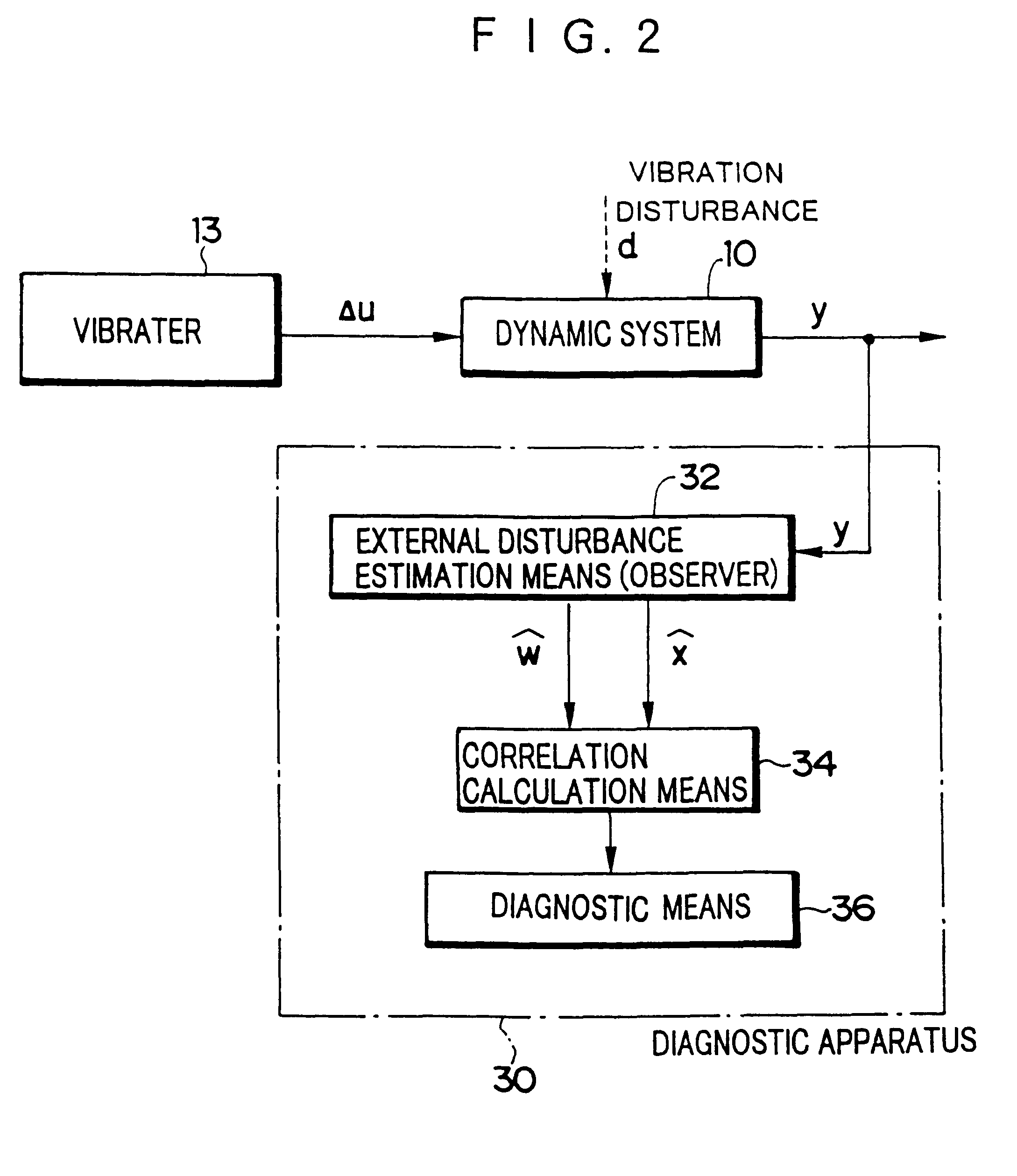

Braking estimation device, anti-lock brake controller, and braking pressure controller

InactiveUS6182001B1Inflated body pressure measurementDigital data processing detailsVibratory signalAtmospheric pressure

An apparatus for diagnosing a fault in a dynamic system includes a controller which controls the dynamic system through use of a control input signal and vibrates the dynamic system through use of an vibration signal irrelevant to the internal state quantity of the dynamic system; an observer for estimating, on the basis of a response output from the vibration dynamic system, total disturbance which is a sum of an internal disturbance vector stemming from a fault in the dynamic system and a vibration disturbance vector occurring in the dynamic system through vibration; a correlation calculation unit which calculates cross-correlation between the thus-estimated total disturbance and the internal state quantity of the dynamic system and separates a component related to the internal disturbance from the total disturbance; and a diagnostic unit for diagnosing a fault in the dynamic system on the basis of the thus-separated component related to the internal disturbance. Since the dynamic system is vibrated, the response output can be increased even when there exists small external disturbance. As a result, a fault or a variation in air pressure in a tire can be highly accurately diagnosed.

Owner:TOYOTA CENT RES & DEV LAB INC

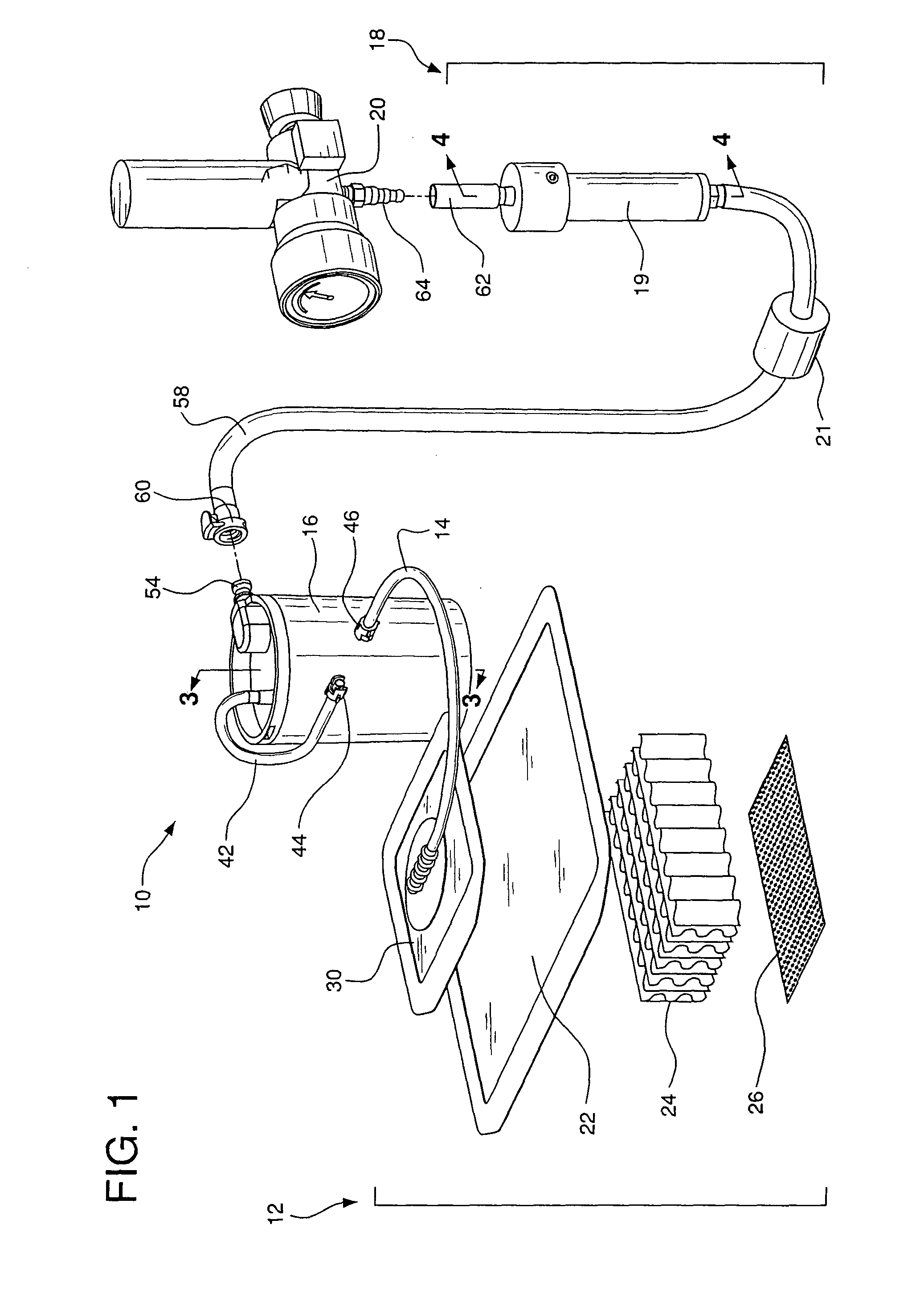

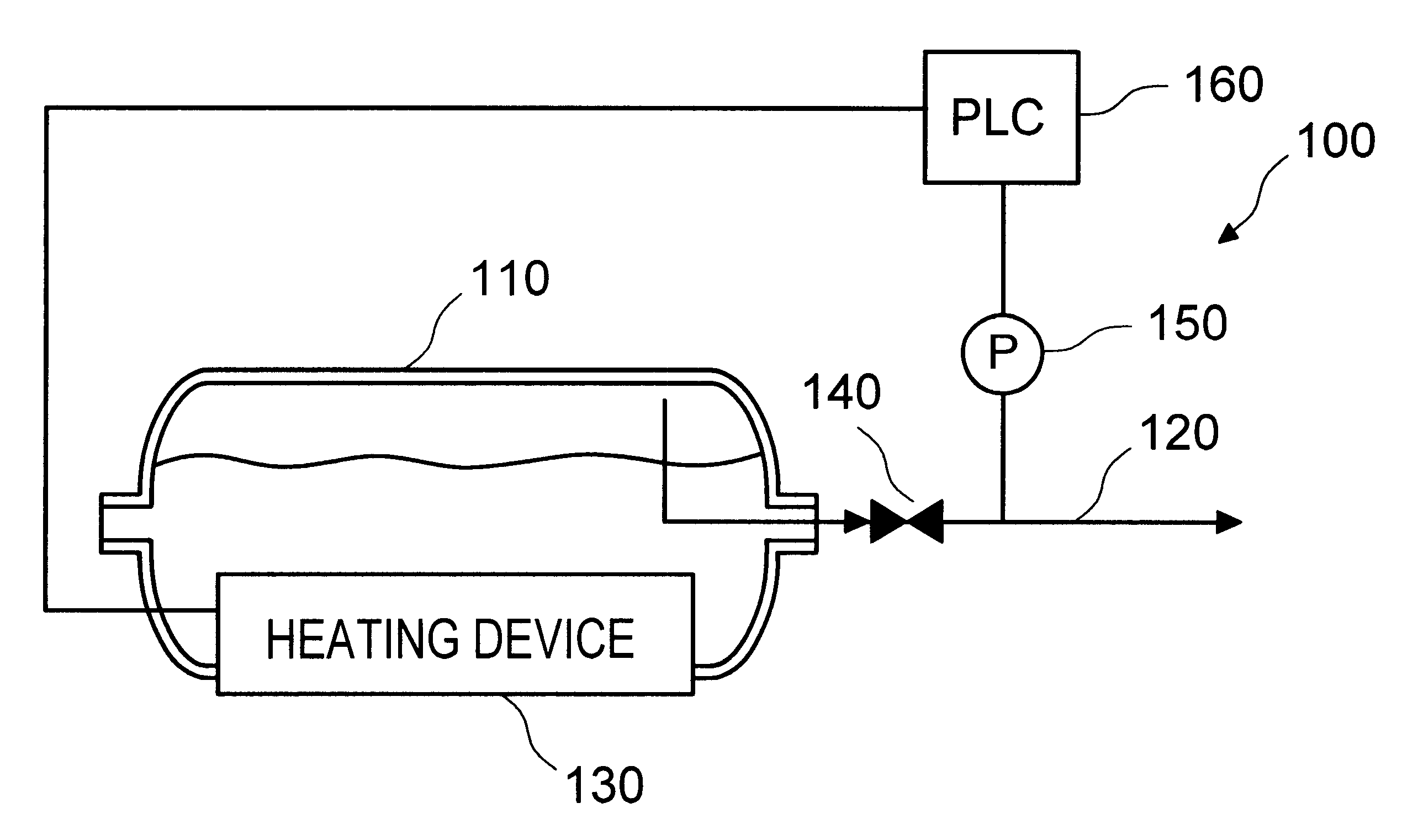

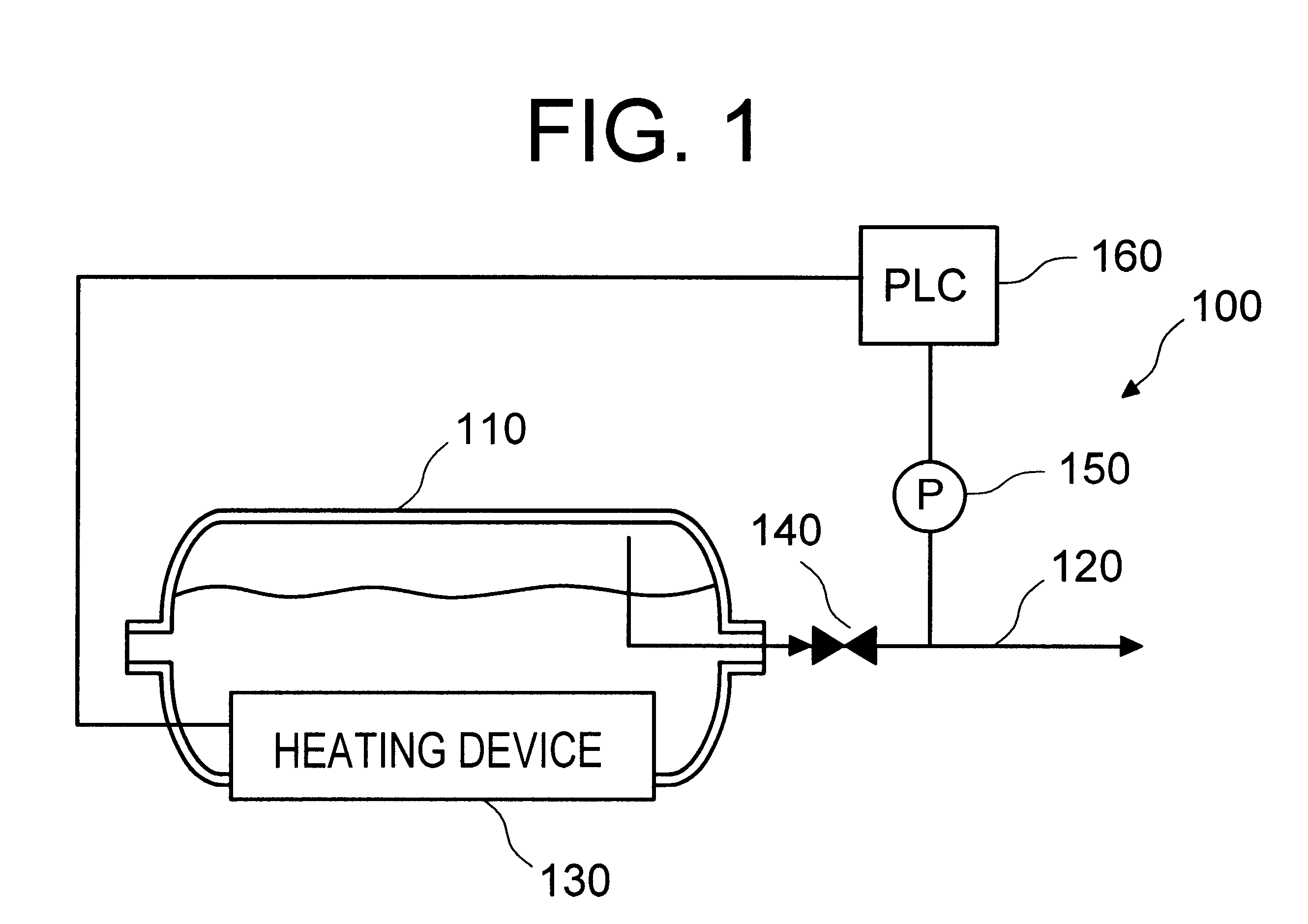

System and method for controlled delivery of liquefied gases from a bulk source

Provided is a novel system and method for delivery of gas from a liquefied state. The system includes (a) a delivery vessel holding a bulk quantity of liquefied gas therein; (b) a heat exchanger disposed on the delivery vessel to provide or remove energy from the liquefied gas only; and (c) a pressure controller for monitoring and adjusting the energy delivered to the vessel. The system and method allow for controlled delivery of liquefied gas from a delivery vessel at a predetermined flow rate. Particular applicability is found in the delivery of gases to semiconductor process tools.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

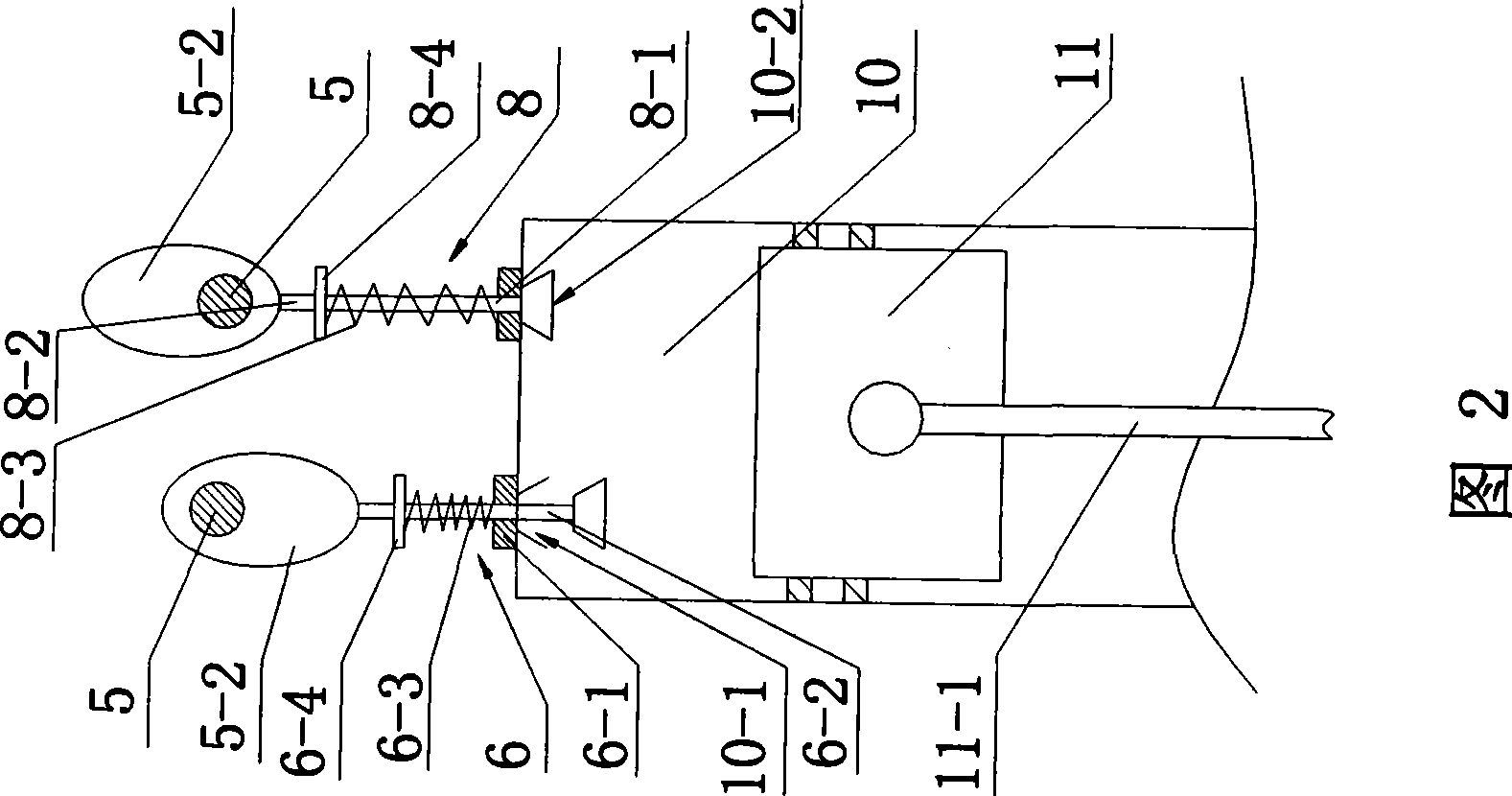

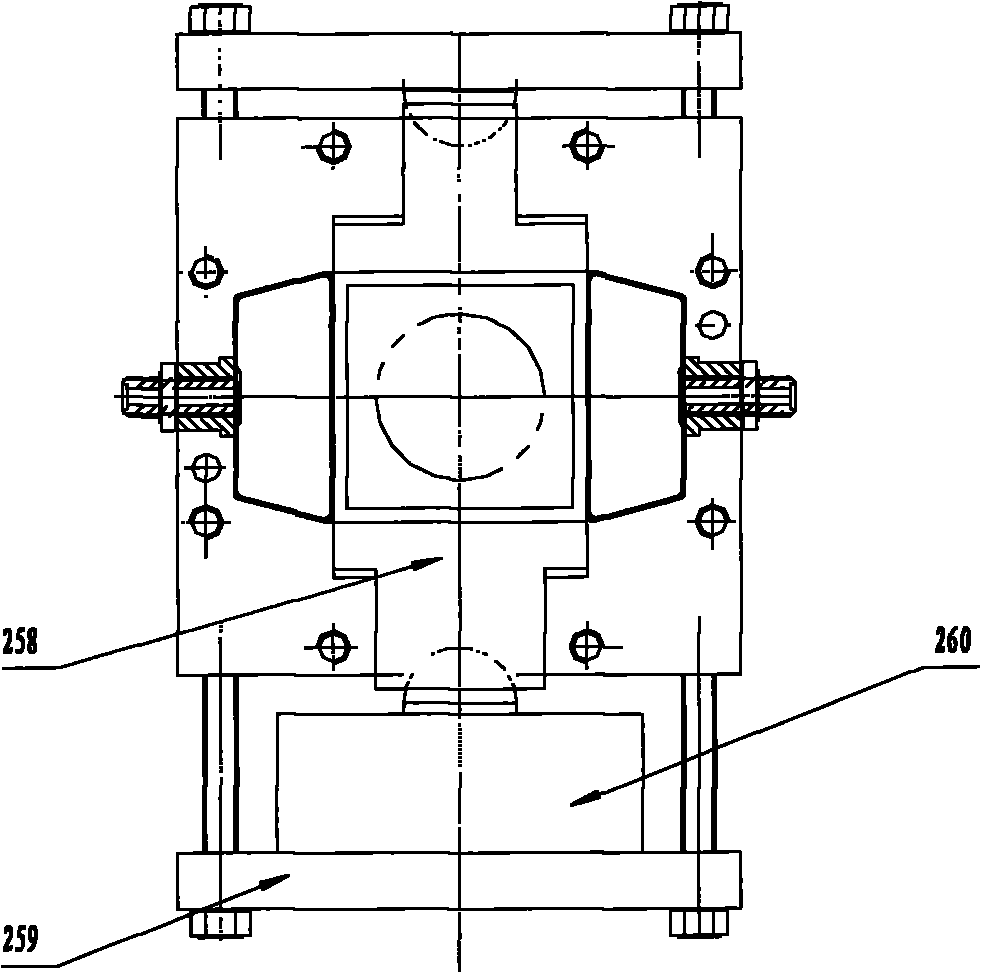

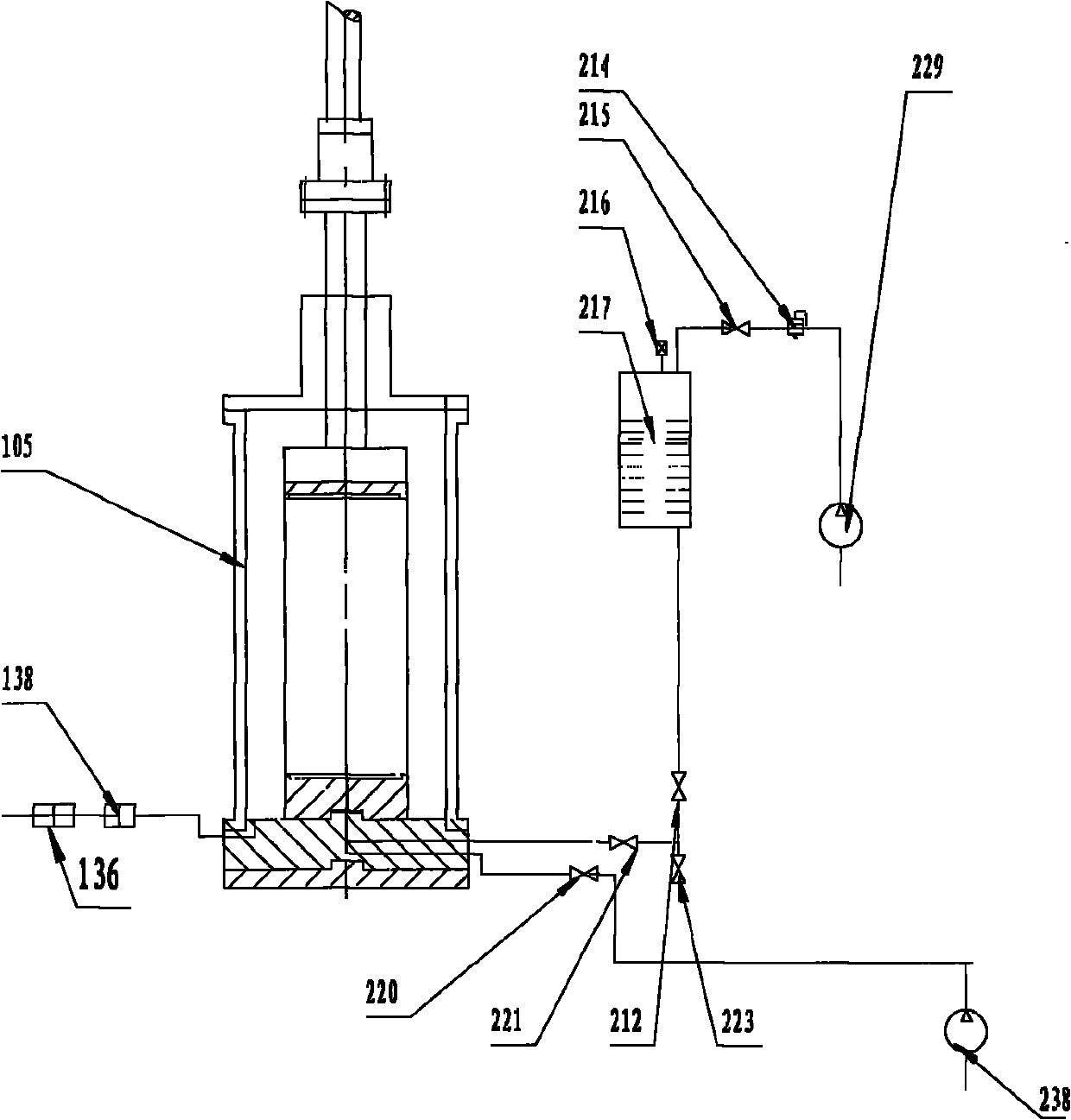

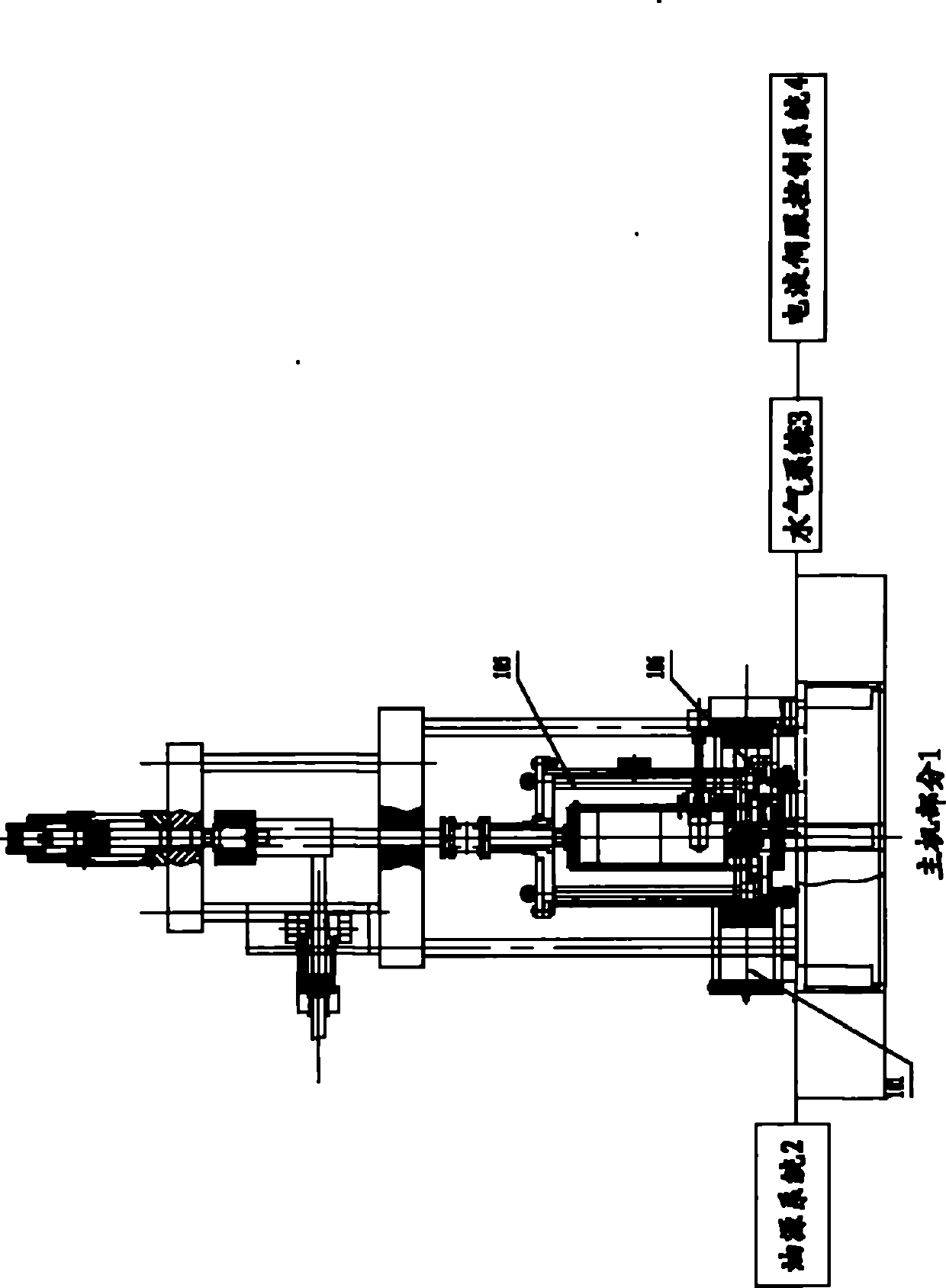

Pressing-twisting multi-shaft loading testing machine

ActiveCN101949800AGreat effortUniform and controllable dynamic and staticMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesControl systemAxial pressure

The invention discloses a pressing-twisting multi-shaft loading testing machine. The pressing-twisting multi-shaft loading testing machine comprises a machine frame, a sample pressure chamber, an axial pressure controller, a confining pressure controller and an oil source system, wherein the sample pressure chamber is arranged on the machine frame and is used for accommodating samples therein; the axial pressure controller is used for applying axial loads to the samples in the sample pressure chamber; the confining pressure controller is used for applying confining pressure loads to the samples in the sample pressure chamber; the oil source control system is used for controlling the axial pressure controller and the confining pressure controller respectively to apply different paths of loads; and the axial pressure controller and the confining pressure controller are configured in a mode that the axial force is coupled with the confining force when the loading of the samples in the sample pressure chamber is buffered. The pressing-twisting multi-shaft loading testing machine can integrate complicated loading such as pressing-twisting combination, plane strain, true triaxiality and the like and is suitable for the tests of static power units of the common coarse-grained soil and ideal soil simulation materials during engineering construction.

Owner:TSINGHUA UNIV

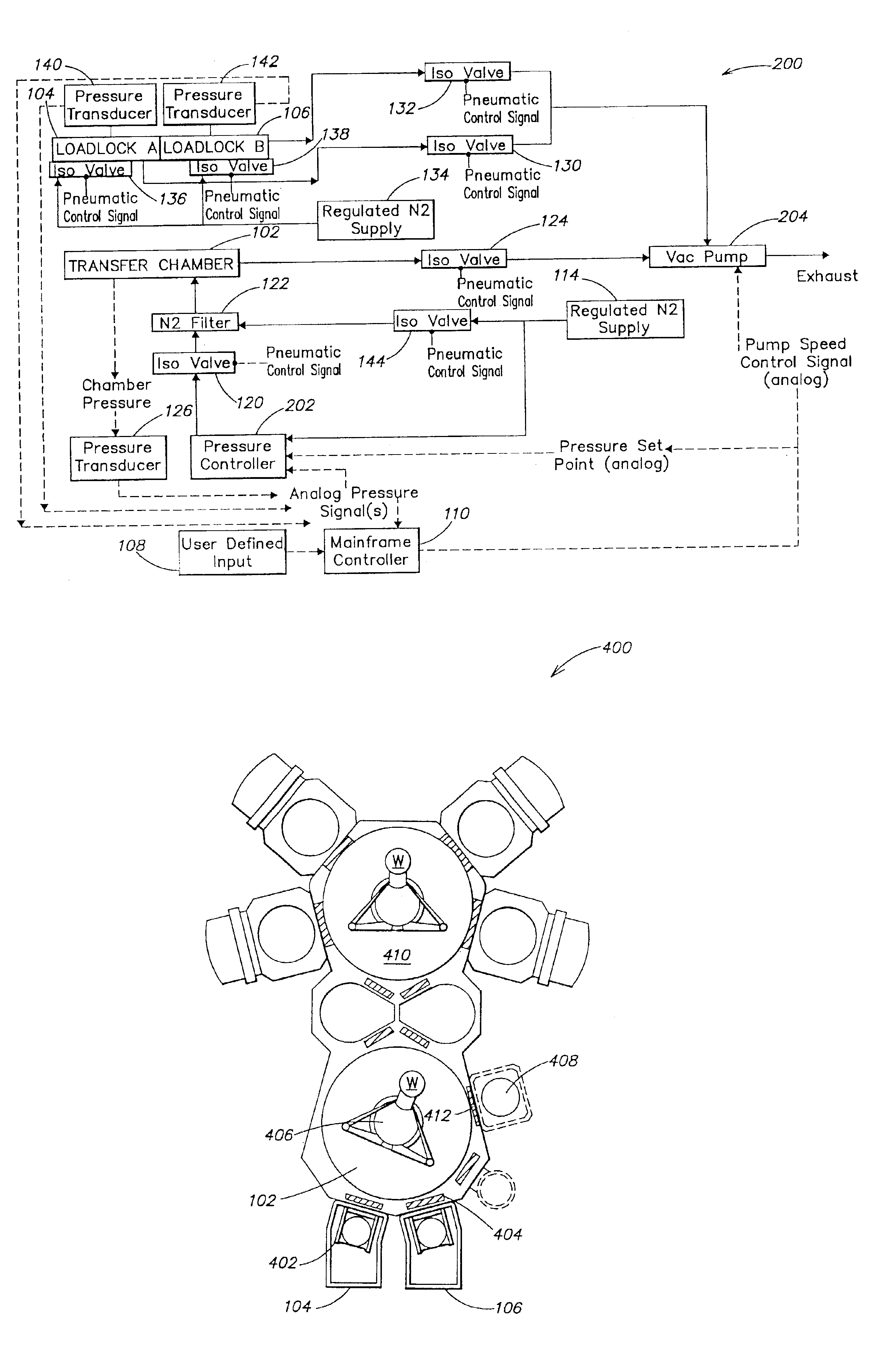

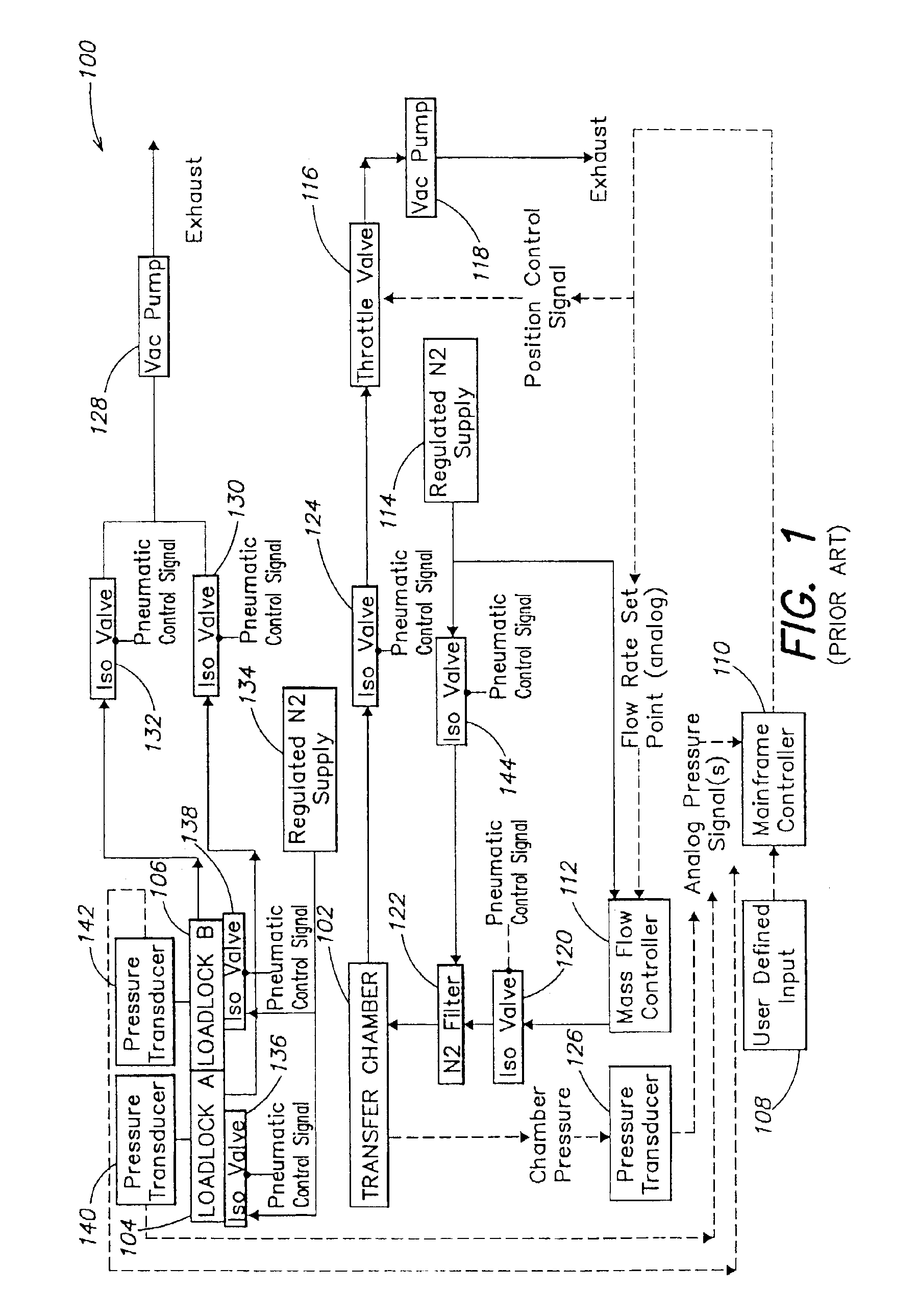

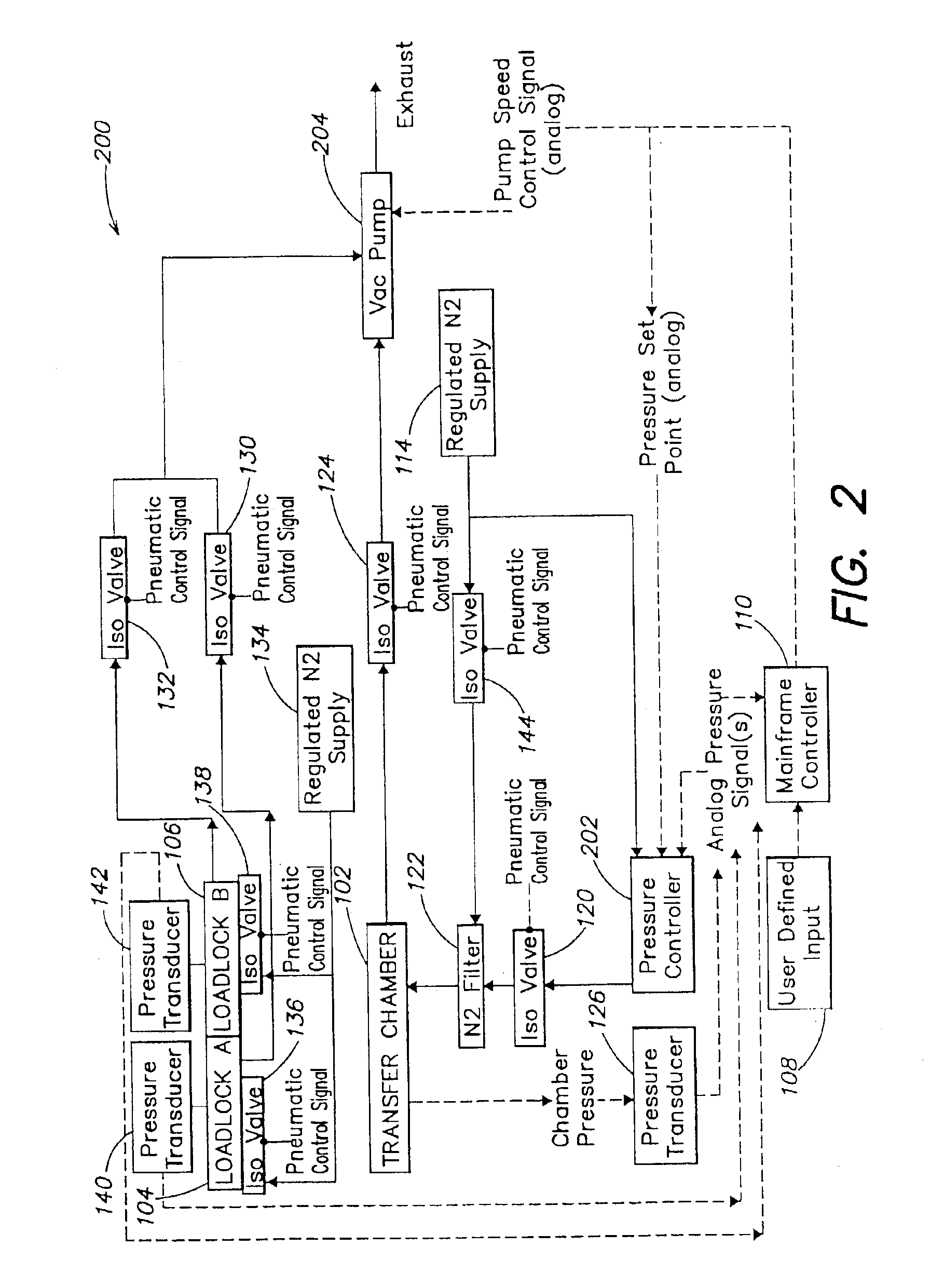

Methods and apparatus for maintaining a pressure within an environmentally controlled chamber

InactiveUS6916397B2Pressurized chemical processLiquid surface applicatorsVacuum pumpPressure measurement

In a first aspect, a system includes (1) a chamber; (2) a variable speed vacuum pump coupled to the chamber; and (3) a pressure controller coupled to the chamber. The pressure controller compares a set point pressure with a pressure measurement for the chamber and adjusts a flow of gas through the pressure controller based on a difference between the pressure measurement and the set point pressure. The system includes a pressure measurement device coupled to the chamber and to the pressure controller, and a main controller coupled to the variable speed vacuum pump, the pressure controller and the pressure measurement device. The pressure measurement device measures a pressure within the chamber and provides a pressure measurement to the pressure controller and the main controller. The main controller (1) adjusts a speed of the variable speed vacuum pump; and (2) provides the set point pressure to the pressure controller.

Owner:APPLIED MATERIALS INC

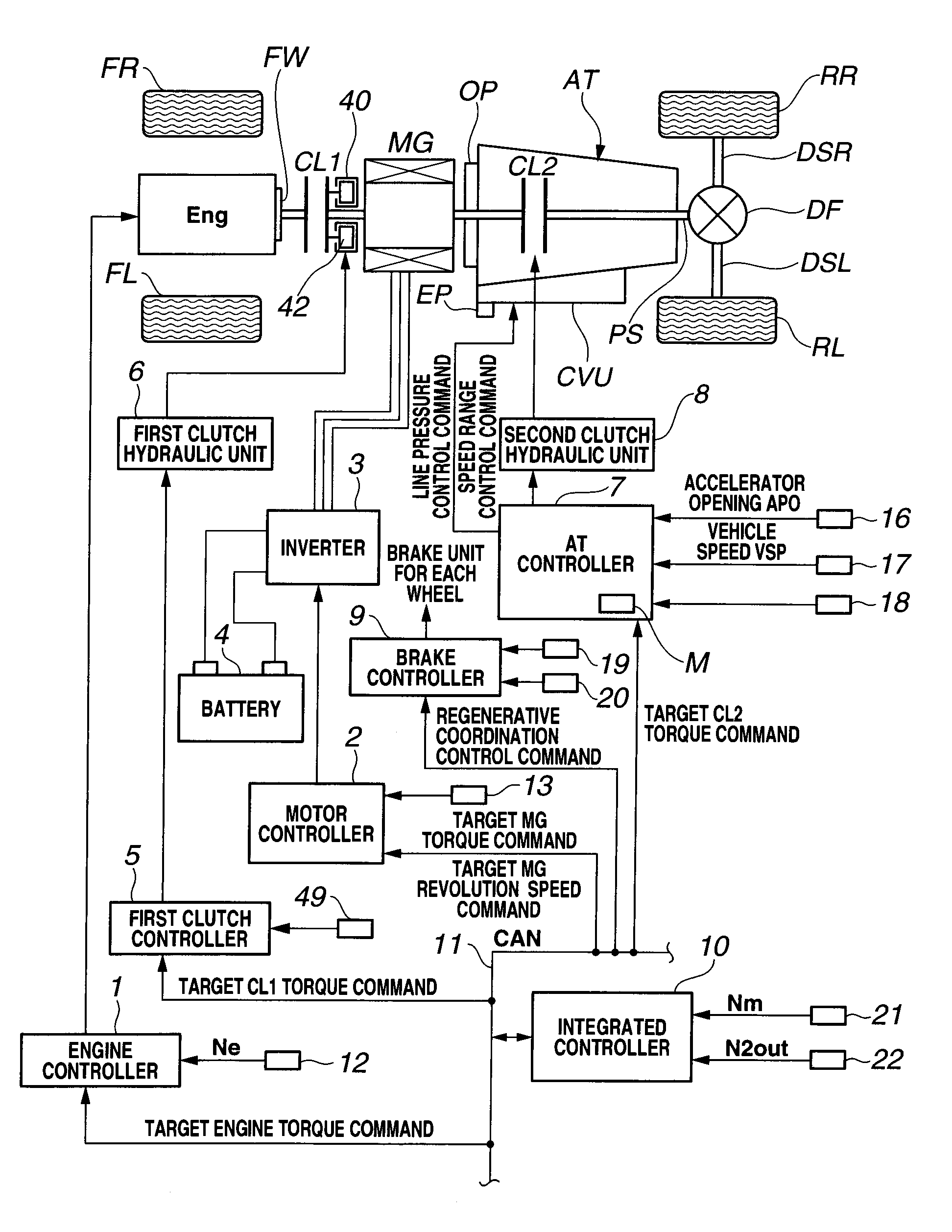

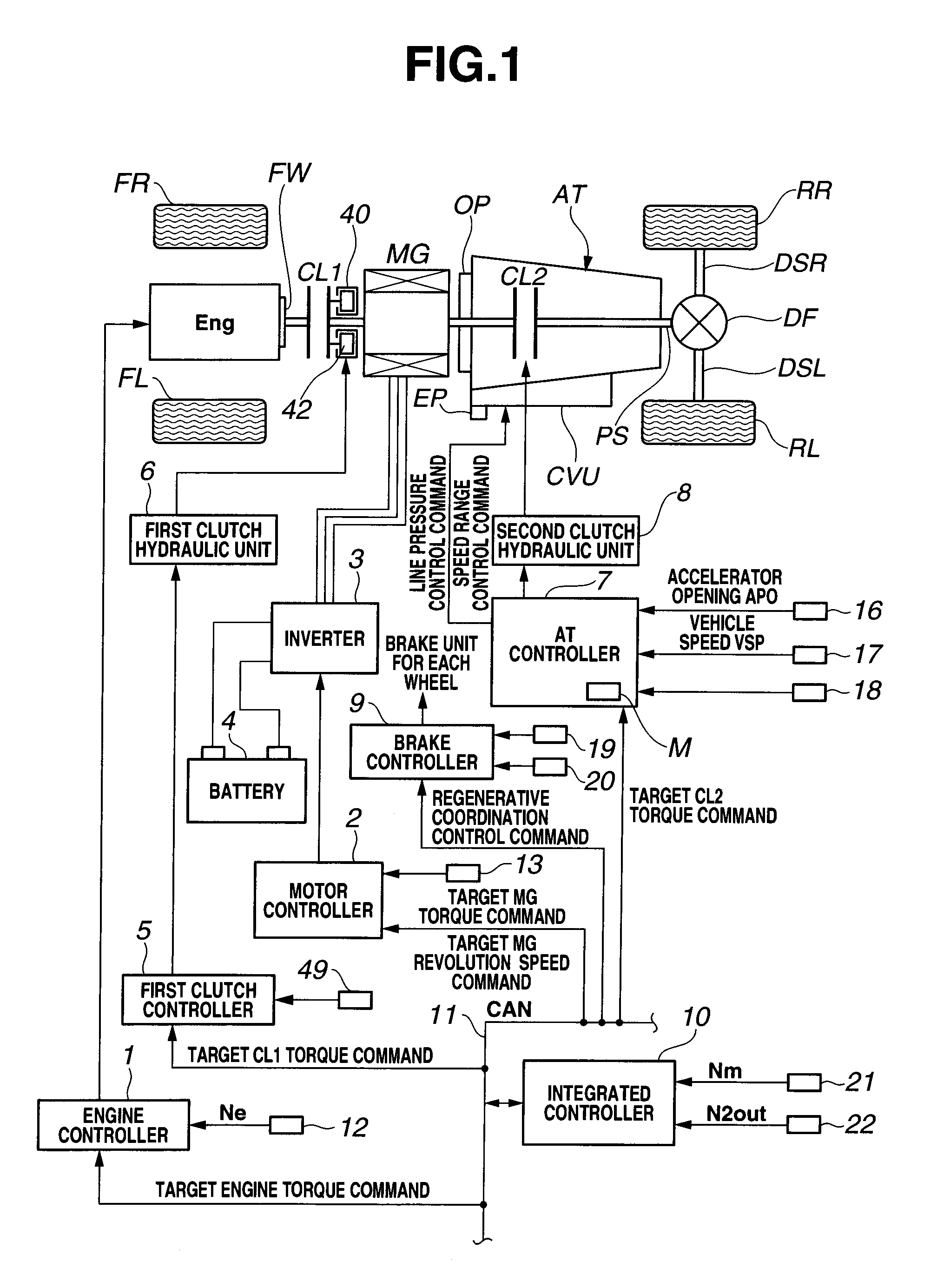

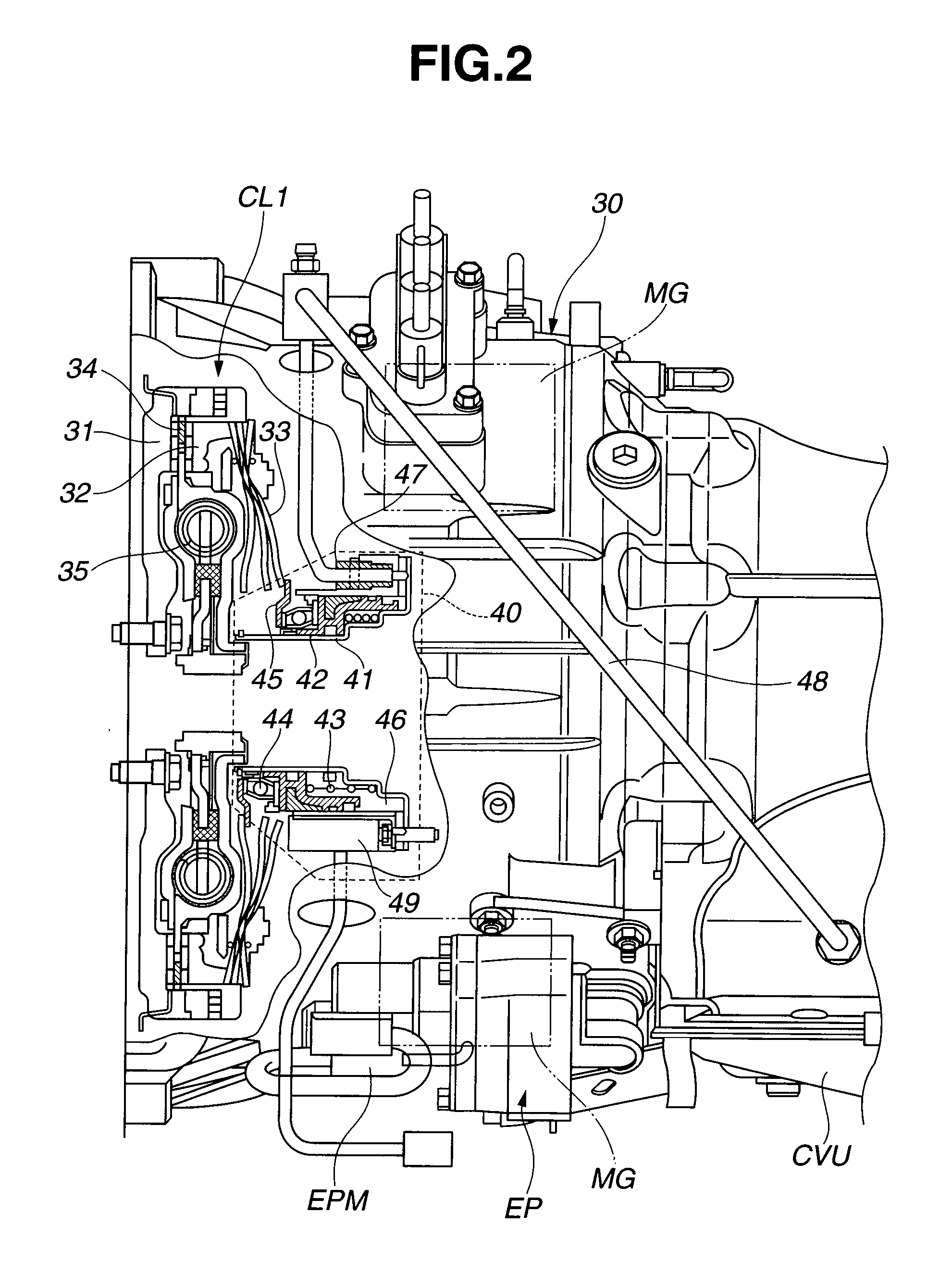

Control apparatus for hybrid vehicle

ActiveUS20100075798A1Easy to getImprove fuel economyClutchesInternal combustion piston enginesSeparated stateMode control

A control apparatus of hybrid vehicle having a first clutch which is in a disengaged state by being supplied with hydraulic fluid and a second clutch which is in an engaged state by being supplied with the hydraulic fluid, has a line pressure controller controlling a line pressure of the hydraulic fluid, and a drive mode controller changing a drive mode between HEV mode in which the first clutch is engaged and the vehicle travels with the engine and the motor / generator being a power source and EV mode in which the first clutch is disengaged and the vehicle travels with only the motor / generator being the power source. The line pressure controller sets the line pressure in HEV mode to a pressure level required for the engagement of the second clutch, and sets the line pressure in EV mode to a higher line pressure than the line pressure in HEV mode.

Owner:JATCO LTD +1

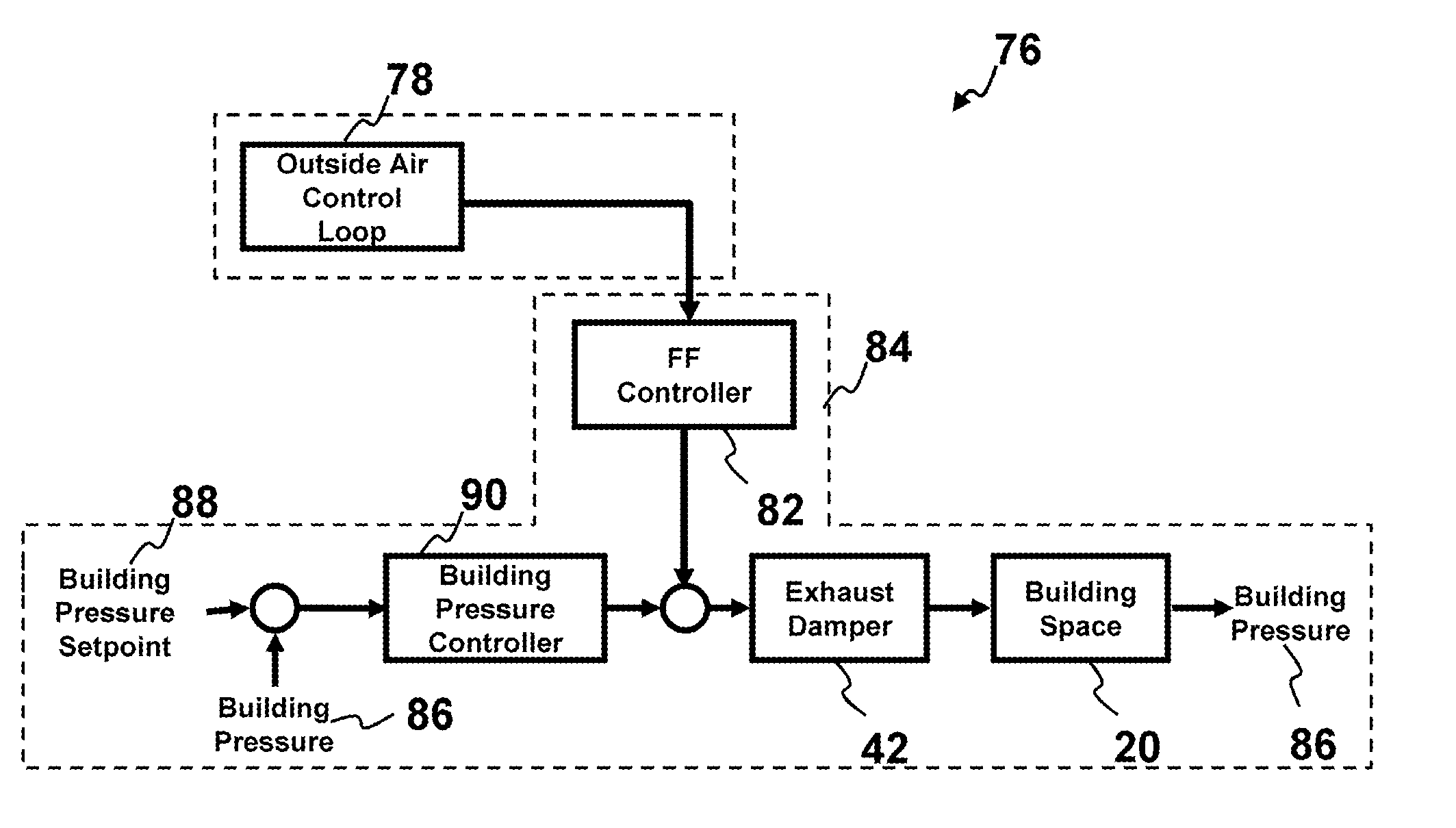

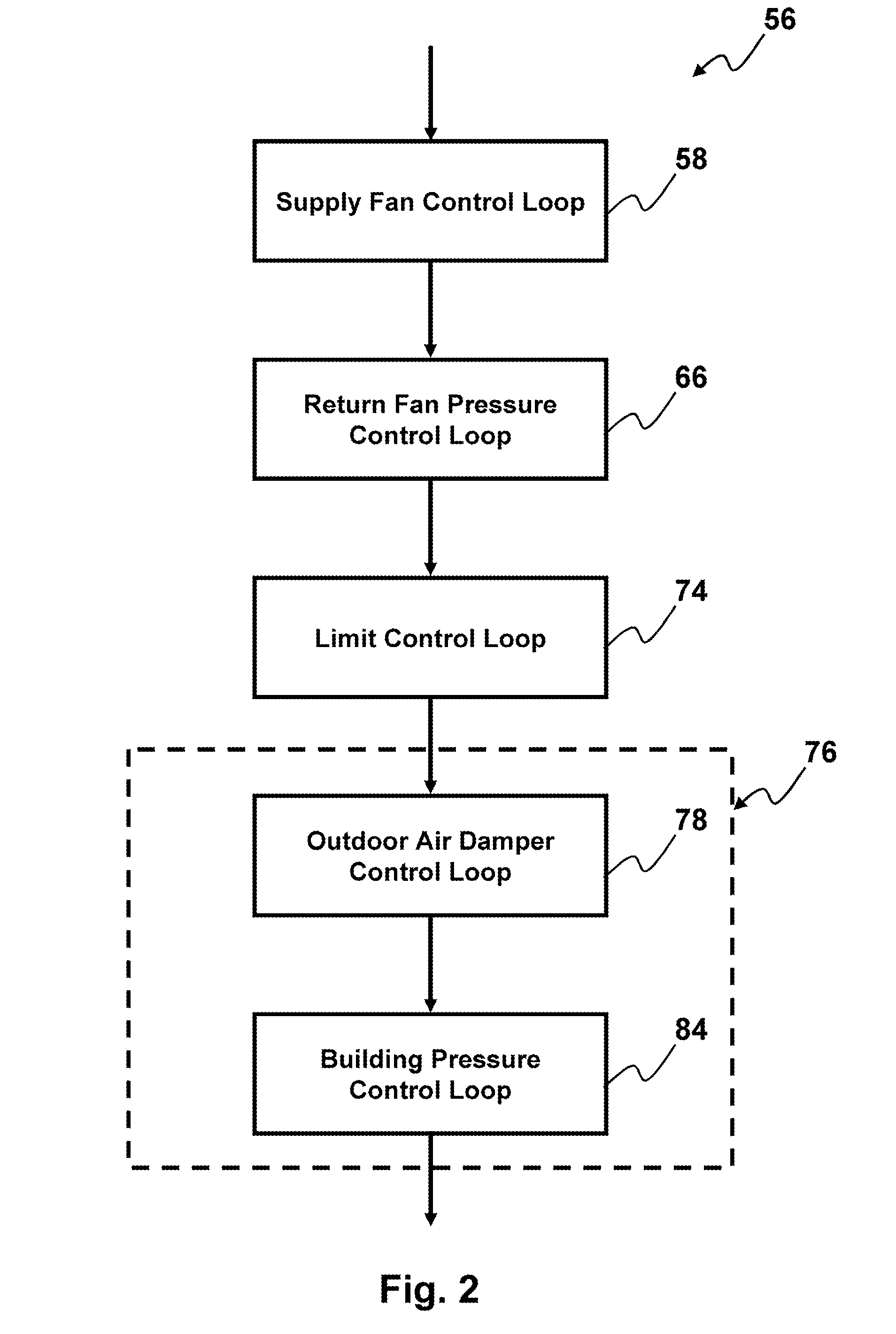

Return Fan Control System and Method

ActiveUS20100057258A1Sampled-variable control systemsMechanical apparatusControl systemSystem pressure

A return fan control system for an HVAC system comprises a supply fan control loop, a return fan control loop and a building pressure control system. The supply fan control loop comprises a duct pressure controller arranged to control a supply fan to a duct pressure setpoint. The return plenum pressure control loop comprises a return plenum pressure controller arranged to automatically control a return fan to a return plenum pressure setpoint determined by a setpoint reset function. The building pressure control system is operable to control a building pressure. The building pressure control system may comprise a building pressure control loop and an outside air control loop cooperatively arranged to control an exhaust damper in response to an outside air intake.

Owner:TRANE INT INC

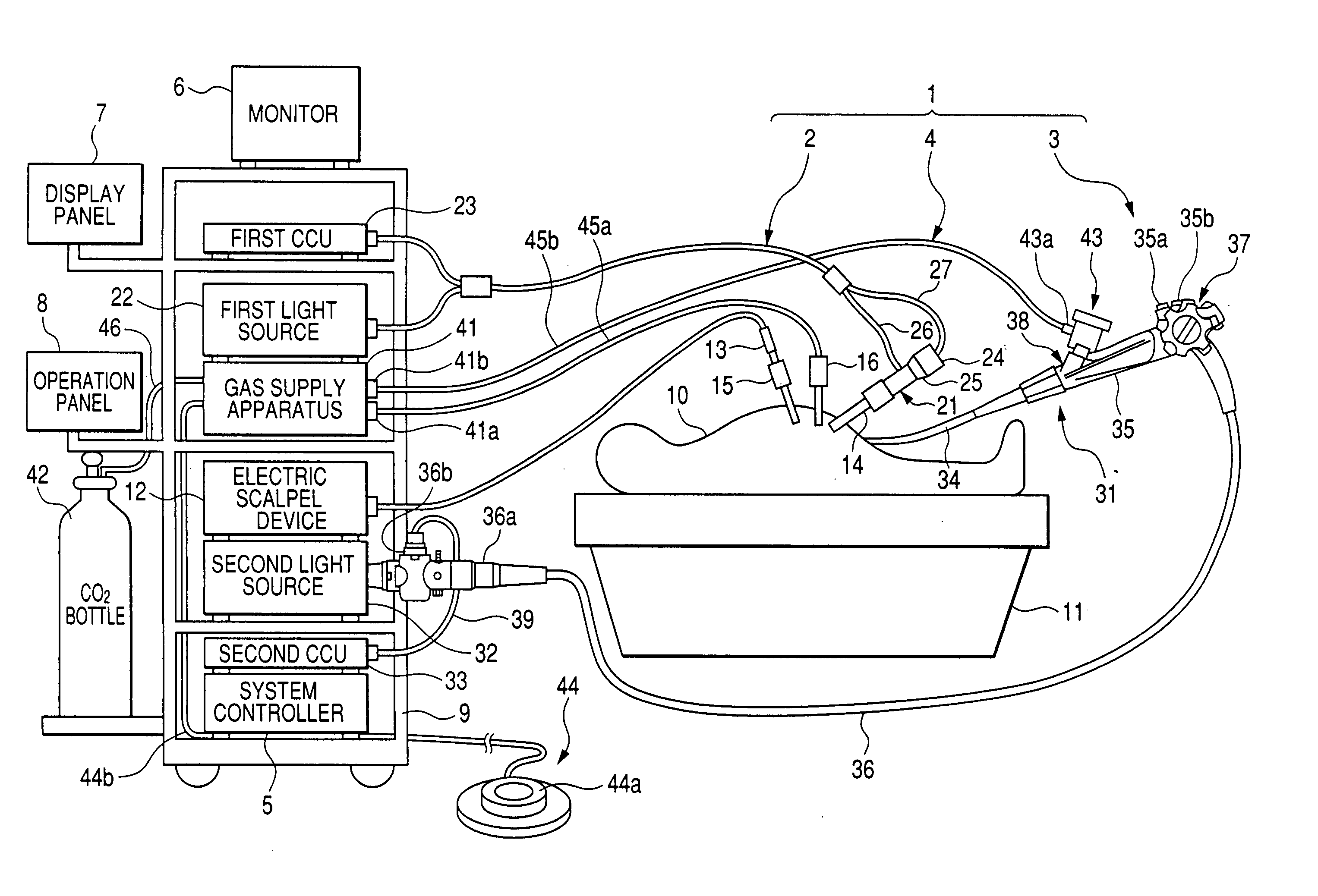

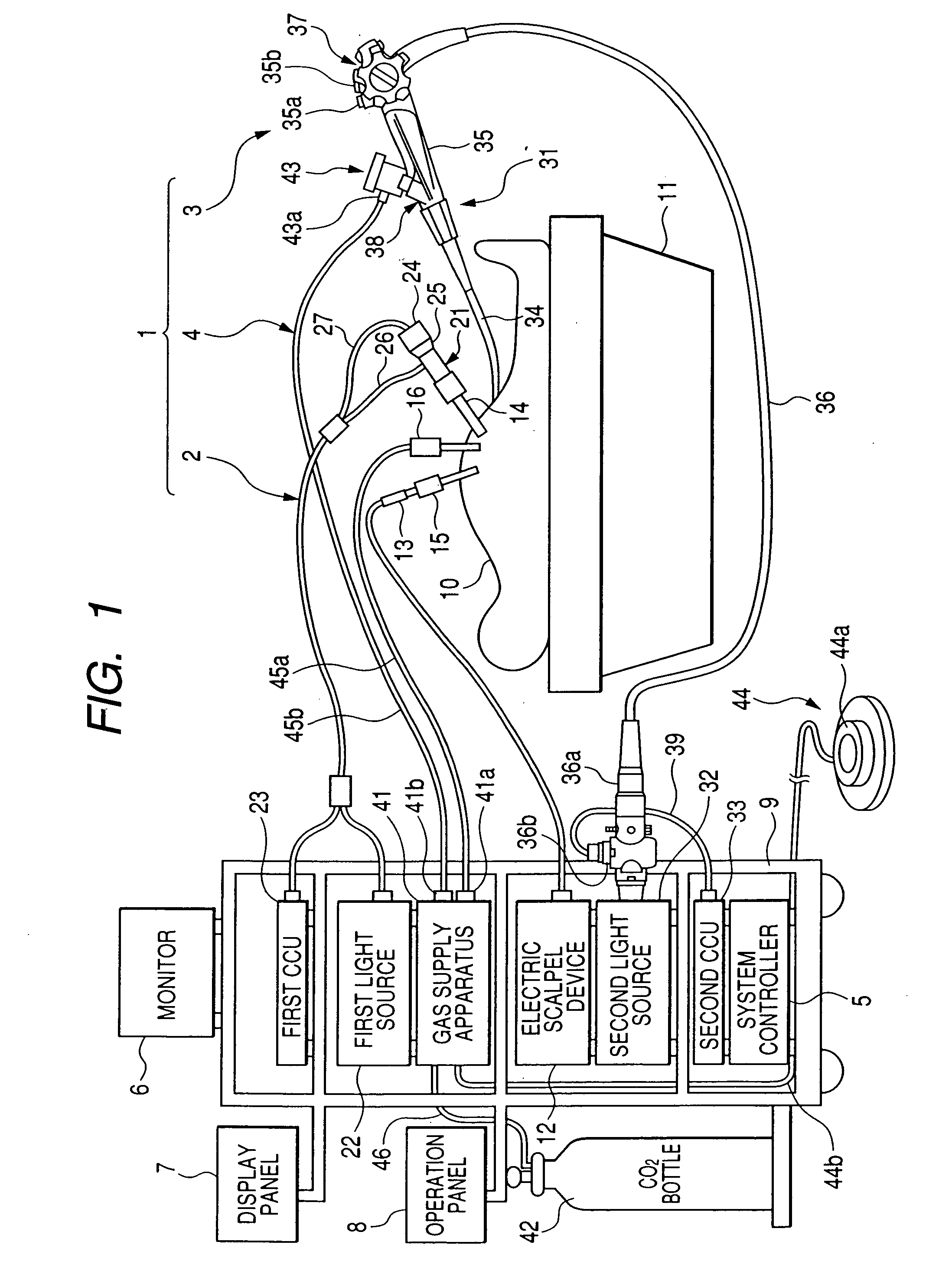

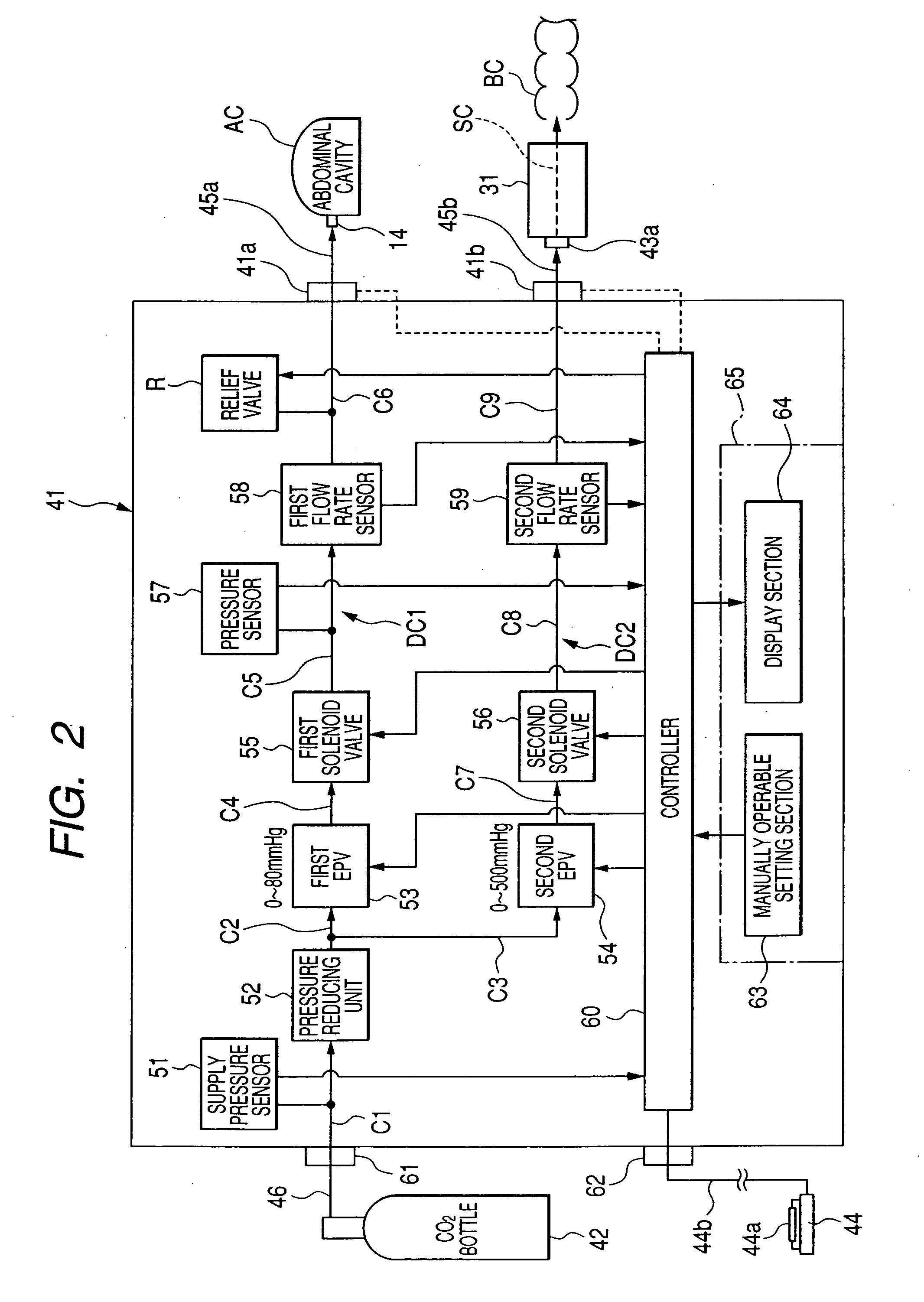

Method and system for supplying predetermined gas into body cavities of a specimen

In a gas supply system, a controller is electrically connected to a pressure regulator and an operation switch. The controller is operative to control the pressure regulator so that a predetermined gas is supplied to a first delivery member directing to a first body cavity with its pressure regulated to a first pressure suitable for the first body cavity. The controller is operative to control the pressure regulator depending on an instruction sent from the operation switch upon operation of the operator so that the predetermined gas is supplied to a second delivery member directing to a second body cavity with its pressure regulated to a second pressure suitable for the second body cavity.

Owner:OLYMPUS CORP

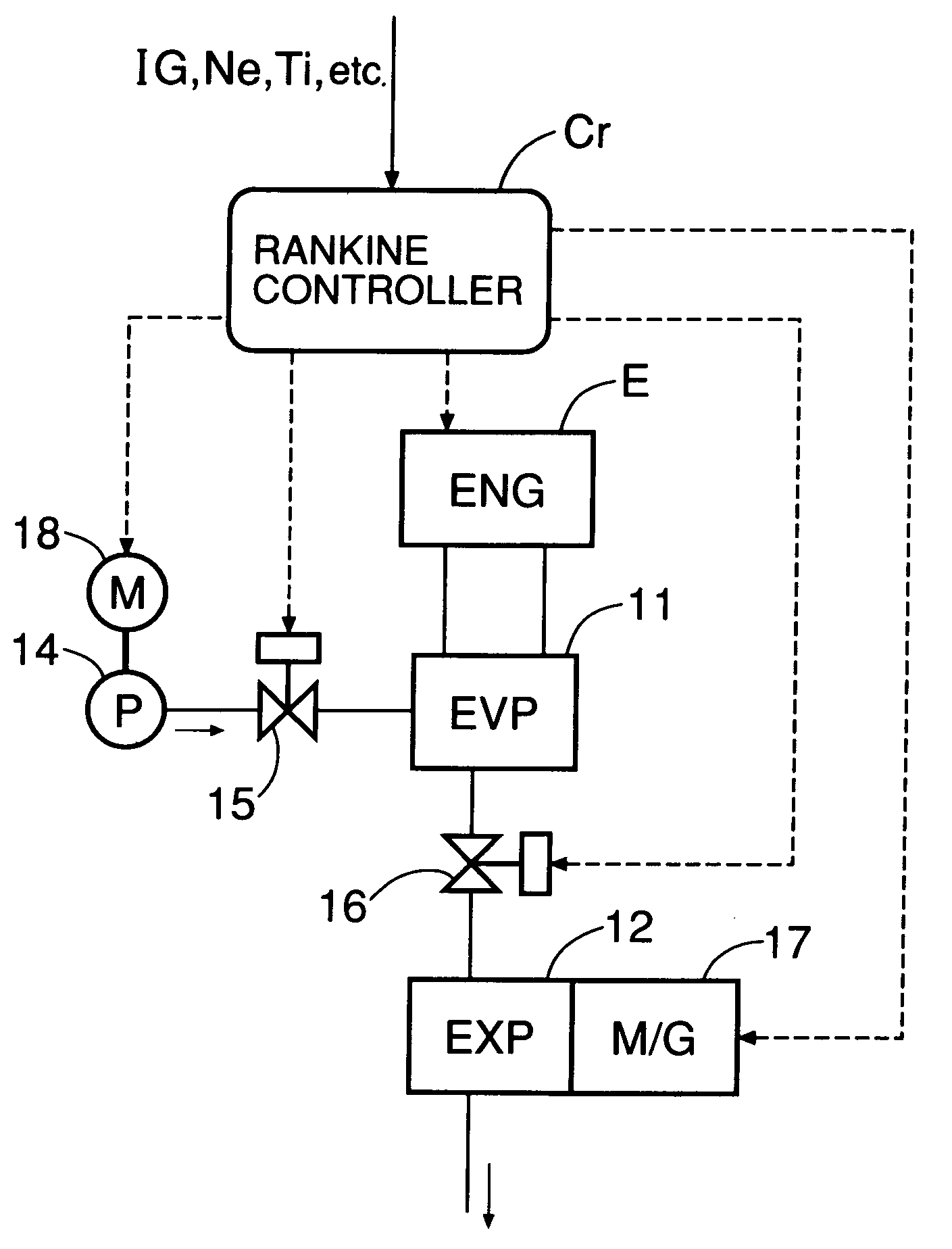

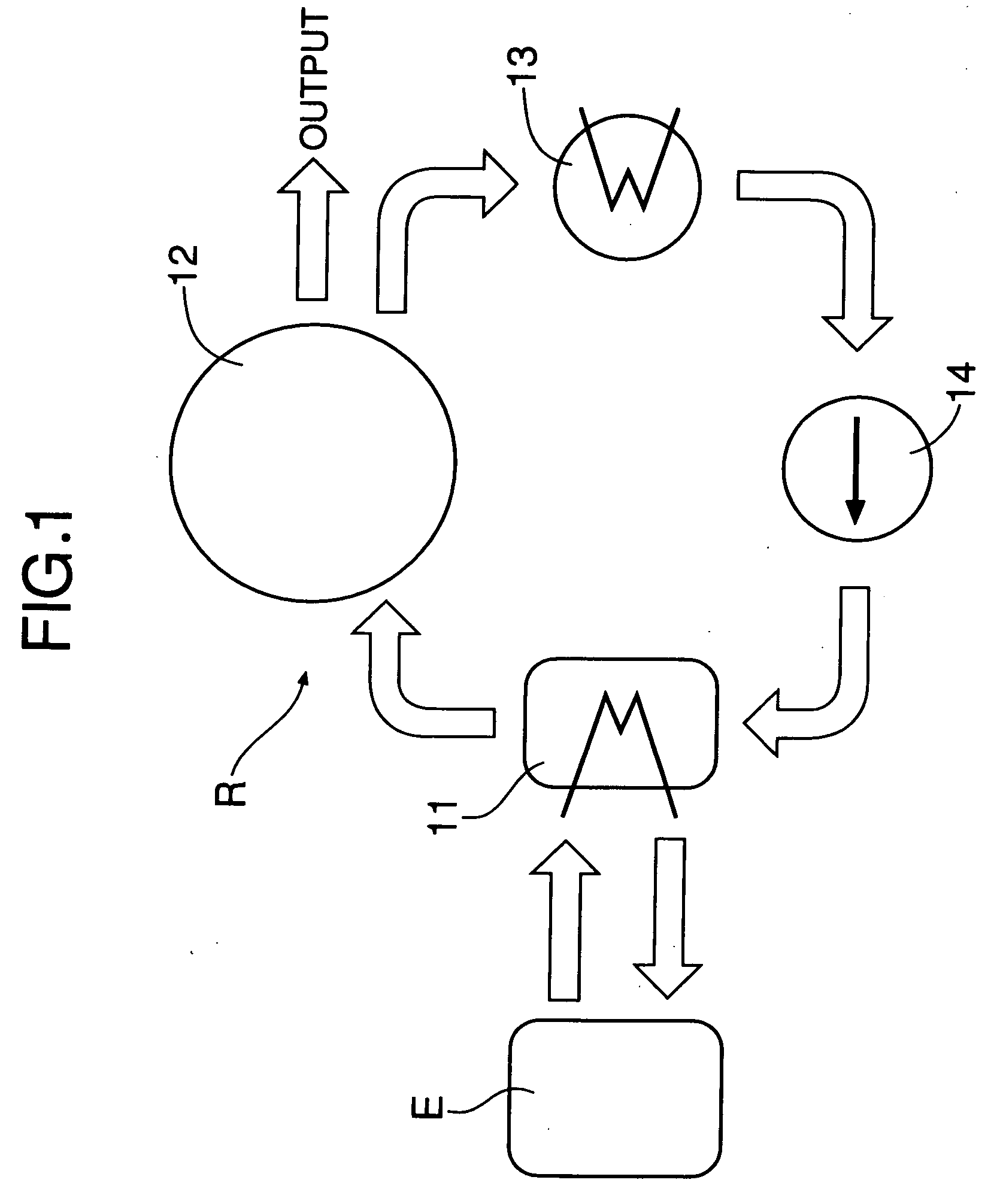

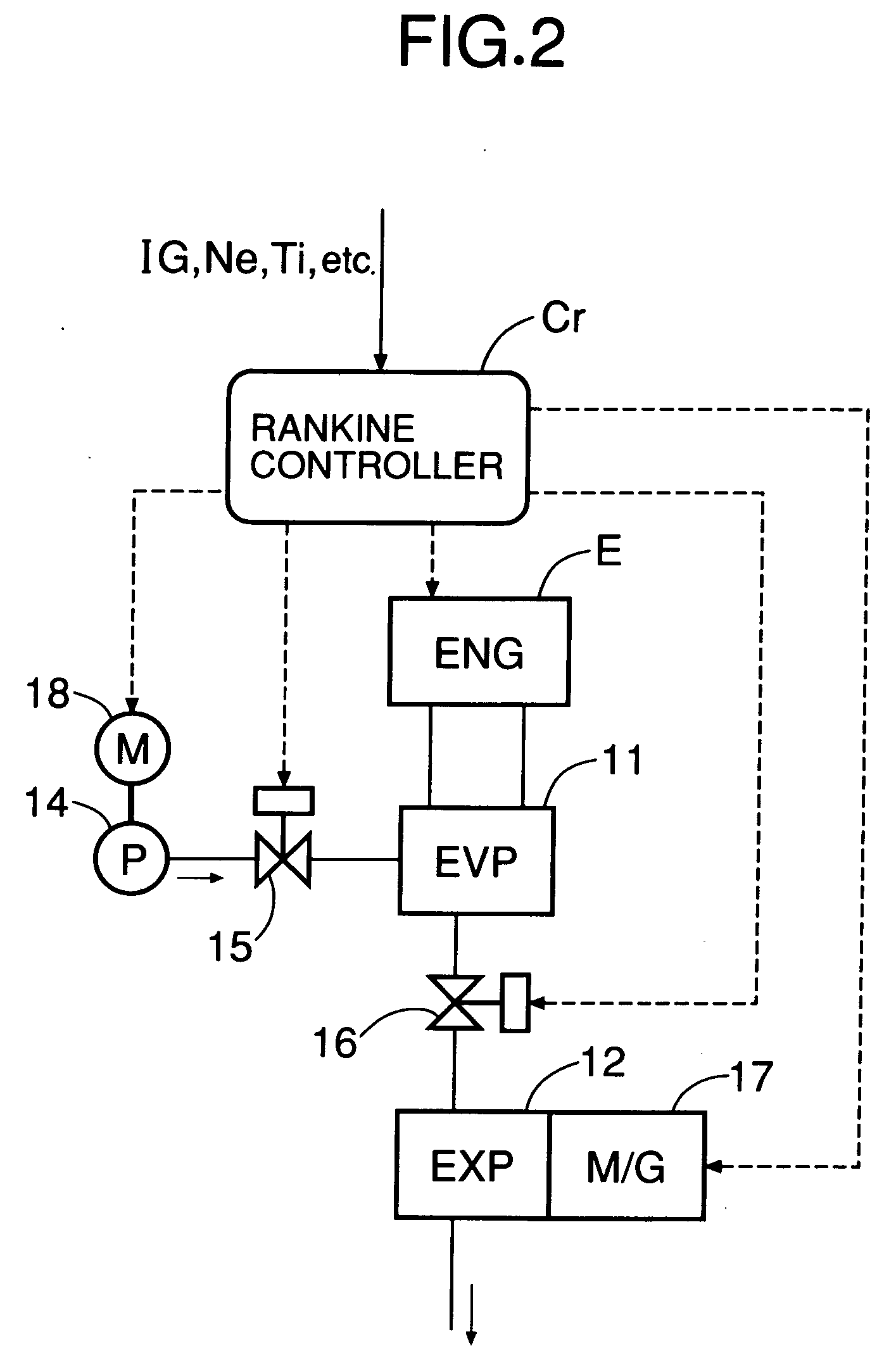

Rankine cycle system

InactiveUS20060254276A1Efficient use ofEffective recoverySteam engine plantsThermal energyTemperature control

A Rankine cycle system includes an evaporator for heating water with thermal energy of exhaust gas of an engine for generating steam with a displacement type expander for converting thermal energy into mechanical energy. A temperature controller manipulates the amount of water supplied to the evaporator so that the temperature of the steam supplied from the evaporator to the expander coincides with a target temperature. A pressure controller manipulates the rotational speed of the expander by changing a load of the expander so that the pressure of the steam supplied from the evaporator to the expander coincides with a target pressure. The temperature controller and / or the pressure controller continue to control the amount of water supplied to the evaporator and / or the rotational speed of the expander in set ranges at least in a state in which the engine has stopped and the thermal energy of the exhaust gas has disappeared.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com