Air injection vortex spinning device with pumping component

A vortex spinning and suction element technology, applied in the field of air-jet vortex spinning devices, can solve the problems of fiber loss or fiber loss, generation of yarn details, deterioration of yarn evenness, etc., so as to improve the utilization rate and reduce false twist. , reducing the effect of high fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

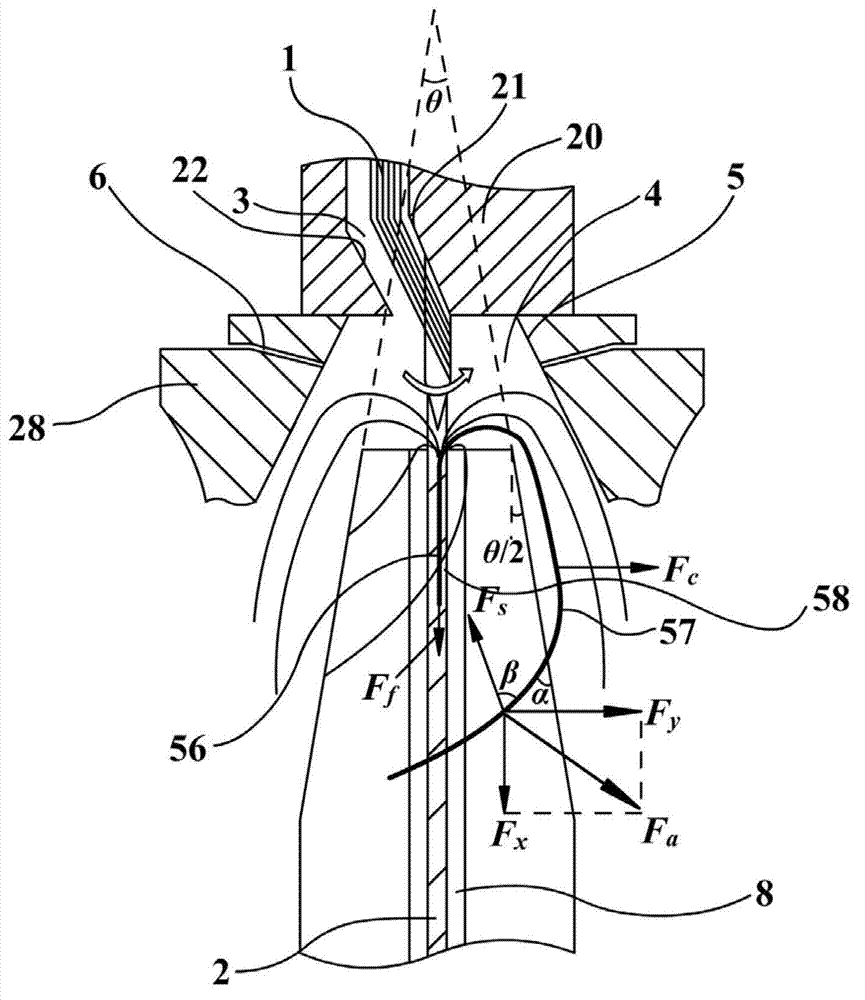

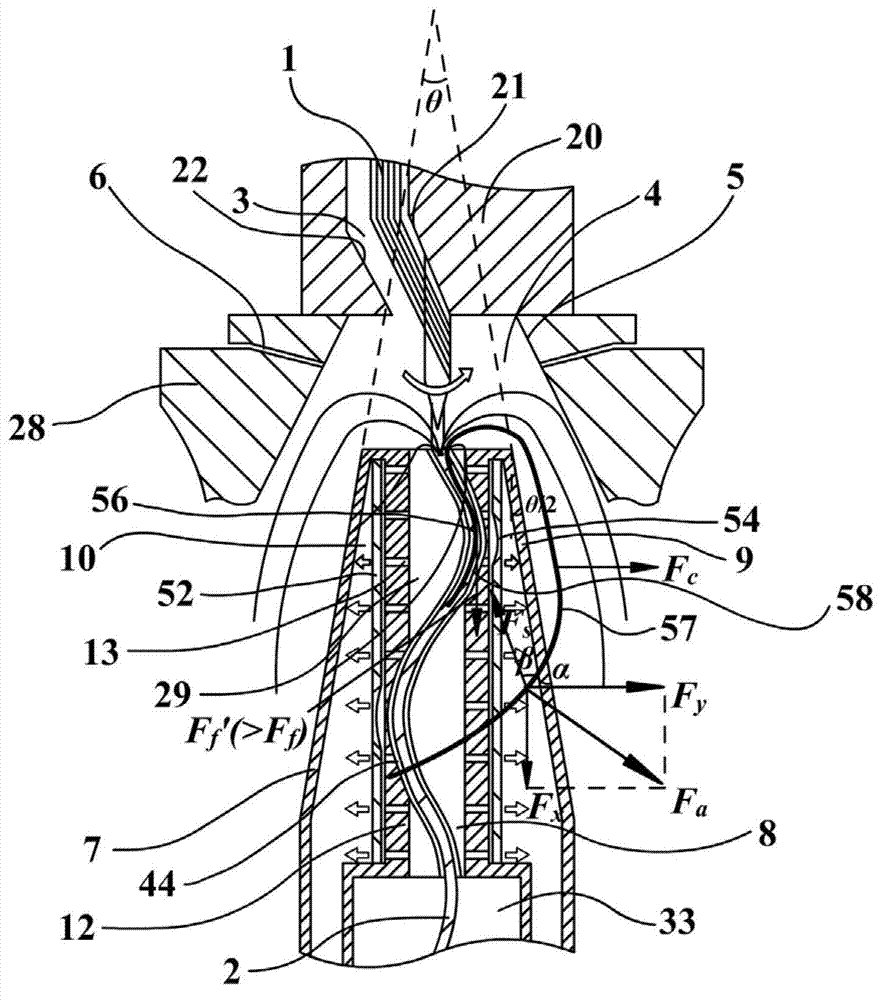

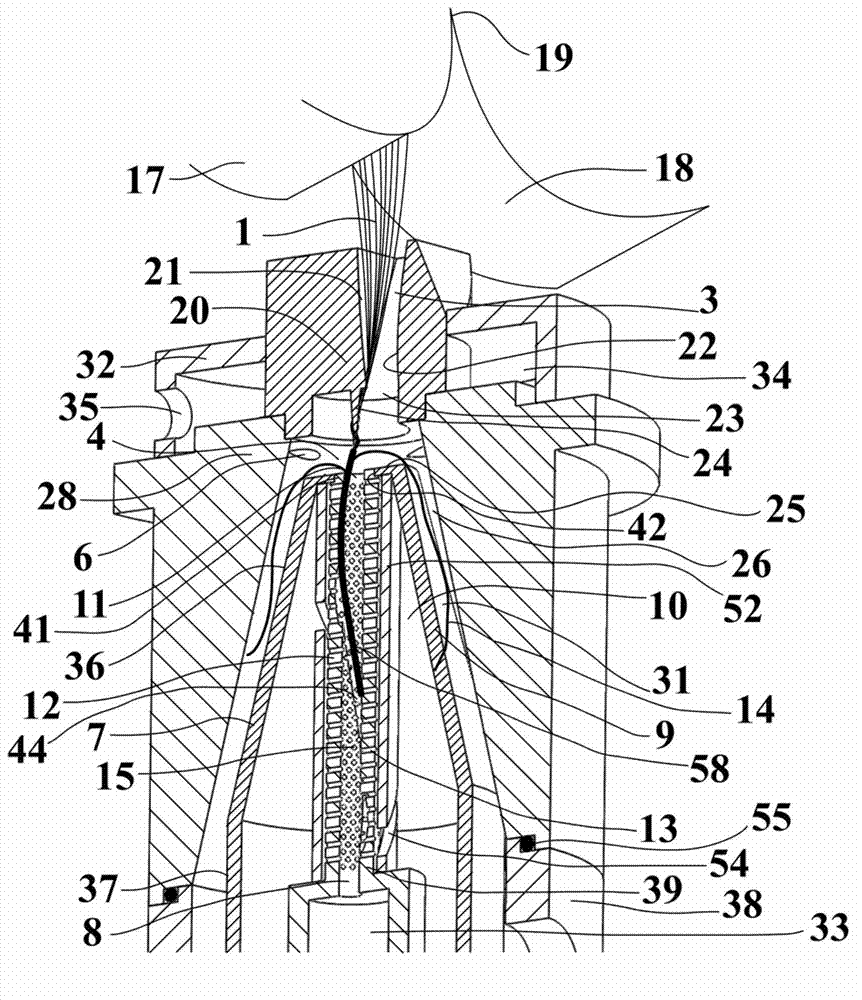

[0032] A threaded yarn introducing channel 8 with a circular cross-section is provided inside the yarn introducing cone 7 along its central axis, for outputting the spun yarn 2 from the twisting zone. The yarn delivery channel 8 is divided into a small diameter section 29 near the inlet 11 and a large diameter section 33 near the outlet 40 . The interior of the wall shell 9 of the yarn drawing cone 7 shown in this embodiment is set to be hollow, so as to form a continuous cavity 10 around the yarn drawing channel 8 and in the circumferential direction of the yarn drawing cone 7 . Simultaneously, in the small-diameter section 29 of the yarn-drawing passage 8, a central line is provided on the side wall 12 between the above-mentioned cavity 10 and the yarn-drawing passage 8 along the radial direction of the circular cross-section of the yarn-drawing passage 8, and the section is a circle. Shaped through hole 13. The through-holes 13 are arranged in several layers in the axial d...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is mainly the cross-sectional shape of the spiral groove 44, such as Figure 10 shown. In this embodiment, the cross-sectional shape of the spiral groove 44 of the small-diameter section 29 of the yarn guiding channel is circular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com