Patents

Literature

115 results about "Plucker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plucker is an offline Web and free e-book reader for Palm OS based handheld devices, Windows Mobile (Pocket PC) devices, and other PDAs. Plucker contains POSIX tools, scripts, and "conduits" which work on Linux, Mac OS X, Microsoft Windows, and Unix. Web pages can be processed, compressed, and transferred to the PDA for viewing by the Plucker viewer.

Fruit plucker

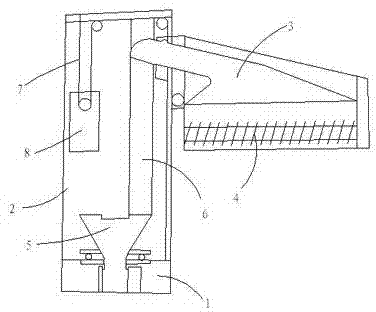

InactiveCN101558710AQuick adjustment of working lengthSuitable for pickingPicking devicesBiochemical engineeringPlucker

The invention relates to a fruit plucker. The fruit plucker comprises pulling rods, flexible shaft components, reset devices, a slide mechanism, clamp handles and shear handles; wherein one end of the first pulling rod is connected with a drive mechanism, while the other end is articulated with one end of the second pulling rod and one end of the third pulling rod respectively; the other end of the second pulling rod is articulated with one end of the first flexible shaft component; the other end of the first flexible shaft component is articulated with one end of the fourth pulling rod and one end of the fifth pulling rod respectively; the other end of the fourth pulling rod and the other end of the fifth pulling rod are articulated with two shear handles; the other end of the third pulling rod is articulated with one end of the second flexible shaft component; the other end of the second flexible shaft component is articulated with one end of the sixth pulling rod and one end of the seventh pulling rod respectively; the other end of the sixth pulling rod and the other end of the seventh pulling rod are articulated with two clamp handles; the two shear handles are formed into an opening-closing structure through articulating; the first reset device is arranged between the two shear handles; the two clamp handles are arranged on the slide mechanism; the second reset device is arranged between the two clamp handles. The fruit plucker has simple structure, easy operation and strong practicality.

Owner:SOUTH CHINA AGRI UNIV

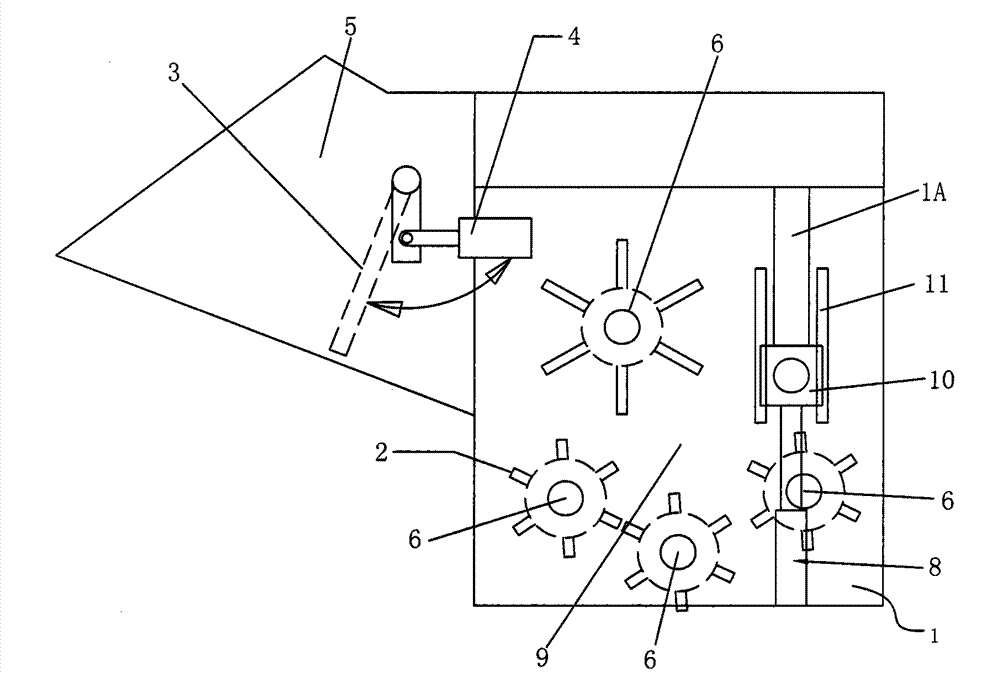

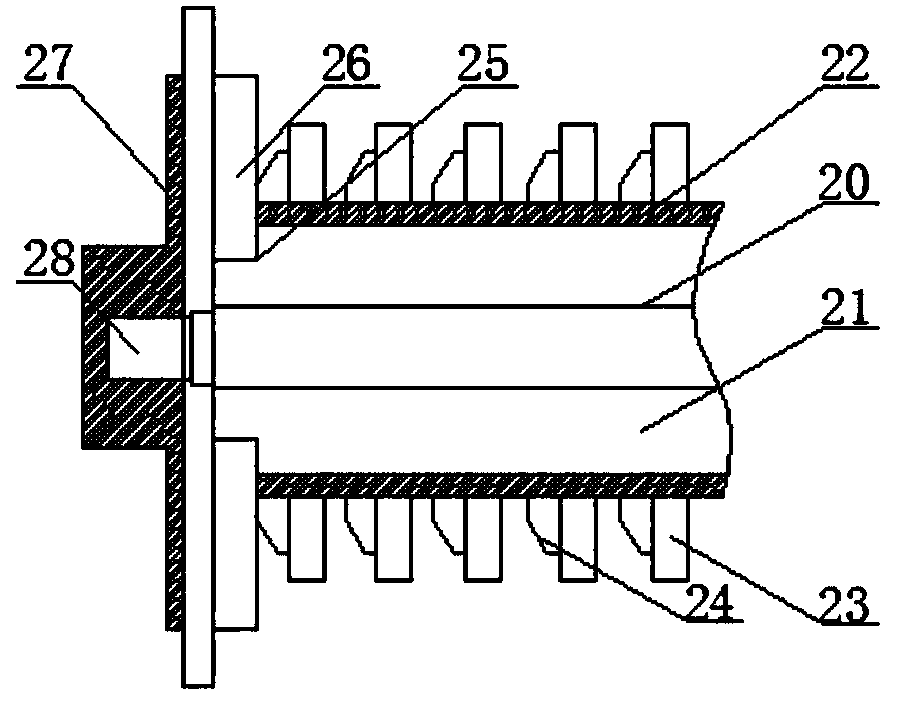

Bale plucker

InactiveCN103668563AComb evenlySimple structureFibre breaking machinesFibre breaking by beater armsEconomic benefitsPlucker

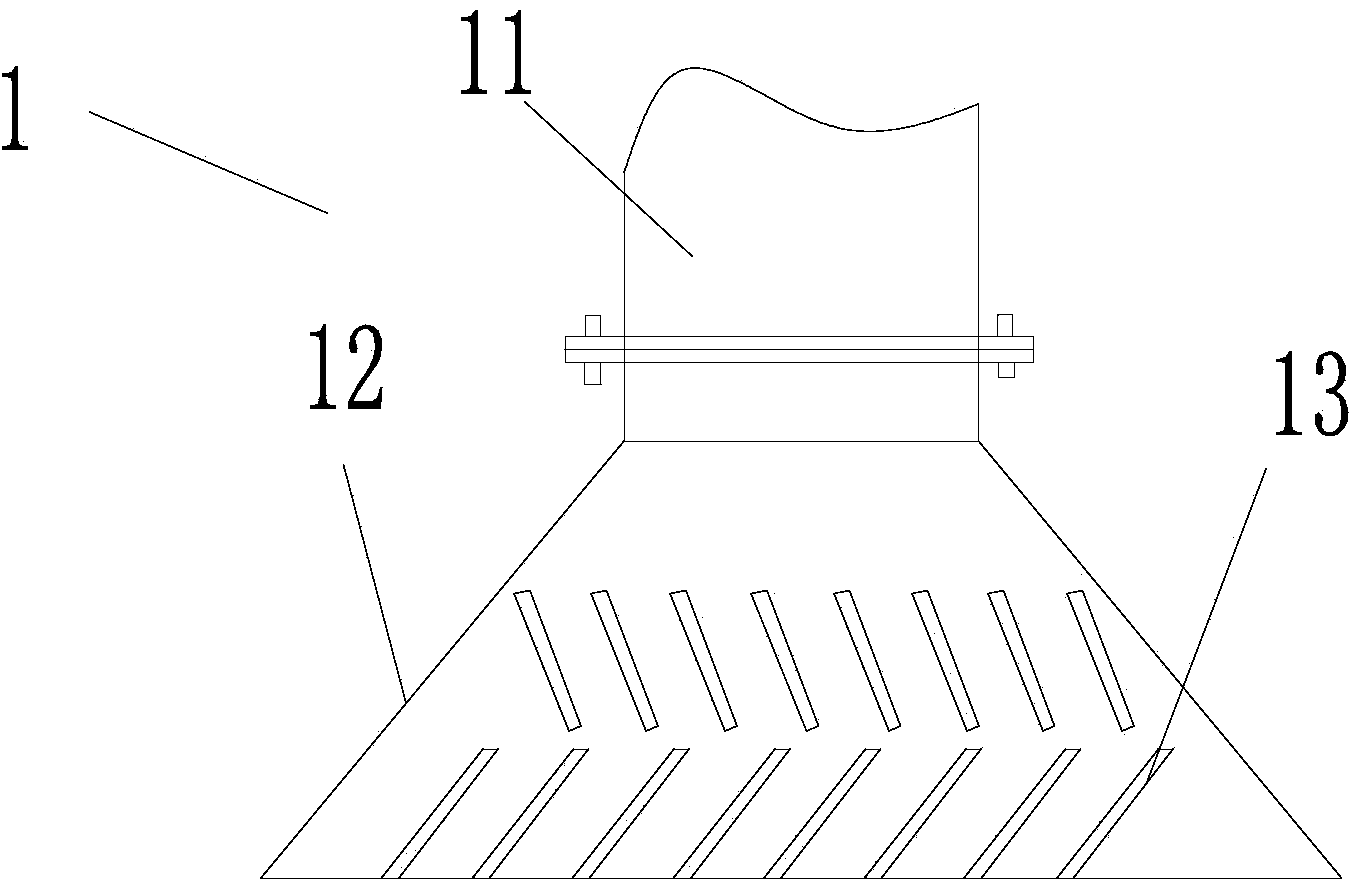

The invention discloses an automatic bale plucker with barrier plates. The bale plucker comprises a suspended hood and a transmission device. The suspended hood comprises an air draft pipeline and a suspended hood body, the suspended hood body is fixedly arranged at the end of the air draft pipeline, N sets of oblique barrier plates are arranged on the inner wall of the suspended hood body, and the inclination directions of every two adjacent barrier plates are opposite. The bale plucker is simple in structure, easy and convenient to operate and high in cotton plucking efficiency, manufacturing cost is reduced, a blocking phenomenon is not prone to occurring, cotton raw materials are scutched more uniformly, working efficiency is improved, and economic benefits are increased.

Owner:张家港市天江精密模具制造有限公司

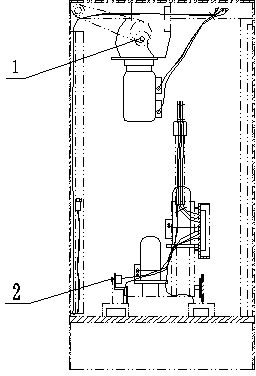

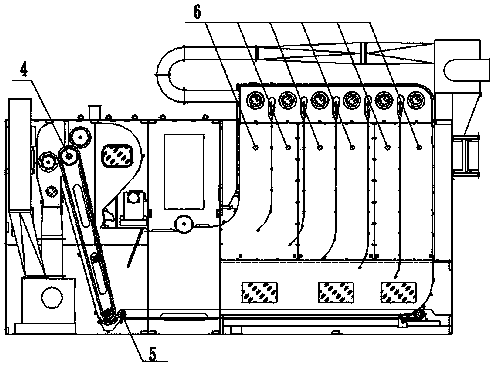

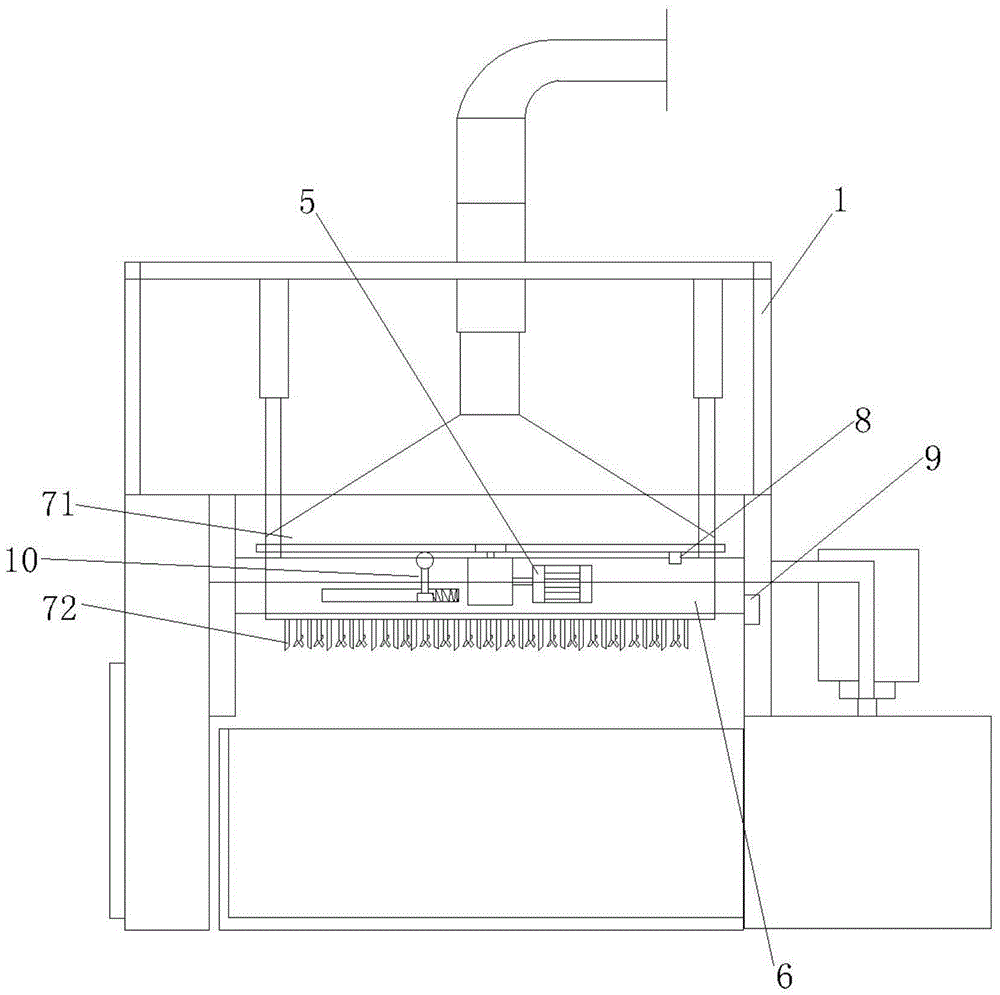

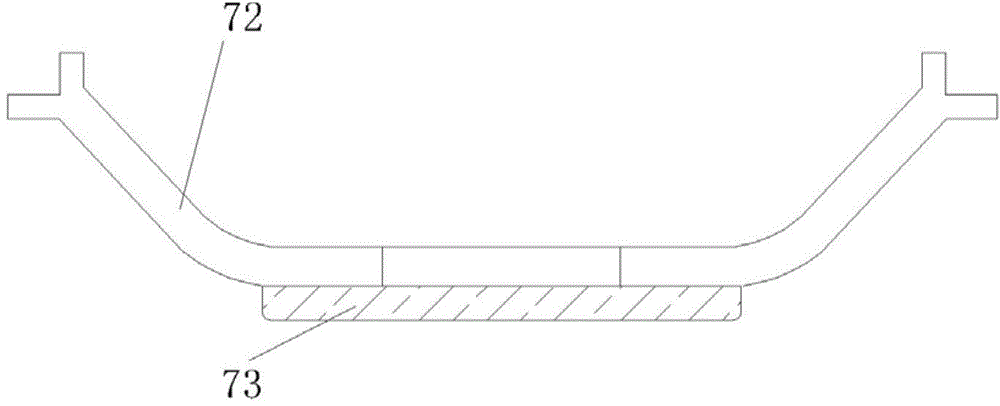

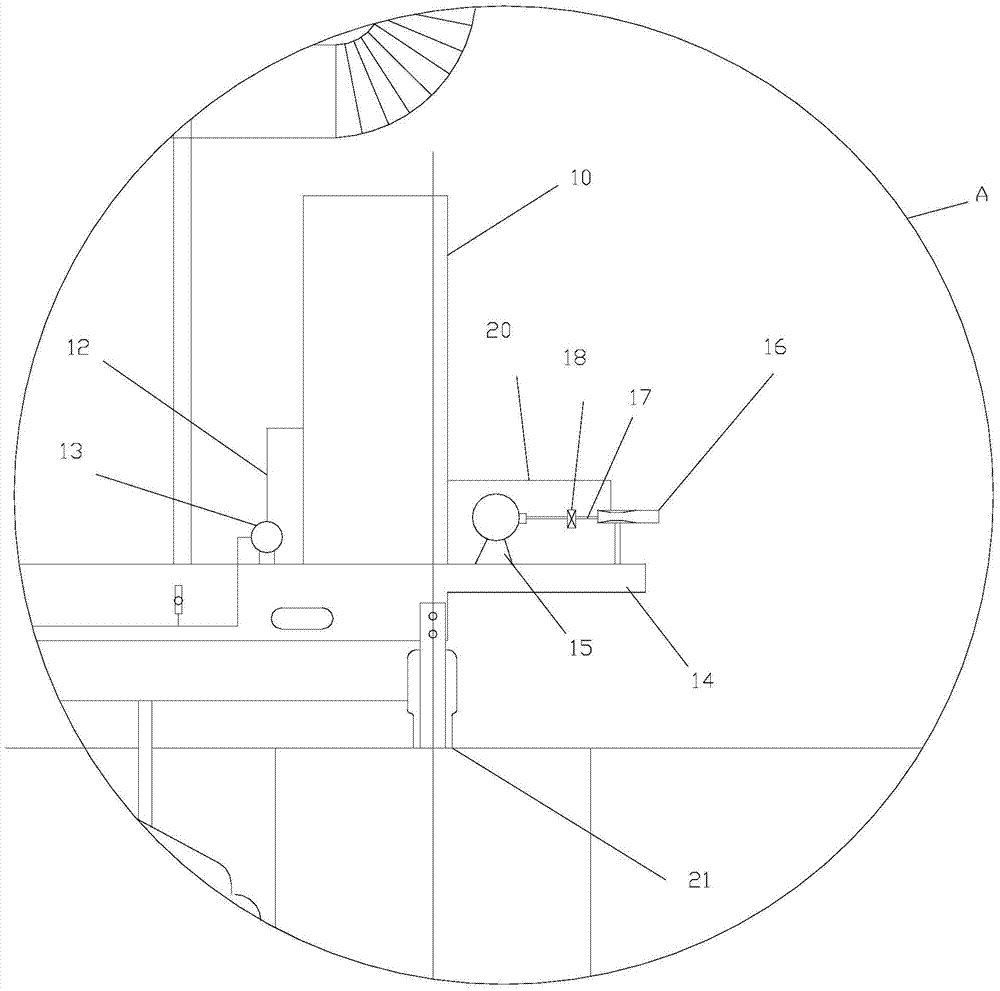

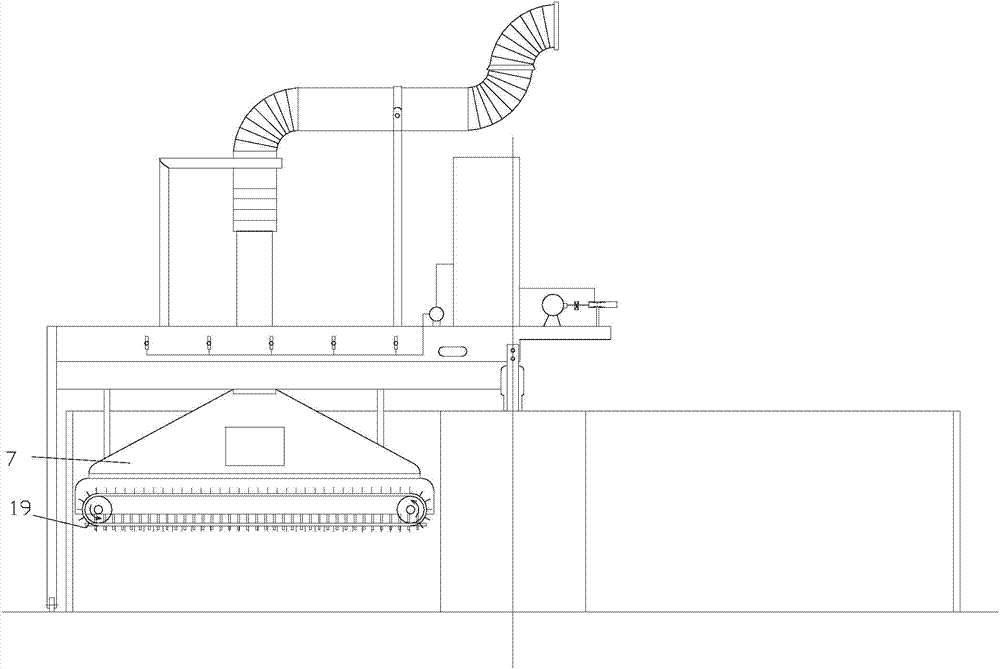

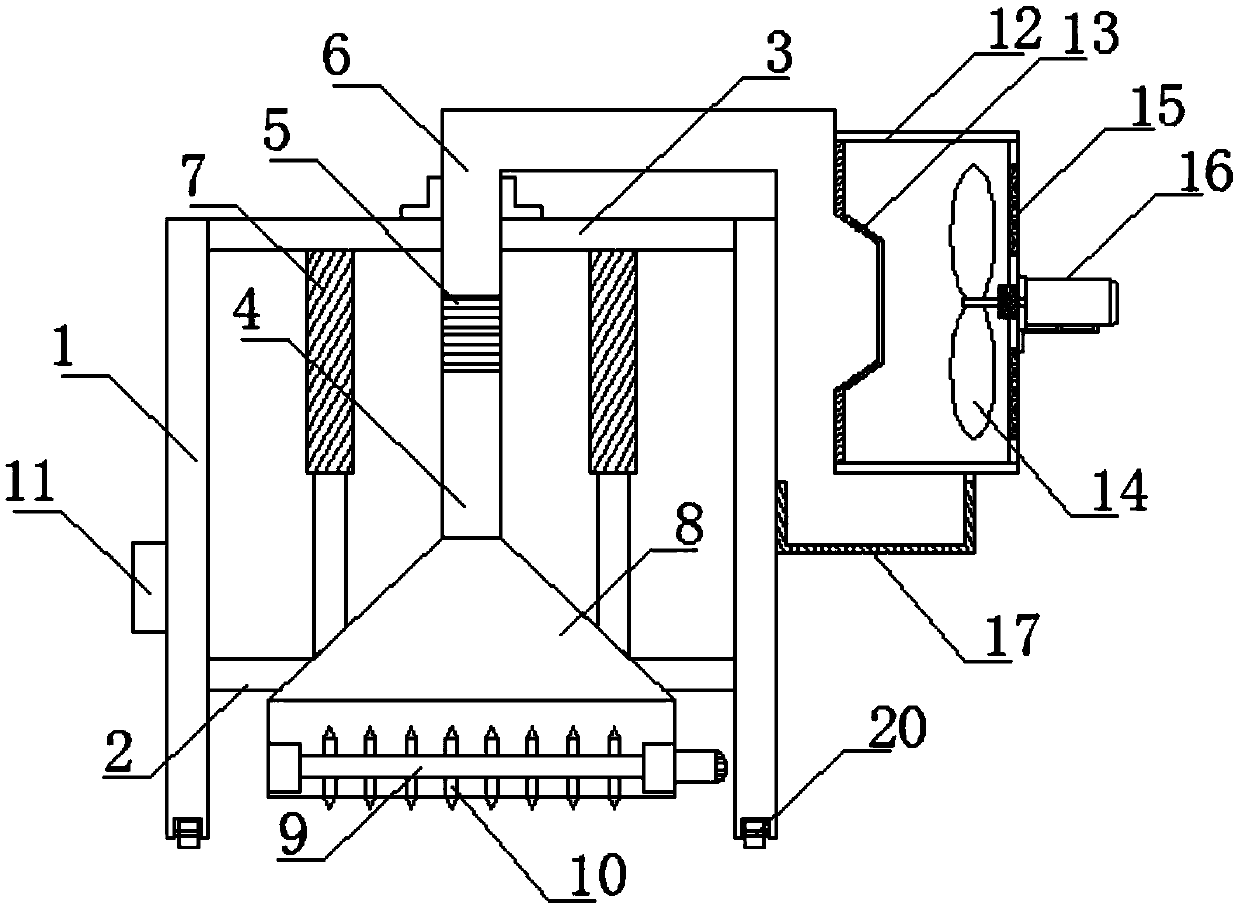

Bale plucker with self-cleaning device

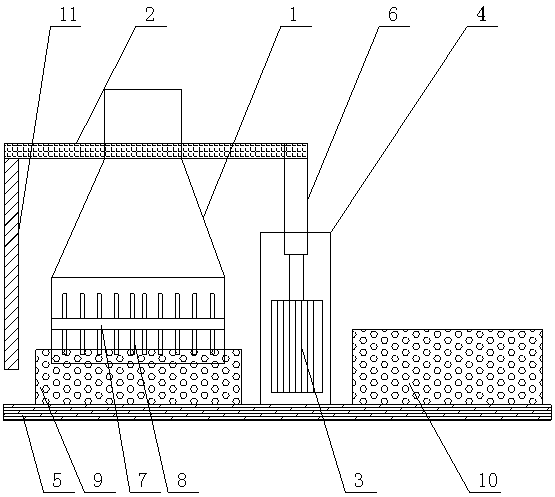

PendingCN108004622AEasy to removeGuarantee normal productionFibre breaking machinesFibre breaking by beater armsSprayerEngineering

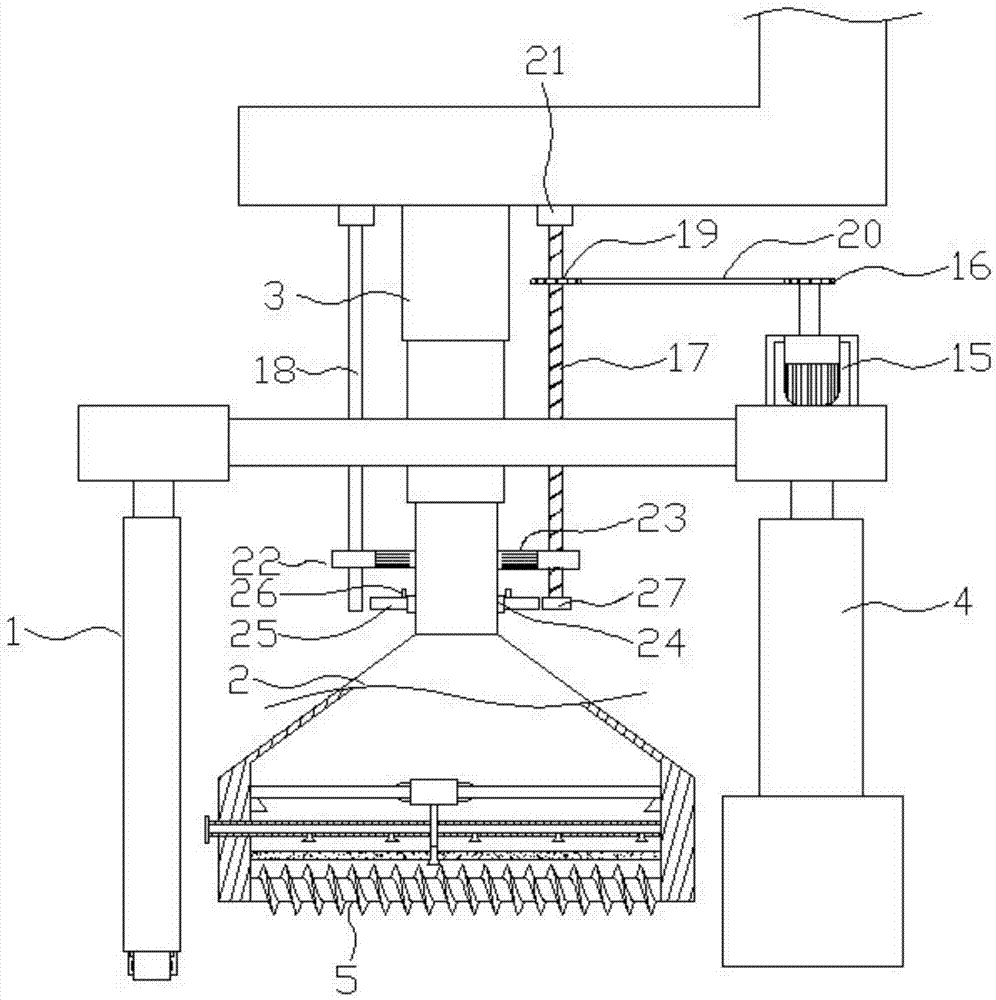

A bale plucker with a self-cleaning device comprises a bale plucker main body, wherein a cleaning strip is arranged above a bale plucking handle; a water delivering tube is arranged above the cleaningstrip; a sprayer is arranged at the lower end of the water delivering tube; one end of the water delivering tube extends out of a cotton suction cover and is connected with a flange; a sliding trackis arranged above the water delivering tube; a rodless cylinder is arranged on the sliding track; a sweeping plate is arranged at the lower end of the rodless cylinder; shearing blades are arranged ontwo sides of the sliding plate; a motor is arranged at the upper end of a central shaft of the bale plucker main body; a driving chain wheel is arranged on a rotating shaft of the motor; a lead screwand a guide column are separately arranged on two sides of a telescopic tube; a driven chain wheel is arranged on the lead screw; the driven chain wheel is connected with the driving chain wheel through a chain; a bearing block is arranged at the upper end of the lead screw; and a cleaning brush is arranged on the inner wall of the cleaning ring. In a working process of the bale plucker, the baleplucking handle and the telescopic tube can be cleaned, and normal operation of the bale plucker is prevented from being affected by flock and the like.

Owner:TAOJIANG HUANYU TEXTILE NEW MATERIAL SCI & TECH

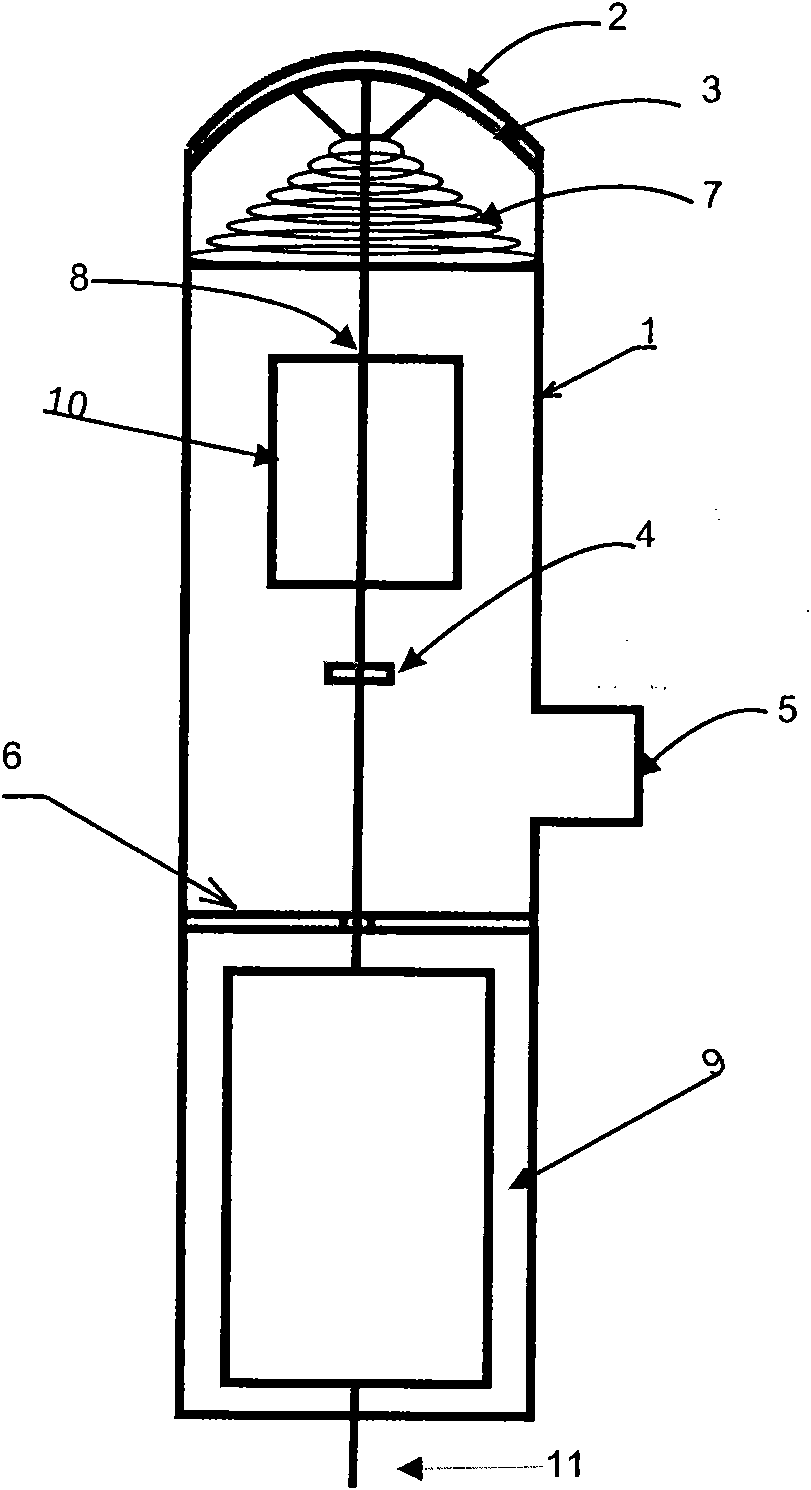

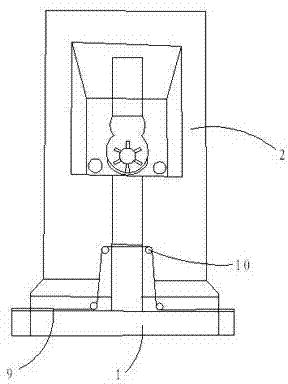

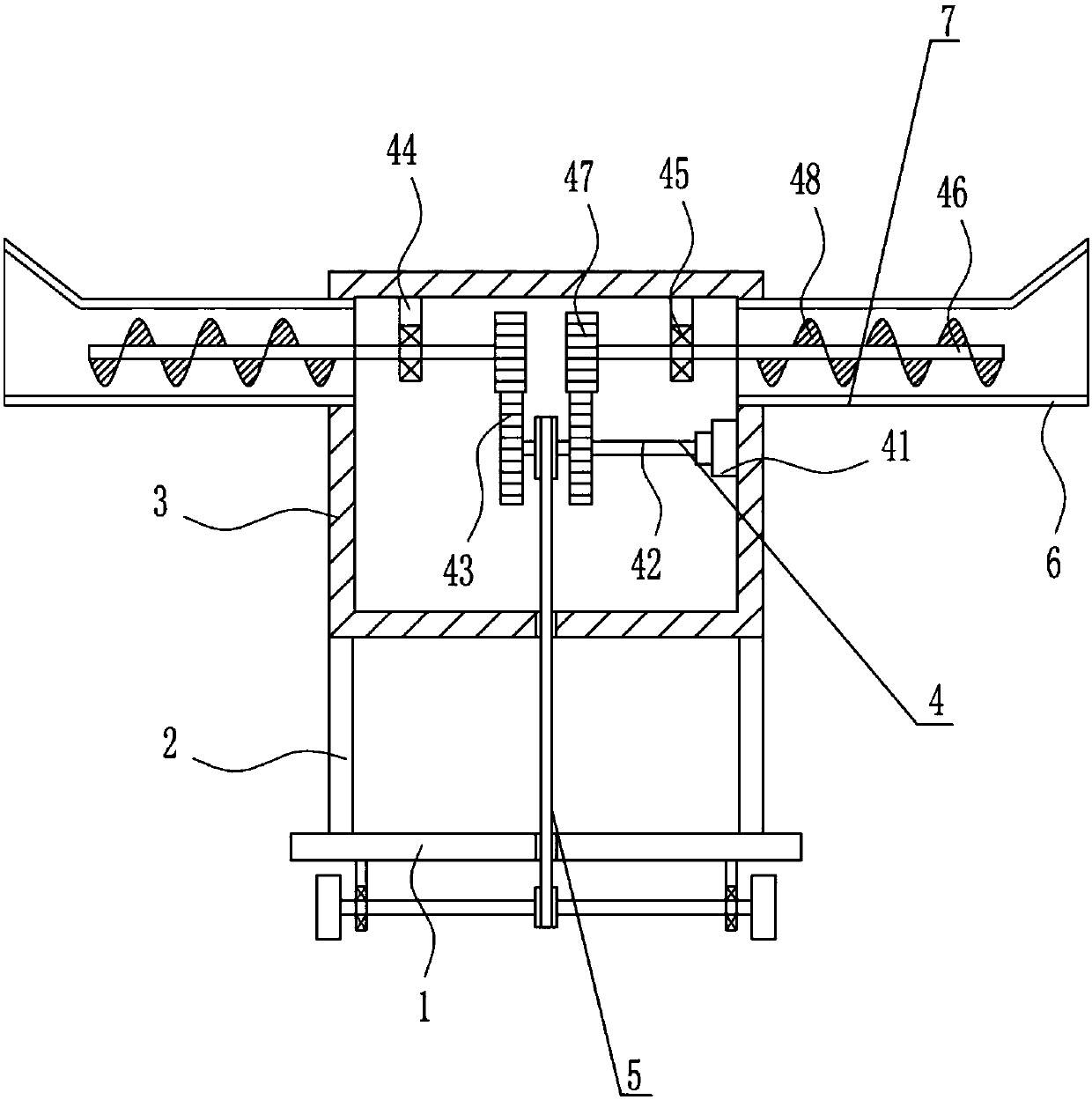

Disc plucker

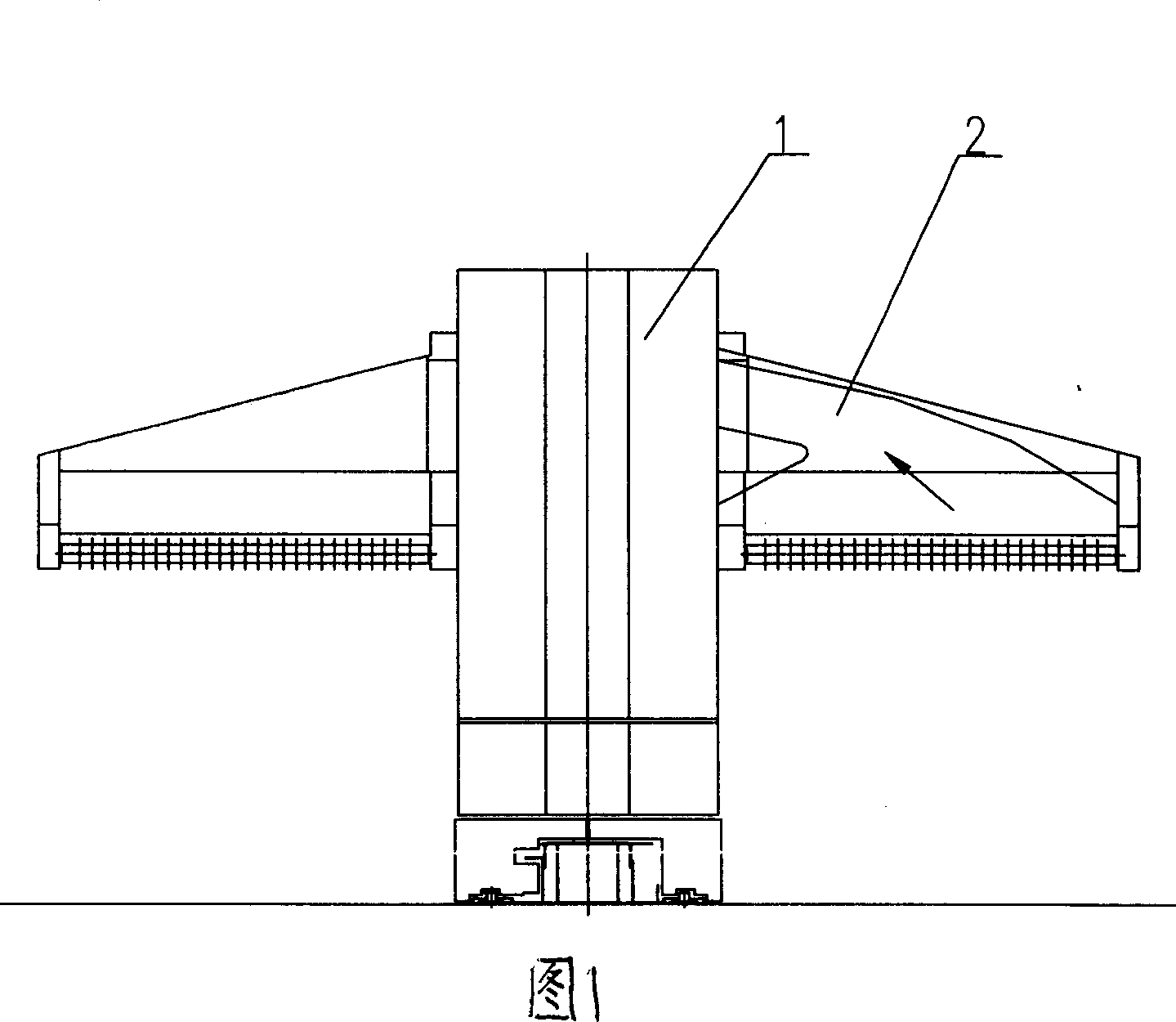

ActiveCN105483867ASimple structureEasy to operateFibre breaking machinesFibre breaking by beater armsCircular discDrive wheel

The invention relates to a disc plucker and belongs to the technical field of textile machinery. The disc plucker comprises a stock bin, a center stand column, a drive floorstand, a drive motor, a drive wheel, a transmission motor, a transmission lead screw and a cotton collecting device; the center of the stock bin is provided with the center stand column; the center stand column is movably provided with the drive floorstand; one end of the drive floorstand extends to the outside of the stock bin; the position, extending to the outside of the stock bin, of the bottom of the drive floorstand is provided with the drive wheel through the drive motor and a transmission belt A, the transmission motor is arranged at the position, on one side of the center stand column, of the drive floorstand, the drive floorstand below the transmission motor is provided with the cotton collecting device through the transmission lead screw, and the transmission motor is connected with the transmission lead screw through a transmission belt B. The disc plucker is simple in structure and convenient to operate, the problems that a cotton collecting hopper of an existing plucker is easy to block, the structure is unwieldy, and efficiency is low are solved, and the disc plucker is particularly suitable for production and use of enterprises.

Owner:HUBEI JINAN TEXTILE GRP CO LTD

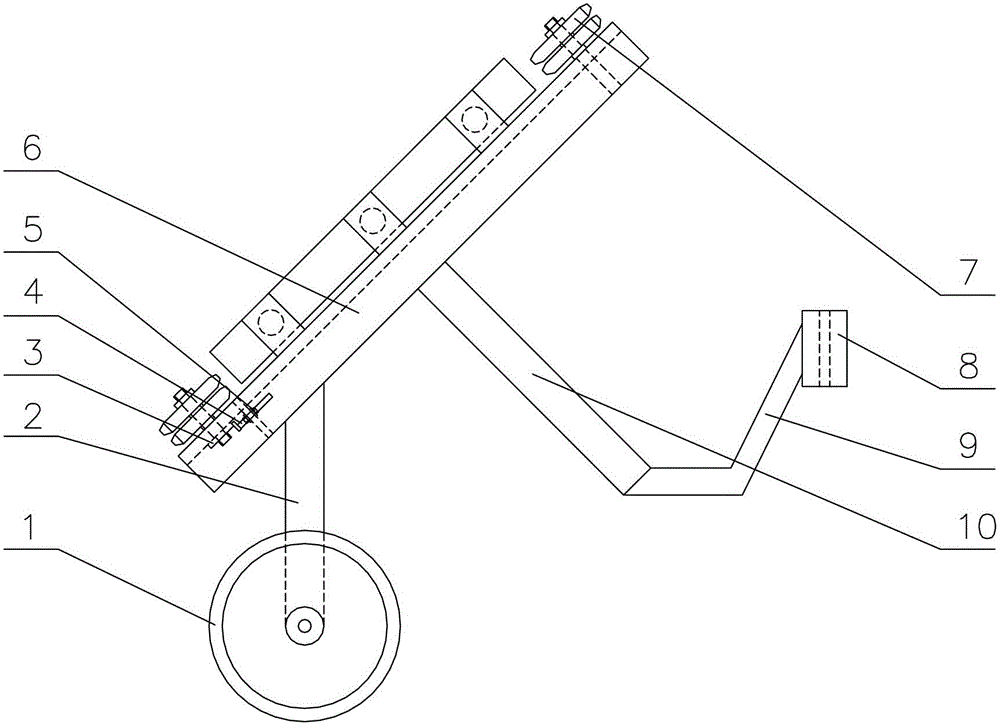

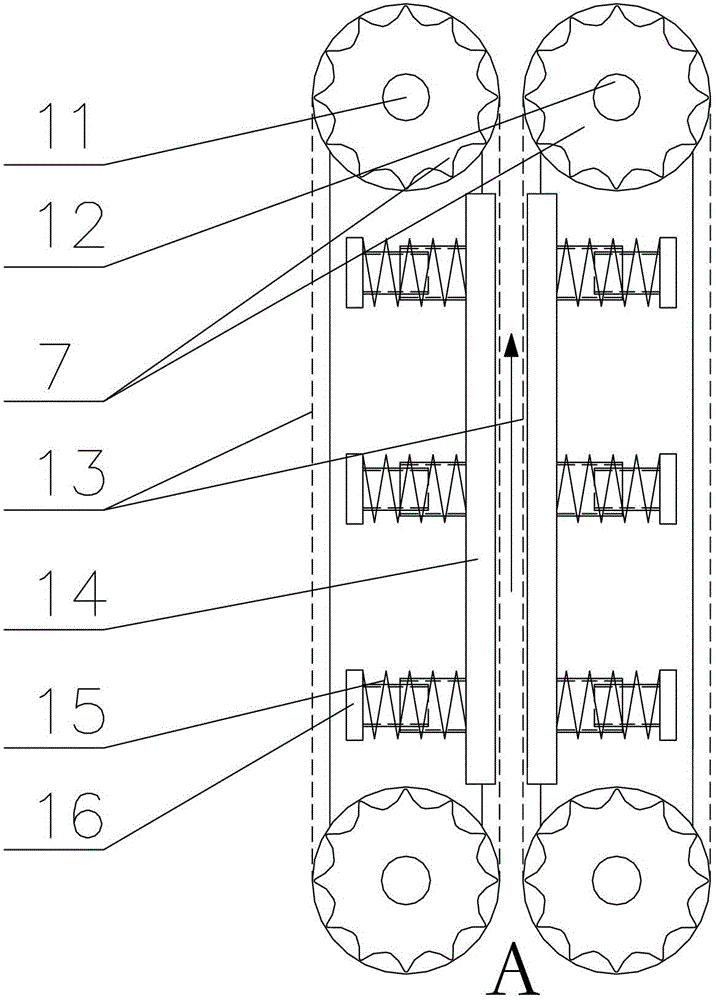

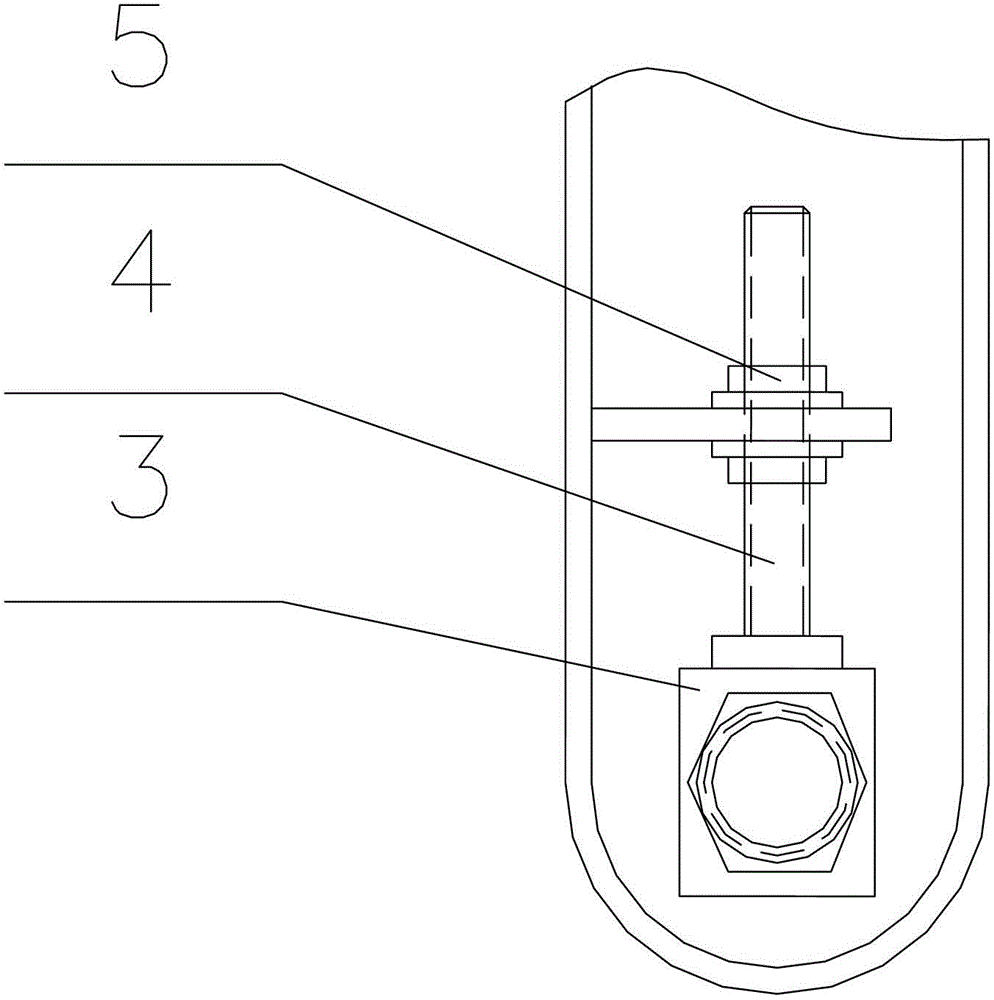

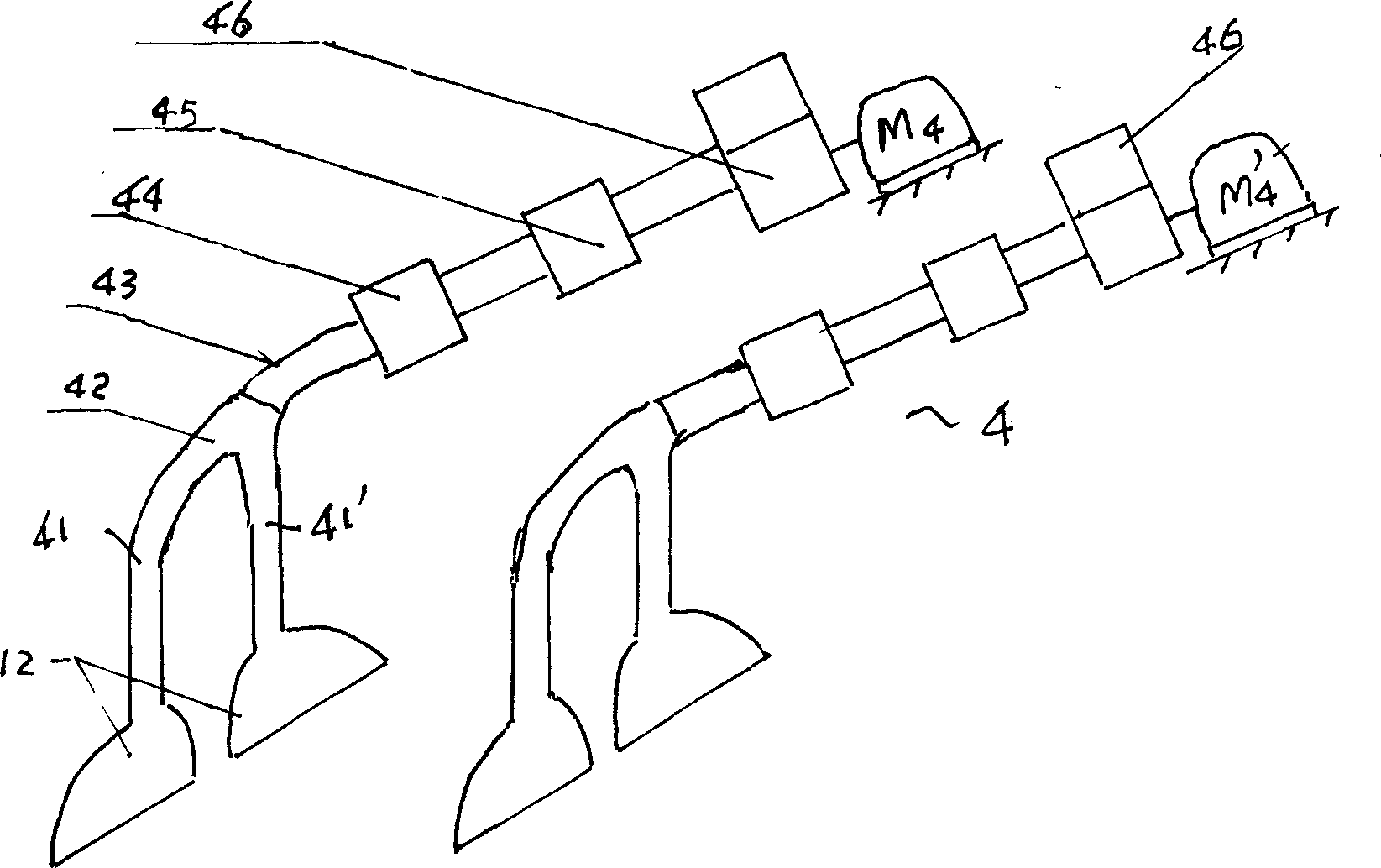

Crop stalk plucker

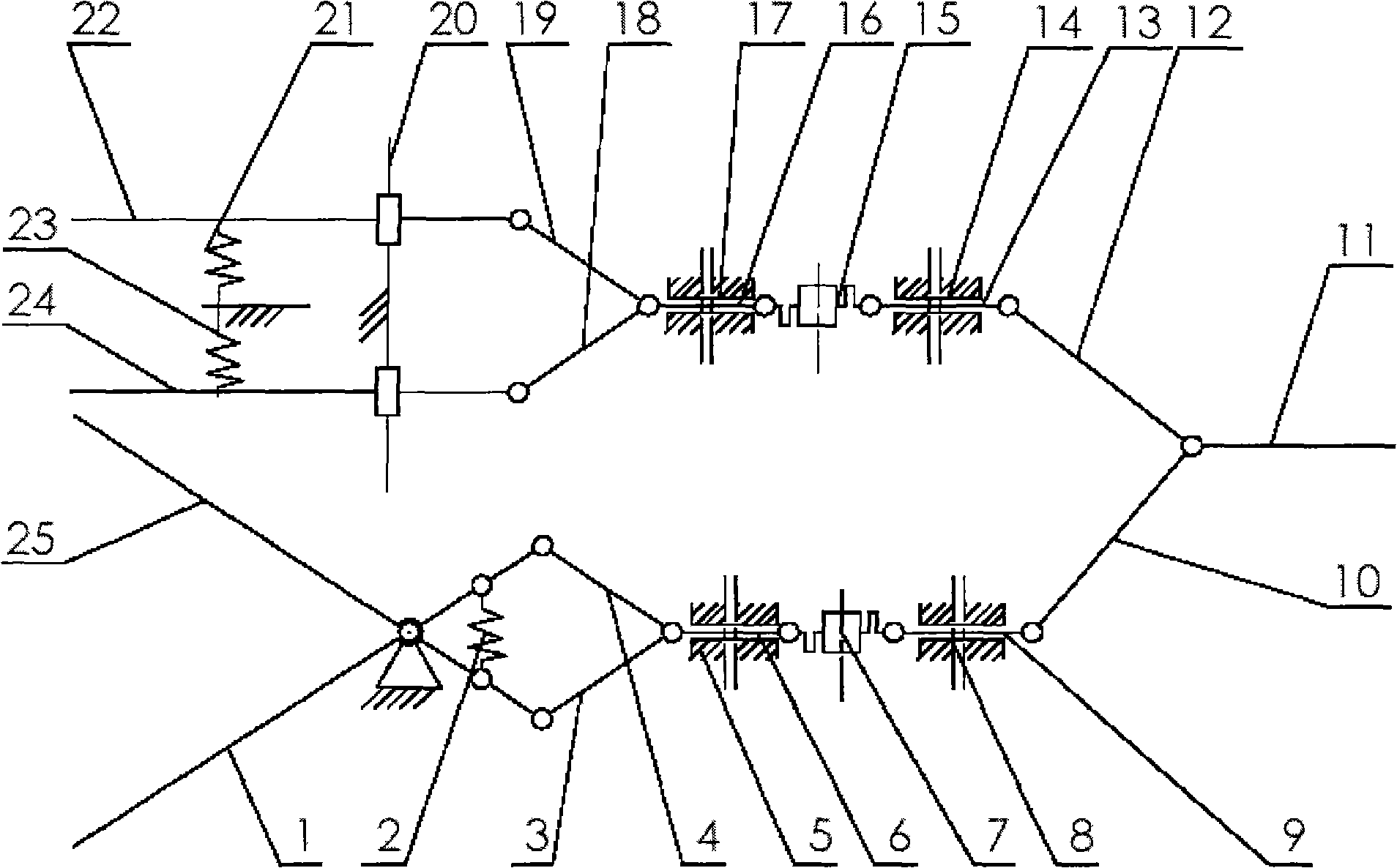

The invention discloses a crop stalk plucker, comprising a double-chained clamping mechanism, a float pressing device, a chain wheel tightness regulating mechanism, a supporting wheel, duplex chain wheels and a connecting mechanism, wherein the double-chained clamping mechanism adopts a pair of duplex chains arranged in parallel side by side to form a clamping clearance, and is driven by the duplex chain wheels for clamping plucked crops; the float pressing device is arranged inside the duplex chains, and a spring is arranged inside the float pressing device; the clamping force between the two duplex chains is adaptively controlled by the function of spring force; the chain wheel tightness regulating mechanism adopts the form of bolt and nut, and the distance between the duplex chain wheels is regulated by wringing the nuts to change the length so as to control the tightness; the supporting wheel is arranged below the front end of the device, and can ensure the stability of equilibrium of the whole machine when working and also achieves certain guide effect. The crop stalk plucker is simple and practical and compact in structure, thereby efficiently improving the work efficiency of stalk plucking and reducing the labor intensity.

Owner:HUNAN AGRICULTURAL UNIV

Automatic bale plucker

InactiveCN103422198AComb evenlySimple structureFibre breaking by beater armsEconomic benefitsEngineering

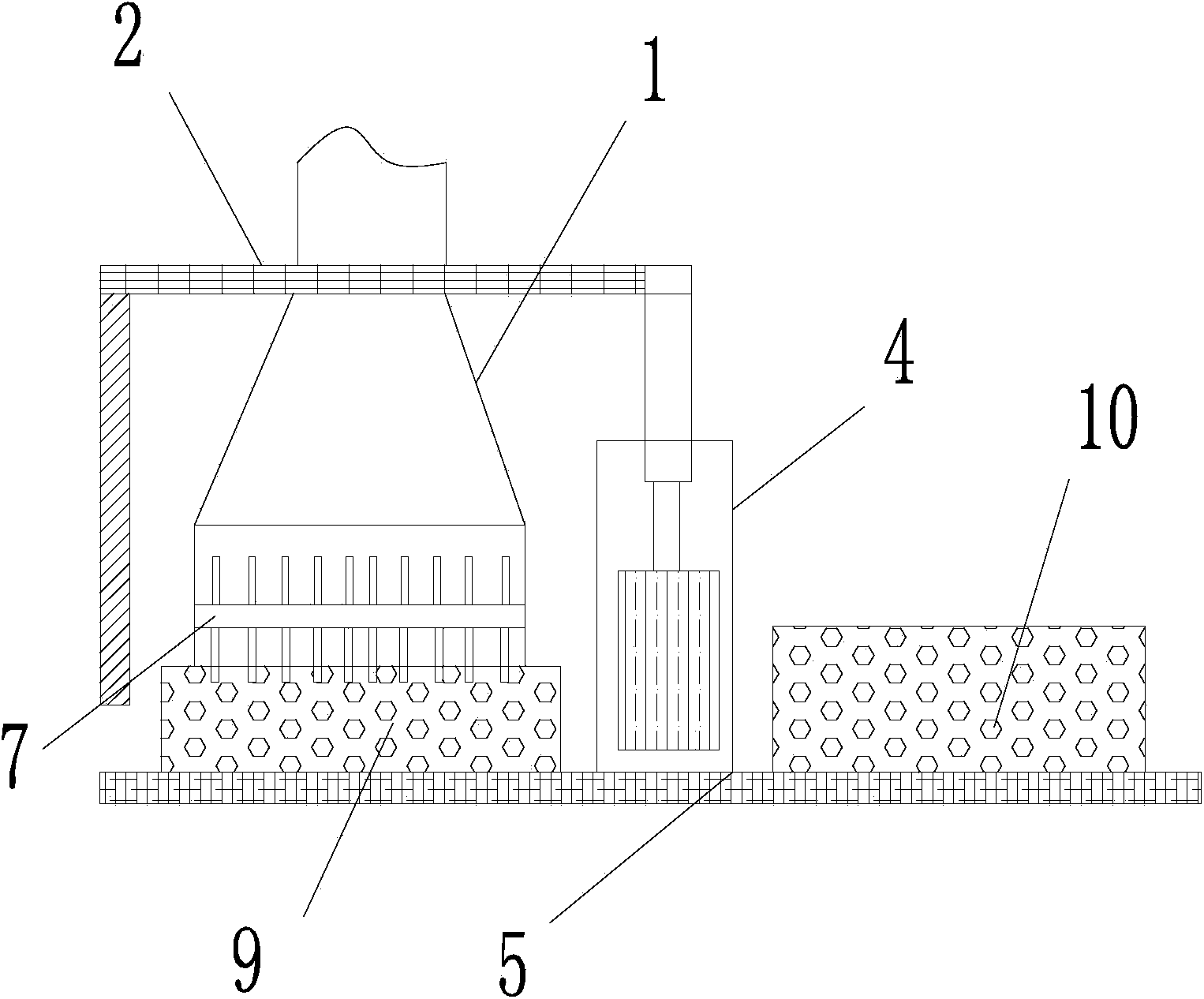

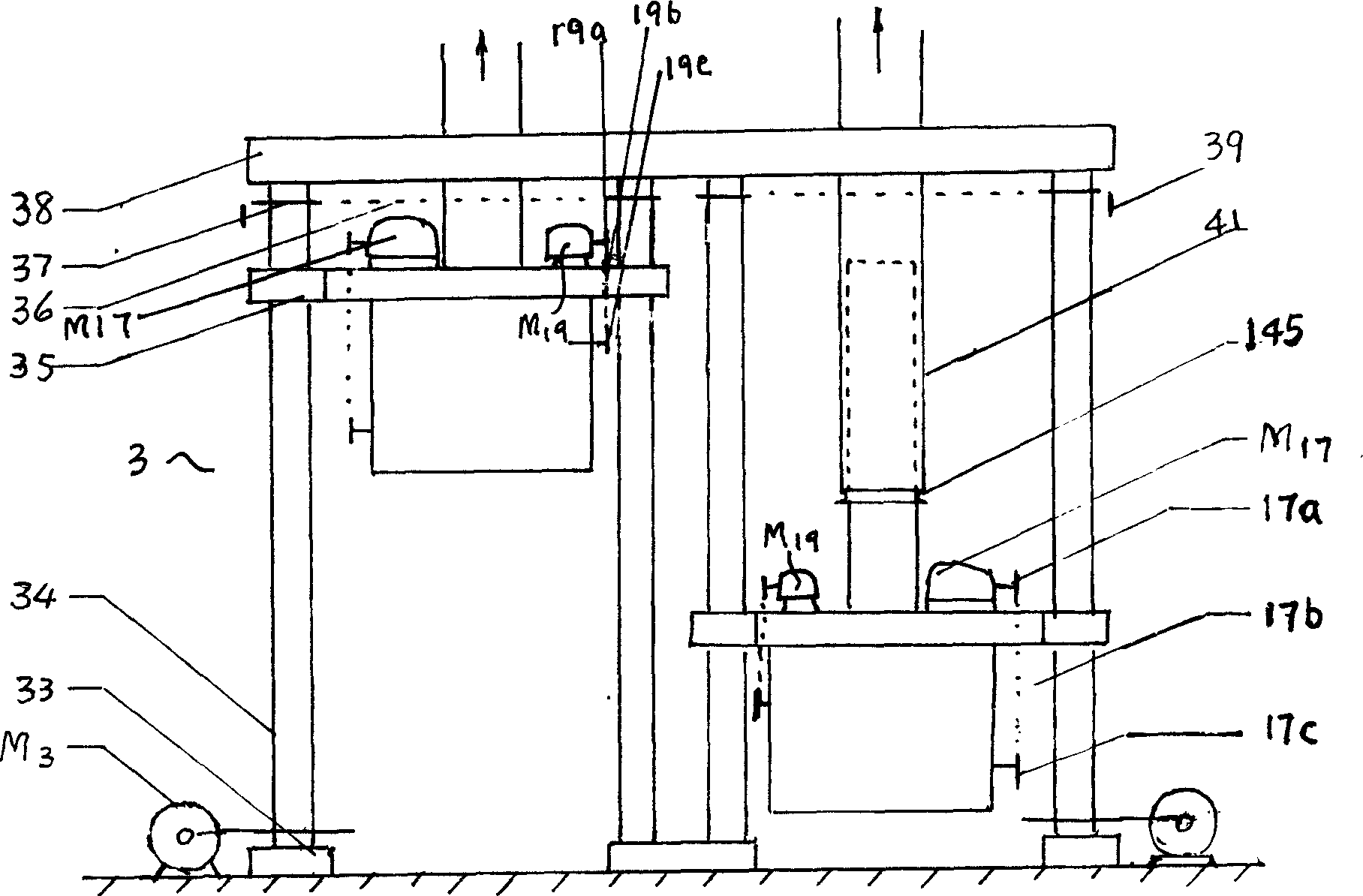

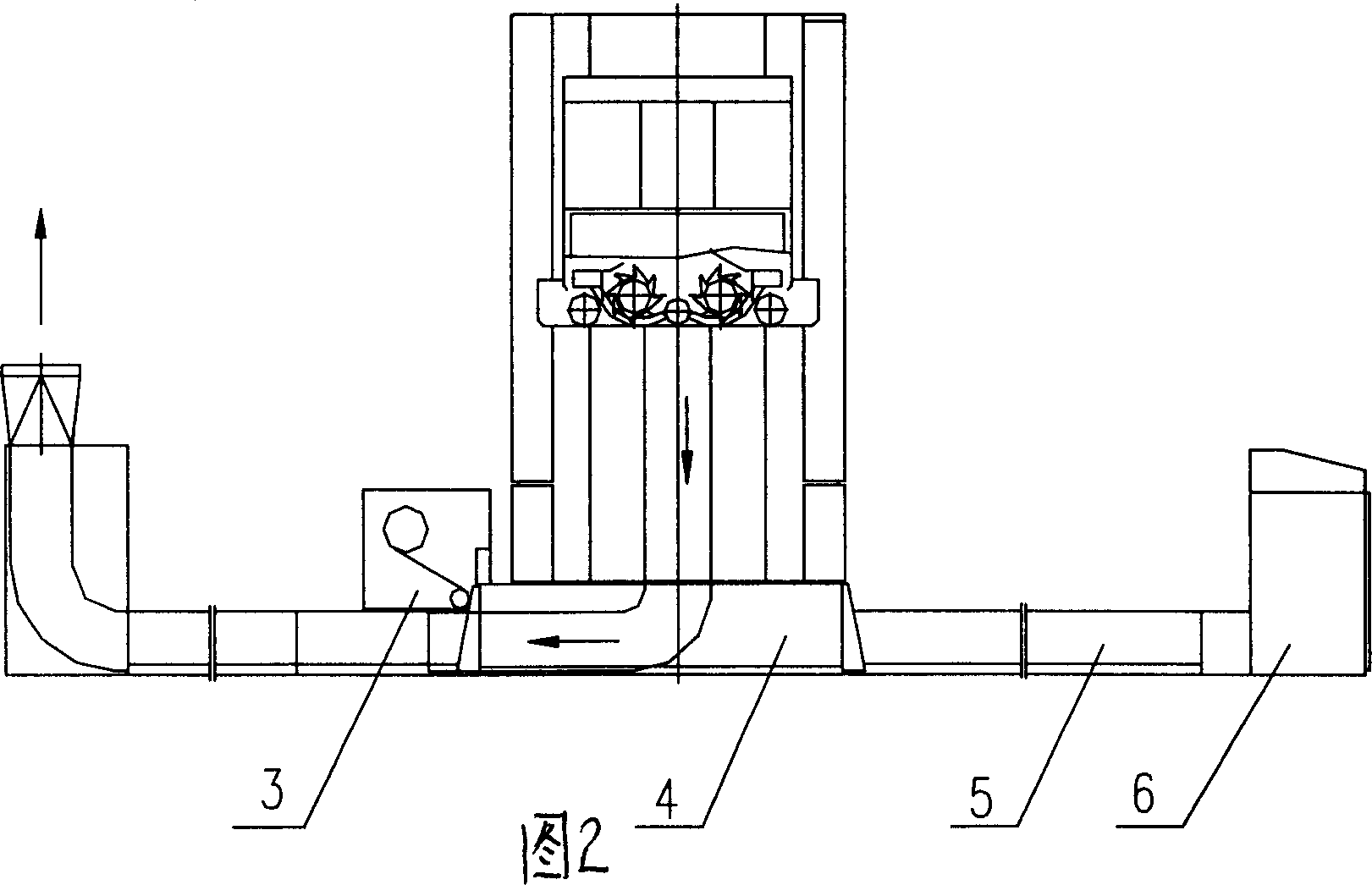

The invention discloses an automatic bale plucker which comprises an air suction hood and a driving device, wherein the driving device comprises a bale plucking arm, a power source and a center post, wherein the center post is fixedly arranged on a base; the power source is arranged inside the center post and drives the bale plucking arm to operate; a lifting device is arranged between the power source and the bale plucking arm; the air suction hood is fixedly arranged on the bale plucking arm; a bale plucking beater is arranged at the bottom of the air suction hood; blades are arranged at the periphery of the bale plucking beater; a cotton storage bin is arranged at the bottom of the air suction hood and is fixedly arranged on the base; a mobile cotton storage bin is also arranged on the base. The automatic bale plucker disclosed by the invention has the advantages of simple structure, simpleness and convenience in operation, reduced production cost, high bale plucking efficiency and low possibility of blocking; cotton raw materials are scutched to be more uniform, the working efficiency is increased and economic benefits are increased.

Owner:张志洲

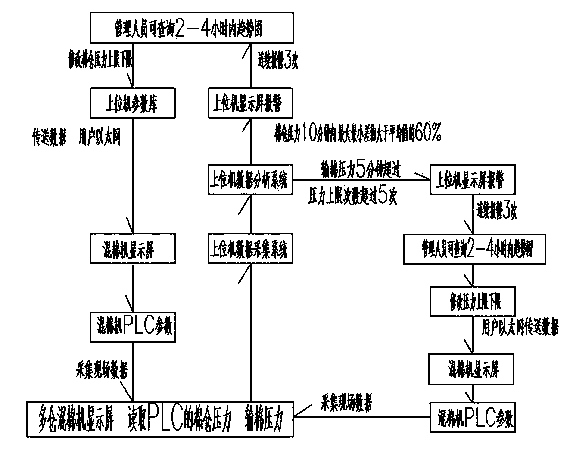

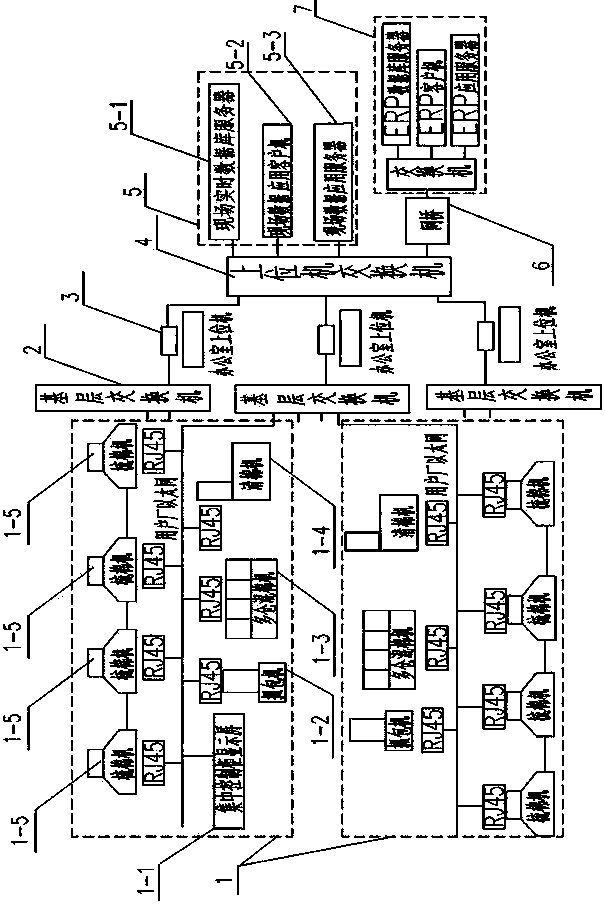

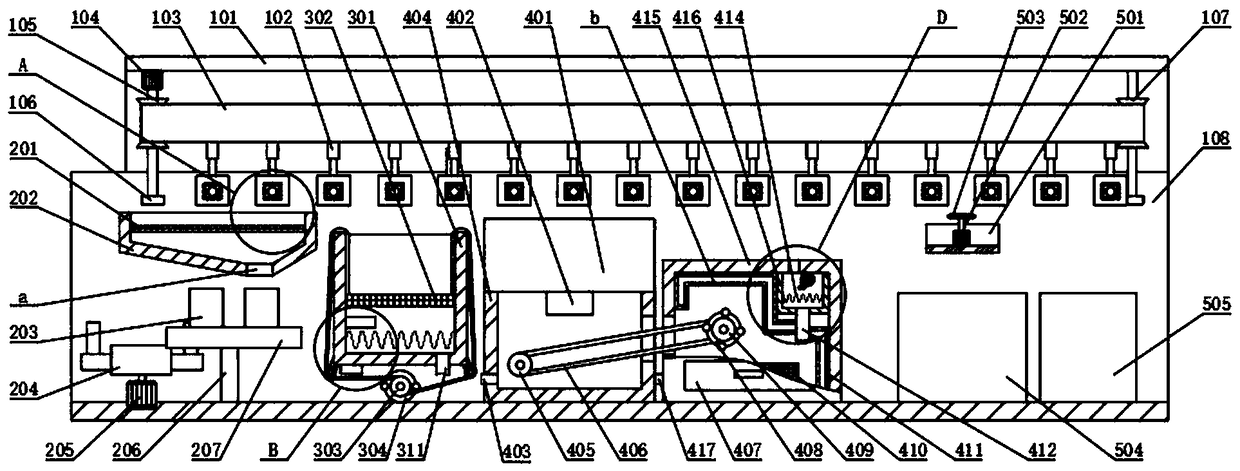

Blowing carding intelligent remote control system and control method thereof

InactiveCN104090530ARealize real-time data collectionRealize process monitoringTotal factory controlProgramme total factory controlHuman–machine interfaceData store

The invention provides a blowing carding intelligent remote control system and a control method thereof. The blowing carding intelligent remote control system and the control method thereof are characterized in that the controller and the man-machine interface of each single machine in a blowing carding device which comprises a plucker, an opener, a multi bin mixer, a scutcher and a carding machine are provided with industrial Ethernet interfaces; and the industrial Ethernet interface of each single machine is connected with an office host computer and a database server through switches to form an industrial Ethernet local area network in a plant, and is connected with a textile enterprise management network through a network bridge. Real-time data acquisition, process monitoring and trend analyzing of blowing carding in an enterprise network environment are realized. Historic data storing and recording are completed. Abnormal conditions can be timely found through data analyzing. The parameters of the system can be remotely modified through Ethernet. The problems of the system are corrected. Stable product quality is realized. Remote monitoring of the blowing carding device is realized.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

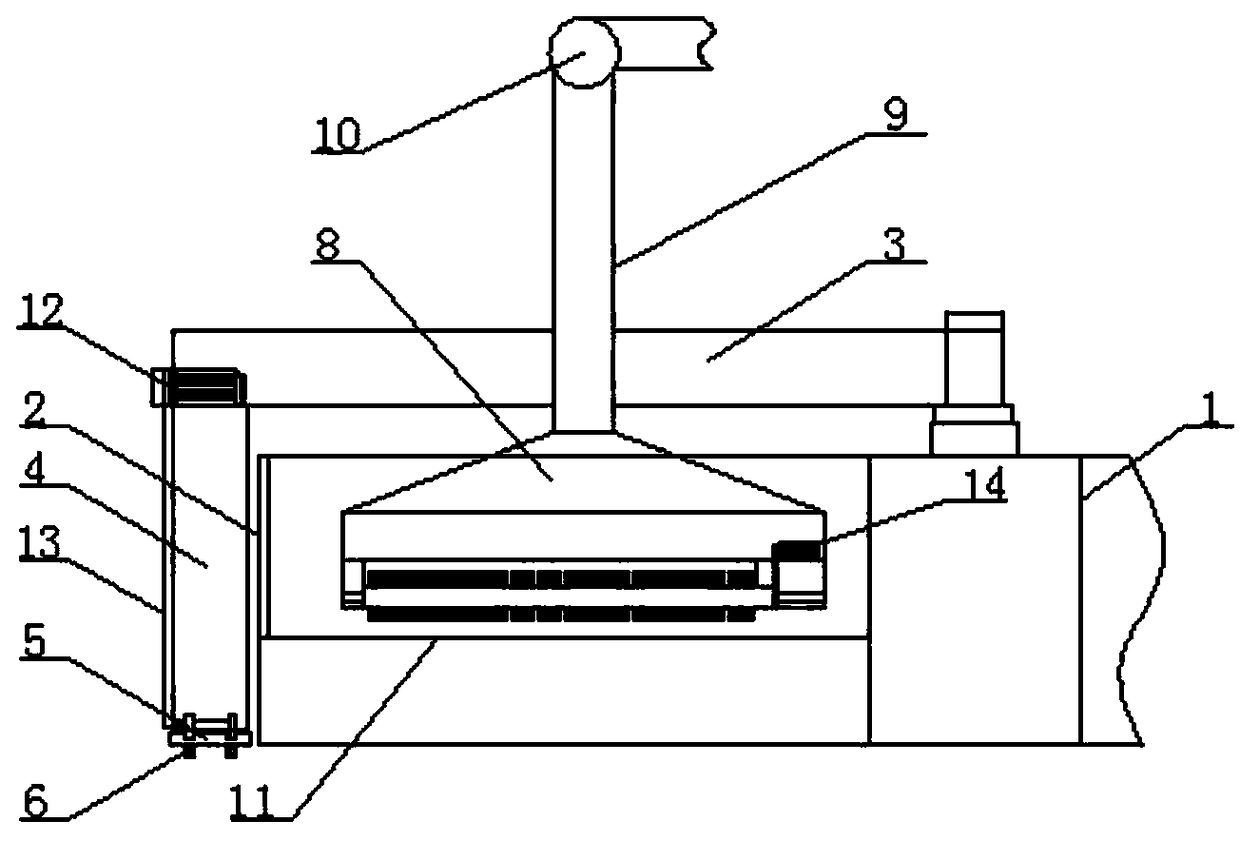

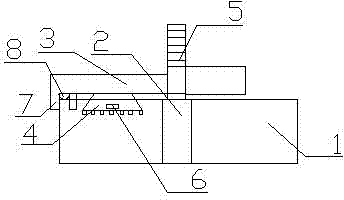

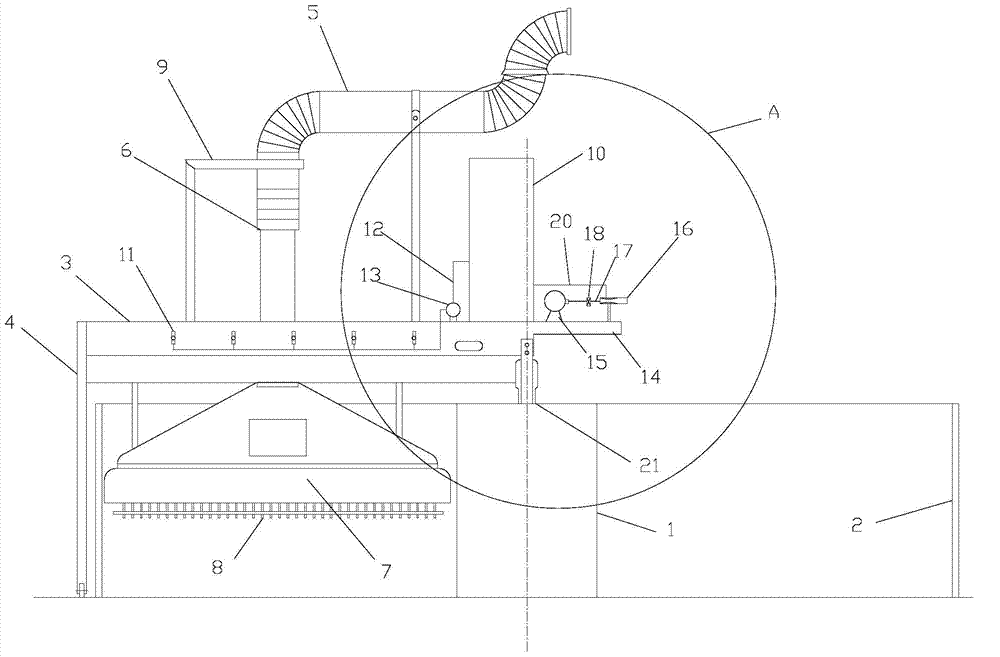

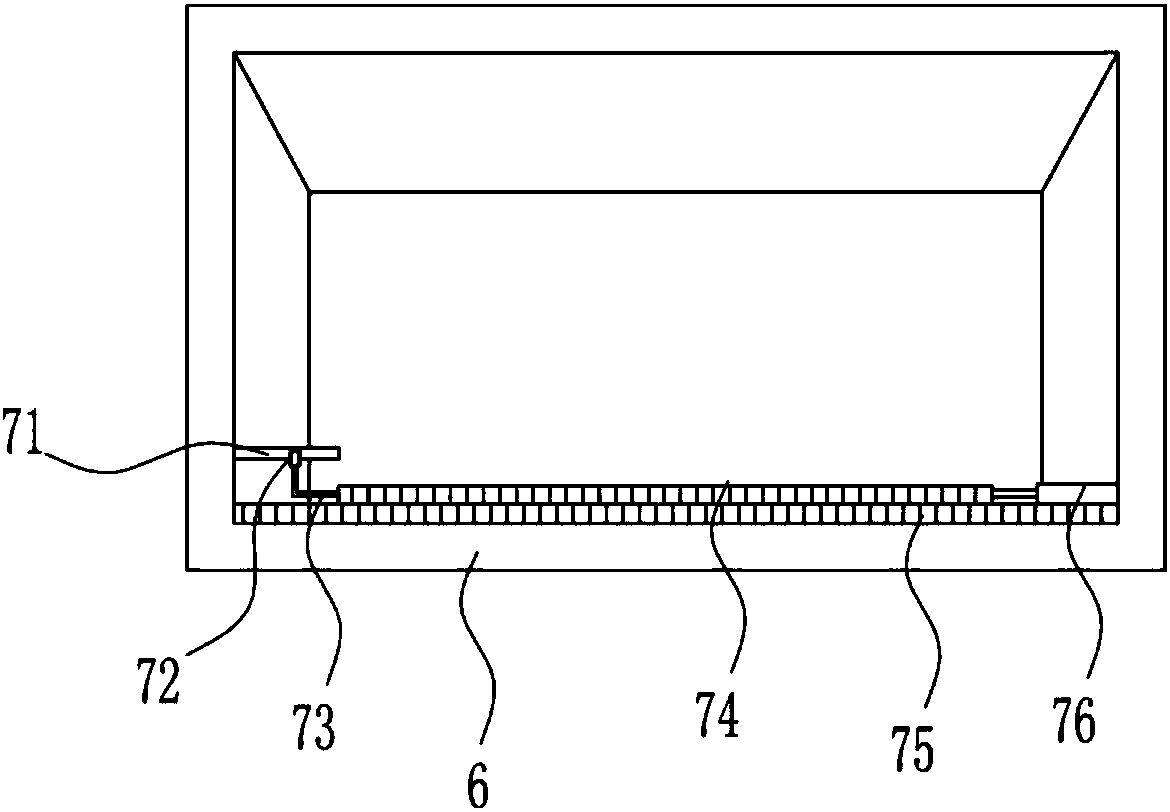

Spray humidifier for bale plucker disk

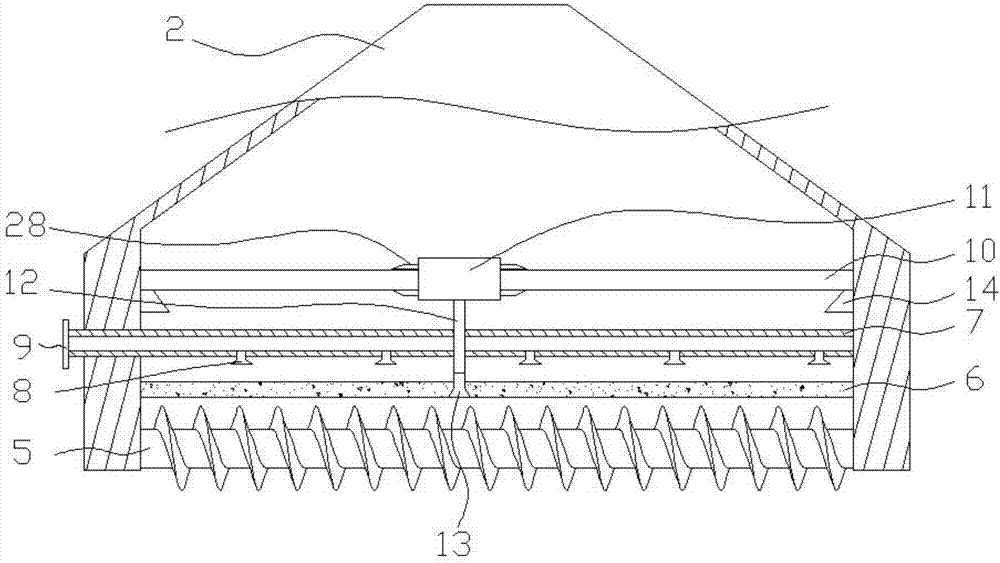

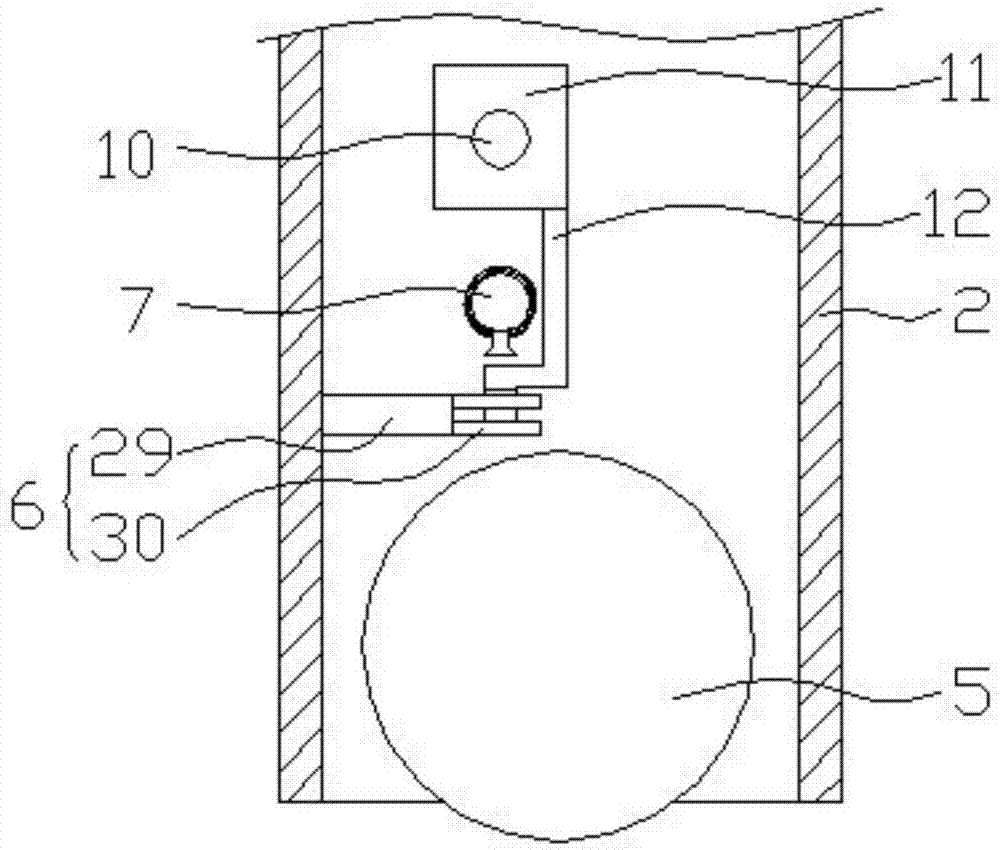

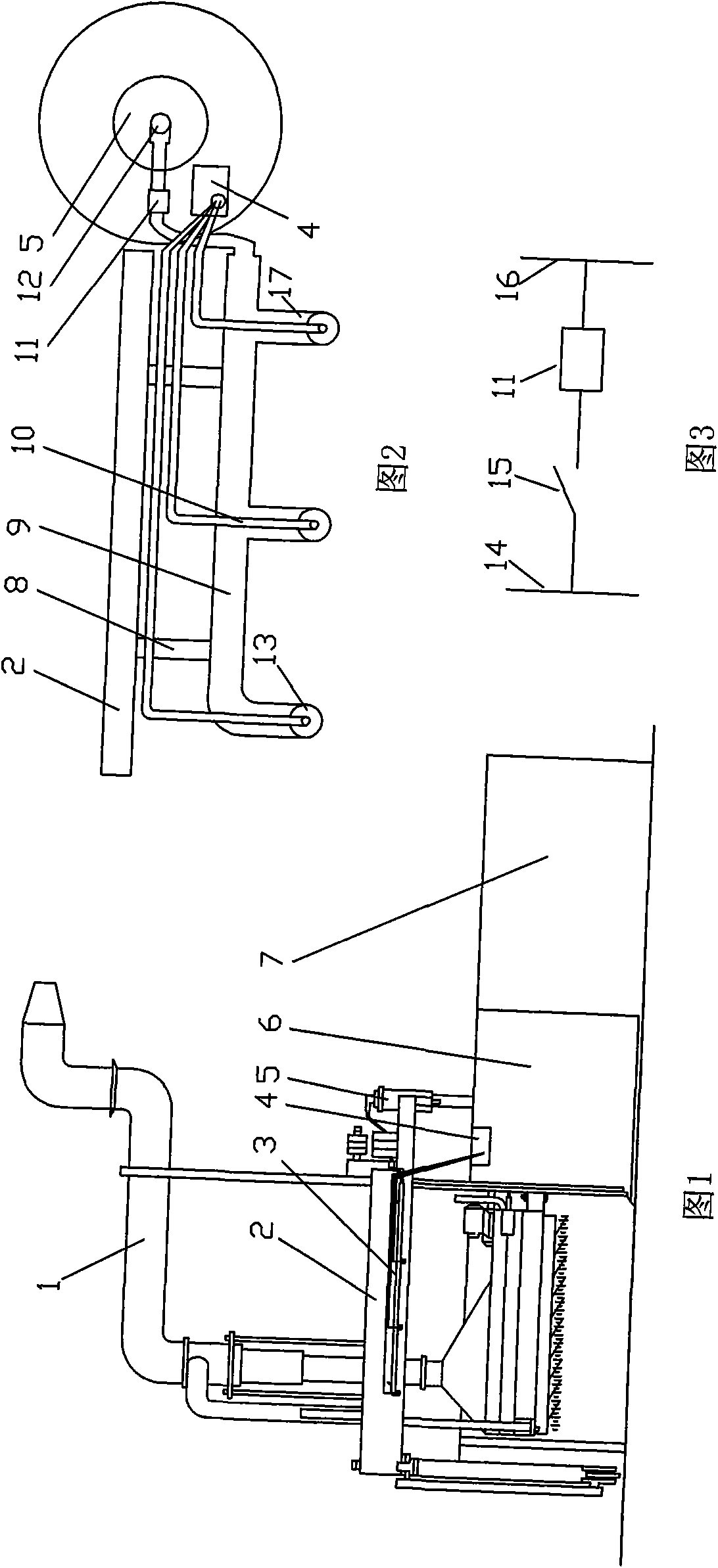

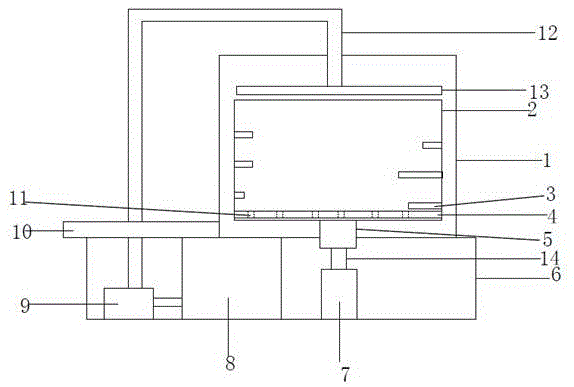

InactiveCN101629749AUniform humidificationSimple structureLighting and heating apparatusFibre cleaning/opening machinesArchitectural engineeringAir pump

The invention discloses a spray humidifier for an A002 type bale plucker disk, which is characterized in that the left side of an A002 type bale plucker wall panel (2) is provided with two screw holes, an air pipe (9) is fixed on the screw holes of the wall panel through a bracket (8), one end of the air pipe (9) is connected with a nozzle (13), and the other end of the air pipe is connected with an electromagnetic valve (11); the electromagnetic valve (11) is connected to a universal rotary head (12) through another section of air pipe, and the universal rotary head (12) is fixed on a slip ring (5) and connected to an air compressor air pump through the air pipe; one end of a water pipe (10) is connected to the nozzle (13) respectively, and the other end of the water pipe (10) is arranged at the bottom of a water tank (4) respectively; and the water tank (4) is welded on an inner wall panel (6). The humidifier has the advantages of reasonable structure design, low production cost, convenient and even humidification, not only reduces the intensity of labor, but also increases the production efficiency of enterprises.

Owner:JIHUA 3542 TEXTILE CO LTD

Bale plucker

InactiveCN1508304ASignificant advantagesSignificant beneficial effectFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsFiberReciprocating motion

The invention is a package catcher, composed of the cotton catching head group linked by cotton table and cotton feeding pipe, and the riser, the cotton catching head only making lift motion and the cotton table able to move back and forth on the trolley wheel; two cotton catching heads become a group, the cotton beam output pipe and two down-inclining dropping boxes set on the case of the cotton catching head, and the cotton catching beater and purifying beater set inside the cotton catching head. The purifying beater can make on-line elimination of the impurities carried by the cotton beam such as cotton seeds, cotton scraps and so on.

Owner:吕恒正

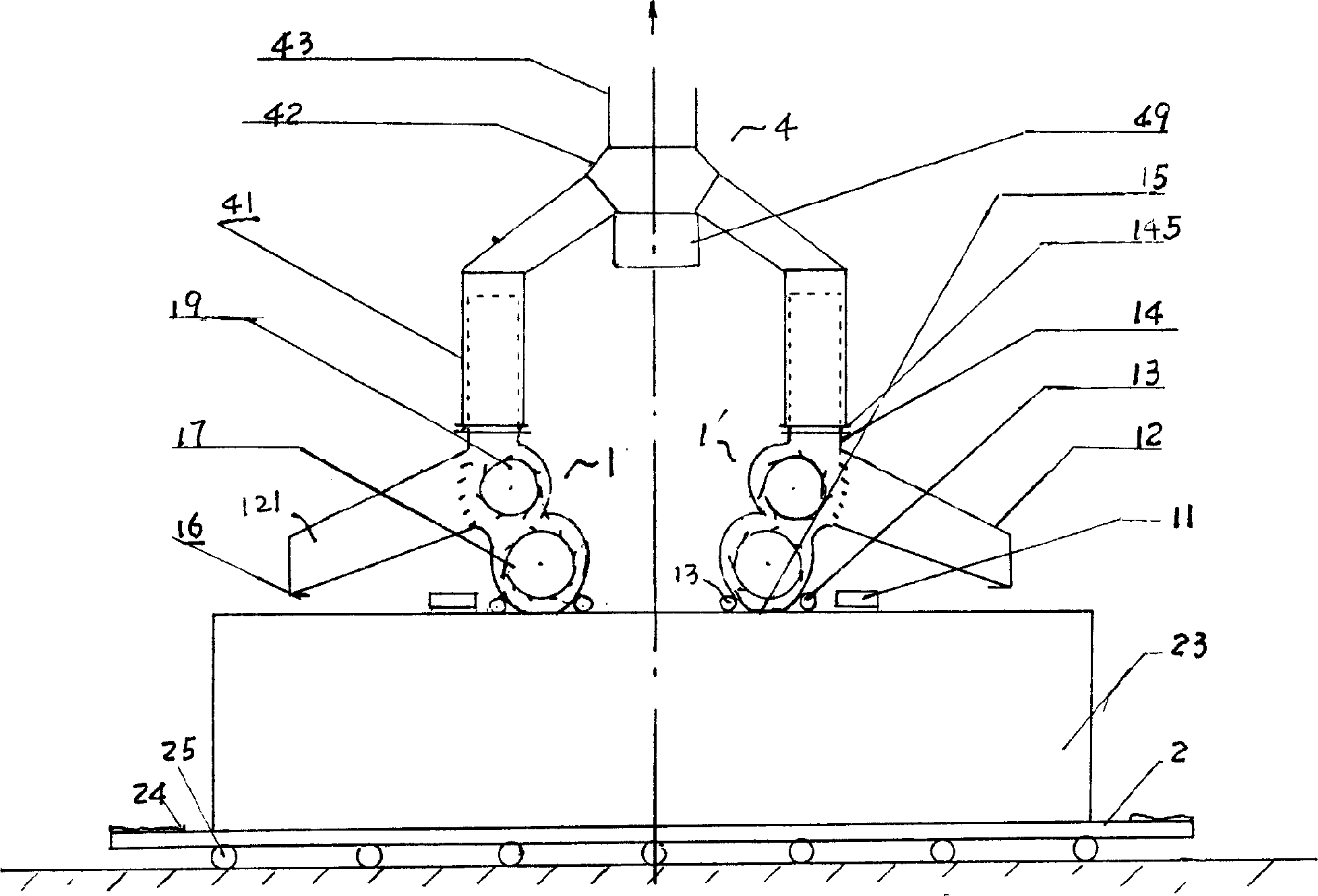

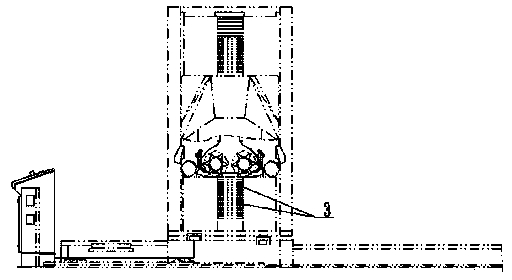

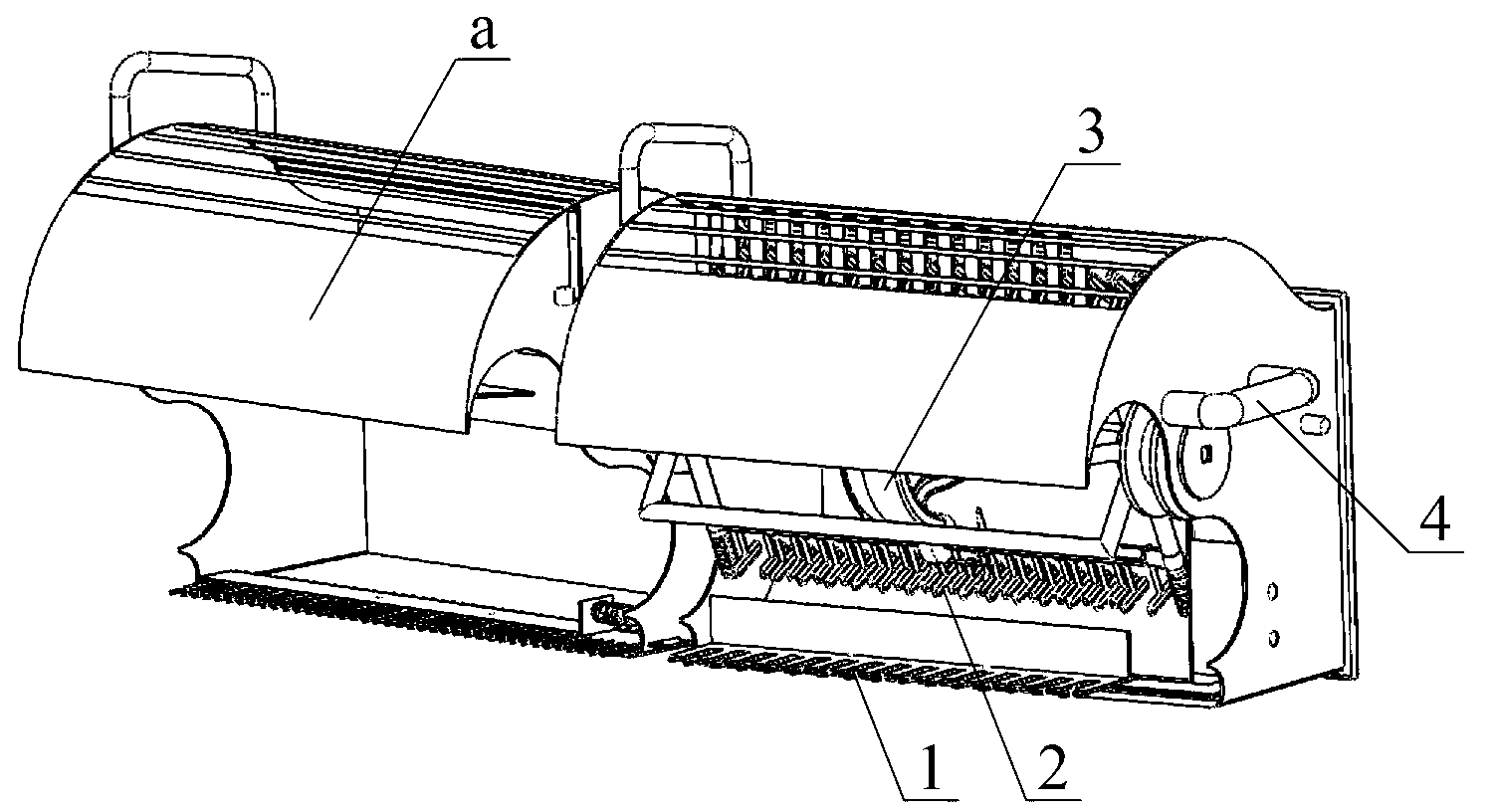

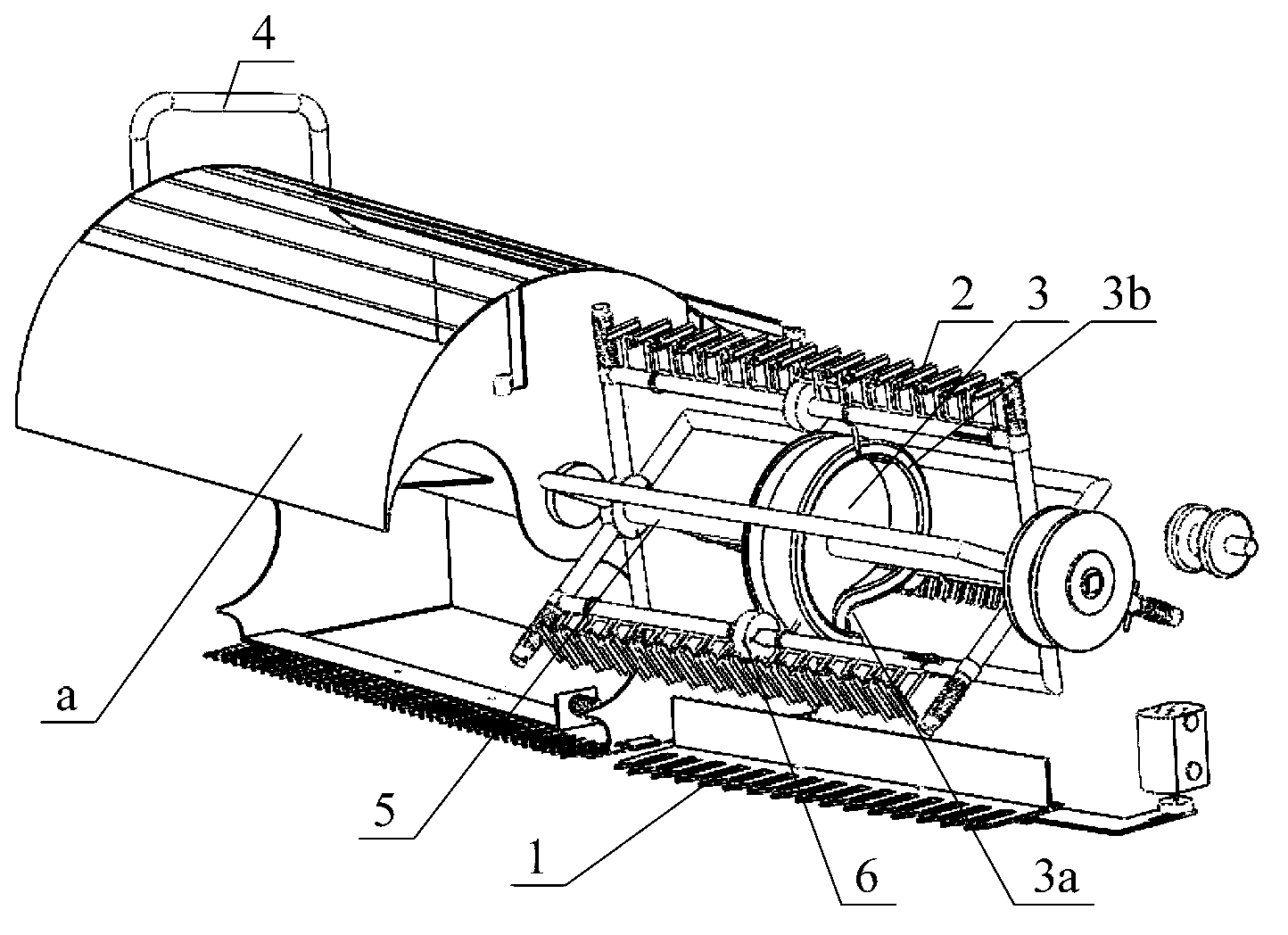

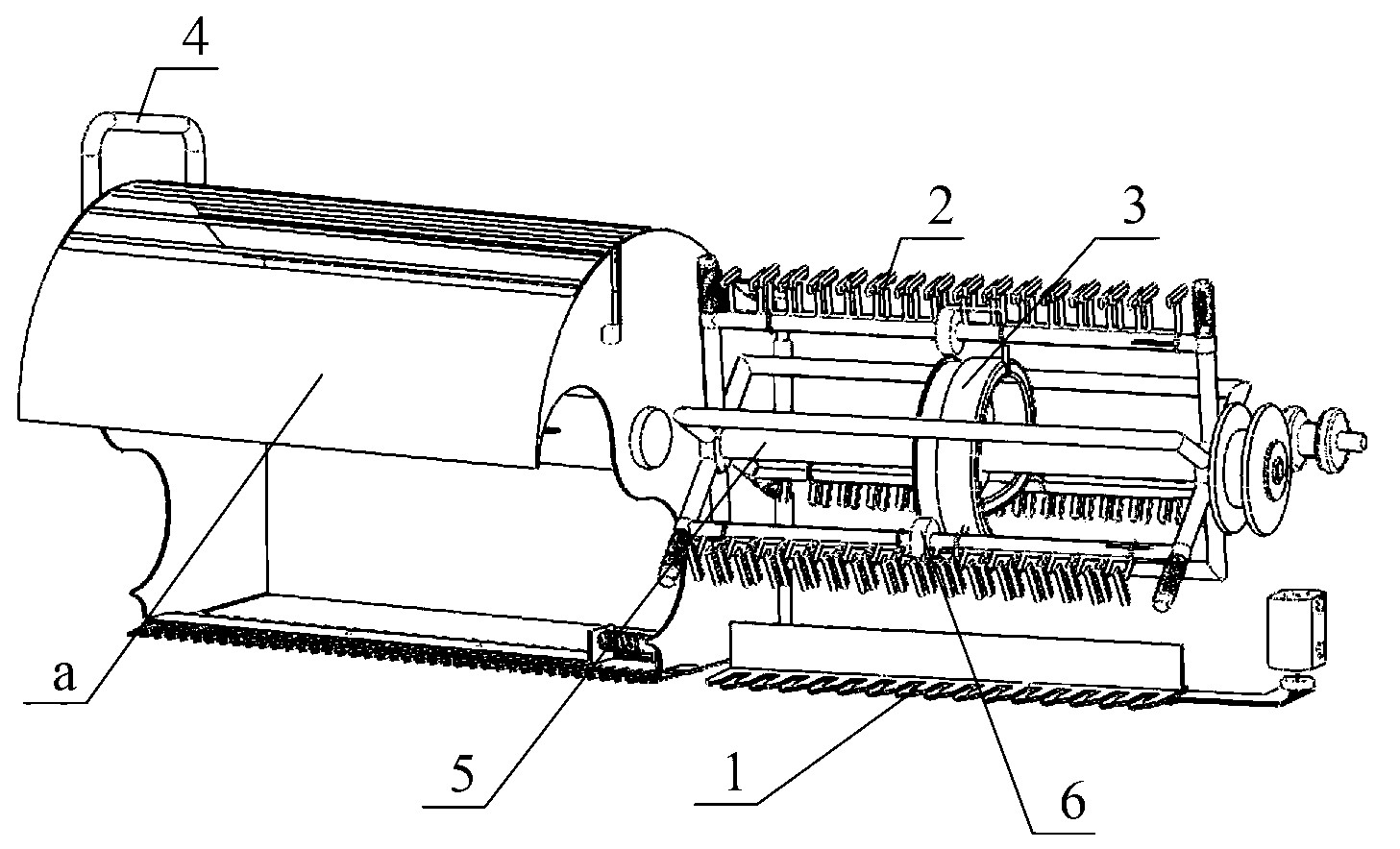

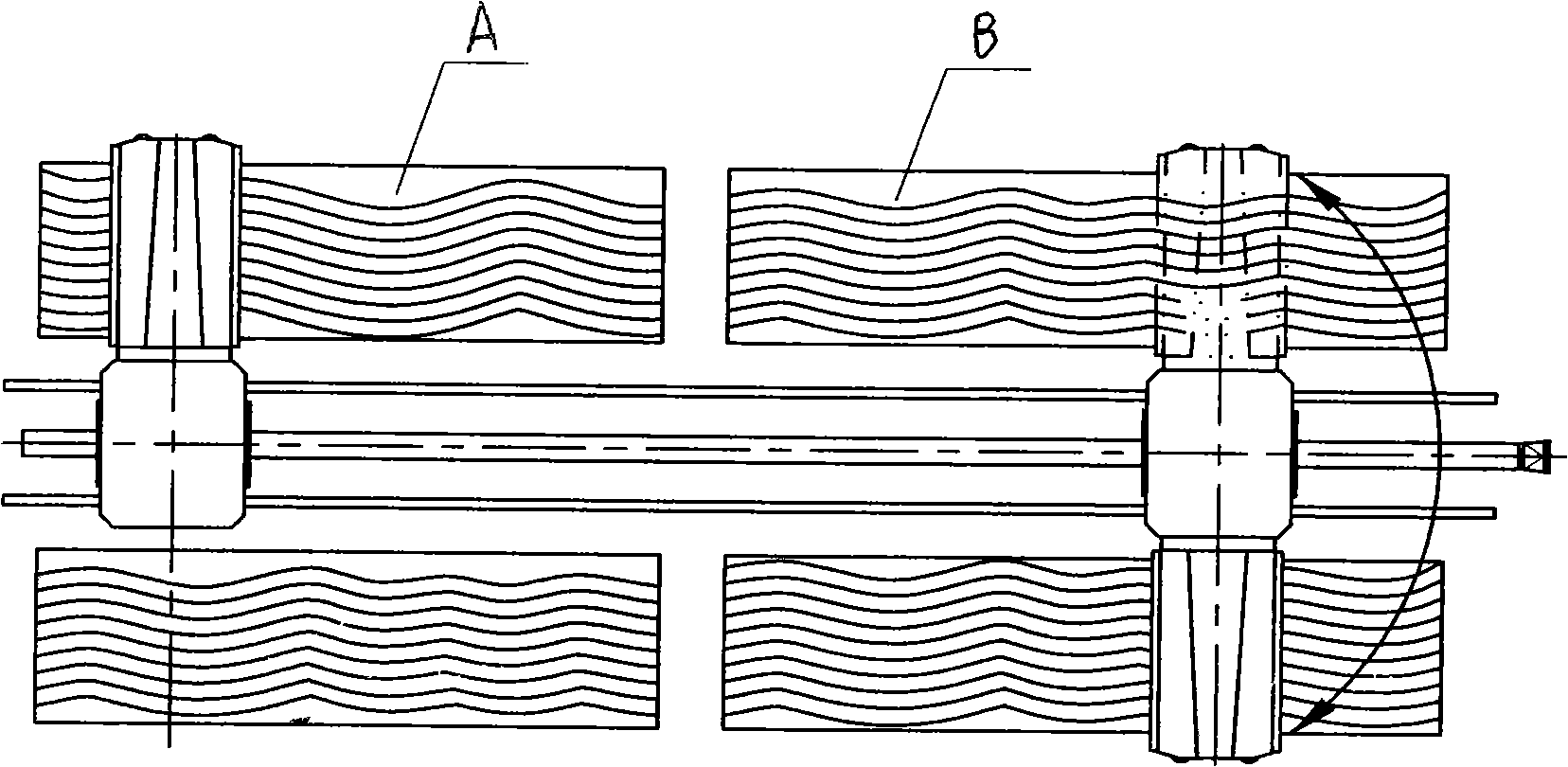

Cotton grasp mechanism adapted for reciprocation bale plucker

The invention relates to a cotton picker used in reciprocated cotton picking machine, wherein it comprises cotton picking arm frame (7) combined with rotational tower; under the frame (7), along the length direction, via the longitudinal vibrator (13), two swing rods (16) are parallel suspended; two ends of each swing rod (16) are both fixed with supports (14) for mounting beater; the left and right supports (14) at same end of two swing rods (16) via hinged connectors form the four bar linkage; two beaters (8) are individually arranged in two independent beater cotton picking areas formed by arm frame protect plate (18), inner baffle plate (17) and rib (12), while they are parallel mounted under two swing rods (160 via four bar linkage; and the transmission device for rotating two beaters (8) synchronously at same direction is arranged at the outer end of cotton picker.

Owner:ZHENGZHOU HONGDA NEW TEXTILE MACHINERY +1

Plucker

The invention discloses a plucker. The plucker comprises an outer barrel, an inner barrel and a base. The inner barrel is movably sleeved with the outer barrel, the inner barrel is of a porous structure, and the inner barrel is provided with multiple rubber protrusions. The outer bottom face of the inner barrel is fixedly connected with a rotary shaft, the rotary shaft is in transmission connection with a motor arranged in the base, the inner barrel is driven by the motor to rotate at high speed, at the moment, slaughtered poultry conducts centrifugal motion in the inner barrel, and at the moment, feathers of the poultry fall off due to the flapping effect of the rubber protrusions. The plucker is simple and reasonable in structure, unhairing can be achieved rapidly, and the whole plucker has a good cleaning function, and is not prone to be stained, comfortable for a user to use and more sanitary.

Owner:廖志标

Plucker

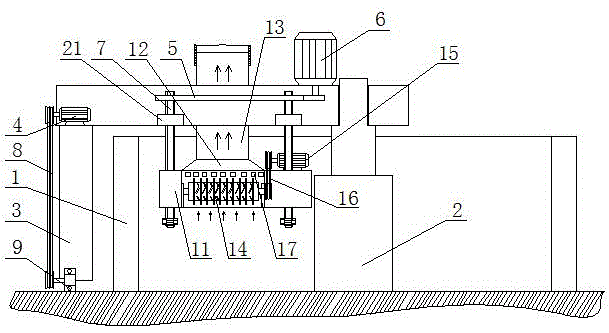

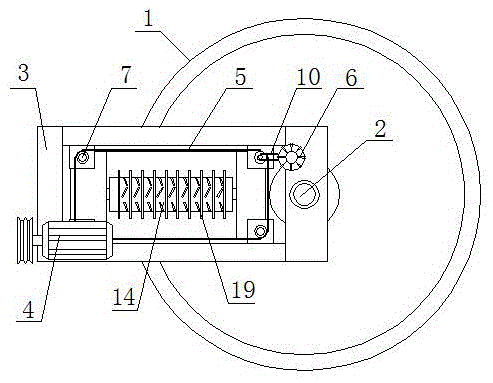

InactiveCN104738142ATo achieve the purpose of hair removal cleanPoultry plucking mechanismsPlastic materialsEngineering

The invention discloses a plucker, which comprises a machine case, hacking rods made of a rubber or plastic material, a baffle plate, a cylinder, a plurality of rotating roller bodies, a lifting rotation roller body and a lifting cylinder, wherein the hacking rods are fixedly arranged on the rotating roller bodies and the lifting rotation roller body; a guide groove is formed in the machine case; the shaft of the lifting rotation roller body is in sliding fit with the guide groove; the rotating roller bodies and the lifting rotation roller body form a hacking space; the lifting rotation roller body and one rotation roller body form a door body; the lifting rotation roller body is driven to ascend by the lifting cylinder; water injection holes are formed in a top plate of the machine case; and hair outlet holes are formed in a bottom plate of the machine case. Due to the structure, after a chicken body and a duck body enter the hacking space, the length directions of the chicken body and the duck body are consistent with those of the roller bodies; the rotation speed of the rotation roller body of a lower hacking cavity is higher than that of the rotation roller body and the lifting rotation roller body of an upper hacking cavity; and under the condition that the chicken body and the duck body are continuously turned over, various parts can contact the hacking rods, so that the target of thoroughly unhairing can be reached.

Owner:杨君忠

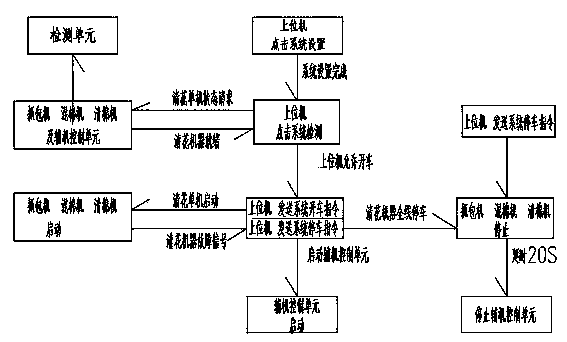

Blowing-carding electrical control system and control method

ActiveCN103382587AWalk fastReduce walking speedContinuous processingProgramme total factory controlFire detectorHuman–machine interface

The invention provides a blowing-carding electrical control system and a control method. The blowing-carding electrical control system comprises a bale plucker, an opener, a multi-bin cotton blending machine, a scutcher, a cotton conveying pipeline, a carding machine, a fan, a metal-fire detector, a dust removal machine, sensors and a control system and is characterized in that the control system comprises a central controller and a human-machine interface, the sensors comprise a bale plucker traveling speed sensor, a picking depth sensor, cotton blending pipeline pressure sensors, cotton blending bin level sensors, a cotton blending machine inclined screen speed sensor, a cotton blending machine flat screen speed sensor and cotton conveying pipeline pressure sensors, the signal output ends of the sensors are connected with the signal input end of a central controllor, and the controllers of the bale plucker, the opener, the multi-bin cotton blending machine and the scutcher are connected with the central controller respectively. The automation control of the online detection and the real-time adjustment of the blowing-carding system can be achieved, situations such as multi-bin useless running, overlarge fluctuation of cotton storage amount, unsteady rear stage cotton conveying and frequent start stop can be avoided, and smooth cotton supply and continuous and even sheet cotton output can be guaranteed.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

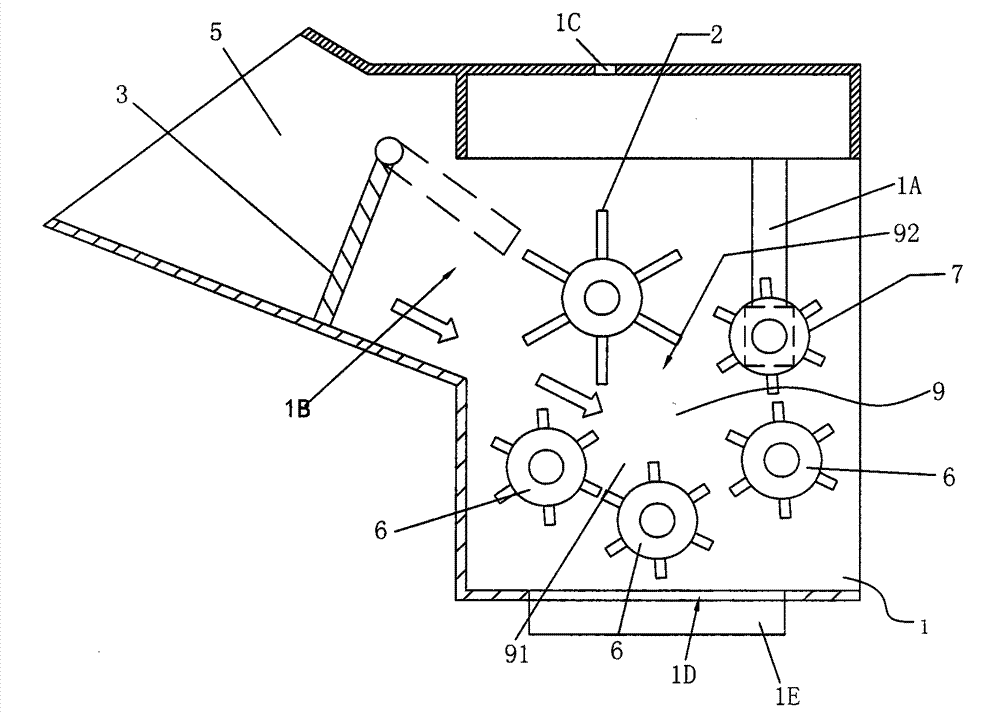

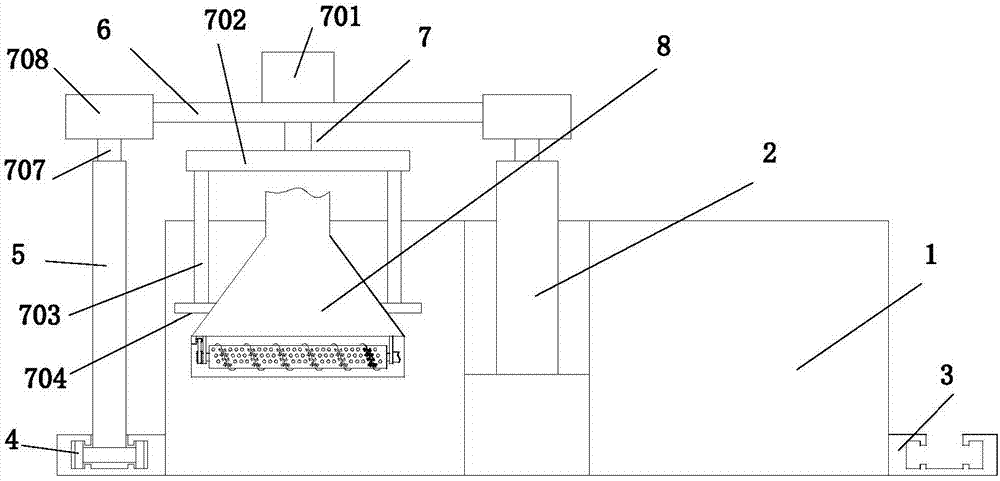

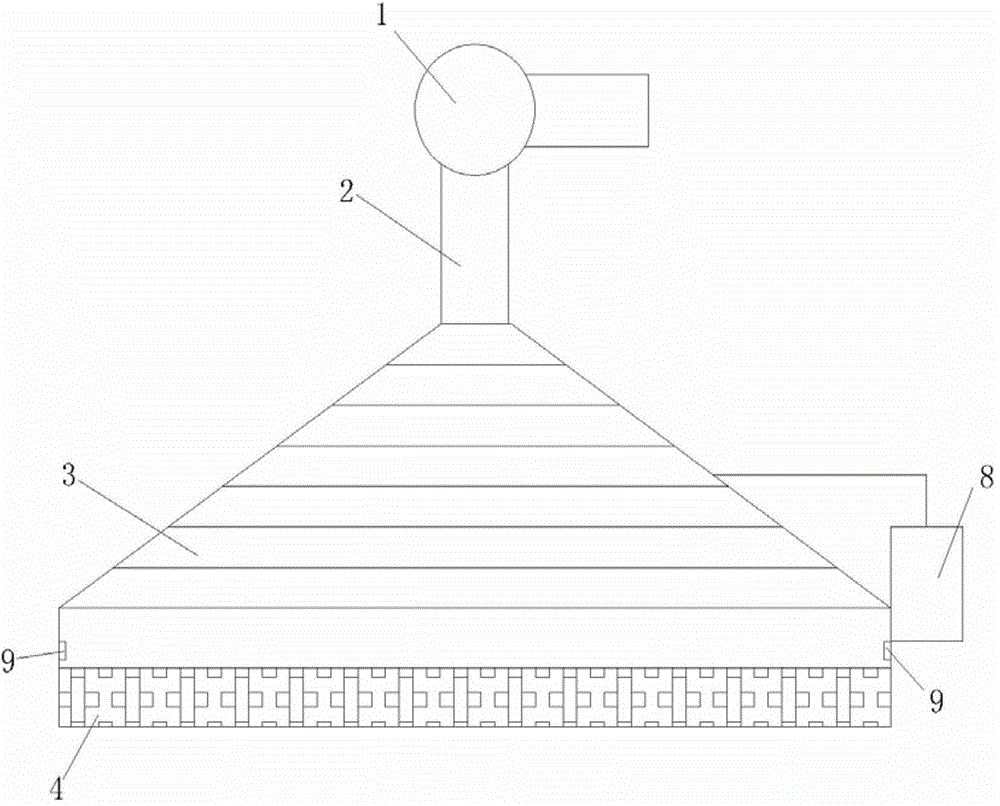

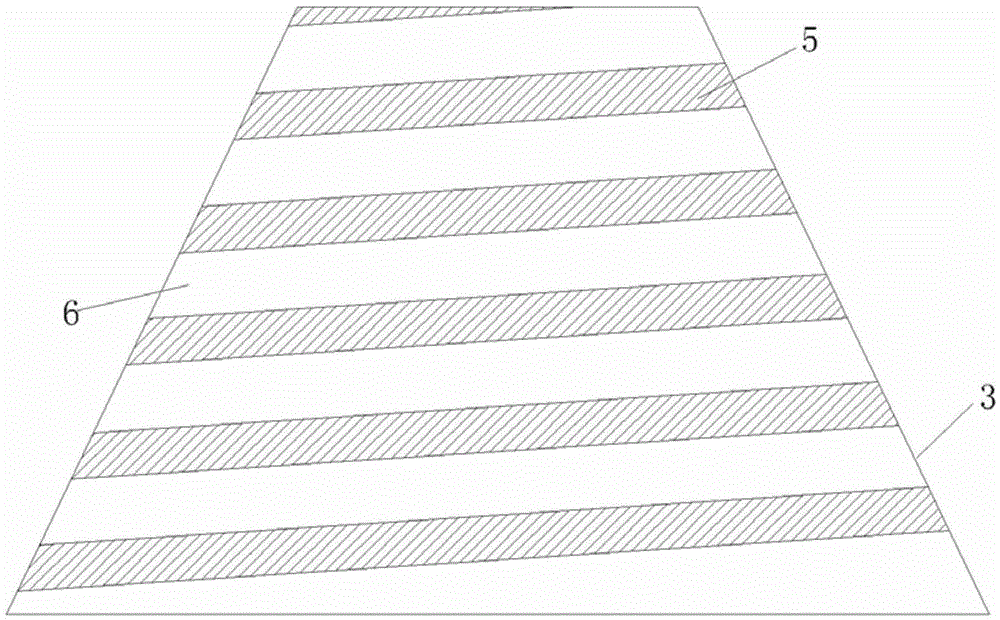

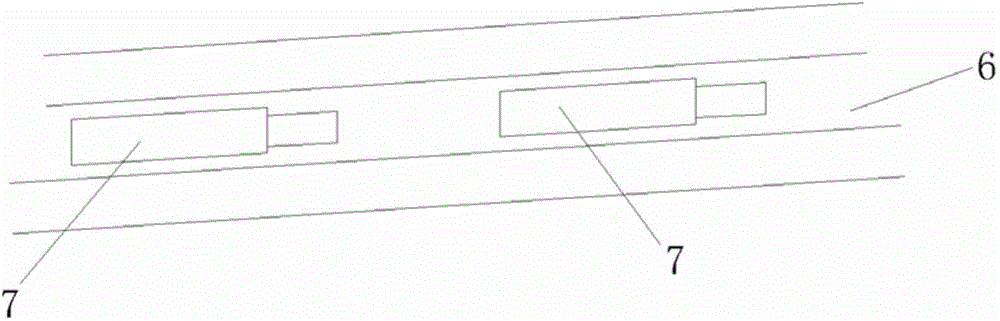

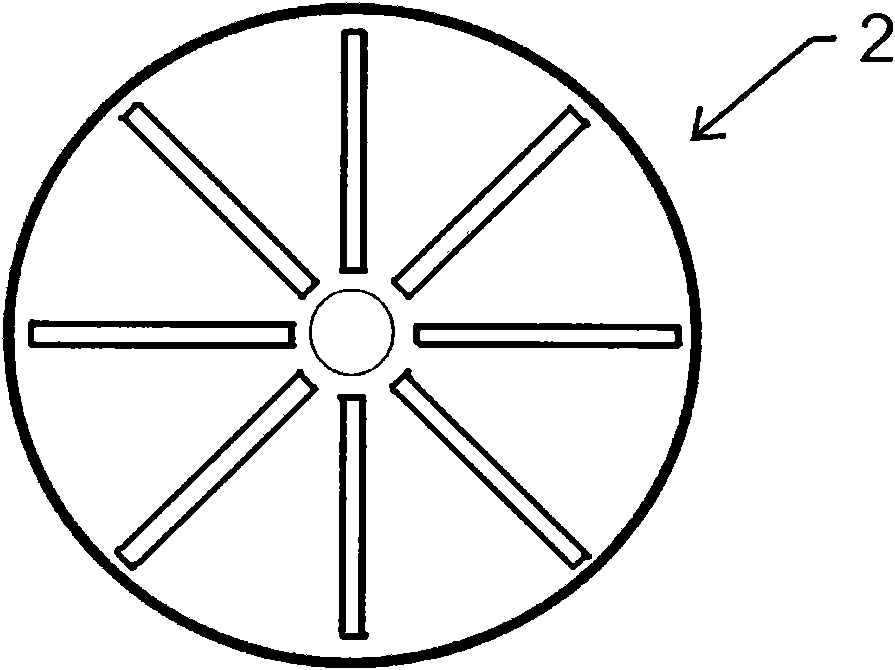

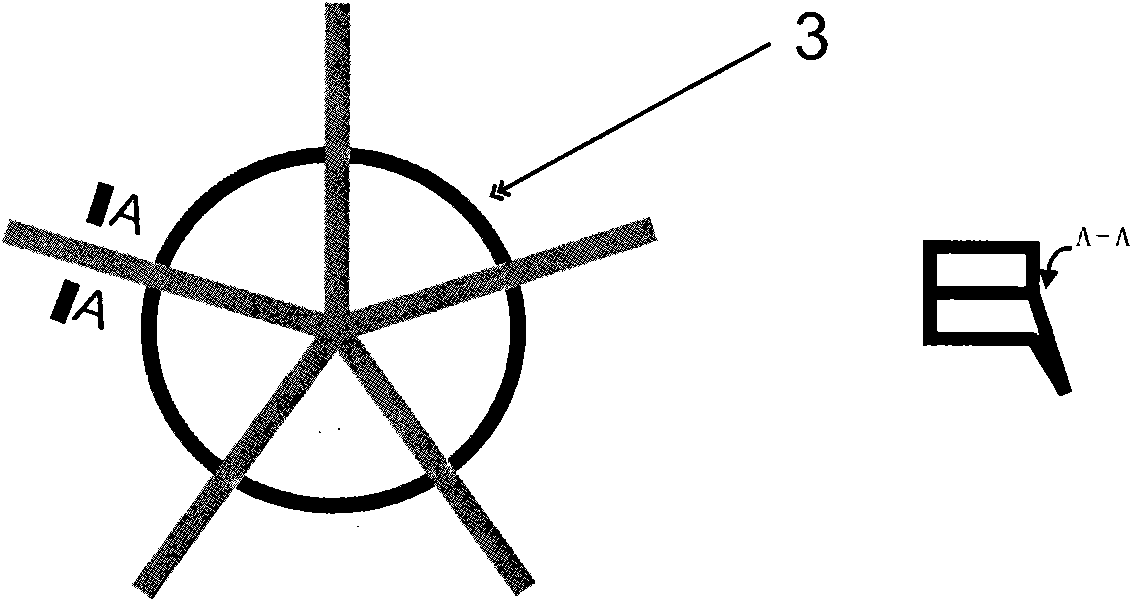

Disk plucker

InactiveCN107217336AIncrease contact areaIncrease contact frictionSafety devices for fibre treatmentFibre breaking machinesCircular discPlucker

The invention discloses a disc plucking machine, which comprises a silo (1), a rotating column (2) is arranged at the central position of the silo (1), an annular guide rail (3) is arranged on the outer wall of the silo (1), and the annular guide rail (3) is provided with a driving trolley (4), a driving column (5) is provided above the driving trolley (4), and a supporting sliding device (6) is provided between the driving column (5) and the rotating column (2) to support sliding The device (6) is provided with a lifting device (7), and the bottom of the lifting device (7) is provided with a cotton collection device (8), and the bottom of the cotton collection device (8) is respectively provided with an impurity removal device (9) and a humidification device (10) . The invention has the characteristics of improving cotton grasping efficiency, improving the impurity removal effect and reducing the clogging frequency of the cotton receiving hopper.

Owner:湖州南浔凯普纺织有限公司

Tea plucker

Provided is a tea plucker. The tea plucker comprises a leaf cutting system which is used for carrying out tea leaf cutting operation, and a main set shell body, and further comprises a screening tea lifting system, wherein the screening tea lifting system comprises a support, a cam, a tea lifting clip assembly and a main shaft, the main shaft is fixedly arranged on the main set shell body, the support is arranged on the main shaft in a rotatable mode, the cam is fixedly arranged on the main shaft, a tea shaking groove is formed in the cam, the cam is provided with am outer edge plane which is in smooth transition, a control groove is formed in the side face of the cam, the tea lifting clip assembly comprises tea lifting clips, a reset spring, a mounting rod, an idler wheel and a control component, the control component and the tea lifting clip are connected, the control component can control the tea lifting clip to open or close, the cam is abutted against the outer edge plane of the cam, the mounting rod is arranged on a supporting rod in a slidable mode, and the reset spring is abutted against the mounting rod. According to the structural design, extraction and tea shaking movement of tea leaves can be achieved, and a clean degree of tea picking through the tea plucker and an integral rate of the tea leaves are improved.

Owner:易涛

Suction cowl device of plucker

The invention relates to the technical field of textile machines, in particular to a suction cowl device of a plucker. The suction cowl device of the plucker comprises a fan, a cotton delivery pipe, a suction cowl and a plucking beater; a plurality of air guide strips spirally arranged are formed on the inner wall of the suction cowl; a groove is formed between every two air guide strips; each groove is provided with electromagnets; the electromagnets are connected with a controller; the inner wall of the opening of the suction cowl is provided with a photoelectric sensor; the photoelectric sensor is electrically connected with the controller. The invention provides the suction cowl device of the plucker, which is high in cotton suction efficiency, and is capable of removing sheet iron in cotton so as to prevent the cotton delivery pipe from being blocked and damaged.

Owner:桐乡市建春塑业股份有限公司

Poultry feather plucker

InactiveCN101946819AFast and clean pluckingImprove ergonomicsPoultry plucking mechanismsPluckerMicromotor

The invention provides a rapid feather plucker which plucks small or infant feathers of the killed poultry after the big feathers of the poultry is removed. The poultry feather plucker comprises a cylindrical shell, wherein one end of the cylindrical shell is fixed with a semi-circular stainless steel cap; the top end of the semi-circular stainless steel cap is provided with a round hole and eight suction sumps for sucking the small feathers of the poultry; an inner end of the cylindrical shell is provided with a micromotor; the middle of a lengthening shaft of the micromotor is provided with a suction pump blading; the other end of the operating shaft of the micromotor is provided with a semi-circular feather clipping five-claw blade tallying with the semi-circular stainless steel cap of the shell; and a drain outlet is arranged in the middle of the cylindrical shell. The plucker is simple to operate and efficient and clean and can improve the existing manual plucking efficiency by over 5 times.

Owner:陈志中

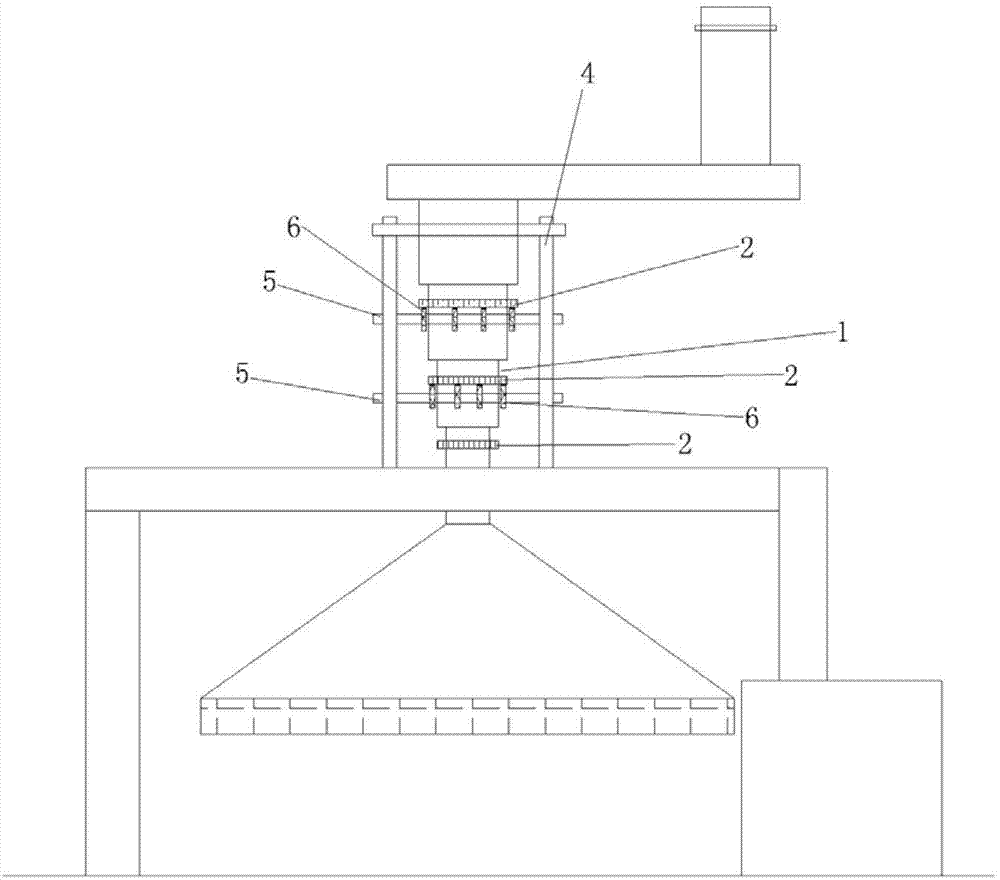

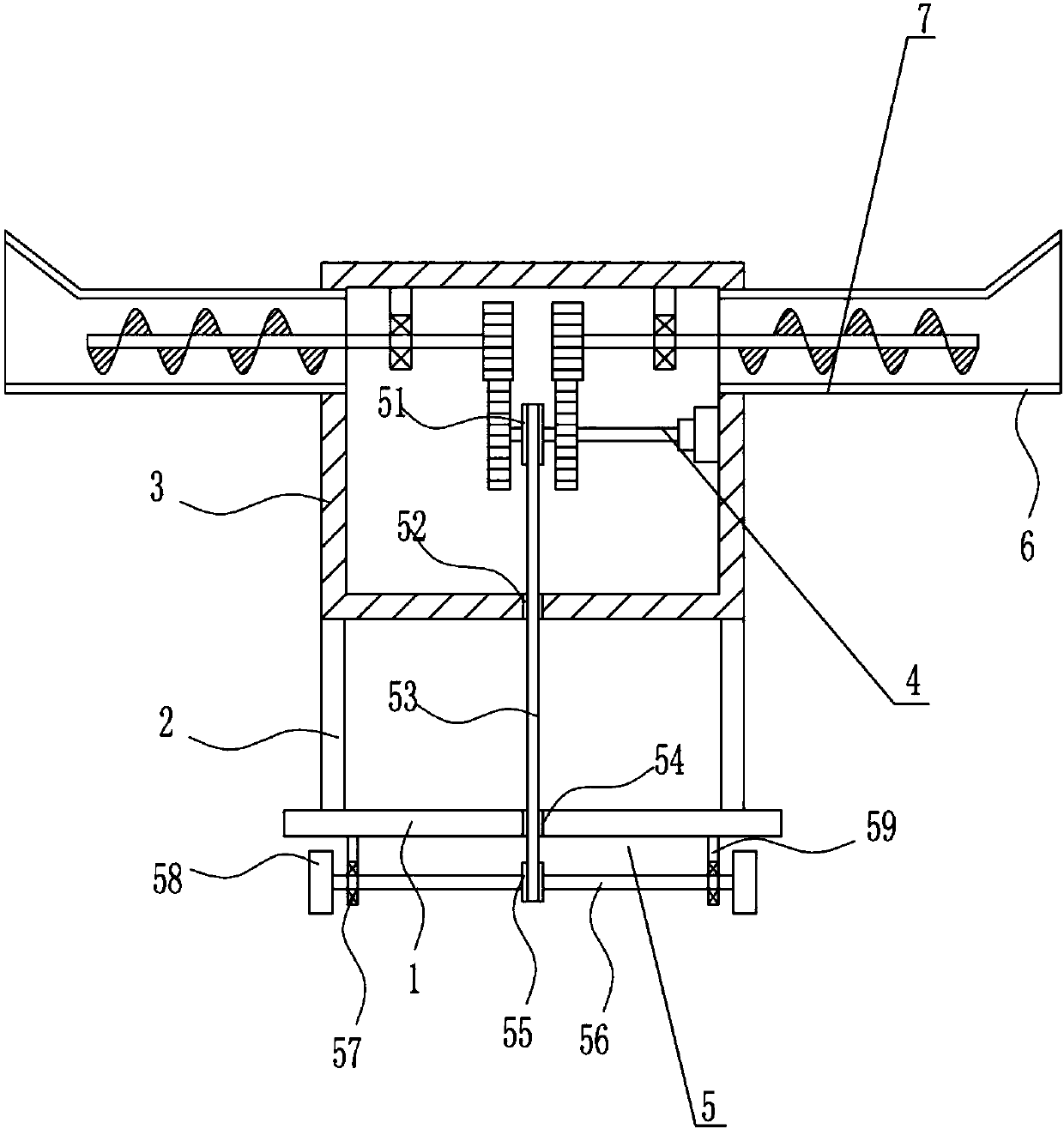

Lifting regulating mechanism for plucker gripper

The invention relates to the technical field of textile machines, in particular to a lifting regulating mechanism for a plucker gripper. The lifting regulating mechanism comprises a rack and a lifting mechanism; the lifting mechanism comprises screws, sprockets, a chain, a motor, the plucker gripper and a gripper support; the plucker gripper comprises a suction cowl and ribs; the bottom part of each rib is provided with an elastic rubber bumper; the bottom end of the suction cowl is provided with a position sensor; the position sensor is electrically connected with a controller; the controller is connected with the motor; a strip groove is formed in the upper side of the gripper support; the strip groove is provided with a chain tightener; the chain tightener comprises an adjustment sprocket, a sprocket shaft, a sliding seat and a spring; the adjustment sprocket is connected with the chain; one end of the spring is supported on the end part of the sliding seat, and the other end of the spring is fixedly arranged in the strip groove. According to the lifting regulating mechanism for the plucker gripper, provided by the invention, the lifting of the plucker gripper can reliably run, the equipment loss is reduced, and the safety performance is improved.

Owner:HUNAN JICHANG SILK

Lifting control device of gripping arm of reciprocating cotton-grapping machine and control method

InactiveCN101338464ASmooth startStop smoothFibre cleaning/opening machinesProgramme control in sequence/logic controllersControl systemDrive motor

Owner:QINGDAO HONGDA TEXTILE MACHINERY

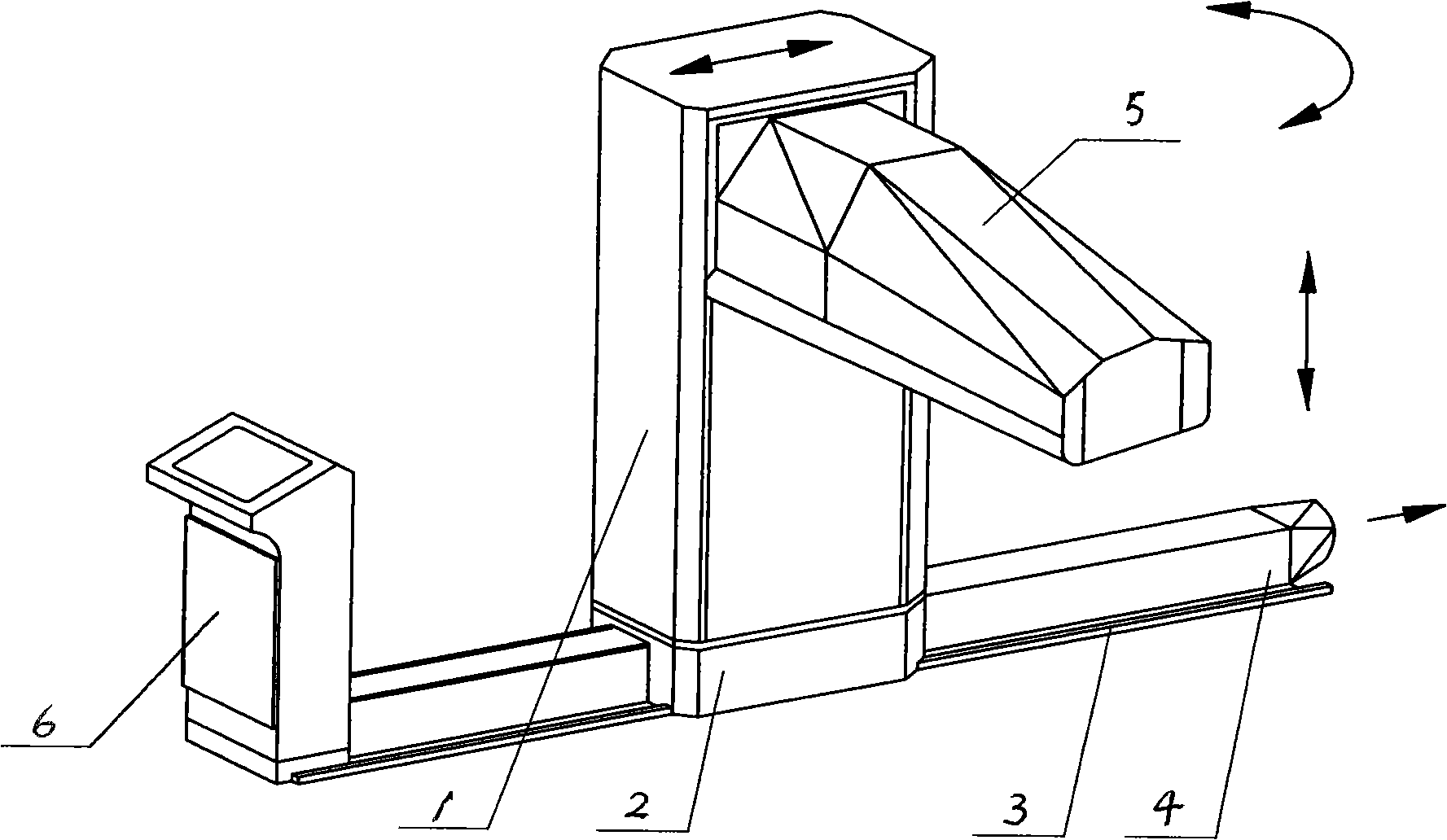

Automatic plucker

ActiveCN104294411AHigh degree of automationFibre breaking machinesFibre breaking by beater armsMotor driveElectrical connection

The invention discloses an automatic plucker which comprises a base and a rack arranged on the base in a rotating mode through a rotating disc. The rotating disc is driven to rotate through a stepping motor, a cotton collecting pipe is vertically arranged on one side of the rack in a sliding mode, a cotton collecting beater is arranged at the lower end of the cotton collecting pipe, the cotton collecting pipe is communicated with a cotton collecting fan, a linkage pipe is arranged in the rack, the linkage pipe is communicated with the upper end of the cotton collecting pipe through a cotton inlet pipe, the base is connected with a conveying belt, a sensor used for detecting the thickness of a cotton layer is arranged below the cotton collecting pipe, and the sensor is in electrical connection with the stepping motor. When the sensor detects the thickness of the cotton layer to be smaller than a set value, the stepping motor drives the rotating disc to rotate, in other words, the rack rotates, the direction is changed so that a cotton layer on the other side can be grabbed, and the automation degree is high.

Owner:JIANGSU JINHUI AUTOMATION TECH

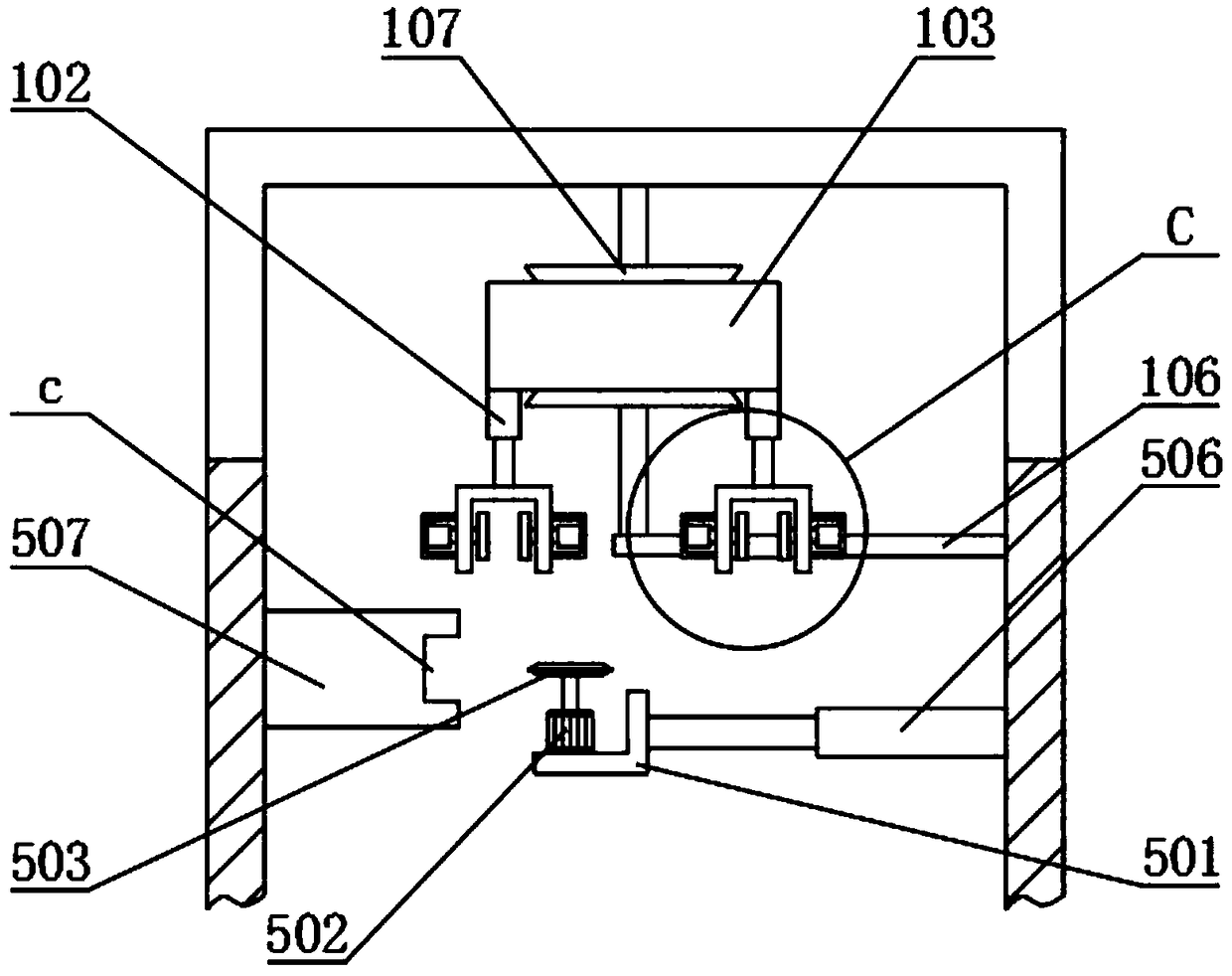

Disc type plucker

InactiveCN108823685APrevent crushingReduce vibrationFibre breaking machinesFibre breaking by beater armsEngineeringPlucker

The invention discloses a disc type plucker, and relates to the field of textile equipment. The plucker structurally comprises an inner wall board, an outer wall board, a platform, a rotary trolley, arail, anti-seismic anchors, a beater, a cotton suction cover, a cotton suction pipe and a cotton suction machine. The outer wall board is arranged outside the inner wall board, and annular cotton placement space is enclosed by the outer wall board and the inner wall board. The anti-seismic anchors are arranged under the rail. A connecting block is arranged at the bottom of the rail, and a grooveis formed in the bottom of the connecting block; the anti-seismic anchors comprise bases, supporting blocks and springs, the supporting blocks are arranged on the bases, the cross section area of eachsupporting block is matched with the area of the groove, the springs sleeve the supporting blocks and connected with the connecting block and the bases, and the bases sleeve the outer sides of the springs. The plucker can avoid that the trolley rotates and crushes the rail, the rail vibration is reduced, the rail deformation is avoided, the using durability of the plucker is strengthened, and a good impurity removing effect is achieved.

Owner:徐应盈

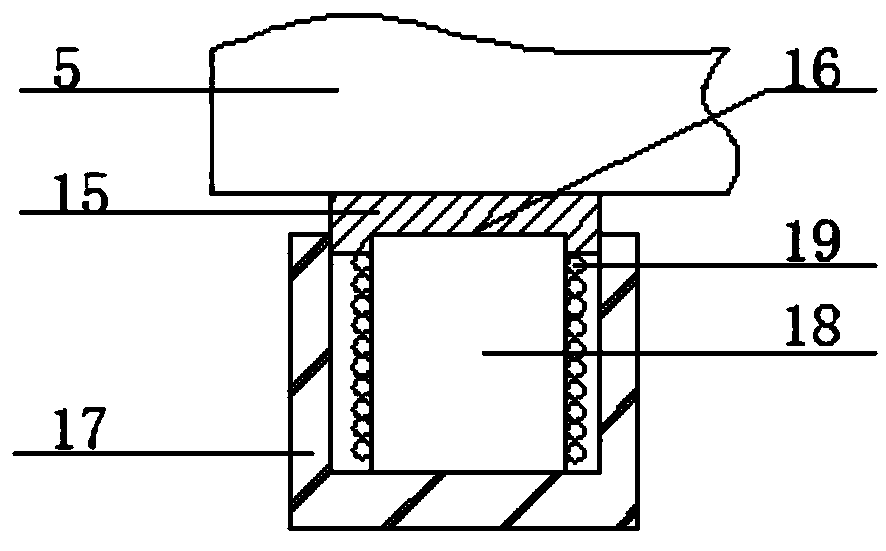

Induction type automatic bale plucker

InactiveCN104514043AHigh lifting precisionLow costFibre breaking machinesFibre breaking by beater armsBall bearingArchitectural engineering

The invention relates to a bale plucker, and specifically relates to an induction type bale plucker. The bale plucker comprises a base, a spindle, a rotating arm, and a tong; the spindle is installed in the middle of the base; the top end of the spindle is fixedly connected with the rotating arm; the bottom end of the rotating arm is fixed with the tong; the rotating arm is fixedly connected with the spindle via a self-locking lead screw lifter; a lateral end of the tong is fixed with a photoelectric inductor; the bottom end of the rotating arm is fixed with a concave groove; a ball bearing is installed inside the concave groove; a lateral edge of the base is encircled inside the concave groove and sticks to the ball bearing; the bale plucker is able to adjust the height of the tong by inducing the plucked amount; the lifting precision is higher; the cost is saved; and the effect is increased.

Owner:JIANGSU KANGYUAN TEXTILE

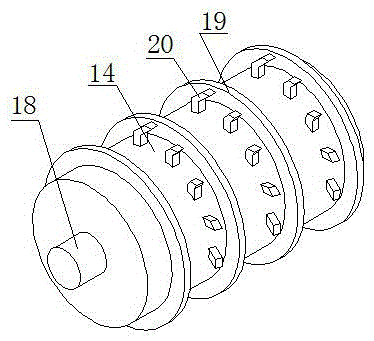

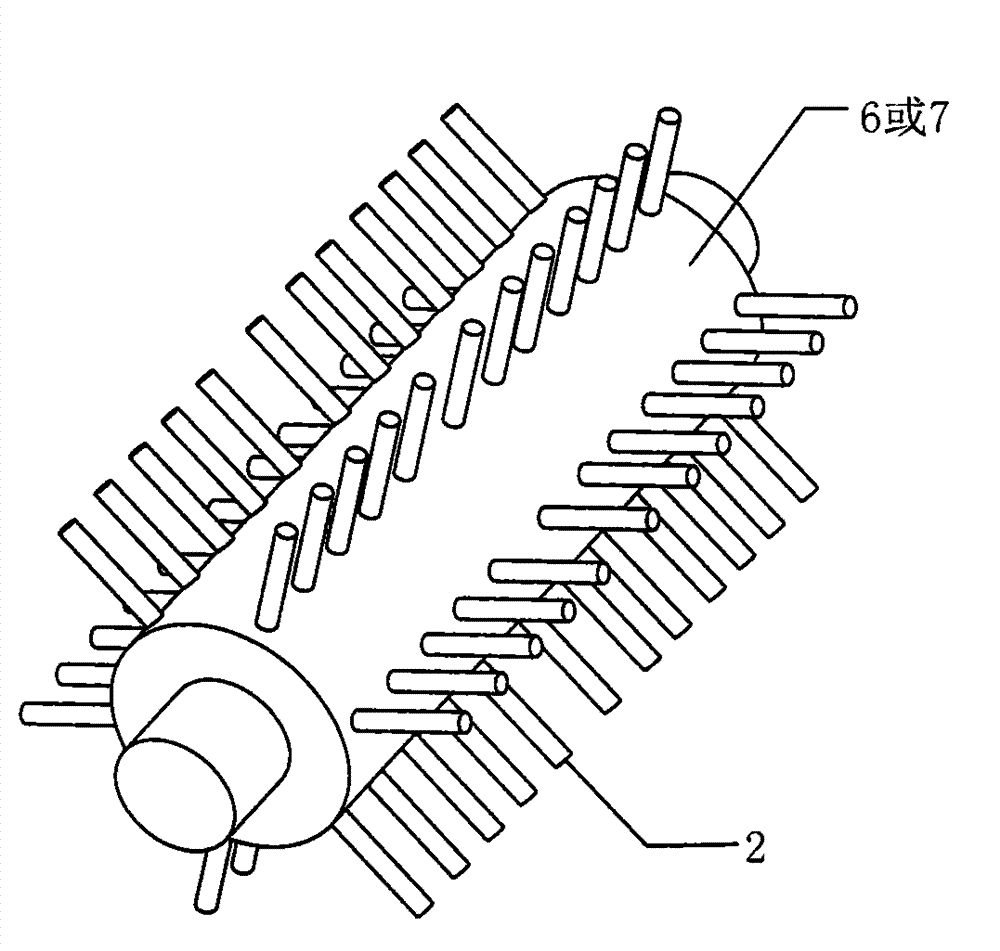

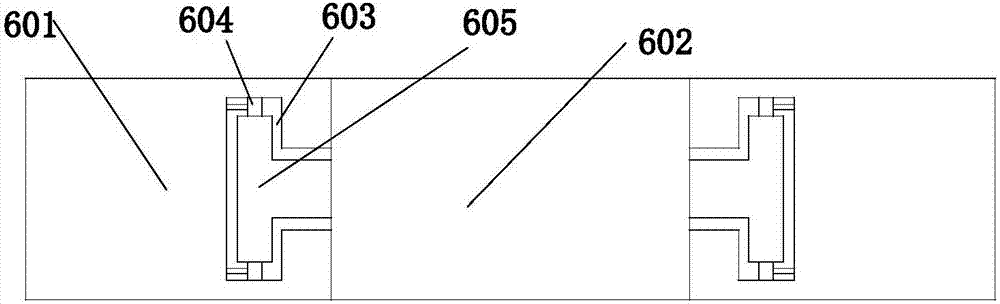

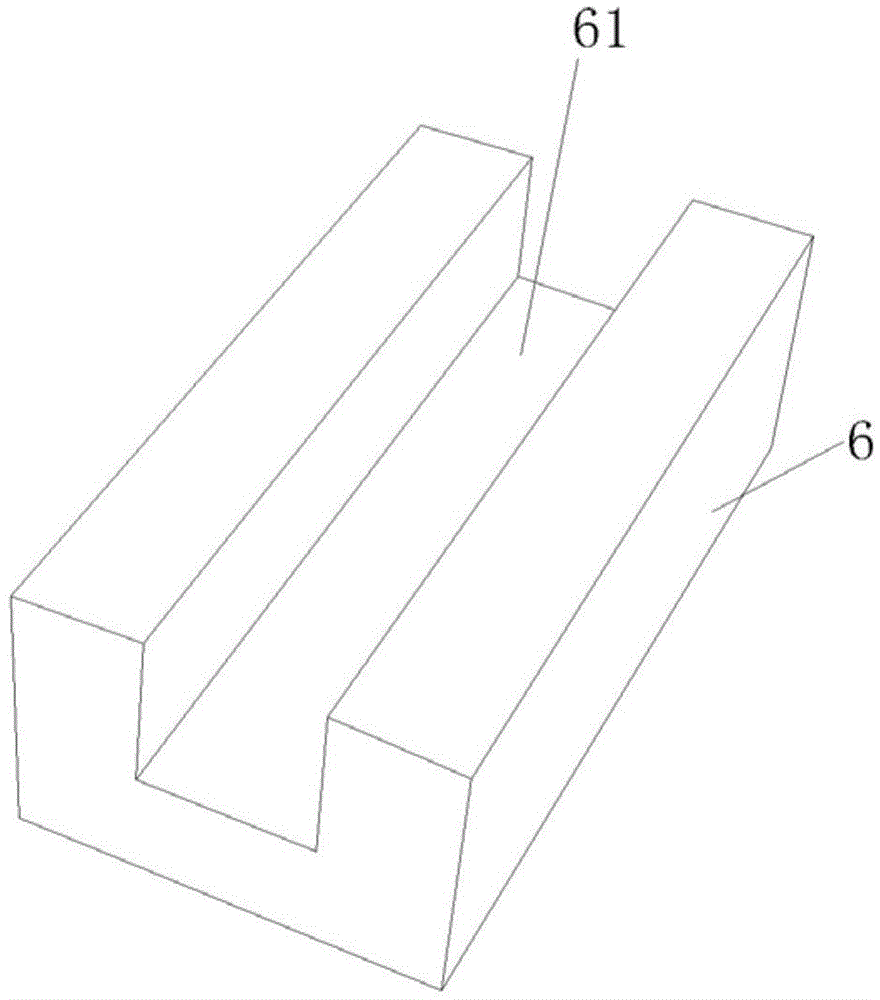

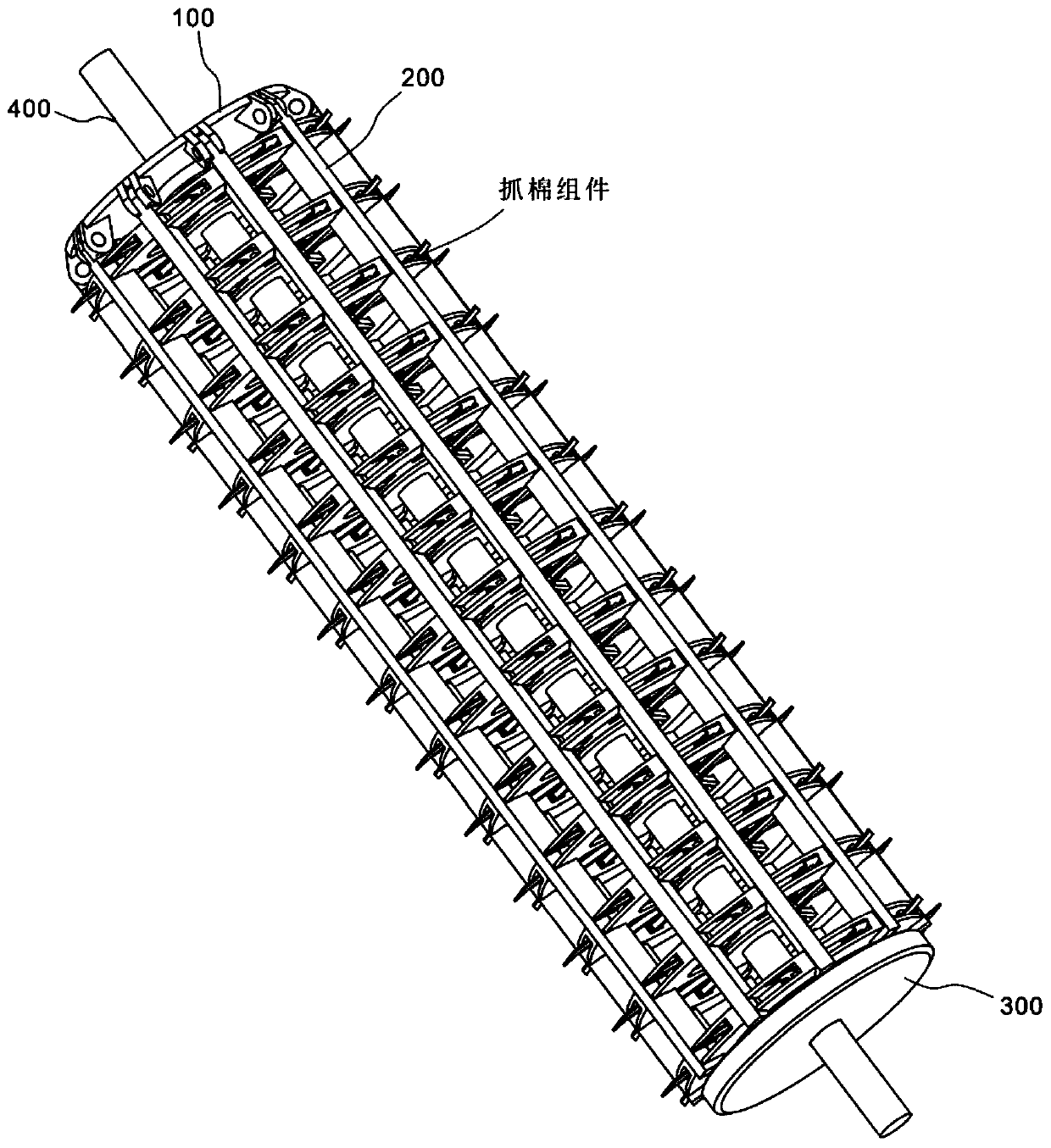

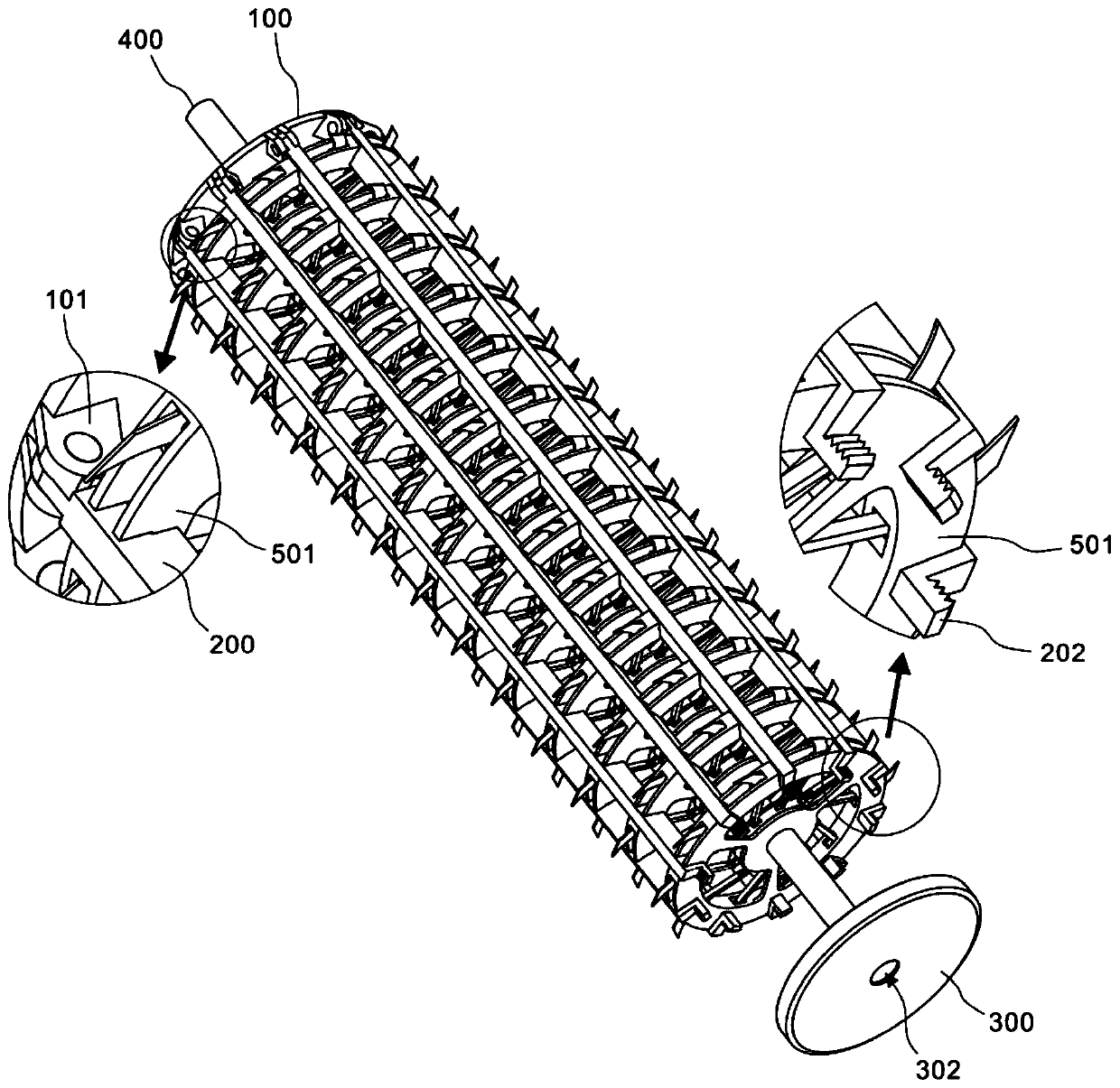

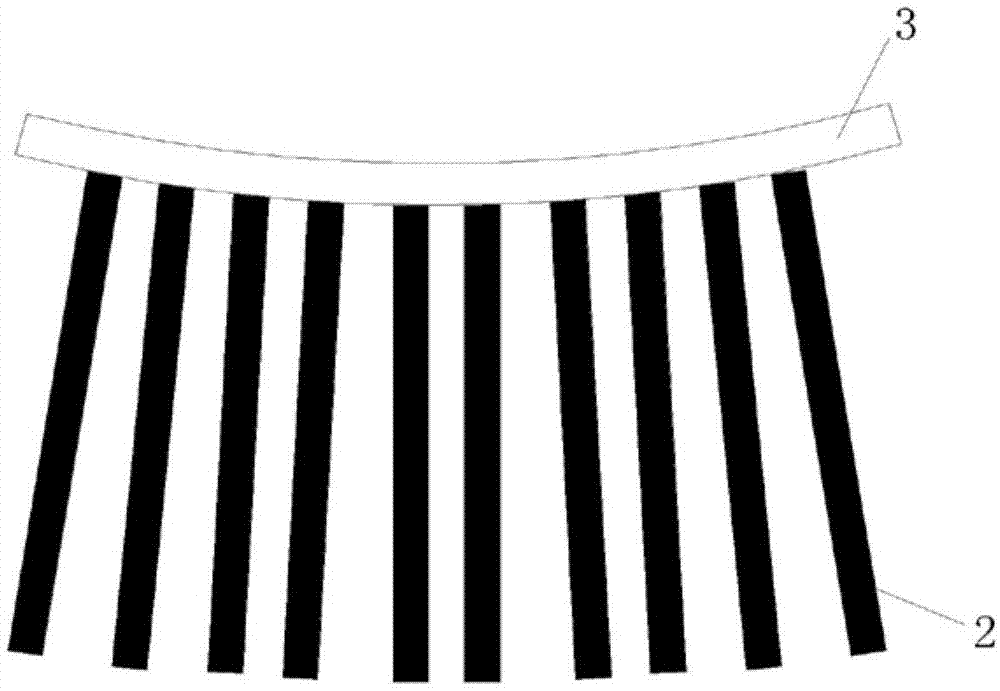

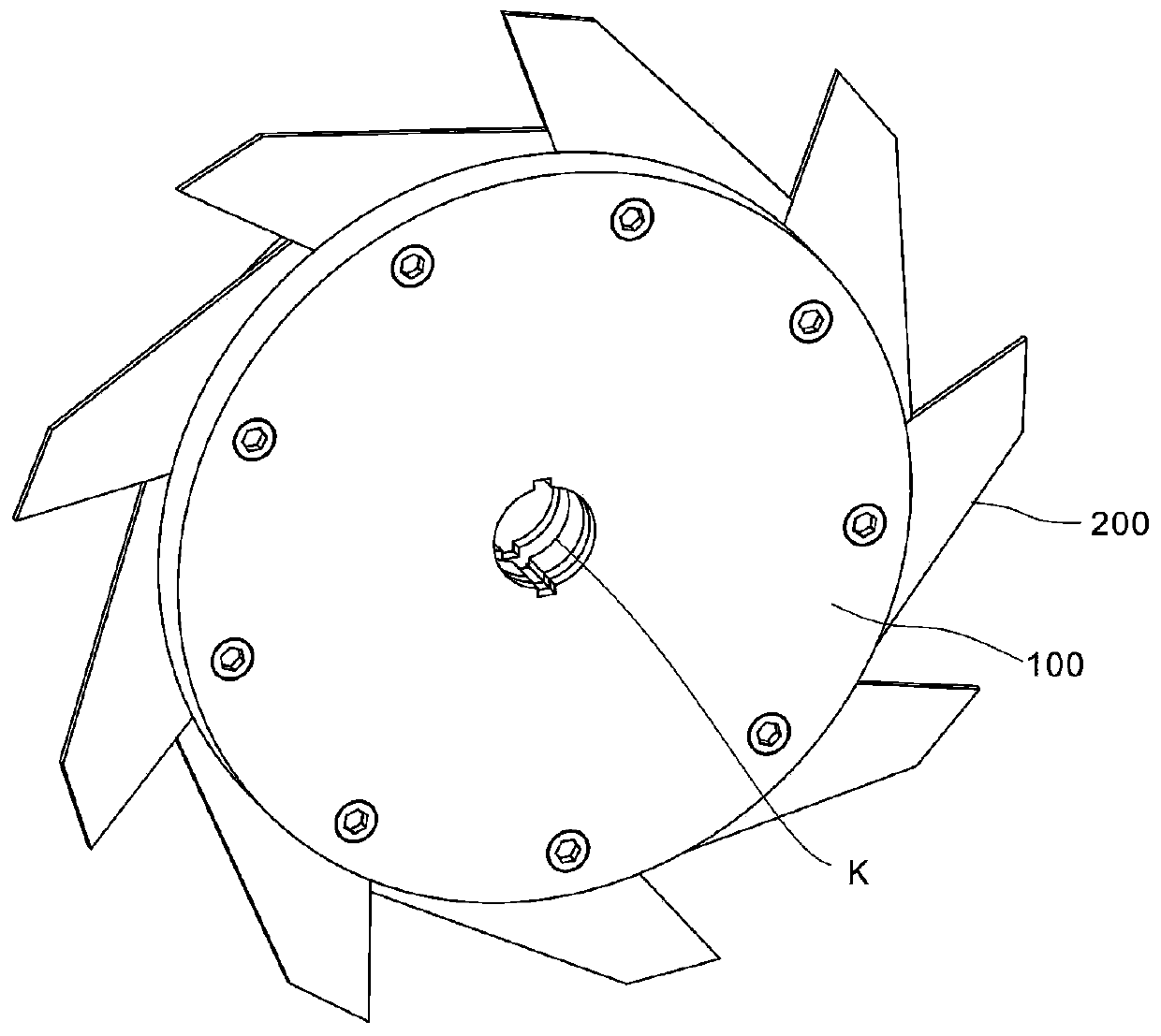

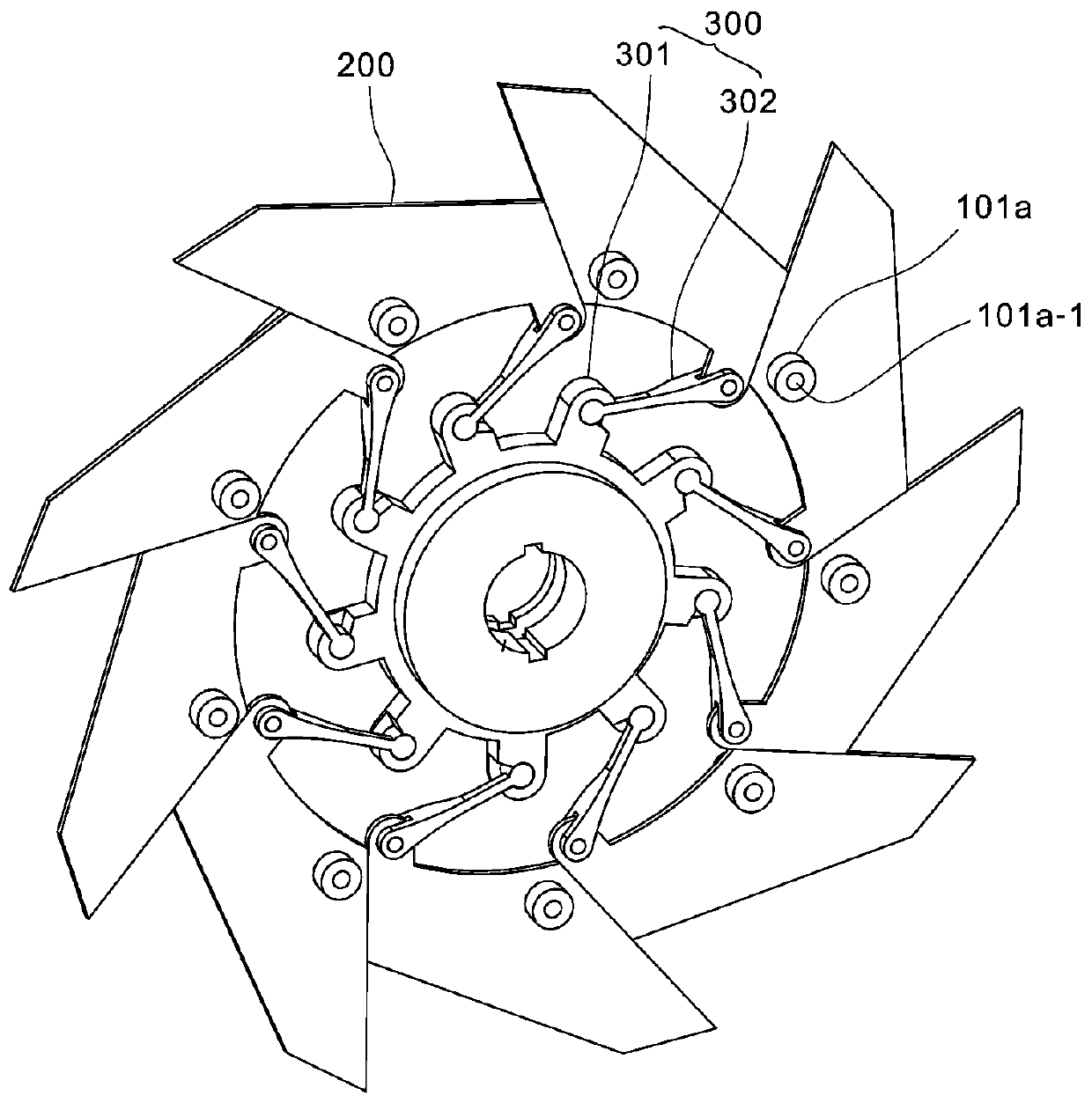

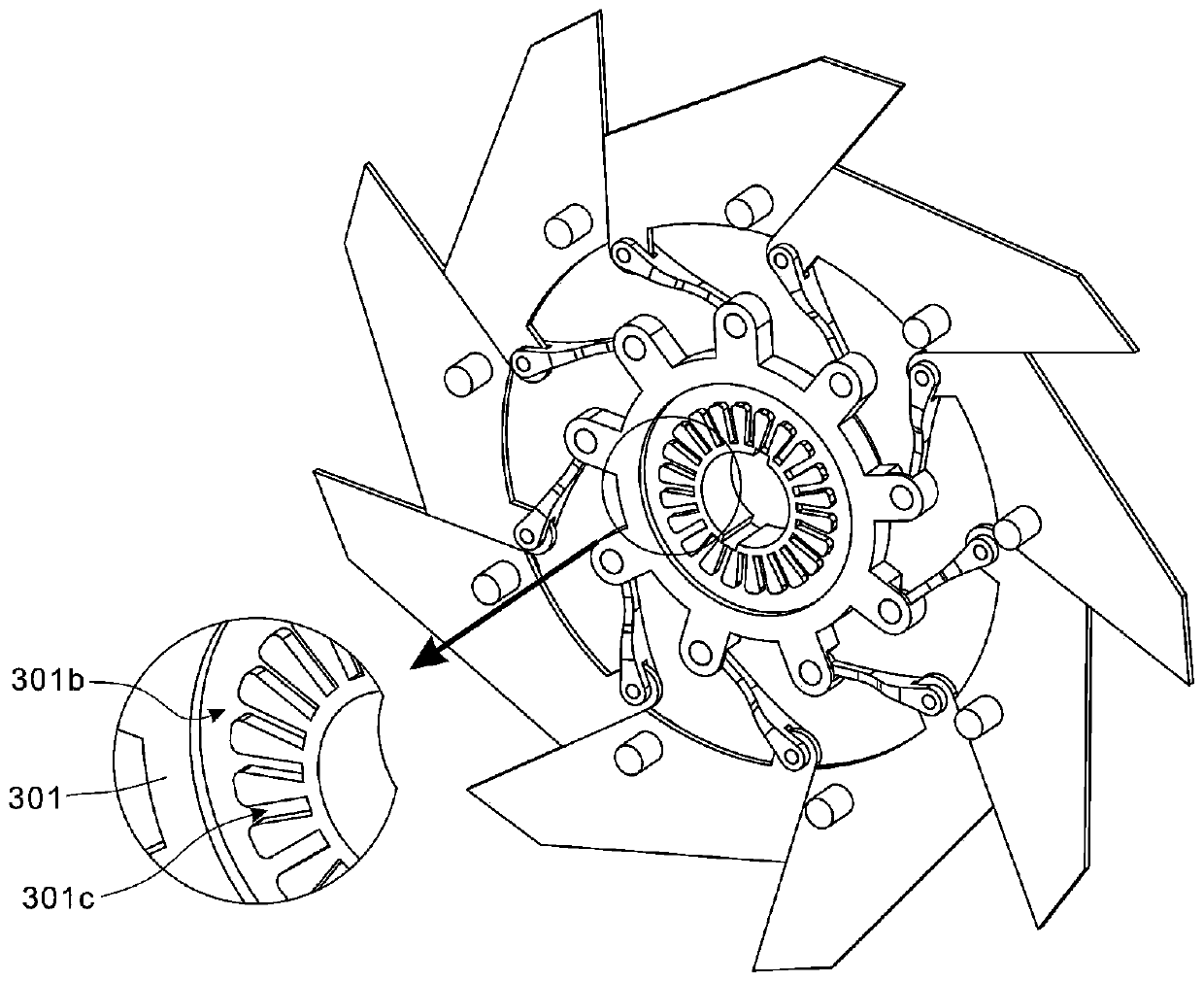

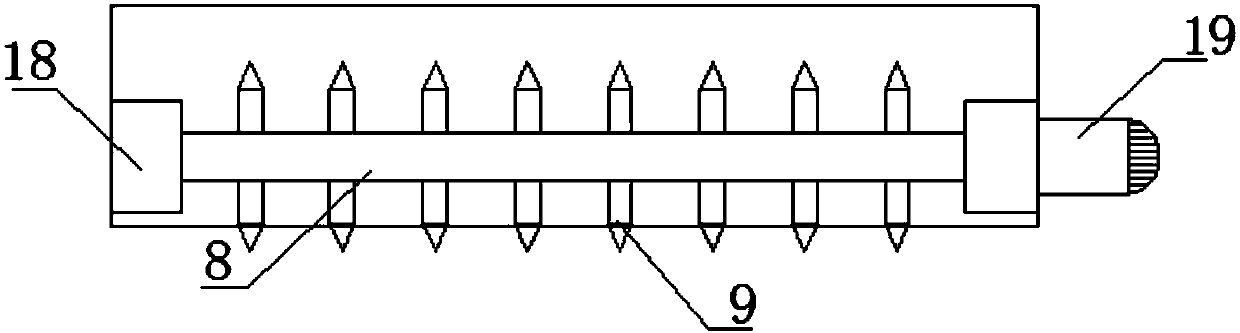

Assembled bale plucker beater

ActiveCN110042509AAchieve regulationIncrease flexibilityFibre breaking by beater armsPluckerEngineering

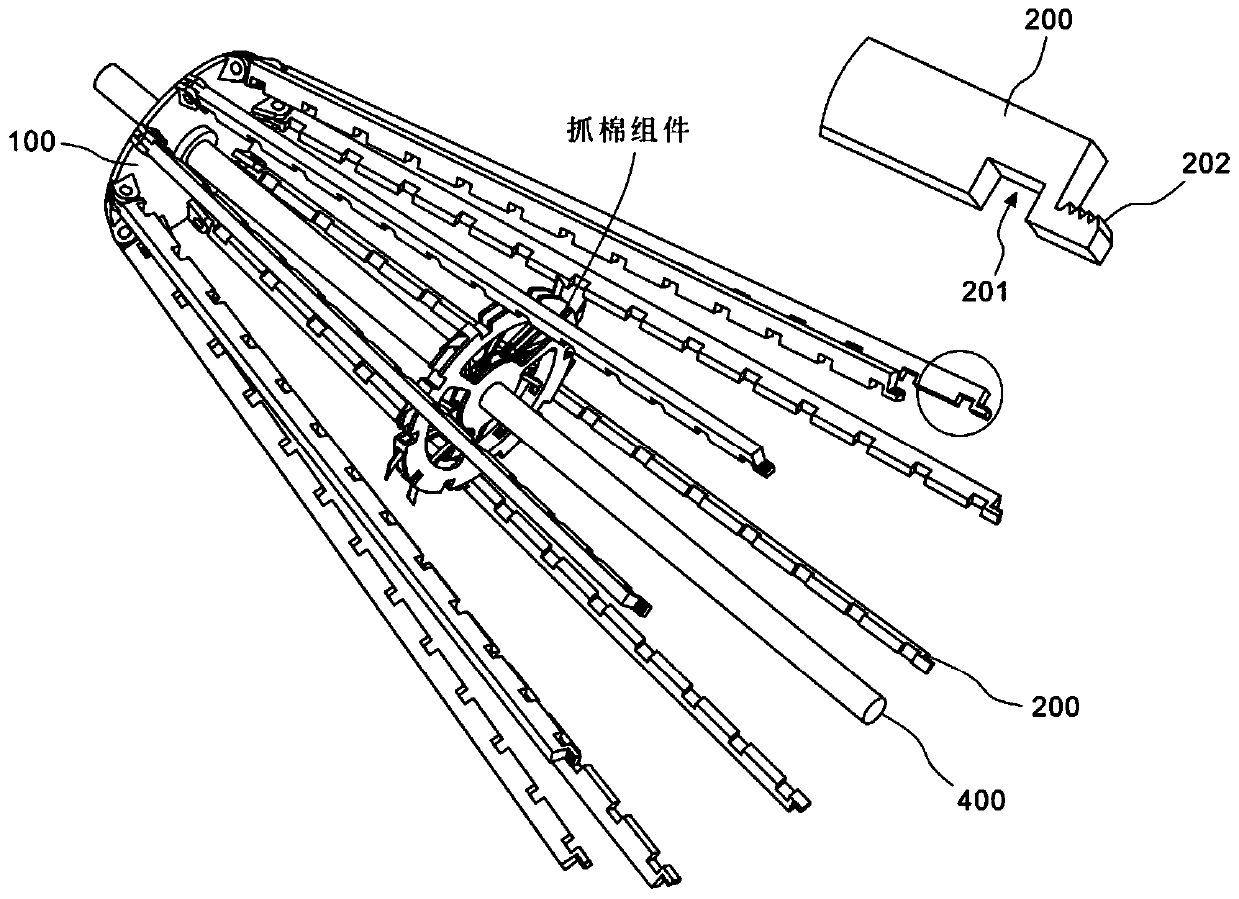

The invention discloses an assembled bale plucker beater which comprises a first end plate, longitudinal rods, a second end plate and a bale plucker assembly; a longitudinal rotating shaft is fixedlyarranged in the axis of the first end plate alternately, and the bale plucker assembly sleeves the rotating shaft; the longitudinal rods are distributed at equal intervals in the peripheral directionof the first end plate, the inner ends of the longitudinal rods are hinged to the edge of the first end plate, the outer ends of the longitudinal rods can rotate in the radial direction so as to pressthe edge of the bale plucker assembly, and the outer ends of the longitudinal rods are fixed through the second end plate. The turnover angle and the exposed height of a blade can be controlled as needed through the bale plucker assembly, the state of the blade can be regulated, meanwhile, the bale plucker assembly exists independently in a modularized mode, multiple bale plucker assemblies can be installed on a bale plucker rotating shaft in parallel as needed, bale plucker beaters of different specifications are formed, the overall specification of the bale plucker is regulated, and the high flexibility and variability are achieved.

Owner:SWOTO PROTECTION & TECH CO LTD +1

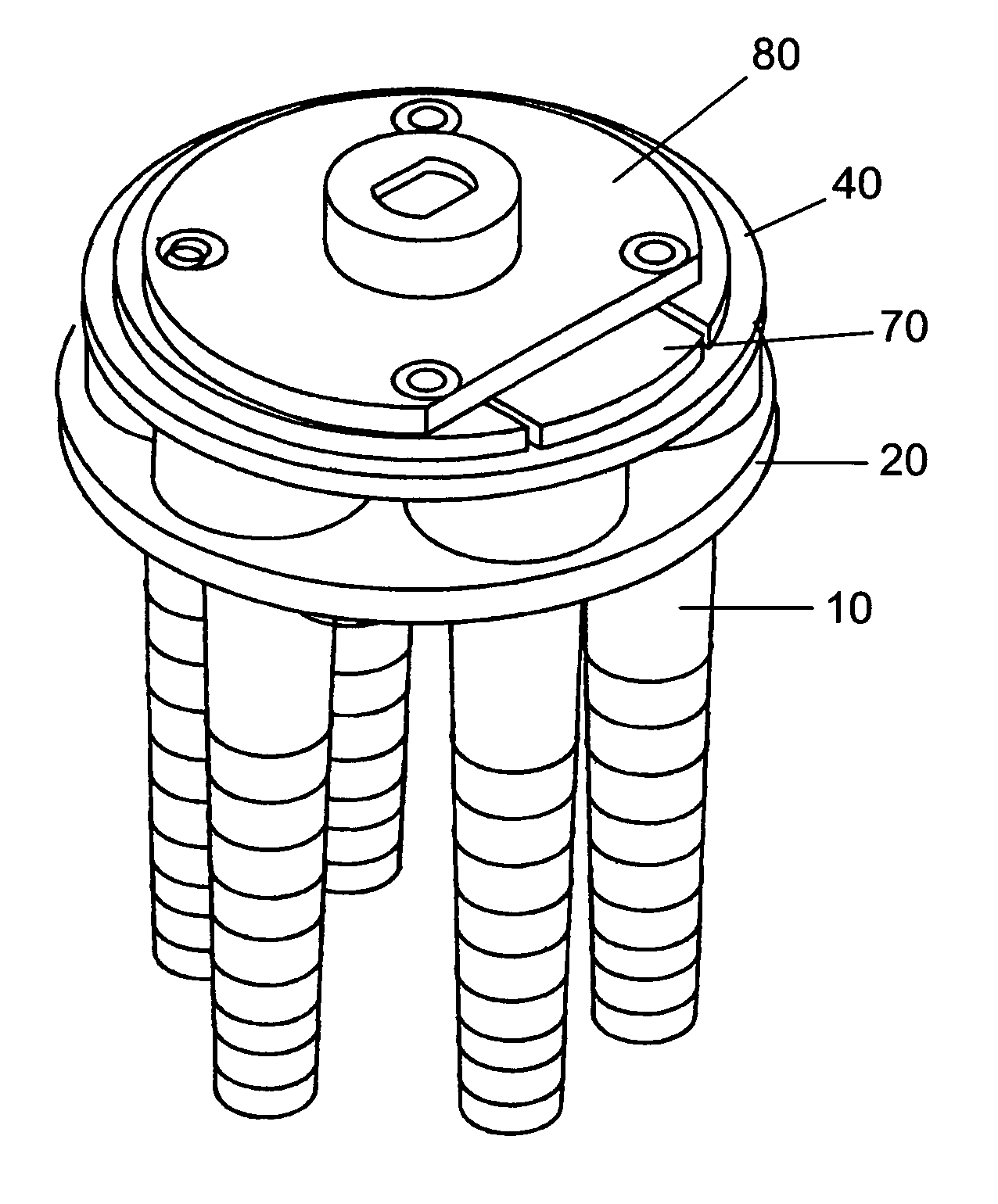

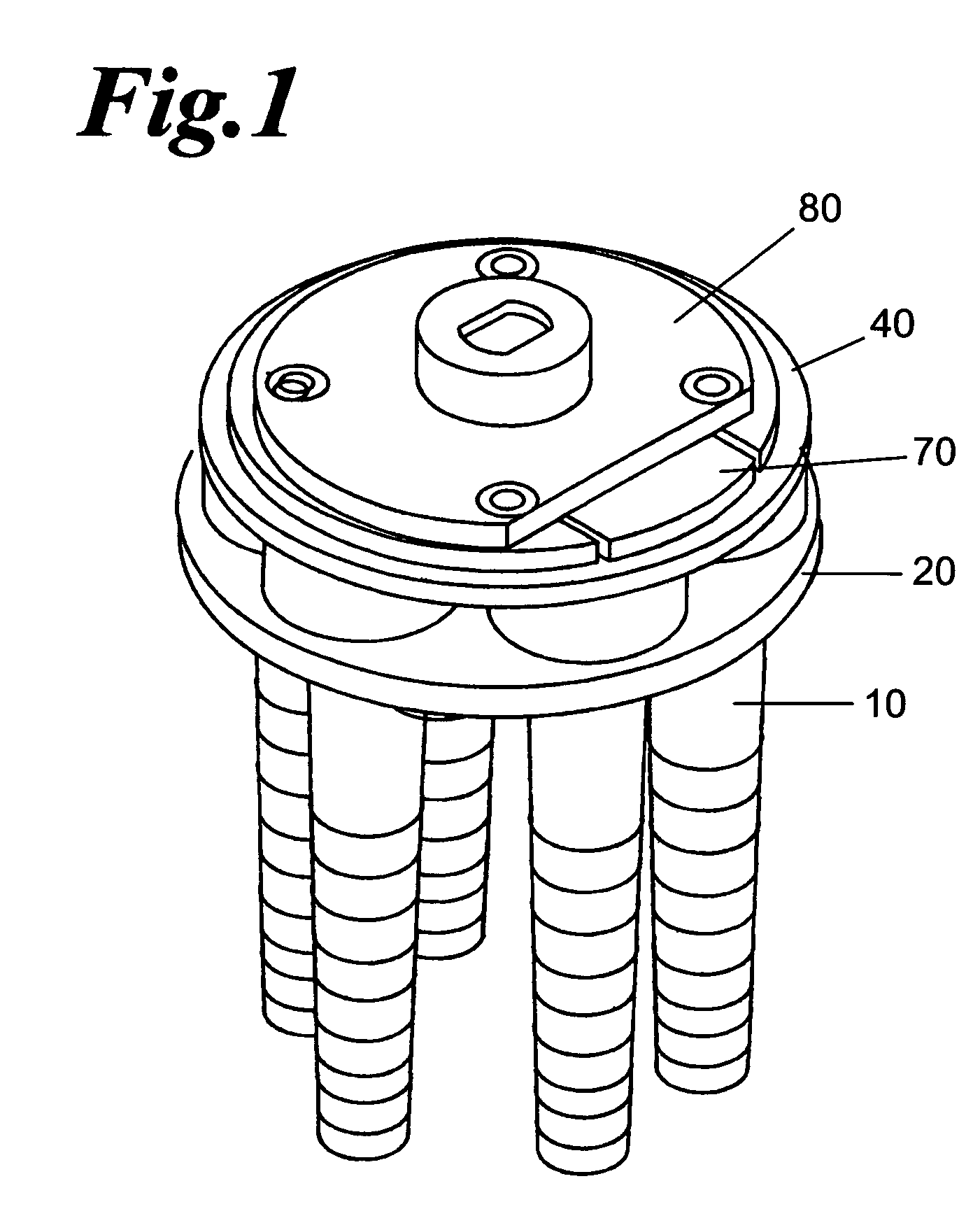

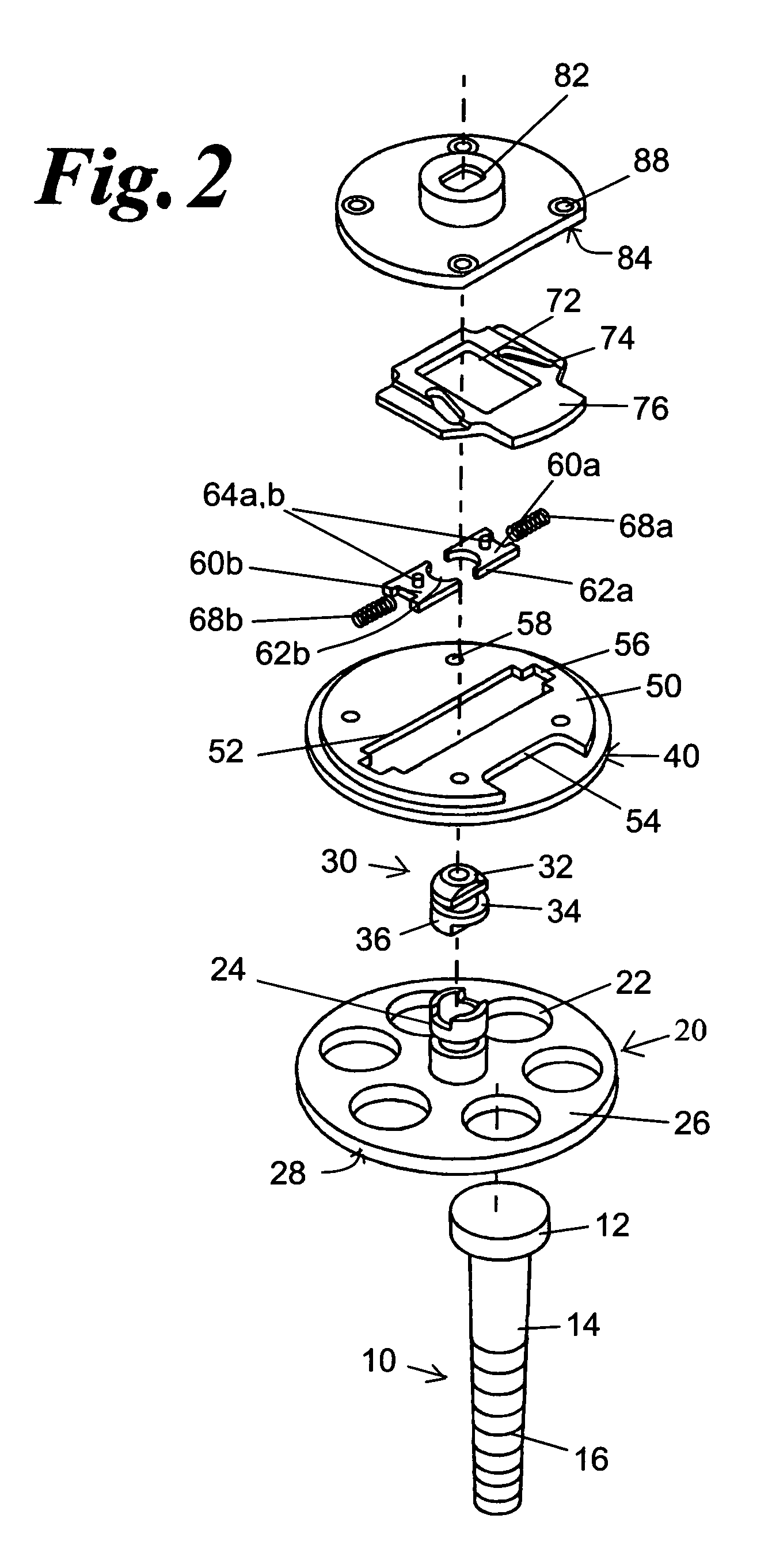

Finger plucker lock

InactiveUS7066805B2Easy insertion and removalIncrease forcePoultry plucking mechanismsLocking mechanismEngineering

A resilient rubber finger and a locking mechanism therefore for use in poultry processing plants for the plucking of feathers off if poultry is provided. The rubber-plucking finger is comprised of an oversized base without an annular recess, and a tapered furrowed shank. A plurality of fingers is inserted into a support base through apertures therein. The diameter of the shank proximate the base is substantially equal to the diameter of the support base aperture to ease insertion and removal. A backing plate is provided to abut the rear of the support plate preventing accidental displacement of the rubber finger from the support plate. The support plate is attached to the backing plate using an integrated centrifugal locking mechanism within the backing plate.

Owner:TURNER RODNEY ALLEN

Cleaning device for bale plucker telescopic tube

ActiveCN104707827AIncrease productivityReduce cloggingHollow article cleaningCleaning using toolsPluckerEngineering

The invention relates to the technical field of textile machines, in particular to a cleaning device for a bale plucker telescopic tube. The cleaning device comprises the four-segment movably nested telescopic tube, the three lower segments of the telescopic tube are each provided with an annular brush, one ends of the brushes make contact with the inner wall of the telescopic tube connected with the brushes in a sleeved mode, the periphery of the telescopic tube is provided with a framework, the framework is provided with an annular installing frame, a plurality of evenly distributed clamping hooks are fixedly arranged on the annular installing frame, each clamping hook comprises an upper bent portion and a lower bent portion, the clamping hooks make contact with the brushes when the telescopic tube stretches and retracts, and flock and impurities on the brushes are cleaned away. The safe and reliable cleaning device for the bale plucker telescopic tube is provided and reduces blocking of the telescopic tube, operation of equipment is stable, and production efficiency of a bale plucker is improved.

Owner:邳州市景鹏创业投资有限公司

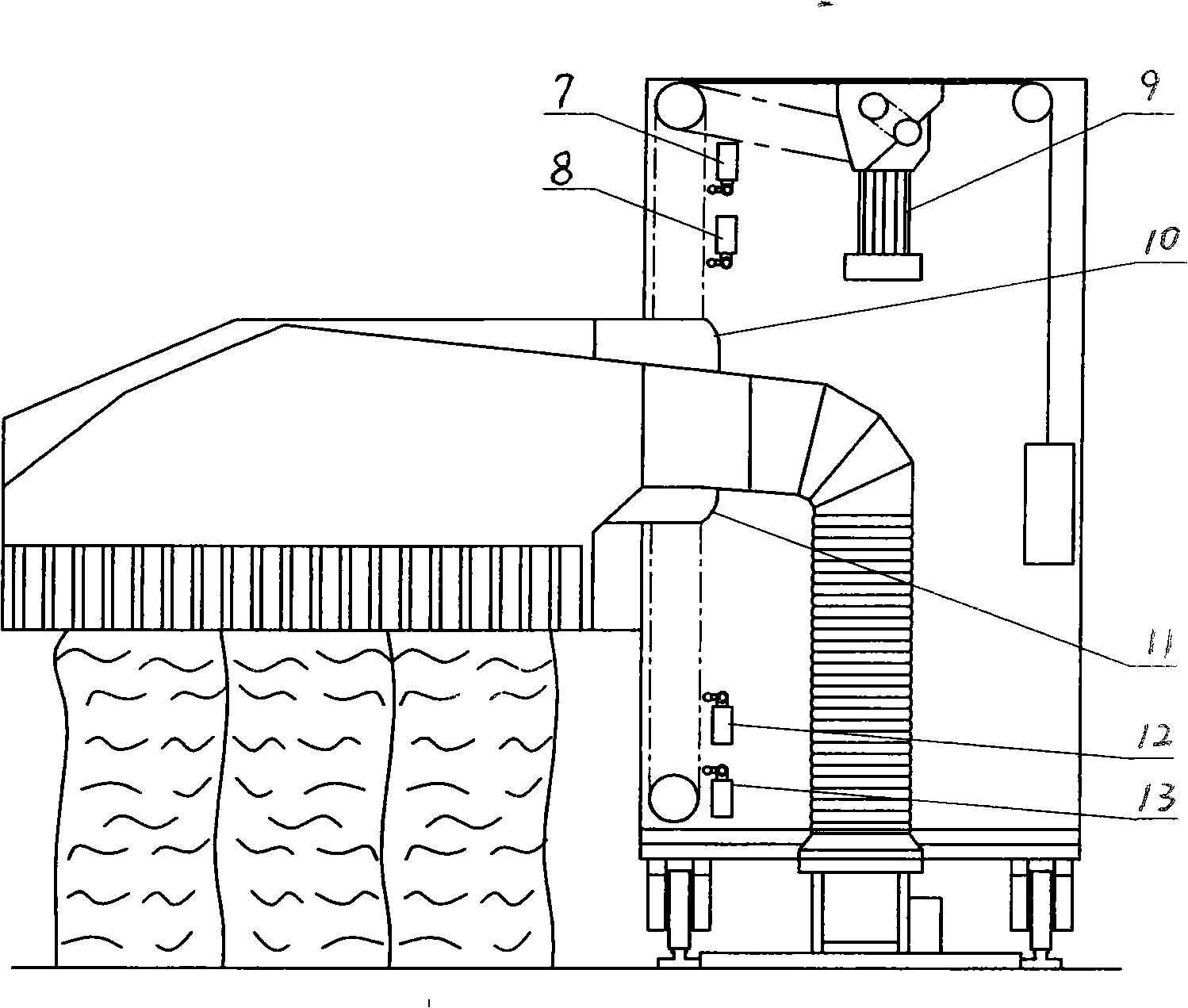

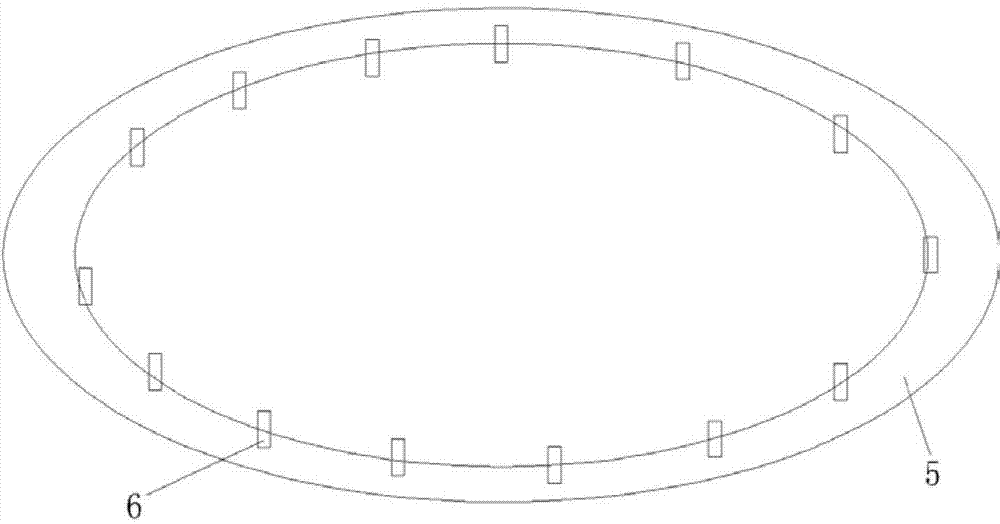

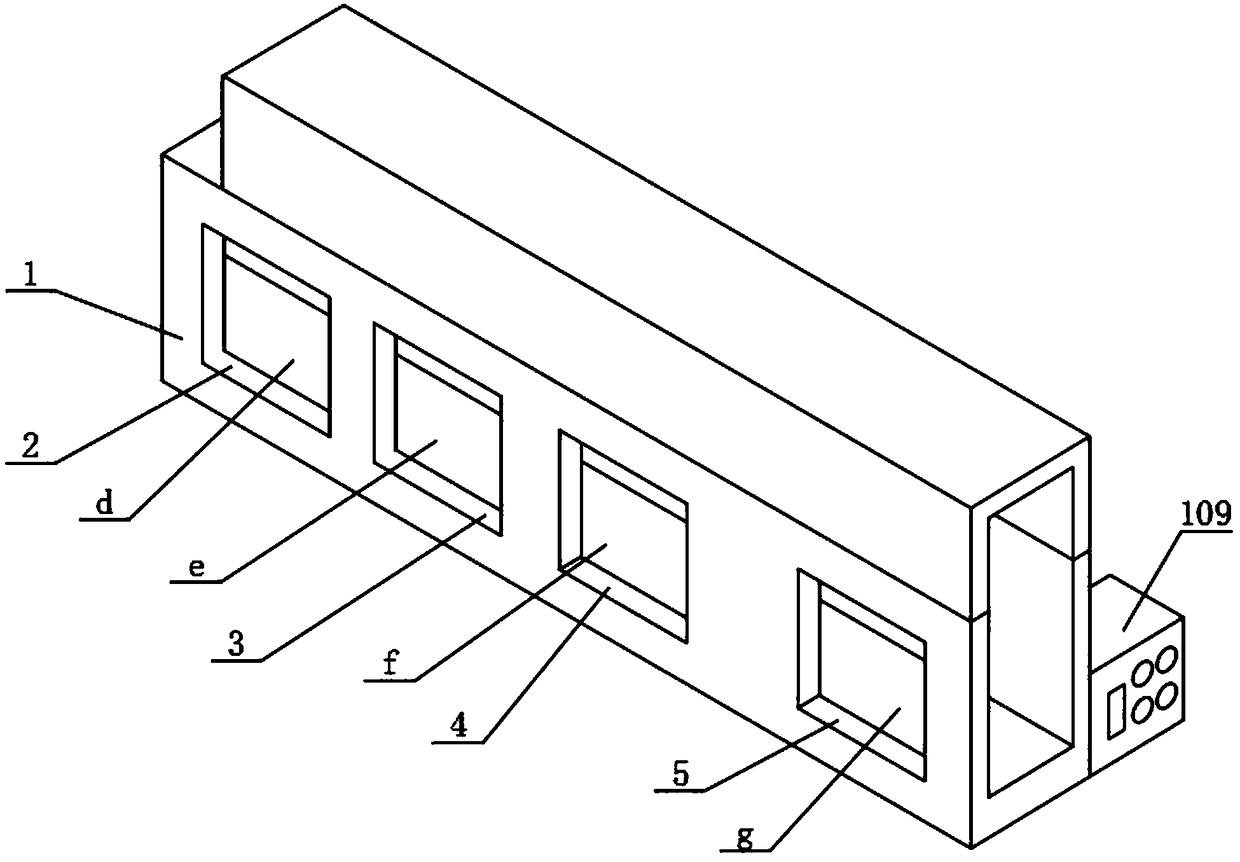

Annular bale plucker

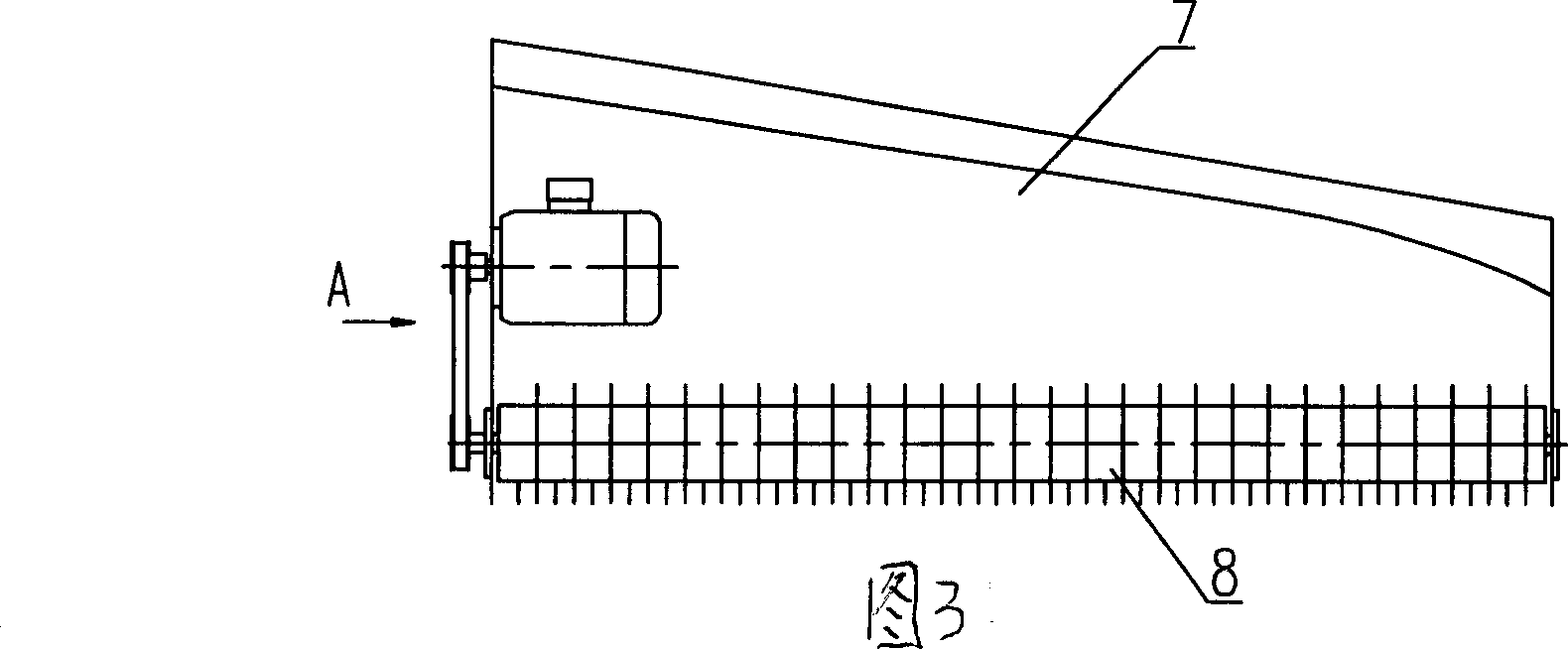

InactiveCN103938299AMoisturize delicately and evenlyImprove dust removal effectFibre breaking machinesFiberPhysical health

The invention discloses an annular bale plucker which comprises an inner ring wall board, an outer ring wall board, a platform, a trolley, a cotton conveying tube, a telescopic tube, a cotton sucking cover, a beater and a support. A reversed extended section is arranged on one side, opposite to the trolley of the platform, an air pump and an atomizing nozzle which can spray mist outwards are arranged on the reversed extended section, a water tank is further connected with a water inlet of the atomizing nozzle through a second water pipe, the air pump is connected with an air inlet of the atomizing nozzle through an air pipe, and an air valve is arranged on the air pipe. According to the bale plucker, the nozzle can spray mist outwards to achieve the main functions of humidification and dust removal. The atomizing nozzle can spray mist outwards 180 degrees away from the nozzle to cover the area between the inner ring wall board and the outer ring wall board, and finally the mist can fall on cotton layers between the inner ring wall board and the outer ring wall board. Mist humidification is fine and even and can be complementary with an existing nozzle to enable the cotton layers to be humidified evenly. On the other hand, the annular bale plucker can prevent cotton fibers from flying to guarantee physical health of operators.

Owner:罗静

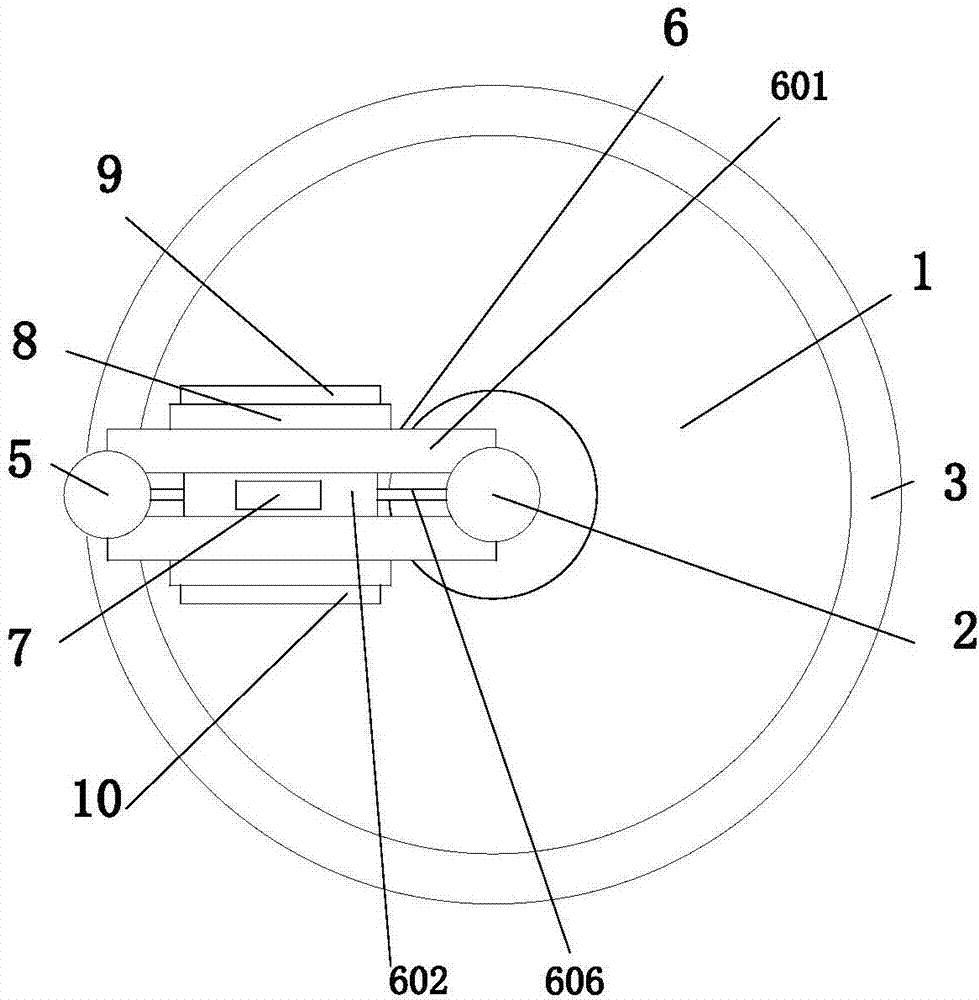

Cotton plucking bearer disk

ActiveCN110055629AAchieve regulationIncrease flexibilityFibre breaking machinesFibre breaking by beater armsEngineeringPlucker

The invention discloses a cotton plucking bearer disk which comprises a shell and blades. The shell comprises a first end cover and a second end cover which are parallel each other, hinge shafts are peripherally and equidistantly distributed in the first end cover, the number of the blades is the same as that of the hinge shafts, the blades are hinged onto the corresponding hinge shafts and clamped in the middle by the first end cover and the second end cover, and the first end cover is detachably connected with the second end cover. According to the cotton plucking bearer disk, overturning angles and exposed heights of the blades can be controlled as required, states of the blades can be adjusted, the cotton plucking bearer disk is independently modular, a plurality of cotton plucking bearer disks can be parallelly mounted on a rotating shaft of a cotton plucker as required, overall specifications of a cotton plucking bearer are adjusted, and the cotton plucking bearer disk has high flexibility and variability.

Owner:安徽新蕾家纺有限公司

Highly-efficient tea plucker

InactiveCN107801486AImprove picking efficiencyPlay a protective effectPicking devicesPluckerEngineering

The invention relates to a tea plucker, specifically to a highly-efficient tea plucker. The invention is to solve a technical problem of providing a highly-efficient tea plucker with advantages of high plucking efficiency, good quality of plucked tea and facilitation of movement. In order to solve the above-mentioned technical problem, the invention provides the highly-efficient tea plucker whichcomprises a base plate, etc., wherein the bottom part of the base plate is provided with a moving mechanism; two sides of the top part of the base plate are correspondingly provided with bilaterally-symmetrical supporting rods; the top parts of the supporting rods are provided with a box body; the left end and the right end of the box body are respectively provided with a feeding hopper; the interior of the box body is provided with a conveying mechanism; a rotating member of the conveying mechanism is connected with a member of the moving mechanism; and the left end and the right end of eachfeeding hopper are respectively provided with a plucking mechanism. The highly-efficient tea plucker provided by the invention achieves the effects of high plucking efficiency, good quality of pluckedtea and facilitation of movement; and the height of the device can be adjusted through a lift-drop mechanism, so tea leaves with different heights can be plucked, and the efficiency of plucking is improved.

Owner:陈玉霞

Automatic cotton plucker

InactiveCN107557916AEasy to absorbEasy to grabFibre breaking machinesFibre breaking by toothed membersElectric machineryPlucker

The invention discloses an automatic cotton plucker which comprises a supporting plate, a suction bin bucket and an air suction box. A supporting column is fixed at each of two ends of the supportingplate, the bottom end of a top plate is fixedly connected with two electric extensible rods, the bottom ends of the electric extensible rods are fixedly connected with the suction bin bucket, a rotating shaft at one end of a cotton plucking roller is fixedly connected with an output shaft of a speed reducing motor, a plurality of plucking teeth are arranged on the cotton plucking roller, the middle of the top end of the suction bin bucket is communicated with a cotton conveying pipe, and an extensible hose is arranged on one section of the cotton conveying pipe. Cotton is stripped and pluckedthrough the plucking teeth, so that convenience is brought to the cotton conveying pipe to absorb the cotton; by arranging the electric extensible rods, height of the suction bin bucket can be adjusted, and convenience is brought to plucking and sucking in the cotton no matter the cotton is more or less; by arranging a shaft sleeve on the rotating shaft of the cotton plucking roller, the shaft sleeve is fixed on the inner wall of the suction bin bucket to prevent the cotton from being close to the rotating shaft, and the circumstance that the rotating shaft of the cotton plucking roller is entangled is prevented.

Owner:湖州世韩进出口有限公司

Plucker for duck slaughtering

InactiveCN109197973AEasy to moveRealize processingPoultry plucking mechanismsBlood collection/stirring apparatusPluckerEngineering

The invention relates to the technical field of duck slaughtering, in particular to a plucker for duck slaughtering, which comprises a main body device, a blood collecting device, a heating device, adefeatherer and a collecting device, wherein the left side of the bottom end of the main body device is fixedly connected with the blood collecting device, and the heating device is arranged at the right side of the blood collecting device; the heating device is fixedly connected with the main body device, and the defeatherer is arranged at the right side of the heating device; the defeatherer isfixedly connected with the main body device, and the collecting device is arranged at the right side of the defeatherer. In the plucker for duck slaughtering provided by the invention, by arrangementof the defeatherer, a drying box and a fan body, the duck feather can be transported through a second conveyor belt, and the preliminary drying of the duck feather can be realized through the drying box on the other hand; by a supporting block and a cutting board, the whole duck is packaged or duck legs are packaged for separate sale according to the needs in the duck processing course, the duck legs can be processed according to the role of a cutter and collected through a collection box.

Owner:湖南芷江和翔鸭业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com