Patents

Literature

53results about "Fibre breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Module wrap removal

InactiveUS20060191241A1Eliminates wrap material contaminationEasy to disassembleOpening closed containersBottle/container closureControl mannerEngineering

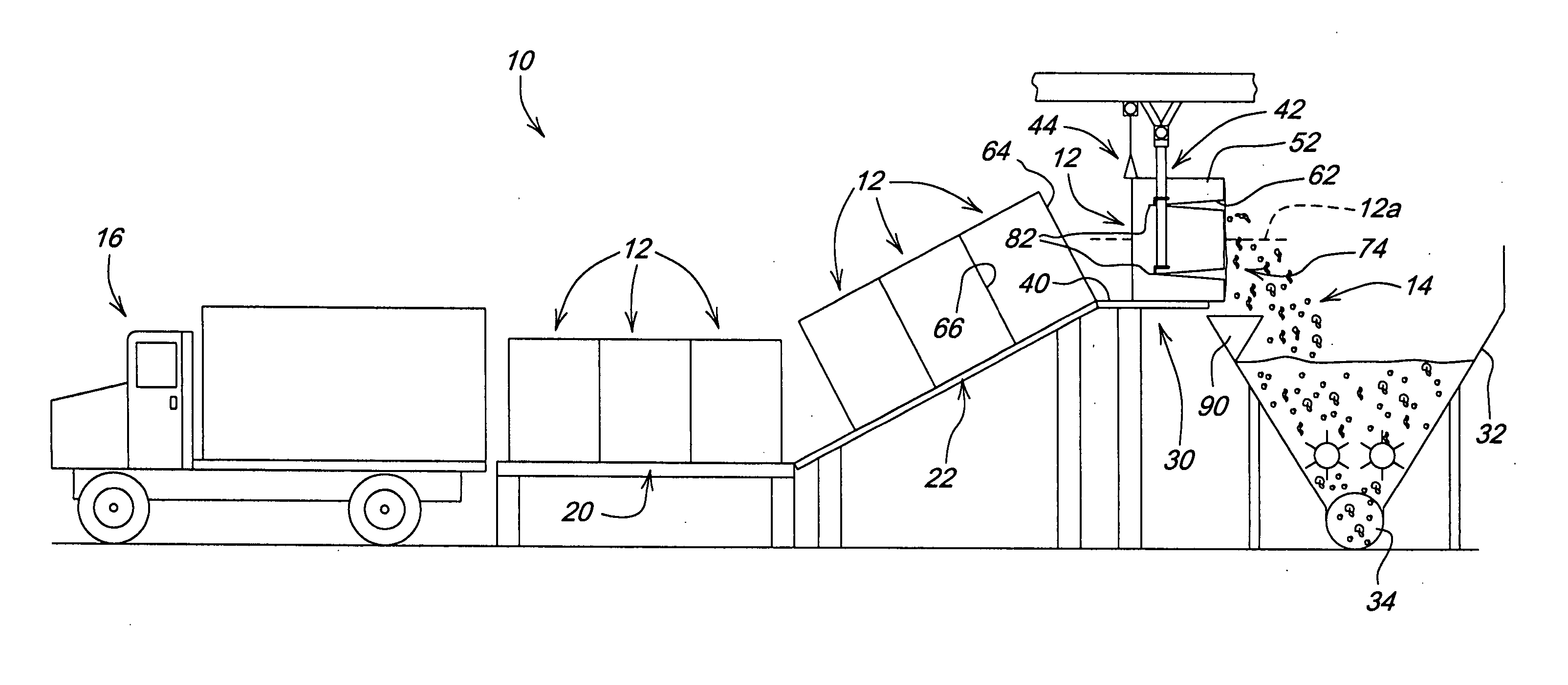

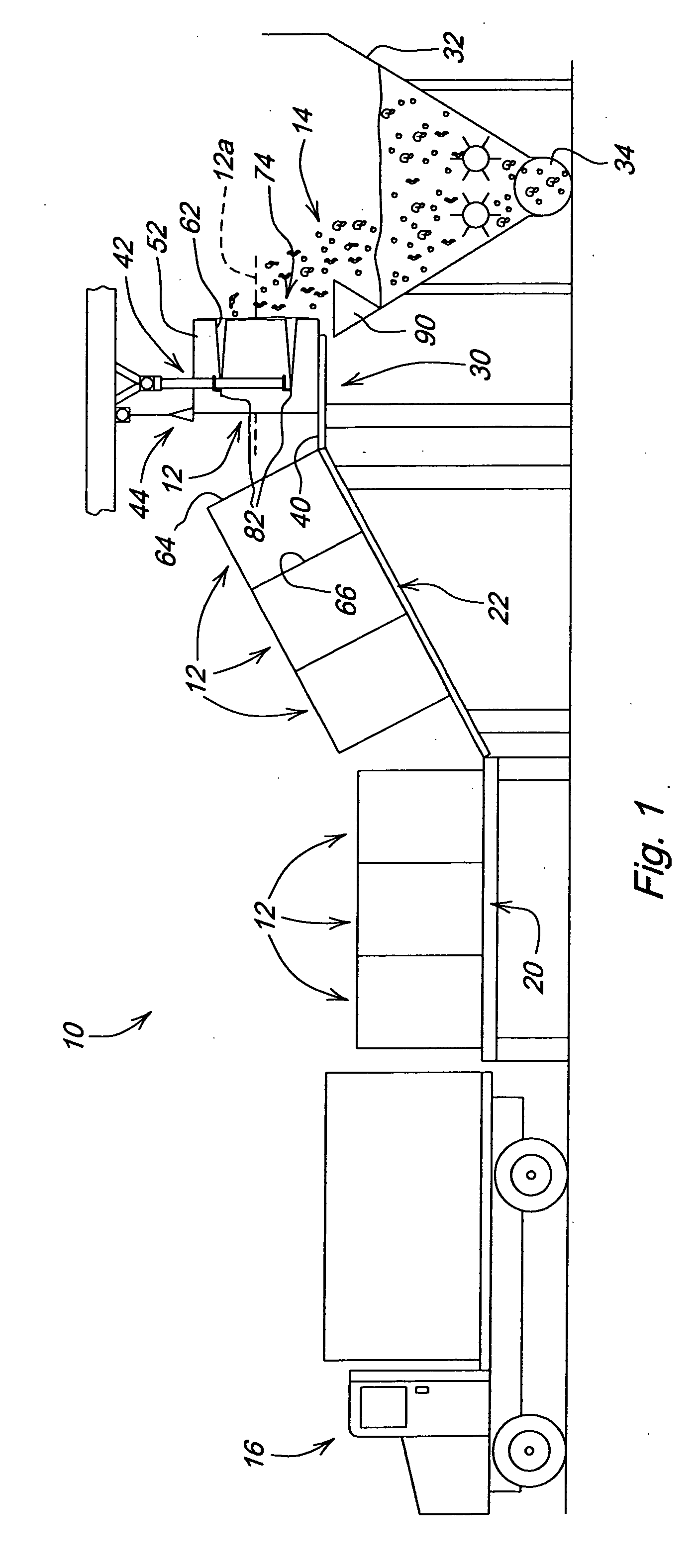

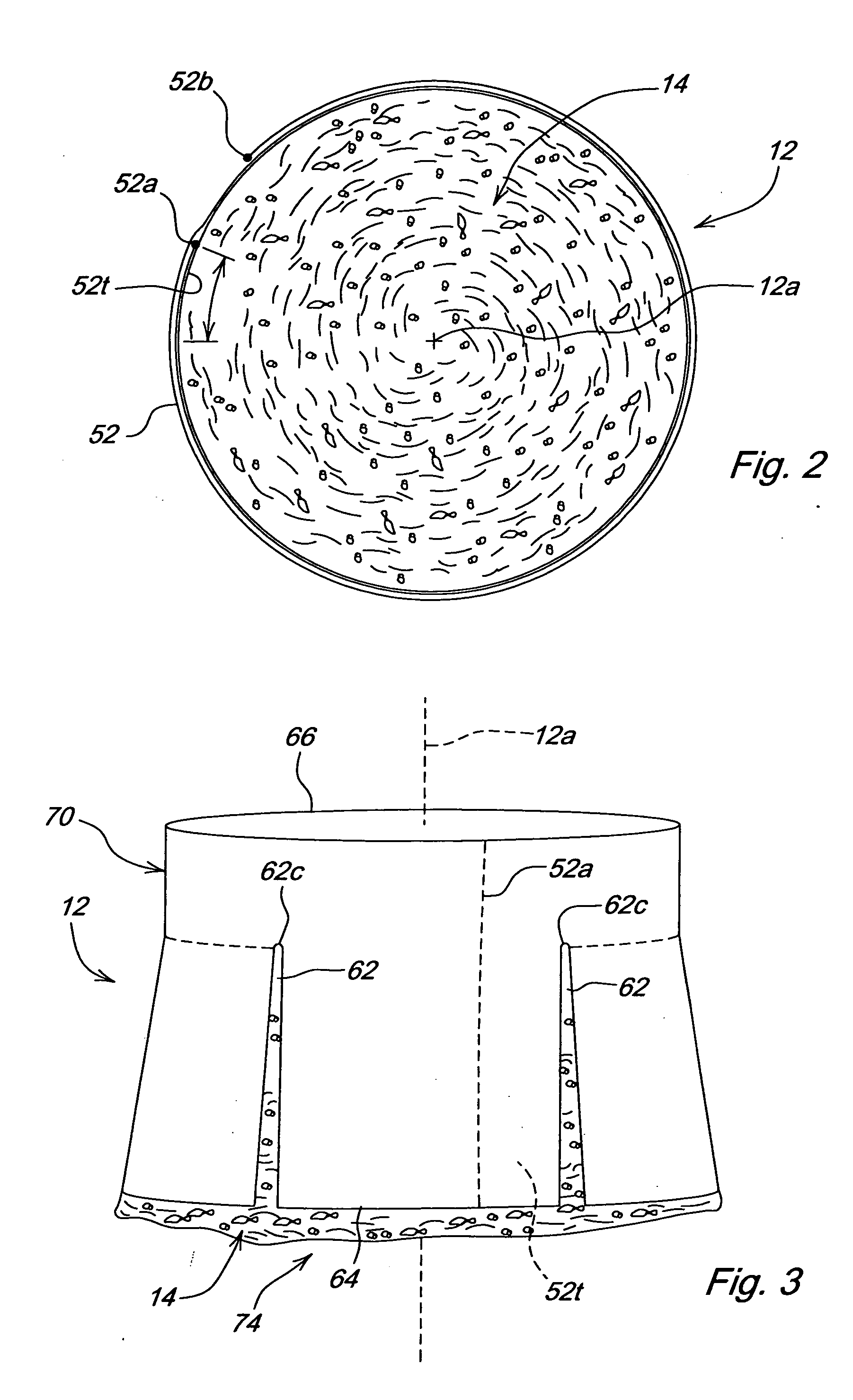

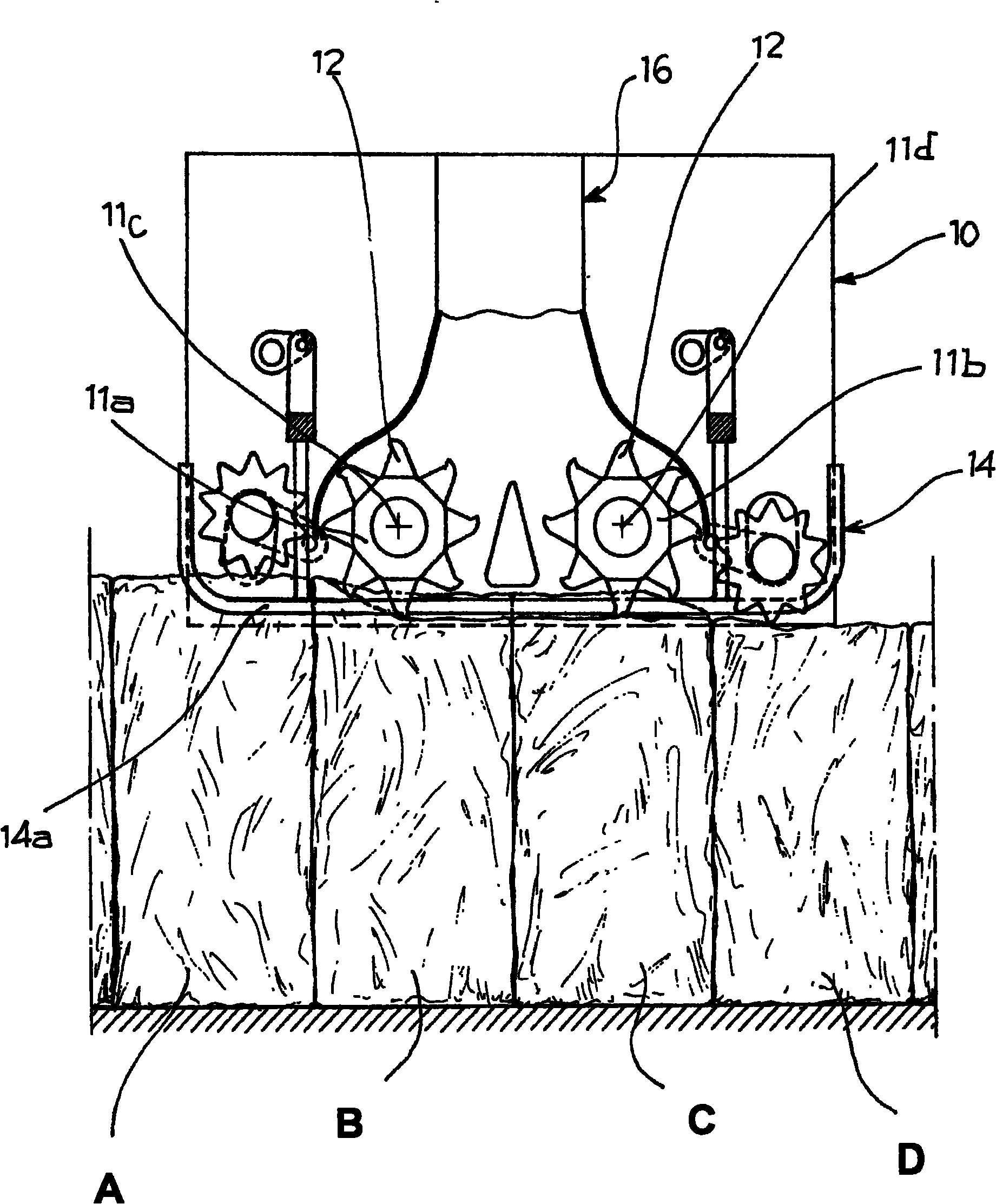

A system wherein plastic wrap on round bales of cotton is partially slit starting at one end of the bale and continuing to a location offset from the opposite end of the bale. One or more partial lengthwise slits allow the cotton to fall into a gin input hopper in a controlled manner and maintain the entire wrap, including any non-adhered inner tail remnants, attached to an intact circumferential wrapper portion at the end of the bale opposite the slit end. The non-slit wrapper end portion is pulled from end of the bale, and the remaining cotton material drops into the receptacle free of contamination by any wrap material.

Owner:DEERE & CO

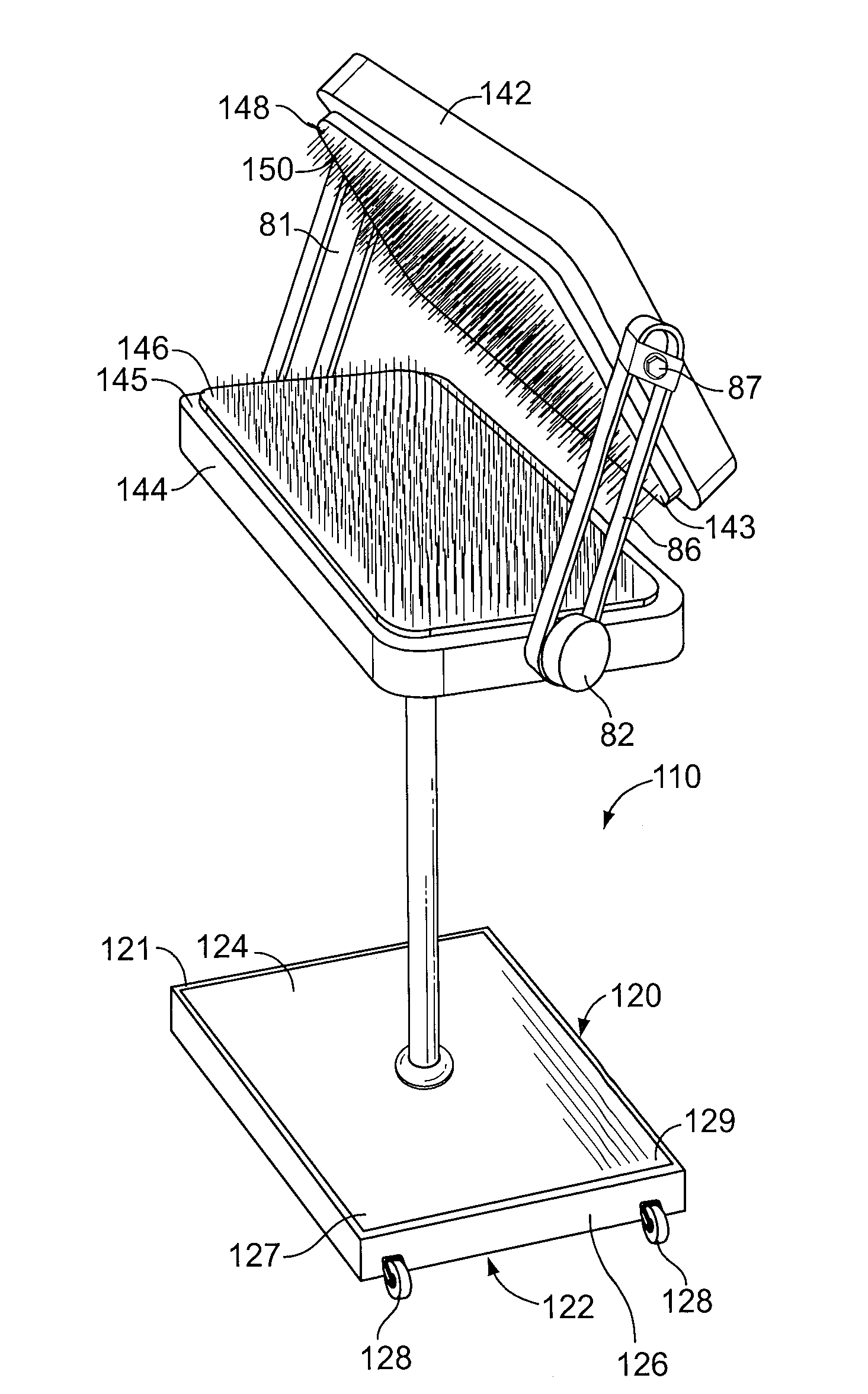

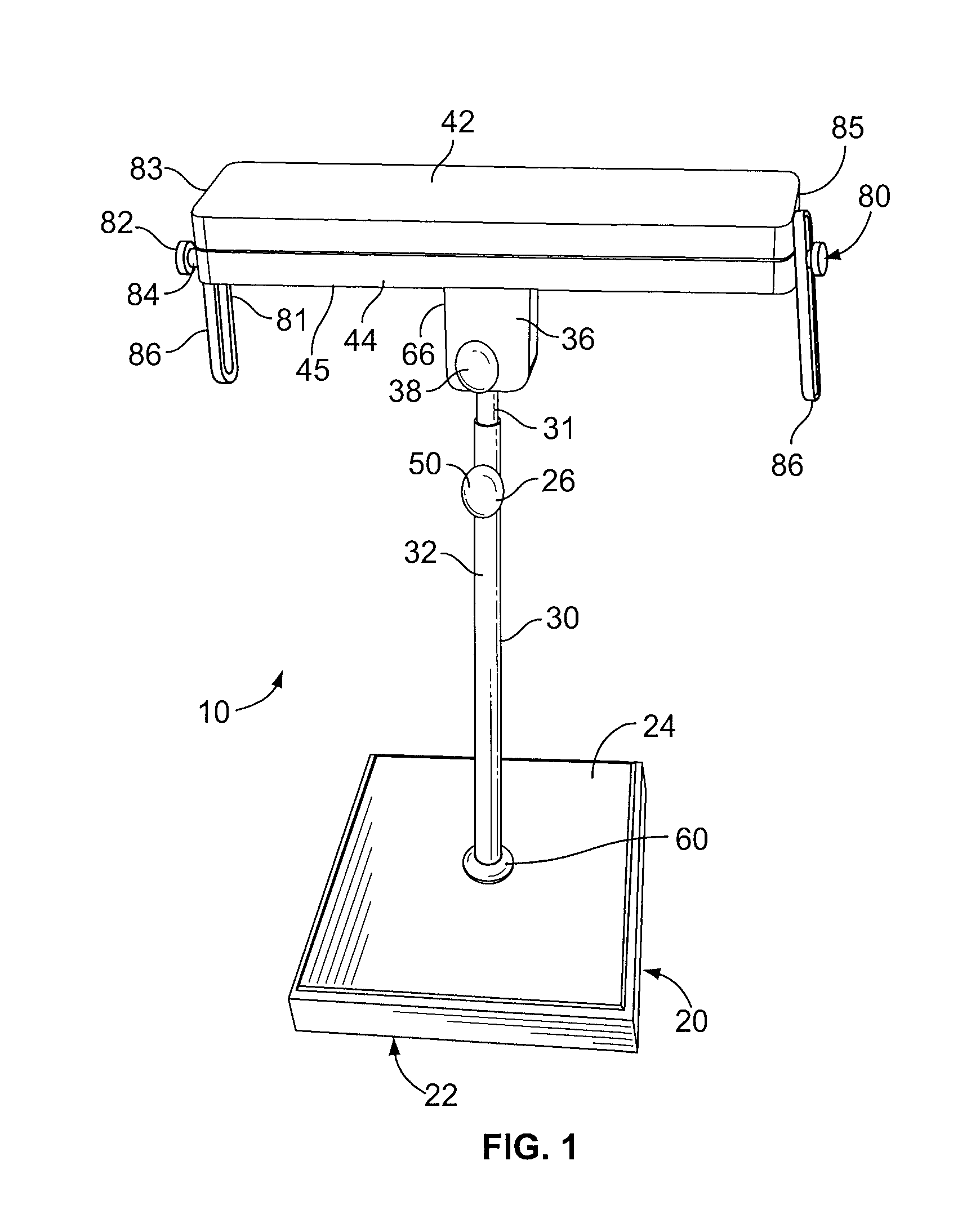

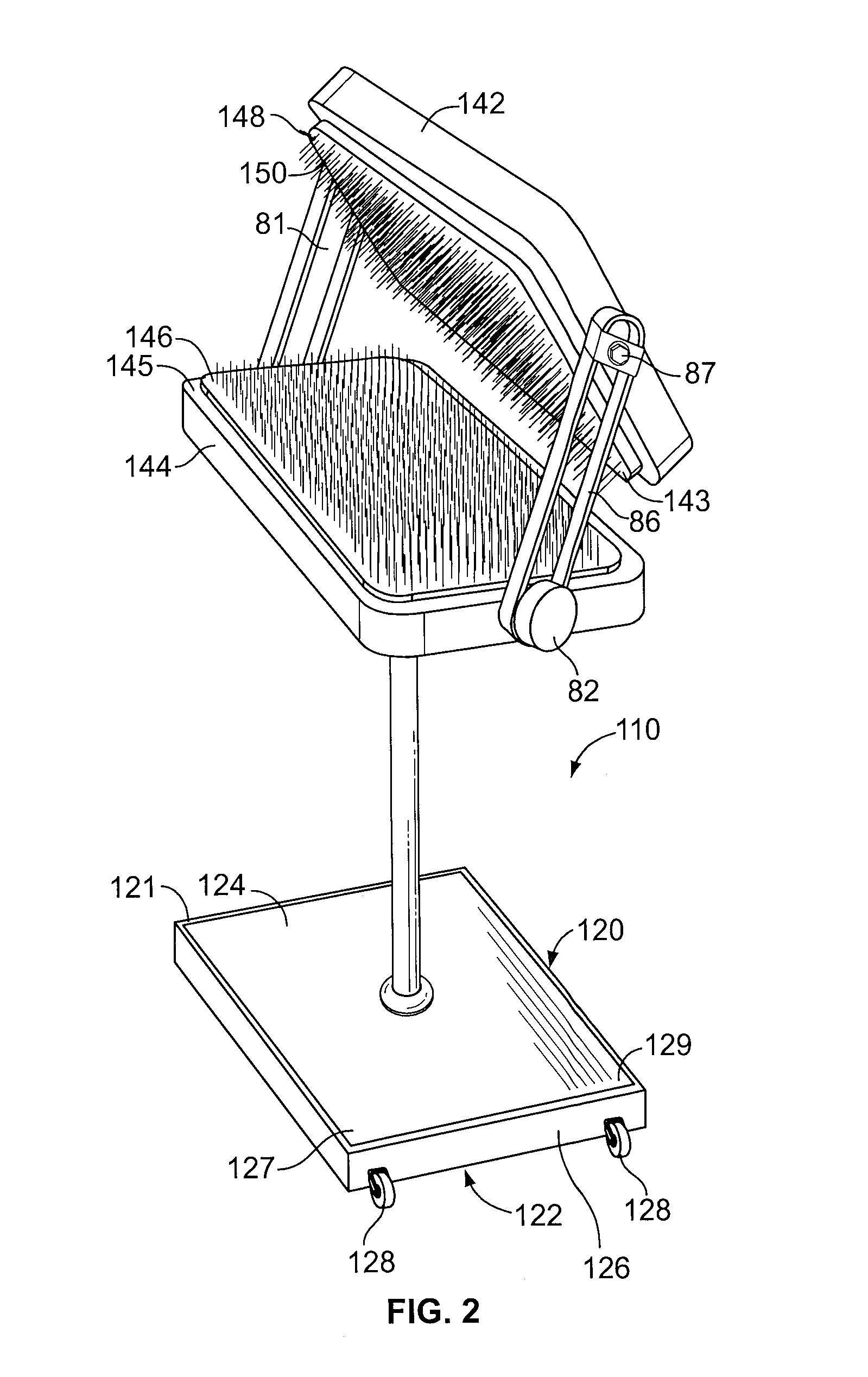

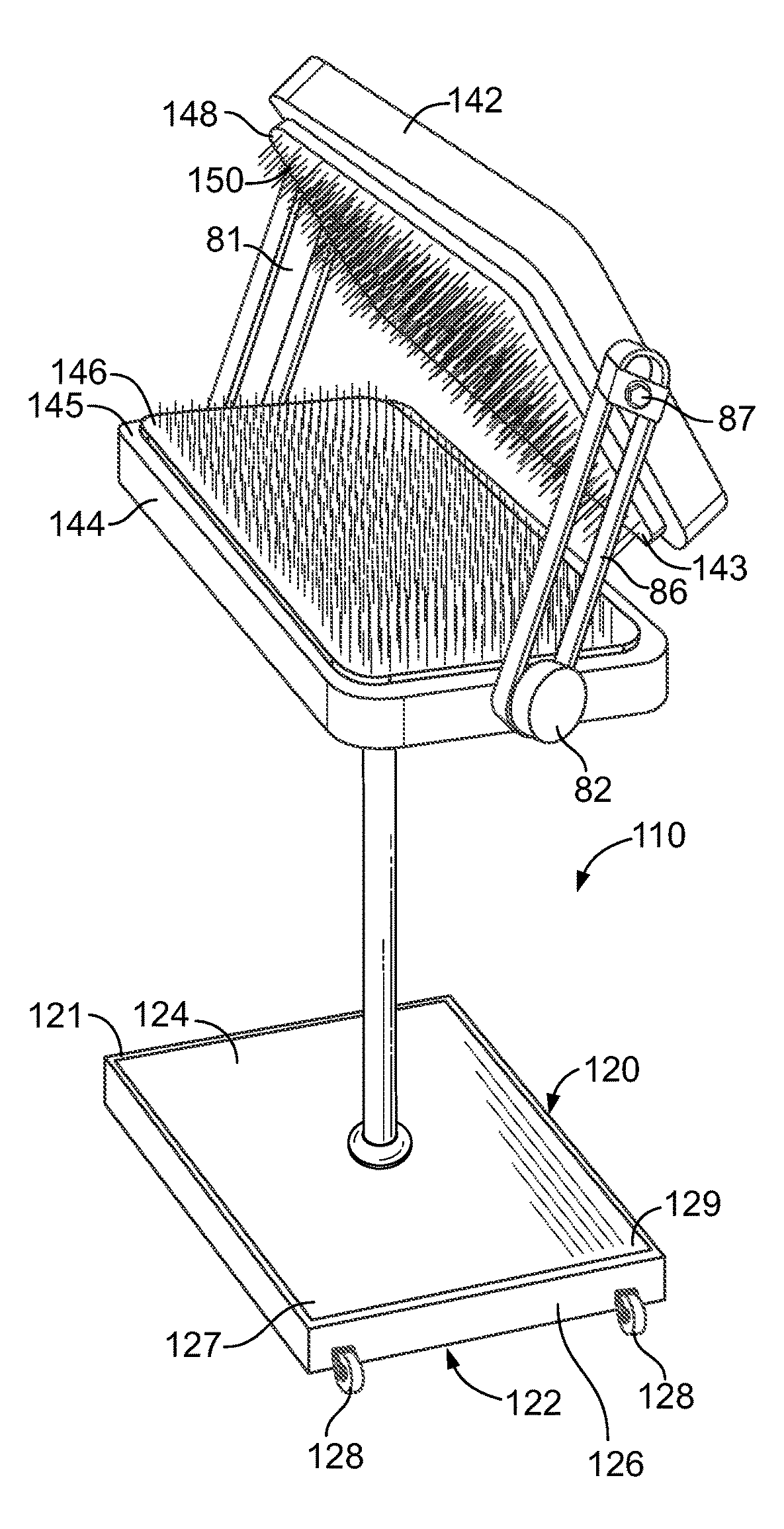

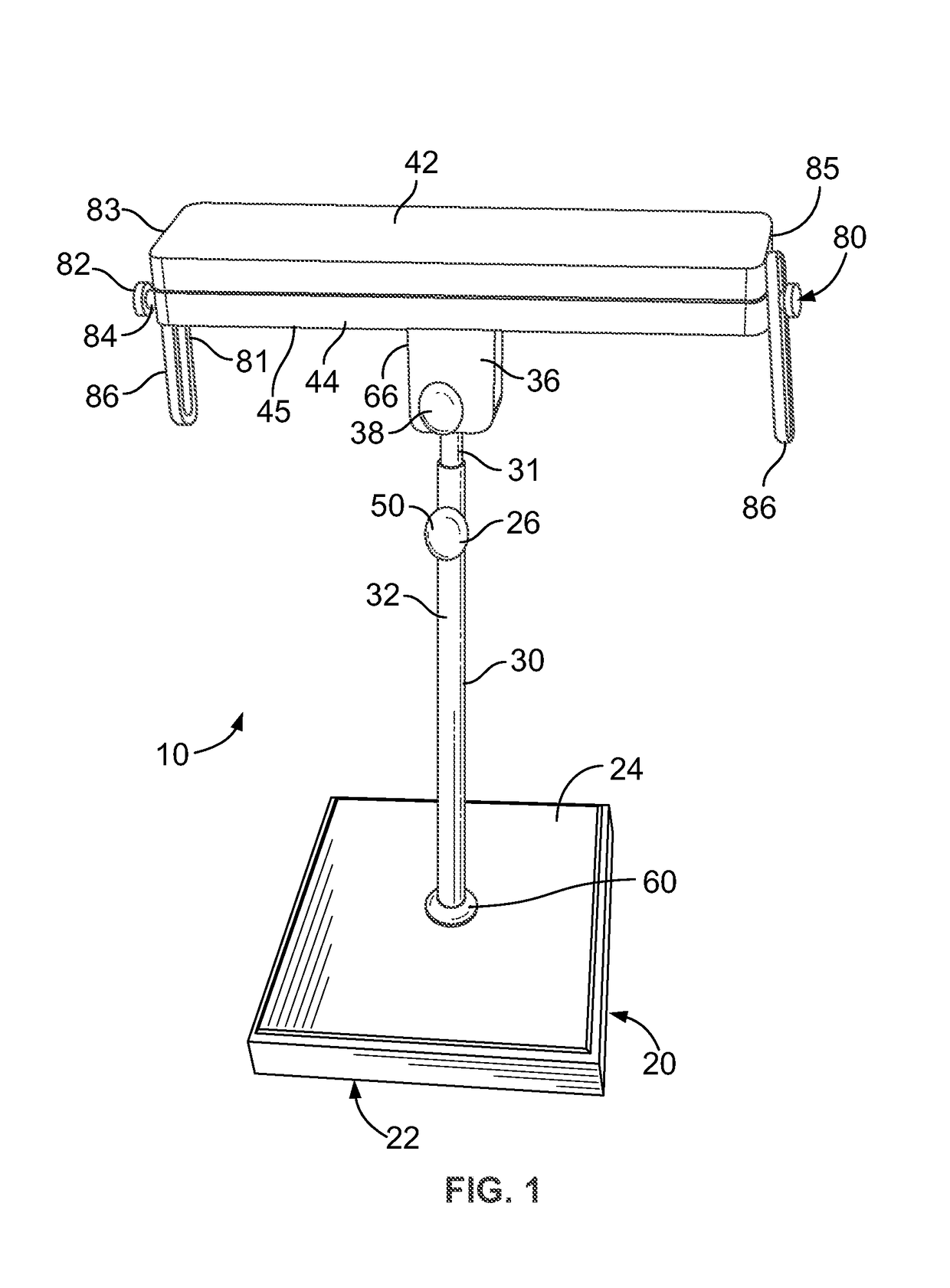

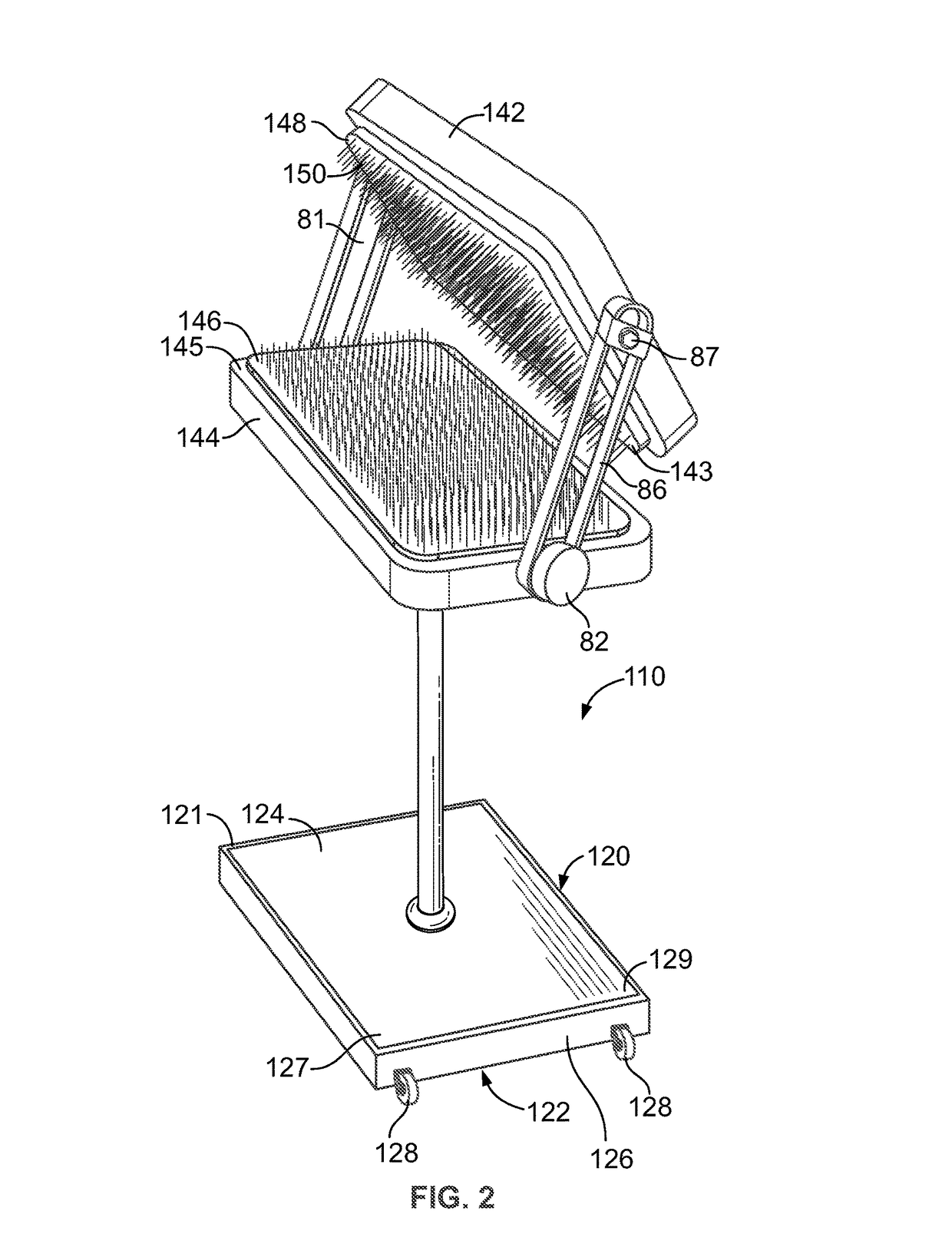

Hair styling device

ActiveUS20140191634A1Improved gripping abilityWithout unnecessary lossCabinetsStands/trestlesBristleEngineering

Owner:SMILEY NADRA SAFIA

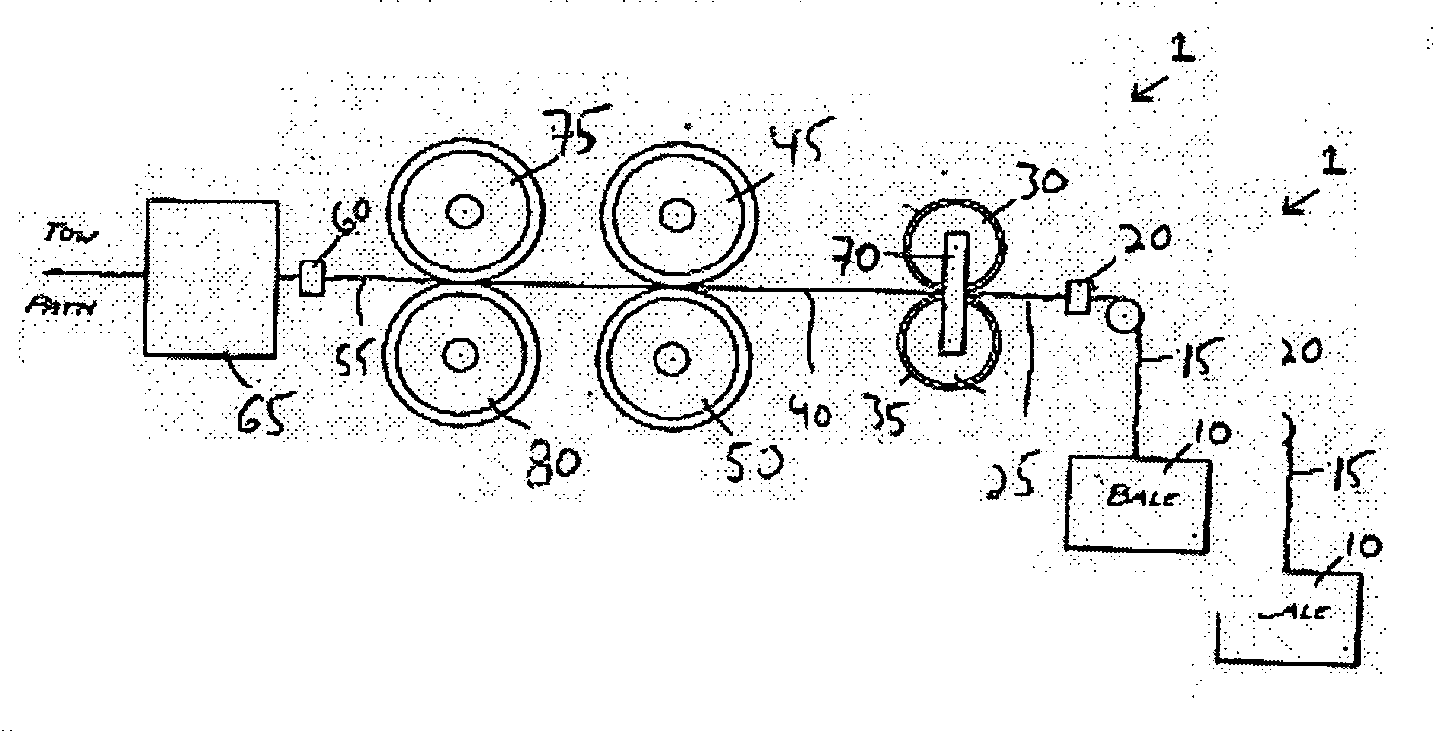

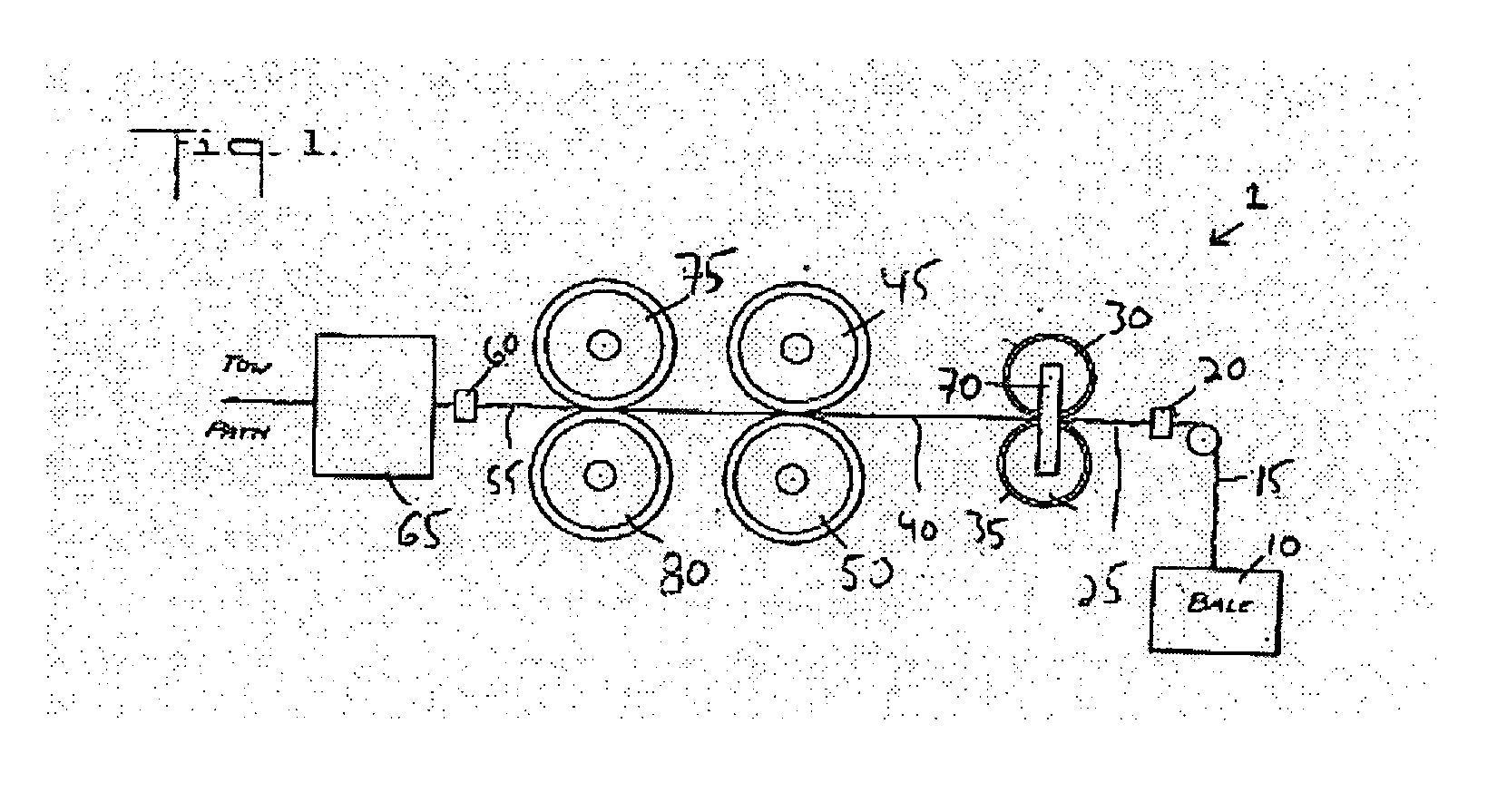

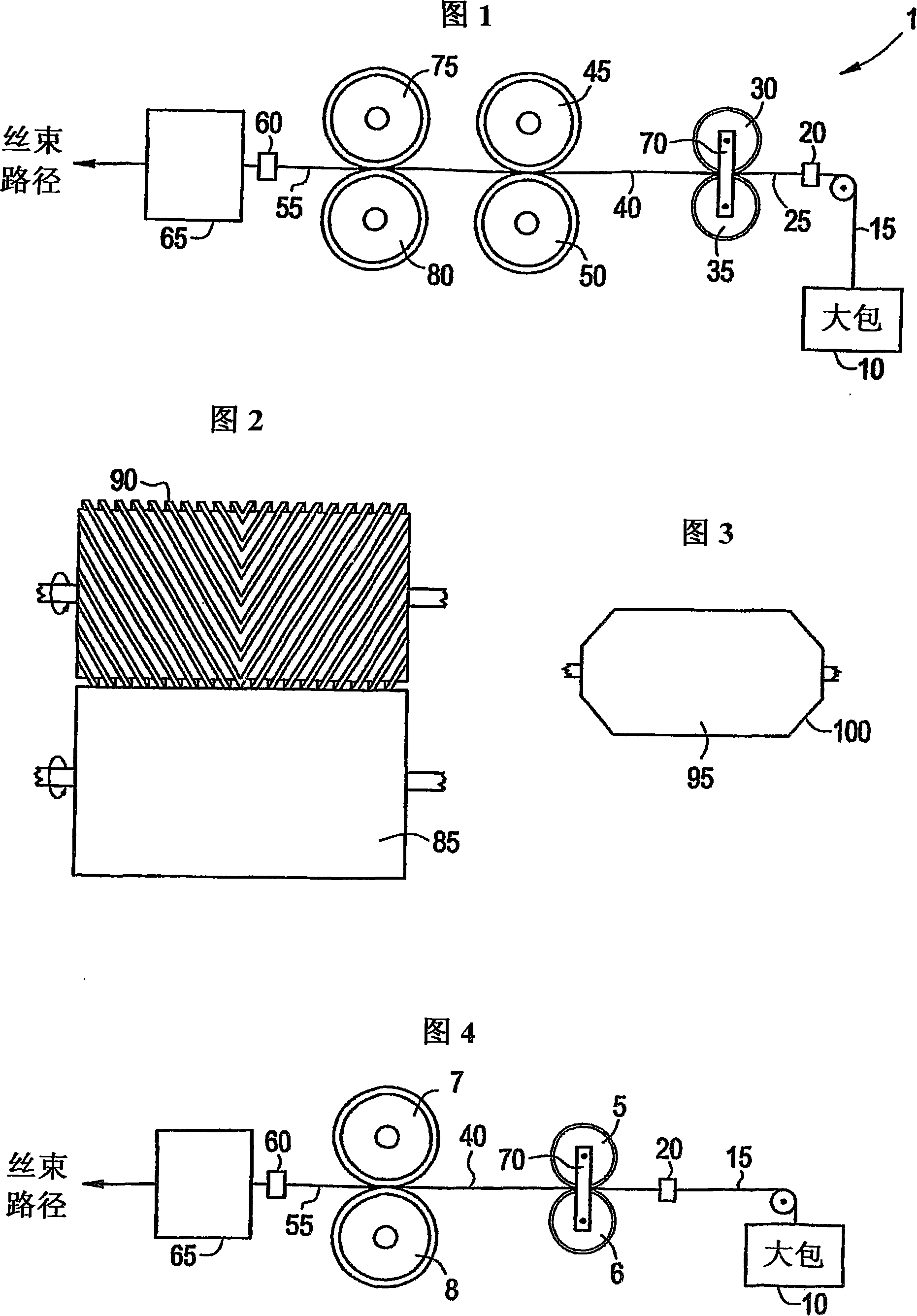

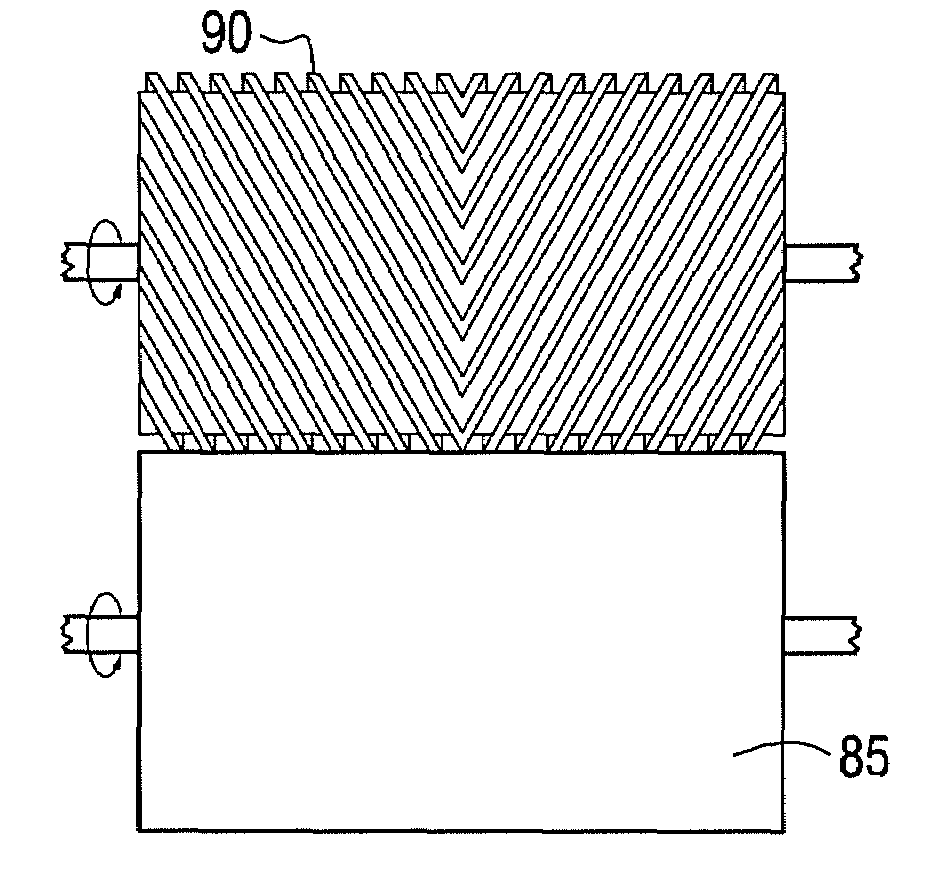

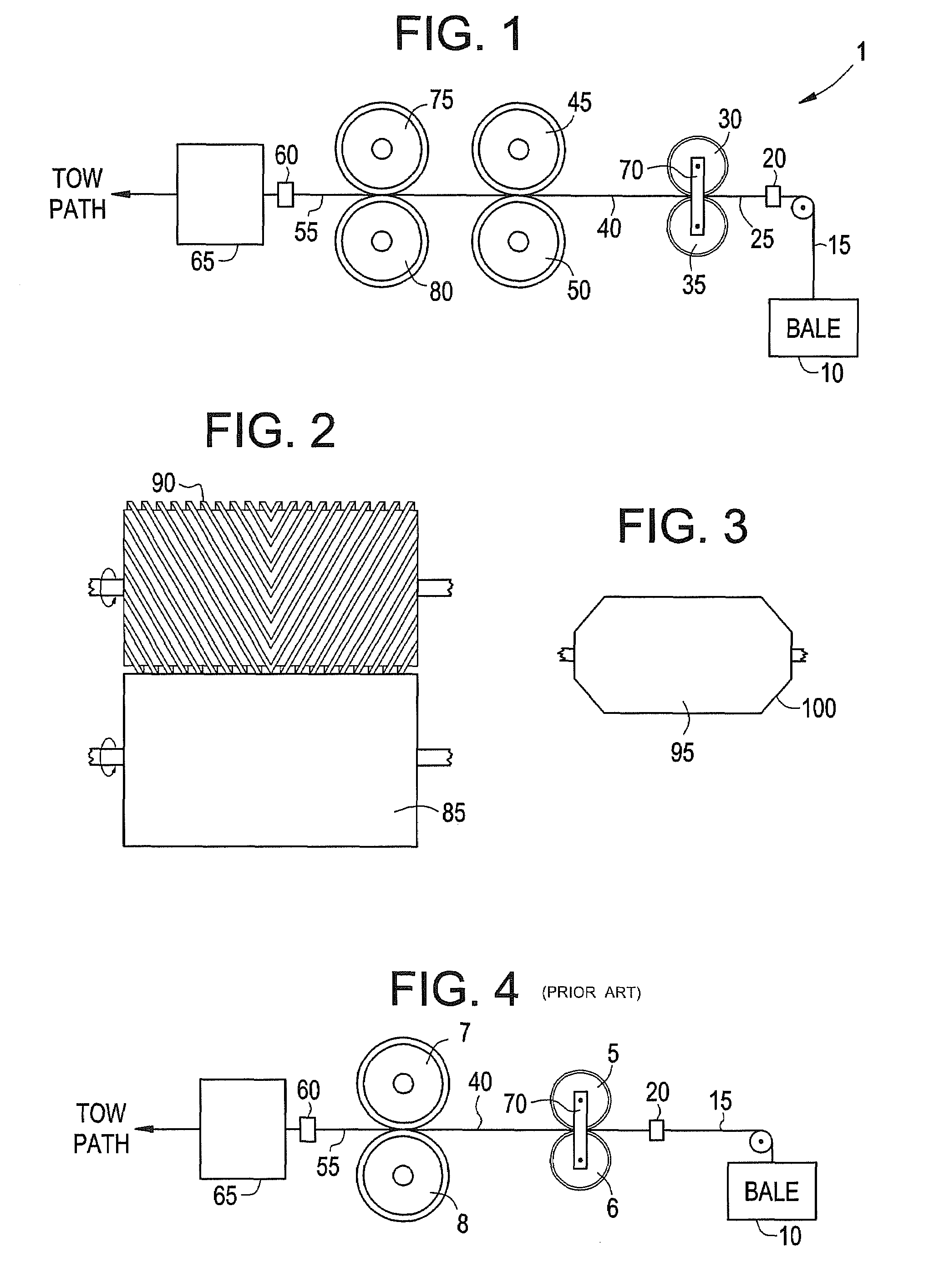

Apparatus for tow opening

An apparatus for opening a crimped multifilament tow comprising: a source of crimped multifilament tow; at least one pair of opposed gripping rollers comprising a first roller which is a metal roller and a second roller which is a smooth-surfaced roller made of a material selected from the group consisting of: polyurethane or silicone rubber; where the multifilament tow passes between and in contact with both of the rollers and filaments of the tow are separated from one another and opened.

Owner:ACETATE INT LLC +1

Apparatus for tow opening

An apparatus for opening a crimped multifilament tow comprising: a source of crimped multifilament tow; at least one pair of opposed gripping rollers comprising a first roller which is a metal roller and a second roller which is a smooth-surfaced roller made of a material selected from the group consisting of: polyurethane or silicone rubber; where the multifilament tow passes between and in contact with both of the rollers and filaments of the tow are separated from one another and opened.

Owner:ACETATE INT LLC

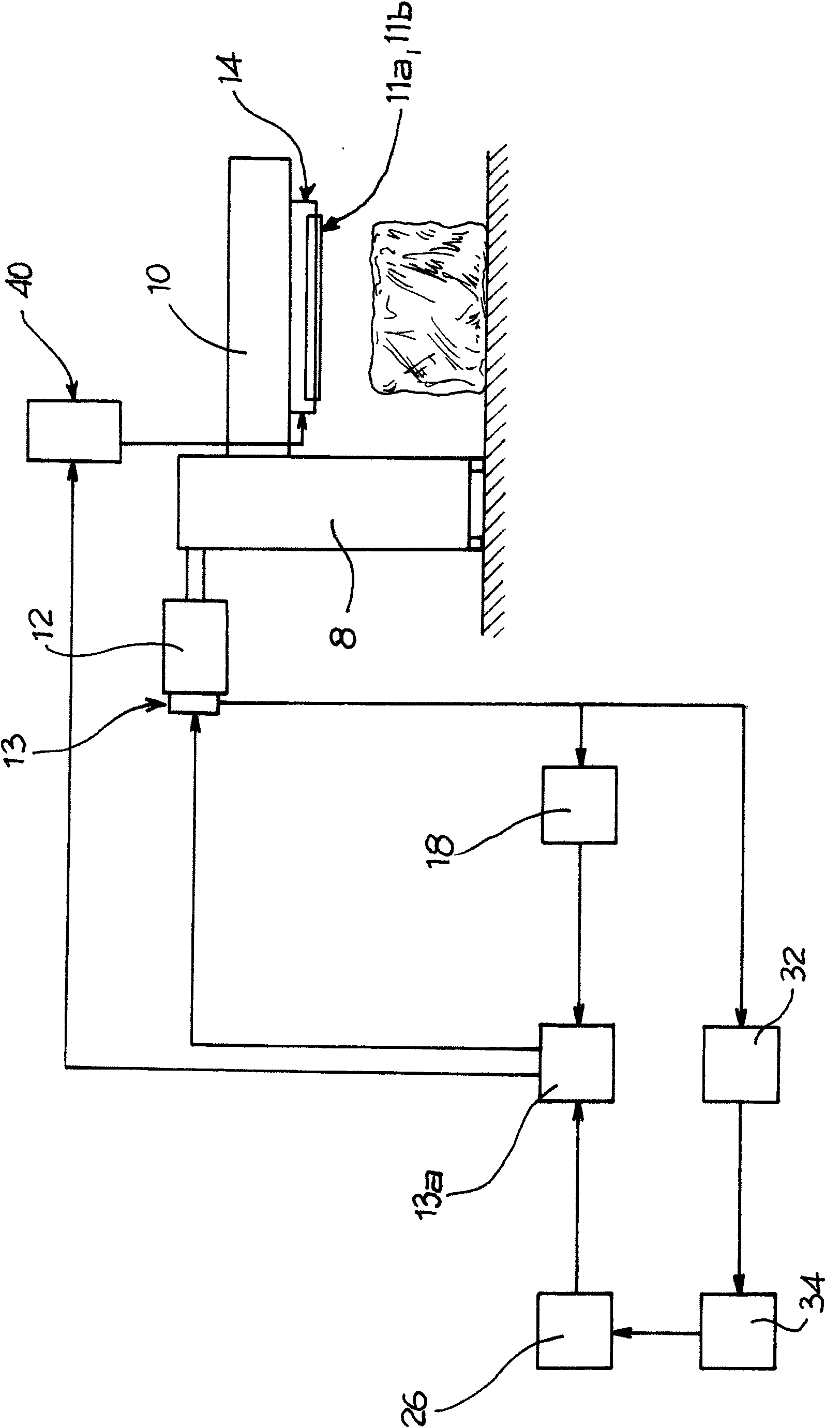

Device and method for the automatic pick-up of fibre from a bale of fibre on a spinning line

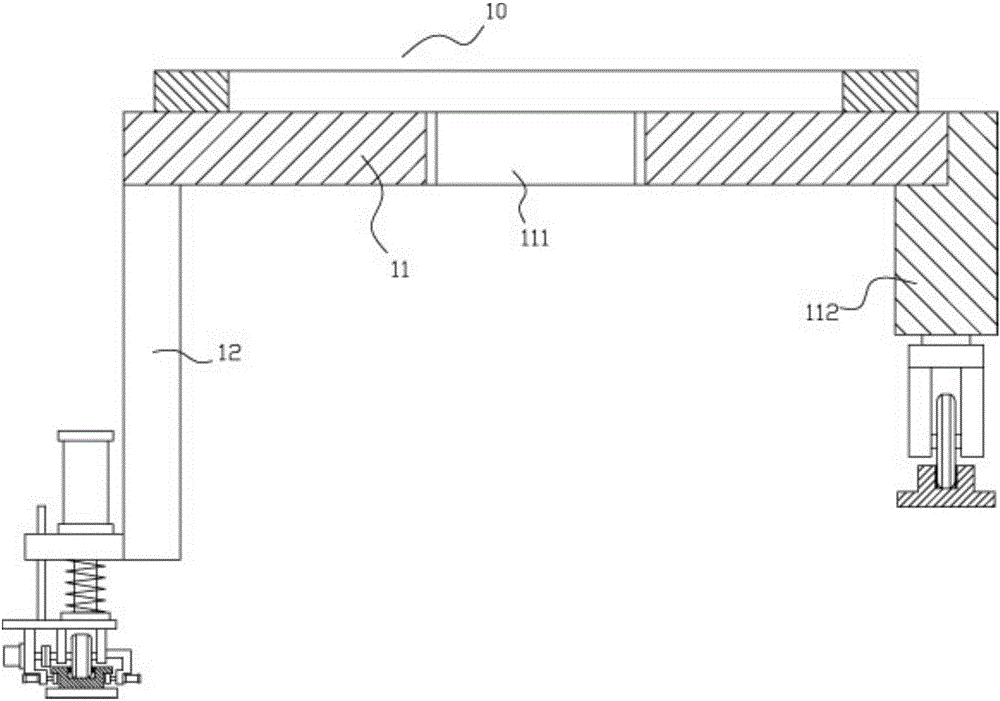

A pick-up device (4) of fibre from bales comprises a translating arm (10) controllable at a constant force or at constant pitch, depending on processing requirements. For control at a constant force or at a constant pitch, selection occurs automatically, on the basis of the conditions of the arm and the type of processing.

Owner:MARZOLI SPA

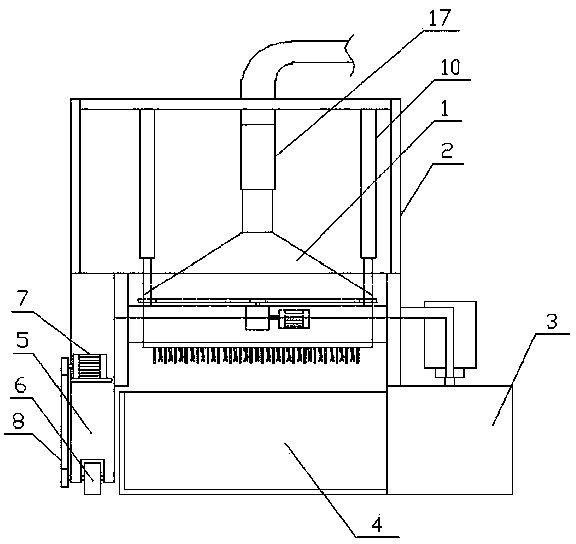

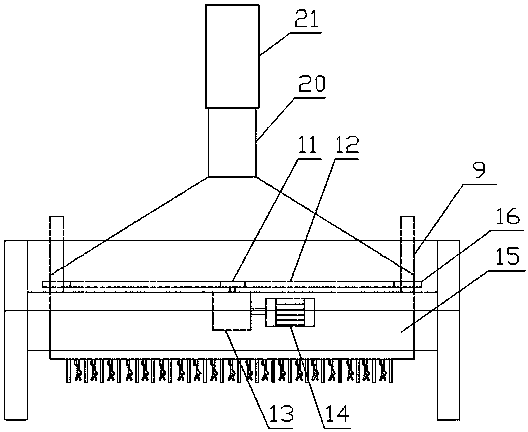

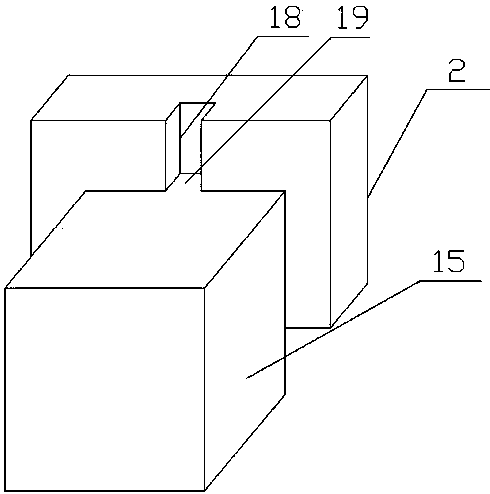

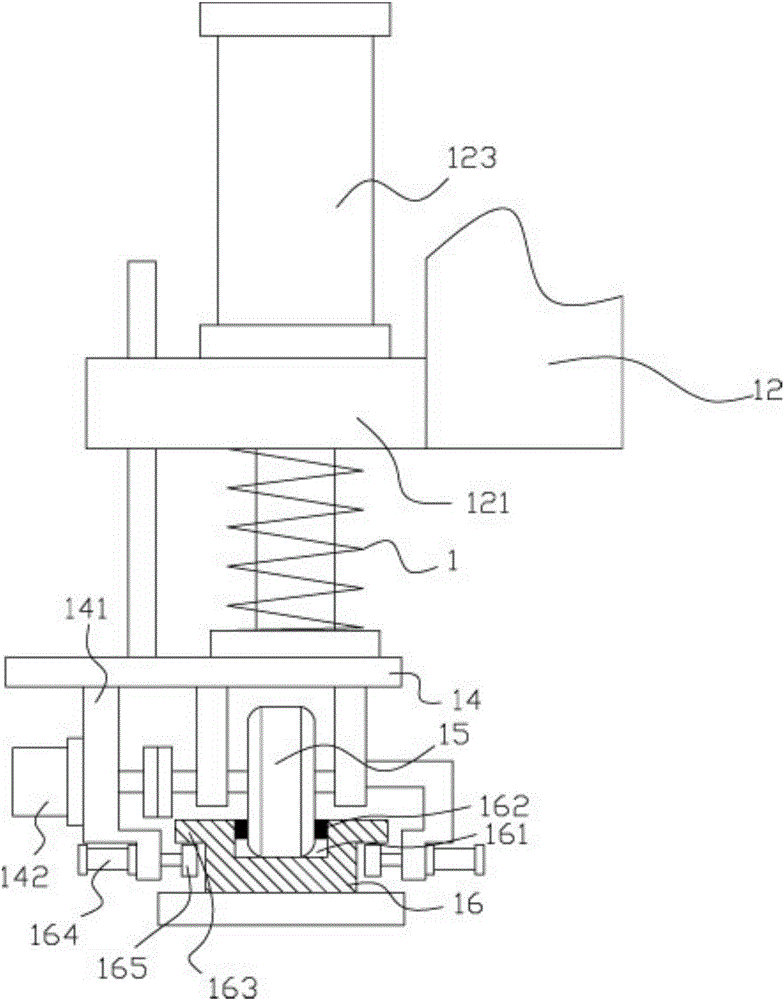

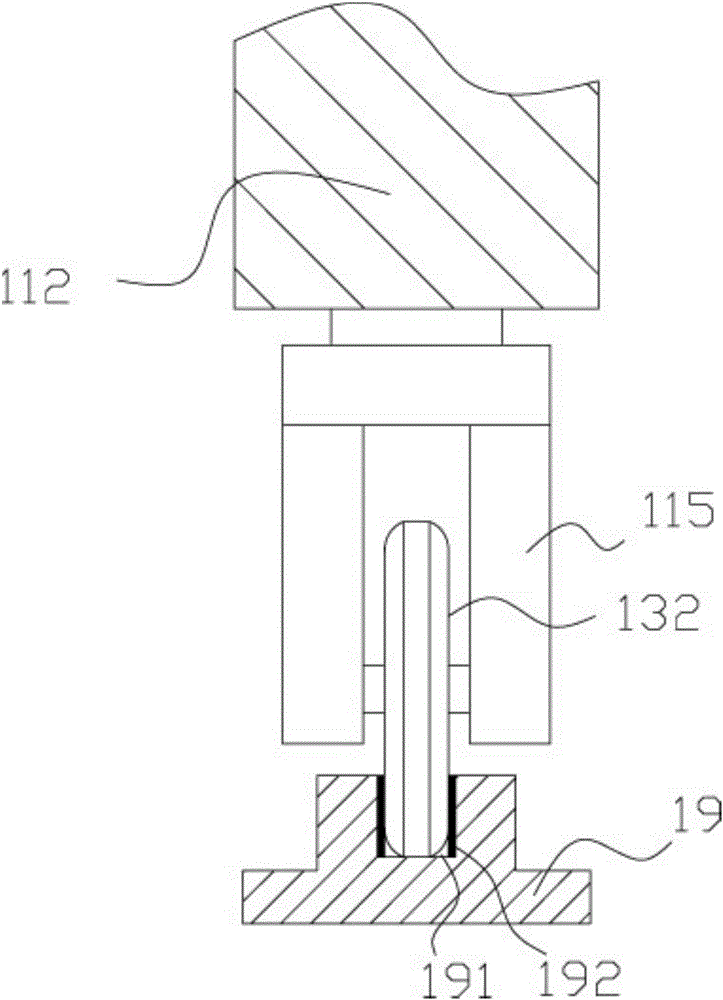

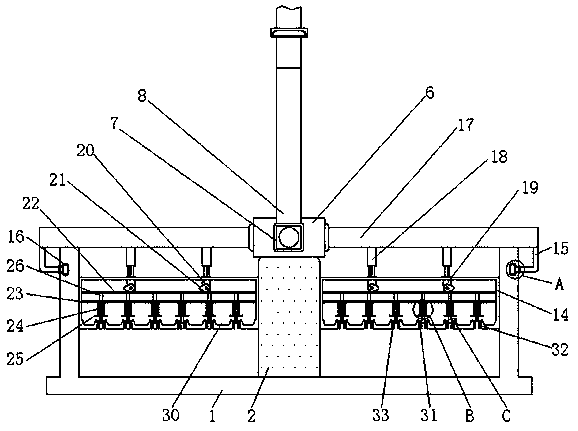

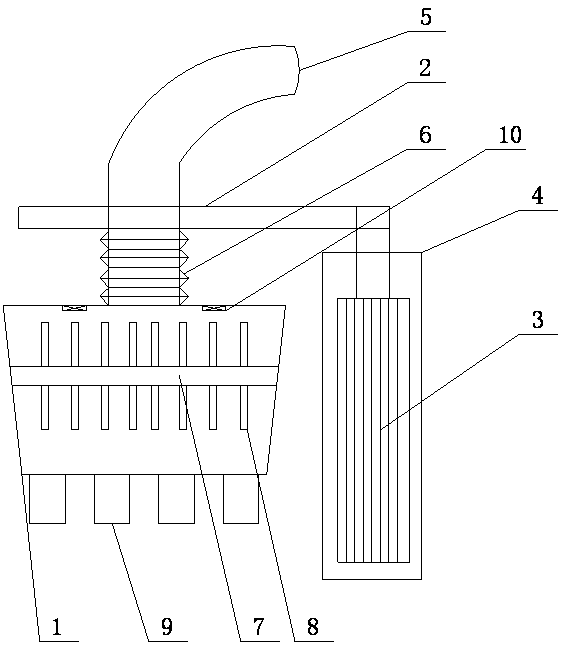

Lifting regulating mechanism for plucker gripper

The invention relates to the technical field of textile machines, in particular to a lifting regulating mechanism for a plucker gripper. The lifting regulating mechanism comprises a rack and a lifting mechanism; the lifting mechanism comprises screws, sprockets, a chain, a motor, the plucker gripper and a gripper support; the plucker gripper comprises a suction cowl and ribs; the bottom part of each rib is provided with an elastic rubber bumper; the bottom end of the suction cowl is provided with a position sensor; the position sensor is electrically connected with a controller; the controller is connected with the motor; a strip groove is formed in the upper side of the gripper support; the strip groove is provided with a chain tightener; the chain tightener comprises an adjustment sprocket, a sprocket shaft, a sliding seat and a spring; the adjustment sprocket is connected with the chain; one end of the spring is supported on the end part of the sliding seat, and the other end of the spring is fixedly arranged in the strip groove. According to the lifting regulating mechanism for the plucker gripper, provided by the invention, the lifting of the plucker gripper can reliably run, the equipment loss is reduced, and the safety performance is improved.

Owner:HUNAN JICHANG SILK

Bale plucker with automatic ascent and descent function

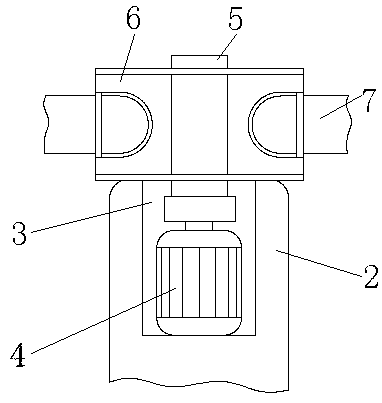

The invention discloses a bale plucker with the automatic ascent and descent function. The bale plucker comprises a bale plucker gripper, an ascent and descent mechanism, a rack, a trolley and a cotton pool, wherein the cotton pool comprises a central cylinder and a side plate arranged on the outer side of the cylinder, the side plate is a cylindrical hollow barrel and arranged on the outer side of the central cylinder concentrically, one end of the rack is rotationally arranged on the upper side of the central cylinder and rotates with the axis of the central cylinder as the axis, the trolley is arranged at the other end of the rack and located on the outer side of the side plate, the bale plucker gripper is fixed to the ascent and descent mechanism, the ascent and descent mechanism is arranged on the rack, and the ascent and descent mechanism comprises a threaded rod, a threaded rod sleeve, a chain wheel, a chain, a speed reducer, a motor and a bale plucker gripper support. Due to the structure, the bale plucker with the automatic ascent and descent function is simple in structure, an automatic ascent and descent function of the bale plucker gripper is achieved, and the bale plucker can continuously pluck bales.

Owner:ZHEJIANG XINMIAN TEXTILE

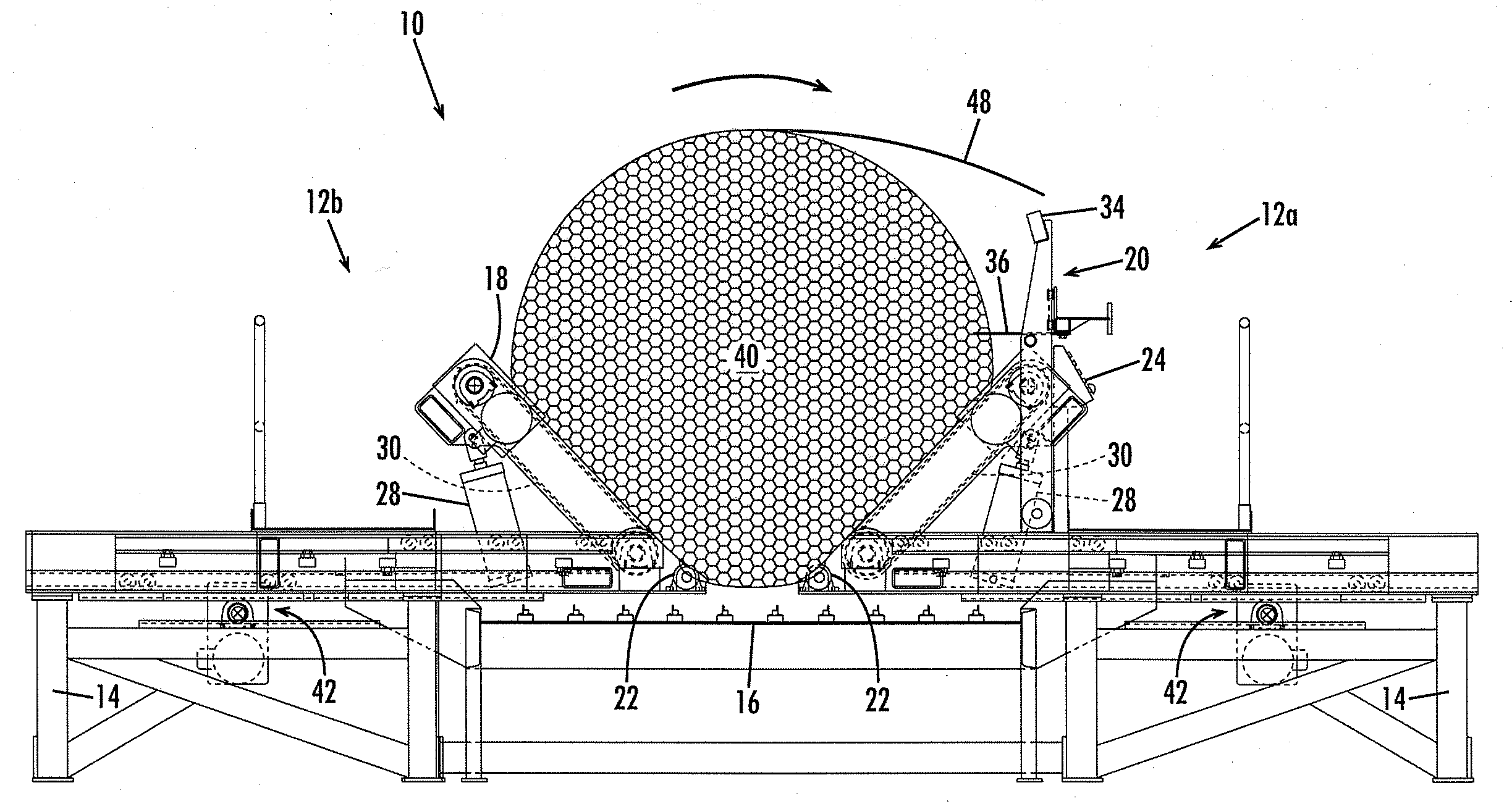

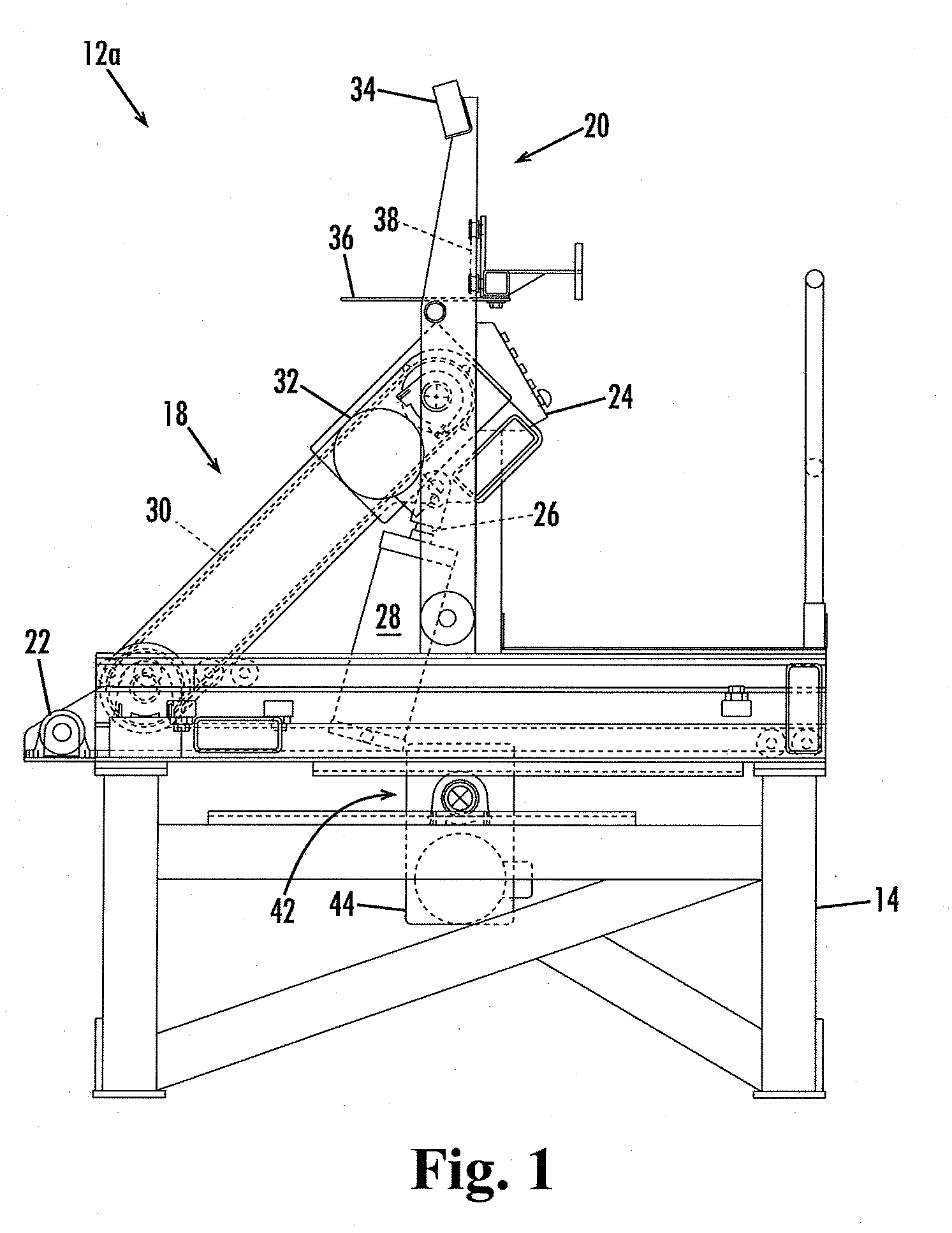

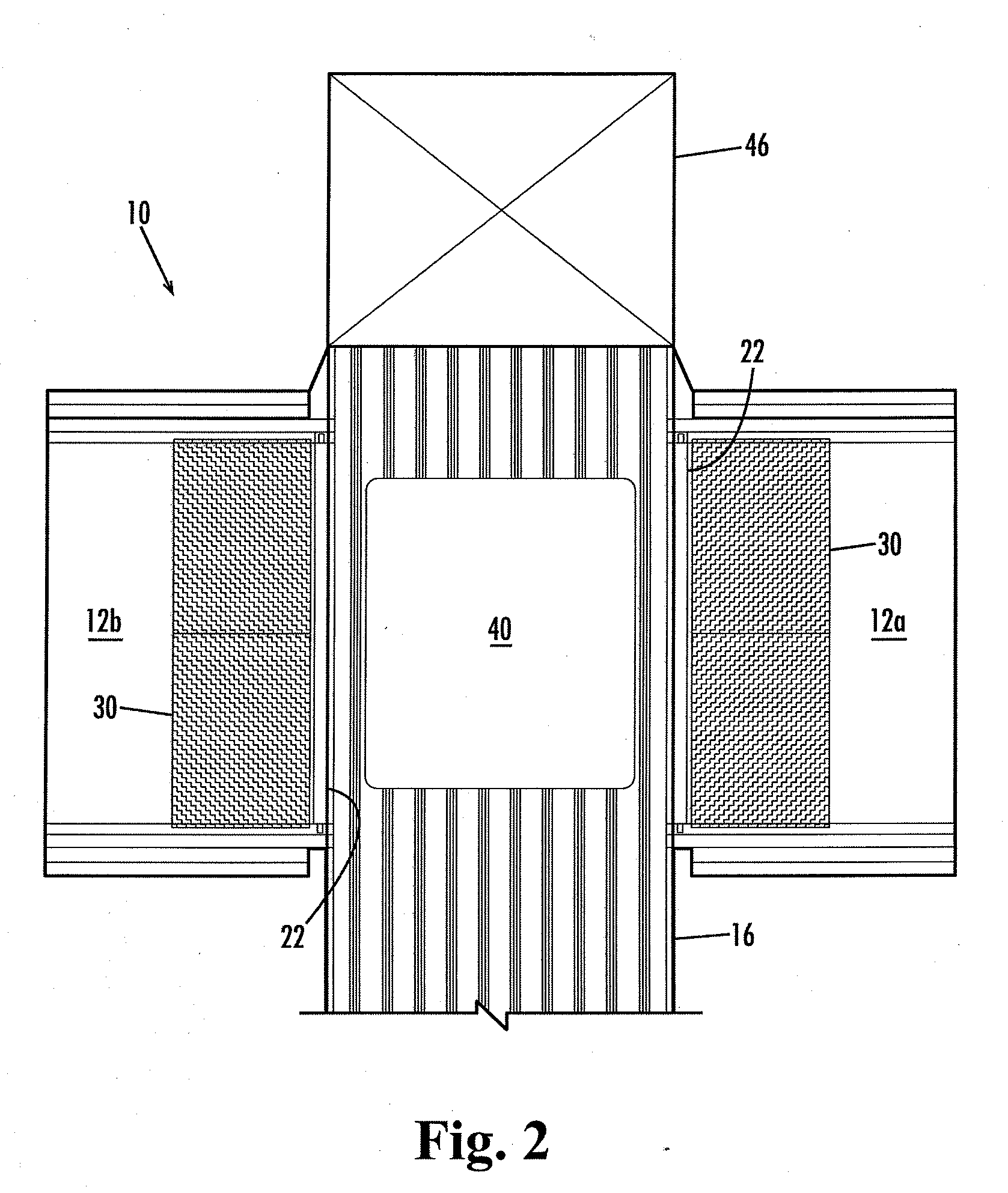

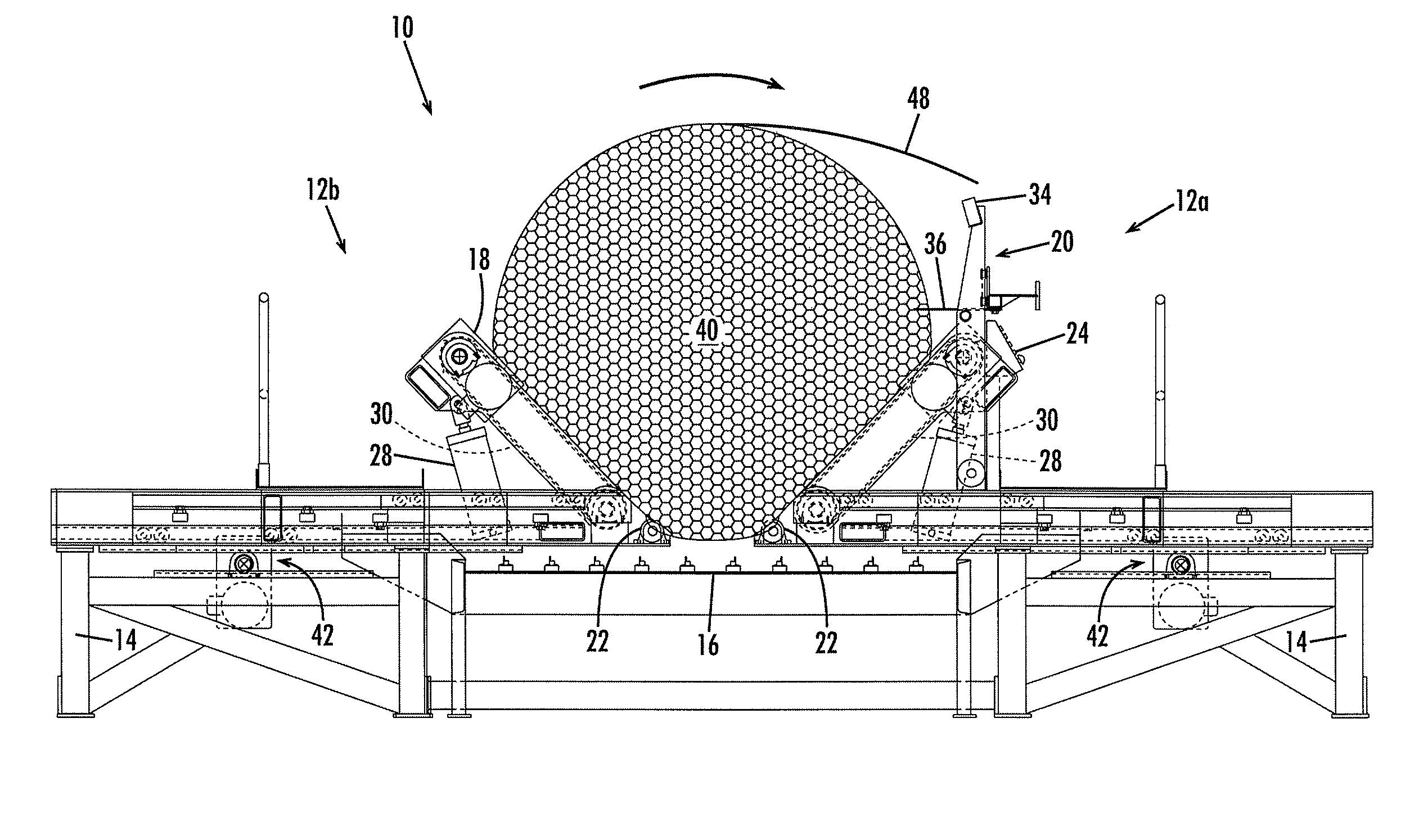

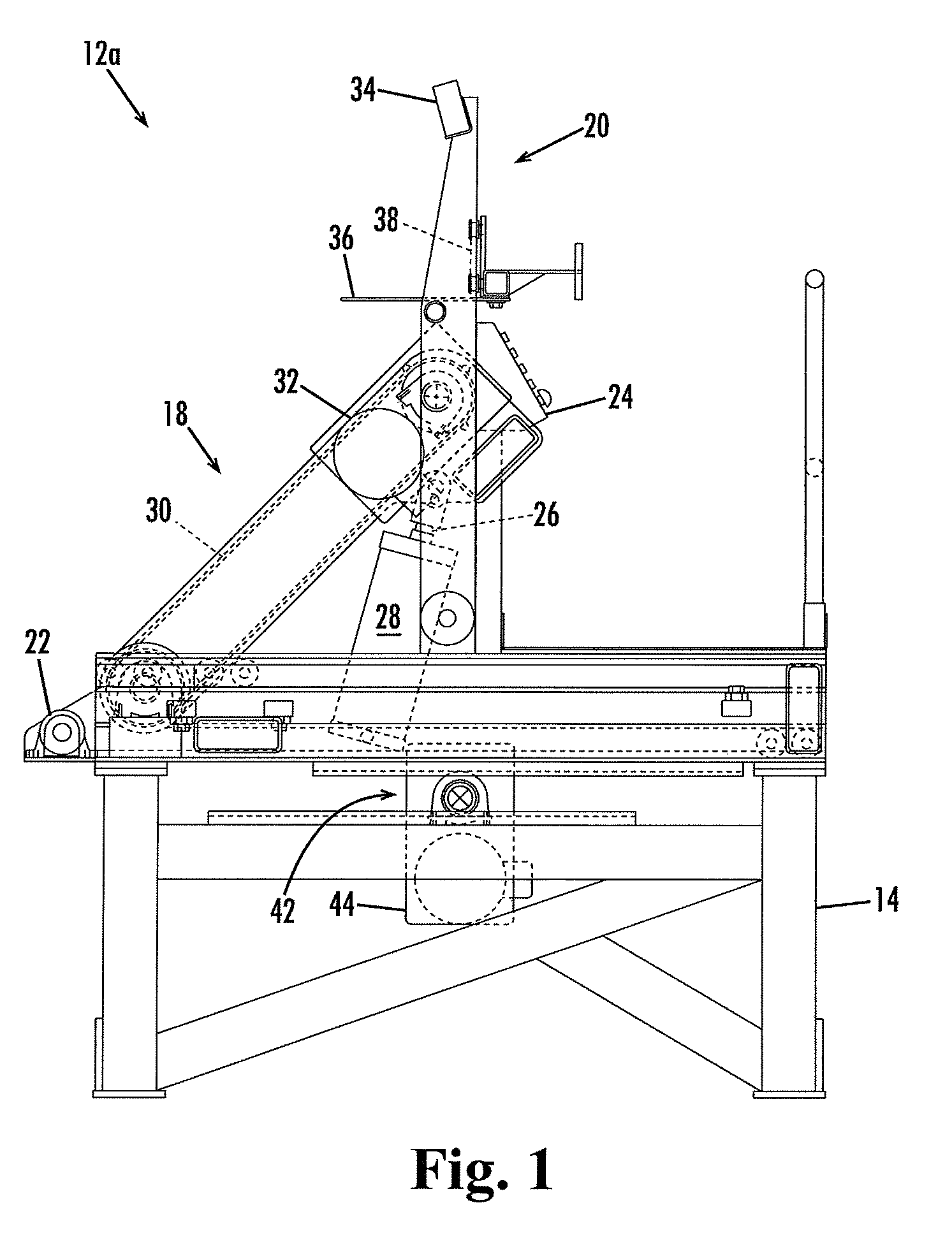

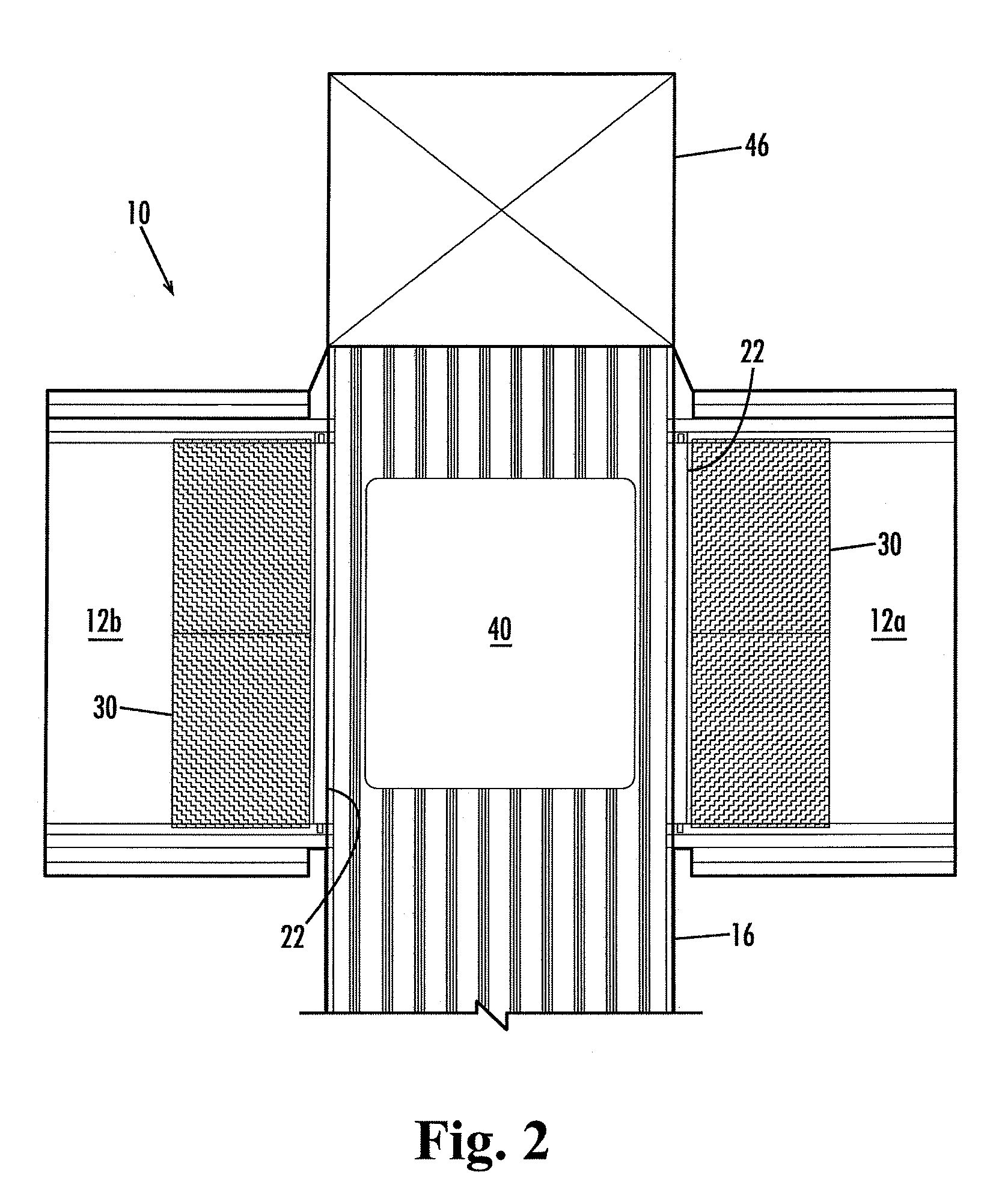

Round cotton module opener

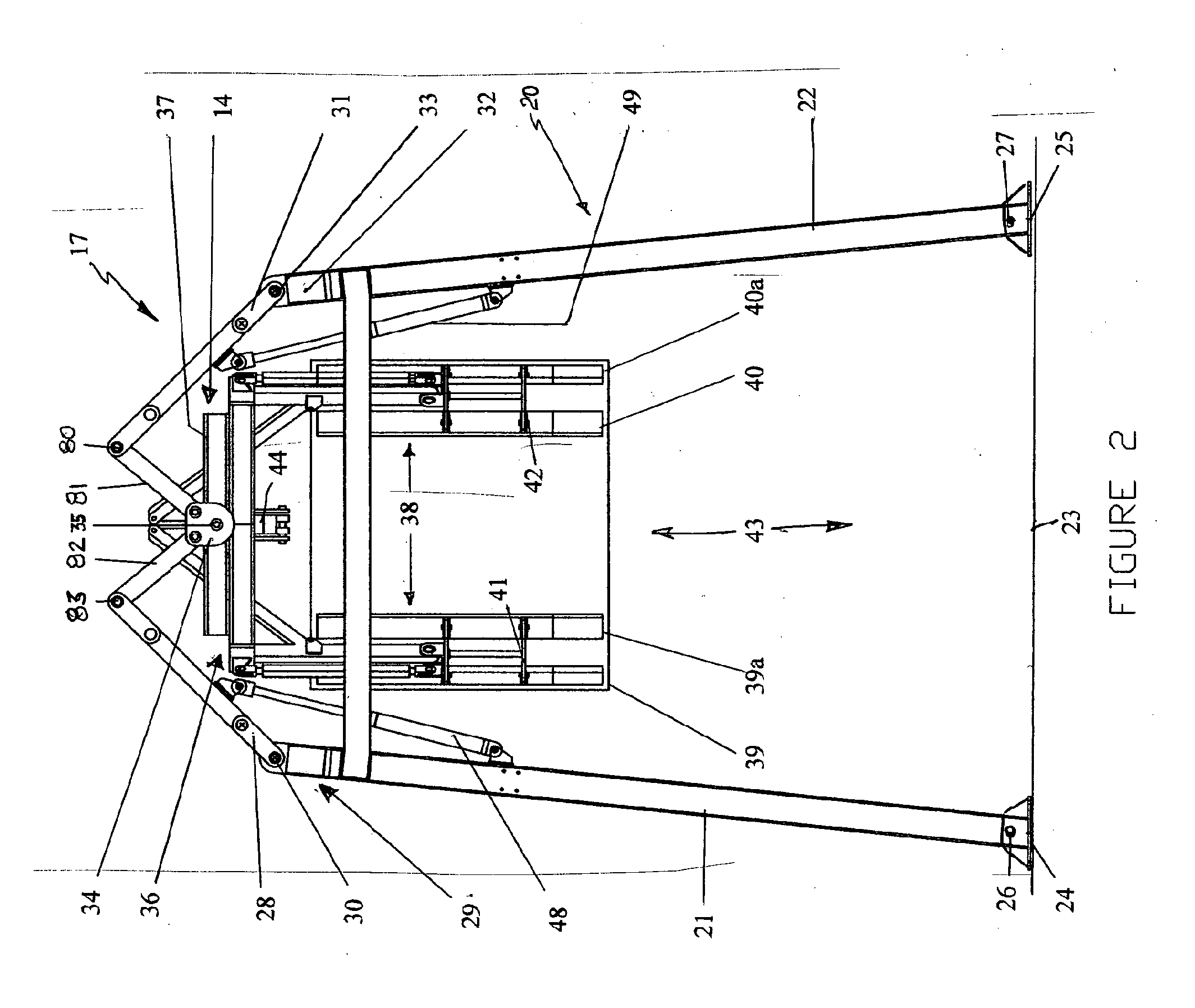

A round module opener for use with a round module of cotton including a first cradle movably mounted to a first frame, the first cradle including a first peeler belt that is configured for rotary motion, and a second cradle movably mounted to a second frame, the second cradle including a second peeler belt that it configured for rotary motion. The first cradle and the second cradle are disposed on opposing sides of a feeder bed such that the first cradle and the second cradle can be moved inwardly toward each other and toward a longitudinal centerline of the feeder bed to engage the round module of cotton.

Owner:CTC DESIGN

Round cotton module opener

A round module opener for use with a round module of cotton including a first cradle movably mounted to a first frame, the first cradle including a first peeler belt that is configured for rotary motion, and a second cradle movably mounted to a second frame, the second cradle including a second peeler belt that it configured for rotary motion. The first cradle and the second cradle are disposed on opposing sides of a feeder bed such that the first cradle and the second cradle can be moved inwardly toward each other and toward a longitudinal centerline of the feeder bed to engage the round module of cotton.

Owner:CTC DESIGN

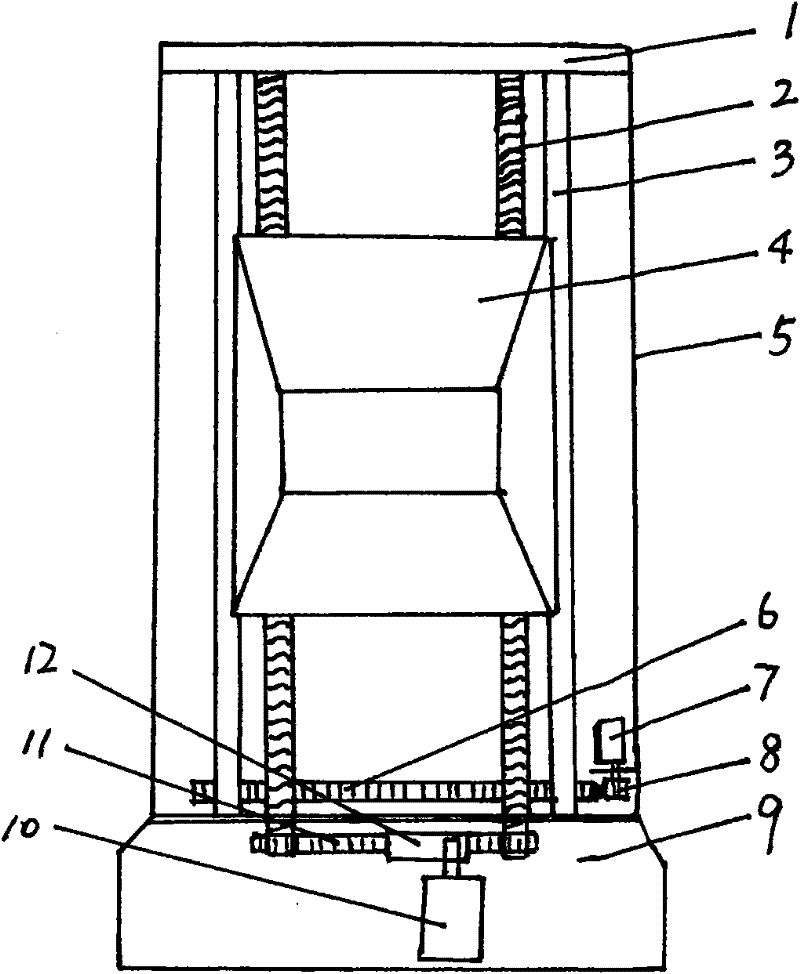

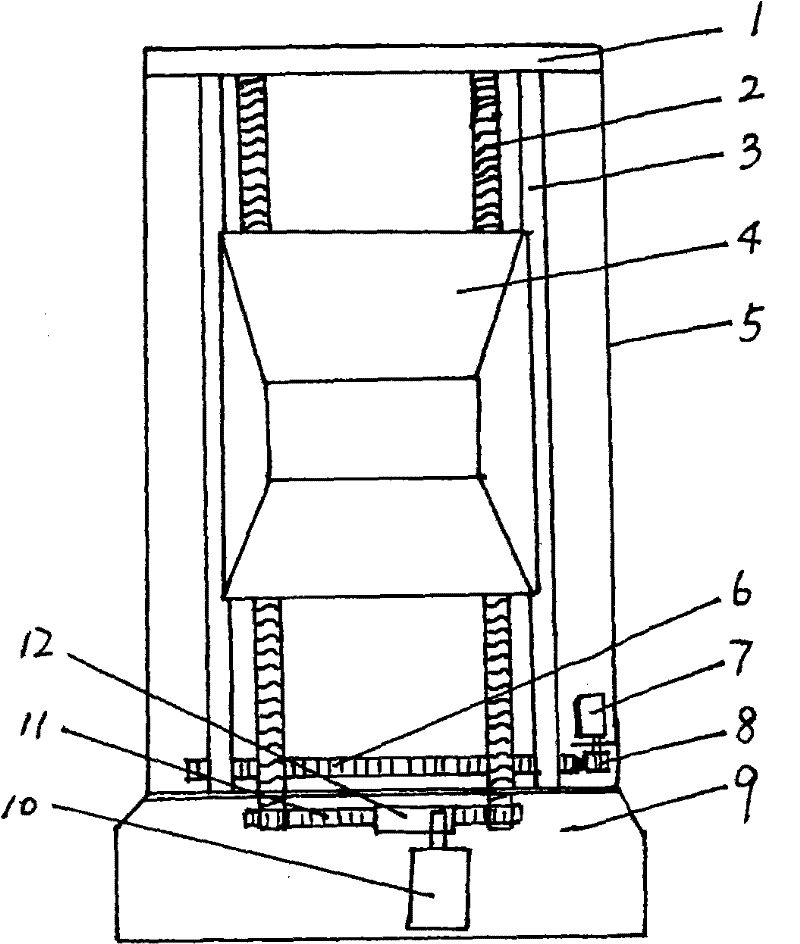

Electric positive-negative rotation double-screw-rod lifting type automatic plucker mechanical device

InactiveCN102409436AAdjustable lifting speedImprove stabilityFibre breakingAutomatic controlElectric motor

The invention relates to an automatic plucker mechanical device, in particular to an electric positive-negative rotation double-screw-rod lifting type automatic plucker mechanical device, which is characterized in that a top cover and a base are connected through an integral support frame, two lifting screw rods are vertically and fixedly arranged between the top cover and the base, two rolling wheel posts are vertically and fixedly arranged between the top cover and the base, a double-screw-rod lifting plucker is connected with the lifting screw rods through lifting screw nuts, rolling wheels arranged on the double-screw-rod lifting plucker are connected with the rolling wheel posts, a driving gear rotating motor is connected with a driving gear, the driving gear is connected with a driven gear, a screw rod rotating motor is connected with a gearbox, the gearbox is connected with a chain, and the chain is connected with the lifting screw rods. Because of the adoption of the technical scheme, the automatic plucker mechanical device has the advantages and positive effects that the lifting speed is adjustable, the stability is good, the automatic plucker mechanical device can automatically and stably rotate and is firm and durable, and the motors can be manually controlled and can also be automatically controlled through singlechip programming.

Owner:YANCHENG KINGDA TEXTILE MACHINERY MFG

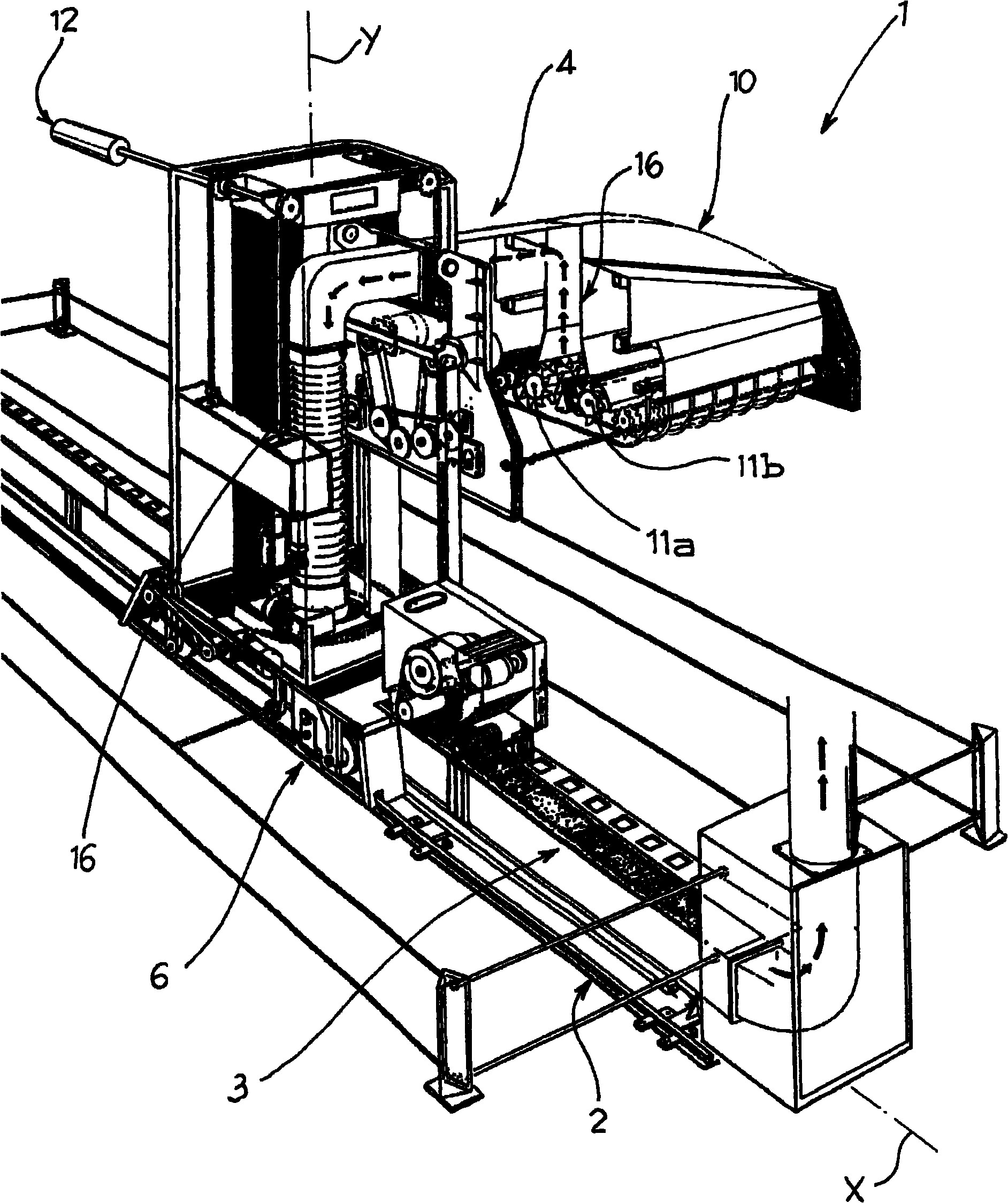

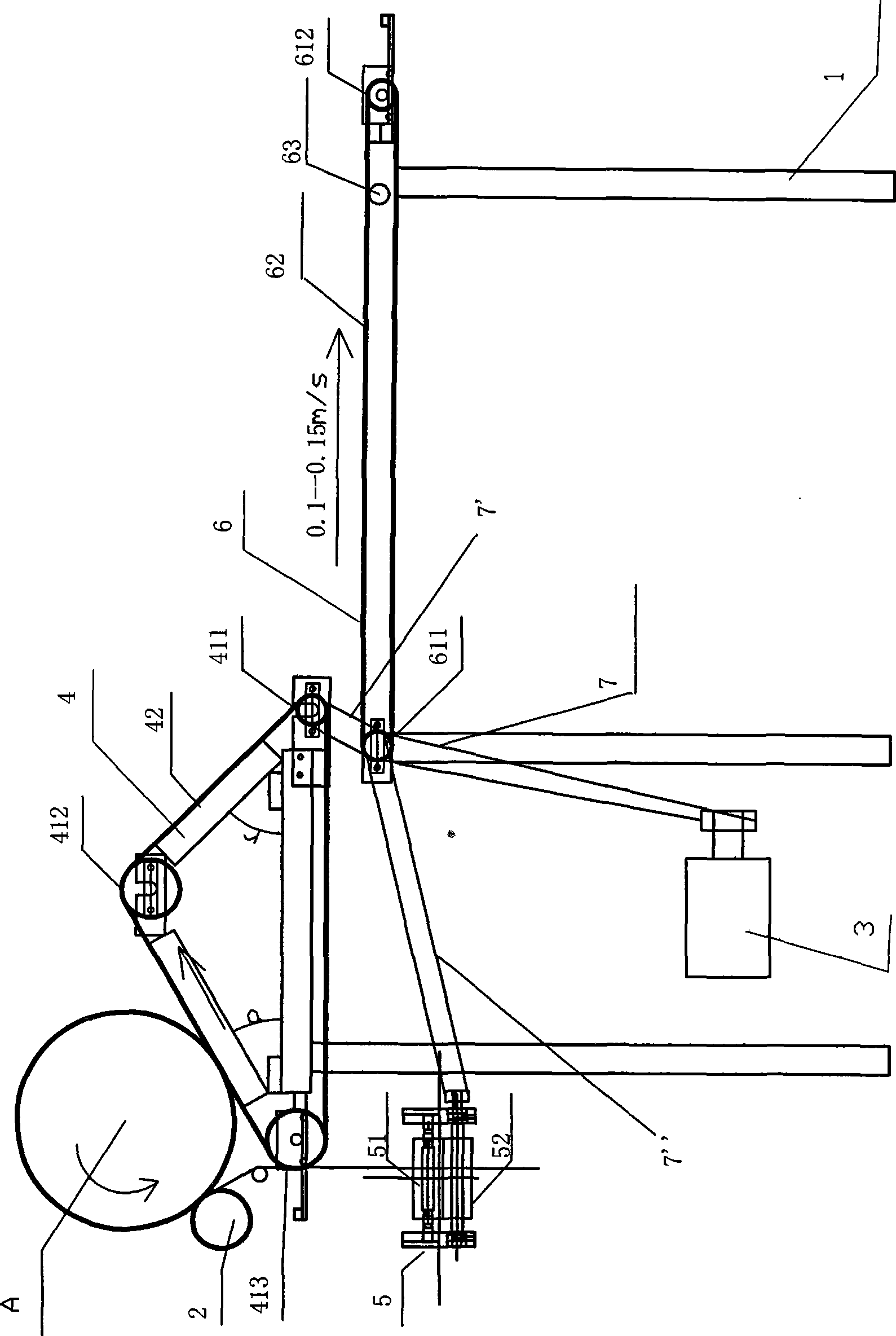

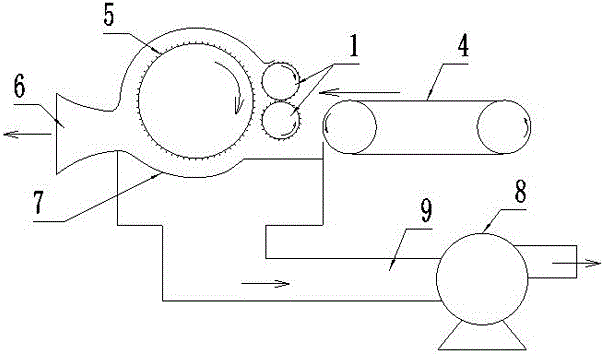

Mechanical device for automatically opening flax round packages from flax

ActiveCN101532192AFlat tow sizeStable tensionHackling machinesFibre breakingTransmission beltEngineering

The invention discloses a mechanical device for automatically opening flax round packages from flax comprising a frame, a guide roller, an electrical motor, and is characterized in that the mechanical device is further provided with a round package uncoil-stand, a string-pulling device and a conveyer device, wherein the electrical motor is connected with the conveyer device via a transmission belt, the conveyer device respectively drives the round package uncoil-stand and the string-pulling device, the round package uncoil-stand is a triangle transmission device consisting of an uncoiling guide roller and an uncoiling belt, the string-pulling device comprises a belt roller and an iron roller, and the conveyer device is a plate-type conveyer device consisting of a conveyer guide roller and a conveyer belt. The invention has high labor efficiency and low labor intensity.

Owner:ZHEJIANG JINYUAN FLAX

Bale opener

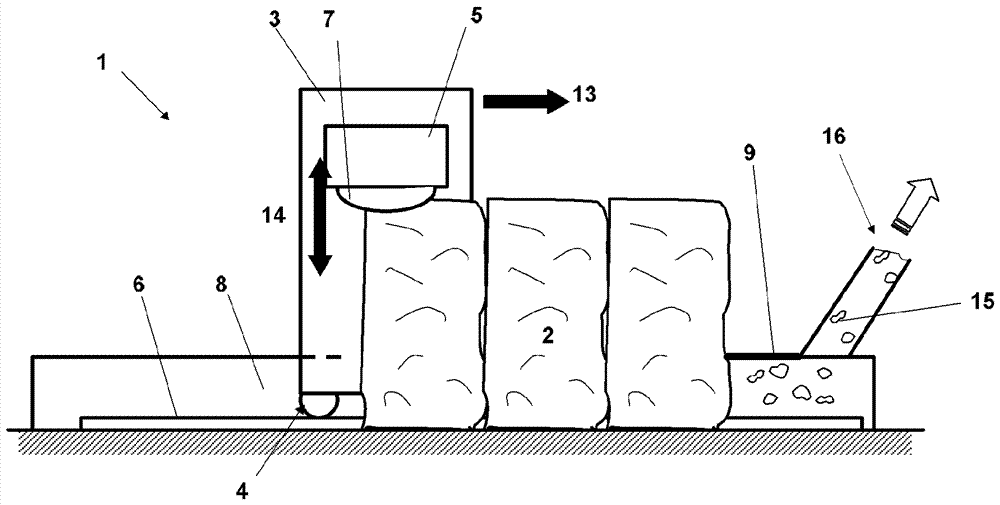

InactiveCN107444724APrevent slidingReduce tractionArticle unpackingFibre breakingMechanical engineeringEngineering

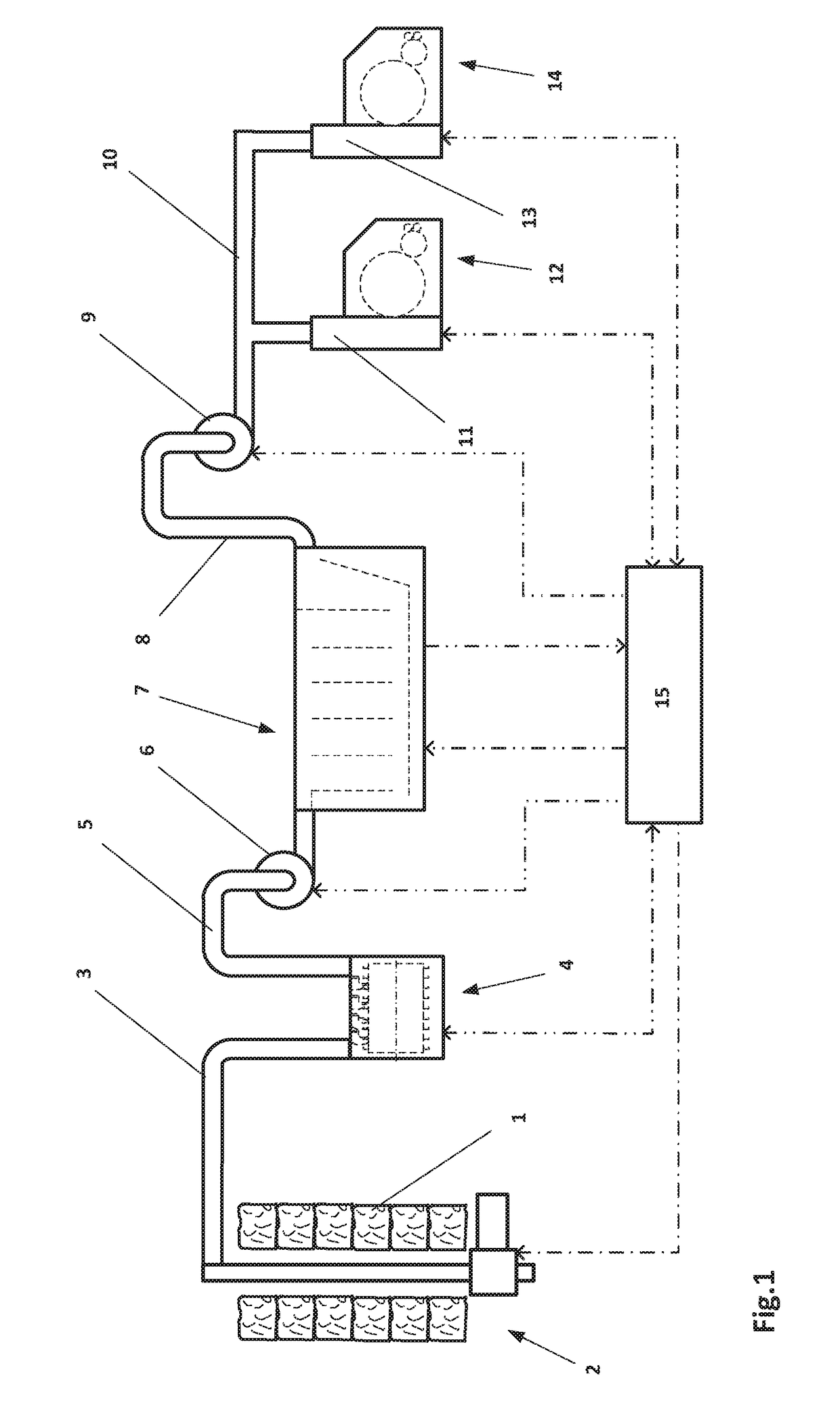

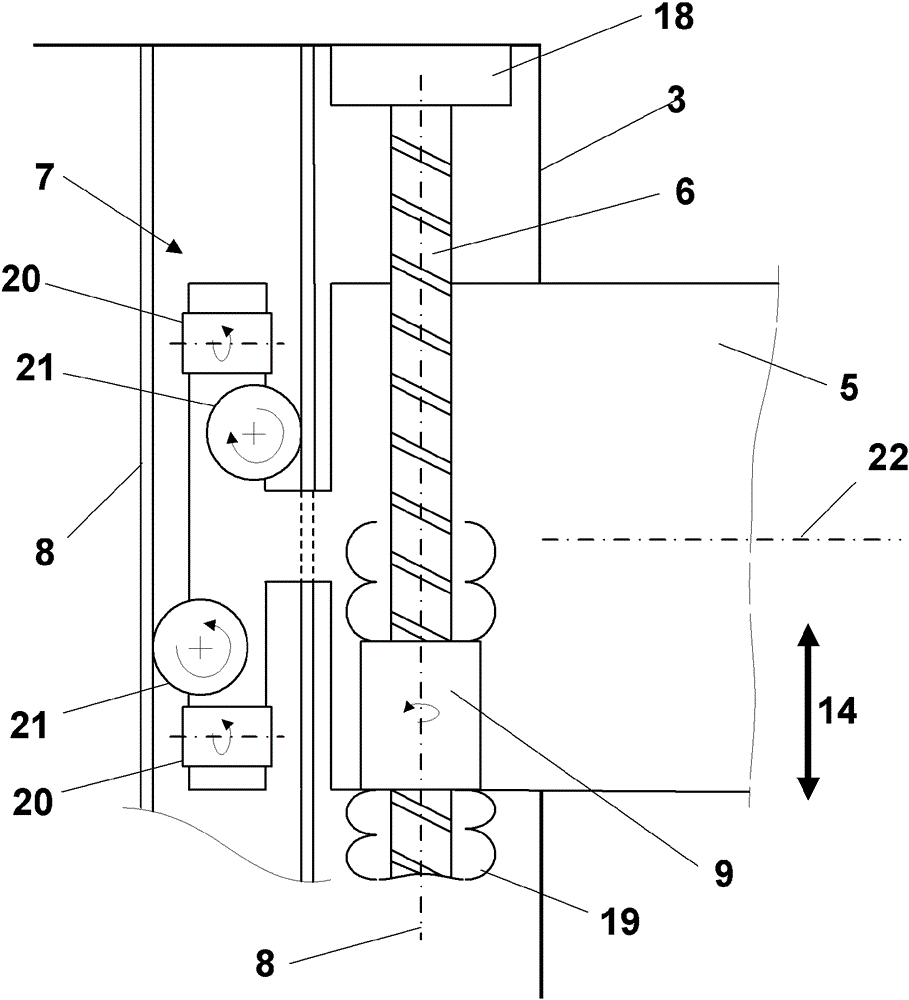

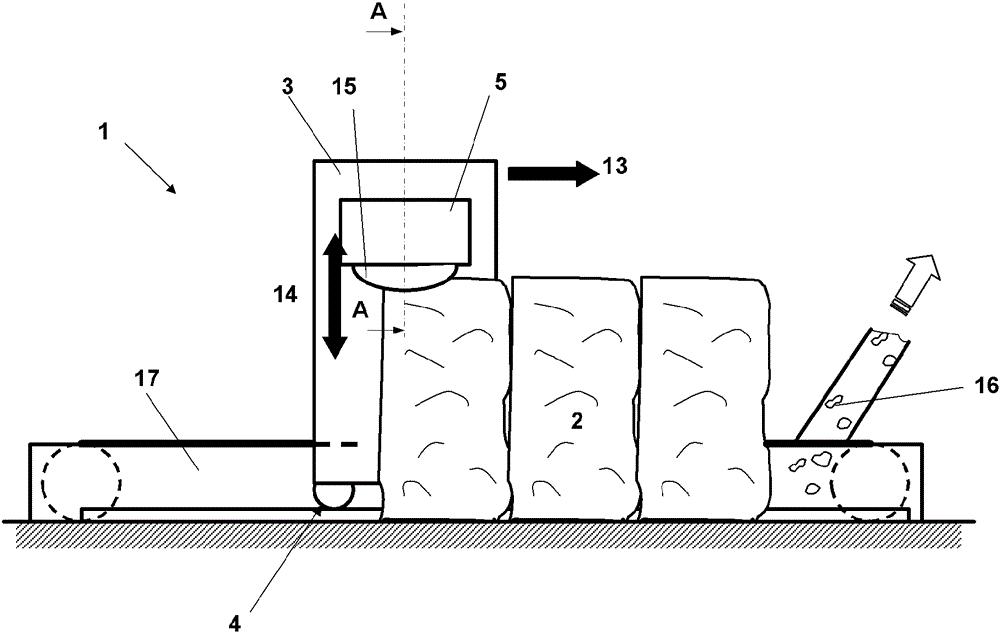

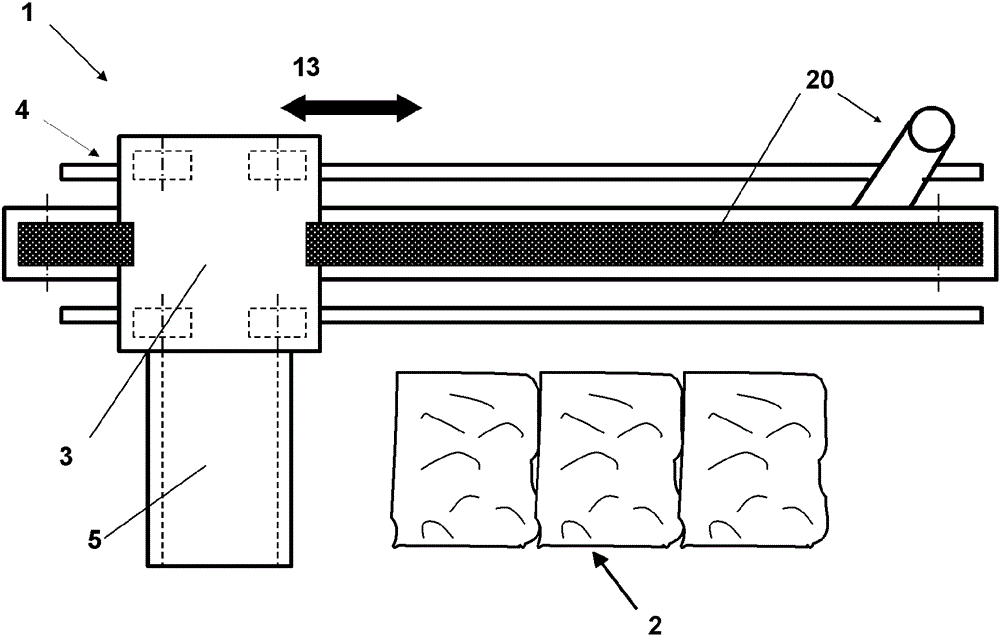

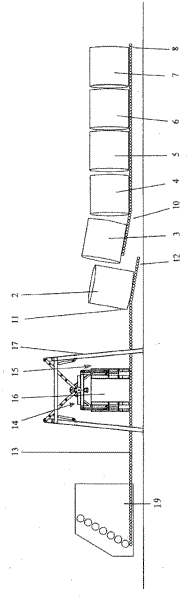

The invention relates to a bale opener (1) for detaching a fiber beam (15) from a fiber bale (2). The bale opener is provided with a transmission device (4) and a detacher tower (3) which is arranged on the transmission device (4). The bale opener is provided with a detacher arm (5), a detacher roller (7) which is mounted thereon, and a fiber beam conveying channel (8). The bale opener is provided with a first driving device for performing height adjustment of the detacher arm (5). The bale opener is provided with a second driving device for the detacher roller (7). The bale opener is provided with a second driving device for rotating the detacher tower (3). The bale opener is provided with a fourth driving device and a fifth driving device for the transmission device (4). The bale opener is provided with a sixth driving device for expanding a cover (9). The bale opener is provided with the first driving device for height adjustment of the detacher arm (5) and is provided with the second driving device for the detacher roller (7). Furthermore the first driving device and the second driving device are synchronous servo motors.

Owner:MASCHINENFABRIK RIETER AG

Adjustable cotton gripping trolley frame with limiting discs

Owner:唐山晟旭纺织有限公司

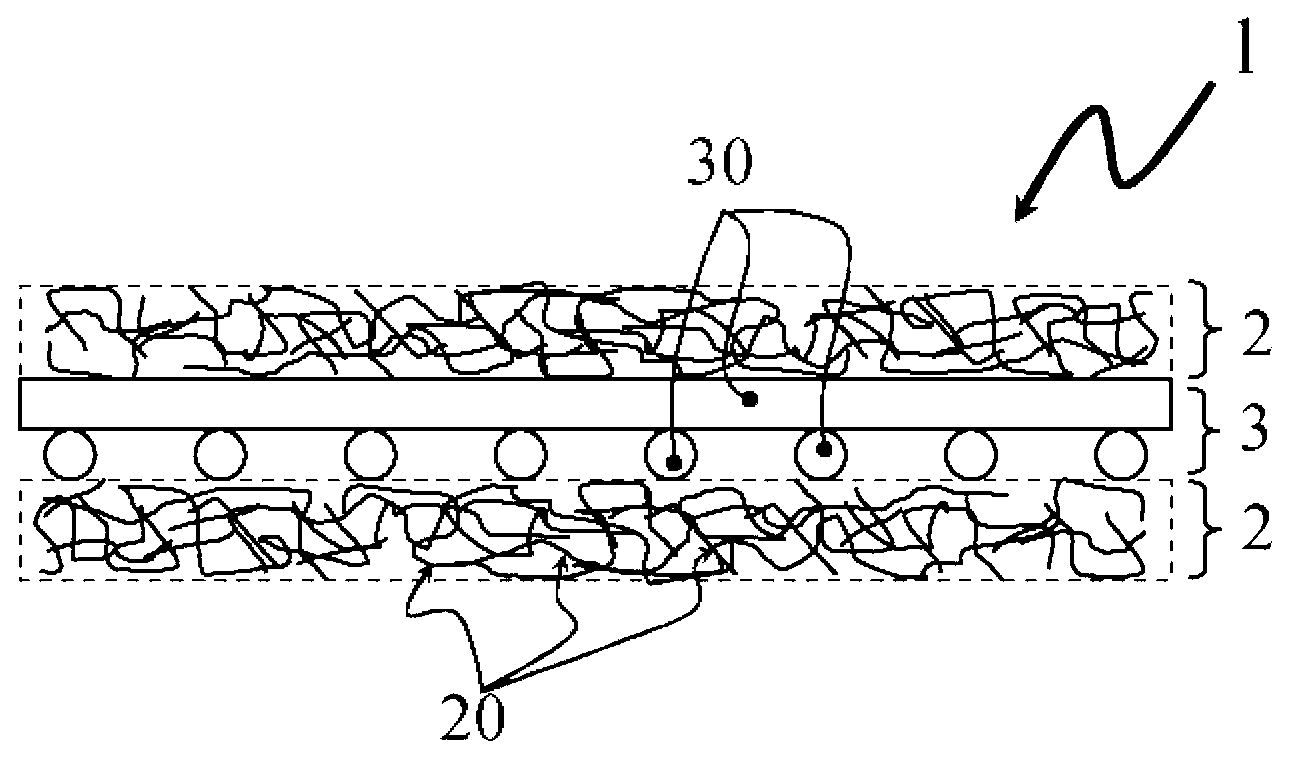

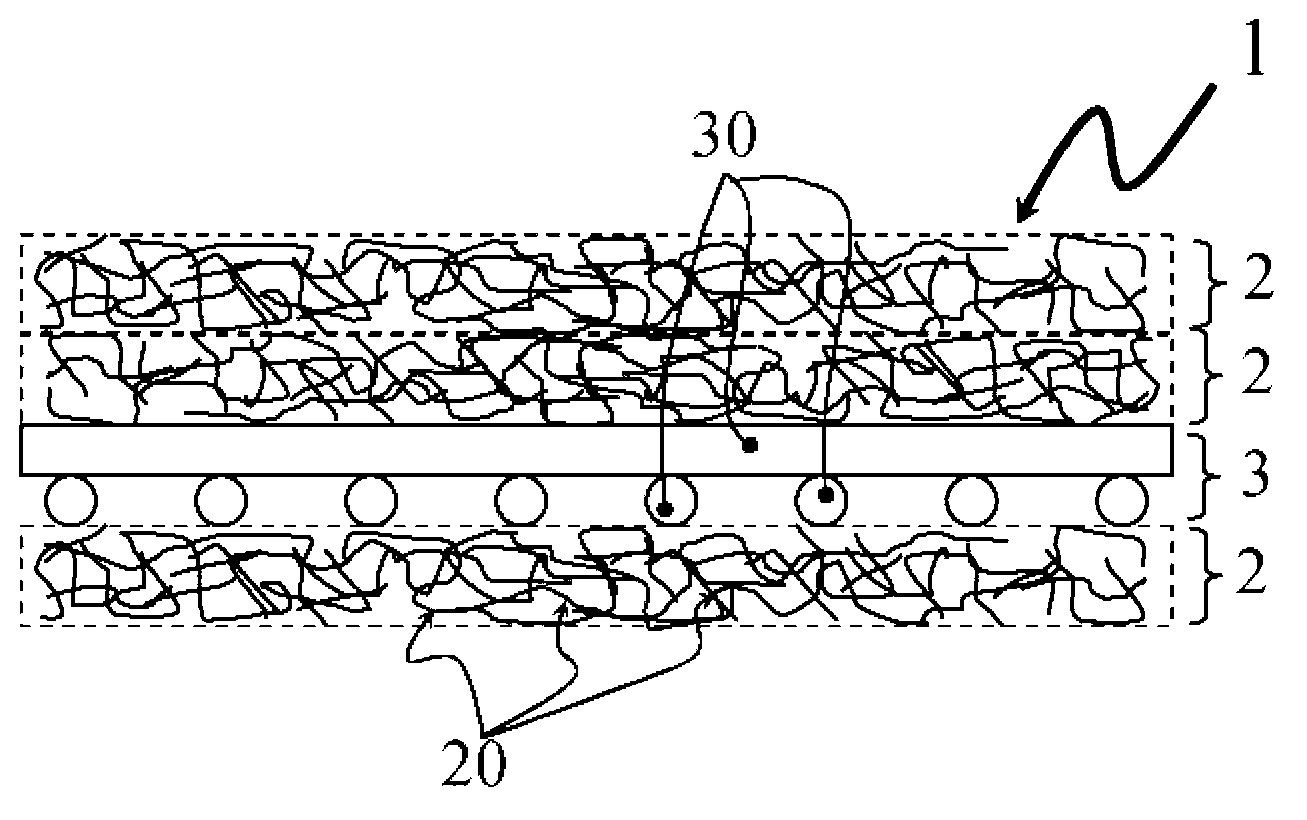

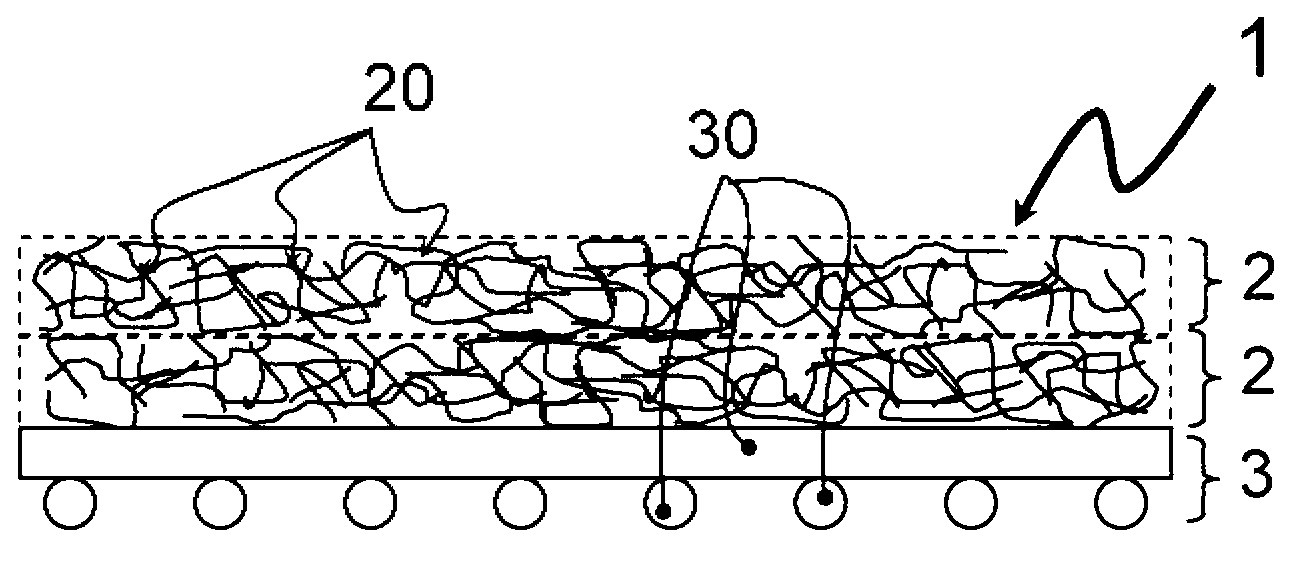

Bamboo fiber mattress core material and production process thereof

PendingCN105640151AImprove product qualityAnti-mite hypoallergenicStuffed mattressesFibre mixingPolyesterYarn

The invention discloses a bamboo fiber mattress core material and a production process thereof, and relates to the technical field of soft furniture product production. The bamboo fiber mattress core material comprises bamboo fiber, polyester staple fiber and polyester fiber. The production process comprises the following production process steps of metering and material preparation, mixing and impurity removal, net paving, baking and pressing, cooling and shaping, and cutting to obtain a finished product. A three-dimensional reticular structure is manufactured; reticular palm yarns are subjected to cooling and shaping after high-temperature drying; finally, edge cutting is performed to obtain the finished product. Any auxiliary agents and adhesives are not added in the production process; any pollution does not exist; the green and environment-friendly effects are achieved. The produced bamboo fiber mattress core material has a three-dimensional space reticular structure. The mattress made of the bamboo fiber mattress core material has the safety characteristics of no irritation, anti-mite performance, and allergy prevention. Moisture sent by the human body during the sleeping can be fast discharged in the use process; the ventilation and damp-proof effects are achieved; the use is comfortable, dry and cool in summer.

Owner:河北自然梦家具有限公司

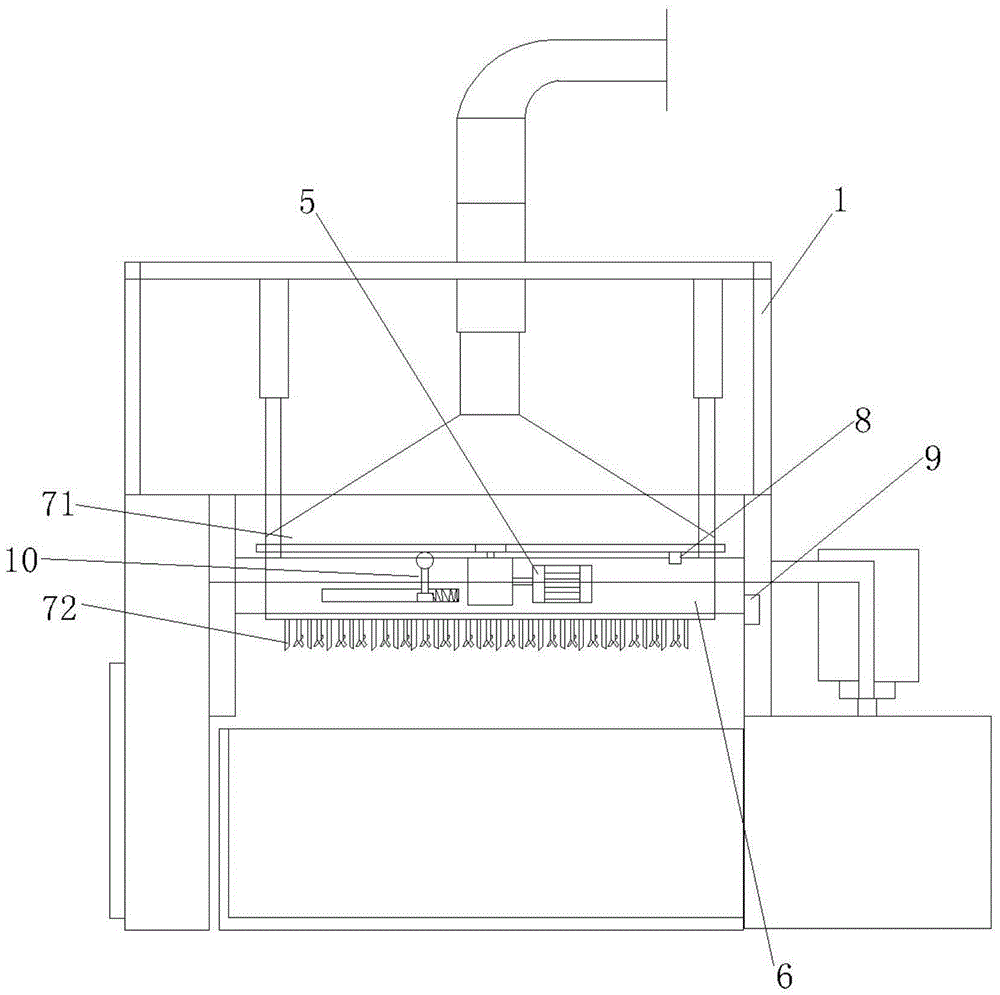

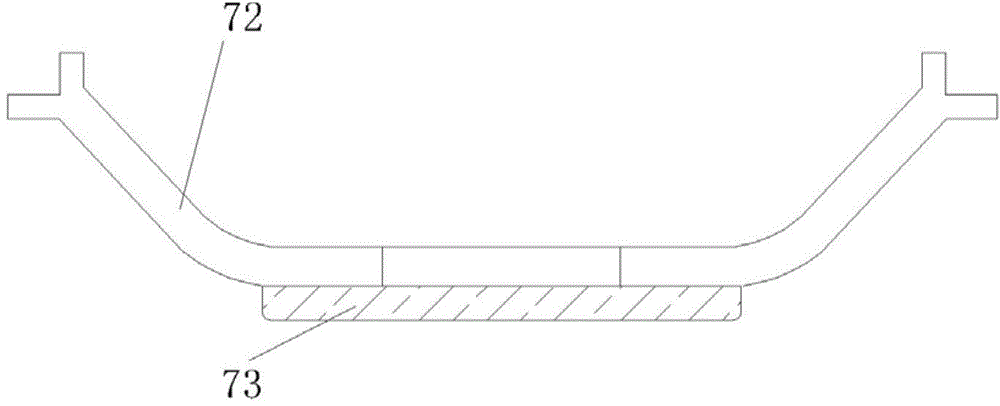

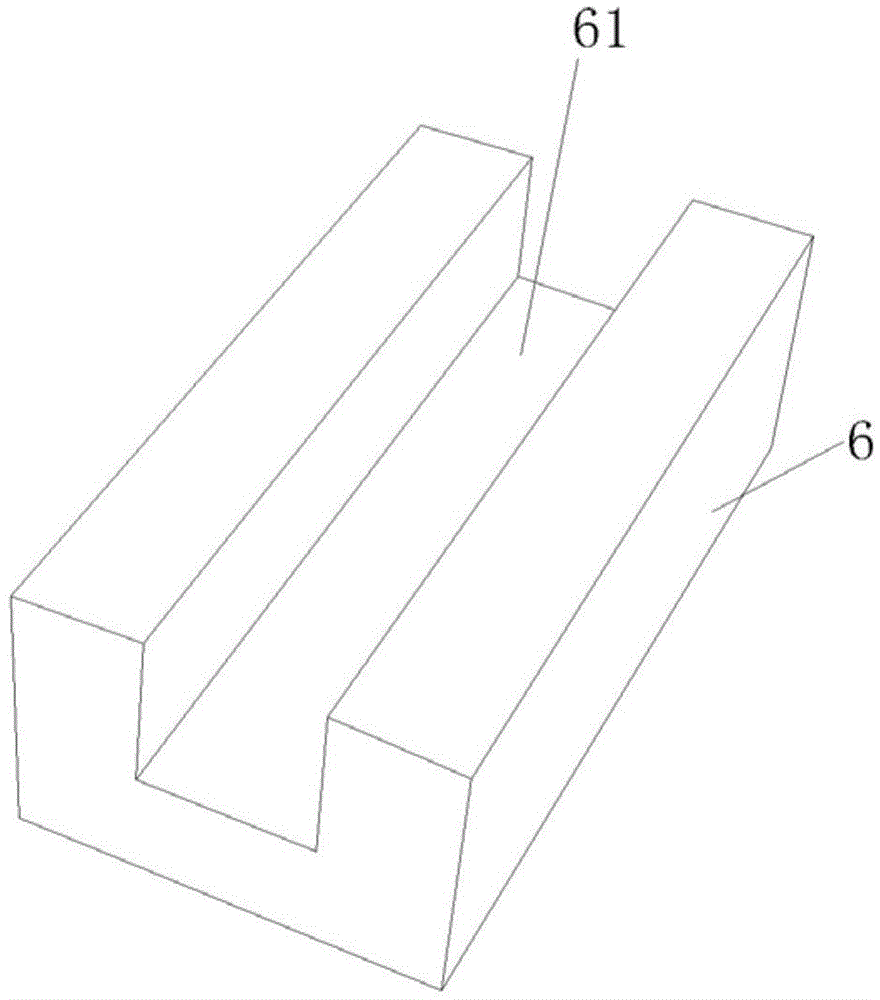

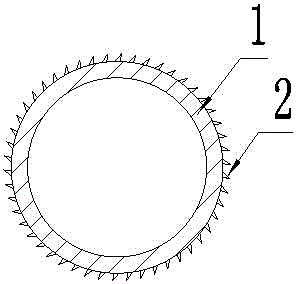

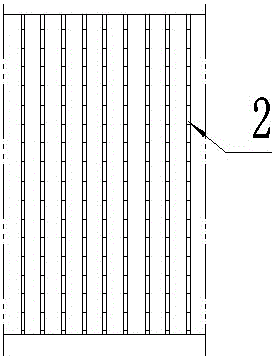

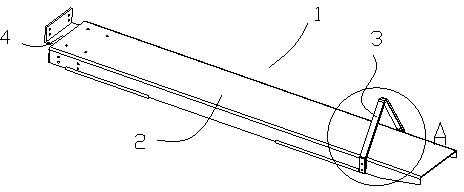

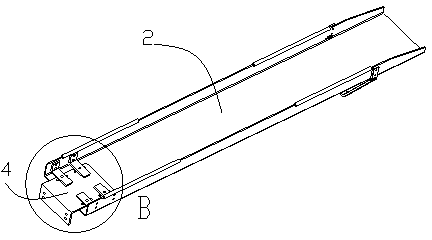

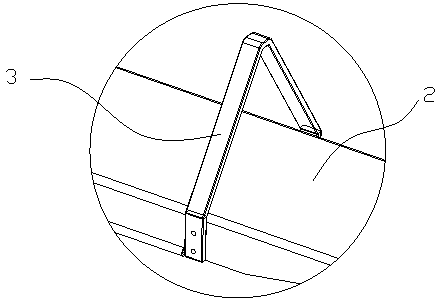

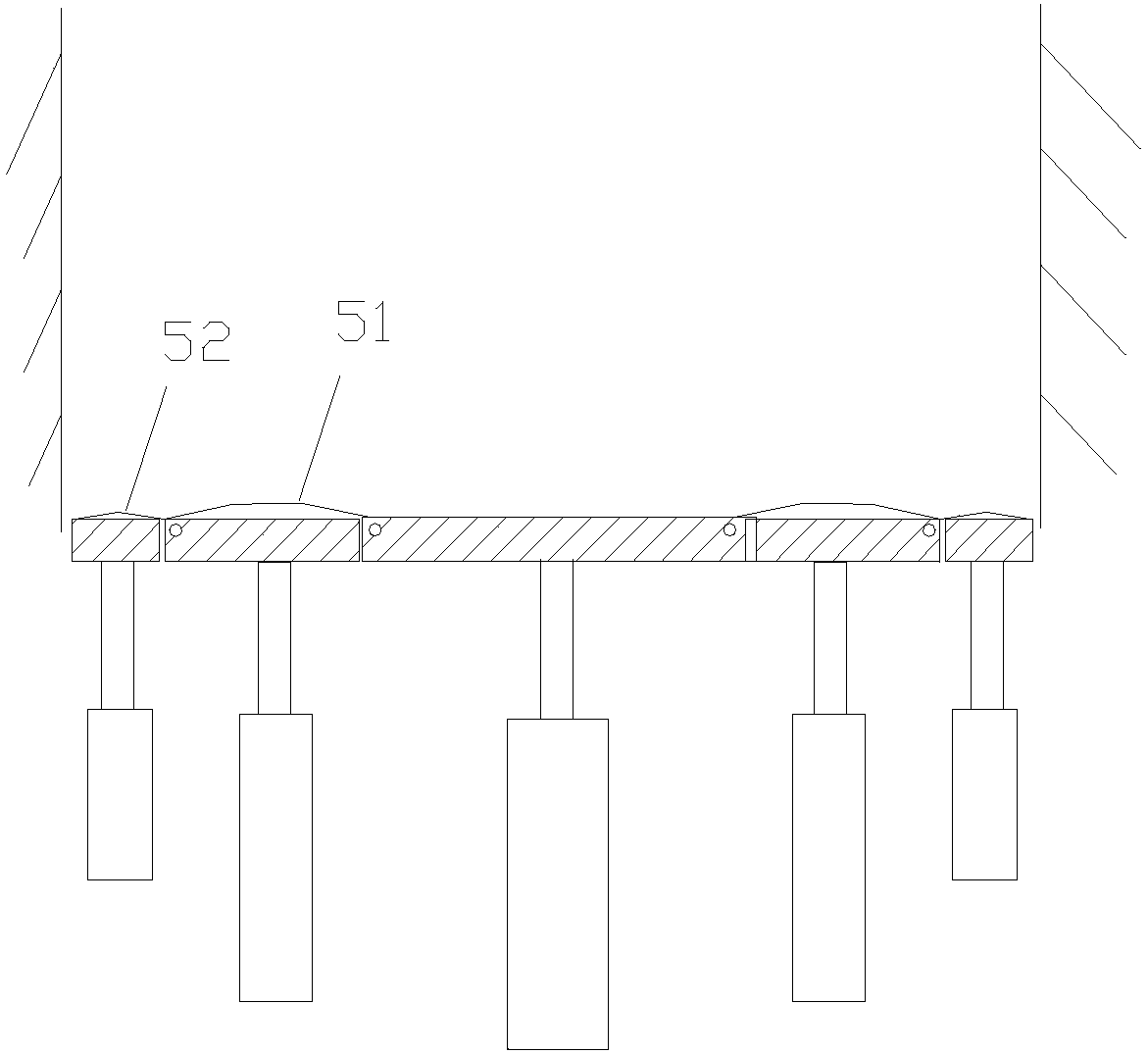

Plucking bed device of bale plucker

The invention discloses a plucking bed device of a bale plucker. The plucking bed device of the bale plucker comprises a strip-shaped plucking bed base plate, the head portion of the plucking bed base plate is provided with a triangular suspension support, the tail portion of the plucking bed base plate is provided with a dismountable fixing seat plate, the base surface of the tail portion of the plucking bed base plate is provided with four L-shaped connecting pieces, and the fixing seat plate is fixedly connected with the connecting pieces through screws. According to the plucking bed device of the bale plucker, by means of adjusting long holes and the L-shaped connecting pieces on the fixing seat plate, a user can adjust the relative lengths of the fixing seat plate and the plucking bed base plate to process raw cotton in different sizes, so that the application range of the bale plucker can be greatly expanded, and high practicality can be obtained.

Owner:赵静

Disc type plucker for spinning process

InactiveCN109371509AEasy to cleanAvoid damageFibre cleaning/openingFibre breakingEngineeringDrive motor

The invention relates to the technical field of pluckers and discloses a disc type plucker for a spinning process. The plucker comprises a supporting device, impurity removing pipes and adsorption columns; a fixing groove is formed in the top of the supporting device, a driving motor is fixedly mounted at the bottom of the inner wall of the fixing groove, a vertical column is also fixedly mountedon an output shaft of the driving motor and fixedly sleeved with an annular sleeve, and transverse columns are fixedly mounted on the left and right sides of the annular sleeve respectively. Accordingto the disc type plucker for the spinning process, through the cooperation among servo motors, cams, linkage plates, the adsorption columns, elastic retractable components and magnetic strips, due tothe downward impact of the cams on the linkage plates and the elasticity of the elastic retractable components, the magnetic stripes with magnetism are driven to adsorb iron impurities in cotton materials, correspondingly the iron impurities in the disc type plucker for the spinning process are removed conveniently, and therefore the iron impurities in the cotton materials are prevented from causing damage.

Owner:章玉春

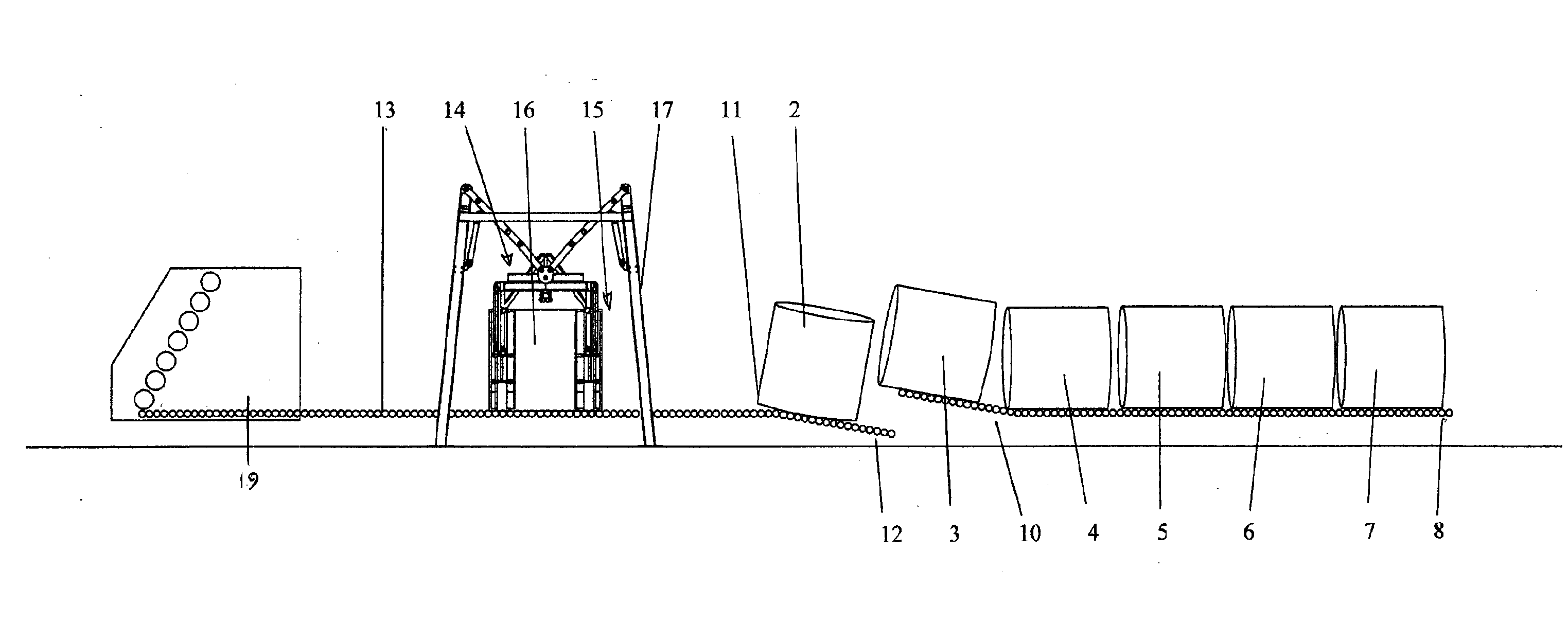

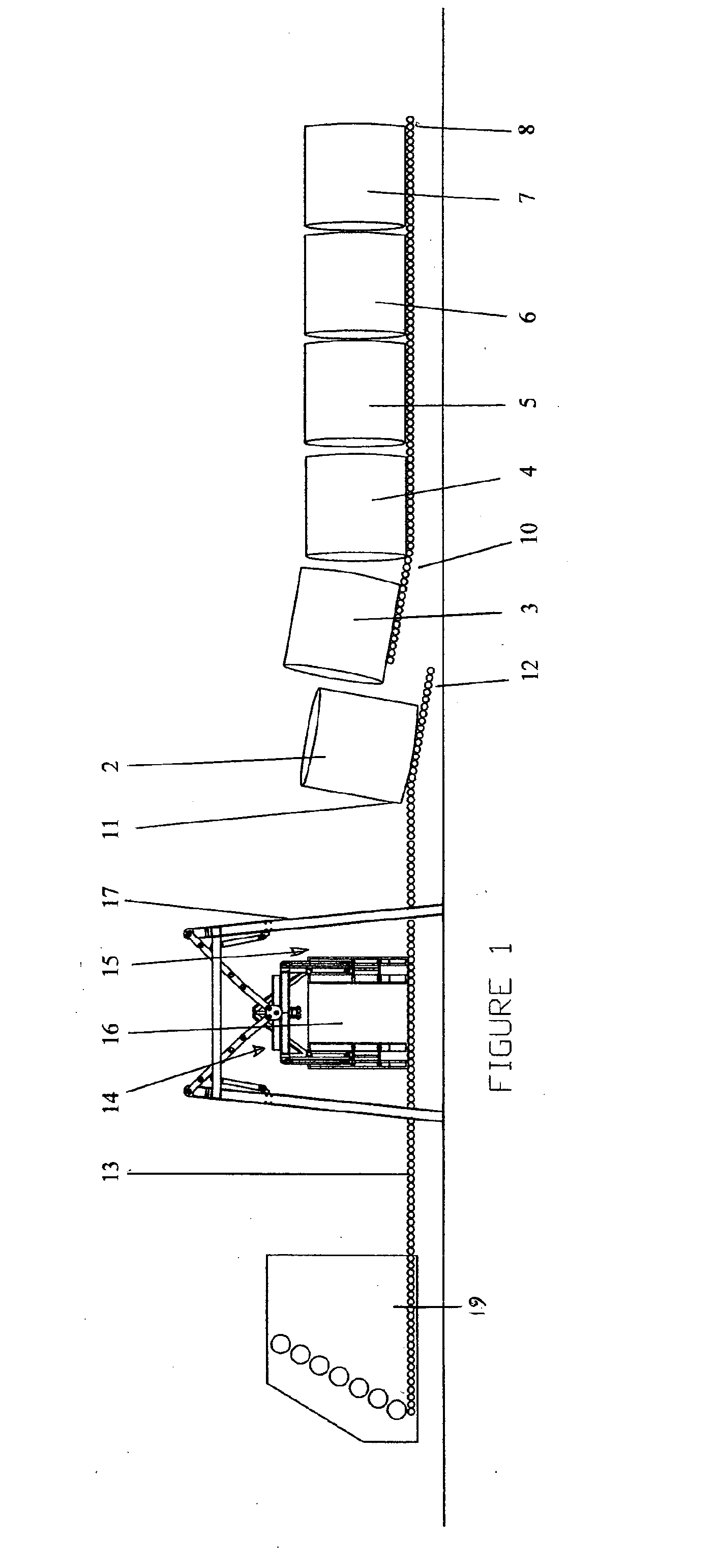

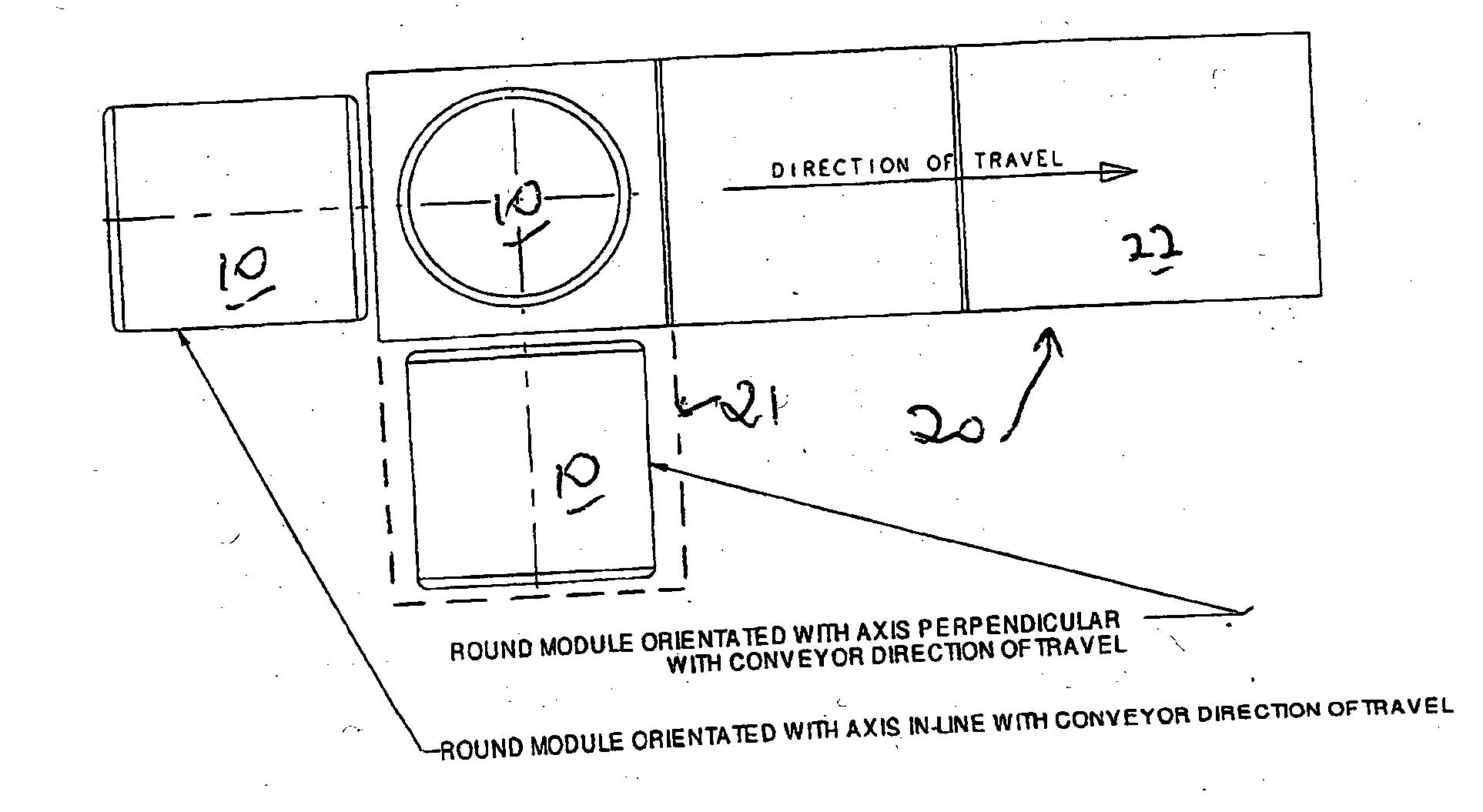

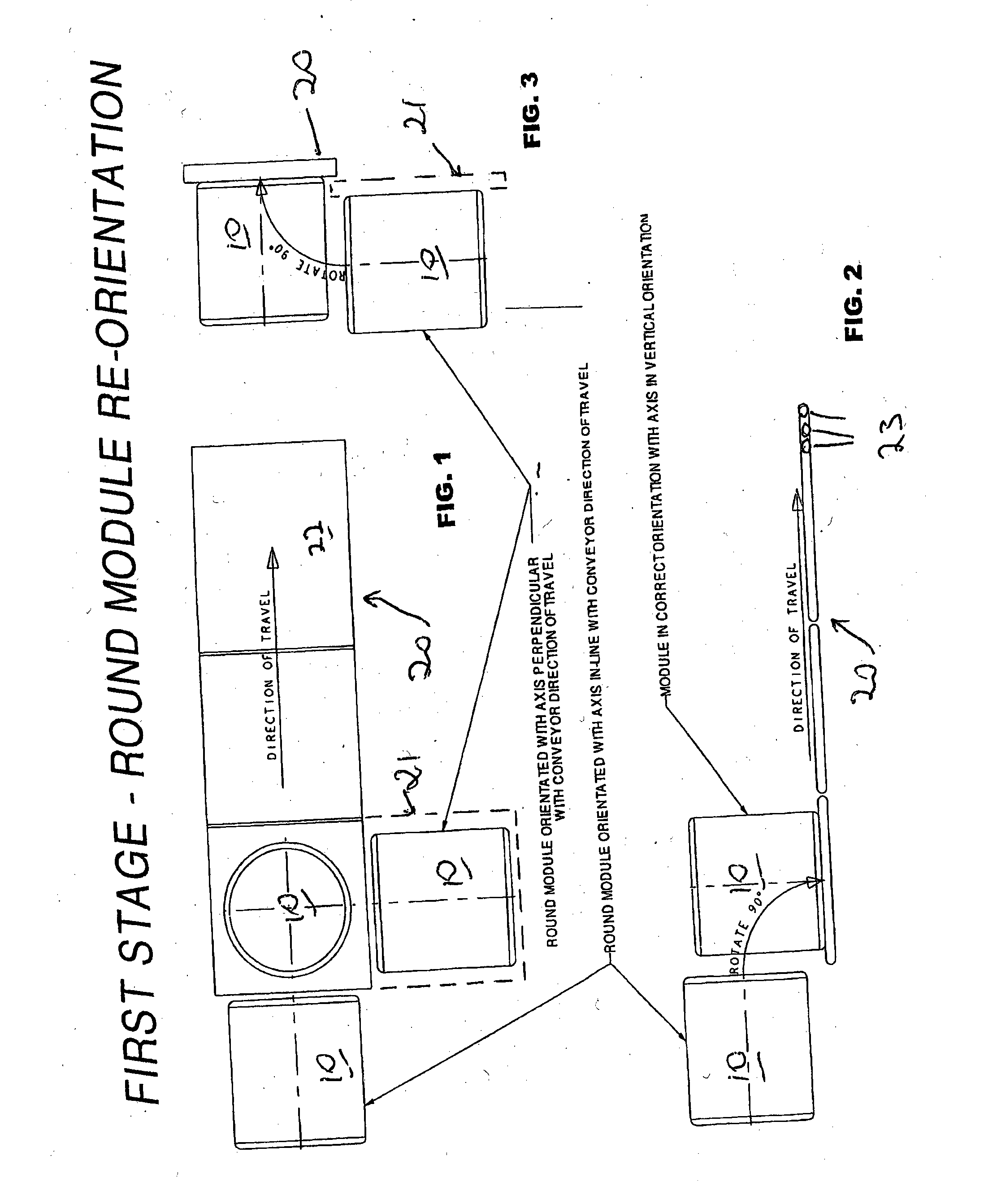

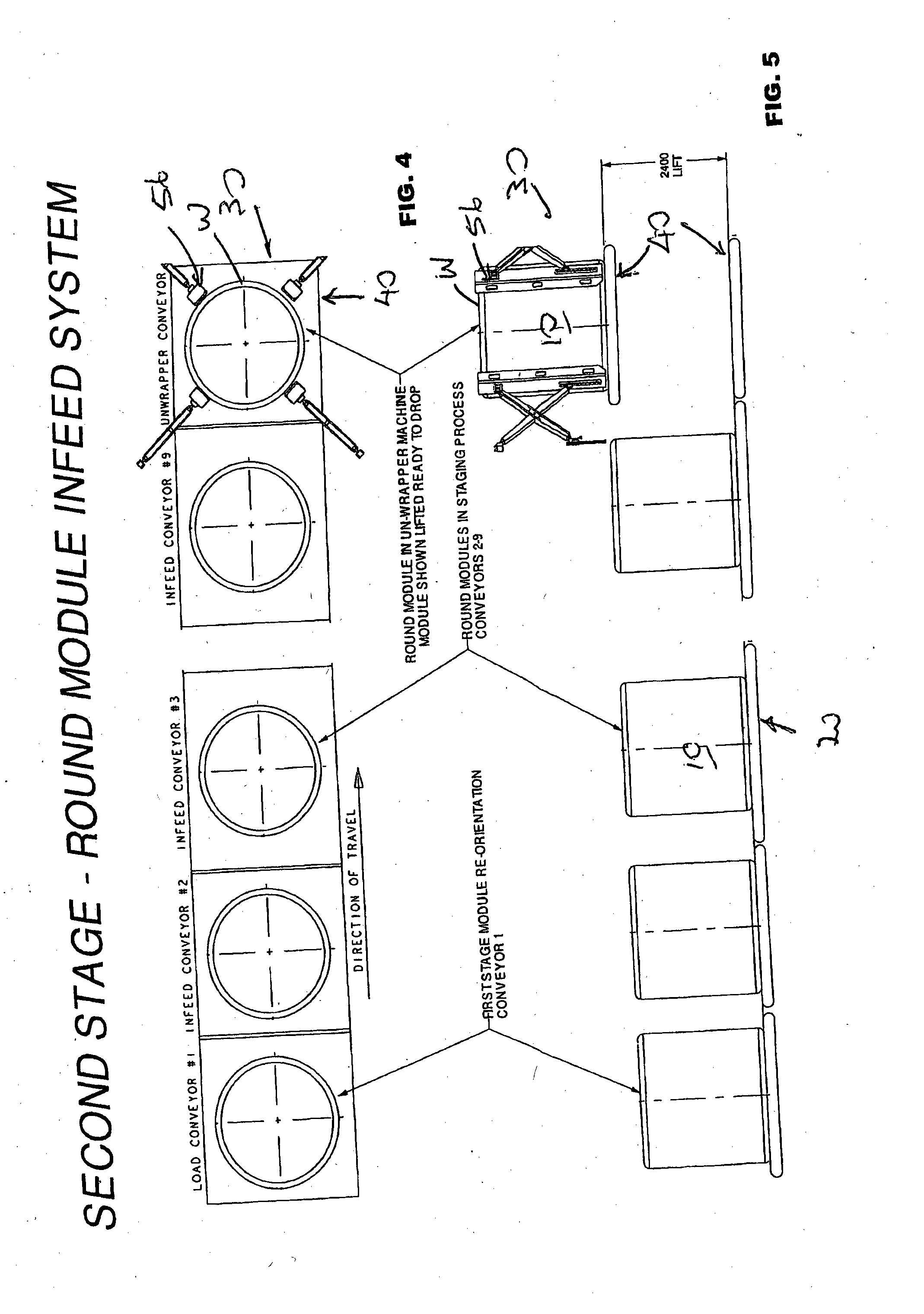

Method and assembly for processing round seed cotton modules

InactiveUS20120219392A1Favorable attitudeArticle unpackingLoading/unloadingEngineeringMechanical engineering

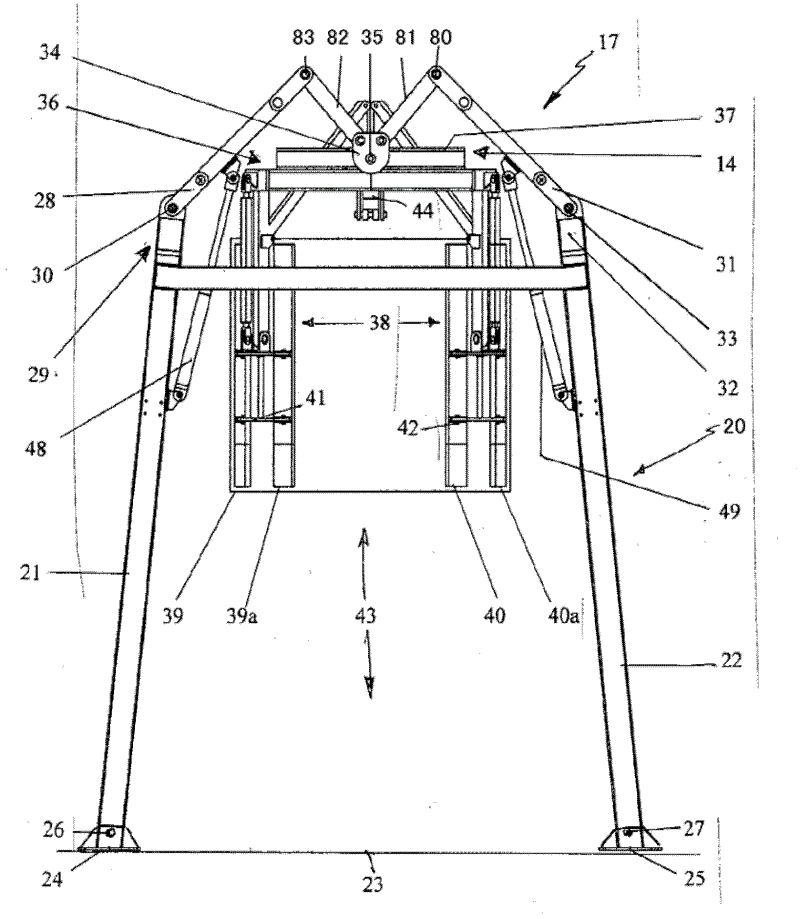

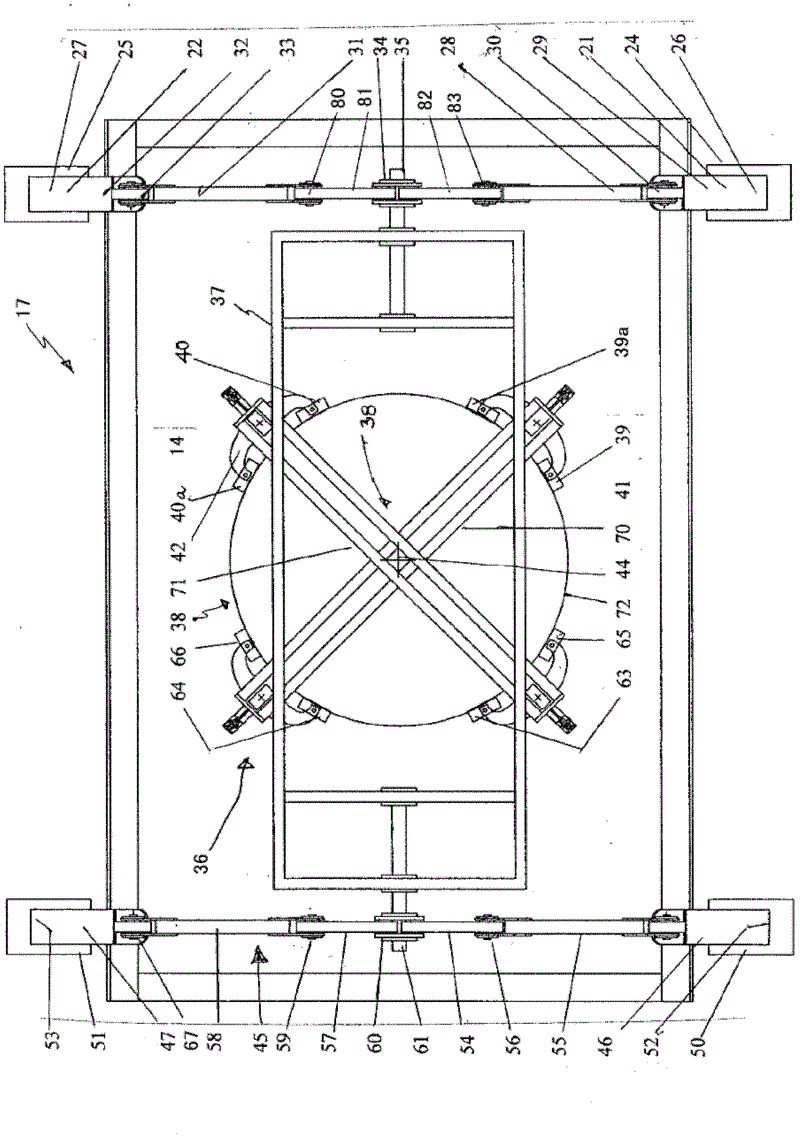

An assembly for enabling the release of produce from a module retained by a plastics sleeve. The apparatus comprises a primary support frame including legs fixed to ground surface via feet. A gantry supports a compression assembly capable of receiving and retaining a module. There are means to enable the compression assembly to move between a non working state in which the compression assembly is elevated above a work station and a working state in which the compression assembly is at a work station in which compression arms are capable of retaining a produce module. The compression assembly includes means to enable the arms to apply a radial force to the module sufficient to allow the compression assembly to remove the plastics sleeve and allow the produce to gravitate through a free end of the module as the plastics sleeve is elevated away from the produce.

Owner:NAMOI COTTON COOP

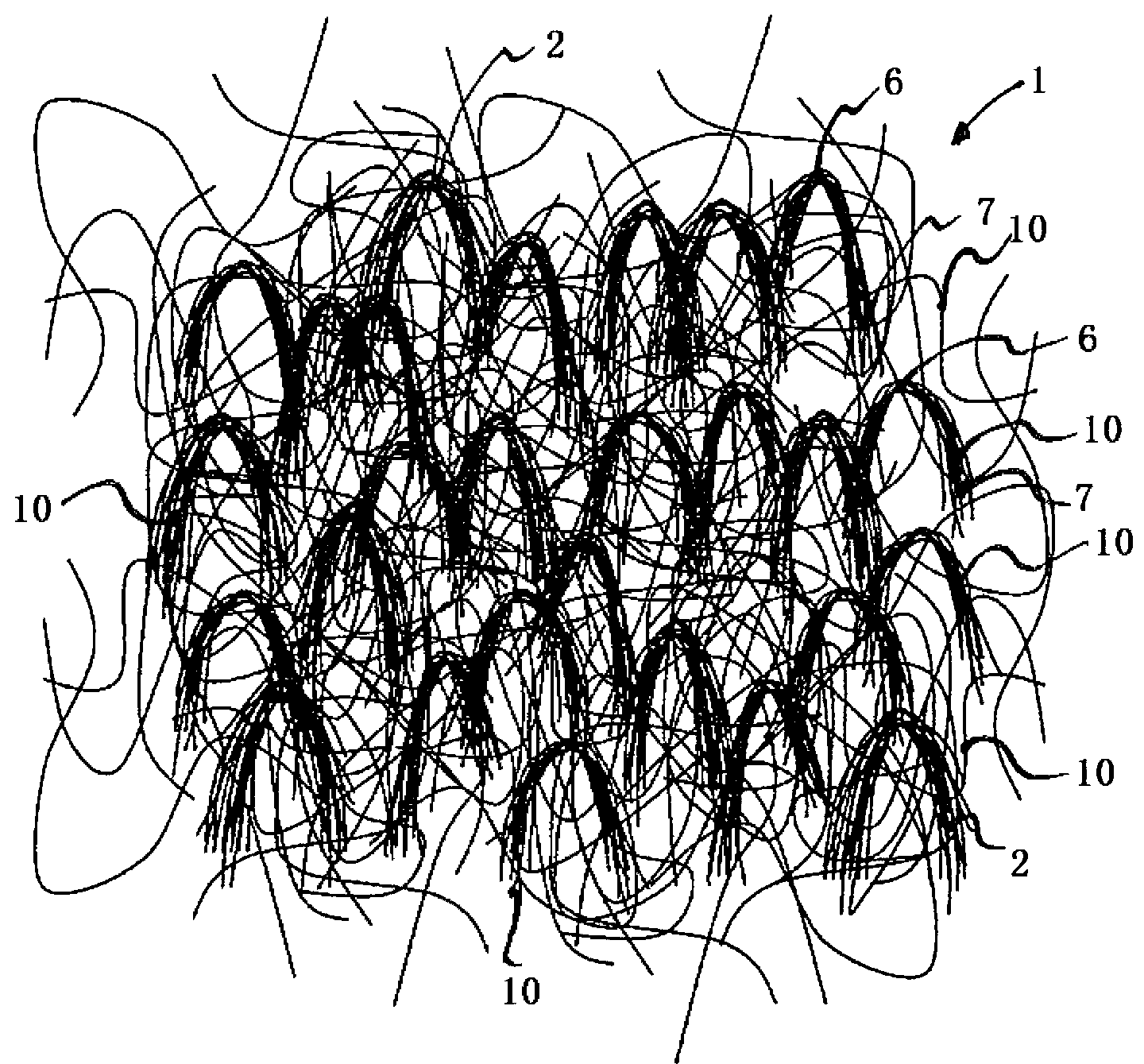

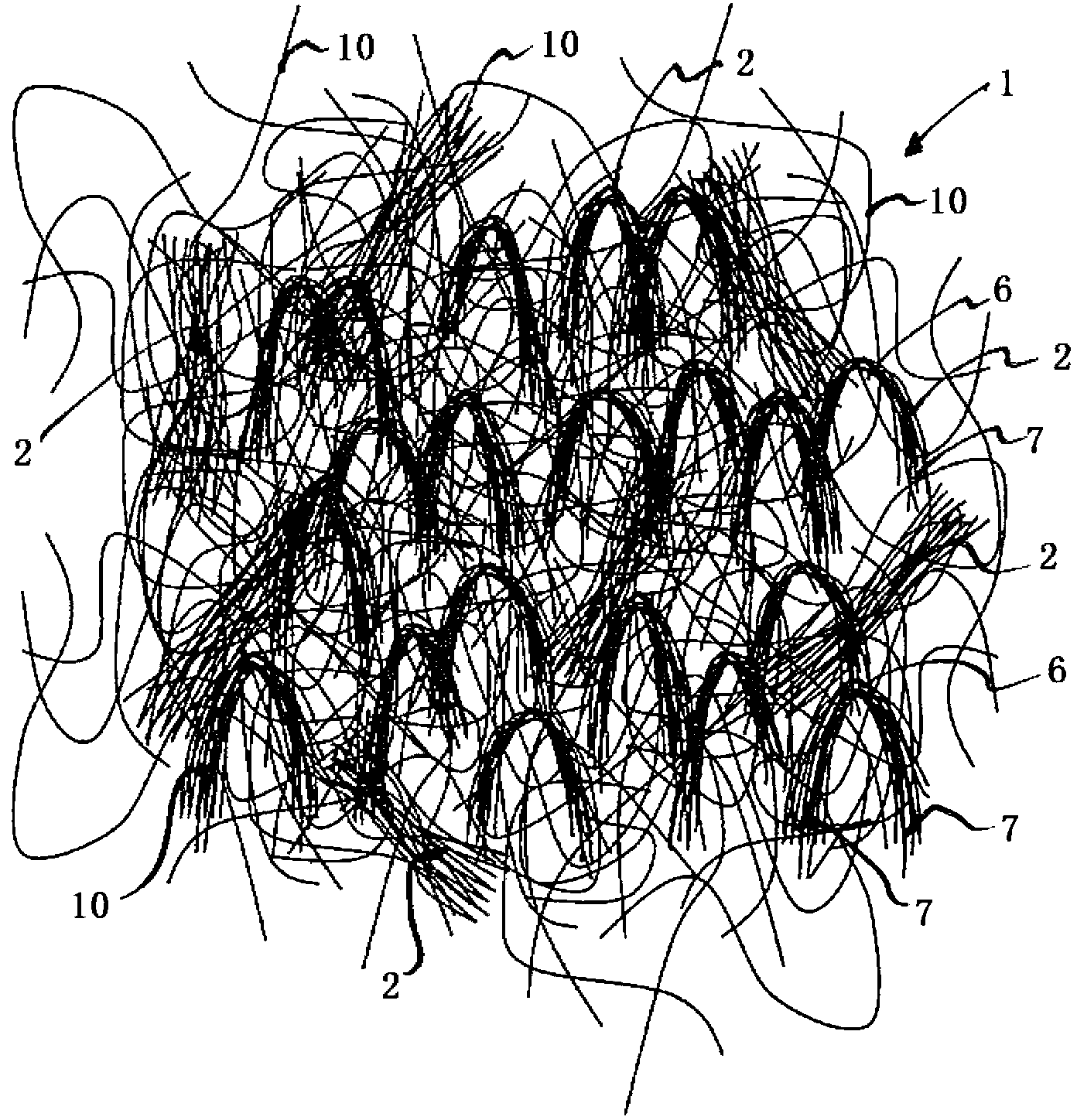

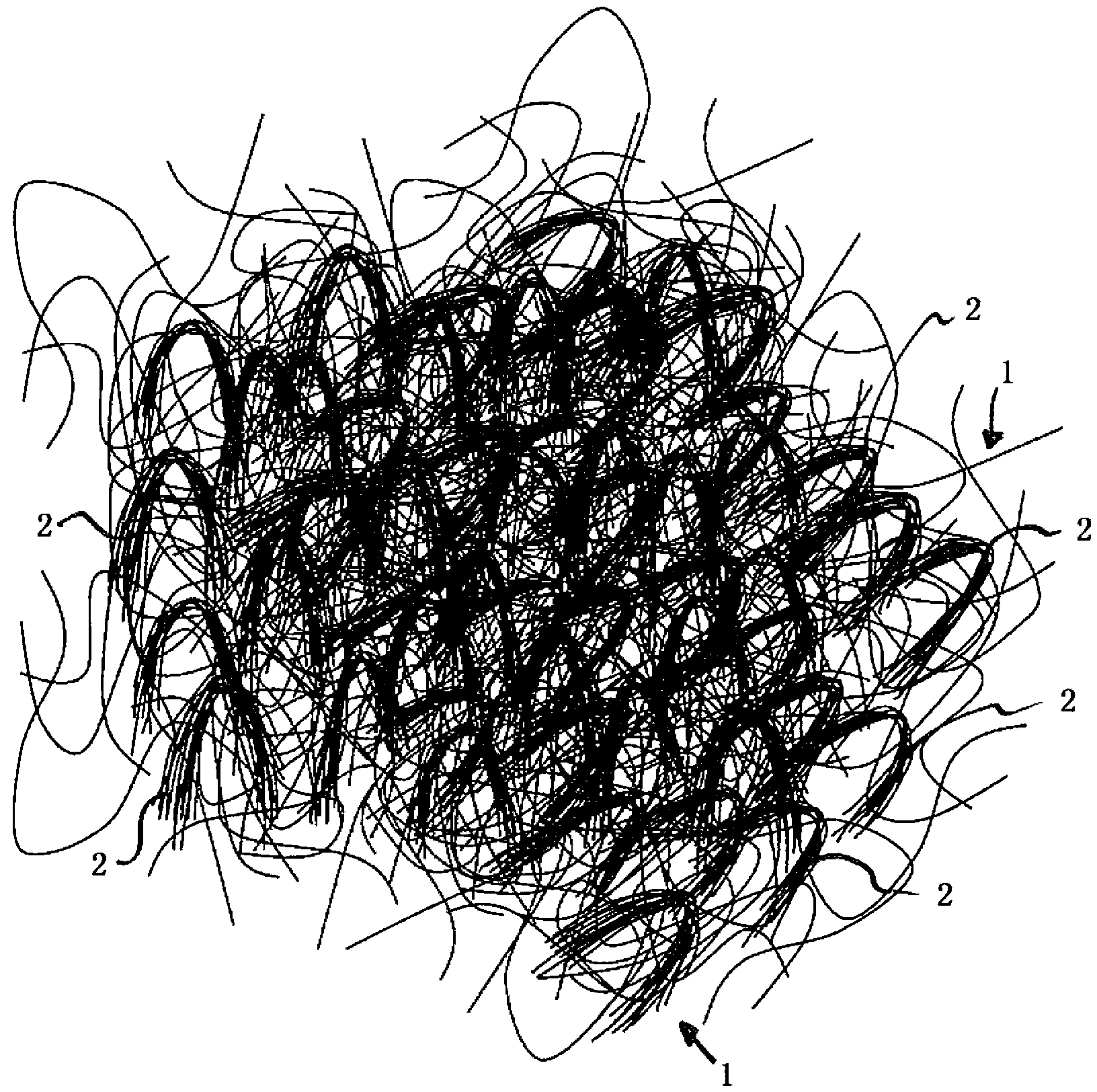

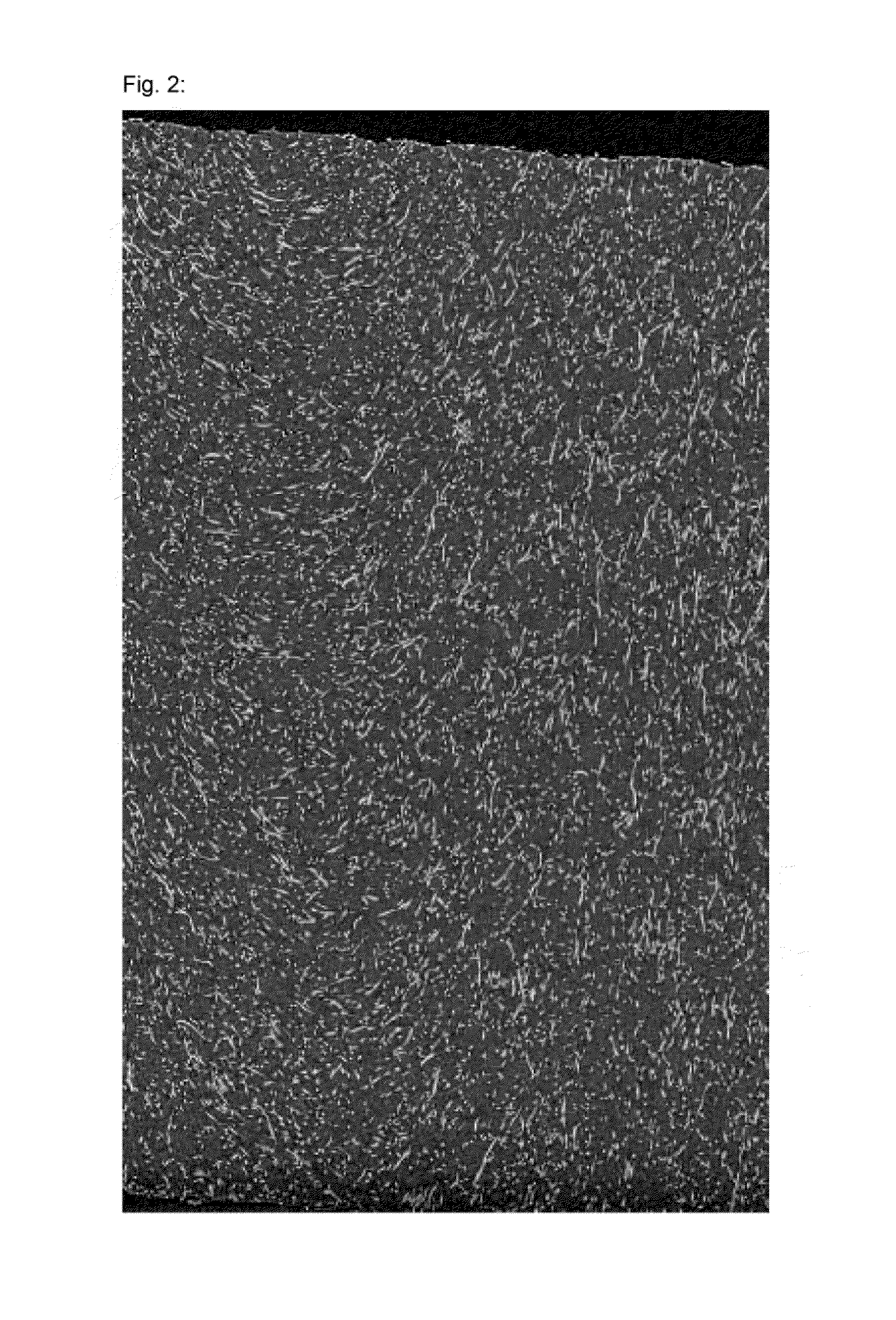

Pile layer having curved bundles

The nonwoven material is composed of a pile layer which has a plurality of bundles comprising carbon fibers, wherein at least some of the bundles have a curved course that comprises a curved vertex area of a first curvature between the bundle ends and at least one bundle end area of a second curvature, located at the bundle ends, wherein the first curvature is greater than the second curvature in particular by at least 50%.

Owner:SGL AUTOMOTIVE CARBON FIBERS

Production Control in a Blow Room

ActiveUS20180355519A1Quality improvementGuaranteed uptimeProgramme controlSafety devices for fibre treatmentLevel measurementProduction area

A system and corresponding method are provided for controlling production in a blow room, the blow room including a controller, a supplying machine having a supplying part, and a machine to be supplied that has a filling level measurement. The supplying machine and the machine to be supplied are connected to the controller. A production area is defined for the supplying machine and includes a minimum production and a maximum production. Production of the supplying part of the supplying machine is determined based on a filling level of the filling level measurement. When production of the production area drops below the minimum production, the supplying part of the supplying machine is shut down, the shutdown taking place independently of the filling level of the machine to be supplied.

Owner:MASCHINENFABRIK RIETER AG

Reinforced nonwoven fabric

A flat textile structure comprising a reinforcing grid and at least one pile layer which is situated in a flat manner on at least one surface of the reinforcing grid, characterized in that the flat textile structure has a weight per unit area of from 40 to 140 g / m2, the pile layer consists predominantly of carbon fibres, the carbon fibres in the flat textile structure have a proportion of the weight per unit area of from 60 to 97%, the reinforcing grid has a proportionate weight per unit area of from 2.5 to 12.5 g / m2 and the flat textile structure is strengthened.

Owner:SGL AUTOMOTIVE CARBON FIBERS

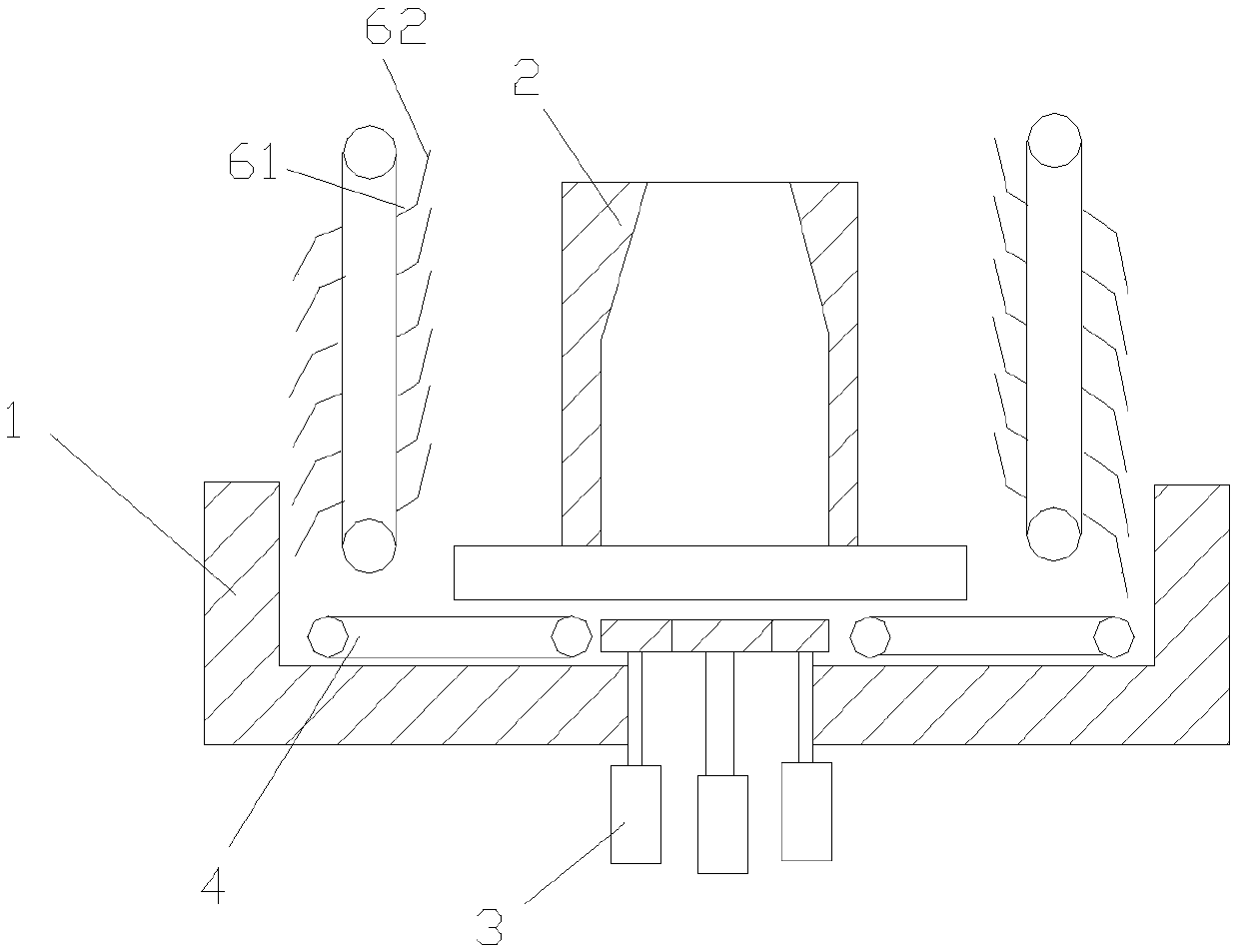

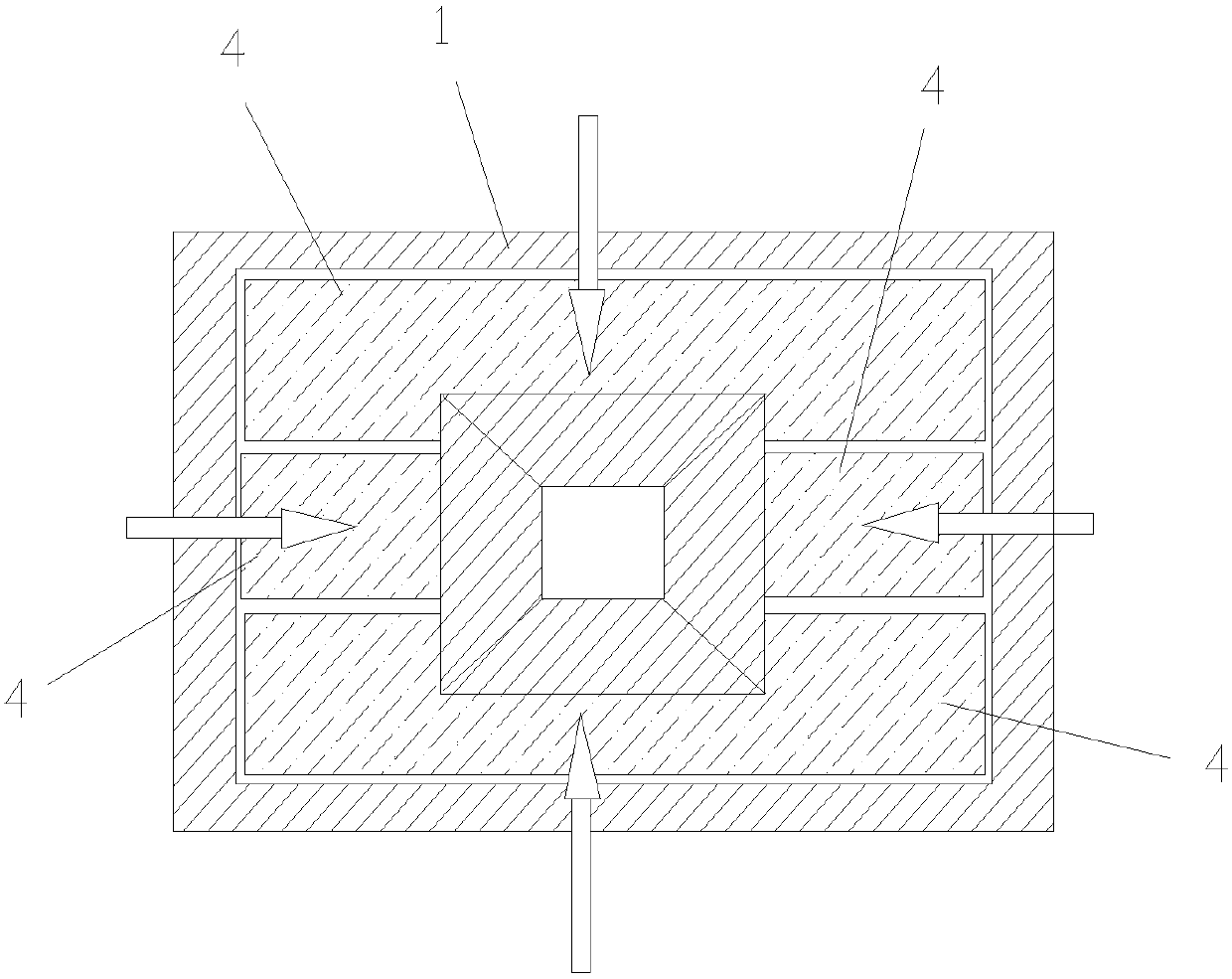

Bale Opener

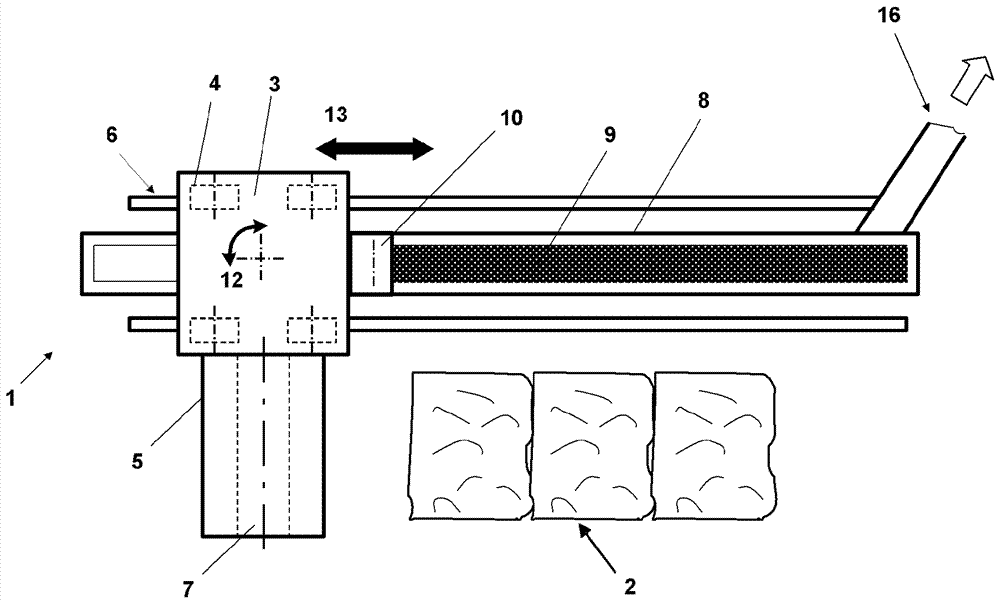

InactiveCN105523387AReduced need for drive powerPrecise positioningBulk conveyorsLoading/unloadingFiberEngineering

The invention relates to a bale opener (1) for the take-off of fiber tufts from fiber bales (2), comprising a take-off tower (3), which is arranged on a horizontal drive (4) or a rotating frame, and comprising a take-off arm (5). The take-off arm (5) is held on the take-off tower (3) in a guide (7) so as to be vertically adjustable. A single lifting spindle (6) having a longitudinal axis (8) in the movement direction of the take-off arm (5) is provided for the vertical adjustment of the take-off tower (3). The lifting spindle (6) is fastened on the take-off tower (3) and the take-off arm is connected to the lifting spindle (6) via a nut (9).

Owner:MASCHINENFABRIK RIETER AG

Bale plucking equipment

The invention discloses bale plucking equipment which comprises an air suction hood and a driving device, wherein the driving device comprises a bale plucking arm, a power source and a center post, wherein the power source is arranged inside the center post and drives the bale plucking arm to operate; the air suction hood is fixedly arranged on the bale plucking arm; a cotton conveying passage is connected to the top of the air suction hood; a bale plucking beater is arranged inside the air suction hood; blades are arranged at the periphery of the bale plucking beater; a cotton sucking port is formed in the bottom of the air suction hood. The bale plucking equipment disclosed by the invention has the advantages of high bale plucking efficiency, no blocking phenomenon, reasonable design, compact structure, simpleness and convenience in operation, higher marketing value and increased economic benefits for enterprises.

Owner:张志洲

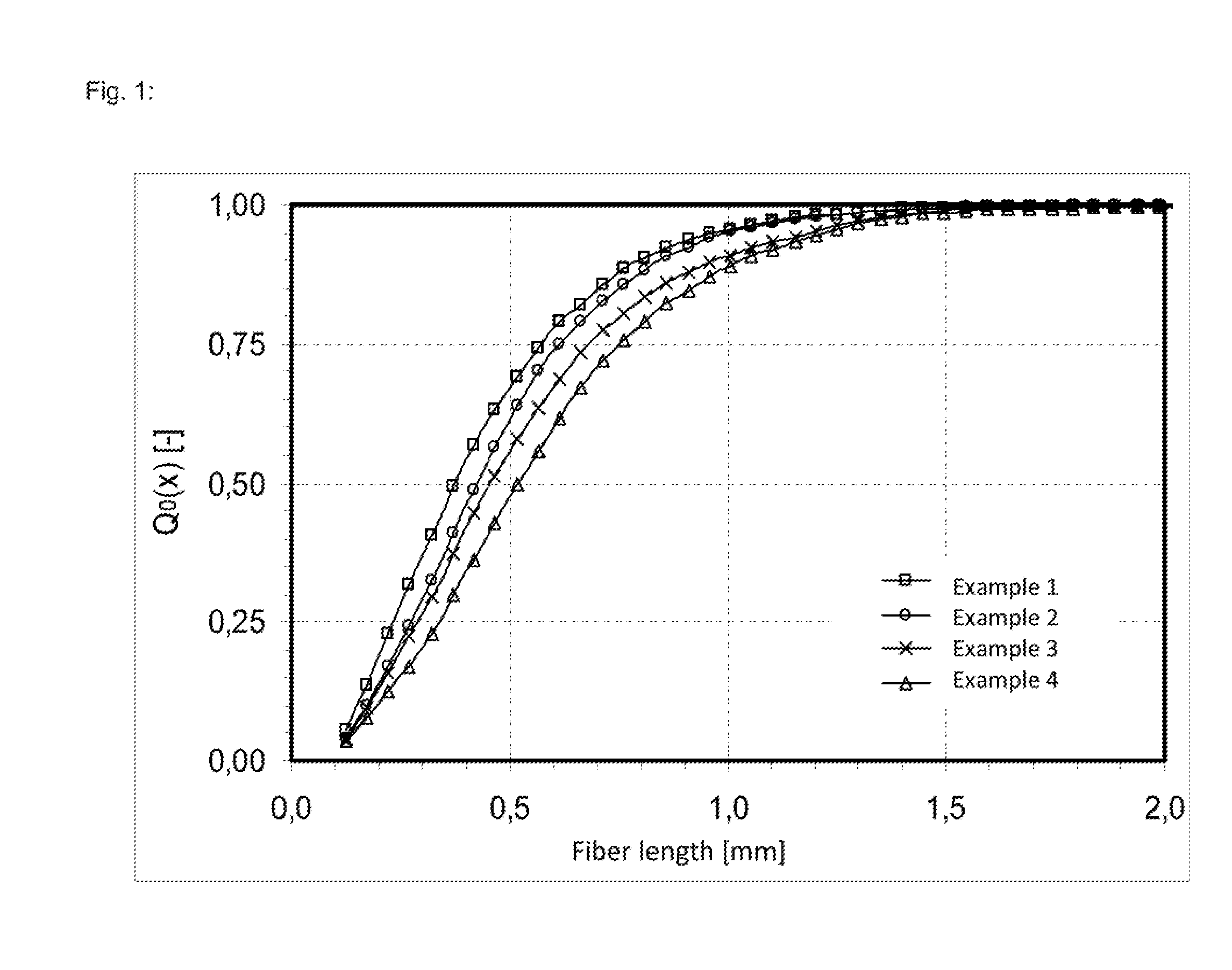

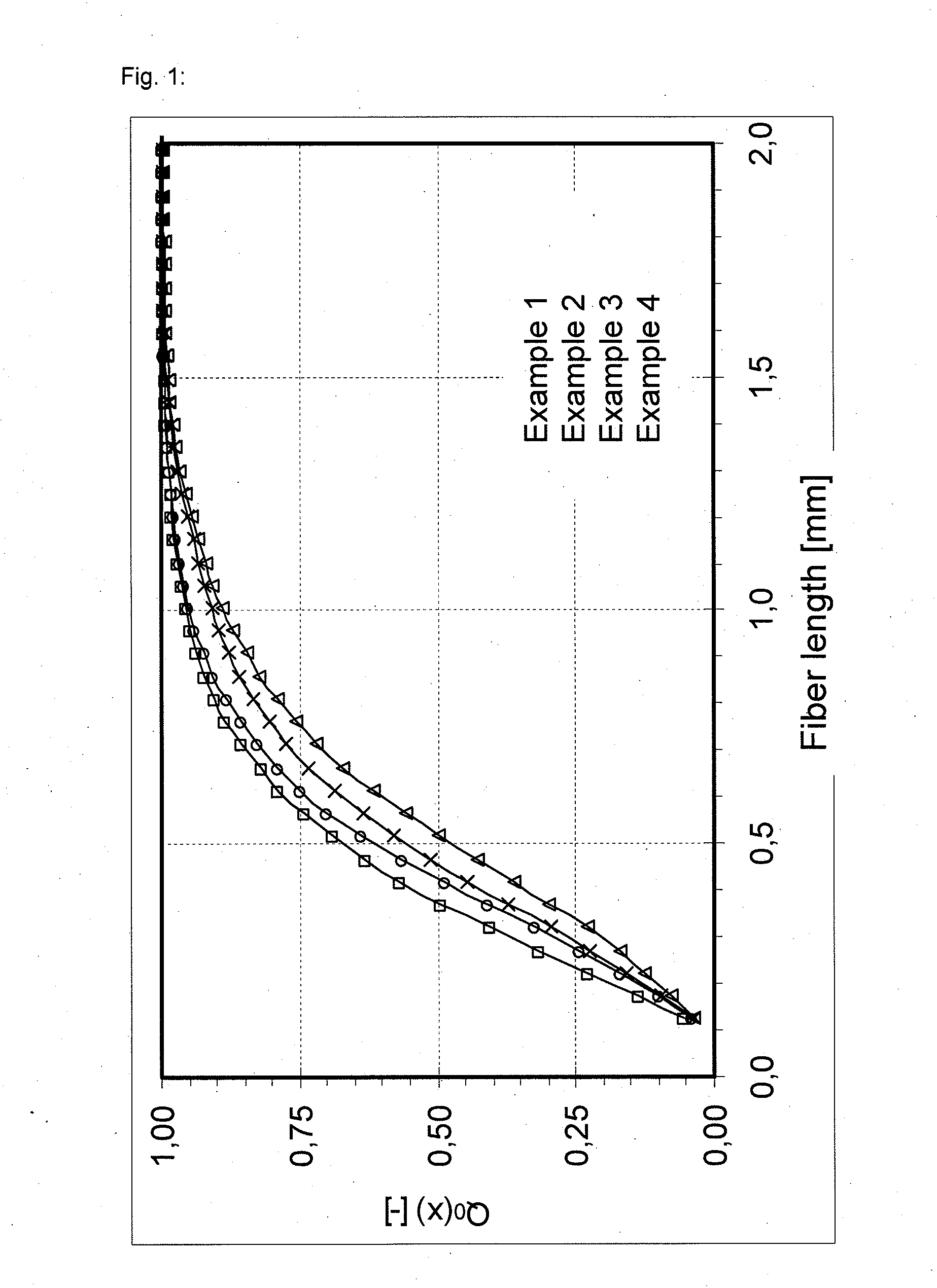

Cellulose fibers with an enhanced metering capability, processes for their production of these and their use to reinforce compound materials

InactiveUS20160244576A1Significant positive effectQuality improvementFibre mixingMonocomponent cellulose artificial filamentCellulose fiberPolymer chemistry

The present invention relates to cellulose fibers with an enhanced metering capability, a process for the production of these and the use of these for the reinforcement of compound materials, in particular thermoplastic polymers.

Owner:LENZING AG

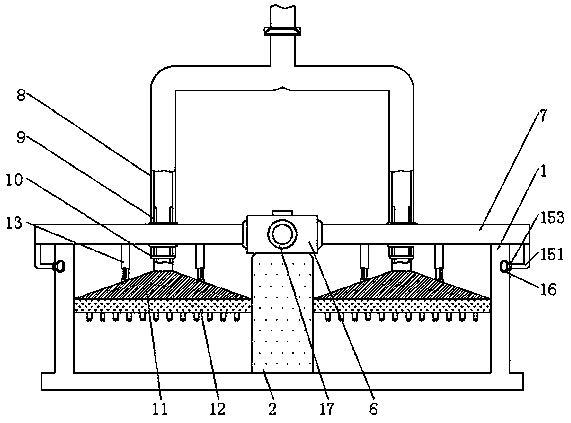

Fiber splitting/mixing mechanism

InactiveCN107699992AScattered realizationScattered in timeFibre mixingFibre breakingFiberEngineering

The invention discloses a fiber splitting / mixing mechanism. The fiber splitting / mixing mechanism comprises a cotton mixing box, and the cotton mixing box is of a structure opened at the top; the fibersplitting / mixing mechanism further comprises a feed guiding tower, lifting platforms and a feed delivery mechanism; the feed delivery mechanism is arranged in a cavity of the cotton mixing box and isused for delivering fiber from the edge of the cotton mixing box to the center of the cotton mixing box; the feed guiding tower is longitudinally communicated, is opposite to the center of the cottonmixing box and is located above the feed delivery mechanism; a cavity inside the feed guiding tower comprises sectioned cavities of which the widths or inner diameters are reduced from bottom to topin sequence, and adjacent sectioned cavities are transferred through transition cavities; the side walls of the transition cavities are slant; multiple lifting platforms are arranged, and each liftingplatform comprises a main lifting platform located in the middle and subsidiary lifting platforms located at the two sides of the main lifting platform, and the subsidiary lifting platforms are in symmetry about the main lifting platform. The fiber splitting / mixing mechanism has the advantages of being high in splitting degree and uniform in mixing.

Owner:ANHUI HANLIAN TEXTILE CO LTD

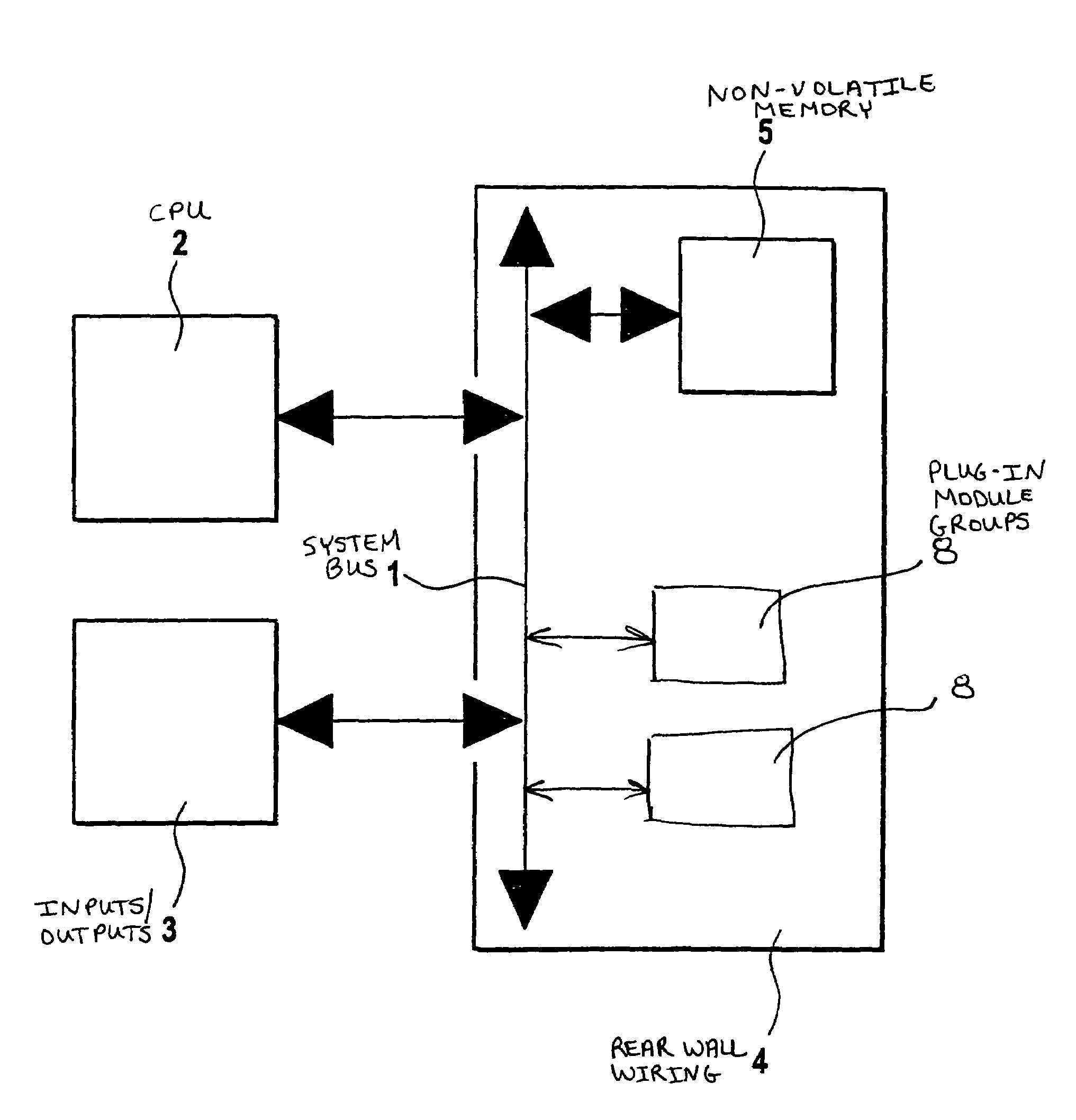

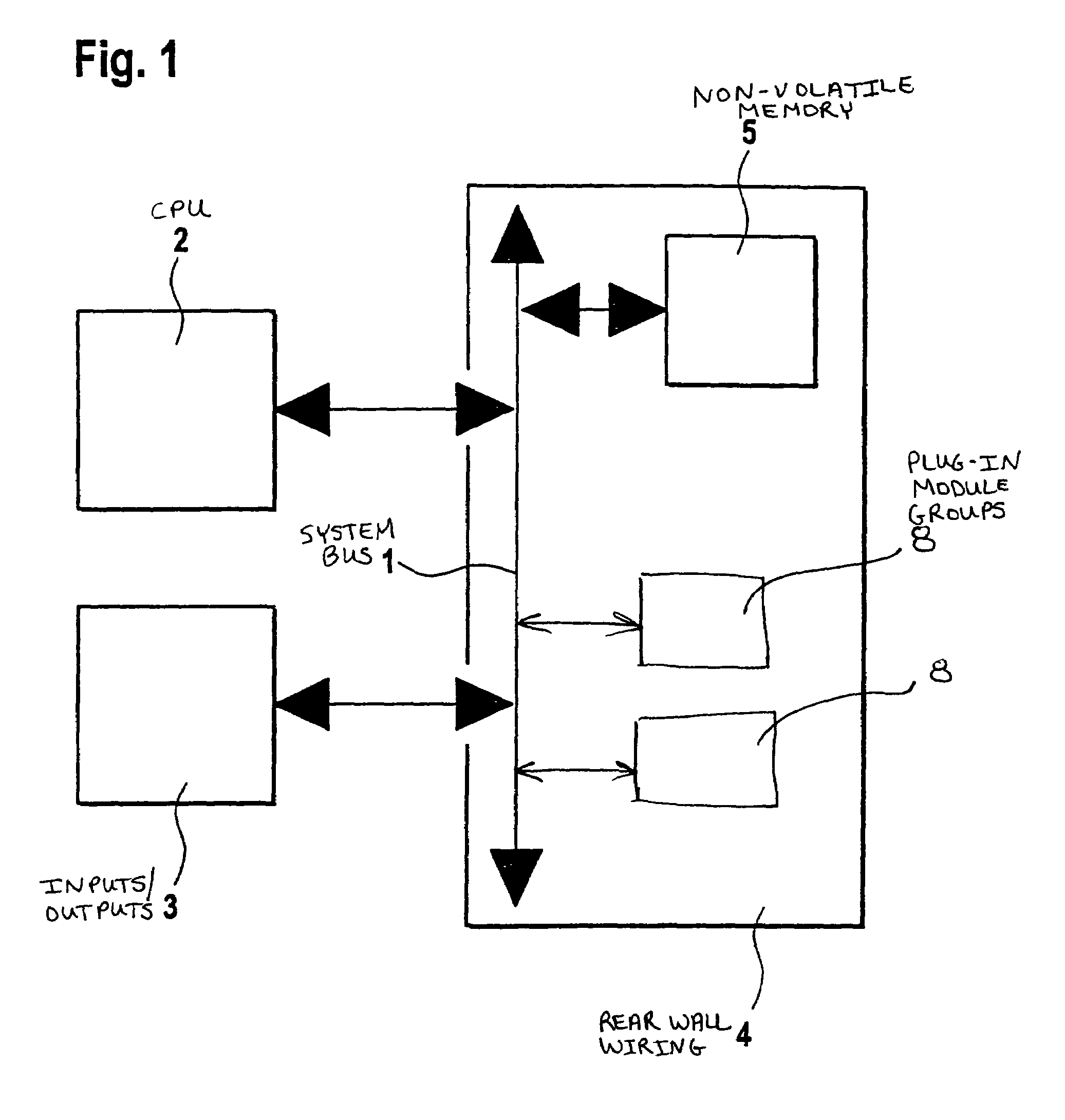

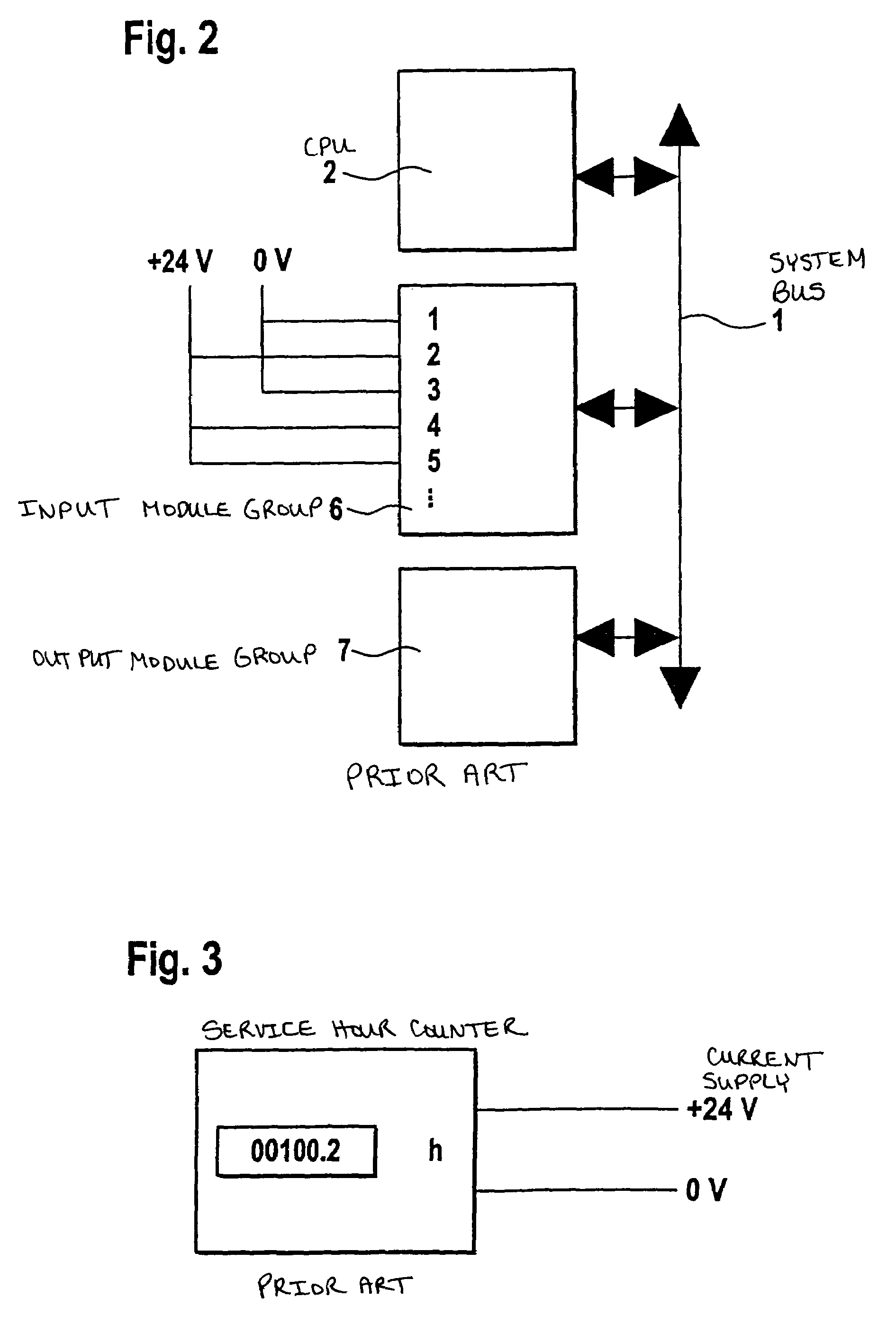

Method and apparatus for electronically controlling fiber processing machines, particularly spinning preparation machines

An apparatus for electronically controlling a fiber processing machine includes at least one plug-in module group and at least one memory for receiving and storing data. A non-volatile memory is disposed physically apart from the plug-in module group whereby the data inputted in the memory are not lost upon switching off a power supply to the apparatus or upon replacing at least one plug-in module group and whereby upon resuming operation of the apparatus the data may be read and further processed.

Owner:TRUETZSCHLER GMBH & CO KG

Cotton module unwrapping method and apparatus

A method of and apparatus for, unwrapping a module of cotton or other fibrous material from a wrapping having at least one layer of plastics-sheet material, the method including the steps of: raising the module to a first, or elevated, position on a lift conveyor or vertically-movable support surface; advancing a plurality of gripper heads, mounted on a support frame, to an advanced position, into gripping engagement with the layer(s) of the sheet material wrapping; lowering the lift conveyor or vertically-movable support surface from the first position towards a second, or lowered, position; and retracting the plurality of gripper heads, to expand the wrapping to progressively release the cotton or other fibrous material from the lower portion to the upper portion of the module.

Owner:QUEENSLAND COTTON

Hair styling device

ActiveUS9750327B2Precise positioningEffective and efficient hair styling conserving timePackaging toiletriesPackaging cosmeticsBristleEngineering

Owner:SMILEY NADRA SAFIA

Cellulose fibers with an enhanced metering capability, processes for their production and their use to reinforce compound materials

InactiveUS20120178856A1Reduce throughputLarge caliberFibre mixingMonocomponent cellulose artificial filamentPolymer scienceCellulose fiber

The present invention relates to cellulose fibers with an enhanced metering capability, a process for the production of these and the use of these for the reinforcement of compound materials, in particular thermoplastic polymers.

Owner:LENZING AG

Method and assembly for processing round seed cotton modules

An assembly for enabling the release of produce from a module retained by a plastics sleeve. The apparatus comprises a primary support frame including legs fixed to ground surface via feet. A gantry supports a compression assembly capable of receiving and retaining a module. There are means to enable the compression assembly to move between a non working state in which the compression assembly is elevated above a work station and a working state in which the compression assembly is at a work station in which compression arms are capable of retaining a produce module. The compression assembly includes means to enable the arms to apply a radial force to the module sufficient to allow the compression assembly to remove the plastics sleeve and allow the produce to gravitate through a free end of the module as the plastics sleeve is elevated away from the produce.

Owner:NAMOI COTTON COOP

Apparatus for tow opening

An apparatus for opening a crimped multifilament tow comprising: a source of crimped multifilament tow; at least one pair of opposed gripping rollers comprising a first roller which is a metal roller and a second roller which is a smooth-surfaced roller made of a material selected from the group consisting of: polyurethane or silicone rubber; where the multifilament tow passes between and in contact with both of the rollers and filaments of the tow are separated from one another and opened.

Owner:ACETATE INT LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com