Bale opener

A technology of unpacking machine and driving device, which is applied in the directions of fiber unpacking, packaging, transportation and packaging, etc., which can solve the problems of complex driving structure of chain drive device, and achieve the effect of avoiding uncontrolled driving and wheel slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

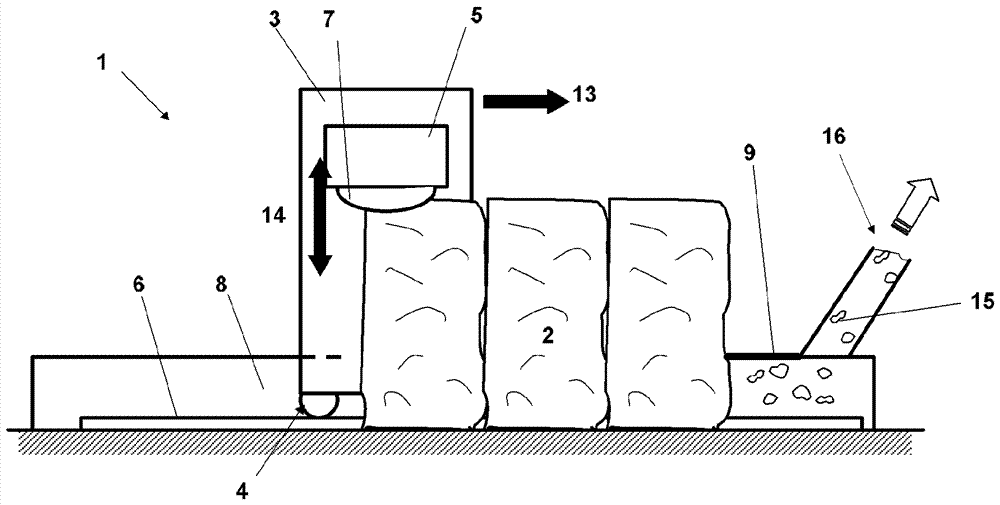

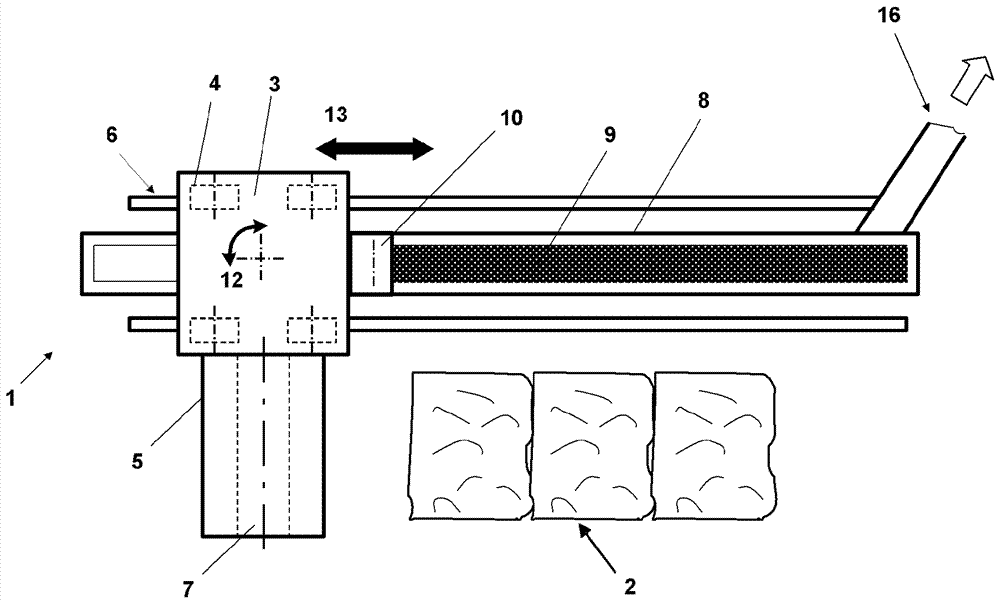

[0021] figure 1 and figure 2 A bale opening machine 1 for opening fiber bundles of a fiber bale 2 is shown schematically. figure 1 The bale opener 1 is shown in top view, and figure 2 The previous view shows the bale opener. The bale opener 1 mainly consists of a breaker tower 3 and a breaker arm 5. The unraveler arm 5 is mounted on one end of the unraveler tower 3 and is arranged freely cantilevered over the fiber bale 2 . The mounting of the unraveler arm 5 on the unraveler tower 3 is designed to be adjustable in height, so that the fiber bales 2 can be continuously unraveled. The movement 14 of the unraveler tower 5 serves in particular to ensure a uniform removal of the fiber bundles 15 from the surface of the fiber bale 2 . Drive means for height adjustment 14 are provided by synchronous servo motors.

[0022] The dismantler tower 3 is equipped with a transmission 4 . With the help of a transmission 4 , the deconsolidator tower 3 moves along the fiber pack 2 on r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com