Bale Opener

A technology of unpacking machine and main shaft, applied in conveyors, transportation and packaging, fiber unpacking, etc., can solve the problems of wear, complex structure of lifting mechanism, complex precise orientation of fiber packages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

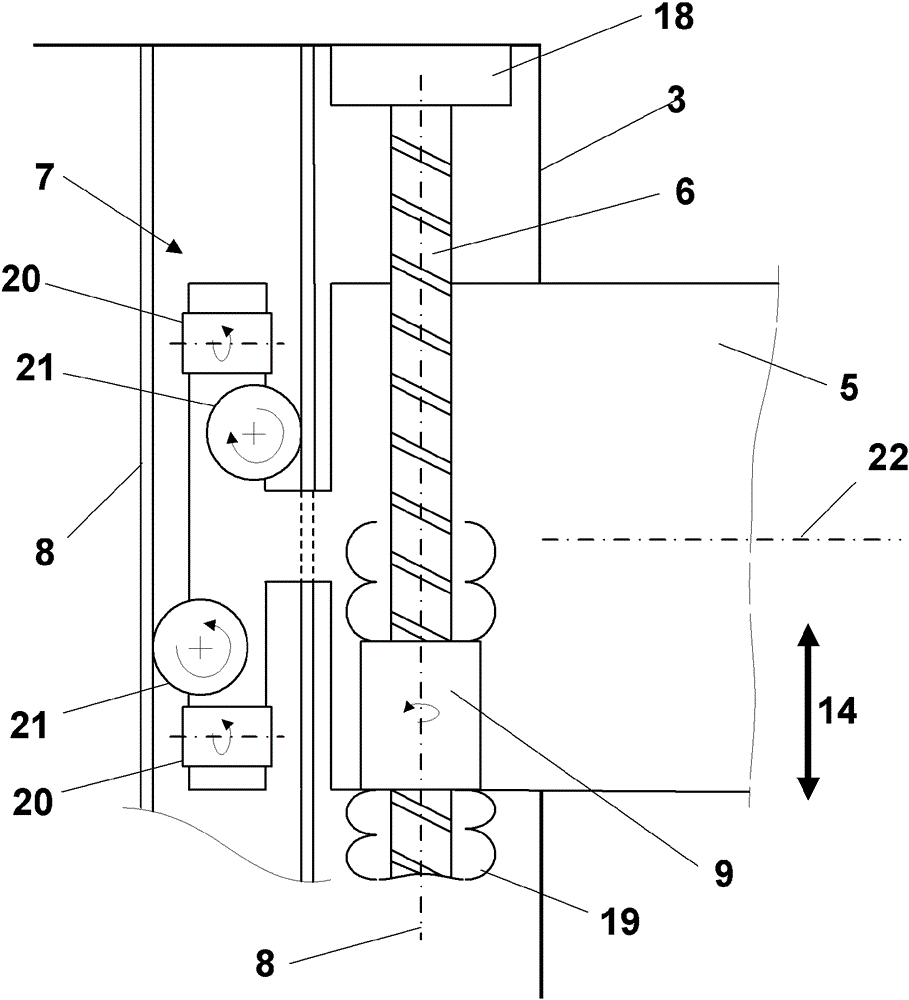

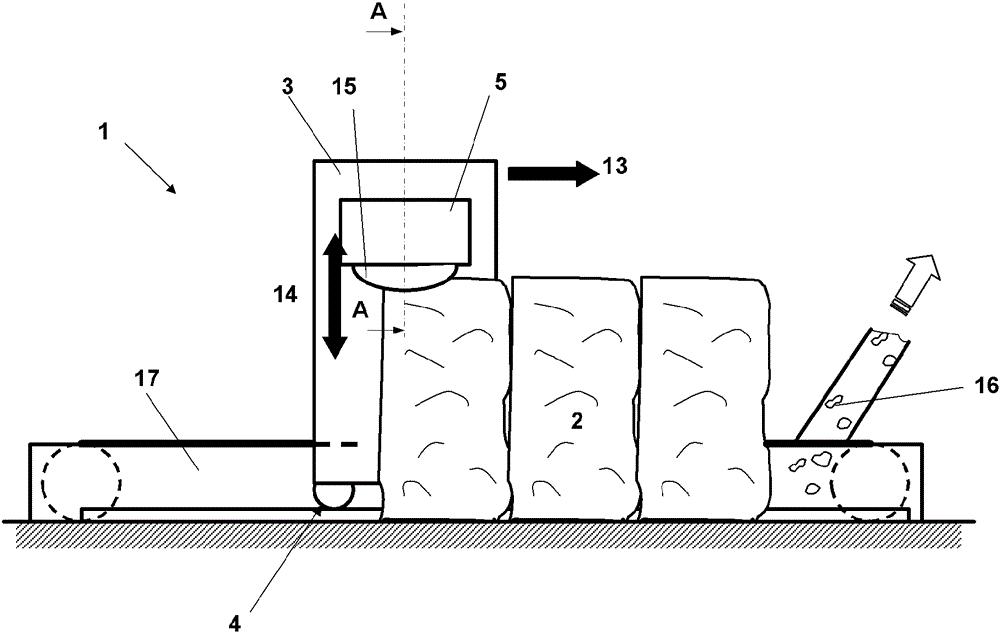

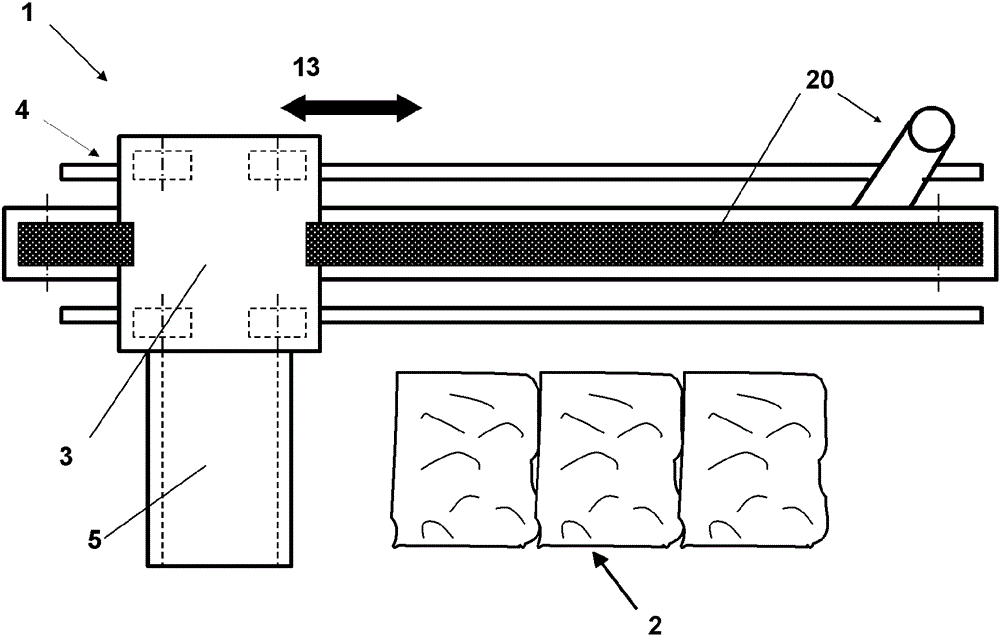

[0029] figure 1 with figure 2 A schematic diagram of a bale unpacking machine 1 for stripping fiber bundles 2 is shown. figure 1 The unpacking machine 1 is shown in plan view and figure 2The unpacking machine 1 is shown in a view. The bag unpacking machine 1 basically consists of a stripping tower 3 and a stripping arm 5 . The stripping arm 5 is fastened on one side to the stripping tower 3 and is arranged to hang freely above the fiber bale 2 . The stripping tower 3 is equipped with a horizontal drive 4 . The stripping tower 3 moves on rails along the fiber pack 2 by means of a drive mechanism 4 . The stripping arm 5 mounted on the stripping tower 3 is guided over the surface of the fiber bale 2 by means of this movement 13 . A stripping unit (typically one or more stripping rollers 15 ) is provided in the stripping arm 1 . Stripping rolls 15 extract fiber bundles 16 from fiber bale 2 . The fiber tow 16 is conveyed through the stripping arm 5 and the stripping tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com