Patents

Literature

51results about How to "Improved gripping ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag mixed active powder concrete

Disclosed is reactive powder concrete mixed with slag, which is a novel engineering material with super-high intensity and super-high durability, particularly cement-based composite material having super-high property prepared and formed via using all kinds of industrial residue as reactive powder. Corresponding to Portland cement, proportion by weight of all composites of the concrete is: the Portland cement holding 1 part, the slag holding 0.40-0.60 part, silicon powder holding 0.20-0.35 part, quartz flour holding 0.20-0.35 part, river sand holding 1.20-1.60 parts, water holding 0.20-0.28 part and a water reducing agent holding 0.02-0.03 part.

Owner:SOUTHEAST UNIV

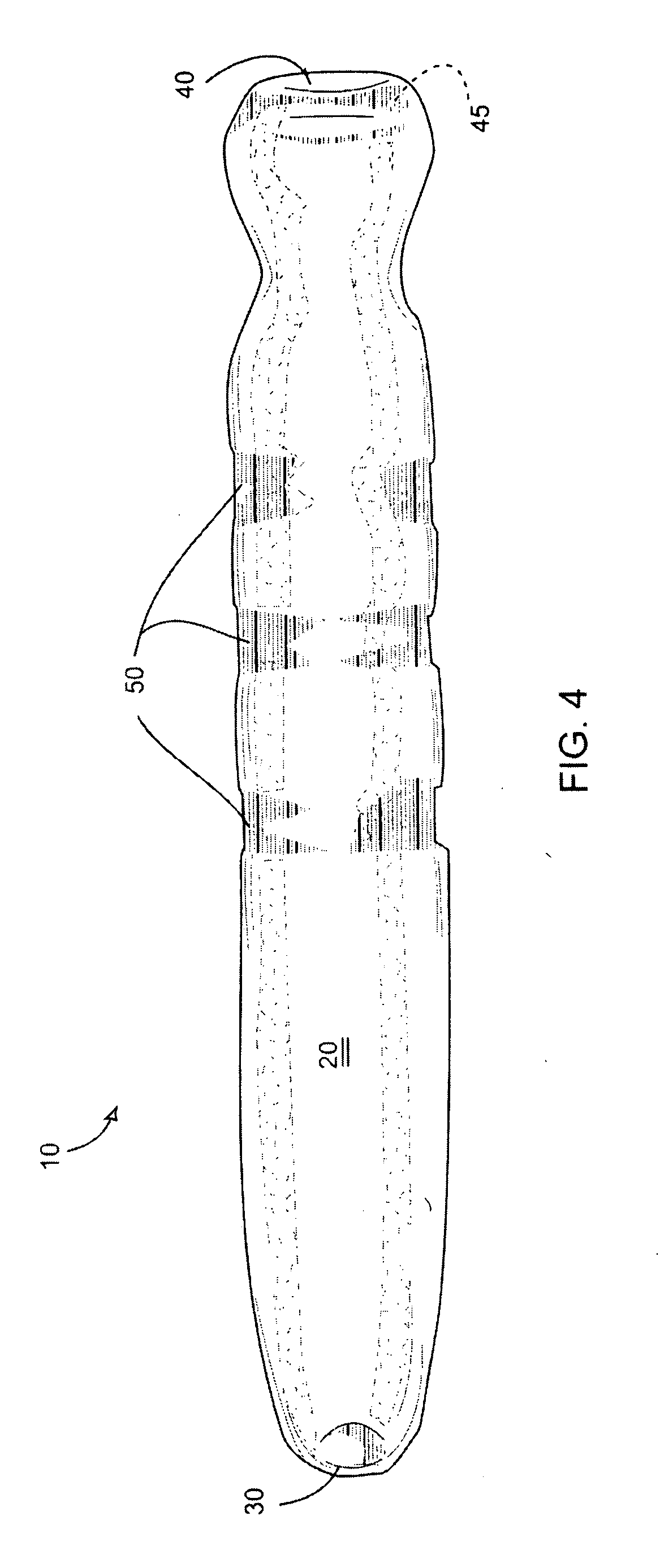

Yoga block

InactiveUS20120214653A1Improved gripping abilityComfortably and conveniently maintainStiltsMuscle exercising devicesSolid baseEngineering

A yoga block in the preferred embodiment of the present invention is a prism-shaped triangular block that provides a stable and solid base on all sides, horizontally and vertically, and is equipped with ergonomically placed hand grooves and multiple level hand slots for tailored use. A yoga block that is prism-shaped and triangular can benefit beginners and advanced yoga practitioners alike in the journey to refine their practice through safe and proper alignment various yoga postures. Furthermore, the present invention in the preferred embodiment is enhanced with large slots at differing height levels, which allows for easy and accurate tracking of improvement and personal goals, creating a truly multi-functional, cost-efficient item for manufacture. A yoga block in the preferred embodiment is preferably composed of lightweight yet sturdy materials such as: foam, cork, or natural wood, but is in no way limited to these suggested materials.

Owner:TSOU ELAINE

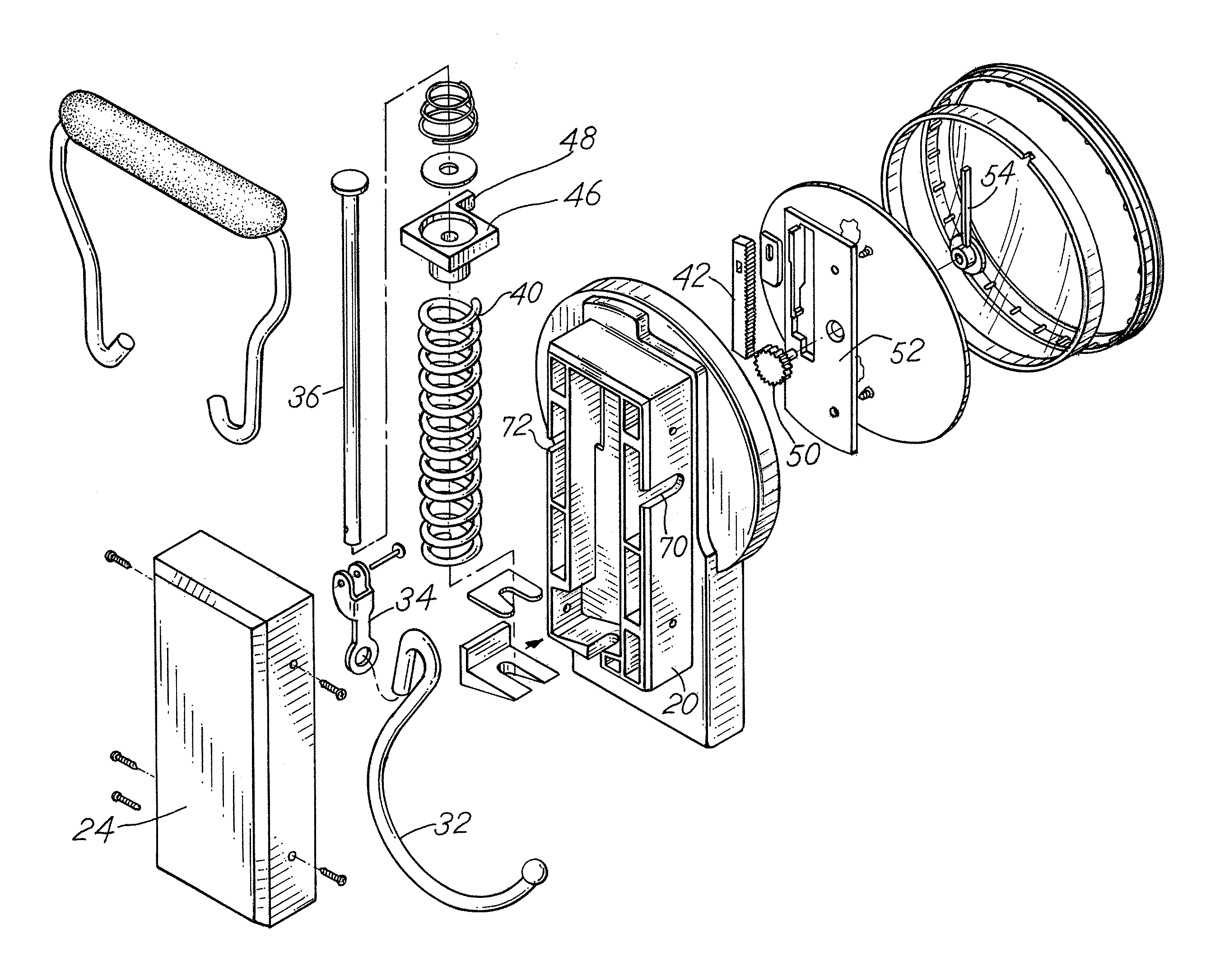

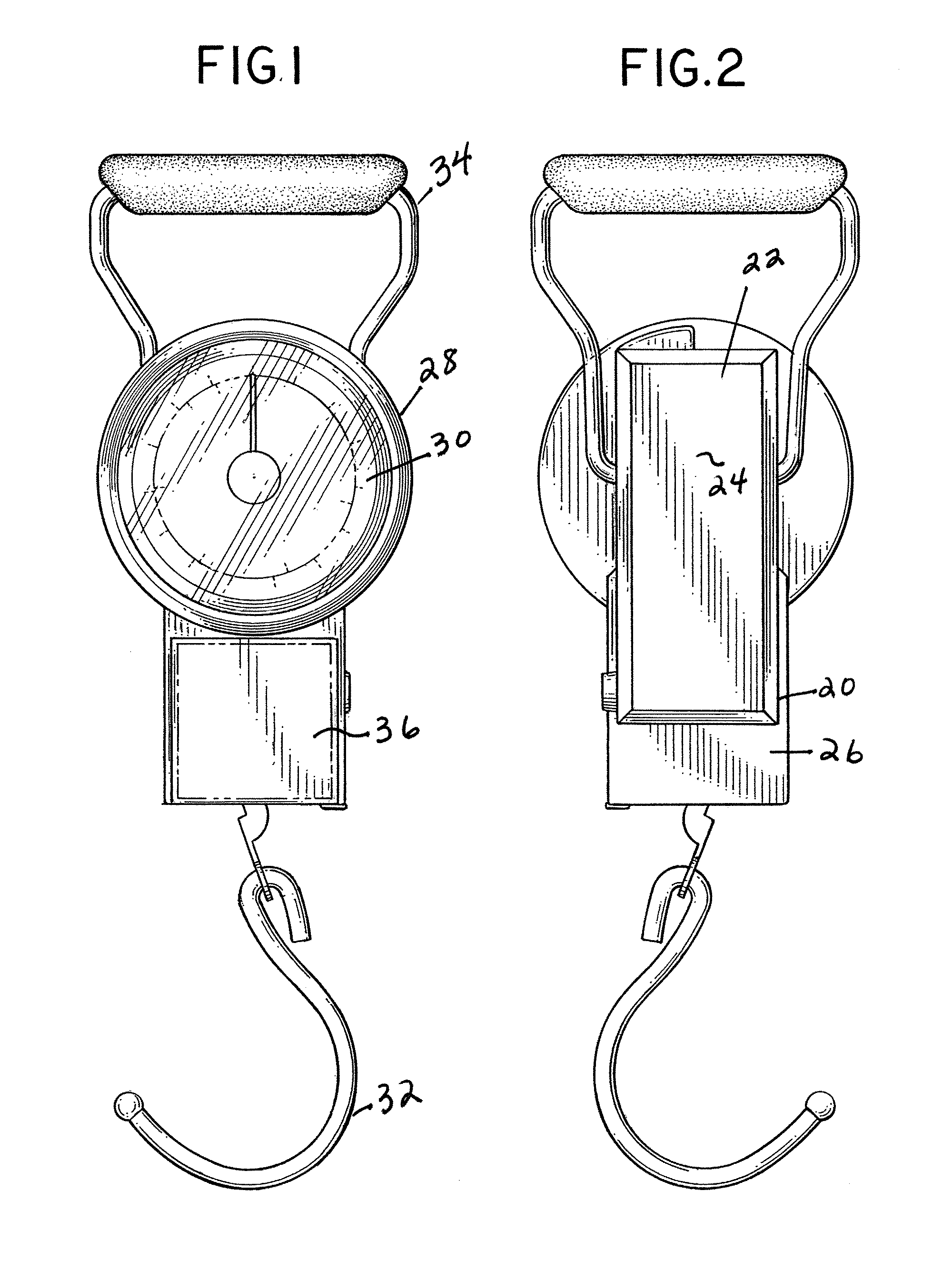

Portable hand held luggage weight and size measurement device

ActiveUS7232961B1Improve comfortAdd featureWeighing apparatus using elastically-deformable membersIndication apparatusSize measurementHand held

A portable hand held device for weighing and measuring the size of a luggage item includes a handle designed to provide support yet comfort with respect to the use of the weighing device and further includes a mechanism which enables recordal of the weight of luggage placed upon a suspension hook of the device.

Owner:TRAVEL CADDY

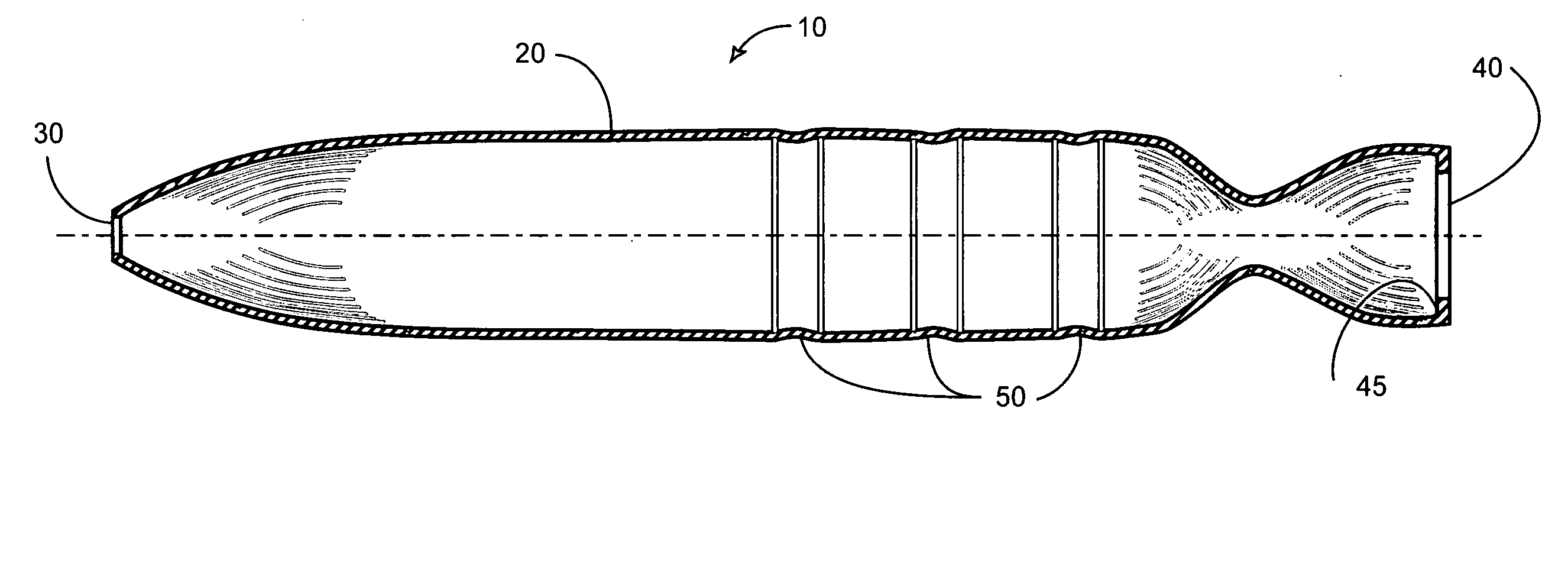

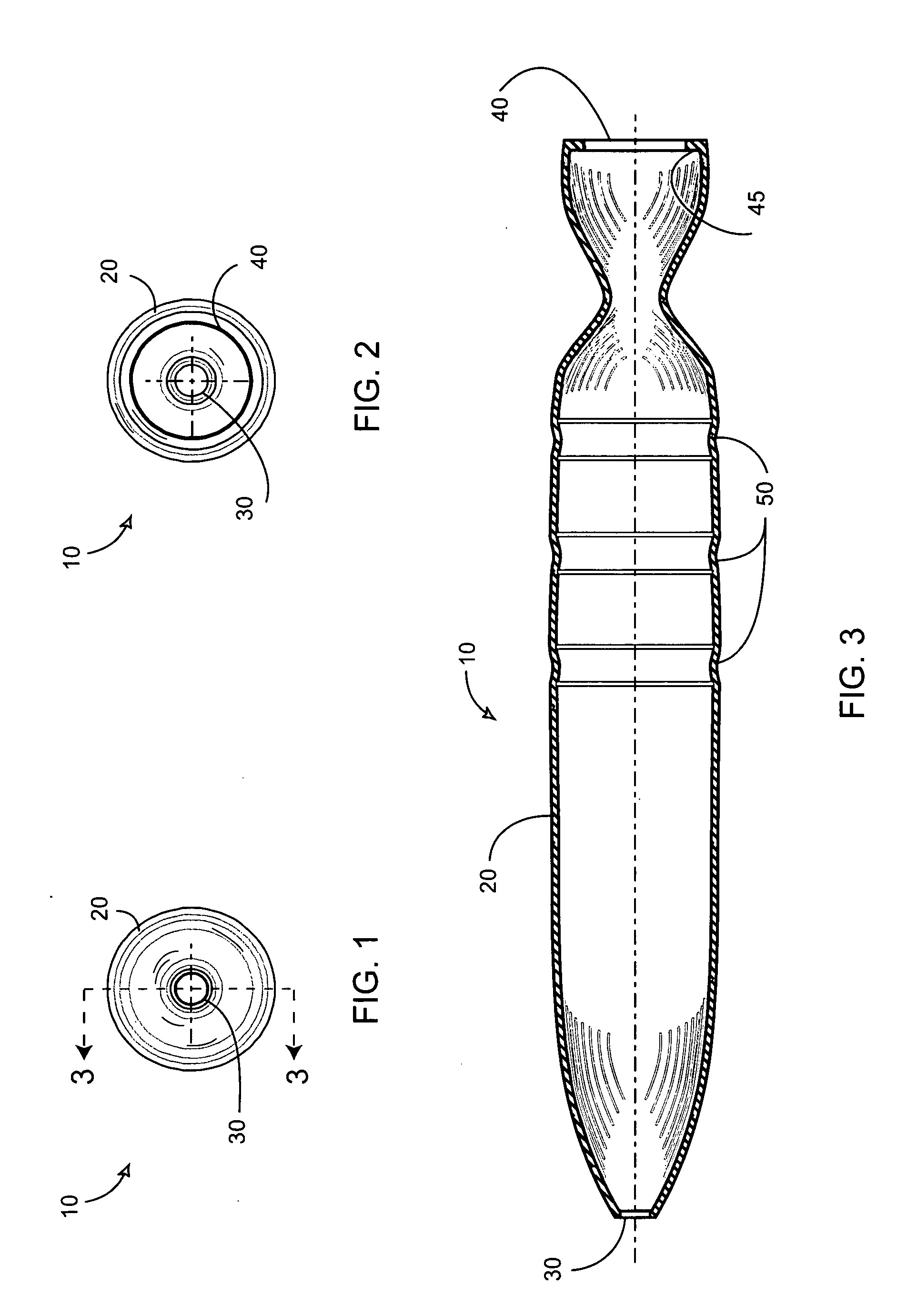

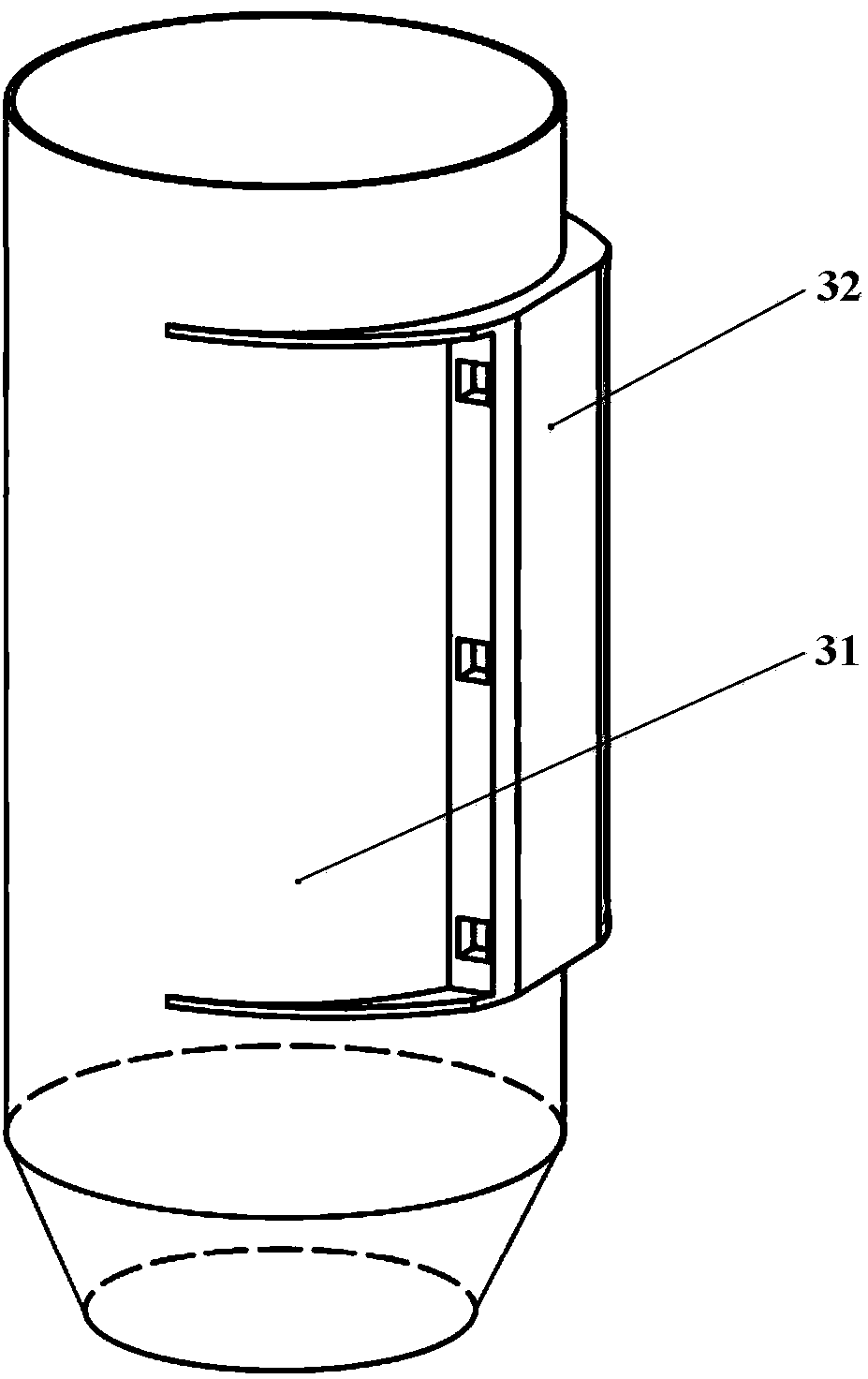

Vaginal dilator for use in vaginal rehabilitation and methods therefor

InactiveUS20080234719A1Reduce internal air pressureReduce the overall diameterSurgeryDilatorsDiseaseVaginal reconstruction

These stents aid in the rehabilitation of transgender patients, vaginismus patients and vaginal reconstruction patients and similar maladies. The glass stent is made from select medical grade borosilicate glass that is non-porous, hypoallergenic, incredibly durable, and incredibly smooth, can be easily sterilized, is lightweight, and greatly reduces friction during removal. By being hollow, the typical suction effect that is created during removal is eliminated as air can enter the vaginal cavity. There is a tapered hour glass area and an open and lipped end so insertion and removal is more easily facilitated. There are also three indentions in the glass as depth guides for the patient that can be both seen and felt but are very smooth. Finally, this stent can be tailored to individual patients if their bodies require different measurements.

Owner:ADAMS JUSTIN BRUCE

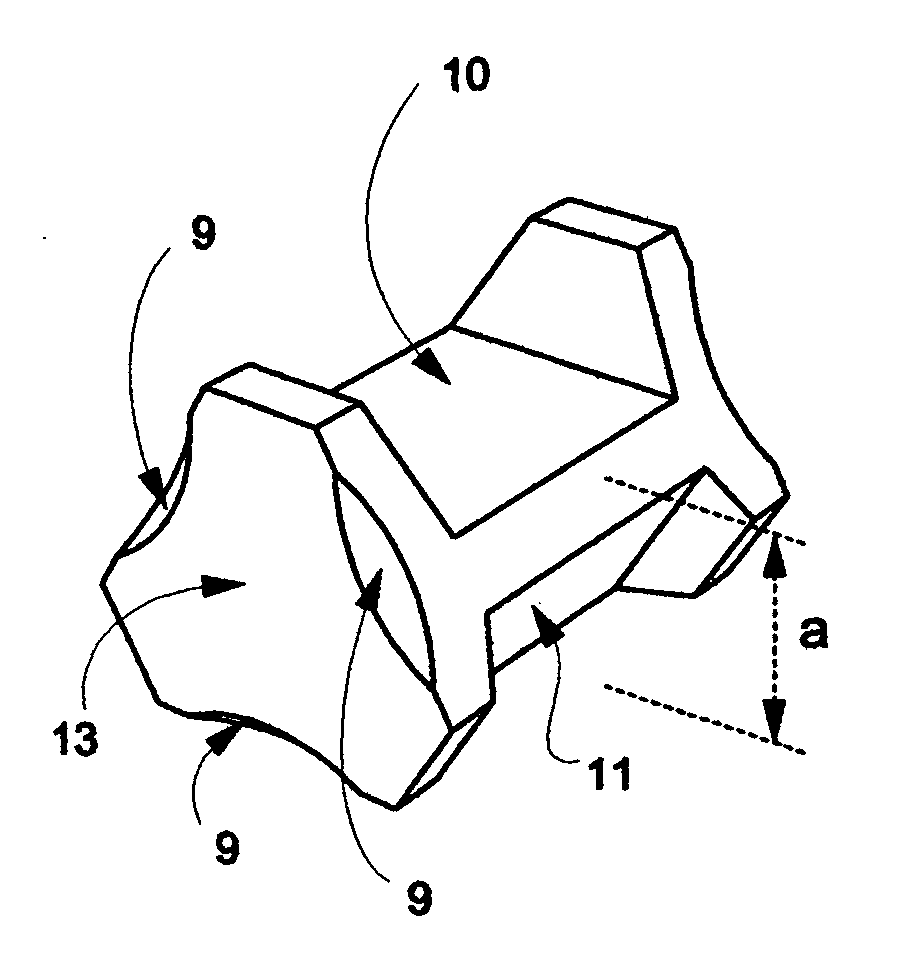

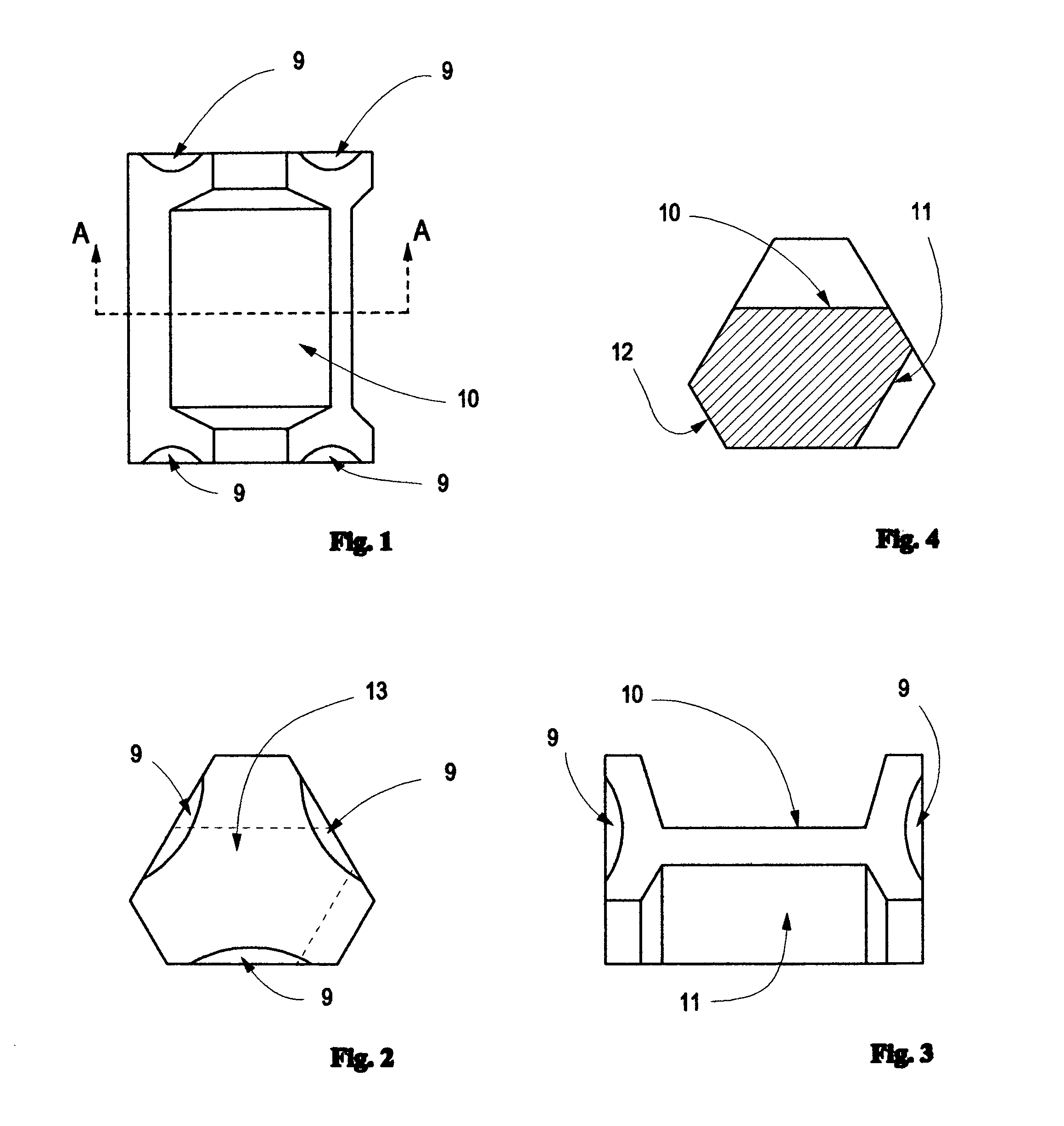

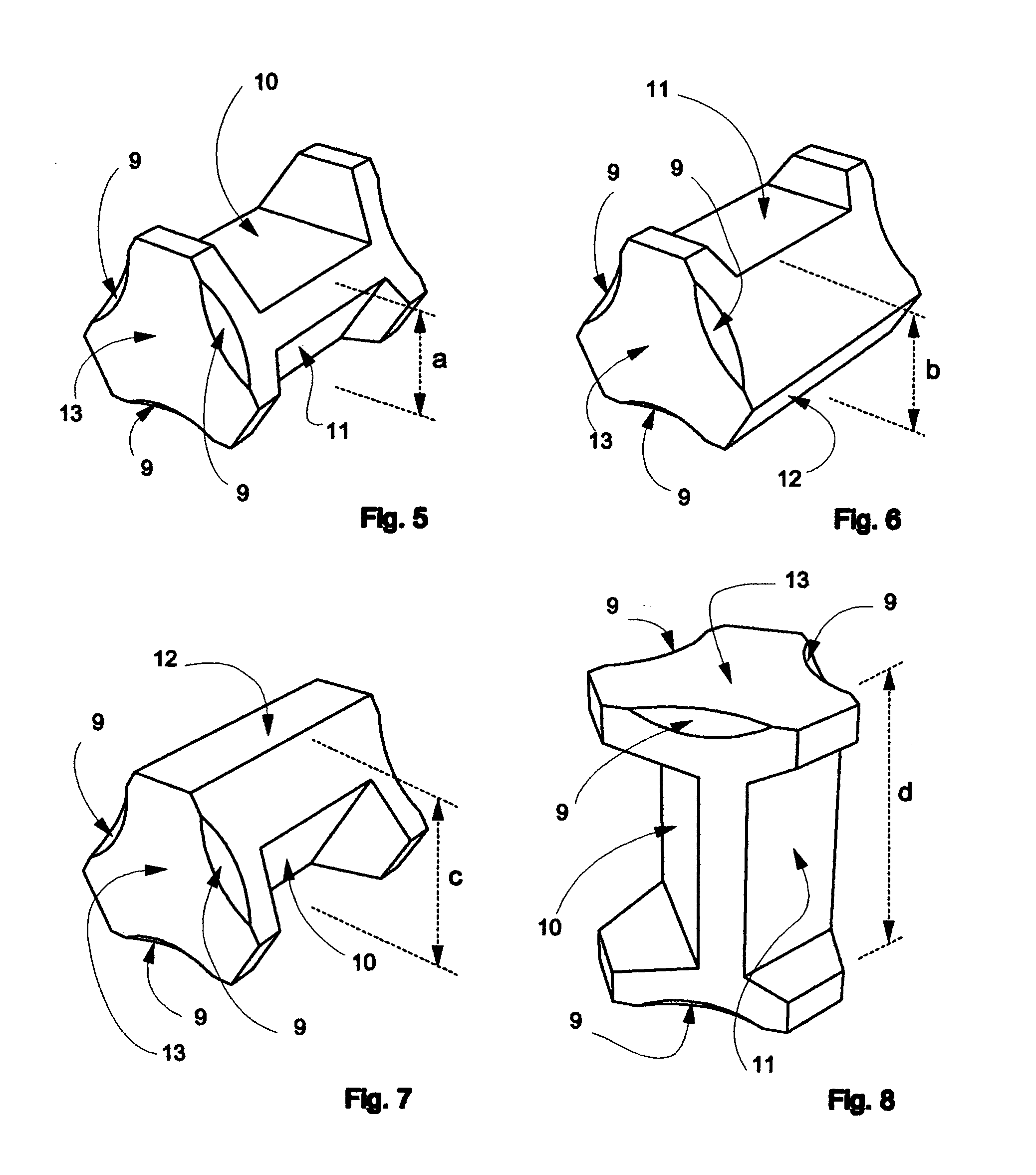

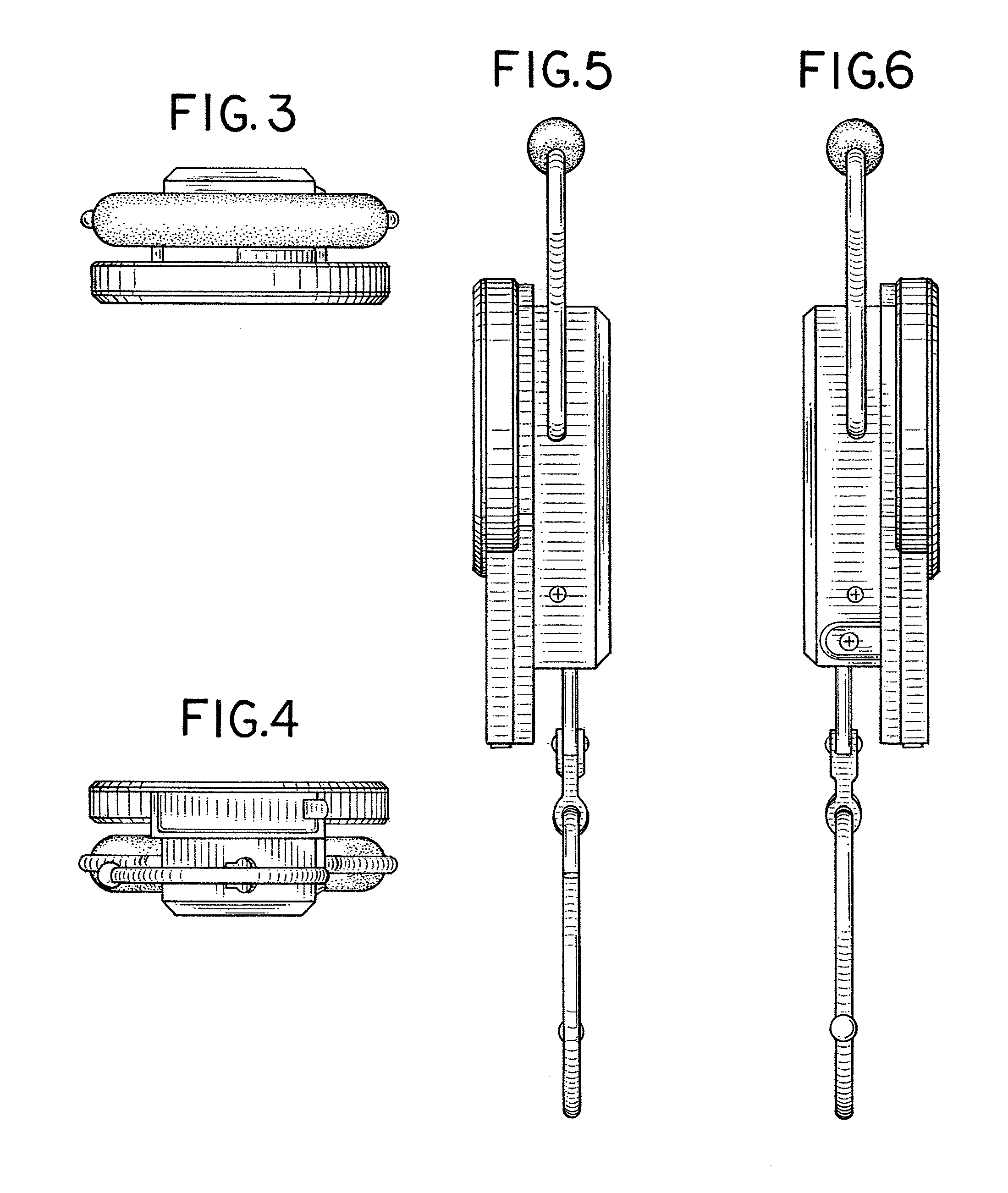

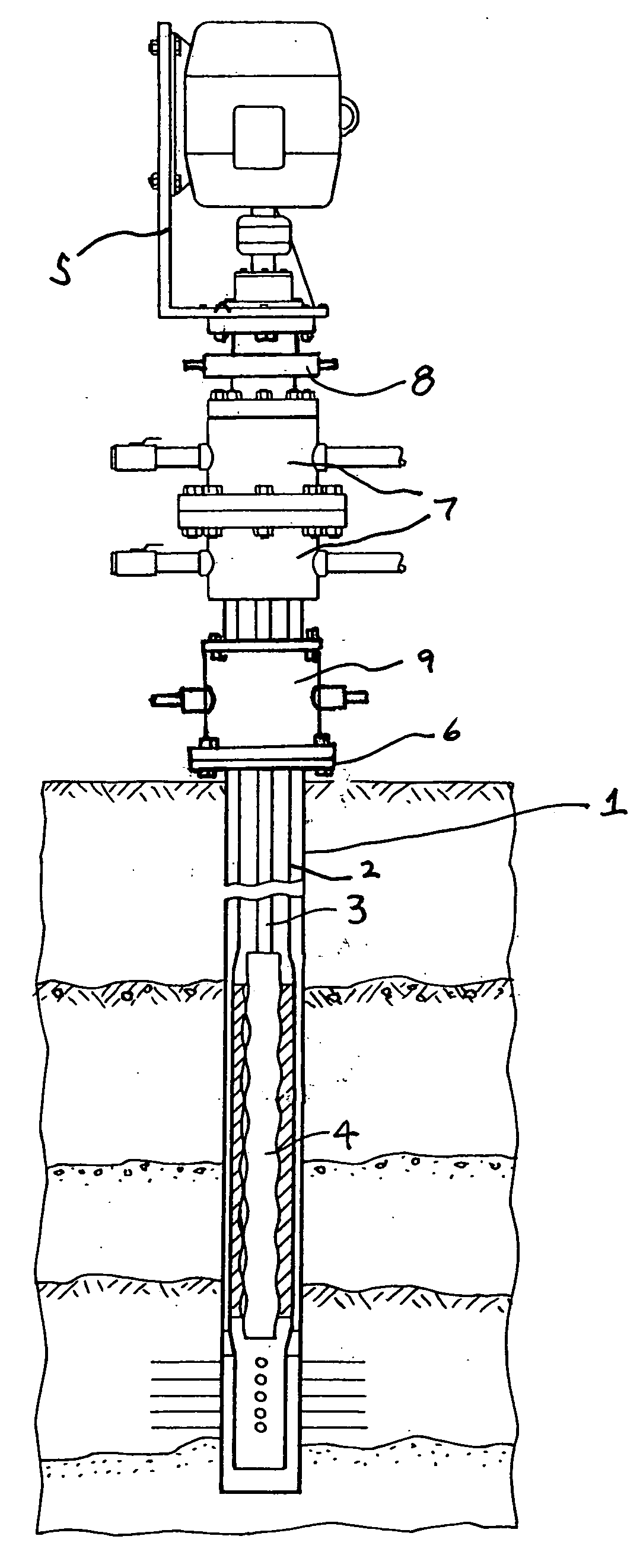

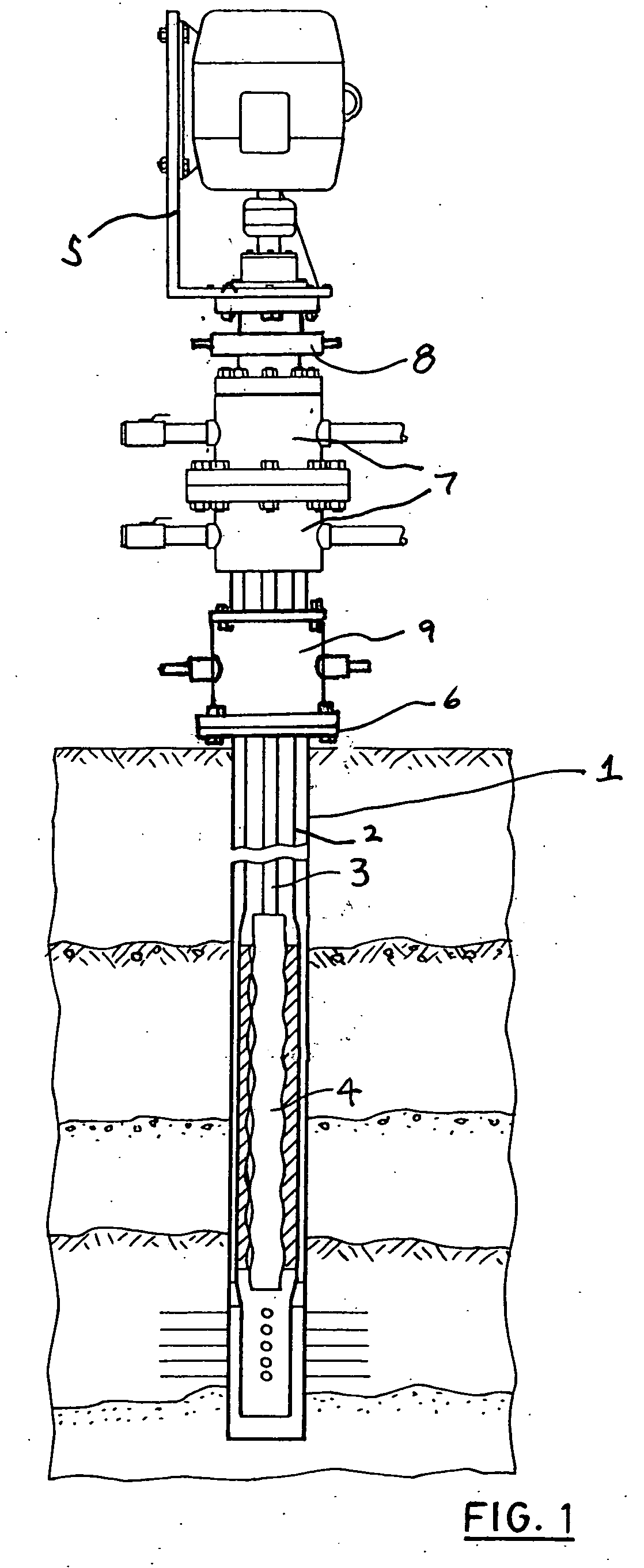

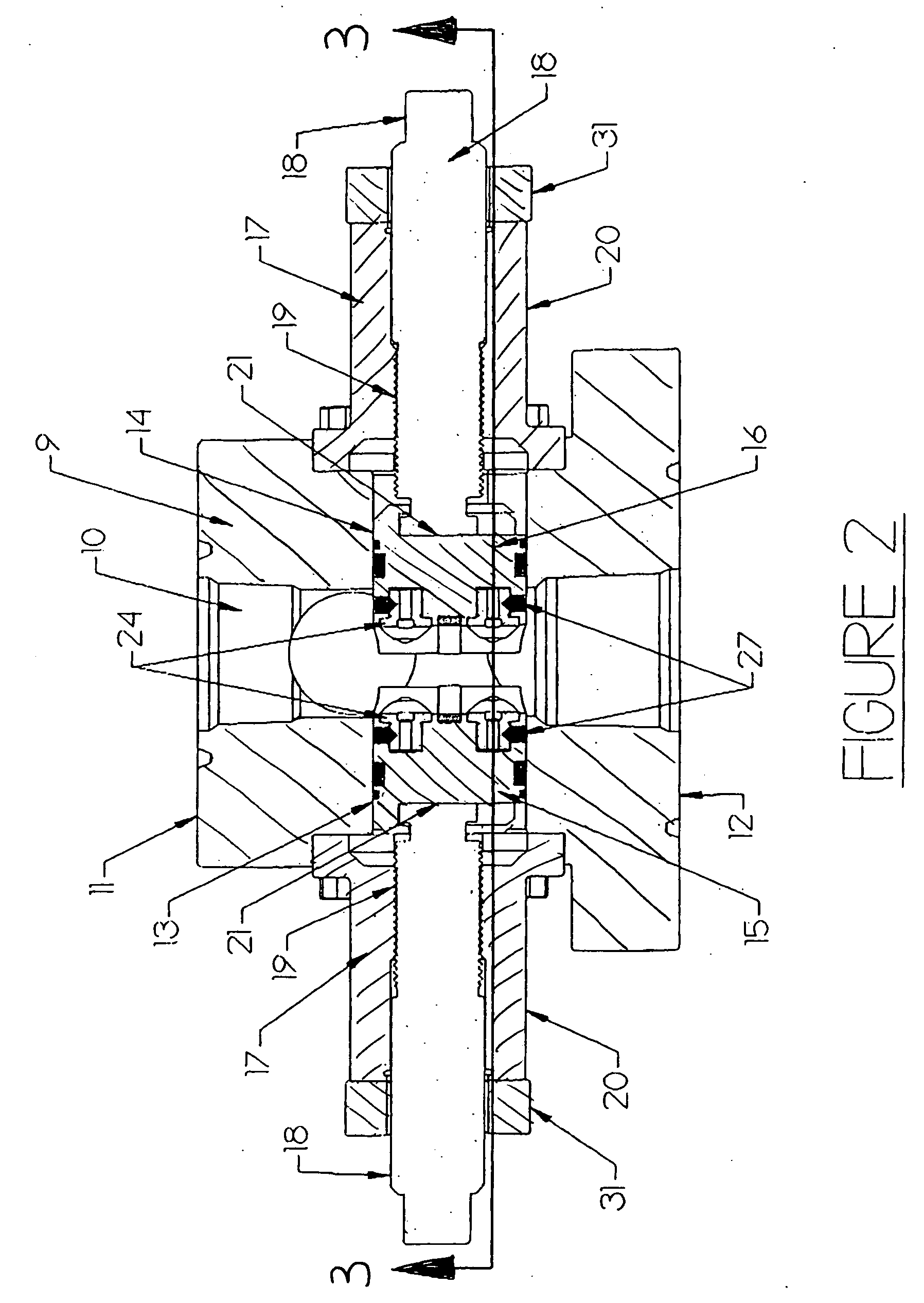

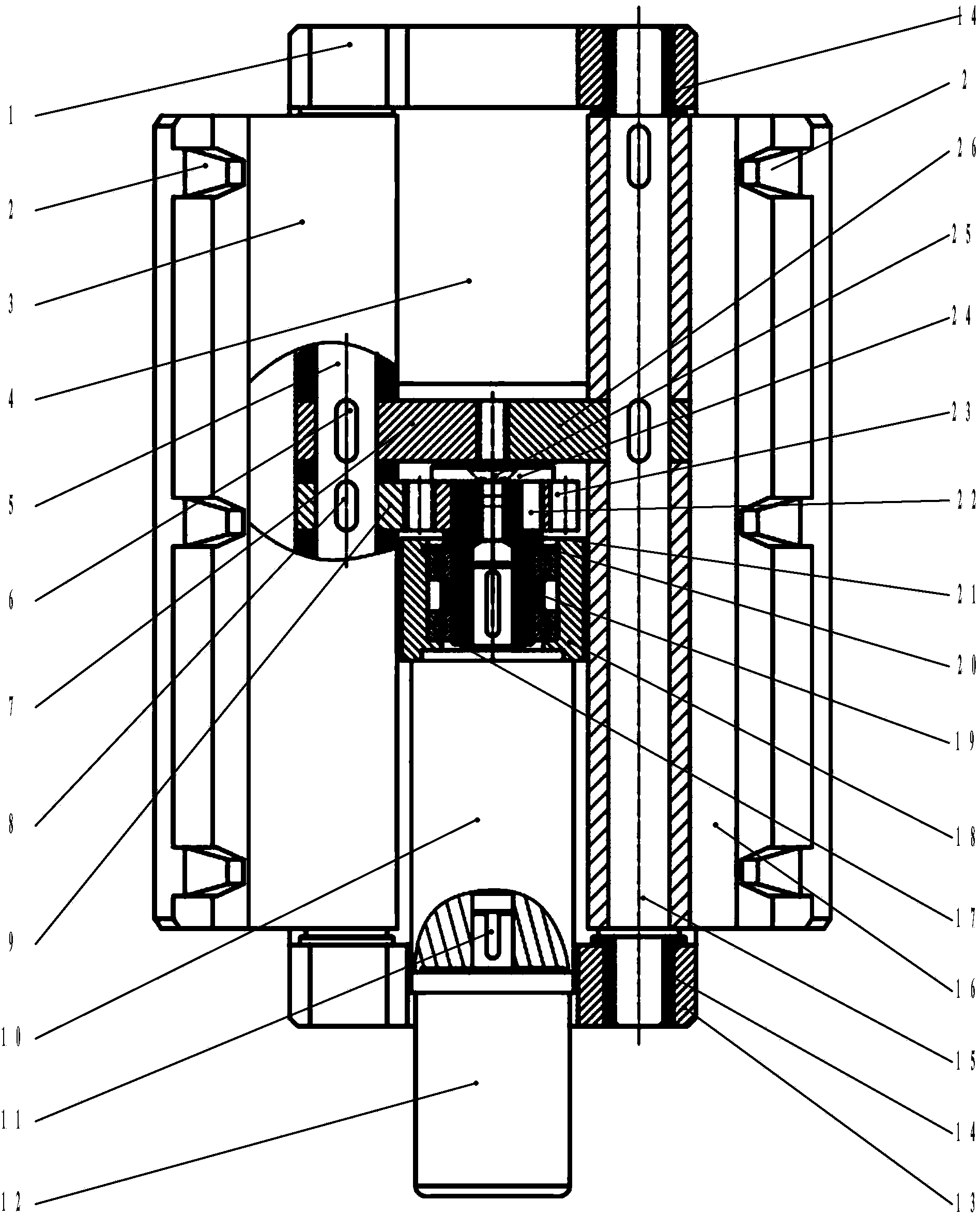

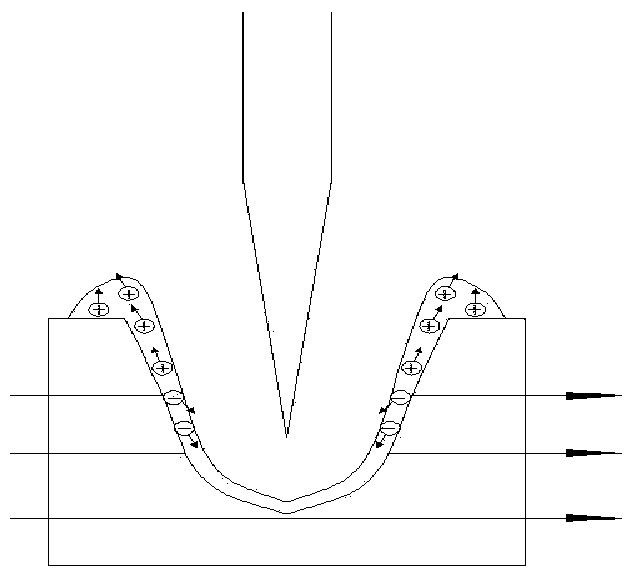

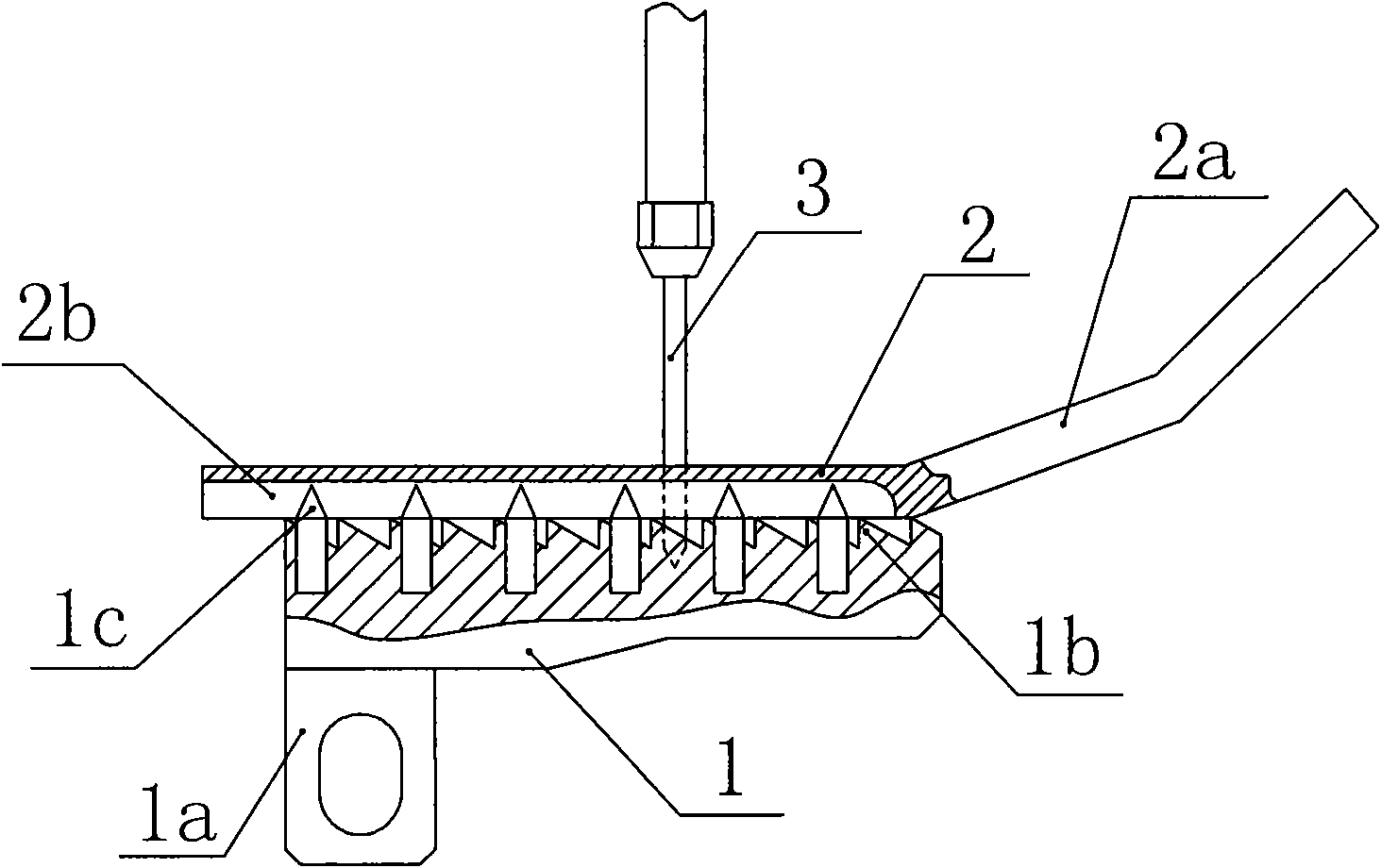

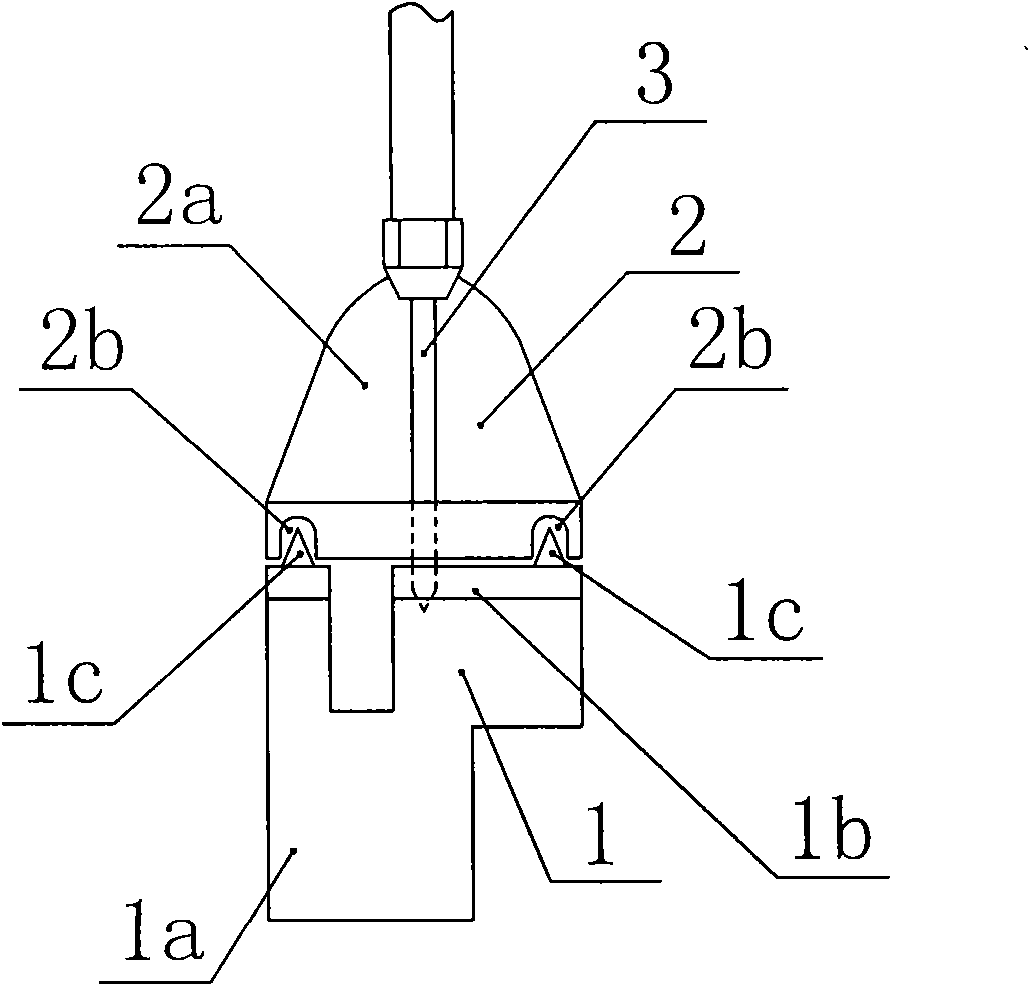

Pump rod clamp and blowout preventer

ActiveUS20050211428A1Enhanced clamping abilityImproved gripping abilityOperating means/releasing devices for valvesDrilling rodsEngineeringActuator

A pump rod clamp for gripping a pump rod in an oil, gas or water well. The pump rod clamp comprises a central housing having a longitudinal bore for receiving a pump rod, a plurality of clamping members receivable within the central housing, and one or more actuators to cause the clamping members to be moved between an activated position where they grippingly engage the pump rod and a deactivated position where they are released from contact with the pump rod. Each of the clamping members have a leading face that includes one or more gripping inserts releasably secured thereto. The gripping inserts having outer faces generally aligned with the pump rod for grippingly engaging the pump rod when the clamping members are in their activated position such that force exerted by each individual clamping member against the pump rod is concentrated and distributed over the outer faces of the one or more gripping inserts of each clamping member.

Owner:MILLENNIUM OILFLOW SYST & TECH

High colorfastness transfer printing method

ActiveCN102797174AHigh color fastnessHigh glossTransfer printing processDyeing processIsobutanolDisperse dye

The invention provides a high colorfastness transfer printing method. An prepared transfer printing ink comprises the following components in percentage by mass: 50-70% of disperse dye, 14-42% of methanol and / or isobutanol, 5-15% of polyvinyl butyral and 1-3% of stabilizing agent double-hydroxy composite metal oxide; and the transfer printing method comprises the following steps of: first, wetting a fabric to be printed by using a polyoxyethylene or polypropylene oxide aqueous solution; and then carrying out transfer printing on the fabric to be printed. The high colorfastness transfer printing method provided by the invention has the advantages of simple process, low cost, strong cohesiveness between a pattern and a fabric after printing and durability; and high colorfastness can be kept under conditions of water washing, Illumination, heating and so on.

Owner:WUXI SAILITE TEXTILE TECH

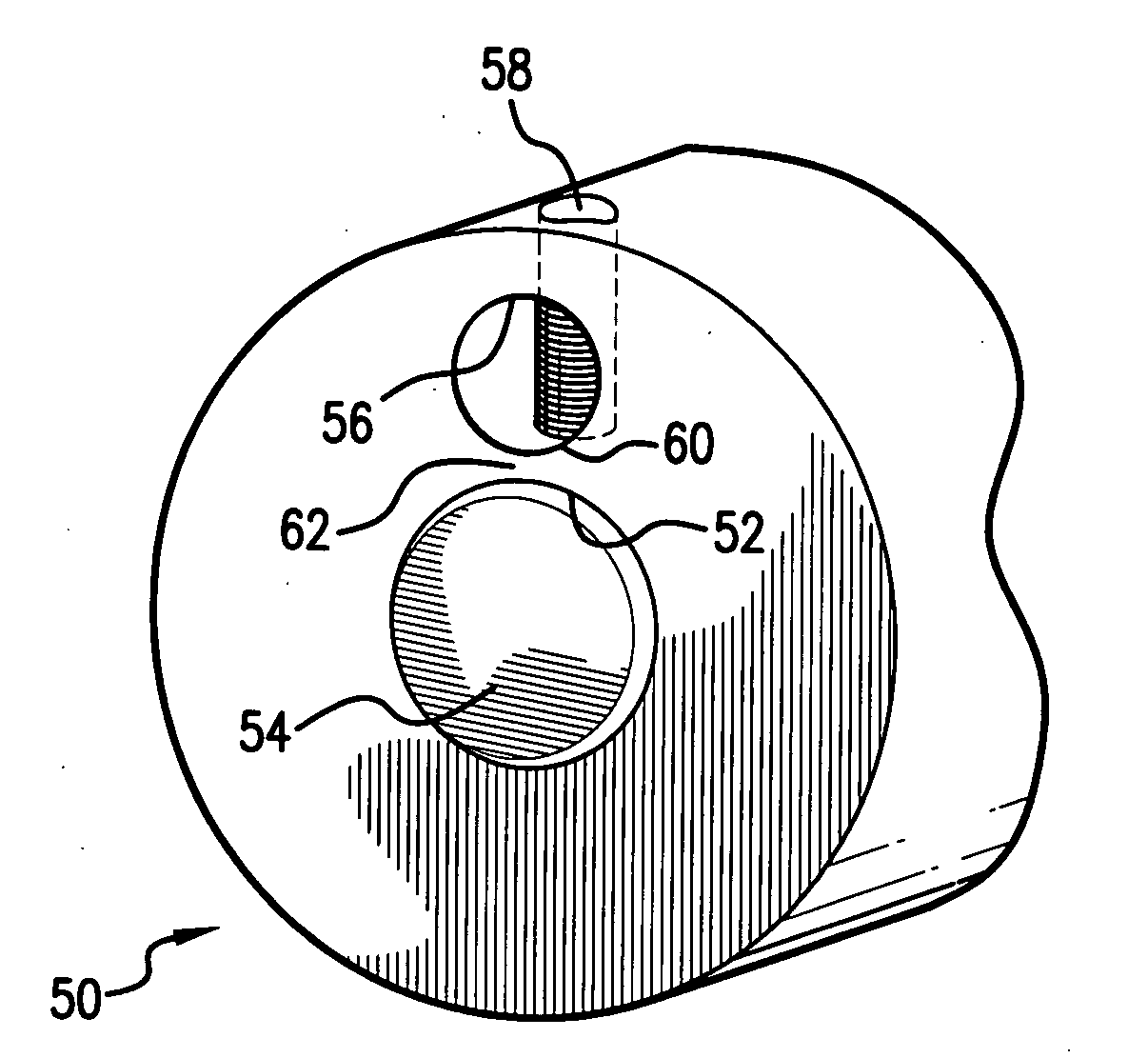

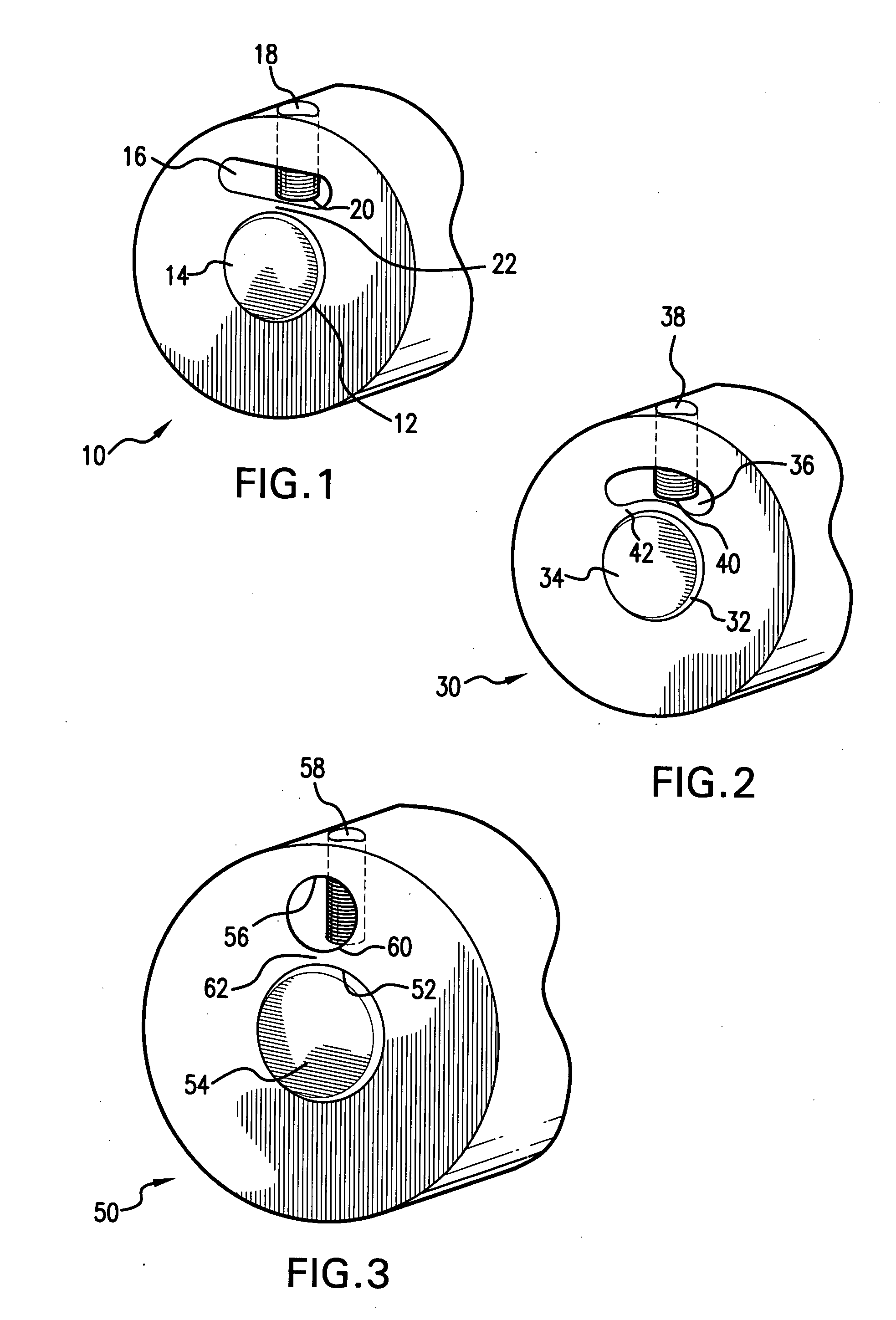

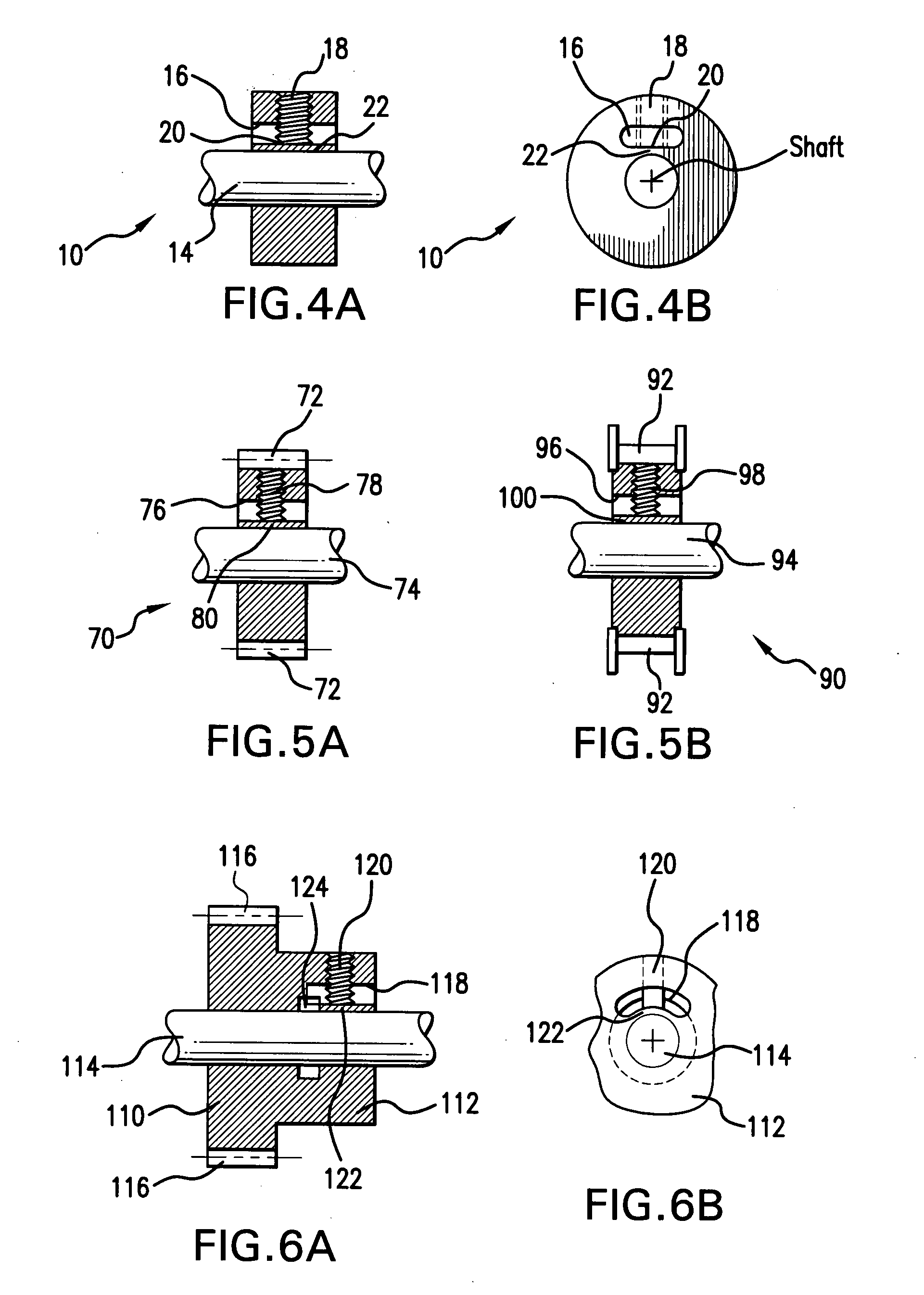

Non-marring shaft collar

InactiveUS20080240849A1Improve gripIncreased operating lifeRod connectionsCouplings for rigid shaftsSet screwEngineering

A shaft collar including a body with a centrally located bore fits over an elongated shaft. An aperture extends laterally across the body in the vicinity of the bore. The aperture extends laterally into the body also, leaving an arcuate segment situated, radially, between the bore and the aperture. A set screw is advanced radially inwardly through the apertures to press against the arcuate segment and deflect same into engagement with the outer diameter of the elongated shaft. The aperture may possess an elliptical cross-section, an arcuate cross-section, or may assume a circular cross-section. The shaft collar can be made from metal or plastic since the tightening process is performed with zero relative motion between the collar and shaft, and therefore there will be no marring or scratching of the shaft.

Owner:DESIGNATRONICS

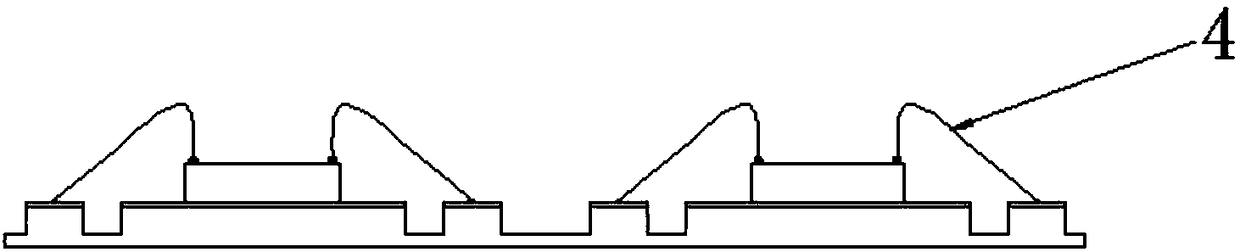

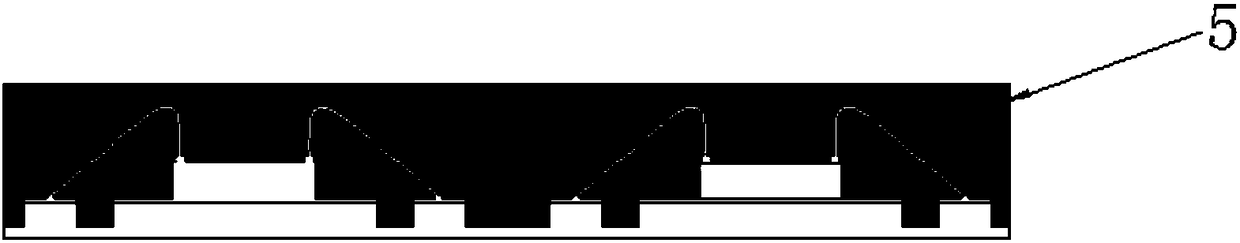

High-reliability planar bump type packaging method and packaging structure

PendingCN108389805AStrong gripping abilityIncrease grip areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringWire bonding

The invention discloses a high-reliability planar bump type packaging method and a packaging structure, and belongs to the field of semiconductor packaging. In the back protection process existing inthe prior art, a simple ink brushing process cannot ensure the effective glue gripping area of metal pins, the area of the pins is small after cutting, and the problem of poor probe contact effect issolved. The high-reliability planar bump type packaging method and the packaging structure are provided, the packaging structure includes a chip bearing base, a wire bonding inner lead bearing base, chips, lead wires and a plastic package body, the chip bearing base comprises base islands and front metal layers of the base islands, the wire bonding inner lead bearing base comprises pins and frontmetal layers of the pins, and an excess metal area, except the back face of a pin metal layer, is provided with an ink layer. A good glue gripping effect is achieved, the contact defect rate is low, the contact effect is good and the detection rate is high during the detection of finished products.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

High-light-color-fastness transfer printing method

ActiveCN102797173AImproved gripping abilityTightly bondedTransfer printing processDyeing processBinding forceAqueous solution

The invention relates to a high-light-color-fastness transfer printing method. An ink for transfer printing comprises the following components in percentage by mass: 40-70% of black disperse dye, 10-30% of red disperse dye, 12-15% of methanol and / or isobutanol, 5-10% of polyvinyl butyral and 3-5% of photostabilizer 622. The transfer printing method comprises the following steps: soaking a textile to be printed in a polyoxyethylene or polyoxypropylene water solution, and carrying out transfer printing. The invention has the advantages of simple technique and low cost; and the printed pattern has the advantages of high binding force with cloth, high light color fastness and high durability.

Owner:WUXI SAILITE TEXTILE TECH

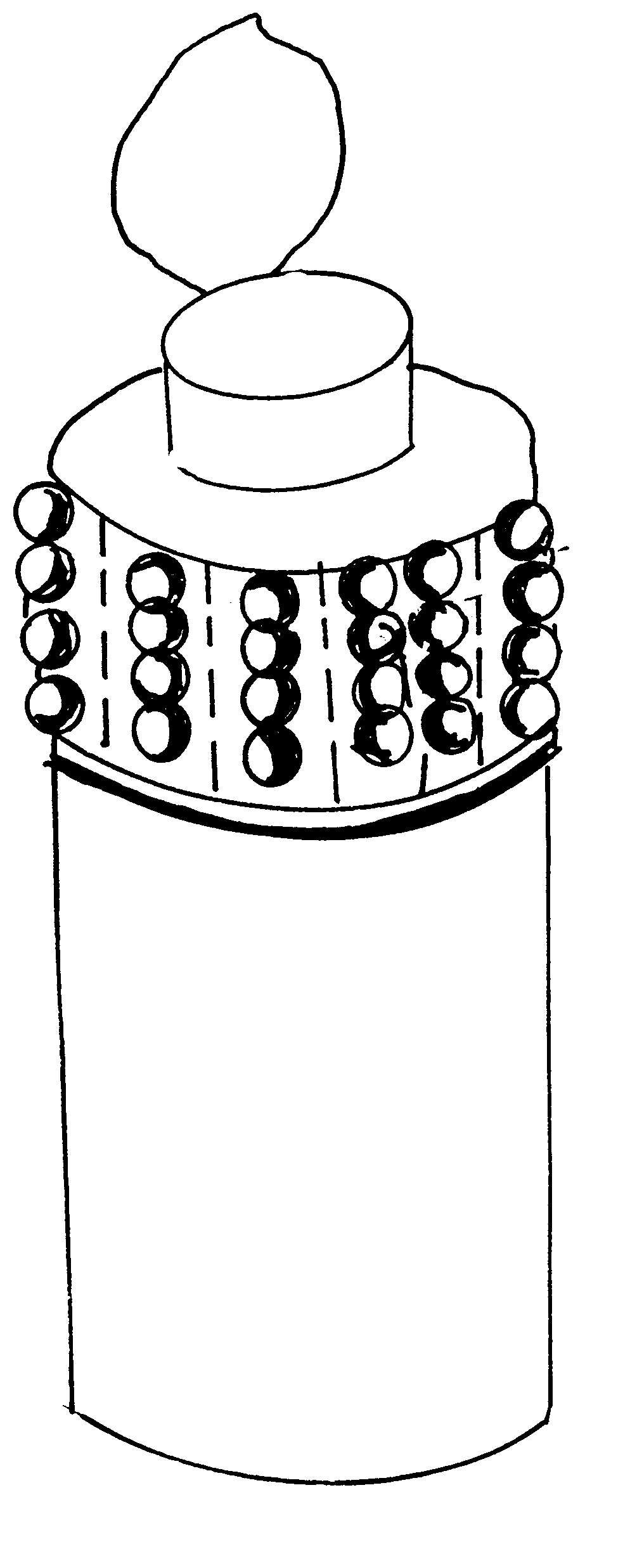

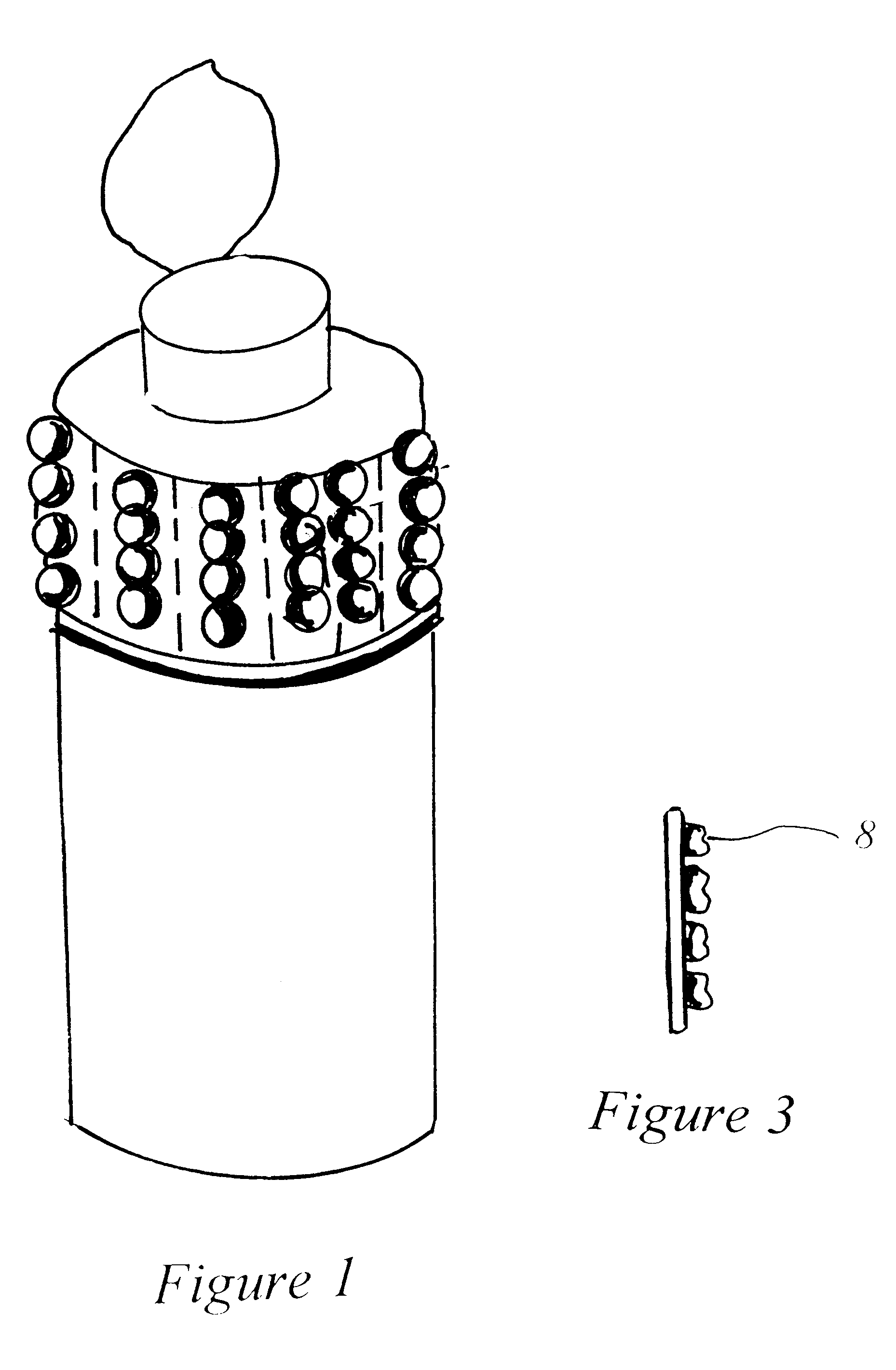

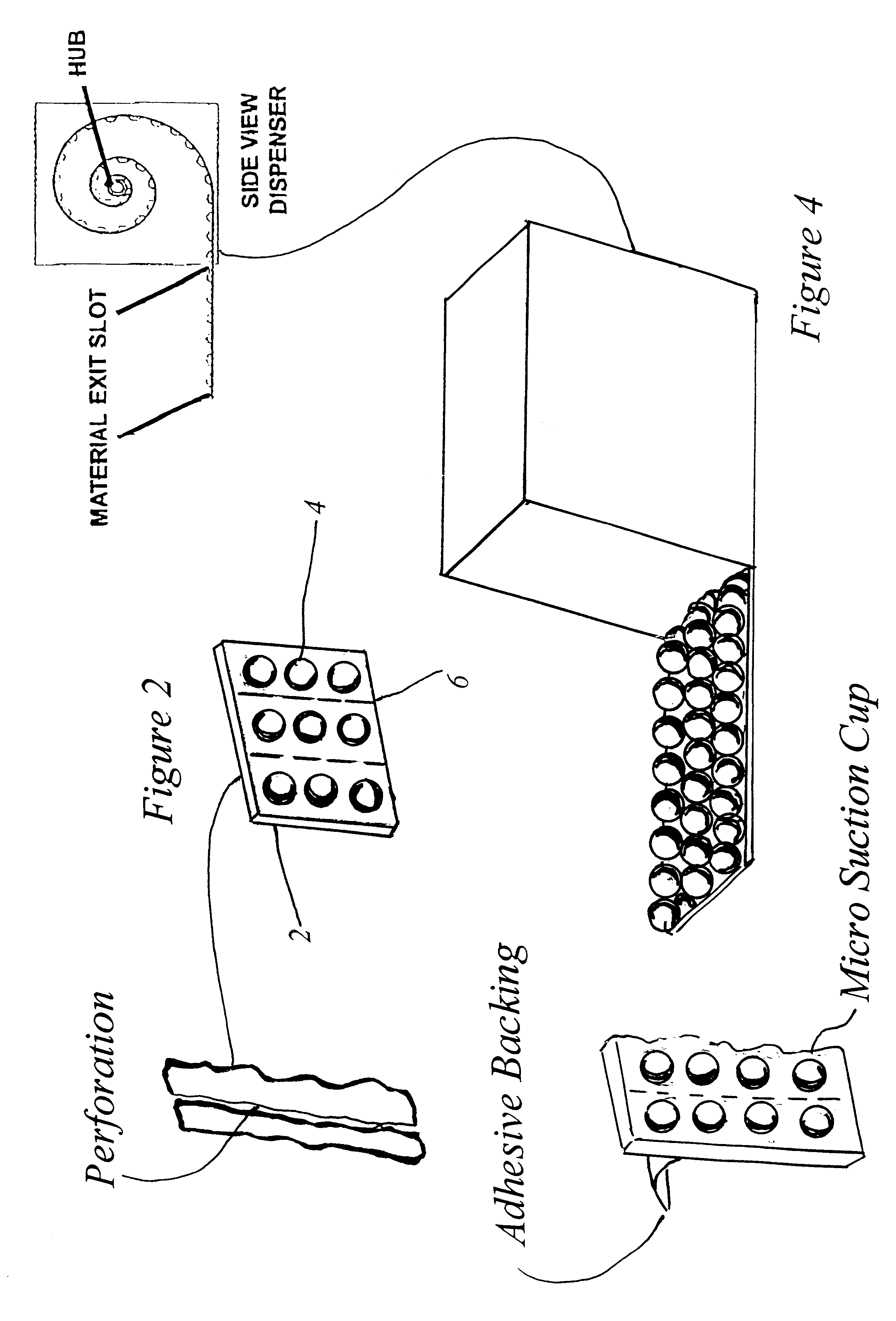

Universal shampoo indentification logo

InactiveUS6367185B1Assisted identificationEasy and efficient to manufactureStampsTeaching apparatusEngineeringBottle

The present invention is that of a new and improved apparatus for assisting a blind or visually impaired person in locating a shampoo bottle or other bottle located within a shower. The apparatus would be a plurality of small adhesive tags attached to each other but allowing a user to separate them by incorporated perforations. Each of the tags would have a plurality of incorporated raised bubbles on its front surface. The back surface would include a peel-away backing, which would cover a sticky coating on the back surface of the small adhesive tags until the small adhesive tags would be ready for use. Each bubble on each of the adhesive tags would be manufactured to include a micro-suction cup top-mounted on each bubble, providing the user with a more secure grip. The plurality of adhesive tags would be designed to come in a roll and would be packaged within a roll dispenser box, with the roll of adhesive tags connected to and surrounding a roller located inside the roll dispenser box. A roll dispenser box would include a slot opening to allow a plurality of small adhesive tags to be removed from the roll dispenser box and attached to a cylindrical object as needed.

Owner:FRASER ANN

Preparation method of inorganic anti-corrosive paint for steel bar

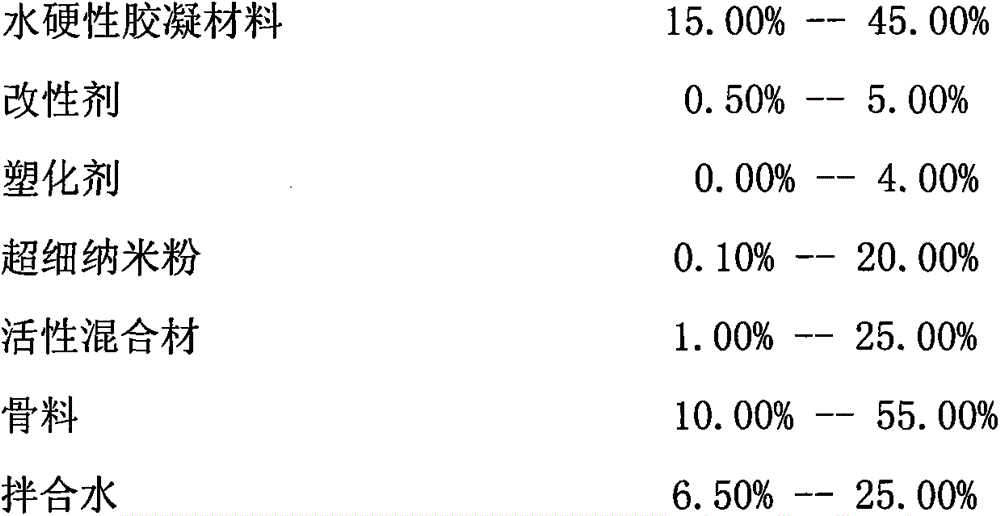

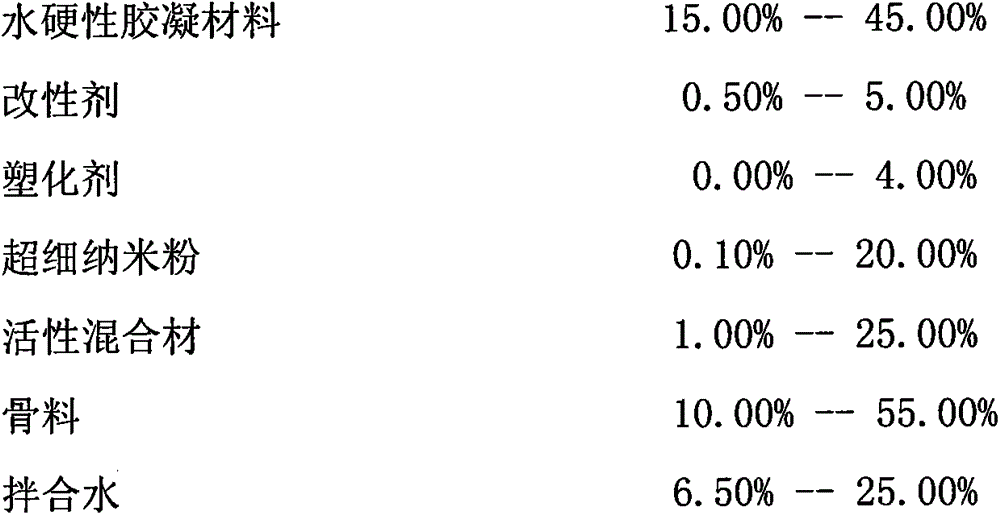

The invention belongs to the technical field of building materials and particularly relates to an inorganic anti-corrosive paint for a steel bar. The inorganic anti-corrosive paint is prepared from a hydraulic cementing material, a modifying agent, a plasticizer, superfine nanometer powder, an active composite material, aggregates and mixing water at a certain ratio. The inorganic anti-corrosive paint prepared by the method disclosed by the invention is quite good in workability; the surface of the steel bar has a quite good adhesive force and is unlikely to sag after being mechanically sprayed with the inorganic anti-corrosive paint; the paint can be rapidly coagulated; the paint formed after solidification is compact in structure, 30 to 70 MPa in compressive strength in one day, 60-150 MPa in compressive strength in 28 days and 100-1000 coulombs in electric flux, so the paint is quite good in chloride penetration resistance. Besides, the paint and concrete have quite good compatibility and quite high bonding strength which is 1.0-2.0 MPa in 28 days. By adopting mechanical operation, the inorganic anti-corrosive paint for the steel bar, disclosed by the invention, can be used for rapidly performing a large-area anti-corrosive treatment on the steel bar at a construction site and is especially applicable to the anti-corrosive treatment of the steel bar in marine concrete. The preparation method disclosed by the invention is simple, convenient and wide in application.

Owner:汪峻峰

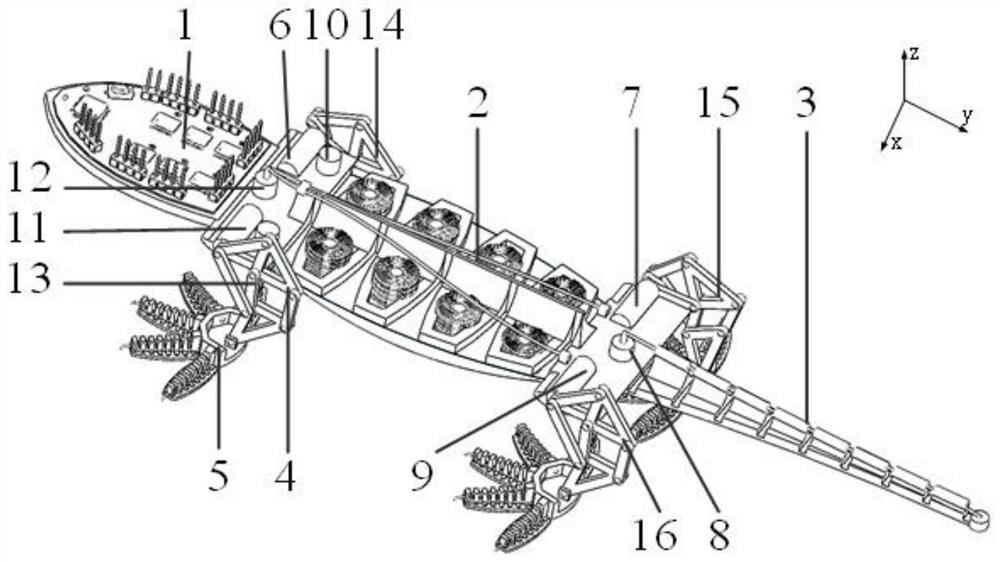

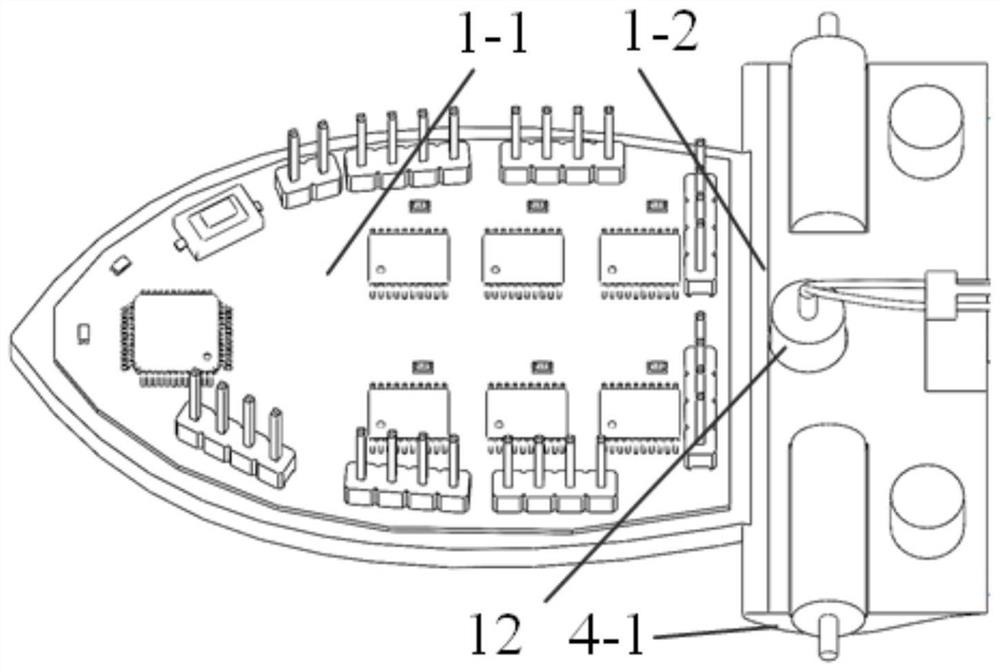

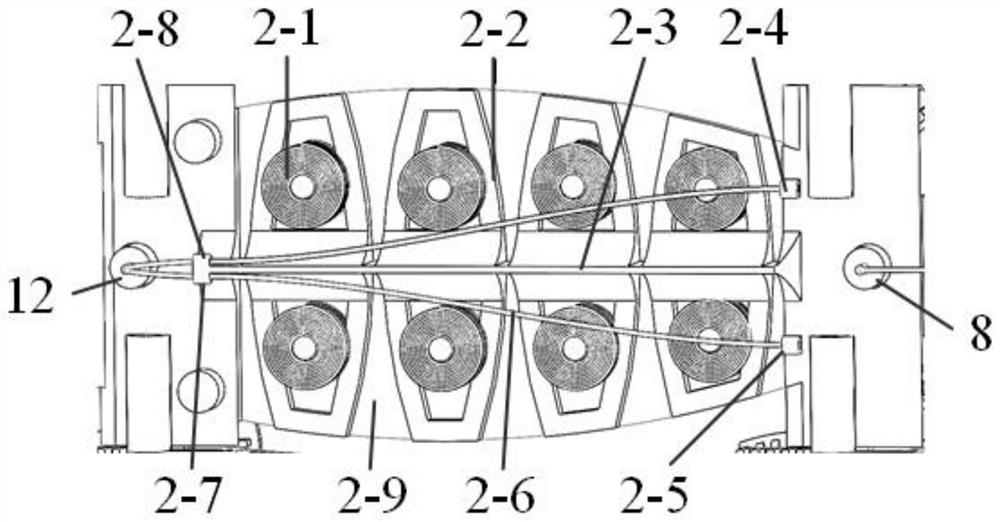

Wind-vibration-resistant climbing and attaching robot imitating Anleski

The invention belongs to the field of intelligent robots, and relates to a wind-vibration-resistant climbing and attaching robot imitating Anleski, which is composed of a body function module, a sole function module, a leg function module, a control and drive function module and a power supply device. The body function module comprises a head, a spine for completing a cross gait advancing function through bending, a flexible abdomen film made of magnetic sensitive rubber, a tail for converting wind energy into advancing power through bending deformation, and a rib frame; wherein the sole function module is composed of toes and toe connecting pieces, and the toes comprise claw thorns and multiple sections of phalanges; and the leg function module comprises a pneumatic function part and a movement function part. According to the robot, by referring to the structural change characteristics of Anlerei in strong wind, the flexible belly part and the flexible tail part capable of adjusting aerodynamic performance and the adhesion soles capable of improving the adhesion capacity are designed, so that the problem of stable climbing in the strong wind environment can be solved, and the robot can adapt to a wall surface with a certain curvature and can adapt to wider and more complex scenes.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

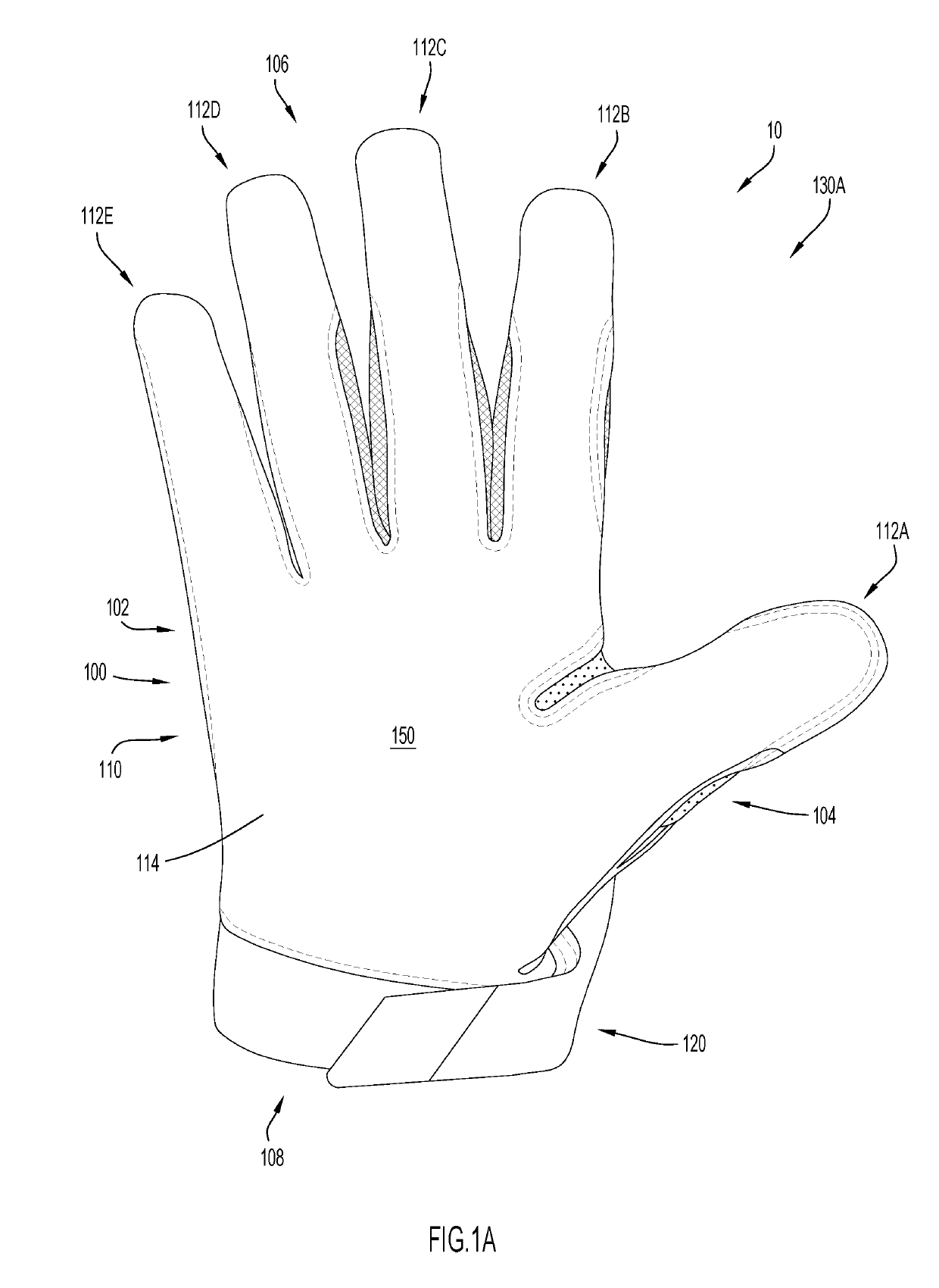

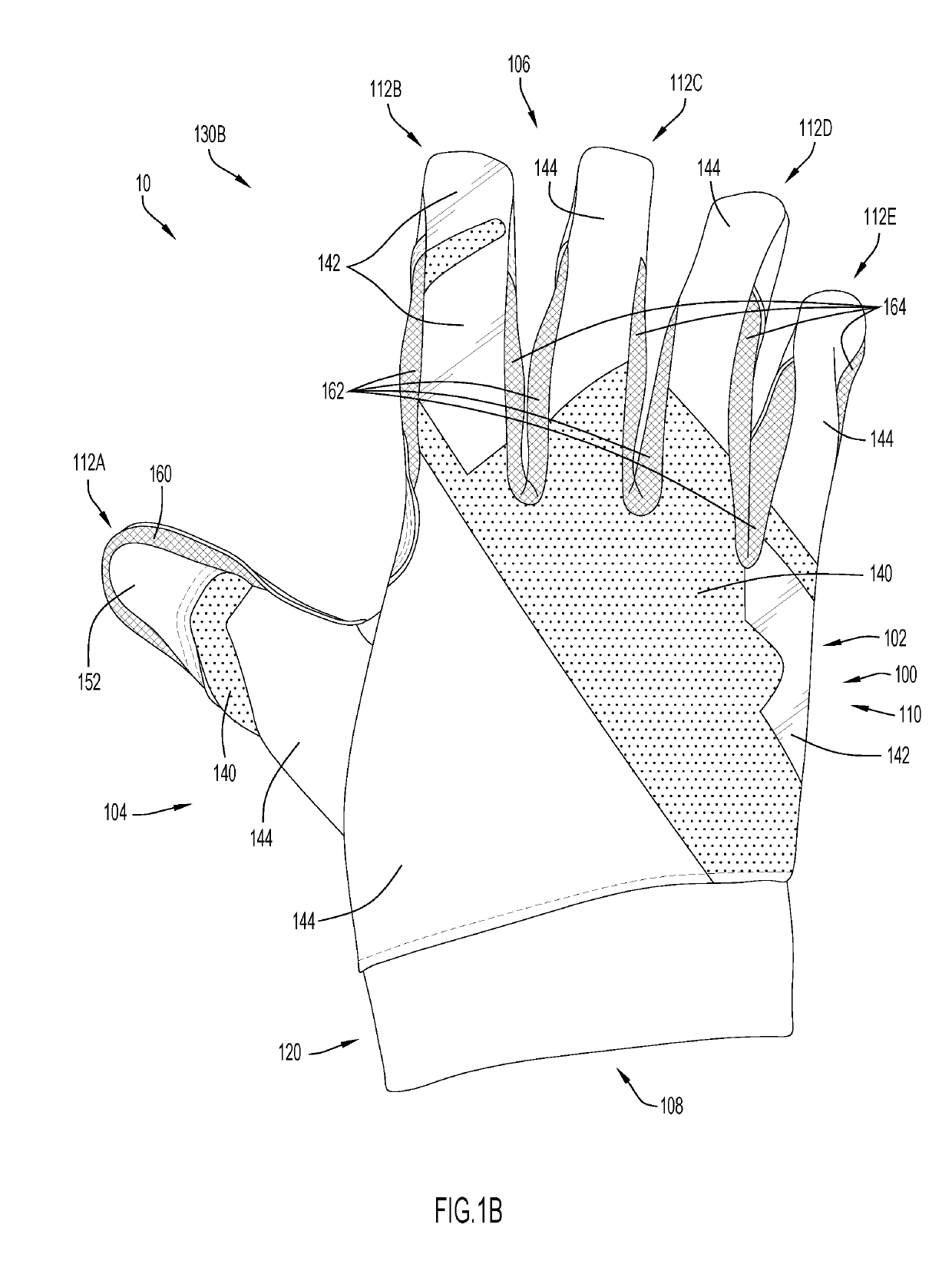

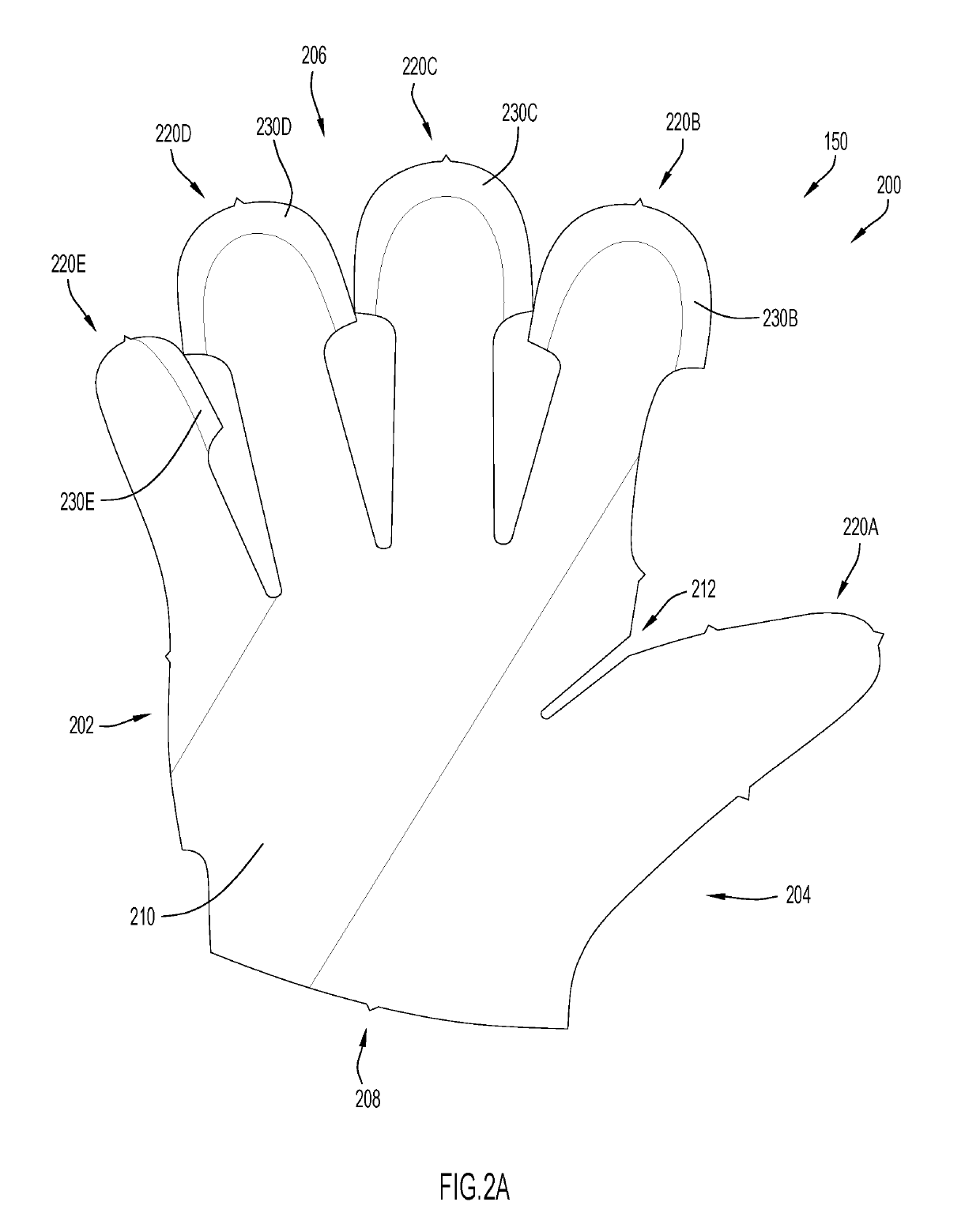

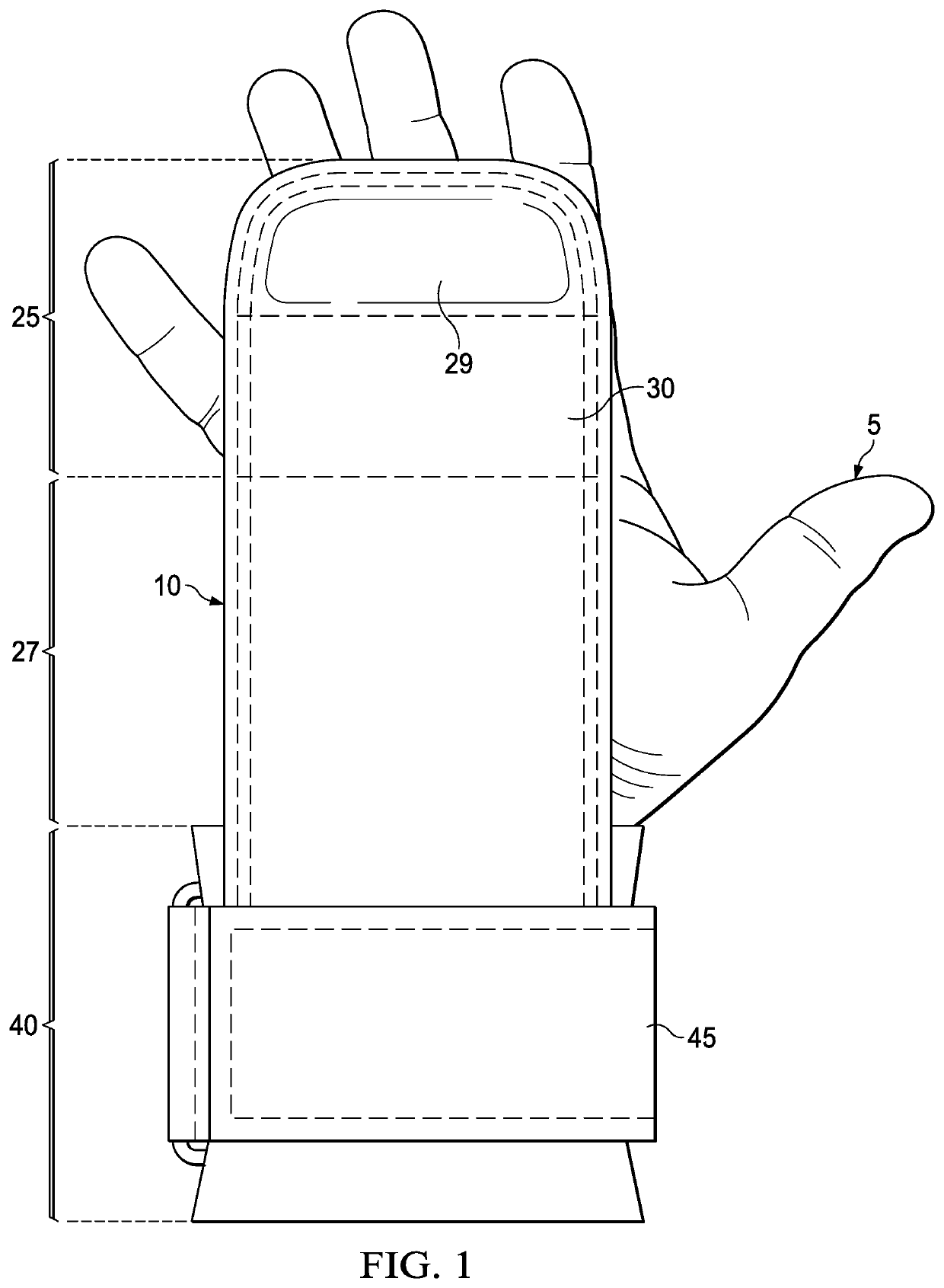

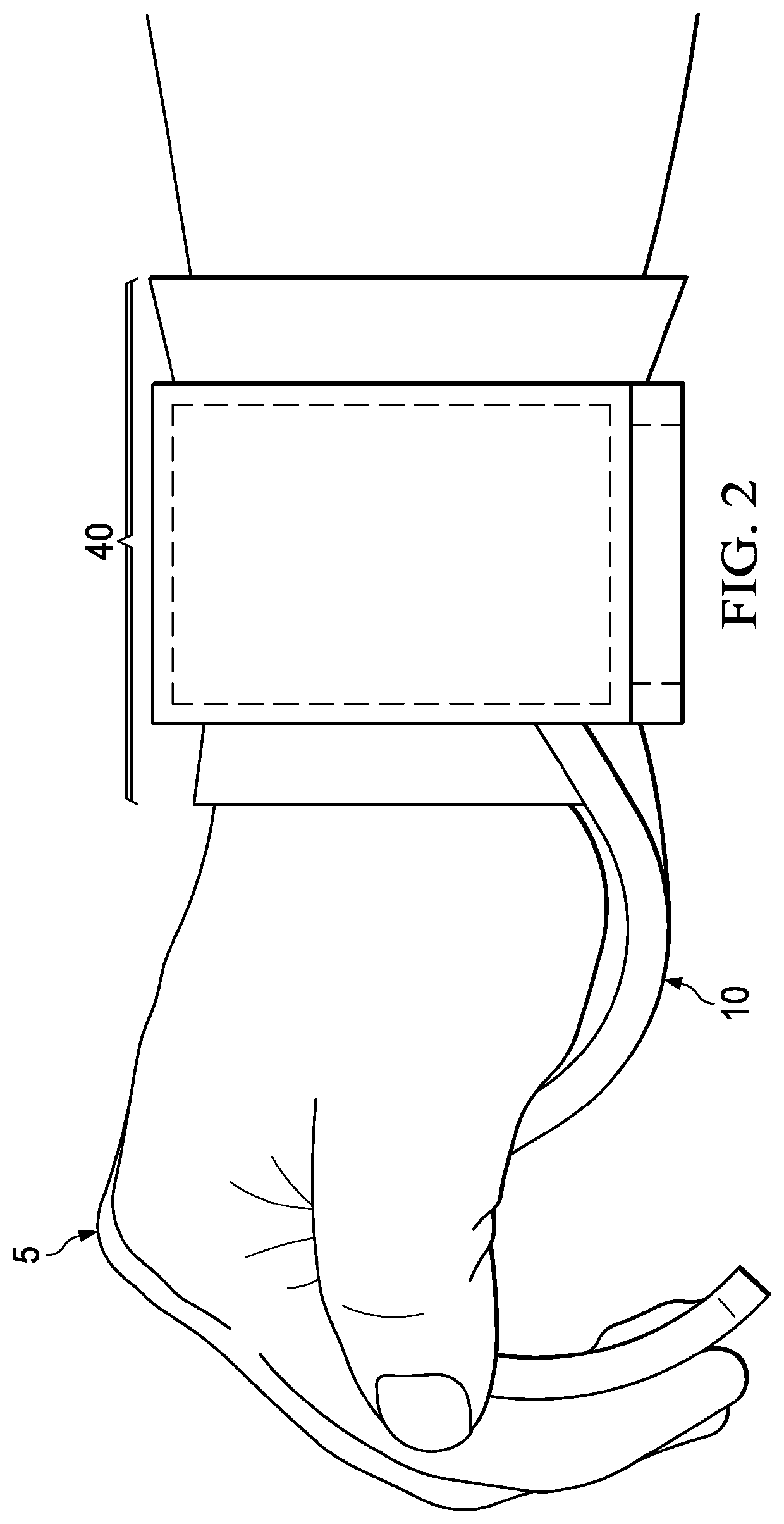

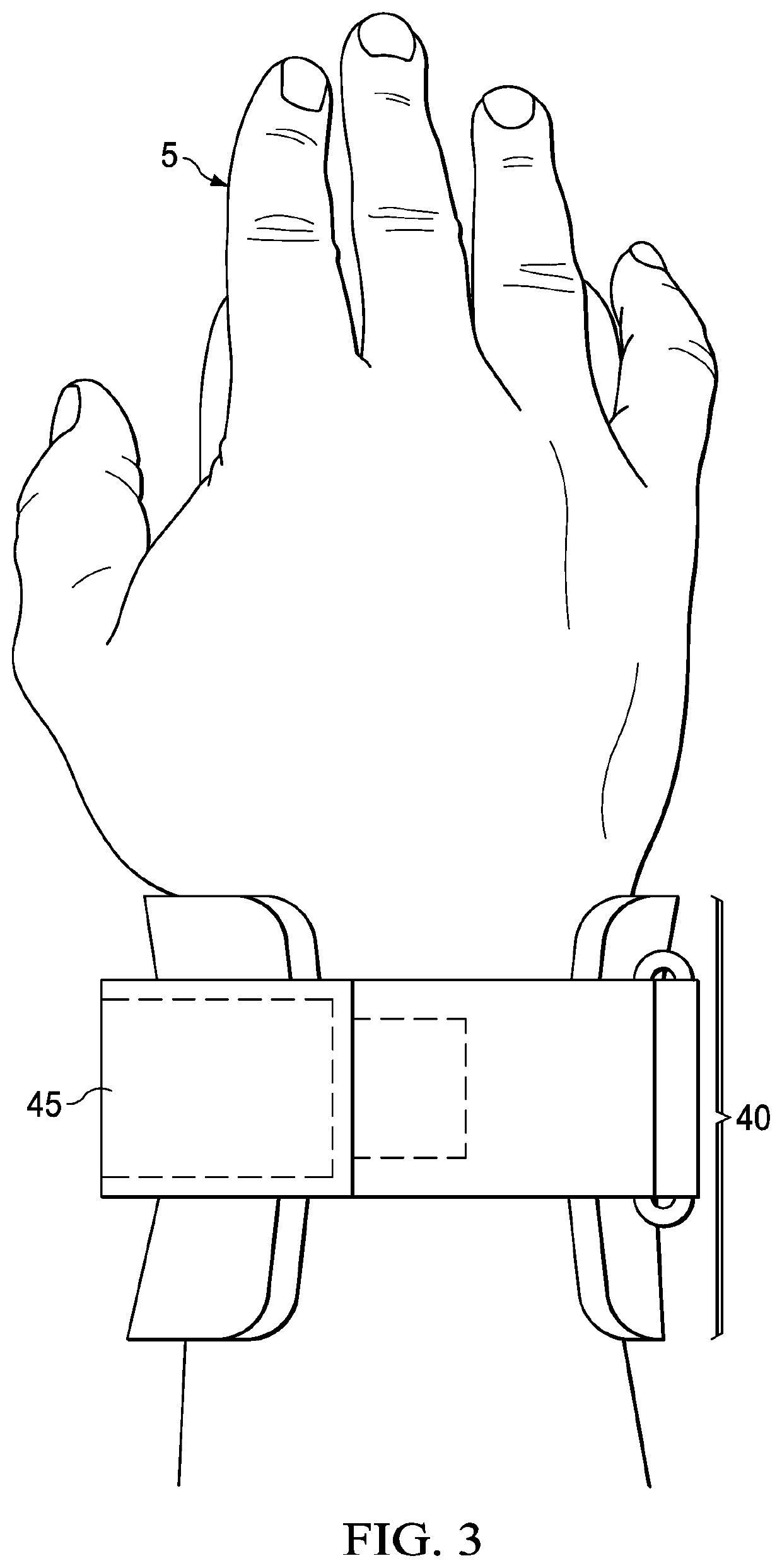

Athletic Glove

InactiveUS20190091547A1Improved gripping abilityGarment special featuresGlovesBiomedical engineering

Owner:UNDER ARMOUR

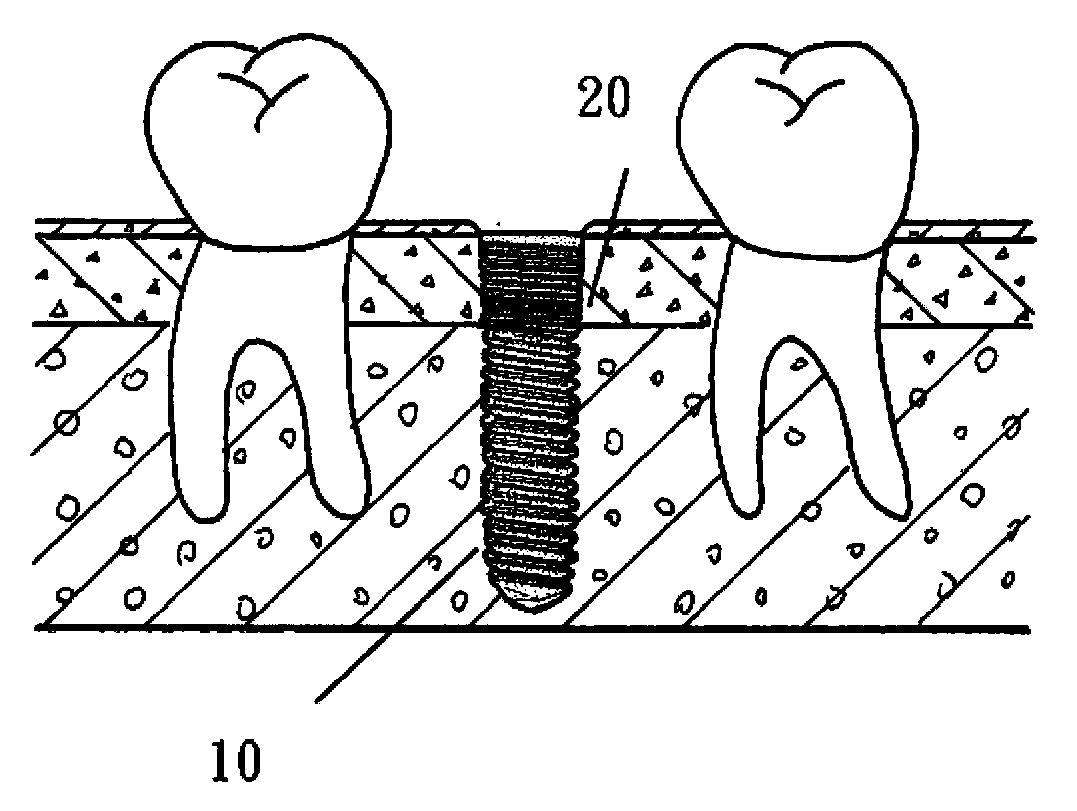

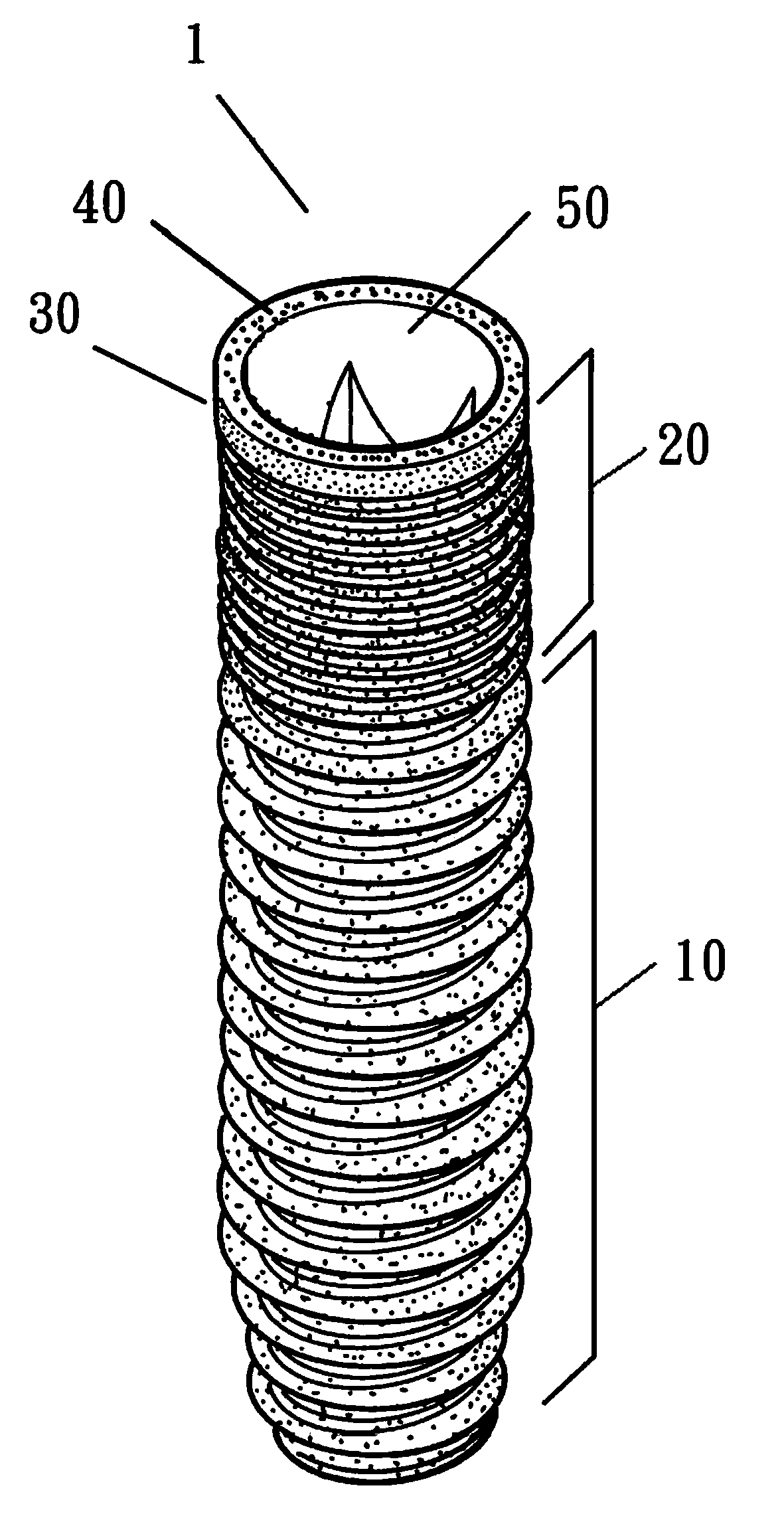

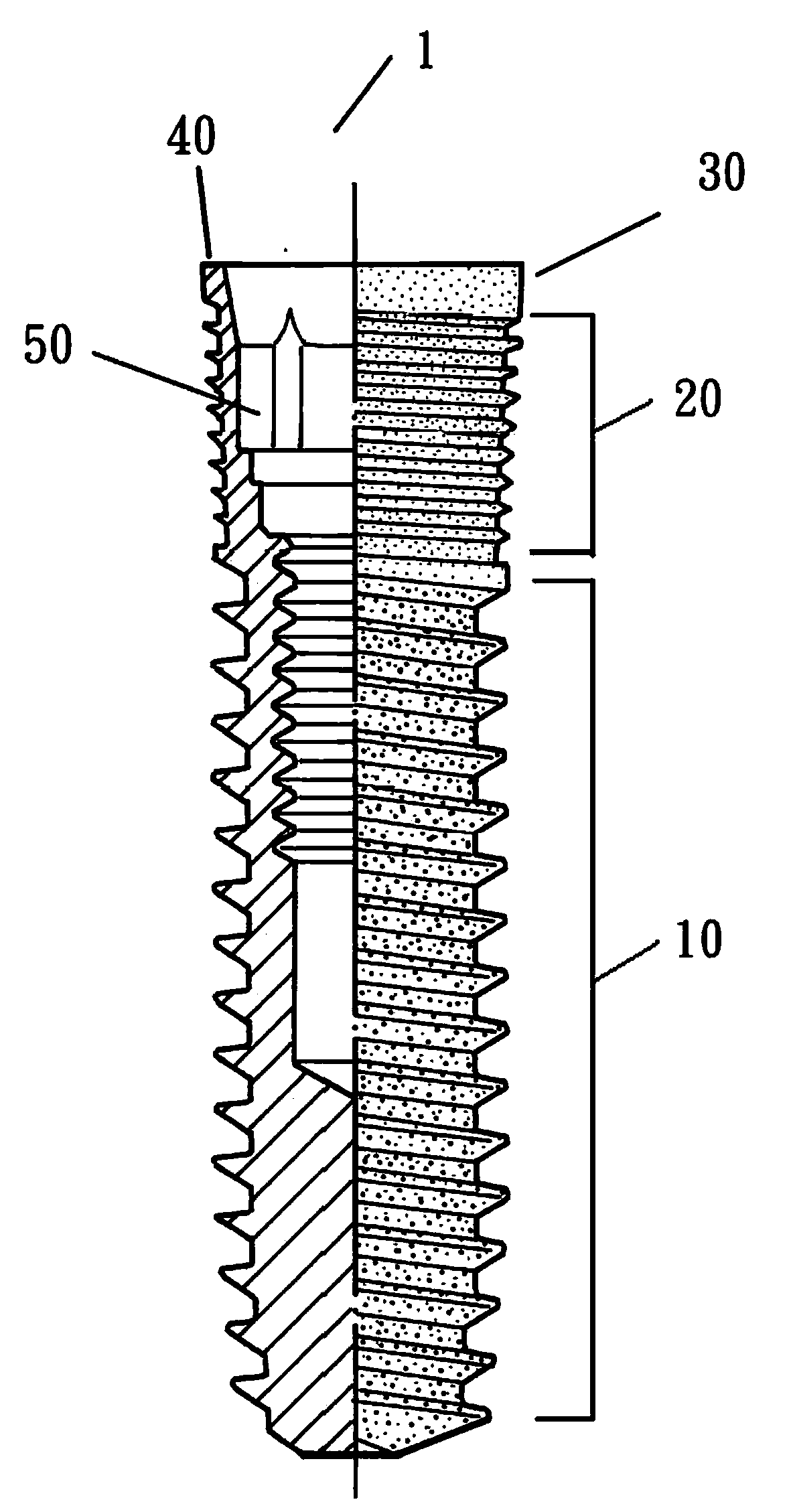

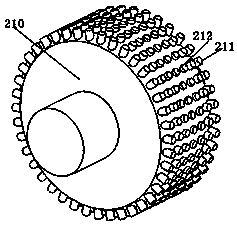

Dental implant having different surface treatment areas

InactiveCN103830013AImproved gripping abilityAvoid necrosisDental implantsOsseointegrationDental implant

A dental implant having different surface treatment areas is formed by a coarse screw tooth zone, a dense screw tooth zone, a neck ring portion, a top portion and a conjugative pore, the coarse screw tooth zone is composed of screw teeth having a wide pitch, the surface of the coarse screw tooth zone is sandblasted, and the sandblasted surface is etched by an acid to form holes having different sizes; the dense screw tooth zone is composed of screw teeth having a narrow pitch, and the surface of the dense screw tooth zone is etched by the acid to make a plurality of small holes distributed in the acid-etched surface; the neck ring portion is positioned at the upper edge of the dense screw tooth zone, and the surface of the neck ring portion is etched by the acid to make a plurality of small holes distributed in the acid-etched surface; the top portion is positioned at the top edge of the dental implant, and the surface of the top portion is etched by the acid to make a plurality of small holes distributed in the acid-etched surface; and the conjugative pore is positioned at the inner edge of the top portion, and is a blind hole provided with a positioning surface and a female screw. The above structure is helpful for the easy screw-in, the reduction of osteocyte necrosis and the improvement of the gripping capability of osteocytes in order to realize osseointegration.

Owner:QIN CHUANG PRECISION TECH

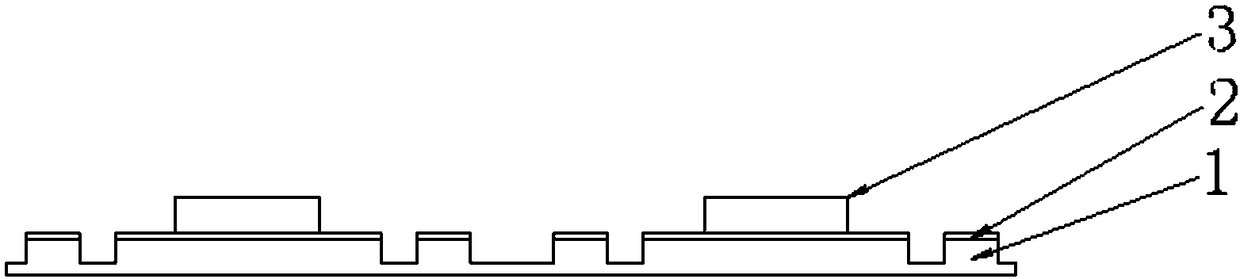

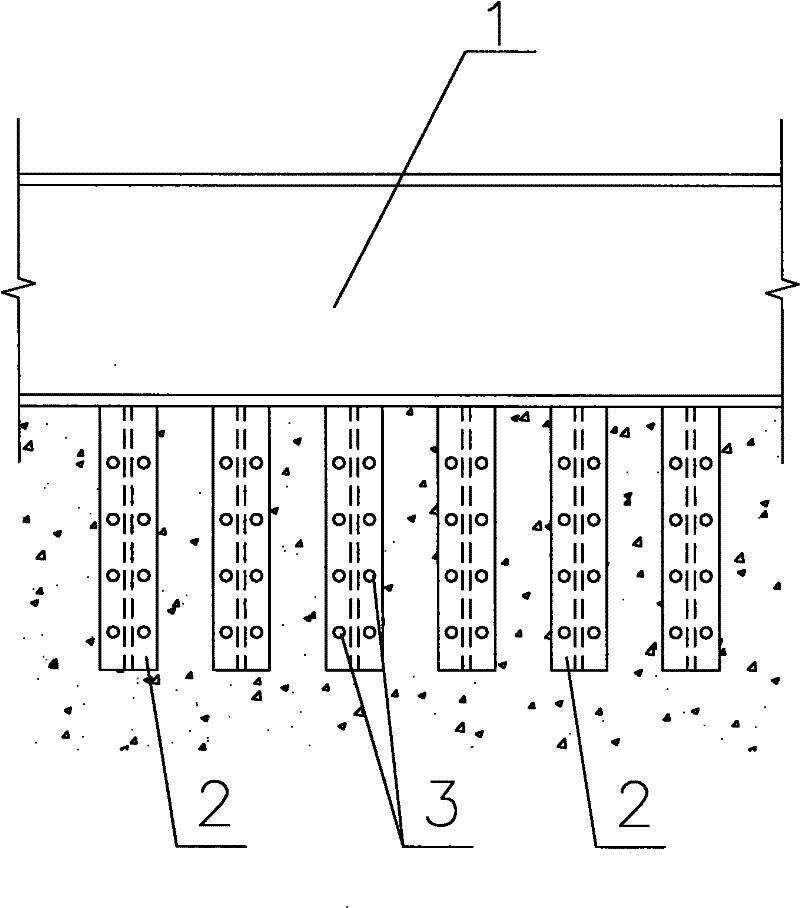

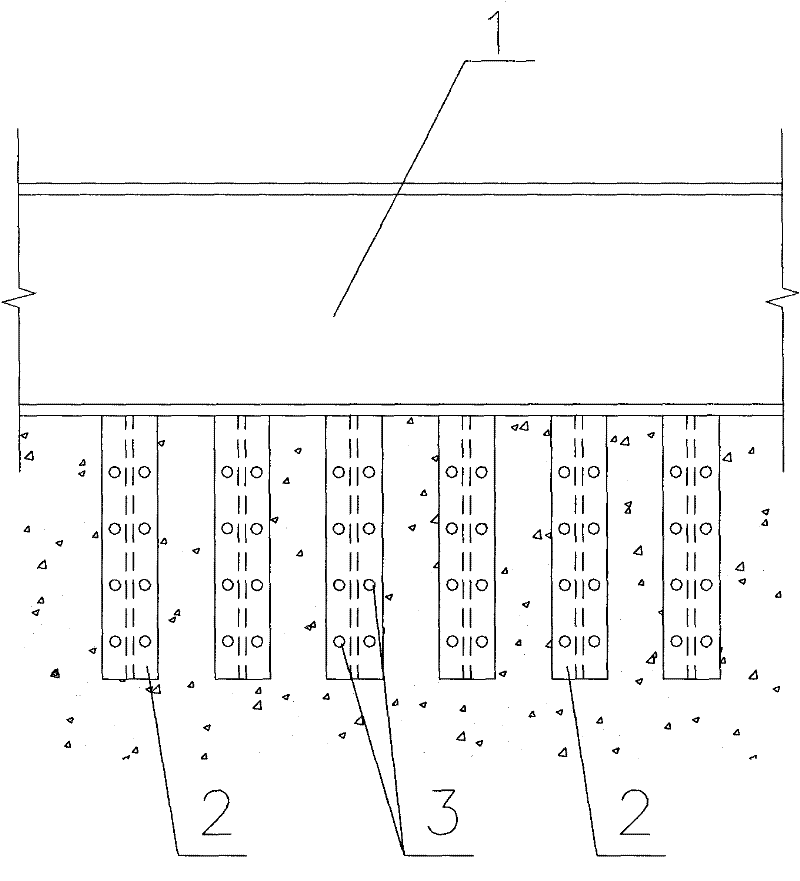

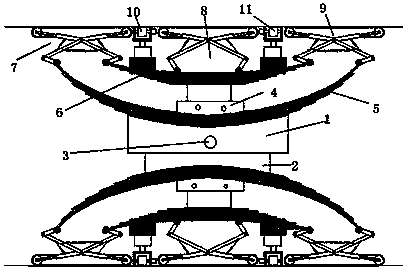

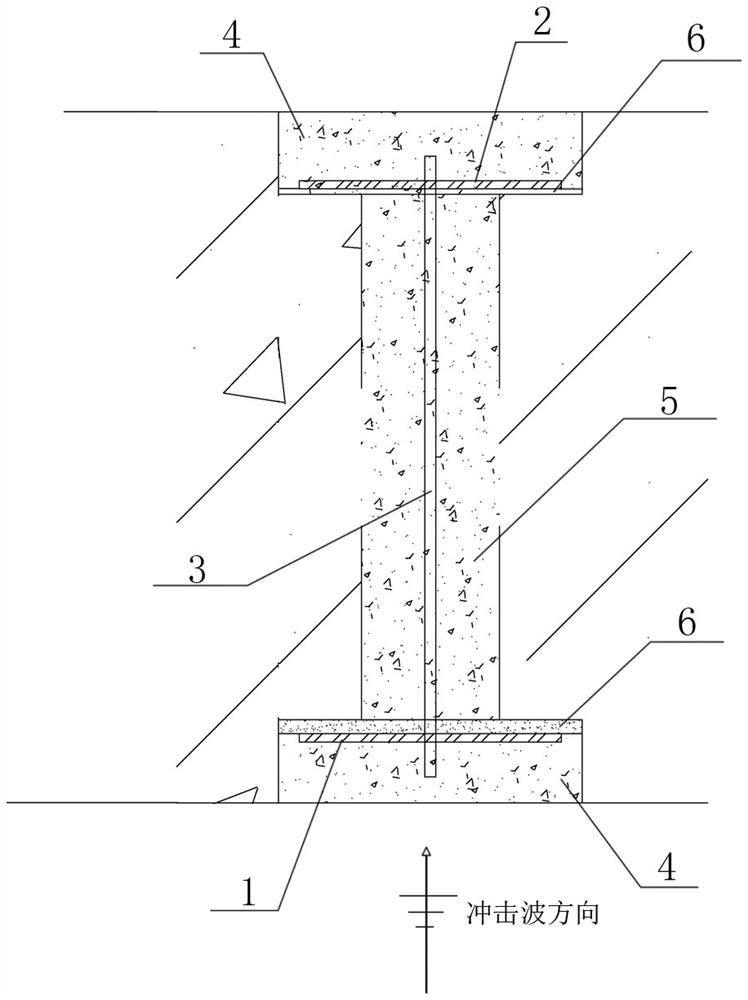

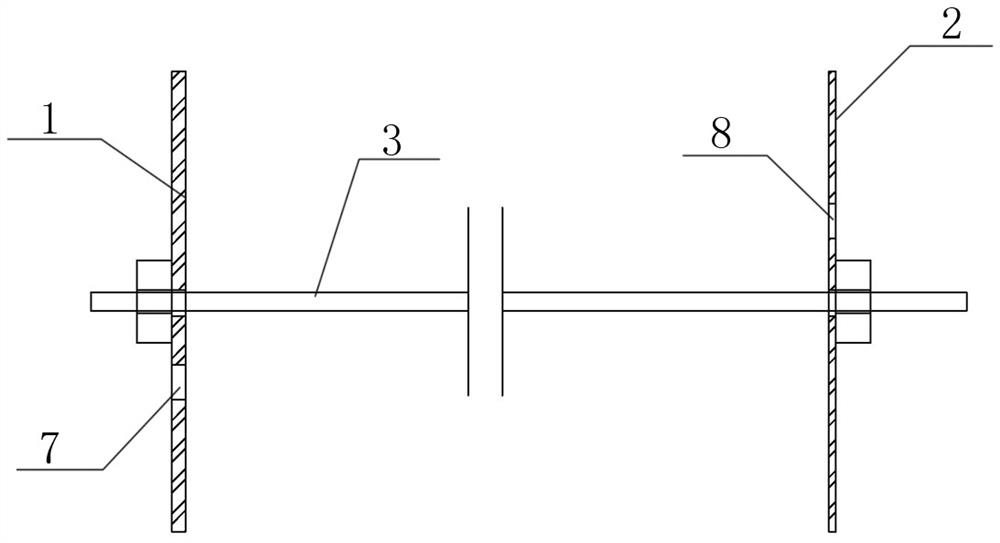

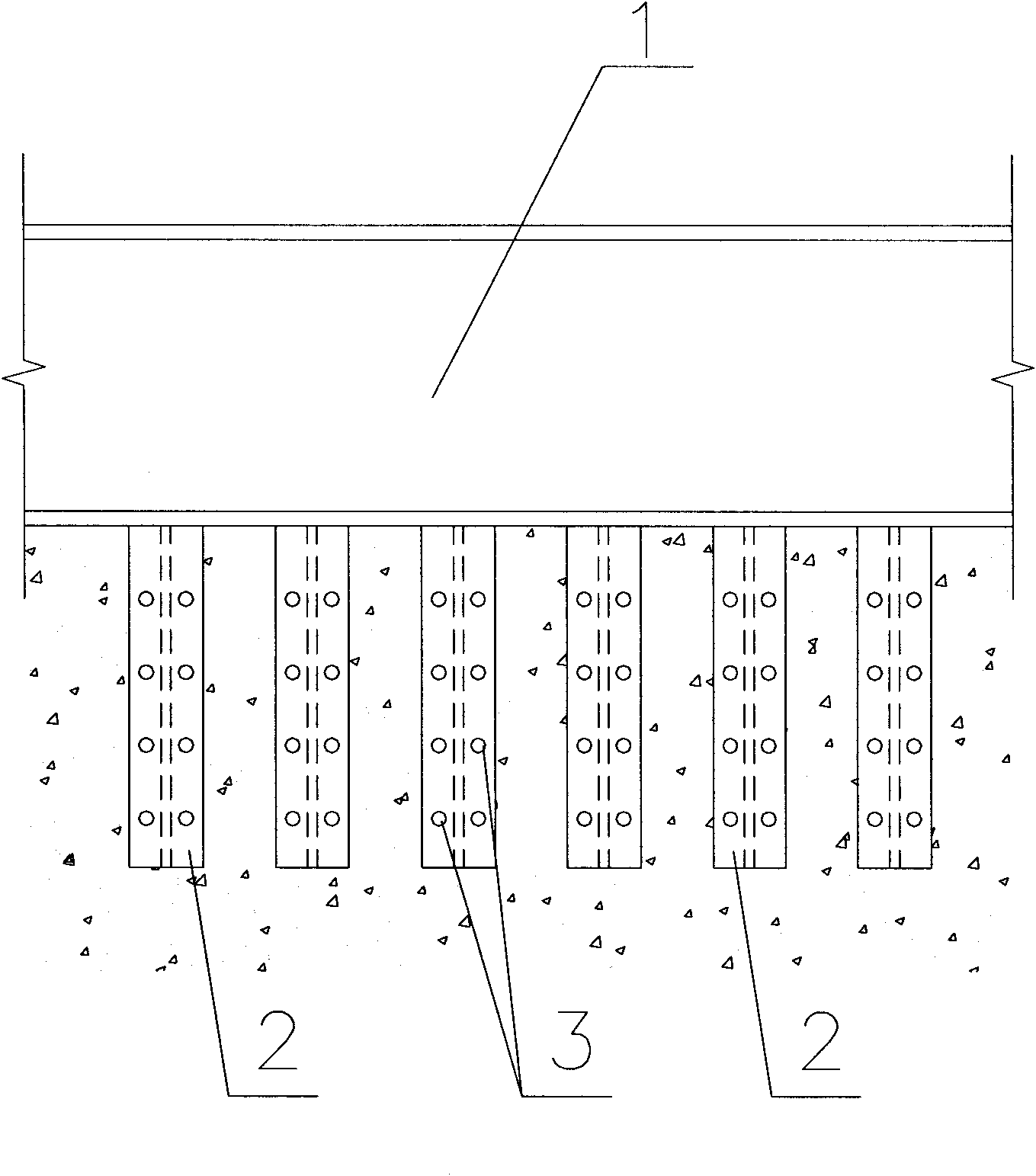

Connected node of horizontal member and foundation of thin steel-plate shear wall

InactiveCN102235033ALarge sectionIncrease girthBuilding constructionsSteel plate shear wallTension field

The invention discloses a connected node of a horizontal member and a foundation of a thin steel-plate shear wall, which belongs to the field of architectural construction engineering, and comprises a horizontal member (1) and a foundation of a thin steel-plate shear wall. The connected node disclosed by the invention is characterized in that anchoring members (2) which are uniformly arranged and welded at a certain interval along the lower length centerline of the horizontal member (1) at the bottom layer are vertically buried into the foundation, a shear key (3) is respectively welded on the front and rear side surfaces (parallel to the horizontal member (1)) of the anchoring members (2), and the shear keys (3) are uniformly arranged at a certain interval. The technical problem solved by the invention is to provide a new connected node, and the node greatly enhances the anchoring capacity (namely, pullout resistant capacity) of the anchoring members (2), thereby effectively balancing a tension field generated by a bottom thin steel-plate shear wall.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST +1

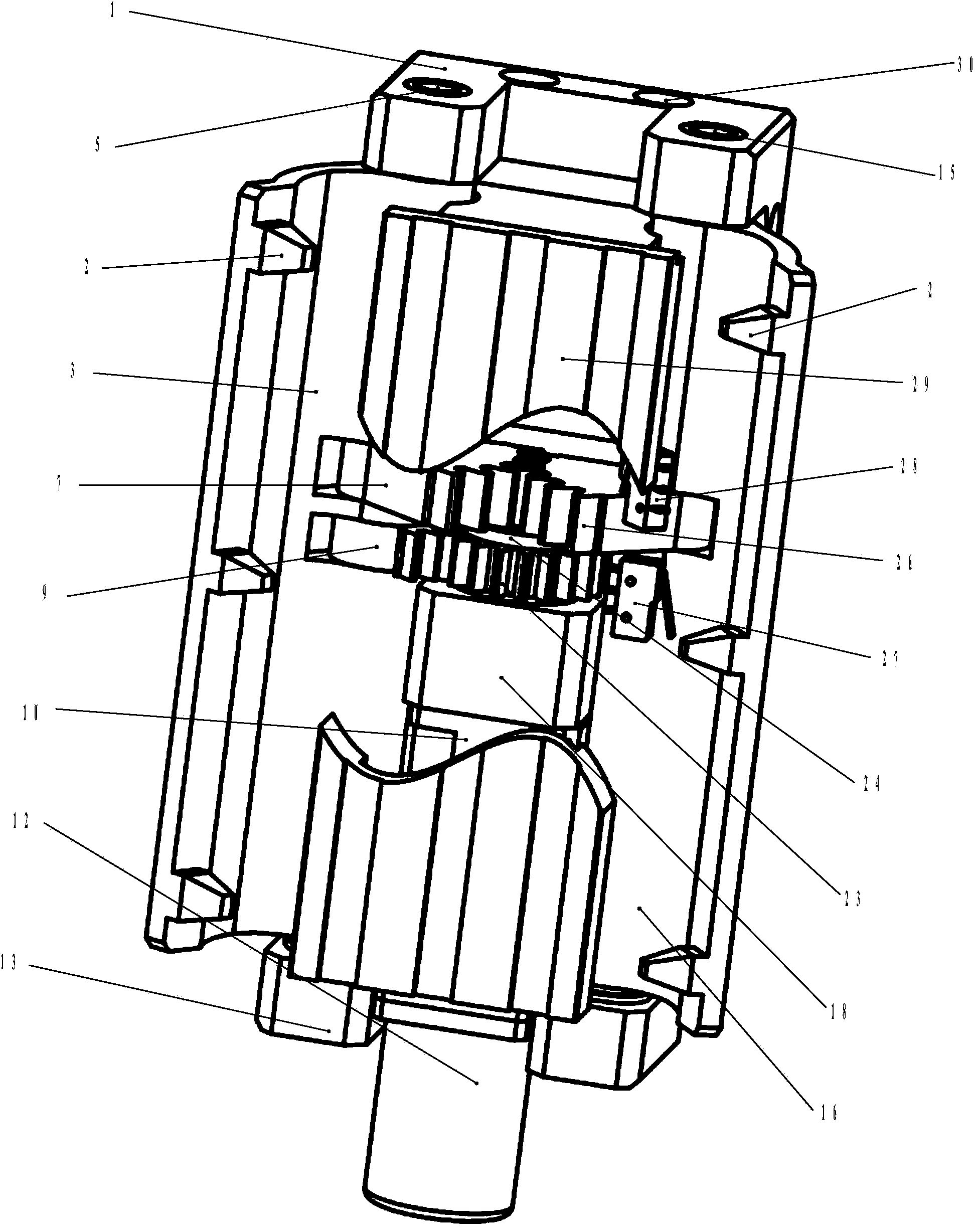

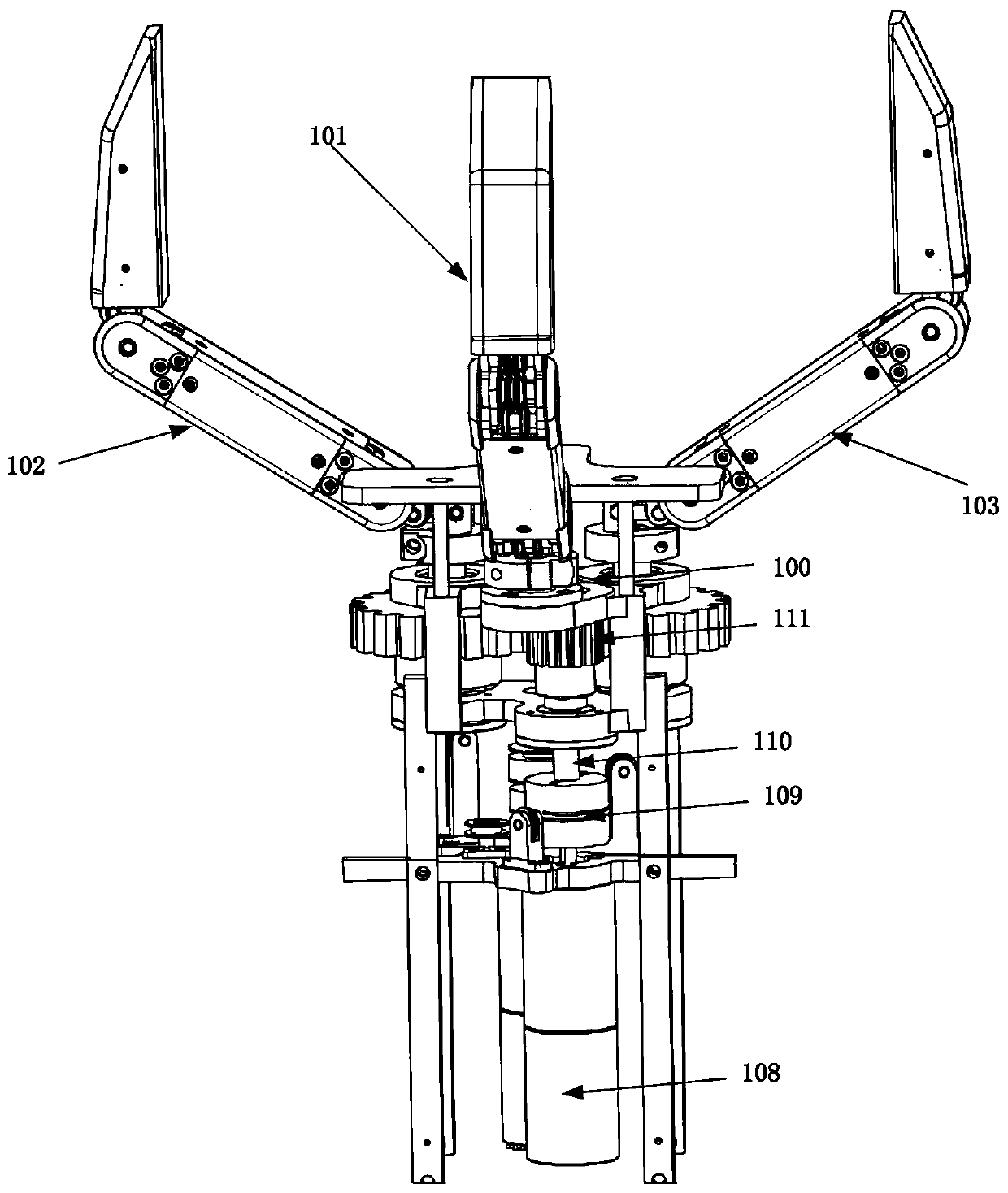

Tong device with posture correction function

The invention discloses a tong device with a posture correction function and used for a small operation space. A step motor 12 is used for power drive of the tong device, power is transmitted to a transmission gear 23 through a planetary reducer 10, the transmission gear 23 is meshed with a half-gear 9 to drive a left jaw 3 to rotate, the left jaw 3 and a right jaw 16 rotate around a left rotary shaft 5 and a right rotary shaft 15 respectively, a left half-gear 7 and a right half-gear 26 are meshed and rotate in opposite directions at the same speed, and accordingly loosening and grasping of the two jaws of the tong device are achieved. The tail ends of the two jaws are provided with clamping teeth 2 with guide structures. When the tong device is used for grasping an object, the clamping teeth 2 are inserted into square holes of an object butt joint unit, and meanwhile posture errors of the grasped object can be corrected; after the object is grasped, the grasped object is attached to a butt joint plate 29, and positioning and fastened grasping of the grasped object are achieved. The tone device has the function of correcting the posture of the grasped object, can improve grasping efficiency and reliability, and is a mechanical device which is compact in structure, strong in loading capacity and suitable for the operation space with strict requirements.

Owner:BEIHANG UNIV

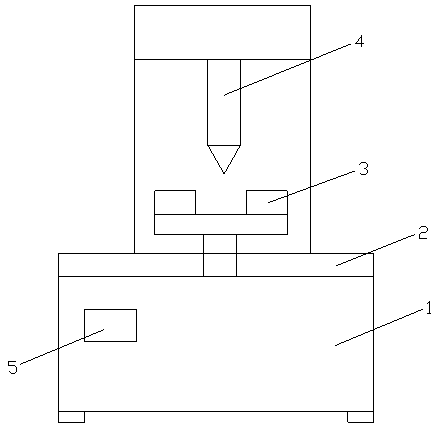

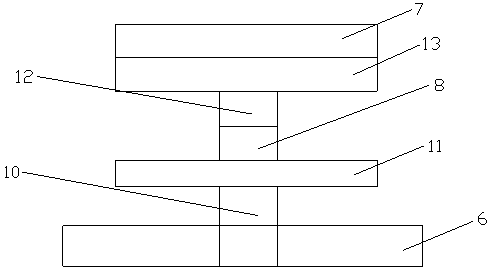

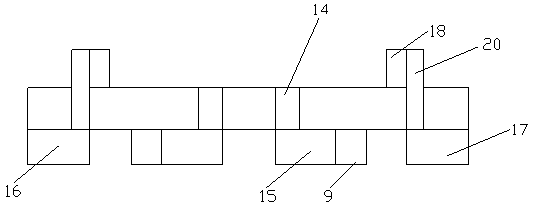

Numerically-controlled vertical drilling device

InactiveCN108311722AImprove accuracy and efficiencyHigh strengthPositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses a numerically-controlled vertical drilling device. The numerically-controlled vertical drilling device comprises a mechanical support, a positioning mechanism, clamping mechanisms, a drilling mechanism and a control device, wherein the positioning mechanism, the drilling mechanism and the control device are installed on the mechanical support; the positioning mechanism comprises an electric guide rail, a rotary plate, a rotary motor and negative-pressure fans; a slide block of the electric guide rail is provided with a connecting rod; a fixed plate is arranged on the connecting rod and provided with the rotary motor; a drive shaft of the rotary motor is provided with a speed reducer; an output shaft of the speed reducer is provided with a speed reduction plate; therotary plate is installed on the speed reduction plate and provided with one or more waste holes; waste bins are arranged on the waste holes, and the negative pressure fan are installed in the waste bins; and the clamping mechanisms are located on the rotary plate. The numerically-controlled vertical drilling device is accurate in positioning, compact in structure and high in efficiency and cleanness.

Owner:周德明

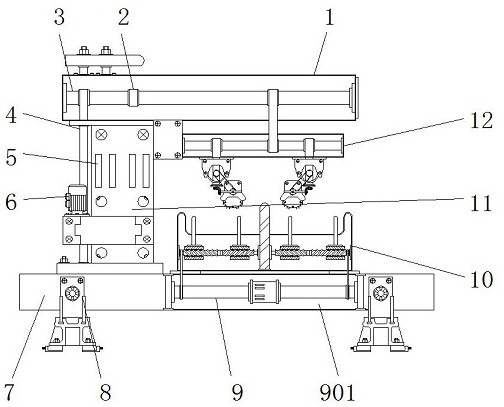

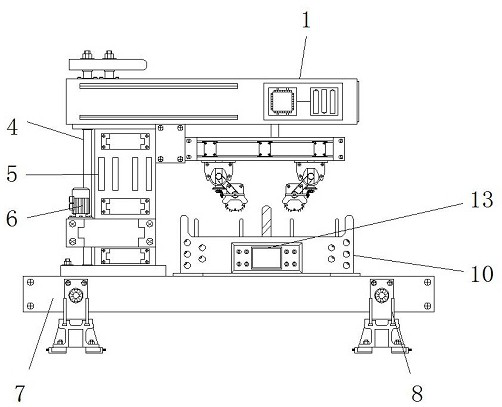

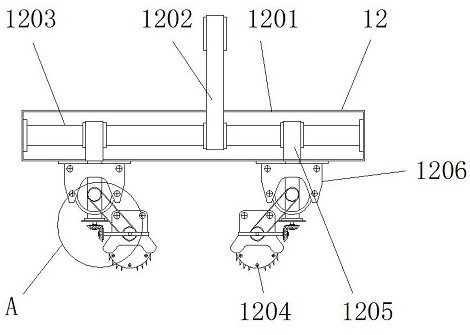

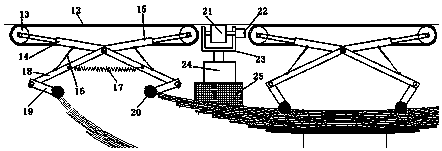

Automatic multi-station shock absorber pressure spring production equipment

InactiveCN112338572AImprove work efficiencyImprove gripping abilityLarge fixed membersPositioning apparatusDrive shaftGear wheel

The invention discloses automatic multi-station shock absorber pressure spring production equipment which comprises a working box and a fixed base. Supporting legs are fixed to two sides of the bottomend of the fixed base, a worktable is fixed to one side of the top end of the fixed base, a working head is mounted in a working wheel, a first gear is mounted at the bottom end of a driving shaft, and a second gear is engaged to one side of the first gear. A first driving motor is started to work, then the first driving motor works to drive a connecting rod to start working, and then the secondgear rotates in the engaging process of the second gear, so that the working wheel which is fixed is adjusted and rotated in position while the working head works, and therefore, multi-angle adjustment can be carried out. In the multi-angle adjusting process, as the working head works to drive the integral equipment to work, the integral work efficiency of the equipment is improved.

Owner:东莞市信恒智能装备科技有限公司

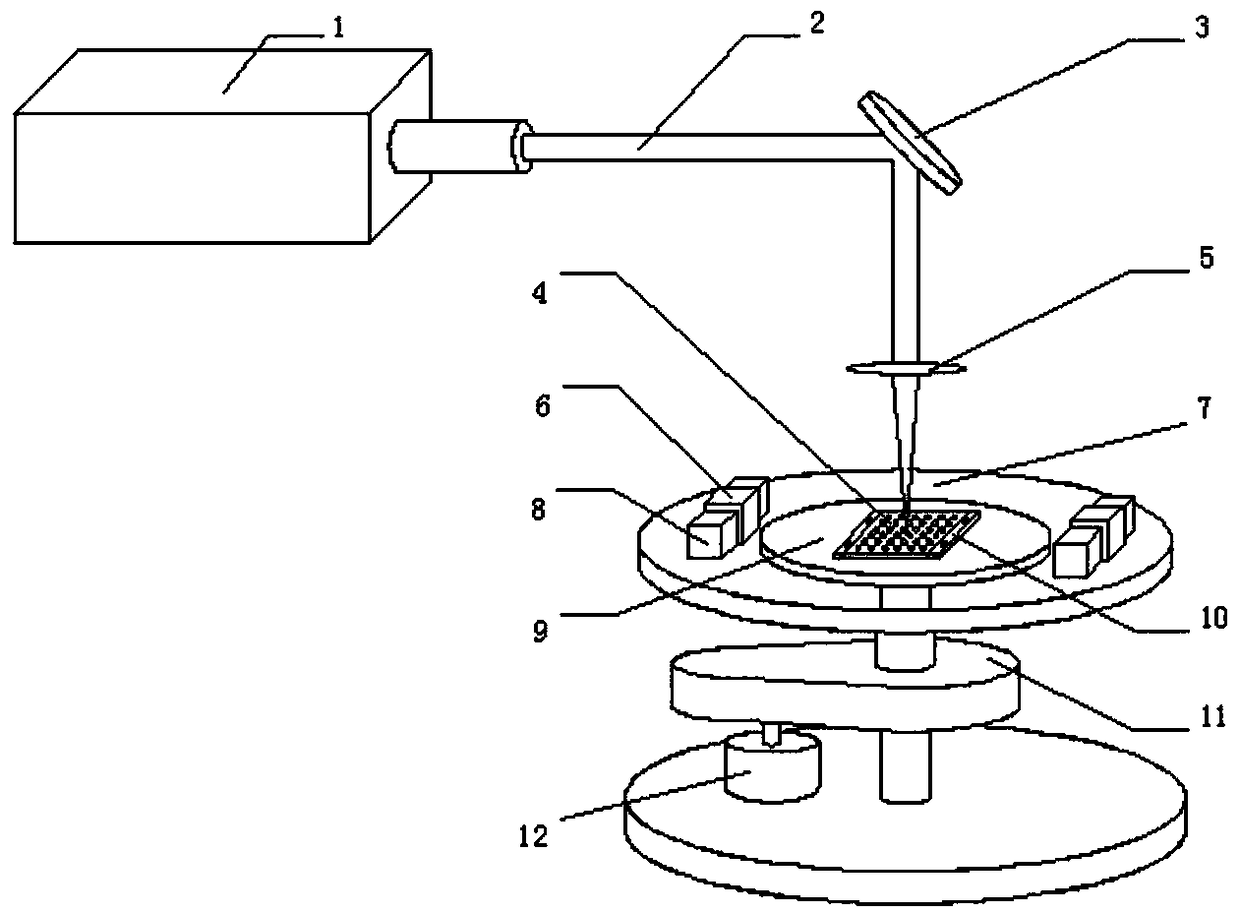

Method of magnetic field assistance laser processing for biomedical electrode

InactiveCN108784677AImprove surface qualityImprove fitDiagnostic recording/measuringSensorsElastomerLaser processing

The invention discloses a method of magnetic field assistance laser processing for a biomedical electrodes and relates to a biomedical electrode. A copper sheet is adopted as an electrode material andclamped on a worktable, and laser beams generated by a fiber laser device pass through a laser galvanometer and a focusing lens in sequence and are focused on the surface of the copper sheet; materials in an illumination area can be melt or gasified and cause a recasting phenomenon, and after recasting, a microneedle array is formed on the surface of the copper sheet; acid pickling and alcohol leaching are conducted on the copper sheet to remove oxidation layers and impurities, a Ag / AgCl cladding layer is formed on the surface of a metal electrode core through electroplating, and that is to say that the metal electrode core with the microneedle array on the surface is obtained. A wire is bonded to the metal electrode core through a conducive silver adhesive and then penetrates through anelastic housing; medical proof fabric is used for binding the wire to the two sides of the elastic housing, and then the biomedical electrode with the microneedle array is formed at last.

Owner:XIAMEN UNIV

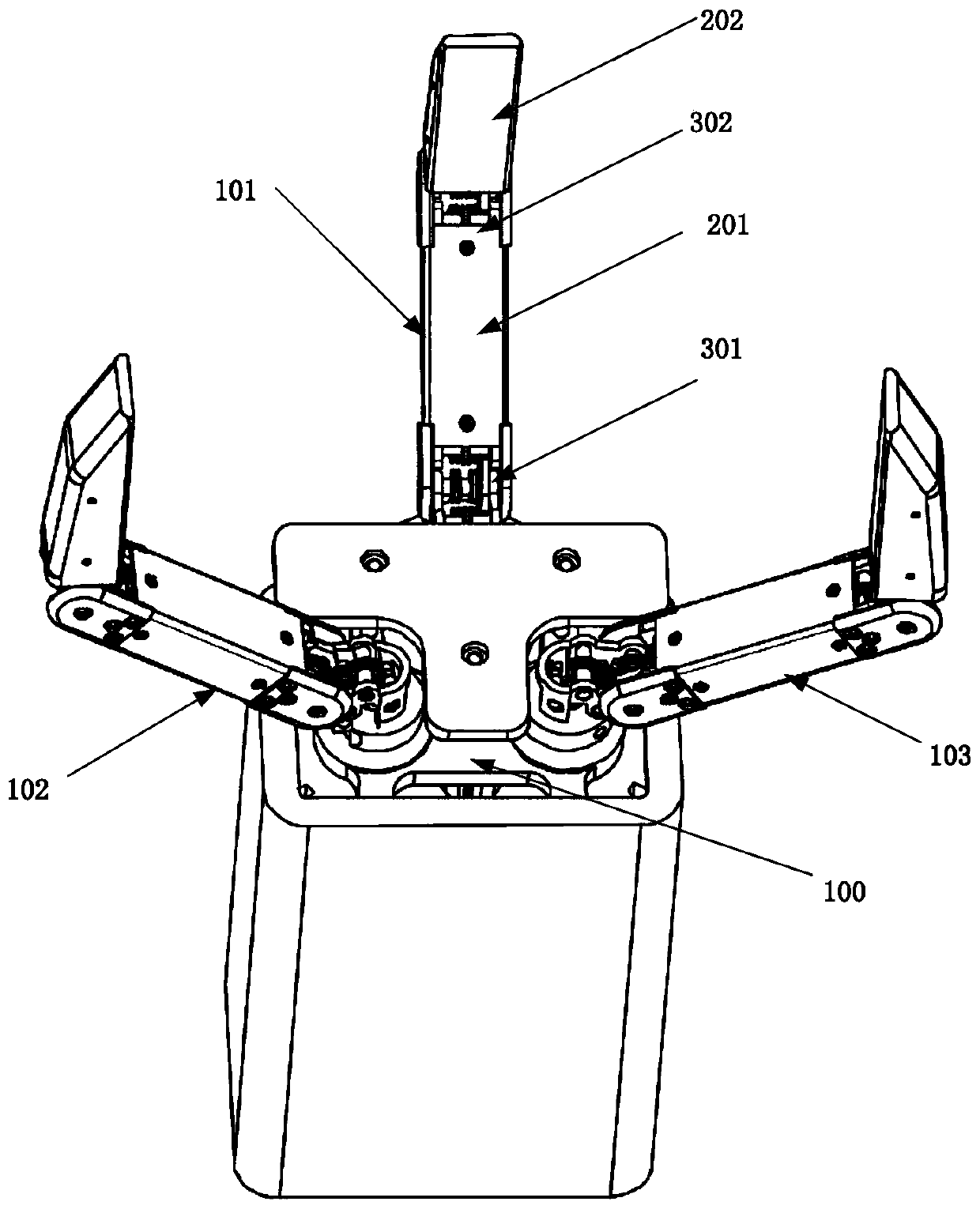

A robotic dexterous hand with parallel adaptive grasping

The invention discloses a parallel self-adaptive grasping robot dexterous hand. The parallel self-adaptive grasping robot dexterous hand comprises a base and fingers. The fingers comprise the first finger, the second finger and the third finger. Each finger comprises a far-end finger rod and a near-end finger rod. The first finger is fixedly connected to the base. The second finger and the third finger can rotate around the central axis perpendicular to the base. In the dexterous hand grasping process, when the near-end finger rods do not make contact with an object, the far-end finger rods linearly and horizontally move to parallelly grasp the object, and the object also can be grasped in a self-adaptive envelope mode according to the different sizes and shapes of the object after the near-end finger rods make contact with the object. Meanwhile, the positions of the rotatable fingers can be adjusted in a large range, so that a plurality of grasping structure states are produced, and the capacity to grasp different shapes of objects is improved. The parallel self-adaptive grasping robot dexterous hand is ingenious in structural design, small in size, few in driver, capable of automatically adapting to different sizes and shapes of objects, high in grasping capacity, large in range, stable and reliable.

Owner:SHENZHEN DH ROBOTICS TECH CO LTD

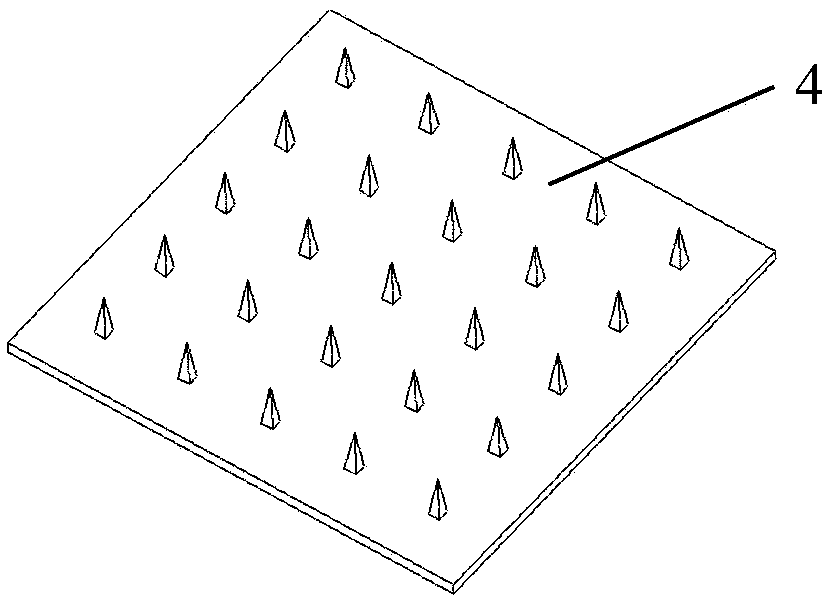

Material grabbing mechanism for portable bag closer

InactiveCN101624760AAvoid hard wearKeep sharpWork-feeding meansSack sewingMechanical engineeringEngineering

The invention relates to a material grabbing mechanism for a portable bag closer, which comprises a material grabbing upper pressure rack and a material grabbing lower retainer, wherein a machine needle passes through the material grabbing upper pressure rack and the material grabbing lower retainer from top to bottom, the upper surface of the material grabbing lower retainer is provided with sawteeth, the material grabbing upper pressure rack and the material grabbing lower retainer can be kept close to each other to feed materials cooperatively, the upper surface of the material grabbing lower retainer is also provided with skid-proof needle points of which the tops are higher than the sawteeth, the lower surface of the material grabbing upper pressure rack is provided with a needle hiding groove, the height of the skid-proof needle points is not greater than the depth of the needle hiding groove, the length of the needle hiding groove is not less than the sum of the diameter of theskid-proof needle points and the forward and backward moving strokes of the skid-proof needle points, and the skid-proof needle points extend into the needle hiding groove when the material grabbing lower retainer is kept close to the material grabbing upper pressure rack. The structure can avoid the hard abrasion generated between the skid-proof needle points and a material feeding upper pressure rack so as to effectively keep the sharpness of the skid-proof needle points and bring the beneficial effect that the material grabbing mechanism grabs materials firmly and feeds the materials reliably.

Owner:余晋

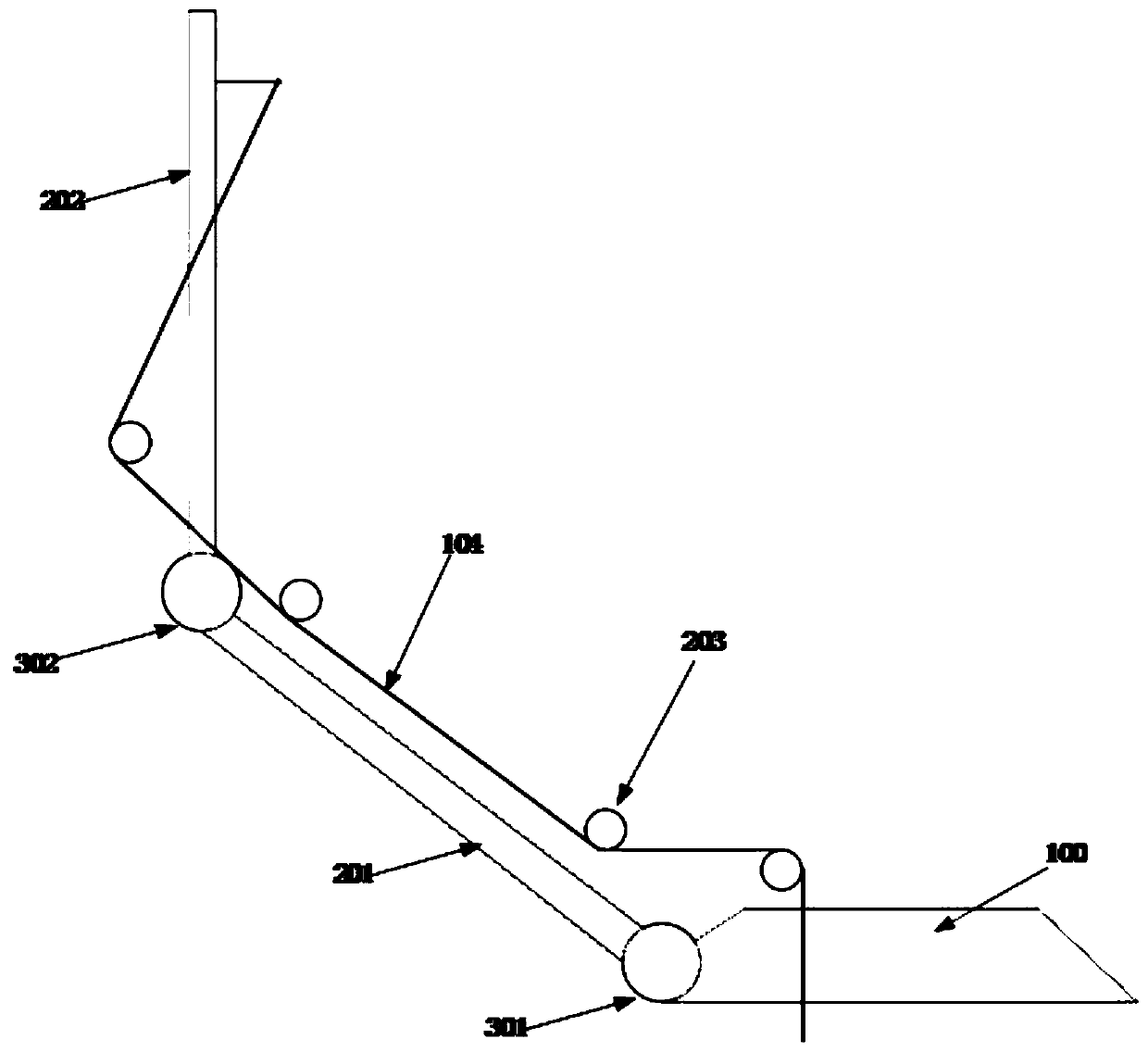

Efficient automatic communication cable laying equipment

InactiveCN108075403AImprove laying efficiencyMove quicklyApparatus for laying cablesEngineeringMonitor equipment

The invention discloses efficient automatic communication cable laying equipment. Rear driving assemblies are connected to the rear end portions of outer arc plates and the rear end portions of innerarc plates; a middle driving assembly is arranged in the middle of each inner arc plate; front driving assemblies are connected to the front end portions of the outer arc plates and the front end portions of the inner arc plates; the rear driving assemblies, the middle driving assemblies and the front driving assemblies abut against the inner wall of a cable pipeline where laying is conducted; Thecommunication cable laying equipment is high in laying efficiency, the laying equipment can quickly drive cables to be laid in the pipeline where laying is conducted, and the laying equipment is highin laying speed, quick in movement and high in wall grasping capability; through the arrangement of camera monitoring equipment, obstacles in front can be well predicted so that direction control assemblies can control the equipment to well avoid the obstacles, direction control wheels carry out control and rotation flexibly and conveniently, belts are adopted for transmission forwarding, the forwarding force is large, and long-distance cable laying can be ensured.

Owner:JINGGANGSHAN UNIVERSITY

Flexible grips

InactiveUS20220062740A1Secure gripImproved gripping abilityGlovesSport apparatusStructural engineeringMechanical engineering

The invention provides a flexible grip for use in weightlifting and weight bearing exercises. More particularly, the flexible grips herein mold to a user's hands and enable secure grip of weights, bars with weights and bars for pulling or lifting.

Owner:CONAWAY CORNELL

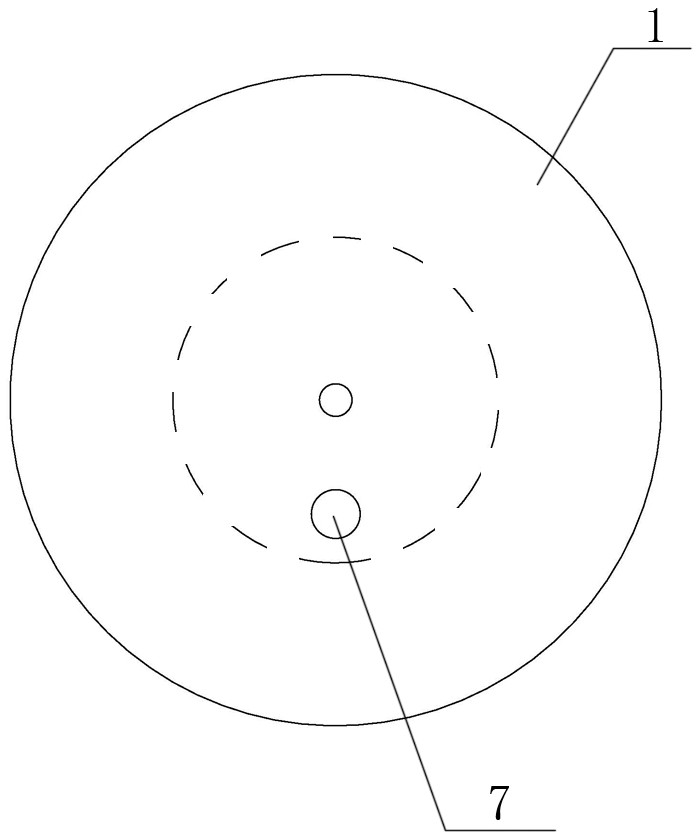

Plugging structure and plugging method for small-section deep hole in civil air defense overhead wall

ActiveCN113622702AEasy tight connectionIncrease frictionBuilding repairsArchitectural engineeringScrew thread

The invention relates to a plugging structure and plugging method for a small-section deep hole in a civil air defense overhead wall, and belongs to the field of civil air defense engineering. A resistance plate and a non-resistance plate are arranged in reaming areas at the two ends of a preformed hole in a manner of being attached to a wall body, and the resistance plate and the non-resistance plate are connected in a pulling manner through a harness cord screw rod. After the whole plugging process is finished, steel plates on the two sides of the hole and bolts are reserved in the structure and cannot be taken out, the thread concave-convex characteristic of the surface of a harness cord bolt is effectively combined with a grouting material to generate larger friction force, the holding and wrapping effect is improved, and the structure strength and plugging and sealing reliability are guaranteed. The shaving and chiseling workload on the original structure concrete in the structure treatment stage is small, and the damage influence on the original concrete structure is small. Grouting plugging operation is simple and convenient, and plugging work of corresponding requirements can be completed at a time. After the plugging measures are completed, the surface treatment traces of the structure are not obvious, and later decoration work is facilitated.

Owner:BEIJING NO 3 CONSTR ENG +1

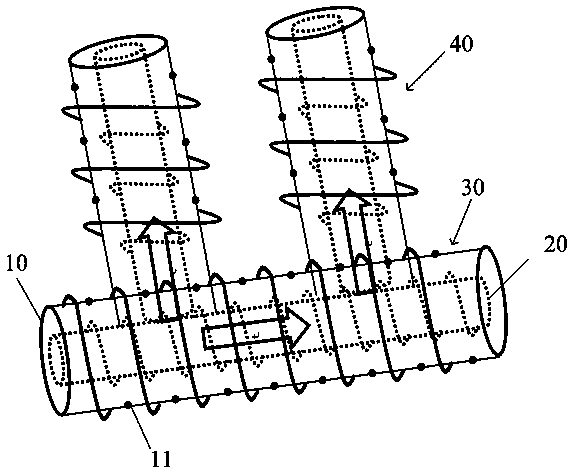

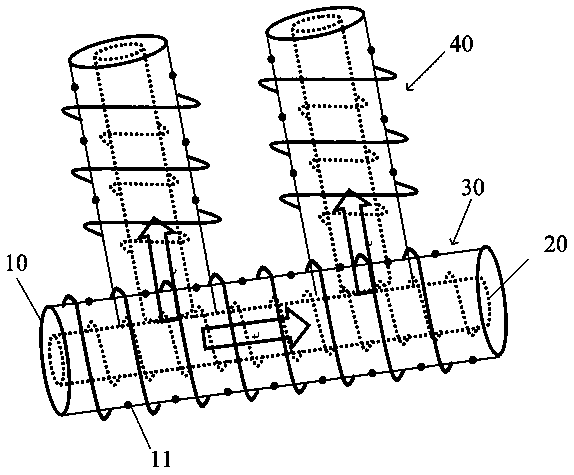

Water passing pipe for precast concrete and preparation method thereof

ActiveCN111255959ASimple and efficient operationGood effectShaping reinforcementsBranching pipesRebarSteel tube

The invention belongs to the technical field of concrete, and particularly relates to a water passing pipe for precast concrete and a preparation method thereof. The water passing pipe is used for solving the problem of temperature cracking of large-volume concrete. The water passing pipe comprises a horizontal pipeline part and vertical pipeline parts which are connected by tee joints, wherein the vertical pipeline parts are arranged on the horizontal pipeline part at equal intervals; the horizontal pipeline part and the vertical pipeline parts comprise hollow plastic corrugated pipes or steel pipes and threaded reinforced concrete pipes coating the exterior; reinforcing steel bars and reinforcing meshes at connectors of the horizontal pipeline part and the vertical pipeline parts are connected by adopting spot welding; and the horizontal pipeline part and the vertical pipeline parts are connected into an integrated structure through cast-in-place precast concrete. The horizontal pipeline part and the vertical pipeline parts respectively achieve the temperature control in the horizontal gradient direction and vertical gradient direction of mass concrete; the "T"-shaped structure formed by the horizontal pipeline part and the vertical pipeline parts can effectively replace the complex structure of laying horizontal water passing pipes in the traditional layering; and the vertical pipeline parts can be used as water passing pipe filling channels, so that the filling efficiency and effect of the water passing pipe can be improved, and internal defects and cracks are reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

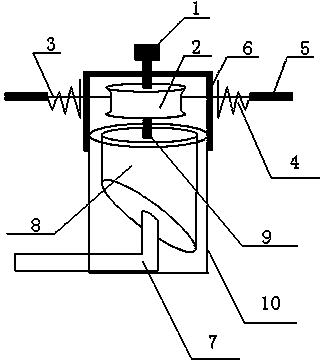

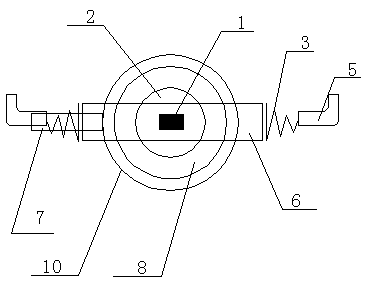

A kind of transformer gas relay butterfly cover fixing device

InactiveCN106057569BImproved gripping abilityNot easy to fall offElectric switchesWire wheelEngineering

The present invention provides a butterfly cover fixing device for transformer gas relay, which comprises a wire wheel central shaft, a wire wheel fixed on the wire wheel central shaft, a knob fixedly connected with the upper end of the wire wheel central shaft, a spring mounting base connected with the wire wheel central shaft through a bearing, two conical springs, two draw wires, two fixing pieces, a screw rod fixedly connected with the lower end of the wire wheel central shaft, a cylinder connected and cooperating with the screw thread of the screw rod and a push rod at the lower end of the screw rod. The two fixing pieces, the two conical springs and the wire wheel are on the same horizontal level. One end of each conical spring is fixedly connected to the spring mounting base while the other end is fixedly connected with the fixing pieces. One end of each draw line is fixedly arranged on the wire wheel while the other end is connected with the other end of each conical spring respectively. The cylinder and the spring mounting base are fixedly connected. The cylinder wall of the cylinder is provided with a hole that allows the push rod to extend beyond. According to the invention, the structure is stable. The device does not come off easily and is convenient to assemble and disassemble.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

A kind of prefabricated concrete water pipe and its preparation method

ActiveCN111255959BImprove filling efficiencyGood filling effectShaping reinforcementsBranching pipesTemperature controlReinforced concrete

The invention belongs to the technical field of concrete, in particular to a prefabricated concrete water pipe and a preparation method thereof, which are used to solve the problem of temperature cracks in large-volume concrete. The water pipe includes horizontal pipe parts and vertical pipe parts connected by a tee, and the vertical pipe parts are arranged on the horizontal pipe parts at equal intervals, both of which include hollow plastic bellows or steel pipes and threaded reinforced concrete coated on the outside The steel bars and steel mesh at the interface between the two pipes are connected by spot welding, and are connected as an integral structure through cast-in-place precast concrete. The two realize the temperature control of the horizontal gradient direction and the vertical gradient direction of mass concrete respectively. The "T" structure formed by the two can effectively replace the traditional complex structure of layered horizontal water pipes; the vertical pipe parts can be used as water pipes Filling channels can improve the filling efficiency and effect of water pipes, and reduce internal defects and cracks.

Owner:SHANGHAI CONSTRUCTION GROUP

Connected node of horizontal member and foundation of thin steel-plate shear wall

InactiveCN102235033BImproved gripping abilityLarge sectionBuilding constructionsSheet steelProblem solve

The invention discloses a connected node of a horizontal member and a foundation of a thin steel-plate shear wall, which belongs to the field of architectural construction engineering, and comprises a horizontal member (1) and a foundation of a thin steel-plate shear wall. The connected node disclosed by the invention is characterized in that anchoring members (2) which are uniformly arranged and welded at a certain interval along the lower length centerline of the horizontal member (1) at the bottom layer are vertically buried into the foundation, a shear key (3) is respectively welded on the front and rear side surfaces (parallel to the horizontal member (1)) of the anchoring members (2), and the shear keys (3) are uniformly arranged at a certain interval. The technical problem solved by the invention is to provide a new connected node, and the node greatly enhances the anchoring capacity (namely, pullout resistant capacity) of the anchoring members (2), thereby effectively balancing a tension field generated by a bottom thin steel-plate shear wall.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST +1

High-light-color-fastness transfer printing method

ActiveCN102797173BHigh color fastnessHigh glossTransfer printing processDyeing processDisperse dyeIsobutanol

The invention relates to a high-light-color-fastness transfer printing method. An ink for transfer printing comprises the following components in percentage by mass: 40-70% of black disperse dye, 10-30% of red disperse dye, 12-15% of methanol and / or isobutanol, 5-10% of polyvinyl butyral and 3-5% of photostabilizer 622. The transfer printing method comprises the following steps: soaking a textile to be printed in a polyoxyethylene or polyoxypropylene water solution, and carrying out transfer printing. The invention has the advantages of simple technique and low cost; and the printed pattern has the advantages of high binding force with cloth, high light color fastness and high durability.

Owner:WUXI SAILITE TEXTILE TECH

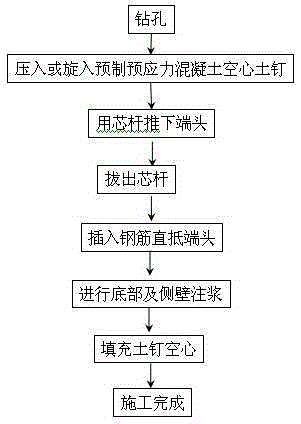

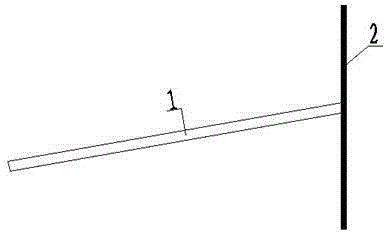

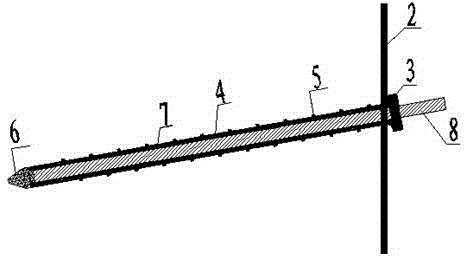

Prefabricated prestressed concrete hollow soil nail and its construction method

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com