Material grabbing mechanism for portable bag closer

A sealing machine and material grabbing technology, which is applied in the direction of cloth feeding mechanism, pocket sewing machine, sewing machine components, etc., can solve problems such as broken thread, slippage, and unsmooth sewing operation, and achieve the effect of maintaining sharpness and avoiding hard wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

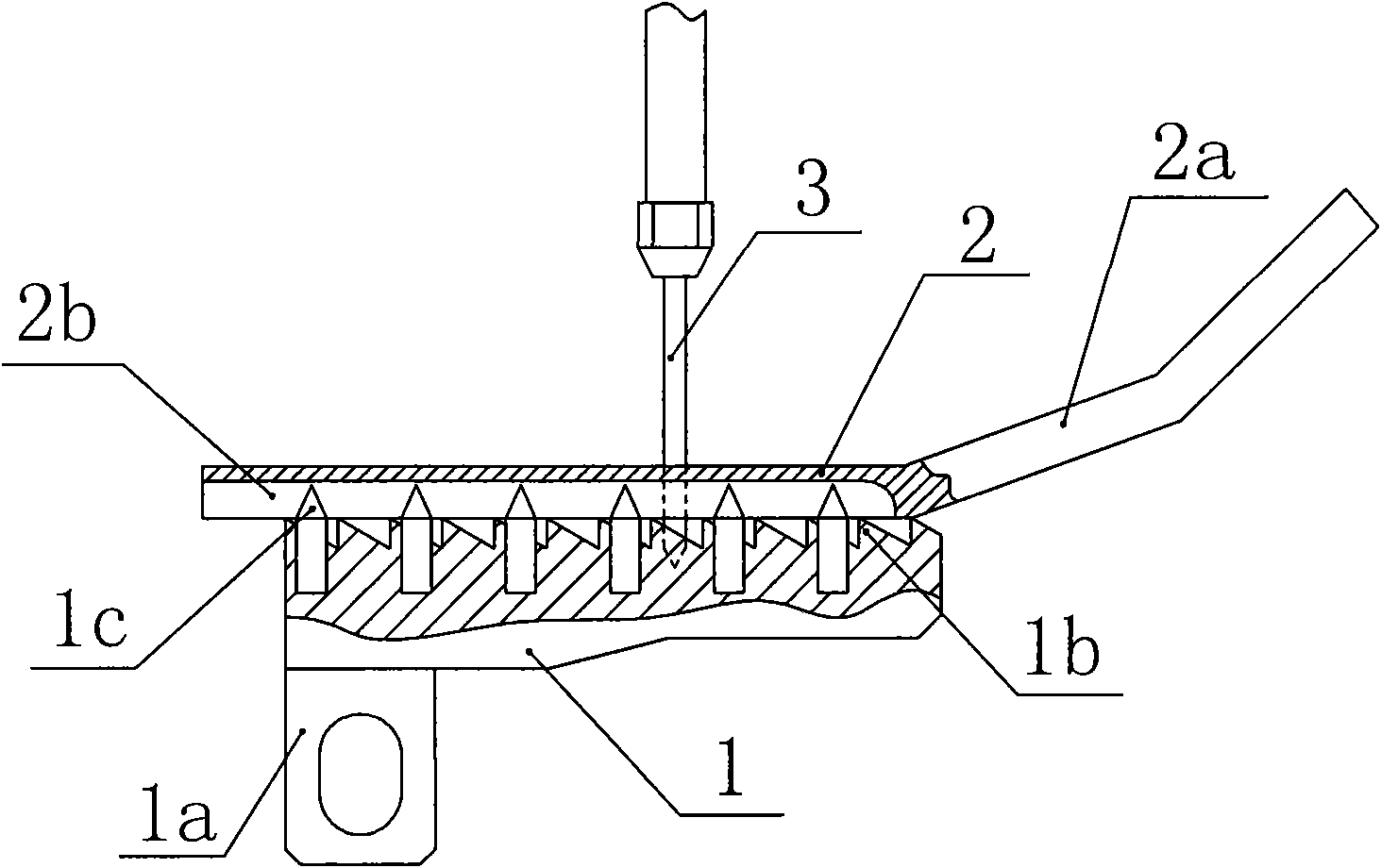

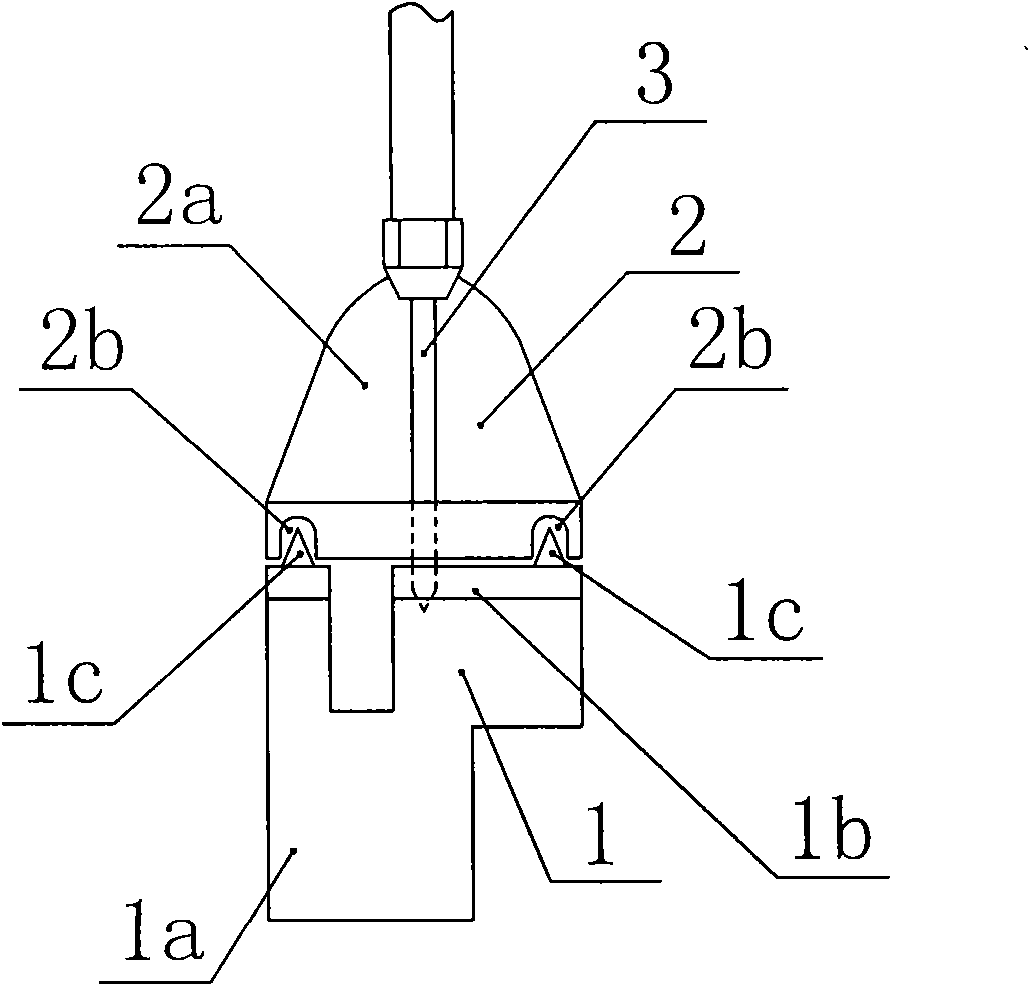

[0015] Such as figure 1 , figure 2 Shown is an embodiment of the grasping mechanism of the hand-held bag sealing machine, which includes the grasping lower tooth frame 1, the grasping upper pressing frame 2, and the needle 3, and the machine needle 3 passes through the grasping upper pressing frame 2 and the grasping The lower feed frame 1 and the lower feed frame 2 are close to and hold up the feed upper press frame 1 and the sewing material so as to grasp the sewing material, and then the feeding lower frame 2 together with the sewing material from figure 1 From the left side to the right side, the feeding upper press frame 1 slides and moves for a certain stroke to feed the material. The right side of the grab material upper press frame 2 is provided with a grab material upper press frame lifting arm 2a to facilitate the insertion of sewing materials. The lower surface of the press frame 2 is provided with a needle hiding groove 2b, and the lower tooth frame 1 for grabbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com