A kind of polycrystalline resin diamond abrasive and preparation method thereof

A polycrystalline diamond and diamond technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited use range of diamond abrasives, reduced grinding efficiency, shortened service life, etc., to achieve lighter color and longer service life , the effect of increasing crystal transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

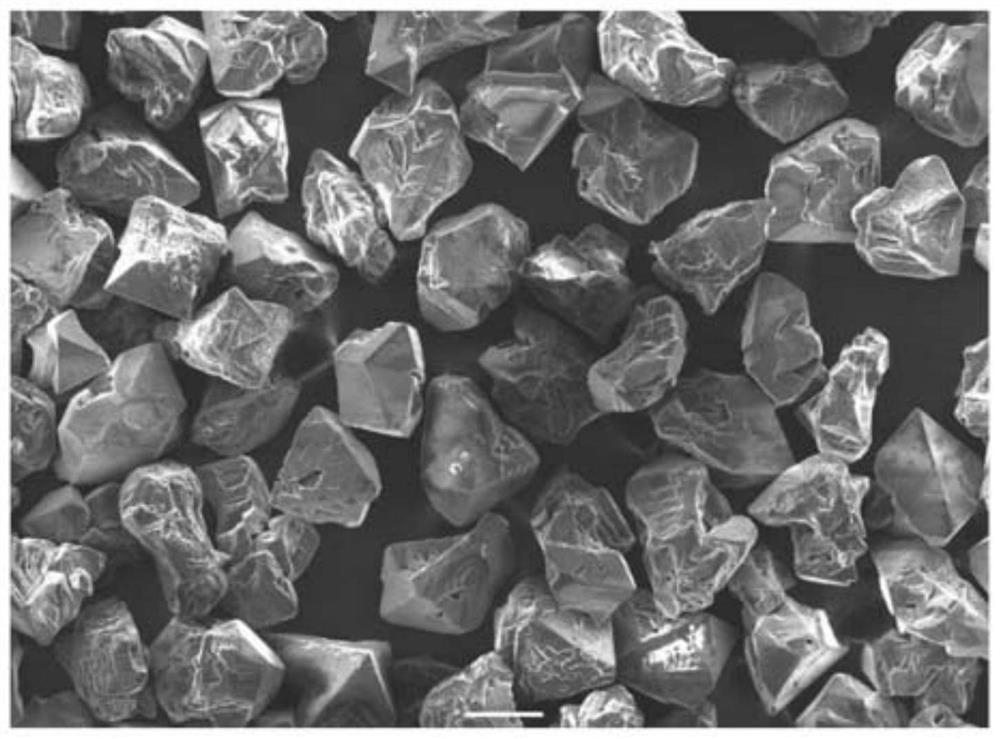

[0022] A preparation method of polycrystalline resin diamond abrasive, specifically, the uniform mixed powder of polycrystalline diamond abrasive, metal and alloy is synthesized and prepared by a high temperature and high pressure method, and the metal and alloy account for 5%-16% of the weight of the mixed powder; the The metal is at least one of copper, aluminum and zinc, and the alloy is at least one of copper-zinc alloy and copper-aluminum alloy. The polycrystalline diamond abrasive of the present application is a commercially available conventional polycrystalline diamond abrasive synthesized by a high temperature and high pressure method.

[0023] Specifically, the cleaned polycrystalline diamond abrasive, metal and alloy powders are uniformly mixed and put into a metal cup. Metal cups are made of stainless steel, zirconium, niobium, molybdenum or tantalum. Then, the pyrophyllite blocks are loaded into the six-sided top press for high temperature and high pressure resyn...

Embodiment 1

[0028] A certain particle size of polycrystalline diamond abrasive synthesized by conventional high temperature and high pressure method is selected as the raw material, and 5.5% of zinc, 3% of copper and 1.5% of Cu85Al15 are added. After mixing evenly, put it into a molybdenum cup, and then put it into a synthesis block and put it into a six-sided top press for high temperature and high pressure synthesis.

[0029] Raise the pressure to 100MPa of the high pressure of the hydraulic system of the press within 50 seconds. After the internal synthesis pressure reached 6300 MPa, the pressure was maintained for 14 minutes.

[0030] Start heating after 80 seconds of pressure increase, the heating temperature is 1350-1450 degrees Celsius, and the heating time is 10 minutes.

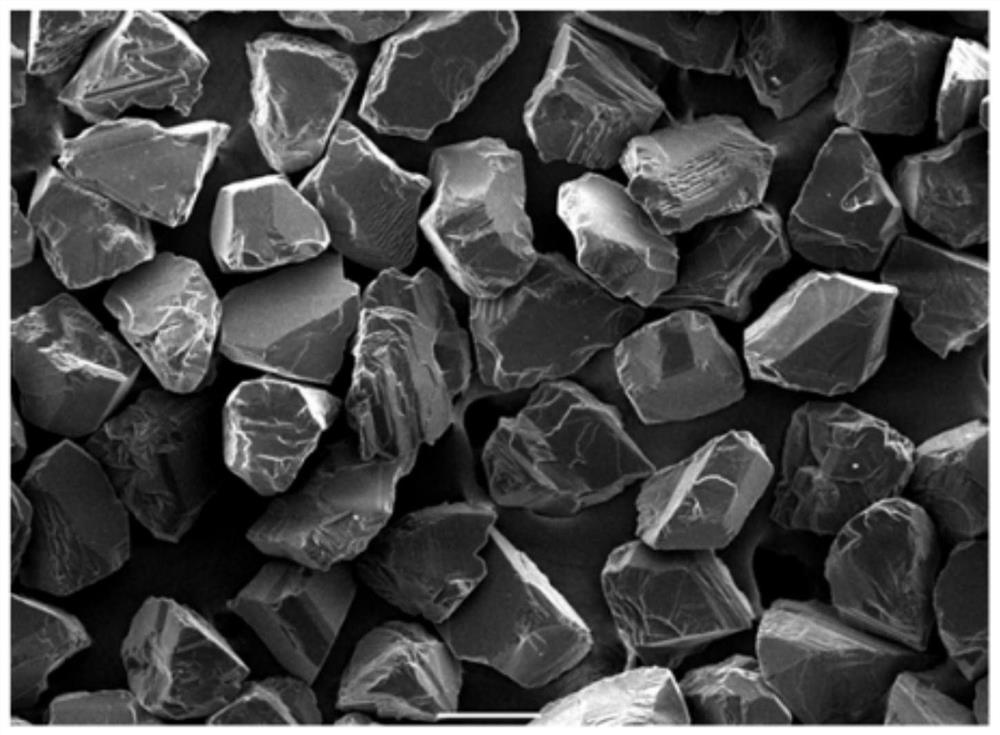

Embodiment 2

[0032] Select polycrystalline diamond abrasive 60 / 80-400 / 500 mesh mixture synthesized by conventional high temperature and high pressure method as raw material, add aluminum 2.5%, copper 1%, Cu85Al15 2.5%, Cu60Zn40 4% and mix them evenly and put them in a molybdenum cup.

[0033] 60 seconds to increase the pressure to the high pressure of the hydraulic system of the press 100MPa. After the internal synthesis pressure reached 6300 MPa, the pressure was maintained for 12 minutes. Heating was started after 70 seconds of pressure increase. Heating temperature to 1350-1450 degrees Celsius, heating time 8 minutes.

[0034] According to the synthesis method of embodiment 1, select the polycrystalline diamond abrasive of different granularity as the polycrystalline resin diamond abrasive that raw material produces and the TI and TTI / TI performance of commercially available single crystal resin diamond abrasive and commercially available polycrystalline resin diamond abrasive The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com