Patents

Literature

296results about How to "Increase touch points" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive slurry for front electrode of solar battery

InactiveCN101118932AImproved peel strengthIncreased fill factor FFSemiconductor devicesElectrical resistance and conductanceElectricity

The present invention relates to a conductive paste for the front surface of the solar energy battery,l comprising an electric phase metal powder, a glass phase and an organic phase; the present invention is provided with zero point zero five to one percent additive on base of the total weight of the conductive paste; the additive is TiO2 powder or SnO2 powder. The front electrode of the solar energy battery adopts the conductive paste, so the present invention not only enhances the peeling mechanical intensity of the front electrode of the battery, but also enhances the filling factor FF of the battery, reduces the resistance in series and enhances the light conversion efficiency; and the present invention makes the battery have a good balance of the synthesis electric capability and the mechanical capability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method of making a brazed metal article and the article formed thereby

InactiveUS7328831B1Increase touch pointsReduce the numberWelding/cutting media/materialsSoldering mediaMetal foamOpen cell

A method of making an article that is comprised of a metal foam in contact with a base metal by an intermediate braze composition, in particular, a method of brazing a metal foam to a base metal via a braze composition. In one preferred method, a polymeric foam is coated with a powdered metal composition and thermally-treated to volatilize the polymeric foam and form an open-cell metal foam. A second polymeric foam is coated with a braze composition. The second coated polymeric foam is thermally-treated to volatilize the polymeric foam. The metal foam is surrounded by the second coated polymeric foam to form a composite metal foam. The composite metal foam is placed in contact with a base metal to form an article. The article is thermally-treated to a brazing temperature to form a brazed metal article.

Owner:PORVAIR

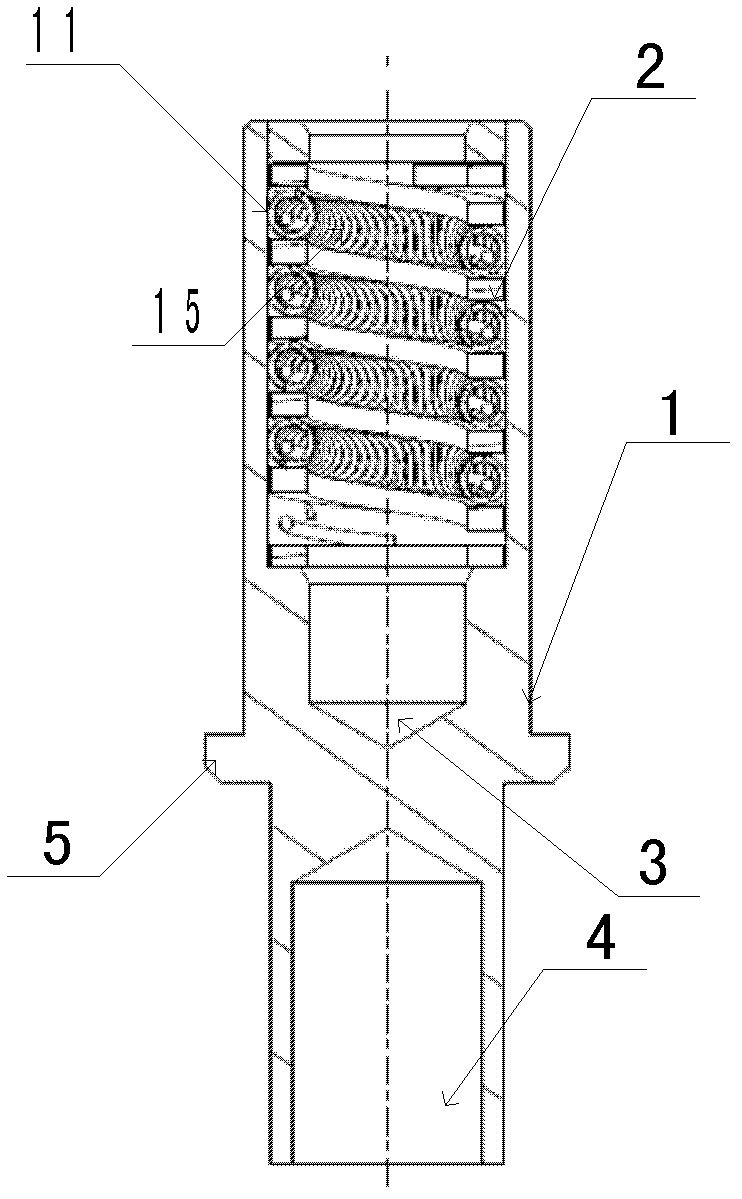

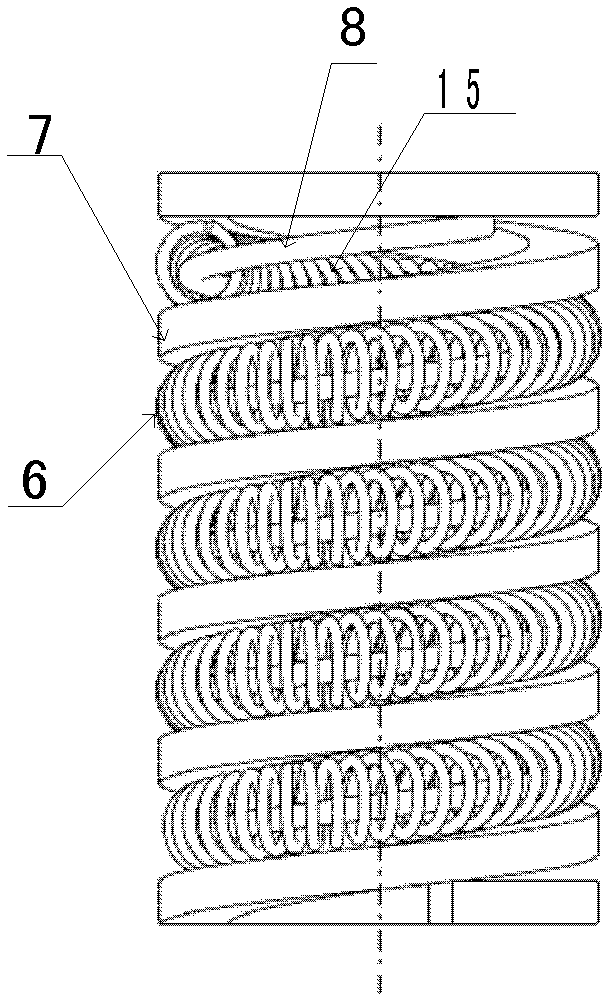

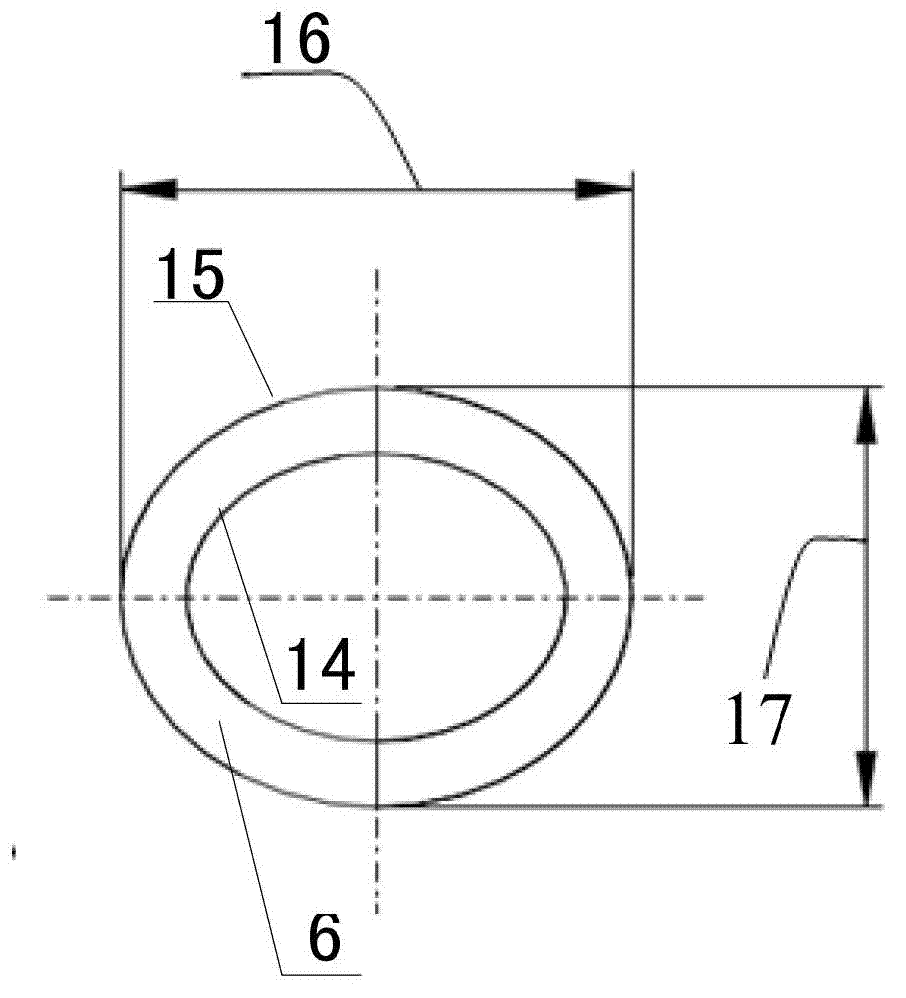

Socket conductor and socket system

InactiveCN102570115BIncrease touch pointsExtended contact pathCoupling device detailsContact impedanceElectrical conductor

The embodiment of the invention discloses a socket conductor and a socket system. The socket conductor comprises a socket body, an inclined oval two-way spiral spring contact finger, a single-line spring and an offset-line spring, wherein the inclined oval two-way spiral spring contact finger is spirally surrounded into a unit ring by a spring wire along an inclined oval track, the unit ring is in two-way spiral wounding along the axial line, the inclined oval two-way spiral spring contact finger is sheathed on the single-line spring and is embedded into a groove of the offset-line spring in an adapting way, the inner circumference of the spring contact finger forms an insertion hole, and the offset-line spring is arranged in a socket body hole. When a plug is inserted into the socket conductor, the inner wall of the inclined oval two-way spiral spring contact finger is extruded by the plug to deform, the inclined oval deformation of the unit ring is gradually generated in the spiral axial direction in the insertion process, the contact points and the contact paths of the plug and the socket conductor are increased, on the basis, the stress deformation degree becomes lenitive, the contact is more reliable, and the contact impedance is more stable.

Owner:深圳市簧中簧电子有限公司

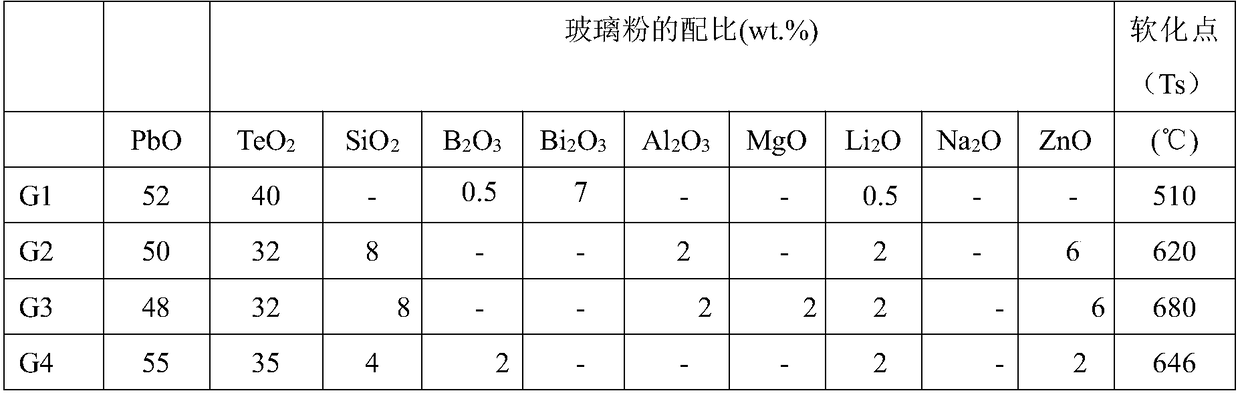

A kind of electronic silver paste and its preparation process

ActiveCN102290118ALow melting pointLow softening pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteElectricity

The invention relates to electronic silver paste and a preparation process thereof, belonging to the technical field of production of such base materials as electronic ceramic components, thick film hybrid circuits, touch components and the like. The electronic silver paste is prepared by mixing and stirring 4-9% of glass powder, 63-80% of silver powder, 12-28% of organic carrier and 0.2-2% of additive, rolling, dispersing and grinding the mixture, then adding 1-2wt% of bismuth stearate, stirring the mixture uniformly and filtering the mixture with a screen. The electronic silver paste and the preparation process have the following beneficial effects: the glass powder system does not contain lead; the minimum grain size and shape of the silver powder are not strictly required; and the silver paste is especially suitable for the positive electrodes of the solar cells on the crystalline silicon solar cell silicon substrates produced in large batch and has excellent electrical property and mechanical property..

Owner:郴州雄风环保科技有限公司

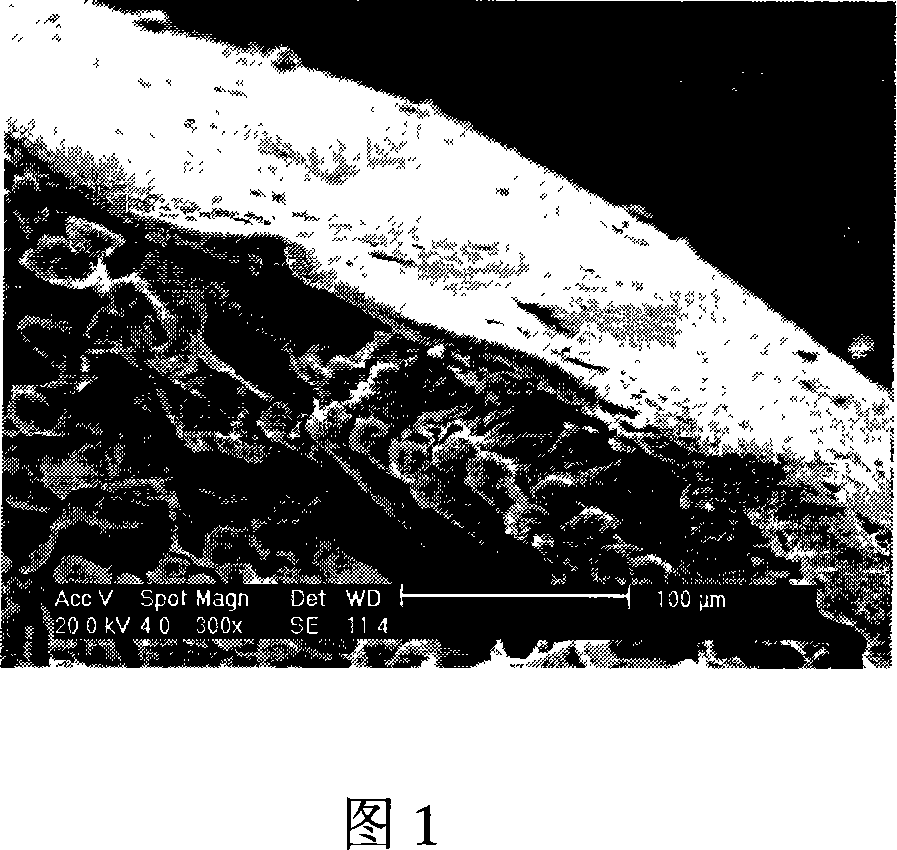

Method for preparing nonwoven tube enhancement type polyvinylidene fluoride hollow fiber membrane

The present invention provides a preparing method of nonwoven tube enhanced PVDF hollow fibre microporous filtering film. The method includes: the fiber slurry is obtained by dispersing polyester staple fibre having a certian lenght to polyacrylamide solution, the nonwoven tube blank is obtained by tube mould, the enhanced nonwoven tube is obtained by grinding, adhesive and baking processing; a film liquid is obtained by using PVDF as film material, using N, N-dimethylformamide as solvent, using kollidon as additive, according to a certain mass ratio of PVDF, solvent and additive; the enhanced nonwoven tube is dipped in the film liquid to process coating, solidify, obtaining enhanced hollow fiber film. The advantages of the invention is the simple process, high strength of the enhanced hollow fiber film, the water flux is 450L / m2.h-950L / m2.h.

Owner:TIANJIN UNIV

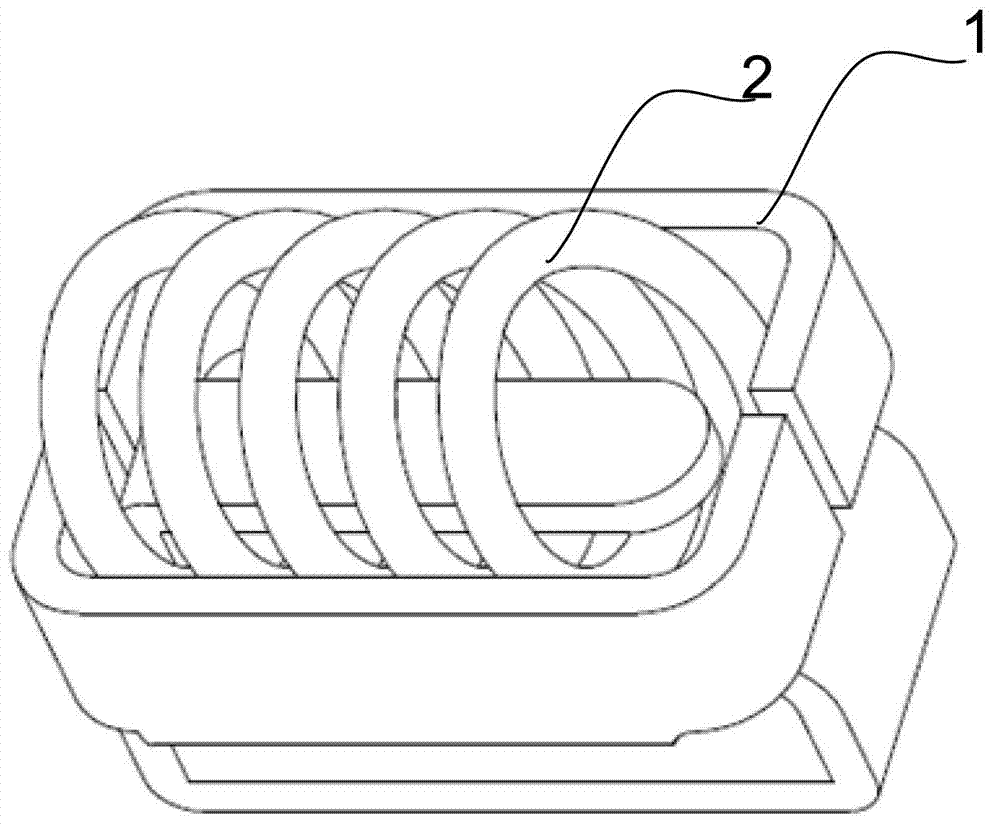

Conductive terminal, circuit board with same and plate-to-plate connector

InactiveCN102810782AIncrease touch pointsReliable contactCoupling contact membersFixed connectionsBoard-to-board connectorEngineering

An embodiment of the invention discloses a conductive terminal, a circuit board with the same and a plate-to-plate connector. The conductive terminal comprises a substrate and a spring contact; the substrate comprises a closed end and an open end, and a fixed rib extending out of the closed end points to the open end; two sides of the opened end can be bent and closed after the spring contact is sleeved on the rib; the spring contact comprises a unit ring which is formed by spirally surrounding a spring wire along an oblique elliptical trace and then spirally winding along an axis in two directions; and the periphery of the unit ring of the spring contact electrically contacts the circuit board connected with the conductive terminal. The closed end and the open end form a placing area of the conductive terminal, so that the conductive terminal is difficult to loose even if electronic and electric equipment shakes or vibrates. The spring contact is provided with multiple contact points, so that the conductive terminal is ensured to reliably be in contact with the circuit board and a contact circuit.

Owner:深圳市簧中簧电子有限公司

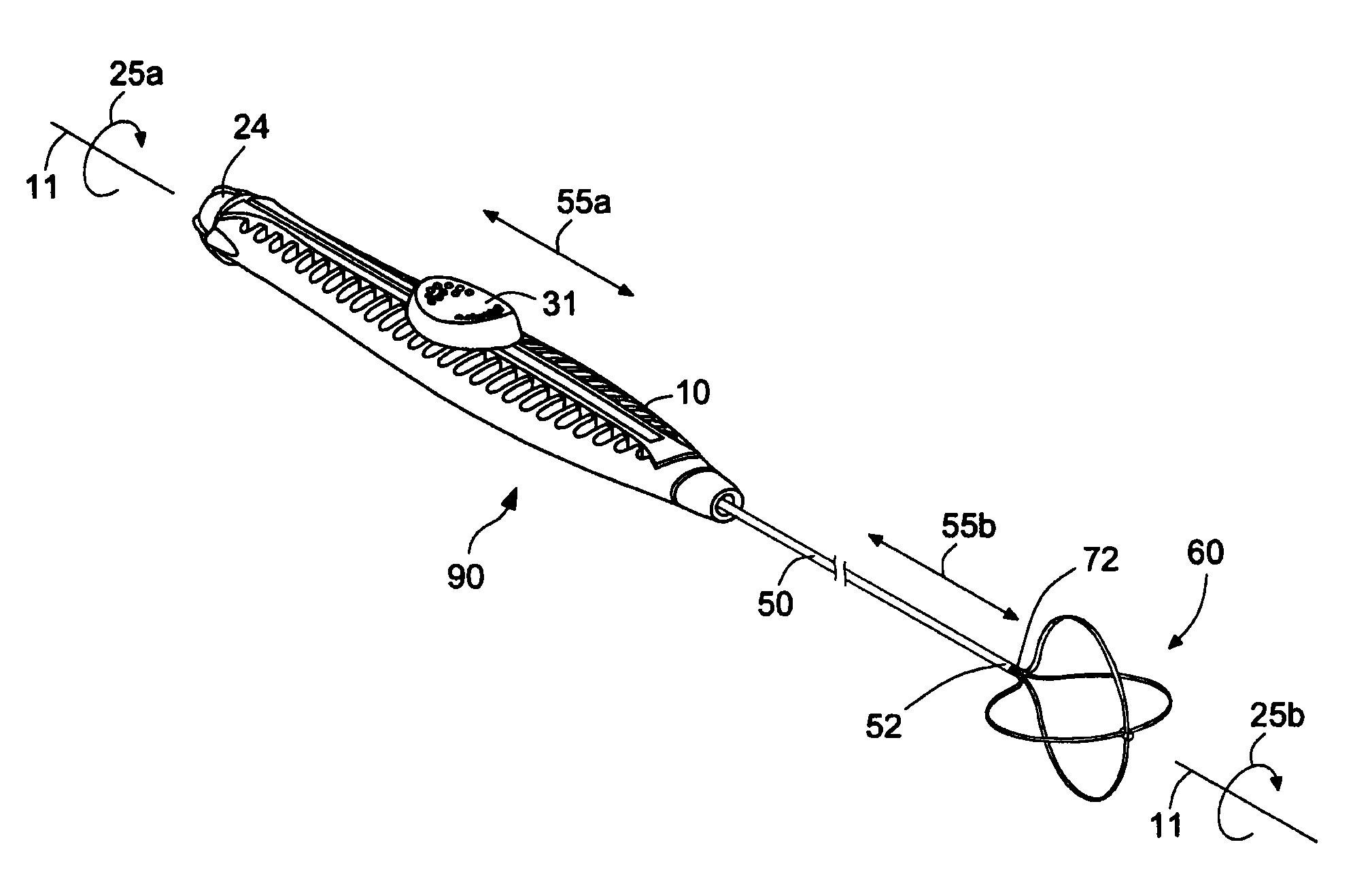

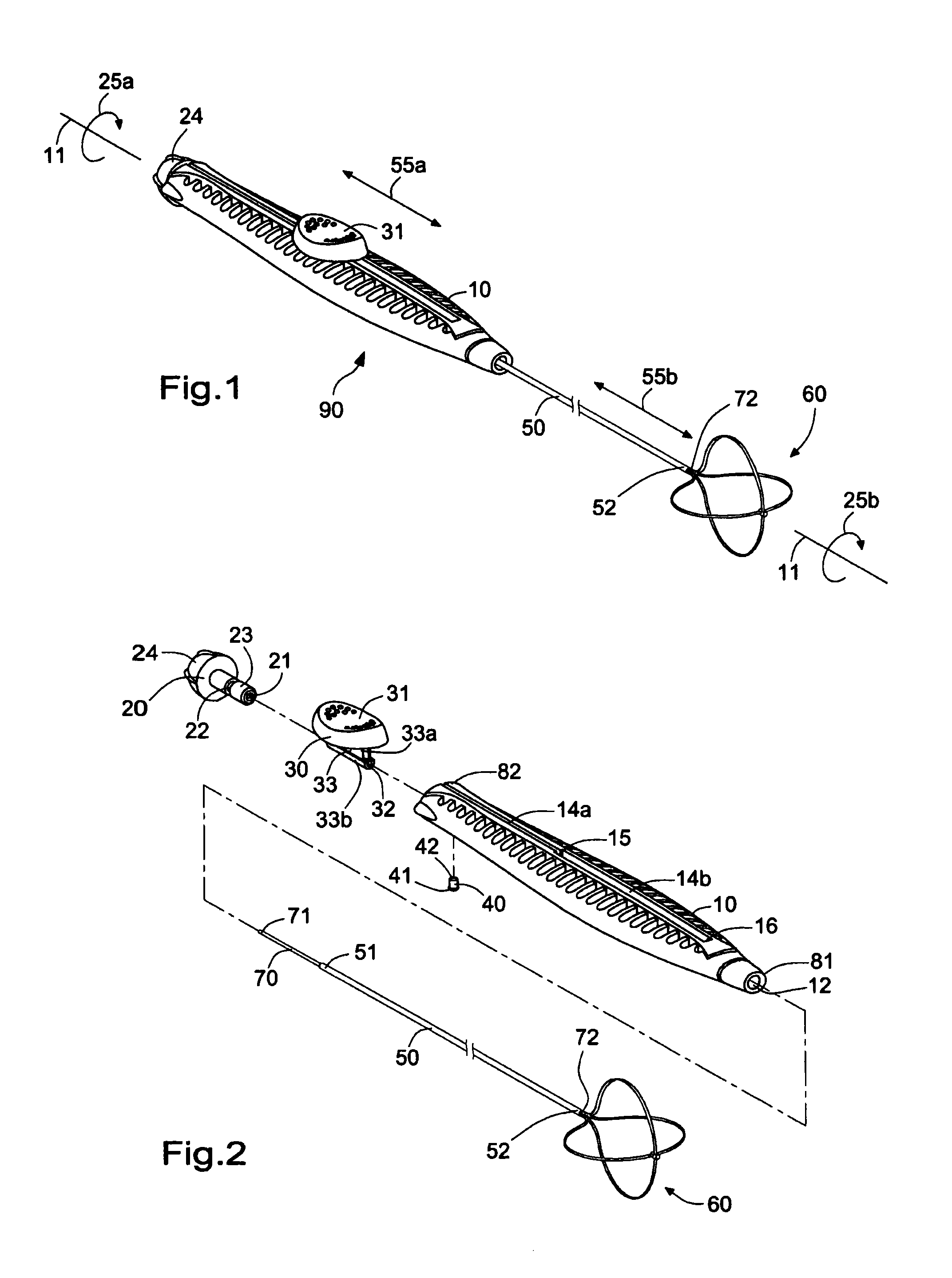

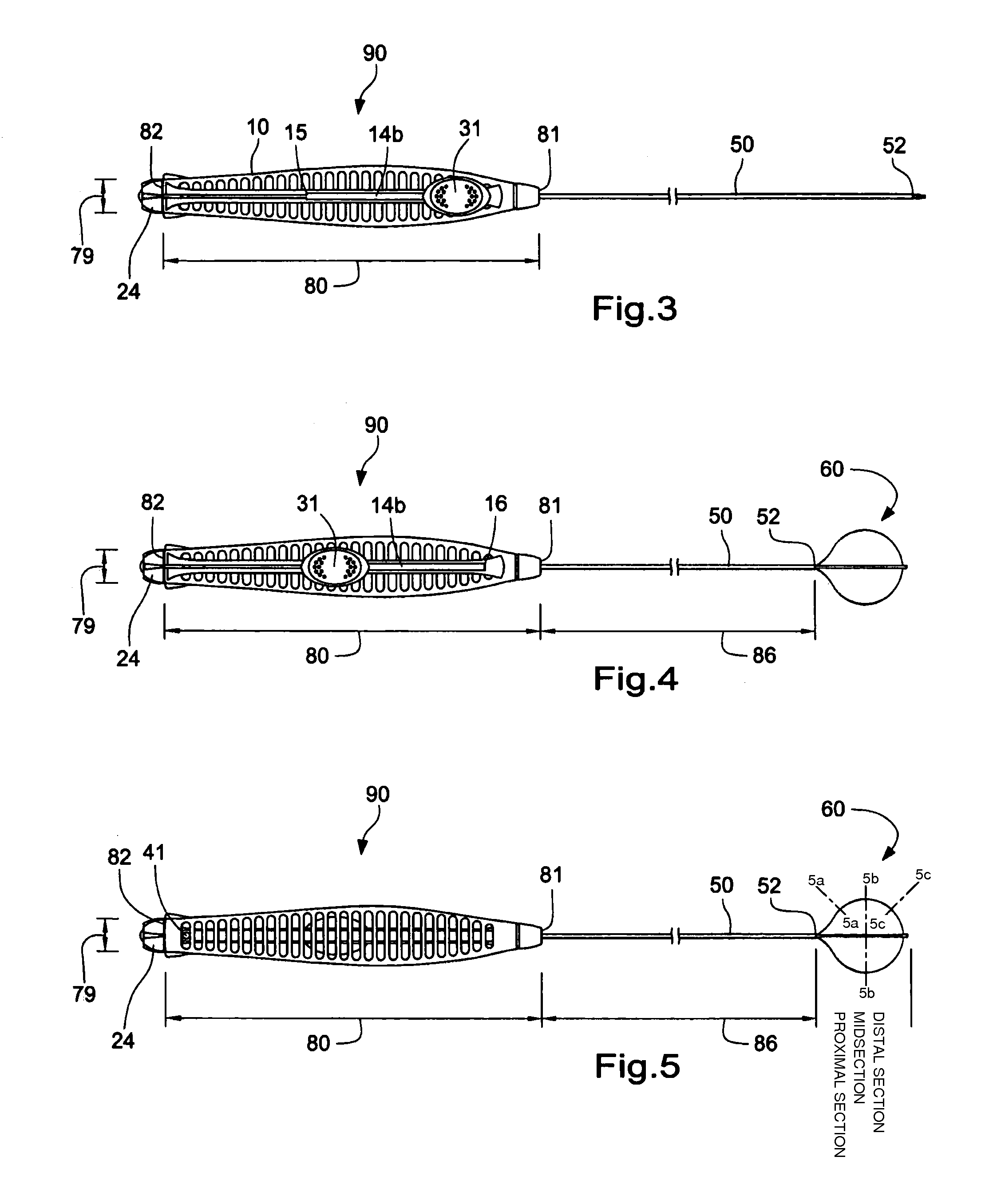

Medical retrieval device

ActiveUS9101383B1Increase pointsLimited degree of movementExcision instrumentsFlexible endoscopyEngineering

A medical retrieval basket used for entrapping and extracting objects such as urinary and biliary calculi from the body comprising a handle assembly, a flexible shaft, and a basket. The basket comprises a plurality of outwardly disposed shape memory wires and is bulbous in shape at its distal end. Located at the intersection point of the wires at the distal end of the basket is a hub that restricts the degree of relative movement between the wires. This hub also serves to increase contact points with the object to be retrieved and to stabilize the orientation of the basket wires. The substantially tipless configuration of the distal end of the basket permits the basket to retrieve objects from difficult to reach locations and reduces tissue trauma caused by the basket tip. The basket wires have varying cross sectional shapes and sizes in different sections of the basket to optimize the performance to the needs of each section within the basket. The flexible shaft contains a drive wire that exhibits different flexibilities within the same strand of material by varied cross sectional shapes or diameters. This permits the distal section of the shaft to be more flexible, which reduces the possibility of the device shaft limiting the deflection of a flexible endoscope.

Owner:ANNEX MEDICAL

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

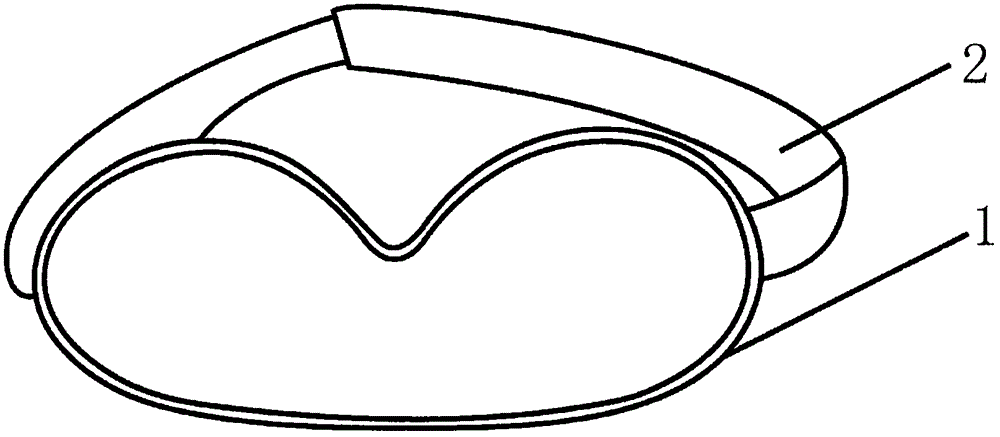

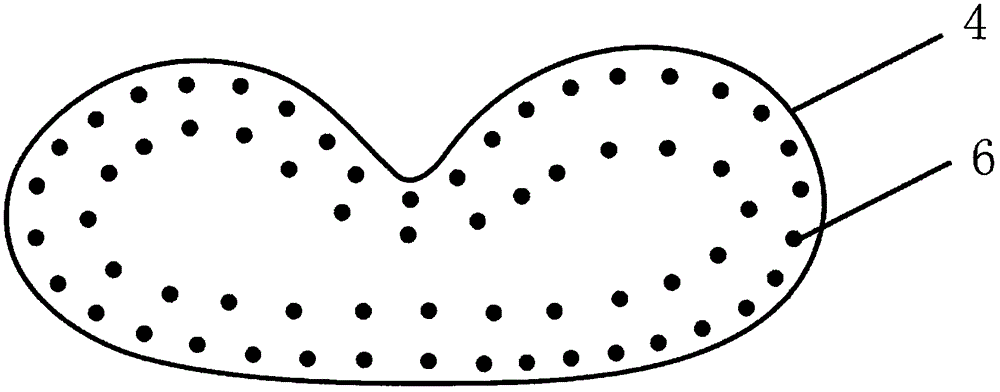

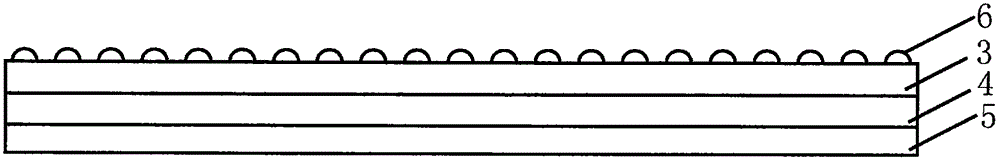

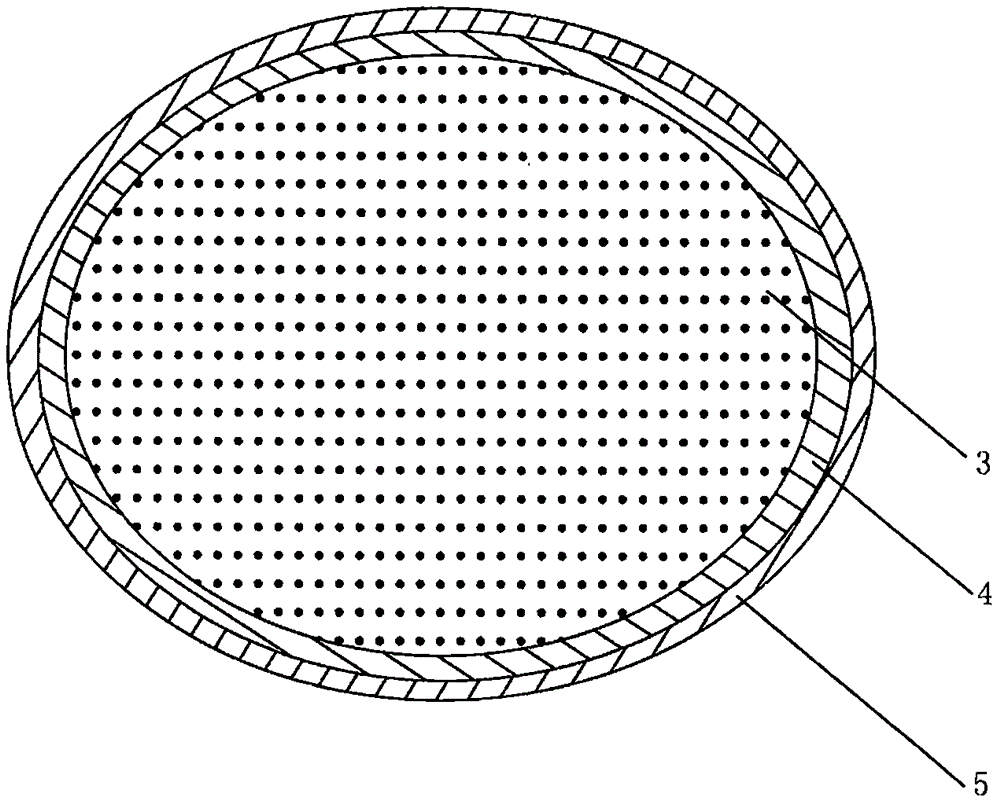

Natural self-heating healthcare physiotherapy patch and preparation method thereof

InactiveCN106236375AGood physical therapySimple structureEye-masksHeat-exchange elementsAdhesiveSlurry

The invention discloses a natural self-heating healthcare physiotherapy patch which comprises a patch body fitting the eye area of a human face, wherein the patch body comprises a first eye contact layer made of soft shading sterile cloth, a second eye contact layer fitting the eyes and a filling layer; fastening belts which can be stuck with each other are fixed on the two sides of the patch body respectively; multiple self-heating far infrared functional bonding particles are distributed on the surface of the second eye contact layer around the area of the eyes; the self-heating far infrared functional bonding particles are formed by heating and drying self-heating far infrared functional bonding slurry; and the self-heating far infrared functional bonding slurry contains raw ore slurry, a far infrared functional aid, an adhesive and a dispersing agent. In the natural self-heating healthcare physiotherapy patch and preparation method thereof disclosed by the invention, multiple self-heating far infrared functional bonding particles are distributed on the surface of the second eye contact layer around the area of the eyes, and perfect effects of prevention, healthcare and physiotherapy can be realized on eye diseases.

Owner:QINGDAO UNIV

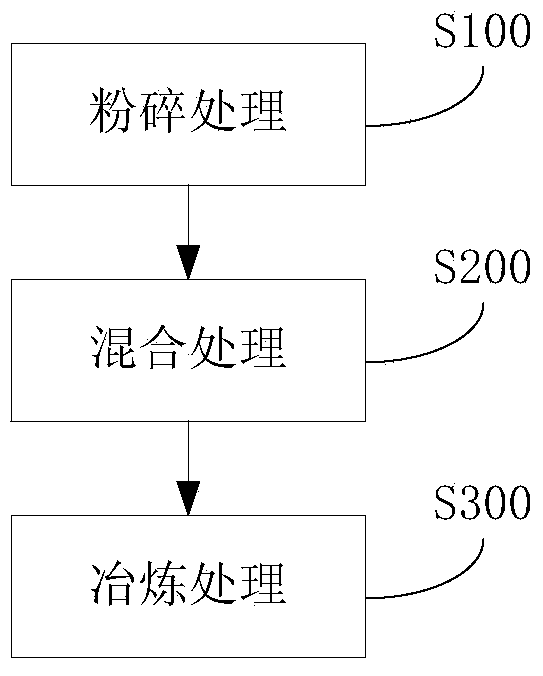

Method for preparing calcium carbide

InactiveCN103708457AReduce manufacturing costReduce the temperatureCalcium carbideEnergy consumptionCalcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: respectively crushing a carbon-base raw material and a calcium-base raw material to obtain carbon-base particles and calcium-base particles of which the average particle sizes are not greater than 50 micrometers; mixing the carbon-base particles and calcium-base particles to obtain a mixture; and smelting the mixture in a gas smelting furnace to obtain the calcium carbide. Since the raw materials are prepared into the ultrafine powders and then mixed and smelted, the method disclosed by the embodiment of the invention can effectively lower the smelting temperature and energy consumption of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

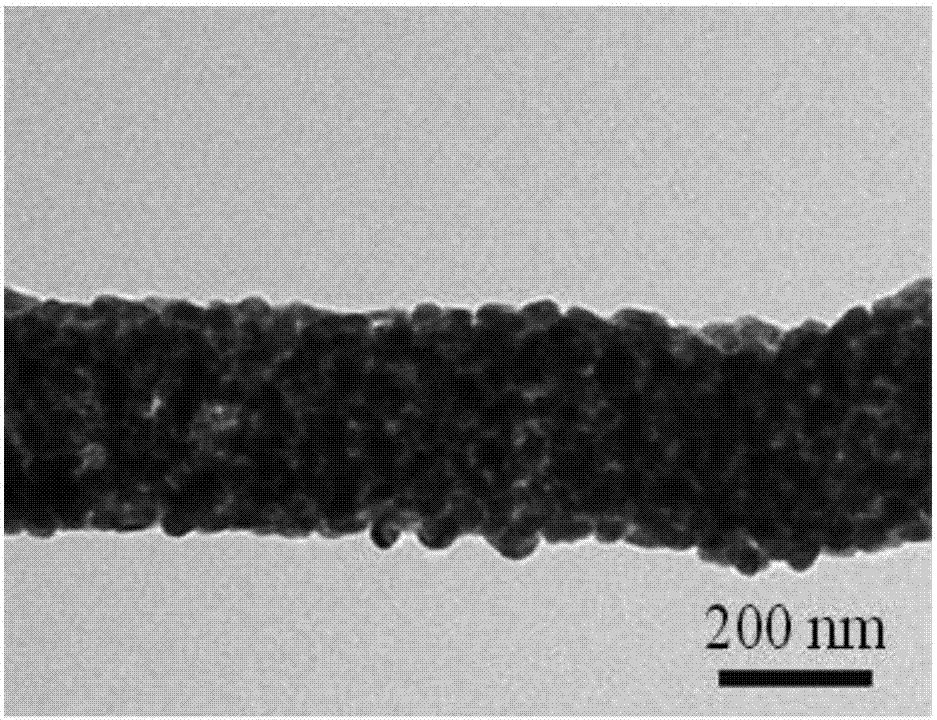

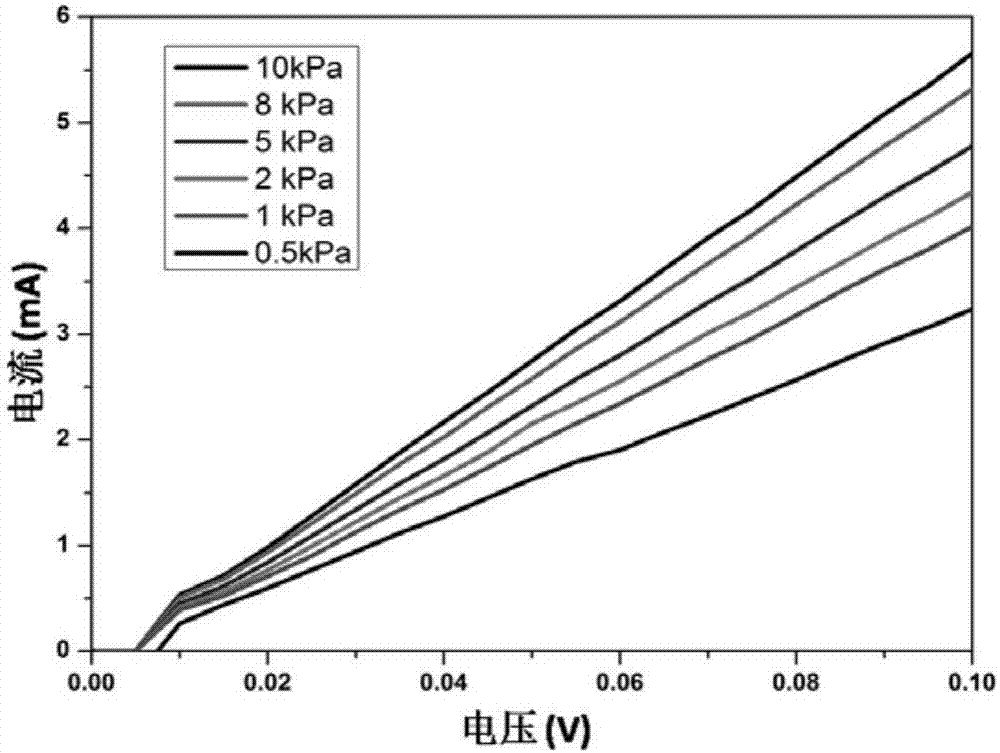

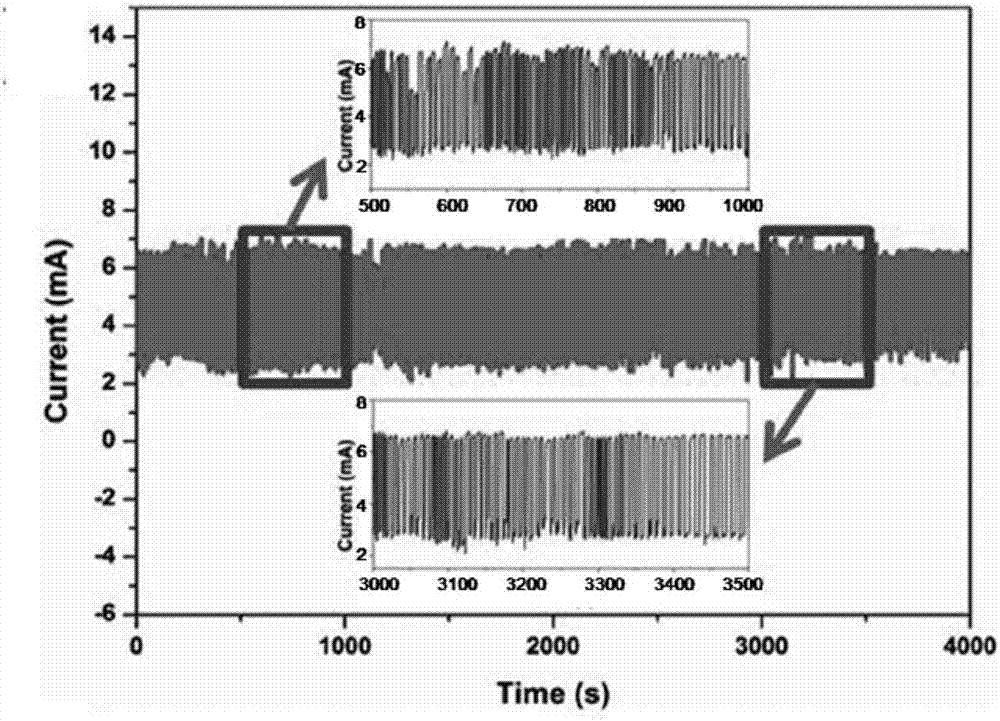

Flexible force-sensitive sensor based on silver-embedded nanofibers and preparation method thereof

ActiveCN107345840AAvoid reunionHigh content of silver nanoparticlesFibre treatmentForce measurementBreathingIon exchange

The invention discloses a flexible force-sensitive sensor based on silver-embedded nanofibers and a preparation method thereof. The sensor comprises a flexible force-sensitive resistance film which is connected to a power supply and a current meter in series. The flexible force-sensitive resistance film comprises a silver-embedded nanofiber film which is formed by alginate / silver nanoparticle composite nanofibers. The alginate / silver nanoparticle composite nanofibers are sodium alginate nanofibers prepared by an electrostatic spinning method, alginate silver nanofibers are made through ion exchange, and the alginate / silver nanoparticle composite nanofibers are obtained through reduction of silver ions. The sensitive resistor of the sensor has good flexibility and can be directly adhered to a skin, the skin is not hurted, the temperature performance and sensitivity are good, and the monitoring of physiological activities such as a pulse, a breathing frequency and a heartbeat can be realized. At the same time, the sensor also has an antibacterial effect and is more safe to directly contact with the skin.

Owner:QINGDAO UNIV

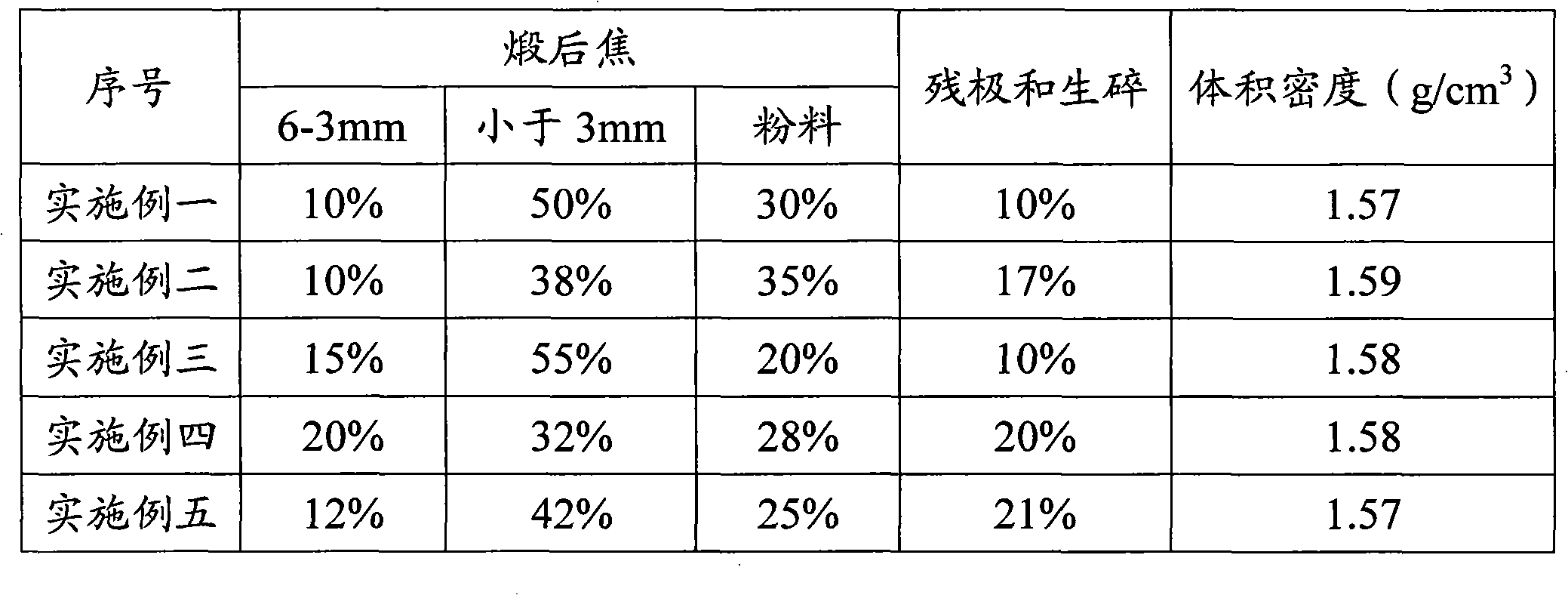

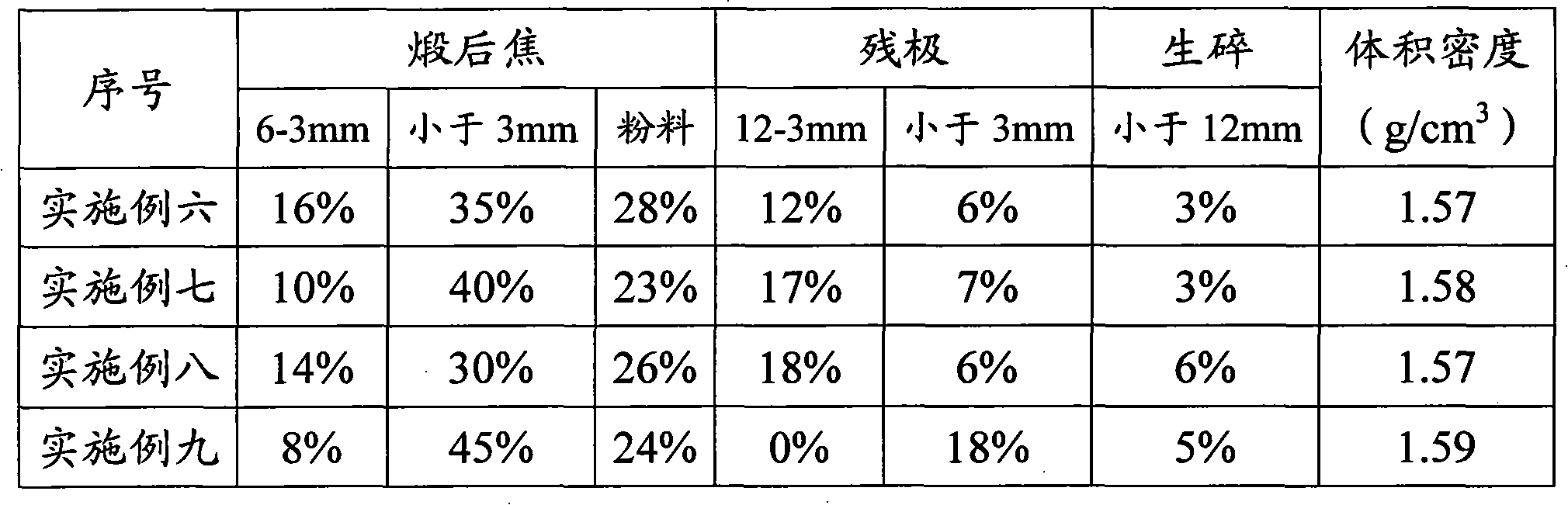

Carbon prebaked anode

The invention discloses a carbon prebaked anode in aluminum electrolysis industry. The aggregate of the carbon prebaked anode comprises calcined coke, residual anode and raw crushed straw, wherein the calcined coke with a particle size ranging from 3 to 6 millimeters accounts for 10 to 20 percent of the total weight of the aggregate, the calcined coke with a particle size ranging from 0 to 3 millimeters accounts for 30 to 55 percent of the total weight of the aggregate and the 200-mesh calcined coke powder accounts for 20 to 35 percent of the total weight of the aggregate. The formula of the anode does not adopt coarse calcined coke like the formula of the conventional carbon prebaked anode and increases the content of the fine calcined coke and 200-mesh calcined coke powder compared with the formula of the conventional carbon prebaked anode, thereby improving the volume density and compression strength of the anode and reduces the resistivity of the anode.

Owner:SNTO TECH GRP

Composite hollow fiber film preparation method based on on-line braiding-phase transfer moulding

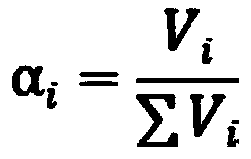

InactiveCN102240509AIncrease touch pointsHigh strengthSemi-permeable membranesHollow fibre membraneMass ratio

A composite hollow fiber film preparation method based on an on-line braiding-phase transfer moulding. The method comprises the following steps: a high-molecular organic membrane material is used as a composite layer material, and the high-molecular organic membrane material, a solvent and an additive are mixed according to a mass ratio, stirred and dissolved uniformly to be prepared into a composite layer casting solution of a composite hollow fiber membrane; textile fabrics are braided into a supporting layer of a fiber braiding pipe through on-line braiding of a braiding machine; supporting layer of a fiber braiding pipe is braided along a core by traction of a traction device of a pultrusion machine and with the core being fixed, and enters into a die through a front end of the core; meanwhile, the composite layer casting solution is dipped in a composite layer casting solution dipping zone in a front end of the die (the composite layer casting solution is injected into a die cavity gradually under pressure), and dragged to a coagulating tank for gelatinization and solidification; and the composite hollow fiber film is obtained. The invention has technical effects that the preparation process is simple; the braiding pipe is braided through the on-line braiding machine, and separating membrane is combined on the braiding pipe synchronized; the braiding pipe and the composite layer have many contact points and are combined tightly; besides, preparation conditions of the tubular composite hollow fiber film to produce a durable composite hollow fiber film with high performance and high strength, at low costs.

Owner:WUHAN MAKER ANBO TECH

Sludge haycite water-permeable brick and preparation method thereof

ActiveCN106242428ASolve the strength problemSolve the contradiction between water permeabilityCeramic shaping apparatusCement mixing apparatusSurface layerBrick

The invention discloses a sludge haycite water-permeable brick and a preparation method thereof. The sludge haycite water-permeable brick comprises a surface layer and a base layer, and is characterized in that the surface layer is prepared from, by weight, 1 part of white cement, 0.05 part of ferric oxide, 1-2 parts of haycite sand of 1 mm to 3 mm, 0.2-0.5 part of yellow sand, 0.02-0.04 part of water reducer and 0.3-0.4 part of water; the base layer is prepared from 1 part of 42.5-grade Portland cement, 0-2 parts of haycite sand with the grain size being 3 mm to 5 mm, 0-2 parts of the haycite with the grain size being 1 mm to 3 mm, 0.2-0.5 part of yellow sand, 0.02-0.04 part of water reducer and 0.3-0.4 part of water. The preparation process comprises the steps that the sludge haycite is crushed and screened, the raw materials of the surface layer and the base layer are weighed in proportion, the raw materials are mixed and stirred, and a brick body is formed and maintained. The sludge haycite water-permeable brick has the advantages of being low in cost, high in strength and good in permeability performance, preventing sliding, resisting wear and the like.

Owner:NINGBO UNIV

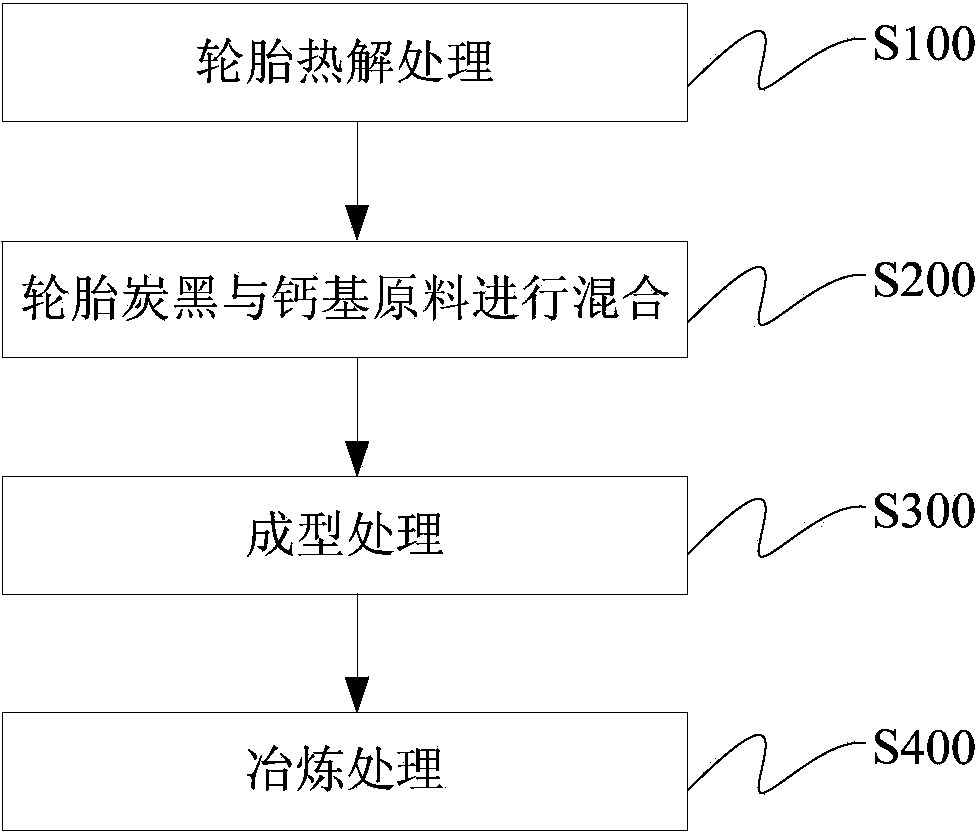

Method for preparing calcium carbide

InactiveCN103708458AReduce manufacturing costLow reaction temperatureCalcium carbideElectric arc furnaceEnergy consumption

The invention discloses a method for preparing calcium carbide, which comprises the following steps: pyrolyzing junked tires to obtain high-temperature oil gas, iron wires and tire carbon black; mixing the tire carbon black with a calcium-base raw material to obtain a mixture; forming the mixture to obtain a massive furnace raw material; and smelting the massive furnace raw material in an arc furnace to obtain the calcium carbide. The technique can obviously lower the temperature and energy consumption, thereby lowering the production cost of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

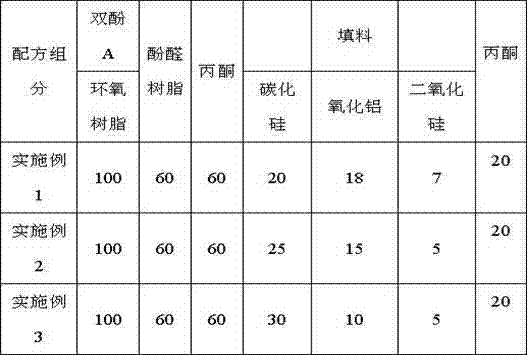

Insulated thermal conductive adhesive and preparation method thereof

InactiveCN102391818AImprove thermal conductivityHigh surface energyNon-macromolecular adhesive additivesEpoxy resin adhesivesNanometreAdhesive

The invention discloses an insulated thermal conductive adhesive, which is prepared by a method comprising the following steps of: (1) preparing an adhesive matrix adhesive liquid; (2) preparing a nano inorganic composite filler solution; and (3) preparing the adhesive. The insulated thermal conductive adhesive consists of the following components in part by weight: 100 parts of bisphenol A epoxy resin, 35 to 100 parts of phenolic resin, 20 to 30 parts of nano silicon carbide, 10 to 20 parts of nano aluminum oxide, 2 to 8 parts of nano silicon dioxide, and 40 to 100 parts of acetone. The thermal conductive performance of the cured adhesive is improved by adding silicon carbide, aluminum oxide and silicon dioxide serving as nano inorganic composite fillers into resin matrix. Meanwhile, the nano inorganic composite fillers have better colloid gap filling effect, so that an insulated adhesive layer is more uniform, the thickness of the insulated adhesive layer can be reduced and the thermal resistance of the insulated adhesive layer is reduced.

Owner:秦会斌

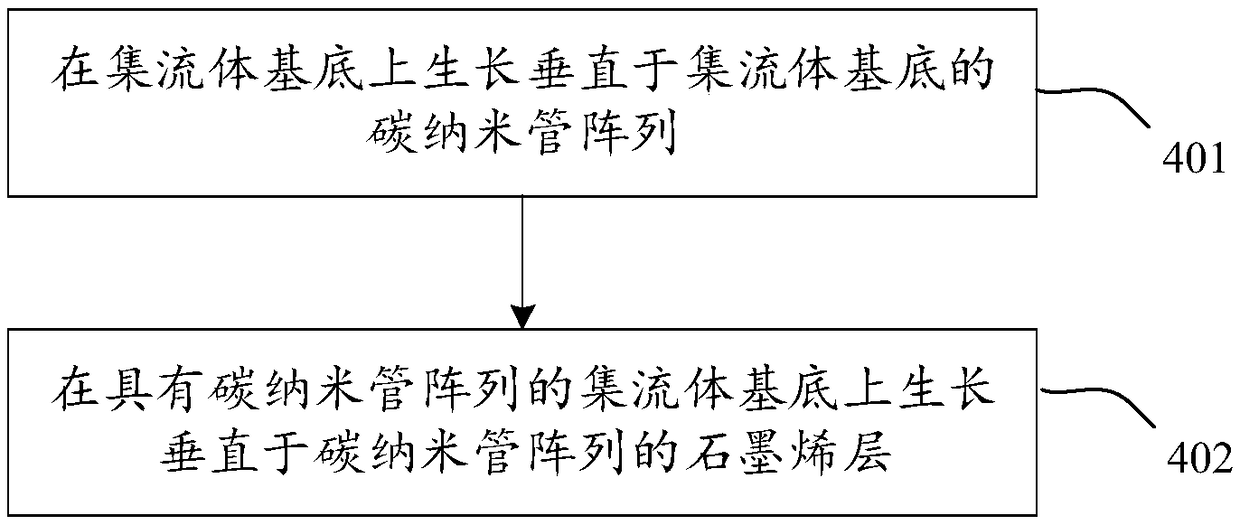

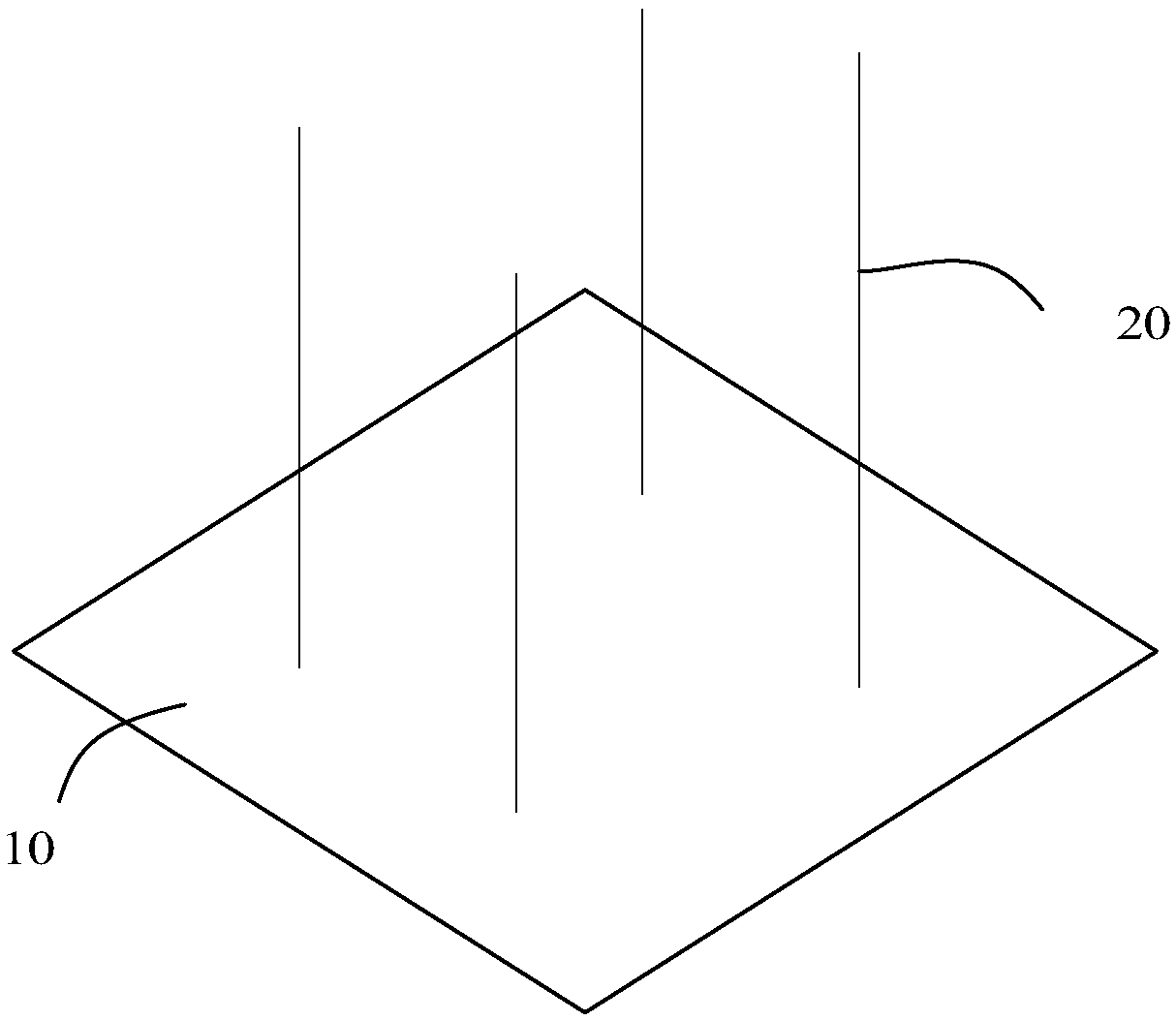

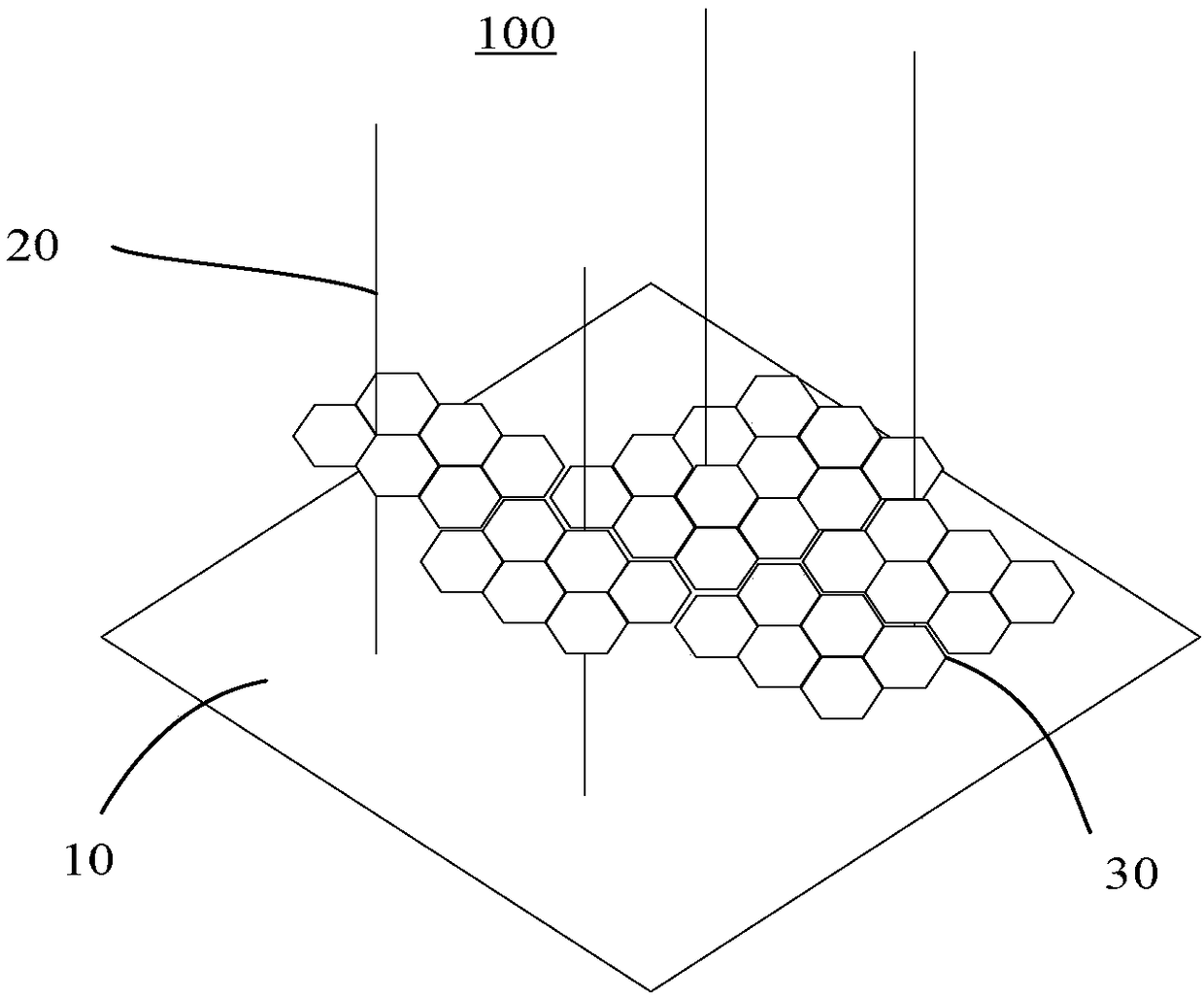

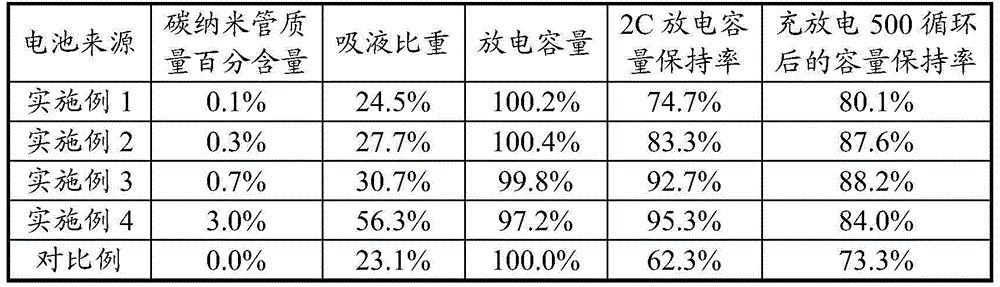

Method for modifying current collector, current collector and energy storage device

ActiveCN108346802AImprove power densityImprove surface roughnessHybrid capacitor electrodesElectrode carriers/collectorsCarbon nanotubeEnergy storage

The invention discloses a method for modifying a current collector, the current collector and an energy storage device to overcome the problem of a few contact points between current collectors and electrodes in the prior art. The method comprises the following steps: allowing a carbon nanotube array perpendicular to the substrate of the current collector to grow on the substrate of the current collector; and allowing a graphene layer perpendicular to the carbon nanotube array to grow on the current collector substrate with the carbon nanotube array.

Owner:HUAWEI TECH CO LTD

Graphite negative electrode material of lithium ion battery and preparation method for graphite negative electrode material

ActiveCN106532045AImprove the ability to absorb electrolyteImprove high rate charge and discharge performanceNegative electrodesState of artCarbon nanotube

The invention discloses a graphite negative electrode material of a lithium ion battery and a preparation method for the graphite negative electrode material. The graphite negative electrode material of the lithium ion battery comprises graphite and carbon nanotubes which uniformly coat the surface of the graphite through a physical coating method; and the carbon nanotubes form a network-shaped structure in the graphite negative electrode material. The preparation method comprises the following steps of 1) preparing a carbon nanotube dispersion solution; 2) coating the graphite with the carbon nanotubes; 3) drying a dispersing agent; and 4) performing carbonization on the dispersing agent and a surfactant. Compared with the prior art, the graphite is coated with the carbon nanotubes in the preparation method, so that the electrolyte absorption capability, the rate capability and the cycling life of the graphite negative electrode material can be effectively improved and prolonged.

Owner:NINGDE AMPEREX TECH

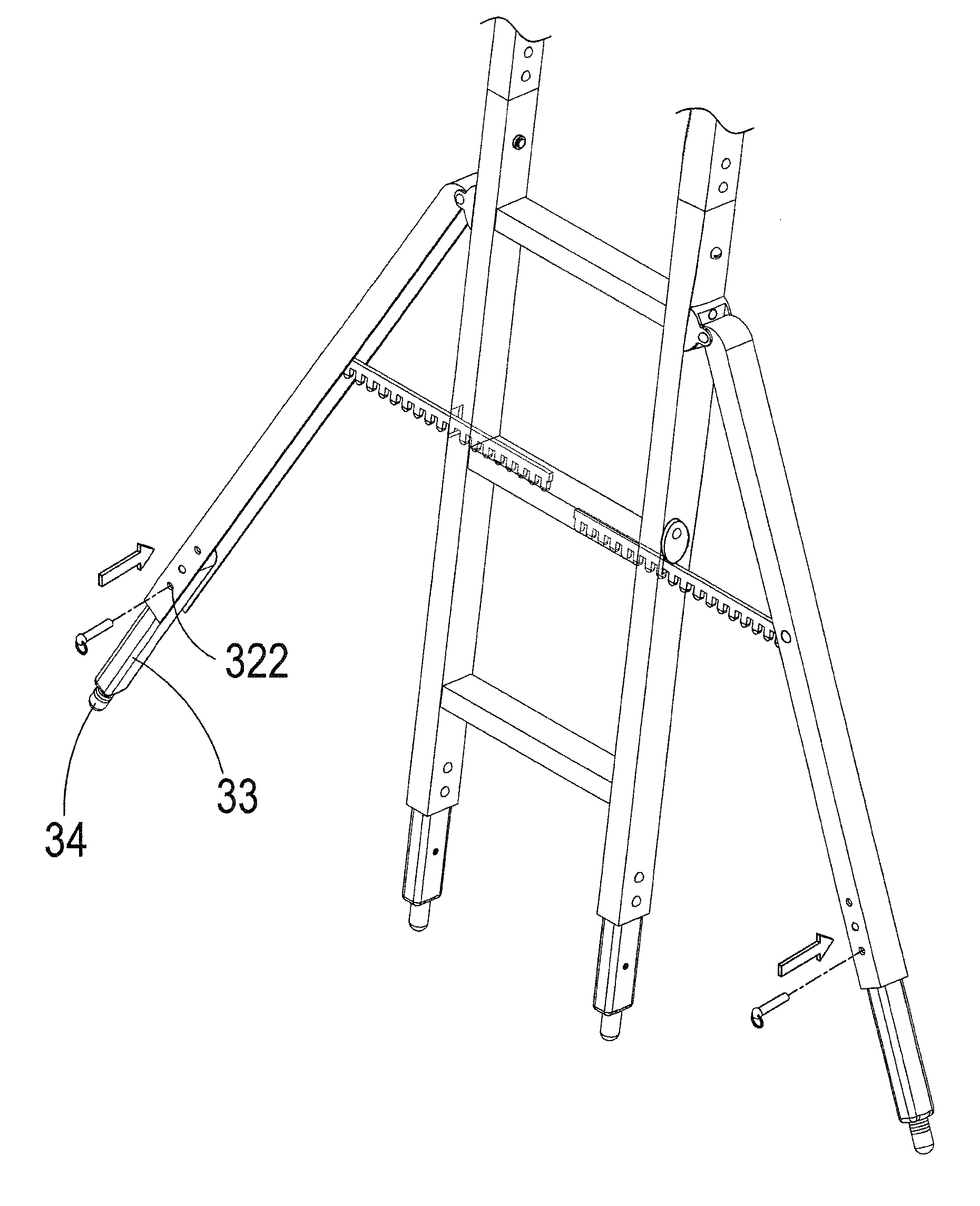

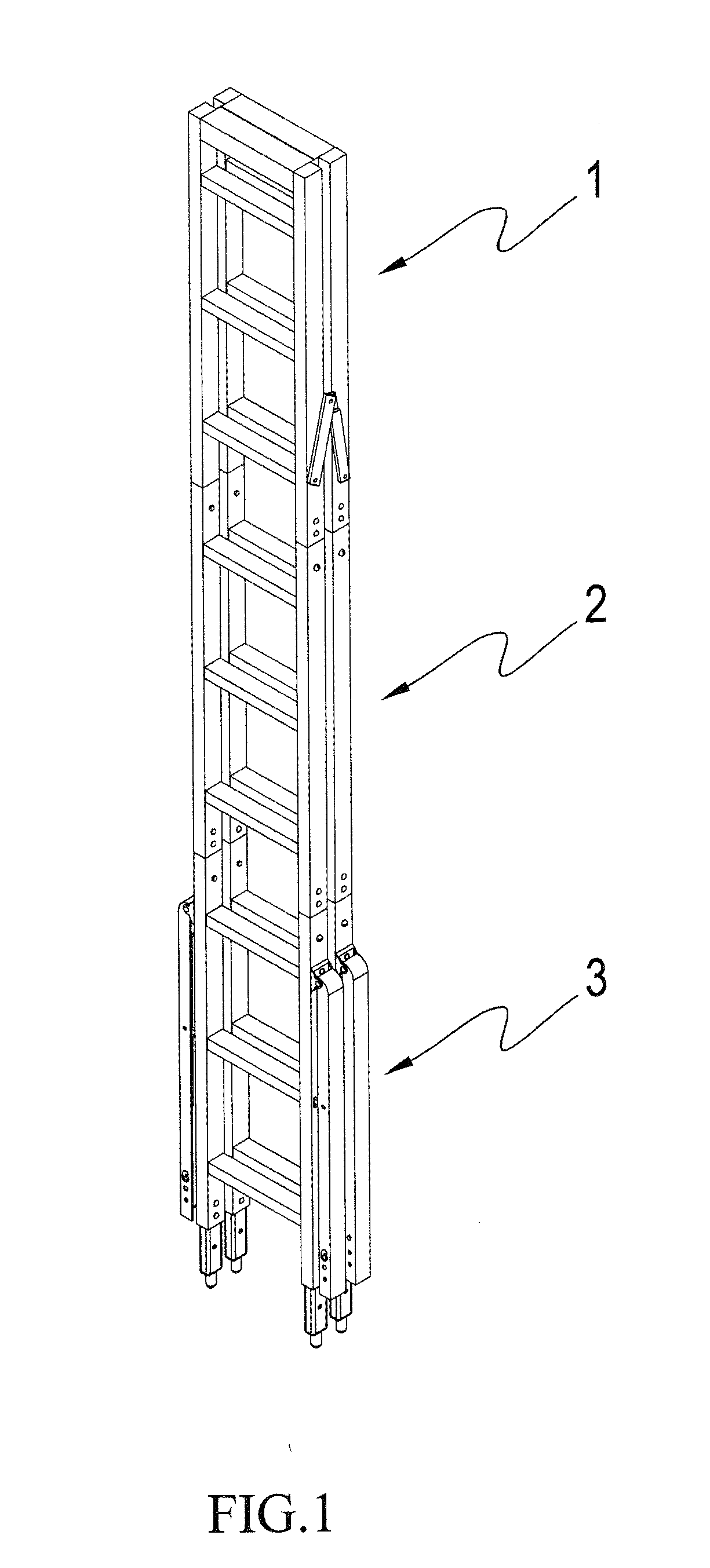

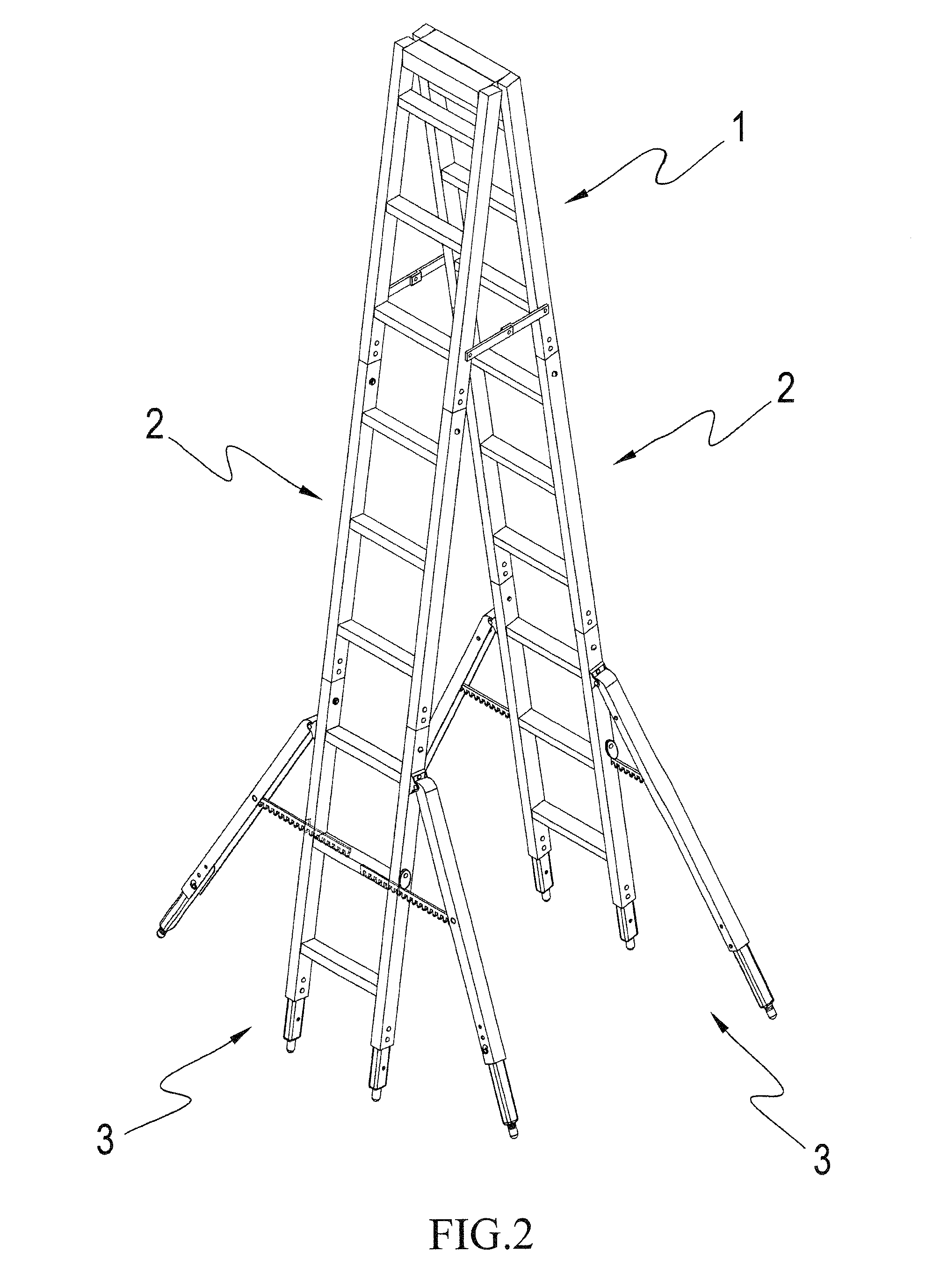

Assembled a-shaped ladder

An assembled ladder is formed by coupling a top ladder segment, a plurality of middle ladder segments, and a plurality of bottom ladder segments together. The bottom ladder segments include a ladder body, support frame assemblies, ancillary frames, adjustable support pads, and adjustable coupling members. The support frame assemblies are respectively set at two sides of the ladder body. The ancillary frames are mounted to the support frame assembly. The adjustable support pads are screwed to the ancillary frames. The adjustable coupling members have an end coupled to the support frame assemblies and are partially received in the receiving space. With the adjustable coupling members fixing the support frame assemblies, the ancillary frames are expanded. Through adjustment made with the adjustable support pads, the ladder can be set more stably to achieve safety and convenience of use.

Owner:YANG PI CHEN

Room-temperature curing conductive adhesive

InactiveCN108410388AImprove conductivityImprove adhesionEpoxy resin adhesivesElectrically-conducting adhesivesAdhesiveRoom temperature

The invention discloses a room-temperature curing conductive adhesive which is prepared from, by weight, 5-30% of substrate resin, 40-70% of conductive fillers, 5-20% of curing agents, 1-7% of accelerators, 15-40% of diluting agents and 1-5% of additives. According to the indoor-temperature curing conductive adhesive, indoor-temperature curing can be achieved, indoor-temperature long-term storageis achieved, curing time is short, volume resistivity is low, adhesive force is high, and the conductive adhesive has good conductive performance. The conductive adhesive is stored at the indoor temperature for a long time, the volume resistivity and the adhesive force are not affected, and the conductive adhesive is high in stability, convenient to store and can be used for a long time.

Owner:TAIYUAN HYPERION NEW MATERIAL CO LTD

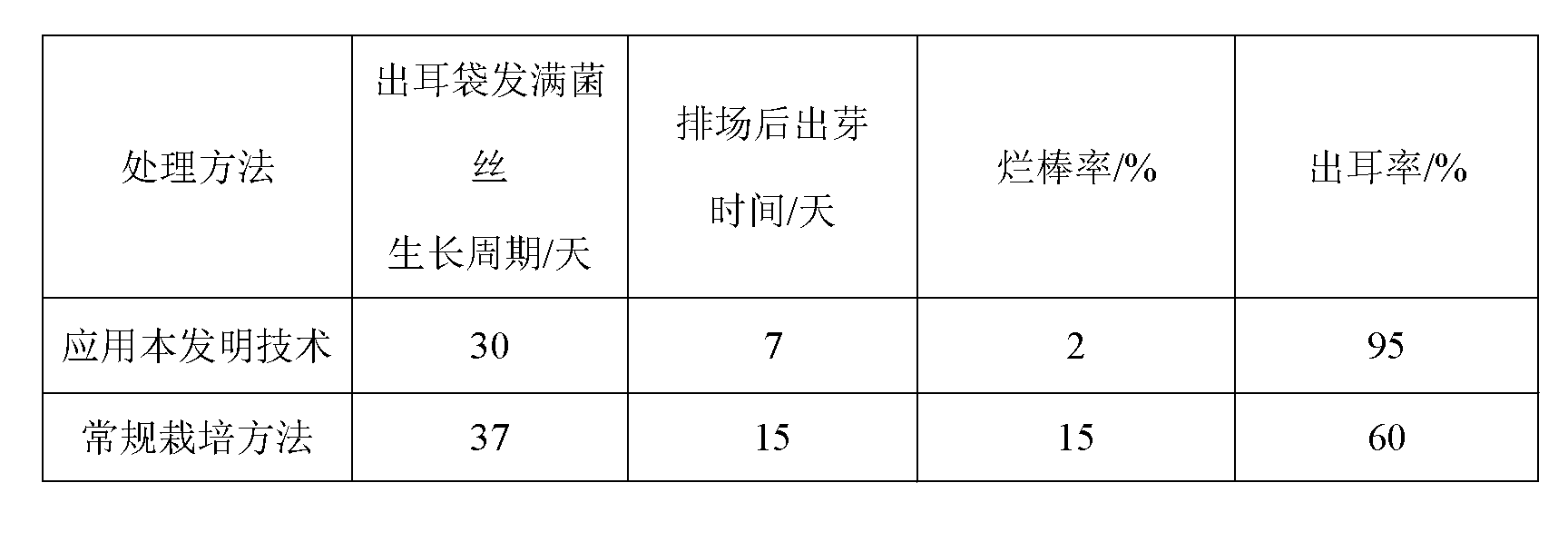

Method for cultivating black fungus by using micropore bag

The invention discloses a method for cultivating black fungus by using a micropore bag. The method includes: punching on a polyethylene plastic bag to obtain the micropore bag, wherein the aperture is 0.2-0.25cm, and the pitch is 3-4 / cm; filling compost in the micropore bag, sleeving a bilayer nonporous bag outside the micropore bag, and performing high-temperature sterilization; inoculating between the material bag and the sleeving bag, and cultivating for fungus growing; and finally removing the bilayer nonporous bag on the outer layer, only retaining the micropore bag, omitting hole pricking, directly arranging on a fungus frame for fungus fruiting, and picking black fungus after fungus fruiting management. The micropore bag improves breathability of a fungus bag and is in favor of increasing fungus growing speed and shortening fungus growth period by 6-8 days. The method of using hole-pricking-free inducement to primordium, directly removing the sleeving bag and arranging on the fungus frame for fungus fruiting is used, so that the problem of proneness to stick rotting caused by heat generated by fungus stick hole pricking is avoided, and the stick rotting rate is lowered by more than 30% compared with that of conventional cultivation.

Owner:WUYI INNOVATION EDIBLE FUNGUS

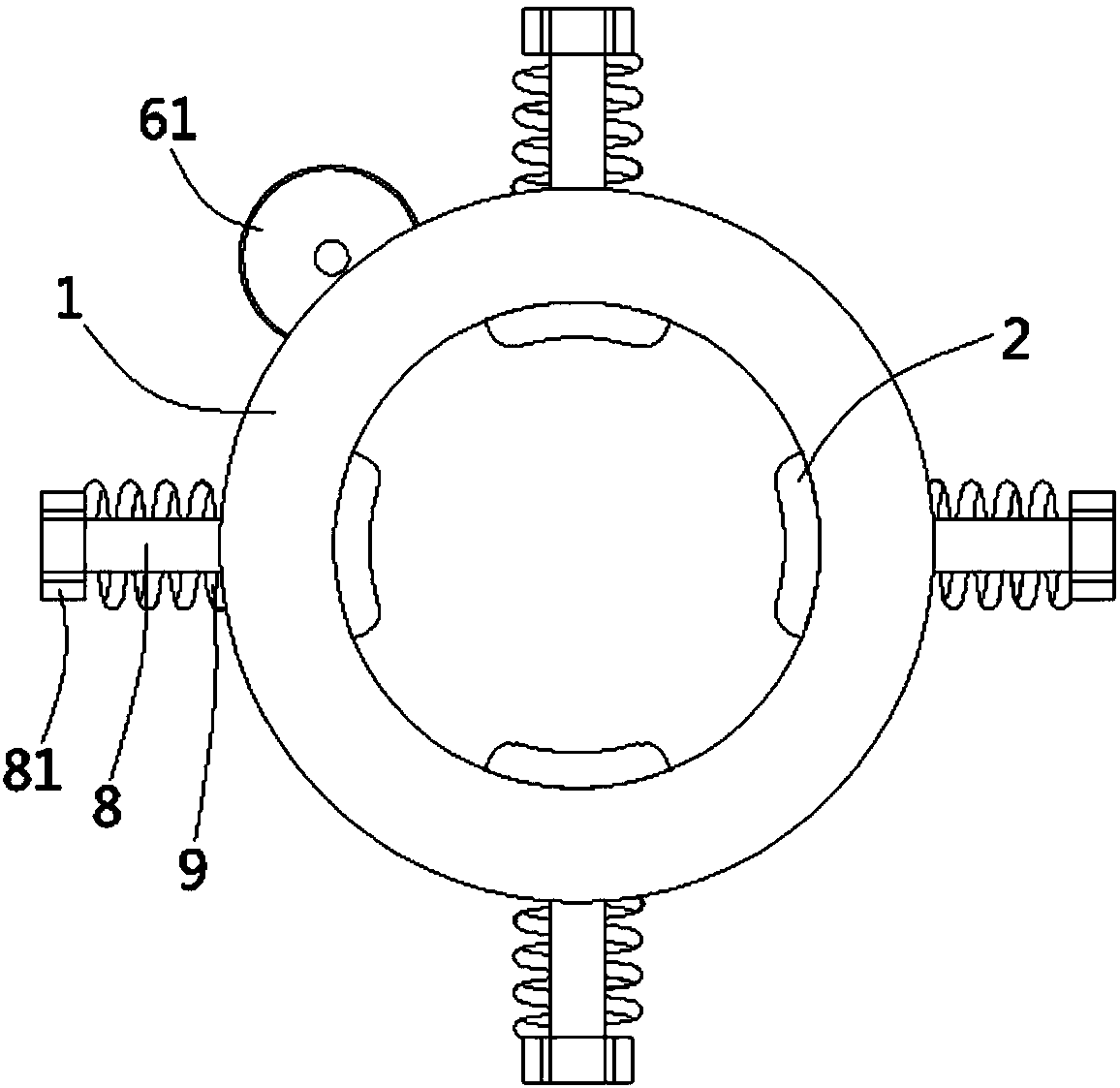

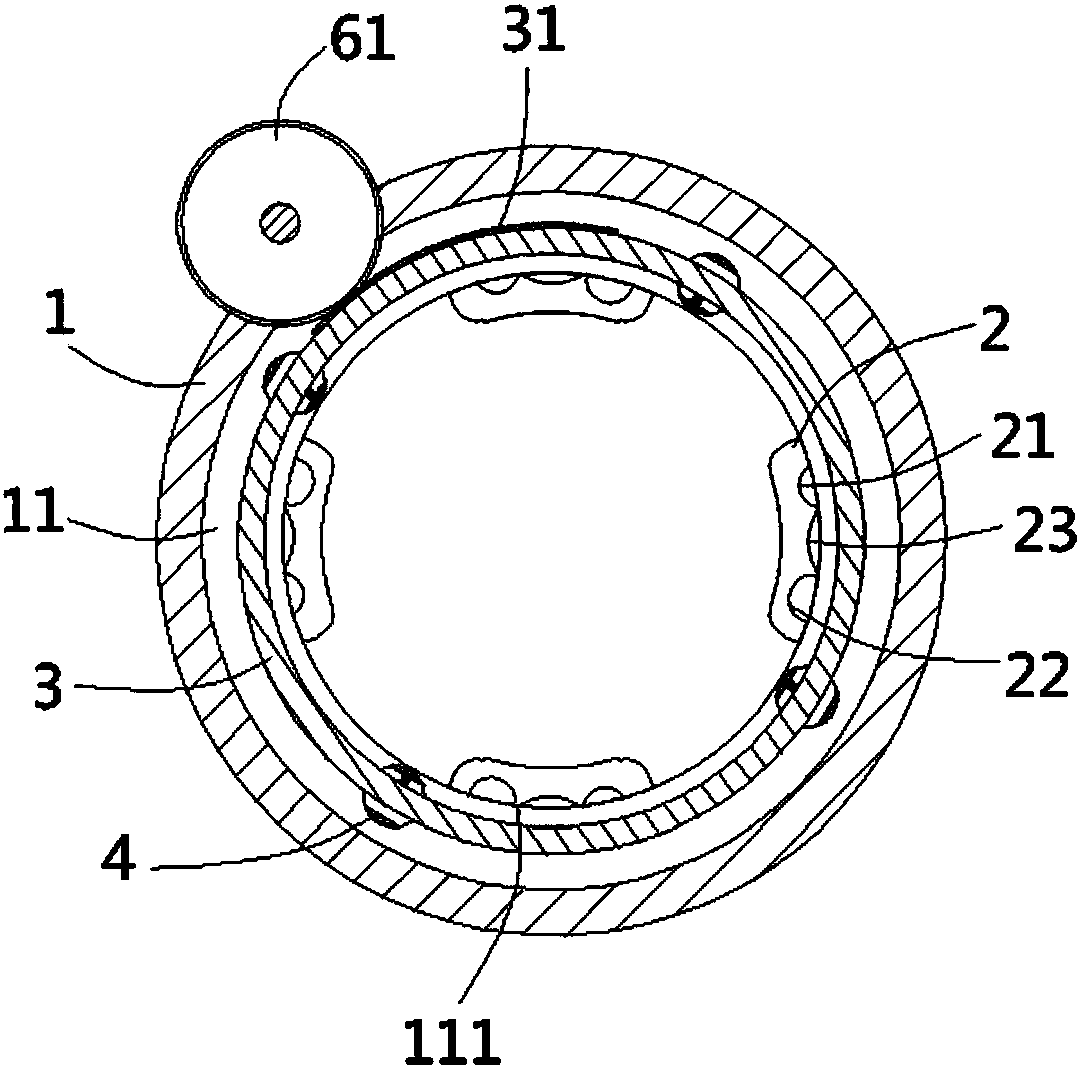

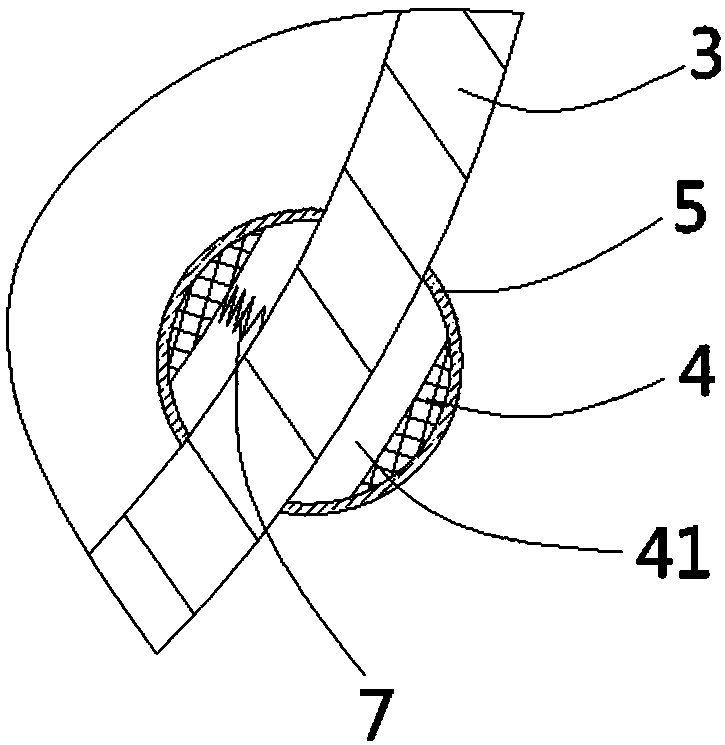

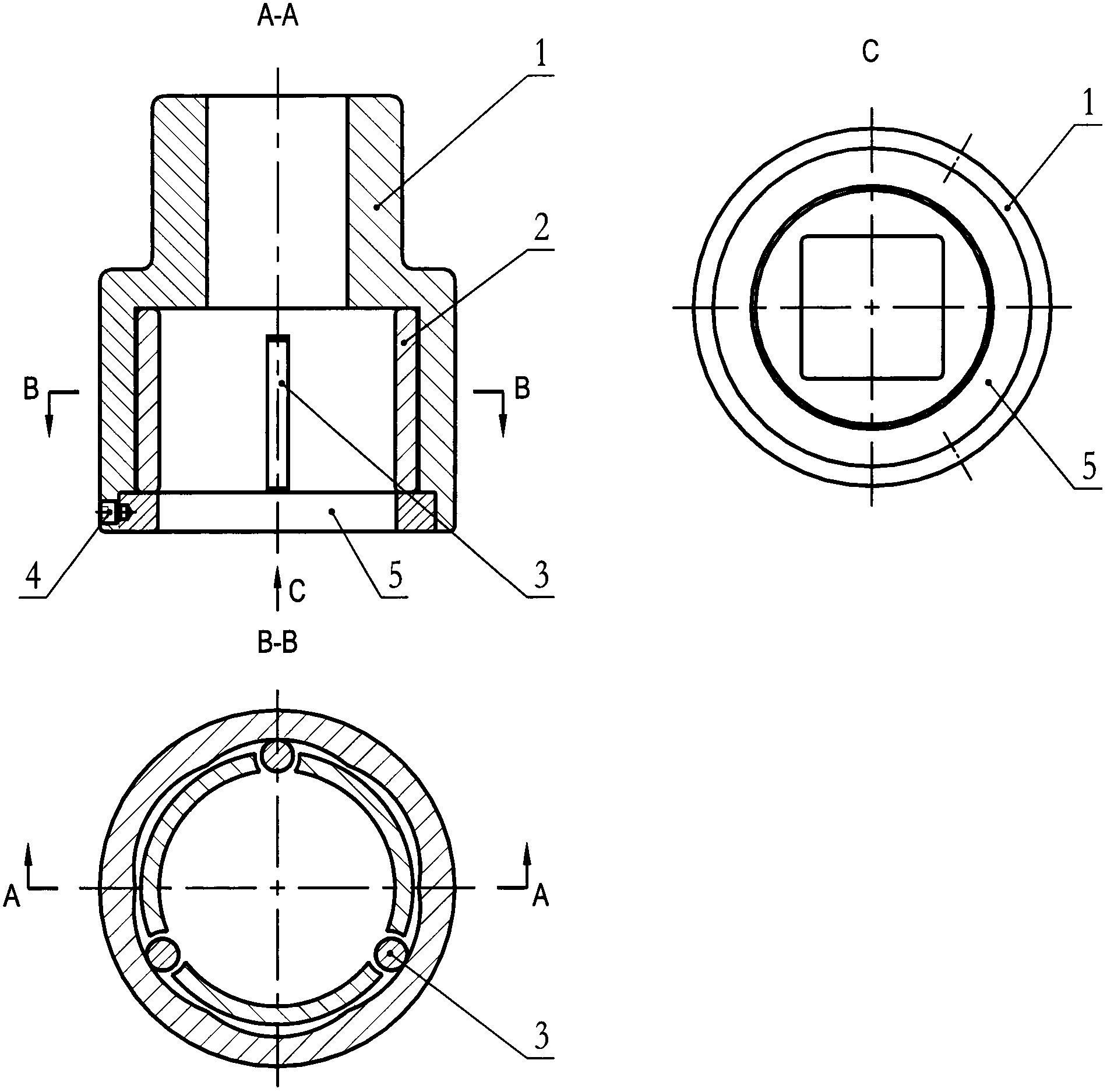

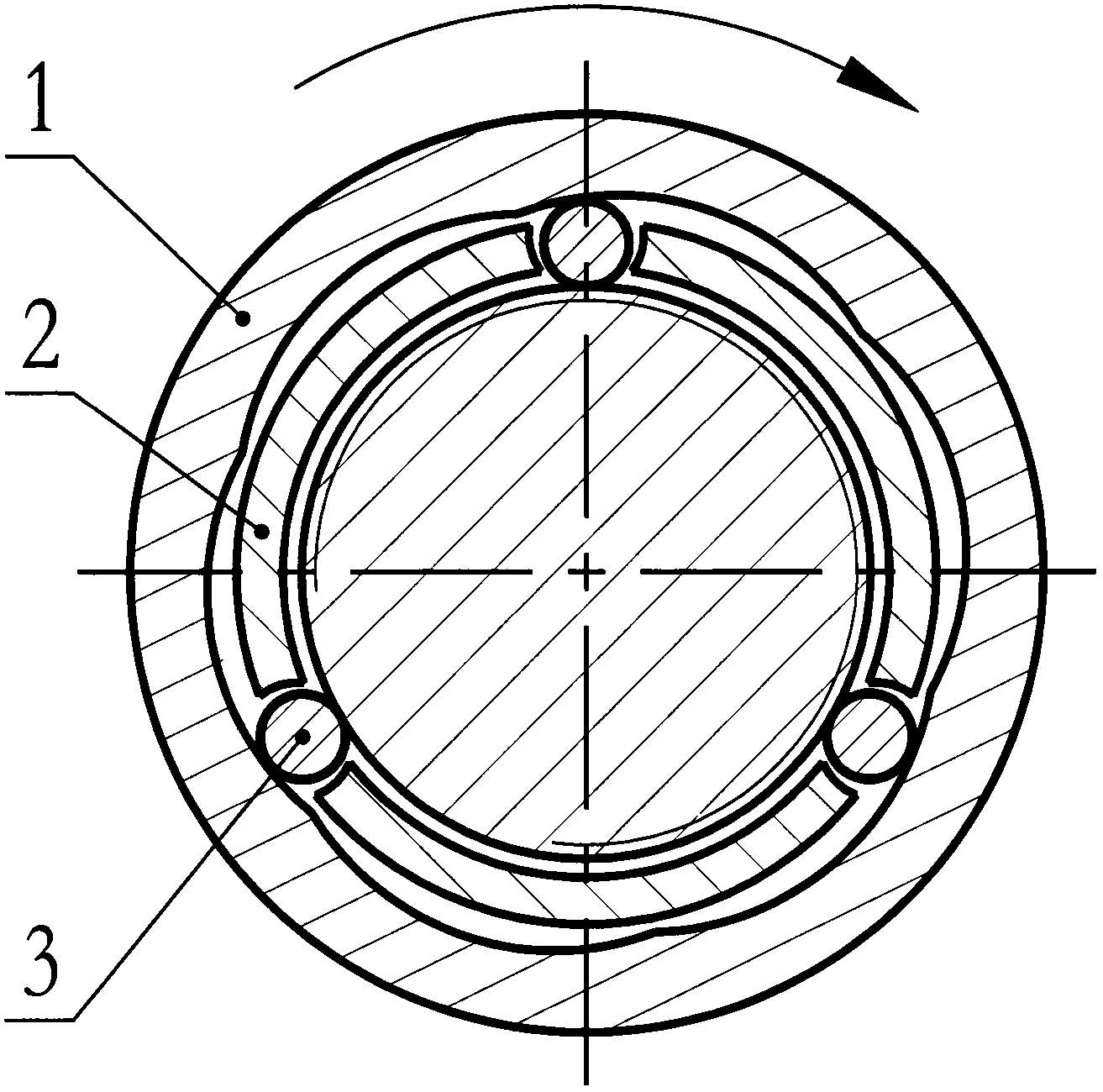

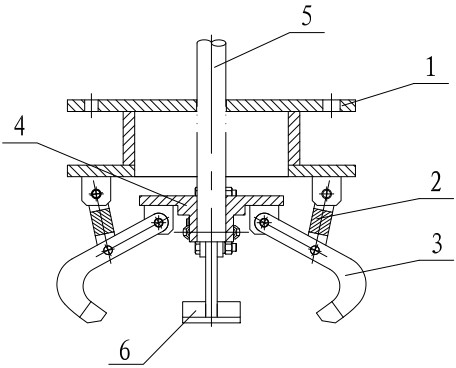

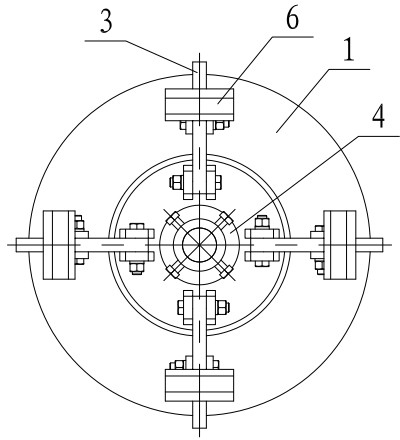

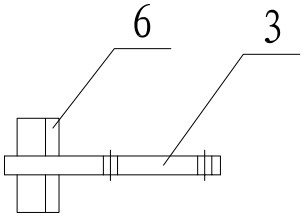

Mechanism used for clamping bearing ring

InactiveCN107553522AIncrease touch pointsReduce clamping forceGripping headsWork holdersEngineeringMechanical engineering

Owner:SUZHOU RUIDAJU AUTOMATIC EQUIP CO LTD

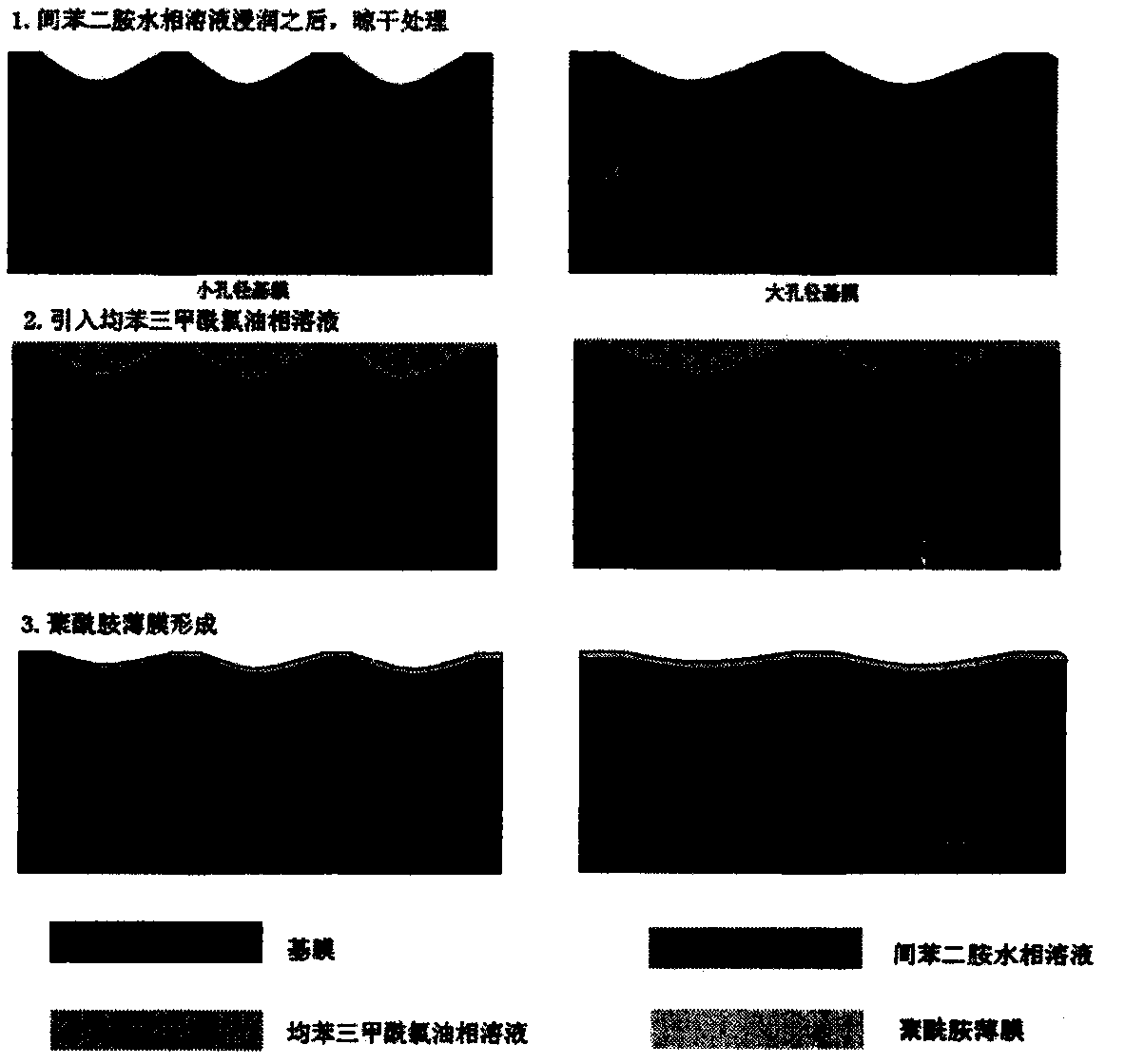

Forward osmosis composite membrane based on large-aperture base membrane, and production method thereof

ActiveCN108295667AGood high temperature resistanceShort mass transfer distanceMembranesSemi-permeable membranesUltrafiltrationChemistry

The invention discloses a forward osmosis composite membrane based on a large-aperture base membrane, and a production method thereof. The forward osmosis composite membrane is formed by the large-aperture base membrane and an ultrathin desalination layer; and a superhydrophilic micro-porous membrane having an aperture of 0.1-1 [mu]m and a porosity reaching up to 85% or more is used as the large-aperture base membrane, the large-aperture base membrane undergoes heat treatment, and then an aqueous solution of a polyamine active monomer and an oil phase solution of an acyl chloride active monomer form the ultrathin desalination polyamide layer on the surface of the base membrane through an interfacial polymerization technology. The production method effectively eliminates the adverse influences of currently adopted small-aperture ultrafiltration membrane structures as the base membrane on the performances of the forward osmosis composite membrane, solves the problem of unstable combination of the ultrathin desalination polyamide layer and the base membrane, greatly improves the intramembrane concentration polarization phenomenon, reduces the mass transfer distance and resistance, improves the water flux, the interception rate and the anti-pollution characteristic of the forward osmosis composite membrane, and has a good application prospect.

Owner:NINGBO UNIV

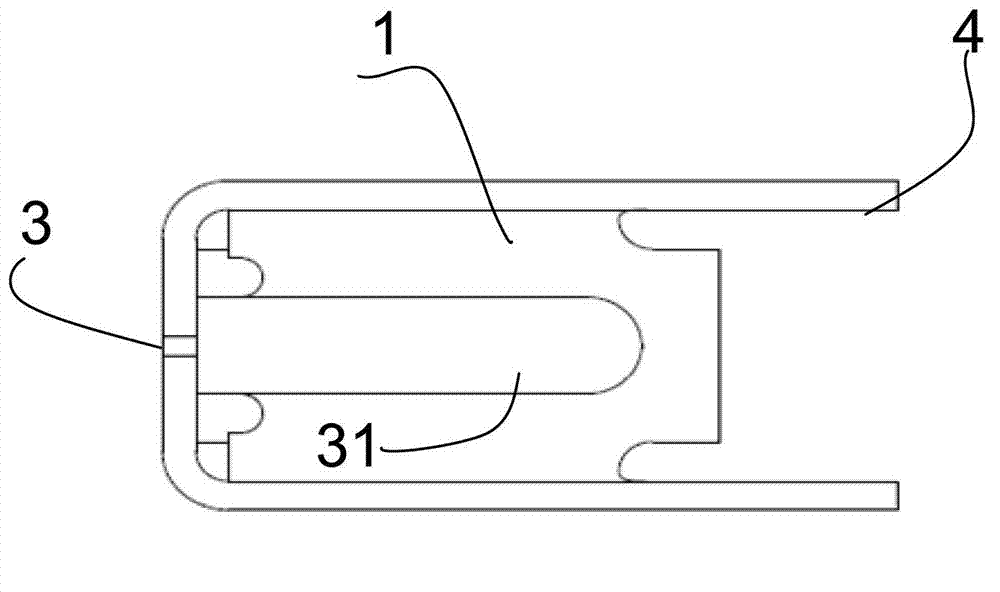

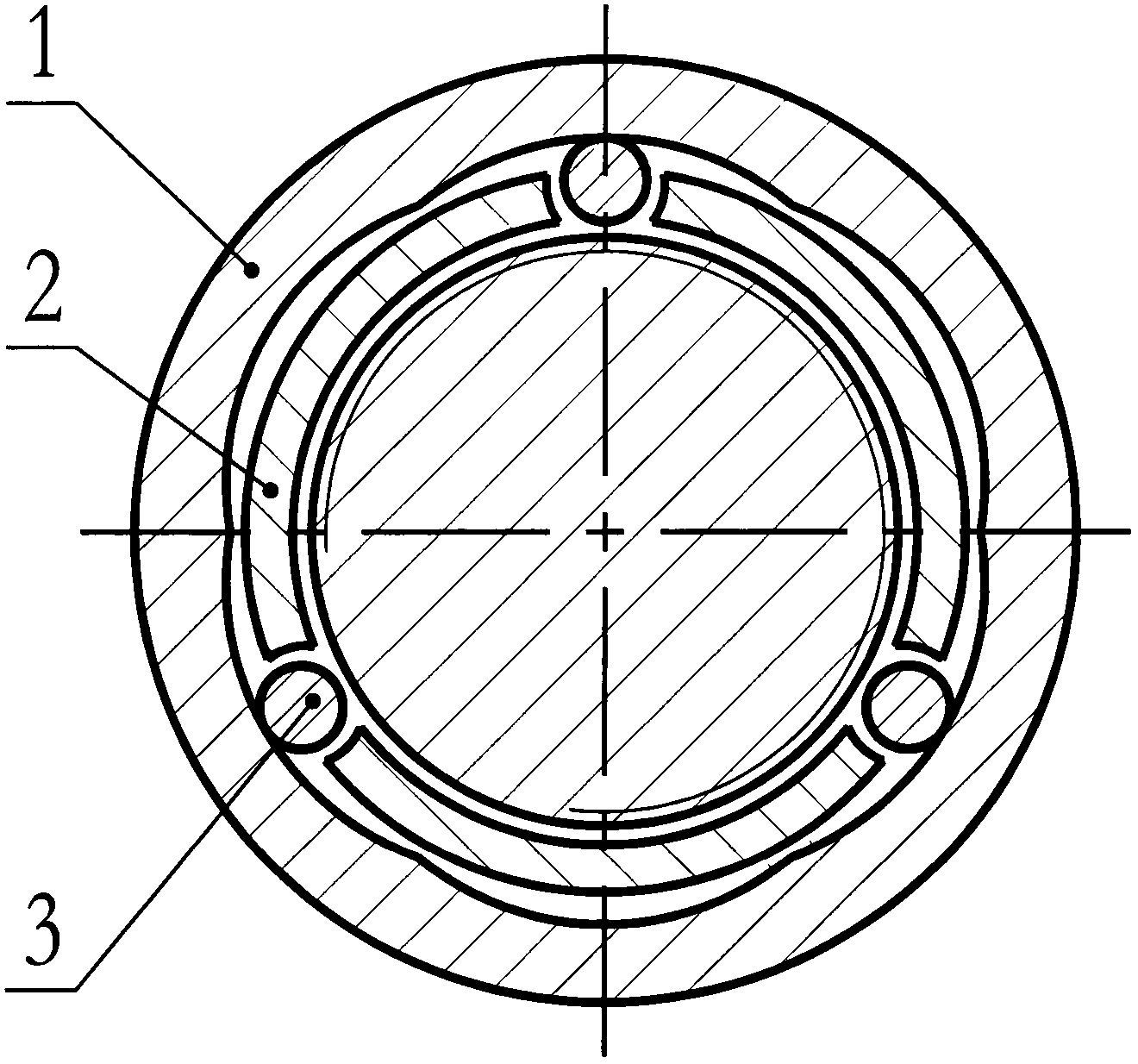

Inserting type stud assembly and disassembly clamp

InactiveCN103419155AEasy to assembleIncrease touch pointsWork holdersMetal-working hand toolsScrew threadUltimate tensile strength

The invention provides an inserting type stud assembly and disassembly clamp which mainly comprises a clamp body, a retainer, three pin rollers and a baffle ring. Grooves in the proper number form a cavity of the clamp body, the retainer is placed in the cavity and provided with three cylindrical grooves, and the baffle ring is connected to the bottom of the clamp body through a fastening screw. In the process of assembly, the inserting type stud assembly and disassembly clamp is inserted into a stud, when the clamp body is rotated, the retainer relatively stands still, groove faces in the cavity of the clamp body squeeze the pin rollers so as to clamp the stud, and clamping is convenient; after the stud is screwed tightly, the clamp body is slightly rotated in the opposite direction, and then the clamp can be disassembled. The inserting type stud assembly and disassembly clamp is convenient to clamp and disassemble, and capable of reducing labor intensity and improving work efficiency; a large number of contact points of the pin rollers and threads exist, the pin rollers are made of wearable bearing steel, and service life is long; meanwhile, the clamp can screw threads with different pitches and even a stud with threads at only one end, and application range is wide.

Owner:SHANGHAI ELECTRIC WIND ENERGY CO LTD

Colorful pervious concrete and preparation method thereof

The invention relates to the technical field of pervious concrete preparation, in particular to colorful pervious concrete. Concrete in each stere is prepared from the following raw materials of, in parts by weight, 80-120 parts of coarse-diameter gravels, 9-15 parts of fine-diameter zeolite, 15-30 parts of cement, 6-8 parts of water, 4-6 parts of additives, 2-4 parts of painting and 0.5-1.5 partsof modified wood fibers. According to the technical scheme of the preparation method of the colorful pervious concrete, fine-diameter zeolite is added to increase the accumulation density of aggregates, the contact points among the aggregates are increased, accordingly the compressive strength of the prepared pervious concrete is improved, meanwhile, zeolite has a special porous structure, and thus the porosity of the pervious concrete is improved further. The modified wood fibers are added into the pervious concrete as well, so that adhesion among granules of the pervious concrete is tighter, the sedimentation rate of cement paste is lowered, meanwhile, the modified wood fibers can bear part of tensile stress, and accordingly the breaking strength of concrete is improved.

Owner:南通鸿基市政工程有限公司

Cap-grabbing manipulator on the smoke guiding vehicle

InactiveCN102275164AStable and reliable gripIncrease touch pointsProgramme-controlled manipulatorCoke ovensManipulatorSingle point

The invention discloses a cap-grabbing manipulator on a smoke guiding vehicle. The structure comprises: four connecting rods are uniformly hinged at the lower end of the bracket, the lower ends of the connecting rods are hinged with the middle parts of the grippers, and the upper ends of the four grippers are Evenly hinged on the movable hanger, the movable hanger is provided with a driving rod, and an auxiliary claw block is also fixedly arranged at the grasping end of each claw hand. Beneficial effects of the present invention: Since the auxiliary claw block is set on the grasping end of the claw hand, the contact point between the grasping end of the claw hand on the cover grasping manipulator on the smoke guiding vehicle and the furnace cover is increased, so that the furnace cover can be stably and reliably Grasping the furnace cover overcomes the disadvantages that the previous grasping end and the furnace cover are a single contact point, and the position of the furnace cover and the position of the cover grabbing manipulator have a large deviation.

Owner:ZHANGJIAGANG CHANGLI MACHINERY

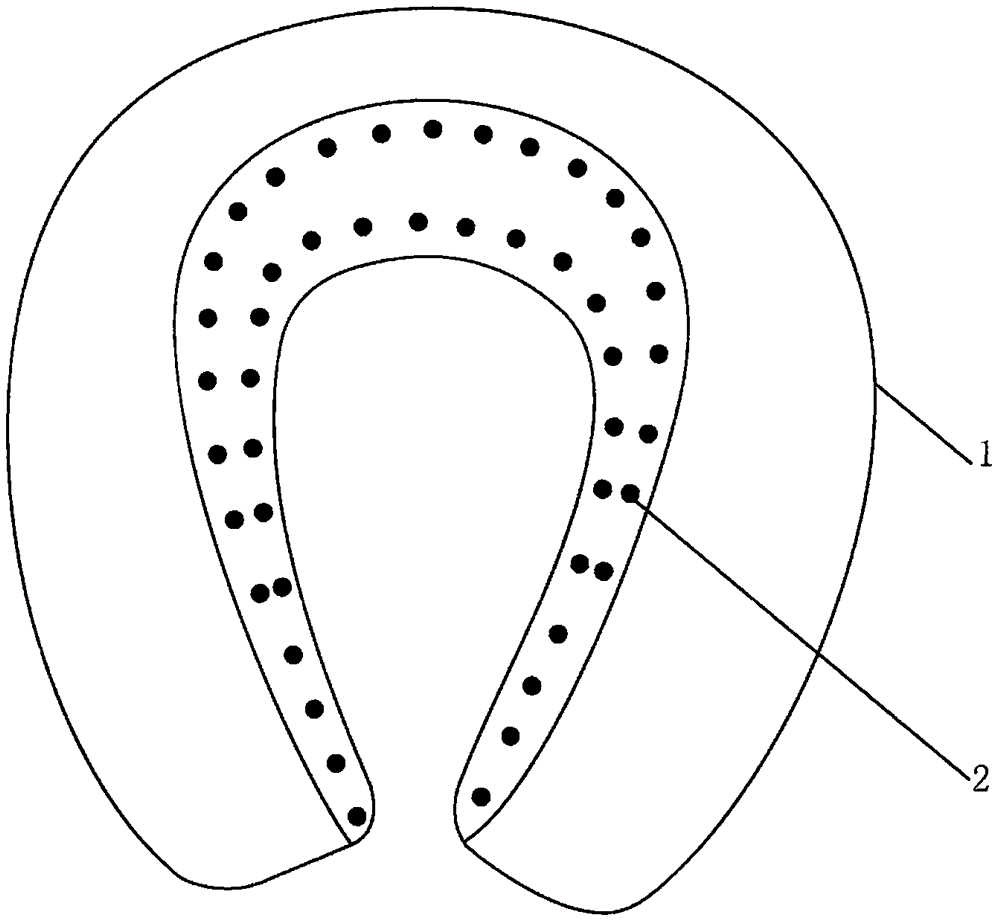

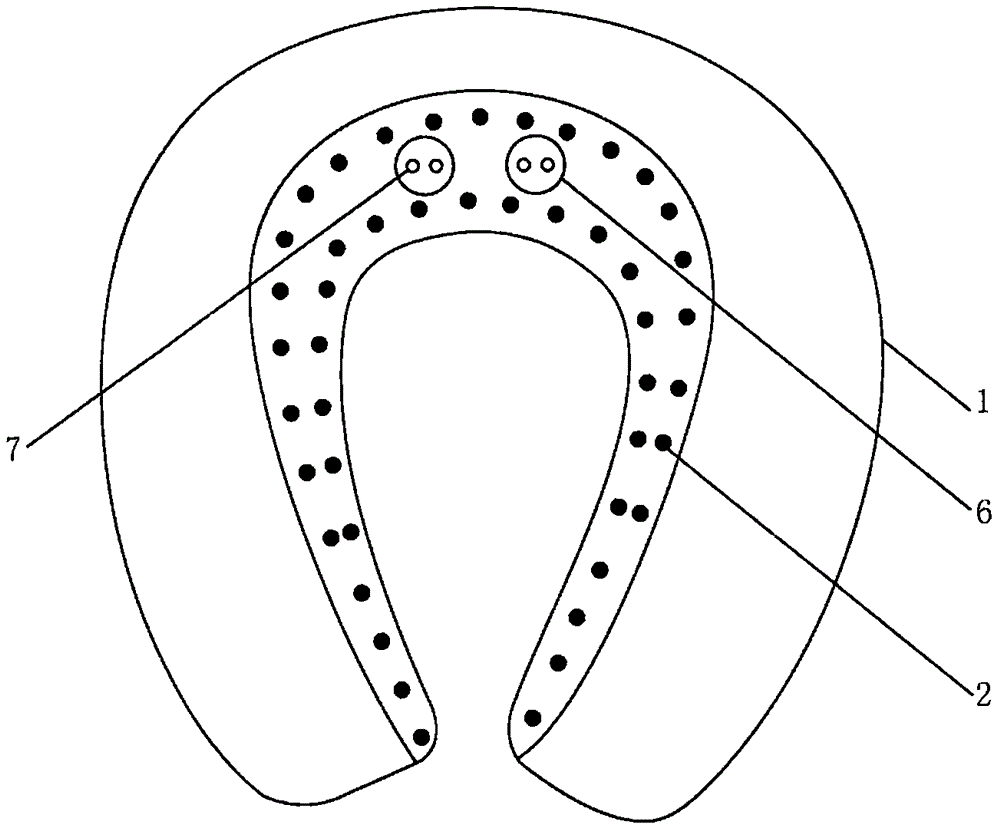

Natural self-heating health-care physiotherapy neck-protecting pillow and preparation method thereof

The invention discloses a natural self-heating health-care physiotherapy neck-protecting pillow. The natural self-heating health-care physiotherapy neck-protecting pillow comprises a filling pillow inner core, a pillow inner core cover and a pillow cover. The filling pillow inner core is of U shape, and the pillow inner core cover is detachably disposed outside the filling pillow inner core in a sleeved mode and is in close contact with the filling pillow inner core; The pillow cover is provided with an opening, and a zipper is arranged at the opening; the pillow cover is disposed outside the pillow inner core cover in a sleeved mode, a plurality of self-heating far infrared functional adhesive particles are distributed on the outer surface of the pillow cover which is in contact with the neck of the human body; the self-heating far infrared functional adhesive particles are made by heating and drying self-heating far infrared functional adhesive pastes; the self-heating far infrared functional adhesive pastes contain 5-40 % of raw ore slurry, 0.01-10% of far infrared functional additives, 50-80% adhesives and 0.1-5% of dispersant. The natural self-heating health-care physiotherapy neck-protecting pillow has better self-heating effect and far-infrared effect, and is more ideal for patients with cervical spondylosis.

Owner:QINGDAO UNIV

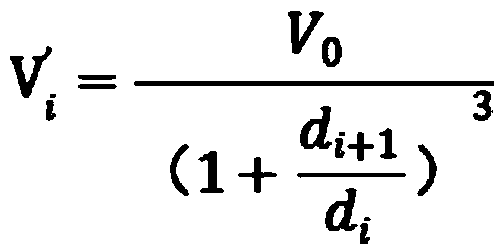

Method for designing old material graded recycled asphalt mixture

ActiveCN110119582AHigh asphalt contentImprove efficiencySolid waste managementDesign optimisation/simulationRoad surfaceEngineering

The invention provides a method for designing an old material graded recycled asphalt mixture, which comprises the following steps of: grading the old asphalt pavement milled and planed old materials,respectively designing the recycled asphalt mixture, adopting a suspended compact structure with the particle size of less than 4.75 mm, fully utilizing old asphalt and fine aggregate in the old materials, and calculating the new asphalt addition amount through a theory by adopting an asphalt film-forming characteristic; designing 4.75-9.5 mm and more than 9.5 mm into a skeleton structure recycled asphalt mixture; adopting the idea that coarse first-grade particles are completely surrounded by fine first-grade particles to construct a coarse aggregate composition mechanism, providing a framework structure recycled asphalt mixture grading design theory, considering the framework structure interference caused by crushing and refining of the coarse aggregates and correcting a recycled asphalt mixture framework structure grading curve . The design theory of the old material graded recycled asphalt mixture is provided. The old material mixing proportion is increased to ensure that the recycled asphalt mixture has the excellent pavement performance and stability, and the method has the important significance for recycling application and popularization of the old asphalt pavement.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

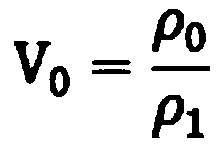

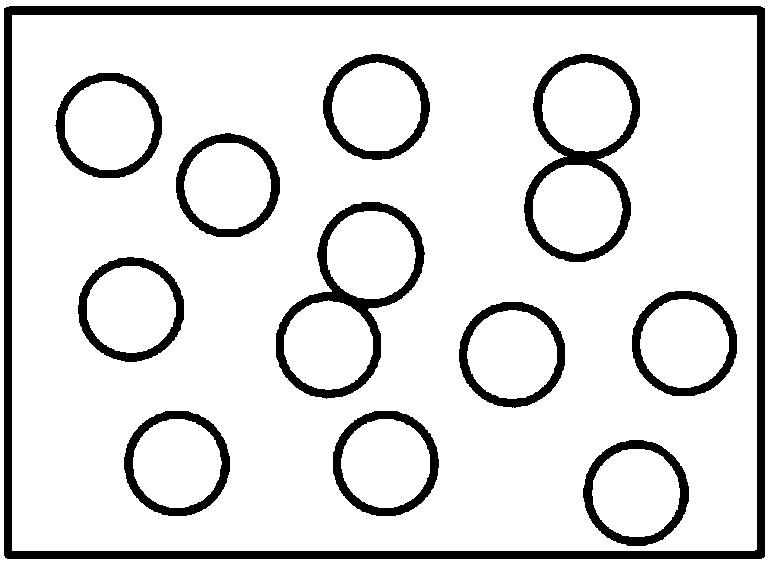

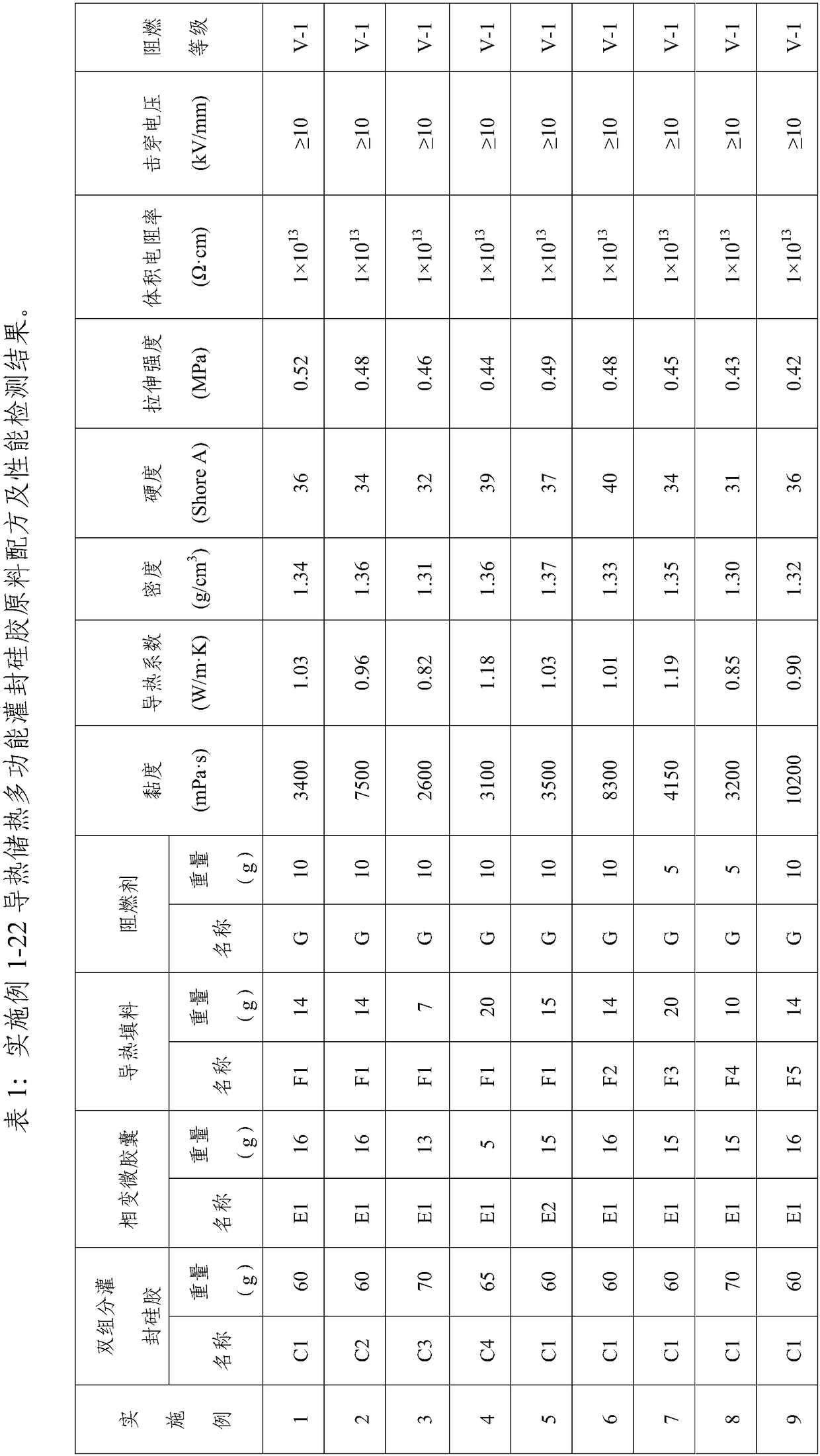

Heat conduction and storage multifunctional pouring silica gel and preparation method thereof

ActiveCN108084957AReduce viscosityImprove mechanical propertiesNon-macromolecular adhesive additivesSecondary cellsTemperature controlSilica gel

The invention relates to heat conduction and storage multifunctional pouring silica gel and a preparation method thereof. The heat conduction and storage multifunctional pouring silica gel consists ofthe following components in percentage by mass: 40-89% of double-component pouring silica gel, 5-20% of phase-change microcapsules, 5-20% of heat conduction packing after surface treatment, and 1-20%of a flame retardant, wherein the heat conduction packing consists of small particle size heat conduction packing and large particle size heat conduction packing through mixing. The preparation method comprises the following steps: performing surface treatment on the heat conduction packing; preparing the heat conduction and storage composite packing; preparing the double-component pouring silicagel; preparing components A1 and B1 of the heat conduction and storage multifunctional pouring silica gel; preparing the heat conduction and storage multifunctional pouring silica gel. Due to surfacetreatment on heat conduction packing of different particle sizes, the dispersibility of the packing in a silica gel substrate is improved, the heat conduction properties of the heat conduction and storage multifunctional pouring silica gel are improved, and due to addition of the phase-change microcapsules, the heat conduction and storage multifunctional pouring silica gel has heat storage temperature control properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

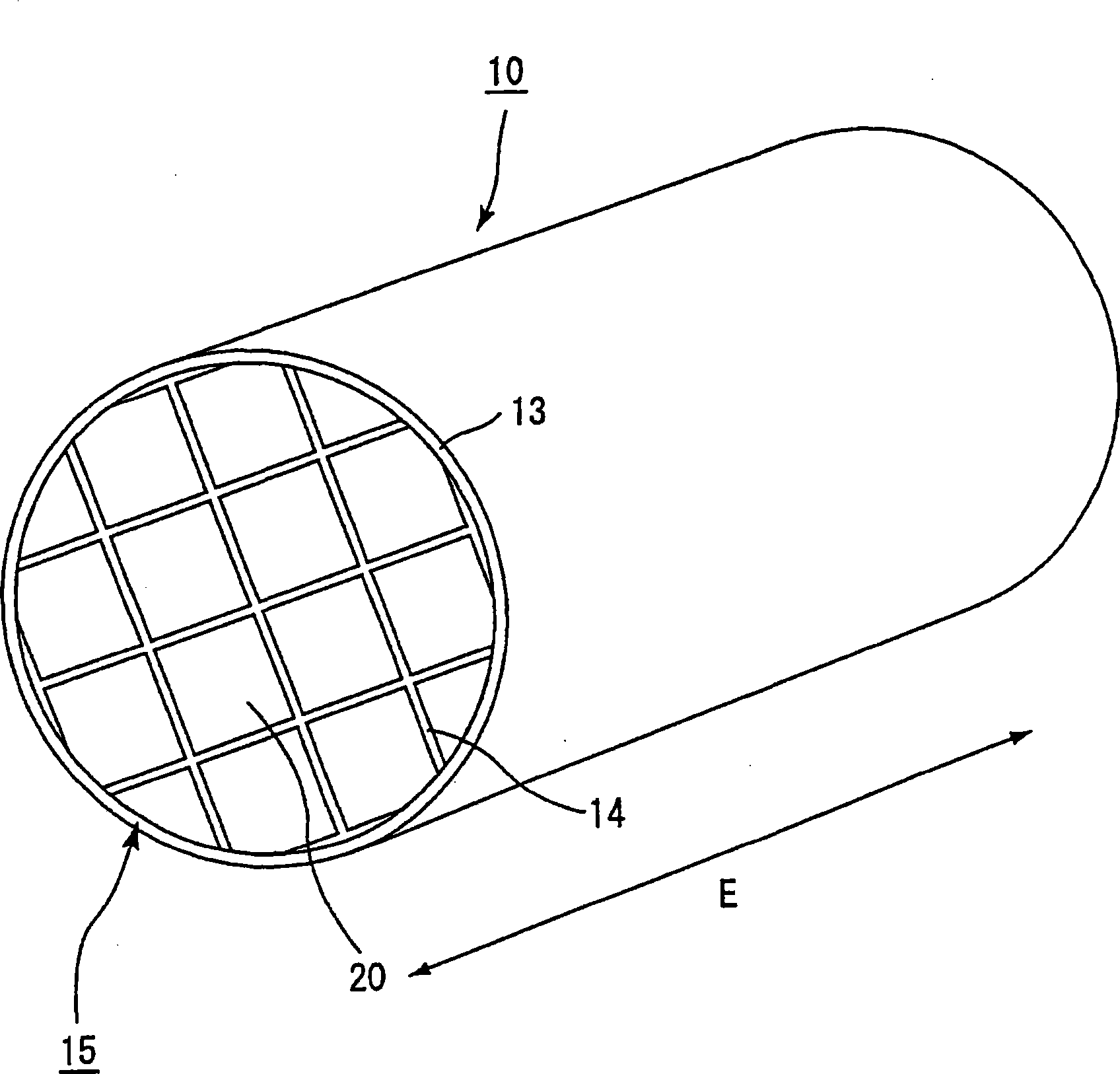

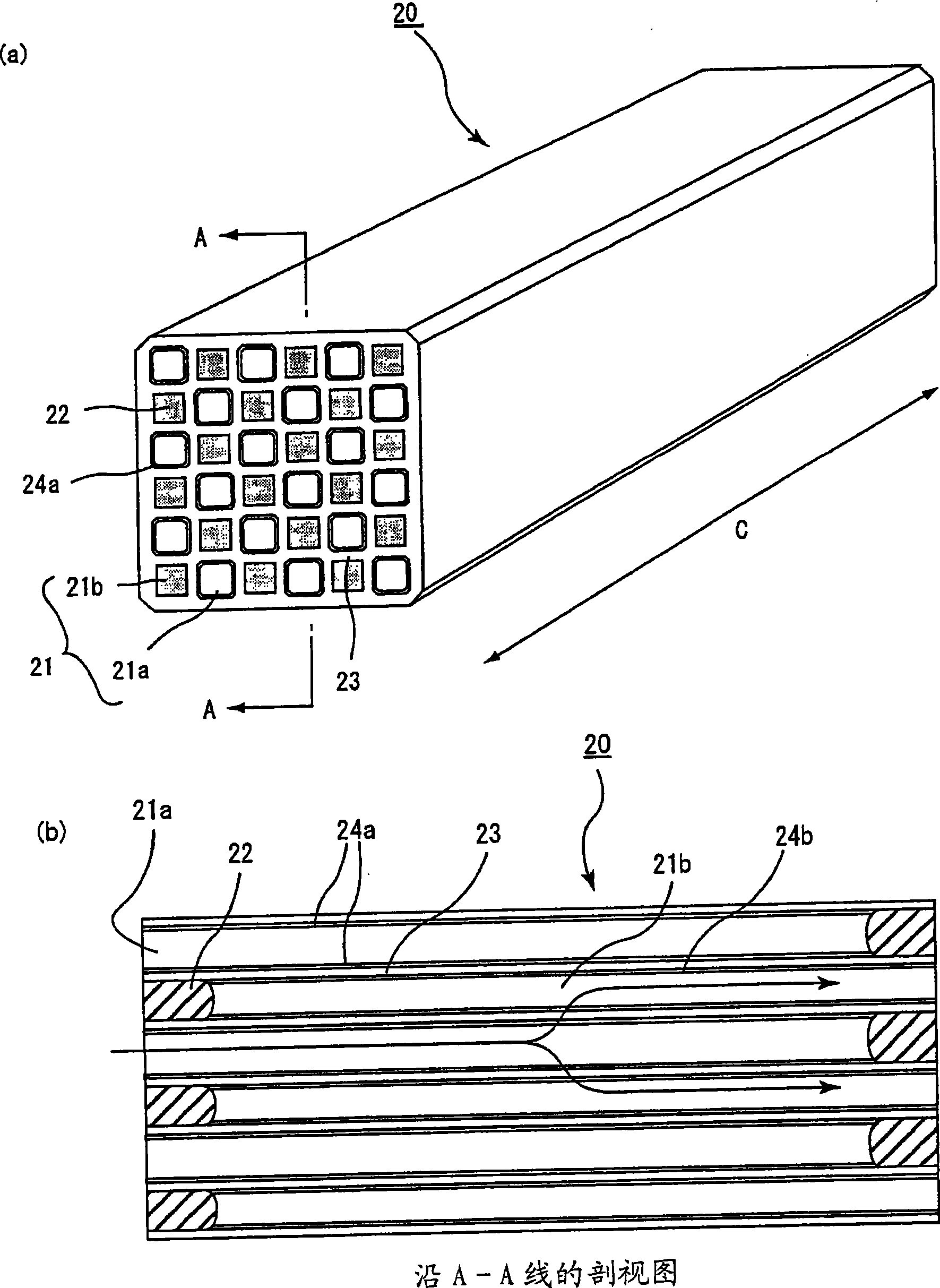

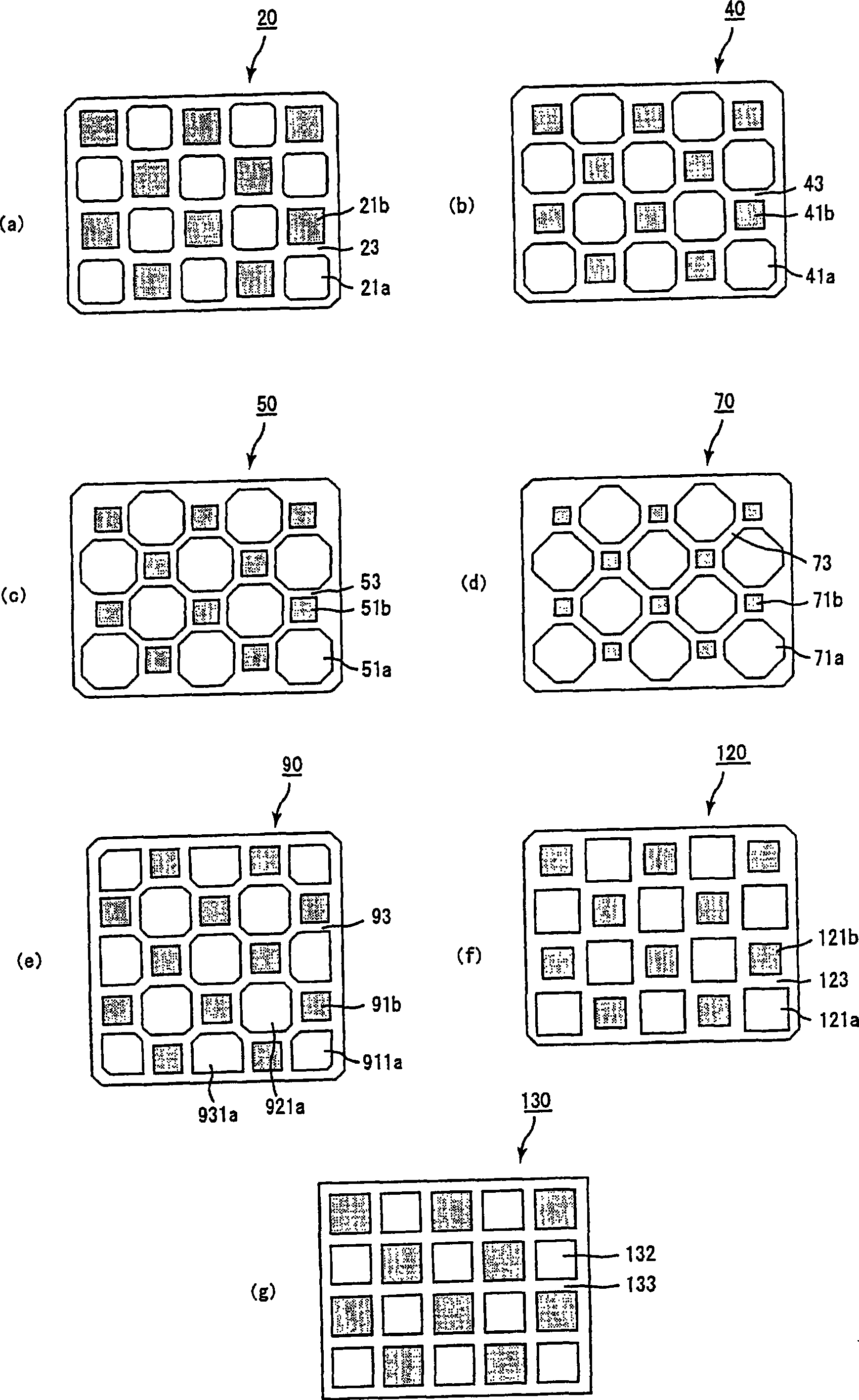

Honeycomb structure

InactiveCN101374590AEfficient combustion removalCombustion removes economically and efficientlyInternal combustion piston enginesDispersed particle filtrationParticulatesCombustion

A honeycomb structure that realizes reduction of the amount of catalyst supported and attains not only satisfactory particulate combustion removal but also suppression of pressure loss increase. The honeycomb structure is a columnar one having multiple cells laid parallelly in the longitudinal direction with a cell wall interposed therebetween, either one end portion of each of the cells being sealed by a sealing member, the cell wall supporting a catalyst, characterized in that the multiple cells consist of large-volume cells and small-volume cells, and that the area of section perpendicular to the longitudinal direction of each of the large-volume cells is larger than the area of section perpendicular to the longitudinal direction of each of the small-volume cells, and that while the large-volume cells are sealed at one end portion of the honeycomb structure,; the small-volume cells are sealed at the other end portion of the honeycomb structure, and that the catalyst support is effected only on the cell wall of the large-volume cells, or alternatively the catalyst support is effected on not only the cell wall of the large-volume cells but also the cell wall of the small-volume cells, provided that the amount of catalyst supported on the cell wall of the large-volume cells, per volume, is greater than the amount of catalyst supported on the cell wall of the small-volume cells.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com